Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389results about How to "Reduce lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

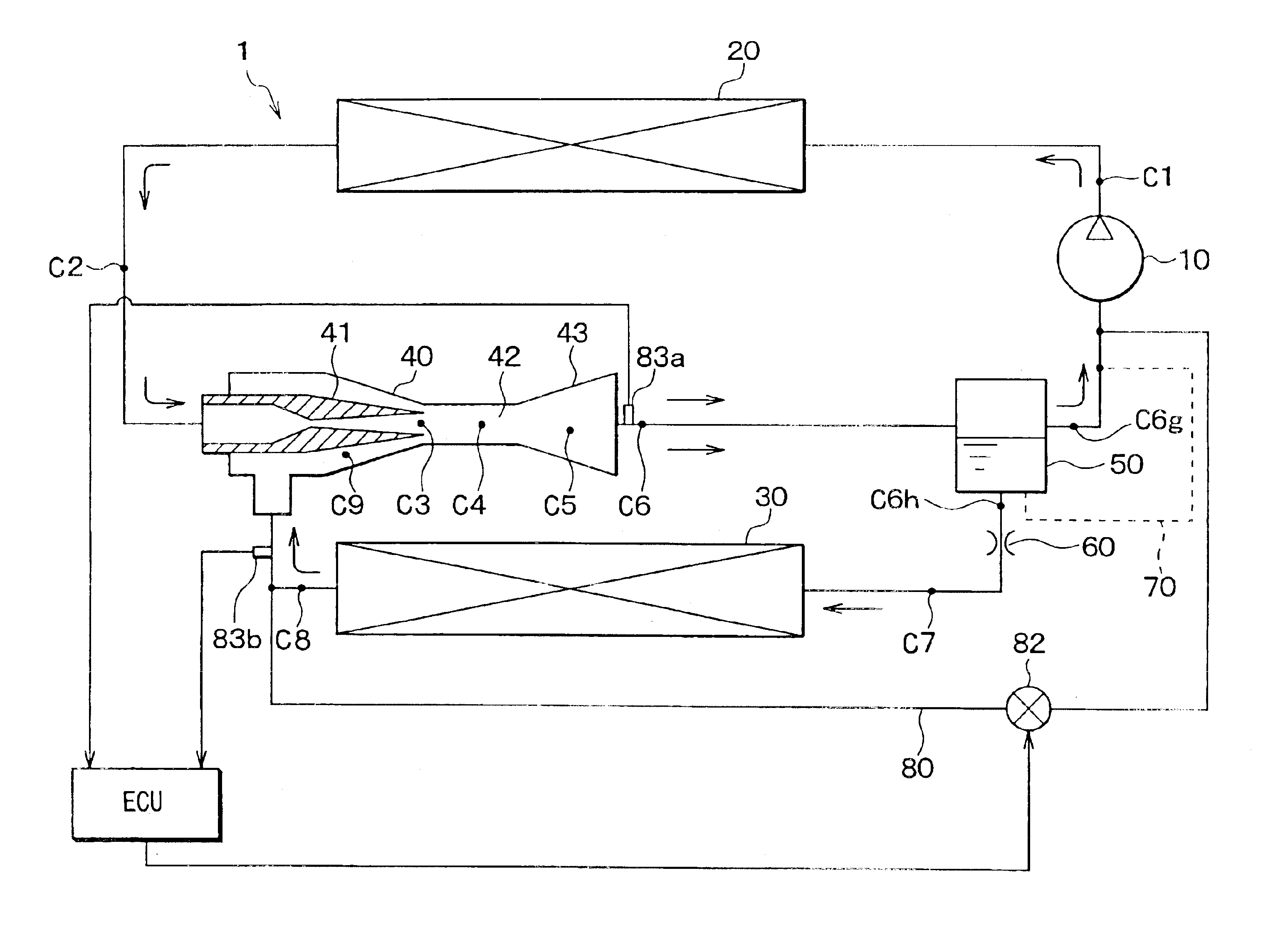

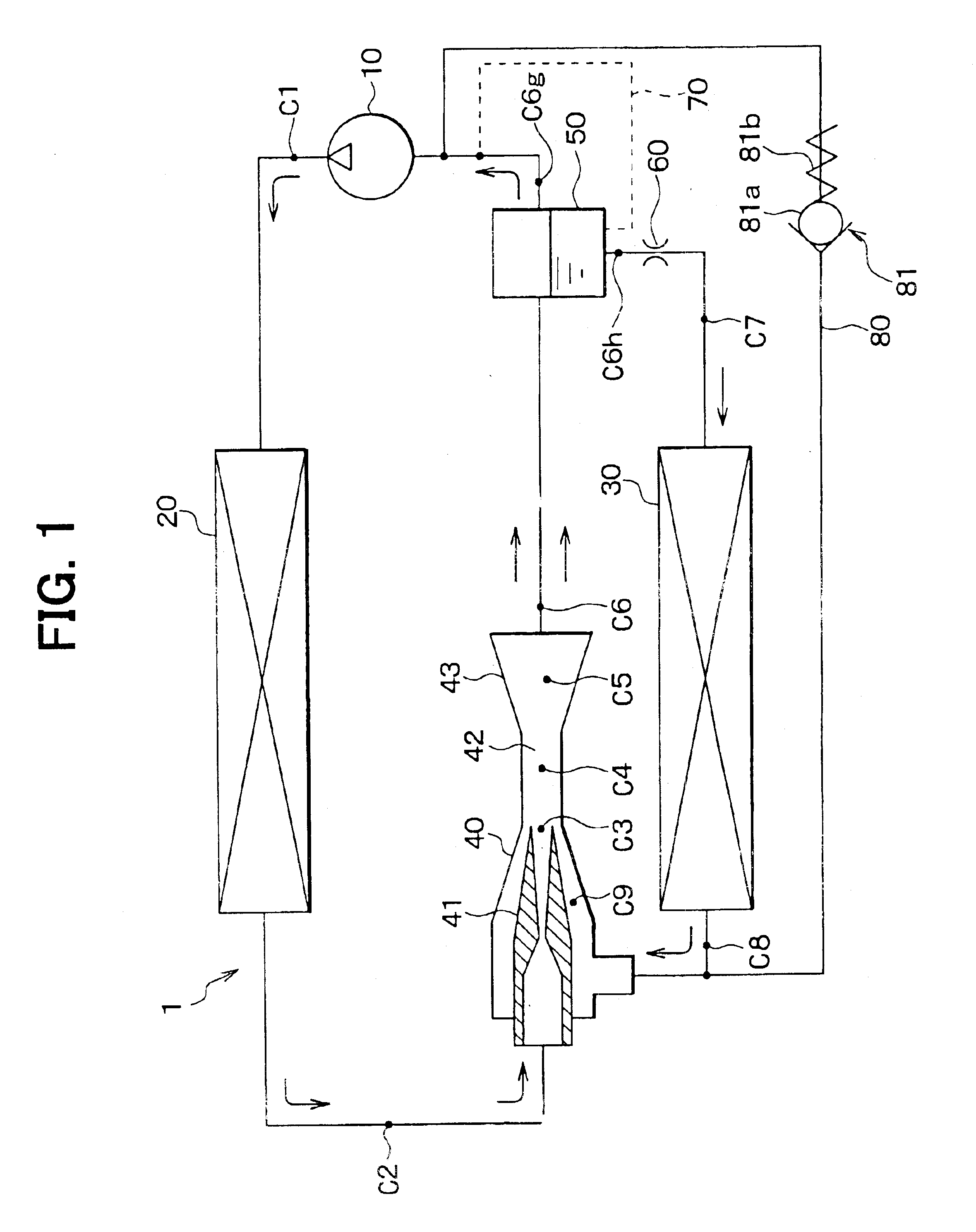

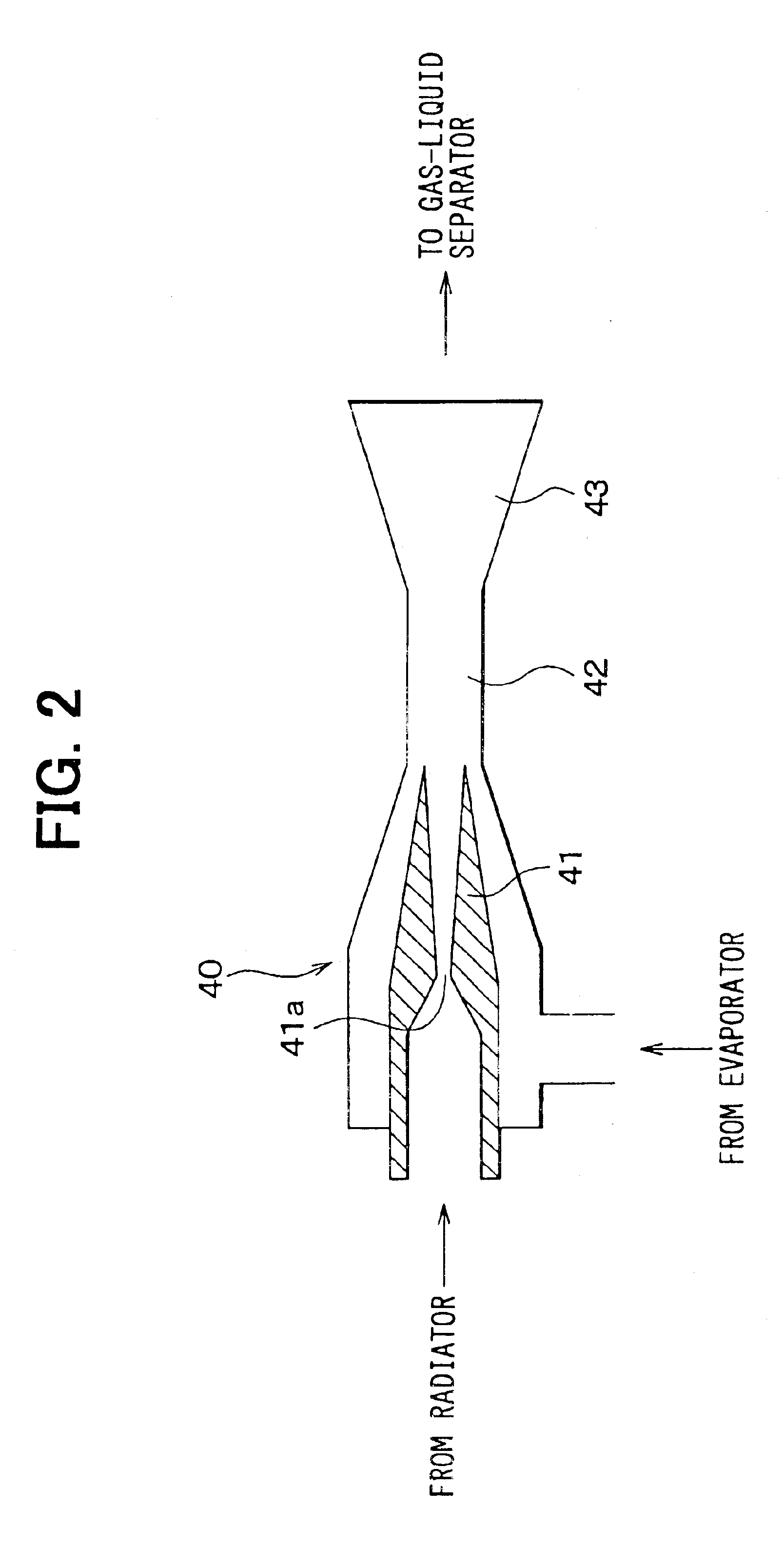

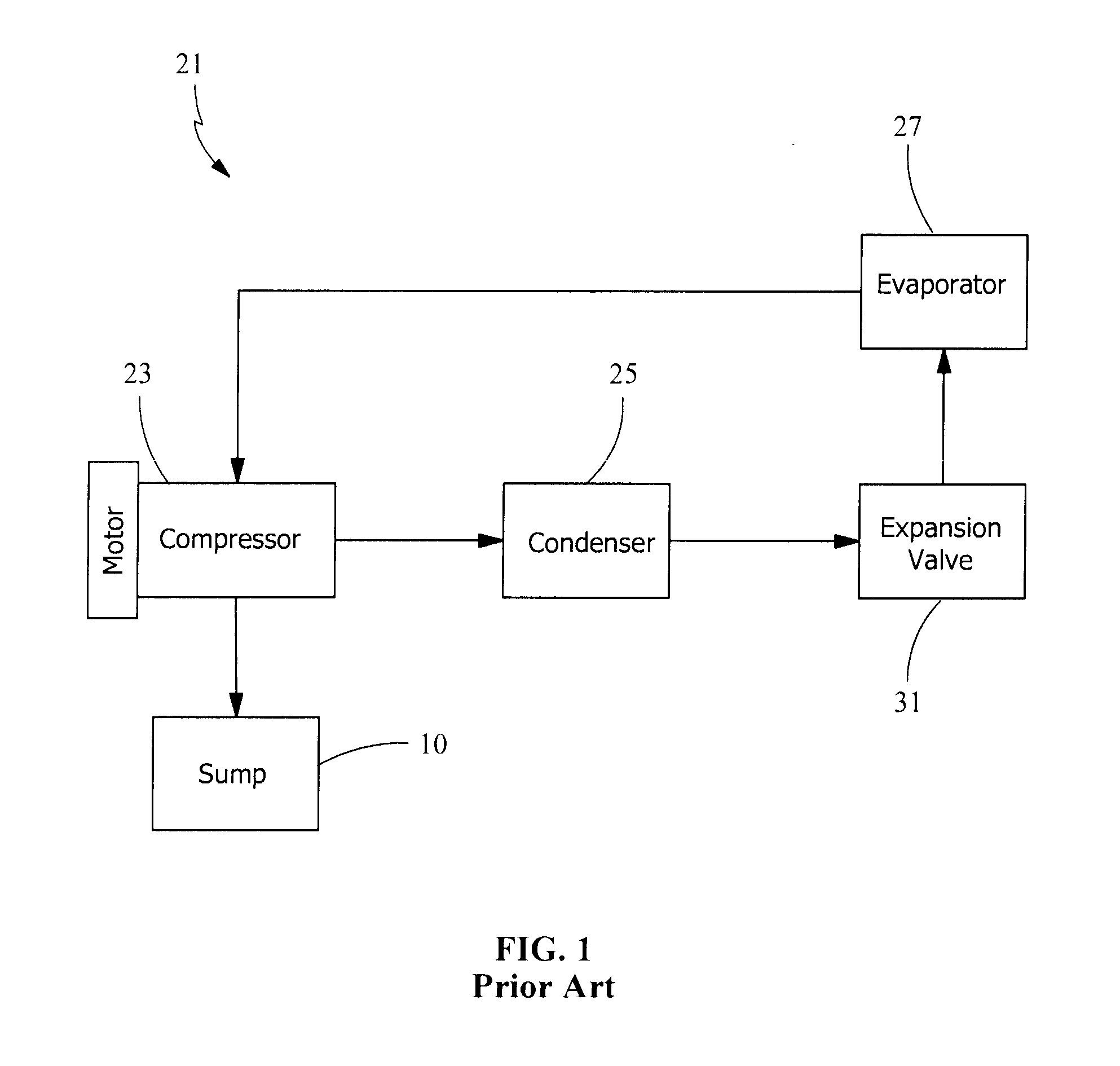

Ejector cycle

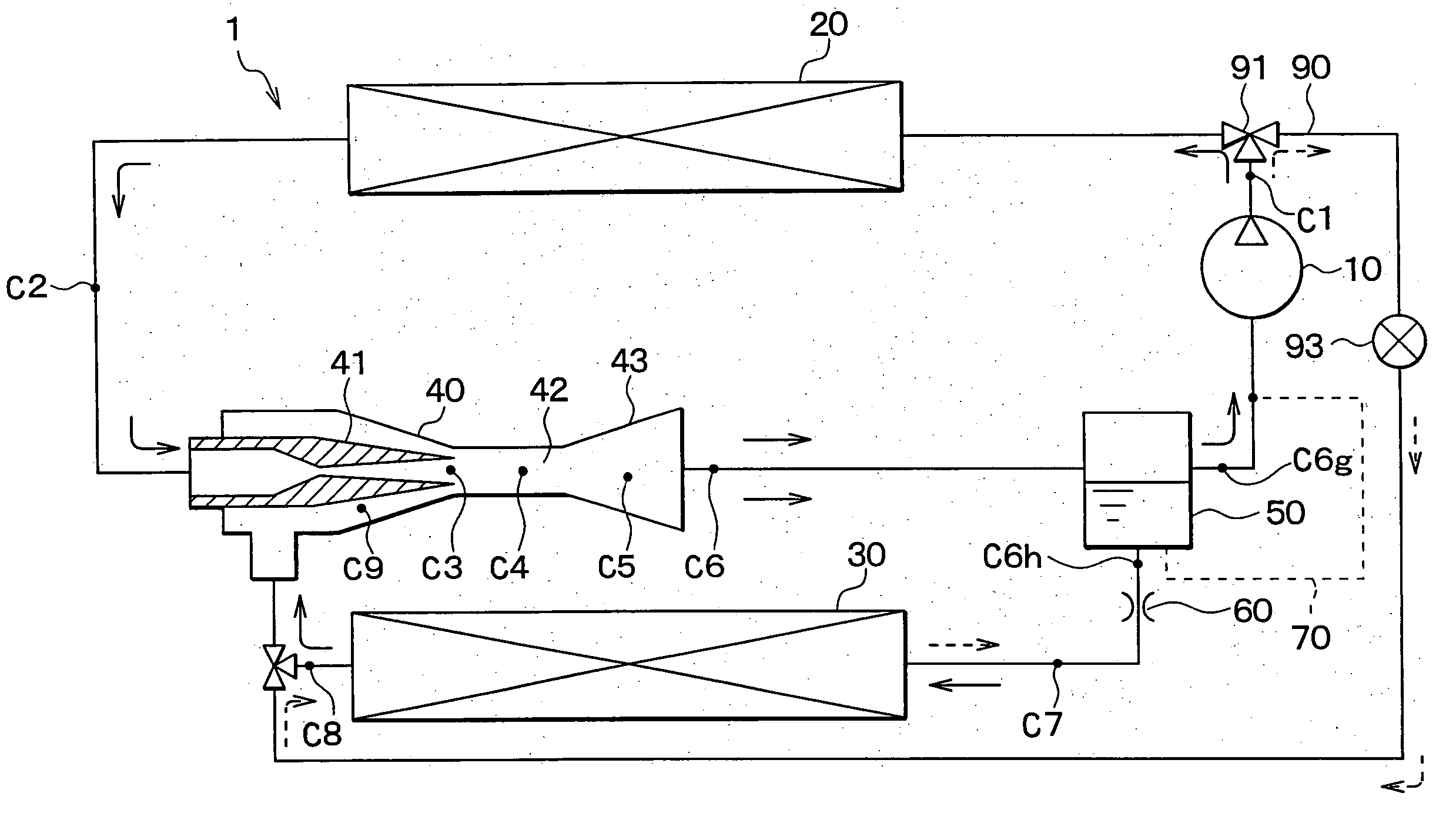

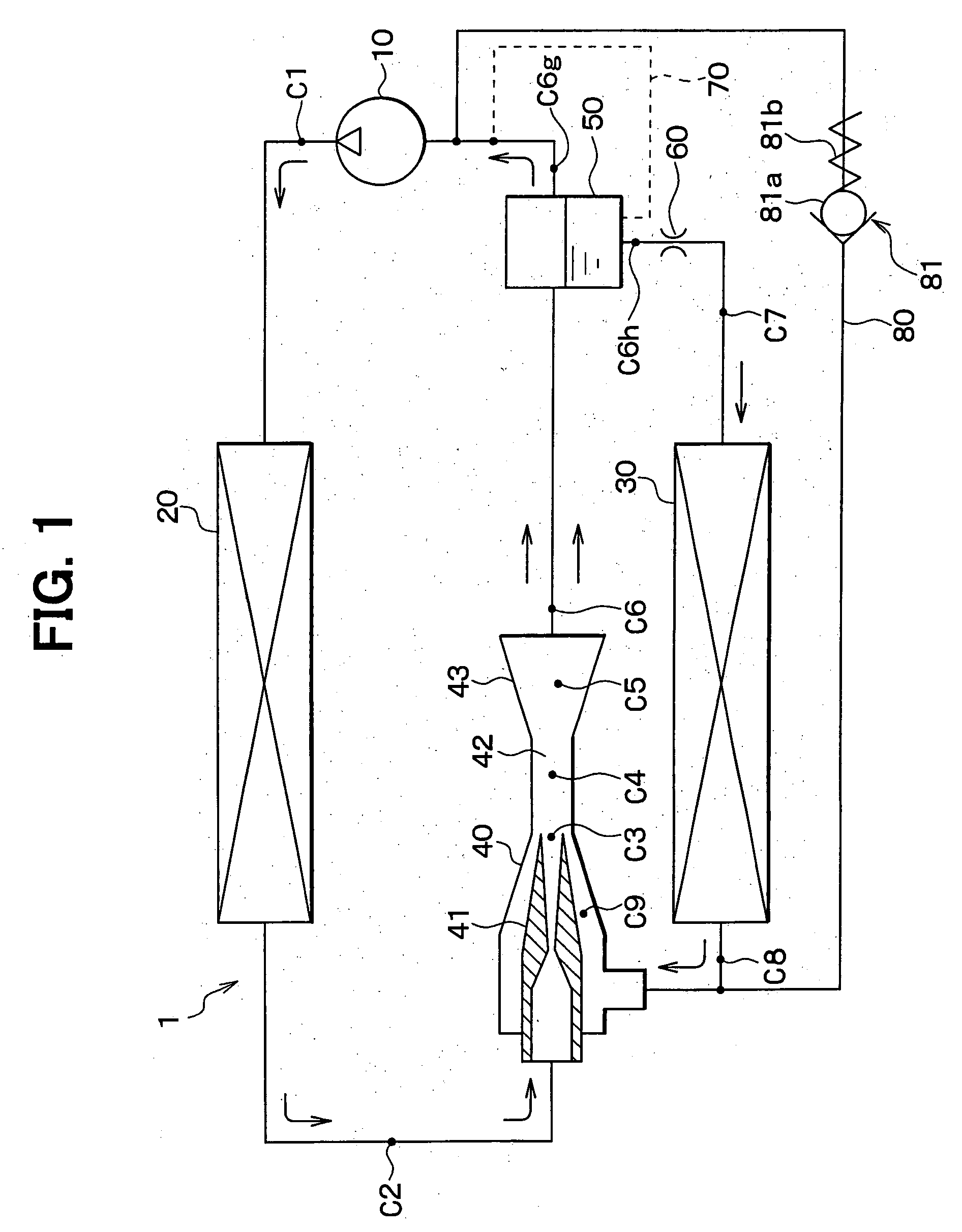

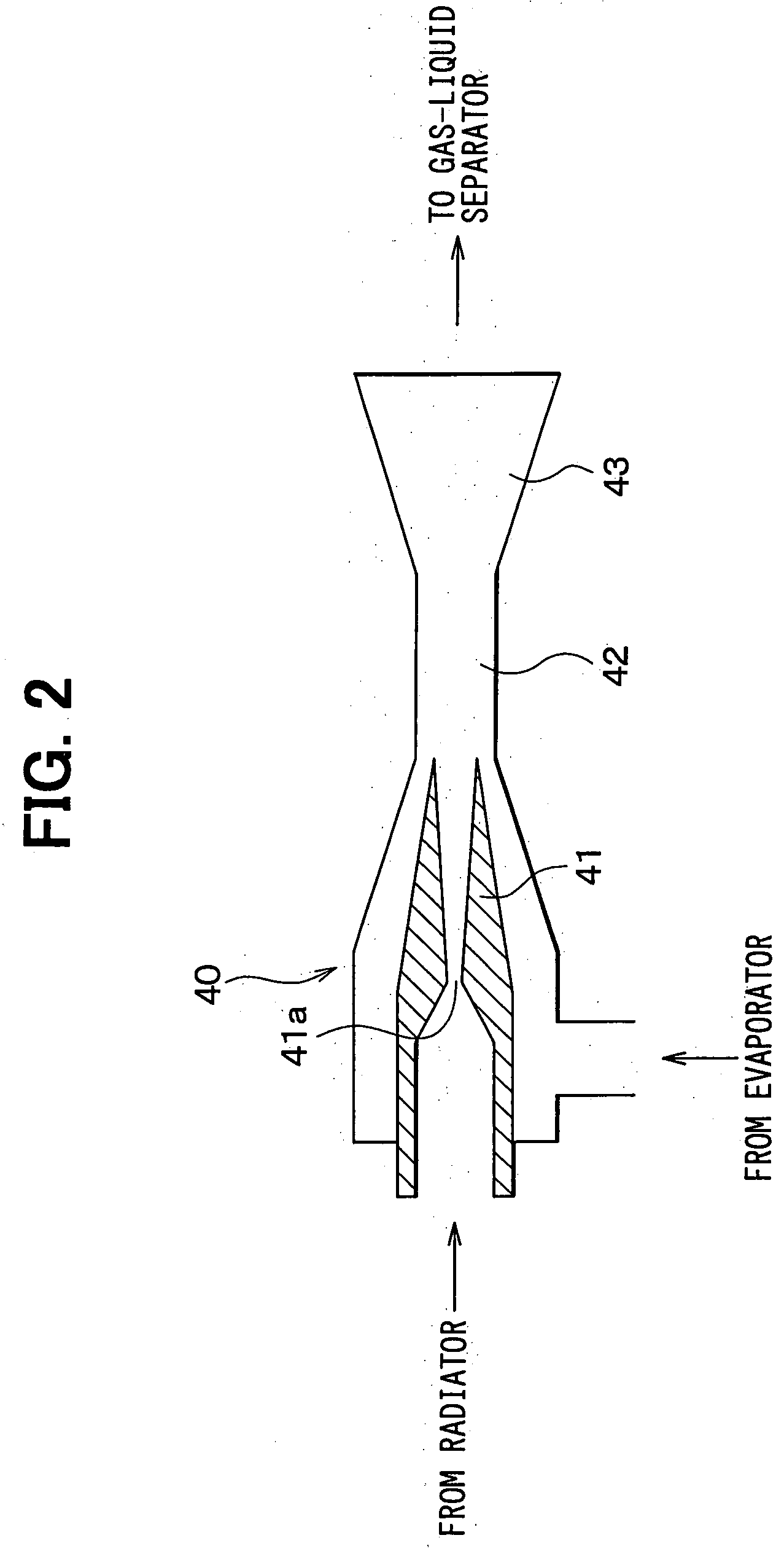

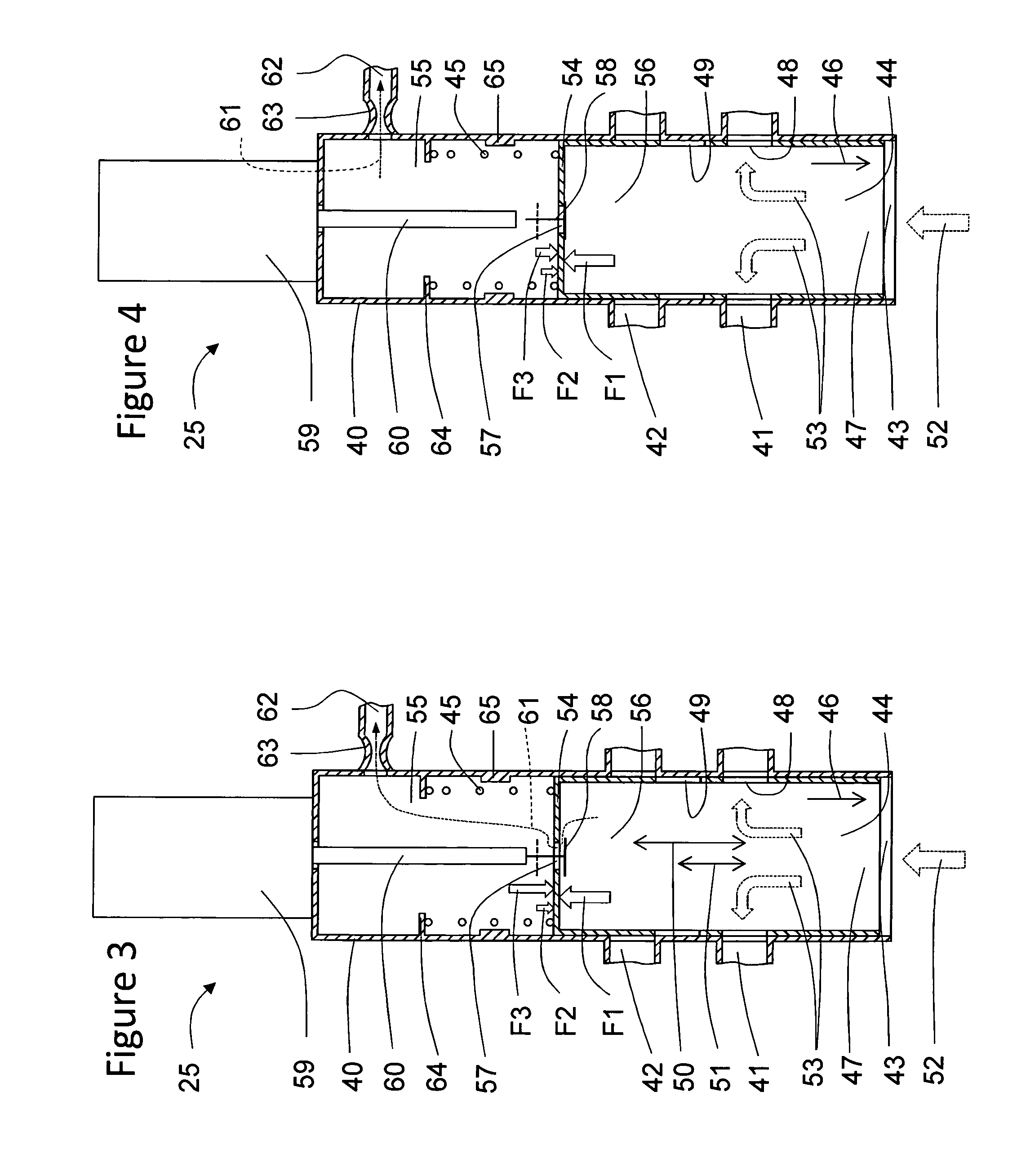

ActiveUS20040003608A1Small sizeReduce lubricationCompressorAir-treating devicesOperation modeCheck valve

In an ejector cycle having an ejector for decompressing refrigerant, a check valve is disposed in an oil return passage through which refrigerant including a lubrication oil is introduced from a refrigerant outlet side of an evaporator to a refrigerant suction side of a compressor while bypassing the ejector. When the lubrication oil amount staying in the evaporator reduces, the check valve is automatically closed, and a normal operation mode of the ejector cycle is automatically set. On the contrary, when a large amount of lubrication oil stays in the evaporator, the check valve is automatically opened, and an oil return mode is automatically set. Therefore, the lubrication oil staying in the evaporator can be controlled equal to or lower than a predetermined amount, thereby effectively returning the lubrication oil to the compressor.

