Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Improve homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

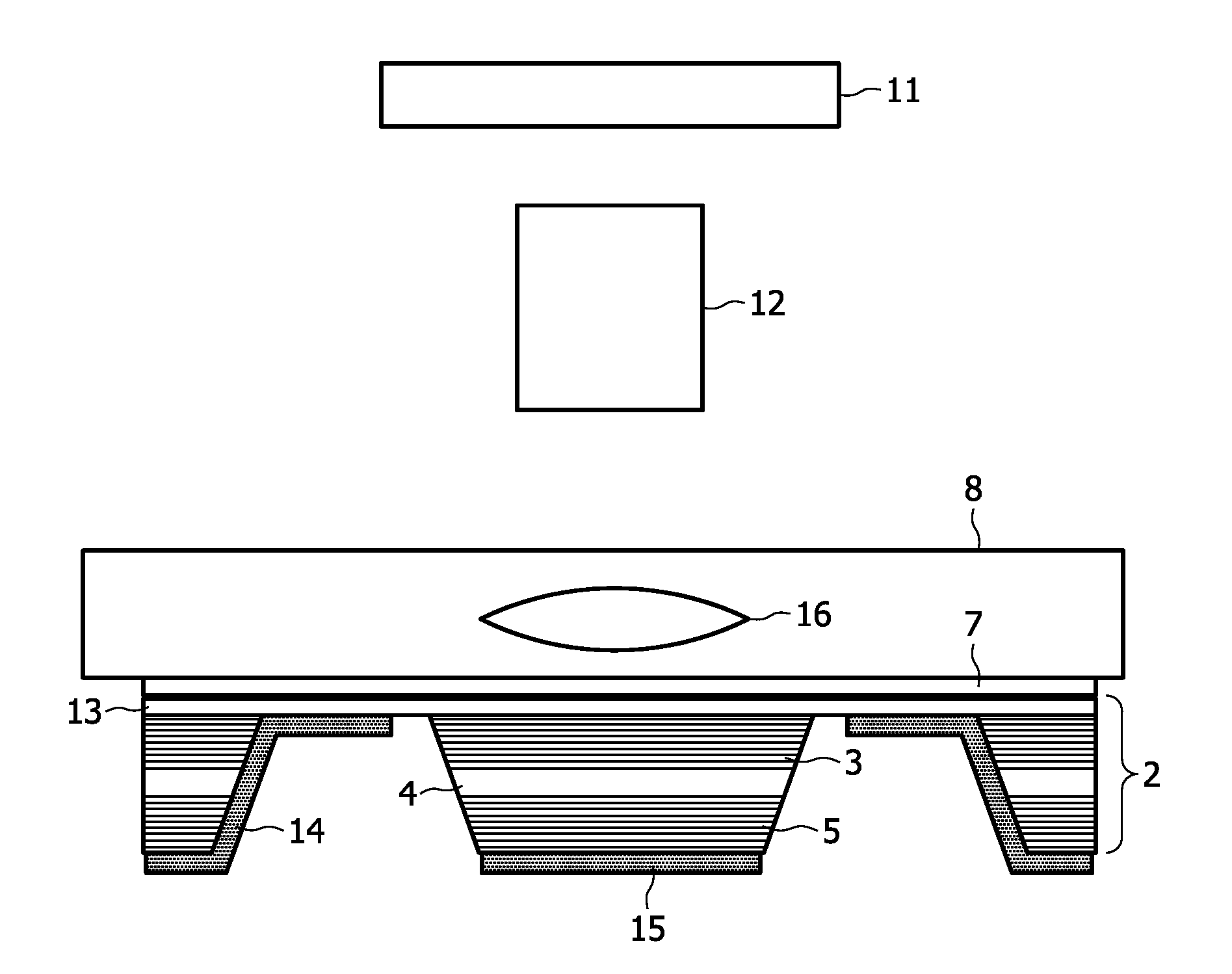

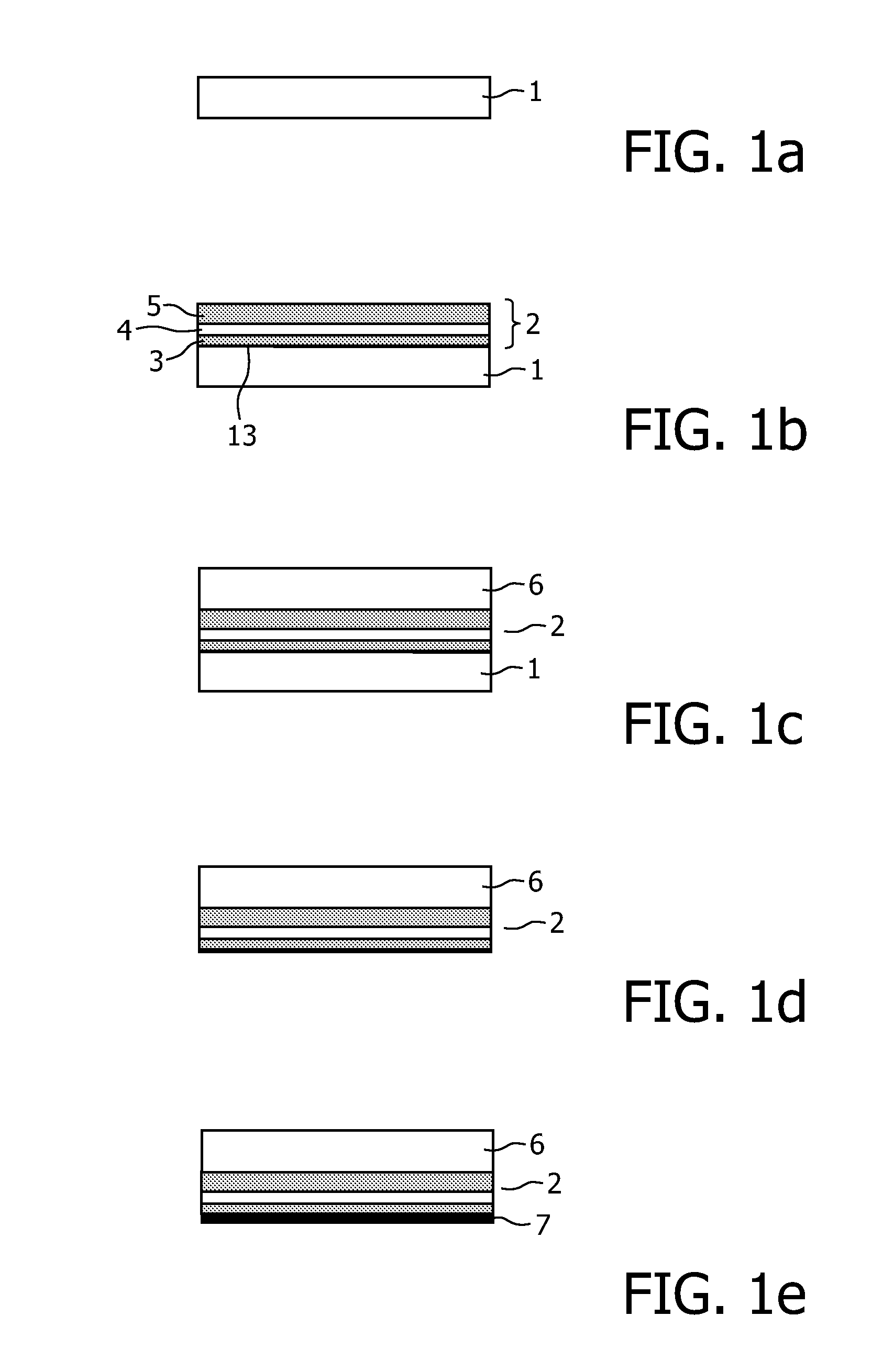

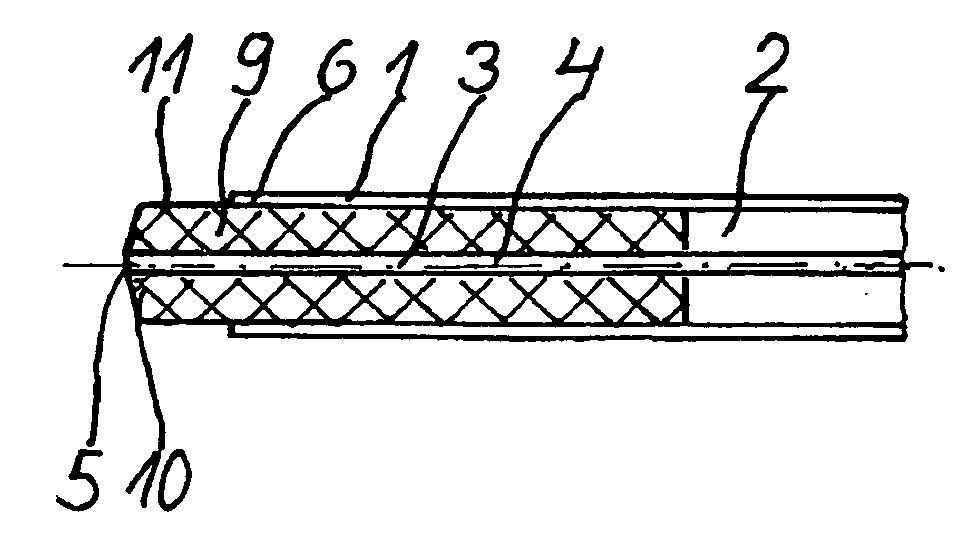

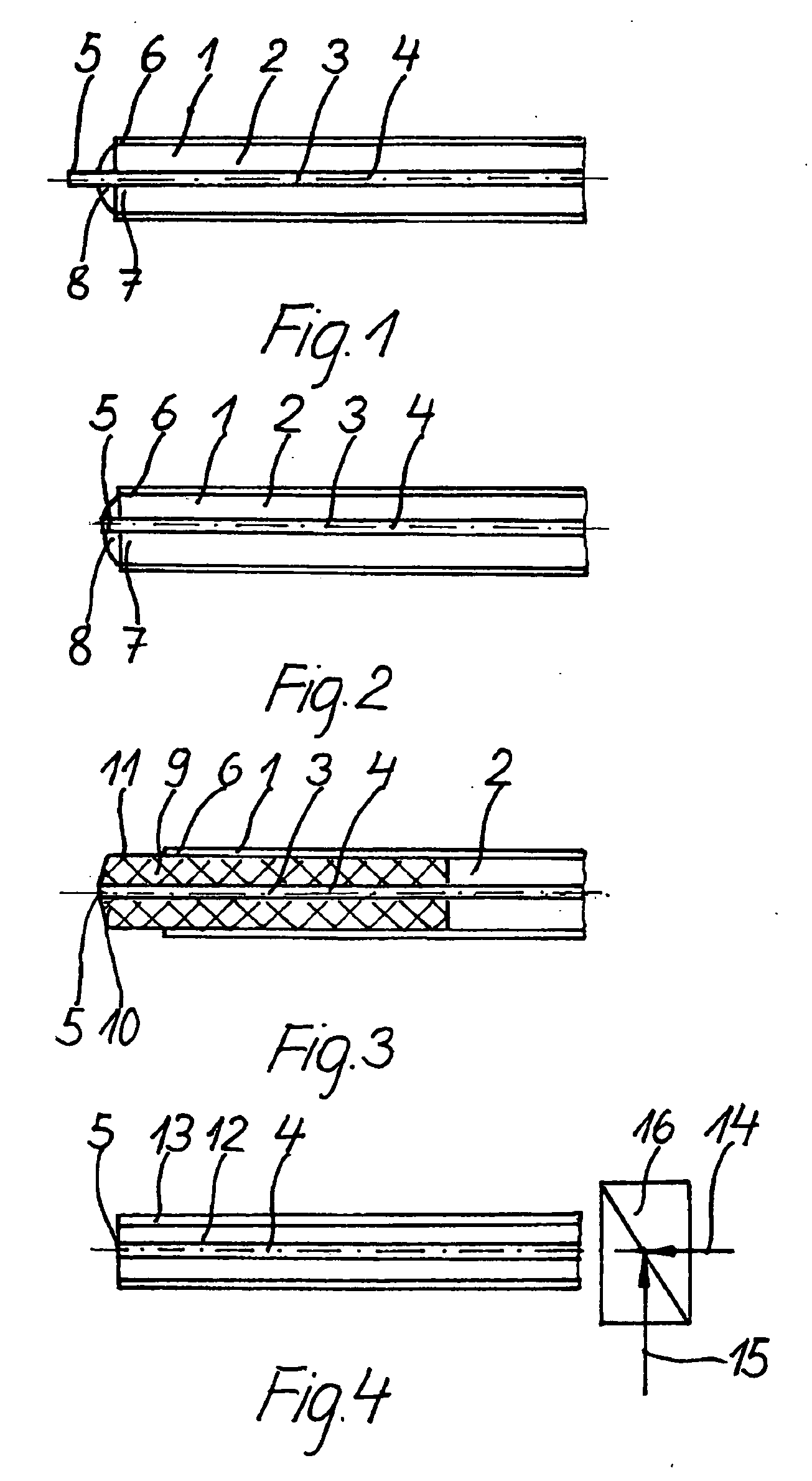

Vertical extended cavity surface emission laser and method for manufacturing a light emitting component of the same

ActiveUS20100195690A1Low thicknessSolve the low heat dissipation efficiencyLaser detailsLaser optical resonator constructionPhysicsSemiconductor

The present invention relates to a method of manufacturing the light emitting component of a VECSEL and the corresponding VECSEL. In the method a layer stack (2) is epitaxially grown on a semiconductor substrate (1). The layer stack comprises an active region (4), an upper distributed Bragg reflector (5) and a n- or p-doped current injection layer (13) arranged between the active region (4) and the semiconductor substrate (1). A mechanical support (6) or submount is bonded to an upper side of the layer stack (2) and the semiconductor substrate (1) is subsequently removed. A metallization layer (7) is optionally deposited on the lower side of the layer stack (2) and an optically transparent substrate (8) is bonded to this lower side. The proposed method allows the manufacturing of such a component in a standard manner and results in a VECSEL with a homogenous current injection and high efficiency of heat dissipation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

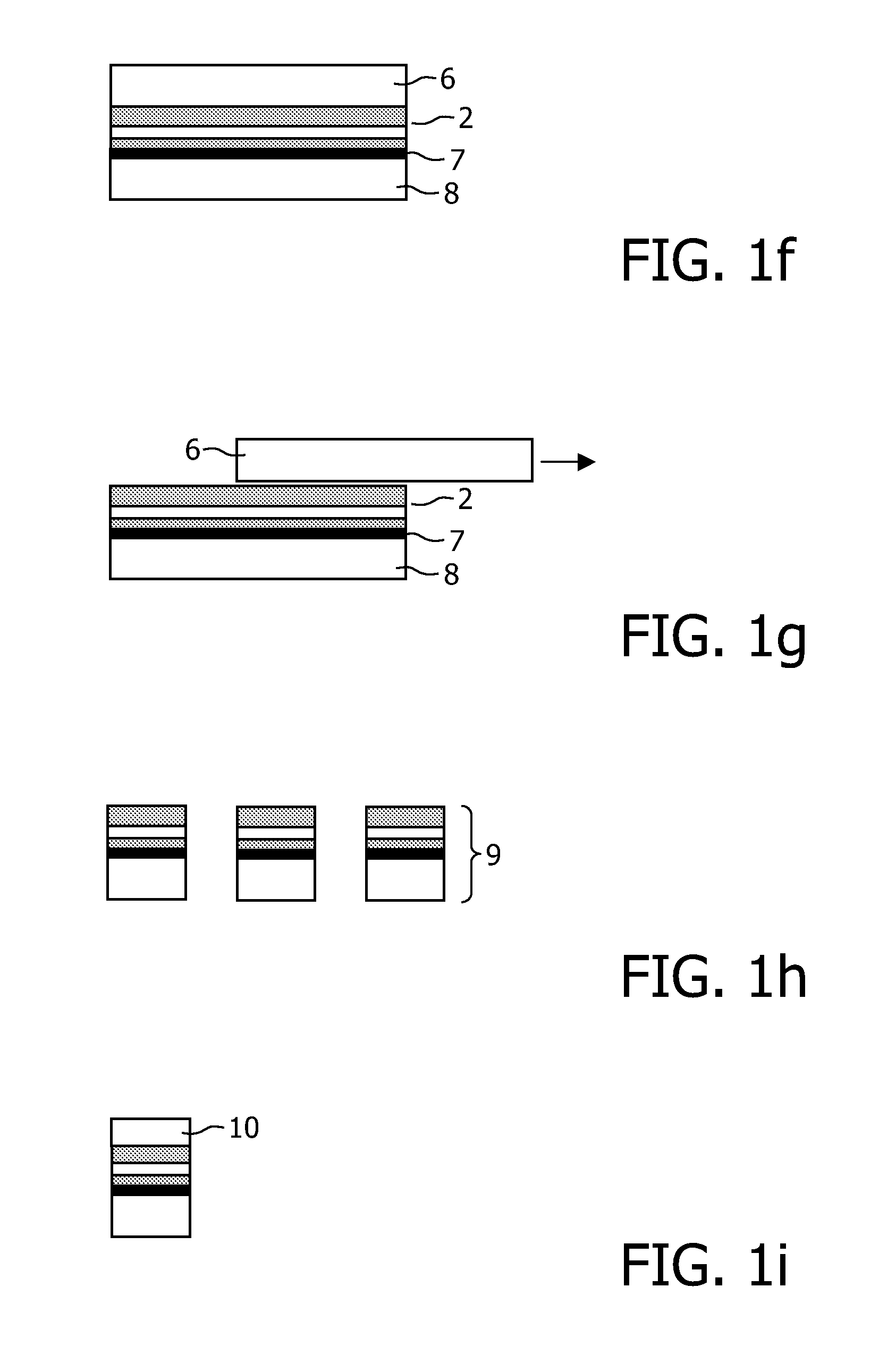

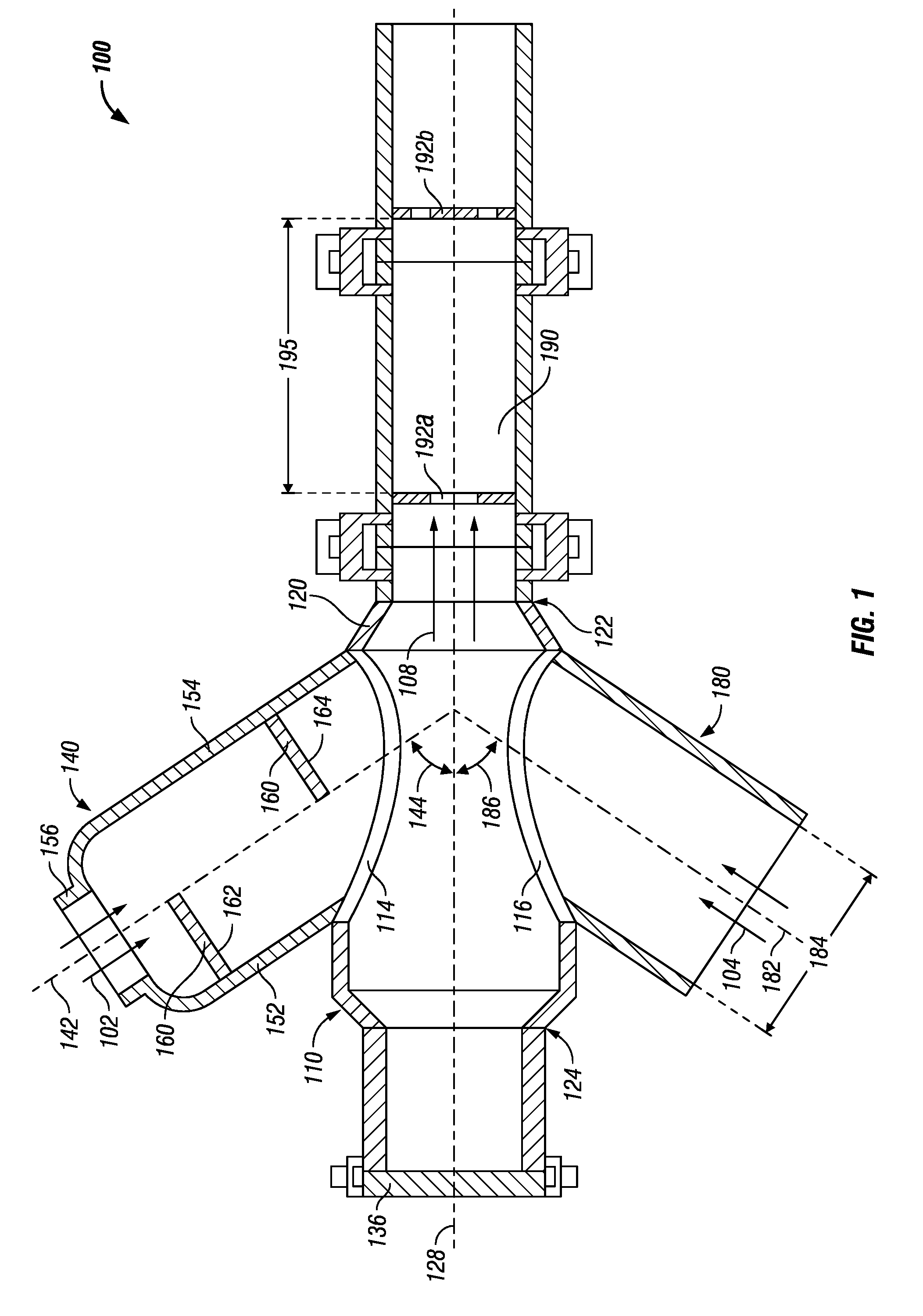

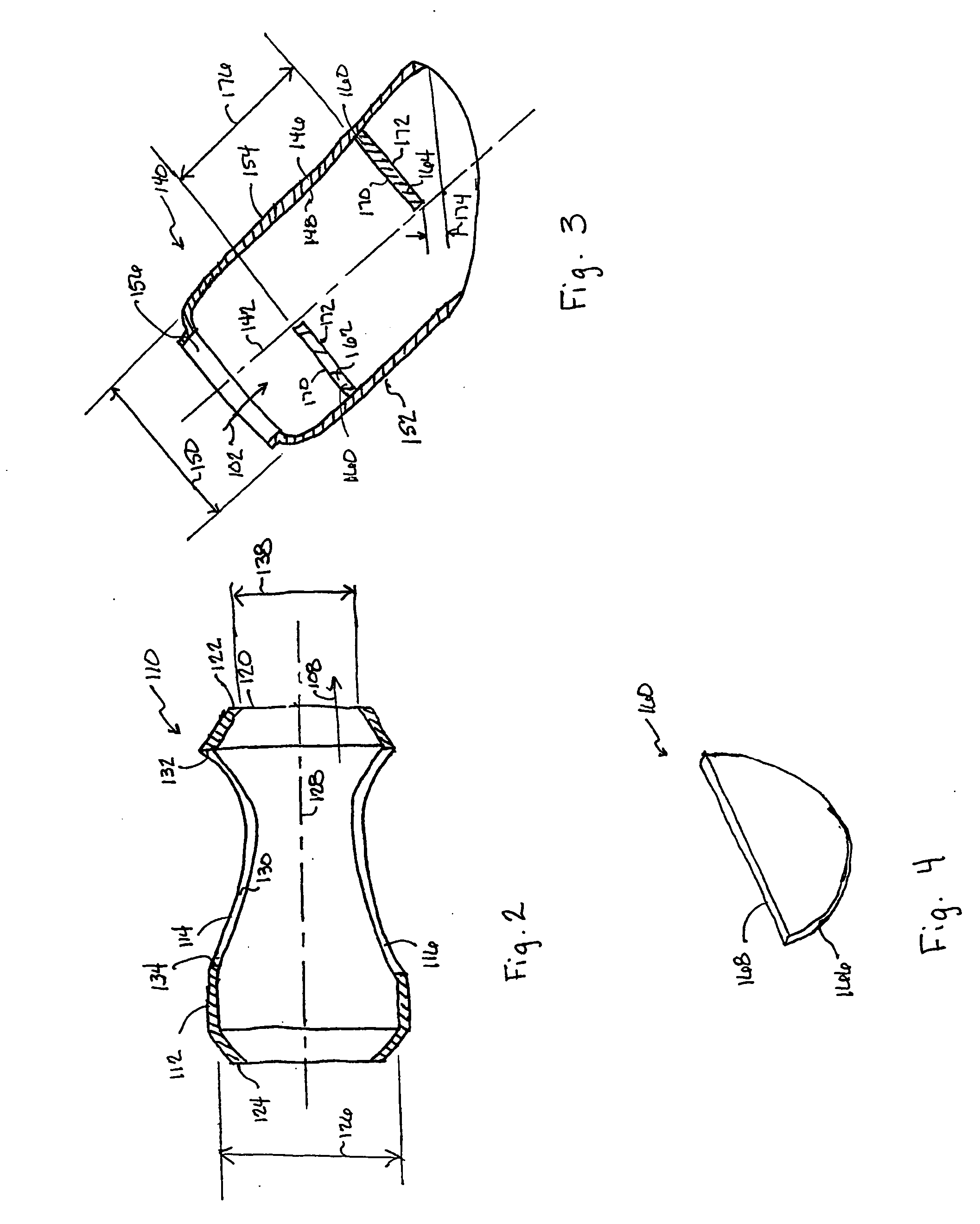

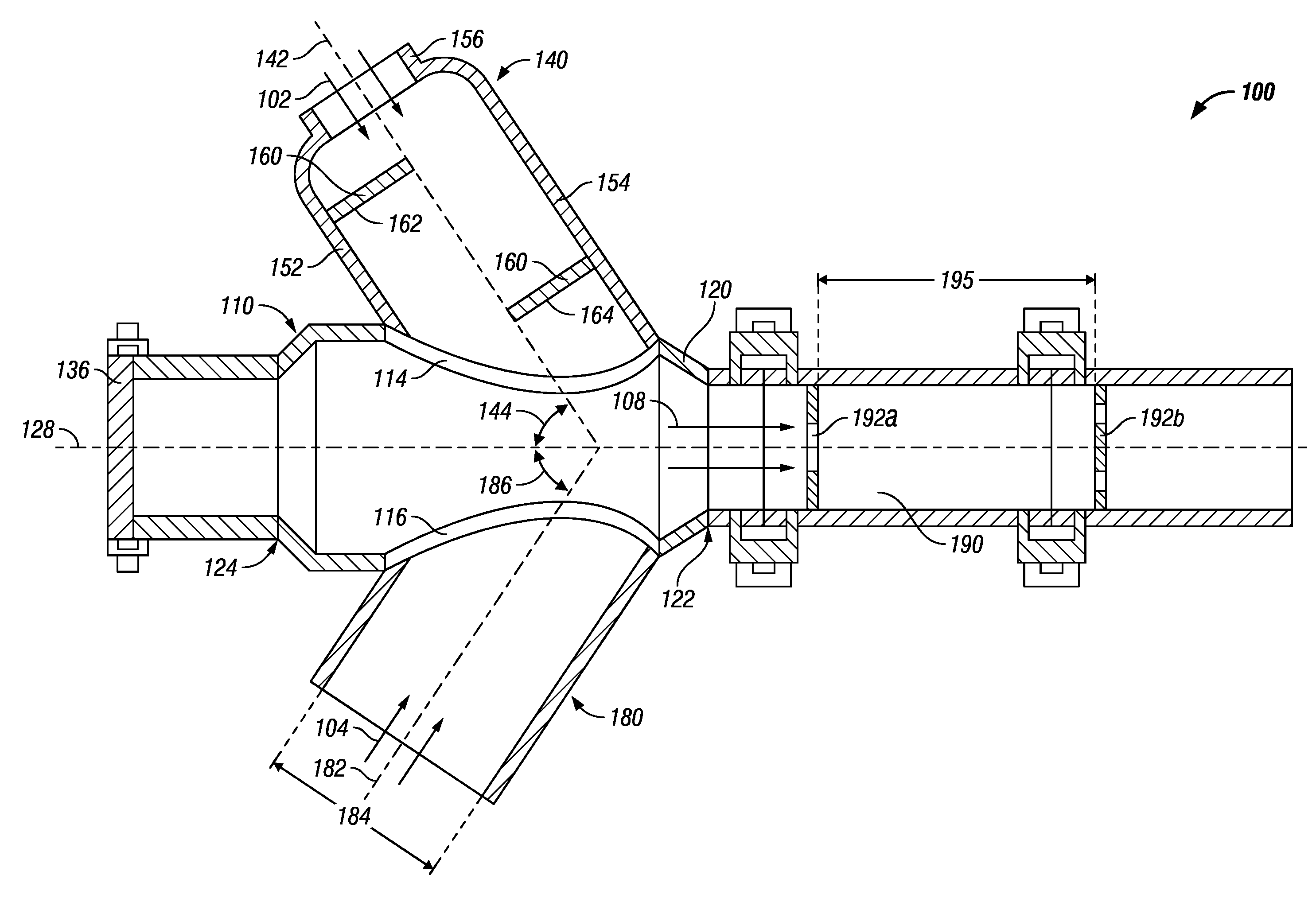

Apparatus for homogenizing two or more fluids of different densities

ActiveUS8079751B2Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingVolumetric Mass DensityEngineering

A blending apparatus for blending a first fluid stream having a first density and a second fluid stream having a second fluid density, the first density being greater than said second density, is discussed. The apparatus includes a first fluid director including a plurality of baffles affixed therein to create turbulence and shear in the first fluid, a cylindrical second fluid director, a primary mixing chamber receiving the first sheared fluid from the first fluid director and receiving the second fluid from the second fluid director, wherein the first fluid and second fluid are mixed in the primary mixing chamber to form a mixed primary fluid stream, and a secondary blending chamber comprising at least one static mixer and coaxially aligned with and receiving the mixed primary fluid stream from the primary mixing chamber.

