Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5752results about "Flanged joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

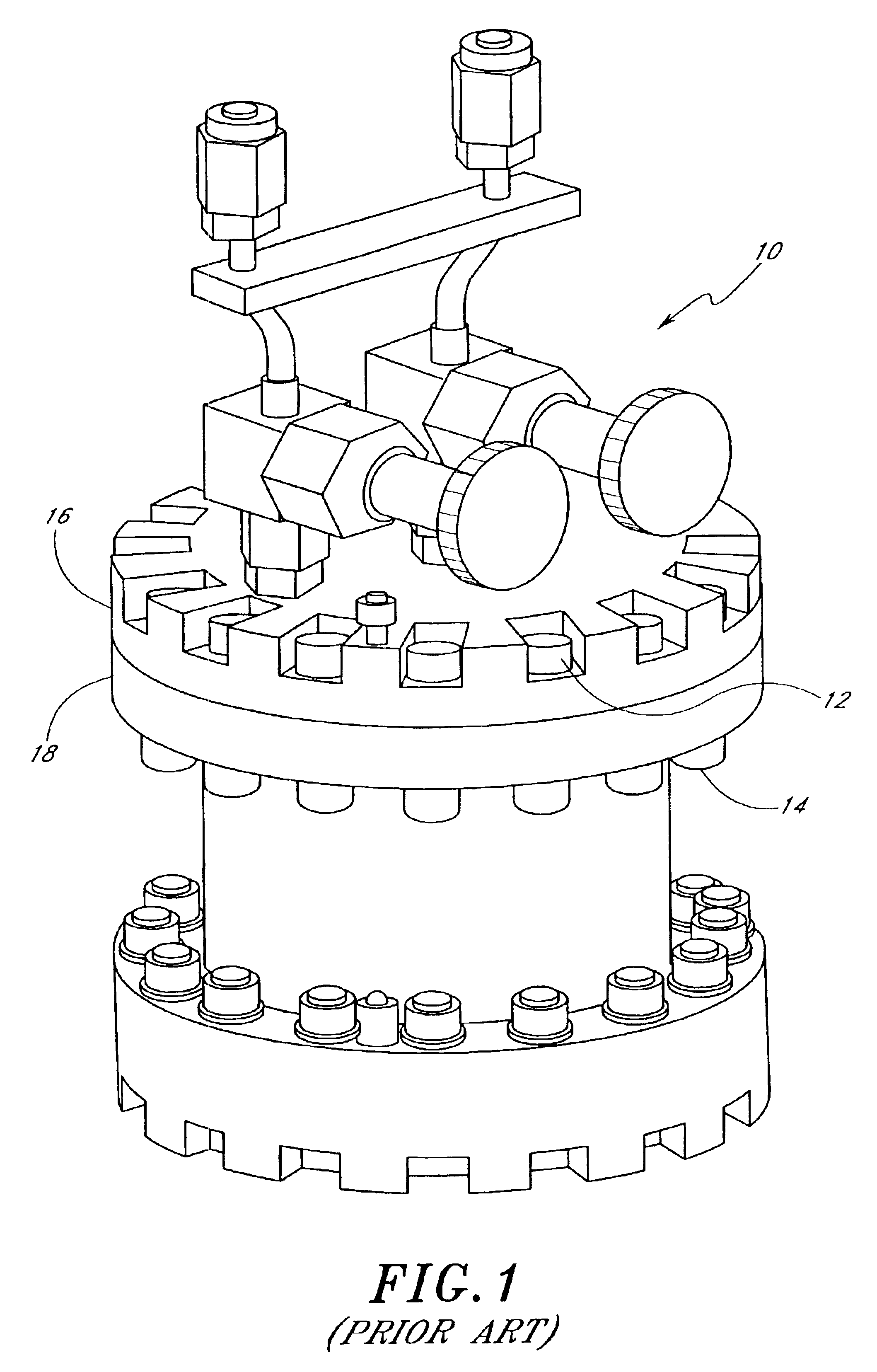

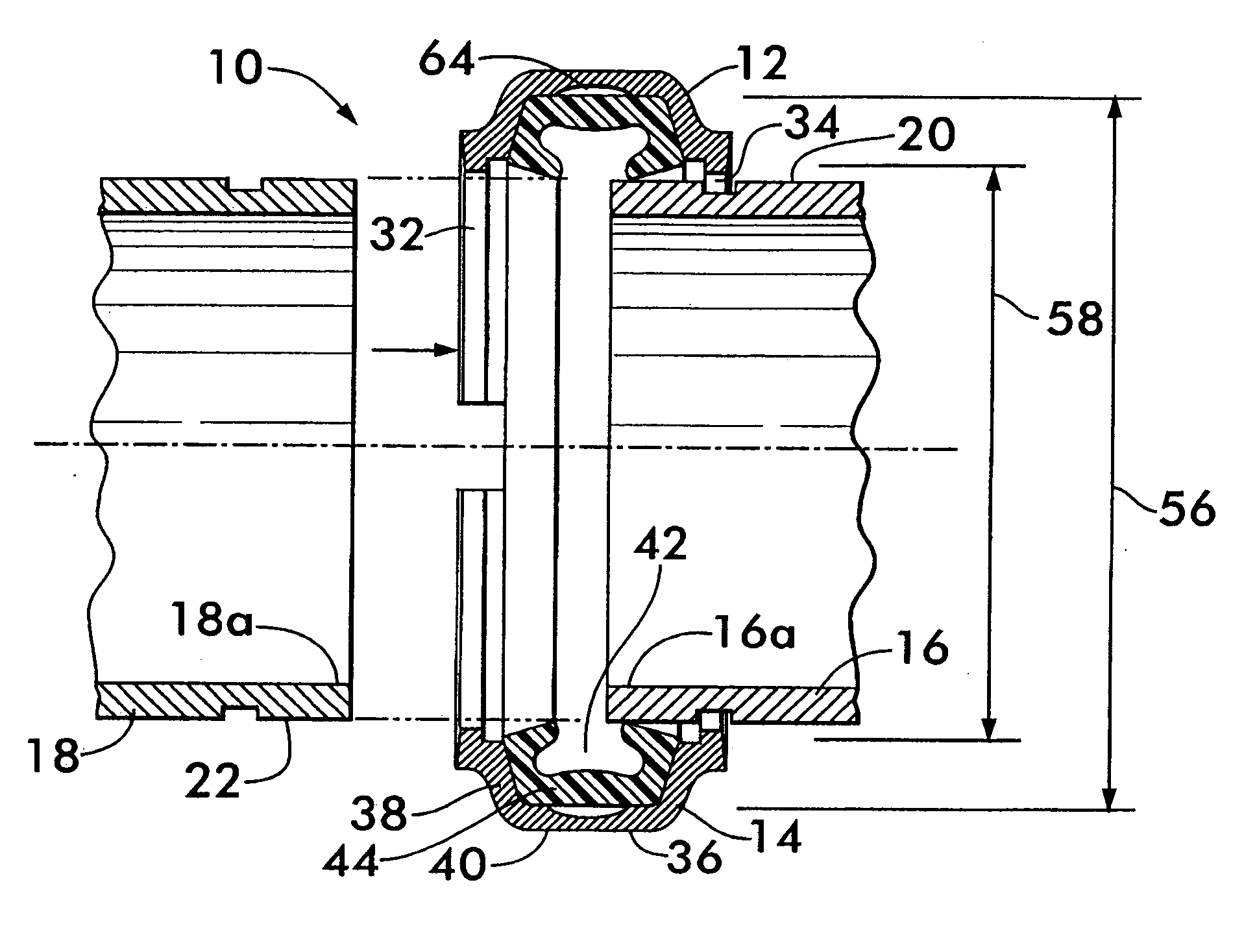

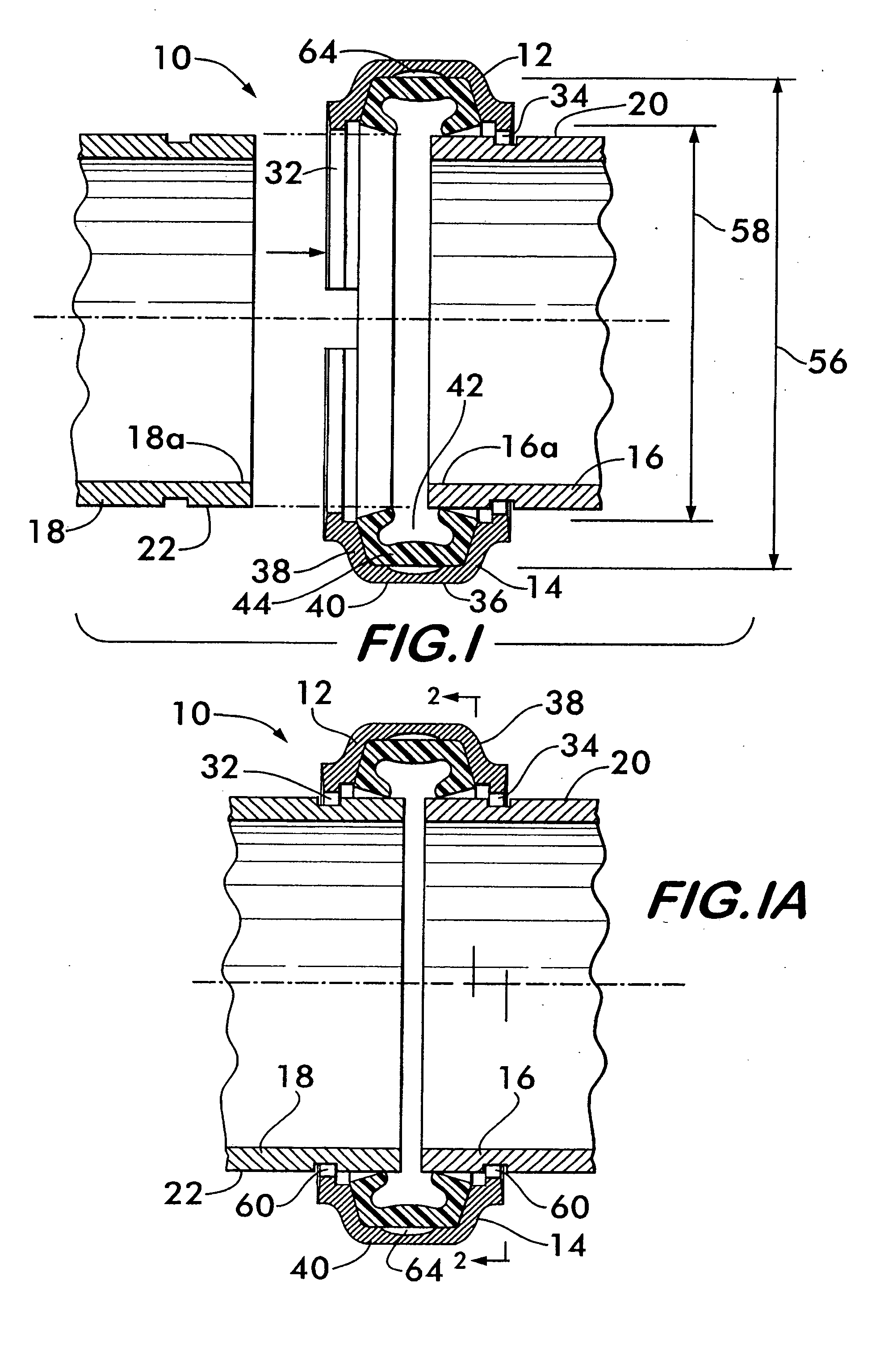

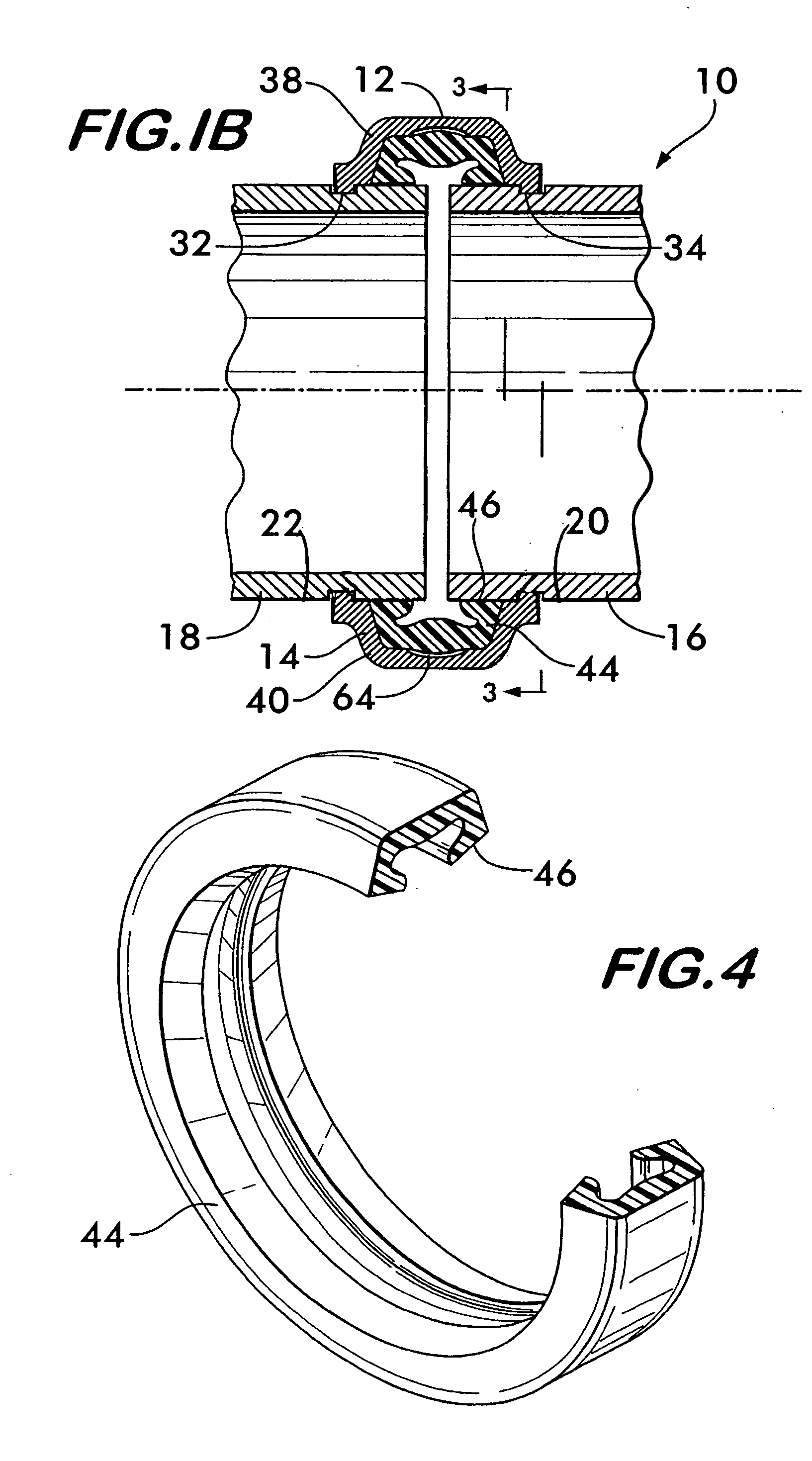

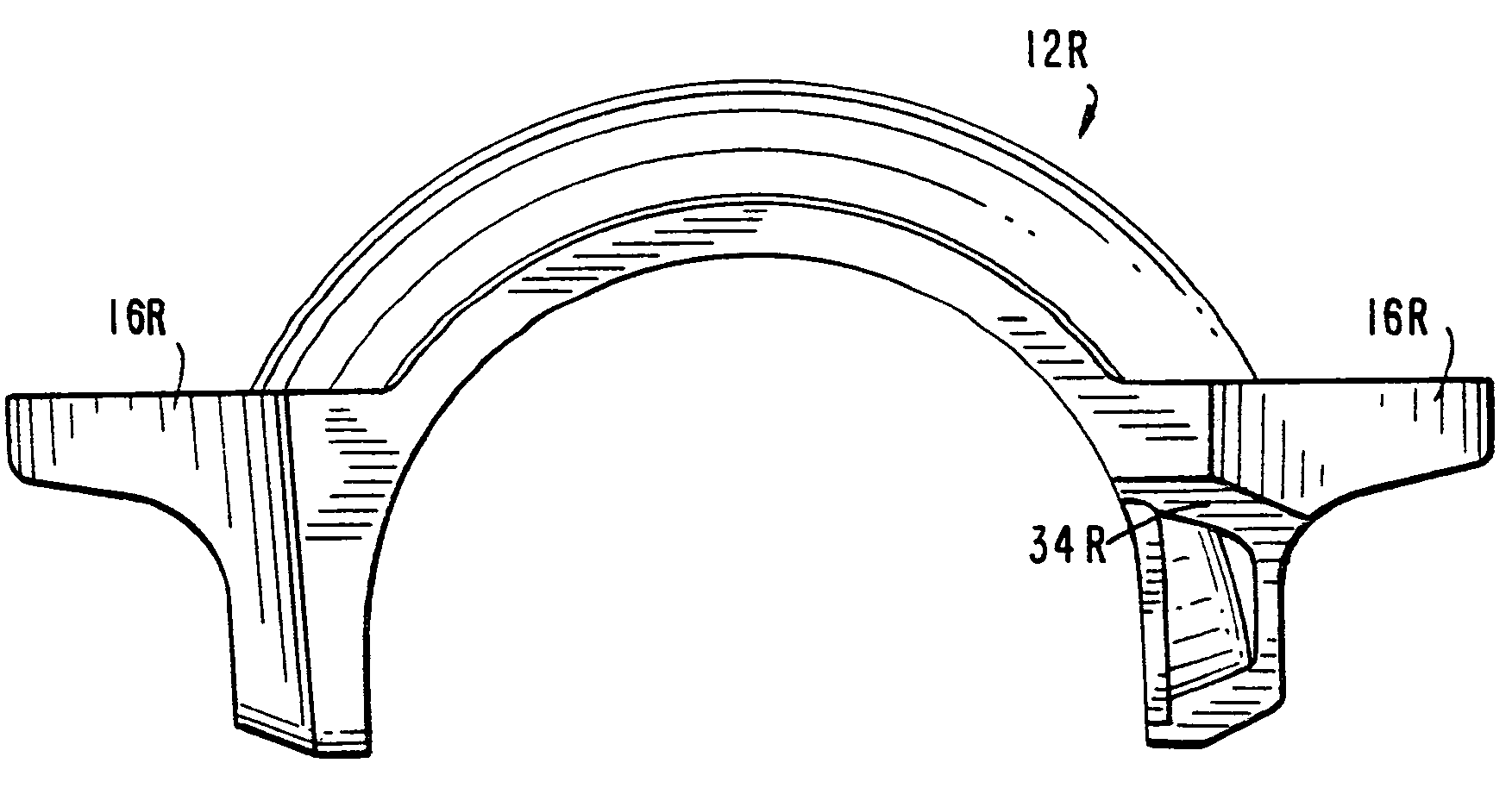

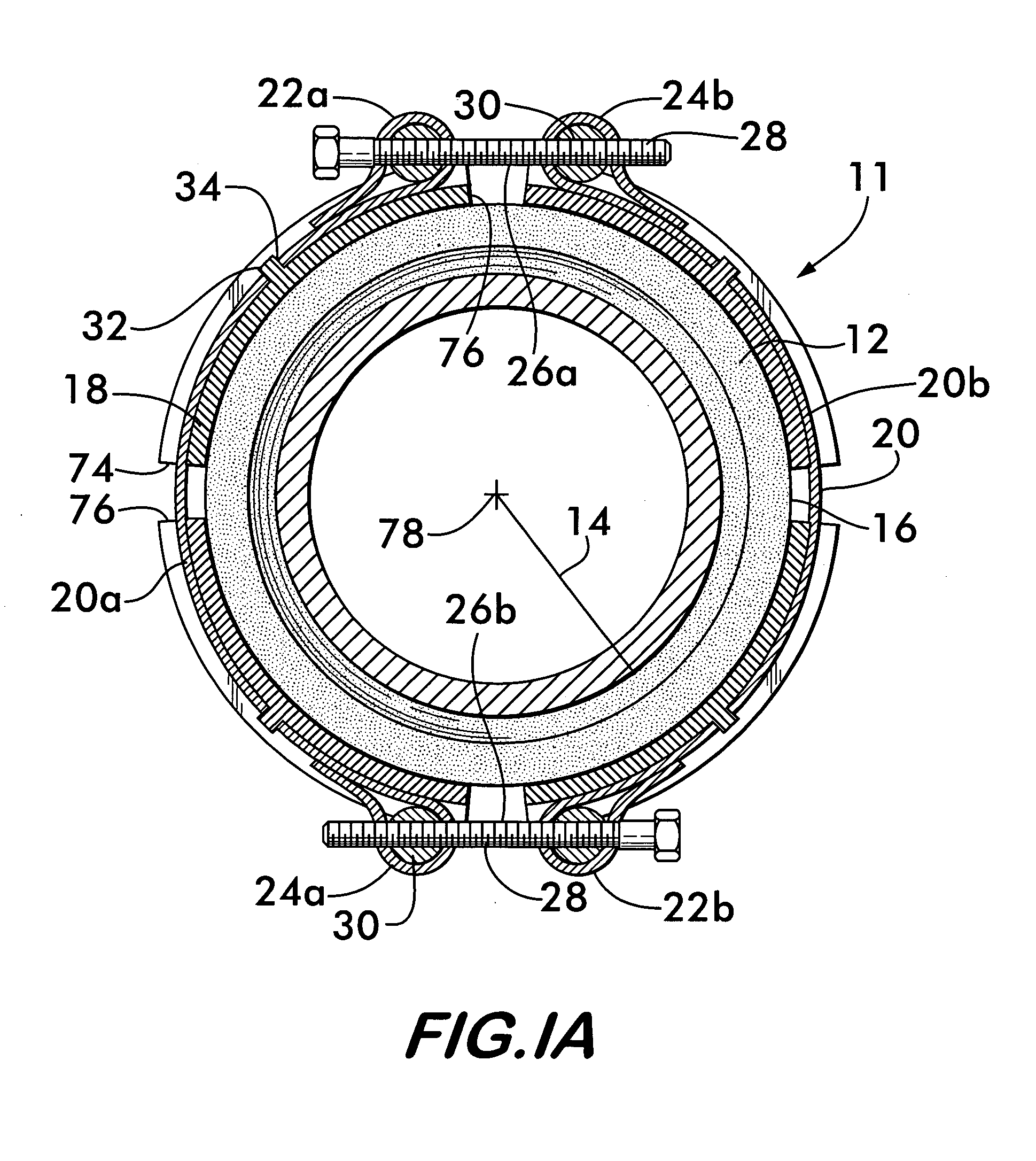

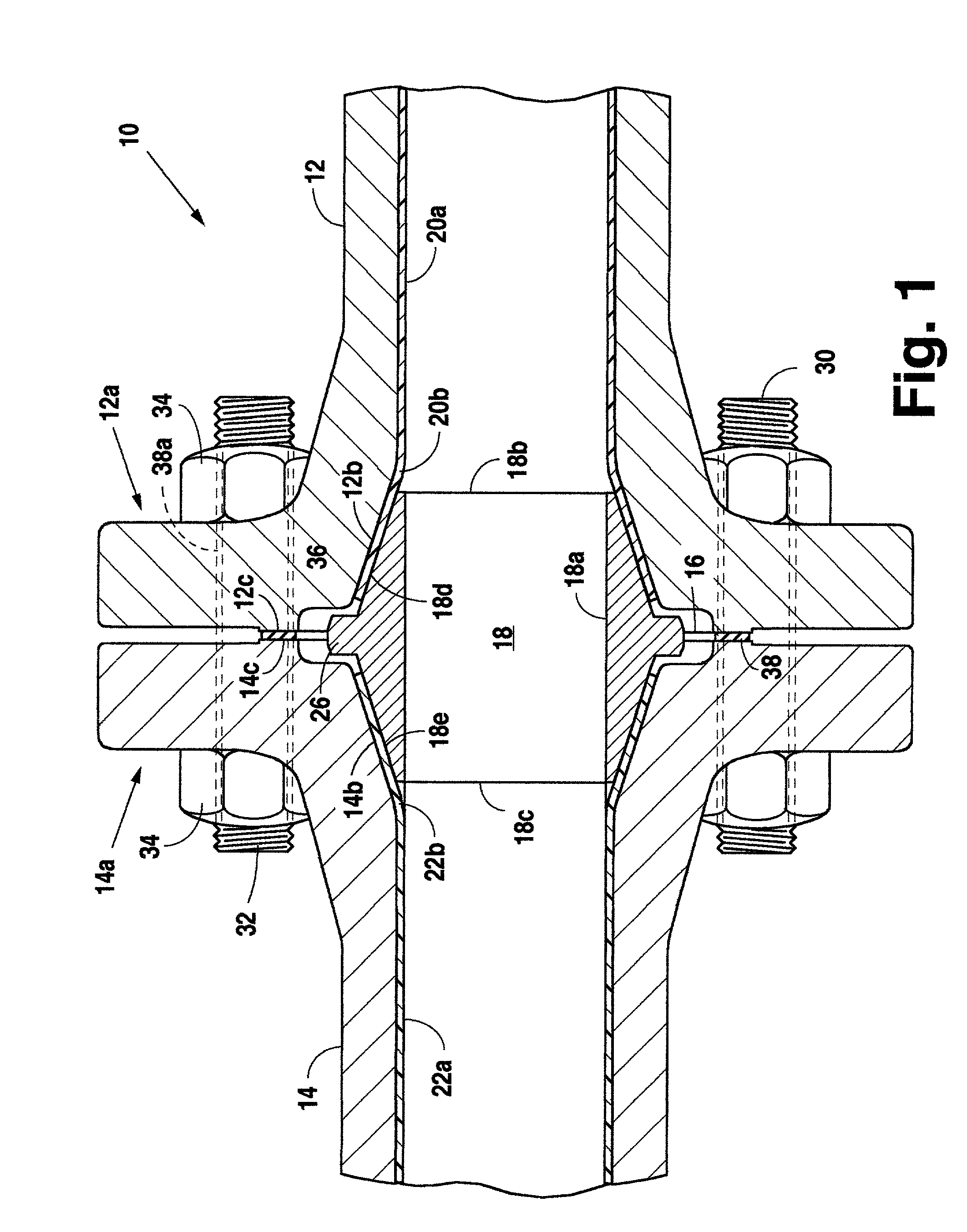

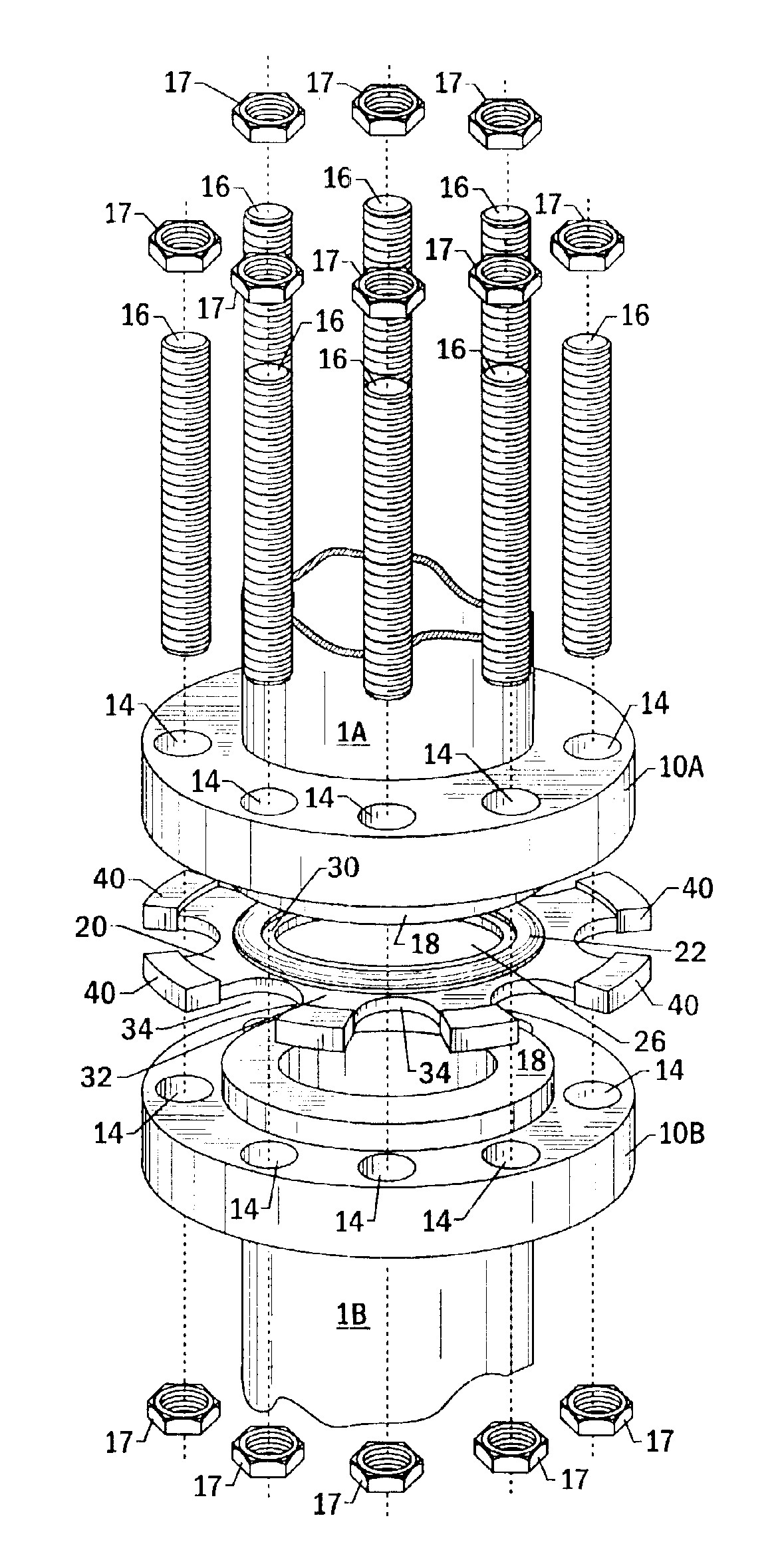

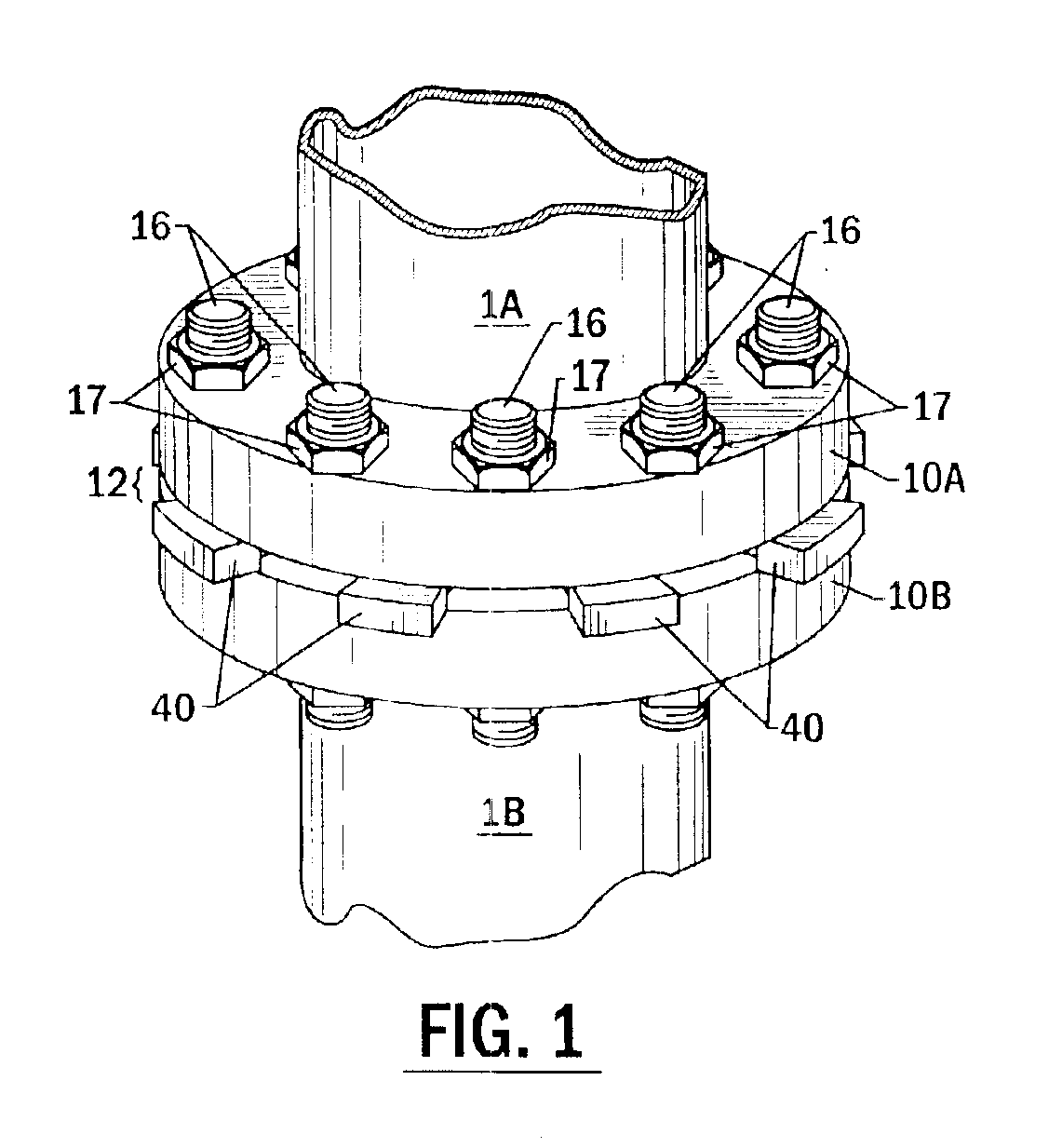

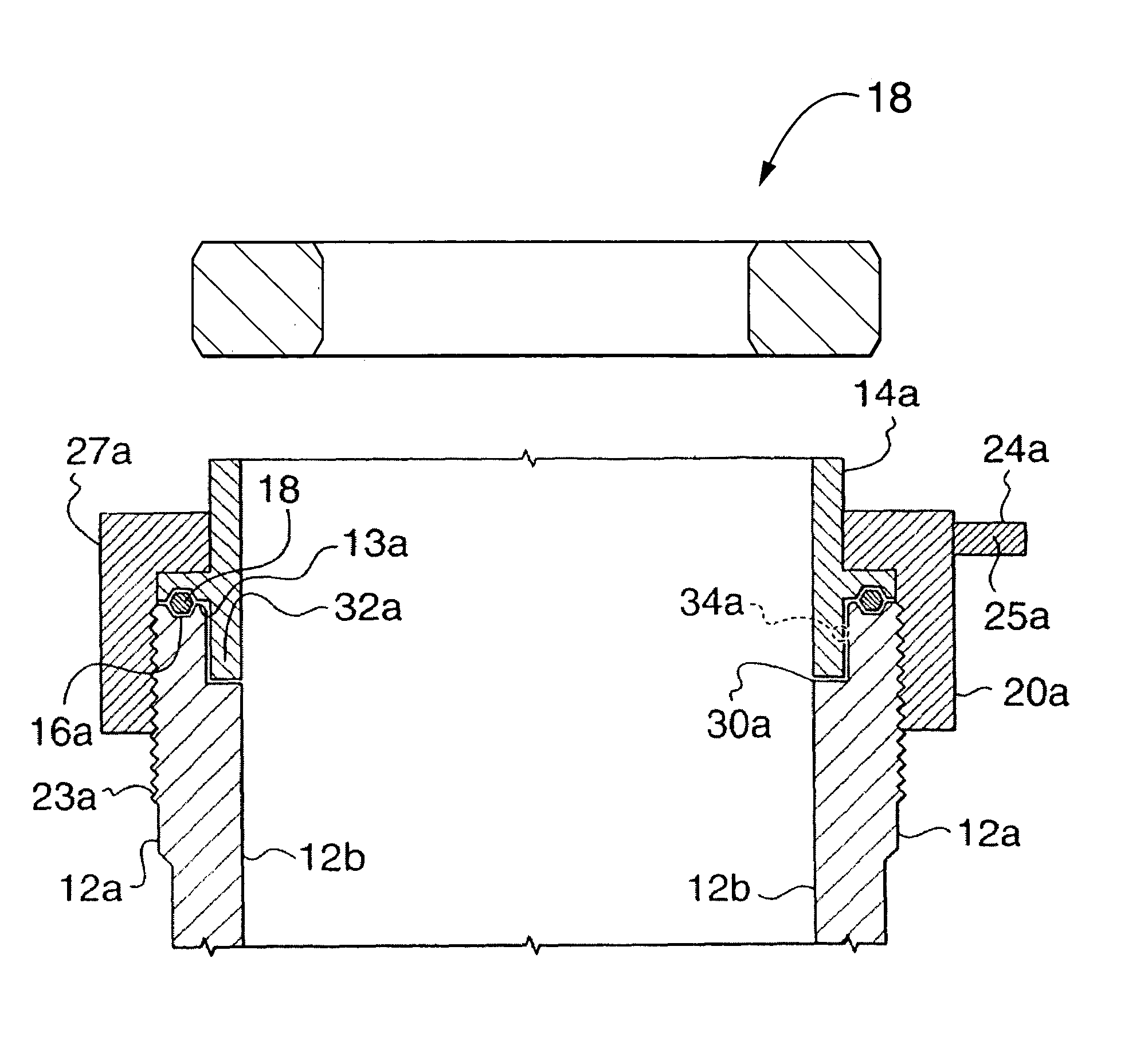

Source chemical container assembly

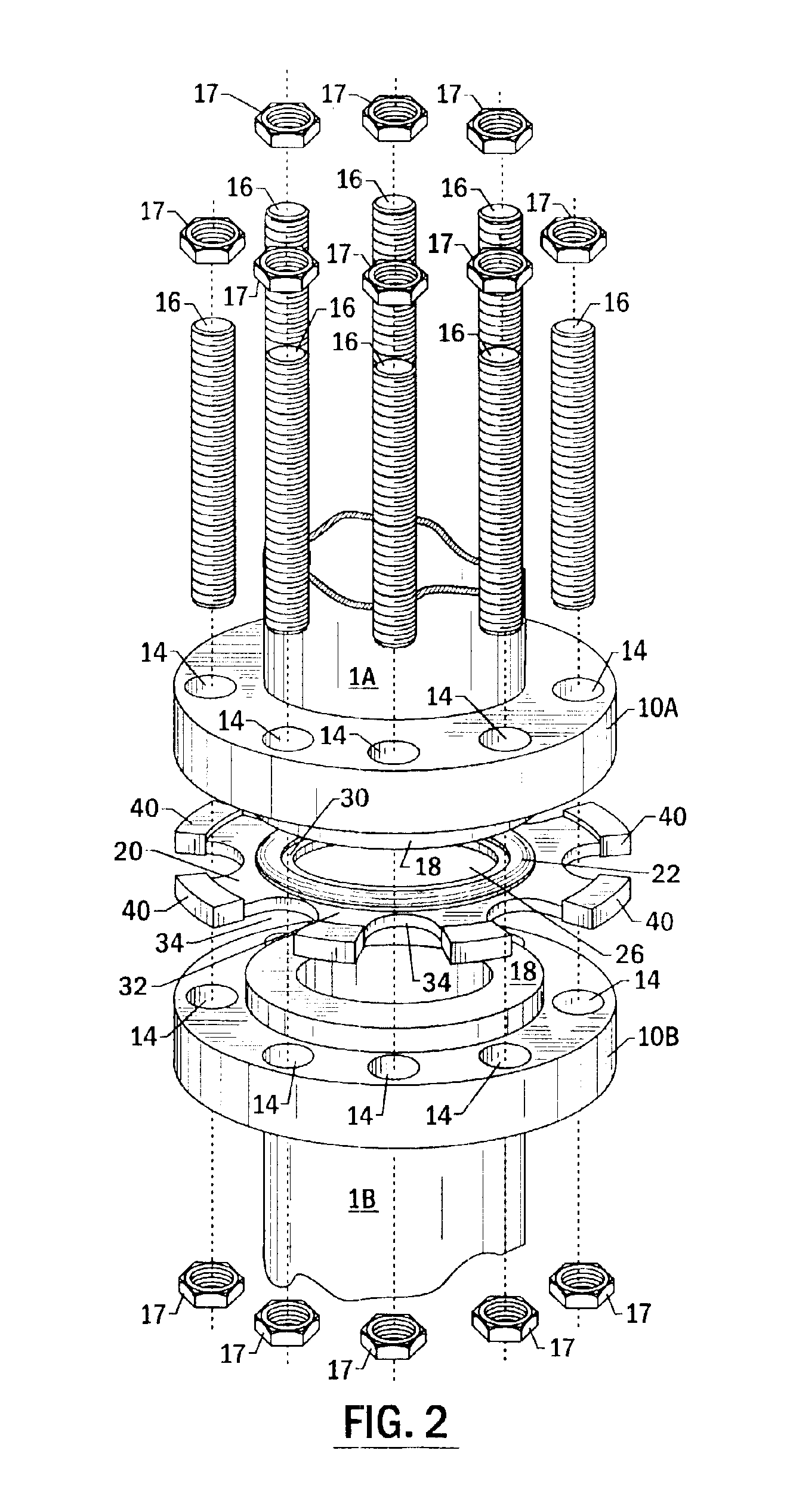

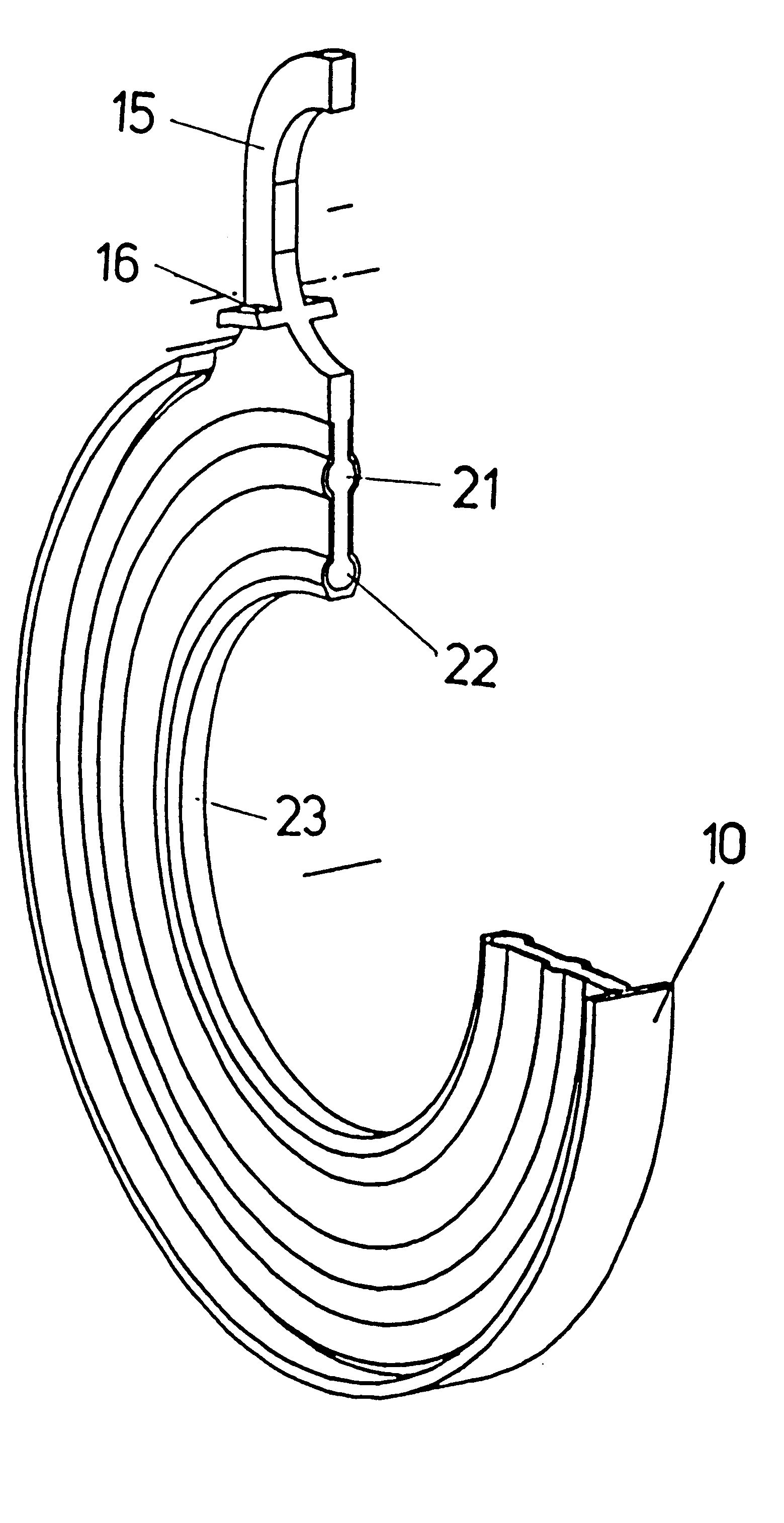

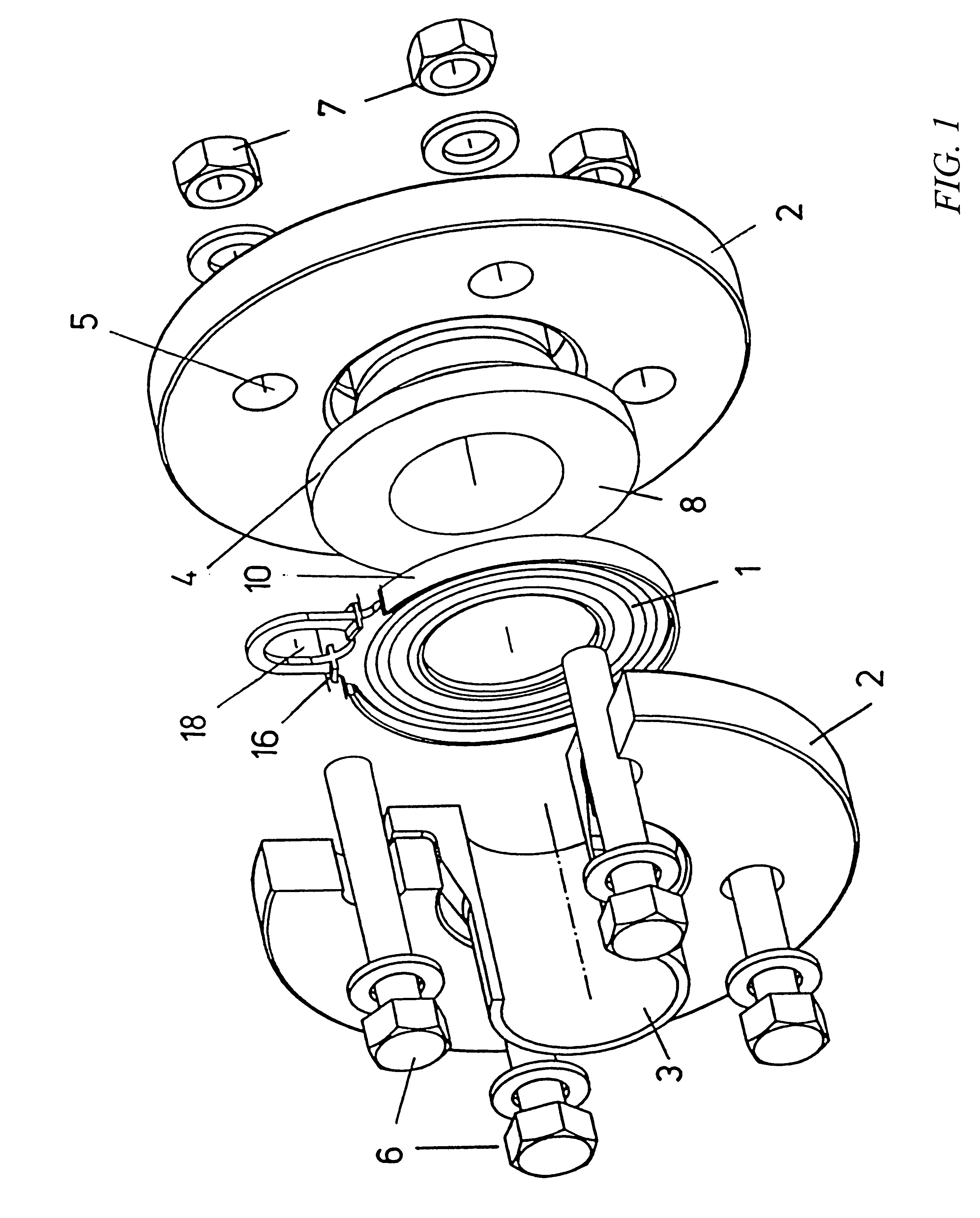

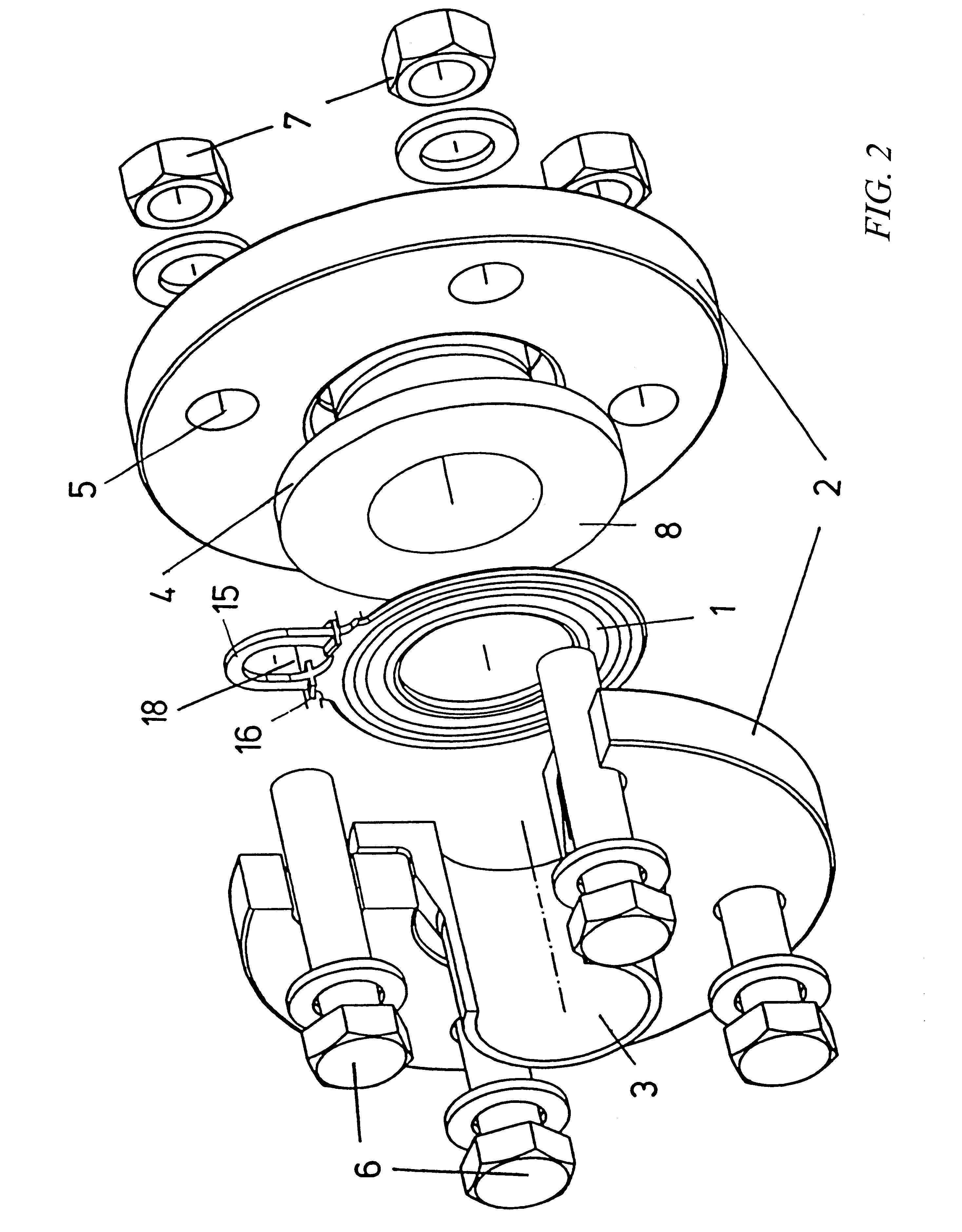

InactiveUS6889864B2Improve sealingHigh compression forceSleeve/socket jointsFlanged jointsVacuum chamberMechanical engineering

The invention relates to a source chemical container assembly, comprising a metal container functioning as a vacuum chamber and provided with a removable closure, which removable closure seals against the metal container with a metal seal. In order to facilitate easy recharging of the container assembly, compressive force is applied to the metal seal through a tension chain. In a preferred embodiment of the invention the metal seal and the tension chain are provided along a circumference of said metal container. The assembly can comprise an inner container in which the source chemical is contained.

Owner:ASM INTERNATIONAL

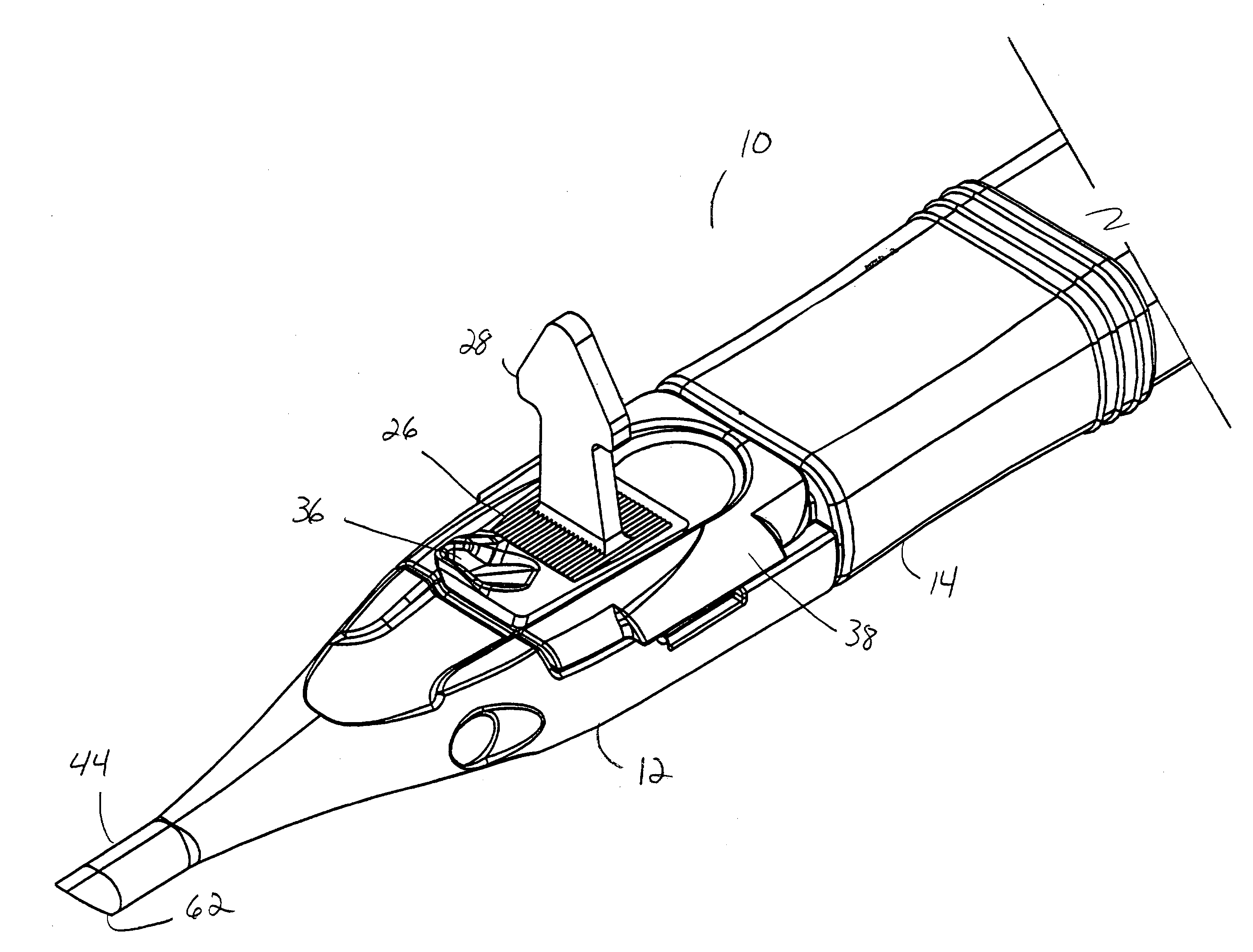

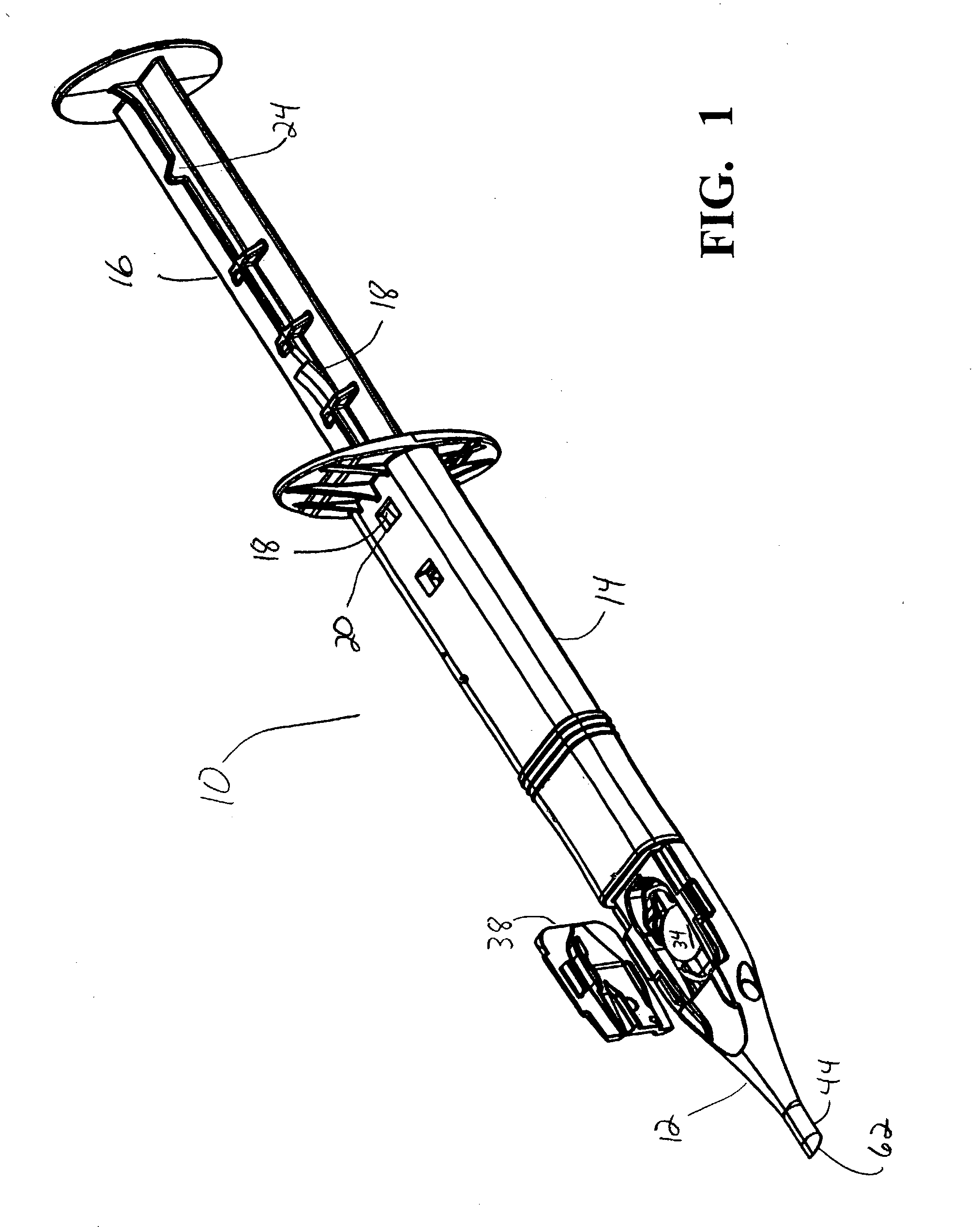

