Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

A water-based epoxy and self-emulsifying technology, which is applied in the field of water-based epoxy curing agent and its preparation, can solve the problems of energy consumption, unfavorable safety production, and non-compliance with environmental protection requirements, and achieve the effect of improving water resistance and improving the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

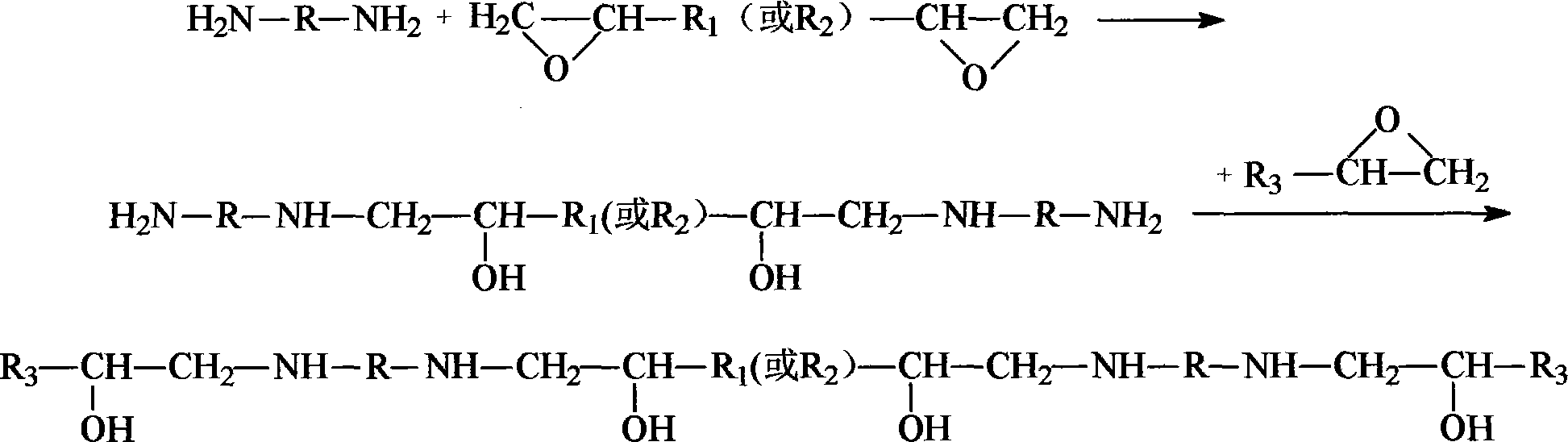

Method used

Image

Examples

Embodiment 1

[0037] Step 1, prepare materials according to the following components and their mass percentages in the total material:

[0038] Component Mass %

[0039] Base Amine: Isophoronediamine 10.5%

[0040] Epoxy resin: 6420 25.7%

[0041] Epoxy terminated polyether: E-220 7.2%

[0042] Epoxy Reactive Diluent: Phenyl Glycidyl Ether 16.6%

[0043] Deionized water 40%

[0044] Step 2: Preparation of Curing Agent Emulsion

[0045] (1) Put the metered isophorone diamine into the reactor as described in step 1, and raise the temperature of the system to 80° C. after stirring;

[0046] (2) Add the metered 6420 epoxy resin and E-220 compatible mixture to the reactor within 30 to 90 minutes as described in step 1, and continue the constant temperature reaction for 3 hours after the addition is completed;

[0047] (3) Add the metered phenyl glycidyl ether dropwise into the reactor within 30 to 90 minutes as described in step 1, and continue the constant temperature reaction for 2 hours...

Embodiment 2

[0051] Step 1, prepare materials according to the following components and their mass percentages in the total material:

[0052] Component Mass %

[0053] Basic Amine: Diaminodiphenylmethane 12.8%

[0054] Epoxy resin: E-51 16.5%

[0055] Epoxy terminated polyether: XR-19 4.2%

[0056] Epoxy reactive diluent: o-cresol glycidyl ether 16.5%

[0057] Deionized water 50%

[0058] Step 2: Preparation of Curing Agent Emulsion

[0059] (1) Put the metered diaminodiphenylmethane into the reactor as described in step 1, and raise the temperature of the system to 70° C. and then keep the temperature constant while stirring;

[0060] (2) Add the metered E-51 and XR-19 compatible mixture to the reactor dropwise within 30 to 90 minutes as described in step 1, and continue the constant temperature reaction for 4 hours after the dropwise addition is completed;

[0061] (3) Add the metered o-cresol glycidyl ether dropwise into the reactor within 30 to 90 minutes as described in step 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com