Patents

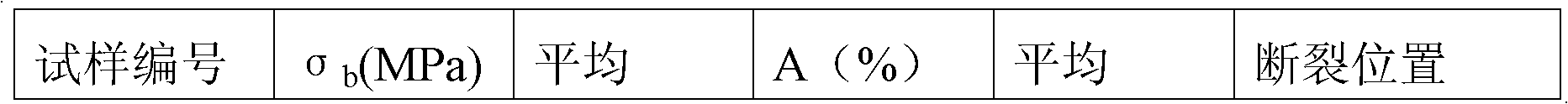

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

475results about How to "Reduce hydrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

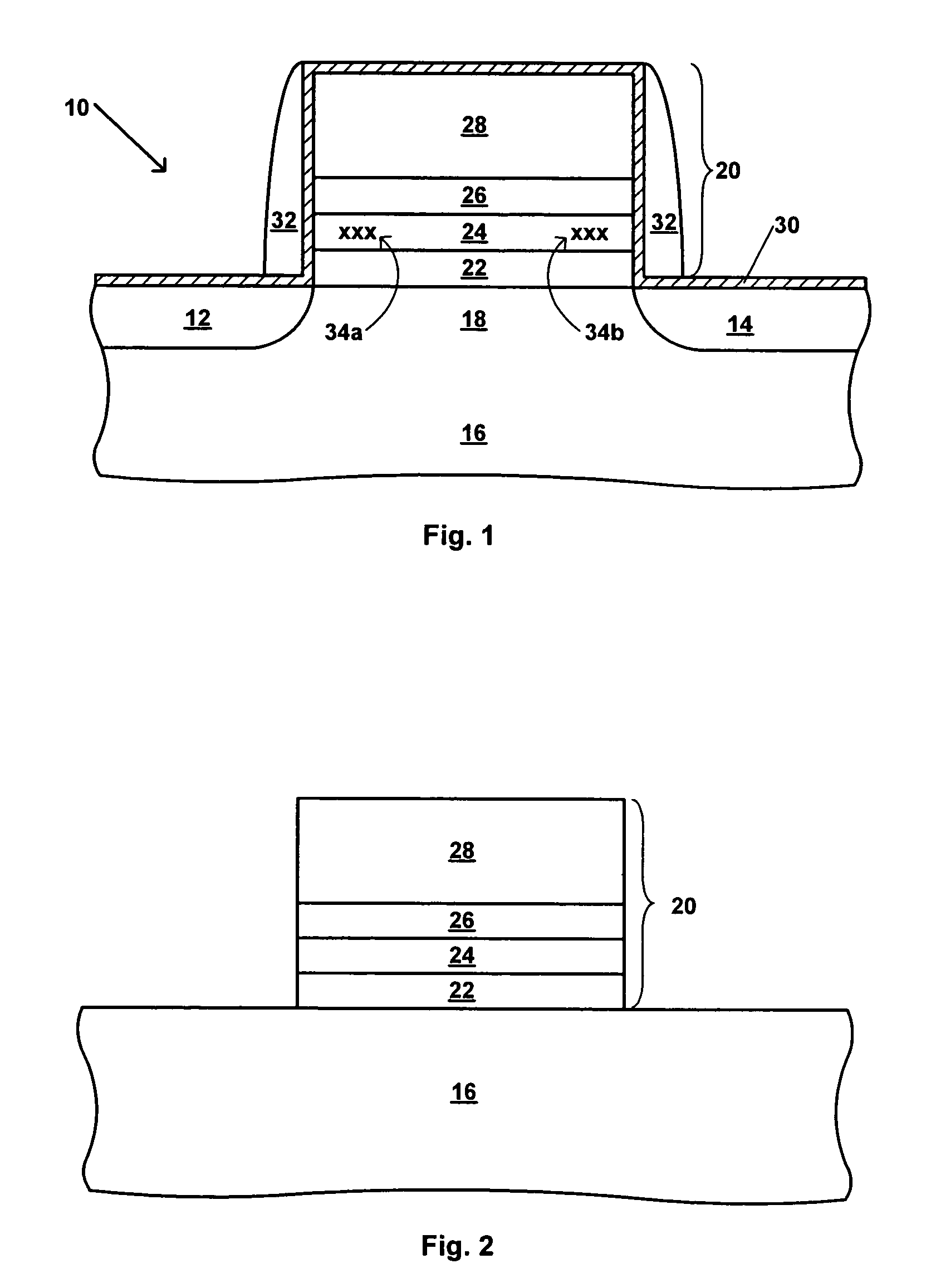

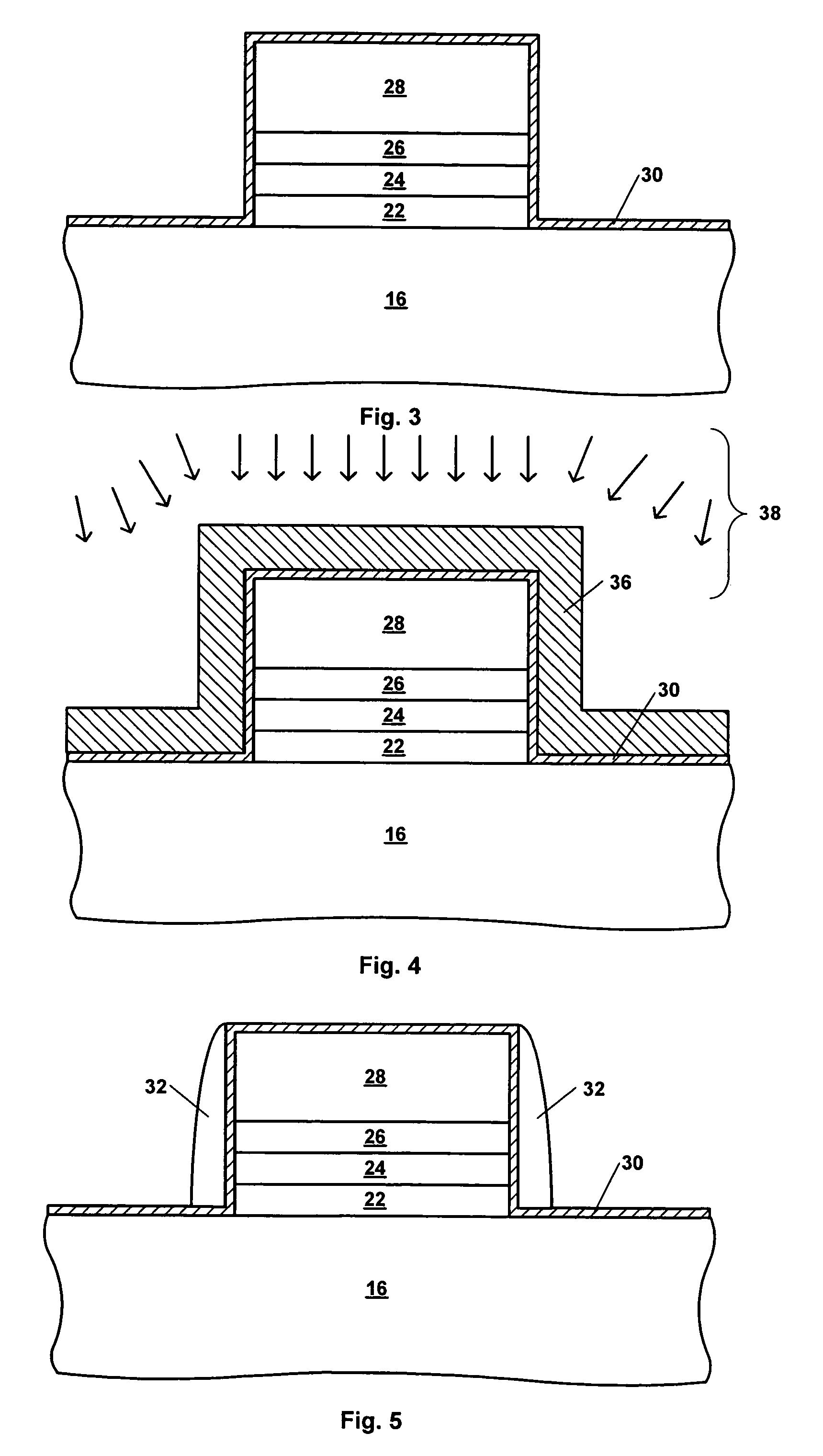

Method of forming a layer and forming a capacitor of a semiconductor device having the same layer

InactiveUS20060014384A1Low hydrogen contentReduce leakage currentSemiconductor/solid-state device manufacturingCapacitorsChemical reactionDevice material

In a method of forming a layer using an atomic layer deposition process, after a substrate is loaded into a chamber, a first reactant is provided onto the substrate. The first reactant is partially chemisorbed on the substrate. A second reactant is introduced into the chamber to form a preliminary layer on the substrate by chemically reacting the second reactant with the chemisorbed first reactant. Impurities in the preliminary layer and unreacted reactants are simultaneously removed using a plasma for removing impurities to thereby form the layer on the substrate. The impurities in the layer may be effectively removed so that the layer may have reduced leakage current.

Owner:SAMSUNG ELECTRONICS CO LTD

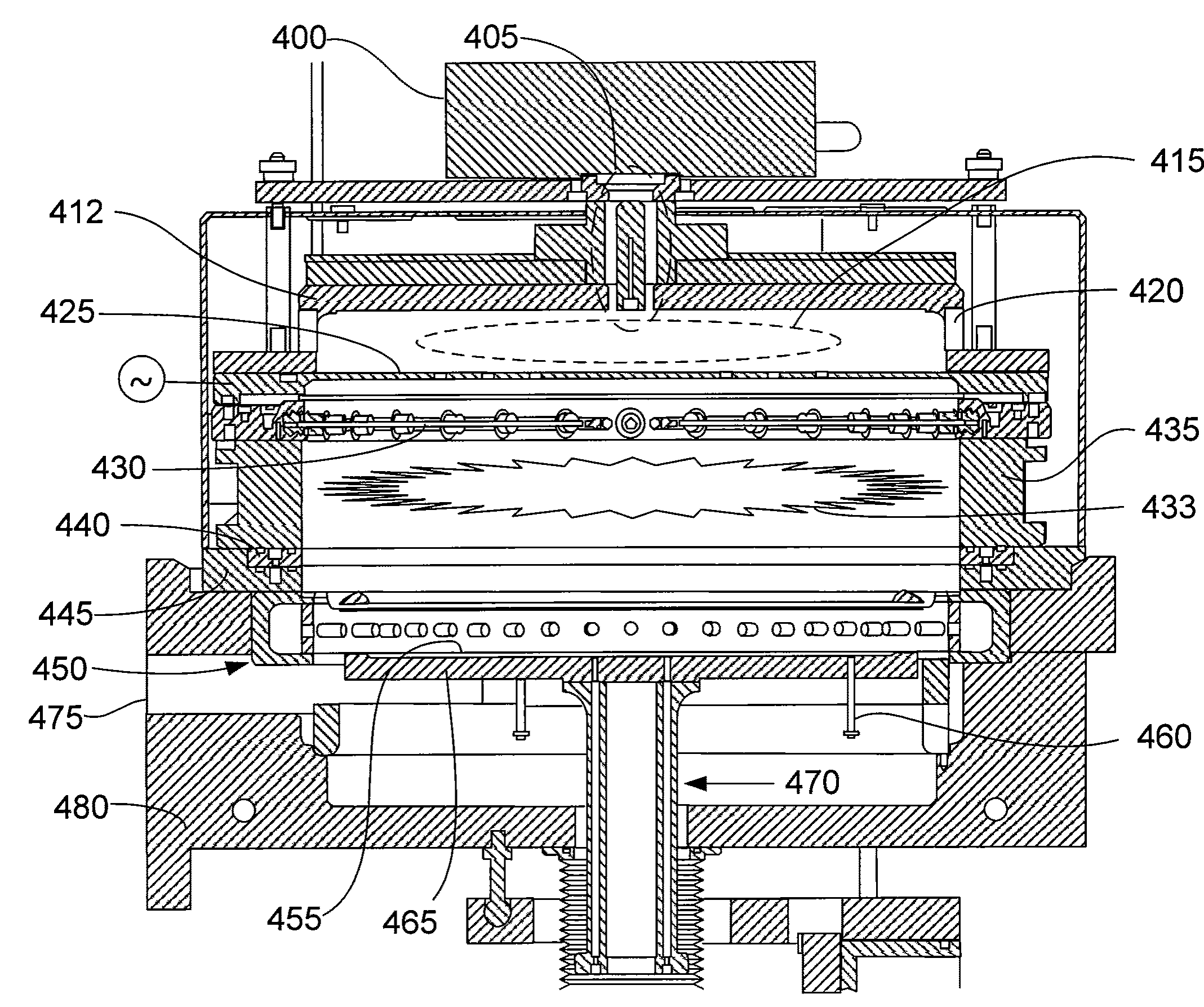

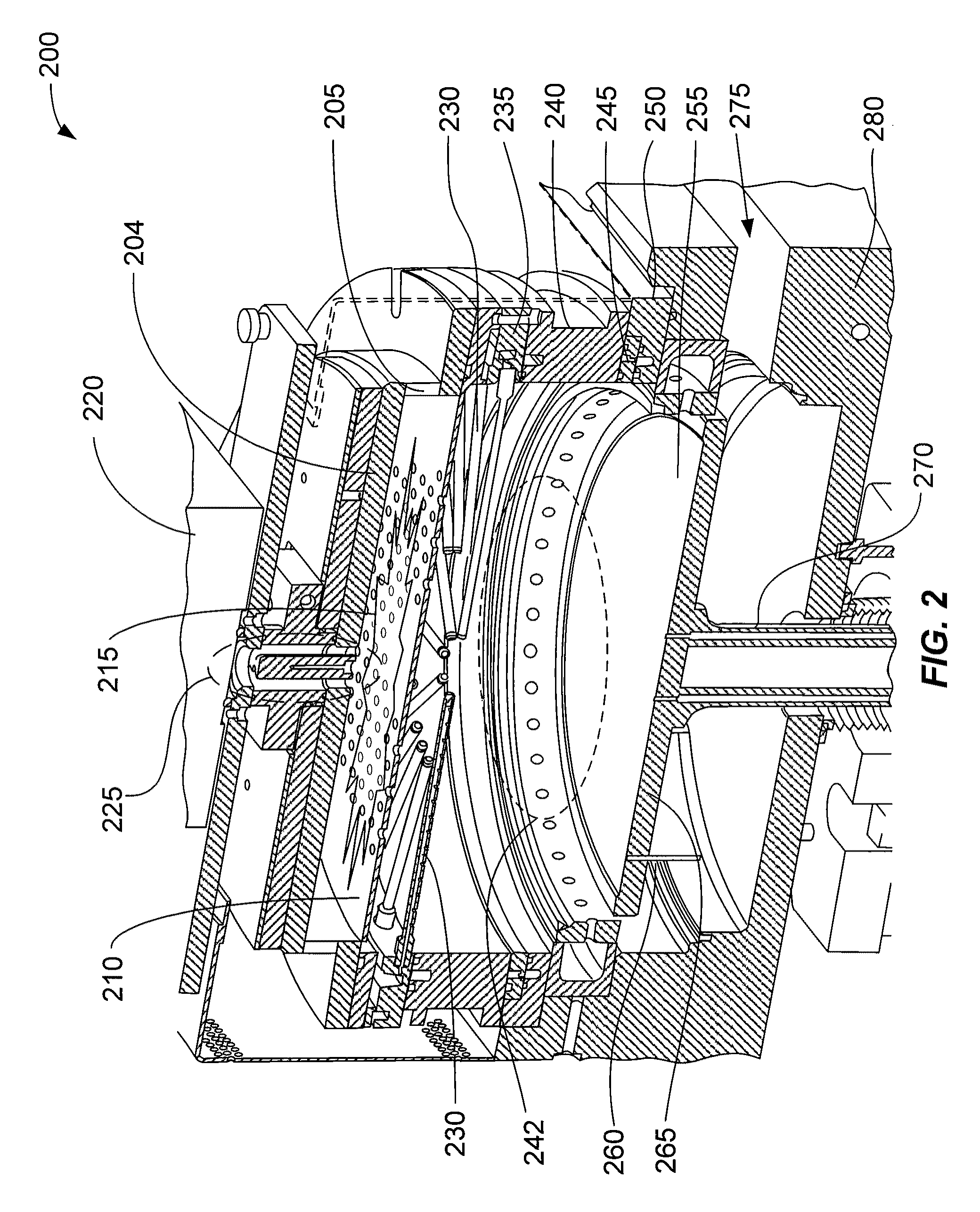

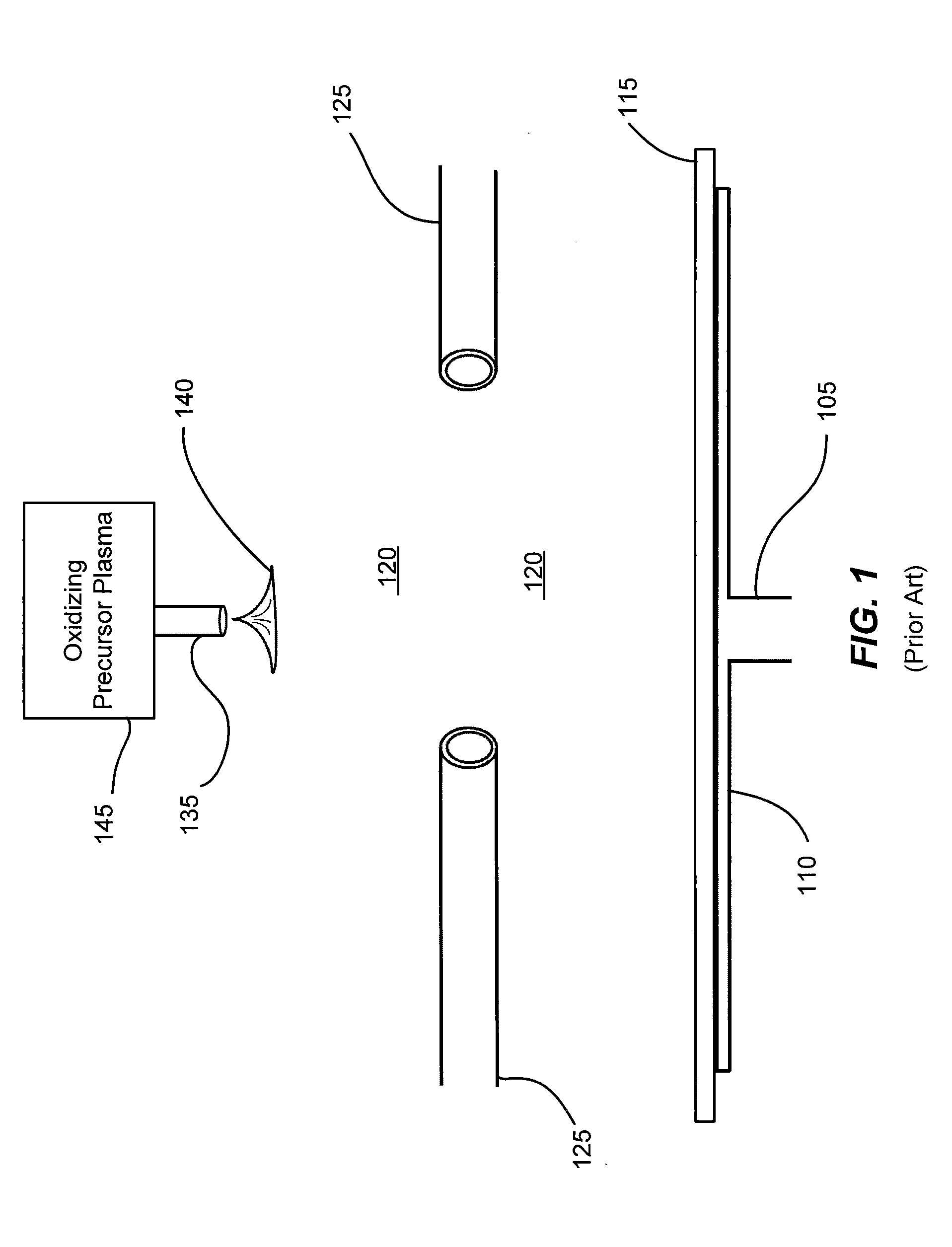

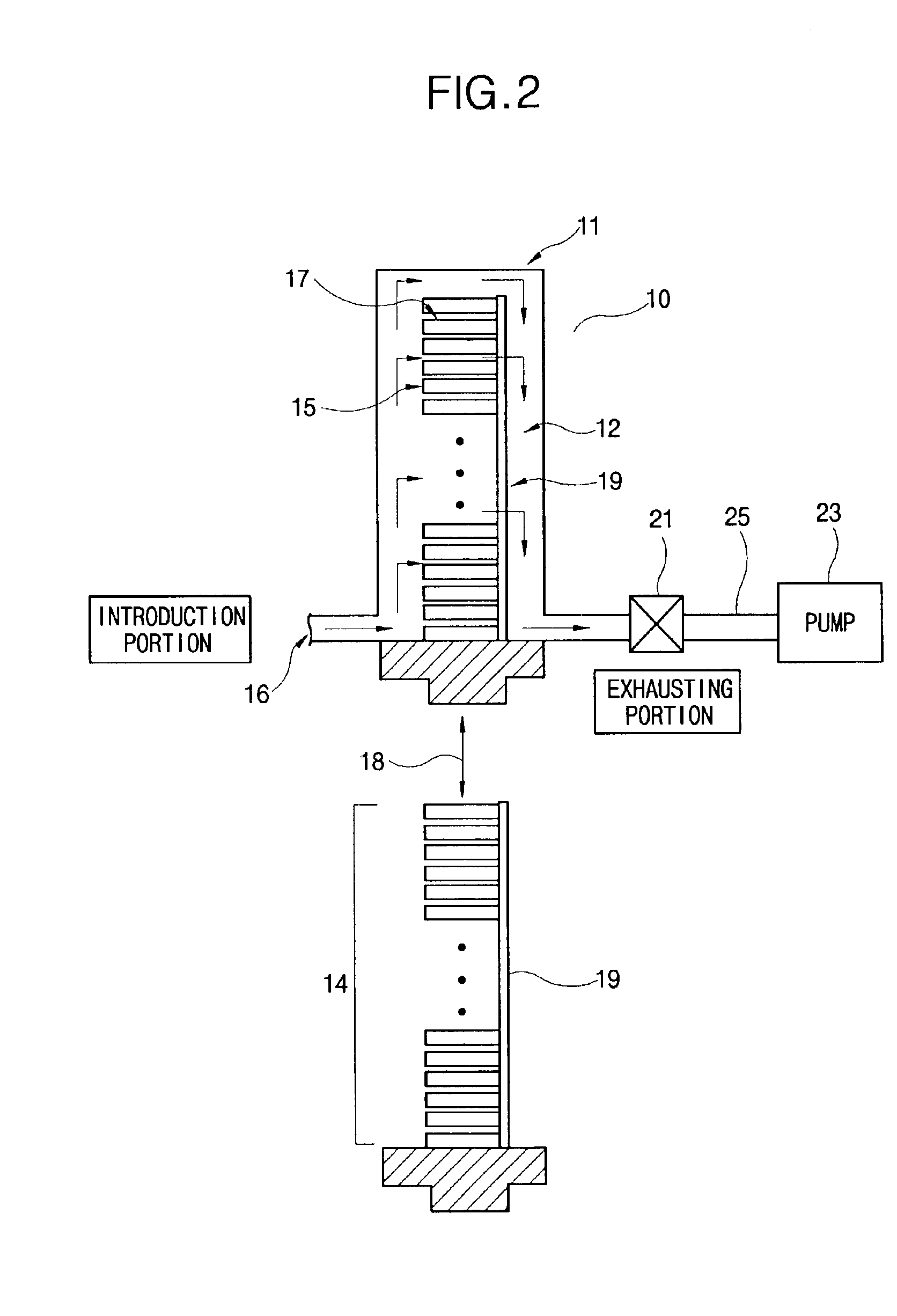

Flowable dielectric equipment and processes

ActiveUS20090280650A1Reduce carbon contentReduce fluorine contentElectric discharge tubesDecorative surface effectsDielectric layerMaterials science

Methods of depositing and curing a dielectric material on a substrate are described. The methods may include the steps of providing a processing chamber partitioned into a first plasma region and a second plasma region, and delivering the substrate to the processing chamber, where the substrate occupies a portion of the second plasma region. The methods may further include forming a first plasma in the first plasma region, where the first plasma does not directly contact with the substrate, and depositing the dielectric material on the substrate to form a dielectric layer. One or more reactants excited by the first plasma are used in the deposition of the dielectric material. The methods may additional include curing the dielectric layer by forming a second plasma in the second plasma region, where one or more carbon-containing species is removed from the dielectric layer.

