Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

980 results about "Self emulsifying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self emulsifying wax is the chemical used to bind oil and water together to form a smooth lotion, crème or and emulsion.

Pharmaceutical compositions for lipophilic drugs

InactiveUS7070802B1Good self-emulsifying performanceShelf-stableCyclic peptide ingredientsCapsule deliveryMonoglycerideCyclosporins

Stable solutions of lipophilic drugs, such as cyclosporin, forming a polar lipid self-emulsifying drug delivery system. The solutions can include lipophilic drugs, such as cyclosporin, dissolved in a polar lipid, such as having a C6-C12 fatty acid monoglyceride content of at least about 50%, surfactants and triglycerides. The composition forms a fine emulsion on exposure to water. The encapsulated dosage form of this composition needs neither a hydrophilic component nor air-tight blister packaging, and is particularly suitable for oral administration.

Owner:WATSON LAB INC

Delivery of tetrahydrocannabinol

InactiveUS20070104741A1Avoiding hepatic first-pass metabolismGood choiceBiocideNervous disorderChylomicronTG - Triglyceride

A self-emulsifying drug delivery system to improve dissolution, stability, and bioavailability of drug compounds of dronabinol or other cannabinoids. The drug compound(s) are dissolved in an oily medium (e.g. triglycerides and / or mixed glycerides and / or free fatty acids containing medium and / or long chain saturated, mono-unsaturated, and / or poly-unsaturated free fatty acids) together with at least one surfactant. The surfactant promotes self-emulsification, thereby promoting targeted chylomicron delivery and optimal bioavailability to a mammalian intestinal lumen. A dosage form can optionally include co-solvents, anti-oxidants, viscosity modifying agents, cytochrome P450 metabolic inhibitors, P-GP efflux inhibitors, and amphiphilic / non-amphiphilic solutes to induce semi-solid formation for targeted release rates.

Owner:MURTY PHARMA

Self-emulsifying composition of OMEGA3 fatty acid

ActiveUS8618168B2Maintain good propertiesAvoid high concentrationsBiocideNervous disorderHydrophilic-lipophilic balanceSelf emulsifying

This invention provides a self-emulsifying composition comprising 50 to 95% by weight in total of at least one compound selected from the group consisting of ω3 polyunsaturated fatty acids and their pharmaceutically acceptable salts and esters; and 5 to 50% by weight of an emulsifier having a hydrophilic lipophilic balance of at least 10. The composition has no or reduced ethanol content, and exhibits excellent self-emulsifying property, dispersibility in the composition, emulsion stability, and absorption property. The composition is adapted for use as a drug.

Owner:MOCHIDA PHARM CO LTD

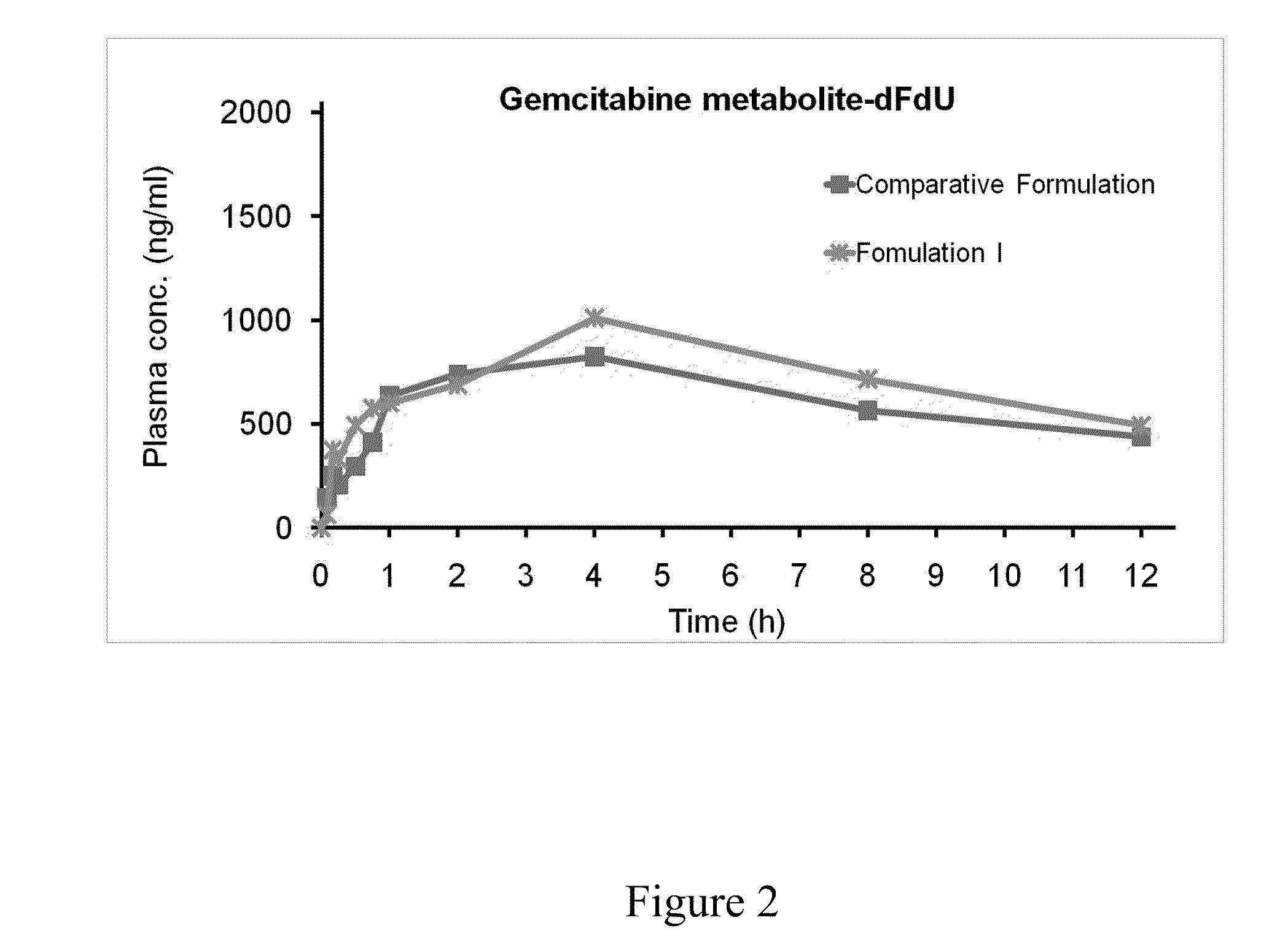

Self-emulsifying pharmaceutical compositions of hydrophilic drugs and preparation thereof

The present invention provides an oral self micro-emulsifying pharmaceutical composition of a hydrophilic drug or a pharmaceutically acceptable salt thereof which, in addition to the hydrophilic drug, one or more solvents for solving the hydrophilic drug to form a drug-solvent solution and a surfactant system, further comprises one or more hydrophilic carrier which are compatible with said drug-solvent solution and the surfactant system. The oral self micro-emulsifying pharmaceutical composition of the invention exhibits comparative bioavailability to that of the hydrophilic drug through injection and is stable during storage. A method for preparing the oral self micro-emulsifying pharmaceutical composition is also provided.

