Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improved lifetime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

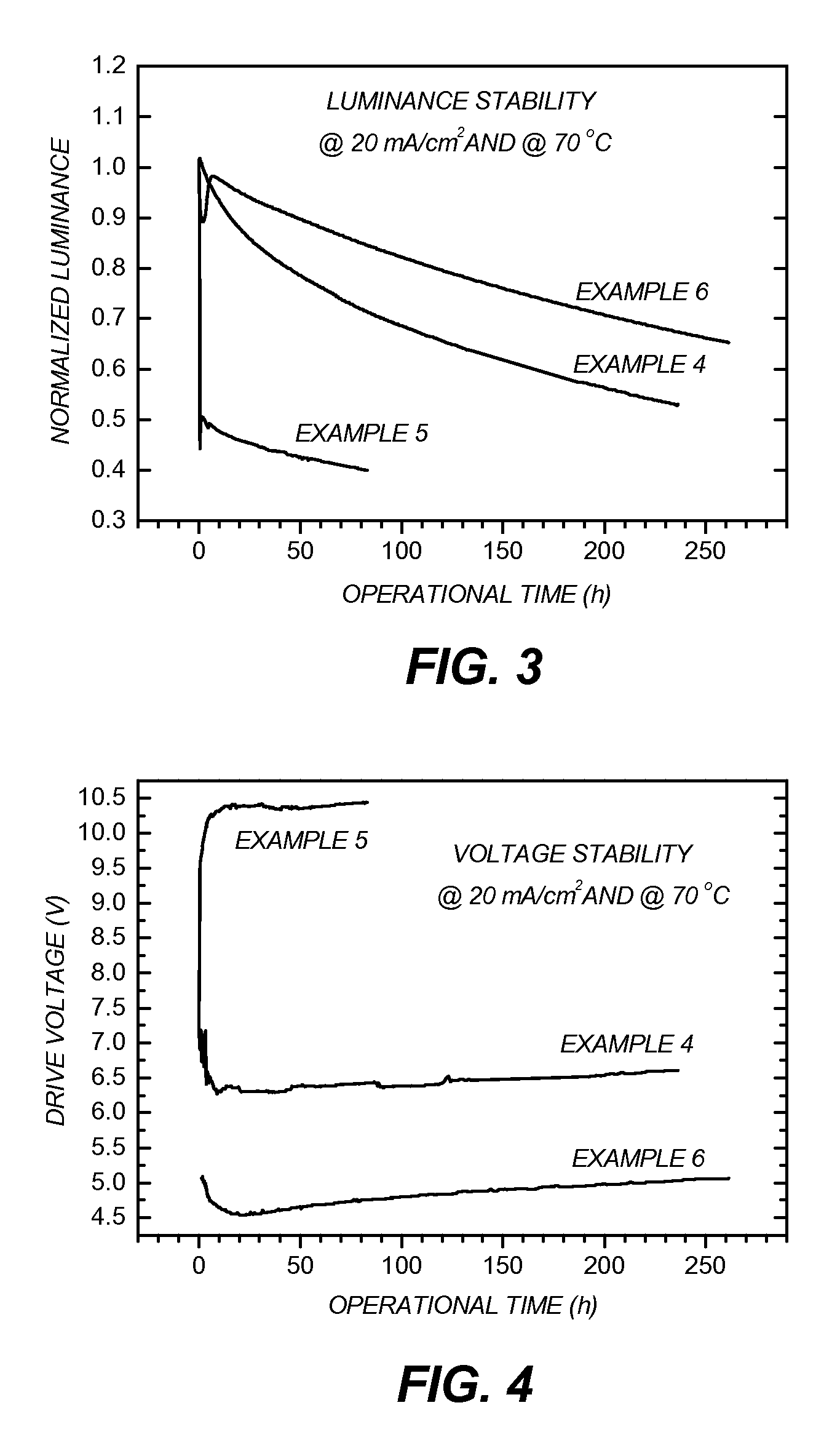

Organic electroluminescent device having an azatriphenylene derivative

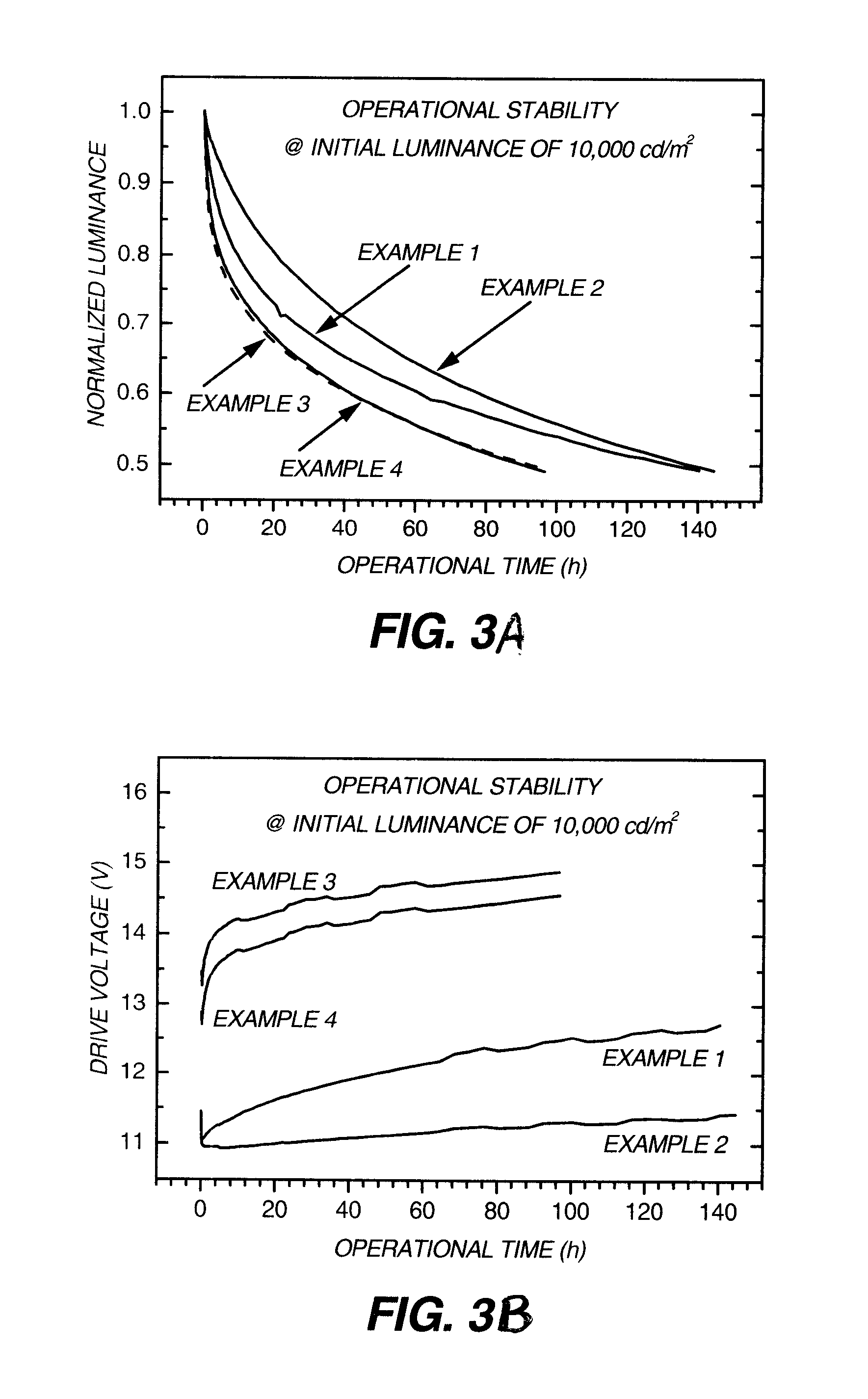

ActiveUS20090115316A1Promote resultsReduce the driving voltageOrganic chemistryDischarge tube luminescnet screensElectricityEngineering

Azatriphenylene derivatives and their use in the electron-transporting layer of an electroluminescent device that comprises an anode, a spaced-apart cathode, and at least one electron-transporting layer disposed between the spaced-apart anode and cathode. Such EL devices provide lower drive voltage, improved power efficiency, and longer operational lifetime.

Owner:GLOBAL OLED TECH

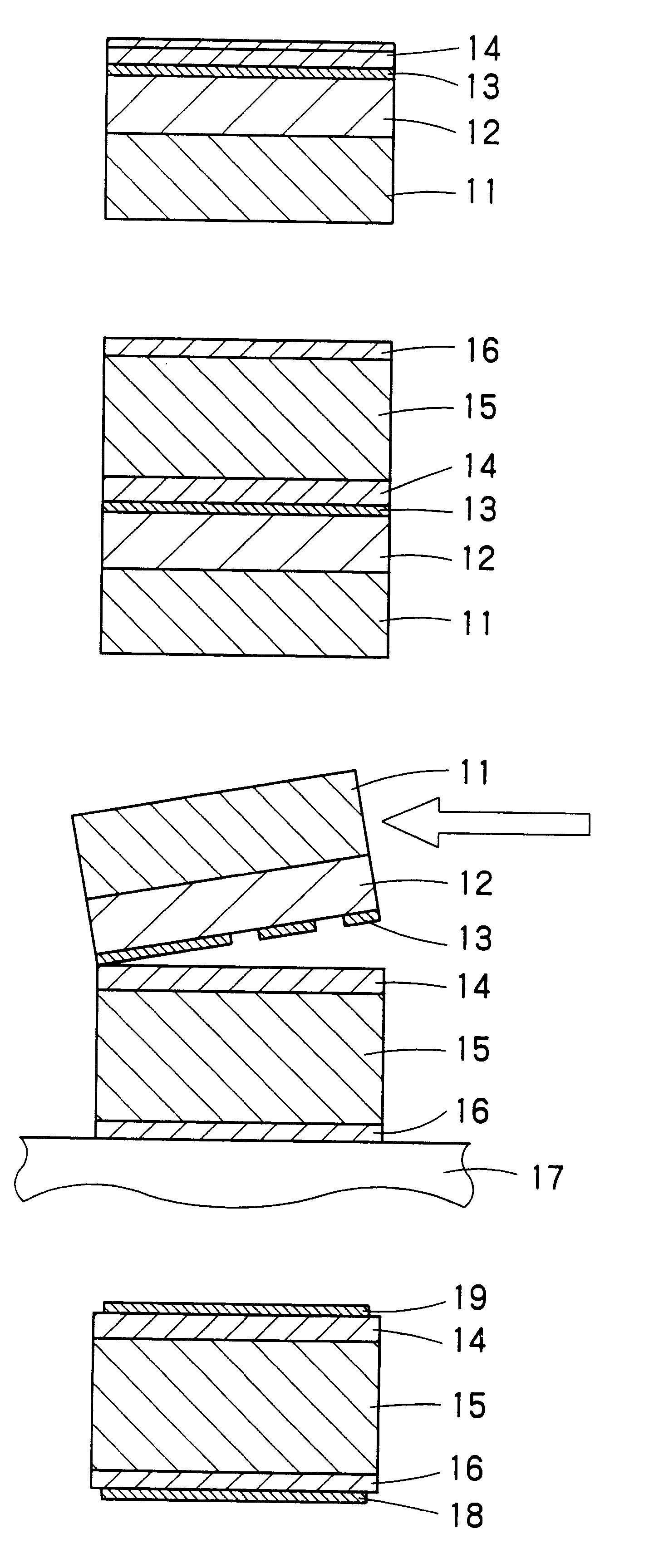

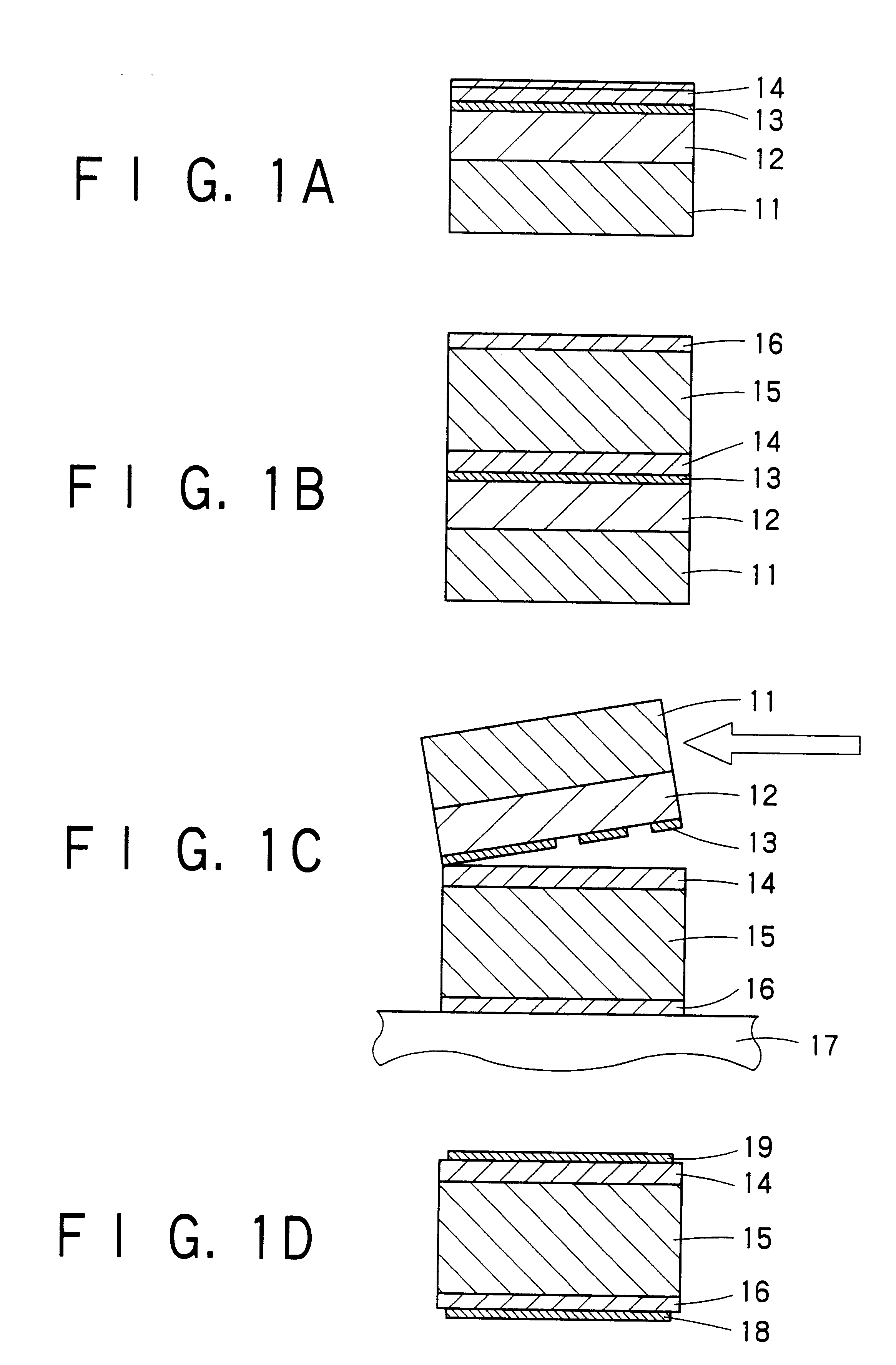

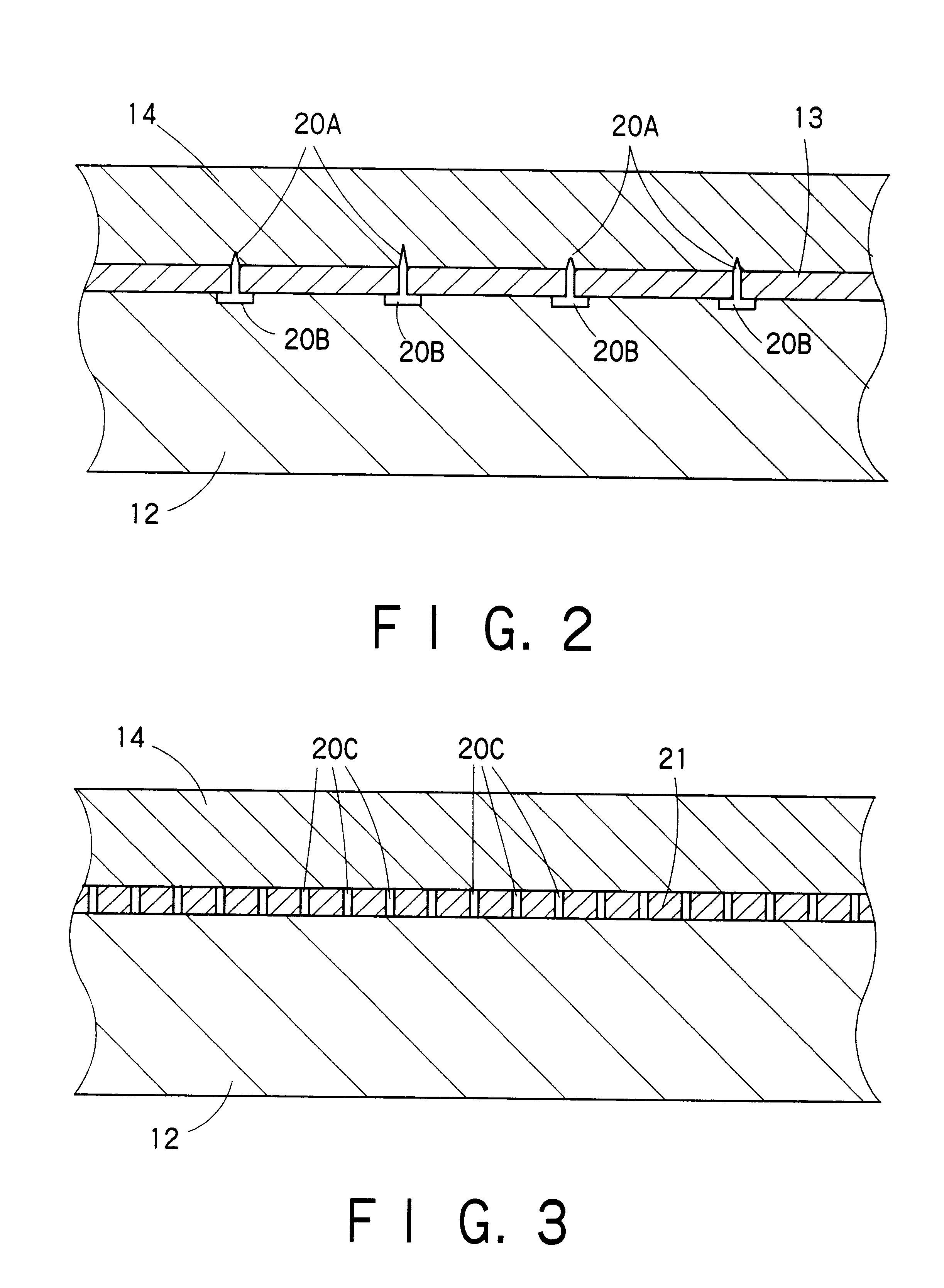

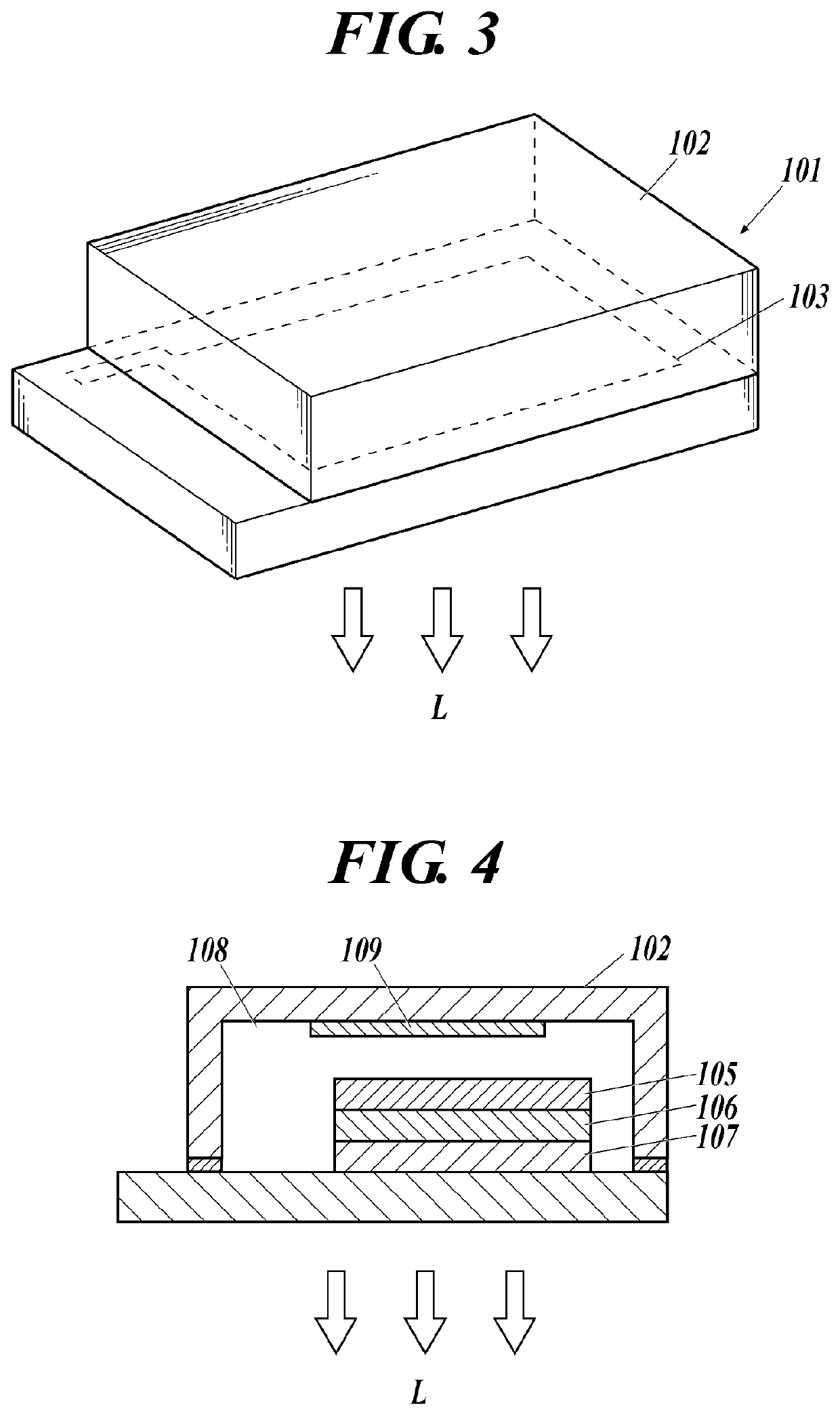

Semiconductor light emitting element, and its manufacturing method

InactiveUS6303405B1Quality improvementImprove electricitySolid-state devicesSemiconductor/solid-state device manufacturingLaser lightHeat stress

A semiconductor light emitting element of nitride compound semiconductors excellent in cleavability, heat radiation and resistance to leakage is made by epitaxially grow a nitride compound semiconductor layers on a substrate of sapphire, for example, and thereafter separating the substrate. For separating the substrate, there are a technique using a abruption mechanism susceptible to a stress such as a "lift-off layer" and a recesses on a substrate. A technique using laser light to cause a local dense heat stress at the abruption mechanism is effective. A nitride compound semiconductor obtained by separating the substrate may be used as a new substrate to epitaxially grow high-quality nitride compound semiconductors thereon.

Owner:ALPAD CORP

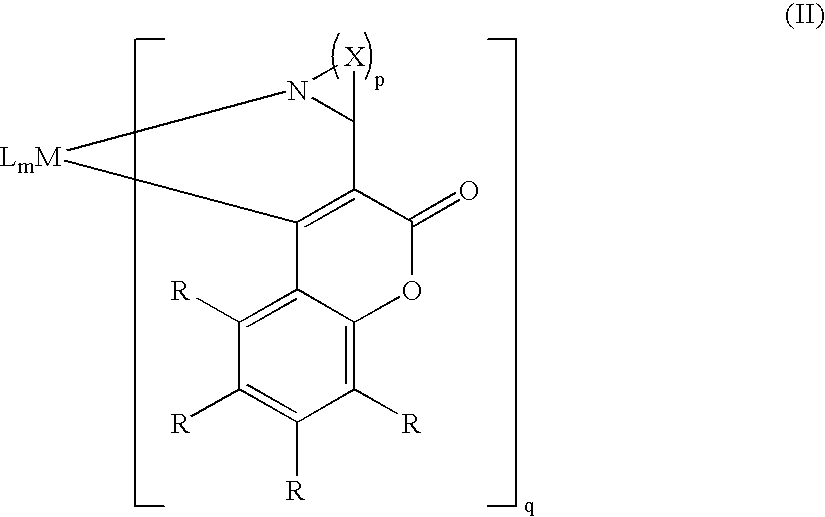

Light emitting device containing phosphorescent complex

ActiveUS20080020237A1Improve efficiencyImproved lifetimeIndium organic compoundsLayered productsChemistryPhosphorescence

An OLED device comprises a cathode, an anode, and has therebetween a light emitting layer comprising a phosphorescent emitter represented by Formula (I):LnM (I)wherein each L is a cyclometallated ligand with at least one containing a coumarin group, M is Ir or Pt, and n is 3 when M is Ir and 2 when M is Pt. The invention also comprised the compound of formula (I).

Owner:GLOBAL OLED TECH

Thin film encapsulation containing zinc oxide

InactiveUS20090079328A1Improved yield and lifetime and consequently light emission efficiencyAccelerate emissionsDischarge tube luminescnet screensLamp detailsSecondary layerOxide

The invention is directed towards an OLED device, comprising a first electrode, a second electrode, one or more organic layers formed between the first electrode and second electrode, at least one organic layer being a light-emitting layer; and a thin film encapsulation layer comprising either (a) at least one first layer of zinc oxide and at least one second layer of a second inorganic compound, or (b) a layer that is a mixture of zinc oxide and a second inorganic compound. The invention is also directed to a method of forming such an OLED device.