Owner:APPLIED MATERIALS INC

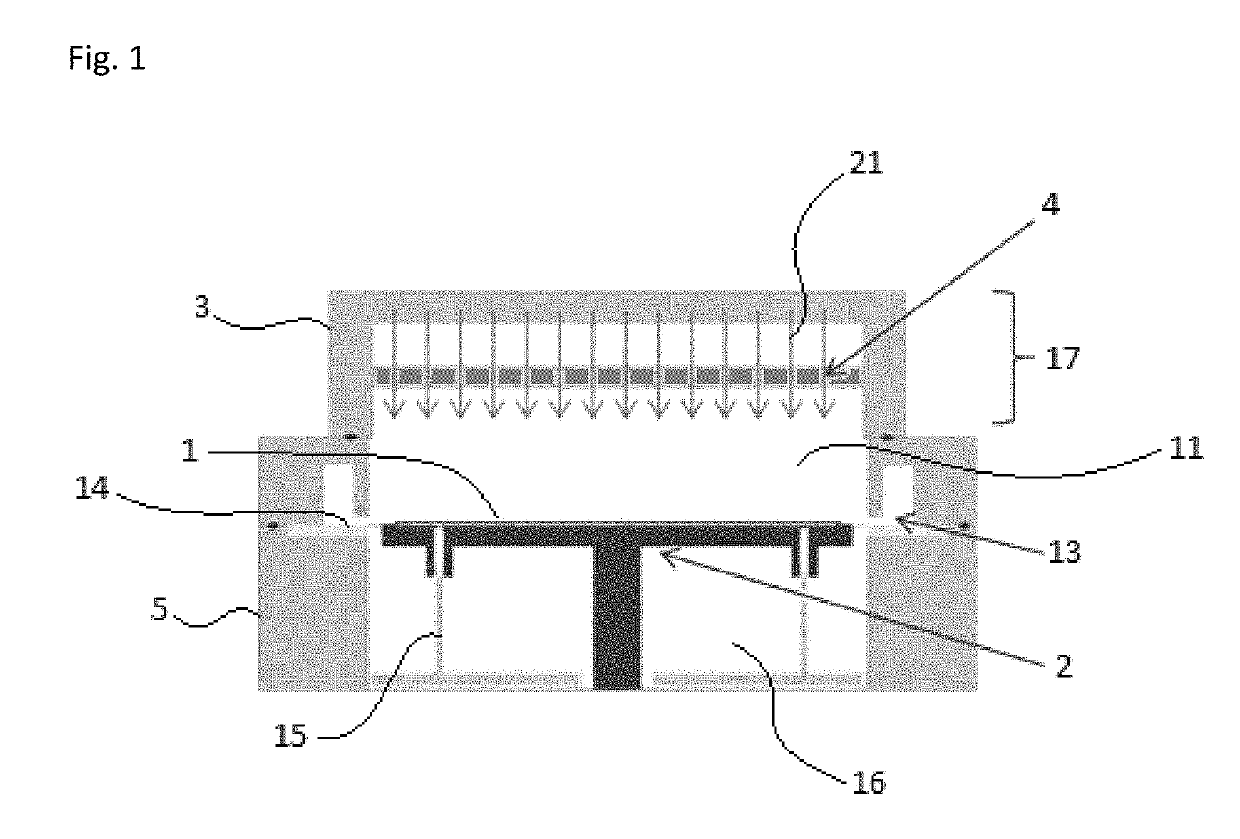

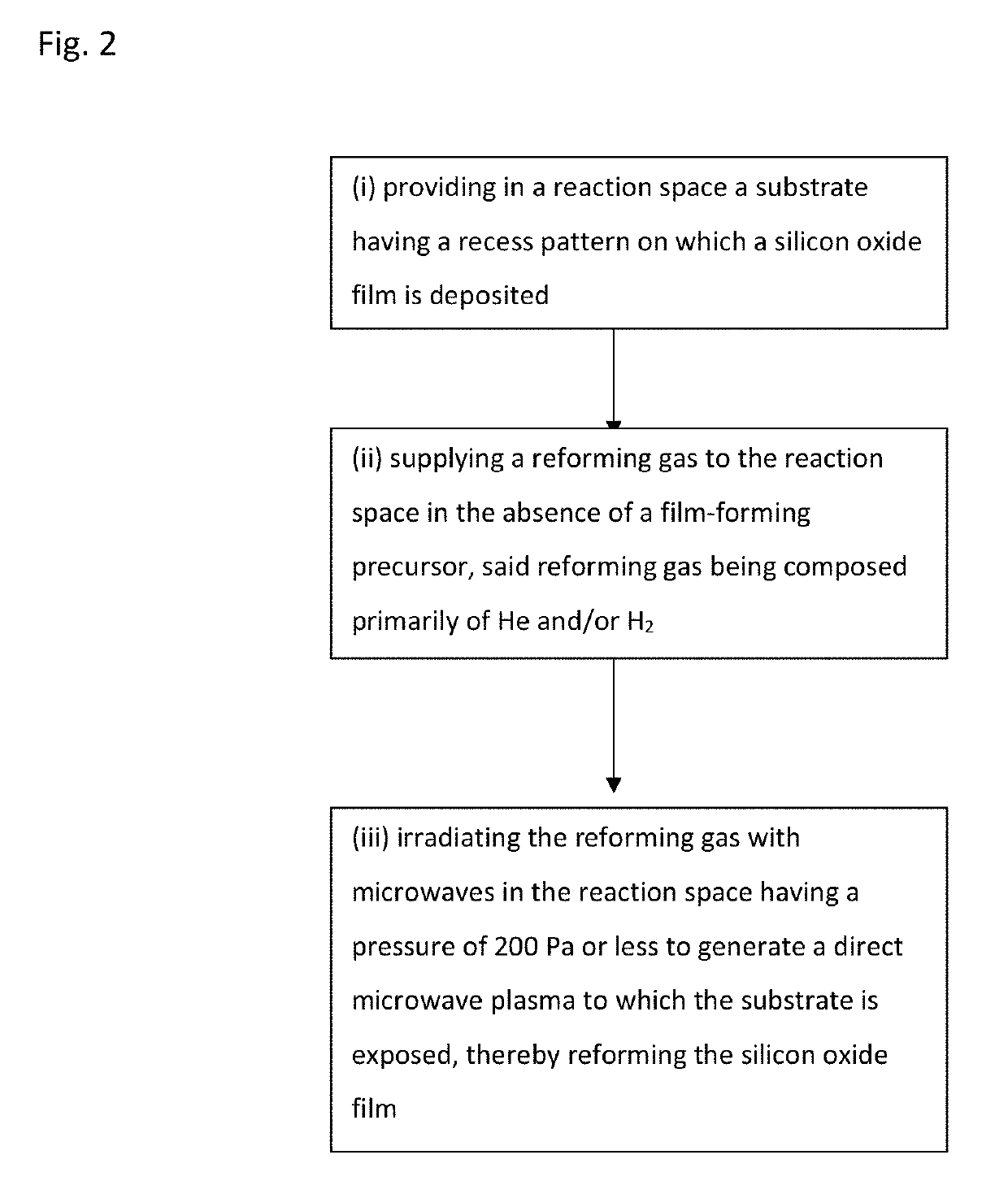

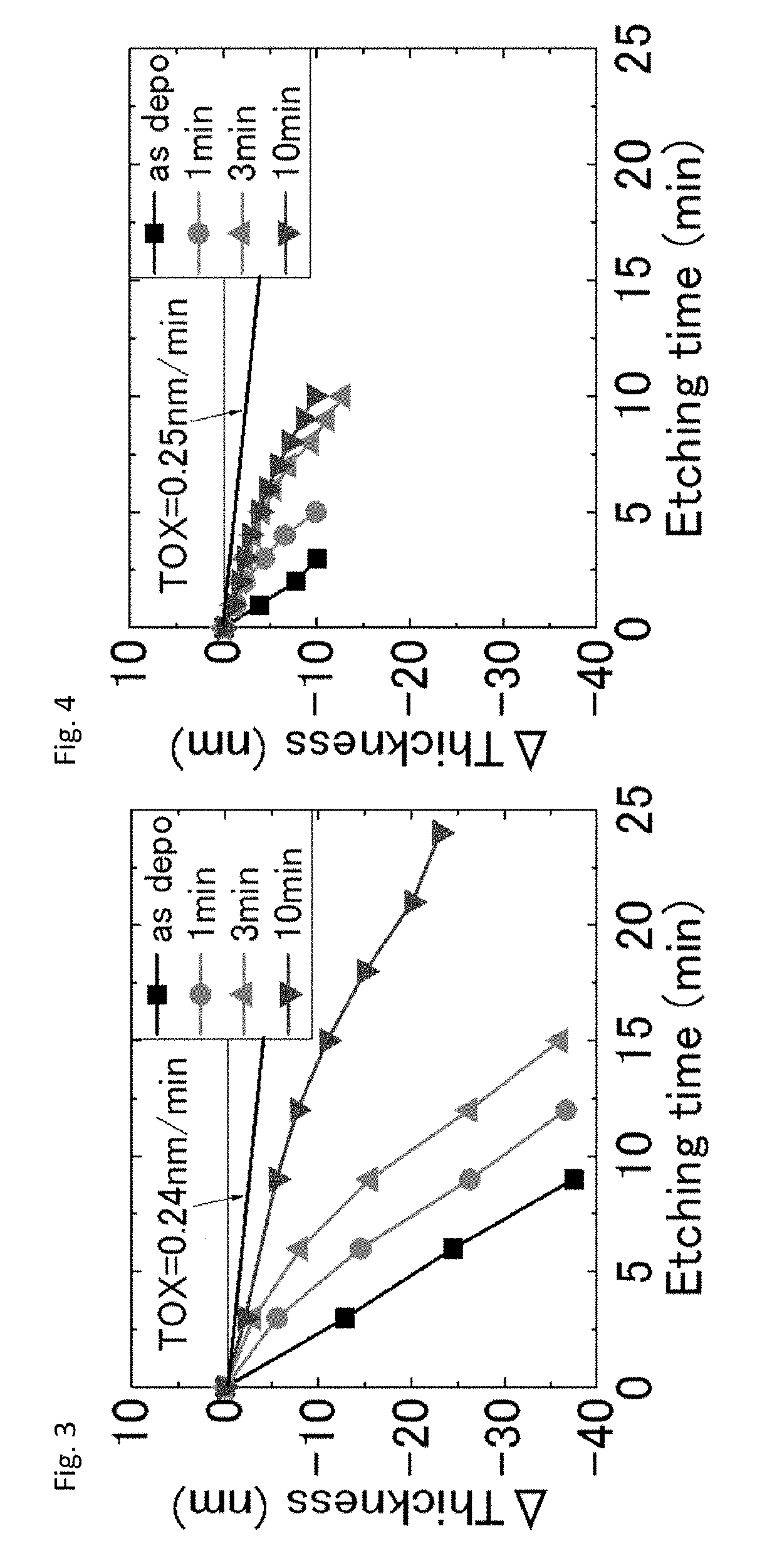

Method of post-deposition treatment for silicon oxide film

ActiveUS20190244803A1High degreeIncrease plasma densityElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveSilicon oxide

A method of post-deposition treatment for silicon oxide film includes: providing in a reaction space a substrate having a recess pattern on which a silicon oxide film is deposited; supplying a reforming gas for reforming the silicon oxide film to the reaction space in the absence of a film-forming precursor, said reforming gas being composed primarily of He and / or H2; and irradiating the reforming gas with microwaves in the reaction space having a pressure of 200 Pa or less to generate a direct microwave plasma to which the substrate is exposed, thereby reforming the silicon oxide film.

Owner:ASM IP HLDG BV

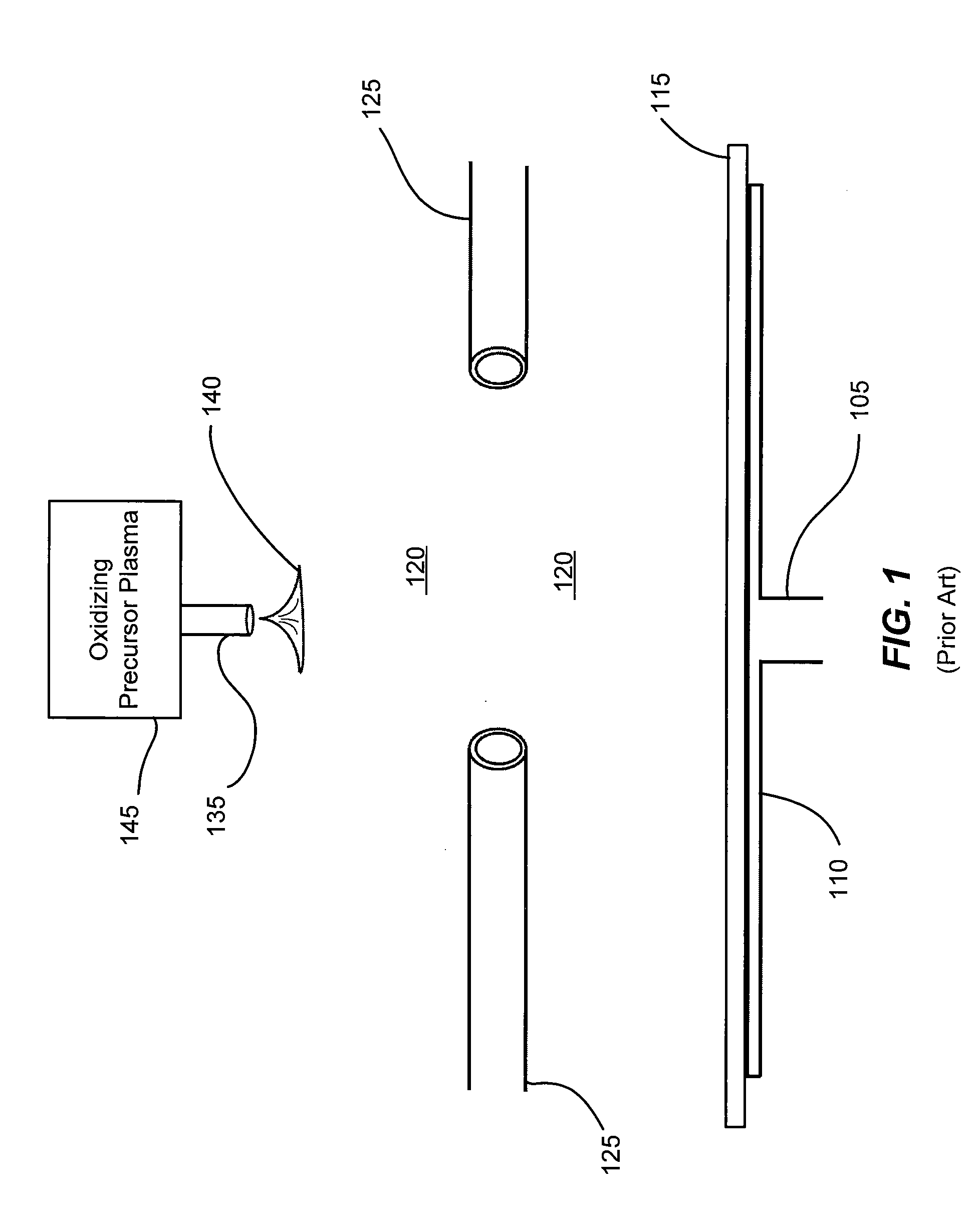

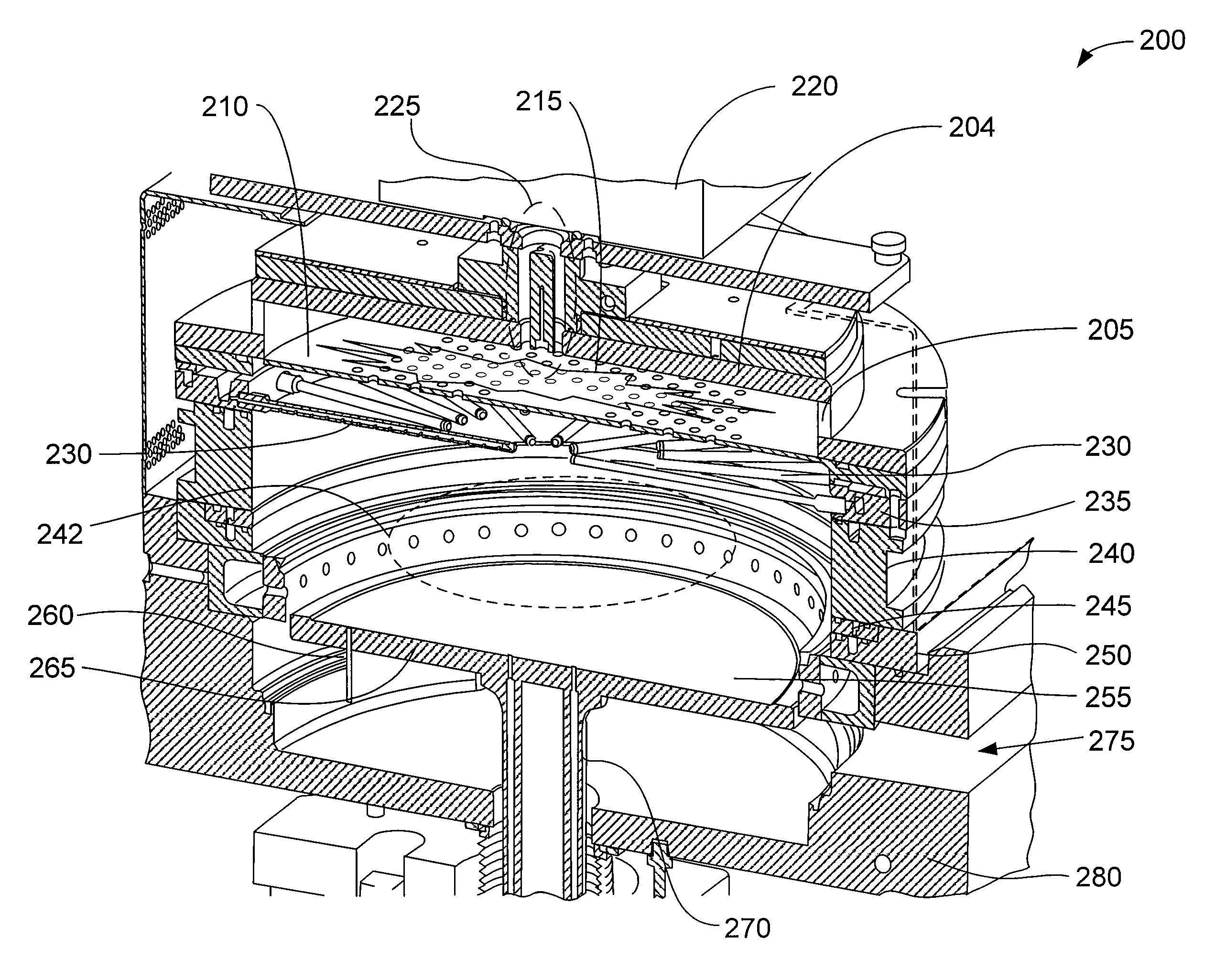

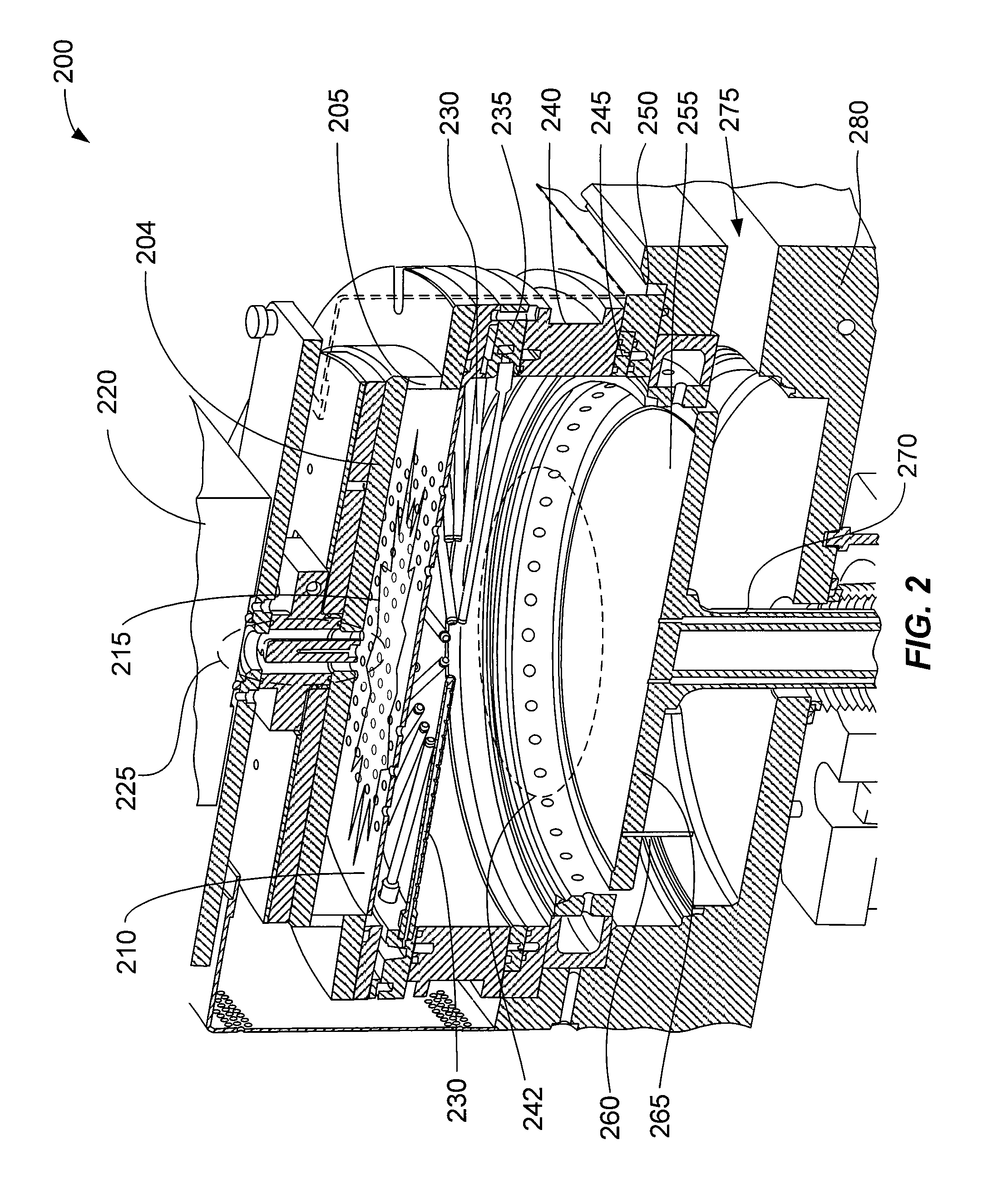

Flowable dielectric equipment and processes

InactiveUS20090277587A1Reduce carbon contentReduce fluorine contentElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaProcess engineering

Substrate processing systems are described that may include a processing chamber having an interior capable of holding an internal chamber pressure different from an external chamber pressure. The systems may also include a remote plasma system operable to generate a plasma outside the interior of the processing chamber. In addition, the systems may include a first process gas channel operable to transport a first process gas from the remote plasma system to the interior of the processing chamber, and a second process gas channel operable to transport a second process gas that is not treated by the remote plasma system. The second process gas channel has a distal end that opens into the interior of the processing chamber, and that is at least partially surrounded by the first process gas channel.