Owner:INNOPHARMAX

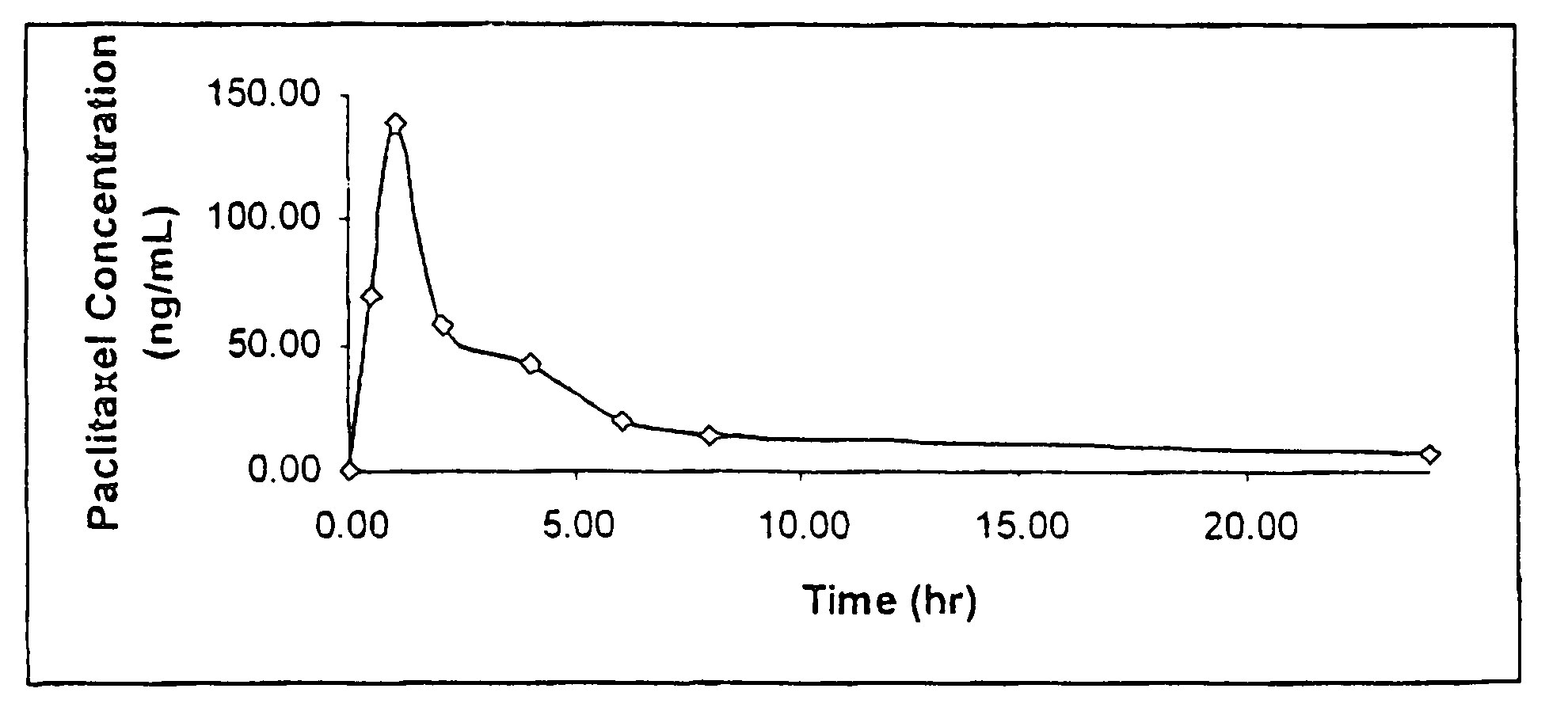

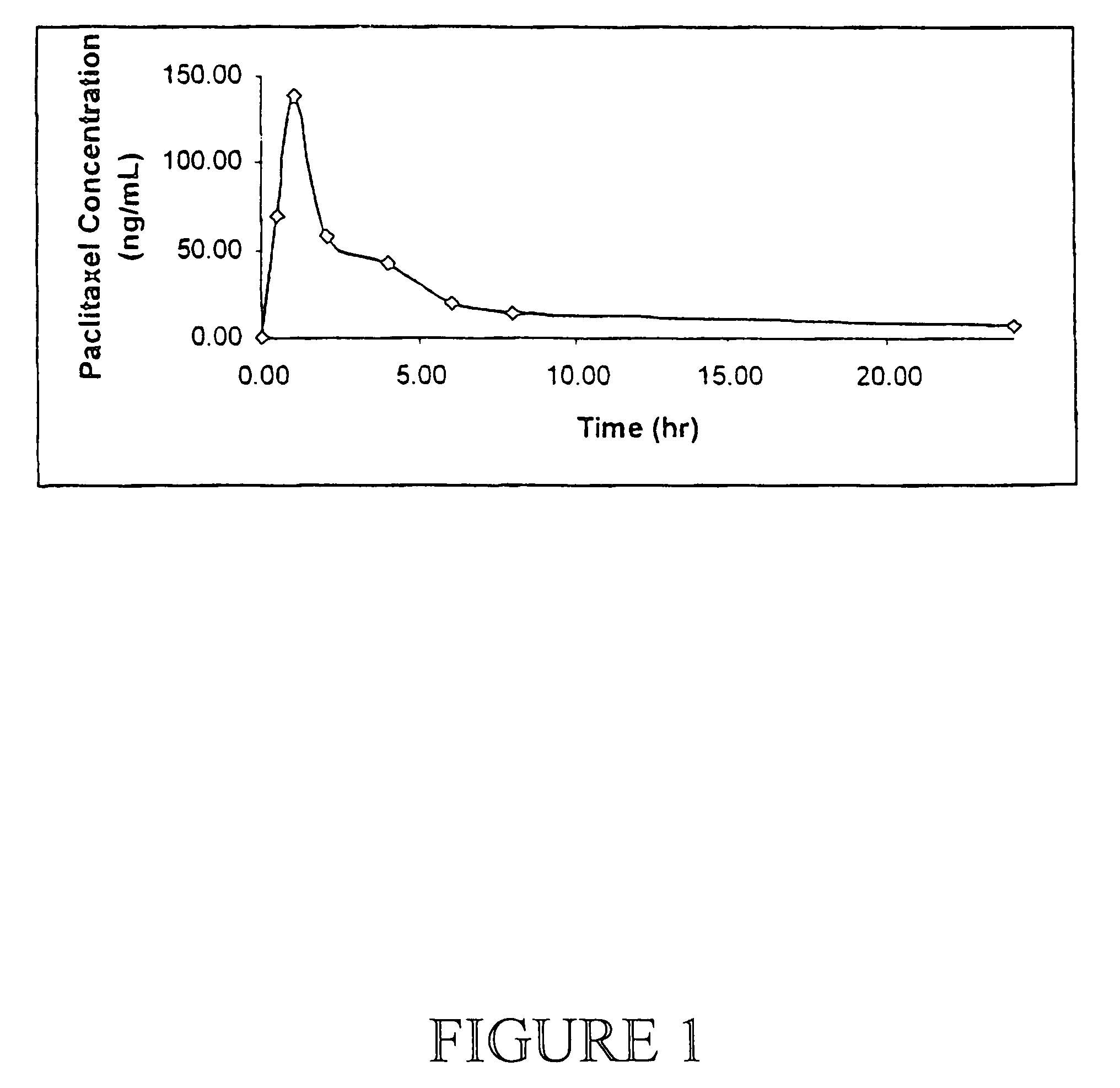

Anticancer compositions

Pharmaceutical dosage forms for anticancer drugs, and paclitaxel in particular, are described in which the active drug is formulated as storage stable self-emulsifying preconcentrate.

Owner:RTP PHARMA

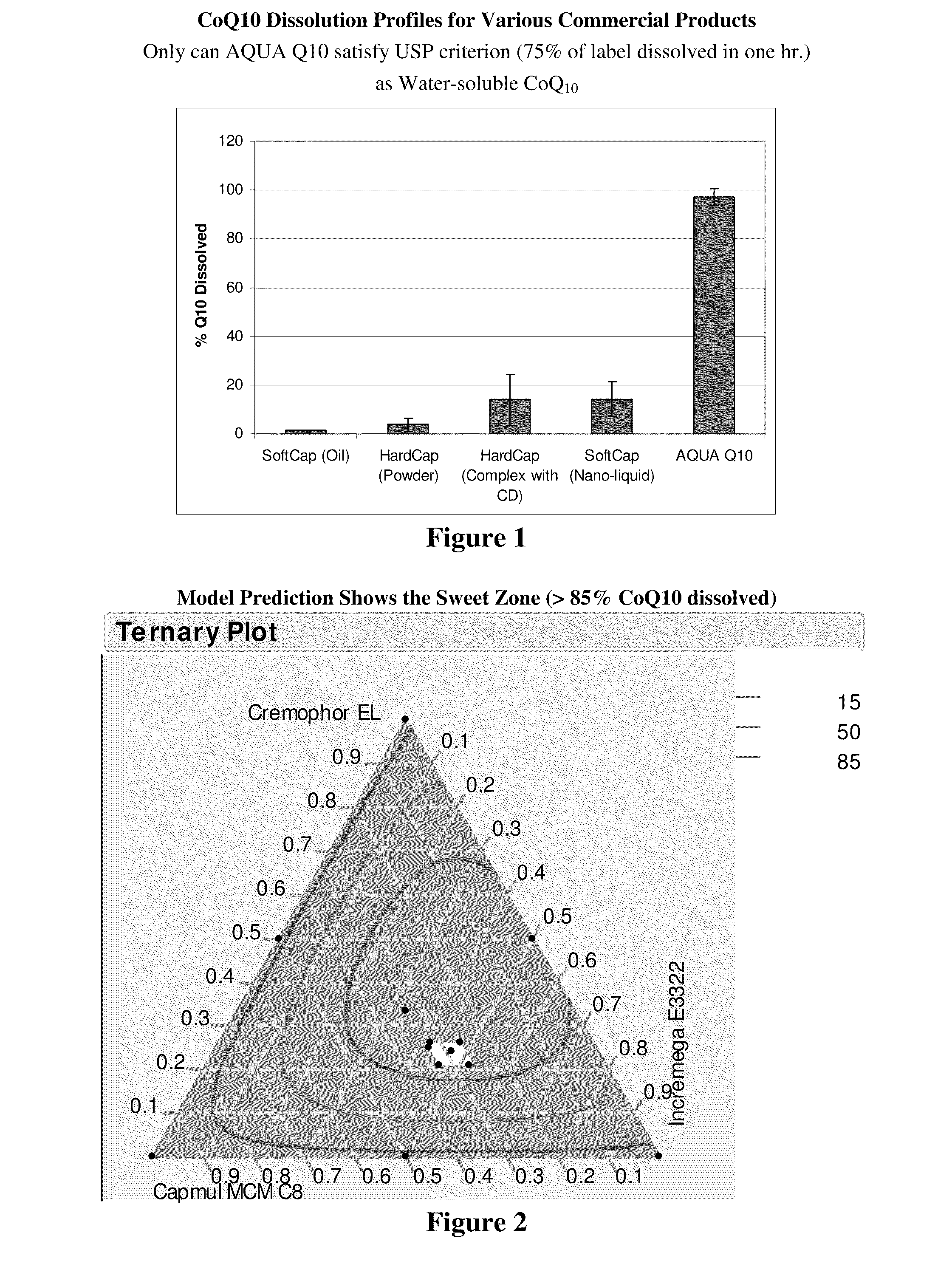

Self emulsifying compositions for delivering lipophilic coenzyme Q10 and other dietary ingredients

InactiveUS20060051462A1Oral administration is convenientIncrease loadOrganic active ingredientsFood ingredientsSolubilityDietary supplement

The present invention provides novel dietary supplement compositions based on the use of a particular oil phase which comprises of Coenzyme Q10 and optionally other lipophilic dietary ingredients of low water solubility and a liquid mixture which comprises one or more emulsifiers, a fatty acid monoester formed between an short chain alcohol of C1 to C4 chain length and a saturated, or mono-unsaturated, or di-unsaturated (both conjugated and non-conjugated) fatty acid of C6 to C24 chain length, or medium chain mono- / di-esters, or the mixture of above. The composition is in a form of self-emulsifiable in the aqueous medium, for example, a simulated gastric fluid, which should provide a high oral bioavailability for the lipophilic dietary ingredients.

Owner:WANG JIMMY X

Self-emulsifying composition of omega3 fatty acid

ActiveUS20140057981A1Maintain good propertiesAvoid high concentrationsBiocideNervous disorderHydrophilic-lipophilic balanceSelf emulsifying

Owner:MOCHIDA PHARM CO LTD

Stabilized solubility-enhanced formulations for oral delivery

ActiveUS20100247632A1Improve bioavailabilityBiocideHydrocarbon active ingredientsSolubilityParticulates

Methods and compositions are described whereby poorly water-soluble beneficial agents such as vitamins and co-factors are formulated into self-emulsifying formulas (SEF) and optionally sorbing the SEF into pores of porous solid particulates, or preparing supersaturated solutions (SSS) and sorbing the SSS into pores of porous solid particulates. These formulations are useful as dosage forms with oral availability.

Owner:HAIMEN PHARMA INC

Omega-3 fatty acid self-emulsifying composition

InactiveUS20180015038A1Reduce the amount requiredImprove compatibilityNervous disorderAntipyreticPolyoxyethylene castor oilEmulsion

A pharmaceutical composition comprising, in relation to 100% by weight of a total amount of a self-emulsifying composition, 70 to 90% by weight of eicosapentaenoic acid ethyl ester as a first medicinal component, 0.5 to 6% by weight of water, 1 to 29% by weight of polyoxyethylene sorbitan fatty acid ester (optionally further comprising polyoxyethylene castor oil) as an emulsifier, 1 to 25 parts by weight of lecithin in relation to 100 parts by weight of the eicosapentaenoic acid ethyl ester, and pitavastatin, rosuvastatin, or a salt thereof as a second medicinal component. The composition is excellent in any one of self-emulsifying property, dispersibility of the composition, emulsion stability, absorbability, and storage stability of the medicinal components and a preparation.

Owner:MOCHIDA PHARM CO LTD

Self-emulsifying composition of omega3 fatty acid

InactiveUS20170348268A1Reduce the amount requiredImprove compatibilityOrganic active ingredientsNervous disorderEmulsionAlcohol

A self-emulsifying composition contains: 70 to 90% by weight in total of one or more compounds selected from the group consisting of ω3 polyunsaturated fatty acids and their pharmaceutically acceptable salts and esters; 1 to 29% by weight of an emulsifying agent selected from among a polyoxyethylene sorbitan fatty acid ester, a sorbitan fatty acid ester, a glycerin fatty acid ester and a polyoxyl castor oil; and 0.5 to 6% by weight of water when the composition is defined to be 100% by weight as a whole. The self-emulsifying composition is excellent in self-emulsifying property, composition dispersibility, emulsion stability, and absorbability, is free from ethanol and polyhydric alcohols or only has such an alcohol added thereto at a reduced concentration, and is useful for foods and pharmaceuticals.