Owner:EASTMAN KODAK CO

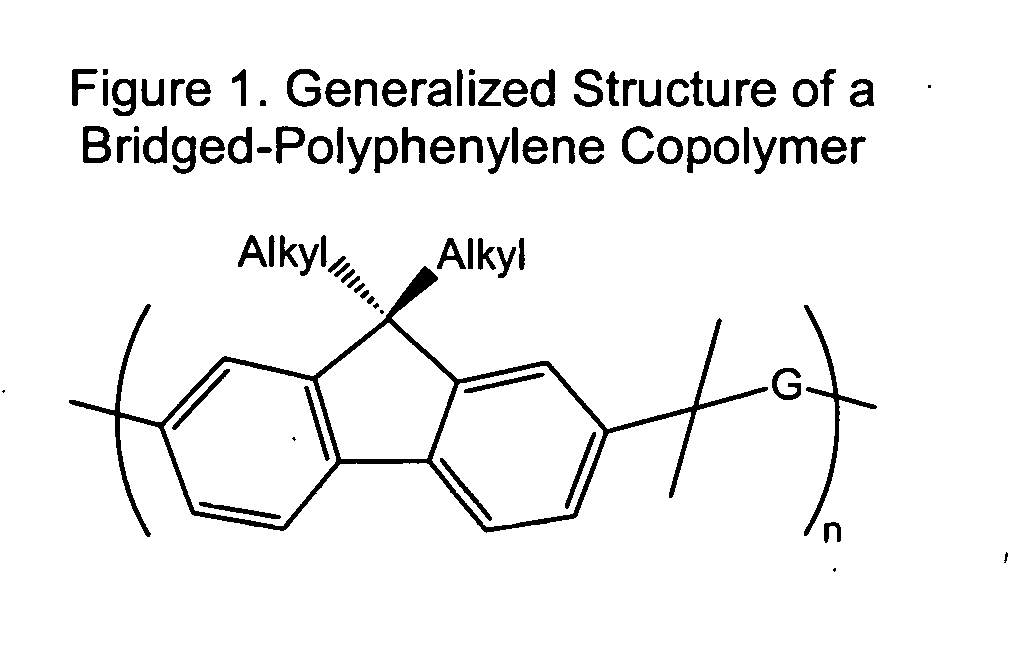

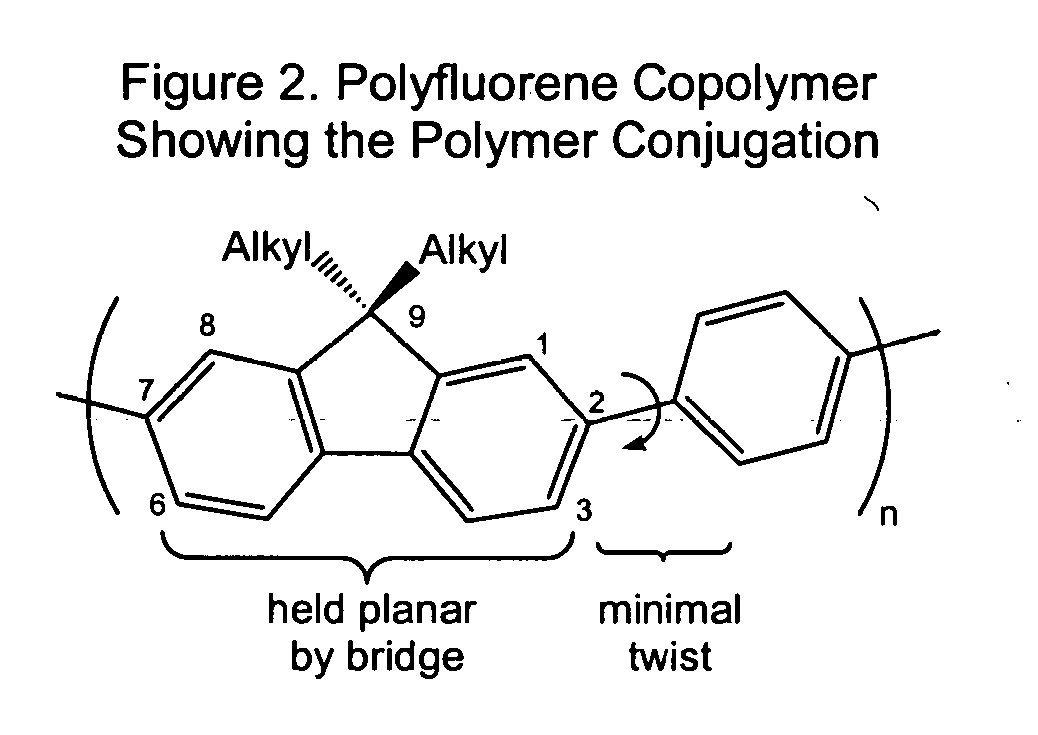

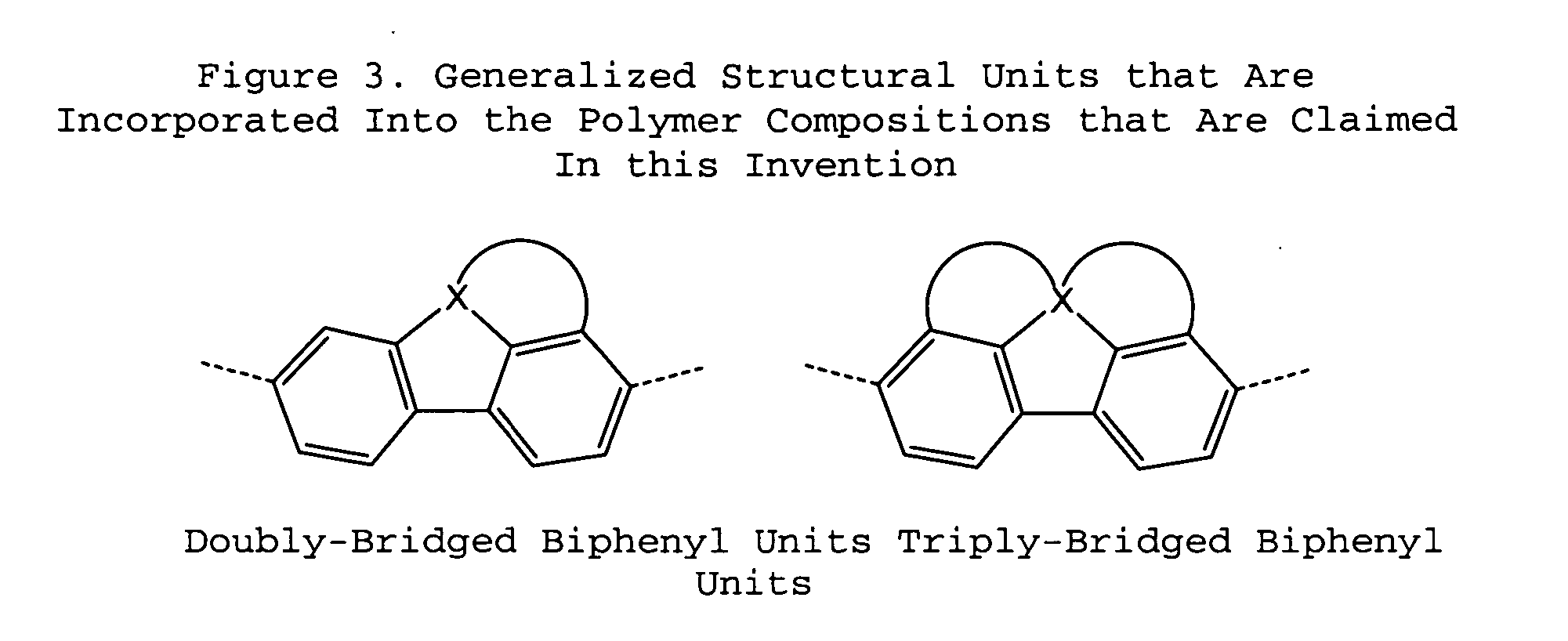

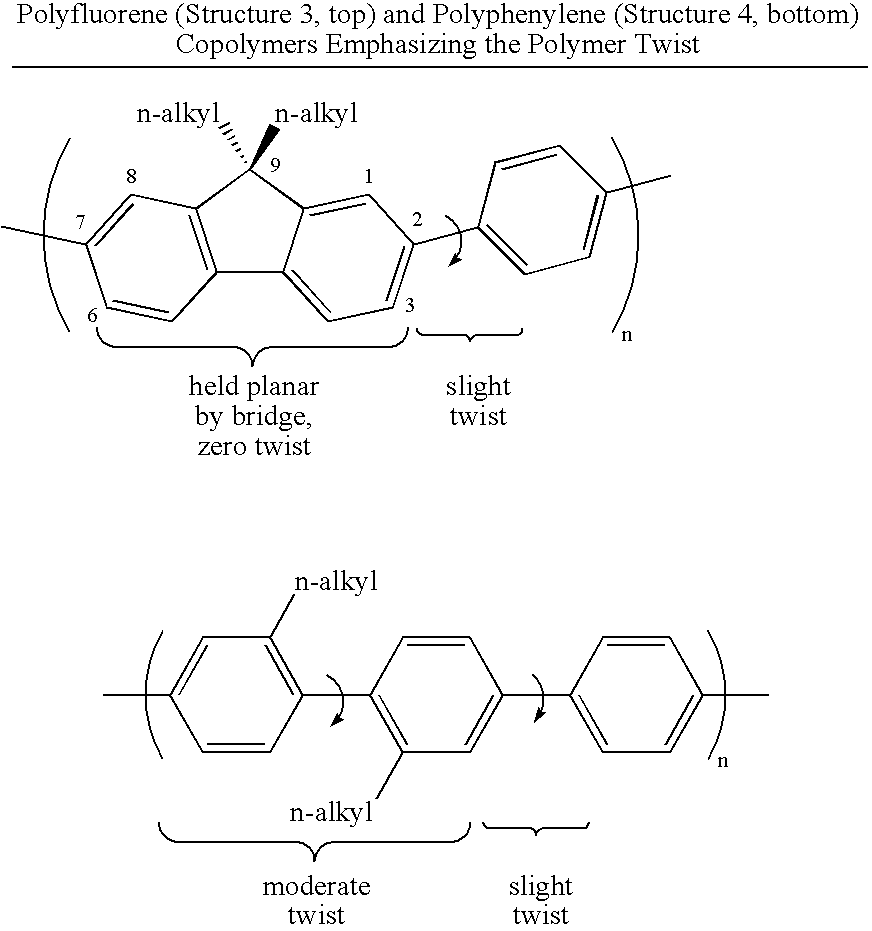

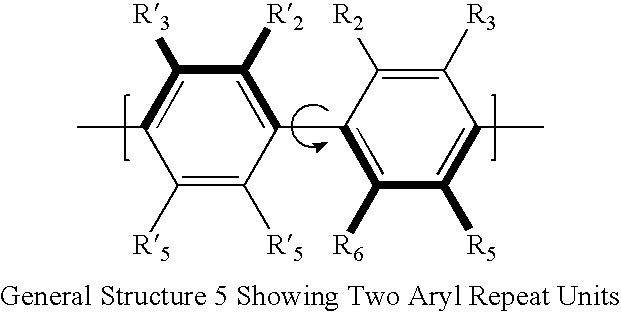

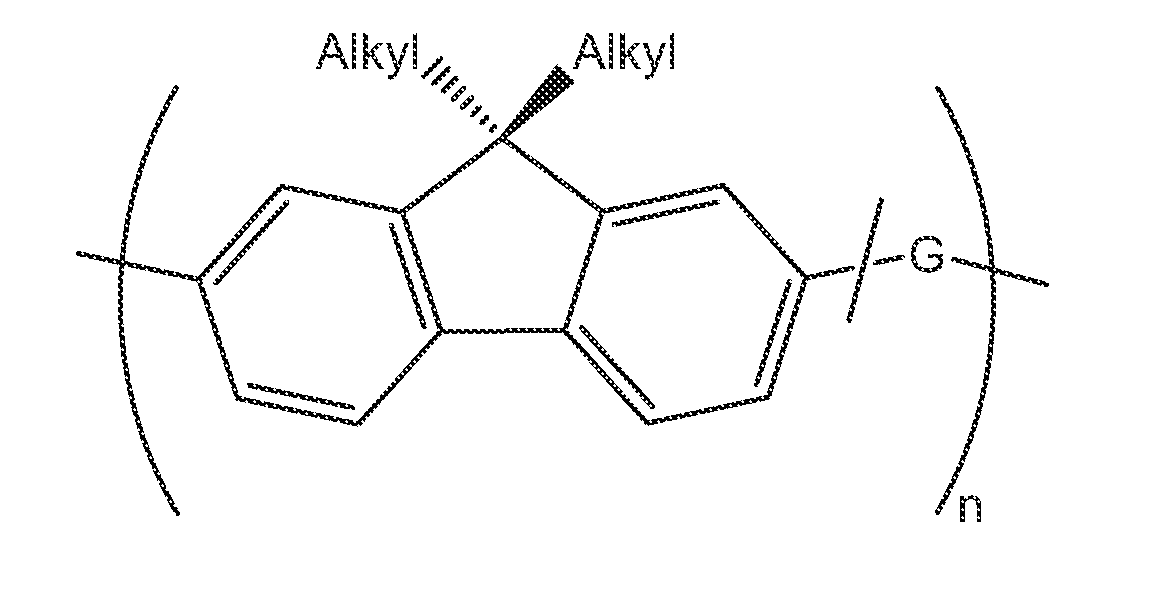

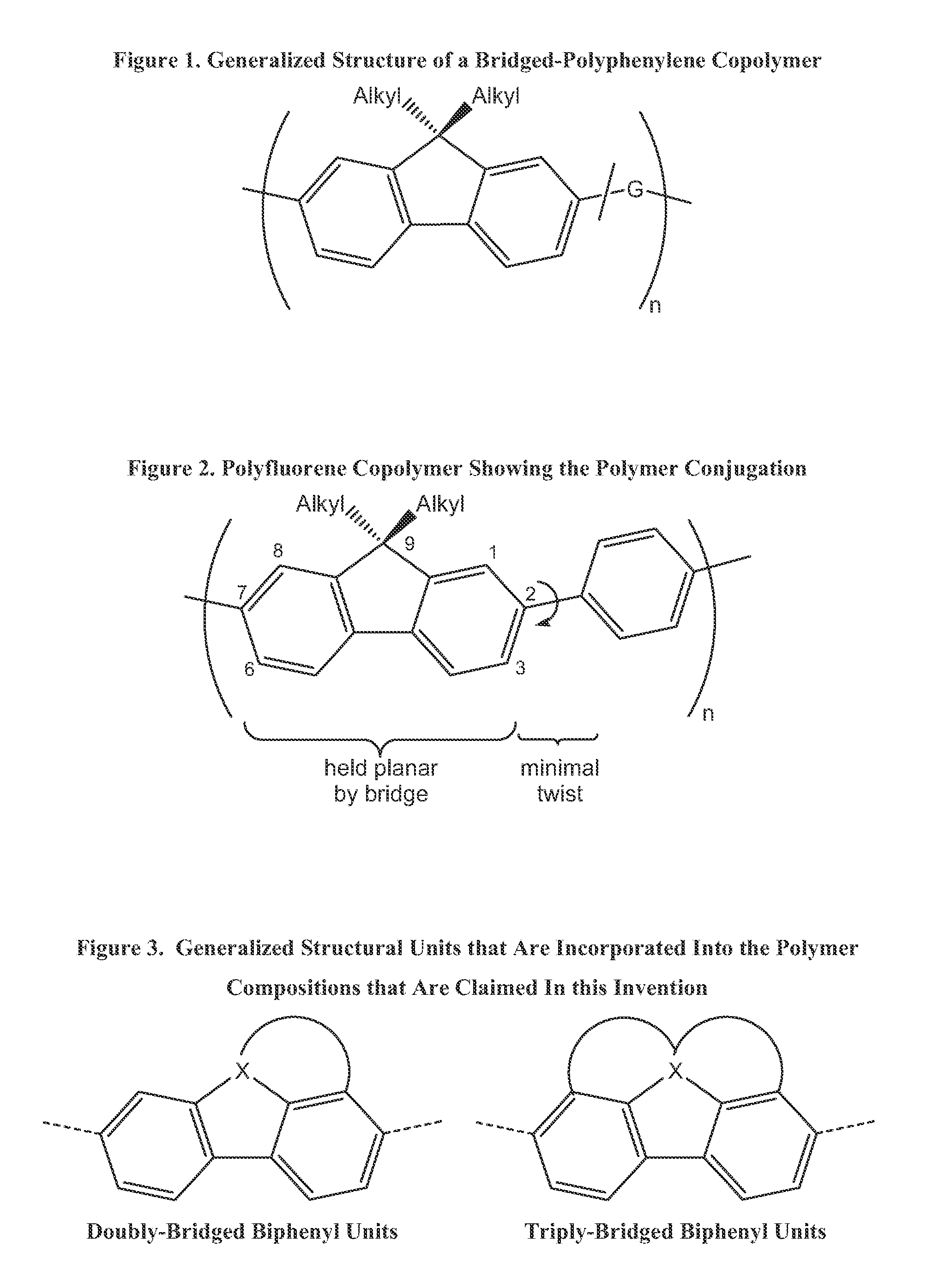

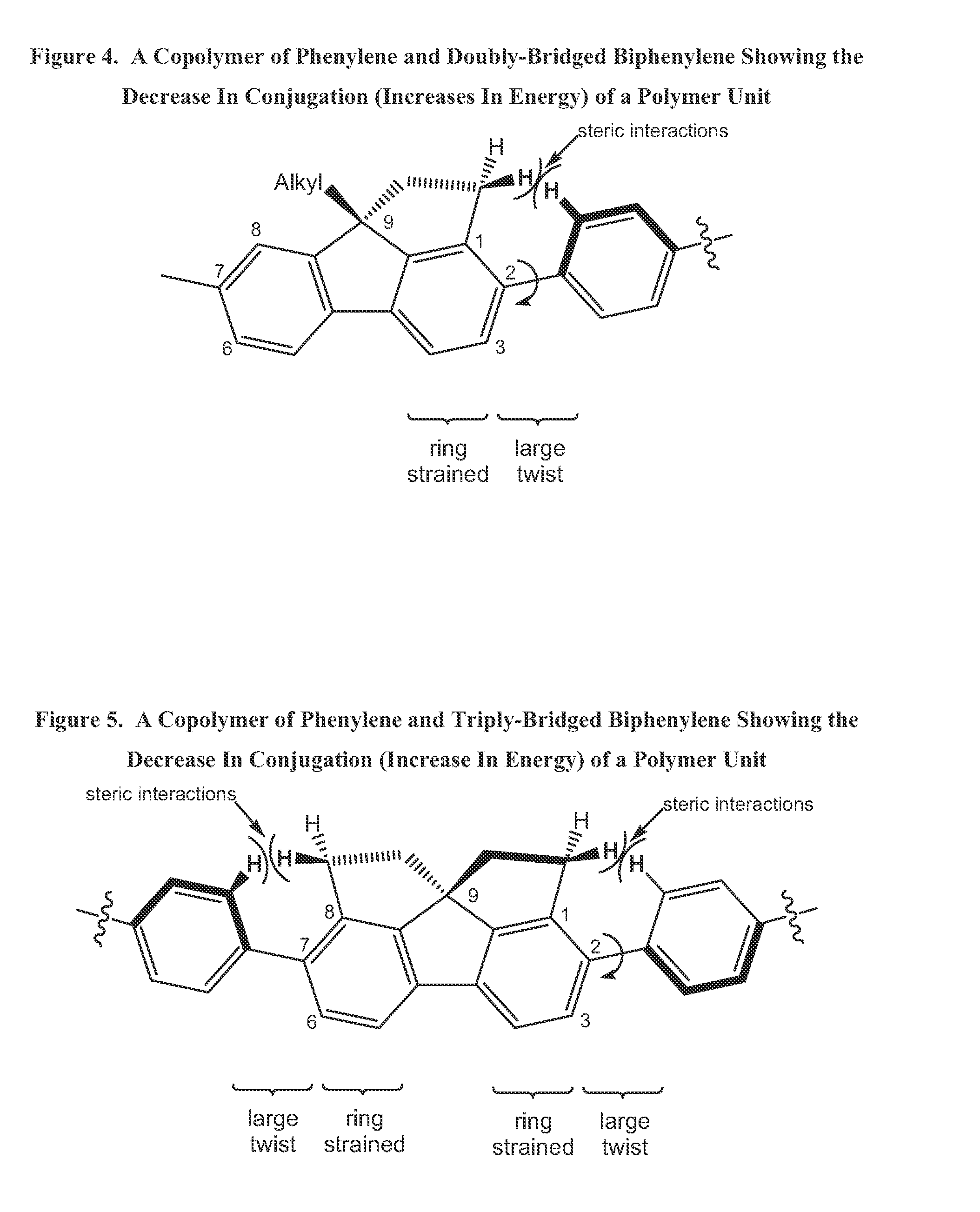

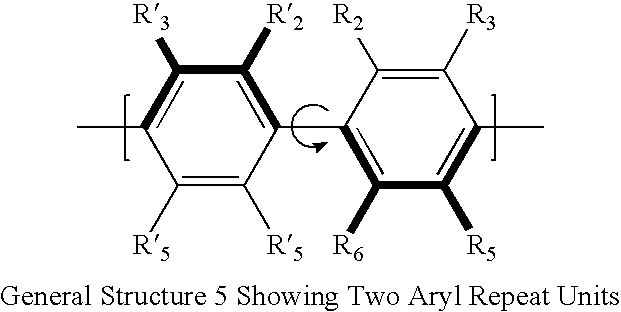

Class of bridged biphenylene polymers

InactiveUS20060094859A1Increase brightnessImproved lifetimeLiquid crystal compositionsDischarge tube luminescnet screensLuminescent polymersPhenyl group

Luminescent polymers having doubly- or multiply-bridged biphenylene repeat units are provided, which are particularly suited as electroluminescent polymers. Monomers necessary for the synthesis of the multiply bridged biphenylene polymers are provided, as are electroluminescent devices utilizing these polymers.

Owner:SUMITOMO CHEM CO LTD

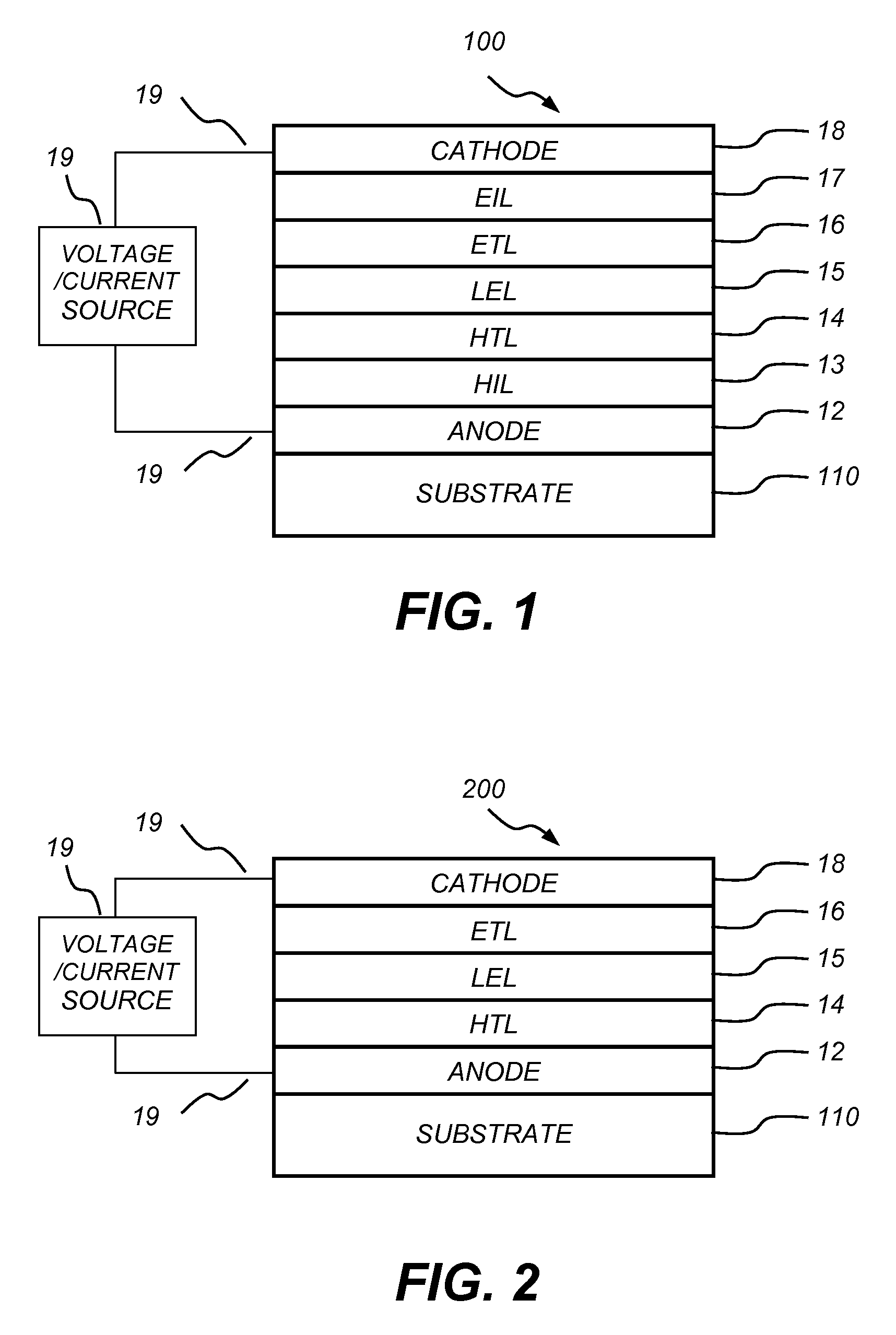

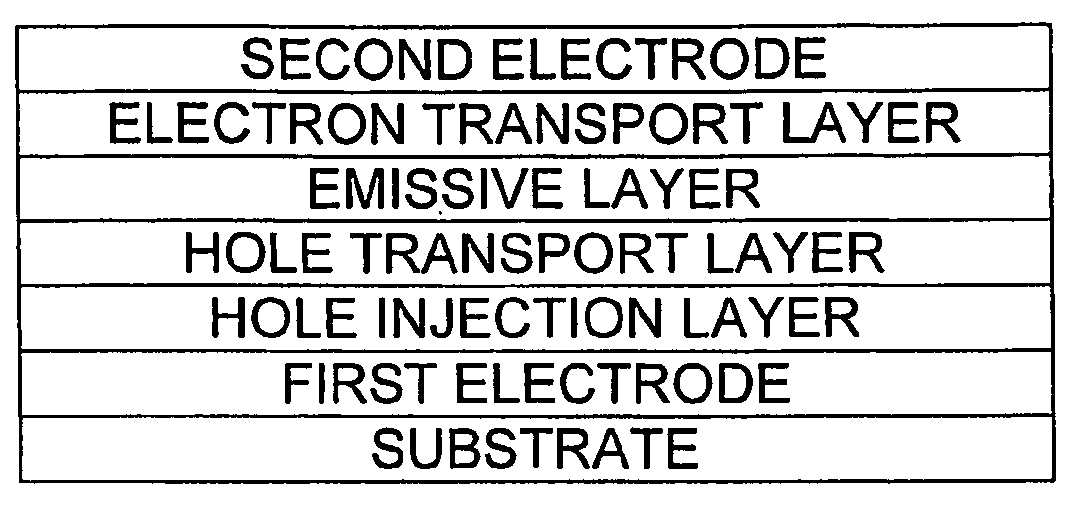

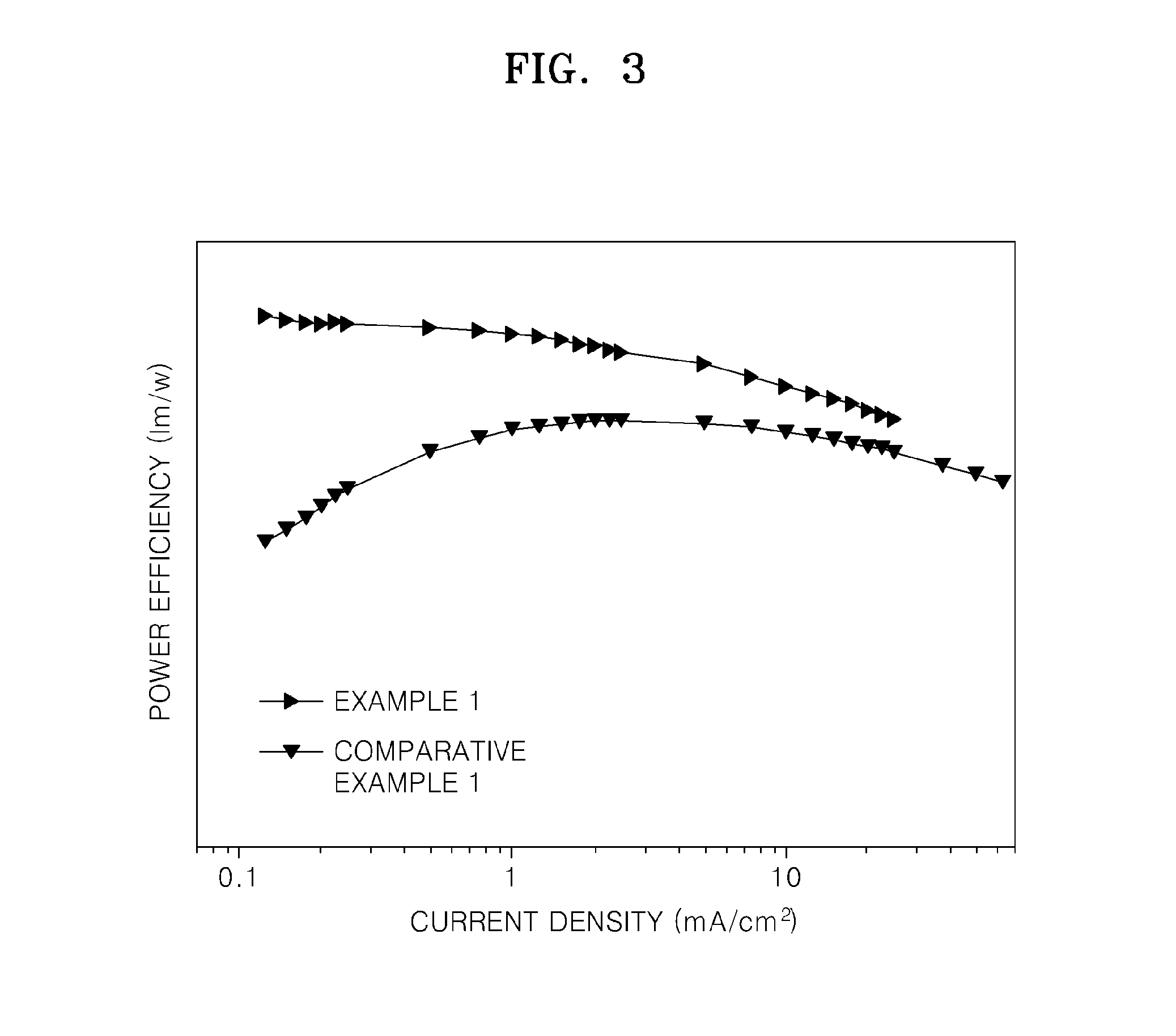

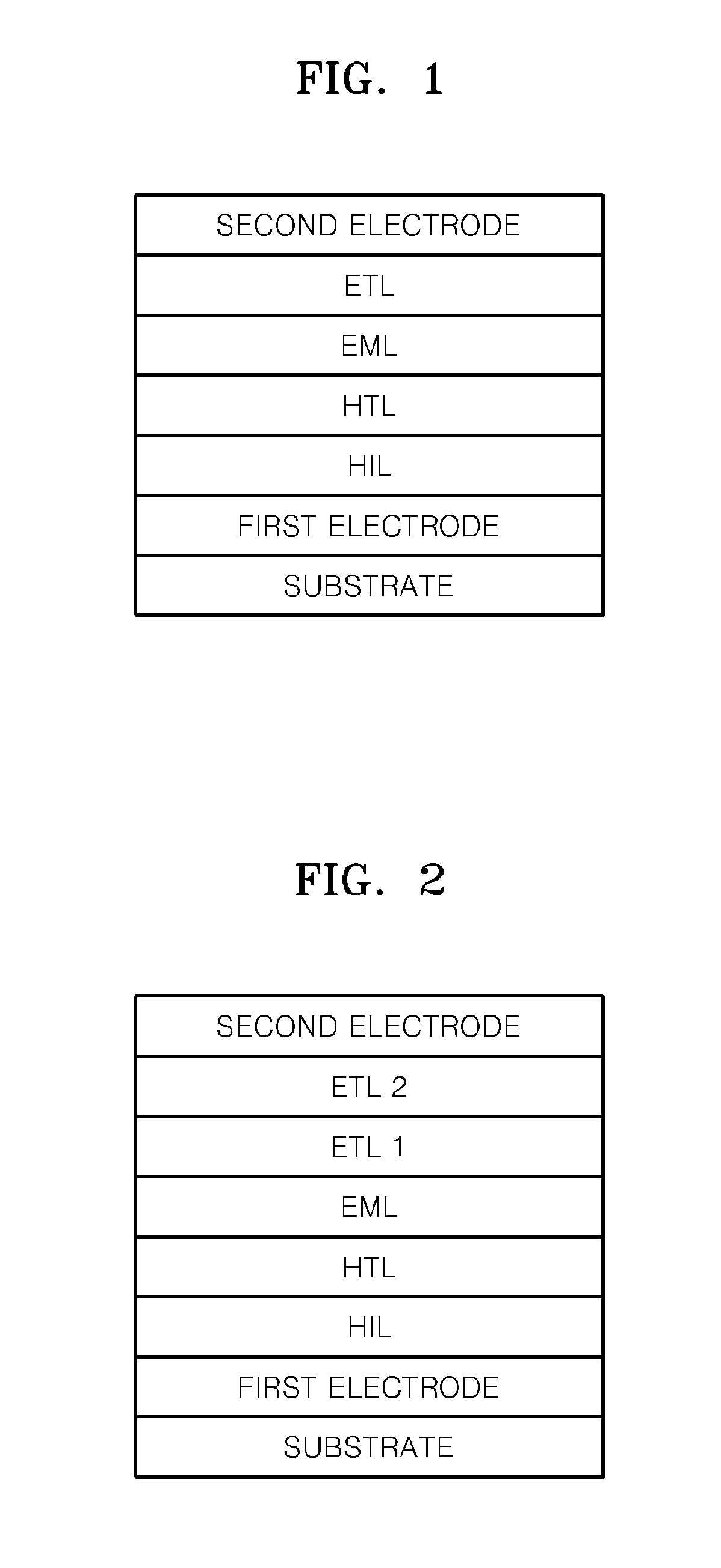

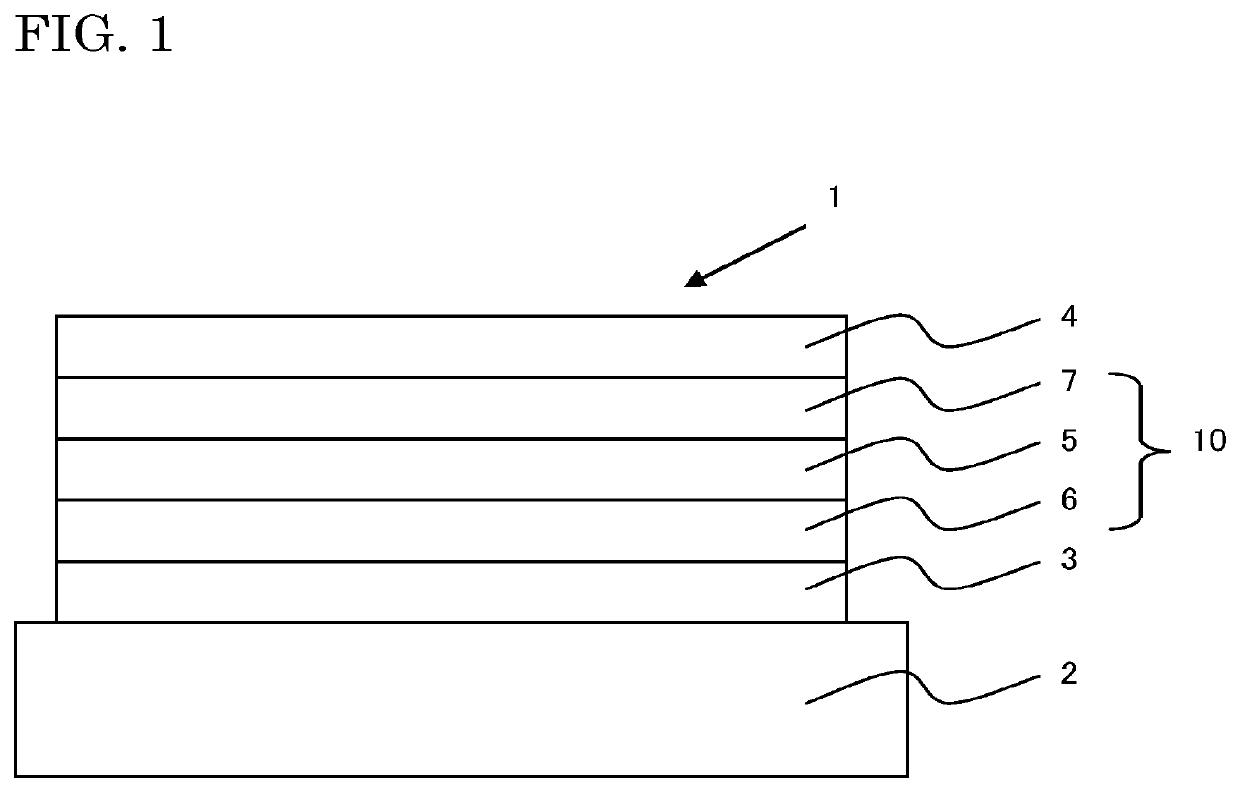

Organic light emitting device

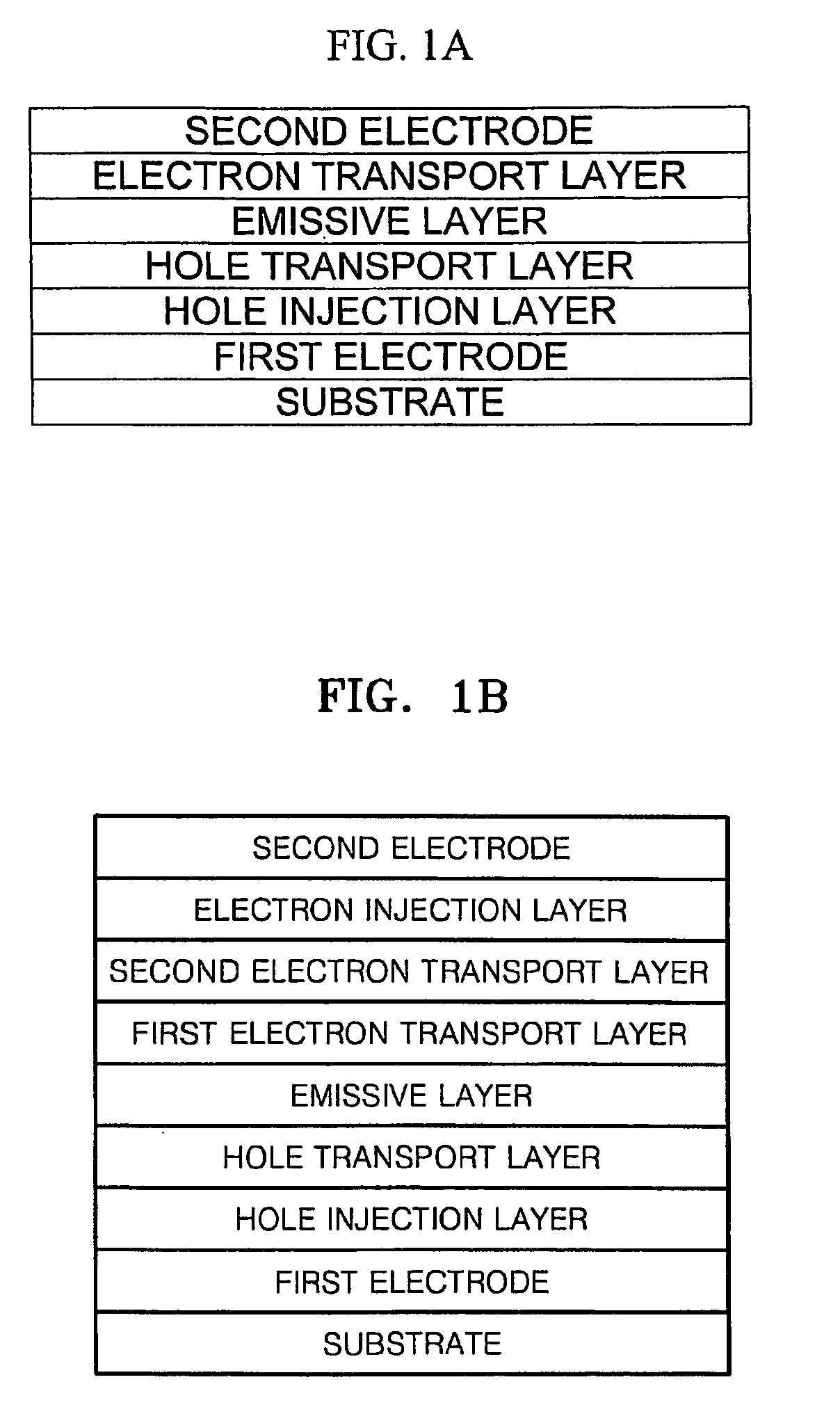

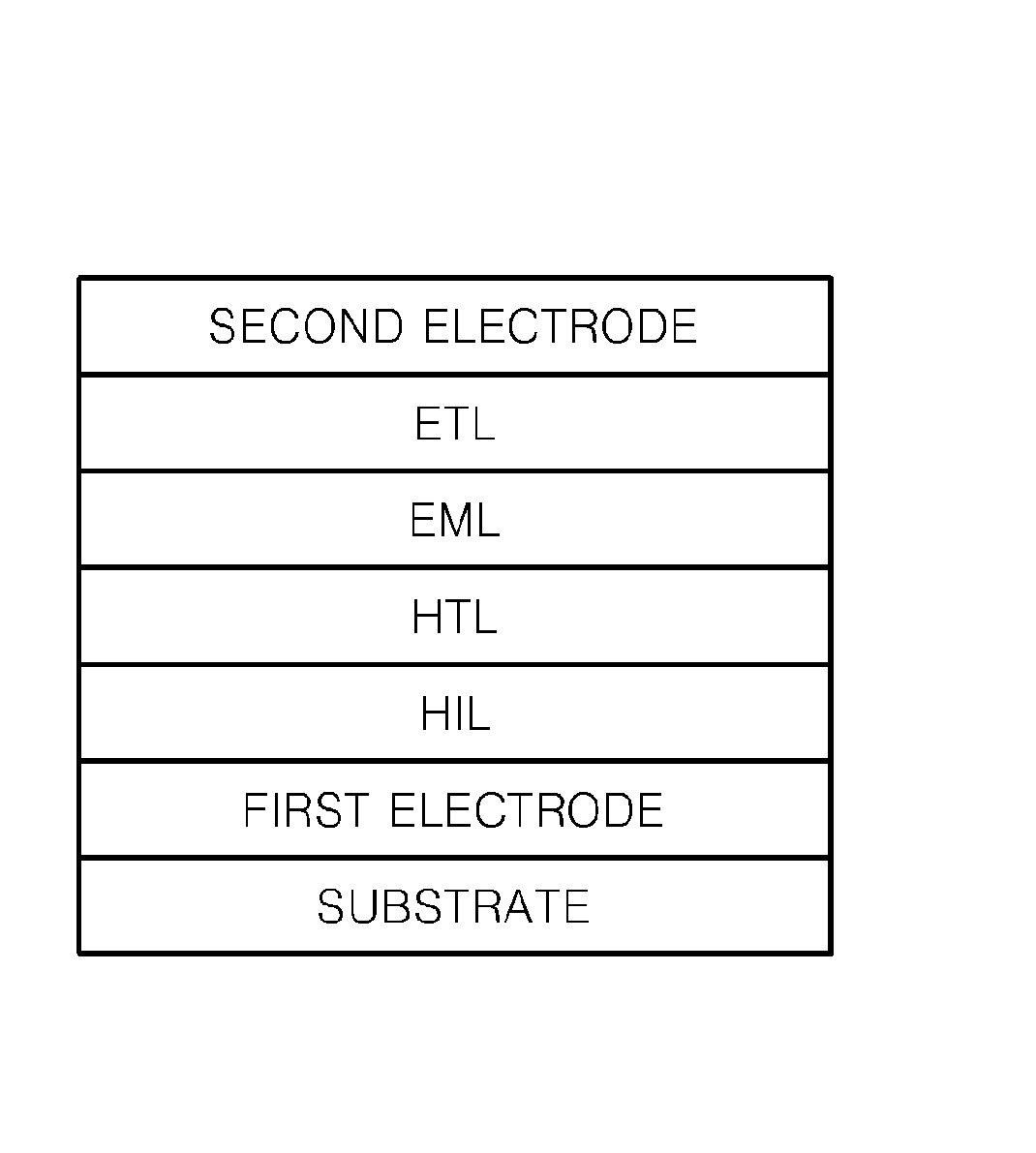

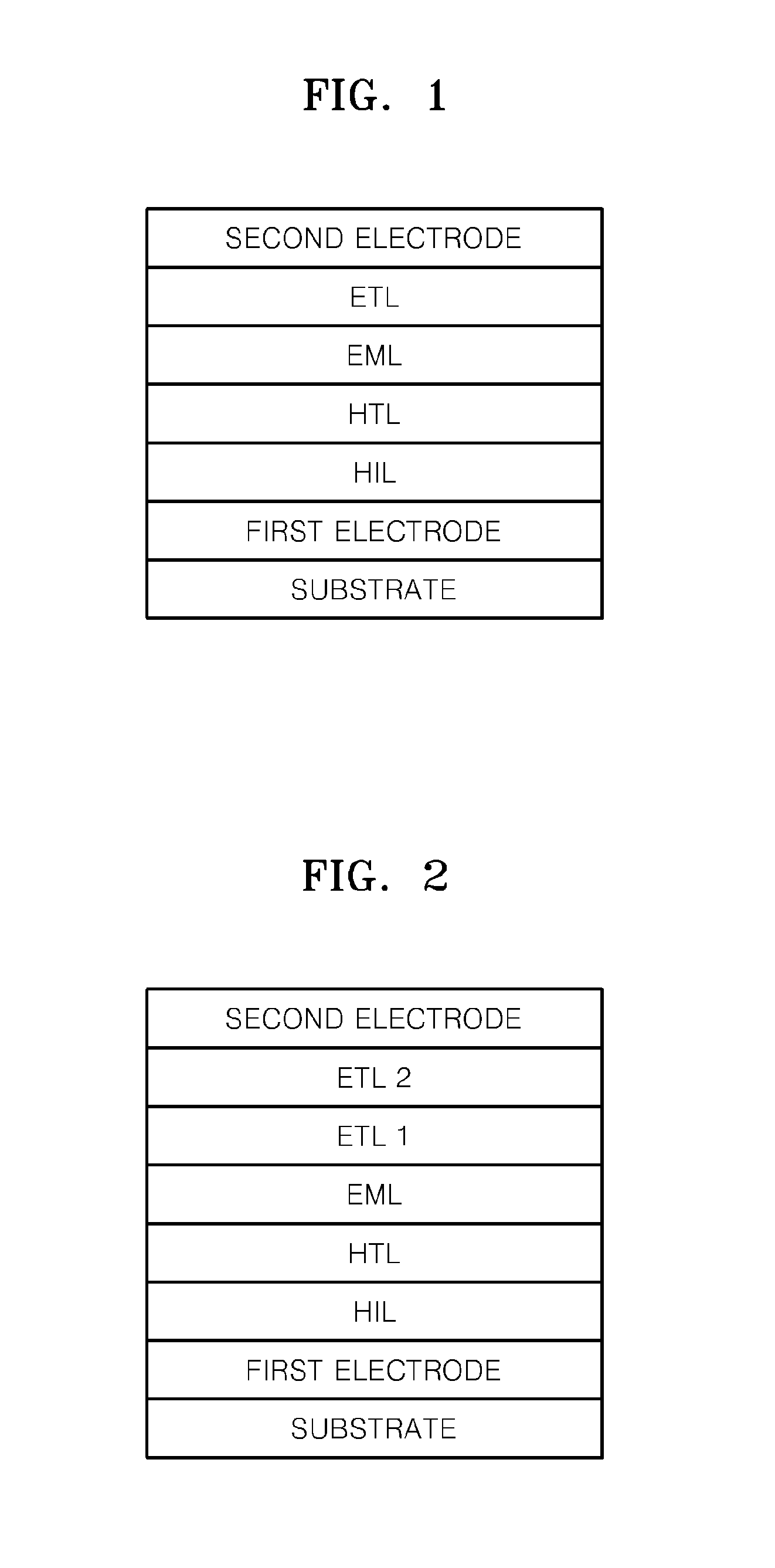

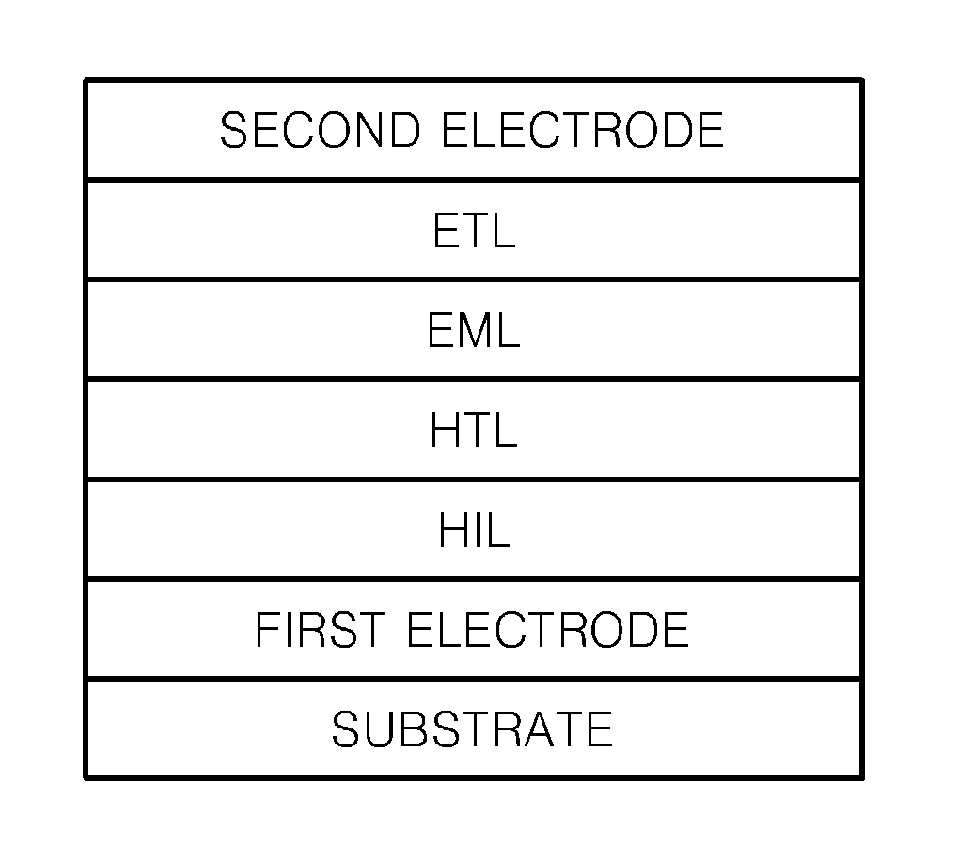

InactiveUS20090167159A1Reduce power consumptionIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesElectron holeHole injection layer

