Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133results about How to "Extended component life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor light emitting element, and its manufacturing method

InactiveUS6303405B1Quality improvementImprove electricitySolid-state devicesSemiconductor/solid-state device manufacturingLaser lightHeat stress

A semiconductor light emitting element of nitride compound semiconductors excellent in cleavability, heat radiation and resistance to leakage is made by epitaxially grow a nitride compound semiconductor layers on a substrate of sapphire, for example, and thereafter separating the substrate. For separating the substrate, there are a technique using a abruption mechanism susceptible to a stress such as a "lift-off layer" and a recesses on a substrate. A technique using laser light to cause a local dense heat stress at the abruption mechanism is effective. A nitride compound semiconductor obtained by separating the substrate may be used as a new substrate to epitaxially grow high-quality nitride compound semiconductors thereon.

Owner:ALPAD CORP

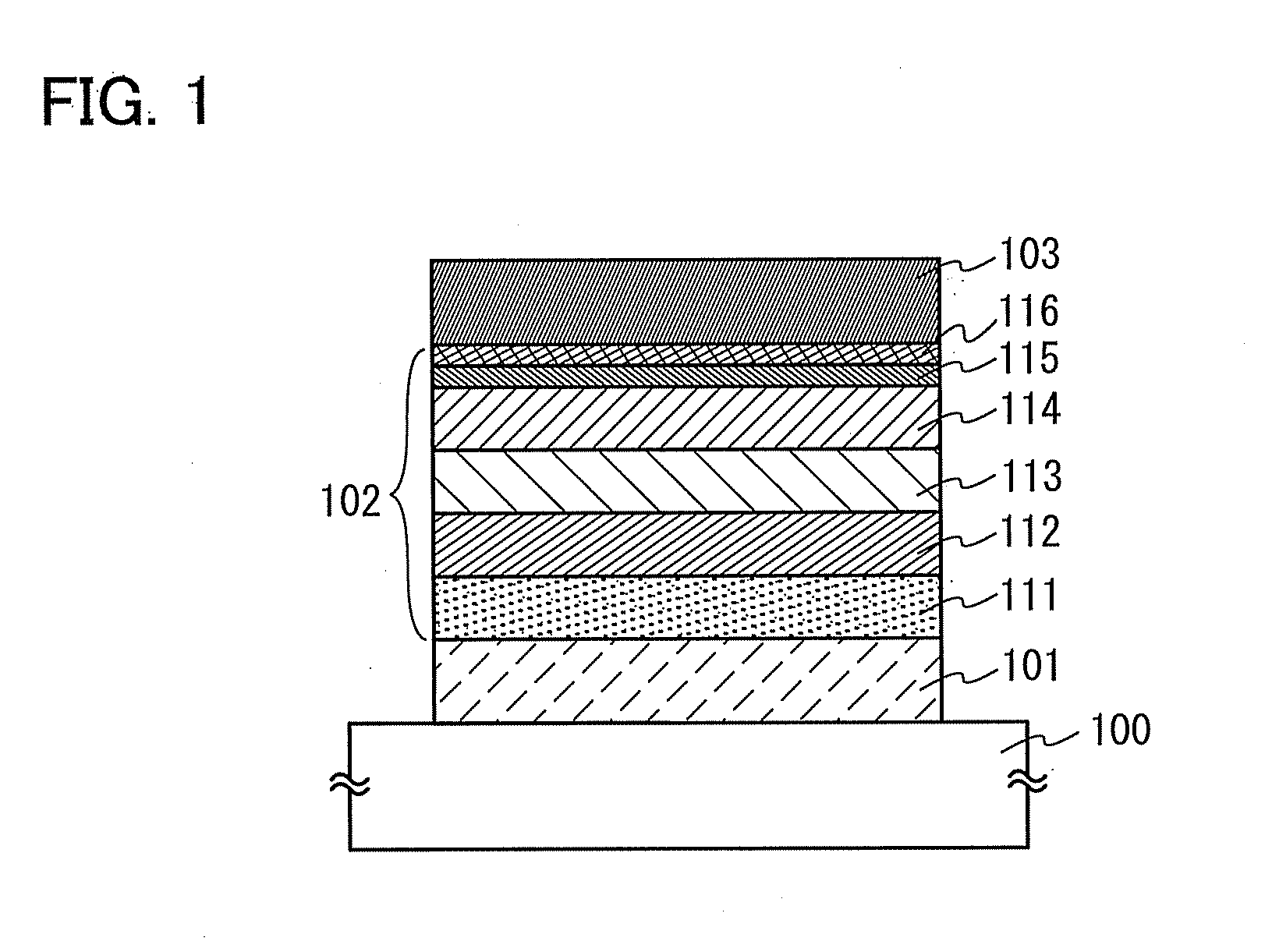

Light-Emitting Element, Light-Emitting Device, Electronic Device, Lighting Device, and Novel Organic Compound

ActiveUS20130048964A1Easy transferHigh luminance regionOrganic chemistrySolid-state devicesIridiumOrganic compound

A light-emitting element includes an EL layer between a pair of electrodes. The EL layer contains a first compound and a second compound. The first compound is a phosphorescent iridium metal complex having a LUMO level of greater than or equal to −3.5 eV and less than or equal to −2.5 eV, and the second compound is an organic compound having a pyrimidine skeleton. The light-emitting element includes an EL layer between a pair of electrodes. The EL layer contains a first compound and a second compound. The first compound is a phosphorescent iridium metal complex having a diazine skeleton, and the second compound is an organic compound having a pyrimidine skeleton.

Owner:SEMICON ENERGY LAB CO LTD

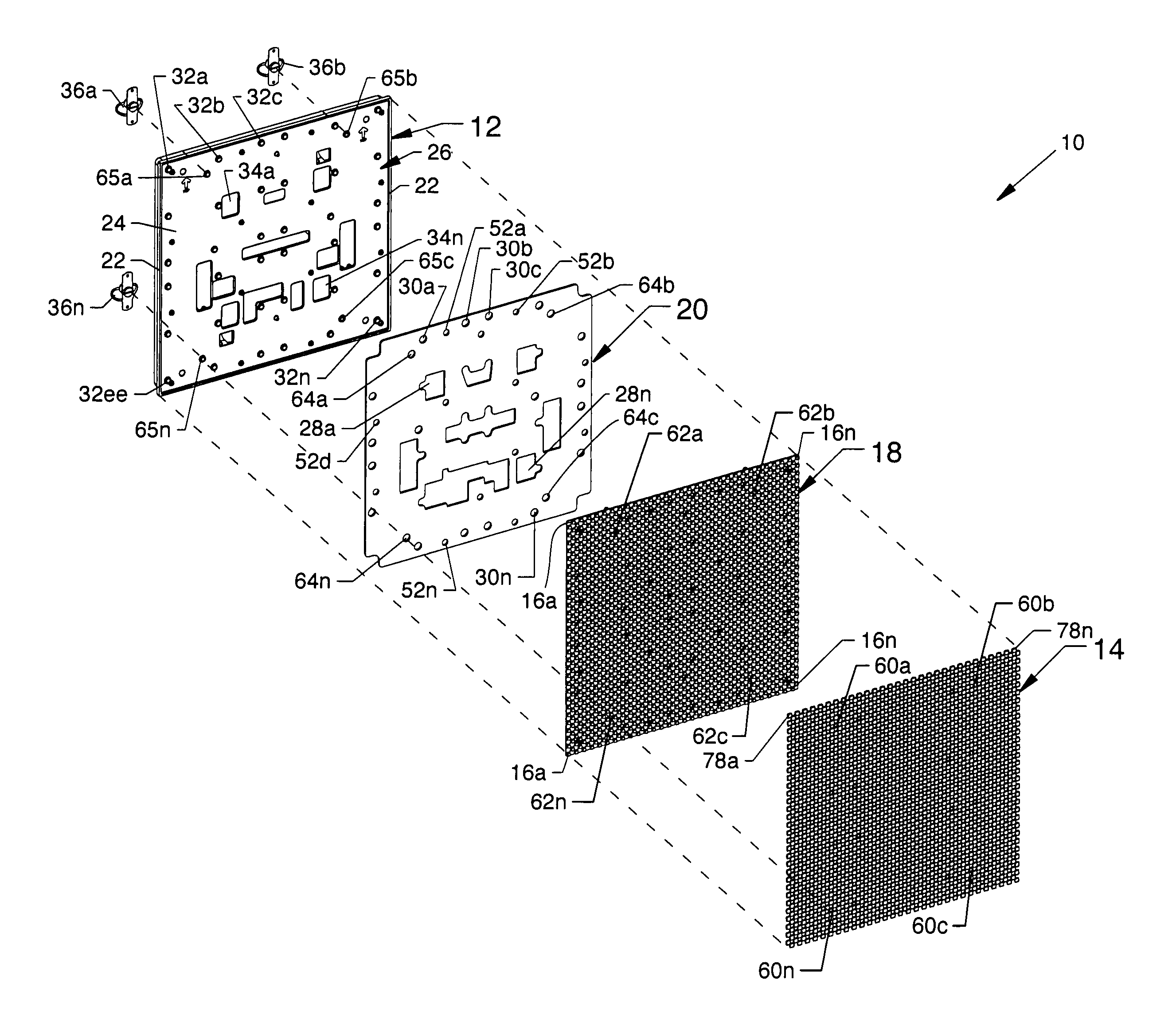

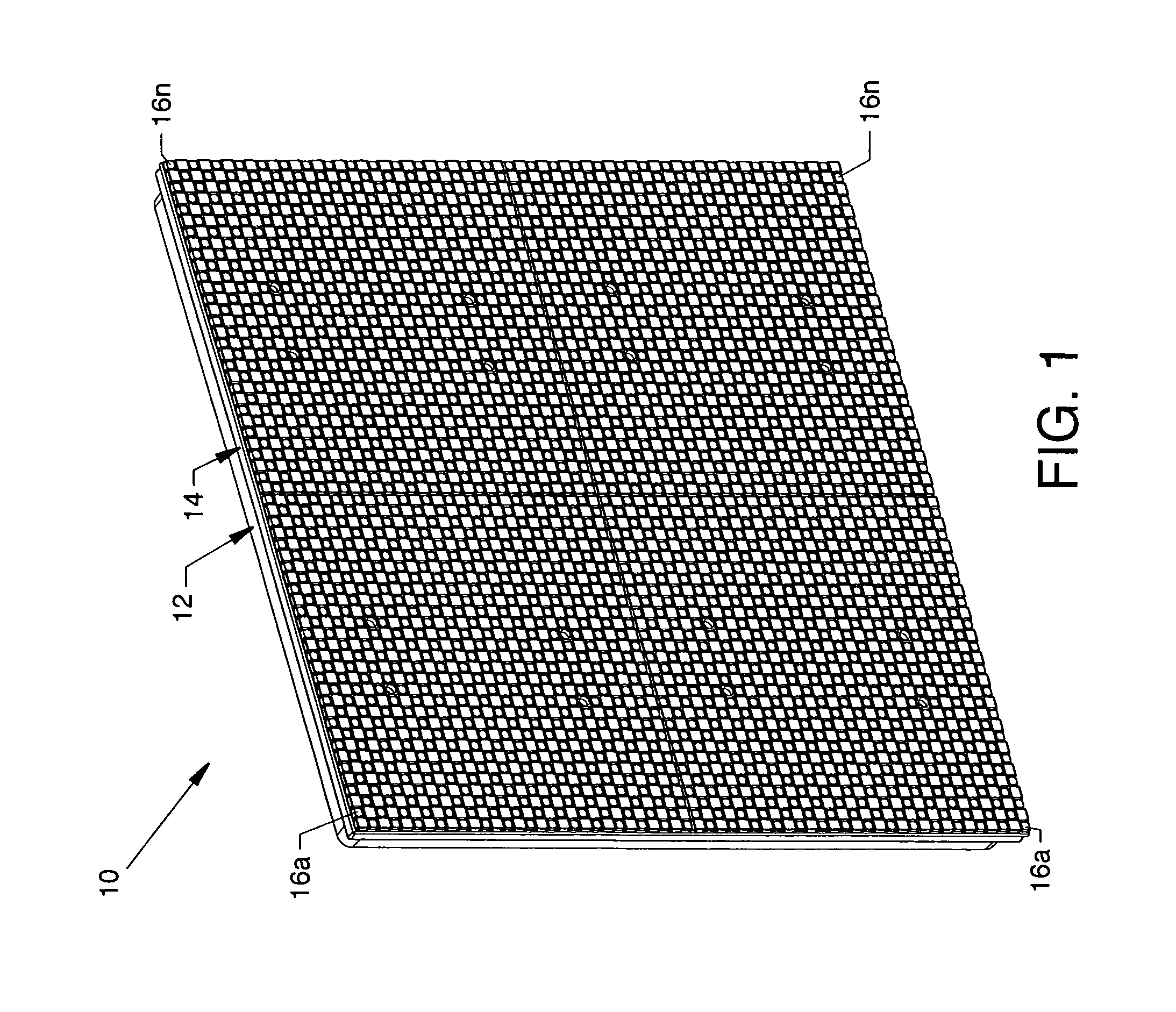

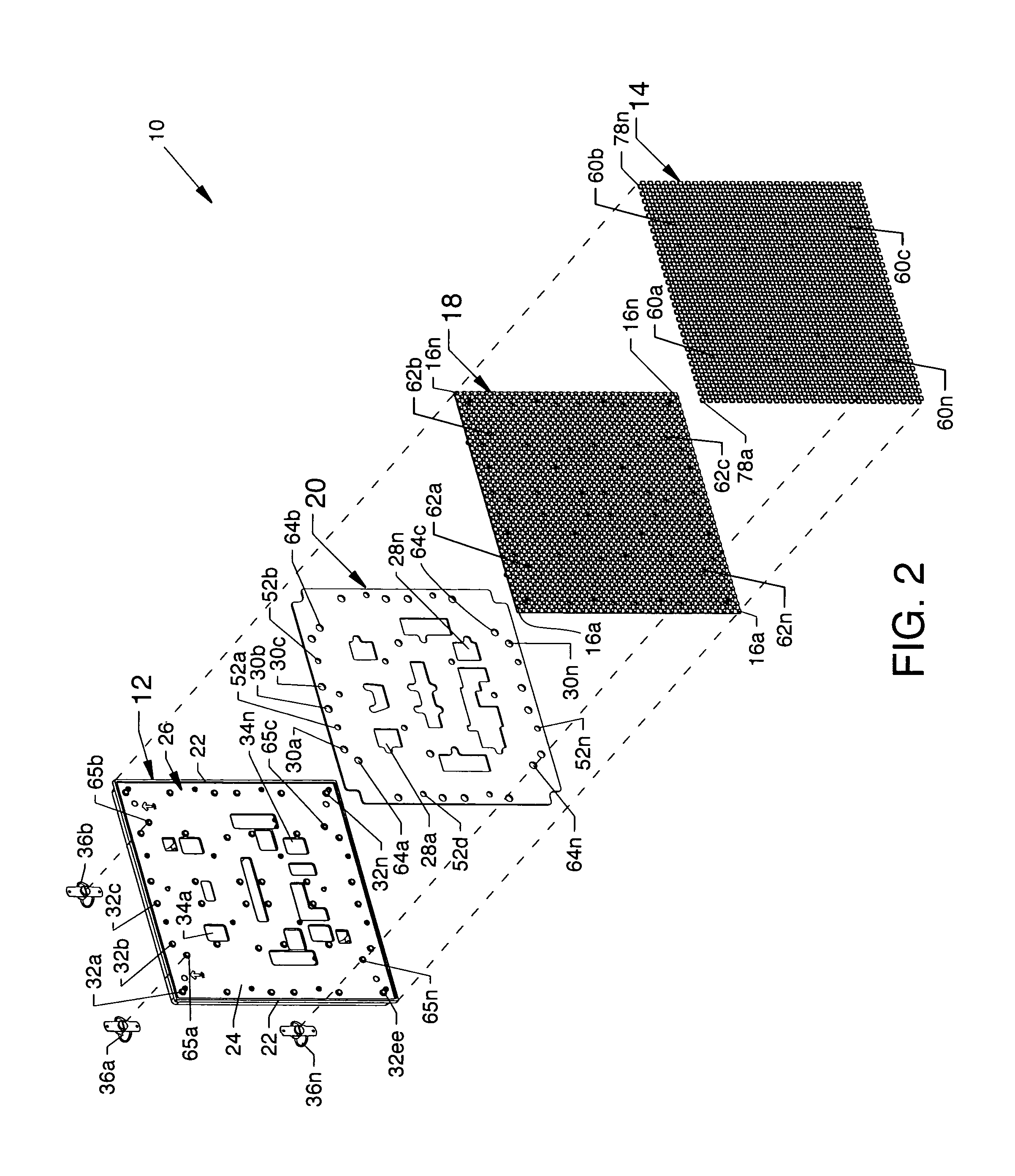

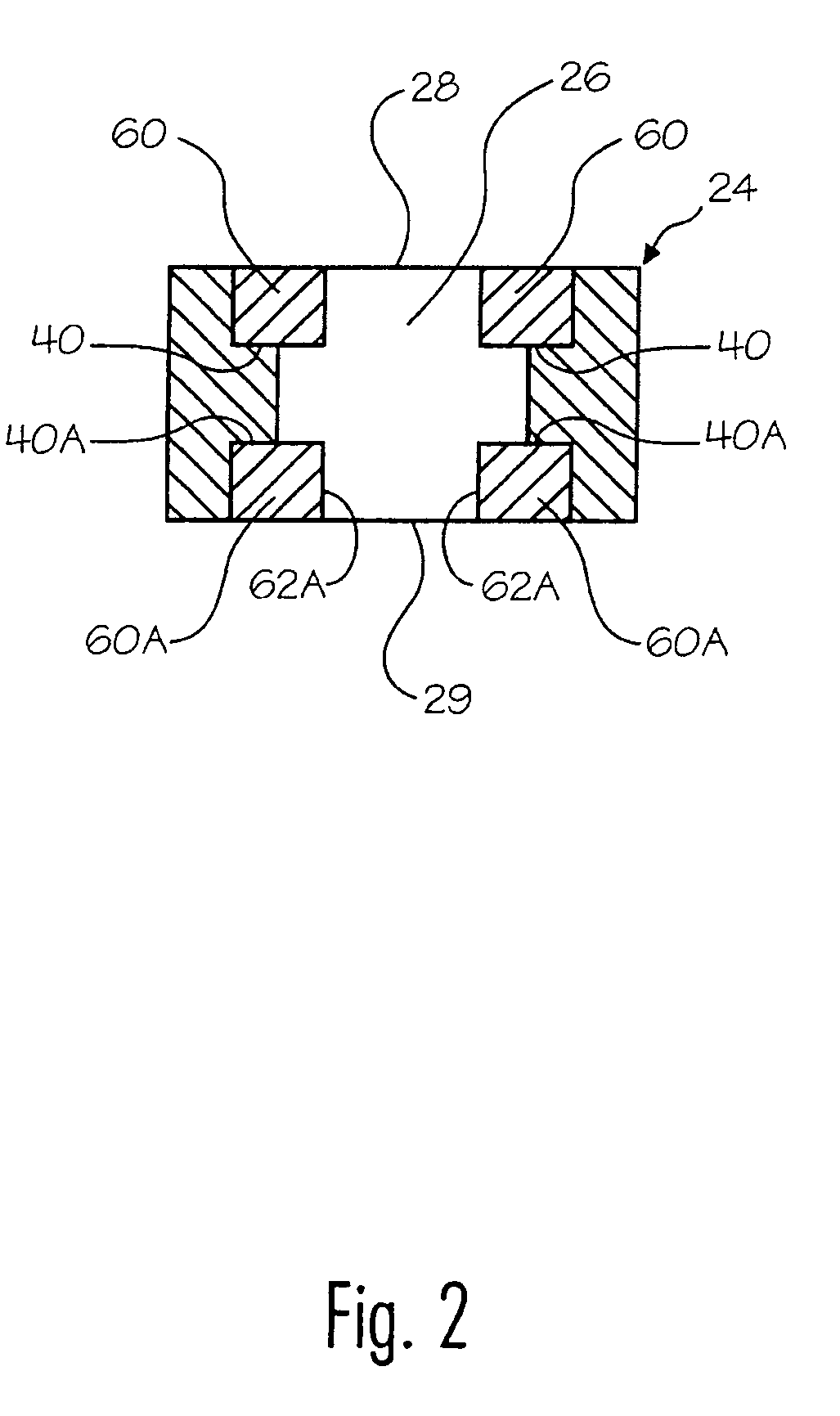

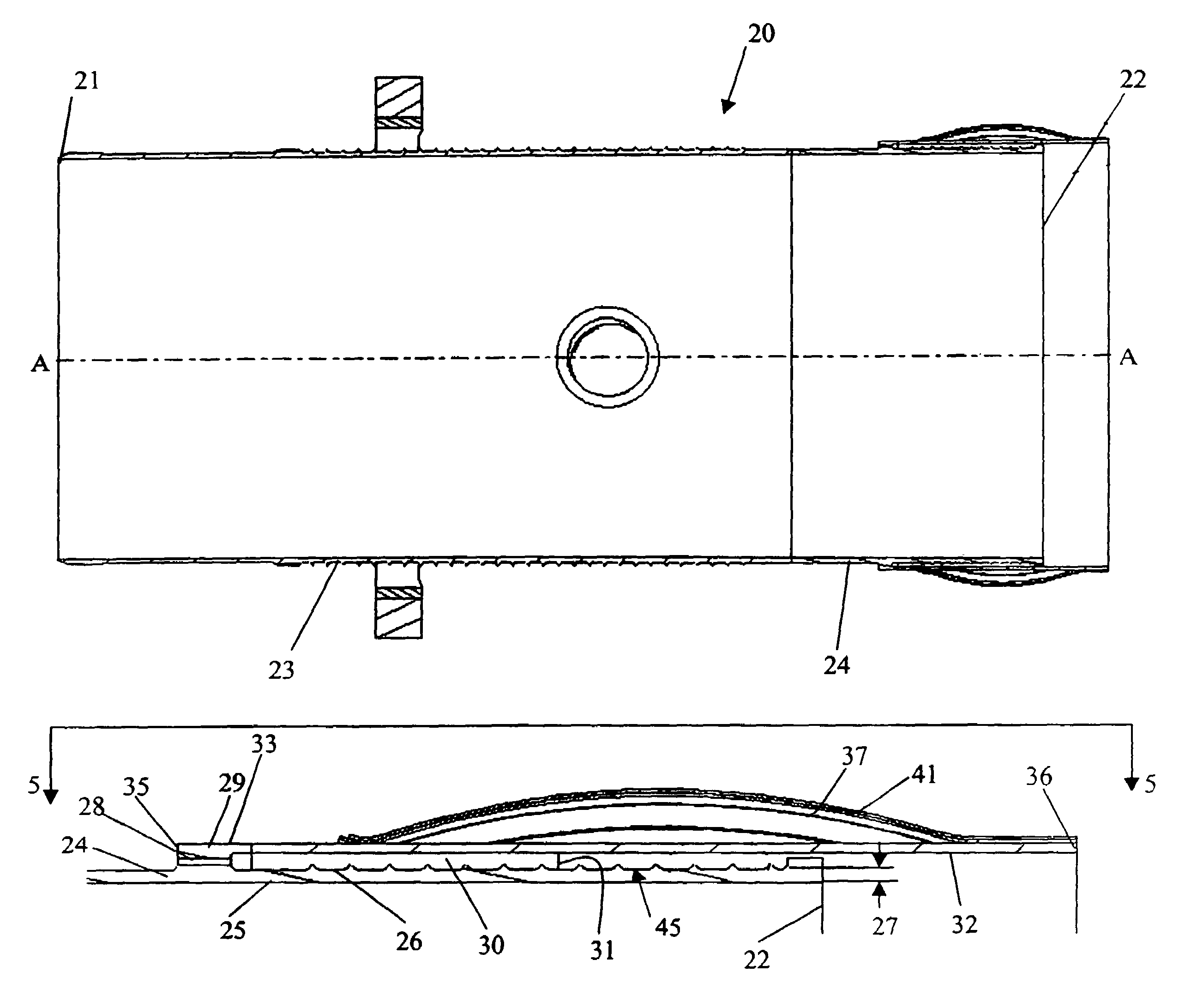

LED display module having a metallic housing and metallic mask

InactiveUS8154864B1Equally distributedReduce heatLighting support devicesDigital data processing detailsLED displayEngineering

The present invention is a robust LED display module for use in an electronic sign which display module includes a metallic housing, a heat conductive interface panel, an LED circuit board and LEDs, and a metallic mask arranged in intimate contact and association therewith, and which components operate synergistically in concert with each other in order to evenly distribute, reduce and dissipate heat along, about and within the structure of the present invention. Display uniformity is provided by the use of major metallic structures in order to prevent warpage and to protect the geometric integrity of the LED display module.