Owner:MOCHIDA PHARM CO LTD

Self-emulsifying composition of omega-3 fatty acid

ActiveUS20170368184A1Reduce the amount requiredImprove compatibilityOrganic active ingredientsNervous disorderΩ 3 pufaSorbitan

A self-emulsifying composition contains: 70 to 90% by weight of at least one compound selected from the group consisting of ω3 polyunsaturated fatty acids and their pharmaceutically acceptable salts and esters; 0.5 to 6% by weight of water; 1 to 29% by weight of a polyoxyethylene sorbitan fatty acid ester as an emulsifier (optionally including a polyoxyl castor oil, and not including lecithin); and lecithin in an amount of 3 to 40 parts by weight in relation to 100 parts by weight of ω3 polyunsaturated fatty acids and the like. The self-emulsifying composition is excellent in self-emulsifying property, composition dispersibility, emulsion stability, and absorbability, is free from ethanol and polyhydric alcohols or only has such an alcohol added thereto at a reduced concentration, and is useful for foods and pharmaceuticals.

Owner:MOCHIDA PHARM CO LTD

Self-emulsifying composition of omega3 fatty acid

InactiveUS20170348273A1Reduce the amount requiredImprove compatibilityOrganic active ingredientsNervous disorderAlcoholEmulsion

A self-emulsifying composition contains: 70 to 90% by weight of at least one compound selected from the group consisting of ω3 polyunsaturated fatty acids and their pharmaceutically acceptable salts and esters; 0.5 to 6% by weight of water; 1 to 29% by weight of a polyoxyethylene sorbitan fatty acid ester as an emulsifier (optionally including a polyoxyl castor oil, and not including lecithin); and lecithin in an amount of 3 to 40 parts by weight in relation to 100 parts by weight of ω3 polyunsaturated fatty acids and the like. The self-emulsifying composition is excellent in self-emulsifying property, composition dispersibility, emulsion stability, and absorbability, is free from ethanol and polyhydric alcohols or only has such an alcohol added thereto at a reduced concentration, and is useful for foods and pharmaceuticals.

Owner:MOCHIDA PHARM CO LTD

Preparation method and application of terminated-type cation water-borne polyurethane color fixing agent

The invention relates to a preparation method of a terminated-type cation water-borne polyurethane color fixing agent, belonging to the field of organic adhesives. The terminated-type cation water-borne polyurethane color fixing agent with solid content of 20-40% of and transparent or translucent yellowish appearance can be prepared by the following steps of: (1) polyurethane prepolymer reaction, (2) terminated reaction, and (3) acid neutralization and ionization reactions. In the invention, partial terminating after prepolymerization is adopted, a small number of isocyanate groups is inactivated and a self-emulsifying method is adopted to synthesize the water-borne polyurethane color fixing agent; in the color fixing process, closed active groups are released through baking at high temperature and are carried out crosslinking reaction with hydroxyl and amino groups on textile fabrics and reactive dyes so that the color fastness to washing of the textile fabric is improved.

Owner:溧阳常大技术转移中心有限公司

Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

InactiveCN101165127AImprove dispersion uniformityNo subsidencePolyurea/polyurethane coatingsEmulsion paintsPolyesterCarbon nanotube

The present invention belongs to the field of chemical technology, and is especially one kind of conducting water soluble polyurethane paint containing carbon nanotube and its preparation process. The conducting paint is prepared through the first modifying carbon nanotube chemically for the surface to carry hydroxyl group, carboxyl group or amino group; the subsequent introducing to polyester polyol or isocyanate terminated polyurethane pre-polymer through chemical bonding and self-emulsifying to prepare water soluble polyurethane dispersoid containing carbon nanotube; and final adding deionized water and assistants through high speed stirring to obtain the conducting paint. The conducting paint can form coating with volume resistivity of 1x10<-5>-4x10<-4. ohm.cm, surface resistivity of 1x10<-1>-2x10<2> ohm, adhesion of 0 grade, shielding effectiveness of 70-85 dB, and long term stability, and has wide application.

