Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Metalworking fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metalworking fluid (MWF) is the name given to a range of oils and other liquids that are used to cool and/or lubricate metal workpieces when they are being machined, ground, milled, etc. MWFs reduce the heat and friction between the cutting tool and the workpiece, and help prevent burning and smoking.

Refrigerator oil, compressor oil composition, hydraulic fluid composition, metalworking fluid composition, heat treatment oil composition, lubricant composition for machine tool and lubricant composition

ActiveUS20100093568A1Improve the level ofImprove balanceGroup 4/14 element organic compoundsOrganic compound preparationChemical compositionMetalworking fluid

The present invention provides a refrigerating machine oil, a compressor oil composition, a hydraulic oil composition, a metalworking oil composition, a heat treating oil composition, a lubricating oil composition for machine tools and a lubricating oil composition which comprise a lubricating oil base oil having % CA of not more than 2, % CP / % CN of not less than 6 and an iodine value of not more than 2.5.

Owner:NIPPON OIL CORP

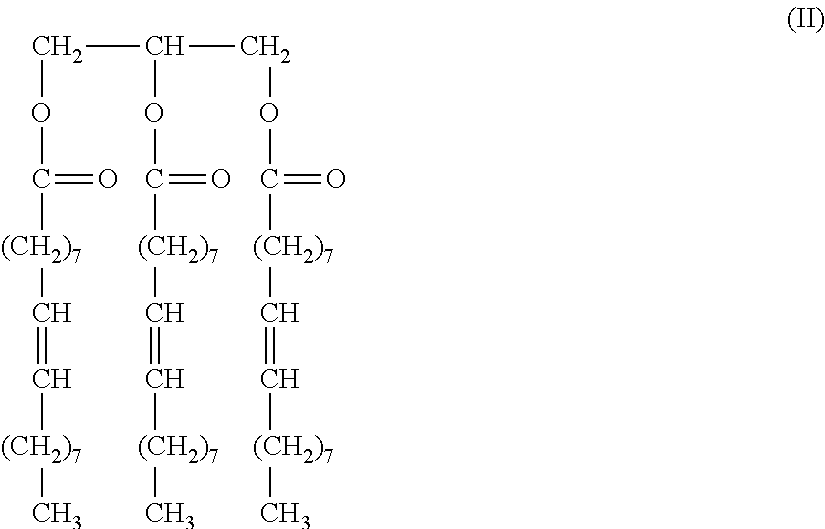

Maleated vegetable oils and derivatives, as self-emulsifying lubricants in metalworking

InactiveUS20090209441A1Effective emulsifyingImprove abilitiesOrganic chemistryLiquid carbonaceous fuelsBiotechnologyVegetable oil

A succinated triglyceride oil derived from maleating triglyceride oil from a plant or land animal is described for use as an emulsifying agent for metalworking fluids. The metalworking fluid would comprise water; as an emulsifier this succinated triglyceride, optionally further reacted with water, Group IA and IIA metals, ammonium hydroxide, various amines, alkanolamines, alkoxylated alkanolamines, and polyamines to form a modified emulsifier; and optionally an oil and other additives.

Owner:THE LUBRIZOL CORP

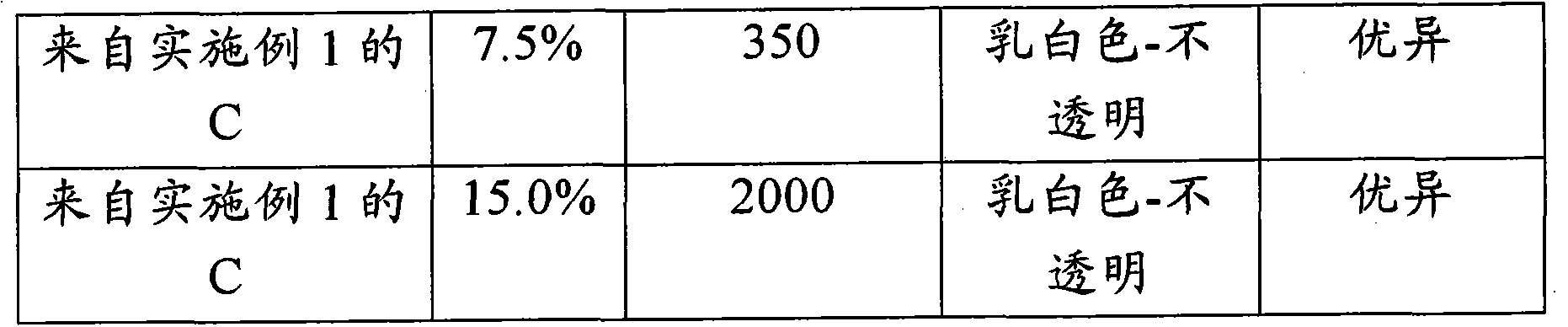

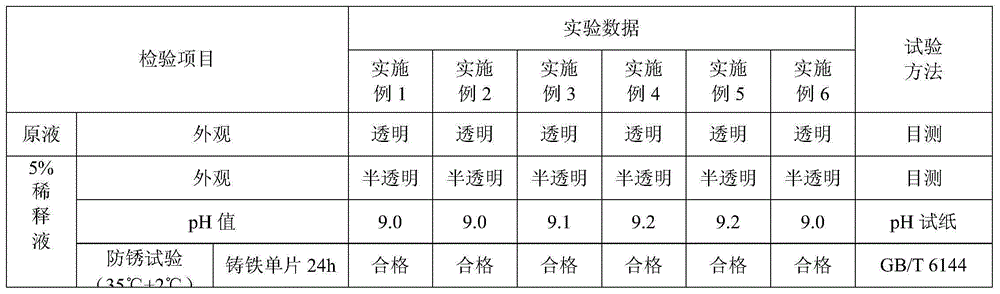

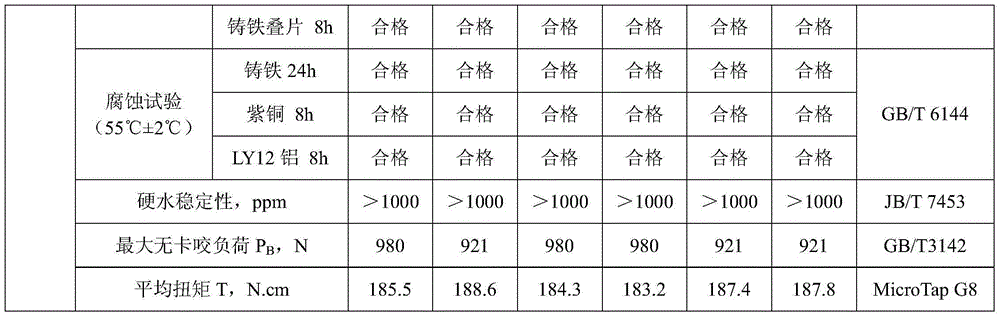

Preparation of metal working fluid special for aluminum alloy

InactiveCN101696367AExcellent lubricity and protection against aluminumExcellent corrosion protectionLubricant compositionCorrosionSemi synthetic

The invention relates to a semi-synthetic metal working fluid special for aluminum and aluminum alloys, which has an excellent lubricating property and protective properties for aluminum and various aluminum alloys. The excellent lubricating property of the metal working fluid is manifested by simultaneously satisfying various processing modes of the aluminum alloys, such as turning, milling, drilling, tapping and the like. The excellent protective properties for the aluminum and the aluminum alloys are manifested by processing various aluminum alloys, generating no corrosion to the aluminum alloys and ensuring the requirements on the luminance brightness of the aluminum alloys. Besides, the metal working fluid also has excellent anti-rust properties and anti-foaming properties, and is added with a biological inhibitor which can effectively inhibit the growth and the reproduction of bacteria, prolong the service life of the metal working fluid and reduce the cost.

