Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1556results about "Paints for electrolytic applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

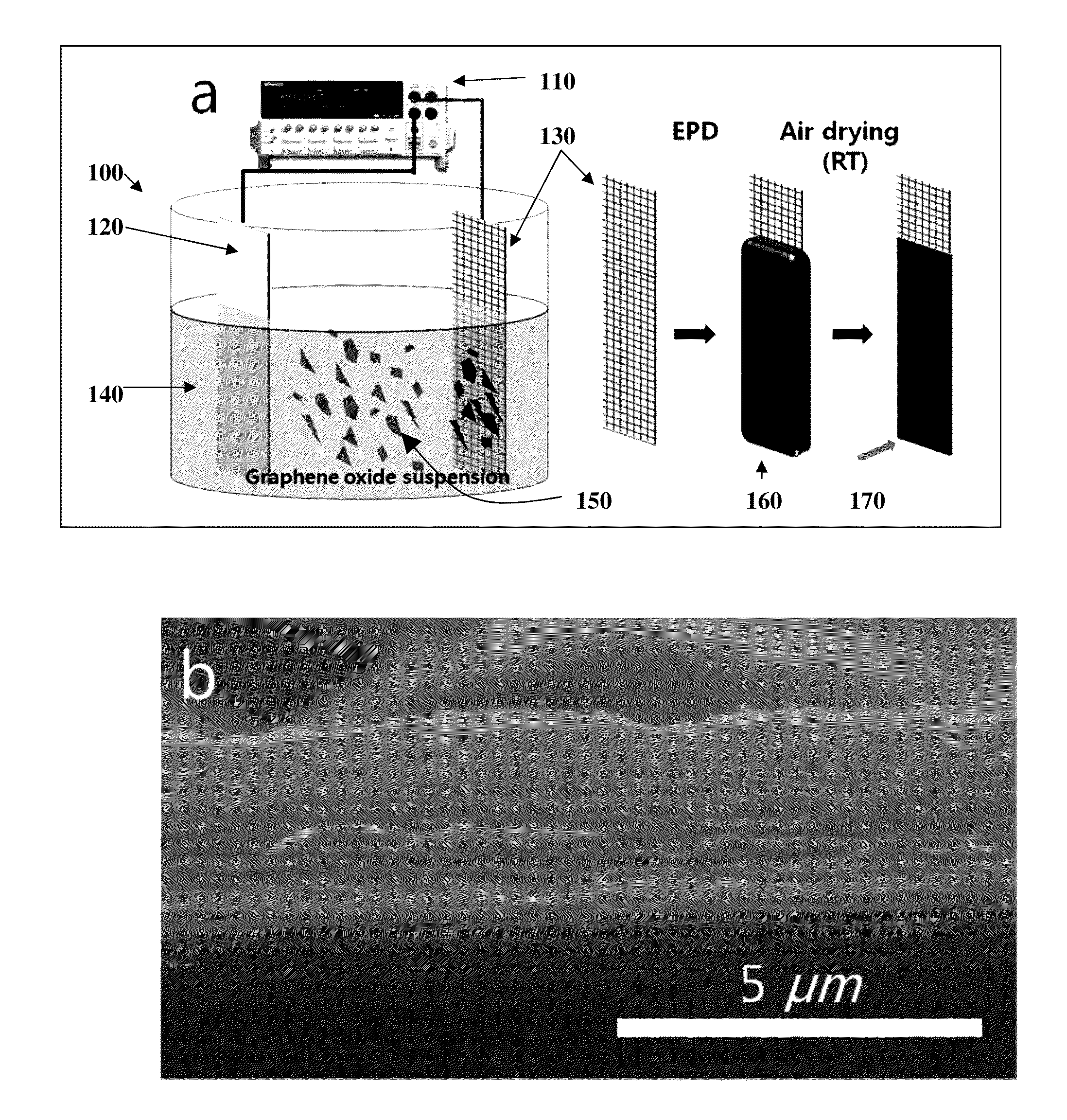

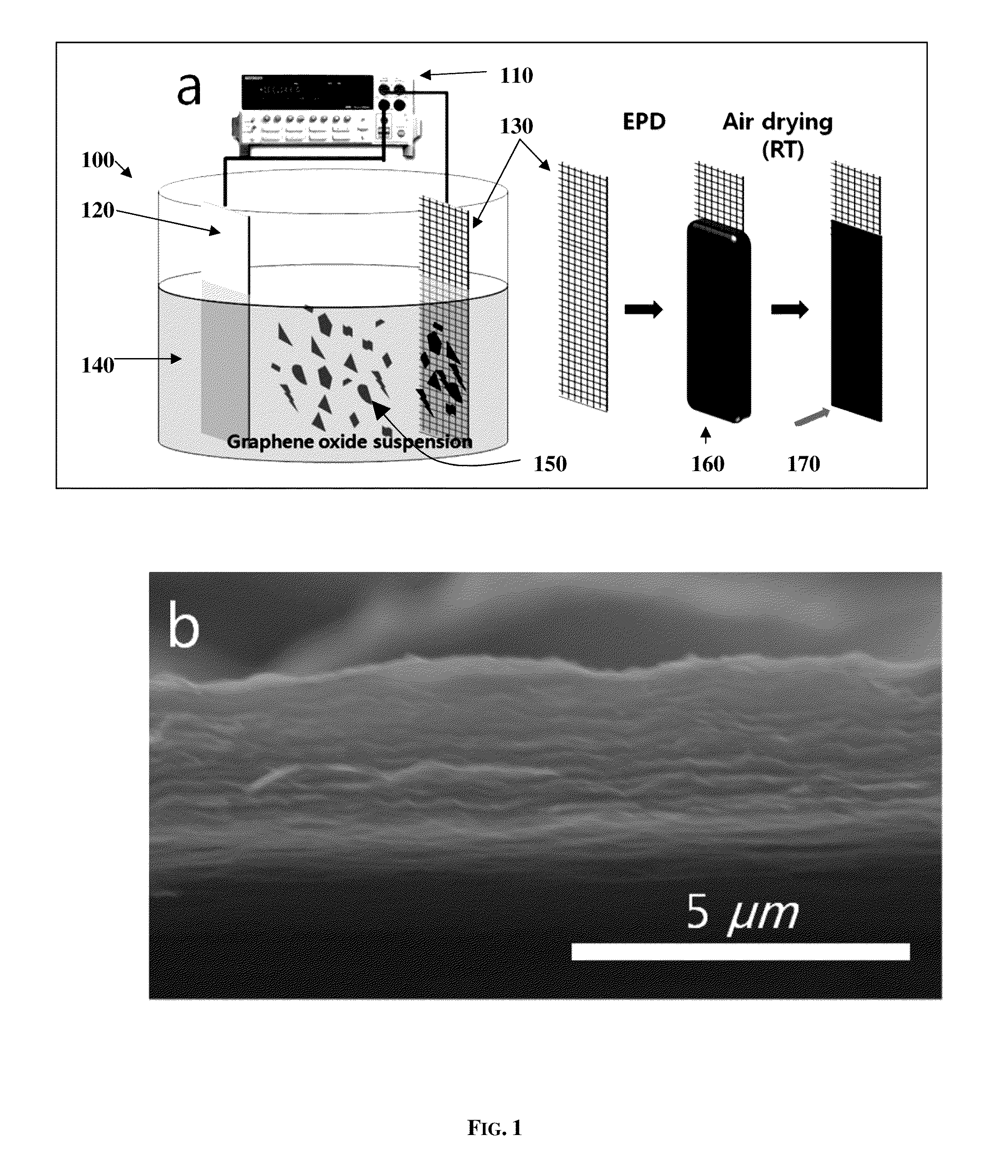

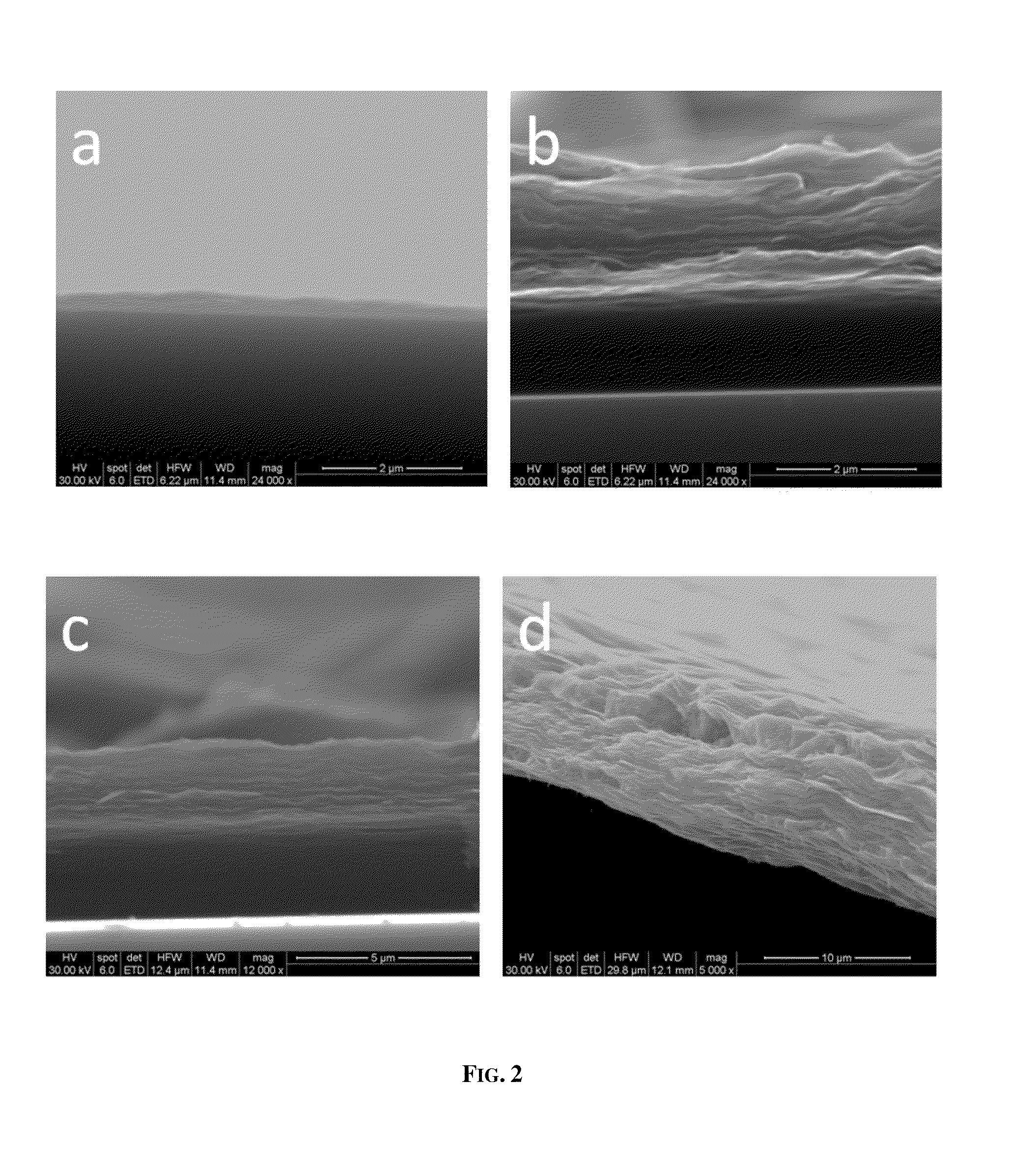

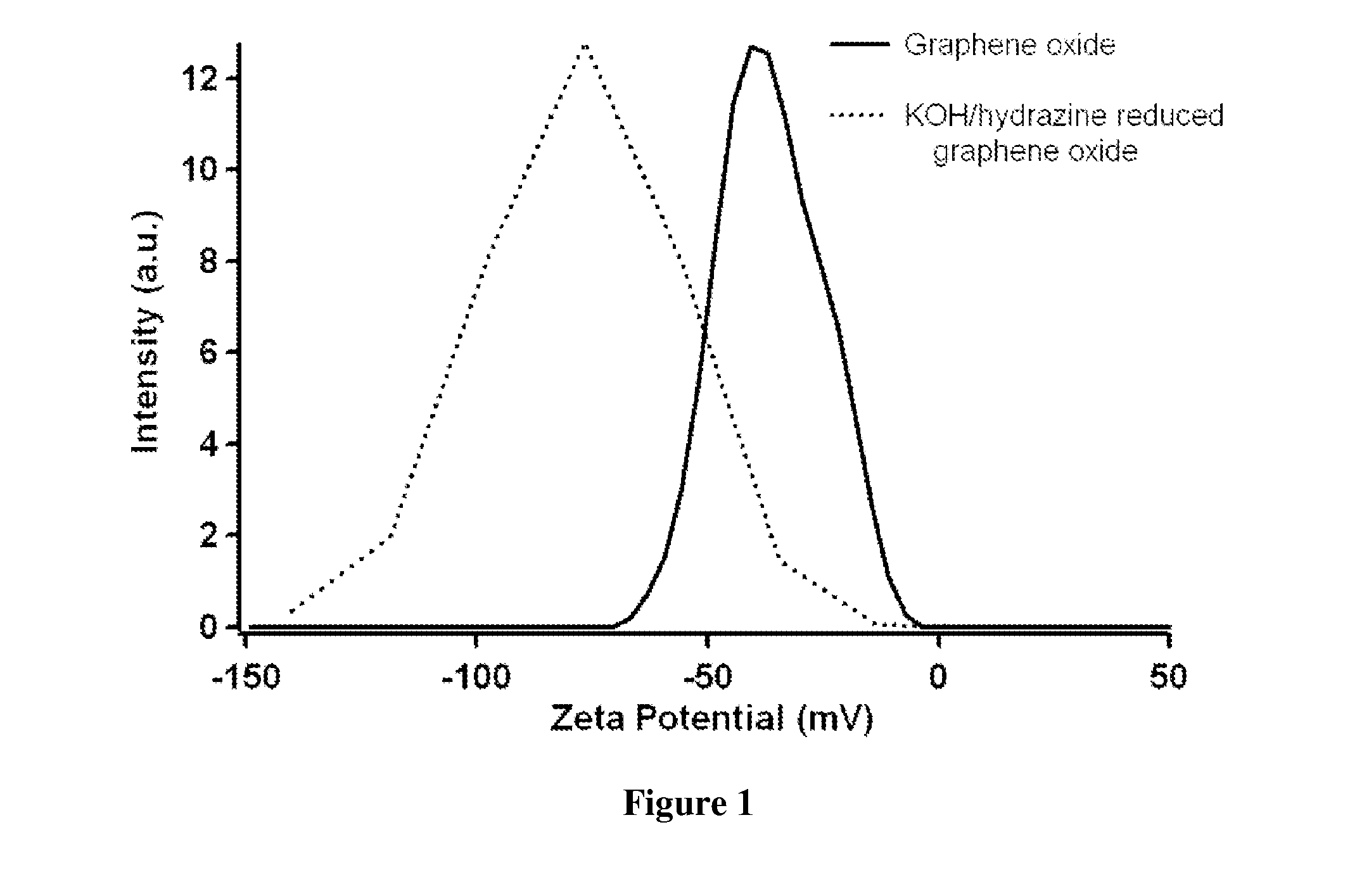

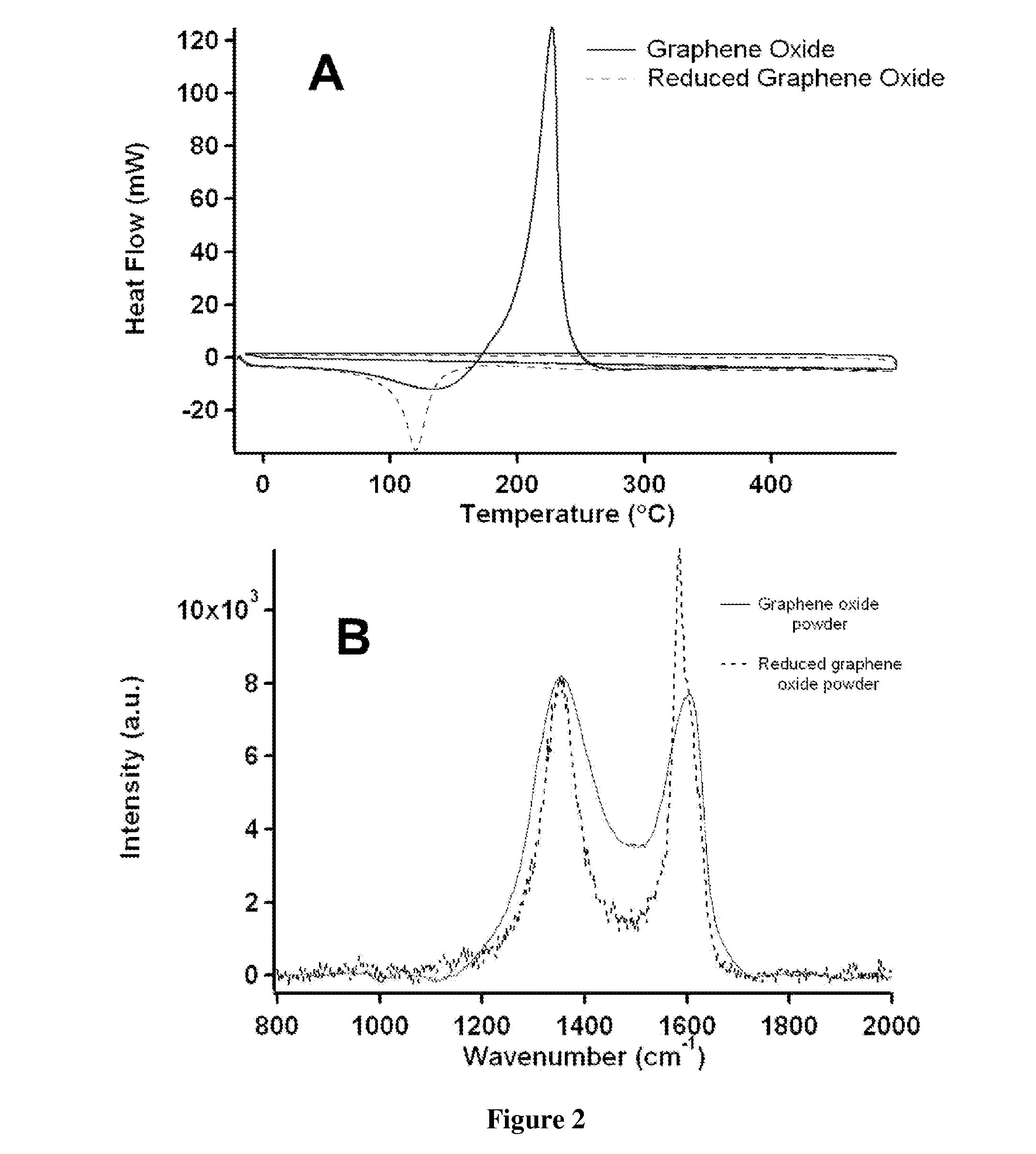

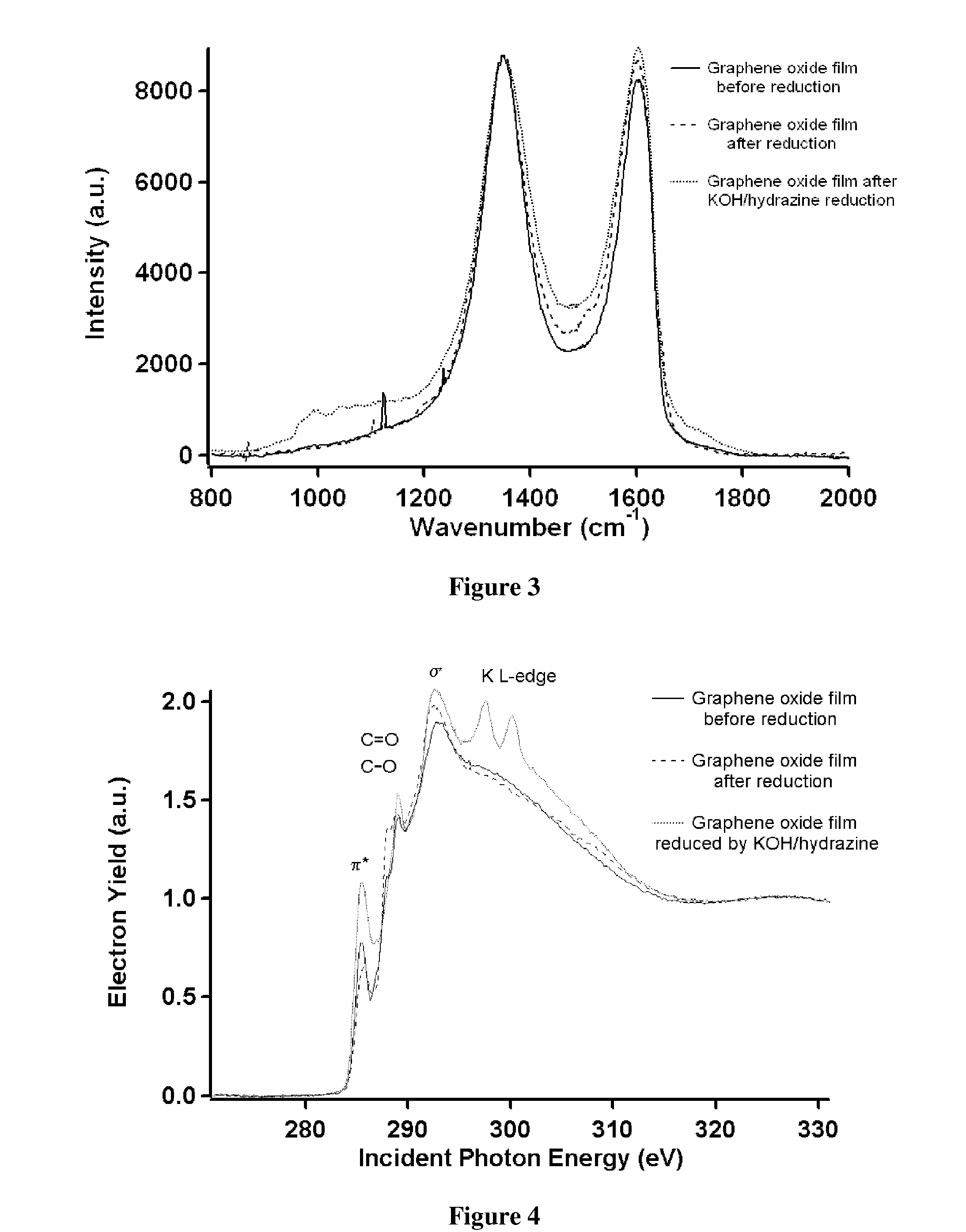

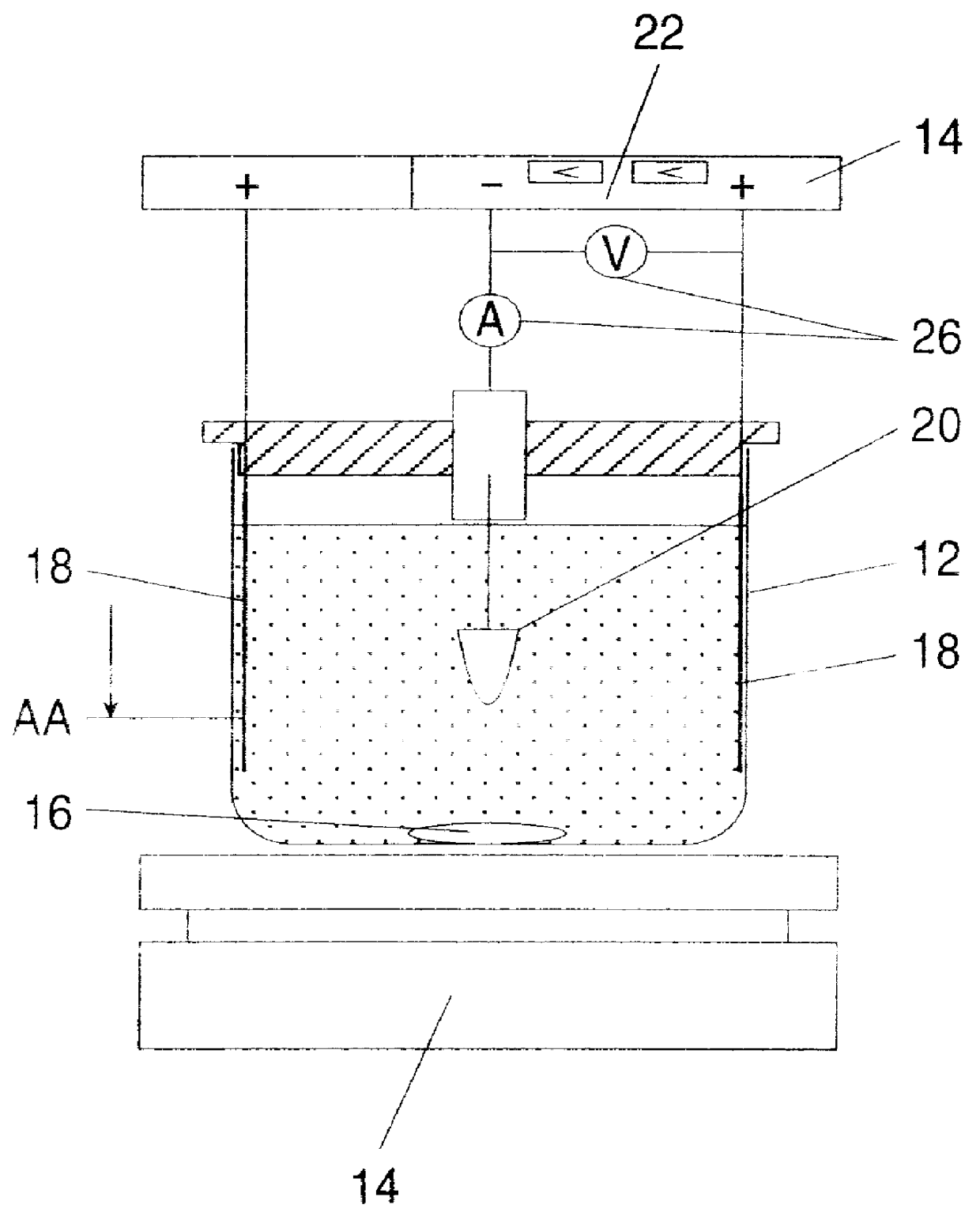

Electrophoretic deposition and reduction of graphene oxide to make graphene film coatings and electrode structures

Owner:RUOFF RODNEY S +4

Methods for coating a metal substrate and related coated substrates

ActiveUS7749368B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrogalvanizationMetallic substrate

Owner:PPG IND OHIO INC

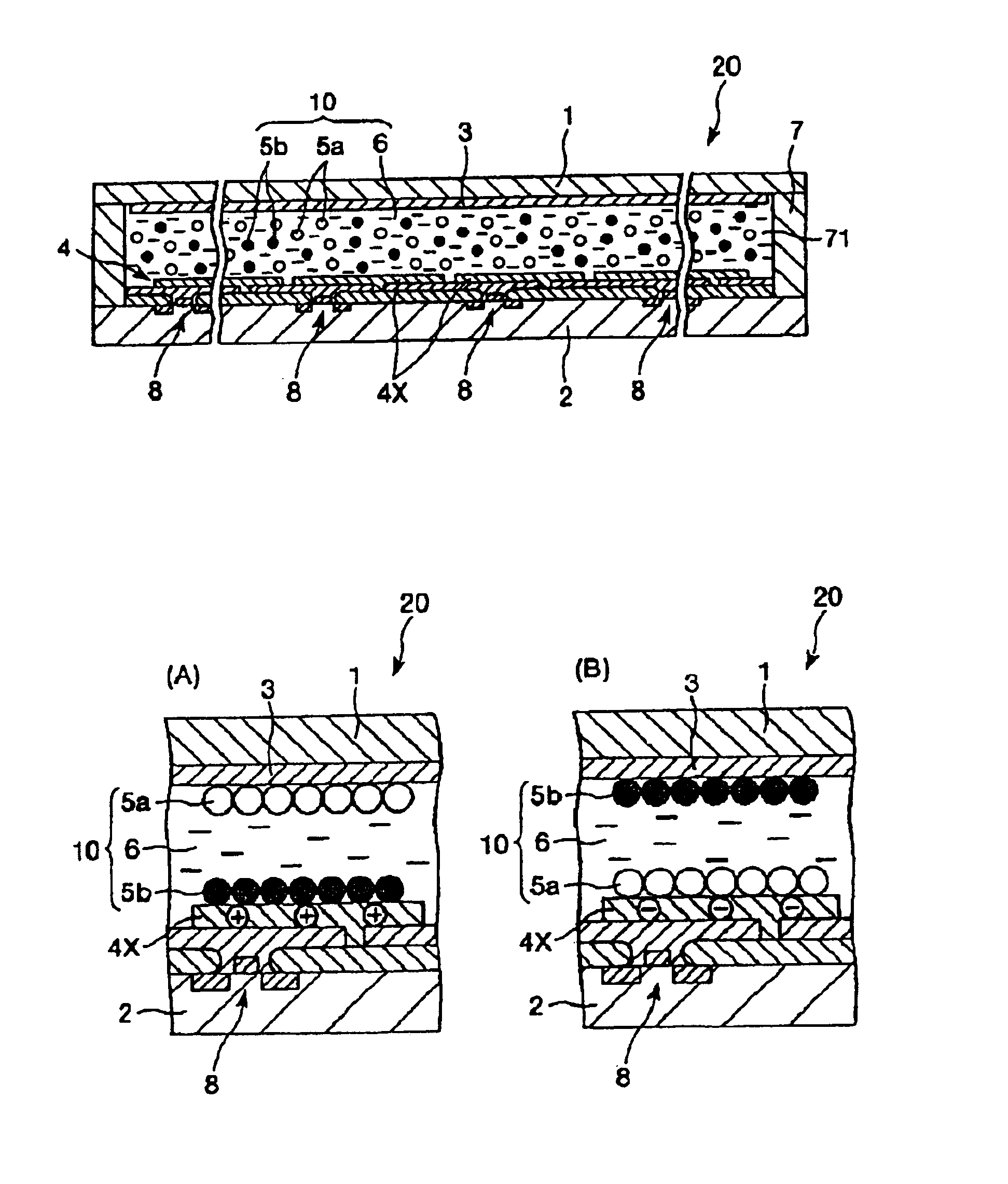

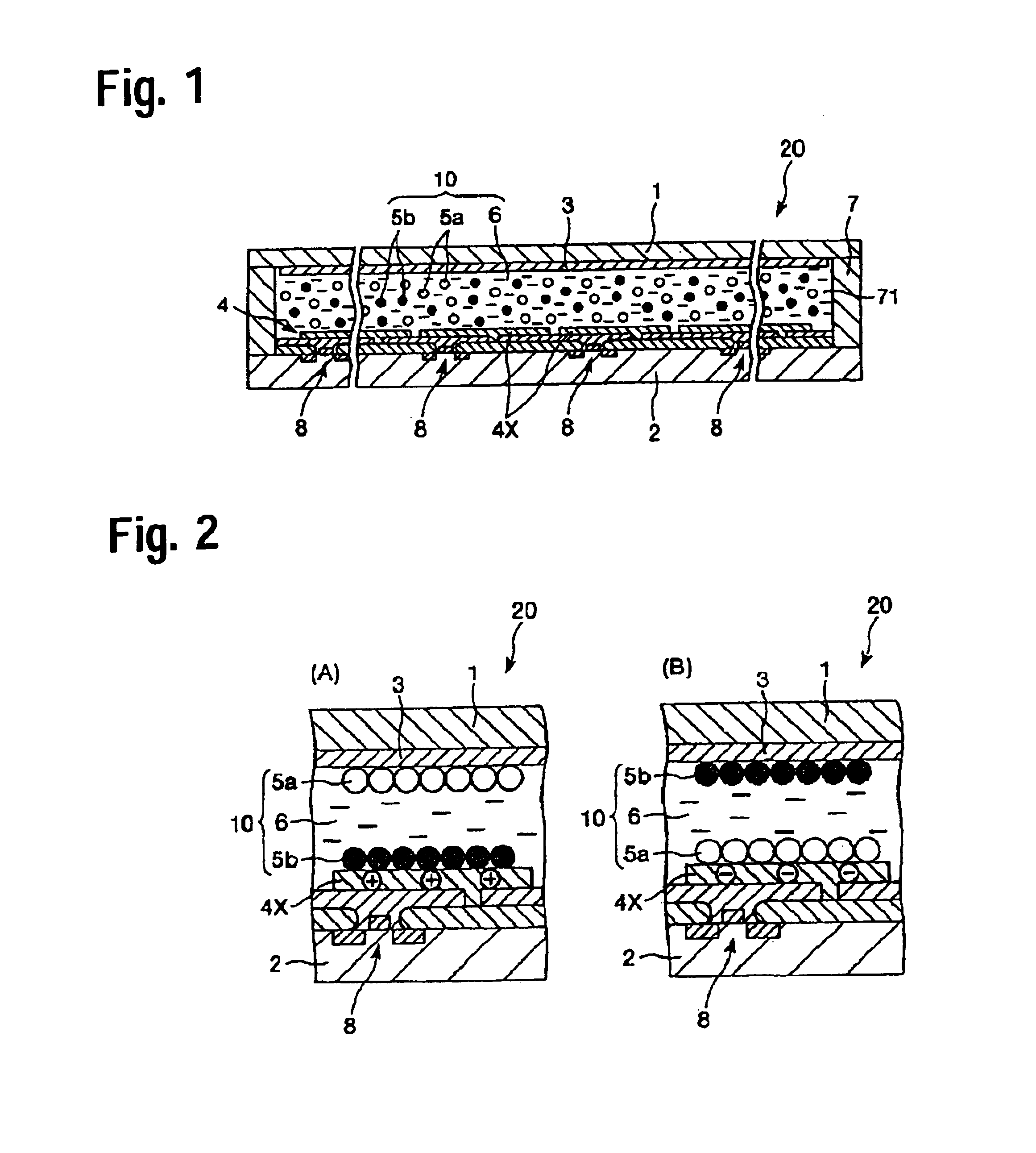

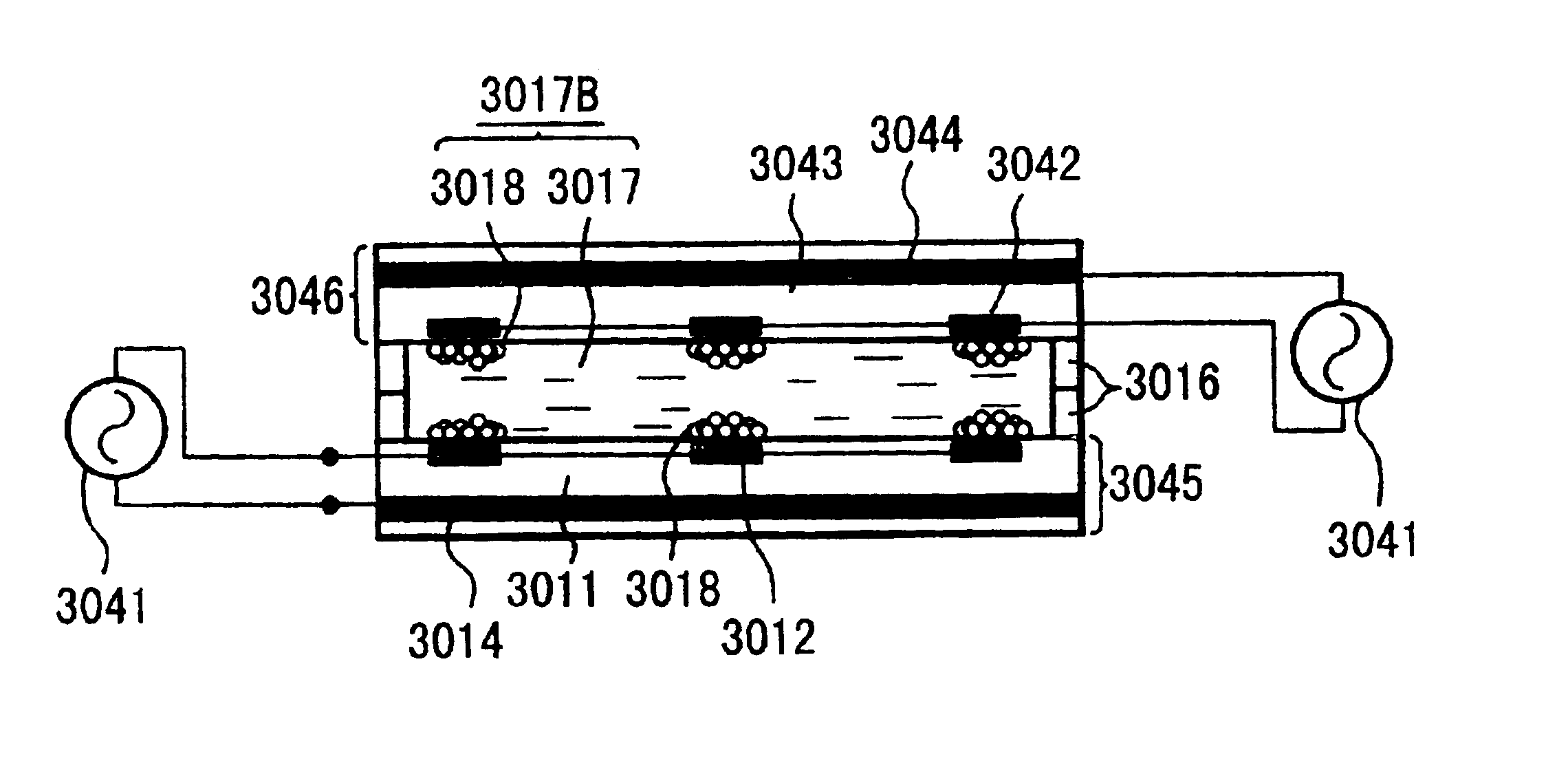

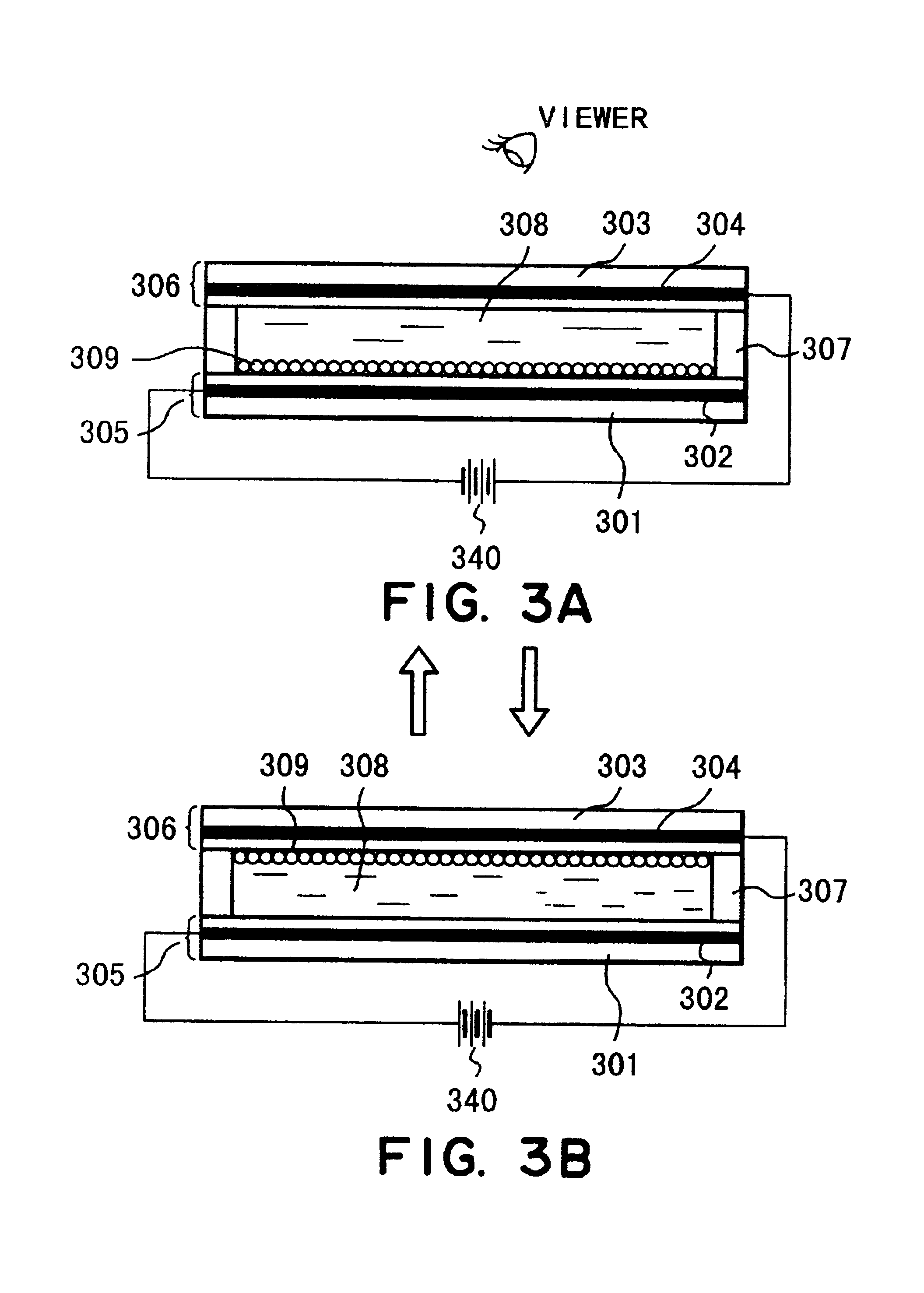

Electrophoretic dispersion, electrophoretic display device, method of manufacturing electrophoretic display device, and electronic system

ActiveUS6947203B2Reduces and prevents aggregationImprove the display effectElectrolysis componentsStatic indicating devicesInorganic particleElectronic systems

To provide an electrophoretic dispersion capable of reducing or preventing the aggregation of electrophoretic particles, an electrophoretic display device using the electrophoretic dispersion, a method of manufacturing the electrophoretic display device, and an electronic system superior in display performance; an electrophoretic display device (electrophoretic display unit) has: a first substrate with a first electrode; a second substrate with a second electrode opposite the first electrode; and an electrophoretic dispersion provided between the first substrate and second substrate. The electrophoretic dispersion (dispersion for electrophoretic display units) includes a liquid phase insulative dispersion medium and electrophoretic particles dispersed in the dispersion medium, the particles electrophoretically migrated under an influence of an electric field. Also included as the electrophoretic particles, inorganic particles and resin particles dyed a color different from that of the inorganic particles and having an electrical polarity opposite to that of the inorganic particles.