Owner:SHANGHAI SAFEGREEN TECH

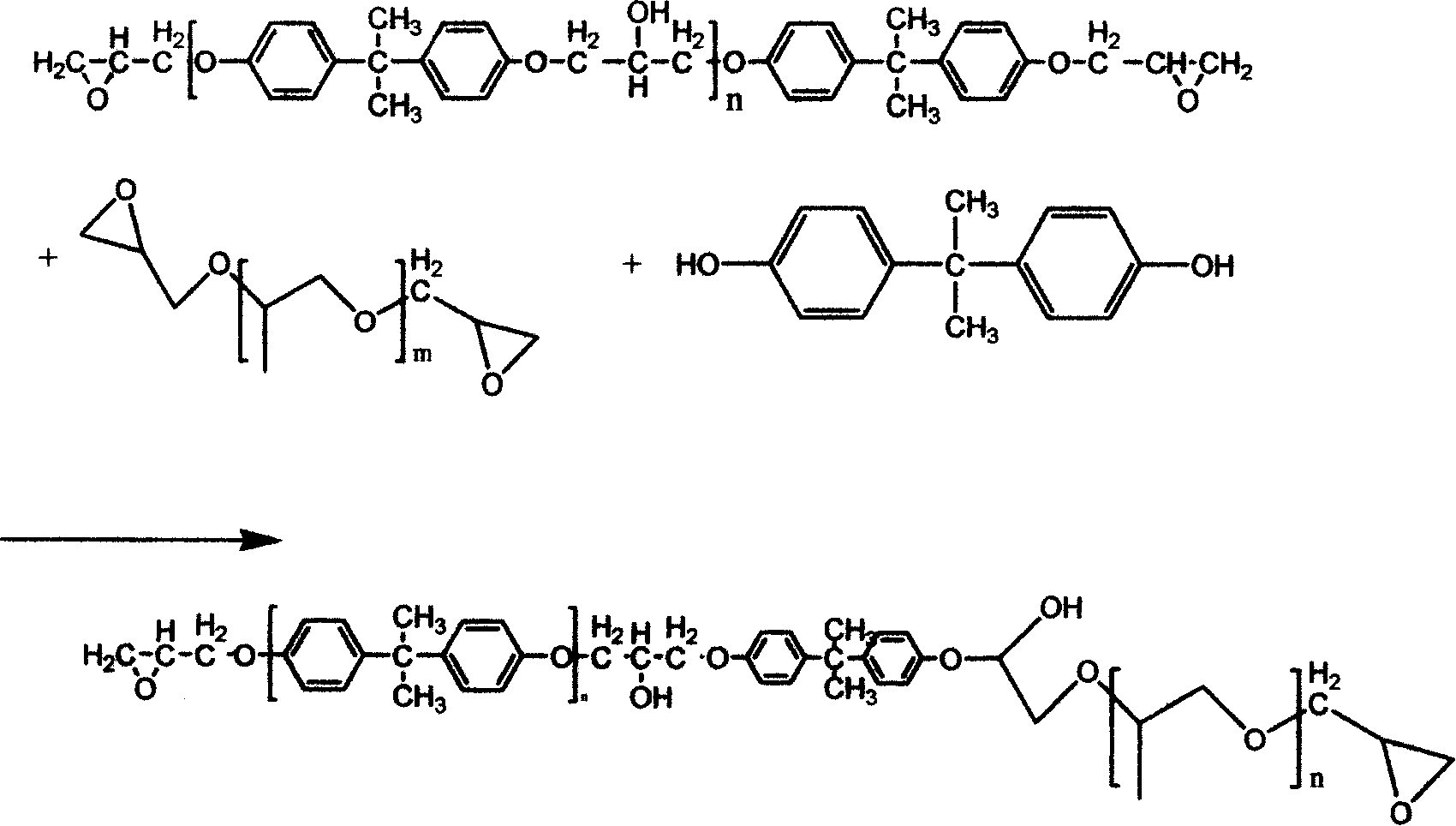

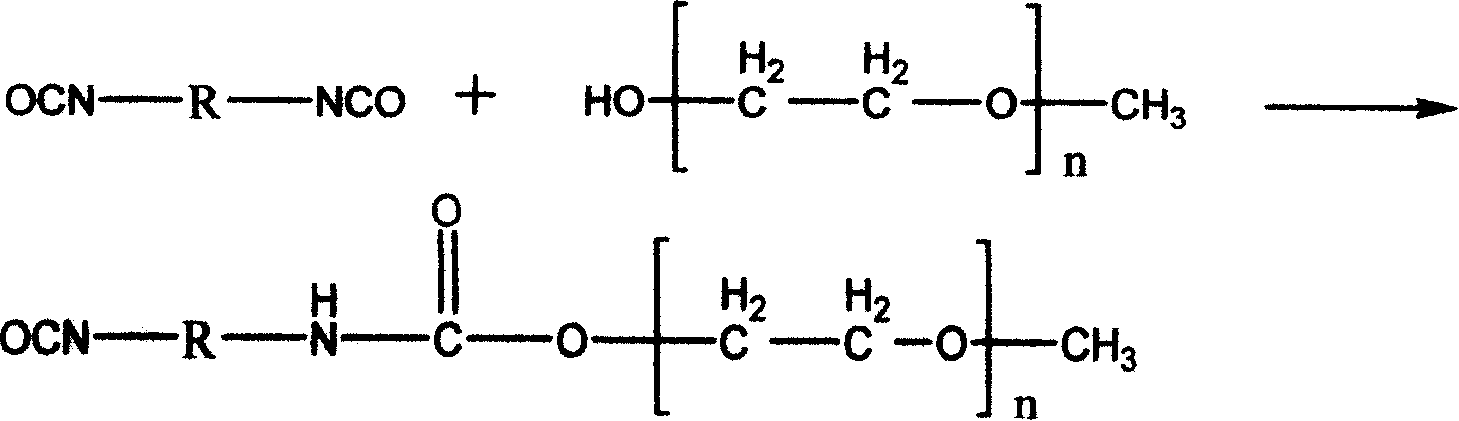

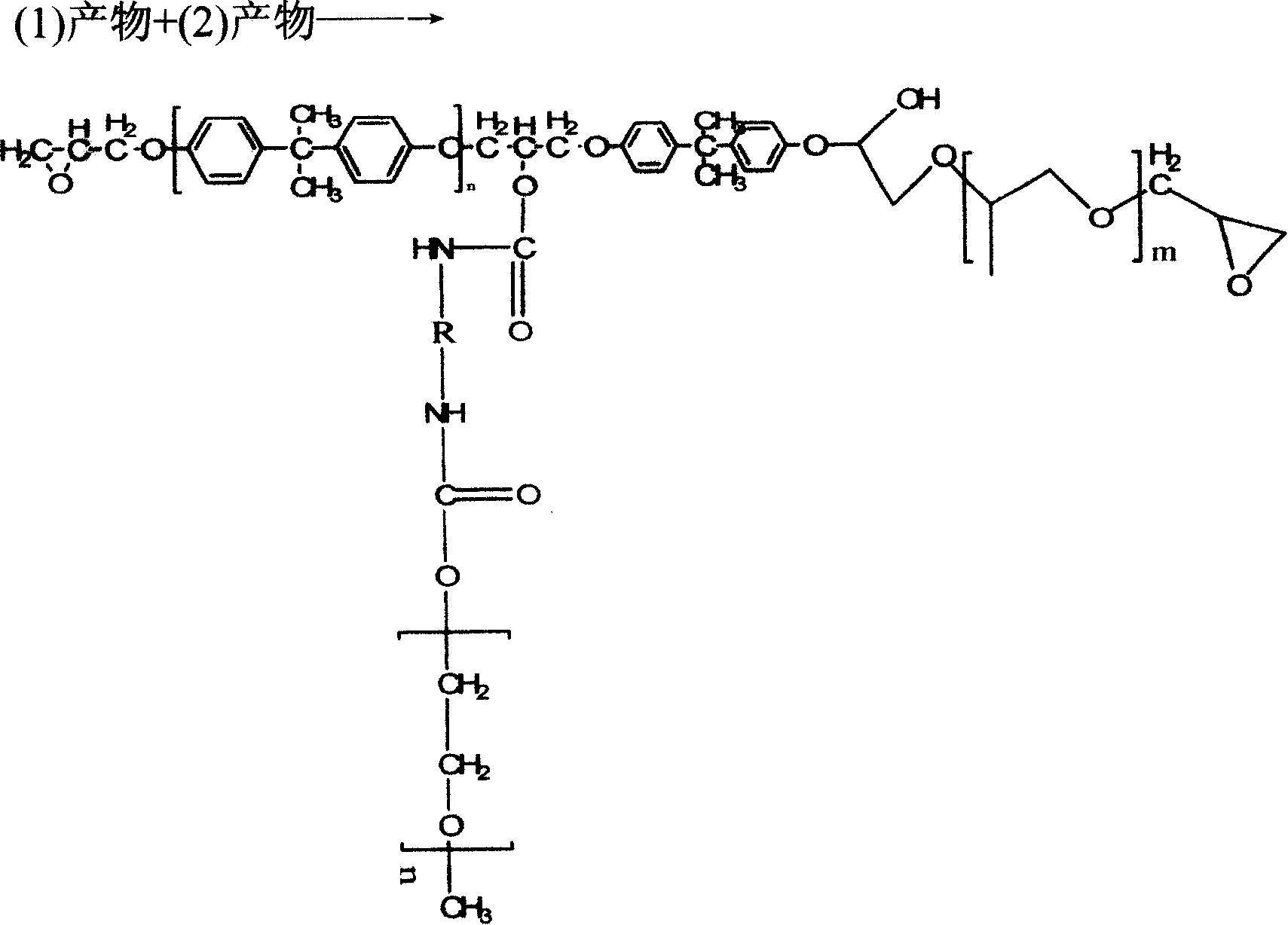

Self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and preparation method thereof

The invention relates to a self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and a preparation method thereof. The sizing agent comprises the following components in part by weight: 10 to 15 parts of self-emulsifying polyurethanes epoxy emulsion, 0.2 to 0.3 part of aid, and 84.7 to 89.8 parts of deionized water. The method for preparing the sizing agent comprises the following steps of: (1) preparing hydrophilic polyurethane prepolymer of the self-emulsifying polyurethanes epoxy emulsion; (2) preparing a prepolymer of which the end group is an epoxy group; (3) adding 6 to 20 parts of neutralizer into the prepolymer of which the end group is an epoxy group for neutralization, pouring the neutralized solution into water for dispersing, and removing the solvent through reduced pressure distillation to obtain the self-emulsifying polyurethanes epoxy emulsion; and (4) adding the aid and the deionized water into the polyurethanes epoxy emulsion in the ratio, and uniformly mixing to obtain the self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers. The self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers and the preparation method thereof have reasonable design. The sizing agent can improve the mechanical property of carbon fiber composite materials, and has excellent dilution stability.

Owner:天津碧海蓝天水性高分子材料有限公司

Oral Dosage Form Of Tetrahydrocannabinol And A Method Of Avoiding And/Or Suppressing Hepatic First Pass Metabolism Via Targeted Chylomicron/Lipoprotein Delivery

ActiveUS20110092583A1Easy to transportPromote lymphatic transportBiocideSenses disorderChylomicronCytochrome P450

Self-emulsifying drug delivery systems are provided to improve dissolution, stability, and bioavailability of drug compounds of dronabinol or other cannabinoids. The drug compound(s) are dissolved in an oily medium (e.g. triglycerides and / or mixed glycerides and / or free fatty acids containing medium and / or long chain saturated, mono-unsaturated, and / or poly-unsaturated free fatty acids) together with at least one surfactant. The surfactant promotes self-emulsification, thereby promoting targeted chylomicron / lipoprotein delivery and optimal bioavailability through the mammalian intestinal tract. A dosage form can optionally include co-solvents, anti-oxidants, viscosity modifying agents, cytochrome P450 metabolic inhibitors, P-GP efflux inhibitors, and amphiphilic / non-amphiphilic solutes to induce semi-solid formation for targeted release rates.

Owner:MURTY RAM B +1

Self emulsifying oily liquid cosmetic

A self emulsification type oily liquid cosmetic composition includes 8 to 30% by mass of the following component A and 50 to 92% by mass of the following component B.Component A: a polyglycerin fatty acid ester having a hydroxyl value of 450 to 700, and a branched fatty acid residue having 16 to 18 carbon atoms and / or a linear unsaturated fatty acid residue having 16 to 18 carbon atoms accounting for 50 to 100% by mass of total constituent fatty acid residues, and in a polyglycerin constituting the polyglycerin fatty acid ester, a total content of a polyglycerin cyclic compound of a dimer and a trimer is from 0 to 3% based on the entire polyglycerin, a total content of a polyglycerin of a undecamer or a higher multimer is from 10 to 30% based on the entire polyglycerin, and each content of a polyglycerin of a tetramer to a decamer is from 4 to 20% based on the entire polyglycerin.Component B: an oily component.

Owner:THE NISSHIN OILLIO GRP LTD

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Maleated vegetable oils and derivatives, as self-emulsifying lubricants in metalworking

InactiveUS20090209441A1Effective emulsifyingImprove abilitiesOrganic chemistryLiquid carbonaceous fuelsBiotechnologyVegetable oil

A succinated triglyceride oil derived from maleating triglyceride oil from a plant or land animal is described for use as an emulsifying agent for metalworking fluids. The metalworking fluid would comprise water; as an emulsifier this succinated triglyceride, optionally further reacted with water, Group IA and IIA metals, ammonium hydroxide, various amines, alkanolamines, alkoxylated alkanolamines, and polyamines to form a modified emulsifier; and optionally an oil and other additives.

Owner:THE LUBRIZOL CORP

Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

ActiveCN101050300AAvoid situations that require high temperaturesThe synthesis process is simple, safe and energy-savingEpoxyAdhesive

This invention relates to a method for preparing self-emulsifying waterborne epoxy curing agent emulsion, which is composed of: primary amine 7-20 wt.%, epoxy resin 12-27 wt.%, epoxy-terminated polyether 3-8 wt.%, epoxy active diluter 10-30 wt.%, and deionized water 35-60 wt.%. The method comprises: adding primary amine into a reactor, slowly dropping a mixture of epoxy resin and epoxy-terminated polyether, reacting at a certain temperature, slowly dropping monofunctional epoxy active diluter, reacting, adding water, and emulsifying to obtain white waterborne epoxy curing agent emulsion. The method has such advantages as simple process, low reaction temperature (below 100 deg.C), high safety and low energy consumption. The obtained waterborne epoxy curing agent emulsion has such advantages as low VOC content, high stability, high water resistance, high compatibility with epoxy resin, high impact resistance, good luster, high toughness and high adhesiveness, and can be used in paint, adhesive and polymer concrete.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

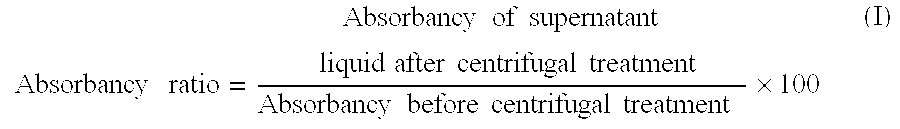

Aqueous pigment dispersion, process for producing the same, and water-based ink comprising the same

A water-based pigment dispersion in which a pigment is dispersed with a water soluble or self-emulsifying thermoplastic resin containing carboxylic group, characterized in that the ratio of the pigment to the thermoplastic resin containing the carboxylic group (pigment / thermoplastic resin containing carboxylic group (weight ratio of effective solid matter)) is 10 / 10 to 10 / 1, the thermoplastic resin containing the carboxylic group is cross-linked with a cross-linking agent after the pigment is dispersed with the thermoplastic resin, and the ratio of the cross-linking agent to the thermoplastic resin containing the carboxylic group (cross-linking agent / thermoplastic resin containing carboxylic group (weight ratio of effective solid matter)) is 1 / 100 to 50 / 100; a process for preparing the same; and a water-based ink containing the same. The water-based pigment dispersion shows excellent light resistance, water resistance, alkali resistance, solvent resistance and stability during the passage of time at the same time.