Owner:MI

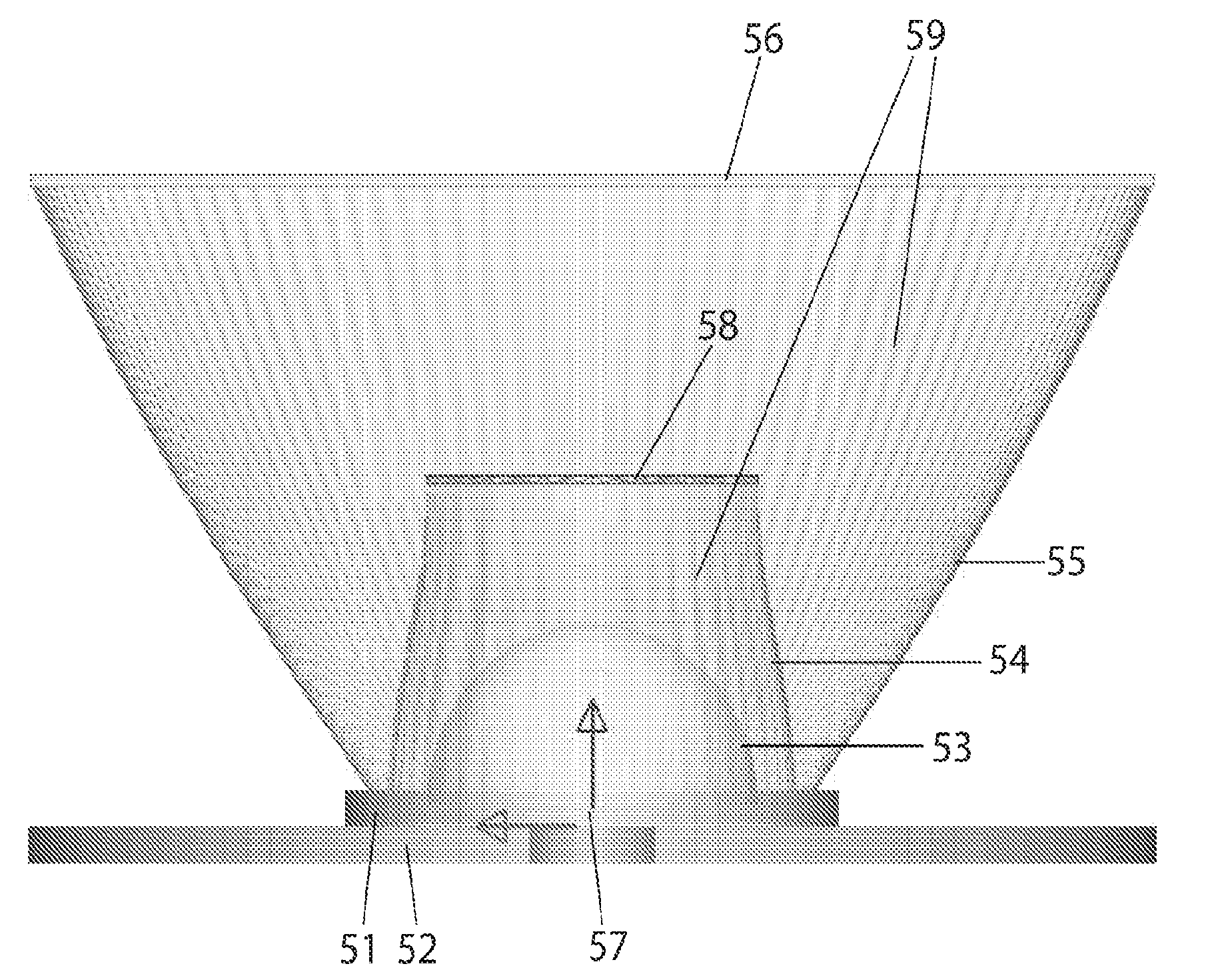

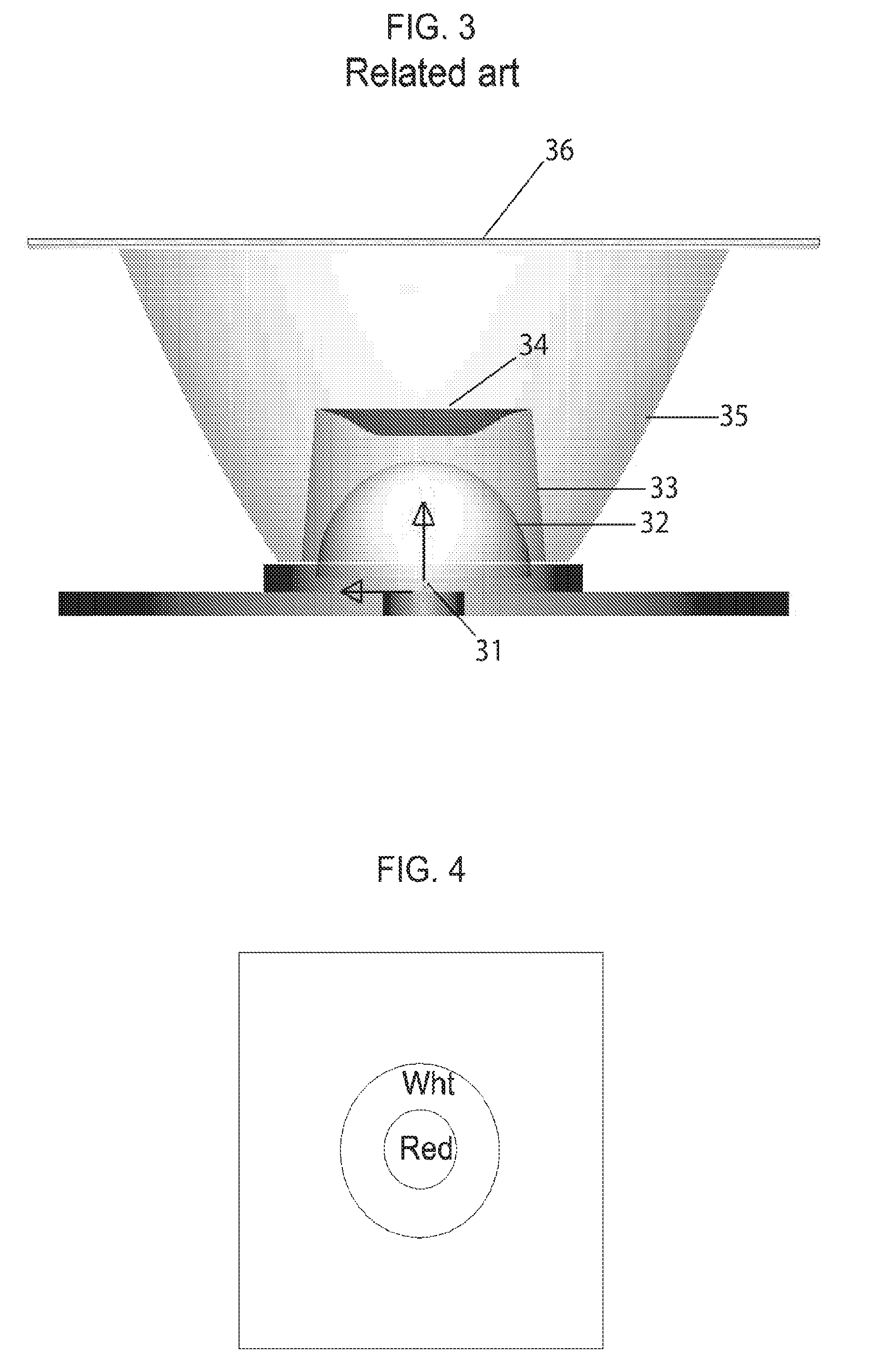

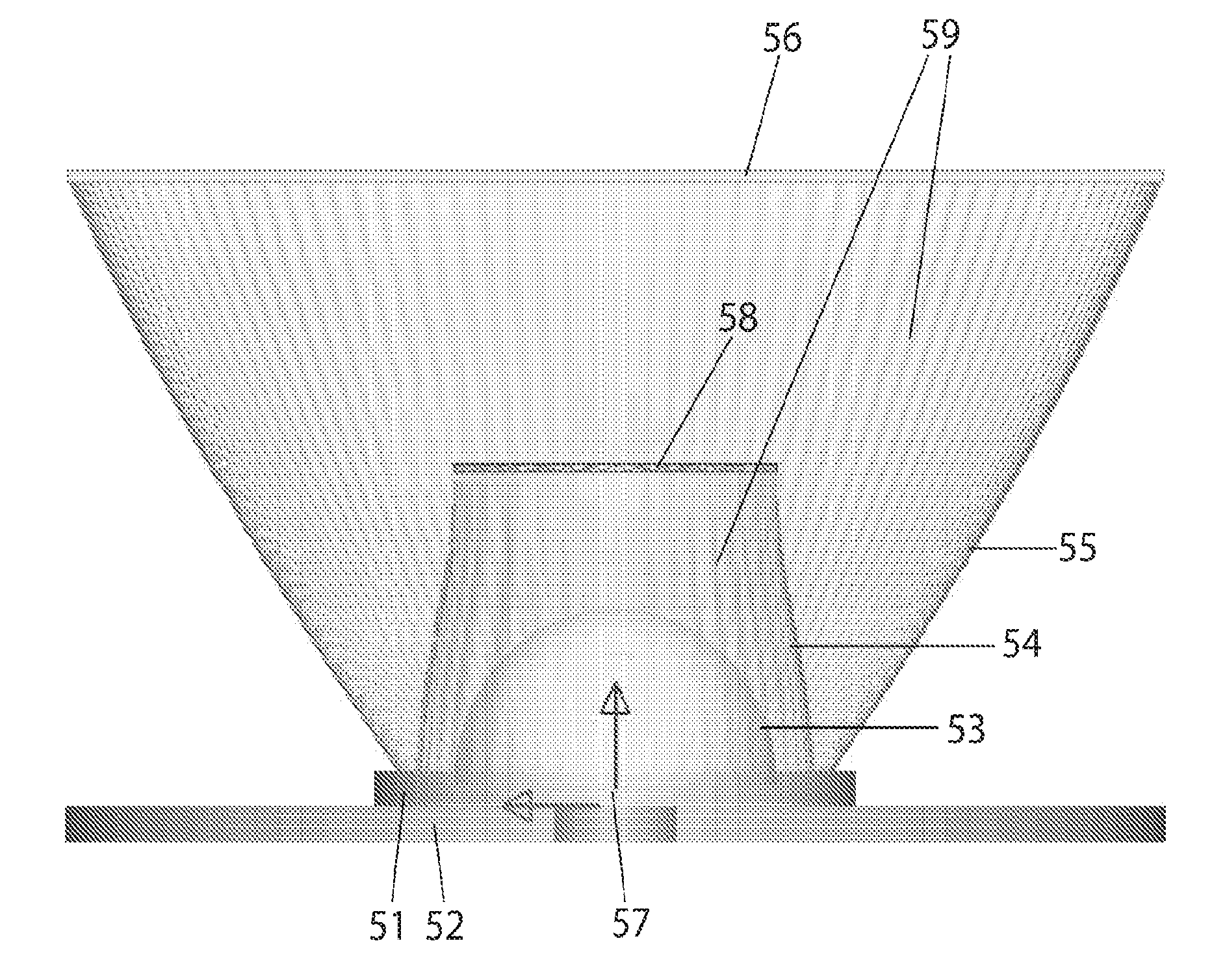

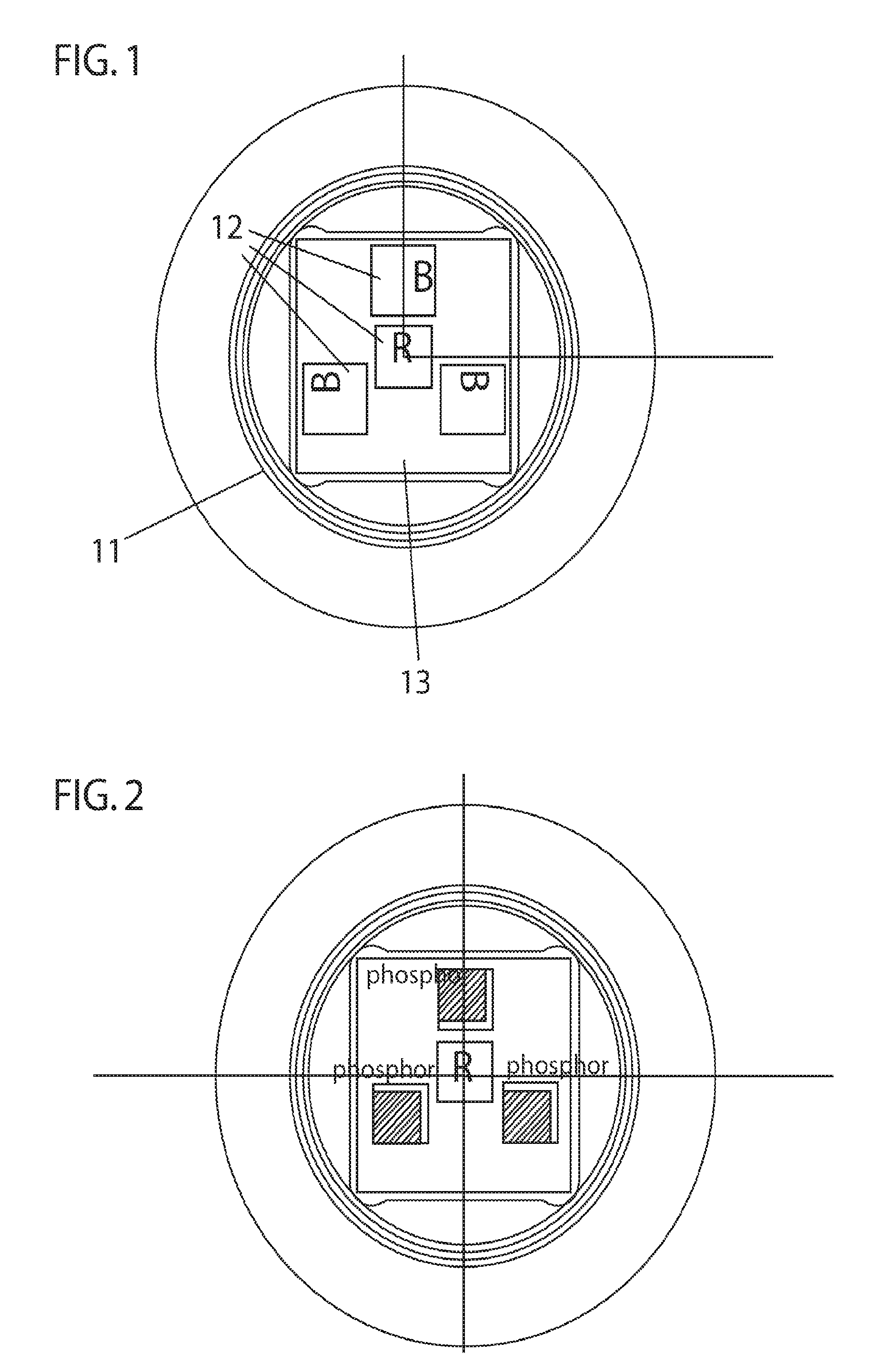

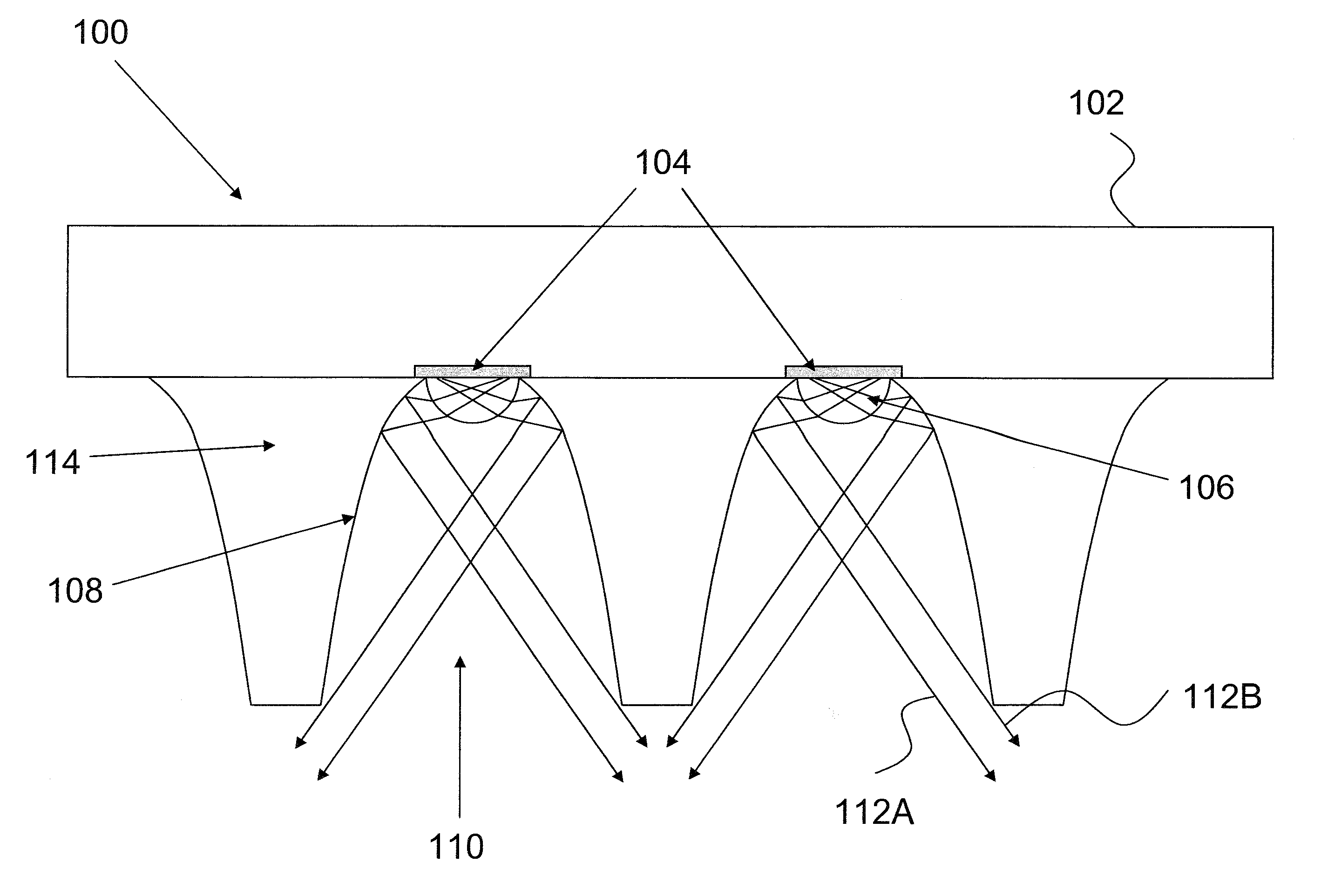

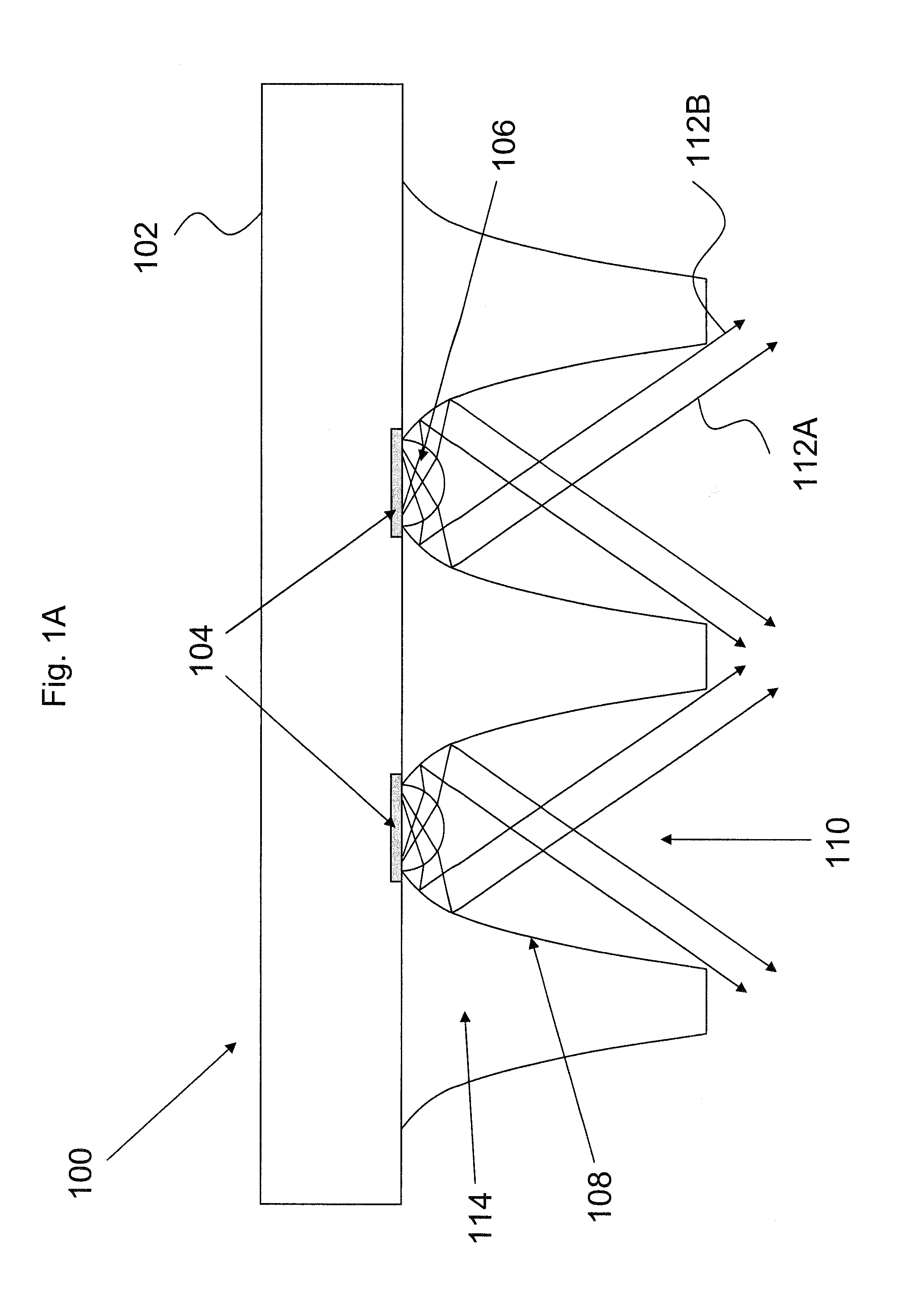

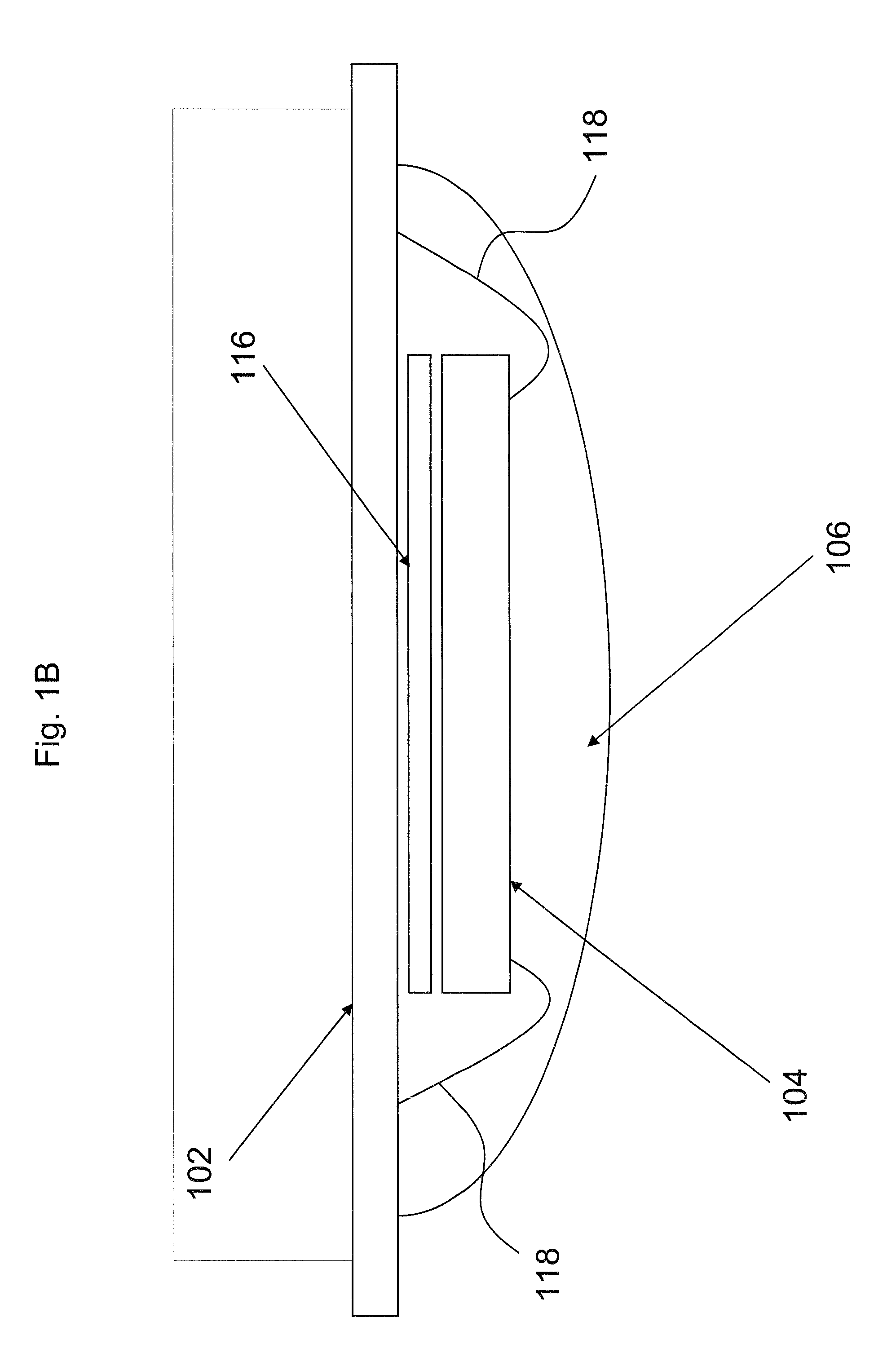

Warm white lighting device

ActiveUS20110051394A1Improved light generationImprove homogenizationNon-electric lightingPoint-like light sourceLensletHuman eye

The present invention relates to warm white light engines including combinations of blue, cyan, and red, red-orange, or amber emitters and one or more phosphors that produce a white light pleasing to the human eye through the use of improved color uniformity and improved collimation of light. Specifically, a micro-lenslet array having an optimized surface is used to disperse light from the light emitter; an innercollimation lens having an optimized cross-sectional shape and micro-ridges is used to disperse light; a TIR reflector having an optimized cross-sectional shape and micro-ridges is used to disperse and redistribute phase as well as provide collimation; and a final micro-lenslet layer includes optimized lenslet design placement and randomization factor to homogenize light to produce a uniform warm white light.

Owner:LIGHTING SCI GROUP

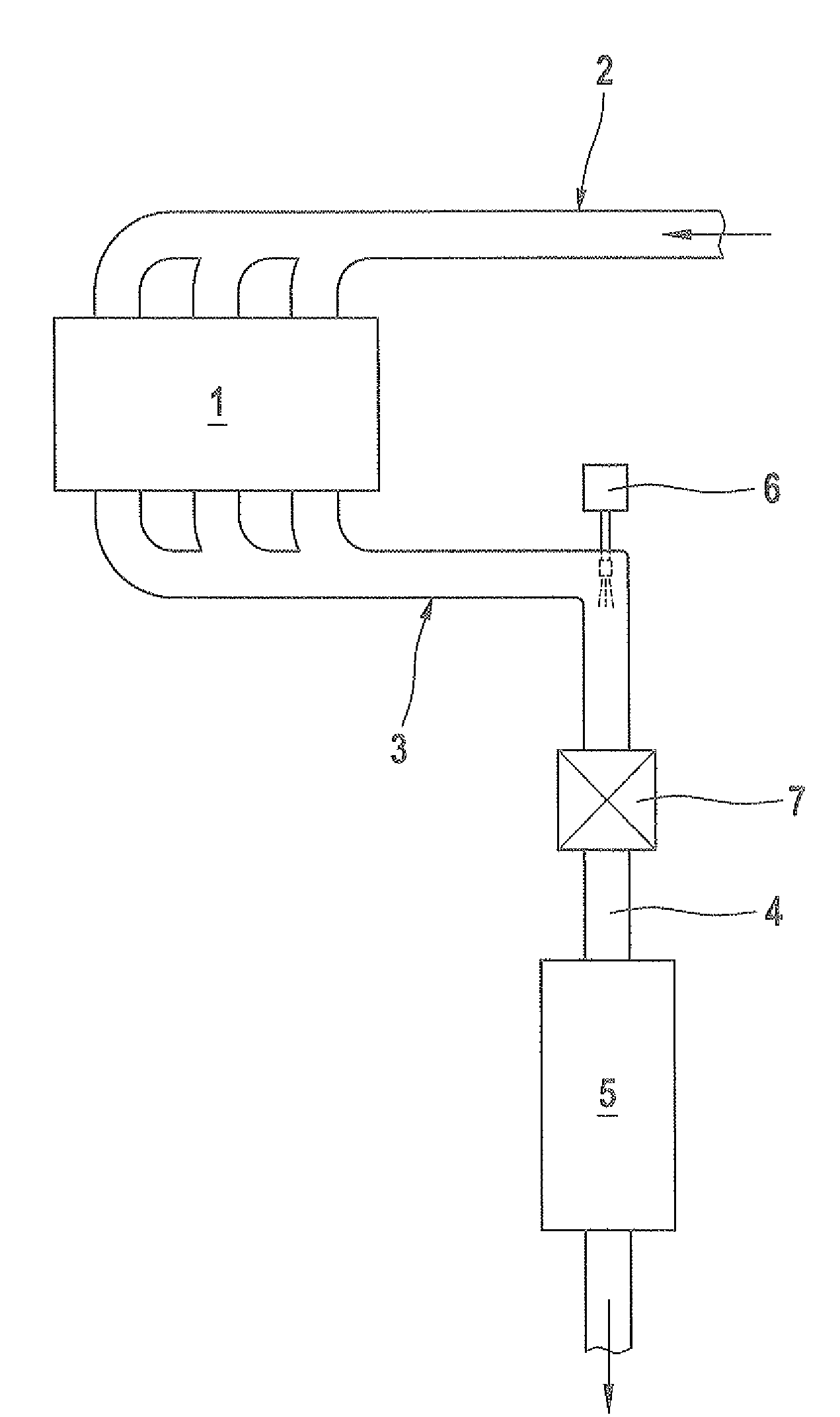

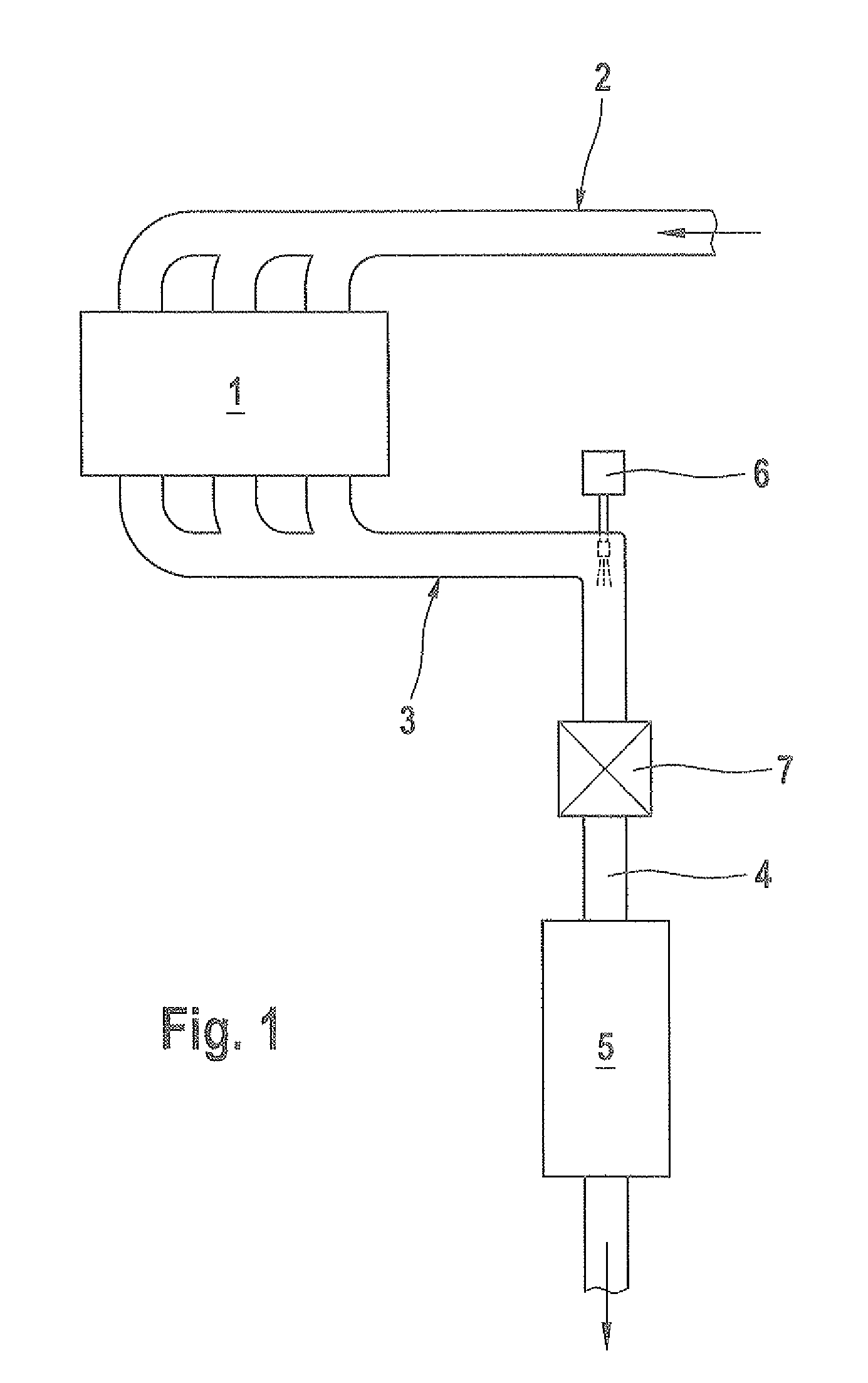

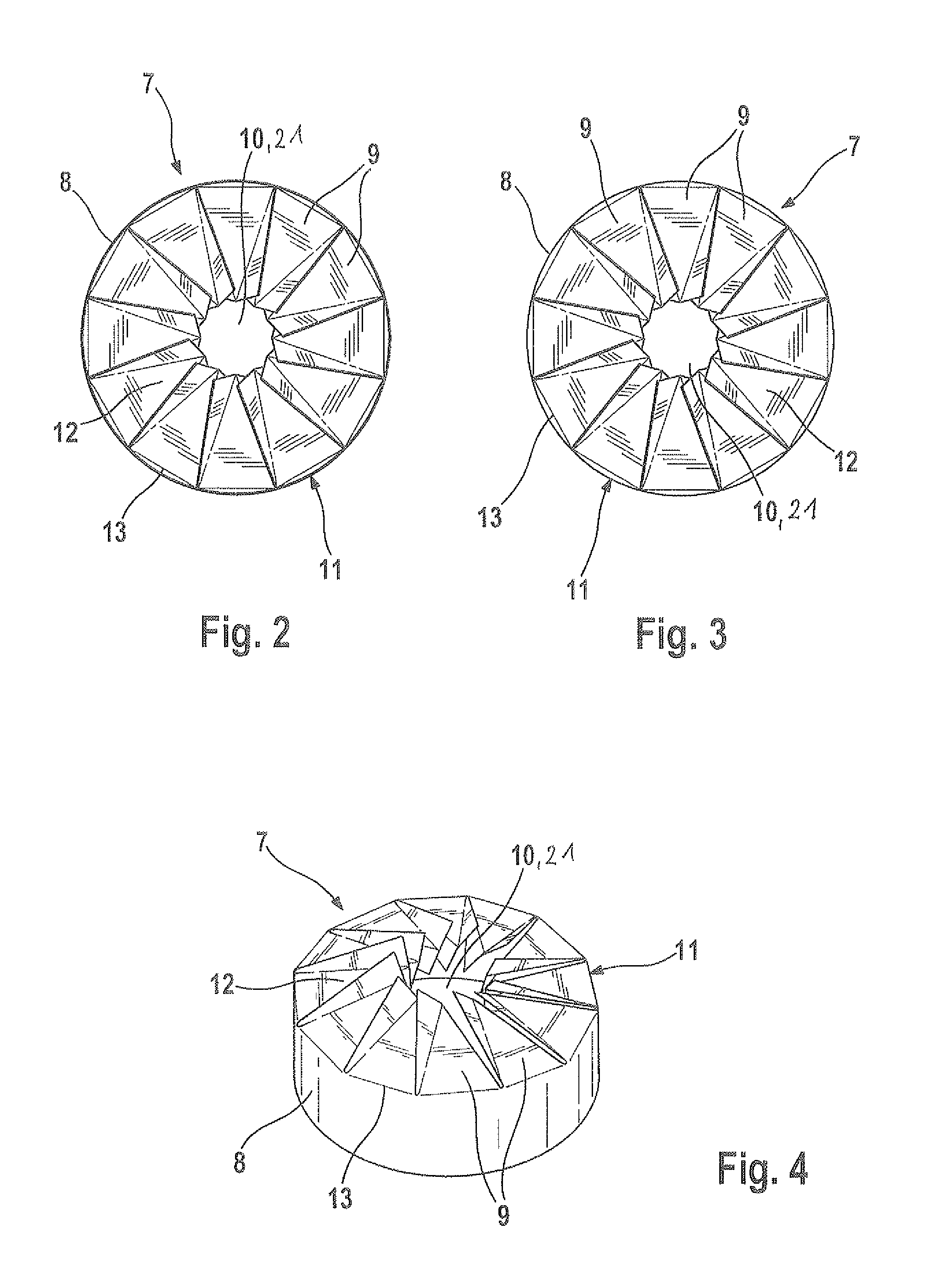

Mixing and/or evaporating device and process for manufacturing same

ActiveUS20080308083A1Low costImprove actionFlow mixersExhaust apparatusAngle of incidenceEngineering

A mixing and / or evaporating device (7) is provided for an exhaust system (3) of an internal combustion engine (1), especially in a motor vehicle. The mixing and / or evaporating device (7) has a tubular body (8), at one axial end of which a plurality of blades (9) are arranged, which blades are located adjacent to each other in the circumferential direction, project radially inwardly and have angles of incidence in relation to one another in the axial direction. For manufacture at a low cost, the tubular body (8) is manufactured together with the blades (9) from a single sheet metal body (11) by shaping.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

