Connector

A technology of connectors and printed substrates, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problems of base insulators that are prone to cracks and cracks, and achieve the effects of improving rigidity, preventing cracks, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

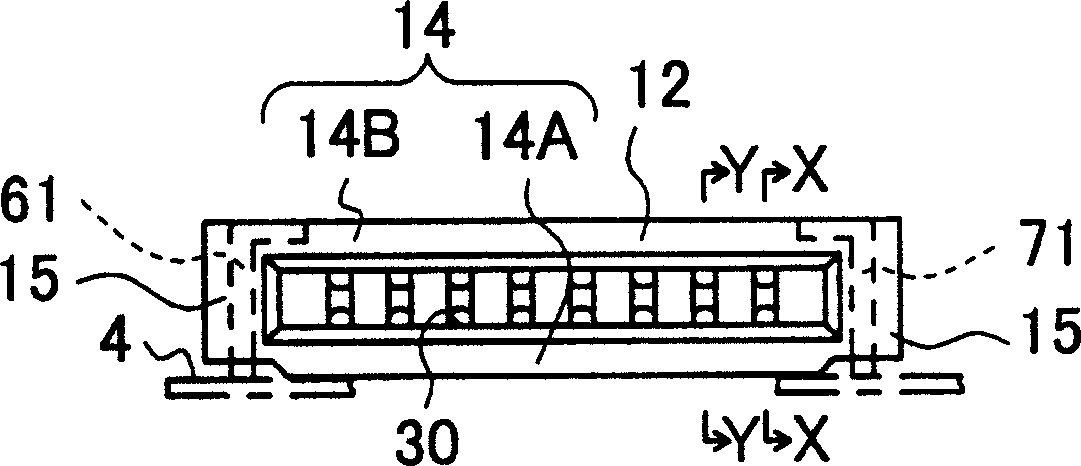

[0042] figure 1 It is an exploded perspective view showing the connector 1 and the FPC 2 according to one embodiment of the present invention. Figure 2A is the plan view of connector 1. Figure 2B is the front view of connector 1. Figure 2C is a side view of connector 1. Figure 2D is the rear view of connector 1. Figure 2E yes Figure 2B The X-X profile. Figure 2F yes Figure 2B The Y-Y profile.

[0043] The FPC 2 includes: a flexible strip-shaped insulating portion; and a conductive line portion provided inside the insulating portion. The line portion has a conduction portion 2A exposed from the front end of the insulating portion.

[0044] The connector 1 is a connector with 10 poles mounted on the printed circuit board 4 and connected to the FPC 2 . The connector 1 has: an insulating socket housing 3 that forms a terminal socket 30 and is mounted on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Installation height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com