Catalyst for preparing aromatic hydrocarbon through methanol conversion as well as preparation method and application thereof

A methanol conversion and catalyst technology, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of not involving material recycling, low total methanol conversion rate, etc., and achieve long life and high selectivity. , the effect of large amount of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0042]

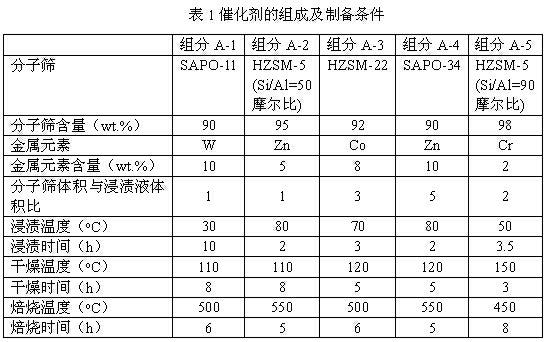

[0043] Examples 1-5 illustrate the preparation of Component A. The specific preparation method of component A is as follows, the molecular sieve modifier is added to the molecular sieve by impregnation method, the modifier is soluble salt of W, Zn, Co, Cr, such as nitrate, chloride, ammonium tungstate and vinegar Acid acid, etc.; molecular sieves are HZSM-5, HZSM-22, SAPO-11 and SAPO-34. The impregnation process of the molecular sieve modifier is as follows: transfer an appropriate amount of molecular sieve powder to an aqueous solution of a certain concentration of soluble salt of the modifier, the volume ratio of the molecular sieve to the impregnating liquid is 1-5, and at 20-90 o C. Immerse for 1-10 hours under the condition of continuous stirring. After the impregnating liquid evaporates, put it at 100-150 o C drying for 3-8 hours at 350-550 o C for 2-8 hours. The prepared components A are respectively denoted as component A-1, component A-2, component A-3...

Embodiment 6-10

[0046]

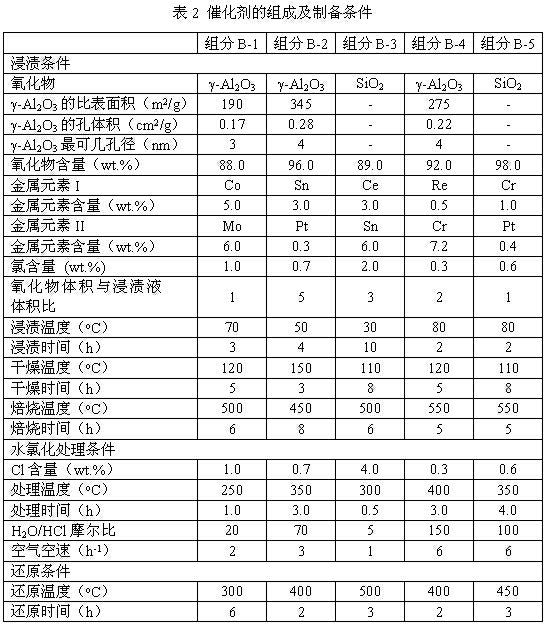

[0047] Examples 6-10 illustrate the preparation of Component B. The specific preparation method of component B is as follows, (1) two kinds of metal elements such as Co, Sn, Ce, Re, Mo, Pt, Sn, Cr are added to the oxide carrier by impregnation method Go, that is, the soluble salt (nitrate) containing the loaded metal element is made into an aqueous solution, and the oxide is transferred to the above aqueous solution. o C soaking for 1-10 hours. The above oxide support is γ-Al 2 o 3 and SiO 2 Any of the metal soluble salts are its nitrates, chlorides, acetates, etc. After the above solution was evaporated to dryness, it was heated at 100-150 o C drying for 3-8 hours at 350-550 o C for 2-8 hours. (2) The material processed by (1) is subjected to water chlorination: at 250-550 o C. Treat the material processed by (1) with steam containing HCl for 0.5-5 hours, wherein H 2 The O / HCl molar ratio is 1.0-150:1, the water vapor containing HCl is brought into the tr...

Embodiment 11-15

[0049]

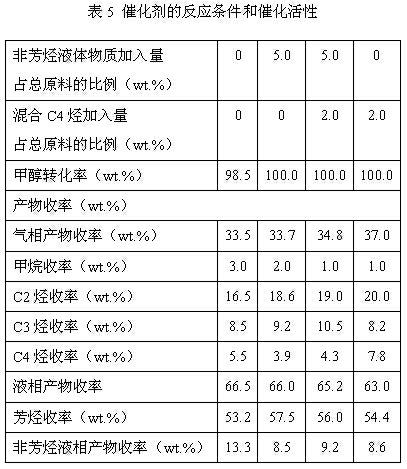

[0050] Examples 11-15 are used to illustrate the preparation method of methanol-to-aromatics catalysts. The specific process is as follows: Component A and Component B are evenly mixed, and then the mixture is extruded into a catalyst, respectively denoted as Catalyst-1, Catalyst-2, Catalyst-3, Catalyst-4 and Catalyst-5. The compatibility of component A and component B in the catalyst is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com