Process for metalworking fluid from heavy alkylate

a technology of metalworking fluid and alkylate, which is applied in the direction of petroleum industry, lubricant composition, etc., can solve the problems of rust formation on iron and steel surfaces, water alone cannot cool the metal surface with full ability, and higher environmental toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

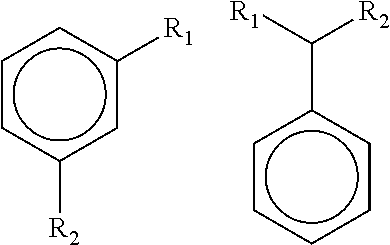

Image

Examples

example 1

[0085]TAILORING OF HEAVY ALKYLATE: 1 Kg. of commercial heavy alkylates (A), a heavy waste of detergent class linear alkyl benzene (LAB), was fractionated by vacuum distillation. The heavier cut, 0.65 Kg. (having 65 weight percent of total alkylate) was taken for base-stock preparation. The typical properties of the alkylate are:

Density at 15° C., gm / ml: 0.8805, Kinetic viscosity at 40° C., cst: 52.73, Viscosity index: 40. Refractive index at 20° C.: 1.49026, Pour point: (−)36° C., Molecular weight: 441±5, Distillation range: 415° C. above, Poly-aromatics or olefinic compounds: Negligible.

example 2

[0086]TAILORING OF ALKYLATE: 1 Kg. of commercial alkylates (B), waste alkyl benzene from other stream of detergent class linear alkyl benzene (LAB), was fractionated by vacuum distillation. The heavier cut, 0.6 Kg. (having 60 weight percent of total alkylate) was taken for base-stock preparation. The typical properties of the alkylate are:

Density at 15° C., gm / ml: 0.8806, Kinetic viscosity at 40° C., cst: 50.11, Viscosity index: 55, Refractive index at 20° C.: 1.49106, Pour point: (−)33° C., Molecular weight: 428±5, Distillation range: 400° C. above, Poly-aromatics or olefinic compounds: Negligible

example 3

[0087]TAILORING OF HEAVY ALKYLATE: 1 Kg. of commercial heavy alkylates (C), a heavy waste fraction of detergent class linear alkyl benzene (LAB) from other stream, was fractionated by vacuum distillation. The heavier cut 0.7 Kg (having 70 weight percent of total alkylate) was taken for base-stock preparation. The typical properties of the alkylate are:

Density at 15° C., gm / ml: 0.8807, Kinetic viscosity at 40° C., cst: 48.32, Viscosity index: 46, Refractive index at 20° C.: 1.49028, Pour point: (−)30° C., Molecular weight: 441±5, Distillation range: 395° C. above, Poly-aromatics or olefinic compounds: Negligible

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com