Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Avoid cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

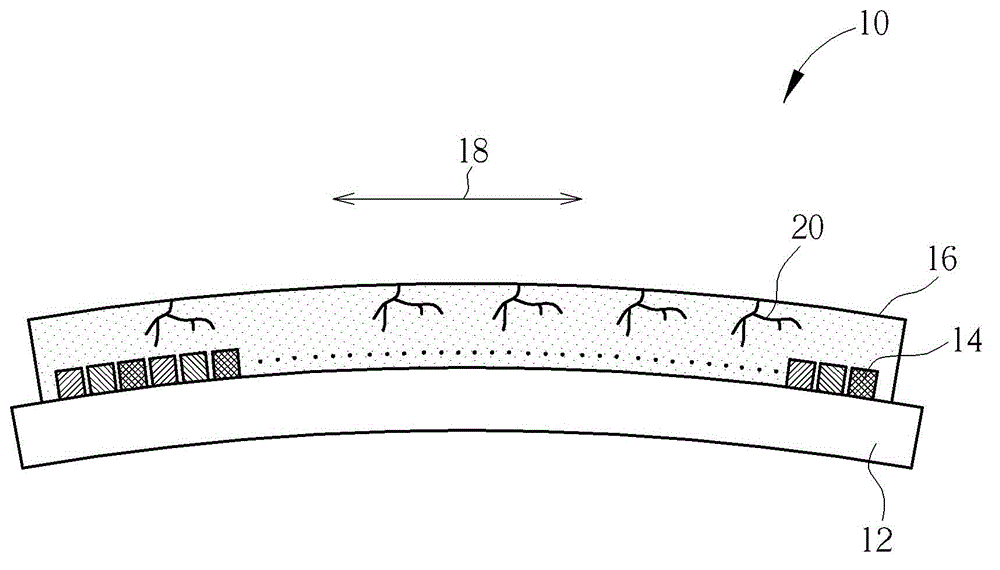

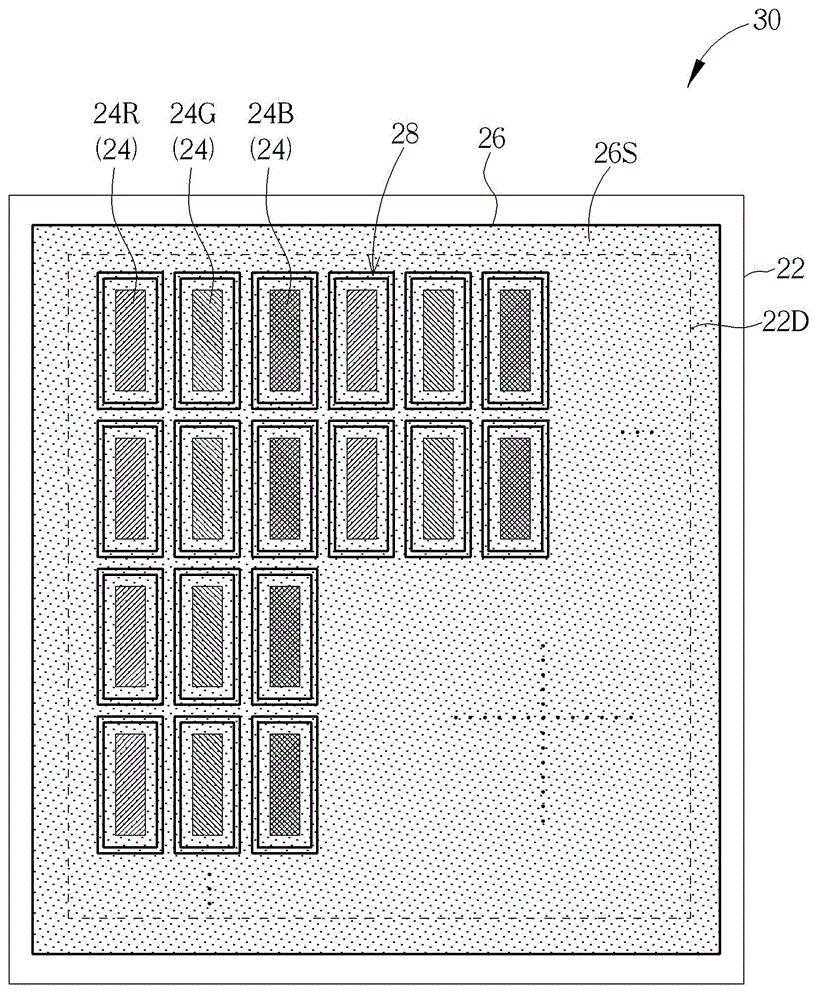

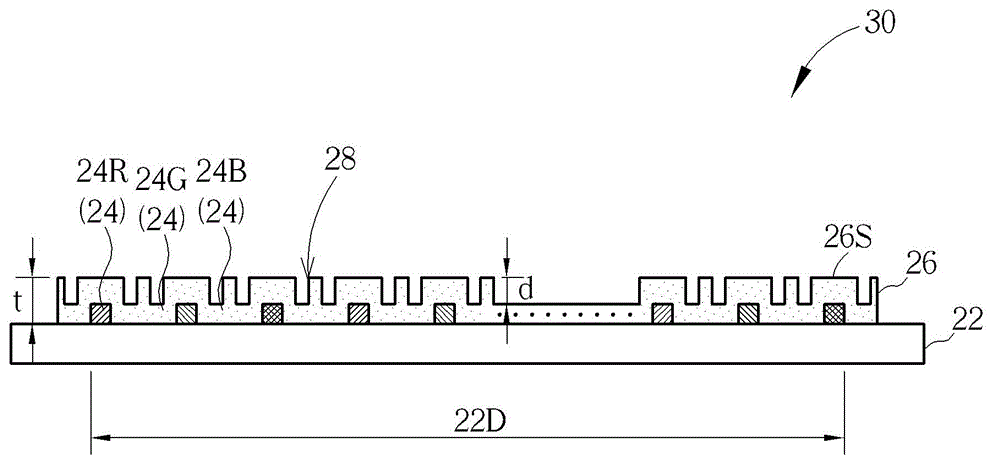

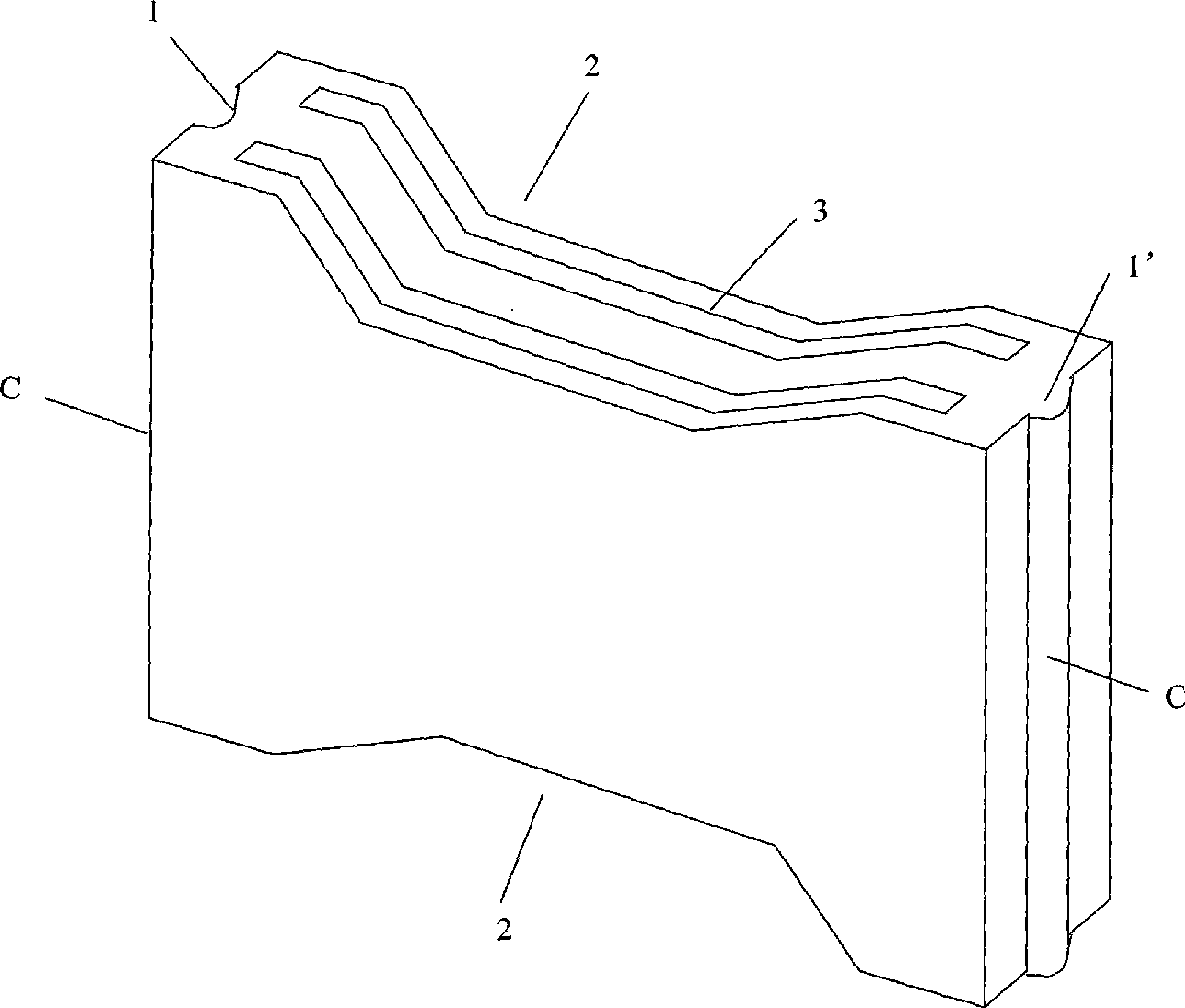

Flexible display panel

ActiveCN103150965AAvoid cracksReduce the chance of water and oxygen intrusionSolid-state devicesIdentification meansEngineeringFlexible display

The invention relates to a flexible display panel comprising a flexible substrate, a plurality of display elements arranged on the flexible substrate, and at least one packaging film layer covering the display elements. An upper surface of the packaging film layer is equipped with a plurality of grooves which at least correspond to a part of the adjacent display elements. The flexible display panel helps to solve problems that a conventional packaging film layer is liabe to crack.

Owner:AU OPTRONICS CORP

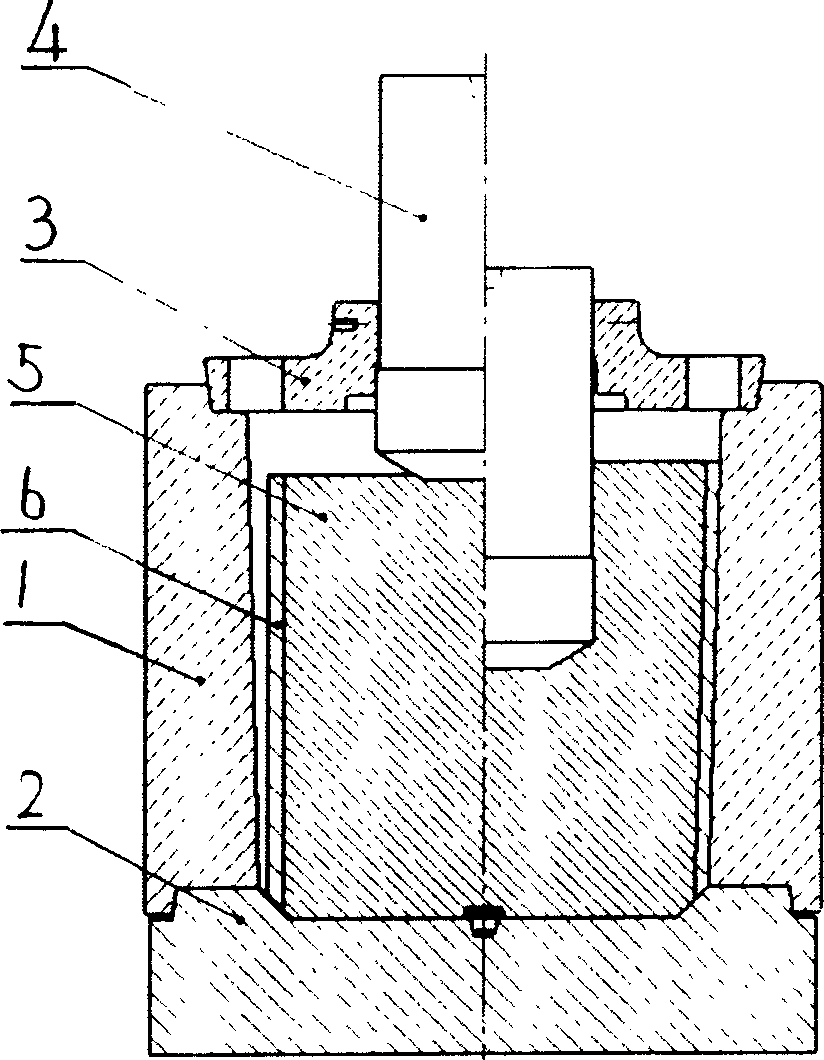

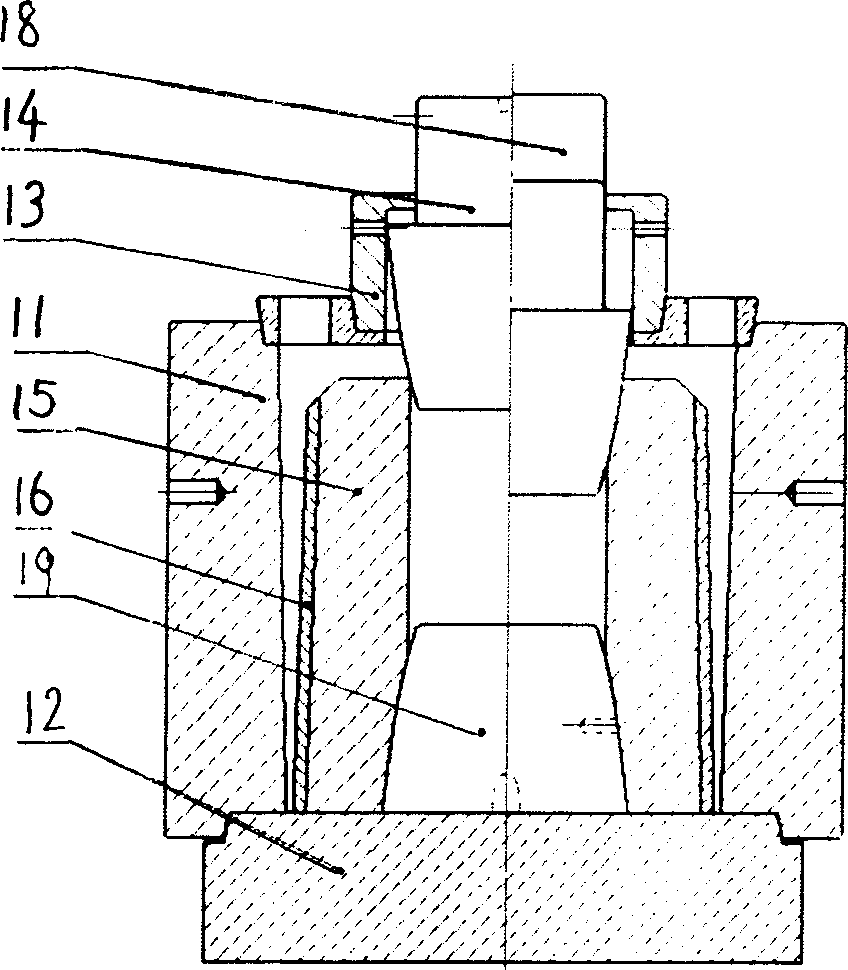

Method for producing circular cog hot forged from generator protective ring and mould

InactiveCN1736630AImprove stress statusAvoid cracksForging/hammering/pressing machinesHollow articlesCrystalliteLubrication

The invention discloses a method and the die for preparation of a hot forging ring billet of the guard ring of generator, and relates to a forging technique and the device of guard ring part of generator. The prior hot forging technique is flat-die forging, easily to produce crack in the process. The invention using confined shaping in die instead of flat-die forging, it improves the state of stress and prevents the crack effectively. With the symmetry of sphere plunger axis in the process of fan boring, the crystal particles are fine and uniform, which provides a perfect condition for cold strain intensification. With the jacket shaping of billet, it can improve lubrication and decrease friction, and can keep the temperature of the hot billet effectively, improving the plasticity and decreasing the shaping pressure. The invention solves the three problems that the crack is easy to produce, the structure property is not uniform, and the shaping pressure is large; compared with the prior technique, the invention has a projecting progress and a distinctive effect.