An organic light emitting device includes a first electrode; a second electrode; an emissive layer disposed between the first electrode and the second electrode; a first hole injection layer disposed between the first electrode and the emissive layer; and a first electron transport layer disposed between the emissive layer and the second electrode. The hole injection layer includes a hole injecting material and a first compound made up of an element selected from the group consisting of Mo, Li, Na, K, Rb, Cs, Be, Mg, Ca, Sr, Ba, and B and an element selected from the group consisting of O, F, S, Cl, Se, Br, and I. The electron transport layer comprises an electron transporting material and a second compound, which is Li2O, MoO3, BaO, or B2O3.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

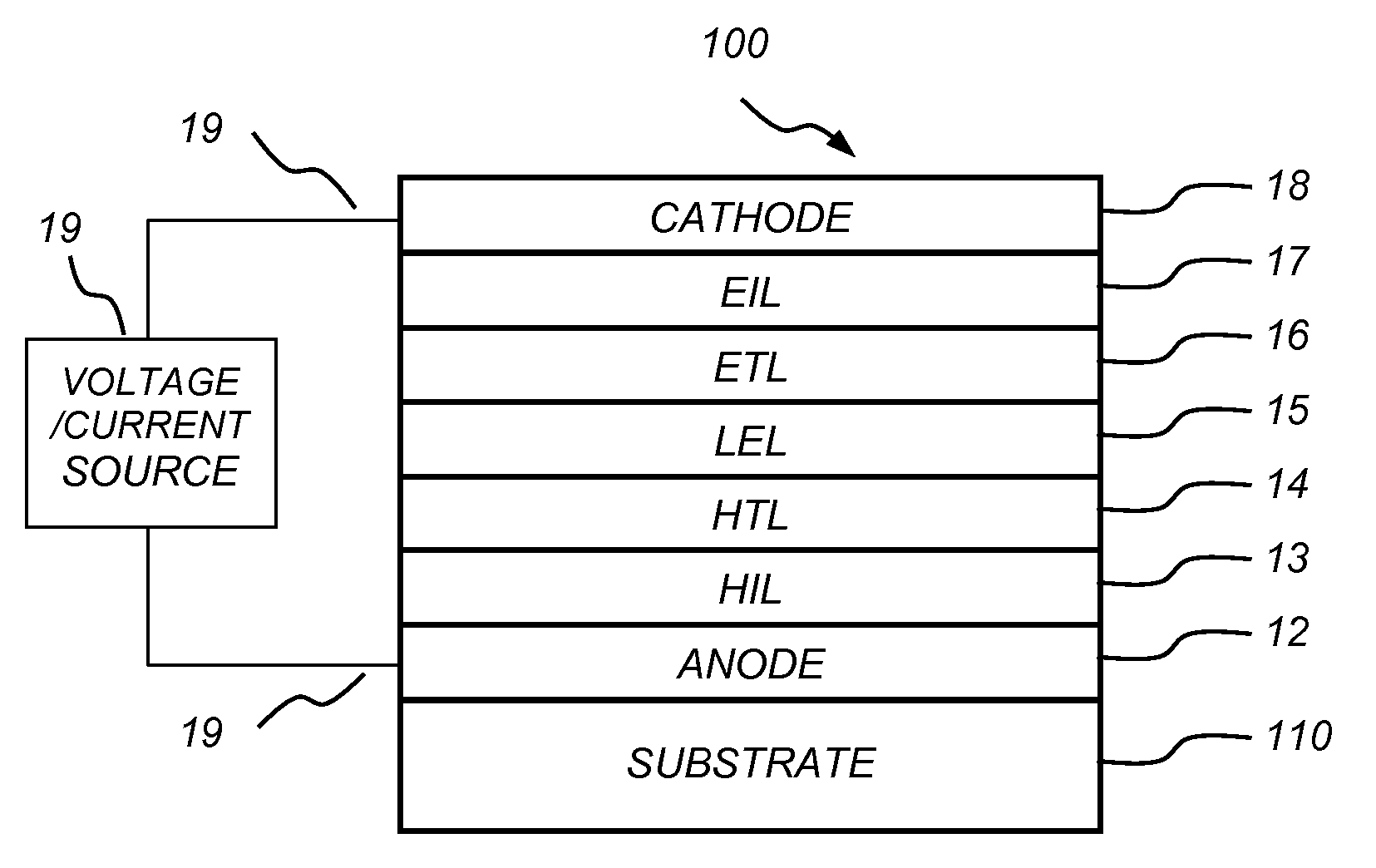

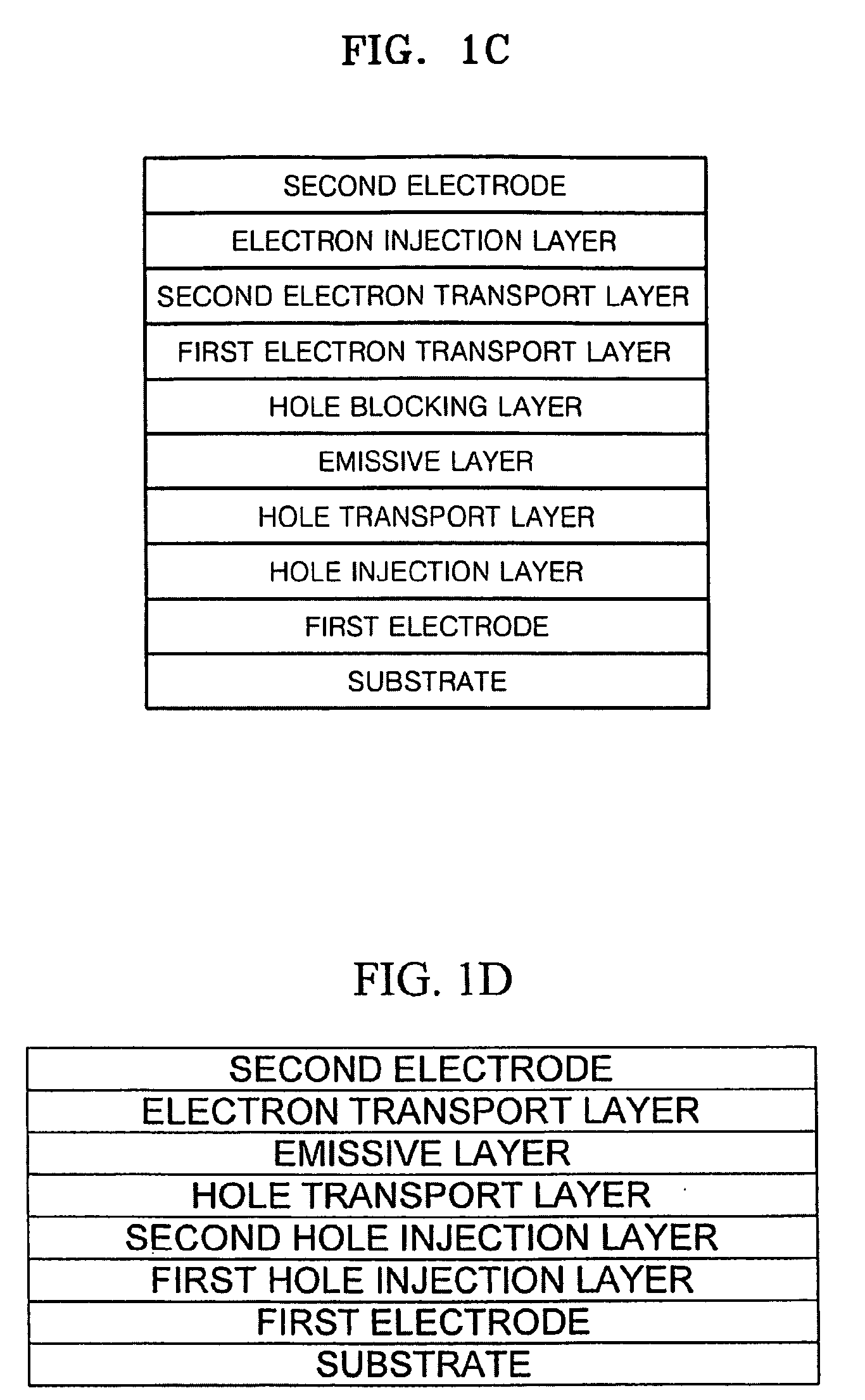

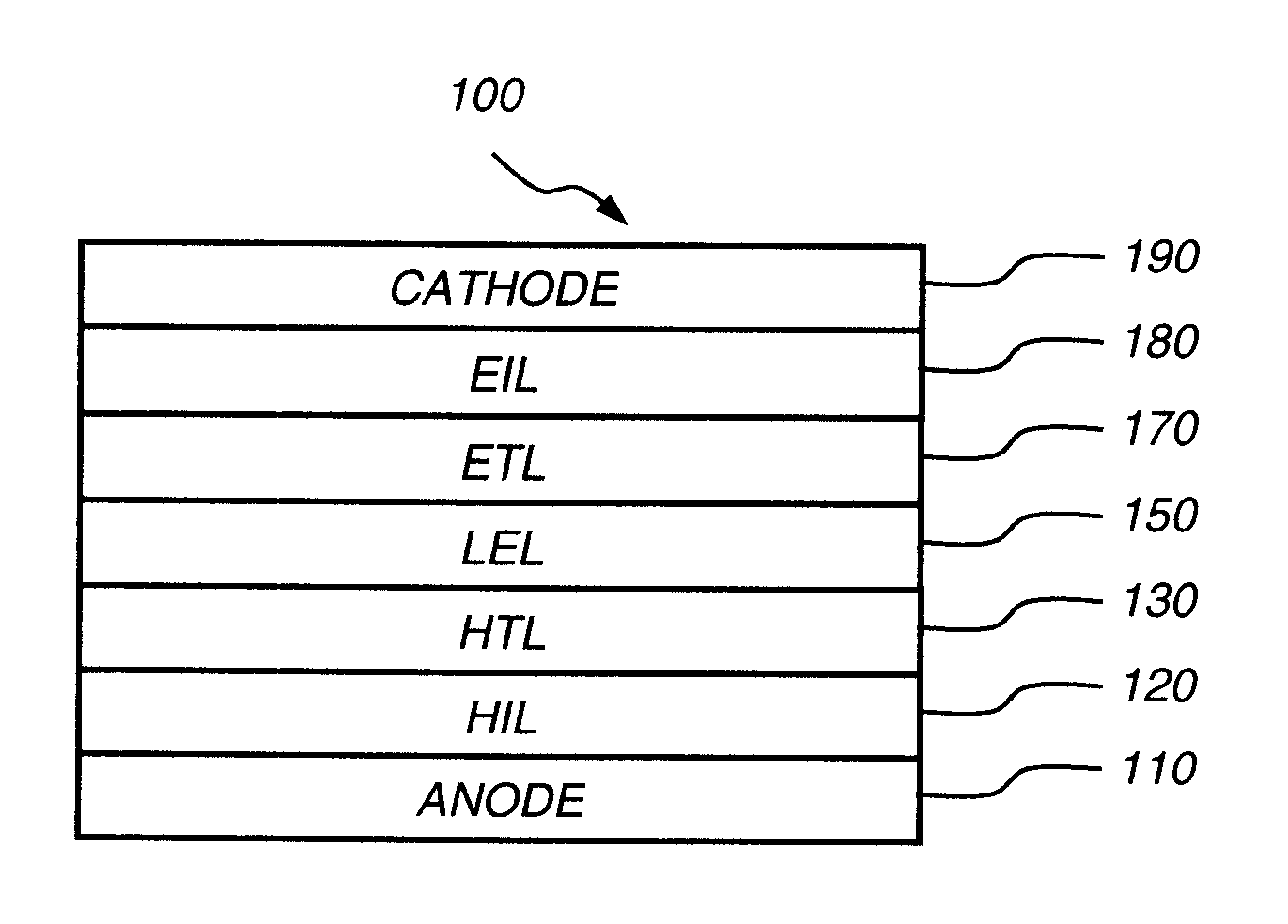

Hole-injecting layer in oleds

InactiveUS20090091242A1Reduce absorptionReduce the driving voltageDischarge tube luminescnet screensLamp detailsHole injection layerElectron transporting layer

An OLED including an anode; a cathode; a hole-injecting layer disposed over the anode, wherein the hole-injecting layer includes a first organic material with a reduction potential greater than −0.1 V and a lesser amount by volume of a second material with an oxidation potential less than 0.7 V, and wherein the second material does not include metal complexes; a hole-transporting layer disposed over the hole-injecting layer; a light-emitting layer disposed between the hole-transporting layer and the cathode; and an electron-transporting layer disposed between the light-emitting layer and the cathode.

Owner:GLOBAL OLED TECH

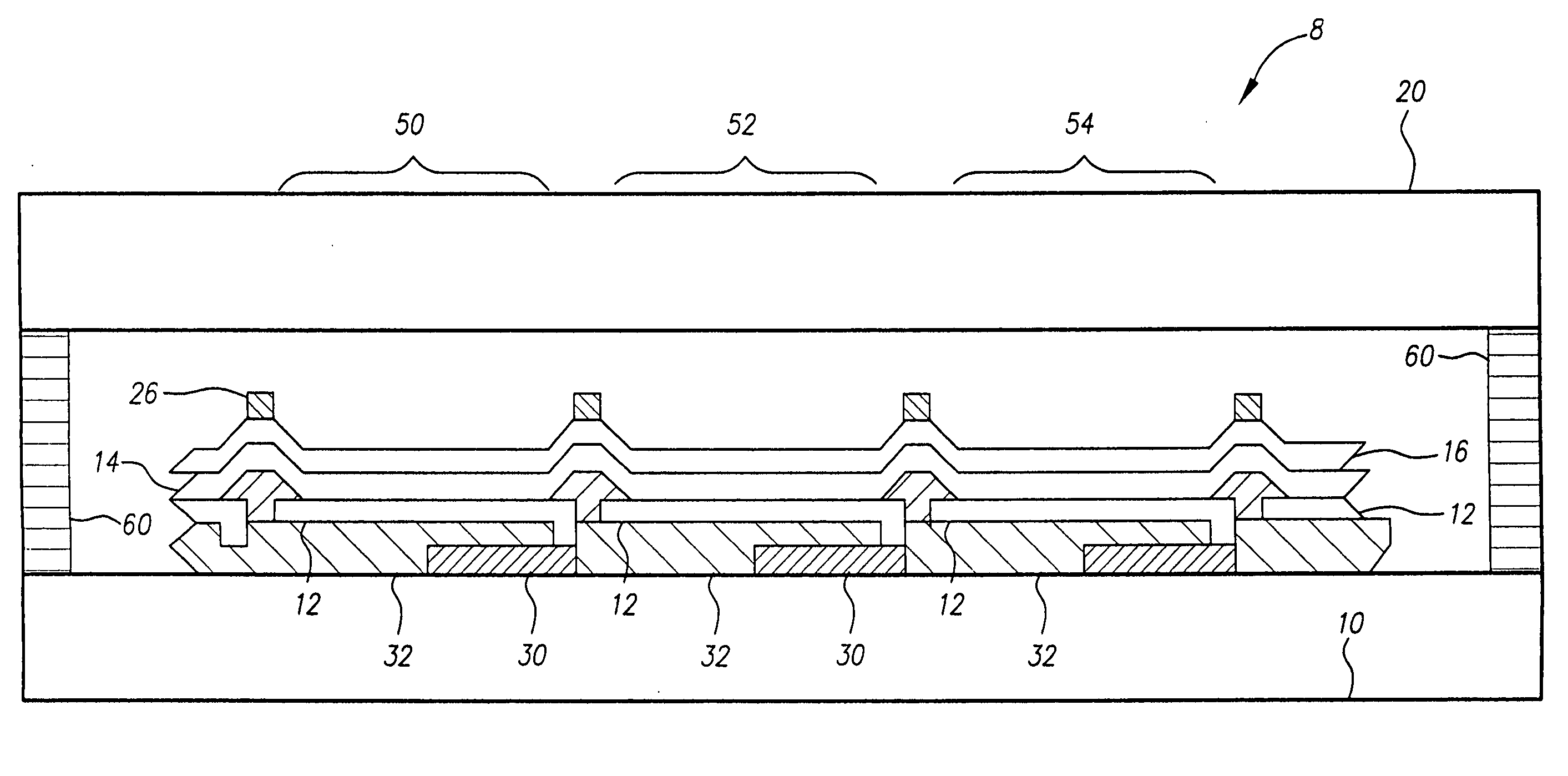

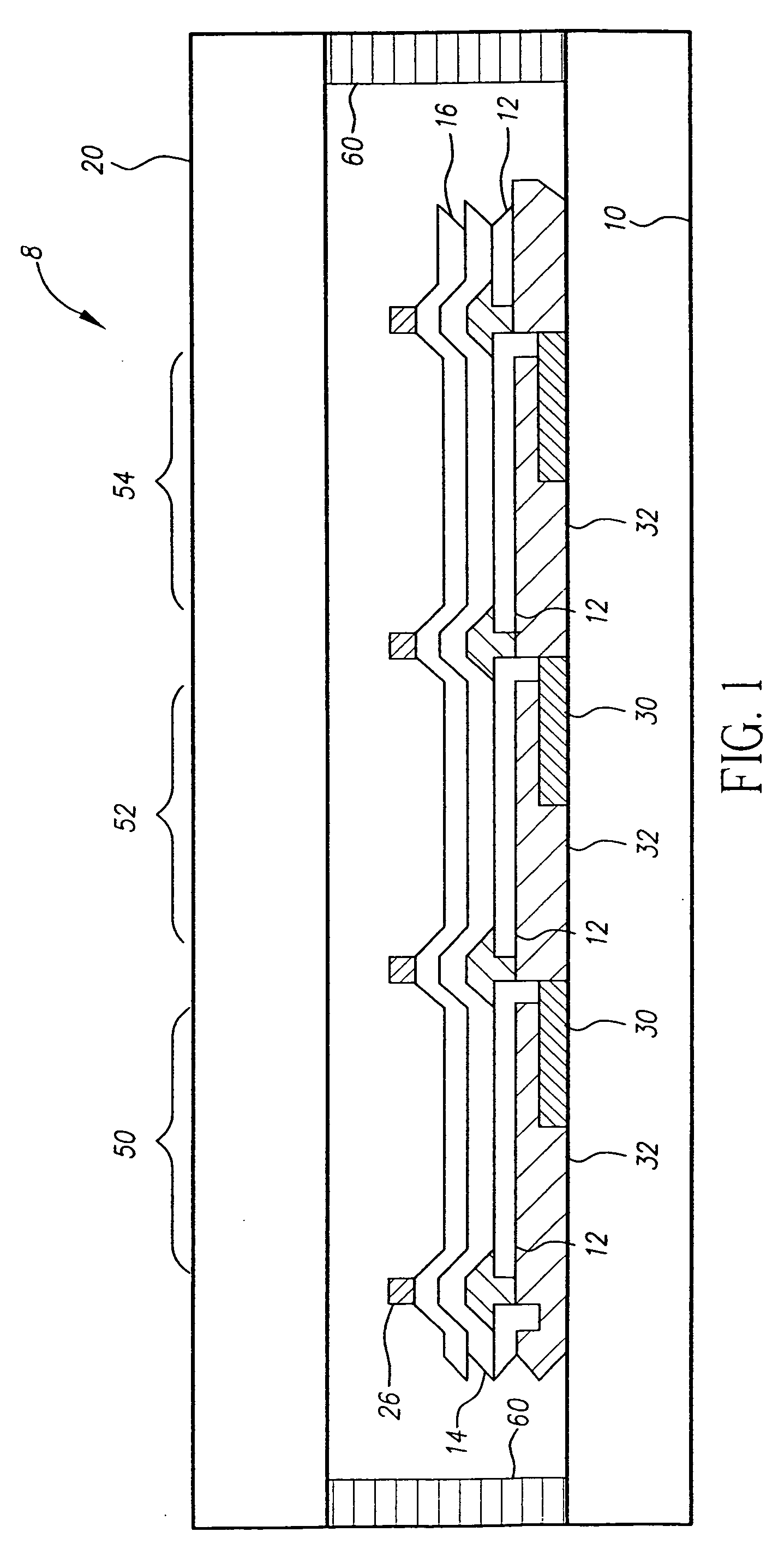

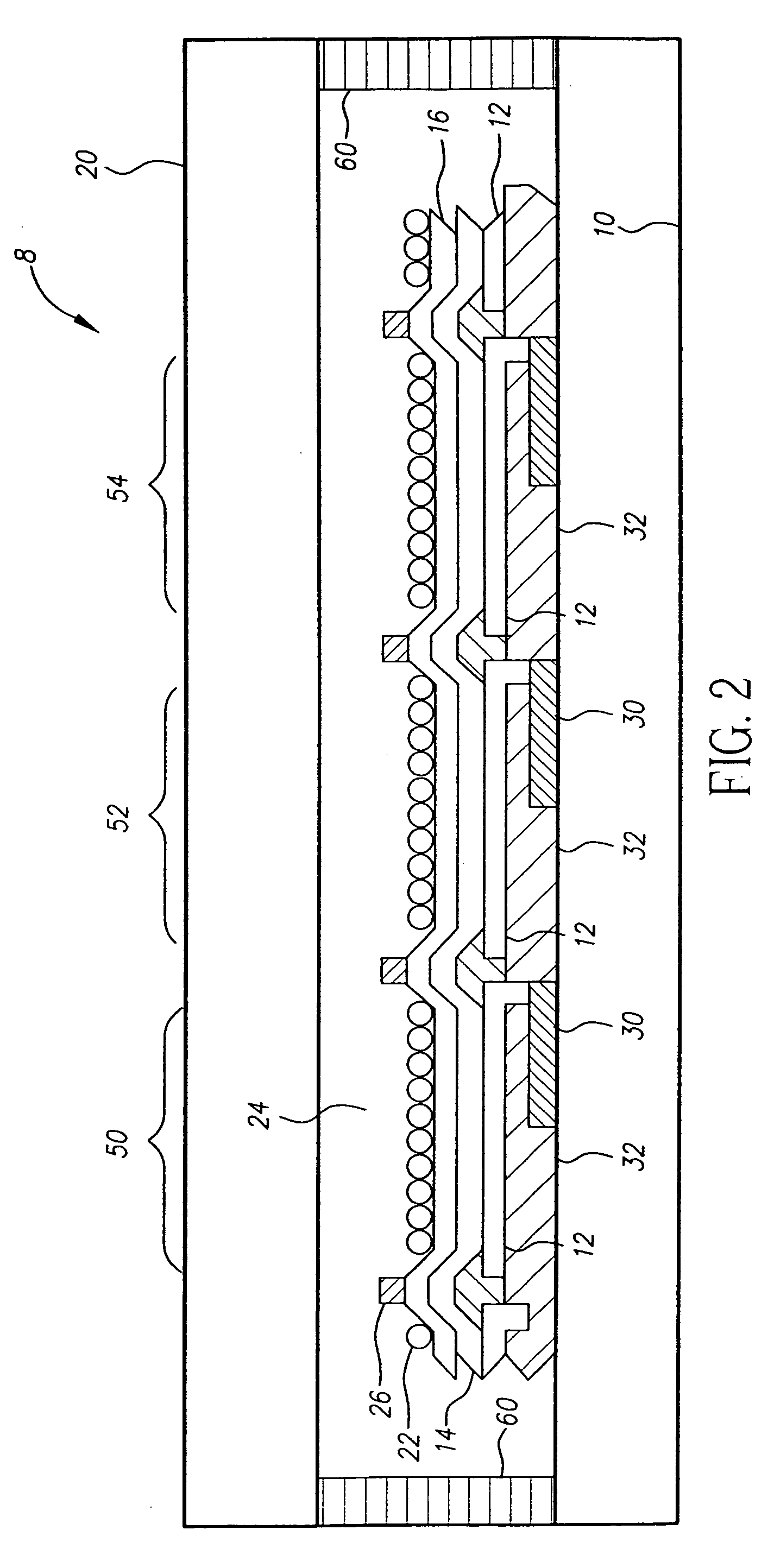

OLED with protective electrode

ActiveUS20080157654A1High yieldImproved lifetimeDischarge tube luminescnet screensElectroluminescent light sourcesAuxiliary electrodeConductive oxide

An OLED device, comprising: a first electrode; a conductive protective electrode comprising a transparent conductive oxide layer wherein the conductive protective electrode is a hermetic layer having a thickness less than 100 nm; one or more organic layers formed between the first electrode and conductive protective electrode, at least one organic layer being a light-emitting layer; and a patterned auxiliary electrode in electrical contact with the conductive protective electrode.