Owner:MIKUNI SHIKISO

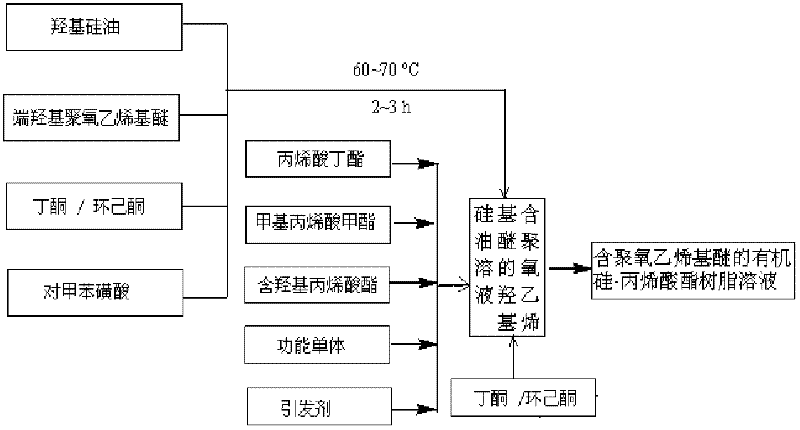

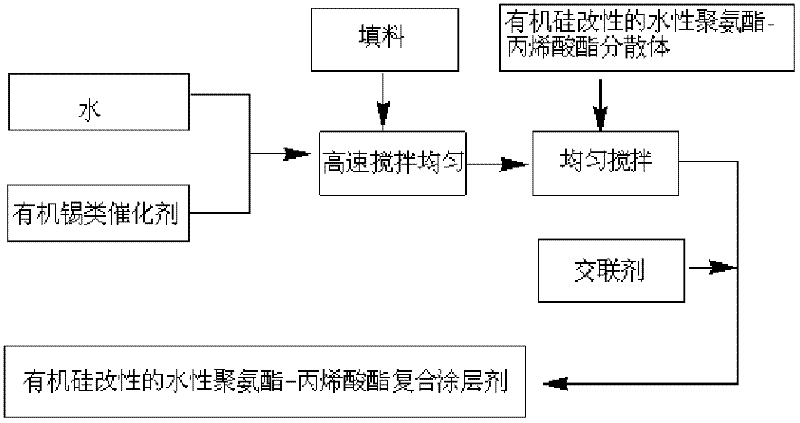

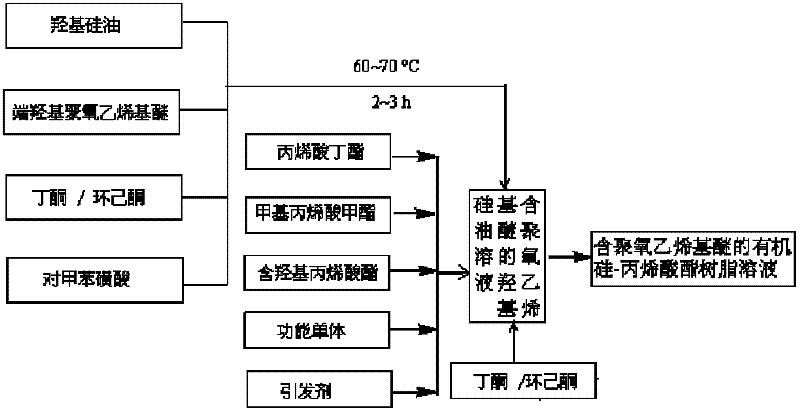

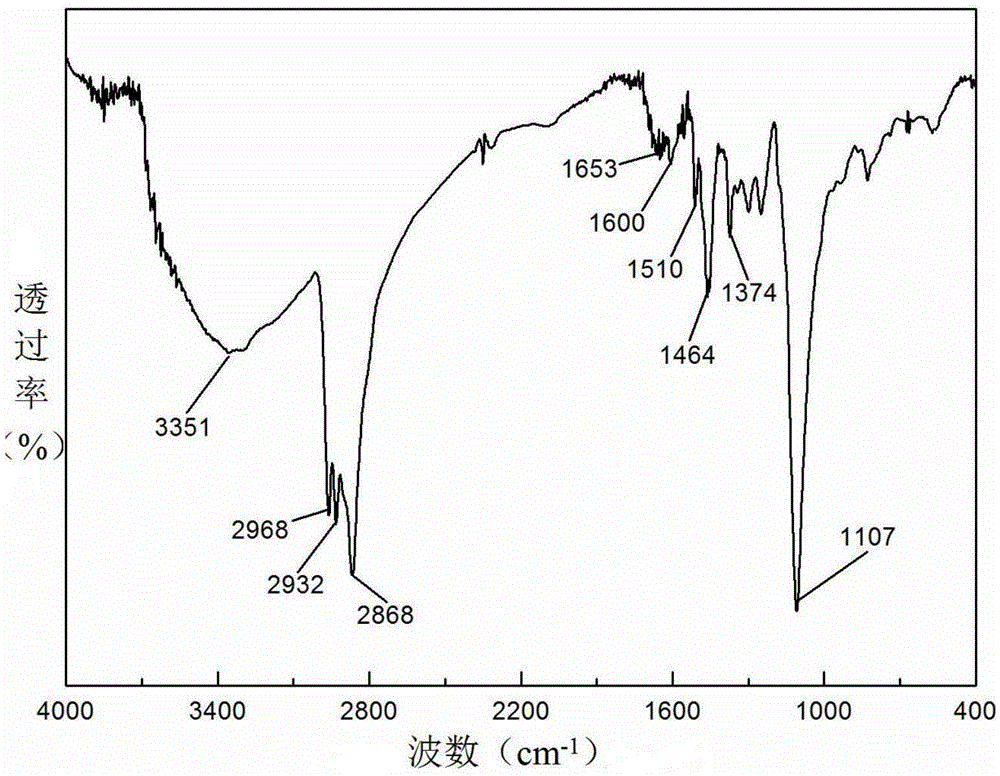

Organosilicon-modified aqueous polyurethane-acrylate composite coating agent and preparation method thereof

InactiveCN102559031AGood compatibilityImprove mechanical propertiesPolyurea/polyurethane coatingsChemical industryVinyl ether

The invention belongs to the technical field of chemical industry, and particularly relates to an organosilicon-modified aqueous polyurethane-acrylate composite coating agent and a preparation method thereof. The method comprises the following steps of: performing hydroxyl condensation reaction by using hydroxyl-terminated silicone oil and polyoxyethylene ether to prepare polyoxyethylene ether-containing hydroxyl silicone oil resin; introducing the polyoxyethylene ether-containing hydroxyl silicone oil resin into isocyanate-terminated polyurethane prepolymer by using a chemical bonding method; preparing organosilicon-modified aqueous polyurethane-acrylate dispersion through a self-emulsification method; and finally preparing the organosilicon-modified aqueous polyurethane-acrylate composite coating agent. According to the method, the problems of poor compatibility among the three components, i. e., organosilicon, polyurethane and acrylate and poor mechanical property of an aqueous composite coating layer of the organosilicon-modified aqueous polyurethane-acrylate composite coating agent are solved well. The preparation method provided by the invention has the advantages of simple process, convenience, high product quality, high input-output ratio and the like. The coating agent has high compatibility and superior mechanical property and is a new-generation environmentally-friendly high-performance chemical product.

Owner:杭州材聚科技有限公司

Controlling spray drift of pesticides with self-emulsifiable esters

InactiveUS20100113275A1Reduce applicationsReduction in spray driftBiocideDead animal preservationSpray driftAgrochemical

Spray drift during the application of agricultural chemicals is reduced by incorporating a self-emulsifiable ester into the liquid to be sprayed.

Owner:DOW AGROSCIENCES LLC

Nonionic self-emulsifying waterborne epoxy curing agent and preparation method thereof

ActiveCN105315437AGood flexibilitySolve the problem of poor acid resistanceEpoxy resin coatingsFirming agentSolvent

The invention discloses a nonionic self-emulsifying waterborne epoxy curing agent and a preparation method thereof. The curing agent is prepared from the following raw materials in percentage by weight: 8-30% of basic amine, 5-25% of epoxy-terminated polyether, 7-25% of polyether amine, 5-10% of epoxy resin, 5-15% of a mono-epoxy compound, 0.5-3% of a silane coupling agent and 30-60% of water. The preparation method comprises the following steps: (1) conducting chain extension and partial blocking on basic amine to obtain a pre-polymer A; (2) conducting partial blocking on polyether amine to obtain a pre-polymer B; (3) combining the pre-polymer A and the pre-polymer B with the chain segment of epoxy resin, and carrying out blocking to obtain the curing agent. The curing agent can be cured with liquid epoxy resin or an epoxy resin dispersion for film forming, and the obtained film is excellent in flexibility, adhesive force, impact resistance and chemical reagent resistance; the curing agent is synthesized at relatively low temperature, and no solvent or catalyst needs to be added, so that safety and environmental protection are ensured, and the controllability is strong.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

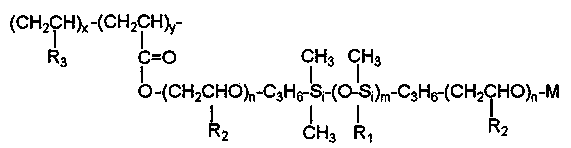

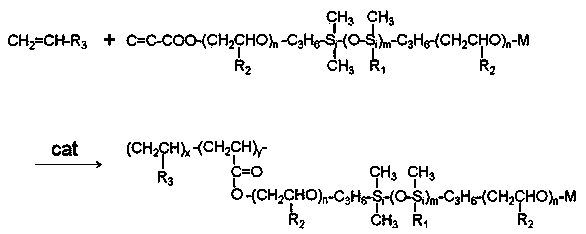

Polyether modified organic silicon defoamer, and preparation method and application thereof

ActiveCN103819630AImprove surface activityGood defoaming activityFoam dispersion/preventionAlkanePolymer science

The invention belongs to the technical field of chemical engineering, and discloses polyether modified organic silicone oil that adopts a comb structure shown in formula (1) and a preparation method and application as a defoamer, and overcomes the service restrictions of conventional organic silicone defoamers. The preparation method comprises the following steps: compounds such as short polyols polydimethyl siloxane or polymethyl phenyl siloxane in which end groups are hydrogen, allyl alcohol polyether, aliphatic esters or alkanes amides that contain end alkenyl are selected as raw materials to synthesize the polyether modified organic silicone oil. According to the invention, as a defoamer, the polyether modified organic silicone oil has good characteristics of self-emulsifying property, self-dispersing property, steady emulsifying property, good defoaming and foam inhibiting performance, high temperature resistance, and acid and alkali resistance.

Owner:威尔(福建)生物有限公司

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

Non-ionic self-emulsifying aqueous epoxy hardener and preparation method and application thereof

InactiveCN101624385AGood self-emulsifying performanceGood flexibilityOrganic compound preparationEpoxy resin adhesivesEpoxyNitrogen

The invention relates to an epoxy hardener, in particular to a non-ionic self-emulsifying aqueous epoxy hardener. The hardener is prepared according to the following steps: adopting hydrophobic alkylamine and hydrophilic diglycidol ether with low molecular weight for reaction so as to obtain a diepoxy compound which has epoxy groups at two ends and a middle nitrogen atom linked with a long hydrophobic alkyl side chain; and adopting alicyclic amine for reaction for purpose of sealing the ends or respectively using the alicyclic amine and hydrophilic amine to seal the two ends, and finally obtaining the amino-terminated non-ionic self-emulsifying aqueous epoxy hardener similar to the structure of surfactant. The hardener can be further mixed with deionized water so that a light-yellow aqueous epoxy resin hardener with 50-60 percent of solids content can be obtained. The hardener has good self-emulsifying effect, is well compatible with epoxy resin and has high stability and good flexibility and surface activating function. The hardener can be widely applied in materials such as aqueous epoxy resin paint, epoxy resin binding agent, aqueous epoxy grouting materials, and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