Owner:DENSO CORP

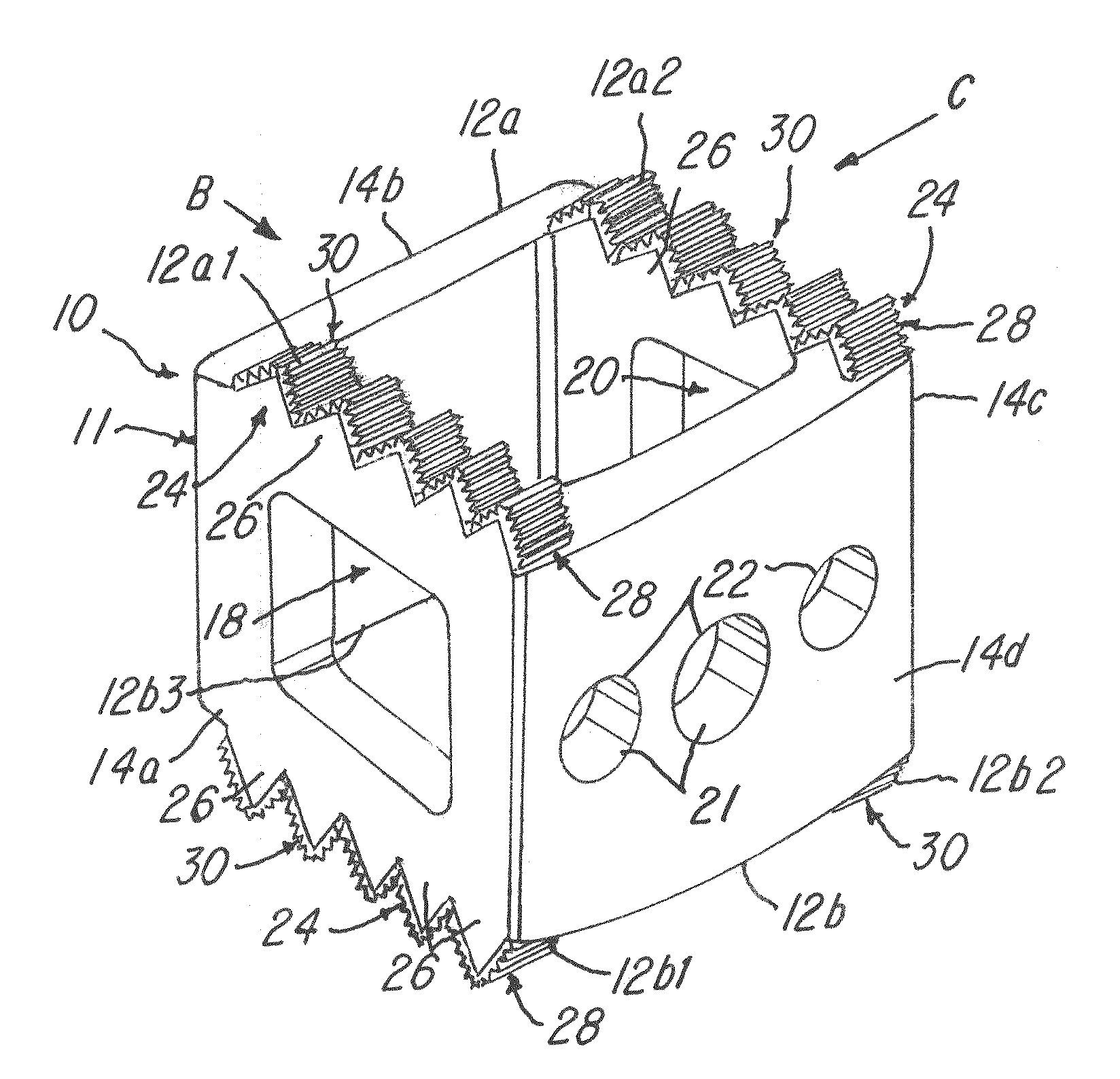

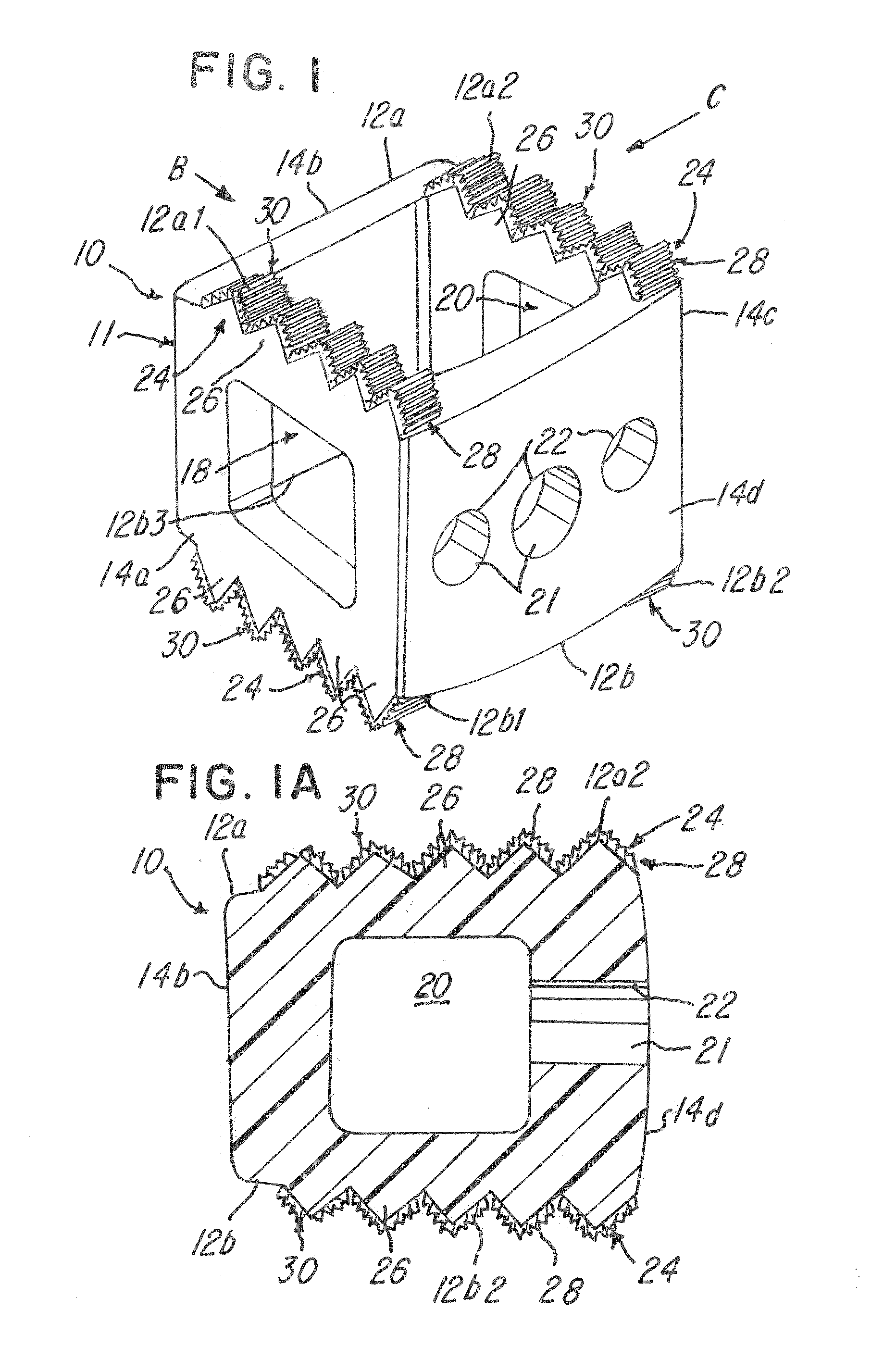

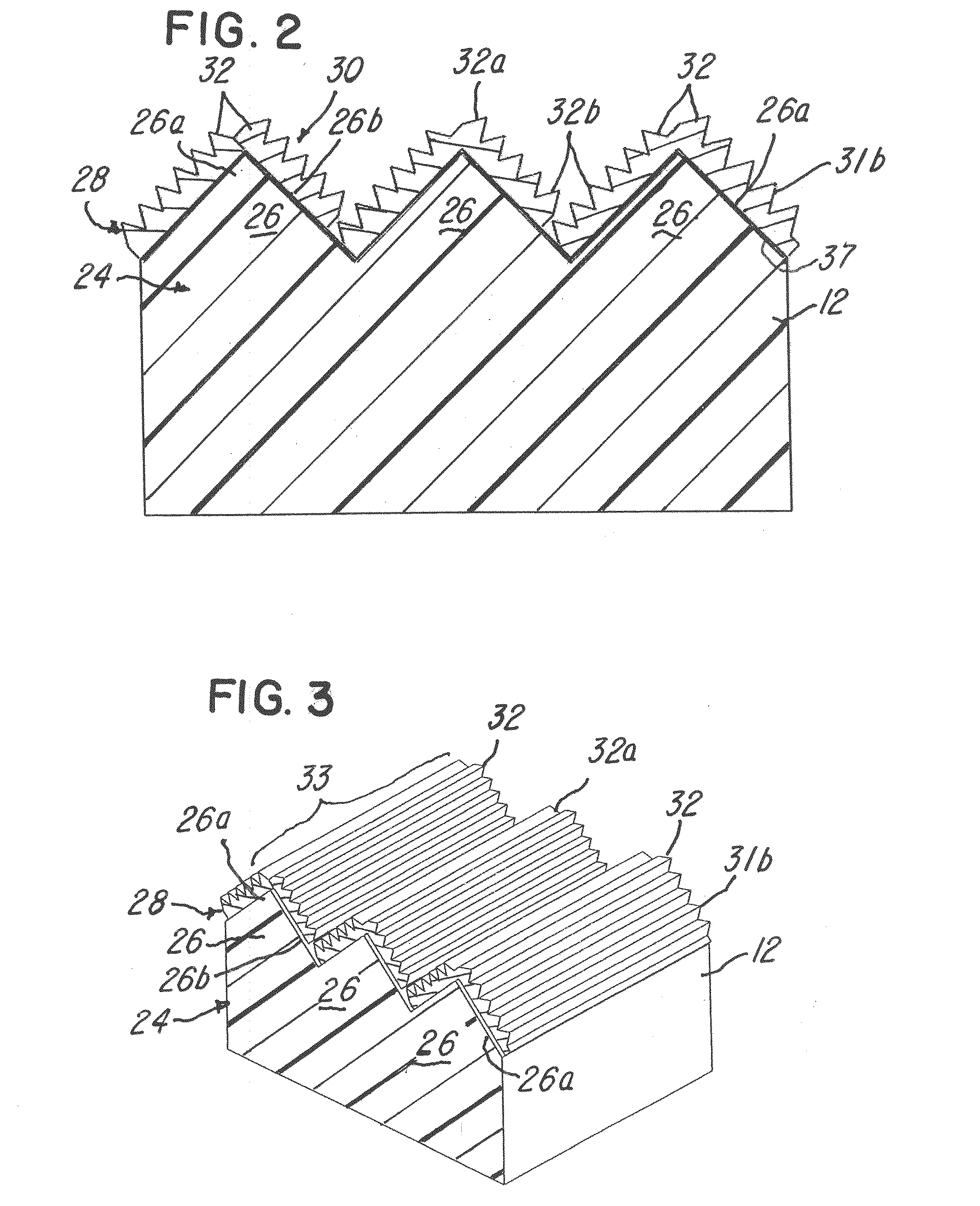

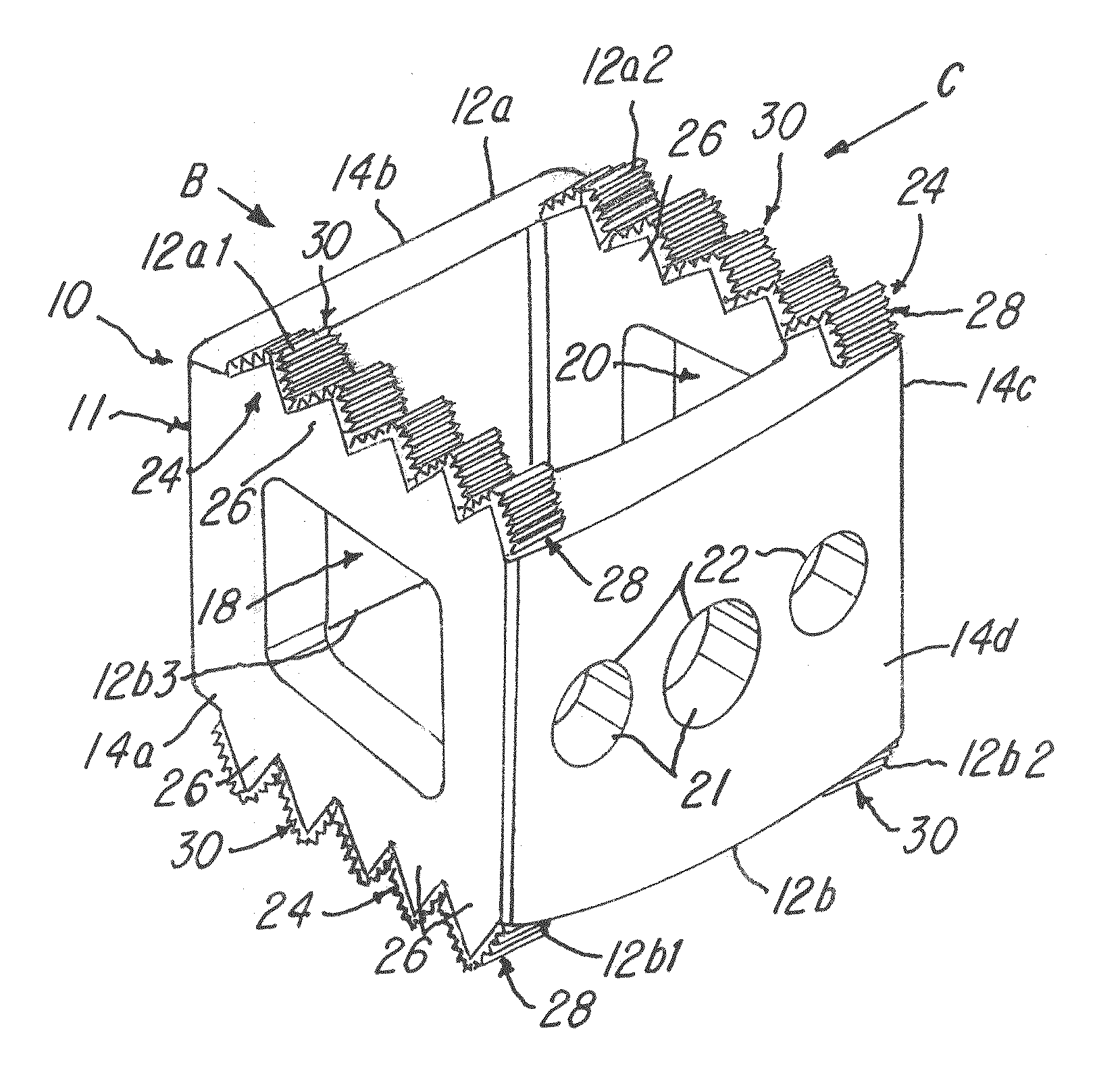

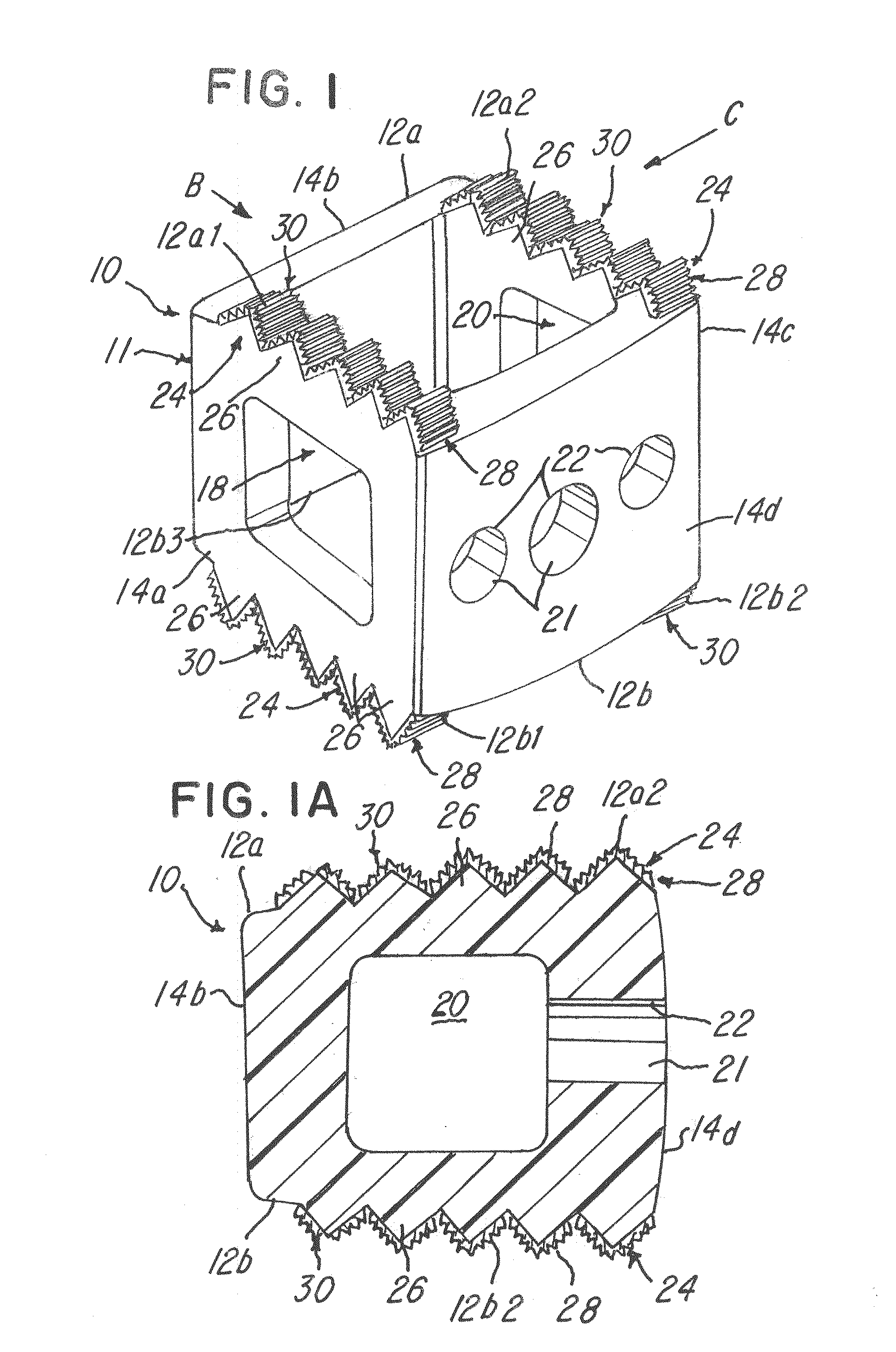

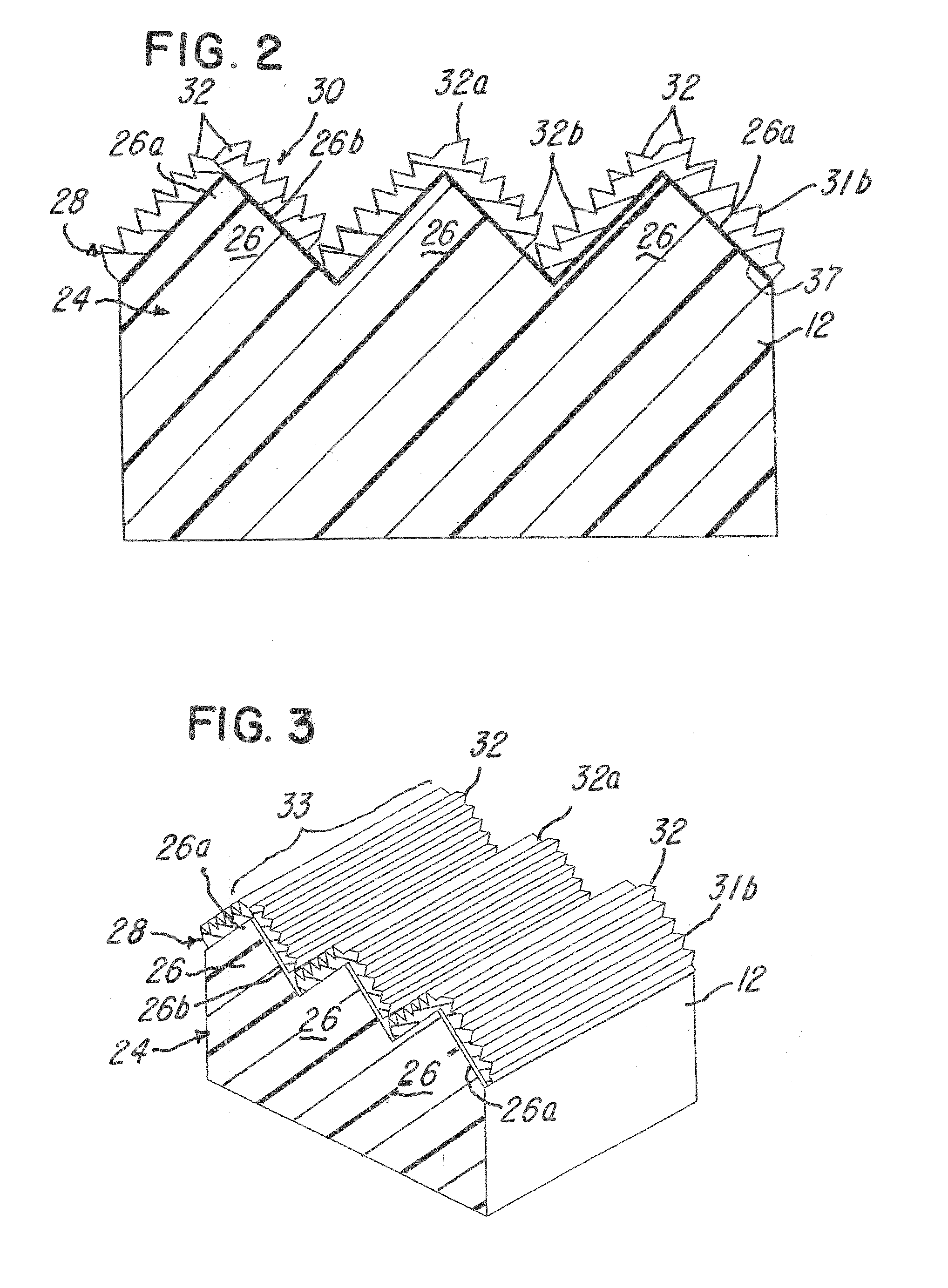

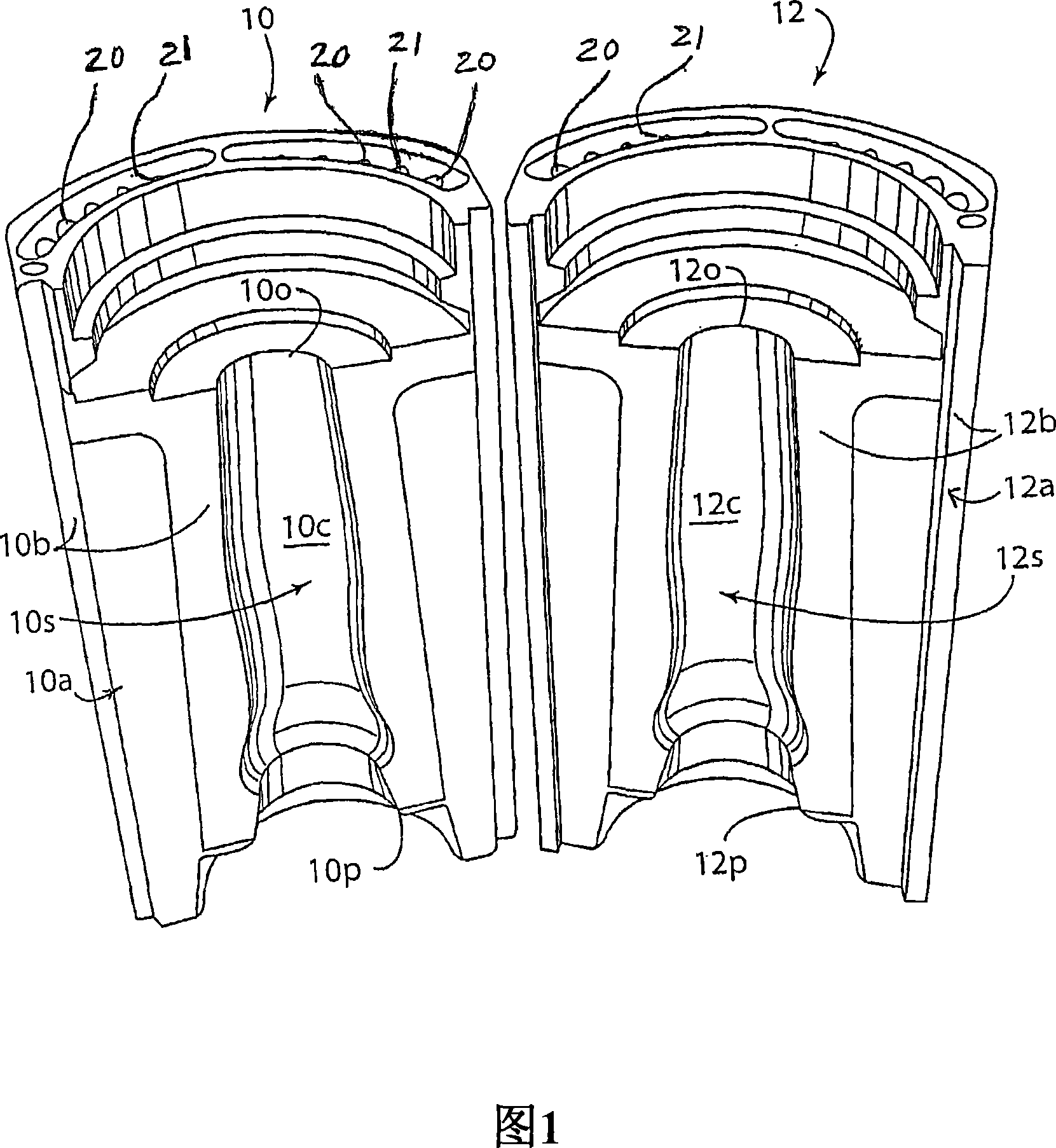

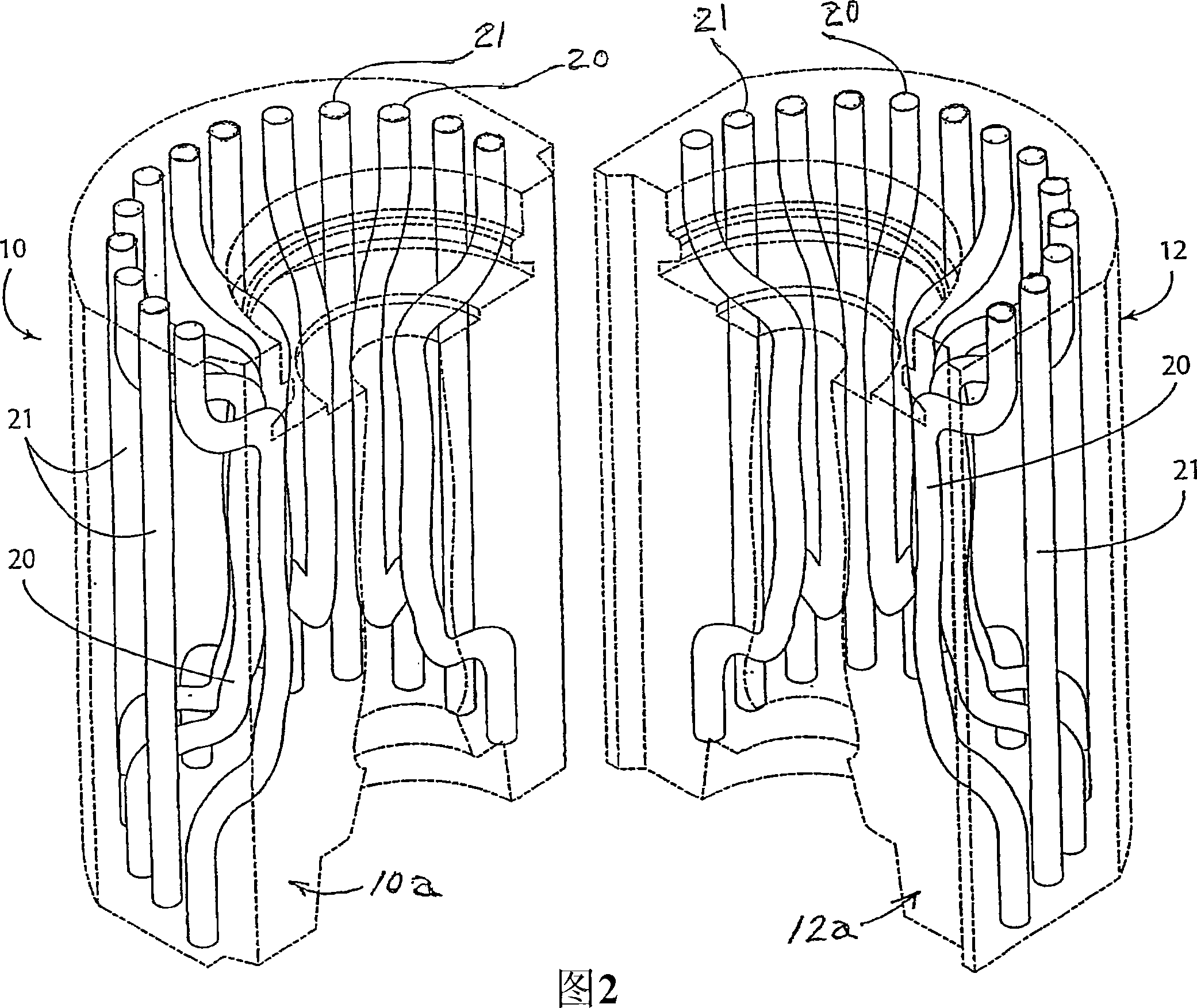

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

ActiveUS20140128980A1Reduce lubricationSimple featuresImpression capsPretreated surfacesSurgical implantPlastic surgery