Owner:E INK CORPORATION

Articles with hydrophilic coating

InactiveUS6866936B2Favorable and associative interactionImprove wet strengthNon-fibrous pulp additionLiquid surface applicatorsWater basedHydrophilic coating

A water-based coating composition suitable for preparing hydrophilic surfaces on various articles is provided which includes a supporting polymer having functional moieties capable of undergoing crosslinking reactions, said supporting polymer soluble in or emulsified in an aqueous based medium; and a hydrophilic polymer, said hydrophilic polymer associated with the supporting polymer. The composition is characterized in that, when crosslinked at the functional moieties, the supporting polymer forms a three-dimensional network which substantially minimizes disassociation of the hydrophilic polymer.

Owner:SURFACE SOLUTIONS LAB

Electrophoretic diamond coating and compositions for effecting same

InactiveUS6258237B1Effective engineering evaluation of material strengthImprove adhesionElectrolysis componentsVolume/mass flow measurementSubstrate surfaceMaterials science

A method of depositing diamond particles on a surface of a substrate is provided. The method is effected by (a) charging the diamond particles by a positive charge to obtain positively charged diamond particles; and (b) electrophoretically depositing the positively charged diamond particles on the surface of the substrate, for obtaining a green diamond particles coat on the surface of the substrate.

Owner:ISCAR LTD

Graphene Films and Methods of Making Thereof

ActiveUS20130156678A1Material nanotechnologyElectrolysis componentsPlanar substrateConformal coating

Provided are methods for forming graphene or functionalized graphene thin films. Also provided are graphene and functionalized graphene thin films formed by the methods. For example, electrophoretic deposition methods and stamping methods are used. Defect-free thin films can be formed. Patterned films can be formed. The methods can provide conformal coatings on non-planar substrates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

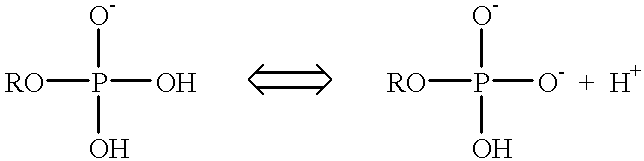

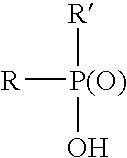

Electrodeposition coatings for use over aluminum substrates

A process for applying a coating on aluminum substrates by anionic electrodeposition of a phosphated epoxy resin made by phosphating a polyepoxide with both phosphoric acid and an organophosphonic acid and / or an organophosphinic acid. The coating has a reduced tendency to form pinholes.

Owner:PPG IND OHIO INC

Process for forming a two-coat electrodeposited composite coating the composite coating and chip resistant electrodeposited coating composition

InactiveUS6248225B1Electrolysis componentsVolume/mass flow measurementPolyurethane coatingAqueous dispersion

A process for applying two electrodeposited coatings, one on top of the other, to an electrically conductive substrate is provided. An electrically conductive first coating is applied to provide for corrosion resistance and a second polyurethane-based coating is applied to the first coating to provide chip resistance. Also, aqueous dispersions of the polyurethane coating compositions are disclosed.

Owner:PPG IND OHIO INC

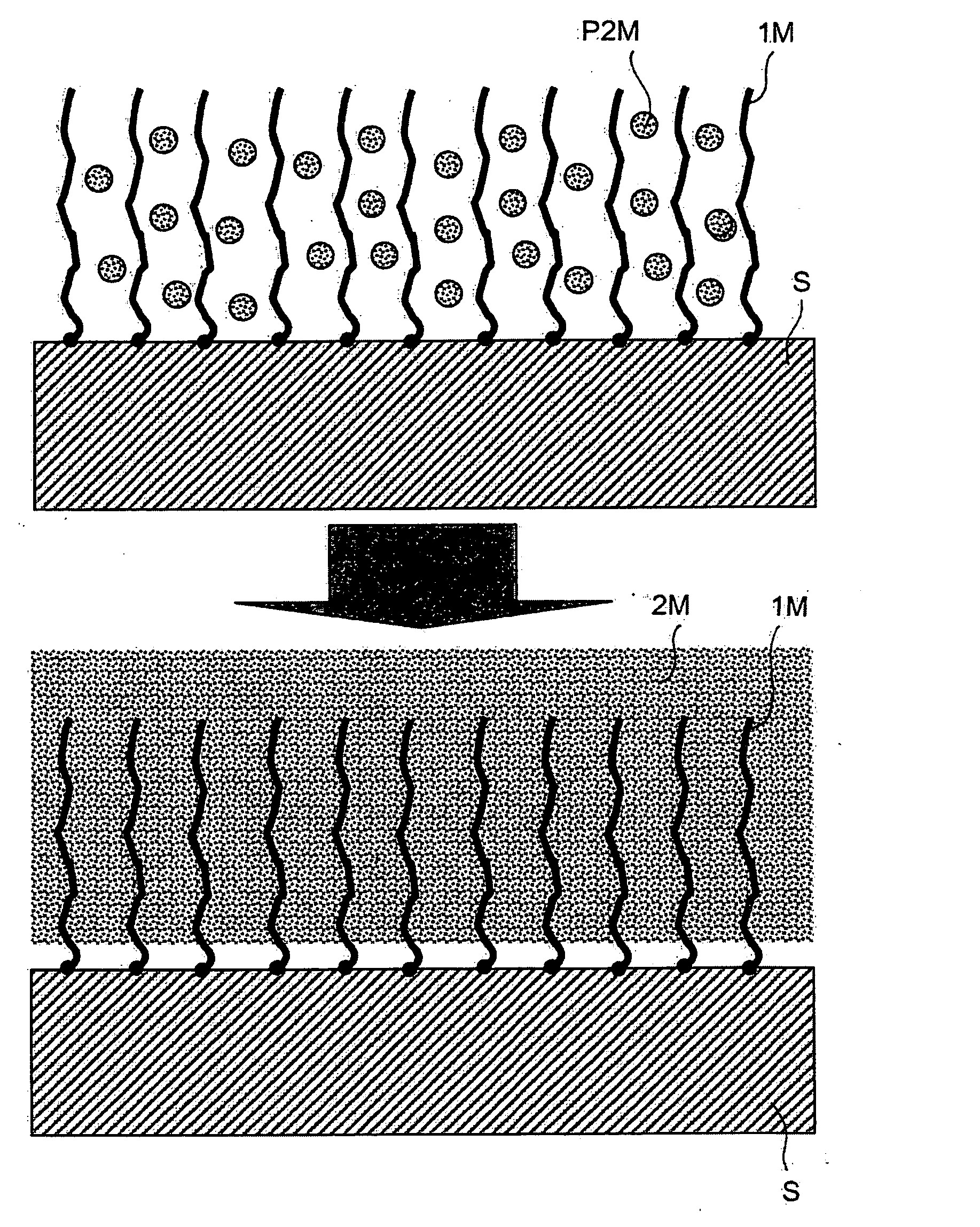

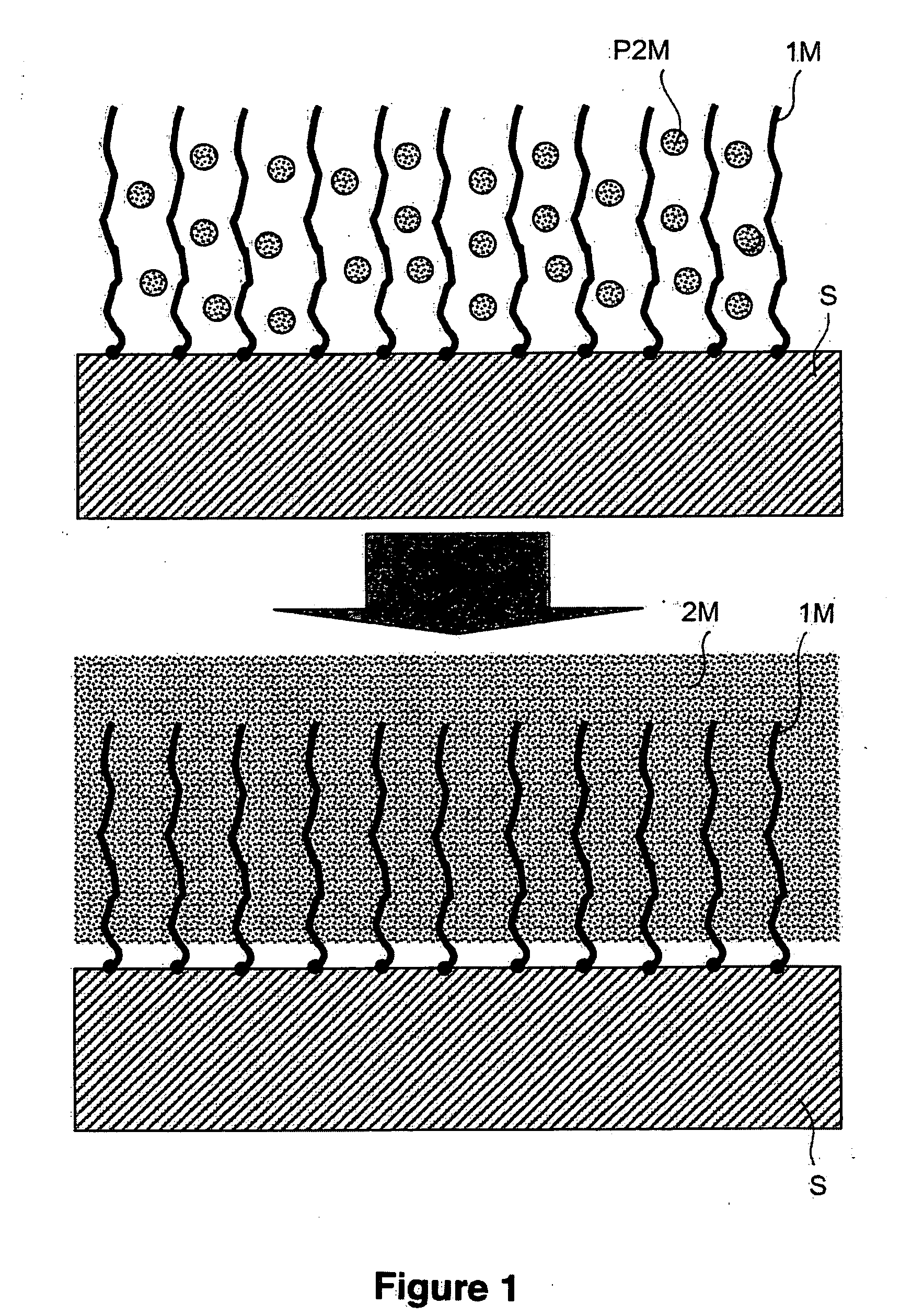

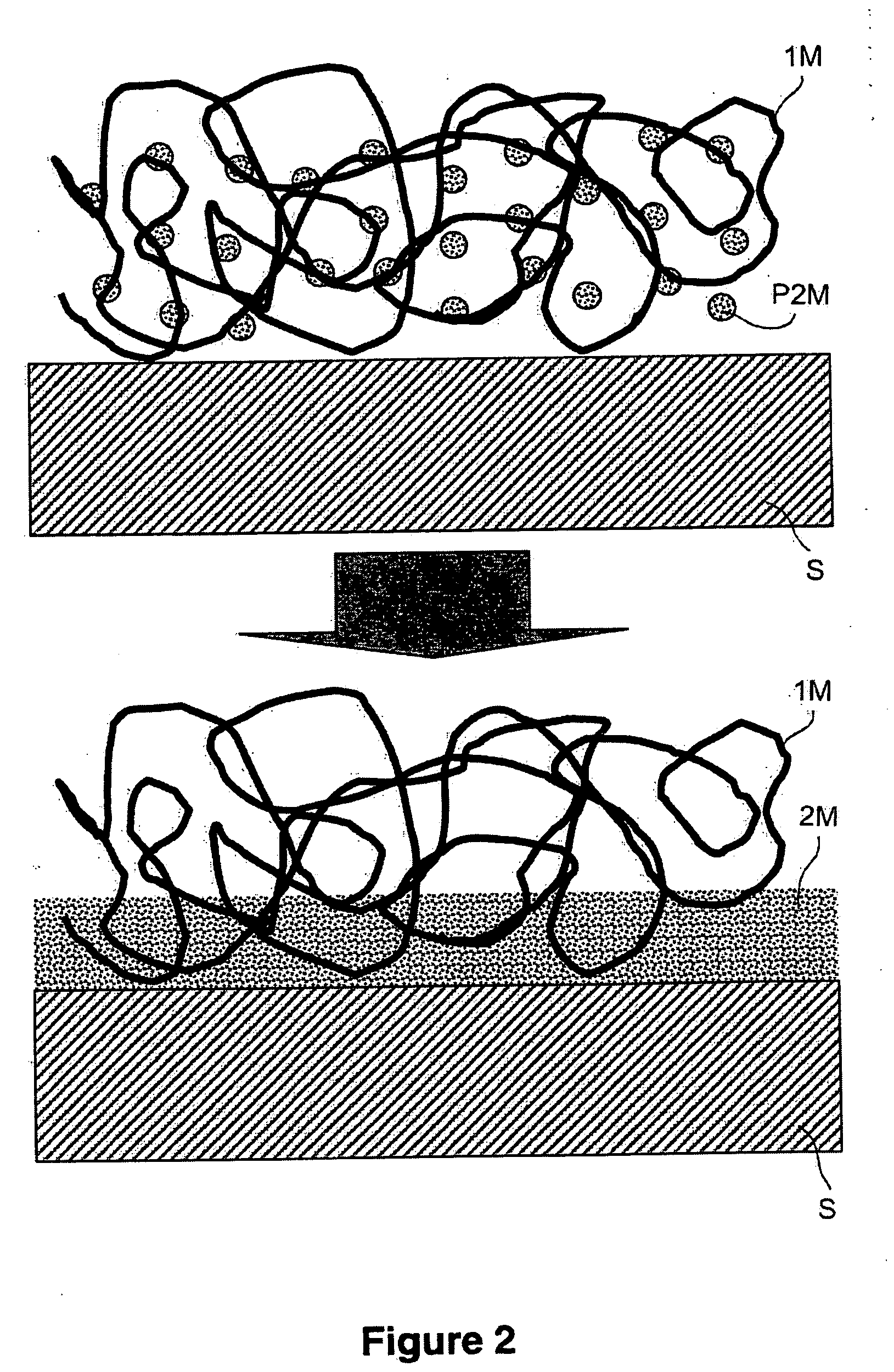

Surface-coating method

ActiveUS20060141156A1Improve adhesionShorten the timePhotography auxillary processesElectrolysis componentsMaterials scienceSurface coating

The invention relates to the deposition or attachment of materials to surfaces. It relates to a process for coating a surface with a first material and a second material, comprising the following steps: placing the first material on the said surface, inserting into the first material placed on the said surface precursor molecules of the second material, converting the said precursor molecules of the second material inserted into the first material into the said second material such that this second material becomes formed on the said surface to be coated and within the said first material placed on the said surface. The object of the process of the invention is to allow the deposition of materials of any type onto surfaces of any type.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

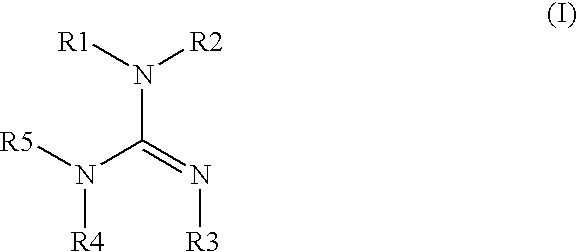

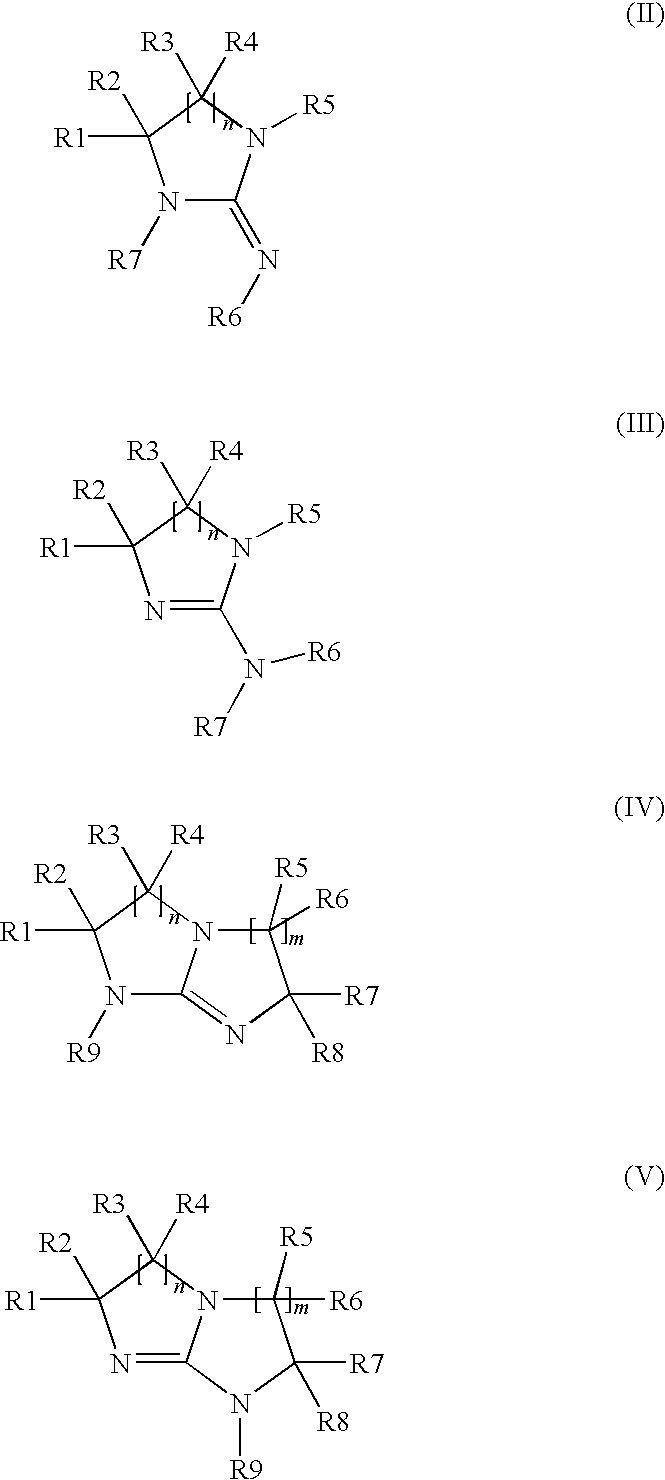

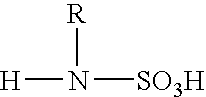

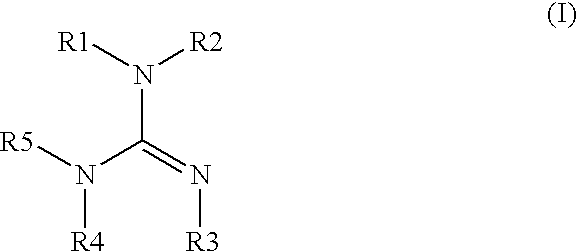

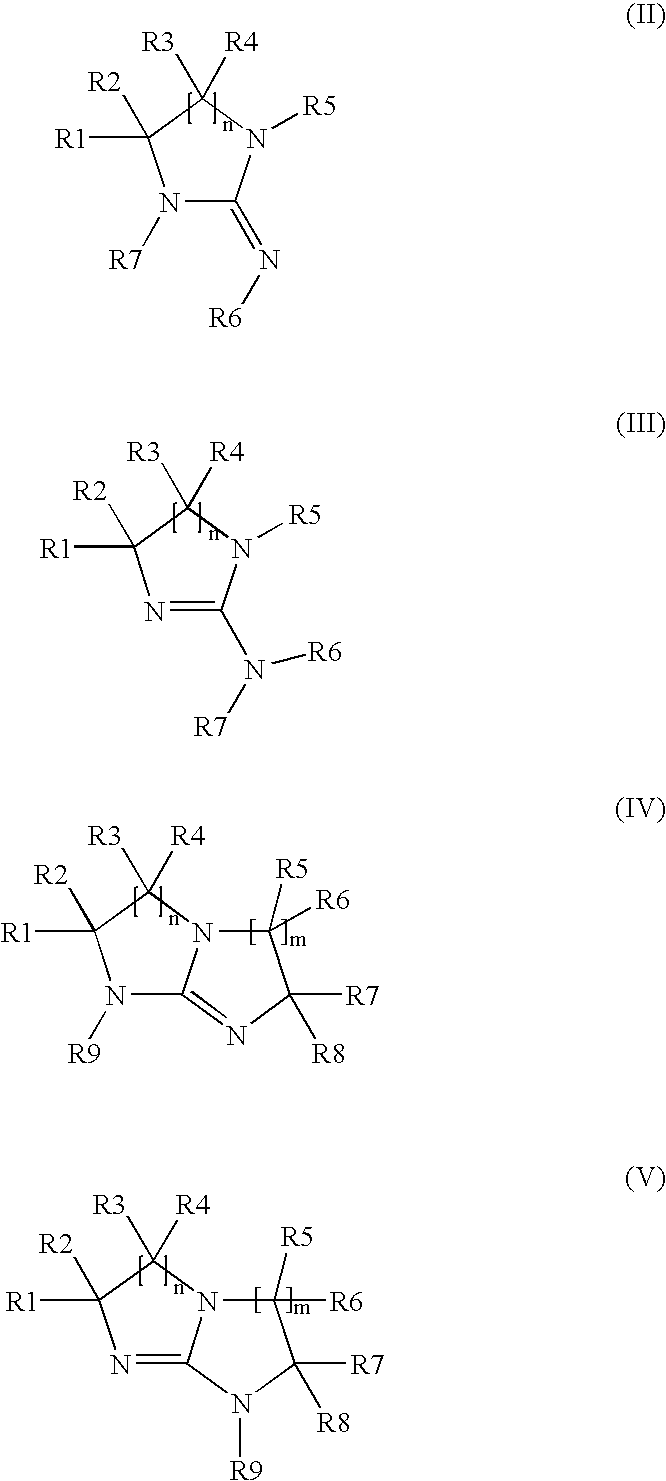

Electrodepositable coating composition containing a cyclic guanidine

The present invention is directed towards an electrocoating composition comprising a cyclic guanidine.