Owner:DEYANG WANXIN POWER STATION PROD DEV

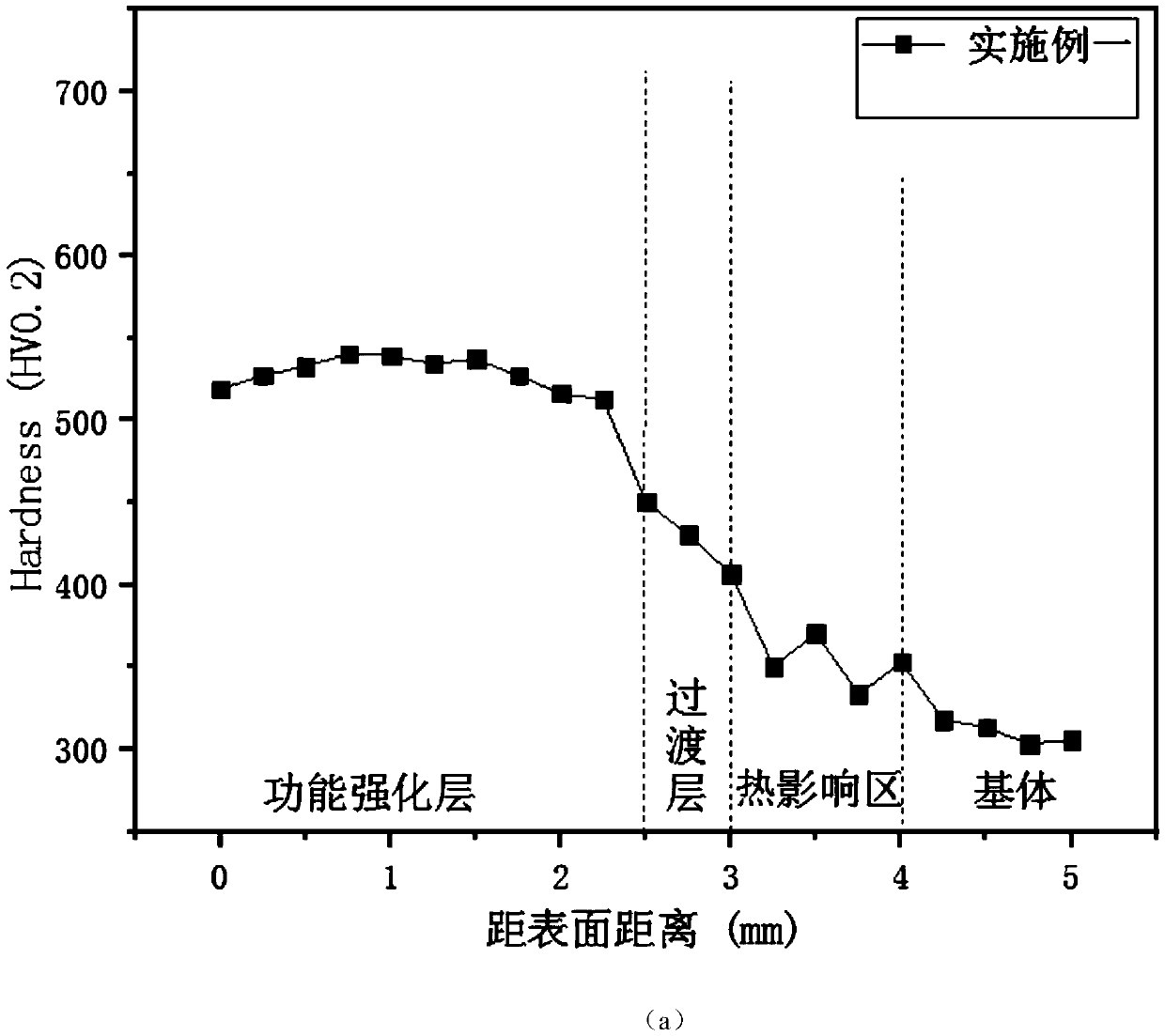

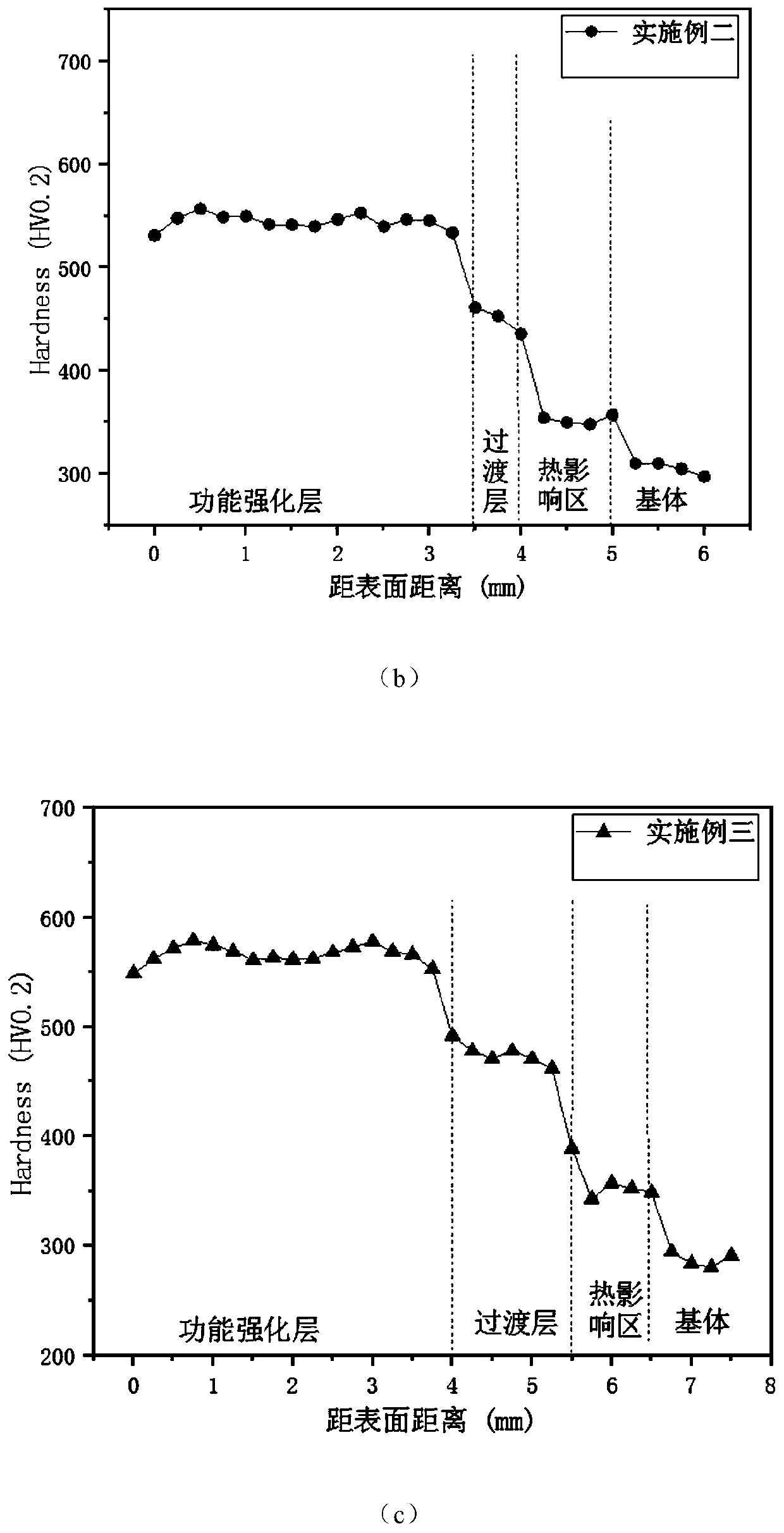

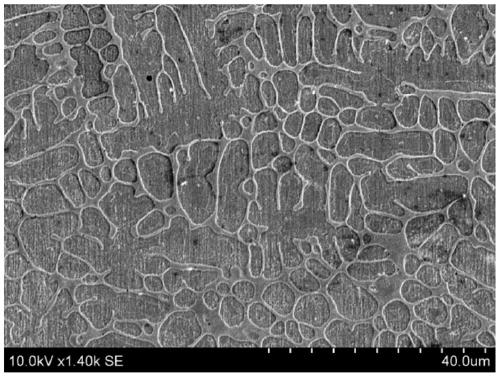

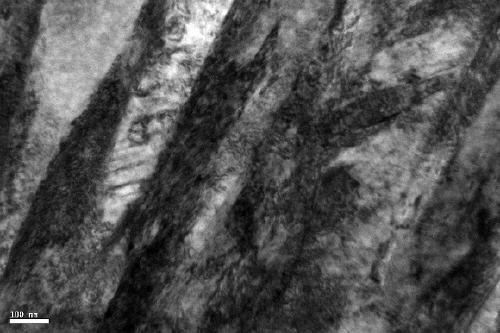

Gradient material steel rail frog prepared by laser cladding

ActiveCN110129674AImprove wear resistanceImprove carrying capacityMetallic material coating processesHeat-affected zoneGradient material

The invention provides a gradient composite material steel rail turnout coating prepared by laser cladding. The composite material is characterized in that a transition layer adopts a Fe-based alloy material, wherein the Fe-based alloy material comprises the following components of, in percentage by weight, 13wt%-17wt% of Cr, 3wt%-6wt% of Ni, 1wt%-1.5wt% of Si, 0.5wt%-1wt% of Mn, 0.3wt%-1.2wt% ofNb, 1wt%-1.5wt% of B, 0.05wt%-0.7wt% of C, 0.5wt%-1.2wt% of V, and the balance Fe; a strengthening layer is arranged above the transition layer, and the strengthening layer adopts a Fe-based metal nano-phase composite material. The preparation method comprises the following steps of preparing the Fe-based metal powder and the Fe-based metal nano-phase composite material coating; preheating a steelrail by using laser scanning heating so as to reduce the temperature gradient; preparing the gradient composite material coating on the surface of the steel rail by utilizing a laser cladding technology, and performing laser scanning heat treatment; and reducing the cooling rate after laser cladding, so that the martensite of the heat affected zone is prevented from being generated, and the cracking property of the coating is reduced. The prepared steel rail frog has the advantages that the hardness curve is smooth, the overall toughness and bearing performance are good, the strength and hardness is higher than a common heavy-load railway frog, the service life is longer, and manufacturing integration is relatively strong.

Owner:BEIJING UNIV OF TECH +2

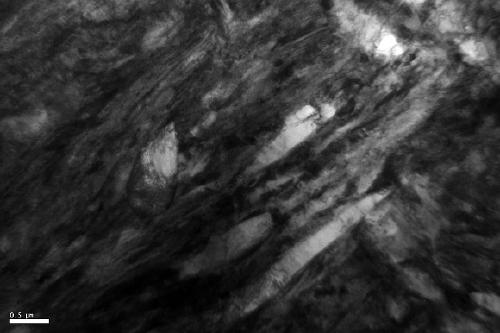

Method for preparing self-supporting diamond film

ActiveCN104561925AGood bonding strengthAvoid cracksChemical vapor deposition coatingTitaniumAcid corrosion

The invention discloses a method for preparing a self-supporting diamond film and belongs to the technical field of chemical vapor deposition diamond films. The method disclosed by the invention comprises the following steps: pre-depositing a titanium metal coating on the upper surface and side surface of a silicon substrate; depositing a molybdenum metal coating on the upper surface of the silicon substrate containing the titanium metal coating; depositing a diamond film on the upper surface of the silicon substrate which is pre-deposited with the titanium / molybdenum metal coating by adopting a chemical vapor deposition method; and finally, obtaining the self-supporting diamond film by using an oxalic acid solution corroding sample, and recycling the silicon substrate. Compared with the prior art, the method disclosed by the invention has the advantages that the diamond film is fast in nucleation, and the deposition time can be shortened; the silicon substrate can be repeatedly used, and the production cost can be reduced; and the environmental pollution caused by conventional acid corrosion of the silicon substrate can be avoided.

Owner:山西新碳超硬材料科技有限公司

Method for forming fiber pipe piece

The invention relates to a method for forming a fiber pipe piece. Fiber cloth is coated outside an air bag; liquid and expansion powder which are used for shaping the air bag in different time periods are filled in the air bag; through heating and pressurizing solidification formation, gas is formed by the liquid to achieve a shaping effect, the expansion powder is expanded to achieve the shaping effect, and the air bag can be sequentially shaped for two times according to different shaping time of the liquid and the expansion powder; therefore, the liquid and the expansion powder are filled into the air bag, and the air bag can be shaped for two times in different time periods along with temperature rise in the heating and pressurizing solidification process, so that the uniformity of the pipe wall of the fiber pipe piece can be effectively improved, cracks are prevented from being generated, and the fiber pipe piece is high in density; and materials in a pipe core are easy to extract, and the using amount of the expansion powder is reduced, so that the production cost is reduced.