Owner:APPLIED MATERIALS INC

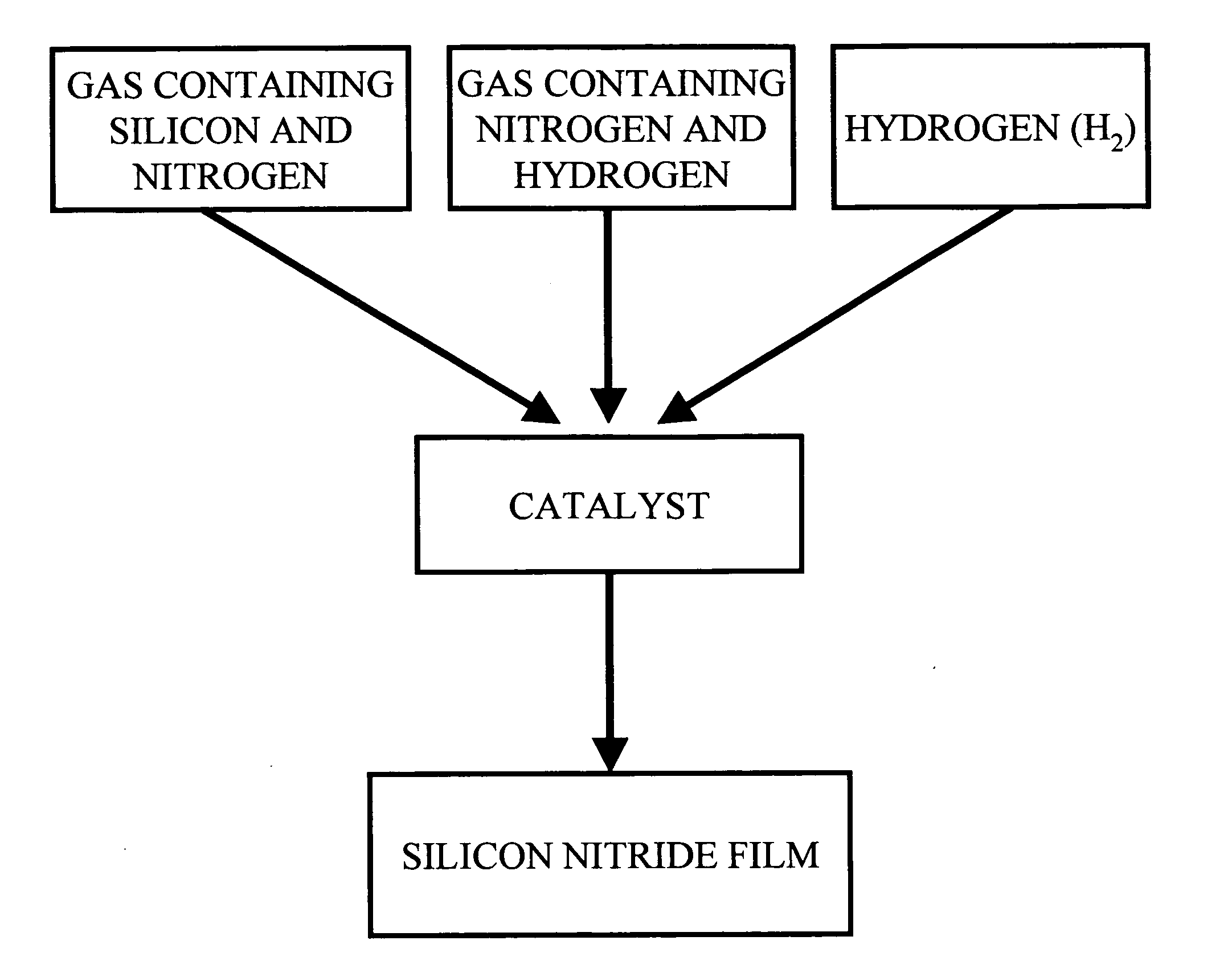

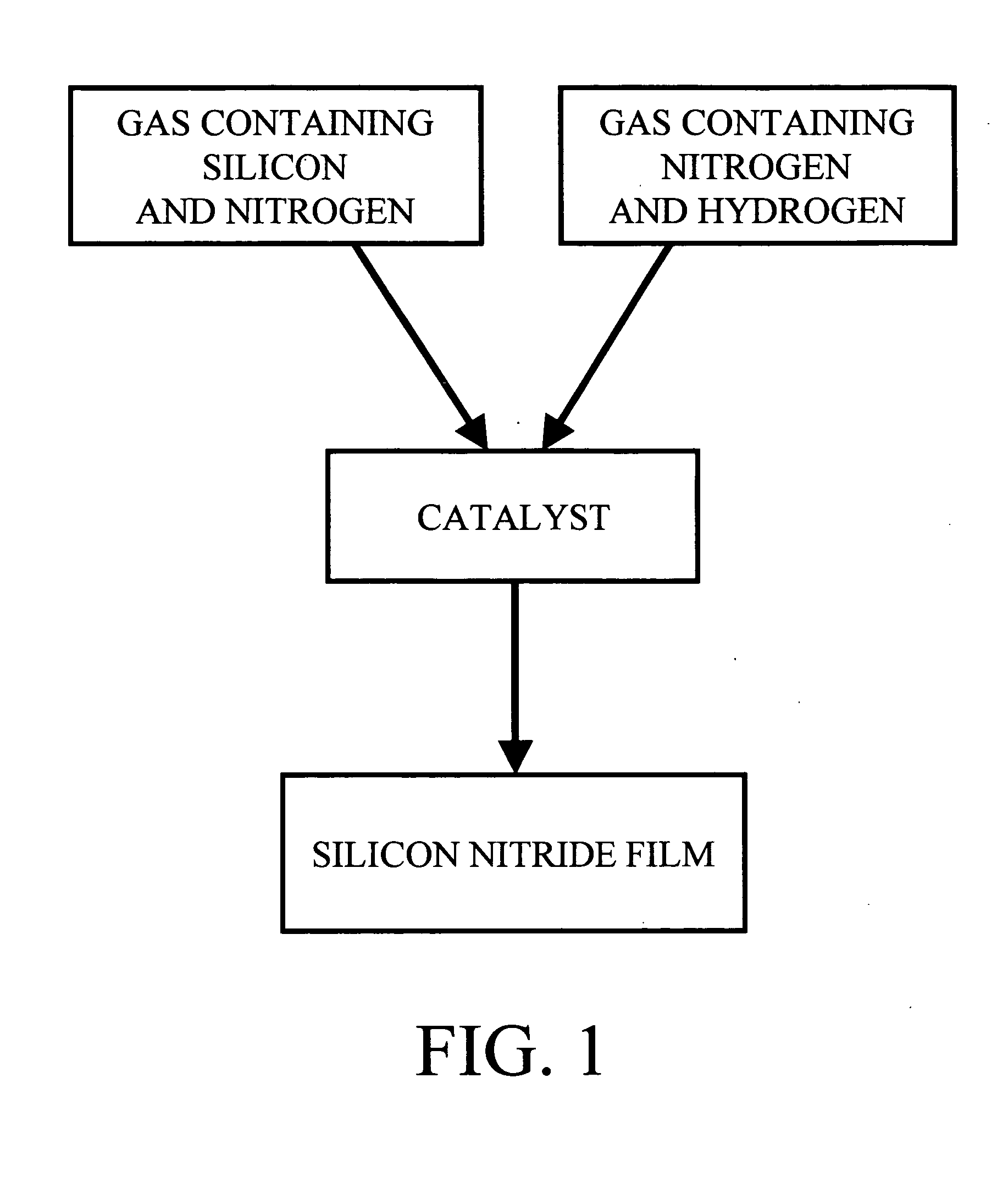

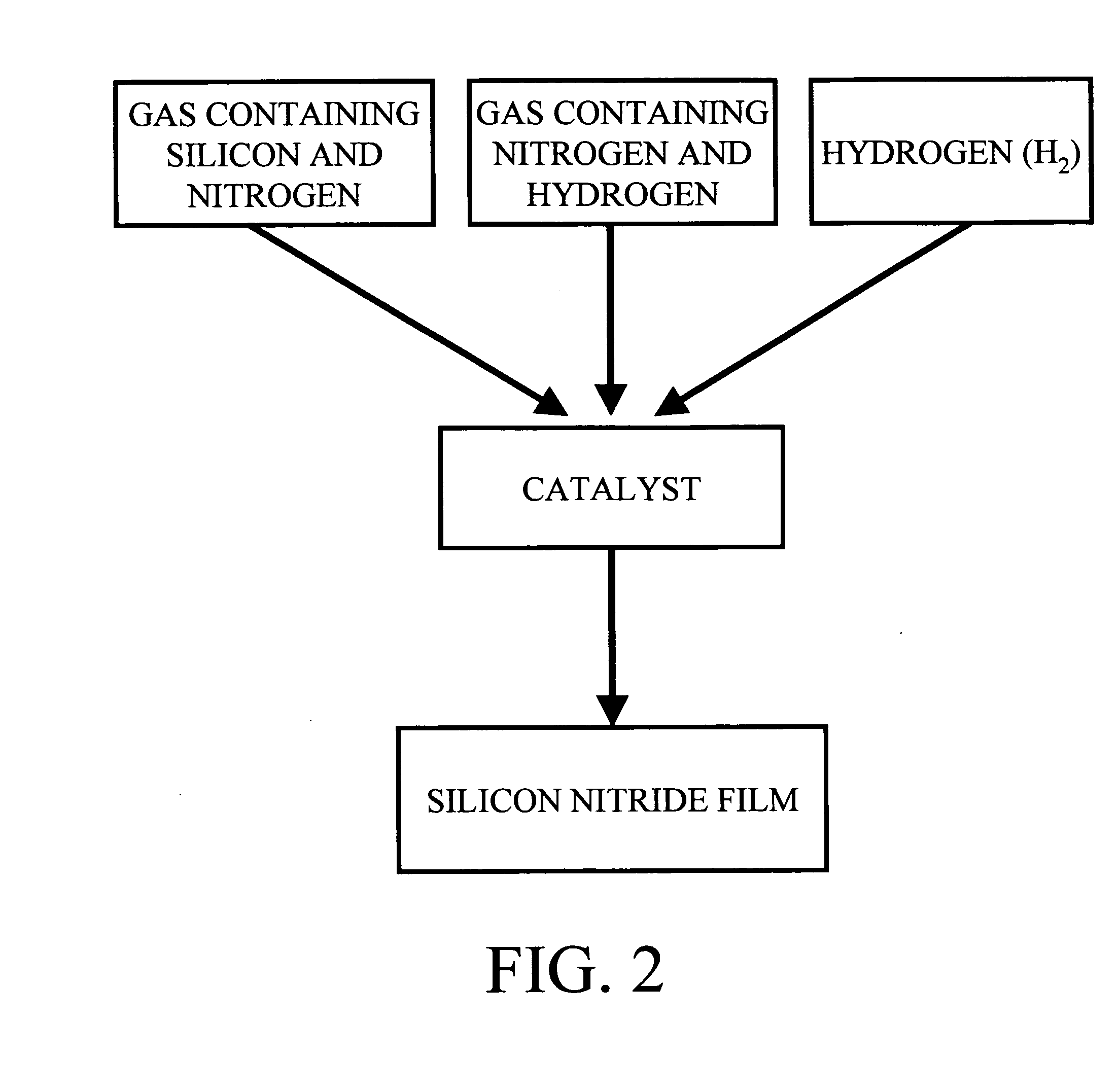

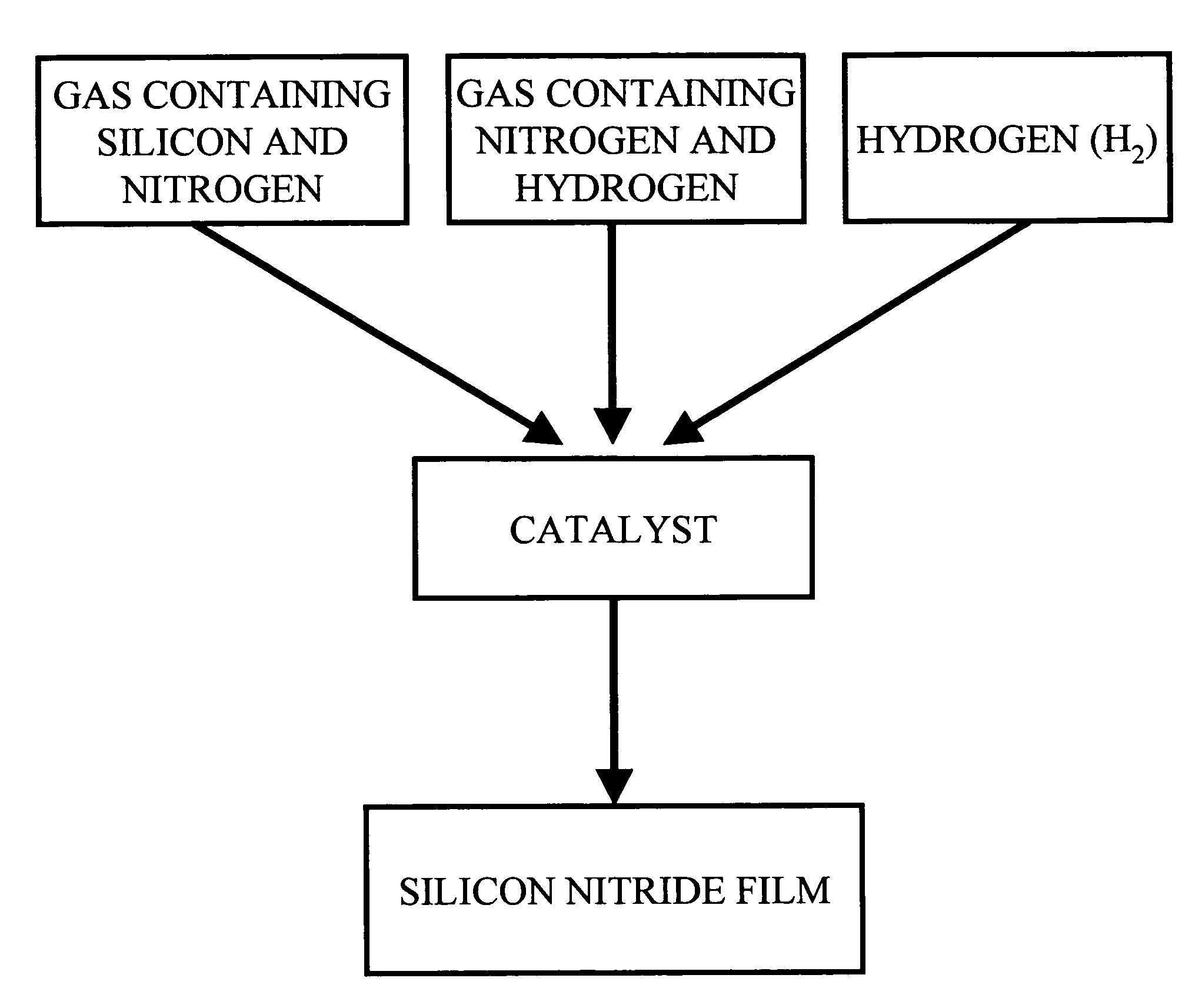

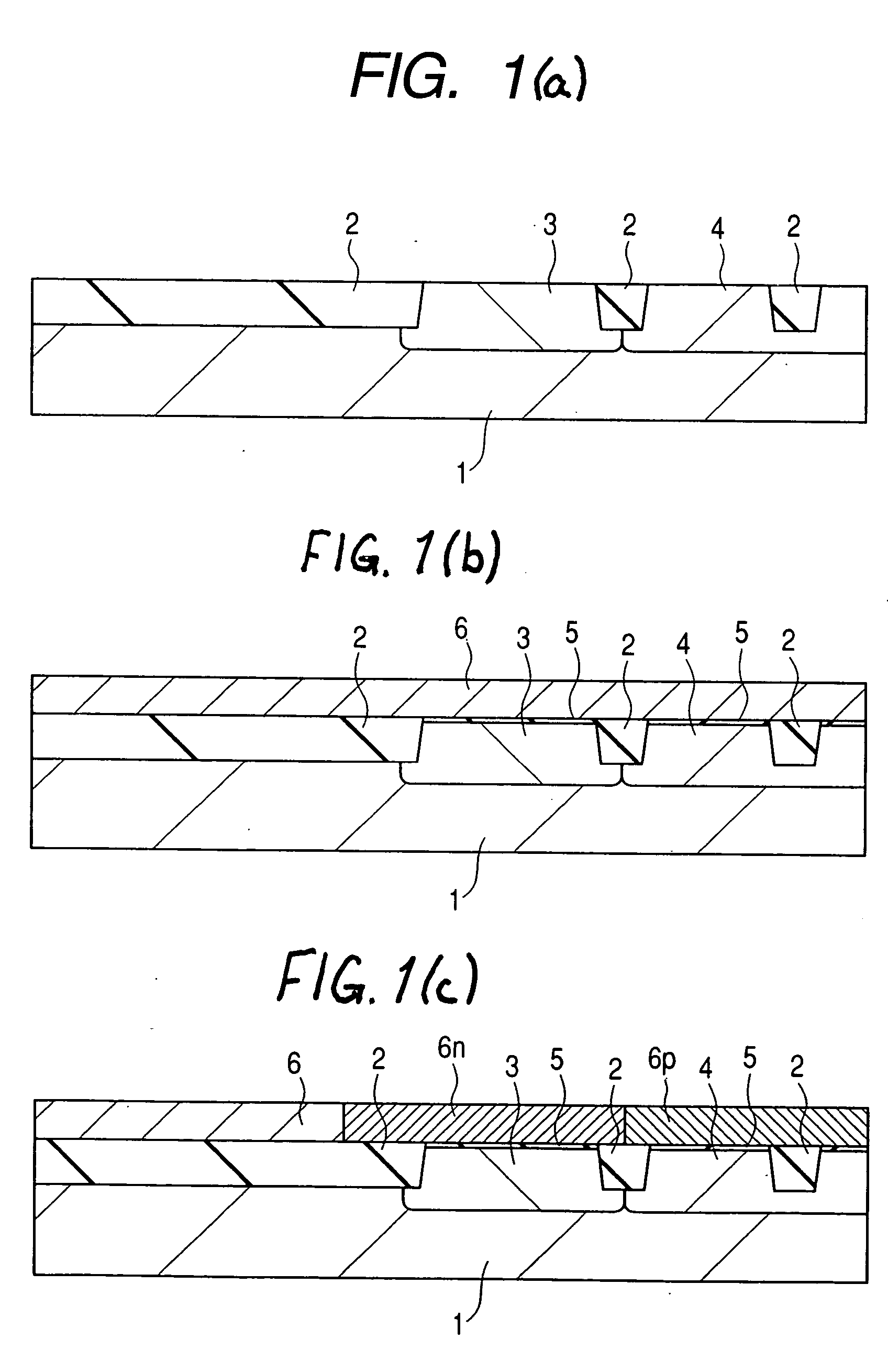

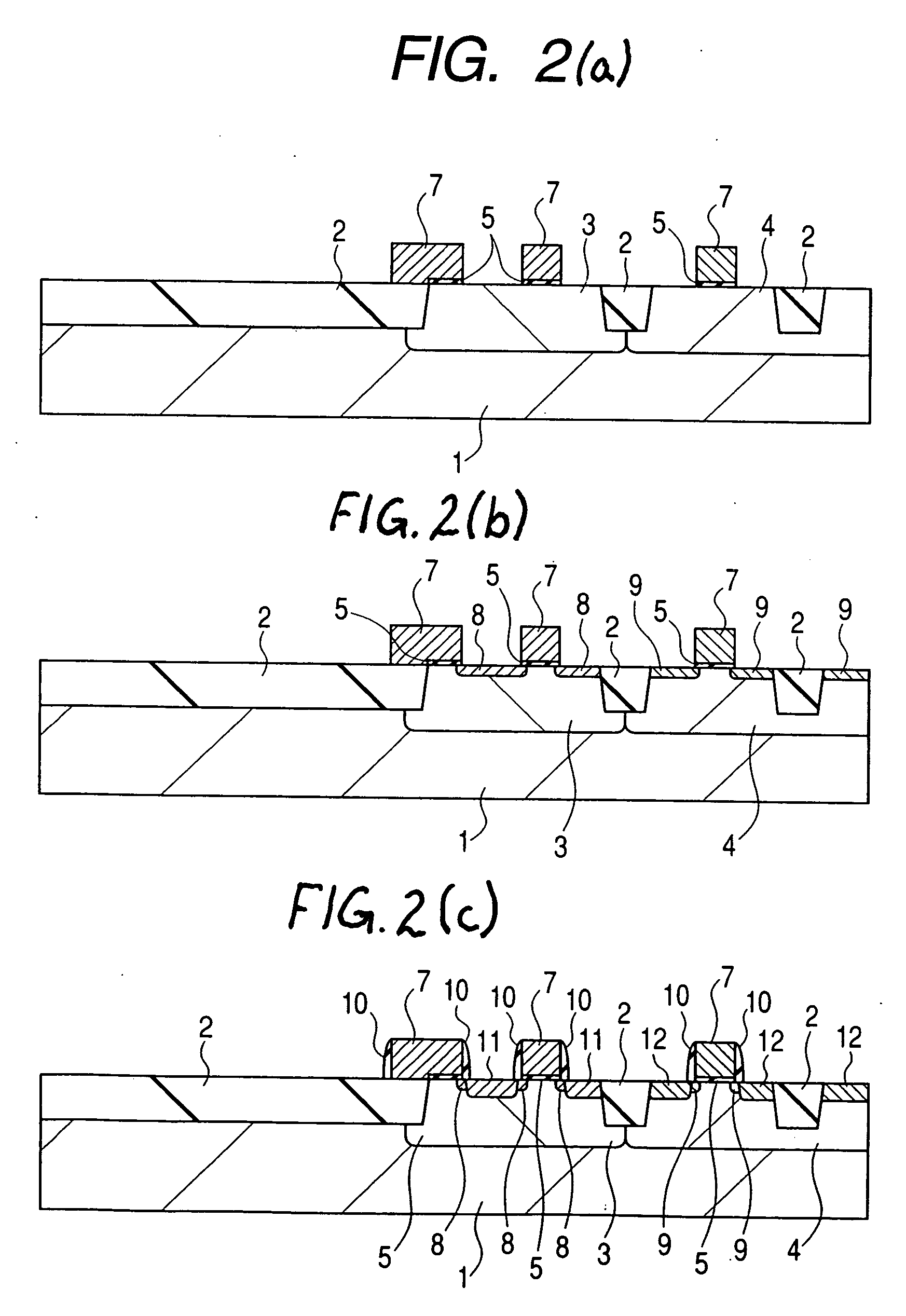

Method of forming silicon nitride film and method of manufacturing semiconductor device

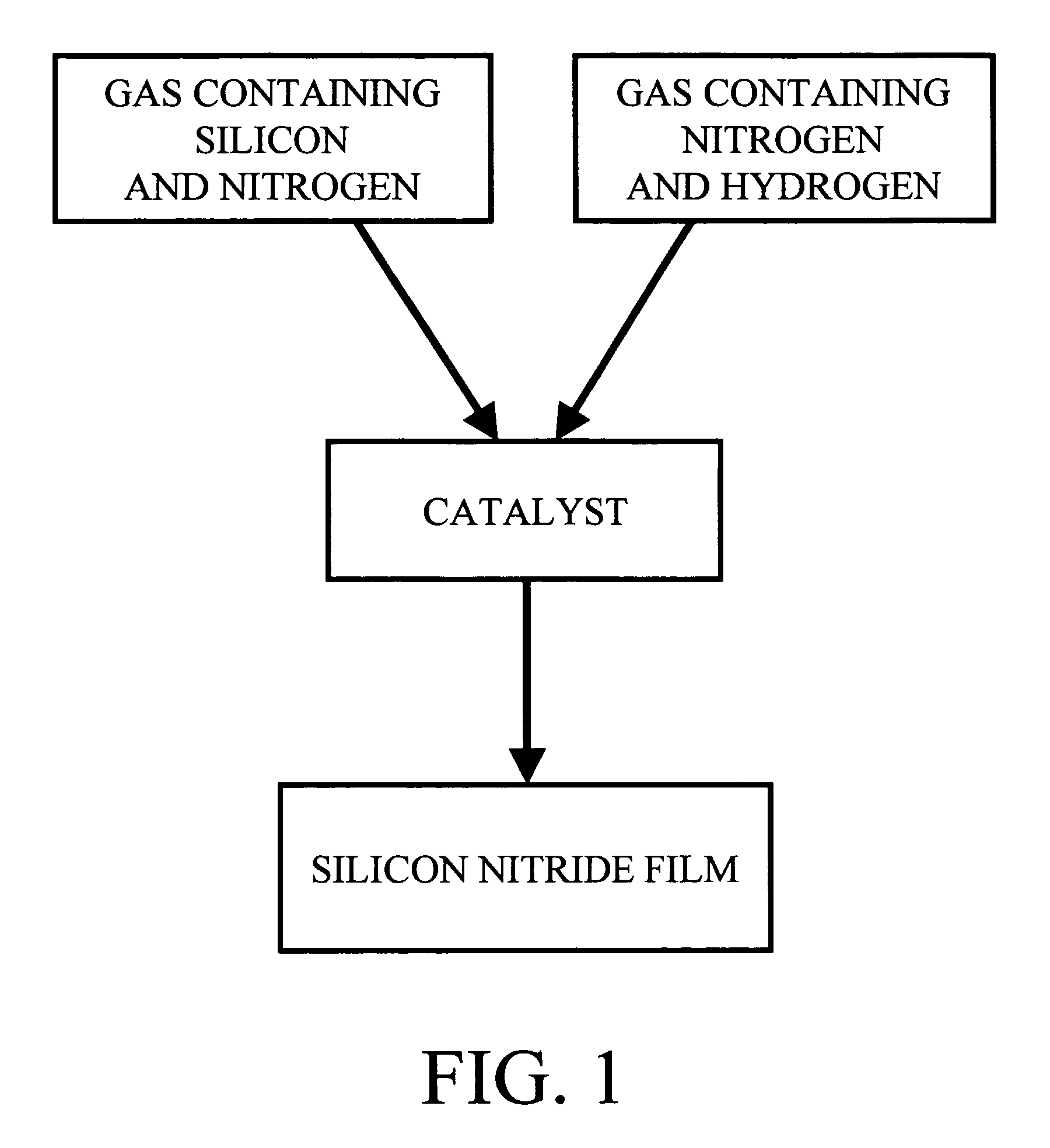

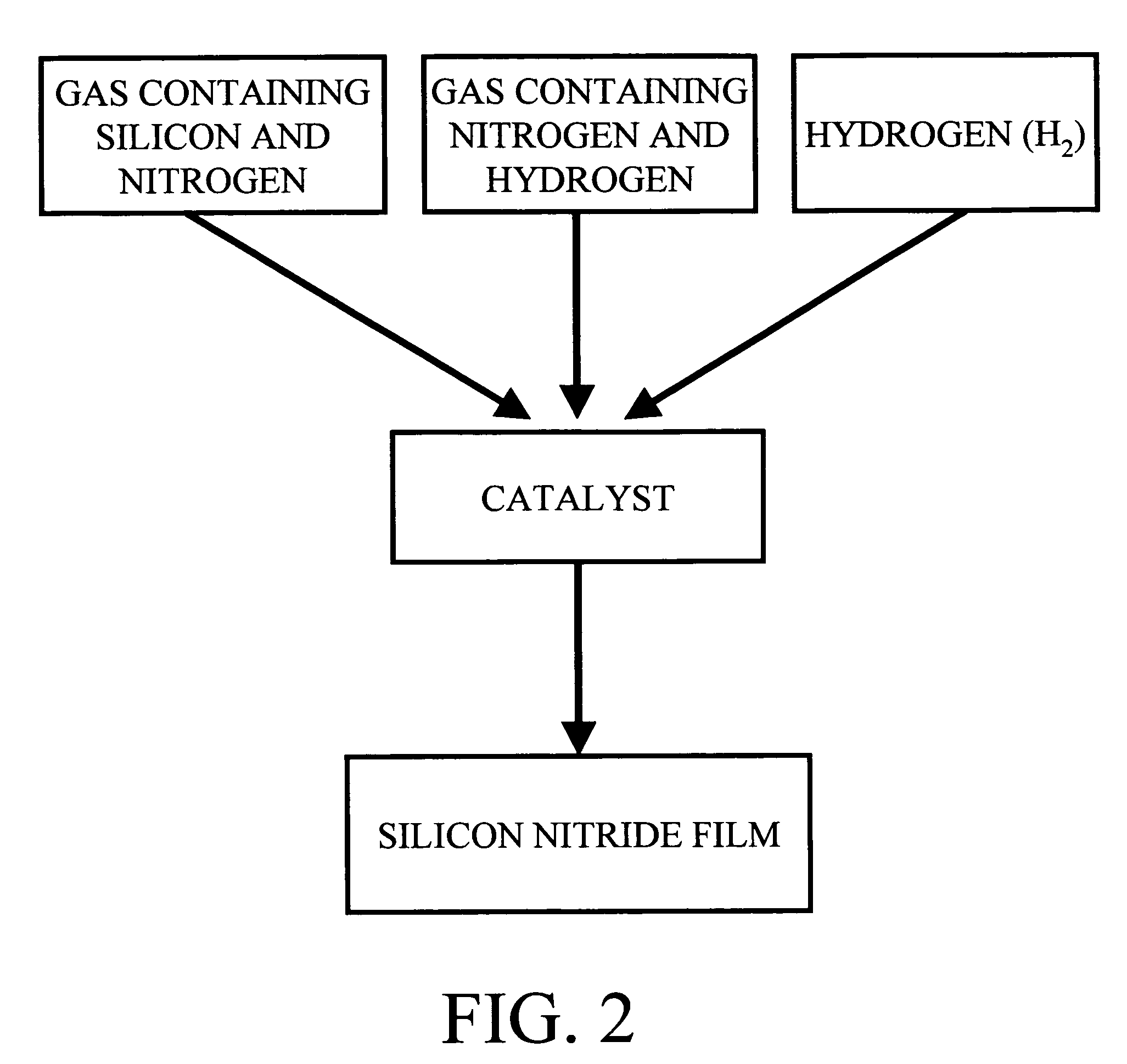

ActiveUS20050196977A1Good step coverageIdeal balanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingInsulation layerHydrogen

A method of forming a silicon nitride film comprises: forming a silicon nitride film by applying first gas containing silicon and nitrogen and second gas containing nitrogen and hydrogen to catalyst heated in a reduced pressure atmosphere. A method of manufacturing a semiconductor device comprising the steps of: forming a silicon nitride film by the method as claimed in claim 1 on a substrate having the semiconductor layer, a gate insulation film selectively provided on a principal surface of the semiconductor layer, and a gate electrode provided on the gate insulation film; and removing the silicon nitride film on the semiconductor layer and the gate electrode and leaving a sidewall comprising the silicon nitride film on a side surface of the gate insulation film and the gate electrode by etching the silicon nitride film in a direction generally normal to the principal surface of the semiconductor layer. A method of manufacturing a semiconductor device comprising the steps of: forming a silicon nitride film by the method as claimed in claim 1 on a substrate including a semiconductor layer; forming an interlayer insulation layer on the silicon nitride film; forming a layer having an opening on the interlayer insulation layer; and etching the interlayer insulation layer via the opening in a condition where an etching rate for the silicon nitride film is greater than an etching rate for the interlayer insulation layer.

Owner:ULVAC INC

Method of forming silicon nitride film and method of manufacturing semiconductor device

ActiveUS7510984B2Good step coverageIdeal balanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenInsulation layer

Owner:ULVAC INC

Method for preparing silicon thin film heterojunction solar cell

InactiveCN1588649AAvoid damageReduce hydrogen contentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon thin film

A prepn. method of silicon thin film heterojunction solar cell includes following steps: cleaning substrate, semiconductor cleaning technology is used to do primary cleaing to substrate surface, then do ultrasonic cleaning in deionized water several times; nitrogen blow drying; prepare nitrinsic amorphous silicon layer by heater chemical vapour phase depositing technology, tungsten filament temp. is measured by pyrometer, temp of heater and sample are determined separately by two electric thermo-couples, temp. is controlled by electric temp. controller; to react and grow thin film on substrate surface; to redeposit a transmitting layer on intrinsic amorphous silicon thin film; front and back electrodes forming, sputtering technology is used to form front and back electrodes; finally to proceed vacuum heat annealing process. The thin film produced by the invention has illumination stability, the photoconduction gain can reach to 10 to the power 6 on Am1.5 100mW / cm2 standard illumination.