Owner:DAKTRONICS

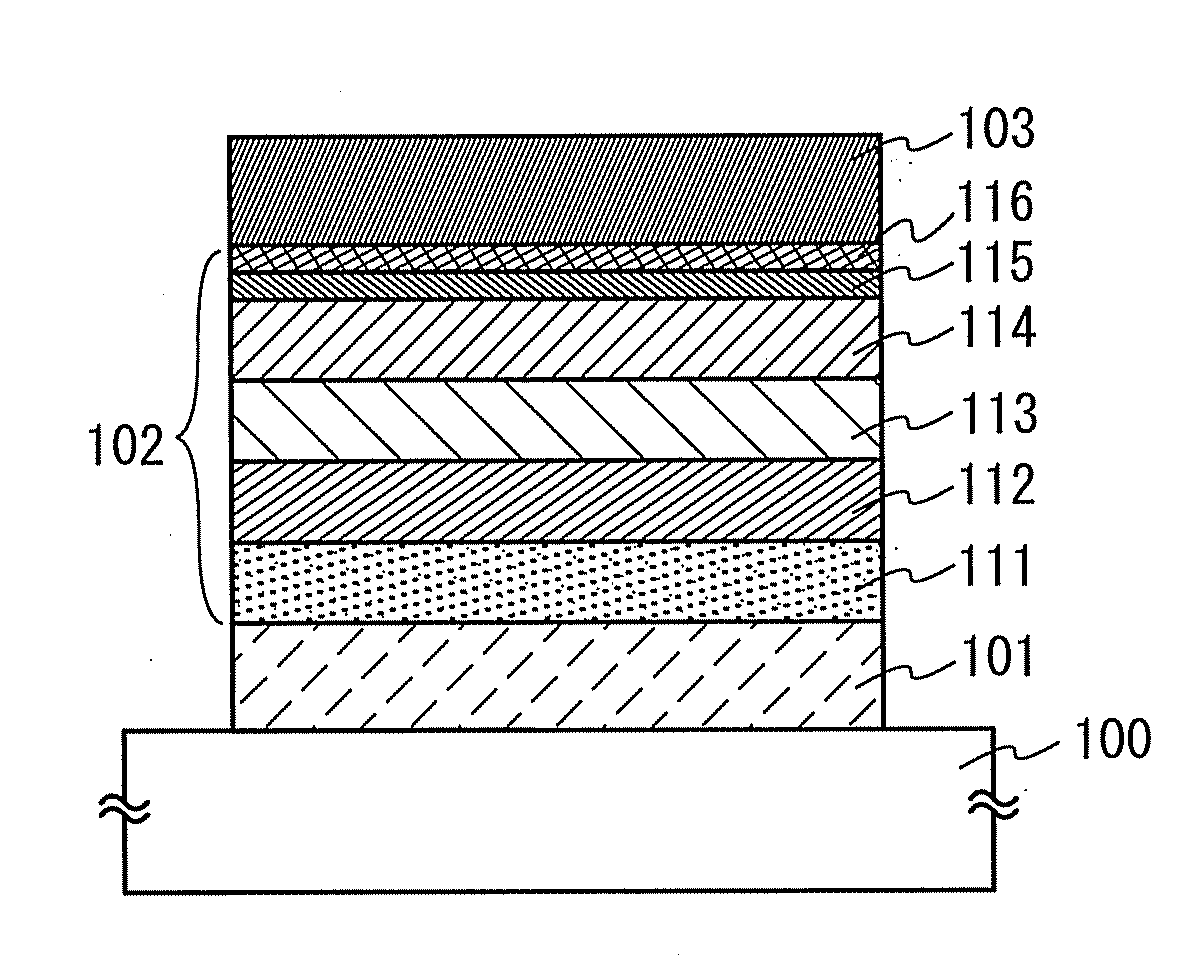

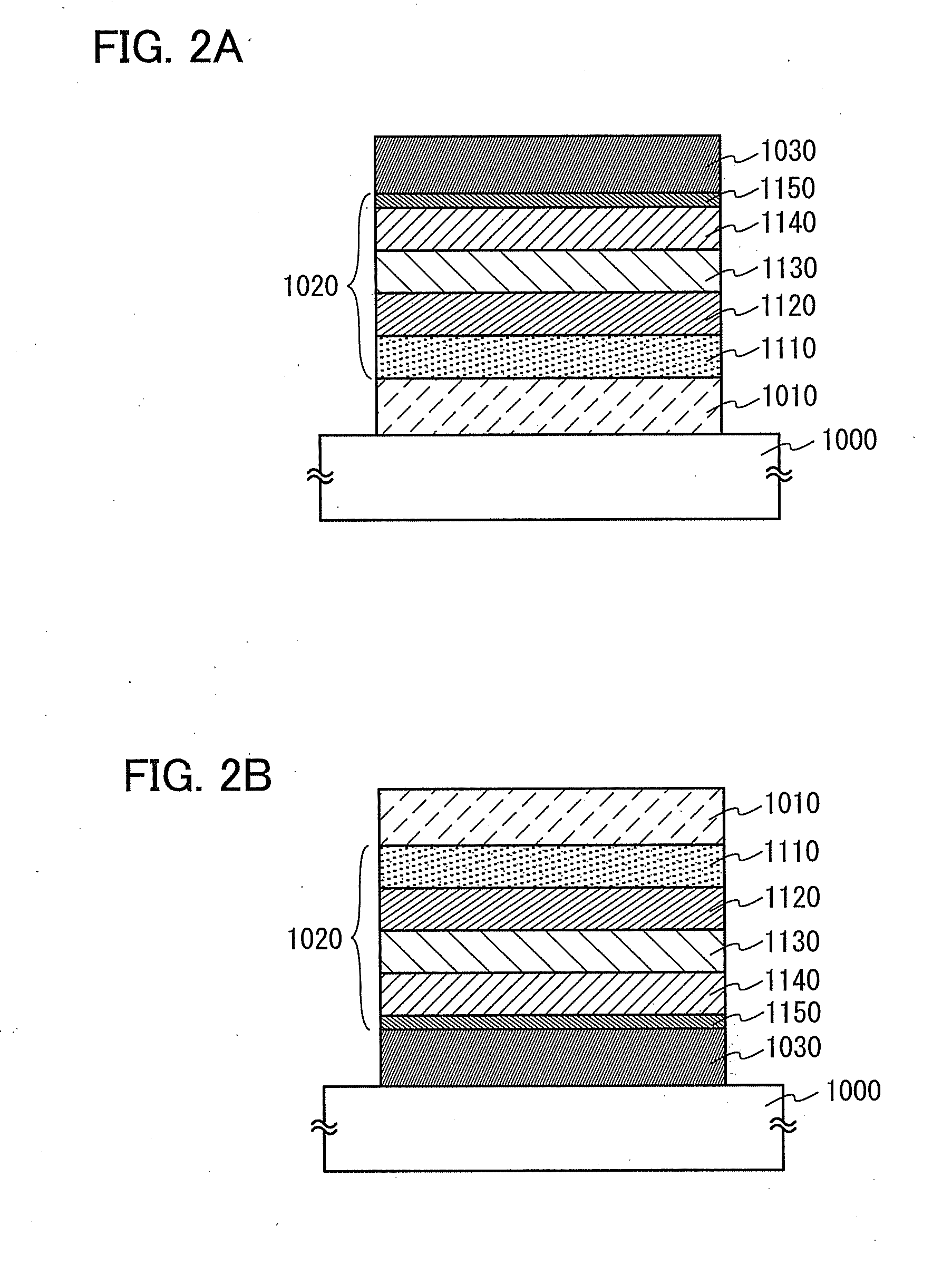

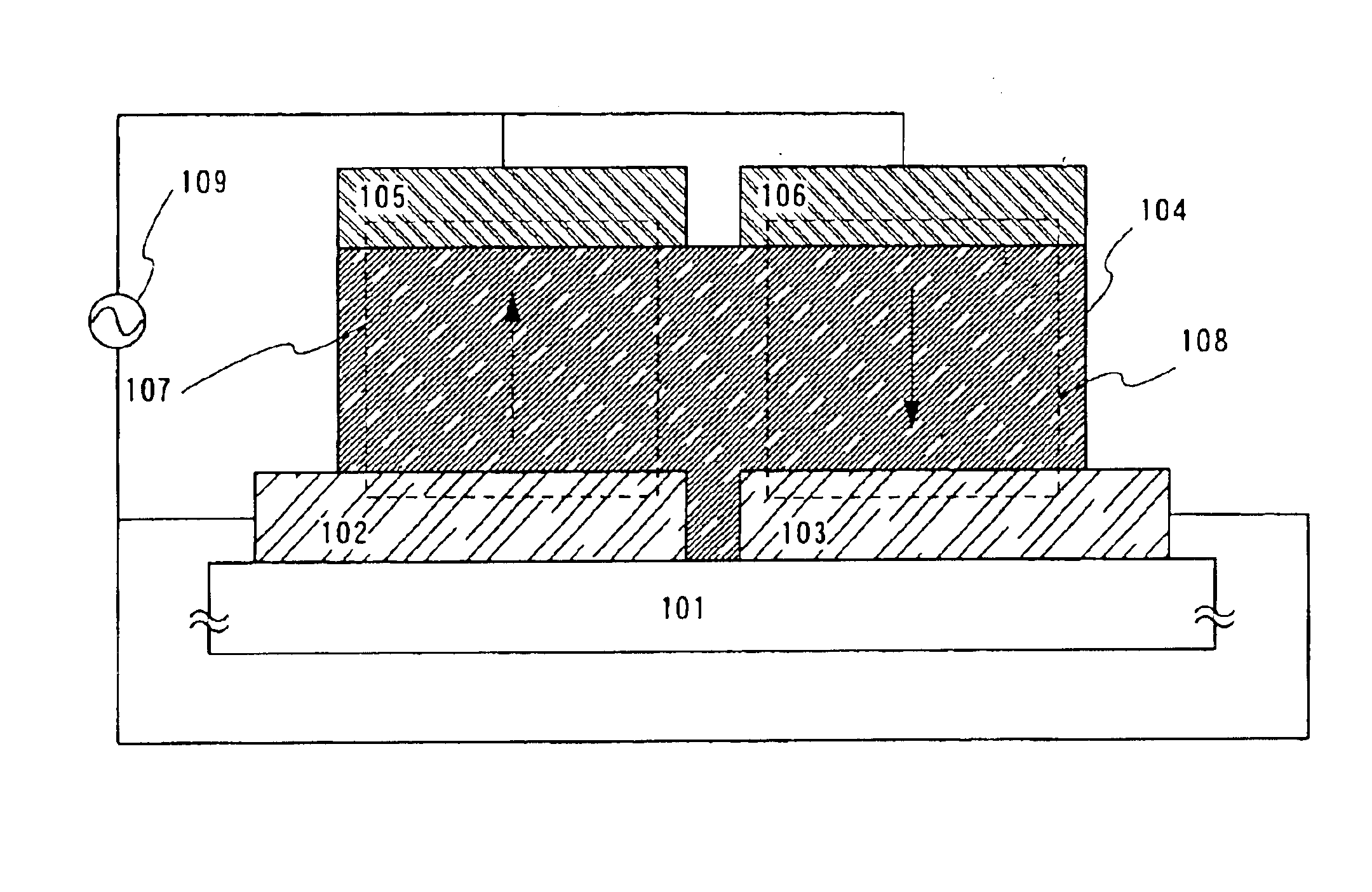

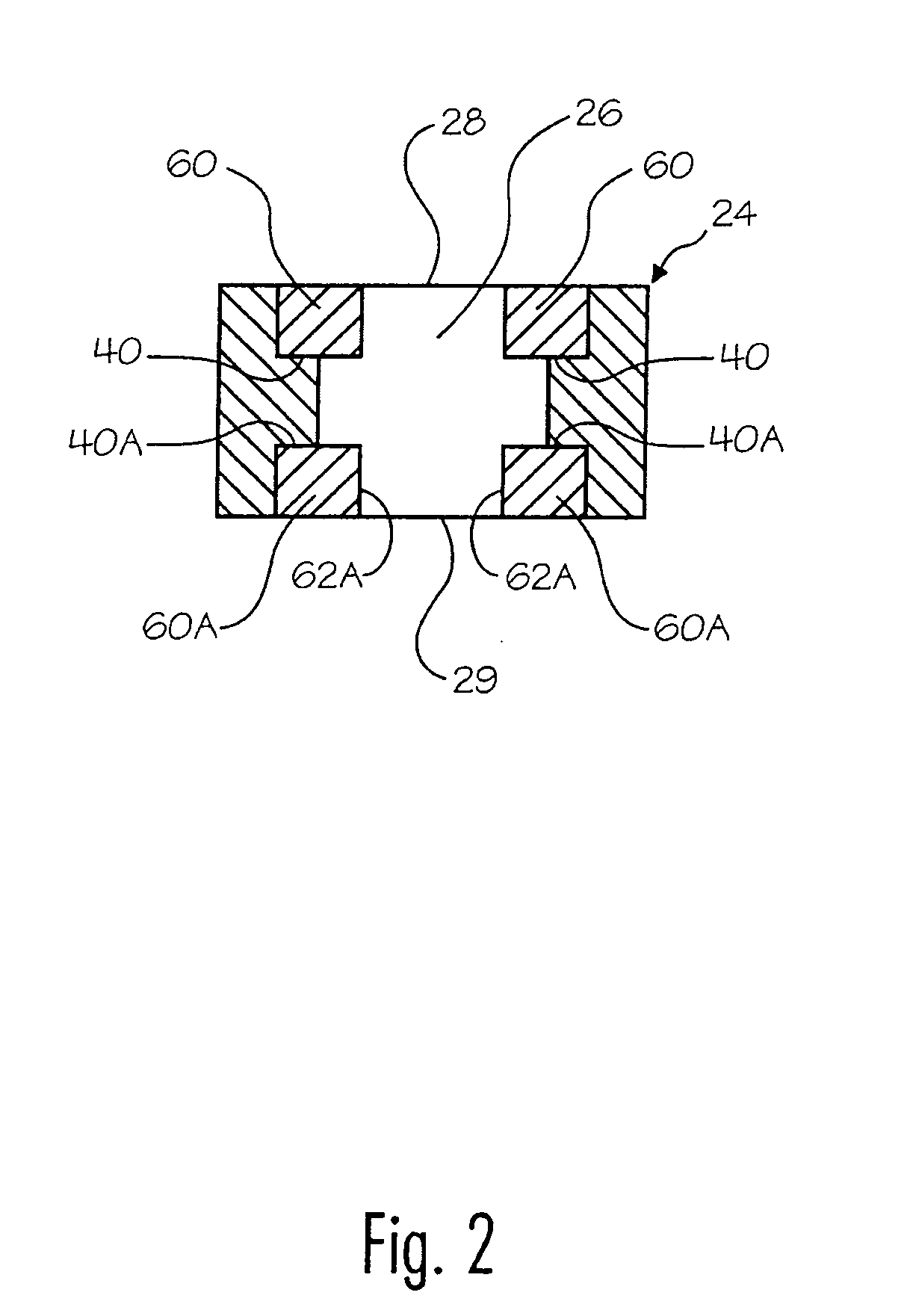

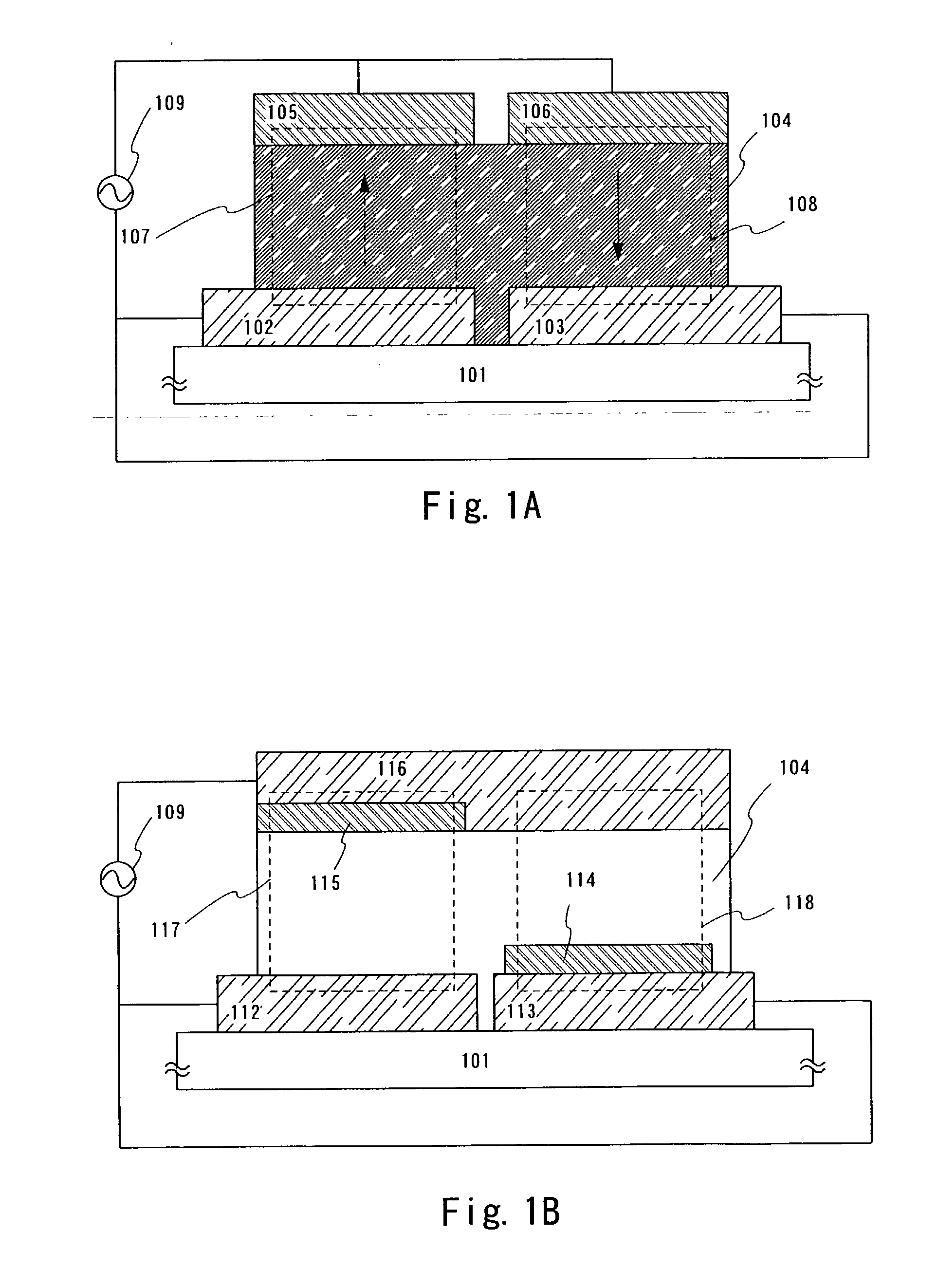

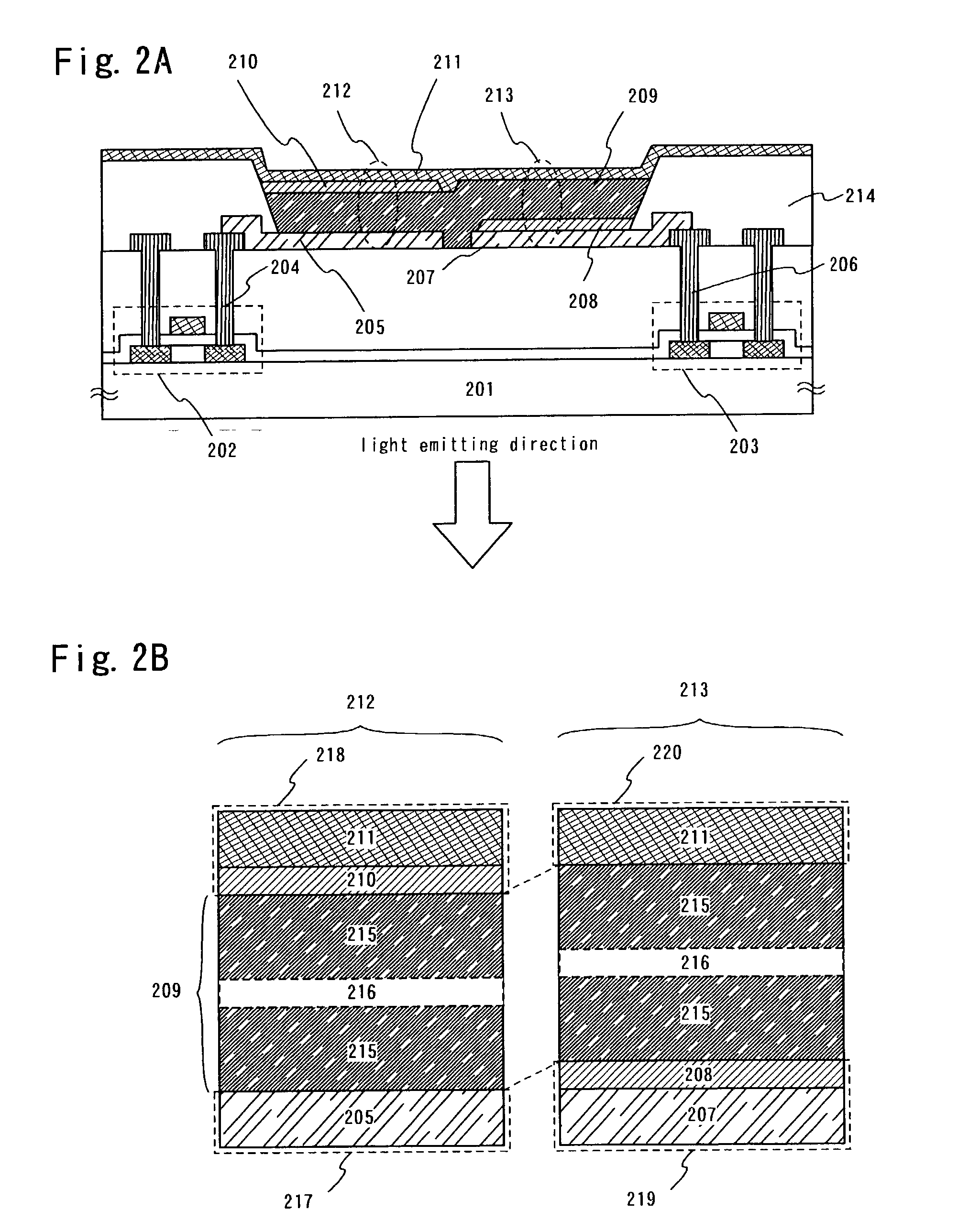

Light emitting device driving by alternating current in which light emission is always obtained

InactiveUS6876007B2Drop in brightness can be suppressedExtended component lifeDischarge tube luminescnet screensElectroluminescent light sourcesElectrical polarityAlternating current

A light emitting device is provided, which uses alternating current drive as a method of driving the light emitting device, and in which light emission is always obtained when voltages having different polarities are alternately applied, and a method of manufacturing the light emitting device is also provided. A first light emitting element made from an anode, an organic compound layer, and a cathode, and a second electrode made from an anode, an organic compound layer, and a cathode are formed. The light emitting elements are formed sandwiching the same organic compound layer. The anode of the first light emitting element and the anode of the second light emitting element, and the cathode of the first light emitting element and the cathode of the second light emitting element, are formed on opposite sides of the organic compound layer, respectively, thus sandwiching the organic compound layer. Note that voltages having an inverse polarity are applied alternately by the alternating current drive, and therefore light can always be emitted by any one of the first light emitting element or the second light emitting element.

Owner:SEMICON ENERGY LAB CO LTD

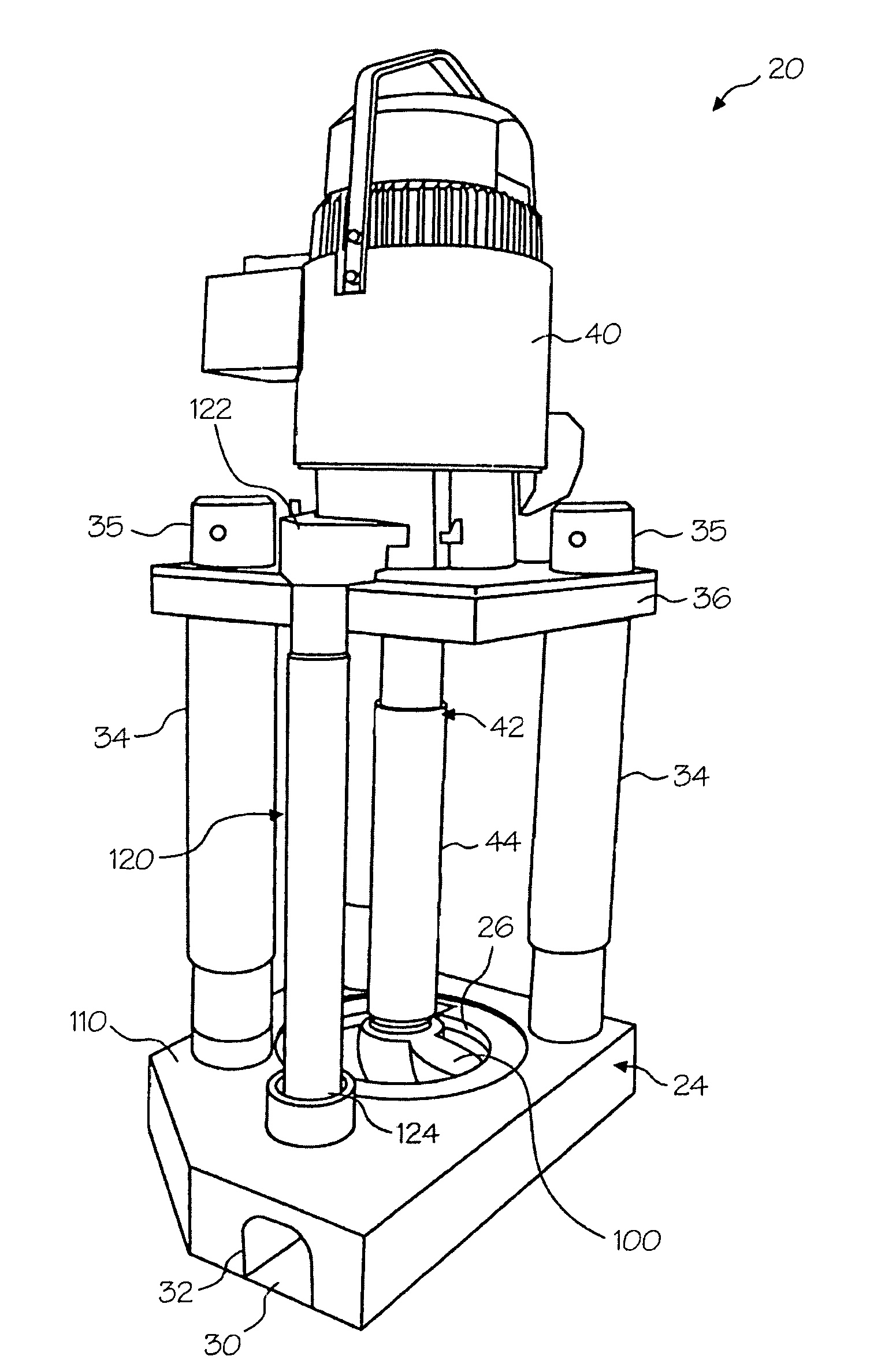

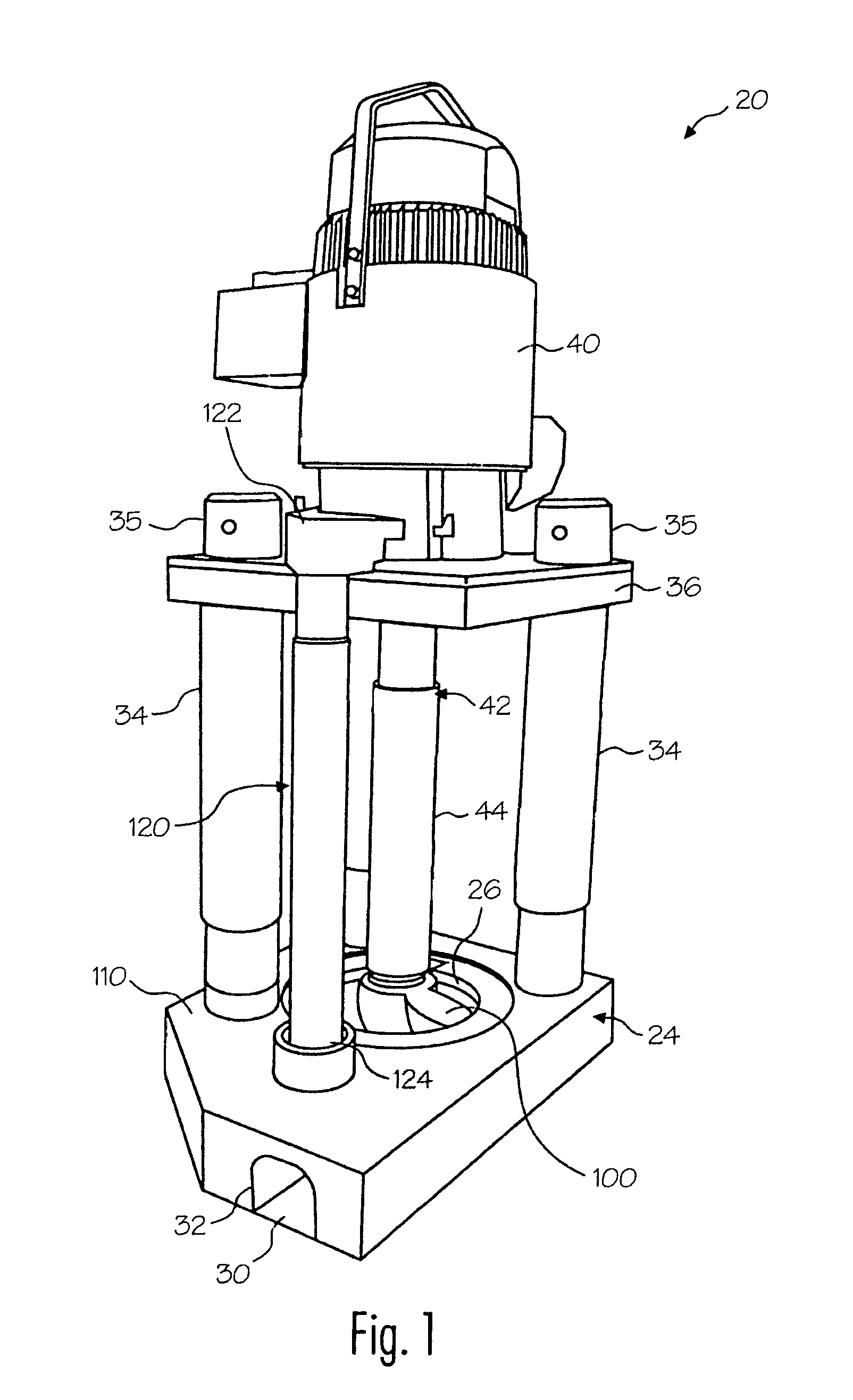

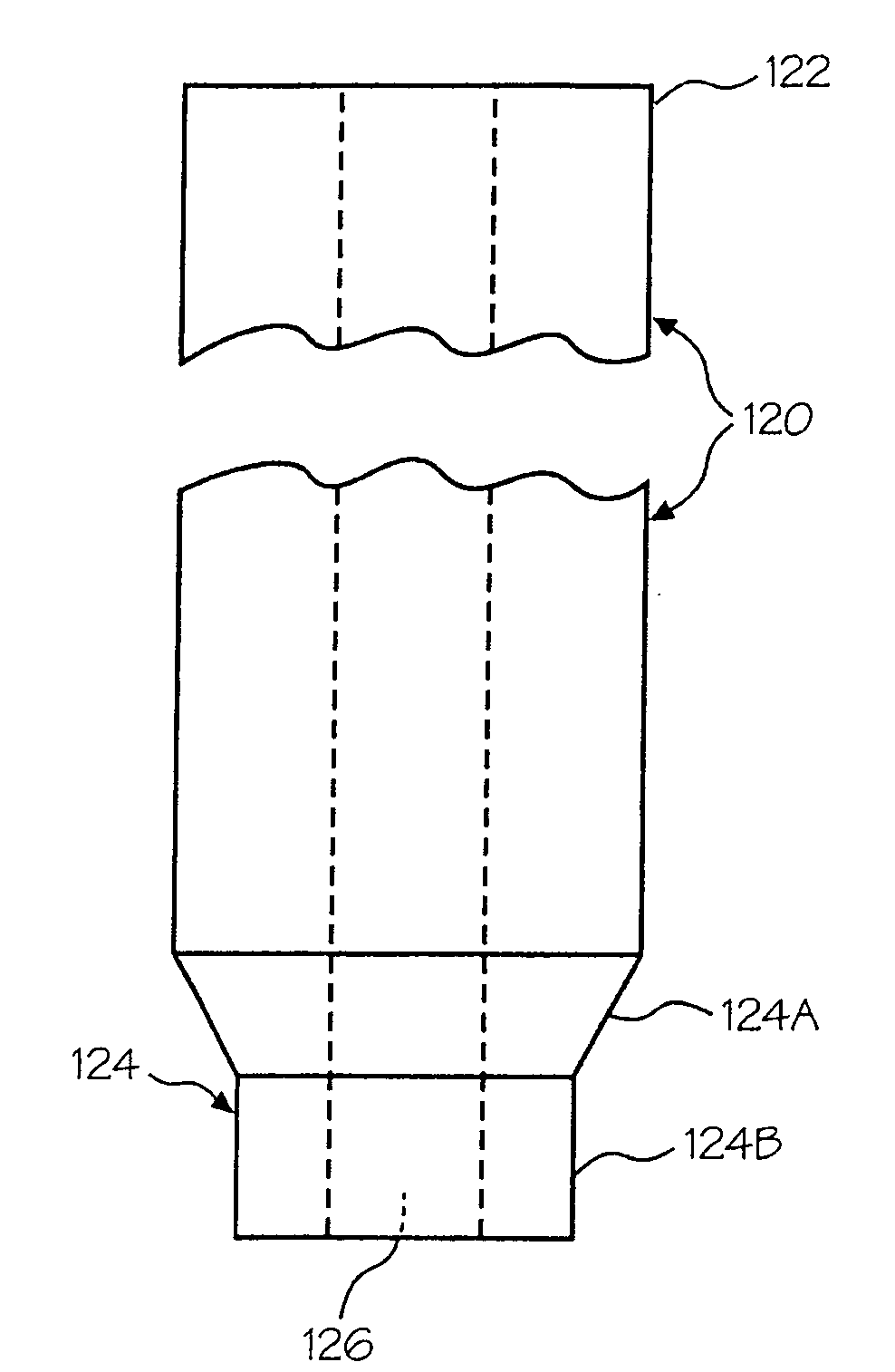

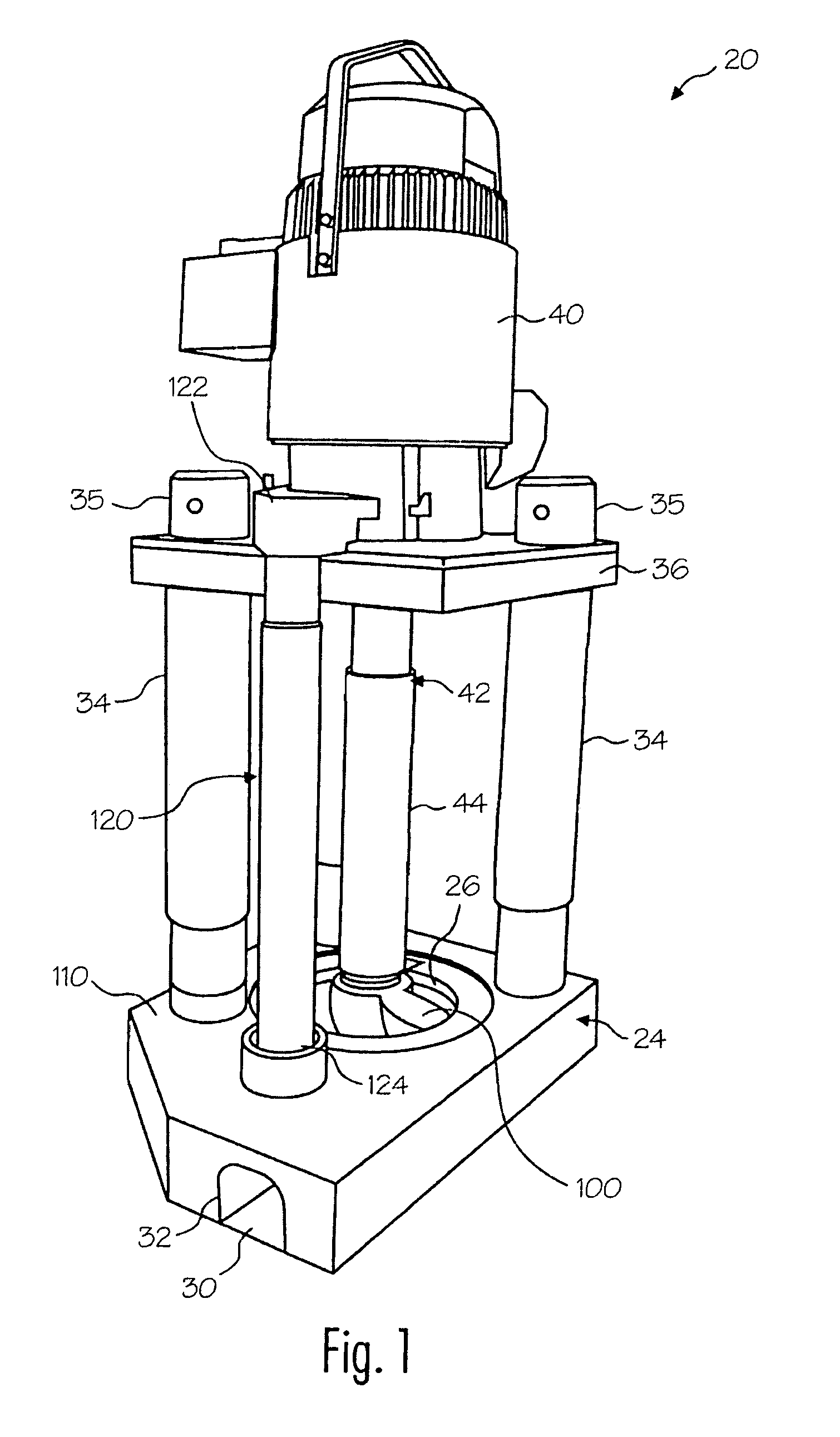

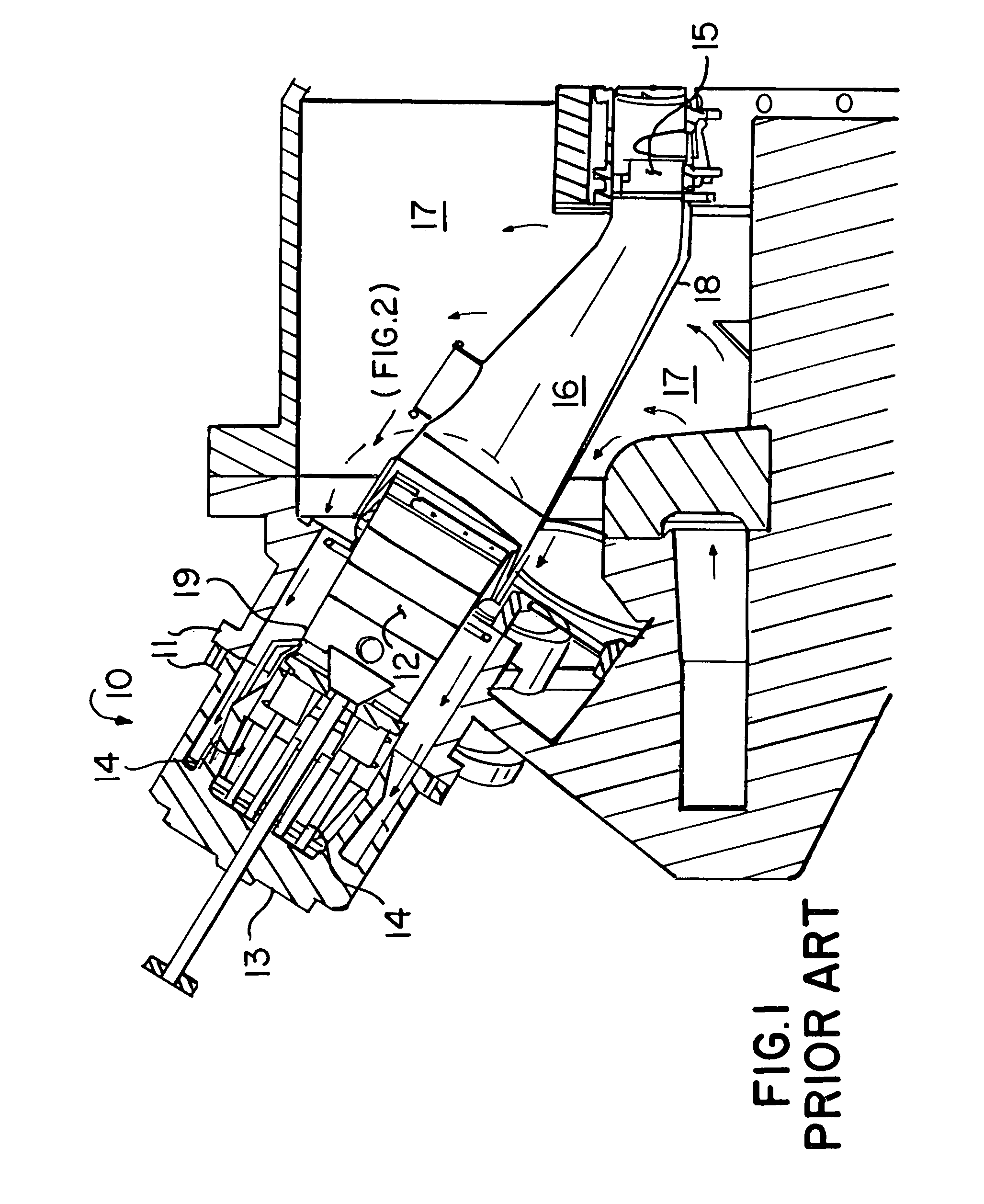

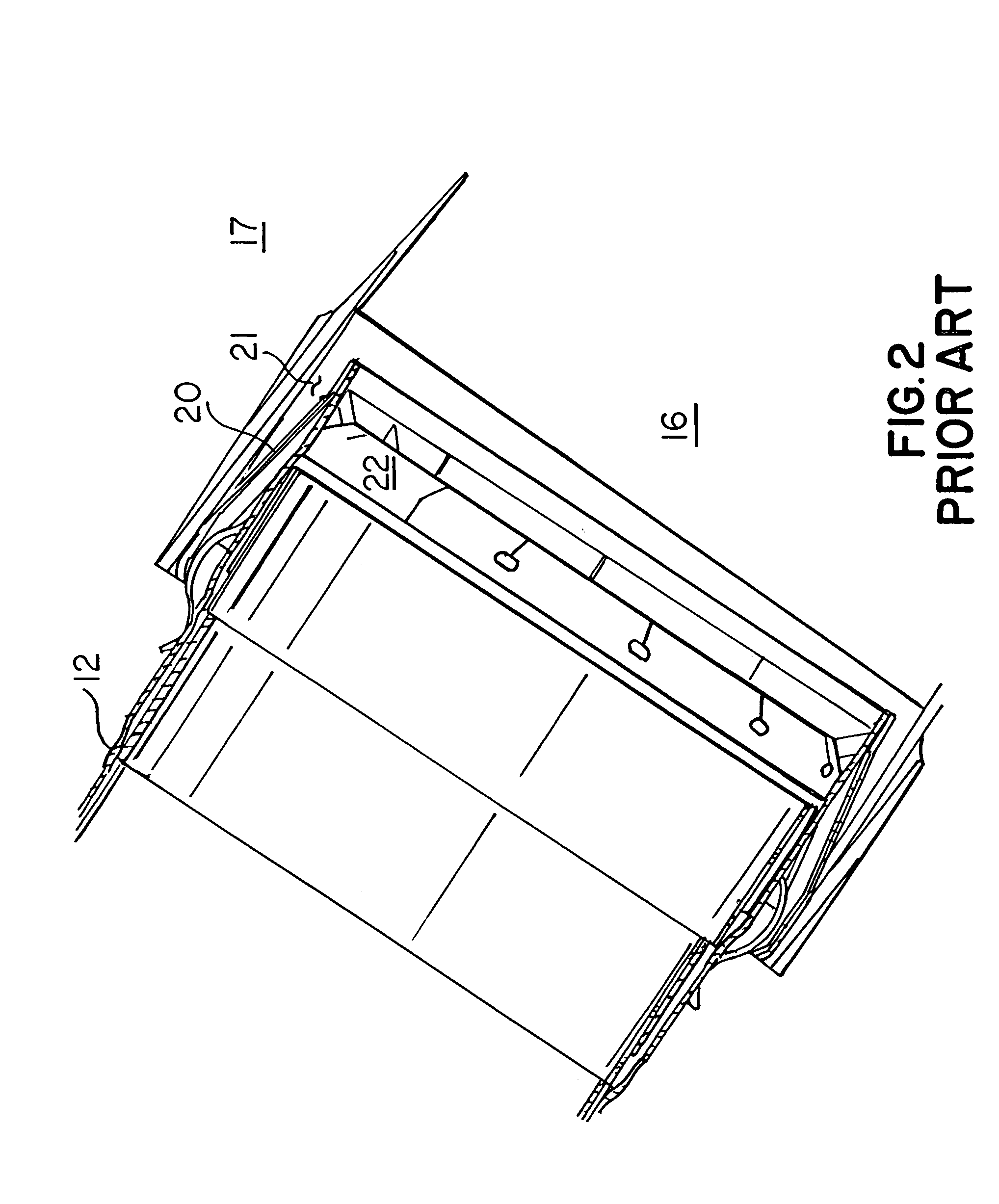

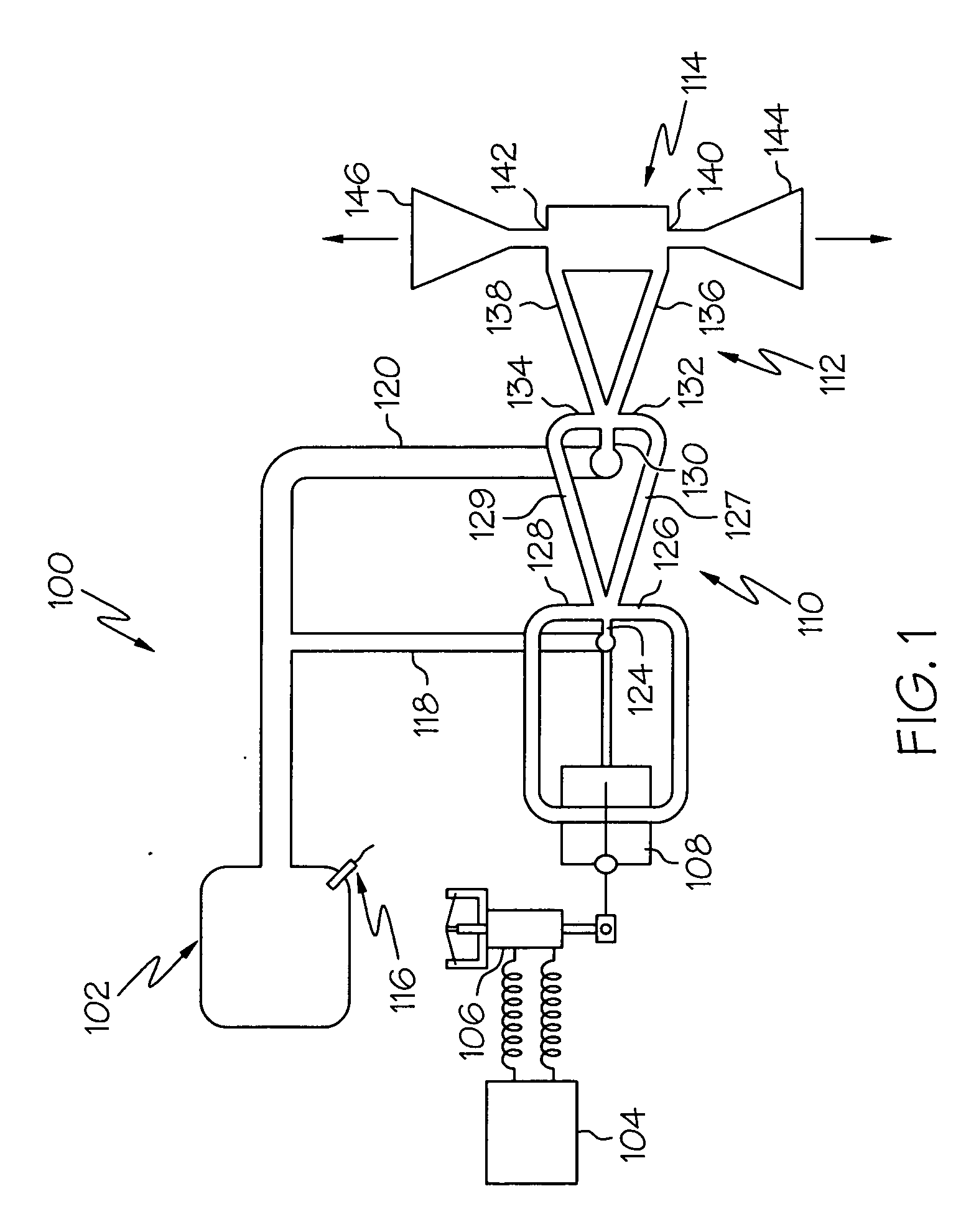

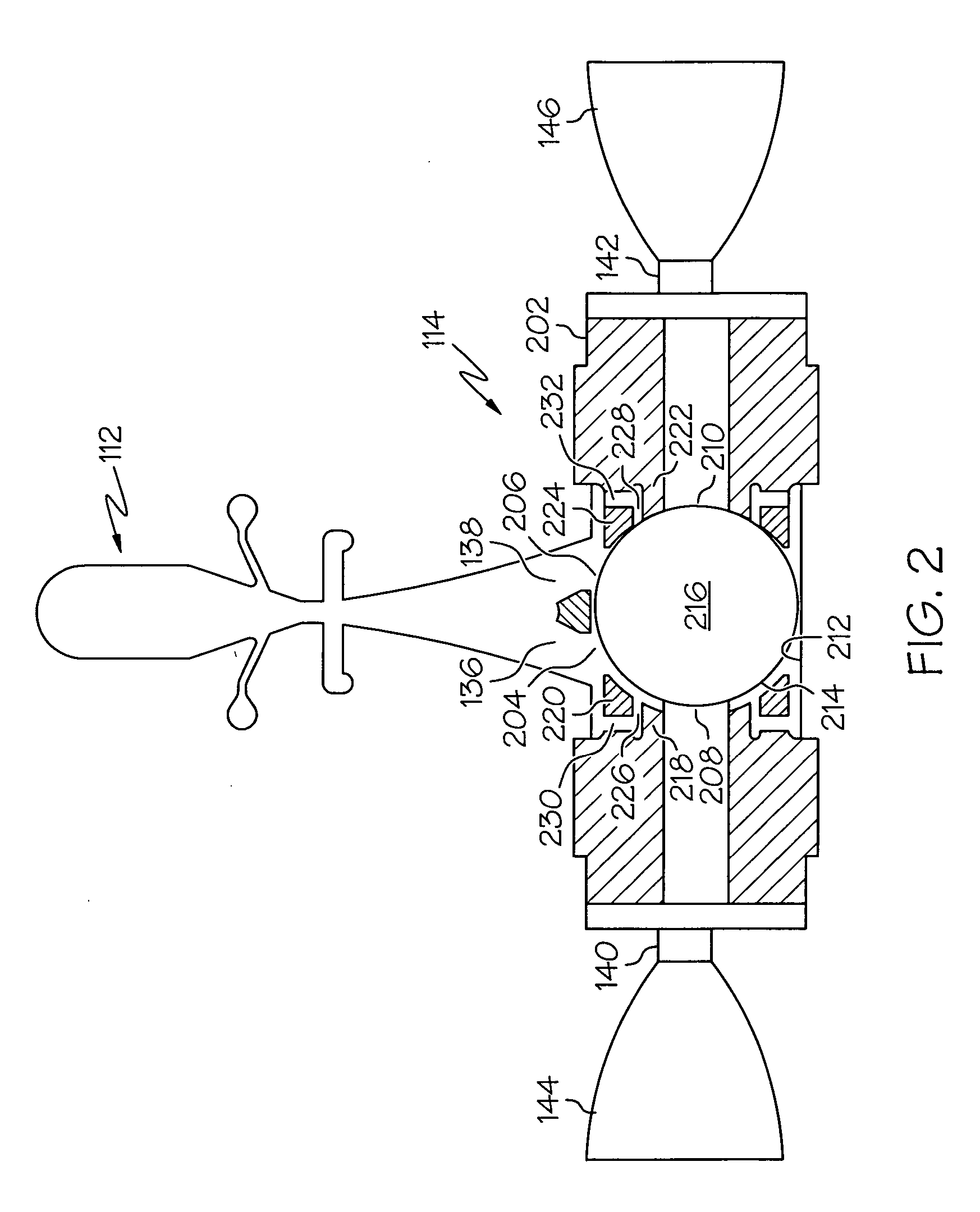

System for releasing gas into molten metal

InactiveUS20080213111A1Reduce amountIncrease the cross-sectional areaSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

