Preparation method of naturally aromatized cigarettes

A natural and fragrant technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of unstable cigarette product quality, shredded incision, unstable cigarette quality, etc. Discomfort relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

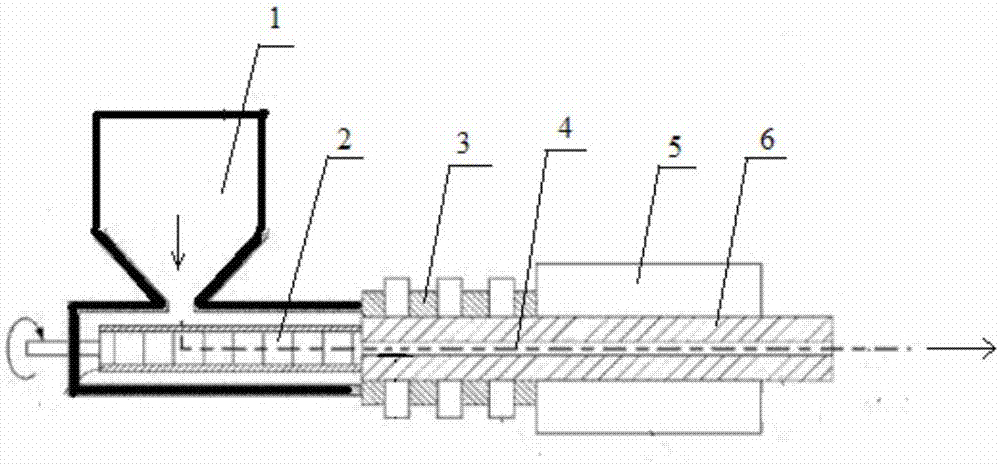

Method used

Image

Examples

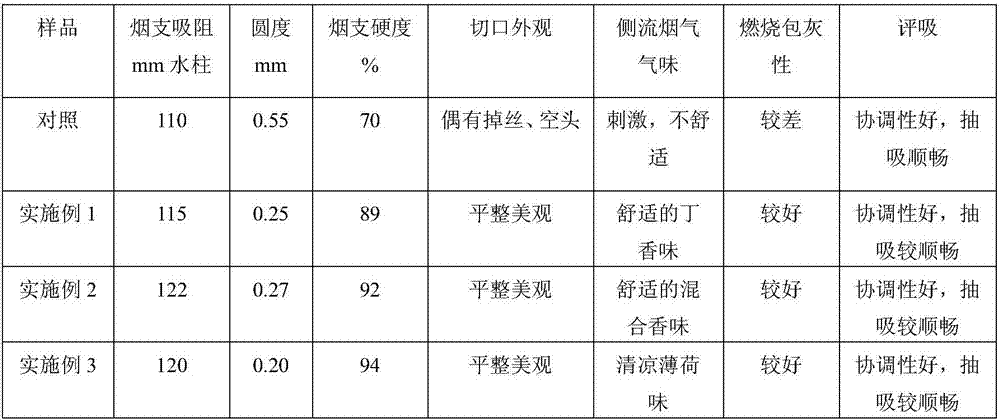

Embodiment 1

[0046] 1) Grinding tobacco leaves and tobacco stems into 100-120 mesh tobacco powder at 40°C; 2) Grinding cloves into 100-120 mesh clove powder at 40°C; 3) Grinding the above tobacco powder, clove powder, sodium bicarbonate, Polyethylene powder and potassium citrate are stirred and mixed uniformly according to the mass ratio of 100:0.1:2:8:0.5 to obtain a mixed powder; 4) the white latex and propylene glycol are stirred uniformly according to a mass ratio of 100:5 to obtain a mixed solution; 5) the above The mixed powder and the mixed solution are mixed and granulated according to the mass ratio of 100:20, properly dried and sieved to obtain reconstituted tobacco / flavor mixed granules with a particle size of 40-60 mesh and a moisture content of 15%; 6) using a continuous feeding device to mix the above The reconstituted tobacco / flavor granules are pressed from one end of a cylindrical mold with a diameter of 7.5mm, and after being solidified, dried and cooled, extruded from the...

Embodiment 2

[0048] 1) Grinding the tobacco leaves into 100-120 mesh tobacco powder at 40°C; 2) Grinding cloves and cardamom into 100-120 mesh mixed spice powder at 40°C at a mass ratio of 1:5; 3) Grinding the above tobacco powder, Mix spice powder, baking powder, polymerized rosin gum powder, and potassium citrate at a mass ratio of 100:0.5:3:5:0.8 and stir and mix evenly to obtain a mixed powder; 4) Mix modified starch aqueous solution and maltooligosaccharide alcohol by mass Stir evenly at a ratio of 100:10 to obtain a mixed solution; 5) Mix and granulate the above-mentioned mixed powder and mixed solution according to a mass ratio of 100:25, dry appropriately, and sieve to obtain a reconstituted product with a particle size of 40-60 mesh and a moisture content of 18%. Tobacco / flavor mixed granules; 6) Use a continuous feeding device to press the above-mentioned reconstituted tobacco / flavor granules from one end of a cylindrical mold with a diameter of 7.5 mm, and extrude from the other ...

Embodiment 3

[0050] 1) Grinding tobacco leaves and stems at 40°C into 100-120 mesh tobacco powder; 2) Grinding mint into 100-120 mesh mint powder at 40°C; 3) Mixing the above tobacco powder and mint powder with urea and polyisobutene , Potassium citrate according to mass ratio 100:1:3:5:1 stirring and mixing to obtain mixed powder; 4) modified chitosan aqueous solution, glycerin is stirred according to mass ratio 100:5 to obtain mixed solution; 5) will The above-mentioned mixed powder and mixed solution are mixed and granulated according to the mass ratio of 100:20, properly dried and sieved to obtain reconstituted tobacco / flavor mixed granules with a particle size of 40-60 mesh and a moisture content of 15%; 6) using a continuous feeding device to The above-mentioned reconstituted tobacco / flavor granules are pressed from one end of a cylindrical mold with a diameter of 7.5mm, and after being solidified, dried and cooled, extruded from the other end to obtain a loose and breathable round ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com