Owner:GLOBAL OLED TECH

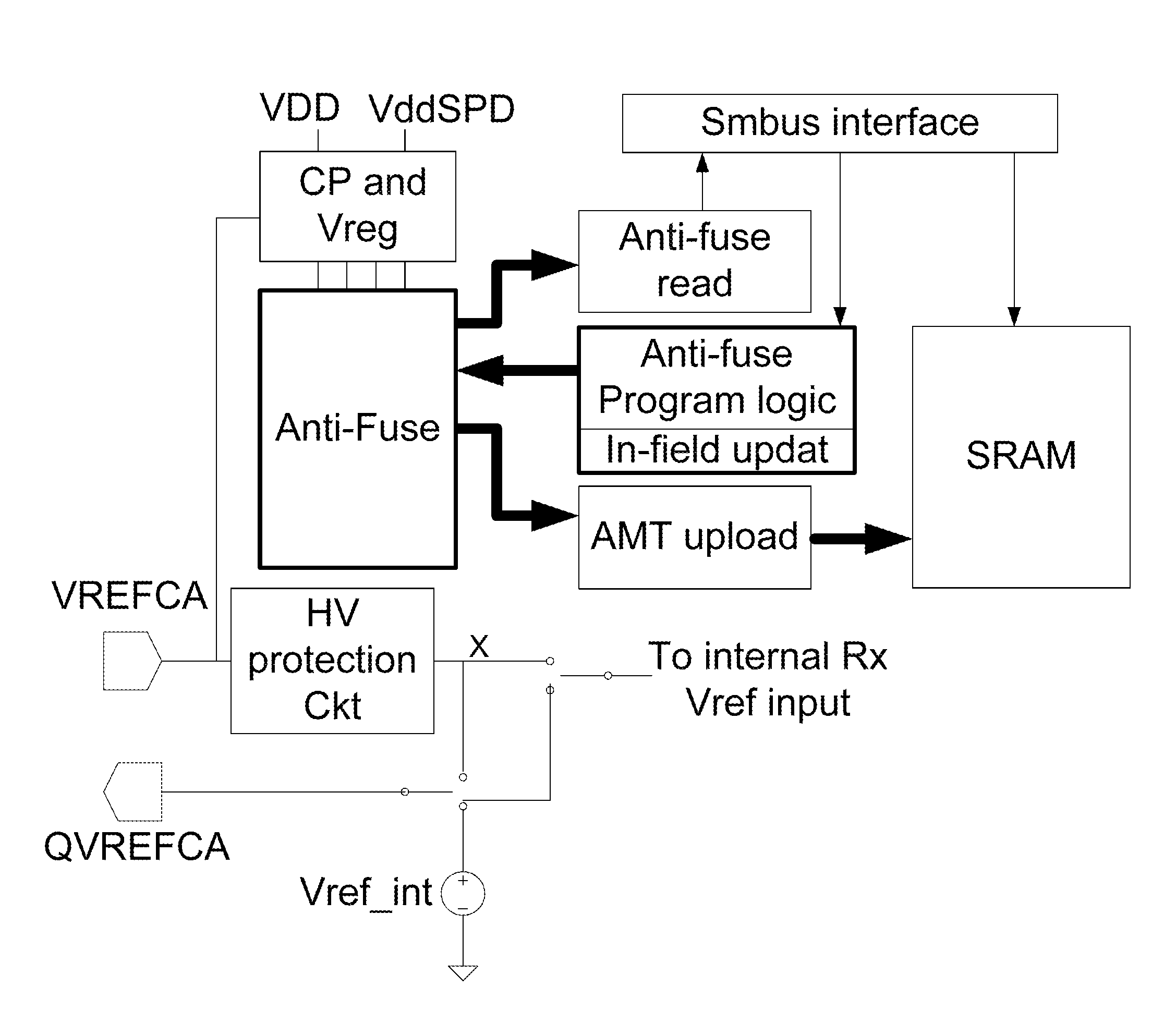

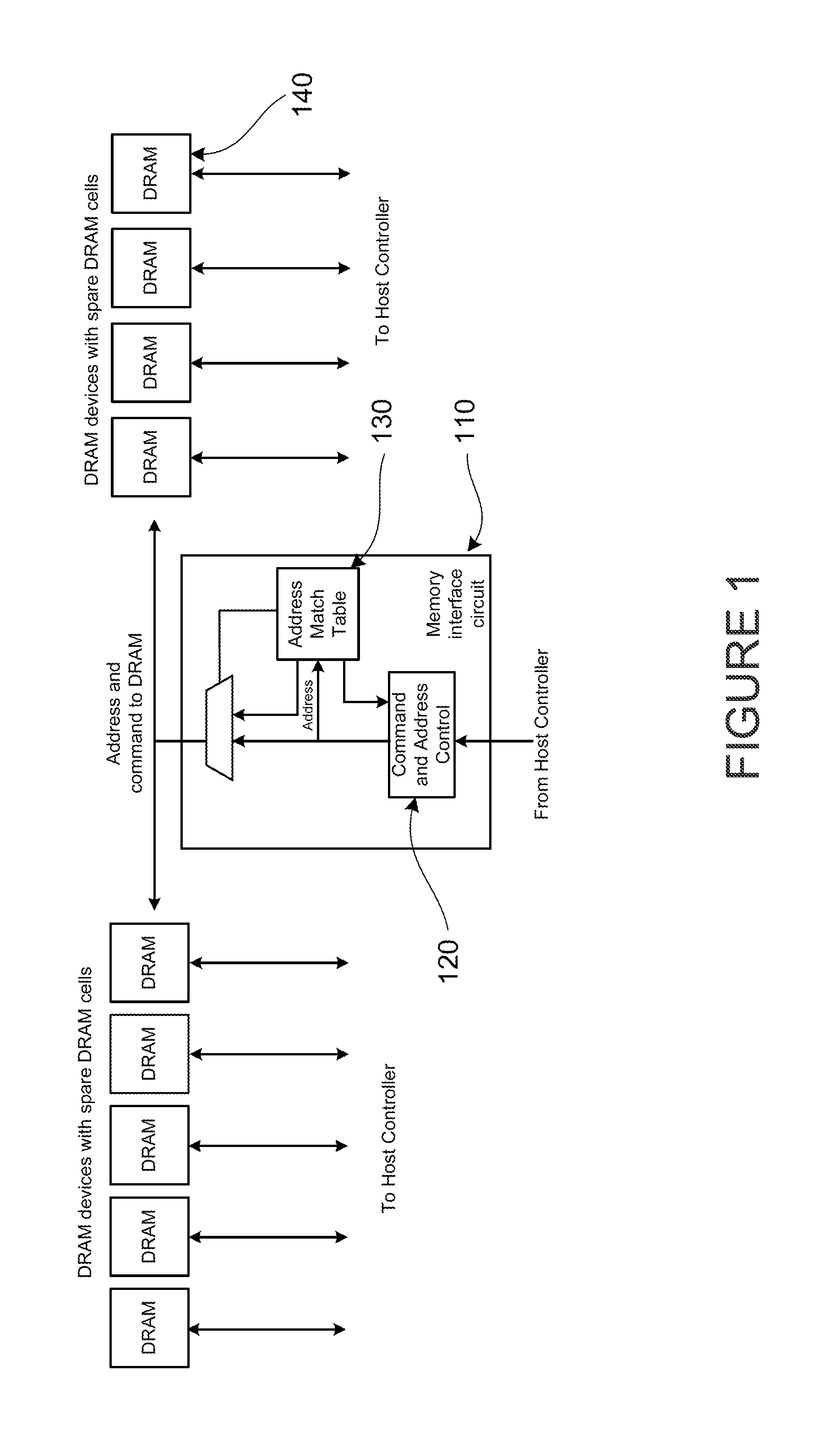

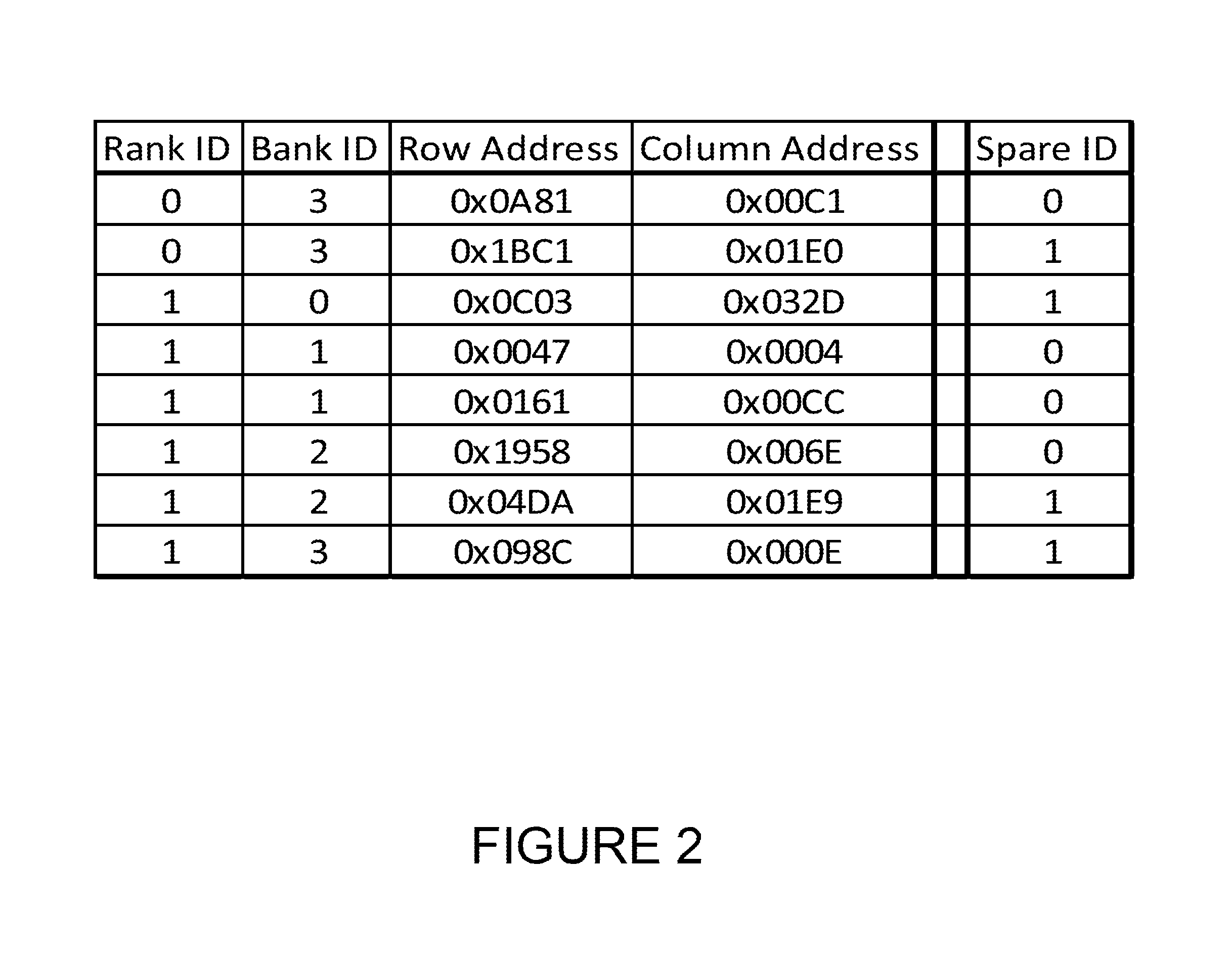

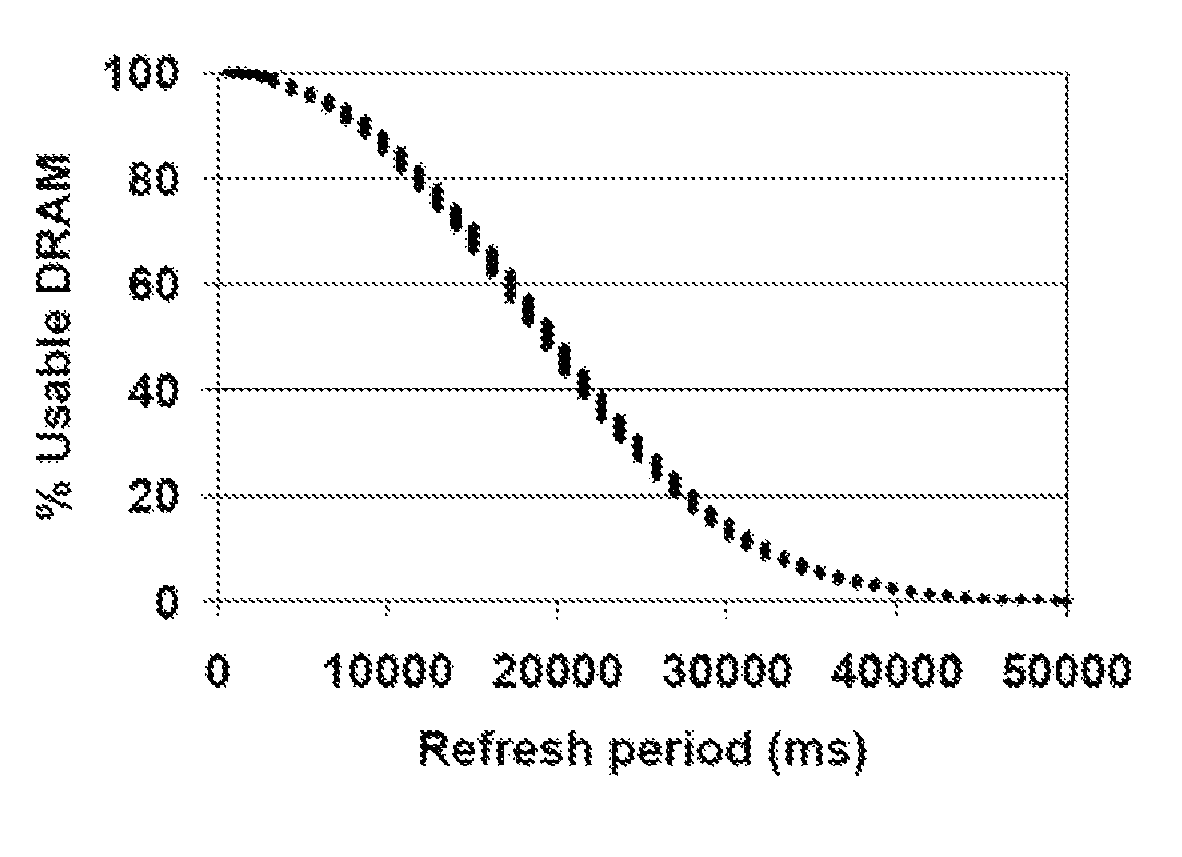

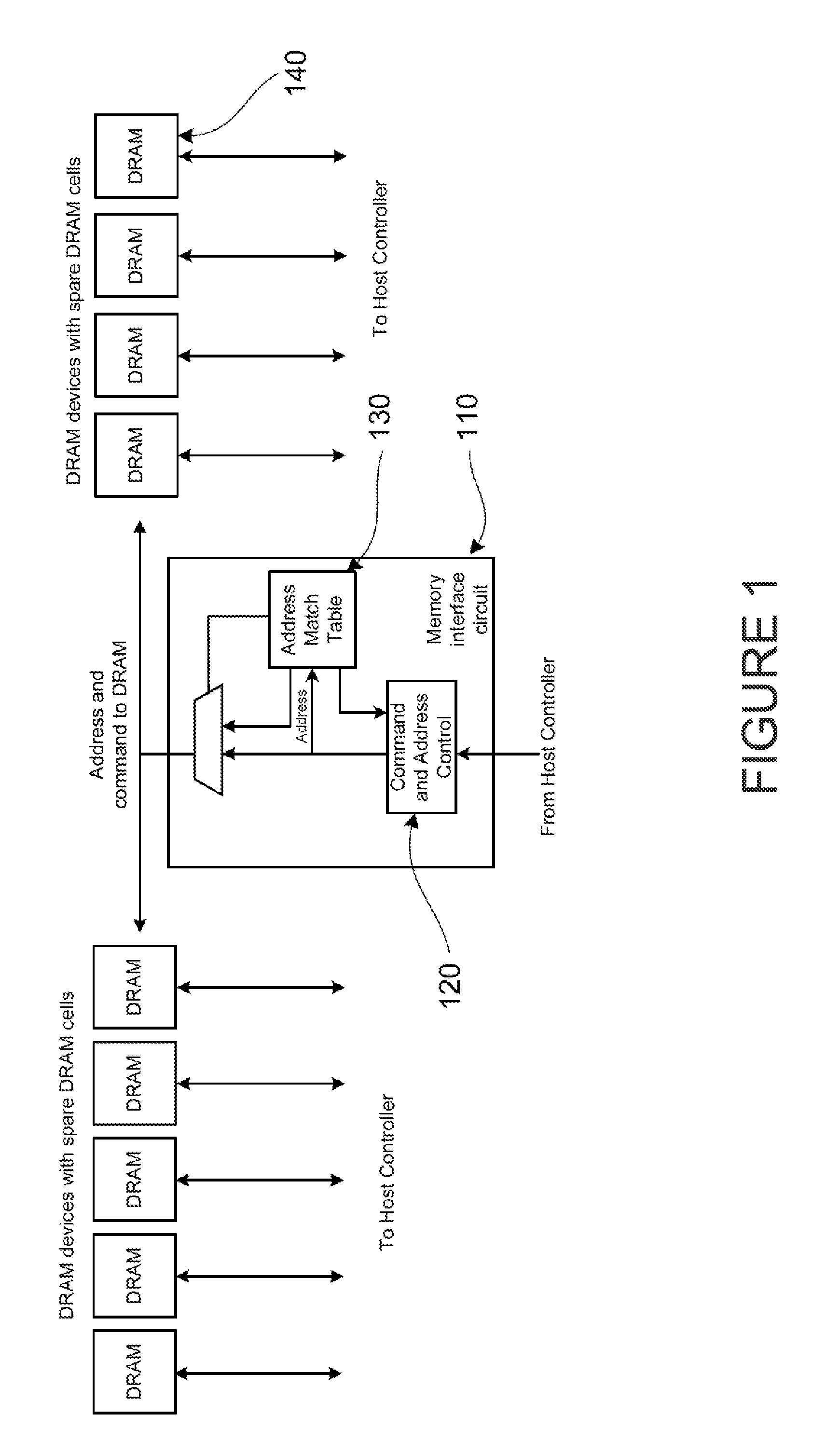

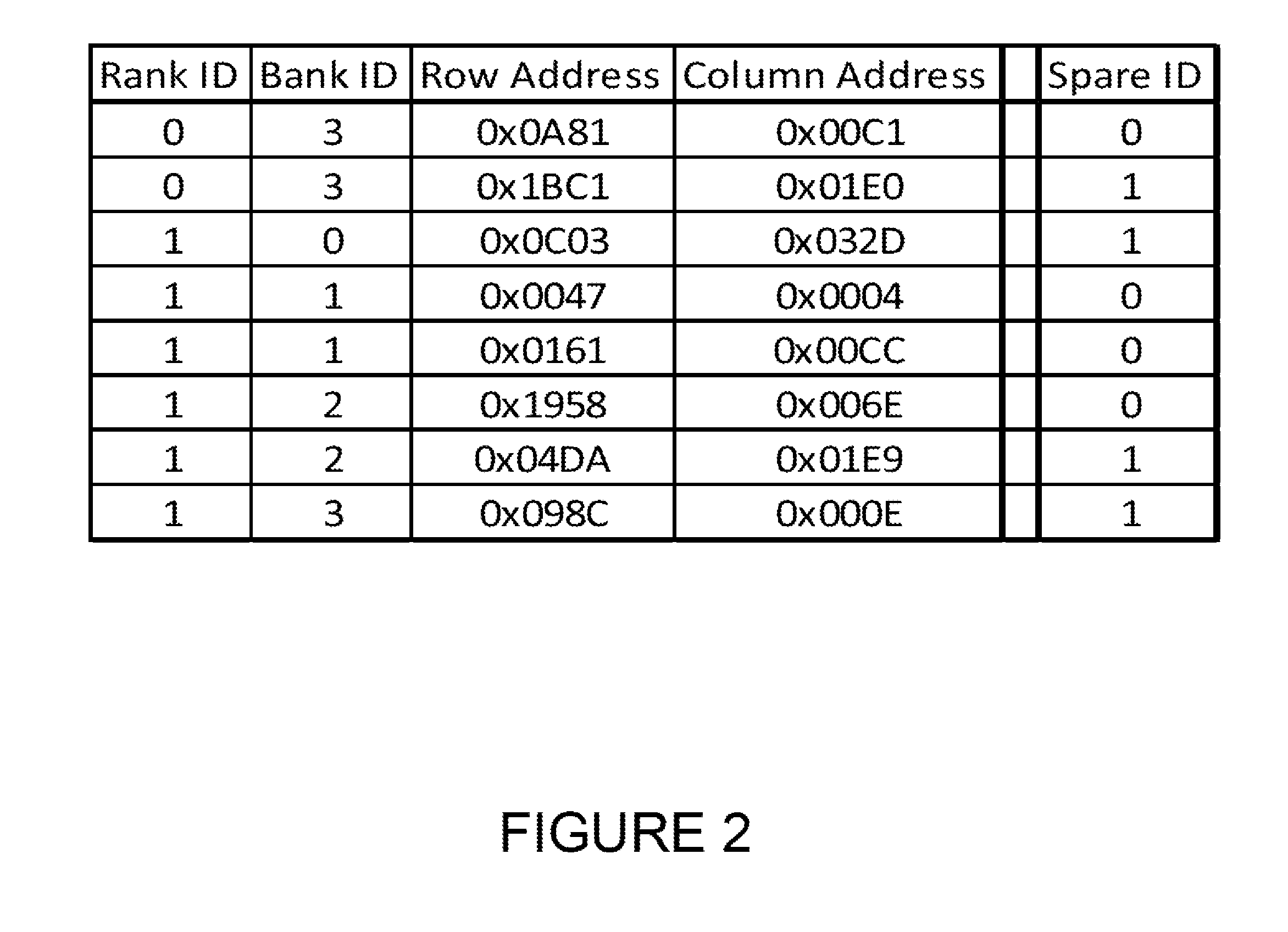

Method of using non-volatile memories for on-DIMM memory address list storage

ActiveUS8861277B1Improve performanceImproved lifetimeRead-only memoriesDigital storageMemory addressDIMM

An integrated circuit device. The device includes an address input(s) configured to receive address information from an address stream from an address command bus coupled to a host controller and an address output(s) configured to drive address information, and is coupled to a plurality of memory (DRAM) devices provided on a DIMM. The device has an address match table comprising a non-volatile memory device configured to store at least a revised address corresponding to a spare memory location and a bad address of at least one of the plurality of memory (DRAM) devices. The device has a control module configured to process and determine whether each address matches with a stored address in the address match table to identify the bad address and configured to replace the bad address with the revised address of the spare memory location.

Owner:RAMBUS INC

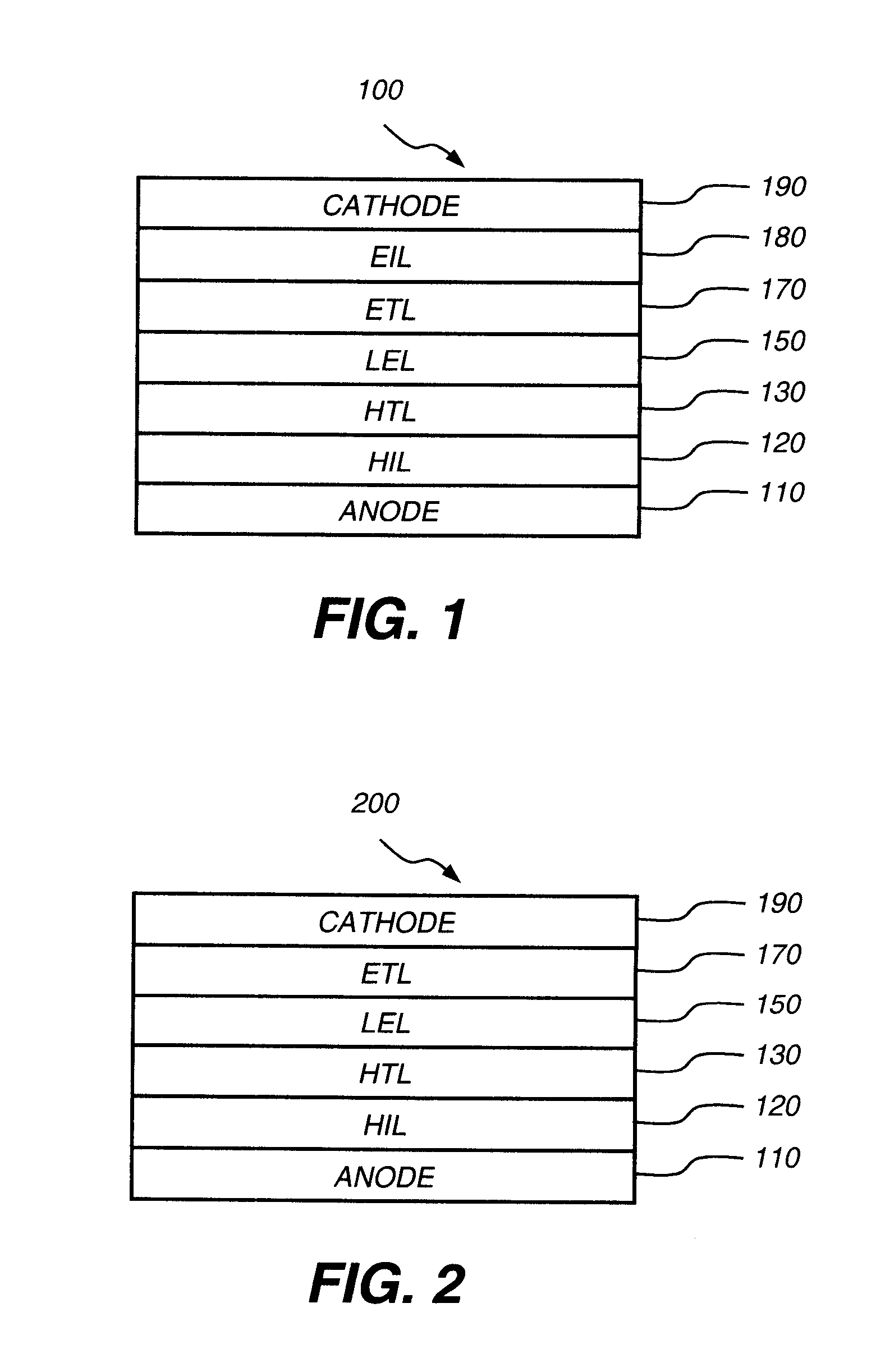

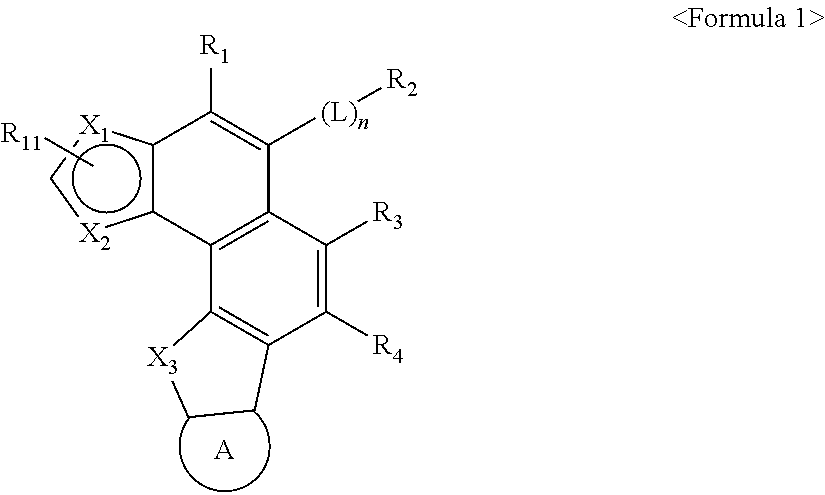

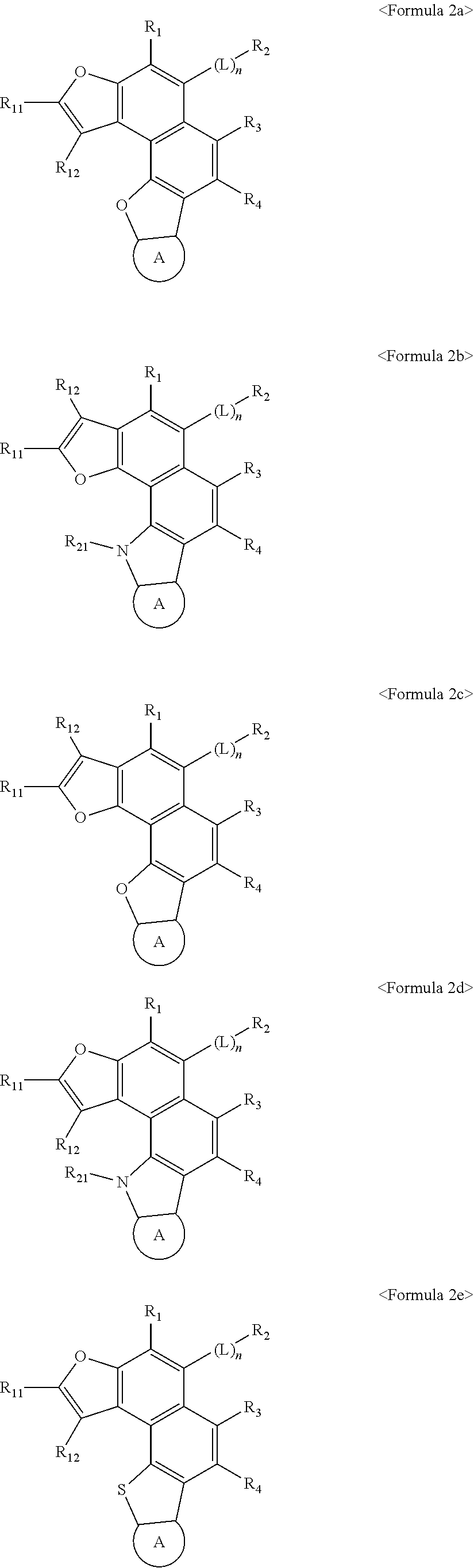

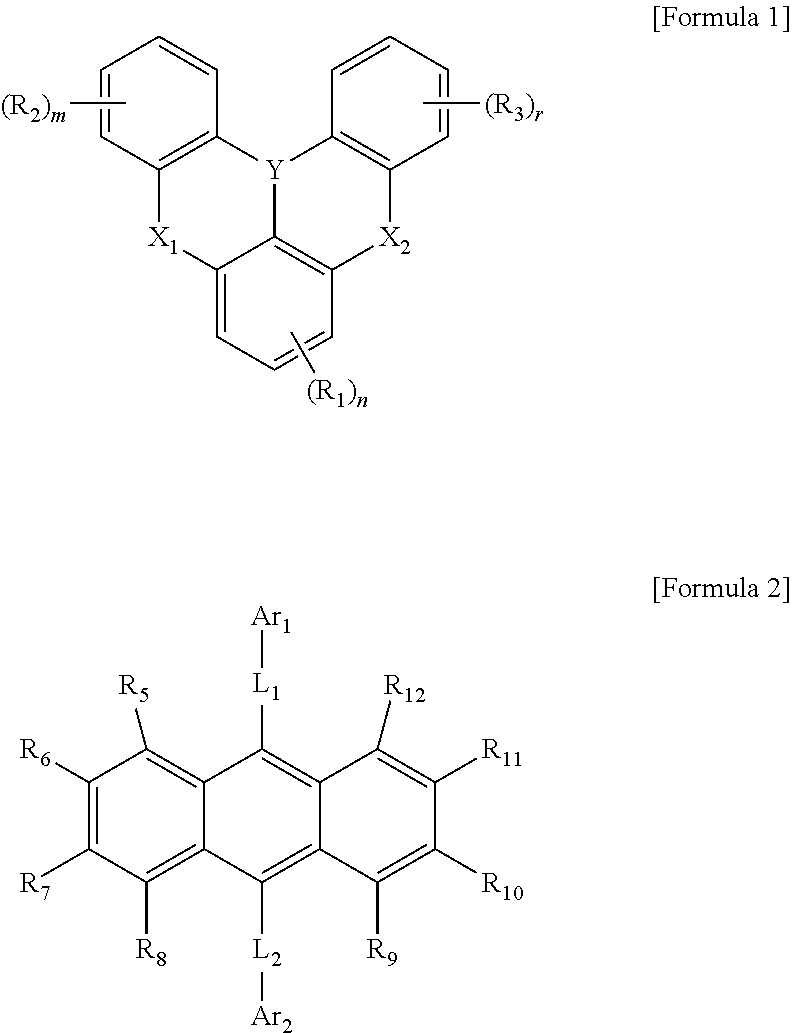

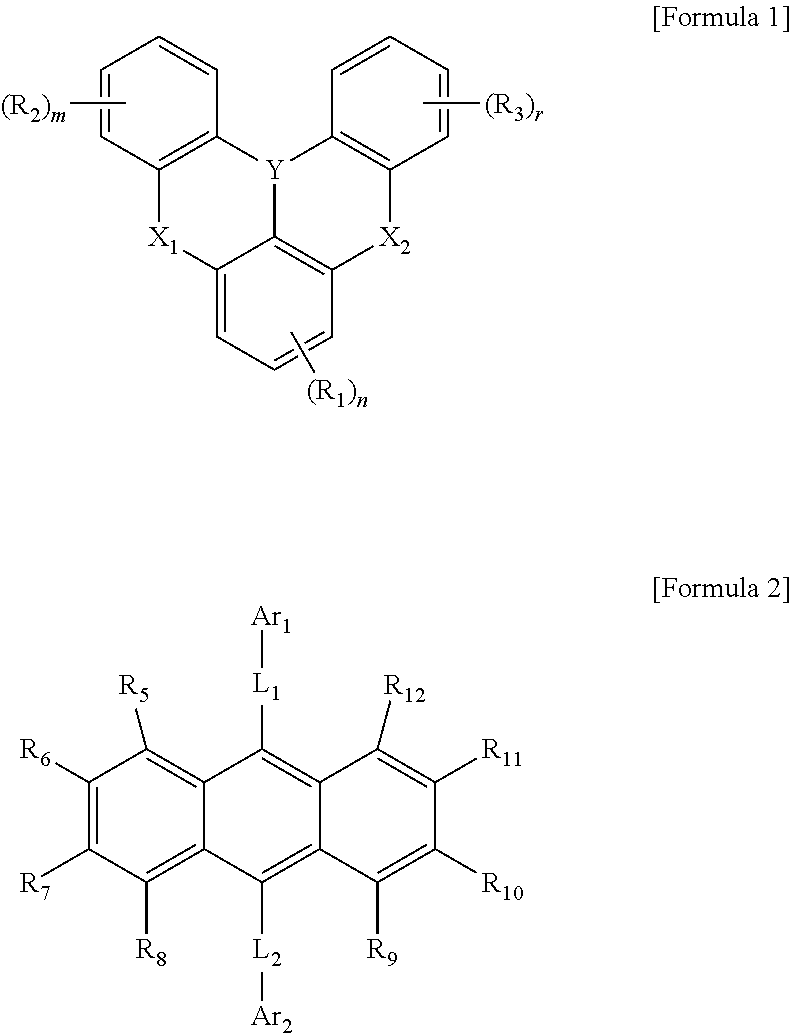

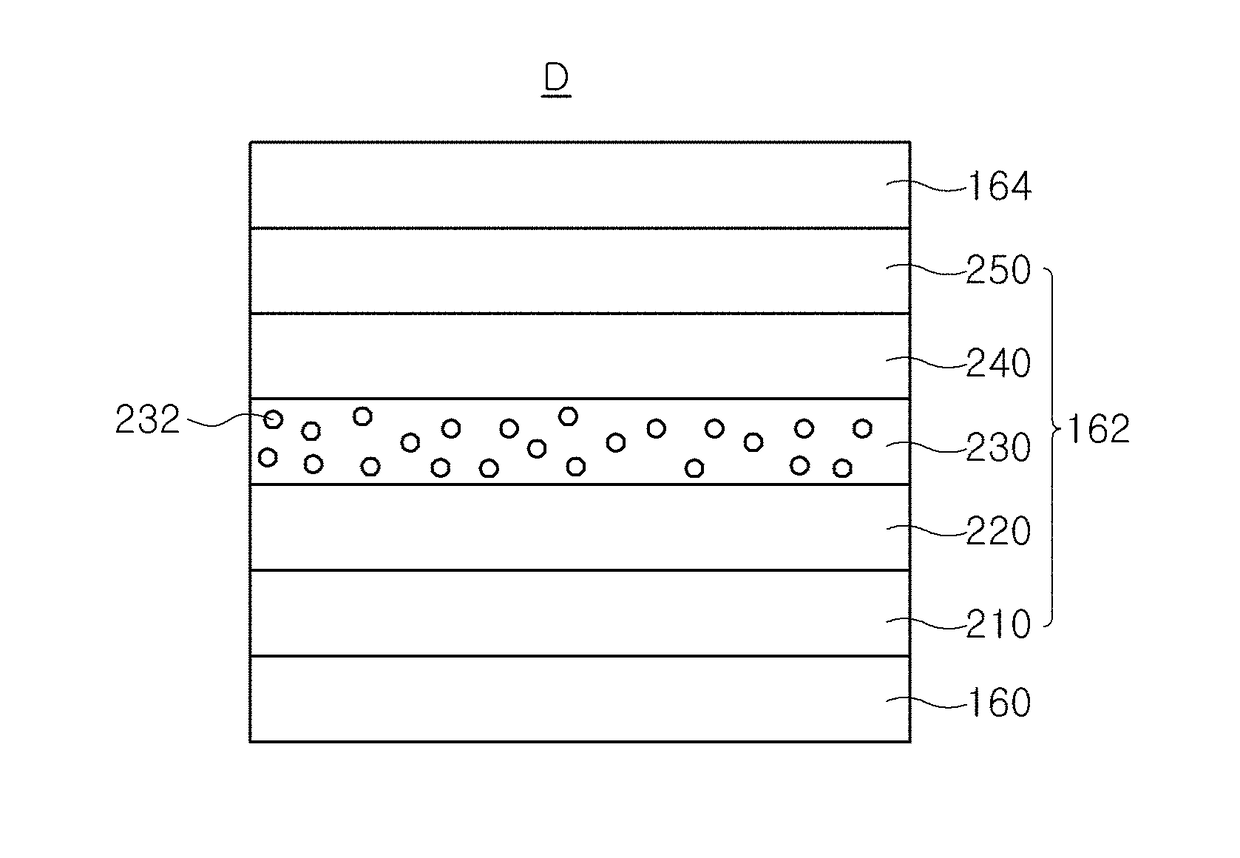

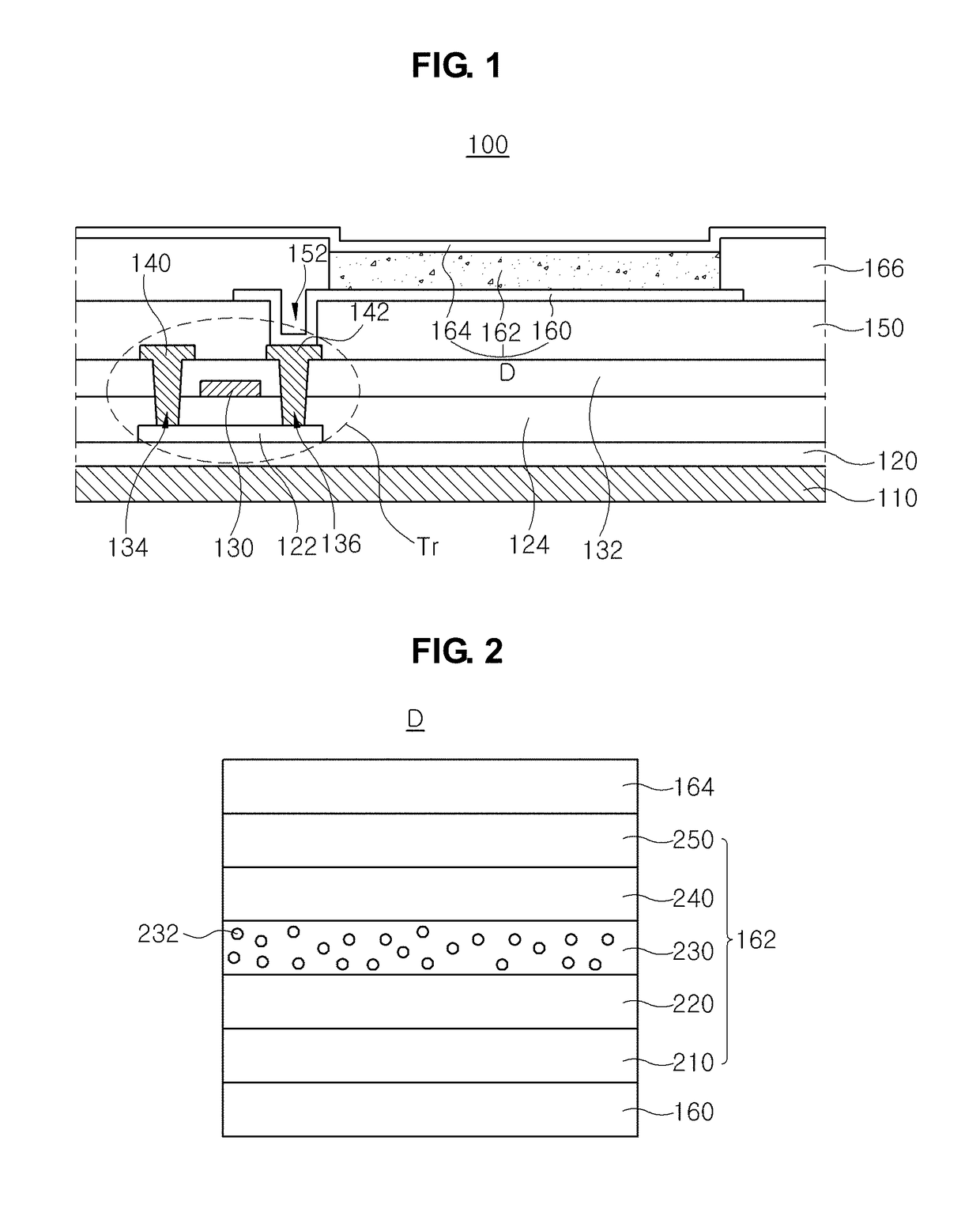

Heterocyclic compounds and organic light-emitting devices including the same

ActiveUS20140027741A1Improve efficiencyImproved lifetimeOrganic chemistrySolid-state devicesDisplay deviceGlass transition

Heterocyclic compounds, synthetic methods for preparing the same, and organic light-emitting display devices comprising the same are described. The subject heterocyclic compounds may comprise an aromatic ring or a heteroaromatic ring fused with a carbazole, dibenzothiophene, or dibenzofurane derivative, the compounds featuring rigid backbone structures with high glass transition temperatures and high melting points. The subject heterocyclic compounds may exhibit high electrical stability, improved charge transport ability, high heat resistance and improved light-emitting properties when used in organic light-emitting devices. Organic light-emitting display devices prepared according to the present invention exhibit lower driving voltages, increased luminescent efficiencies and longer lifetimes.

Owner:SAMSUNG DISPLAY CO LTD

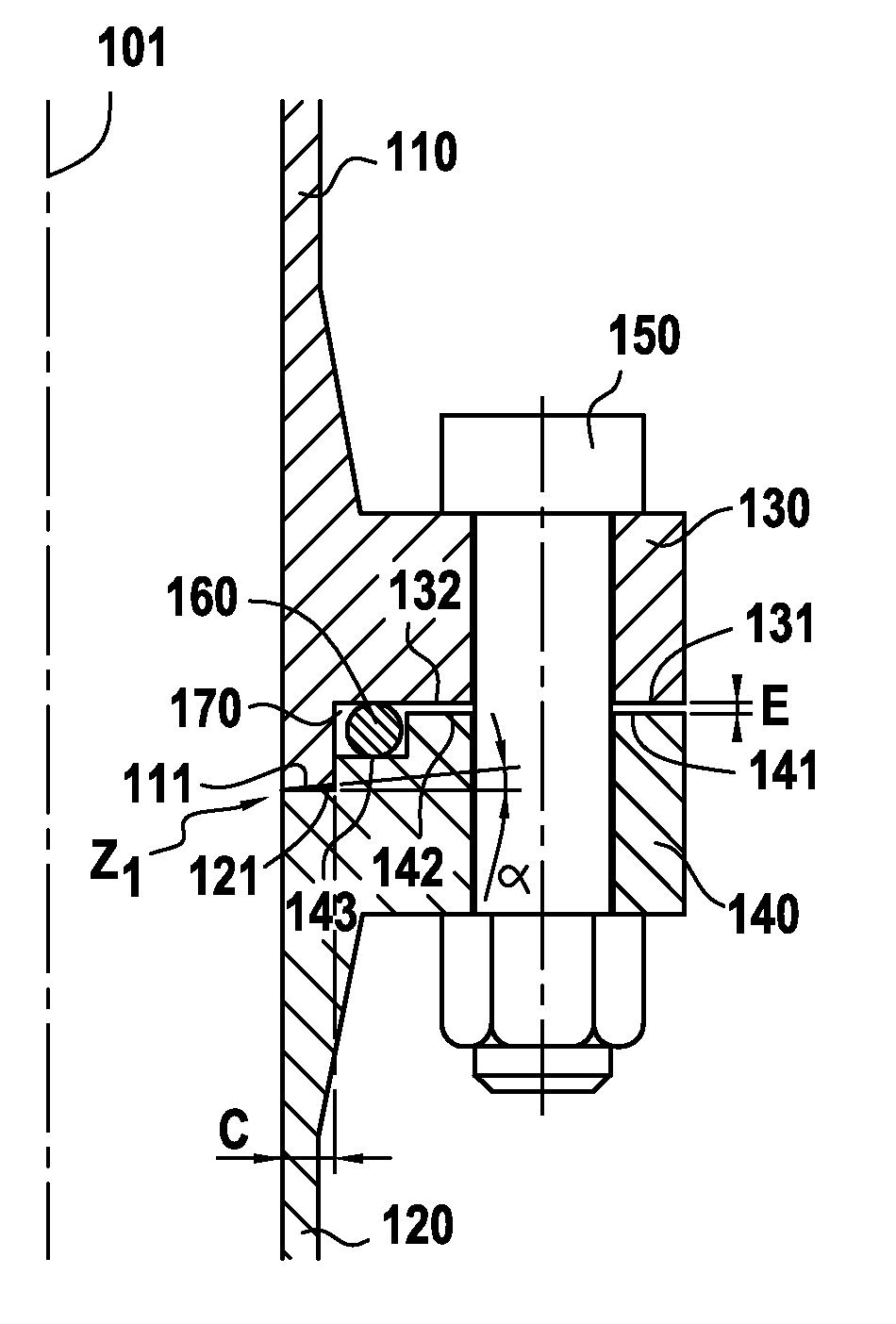

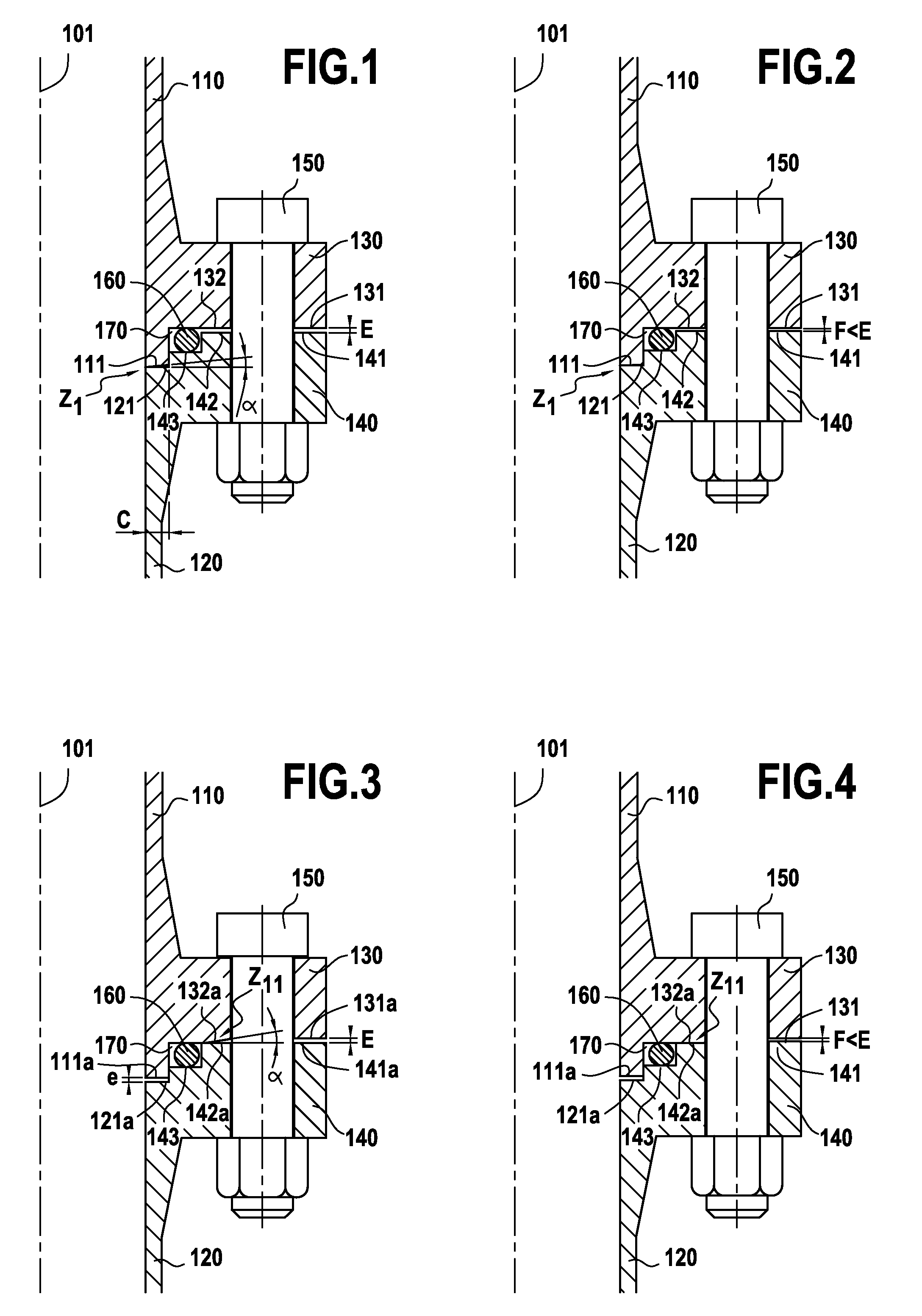

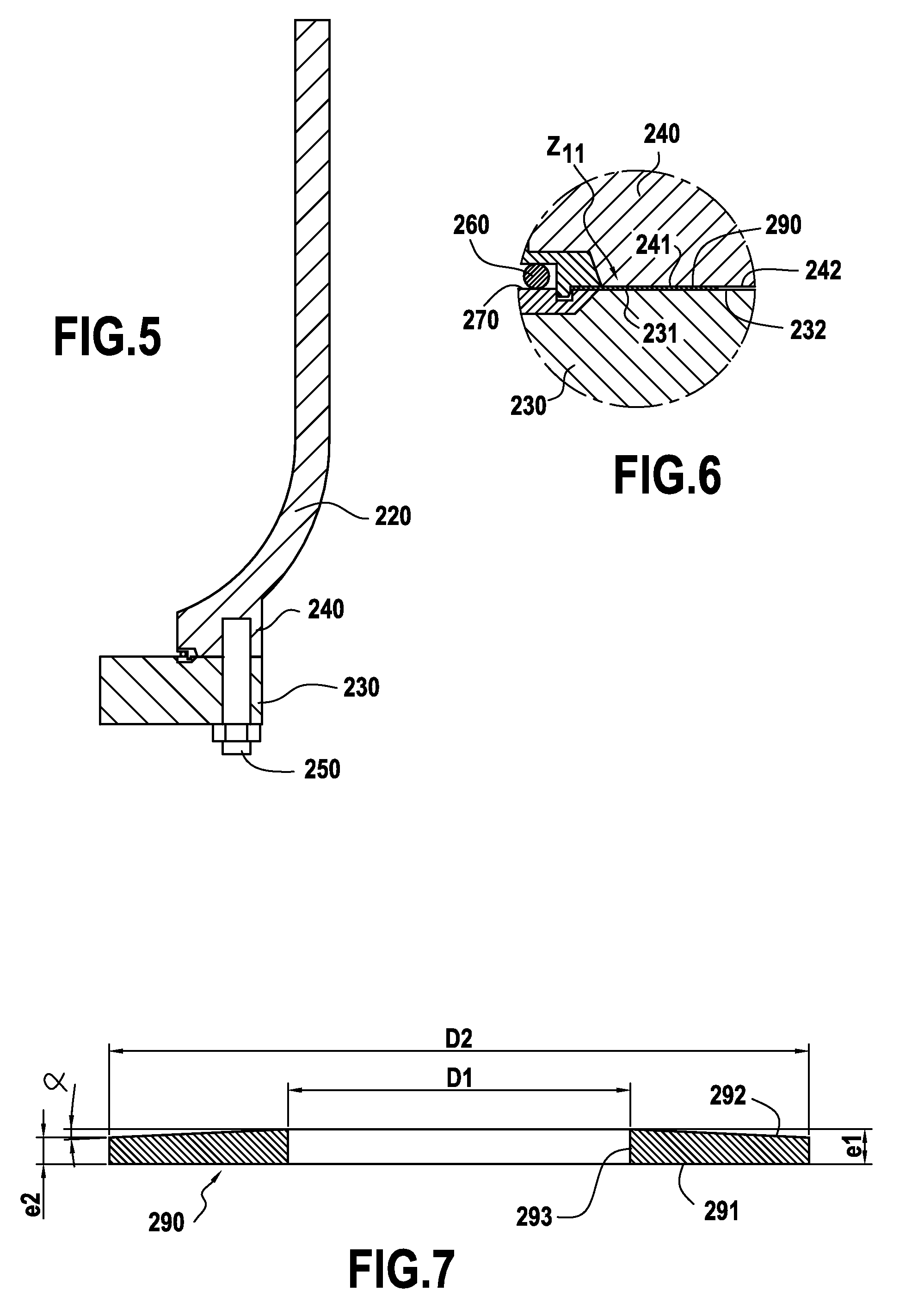

Device for pre-stressed sealed connection with flanges

InactiveUS20100295298A1Small contact surfaceReduce diameterEngine sealsFlanged jointsPre stressingEngineering