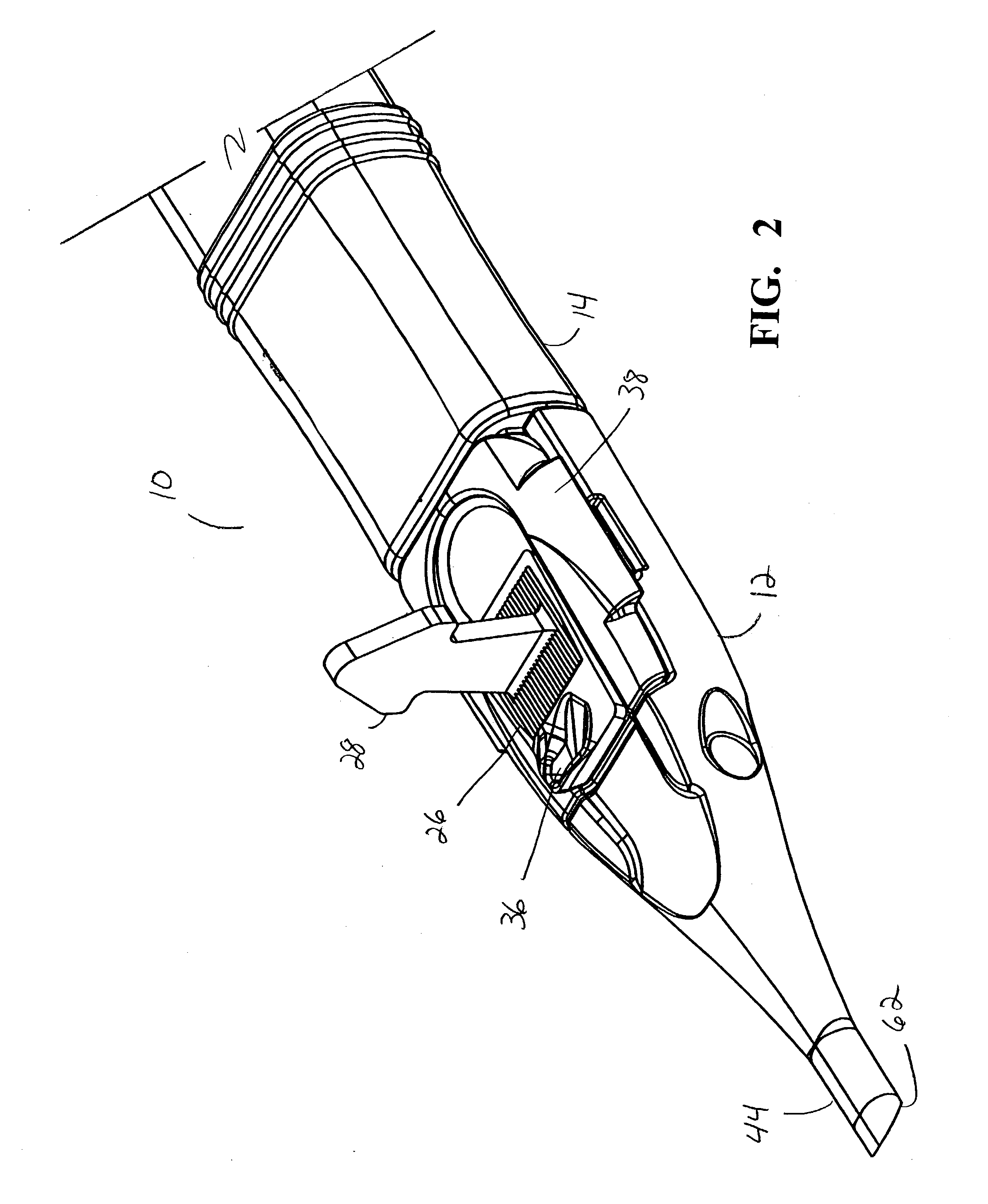

Lens delivery system

A lens delivery system having a plunger, an injector body and a nozzle portion connected to the injector body, the nozzle portion having a hinged lid and a hollow body with a lens holding platform formed beneath the hinged lid. The cartridge has an elongated nozzle tube or tip with a bore, the bore communicating with the lens holding platform. The bottom of the bore is rounded, which causes the edges of the lens between the lens haptics to fold upwardly as the lens is pushed down the bore from the platform by the plunger. A removable pin fits into the lid and prevents the lens from moving down the bore of the tip during shipment and storage.

Owner:ALCON INC

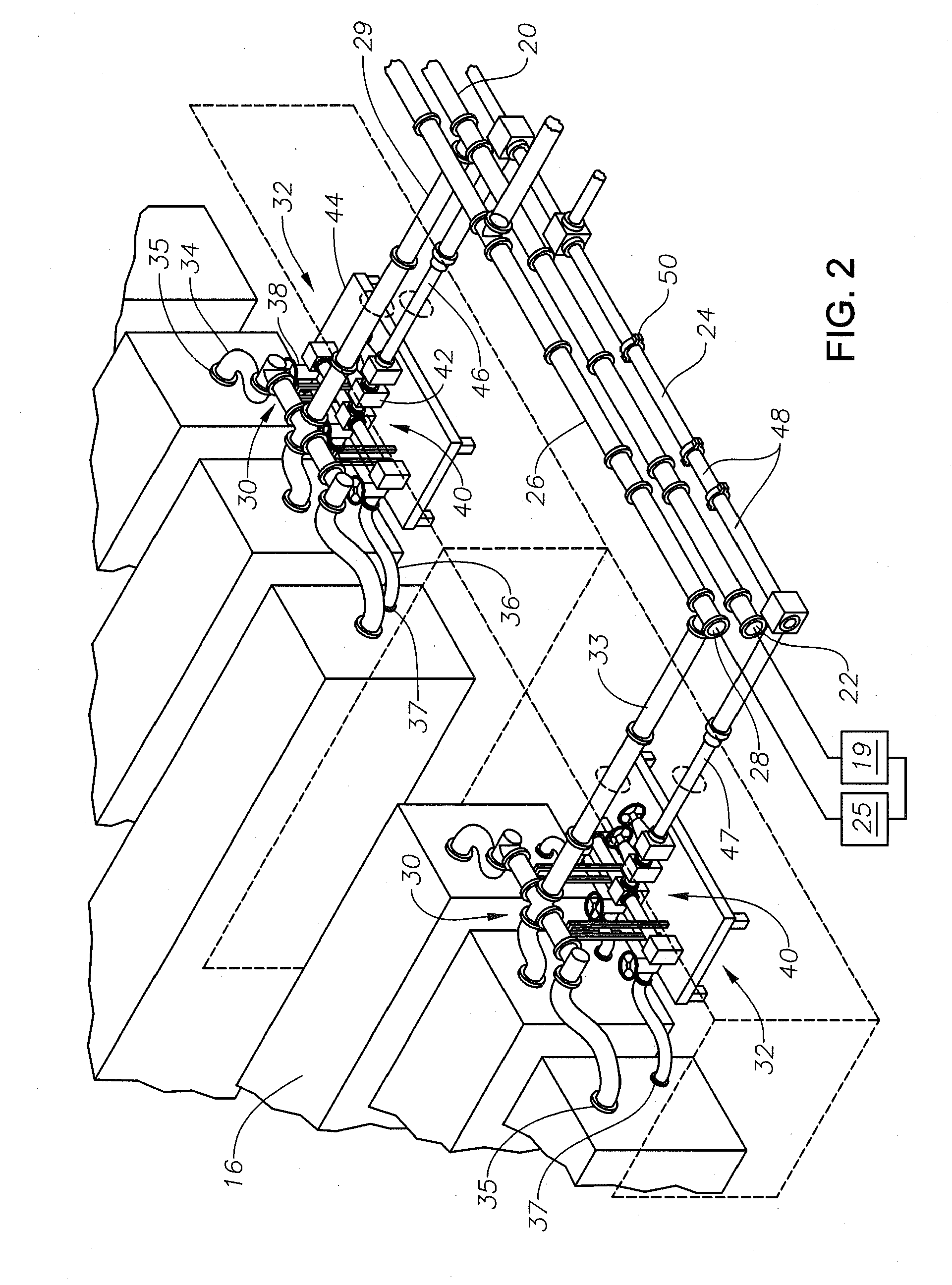

Delivery System for Fracture Applications

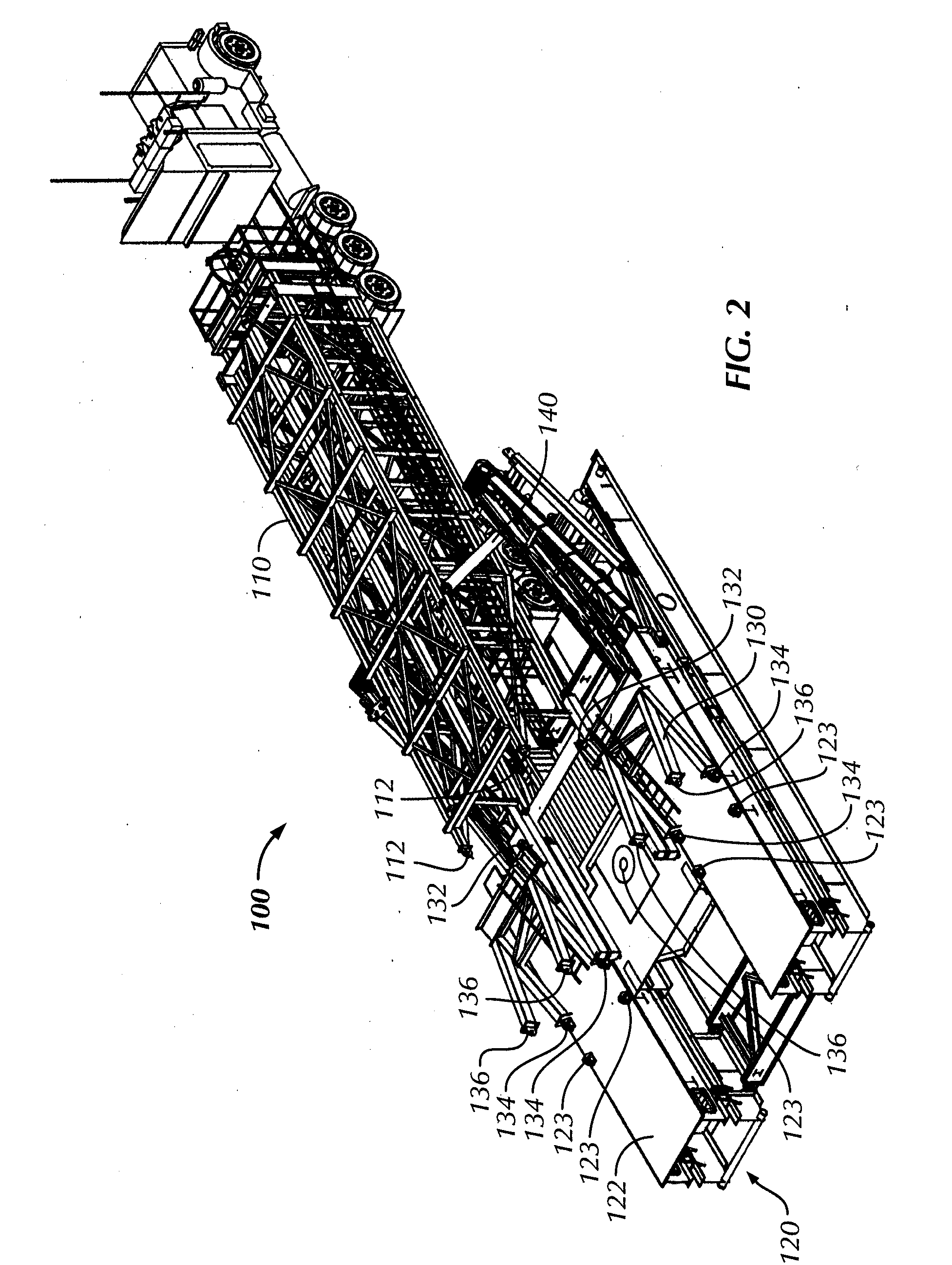

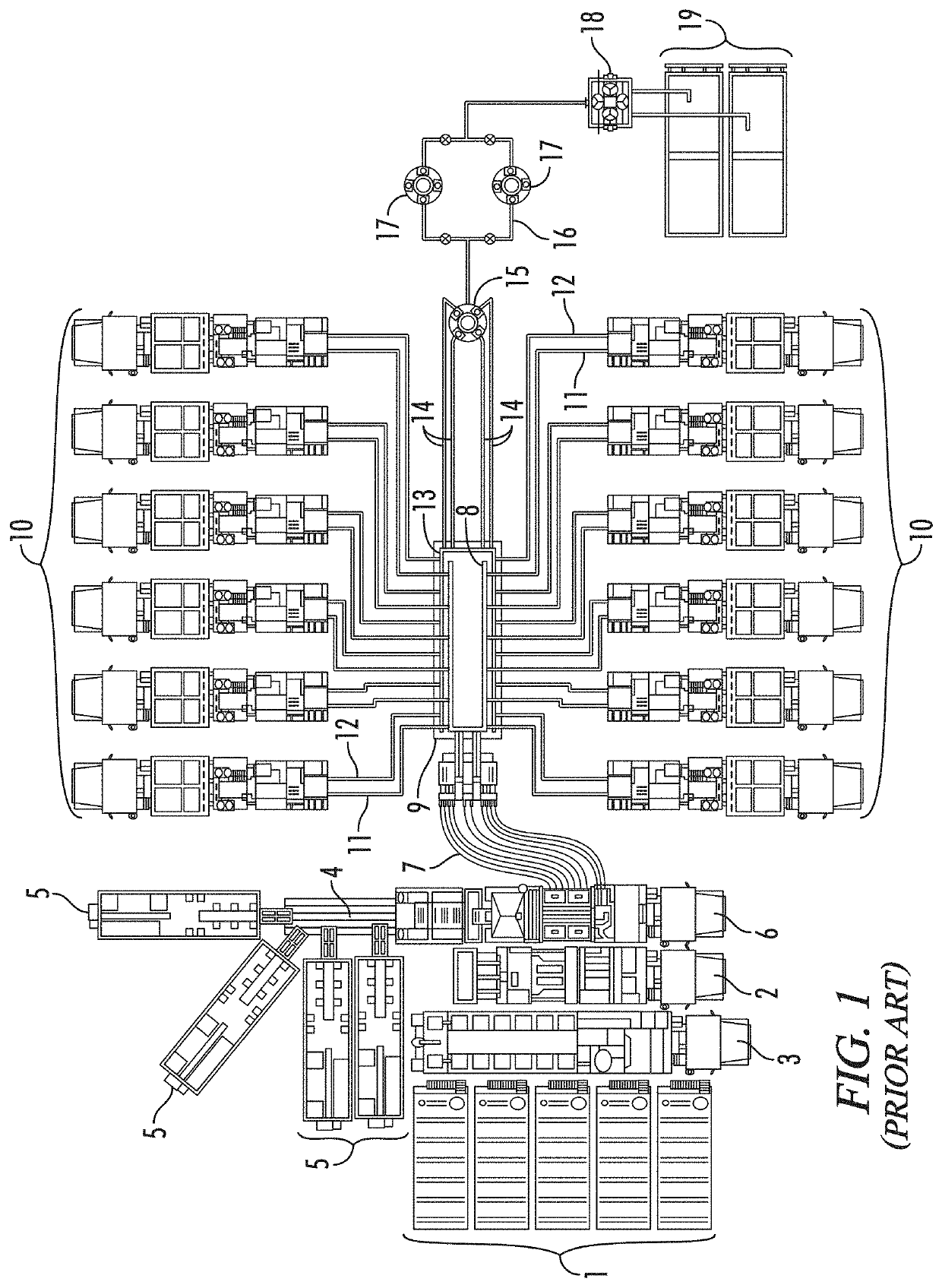

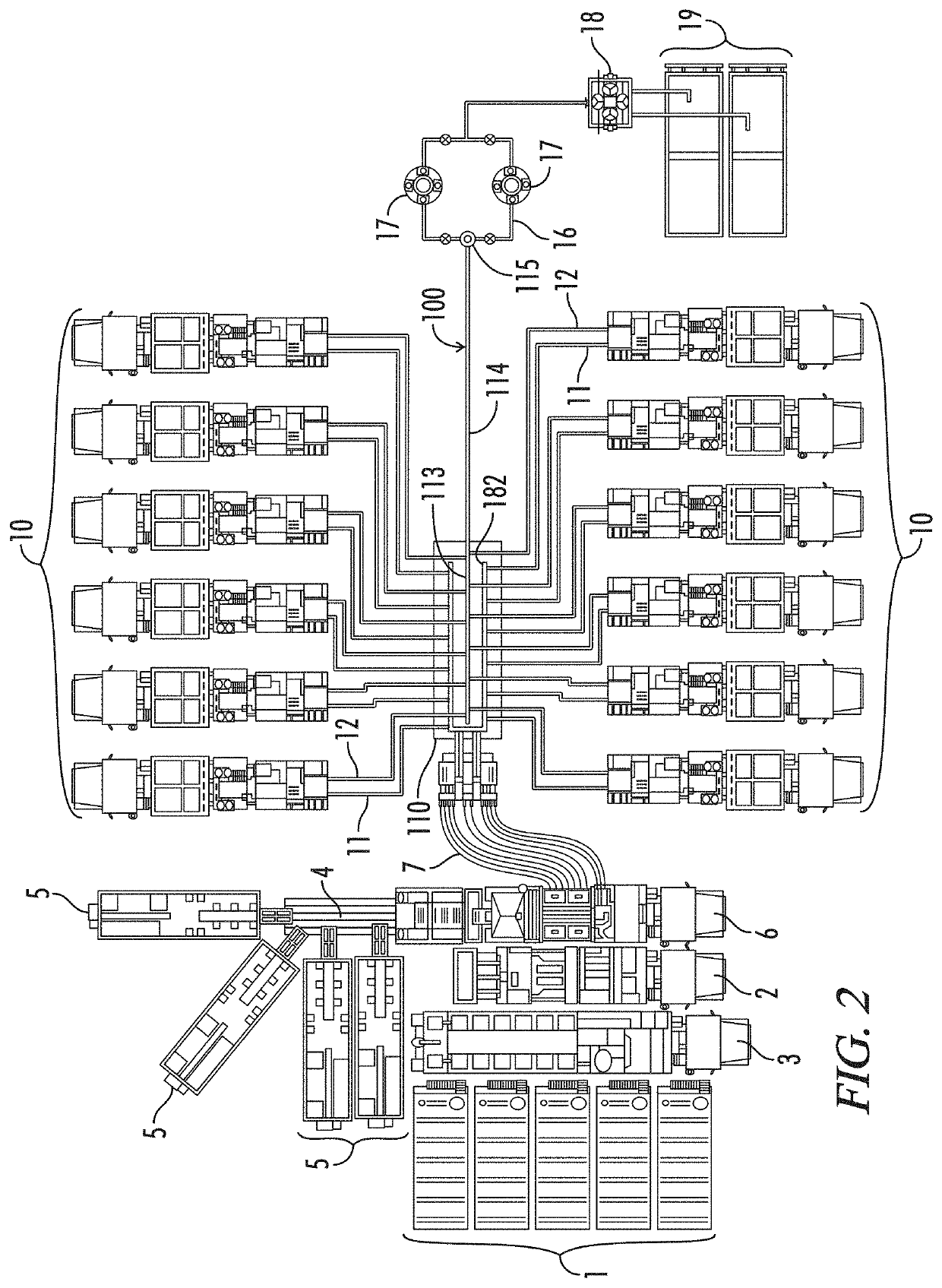

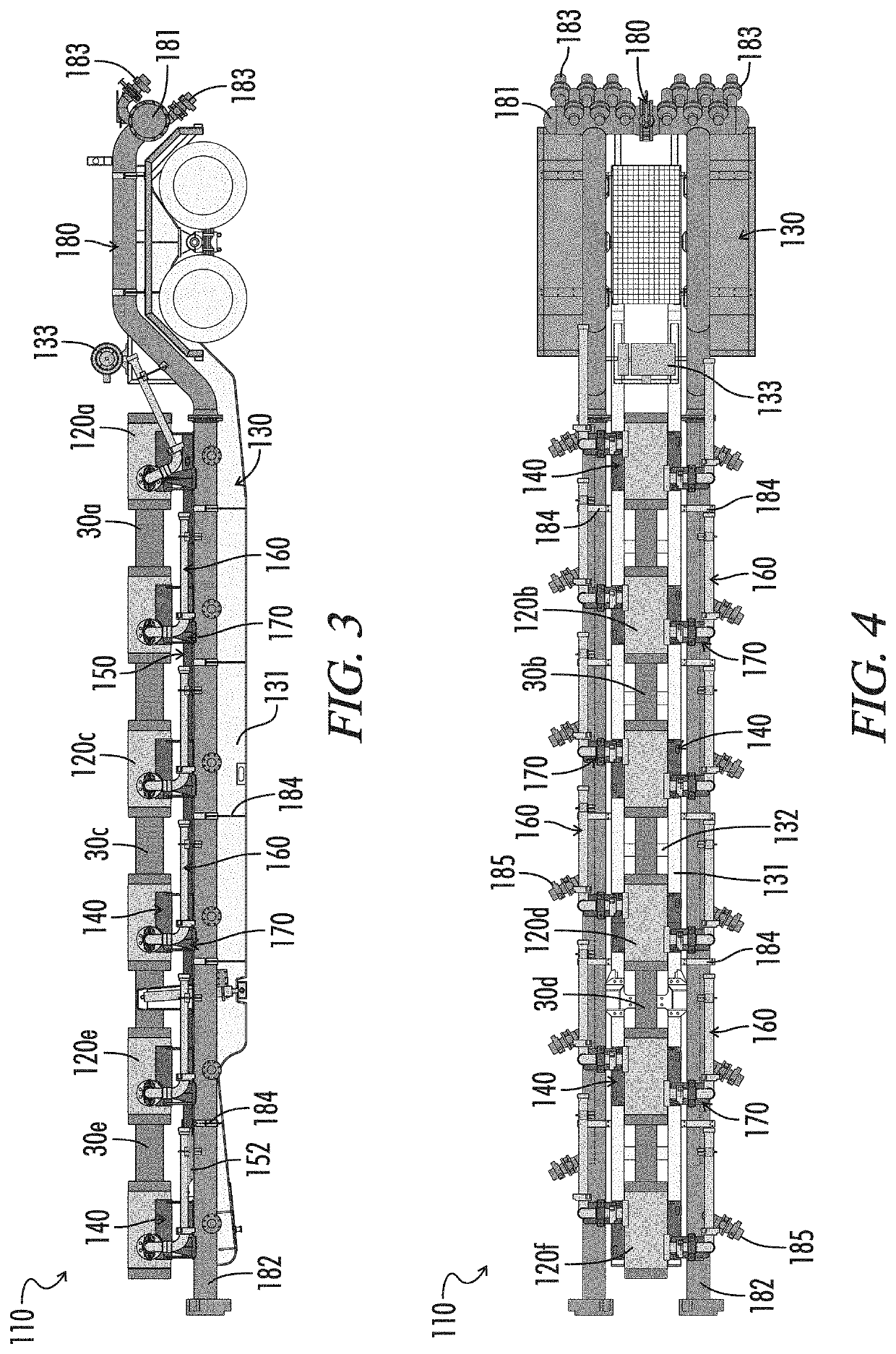

ActiveUS20130284455A1Readily configured and assembledFlanged jointsDrilling rodsTelecommunicationsTruck

Described herein is a modular, adjustable system for distributing fluids to one or more wellbores. The system is readily configured and assembled at a well site, and allows for one portion of the system to be isolated for service or repair while the remainder of the system continues to operate. The system includes a plurality of pump skids having both a distribution junction in fluid communication with inlets to of plurality of pump trucks and an exit junction in fluid communication with outlets of the plurality of pump trucks.

