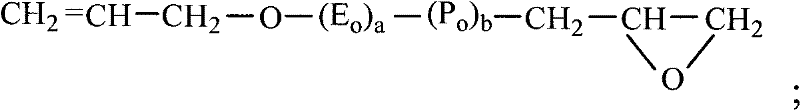

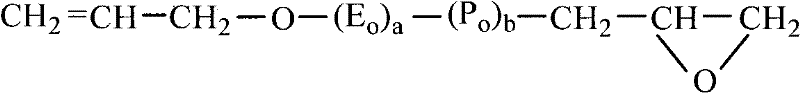

Preparation method for polysiloxanes-amidopolyether block copolymer

A technology of siloxane amine-based polyether and block copolymer, applied in textiles, papermaking, fiber processing, etc., can solve the problem of decreased fabric hand, achieve smooth hand, reduce pollution, low color and small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

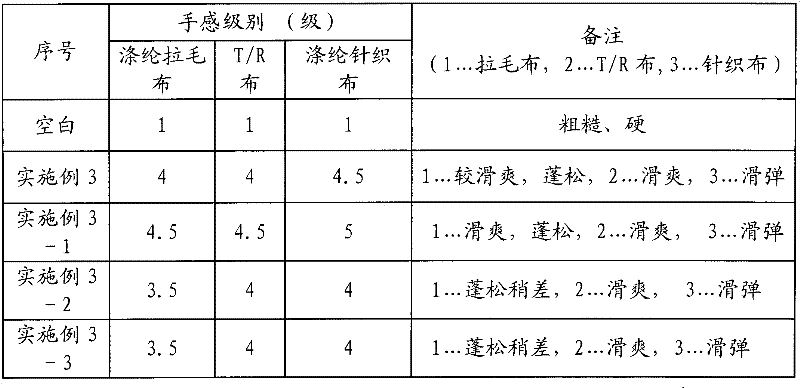

Examples

Embodiment 1

[0041] Preparation of α, ω-hydrogen siloxane intermediates

[0042] Add D 4\579.0g 1,1,3,3-Tetramethyldisiloxane 21.0g, start the stirrer, add 12g of concentrated sulfuric acid, heat up to 50-70°C for 8 hours, slowly add ~22g of baking soda, then add 100g of water, stirred for 15 minutes, poured into a separatory funnel, after standing still, let off the lower aqueous solution, repeated several times until neutral. Then, water and low boilers were distilled off, and the product was a colorless transparent liquid. The measured viscosity is 40-50mPa·S, and the hydrogen content is 0.05%±0.002%.

Embodiment 1-1

[0044] The same device, formula and condition as in Example 1, the catalyst was changed to 12g acid clay, and the acid clay was removed by filtration after the reaction.

Embodiment 2

[0046] Preparation of α, ω-diepoxysiloxane intermediates

[0047] In the same device as in Example 1, add 300.0 g of α, ω-hydrogen siloxane, 20.0 g of allyl glycidyl ether, 5 g of isopropanol, and 190 g of toluene to start stirring, heat up to 75 ° C, add platinum 1, 3-divinyltetramethyldisiloxane chelate toluene solution (Pt content 0.5%) 0.68g, 80 ~ 95 ℃ until 29S i NMR no Si-H detected, then at 120 ℃ and 50mmHg, vacuum distillation Toluene, excess reactants were removed. And determine its epoxy value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com