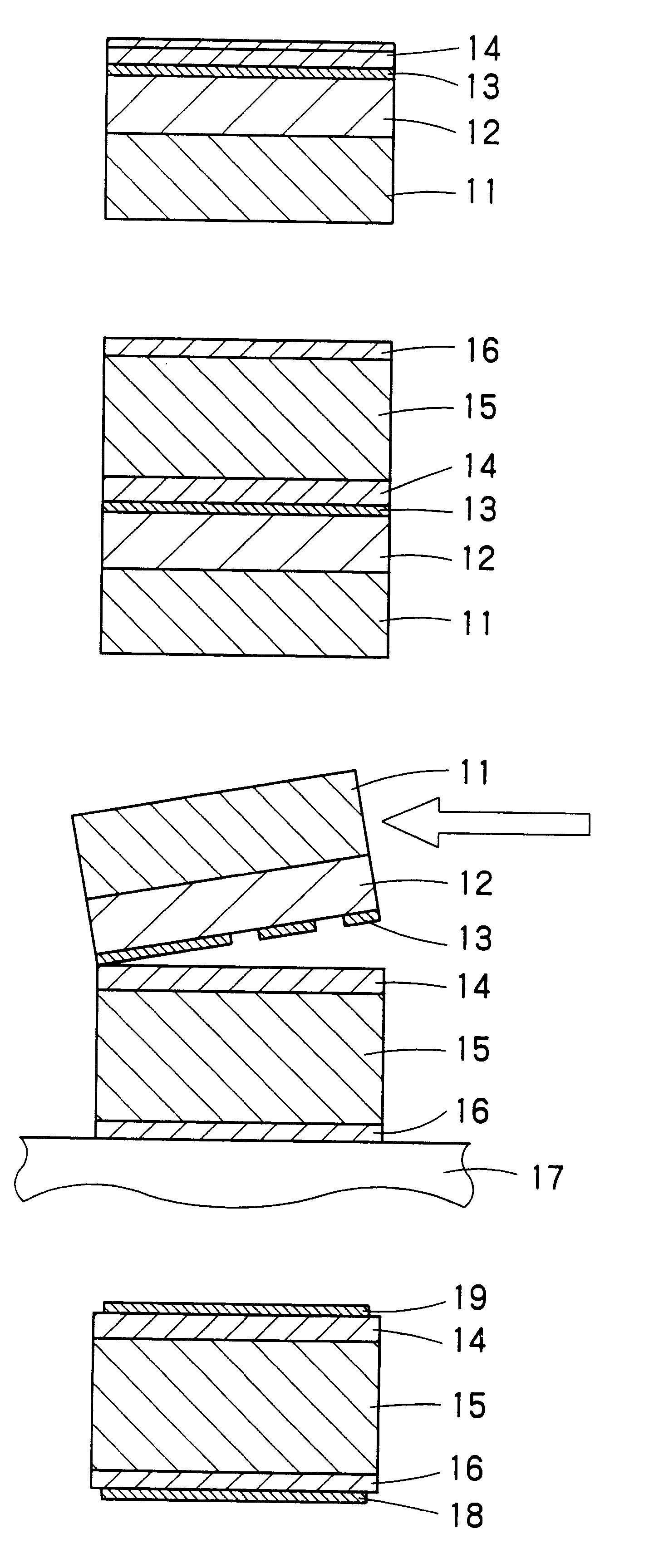

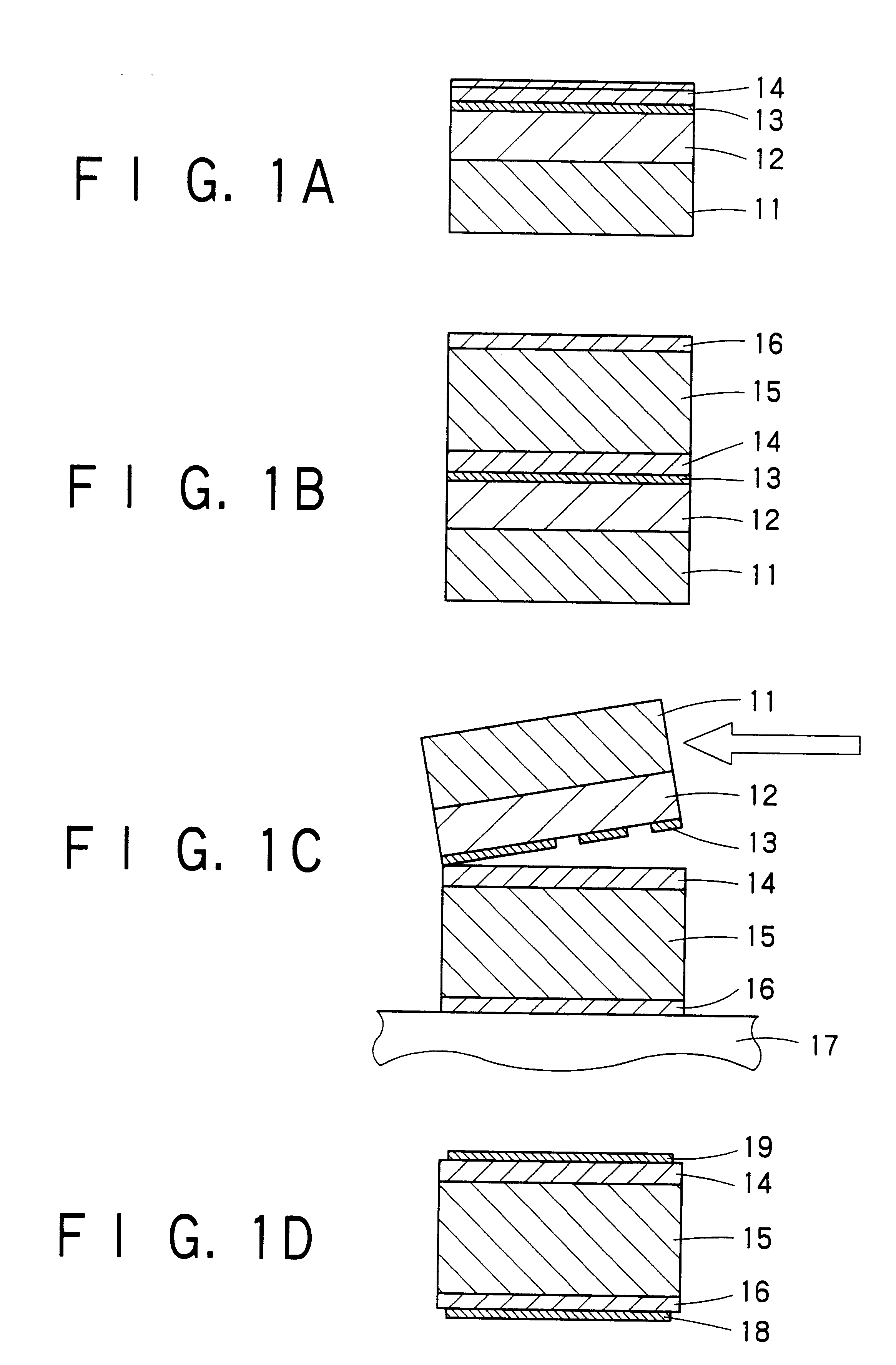

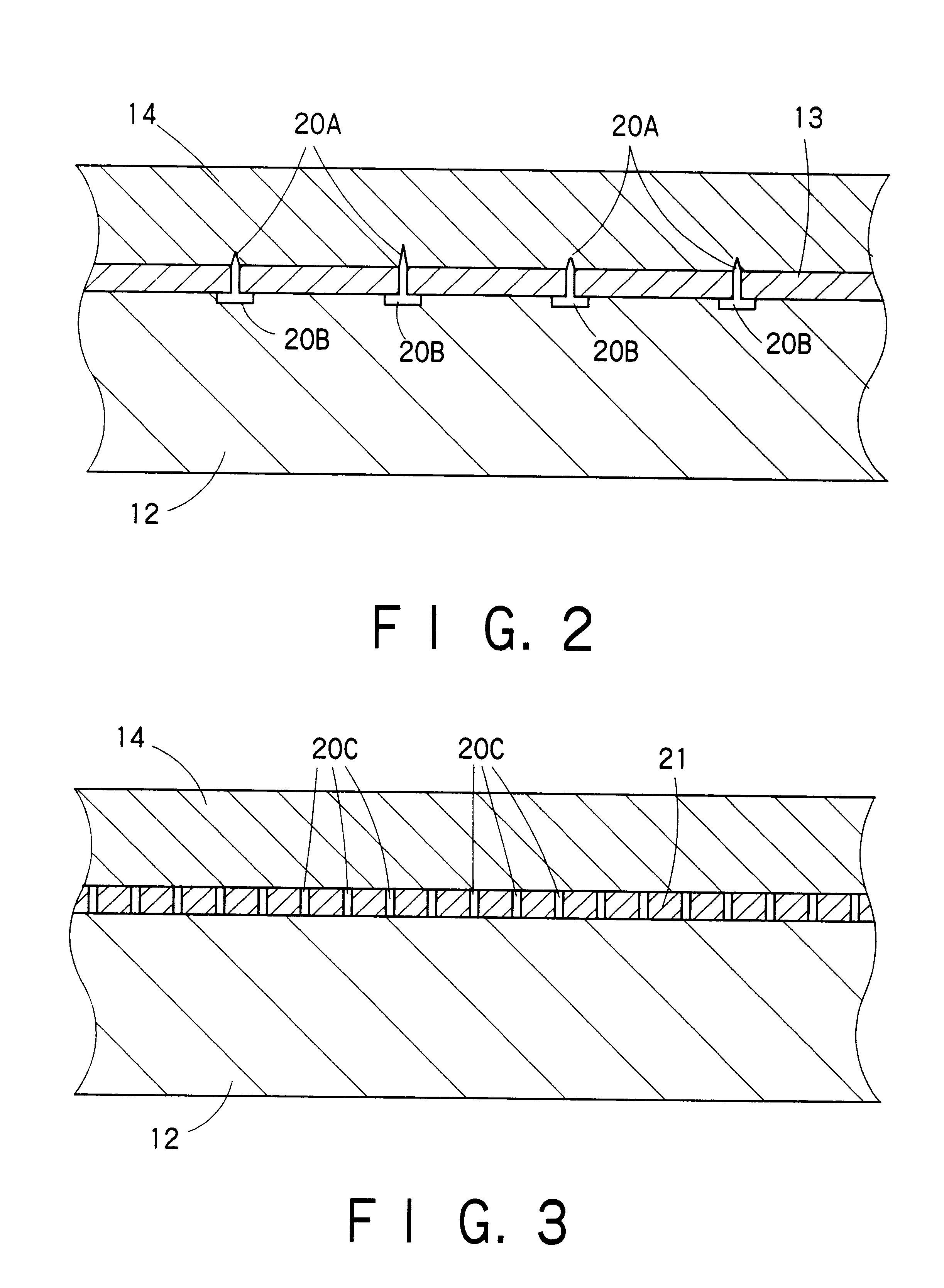

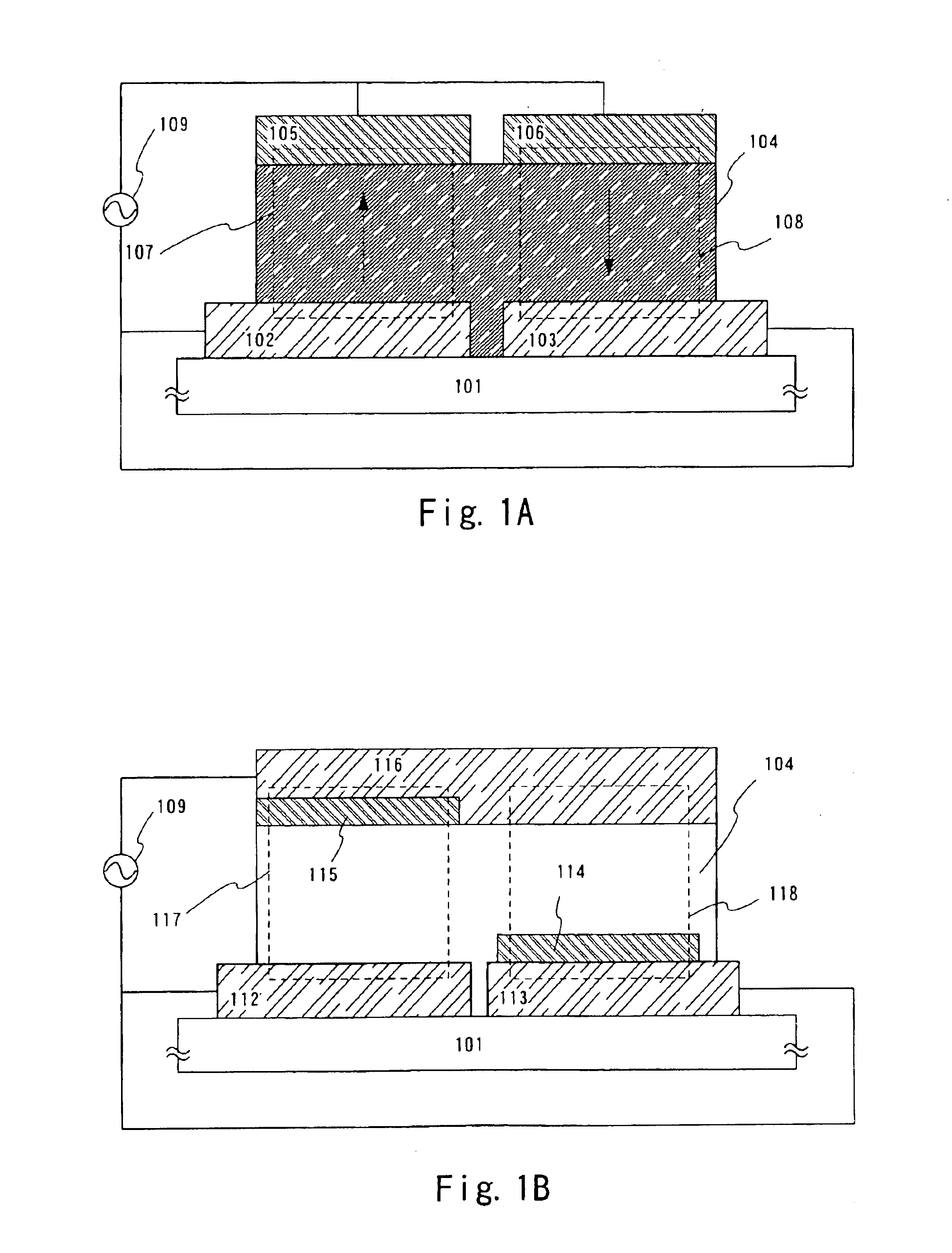

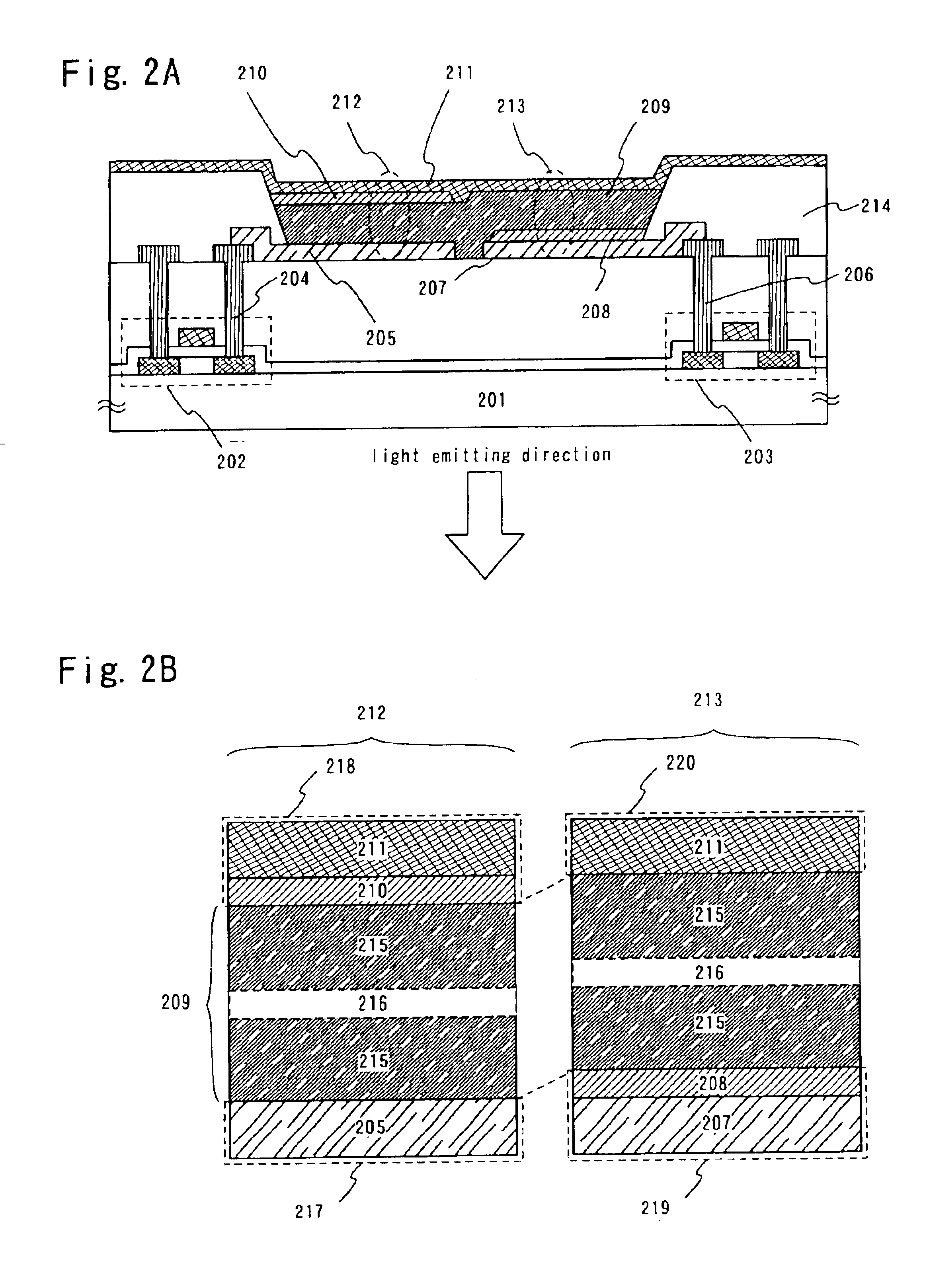

Light emitting device and manufacturing method thereof

InactiveUS20030094612A1Drop in brightness can be suppressedExtended component lifeElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsAlternating current

A light emitting device is provided, which uses alternating current drive as a method of driving the light emitting device, and in which light emission is always obtained when voltages having different polarities are alternately applied, and a method of manufacturing the light emitting device is also provided. A first light emitting element made from an anode, an organic compound layer, and a cathode, and a second electrode made from an anode, an organic compound layer, and a cathode are formed. The light emitting elements are formed sandwiching the same organic compound layer. The anode of the first light emitting element and the anode of the second light emitting element, and the cathode of the first light emitting element and the cathode of the second light emitting element, are formed on opposite sides of the organic compound layer, respectively, thus sandwiching the organic compound layer. Note that voltages having an inverse polarity are applied alternately by the alternating current drive, and therefore light can always be emitted by any one of the first light emitting element or the second light emitting element.

Owner:SEMICON ENERGY LAB CO LTD

System for releasing gas into molten metal

InactiveUS20080211147A1Reduce amountIncrease the cross-sectional areaMelt-holding vesselsSpecific fluid pumpsMetallurgyProduct gas

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

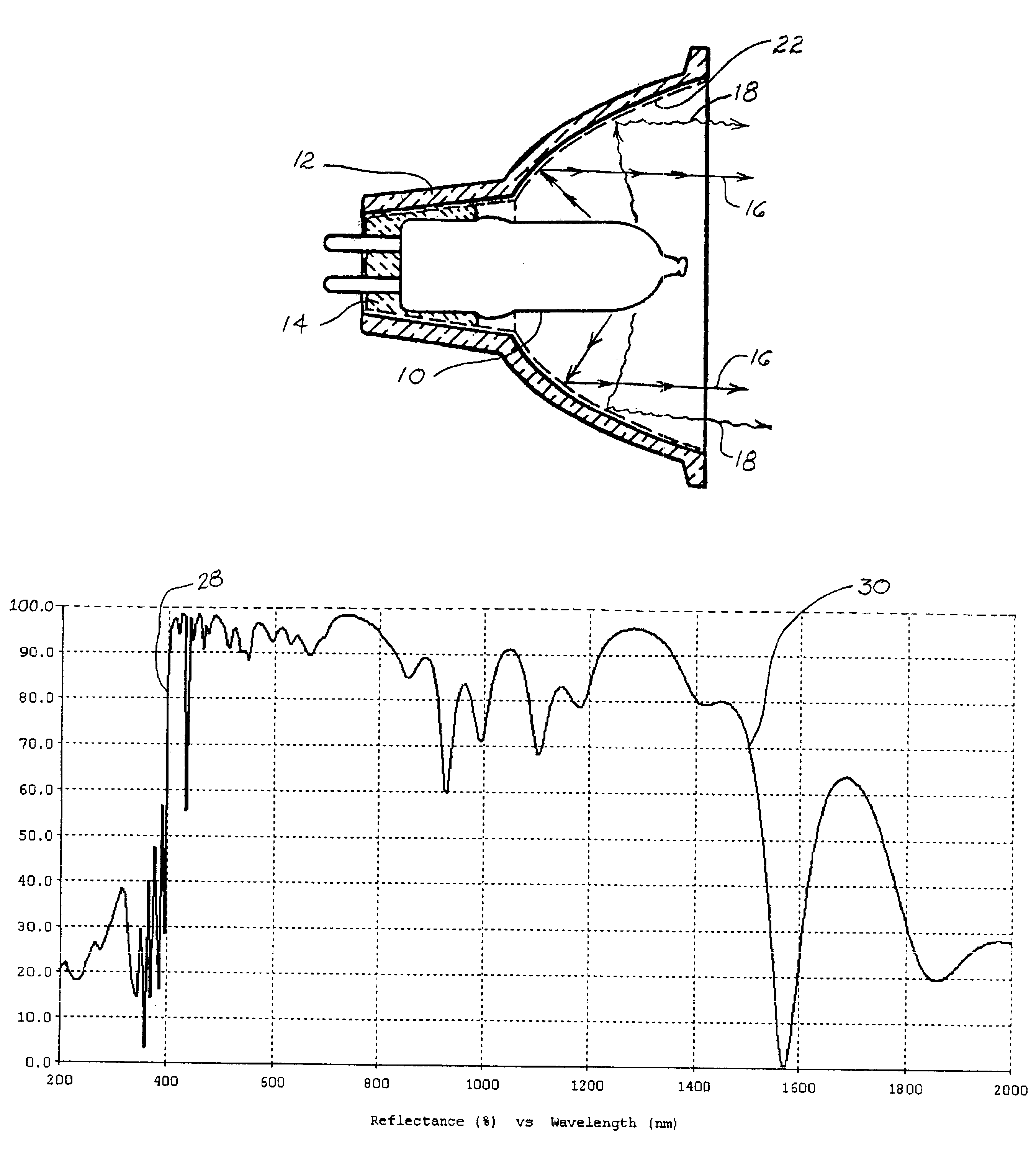

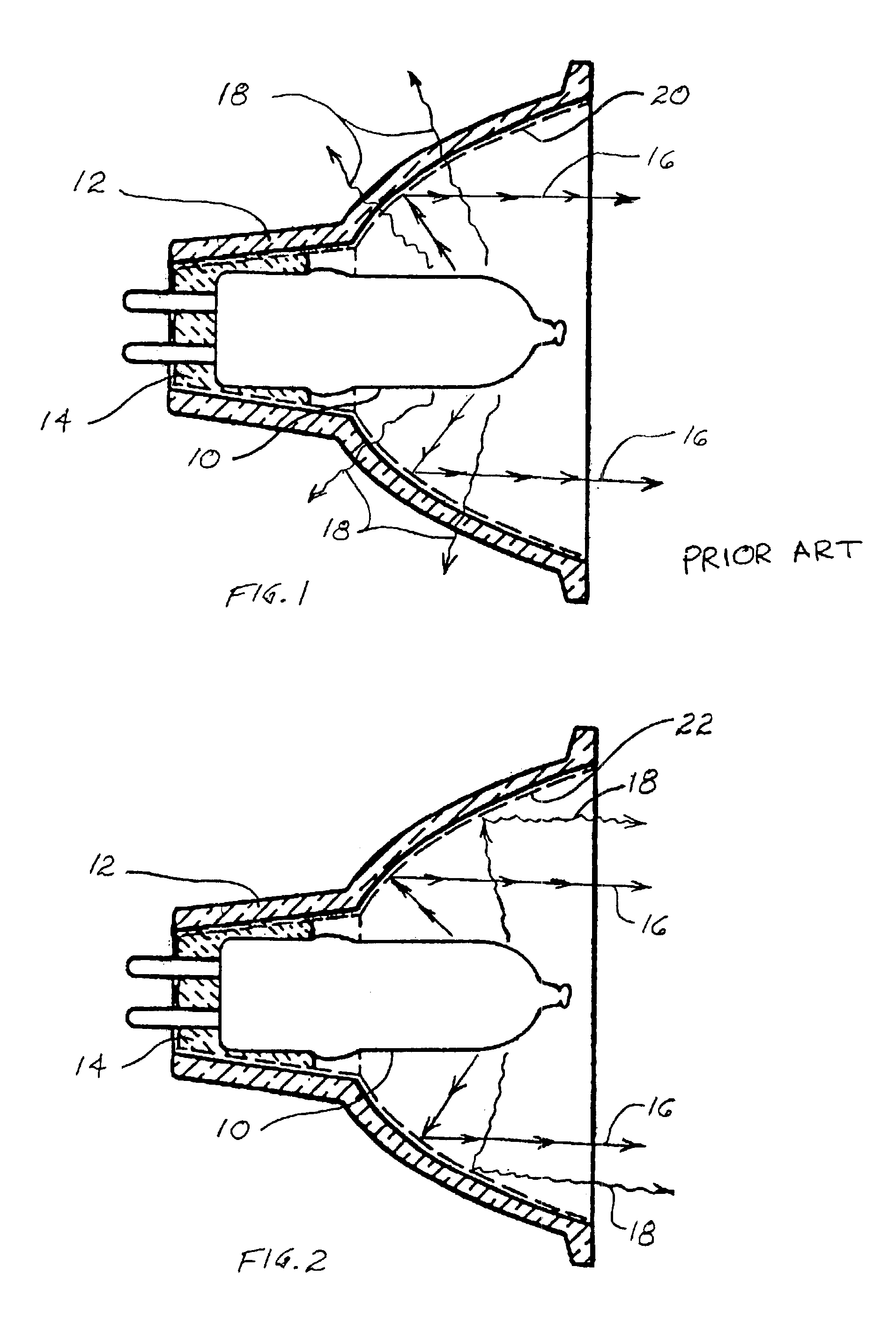

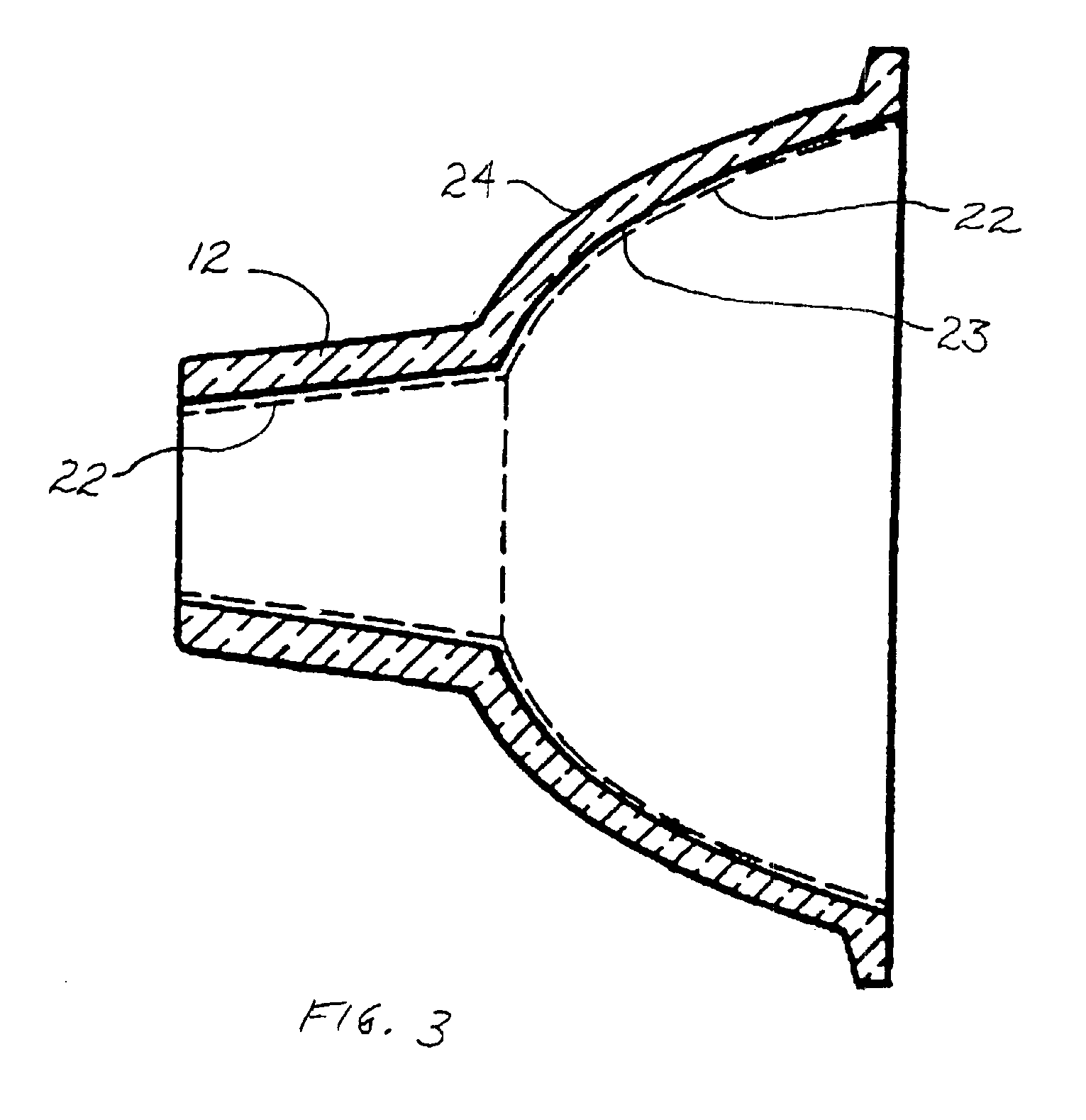

Broad spectrum reflective coating for an electric lamp

InactiveUS6534903B1Eliminate the effects ofReduce amountIncadescent screens/filtersMirrorsRefractive indexElectromagnetic spectrum

An interference coating (22) for reflecting both visible light and a portion of the region of the infrared spectrum is disclosed. The coating includes a dichroic structure of a plurality of layers of a material having a low index of refraction and a plurality of layers of a material having a high index of refraction. The coating has an average spectral high reflectance of at least 80% for wavelengths in the visible light section of the electromagnetic spectrum and of at least 50% for wavelengths in a portion of the infrared section of the electromagnetic spectrum at least 150 nm wide.

Owner:GENERAL ELECTRIC CO

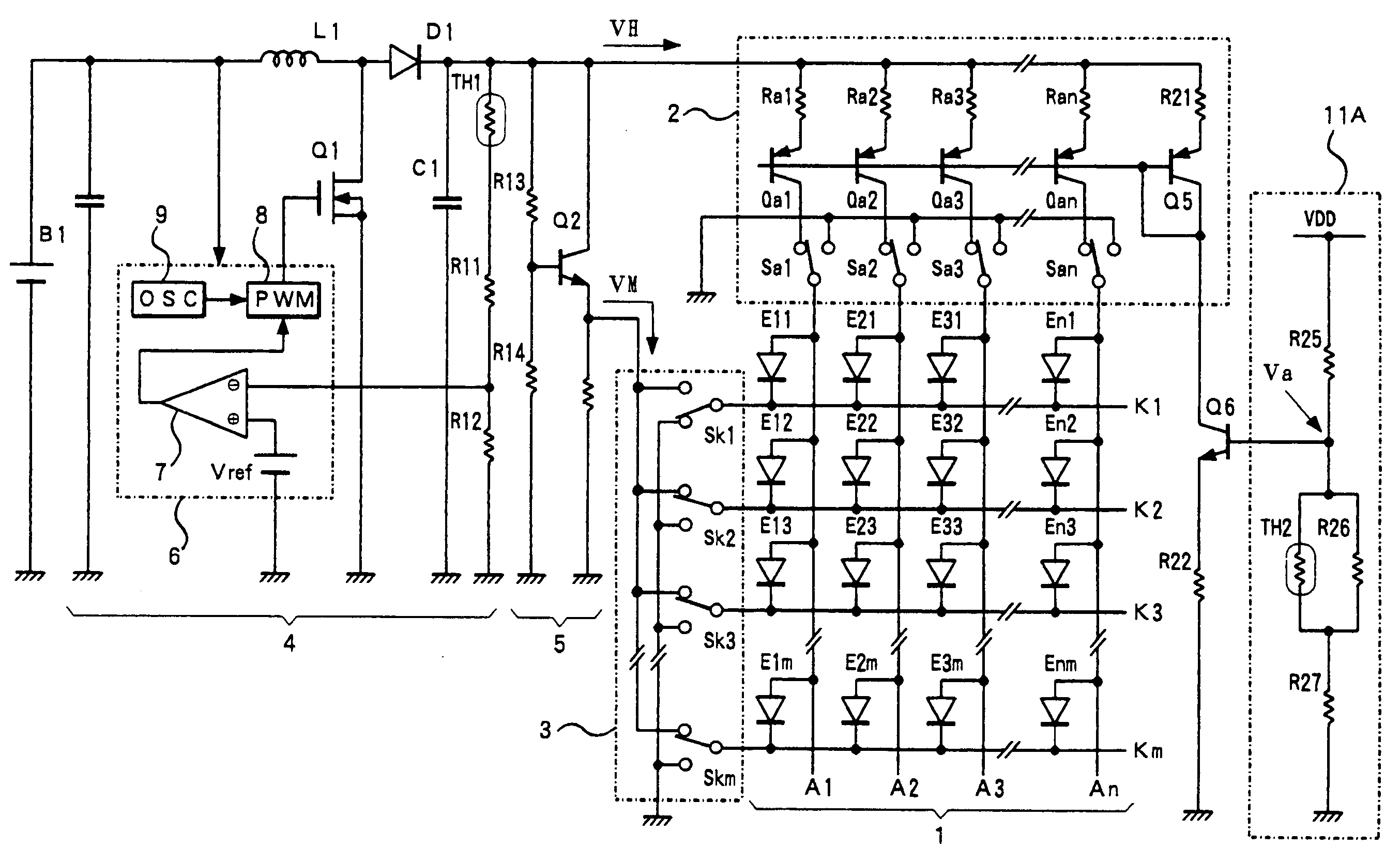

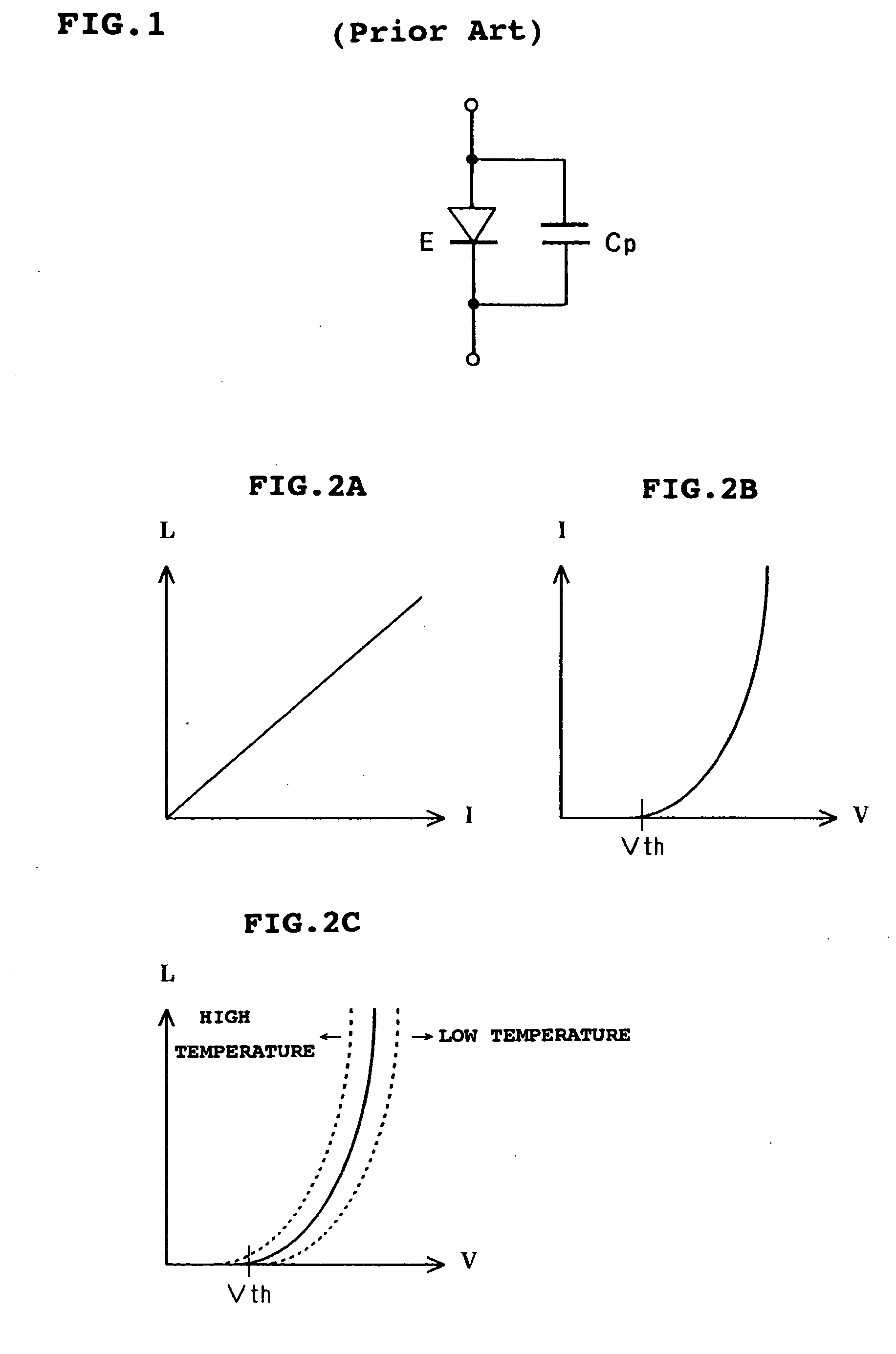

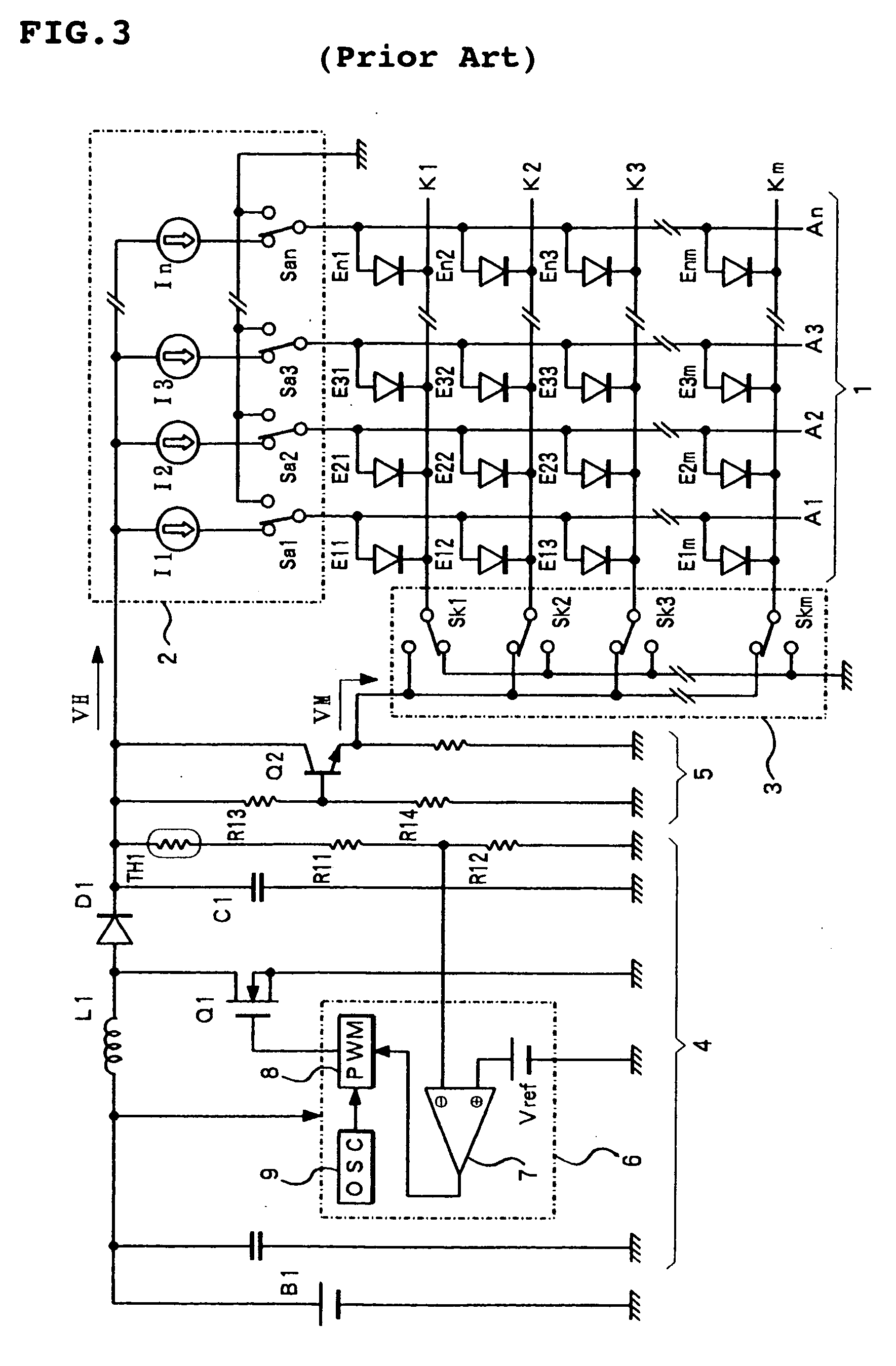

Drive method and drive device of a light emitting display panel

InactiveUS20050012698A1Prolonged life timeExtended component lifeTelevision system detailsStatic indicating devicesThermistorEngineering

The present invention is to provide a drive device which can prolong the lifetime of light emitting elements constituting a display panel in an environment of a high temperature. A thermistor TH1 is provided in a voltage boosting circuit 4 which drive and light the light emitting elements E11 to Enm in a light emitting display panel 1, and by this thermistor first light emission control means is constituted which drive and light the light emitting elements at an approximately constant light emission intensity value regardless of the level of the environmental temperature. Meanwhile, a current mirror circuit is arranged in an anode line drive circuit 2 which supplies a constant current to the respective light emitting elements E11 to Enm, and second light emission control means in which a current value is controlled by a control voltage Va from a temperature detection means 11A provided with a thermistor TH2 is constructed. The second light emission control means drives and lights the light emitting elements so that the intensity value becomes smaller than the constant light emission intensity value controlled by the first light emission control means in the case where a state in which the environmental temperature exceeds a predetermined value (for example, 50° C.) is detected.