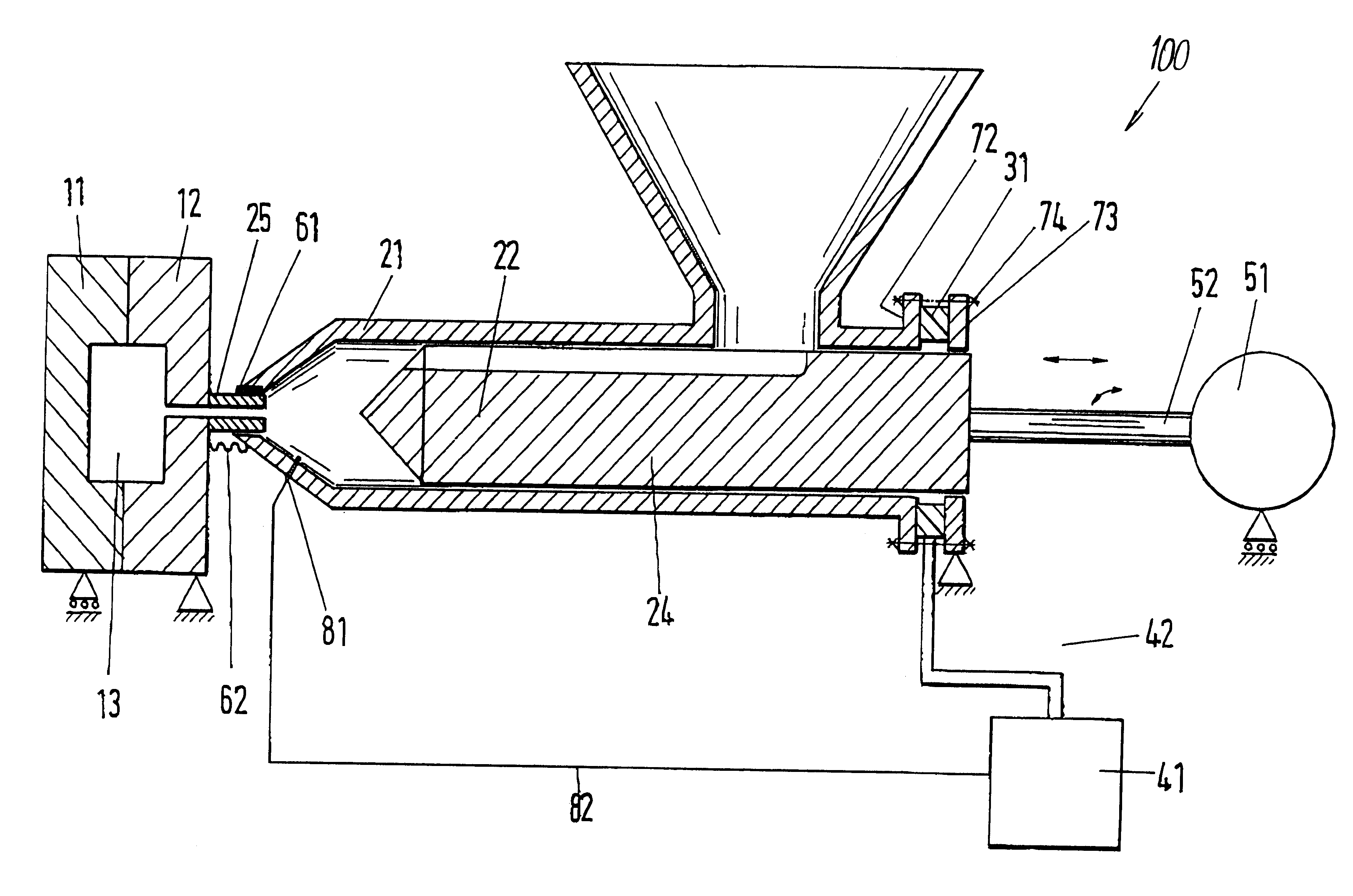

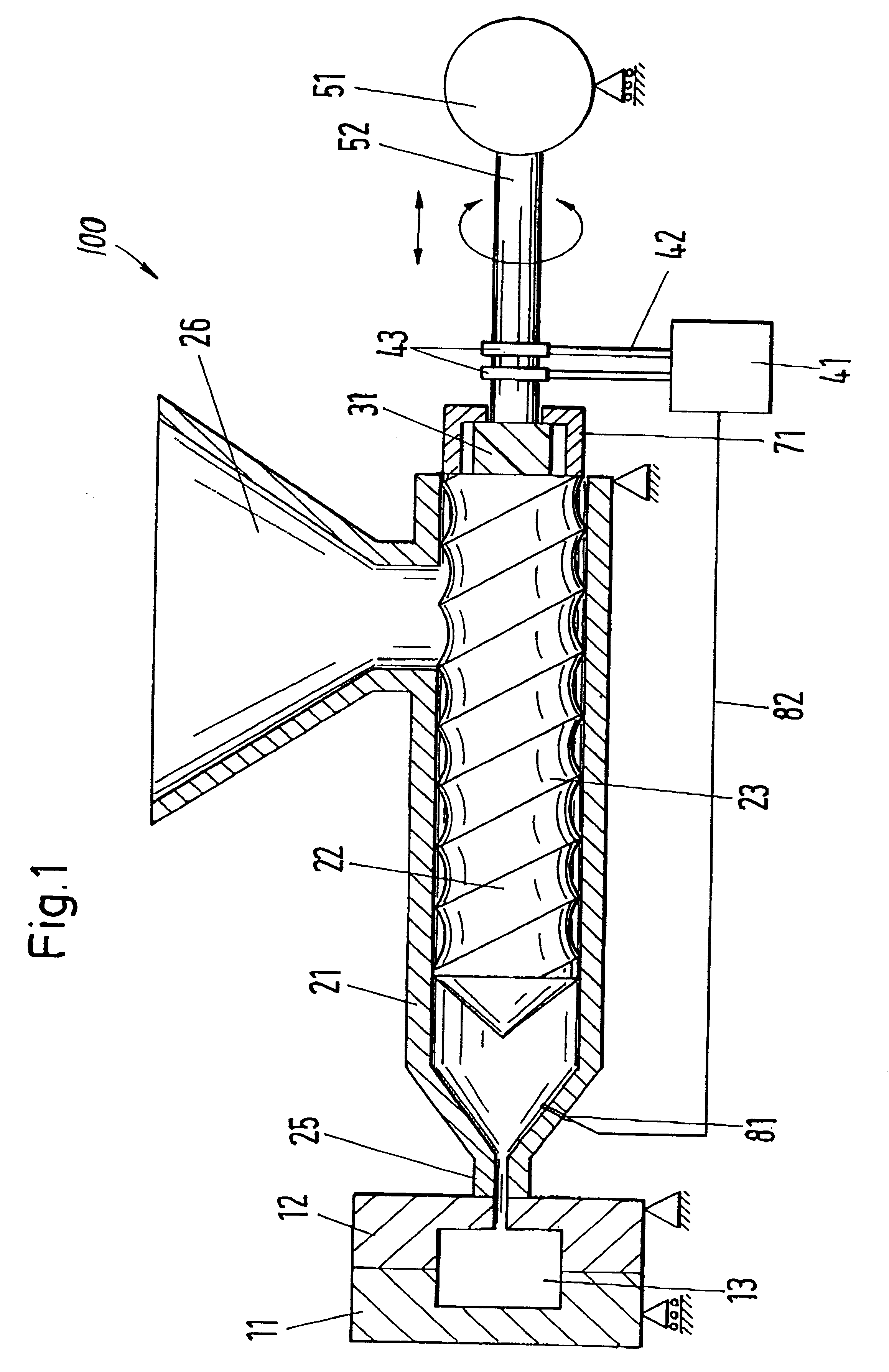

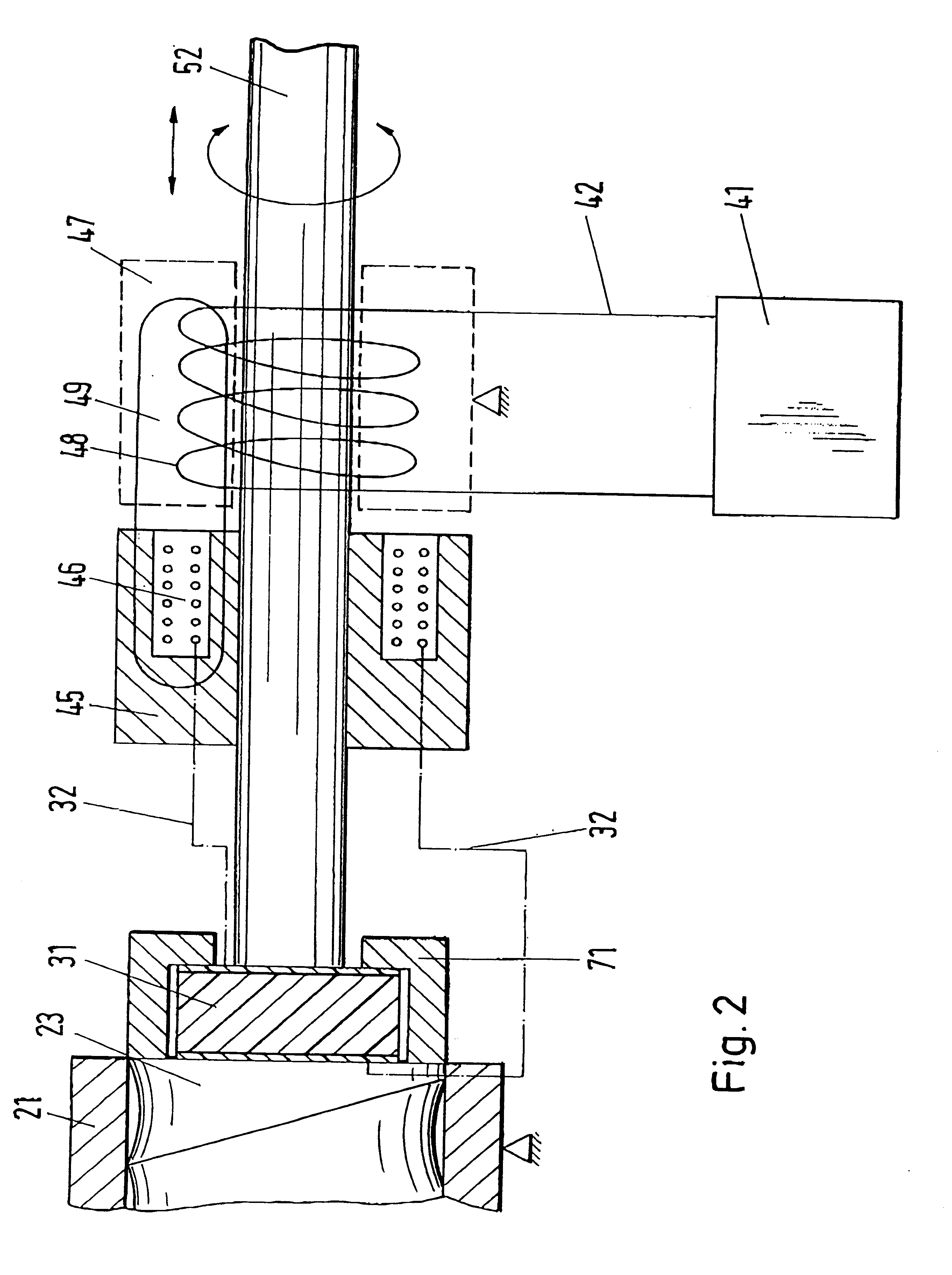

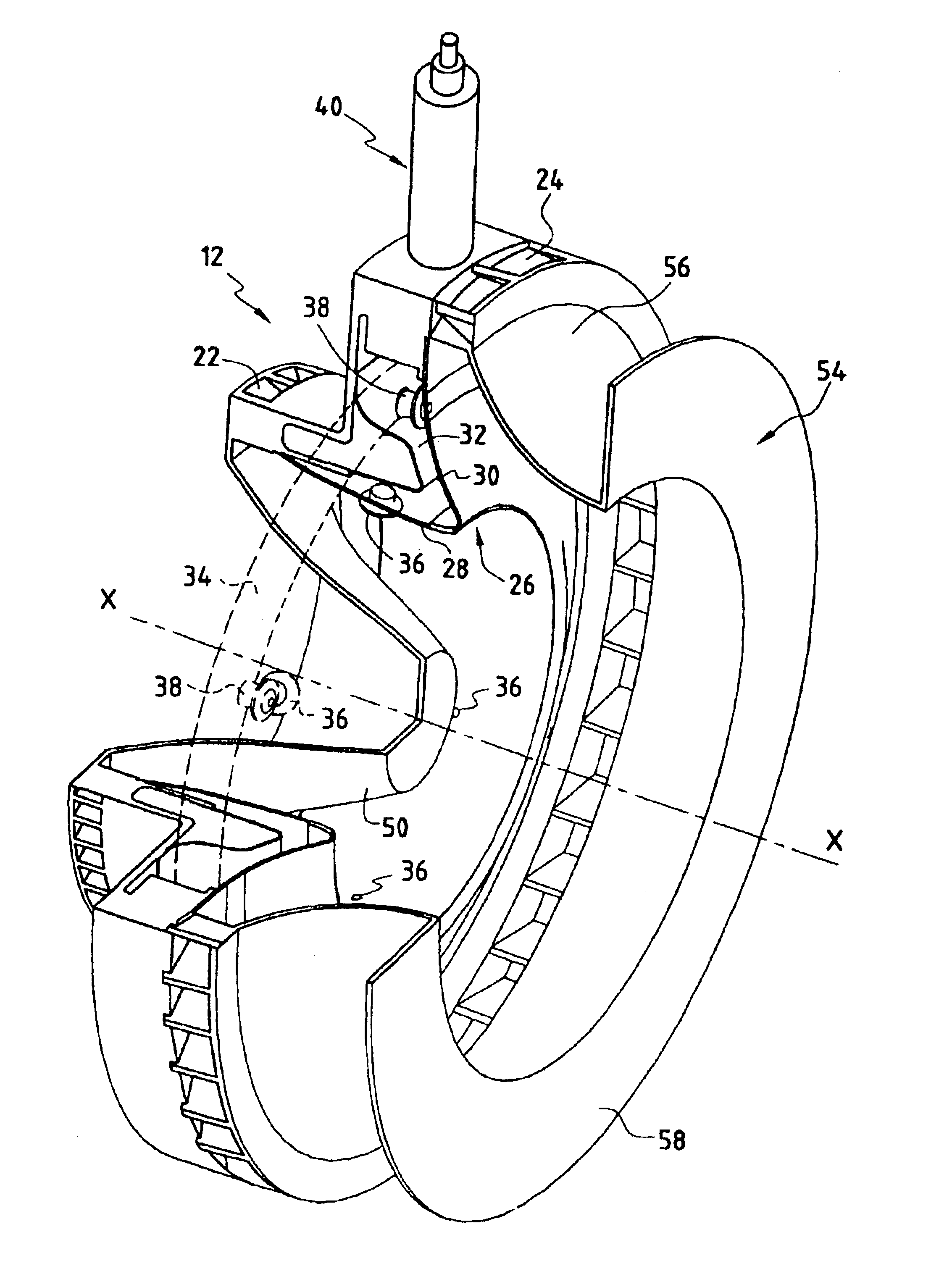

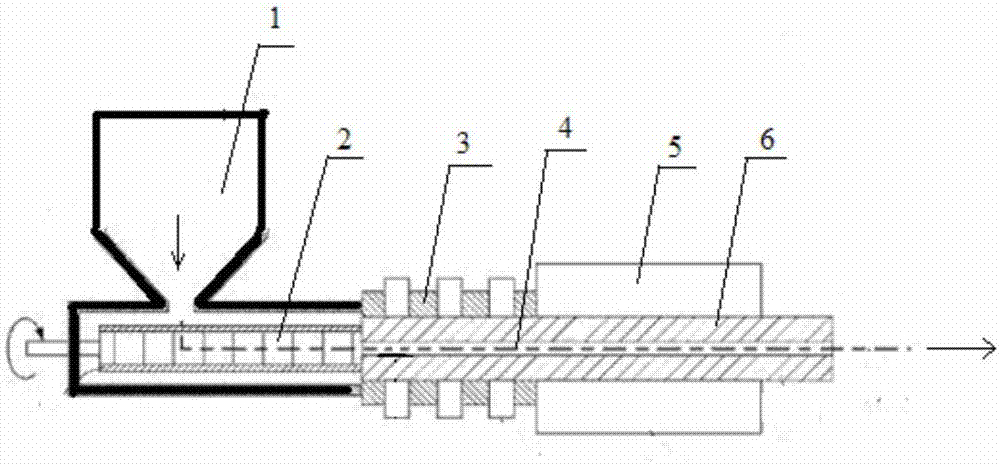

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

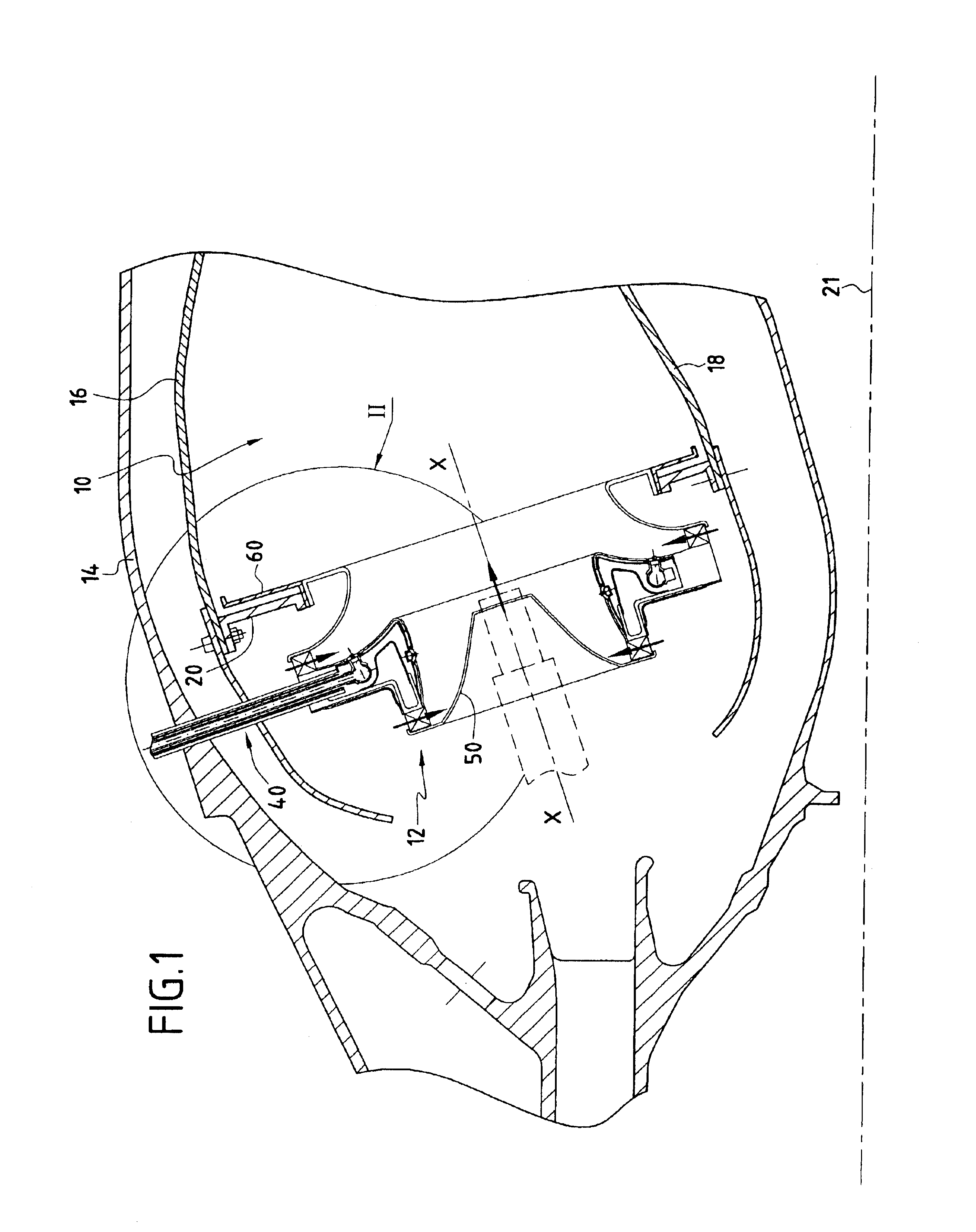

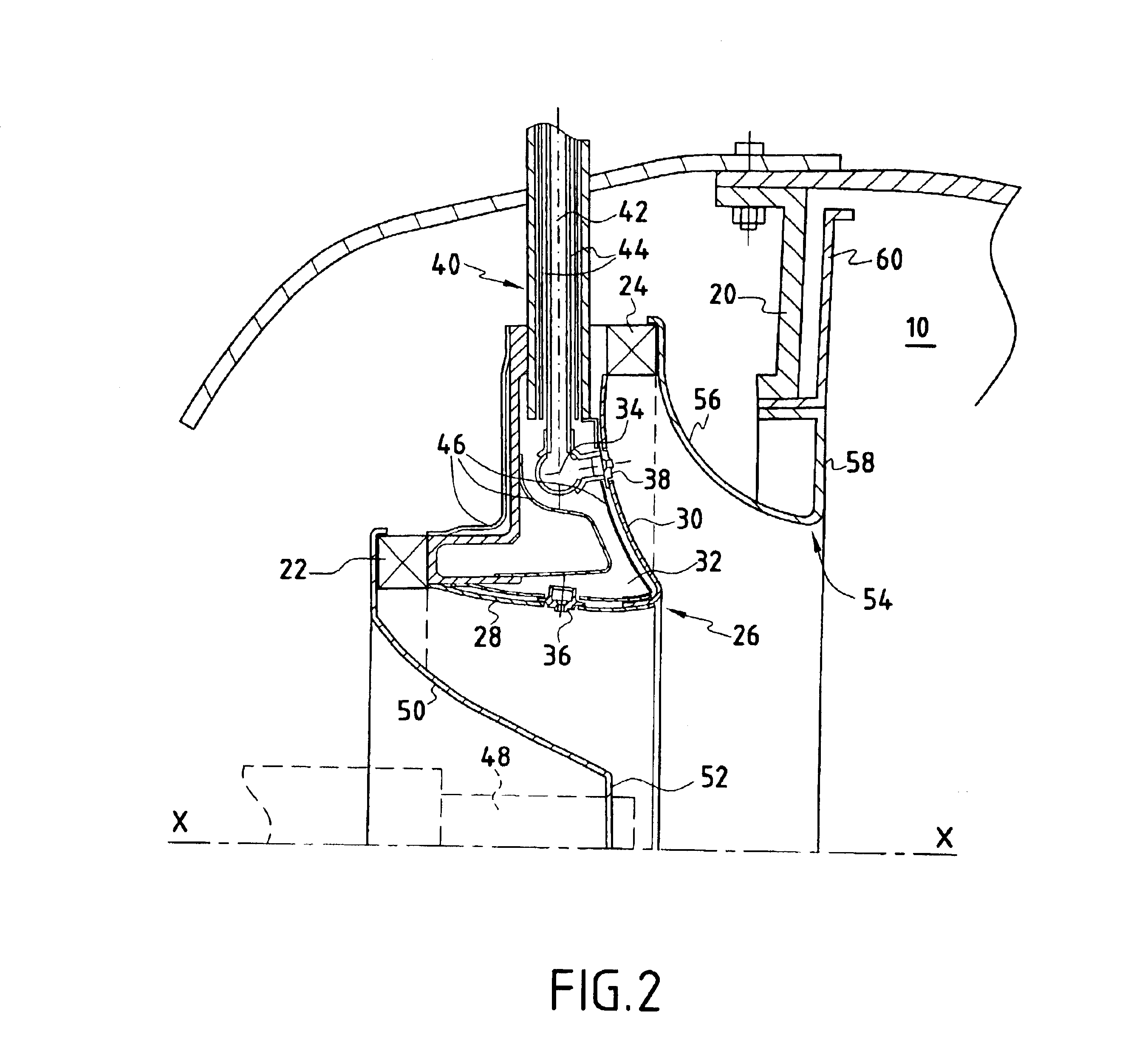

Multimode system for injecting an air/fuel mixture into a combustion chamber

InactiveUS6799427B2Controlling the riskMitigate such drawbackTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion chamberEngineering

The invention provides an injection system for injecting an air / fuel mixture into a combustion chamber of a gas turbine engine, the injection system having a longitudinal axis and comprising fuel injection means, interposed between first and second air injection means, the fuel injection means being disposed in an annular internal cavity of a Venturi, the fuel injection means comprising at least a first fuel admission circuit provided with at least one fuel injection orifice, and a plurality of second fuel admission circuits independent from the first fuel admission circuit(s), each being provided with at least one fuel injection orifice so as to define a plurality of independent modes of injecting the air / fuel mixture depending on determined operating speeds of the engine, the fuel injection orifice of the first fuel admission circuit being formed in the upstream wall of the Venturi so as to inject fuel towards the combustion chamber in a general direction that is substantially perpendicular to a flow of air coming from the first air injection means, and the fuel injection orifices of the second fuel admission circuits being formed in the downstream wall of the Venturi so as to inject fuel towards the combustion chamber in a general direction that is substantially perpendicular to a flow of air coming from the second air injection means.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

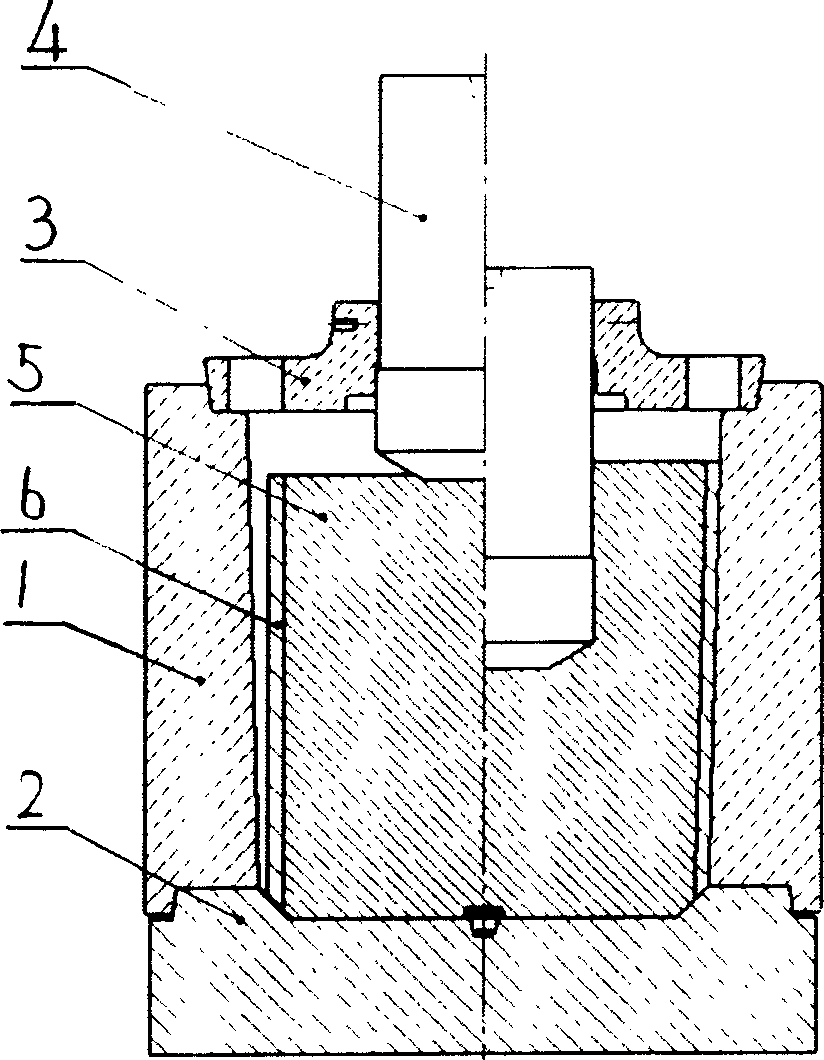

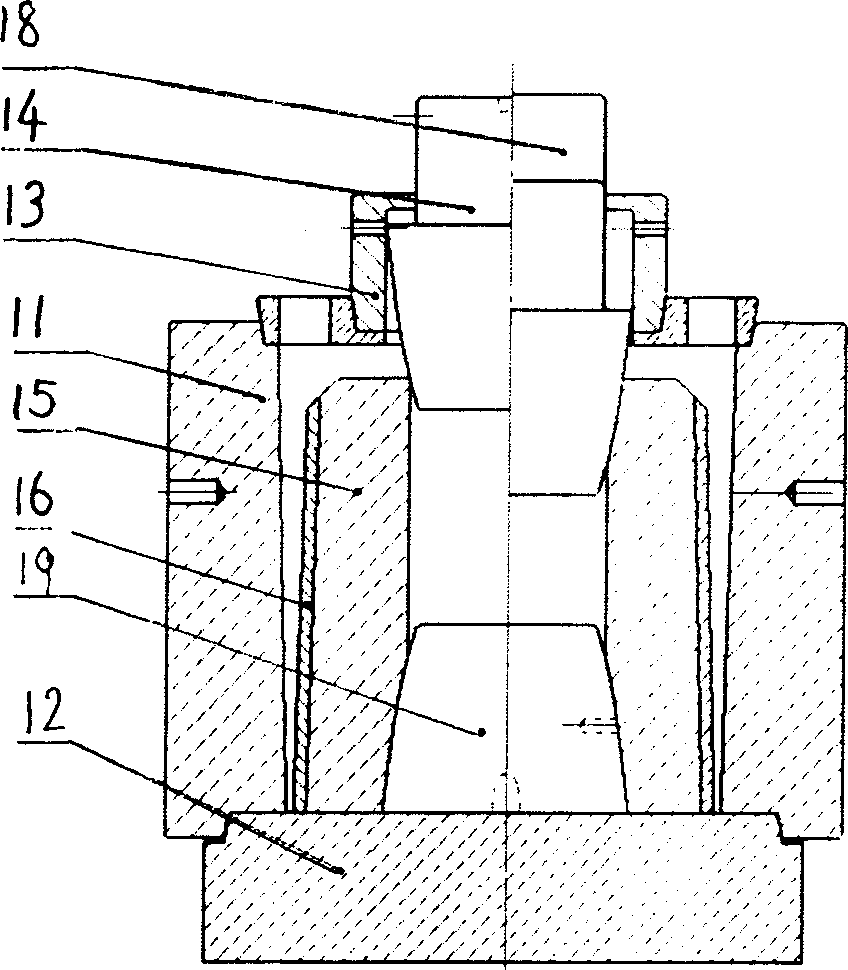

Method for producing circular cog hot forged from generator protective ring and mould

InactiveCN1736630AImprove stress statusAvoid cracksForging/hammering/pressing machinesHollow articlesCrystalliteLubrication

The invention discloses a method and the die for preparation of a hot forging ring billet of the guard ring of generator, and relates to a forging technique and the device of guard ring part of generator. The prior hot forging technique is flat-die forging, easily to produce crack in the process. The invention using confined shaping in die instead of flat-die forging, it improves the state of stress and prevents the crack effectively. With the symmetry of sphere plunger axis in the process of fan boring, the crystal particles are fine and uniform, which provides a perfect condition for cold strain intensification. With the jacket shaping of billet, it can improve lubrication and decrease friction, and can keep the temperature of the hot billet effectively, improving the plasticity and decreasing the shaping pressure. The invention solves the three problems that the crack is easy to produce, the structure property is not uniform, and the shaping pressure is large; compared with the prior technique, the invention has a projecting progress and a distinctive effect.