Owner:JIANGSU ZHENGHE SPORTS GOODS CO LTD

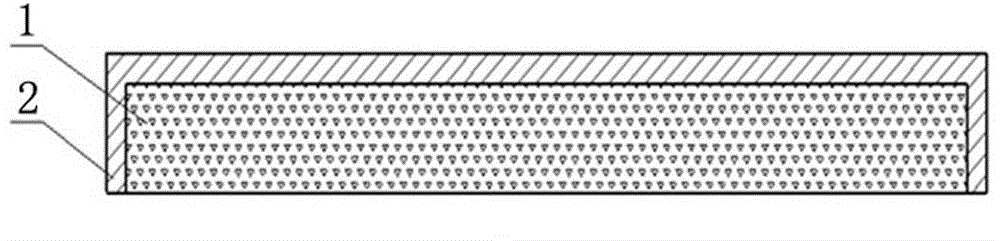

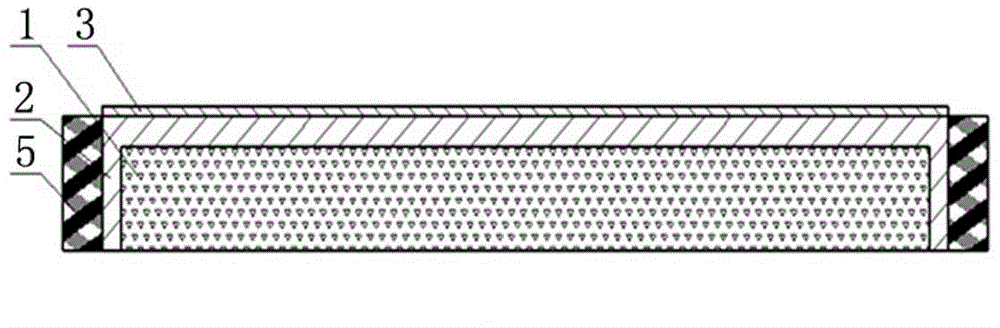

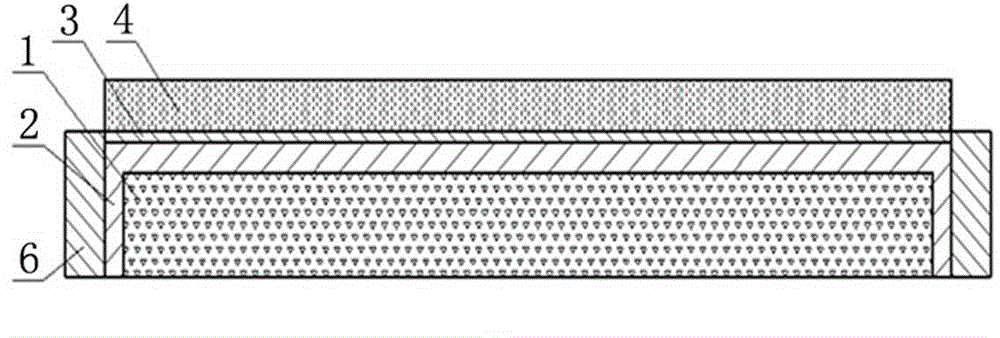

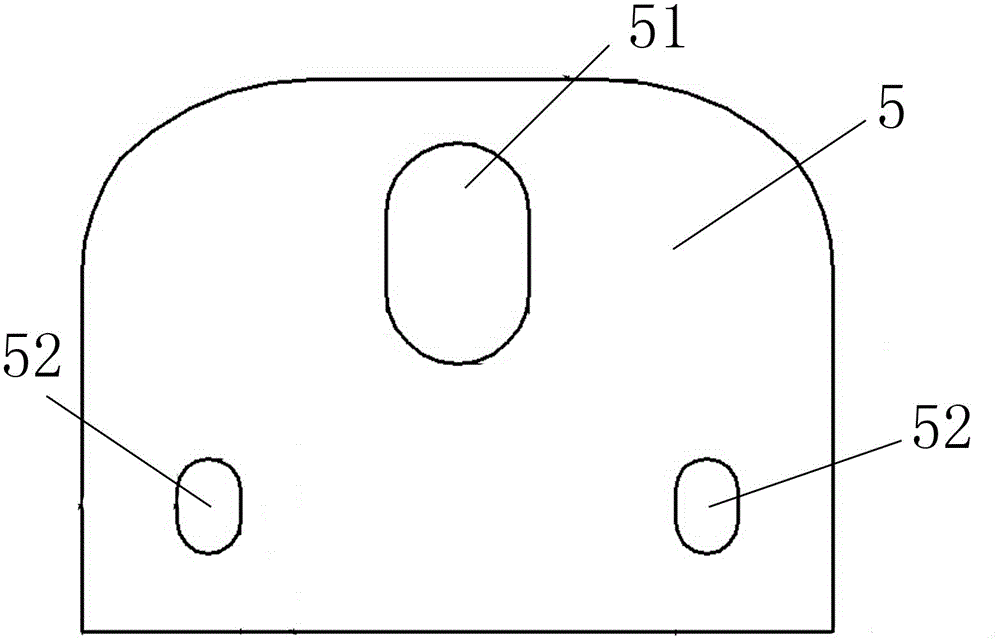

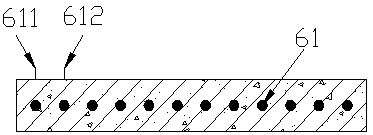

Mould-locking linkage recycled aggregate self-conserving heat plate

InactiveCN101446120ASolve the problem of wall cracksAvoid cracksSolid waste managementHeat proofingDouble rowConstruction aggregate

The invention discloses a mould-locking linkage recycled aggregate self-insulating plate. Rectangular double-row holes are arranged in an insulation plate. Heat insulation materials are filled in the double-row holes. The insulation plate is made of clay brick recycled aggregates. A method for producing the mould-locking linkage recycled aggregate self-insulating plate is also disclosed by the invention. The mould-locking linkage recycled aggregate self-insulating plate fully develops the functions of the clay brick recycled aggregates and improves the added value of the clay brick recycled aggregates greatly. The mould-locking recycled aggregates solve the crack problem of wall surface well, have good insulation performance, solve problems of heat bridge and cold bridge well and have the advantages of good durability, high construction efficiency, strong impermeability, etc.

Owner:杨德志

Steel bridge floor cracking inhibition paving structure and construction method thereof

The invention discloses a steel bridge floor cracking inhibition paving structure and a construction method thereof. The bridge floor paving structure comprises cracking inhibition bonding layers I, wherein the cracking inhibition bonding layers I are paved on the upper surface of a steel bridge floor; the cracking inhibition bonding layers I are firmly combined in sequence from bottom to top and comprise a lower bonding layer I and a cracking inhibition layer I; the lower bonding layer I is made of polymers, and the cracking inhibition layer I is made of fiber reinforced plastics with functions of cracking inhibition strengthening and water prevention. The invention enables the bridge surface paving structure to be firmly bonded with the steel bridge floor, ensures the deformation stress coordination of the steel bridge floor and the bridge floor paving structure and the use performance of bridges, has the functions of water and rust prevention and cracking prevention and resistance and the effect of strengthening the steel bridge floor, greatly prolongs the service life of the bridge floor paving structure and the steel bridge floor, reduces the maintenance cost, and can be finished by simple operation of coating, maintenance, cold mixture and pavement; and a bridge surface paving layer has simple construction process and is economic and durable.

Owner:易志坚

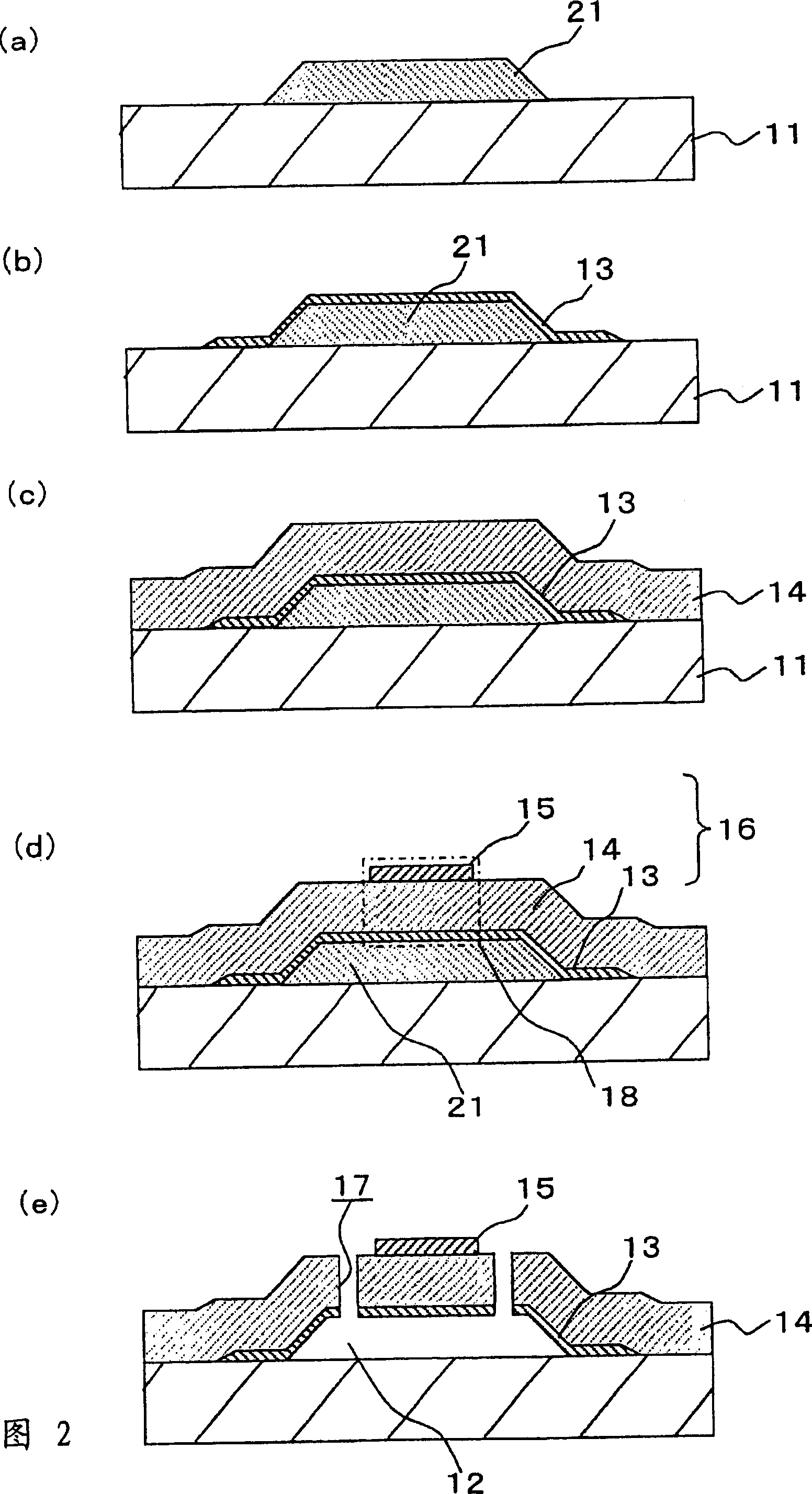

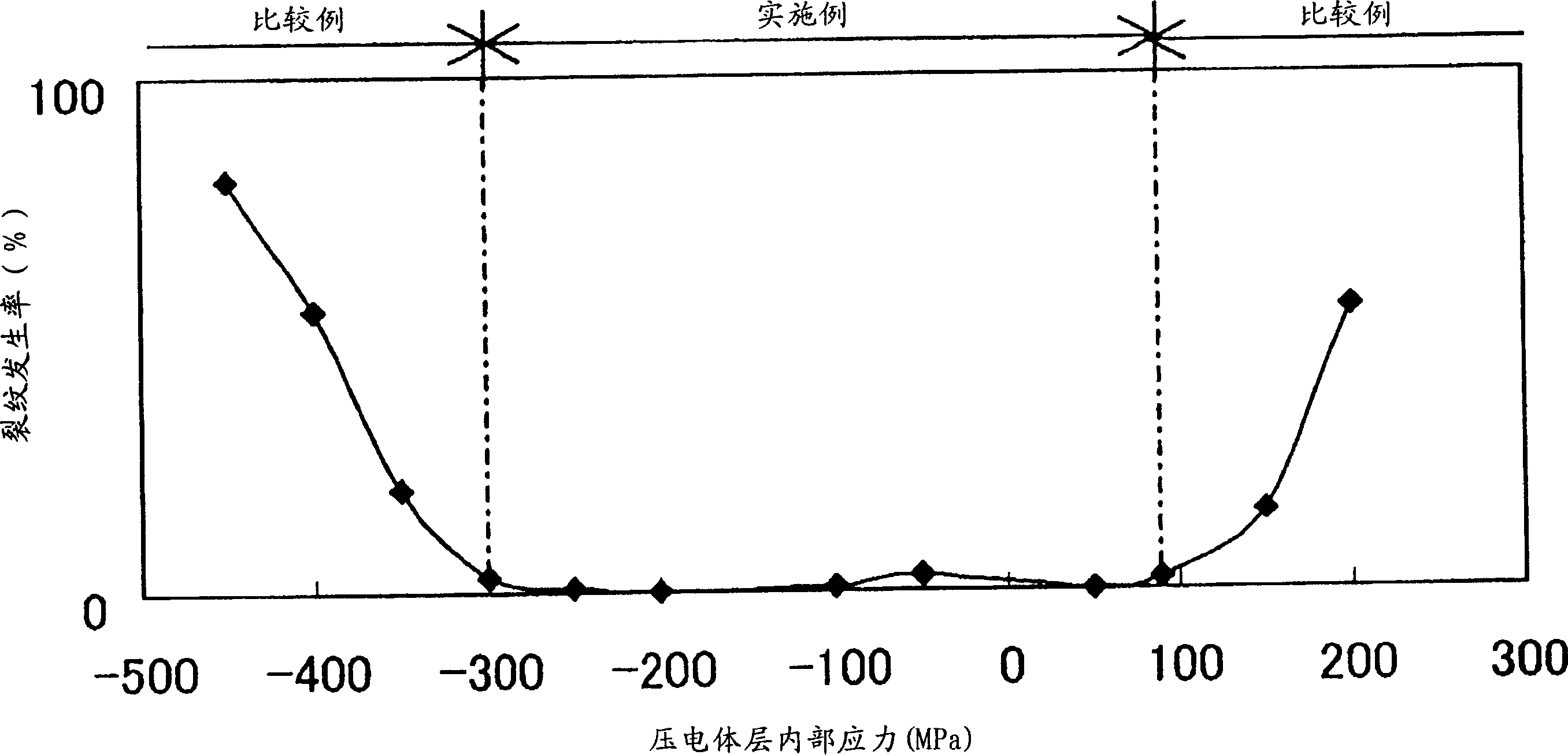

Piezoelectric resonator element and method of manufacturing same

InactiveCN1838531AAvoid cracksImprove yieldPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric resonatorsOptoelectronics

A piezoelectric resonator element and method of manufacturing same are provided. The piezoelectric resonator element having a lower electrode, a piezoelectric substance layer, and an upper electrode disposed in this order on a substrate with an air layer between the substrate and the lower electrode, and having a laminated structure of the lower electrode, the piezoelectric substance layer, and the upper electrode in at least a part of the piezoelectric resonator element, wherein internal stress of the piezoelectric substance layer is -300 MPa to 90 MPa.

Owner:SONY CORP

Method for manufacturing flawless millipore/mesoporous film by adopting mould plate technique and film thereof

InactiveCN101172614AReduce the temperatureAvoid cracksCrystalline aluminosilicate zeolitesChemistryCrazing

The invention provides a production method of non-crack micro or a meso pore membrane used for eliminating a template agent with the adoption of an ultraviolet photolysis technology, and the non-crack micro or the meso pore membrane thereof. Non-crack micro or the meso pore membrane is prepared by eliminating an organic matter (including a guiding agent, a template agent, a surfactant, and an organic matter in creatures, etc.) which is mainly composed of an organic template agent in the pore channel of the non-crack micro or the meso pore membrane, with the adoption of the ultraviolet photolysis technology. The technology not only avoids the generation of crack in the micro or the meso pore membrane, but also operates conveniently and saves the energy, thereby greatly shortening the time to remove the organic template agent.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Watertight cement

The invention discloses watertight cement and belongs to the technical field of cement. The watertight cement is formed by mixing the following raw materials in percentage by weight: 70 to 80 percent of silicate cement, 10 to 20 percent of sodium silicate, 5 to 10 percent of gypsum, 2 to 5 percent of fiberglas and 3 to 5 percent of building gelatin powder. The watertight cement has the advantages of good waterproof effect, low cost, simple construction and the like.

Owner:葛洲坝宜城水泥有限公司

Aerated concrete block and preparing method thereof

The present invention relates to an air-entrained concrete block and its manufacturing method, comprising cement, lime, polypropylene fiber and other components including one of fly ash, sand, gypsum, aluminum powder and waste slurry species or several. By optimizing the ingredients and process parameters of air-entrained concrete, the obtained air-entrained concrete blocks have the advantages of high strength, low shrinkage and crack prevention. At the same time, modified polypropylene fibers can improve the tensile strength of concrete structural materials, Impact strength, reduce the drying shrinkage value of concrete structural materials and prevent the formation and expansion of cracks during cement curing.

Owner:欧士玺

Hanging method of special-shaped reinforced concrete prefabricated column

The invention discloses a hanging method of a special-shaped reinforced concrete prefabricated column. The method comprises the steps that (1) a hanging starting point position on a special-shaped column is computed; (2) a turning hanging point position on the special-shaped column is computed; (3) sleeve pipes are buried at the hanging starting point and the turning hanging point in advance; (4) long-rod screws penetrate into the pre-buried sleeve pipes of the turning hanging point respectively; (5) special-shaped column demoulding and turning are carried out; (6) preparing before hanging of the special-shaped column is carried out; (7) hanging of the special-shaped column is carried out; (8) a special-shaped column foot is stabilized and is inserted into a cup-shaped foundation; (9) special-shaped column aligning is carried out; (10) a crowbar is used for prying a wedge, or a hammer is used for striking the wedge, so that the center line of the column body is aligned with the center line of the cup bottom; (11) crane unhooking is carried out, and the special-shaped column is placed to the cup-shaped foundation bottom; (12) the wedge on the periphery is tightly stricken; (13) special-shaped column perpendicularity correction is carried out; and (14) grouting is carried out immediately after correction is carried out. During component prefabricating, a hanging hole is reserved, and the shortcomings that hanging point sliding and component corner damage which can happen easily through a conventional binding method are overcome.

