Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "With self-emulsifying function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

ActiveCN101050300AAvoid situations that require high temperaturesThe synthesis process is simple, safe and energy-savingEpoxyAdhesive

This invention relates to a method for preparing self-emulsifying waterborne epoxy curing agent emulsion, which is composed of: primary amine 7-20 wt.%, epoxy resin 12-27 wt.%, epoxy-terminated polyether 3-8 wt.%, epoxy active diluter 10-30 wt.%, and deionized water 35-60 wt.%. The method comprises: adding primary amine into a reactor, slowly dropping a mixture of epoxy resin and epoxy-terminated polyether, reacting at a certain temperature, slowly dropping monofunctional epoxy active diluter, reacting, adding water, and emulsifying to obtain white waterborne epoxy curing agent emulsion. The method has such advantages as simple process, low reaction temperature (below 100 deg.C), high safety and low energy consumption. The obtained waterborne epoxy curing agent emulsion has such advantages as low VOC content, high stability, high water resistance, high compatibility with epoxy resin, high impact resistance, good luster, high toughness and high adhesiveness, and can be used in paint, adhesive and polymer concrete.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

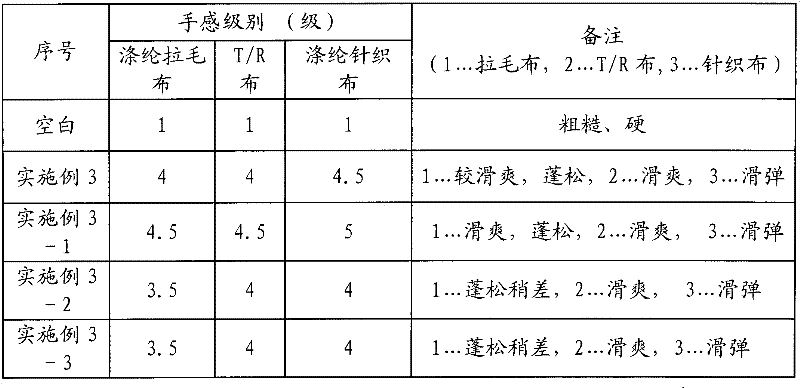

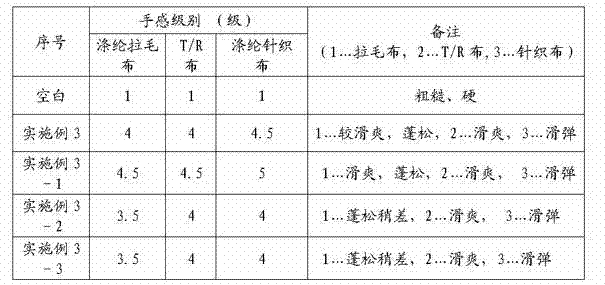

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295ABroad encapsulationWide penetration abilityFibre treatmentPolyelectrolyteEmulsion