Owner:VAULT PRESSURE CONTROL LLC

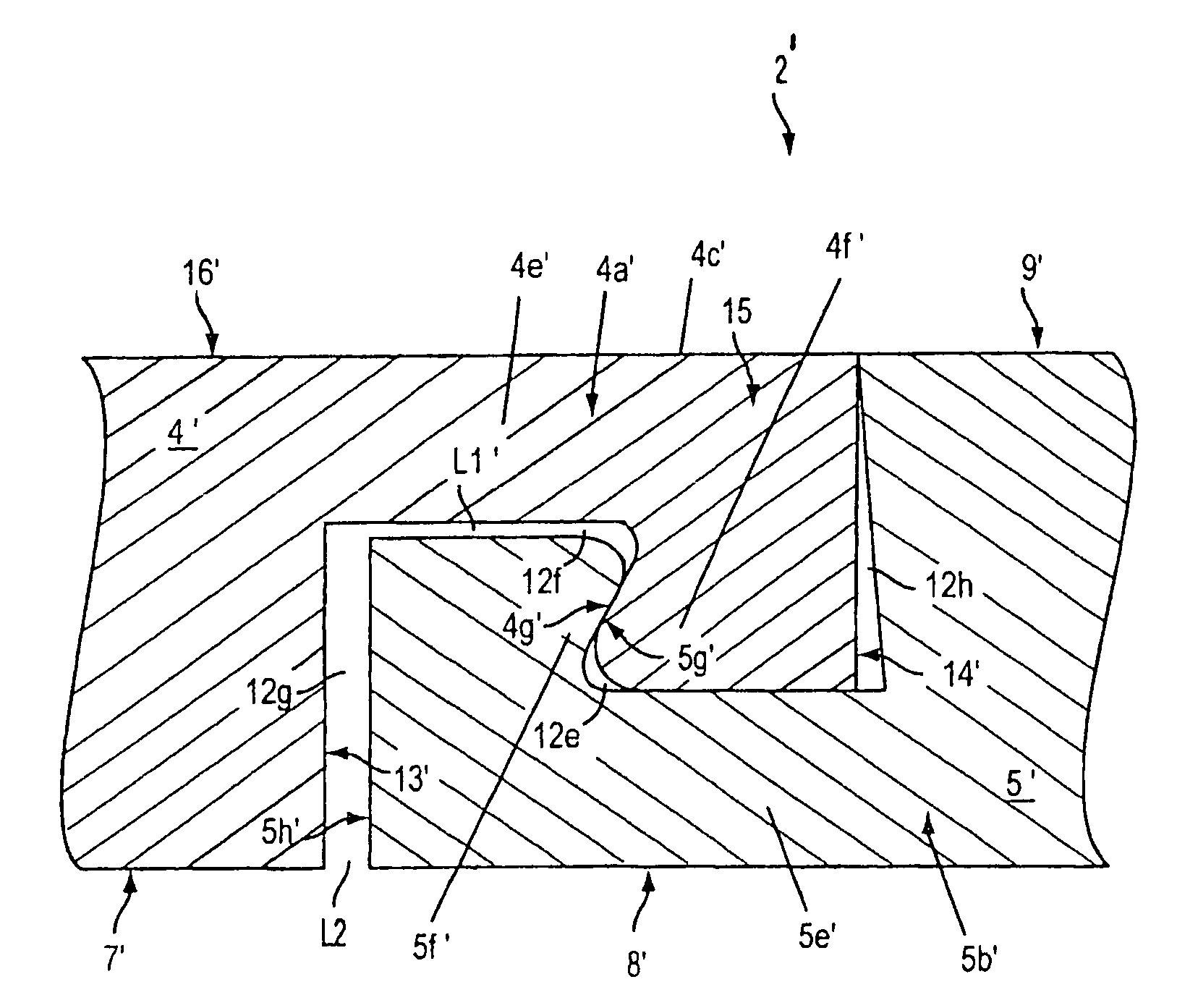

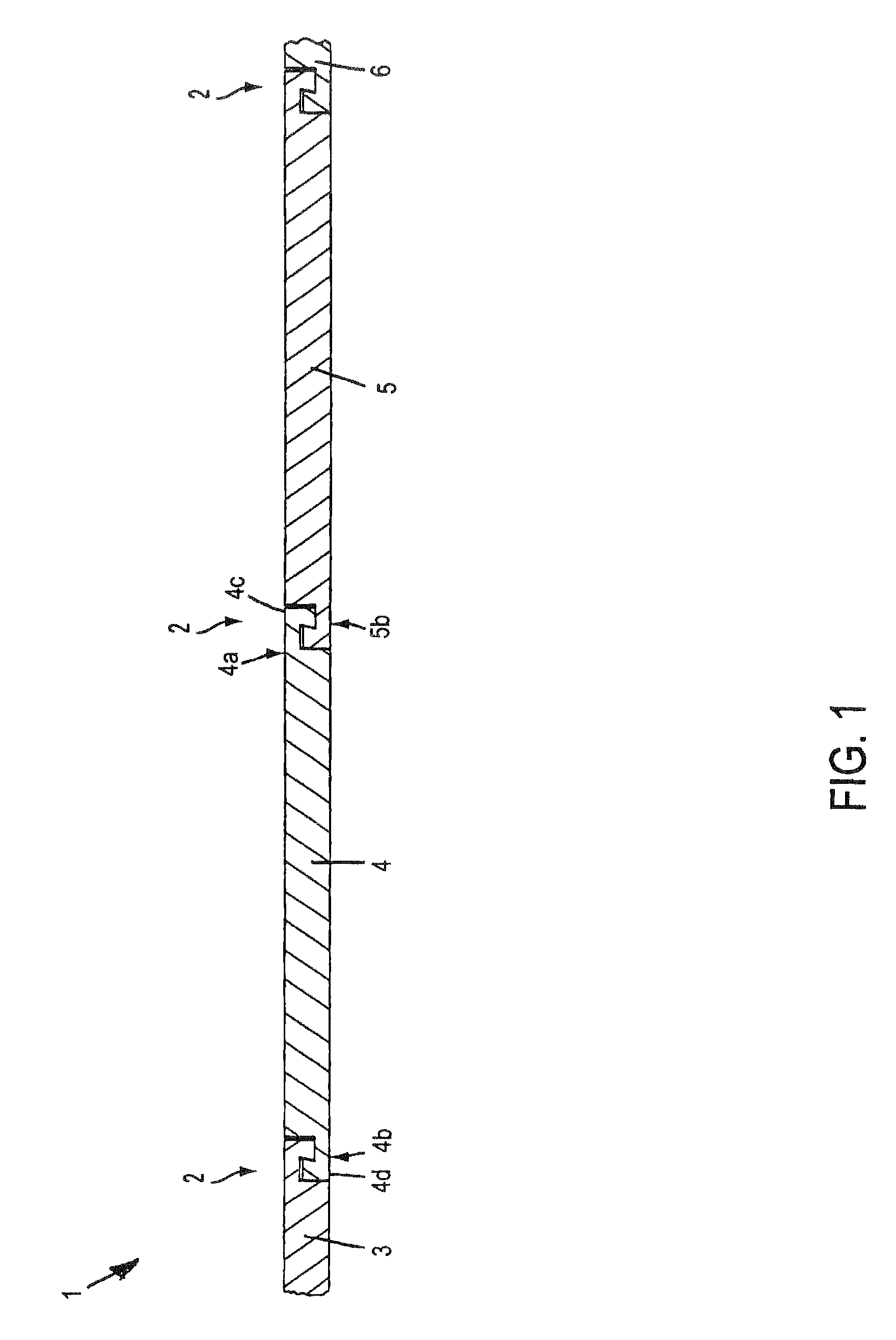

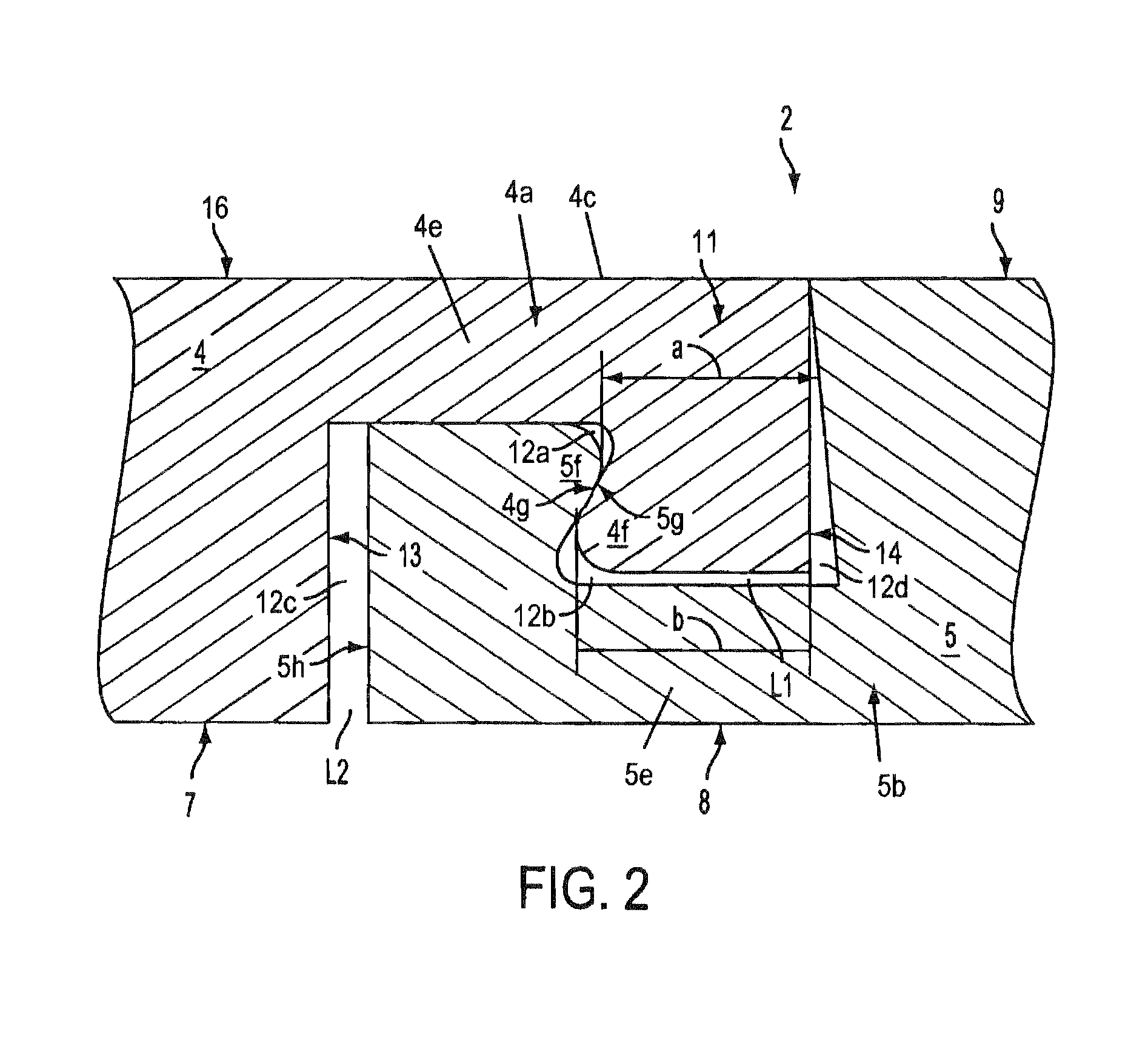

Panel and panel fastening system

InactiveUS7896571B1Reduce the amount requiredLower elastic deformabilityFlanged jointsTongue/grooves making apparatusFront edgeEngineering

A panel fastening system, especially for floor panels. The floor panels are fitted with retaining profiles on their edges, whereby the retaining profile of a front edge and the retaining profile of the opposite back edge and the retaining profile of a left edge and the retaining profile of the opposite right edge of a panel match each other in such a way that similar panels can be fixed to one another. The mutually matching retaining profiles have complementary hook elements that can be hooked into one another and the hook elements have retaining surfaces by means of which the panels are held against each other when mounted in such a way that a gap-free surface is obtained.

Owner:AKZENTA PANEELE PROFILE GMBH

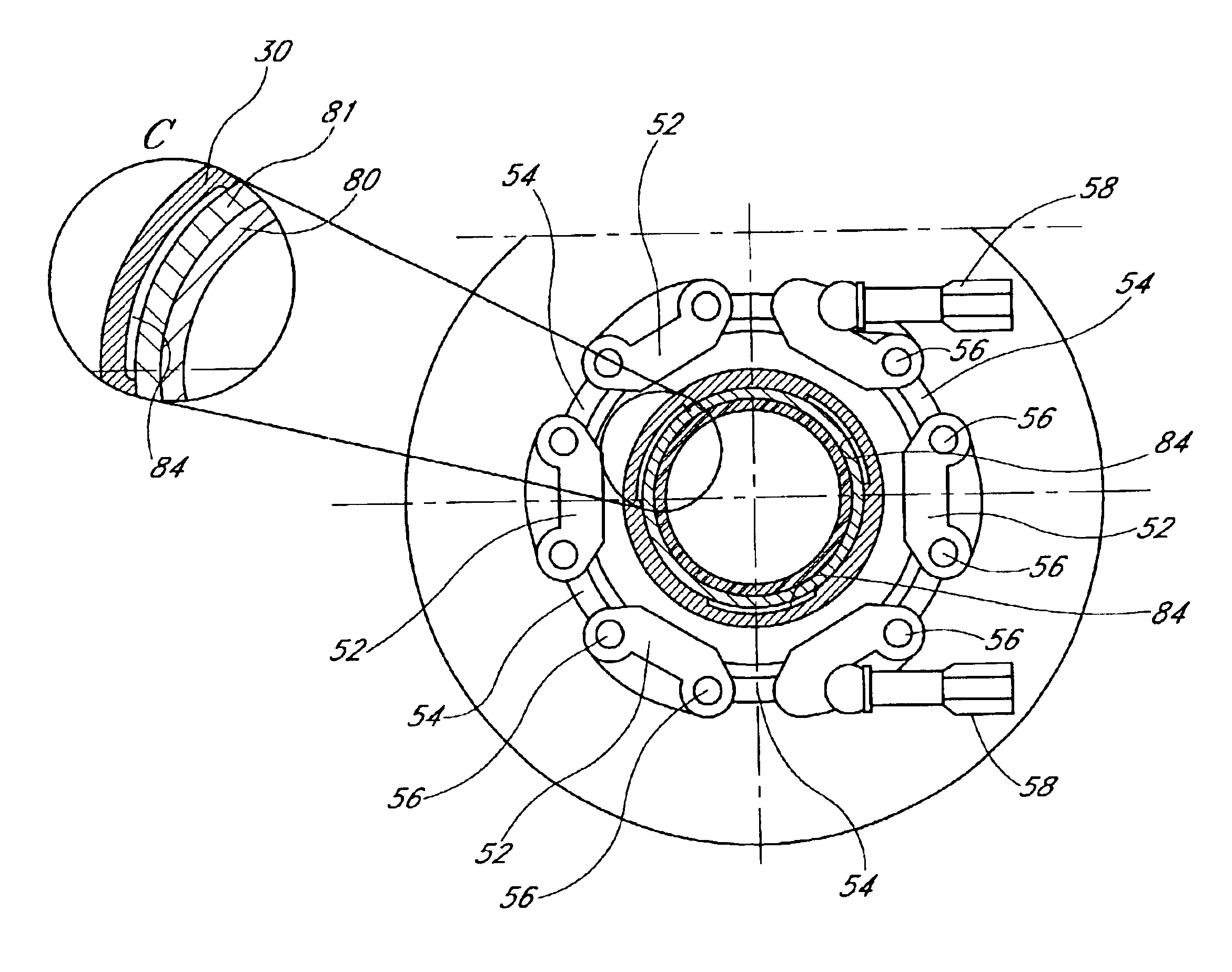

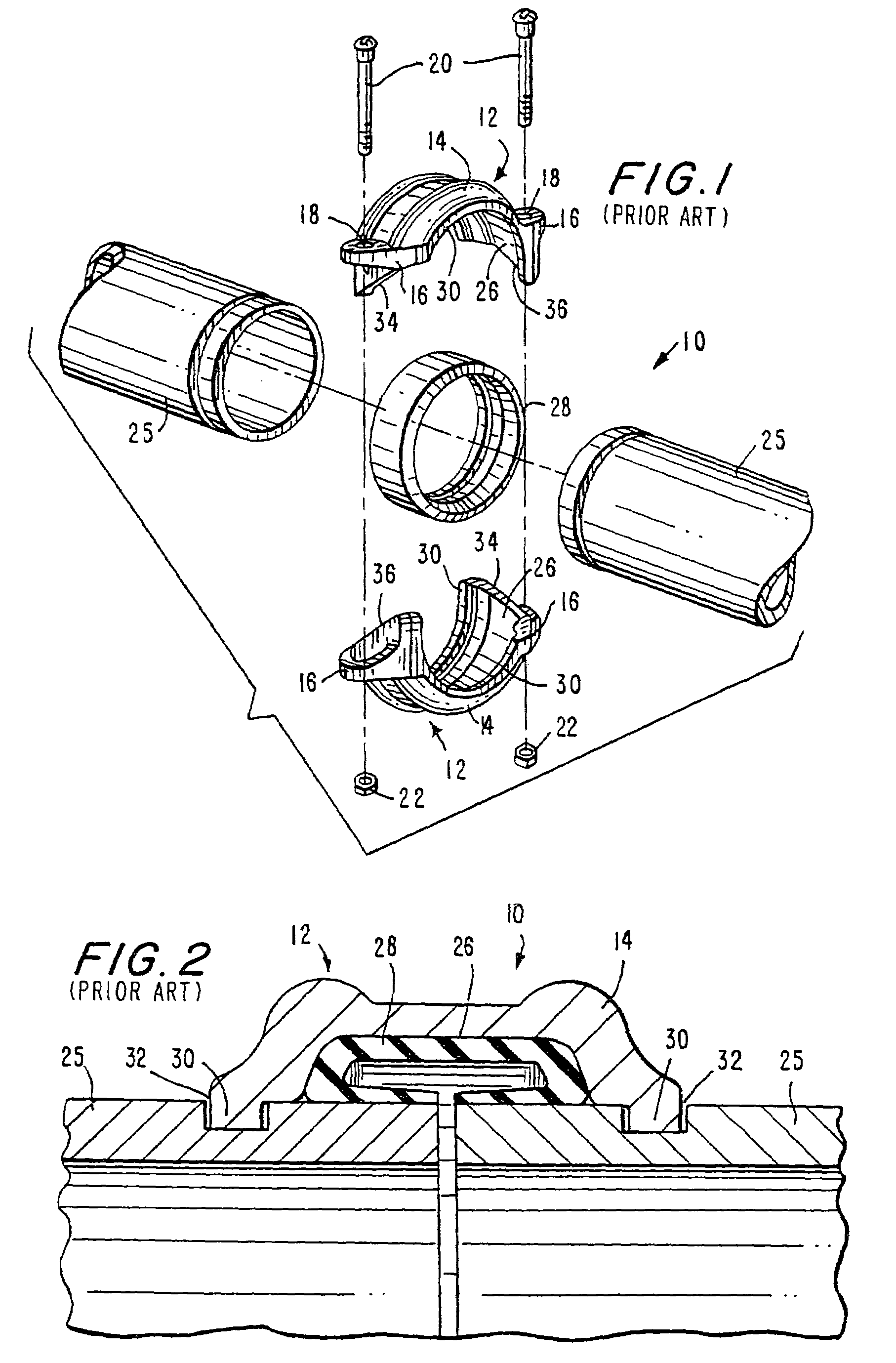

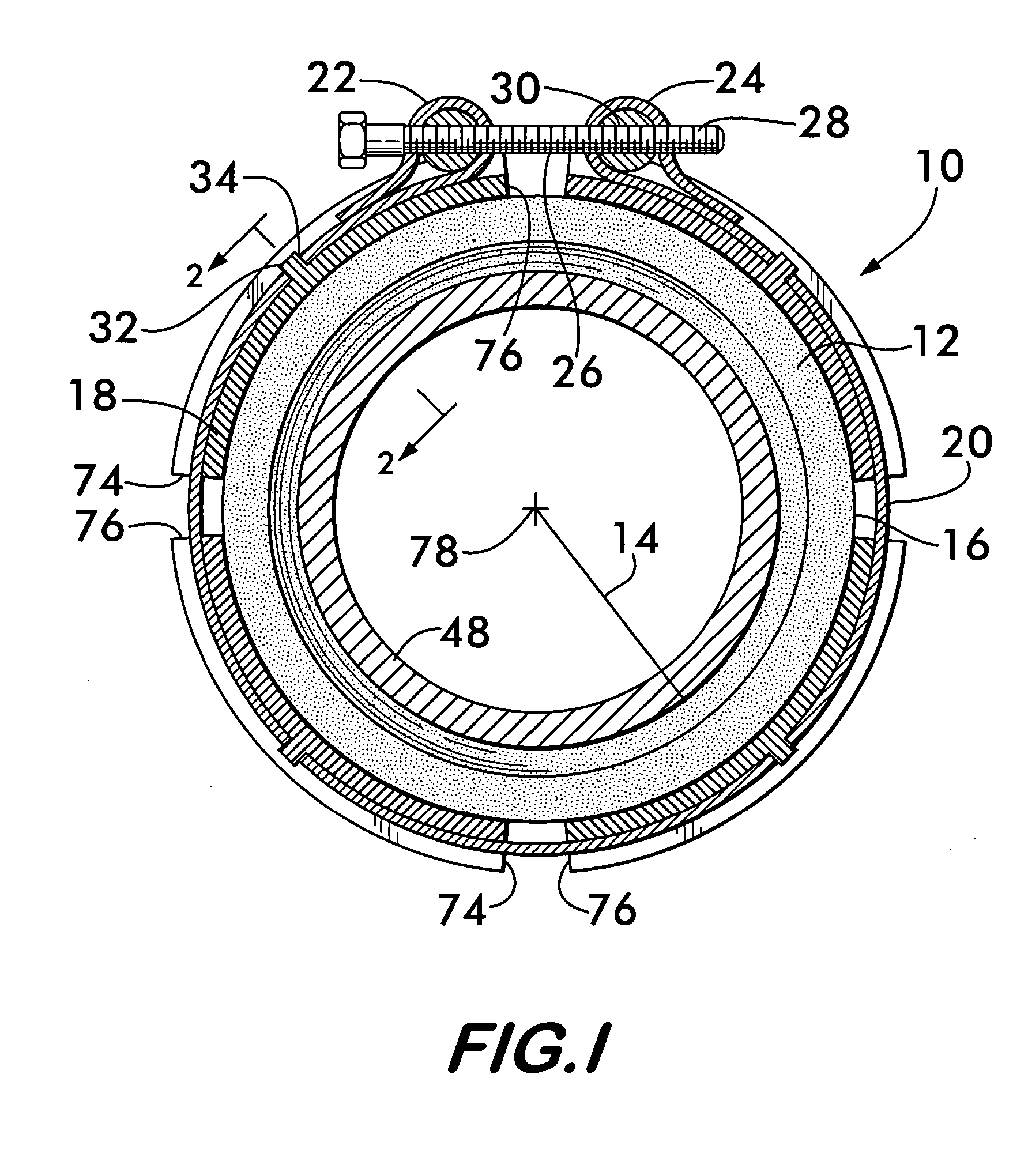

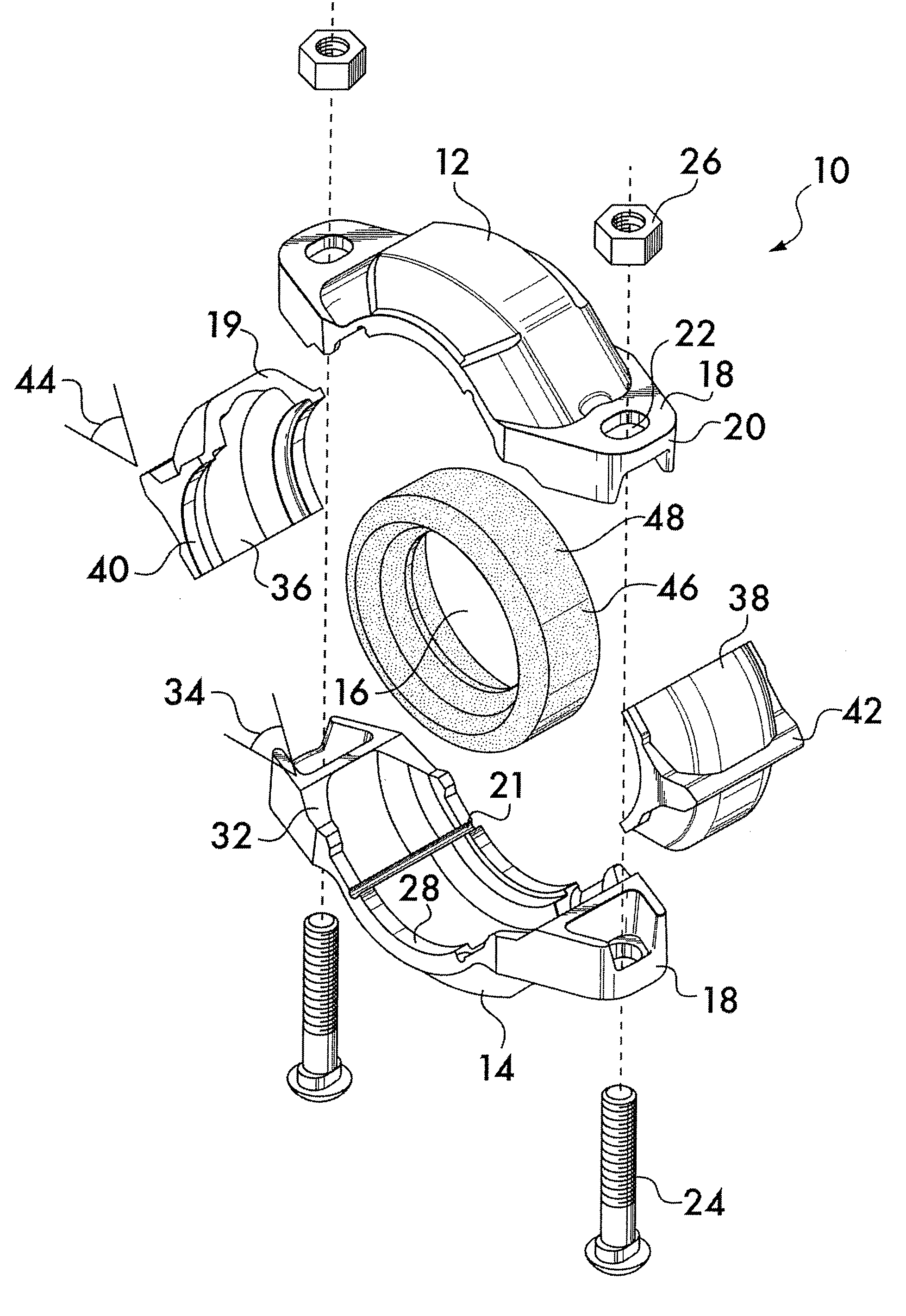

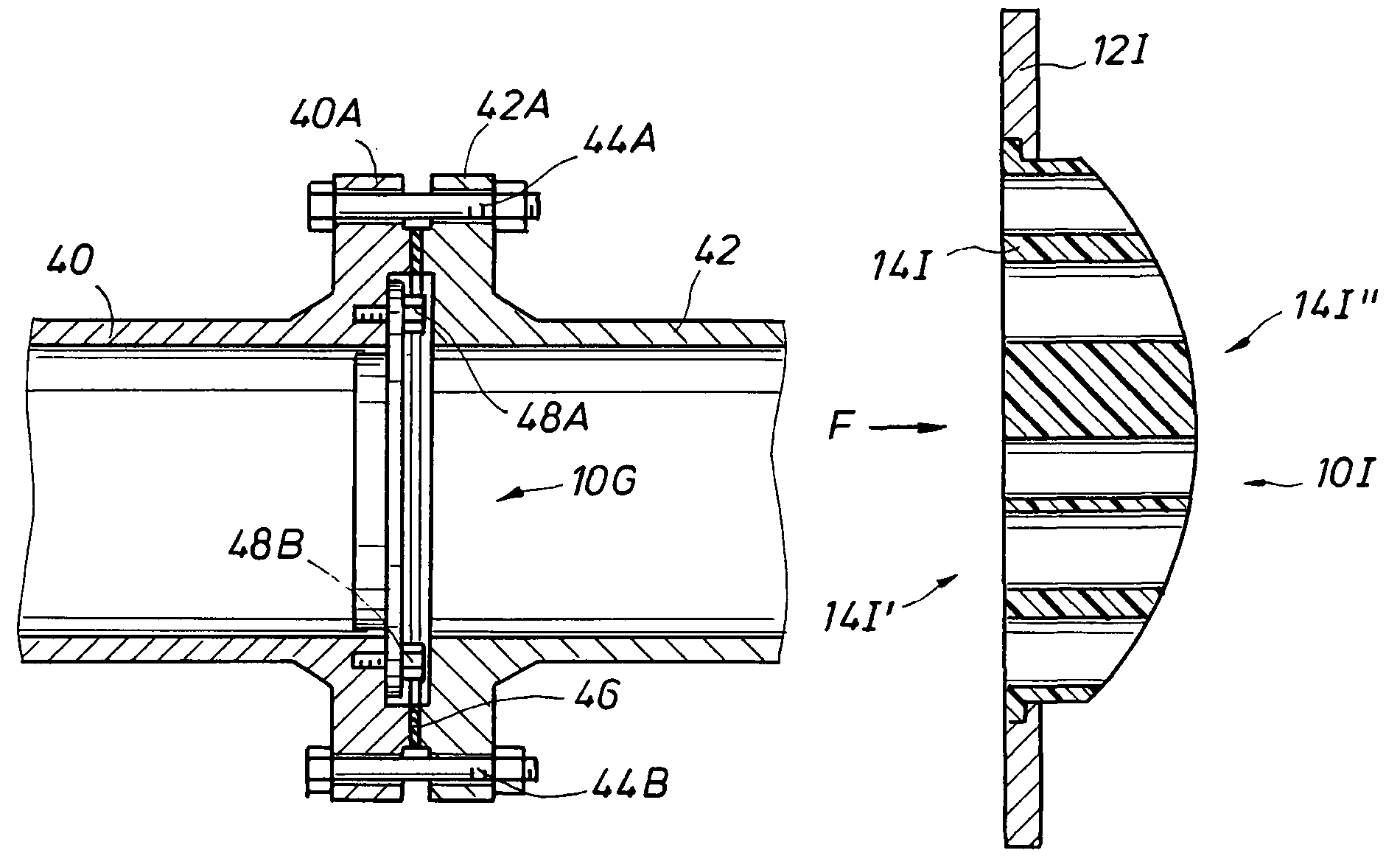

Deformable mechanical pipe coupling

A deformable mechanical pipe coupling is disclosed. The coupling has a plurality of interconnectable segments that straddle the ends of pipe elements to be joined. The segments have arcuate surfaces that engage outer surfaces of the pipe elements. The outer surfaces subtend an angle of less than 180° and have radii of curvature greater than the radii of curvature of the pipe element outer surfaces. The segments have adjustably tightenable connection members for connecting the segments to one another. When the connection members are tightened, the arcuate surfaces deform and conform to the radius of curvature of the outer surface of the pipe elements.

