Mold core for solving breakage of core head thereof, and preparation method of precision cast component

A technology of core and core head, applied in the direction of core, casting molding equipment, casting mold, etc., can solve the problems of easy fracture and high rejection rate of castings, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

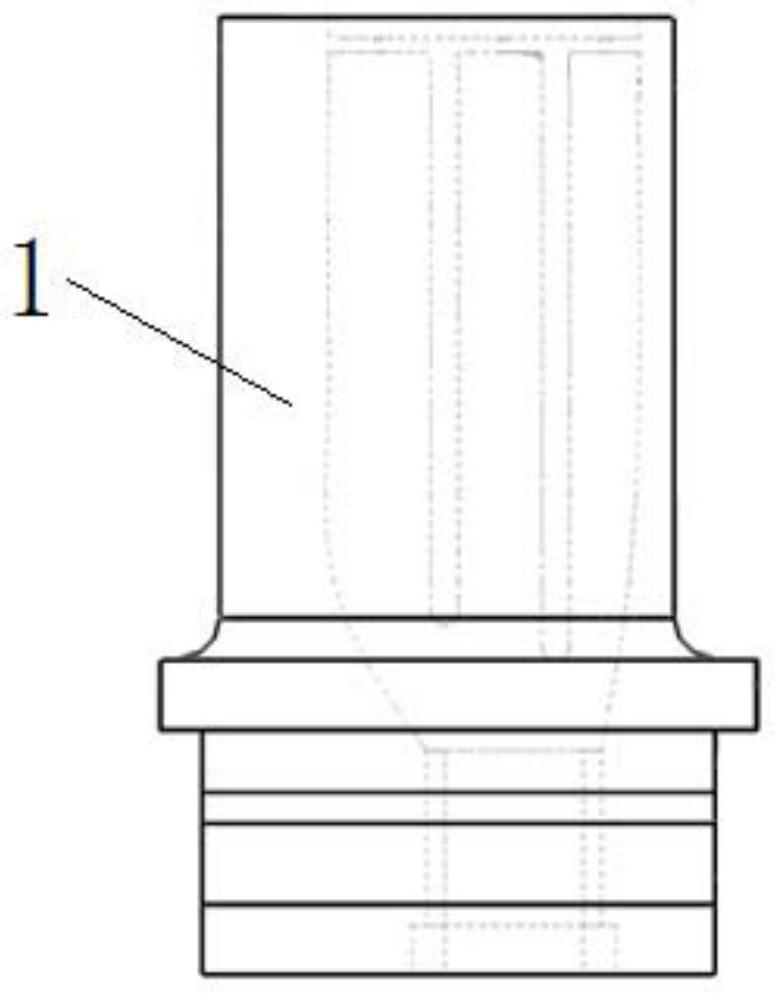

[0028] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a core that solves the fracture of the core core head includes a blade root core head 2, a core blade body 3, and several core rods 4 arranged in sequence from bottom to top. The mandrel 4 extends beyond the designed end of the hollow blade 1 .

[0029] Such as Figure 4 As shown, the design length of the core rod 4 is increased, the traditional tip core head 7 is omitted, and the pressure or bending moment on the core rod 4 can be reduced when manufacturing the core, thereby ensuring that the core rod 4 The quality of the molding can be improved, and problems such as bending, cracking, and fracture of the core rod 4 during the molding process can be avoided, and the quality factors of the core can be avoided from affecting the subsequent casting work.

Embodiment 2

[0031] As shown in FIG. 5 , on the basis of the above embodiments, in this embodiment, the free end of the mandrel 4 is connected with a mold insert block 6 .

[0032] After the core preparation is completed, the core is used to cast the wax pattern 5 of the hollow blade 1, and the end face of the hollow blade 1 and the core rod 4 at the same end is provided with a mold groove, and the mold inlaid block with the same profile as the groove is used 6 can make the groove shape.

[0033] After the preparation of the core is completed, the core rod 4 has sufficient strength to avoid bending and breaking due to the pressure of the mosaic block 6 .

[0034] The core rod 4 is detachably connected to the mold inlay block 6, and the mold inlay block 6 can be quickly removed after the wax mold 5 is formed.

Embodiment 3

[0036] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a method for preparing precision casting parts that solves the fracture of the core core head includes the following steps:

[0037] Step S1: Design the casting rough drawing, design and manufacture the core according to the casting rough drawing, so that the length of the core rod 4 exceeds the designed end surface of the hollow blade 1 . The design length of the core rod 4 is increased, and the traditional tip core head 7 is omitted. When the core is manufactured, the pressure or bending moment on the core rod 4 can be reduced and avoided, thereby ensuring that the core rod 4 The quality of the molding can be improved, and problems such as bending, cracking, and fracture of the core rod 4 during the molding process can be avoided, and the quality factors of the core can be avoided from affecting the subsequent casting work. This solution does not use the traditional blade top core 7, and can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com