Owner:PPG IND OHIO INC

Electrodepositable coating composition containing a cyclic guanidine

The present invention is directed towards an electrocoating composition comprising a cyclic guanidine.

Owner:PPG IND OHIO INC

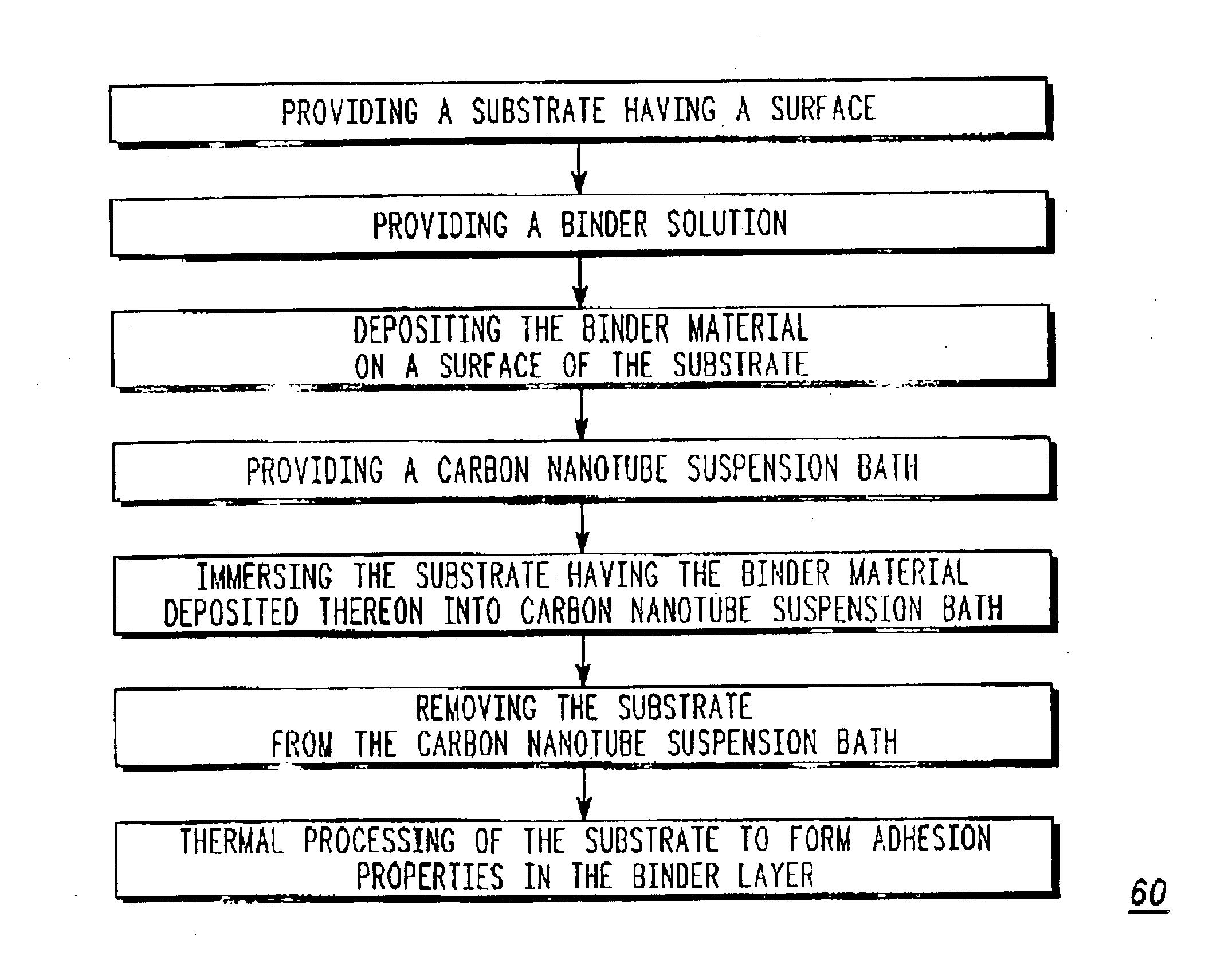

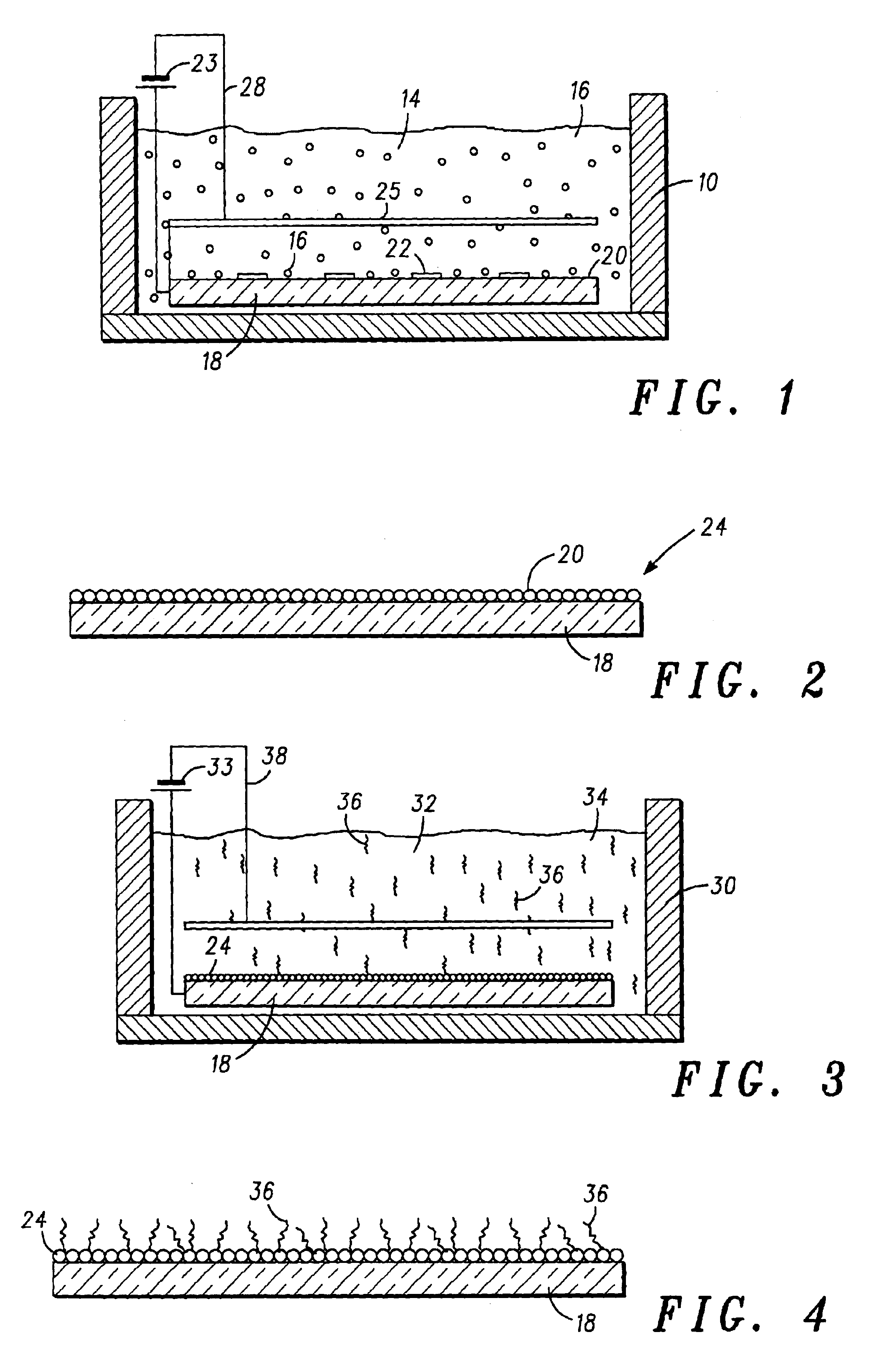

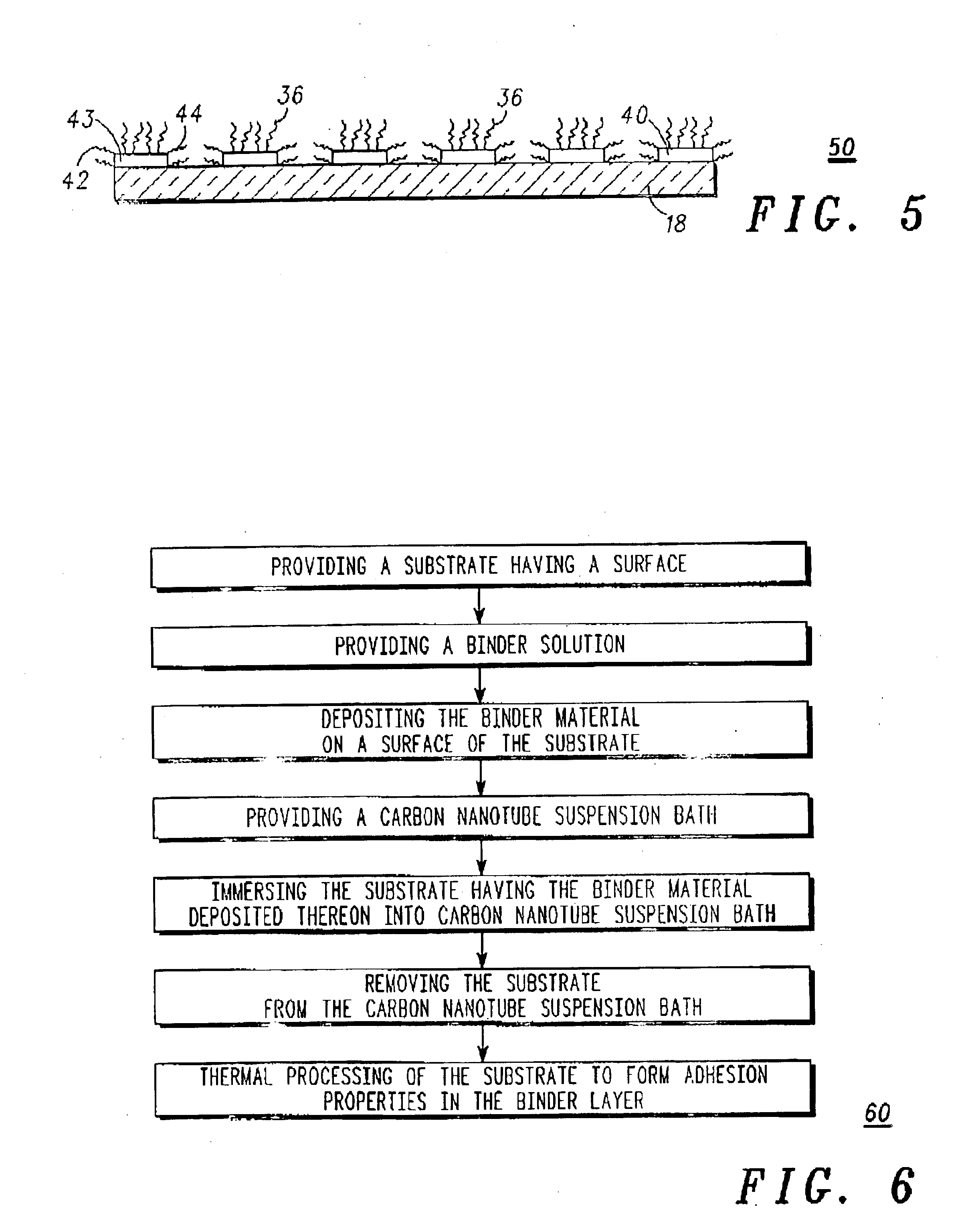

FED cathode structure using electrophoretic deposition and method of fabrication

InactiveUS6902658B2High densityVolume/mass flow measurementNanoinformaticsField emission deviceElectrophoresis

A method of fabricating a field emission device cathode using electrophoretic deposition of carbon nanotubes in which a separate step of depositing a binder material onto a substrate, is performed prior to carbon nanotube particle deposition. First, a binder layer is deposited on a substrate from a solution containing a binder material. The substrate having the binder material deposited thereon is then transferred into a carbon nanotube suspension bath allowing for coating of the carbon nanotube particles onto the substrate. Thermal processing of the coating transforms the binder layer properties which provides for the adhesion of the carbon nanotube particles to the binder material.

Owner:MOTOROLA SOLUTIONS INC

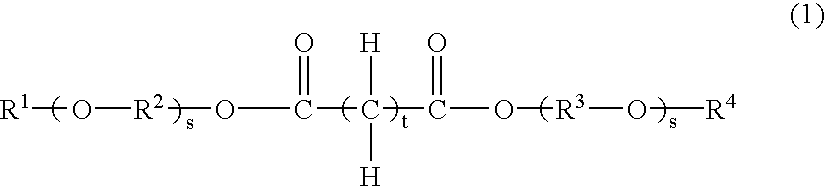

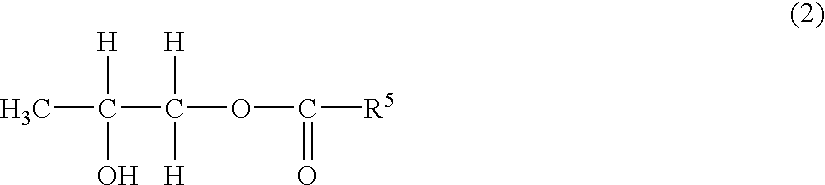

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS20030151032A1High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleResin-Based Composite

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultra fine particles with the average particle size of 0.1 mum or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mum and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

Single-layer and multilayer graphene, method of manufacturing the same, object including the same, and electric device including the same

ActiveUS20120308884A1High densityImprove discharge capacityElectrolysis componentsCarbon compoundsReducing atmosphereCvd graphene

Graphene is formed with a practically uniform thickness on an uneven object. The object is immersed in a graphene oxide solution, and then taken out of the solution and dried; alternatively, the object and an electrode are immersed therein and voltage is applied between the electrode and the object used as an anode. Graphene oxide is negatively charged, and thus is drawn to and deposited on a surface of the object, with a practically uniform thickness. After that, the object is heated in vacuum or a reducing atmosphere, so that the graphene oxide is reduced to be graphene. In this manner, a graphene layer with a practically uniform thickness can be formed even on a surface of the uneven object.

Owner:SEMICON ENERGY LAB CO LTD

Processes for preparing ink jet inks

A process for the preparation of an ink which comprises mixing an ink vehicle, a colorant and a latex containing a polymer with epoxy groups, and wherein said latex is generated by the polymerization of a mixture of olefinic monomers, and wherein at least one of said olefinic monomers is an unsaturated epoxide monomer and which polymerization is accomplished in the presence of an anionic surfactant, and a nonionic surfactant.

Owner:XEROX CORP

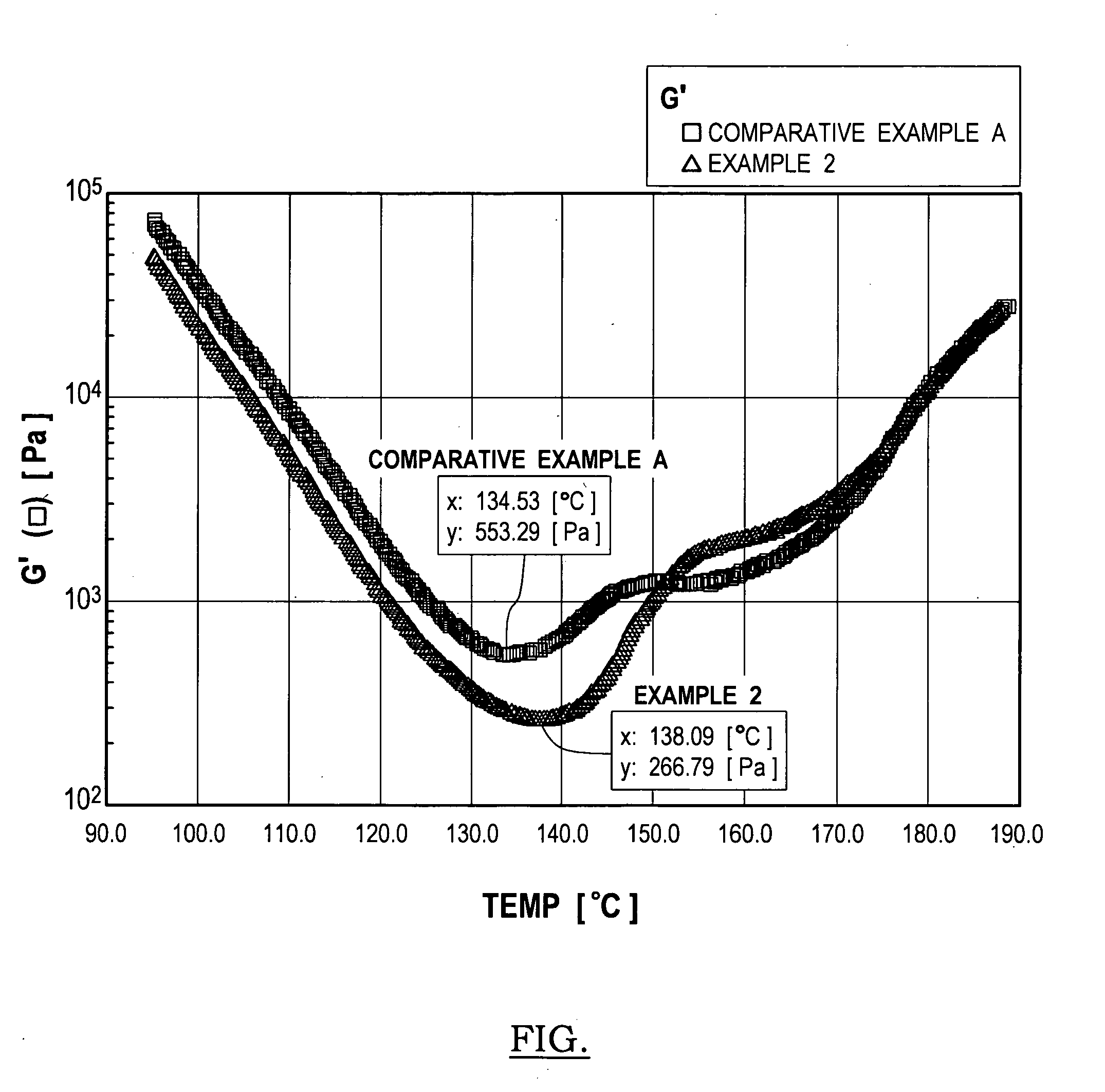

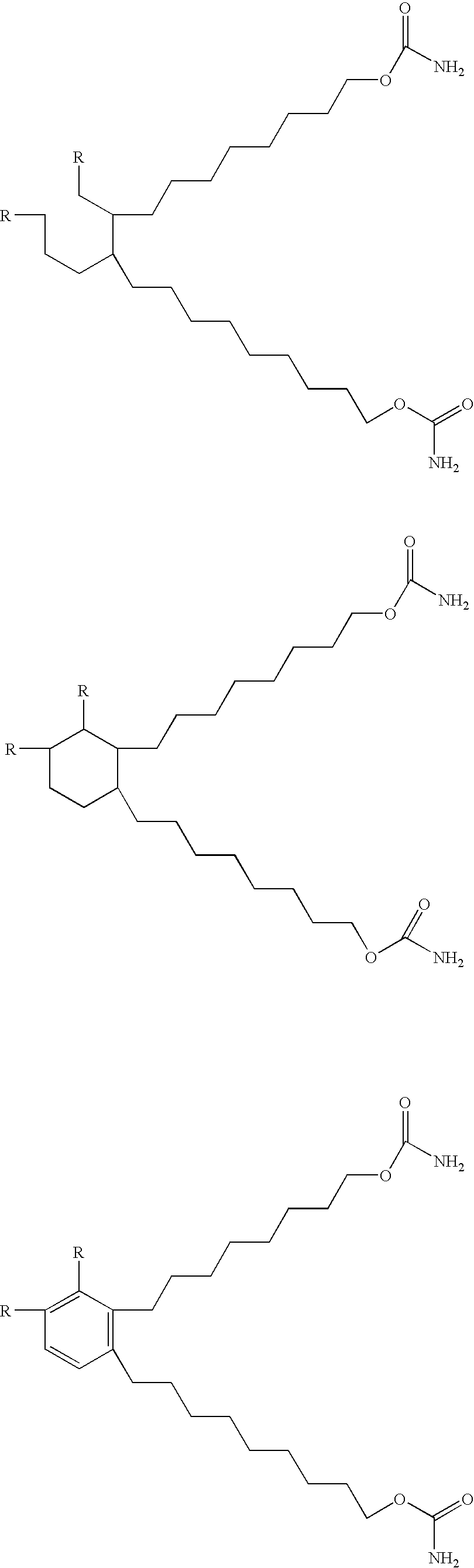

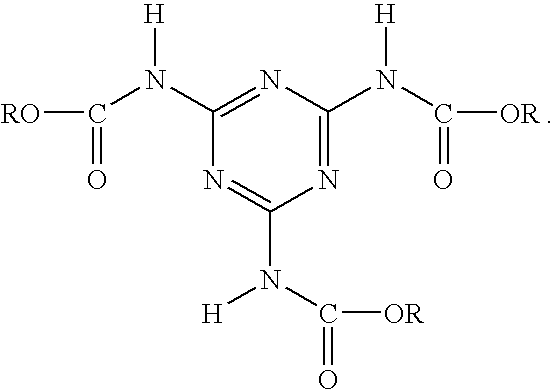

Use of carbamate-modified aminoplast resins to improve the appearance and performance of powder coatings

InactiveUS20050182189A1Low viscosityPowdery paintsPaints for electrolytic applicationsCarbamatePowder coating

A powder coating composition comprising at least about 0.1% by weight of a reaction product of an aminoplast and a compound having one carbamate group has improved smoothness.