Owner:益田润石(北京)化工有限公司

Poly (trimethylene-ethylene ether) glycol lube oils

A lube oil composition is disclosed which comprises poly(trimethylene-ethylene ether) glycol and at least one lube oil additive. The base stock can be optionally mixed with other base stocks. Preferably, the composition is used as hydraulic fluid, brake fluid, heat transfer fluid, compressor lubricant, textile and calender lubricant, metalworking fluid, refrigeration lubricant, two-cycle engine lubricant or crankcase lubricant.

Owner:EI DU PONT DE NEMOURS & CO

Gear cutting oil

Metalworking fluids contain active sulfur, a certain kind of inactive sulfur called “available sulfur”, and fat in a base oil of a lubricating viscosity. The metalworking fluids are chlorine free and phosphorous free. Boundary lubrication is provided by the fat, while extreme pressure lubrication is provided by the sulfur. Available sulfur is inactive sulfur minus any contribution of inactive sulfur from sulfurized saturated fats. Active sulfur and available sulfur are present in balanced proportions, while fat is present at an amount effective to provide boundary lubrication. Use of the fluids reduces tool wear over a long period of action and over a variety of boundary and extreme pressure conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Alkali Metal Borate and Lubricating Compositions Thereof

The present invention relates to a lubricating composition containing an alkali metal borate. The invention further provides for a method of lubricating a device with grease or a metalworking fluid by employing the lubricating composition containing the alkali metal borate.

Owner:THE LUBRIZOL CORP

Process for metalworking fluid from heavy alkylate

InactiveUS20050215440A1Component is toxicHigh specific and latent heatWork treatment devicesLiquid carbonaceous fuelsMetalworking fluidVegetable oil

The process relates to composition of metalworking fluid and for its preparation based on heavy alkyl benzenes having 22 to 26 carbon atoms to replace mineral oil and process for the same. A process for heavy alkylate based less toxic metalworking fluid composition comprising of heavy alkyl benzene, one emulsifier which is a sodium oleate, sulfonate or mixtures thereof, a vegetable oil as lubricity booster, an antioxidant, a fungicide, an extreme pressure additive, an antirust, a co-surfactant, a coupling agent and alkali component. The process comprising of removing of insoluble matter from the heavy alkylate, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture at 20-120° C., followed by conditioning of the metal working fluid concentrate which can be used as emulsion in water.