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

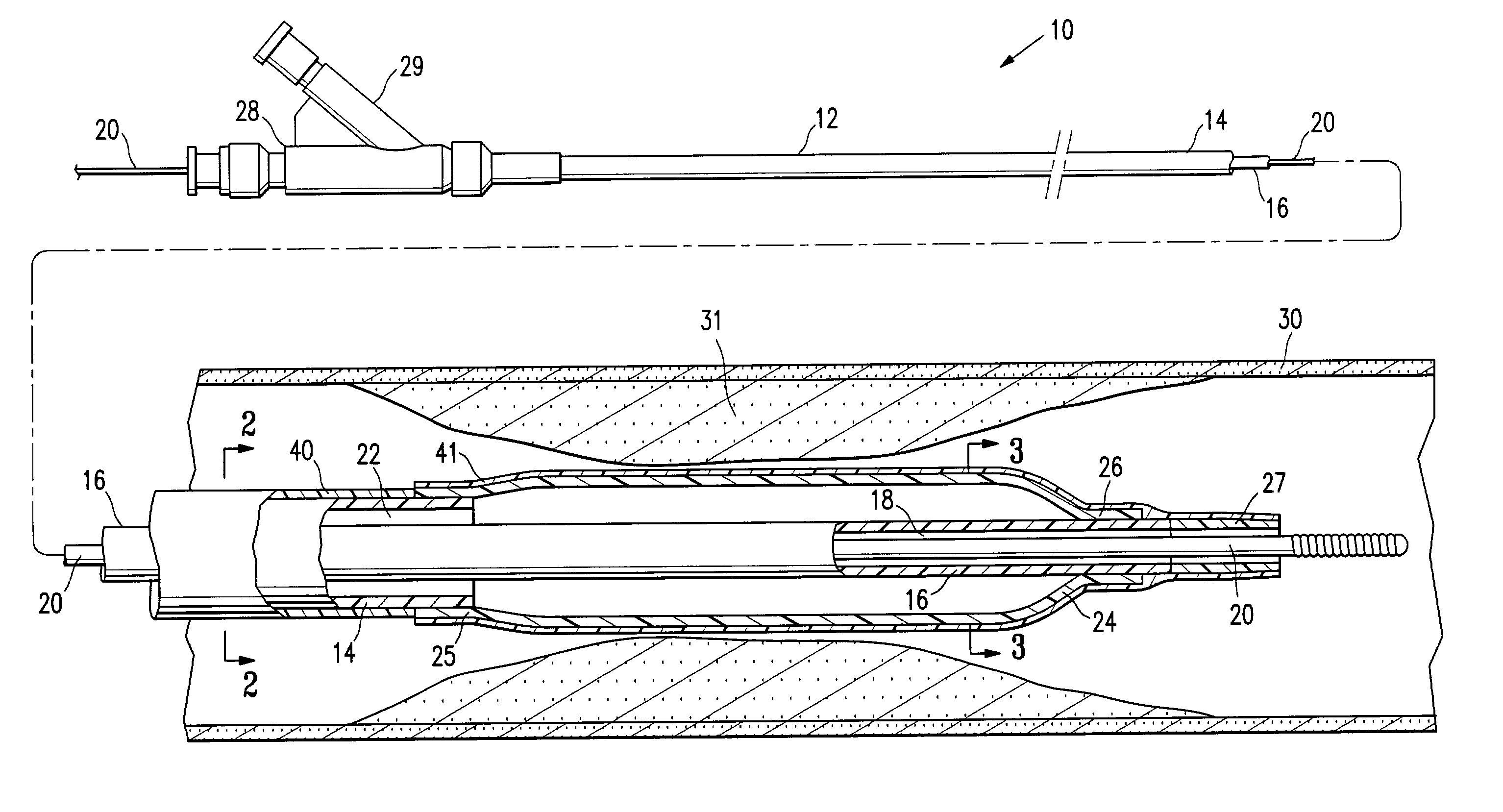

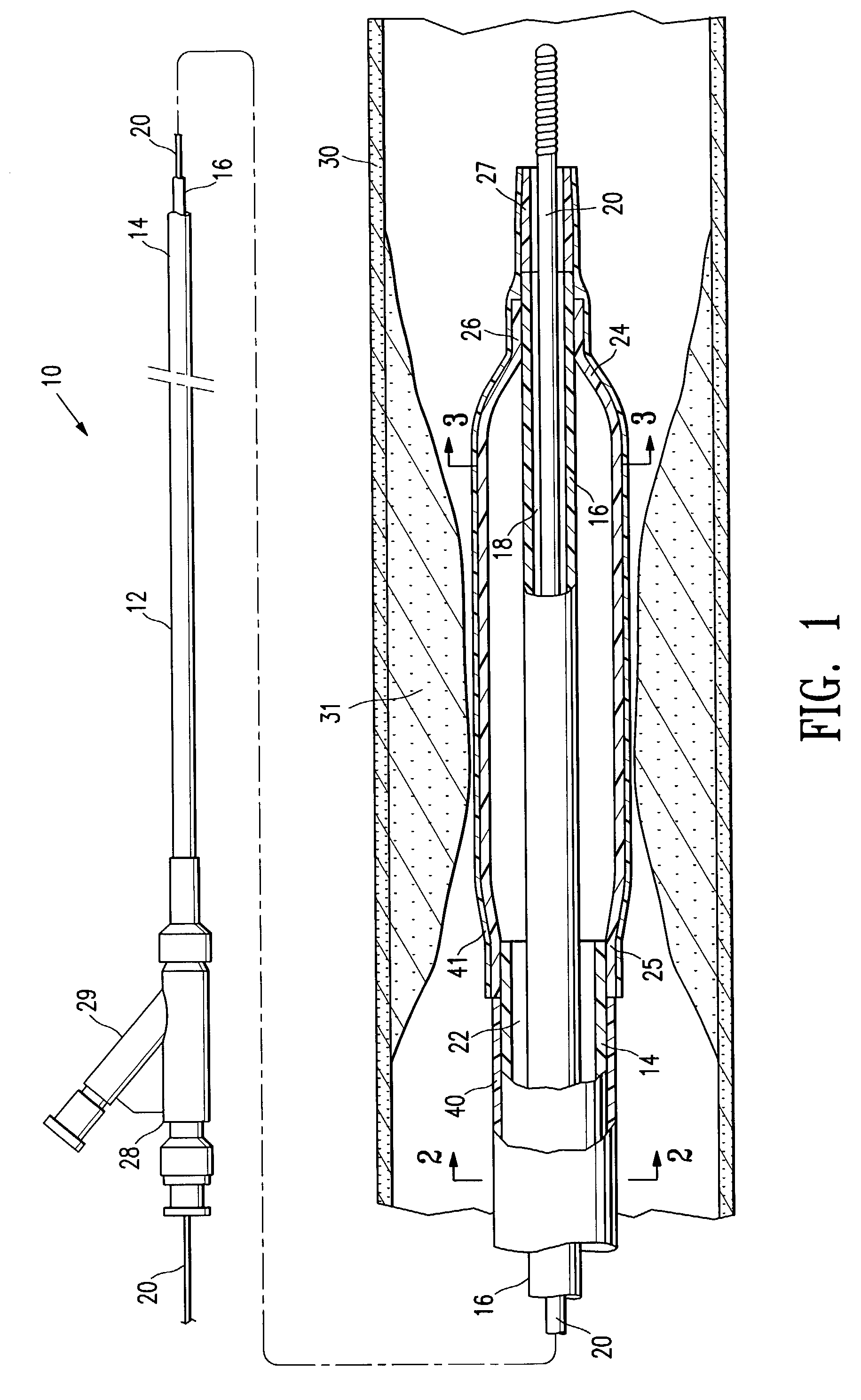

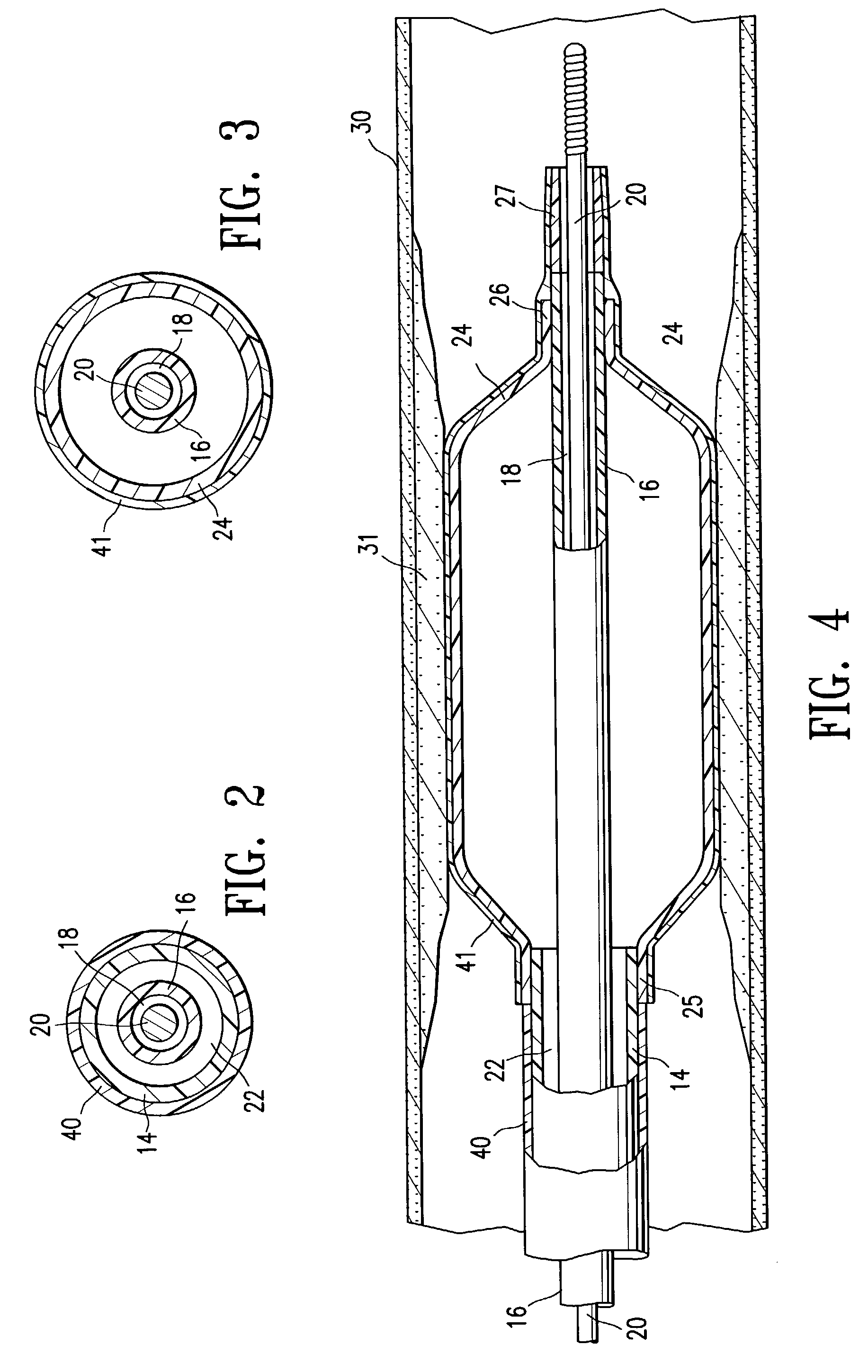

Reduced slippage balloon catheter and method of using same

InactiveUS7025752B2High slip angleLess lubriciousStentsBalloon catheterBalloon catheterBalloon dilatation

A balloon catheter having a balloon with a reduced slippage lubricious coating, and a method of performing a medical procedure such as a balloon dilatation procedure in a patient's blood vessel. The second coating (i.e., the balloon coating) is lubricious to facilitate movement of the catheter in the patient's body lumen, yet has sufficiently low lubricity such that the slippage of the inflated balloon from a desired site within the blood vessel is reduced compared to a balloon coated with the first lubricious coating.

Owner:ABBOTT CARDIOVASCULAR

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

InactiveUS20120022653A1Reduce lubricationSimple featuresSpinal implantsCoatingsEngineeringSurgical implant