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

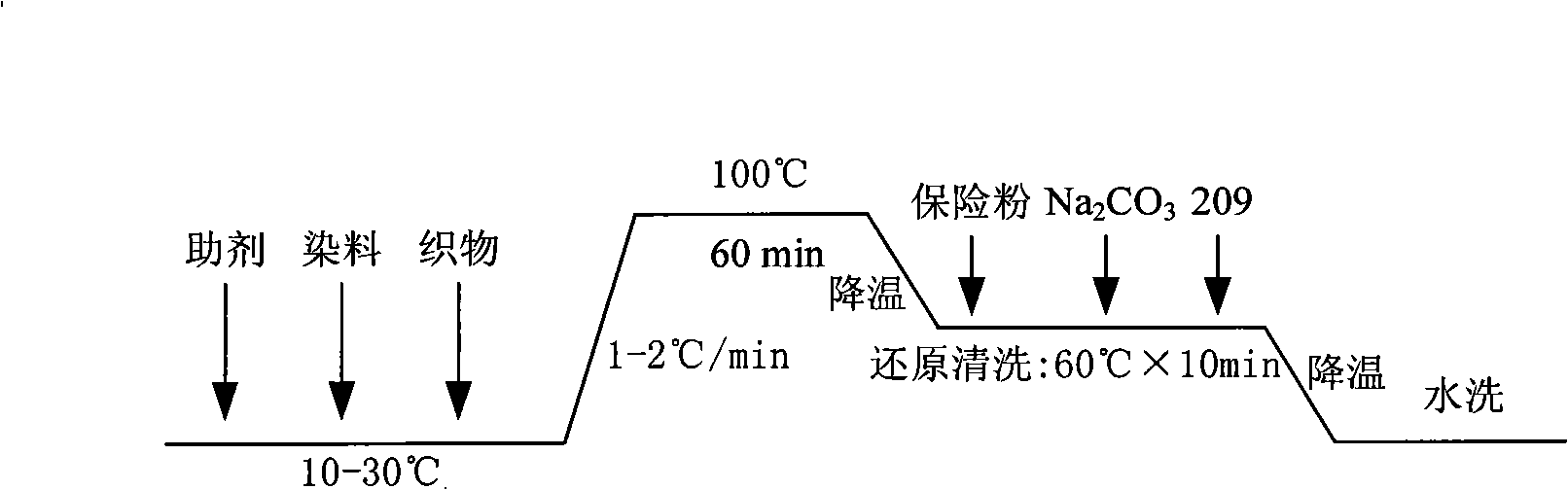

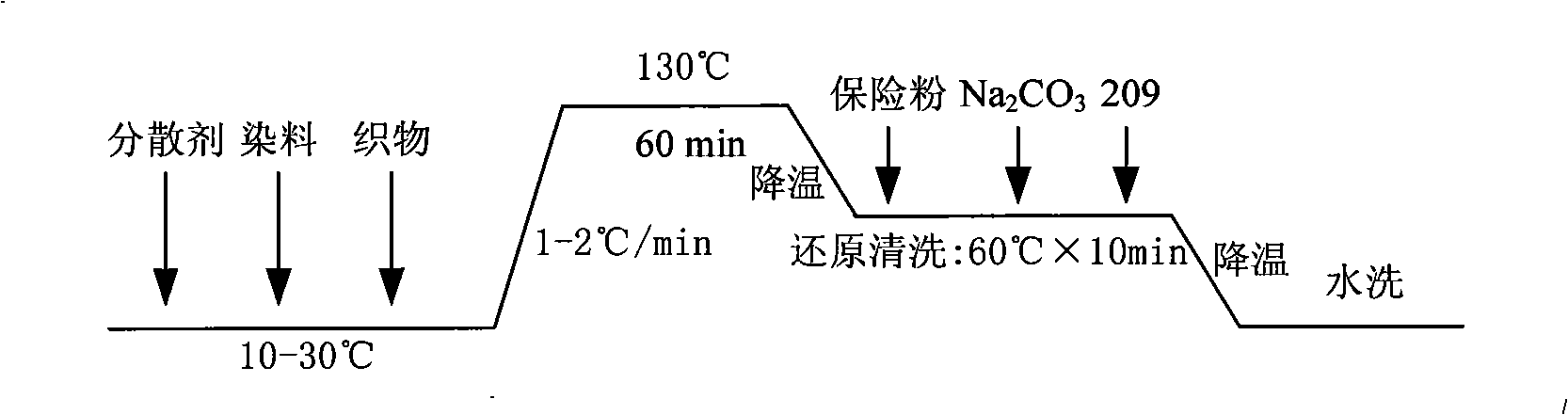

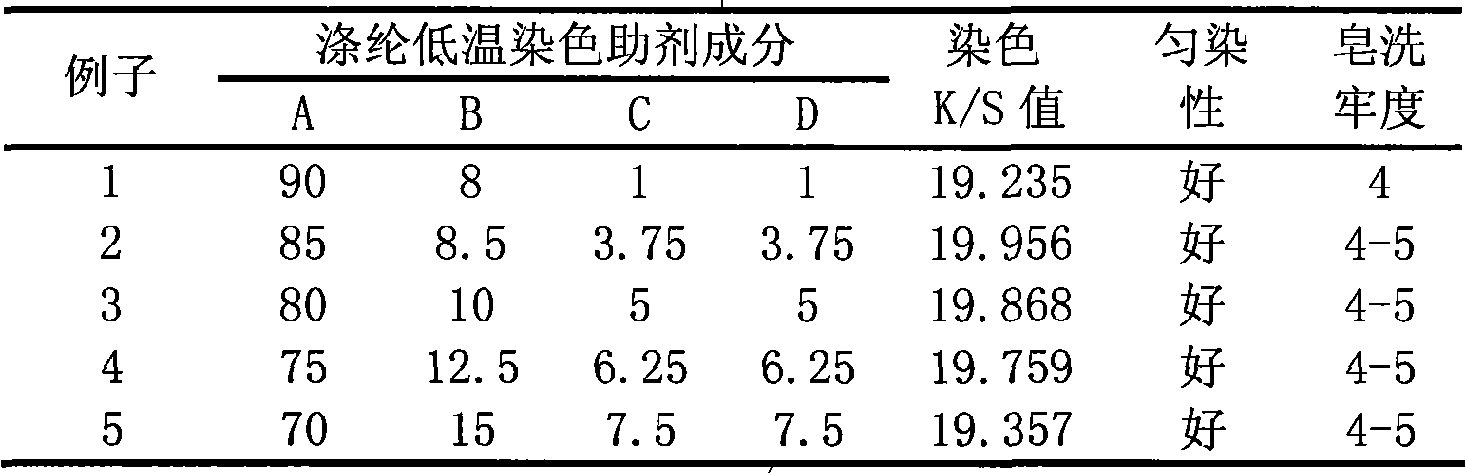

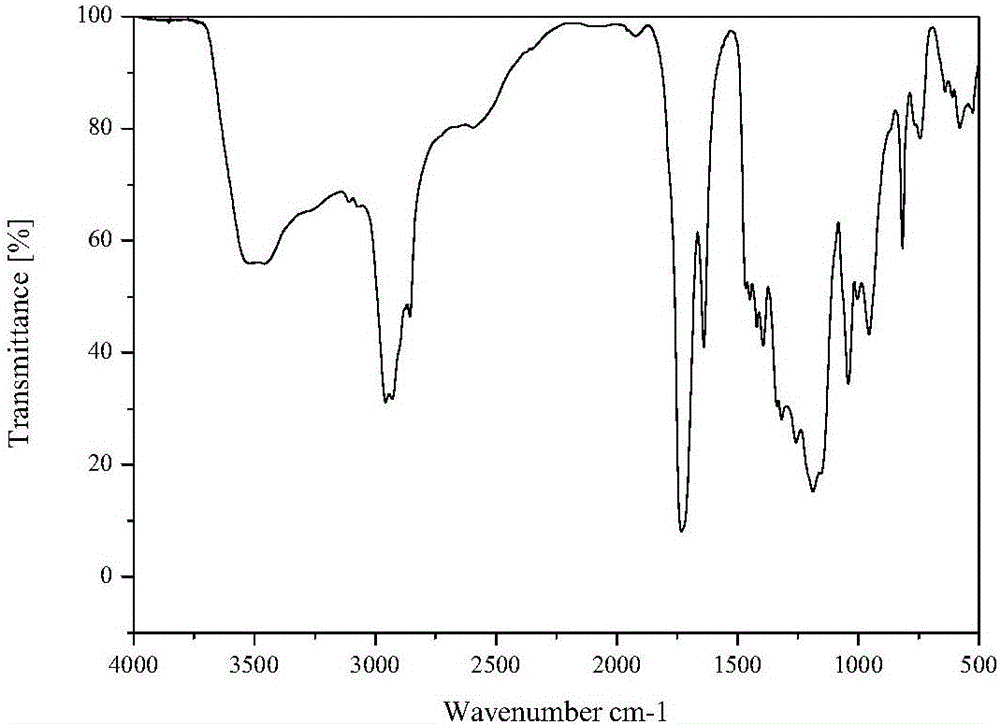

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Glass fiber infiltration agent composition

The invention relates to a combination of glass fiber infiltration agent, which comprises a film forming agent, a coupling agent and other promoters. The film forming agent is unsaturated and polyester type, and the unsaturated polyester is made into emulsion by emulsification, wherein, the unsaturated polyester is made from carboxyl sulfonate, polyol and polybasic acid by catalysis; the catalyst is titanate esters agent; the preparation technique includes the steps: 1 to 10 weight portions of carboxyl sulfonate and 50 to 150 weight portions of polyol react under the temperature of 150 to 200 DEG C; after being cooled, the obtained material is added with 40 to 95 weight portions of polybasic and titanate esters catalyst that is 0.05 to 1 percent of the mass of the film forming agent to react under the temperature of 160 to 230 DEG C; then the obtained material are cooled, crushed and made into emulsion; at last the emulsion is mixed with the coupling agent and other promoters to produce the infiltration agent. The invention has the advantages that: the unsaturated polyester emulsion is adopted as matrix and the sulfonate monomers with hydrophilicity is used for preparing the film forming agent, so the film forming agent has self-emulsifying function and can be dissolved in solution more easily; in addition, the titanate esters is employed as catalyst, which avoids the occurrence of polyester gel and better protects of glass fiber.