Owner:VICTAULIC

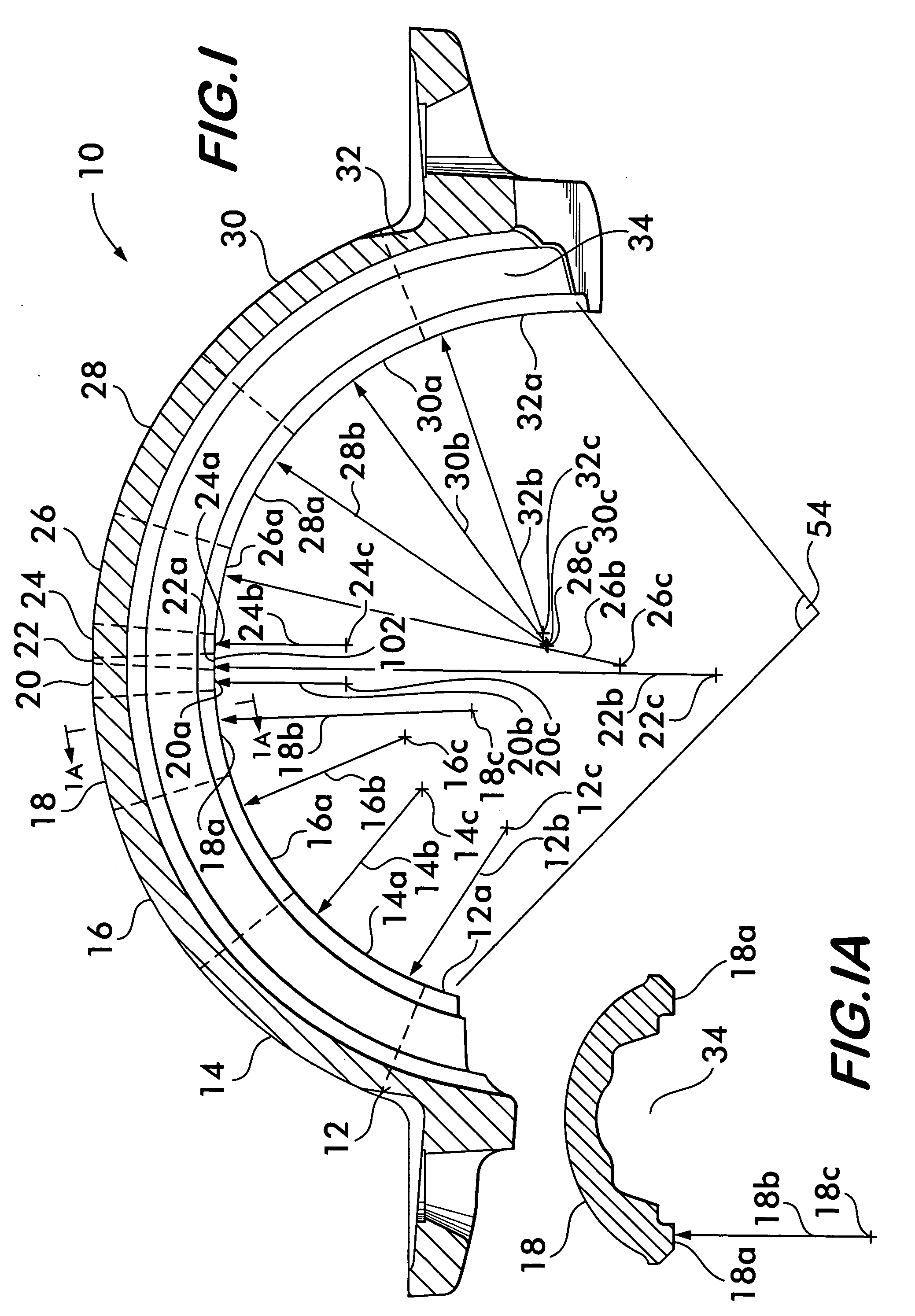

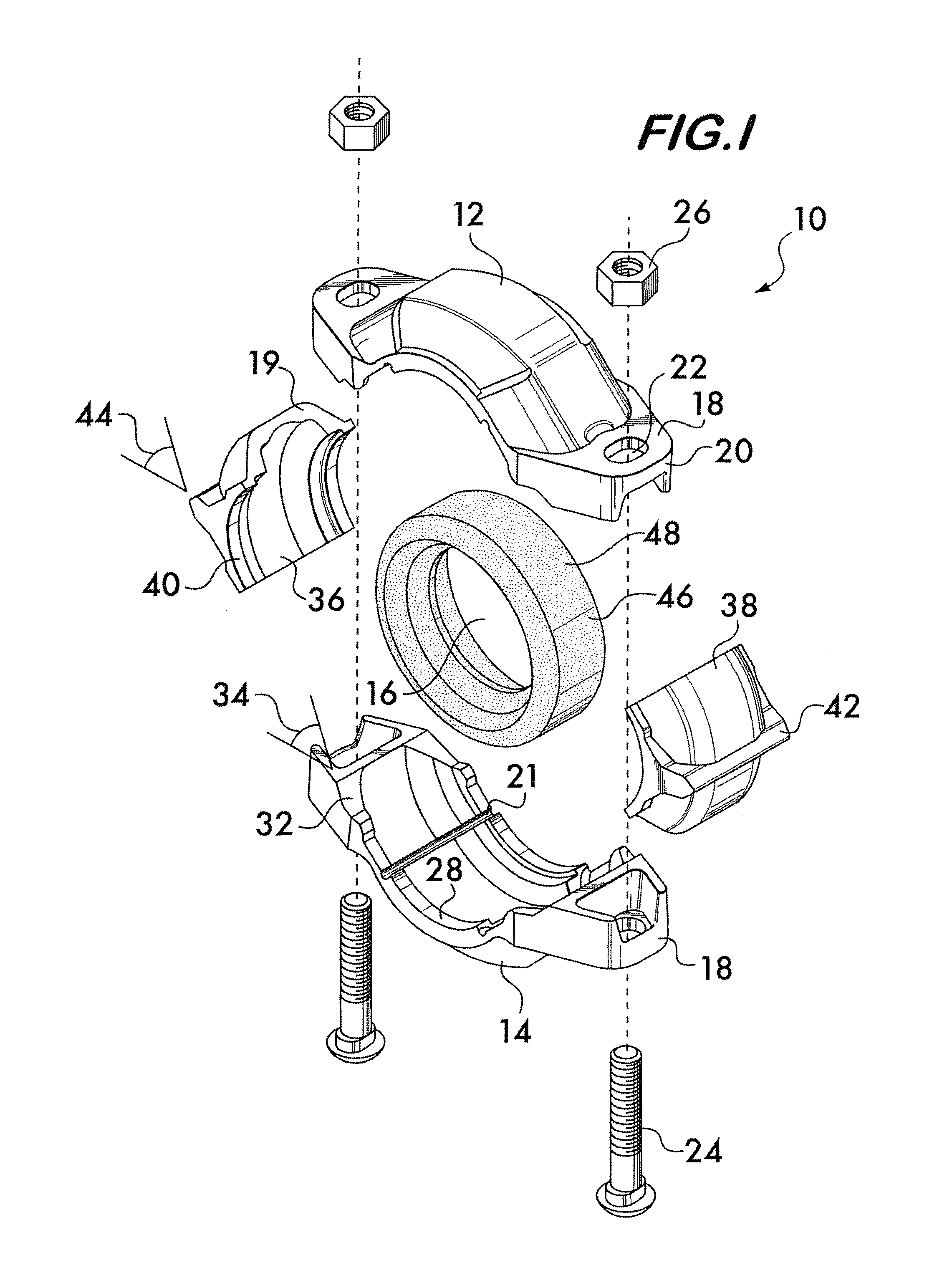

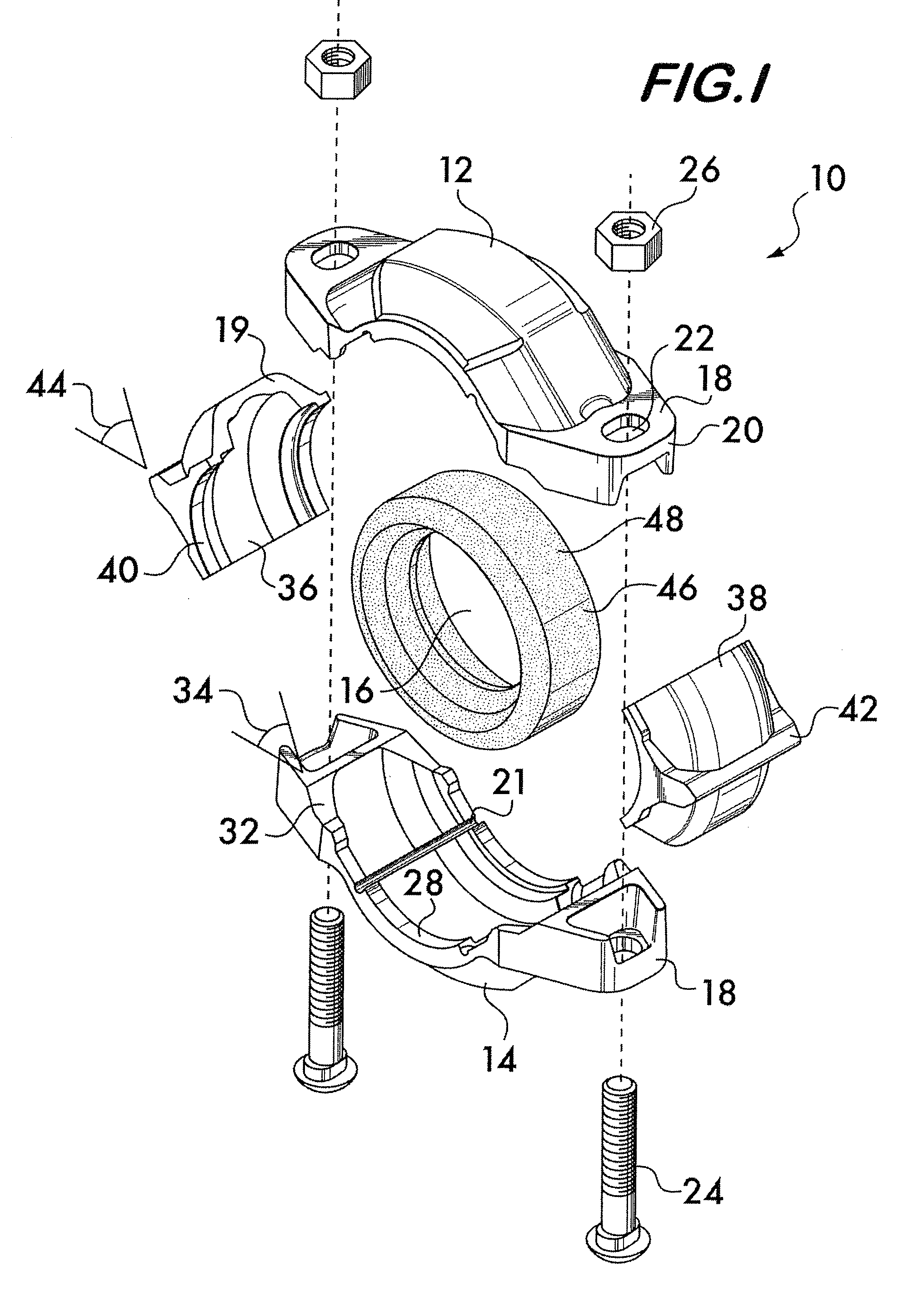

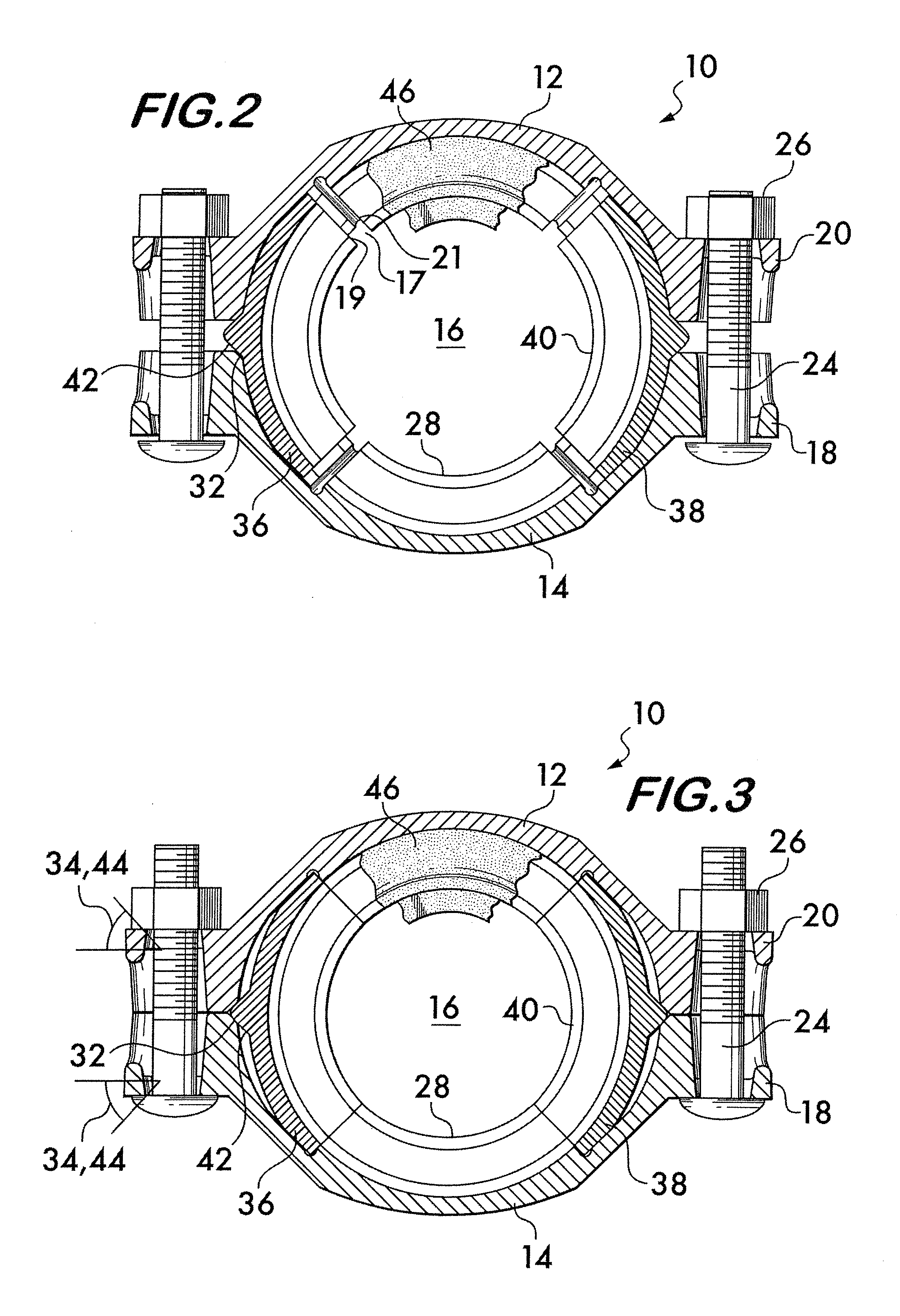

Anti-mismatch of near-sized coupling segments

A series of successively sized segmented arcuate pipe couplings in which anti-mismatch members are provided to prevent the inadvertent connection of two different, but closely sized coupling segments together. The anti-mismatch features are provided on the ends of the arcuate coupling segments which (a) will nest when the proper coupling segments are brought together, but (b) will be in an interference non-nested relationship when a mismatch is attempted. This will prevent the fully bolt tightened connection of the size mismatched coupling segments, as well as a visual indication to a user that a size mismatch is being attempted.

Owner:VICTAULIC

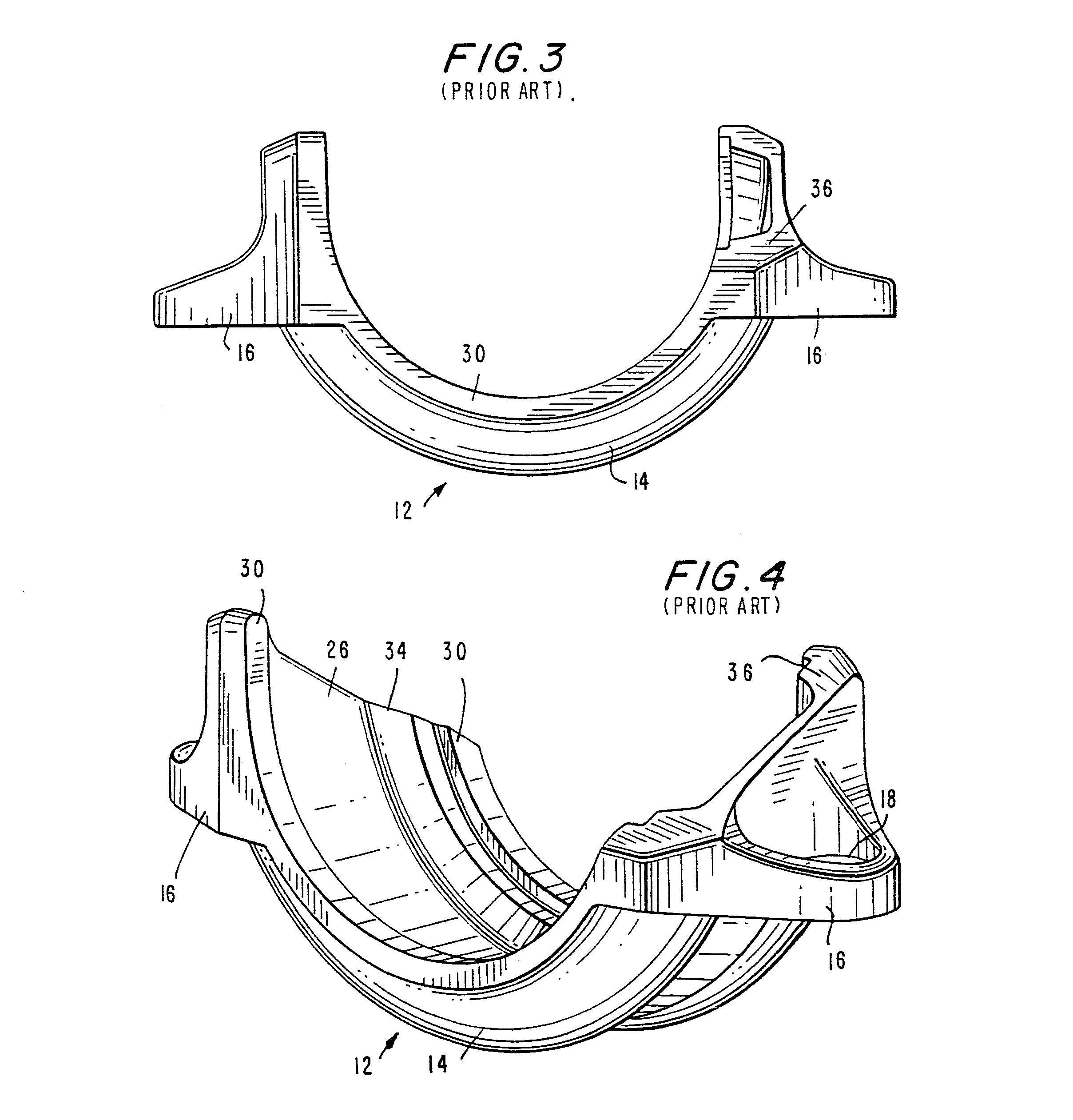

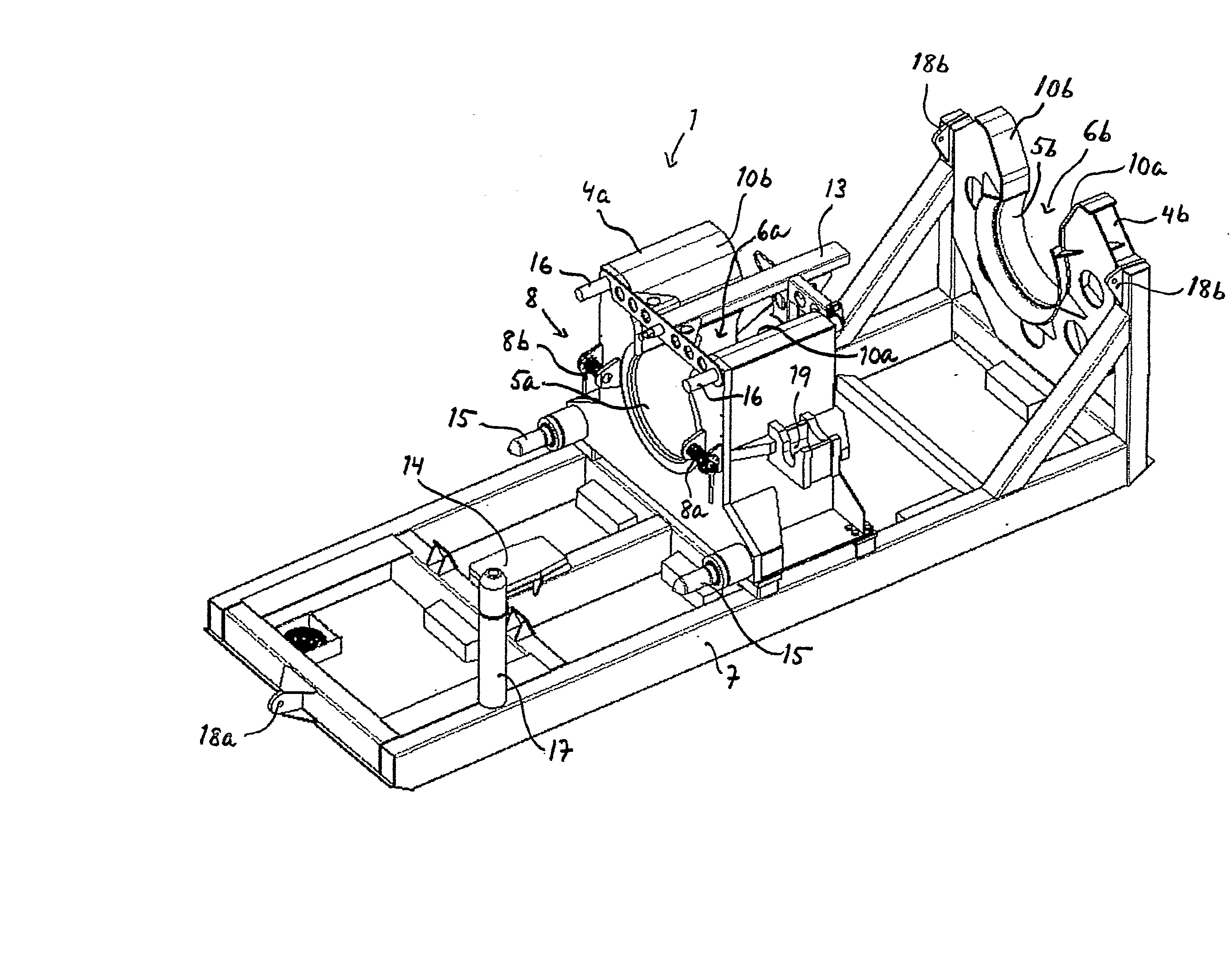

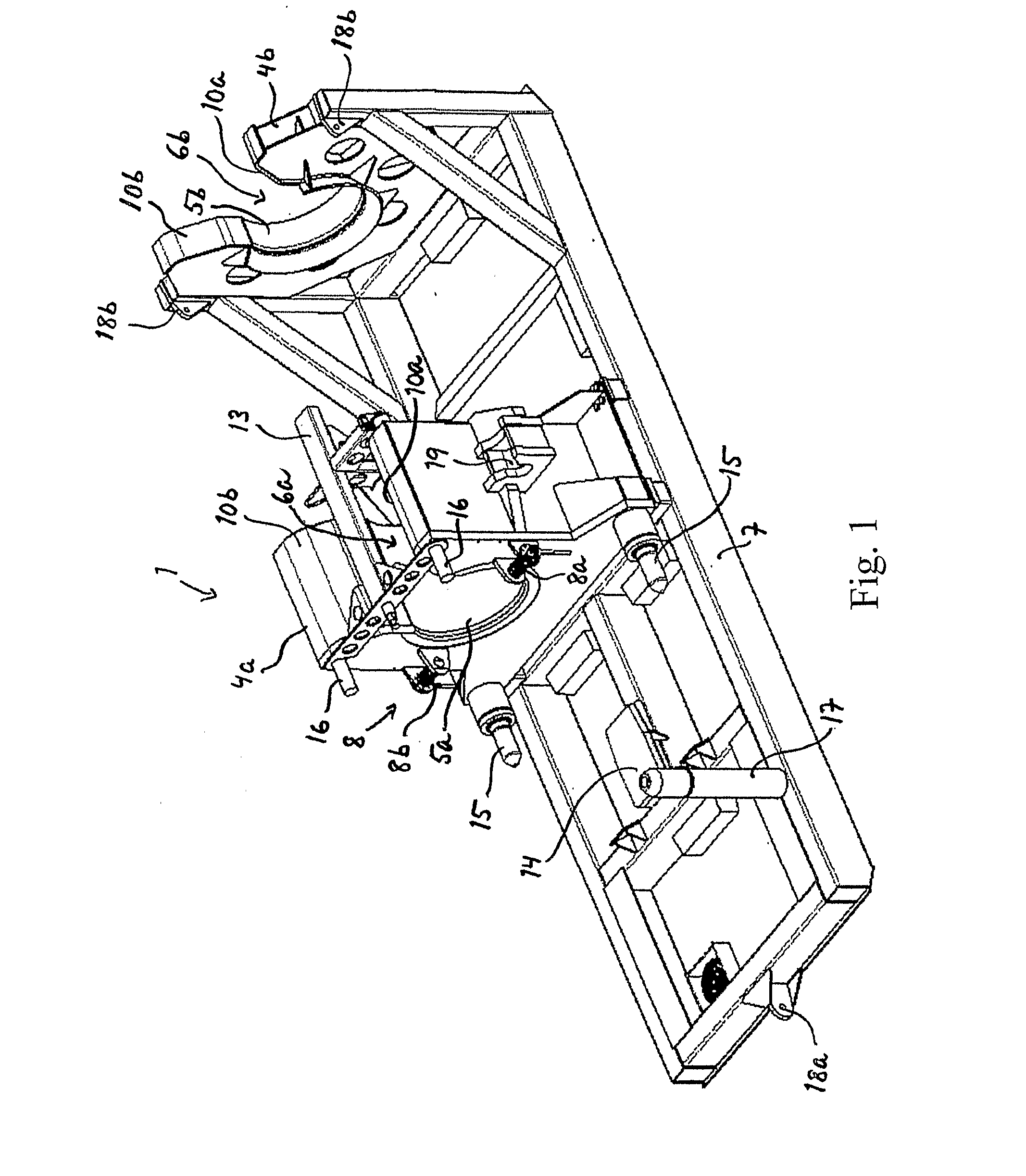

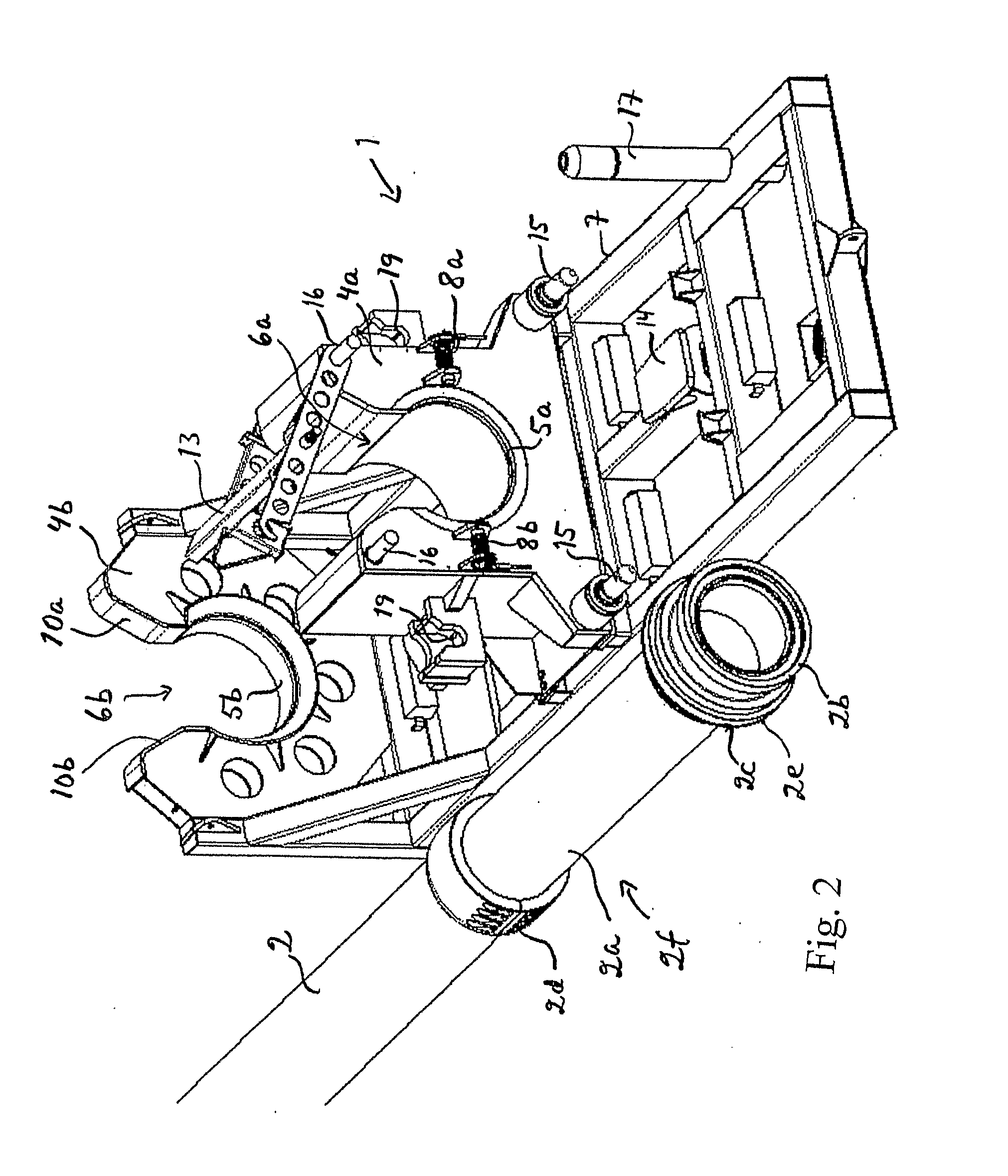

Portable drilling rig apparatus and assembly method

Owner:INTEGRATED DRILLING EQUIP

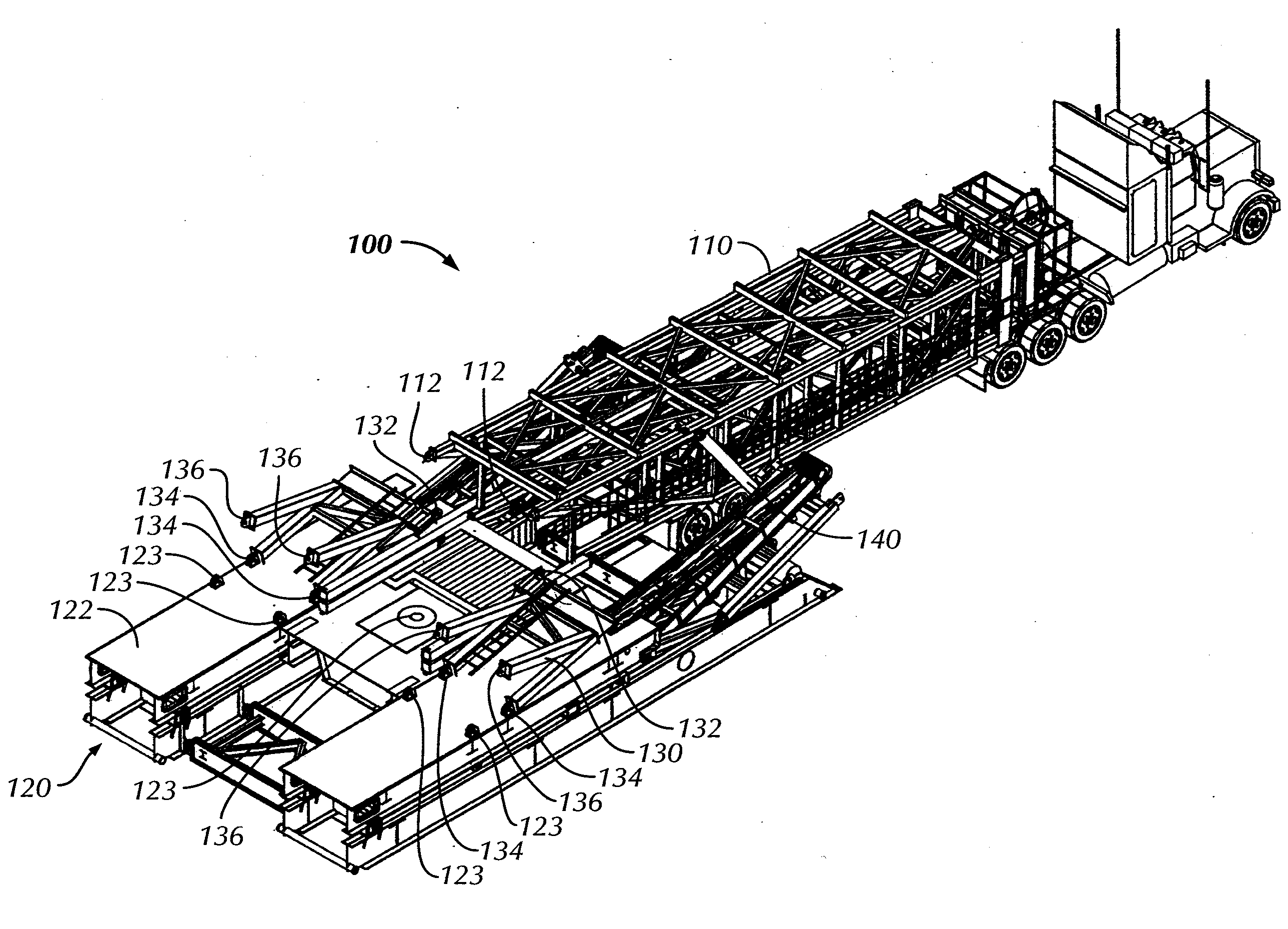

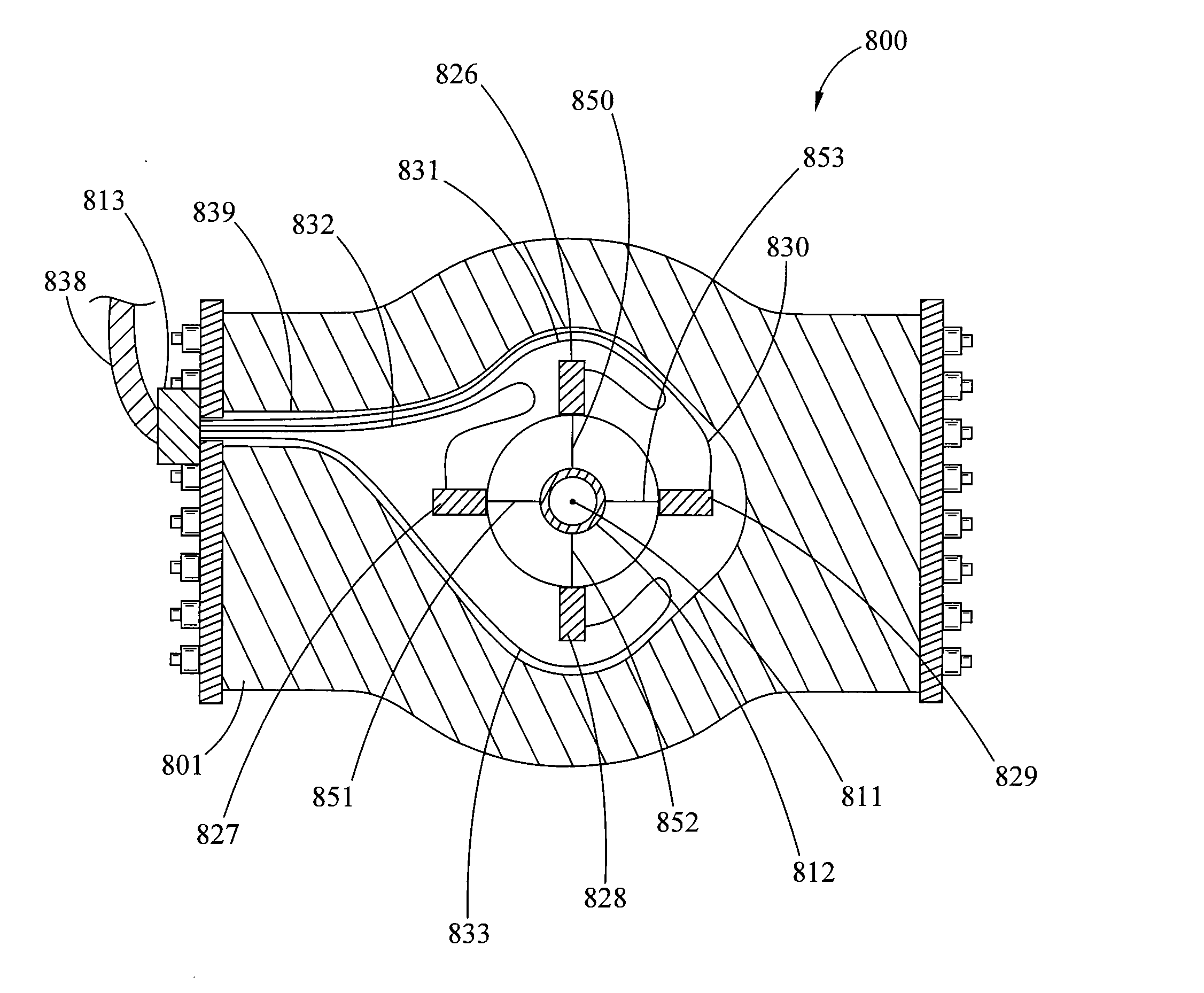

Frac manifold missile and fitting

A missile flow line is assembled in a frac manifold to manifold the discharge from a plurality of pumps. The missile comprises at least two junction fittings joined by a flange union to at least one spooled pipe to form a conduit. The junction fittings comprise a fitting body having a primary bore and at least two feed bores. The primary bore extends axially through the body between primary union faces adapted for connection to a flowline component by a flange union. The feed bores extend radially through the body from a feed union face to an intersection with the primary bore. The feed union faces are adapted for connection to pump discharge lines by a flange union. The intersections of the feed bores with the primary bore are offset axially from each other along the primary bore.

Owner:KHOLLE MAGNOLIA 2015 LLC

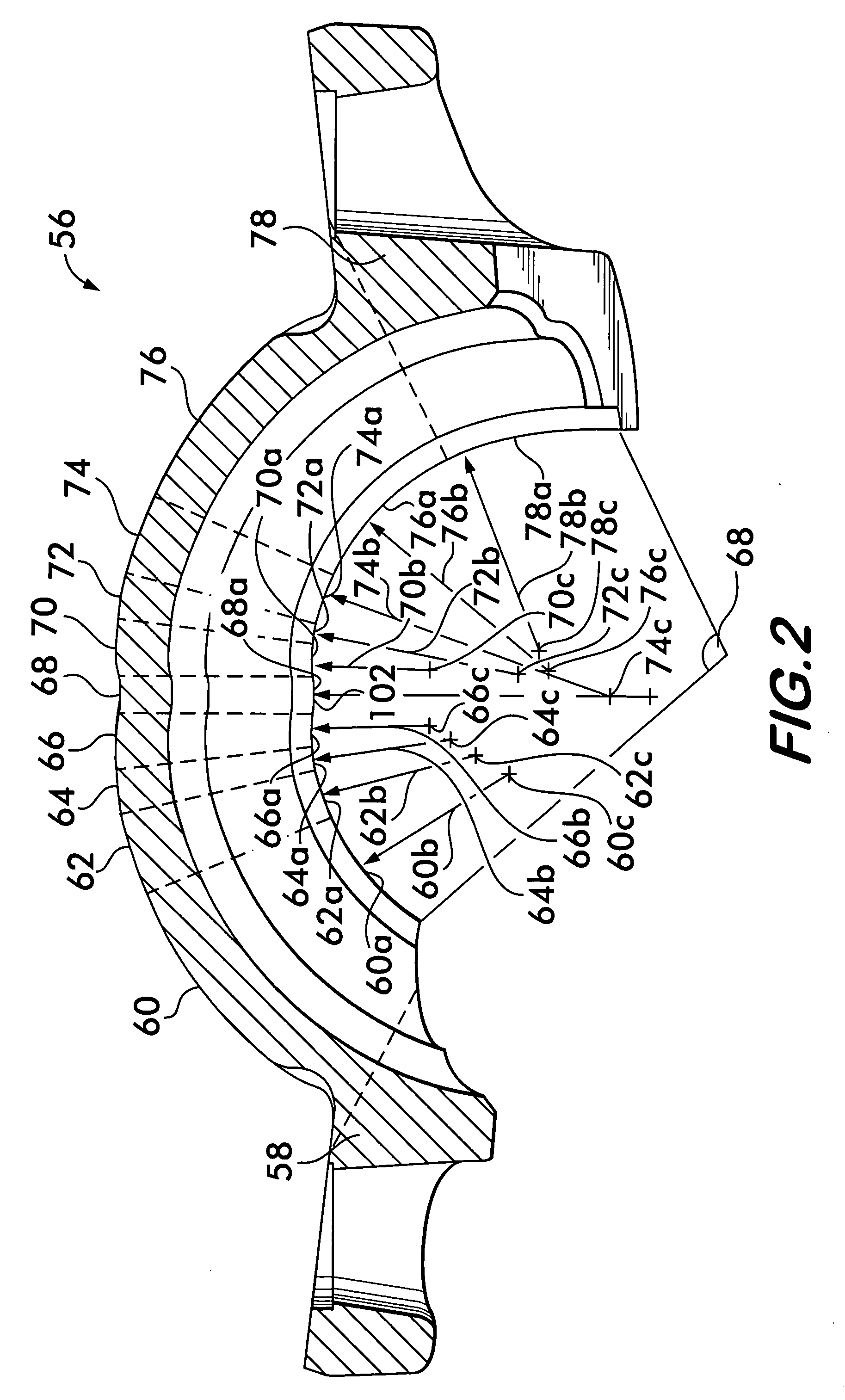

Deformable pipe coupling having multiple radii of curvature

A pipe coupling for joining pipe elements end-to-end is disclosed. The pipe coupling is formed of segments attached to one another circumferentially straddling the pipe elements. The segments are formed from sub-sections connected to one another end-to-end. Each sub-section has a surface region disposed to engage the outer surfaces of the pipe elements. Each surface region has a different radius of curvature from a surface region on a neighboring sub-section. The radii are selected so that when the coupling segments are deformed around the pipe elements, portions of surface regions of selected sub-sections contact the pipe elements, while portions of surface regions of those sub-sections between the selected portions remain in spaced relation away from the pipe elements. A constant and minimal torque is required to bolt the segments together as a result.