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

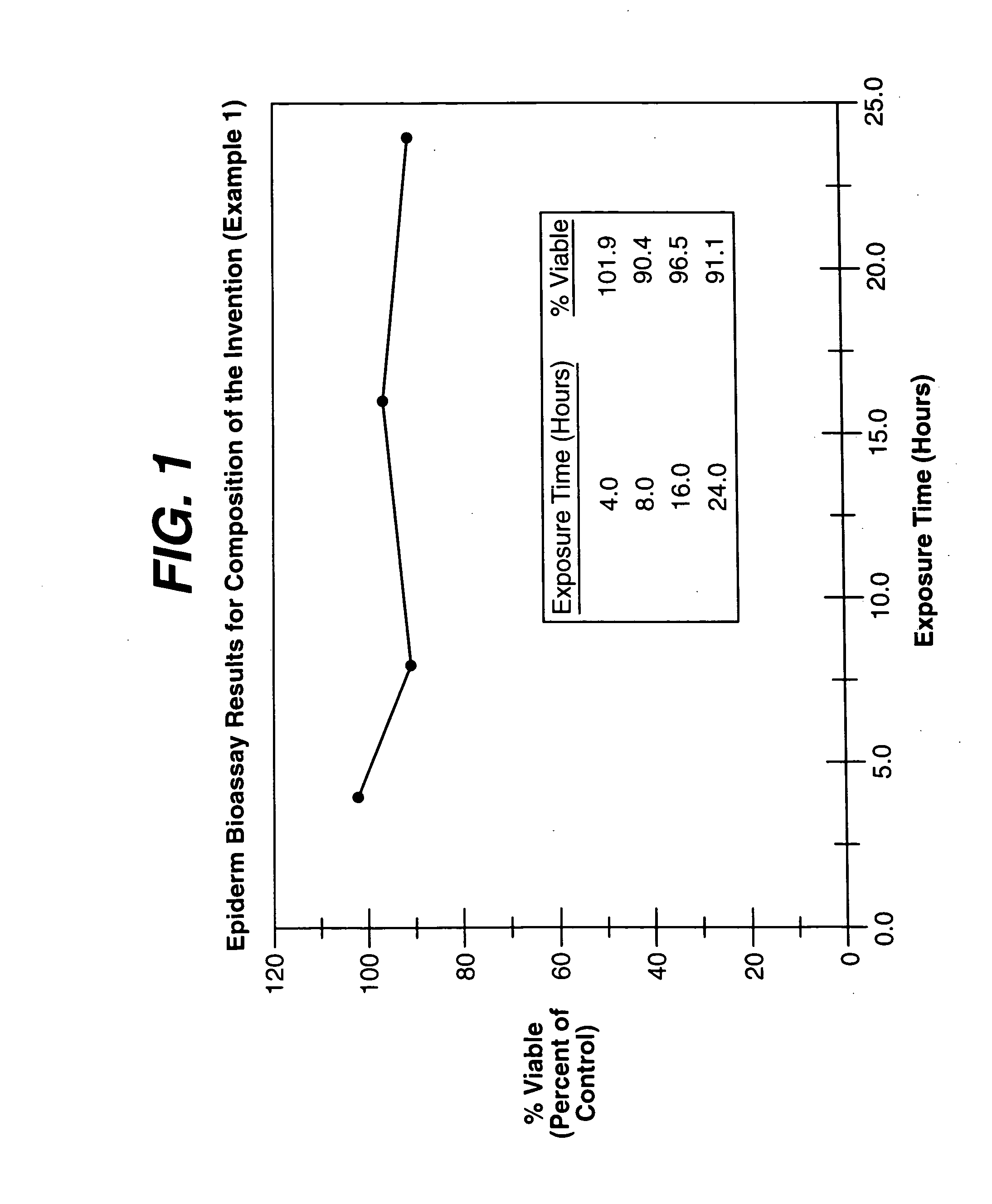

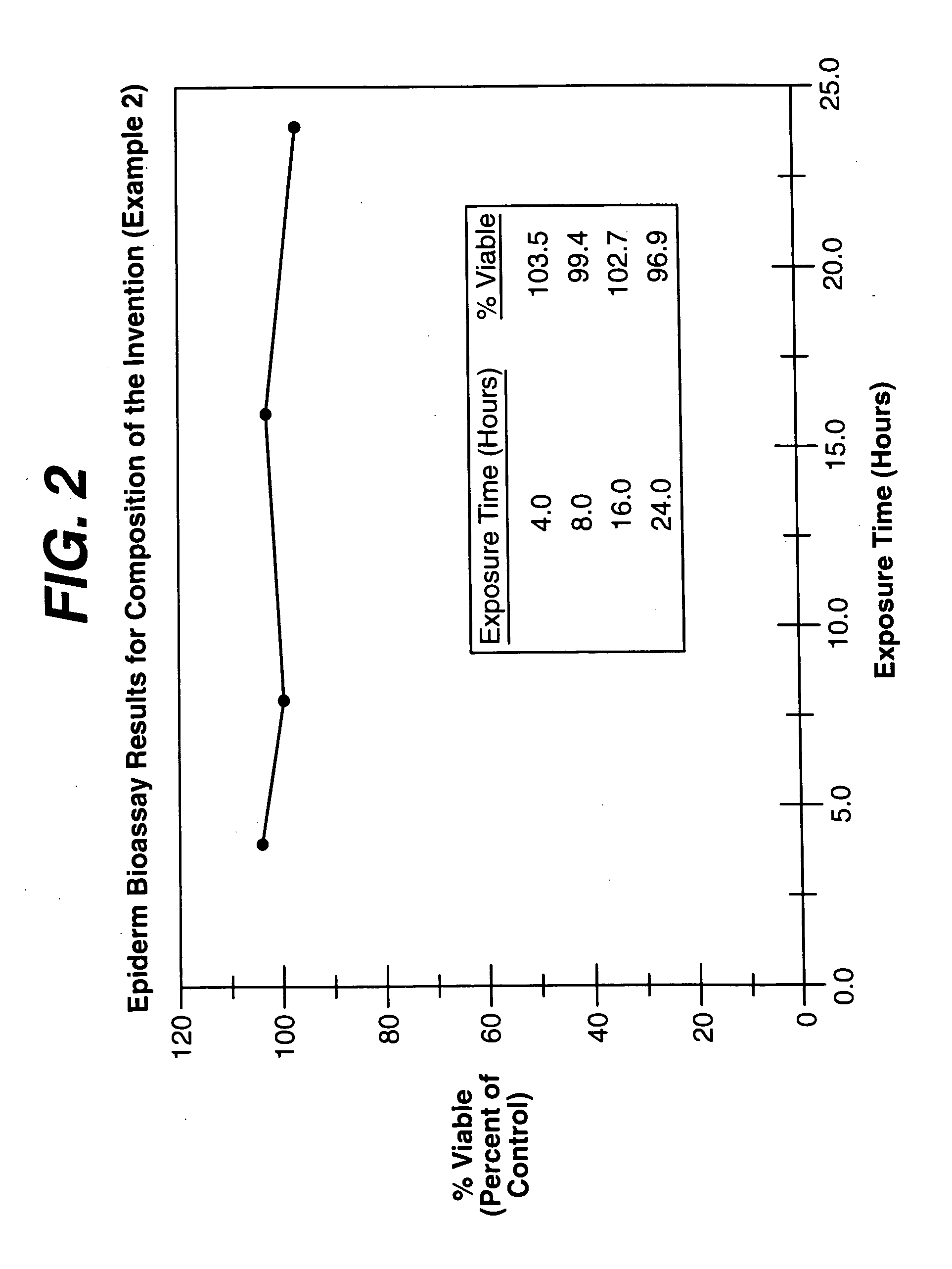

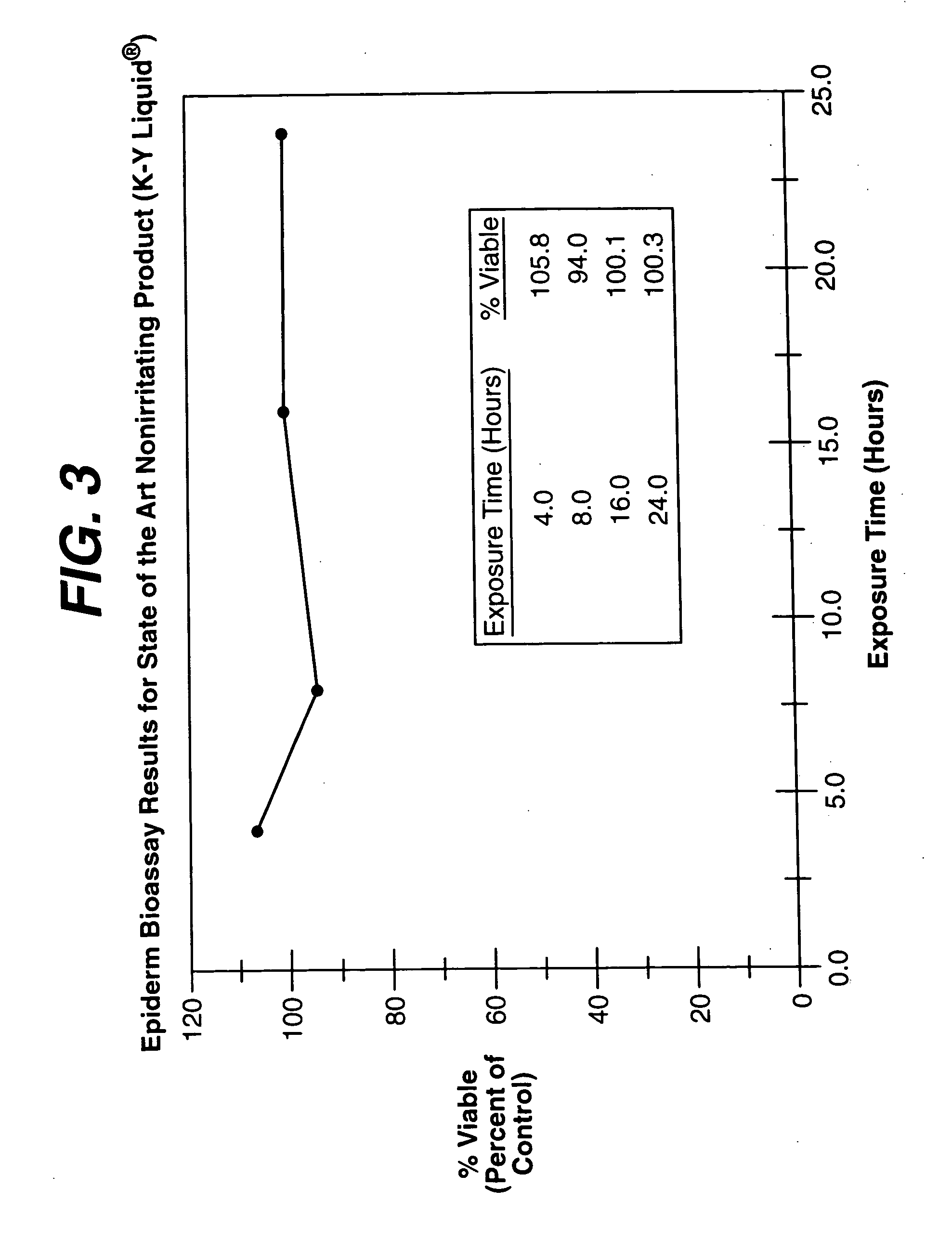

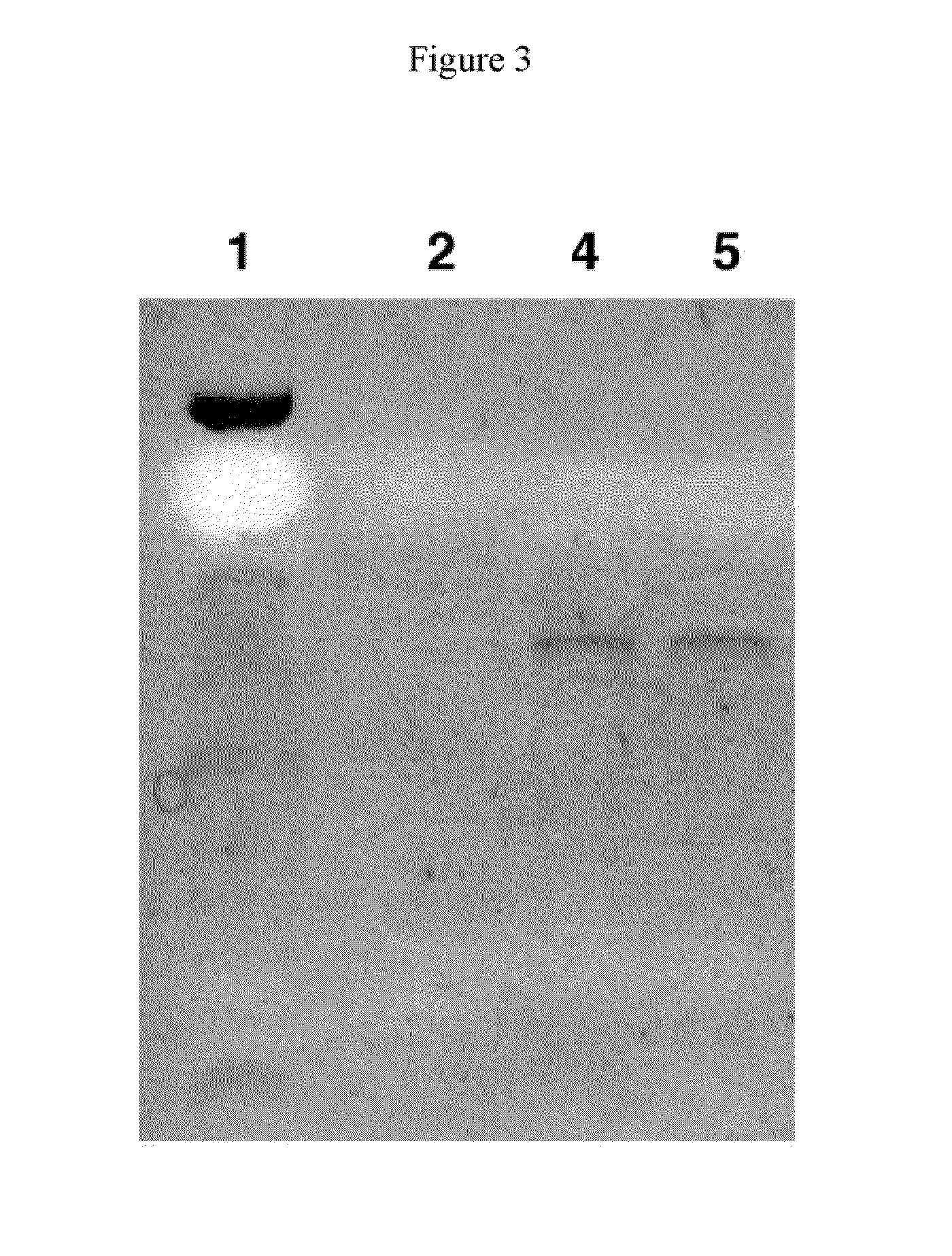

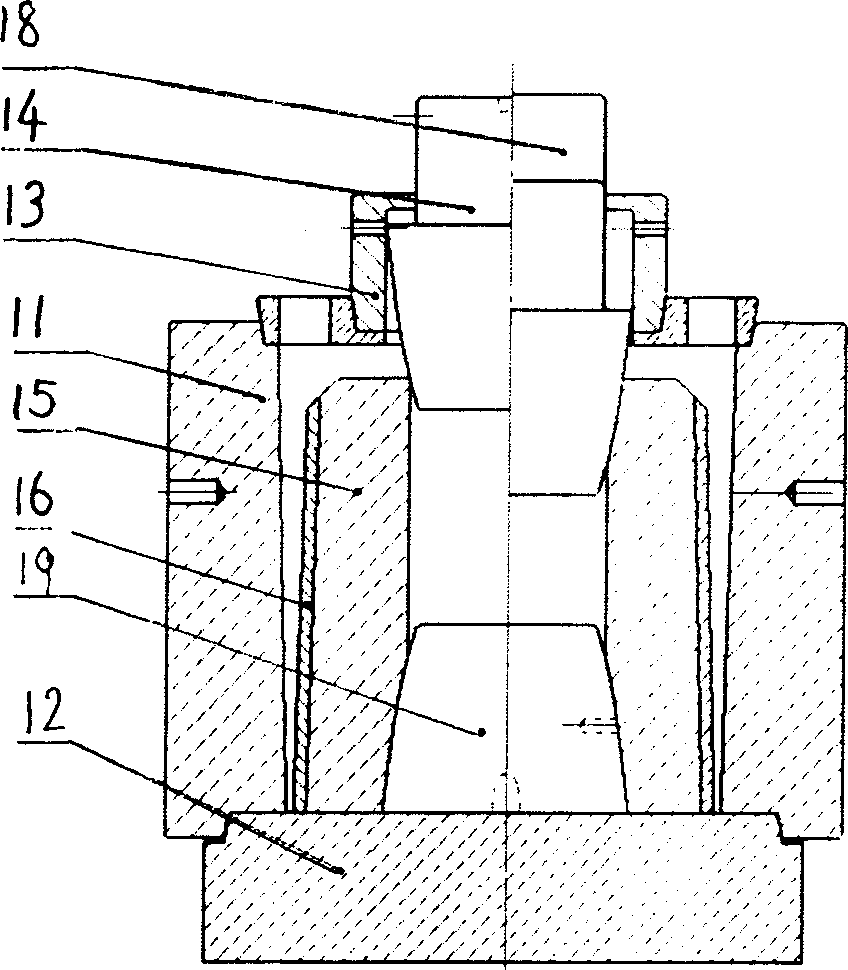

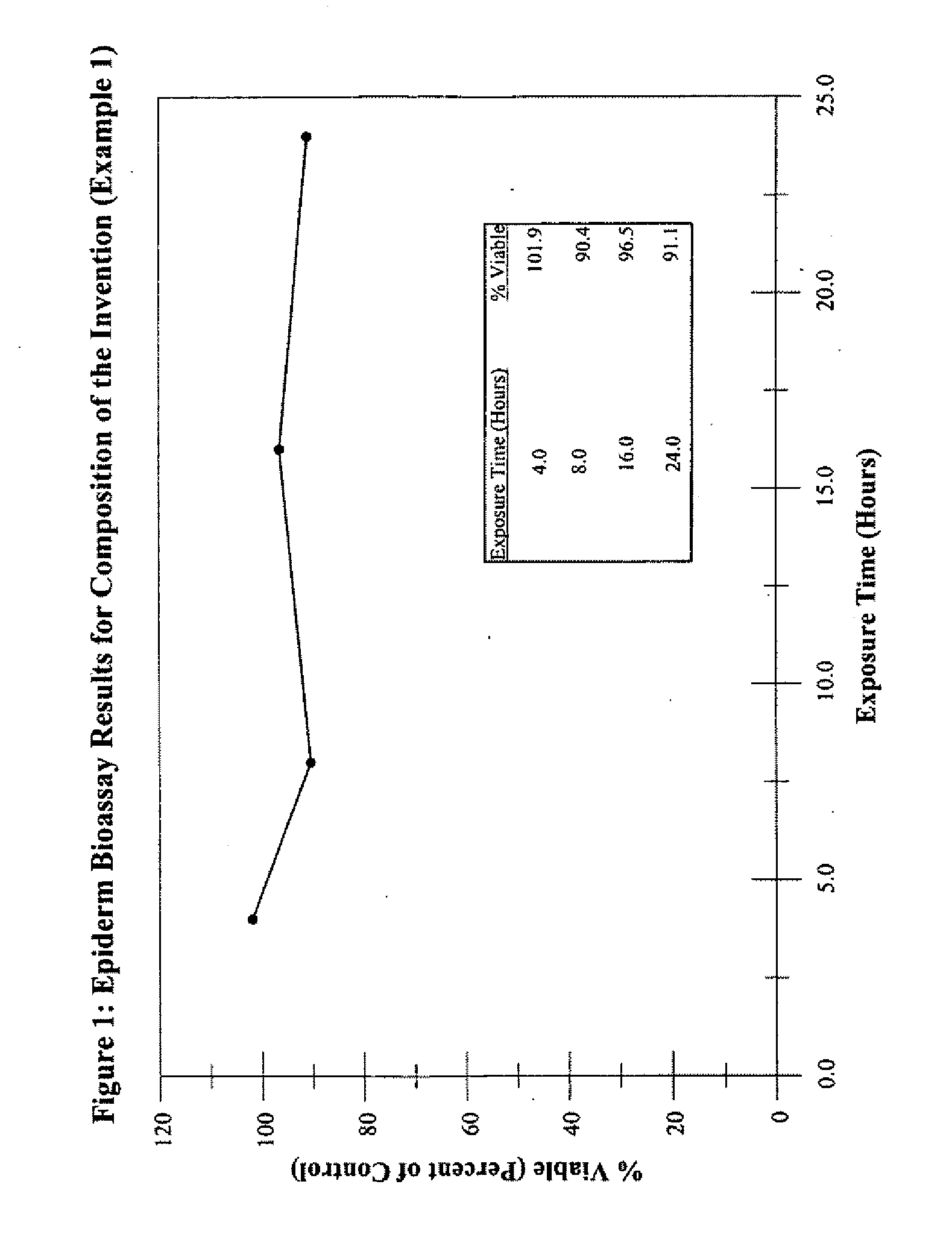

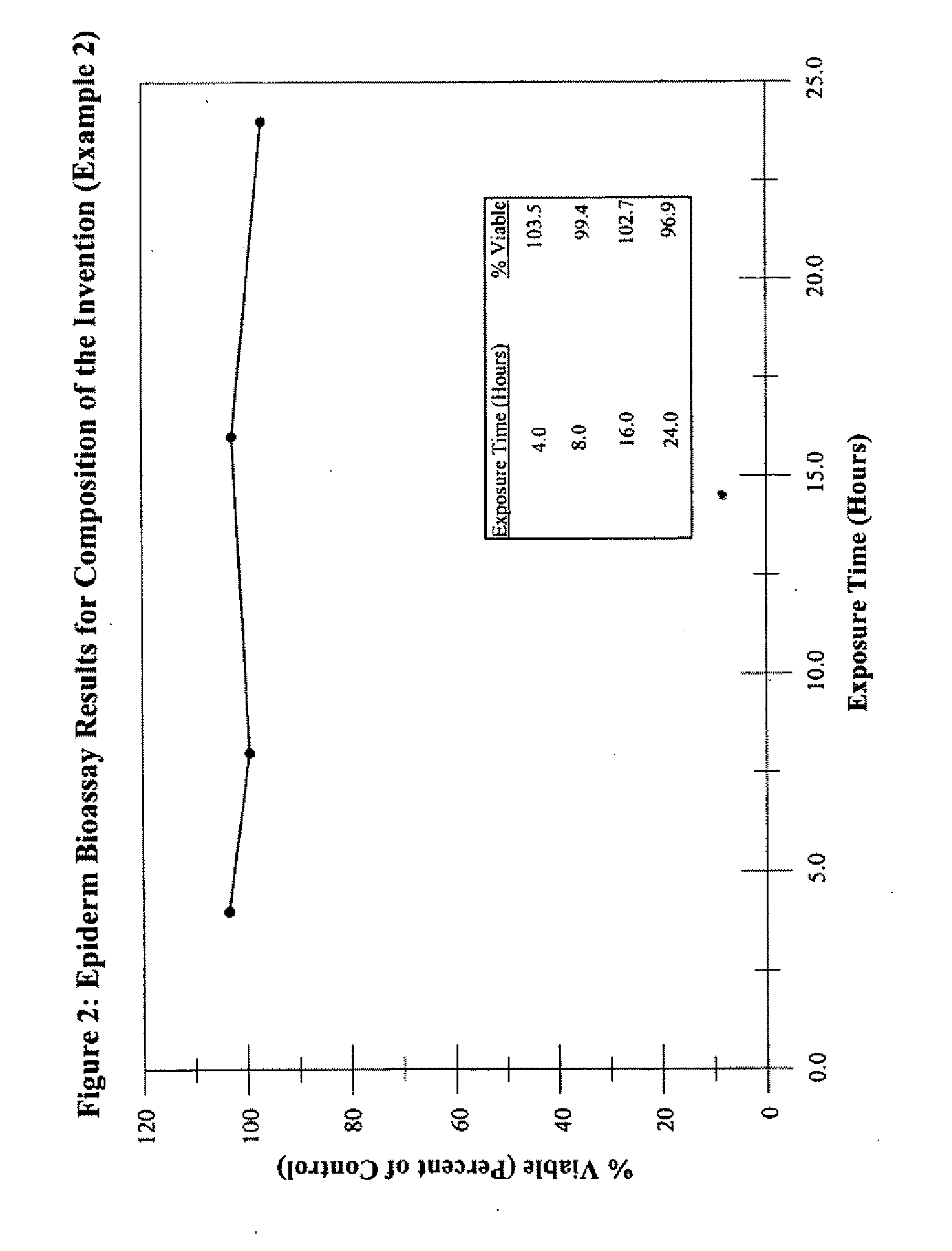

Warming and nonirritating lubricant compositions and method of comparing irritation

ActiveUS20050042248A1Capacitive effectIncrease temperatureBiocideHydroxy compound active ingredientsAlcoholPolyol

This invention relates to substantially anhydrous warming, non-toxic and nonirritating lubricating compositions containing polyhydric alcohols and an insulating agent as well as gel and jelly compositions related thereto. The invention also relates to methods of using such compositions for lubrication, administration of active ingredients and for preventing or treating dysmenorrhea.

Owner:RECKITT BENCKISER HEALTH LTD +1

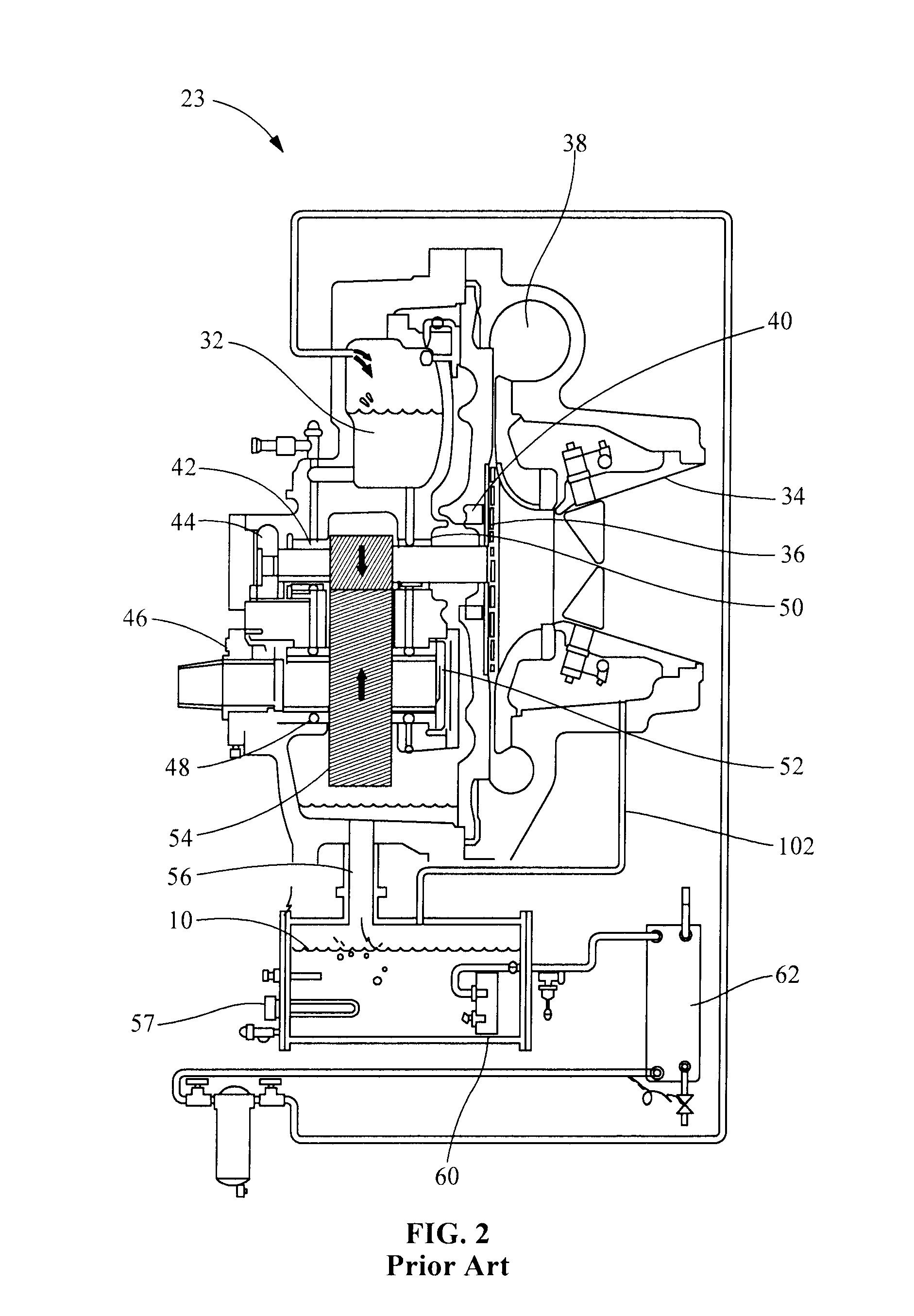

Ejector cycle

InactiveUS6834514B2Small sizeReduce lubricationCompressorAir-treating devicesOperation modeEngineering

Owner:DENSO CORP

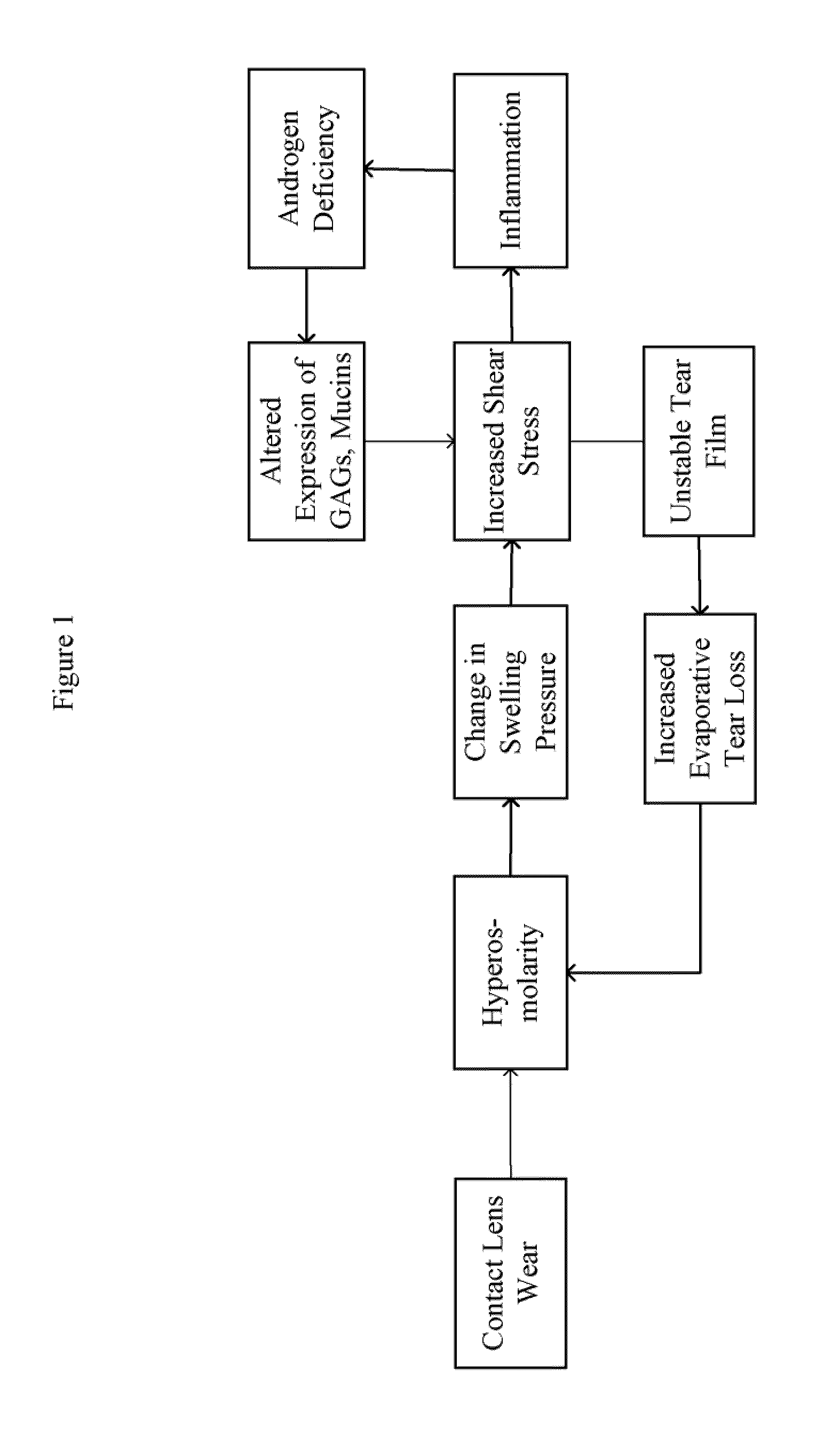

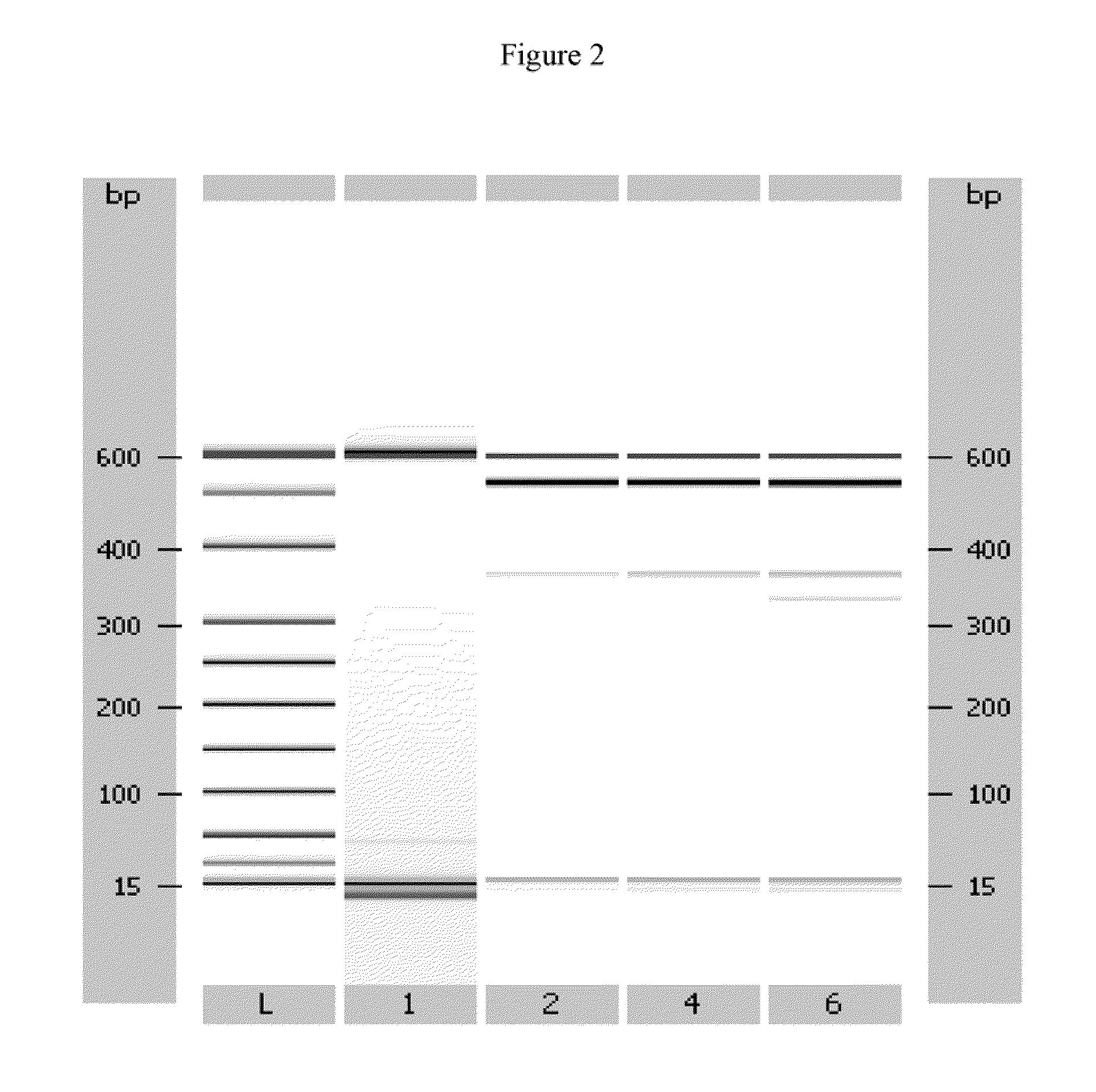

Ophthalmic Device, and Method of Use Thereof, for Increasing Ocular Boundary Lubrication

ActiveUS20110142908A1Reduce lubricationPromote hyperosmolarityOrganic active ingredientsSenses disorderLipid formationShear stress

The present invention provides an ophthalmic device, and method of use thereof, for an individual wearing an ophthalmic lens to increase ocular surface boundary lubrication. The invention device comprises an ophthalmic lens and a sacrificial mechanism disposed on the ophthalmic lens, wherein the sacrificial mechanism comprises a plurality of surface bound receptors, such as PRG4, hyaluronic acid, and DNA aptamers, that reversibly bound to a lubricating composition comprising a gel forming agent, a surfactant, or a combination thereof, effectively inhibiting or preventing protein and lipid adsorption on the surface of the lens, and mitigate shear stress and reduce the friction between the lens and the ocular surface of the individual in need.

Owner:RGT UNIV OF CALIFORNIA +1

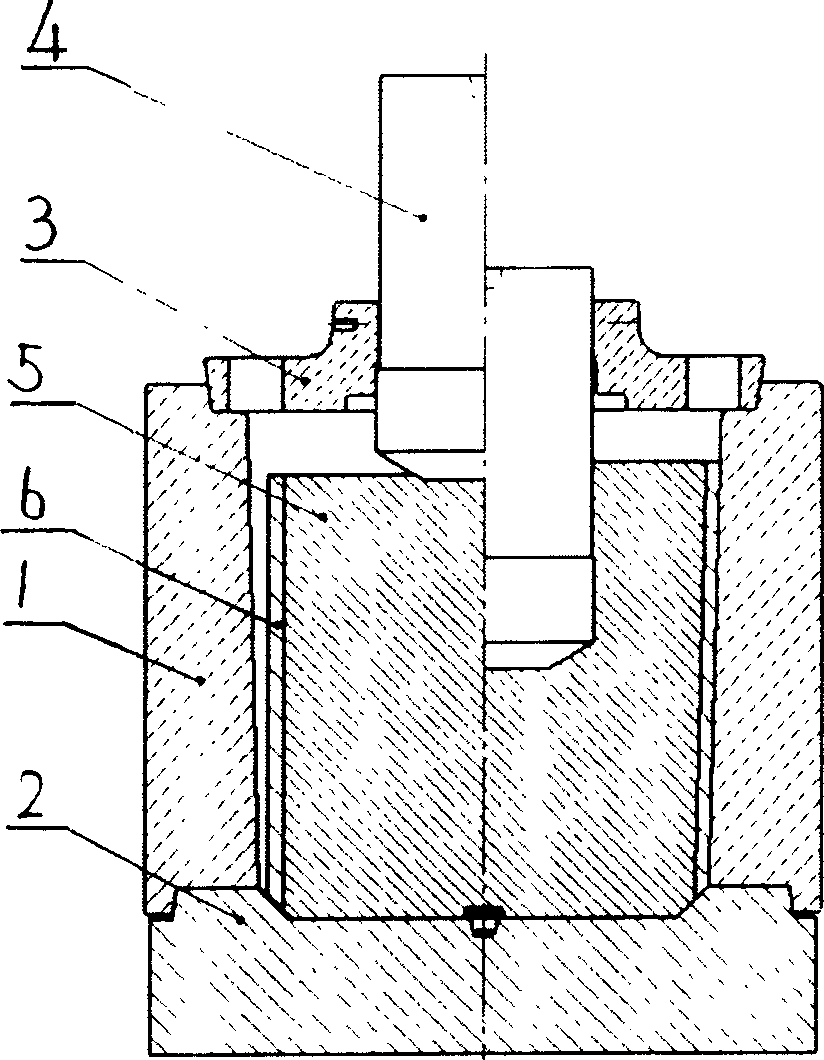

Method for producing circular cog hot forged from generator protective ring and mould

InactiveCN1736630AImprove stress statusAvoid cracksForging/hammering/pressing machinesHollow articlesCrystalliteLubrication

The invention discloses a method and the die for preparation of a hot forging ring billet of the guard ring of generator, and relates to a forging technique and the device of guard ring part of generator. The prior hot forging technique is flat-die forging, easily to produce crack in the process. The invention using confined shaping in die instead of flat-die forging, it improves the state of stress and prevents the crack effectively. With the symmetry of sphere plunger axis in the process of fan boring, the crystal particles are fine and uniform, which provides a perfect condition for cold strain intensification. With the jacket shaping of billet, it can improve lubrication and decrease friction, and can keep the temperature of the hot billet effectively, improving the plasticity and decreasing the shaping pressure. The invention solves the three problems that the crack is easy to produce, the structure property is not uniform, and the shaping pressure is large; compared with the prior technique, the invention has a projecting progress and a distinctive effect.

Owner:DEYANG WANXIN POWER STATION PROD DEV

Warming and Nonirritating Lubricant Compositions and Method of Comparing Irritation

This invention relates to substantially anhydrous warming, non-toxic and nonirritating lubricating compositions containing polyhydric alcohols, a gelling agent and alternatively a pH adjusting agent for treating fungal and bacterial infections. The invention also relates to methods of using such compositions for warming, lubrication, administration of active ingredients and for preventing or treating dysmenorrhea.

Owner:AHMAD NAWAZ +2

Drilling fluid lubricant prepared from waste plant oil and preparation method thereof

InactiveCN104371674AImprove protectionHigh flash pointDrilling compositionActive agentReaction temperature

The invention provides a drilling fluid lubricant prepared from waste plant oil and a preparation method thereof. The lubricant is composed of the following raw materials in parts by weight: 70 to 80 parts of waste plant oil, 10 to 20 pats of lower alcohols, 1 to 5 parts of surfactant, and 1 to 5 parts of high temperature resistant processing agent. The preparation method comprises the following steps: step a, carrying out a pretreatment on raw materials: removing impurities from waste plant oil; step b, carrying out esterification conversion: adding lower alcohols and the waste plant oil preprocessed in step a into a reactor with / without a catalyst to carry out esterification reactions or ester exchange reactions, wherein the reaction temperature is 60 to 120 DEG C, and the reaction time is 3 to 8 hours; step c, refining and separating the reaction products: precipitating and separating the reaction products obtained in the step b, and then refining the reaction products to obtain a refined product; step d, carrying out performance improvement: adding the surfactant and the high temperature resistant processing agent so as to obtain a finished product.