Owner:上海新天和树脂有限公司 +2

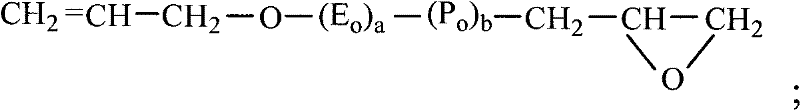

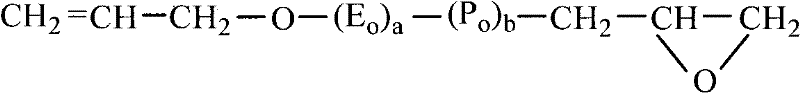

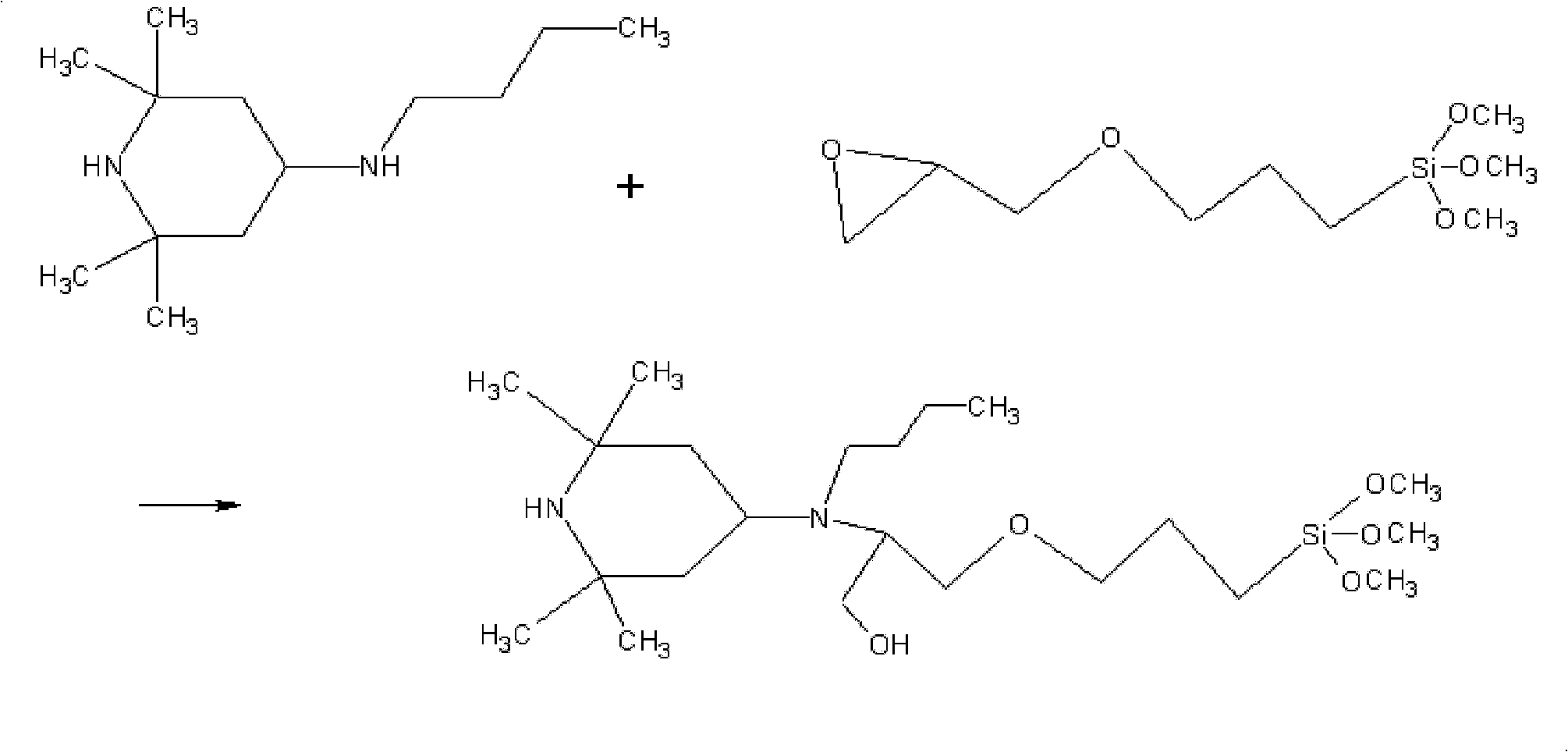

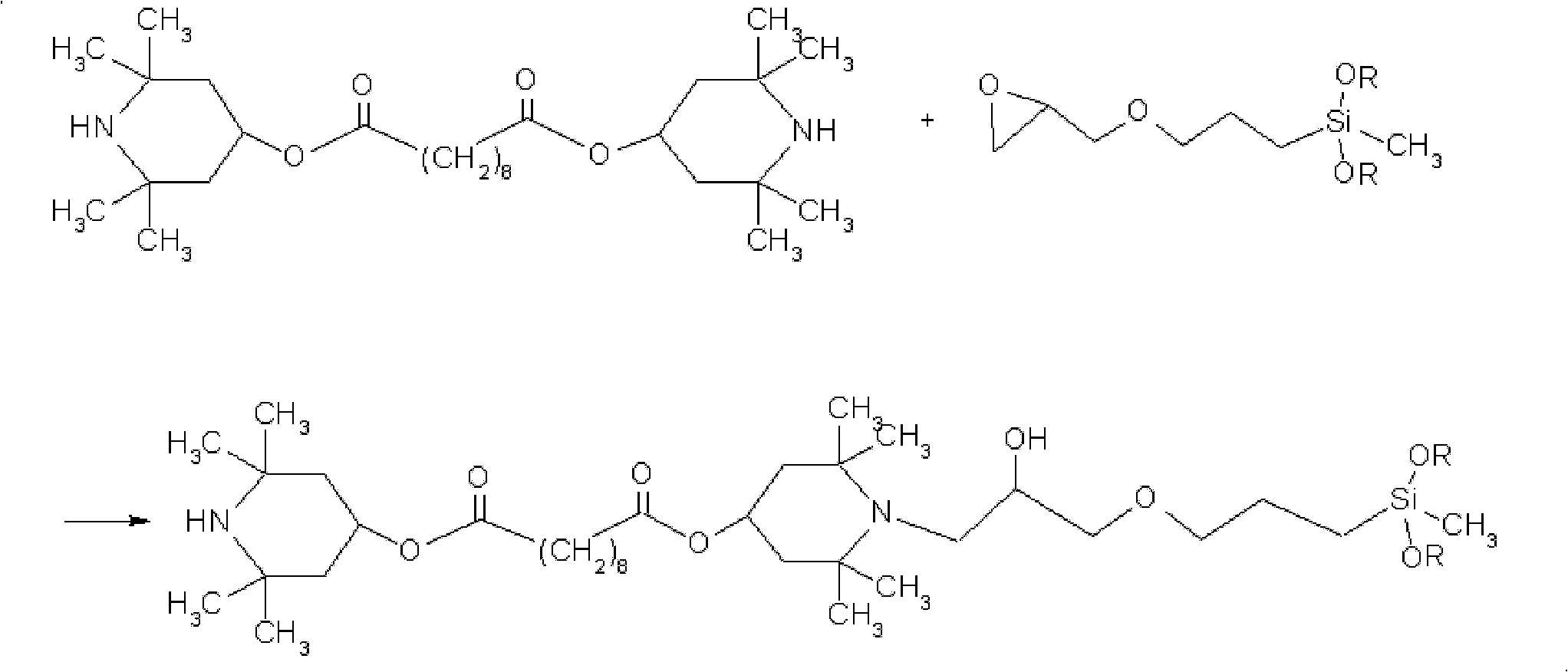

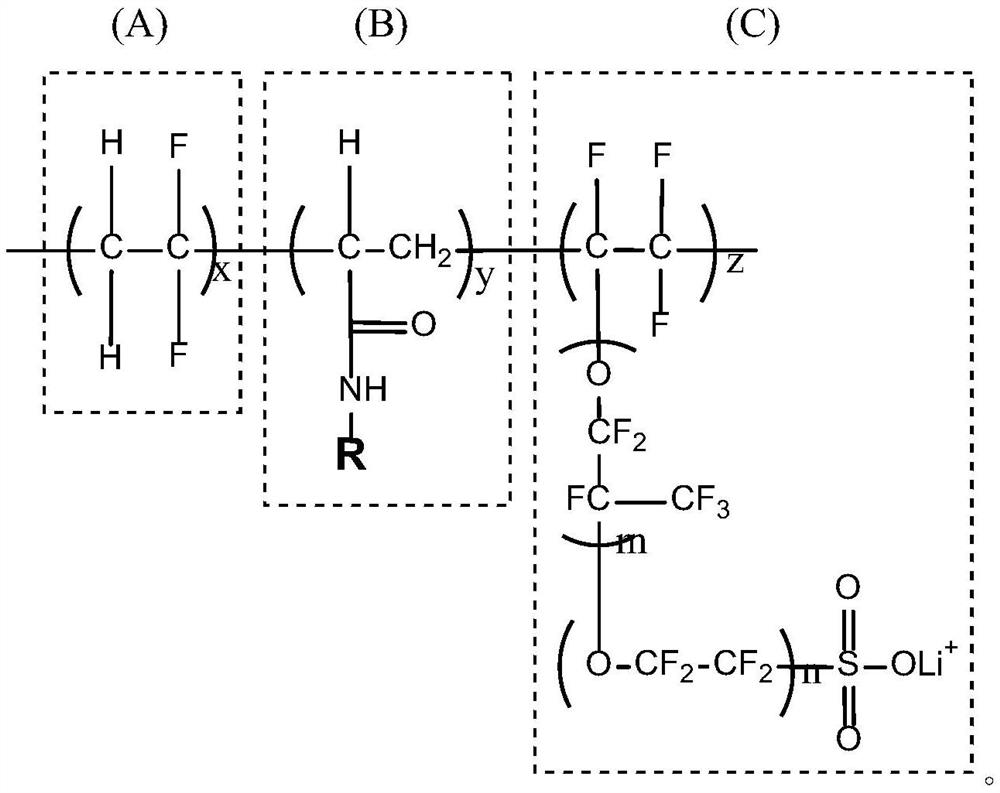

Method for preparing modified block polyether amino silicone oil

InactiveCN102911365AWith self-emulsifying functionImprove hydrophilicityVegetal fibresSilicone oilHydrophily

The invention discloses block polyether amino silicone oil, particularly relates to a method for preparing modified block polyether amino silicone oil and aims at overcoming defects of existing technologies. The method for preparing the modified block polyether amino silicone oil is simple in preparation process and operation, short in reaction time, mild in reaction conditions, easy to implement and capable of improving hydrophily and inhibiting yellowing, and raw materials are easy to obtain; and the block polyether amino silicone oil is synthesized and modified by an epoxy compound to obtain the modified block polyether amino silicone oil.

Owner:ZHEJIANG HAPPY CHEM

Environmental-friendly aqueous epoxy floor coating

InactiveCN1702132AWith self-emulsifying functionImprove performanceEmulsion paintsEpoxy resin coatingsEmulsionChemistry

The invention provides a formulation and the method for preparation of a green environment-friendly water-based epoxy terrace-using coating. The green environment-friendly water-based epoxy terrace-using coating comprises the first and the second component, the constituent and weight ratio of the first component being as the following: water-based epoxy curing agent 28-32, water 10-20, defoamer 0.2-0.5, wetting agent 0.2-0.5, leveling agent 0.2-0.5, consolute agent 1-5, phthalocyanine green 3-6, ferrite yellow 4-6, titanium dioxide 1-3, blanc fixe 20-30, silicon micronized quartz powder 10-15, and talcum powder 5-8; and the constituent and weight ratio of the second component being: water-based epoxy emulsion A 15-25, water-based epoxy emulsion B 20-28, and water 1-6. The first component: the second component is 1.25: 1, homogeneously mixing them. The prepared green environment-friendly water-based epoxy terrace-using coating can ensure the lacquer film having good brightness, adhesive force, strong chemical resistance, nice environmental protection property, and low containing of VOC.

Owner:董善刚 +2

Crosslinking self-emulsifying cation full fluorine copolymer soap-free emulsion and preparation thereof

The invention belongs to the polymer chemistry field, in particular to a cross-linking self-emulsifying cationic perfluorocopolymer soap-free emulsion and a preparation method thereof. The soap-free emulsion overcomes the problems of the prior art such as poor film forming property, low conversion rate of fluoride monomer, and adverse impact on water resistance and oil resistance of fluorine-containing emulsion products and environmental protection. The technical proposal is as follows: the cross-linking self-emulsifying cationic perfluorocopolymer soap-free emulsion is prepared by the following method: (1) preparing a monomer pre-emulsion mixture: mixing a cationic monomer with vinyl monomer, perfluoroalkyl (methyl) acrylate and a functional monomer to obtain a mixture solution A; and then mixing the mixture solution A with an oil soluble initiator to obtain a mixture solution B, pre-emulsifying and evenly mixing the mixture solution B by ultrasonic agitation or mechanical agitation; (2) preparing a water soluble perfluoroalkyl acrylate prepolymer; and (3) preparing the perfluoroacrylate copolymer soap-free emulsion. The cross-linking self-emulsifying cationic perfluorocopolymer soap-free emulsion has the advantages of good stability, good film forming property of film coating, high conversion rate of the fluoride monomer, safety and environmental protection.

Owner:SHAANXI UNIV OF SCI & TECH

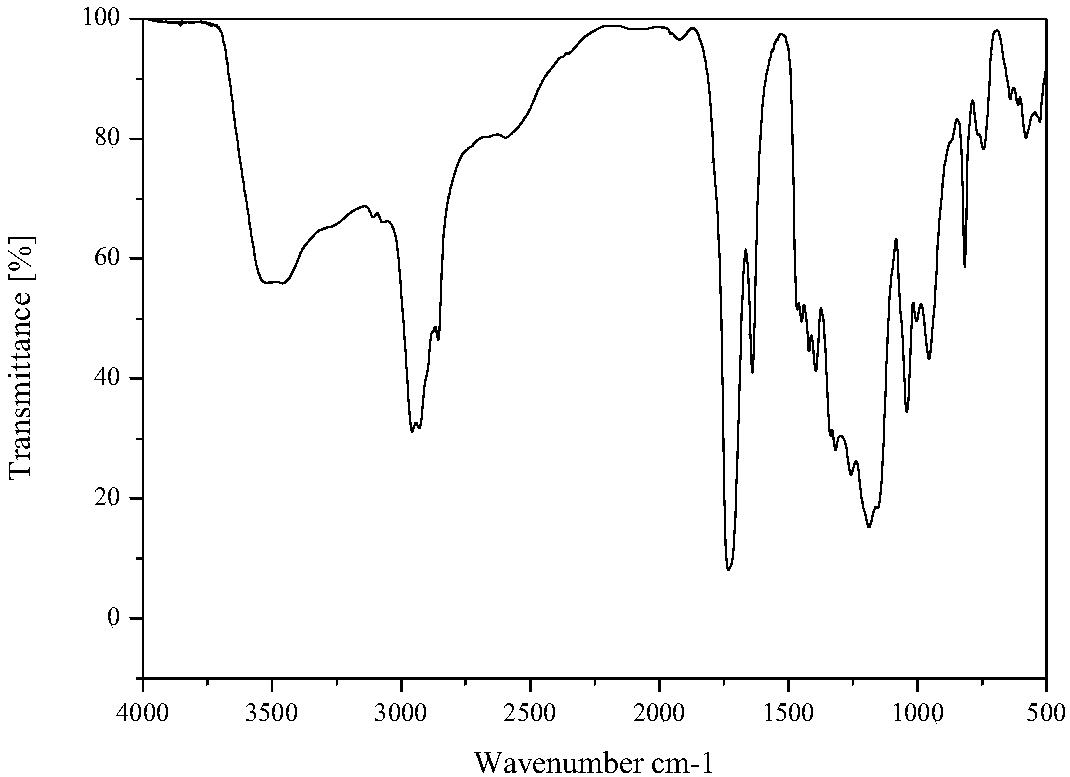

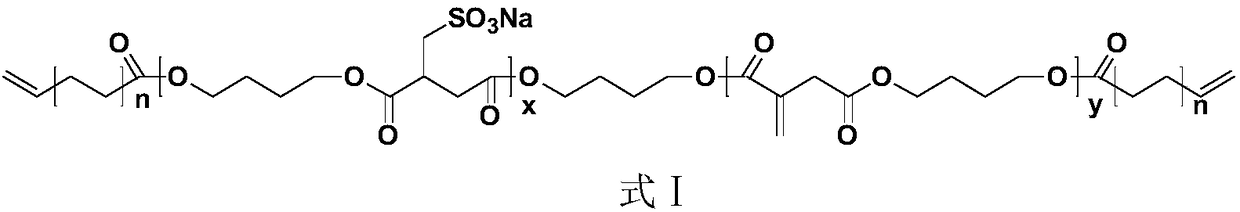

Novel self-emulsifying water-based polyester emulsion and preparation method thereof

ActiveCN106432706ANovel preparation methodWith self-emulsifying functionPolyester coatingsPolyesterPolymer science

The invention provides novel self-emulsifying water-based polyester emulsion and a preparation method thereof. The preparation method includes the following steps that itaconic acid, methyl-butanedioic acid-5-sodium sulfonate and 1,4-butanediol are subjected to condensation polymerization, then terminal hydroxyl water-based polyester-poly(itaconic acid butanediol-co-methyl-butanedioic acid-5-sodium sulfonate butanediol)ester (PBIINa) is obtained, and the PBIINa and terminal olefine acid are heated to 110-160 DEG C under nitrogen protection, and terminal olefine acid modified water-based polyester is obtained after an esterification reaction. The terminal olefine acid modified water-based polyester is dispersed in water, and then the water-based polyester emulsion is obtained. The preparation method of the water-based polyester emulsion is novel and has a self-emulsifying function, an emulsifying agent does not need to be added, organic solvent is not contained, and the water-based polyester emulsion can be used as emulsion coating and has broad market prospects. The steps are simple, operation is convenient, and practicability is high.

