Nonionic self-emulsifying waterborne epoxy curing agent and preparation method thereof

A water-based epoxy, self-emulsifying technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problem that the acid resistance, wear resistance and hardness of the paint film cannot meet the needs of the market, and the investment in research and development of new curing agents Hysteresis, general product performance and other problems, to achieve the effect of excellent heat resistance, improved heat resistance, excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

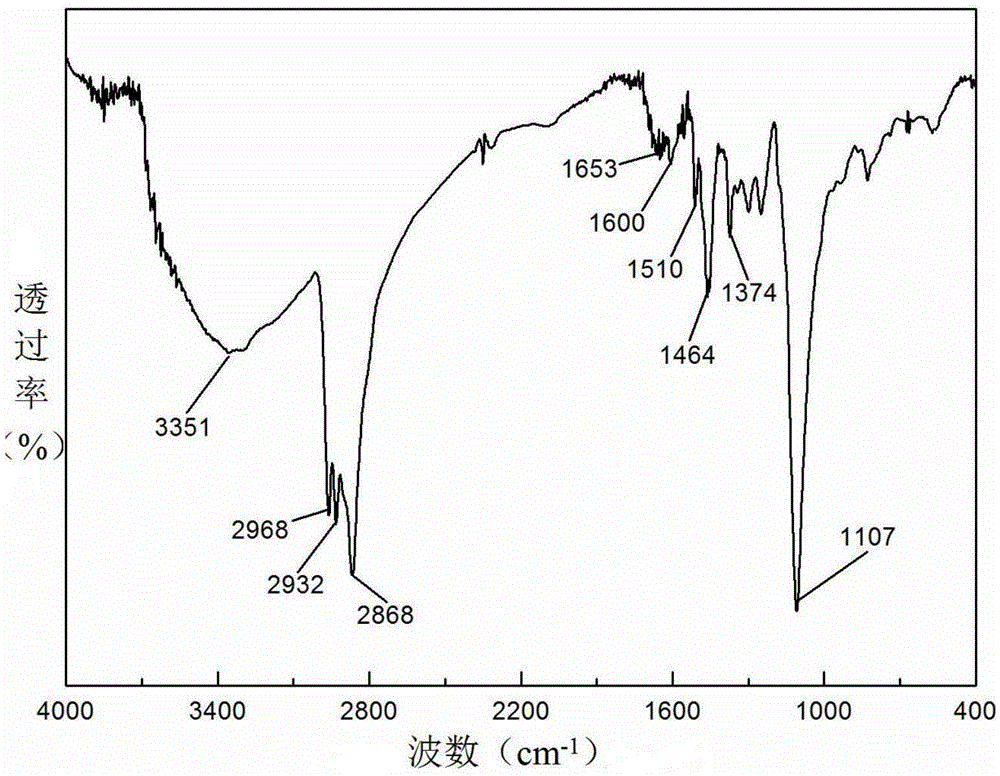

Image

Examples

preparation example Construction

[0055] Corresponding to the above formula system, the preparation method of this kind of nonionic self-emulsifying water-based epoxy curing agent comprises the following steps:

[0056] 1) Add epoxy-terminated polyether to the basic amine, and extend the chain of the basic amine. After the reaction is complete, add a monoepoxy compound to partially block the primary amine groups in the system to obtain prepolymer A;

[0057] 2) Adding monoepoxides to polyether amines, partially capping the primary amino groups in the system, to obtain prepolymer B;

[0058] 3) Mix prepolymers A and B, add epoxy resin, and after the reaction is complete, add monoepoxide and silane coupling agent to end-block the remaining primary amino groups in the system;

[0059] 4) Constant temperature, adding water to disperse to obtain nonionic self-emulsifying water-based epoxy curing agent.

[0060] Preferably, corresponding to the above-mentioned formula system, the preparation method of this kind of ...

preparation example 1

[0084]1) Add 90.00g of tetraethylenepentamine to a four-necked round-bottom flask equipped with a thermometer, condenser, dropping funnel and stirrer, raise the temperature to 60°C, and slowly add 45.00g of ethylene glycol dropwise after the temperature is constant Diglycidyl ether XY669 (Guangzhou Cool Special Chemical Co., Ltd.) carries out chain extension and reacts for 3 hours; after the reaction is completed, 31.64 g of butyl glycidyl ether is added thereto to cap the primary amino groups in the system, and reacted for 3 hours to obtain a prepolymer Object A;

[0085] 2) Add 121.50g polyetheramine T403 (M w =440, Huntsman Chemical Trading Ltd.), keeping the temperature of the system at 60°C, slowly adding 65.10g of butyl glycidyl ether to partially cap it, and reacting for 4h to obtain prepolymer B;

[0086] 3) Mix the above prepolymers A and B uniformly at 50°C, then add 78.43g of epoxy resin E-51 to it for epoxy-amine addition, react for 5h, and then add 6.51g of butyl...

preparation example 2

[0093] 1) Add 270.00g polyethyleneimine (M w =600, Chengdu Best Reagent Co., Ltd.), heat up to 80°C, and slowly add 116.82g of polyethylene glycol diglycidyl ether XY215 (epoxy value=0.34, Anhui Hengyuan Chemical Co., Ltd.) Carry out chain extension and react for 4 hours; after the reaction is completed, add 32.55 g of butyl glycidyl ether to cap the primary amino groups in the system, and react for 4 hours to obtain prepolymer A;

[0094] 2) Add 72.00g polyetheramine D230 (M w =230, BASFCorporation), keep the temperature of the system at 50°C, slowly add 47.00g of phenylglycidyl ether to it for partial capping, and react for 6h to obtain prepolymer B;

[0095] 3) Mix the above prepolymers A and B uniformly at 80°C, then add 45.00g of epoxy resin E-20 to it for epoxy-amine addition, react for 2 hours, and then add 20.64g of butyl shrink resin after the reaction is completed Glyceryl ether and 25.99g γ-glycidyl etheroxypropyl triethoxysilane capped the remaining primary amine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com