Owner:CHINA PETROCHEMICAL CORP +1

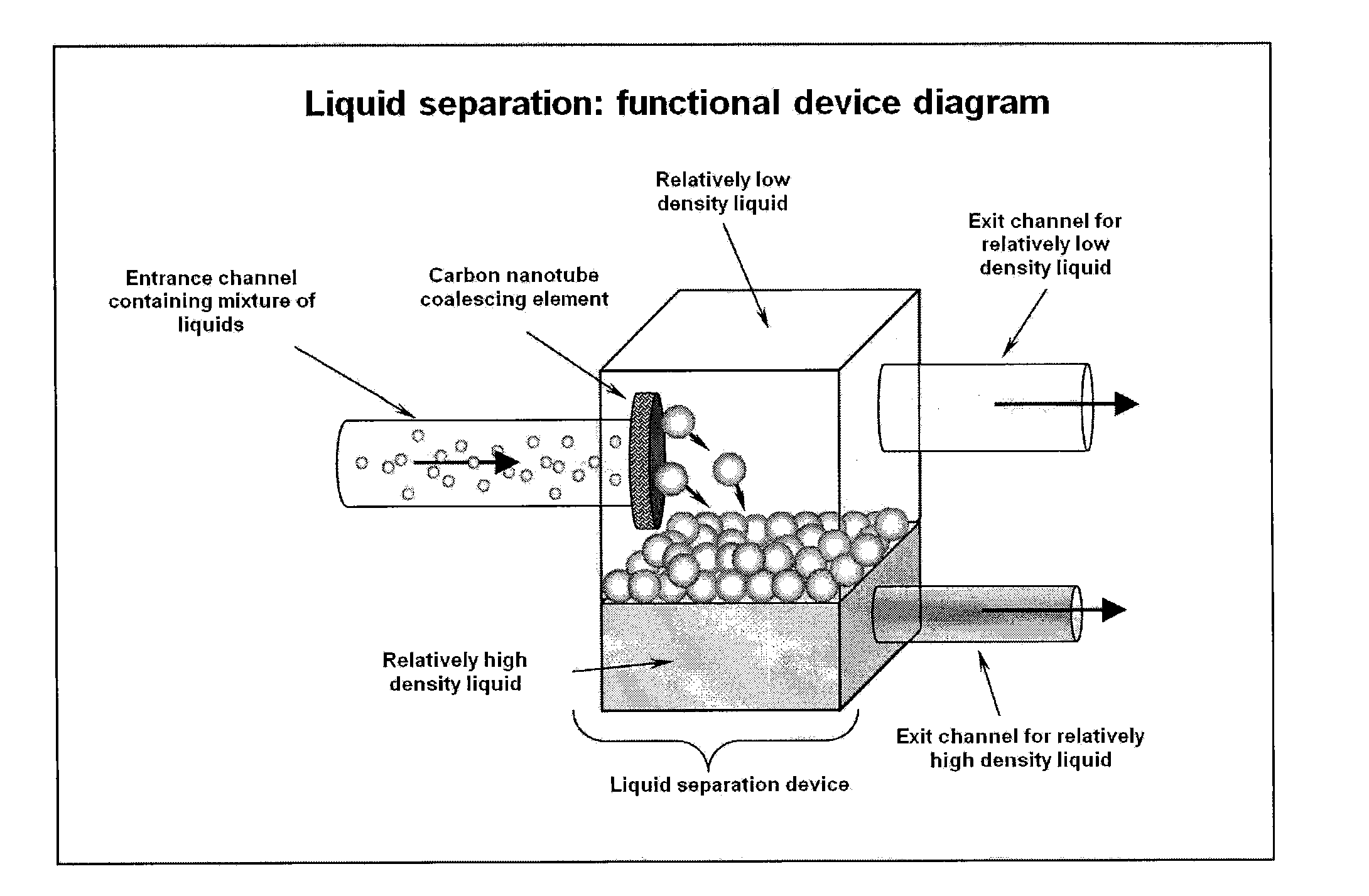

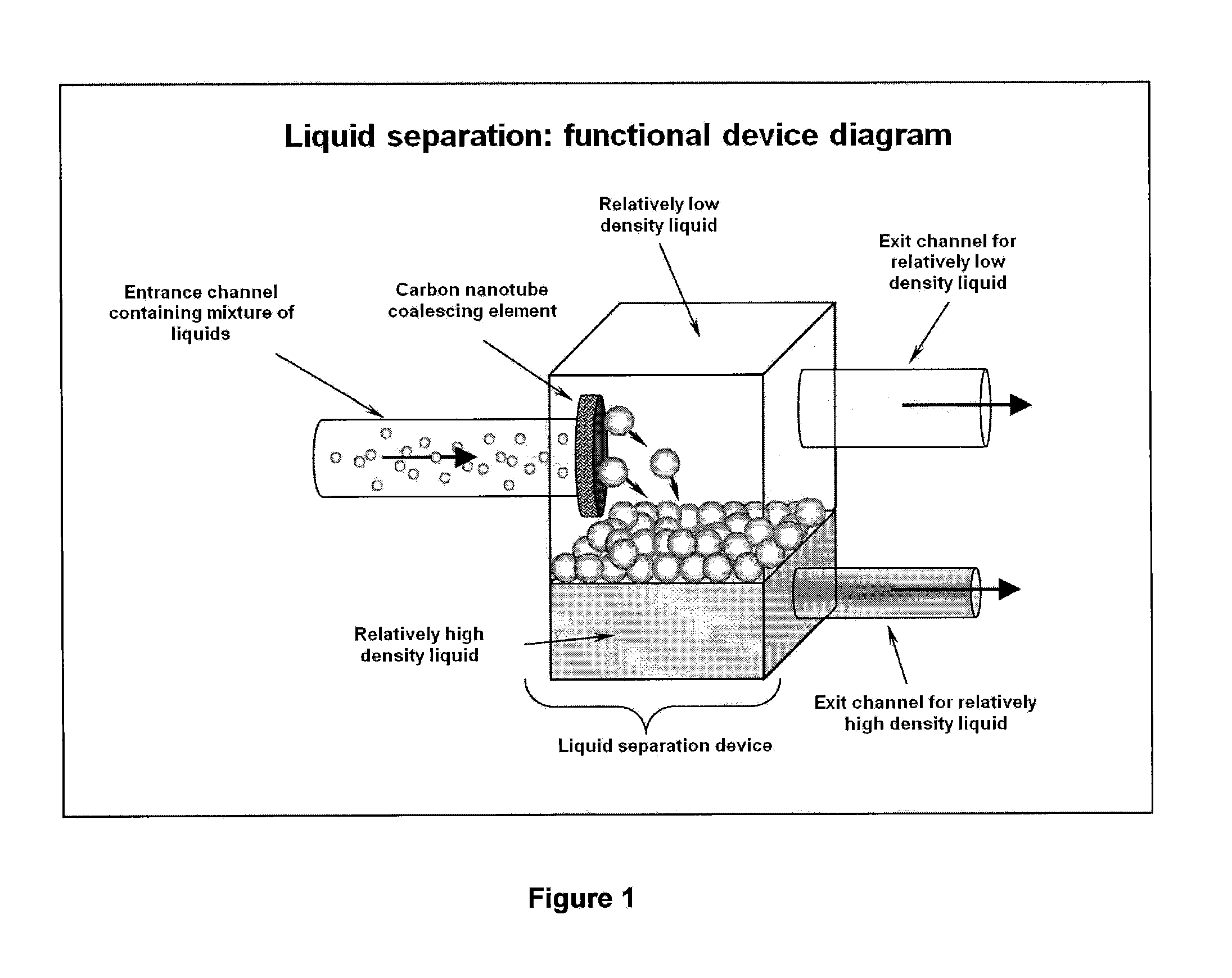

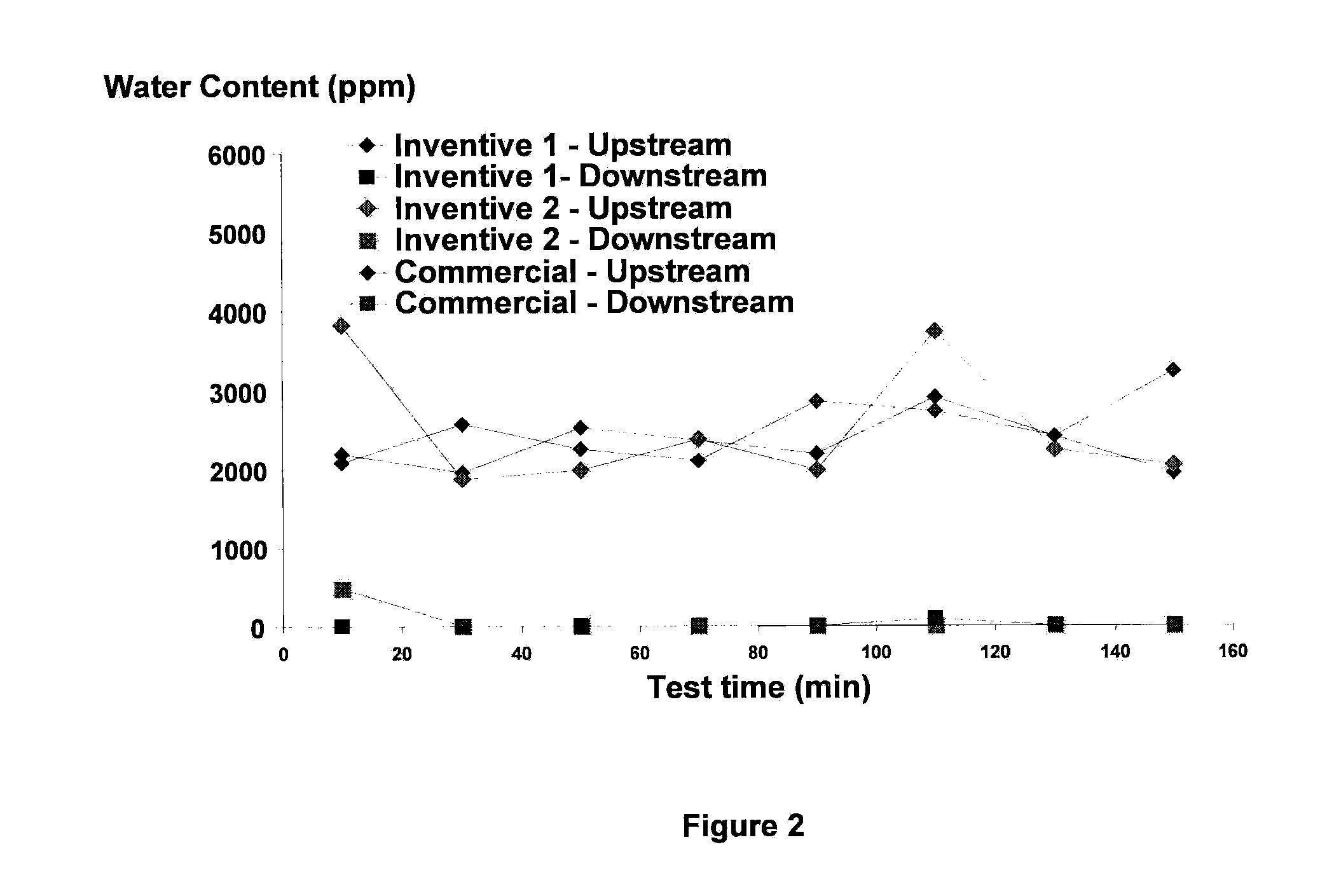

Carbon nanotube material and method for the separation of liquids

ActiveUS20100116751A1Reduce lubricationHarderSemi-permeable membranesLiquid suspension thickening by filtrationFiberCarbon nanotube

Owner:MULTIPURE INT

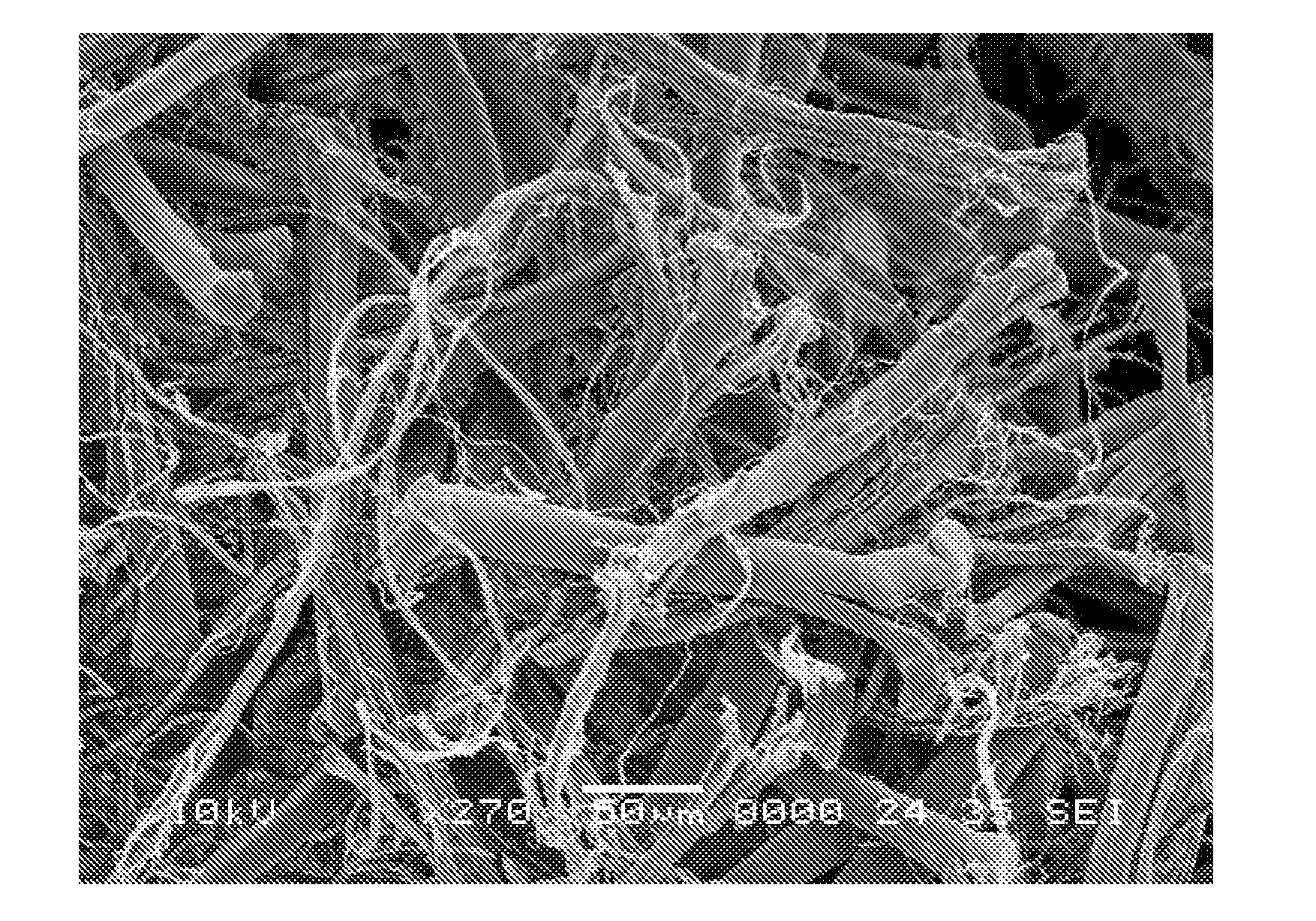

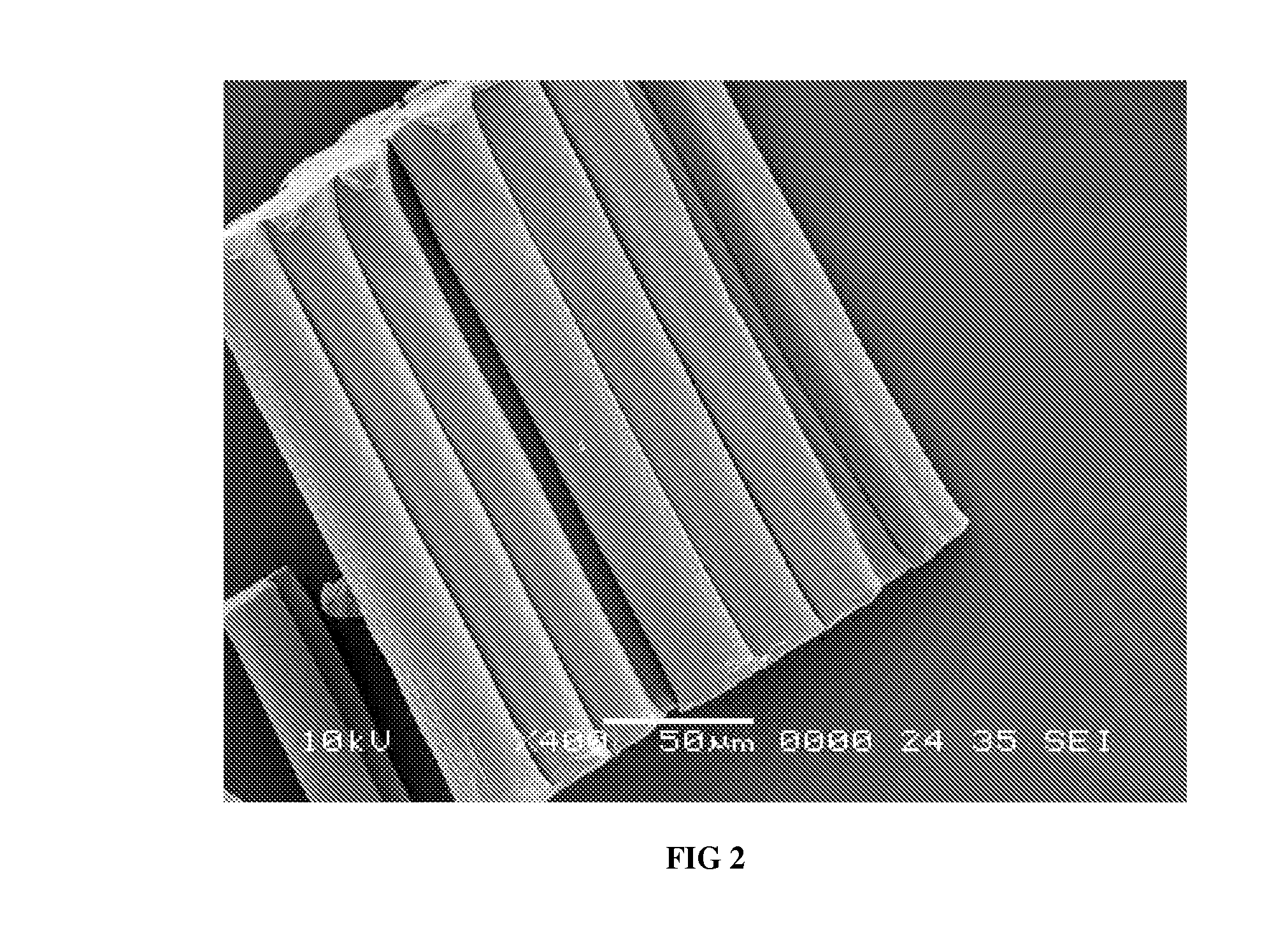

Solid lubricating composite material and manufacturing method thereof

InactiveCN101717682AReduce lubricationLow self-lubricating propertiesBase-materialsElectricityCarbon nanotube

The invention discloses a solid lubricating composite material and a manufacturing method thereof. Raw materials for the solid lubricating composite material comprise carbon nano tube, boron oxide and polytetrafluoroethylene. The manufacturing method comprises the following steps: grinding the carbon nano tube in a ball mill to form sectional structures, adding ethanol and surface dispersant into the carbon nano substances of the sectional structures, and treating the mixture by ultrasonic wave to obtain carbon nano liquid; taking boron oxide powder, polytetrafluoroethylene powder and the carbon nano liquid in percentage by weight, and mixing the three substances and stirring the mixture at a high speed to disperse the carbon nano liquid into the boron oxide and polytetrafluoroethylene powder so as to obtain a mixture; and die-pressing and molding the mixture, and demoulding the mixture to obtain the finished product solid lubricating composite material. The solid lubricating composite material prepared from the combination of the carbon nano tube and the polytetrafluoroethylene with self-lubricating property greatly improves the technical indexes such as low friction coefficient, self-lubricating property, abrasion resistance and the like, can conduct heat and electricity and eliminate static electricity produced by friction, and can be continuously produced in batch with lower cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

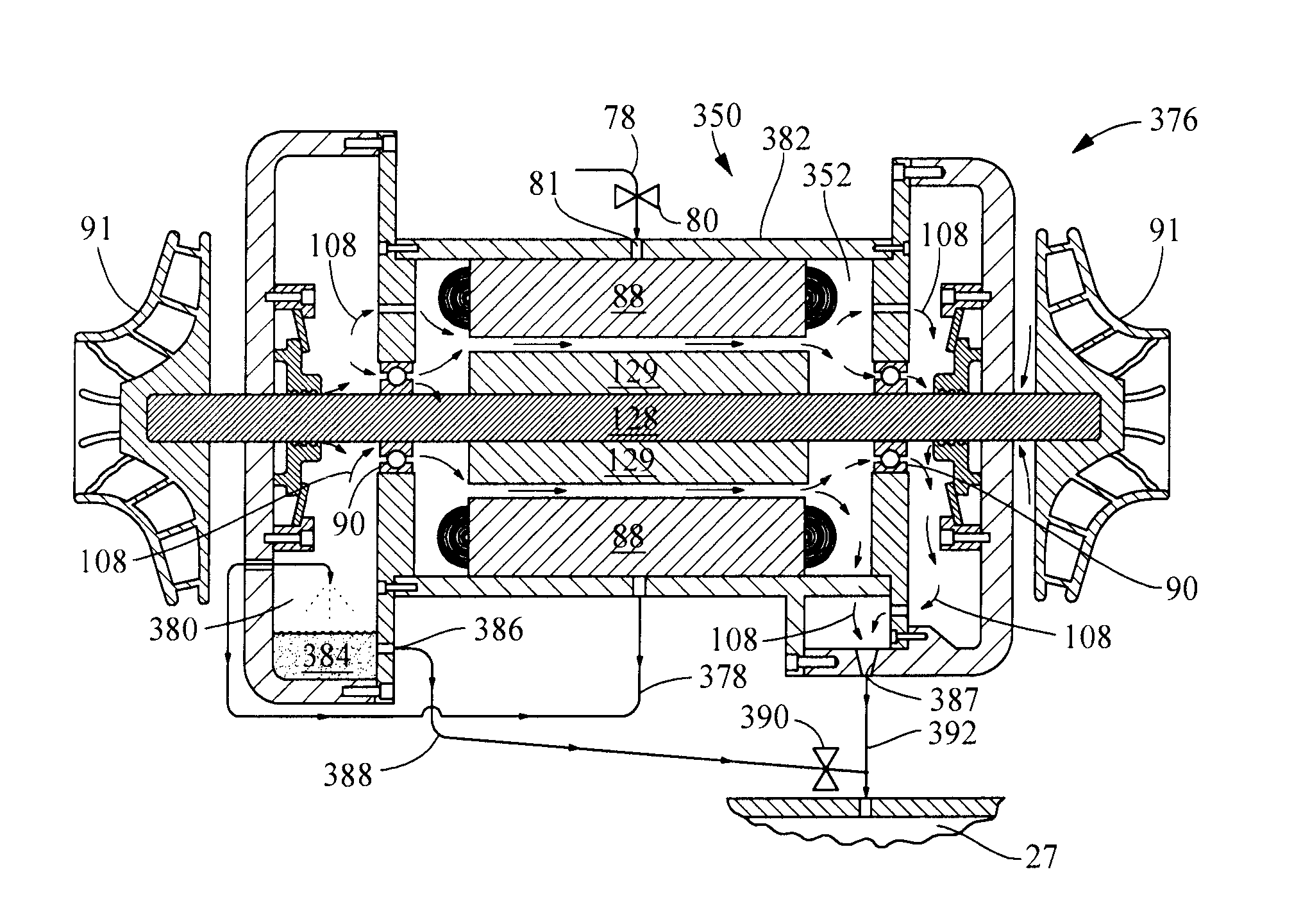

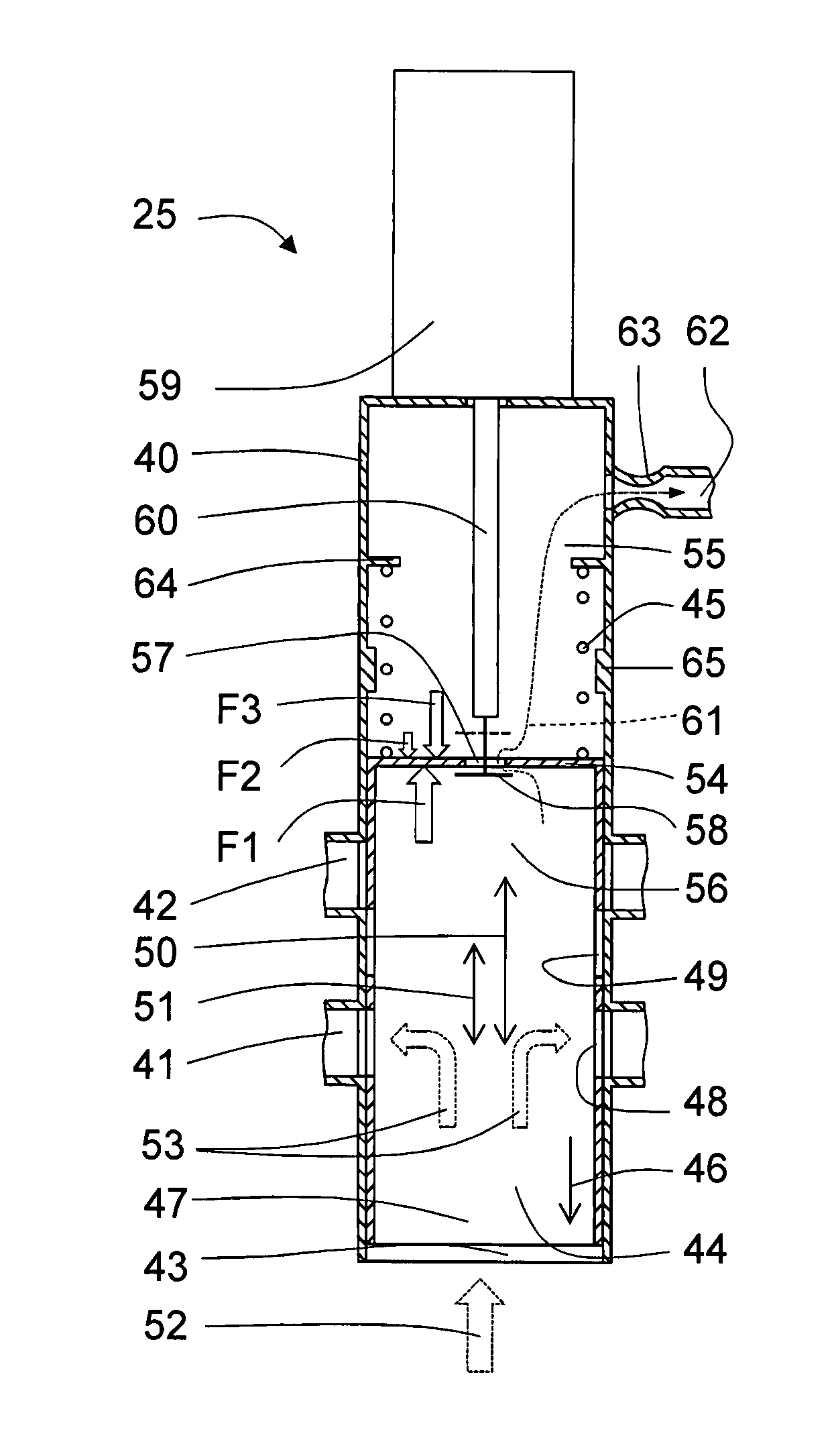

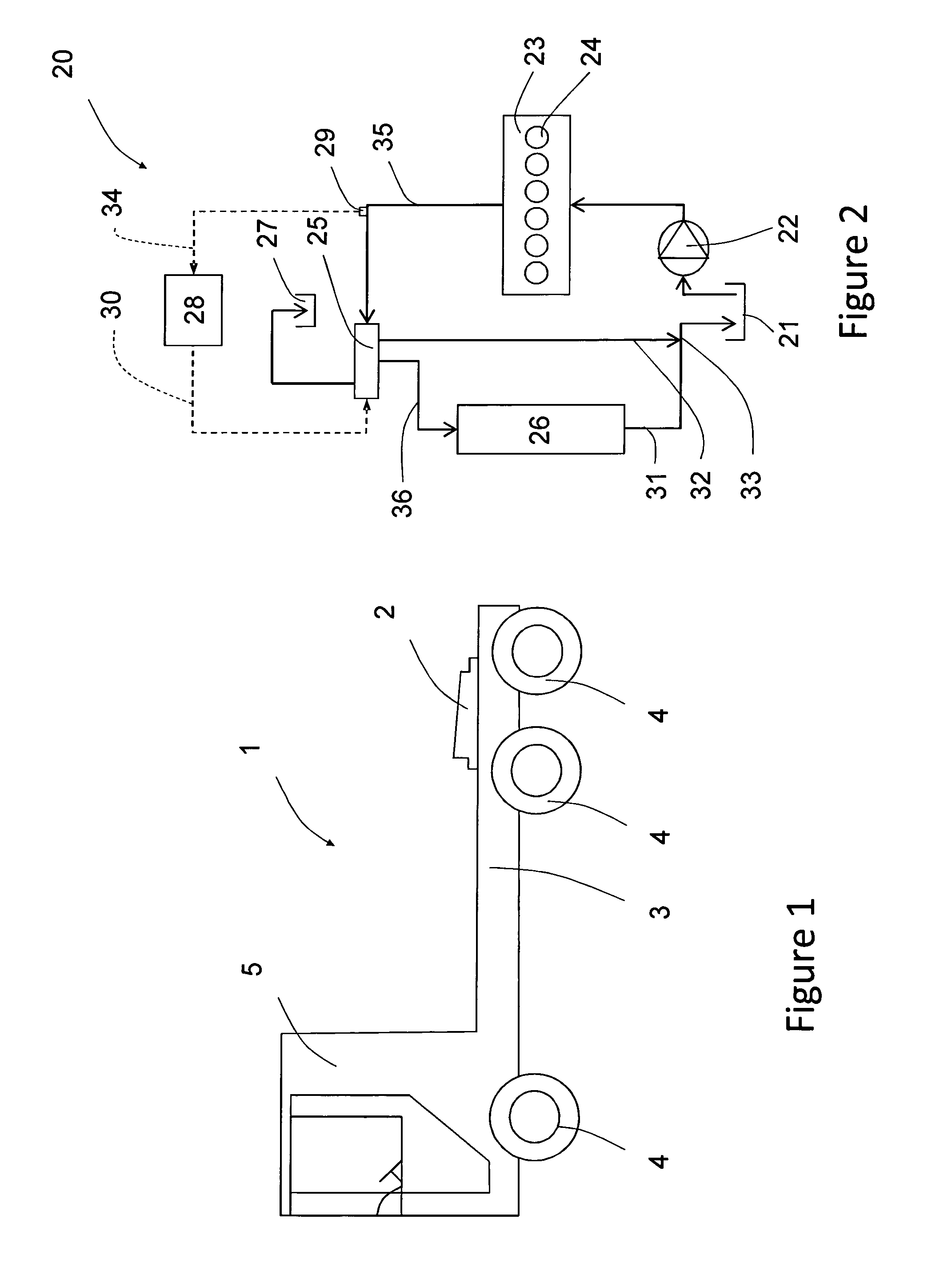

Lubrication and cooling system

ActiveUS20160003510A1Reduce pressureSolve absorptionCompressorPump componentsLubricationAutomotive engineering