Owner:VICTAULIC

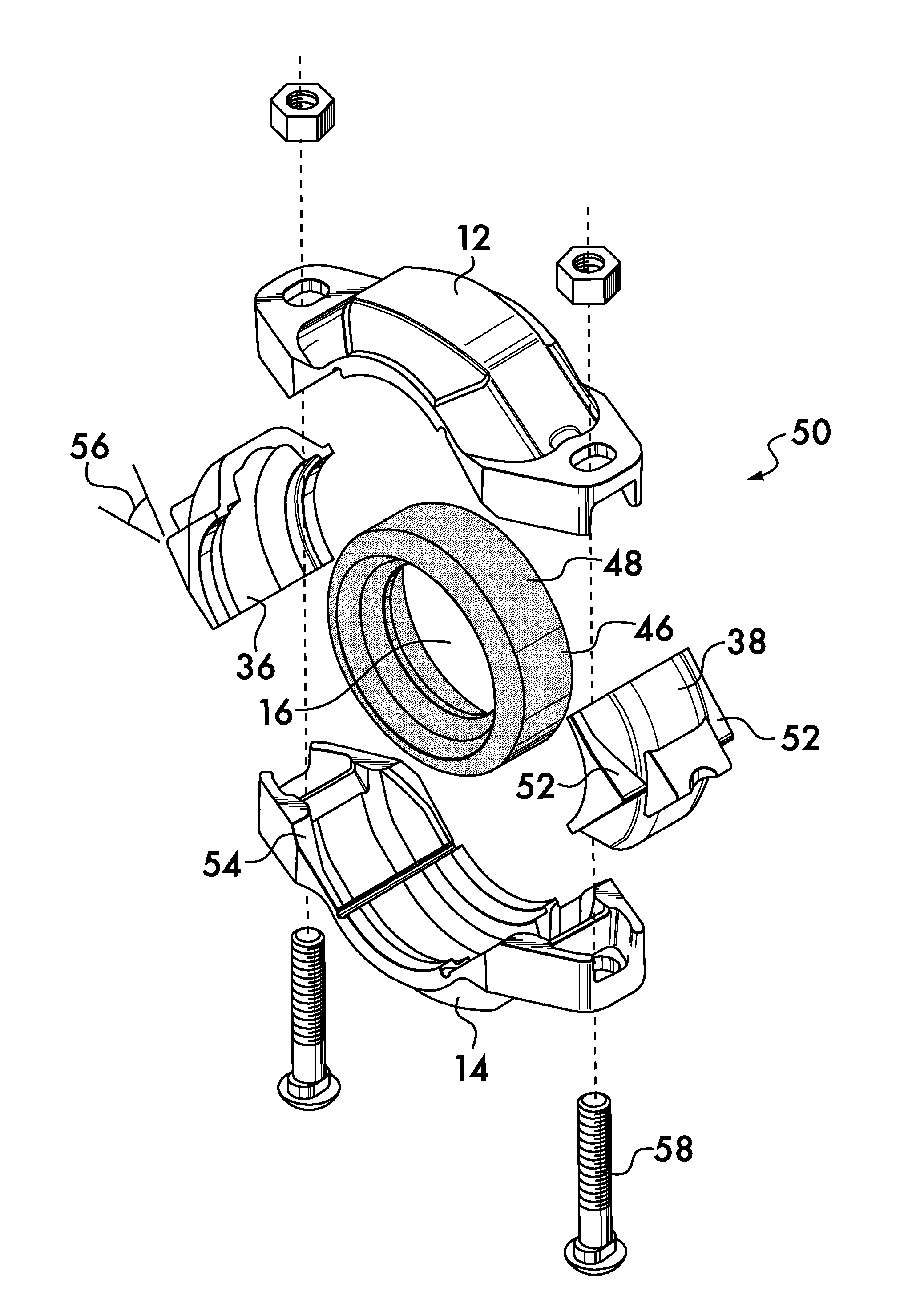

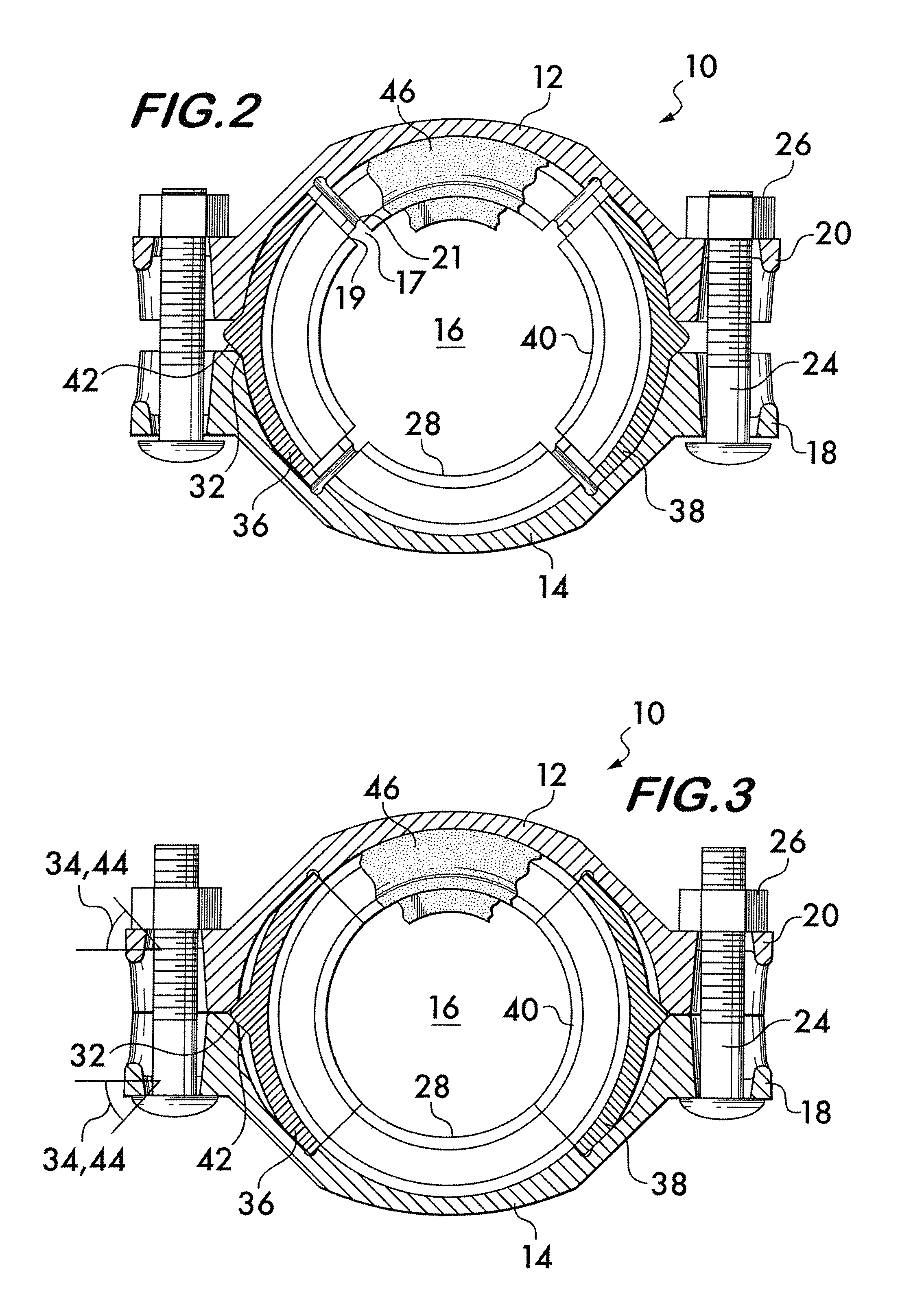

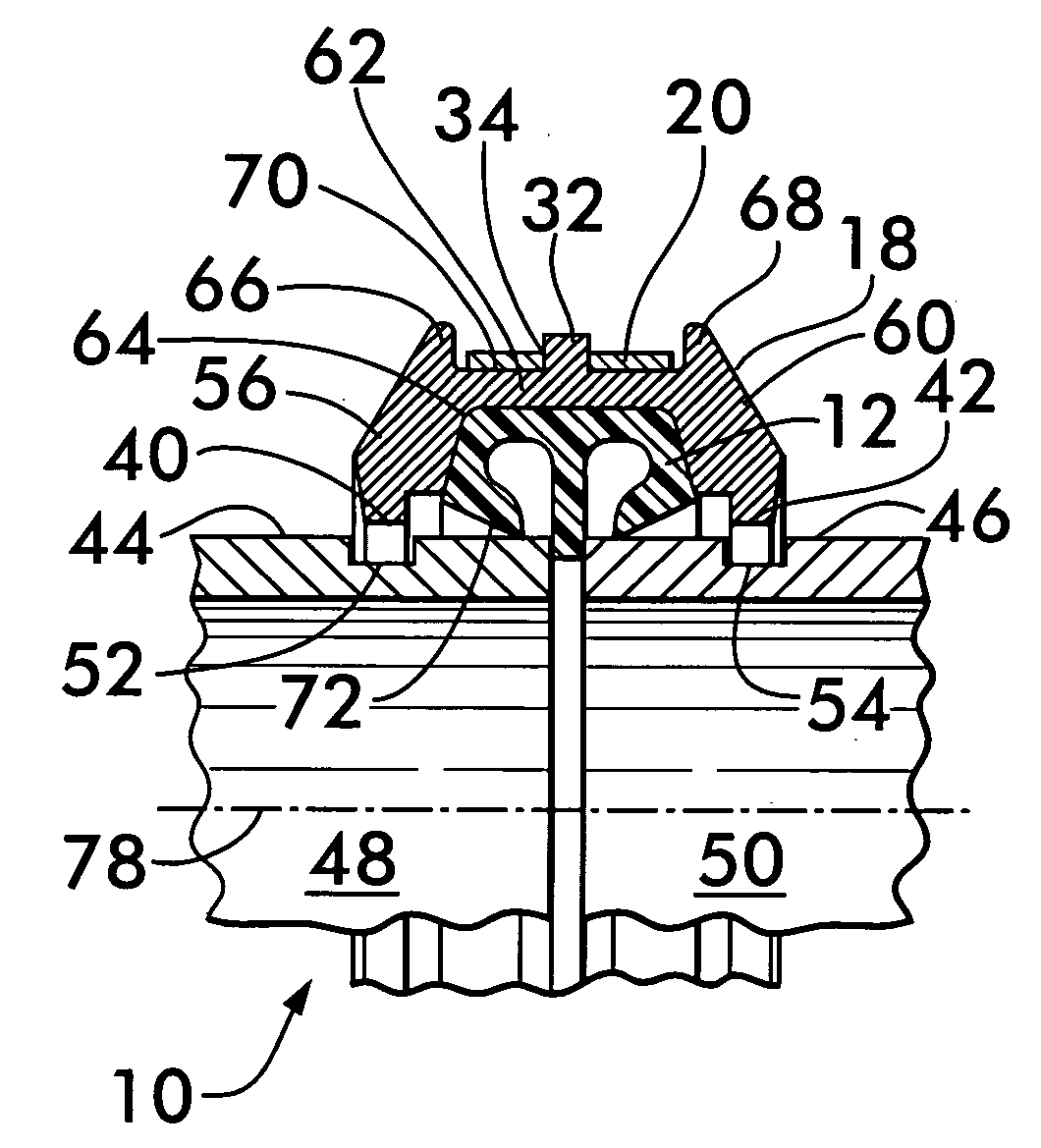

Pipe coupling having movable gripping bodies

A coupling for securing pipe elements together in end-to-end relation has segments joined end-to-end by adjustable connection members. The segments surround a central space which receives the pipe elements. One or more gripping bodies are captured between the segments. The gripping bodies are arranged opposite to each other. The segments have angularly oriented reaction surfaces on the connection members. The gripping bodies have angularly oriented contact surfaces which interface with the reaction surfaces. When the segments are drawn toward each other by the connection members, interaction between the reaction surfaces and the contact surfaces forces the gripping bodies radially inwardly. Inwardly facing arcuate surfaces on the segments and the gripping bodies engage and retain the pipe elements.

Owner:VICTAULIC

Pipe coupling having compression band

ActiveUS20050258641A1Keep the distanceLimit motionSleeve/socket jointsPipe supportsCouplingEngineering

Owner:VICTAULIC

Method and a coupler for joining two steel pipes

InactiveUS7107662B1Improve sealingPipe elementsPipe protection by thermal insulationMechanical engineering

A method and apparatus for coupling together the ends of two steel pipe sections, each of which contains a permeable inner liner, in which not only are the pipe ends held in abutting engagement, but gas contained within the liner of one pipe section is effectively channeled into the liner of the other pipe section.

