Multifunctional organic silicon finishing agent and preparation method thereof

A silicone and finishing agent technology, applied in fiber treatment, textiles and papermaking, etc., to achieve the effects of outstanding anti-yellowing performance, excellent anti-ultraviolet performance, and good whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A multifunctional silicone finishing agent, which comprises the following components in mass percent: 20% of anti-ultraviolet polyether silicone oil, 8% of isobutanol, phosphate betaine type gemini surfactant and fatty alcohol polyoxyethylene ether (10 ) 1:1 compound emulsifier 8%, pH buffer 5%, deionized water 59%.

[0018] The preparation method of the above-mentioned multifunctional organosilicon finishing agent comprises the following steps:

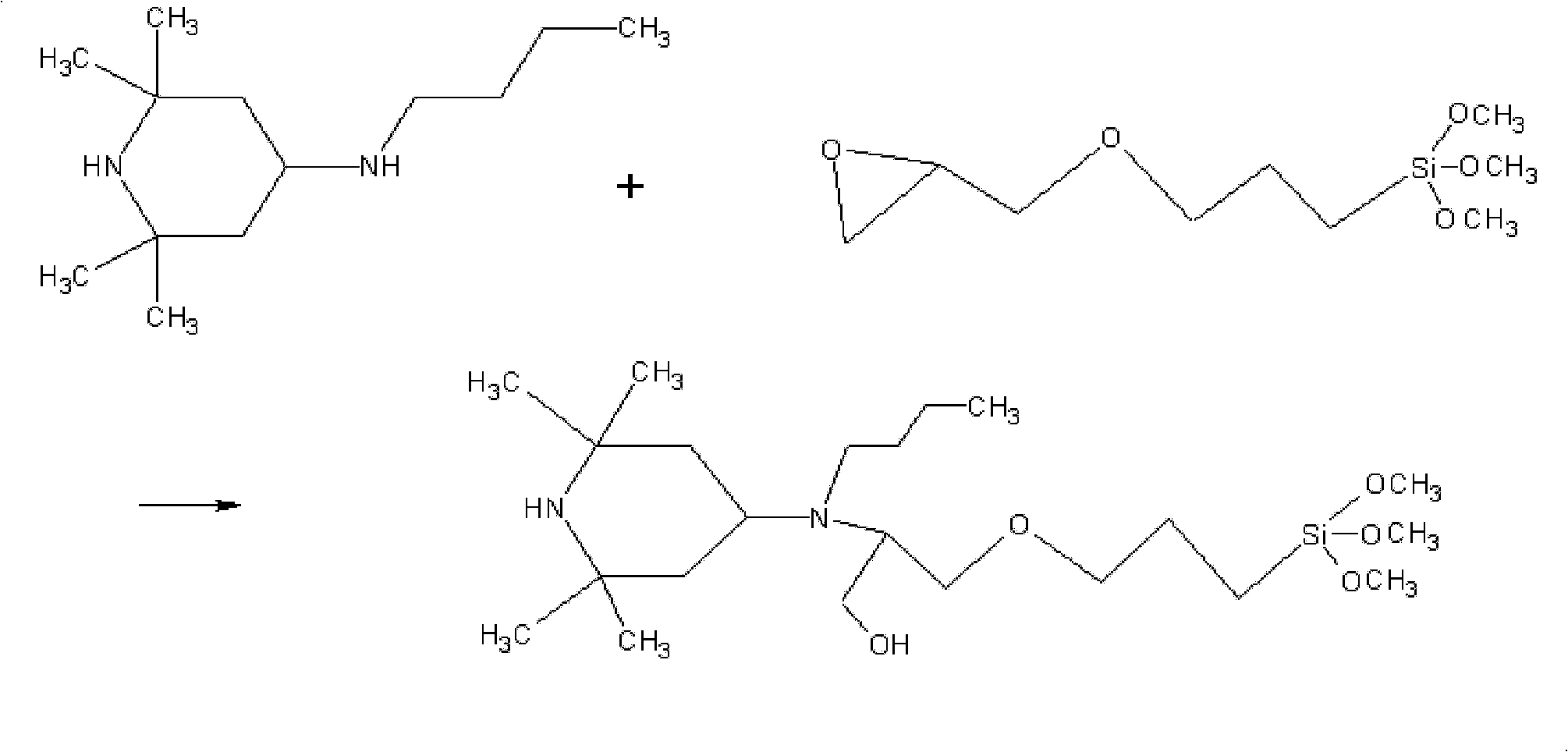

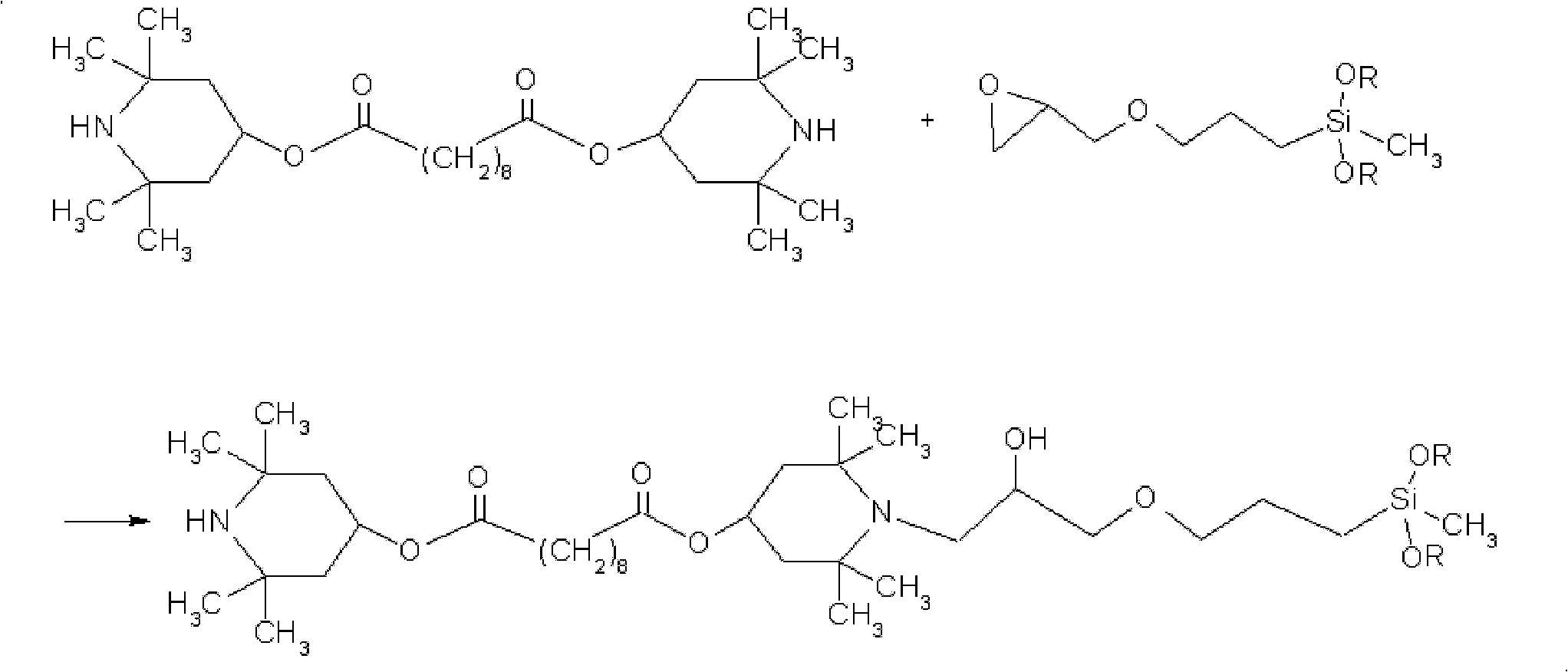

[0019] 1. Take 100 parts of water-soluble silicone containing epoxy groups, add 100 parts of light-stabilizing substances-N-butyl-tetramethylpiperidinamine or tetramethylpiperidinol compounds, and heat up to 70 After reacting for 4 hours at ℃, raise the temperature to 120℃, react for 6 hours, and discharge the material to obtain a colorless to slightly yellow transparent finished product, which is the anti-ultraviolet polyether modified silicone oil;

[0020] 2. Add metered deionized water, phosphate betaine type gemini surfa...

Embodiment 2

[0022] A multifunctional silicone finishing agent, which comprises the following components in mass percent: 14% of anti-ultraviolet polyether silicone oil, 10% of isobutanol, phosphate betaine type gemini surfactant and fatty alcohol polyoxyethylene ether (10 ) 1:1 compound emulsifier 9%, pH value buffer 3.5%, deionized water 63.5%.