Owner:COUNCIL OF SCI & IND RES

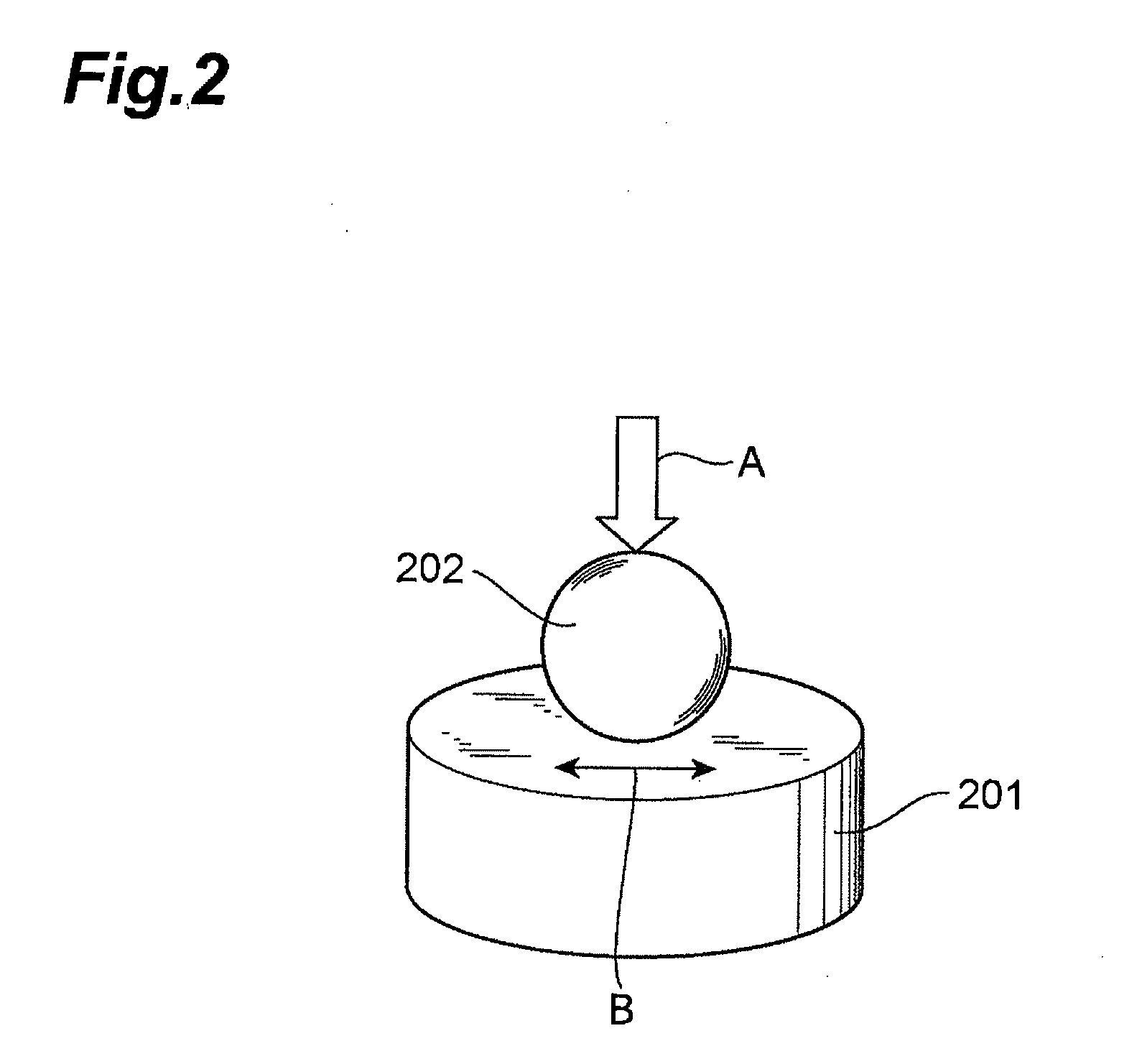

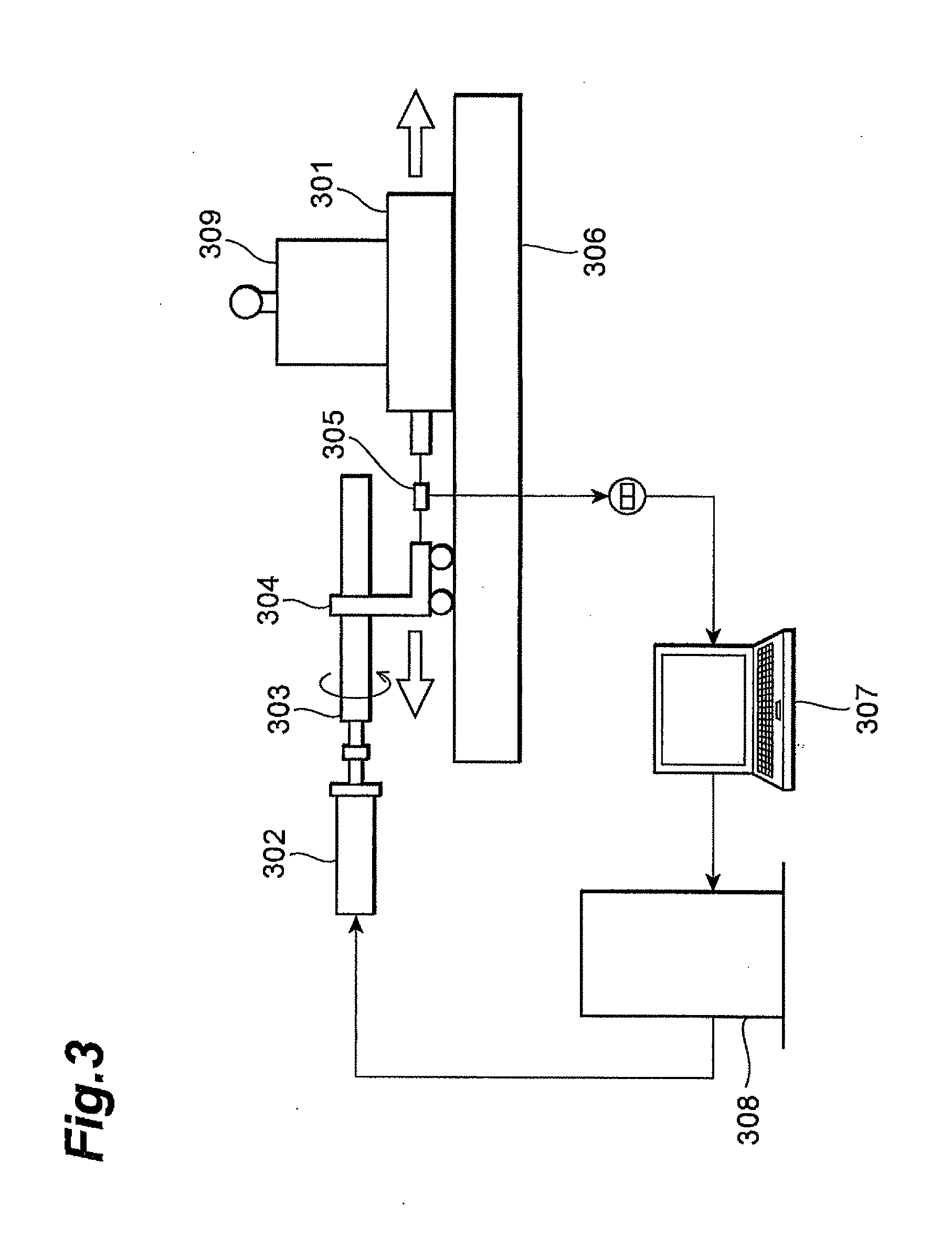

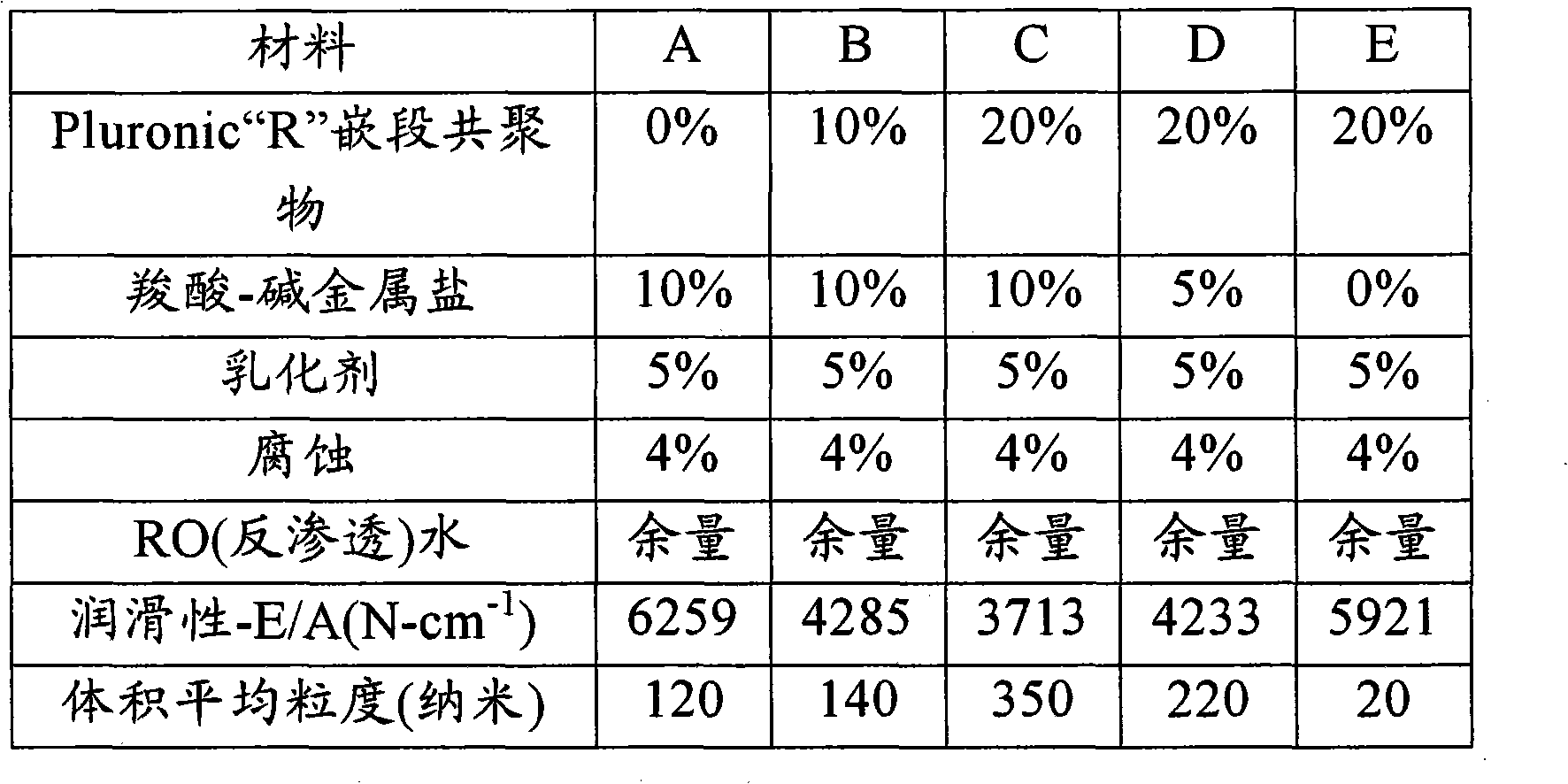

Formulation of a metalworking fluid

Non-oil containing metalworking fluids, also known as synthetic metalworking fluids having an engineered particle size of greater than 120 nanometers upon dilution. The expansive particle size results in a substantial increase in lubricity, suitable for the heavy-duty operations previously attainable only with oil-containing products. Additionally, this non-oil containing metalworking lubricant optionally incorporates positive attributes of oil-containing products, including excellent corrosion inhibition and heavy-duty operation capable lubricity.