Owner:SHANGHAI JIAO TONG UNIV

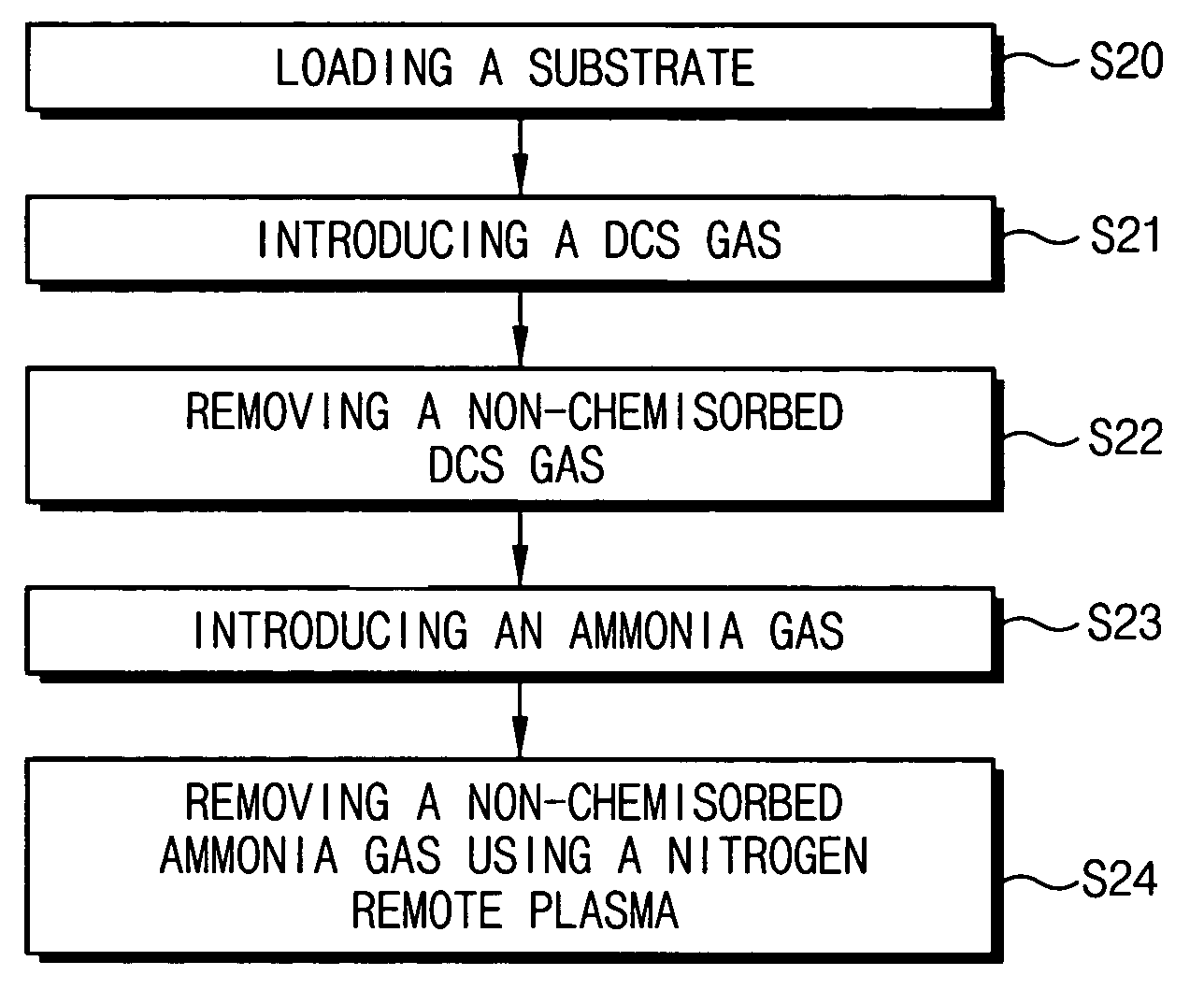

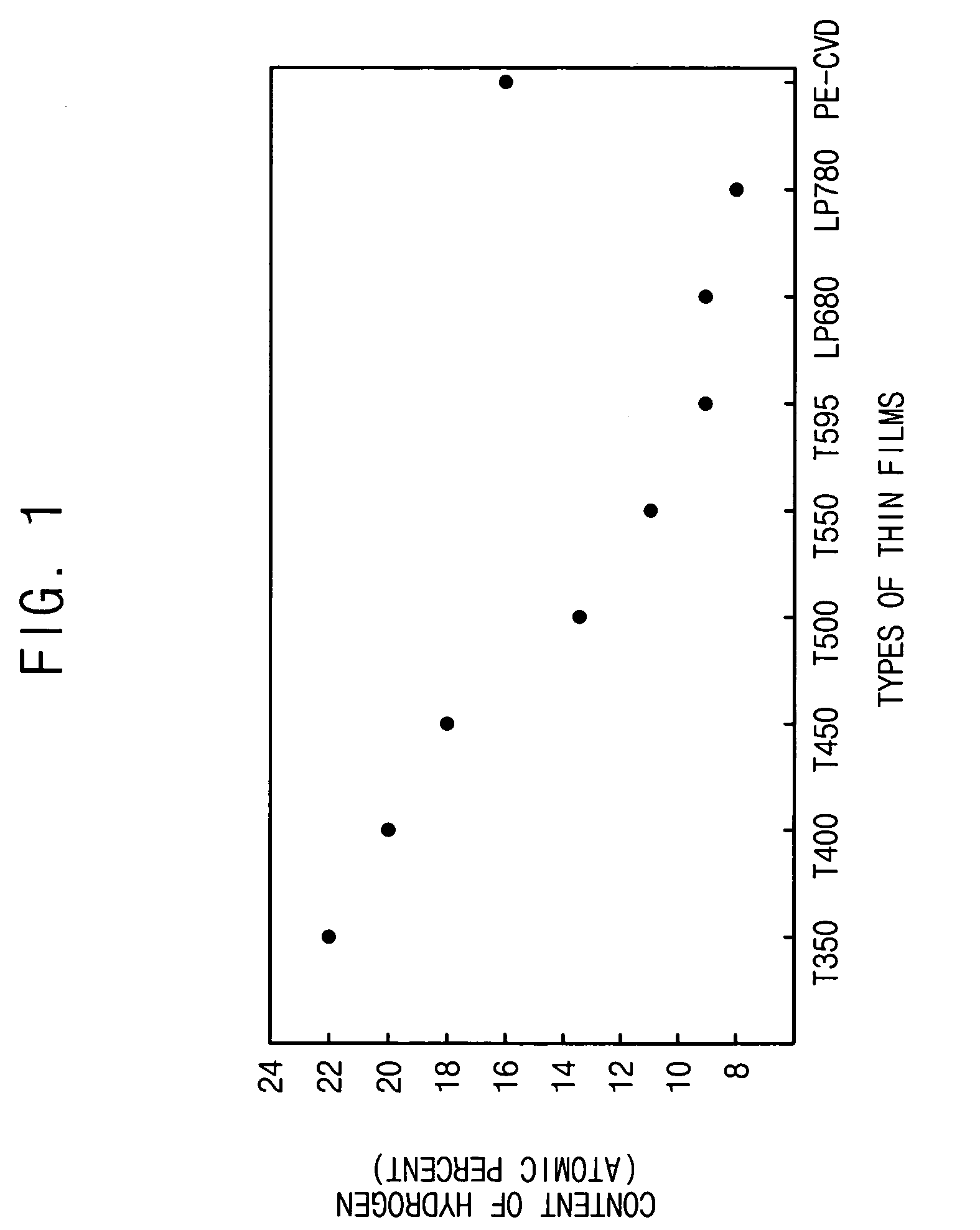

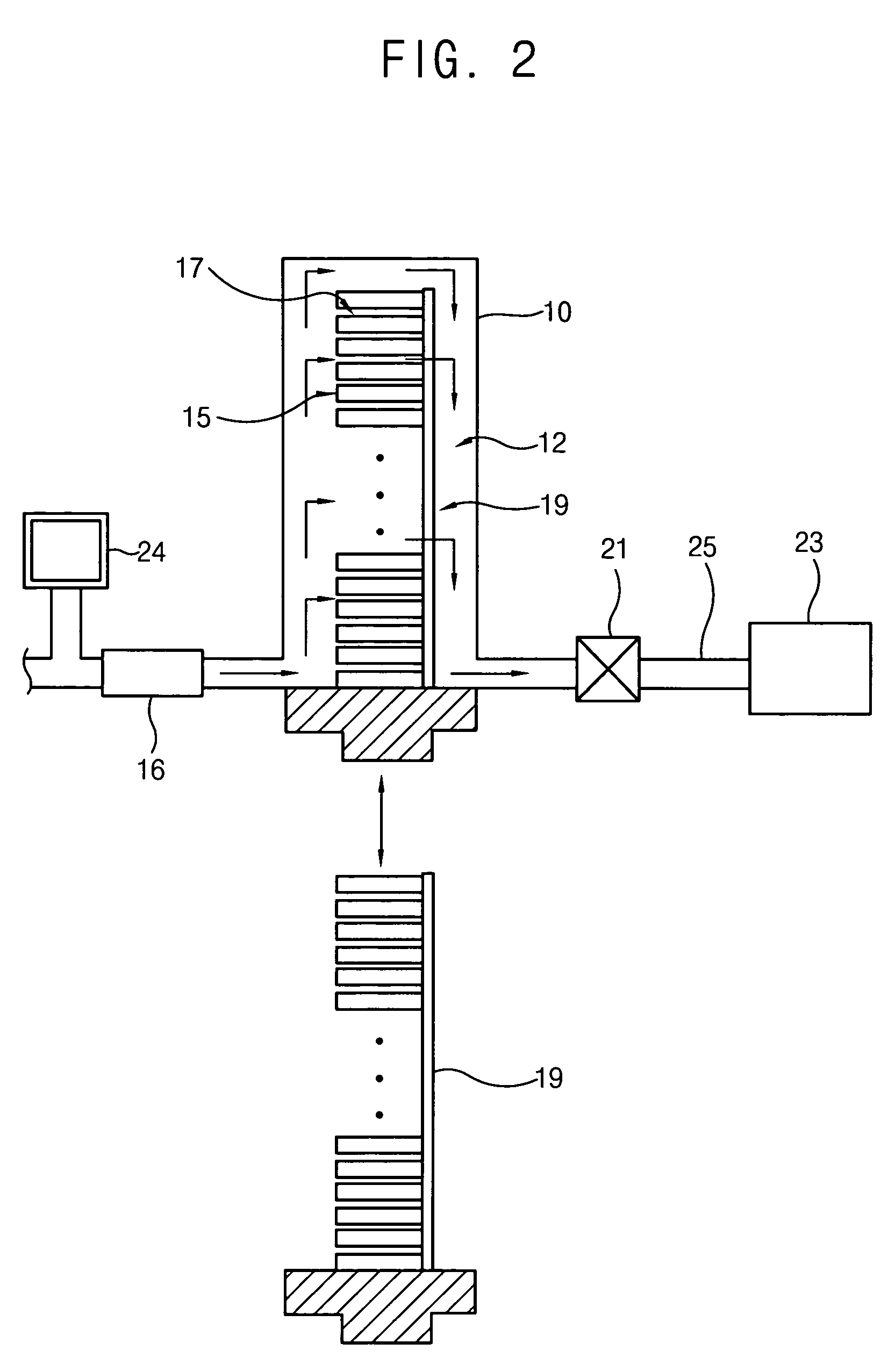

Method of forming a thin film with a low hydrogen content on a semiconductor device

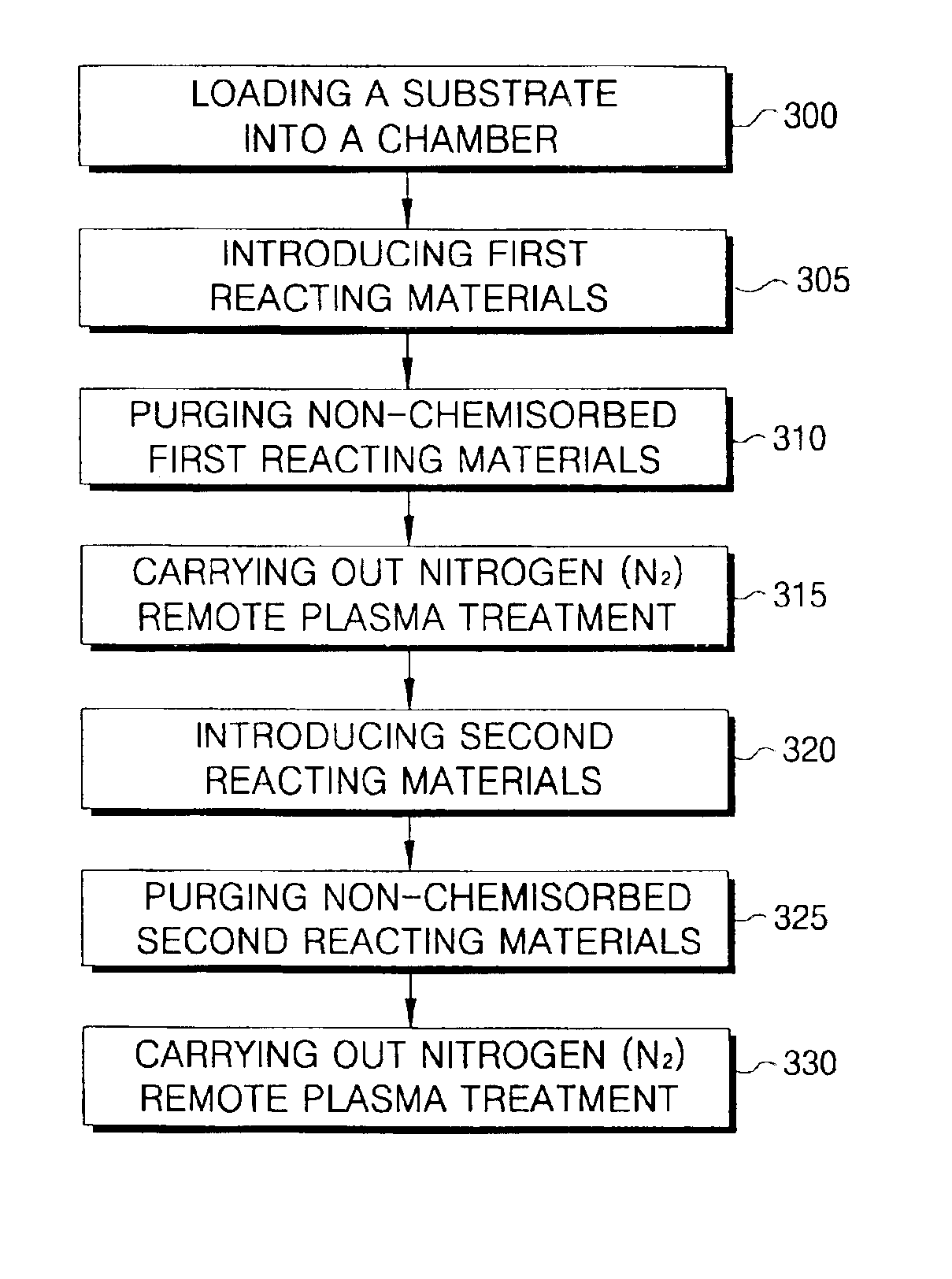

InactiveUS6933245B2Reduce hydrogen contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaChemisorption

A method of forming a thin film with a low hydrogen contents is provided by positioning a substrate inside a processing chamber, and supplying reacting materials into the chamber, chemisorbing a portion of the reacting materials onto the substrate. Then, a nitrogen (N2) remote plasma treatment is performed to reduce the hydrogen content of thin film layer formed by chemisorption of the reacting materials on the substrate. Accordingly, a thin film is formed having a low hydrogen content, since the hydrogen bonds in the thin film layer formed by chemisorption of the reacting materials are removed.

Owner:SAMSUNG ELECTRONICS CO LTD

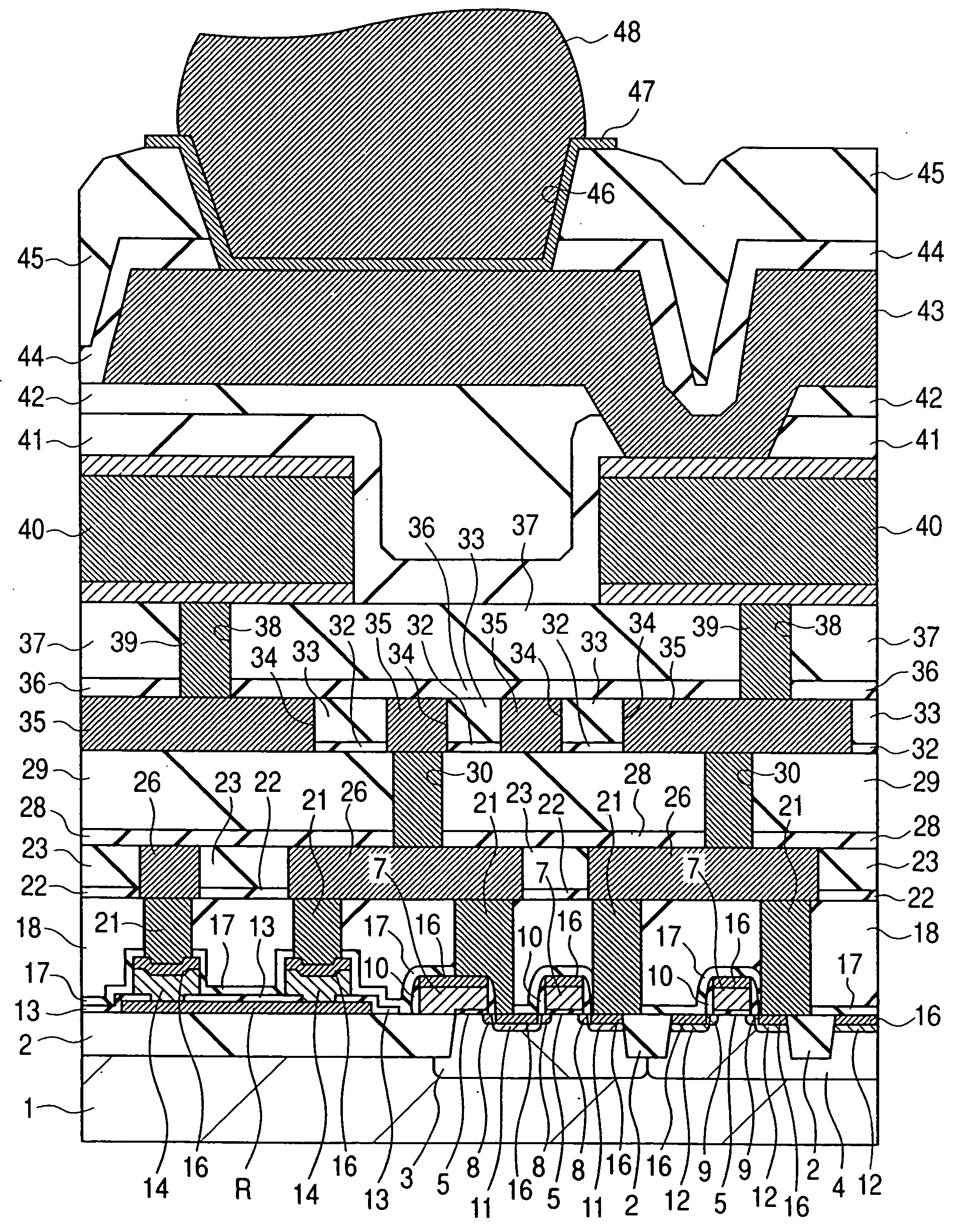

Semiconductor integrated circuit device and process for manufacturing the same

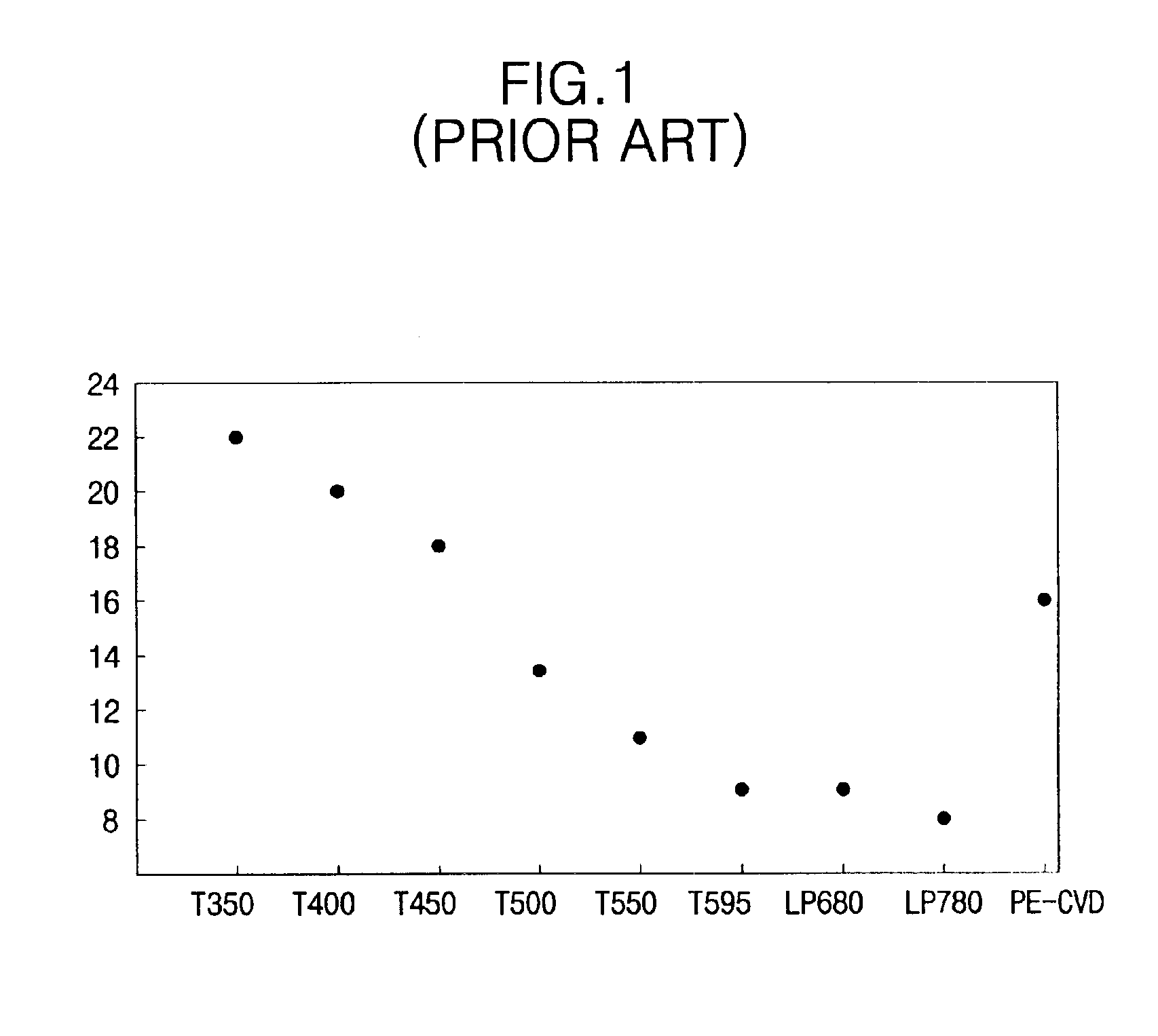

InactiveUS20050020021A1Image degradationLess fluctuationTransistorSolid-state devicesDevice materialHydrogen content

In the manufacture of a semiconductor device having a high-performance and high-reliability, a silicon nitride film 17 for self alignment, which film is formed to cover the gate electrode of a MISFET, is formed at a substrate temperature of 400° C. or greater by plasma CVD using a raw material gas including monosilane and nitrogen. A silicon nitride film 44 constituting a passivation film is formed at a substrate temperature of about 350° C. by plasma CVD using a raw material gas including monosilane, ammonia and nitrogen. The hydrogen content contained in the silicon nitride film 17 is smaller than that contained in the silicon nitride film 44, making it possible to suppress hydrogen release from the silicon nitride film 17.

Owner:RENESAS ELECTRONICS CORP

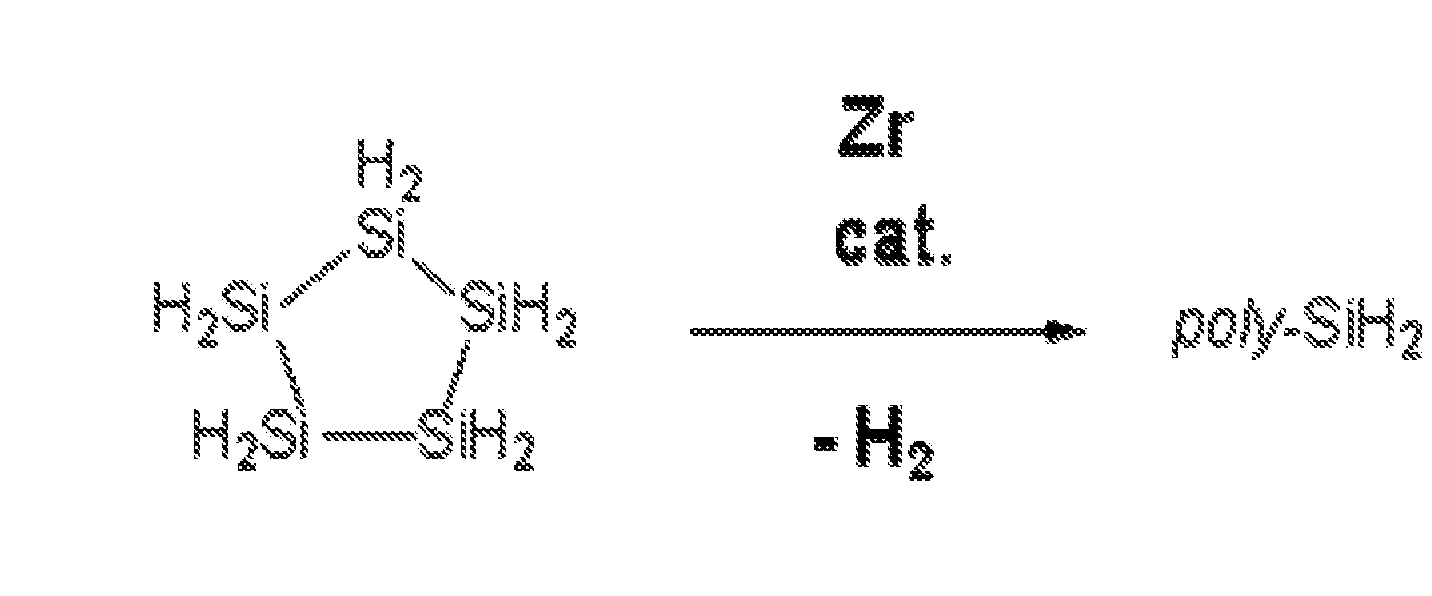

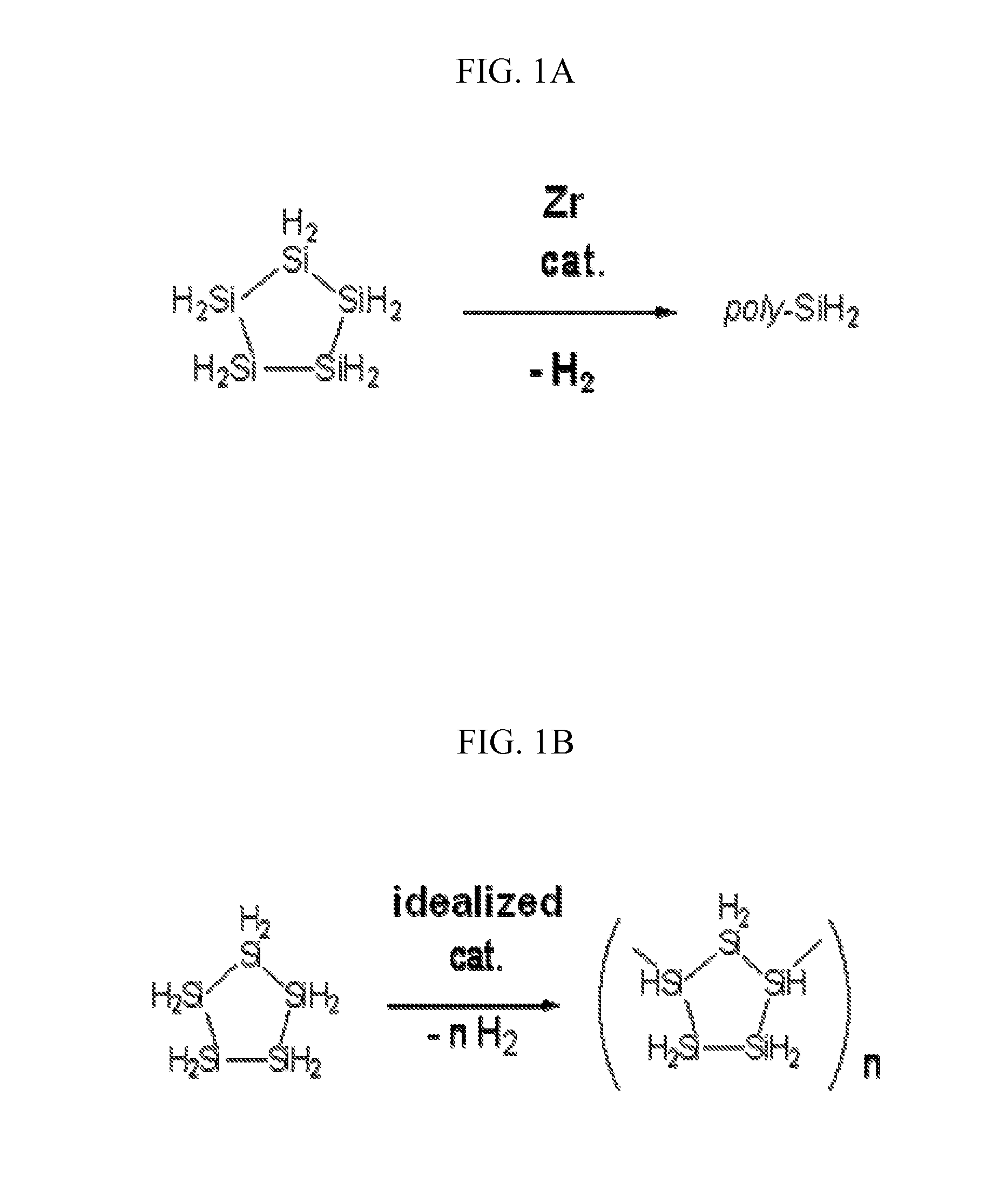

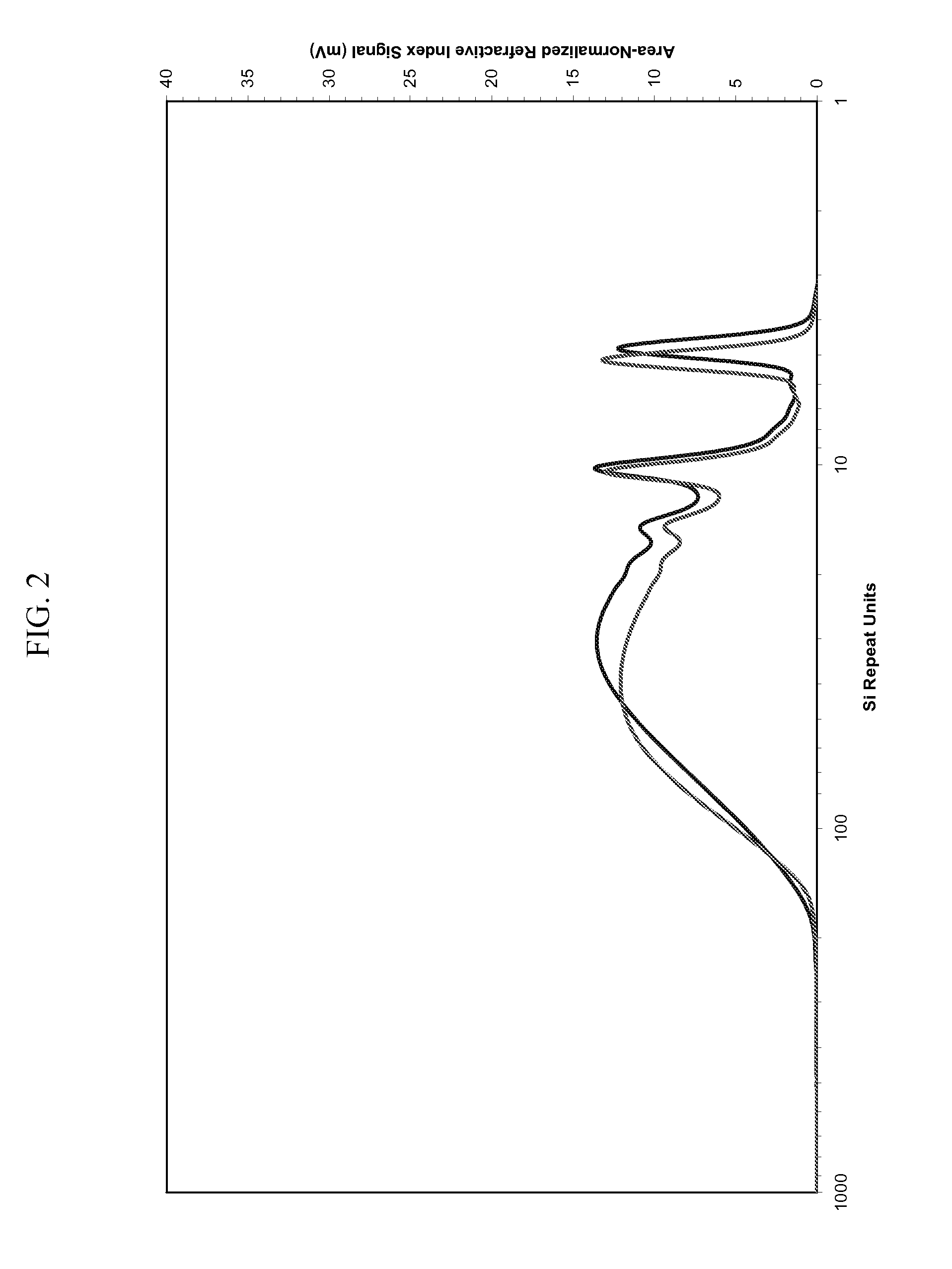

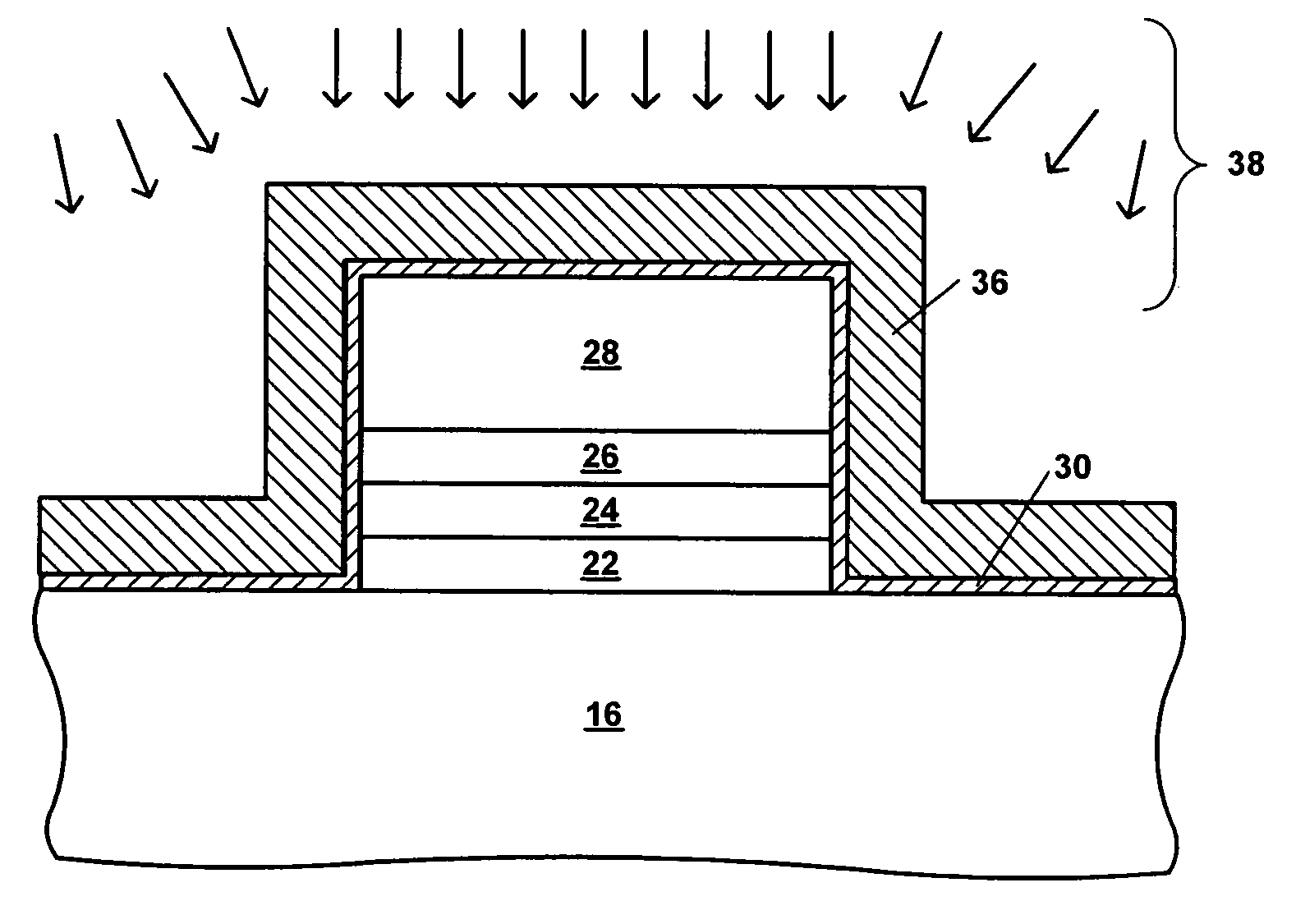

Silicon Polymers, Methods of Polymerizing Silicon Compounds, and Methods of Forming Thin Films from Such Silicon Polymers

ActiveUS20080085373A1Reduce hydrogen contentSufficient formSilicon organic compoundsSolid-state devicesSilanesCompound (substance)

Compositions and methods for controlled polymerization and / or oligomerization of hydrosilanes compounds including those of the general formulae SinH2n and SinH2n+2 as well as alkyl- and arylsilanes, to produce soluble silicon polymers as a precursor to silicon films having low carbon content.