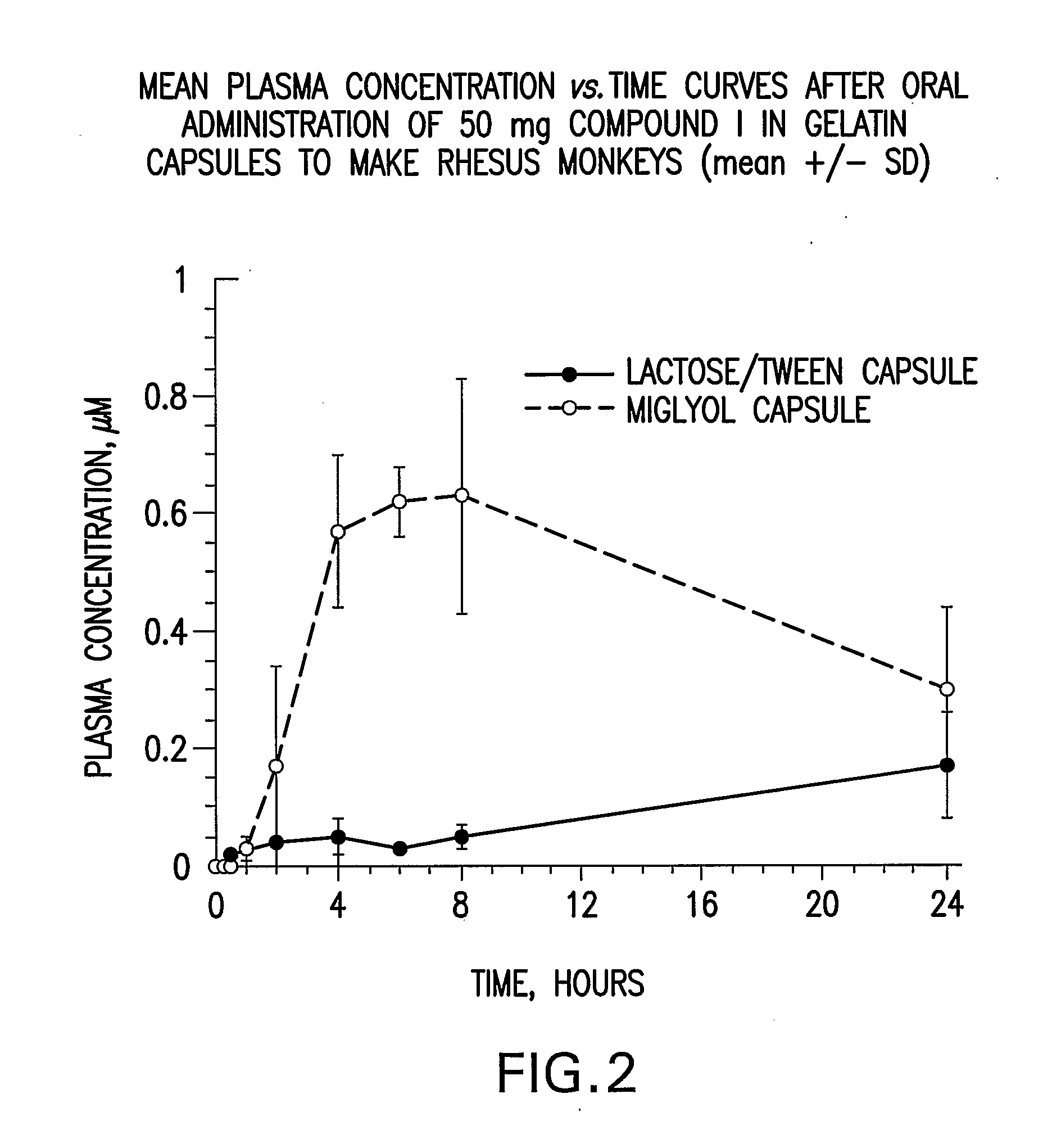

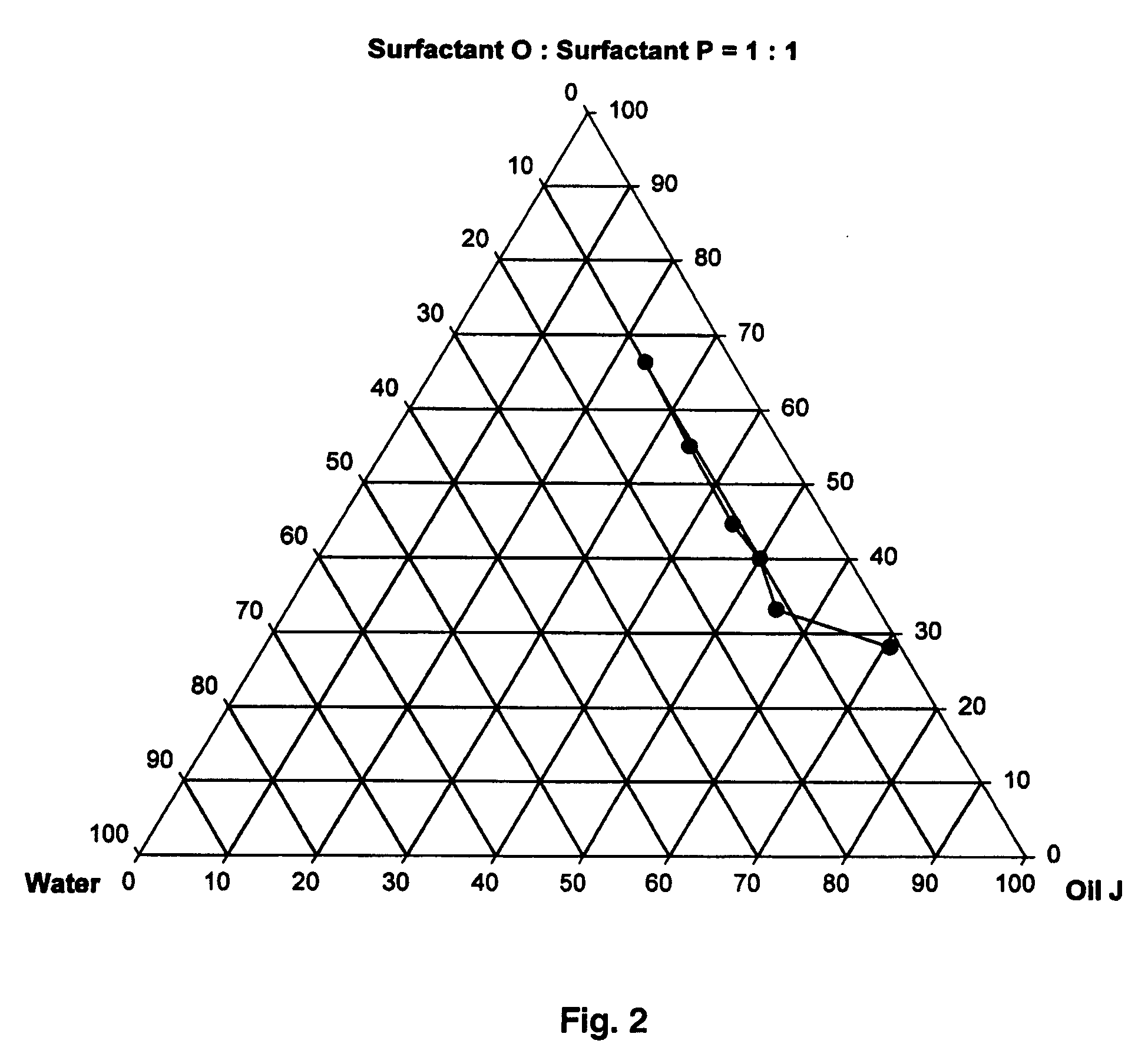

Liquid and Semi-Solid Pharmaceutical Formulations for Oral Administration of a Substituted Amide