Owner:凯密特尔有限公司

Environment-friendly semisynthetic cutting fluid for titanium alloys as well as preparation method and application of cutting fluid

InactiveCN105176656AImprove processing efficiencyExtend your lifeLubricant compositionMetalworking fluidActive agent

The invention belongs to the field of metal processing fluids and discloses an environment-friendly semisynthetic cutting fluid for titanium alloys as well as a preparation method and an application of the cutting fluid. The cutting fluid comprises components in percentage by mass as follows: 20%-30% of base oil, 4%-6% of a lubricant, 6%-10% of an extreme pressure agent, 10%-15% of mixed alcohol amine, 4%-8% of an anti-rusting agent, 2%-4% of a pH (potential of hydrogen) stabilizer, 15%-25% of a surfactant, 1%-2% of a hard water stabilizer, 1%-3% of a coupling agent, 2%-4% of a sterilizing mildew preventive and the balance of water. The cutting fluid doesn't contain mineral oil, sulfur, phosphorus, chlorine, boron, phenol, formaldehyde, secondary amine, heavy metals, sodium nitrite and other poisonous and harmful substances and is environment-friendly. The cutting fluid has excellent extreme pressure performance for lubrication, rust prevention and corrosion prevention performance and hard water stability and long service life, and can meet requirements of cutting processing including turning, milling, boring, drilling, tapping and the like of various titanium alloys, the titanium alloy processing efficiency can be improved by 40%, and the service life of a cutting is prolonged by 30%.

Owner:GUANGZHOU MECHANICAL ENG RES INST +1

Metalworking fluid compositions and preparation thereof

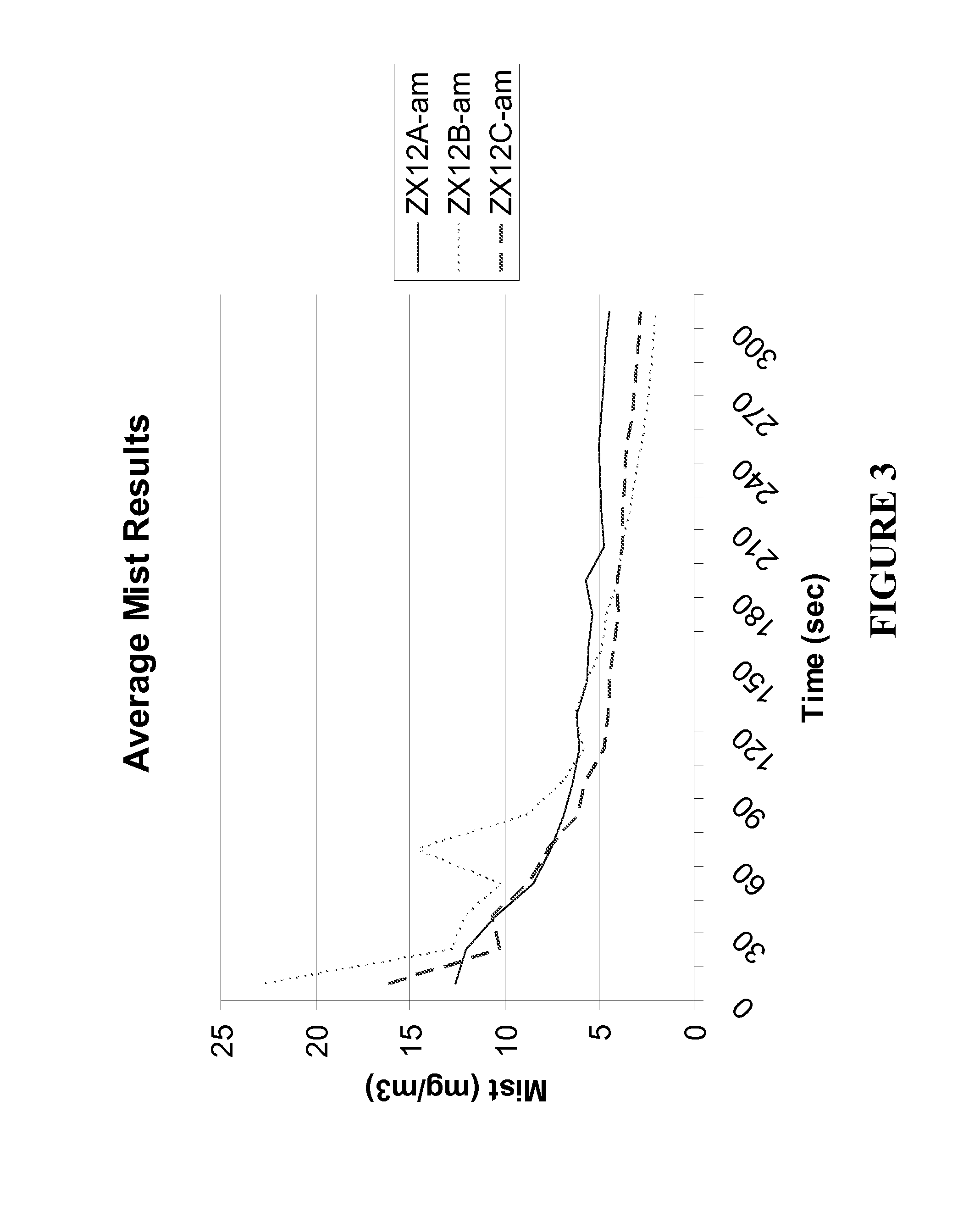

InactiveUS20120010113A1Reduce mist formationReduce formationAdditivesBase-materialsMetalworking fluidBase oil

A metalworking fluid composition comprising an isomerized base oil having consecutive numbers of carbon atoms and less than 10 wt % naphthenic carbon by n-d-M is provided. The metalworking fluid has reduced mist formation, low foaming tendency and excellent air release properties, and excellent wear properties.

Owner:CHEVROU USA INC

Method and apparatus for measuring a variable in a lubricant/coolant system

An automatic system for monitoring / controlling a variable of a machine or metalworking fluid system also achieves cleaning and optionally, a calibration check of the sensor of the variable. The system includes one or more sensors for variables such as pH, fluid concentration, conductivity, temperature and the like, a supply of a cleaning agent and associated valves and conduits for connecting the automatic system to a fluid to be measured. A cleaning cycle can be scheduled as necessary to clean and / or check calibration of the sensors and ensure accurate measurement of sensed variables. If desired, the data regarding the sensed variables may be utilized to perform corrective action in real time.

Owner:MASTER CHEM

Water-based metal working fluid

InactiveUS7018959B2Easy to recycleImprove the lubrication effectWork treatment devicesAdditivesWater basedMetalworking fluid

A water-based, recyclable metalworking fluid comprises a polyalkylene glycol, an alkanolamine, a polyglycol surfactant, a polyol surfactant, a biocide and a corrosion inhibitor. The biocide may comprise a mixture of biocidal compounds effective against bacterial and fungal organisms. The material may also include an isoalkoxy amine oxide and a glycol ether. The composition may also include ancillary ingredients such as viscosity controlling agents, defoamers, coloring agents and the like. It is a notable feature of the composition of the present invention that it is free of hazardous materials and fatty acids. Also disclosed is a method for using the composition in a metal-shaping operation.