Owner:ENSURGE MICROPOWER ASA

Process for fabrication of spacer layer with reduced hydrogen content in semiconductor device

ActiveUS6949481B1Reduce hydrogen contentRead-only memoriesSemiconductor/solid-state device manufacturingHydrogen contentEngineering

Process for fabricating a semiconductor device including steps of providing a semiconductor substrate having formed thereon a semiconductor device; depositing over the semiconductor device a spacer layer, the spacer layer having a first hydrogen content; and applying a treatment to reduce the first hydrogen content to a second hydrogen content. The invention is particularly useful when applied to flash memory devices such as a charge trapping dielectric flash memory device.

Owner:MONTEREY RES LLC

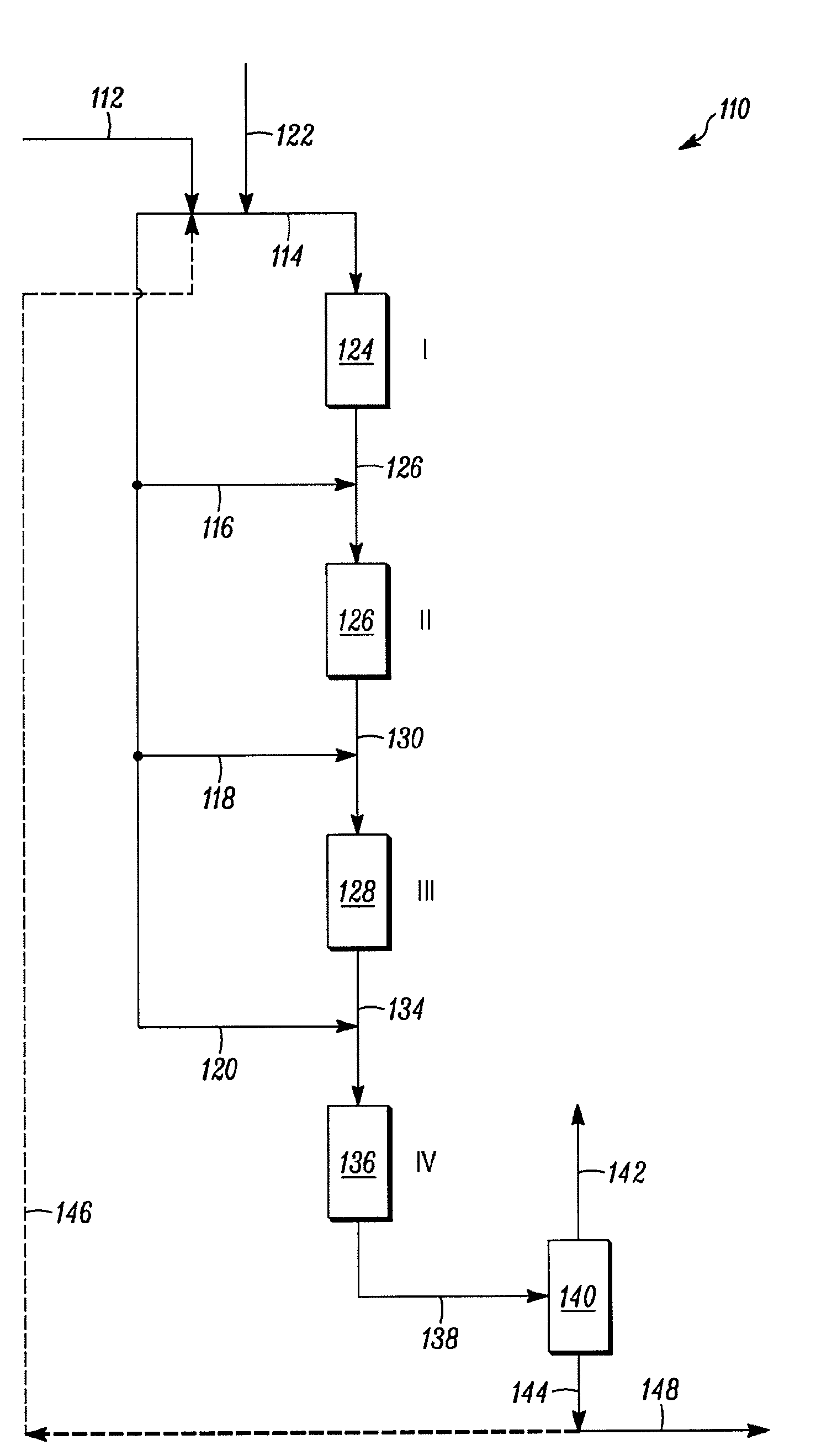

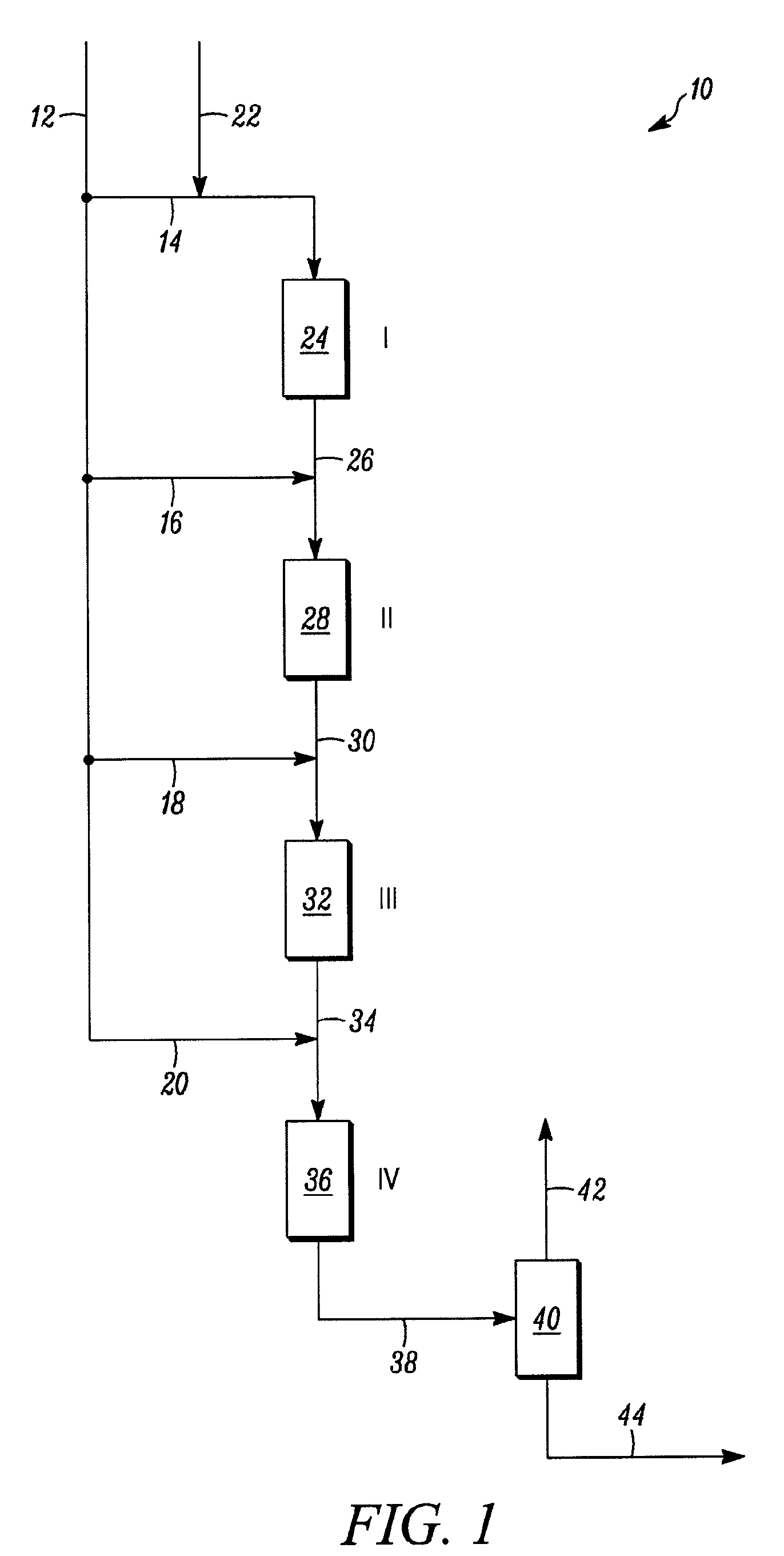

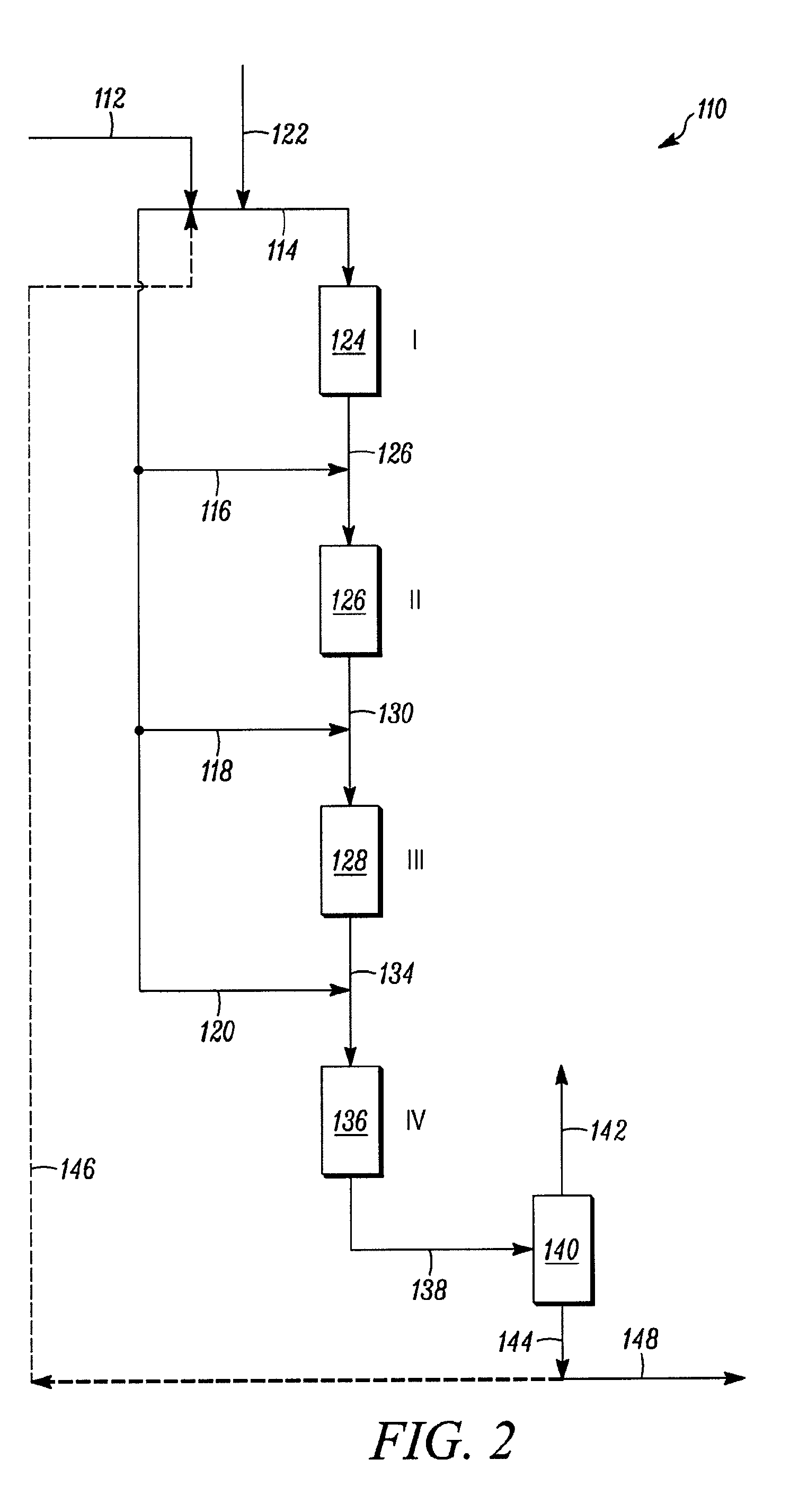

Multi-Staged Hydroprocessing Process And System

InactiveUS20090321319A1Reduce and eliminate for heatConsiderable cost savingCatalytic naphtha reformingTreatment with hydrotreatment processesHydrogenReaction zone

Methods and systems of processing a hydrocarbonaceous feed stock flows are provided. In one aspect, the method includes providing two or more hydroprocessing stages disposed in sequence, each hydroprocessing stage having a hydroprocessing reaction zone with a hydrogen requirement and each stage in fluid communication with the preceding stage. A hydrogen source is provided substantially free of hydrogen from a hydrogen recycle compressor. The hydrocarbonaceous feed stock flow is separated into an portions of fresh feed for each hydroprocessing stage, and then supplying the first portion of fresh feed with hydrogen from the hydrogen source in an amount satisfying substantially all of the hydrogen requirements of the hydroprocessing stages to a first hydroprocessing zone.

Owner:UOP LLC

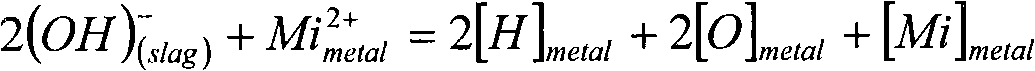

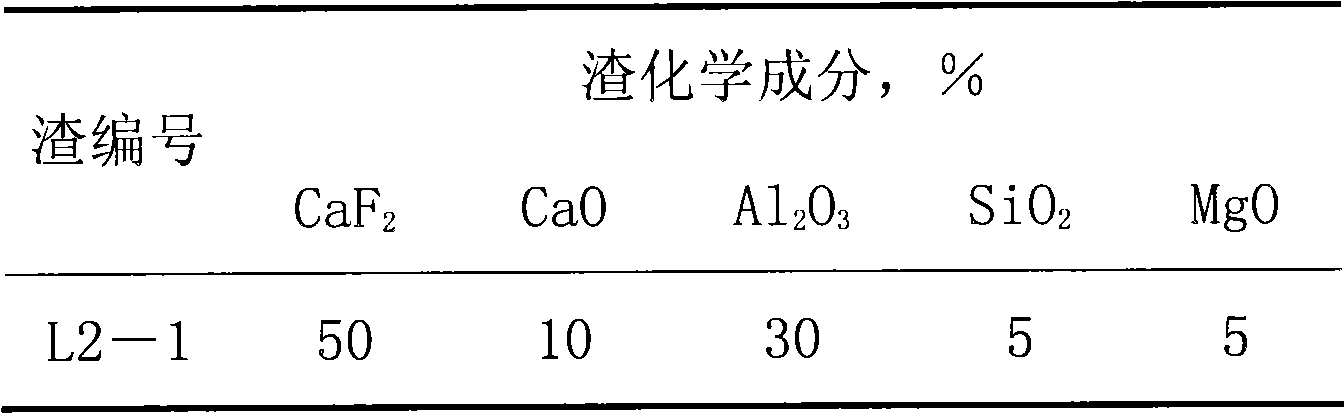

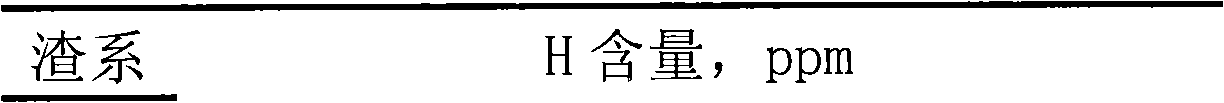

Electroslag remelting slag system with low hydrogen permeability, preparation method and using method thereof

The invention discloses an electroslag remelting slag system with low hydrogen permeability, and a preparation method and a using method thereof. The slag system is prepared from the following chemical compositions in percentage by weight: 45 to 50 percent of CaF2, 10 to 15 percent of CaO, 30 to 35 percent of Al2O3, 5 to 10 percent of SiO2, and 5 to 10 percent of MgO, wherein the MgO is adopted toreplace partial CaO. The preparation method is to crush the compositions into particles after melting, and bake the particles. The using method adopts pre-melting slag and argon protection to carry out electroslag remelting. Compared with the prior art, the slag system and the methods have the advantages that: the slag system has low hydrogen permeability, can effectively reduce the hydrogen content in steel in the remelting initial stage to ensure that the hydrogen content in the steel in the normal remelting stage is maintained at a lower level, and the hydrogen content in the remelted steel is less than 1.5ppm.

Owner:BAOSHAN IRON & STEEL CO LTD +1

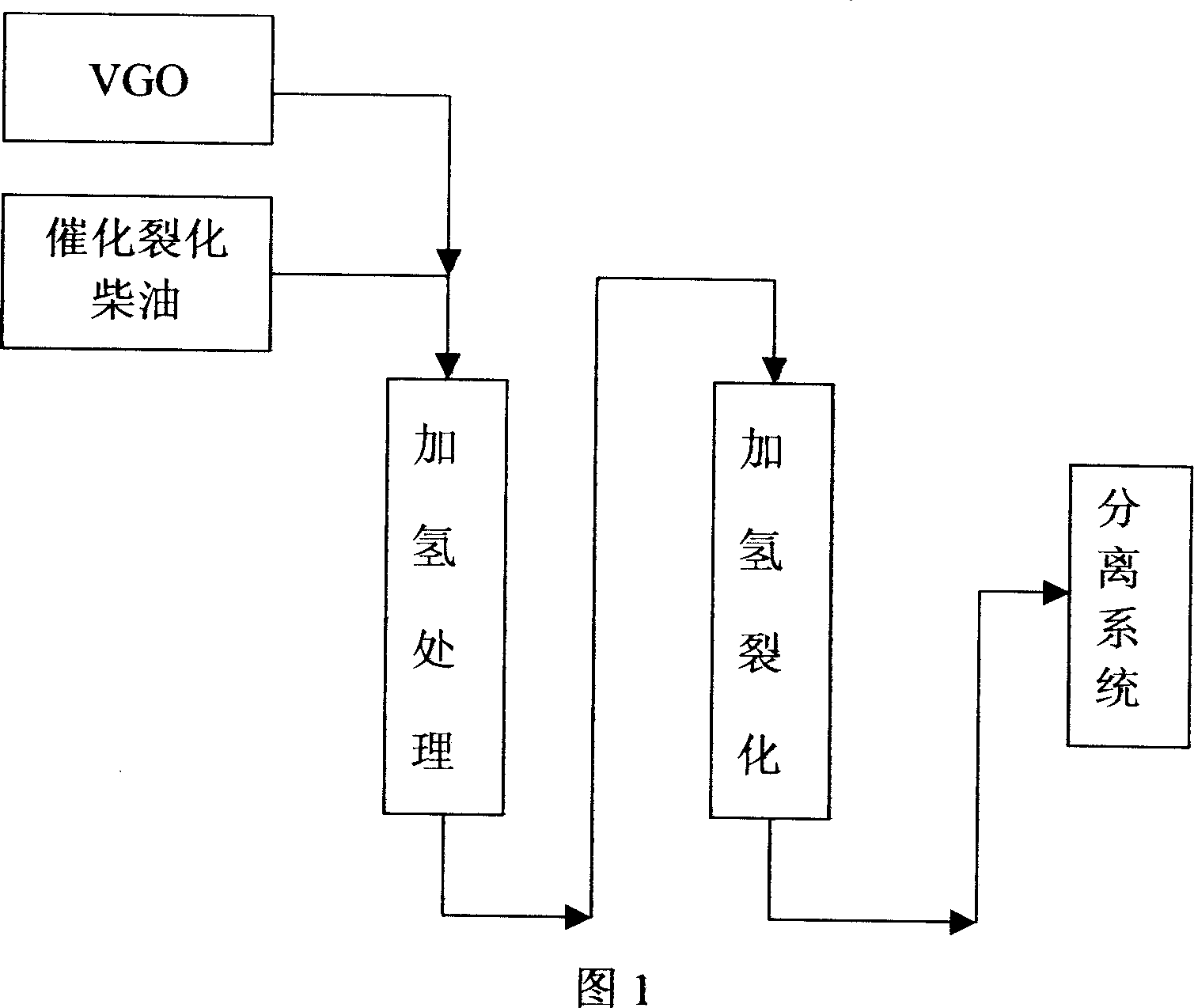

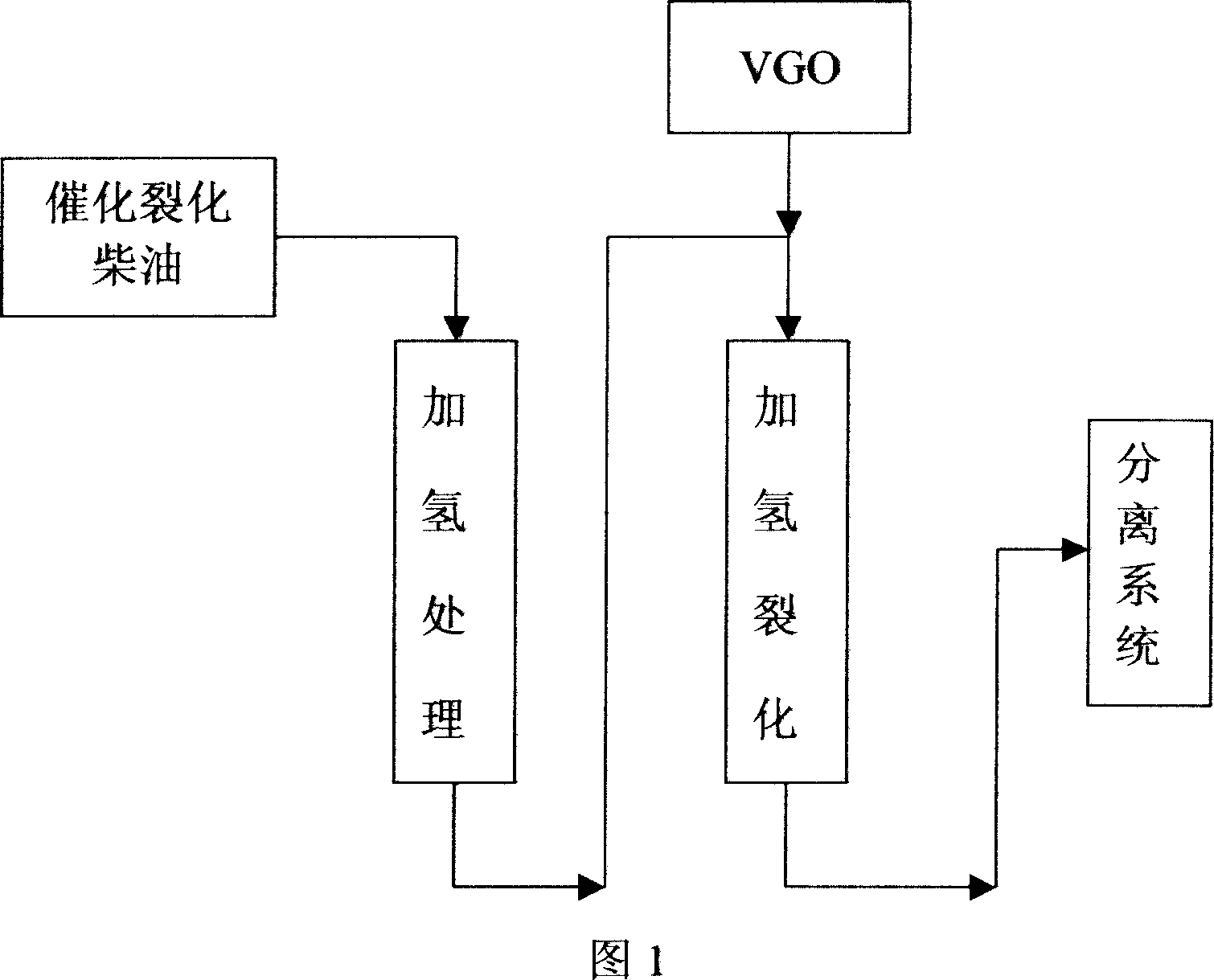

Hydrocracking method for producing chemical raw material

ActiveCN1955257AHigh yieldIncrease the potential content of aromaticsHydrocarbon oil crackingHexadecaneCatalytic reforming

This invention relates to a hydrocracking preparation of chemical materials production. Poor quality catalytic cracking Diesel and heavy hydrocracking material is mixed according to a proportion, and then hydrogenation and hydrocracking are conducted. The yield of heavy naphtha reaches 40wt% by controlling operating conditions, making sure the yield of tail oil 20wt%. The quality features of this poor quality catalytic cracking Diesel are high density, high content of aromatic hydrocarbon and low value of hexadecane. The density of the poor quality catalytic cracking diesel oil is above 0.95g / ml, and the aromatic hydrocarbon is over 90wt% and the value of hexadecane is under 20. Comparing with present technology, this invention combines poor quality catalytic cracking diesel and VGO organicly. High quality chemical material is effectively transformed with obtaining low BMCI value of tail oil, which is high quality material for ethylene preparation by steam cracking.