The prestressed flanged leaktight connection device comprises a first flange (130) presenting a first contact surface (111), a second flange (140) presenting a second contact surface (121) situated facing the first contact surface (111), a sealing gasket (160) received in a gasket housing (170) formed between the first and second contact surfaces and clamping elements (150) for clamping together the first and second flanges (130, 140). The first and second contact surfaces present a localized bearing zone (Z1) forming a dog situated in the vicinity of the sealing gasket (160). At least one (111) of the first and second contact surfaces presents, in the localized bearing zone (Z1) a surface of specified shape, e.g. conical, such that before tightening of the tightening elements (150), contact between the first and second flanges (130, 140) at the localized bearing zone (Z1) is limited to a fraction of the surface of the localized bearing zone (Z1), whereas after tightening of the tightening elements (150; 250) the contact is distributed evenly over all of the localized bearing zone (Z1).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

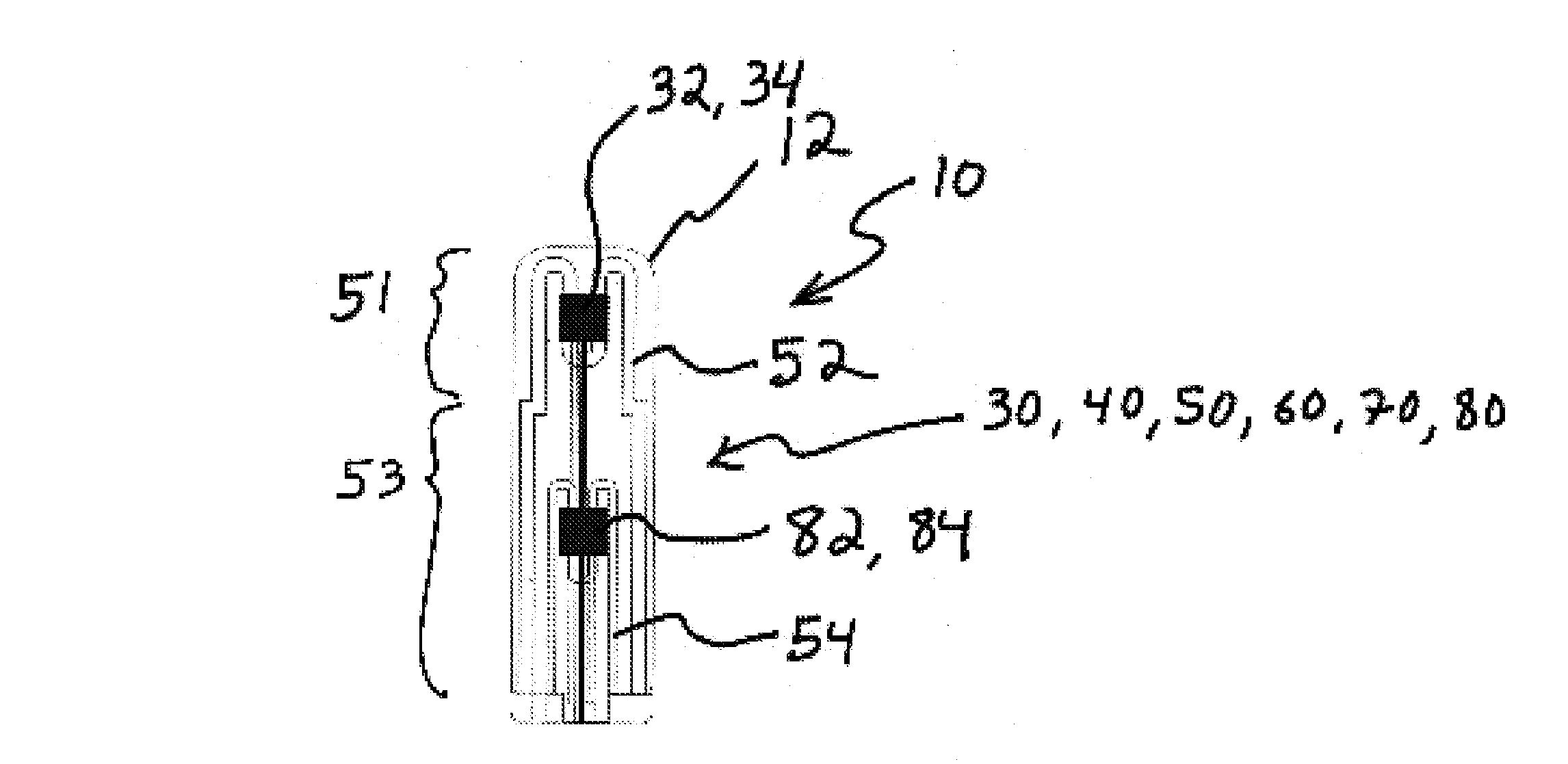

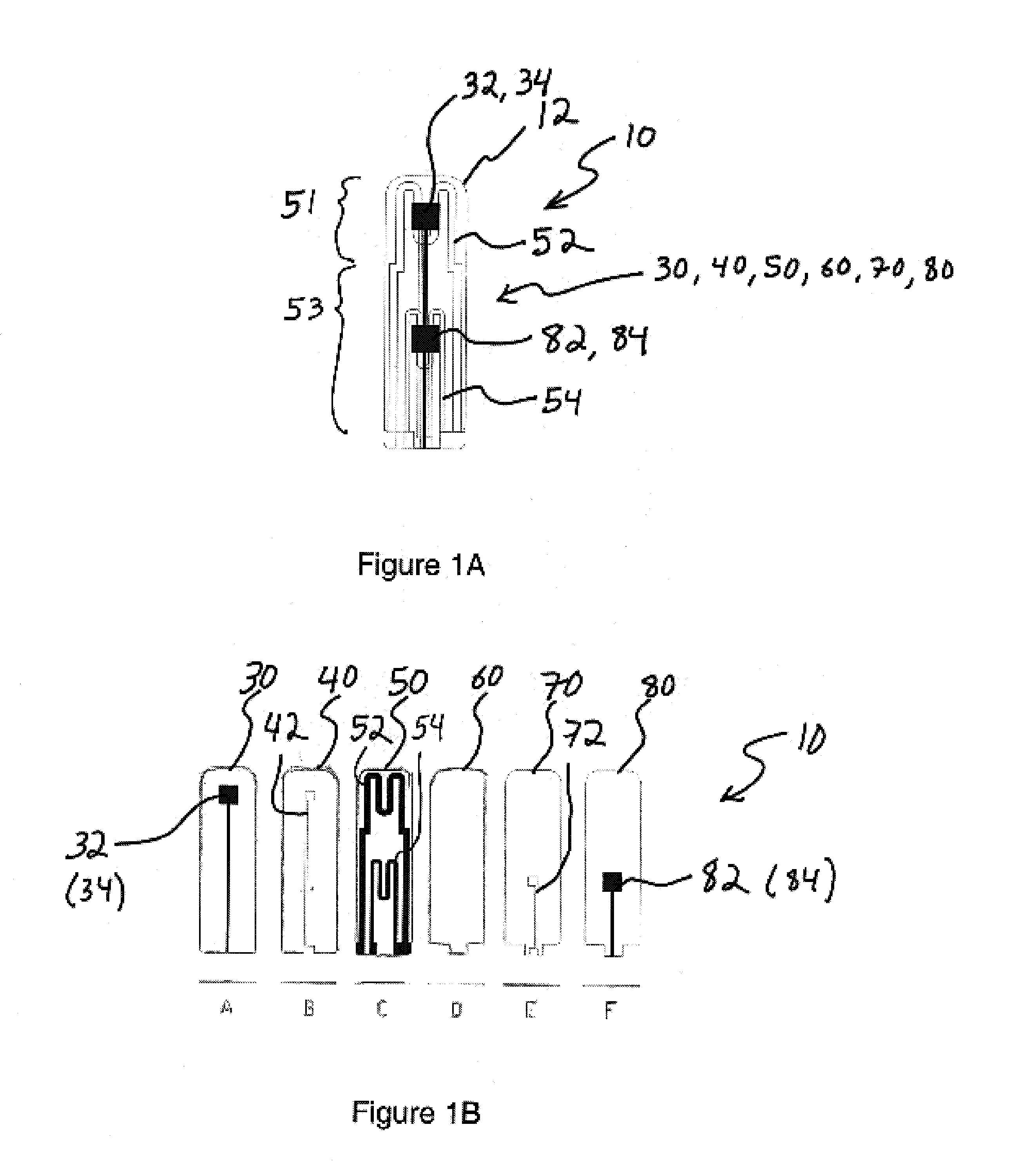

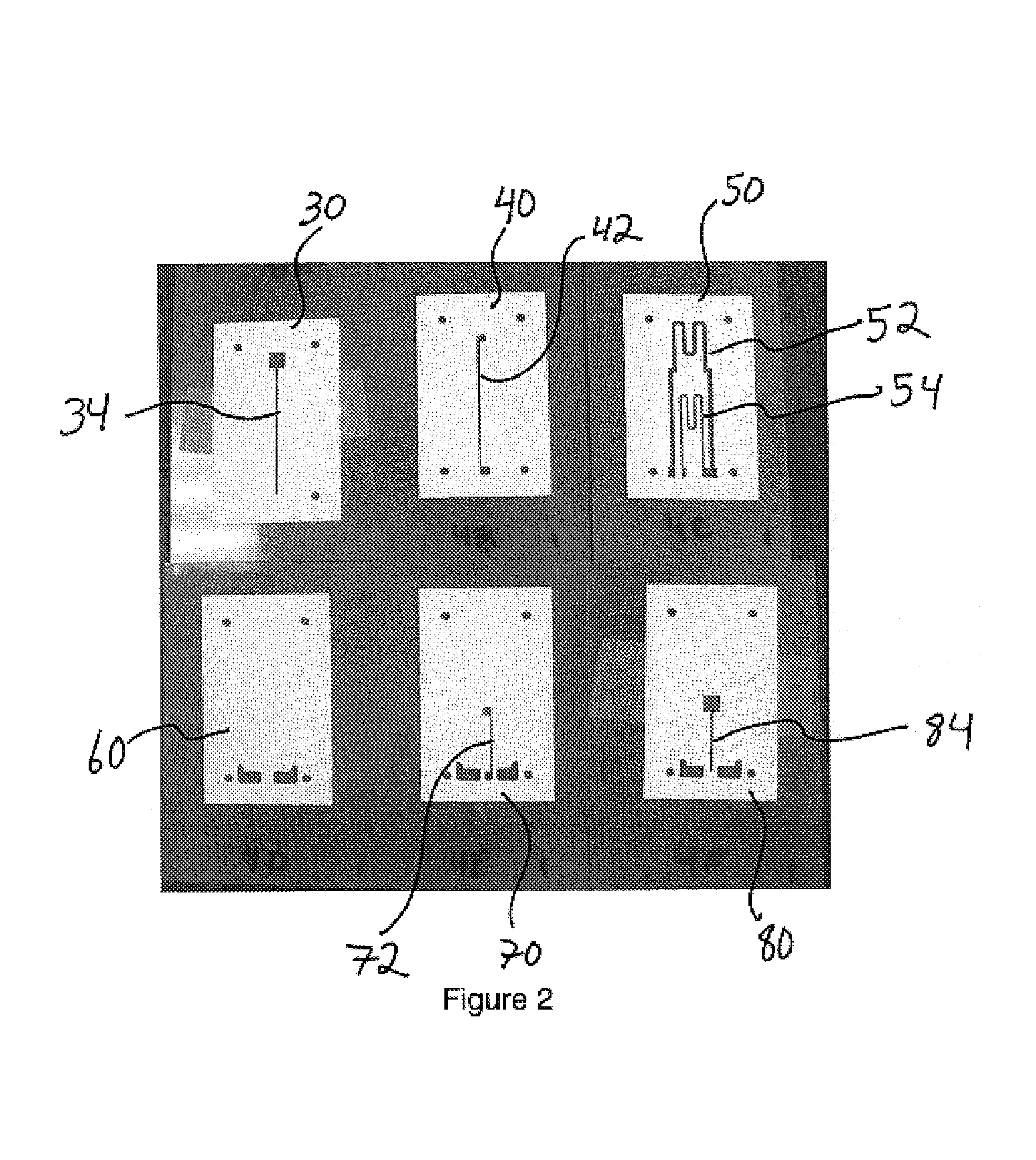

Multilayer ceramic NOx gas sensor device

InactiveUS7611612B2Faster sensor light off timeReduce gas emissionsWeather/light/corrosion resistanceVolume/mass flow measurementExhaust gas emissionsMiniaturization

A mixed potential NOx sensor apparatus for measuring the total NOx concentration in a gas stream is disclosed. The NOx sensing apparatus comprises a multilayer ceramic structure with electrodes for sensing both oxygen and NOx gas concentrations and includes screen-printed metalized patterns that function to heat the ceramic sensing element to the proper temperature for optimum performance. This design may provide advantages over the existing technology by miniaturizing the sensing element to provide potentially faster sensor light off times and thereby reduce undesired exhaust gas emissions. By incorporating the heating source within the ceramic sensing structure, the time to reach the temperature of operation is shortened, and thermal gradients and stresses are minimized. These improvements may provide increased sensor performance, reliability, and lifetime.

Owner:EMISENSE TECH

Organic light emitting device

ActiveUS20090128012A1Reduce power consumptionReduce voltageDischarge tube luminescnet screensElectroluminescent light sourcesAlkaline earth metalOrganic light emitting device

An organic light emitting device includes an electron transport layer including an electron transport material and a metallic compound represented by Formula 1:Formula 1:XaYb wherein X is an alkaline metal, an alkaline earth metal, or a transition metal, and Y is one of a Group 7 element and an organic group C1-C20, and a is an integer within the range of 1 to 3, and b is an integer within the range of 1 to 3.

Owner:SAMSUNG DISPLAY CO LTD

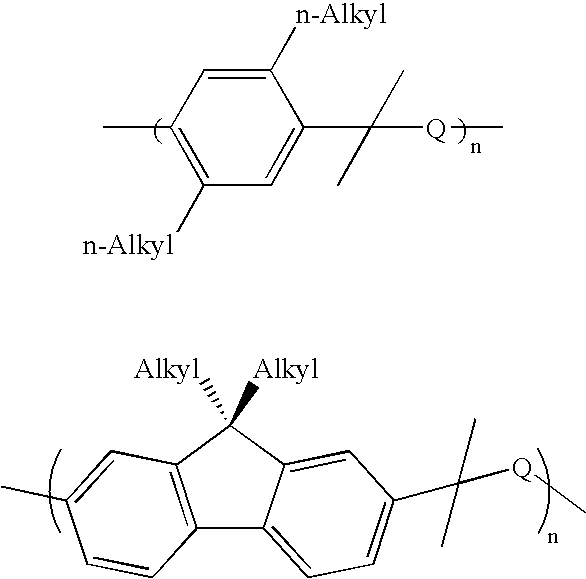

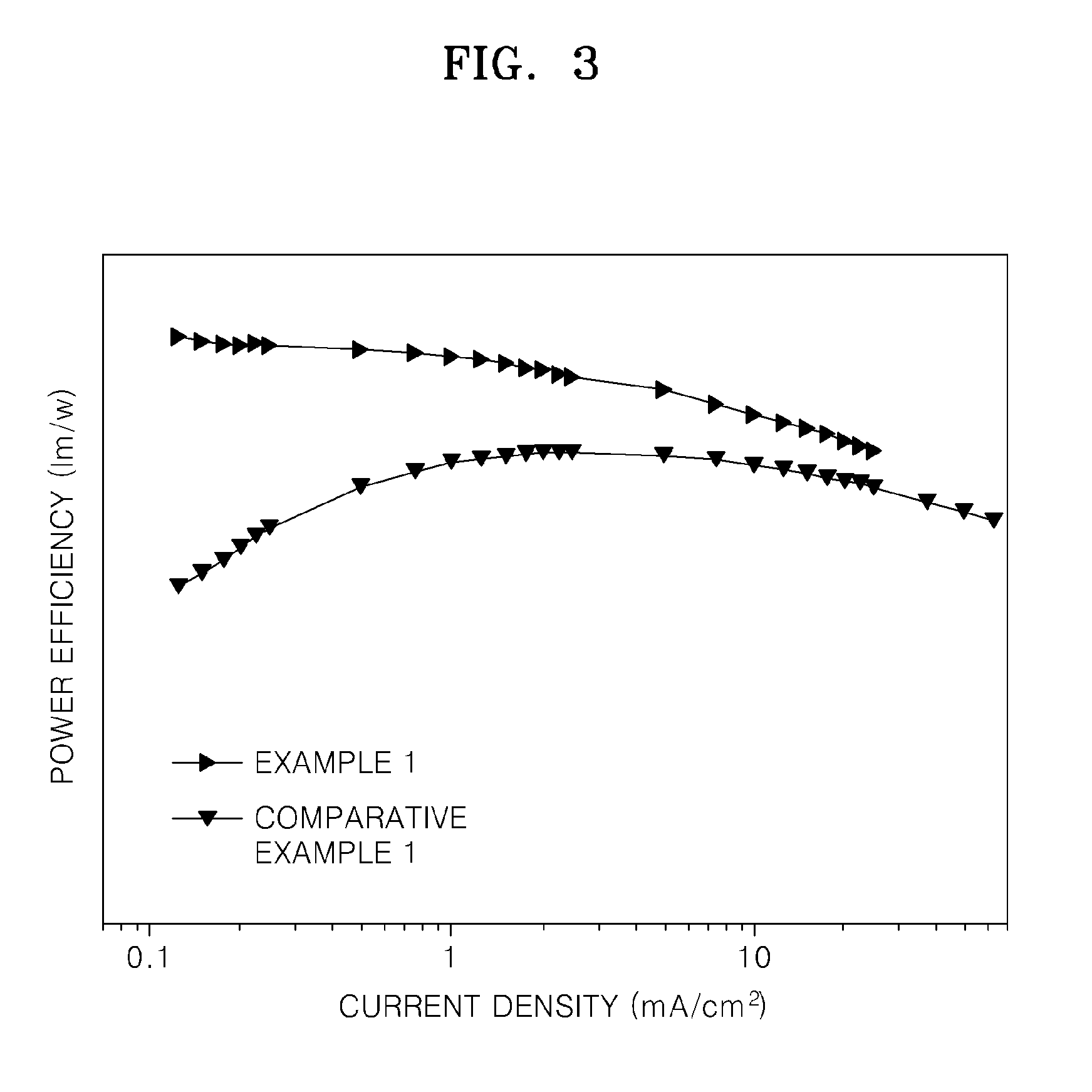

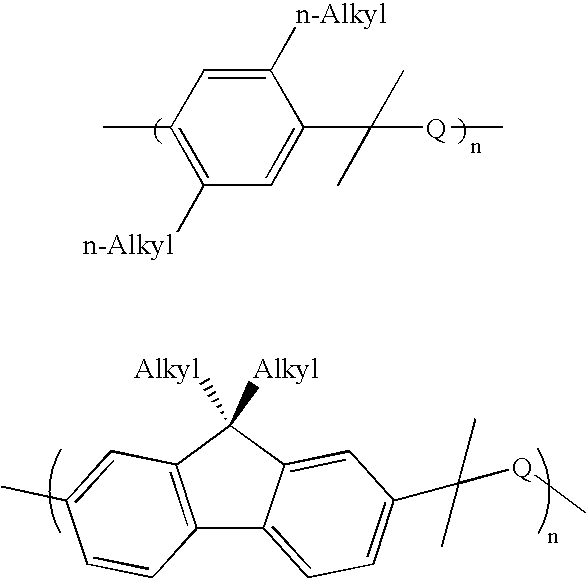

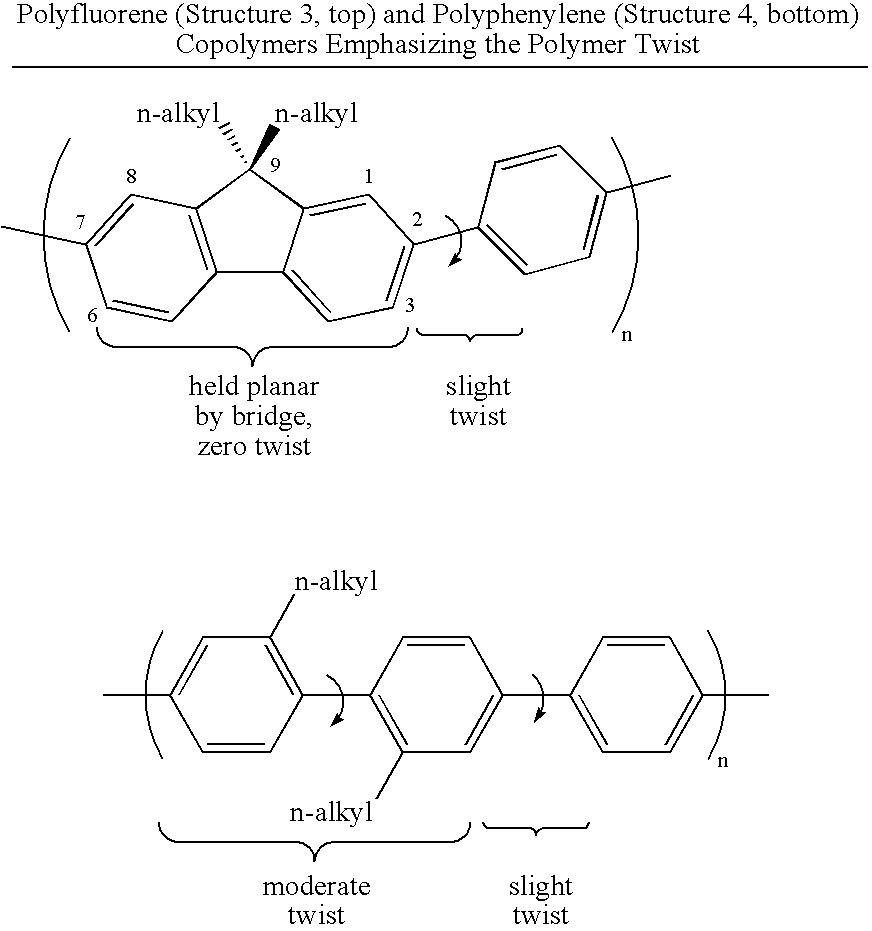

High bandgap arylene polymers

ActiveUS8822633B2Increase brightnessImproved lifetimeElectroluminescent light sourcesConductive materialLuminescent polymersPhotochemistry

Luminescent polymers having sterically twisted arylene repeat units are provided, which are particularly suited as electroluminescent polymers. Monomers necessary for the synthesis of the sterically twisted polyarylene are provided, as are electroluminescent device utilizing these polymers.

Owner:SUMITOMO CHEM CO LTD

Class of bridged biphenylene polymers

InactiveUS20130027636A1Increase brightnessImproved lifetimeMaterial nanotechnologyElectroluminescent light sourcesPolymer scienceLuminescent polymers

Luminescent polymers having doubly- or multiply-bridged biphenylene repeat units are provided, which are particularly suited as electroluminescent polymers. Monomers necessary for the synthesis of the multiply bridged biphenylene polymers are provided, as are electroluminescent devices utilizing these polymers.

Owner:SUMITOMO CHEM CO LTD

Memory parametric improvements

ActiveUS9069717B1Improve performanceImproved lifetimeDetecting faulty computer hardwareMemory adressing/allocation/relocationMemory interfaceIntegrated circuit

An integrated circuit memory interface device coupled to a dynamic random access memory device is provided. The device includes an address match table. The address match table includes a plurality of first addresses. Each of the first addresses is associated with a memory cell having a refresh characteristic outside of a specification for a DRAM device. The device has a plurality of second addresses. Each of the second addresses is associated with a refresh characteristic within a specification of the DRAM device and outside of a predetermined refresh characteristic range characterized to eliminate accesses to memory cells not meeting the predetermined refresh characteristic range.

Owner:RAMBUS INC

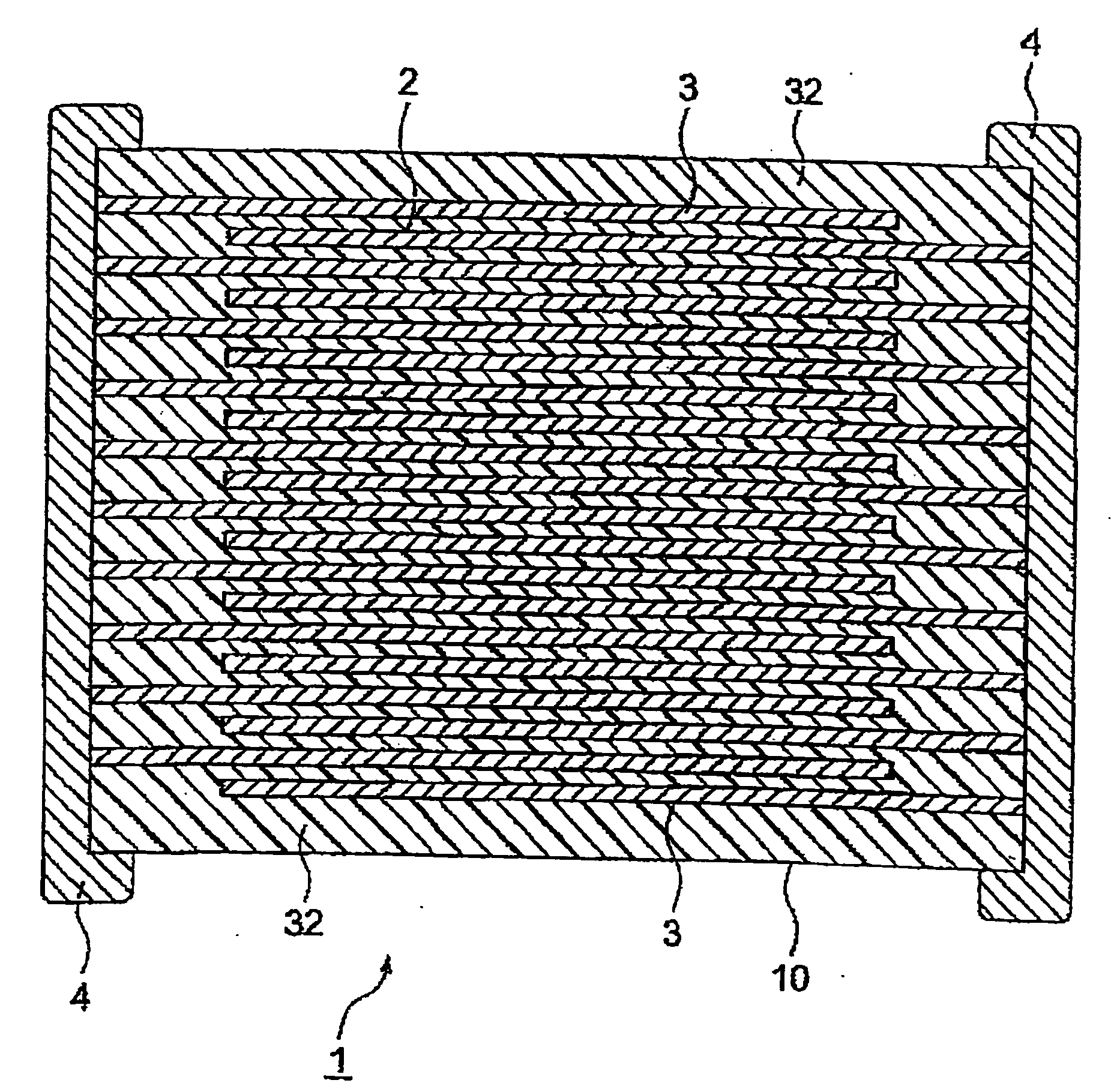

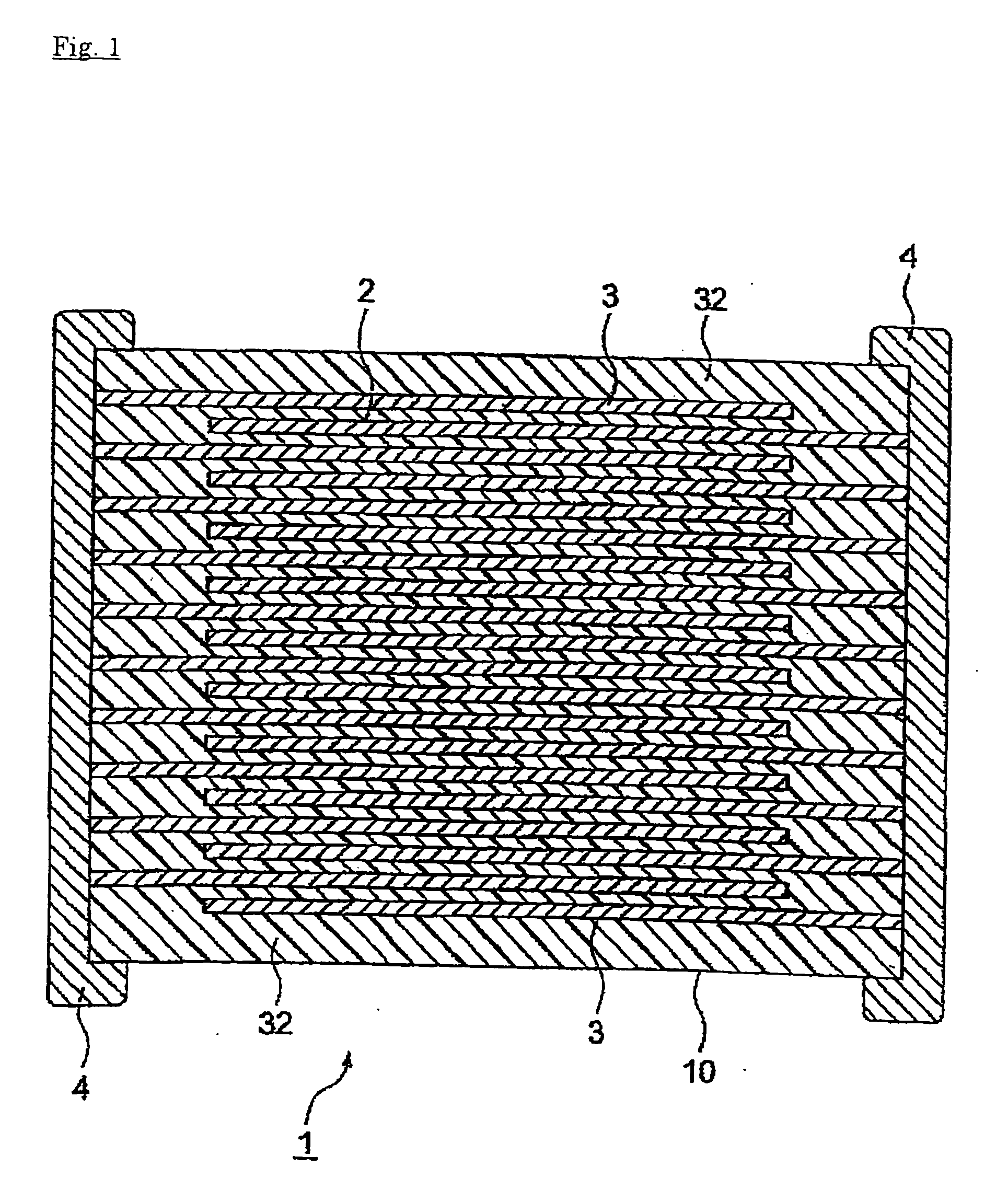

Dielectric ceramic composition and an electronic component

ActiveUS20090246508A1Excellent characteristicsExcellent lifetimeMaterial nanotechnologyFixed capacitor dielectricBarium titanateElectronic component

A dielectric ceramic composition comprises, a main component including barium titanate, a first subcomponent including MgO, a second subcomponent including sintering aids of SiO2 compound, a third subcomponent including at least one of V2O5, Nb2O5 and WO3, a fourth A subcomponent including RA oxide (note that, RA is at least one selected from Tb, Gd and Dy), a fourth B subcomponent including R oxide (note that, R is at least one selected from Ho, Y and Yb), and a fifth subcomponent including MnO or Cr2O3.