Owner:TOHOKU PIONEER CORP

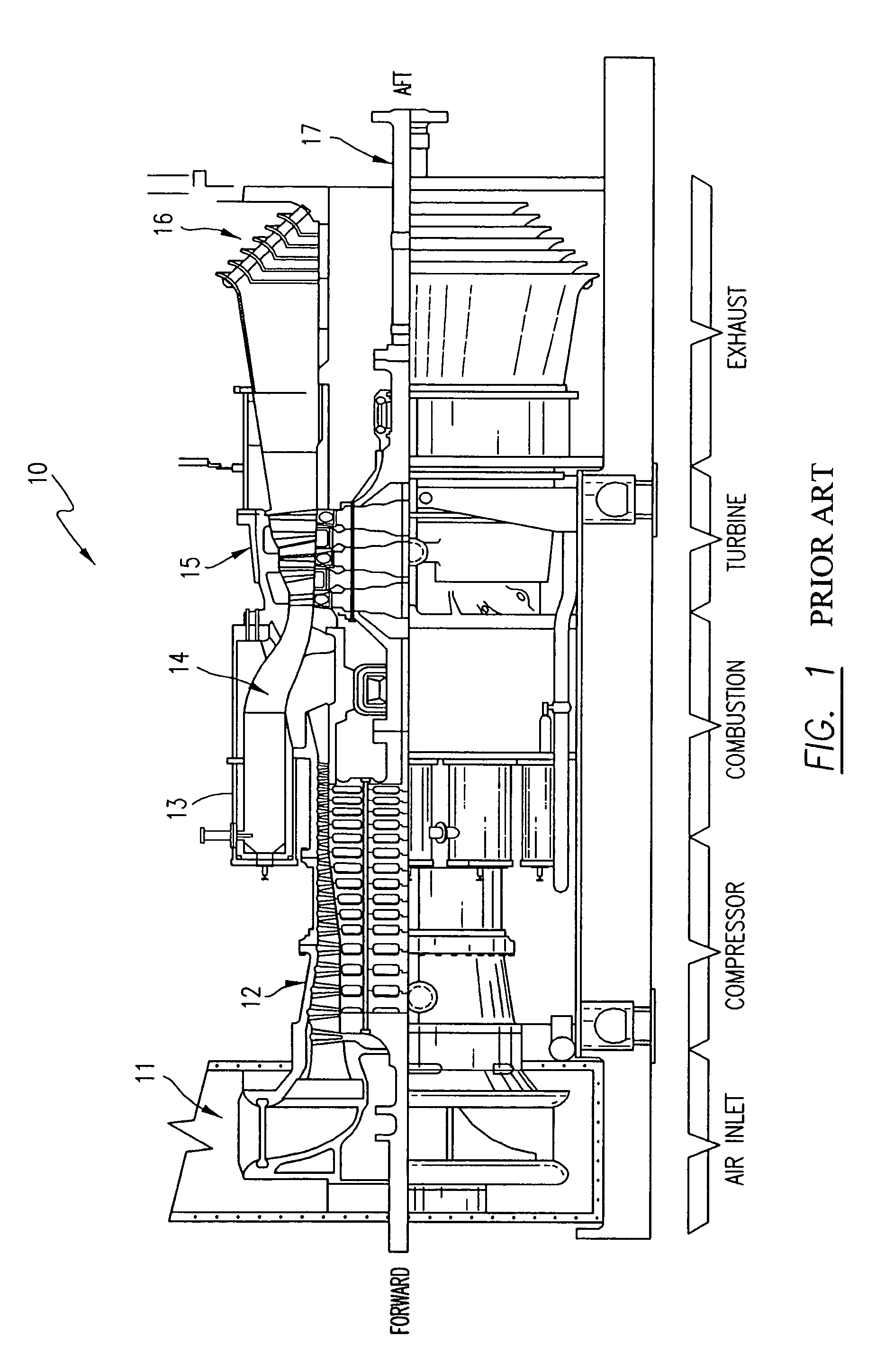

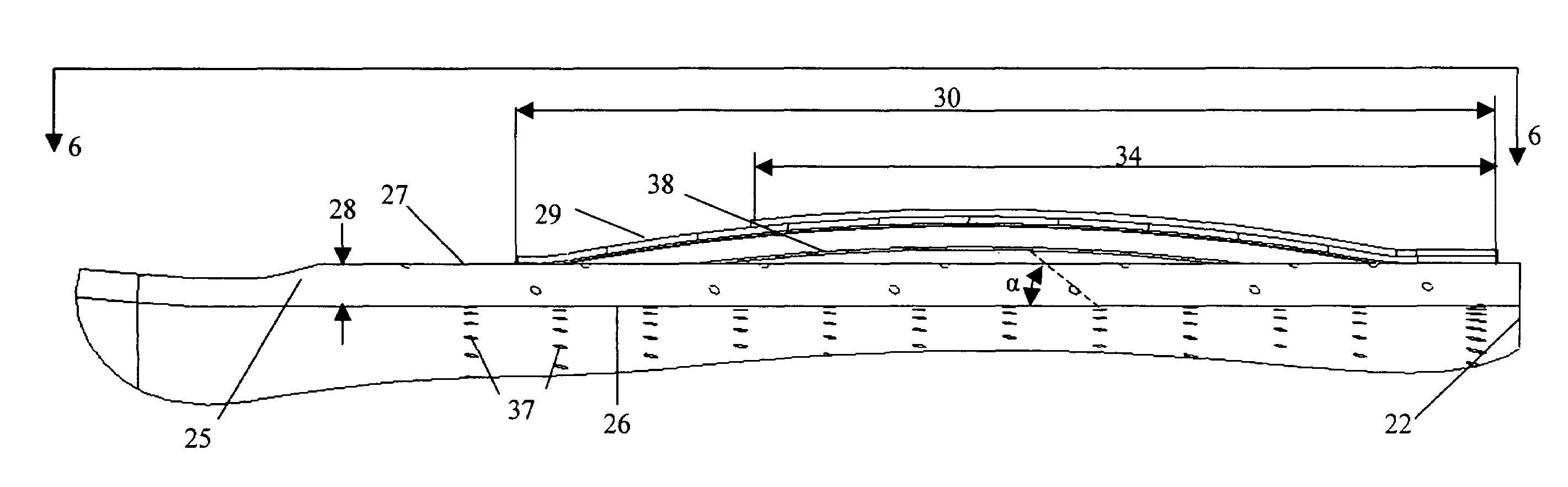

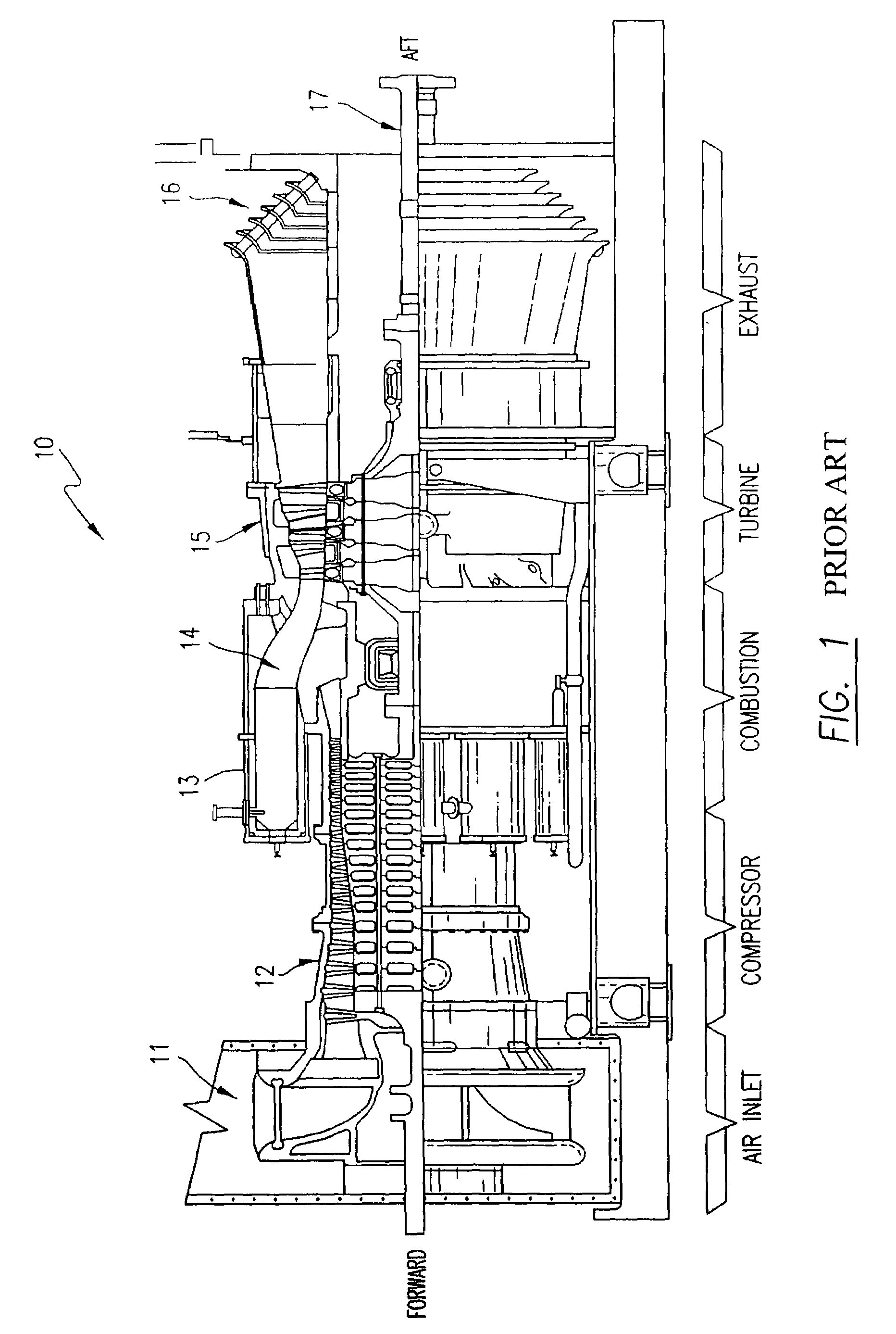

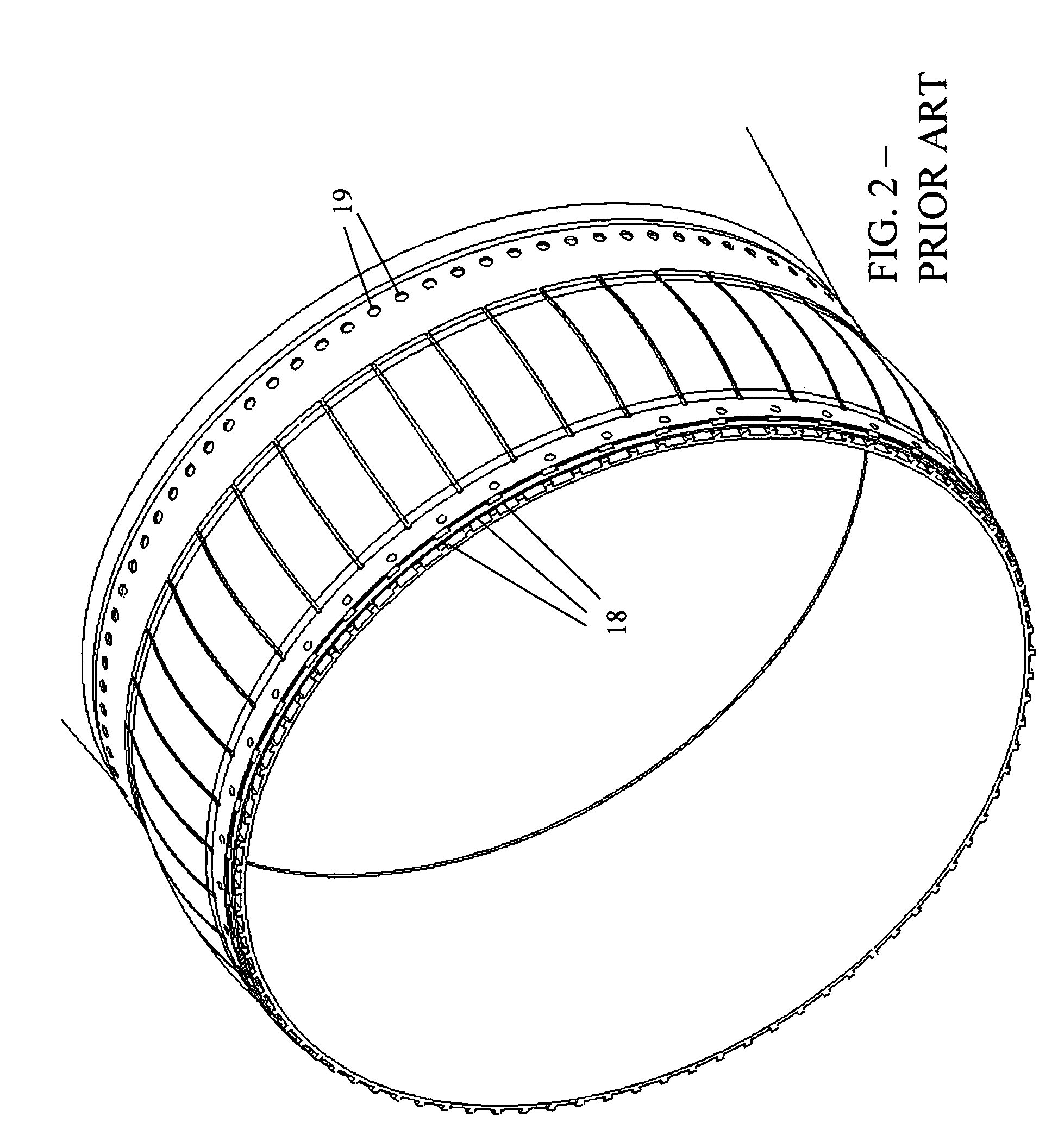

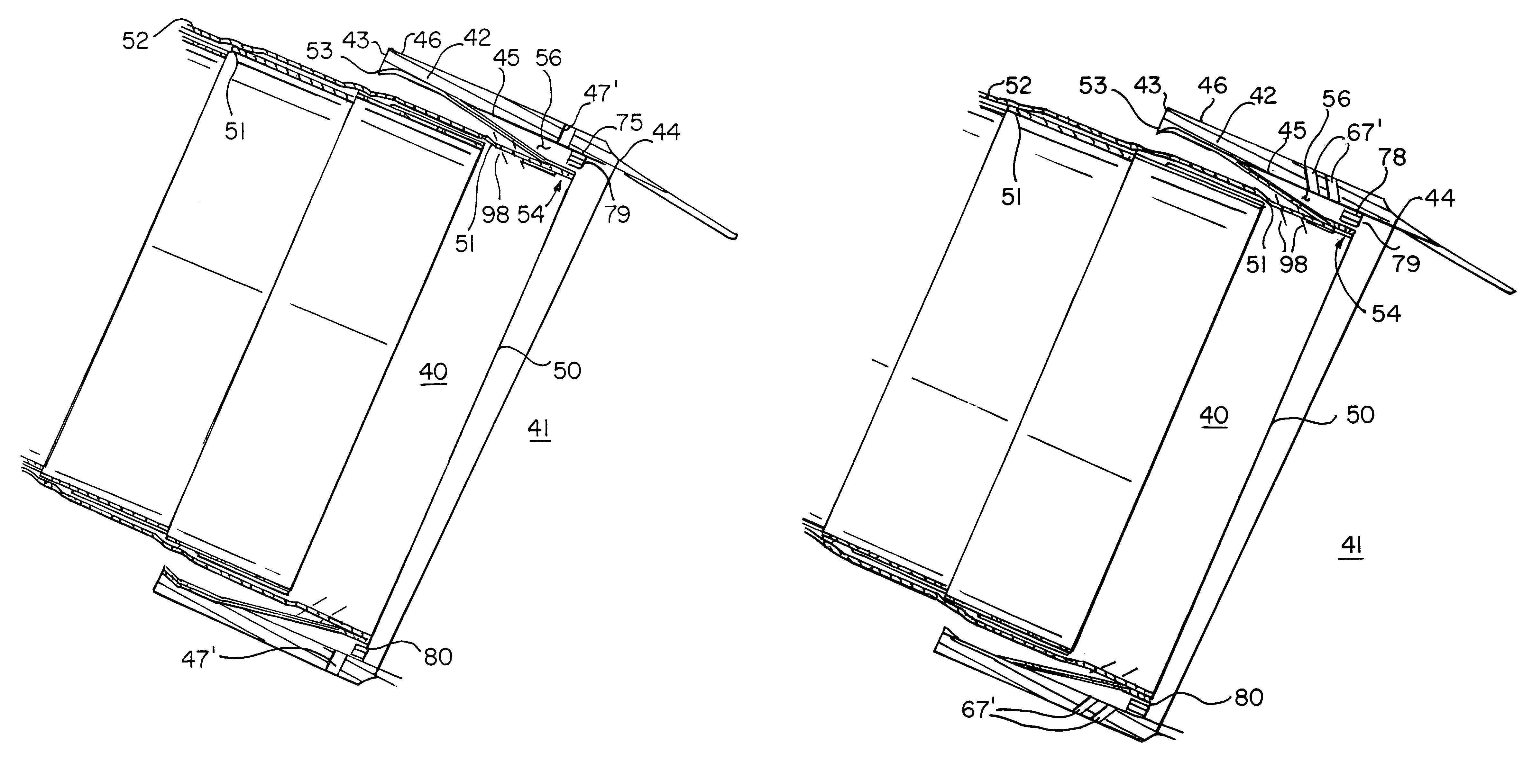

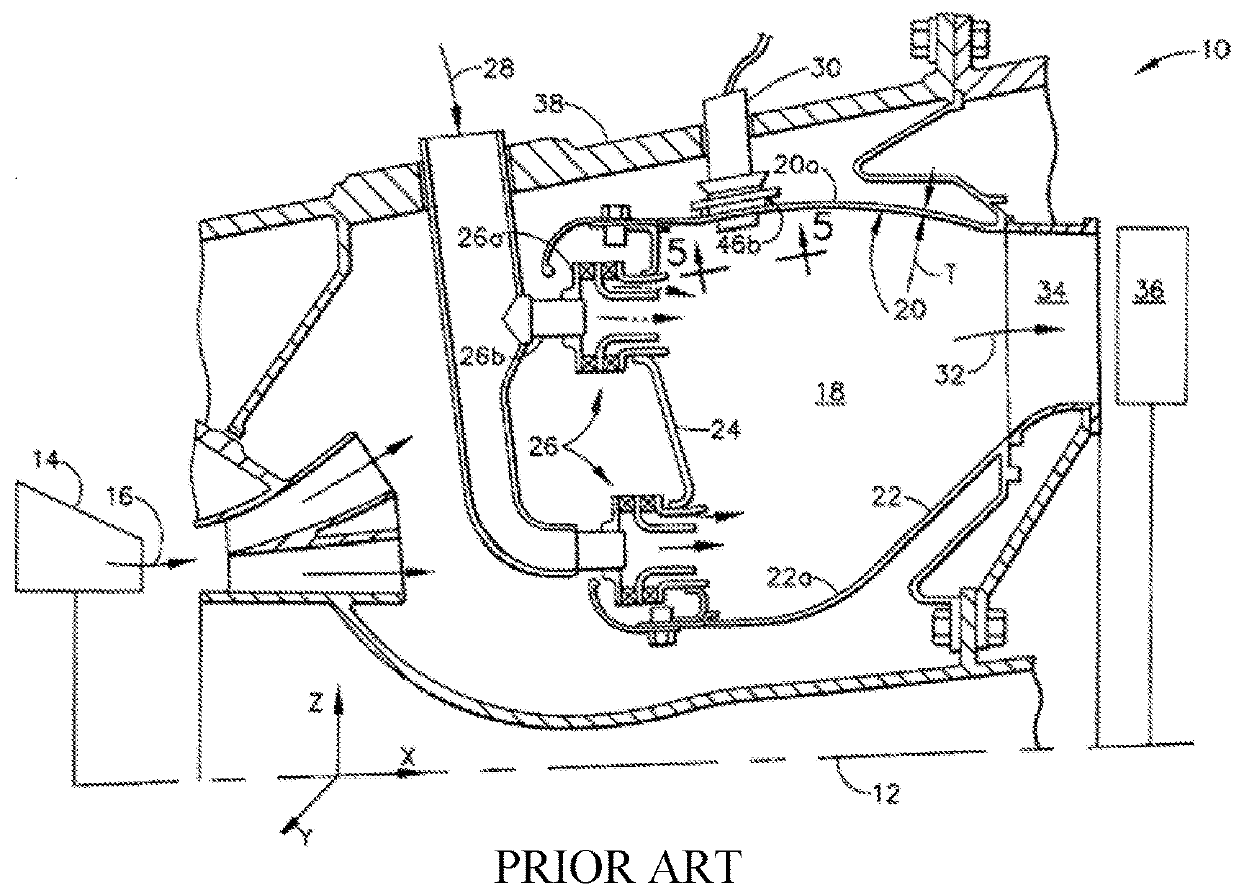

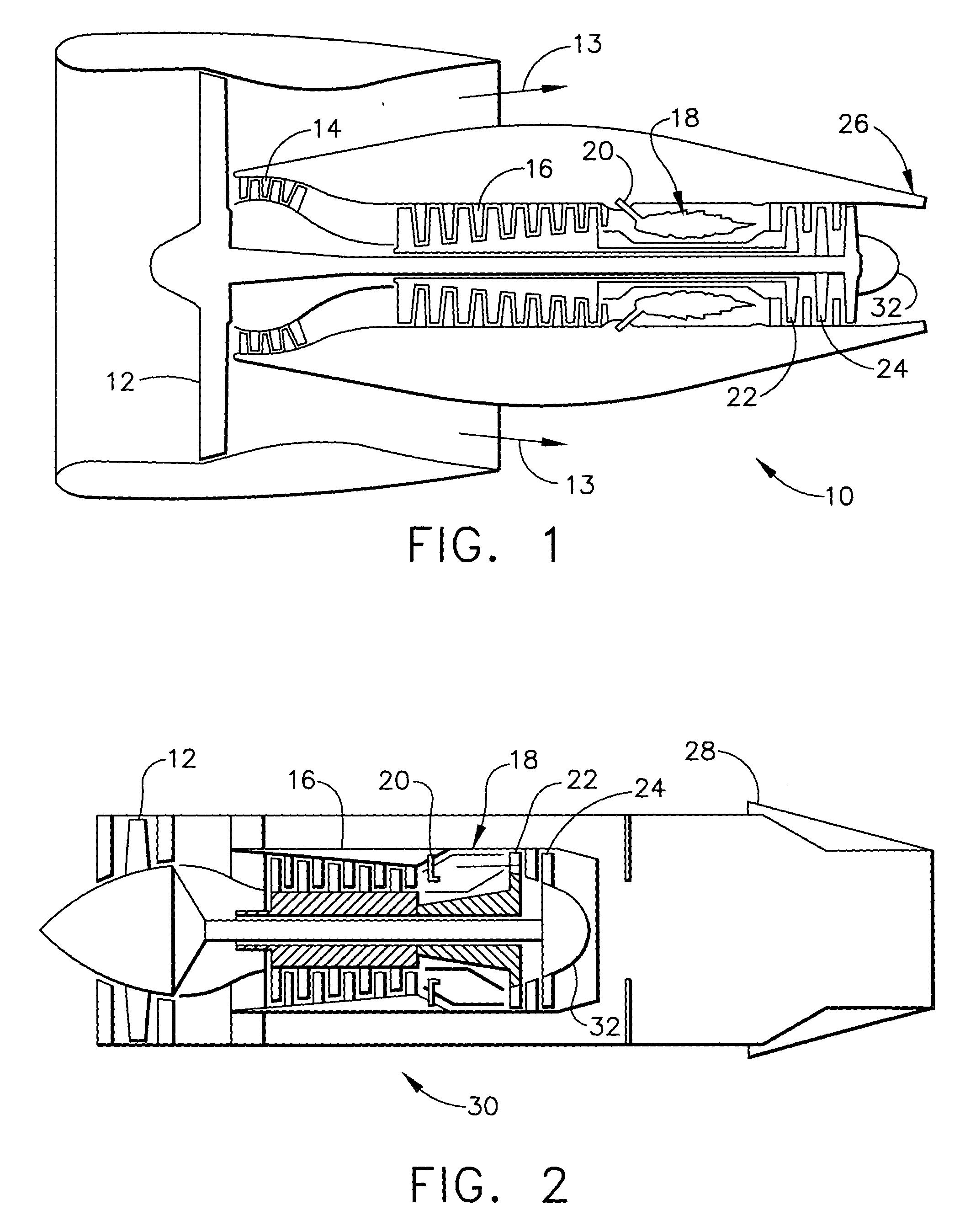

Combustion liner seal with heat transfer augmentation

ActiveUS7007482B2Extended component lifeImprove effectivenessContinuous combustion chamberTurbine/propulsion engine coolingCombustionCooling fluid

A gas turbine combustion liner is disclosed having an alternate interface region between it and a transition duct where the cooling effectiveness and heat transfer along the aft end of the combustion liner is improved, resulting in extended component life. The region of the combustion liner proximate its second end comprises a plurality of first feed holes, a plurality of spring seals that seal against a transition duct, a cooling ring having a plurality of second feed holes, that with the first feed holes pass a cooling fluid into an annulus formed between the cooling ring and combustion liner. The cooling fluid passes over a means for augmenting the heat transfer proximate the combustion liner second end, wherein the heat transfer augmentation preferably comprises a plurality of raised ridges that increases the surface area of the outer liner wall to turbulate the cooling fluid and maximize the cooling effectiveness.

Owner:H2 IP UK LTD

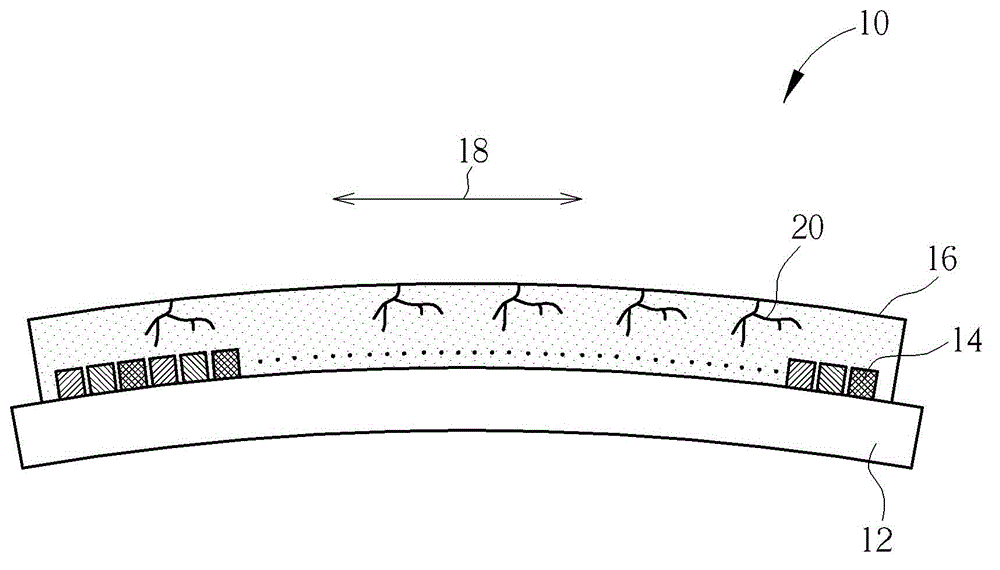

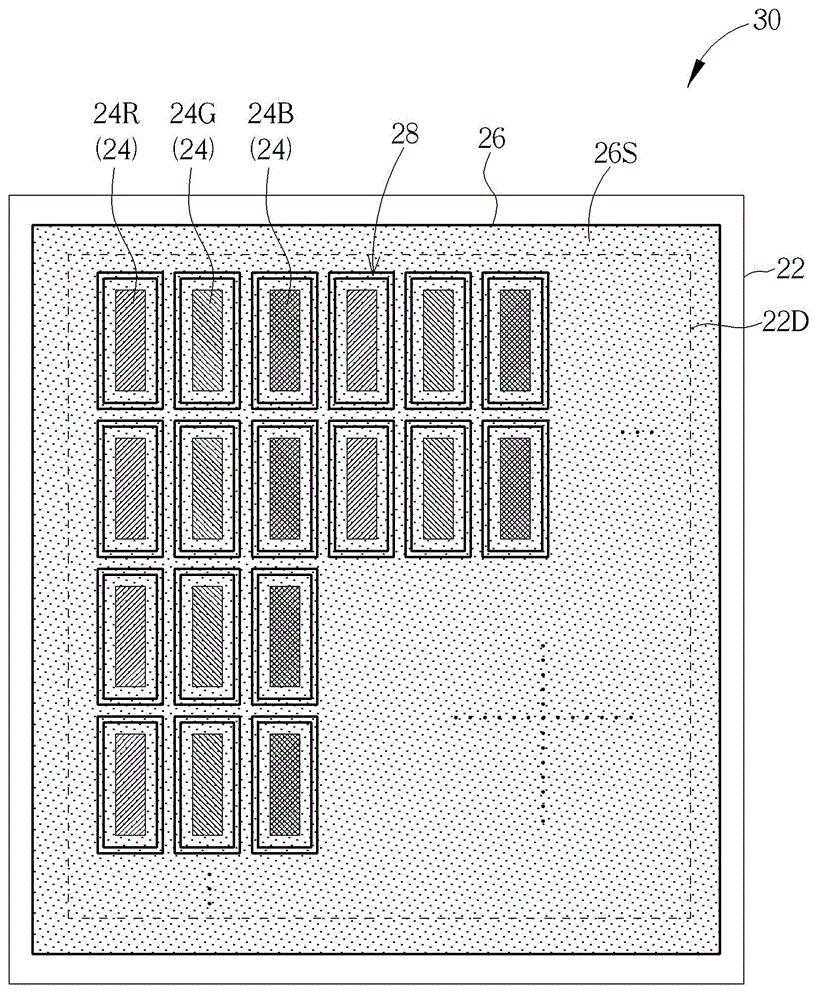

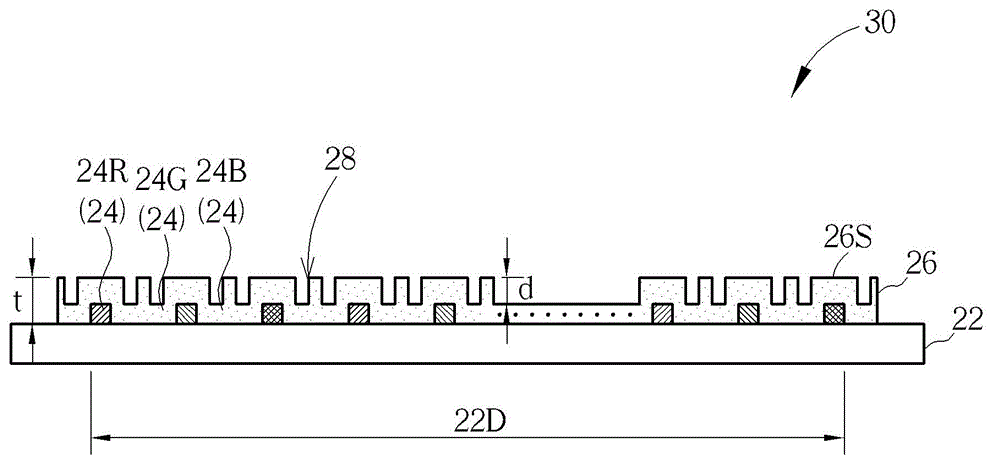

Flexible display panel

ActiveCN103150965AAvoid cracksReduce the chance of water and oxygen intrusionSolid-state devicesIdentification meansEngineeringFlexible display

The invention relates to a flexible display panel comprising a flexible substrate, a plurality of display elements arranged on the flexible substrate, and at least one packaging film layer covering the display elements. An upper surface of the packaging film layer is equipped with a plurality of grooves which at least correspond to a part of the adjacent display elements. The flexible display panel helps to solve problems that a conventional packaging film layer is liabe to crack.

Owner:AU OPTRONICS CORP

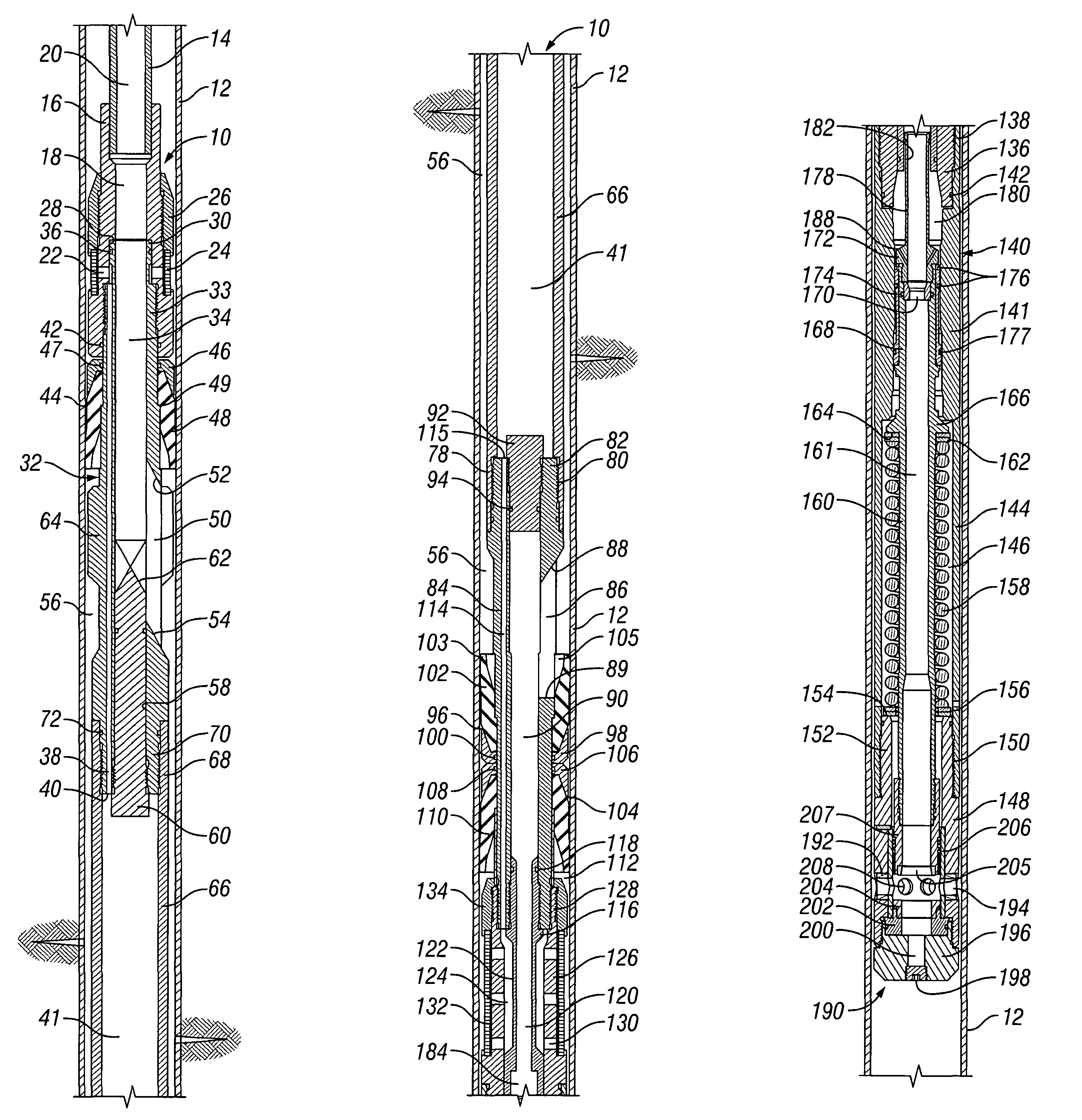

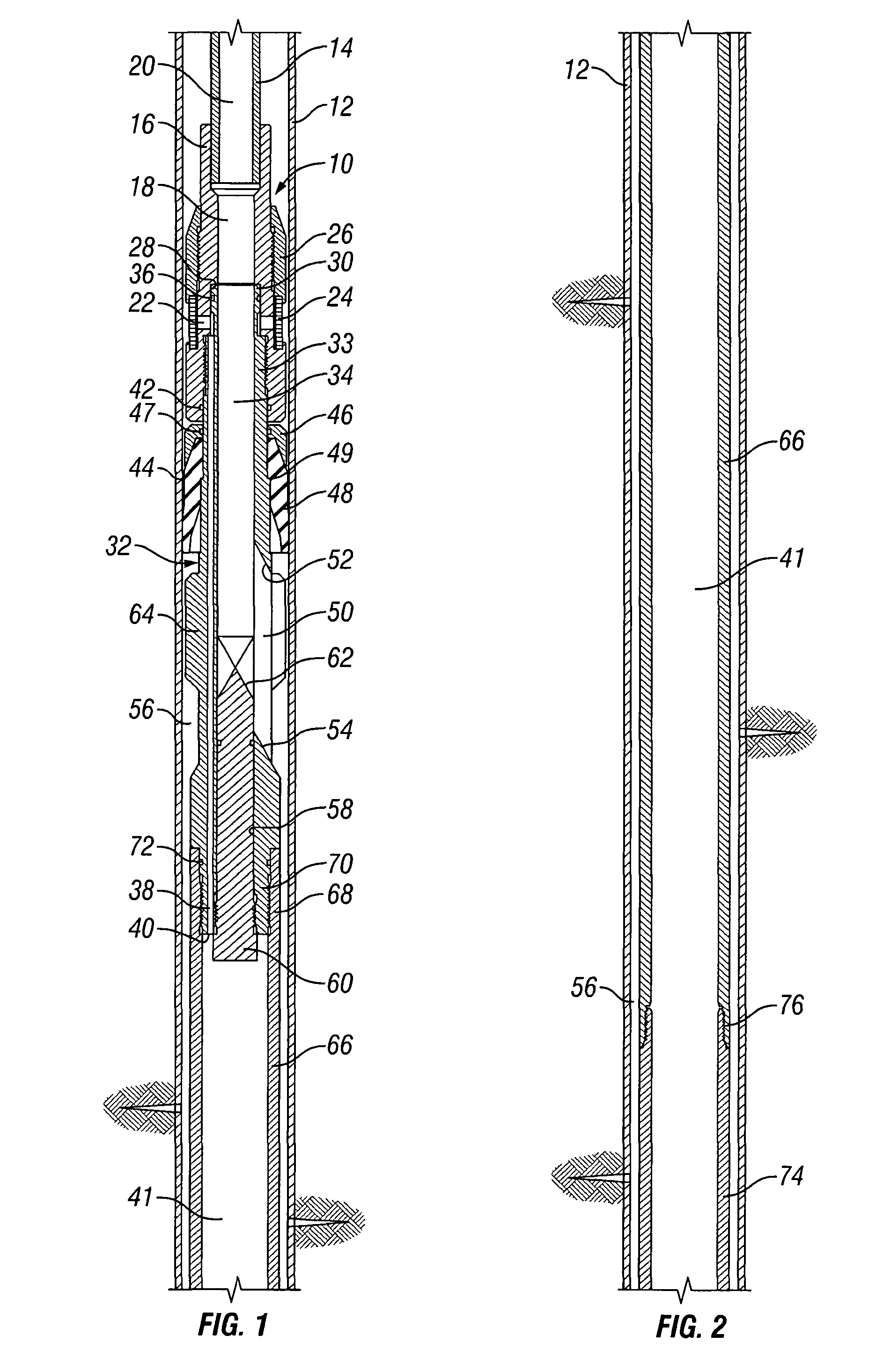

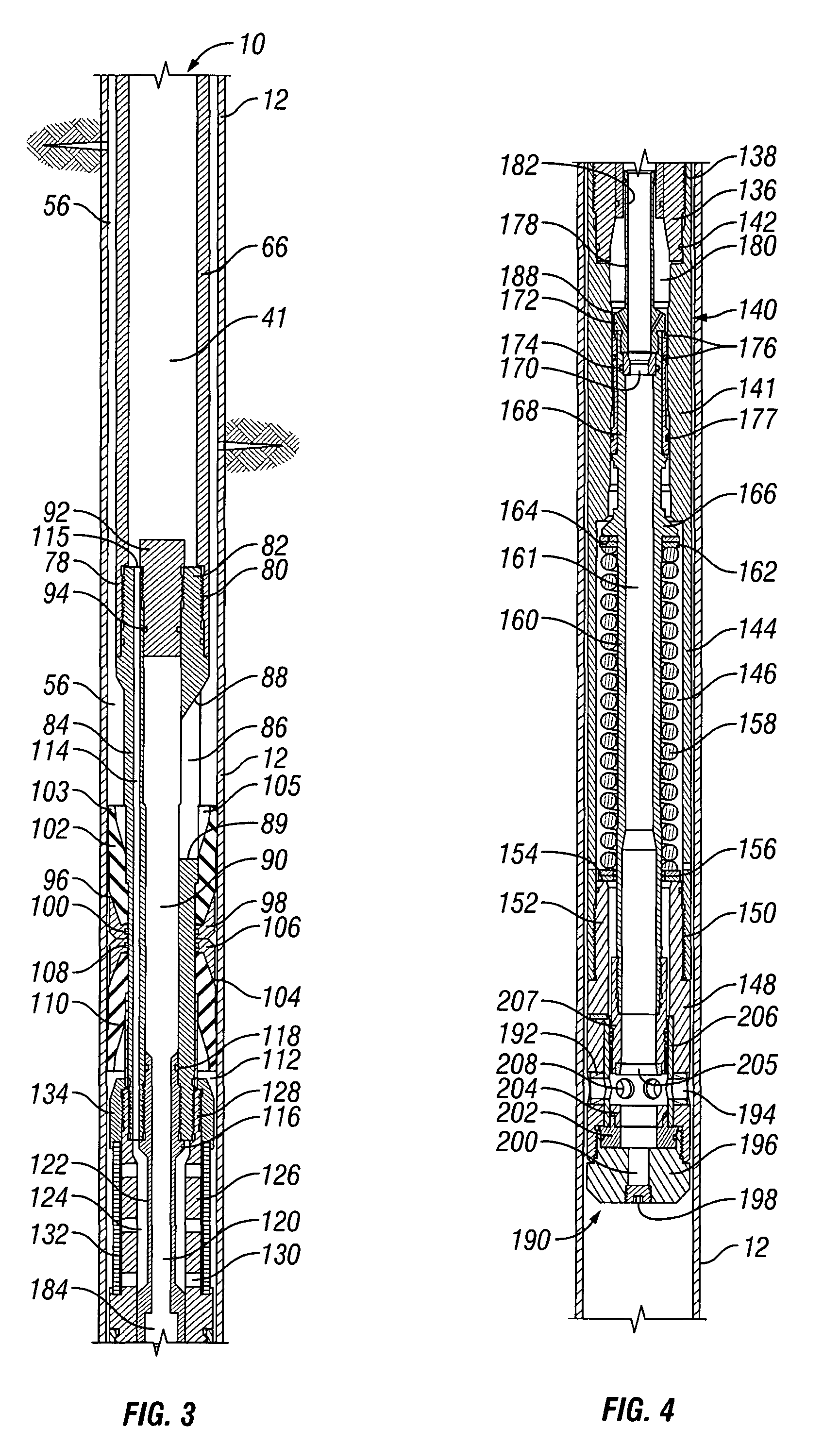

Method and apparatus for cleaning a fractured interval between two packers

InactiveUS7011157B2Minimize erosive wearEasy to moveCleaning apparatusFluid removalFracturing fluidEngineering

A method and apparatus for fluid treatment of a selected interval of a well and then cleaning the selected interval and the apparatus of treatment residue. An straddle tool is run into the well to treatment depth on fluid supplying tubing and has upper and lower packers that establish sealing with the casing and define an annular interval between the packers and between the tool and casing. Fluid, such as fracturing fluid, is pumped through the tubing to the tool and is diverted through an outlet port of the tool into an upper portion of the annular interval. Fluid then flows from a lower portion of the annular interval through an inlet port below the outlet port and at low flow rate is dumped into the casing through a pressure responsive dump valve. The outlet port and inlet port are located to accomplish cleaning of residue from the packers.

