Phase change thermal insulating wall body of fabricated type building

A thermal insulation wall and prefabricated technology, applied in buildings, building components, building structures, etc., can solve problems such as cracking of phase change layers, and achieve the effects of avoiding cracks, reducing internal stress, and facilitating assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

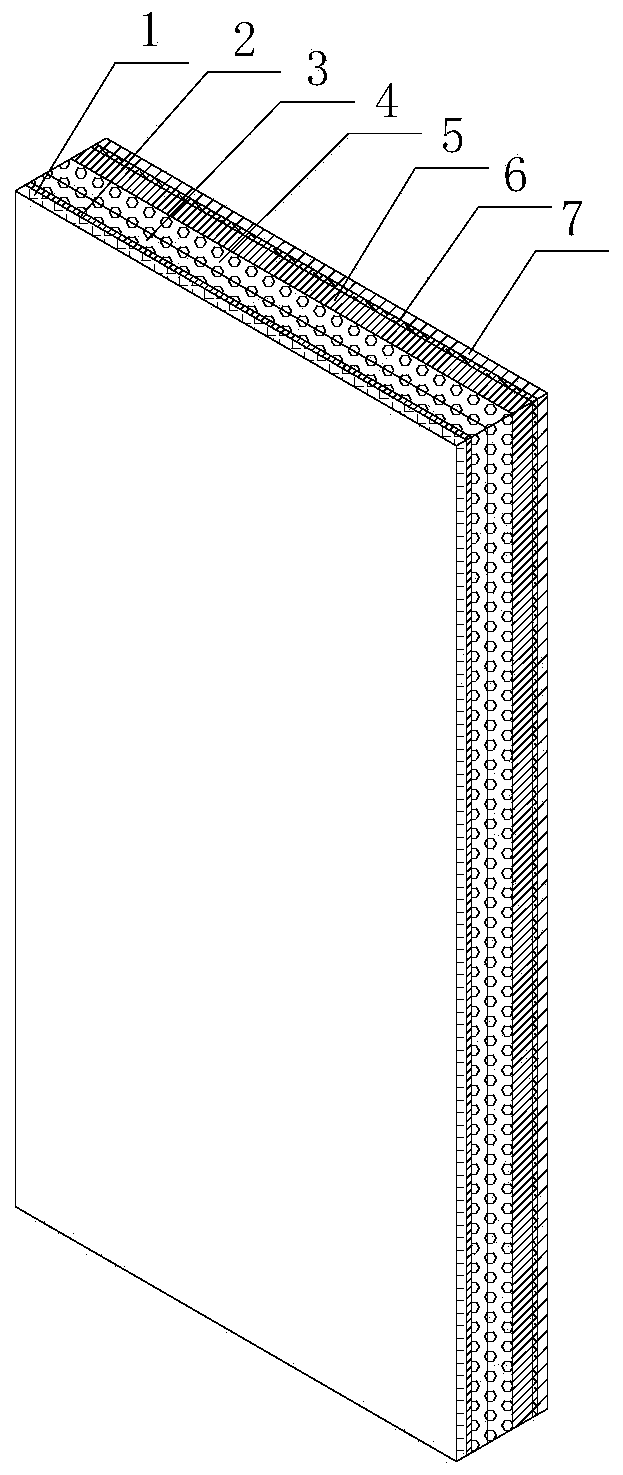

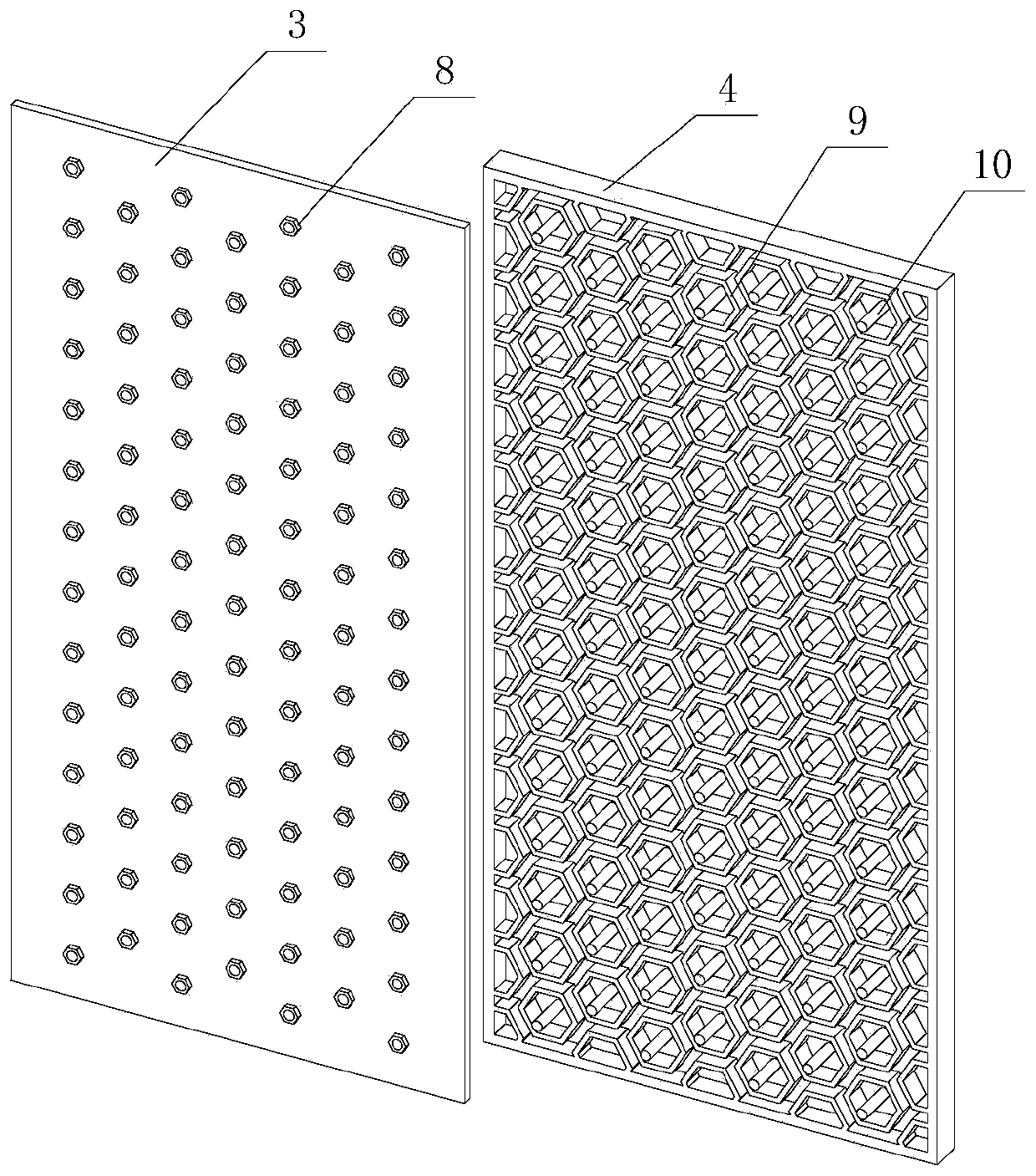

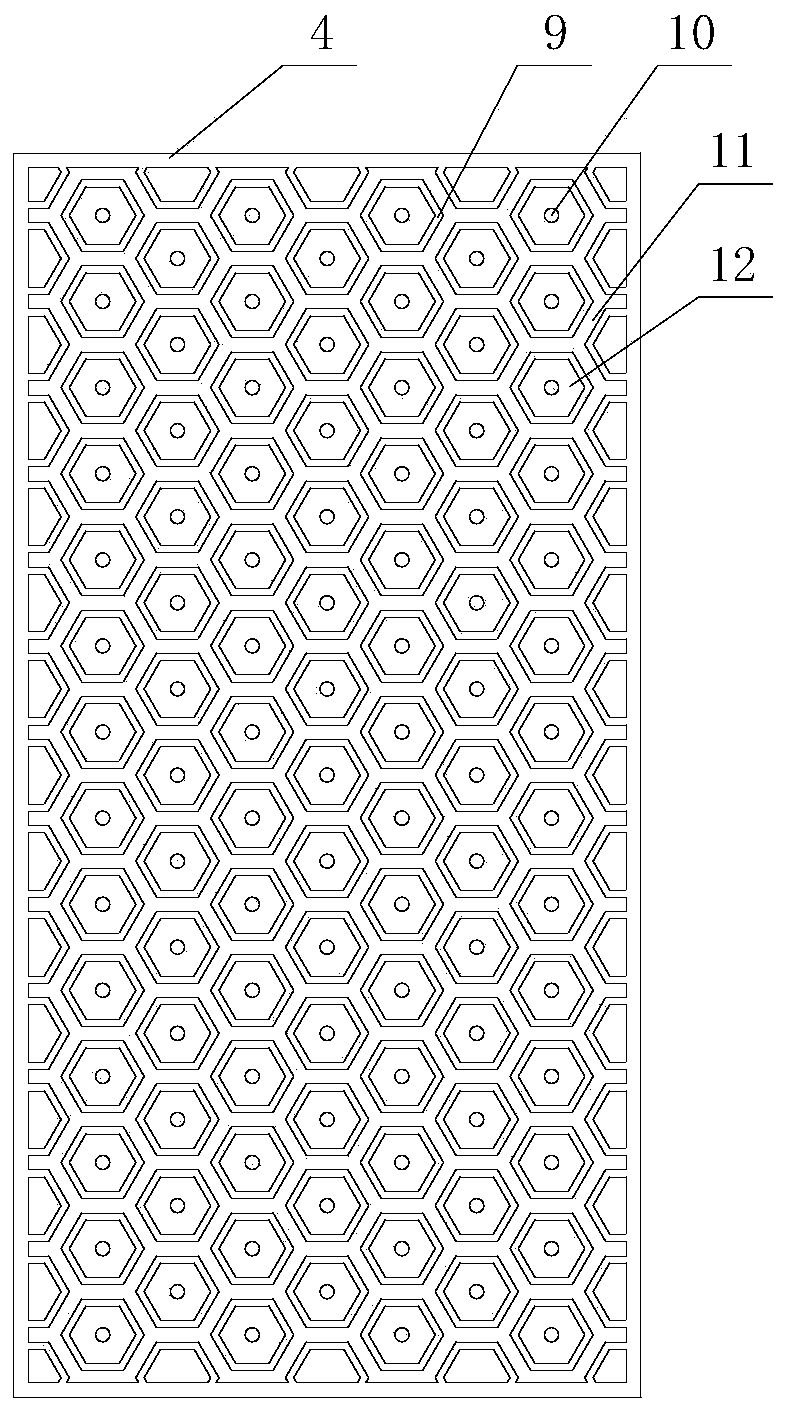

[0032] A phase-change thermal insulation wall of a prefabricated building of the present invention is realized in the following way: a phase-change thermal insulation wall of a prefabricated building of the present invention includes an outdoor wall surface (1), a steel wire mesh (2), and a phase-change outer layer (3), phase change inner layer (4), main body of wall (5), insulation layer (6) and interior decoration surface (7), and arrange in order from outside to inside, described phase change outer layer (3) also It includes a nut (8), a perforation (18) and a cover plate (19), the nut (8) is placed on one side of the phase change outer layer (3), and the wind cover plate is placed on the phase change outer layer On the other side of the layer (3), the air cover plate is a regular hexagonal plate, and the phase change outer layer (3) is provided with a perforation (18), and the perforation (18) runs through the center of the air cover plate, The phase-change inner layer (4)...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is: the hollow cavity (12) is built with a reinforcing net (15); when in use, the interior of the air wall is reinforced to improve the structural strength and avoid cracks.

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is: the hollow cavity (12) is built with a sound insulation layer (16); when in use, it can add sound insulation effect to the wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com