Owner:ARANT AS TRUSTEE MR GENE W +1

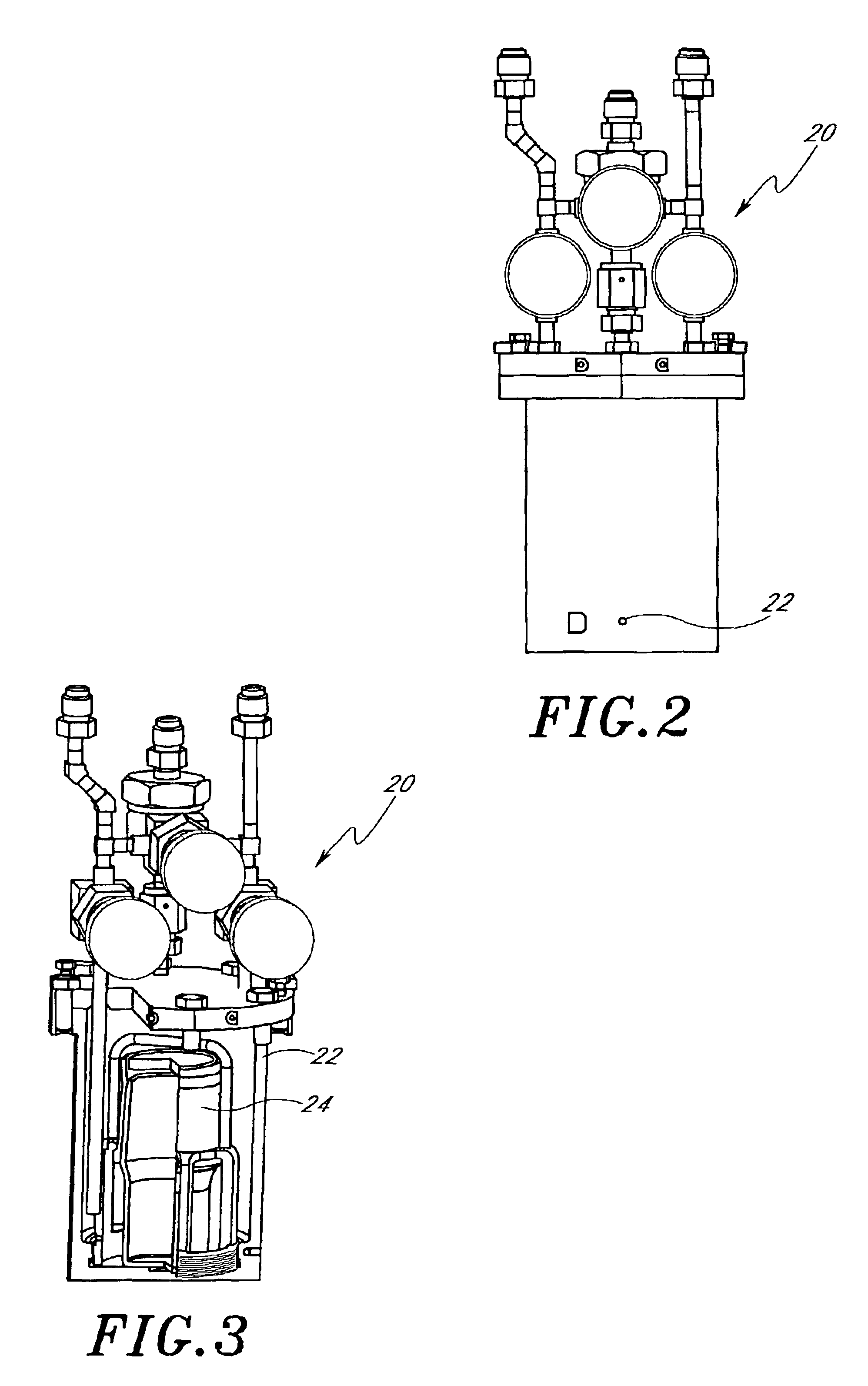

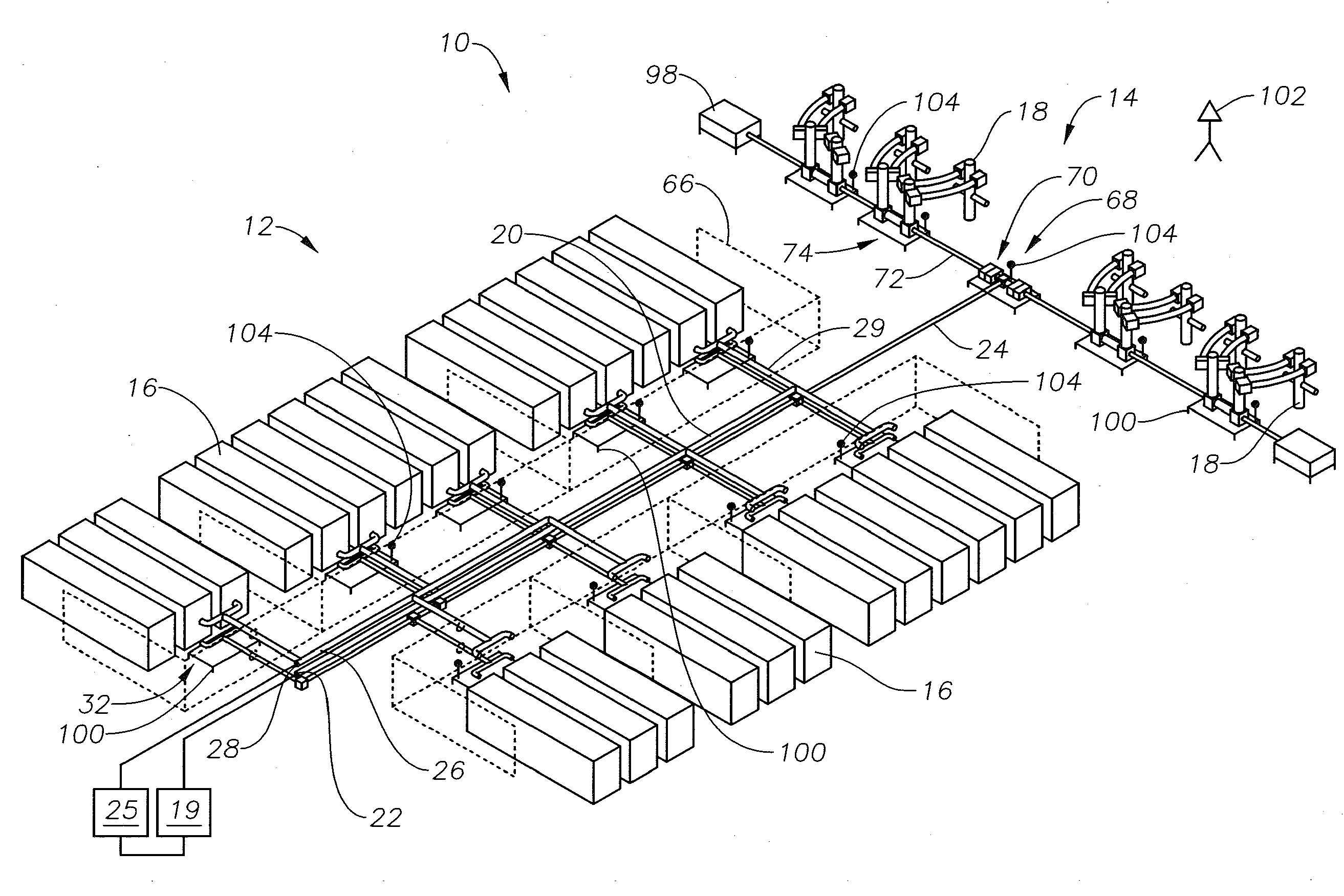

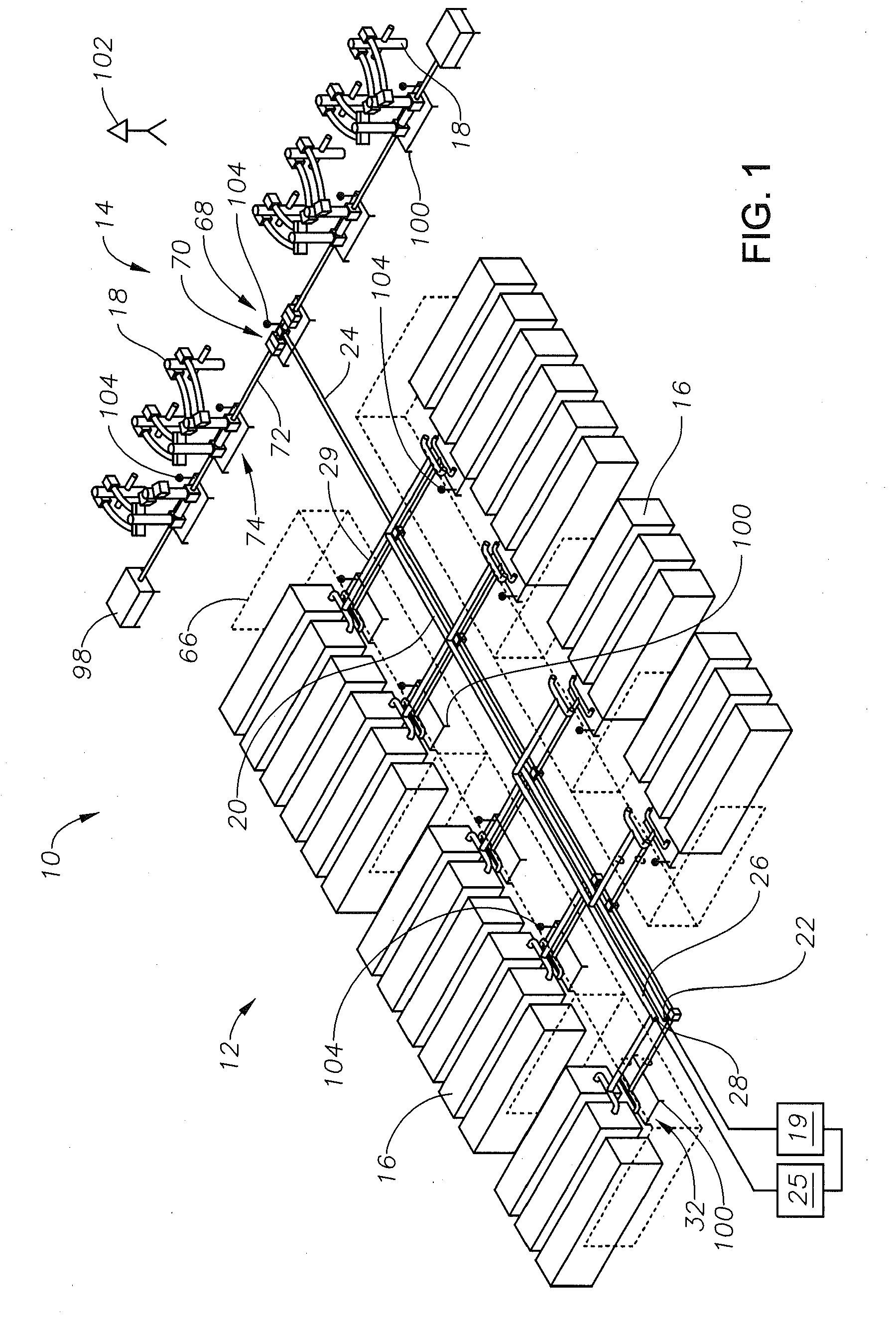

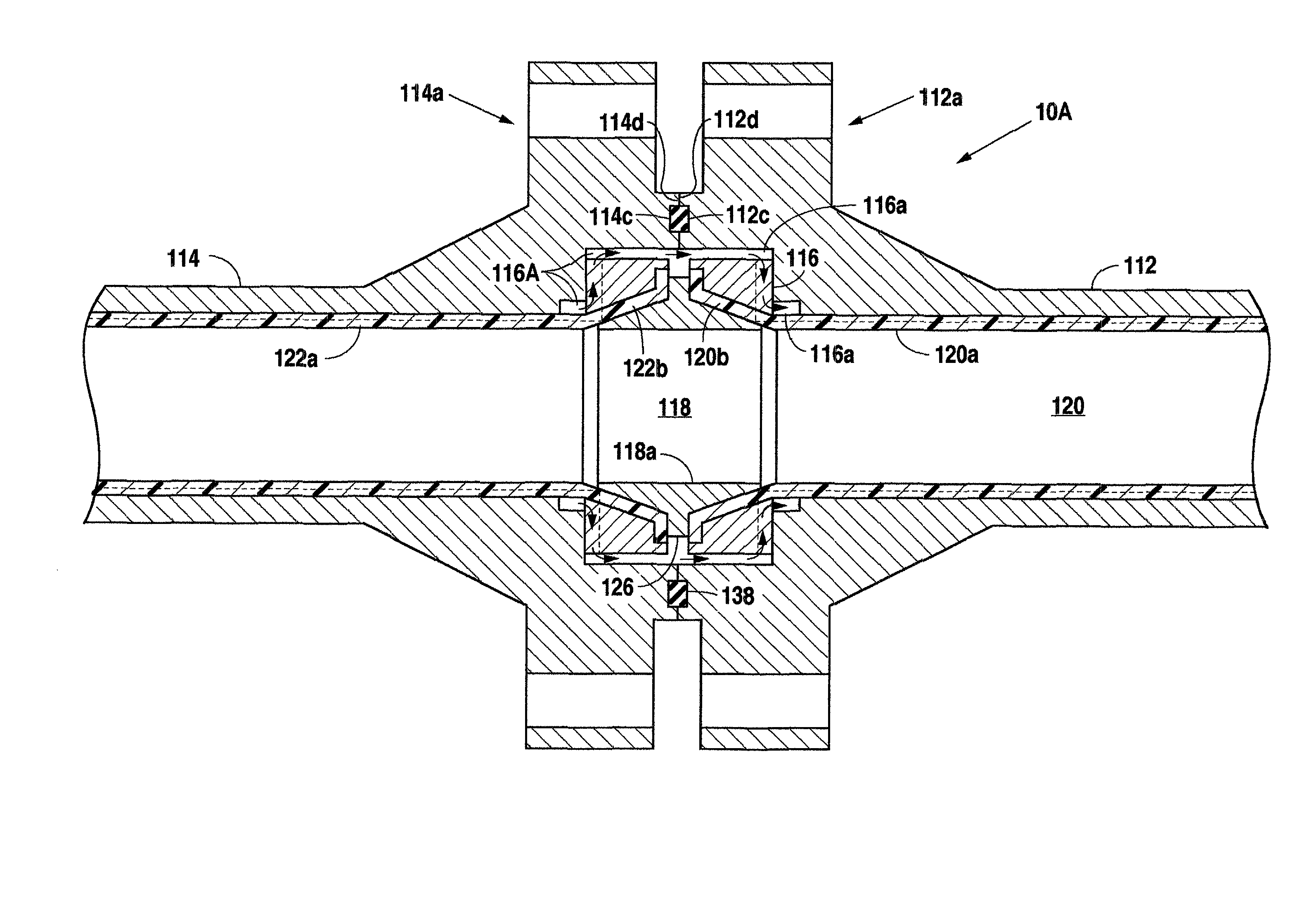

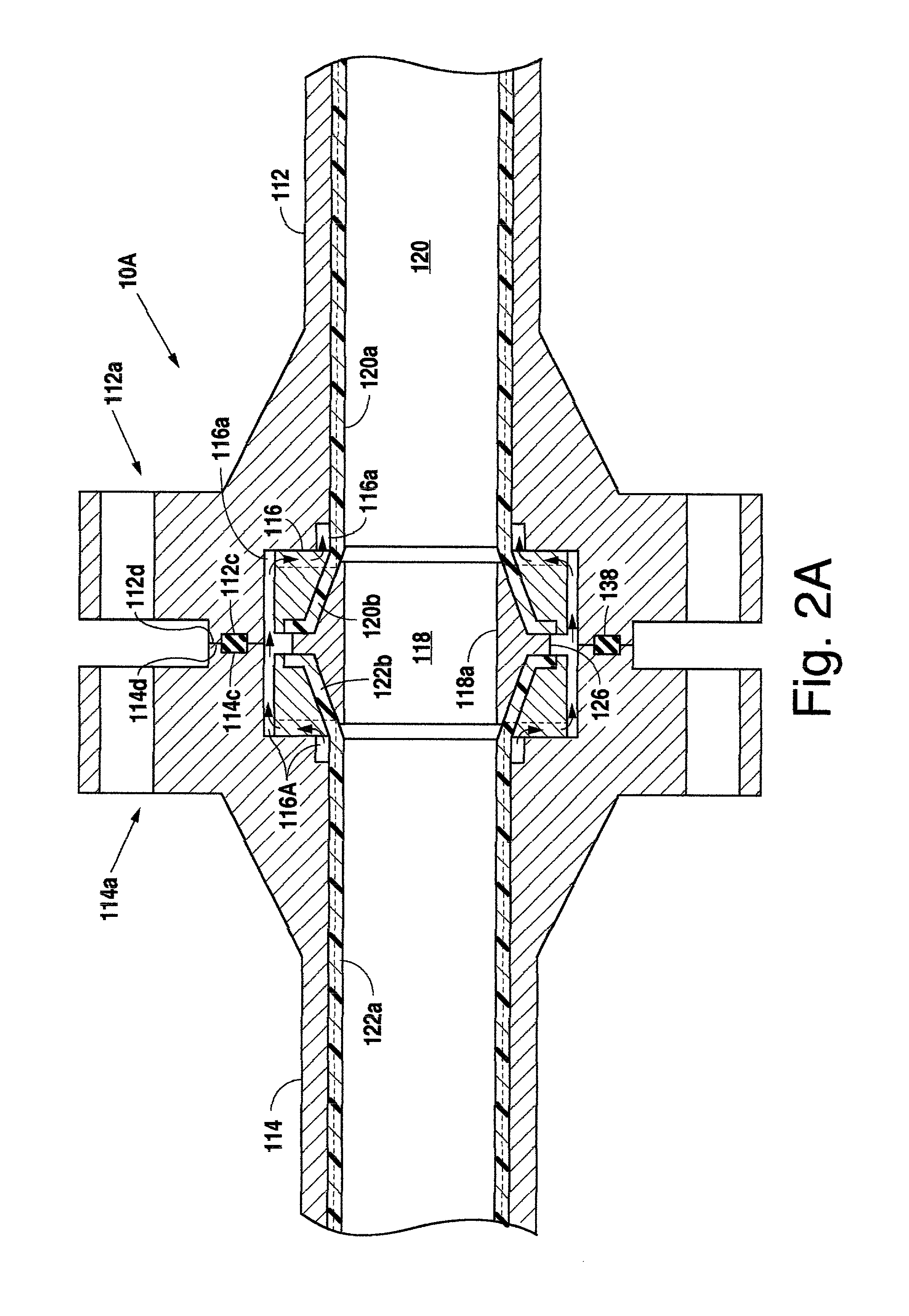

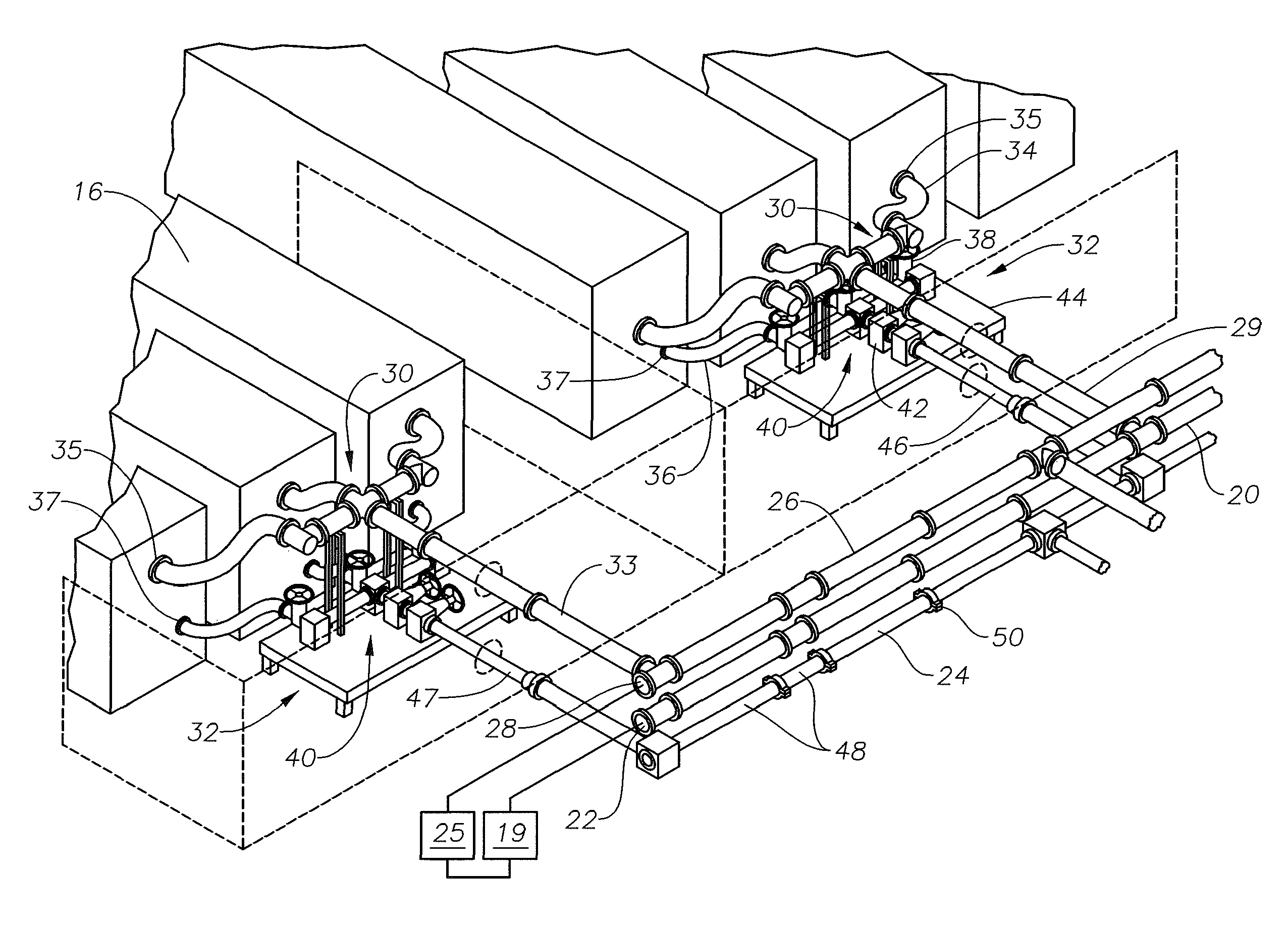

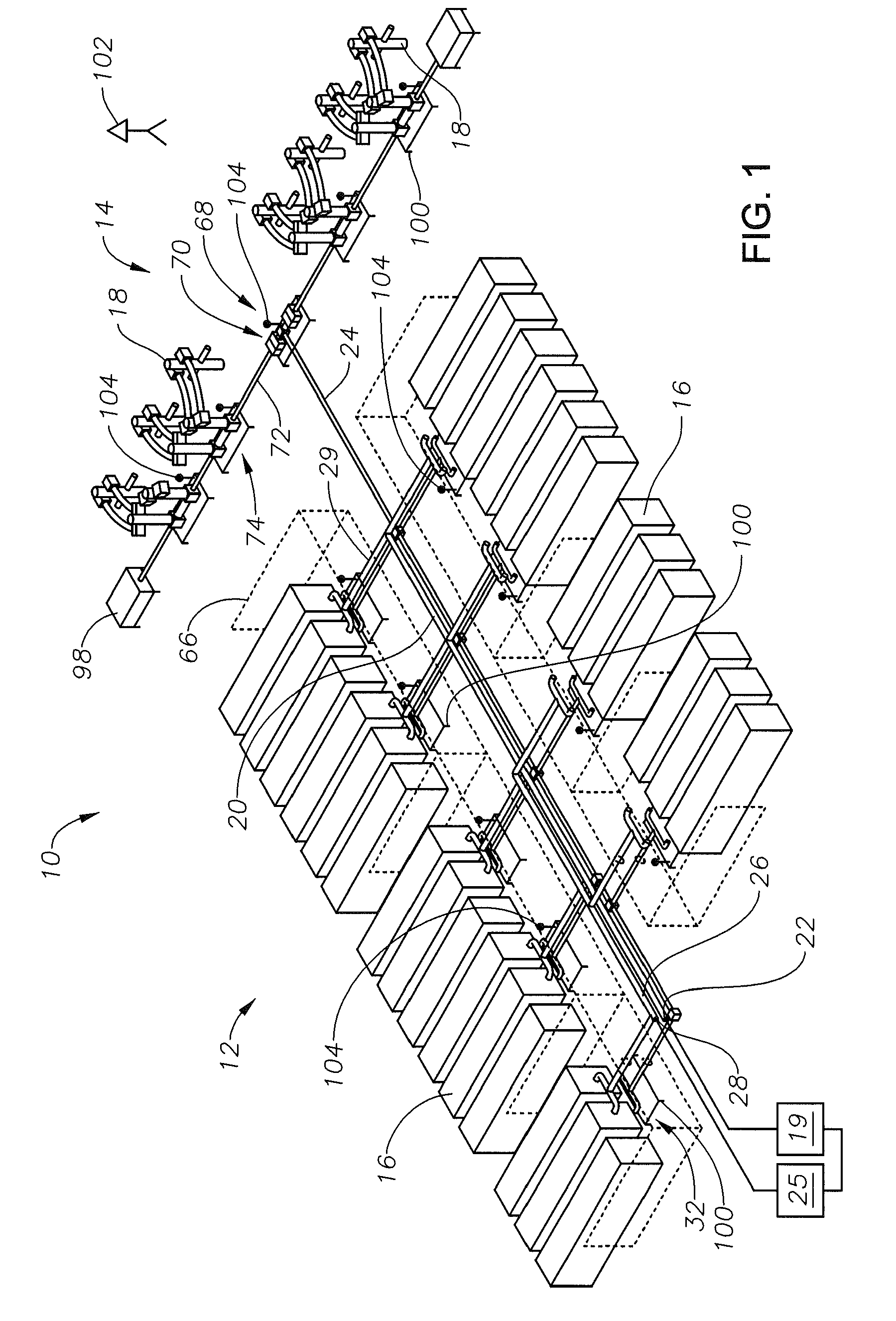

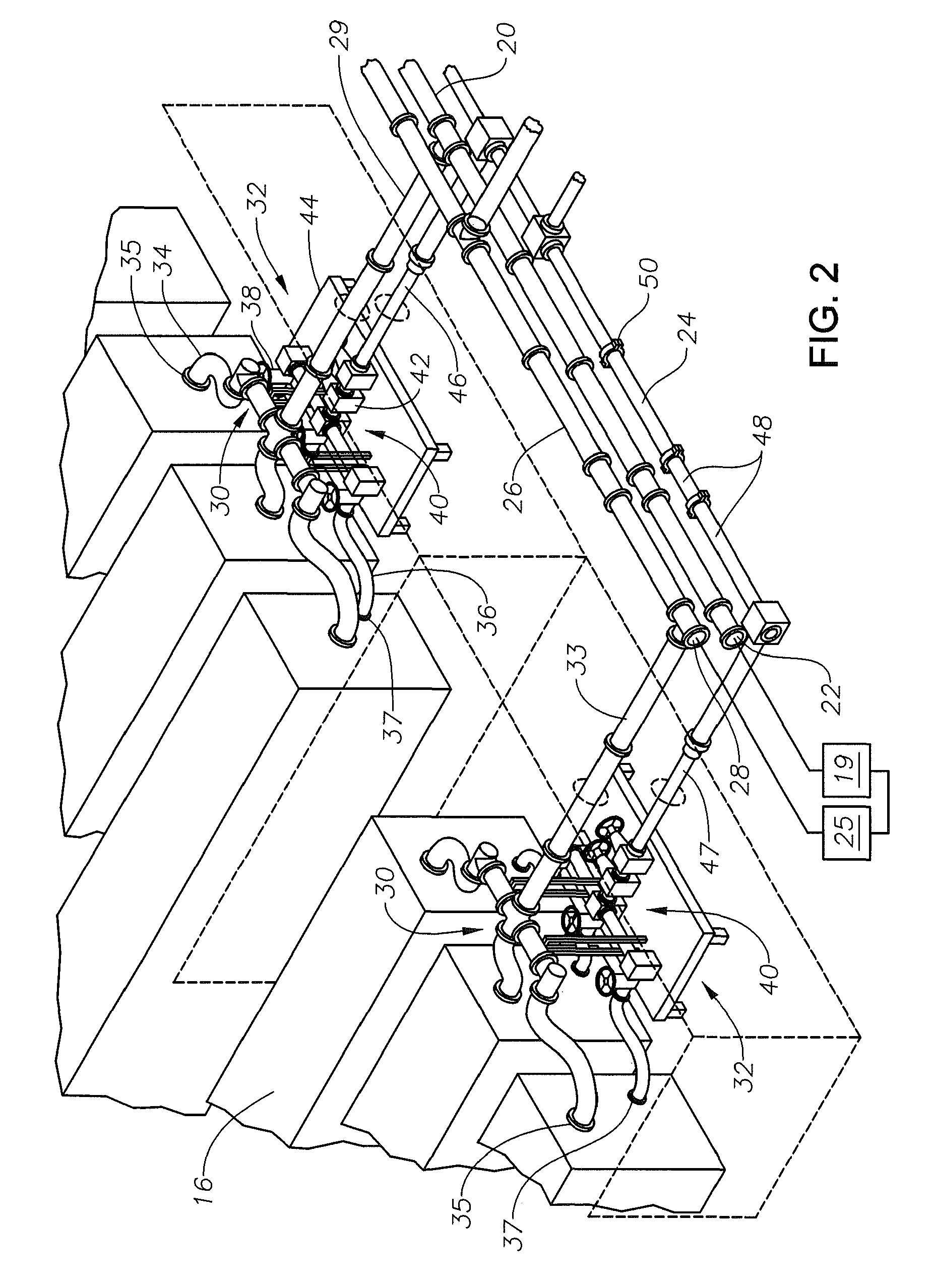

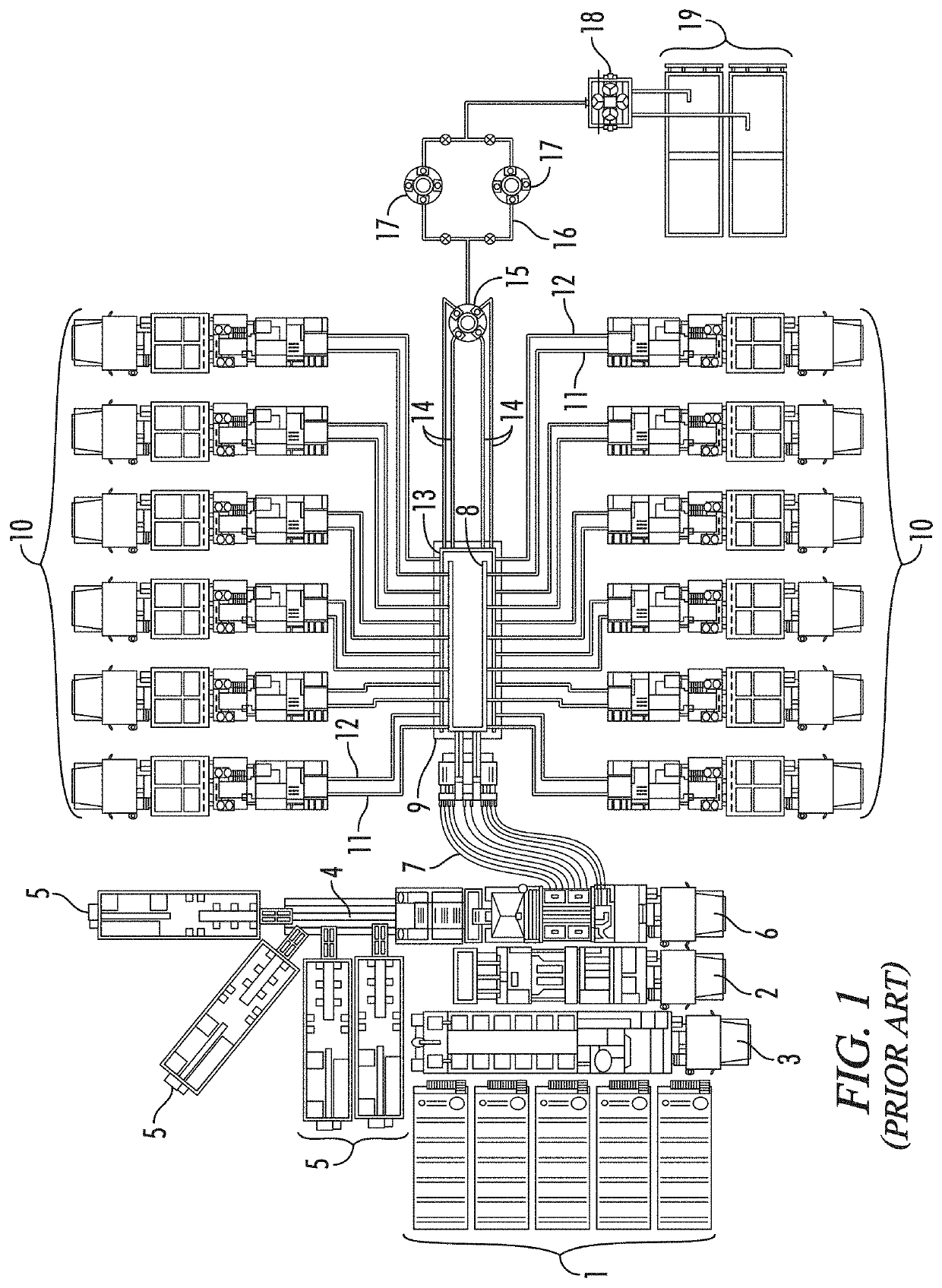

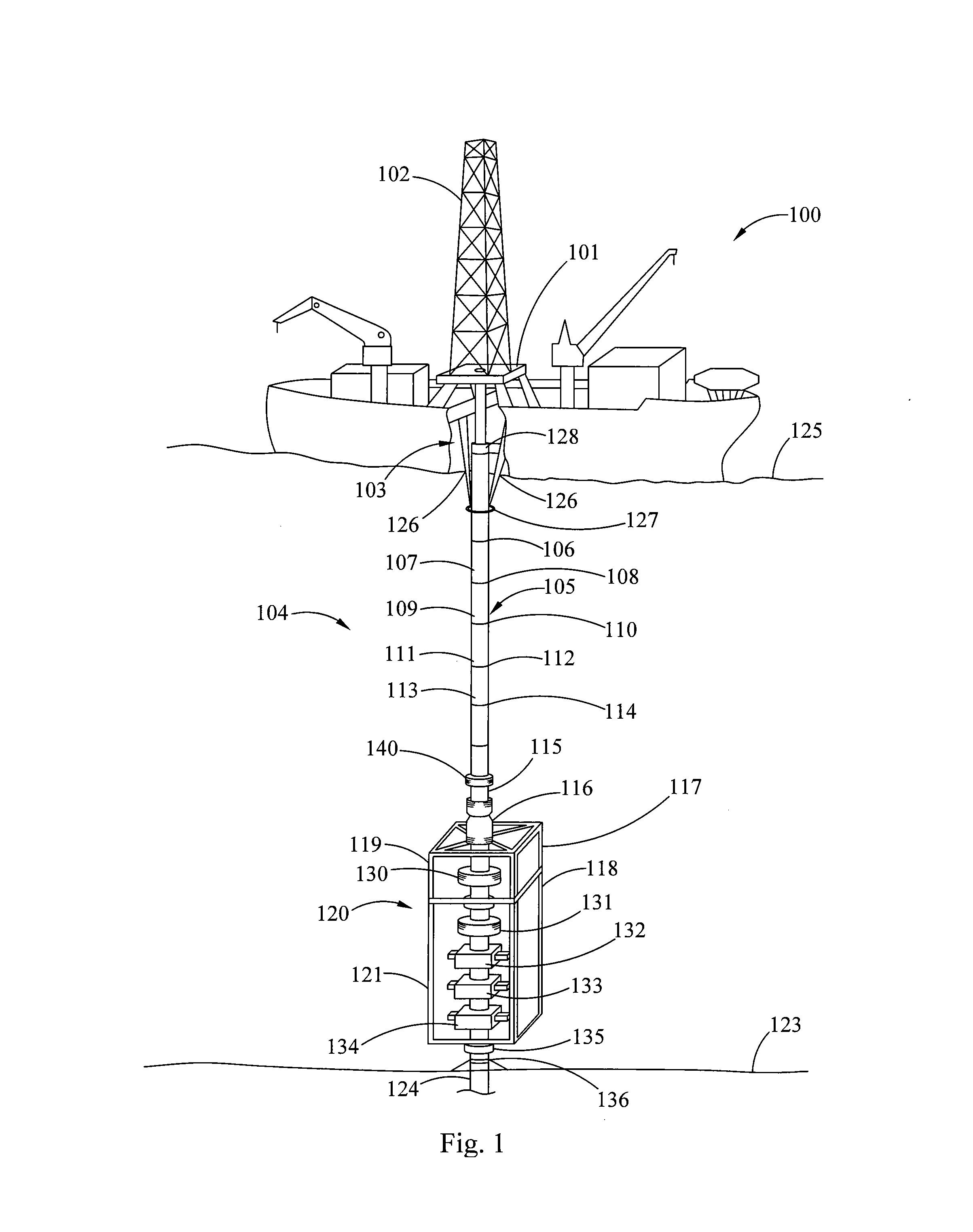

Delivery system for fracture applications

ActiveUS9127545B2Readily configured and assembledFlanged jointsFluid removalTelecommunicationsModularity

Described herein is a modular, adjustable system for distributing fluids to one or more wellbores. The system is readily configured and assembled at a well site, and allows for one portion of the system to be isolated for service or repair while the remainder of the system continues to operate. The system includes a plurality of pump skids having both a distribution junction in fluid communication with inlets to of plurality of pump trucks and an exit junction in fluid communication with outlets of the plurality of pump trucks.

Owner:VAULT PRESSURE CONTROL LLC

4-Way Compression Grooved Coupling

InactiveUS20110154646A1Improve installation efficiencyEliminate relative motionSleeve/socket jointsFlanged jointsCouplingEngineering

A pre-assembled pipe coupling for joining and sealing two grooved-ended pipe segments without disassembling the coupling is disclosed. The coupling has a housing with upper and lower arcuate housing segments and left and right bridge segments. Each bridge segment has at least one set of dihedrally angled faces that engage corresponding faces each in the upper and lower housing segments. Drawing the upper and lower segments inwardly together along a first axis, presses each bridge segment inward along a second axis roughly tangential to the first axis. All segments are loosely pre-assembled with bolts and nuts into a coupling and all segments each have radially inwardly projecting lands that mate with end grooves in the pipes to be joined. The coupling also has a one-piece circular sealing gasket that has an inward circumferential and centrally positioned pipe stop that has an inner diameter smaller than an outer diameter of the pipes to be joined. The gasket has two circumferential sealing lips axially outward from the pipe stop, the inner diameter each sealing lip larger than the outer diameter of the pipe segments to be joined.Method for joining and sealing two grooved-ended pipe segments with a pre-assembled pipe coupling, without disassembling the coupling, is also disclosed.

Owner:SHURJOINT METALS INC

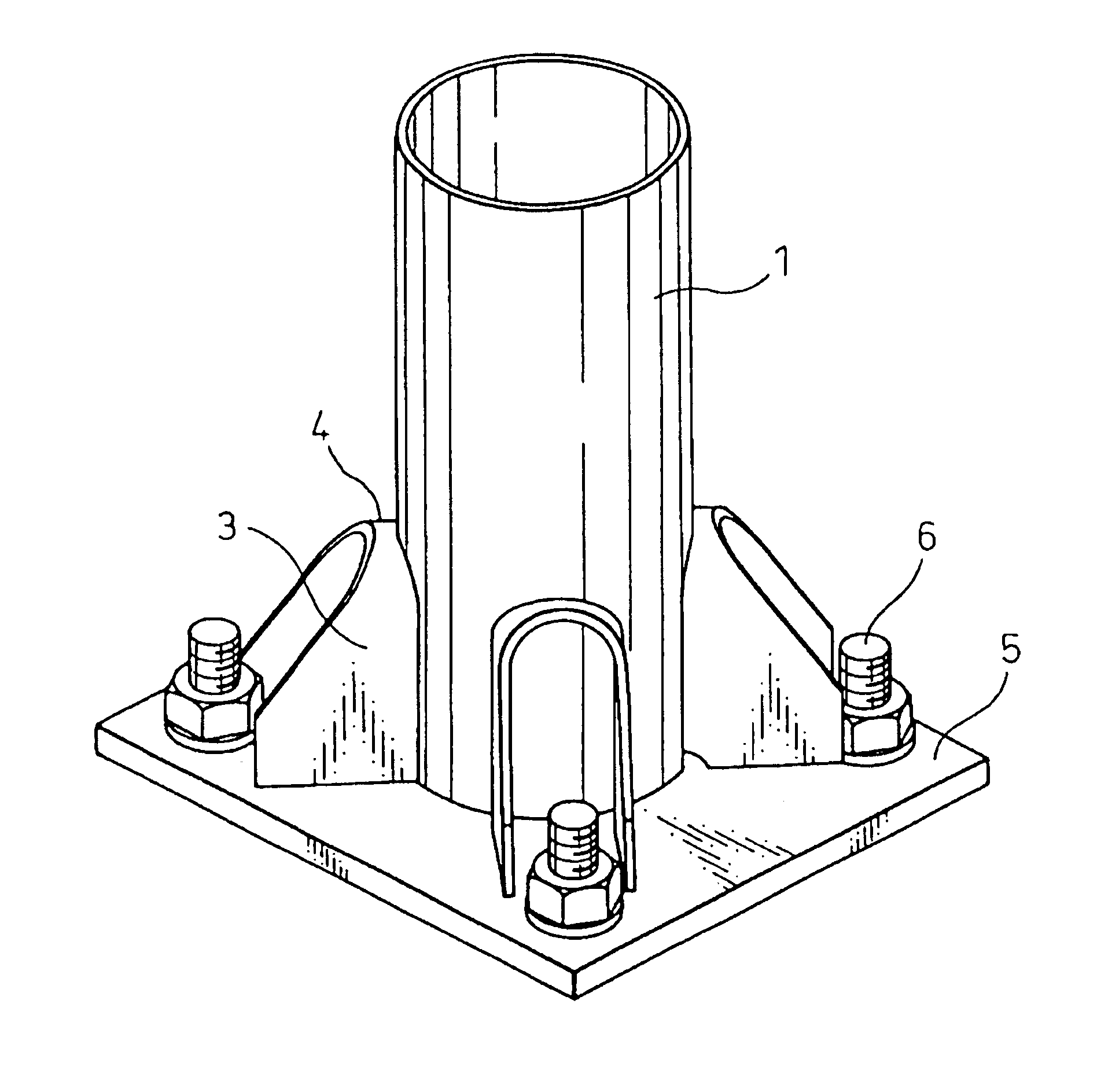

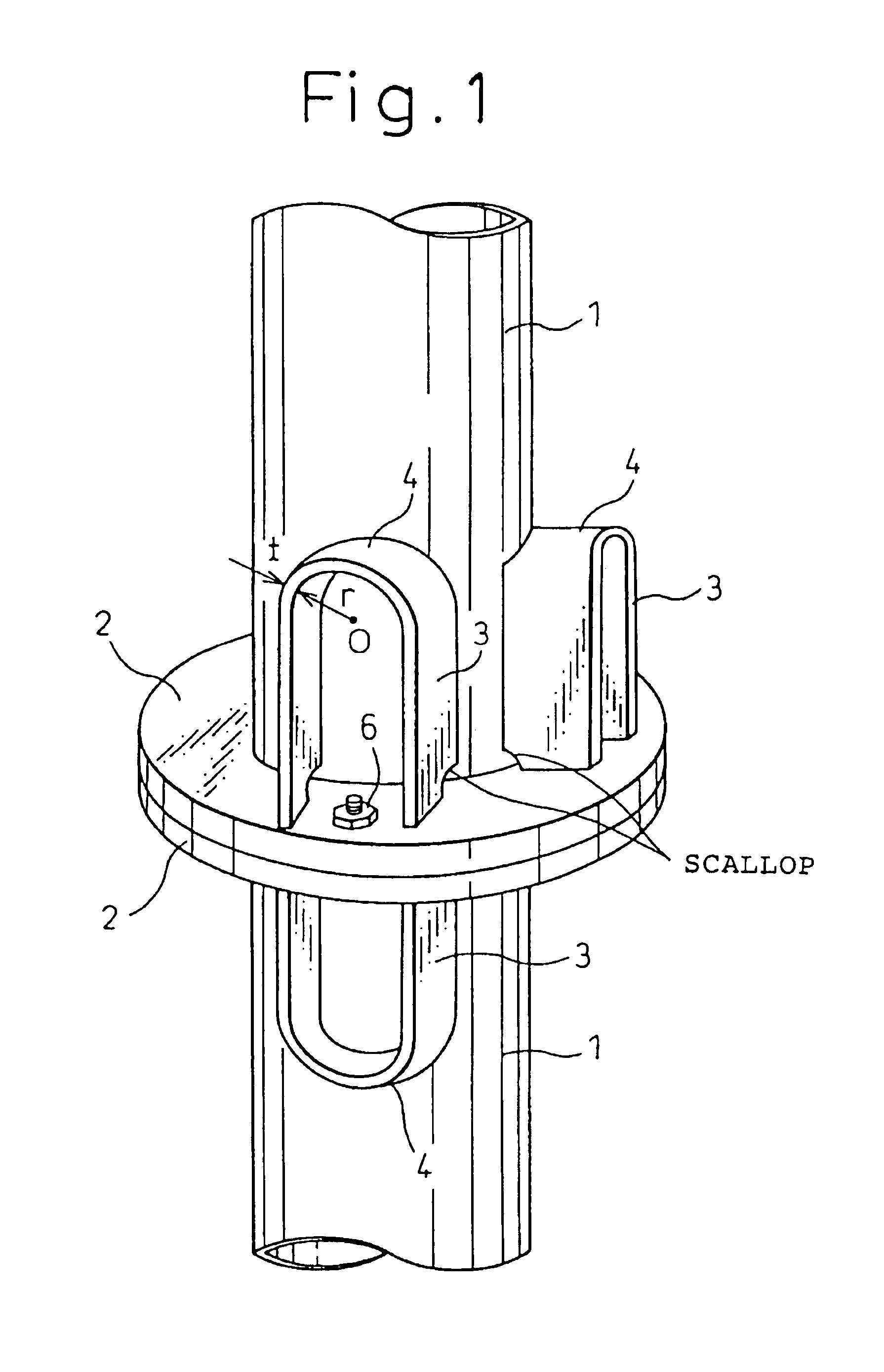

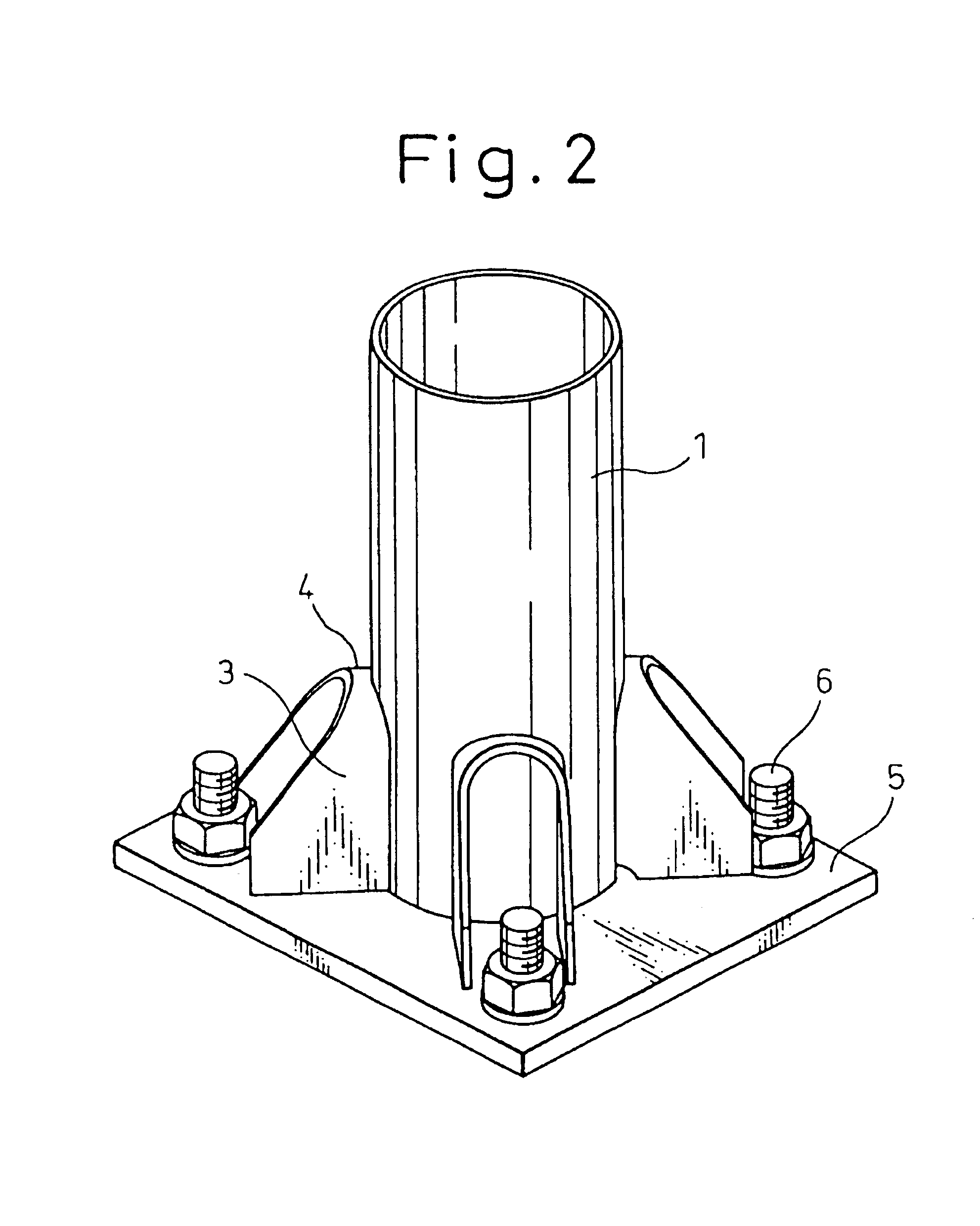

Joining structure

InactiveUS6857808B1Reduce stiffnessReduce stress concentrationMachine supportsFoundation engineeringStress concentrationPrincipal stress

The present invention provides a joining structure capable of greatly improving the proof stress and the fatigue property by alleviating the stress concentration and residual stress caused by welding heat at one or both ends of a tabular member.In the present invention, one or both ends 4 of a tabular member 3 such as a reinforcing rib, fixed to the surface of a structural member 1 in the direction of the principal stress of the structural member 1 so as to protrude in the shape of T, is / are bent in a direction deviating from the direction of the principal stress and, by this, the rigidity at the end(s) 4 of the tabular member 3 decreases and the stress concentration is alleviated. It is preferable to bend one or both ends of a tabular member 3 in the shape of an gradual curve and to the extent that each bent end is formed at a right angle to the direction of the principal stress. The tabular member may have the shape of a flat plate, or it may be bent so that it has the shape of U or V as a whole. Further, the tabular member may be welded to a structural member or formed as an integral part of a structural member.

Owner:NIPPON STEEL CORP +2

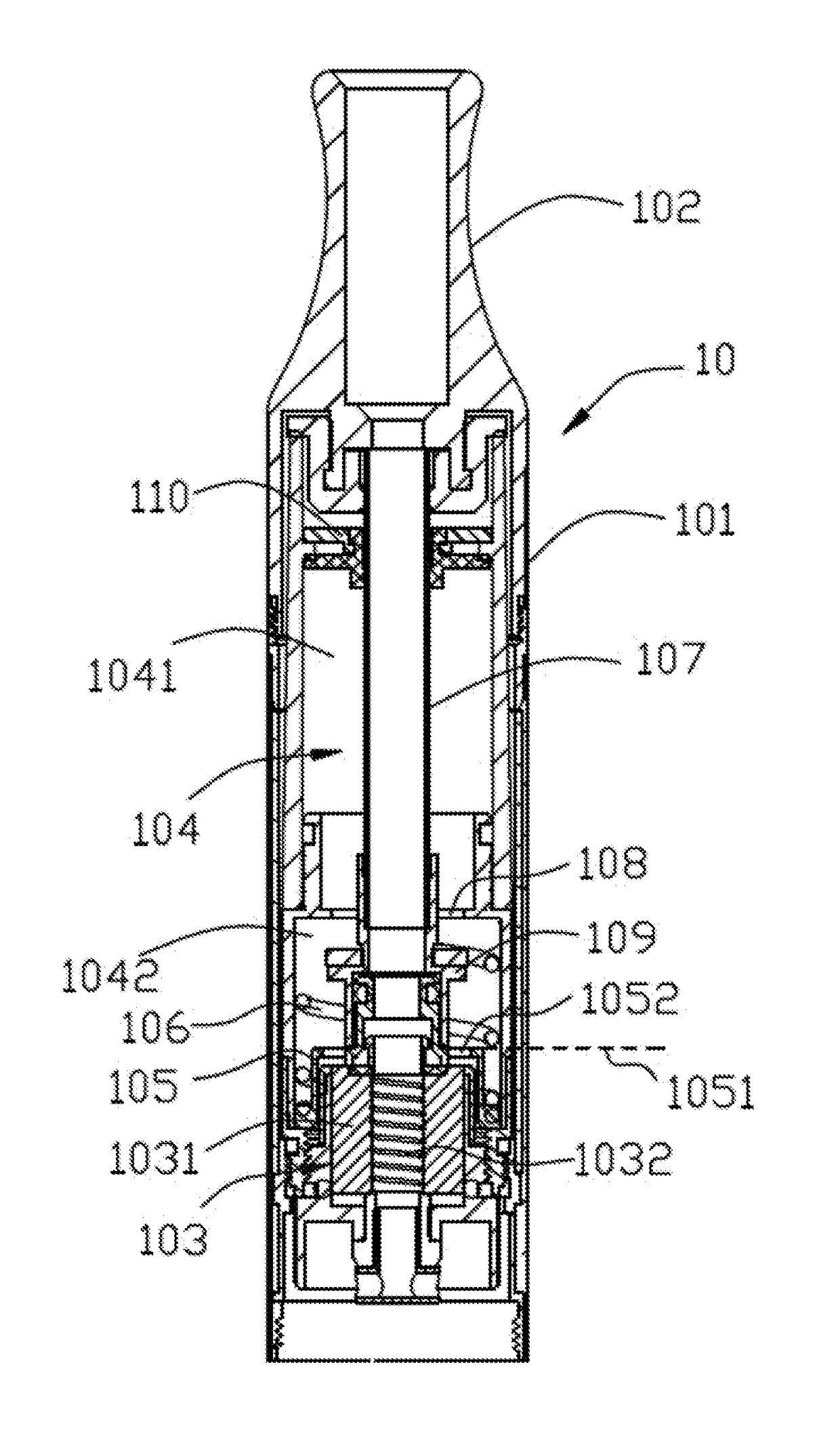

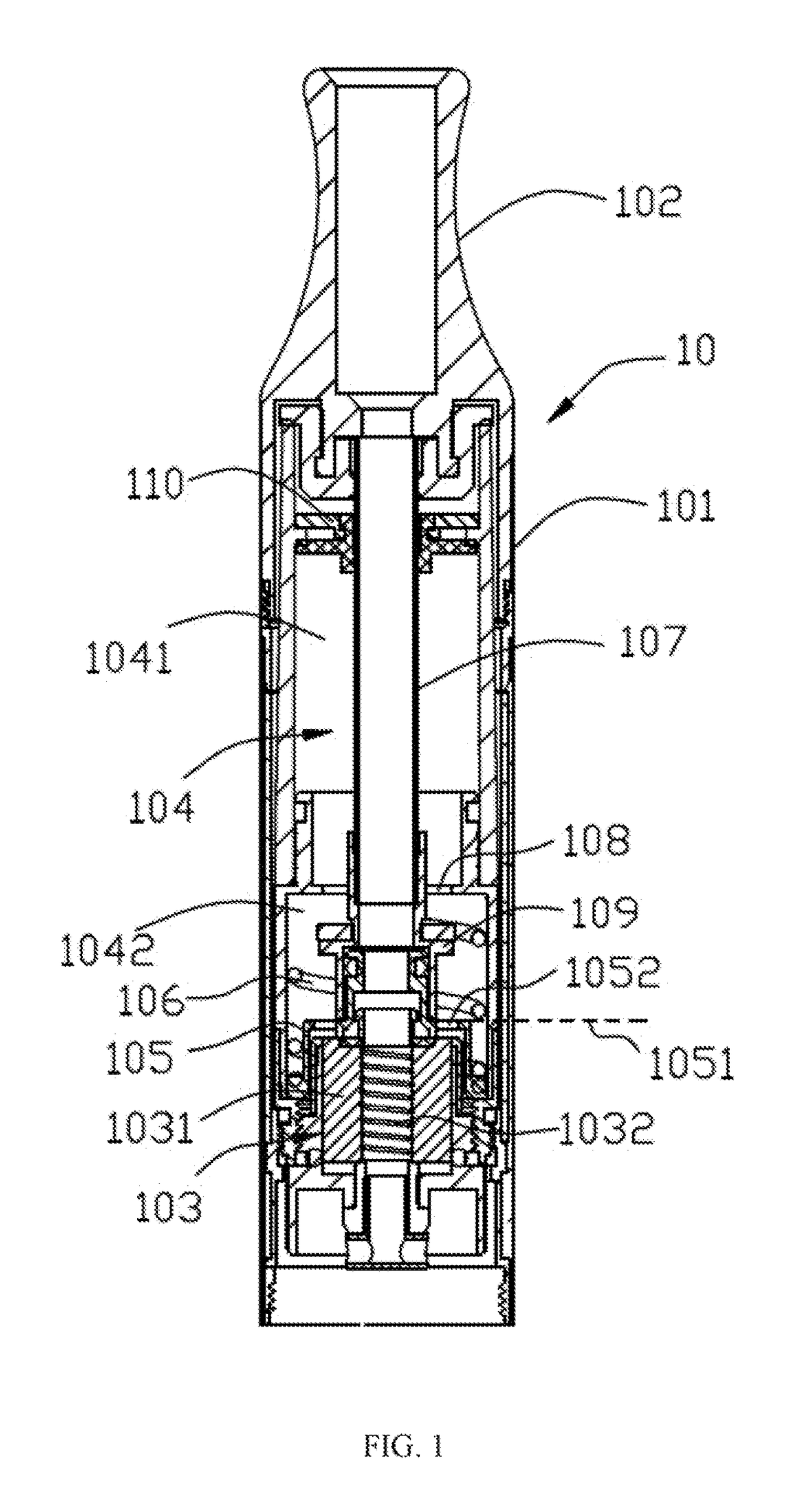

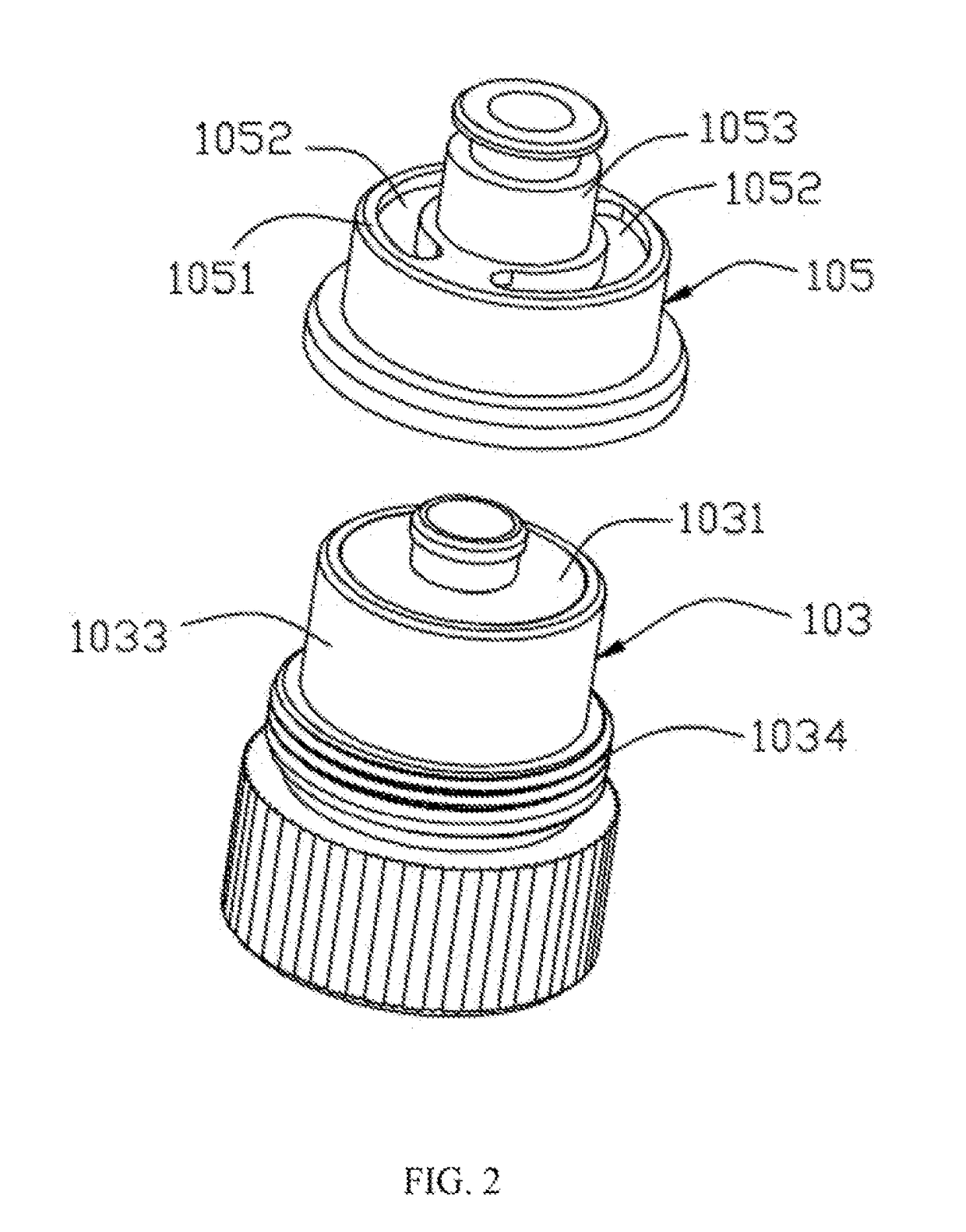

Atomizer and electronic cigarette having same

An exemplary atomizer includes a main body of housing, a mouthpiece, an atomizing core, an atomizing cover. The main body of housing defines a liquid chamber configured for storing tobacco liquid. The mouthpiece is detachably connected with an end of the main body of housing. The atomizing core arranged in the main body of housing. The atomizing cover is arranged in the liquid chamber. The atomizing core is arranged in the atomizing cover. The atomizing cover has a top surface, and the top surface defines at least one liquid inlet. The atomizing core includes a heating element and a liquid conducting element surrounding the heating element. The liquid conducting element is configured for absorbing tobacco liquid flowed from the at least one liquid inlet, and the heating element is configured for atomizing the tobacco liquid in the liquid conducting element.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Flowline junction fittings for frac systems

ActiveUS10662749B1Limiting transverse movementPipe supportsFlanged jointsClassical mechanicsStructural engineering

Flowline junction fittings are assembled to missiles of frac manifolds. The fittings have a body with a primary bore, at least four secondary bores, and a tertiary bore. The bores extend from union faces adapted for connection to flowline components by a flange union. The tertiary bore intersects with the primary bore at an angle of approximately 90°. Goat head fittings are assembled to well heads. The goat heads have a body with a primary bore and at least four secondary bores. The bores extend from union faces adapted for connection to flowline components by a flange union. The intersections between the secondary bores and the primary bore have an interior angle of substantially less than 90°.