Owner:SCHLUMBERGER TECH CORP

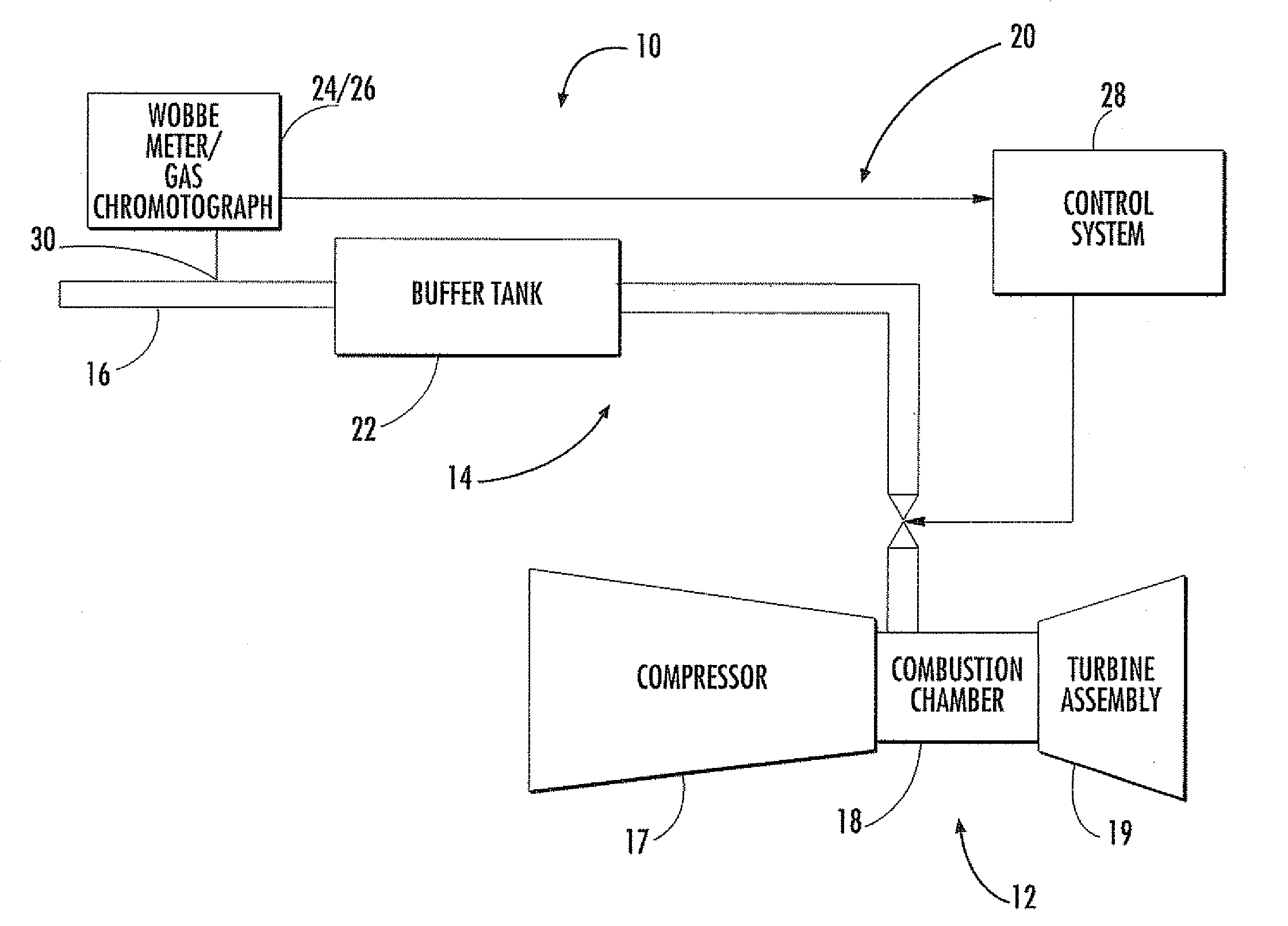

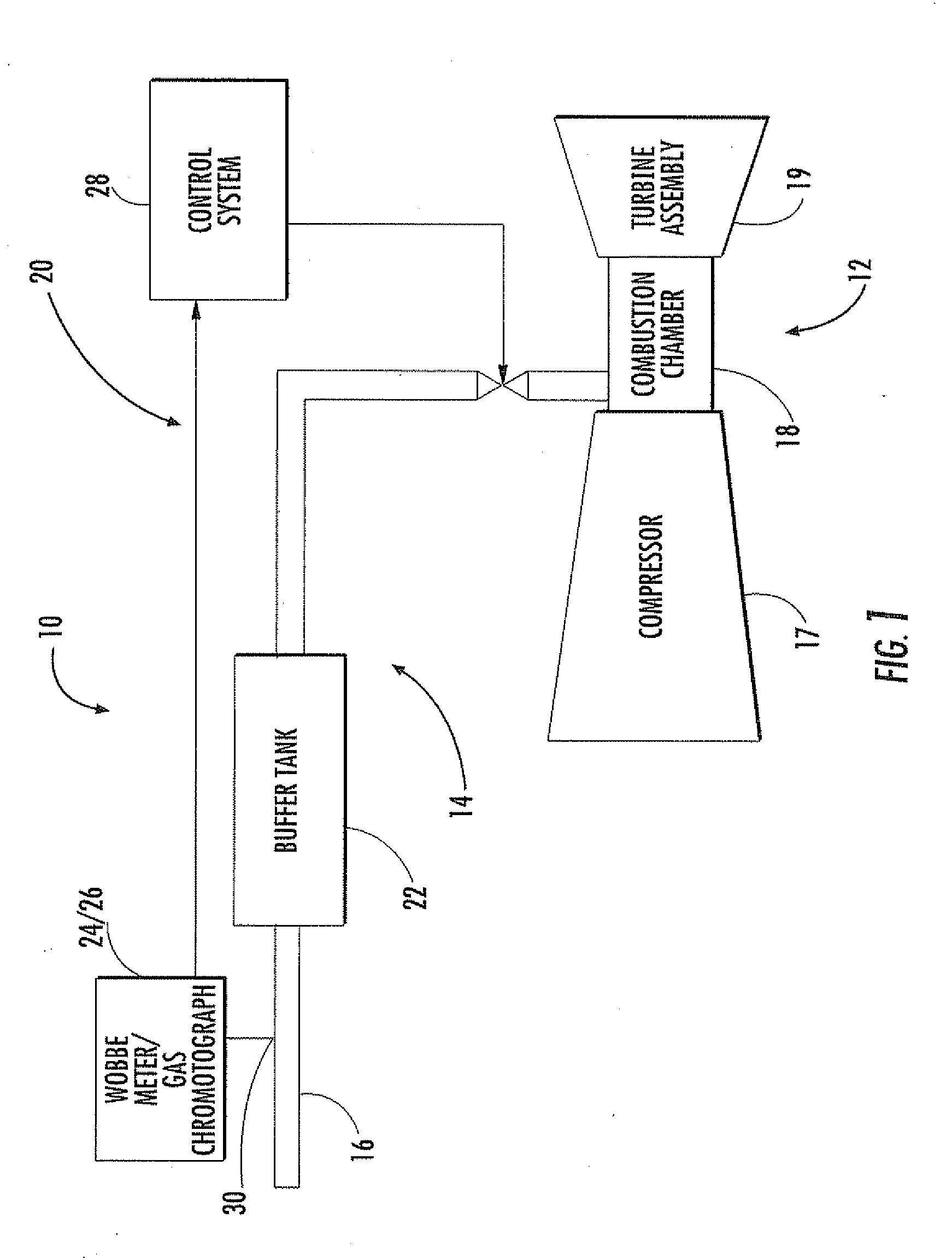

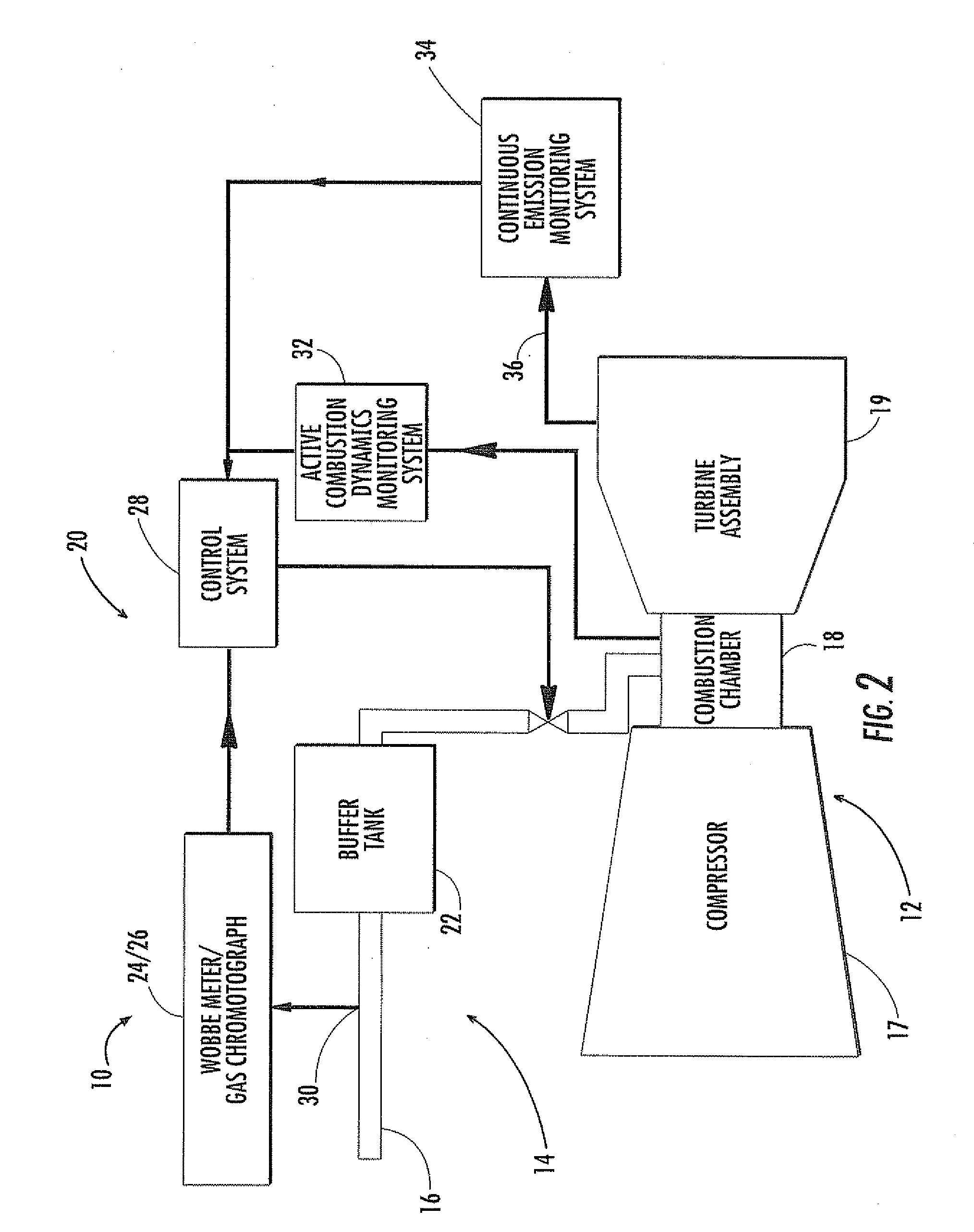

Integrated Fuel Gas Characterization System

InactiveUS20080115482A1Reduce temperature peaksAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlBuffer tankEngineering

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, and an integrated fuel gas characterization system. The integrated fuel gas feed system can include a buffer tank. The integrated fuel gas characterization system for determining the amount of energy provided by the fuel prior to combustion of the fuel in the combustion stage. The integrated fuel gas characterization system minimizes megawatt swings by adjusting the operating parameters of the gas turbine engine based on the rate of change in fuel gas energy content. The integrated fuel gas characterization system also provides improved turbine engine start-up reliability by tuning the turbine engine operating parameters using fuel gas energy content measurements obtained prior to actual start-up.

Owner:SIEMENS ENERGY INC

Combustion liner having improved cooling and sealing

ActiveUS7269957B2Maximize lengthExtended component lifeContinuous combustion chamberEfficient propulsion technologiesCombustionEngineering

A gas turbine combustion liner is disclosed having an alternate interface region between it and a transition duct where the cooling effectiveness along the aft end of the combustion liner is improved, resulting in extended component life, while utilizing a simpler combustion liner geometry. The region of the combustion liner proximate its second end comprises a plurality of spring seals that seal against a transition duct while admitting a cooling fluid to pass into a passage, formed between the combustion liner and spring seals, that feeds a plurality of cooling holes located in the combustion liner proximate the liner second end. Depending on the cooling requirements, the cooling holes can be angled both axially and circumferentially to maximize the cooling effectiveness.

Owner:ANSALDO ENERGIA SWITZERLAND AG

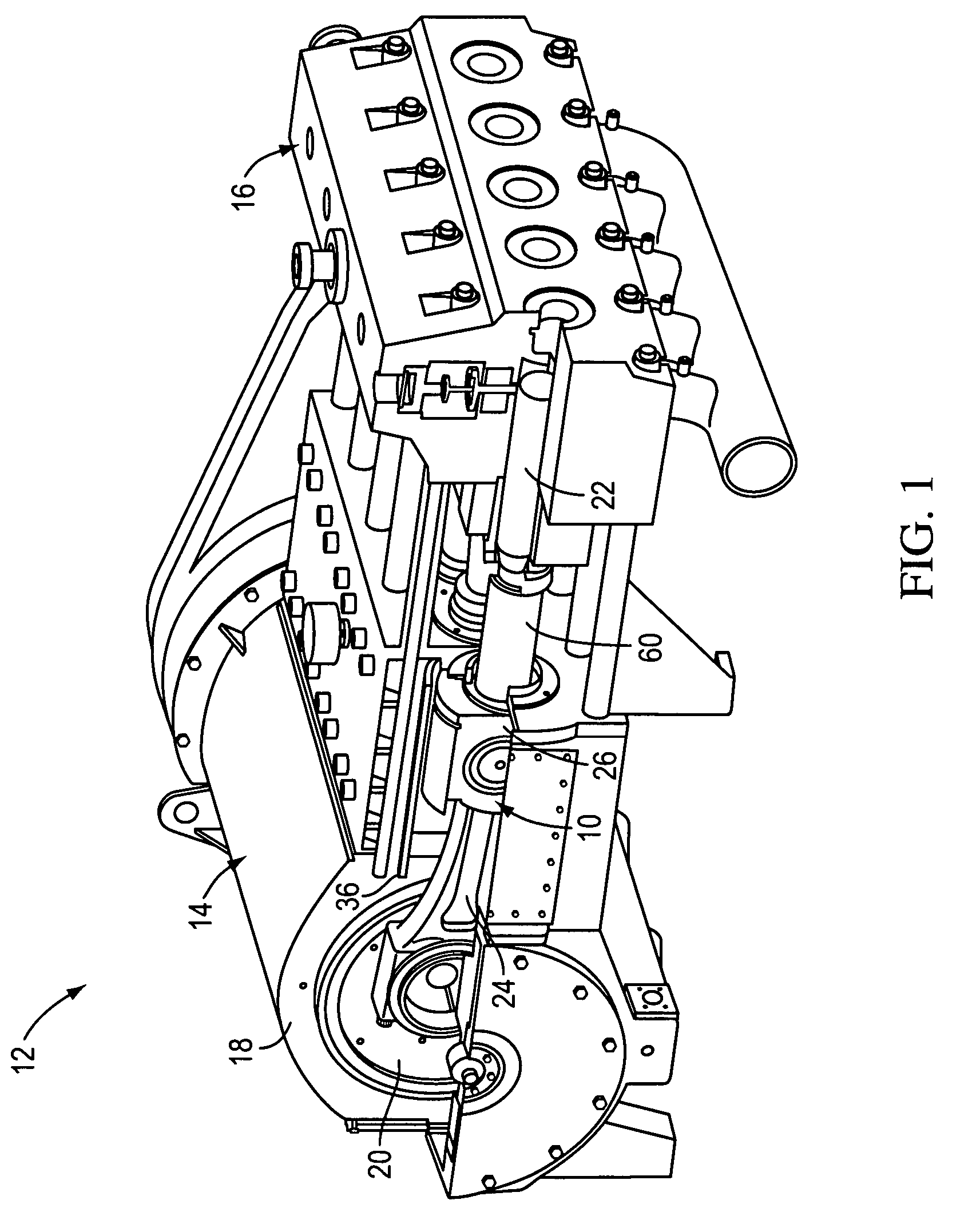

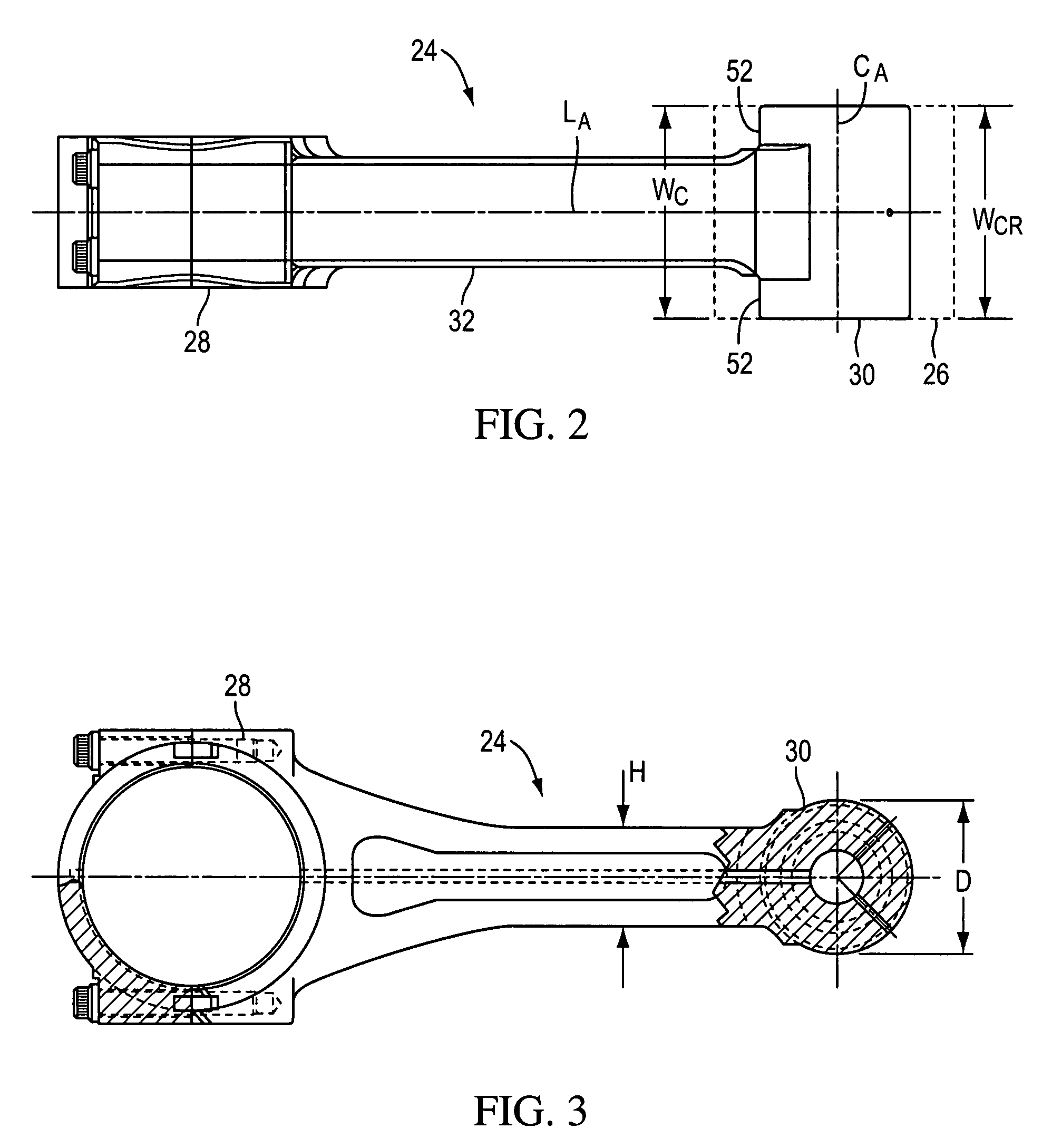

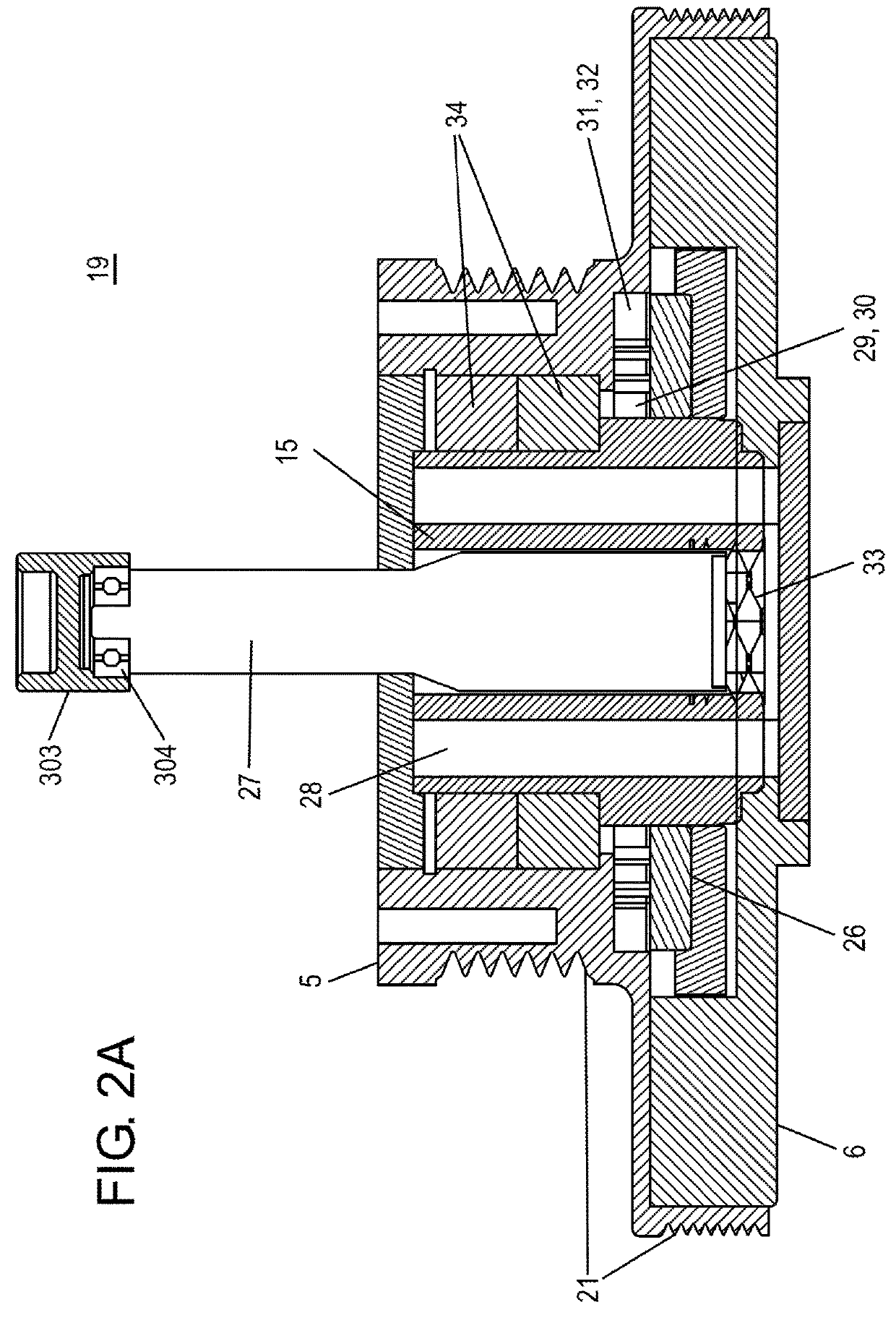

Pump crosshead and connecting rod assembly

ActiveUS7610847B2Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

Cooling and sealing design for a gas turbine combustion system

ActiveUS7096668B2Reduce metal temperatureExtended component lifeBurnersContinuous combustion chamberCombustion systemGuide tube

An interface region between a combustion liner and a transition duct of a gas turbine combustor is disclosed having improved cooling such that component life is increased and metal temperatures are lowered. An aft end of a combustion liner is telescopically received within the transition duct such that a combustion liner seal is in contact with an inner wall of the transition duct inlet ring. Increasing the dedicated cooling air supply to the combustion liner aft end, coupled with a modified combustion liner aft end geometry, significantly reduces turbulence and flow re-circulation, thereby resulting in lower metal temperatures and increased component life. Multiple embodiments of the interface region are disclosed depending on the amount of cooling required.

Owner:H2 IP UK LTD

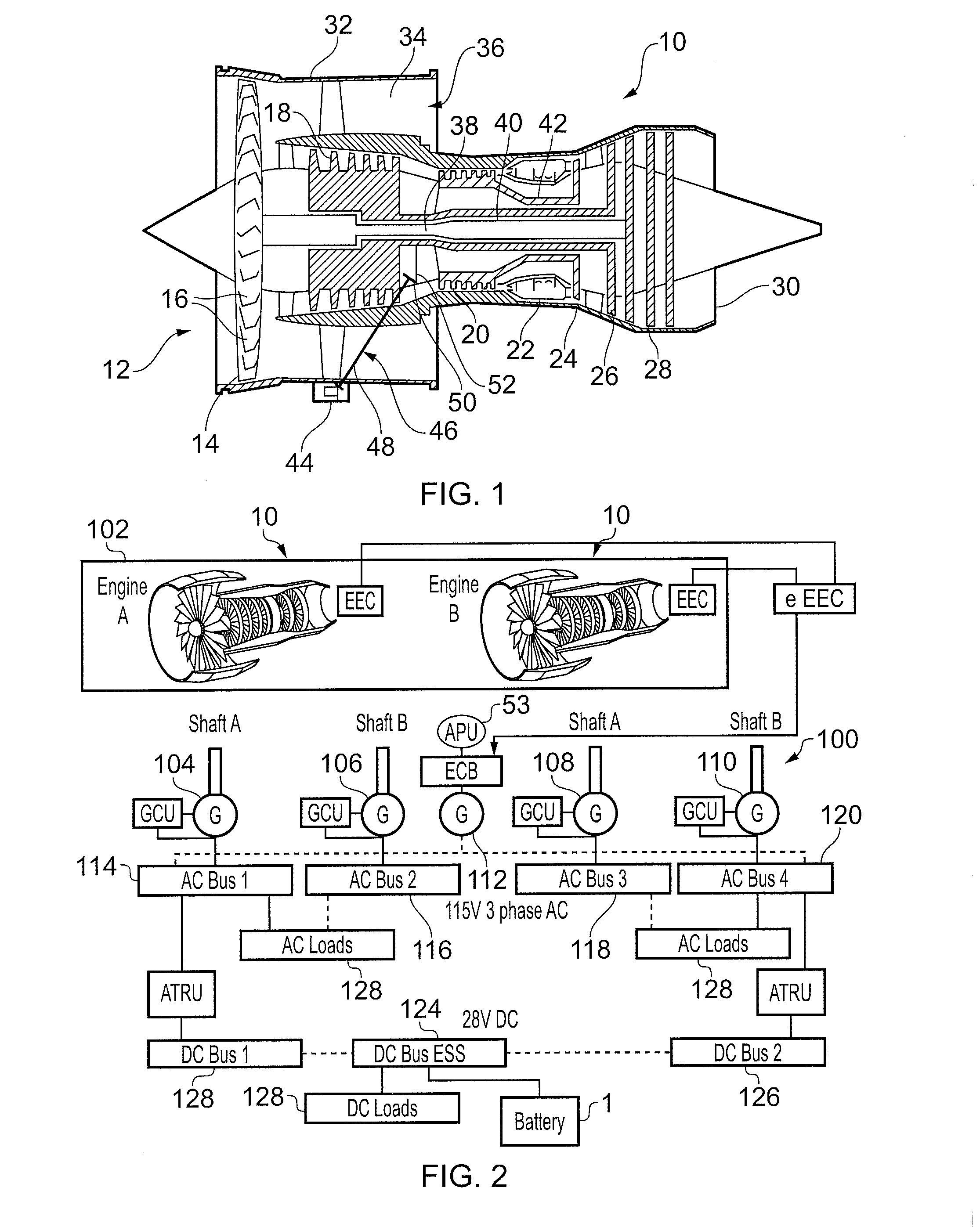

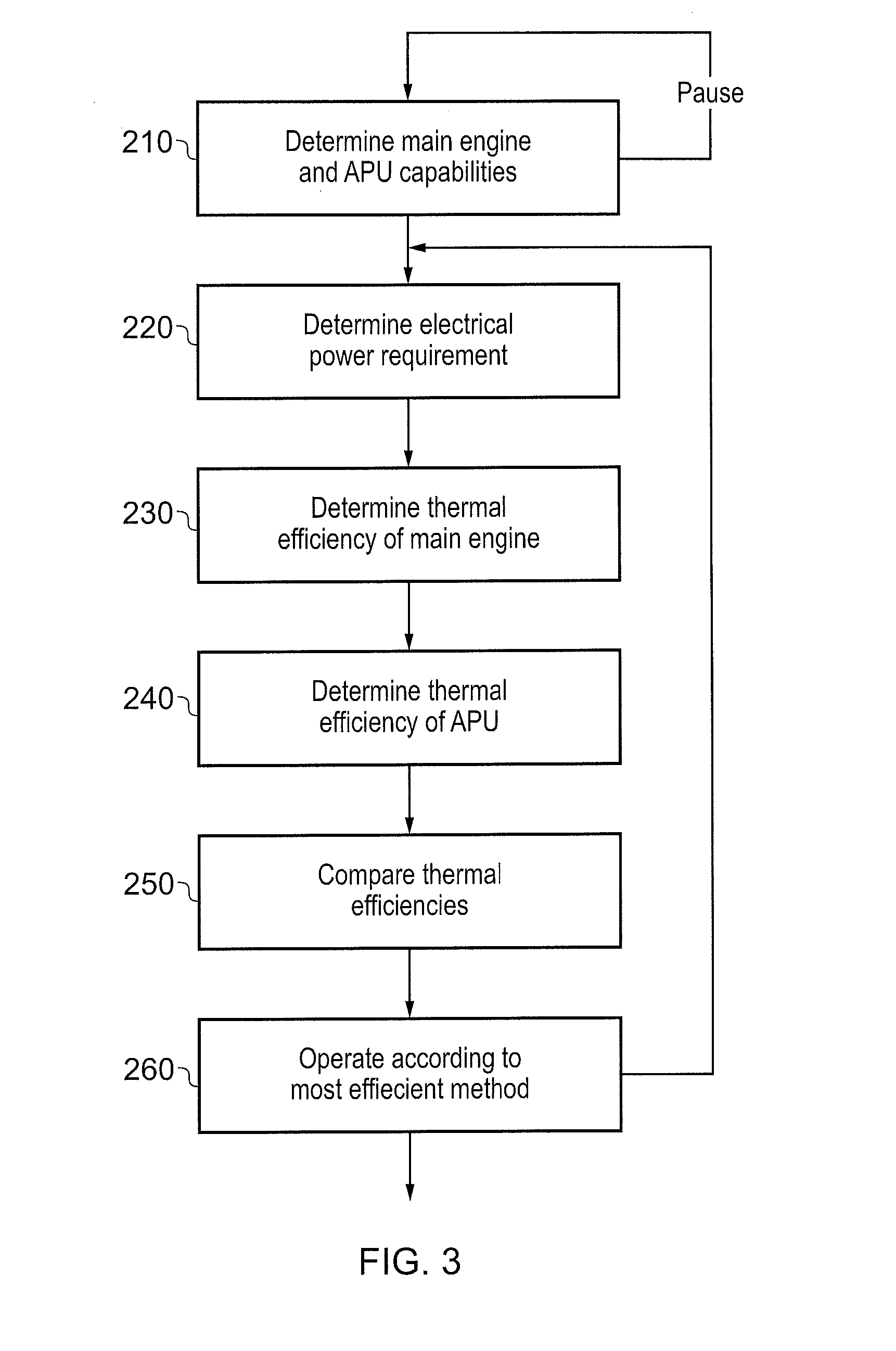

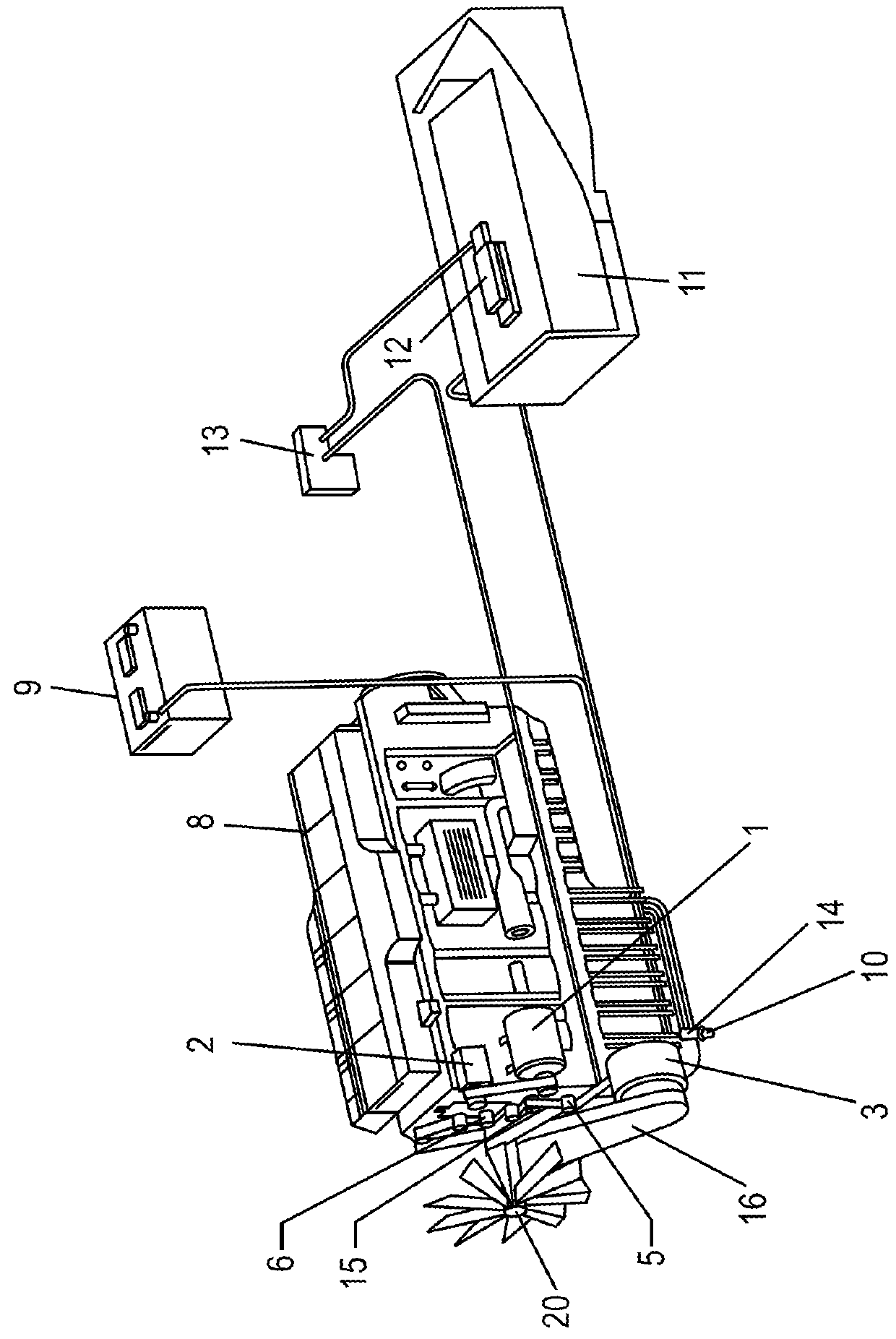

Method of controlling an aircraft electrical power generation system

InactiveUS20140125121A1Increase redundancyOperational securityBatteries circuit arrangementsElectric power distributionEngineeringOperation mode

A method of operating an electrical power generation system on an aircraft. The method includes assessing a required electrical power of the aircraft, assessing whether a first and a second electrical power source are able to provide the required electrical power in combination, assessing a predetermined condition, determining an operating mode of the first and second electrical power sources to match the predetermined condition, and operating the first and second electrical power sources according to the determined operating mode.