Owner:DEYANG WANXIN POWER STATION PROD DEV

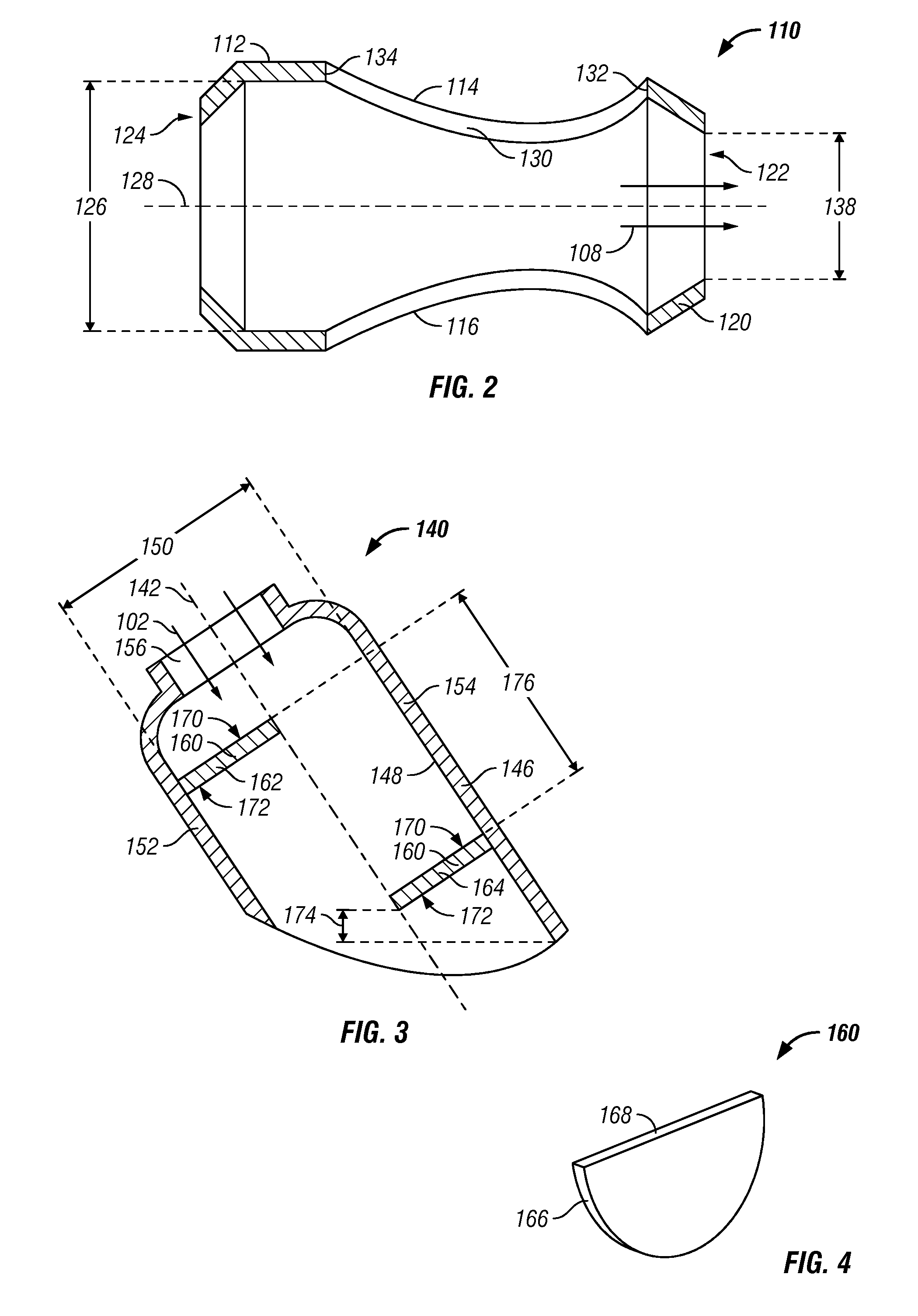

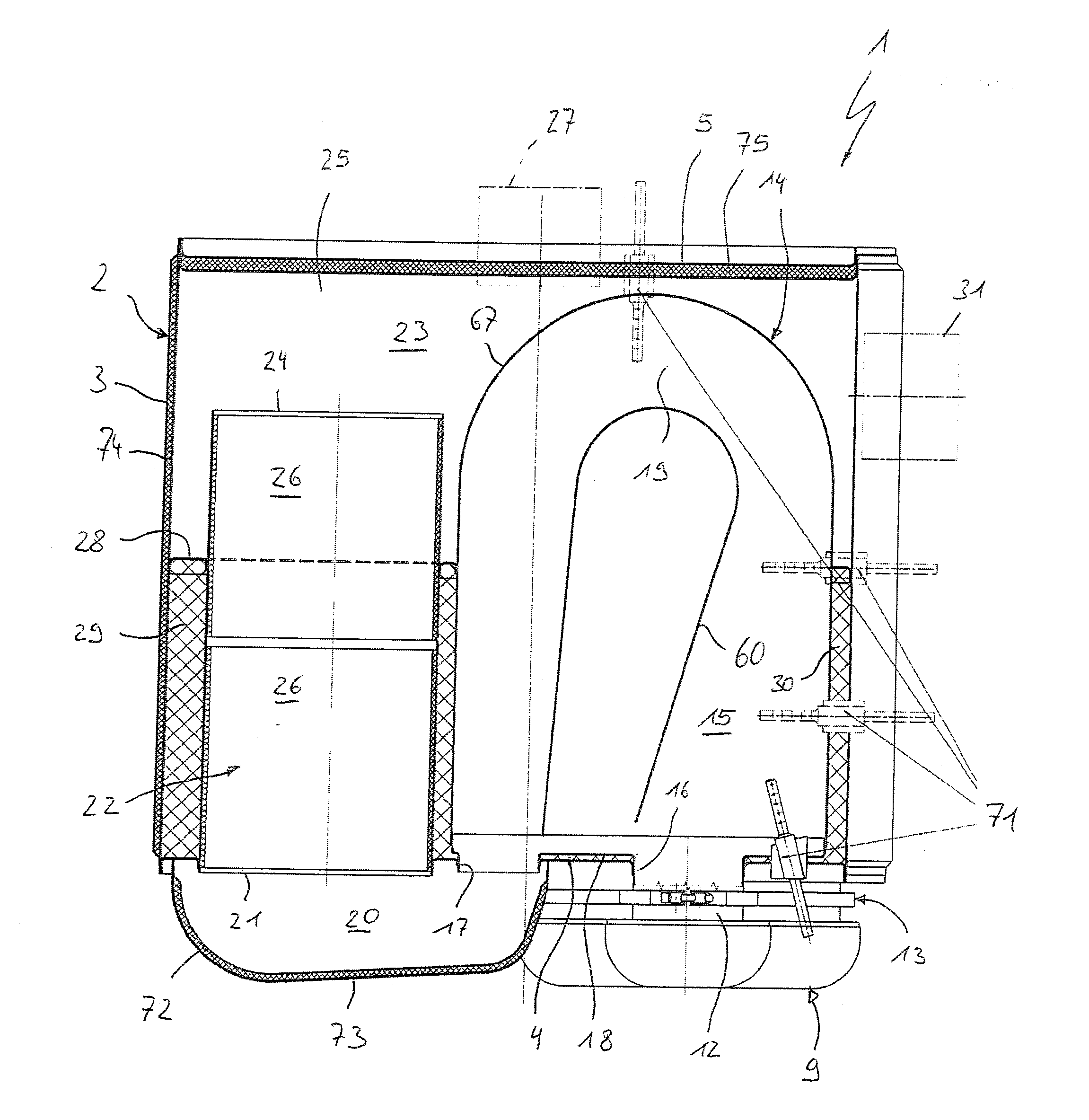

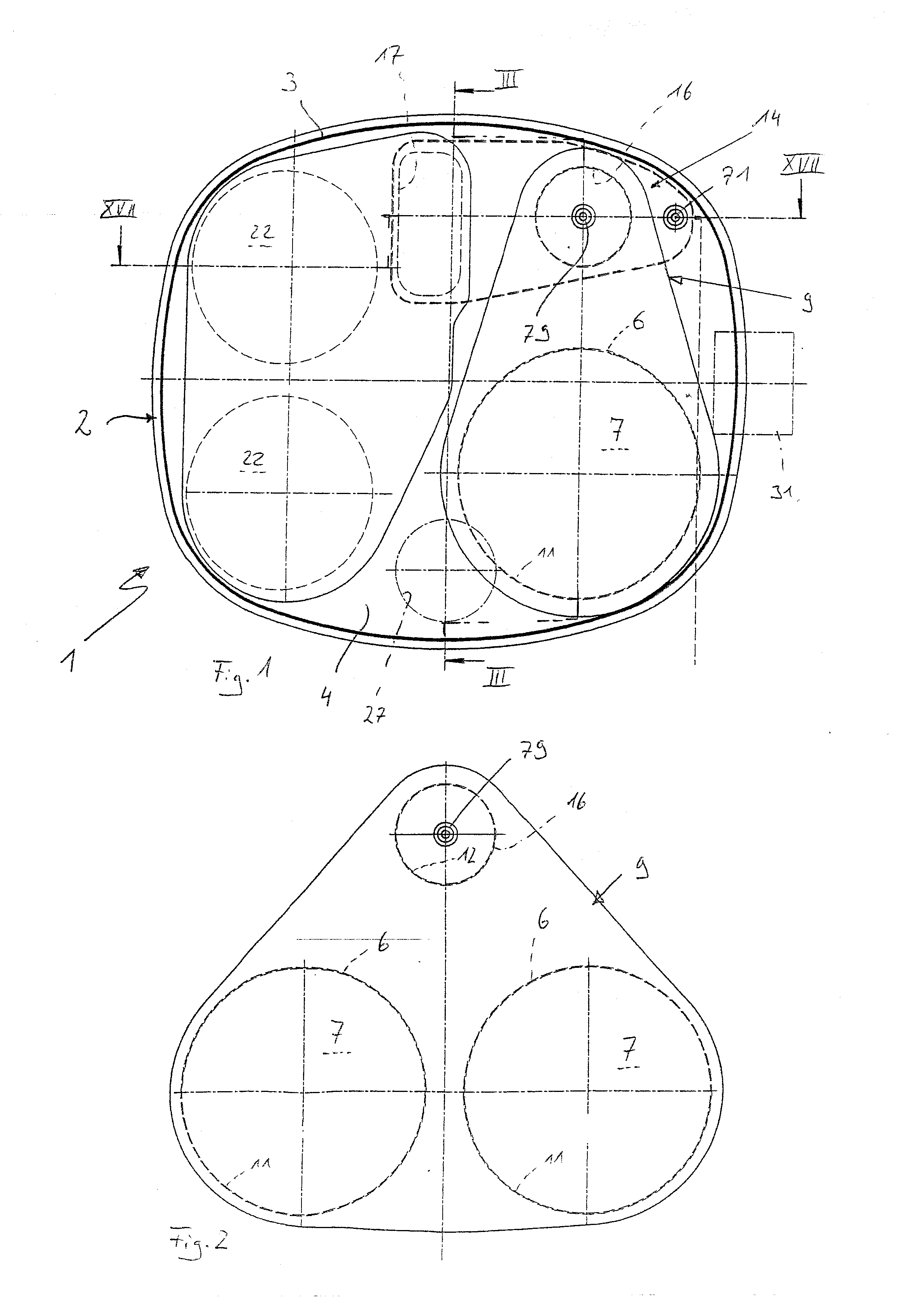

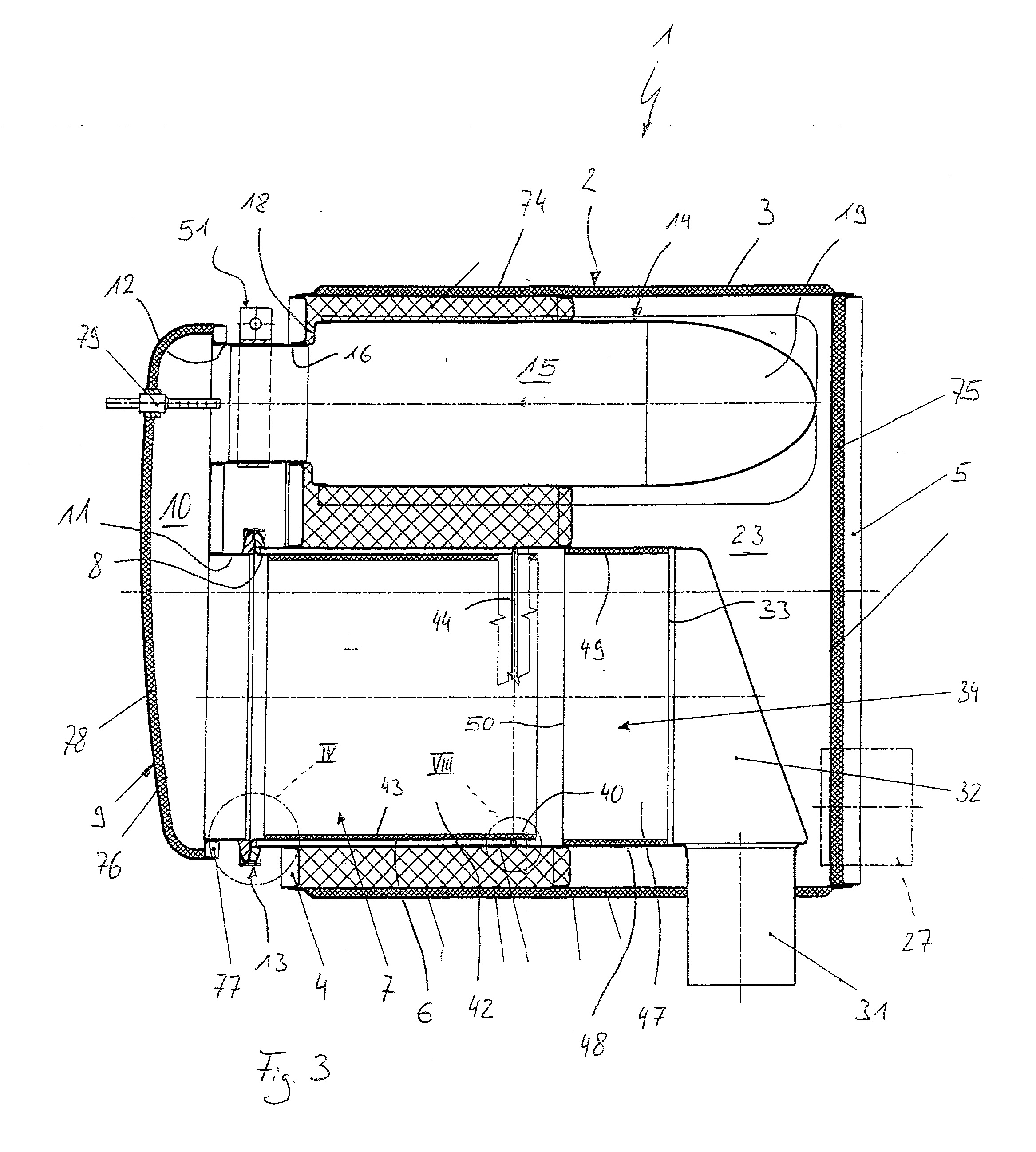

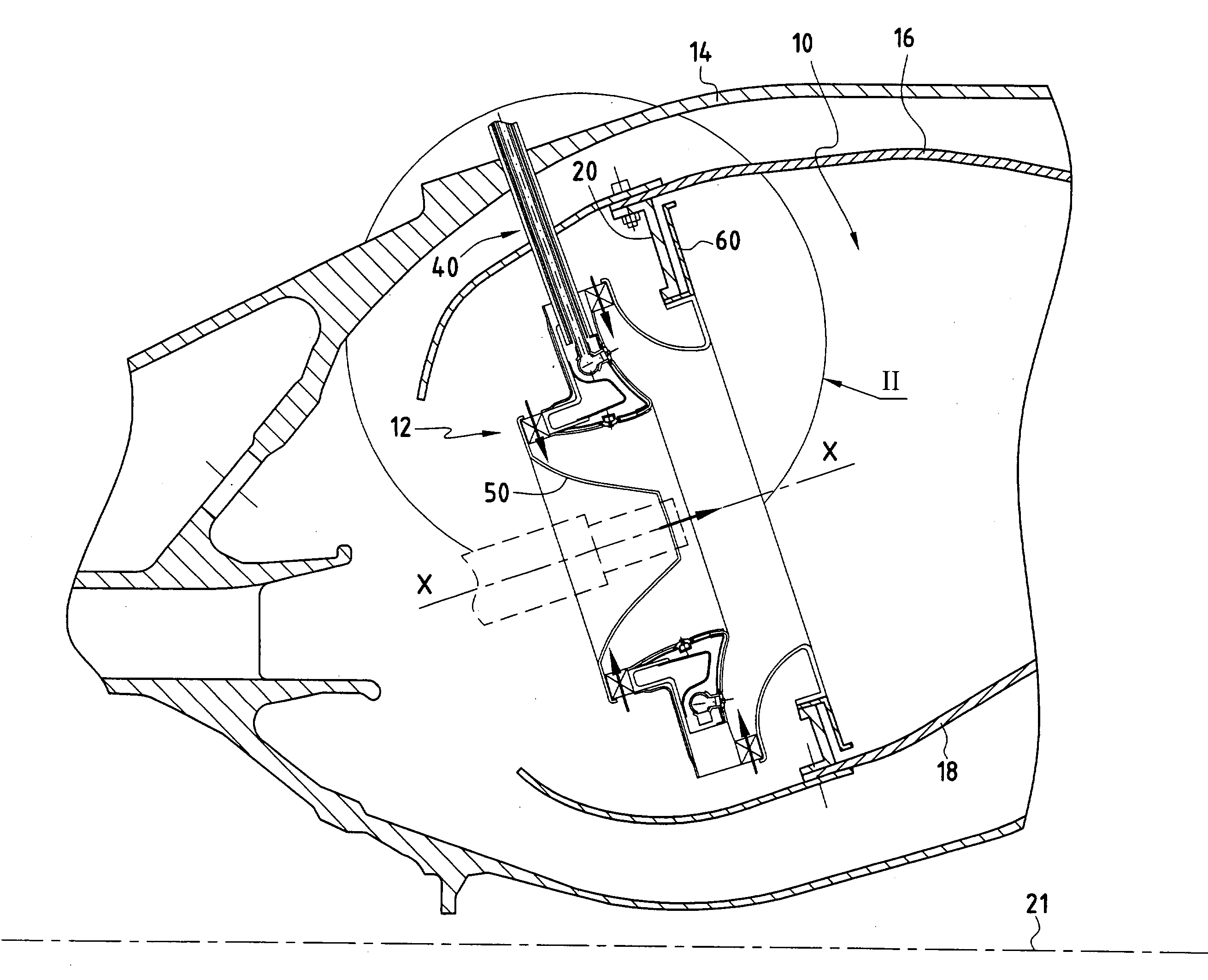

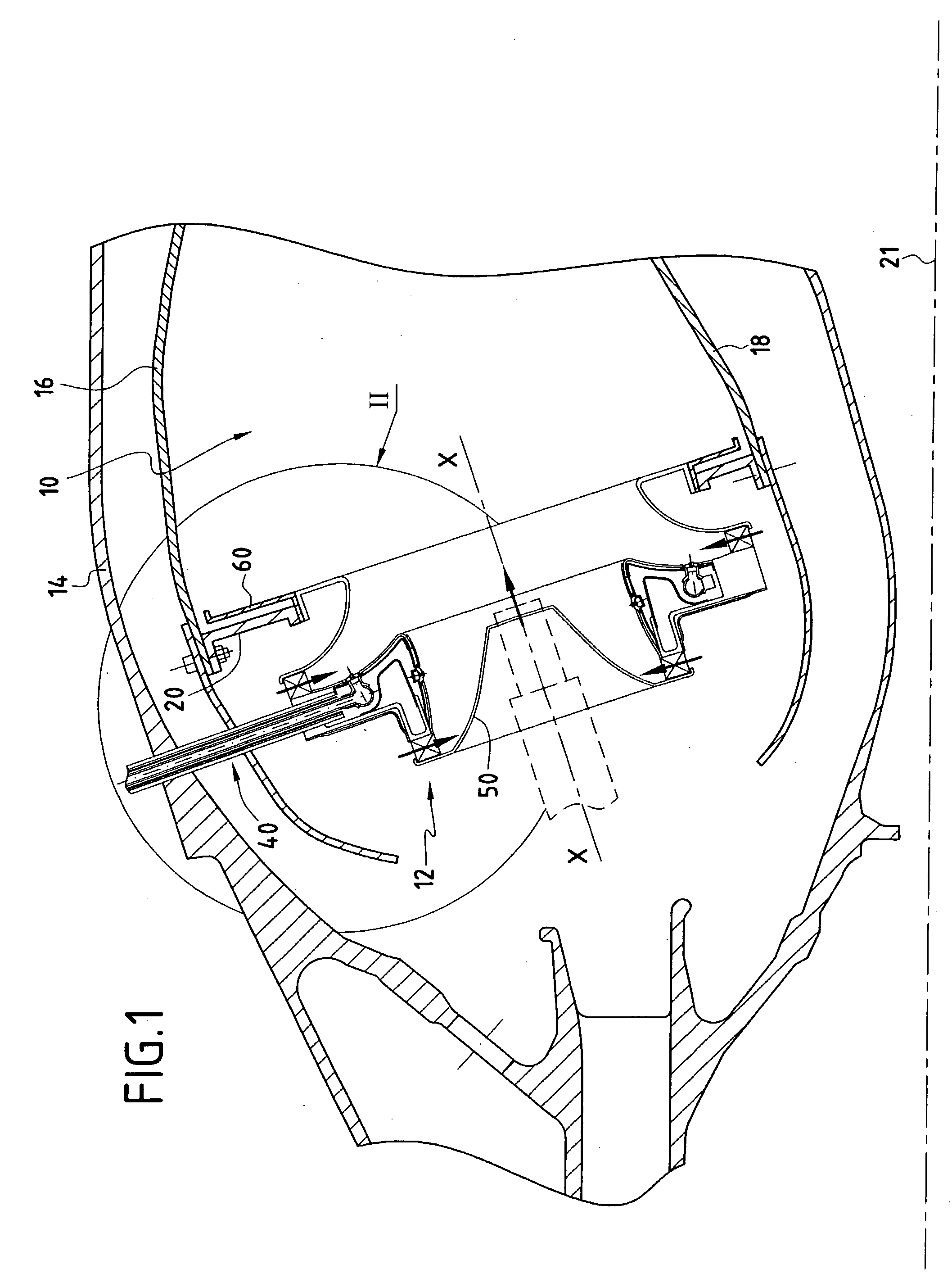

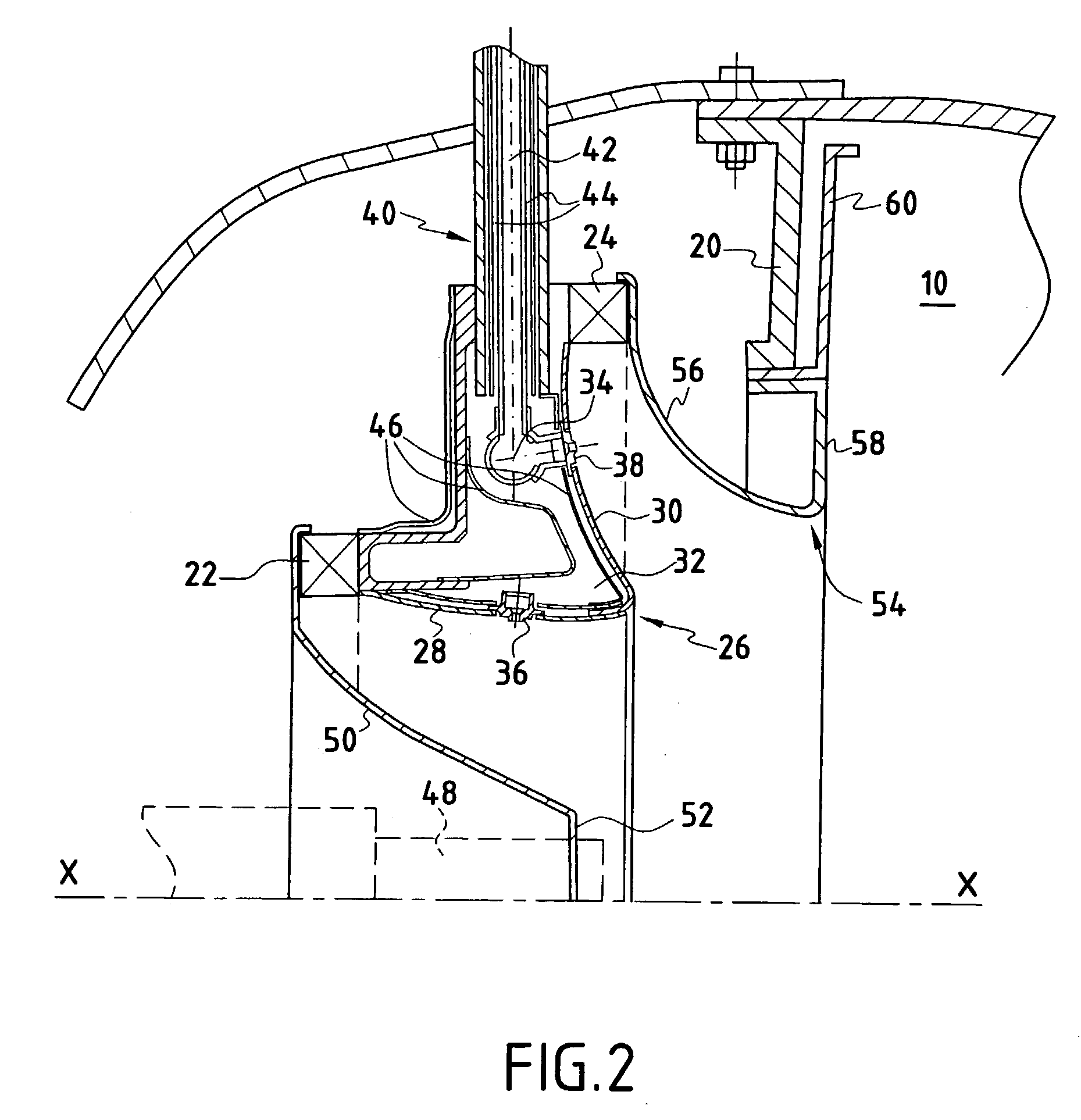

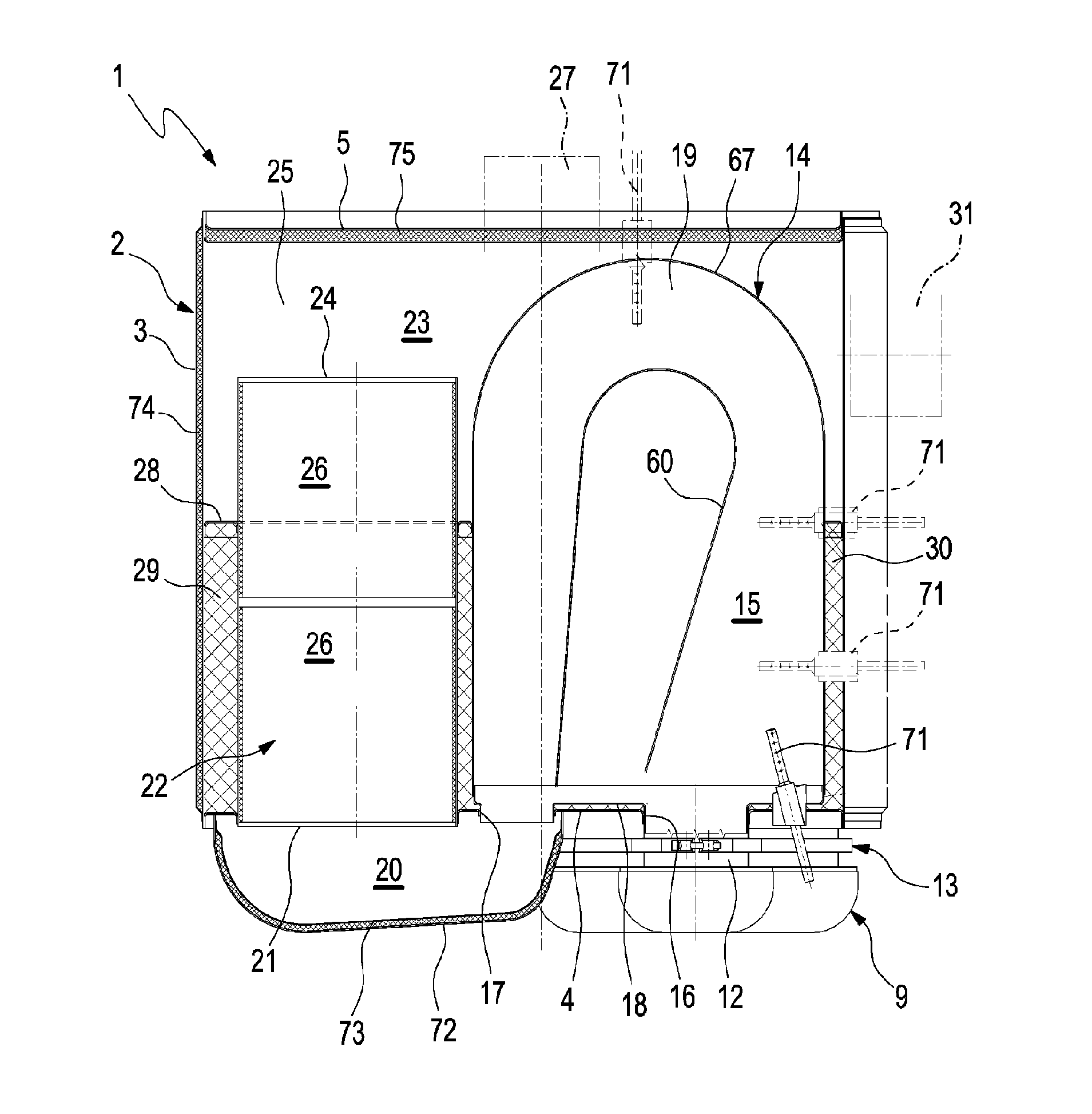

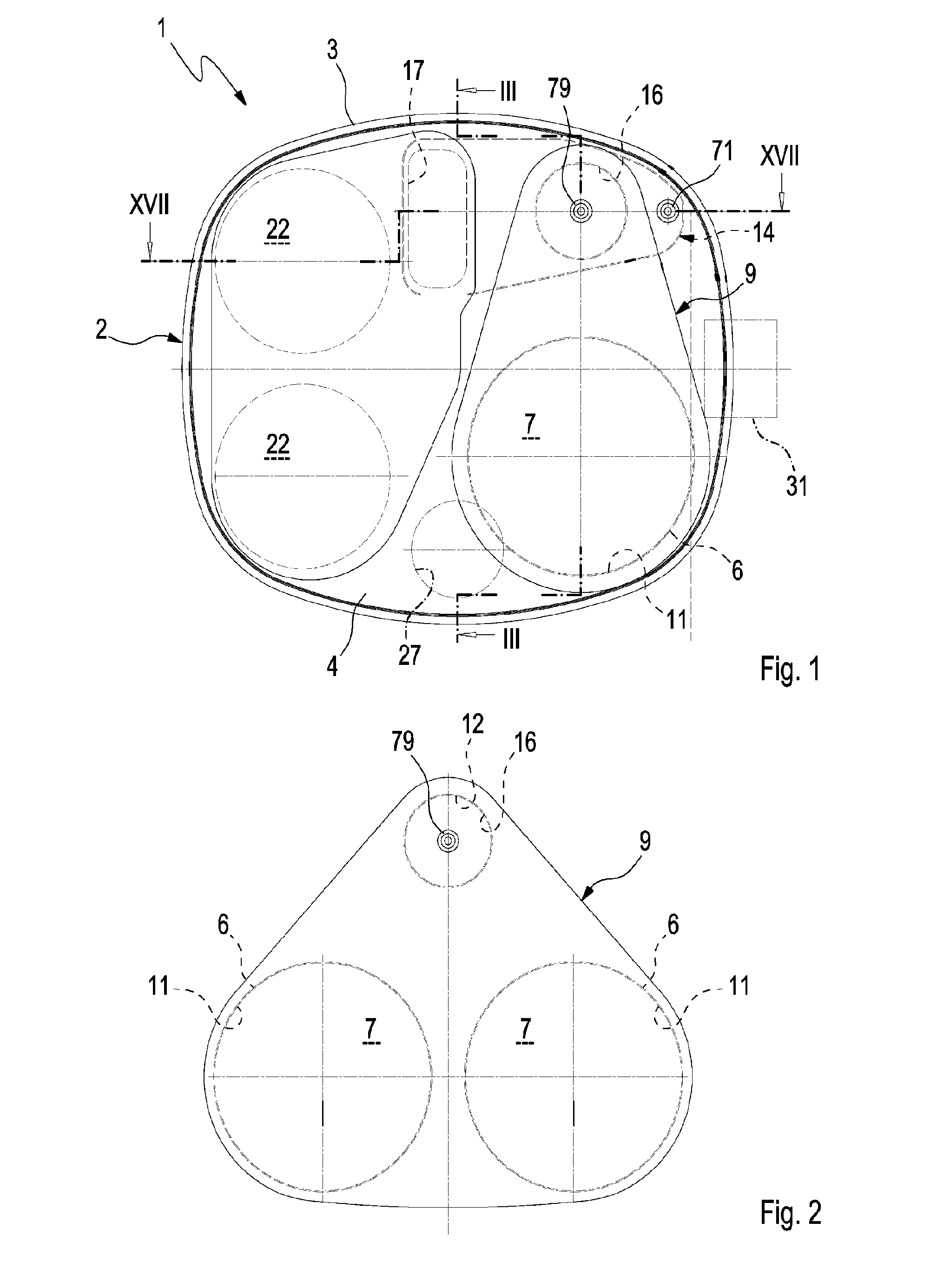

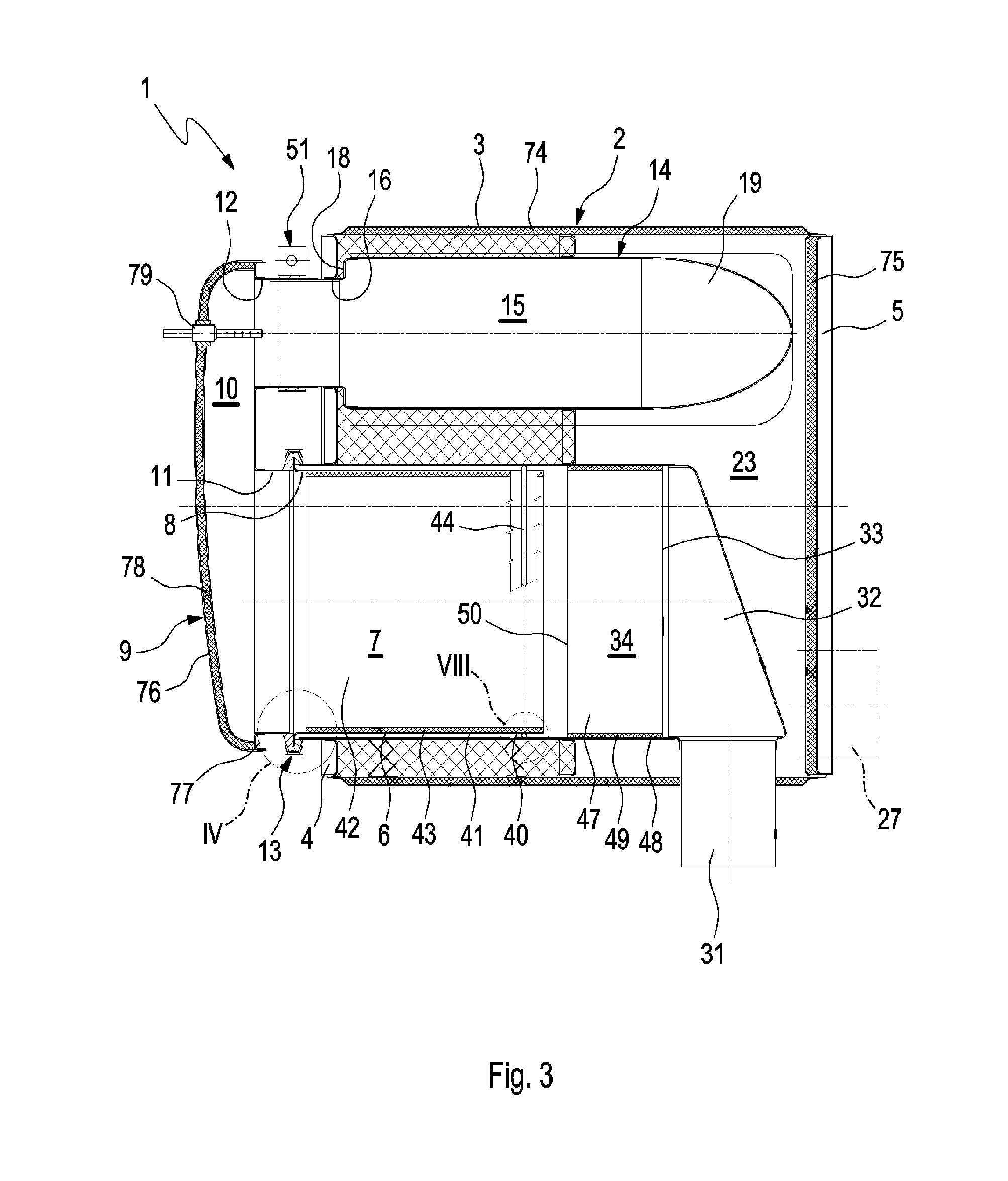

Exhaust gas-treating device

ActiveUS20100242451A1Improve homogenizationSpeed up evaporationInternal combustion piston enginesSilencing apparatusInterior spaceExhaust fumes

An exhaust gas-treating device (1) for an exhaust system of an internal combustion engine, especially of a motor vehicle, is provided with a housing (2), which has a jacket (3) extending circumferentially on the side and at least one bottom (4). The homogenization of the exhaust gas flow is improved with a mixing housing (14), which is arranged in the interior space (23) of the housing (2) and which has a mixing chamber (15). An inlet (16) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15). An outlet (17) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15).

Owner:VOLVO LASTVAGNAR AB +1

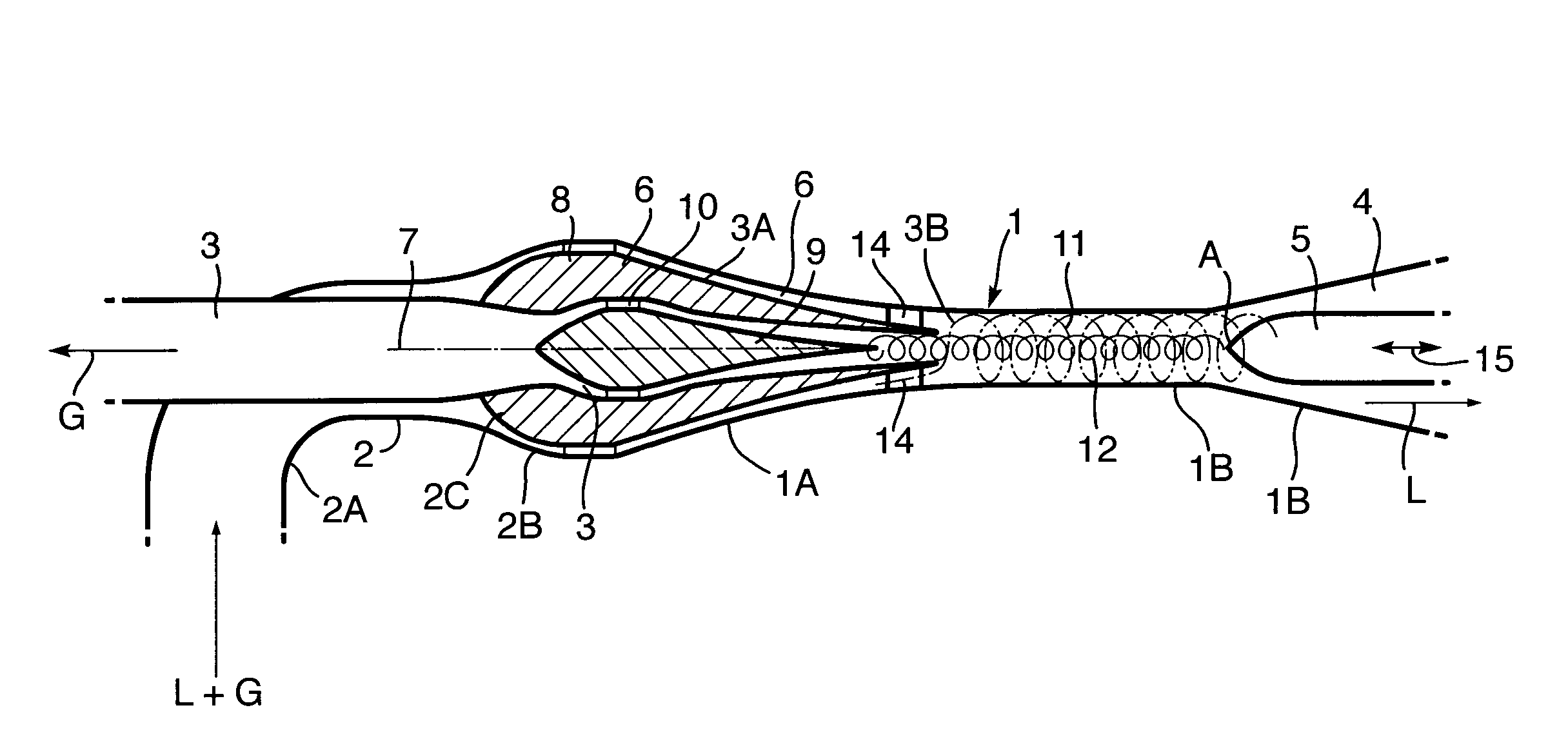

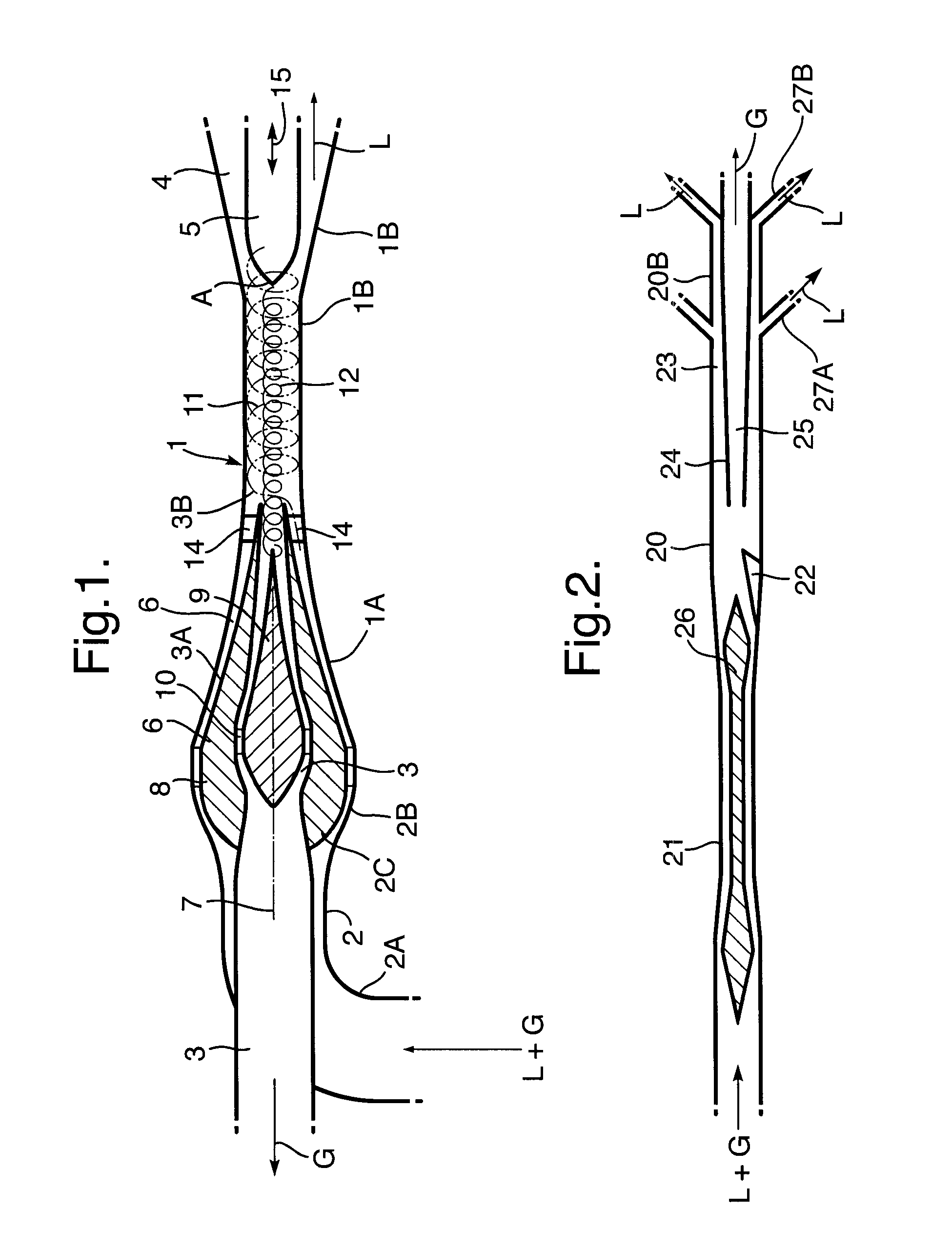

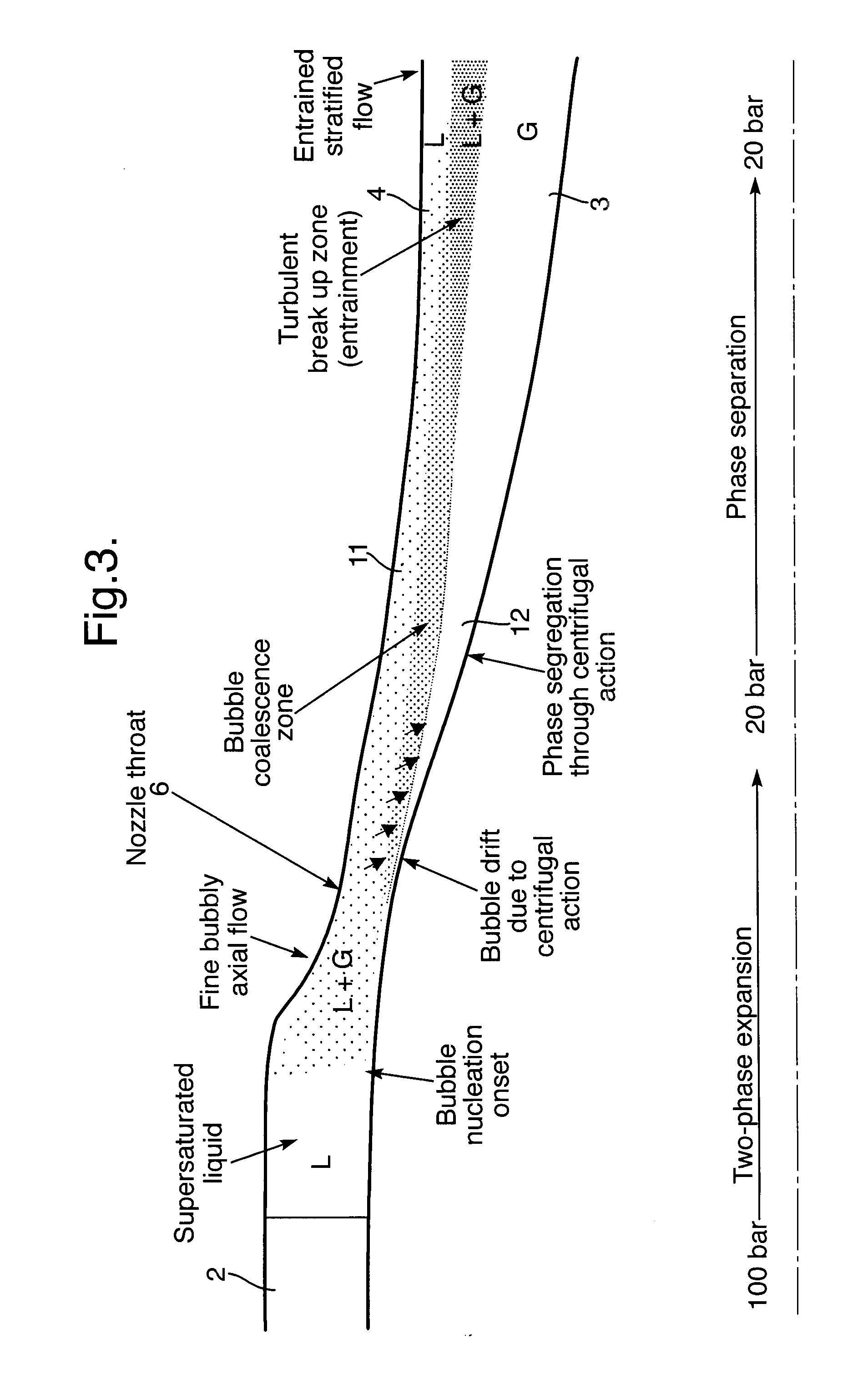

Cyclonic liquid degassing separator and method for degassing a fluid mixture

ActiveUS20090205488A1Reduce static pressureLow speed of soundLiquid degasificationReversed direction vortexEvaporationProduct gas

A method and cyclonic separator are disclosed for degassing a fluid mixture comprising a carrier liquid and gaseous and / or vaporizable components, wherein: the fluid mixture is accelerated in a throat section (6, 21) of a vortex tube (1, 20) such that the static pressure of the fluid mixture is decreased and vaporizable components evaporate into a gaseous phase and the fluid mixture flows as a substantially homogeneously dispersed gas-liquid mixture through the throat section; the accelerated fluid mixture is induced to swirl within a tubular mid section of the vortex tube such that the fluid mixture is separated by centrifugal forces into a degassed liquid fraction and a gas enriched fraction; the degassed liquid fraction is induced to flow into a annular liquid outlet conduit (4, 21); and the gas enriched fraction is induced to flow into a central gas outlet conduit (3, 24). An advantage of inducing the fluid mixture to flow as a substantially homogeneously dispersed gas-liquid mixture through the throat section is that the velocity of sound in such a mixture is low, thereby increasing the Mach number and the pressure reduction in the throat section and enhancing evaporation of gas bubbles in the mixture.