Owner:ZHEJIANG JINXIN CONSTR ENG

Gel column mounting method

InactiveCN1586699AExtended use timeAvoid cracksIon-exchange process apparatusIon-exchanger regenerationEngineeringSlurry

The present invention provides a gel column mounting method. Gel slurry is first heated and boiled, and then transferred with improved slender transfer pipet into rotating gel pipe along the inner wall of gel pipe under liquid surface, so as to prepare gel column. By means of boiling, deairing and transferring gel slurry under liquid surface, the present invention can defoam, swell and sterilize. The gel slurry has flat surface during being transferred into the gel pipe. The method is simple, saving in time and convenient, and has no need of special apparatus and column mounting success rate up to 100 %.

Owner:DALIAN UNIVERSITY

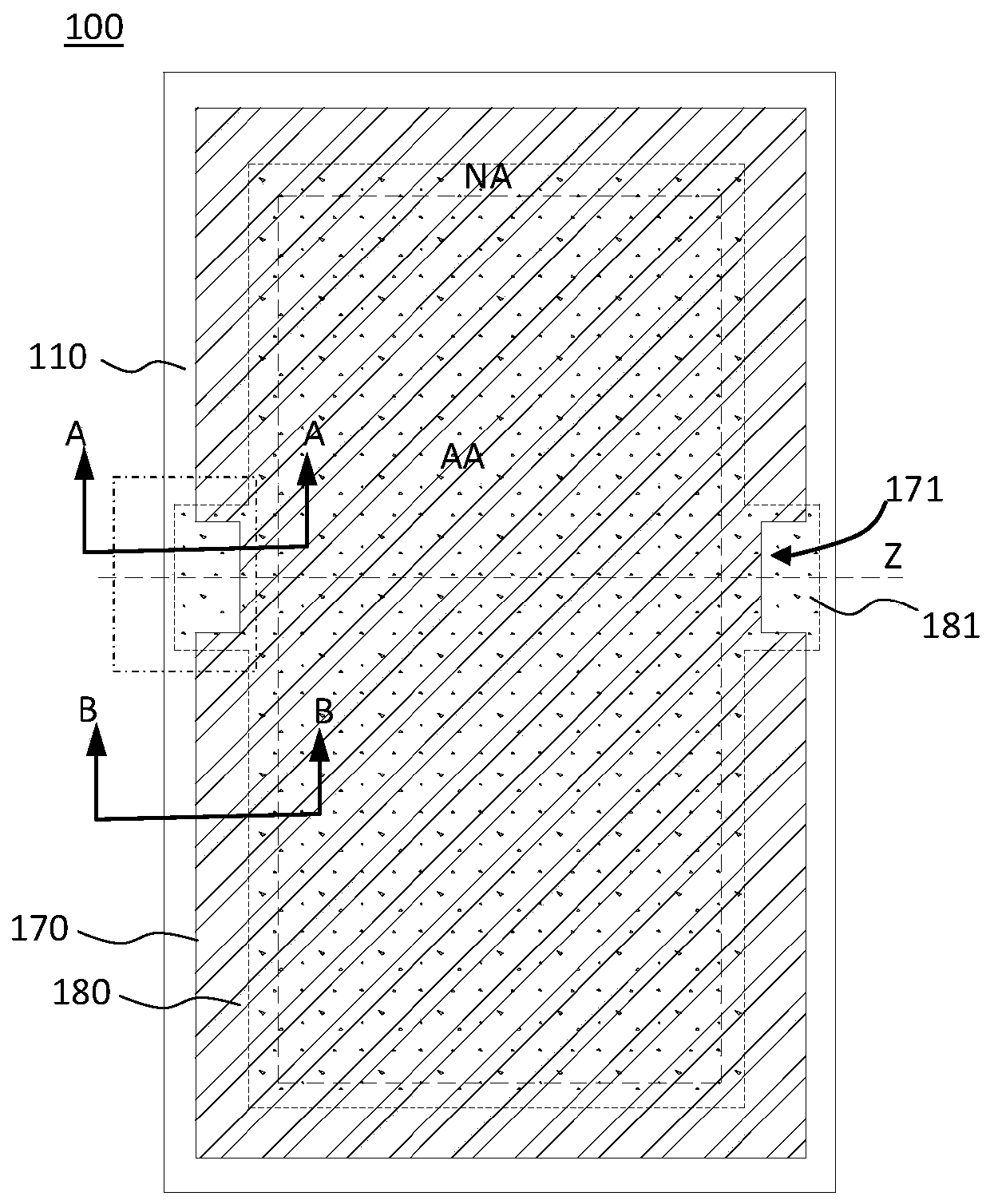

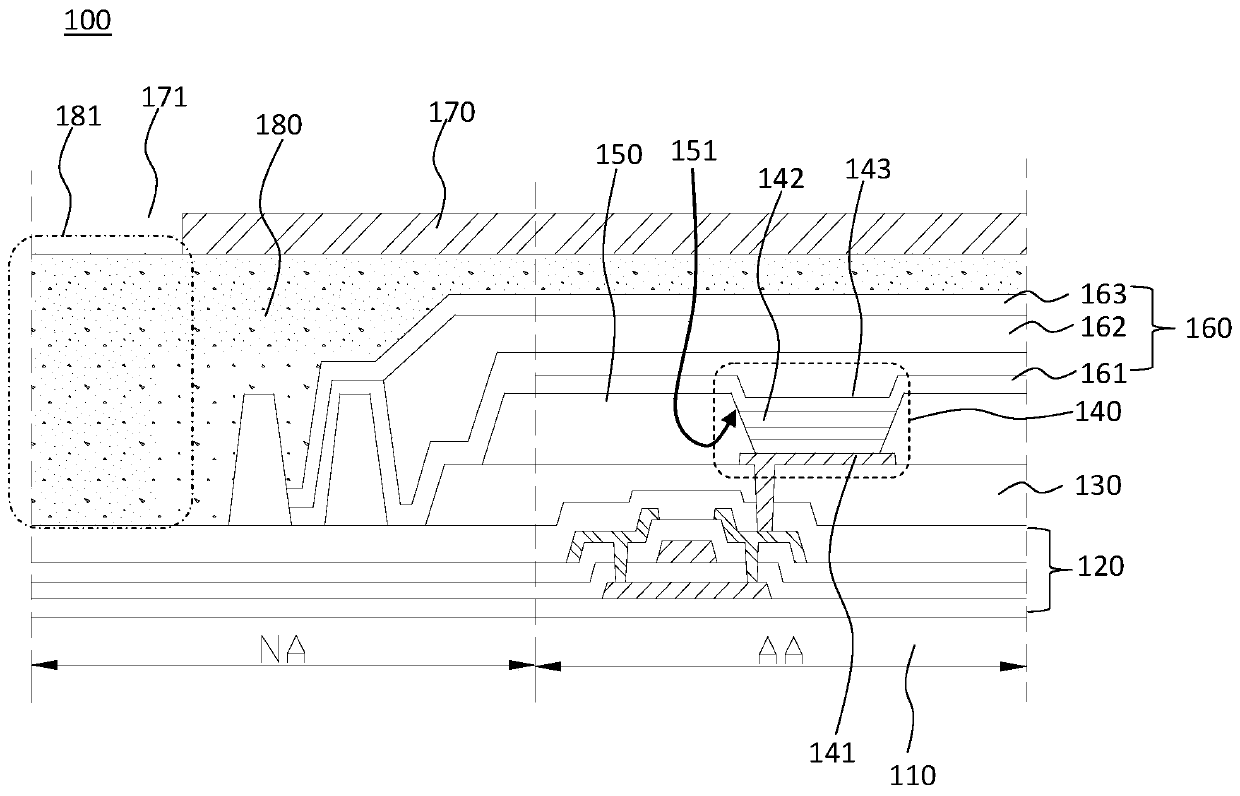

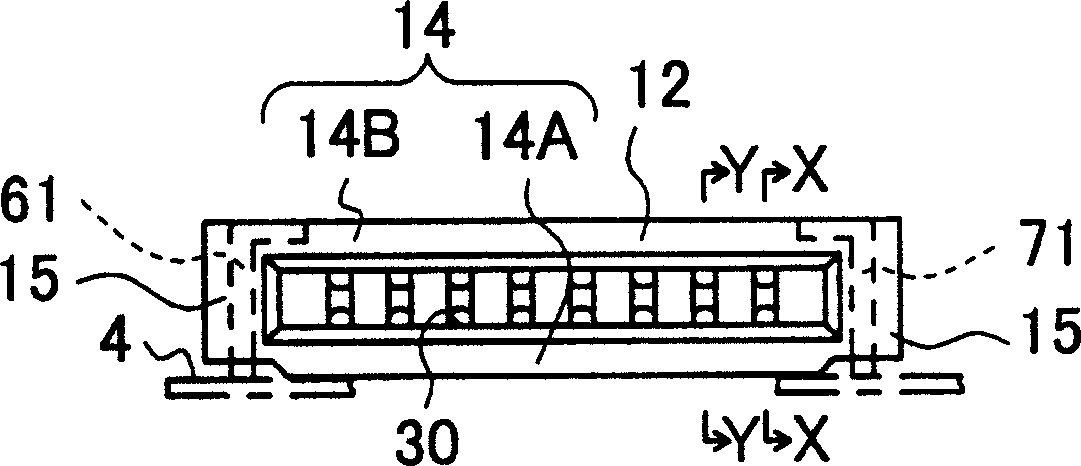

Display panel and display device

ActiveCN110416273AImprove bending reliabilityAvoid cracksSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

The invention relates to a display panel and a display device. The display panel comprises a substrate, an array layer, a light-emitting functional layer, a packaging layer, a polarization functionallayer and a first buffer layer, wherein the substrate, the array layer, the light-emitting functional layer and the packaging layer are arranged in sequence; the polarization functional layer is positioned on the side, which is away from the light-emitting functional layer, of the packaging layer; the first buffer layer is positioned on at least one side surface of the polarization functional layer and contacted with the polarization functional layer; the edge of polarization functional layer is sunken towards the center of the polarization functional layer in the direction parallel to the display panel to form at least one notch; the edge of the first buffer layer protrudes in the direction away from the center of the first buffer layer in the direction parallel to the display panel to form at least one protruding portion; the display panel is a bendable display panel; the protruding portion is overlapped with the notch; and the bending axis of the display panel passes through the protruding an overlapping area of the protruding portion and the notch. The invention further provides a display device including the display panel. According to the invention, the bending reliability ofthe display panel can be improved, and the generation of cracks of a film layer in the display panel is avoided when the display panel is bent.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

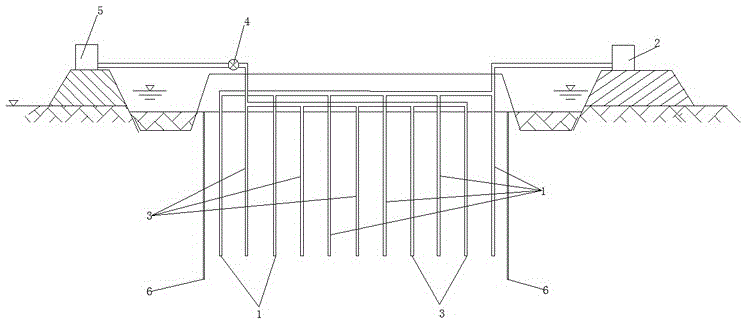

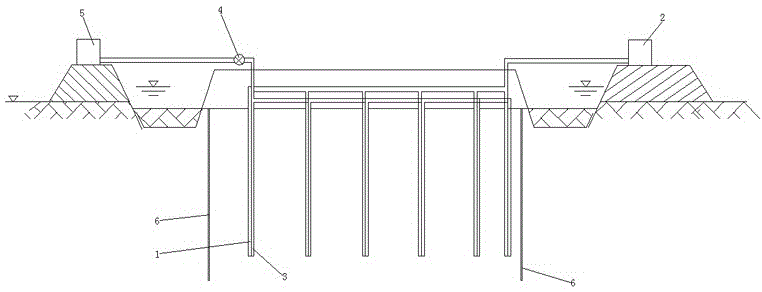

Air pressure split foundation strengthening treatment structure and method adopting air pressure split foundation strengthening treatment structure

InactiveCN106592572AImprove pumping efficiencyAvoid cracksSoil preservationPneumatic pressureDischarge efficiency

The invention discloses an air pressure split foundation strengthening treatment structure. The air pressure split foundation strengthening treatment structure comprises a vacuum preloading sealing treatment system and a high-pressure air injection system of a construction area soil body. The high-pressure air injection system comprises a high-pressure air injection pipe and a high-pressure air injection device which are arranged in the construction area soil body in a beating manner. An air and water discharging plate is arranged in the construction area soil body in a beating manner and provided with a discharging end connected with the outside. The discharging end is provided with a valve. A waterproof curtain is arranged around the construction area soil body in a beating manner. Bentonite is added in cemented soil used for the waterproof curtain. The invention further provides a method adopting the above air pressure split foundation strengthening treatment structure for foundation strengthening treatment. According to the provided above structure and method, the discharging efficiency of water in the soil body can be improved, meanwhile, the erosion of underground water on the cemented soil forming the waterproof curtain can be reduced after the bentonite is added in the waterproof curtain, and the soil body strengthening effect is enhanced.