Owner:TDK CORPARATION

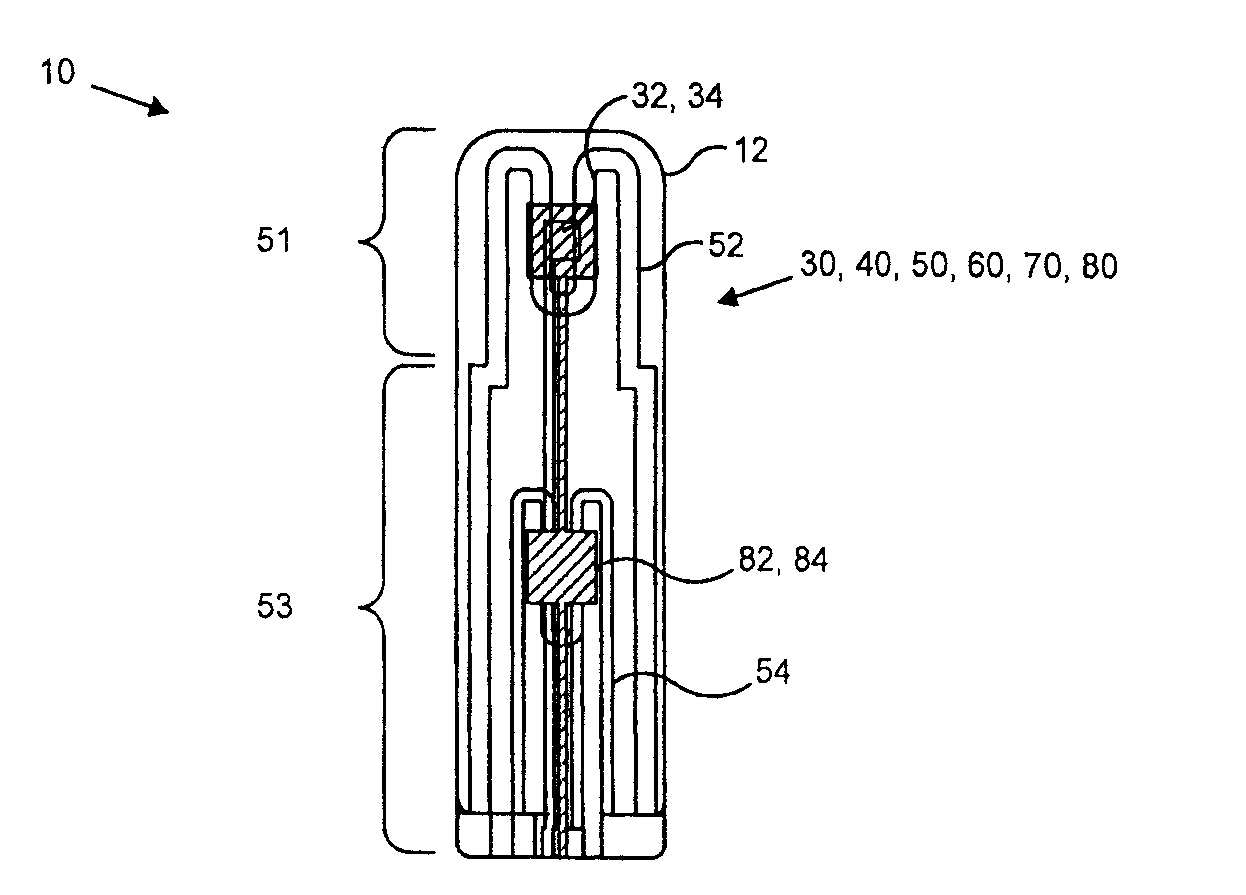

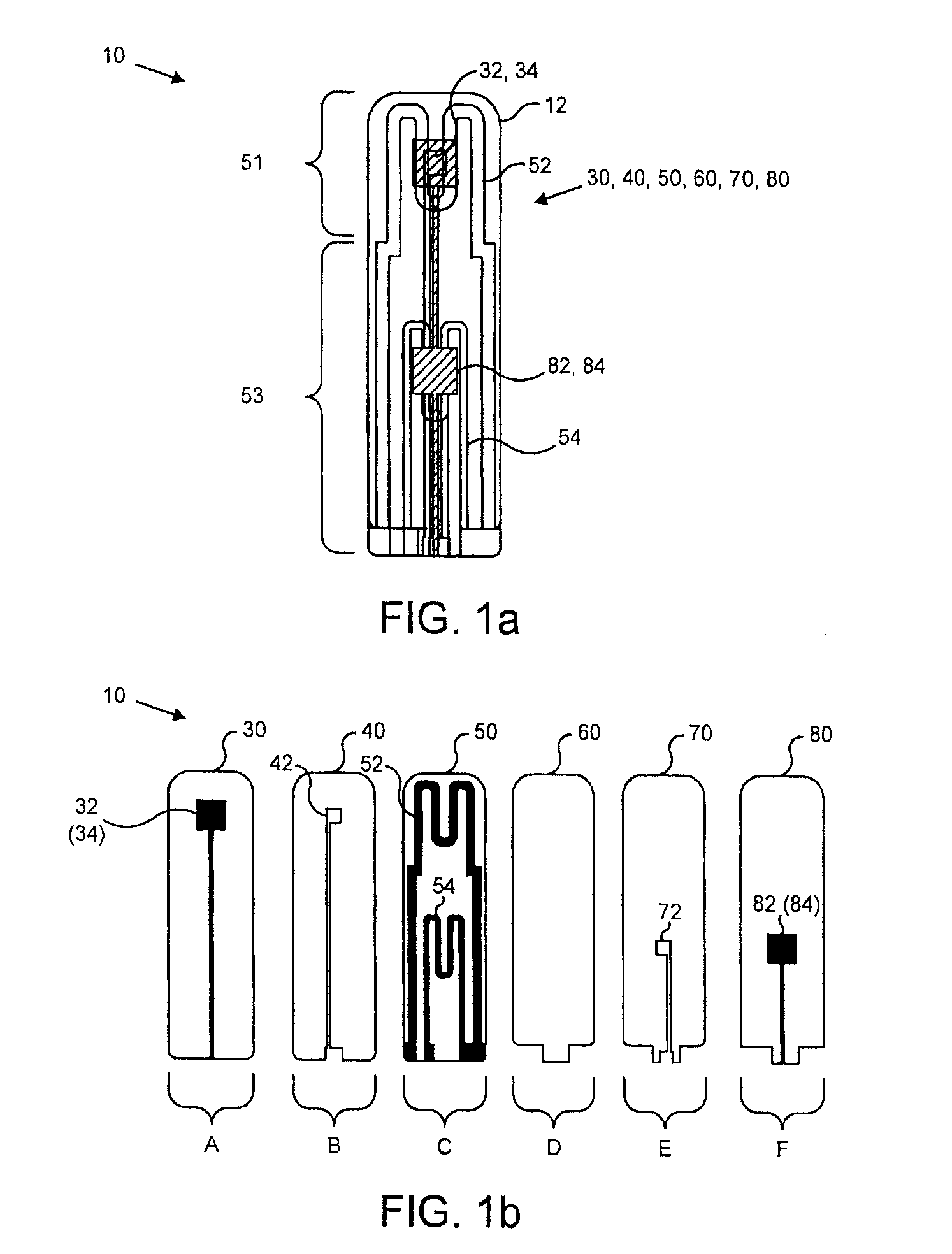

MULTILAYER CERAMIC NOx GAS SENSOR DEVICE

InactiveUS20100096264A1Faster sensor light off timeReduce gas emissionsWeather/light/corrosion resistanceVolume/mass flow measurementMiniaturizationExhaust gas emissions

A mixed potential NOx sensor apparatus for measuring the total NOx concentration in a gas stream is disclosed. The NOx sensing apparatus comprises a multilayer ceramic structure with electrodes for sensing both oxygen and NOx gas concentrations and includes screen-printed metallized patterns that function to heat the ceramic sensing element to the proper temperature for optimum performance. This design may provide advantages over the existing technology by miniaturizing the sensing element to provide potentially faster sensor light off times and thereby reduce undesired exhaust gas emissions. By incorporating the heating source within the ceramic sensing structure, the time to reach the temperature of operation is shortened, and thermal gradients and stresses are minimized. These improvements may provide increased sensor performance, reliability, and lifetime.

Owner:EMISENSE TECH

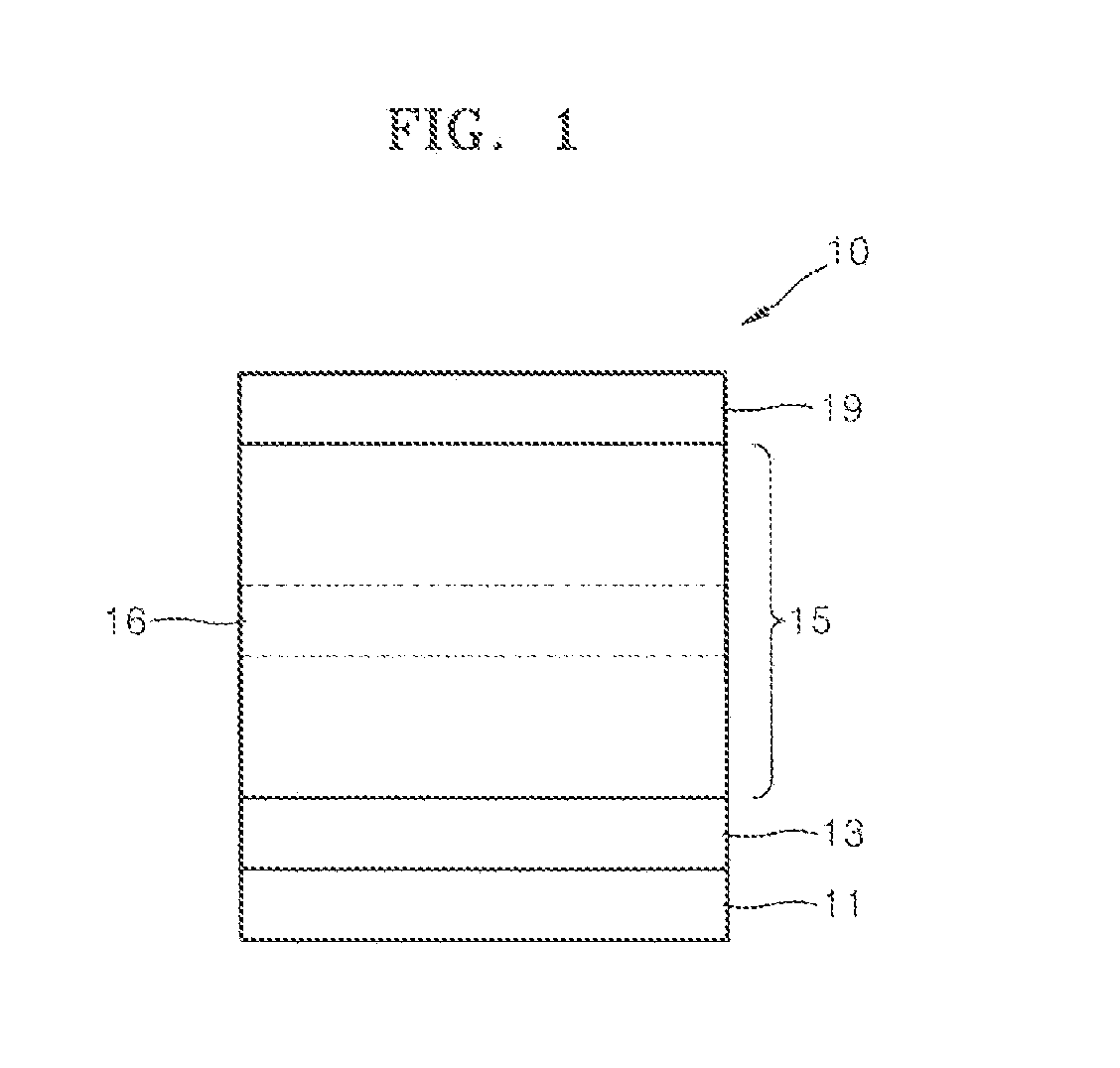

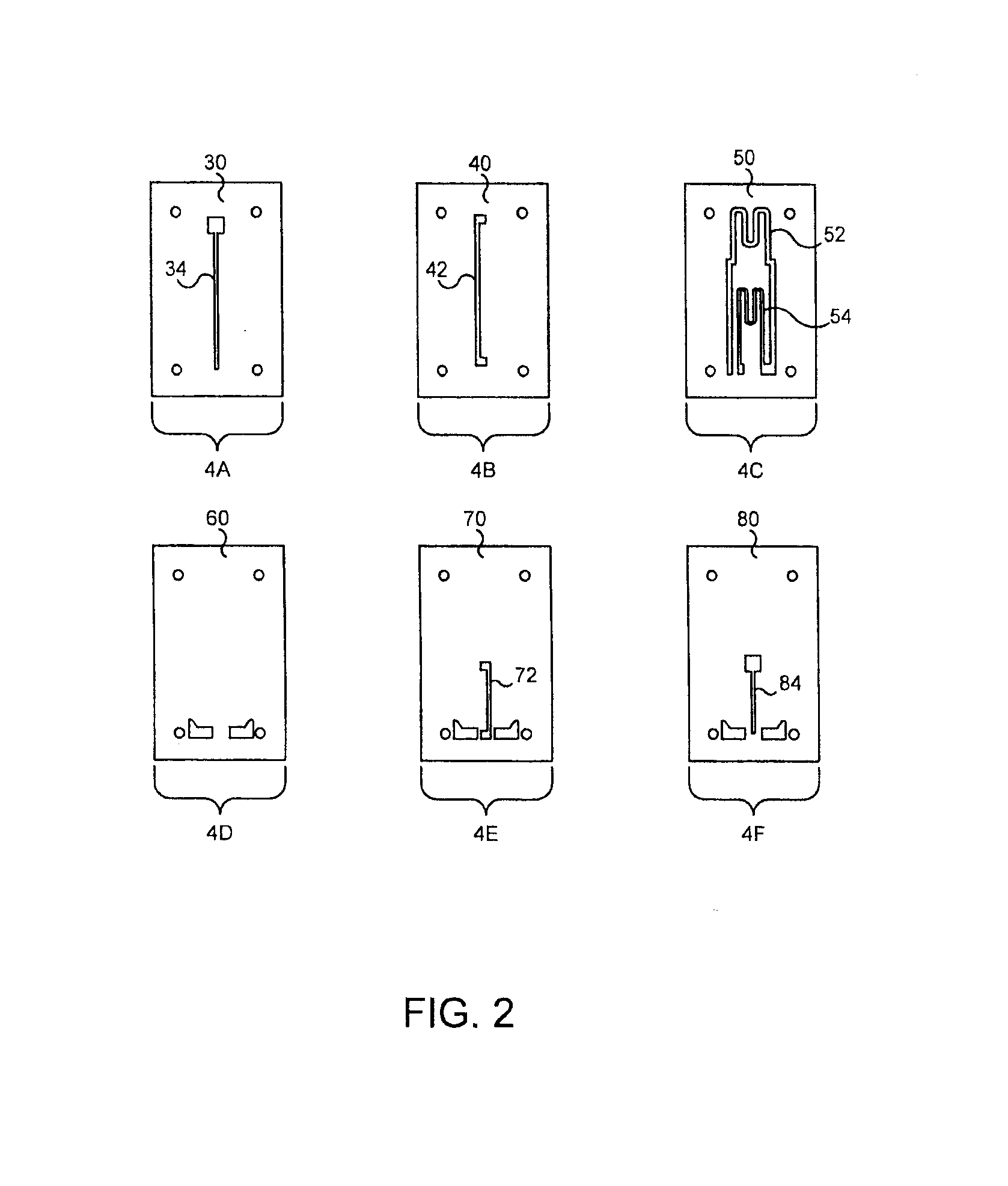

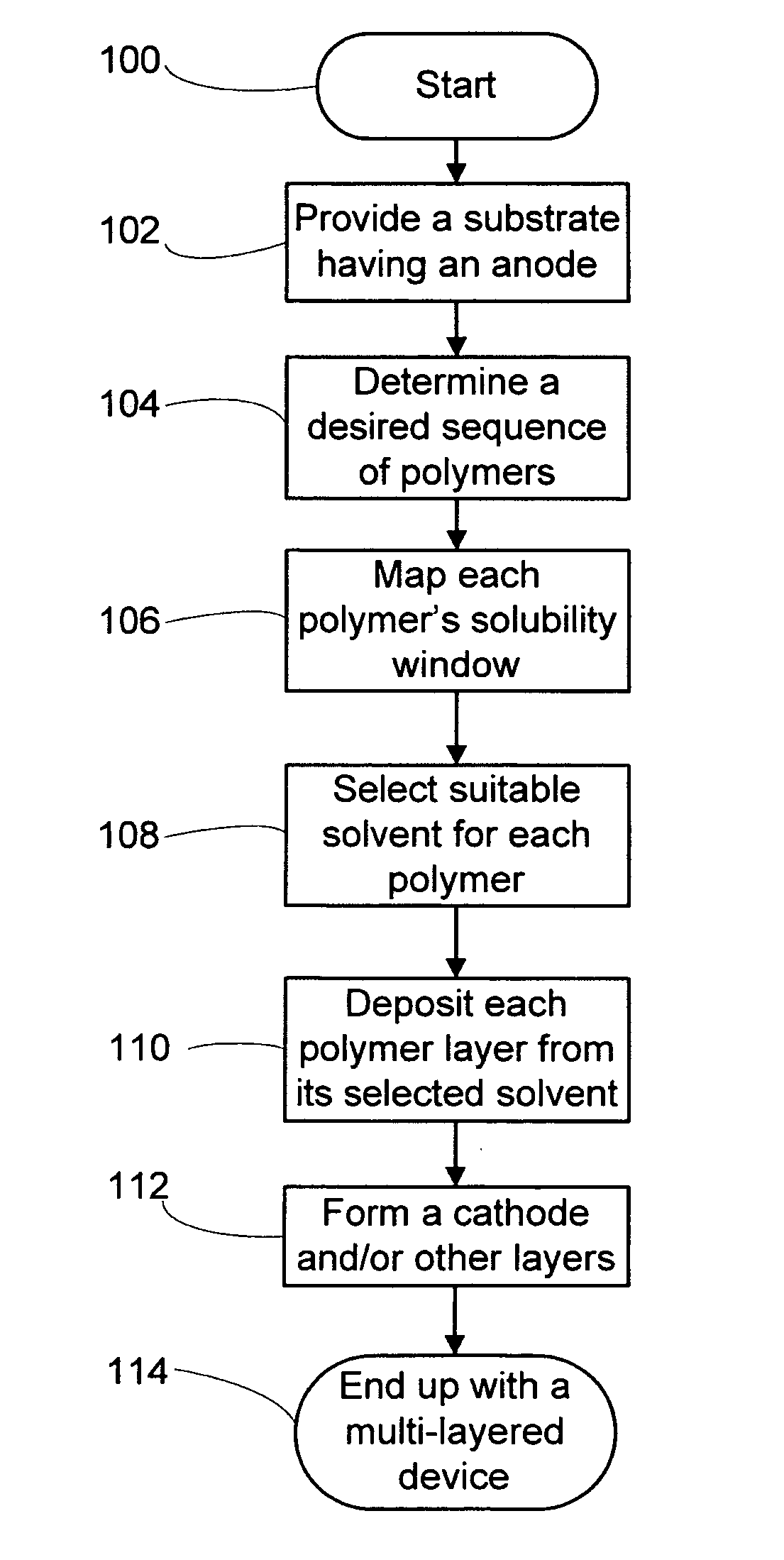

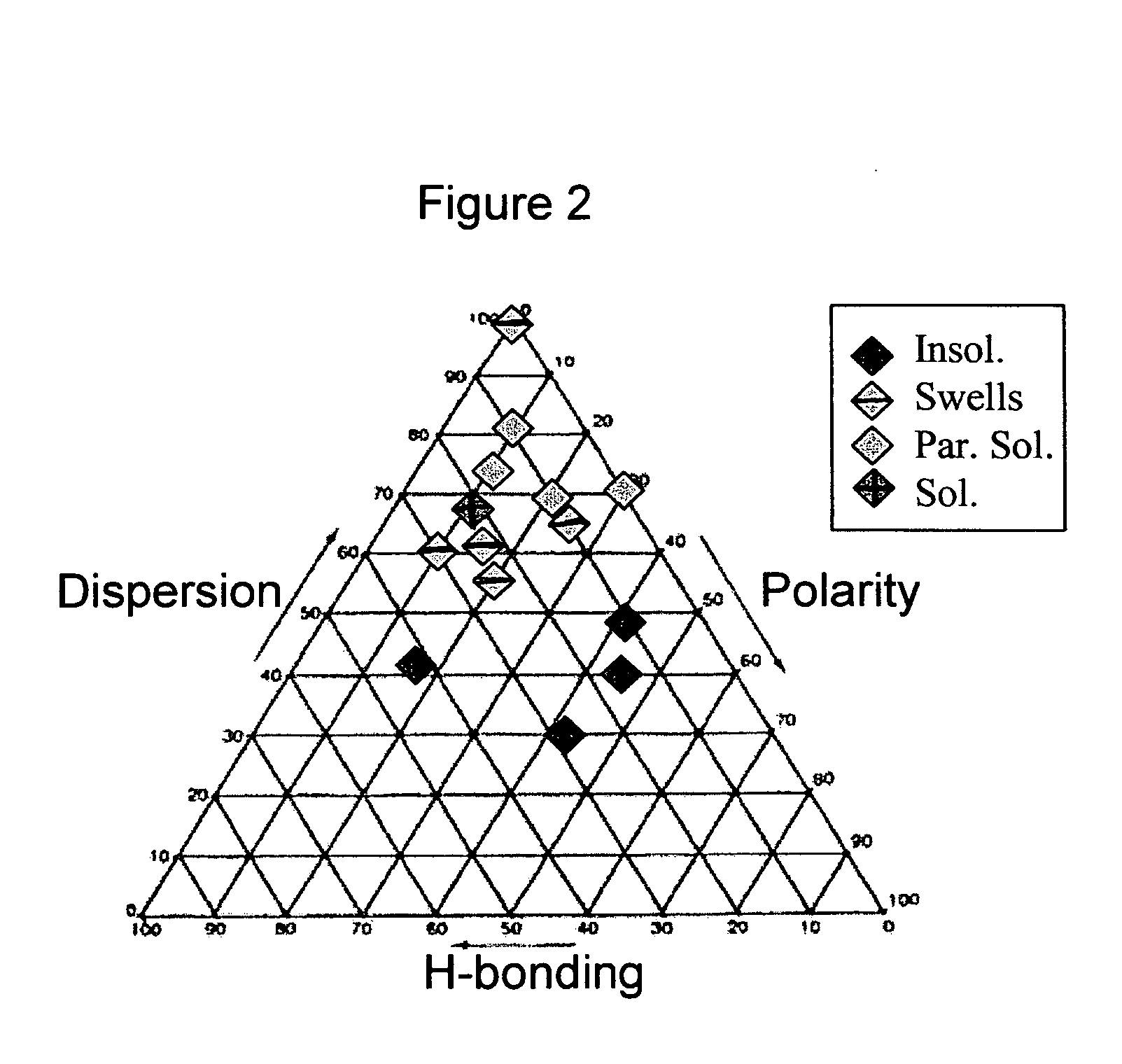

Multi-layered device and method for making the same

InactiveUS20050136285A1Improve adhesionGood electrical contactDischarge tube luminescnet screensFinal product manufactureSolubilitySolvent based

The invention relates to a multi-layered device and a method for making a multi-layered device. The method comprises the steps of determining a desired sequence of two or more polymers in a multi-layered device; for each of the two or more polymers in the desired sequence, identifying a solubility window in a solubility graph, and selecting a solvent based on the solubility window such that the solvent does not dissolve a preceding polymer in the desired sequence; depositing each of the two or more polymers from its selected solvent; and forming a multi-layered device having the two or more polymers in the desired sequence.