Owner:SHELL OIL CO

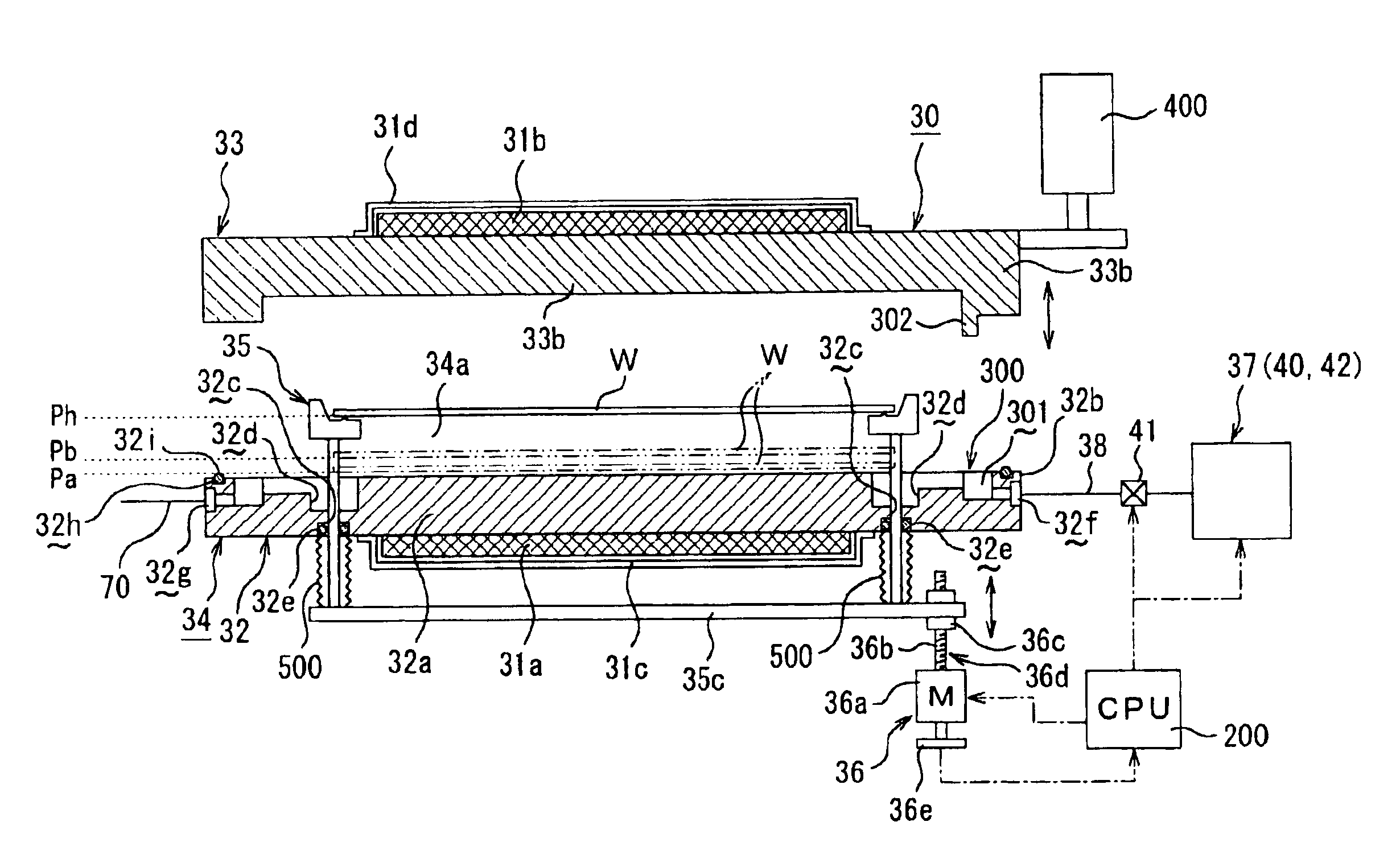

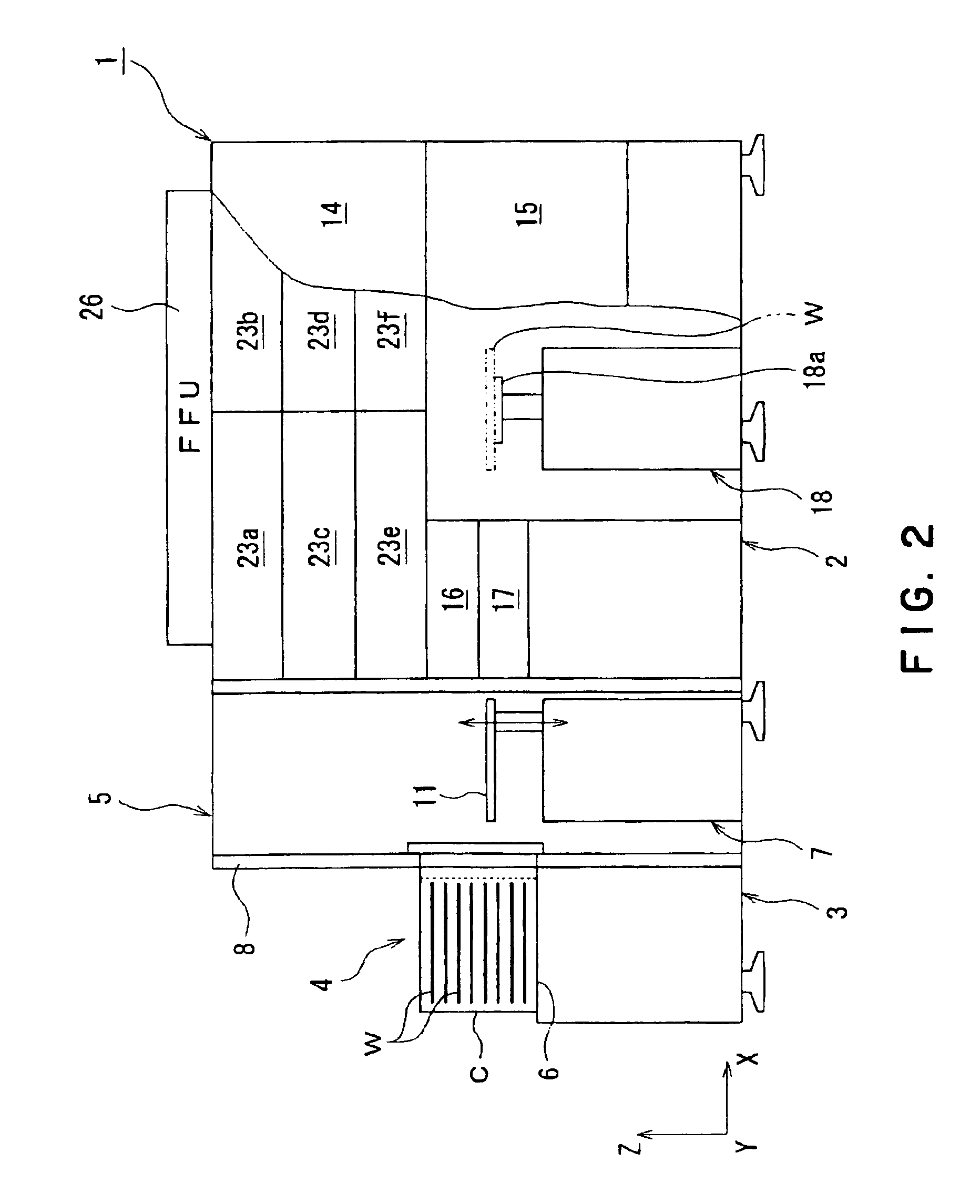

Substrate processing method and apparatus

ActiveUS6954585B2Uniform processingUniform supplyDrying solid materials with heatMuffle furnacesEngineering

A method for heating a wafer to a predetermined temperature, the wafer being held by a holding unit and being accommodated in a processing container equipped with a heater. The wafer is heated to a processing temperature while positioning the wafer at an adjacent position that results form making the wafer approach the heating surface of the heater. After heating the wafer to the predetermined temperature, the wafer is separated from the flat bottom surface of the container body to a processing position. In this state, a processing chamber of the processing container is supplied with a processing fluid, while the holding unit and the heater are relatively moved close to and apart from each other intermittently or continuously. Accordingly, it is possible to quickly heat the substrate to a processing temperature while supplying the substrate with the processing fluid uniformly. This improves throughout and the homogenization in processing.

Owner:TOKYO ELECTRON LTD

Multimode system for injecting an air/fuel mixture into a combustion chamber

InactiveUS20040025508A1Controlling the riskMitigate such drawbackContinuous combustion chamberGas turbine plantsCombustion chamberInjection air

The invention provides an injection system for injecting an air / fuel mixture into a combustion chamber of a gas turbine engine, the injection system having a longitudinal axis and comprising fuel injection means, interposed between first and second air injection means, the fuel injection means being disposed in an annular internal cavity of a Venturi, the fuel injection means comprising at least a first fuel admission circuit provided with at least one fuel injection orifice, and a plurality of second fuel admission circuits independent from the first fuel admission circuit(s), each being provided with at least one fuel injection orifice so as to define a plurality of independent modes of injecting the air / fuel mixture depending on determined operating speeds of the engine, the fuel injection orifice of the first fuel admission circuit being formed in the upstream wall of the Venturi so as to inject fuel towards the combustion chamber in a general direction that is substantially perpendicular to a flow of air coming from the first air injection means, and the fuel injection orifices of the second fuel admission circuits being formed in the downstream wall of the Venturi so as to inject fuel towards the combustion chamber in a general direction that is substantially perpendicular to a flow of air coming from the second air injection means.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Warm white lighting device

ActiveUS8231250B2Extended service lifeImprove color mixingNon-electric lightingPoint-like light sourcePhosphorEffect light

The present invention relates to warm white light engines including combinations of blue, cyan, and red, red-orange, or amber emitters and one or more phosphors that produce a white light pleasing to the human eye through the use of improved color uniformity and improved collimation of light. Specifically, a micro-lenslet array having an optimized surface is used to disperse light from the light emitter; an innercollimation lens having an optimized cross-sectional shape and micro-ridges is used to disperse light; a TIR reflector having an optimized cross-sectional shape and micro-ridges is used to disperse and redistribute phase as well as provide collimation; and a final micro-lenslet layer includes optimized lenslet design placement and randomization factor to homogenize light to produce a uniform warm white light.