Owner:CHINA PETROLEUM & CHEM CORP +2

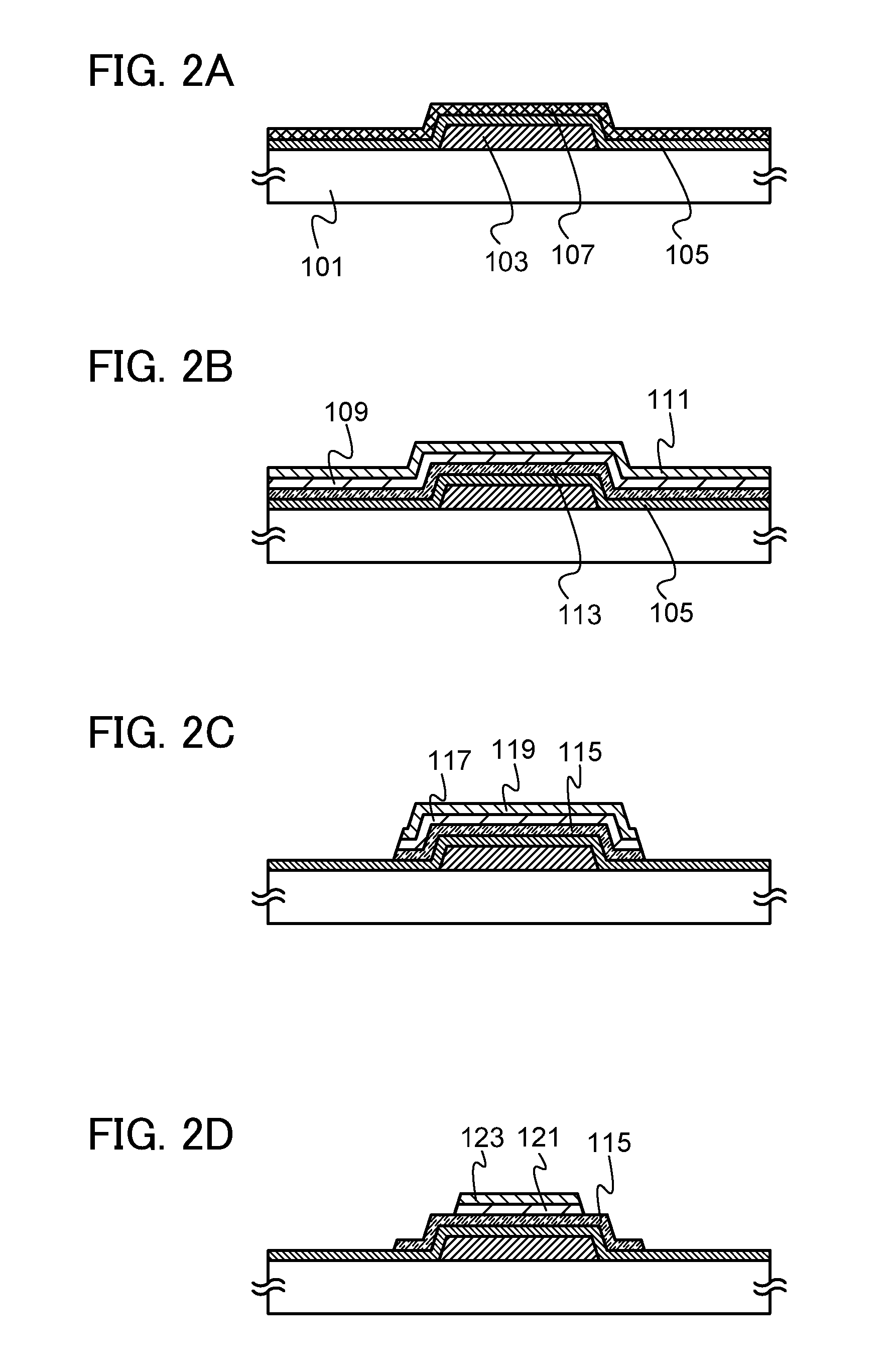

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

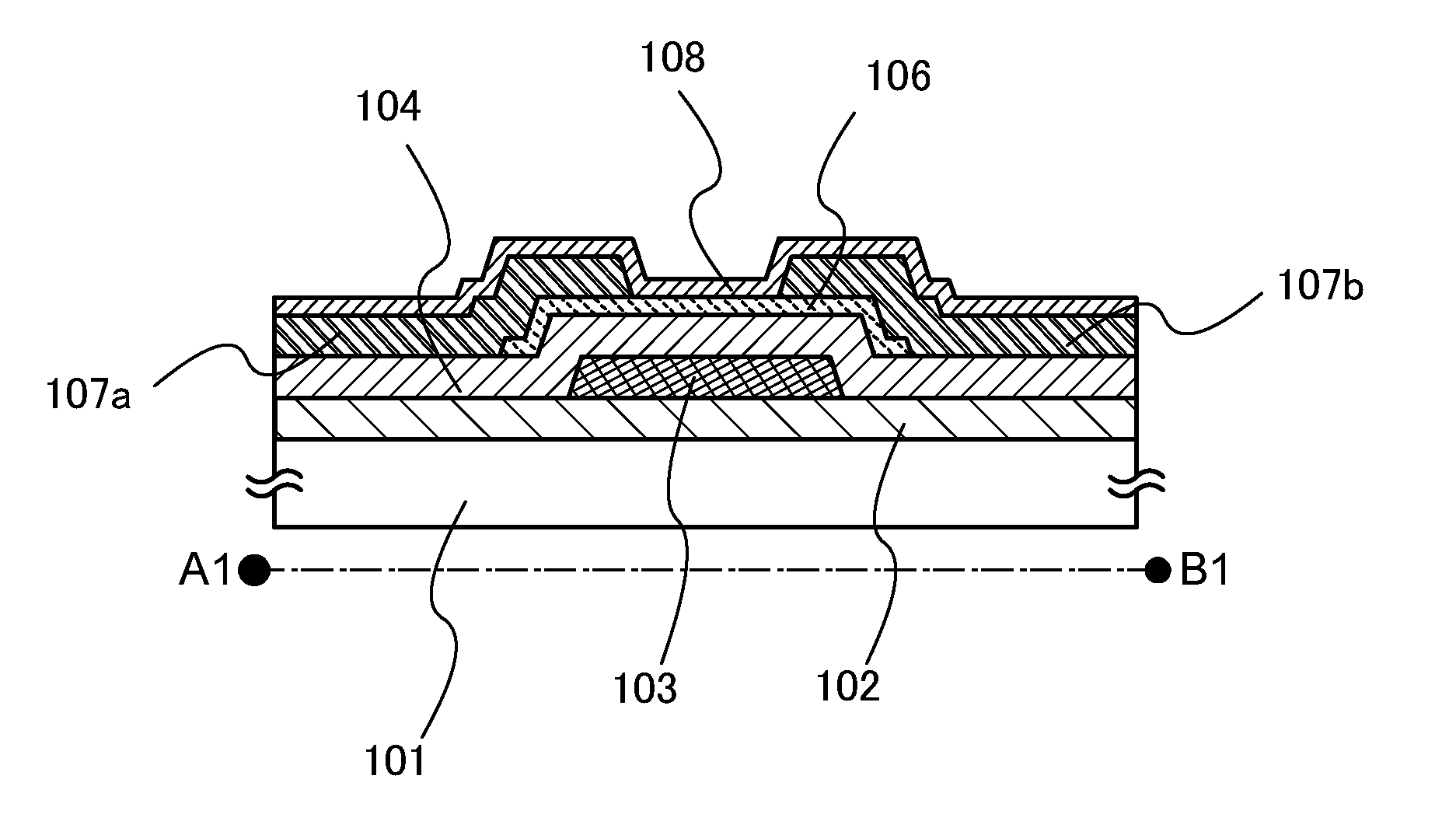

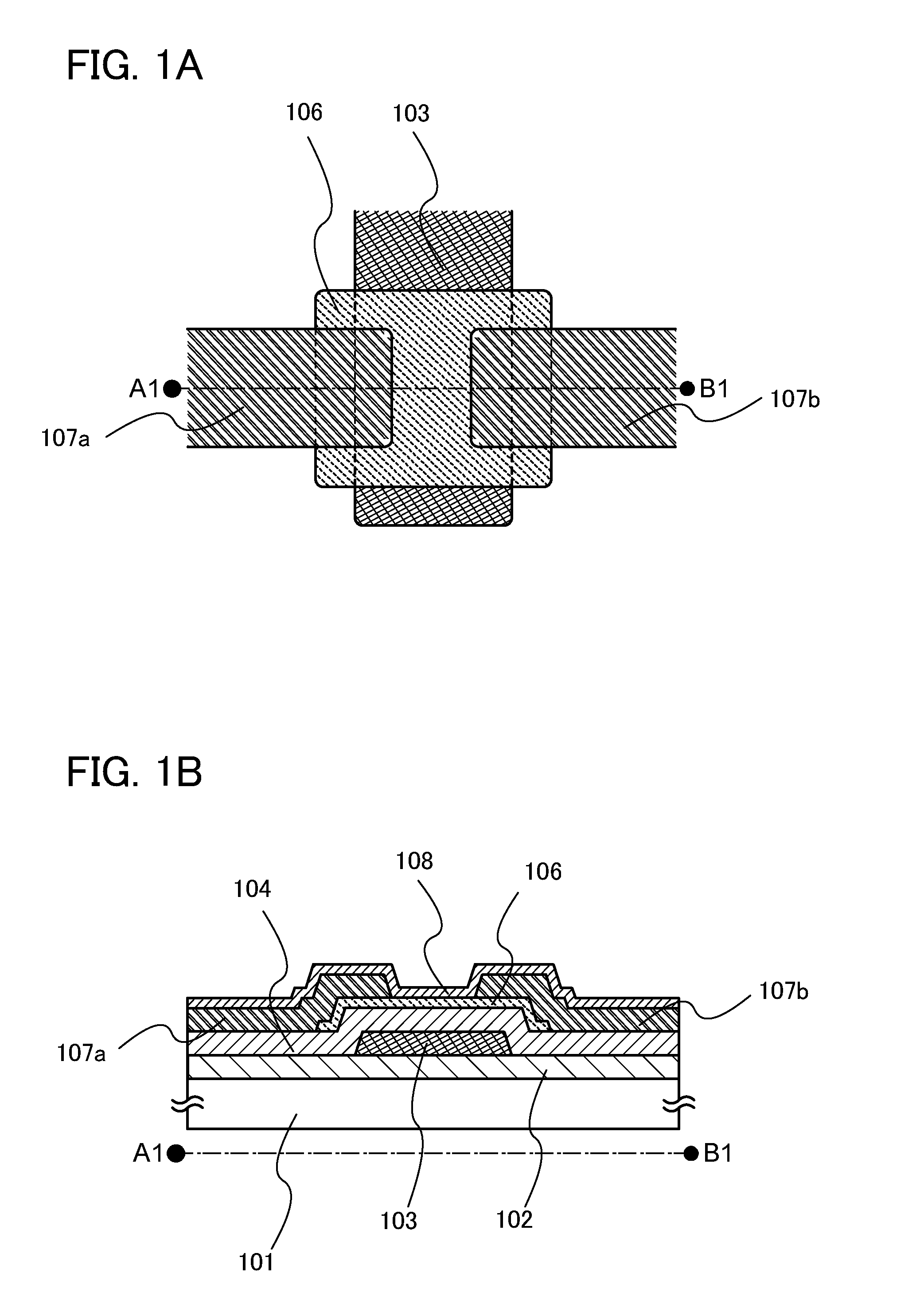

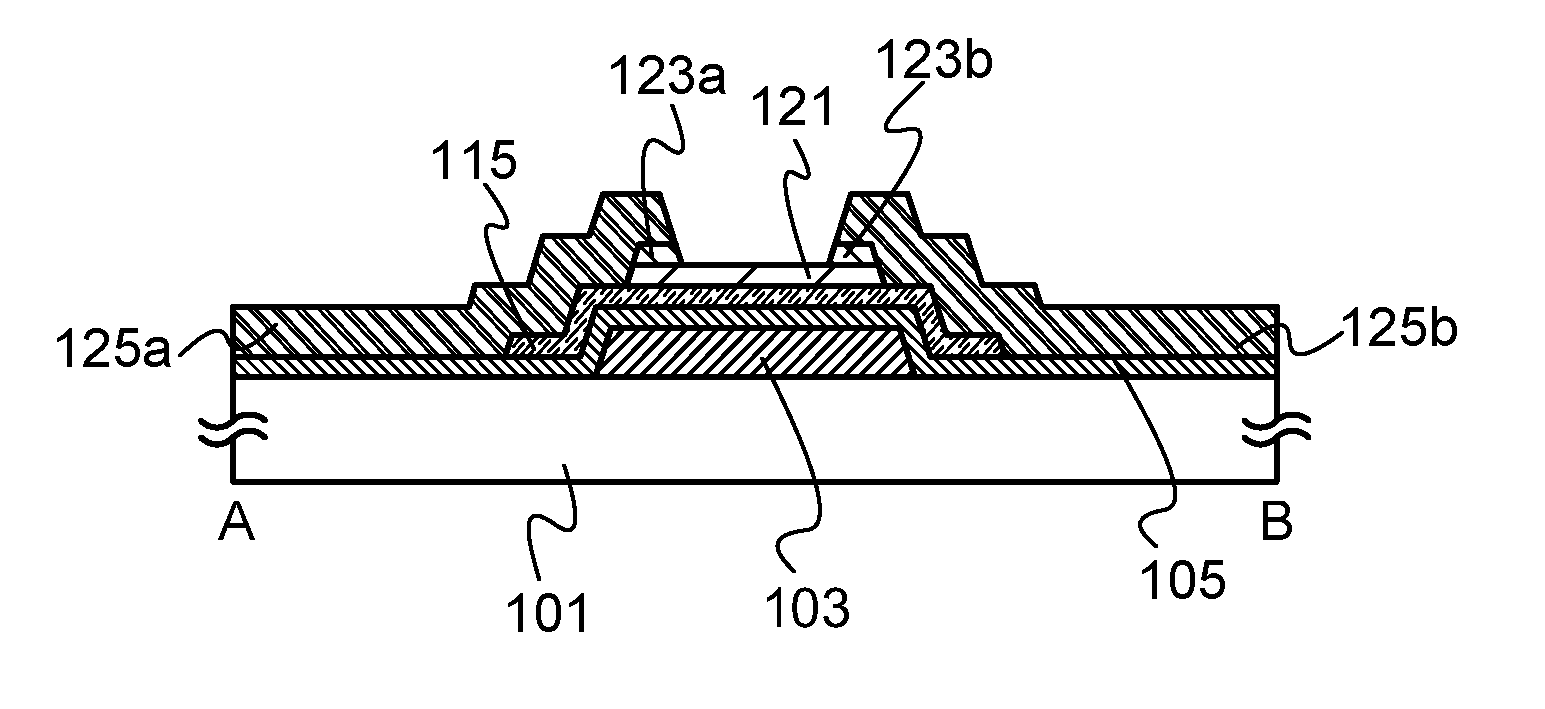

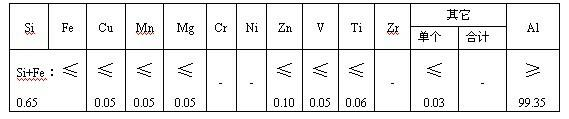

Semiconductor device

ActiveUS20120001168A1Excellent electrical propertiesEasy transferTransistorHydrogen concentrationSilicon

In a transistor including an oxide semiconductor, hydrogen in the oxide semiconductor leads to degradation of electric characteristics of the transistor. Thus, an object is to provide a semiconductor device having good electrical characteristics. An insulating layer in contact with an oxide semiconductor layer where a channel region is formed is formed by a plasma CVD method using a silicon halide. The insulating layer thus formed has a hydrogen concentration less than 6×1020 atoms / cm3 and a halogen concentration greater than or equal to 1×1020 atoms / cm3; accordingly, hydrogen diffusion into the oxide semiconductor layer can be prevented and hydrogen in the oxide semiconductor layer is inactivated or released from the oxide semiconductor layer by the halogen, whereby a semiconductor device having good electrical characteristics can be provided.

Owner:SEMICON ENERGY LAB CO LTD

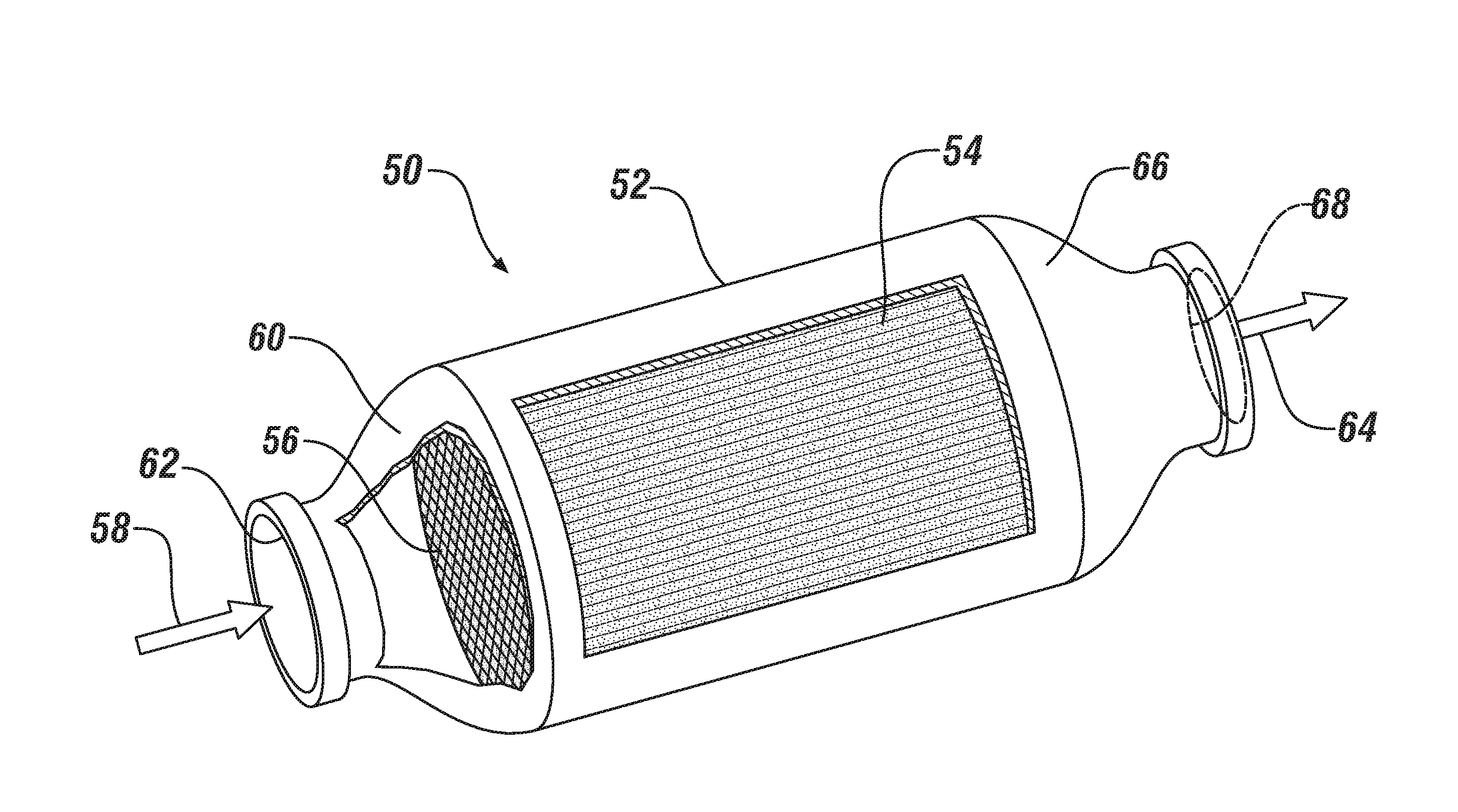

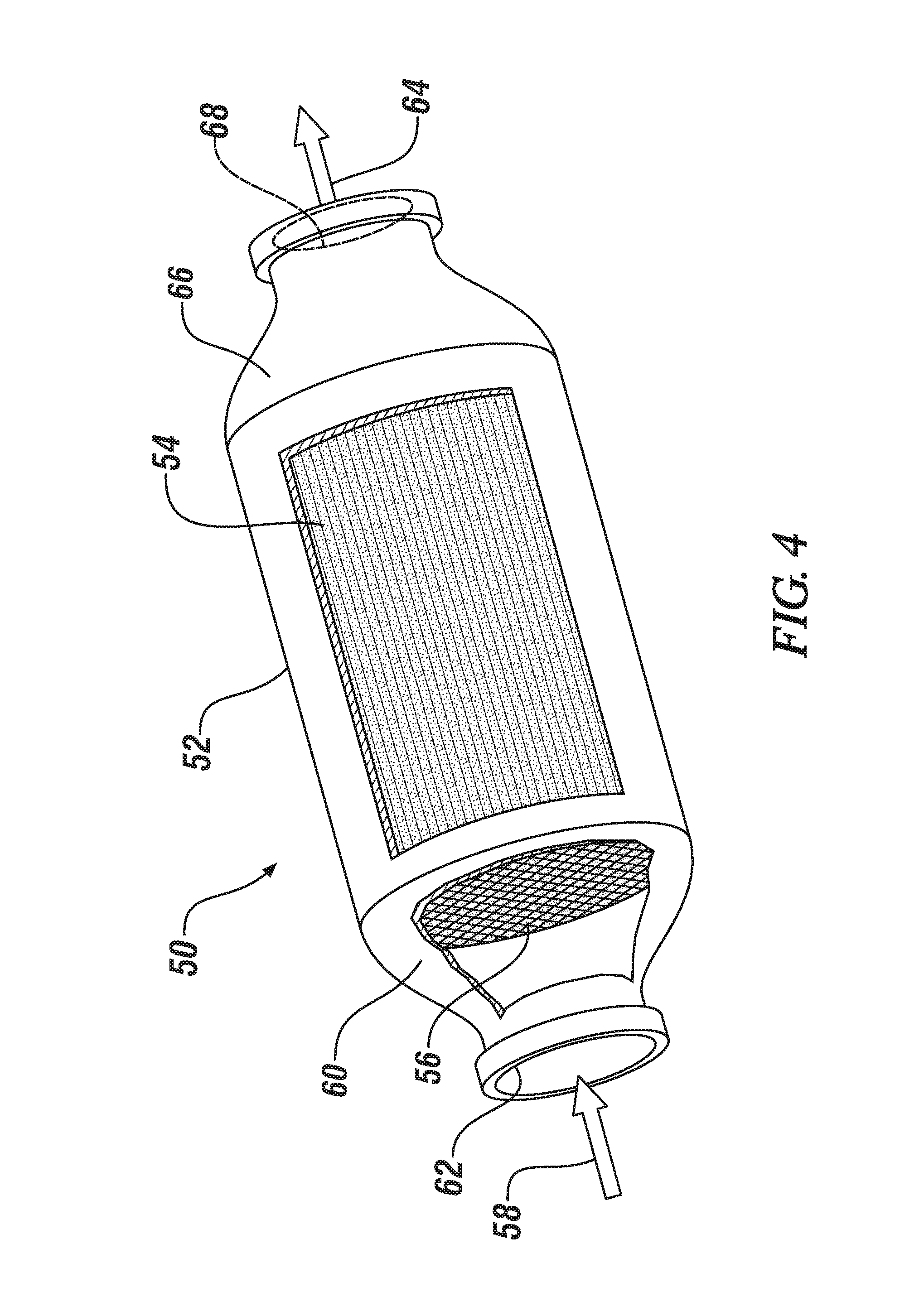

Nitric oxide oxidation over silver-based catalysts

InactiveUS20130294989A1Reduce tailpipe emission of NOxEfficient oxidationCombination devicesNitrogen compoundsHydrogenNitrogen

Ag / Al2O3 materials may be packaged in a suitable flow-through reactor, close coupled to the exhaust manifold of a diesel engine, and upstream of other exhaust gas treatment devices, such as a diesel oxidation catalyst and a selective reduction catalyst for NOx. The silver / alumina catalyst material uses hydrogen in a cold-start engine exhaust and serves to oxidize NO to NO2 in the relatively low temperature, hydrocarbon-containing, exhaust during a short period following the engine cold start, and to temporarily store NOx during the start-up period. After the exhaust has heated downstream catalytic devices, the silver yields its nitrogen oxides for conversion to nitrogen by the then-operating devices before NOx is discharged to the atmosphere.

Owner:GM GLOBAL TECH OPERATIONS LLC

Combined hydrocracking method

ActiveCN101003746AEffective crackingIncrease the potential content of aromaticsHydrocarbon oil crackingPolycyclic aromatic hydrocarbonHigh density

This invention relates to a hydrogenation cracking method. The method comprises: hydrogenating inferior catalytically cracked diesel oil, mixing the hydrogenation products with VGO and other raw materials, introducing into a second hydrogenation cracking zone, and separating to obtain light products and hydrogenation tail oil. The inferior catalytically cracked diesel oil is obtained by hydrogenation-transfer catalytic cracking of heavy oil and residual oil, and has such characteristics of high density, high polycyclic aromatic hydrocarbon content, and low hexadecane number. The method combines inferior catalytically cracked diesel oil and VGO, and can produce large quantities of high-quality heavy naphtha with high content of aromatic hydrocarbon, and tail oil with low MCI value.

Owner:CHINA PETROLEUM & CHEM CORP +3

Method for extruding and precisive roller forging thermal strength titanium alloy blades

InactiveCN1439467AReduce deformationPrevent oxidationEngine componentsMetal rollingHydrogenAir compressor

A technology for manufacuring Ti-alloy blade of air compressor by thermal sequence and precise forging includes such steps as blanking, coating glass lubricant, thermal squeezing, grinding for removing glass lubricant, chemical milling for removing polluted layer, vacuum recrystallizing, annealing, machining cog and arc corner hot forging removing glass lubricant and polluted layer again, vacuum dehydrogenating recrystallizing, annealing, calibrating, annealing and precise machining. Its advantages are simple process, low cost and high performance of product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

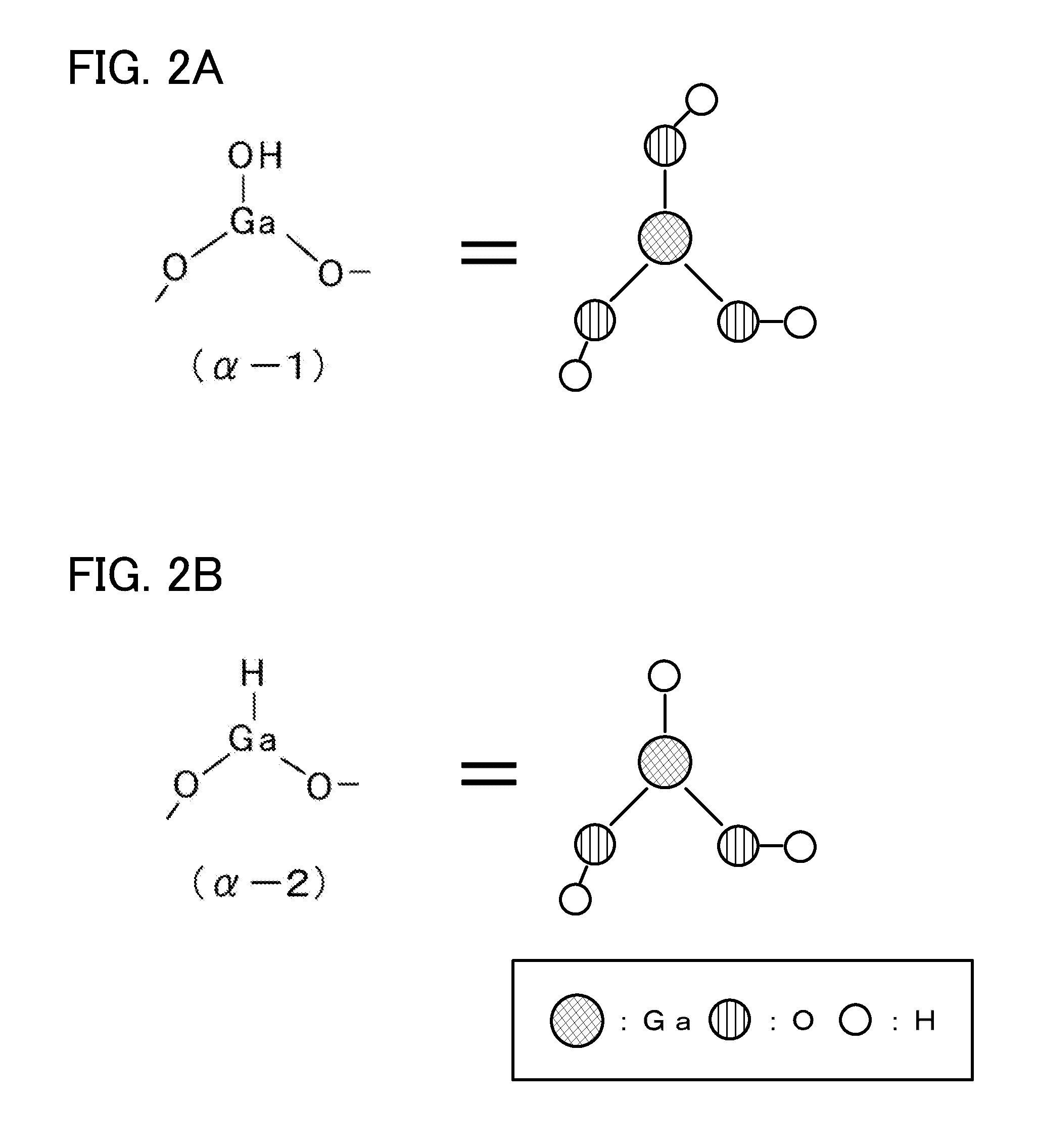

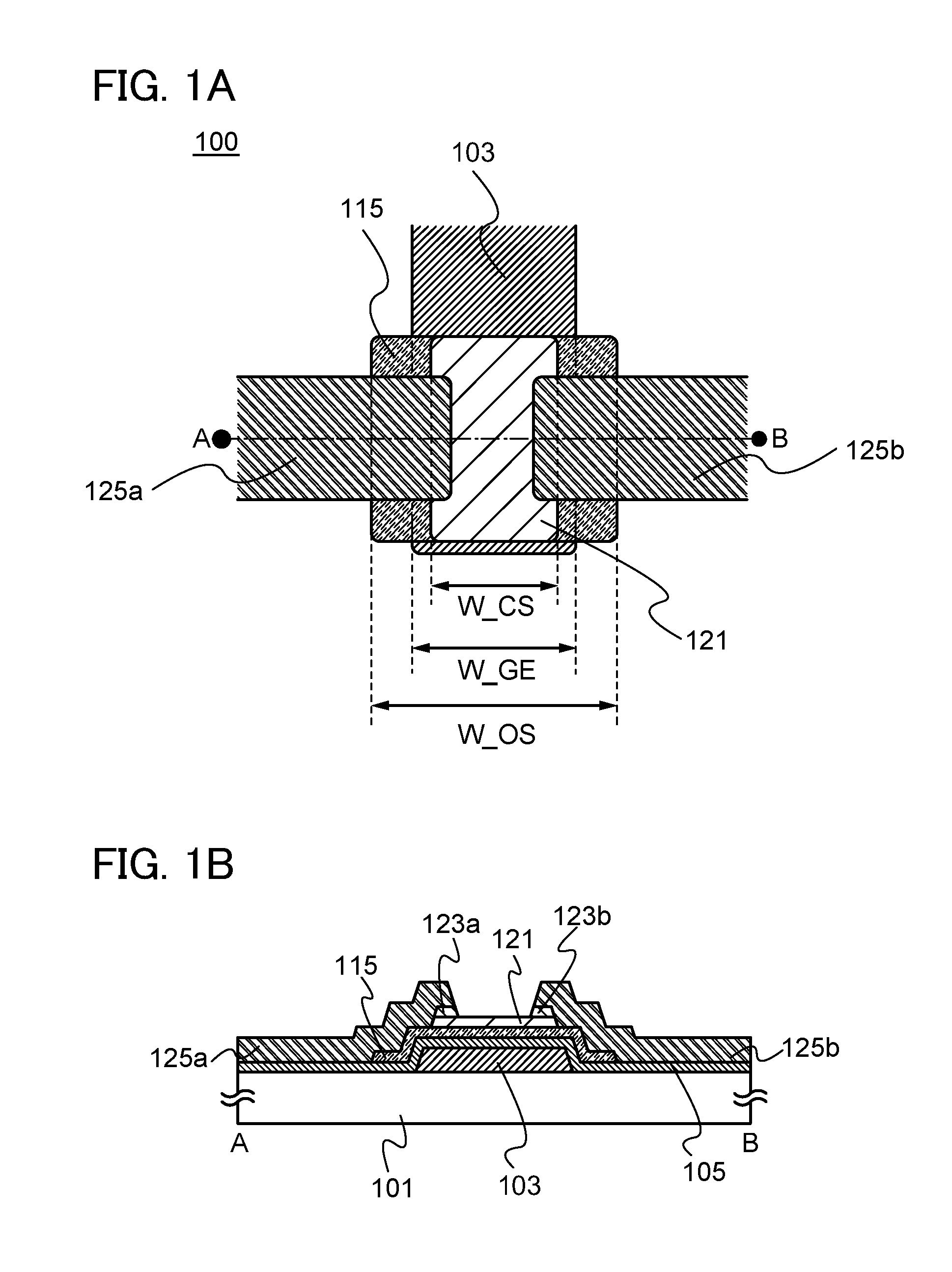

Semiconductor device and manufacturing method thereof

ActiveUS20120241738A1Effective diffusionOxygen deficiency in the oxide semiconductor film can be reducedTransistorSemiconductor/solid-state device manufacturingHydrogenEngineering

A semiconductor device having excellent electric characteristics and a method for manufacturing the semiconductor device are provided. A method for manufacturing a semiconductor device includes the steps of: forming a gate electrode; forming a gate insulating film to cover the gate electrode; forming an oxide semiconductor film over the gate insulating film; forming a hydrogen permeable film over the oxide semiconductor film; forming a hydrogen capture film over the hydrogen permeable film; performing heat treatment to release hydrogen from the oxide semiconductor film; forming a source electrode and a drain electrode to be in contact with a part of the oxide semiconductor film; and removing an exposed portion of the hydrogen capture film to form a channel protective film formed of the hydrogen permeable film. A semiconductor device manufactured by the above method is also provided.