[0023] The preparation method of the above-mentioned multifunctional organosilicon finishing agent comprises the following steps:

[0024] 1. Take 100 parts of water-soluble silicone containing epoxy groups, add 200 parts of N-butyl-tetramethylpiperidinamine or tetramethylpiperidinol compounds with light stabilizing effect, and heat up to 80°C After reacting for 4.5 hours, raise the temperature to 125°C, react for 7 hours, and discharge the material to obtain a colorless to slightly yellow transparent finished product, which is the anti-ultraviolet polyether modified silicone oil;

[0025] 2. Add metered deionized water, phosphate betaine type ...

Embodiment 3

[0027] A multifunctional silicone finishing agent, which comprises the following components in mass percentage: 8% of anti-ultraviolet polyether silicone oil, 12% of isobutanol, phosphate betaine type gemini surfactant and fatty alcohol polyoxyethylene ether (10 ) 1:1 compound emulsifier 10%, pH value buffer 2%, deionized water 68%.

[0028] The preparation method of the above-mentioned multifunctional organosilicon finishing agent comprises the following steps:

[0029] 1. Take 100 parts of water-soluble silicone containing epoxy groups, add 300 parts of light-stabilizing substances-N-butyl-tetramethylpiperidinamine or tetramethylpiperidinol compounds, and heat up to 90 After reacting for 5 hours at ℃, raise the temperature to 130℃, react for 8 hours, and discharge the material to obtain a colorless to slightly yellow transparent finished product, which is the anti-ultraviolet polyether modified silicone oil;

[0030] 2. Add metered deionized water and phosphate betaine type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com