Owner:MASCO CORP +2

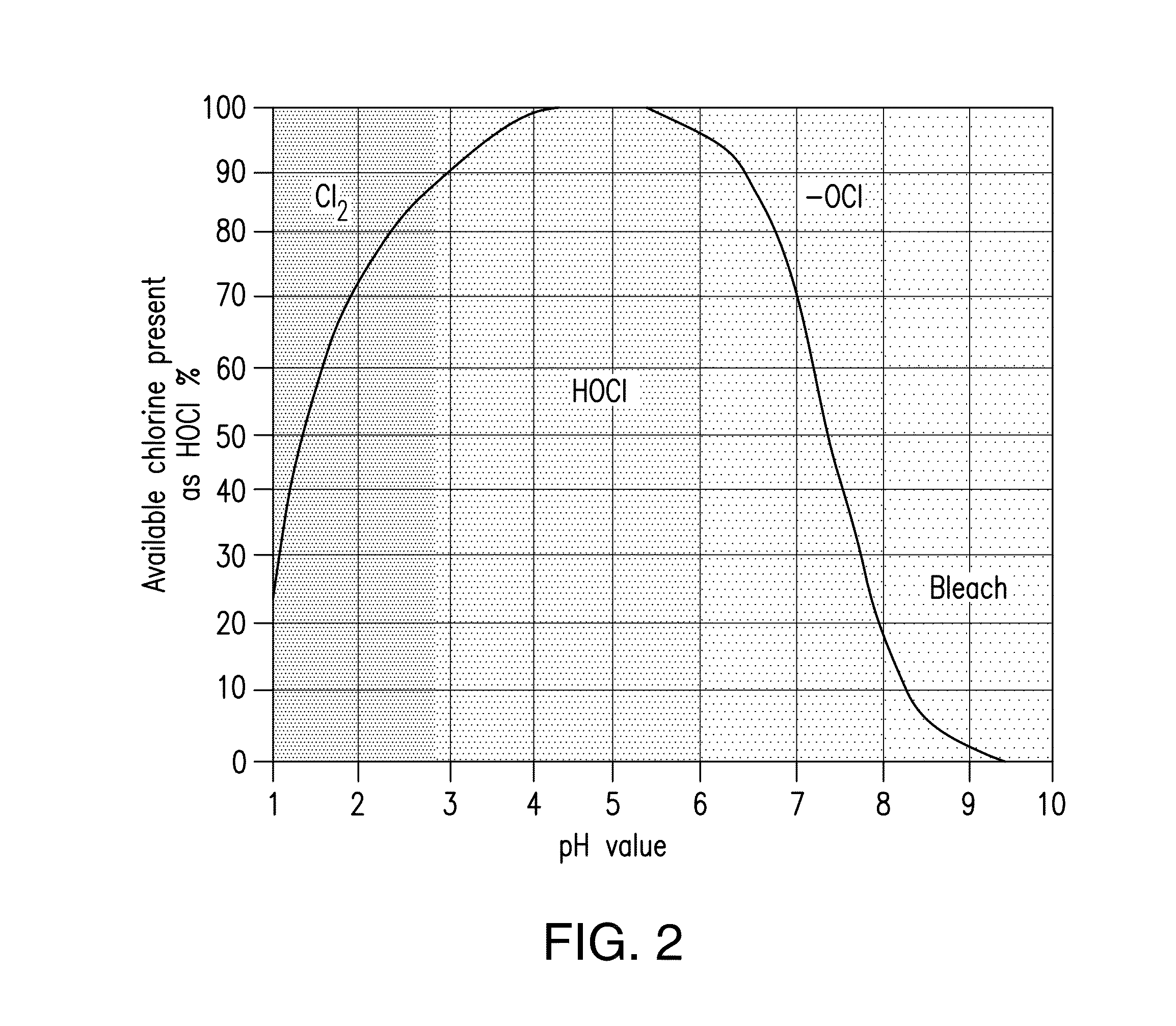

Method for Producing Shelf Stable Hypochlorous Acid Solutions

InactiveUS20150119245A1Extended shelf lifeReduce needBiocideElectrolysis componentsCooling towerMetalworking fluid

A method for production and storage of hypochlorous acid is disclosed. The method comprises using high purity water achieved by a combination of softening and reverse osmosis steps. The shelf life is further improved by storing the hypochlorous acid in opaque PET bottles or Nylon / PE bags or nylon bags in a box. Solutions stored in opaque PET bottles exhibit the best stability. Anticipated uses of the extended life hypochlorous acid solution include sanitizer for food contact and non-food contact surfaces, a streak-free cleaner for smooth surfaces and a cut flower life extender. Other biocide uses include water treatment in oil and gas production, cooling tower, lazy river and swimming pools, process water distribution systems, drinking water, portable humidifier, fish tanks and treatment of metalworking fluids and lubricants.

Owner:AQUAVERT CLEAN INC

Process for metalworking fluid from heavy alkylate

The present invention relates to composition of metalworking fluid based on heavy alkyl benzenes having 20 to 22 alkyl carbon atoms and process for the preparation thereof. The heavy alkyl benzene based, less toxic, soluble metalworking fluid composition comprises heavy alkyl benzene, emulsifier, lubricity booster, antioxidant, fungicide, extreme pressure additive, antirust, co-surfactant, coupling agent and alkali component. The process comprises tailoring the heavy alkyl benzene, removing of insoluble matter from the heavy alkylate, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture at 20-120° C., followed by conditioning of the soluble metal working fluid concentrate which can be used as emulsion in water.

Owner:COUNCIL OF SCI & IND RES

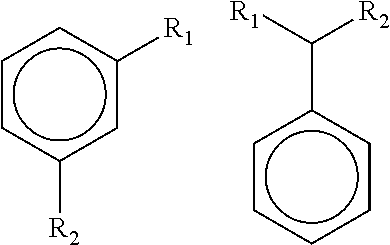

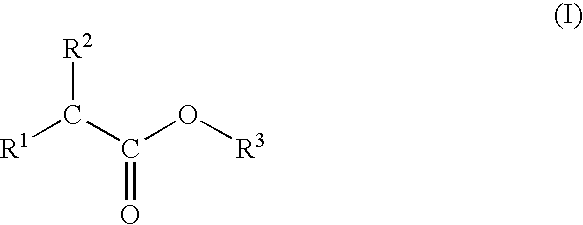

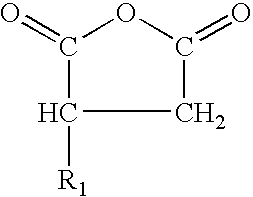

Alpha branched esters for use in metalworking fluids and metalworking fluids containing such esters

Alpha branched esters for use in a metalworking fluid represented by the formula (I): wherein R1, R2, and R3 are each independently selected from a hydrocarbon group having one to thirty-six carbon atoms are described. The hydrocarbon groups may be independently an alkyl group, an alkenyl group, an aryl group, or an allyl group; substituted or unsubstituted; branched, cyclic, or linear. Also provided are metalworking concentrates comprising the alpha branched ester, as described above, and, optionally, a hydrocarbon oil, as well as metalworking fluids including water, and the alpha branched esters of the invention. The invention also includes methods of preparing the metalworking fluid and composition of the invention, as well as methods of improving the operating life of the fluid or composition.

