Methods of providing article with corrosion resistant coating and coated article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

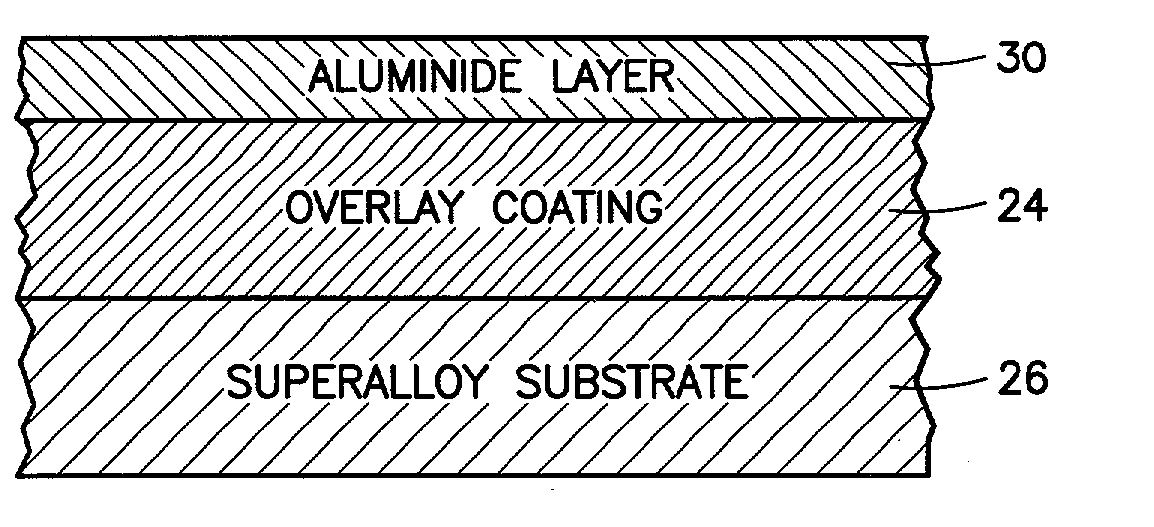

[0022] As illustrated in FIG. 1, a turbine blade composed of a superalloy material and incorporating the present invention is illustrated generally by the reference numeral 10. The turbine blade includes an airfoil 12, a serrated blade root 14 (used to attach the blade to the rotatable turbine disk) and a platform 16 located between the airfoil and serrated root. The region between the underside of the blade platform 18 and the root is referred to as the neck 19. Typically, turbine blades (and other gas turbine engine components) are composed of a directionally solidified nickel-based alloy, e.g., consisting of a single crystal or with multiple columnar grains oriented parallel to the direction of growth. Typical compositions of such alloys are shown in Table 1. Exemplary U.S. Patents describing columnar and single crystal and directionally solidified alloys include Nos. 4,209,348; 4,643,782; 4,719,080 and 5,068,084, each of which is expressly incorporated by reference herein. Cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com