Owner:SEMICON ENERGY LAB CO LTD

Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

InactiveCN102181754AReduced responseLess rigidRoll mill control devicesMetal rolling arrangementsMaterials preparationFiltration

The invention relates to a light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and a preparation method. The iron-silicon rate of the woolen ranges between 4.3-5.3. The process of the preparation technology is sequentially as follows: material preparation, batching, feeding, melting, stirring, primary refining of a smelting furnace, drossing, sampling, ingredient adjustment, secondary refining of the smelting surface, drossing, converter, primary refining in a holding furnace, intensified refining in the holding furnace, online addition of AL-Ti-C wire intermediate alloy refiner, Ar online degassing, filtration, continuous casting into 7.0-7.5mm cast rolling plates, cold rolling, high-temperature homogenizing annealing of a primary sheet strap, cold rolling, trimming of a rereeling machine, cold rolling, intermediate annealing of a secondary sheet strap, cold rolling to 0.26-0.32mm, trimming of the rereeling machine, and packaging. The cost is low, the quality is stable, the calendaring of the aluminum foil and grain refining are good in effect, and the probability of generating pinholes is low during production.

Owner:江阴新仁铝业科技有限公司

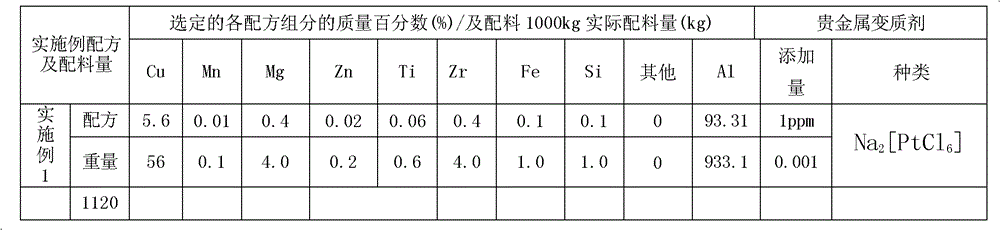

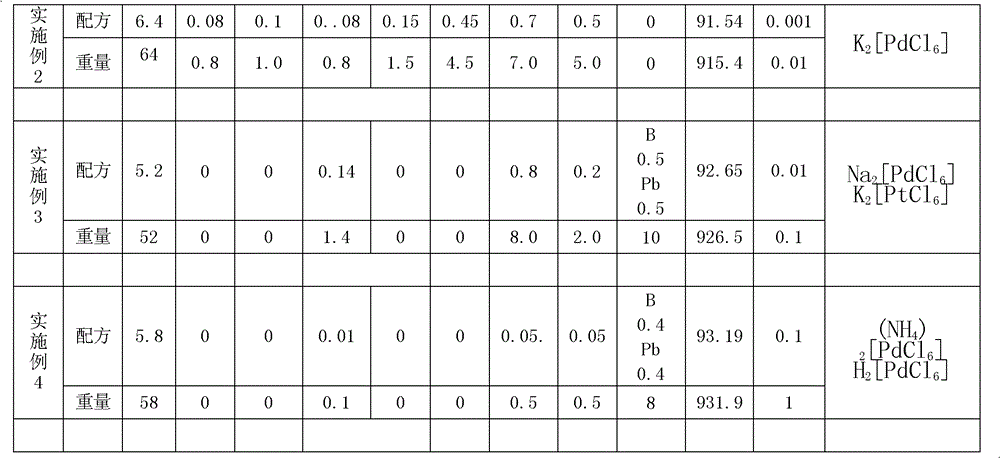

Noble-metal-modified aluminum alloy material and preparation method thereof

The invention discloses a noble-metal-modified aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 5.0-6.5% of Cu, at most 0.1% of Mn, at most 0.5% of Mg, at most 0.15% of Zn, at most 0.2% of Ti, at most 0.5% of Zr, at most 0.6% of Bi, at most 0.6% of Pb, and the balance of Al and inevitable trace impurities; the noble metal modifier accounts for 1ppm-0.1% of the total amount; and the content of any single impurity element is at most 0.05%, and the total content of the impurity elements is at most 0.1%. The invention can effectively reduce the generation of pinholes, and has the effect of high modification efficiency.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

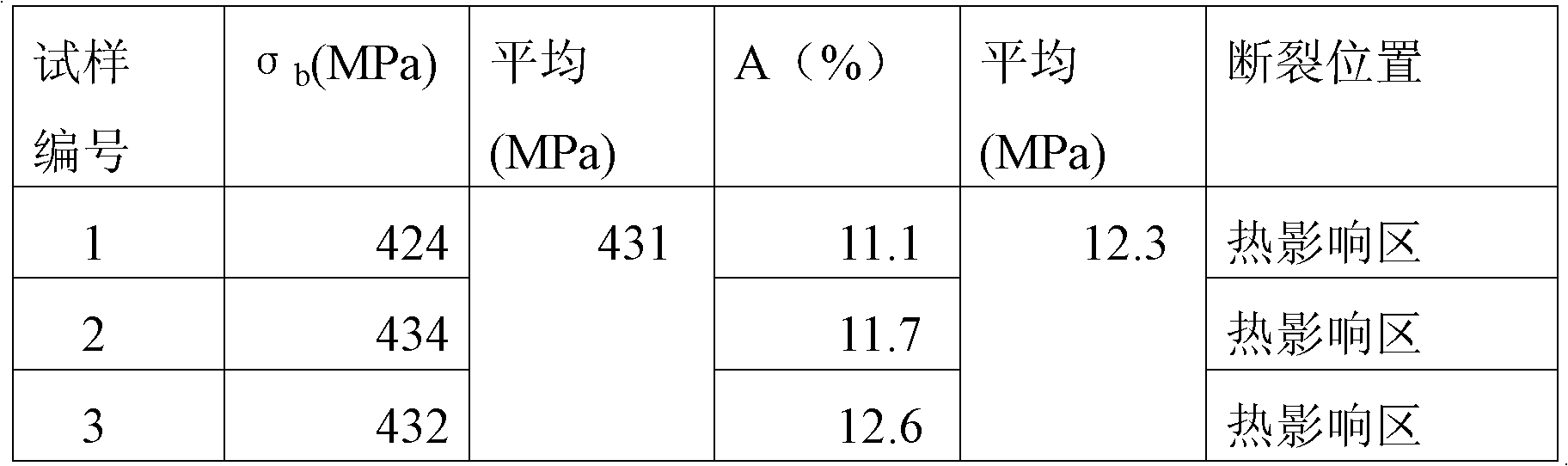

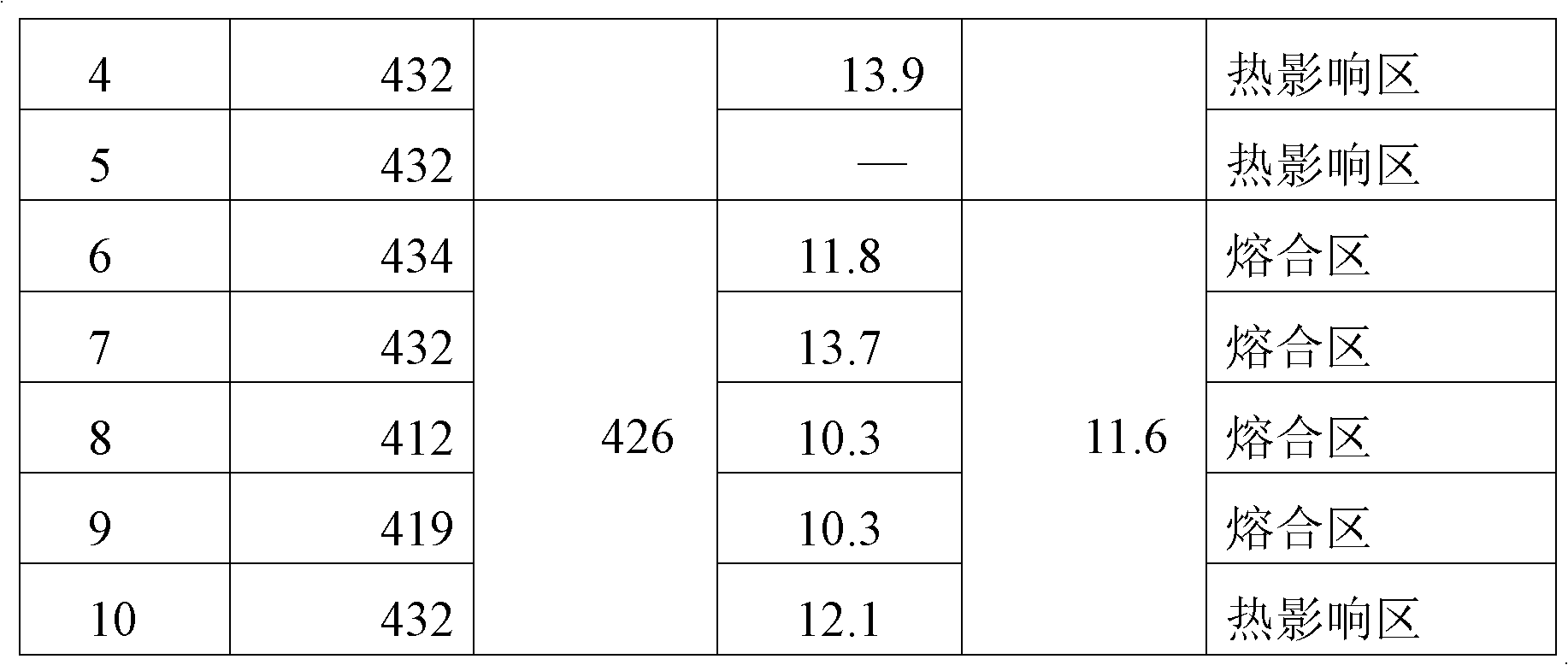

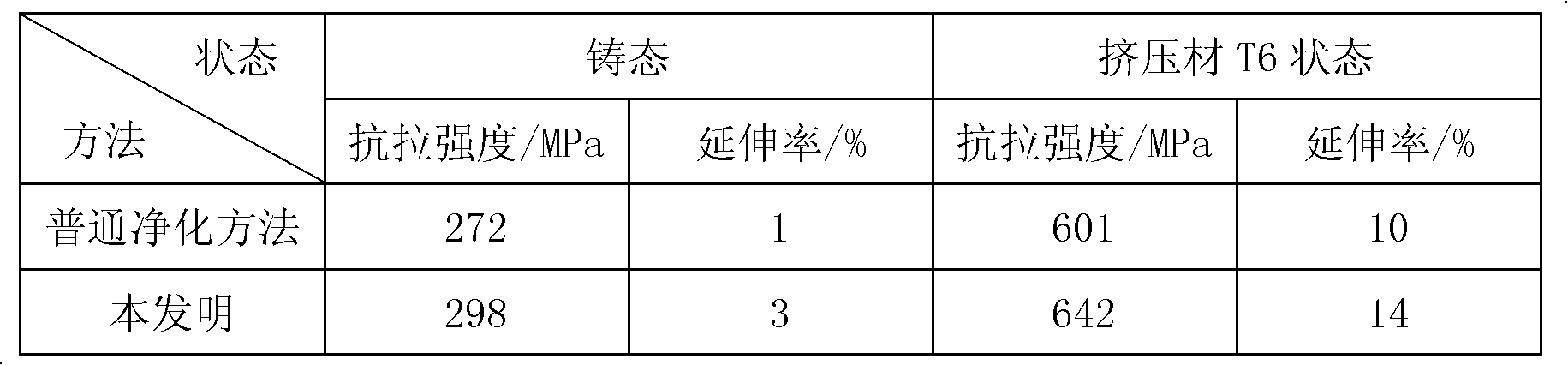

Aluminum alloy welding wire for aerospace and preparation method of aluminum alloy welding wire for aerospace

InactiveCN105779831AHigh tensile strengthImprove plasticityMetallic material coating processesCrack resistanceToughness

The invention relates to an aluminum alloy welding wire for aerospace and a preparation method of the aluminum alloy welding wire for aerospace. The aluminum alloy welding wire for aerospace is characterized by comprising the following chemical components in percentages by mass: 6.2-7.0% of Cu, 0.06-0.10% of Ti, 0.1-0.5% of Cr, 0.05-0.2% of V, 0.1-0.5% of Mn, 0.5-1.5% of Sc, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.2% of Mg, less than or equal to 0.2% of Fe, less than or equal to 0.2% of Si, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for aerospace comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for aerospace provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common 5556, 5654, 2319 or 2325 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122AImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

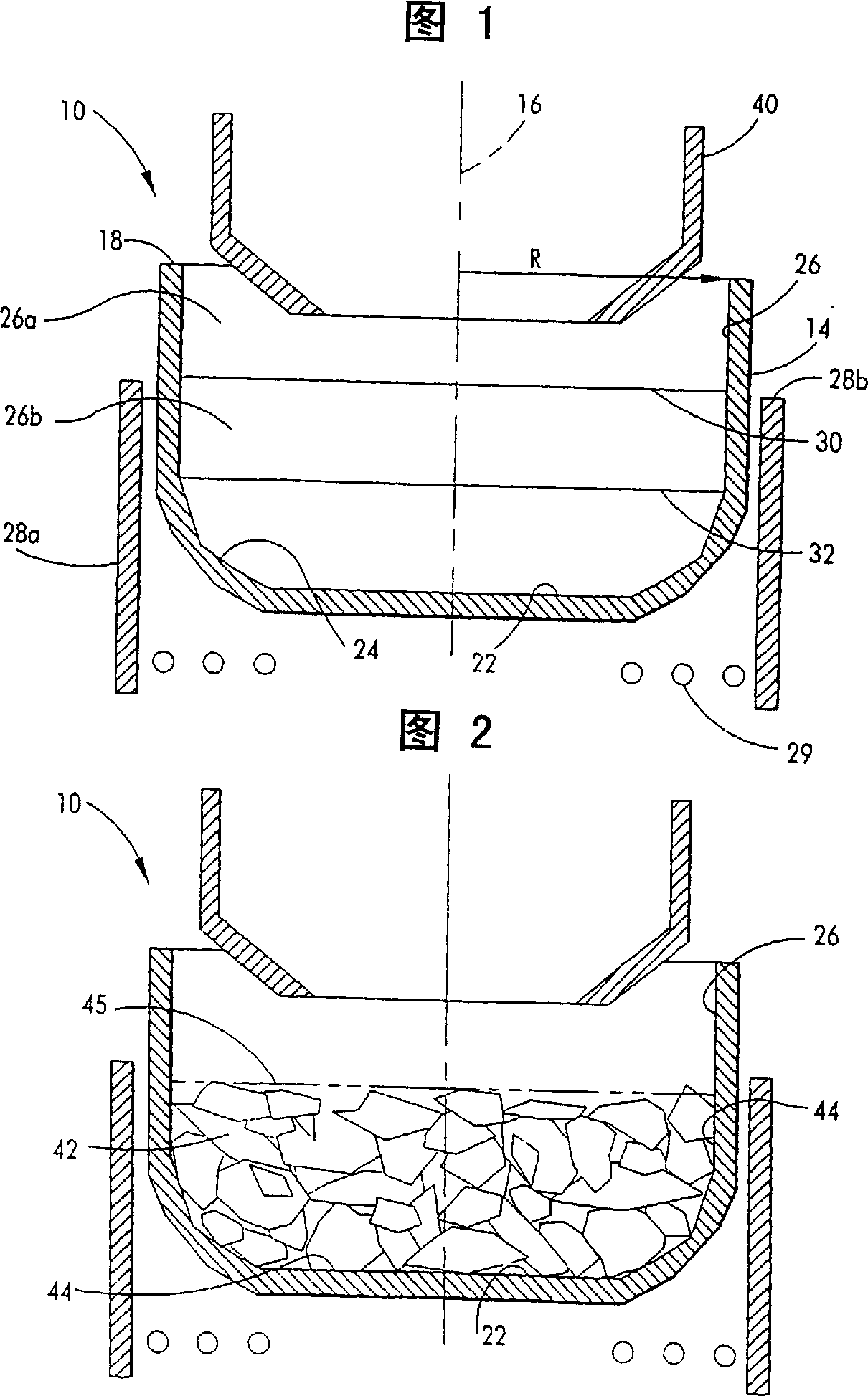

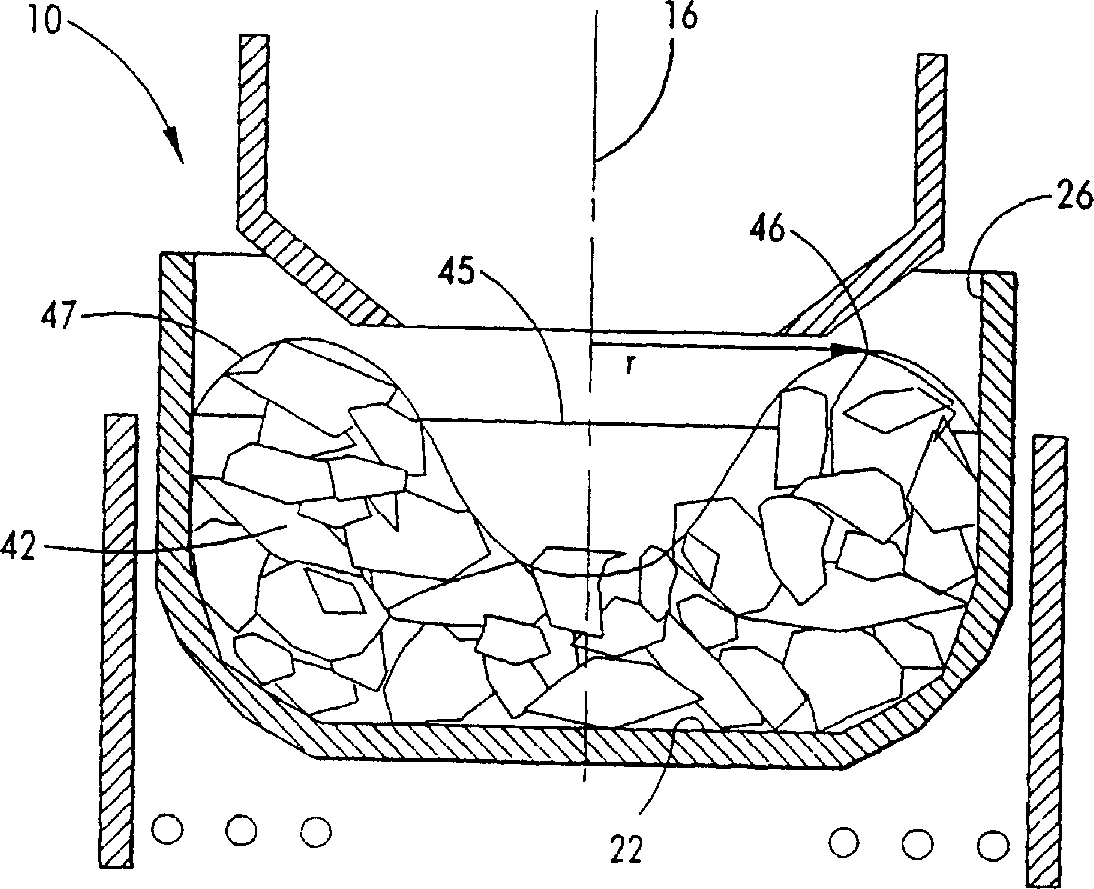

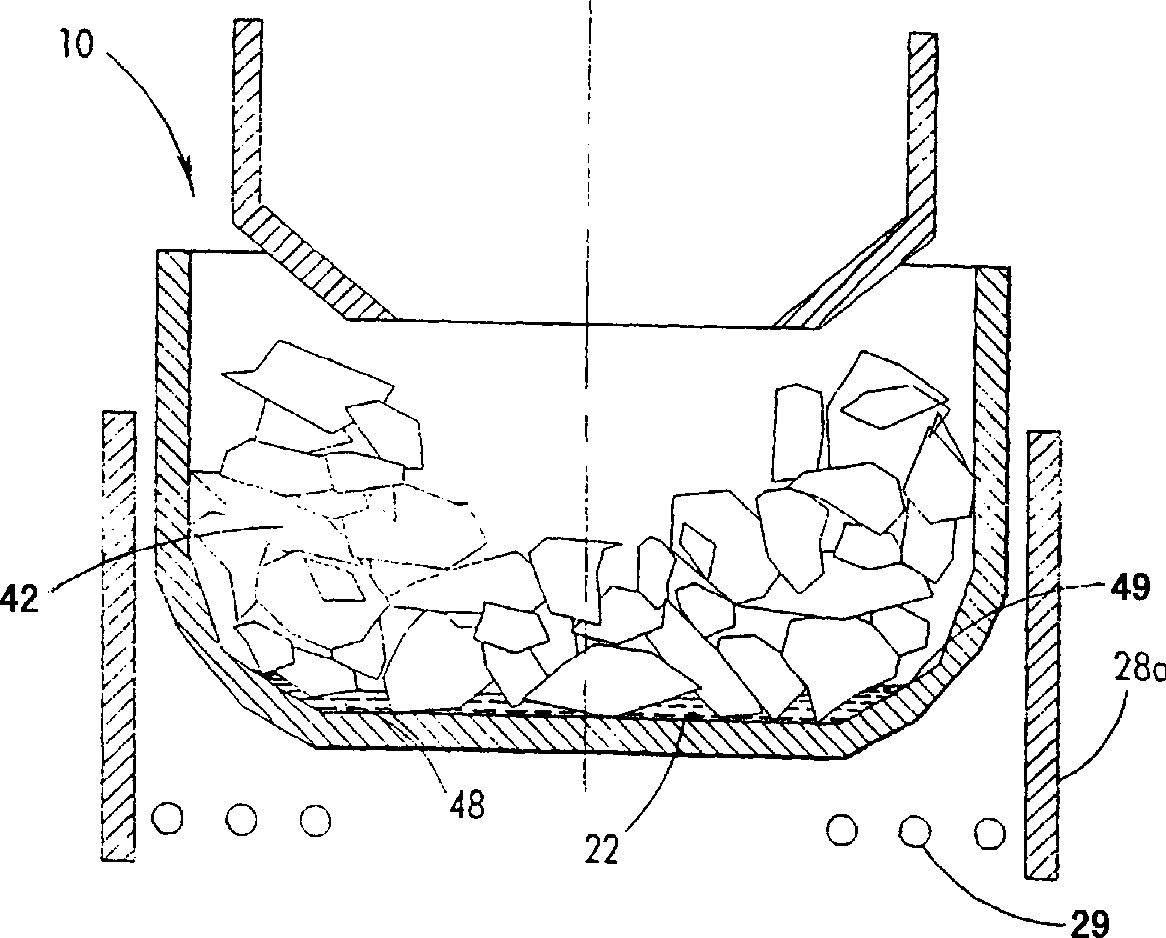

Process for preparing silicon melt from polysilicon charge

InactiveCN1276026AReduce hydrogen contentIncrease productionPolycrystalline material growthBy pulling from meltHydrogenCzochralski method

A process for preparing a silicon melt from a polysilicon charge, for use in the production of single crystal silicon ingots by the Czochralski method, in a crucible which has a bottom, a sidewall formation, a centerline which is substantially parallel to the sidewall formation and which intersects a geometric centerpoint of the bottom, and a radius extending from the centerline to the sidewall formation. In the process, the crucible is loaded with chunk polysilicon to form a charge having a bowl-like shape, wherein initially the load generally slopes radially upwardly and outwardly from the centerline toward the sidewall formation to an apex and then slopes generally downwardly and outwardly from the apex to the sidewall formation. The bowl-shaped chunk polysilicon charge is heated to form a partially melted charge, and granular polysilicon is fed onto the partially melted charge to form a mixed charge of chunk and granular polysilicon. As the mixed charge is further heated to form a silicon melt, the unmelted chunk polysilicon present above the melt surface acts to deflect any molten silicon that may be splattered as granular polysilicon rapidly melts and hydrogen is released.