Owner:KHOLLE MAGNOLIA 2015 LLC

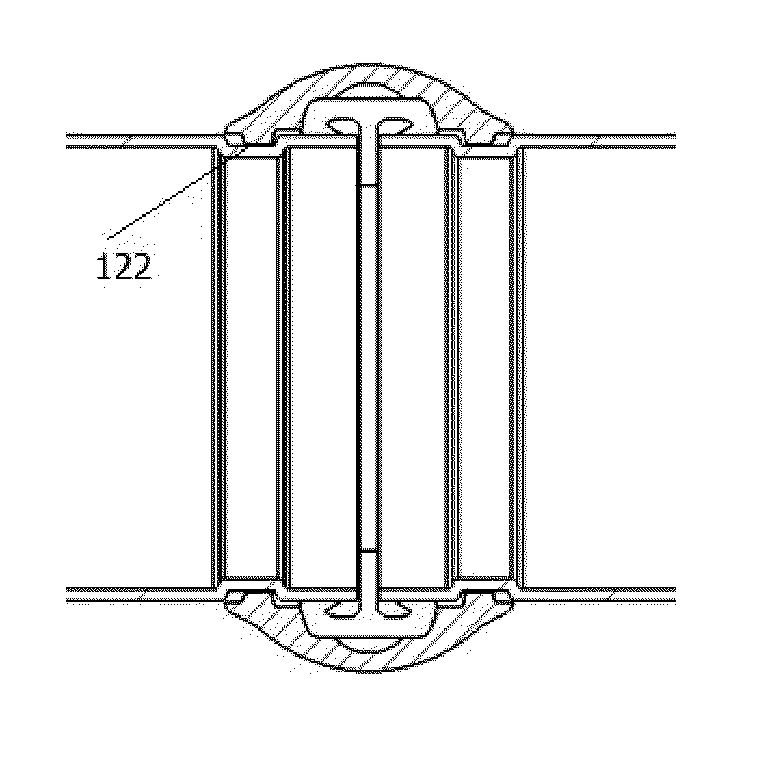

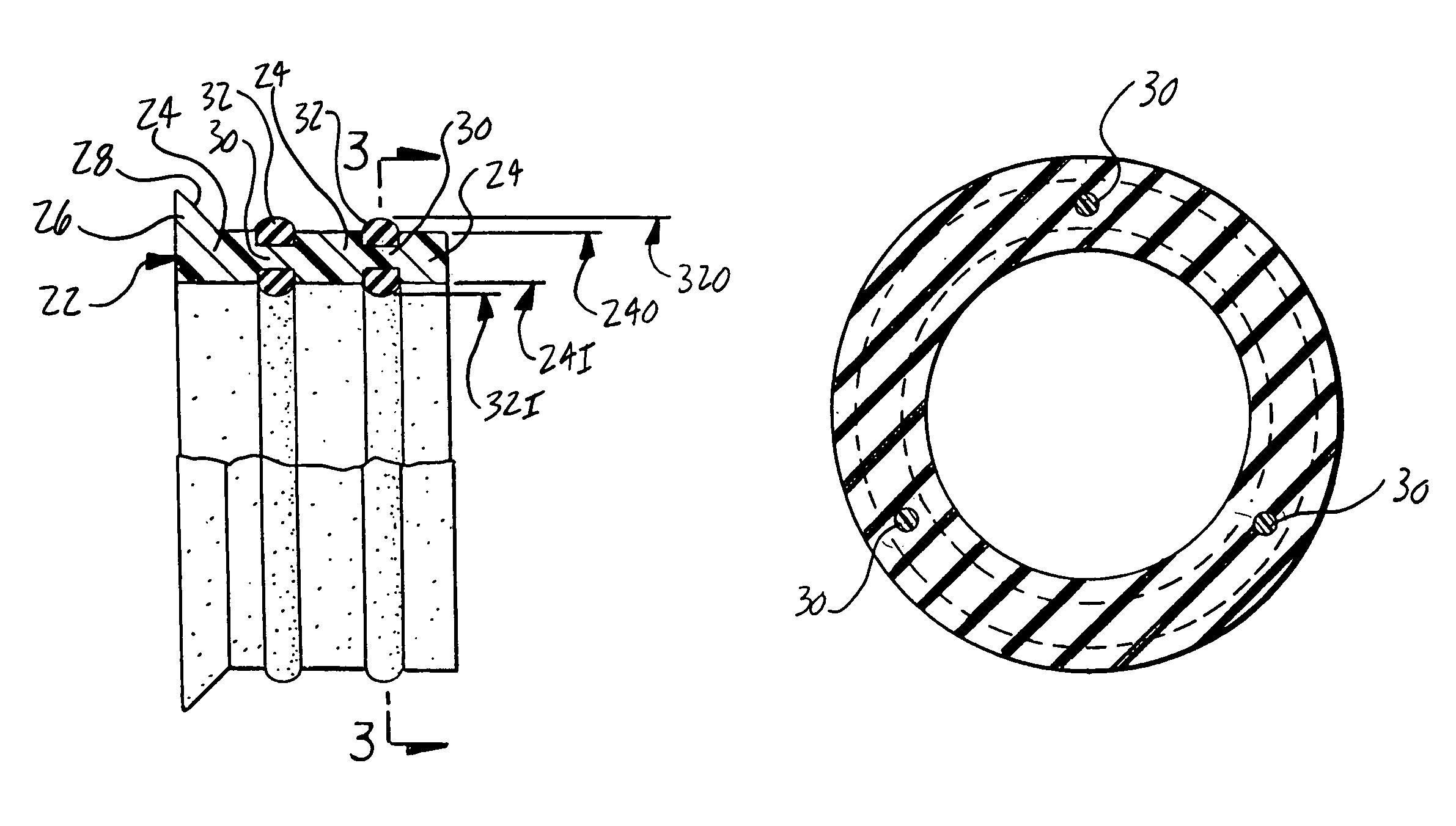

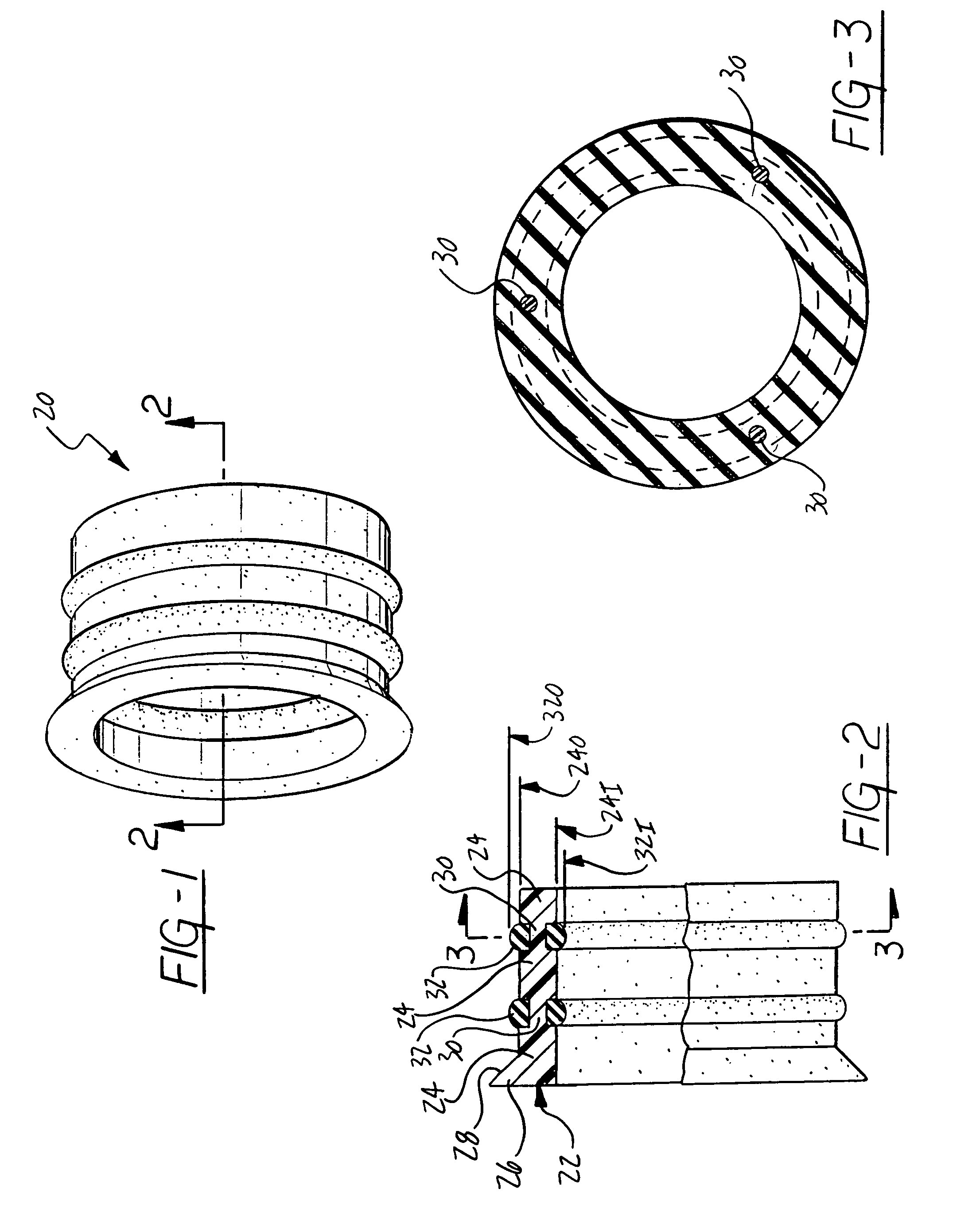

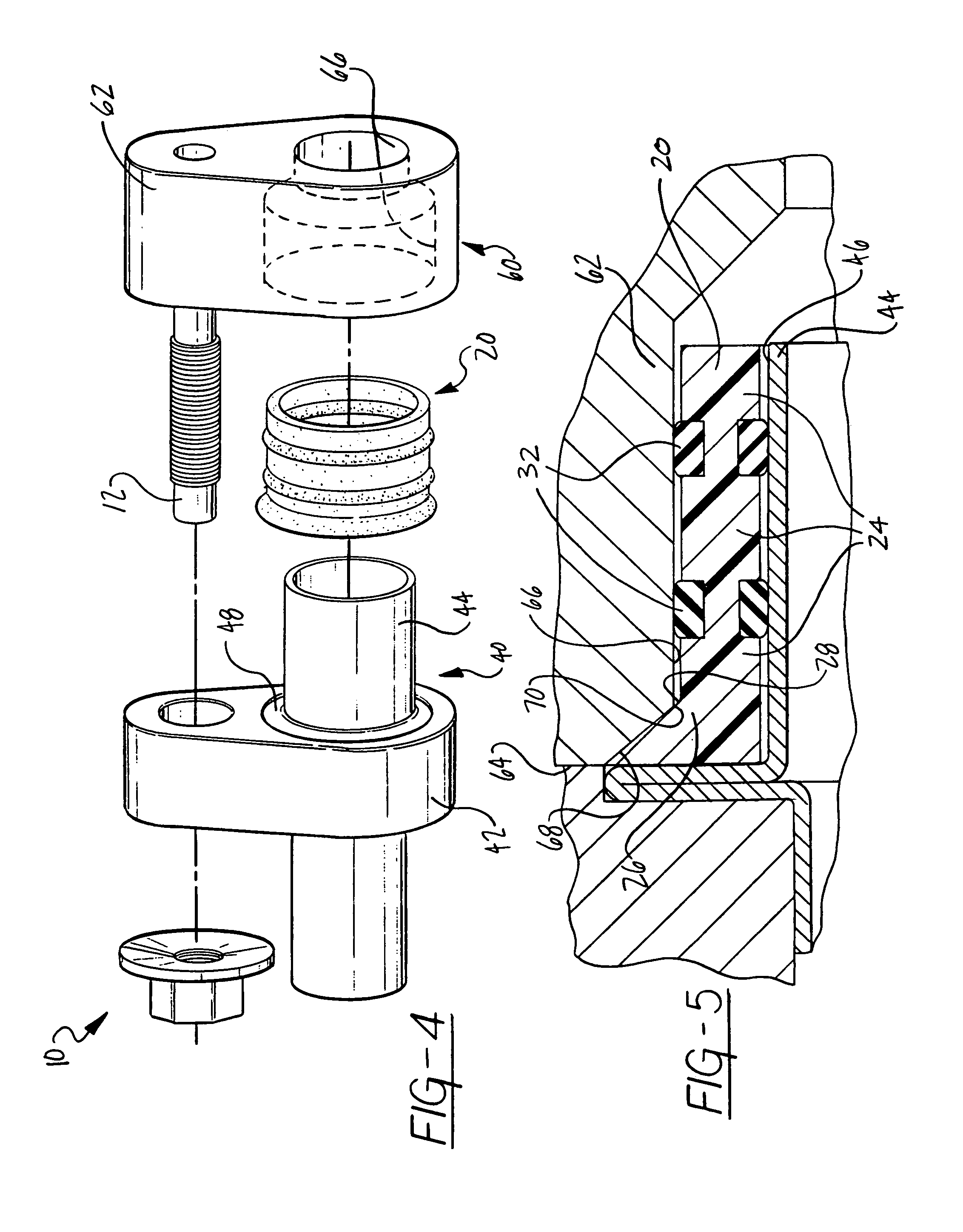

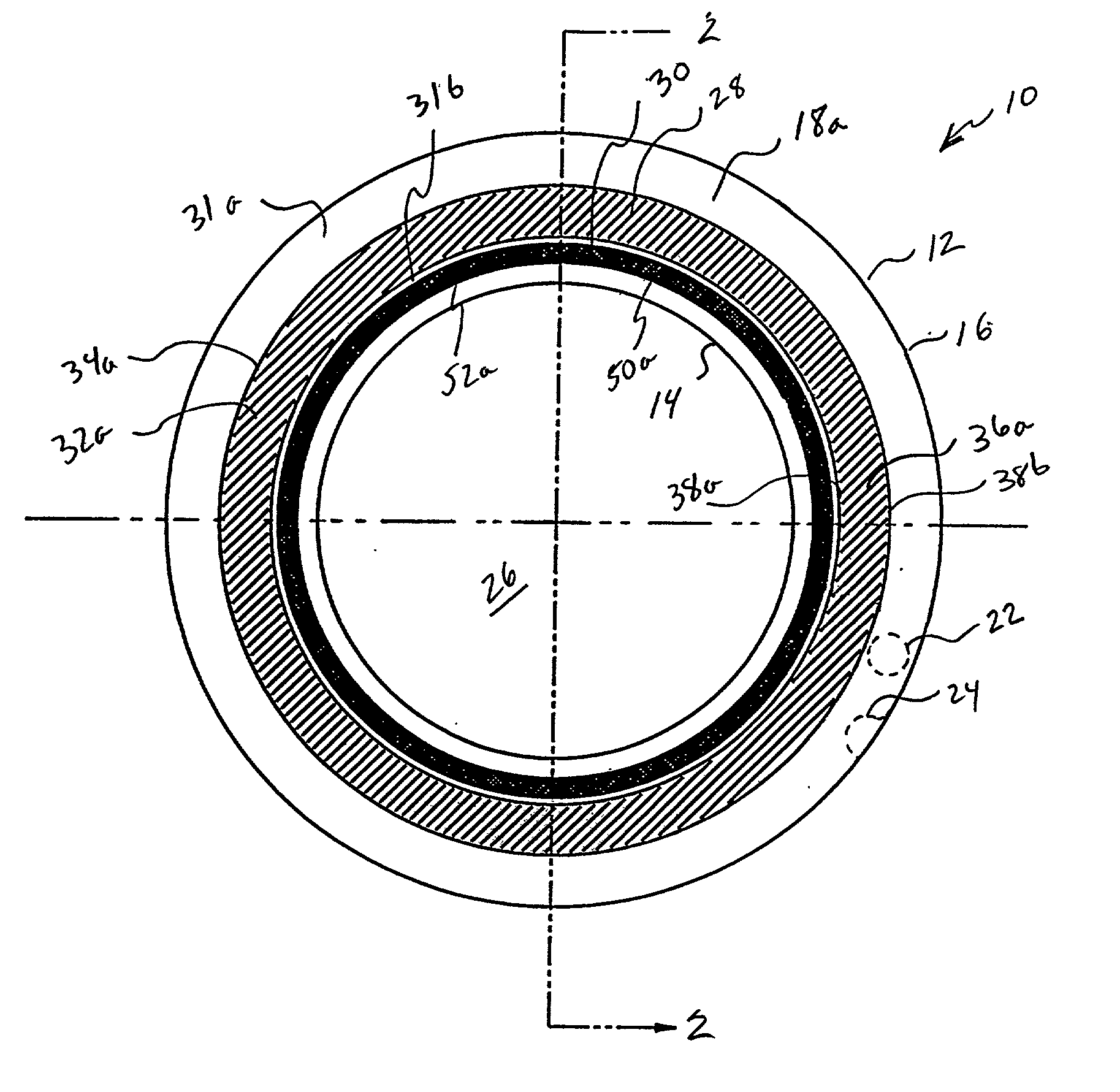

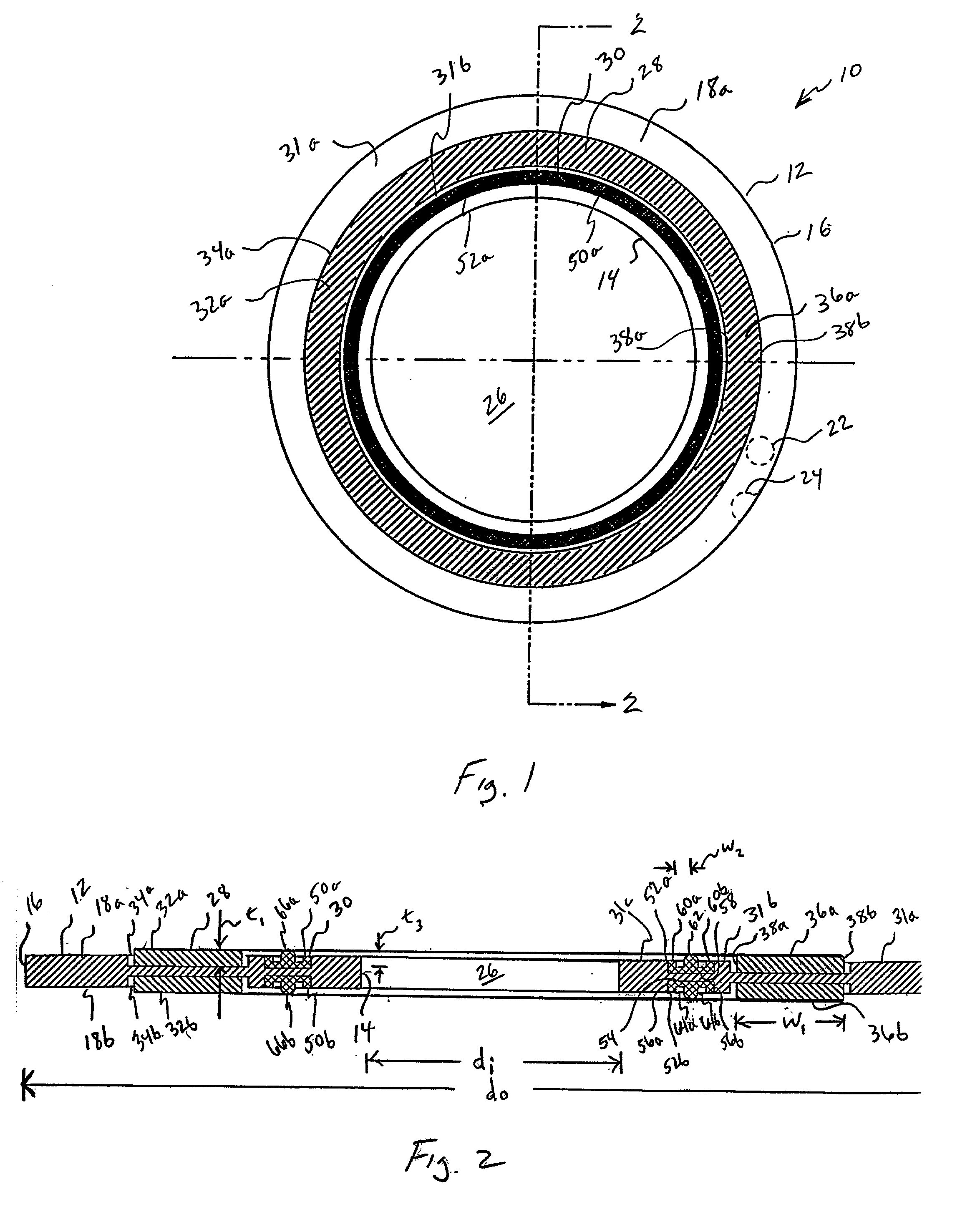

Composite sleeve for sealing a tubular coupling

InactiveUS7407165B1Simpler and more controllable manufacturing processProduct qualitySleeve/socket jointsFlanged jointsCouplingEngineering

A composite sleeve seal for sealing a conduit connection including a body portion having collar sections spaced apart from one another to define gaps therebetween, and being interconnected to one another by link segments spanning the gaps. A seal portion interposes the collar sections in the gaps and surrounds the link segments to positively interlock the seal portion with the body portion to form the composite sleeve seal as one integral component.

Owner:HUTCHINSON FTS

Pipeline Termination Skid, a Connection Arrangement Comprising Such a Pipeline Termination Skid and a Pipeline Termination

ActiveUS20070269270A1Facilitate pipe-laying operationReduce demandPipe laying and repairFlanged jointsOcean bottomSlide plate

A pipeline termination skid to be mounted to a pipeline end section to support a pipeline hub during the connection of the pipeline hub to a corresponding spool piece hub. The pipeline termination skid is so designed that a pipeline end section may be mounted thereto subsea by lowering the pipeline end section into a seat of one or several holding devices of the pipeline termination skid and thereafter displacing the pipeline termination skid along the pipeline end section so that the respective seat is brought into engagement with an alignment element secured about the pipeline end section so as to thereby fix the pipeline end section axially and radially in relation to the pipeline termination skid. A connection arrangement includes the pipeline termination skid, a pipeline termination designed for co-operation with the termination skid and a method for subsea connection of a pipeline to a spool piece.

Owner:VETCO GRAY SCANDINAVIA

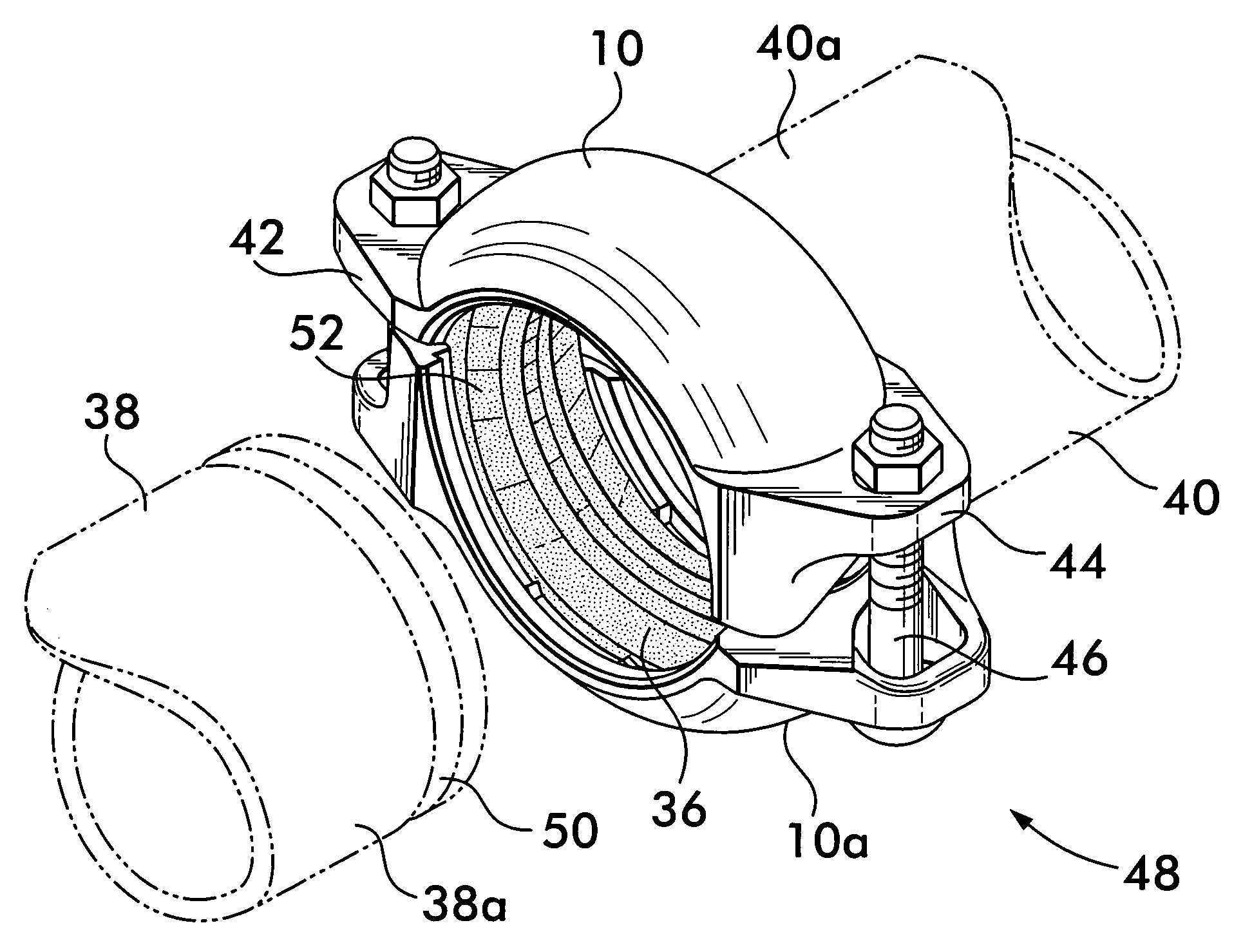

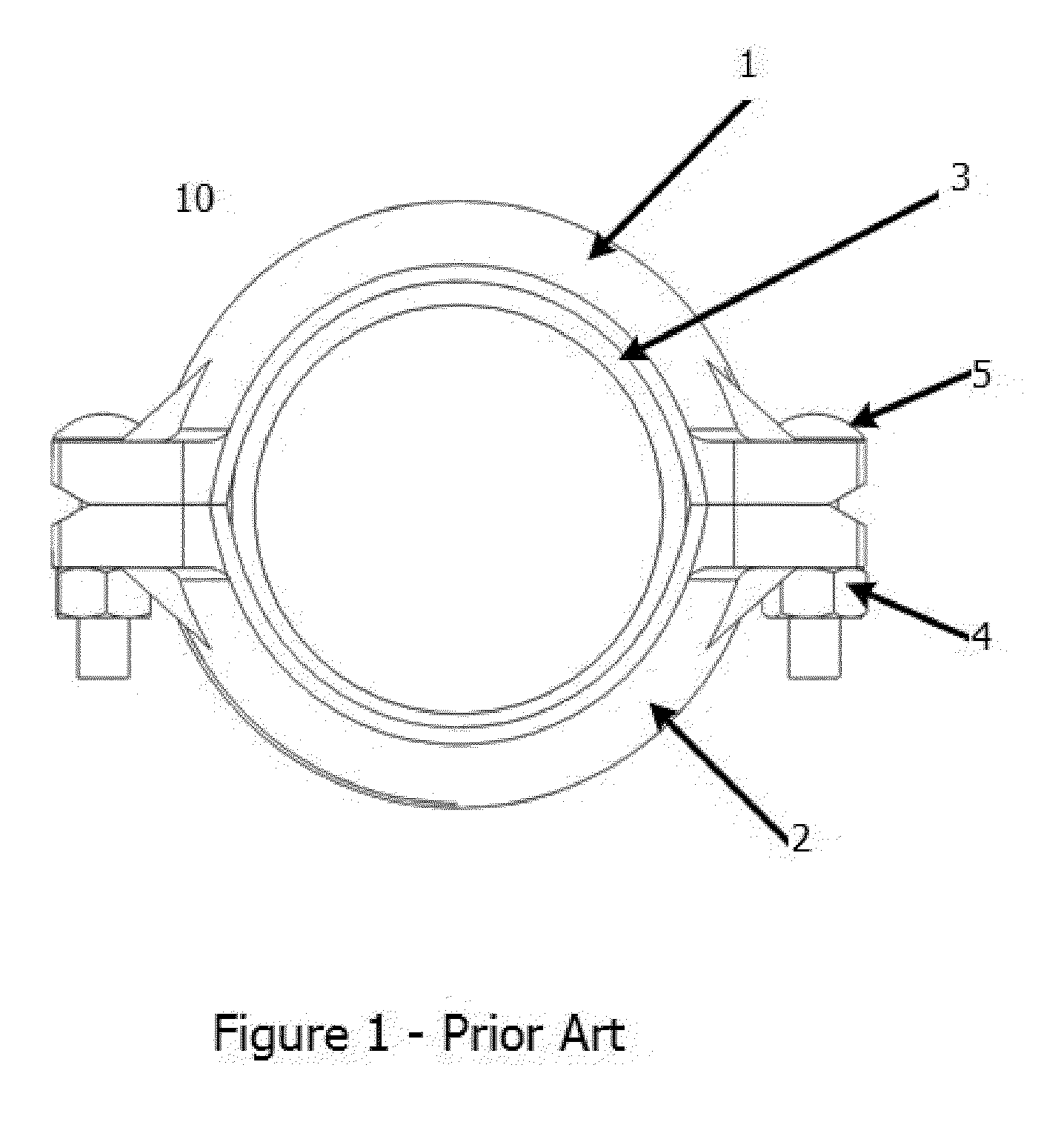

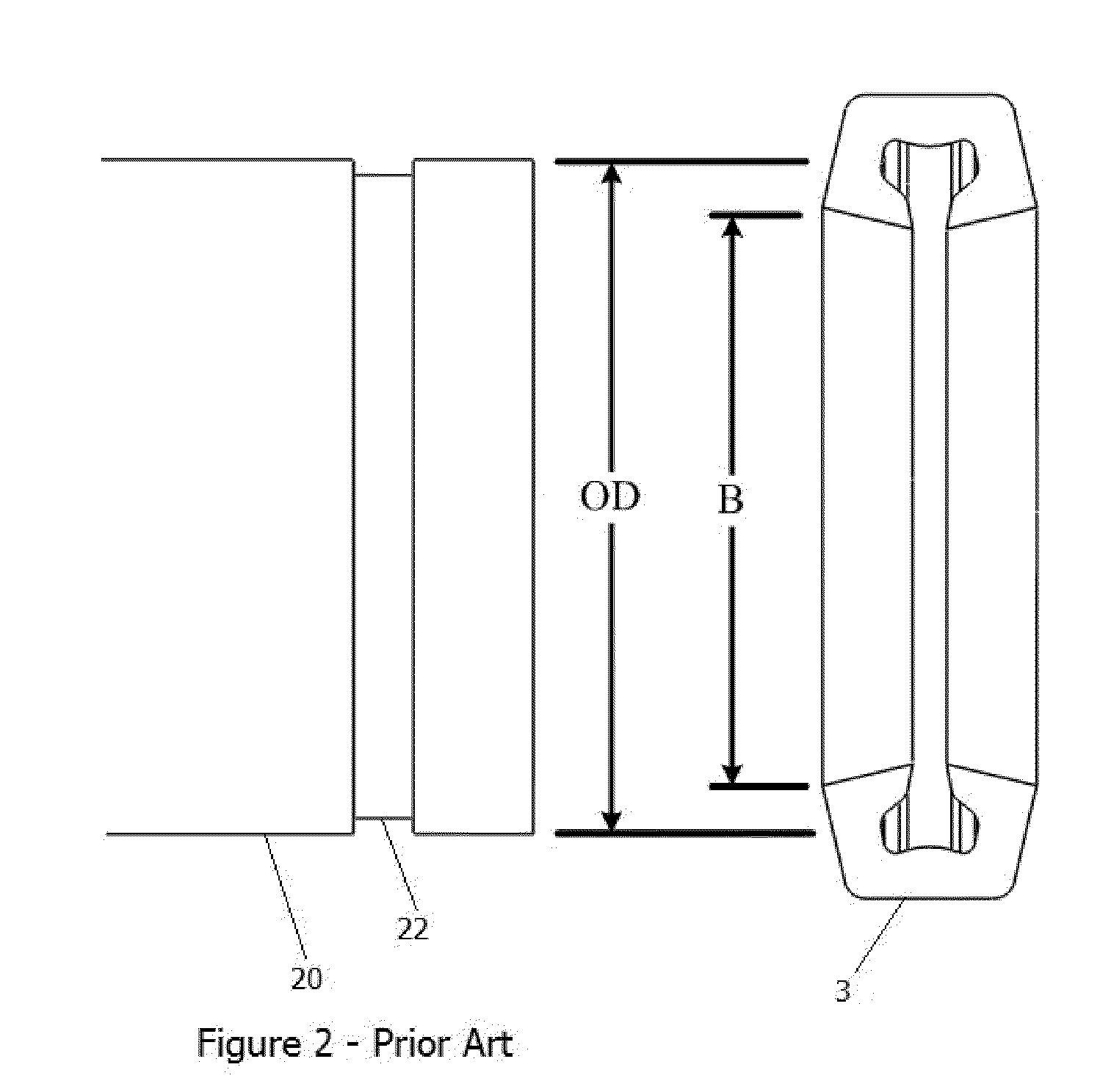

Clamp for joining tubular bodies

InactiveUS6877780B2High strengthImprove leakageSleeve/socket jointsFlanged jointsHermetic sealEngineering

A band clamp used to connect tubular bodies such as vehicle exhaust system components. The band clamp has a band extending from a first end to a second end and includes a pair of spaced ribs extending at least part way between the first and second ends. A tightening mechanism is connected to the band and includes two clamp members movable toward and away from each other for tightening and loosening of the band. The band clamp further includes a gasket located on an inner surface of the band between the ribs and extending between the first and second ends. The use of the ribs with the interposed gasket provides a mechanical interlock of the band clamp with the tubular bodies while providing a hermetic seal at the junction between the two bodies.

Owner:BREEZE TORCA PRODS

Pipe coupling having movable gripping bodies

A coupling for securing pipe elements together in end-to-end relation is disclosed. The coupling has segments joined end-to-end by adjustable connection members. The segments surround a central space which receives the pipe elements. One or more gripping bodies are captured between the segments. The gripping bodies are arranged opposite to each other. The segments have angularly oriented reaction surfaces on the connection members. The gripping bodies have angularly oriented contact surfaces which interface with the reaction surfaces. When the segments are drawn toward each other by the connection members, interaction between the reaction surfaces and the contact surfaces forces the gripping bodies radially inwardly. Inwardly facing arcuate surfaces on the segments and the gripping bodies engage and retain the pipe elements.

Owner:VICTAULIC

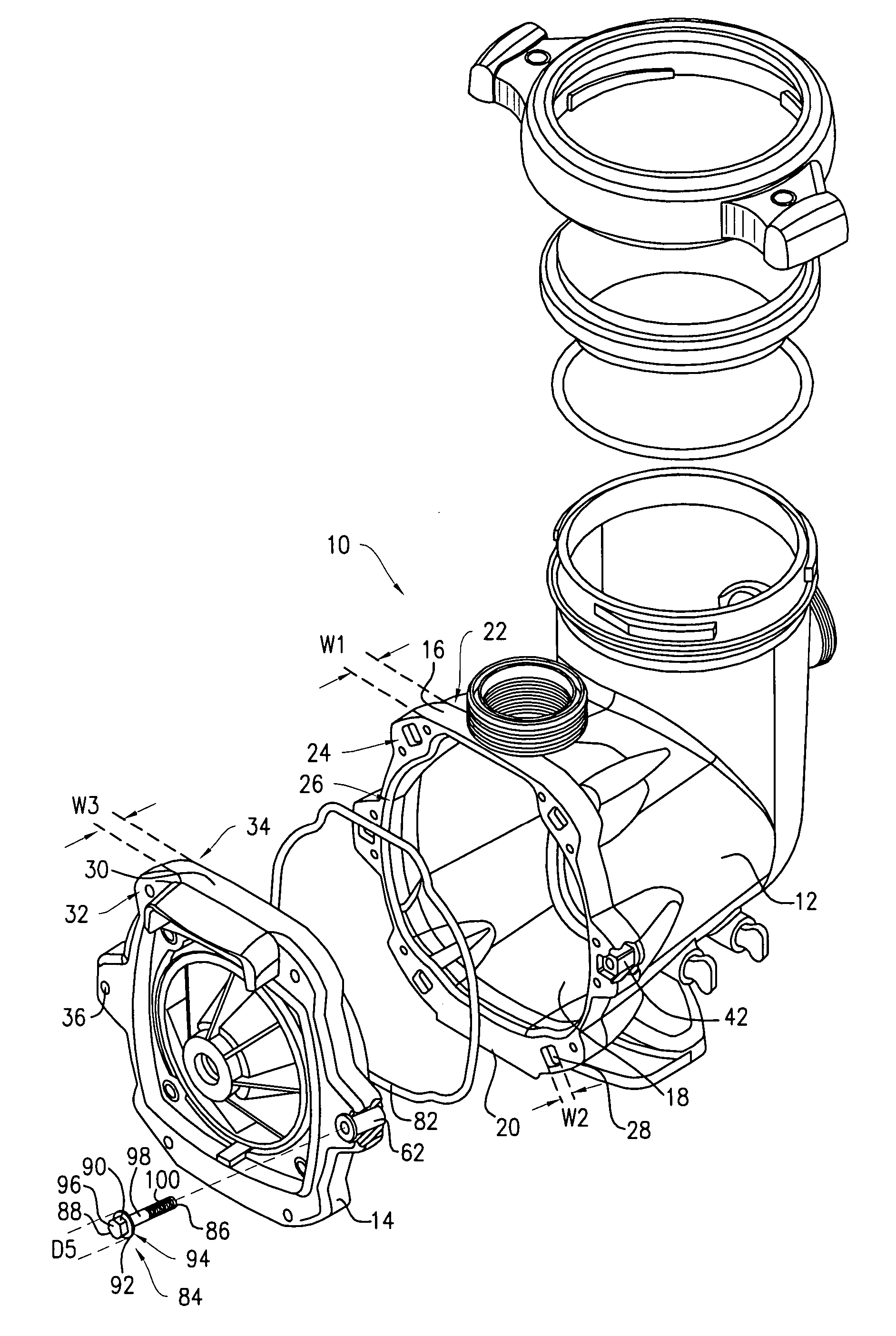

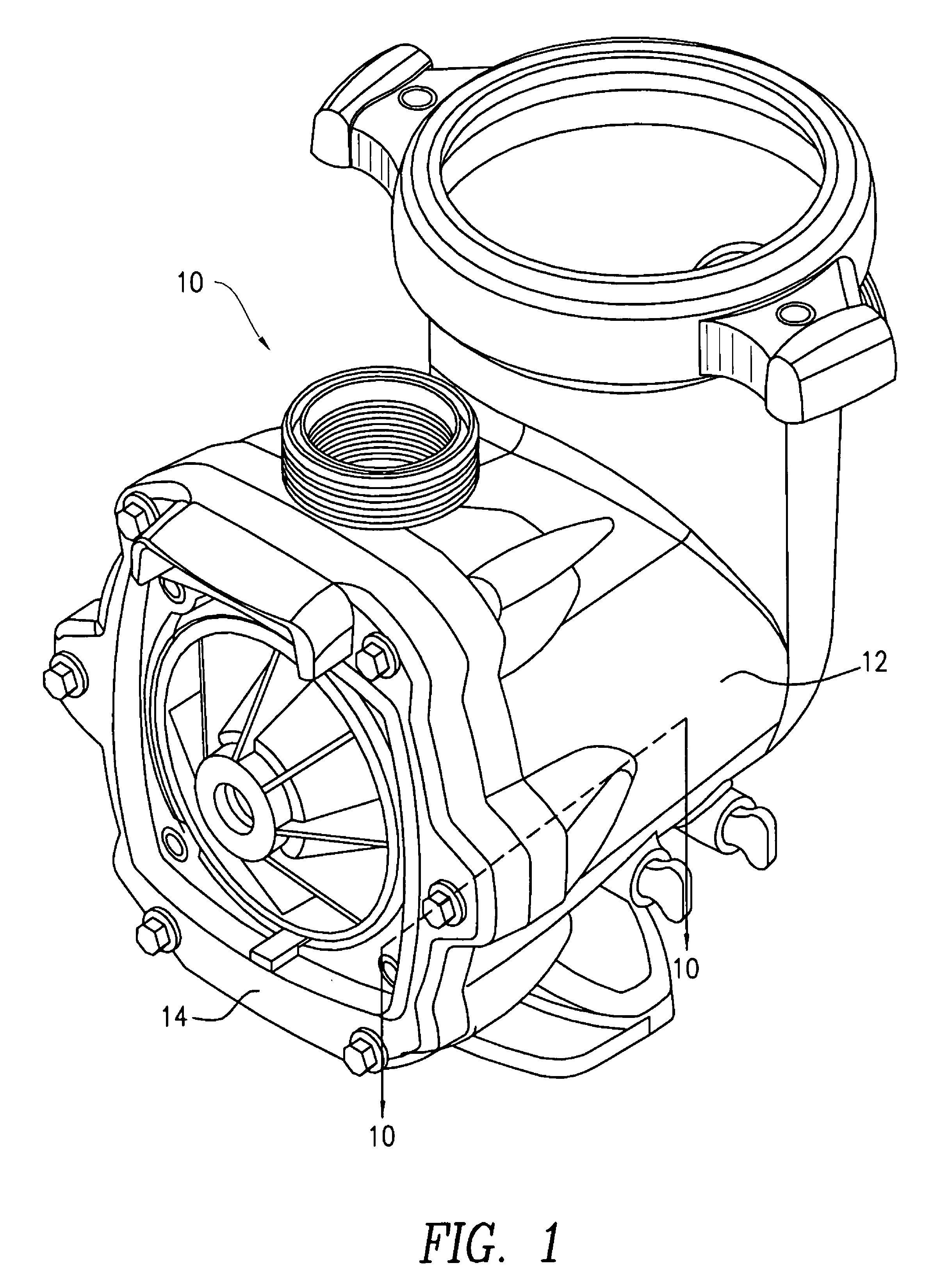

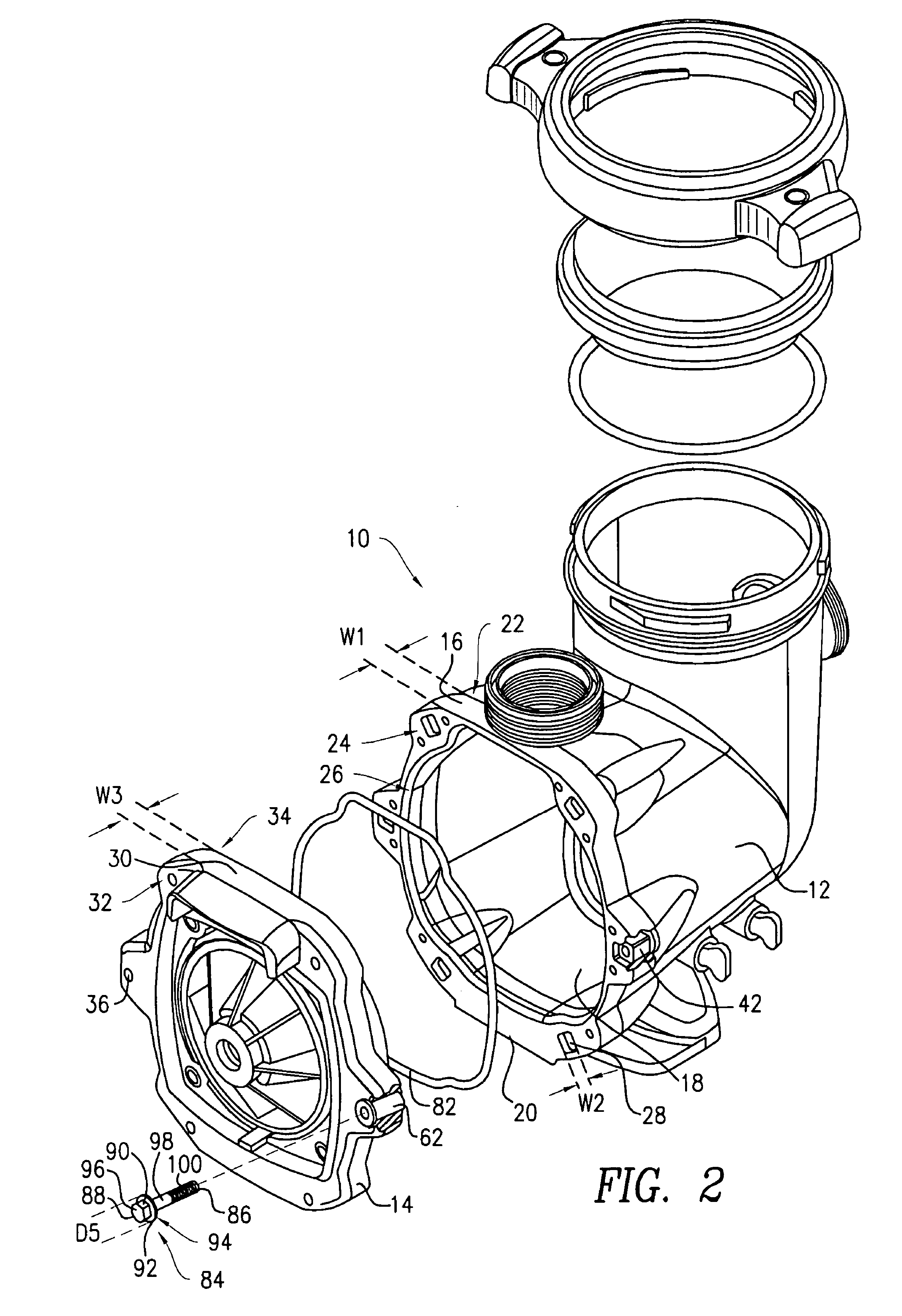

Pump housing coupling

ActiveUS8182212B2Readily and reliably in alignmentDissembled and subsequently completely reassembledReaction enginesPumpsCouplingEngineering

An assembly is disclosed for forming a fluid-tight seal between a pump housing and a seal plate. The housing includes a first flange with a first plurality of apertures formed therein, and the seal plate includes a second flange with a second plurality of apertures formed therein. A gasket is provided between the pump housing and the seal plate. A plurality of inserts extend through the first plurality of apertures, and a plurality of spacers extend through the second plurality of apertures. A plurality of threaded connectors are used to couple the seal plate to the pump housing to form a fluid-tight seal. The dimensions of the inserts and spacers are selected so as to inhibit crushing of the gasket and the flanges when the connectors are fully tightened.

