Drilling fluid lubricant prepared from waste plant oil and preparation method thereof

A technology for discarding vegetable oils and lubricants, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of solid control equipment removal, poor cooling drilling performance, poor lubrication performance, etc., and achieve good economic and social benefits. , Conducive to environmental protection, excellent lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

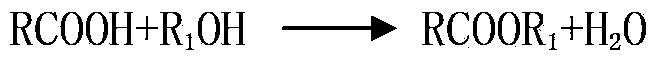

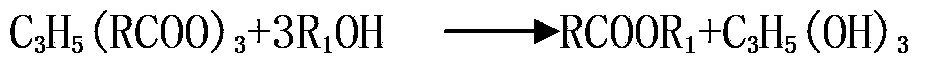

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the preparation method of vegetable oil drilling fluid lubricant of the present invention

[0055] (1) After the waste vegetable oil settles for 24 hours, centrifuge it with a centrifuge for 0.5 hours to remove impurities such as sediment and water;

[0056] (2) Take 800.0g of centrifuged waste vegetable oil, add 100.0g of methanol and 25.0g of catalyst p-toluenesulfonic acid, keep the temperature at 90°C, and react for 6h;

[0057] (3) After the product settles for 6 hours, separate the glycerin, and then carry out rectification at 100°C to remove unreacted methanol;

[0058] (4) Add 40g nonionic surfactant fatty acid sorbitol ( Pan 85) and 30g of sulfonated lignite resin to get it.

Embodiment 2

[0059] Embodiment 2: the method for measuring the lubricity of the vegetable oil drilling fluid lubricant of the present invention

[0060] Preparation of fresh water base slurry: Accurately measure 300mL of distilled water with a measuring cylinder, add accurately weighed 18.00g of sodium bentonite under high-speed stirring at 10,000RPM, stir at high speed for 20 minutes, keep it sealed at room temperature for 24 hours, and prepare 6% sodium bentonite slurry. Referred to as base pulp.

[0061] Preparation of 4% saline base slurry: Take 300mL base slurry, add 12.00gNaCl, stir at 10000RPM at high speed for 5min, and make 4% brine slurry, referred to as 4% brine base slurry.

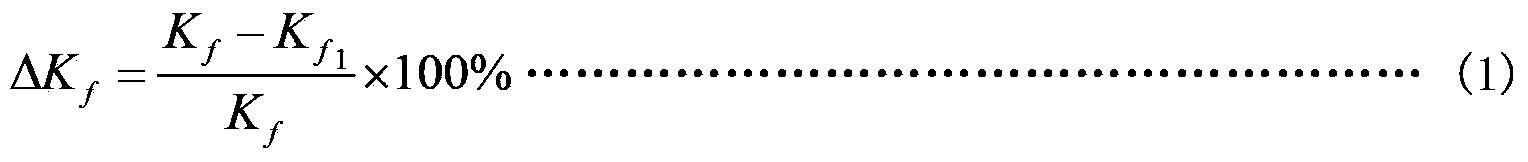

Embodiment 2-1

[0062] Example 2-1: Lubrication performance test method at room temperature

[0063] Determination of extreme pressure lubrication performance of fresh water slurry: prepare two 300mL base slurries, add 1% of the developed vegetable oil drilling fluid lubricant to one of them, stir the two slurries at high speed at 10000RPM for 5min, and measure them with EP extreme pressure lubrication instrument The extreme pressure lubrication coefficient of base slurry before and after adding samples.

[0064] Determination of the adhesion coefficient of fresh water slurry: Prepare two 300mL base slurry, add 1% of the developed vegetable oil drilling fluid lubricant to one of them, and after stirring at 10000RPM for 5min at high speed, measure the base slurry with an adhesion coefficient tester. Adhesion coefficient before and after slurry addition.

[0065] Determination of extreme pressure lubrication performance of brine slurry: prepare two 300mL brine base slurries, add 1% of the deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com