Owner:LIGHTING SCI GROUP

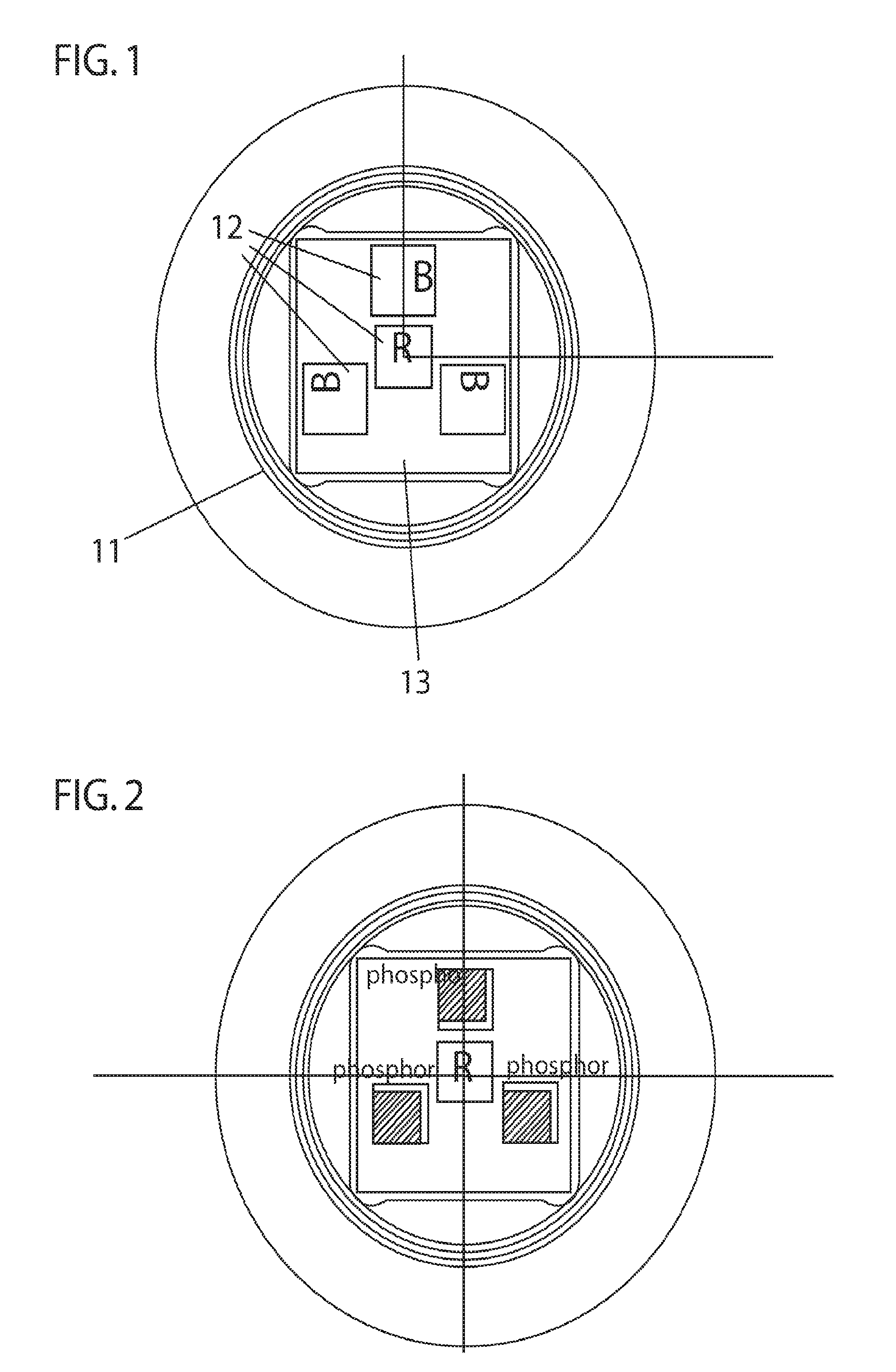

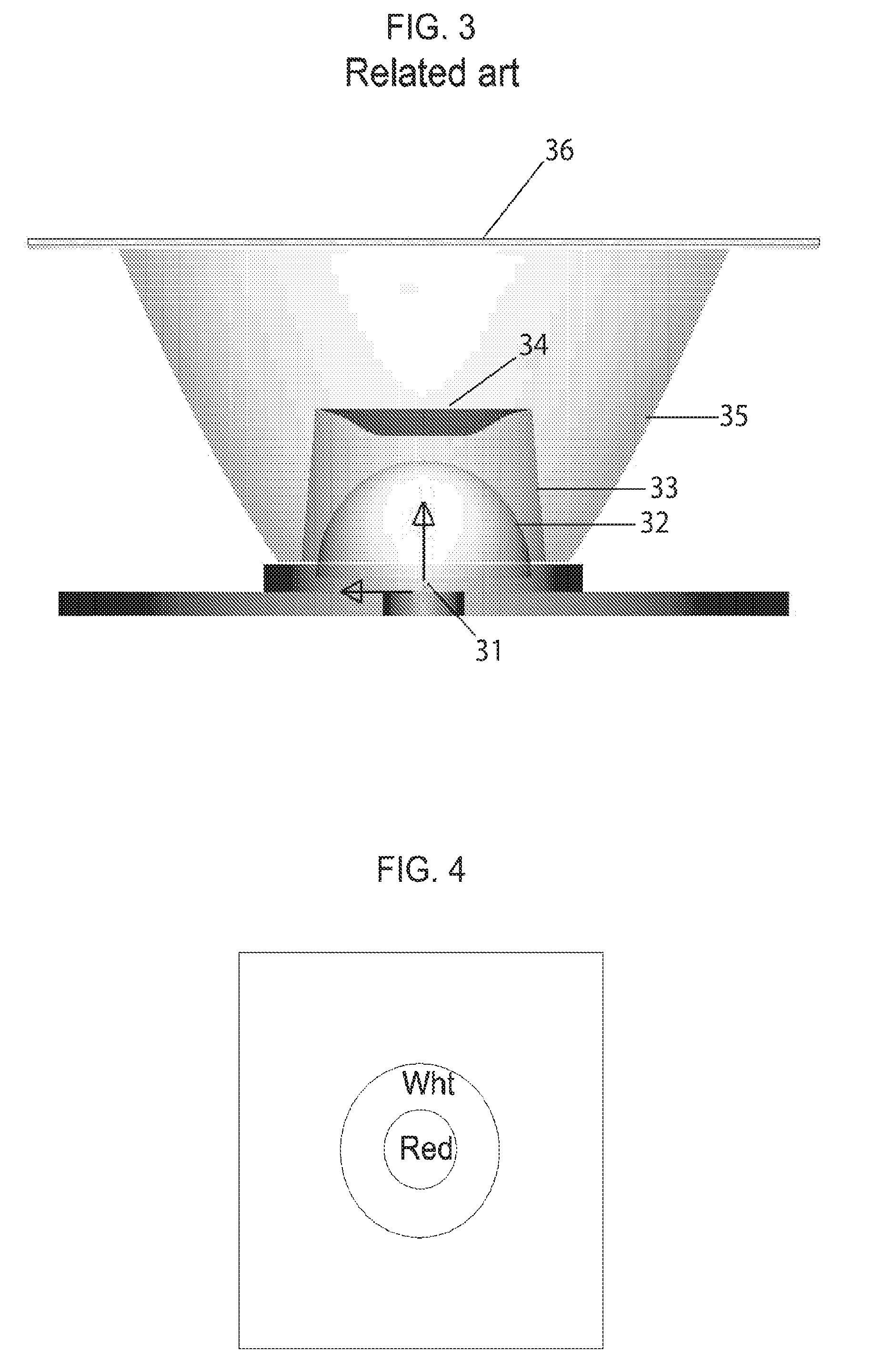

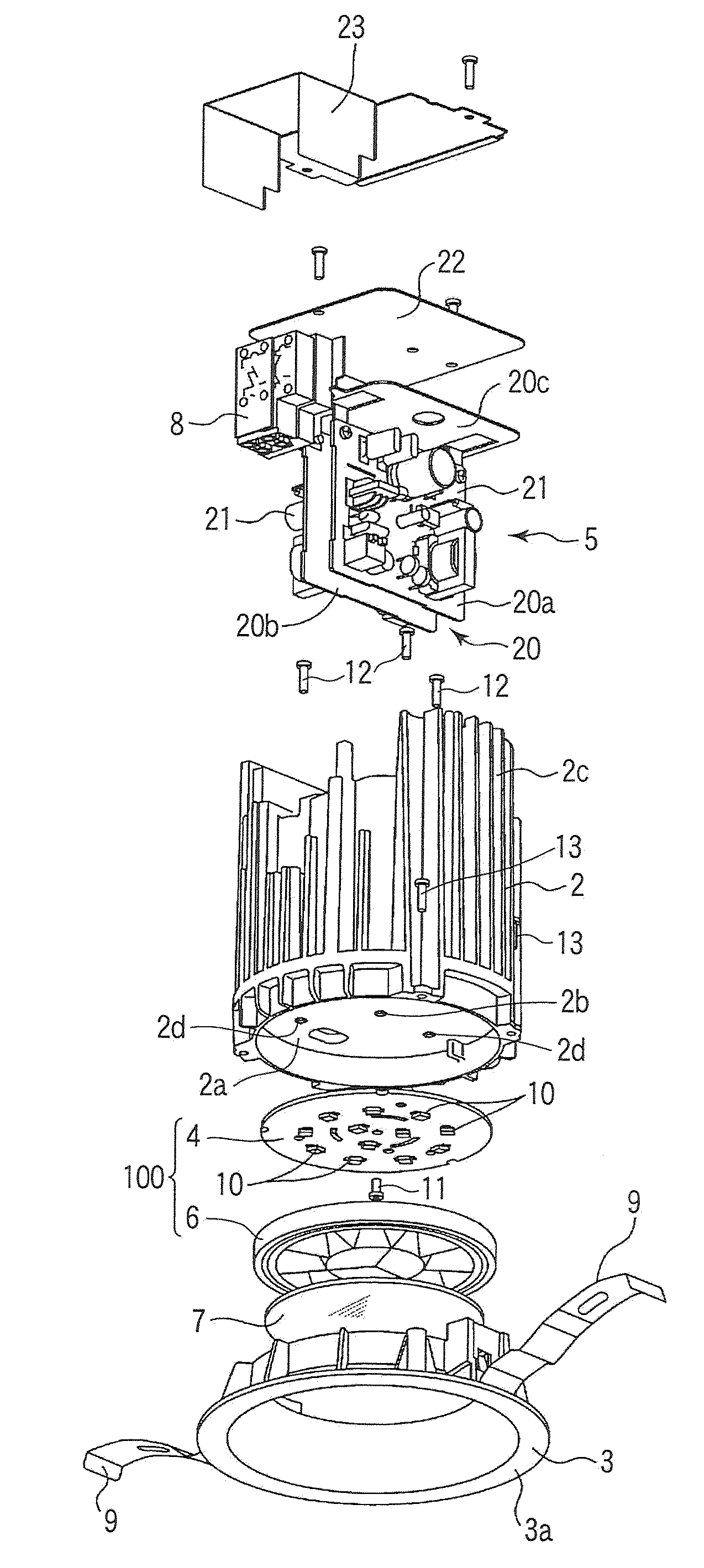

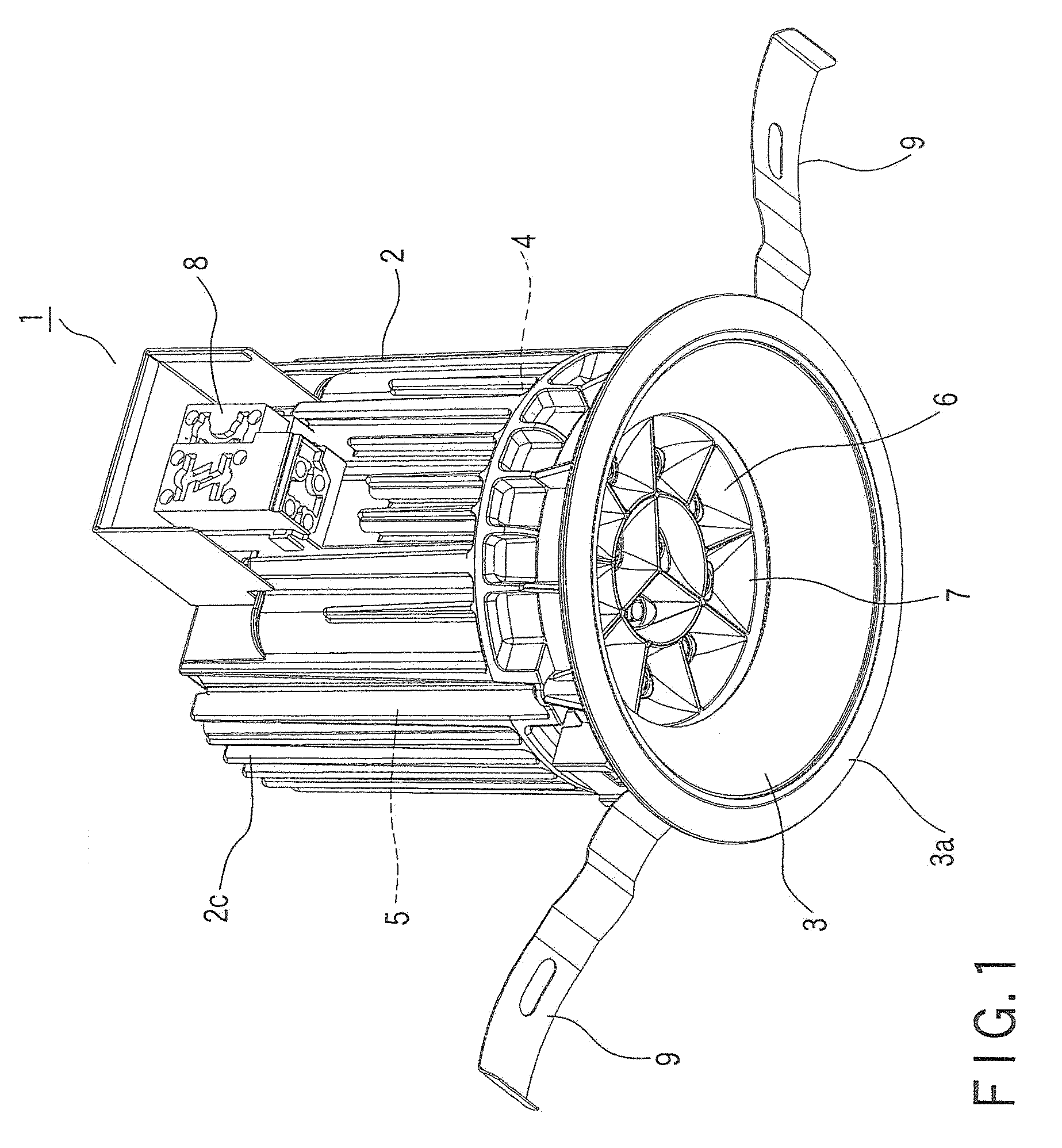

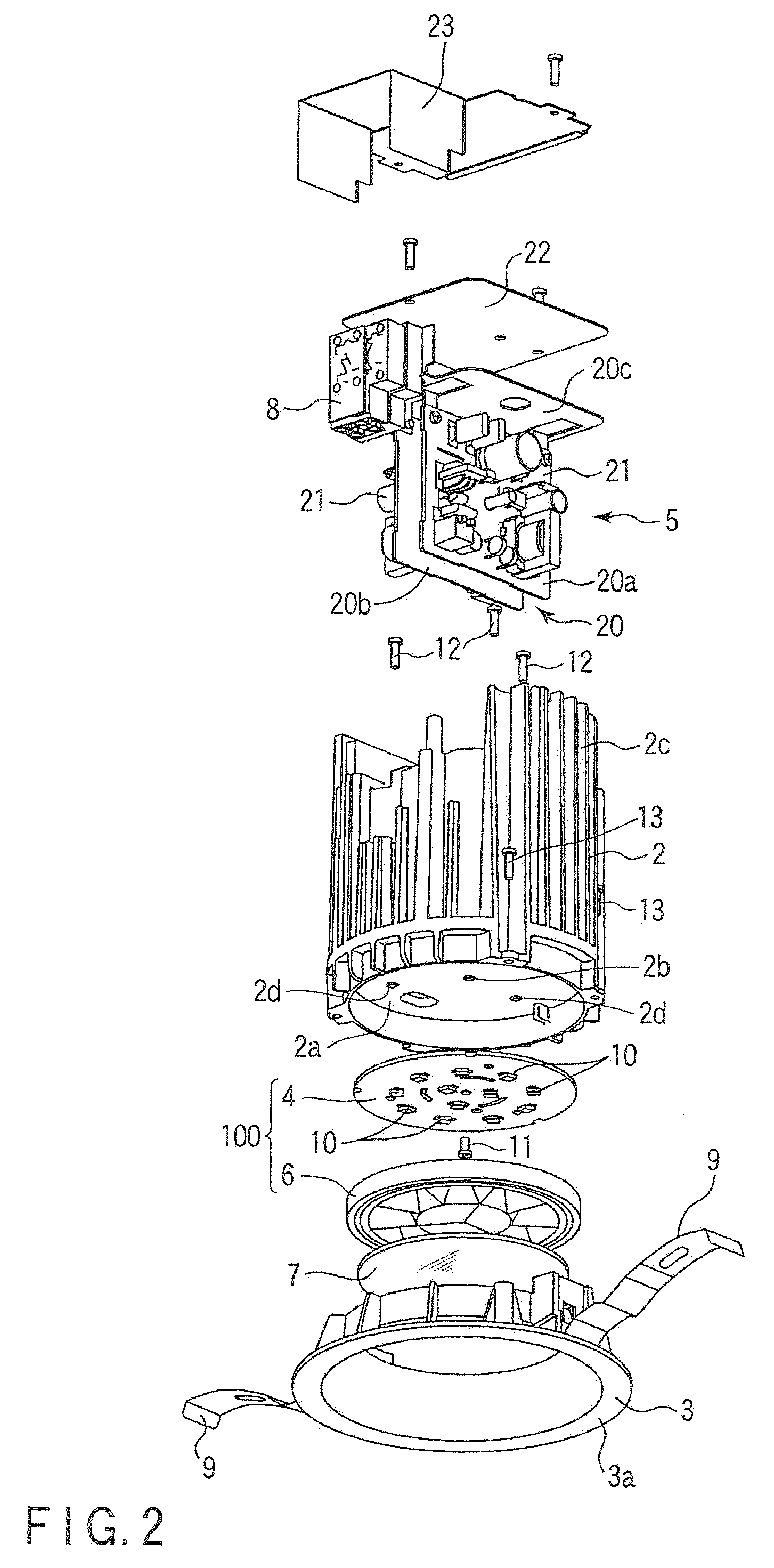

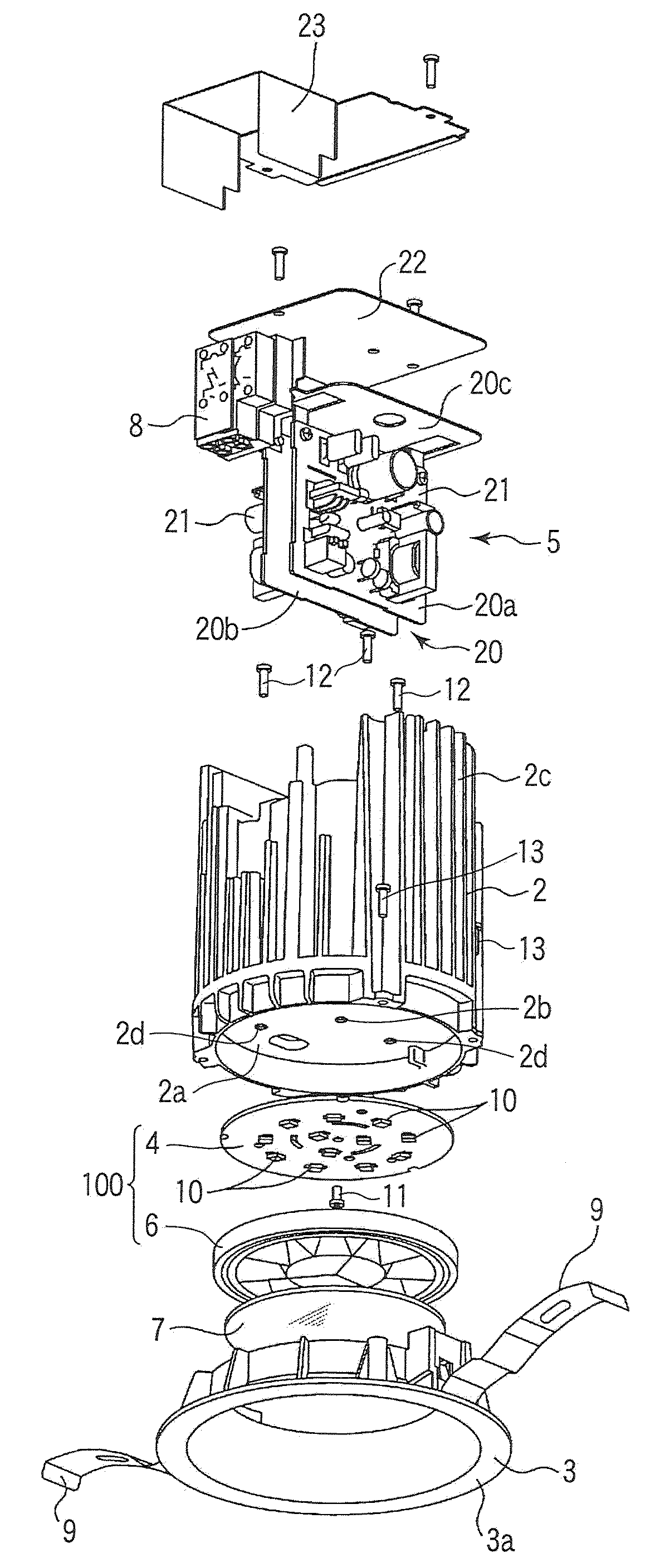

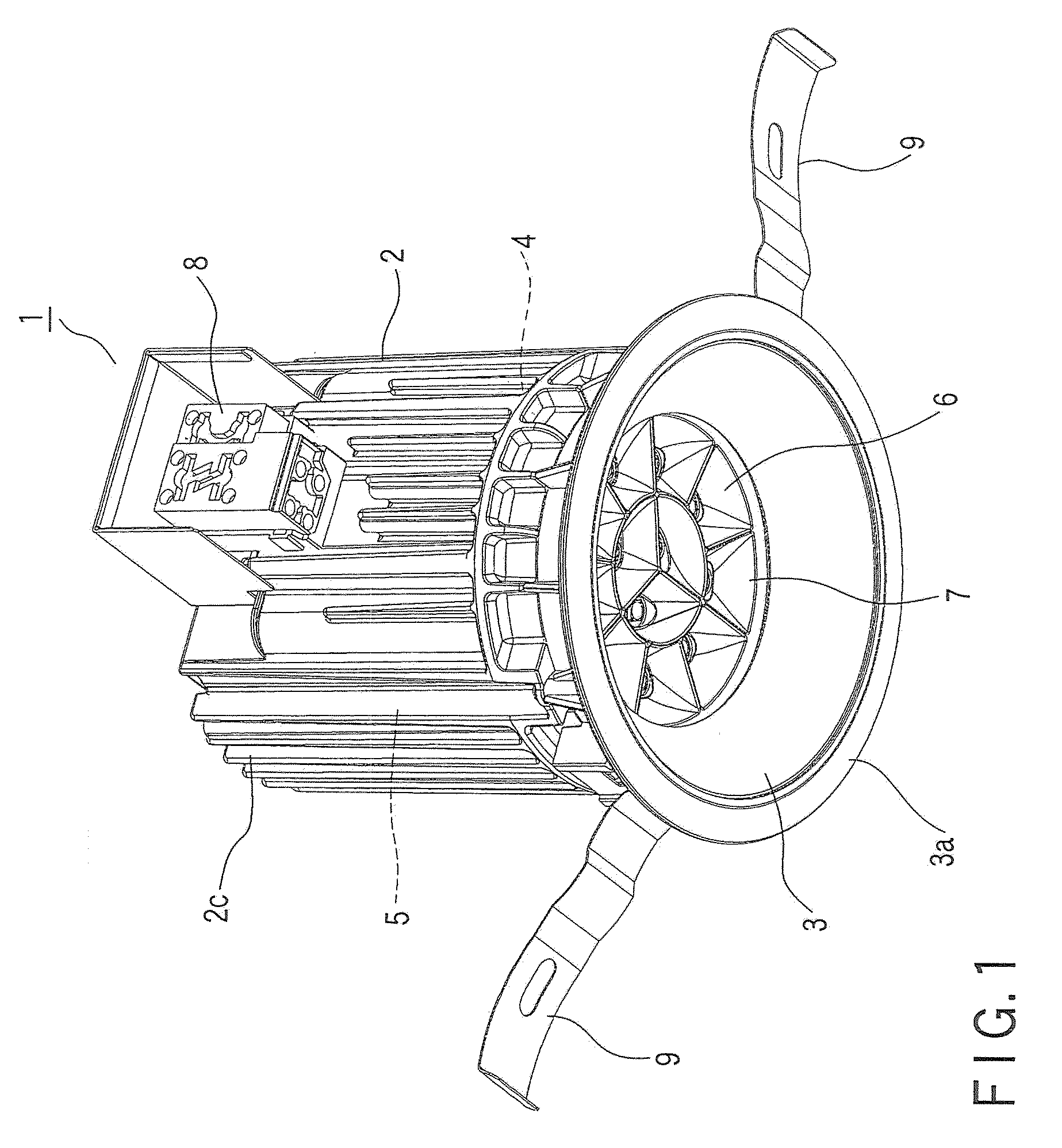

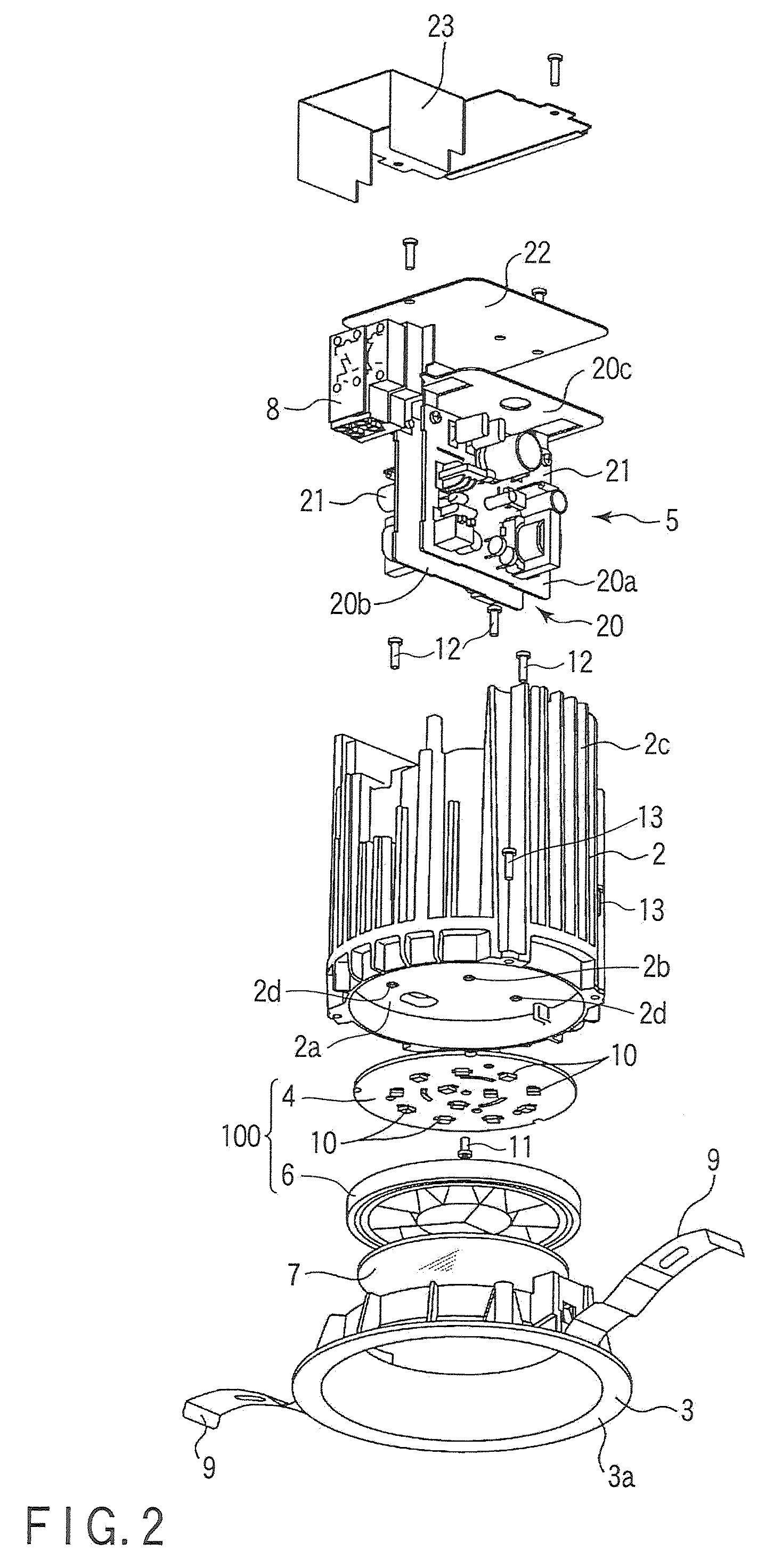

Light source unit and lighting apparatus having light-emitting diodes for light source

InactiveUS8128263B2Improve homogenizationPoint-like light sourceLighting support devicesEngineeringThermal radiation

Owner:TOSHIBA LIGHTING & TECH CORP

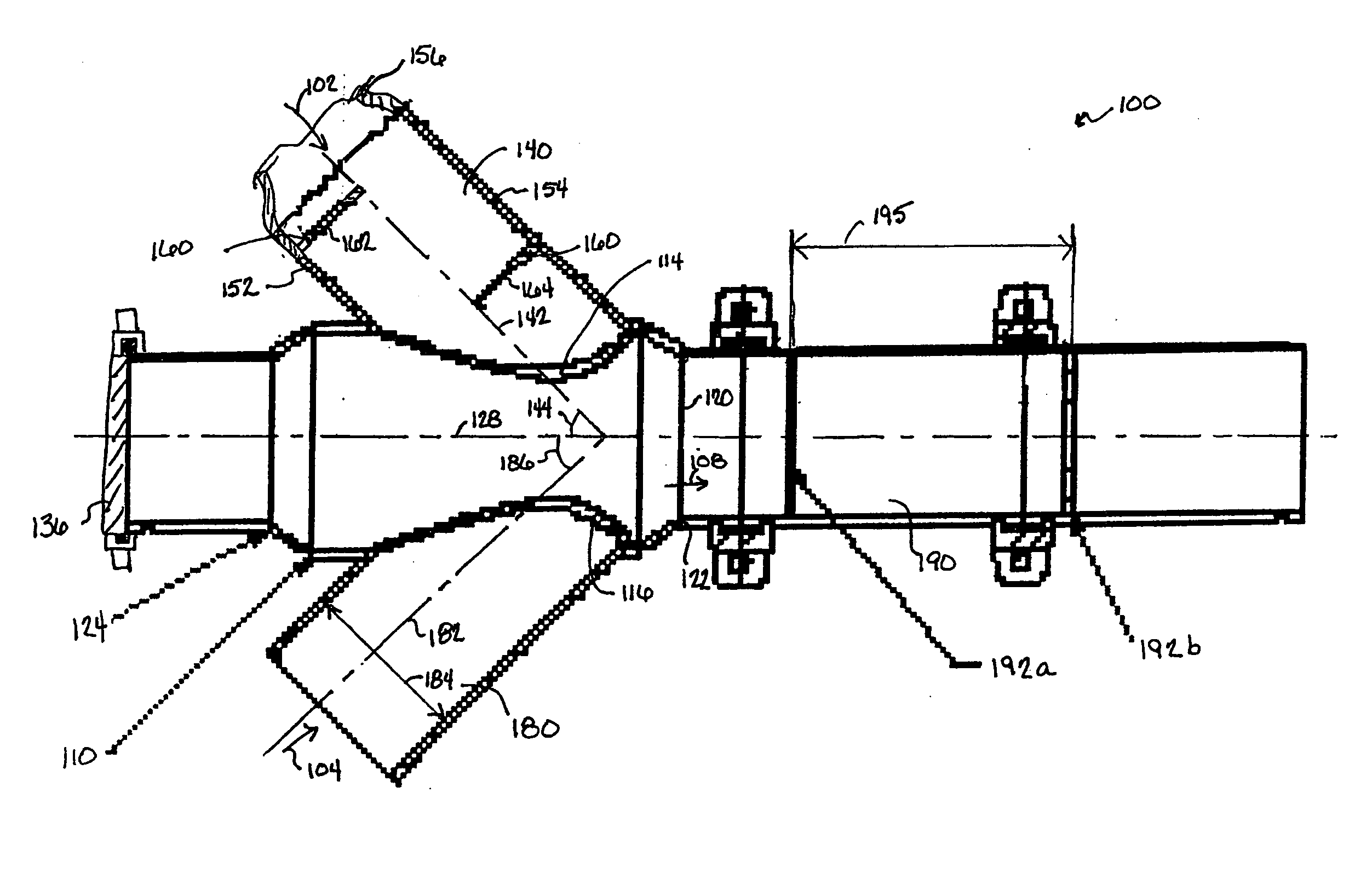

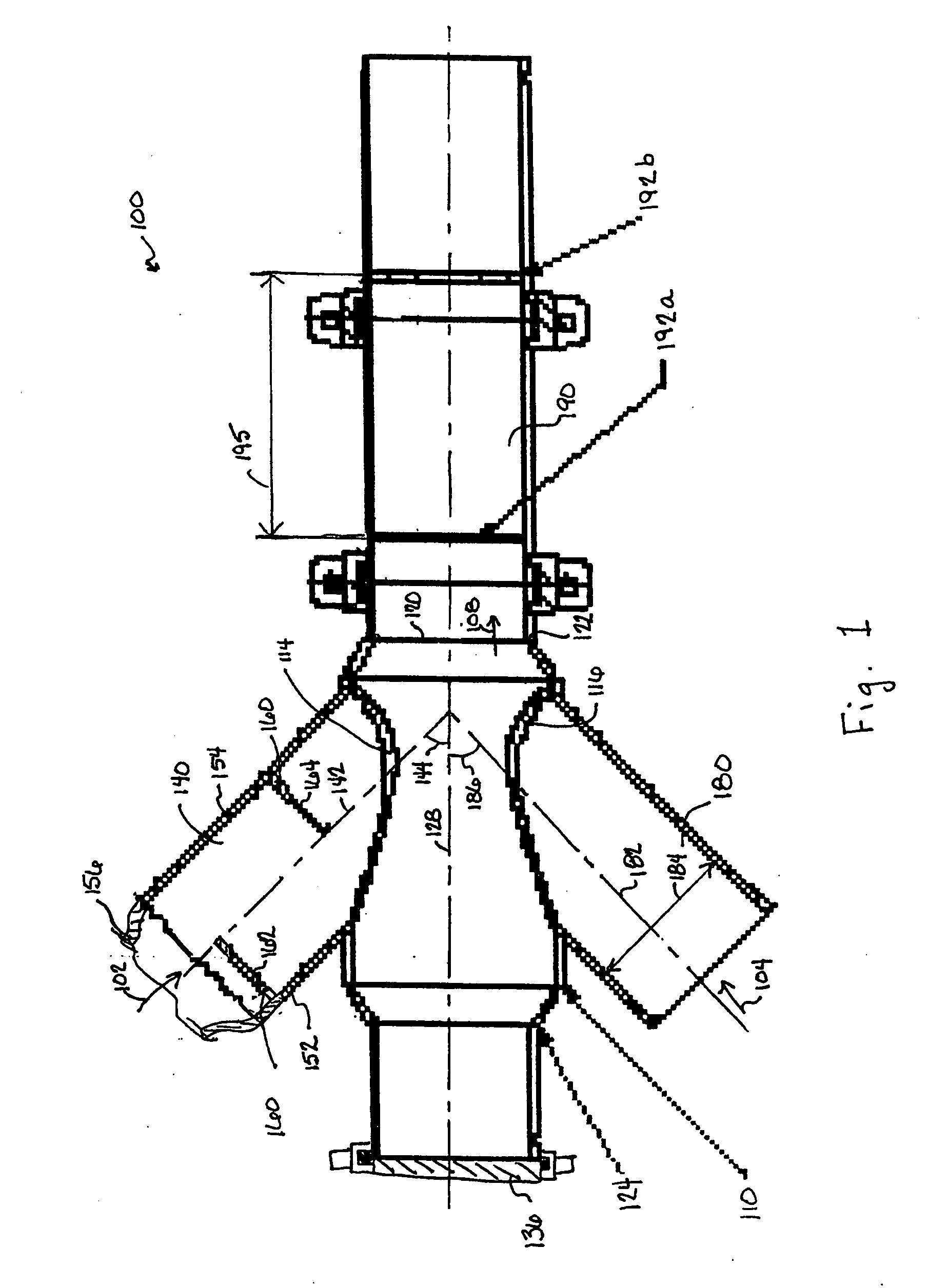

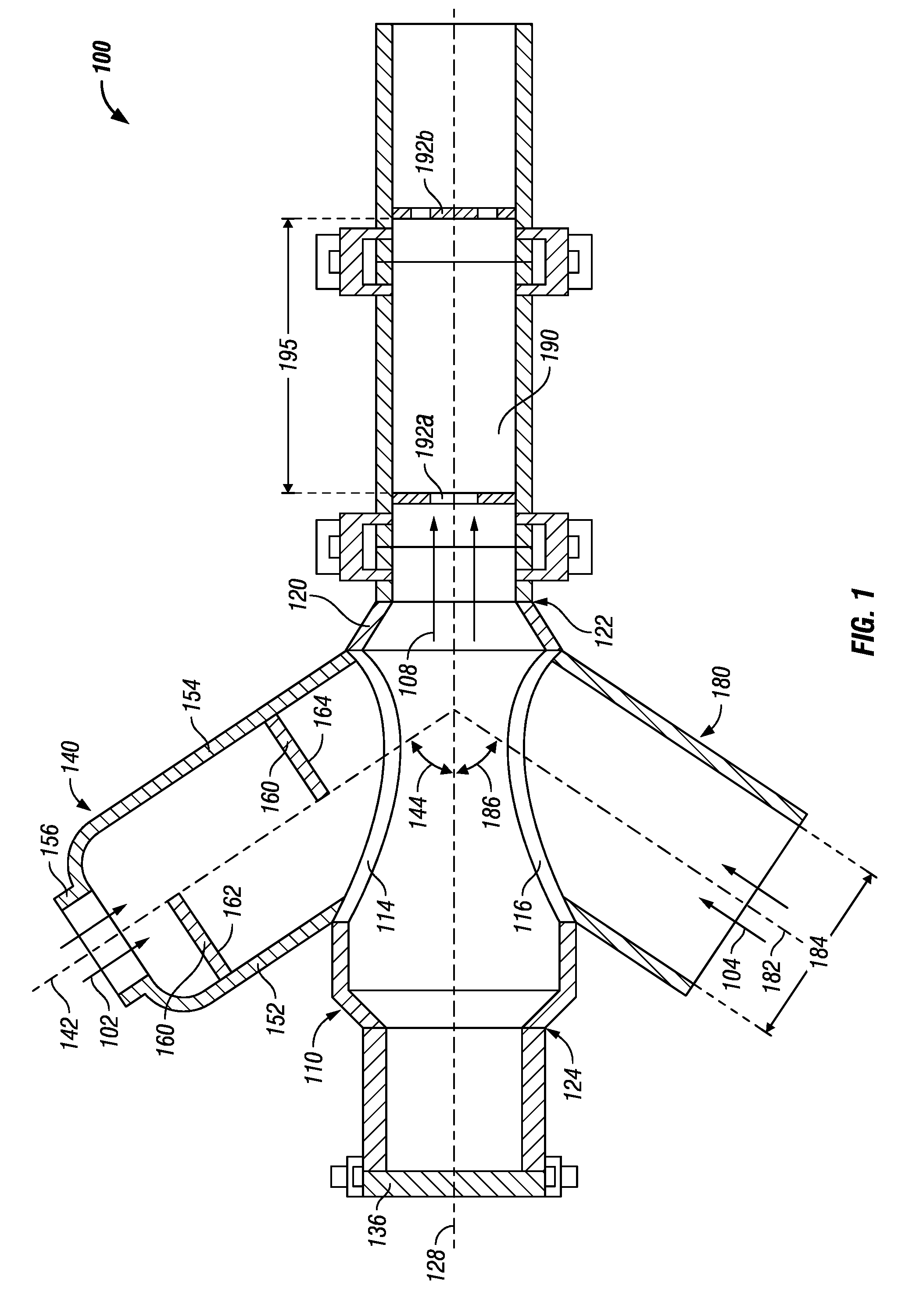

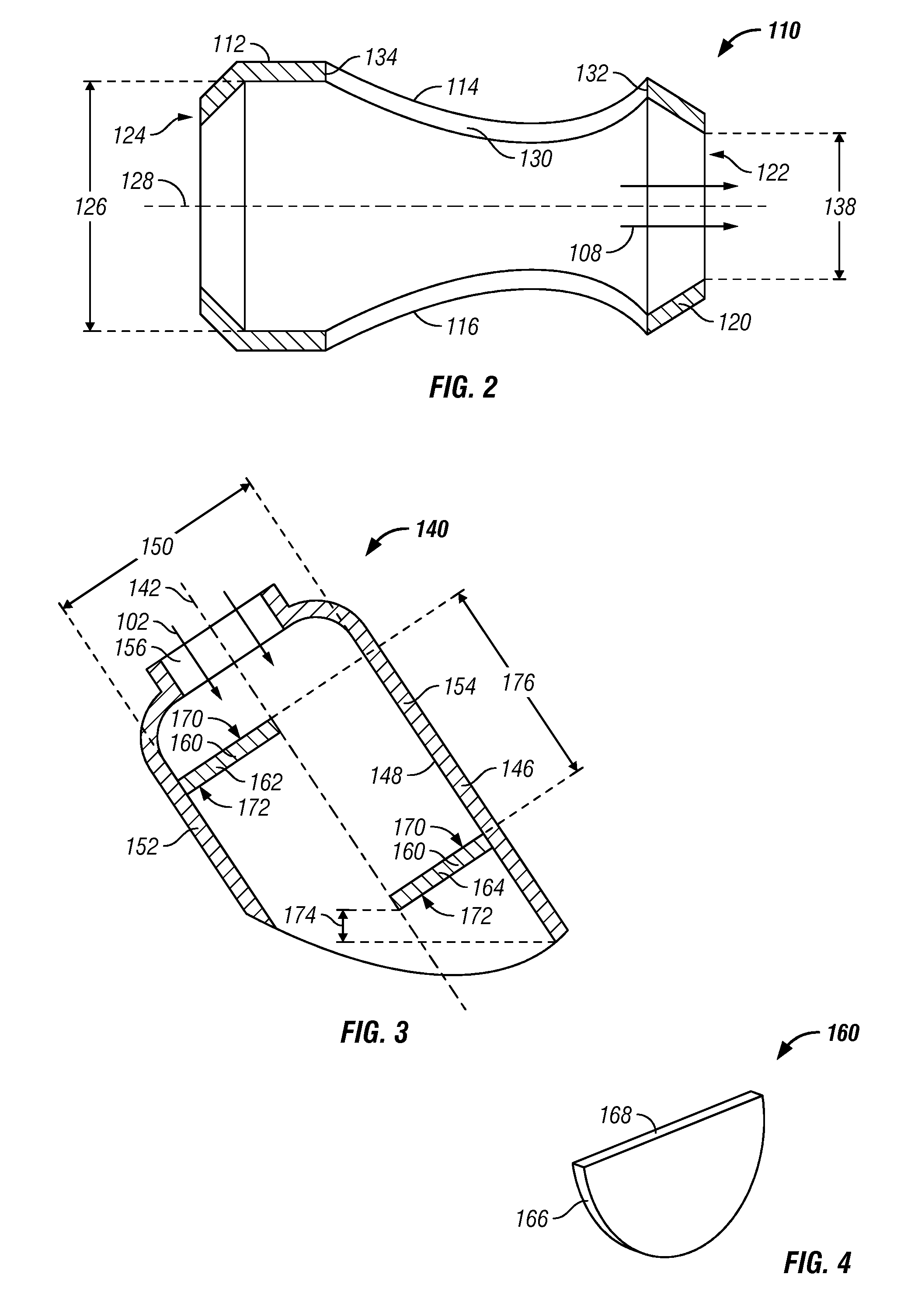

Apparatus and method for homogenizing two or more fluids of different densities

InactiveUS20060056271A1Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingHigh densityVolumetric Mass Density

An apparatus for blending two or more fluid streams, wherein a first fluid has a higher density than the other fluids, includes a first fluid director and at least a second fluid director providing fluid communication of a first and second fluid stream, respectively, to a primary mixing chamber. The first fluid director includes one or more baffles to disturb the first fluid stream and to direct it toward a rearward portion of the first inlet to the primary mixing chamber. A secondary blending chamber is in fluid communication with the primary chamber outlet and includes at least one, and preferably two static mixers. When two static mixers are serially retained in the secondary blending chamber, they may be skewed rotationally relative to each other such that the orifice profiles of each static mixer are not in alignment.

Owner:KAPILA MUKESH +1

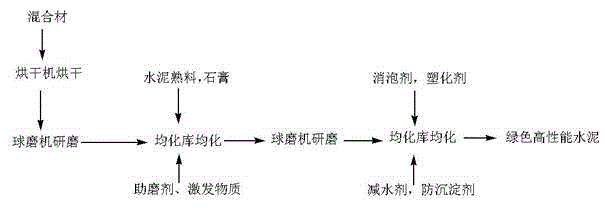

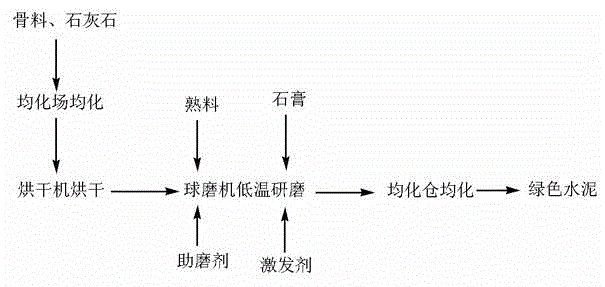

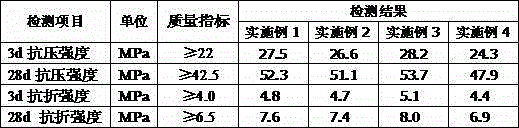

Environment-friendly high-performance cement and production method thereof

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

Heat management subsystems for LED lighting systems, LED lighting systems including heat management subsystems, and/or methods of making the same

InactiveUS20130021775A1Facilitated DiffusionImprove homogenizationFurnace componentsPoint-like light sourceLighting systemLight source

Certain example embodiments relate to improved lighting systems and / or methods of making the same. In certain example embodiments, a lighting system includes a glass substrate with one or more apertures. An LED or other light source is disposed at one end of the aperture such that light from the LED directed through the aperture of the glass substrate exits the opposite end of the aperture. Inner surfaces of the aperture have a mirroring material such as silver to reflect the emitted light from the LED. In certain example embodiments, a remote phosphor article or layer is disposed opposite the LED at the other end of the aperture. In certain example embodiment, a lens is disposed in the aperture, between the remote phosphor article and the LED.

Owner:GUARDIAN GLASS LLC

Endoprobe

InactiveUS20080097415A1Improve visibilityEasy constructionLaser surgerySurgical instrument detailsLaser lightMicrosurgery

An endoprobe for ophthalmic microsurgery for intraocular treatment of the eye and that affords a surgeon good visibility regardless of the distance from the treatment site in the eye. The endoprobe includes a stainless steel cannula enclosing one or more optical fibers and a laser fiber. A distal end of the optical fibers can be closed by a transparent lens-shaped structure such that an illuminating light transmitted through the optical fibers is radiated and transmitted laser light can exit from the laser fiber, or such that the laser fiber is embedded in a transparent shaped element. The laser fiber may have a covering for transporting light. The laser light may be injected directly into the laser fiber and the illuminating light is injected via at least one optical element into the covering of the laser fiber or into the transparent shaped element.