Owner:MEMC ELECTONIC MATERIALS INC

Processing method of anti-fatigue aluminum alloy foaming die cast

The invention discloses a processing method of an anti-fatigue aluminum alloy foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements La, Ce and Y are added to the aluminum alloy, so that the hydrogen content in the alloy and the alloy yielding anisotropy can be reduced, the alloy plasticity and the anti-fatigue property of the alloy are obviously increased, and at the same time the wear resistance, thermal resistance and high-temperature strength of the alloy can also be improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州晨润工贸有限公司

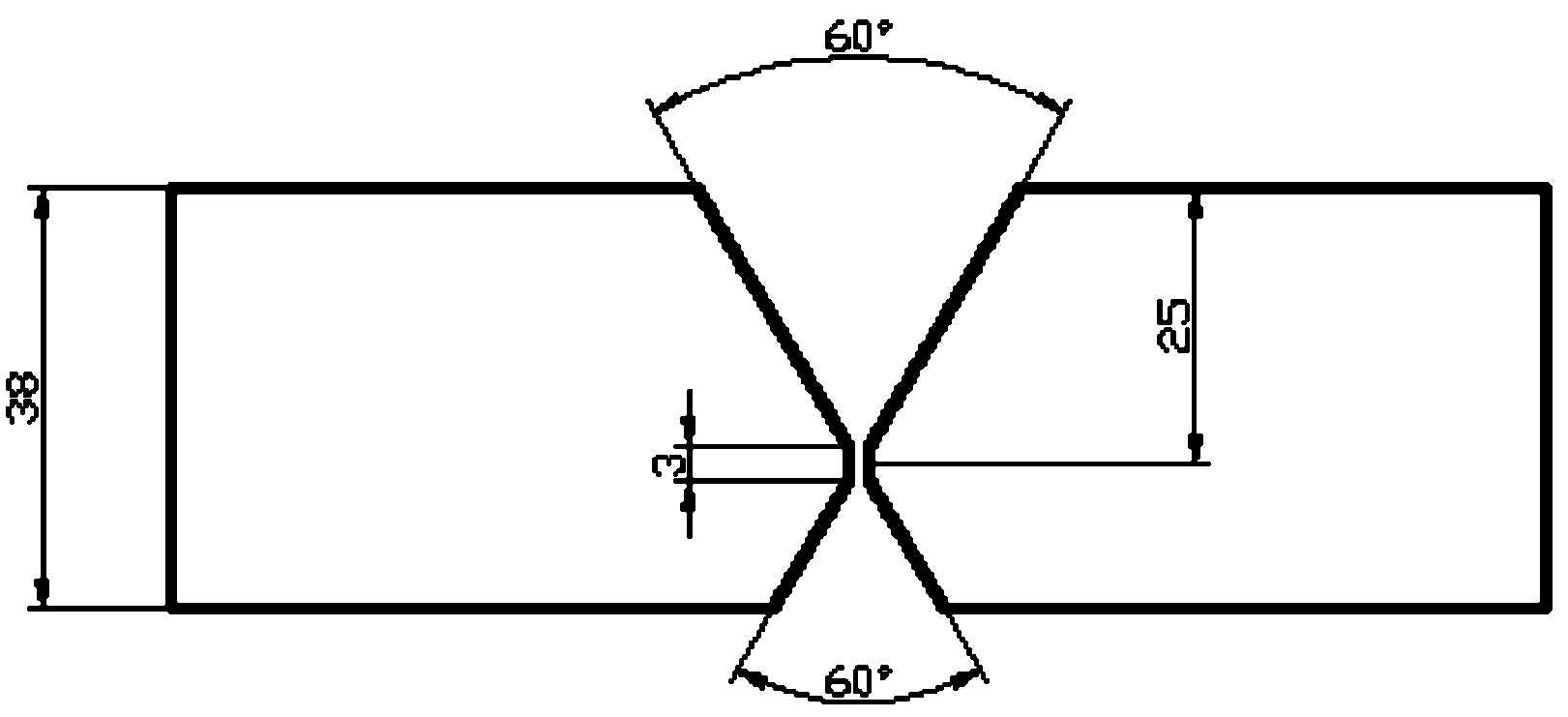

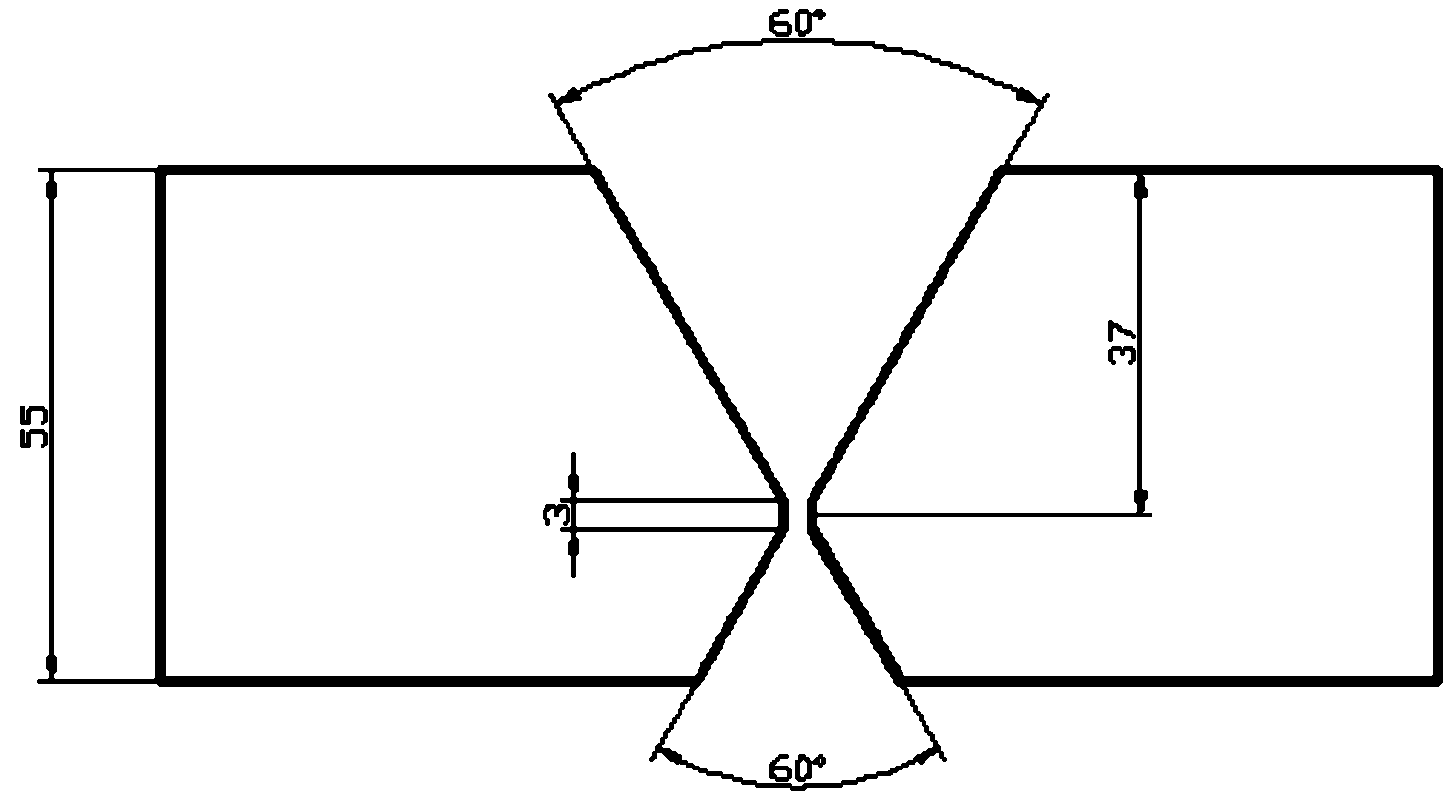

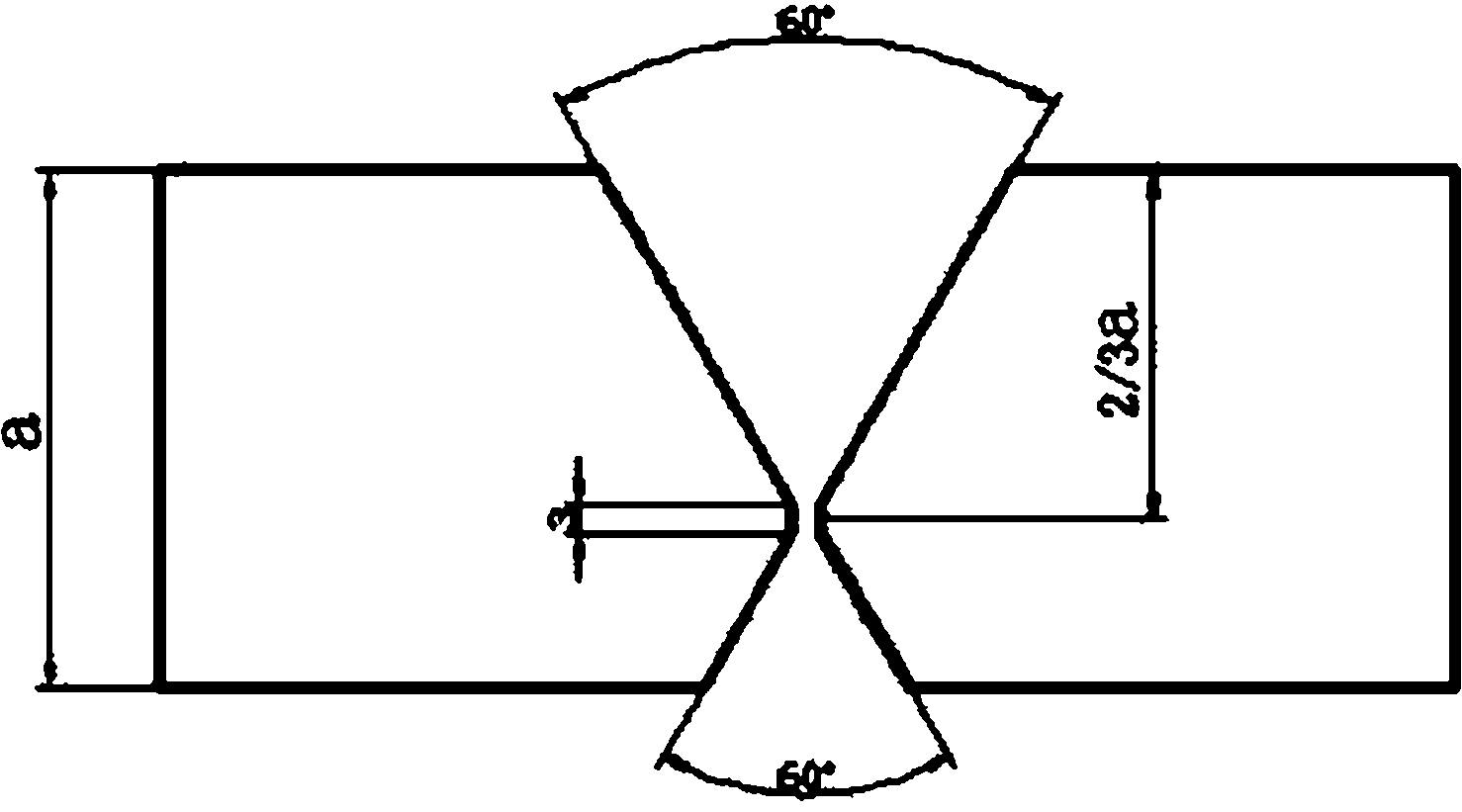

Welding method of high-strength steel for pressure steel pipe of 610MPa hydropower station

InactiveCN102101210AReduce the tendency to produceImprove toughnessArc welding apparatusAluminum silicateStress relief

The invention relates to a welding method of high-strength steel for a pressure steel pipe of a 610MPa hydropower station, belonging to the technical field of steel pipe welding. In the method, a constant-strength low-hydrogen electric welding rod is used for priming, and a constant-strength matched welding rod is adopted to continuously weld and fill a weld pass by adopting a submerged-arc welding method, wherein the welding line energy is strictly controlled to be about 30-40kJ / cm, and the interpass temperature is controlled to be 100-150 DEG C; and after welding, an aluminum silicate plate is used for covering a welding joint for slow cooling so as to realize the welding of a steel plate for a steel pipe for a 610MPa hydropower station without preheating before welding and heat treatment after welding. The method solves the problems that the traditional steel for the pressure steel pipes of the 610MPa hydropower station needs to be preheated before welding and subjected to stress relief heat treatment after welding, and the welding efficiency is low.

Owner:SHOUGANG CORPORATION

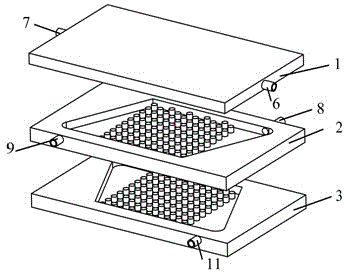

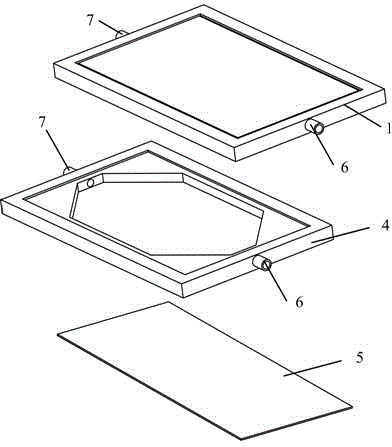

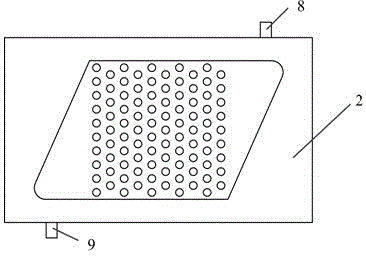

Self-heating staggered-arrangement micro-boss array type alcohol reforming device

InactiveCN103601151AEnhance heat and mass transferHigh heat and mass transfer efficiencyHydrogenHydrogen fuel cellHydrogen fuel

The invention discloses a self-heating staggered-arrangement micro-boss array type alcohol reforming device. The self-heating staggered-arrangement micro-boss array type alcohol reforming device comprises a hydrogen purification component, a reforming hydrogen production plate and a catalytic combustion plate sequentially from top to bottom. A reforming hydrogen production cavity is arranged in the reforming hydrogen production plate and loaded with a hydrogen production catalyst which is used for alcohol reformation so as to produce hydrogen; a catalytic combustion cavity is arranged in the catalytic combustion plate and loaded with a combustion catalyst which is used for alcohol combustion and heat supply. Heat is supplied for the reforming hydrogen production through alcohol combustion, so that the natural operation of the alcohol reforming device can be realized. Staggered-arrangement micro-boss array structures are arranged in the reforming hydrogen production cavity and the catalytic combustion cavity, so that the specific area is large and the heat transfer and mass transfer efficiency is high. In addition, the alcohol reforming device comprises the hydrogen purification component, so that the fuel conversion efficiency of the reforming hydrogen production cavity can be improved, and hydrogen at an outlet can be directly used for a hydrogen fuel battery. The self-heating staggered-arrangement micro-boss array type alcohol reforming device is compact in structure, convenient for catalysts to load, easy for the whole structure to assemble, and capable of being used in intermediate and small flow alcohol reforming hydrogen production situations.

Owner:ZHEJIANG UNIV

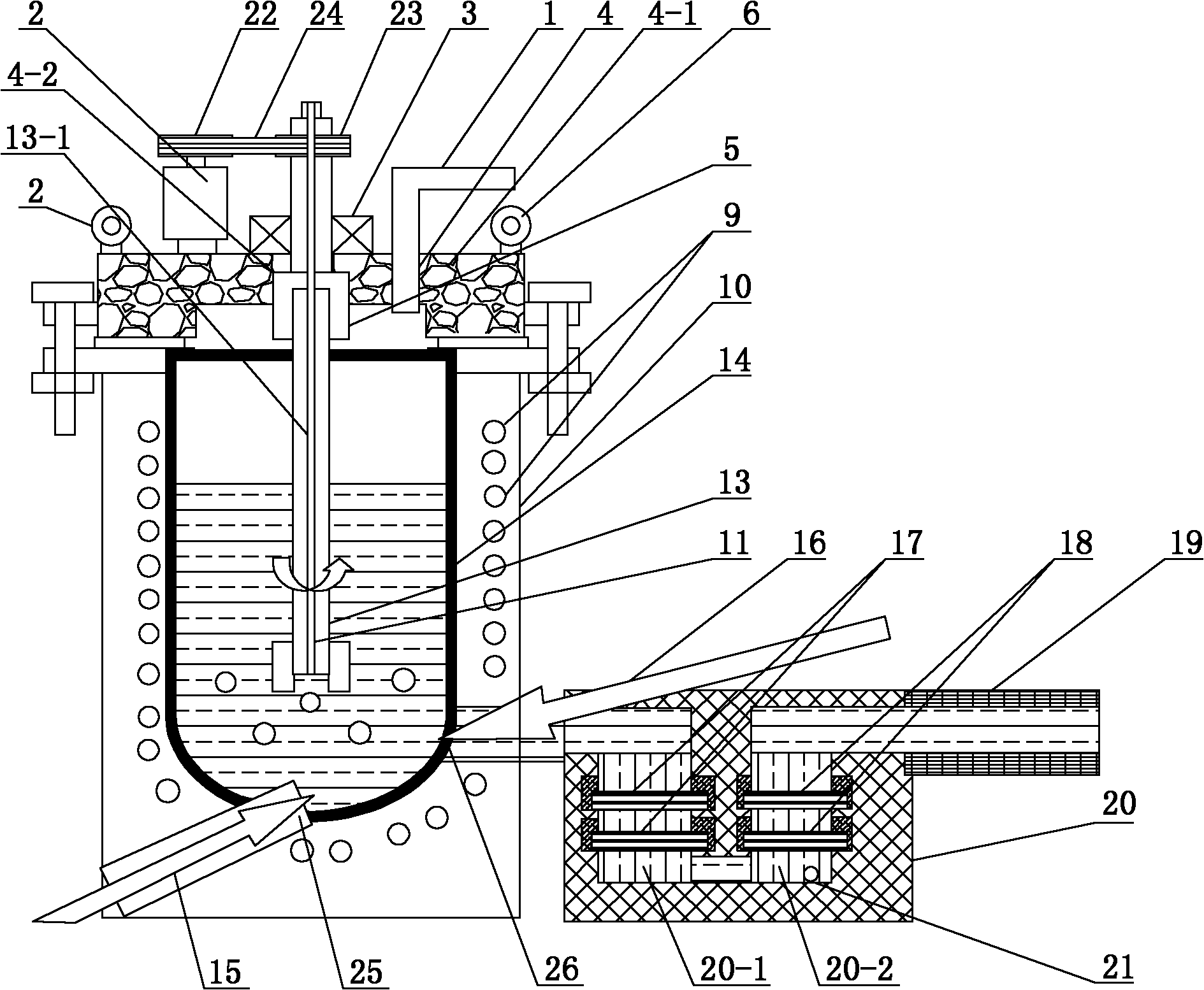

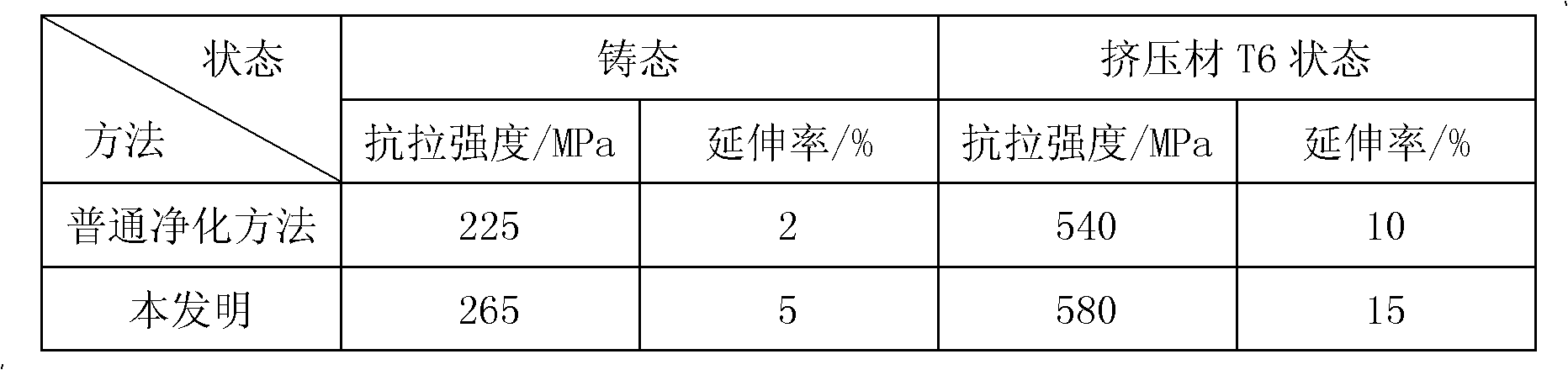

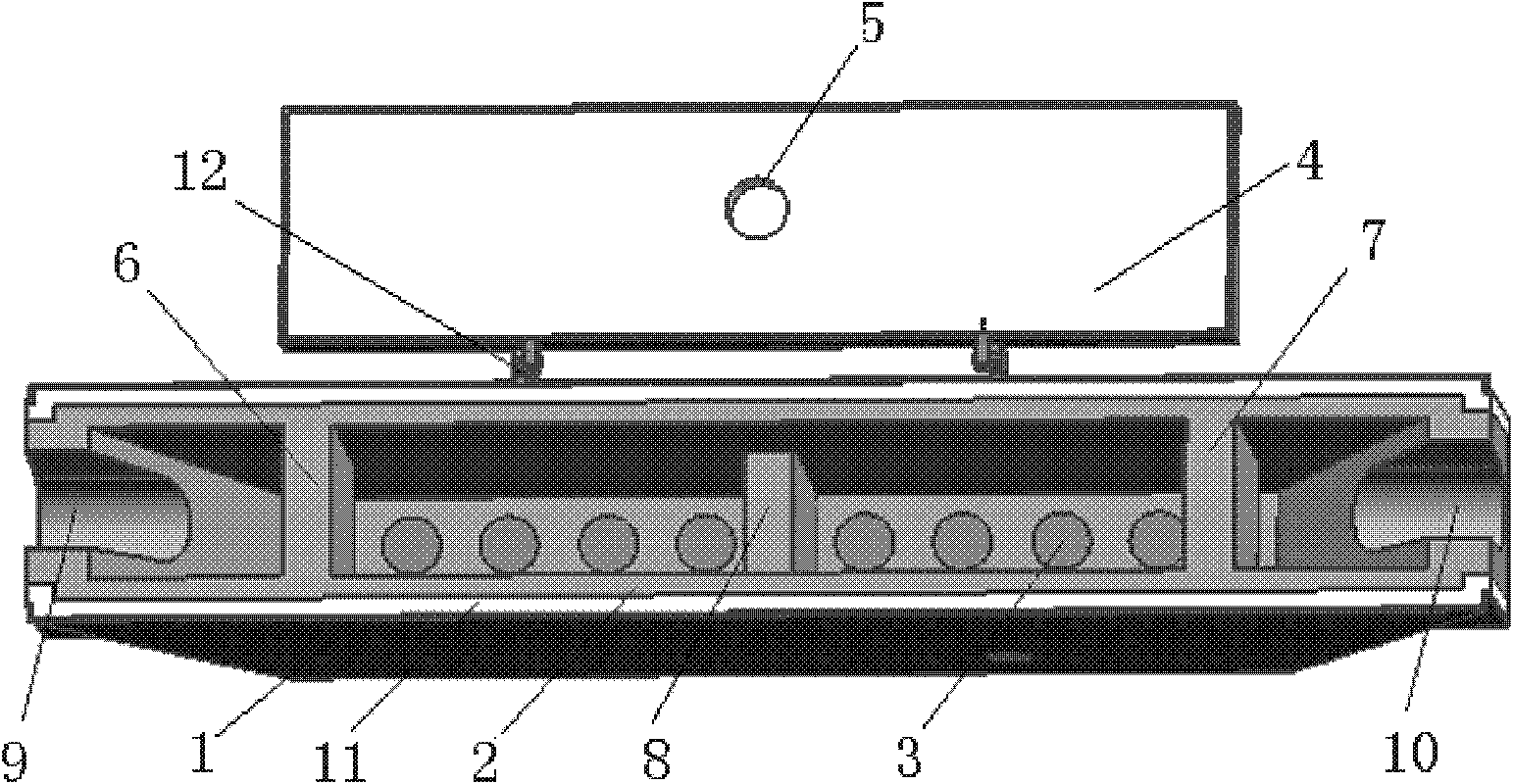

Aluminum alloy smelting-purifying device and smelting-purifying method

The invention discloses an aluminum alloy smelting-purifying device and a smelting-purifying method, relates to a smelting device and a smelting method and aims at solving the problems that the existing aluminum alloy smelting-purifying device is complex in structure, big in volume and low in smelting purity; and the existing aluminum alloy smelting-purifying method causes the aluminum alloy to generate cracks easily and the crack parts are easy to corrode. The upper end of a graphite rotator penetrates through a stepped hole and is installed on a furnace cover by a bearing; an argon tube is arranged in the central through hole of the graphite rotator in a penetration way; a crucible is communicated with the inlet of a filter box through a liquid metal filter outlet; and the filter box is internally provided with a first filter cavity and a second filter cavity. The smelting-purifying method includes the steps as follows: firstly, cleaning the inner surface of the crucible; secondly, spraying zinc oxide aqueous solution; thirdly, adding primary aluminum and a master alloy and adding alloying elements; fourthly, introducing argon; fifthly, slagging; sixthly, standing; seventhly, vacuumizing; eight, entering the filter box for filtration; ninth, discharging melt out of the filtering box; and tenth, discharging solid blocky metal compound impurities out of the crucible. The aluminum alloy smelting-purifying device and the smelting-purifying method are used for the smelting and purification of the aluminum alloy.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

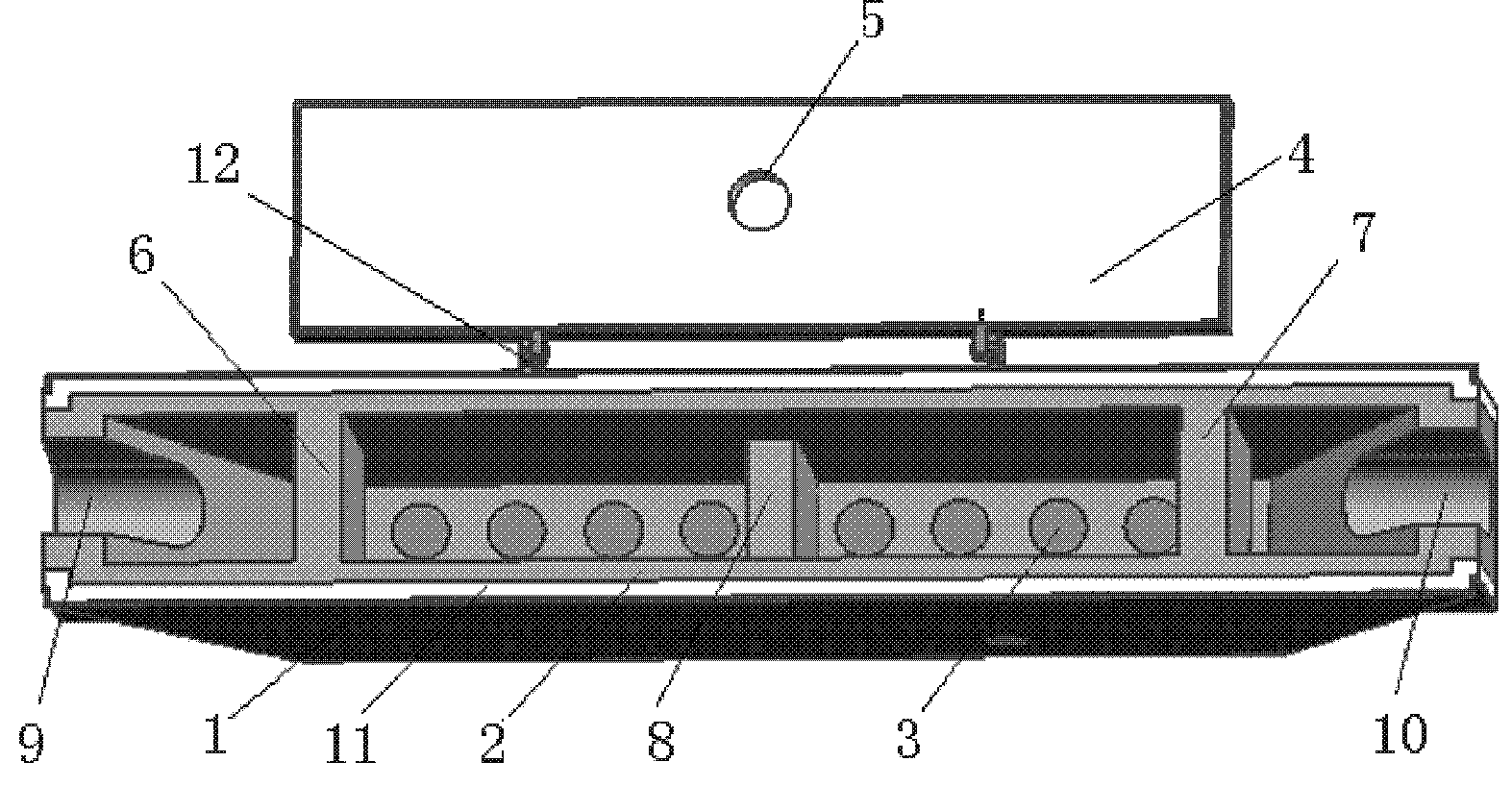

Runner type online degassing device

The invention belongs to the technical field of metallurgy, and relates to a runner type online degassing device, which comprises a runner shell, a degassing chamber, gas permeable bricks, a heat insulating cover, a vent, a first baffle plate, a second baffle plate, a middle baffle plate, a gas inlet, an inlet and an outlet; the degassing chamber is arranged in the runner shell; the heat insulating cover is movably connected with the runner shell, and is provided with the vent; two ends of the degassing chamber are provided with the inlet and the outlet; the middle of the degassing chamber is provided with the middle baffle plate; the first baffle plate is arranged between the middle baffle plate and the inlet; the second baffle plate is arranged between the middle baffle plate and the outlet; gaps are reserved between the bottoms of the first and second baffle plates and the degassing chamber; the bottom of the middle baffle plate is fixedly connected with the degassing chamber; the gas permeable bricks are embedded on the bottom of the degassing chamber and arranged between the first baffle plate and the middle baffle plate and between the second baffle plate and the middle baffle plate; and the bottoms of the gas permeable bricks are provided with the gas inlet. The runner type online degassing device has low requirement on space, is provided with the submerged baffle plates and the heat insulating cover, reduces gas absorption again and surface oxidation of degassed aluminium liquid, and has good degassing purification effect.

Owner:江西金达通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com