Owner:ROLLS ROYCE PLC

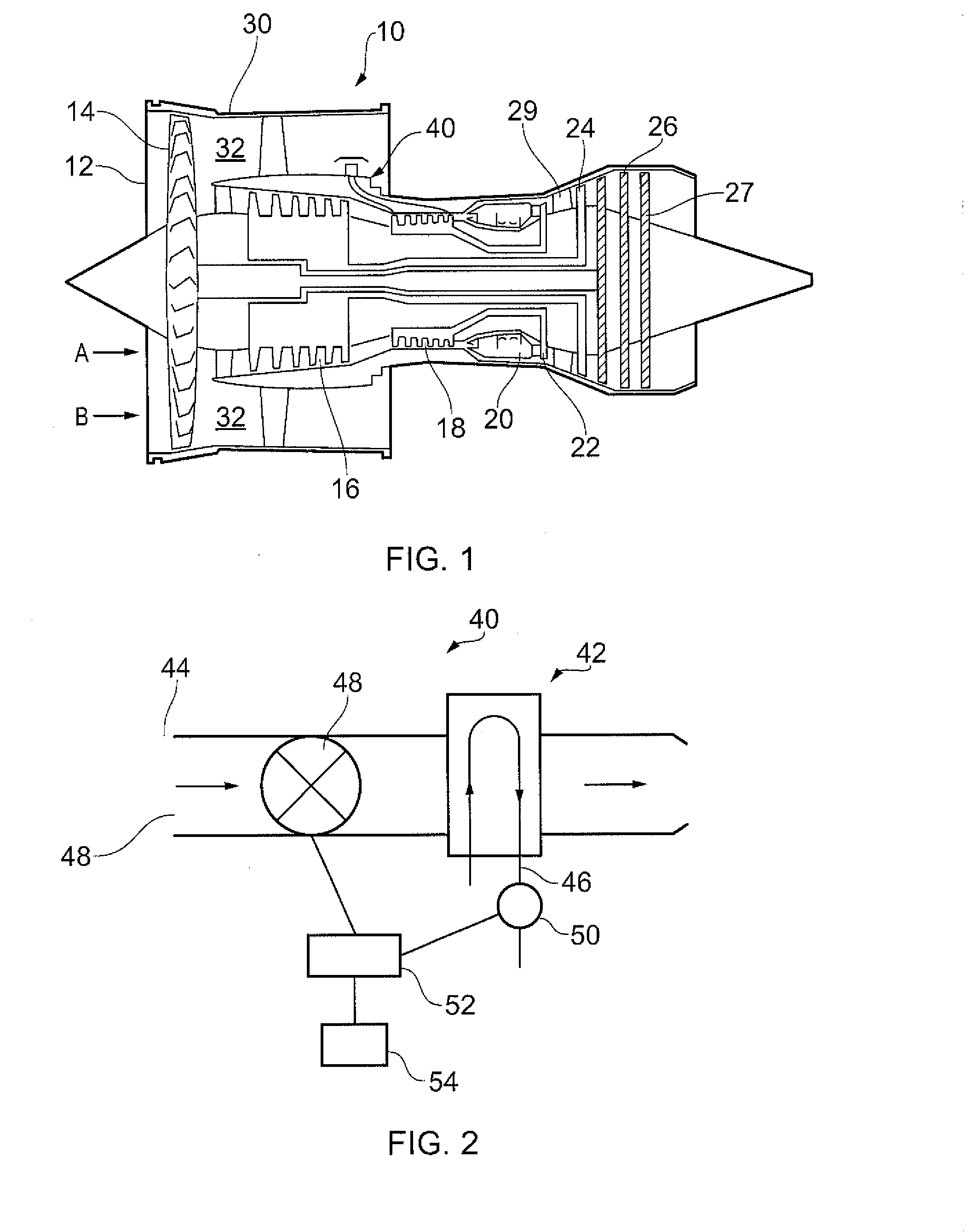

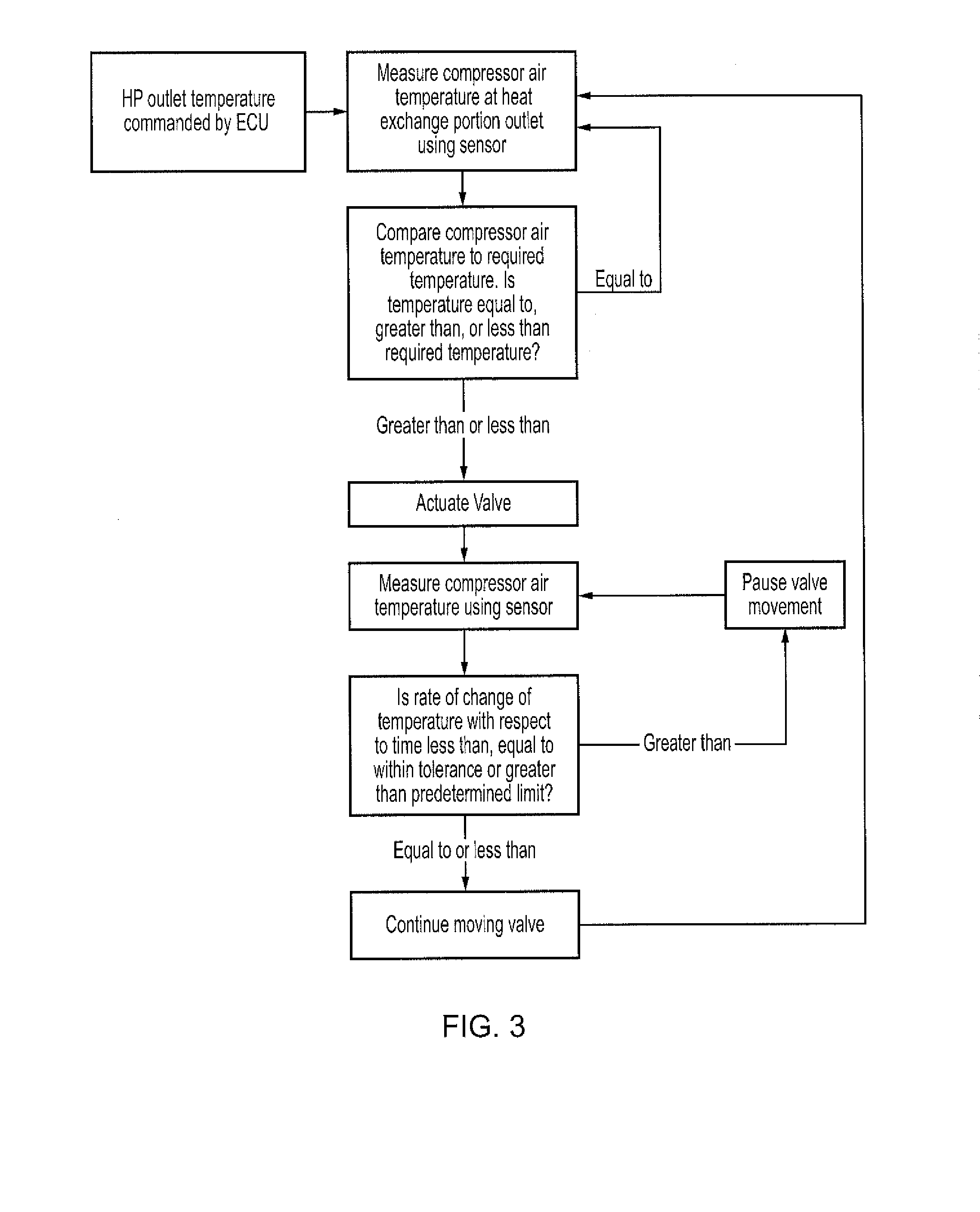

Heat exchange arrangement

ActiveUS20140341704A1Easy to controlEliminate and reduce thermally induced stressEngine fuctionsTurbine/propulsion engine coolingEngineeringGuide tube

A heat exchange arrangement for a gas turbine engine. The arrangement includes a first conduit for an engine component cooling fluid and a second conduit for a second fluid. The arrangement further includes a heat exchange portion in which fluids flowing through the first and second conduits are in a heat exchange relationship. A valve is provided, which is configured to moderate the mass flow rate of one of the fluids through the heat exchange portion. The arrangement includes divert valve in the first conduit which diverts flow to the second conduit as the flow in the second conduit is moderated to reduce thermal shock in the heat exchange portion.

Owner:ROLLS ROYCE PLC

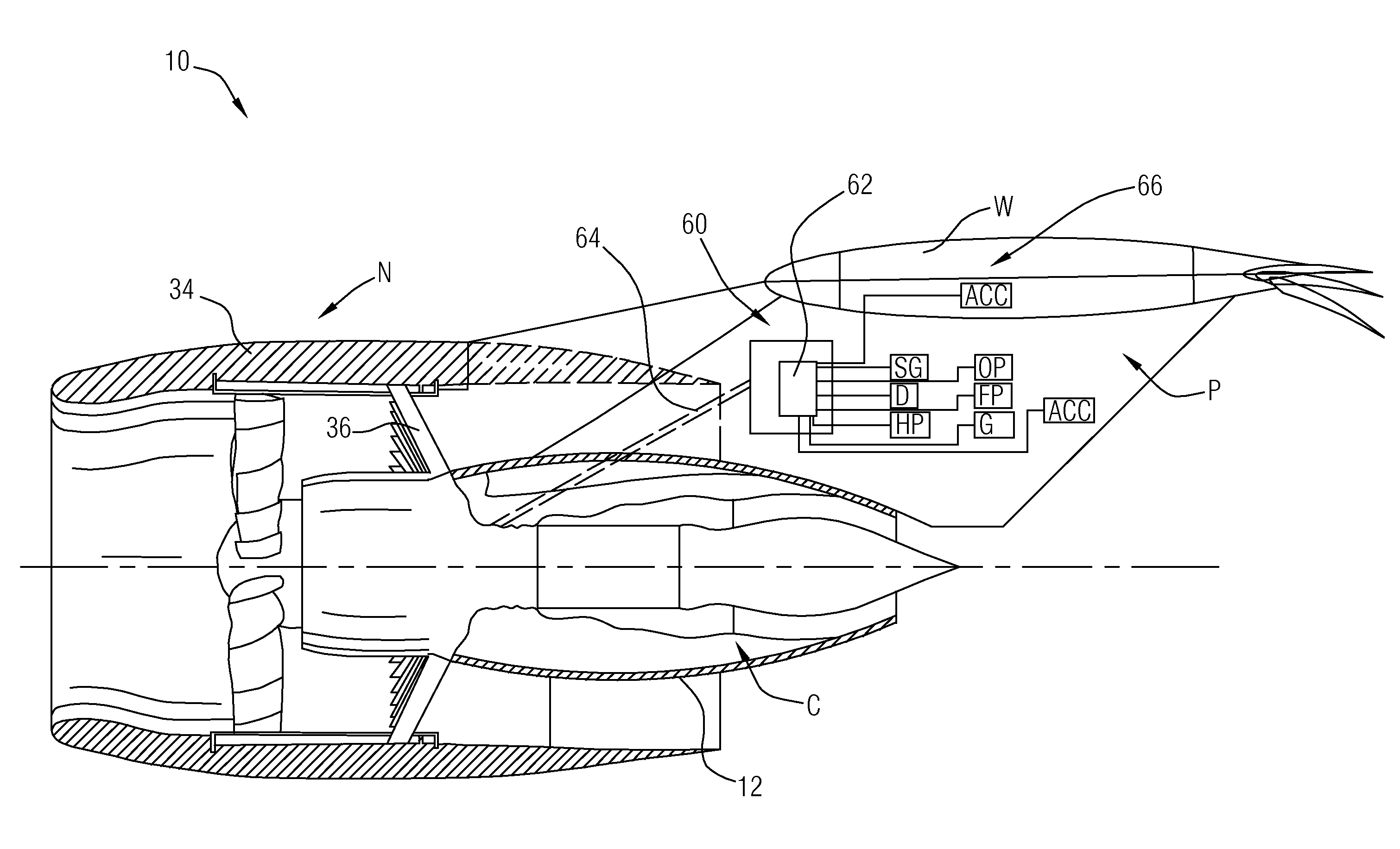

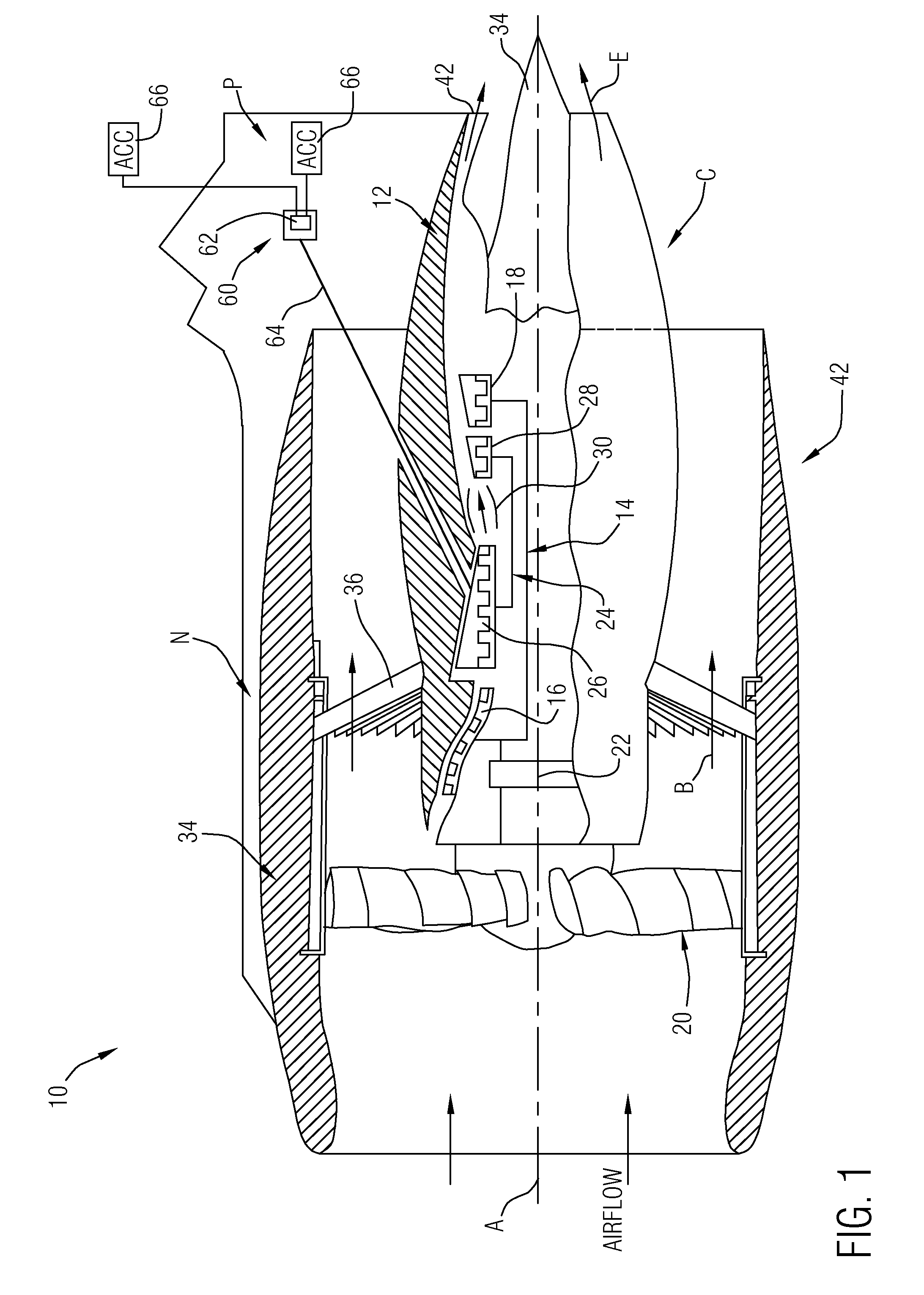

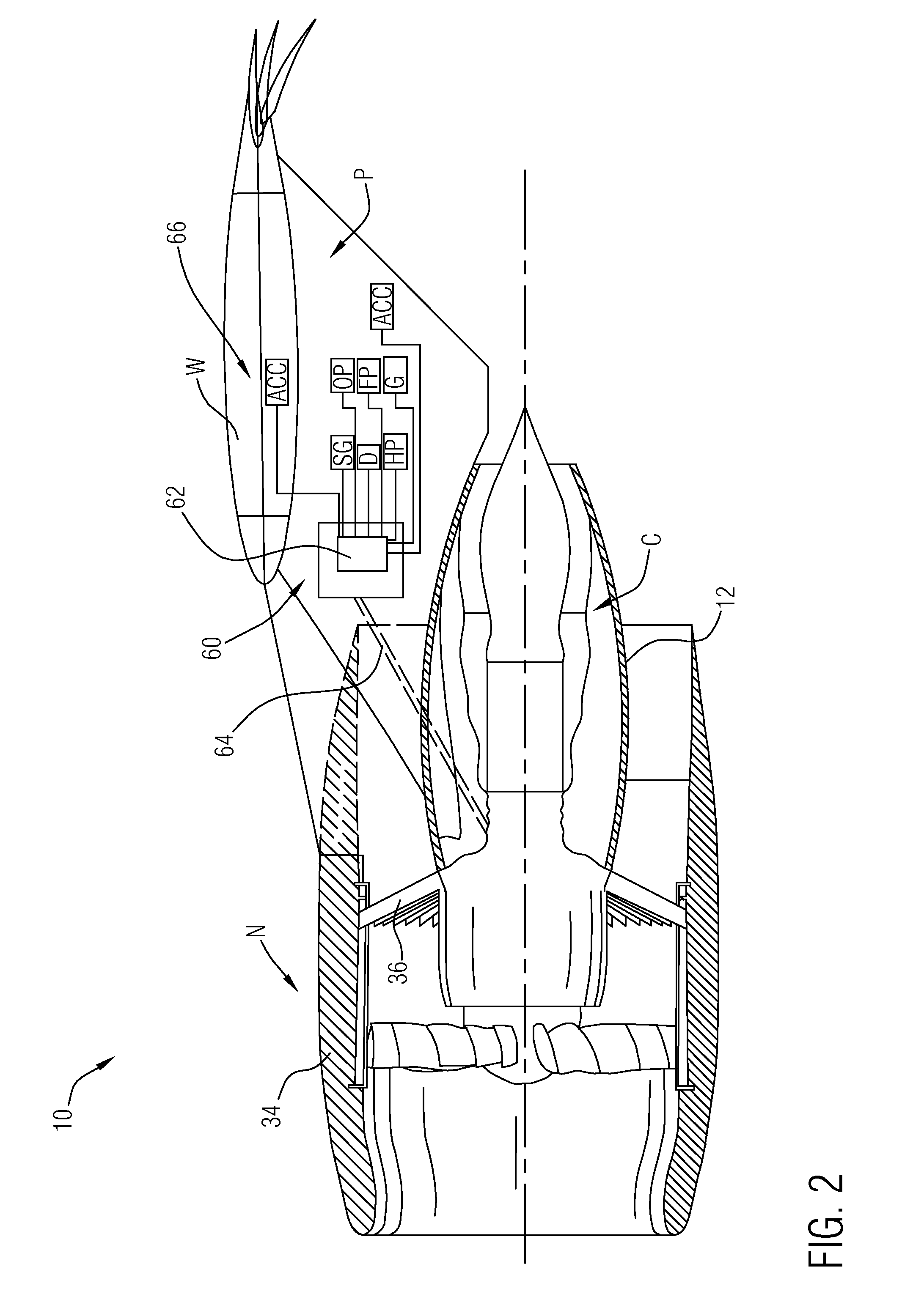

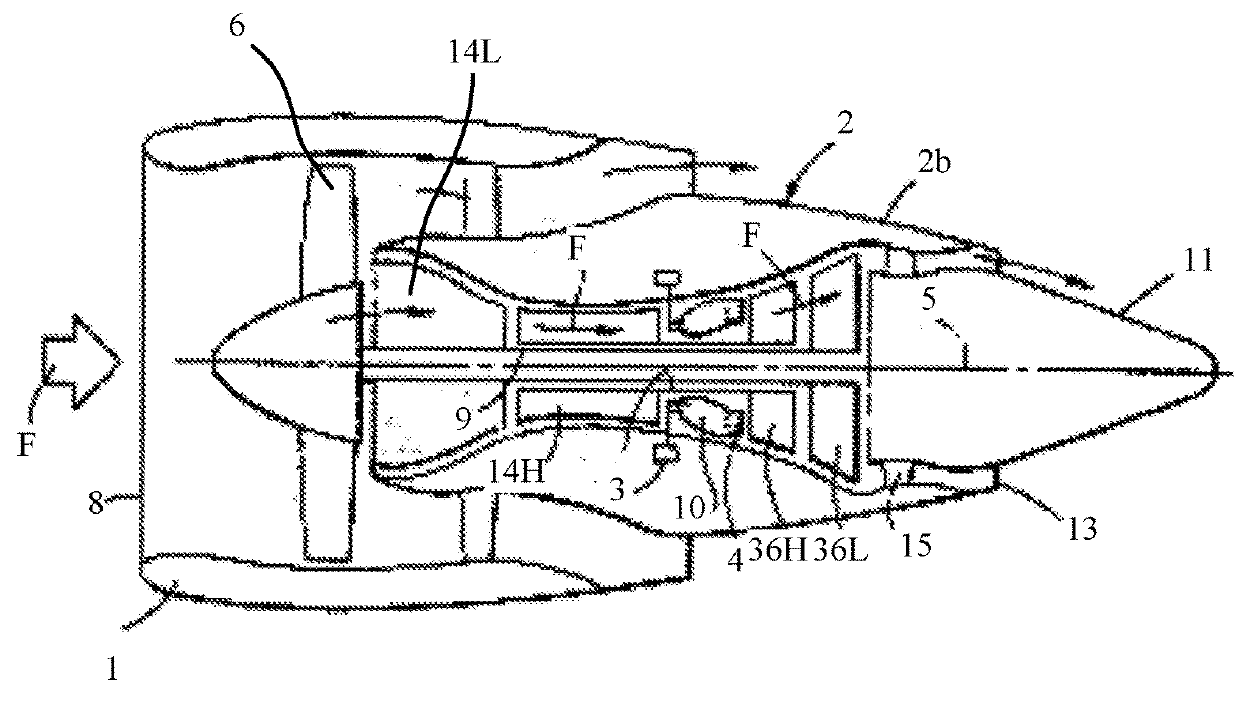

Gas turbine engine with pylon mounted accessory drive

ActiveUS20090139243A1Facilitates direct driveSave weight and spaceEngine fuctionsGas turbine plantsNacelleGas turbines

A gas turbine engine includes an accessory gearbox within an engine pylori. The accessory components may be mounted within the engine pylori to save weight and space within the core nacelle as well as provide a relatively lower temperature operating environment.

Owner:RAYTHEON TECH CORP

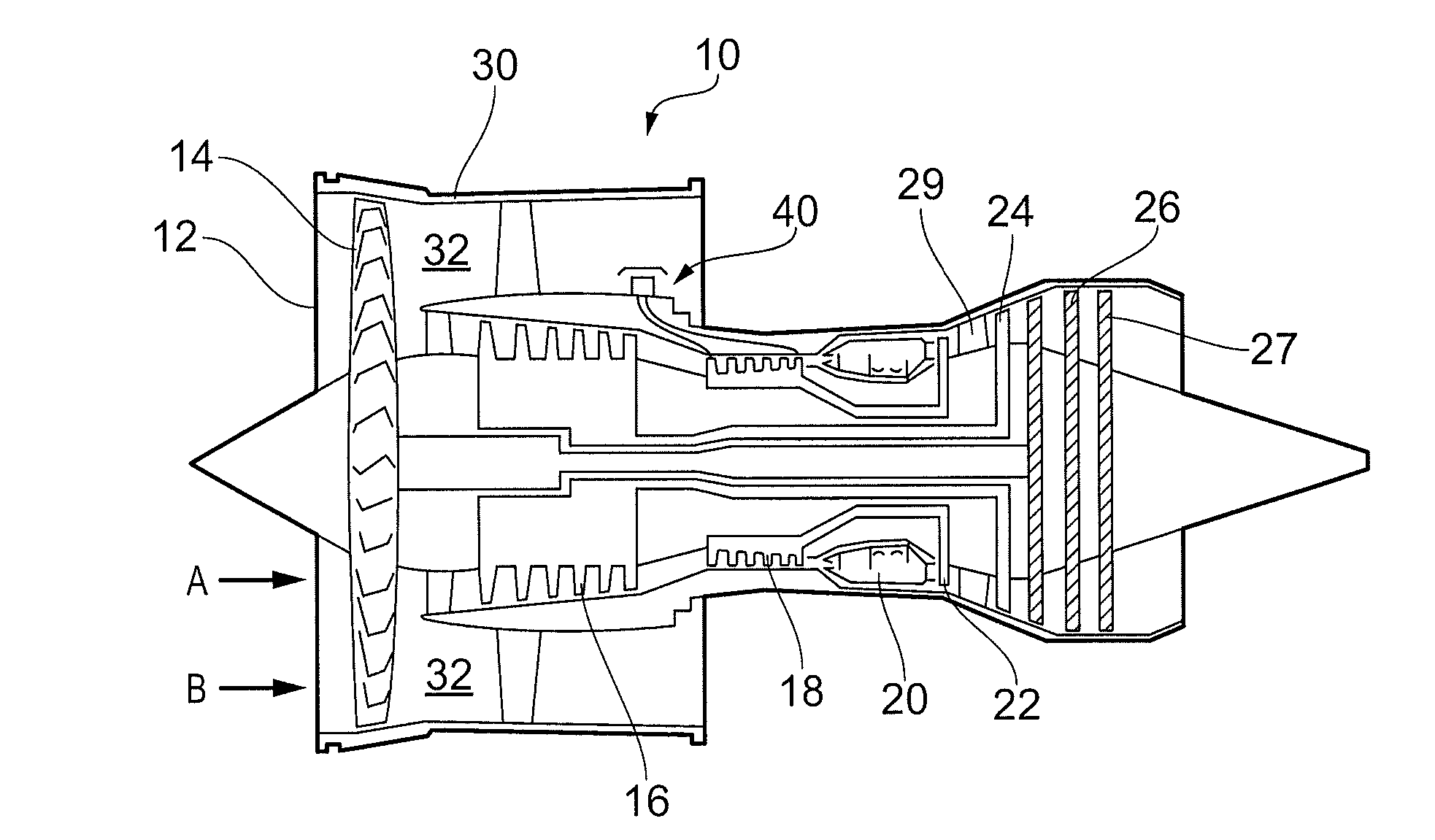

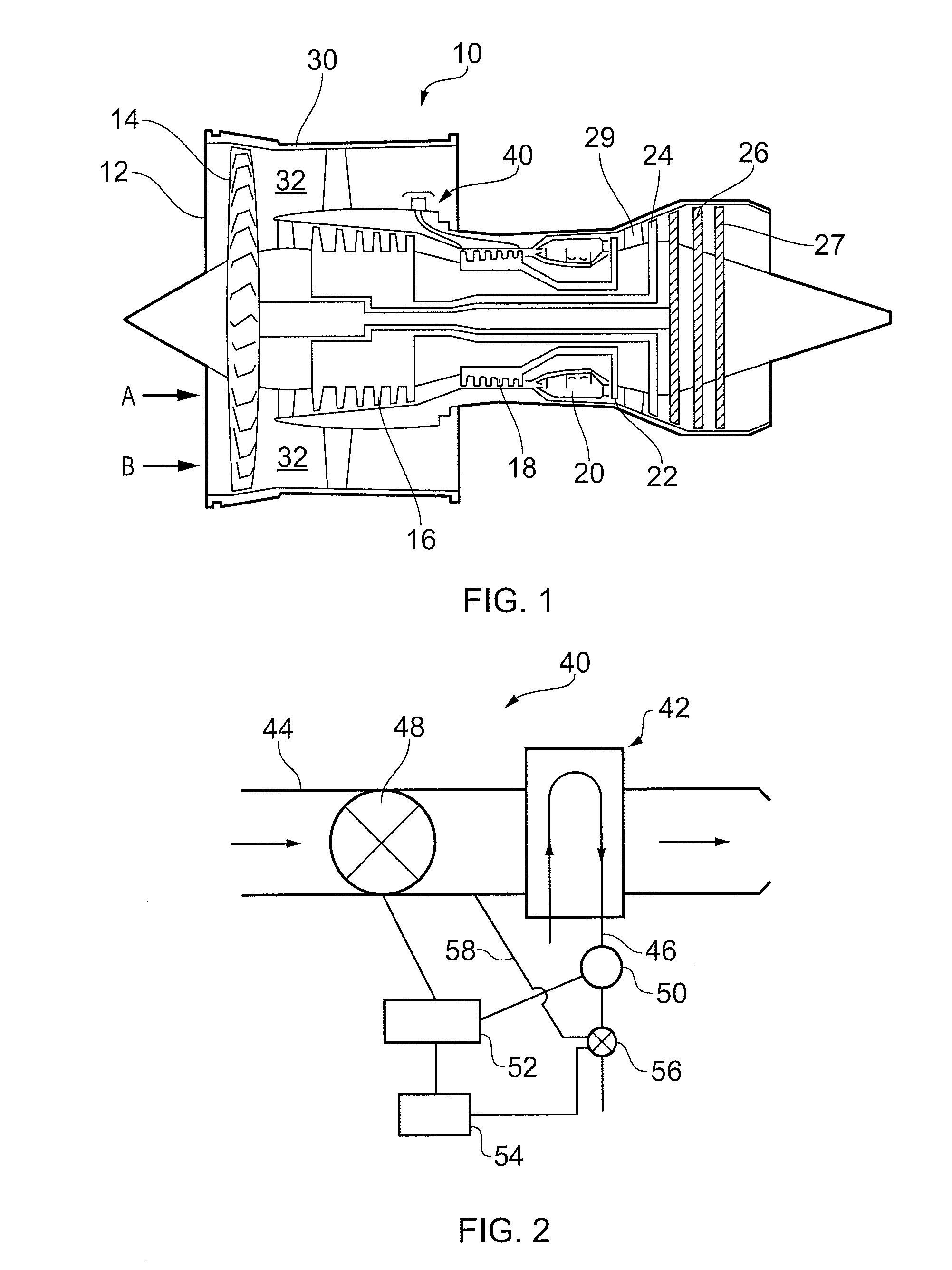

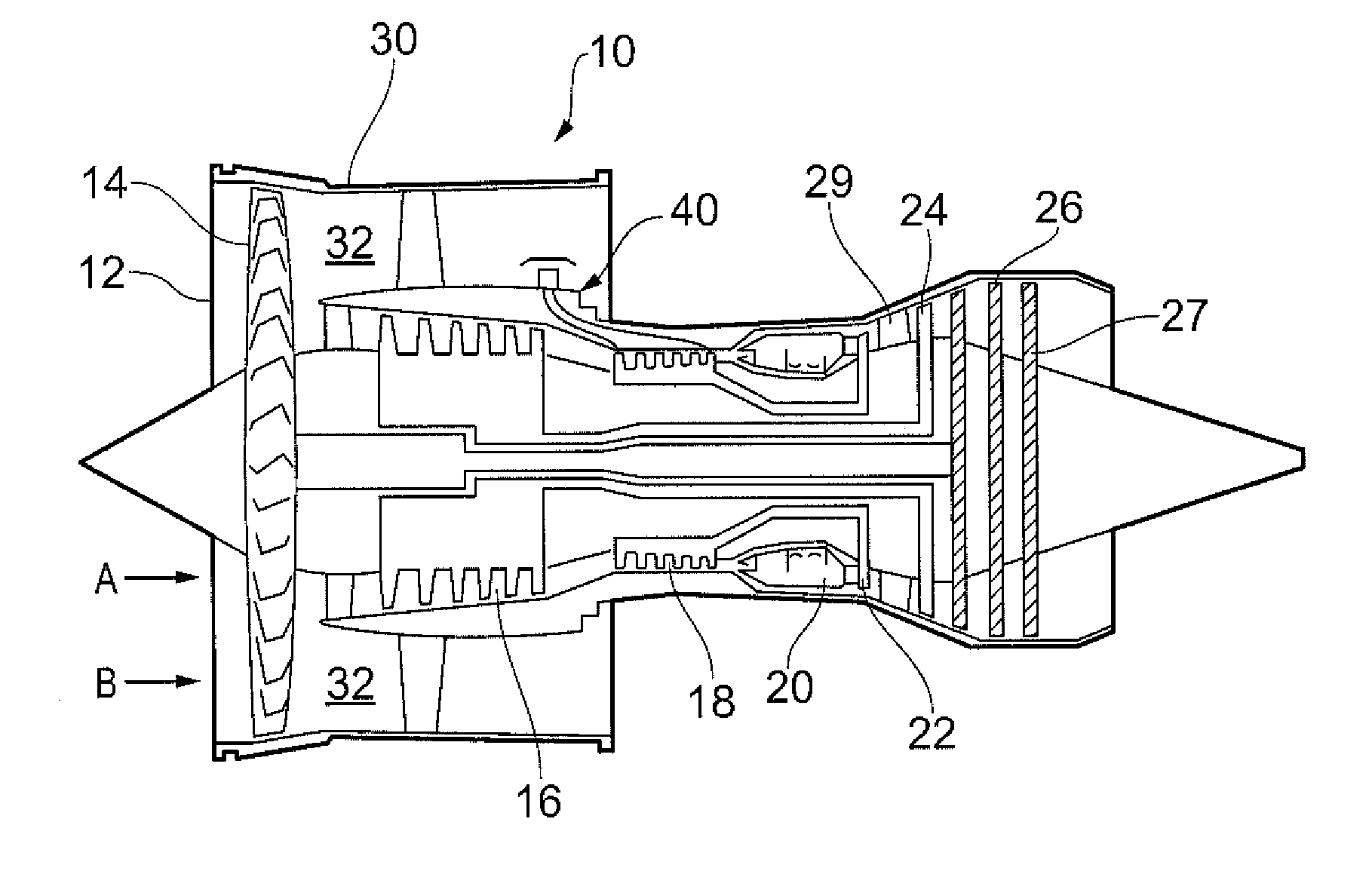

Heat exchange arrangement

InactiveUS20140131027A1Easy to controlEliminates and reduces thermally induced stressTemperatue controlGas turbine plantsEngineeringCooling fluid

A heat exchange arrangement (40) for a gas turbine engine (10). The arrangement (40) comprises a first conduit (46) for an engine component cooling fluid and a second conduit (44) for a second fluid. The arrangement further comprises a heat exchange portion (42) in which fluids flowing through the first and second conduits (46, 44) are in a heat exchange relationship. A valve 48 is provided, which is configured to moderate the mass flow rate of one of the fluids through the heat exchange portion (42). The arrangement comprises a temperature sensor (50) configured to sense a temperature of one of the fluids after said fluid has passed through the heat exchange portion (42) and a controller (52). The controller (52) is configured to control the valve (48) in response to a rate of change of the temperature with respect to time of the fluid sensed by the temperature sensor (50).

Owner:ROLLS ROYCE PLC

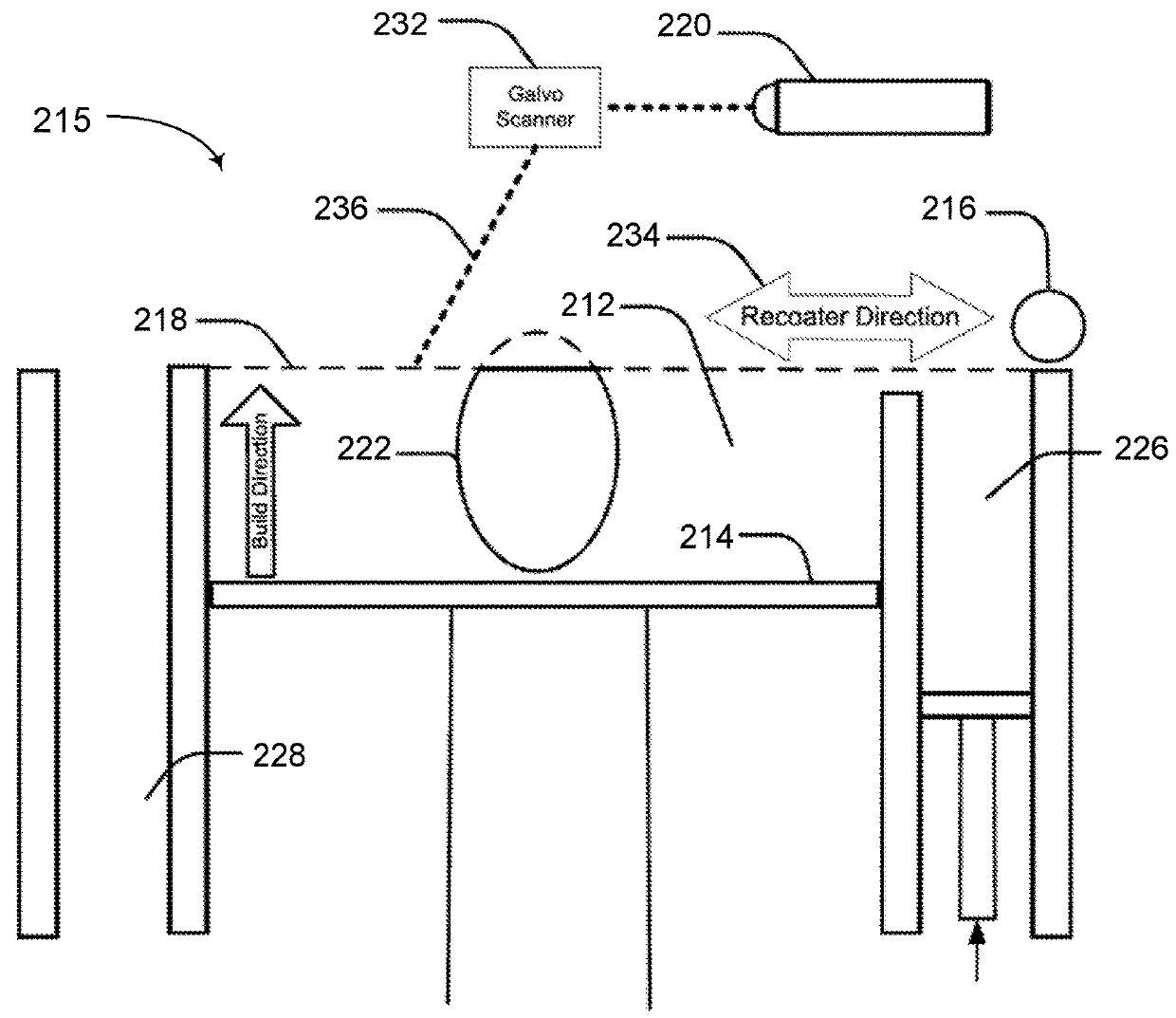

Feature based cooling using in wall contoured cooling passage

ActiveUS20180179956A1Prevent hot-spots and uneven heat distributionExtended component lifeContinuous combustion chamberEngine fuctionsHeat distributionEngineering

A combustion liner or component produced through the use of additive manufacturing techniques. The combustion liner or other component may be formed having a feature based optimized cooling circuit at least partially embedded in the thickness of the material. The internal cooling circuit, may be used, along with other benefits, to control the temperature of the component and prevent hot-spots and uneven heat distribution across the surface of the component.