Owner:CARL ZEISS MEDITEC AG

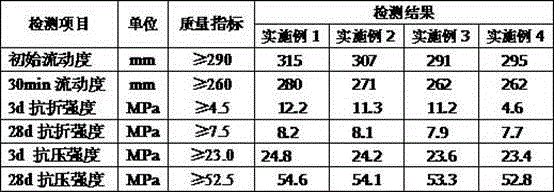

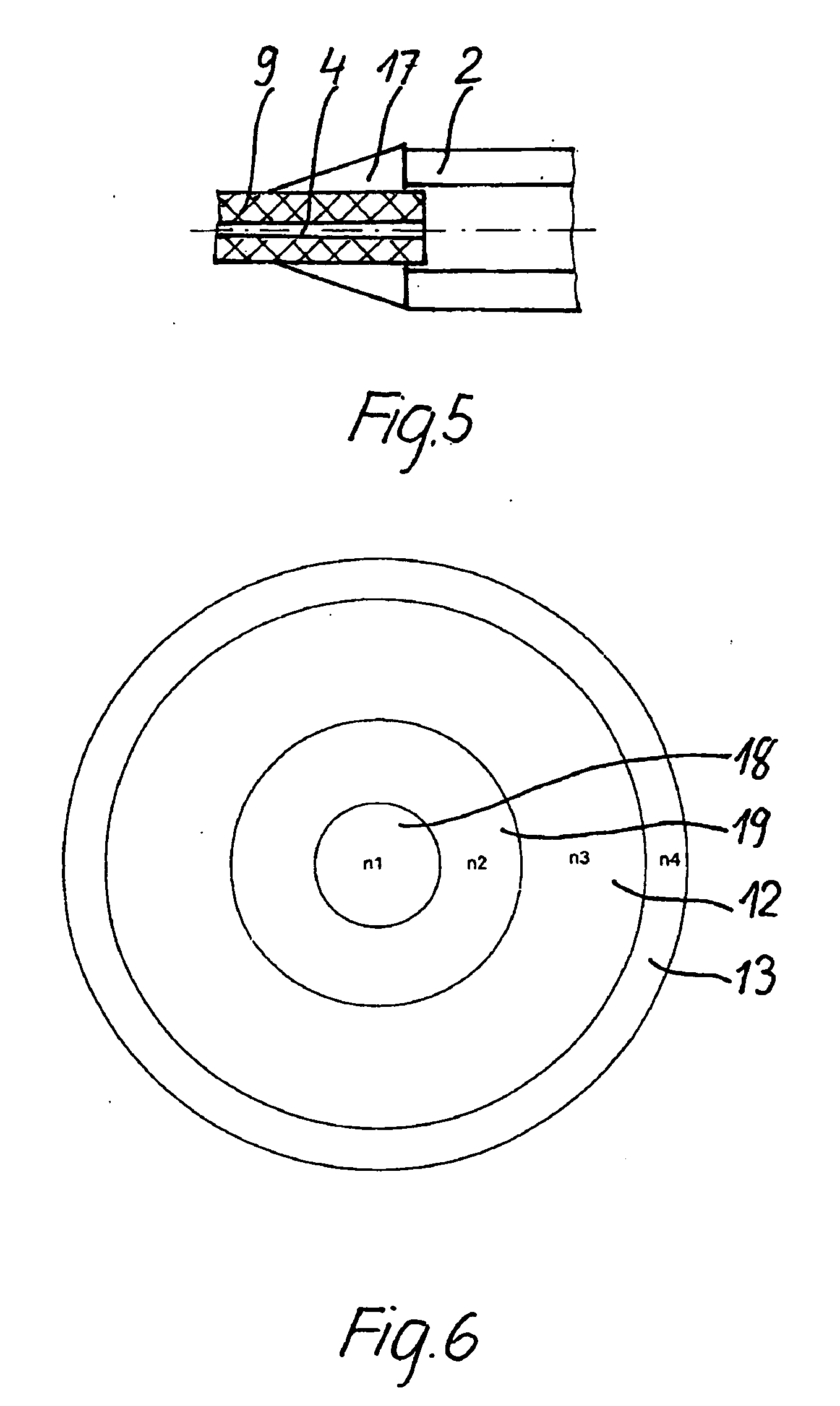

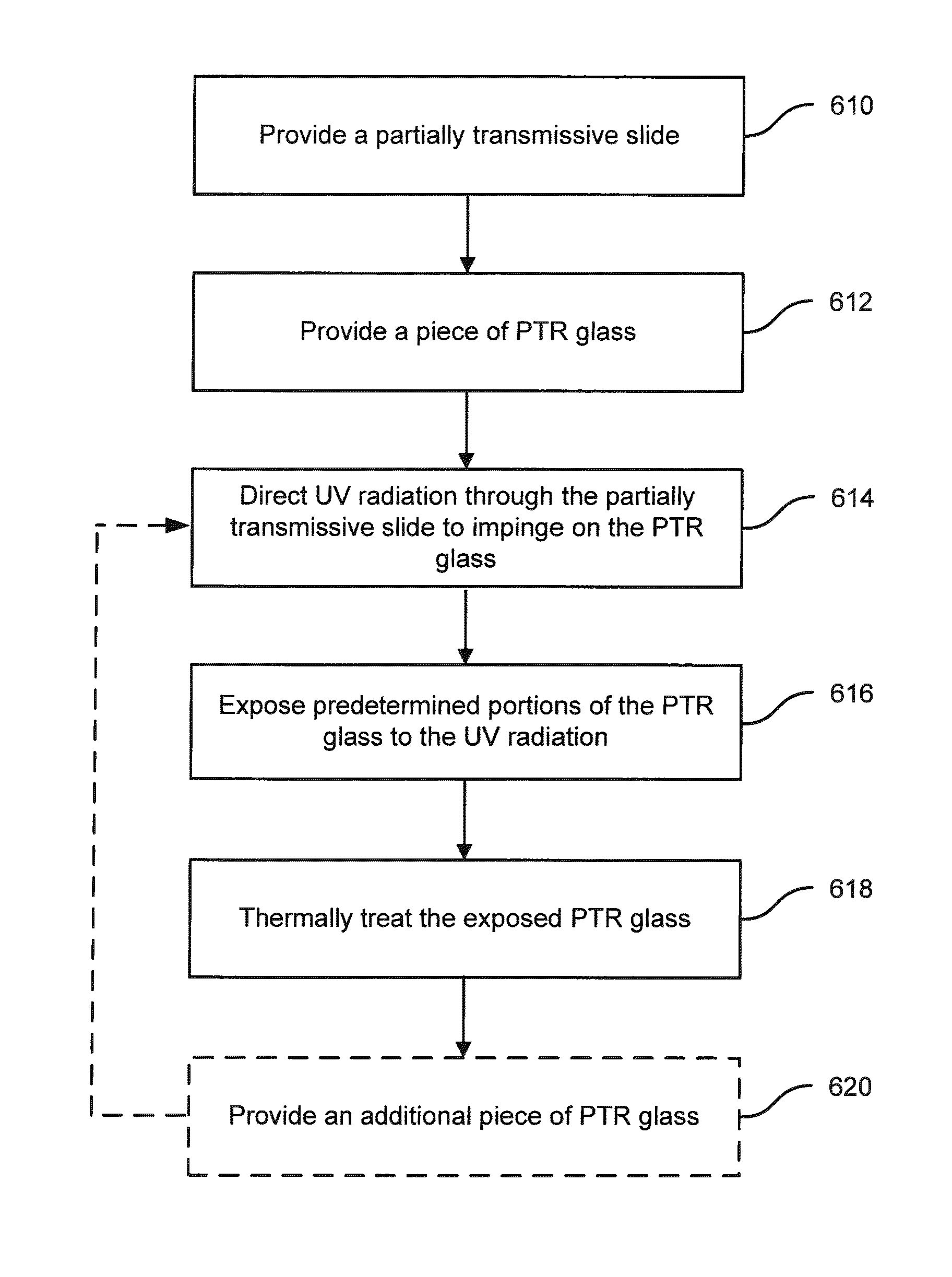

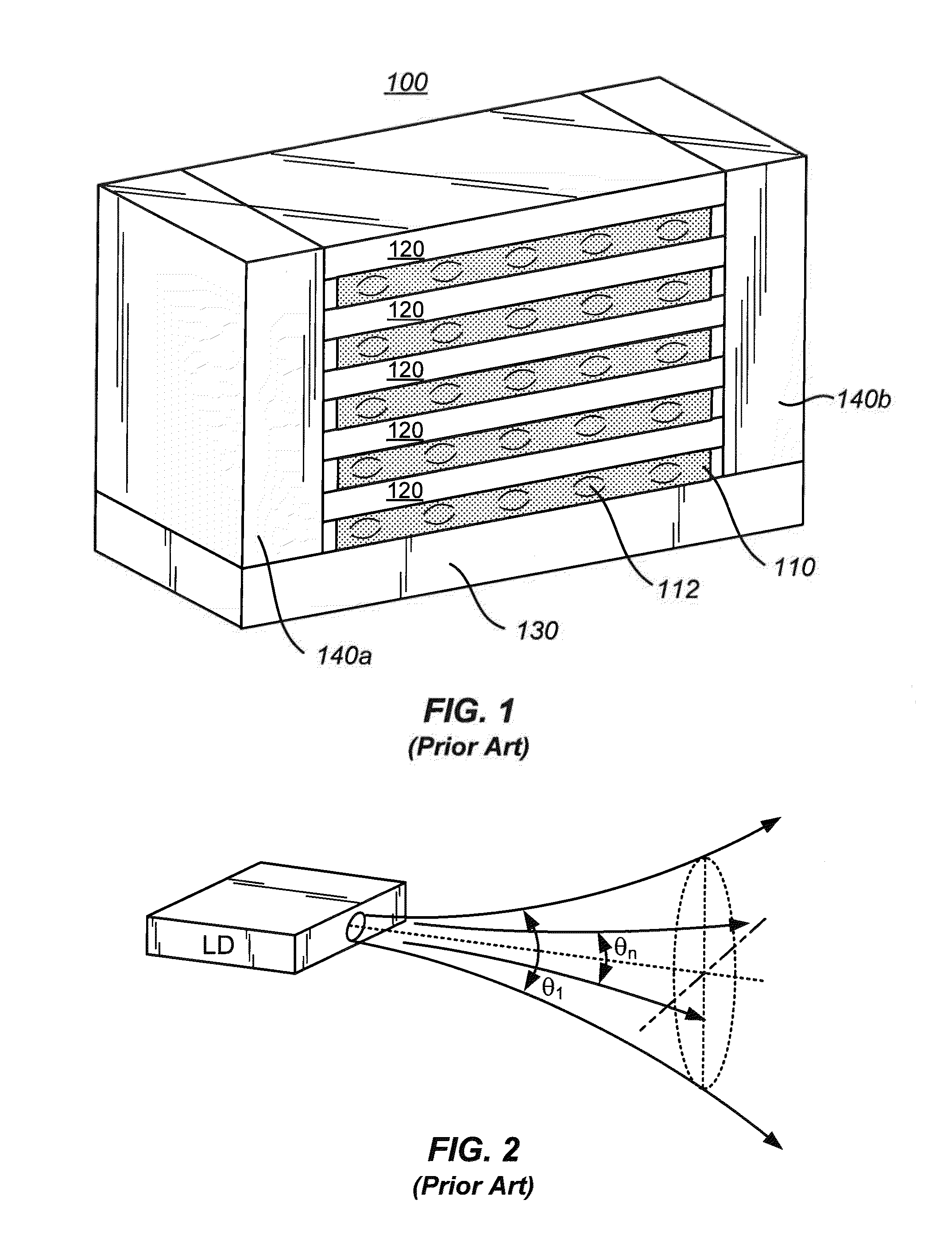

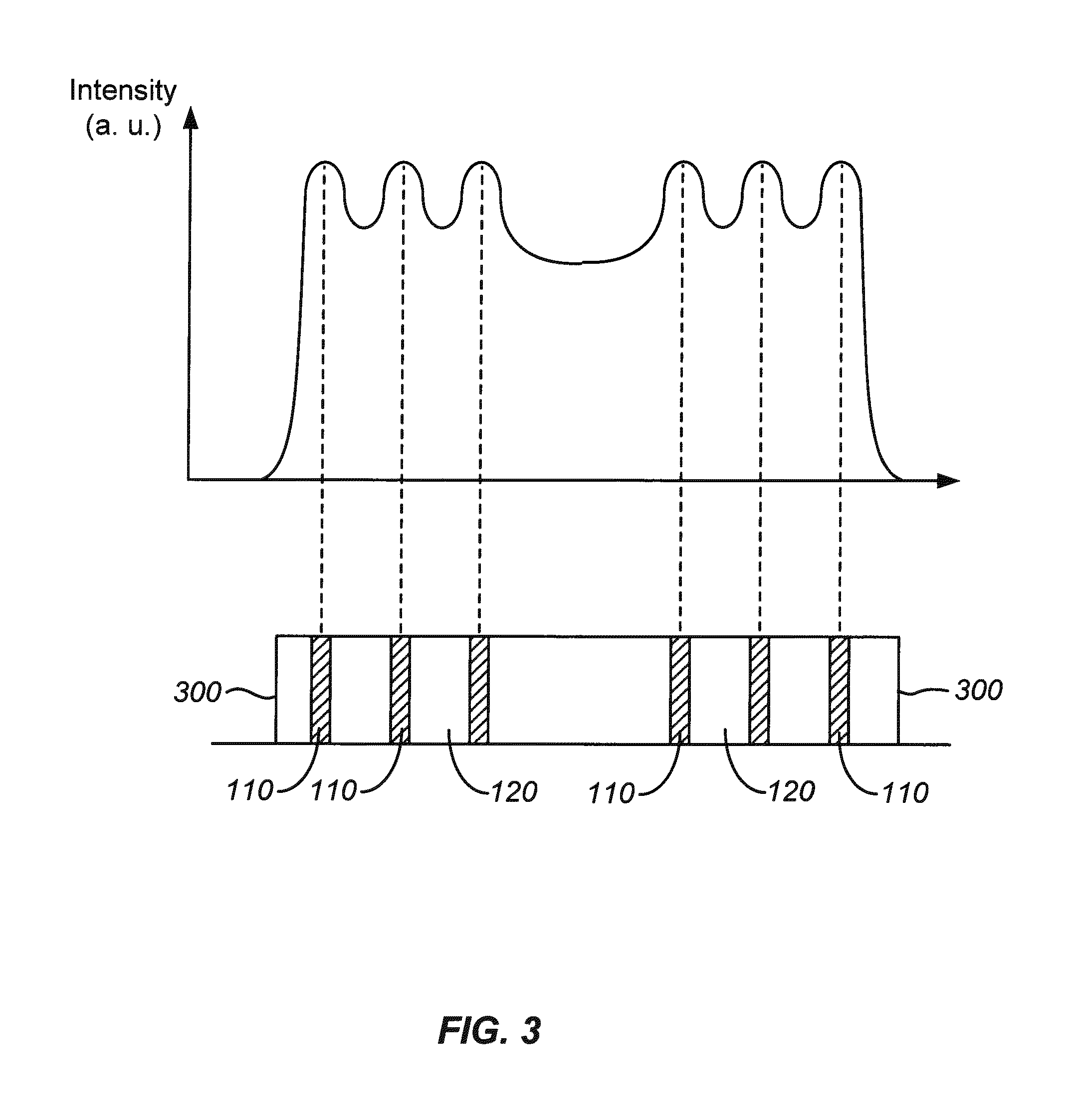

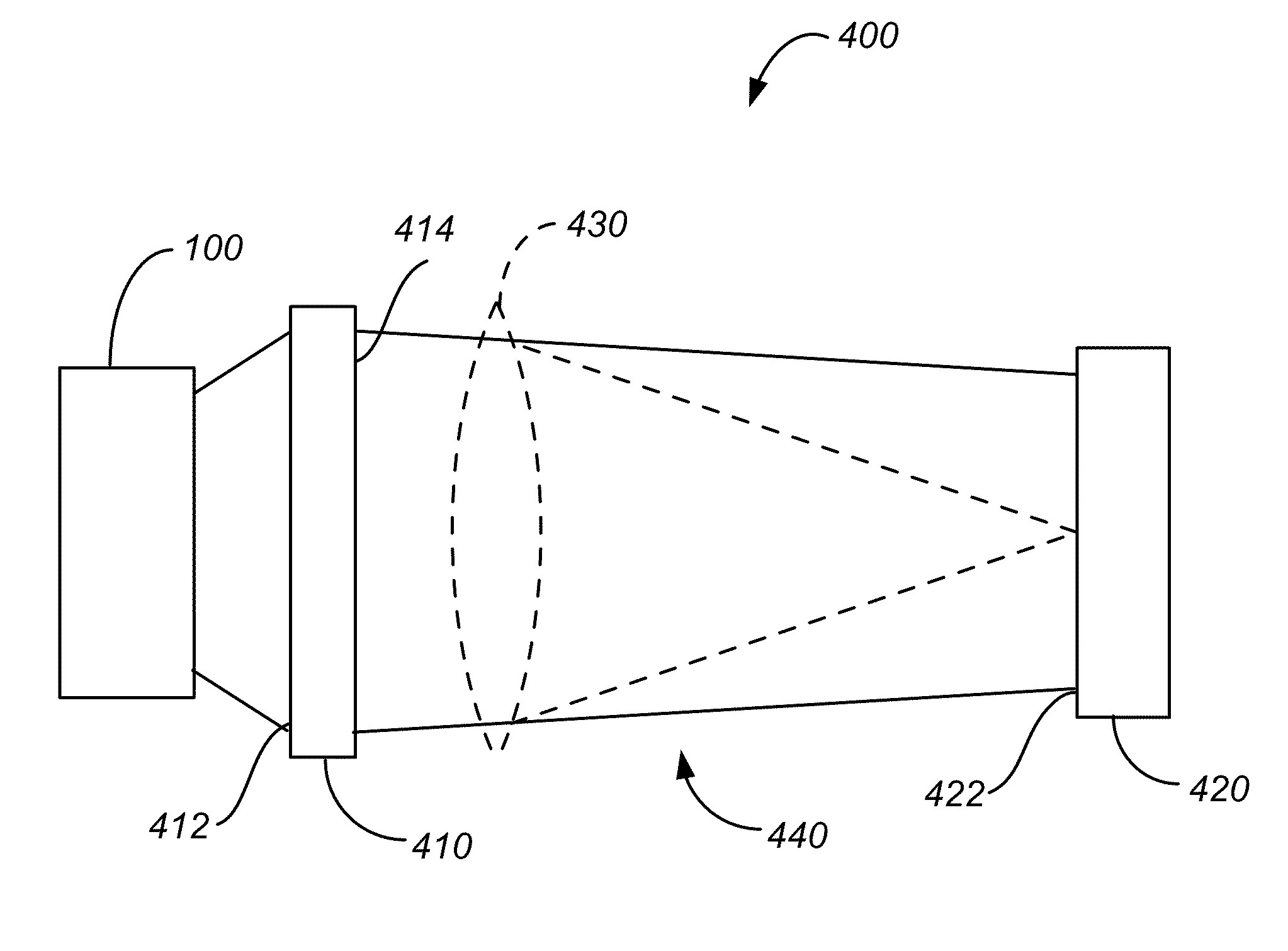

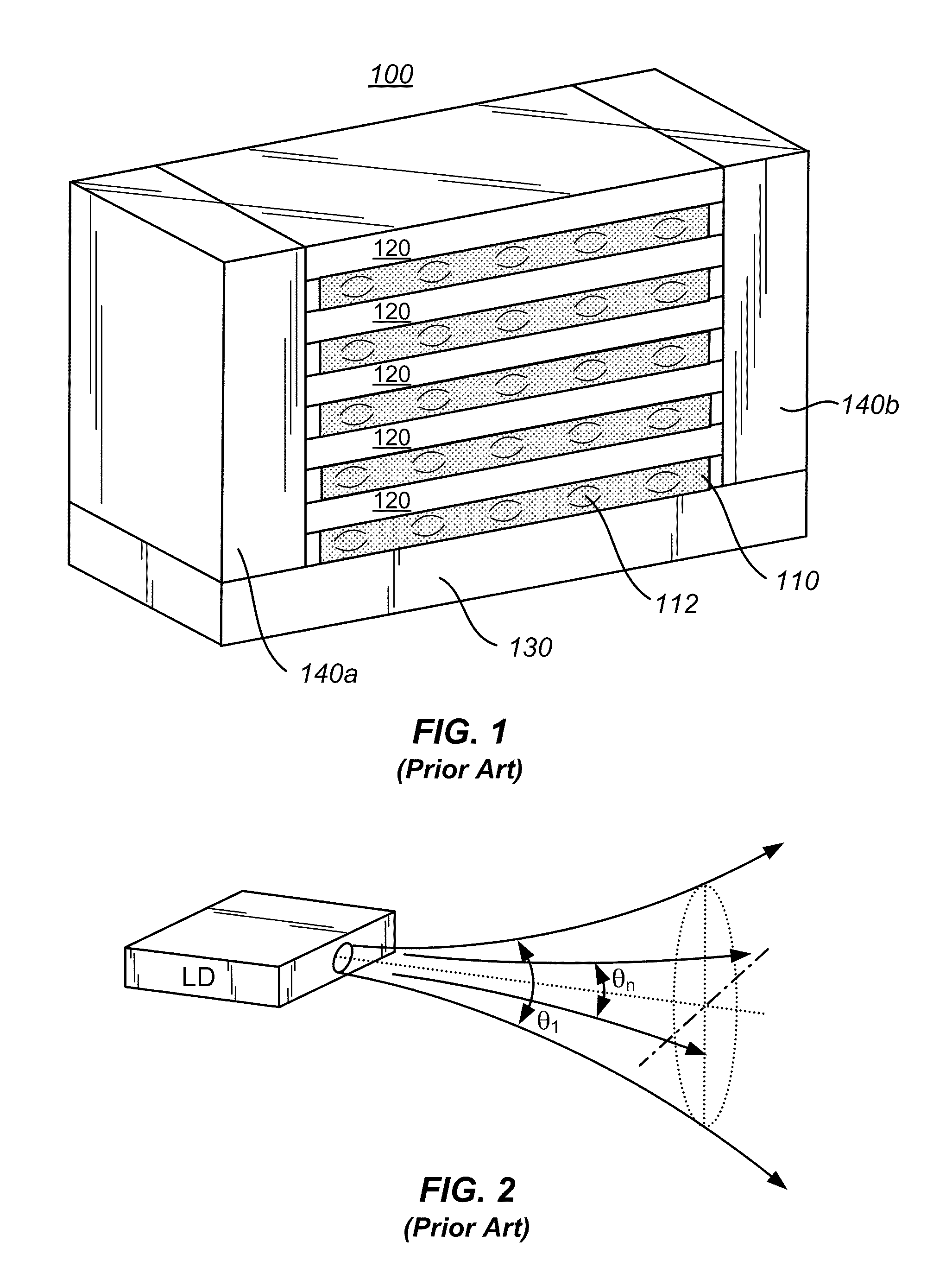

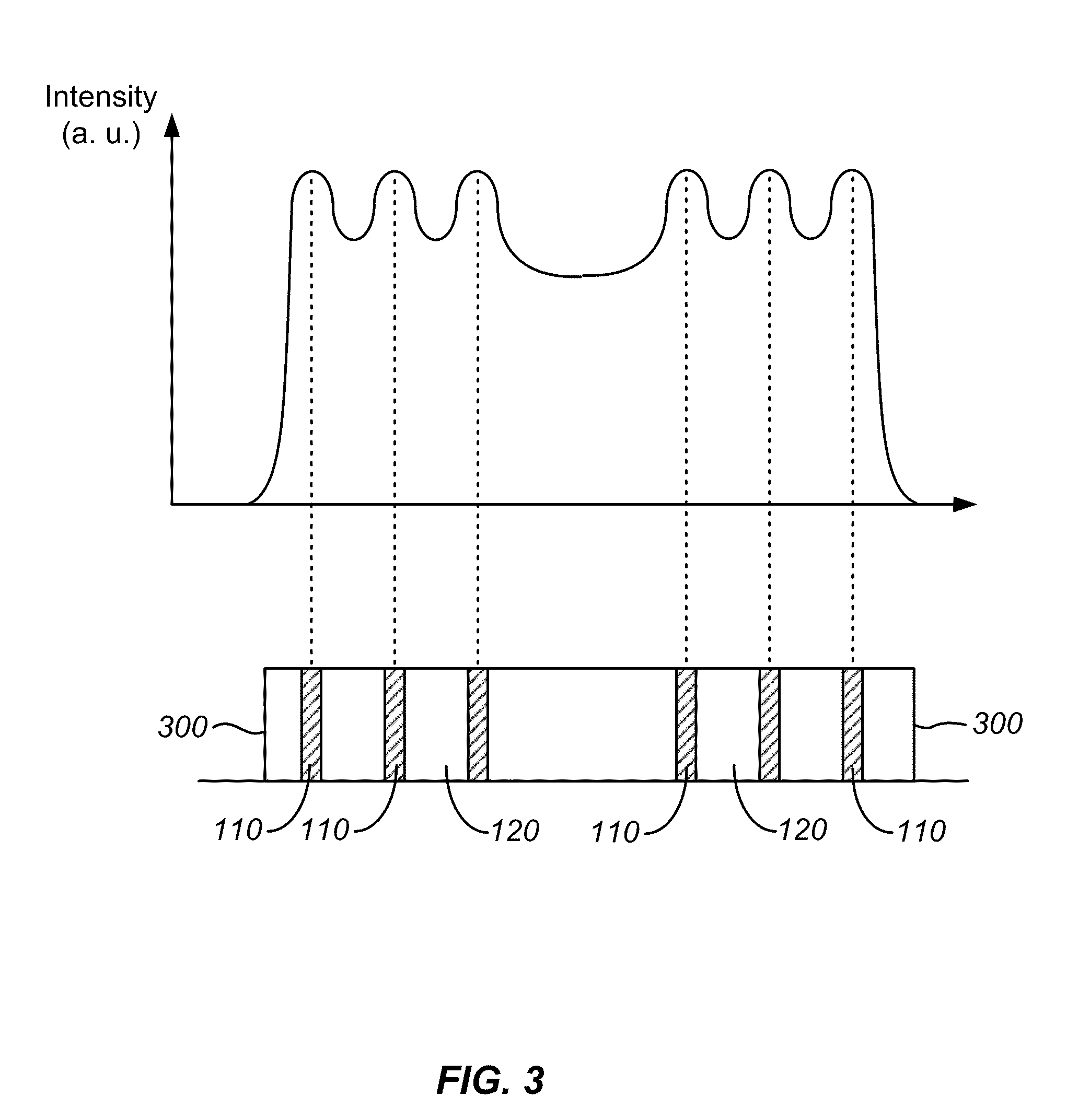

Method and system for homogenizing diode laser pump arrays

ActiveUS9331452B2Improve extraction efficiencyHigh beam qualitySemiconductor laser arrangementsLaser arrangementsAudio power amplifierUltimate tensile strength

An optical amplifier system includes a diode pump array including a plurality of semiconductor diode laser bars disposed in an array configuration and characterized by a periodic distance between adjacent semiconductor diode laser bars. The periodic distance is measured in a first direction perpendicular to each of the plurality of semiconductor diode laser bars. The diode pump array provides a pump output propagating along an optical path and characterized by a first intensity profile measured as a function of the first direction and having a variation greater than 10%. The optical amplifier system also includes a diffractive optic disposed along the optical path. The diffractive optic includes a photo-thermo-refractive glass member. The optical amplifier system further includes an amplifier slab having an input face and position along the optical path and separated from the diffractive optic by a predetermined distance. A second intensity profile measured at the input face of the amplifier slab as a function of the first direction has a variation less than 10%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Environment-friendly cement and production method thereof

ActiveCN103601382AReduce crushing efficiencyImprove liquidityCement productionMethods of productionToxic industrial waste

The invention discloses environment-friendly cement. The raw materials include various industrial waste residues, limestone, cement clinker, gypsum, a grinding aid and an excitation substance. The environment-friendly cement is characterized in that the weight parts of the raw materials are as follows: 50-60 parts of admixture, 32-40 parts of cement clinker, 4-8 parts of gypsum, 0.03-0.05 part of grinding aid and 3-5 parts of excitation substance. Since the production process of the environment-friendly cement adopts a low-temperature mechanical-chemical co-excitation technology, the mixing amount of the admixture is large, multiple industrial waste residues can be used as raw materials, the raw materials are widely available, the cost is low, a great quantity of industrial waste residues can be consumed, the waste is turned into wealth, and the performance of the obtained product is remarkably improved from the quality index.

Owner:广西云燕特种水泥建材有限公司

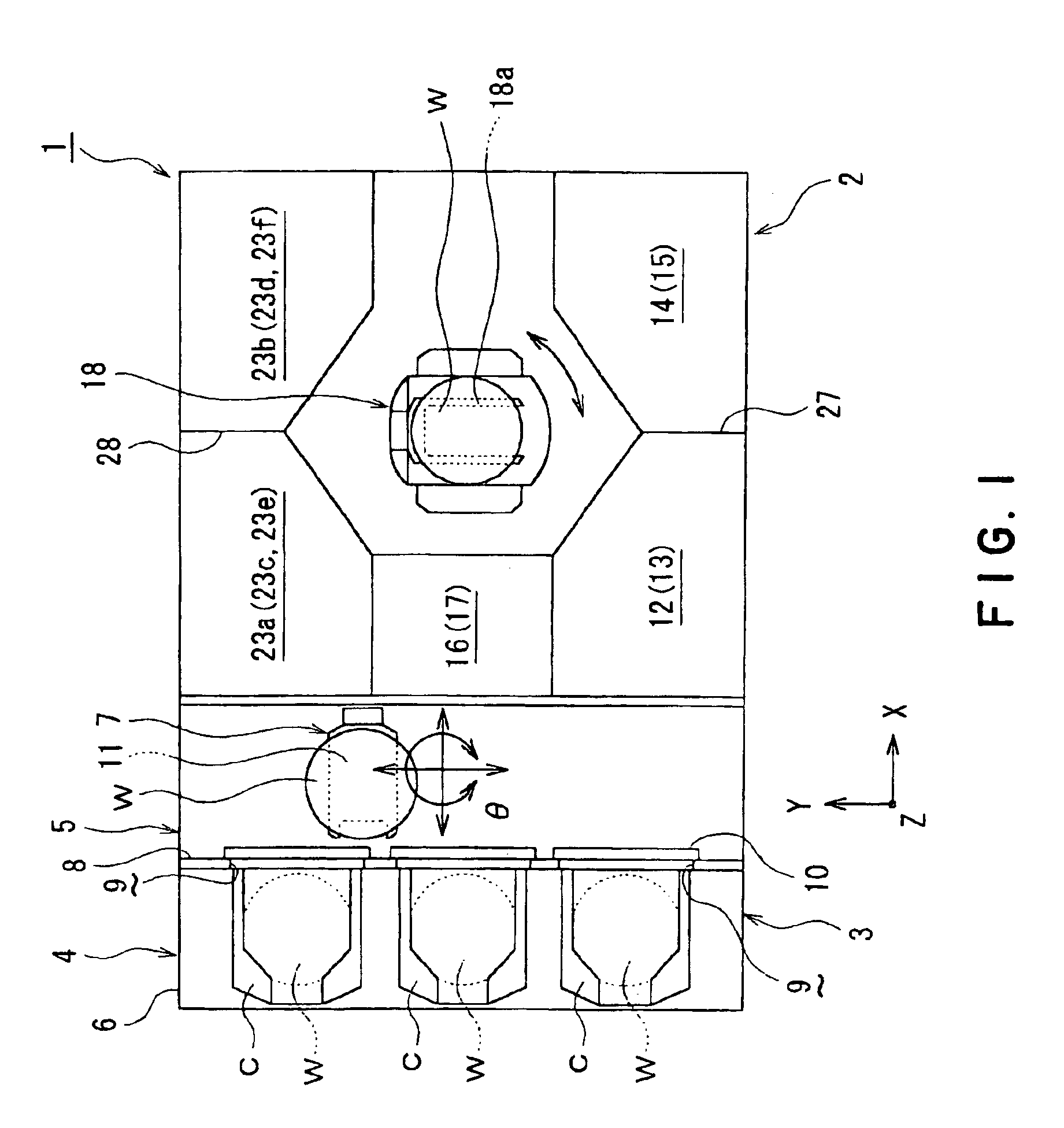

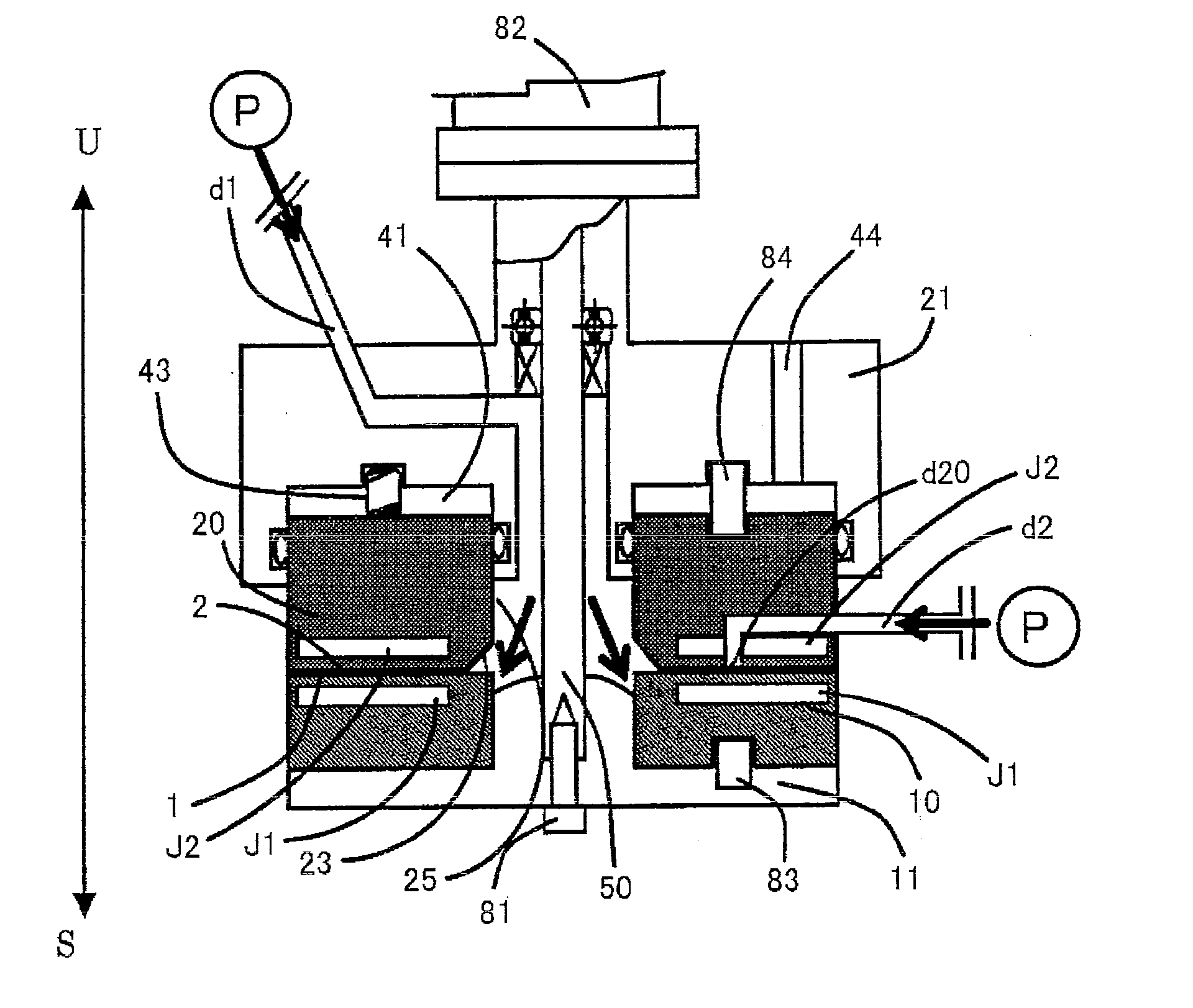

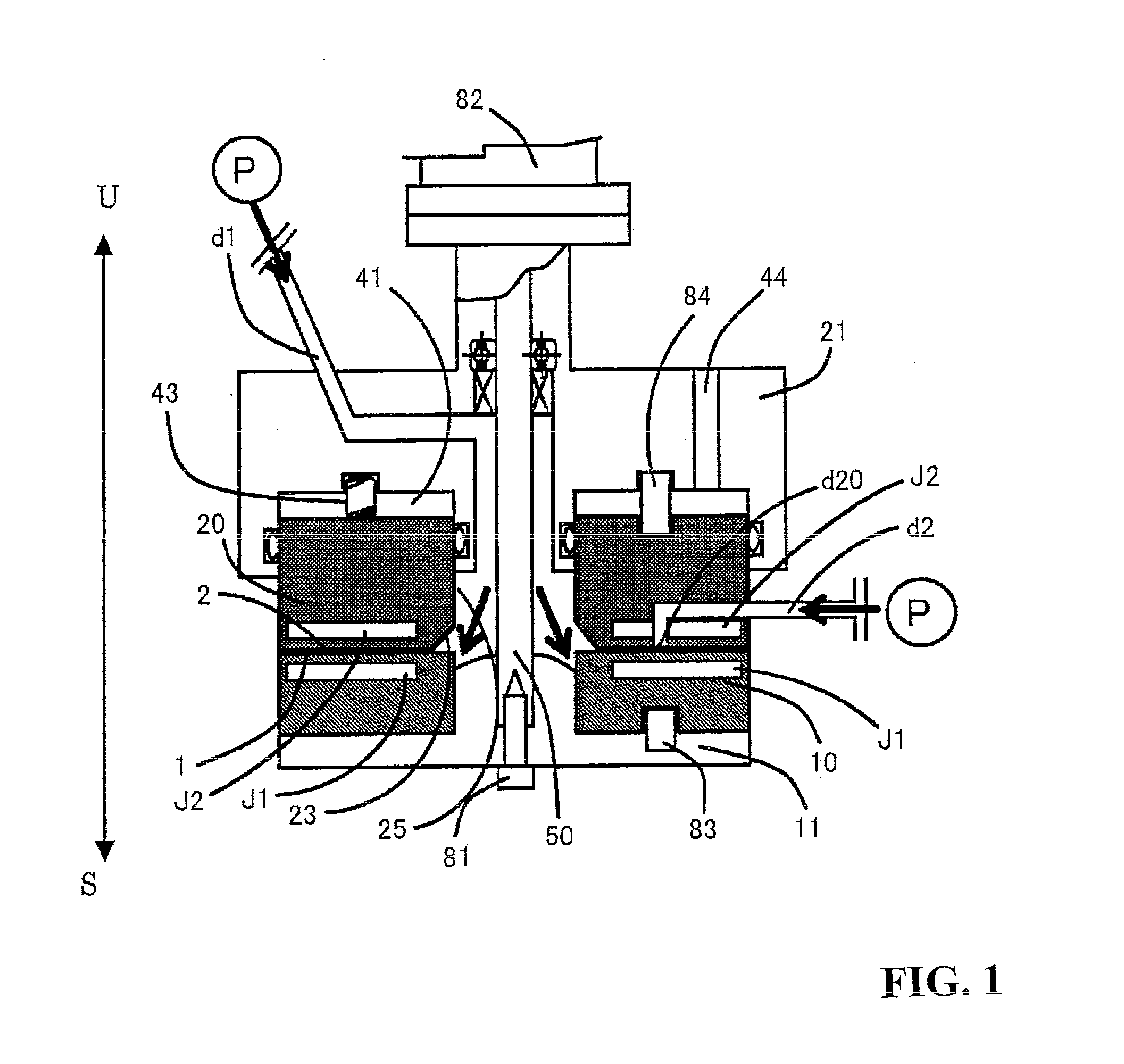

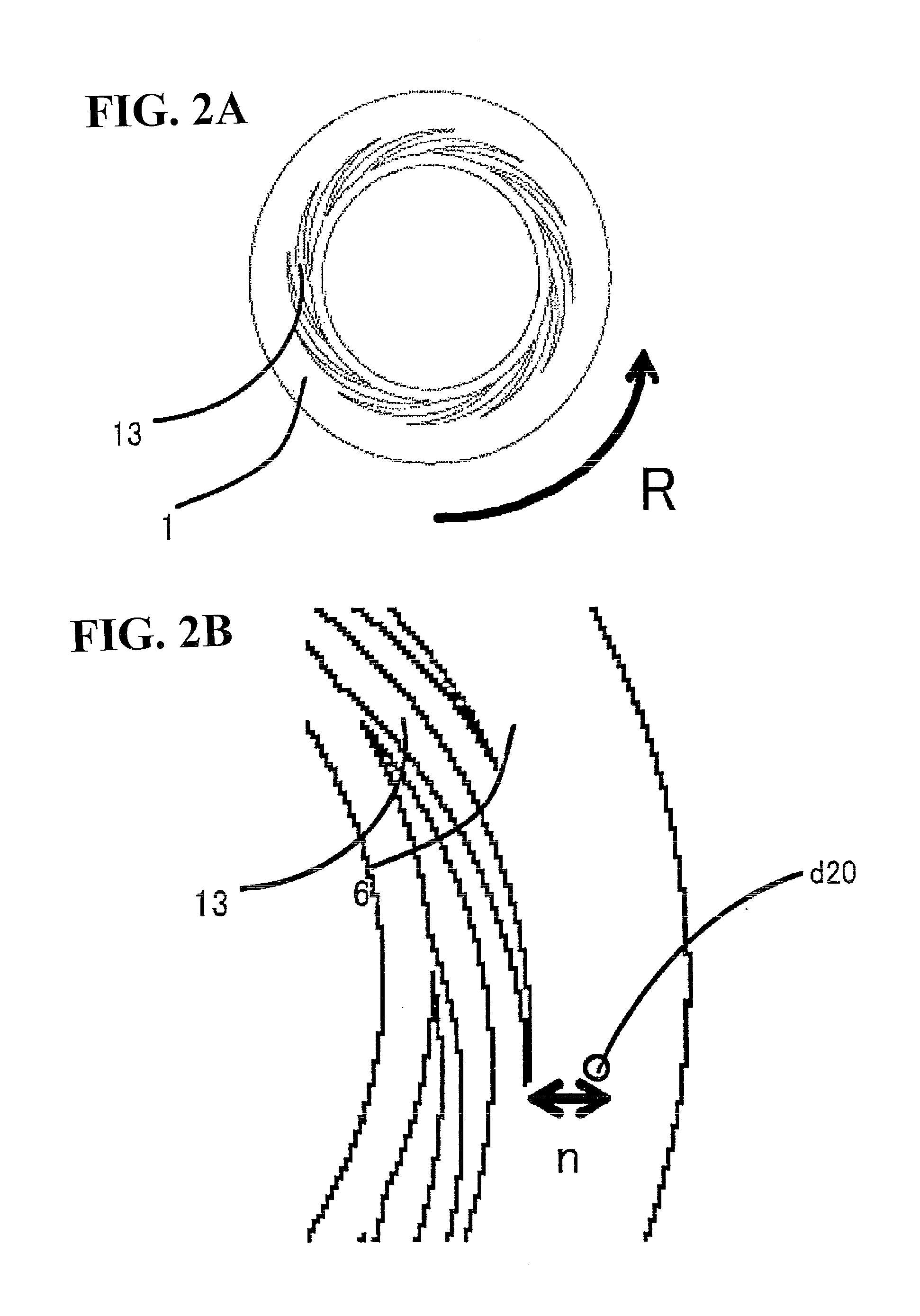

Fluid processing apparatus and processing method

ActiveUS20100319785A1Solve the real problemMinimize disturbanceFlow mixersServomotor componentsEngineering

A fluid is processed between processing surfaces capable of approaching to and separating from each other, at least one of which rotates relative to the other. A first fluid containing a material to be processed is introduced between processing surfaces 1 and 2, by using a micropump effect acting with a depression 13 arranged on the processing surfaces from the center of the rotating processing surfaces. A second fluid containing a material to be processed, independent of this introduced fluid, is introduced from another fluid path d2 that is provided with an opening d20 leading to the processing surfaces, whereby the processing is done by mixing and stirring between the processing members 1 and 2. In a plane along the processing surfaces, directionality accompanies the introducing direction from the opening of the second fluid into the processing surfaces. Regarding the introducing direction of the second fluid, it is an outward direction away from the center for the fluid in the radial direction on the processing surface, and it is a forward direction for the fluid in the rotation direction of the fluid between the rotating processing surfaces.

Owner:M TECH CO LTD

Exhaust gas-treating device

ActiveUS8596044B2Improve homogenizationSpeed up evaporationInternal combustion piston enginesSilencing apparatusInterior spaceExhaust fumes

An exhaust gas-treating device (1) for an exhaust system of an internal combustion engine, especially of a motor vehicle, is provided with a housing (2), which has a jacket (3) extending circumferentially on the side and at least one bottom (4). The homogenization of the exhaust gas flow is improved with a mixing housing (14), which is arranged in the interior space (23) of the housing (2) and which has a mixing chamber (15). An inlet (16) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15). An outlet (17) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15).

Owner:VOLVO LASTVAGNAR AB +1

Method and system for homogenizing diode laser pump arrays

ActiveUS20110043900A1Improve extraction efficiencyHigh beam qualityLaser detailsSemiconductor laser optical deviceAudio power amplifierDiffraction optics

An optical amplifier system includes a diode pump array including a plurality of semiconductor diode laser bars disposed in an array configuration and characterized by a periodic distance between adjacent semiconductor diode laser bars. The periodic distance is measured in a first direction perpendicular to each of the plurality of semiconductor diode laser bars. The diode pump array provides a pump output propagating along an optical path and characterized by a first intensity profile measured as a function of the first direction and having a variation greater than 10%. The optical amplifier system also includes a diffractive optic disposed along the optical path. The diffractive optic includes a photo-thermo-refractive glass member. The optical amplifier system further includes an amplifier slab having an input face and position along the optical path and separated from the diffractive optic by a predetermined distance. A second intensity profile measured at the input face of the amplifier slab as a function of the first direction has a variation less than 10%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Kiwi fruit micro-powder and preparation process thereof

ActiveCN104473071ASave raw materialsHigh nutritional valueFood preparationAdditive ingredientKiwi fruit

The invention provides kiwi fruit micro-powder and a preparation process thereof, and relates to fruit powder and a preparation method of the fruit powder. According to the technical scheme provided by the invention, the preparation process of the kiwi fruit micro-powder comprises the following steps: cleaning kiwi fruit, draining off, and cutting into slices for later use; enclosing the cut kiwi fruit into a charging tray; putting into a vacuum drying room, dewatering and drying; crushing the dried kiwi fruit in a fully-closed state under the protection of nitrogen, and then sieving, so as to obtain micro-powder; and bagging the micro-powder in a low-temperature environment, and sealing in vacuum. The preparation process disclosed by the invention is advanced; 100% of skin, pulp and seeds of the kiwi fruit are utilized; raw materials are fully saved; the utilization efficiency is improved; and the kiwi fruit micro-powder is good in keeping of nutritional ingredients, good in color and luster, and convenient to store and transport for a long period of time.