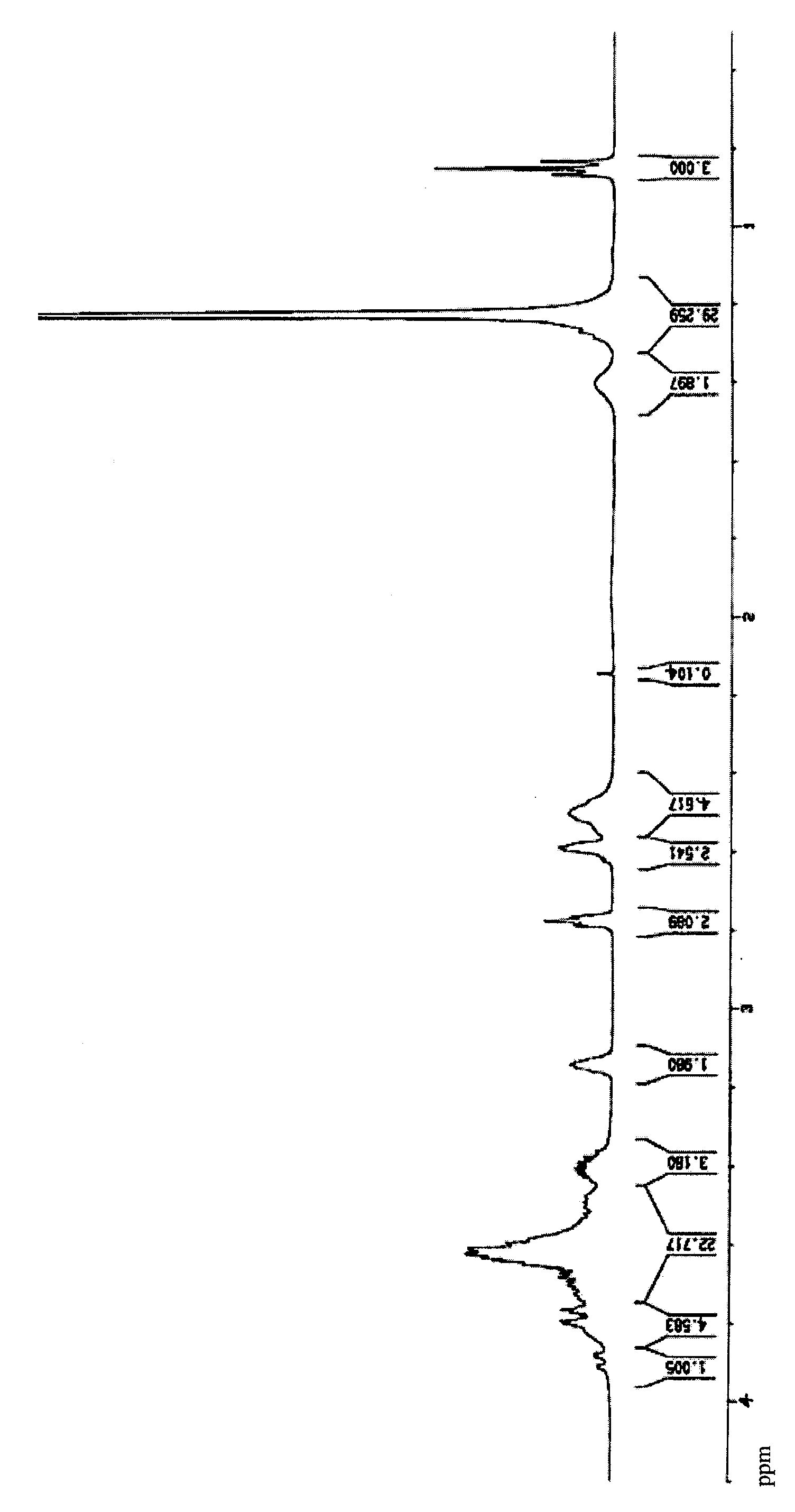

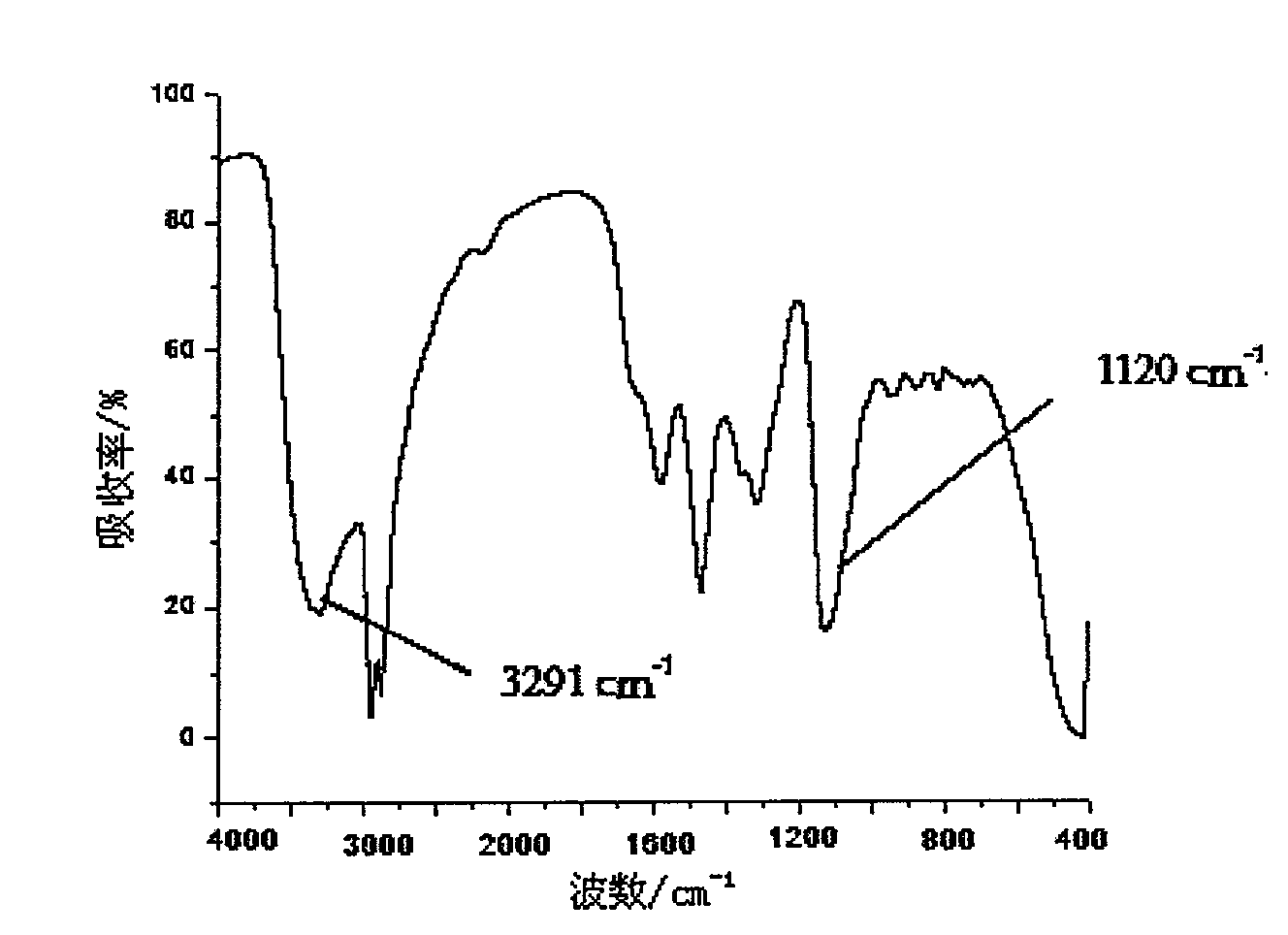

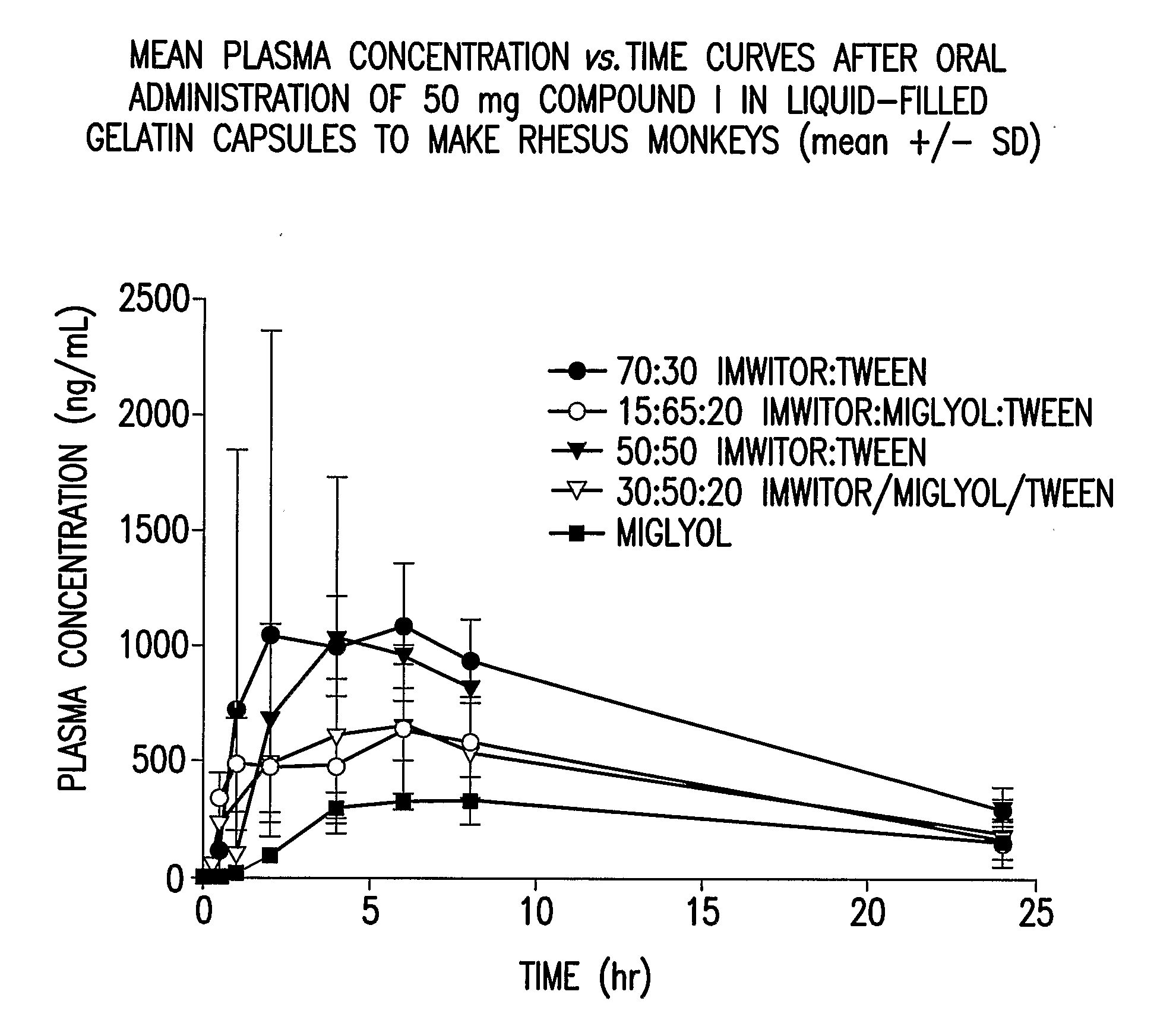

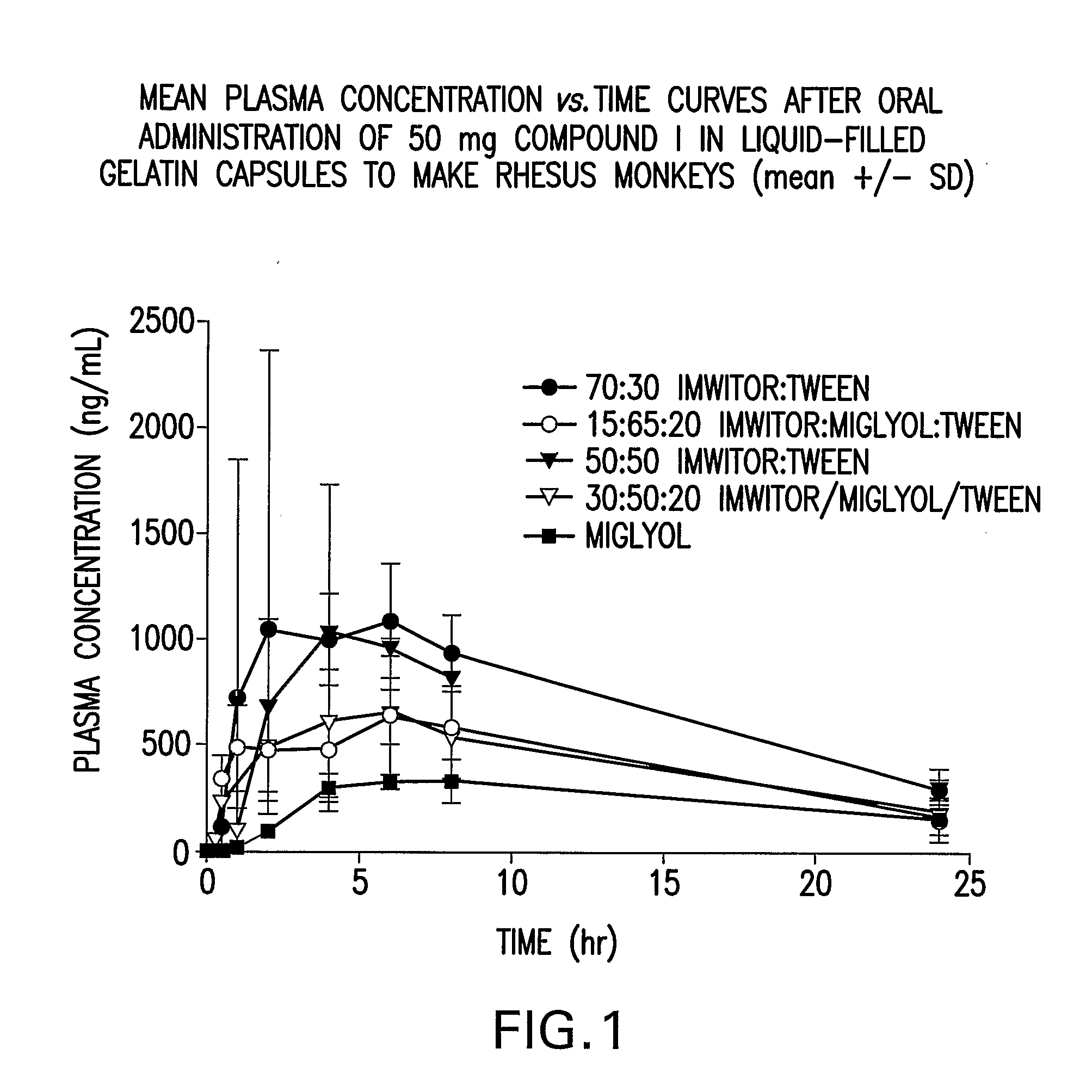

InactiveUS20070298099A1Improve oral bioavailabilityImprove compoundBiocideNervous disorderAntioxidantSolvent

N-[1S,2S]-3-(4-chlorophenyl)-2-(3-cyanophenyl)-1-methylpropyl]-2-methyl-2-{[5-trifluoromethyl]pyridine-2-yl}oxy}propanamide (Compound I) has surprisingly improved solubility and bioavailability in a lipophilic vehicle comprising a pharmaceutically acceptable digestible oil, a surfactant, or a cosolvent, or a mixture of any two or more thereof. In one embodiment of the present invention are self-emulsifying or self-microemulsifying composition comprising 1) Compound I; 2) a surfactant having an HLB of 1 to 8; and 3) a surfactant having an HLB of over 8 to 20; and optionally, 4) a digestible oil and / or cosolvent and / or antioxidant or preservative.