Owner:QINGDAO UNIV OF SCI & TECH

Aquosity metallic protective paint and method for producing the same

InactiveCN101130662AImprove stabilityHigh hardnessLiquid surface applicatorsEmulsion paintsWater basedLow speed

The invention discloses a water-based metallic protective paint, which comprises the following steps: adding water-soluble resin, butyl ether, ammoniac water and deionized water into charge make-up pot; stirring at low speed evenly; adding into aids; mixing evenly; adding into colour filler; scattering above 20 min with high speed at 1200rpm; grinding; driving the pigment paste into allocating tank; stirring with low speed; mixing evenly; adding into dry material; stirring at least above 15min; adding into water; diluting. This product can form continuous paint film, which possesses good hardness, strong adhesive force and low price.

Owner:刘善江

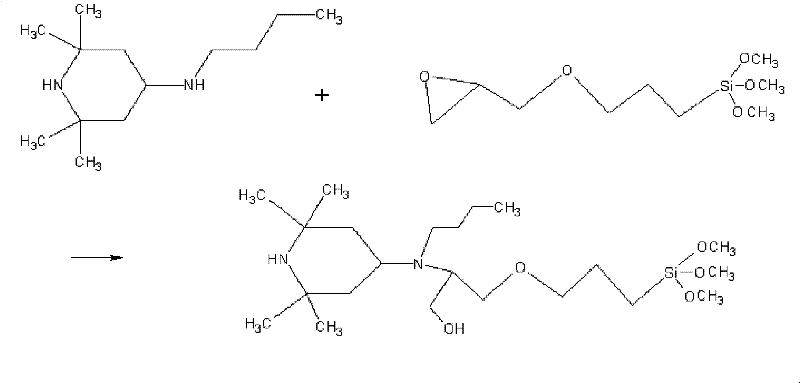

Preparation method for epoxy methacrylate composite emulsion

InactiveCN103833887AImprove difficult emulsification and other problemsReduce remaining amountCoatingsMethacrylateEpoxy

The invention provides a preparation method for epoxy methacrylate composite emulsion. The preparation method comprises the steps of preparing epoxy methacrylate by using epoxy resin E-51 and 2,2,6,6-tetramethyl-4-hydroxyl oxide piperidine as raw materials; preparing epoxy methacrylate pre-emulsion by mixing epoxy methacrylate with butyl acrylate and methyl methacrylate uniformly; then preparing acrylate pre-emulsion by mixing butyl acrylate, methacrylic acid and methyl methacrylate uniformly; finally mixing 60-70% of the prepared acrylate pre-emulsion with NaHCO3, an emulsifier CO-436, ammonium persulfate and distilled water uniformly; dropwise adding a mixed solution composed of ammonium persulfate, distilled water and the residual acrylate pre-emulsion and then dropwise adding the epoxy methacrylate pre-emulsion to obtain the epoxy methacrylate composite emulsion. The method effectively overcomes the problems of poor compatibility between epoxy resin and acrylic resin and difficult emulsification of the epoxy resin, and increases graft copolymerization and grafting ratio between acrylic acid and the epoxy resin.

Owner:NANJING FORESTRY UNIV +1

Multifunctional organic silicon finishing agent and preparation method thereof

The invention discloses a multifunctional organic silicon finishing agent and a preparation method thereof. The multifunctional organic silicon finishing agent comprises the following components in percentage by mass: anti-ultraviolet polyether organic silicon oil, isobutyl alcohol, composite emulsifier of phosphate betaine type gemini surfactant and fatty alcohol-polyoxyethylene ether in a ratio of 1:1, pH buffering agent and deionized water. The preparation method for the multifunctional organic silicon finishing agent comprises the following steps of: modifying organic silicon by adopting a special heterocyclic hindered ammonia compound, substituting the conventional amino, introducing a polyether functional unit on the main chain of the organic silicon, introducing the hindered ammonia compound on the branched chain, and synthesizing multifunctional organic silicon oil. The finishing agent keeps the original advantages of the amino silicon oil, and is particularly suitable for soft finishing and anti-ultraviolet finishing of bleached fabrics and light color fabrics; and the finishing agent can be prepared into silicon oil micro-emulsion of various proper concentrations by full emulsifying and has strong usability.

Owner:NANTONG UNIVERSITY

Waterborne self-emulsifying epoxy modified alkyd resin and anticorrosive coating thereof

InactiveCN108559371AThe preparation method or process is simpleGood storage stabilityAnti-corrosive paintsPolyester coatingsVolatile organic compoundPolymer chemistry

The invention discloses waterborne self-emulsifying epoxy modified alkyd resin, a preparation method thereof, and an anticorrosive coating prepared by the epoxy modified alkyd resin, and belongs to the technical field of chemical engineering. According to the epoxy modified alkyd resin, hydrophilic macromolecular chain segments are introduced in an alkyd resin main chain, epoxy resin is grafted tothe alkyd resin, the epoxy modified alkyd resin is prepared through self-emulsifying, the preparation method and technology are simple, the modified resin has self-emulsifying capacity, it is not necessary to add emulsifier and amine for salifying, and the epoxy modified alkyd resin has good storage stability, better physical property and better corrosion resistance property. When the prepared resin is applied to steel-structure protective undercoat, the prepared coating does not contain volatile organic matters and is more environmentally friendly, the construction is safe, and the comprehensive performance of coatings is better.

Owner:李嘉顺

Water-borne epoxy resin for anticorrosive coating, application and preparation method of water-borne epoxy resin

InactiveCN112852261AThe preparation process is shortReduce energy consumptionAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolyethylene glycol

The invention discloses water-borne epoxy resin for an anticorrosive coating, application and a preparation method of the water-borne epoxy resin; according to the preparation method, the self-emulsifying function of the epoxy resin is achieved by introducing a highly hydrophilic polyethylene glycol branched chain to a molecular chain of the epoxy resin; meanwhile, due to the fact that the molecular chain segment is short, under the action of polyethylene glycol, the solid content can be up to 66.7%. Besides, no extra alcohol-soluble solvent or other high-boiling-point organic solvents are needed in the preparation process of the water-based emulsion, the production process and the product use process are very environment-friendly, and the water-based epoxy resin can be mixed with a water-based ammonia curing agent to be cured into a film for corrosion prevention.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +2

Sucralfate self-emulsifying microcapsule and preparation method thereof

InactiveCN105287438AImprove stabilityGood treatment effectOrganic active ingredientsDigestive systemSide effectPatient compliance

A sucralfate self-emulsifying microcapsule is composed of solid powder or particles prepared from sucralfate, lipid, surfactant, and a wall material; the capsule core is composed of a sucralfate self-emulsifying composition, and the capsule core is wrapped by a wall material. The microcapsule is prepared through a spray drying method and a spray-coagulation method. The provided microcapsule is a novel upper digestive tract mucosa protective agent. The microcapsule has the advantages of wide range of indication, more unique and comprehensive action mechanism, and no prominent clinical side effect. Moreover, the frequency of daily drug taking is reduced by 50%, compared with conventional dosage forms. The microcapsule is user-friendly. The compliance of patients is increased, and the microcapsule is beneficial for more clinical patients. The particles in microcapsule are small, have a self-emulsifying function, are not affected by the gastrointestinal functions of patients, and can be well absorbed, and thus a good treatment effect can be achieved. The microcapsule is especially suitable for children, the old, and the patients, who have bad gastrointestinal functions, and can reduce the burden on stomach and intestines.