Owner:BASF CORP

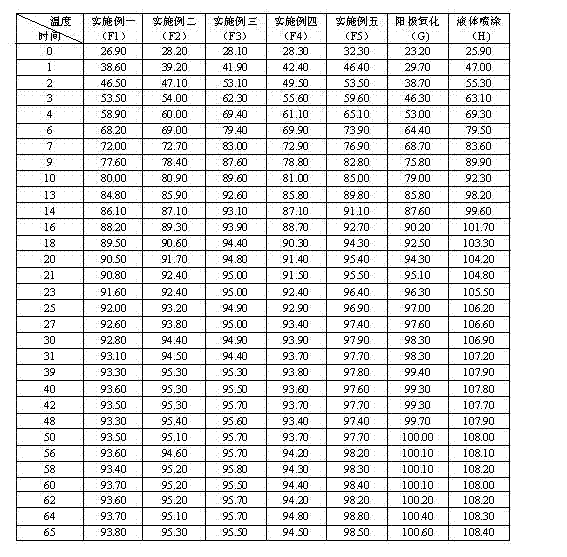

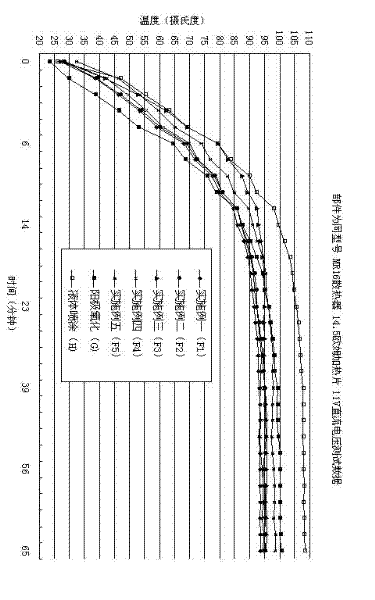

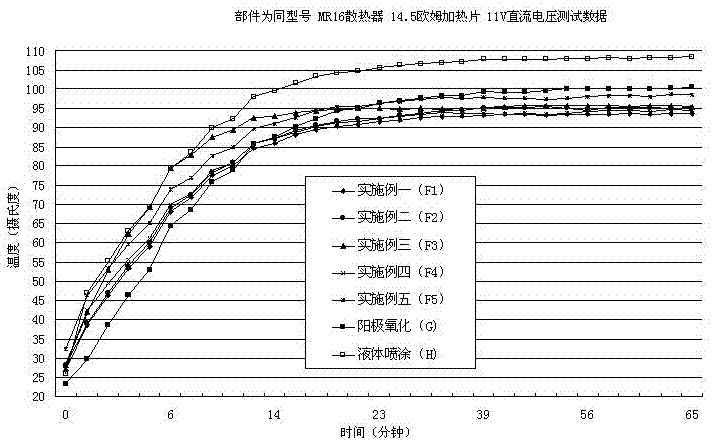

Radiating material and preparation method of radiating material

InactiveCN102181212AImprove cooling effectNo dead endsElectrophoretic coatingsPolyurea/polyurethane coatingsThermal insulationMixed materials

The invention discloses a radiating material and a preparation method of the radiating material. The radiating material comprises a component A and a component B, wherein the component A is an ionic modified resin, or a mixture of more than one ionic modified resin, or a composite of more than one ionic modified resin; and the component B is one or more mixed material with the far infrared emission rate greater than 0.80 or thermal conduction coefficient greater than 5W / m.K, and grain size smaller than 30mu. In use, the radiating material can not only improve the radiating performance of metal parts, but also achieve certain other special functions (for example, self-cleaning, infrared stealth, thermal insulation, corrosion resistance, thermostability, self-lubricating, insulation and other properties), and can be prepared into most needed color according to requirement.

Owner:东莞市中科智恒新材料有限公司

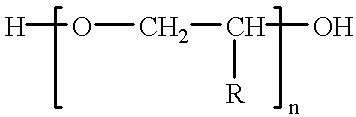

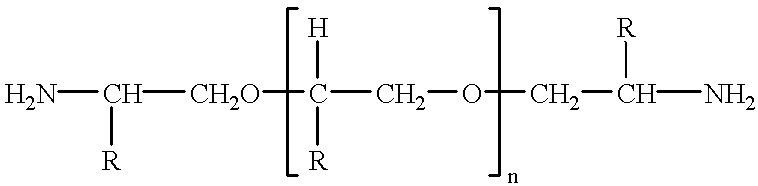

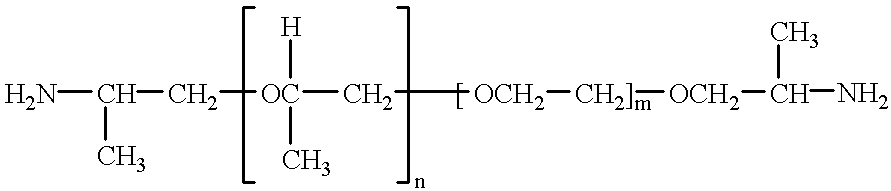

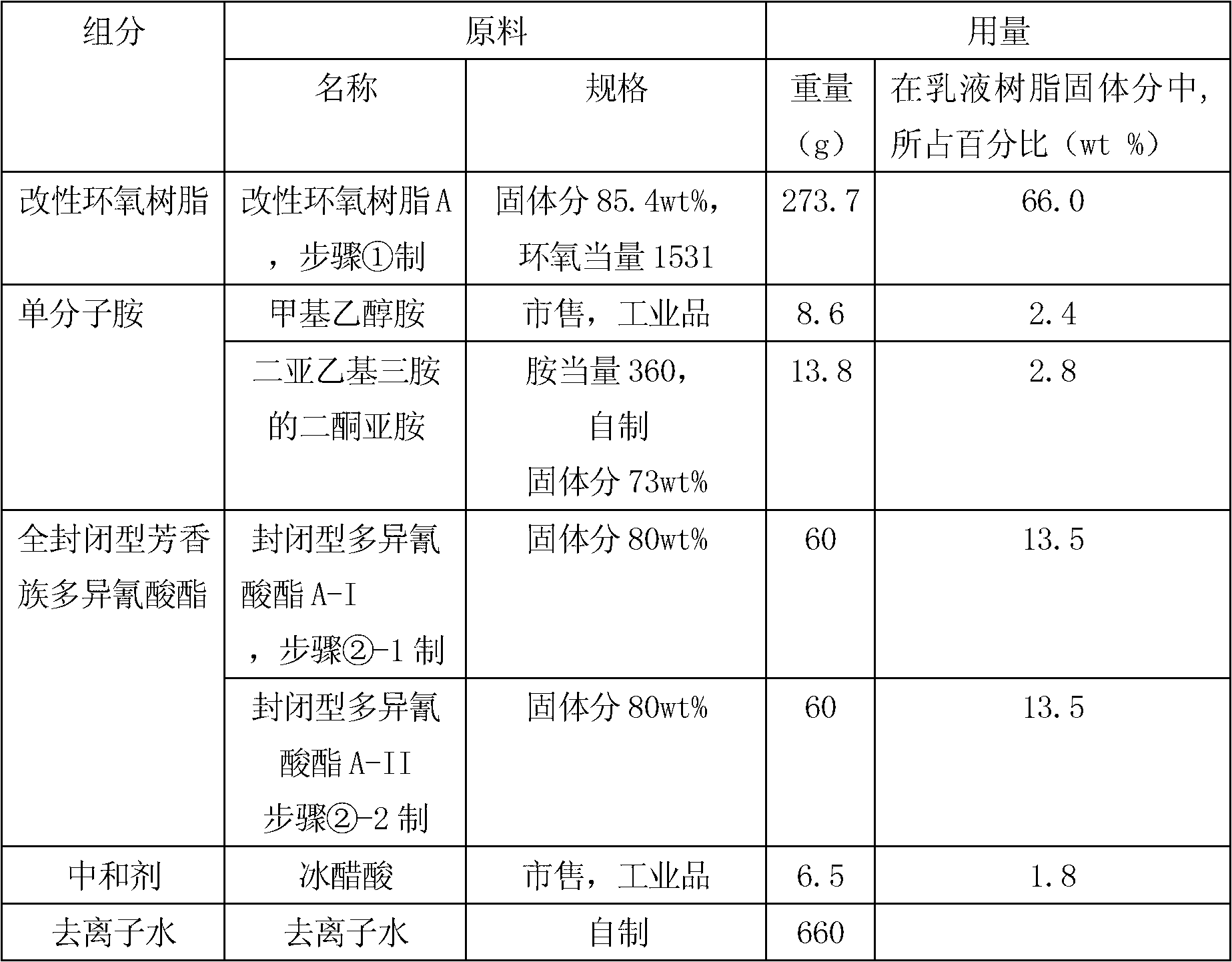

Resin emulsion for cathode electrophoretic coating with high throwing power and preparation method thereof

ActiveCN102838846ASuitable glass transition temperatureIncrease construction voltagePaints for electrolytic applicationsEpoxy resin coatingsOrganic acidEmulsion

The invention relates to resin emulsion for cathode electrophoretic coating with high throwing power and a preparation method of the resin emulsion, wherein the emulsion is obtained by the following steps: heating and mixing modified epoxy resin aminated by various single molecular amines and one or two of fully-closed aromatic polyisocyanates; using organic acid to neutralize the mixture; and using de-ionized water to disperse the mixture, wherein the weight ratio of raw materials in the resin emulsion solid is as follows: 45-70wt% of modified epoxy resin, 4-10wt% of total single molecular amines, 20-40wt% of fully-closed aromatic polyisocyanates and 1.6-3.5wt% of organic acid; the modified epoxy resin is obtained by replacing part of solvent with plasticizer, and using flexible polymer to extend chain of bisphenol A epoxy resin to be of molecular weight of 1500-3000; in the modified epoxy resin solid, the content of flexible polymer is 10-35% and the content of the plasticizer is 4-14%. The resin emulsion is stable and low in solvent content; the film has smooth appearance and throwing power of more than 22cm.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