Owner:GENERAL ELECTRIC CO

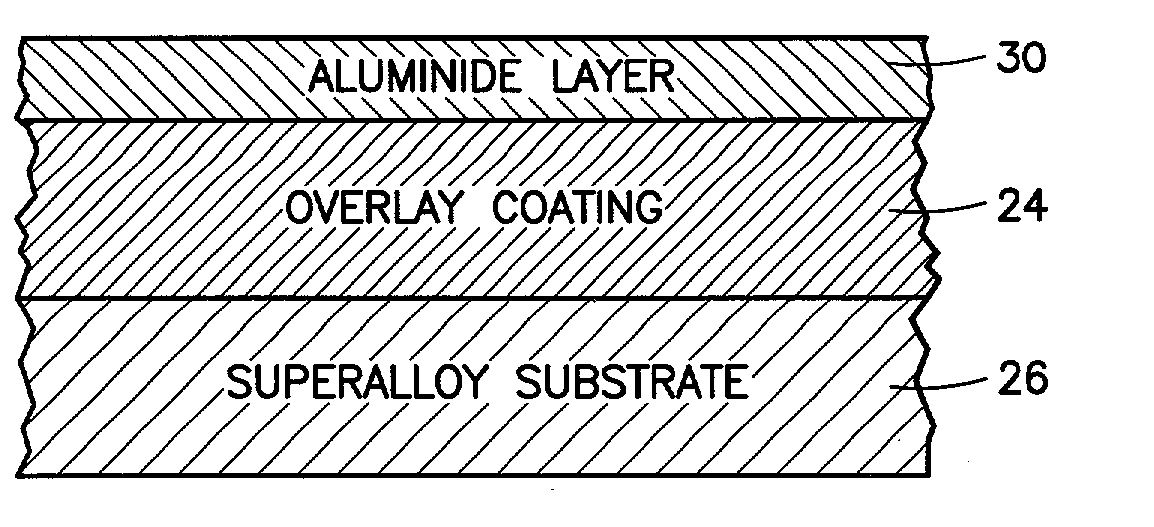

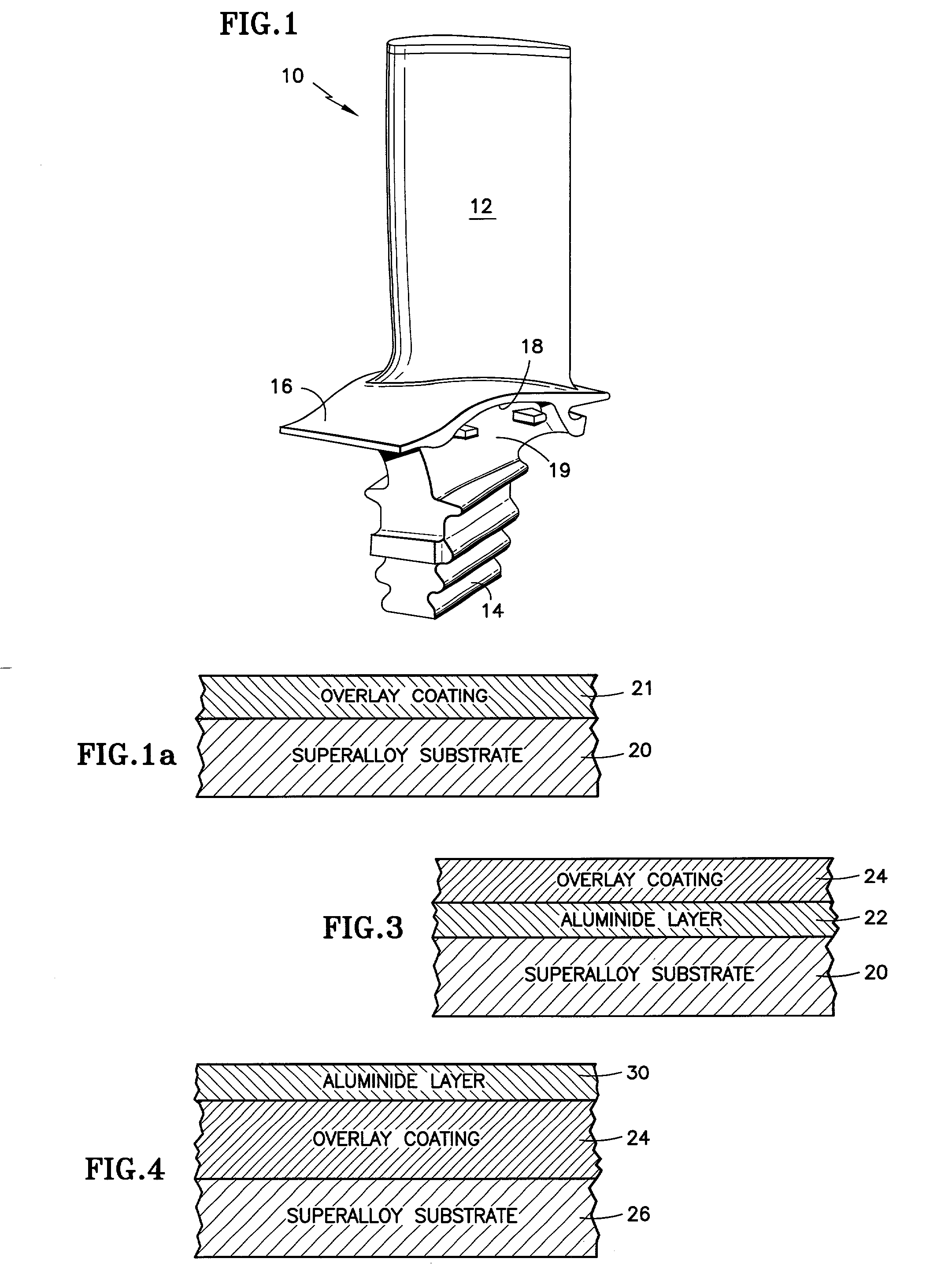

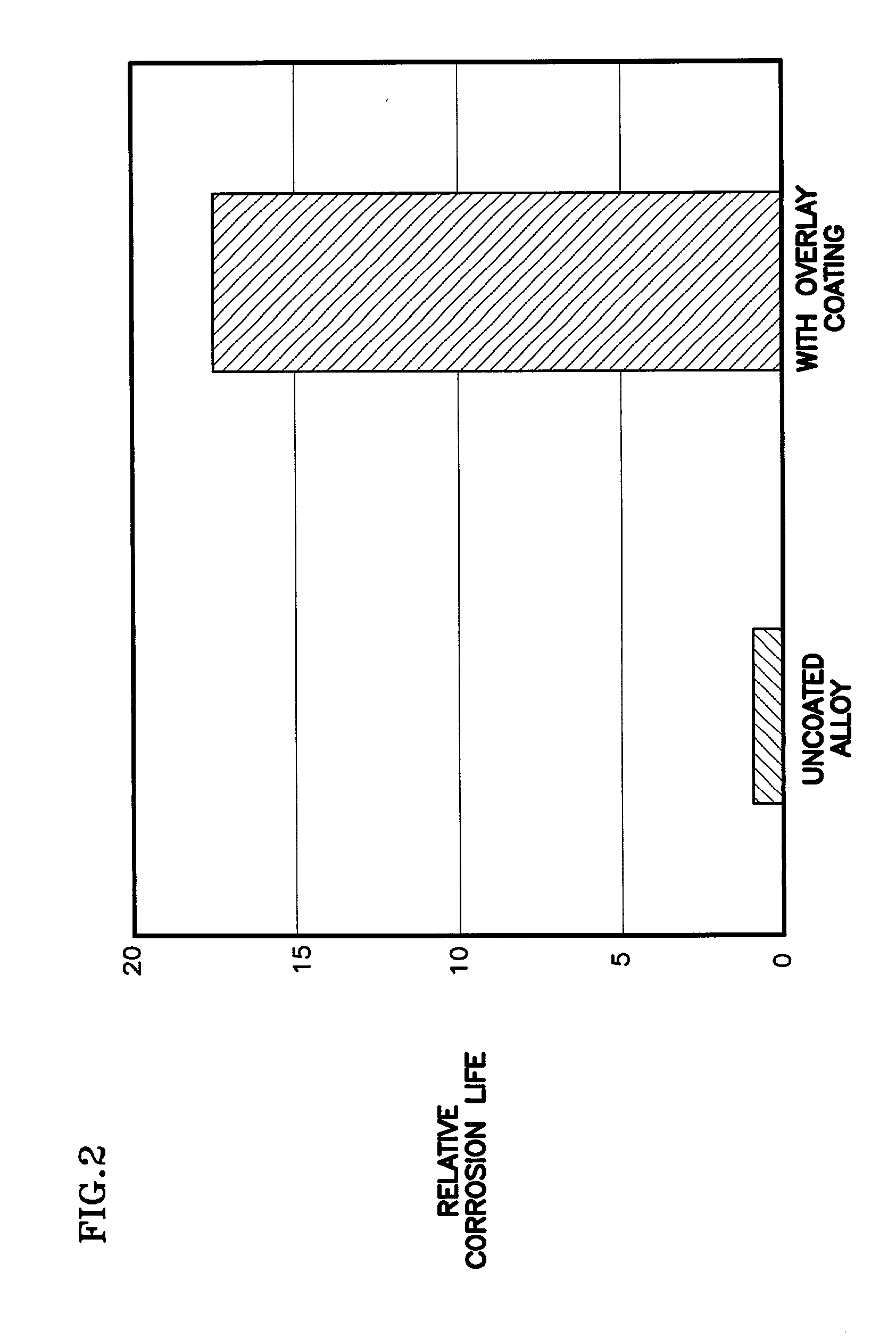

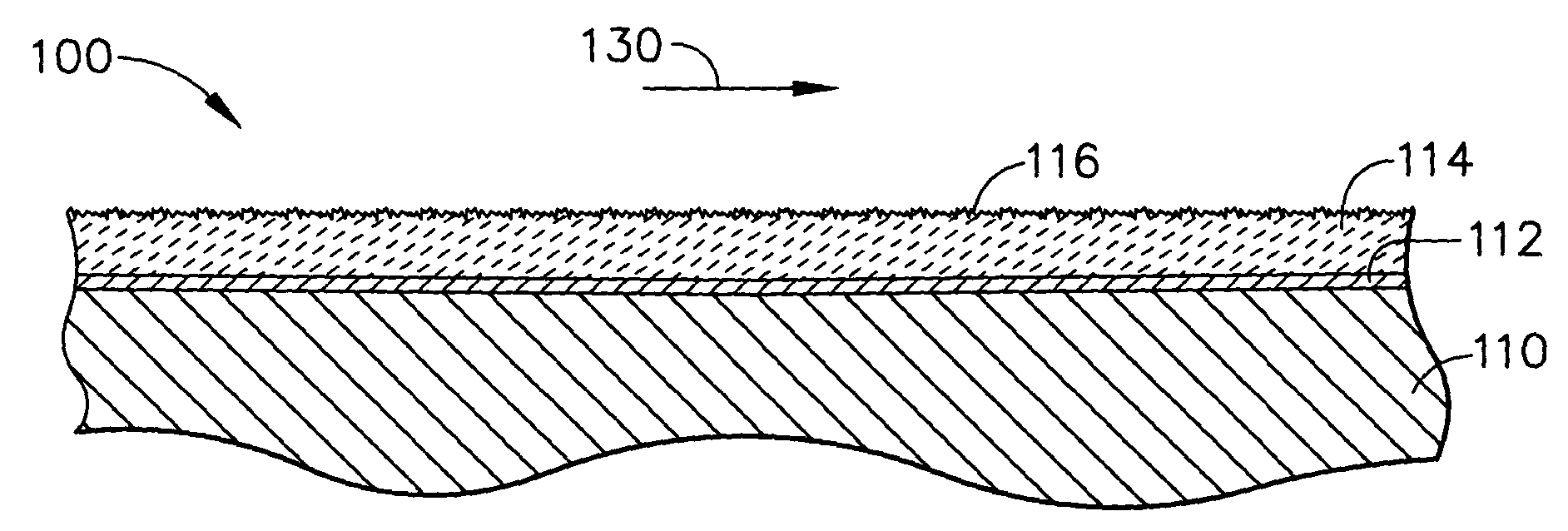

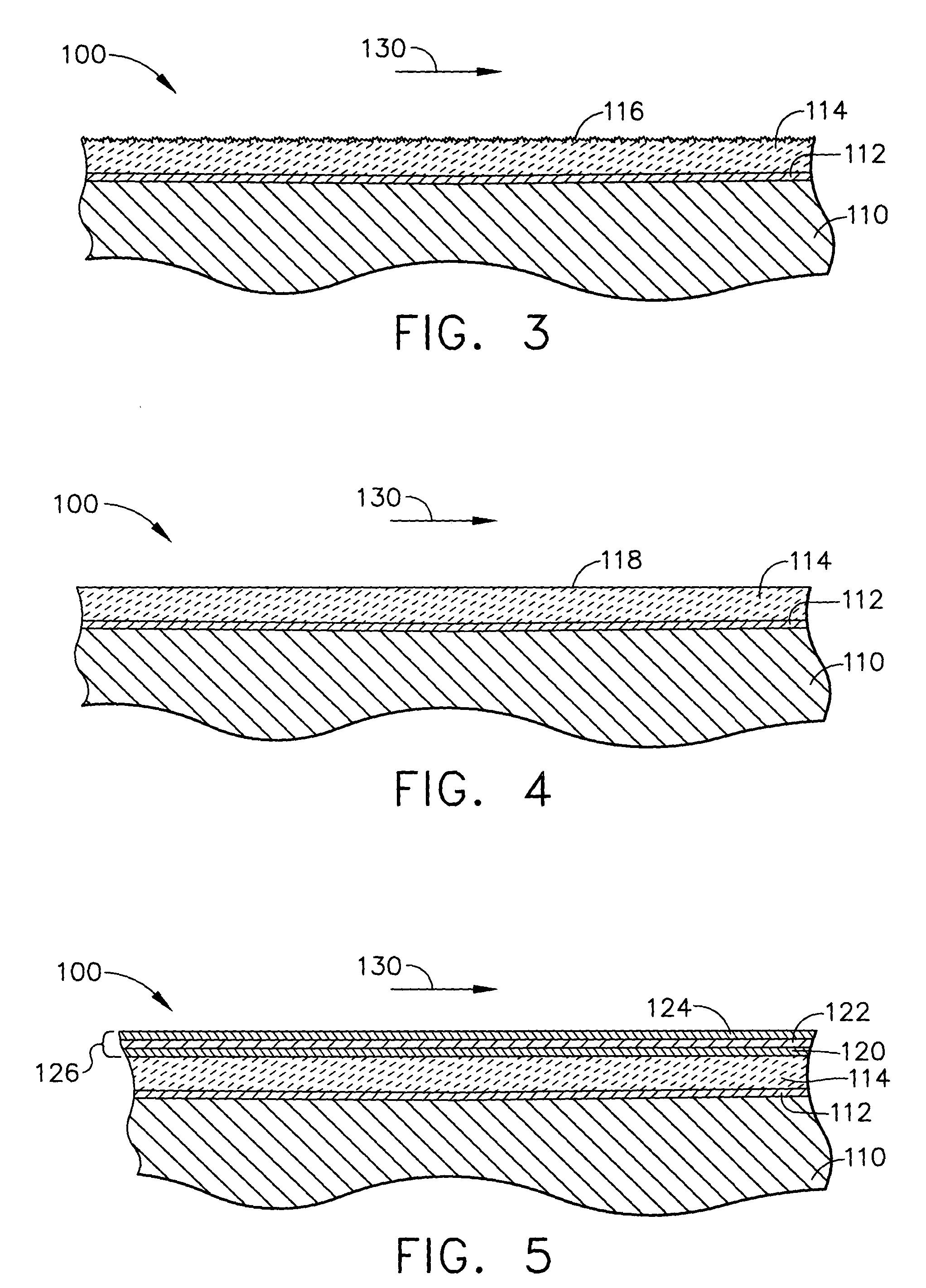

Methods of providing article with corrosion resistant coating and coated article

InactiveUS20020130047A1Increased durabilityMaximize protectionLiquid surface applicatorsMolten spray coatingCorrosion resistantAluminide

According to the invention, an article that is exposed to high temperature e.g., over 1000.degree. C. during operation is disclosed. In one embodiment, a method for a gas turbine engine includes a directionally solidifed metallic substrate, e.g., a superalloy, which defines an airfoil, a root and a platform located between the blade and root. The platform has an underside adjacent the root, and a corrosion resistant overlay coating such as an MCrAlY or a noble metal containing aluminide or corrosion inhibiting ceramic is located on portions or the blade not previously covered with such coatings, e.g., the underside of the platform and the neck. The applied coating prevents corrosion and stress corrosion cracking of blade in these regions. Where the airfoil is also created, the airfoil coating may have a composition different from that of the coating on the underplatform surfaces.

Owner:UNITED TECH CORP

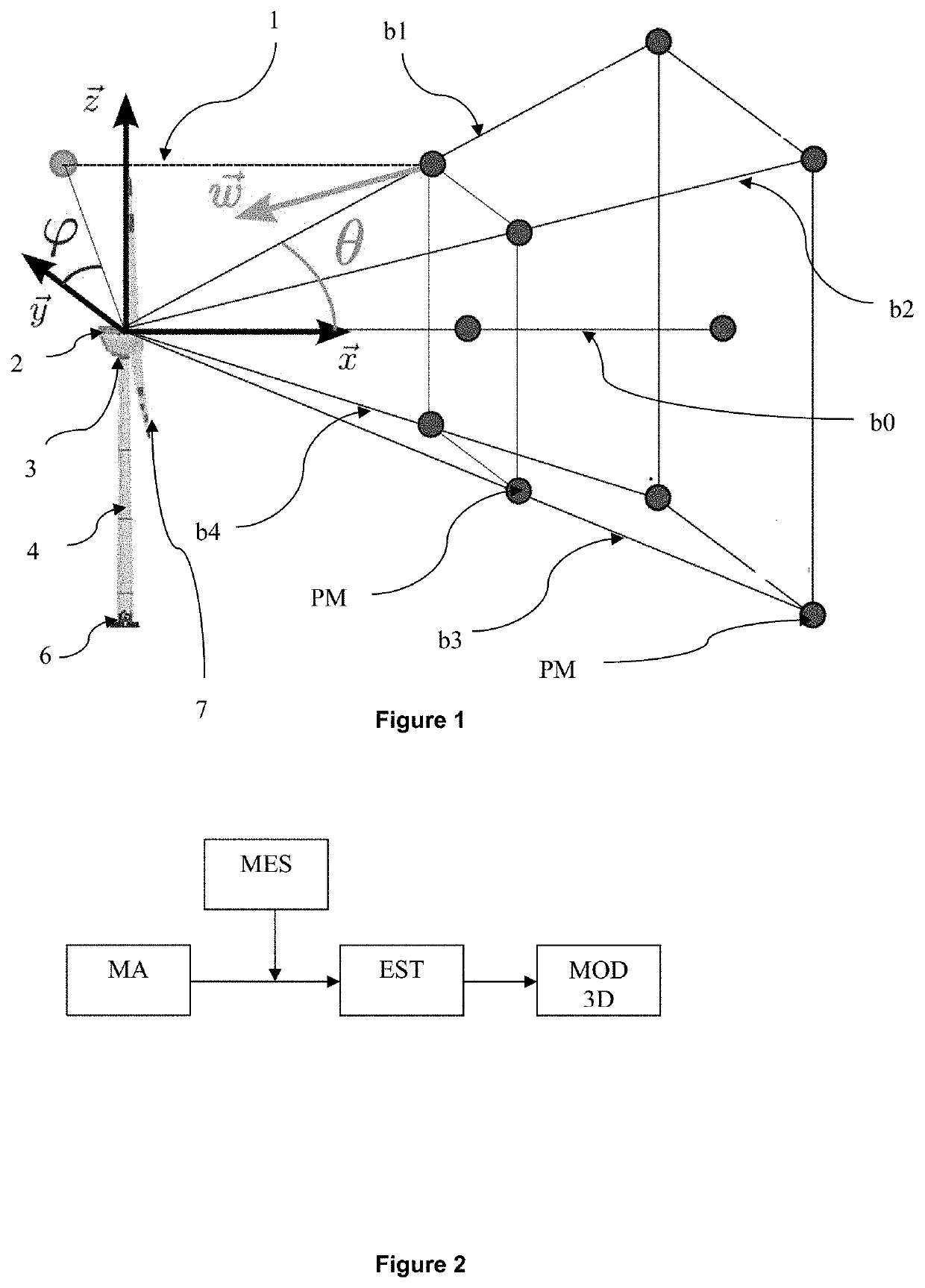

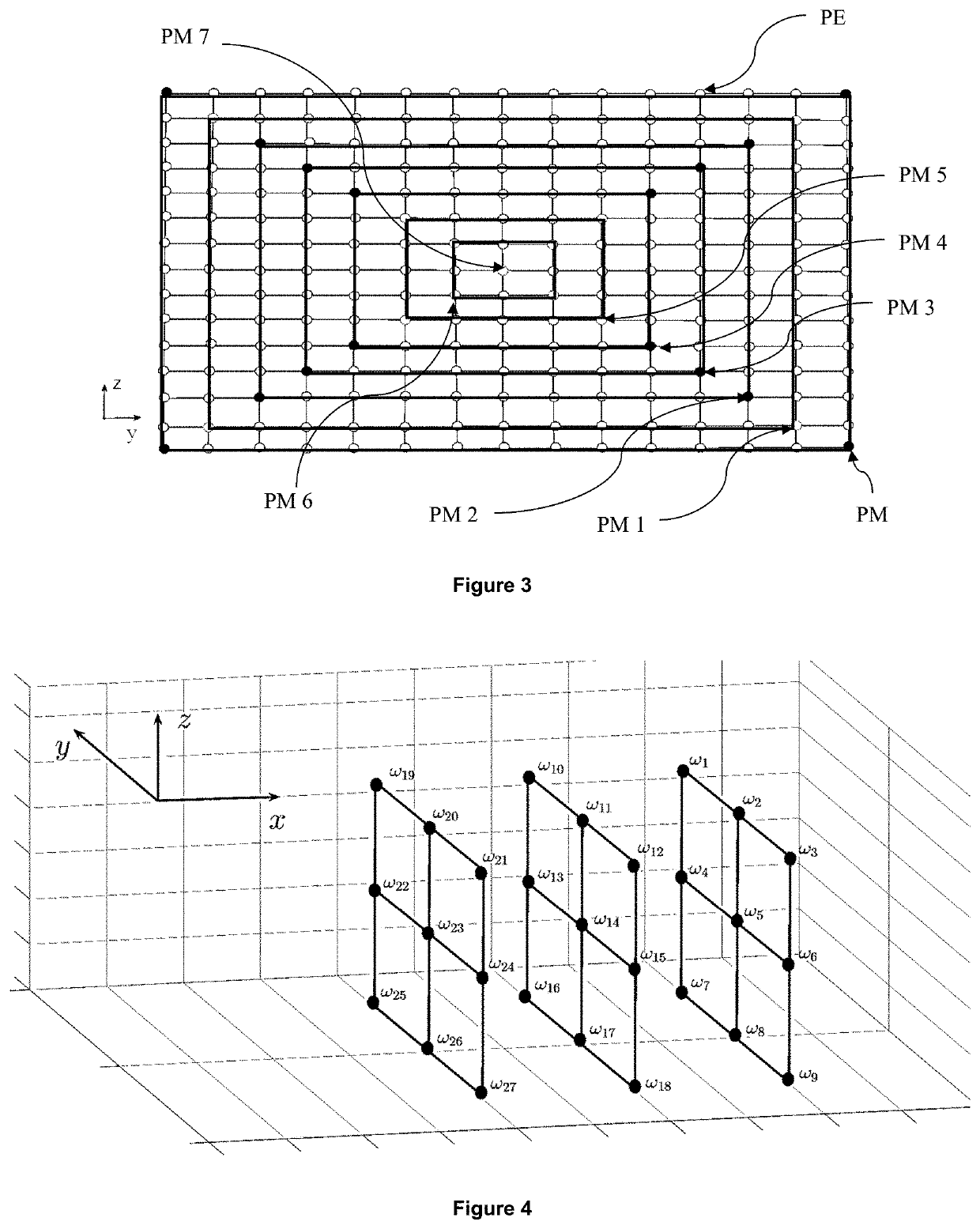

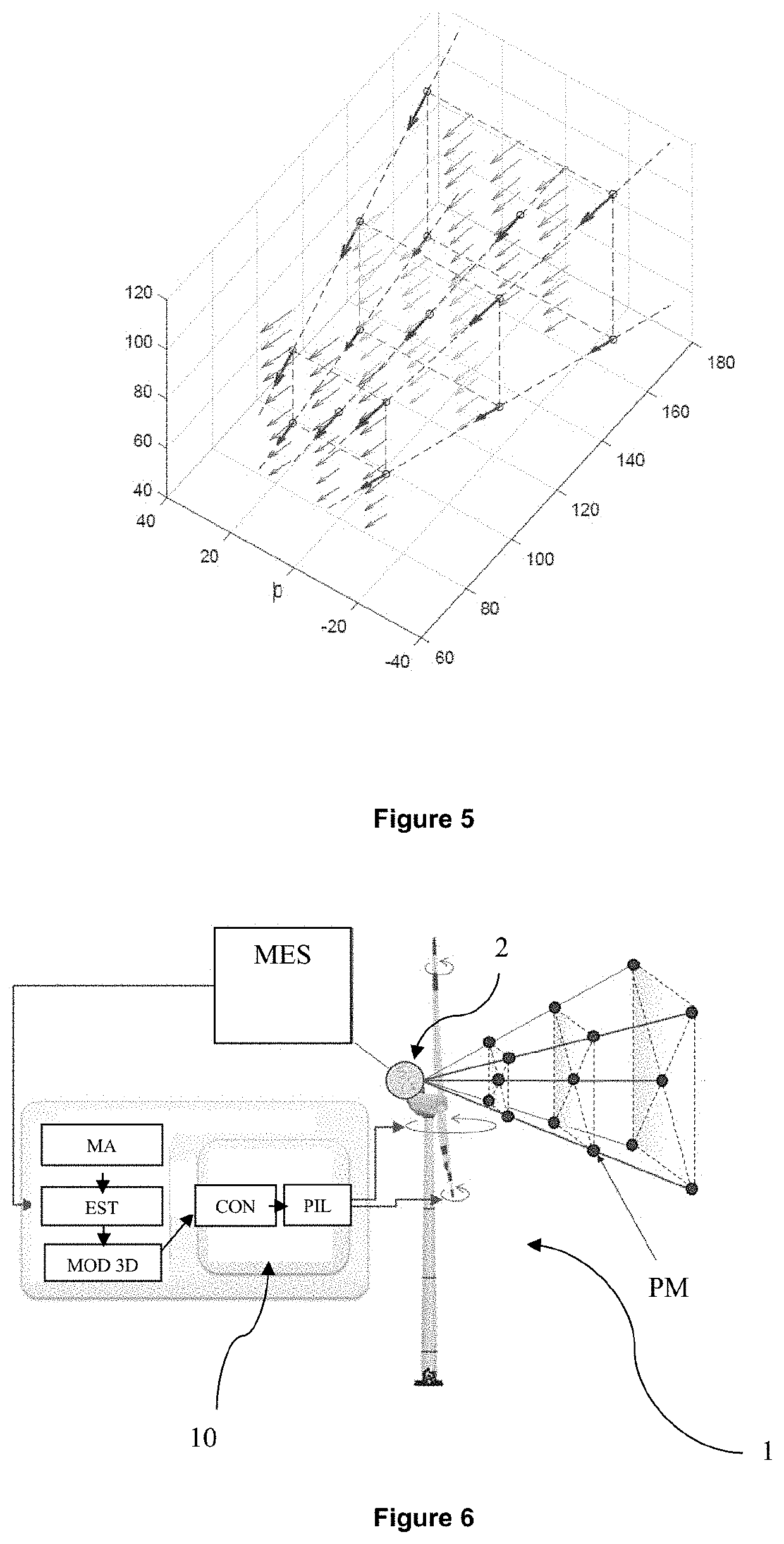

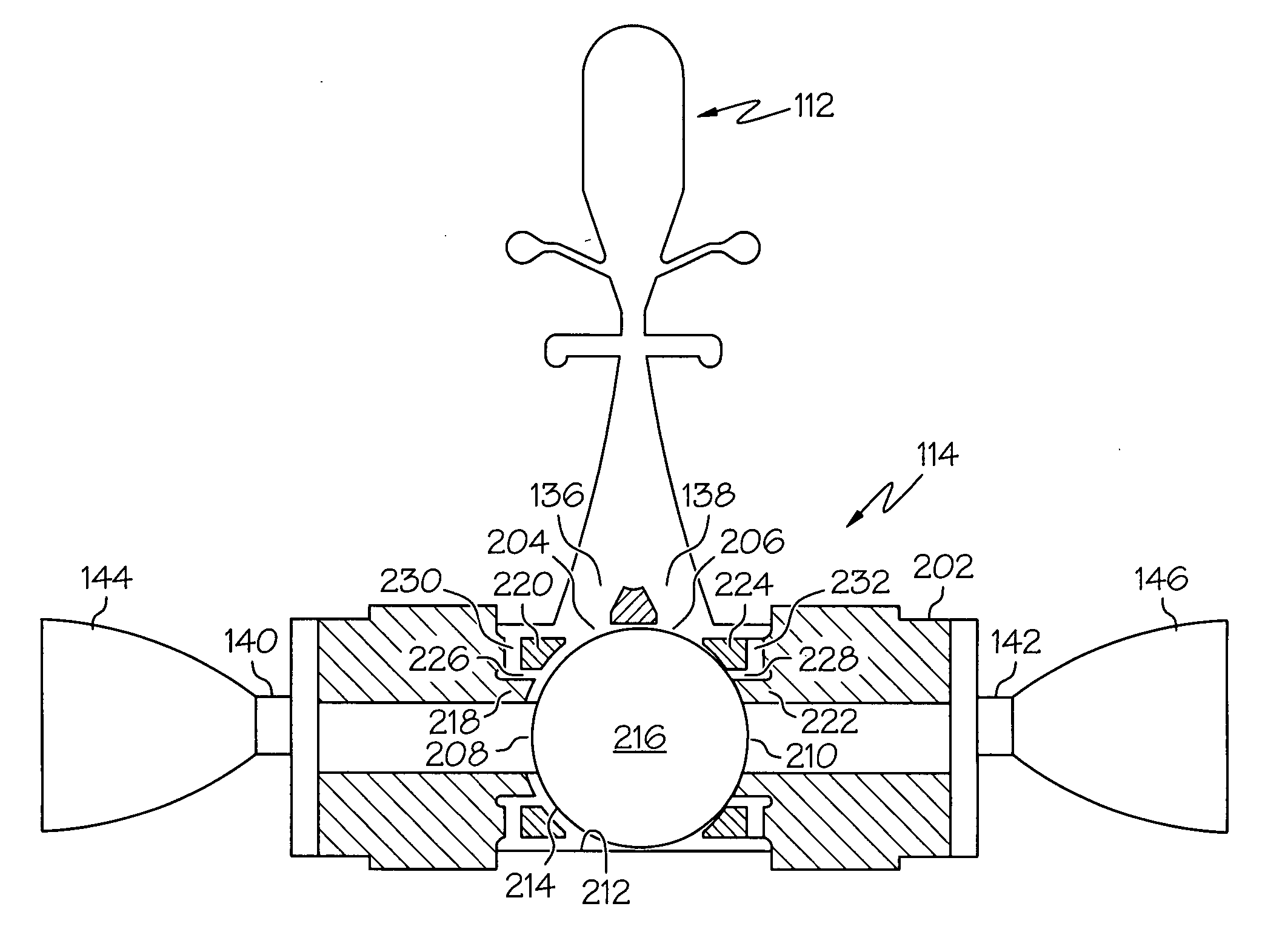

Method for acquiring and modelling an incident wind field by means of a lidar sensor

ActiveUS20200124026A1Reliable and accurate measurementSufficiently robust and accurate informationWind motor controlEngine fuctionsWind fieldAtmospheric sciences

The object of the invention relates to a method for acquisition and modelling of an incident wind field by a LiDAR sensor. Acquisition and modelling include a step of estimating the wind amplitudes and directions for a set of discretized points, and a step of incident wind field reconstruction in three dimensions and in real time. The invention also relates to a method of controlling and / or monitoring a wind turbine equipped with such a LiDAR sensor from the incident wind field reconstructed in three dimensions and in real time.

Owner:INST FR DU PETROLE

Diverter valve with multiple valve seat rings

InactiveUS20050263194A1Reduce impact stressExtended component lifeDirection controllersServomotor componentsEngineeringImpact area

A diverter valve includes a valve bore having a set of valve seats associated with each fluid outlet port. Each set of valve seats is at least partially separated from one another by a flow channel. The valve seat configuration increases the impact area for the valve element. As a result, the impact force upon seating against the valve seats is reduced. Moreover, by including flow channels between the sets of valve seats, the switching force and performance of the valve element is not adversely affected.

Owner:HONEYWELL INT INC

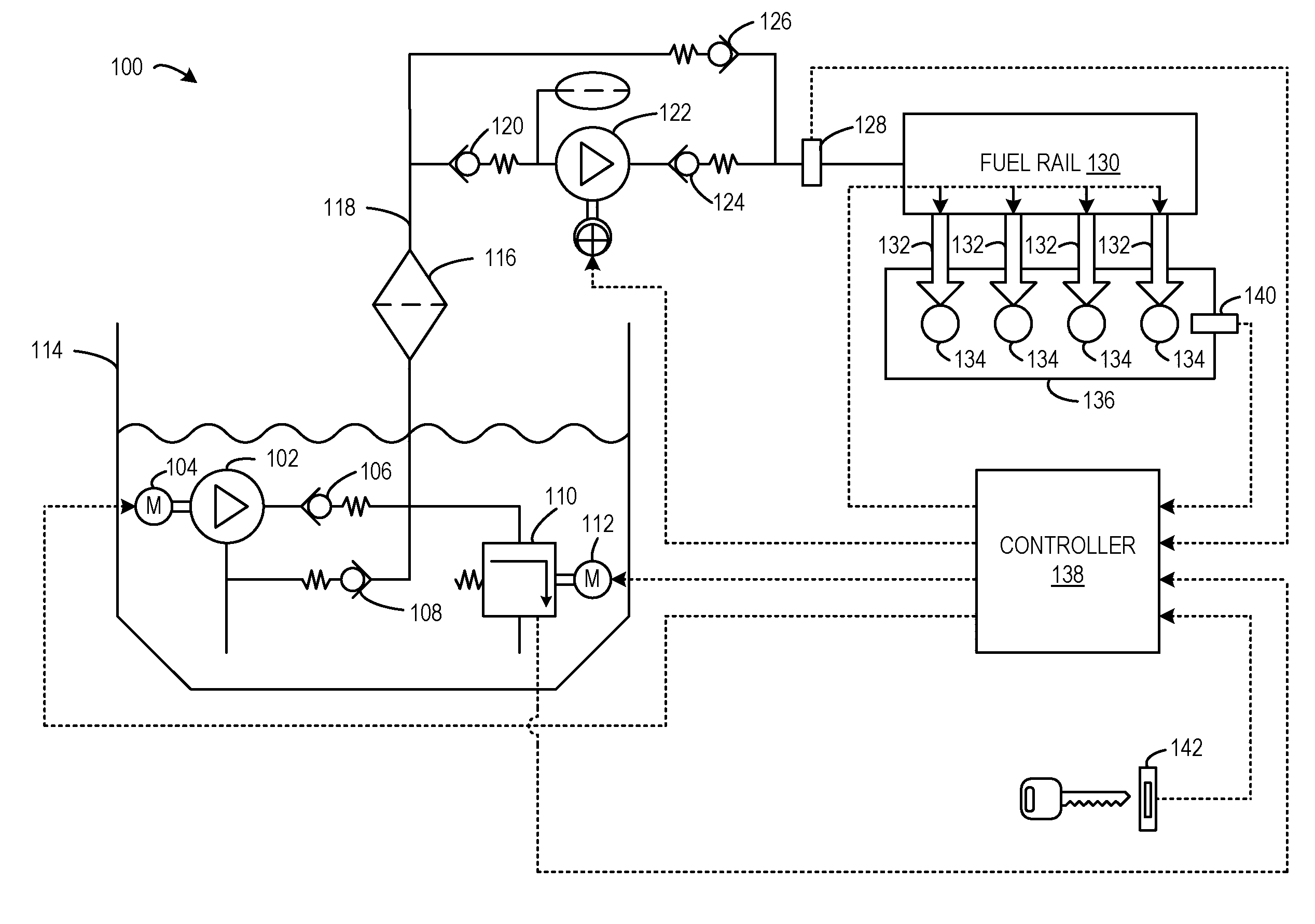

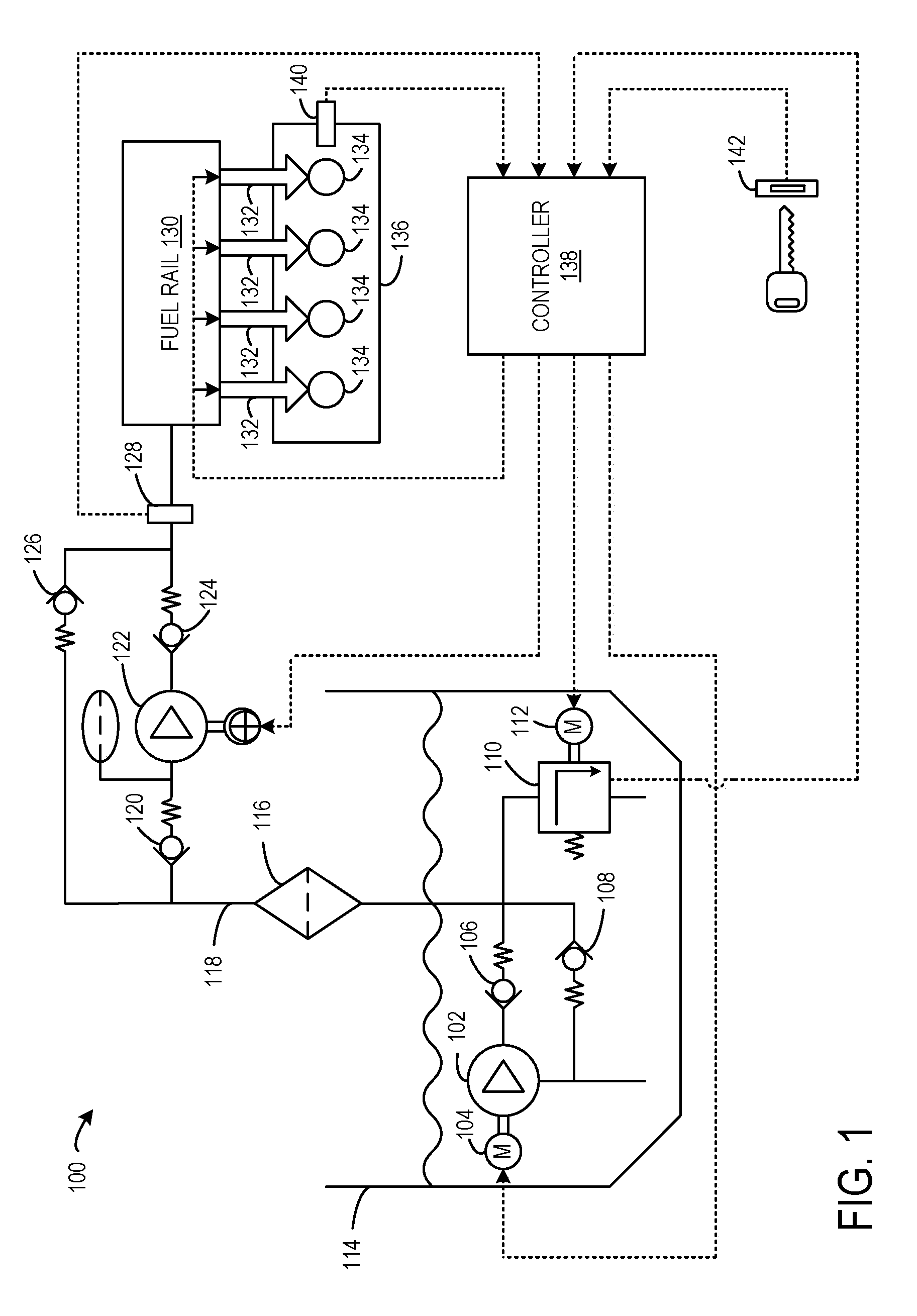

Fuel system with electrically-controllable mechanical pressure regulator

InactiveUS20110000463A1Increase power efficiency and rangeDecrease engine power and efficiencyElectrical controlExhaust apparatusAutomotive engineeringSet point

A method for operating an engine direct injection fuel system is provided. The direct injection fuel system includes a mechanical fuel pressure regulator that has a spring actuatable by an electric motor. The method includes adjusting a preload of the spring by operating the electric motor to adjust a set-point fuel pressure from a first set-point fuel pressure to a second set-point fuel pressure in response to an operating condition, and maintaining the preload of the spring mechanically when the electric motor is not operating.