Owner:KUNMING JIDA PHARMA

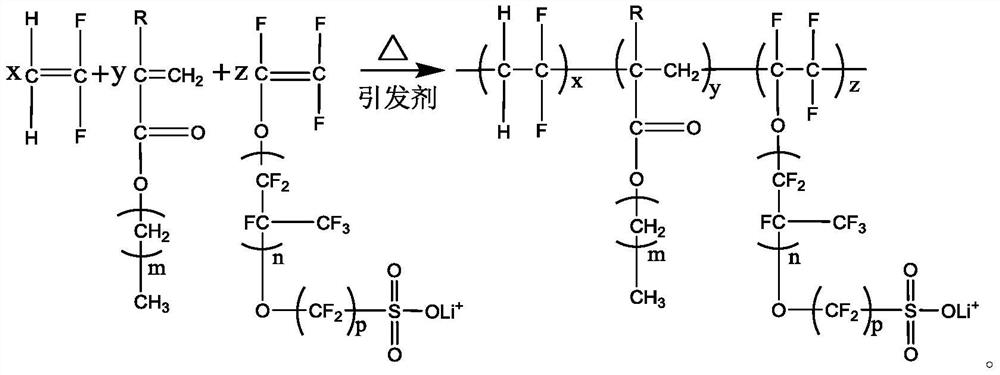

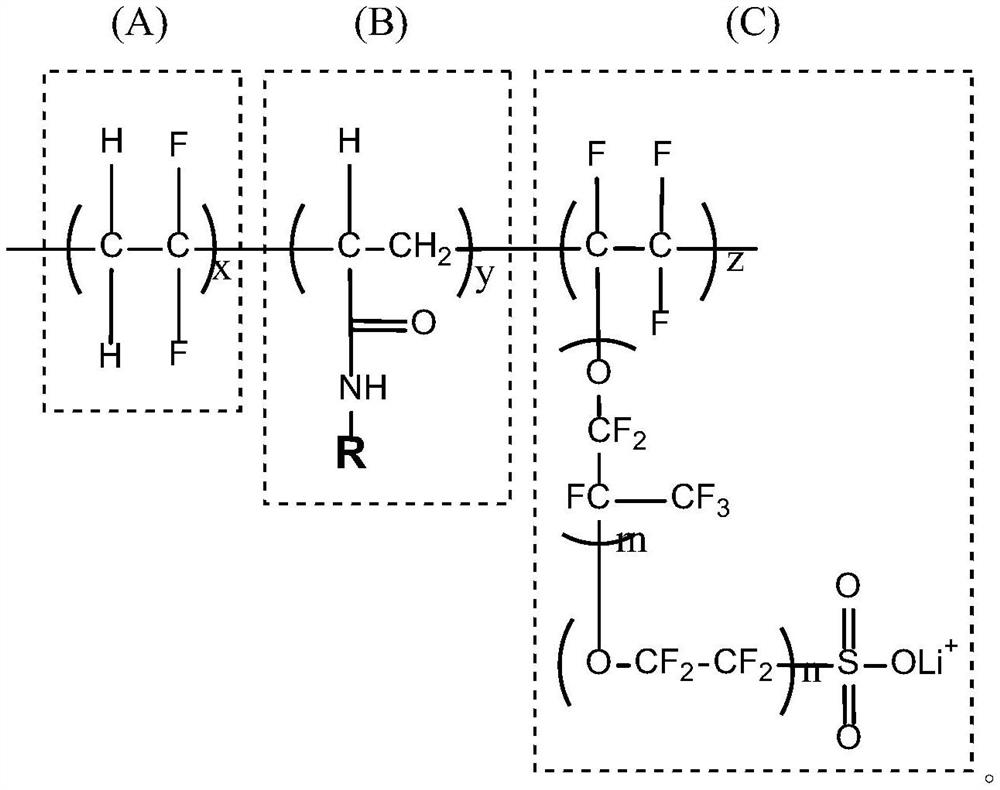

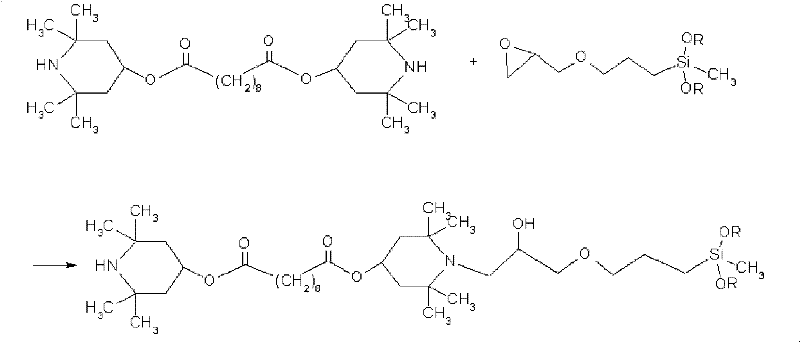

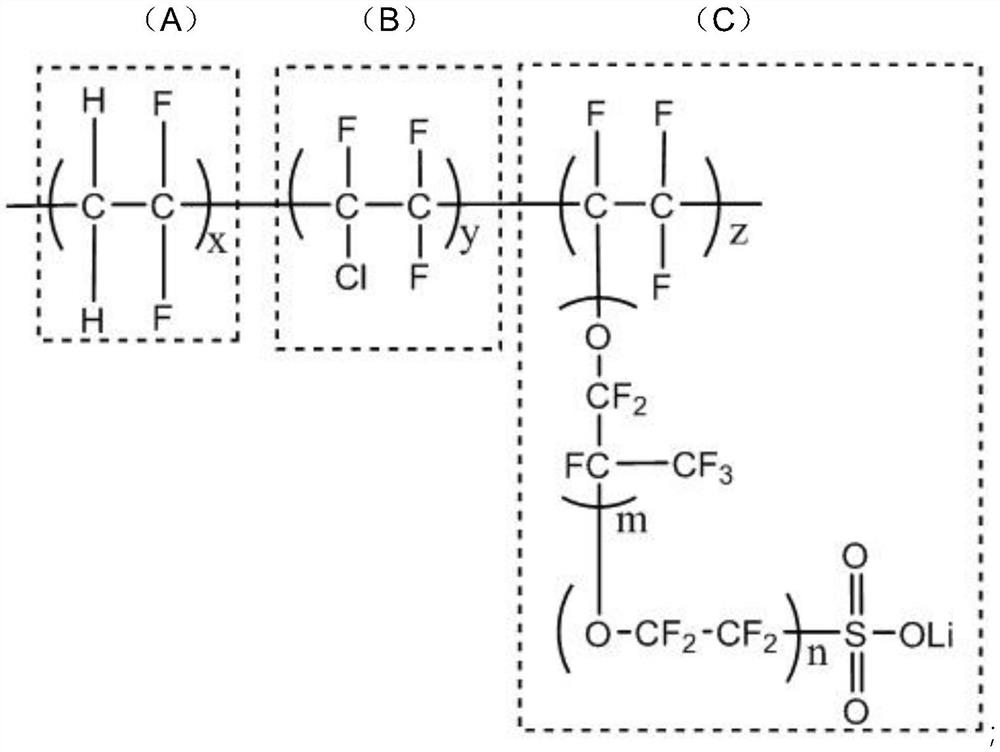

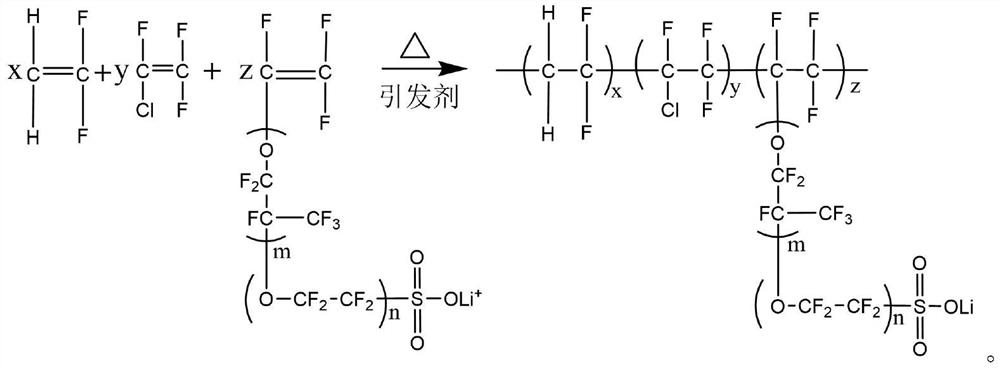

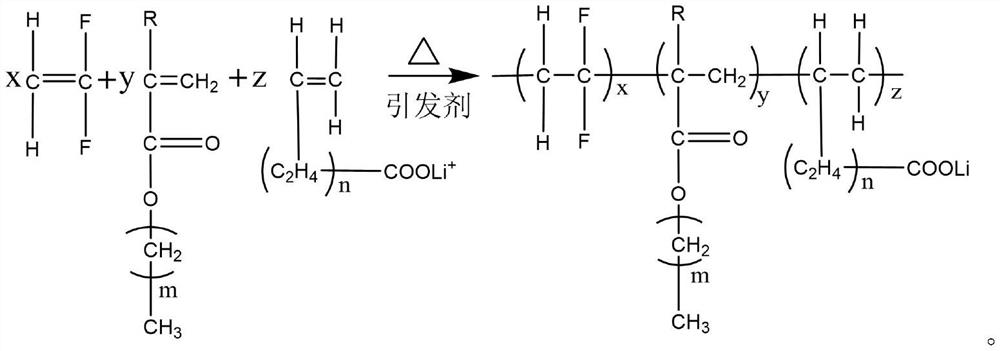

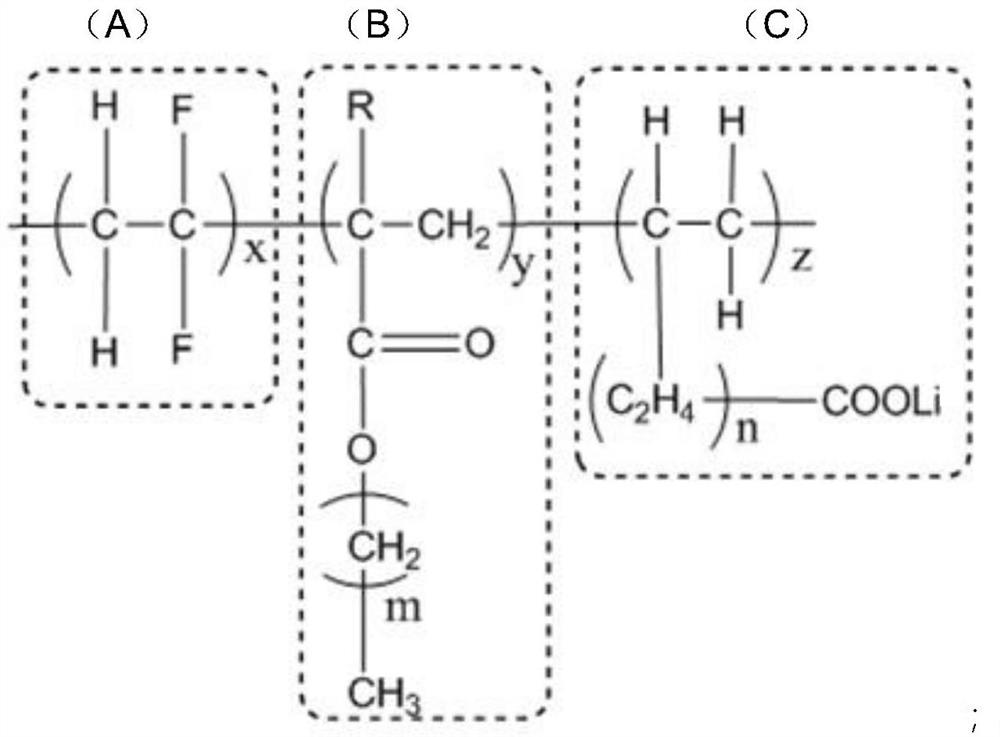

Lithium sulfonate-containing ionic copolymer and preparation method thereof

ActiveCN112210033AImprove transmission efficiencyImprove ionic conductivityMonomer compositionVinyl ether

The invention discloses a lithium sulfonate-containing ionic copolymer and a preparation method thereof. The lithium sulfonate-containing ionic copolymer comprises x mole parts of a polyvinylidene fluoride structural unit (A) composed of vinylidene fluoride monomers, y mole parts of an acrylate structural unit (B) composed of acrylate monomers and z mole parts of a perfluorovinyl ether lithium sulfonate structural unit (C) composed of perfluorovinyl ether lithium sulfonate monomers. The copolymer composed of the three compound structural units retains the advantage structure of polyvinylidenefluoride, so enough mechanical strength and thermal stability of the copolymer are ensured; by introducing a lithium ion high-efficiency transmission structural unit, a polar group and a large numberof super-stable structural units, the defects of the existing PVDF used as a polymer lithium ion battery material are overcome, the transmission efficiency of lithium ions is optimized, the ionic conductivity of a lithium battery is improved, the polarization of the battery in the charging process is reduced, and the charging and discharging performance of the battery is improved; and a new material and a new method are provided for further development and application of the lithium battery.