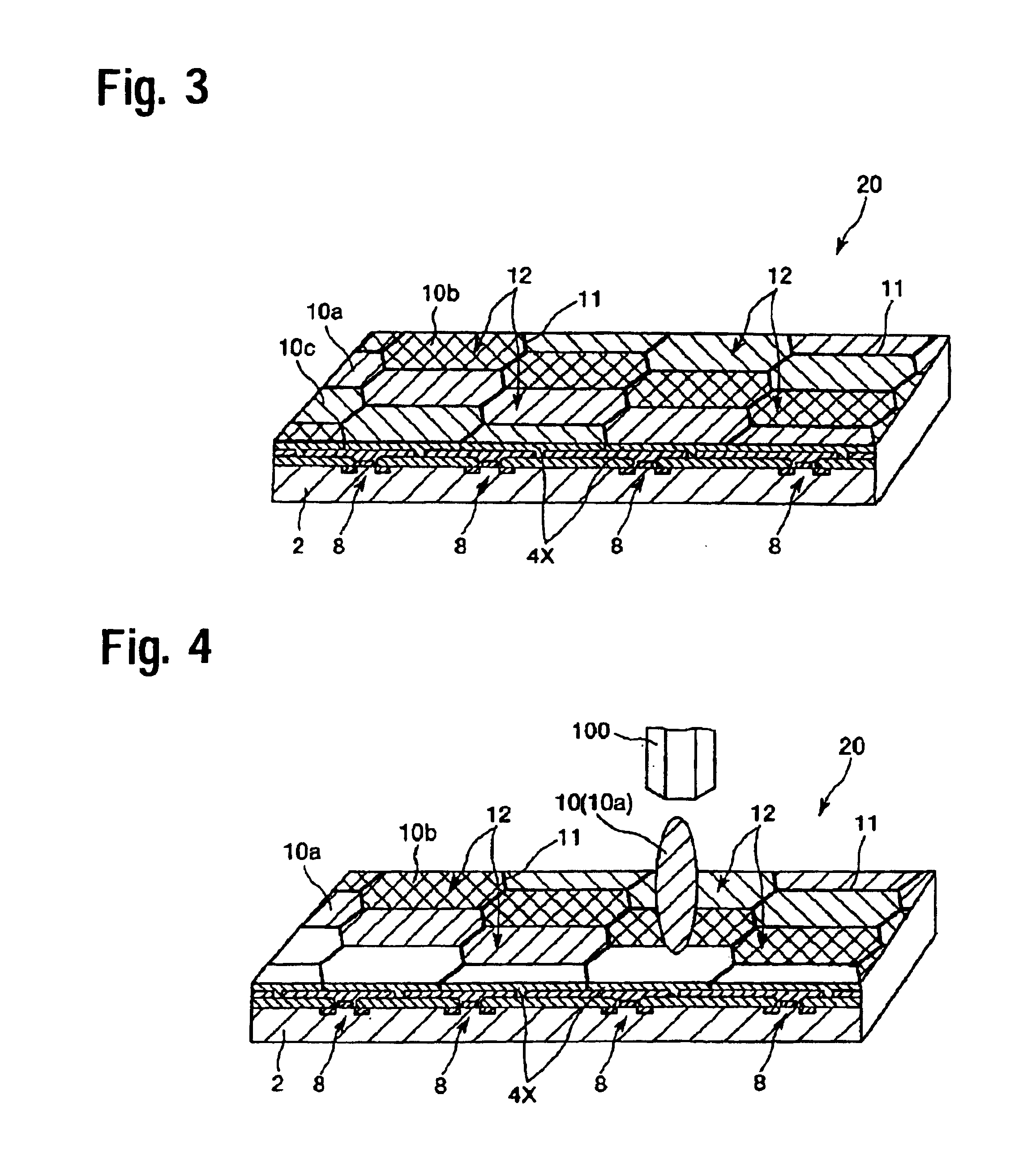

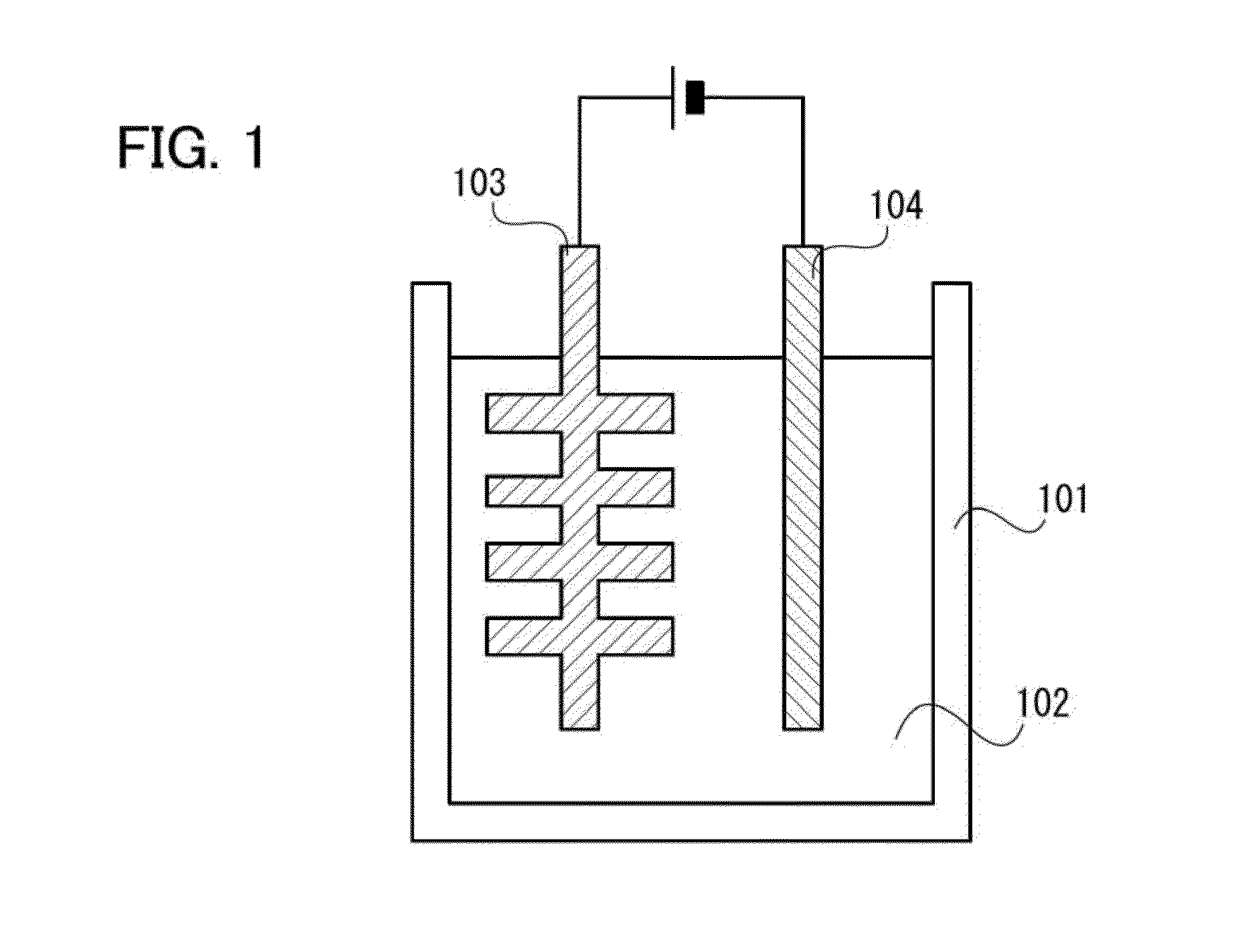

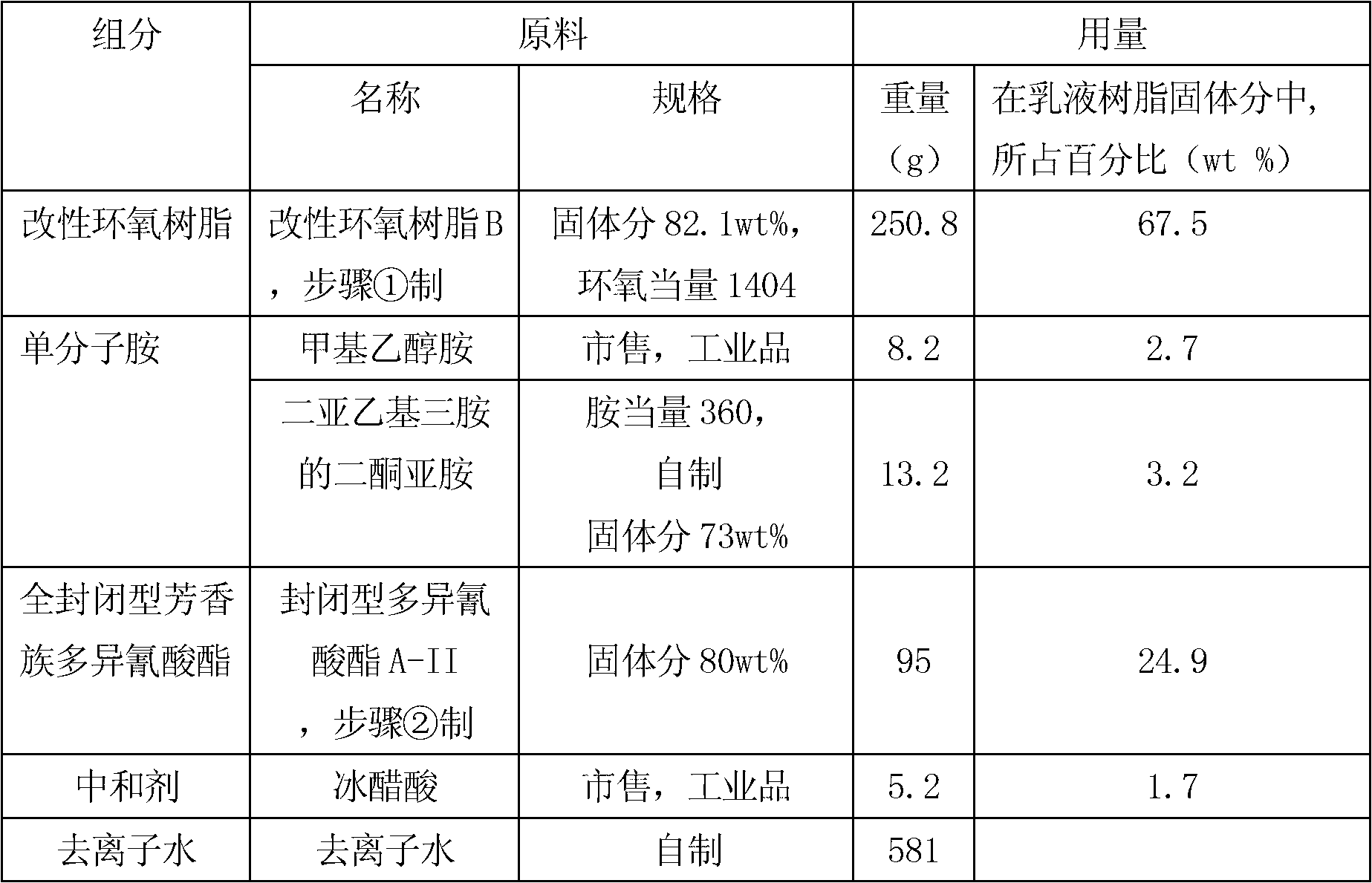

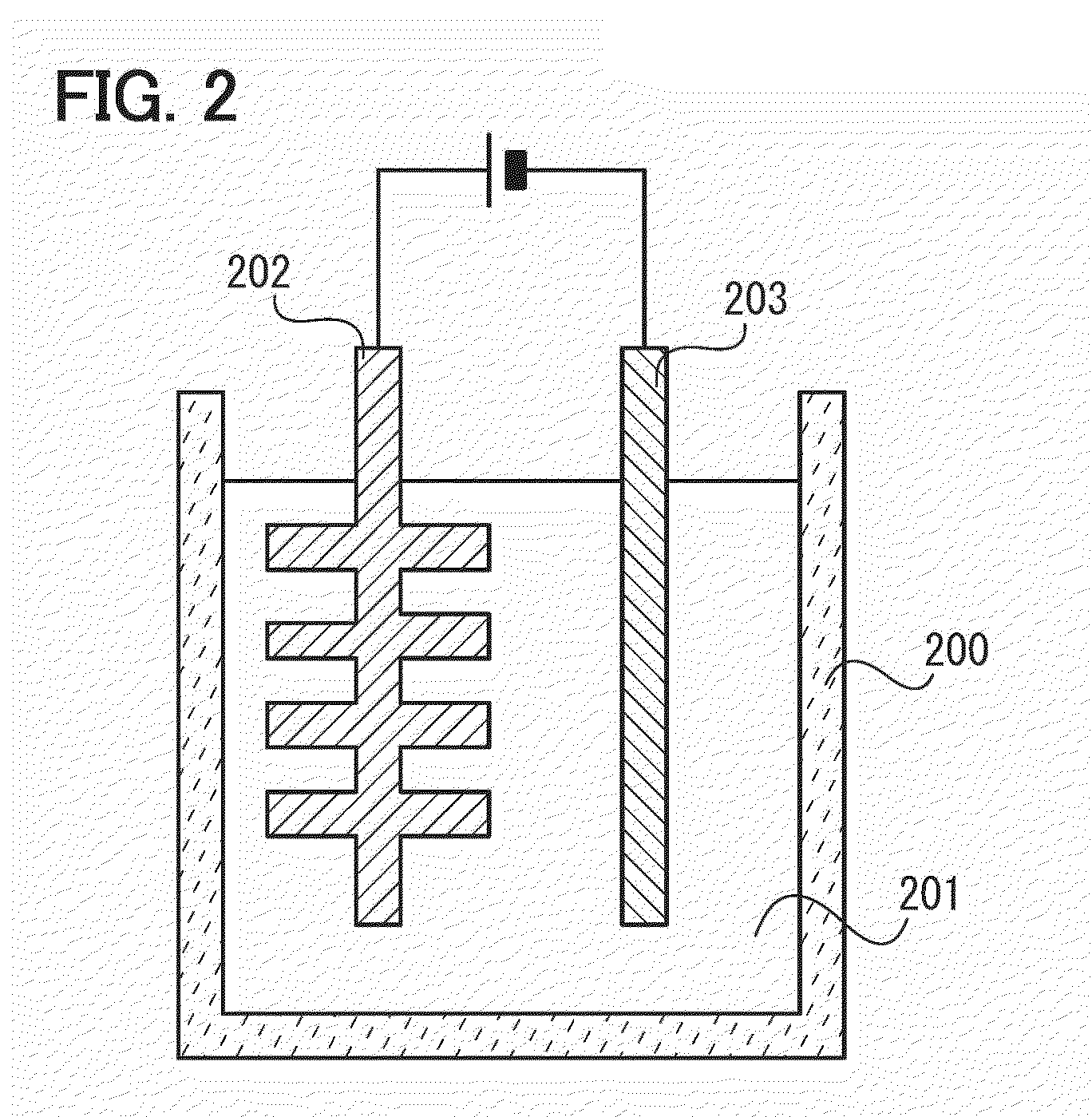

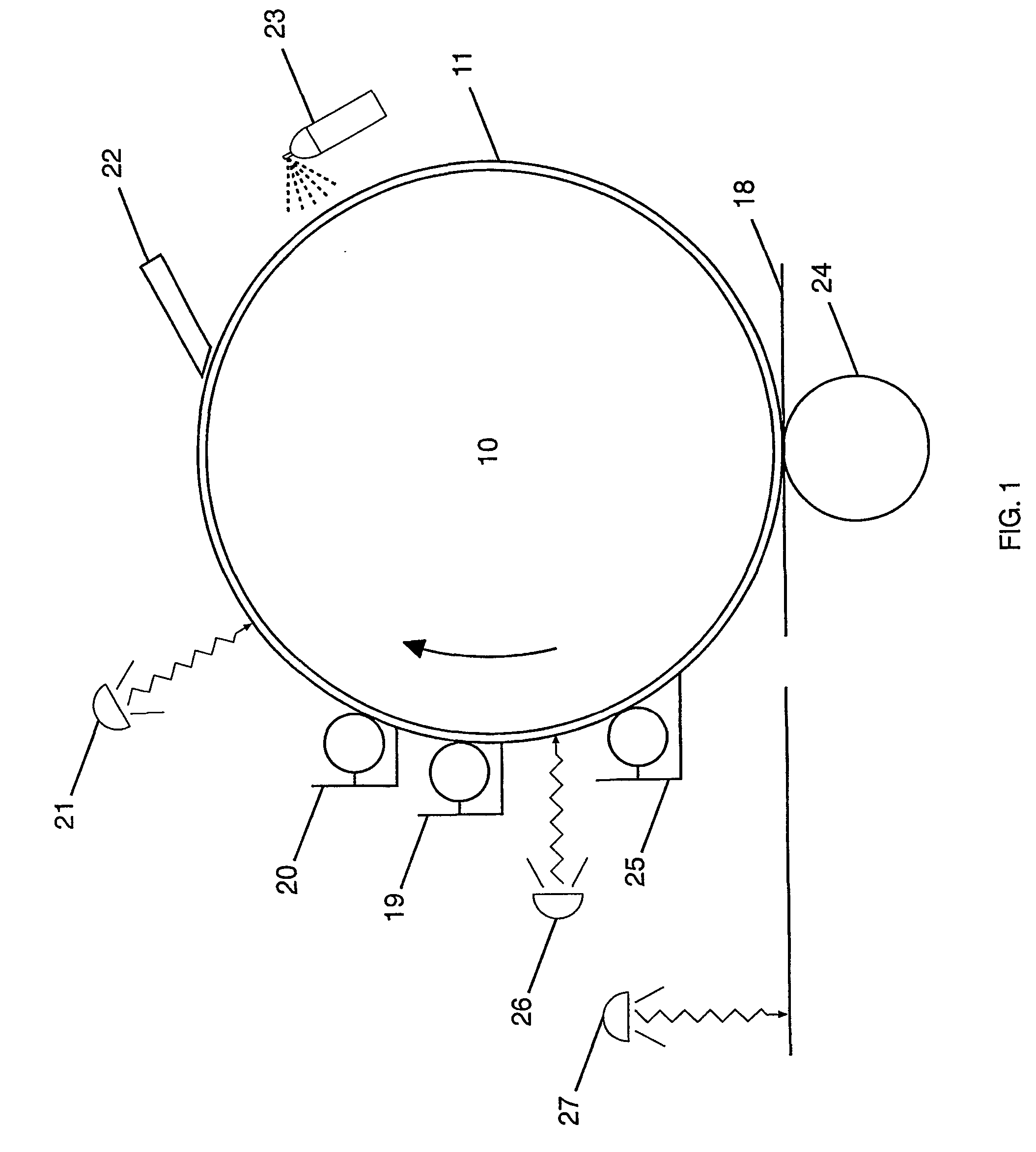

Apparatus and process for producing electrophoretic device

InactiveUS6919003B2Easily and evenly distributedLiquid surface applicatorsElectrolysis componentsElectrophoresisEngineering

A system (apparatus and process) for producing an electrophoretic (display) device is provided for allowing production of such a device wherein electrophoretic particles in the dispersion liquid are easily and evenly distributed to respective cells (pixels) between two substrates of the device even in the case of a very small gap between the two substrates or the case of using a flexible substrate. The system includes a storage unit for a dispersion liquid containing the charged phoretic particles dispersed therein, a stirrer for stirring the dispersion liquid, a substrate-holder for holding the substrate in the dispersion liquid, and a voltage source for applying a voltage to the electrodes formed on the substrate thereby depositing the electrophoretic particles on the electrodes.

Owner:CANON KK

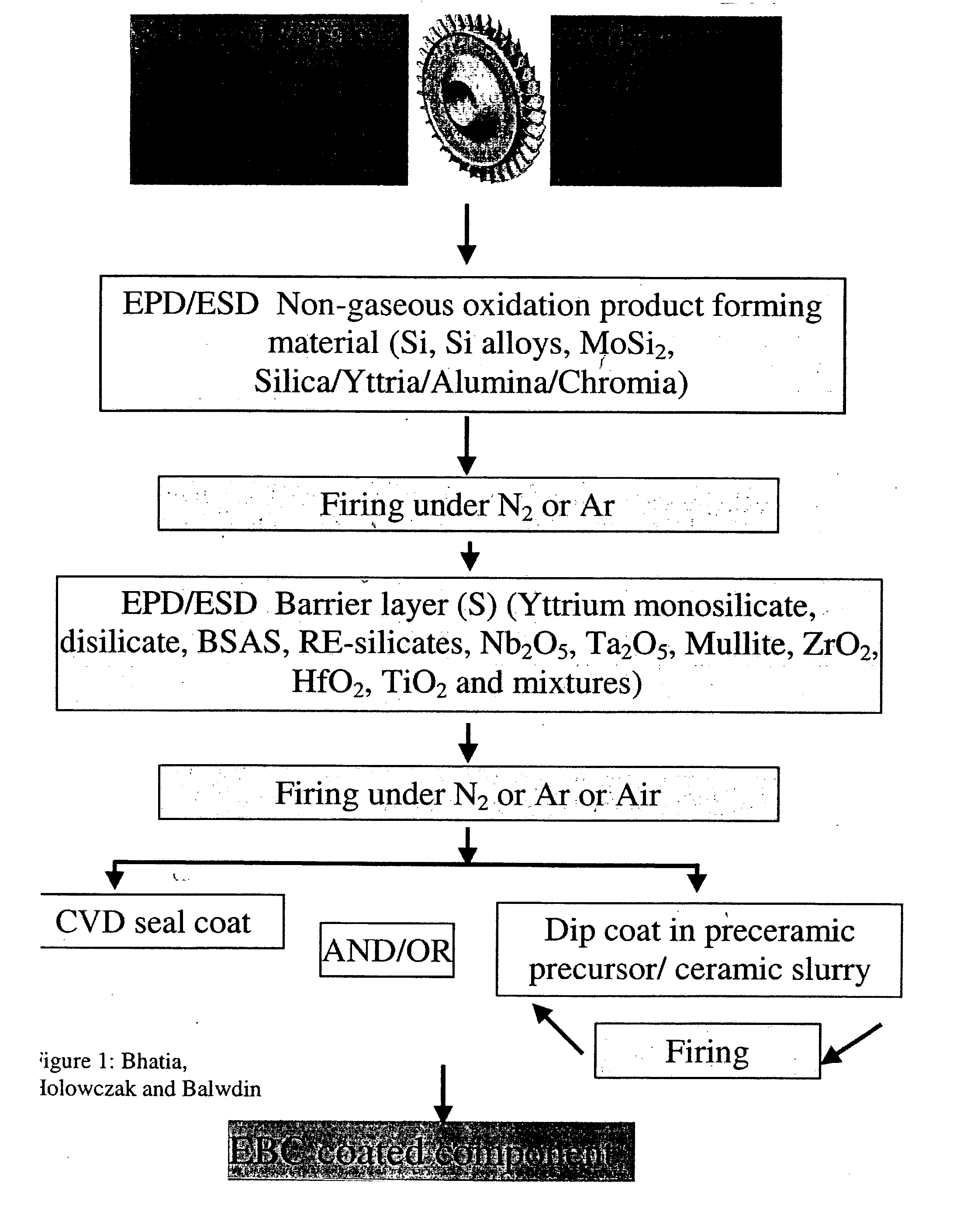

Non-line-of-sight process for coating complexed shaped structures

ActiveUS20060029733A1Difficult to coatLiquid surface applicatorsElectrolysis componentsOrganic chemistryProtective barrier

Non-line-of-sight process for coating complexed shaped structures of Si-based substrates with protective barrier layers.