Owner:ZSCHIMMER & SCHWARZ INC

Drilling fluid system

ActiveUS20160102268A1Life is preservedHigh viscosityAdditivesDrilling compositionMetalworking fluidFluid system

An aqueous based metalworking fluid that is environmentally friendly and process for metalworking with the fluid. The metalworking fluid is sampled at periodic intervals and replenished to predetermined operating specifications with the aqueous based metalworking fluid without the need for individual boosters.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Castor oil modified multi-functional lubricant and preparation method thereof

InactiveCN105175698AHigh viscosity indexAvoid Pollution HazardsBase-materialsWater basedMetalworking fluid

The embodiment of the invention discloses a castor oil modified multi-functional lubricant prepared through a polymerization reaction of the following raw materials: refined castor oil, straight-chain or branched-chain dibasic acid and polypropylene glycol or polyethylene glycol; the invention also discloses a preparation method of the castor oil modified multi-functional lubricant. The method comprises the steps: mixing the refined castor oil, the straight-chain or branched-chain dibasic acid and polypropylene glycol or polyethylene glycol, introducing nitrogen for protection, adding a certain amount of a catalyst, undergoing the polymerization reaction at a certain temperature to a certain viscosity, cooling, vacuumizing and dewatering, and thus obtaining the finished product. Compared with a conventional lubricant base oil mineral oil, the castor oil modified multi-functional lubricant prepared by the method is a plant oil-based lubricant, is renewable, is biodegradable easily, has good lubricity and extreme pressure performance, is easy to emulsify, can be used as a lubricant to replace mineral oil and is ideally applied in oil-based and water-based metalworking fluid formulas.

Owner:GUANGZHOU MIQI CHEM

Metal working fluid composition and method of detecting fluid deterioration

ActiveUS20150064741A1Analysis using chemical indicatorsOrganic chemistryMetalworking fluidFluid composition

A wear-indicating metalworking fluid is provided that includes a lubricant base; and a wear-indicating agent. A method of determining wear in a metalworking fluid includes providing wear-indicating metalworking fluid that contains a lubricant base and a wear indicating agent; and observing the visual appearance of the metalworking fluid. A change in visual appearance of the metalworking fluid when compared to an unused metalworking fluid indicates wear of the metalworking fluid.

Owner:ILLINOIS TOOL WORKS INC

Method for suppressing growth of mycobacteria in metalworking fluids

InactiveUS6951618B2Reduce riskGrowth inhibitionBiocideDead animal preservationMicroorganismMycobacterium immunogenum

A method for suppressing the growth of mycobacteria associated with hypersensitivity pneumonitis, in particular Mycobacterium immunogenum, in metalworking fluids is described. The method uses antimicrobial or biocidal compositions which include a metal complex comprising disodium monocopper (II) citrate and an isothiazolone mixture preferably comprising 5-chloro-2-methyl-4-isothiazolin-3-one 2-methyl-4-isothiazolin-3-one. Also described are methods for detecting and identifying the mycobacteria.

Owner:ROSSMOORE HAROLD W

Metalworking fluid

InactiveCN1922293AImprove featuresImprove processing efficiencyBase-materialsMetalworking fluidWater insoluble

A first metalworking fluid of the present invention is characterized by containing an ester oil and a hydrocarbon oil having a kinematic viscosity of 1-20 mm<2> / s at 40 1 / 2 C. A second metalworking fluid of the present invention is characterized in that it contains an ester oil as the base oil and has a moisture content of 200-20,000 ppm. The first and second metalworking fluids are excellent in characteristics of a water-insoluble oil solution for nonferrous metalworking and also excellent in characteristics of an oil solution for cutting / grinding wherein a very slight amount of the oil solution is supplied. These metalworking fluids enable to improve the processing efficiency, and also enable to make life of a processing tool longer.

Owner:NIPPON OIL CO LTD

Polymeric Polyol Esters Used in Metalworking Fluids

ActiveUS20070287645A1Improved solubility characteristicLow acid valueLiquid carbonaceous fuelsLubricant compositionMetalworking fluidPolyolester

Polymeric polyol ester additives for metal working applications are described that have lower pour points and improved solubility in API Group II and III basestocks. The polymeric polyol ester contains linear monocarboxylic acid, alkanedioic acid, alk(en)yl substituted succinic acid or anhydride, trihydric alcohol and pentaerythritol.

Owner:THE LUBRIZOL CORP

High-property water-based emulsion cutting fluid composite

ActiveCN101613634ALow pour pointModerate viscosityAdditivesBase-materialsWater basedMetalworking fluid

The invention provides a high-property water-based emulsion cutting fluid composite, belonging to the field of metalworking fluid products. The composite is a water soluble product and comprises mineral oil, pentaerythritol fatty acid synthetic esters, a compound acidamide anti-rusting agent, an emulsifier, a corrosion inhibitor, a sulfide aliphatic acid ester extreme pressure lubricant, a bactericide and a defoamer; wherein, the compound acidamide anti-rusting agent is the composite of a component A, namely polycarboxylic acid hydramine acidamide and a component B, namely a mixture of triazole and a cosolvent butyl ether diglycol, thereby obviously improving the anti-rusting property of the product and broadening the anti-rusting applicability of diverse metals. The components of the composite product of the invention are scientific and reasonable in selection and use and balanced and harmonious in proportioning, thus achieving the effects of complementary action and synergy, therefore, the water-based emulsion cutting fluid of the invention not only enjoys high lubricating property, high anti-rusting property, high emulsibility, high antibacterial ability and high stability and has long service life, but also produces no pollution to the environment, does no harm to human bodies and satisfies the requirements of high-difficulty machining on the cutting fluid.

Owner:BOER TECH WUHAN

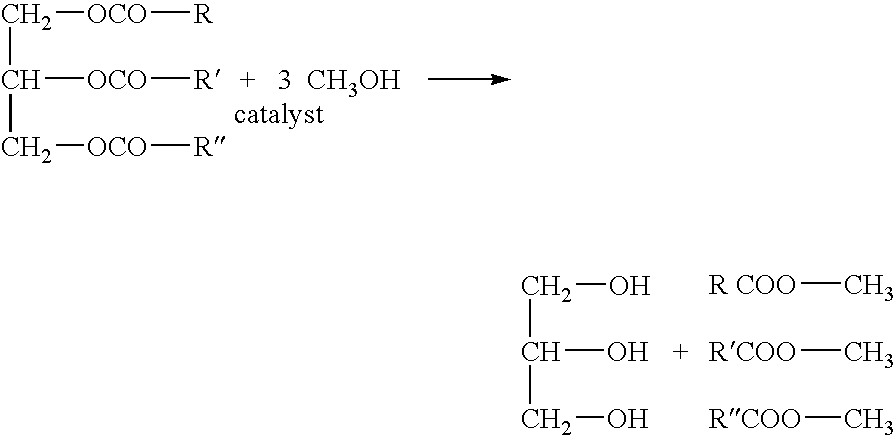

Composition of water-soluble metalworking fluid using distillation residue generated in production of biodiesel

InactiveUS20080171680A1Less harmful to the environmentAdditivesBase-materialsBiodieselMetalworking fluid

A composition of a water-soluble metalworking fluid used in metal machining is formed by adding 5 to 70 wt % additive to 5 to 95 wt % distillation residues that is generated in production of biodiesel and used as lubricating base oil, and 0 to 70 wt % ion exchange water.