Owner:氟金(上海)新材料有限公司

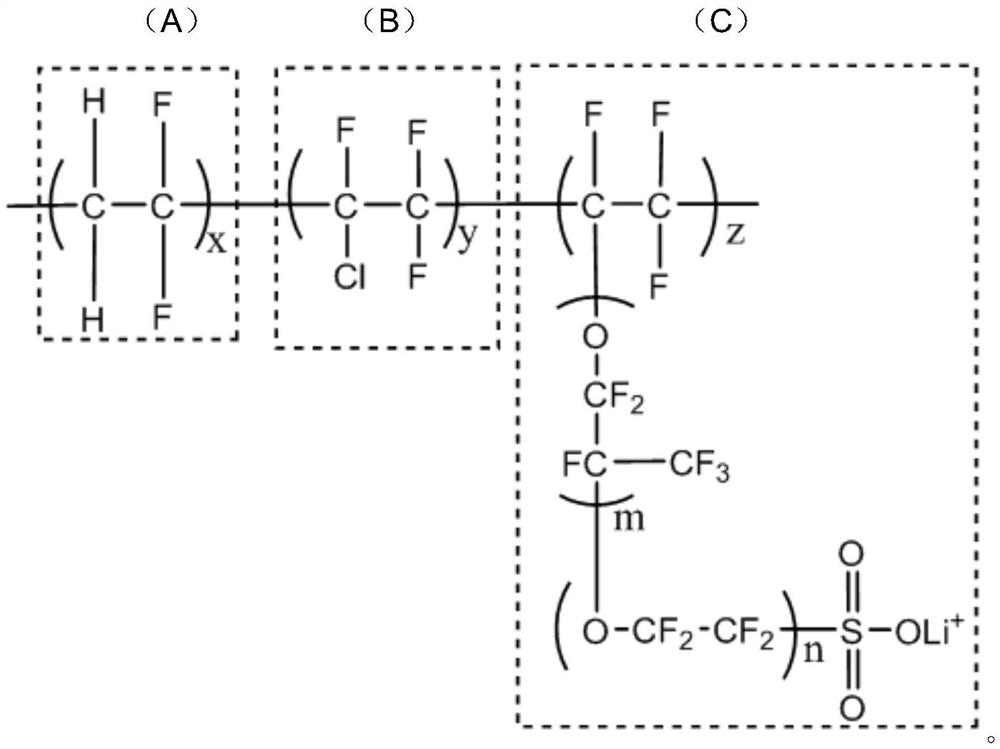

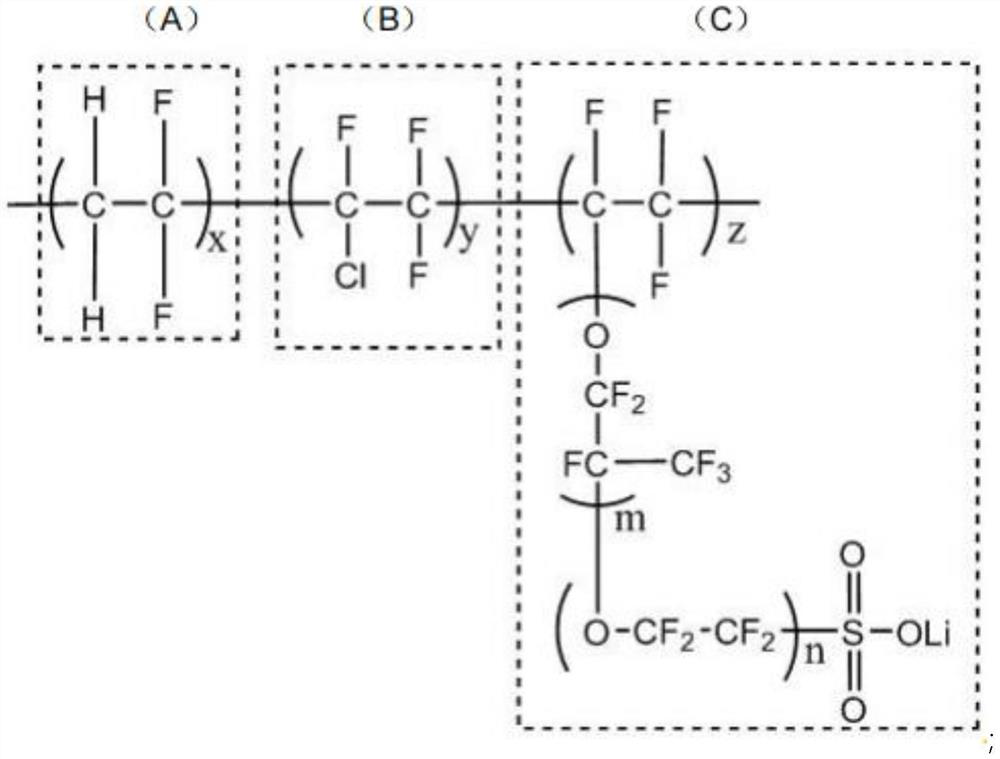

Polyelectrolyte material applicable to lithium battery and preparation method of polyelectrolyte material

ActiveCN112210034AAvoid chemical degradationWith self-emulsifying functionLi-accumulatorsVinyl etherLithium-ion battery

The invention discloses a polyelectrolyte material applicable to a lithium battery and a preparation method of the polyelectrolyte material. The polyelectrolyte material comprises a polyvinylidene fluoride structural unit, a chlorotrifluoroethylene structural unit and a perfluorovinyl ether lithium sulfonate structural unit. The preparation method comprises the following steps: respectively addinga vinylidene fluoride monomer, a chlorotrifluoroethylene monomer, a perfluorovinyl ether lithium sulfonate monomer and an initiator into a reaction device, and carrying out one-step copolymerizationby virtue of a polymerization reaction method. According to the invention, the advantage structure of polyvinylidene fluoride is retained, so the sufficient mechanical strength and the sufficient thermal stability of the polyelectrolyte material are ensured; and an efficient lithium ion transmission structure unit, a polar group and a large number of the ultra-stable structure units are introducedso as to overcome the defects of the existing PVDF serving as a polymer lithium ion battery material, optimize lithium ion transmission efficiency, improve the ionic conductivity of the lithium battery, decrease the polarization of the battery in the charging process and enhance the charging and discharging performance of the battery; and a new material and a new method are provided for further development and application of the lithium battery.

