Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

516results about How to "Guaranteed height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

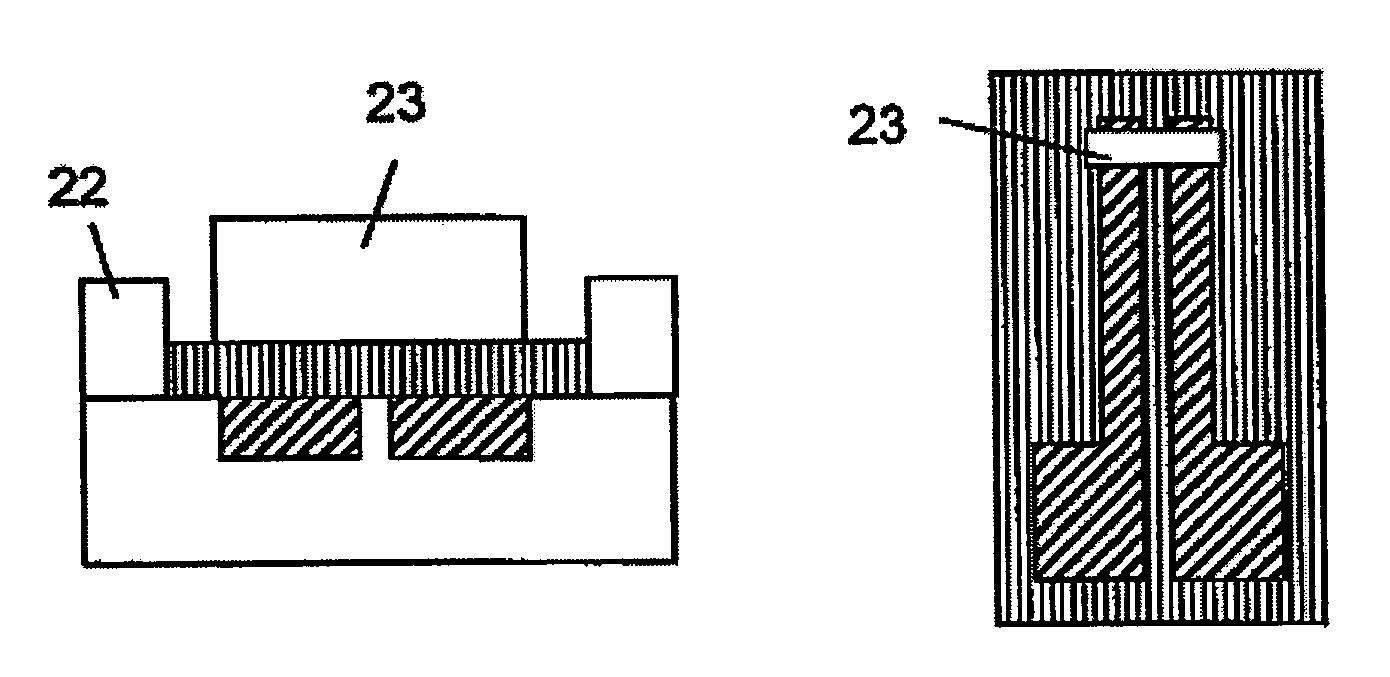