Owner:GENERAL ELECTRIC CO

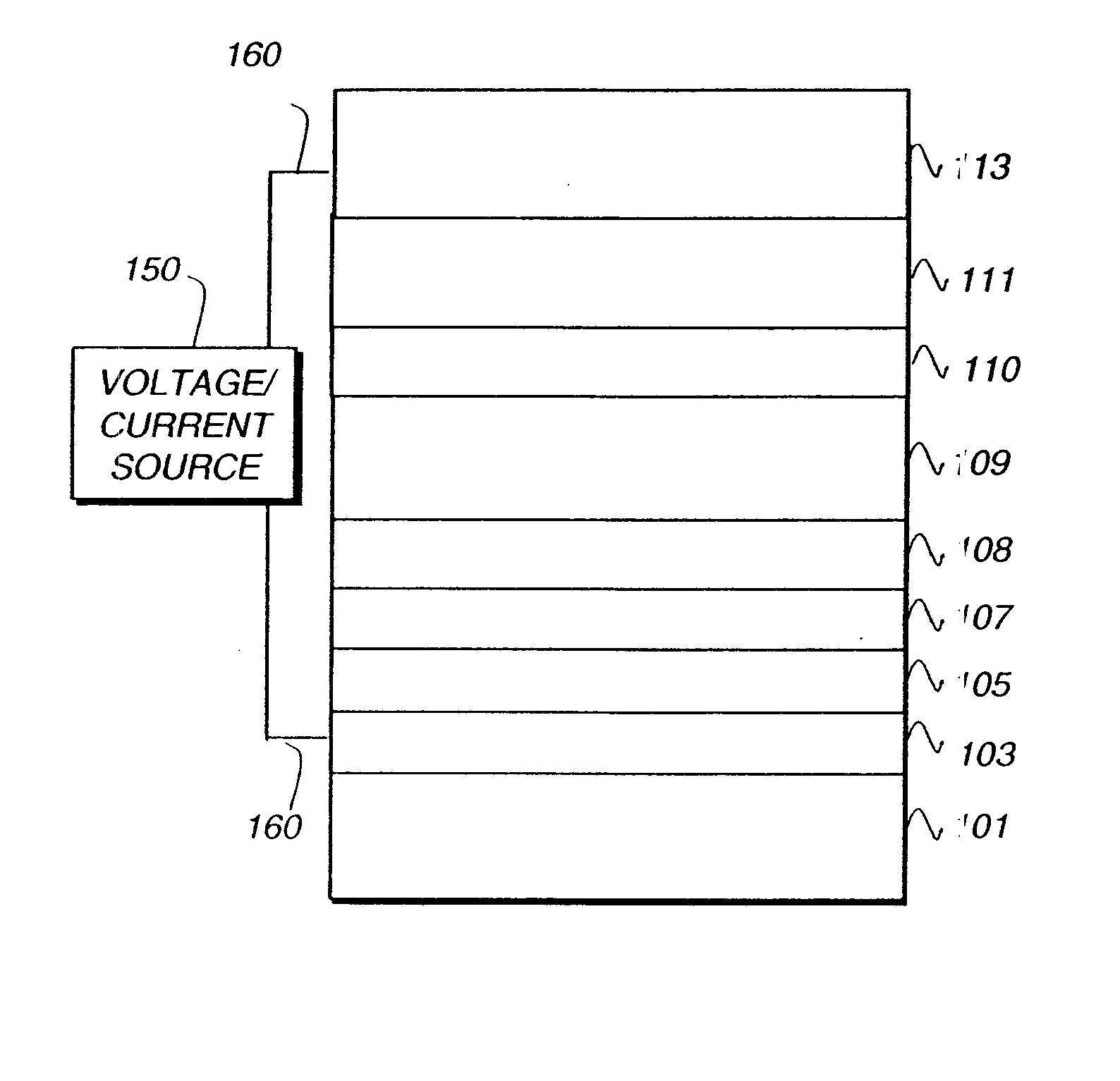

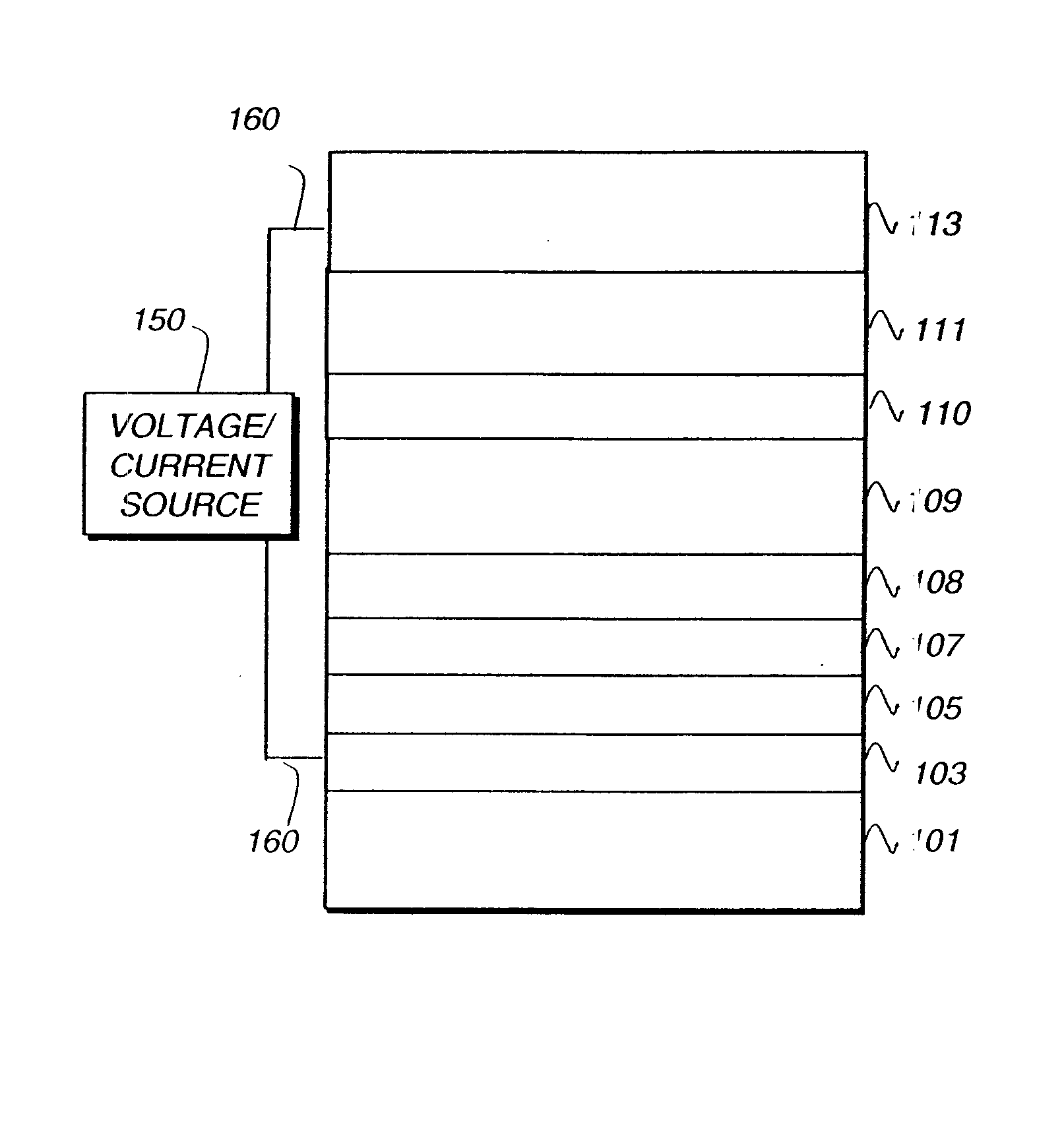

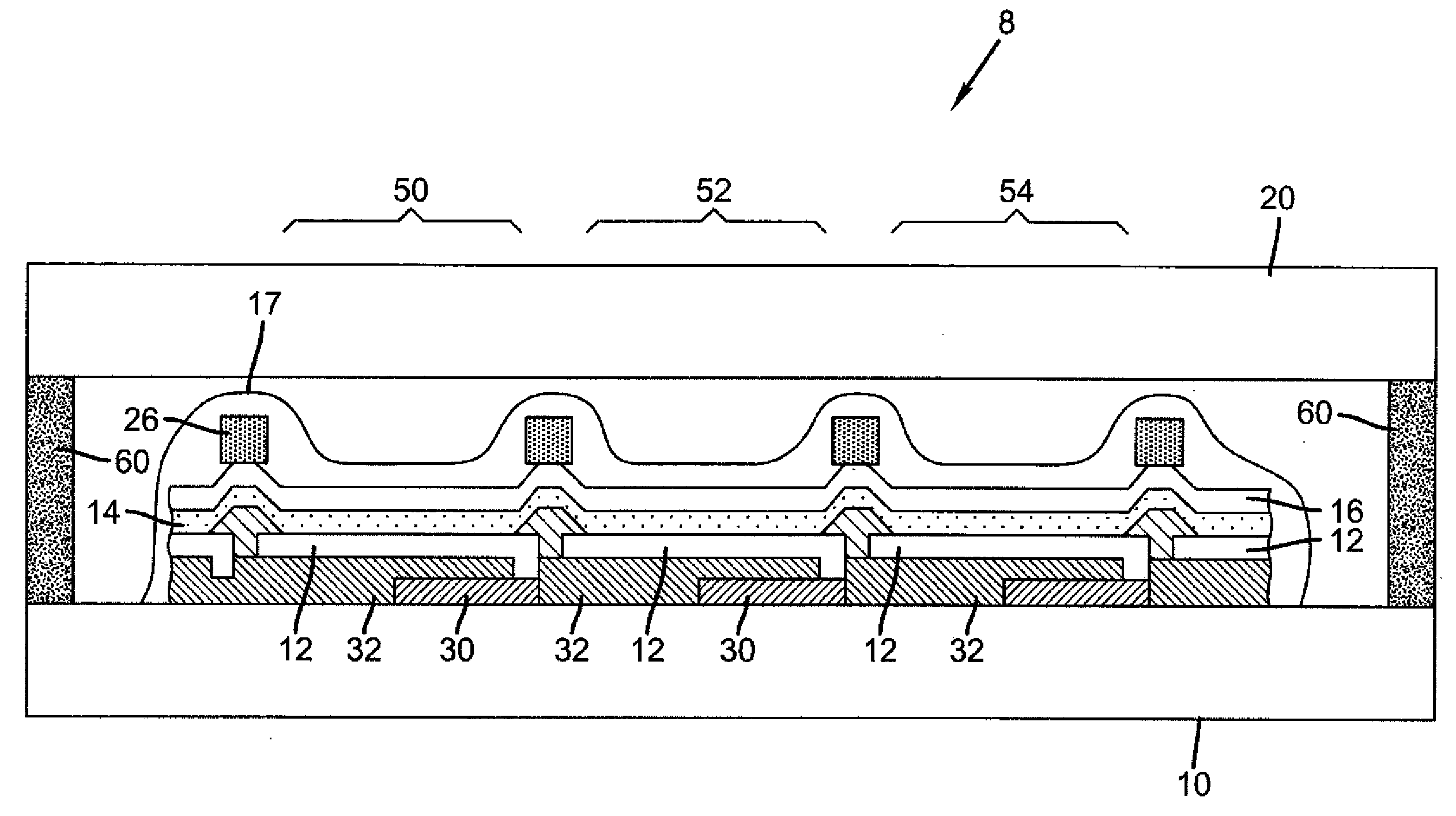

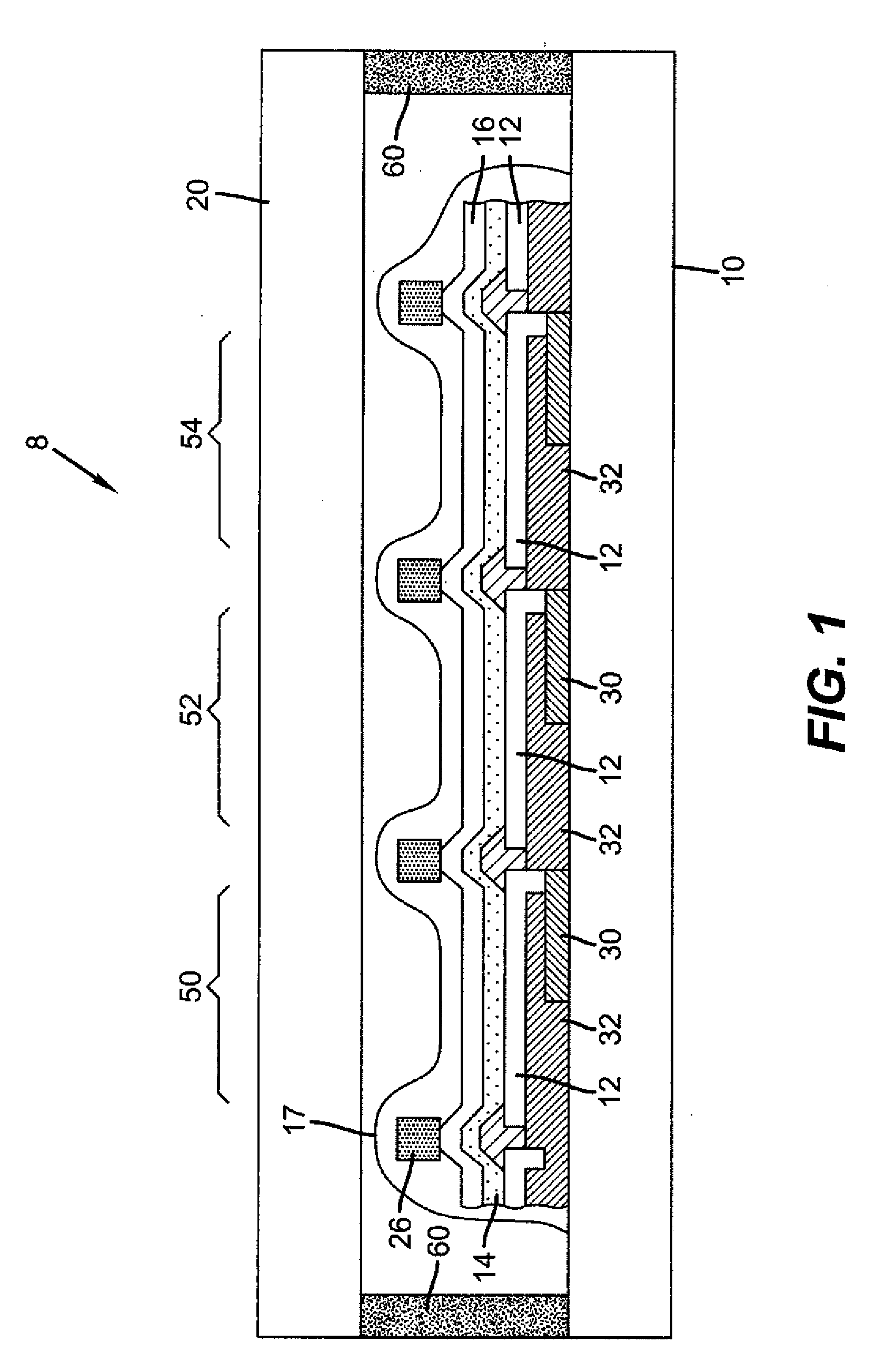

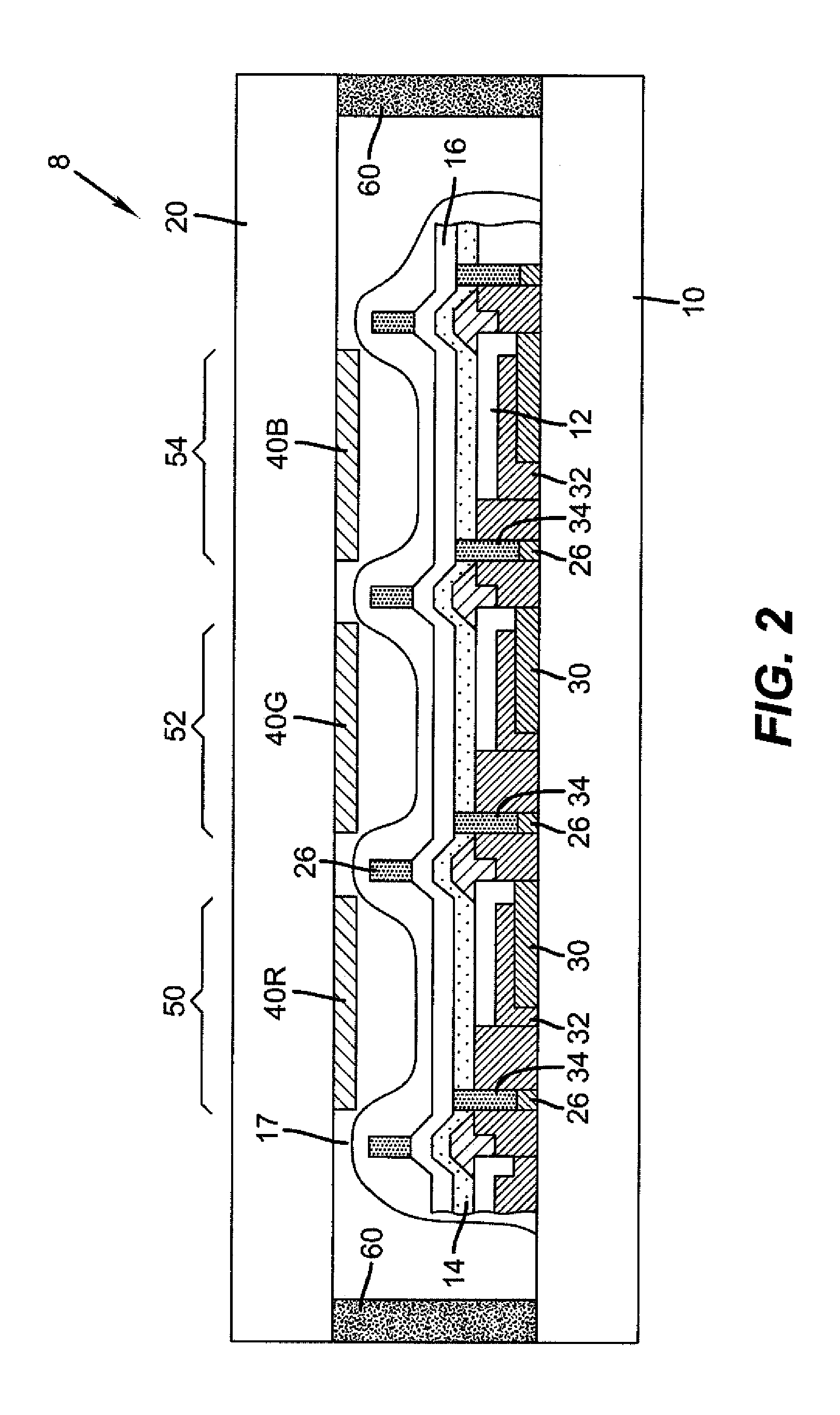

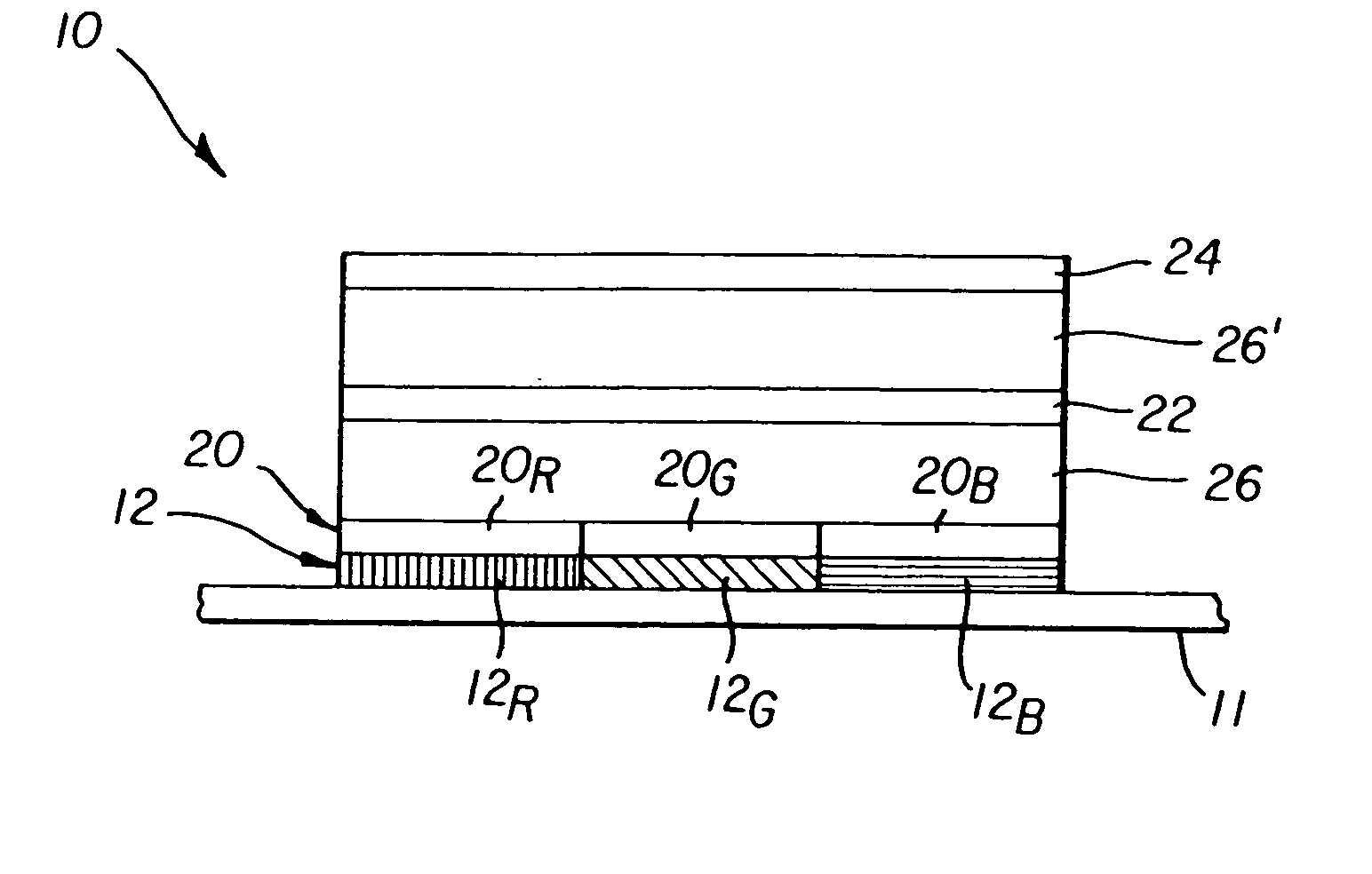

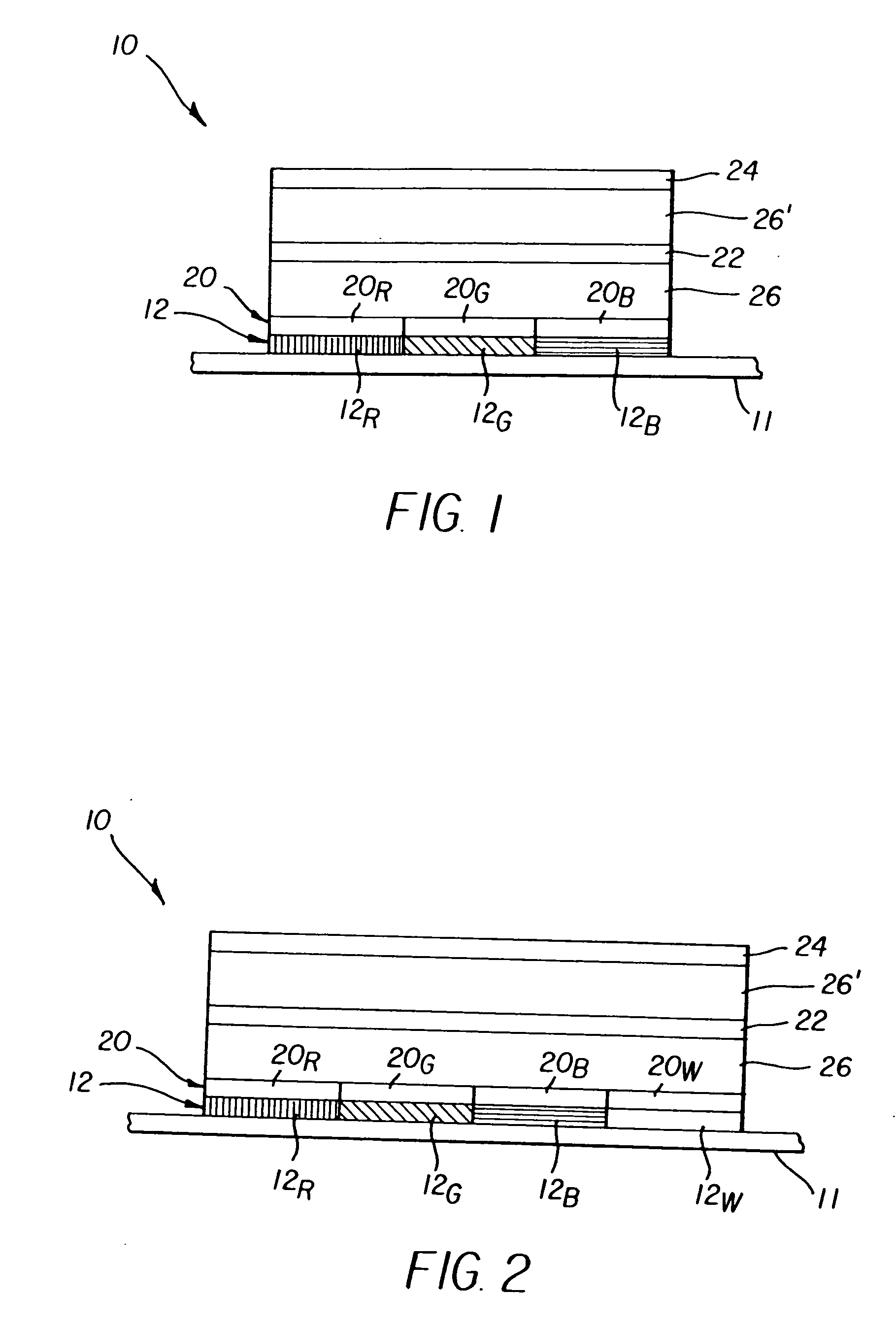

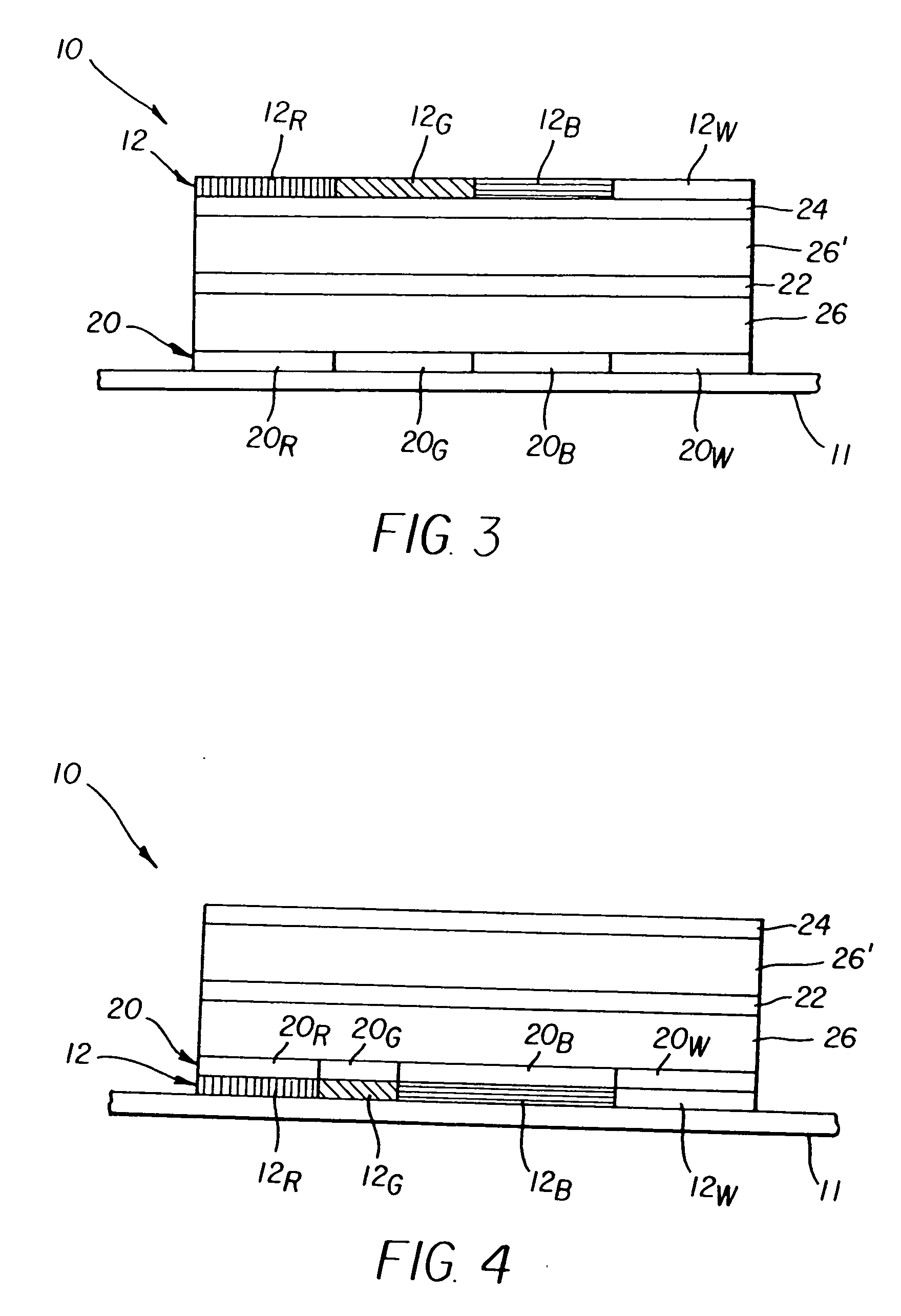

Stacked OLED display having improved efficiency

InactiveUS20050218418A1Improve efficiencyImproved lifetimeStatic indicating devicesSolid-state devicesElectrical conductorSingle electrode

An OLED device having a pixel, including a plurality of light transmissive filters; a first electrode layer defining a corresponding plurality of separately addressable electrodes; a first layer of white light emitting OLED material; a doped organic conductor layer; a second layer of white light emitting OLED material; and a second electrode layer defining a single electrode coextensive with the plurality of color filters.

Owner:EASTMAN KODAK CO

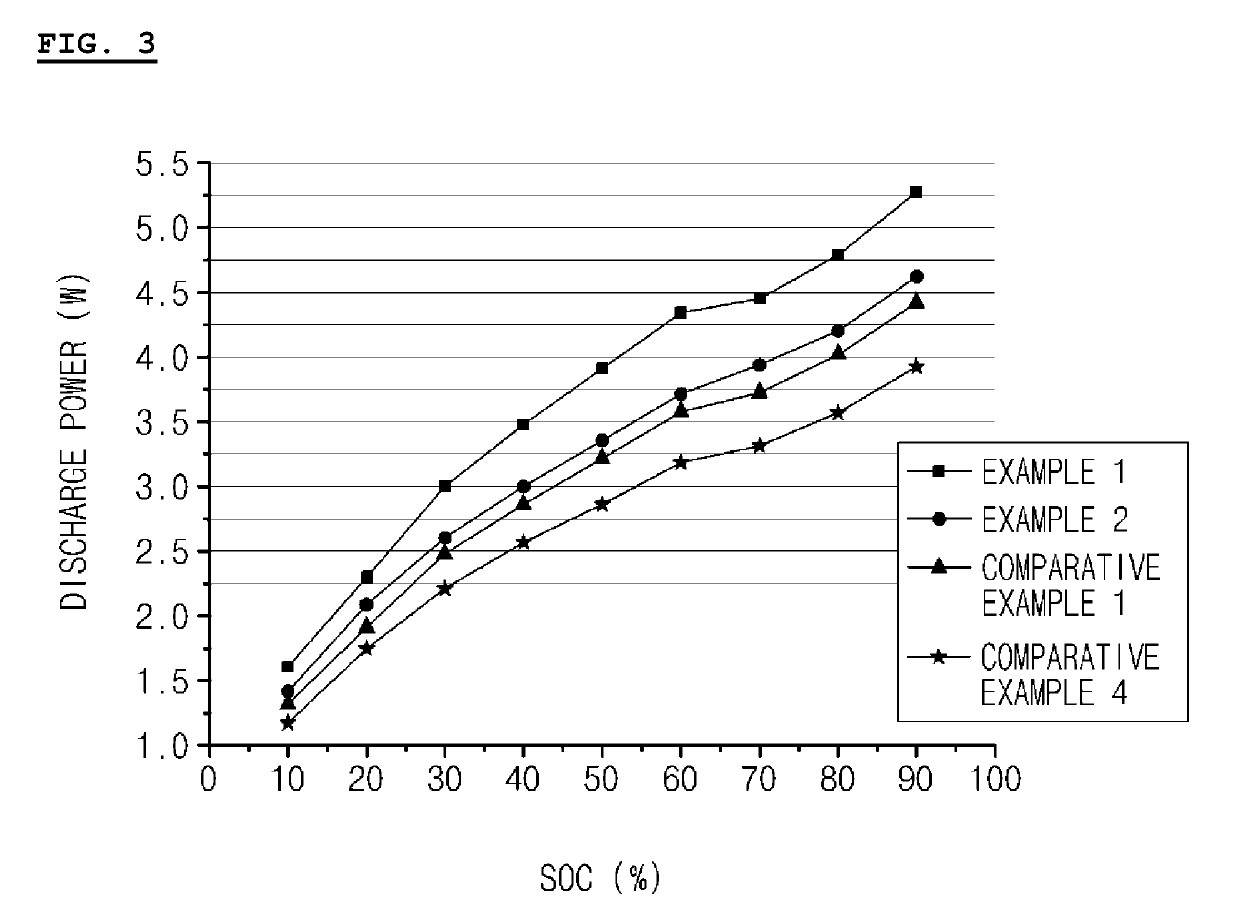

Organic light emitting device

ActiveUS7973467B2Excellent characteristicsImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesAlkaline earth metalOrganic light emitting device

An organic light emitting device includes an electron transport layer including an electron transport material and a metallic compound represented by Formula 1:XaYb Formula 1:wherein X is an alkaline metal, an alkaline earth metal, or a transition metal, and Y is one of a Group 7 element and an organic group C1-C20, and a is an integer within the range of 1 to 3, and b is an integer within the range of 1 to 3.

Owner:SAMSUNG DISPLAY CO LTD

High Bandgap Arylene Polymers

ActiveUS20090036622A1Increase brightnessImproved lifetimeElectroluminescent light sourcesConductive materialLuminescent polymersMonomer

Luminescent polymers having sterically twisted arylene repeat units are provided, which are particularly suited as electroluminescent polymers. Monomers necessary for the synthesis of the sterically twisted polyarylene are provided, as are electroluminescent device utilizing these polymers.

Owner:SUMITOMO CHEM CO LTD

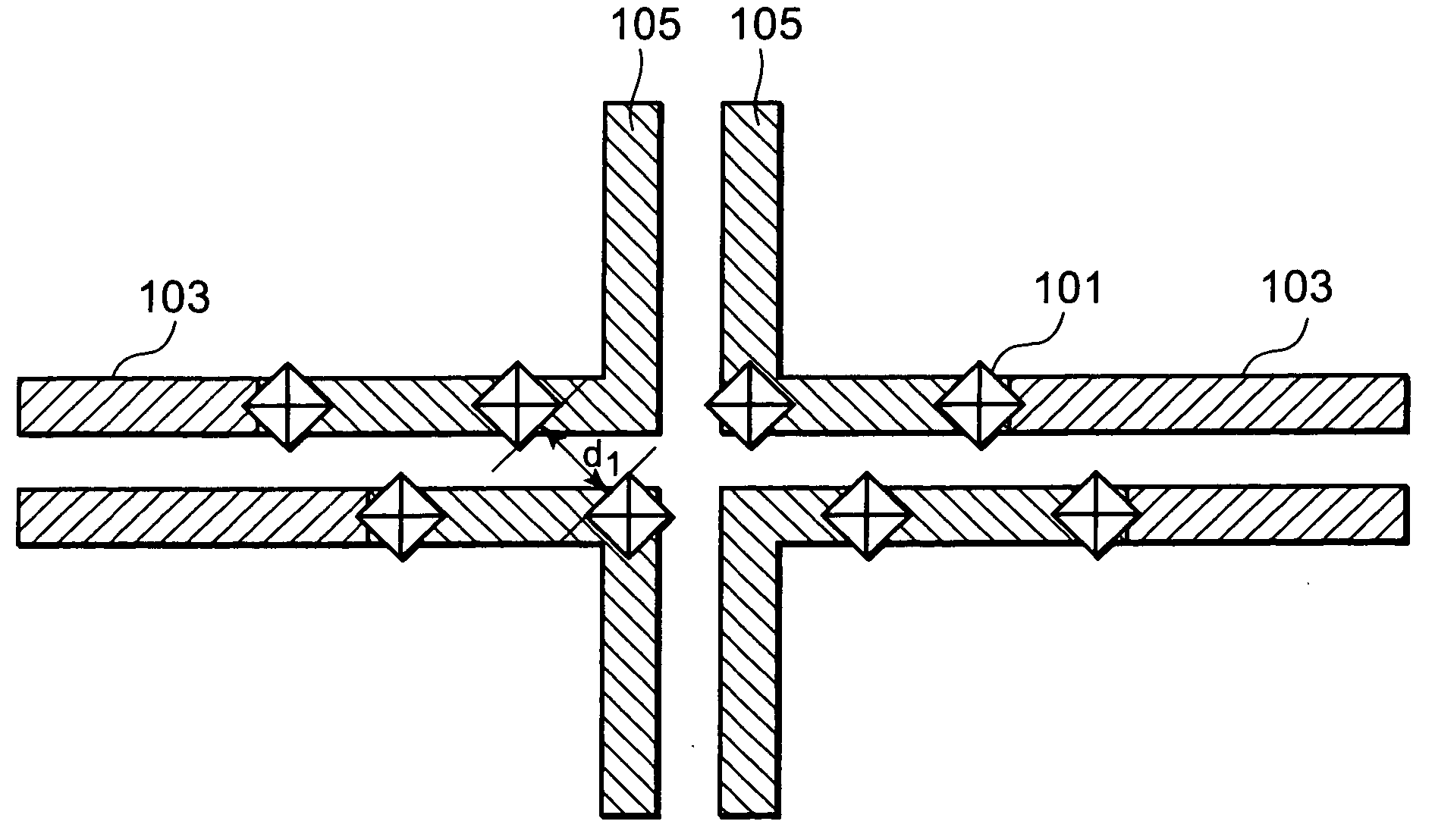

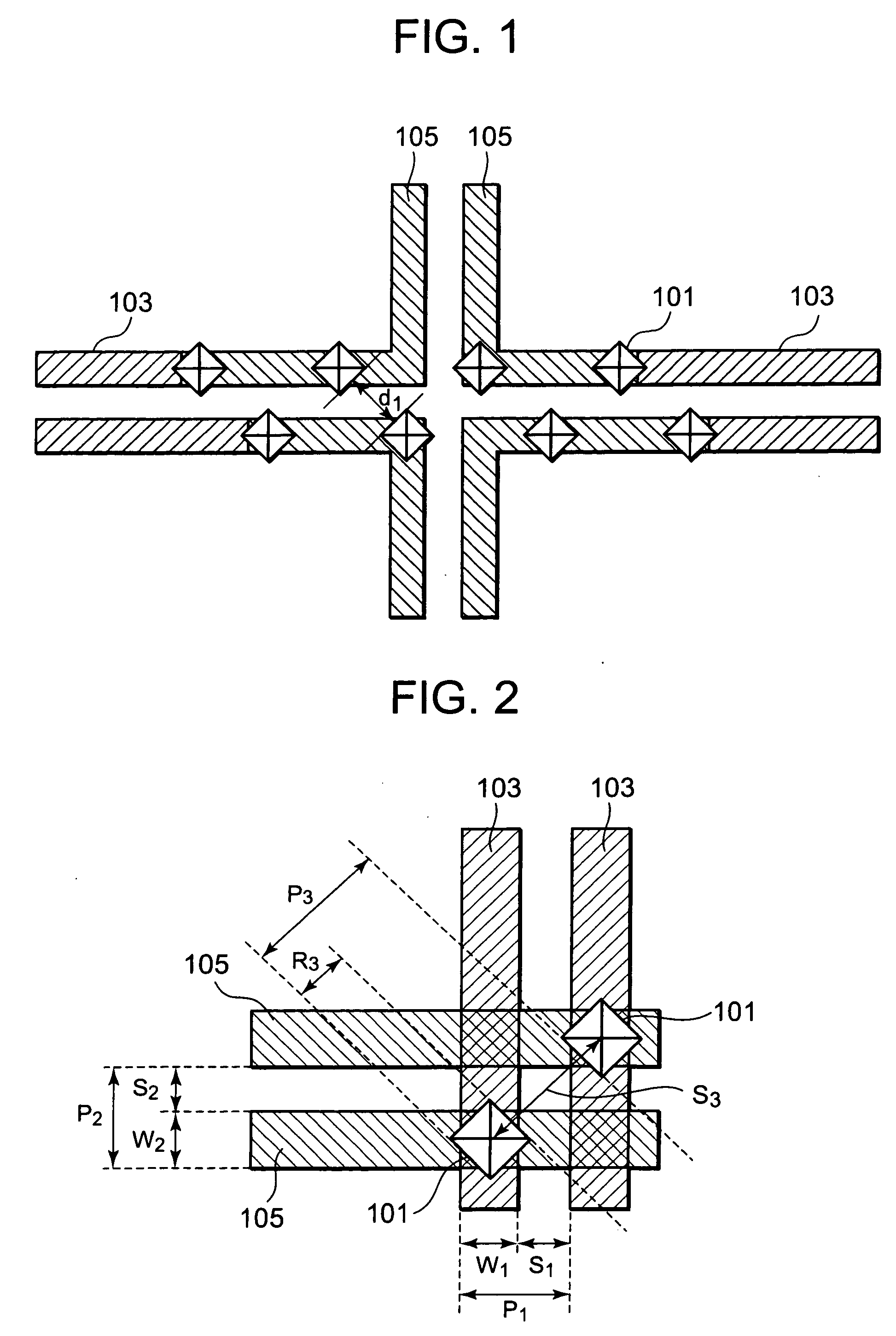

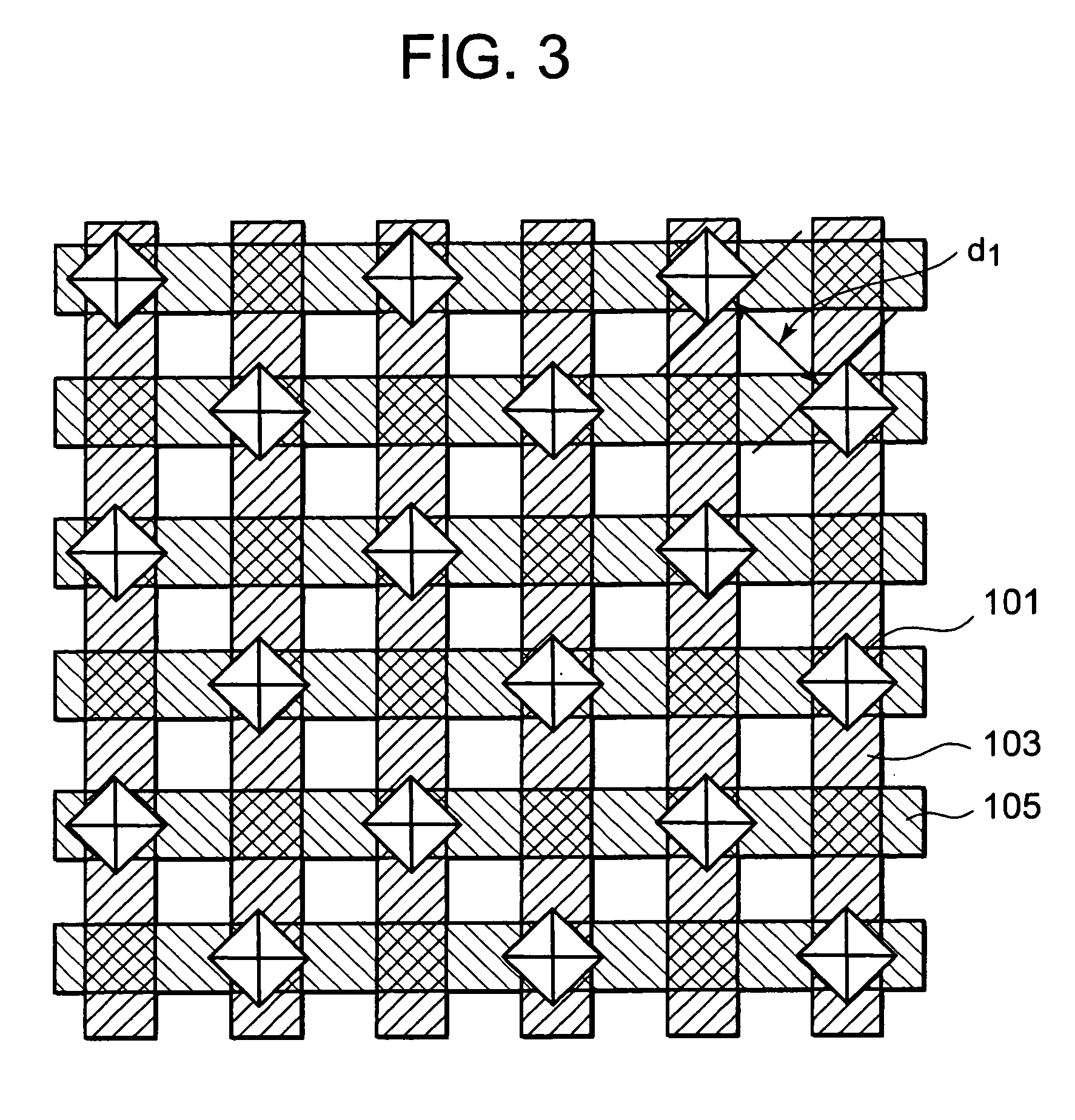

Reticle, and method of laying out wirings and vias

ActiveUS20090186284A1Large minimum distanceIncrease minimum distanceSemiconductor/solid-state device detailsSolid-state devicesDiagonalEngineering

Provided is a reticle used for forming a plurality of vias for connecting first wirings provided in a first wiring layer and second wirings provided in a second wiring layer formed above the first wiring layer. The first wirings and the second wirings are provided along one of a first direction and a second direction, and the first direction and the second direction perpendicularly cross each other. The reticle includes a plurality of via opening patterns for forming the plurality of vias. Each of the plurality of via opening patterns has a rectangular shape, and is arranged to cause each side of each of the via opening patterns to be diagonal with respect to the first direction and the second direction.

Owner:RENESAS ELECTRONICS CORP

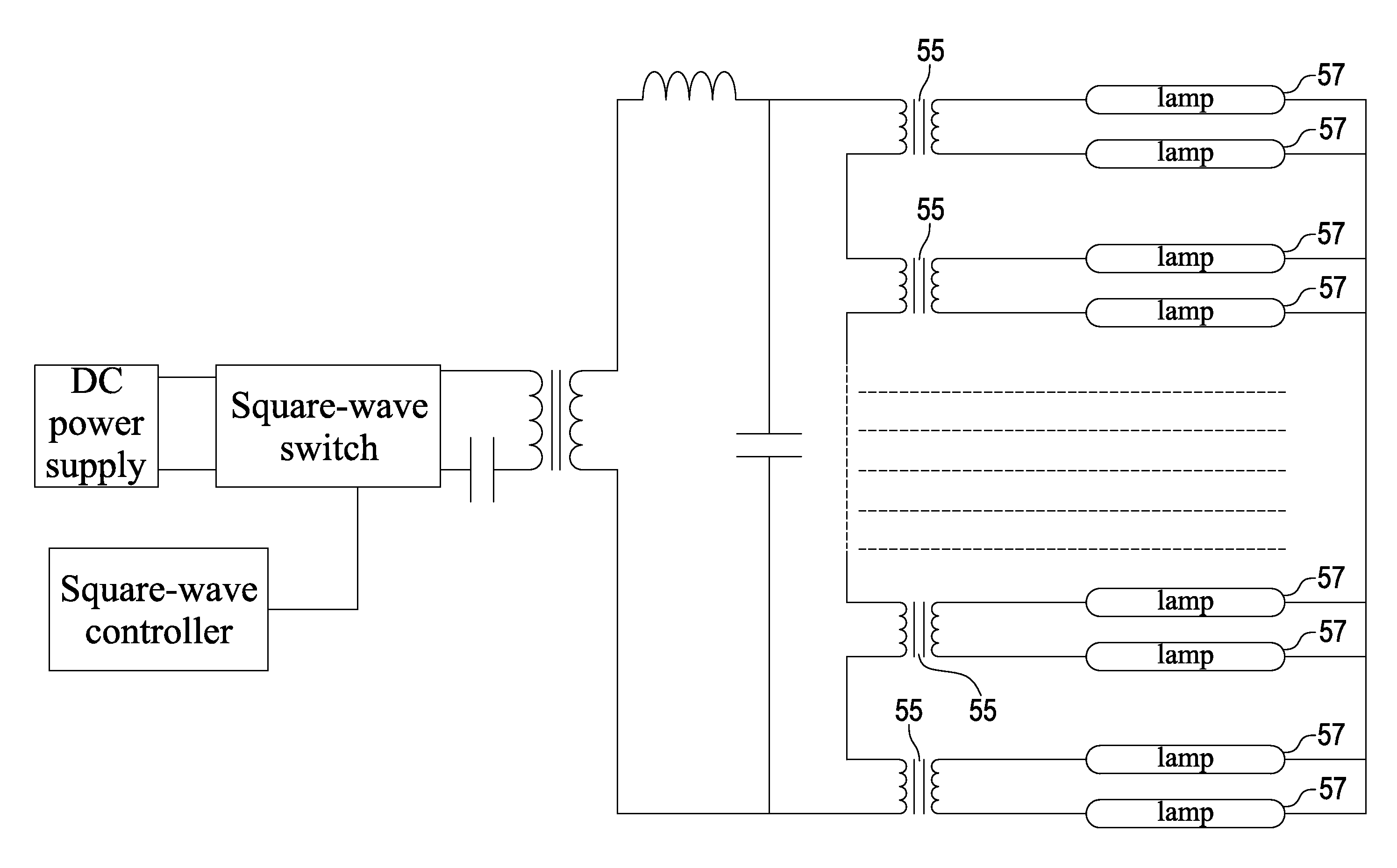

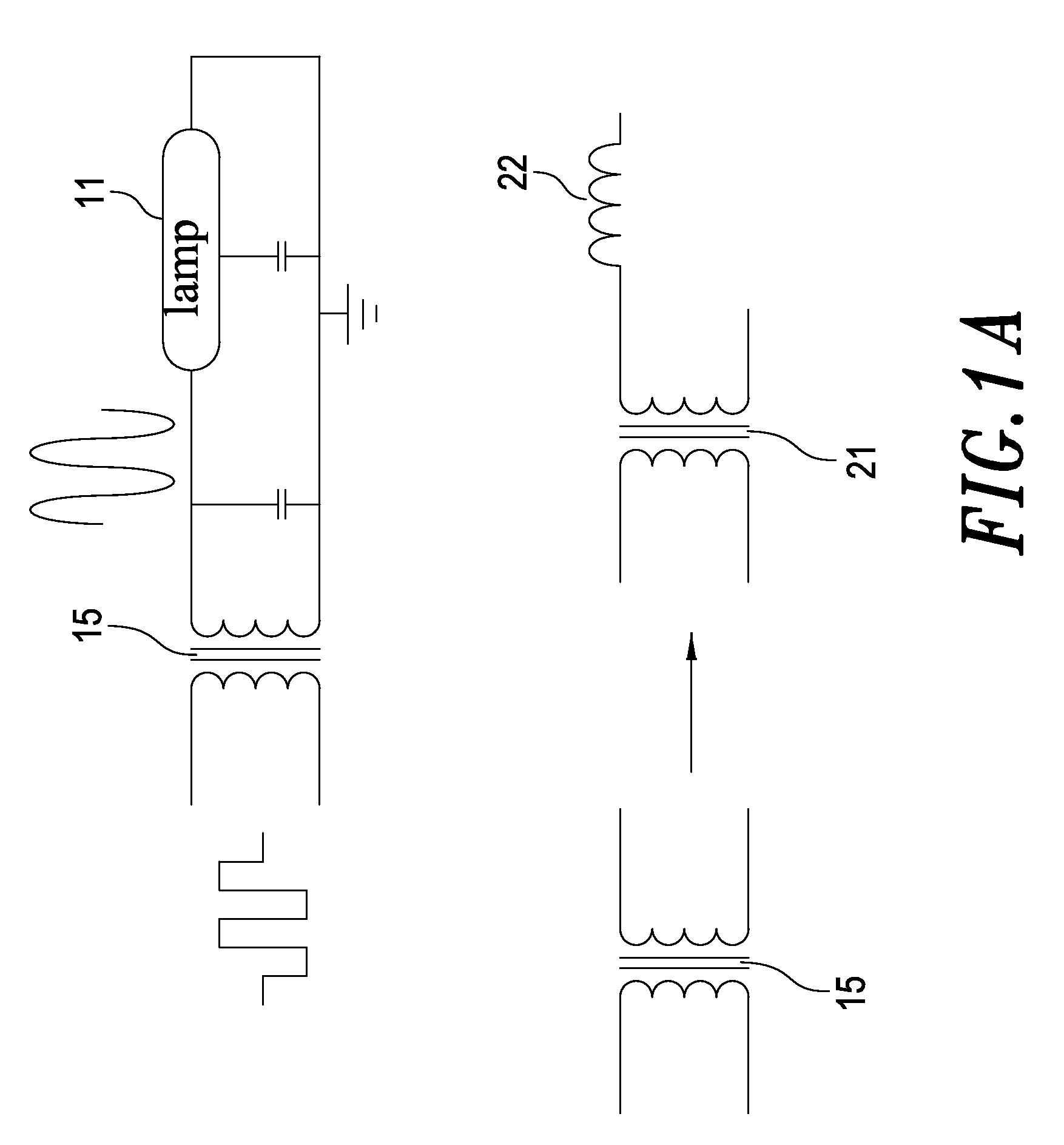

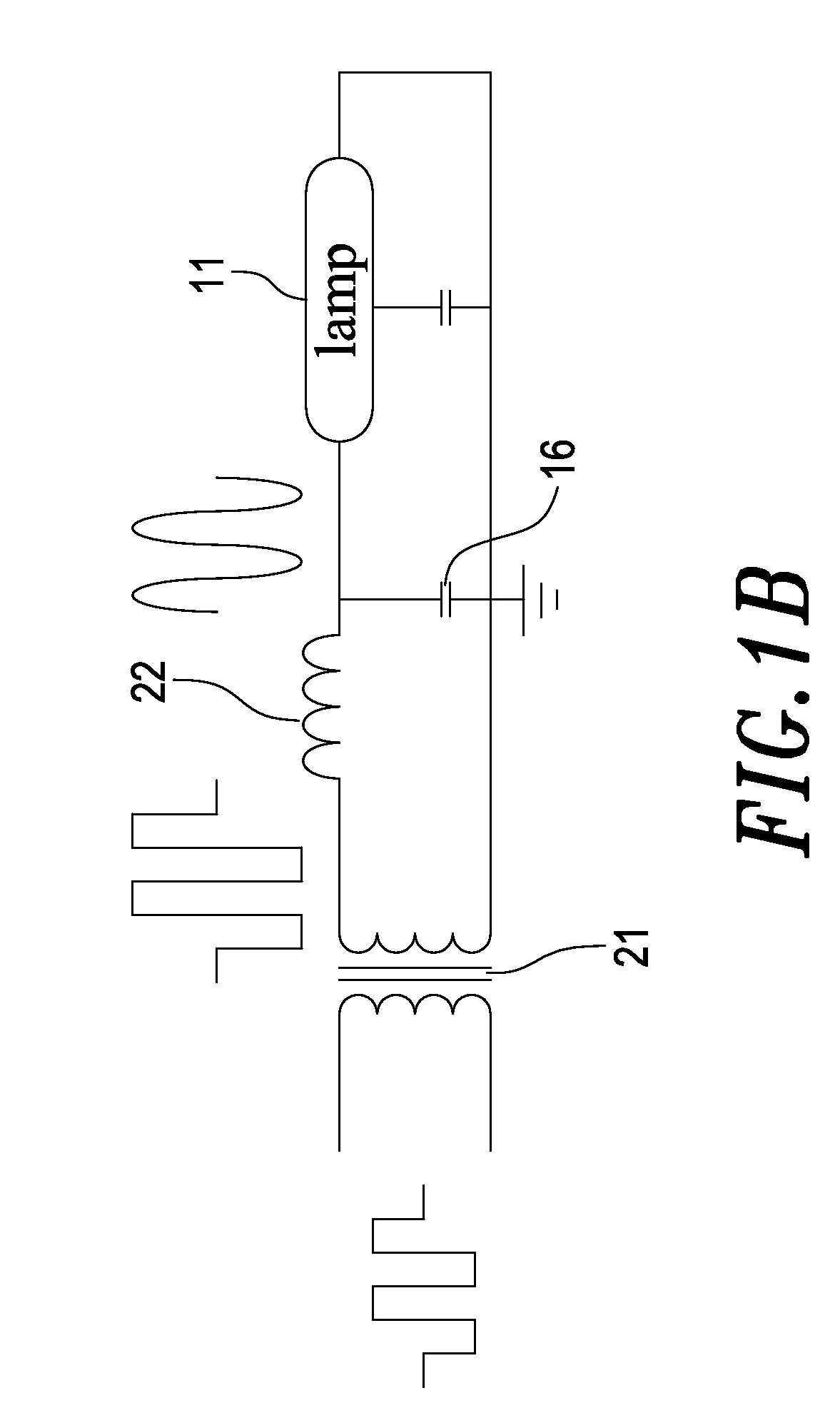

Coupled lamp driving device

InactiveUS20080265790A1Effective balanceUniform brightnessElectrical apparatusElectric light circuit arrangementAlternating currentAC power

A coupled lamp driving device is described, comprising an alternating current (AC) power supply providing a sine-wave to two ends of each of a plurality of coupled transformers each having a primary side connected to each other at a primary side thereof and a secondary side; the plurality of coupled transformers connected to each other at the primary side thereof directing the sine-wave signal from the AC power supply to the two sides of the primary side of each of the coupled transformers and connected to an end of one of a plurality of lamps at one end of the secondary side thereof and connected to a reference level at the other end thereof, and the plurality of lamps each having the other end connected to a reference level. Since the primary sides of the coupled transformers are connected in series, a current flown on the primary side of each of the coupled transformers is equal to each other, respectively. Further, since the numbers of coils of the primary and secondary sides, respectively, are equal to each other, currents flown on the secondary side of each of the coupled transformers are also the same. Therefore, the luminance of each of the plurality of lamps can be maintained uniformly.