Owner:氟金(上海)新材料有限公司

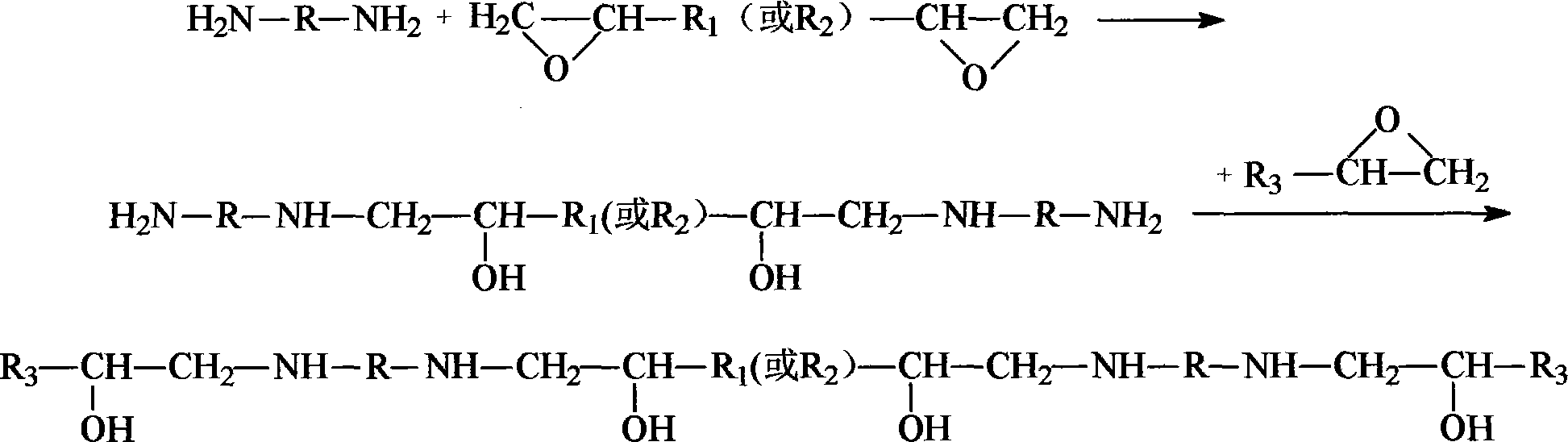

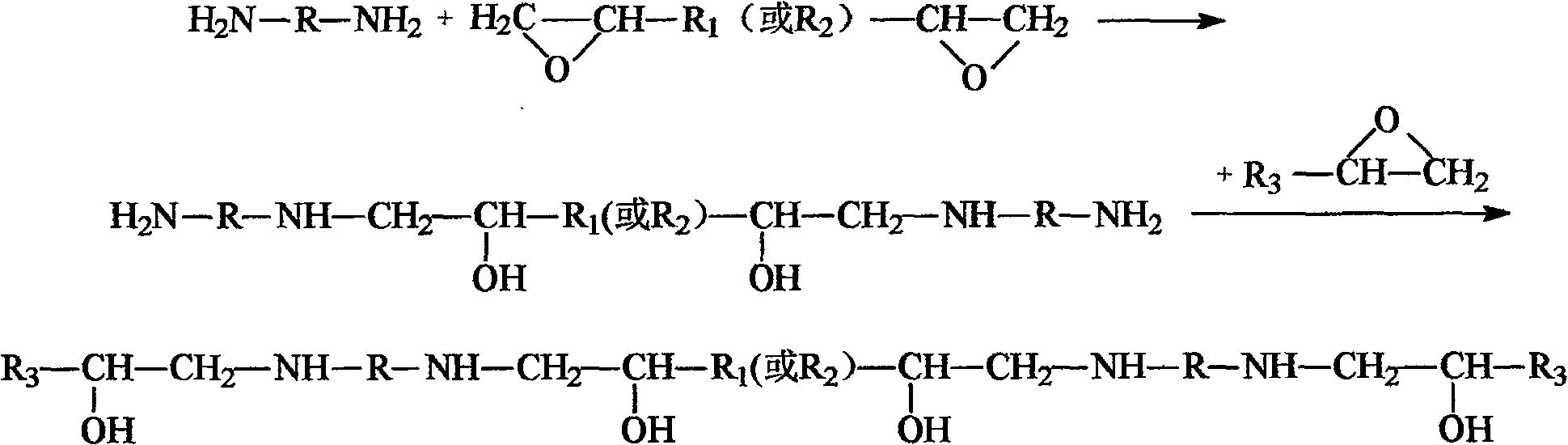

Aqueous epoxy resin curing composition and preparation method thereof

The invention provides an aqueous epoxy resin curing composition and a preparation method thereof and relates to resin curing compositions and preparation methods thereof. The aqueous epoxy resin curing composition is prepared from the ingredients in percentage by mass: 21% to 39% of curing agent, 19% to 37% of epoxy resin and 35% to 55% of deionized water, wherein the curing agent is prepared through subjecting polyamine to chain extension by a polybasic epoxy long-chained compound and epoxy resin and carrying out modifying and terminating synthesis, the mole ratio of the polybasic epoxy long-chained compound to the polyamine is 1: (1.2 to 4), and the mole ratio of the epoxy resin to polyethylene polyamine is 1:(1.2 to 4). The aqueous epoxy resin curing composition is obtained through uniformly mixing 21% to 39% by mass of self-emulsifying aqueous epoxy resin curing agent, 19% to 37% by mass of epoxy resin and 35% to 55% by mass of deionized water. Preparation processes of the aqueous epoxy resin curing agent and the aqueous epoxy resin composition are simple and convenient and are pollution-free to environments, and physicochemical properties such as hardness and gloss are excellent.

Owner:沈阳百辰化学科技有限公司

Synthesis method of dimer acid emulsifier

PendingCN113441079AImprove stabilityGood emulsifying effectTransportation and packagingMixingPtru catalystExplosive Agents

The invention discloses a synthesis method of a dimer acid emulsifier, the synthesis method comprises the following steps: (1) adding dimer acid into a reactor, stirring and heating to 80 DEG C, and starting a vacuum pump; (2) adding polyol and a catalyst solution, continuously heating to 150-190 DEG C, stirring and reacting for 2-5 hours, and controlling the heating speed at 20-30 DEG C / h to obtain an intermediate containing a lipid group; (3) cooling the intermediate containing the lipid group in the step (2) to 120 DEG C, adding a diluent, then adding polyamine or alcohol amine, controlling the temperature to be 120-180 DEG C for reaction, stirring and reacting for 1-2 hours in a vacuum state, controlling the heating speed to be 10-20 DEG C / h, and stopping the reaction after all water generated by the reaction is evaporated; and (4) cooling and discharging to obtain the emulsifier with the content of 70% or above. The emulsifier is used for industrial colloidal explosives, the emulsibility in the product preparation process is greatly improved, the emulsifier can be smoothly emulsified under the condition that the stirring strength in the emulsion preparation process is reduced, the emulsifier has a certain self-emulsifying function, and the stability of colloid is greatly improved after the emulsification is finished.

Owner:昆明澳融科技有限责任公司

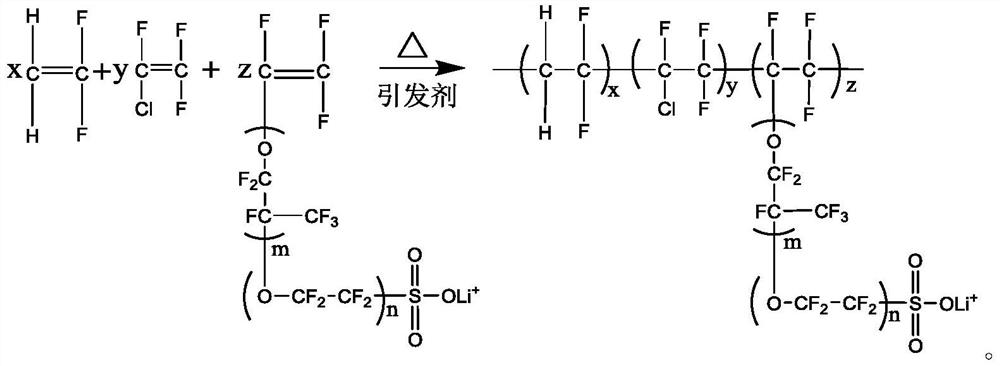

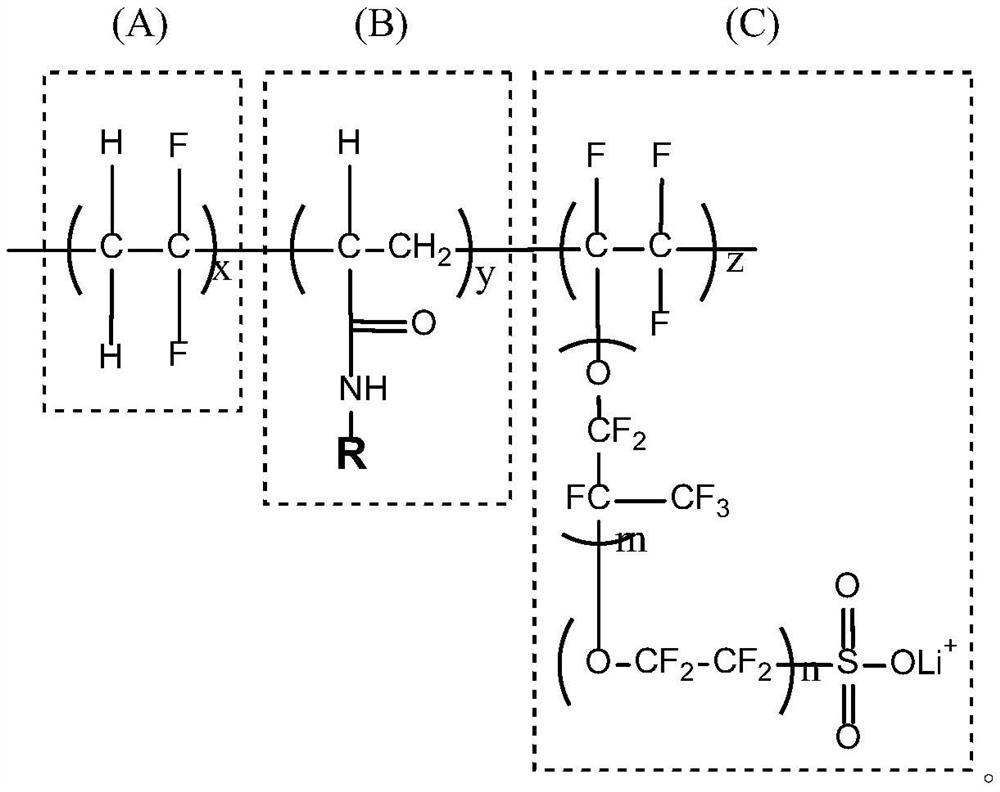

Polyvinylidene fluoride-based terpolymer and preparation method thereof

ActiveCN112500519AImprove transmission efficiencyImprove ionic conductivitySecondary cellsVinyl etherLithium-ion battery

The invention relates to a polyvinylidene fluoride-based terpolymer and a preparation method thereof. The polyvinylidene fluoride-based terpolymer comprises a polyvinylidene fluoride structural unit,an acrylamide structural unit and a perfluorovinyl ether lithium sulfonate structural unit, the preparation method comprises the following steps: respectively adding a vinylidene fluoride monomer, anacrylamide monomer, a perfluorovinyl ether lithium sulfonate monomer and an initiator into a reaction device, and carrying out one-step copolymerization by virtue of a polymerization reaction method.According to the invention, the advantage structure of polyvinylidene fluoride is retained, enough mechanical strength and thermal stability of the copolymer are ensured, the defects of the existing PVDF as a polymer lithium ion battery material are overcome by introducing a lithium ion high-efficiency transmission structural unit, a polar group and a large number of super-stable structural units,the transmission efficiency of lithium ions is optimized, the ionic conductivity of the lithium battery is improved, the polarization of the battery in the charging process is reduced, the charging and discharging performance of the battery is improved, and a new material and a new method are provided for further development and application of the lithium battery.

Owner:氟金(上海)新材料有限公司

Multifunctional organic silicon finishing agent and preparation method thereof

Owner:NANTONG UNIVERSITY

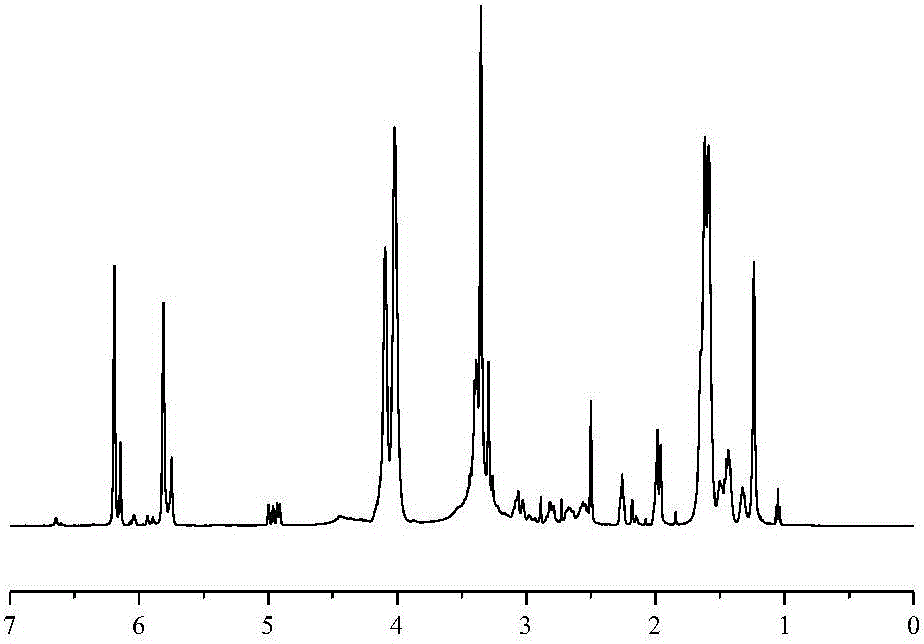

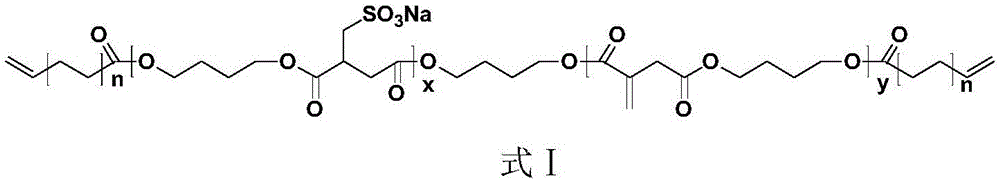

A kind of self-emulsifying aqueous polyester emulsion and preparation method thereof