Owner:WENZHOU UNIVERSITY

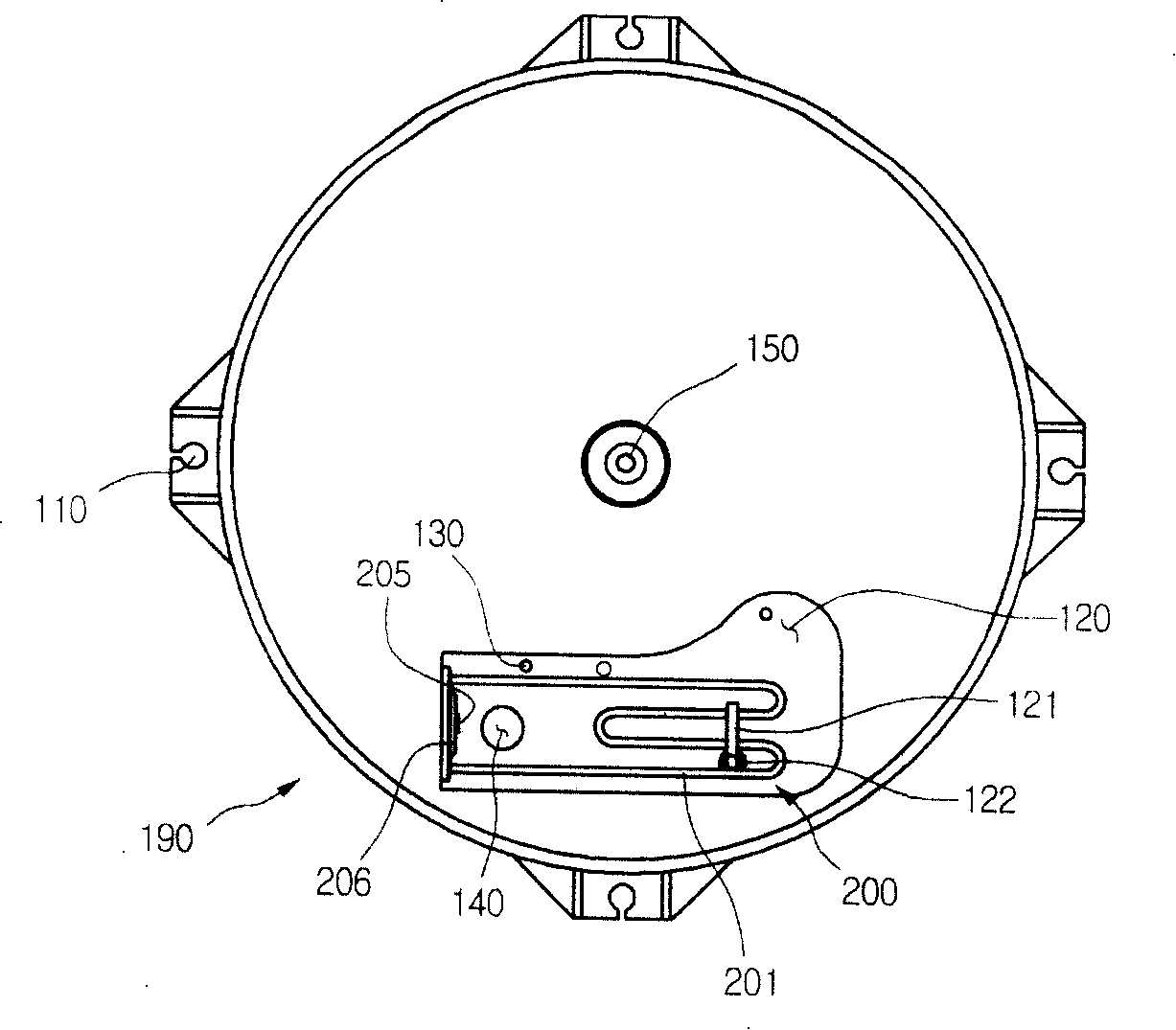

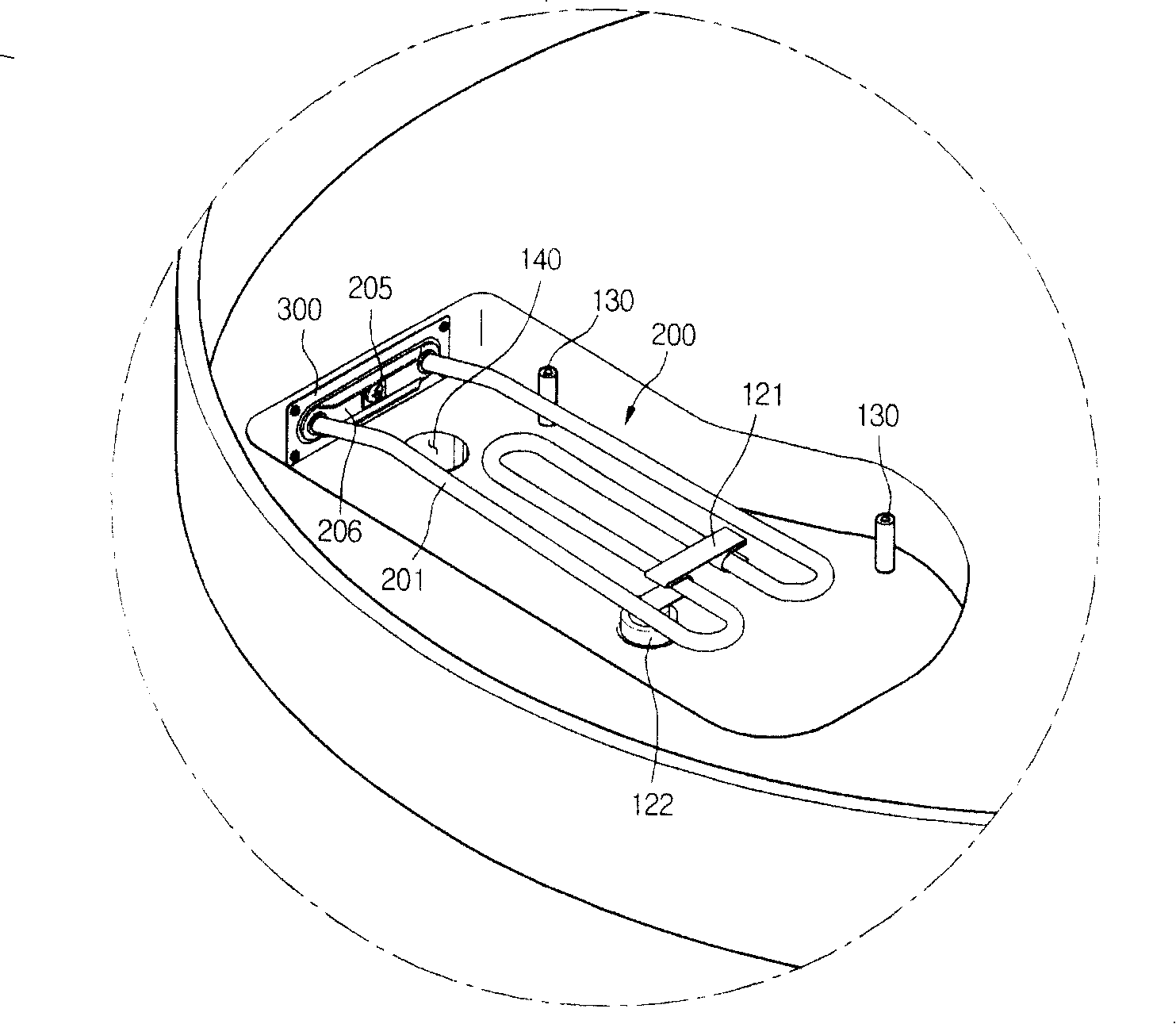

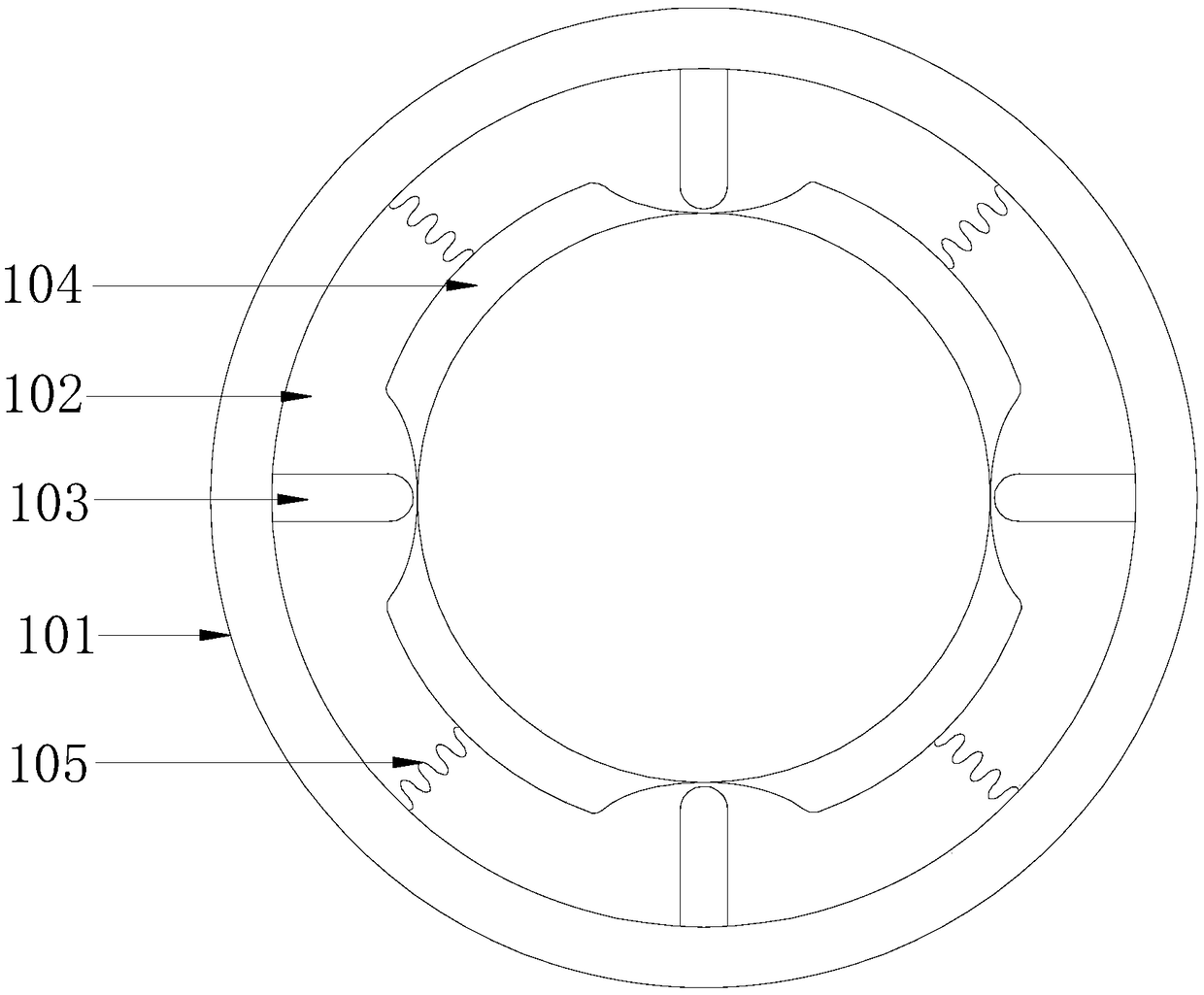

Mounting structure of washing machine heater and mounting method therefor

InactiveCN101177904AAvoid cracksAvoid crackingOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses an installation structure of a washing machine heater and an installation method thereof. The installation structure comprises a heater for heating washing water and a heater patchhole; the installation structure is also provided with a first bracket with a heater patchhole forming part that forms a heater patchhole, a second bracket combined with the first bracket and fixed on an external barrel together with the first bracket, a bracket patchhole used for inserting a part of the first bracket, the external barrel of the bracket patchhole forming part that forms the bracket patchhole, and a sealing part that seals the part between the heater and the external barrel; the sealing part and the heater patchhole form a part contact. The installation method comprises a preparation stage and an installation stage for the above parts. The first bracket and the second bracket are arranged for the invention, so as to directly press the sealing parts on the first bracket and the second bracket, so the pressure pressed on the sealing part is cut off by the first bracket and the second bracket and not transferred outside the barrel, thus reducing the stress, caused by the pressure, inside the external barrel and preventing crackle from occurring in the external barrel.

Owner:NANJING LG PANDA APPLIANCES

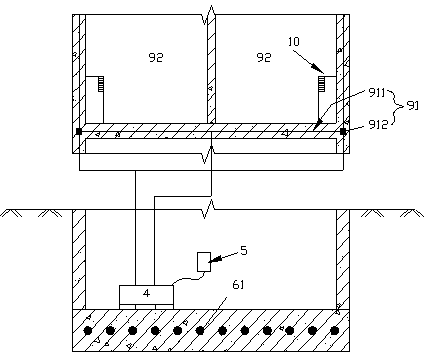

Building structure provided with temperature control device

ActiveCN108360523AAvoid cracksMaintain the balance of the underground temperature fieldHeating fuelMechanical apparatusWater pipeEngineering

The invention discloses a building structure provided with a temperature control device. The building structure comprises a concrete foundation and an upper structure on the concrete foundation, wherein an upper structure terrestrial heat exchanging system is arranged in the upper structure; the building structure further comprises a water pipeline and the temperature control device connected withthe water pipeline; the water pipeline is formed by connecting water pipes horizontally paved in the concrete foundation end to end; the temperature control device comprises a water tank, a water pump, a reversing valve and a controller; the reversing valve has a first communicating state and a second communicating state; when the reversing valve is in the first communicating state, cooling wateris introduced in the water pipeline; and when the reversing valve is in the second communicating state, the water pipeline is used for heating and cooling the upper structure after the building structure is constructed. The building structure overcomes the defects that the horizontal type ground-source heat pump system occupies a large area, a vertical type ground-source heat pump system is difficult in construction, and the pile bearing capacity is influenced by a certain extent, improves the working efficiency of the ground-source heat pump system and creates healthy and comfortable workingand living environments.

Owner:YANCHENG INST OF TECH

Metallurgical furnace oxygen lance slag scraper with rotary scraping and impacting

ActiveCN109402324AAvoid cracksPrevent leakageManufacturing convertersProcess efficiency improvementSlagConical teeth

The invention discloses a metallurgical furnace oxygen lance slag scraper with rotary scraping and impacting, structurally comprising: a slag scraping device, a power supply frame, a support and a transmission shaft. The metallurgical furnace oxygen lance slag scraper with rotary scraping and impacting has the advantages that a power supply mechanism and a scraping structure can cooperate with each other such that triangular conical teeth on the surface of a threaded bar provide spiral rotational scraping for slag on the surface of an oxygen lance under the rotational action of the scraping structure so that the slag is cracked; gas leakage due to the oxygen lance breakage caused by surface scratches of the oxygen lance under the action of a traditional slag scraper is avoided; a circularframe rotates synchronously with a scraping barrel, a vibrating plate is ejected out under the action of an ejector rod, the slag that is cracked is impacted, the cracks are extended to break the slagunder the action of external force, the slag on the surface of the oxygen lance is broken to fall under the impact action, and it is avoided that gas leakage is caused by cracking and scratches of the surface of the oxygen lance due to the action of the traditional slag scraper.

Owner:泉州台商投资区长矽工业设计有限公司

Concrete formula and concrete road paving method

The invention relates to a concrete formula and a concrete road paving method. The concrete formula is prepared from, by weight, 350-450 parts of stone, 20-30 parts of water-absorbing resin ball, 60-120 parts of water-borne acrylic acid, 30-80 parts of elastic rubber grain, 120-200 parts of cement, 150-200 parts of sand, 20-30 parts of fly ash, 80-120 parts of diluent, 50-80 parts of waterborne polyurethane. The grain diameter of the elastic rubber grain is 0.3-0.85 cm; the diluent adopts water. The resilience of the elastic rubber grain is less than that of the water-absorbing resin; when a tire leaves a point of force application, the water-absorbing resin can recover the original shape in advance, and then the elastic rubber grain can slowly recover the original shape, thus the strong absorption of moisture penetrated in the road can be reduced, thereby avoiding moisture in the road taking away from the road surface under the effect of strong absorbing force.