A system for reducing the refrigerant pressure in an oil sump (10) or in a cavity (352) of a housing. The invention is particularly useful for reducing pressure in a compressor (23) for heat pump applications that has been validated for water chiller operations or in turbine and generator systems in ORC systems generating electricity using refrigerant, the ORC systems essentially being a heat pump application operating in reverse. An auxiliary compressor (509), an auxiliary condenser (709) or an ejector pump (609) may be used to reduce pressure in the oil sump (10), to separate refrigerant from oil. The auxiliary compressor (509), the auxiliary condenser (709) or the ejector pump (609) may also be used to reduce the pressure of refrigerant in the housing of a compressor in heat pump applications at temperatures and pressures at which the compressor was validated for water chiller applications and of the turbine and generator in ORC applications.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

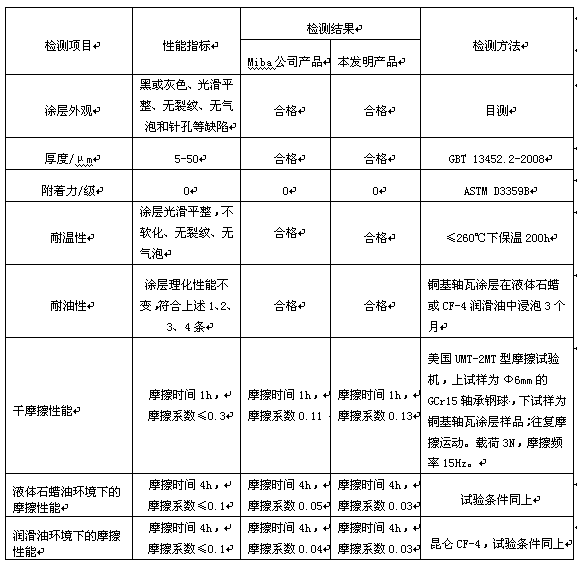

Method for preparing solid lubricant coating on copper base bearing bush

ActiveCN103849311AImprove the lubrication effectImprove bindingCoatingsLubricant compositionOil viscosityWear resistance

The invention discloses a method for preparing a solid lubricant coating on a copper base bearing bush. According to the invention, a selected suitable coating coats on the surface of the copper base bearing bush to form a curing coating. The coating has good adhesion with the metal copper alloy substrate, and can be used for a long time under 260 DEG C; and the coating has good lubricity, wear resistance and anti-copper sticking property, and can significantly reduce the friction coefficient of the alloy layer of the copper base bearing bush and reduce the phenomena of scratching, copper sticking and burnout of the copper base bearing bush and crankshaft under start and stop state, low machine oil viscosity state and oil free state, so as to improve wear resistance, emergency operation capability and service life of the copper base bearing bush.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

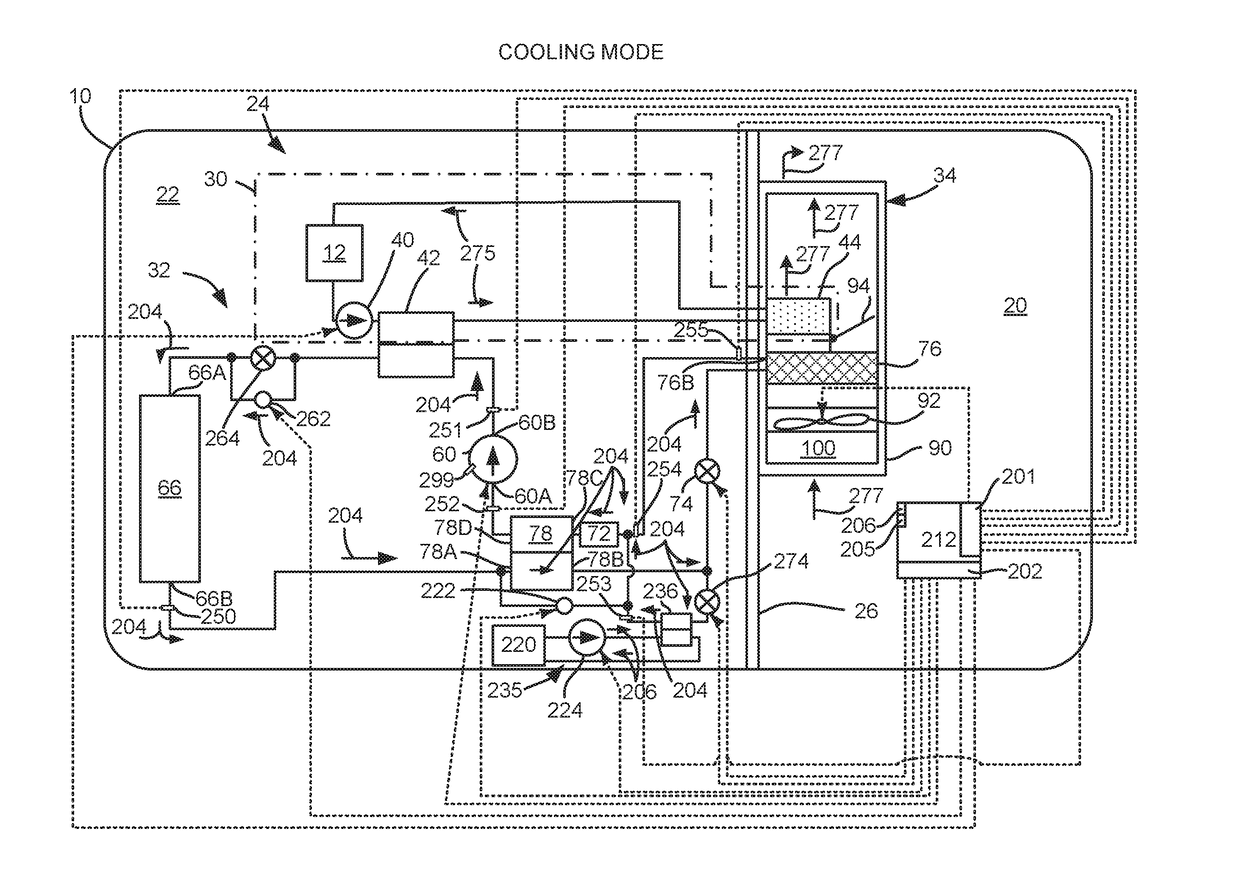

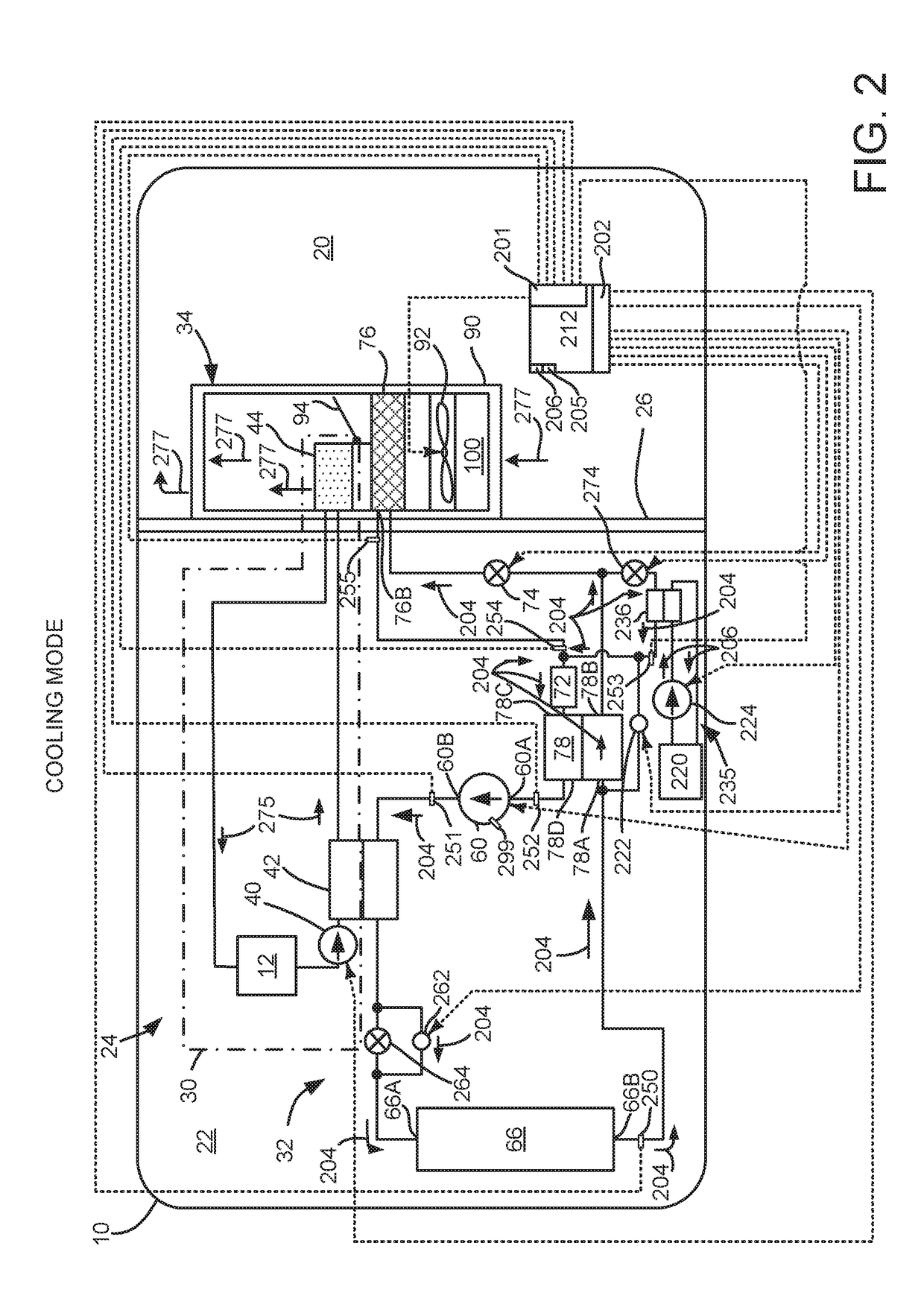

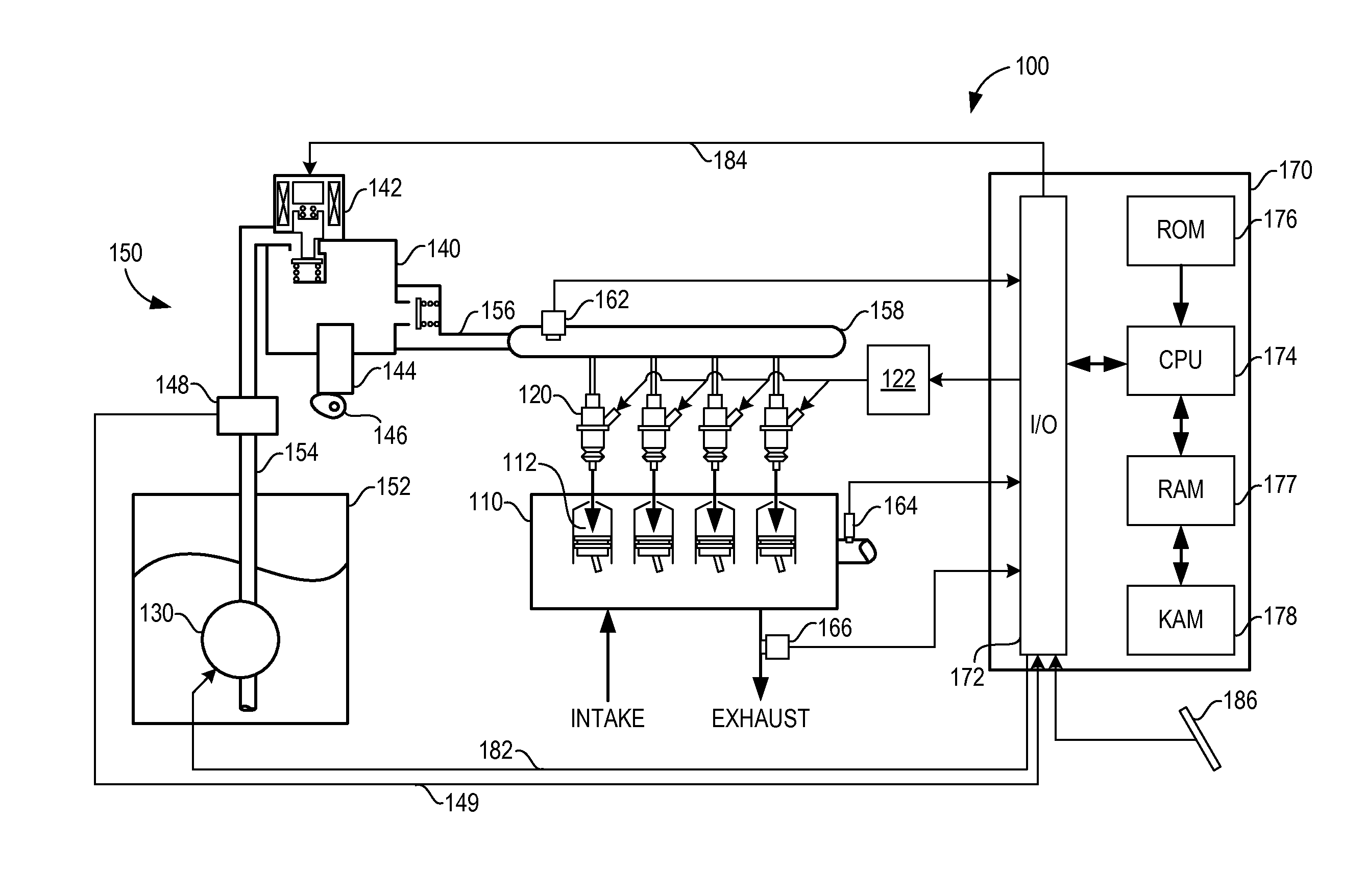

Method and system for operating a heat pump of a vehicle

ActiveUS20170240024A1Reduce the possibilityReduce speed of compressorAir-treating devicesCompression machinesMobile vehicleOperation mode

Methods and systems for providing control of a heat pump of a motor vehicle are presented. In one operating mode, speed of a heat pump compressor is controlled responsive to an outlet pressure of the heat pump compressor. In a second operating mode, speed of the heat pump compressor is controlled responsive to a pressure ratio between an inlet and an outlet of the heat pump compressor.

Owner:FORD GLOBAL TECH LLC

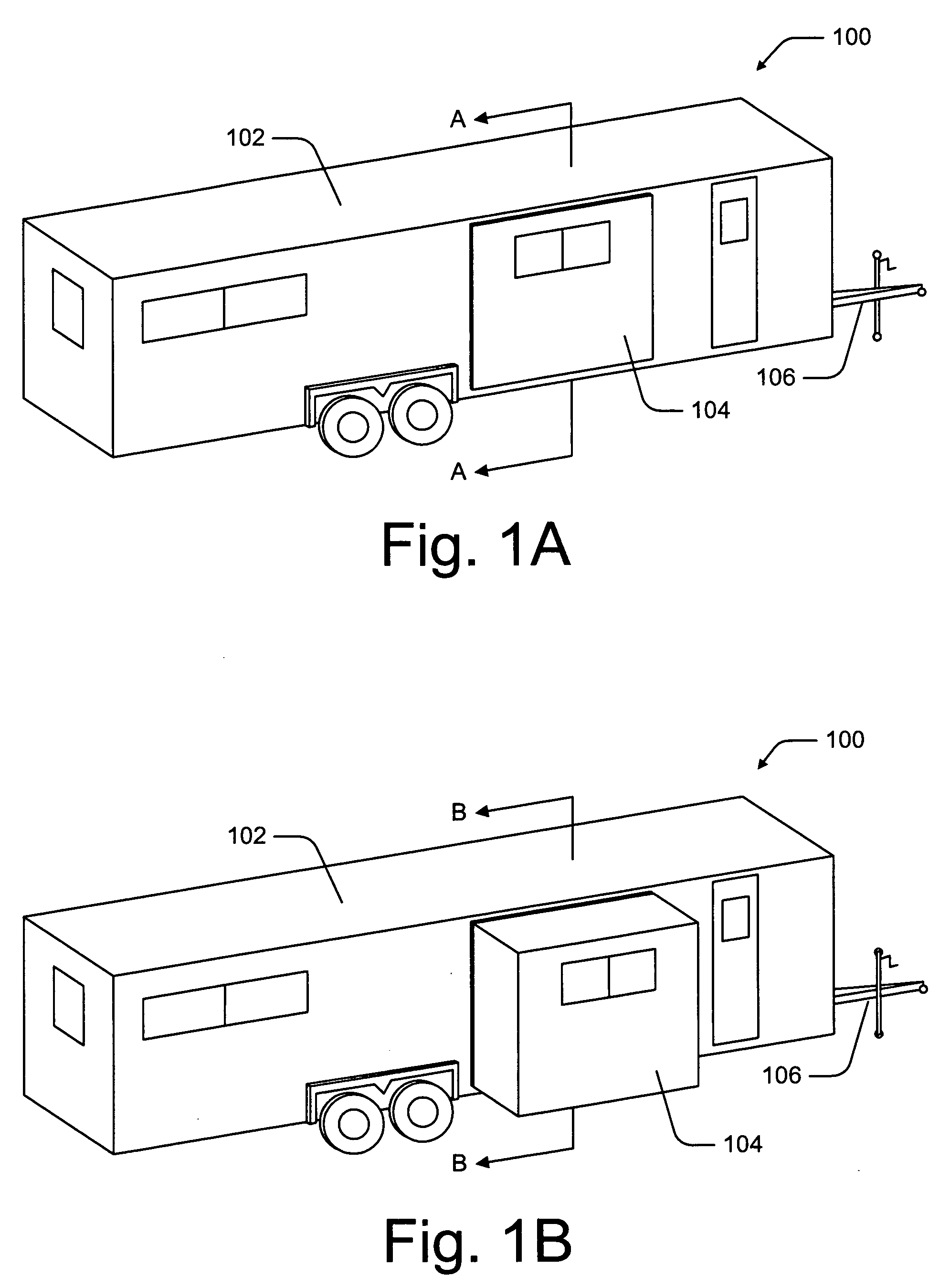

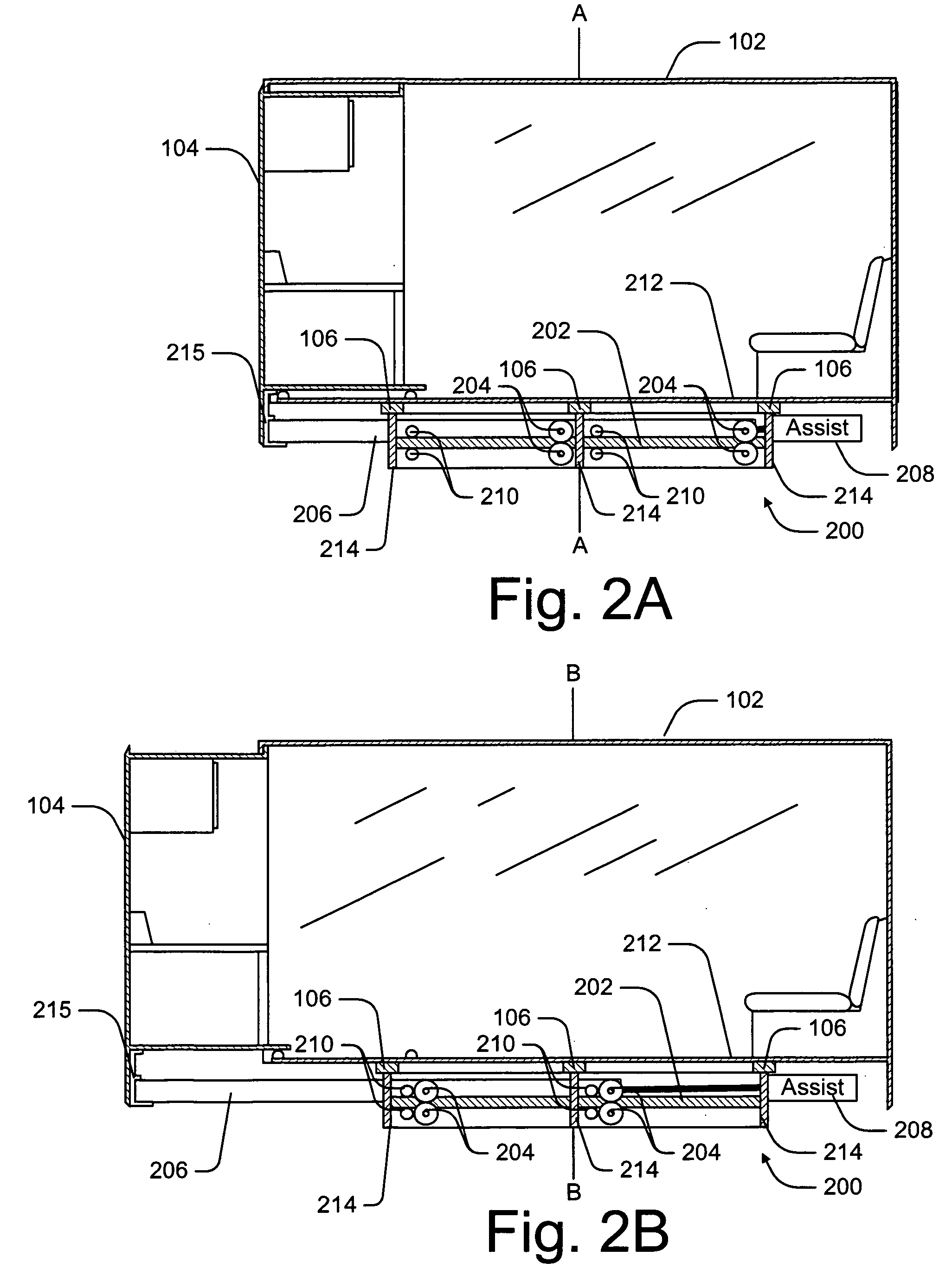

Slide-out guide and carrier

InactiveUS20080315607A1Facilitate passageFacilitate deploymentVehicle with living accommodationItem transportation vehiclesEngineeringMechanical engineering

A slide assembly is provided to couple a slide-out component disposed in an opening of a vehicle body to the vehicle body. The slide assembly includes a complementary contoured guide member, roller(s), and a support member, all generally enclosed by a mountable housing. The support member and roller(s) are coupled to roll along the guide member. In a particular embodiment, rollers are mounted in pairs on the top and bottom sides of the guide member. Due to the complementary contours of the roller and guide member, the slide assembly has a self-aligning characteristic. In one embodiment, the guide member includes a single portion that is horizontal with respect to the vehicle body, and only allows movement of the slide-out component in a horizontal direction. In another embodiment, the guide member includes multiple sections, each section having a portion that is horizontal with respect to the vehicle body and a portion that is inclined with respect to the vehicle body, thus allowing movement of the slide-out horizontally and vertically with respect to the vehicle body.

Owner:HERSON WILLIAM W +1

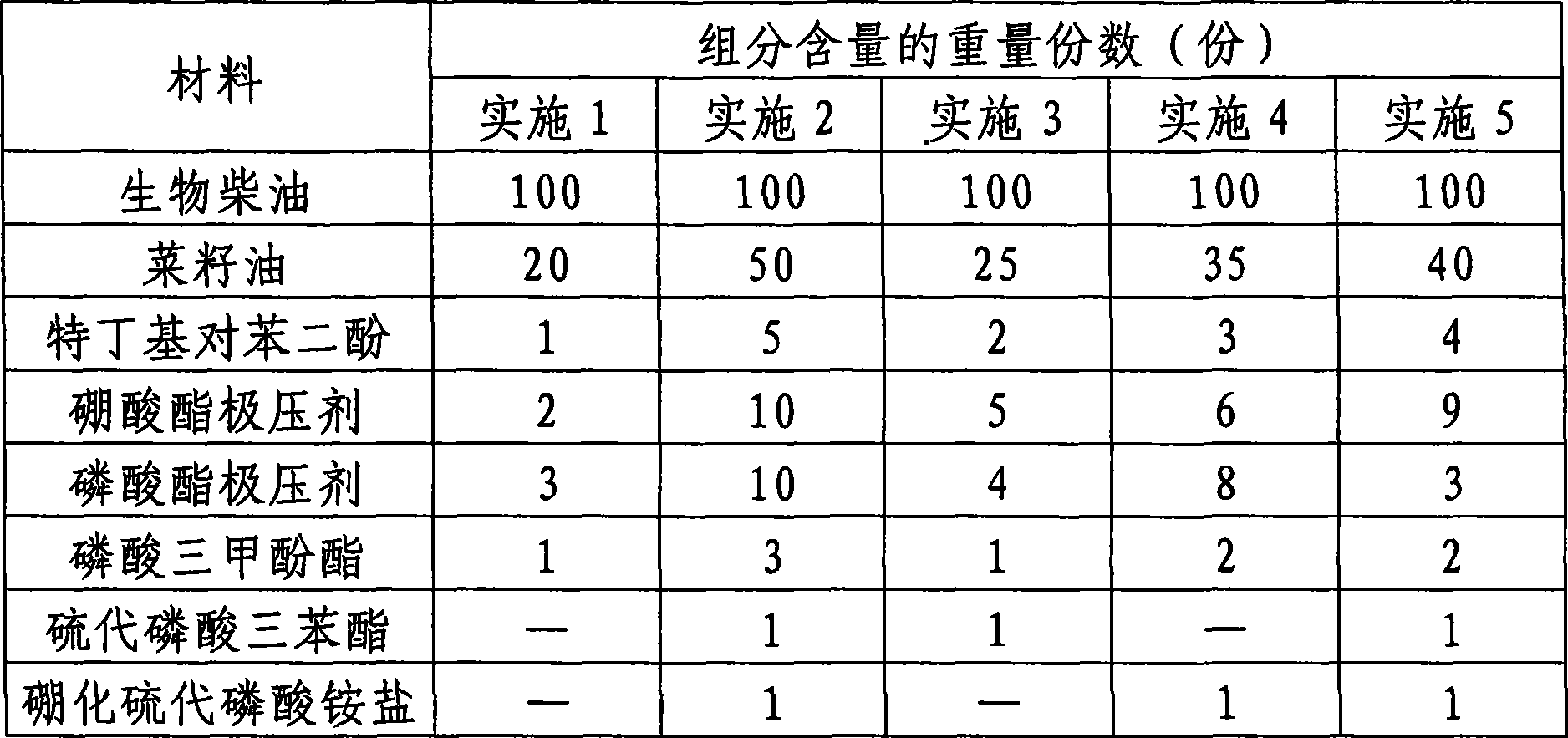

Drawing oil special for aluminum wire and production process thereof

The invention relates to special wire drawing oil for an aluminum wire, which is characterized in that the special wire drawing oil for the aluminum wire comprises biodiesel, colza oil, an antioxidant, a polyester extreme pressure agent and a phosphor-bearing antiwear agent, wherein the compositions by mass portion of the special wire drawing oil for the aluminum wire are: 100 portions of the biodiesel, 20 to 50 portions of the colza oil, 1 to 5 portions of the antioxidant, 5 to 20 portions of the polyester extreme pressure agent and 1 to 5 portions of the phosphor-bearing antiwear agent. The invention relates to a method for manufacturing the special wire drawing oil for the aluminum wire, which comprises the following steps: a. weighing up the biodiesel, the colza oil, the antioxidant, the polyester extreme pressure agent and the phosphor-bearing antiwear agent for standby according to the weight proportion; b. adding the biodiesel into a container at normal temperature, and adding the colza oil into the container, so as to form a solution after uniform stirring; and c. adding the antioxidant, the polyester extreme pressure agent and the phosphor-bearing antiwear agent to the solution in the step b, and uniformly stirring the solution until no deposit exists. The special wire drawing oil for the aluminum wire has low kinematic viscosity, good fluidity, good lubricating effect and strong safety.