Owner:LOGAH TECH CORP

Organic electroluminescent element

PendingUS20210053998A1Improve efficiencyImproved color characteristicSolid-state devicesSemiconductor/solid-state device manufacturingAnthraceneSimple Organic Compounds

The present disclosure relates to an organic electroluminescent element, and more particularly to an organic electroluminescent element including a novel boron-based organic compound and anthracene-based organic compound in one or more organic layers included in the organic electroluminescent element. The present disclosure may provide an organic electroluminescent element, which is prevented from deterioration in color characteristics and has characteristics such as long lifetimes, as a result of using a host material having a specific structural formula despite having high polarity.

Owner:MATERIAL SCIENCES CORPORATION

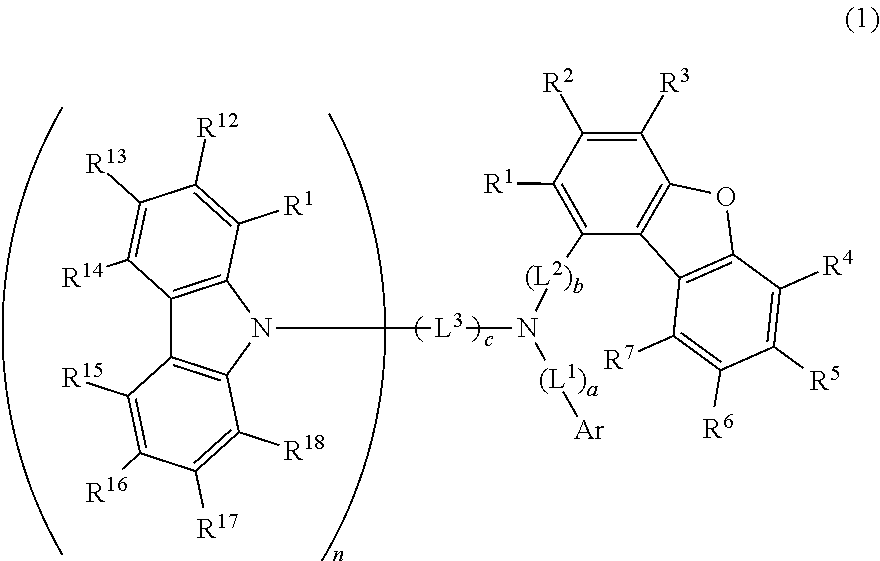

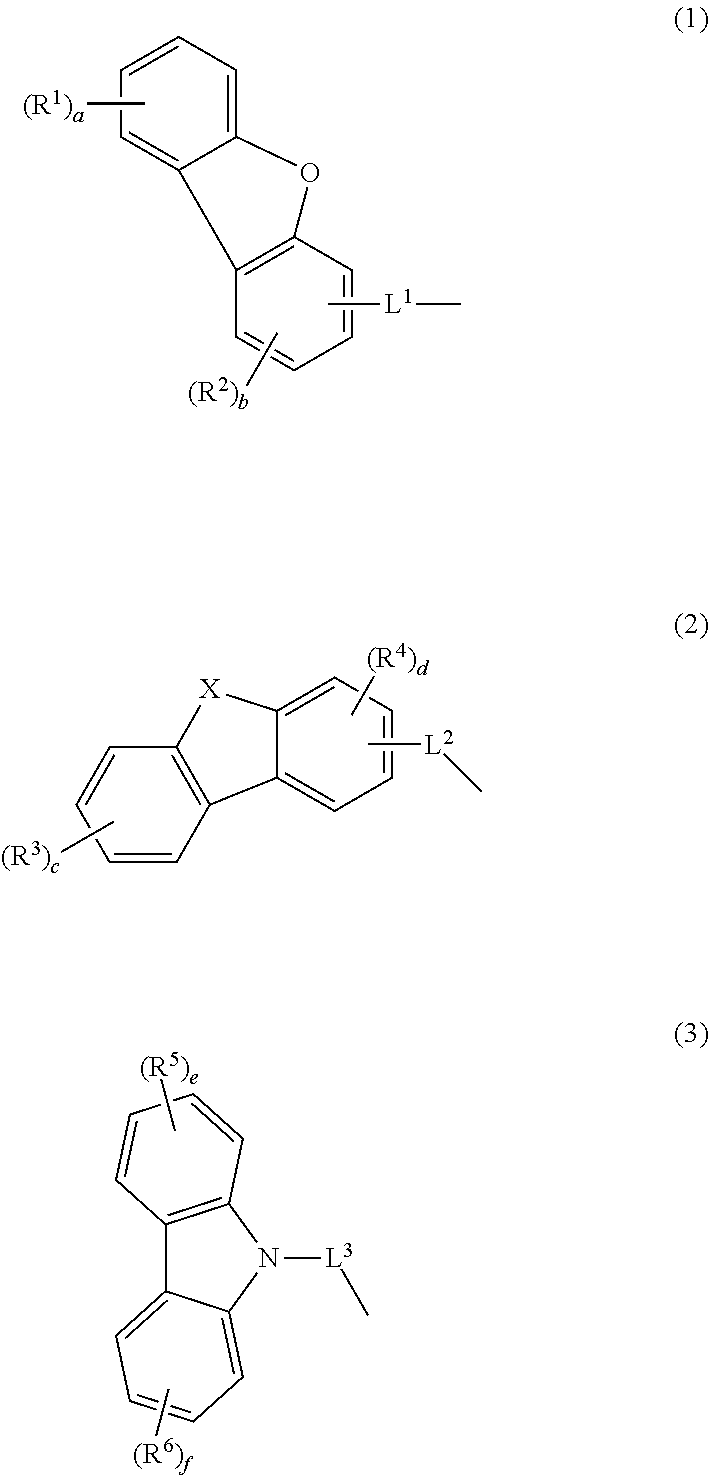

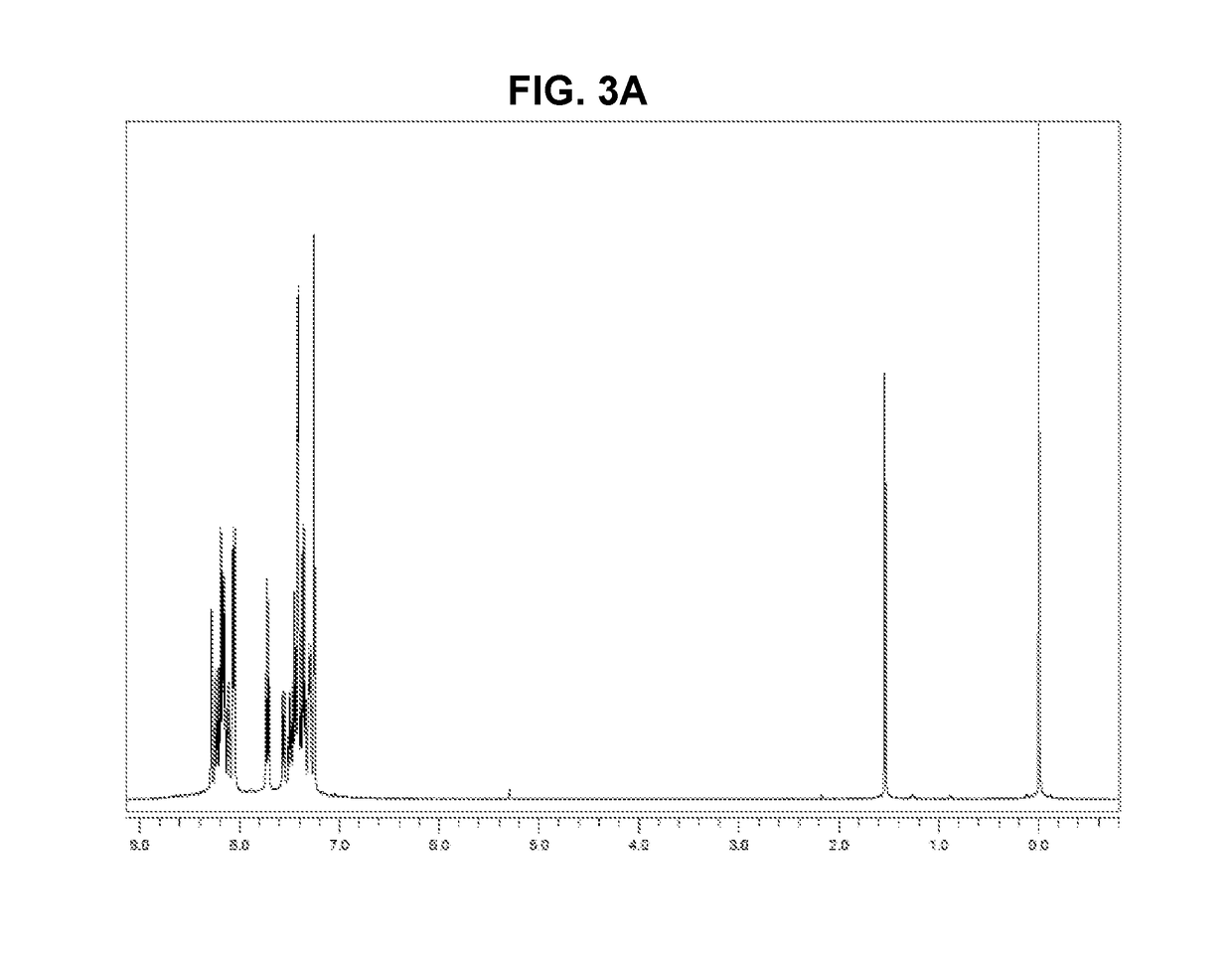

Compound, material for organic electroluminescent element, organic electroluminescent element, and electronic device

ActiveUS20200392122A1Improve efficiencyImproved lifetimeOrganic chemistrySolid-state devicesPhysical chemistryOrganic electroluminescence

A compound represented by formula (1):wherein R1 to R7, R11 to R18, L1 to L3, a to c, n, and Ar are as defined in the description,provides an organic electroluminescence device having an emission efficiency and a device lifetime further improved.

Owner:IDEMITSU KOSAN CO LTD

Organic compound, organic light emitting diode and organic light emitting display device

ActiveUS20180151811A1High triplet energy and stabilityHigh energyOrganic chemistrySolid-state devicesPhysicsOrganic compound

The present invention provides an organic compound of following formula and an organic light emitting diode and an OLED device including the organic compound.

Owner:LG DISPLAY CO LTD +1

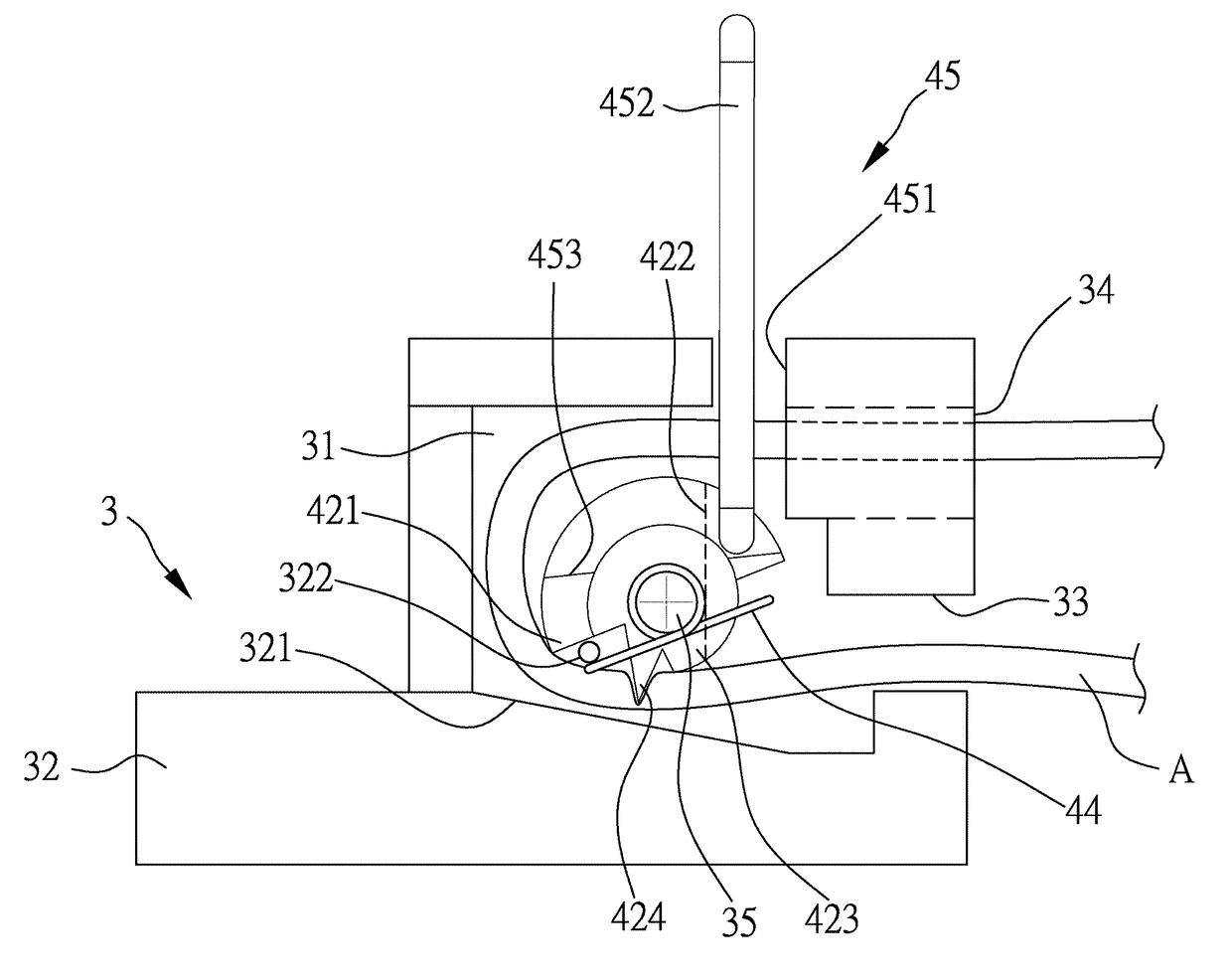

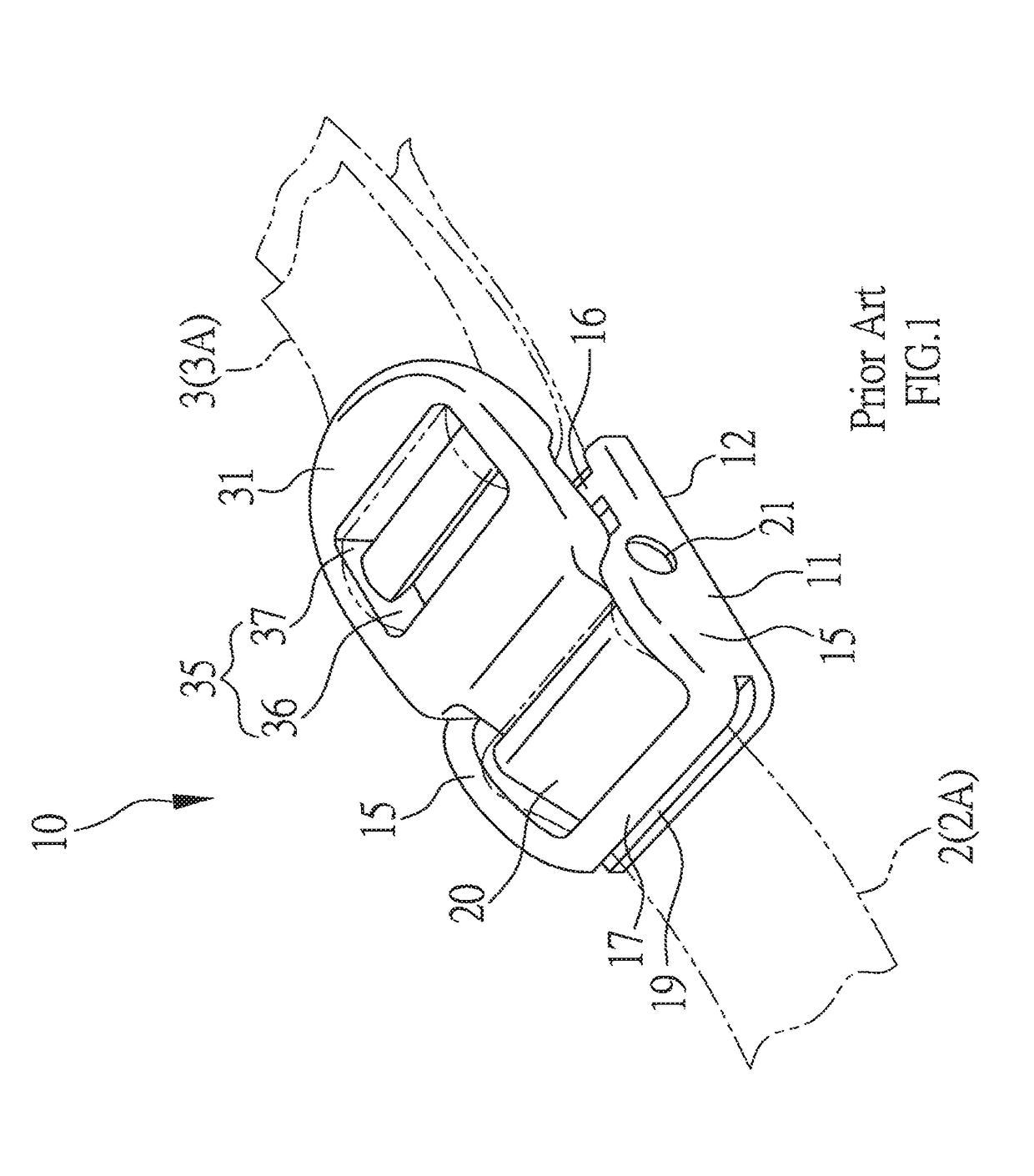

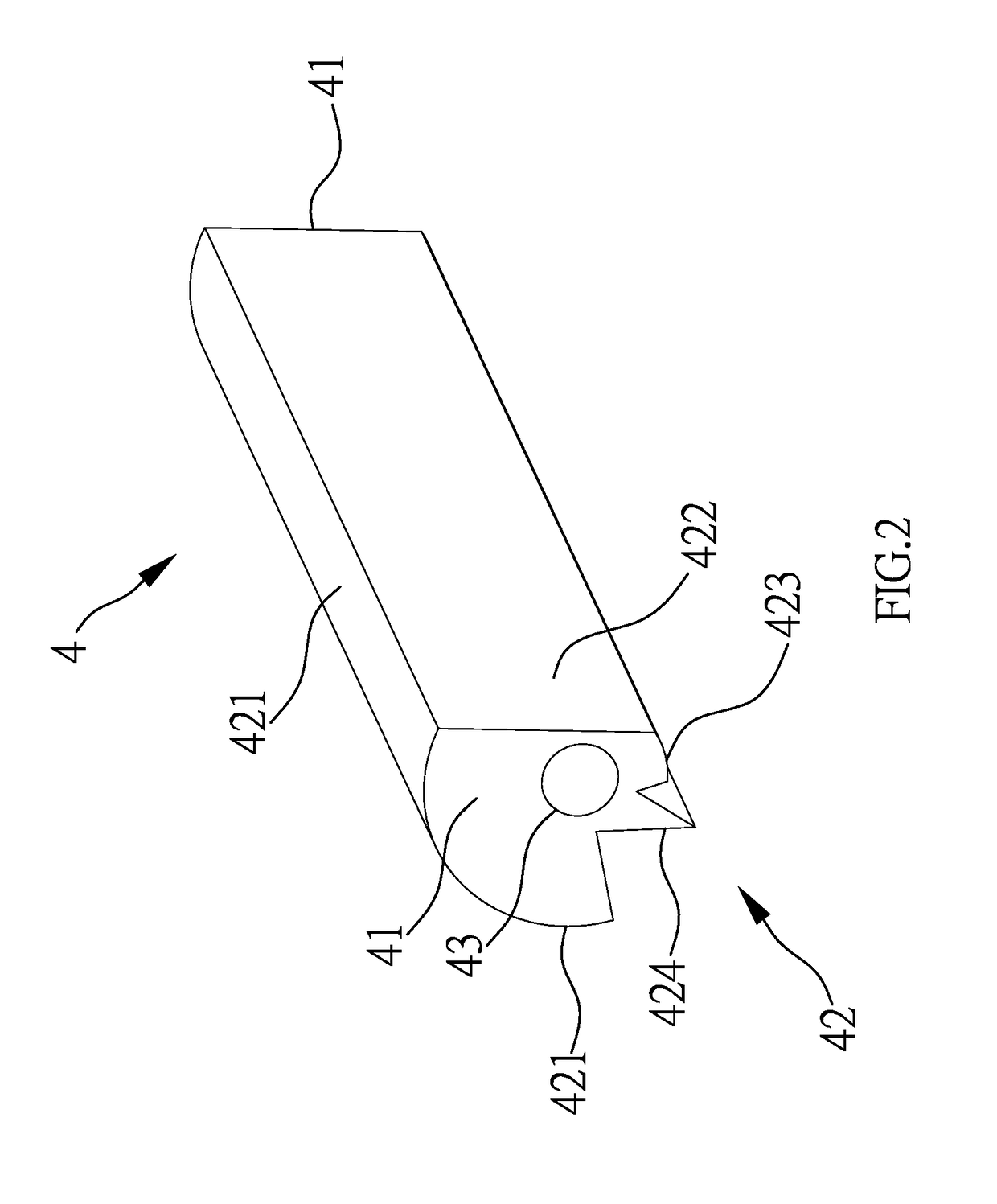

Buckle

Owner:TSAI YUN CHAN

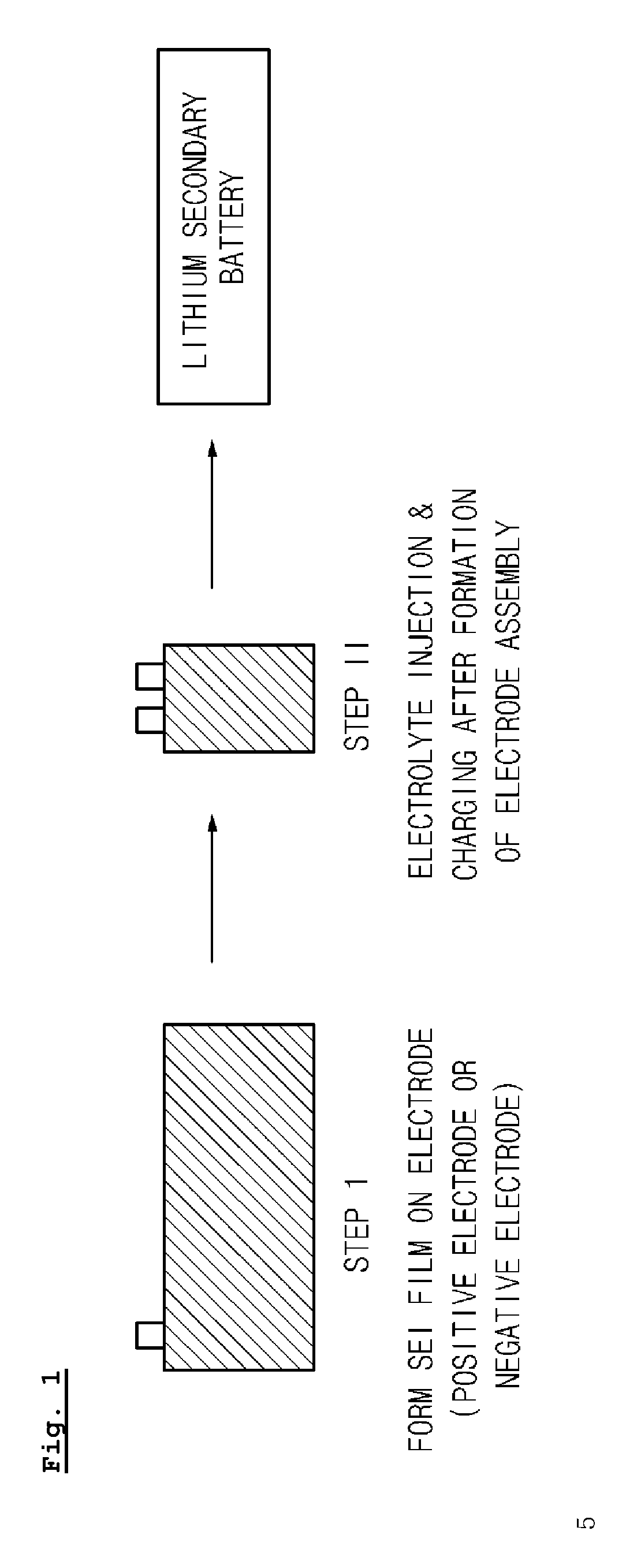

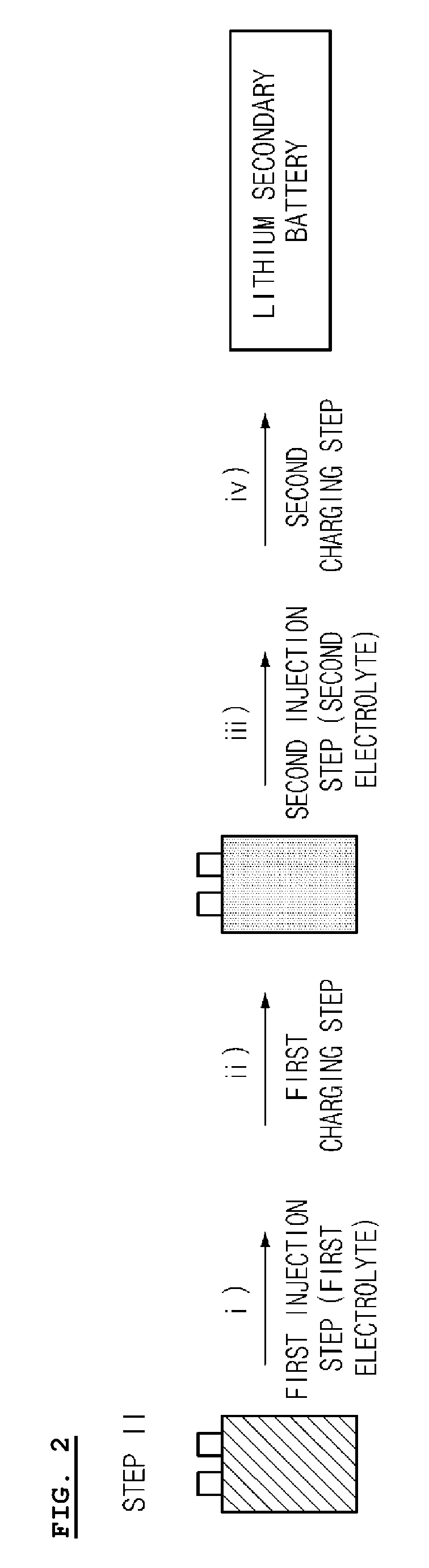

Manufacturing method of lithium secondary battery

ActiveUS10263293B2Excellent characteristicsImproved lifetimeElectrode rolling/calenderingFinal product manufactureEngineeringLithium-ion battery

Provided is a method of preparing a lithium secondary battery which may simultaneously improve output characteristics and lifetime characteristics of the lithium secondary battery by preparing an electrode on which an SEI film is formed through a pretreatment process, putting an electrode assembly including the electrode in a battery case, and injecting an electrolyte thereinto.

Owner:LG ENERGY SOLUTION LTD

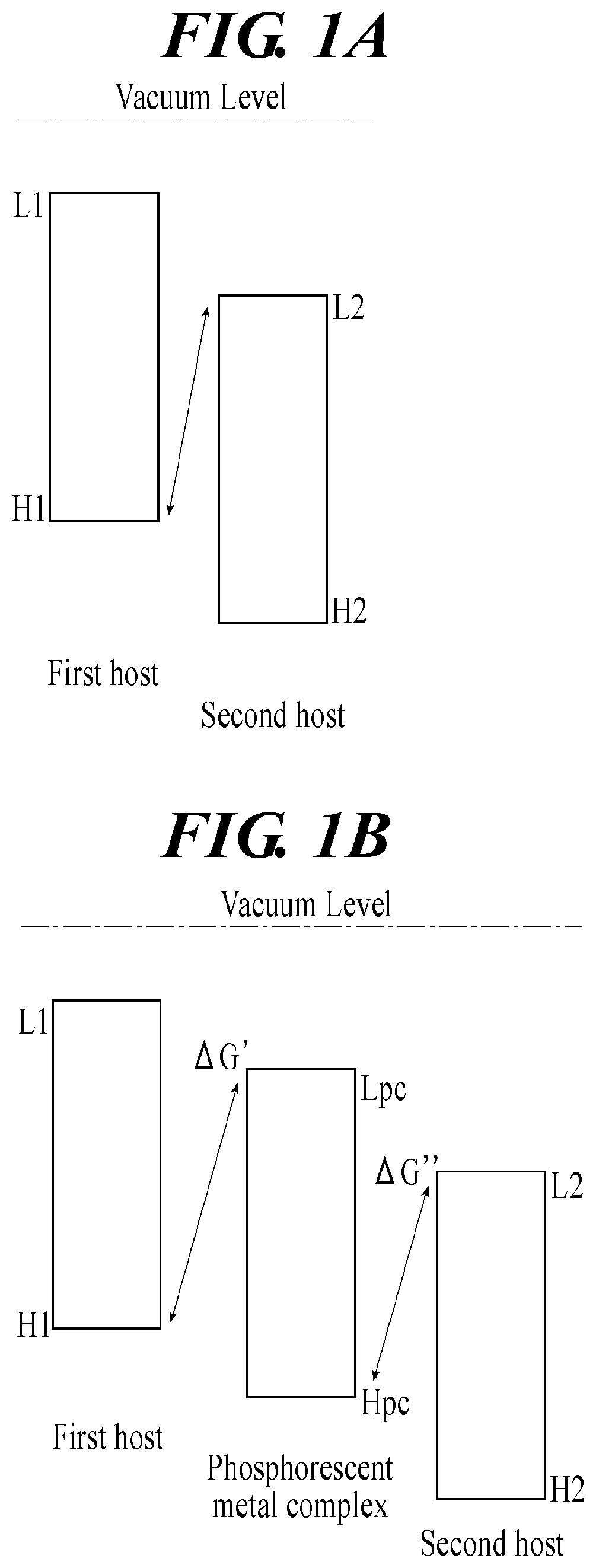

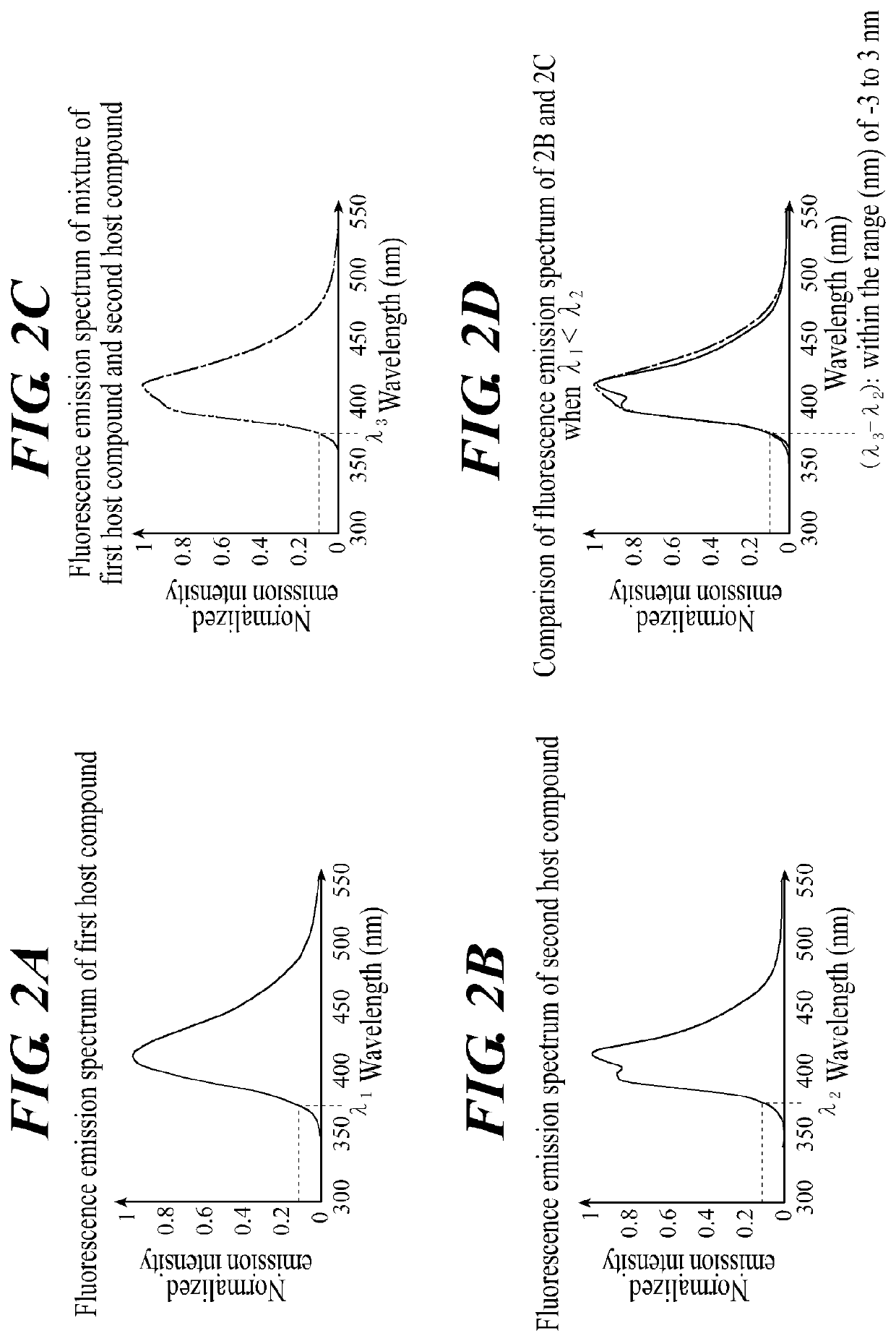

Organic electroluminescence element

InactiveUS20200006687A1Improved element lifetimeImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceMaterials science

An organic electroluminescent element including a light emitting layer containing a first host compound, a second host compound, and a phosphorescent metal complex disposed between a cathode and an anode, wherein the first and the second host compounds satisfy the requirements that: in comparison of emission bands of maximum emission intensity in fluorescence emission spectra of single films of the first host compound alone, the second host compound alone, and a mixture of the first and the second host compounds, a difference between a wavelength of a fluorescence emission end located on a longer wavelength side among fluorescence emission ends of the first host compound and the second host compound, and a wavelength of a fluorescence emission end of the mixture is −3 to 3 nm; and a LUMO energy level and a HOMO energy level of the first host compound and the second host compound satisfy specific relationships.

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com