Owner:HAYWARD IND INC

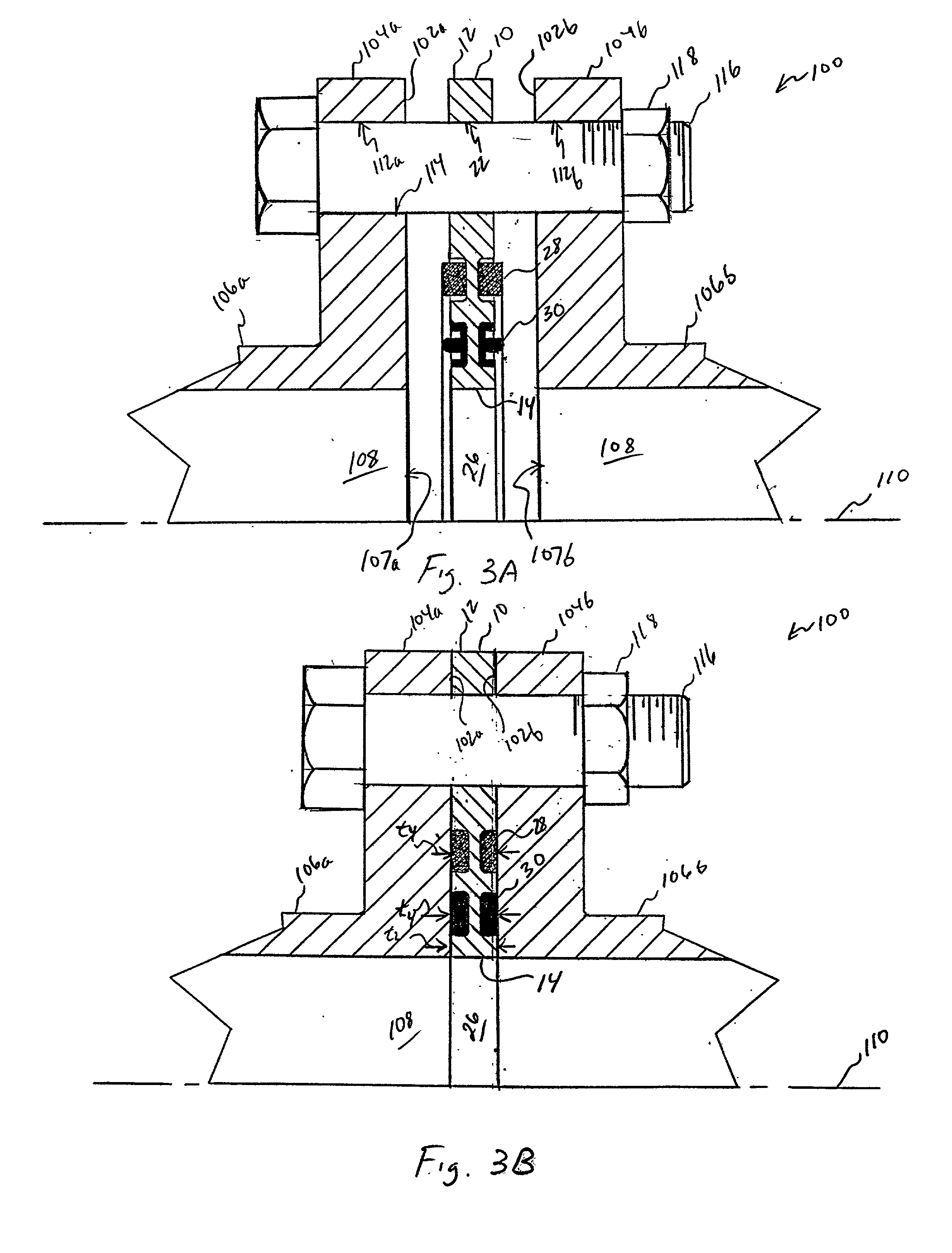

"flame resistant pipe flange gasket"

InactiveUS20020030326A1Increase the tensile stressMinimum of torque lossSleeve/socket jointsEngine sealsEngineeringFlange

A flame resistant gasket for interposition between the interface surfaces of a pair of mating pipe flanges. The gasket includes a metal retainer member having generally planar first and second surfaces with at least one aperture formed therethrough which is configured for generally coaxial registration with a fluid passageway defined through the pipe flanges. At least one generally annular, flame resistant outer seal member is supported on the retainer member as disposed coaxially with the aperture thereof a spaced-apart, radially outward distance therefrom. The outer seal member has oppositely-disposed first and second outer radial sealing surfaces for abutting contact with a corresponding one of the interfaces surfaces, and is compressible axially between the interface surfaces for effecting a first fluid-tight seal about the fluid passageway. At least one generally annular, elastomeric inner seal member optionally is attached to the retainer member as disposed coaxially with the aperture thereof radially inwardly of the outer seal member. The inner seal member has oppositely-disposed first and second inner radial sealing surfaces for abutting contact with a corresponding one of the interfaces surfaces, and is compressible axially between the interface surfaces for effecting a second fluid-tight seal about the fluid passageway.

Owner:PARKER HANNIFIN CORP

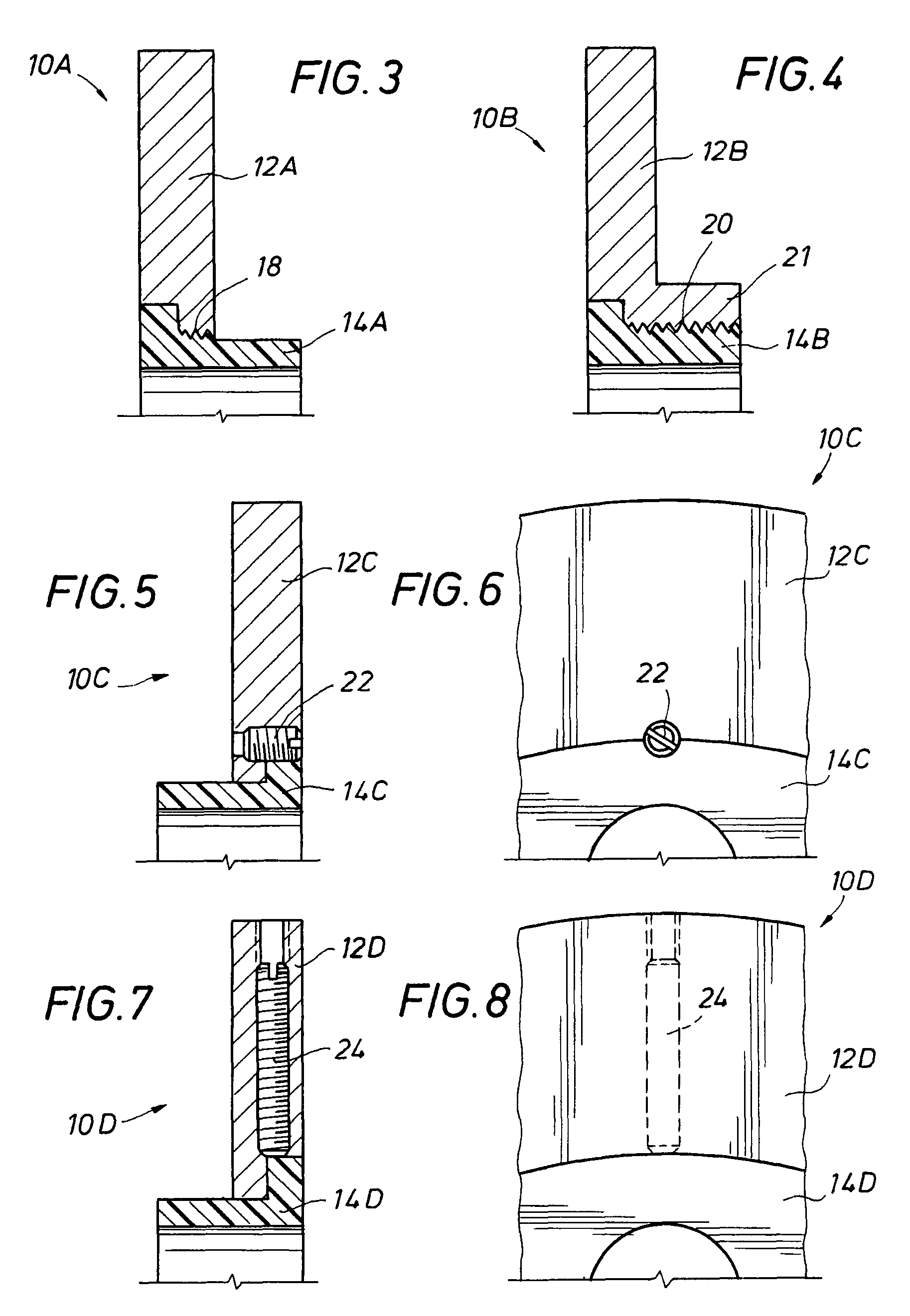

Multiple material piping component

The piping component is comprised in part of a metal housing that is positionable with a metal pipe. The metal housing forms an opening in which a piping component body is inserted. The body of the piping component can be fastened to the metal housing using an epoxy adhesive, a set screw connection, a threaded connection, press fit connection, a key connection or a pin connection or a combination of these connections. The body is comprised of plastic, which is less expensive than metal and facilitates forming, including machining or molding, while maintaining its structural integrity in a hostile fluid environment, such as in oil or gas. Piping components such as flowmeters, flow conditioners, small volume provers, static mixers, samplers, and valves are contemplated for use with these multiple materials.

Owner:SAVANT MEASUREMENT CORP

Constant seating stress gasket system

InactiveUS6869081B1Reduce and eliminate needCreep relaxation is limitedSleeve/socket jointsEngine sealsResal effectEngineering

A gasket system for sealed interfaces utilizes a carrier ring having inner and outer compression stops to account for and control flange rotation effects in order to achieve a uniform and constant gasket seating stress across the sealing region. The inner compression stop provides a fixed fulcrum for flange rotation. The inner and outer compression stops have different heights, dependent upon the characteristic flange rotation, that allow the orientation of the sealing material to be angularly matched to the flange side profile and that allow the sealing material to be fully captured within the sealing region upon full compression, minimizing creep relaxation. A visual compression indicator on the circumference of the carrier ring permits assembly of the interface without the use of specialized or calibrated tools.

Owner:JJENCO

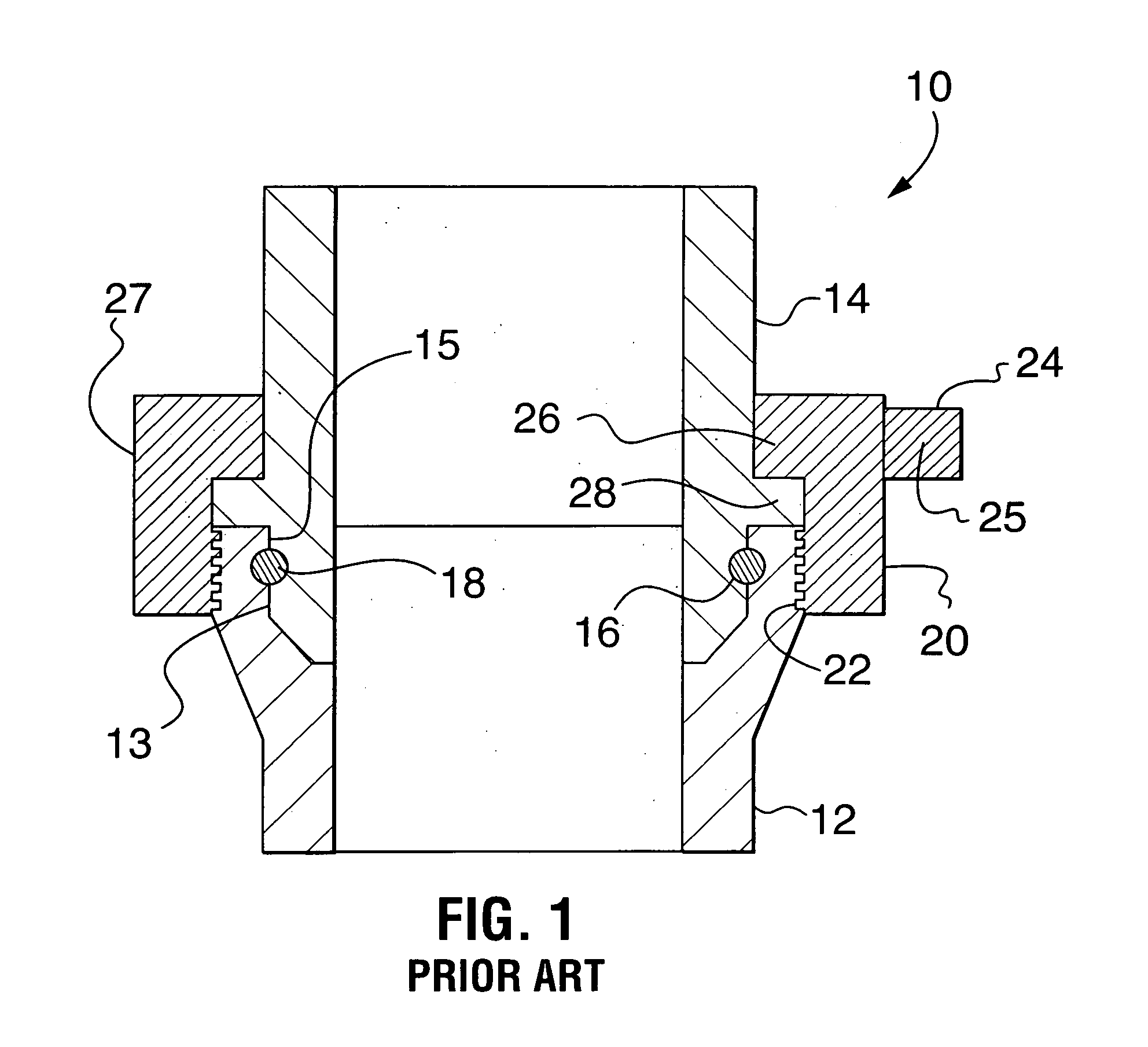

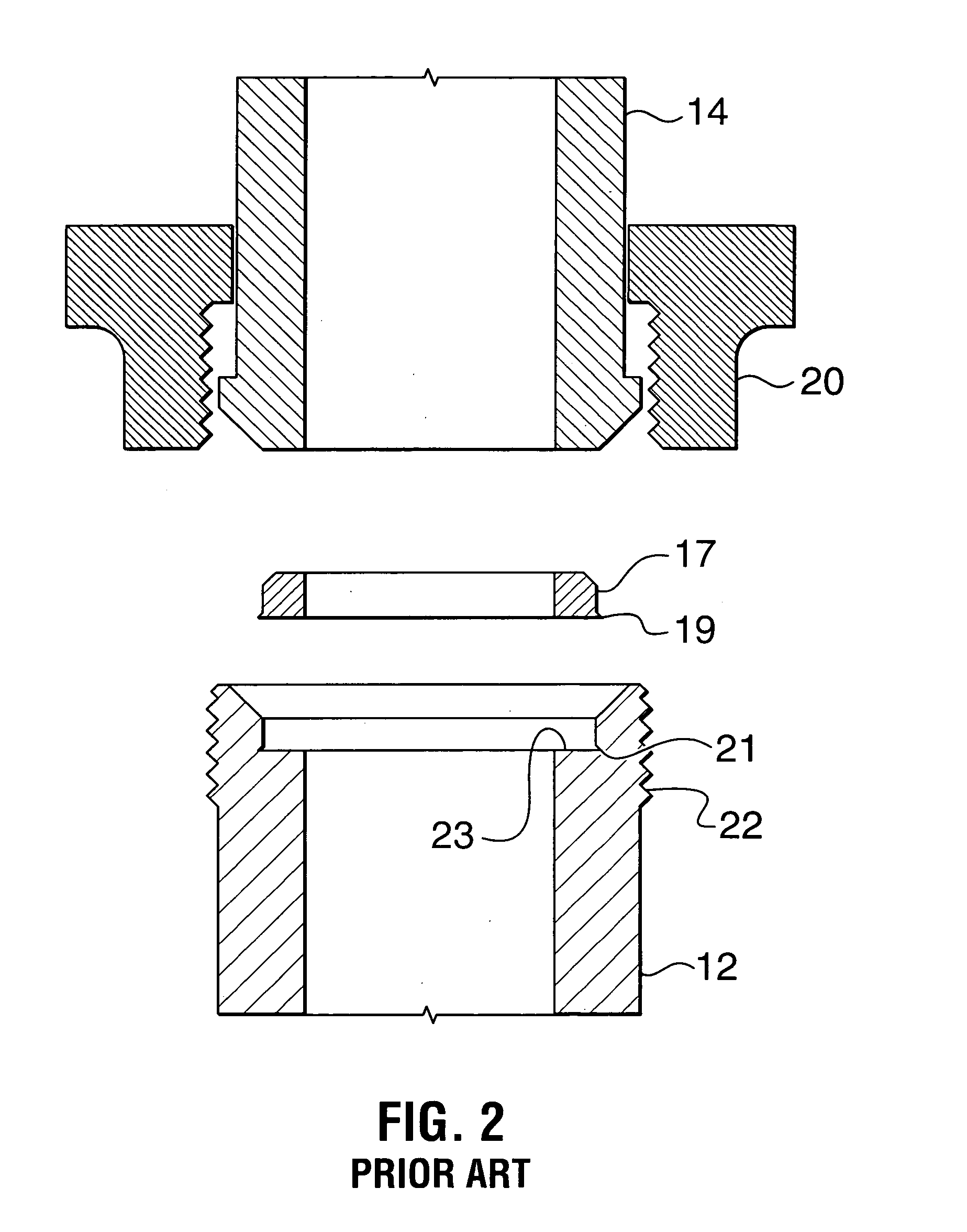

Metal ring gasket for a threaded union

InactiveUS7125055B2Improve sealingFlanged jointsFluid pressure sealed jointsHigh pressureScrew thread

A metal ring gasket for a threaded union provides a high-pressure, fluid-tight, metal-to-metal seal between subcomponents of a fluid conduit. The metal ring gasket is made of carbon steel or stainless steel depending on a composition of the fluid to be conveyed through the conduit. The metal ring gasket has beveled corners and is received in a beveled annular groove on mating surfaces of the subcomponents of the threaded union. When compressed in the annular groove between the subcomponents, the metal ring gasket creates an energized, high-pressure, fluid-tight seal that is highly resistant to pressure and is capable of maintaining a seal even at elevated temperatures resulting from direct exposure of the fluid conduit to fire.

Owner:OIL STATES ENERGY SERVICES +1

Laser assisted riser disconnect and method of use

There is provided a high power laser-riser blowout preventer package and laser module for use with a subsea riser. The laser module and laser-riser package use high power laser energy to quickly cut the riser permitting an offshore drilling rig to quickly, and in a controlled manner disconnect from a blowout preventer.

Owner:FORO ENERGY

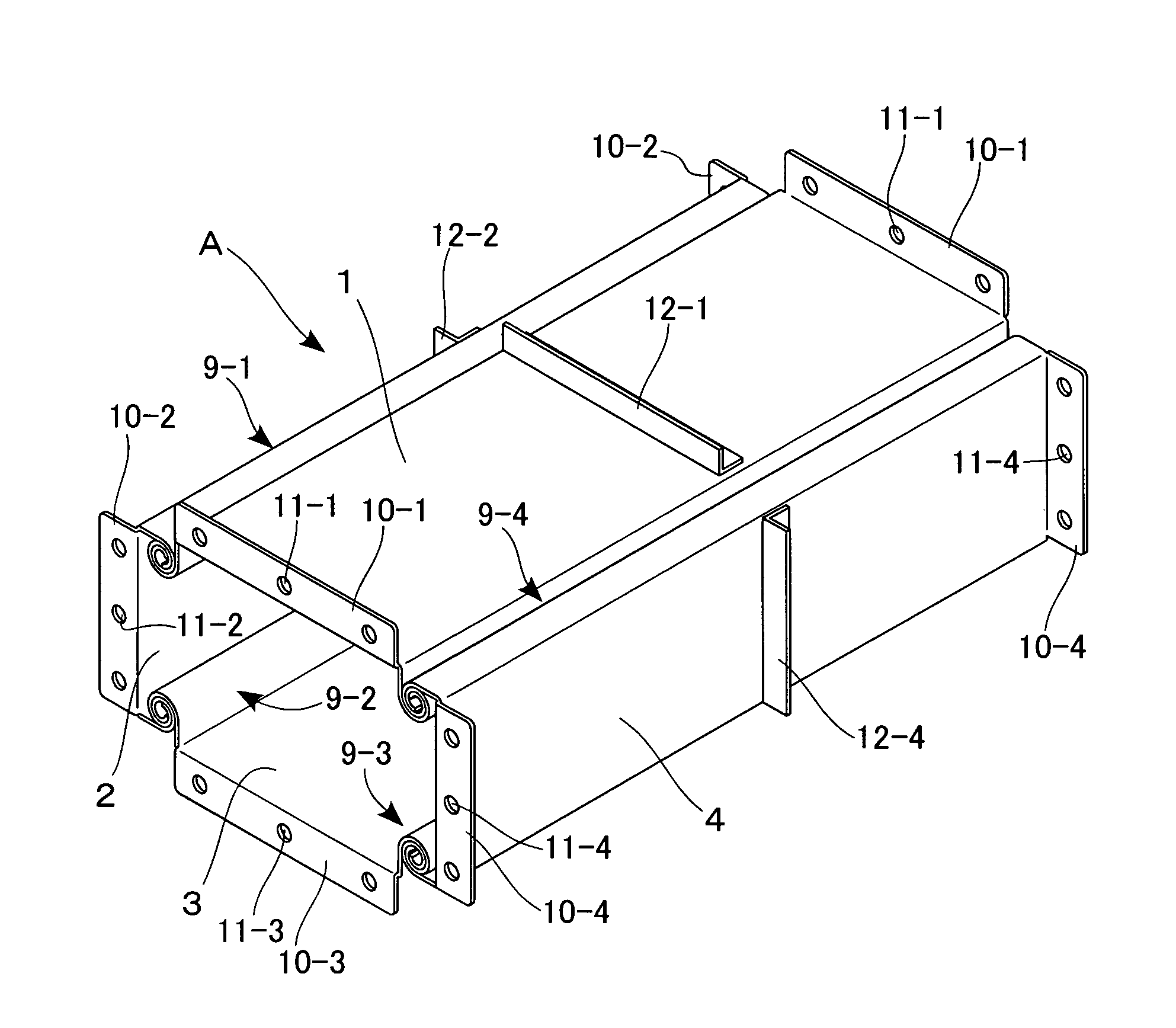

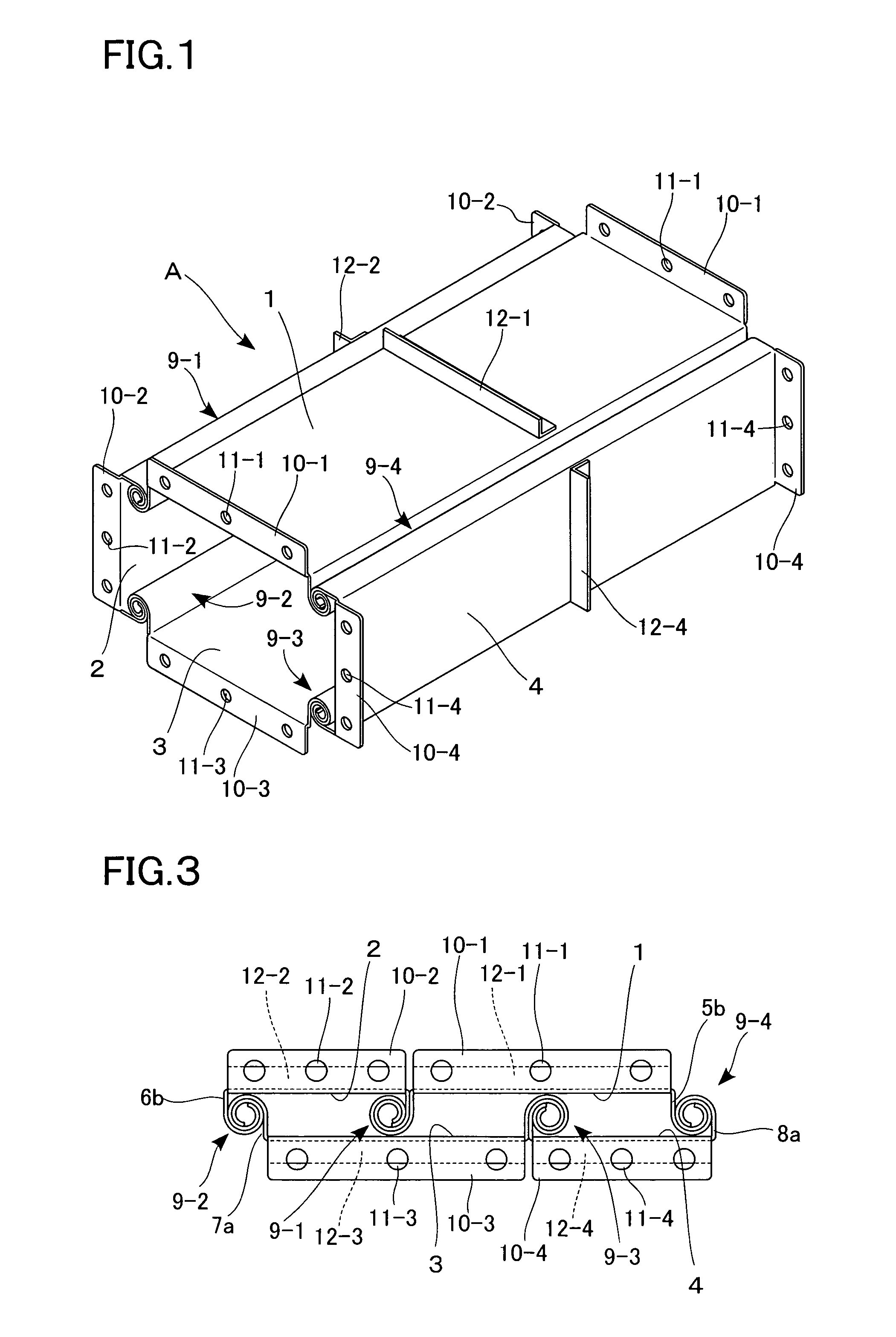

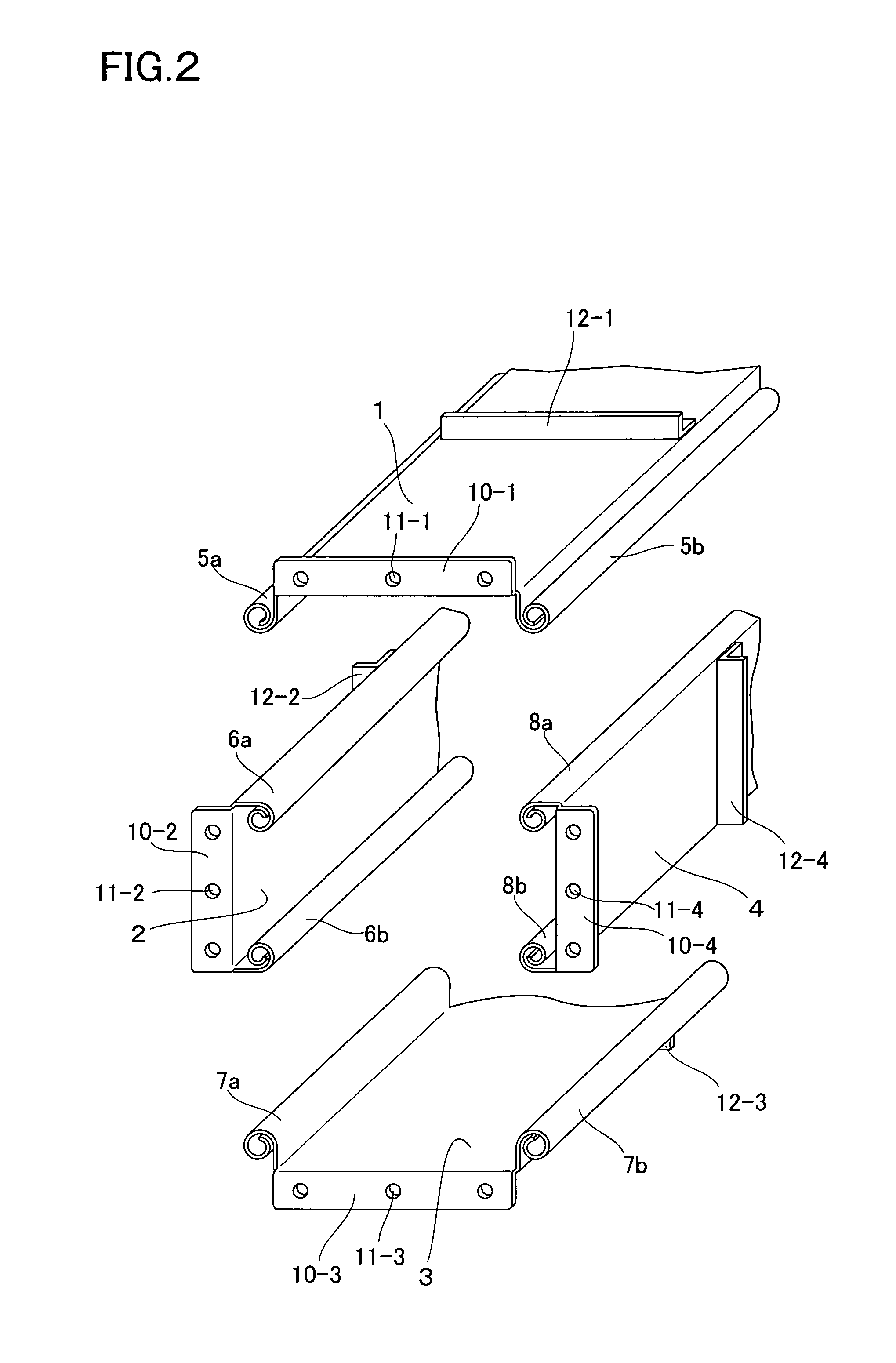

Duct unit for air-conditioner

InactiveUS6957670B1Reduce capacitySufficient workspaceDucting arrangementsFlanged jointsMetal sheetStructural engineering

An object of the present invention is to provide an air-conditioning duct unit capable of being made compact when transported to largely reduce the cost of transport inside and outside a building as well as the cost of transportation by a truck.A duct unit A of the present invention has upper and lower wall portions 1 and 3 and right and left wall portions 2 and 4 formed of metal sheets, and spin locks curved into a curled shape, the spin locks being provided on the wall portions 1 to 4 at two side edges of the same along the longitudinal direction. One of the pair of spin locks provided on each adjacent pair of the wall portions is inserted in the other to form one of lock joints 9-1 to 9-4 rotatably. The wall portions 1 to 4 are linked so that the duct unit A can be changed in shape. Consequently, the duct unit can be folded so as to be flattened.

Owner:FUJI KUUCHOU KOUGYOU CO LTD

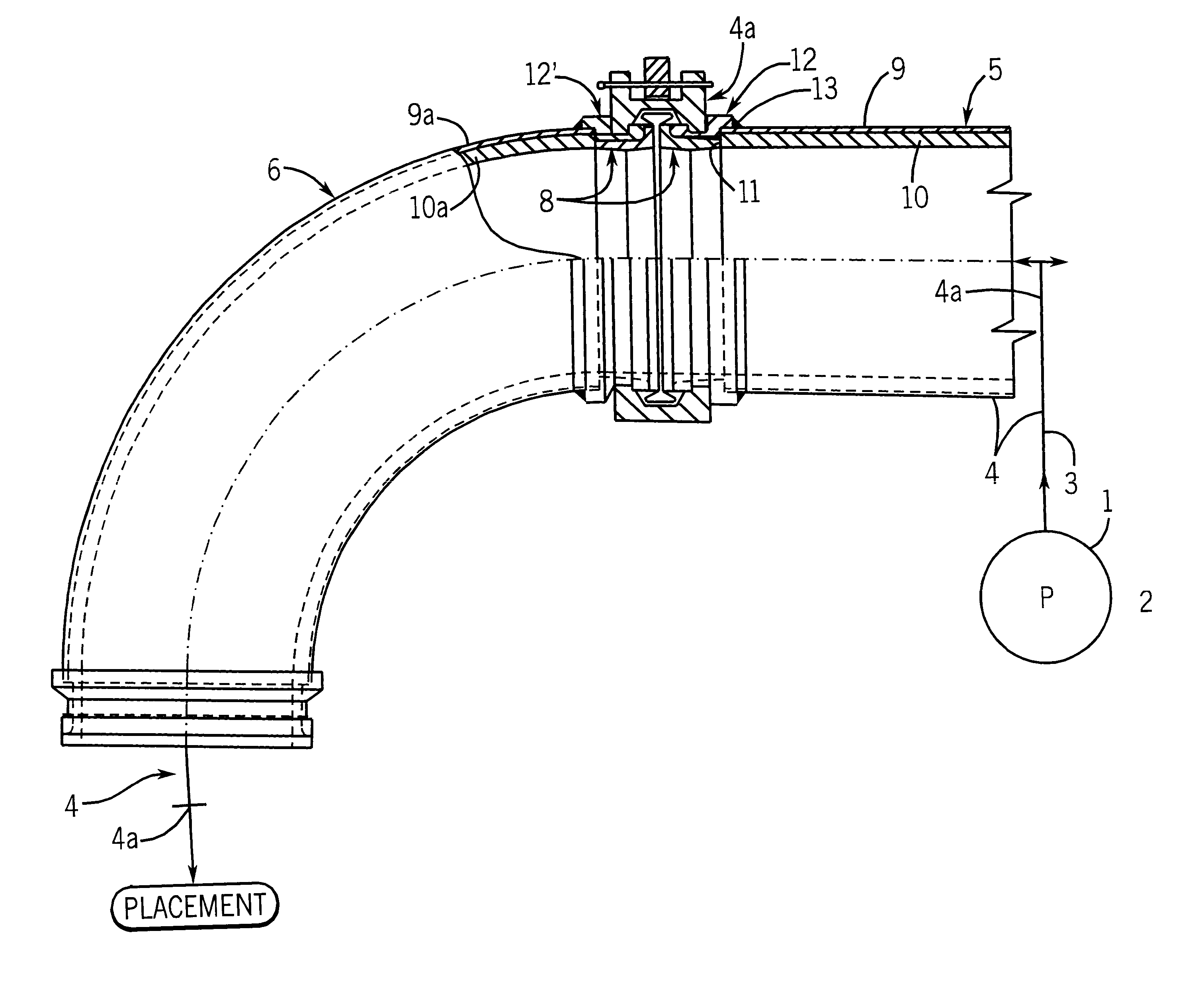

Pipe having replaceable wear resistant lined coupler

InactiveUS6467812B1Rapid and cost-effective formationQuick inexpensive replacementFlanged jointsThermal insulationWear resistantEngineering

A pipe section for concrete includes an end coupler interconnecting to another pipe section in a flow line. The coupler has an outer clamp secured extended from the pipe end with a coupling groove. An encircling clamp has sides located in the grooves of adjacent pipe sections to lock the pipe section together. The body and pipe end form an inner recess extending from the pipe end. An insert liner has a tubular portion matching the recess, with the outer surface of the tubular portion tapered to form a gap within the recess. The insert liner has an outer flange matching the outer diameter of the body and abuts the body. The inner wall of the liner has a central transition point from which the wall tapers inwardly in opposite directions to the outer end. The body member is formed of a high strength ductile steel. The insert liner is formed of a wear resistant material having a Rockwell hardness of 80 to 90. A carbide alloy consisting essentially of carbides, martensite, bainite and austenite, and 12-15% chromium, 2-3% carbon and traces nickel, molybdenum and austenite. A toughened ceramic is disclosed. The liner is adhesively bonded to the body using an epoxy adhesive which is responsive to heat for release of the liner. The liner is inserted by applying adhesive on the tubular portion and then pushing the liner into the recess.

Owner:CONSTR FORMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com