Owner:GUANGDONG WEIQI ELECTRIC MATERIAL

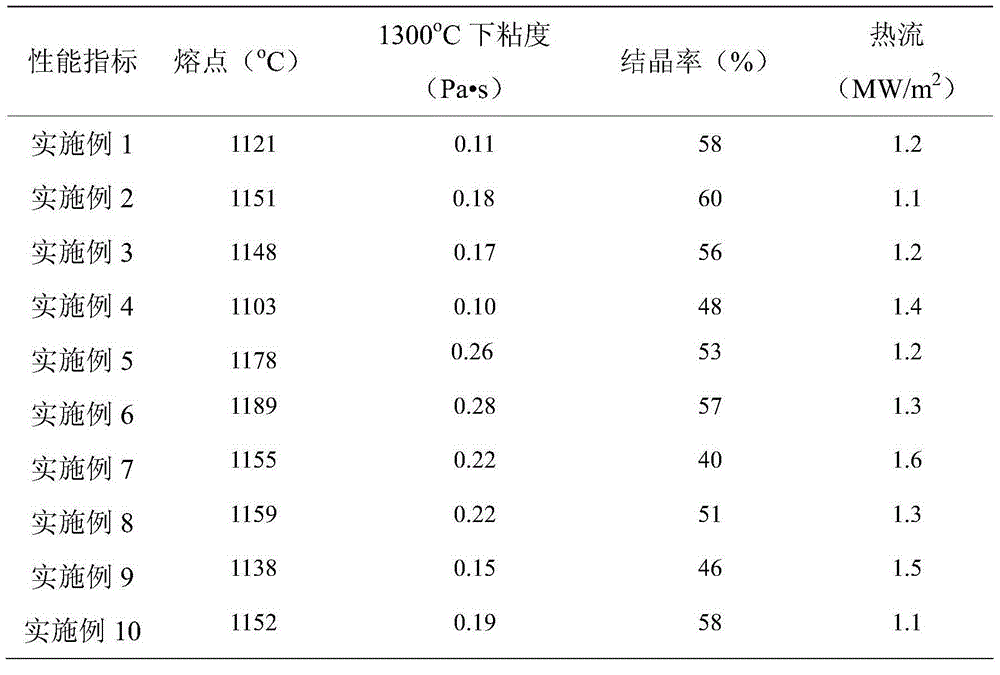

Novel medium manganese steel casting powder for automobile and application thereof

The invention relates to a novel medium manganese steel casting powder for an automobile and application of the novel medium manganese steel casting powder and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises, by mass, CaO 29%-37%, Al2O3 16%-25%, SiO2 11%-15%, MgO 2%-7%, Na2O 10%-14%, Li2O 1%-5%, MnO 1%-7% and F- 9%-13%. The melting point of the casting powder is 1,100-1,200 DEG C; at 1,300 DEG C, the viscosity of the casting powder is 0.10-0.30 Pa*s, and the crystallizing rate is 40%-70%; the heat flow is 1.1-1.6 MW / m<2> in the continuous casting process. The designed casting powder can be well used in the medium manganese steel continuous casting process for the automobile with the mass percentage of Mn being 3.0%-15.0%.

Owner:CENT SOUTH UNIV

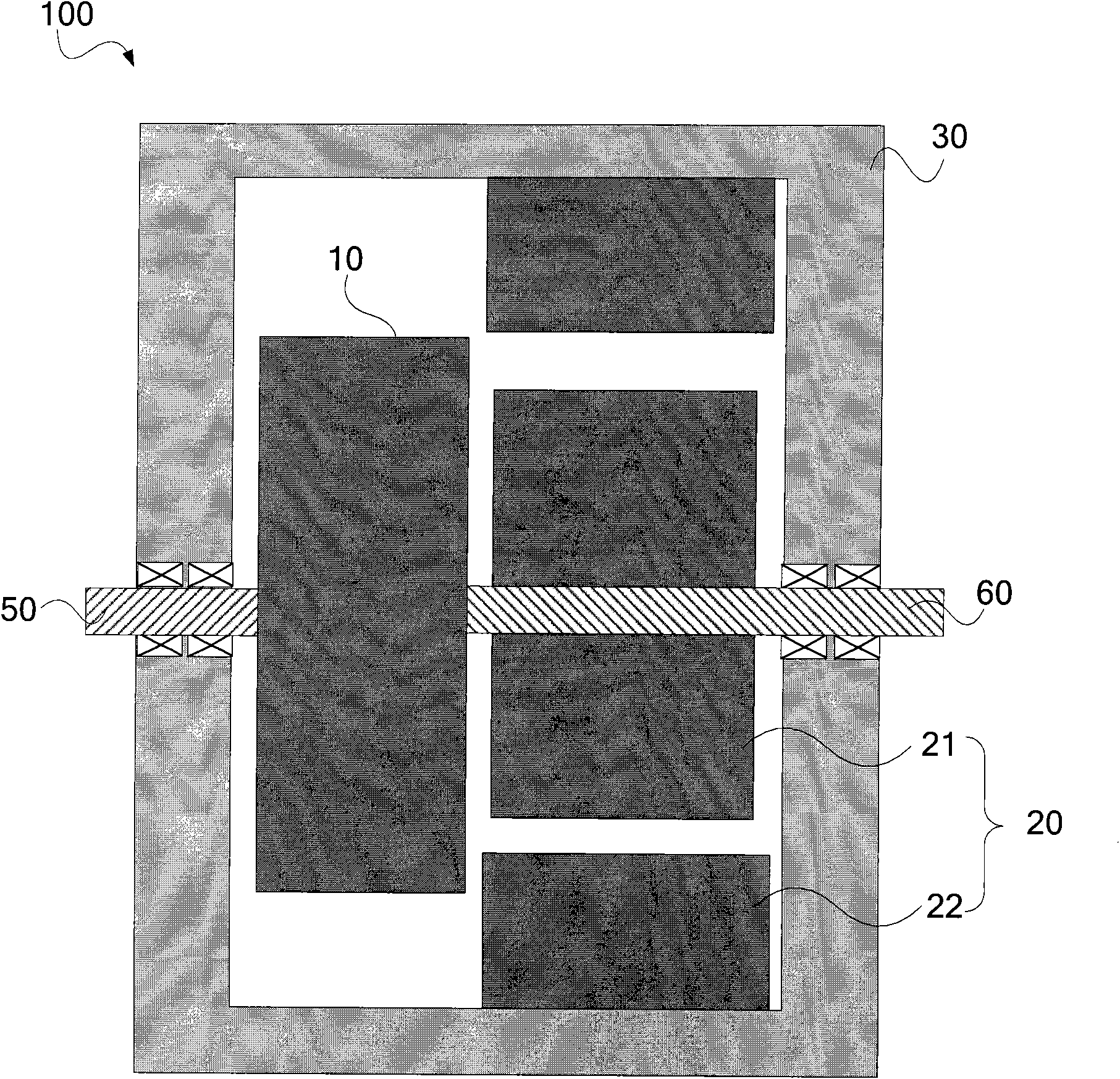

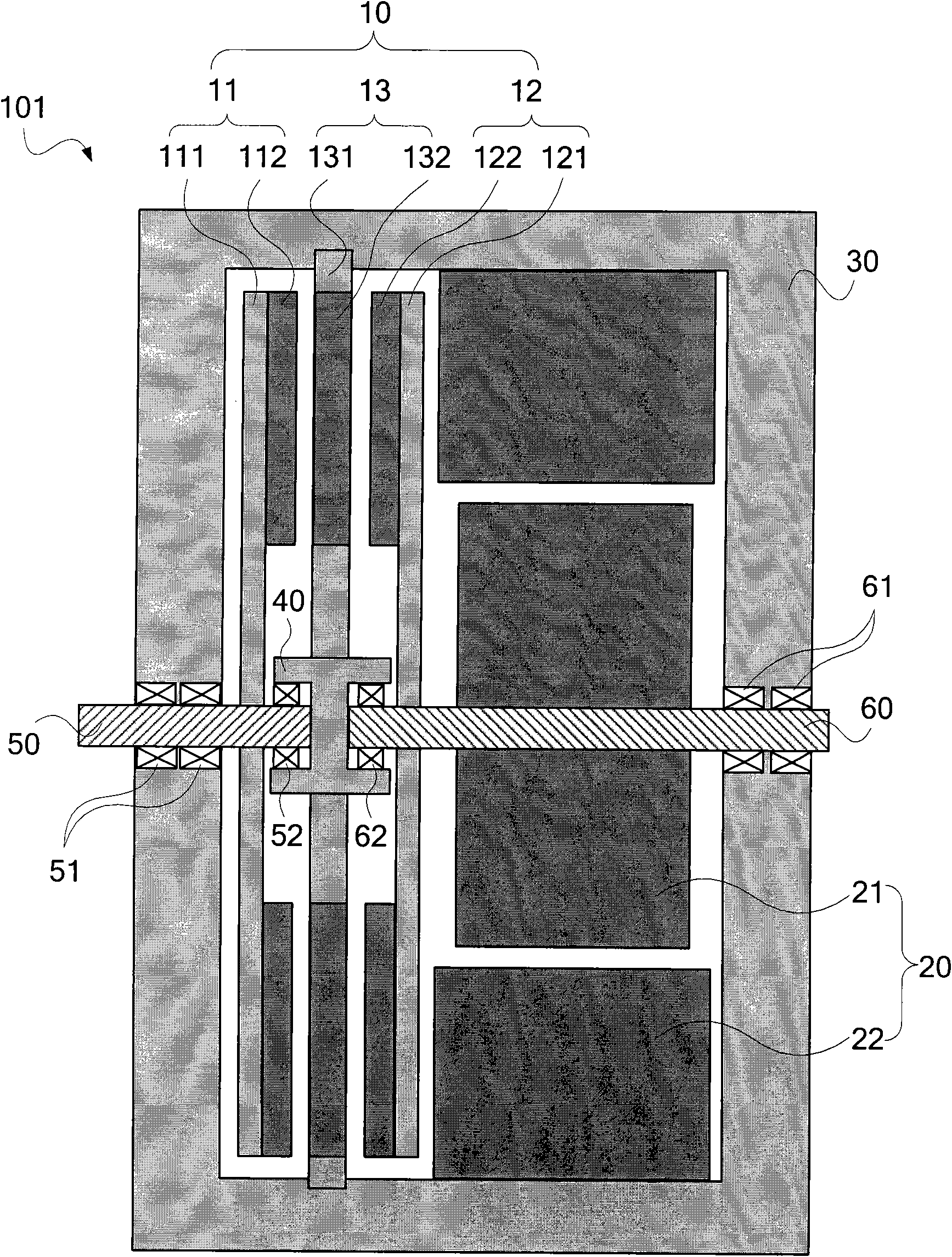

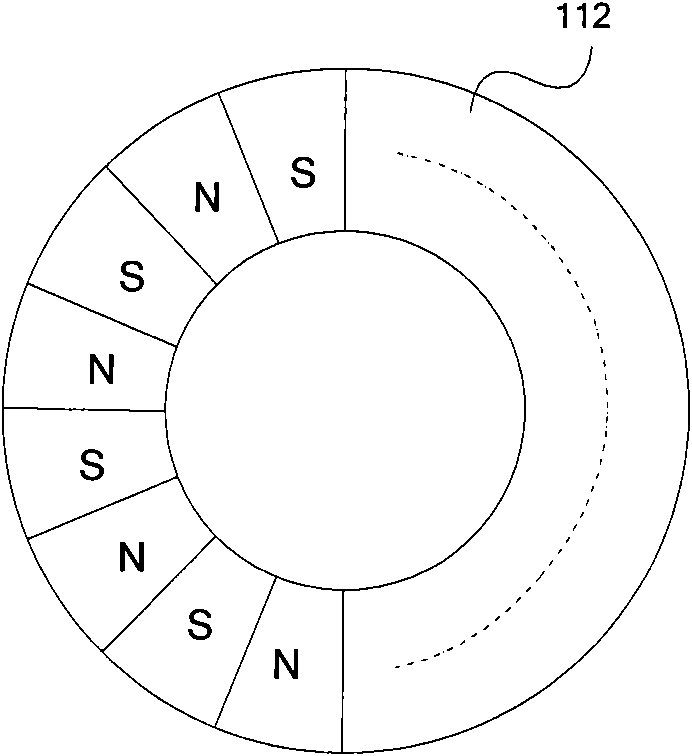

Integrated motor

InactiveCN101604901ACompact structureReduce lubricationDynamo-electric brakes/clutchesDynamo-electric gearsSupporting systemGeneral purpose

The invention provides an integrated motor comprising a permanent-magnetic gear and a general-purpose motor with rotors and stators, wherein the permanent-magnetic gear and the general-purpose motor are arranged in a case; the permanent-magnetic gear is connected with an external loading or a driving source by a low-speed rotating shaft, on one side and the permanent-magnetic gear is connected with the rotors of the general-purpose motor by a high-speed rotating shaft on the other side; or , the permanent-magnetic gear is connected with the rotors of the general-purpose motor by the low-speed rotating shaft on one side, and the permanent-magnetic gear is connected with the external loading or the driving source by the high-speed rotating shaft on the other side. As the permanent-magnetic gear and the general-purpose motor share a supporting system, a rotating shaft system, a bearing system, a radiation system, and the like, the whole integrated motor has simple and compact structure. In addition, the permanent-magnetic gear and the general-purpose motor of the integrated motor can be a radial or axial magnetic-flux permanent-magnetic gear and a radial or axial flux general-purpose motor according to the actual need.

Owner:SIEMENS AG

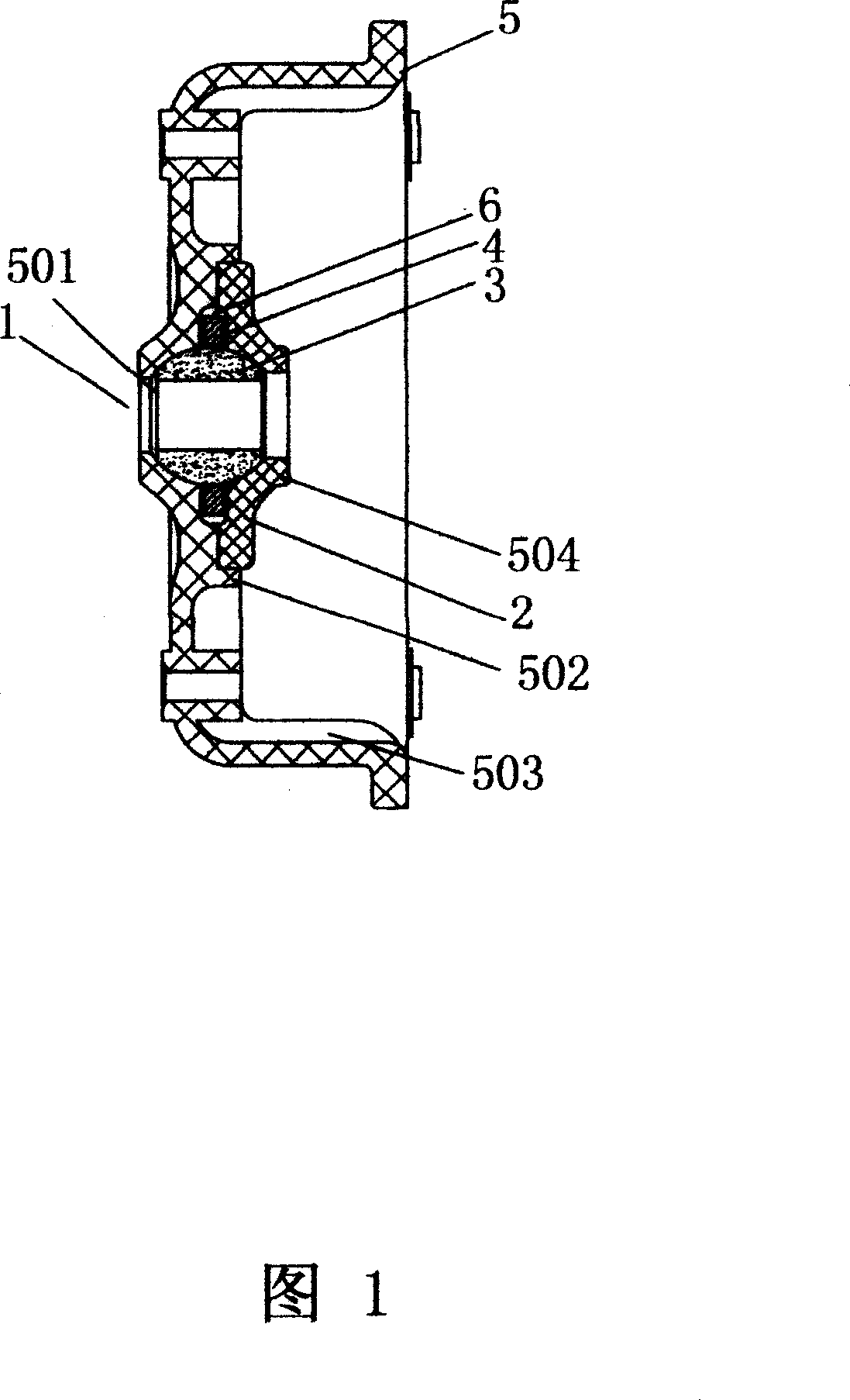

Method for mounting plastic electric machine casing and bearing device

InactiveCN1949632AHigh shaft positioning accuracyExcellent matching adjustment performanceManufacturing dynamo-electric machinesEngineeringInjection moulding

Owner:罗世明

Bottle conveyor lubricant composition and method of using the same

InactiveUS20100069274A1Eliminate the effects ofImprove detergencyLavatory sanitoryLiquid carbonaceous fuelsActive agentSurface-active agents

A bottle conveyor lubricant composition used for polyalkylene terephthalate containers, characterized by comprising (A) a specific chelating compound, and (B) water, and further optionally containing (C) a nonionic surfactant, (D) a water-soluble solvent, (E) a cationic surfactant, and / or (F) an anionic surfactant. Using the specific chelating compound as a main component makes it possible to obtain a bottle conveyor lubricant suitable for moving and conveying PET containers on a stainless steel conveyor. Furthermore, by adding a specific surfactant, it is possible to obtain a bottle conveyor lubricant that can be used alone to enable PET containers to be moved and conveyed not only on stainless steel conveyors but also on resin conveyors. Moreover, the composition has excellent detergency, lubricating ability, sterilizing ability, scale suppressing ability, and stress crack preventing ability, and has an excellent effect of suppressing occurrence of deposit upon being mixed with a beverage. A method of using the composition is also provided.

Owner:JOHNSONDIVERSEY INC

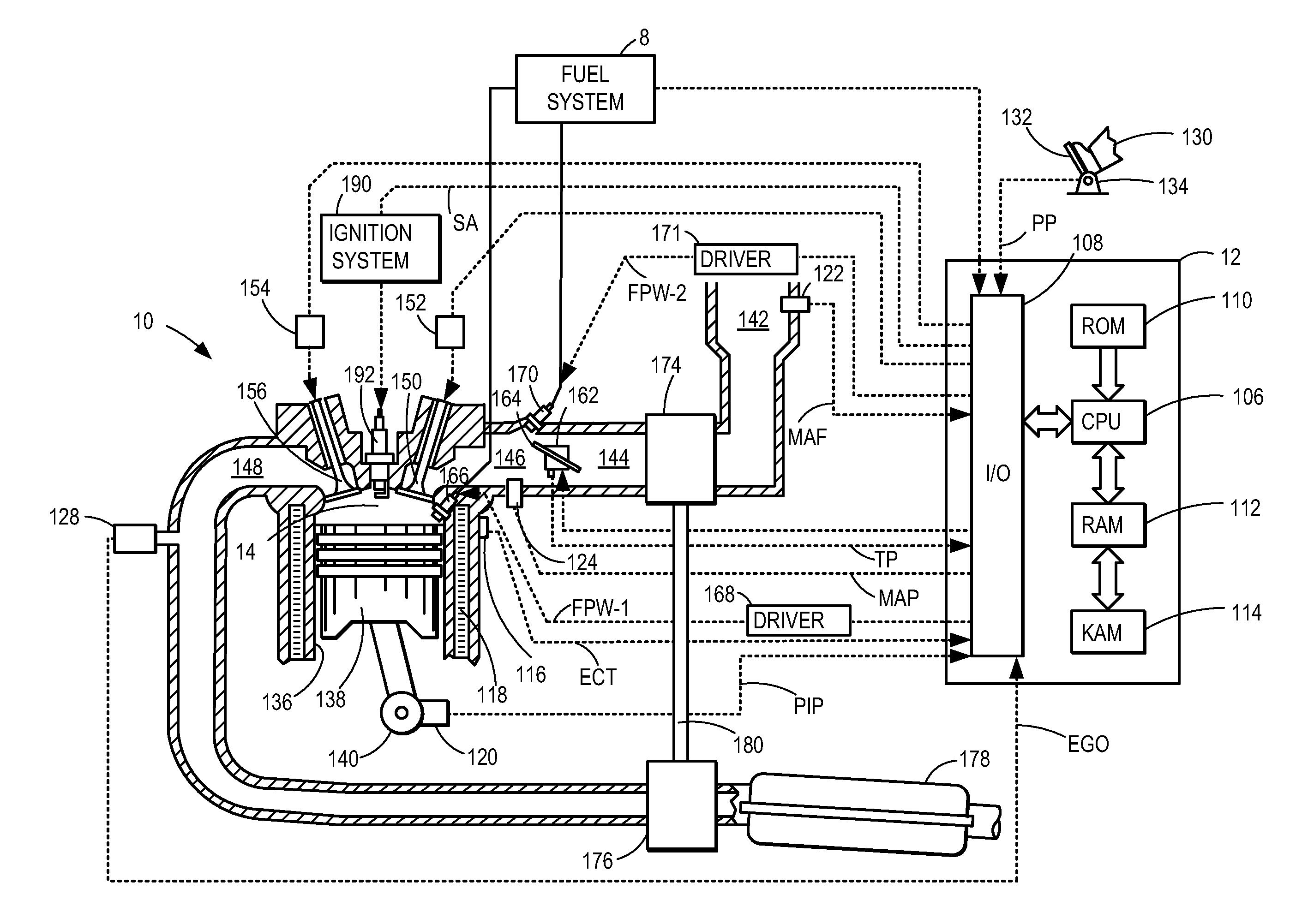

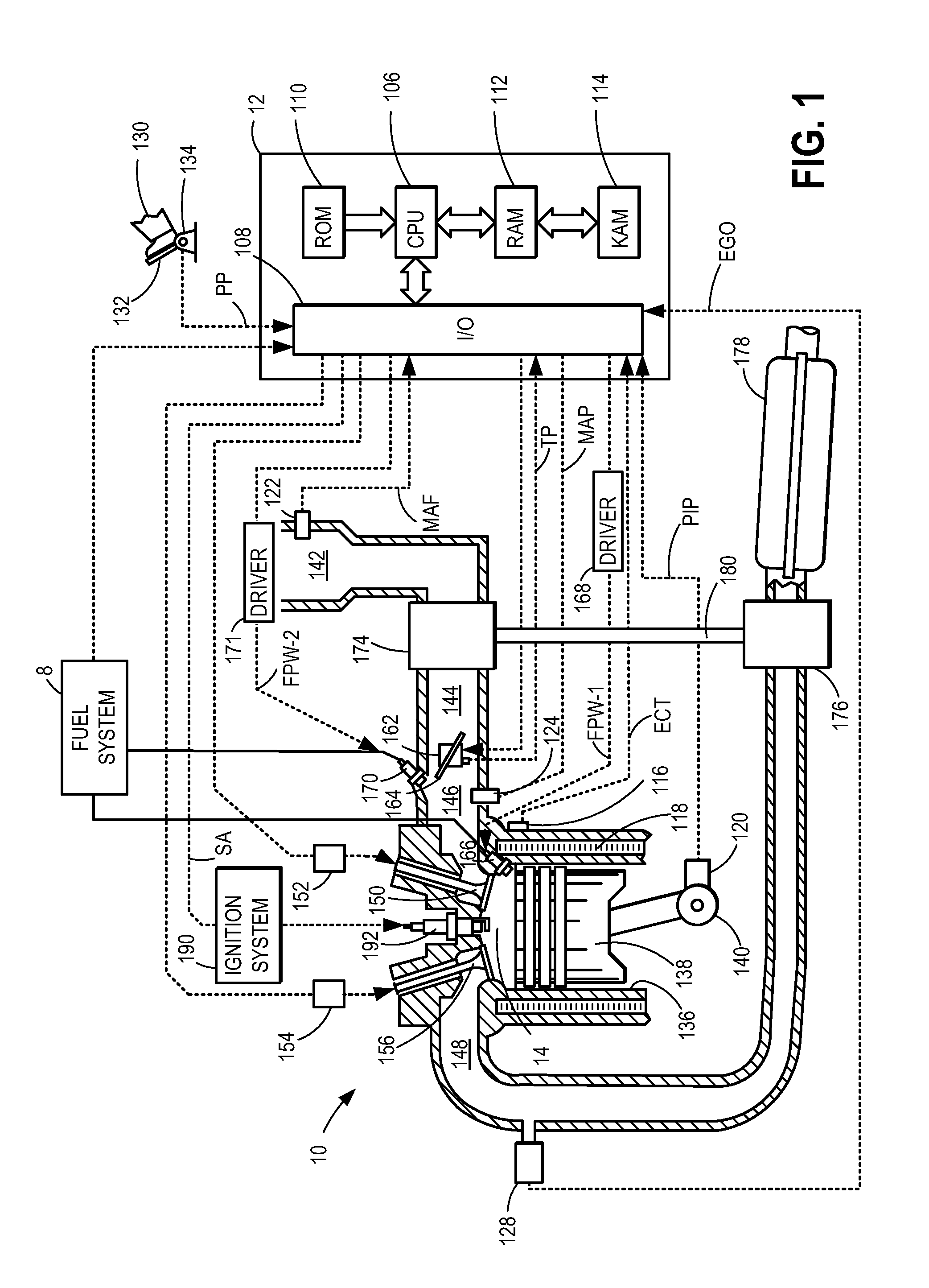

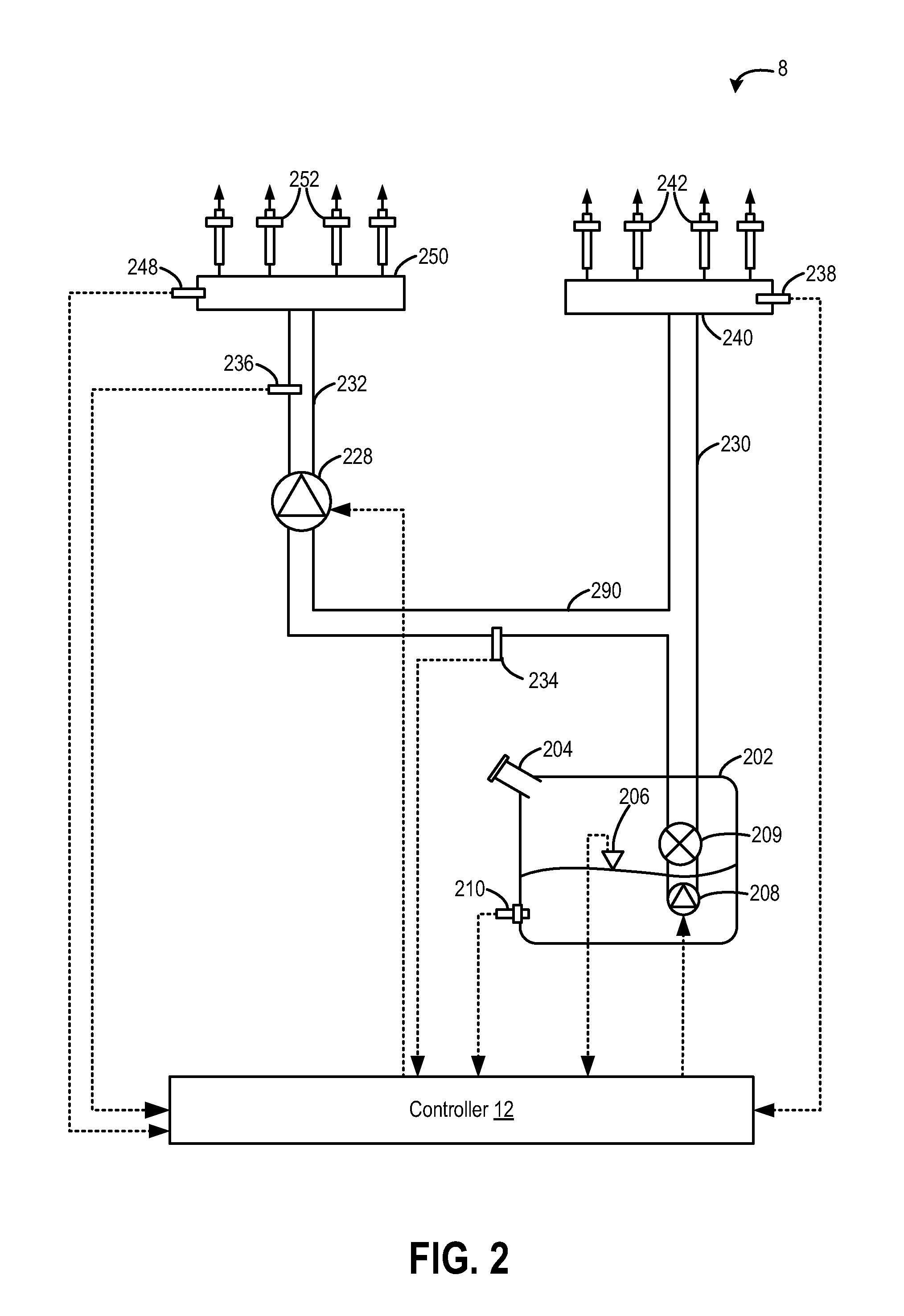

Robust direct injection fuel pump system

ActiveUS20150198081A1Improve engine performanceReducing vehicle emissionElectrical controlCombustion enginesPressure differencePump pressure

A method for a PFDI engine may comprise, during a first condition, comprising direct-injecting fuel to the PFDI engine, estimating a fuel vapor pressure, and setting a fuel lift pump pressure greater than the fuel vapor pressure by a threshold pressure difference, and during a second condition, comprising port-fuel-injecting fuel to the PFDI engine, setting a DI fuel pump command signal greater than a threshold DI fuel pump command signal without supplying fuel to a DI fuel rail.