Owner:无锡交通建设工程集团有限公司

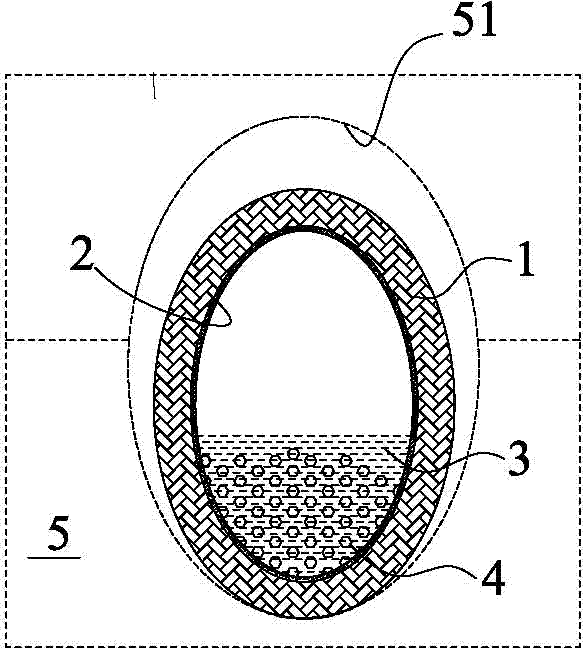

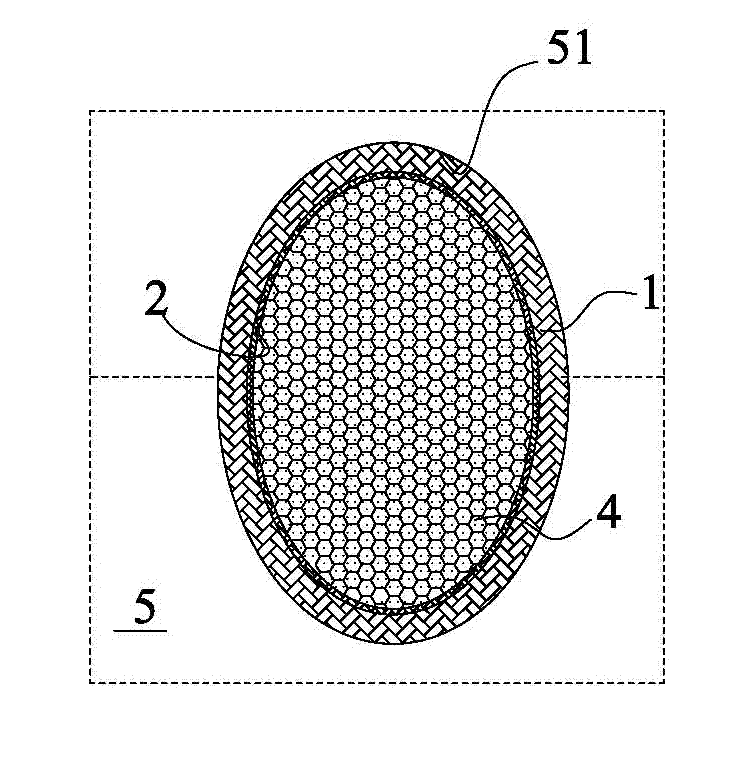

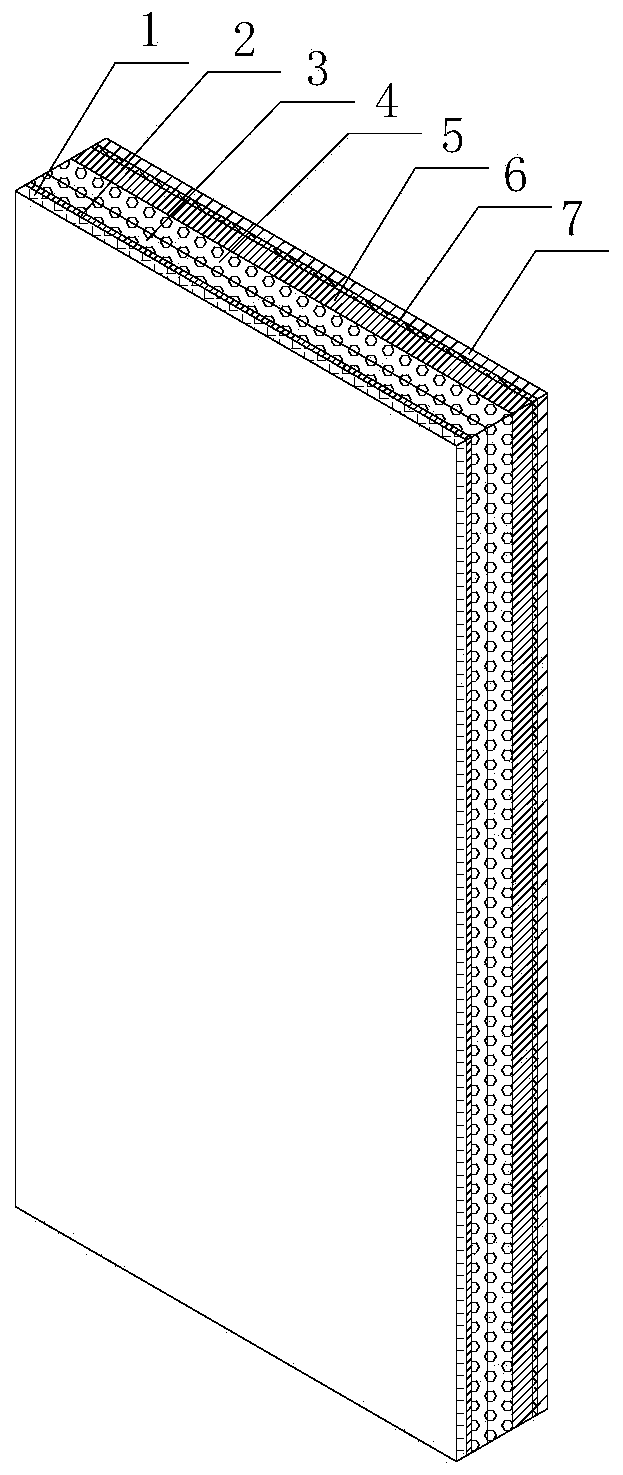

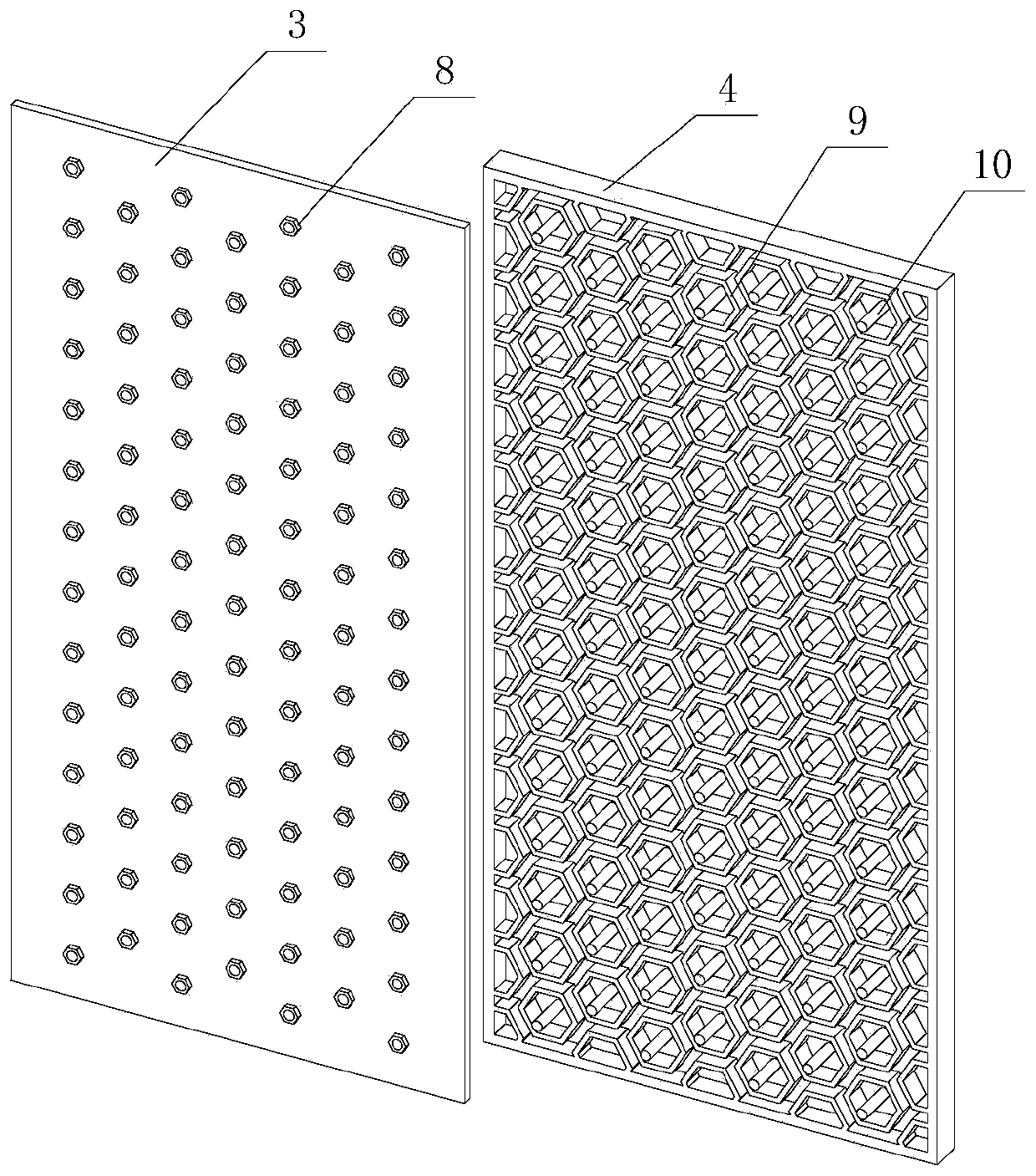

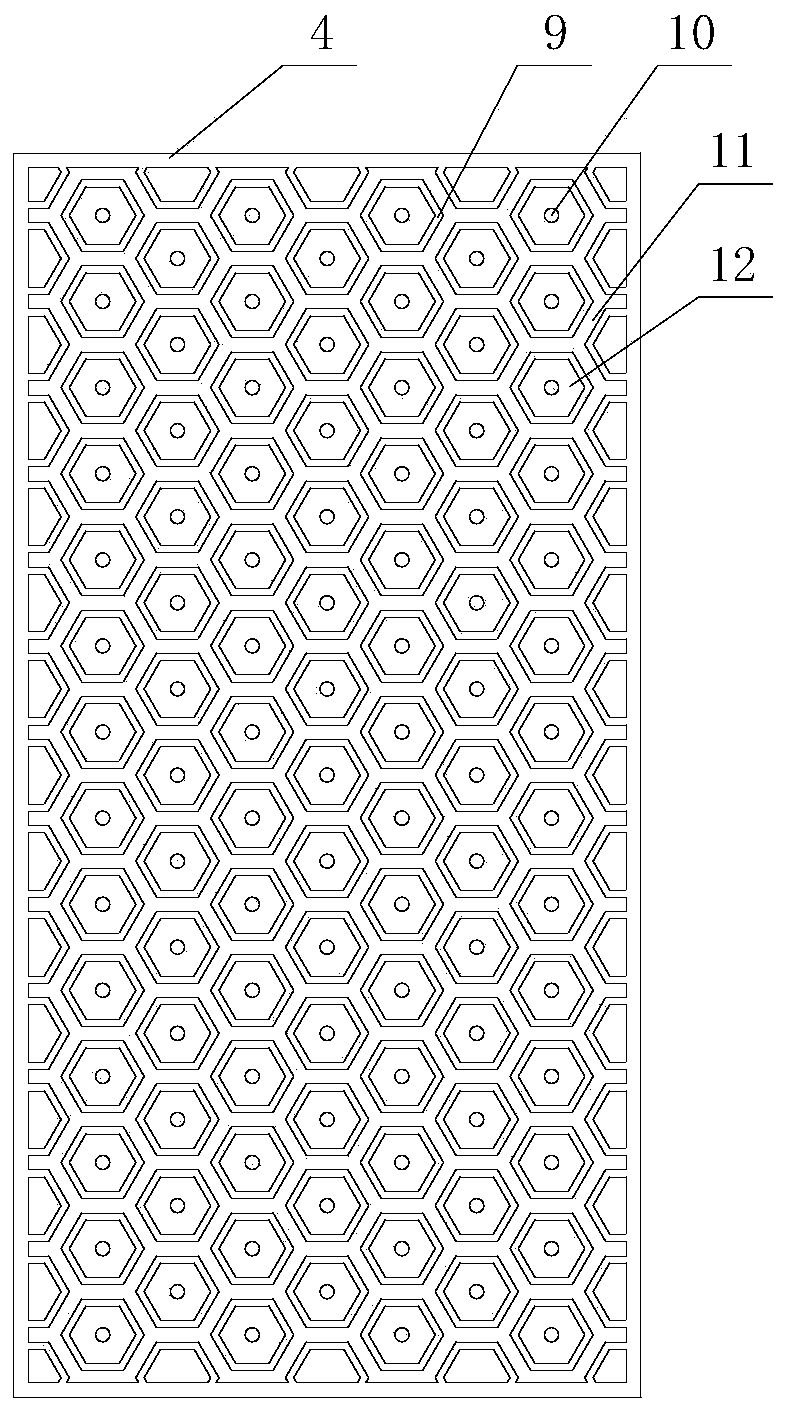

Phase change thermal insulating wall body of fabricated type building

The invention provides a phase change thermal insulating wall body of a fabricated type building and discloses a filling cavity formed by a honeycomb trough which is of dense and even distribution, and a phase change thermal insulating wall body which realizes buffer deformation for volume expansion of phase change materials during phase change to solve the problem of cracks in a phase change layer. The wall body is characterized in that, the wall body comprises an outdoor wall body surface, a steel mesh, a phase change outer layer, a phase change inner layer, a main wall body, a thermal insulating layer and an indoor decorative surface which are arranged in sequence from outside to inside; the wall body can realize buffer deformation for volume expansion of the phase change materials during phase change, so the internal stress of the phase change layers is lowered and occurrence of cracks is avoided; and the honeycomb trough of dense and even distribution is utilized to form a phase change material filling cavity which is densely distributed on a wall surface, and thermal insulating effect of the entire wall surface is guaranteed.