Owner:KOREA HOUGHTON

Water-miscible metal working fluids with reduced aerosol inhalation toxicity

The present invention provides a process for producing a water-miscible metalworking fluid involving combining about 90 wt. % to about 5 wt. %, based on the weight of the fluid, of water and one or more additives chosen from plasticizers, chelating agents, biocides, surfactants, dispersants, dyes, odorants, extreme pressure agents, anti-oxidants and corrosion inhibitors with about 10 wt. % to about 95 wt. %, based on the weight of the fluid, of a polyether polyol produced by mixing an active hydrogen compound with a double metal cyanide (DMC) catalyst in a reactor vessel, charging to the reactor vessel a mixture containing two or more alkylene oxides to activate the catalyst, and continuously feeding one or more alkylene oxides to produce the polyether polyol, wherein a 1% solution in water of the polyether polyol has a cloud point of from greater than about 32° C. to less than about 53° C., the polyether polyol has a number average equivalent weight of from greater than about 1,600 Da to about 10,000 Da, and a four-hour aerosol inhalation exposure to the polyether polyol has a LC50 of greater than about 5 mg / L. The water-miscible metalworking fluid produced by the inventive process may find use in cooling and / or lubricating metal surfaces during one or more of grinding, cutting, boring, drilling and turning of metal parts.