Owner:RAYTHEON TECH CORP

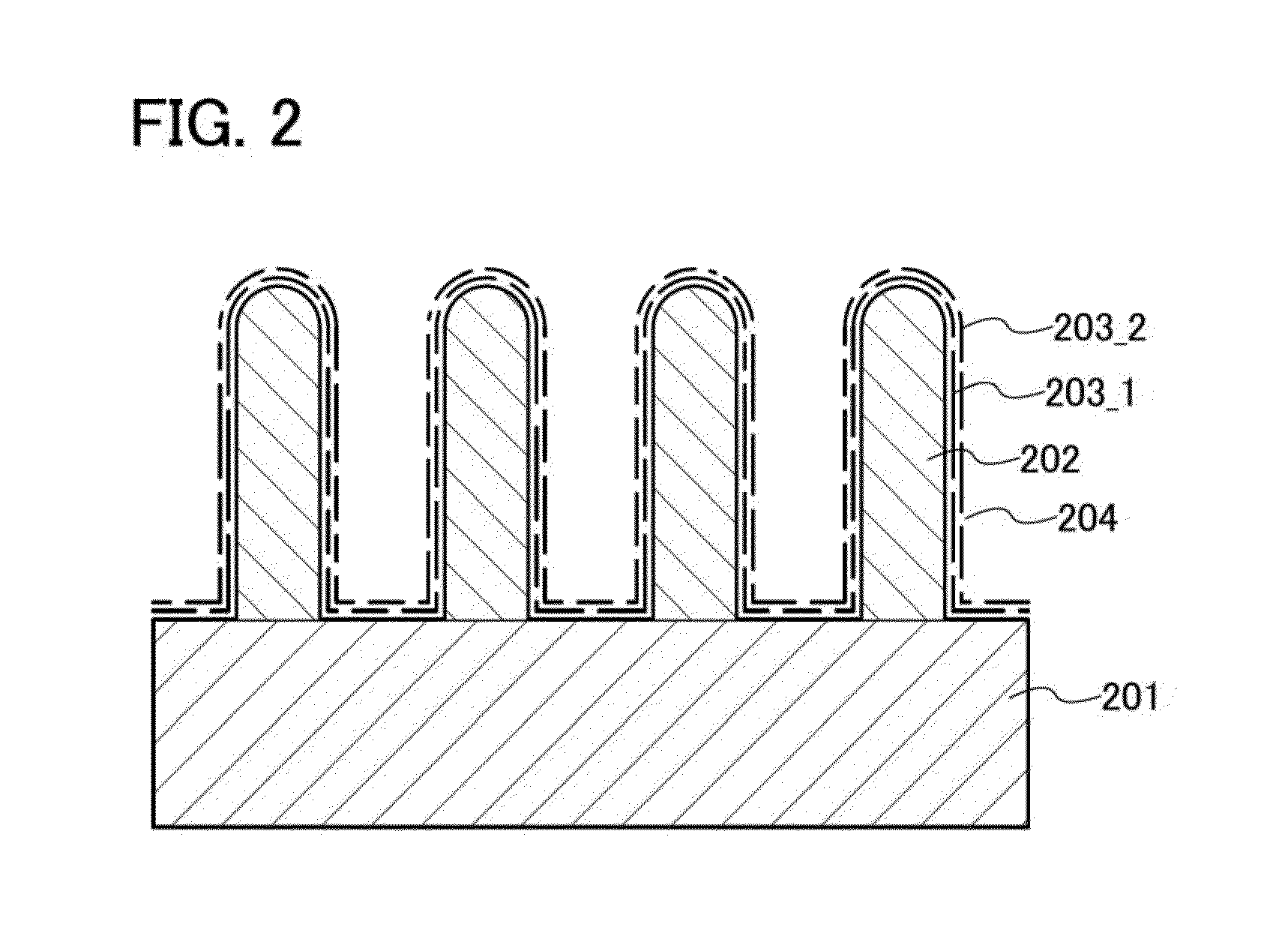

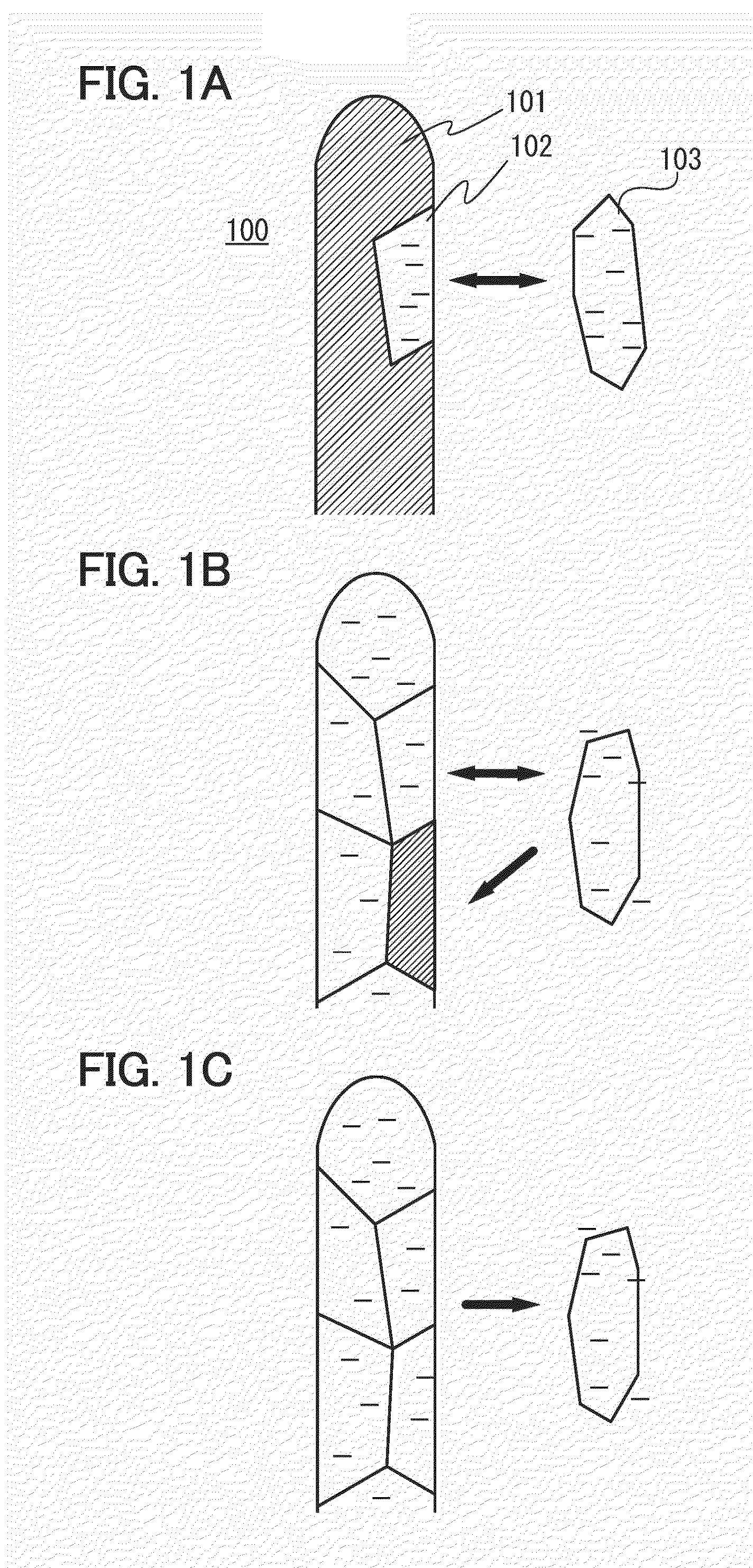

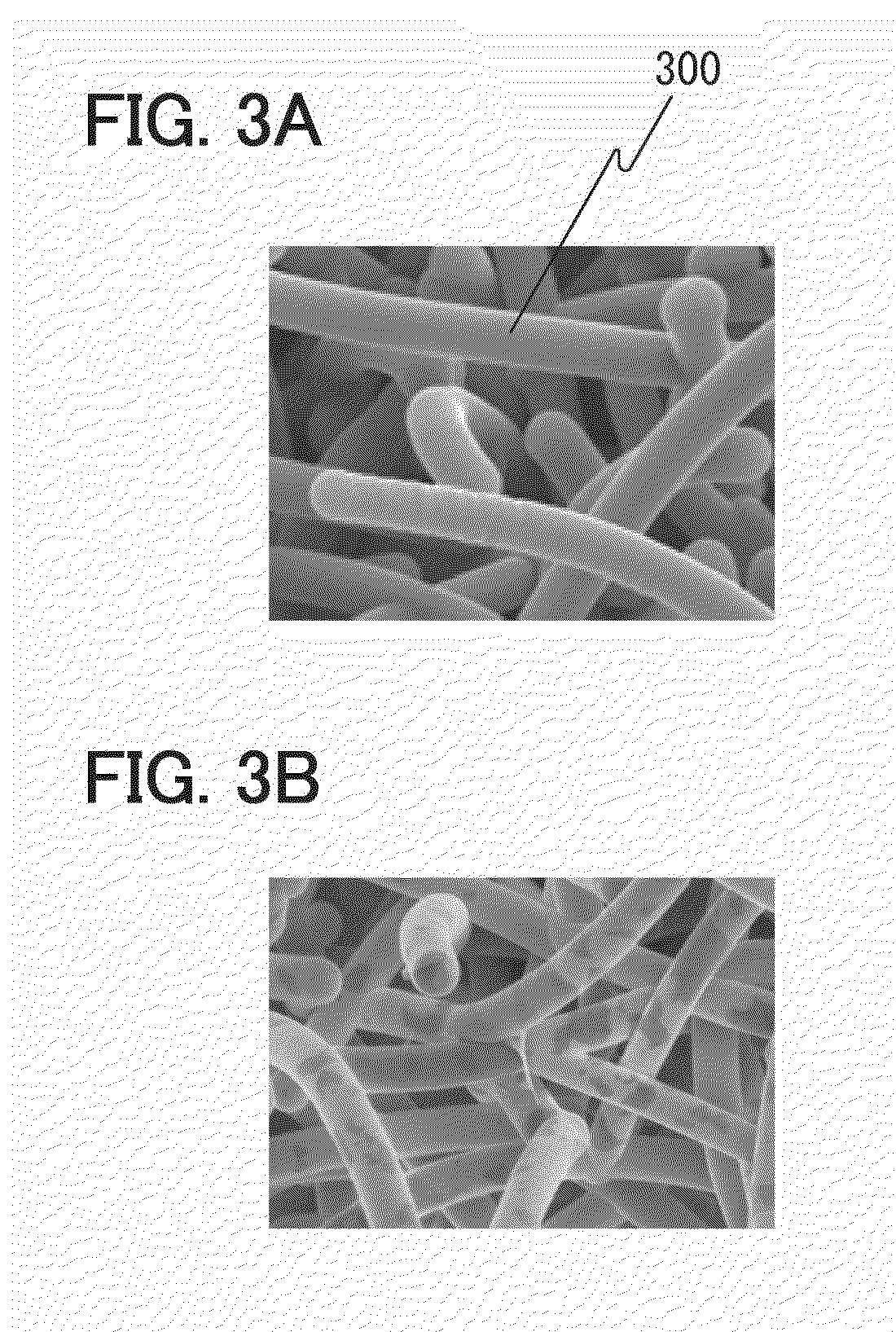

Method for manufacturing graphene-coated object, negative electrode of secondary battery including graphene-coated object, and secondary battery including the negative electrode

ActiveUS20130045418A1Uniform thicknessEfficient depositionMaterial nanotechnologyElectrolysis componentsGrapheneMaterials science

To form graphene to a practically even thickness on an object having an uneven surface or a complex surface, in particular, an object having a surface with a three-dimensional structure due to complex unevenness, or an object having a curved surface. The object and an electrode are immersed in a graphene oxide solution, and voltage is applied between the object and the electrode. At this time, the object serves as an anode. Graphene oxide is attracted to the anode because of being negatively charged, and deposited on the surface of the object to have a practically even thickness. A portion where graphene oxide is deposited is unlikely coated with another graphene oxide. Thus, deposited graphene oxide is reduced to graphene, whereby graphene can be formed to have a practically even thickness on an object having surface with complex unevenness.

Owner:SEMICON ENERGY LAB CO LTD

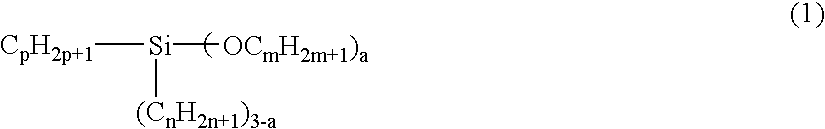

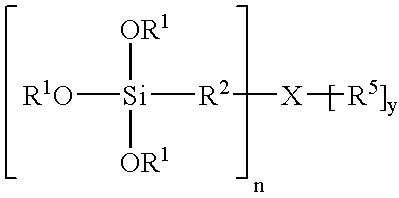

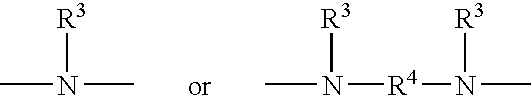

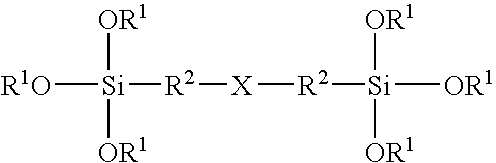

Silane coatings for bonding rubber to metals

InactiveUS6919469B2Improve corrosion resistanceImproving polymer adhesionSilicon organic compoundsPretreated surfacesSilanesPolymer

Owner:UNIVERSITY OF CINCINNATI

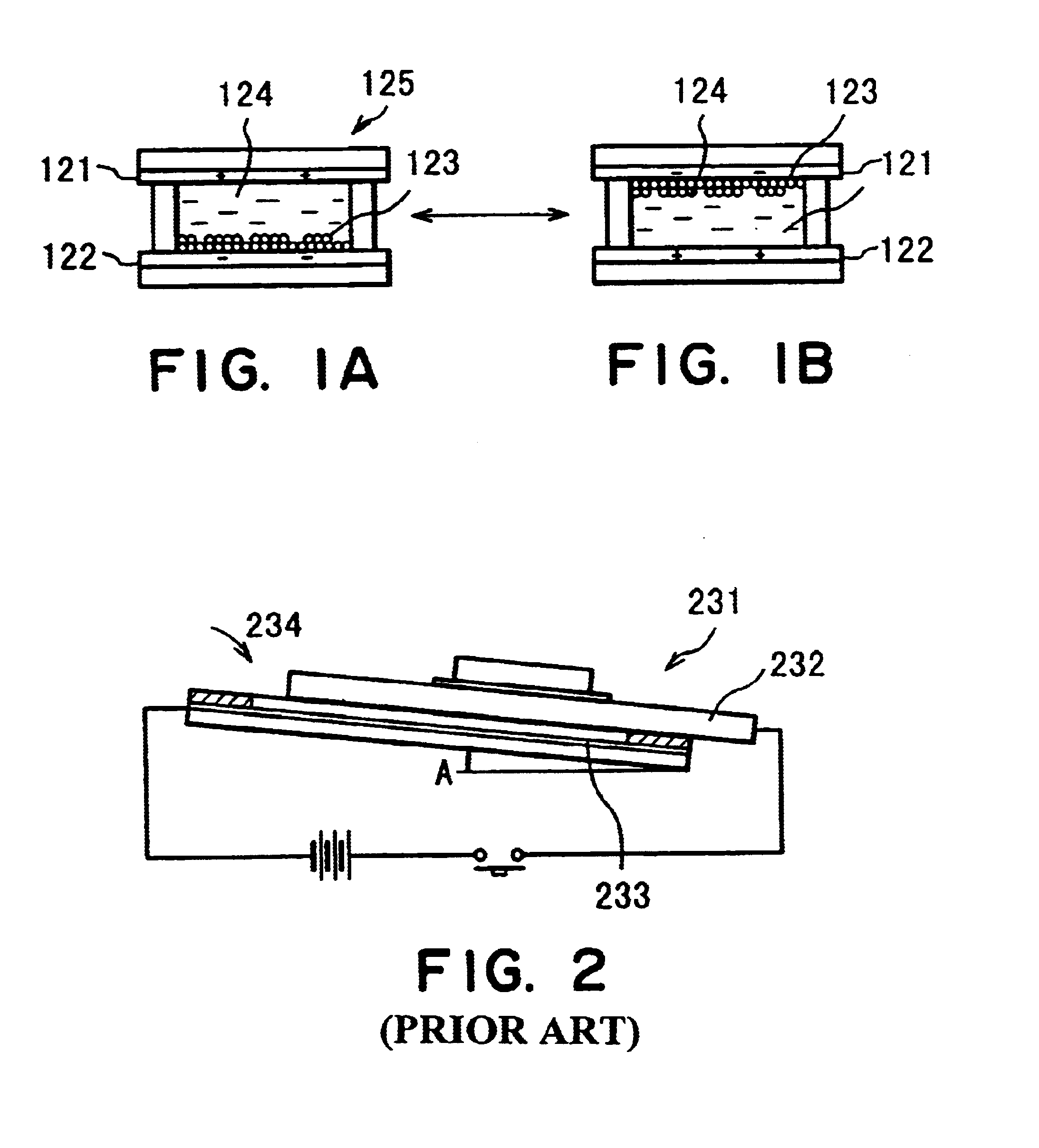

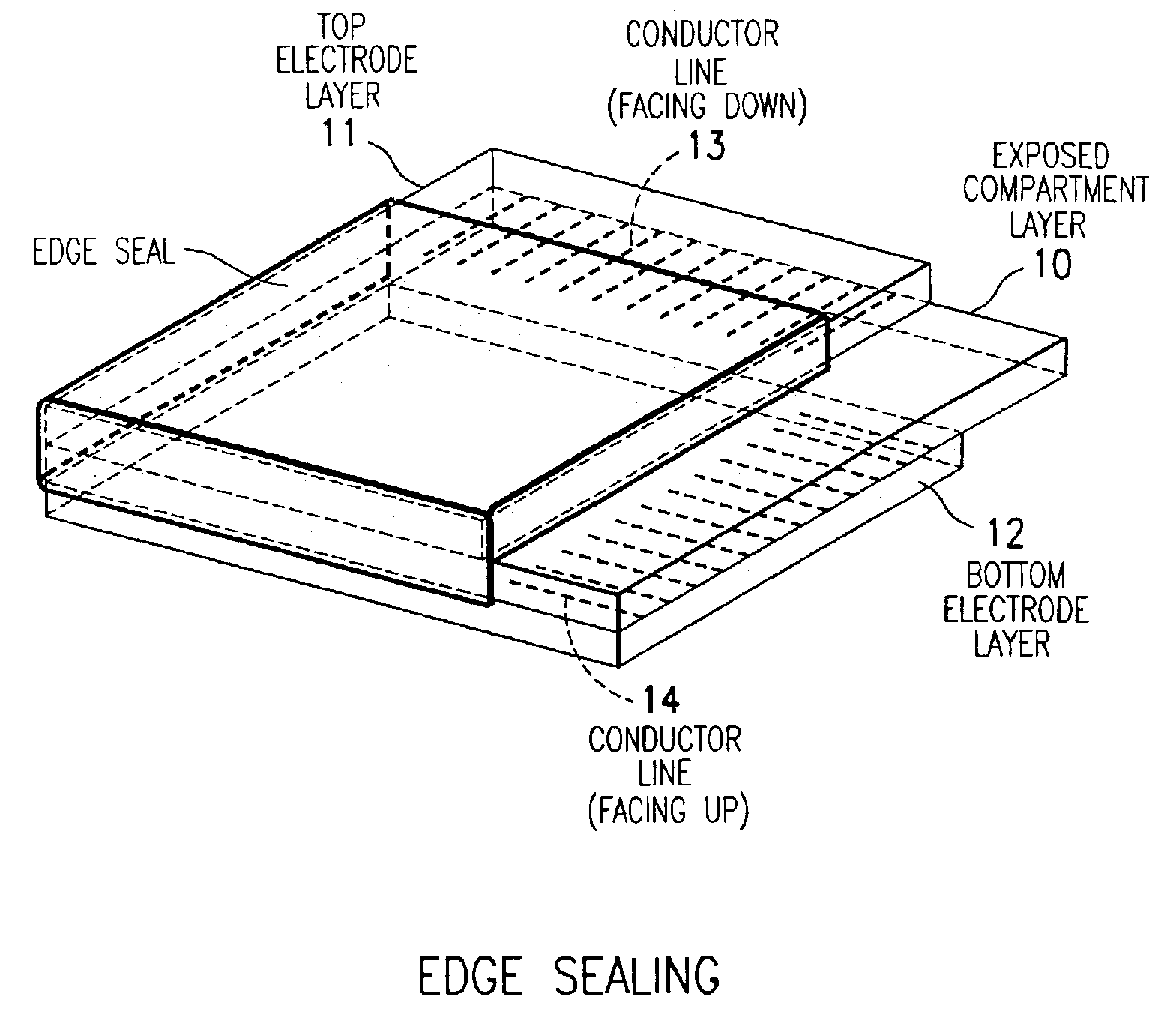

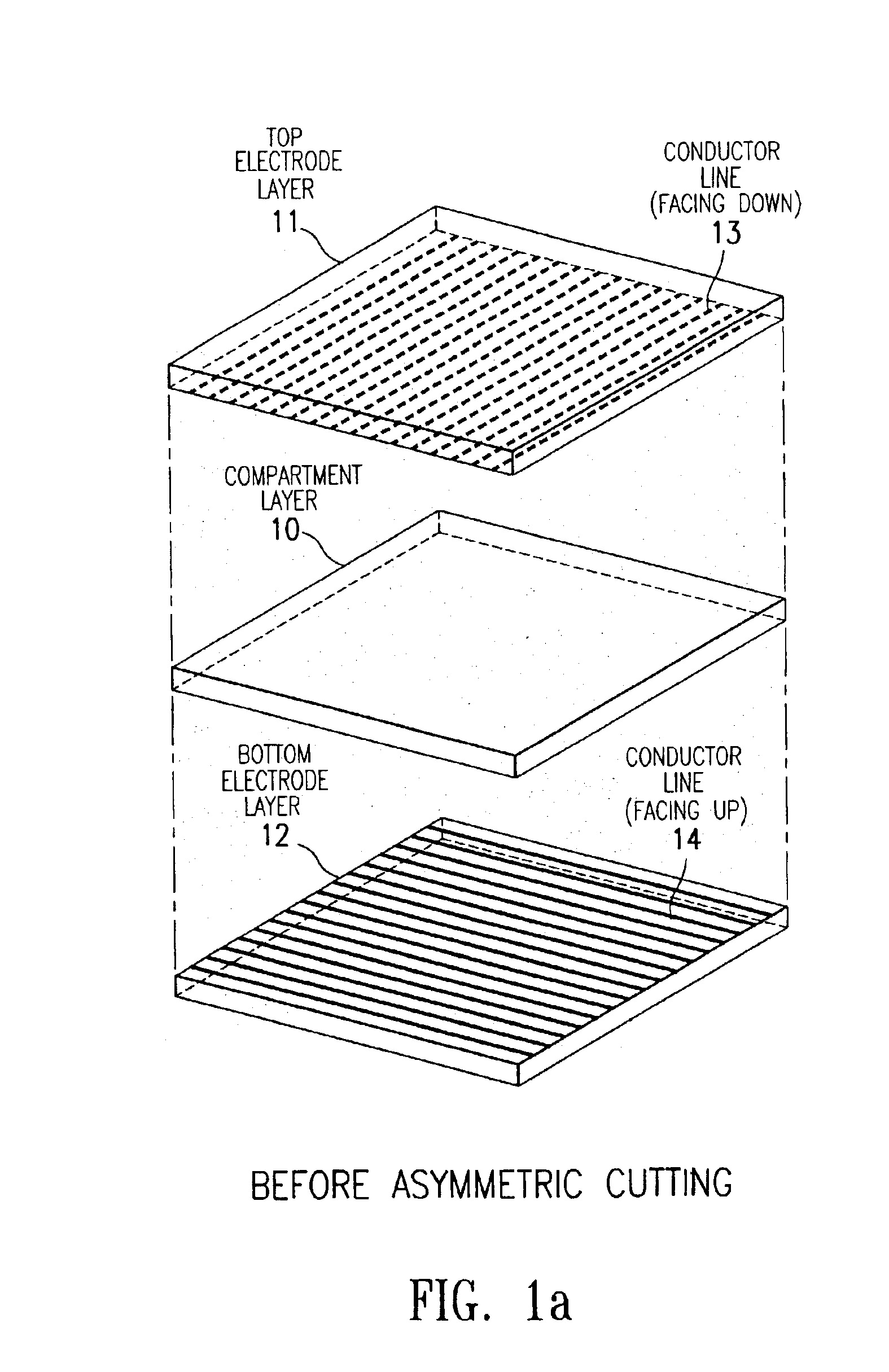

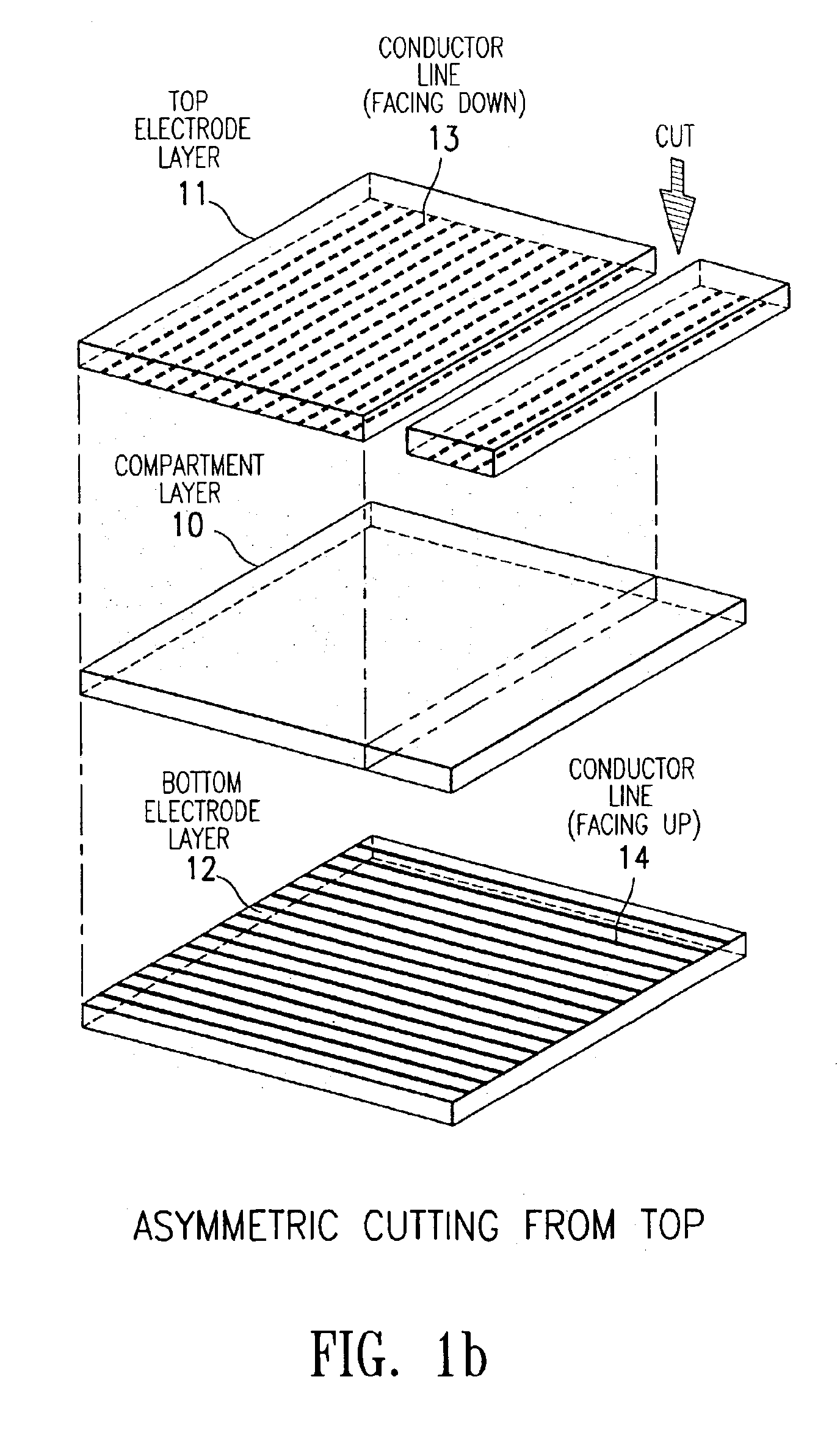

Compositions and processes for format flexible, roll-to-roll manufacturing of electrophoretic displays

InactiveUS6873452B2High yieldImprove throughputSludge treatmentVolume/mass flow measurementCell layerDisplay device

The present invention is directed to a process which comprises removing and stripping off part of the display panel in order to expose and connect the conductor lines on an electrode plate to a driver circuitry. More specifically the process involves (1) preparing a display panel having filled display cells sandwiched between a first and a second substrate layers, preferably by a roll-to-roll process; (2) removing part of a first substrate by asymmetrical cutting by, for example, a die, diamond, knife or laser cutting method to expose the layers underneath (which may include adhesive layer, primer layer, display cell layer and in the case of a display prepared by the microcup technology, the microcup layer and the sealing layer); and (3) stripping off the exposed layers by a stripping solvent or solution. After stripping, the conductor lines on the second substrate are exposed and ready for connection to the driver circuitry.