Owner:南通伟创建设集团有限公司 +1

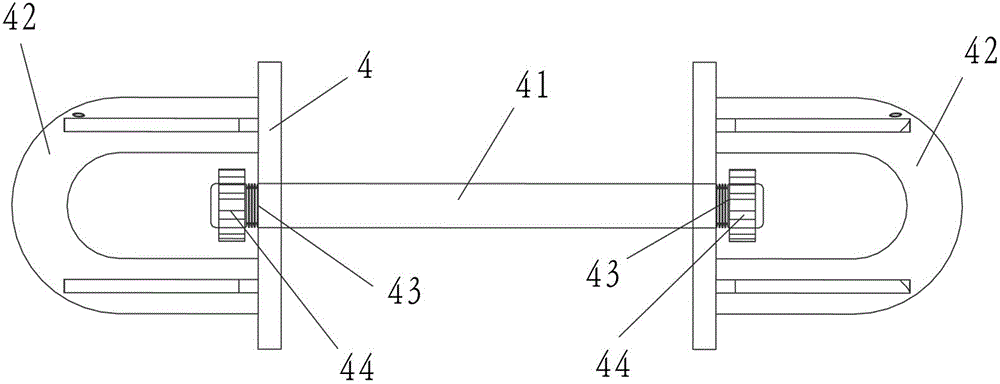

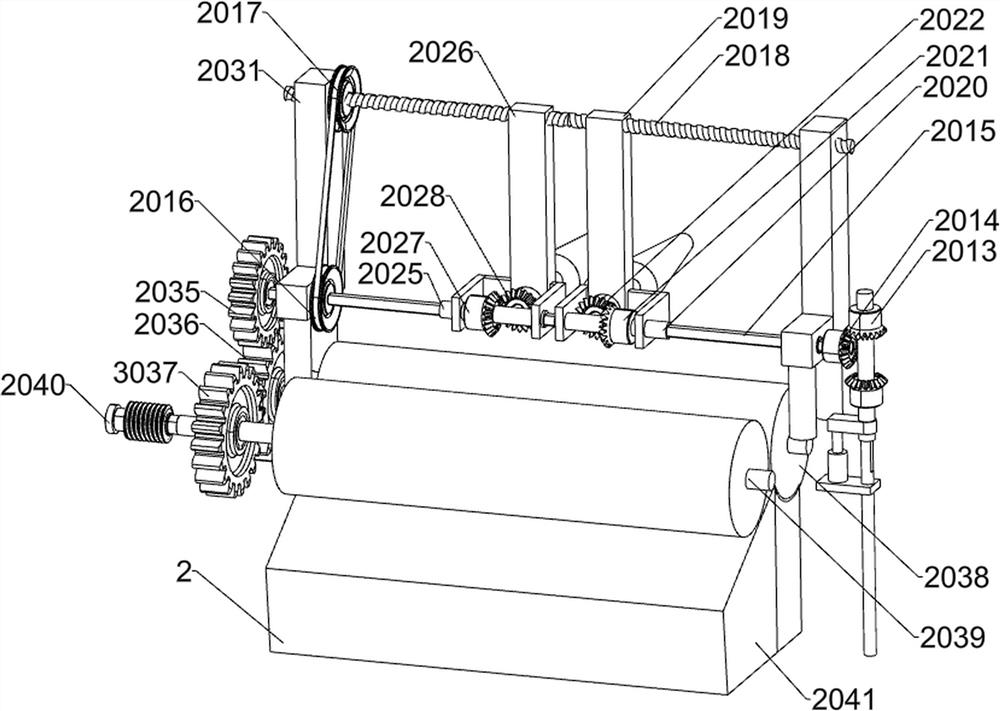

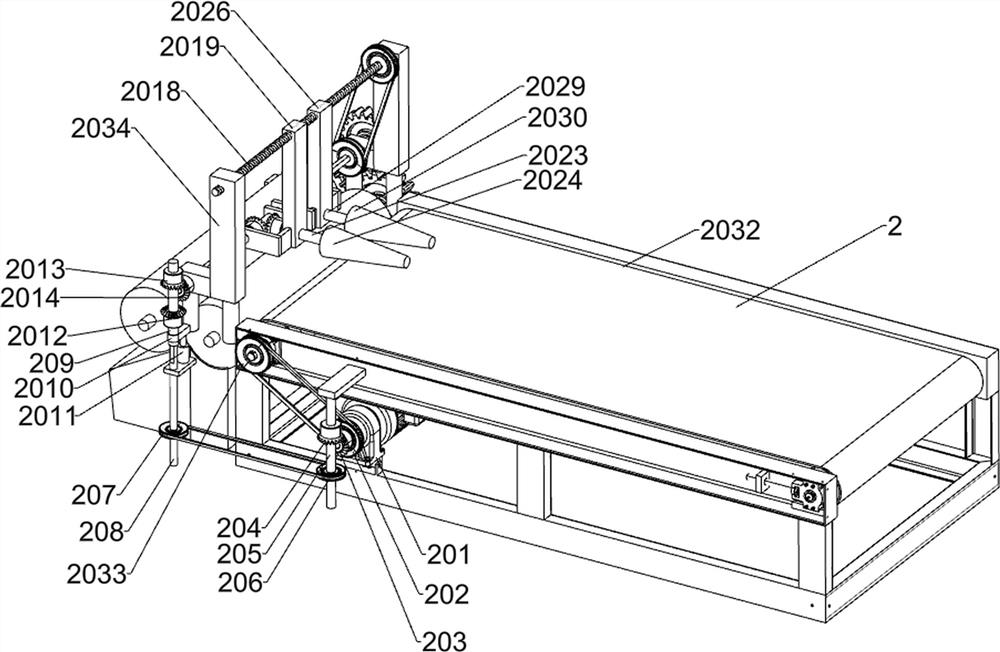

Bamboo shell spreading device capable of preventing cracks from being generated

ActiveCN112297165AAvoid cracksImprove efficiencyBio-packagingWood compressionHot pressStructural engineering

The invention relates to the field of bamboo products, in particular to a bamboo shell spreading device capable of preventing cracks from being generated. According to the bamboo shell spreading device, the technical purpose that the cracks can be prevented from being generated is achieved. According to the technical scheme, the bamboo shell spreading device capable of preventing the cracks from being generated comprises a bottom frame, an unfolding unit, a hot pressing unit, a cleaning unit, a collecting box and a control screen; the bottom frame is connected with the unfolding unit; the bottom frame is connected with the hot pressing unit; the bottom frame is connected with the cleaning unit; the bottom frame is connected with the collecting box; the bottom frame is connected with the control screen; the unfolding unit is connected with the hot pressing unit; the hot pressing unit is connected with the cleaning unit; and the collecting box is arranged on the side of the cleaning unit. According to the bamboo shell spreading device capable of preventing the cracks from being generated, automatic flattening treatment on bamboo shells is achieved, the cracks can be prevented in theflattening process, then dewaxing and cleaning are conducted on the bamboo shells, manual treatment is replaced, and efficiency is greatly improved.

Owner:泰兴市康森爱特传动设备科技有限公司

Method for packaging display panel

ActiveCN108470850AReduce forceAvoid cracksSolid-state devicesSemiconductor/solid-state device manufacturingSolid-stateEngineering

The invention provides a method for packaging a display panel. The method comprises: at least two stacked solid-state packaging layers are formed at one side, away from a first substrate, of a first electrode layer, wherein the melting points of the packaging layers are different; the first substrate and a second substrate are paired, so that a spaced pad corresponds to a pixel defining layer; andthen all packaging layers are heated and pressures are applied to the first substrate and / or the second substrate, so that the first electrode layer and the second electrode layer are in contact. During the packaging process of the display panel, all packaging layers are transformed from solid states to liquid states successively and all corresponding packaging layers are compressed one by one; and during the compression processes of all packaging layers, the stresses generated inside the packaging layers are small because of the small deformation quantities of all packaging layers, so that the acting force on the first electrode layer by the whole packaging layer is reduced and thus the cracks at the first electrode layer are avoided. Therefore, the yield of the OLED display panel is improved.

Owner:BOE TECH GRP CO LTD

Lightweight and high strength and ductility automotive steel using silicon instead of aluminum and preparation method of the steel

The invention relates to lightweight and high strength and ductility automotive steel using silicon instead of aluminum. An alloy comprises, by weight percentage, 0.1-0.4 wt% of C, 3.5-5.5 wt% of Si,4.0-6.0 wt% of Mn, 0.5-1.0 wt% of Ni, 0.01-0.1 wt% of Ti and the balance Fe. The invention further relates to a preparation method of the lightweight and high strength and ductility automotive steel using silicon instead of aluminum. The preparation method includes the alloy component weighing and taking, smelting, casting and hot rolling procedure. The lightweight and high strength and ductilityautomotive steel using silicon instead of aluminum and the preparation method of the steel are provided. The material has excellent mechanical performance, and is low in production cost and simple inprocess, a series of problems caused by lightweight aluminum are compensated very well, and great application prospects are achieved.

Owner:DONGGUAN UNIV OF TECH

Mold core for solving breakage of core head thereof, and preparation method of precision cast component

ActiveCN111730030AAvoid cracksReduce bending momentFoundry mouldsFoundry coresManufacturing engineeringIndustrial engineering

The invention discloses a mold core for solving breakage of a core head thereof, and a machining method. The machining method comprises the following steps of: designing a cast blank drawing; designing and manufacturing a mold core according to the cast blank drawing, wherein the mold core comprises a vane root core head, a mold core vane body and a mold core rod that are sequentially arranged from bottom to top, and the mold core rod extends out of the designed end part of a hollow vane; designing and manufacturing a wax pattern mold and a mold insert according to the cast blank drawing, wherein the mold insert is provided with a hole which is installed in a manner of being matched with the mold core rod; putting the mold core into the wax pattern mold and then connecting the mold insertwith the mold core rod of the mold core; pressing a wax pattern inside the wax pattern mold; and taking out the wax pattern after the wax pattern is pressed. The machining method disclosed by the invention has the beneficial effects that a long core rod is adopted to save a core head at the top of the vane, so that the bending torque and pressure applied to the mold core in a manufacturing processof the mold core can be reduced; crack formation, deformation or inclination of the mold core rod in a molding process can be beneficially prevented; and thus the molding precision and percent of pass of cast pieces in the later period are not affected.

Owner:DONGFANG TURBINE CO LTD

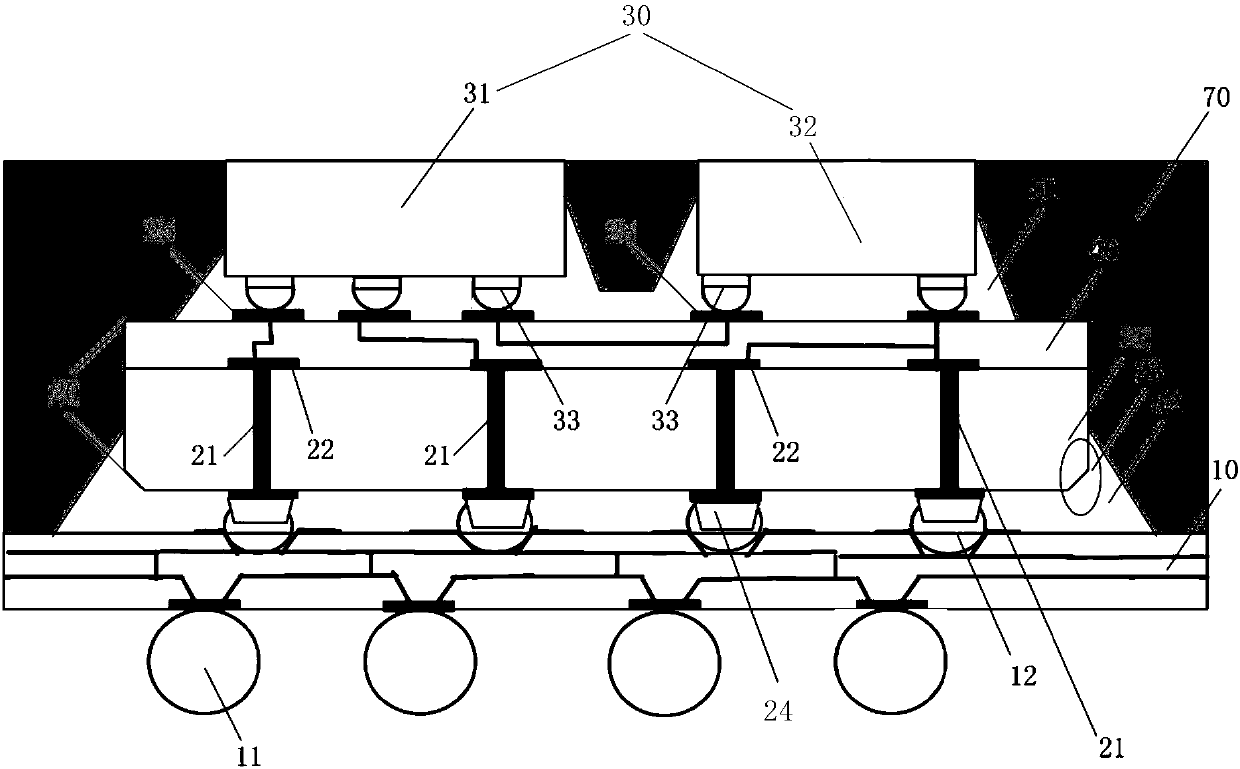

Integrated packaged semiconductor device

ActiveCN109727944AAvoid cracksImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention discloses an integrated packaged semiconductor device. The integrated packaged semiconductor device comprises: a signal transfer substrate, wherein the periphery of a bottom surface of the signal transfer substrate is provided with a chamfer; a package substrate, wherein the upper surface of the package substrate carries the signal transfer substrate; a chip, wherein the upper surface of the signal transfer substrate carries the chip; and first filling glue filling the position between the package substrate and the signal transfer substrate, wherein the difference in thermal expansion coefficient of the signal transfer substrate relative to the package substrate is greater than that of the signal transfer substrate relative to the chip. The periphery of the bottom surface ofthe signal transfer substrate is provided with the chamfer, namely, a sharp right angle which is easy to concentrate stress is cut or polished to form a chamfer, and the purpose is to disperse the stress to avoid cracking of the filled first filler due to too much stress so as to improve the yield of integrated packaged semiconductor devices.