Owner:MERCK SHARP & DOHME CORP

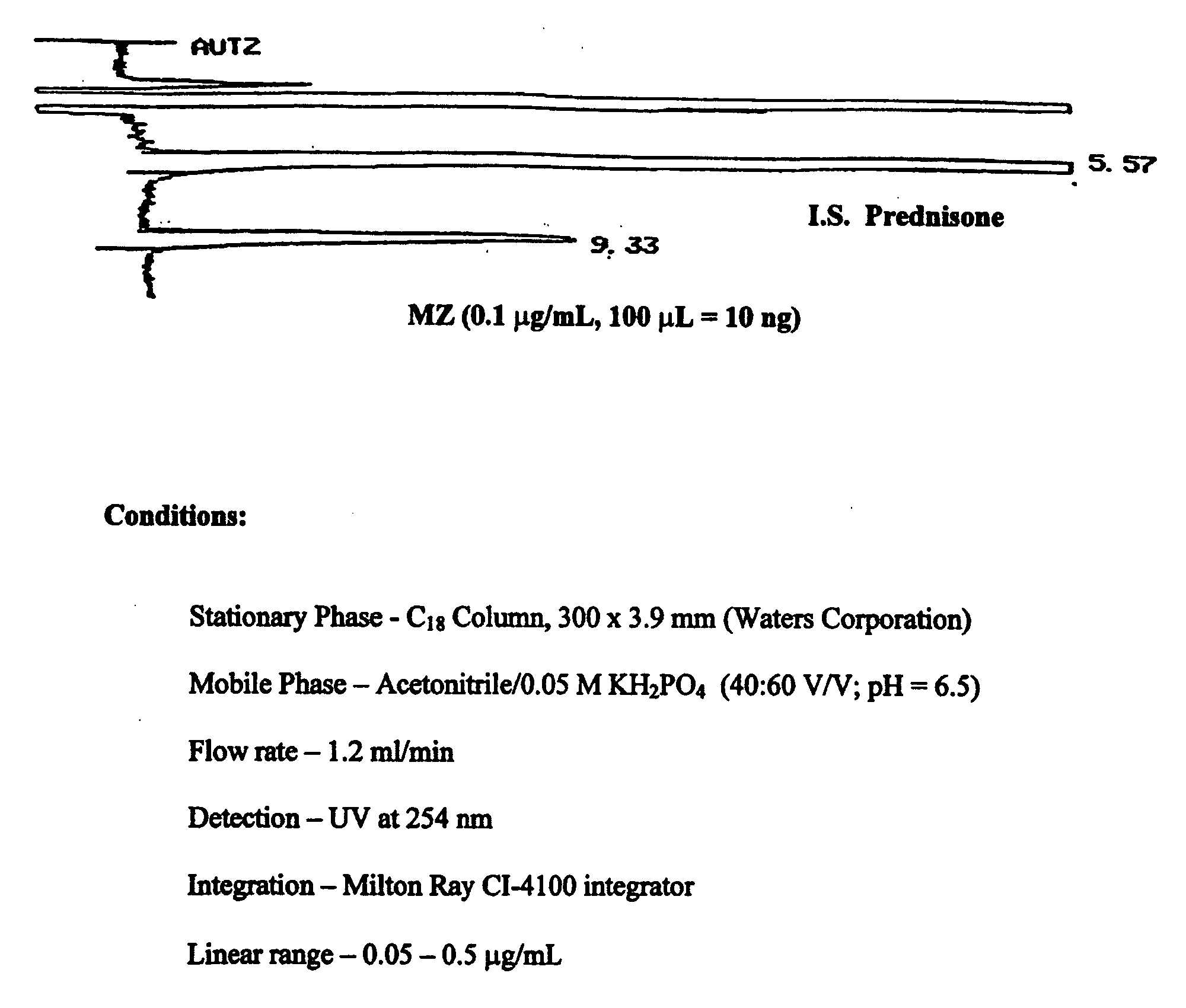

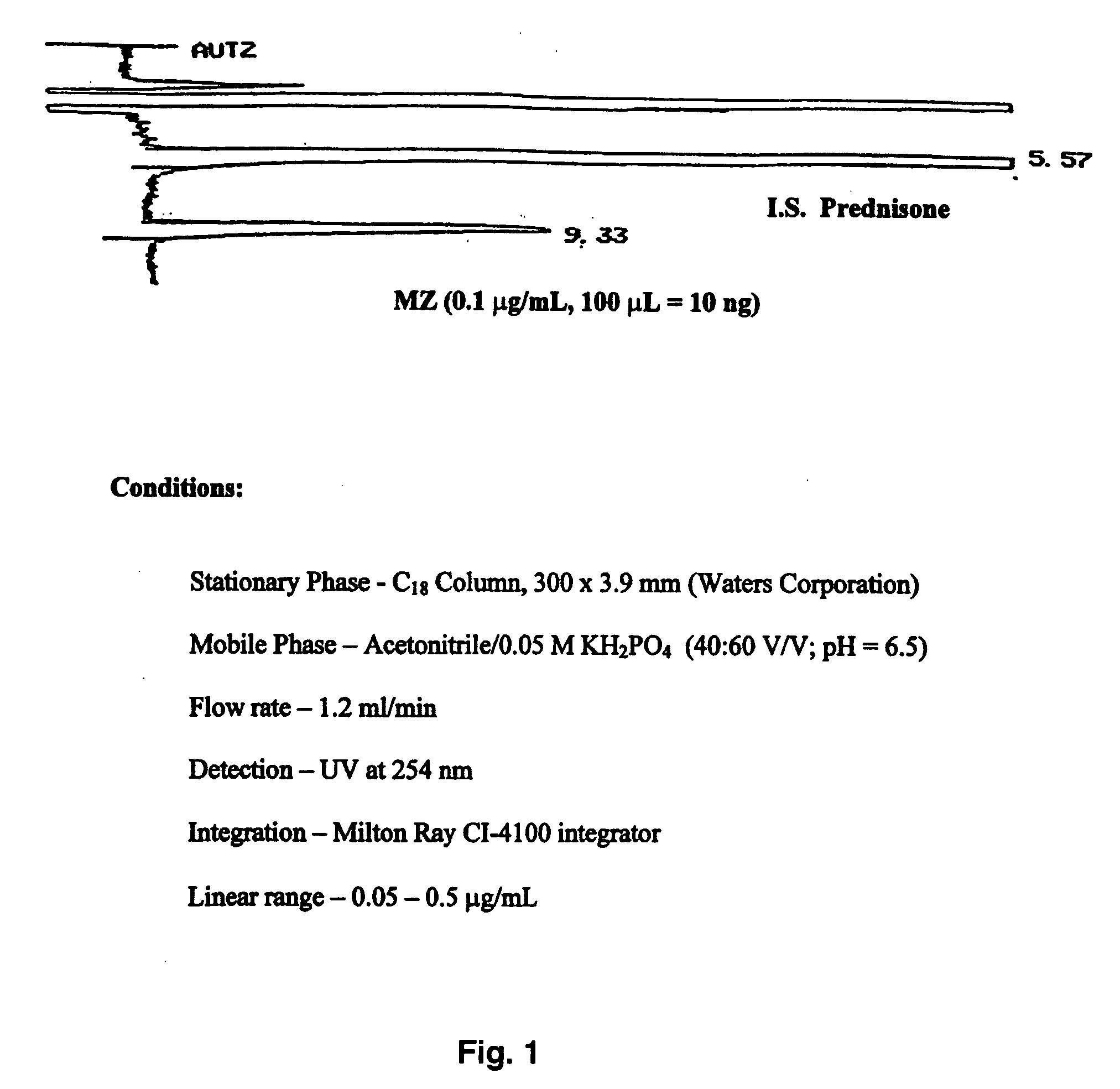

Parenteral and oral formulations of benzimidazoles

ActiveUS20090048322A1Good treatment effectImprove drug solubilityOrganic active ingredientsBiocideBenzimidazole derivativeMebendazole

Provided herein are drug delivery systems, such as self-nanoemulsifying drug delivery systems, self-emulsifying drug delivery systems and parenteral microemulsion formulations, suitable for parenteral or oral delivery to a subject. The drug delivery systems may comprise a benzimidazole derivative, e.g., mebendazole, an oil, a surfactant, a cosurfactant and a dipolar aprotic solvent in a microemulsion formulation. Also provided are methods for improving the bioavailability of a benzimidazole derivative during treatment of a pathophysiological condition by using a formulation combining a particular emulsion droplet diameter and ratio of the surfactant:cosurfactant therein, for increasing concentration and retention of a benzimidazole derivative in the lung via a parenterally administerable microemulsion with droplet size of about 35 nm to less than 100 nm and for defining hemolytically safe microemulsions of a benzimidazole derivative during a therapeutic treatment via a parenterally administerable microemulsion with a surfactant:cosurfactant content by weight of about 6% to 48%.

Owner:UNIV HOUSTON SYST

Method for preparing self-emulsification aqueous epoxy resin emulsion

The invention relates to a method for preparing self-emulsifying aqueous epoxy resin emulsion, which is characterized in that the emulsion is made through the following two steps: (1) introducing hydrophilic groups to both ends of the main chain and the side chain through chain extending and grafting reaction to form aqueous epoxy resin; (2) Adding water to the produced aqueous epoxy resin and aqueous epoxy resin emulsion is obtained through self-emulsifying reaction. The self-emulsifying aqueous epoxy resin emulsion has excellent water dispersibility and processability. After film-forming by the firming agent, the self-emulsifying aqueous epoxy resin emulsion has excellent decoration effect and certain flexibility.

Owner:上海华谊涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com