Owner:FORD GLOBAL TECH LLC

Formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and formula system for molding agent thereof

InactiveCN106424704ASmall expansion coefficientReduce lubricationTransportation and packagingMetal-working apparatusShrinkage rateStearic acid

The invention discloses a formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and a formula system for a molding agent thereof. The formula system for the molding agent of the low-shrinkage-rate stainless steel powder injection molding feedstock comprises stearic acid, an antioxidant, paraffin, high-density polyethylene, polyethylene-acetate, high molecular polymer wax and polyformaldehyde, wherein mass percentage of polyformaldehyde is not greater than 90%. The invention further discloses a formula system for low-shrinkage-rate stainless steel powder injection molding feedstock comprises stainless steel powder and the formula system of the molding agent. The formula system for low-shrinkage-rate stainless steel powder injection molding feedstock and the formula system for the molding agent thereof disclosed by the invention realize relatively high powder loading amount and relatively high shrinkage rate, have relatively high melt index as well as excellent blank strength and molding property, and are especially suitable for manufacturing and molding large-specification thin-wall products.

Owner:DONGGUAN HUAJING POWDER METALLURGY +1

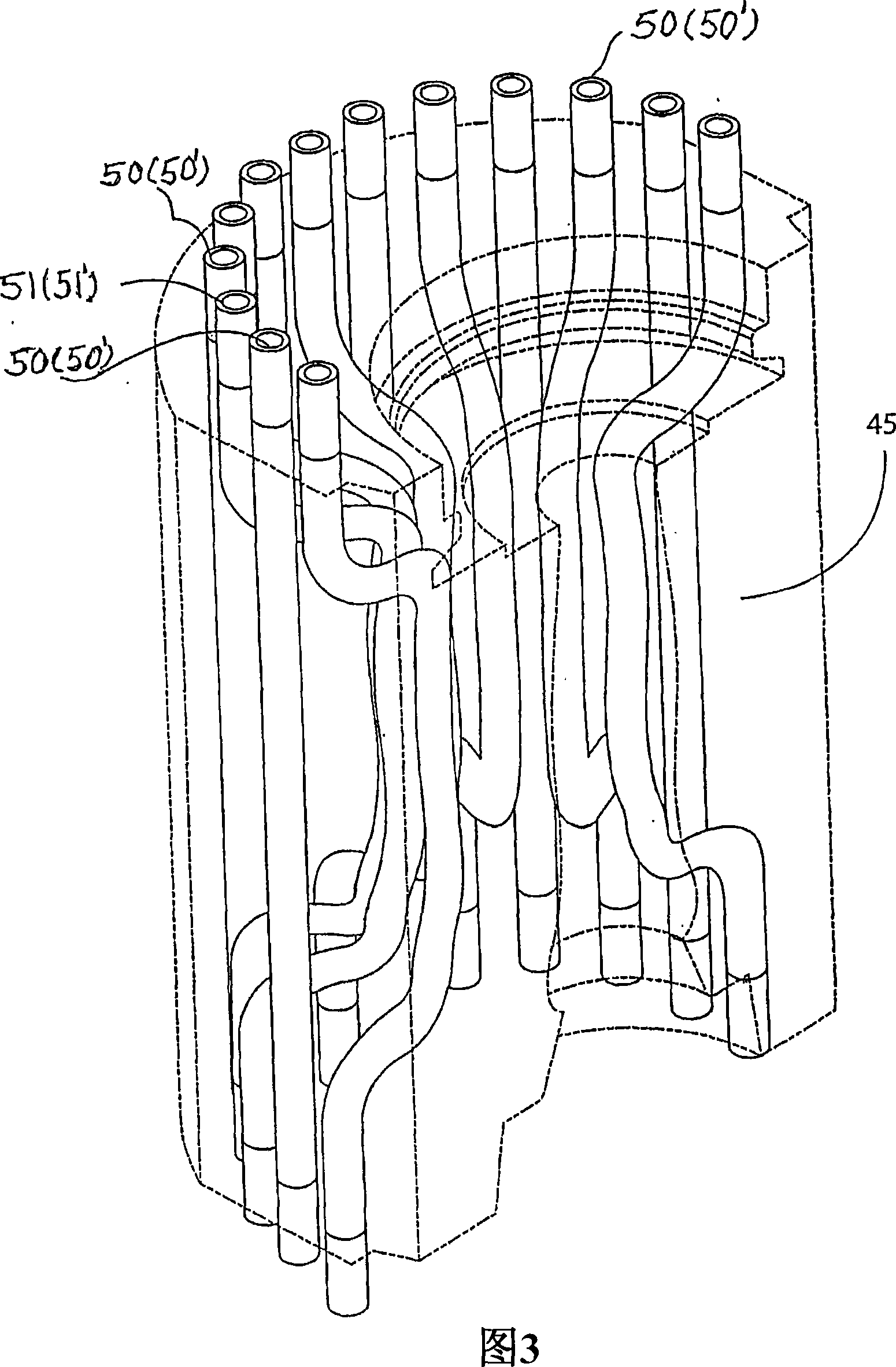

Glass-forming die and method

InactiveCN101193827AExtend your lifeUniform temperatureFoundry mouldsGlass pressing apparatusTemperature controlEngineering

Glass-forming die, such as a parsain- forming or bottle- forming die, includes a die body having a molding surface with a curved contour to form at least a portion of a glass bottle or other article to be made. The die body has one or more cooling passages inside the body wherein the cooling passages is / are non-linear (non-straight) along at least a portion of their length to improve temperature control of the die during the glass forming operation. To this end, the cooling passages are curved in a manner to generally follow the curved contour along at least a portion of the length of the curved contour, and may include heat radiating or turbulating elements in the cooling passage. The glass- forming die alternately, or in addition, can include integral cooling fins, ribs or other heat radiating element on one or more exterior regions of the die.

Owner:HOWMET CORPORATION

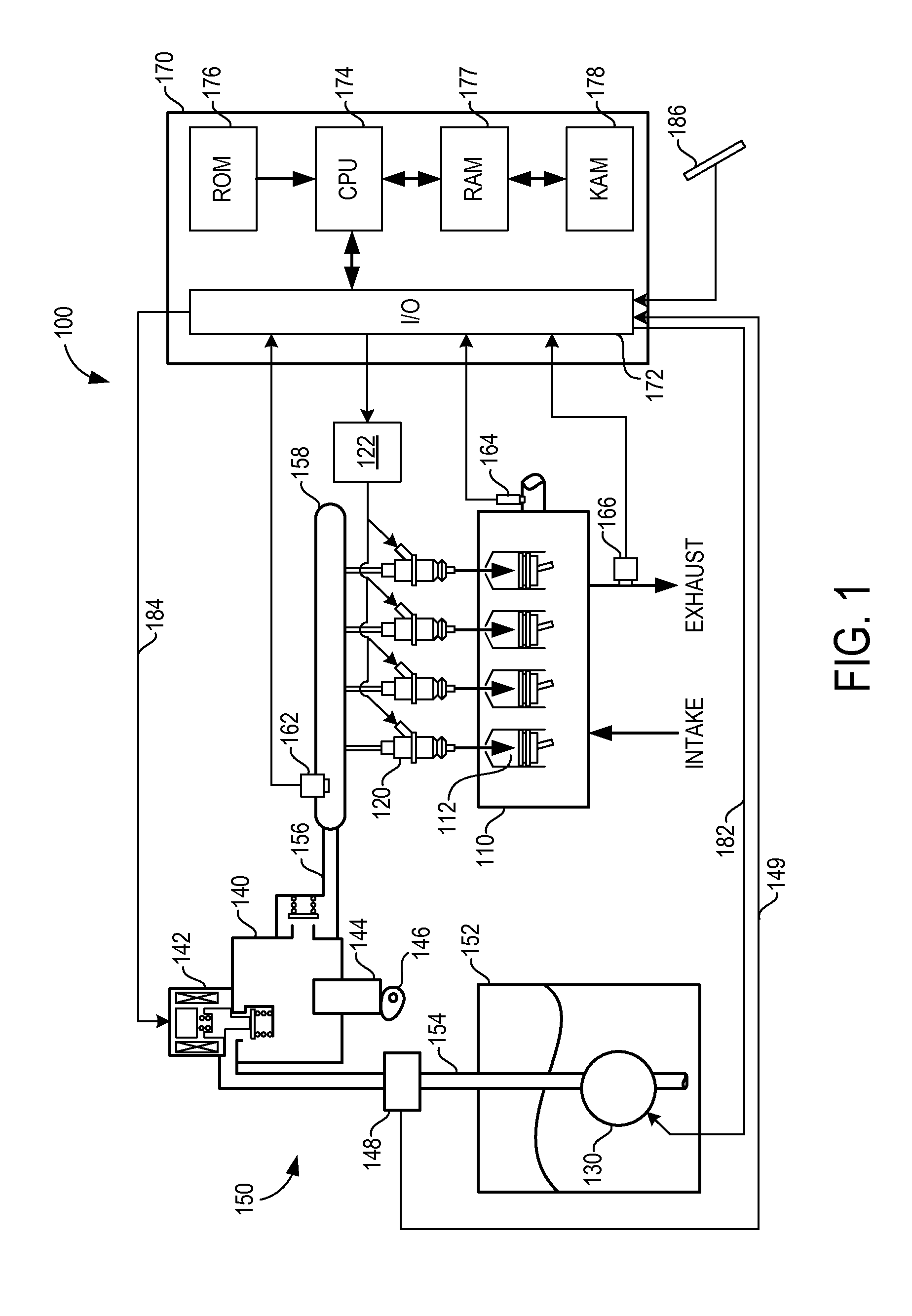

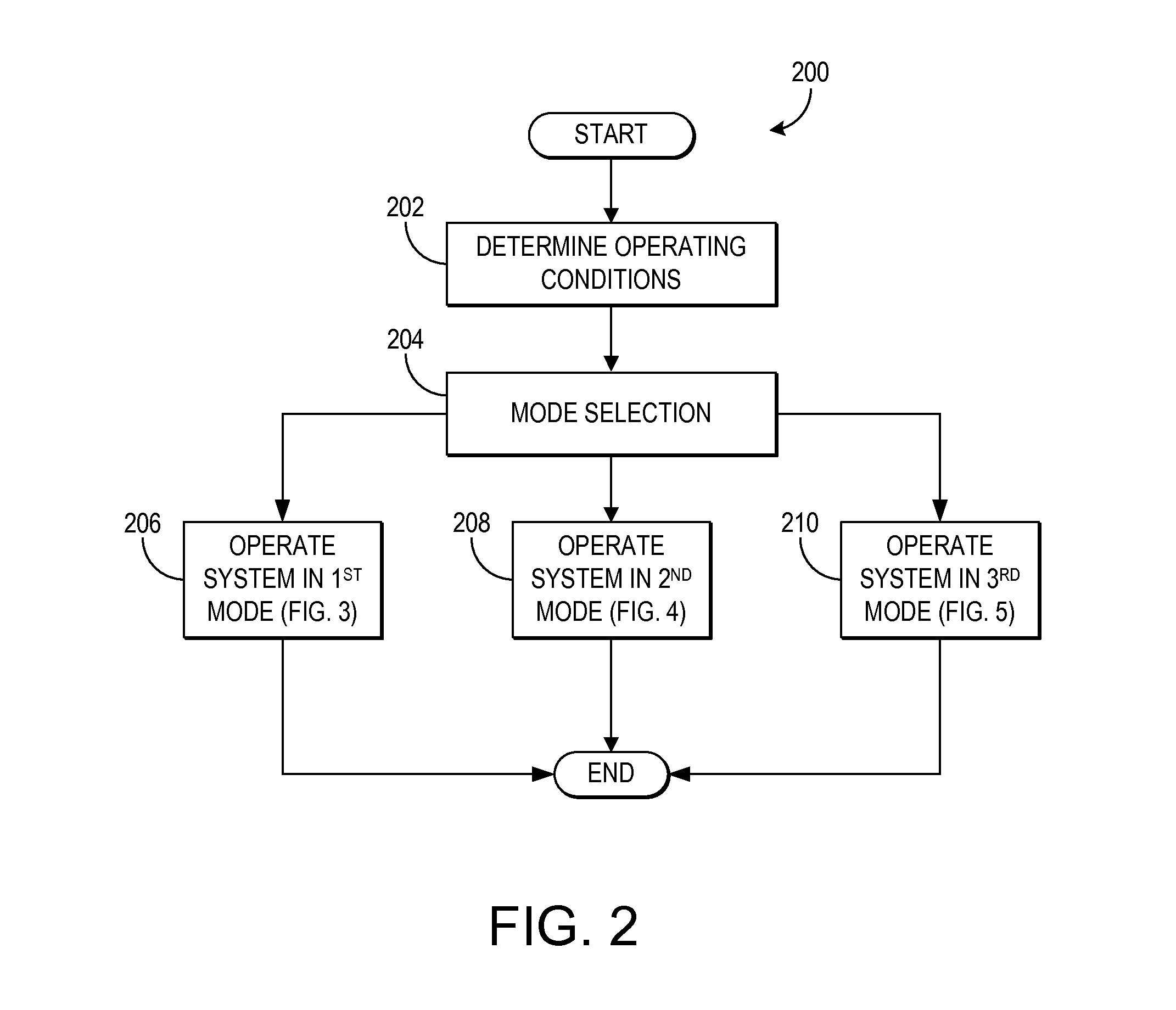

Methods and systems for a fuel system

InactiveUS20140230794A1Avoid vaporizationImprove system efficiencyElectrical controlMachines/enginesCapacitanceOperation mode

Various methods and system are described for a fuel system which includes a fuel composition sensor and a fuel lift pump disposed upstream of the sensor. The system may be operated in each of three different modes of operation. In each of the modes, a fuel lift pump voltage is adjusted responsive to a fuel capacitance output by the sensor, while a variable such as sensor temperature or fuel pump pressure is maintained depending on the mode of operation.

Owner:FORD GLOBAL TECH LLC

A fluid control valve

ActiveUS20170051644A1Small dimensionEasy to startOperating means/releasing devices for valvesCoolant flow controlFluid controlEngineering

A fluid control valve includes a cylindrical housing with at least one opening through a housing wall, a cylindrical main valve axially movably arranged inside the housing for controlling a fluid flow through the at least one opening and a main valve spring member acting on the main valve. The main valve includes a base wall defining a fluid control volume and fluid main volume in the cylindrical housing. The base wall includes an opening for fluidly connecting the fluid control volume with the fluid main volume. The fluid control valve further includes a pilot valve positioned at the base wall opening, which pilot valve is moveably arranged for controlling a fluid flow through the base wall opening, and an electro-mechanical actuator configured to act on the pilot valve for controlling the main valve via the pilot valve. A method for adjusting the axial position of a cylindrical main valve of a fluid control valve is also provided.

Owner:VOLVO LASTVAGNAR AB

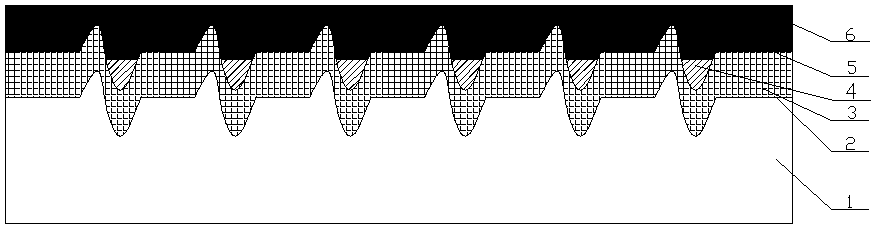

Magnetic-fluid-coated textured surface lubricating substrate and processing method thereof

PendingCN107557784AImprove wear resistanceEasy to useSuperimposed coating processLaser beam welding apparatusLaser processingThin membrane

The invention provides a magnetic-fluid-coated textured surface lubricating substrate and a processing method of the magnetic-fluid-coated textured surface lubricating substrate and belongs to the field of machine manufacturing. For the problems that a hard coating is low in bonding strength and easily peeled off, active processing of the micro-texture composite morphology, coating and magnetic fluid lubricating is conducted on the surface mainly bearing the friction and wear of the substrate material. The processing method comprises the steps that texturing processing is conducted on the surface of the substrate through a laser processing technology, the hard coating serves as a hard support layer, texturing processing is conducted on the surface of the magnetic hard surface through the laser processing technology, a magnetic film is deposited in the microstructure through an electro-deposition technology, magnetizing is conducted, and finally the texturing surface is coated with themagnetic fluid as a lubricating phase. By the adoption of the magnetic-fluid-coated textured surface lubricating substrate and the processing method, the service life of the substrate is prolonged, the wear to the material is reduced, and the bonding strength of the coating is enhanced.

Owner:JIANGSU UNIV +2

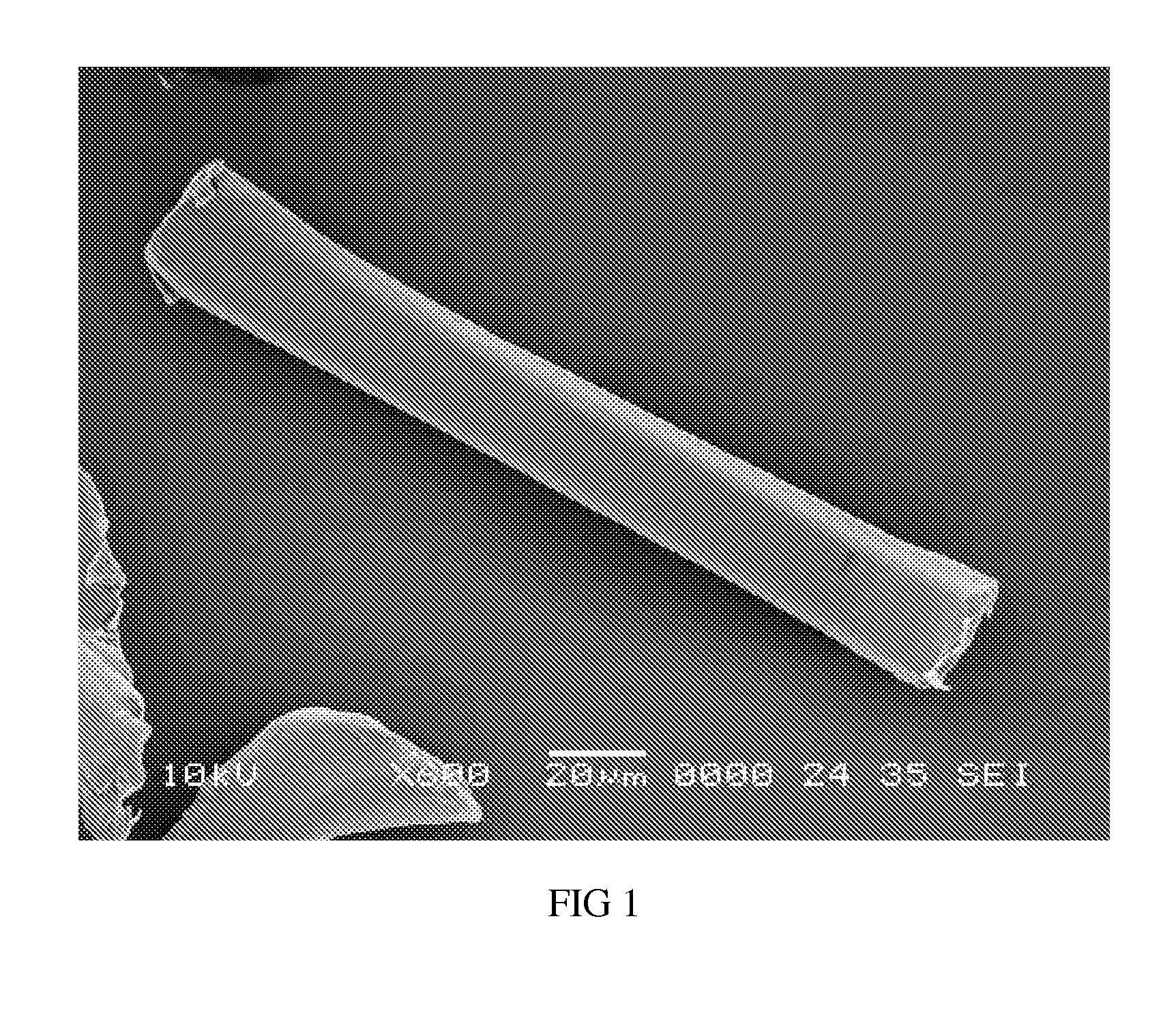

Method of making hydrophilic fluoropolymer material

ActiveUS20100224710A1Increase the areaIncrease roughnessGas current separationGrain millingPolymer scienceFluoropolymer

A fluoropolymer material exhibiting an increased hydrophilicity prepared by processing the material in a jet mill.

Owner:TORAY FLUOROFIBERS AMERICA

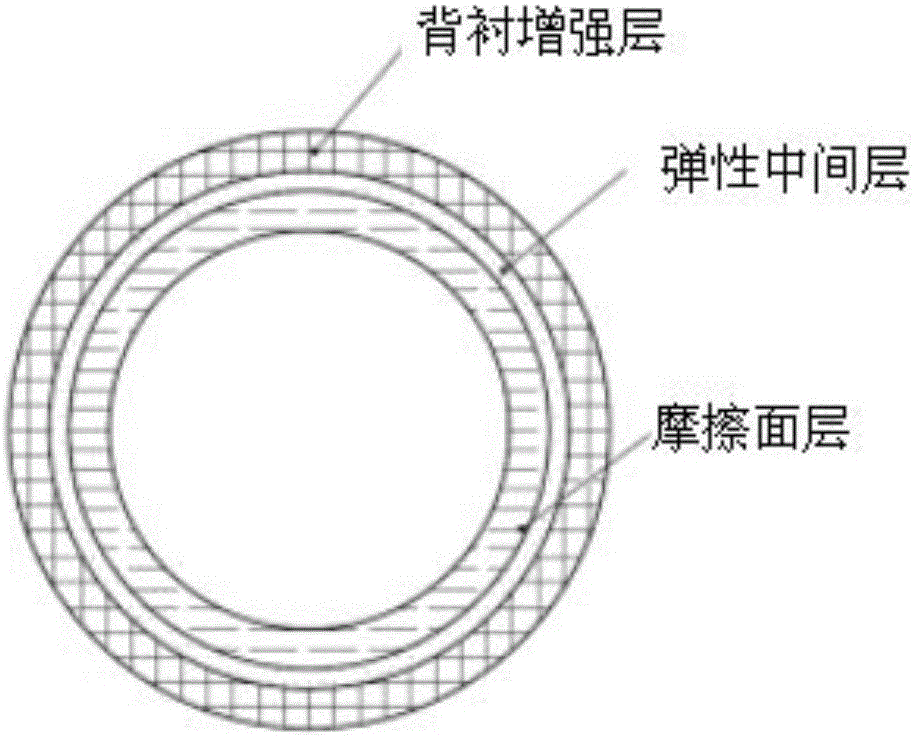

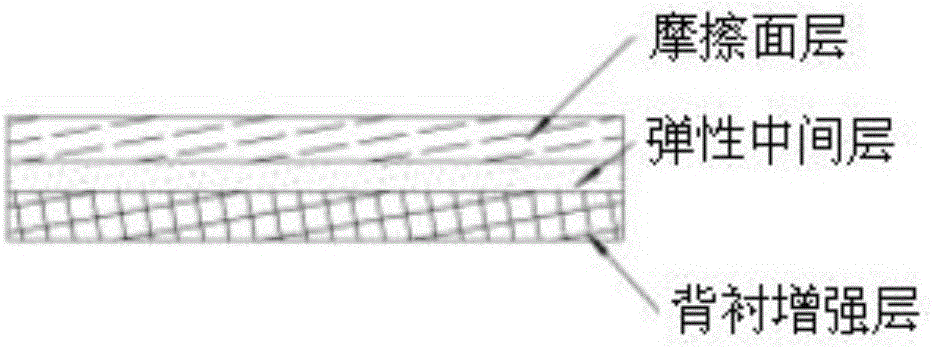

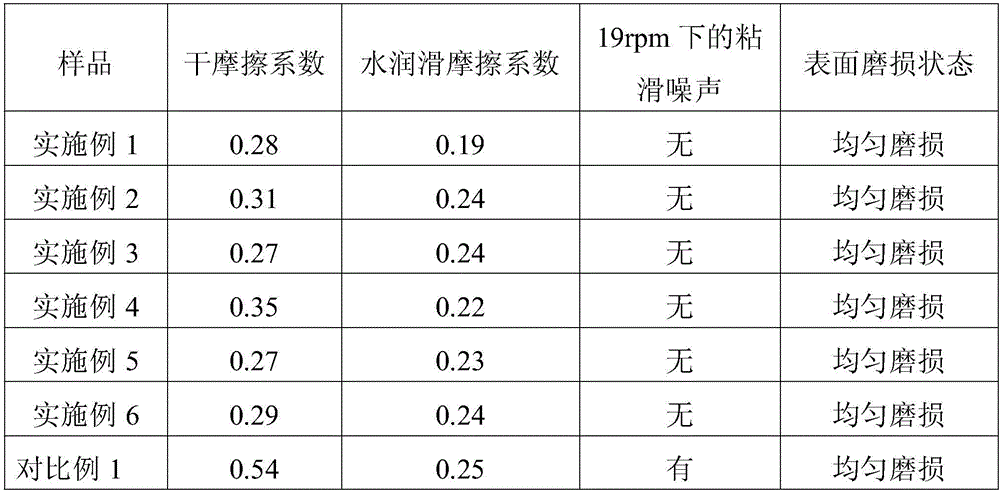

Deformation adaptive macromolecule bearing composite material and preparation method and application thereof

InactiveCN106142795AIncrease flexibilityImprove impact resistanceSynthetic resin layered productsBearing componentsLubricationResin composite

The invention discloses a deformation adaptive macromolecule bearing composite material and a preparation method and application thereof, and belongs to the technical field of sliding bearings. The problems that a rubber sliding bearing friction layer in the prior art is large in low-speed friction coefficient and has stick slip noise, and a resin sliding bearing friction layer cannot adapt to stress concentration and bearing damage caused by shaft deformation are solved. A backing enhancement layer, an elastic middle layer and a friction surface layer are tightly arranged from outside to inside in sequence according to the composite material. The backing enhancement layer is prepared from fiber reinforced resin composite materials, the elastic middle layer is prepared from flexible polyurethane, the hardness value of the elastic middle layer is Shaw 70-85 A, the friction surface layer is prepared from the composite material of rigid polyurethane and lubricating agent, and the hardness value of the friction surface layer is Shaw 50-80 D. The composite material can produce adaptivity for deformation of a shaft, has low water lubrication and dry friction coefficients, produces no stick slip noise under low-speed conditions, and is applicable to being used as the sliding bearing friction layer material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

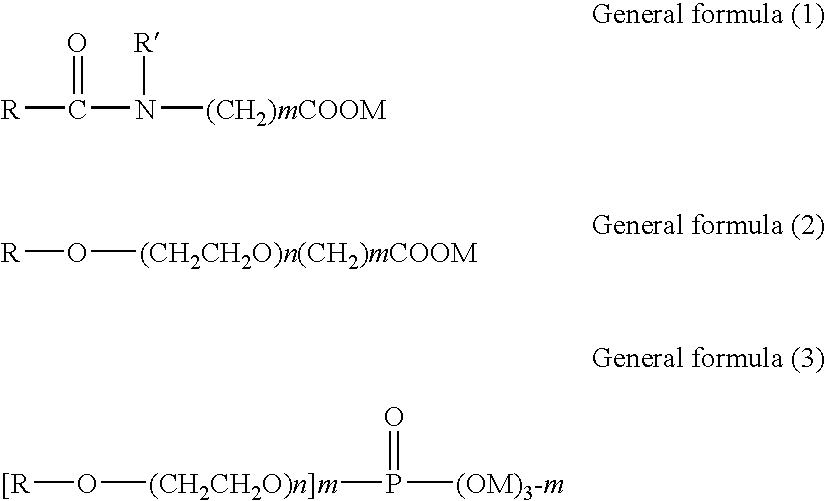

Ultra-low-sulfur diesel lubricating property improver and preparation method thereof

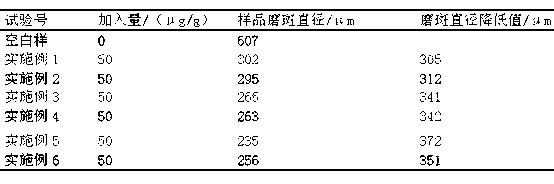

InactiveCN103173254AImprove conversion rateReduce lubricationLiquid carbonaceous fuelsFuel additivesBiodieselMonoglyceride

The invention relates to an ultra-low-sulfur diesel lubricating property improver and a preparation method thereof. The improver is a mixture of monoglyceride, fatty acid and low-molecular-weight alcohol. The improver has acid value being lower than 30.0mgKOH / g and a condensation point being lower than -1 DEG C. according to the preparation method, biodiesel co-product glycerin and low-molecular-weight alcohols serving as the raw materials have esterification reaction with the fatty acid in the presence of an ionic liquid catalyst to generate the mixture of monoglyceride, fatty acid and low-molecular-weight alcohols, namely the ultra-low-sulfur diesel lubricating property improver, wherein the addition of the improver relative to low-sulfur diesel is 50mu g / g, the temperature is 100-170 DEG C, the pressure is 0.1-0.2MPa and the time is 1-2 hours. The detailed preparation method refers to the specification. The low-sulfur diesel lubricating property improver has low acid value and high lubrication improvement property, can be directly used without use of antioxidants and cleaning agents; production cost is low, the production process is clean and the production flow is short.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com