Owner:CHANGXIN MEMORY TECH INC

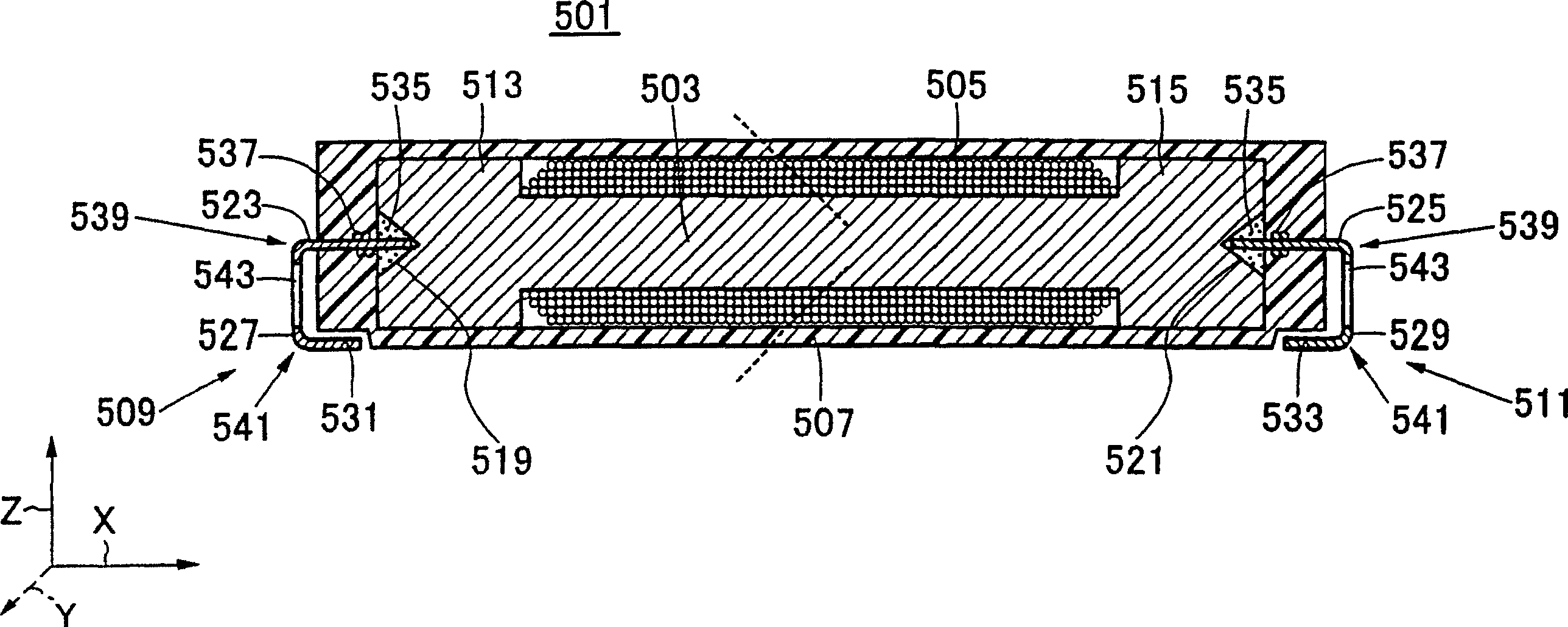

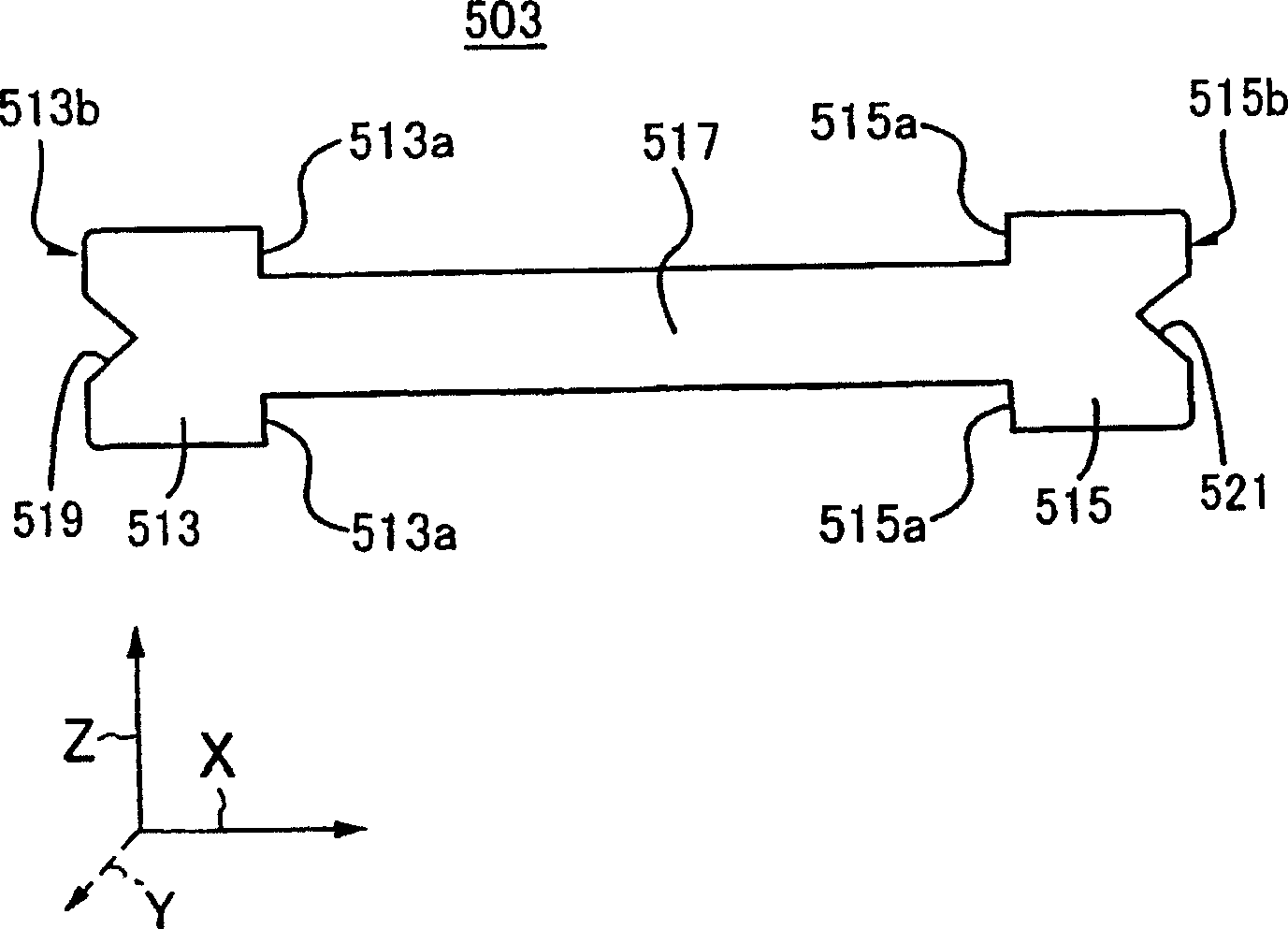

Coil device

ActiveCN1875441ASecure winding areaAvoid cracksTransformers/inductances casingsMagnetic coreEngineering

A coil device in a part-winding form and a method for manufacturing a coil device are disclosed. The size of the core is small, and the windings do not collapse even though the form is simple. The coil device (501) comprises a ferrite core (503) and a coil (505) provided around the core. The coil (505) has at least a first coil portion (551) and a second coil portion (553). The boundary end surface (CF1), on the second coil side, of the first coil is so inclined that the inner circumferential side is nearer the second coil portion than the outer circumferential side. The boundary end surface (CF2), on the first coil side, of the second coil portion is so inclined that the outer circumferential side is nearer the first coil portion than the inner circumferential side.

Owner:TDK CORPARATION

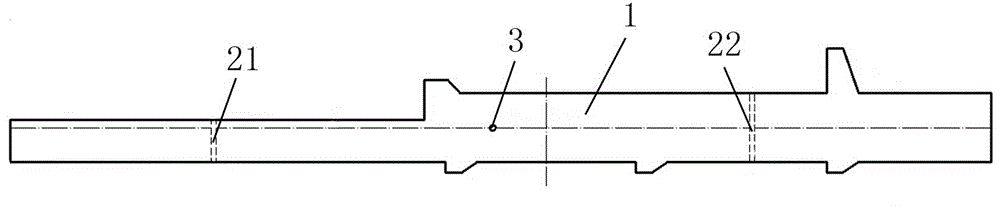

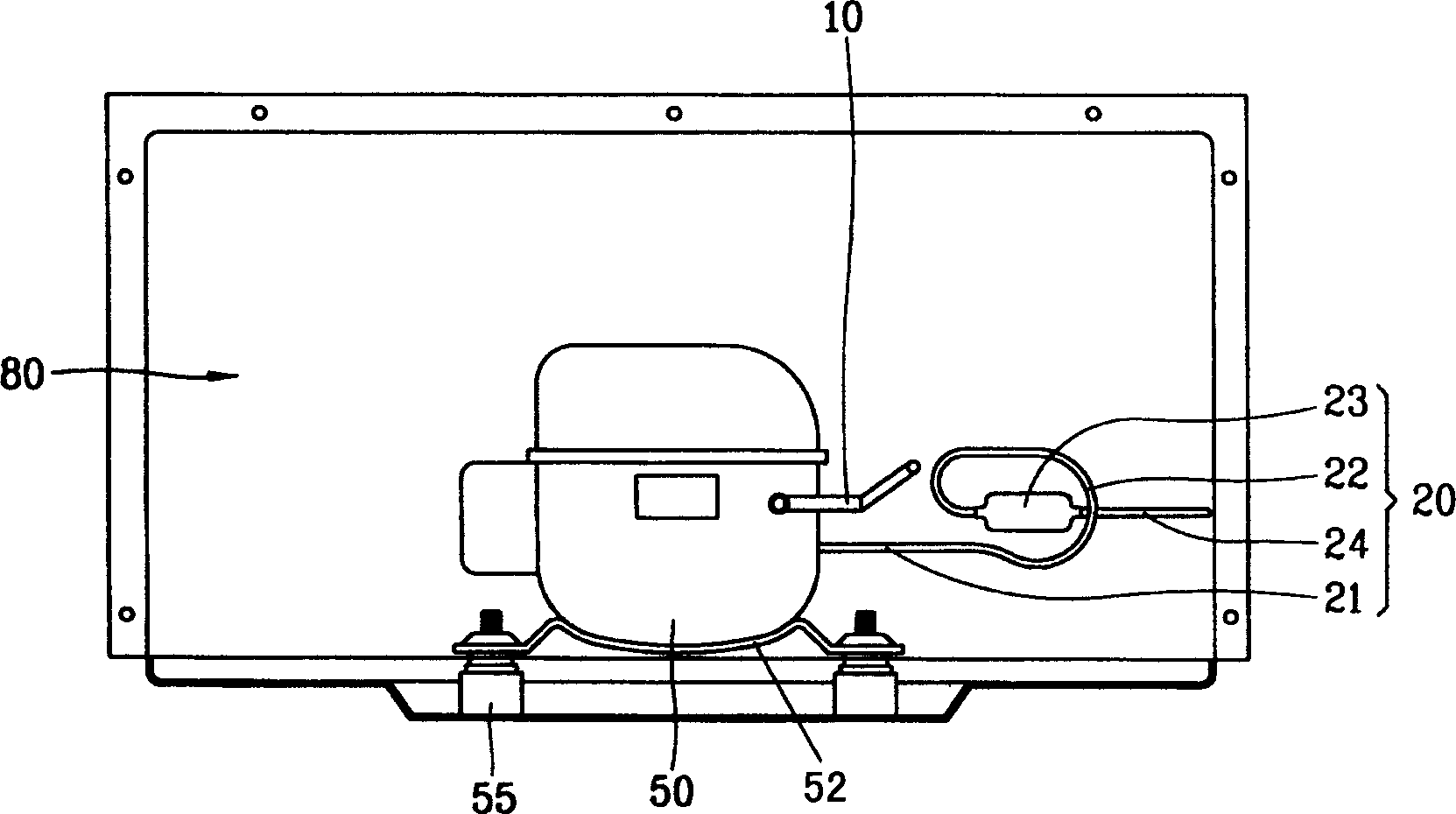

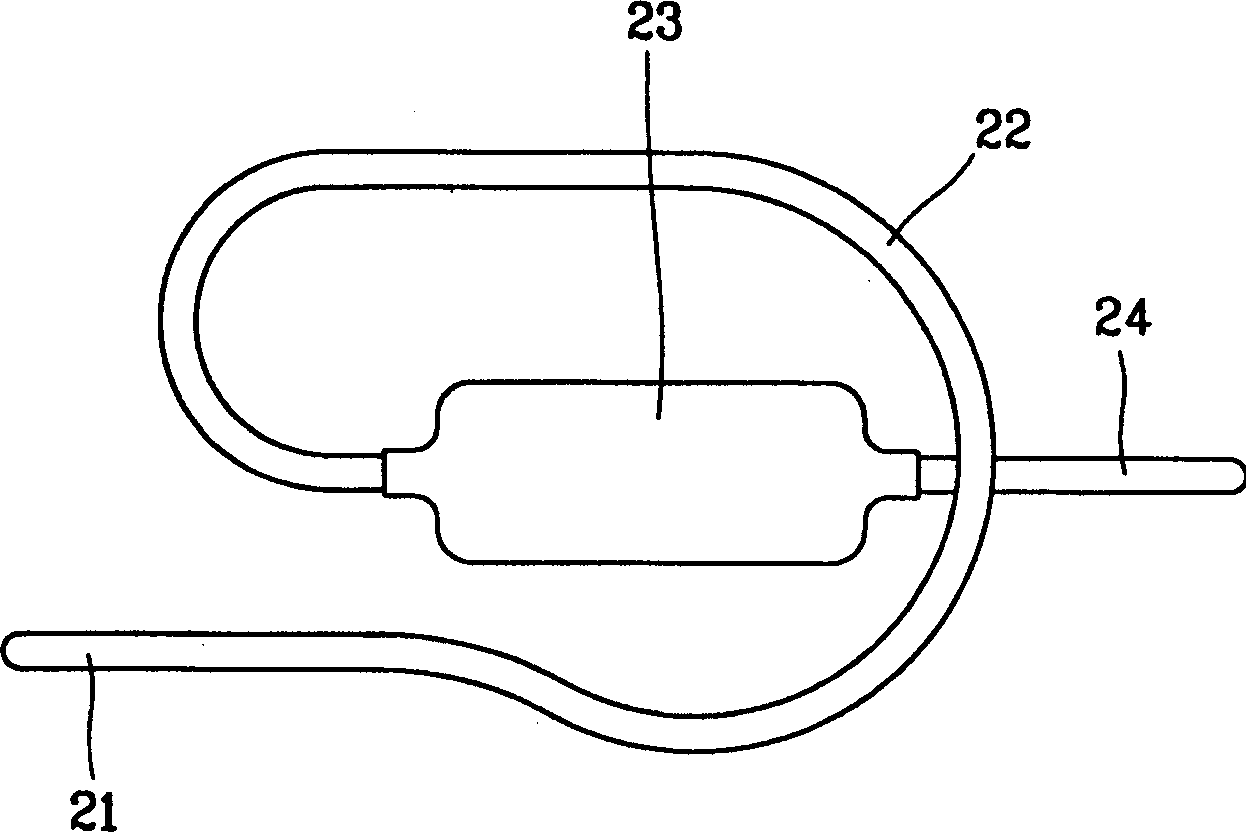

Sucting tube of refrigerator

An intake tube for refrigerator consists of a compressor-connecting pipe, a annular pipe, a silencer, and distiller-connecting pipe. The annular pipe is shaped in polyhedron. It makes multiple strengthened portions and linear stressed portions respectively, so that it can prevent intake tube from breaking as vibrations or impacts occur.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

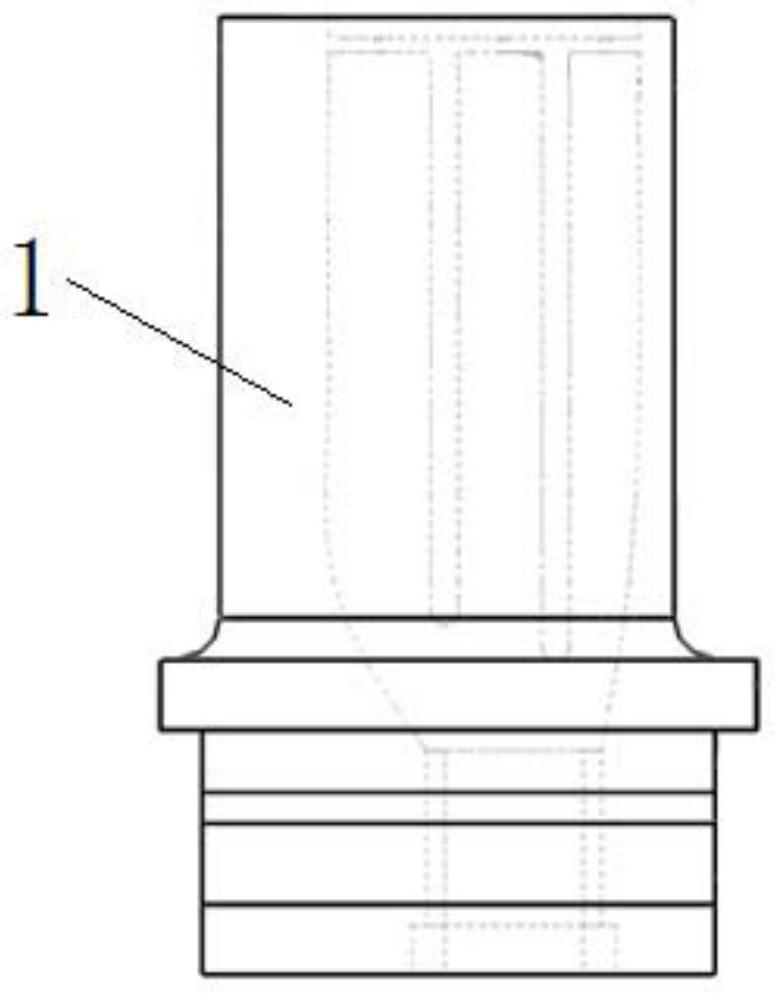

Connector

InactiveCN1512625AImprove rigidityAvoid cracksCouplings bases/casesEngineeringMechanical engineering

Owner:JST MFG CO LTD

Novel chilling block for casting

The invention discloses a novel chilling block for casting. The chilling block is provided with a bottom surface, a top surface and side surfaces, wherein the bottom surface is used for being in contact (including direct contact and indirect contact) with the surface of a casting, the bottom surface and the top surface are connected (including direct connection and indirect connection) through the side surfaces, and the cross section area of the chilling block is gradually reduced from the bottom surface to the top surface. The novel chilling block is simple and ingenious in structure and easy to machine, the corresponding technical effect can be effectively achieved, the chilling effect at the edge junction is gently transited, and the situation that the casting cracks at the edge of the chilling block is effectively avoided. Besides, due to a polygon structure, the heat dissipation area is enlarged, the conduction of heat energy is improved, the chilling effect of the chilling block is improved, the product quality of the casting is ensured, and the quality of the casting is improved.

Owner:SHANGHAI HULIN HEAVY IND

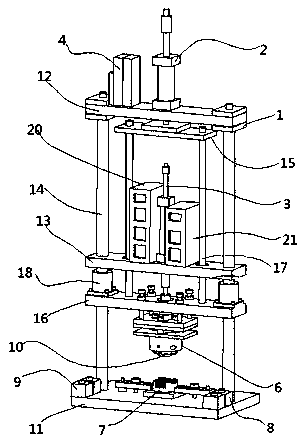

Novel hot melting equipment

The invention discloses novel hot melting equipment. The novel hot melting equipment is mainly used in the technical field of plastic hot melting of electronic products. The novel hot melting equipment comprises a work frame. The work frame comprises a bottom plate, a top plate and a first fixing plate and further comprises a first driving unit, a second driving unit and a product fixing jig whichare arranged on the work frame. The first driving unit is fixed to the first fixing plate. The second driving unit is fixedly connected to the top plate. The product fixing jig is fixedly connected to the bottom plate. The mounting positions of the first driving unit and the second driving unit are matched with the position of the product fixing jig. According to the novel hot melting equipment,by the adoption of the technical scheme, the no pre-pressure and no-cooling time problems of existing hot melting equipment can be solved, the production cost can be lowered, and the production efficiency is improved.

Owner:东莞市托圣斯电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com