ActiveCN106432706BNovel preparation methodWith self-emulsifying functionPolyester coatingsPolyesterPolymer science

The invention provides novel self-emulsifying water-based polyester emulsion and a preparation method thereof. The preparation method includes the following steps that itaconic acid, methyl-butanedioic acid-5-sodium sulfonate and 1,4-butanediol are subjected to condensation polymerization, then terminal hydroxyl water-based polyester-poly(itaconic acid butanediol-co-methyl-butanedioic acid-5-sodium sulfonate butanediol)ester (PBIINa) is obtained, and the PBIINa and terminal olefine acid are heated to 110-160 DEG C under nitrogen protection, and terminal olefine acid modified water-based polyester is obtained after an esterification reaction. The terminal olefine acid modified water-based polyester is dispersed in water, and then the water-based polyester emulsion is obtained. The preparation method of the water-based polyester emulsion is novel and has a self-emulsifying function, an emulsifying agent does not need to be added, organic solvent is not contained, and the water-based polyester emulsion can be used as emulsion coating and has broad market prospects. The steps are simple, operation is convenient, and practicability is high.

Owner:QINGDAO UNIV OF SCI & TECH

Styrene-acrylate aqueous dispersoid with amphiphilic structure and preparation method thereof

The invention discloses a styrene-acrylate aqueous dispersoid with an amphiphilic structure and a preparation method thereof. The preparation method comprises the following steps of: mixing 1-10 parts of reactive emulsifying agent, 14-38 parts of styrene, 12-32 parts of alpha-methyl styrene, 40-60 parts of acrylate monomer, 1-2 parts of initiator and 0-1 part of chain transfer agent, and preparing into a composition A; dissolving 0.2-0.5 part of initiator in 2-5 parts of solvent, and preparing into a composition B; adding 30-50 parts of solvent into a reaction kettle, rising the temperature to 80-100 DEG C, firstly adding 10-20 parts of composition A, reacting for 20-40 minutes, then dropping the remaining amount of the composition A, and then adding the composition B; and adding 13.5-20.2 parts of amine substances into the reaction kettle for carrying out neutralization, dispersing reaction products with water and obtaining the styrene-acrylate aqueous dispersoid. The styrene-acrylate aqueous dispersoid prepared by the invention has the characteristics of high solid content, low viscosity, fast drying, excellent storage stability and the like, the process is simple, and the safety and the energy conservation are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Crosslinking self-emulsifying cation full fluorine copolymer soap-free emulsion and preparation thereof

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of self-emulsifying cationic epoxy emulsion

InactiveCN103497617BNarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsCarbon chainSelf emulsifying

Owner:ZHAOQING UNIV

Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

ActiveCN100569826CAvoid situations that require high temperaturesThe synthesis process is simple, safe and energy-savingEpoxyAdhesive

This invention relates to a method for preparing self-emulsifying waterborne epoxy curing agent emulsion, which is composed of: primary amine 7-20 wt.%, epoxy resin 12-27 wt.%, epoxy-terminated polyether 3-8 wt.%, epoxy active diluter 10-30 wt.%, and deionized water 35-60 wt.%. The method comprises: adding primary amine into a reactor, slowly dropping a mixture of epoxy resin and epoxy-terminated polyether, reacting at a certain temperature, slowly dropping monofunctional epoxy active diluter, reacting, adding water, and emulsifying to obtain white waterborne epoxy curing agent emulsion. The method has such advantages as simple process, low reaction temperature (below 100 deg.C), high safety and low energy consumption. The obtained waterborne epoxy curing agent emulsion has such advantages as low VOC content, high stability, high water resistance, high compatibility with epoxy resin, high impact resistance, good luster, high toughness and high adhesiveness, and can be used in paint, adhesive and polymer concrete.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Dimer acid emulsifier

PendingCN113443947AImprove stabilityGood emulsifying effectTransportation and packagingMixingPolymer sciencePolyol

The invention discloses a dimer acid emulsifier which is prepared from dimer acid, polyol, a catalyst, a diluent and polyamine or alcohol amine. The mass ratio of the dimer acid to the polyol is 100: (10-30); the addition amount of the catalyst is 0.01-0.1%. The dimer acid, the polyol and the catalyst react to obtain an intermediate containing a lipid group, namely dimer acid polyol ester, and the mass ratio of the dimer acid polyol ester to the polyamine or alcohol amine is 100: (5-40); the addition amount of the diluent is 50% of that of the dimer acid. Compared with the prior art, the emulsifier has the advantages that the emulsifier is used for industrial colloidal explosives, the emulsibility in the product preparation process is greatly improved, the emulsifier can be smoothly emulsified in the state of reducing the stirring strength in the emulsion preparation process, the emulsifier has a certain self-emulsifying function, and the stability of colloid is greatly improved after the emulsification is finished.

Owner:昆明澳融科技有限责任公司

Polyelectrolyte material for lithium battery application and preparation method thereof

ActiveCN112210034BAvoid chemical degradationWith self-emulsifying functionLi-accumulatorsVinyl etherElectrical battery

A polyelectrolyte material for lithium battery applications and a preparation method thereof, the polyelectrolyte material includes polyvinylidene fluoride structural units, chlorotrifluoroethylene structural units and perfluorovinyl ether sulfonate lithium structural units; the preparation method includes : In a reaction device, vinylidene fluoride monomer, chlorotrifluoroethylene monomer, perfluorovinyl ether sulfonate lithium monomer and initiator are respectively added, and the reaction method is used for one-step copolymerization. The invention retains the advantageous structure of polyvinylidene fluoride, ensures that the polyelectrolyte material has sufficient mechanical strength and thermal stability, and overcomes the existing problems by introducing efficient lithium ion transport structural units, polar groups and a large number of ultra-stable structural units. There are deficiencies in PVDF as a polymer lithium-ion battery material, which optimizes the transmission efficiency of lithium ions, improves the ionic conductivity of lithium batteries, reduces the polarization of the battery during charging, and improves the charge and discharge performance of the battery. It provides new materials and methods for the further development and application of lithium batteries.

Owner:氟金(上海)新材料有限公司

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295BBroad encapsulationWide penetration abilityFibre treatmentPolyelectrolytePolymer science

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

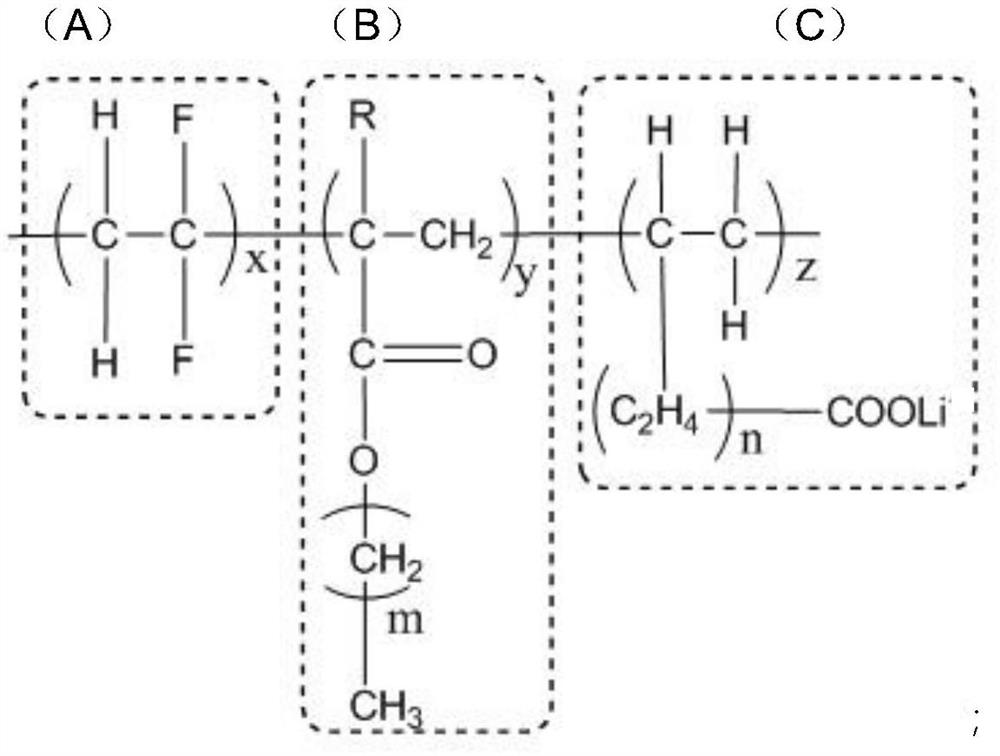

Lithium carbonate ion-containing copolymer and preparation method thereof

ActiveCN112239519BWith self-emulsifying functionReduce usageSecondary cellsOrganic electrolytesEngineeringStructural unit

A lithium carbonate ion-containing copolymer and a preparation method thereof, the lithium carbonate ion-containing copolymer includes a polyvinylidene fluoride structural unit, an acrylate structural unit and a vinyl lithium carbonate structural unit; the preparation method comprises: in a reaction device , respectively adding vinylidene fluoride monomer, acrylate monomer, vinyl lithium carbonate monomer and initiator, and one-step copolymerization by polymerization reaction method. The invention retains the advantageous structure of polyvinylidene fluoride, ensures that the copolymer has sufficient mechanical strength and thermal stability, and overcomes the existing problems by introducing efficient lithium ion transport structural units, polar groups and a large number of ultra-stable structural units. The shortcomings of PVDF as a polymer lithium-ion battery material optimize the transmission efficiency of lithium ions, improve the ionic conductivity of lithium batteries, reduce the polarization of the battery during charging, and improve the charge and discharge performance of the battery. The further development and application of lithium batteries provides new materials and methods.

Owner:氟金(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com