Owner:FORD GLOBAL TECH LLC

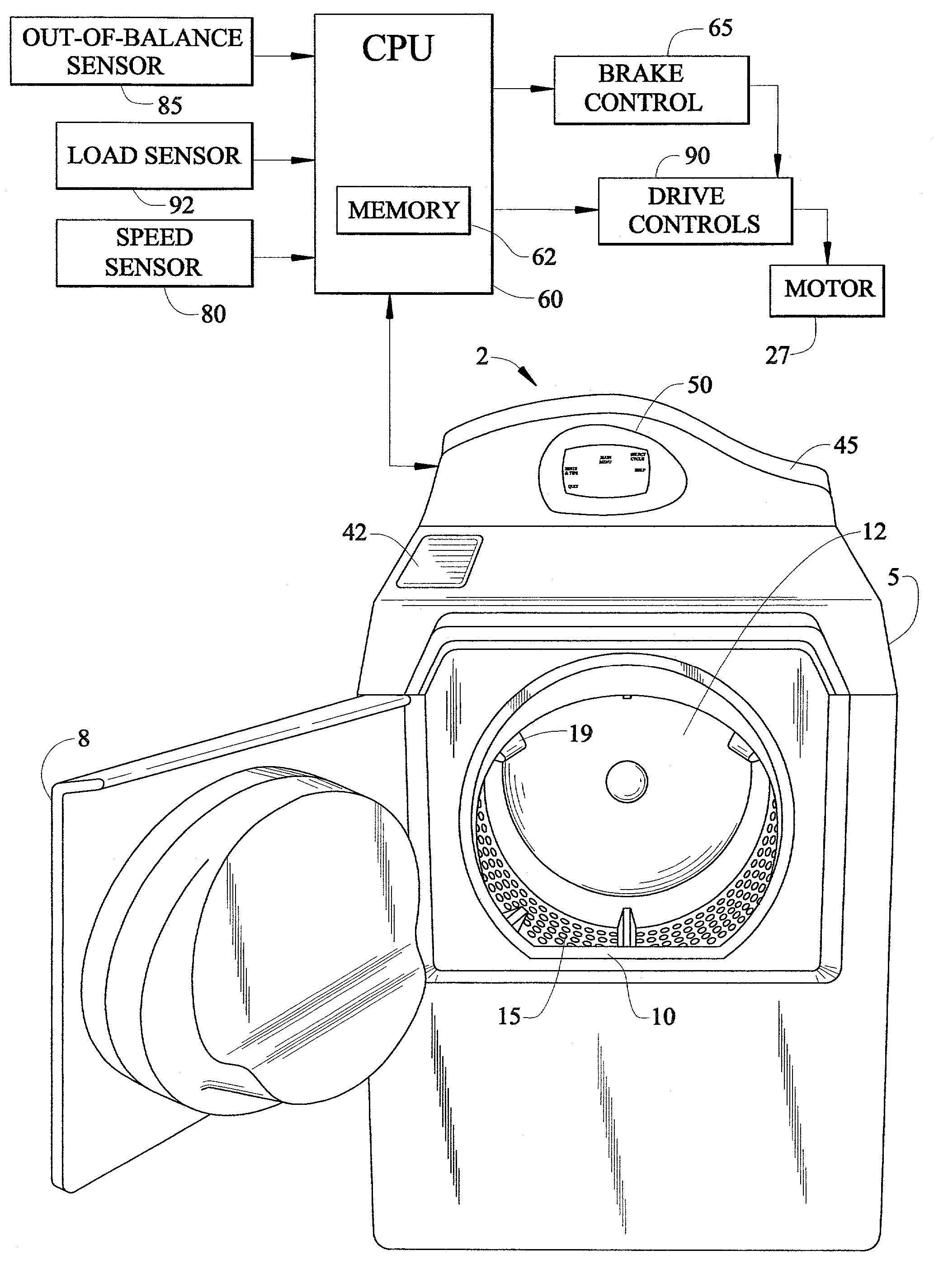

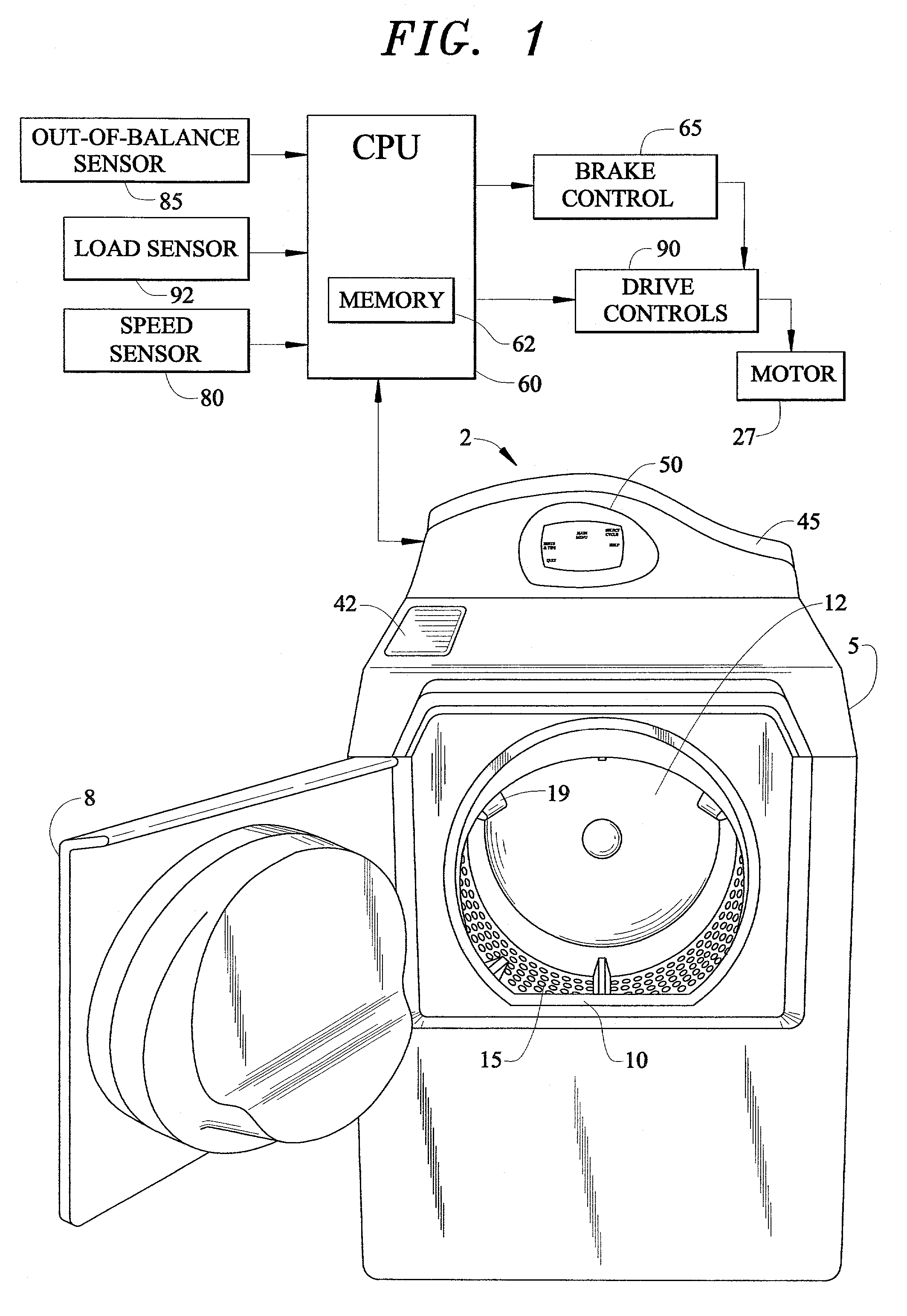

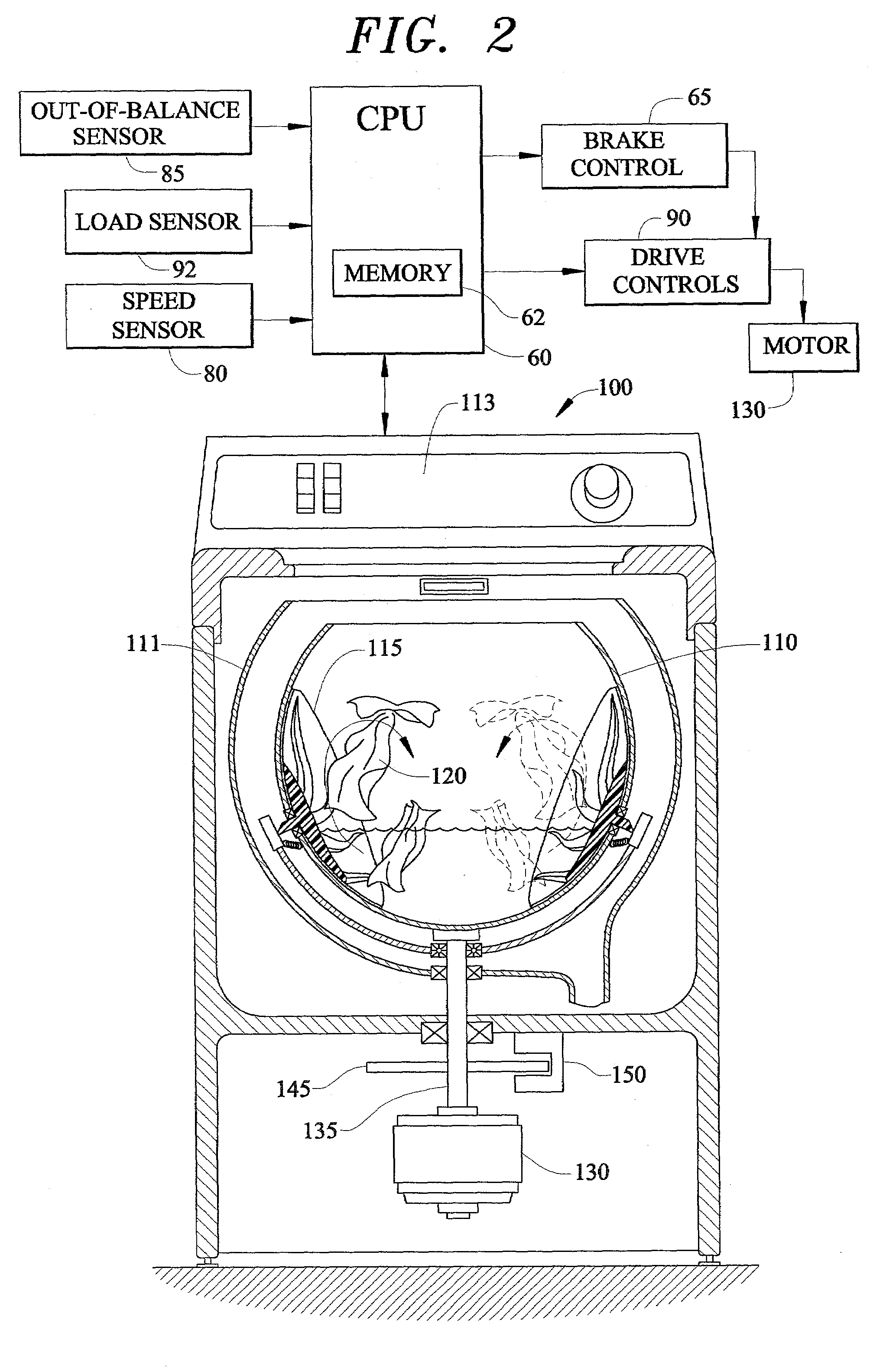

Braking control system for a washing machine

InactiveUS7039976B2Shorten the timeEffective brakingOther washing machinesControl devices for washing apparatusControl systemSpins

An inner tub of a washing machine is rapidly braked during a portion of a deceleration phase following an extraction phase of an overall spin cycle. A controller establishes the braking operation over a critical speed band or resonant frequency zone during which excessive vibrations would be developed. The critical speed band is preferably determined based on one or more signals received from speed, load, and / or out-of-balance sensors.

Owner:MAYTAG

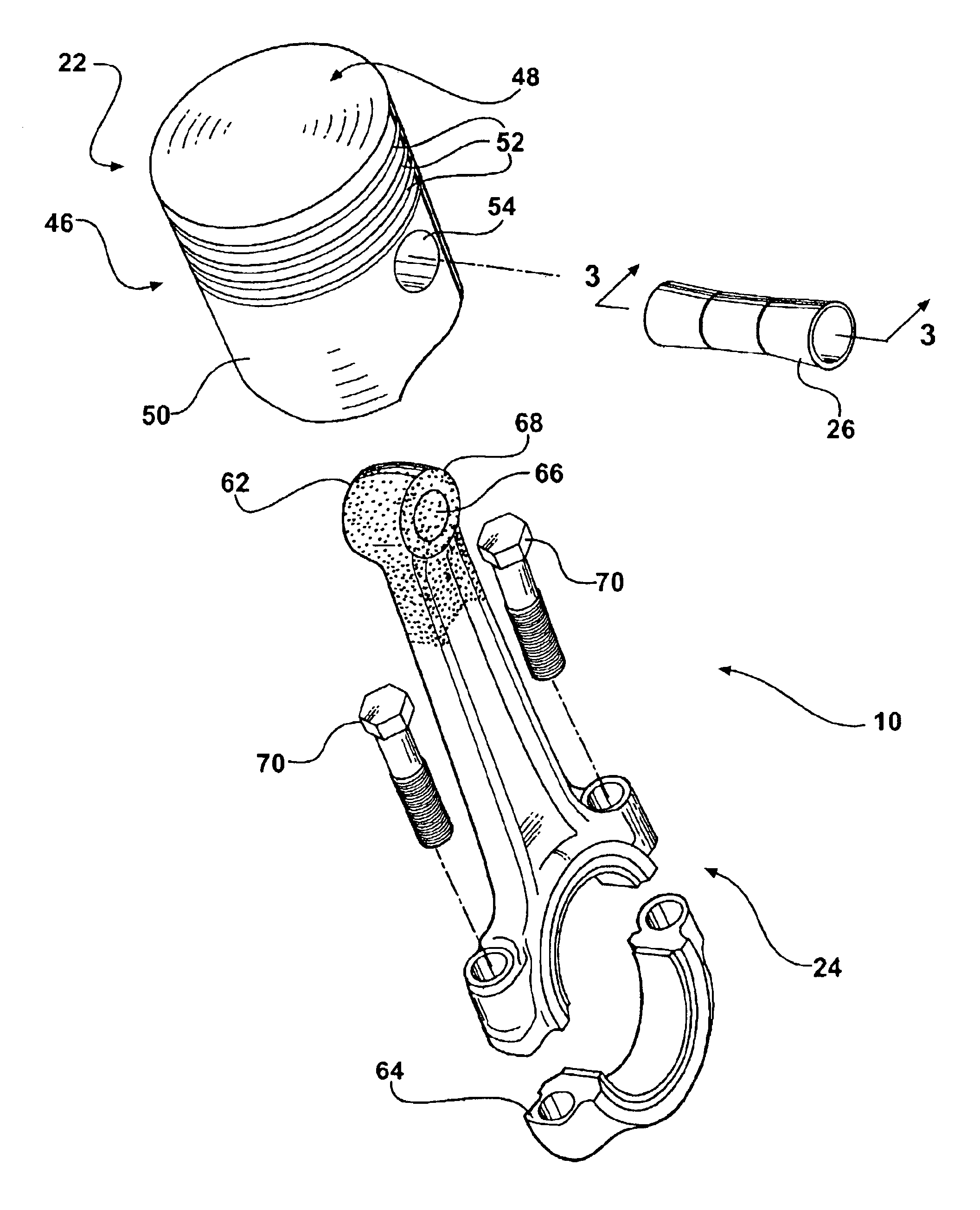

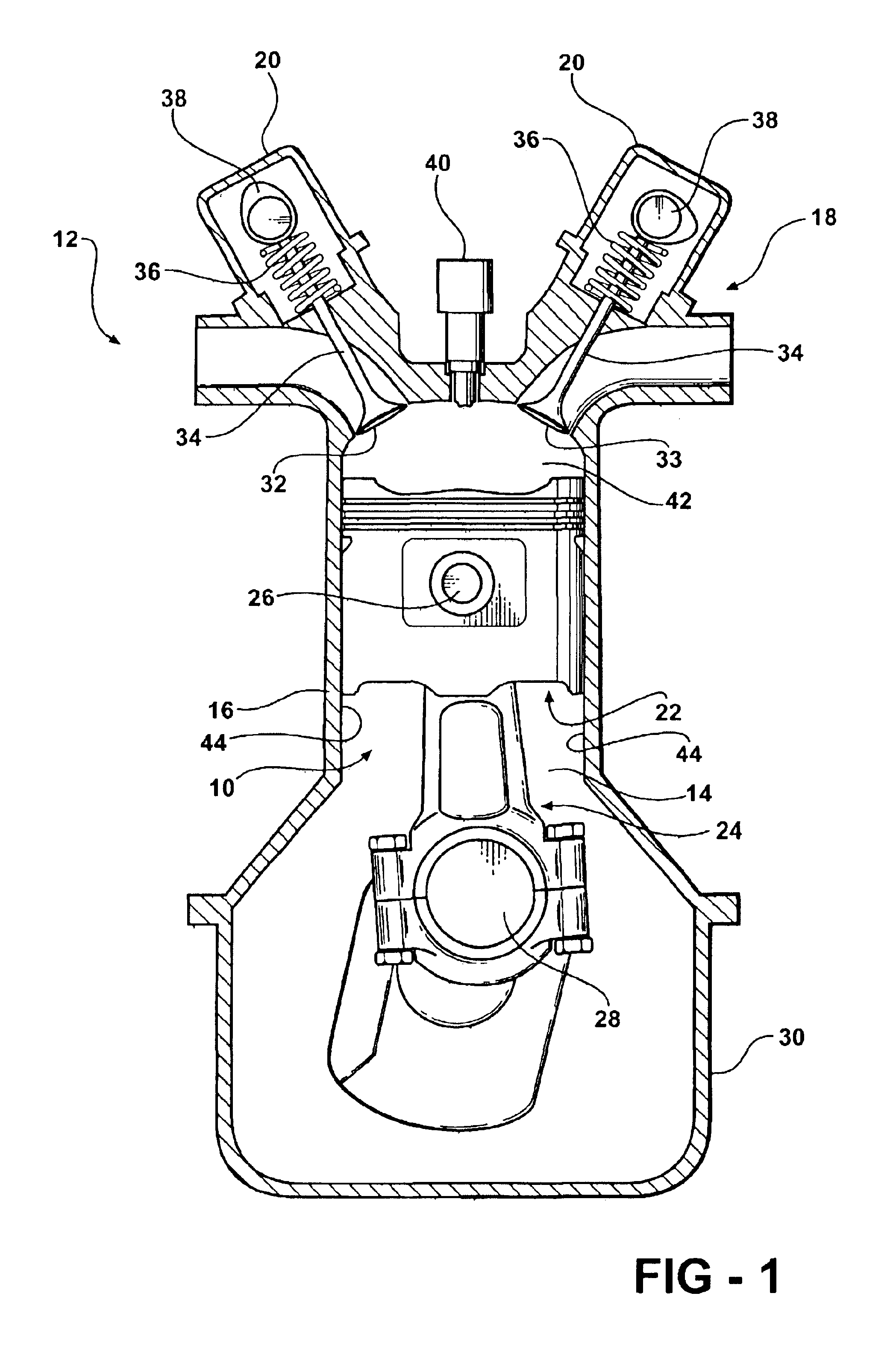

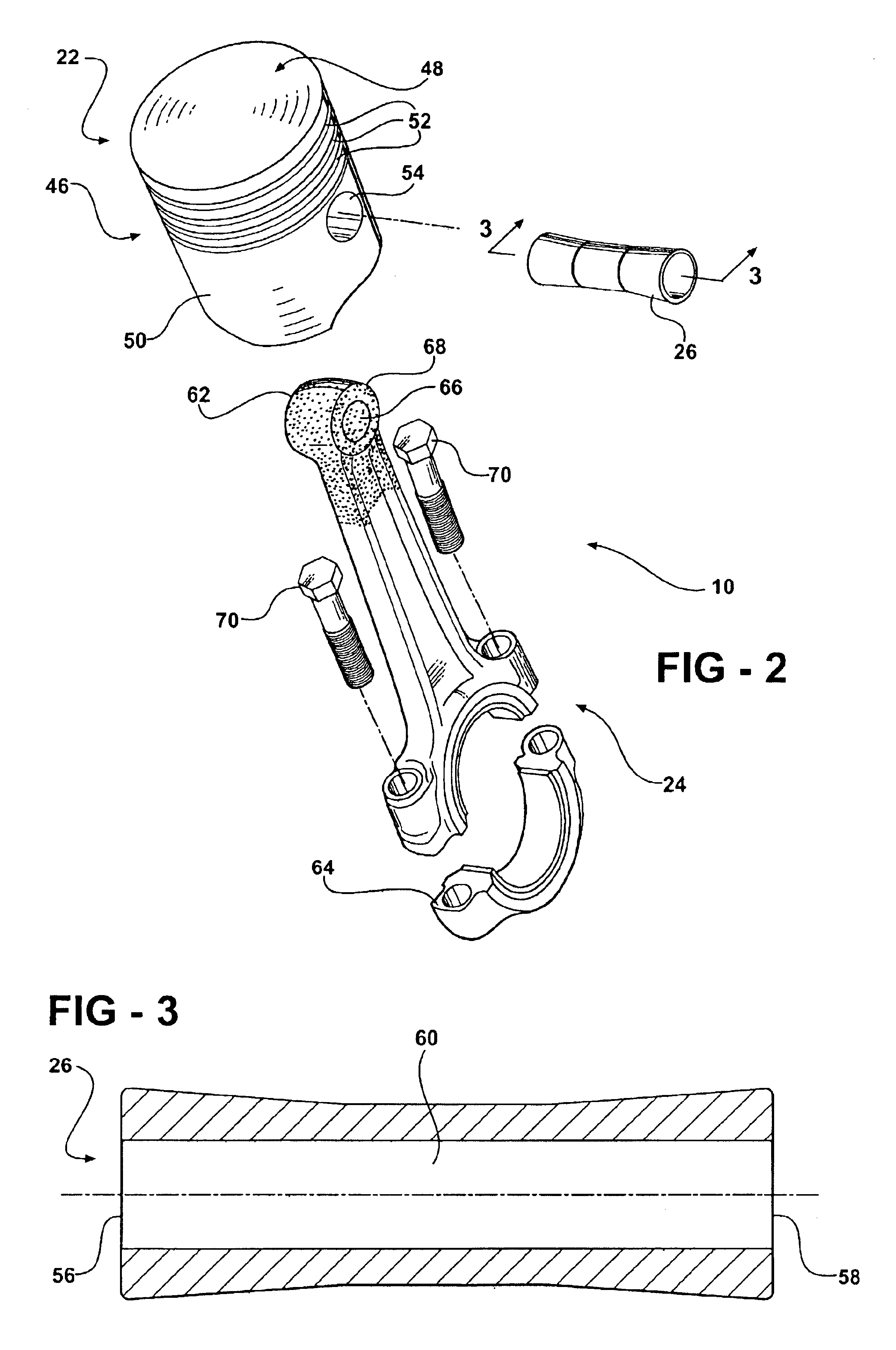

Piston and connecting rod assembly having phosphatized bushingless connecting rod and profiled piston pin

InactiveUS6923153B2Improve wear resistanceAvoid seizuresConnecting rodsPlungersEngineeringInternal combustion engine

The present invention relates to a connecting rod and piston pin assembly for an internal combustion engine to improve wear of the piston / connecting rod pivot point and reduce deformation of the pin bore. To this end, the assembly includes a piston having a pin bore, a connecting rod having a bore adapted to be aligned with the piston pin bore and piston pin interconnecting the piston and the connecting rod through engaging their respective bores. The piston pin has a profiled outer circumference that is substantially circular in cross-section with a larger diameter at the distal ends than at the center portion. One end of the connecting rod includes a phosphatized coating and is adapted to facilitate movement between the connecting rod bore and the profiled piston pin.

Owner:MAHLE TECH

Optical reflector for reducing radiation heat transfer to hot engine parts

InactiveUS20050048305A1Extended component lifeLess mean timePig casting plantsRotary propellersOptical reflectionCoating system

A high temperature gas turbine component for use in the gas flow path that comprises a specular optical reflector coating system. A thin specular optical reflector coating system is applied to the gas flow path of the component, that is, the surface of the component that forms a boundary for hot combustion gases. The component typically includes a thermal barrier coating overlying the high temperature metallic component that permits the component to operate at elevated temperatures. The thermal barrier coating must be polished in order to provide a surface that can suitably reflect the radiation into the gas flow path. The thin reflector coating system comprises a thin high temperature and corrosion resistant refractory stabilizing layer, which is applied over a thin reflective metal layer, which is applied over a thin high temperature and corrosion resistant refractory sealing layer. The coating system is applied over the polished thermal barrier coating by a process that can adequately adhere the reflector to the polished surface without increasing the roughness of the surface. The coating system reflects radiation back into the hot gas flow path or into the atmosphere. The reflected radiation is not focused onto any other hardware component. The design of the component is such that the radiation is returned to the gas flow path or sent to the atmosphere rather than absorbed into a component that only serves to increase the temperature of such a component.

Owner:GENERAL ELECTRIC CO

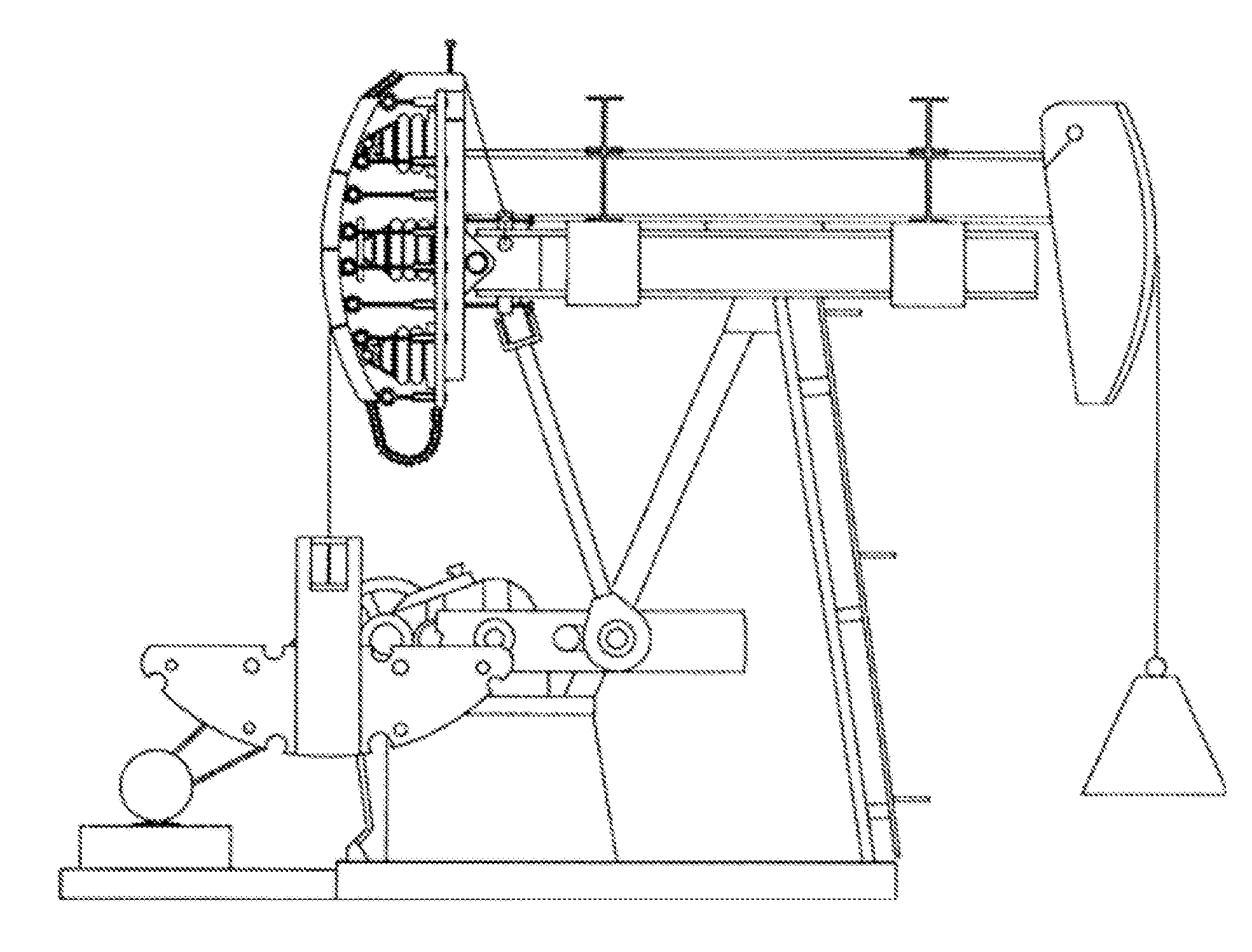

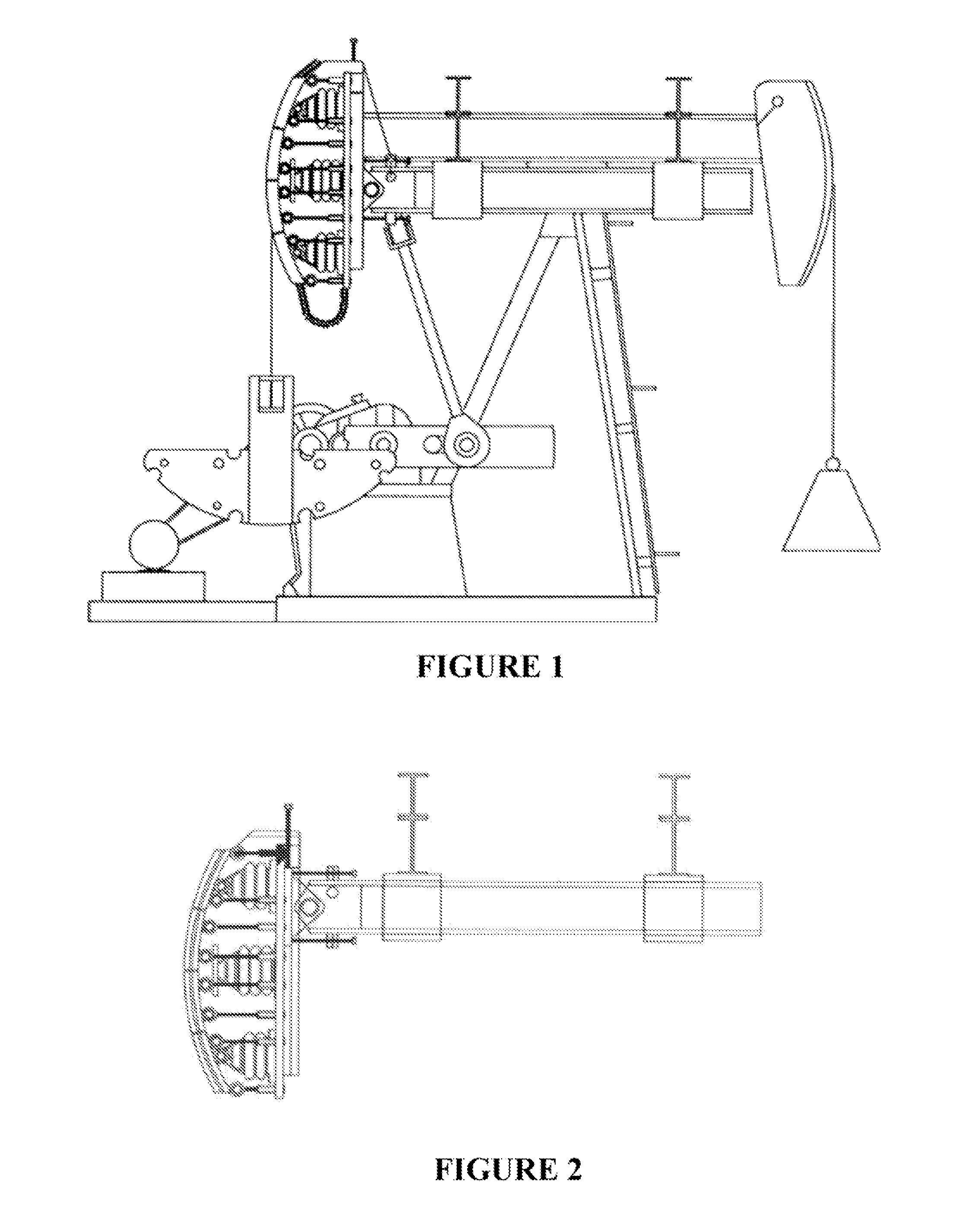

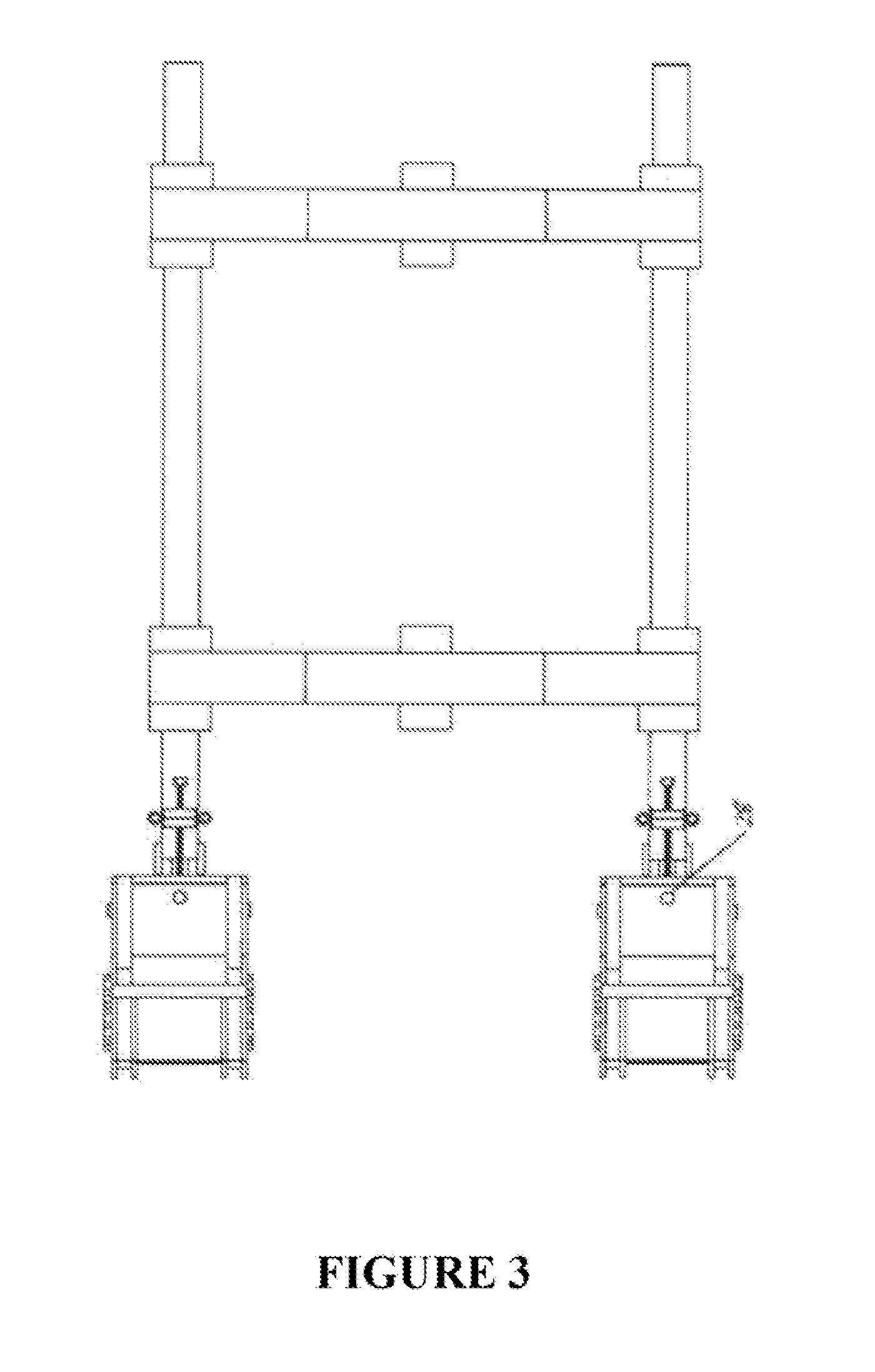

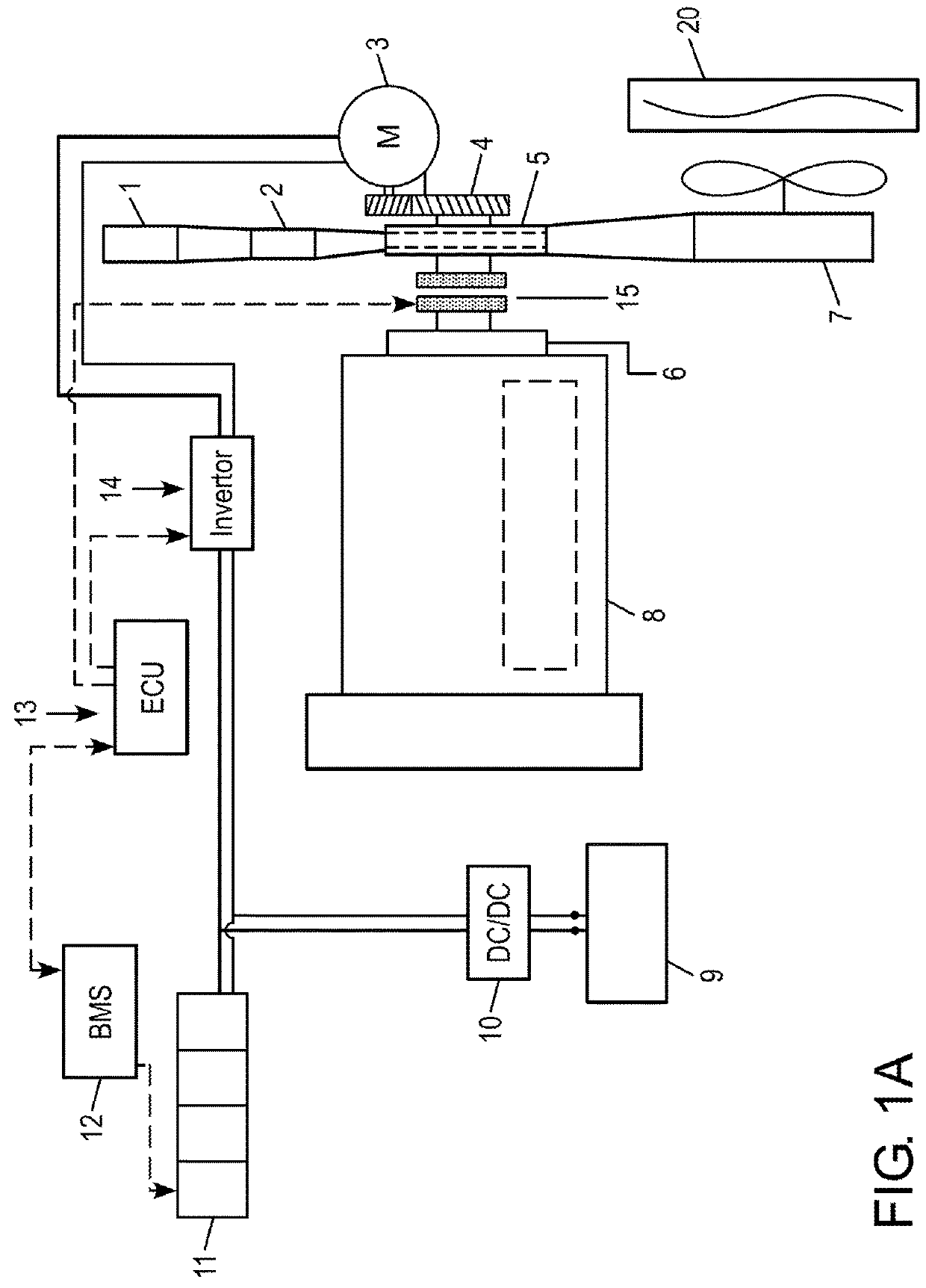

Cross-Jack Counterbalance System

InactiveUS20110314959A1Reduce energy consumptionExtended component lifeControlling membersControlled membersReciprocating pumpPre-existing

The device is a counterbalance system and method to reduce the work of conventionally balanced, reciprocating cantilevered beam pumping units, and comprises a pair of transversely oriented support mounts attached to the cantilevered beam or walking beam of a pre-existing reciprocating pumping unit, attaching on either side of the pivoting-fulcrum, mounting point of the cantilevered walking beam. These transverse mounting points terminate individually on either side of said walking beam in channel-like saddles that support independent, parallel beams, which in turn cantilever themselves in tandem with said walking beam of the pumping unit; moreover, the position of the parallel beams by virtue of the transverse mounts creates a new center of gravity corresponding to the center of the pivoting mounting point of the walking beam, eliminating counter-productive torque forces on the walking beam as it tilts from horizontal.

Owner:GUIDEMASTER MFG

Front End Motor-Generator System and Hybrid Electric Vehicle Operating Method

ActiveUS20180162355A1Increase in sizeMinimize engine loadHybrid vehiclesVehicle sub-unit featuresClutchElectric generator

Owner:BENDIX COMML VEHICLE SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com