Owner:BAYER MATERIALSCIENCE AG

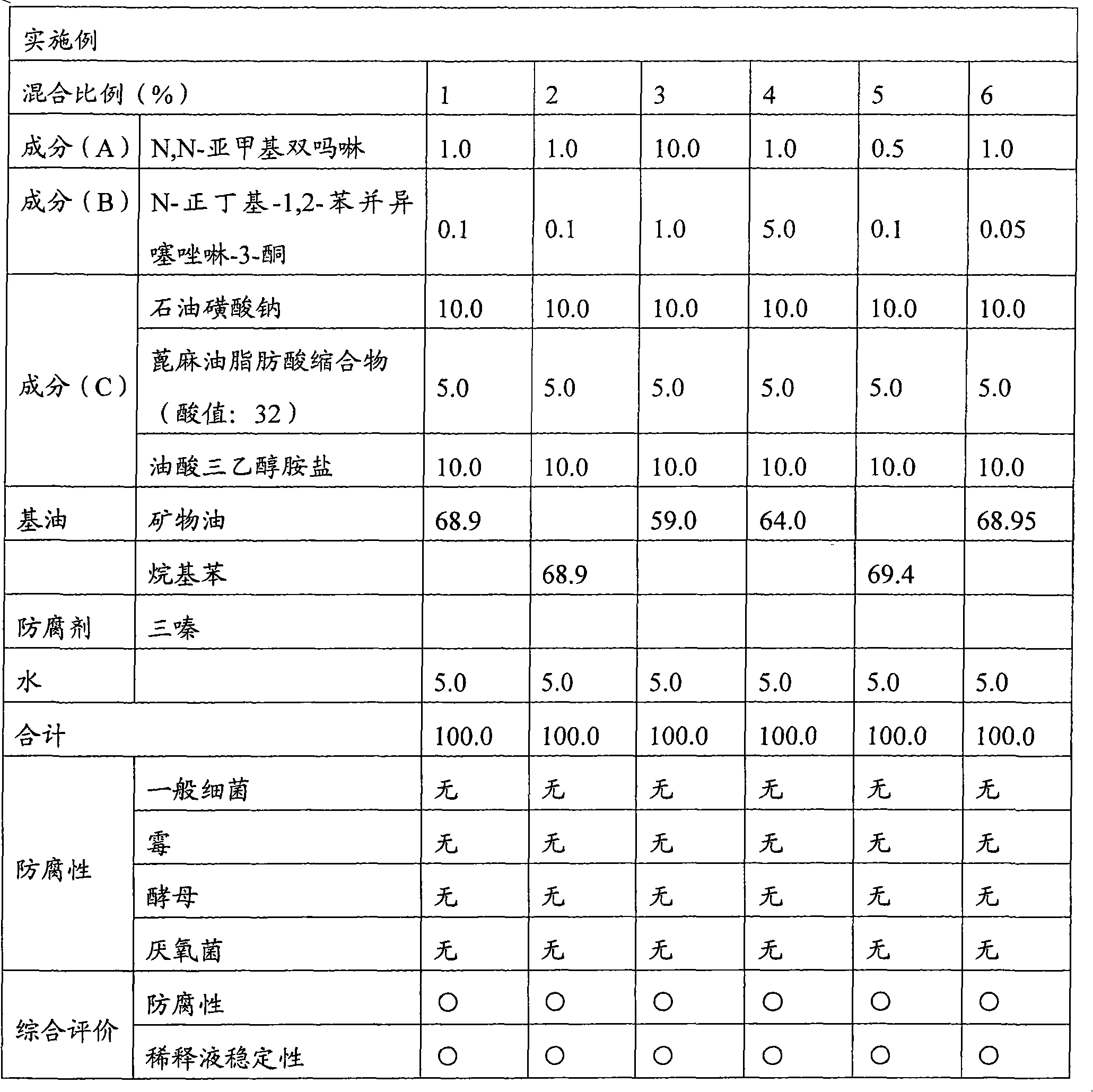

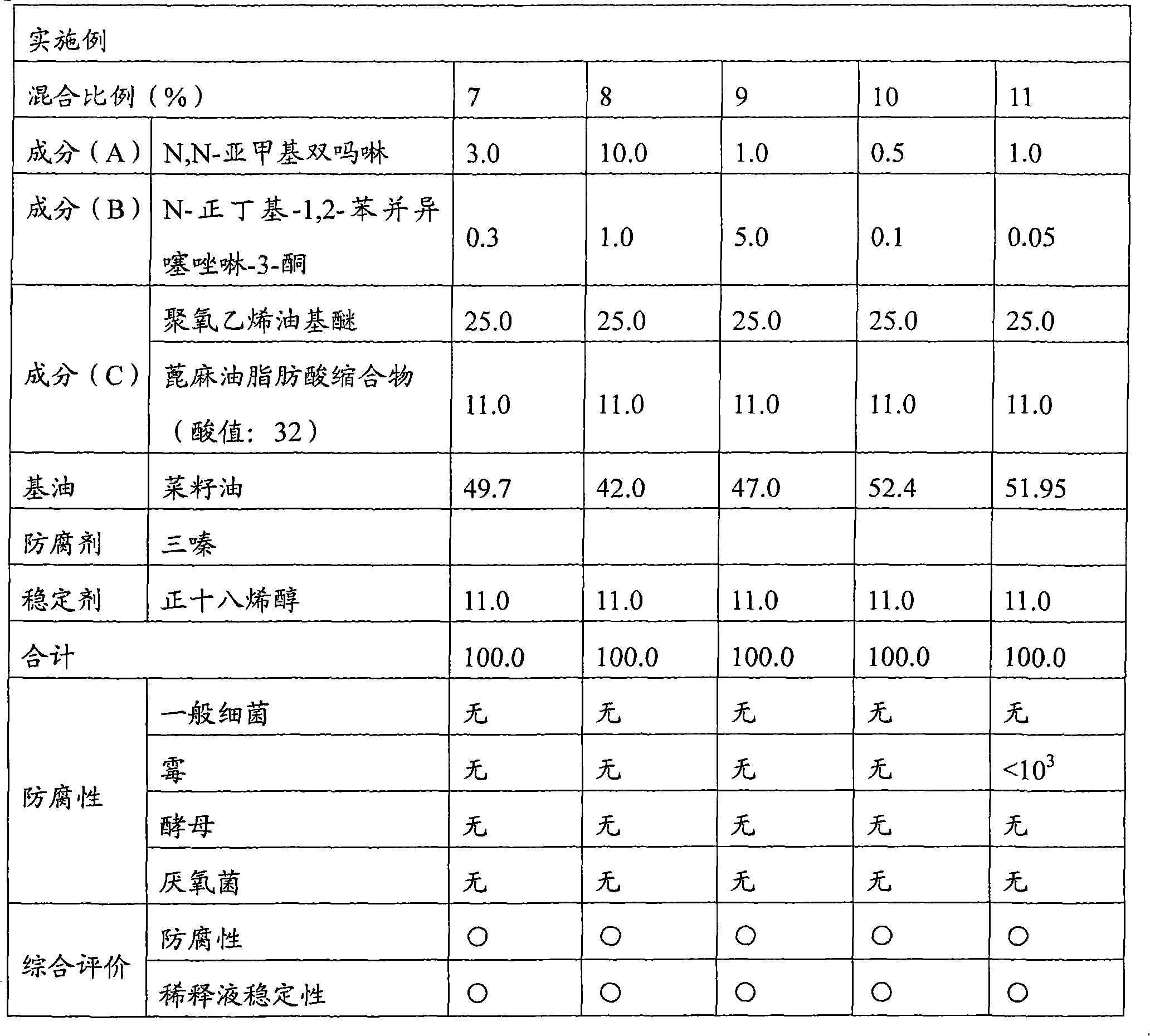

Metalworking fluid and metalworking method

InactiveCN101631846ABad influence reductionImprove anti-corrosion performanceAdditivesMetalworking fluidMorpholine

Disclosed is a water-soluble metalworking fluid having excellent decay resistance, which is widely applicable to metalworking such as cutting, grinding, form rolling, pressing and plastic working. Also disclosed is a metalworking method using such a metalworking fluid. Specifically disclosed are a metalworking fluid characterized by containing a morpholine compound and an isothiazoline compound, and a metalworking method using such a metalworking fluid.

Owner:KYODO YUSHI CO LTD

Water-miscible metal working fluids with reduced aerosol inhalation toxicity

The present invention provides a process for producing a water-miscible metalworking fluid involving combining about 90 wt.% to about 5 wt.%, based on the weight of the fluid, of water and one or more additives chosen from plasticizers, chelating agents, biocides, surfactants, dispersants, dyes, odorants, extreme pressure agents, anti-oxidants and corrosion inhibitors with about 10 wt.% to about 95 wt.%, based on the weight of the fluid, of a polyether polyol produced by mixing an active hydrogen compound with a double metal cyanide (DMC) catalyst in a reactor vessel, charging to the reactor vessel a mixture containing two or more alkylene oxides to activate the catalyst, and continuously feeding one or more alkylene oxides to produce the polyether polyol, wherein a 1% solution in water of the polyether polyol has a cloud point of from greater than about 32 DEG C to less than about 53 DEG C, the polyether polyol has a number average equivalent weight of from greater than about 1,000 Da to about 10,000 Da, and a four-hour aerosol inhalation exposure to the polyether polyol has a LC50 of greater than about 5 mg / L. The water-miscible metalworking fluid produced by the inventive process may find use in cooling and / or lubricating metal surfaces during one or more of grinding, cutting, boring, drilling and turning of metal parts.

Owner:BAYER MATERIALSCIENCE AG

Sustainable base oils for lubricants

Sustainable lubricant compositions made from recycled thermoplastic polyesters and other reclaimed or biorenewable reactants and a method of formulating them are disclosed. The lubricant compositions comprise a polyester base oil, which incorporates recurring units from a digested thermoplastic polyester, a low-molecular-weight polyol, and C8-C24 fatty acid. The base oil has a number-average molecular weight within the range of 300 to 5000 g / mol, a hydroxyl value less than 50 mg KOH / g, and a viscosity at 40° C. less than 5000 cSt. Some of the lubricant compositions comprise the polyester base oil and one or more additives including anti-wear agents, corrosion inhibitors, antioxidants, thickeners, detergents, and the like. The lubricants have properties that rival those of commercial products made from nonrenewable hydrocarbon blends or polyol esters and are useful for many practical applications such as internal combustion engine oils, gear lubrication oils, hydraulic oils, compressor oils, metal working fluids, and lubricating greases.

Owner:RESINATE MATERIALS GRP

Water-soluble metalworking fluid, metalworking liquid, and metalworking method

InactiveUS20150299599A1Easy to processHardly causes rotting deteriorationAdditivesMetal working apparatusMetalworking fluidSulfur

Provided are a water-soluble metalworking oil agent (cutting oil agent or grinding oil agent) and a metalworking liquid, each of which has excellent cutting machining performance or grinding machining performance of aluminum or aluminum alloys, hardly causes rotting deterioration, and has excellent emulsion dispersion stability and stability of undiluted liquid, by containing specified components (A) to (E) as essential components without containing a machinability-improving agent with a high environmental load, such as chlorine, sulfur, and phosphorus. Provided is also a metalworking method using the same.

Owner:IDEMITSU KOSAN CO LTD

Treatment agent and treatment method for regeneration and recycling waste water-based metal working fluid

PendingCN110846119AImprove the lubrication effectEasy to cleanLubricant compositionMachine shopMetalworking fluid

The invention discloses a treatment agent and treatment method for regeneration and recycling waste water-based metal working fluid. The treatment agent comprises the following raw materials in percentage by weight: 20-30% of an emulsifier, 10-15% of an alkali regulator, 3-5% of an antibacterial agent, and 2-5% of a non-ferrous metal corrosion inhibitor, with the balance being deionized water, summing to 100%, wherein the emulsifier is one or a mixture of two or more selected from the group consisting of NEUF192, self-emulsifying ester Priolube, T-80, castor oil polyoxyethylene ether, polyethylene glycol laurate and polyethylene glycol oleate. According to the invention, residual effective components are effectively utilized to emulsify and dissolve invaded lubricating oil and to convert the lubricating oil into effective components of the metal working fluid for utilization, and effective components in the waste working fluid are not damaged; the regenerated waste metal working fluidcan stably operate in a machine tool for a long time and guarantees that metal processing process is smoothly carried out; and the regenerated fluid returns to a machining workshop to be continuouslyused, so emission is truly avoided, and no secondary pollutants are generated.

Owner:HUBEI CHENGXIANG TECH

Medium for detecting microorganisms

InactiveUS20090035808A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFungicideMicroorganism

Provided is a culture medium for microorganisms present in contaminated working fluids such as coolants. More particularly, said culture medium is particularly suitable for supporting growth of microorganisms colonizing metalworking fluids and allows for specific detection of both bacterial microorganisms and fungal microorganisms the latter depending on the added selective agents which can be antibiotics for the detection of fungal contamination or fungicides for the detection of bacterial contamination. Furthermore, devices and kits comprising the culture medium of the present invention are described as well as a method of detecting microbial contamination of metalworking fluids.

Owner:UNIV OF BREMEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com