Owner:南阳市三辰生物科技有限公司

Apparatus and Method for Homogenizing Two or More Fluids of Different Densities

ActiveUS20100226198A1Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingHigh densityVolumetric Mass Density

An apparatus for blending two or more fluid streams, wherein a first fluid has a higher density than the other fluids, includes a first fluid director and at least a second fluid director providing fluid communication of a first and second fluid stream, respectively, to a primary mixing chamber. The first fluid director includes one or more baffles to disturb the first fluid stream and to direct it toward a rearward portion of the first inlet to the primary mixing chamber. A secondary blending chamber is in fluid communication with the primary chamber outlet and includes at least one, and preferably two static mixers. When two static mixers are serially retained in the secondary blending chamber, they may be skewed rotationally relative to each other such that the orifice profiles of each static mixer are not in alignment.

Owner:MI

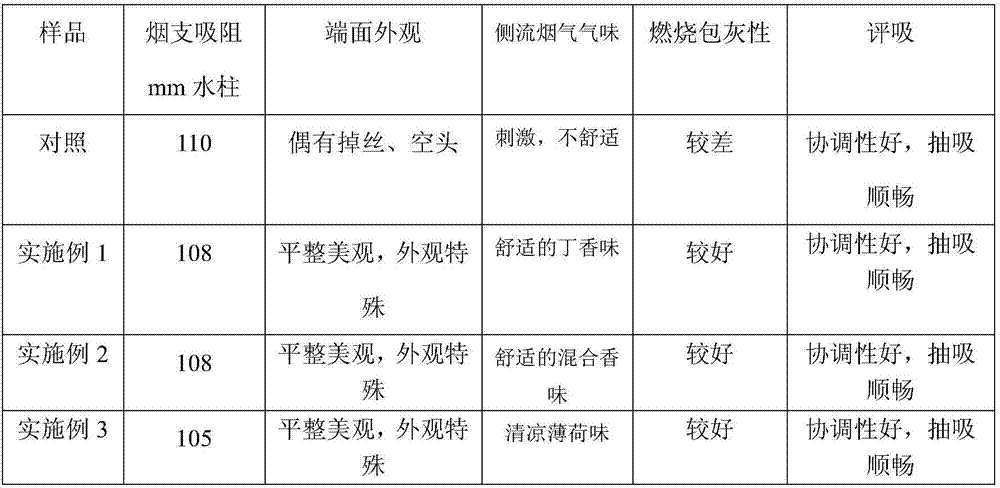

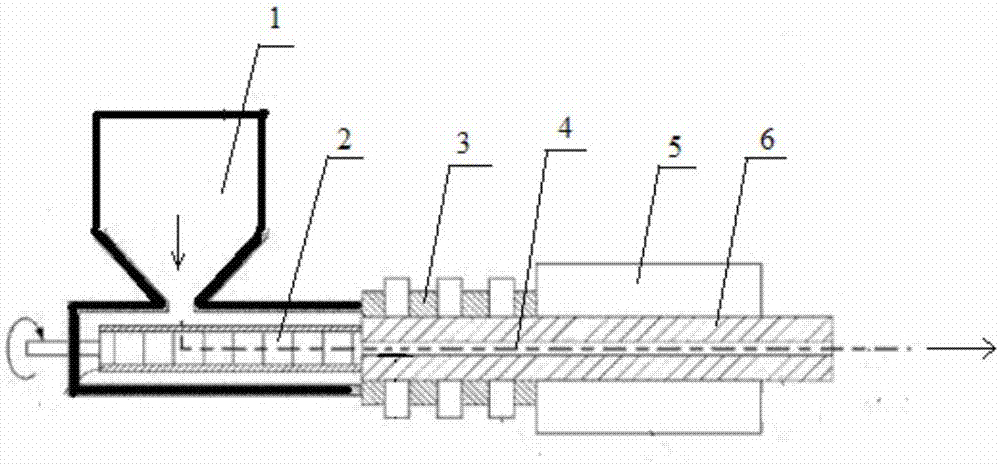

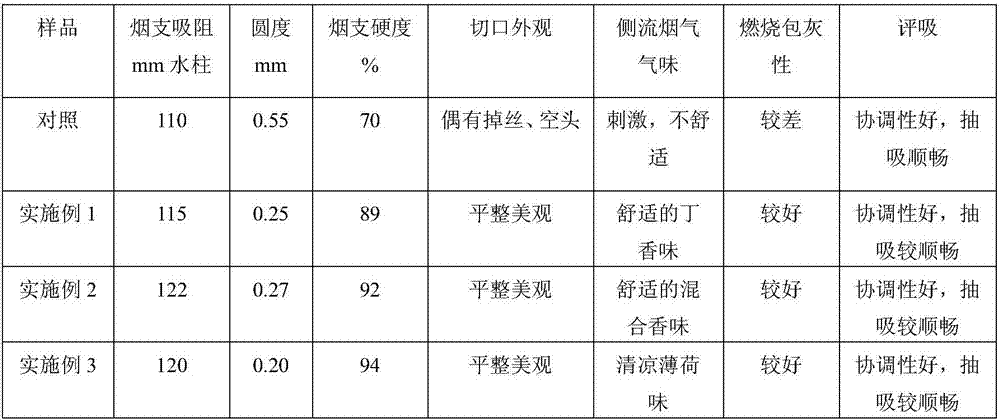

Preparation method of specially-shaped cigarettes with naturally endowed aroma

The invention discloses a preparation method of specially-shaped cigarettes with naturally endowed aroma. The preparation method comprises the following steps: respectively grinding a tobacco raw material and natural plant perfumes into powder, and uniformly mixing the powder, thus obtaining mixed powder; uniformly stirring a combustion promoter, an adhesive and a humectant, thus obtaining a mixedsolution; carrying out mixed granulation on the mixed powder and the mixed solution, and carrying out drying, thus obtaining tobacco particles; preparing the tobacco particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding withfilter sticks, thus obtaining the specially-shaped cigarettes with high homogenization, good stability and naturally endowed aroma. The cigarettes are smooth in smoking, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

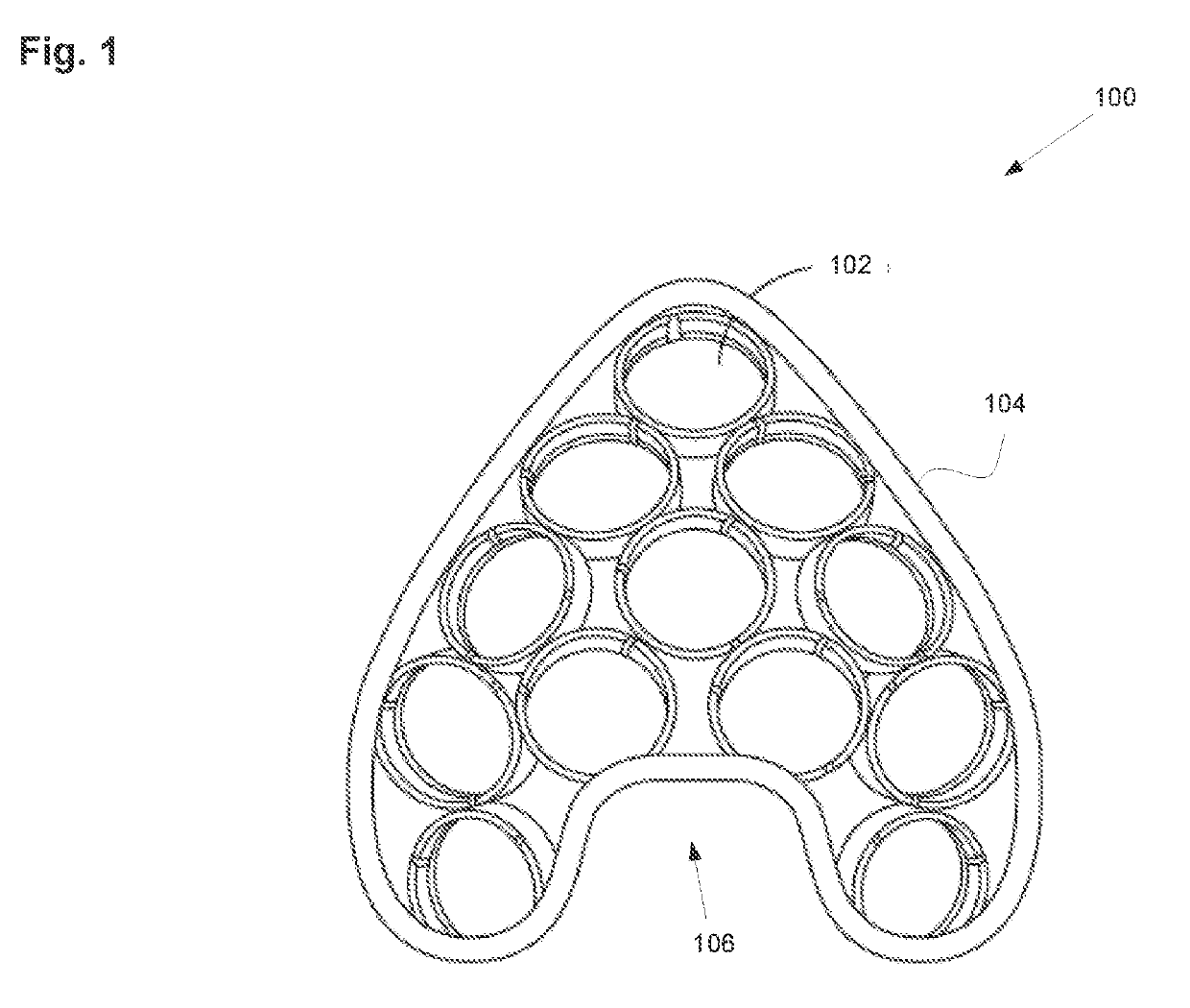

Light source unit and lighting apparatus having light-emitting diodes for light source

InactiveUS20100067226A1Improve homogenizationLighting support devicesPoint-like light sourceEngineeringThermal radiation

A light source unit is provided with a substrate and segments of a reflector. The substrate has a plurality of light-emitting devices mounted on its central and peripheral portions. The segments correspond to the light-emitting devices, individually. The segment corresponding to the light-emitting devices mounted on the central portion are higher in thermal radiation capacity than the segment corresponding to the light-emitting devices mounted on the peripheral portion.

Owner:TOSHIBA LIGHTING & TECH CORP

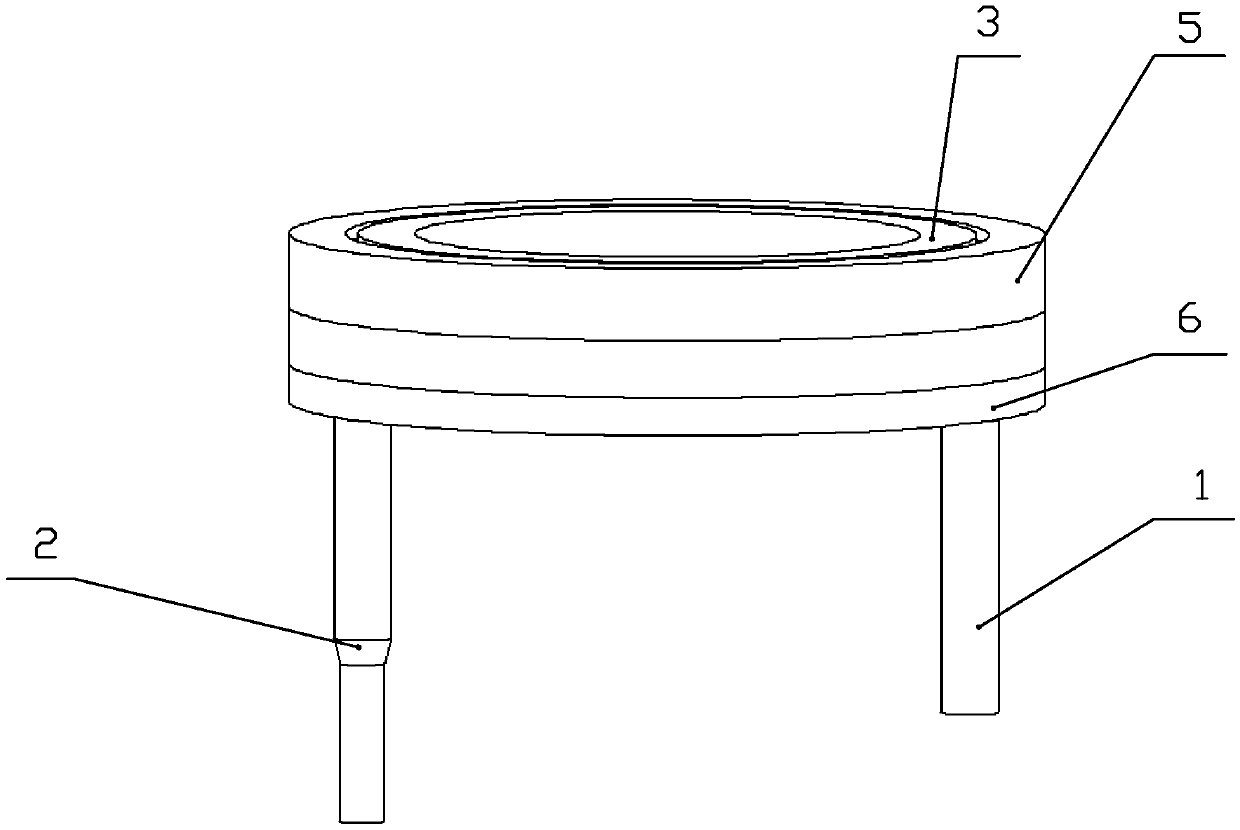

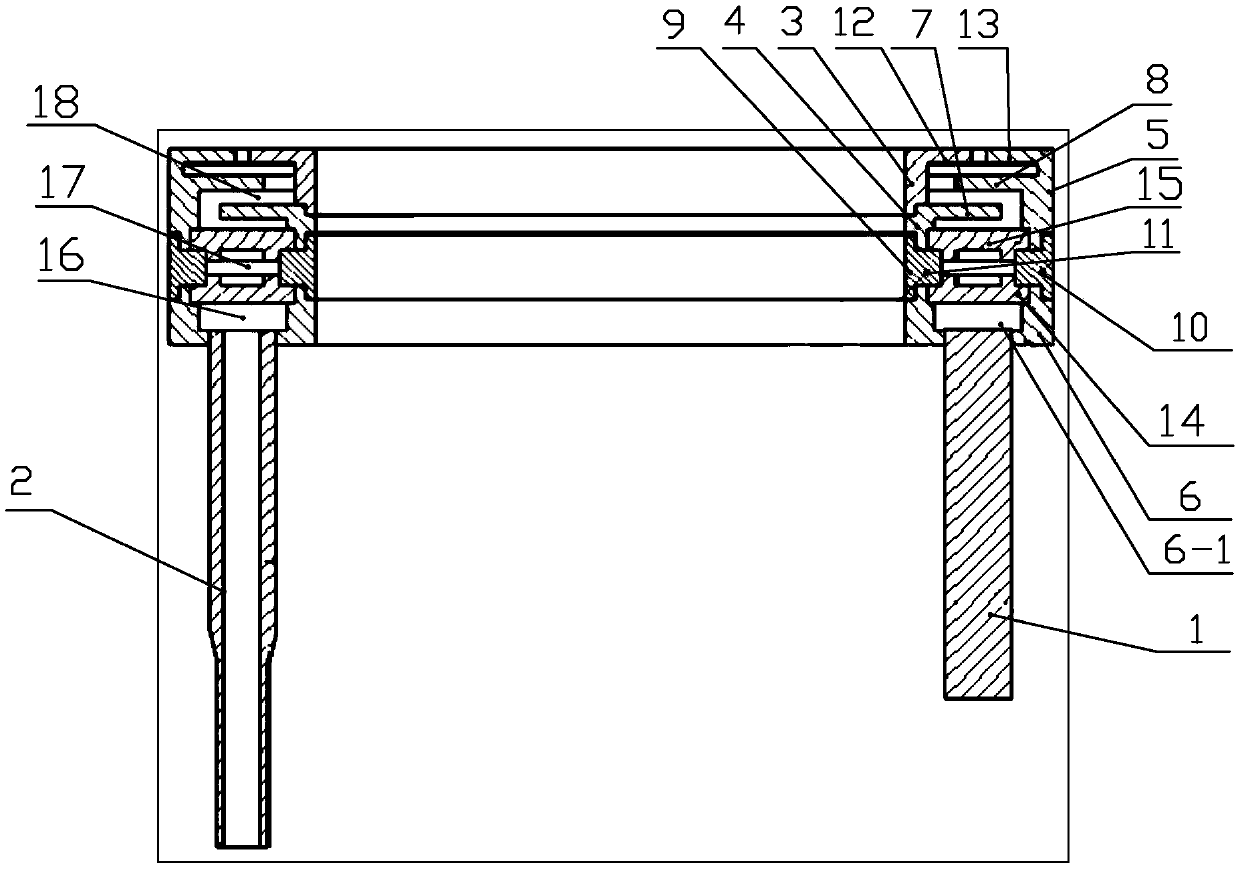

Hall thruster gas distributor structure with porous material partition plates

ActiveCN109555658AImprove homogenizationIncrease profitMachines/enginesUsing plasmaBiochemical engineeringIon beam

The invention discloses a Hall thruster gas distributor structure with porous material partition plates, and belongs to the technical field of Hall thrusters. The problem that according to an existingHall thruster, on the condition of ensuring the gas homogenization degree, an ion beam flows back and is likely to be deposited on the partition plate, and therefore the service life of an anode is shortened is solved. A first baffle is fixedly arranged on the side wall, close to an outer ring of a top shell layer, on a lower inner ring of the top shell layer, a gap is formed between the first baffle and the inner wall of the outer ring of the top shell layer, a second baffle is fixedly arranged on the side wall, close to an upper inner ring of the top shell layer, of the outer ring of the top shell layer, the second baffle is located above the first baffle, a gap is formed between the second baffle and the upper inner ring of the top shell layer, a gap is formed between the second baffleand the first baffle, the first-stage partition plate and the second-stage partition plate are both made from porous materials and gaps are formed between the first-stage partition plate and the bottom of an annular groove, between the first-stage partition plate and the second-stage partition plate and between the second-stage partition plate and the first baffle.

Owner:HARBIN INST OF TECH

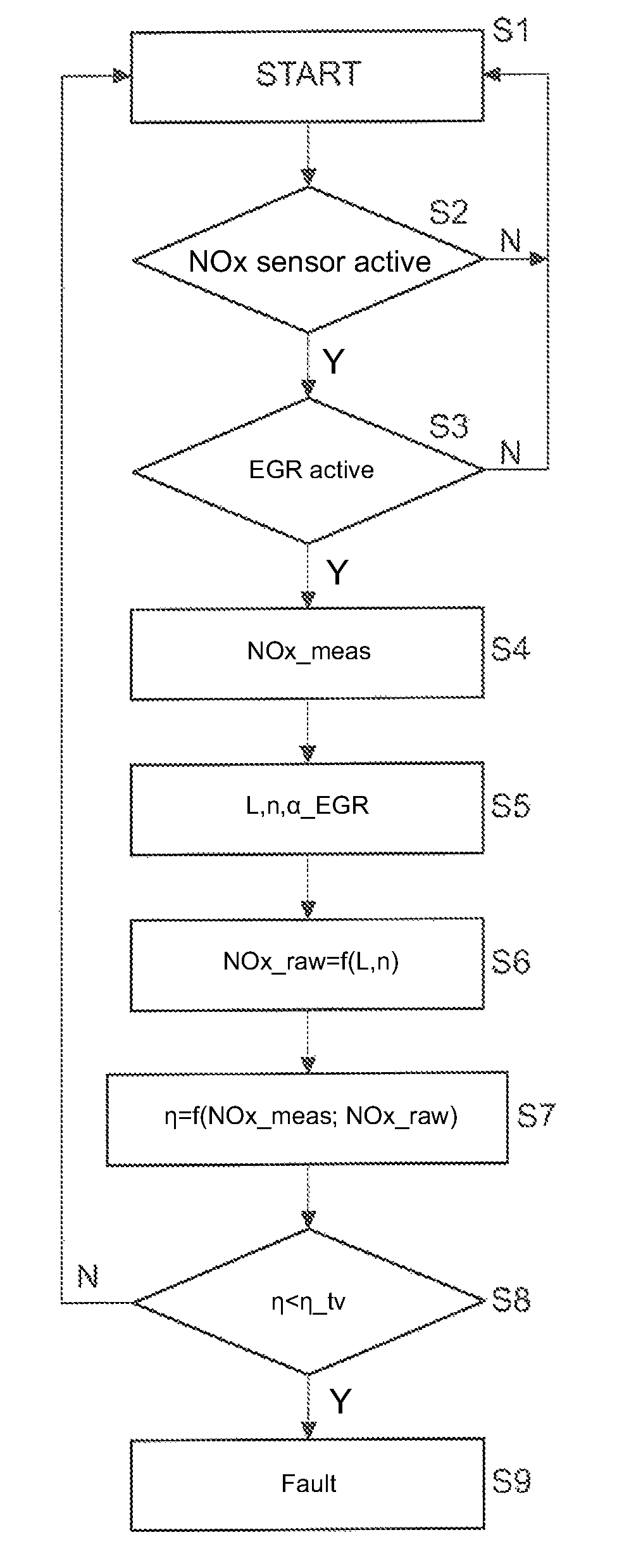

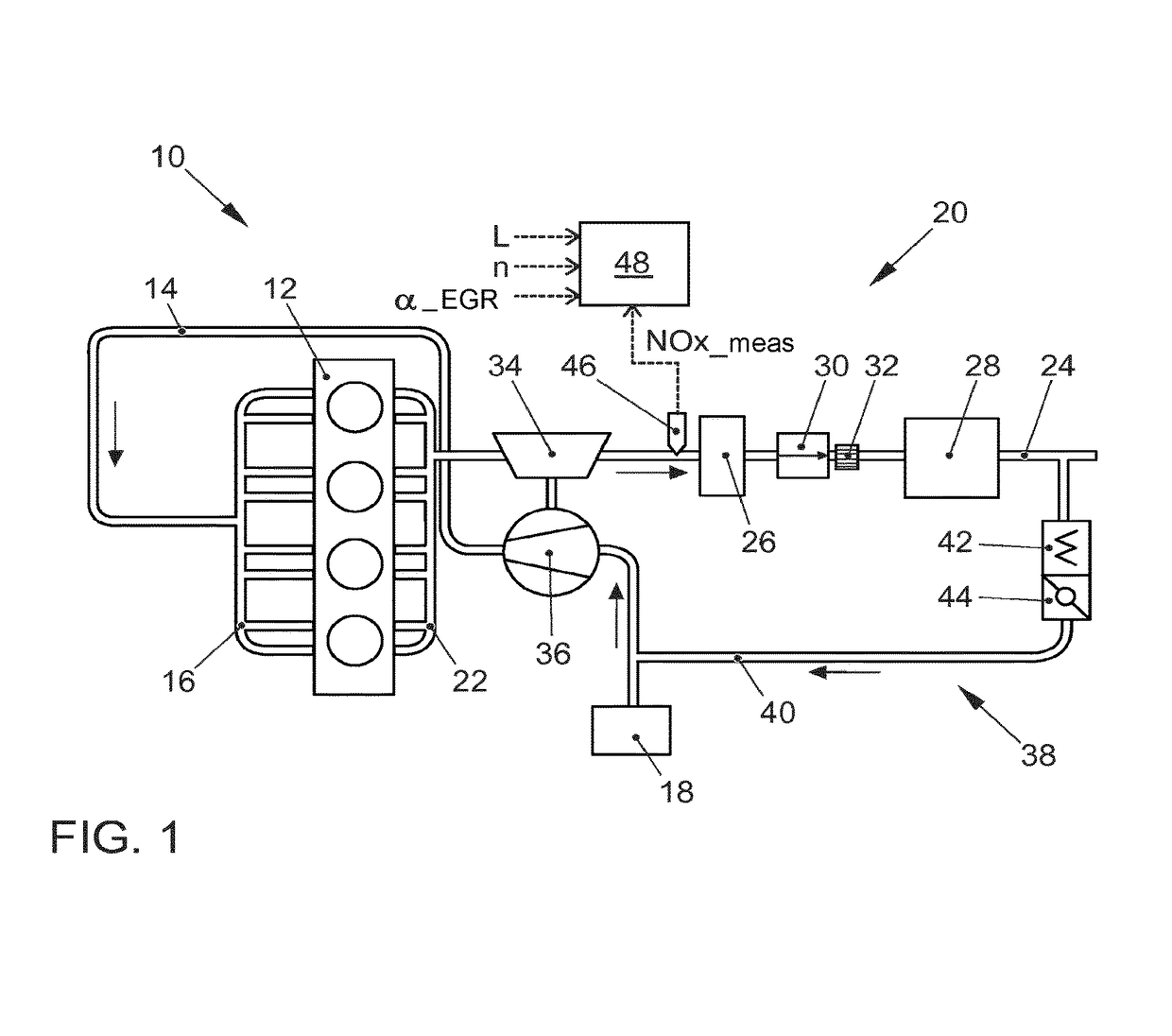

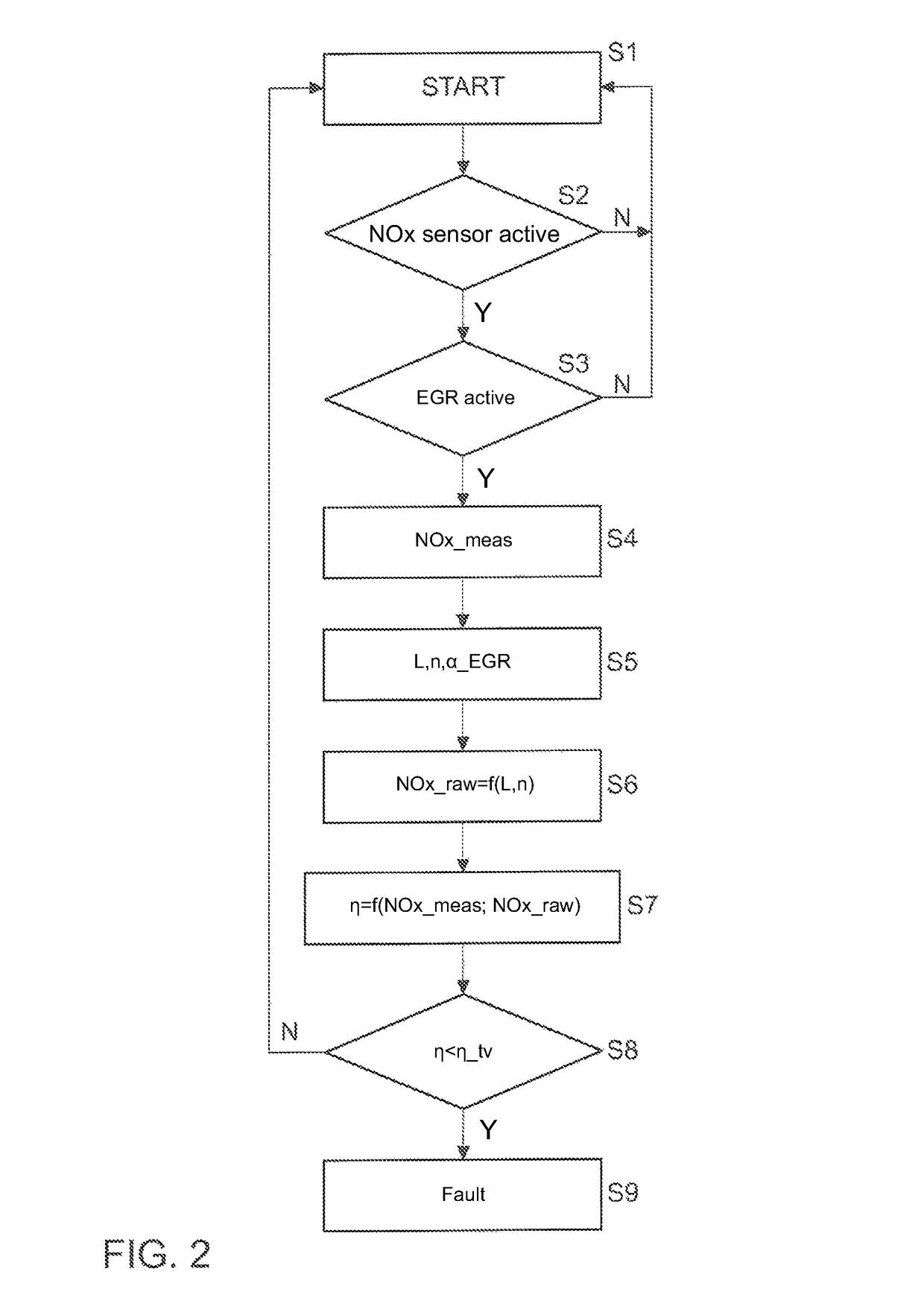

Method for diagnosing an exhaust gas catalytic converter, diagnosis device and motor vehicle having such a device

ActiveUS9593617B2High precisionMethod is suitableVehicle testingElectrical controlExhaust gas recirculationMotorized vehicle

A method for diagnosing an exhaust-gas catalytic converter (28) arranged in an exhaust-gas system (20) of an internal combustion engine (12) for the catalytic conversion of at least one exhaust-gas component from the internal combustion engine (12), which has an exhaust-gas recirculation means with which a partial stream of the exhaust gas can be drawn off downstream of the catalytic converter (14) and fed into the combustion air of the internal combustion engine (12), involves determining the current raw emission (NOx—raw) of the internal combustion engine (12) in of the exhaust-gas component; measuring the current concentration of the exhaust-gas component (NOx—meas) in the exhaust gas upstream of the catalytic converter (28); and determining a diagnostic value for the catalytic converter (28) in terms of the conversion of the exhaust-gas component as a function of the modelled raw emission (NOx—raw) from the internal combustion engine (12) and the measured concentration of the exhaust-gas component (NOx—meas). The invention further relates to a diagnostic device configured to perform the method and a motor vehicle having such a device.

Owner:VOLKSWAGEN AG

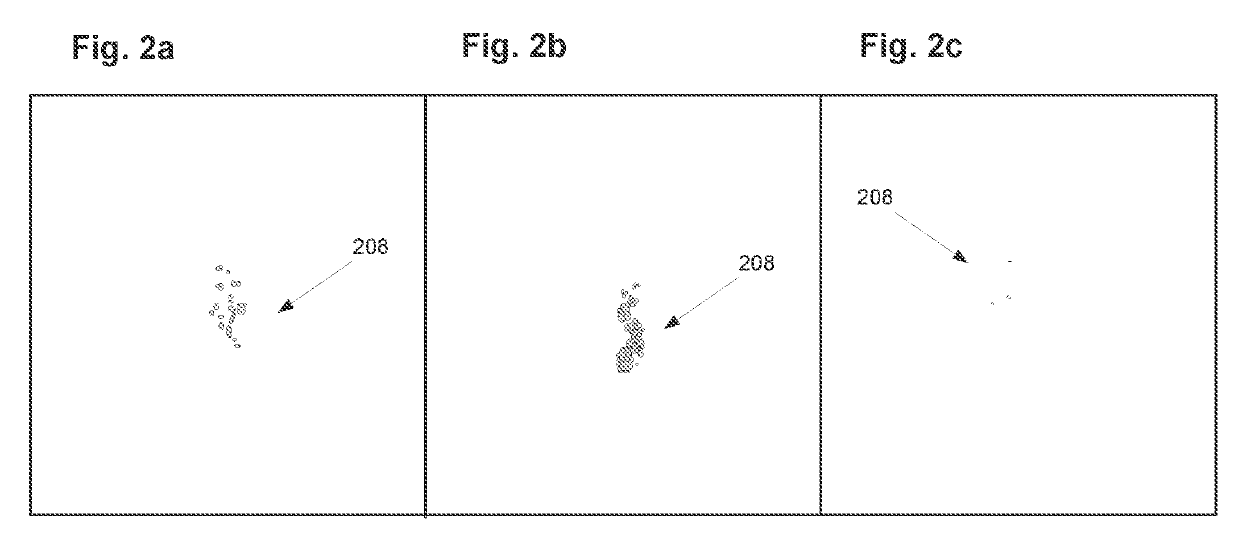

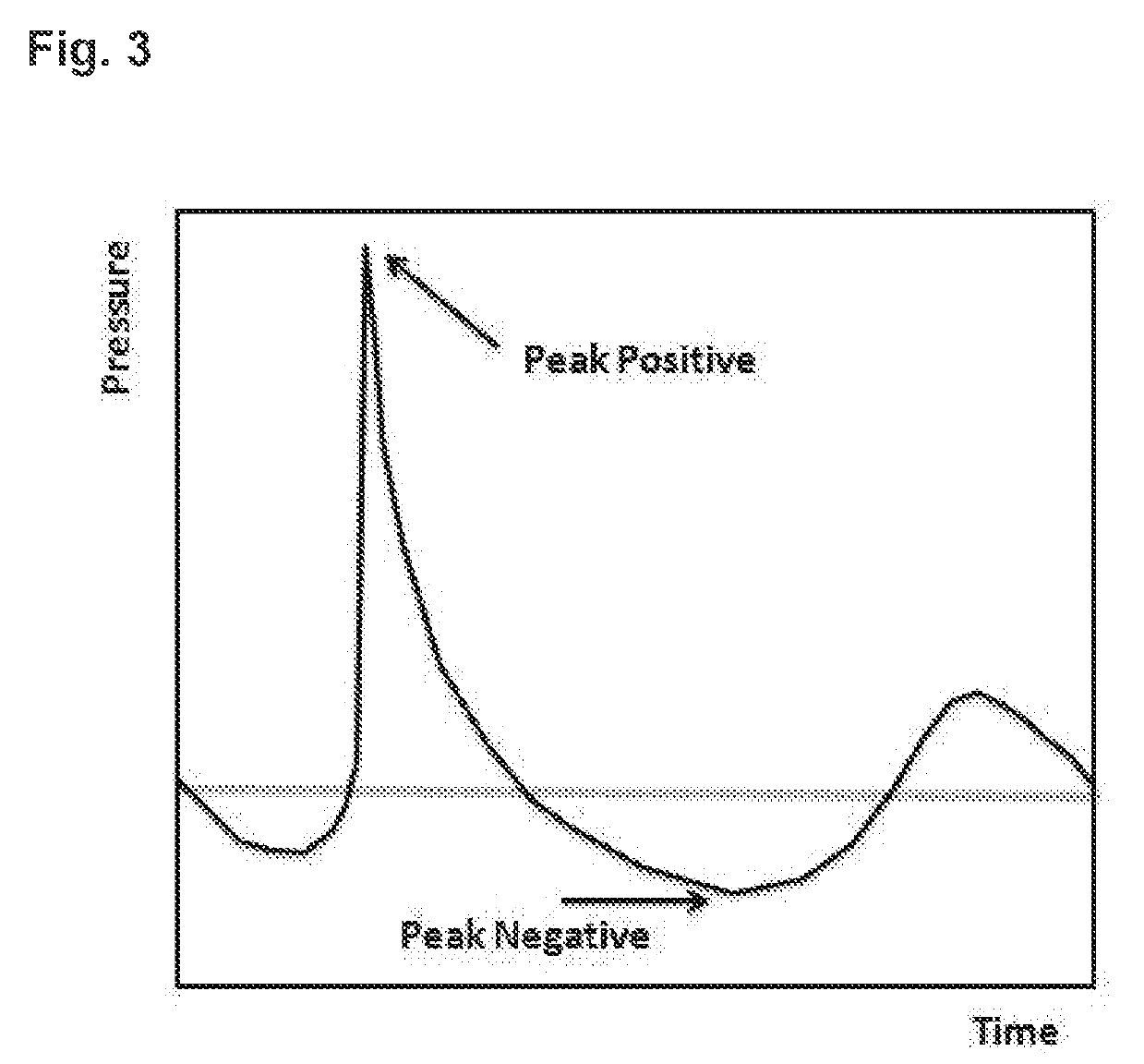

Histotripsy excitation sequences optimized for bubble cloud formation using shock scattering

PendingUS20190275353A1Lower potentialIncrease probabilityUltrasound therapySurgerySonificationTransducer

Owner:RGT UNIV OF MICHIGAN +1

Preparation method of naturally aromatized cigarettes

The invention discloses a preparation method of naturally aromatized cigarettes. The preparation method comprises the following steps: grinding a tobacco raw material and natural plant perfumes into powder respectively, and uniformly mixing the powder with a pore-foaming agent, hot melt adhesive powder and a combustion improver, thus obtaining mixed powder; uniformly stirring an adhesive and a humectant, thus obtaining a mixed solution; carrying out mixed granulation on the mixed powder and the mixed solution, and preparing the obtained reconstituted tobacco / perfume composite particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; and wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carryingout compounding with filter sticks, thus obtaining the cigarettes which are high in hardness, are mellow and full, and have regular and attractive cutting faces. The cigarettes are high in homogenization degree and good in stability, the problem that the homogenization is difficult to satisfy existing in the existing cigarettes is fundamentally solved, and the phenomena of tobacco shred falling atthe cut opening and empty head existing in the conventional cigarettes are avoided. The cigarettes are smooth in smoking and strong in satisfaction, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com