Owner:E INK CALIFORNIA

Energy ray-curable inkjet printing ink

InactiveUS20090118388A1Low viscosityHigh sensitivityMixing methodsDuplicating/marking methodsPrinting inkKetone

An energy beam curable type ink jet printing ink comprising (A) a colorant, (B) a compound having at least one ethylenically unsaturated bond which can be polymerized by the application of an energy beam and (C) a photopolymerization initiator, whereinthe component (B) is a compound having at least one methacryloyl group as a sole polymerizable unsaturated group and the component (C) is a 2-alkyl-2-amino-2-benzyl-1-(4-morpholinophenyl)ethan-1-one.This ink has low viscosity, high sensitivity and sufficiently high film strength after curing.

Owner:JSR CORPORATIOON

Methods for coating a metal substrate and related coated substrates

ActiveUS20080145678A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsYttriumMetallic substrate

Owner:PPG IND OHIO INC

Hybrid coating compositions

InactiveUS6896934B2Easy to cleanImprove acid resistanceElectrolysis componentsVolume/mass flow measurementScreen printingFrit

The present invention provides a composition for use in forming an abrasion-resistant easy-to-clean coating on a substrate. The composition according to the invention includes a mixture of a fluorocarbon polymer component and an enamel-forming component. The enamel-forming component includes at least a first lead-free and cadmium-free glass frit. The first lead-free and cadmium-free glass frit includes from about 30% to about 50% P2O5, from about 15% to about 30% Al2O3, and from about 2% to about 40% X2O where X=Na and / or K. The present invention also provides a method of forming an abrasion-resistant easy-to-clean coating on a substrate. The method includes applying the composition according to the invention to a substrate and sintering the applied composition to fuse an abrasion-resistant easy-to-clean coating to the substrate. The method can be used to apply the composition to a variety of substrate materials such as metals, glass, ceramics, and stone, using a variety of application techniques such as wet spraying, screen printing, electrophoresis, dry electrostatic deposition, wet dipping, and flow coating.

Owner:FERRO FRANCE S A R L

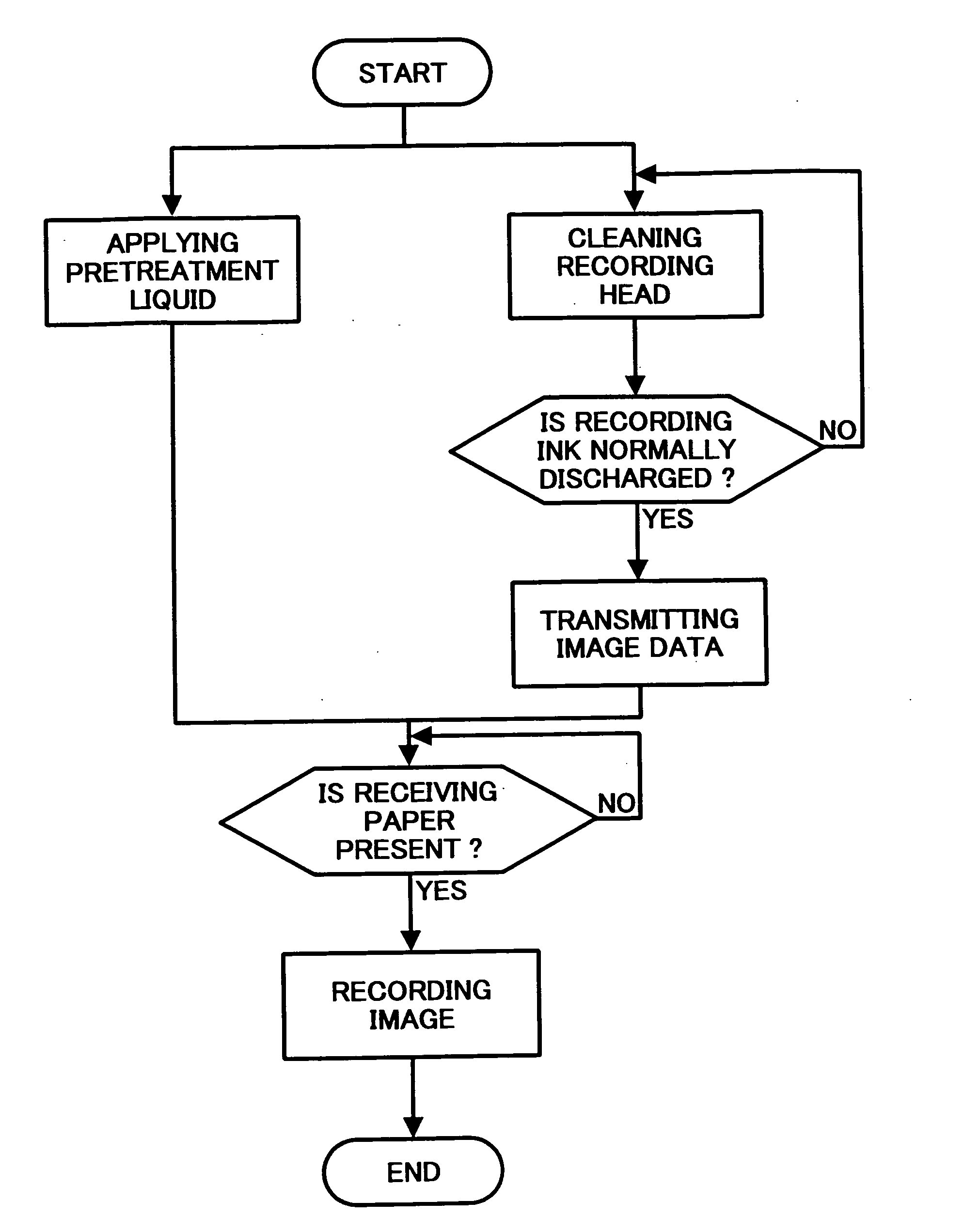

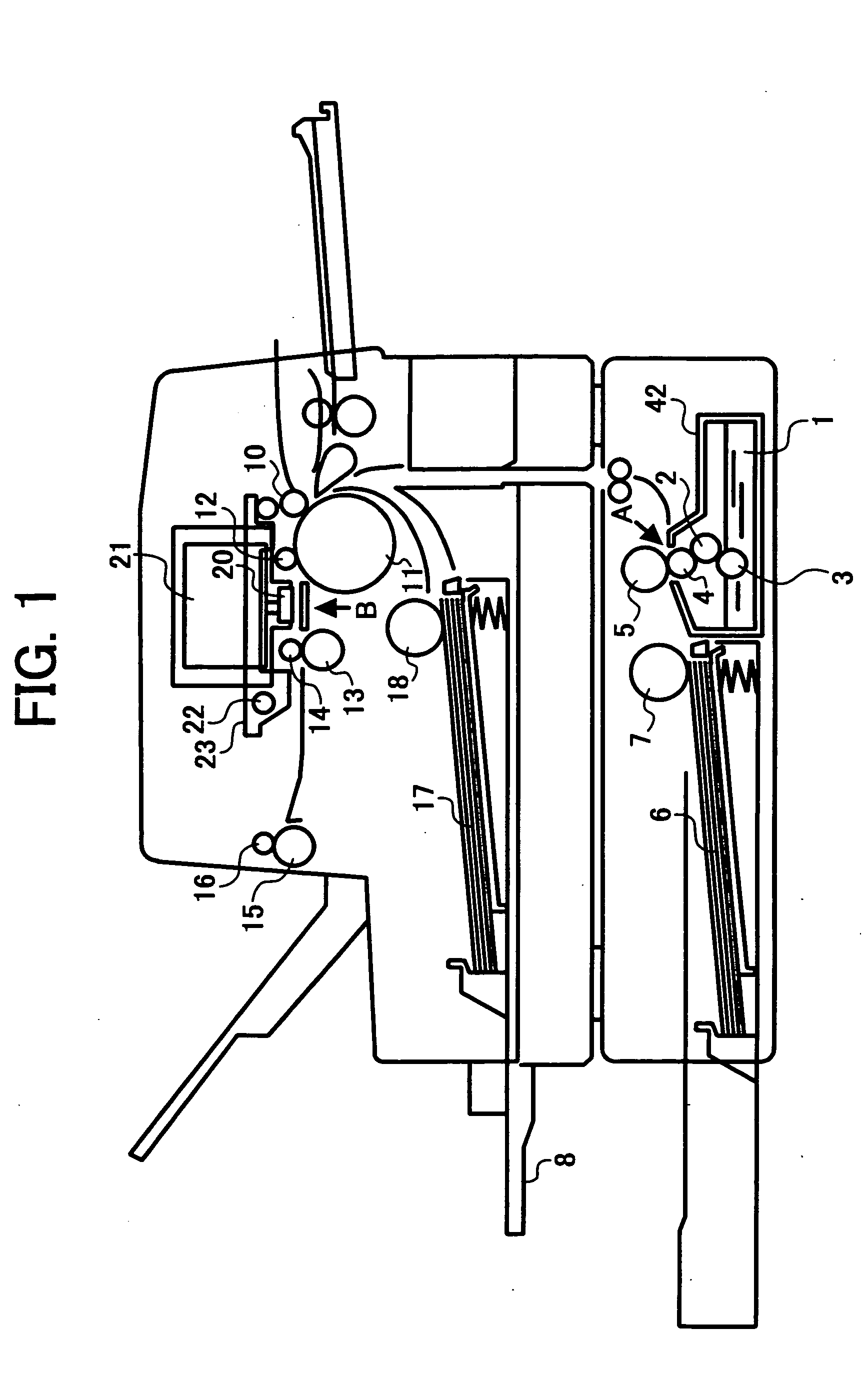

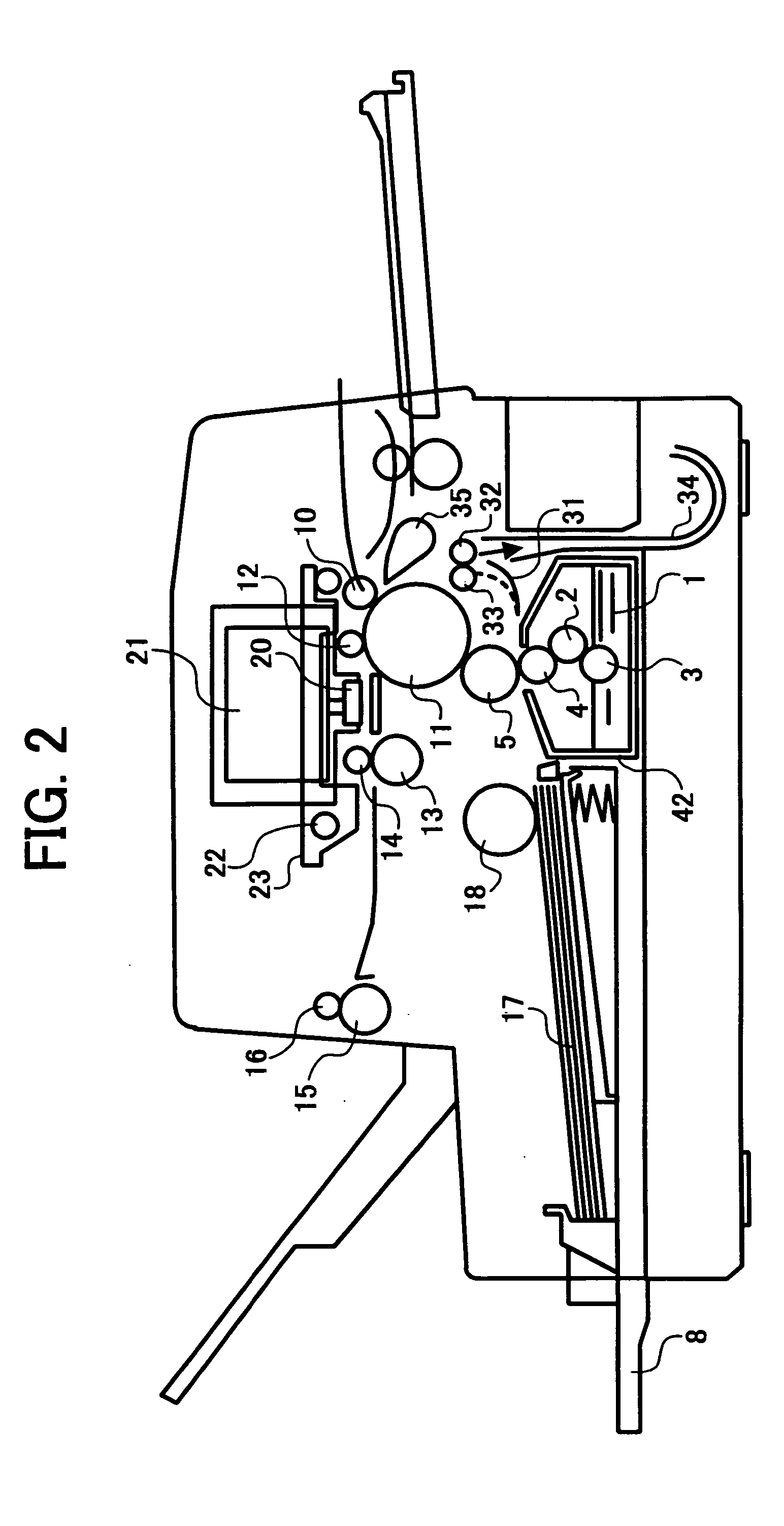

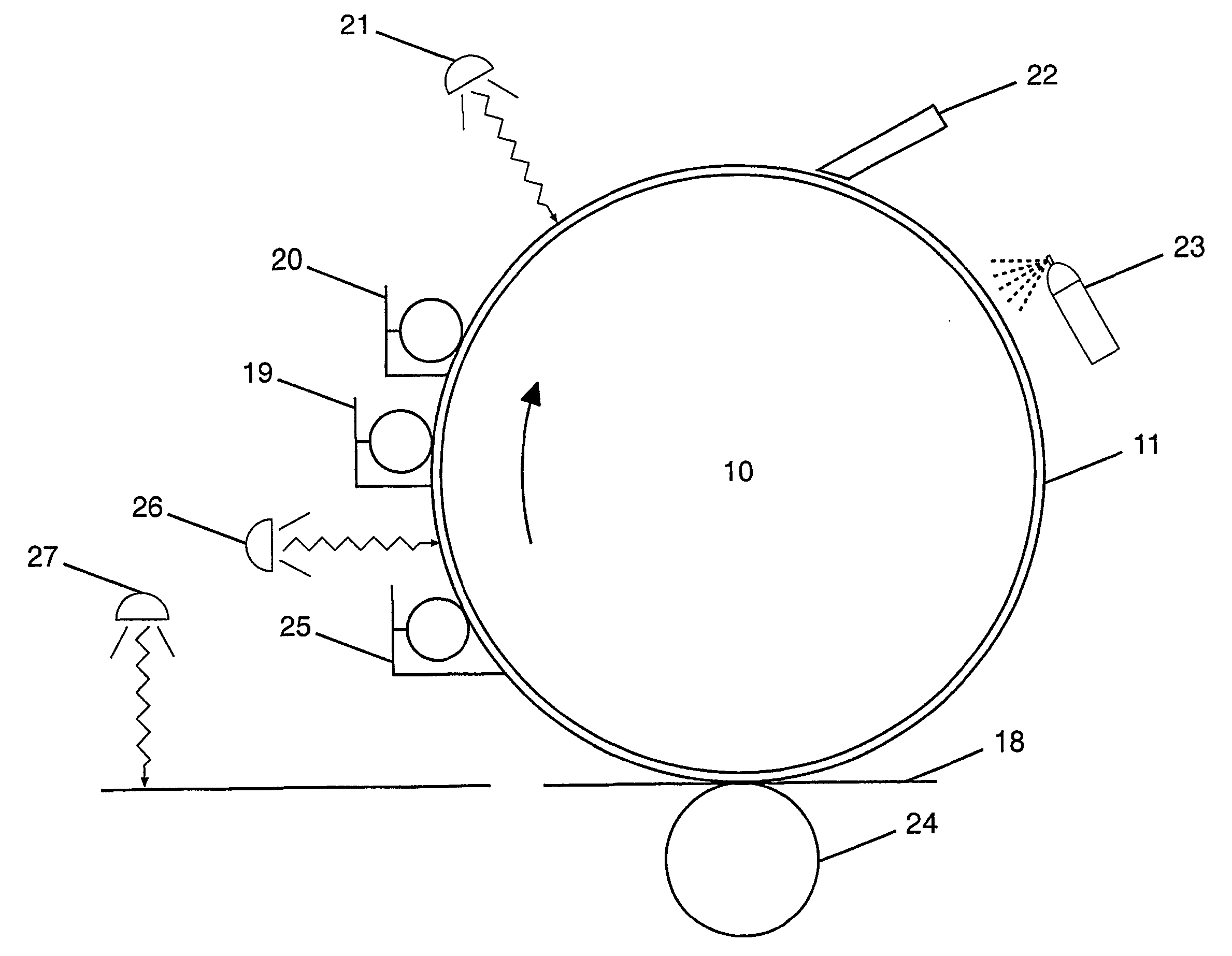

Pretreatment liquid for recording material and image recording method using the pretreatment liquid

InactiveUS20050007431A1Improve water resistanceHigh image densityMeasurement apparatus componentsDuplicating/marking methodsSolubilityImage recording

An image recording method including: applying a pretreatment liquid on a surface of a recording material; and discharging a recording ink according to image signals to form an ink image on the pretreatment liquid on the surface of the recording material before the pretreatment liquid applied to the recording material has dried, wherein the recording ink includes a solvent and a component dispersed or dissolved in the solvent, wherein the pretreatment liquid includes a compound depressing at least one of the dispersibility and solubility of the component in the recording ink in an amount of 10 to 80% by weight based on total weight, and wherein the pretreatment liquid has a viscosity of from 10 to 10,000 mPa·s at 25° C.

Owner:RICOH KK

Method of printing variable information

The gel method of printing variable information of the present invention involves applying inks onto a substrate that is part of or attached to a cylinder of the printing machine. Imaging is by means of an energy source in the UV, visible or infrared regions, modulated to represent a digital image pattern that has been composed on a computer. The consequence of imaging is to gel the ink and increase its adhesion to the substrate of the printing cylinder. The non-gelled background ink with lower adhesion is then removed by a squeegee action and returned to an ink reservoir. The remaining image is transferred to an offset blanket or directly to print stock by pressure. The process does not use a master, but produces an image that is erased after printing with each cylinder rotation so that the next rotation producing the next print can have fresh information written upon it.

Owner:KODAK IL

Electrodeposition bath with water-soluble polyvinyl alcohol (co) polymers

InactiveUS6951602B1Liquid surface applicatorsElectrolysis componentsWater solublePVA - Polyvinyl alcohol

The invention relates to the use of a water-soluble polyvinyl alcohol (co)polymer or a mixture of polyvinyl alcohol (co)polymers as additives in aqueous electrodeposition baths, to electrodeposition baths comprising a polyvinyl alcohol (co)polymer, and to a method of coating an electrically conductive substrate.

Owner:BASF COATINGS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com