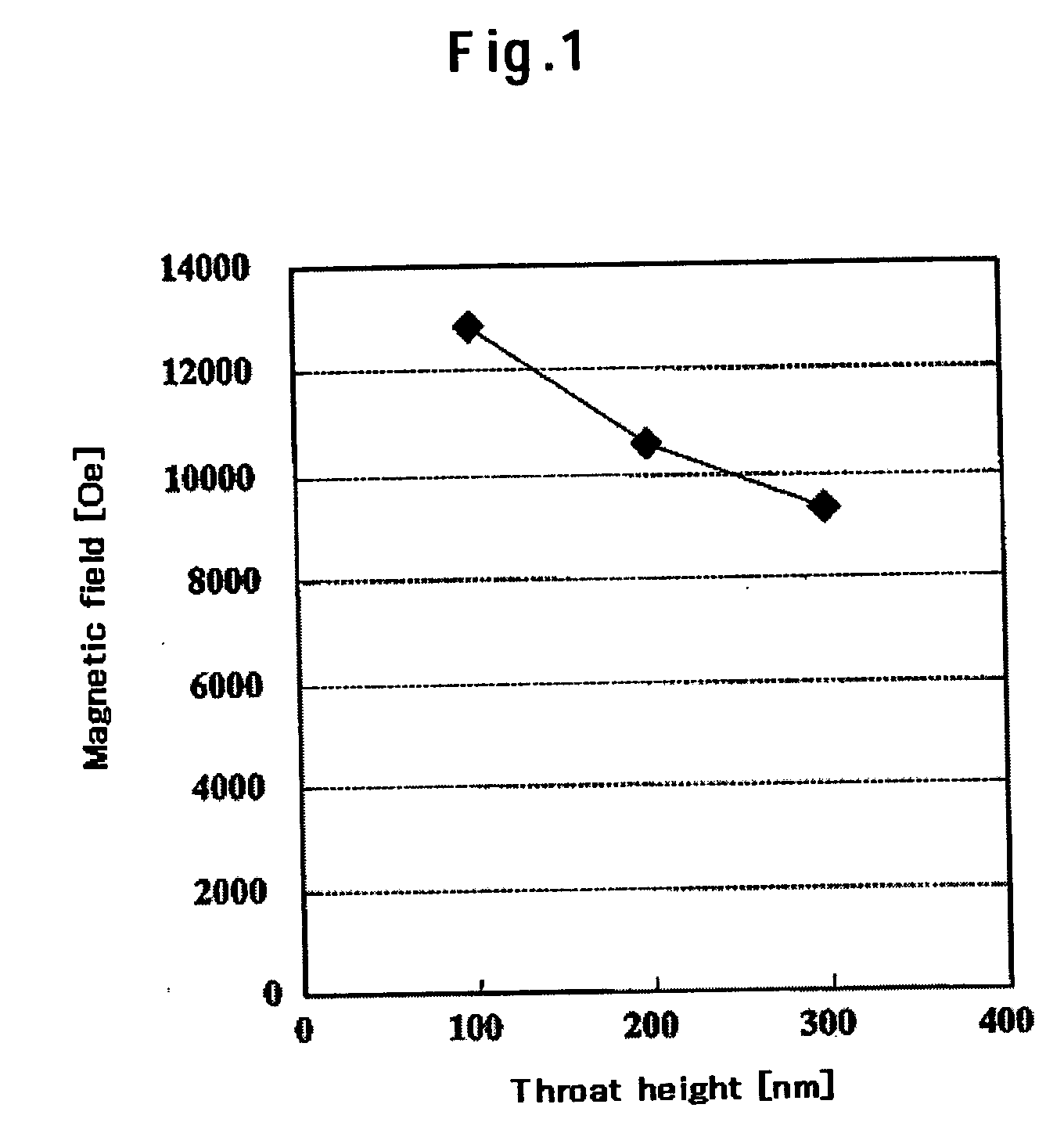

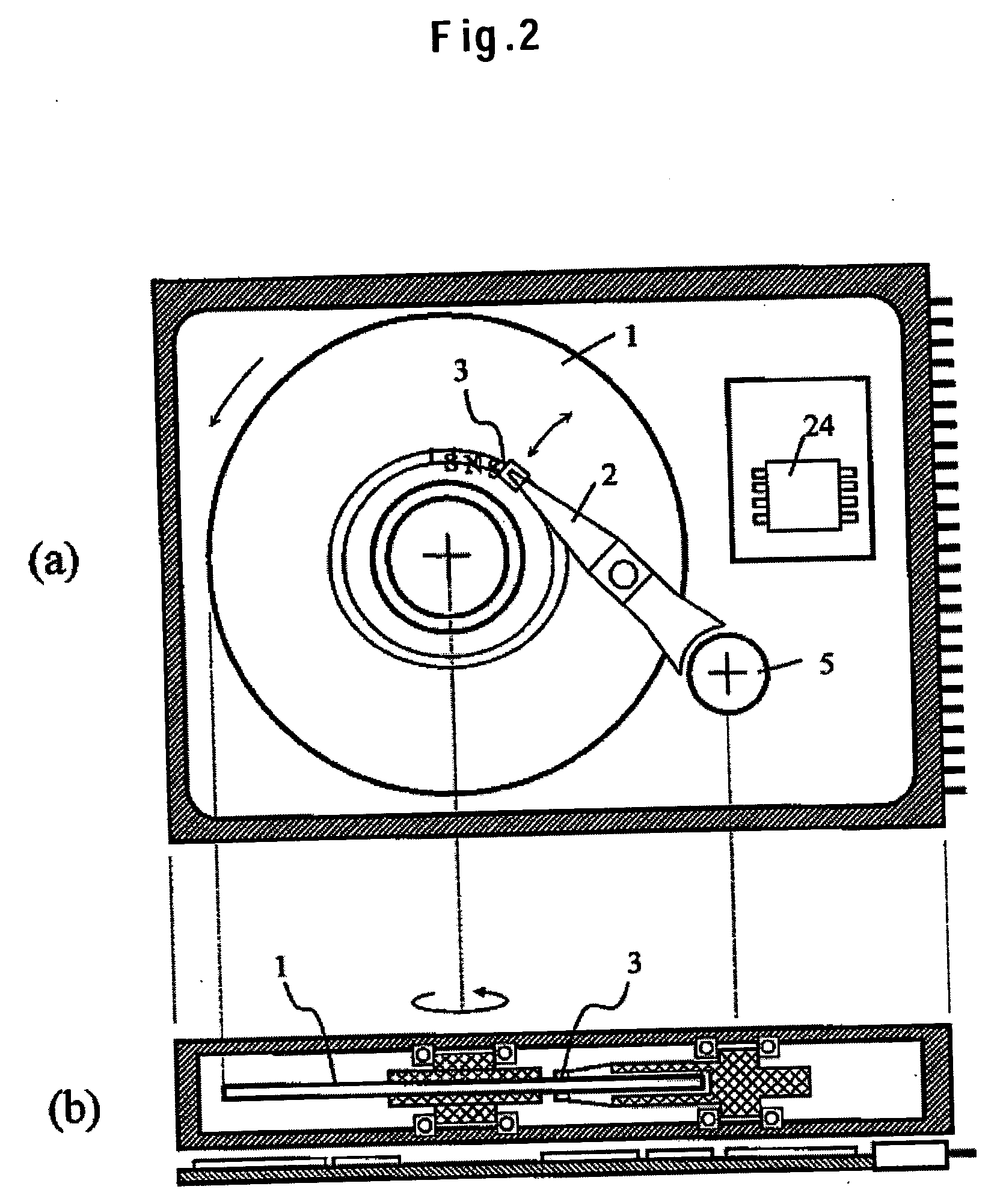

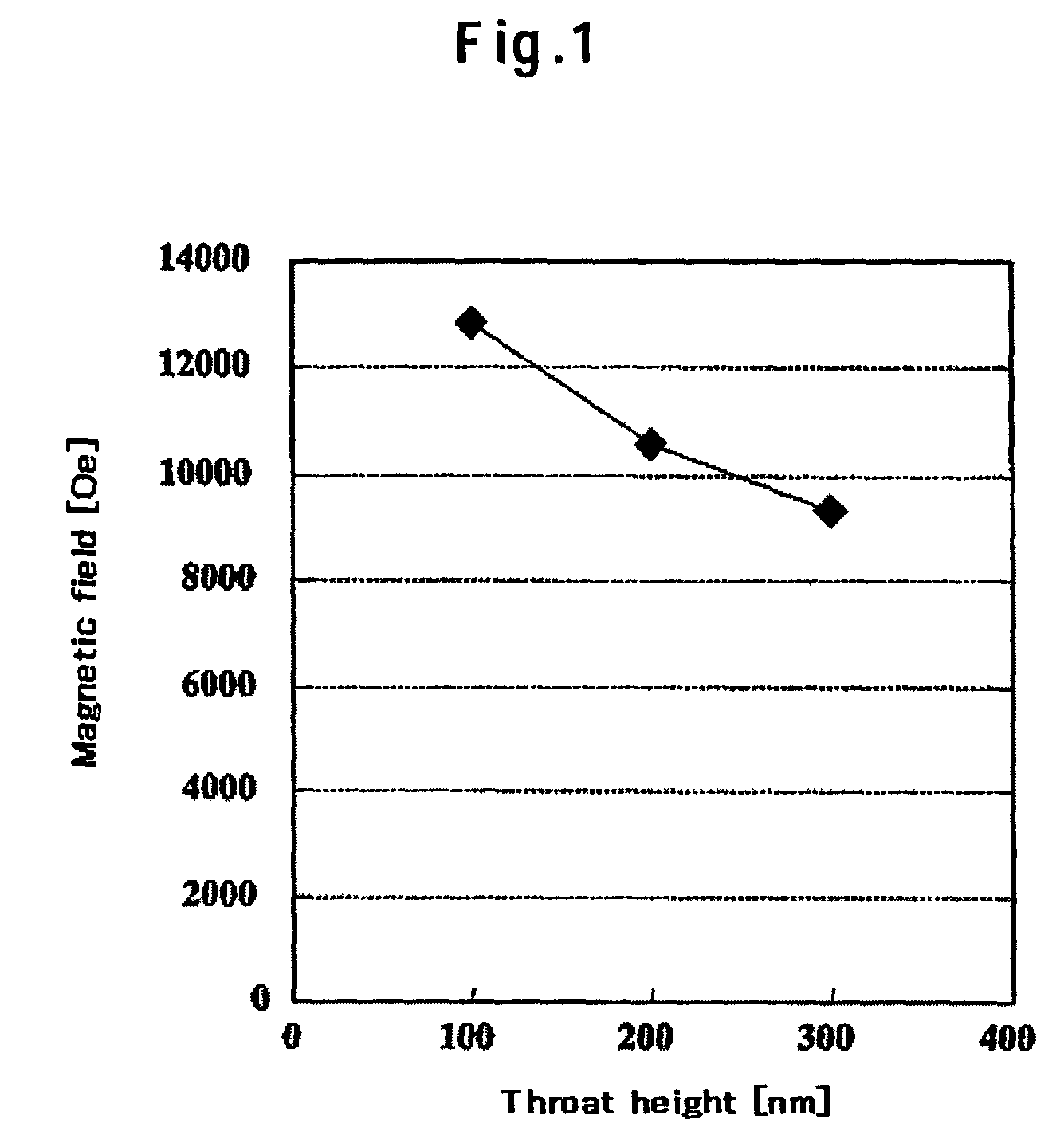

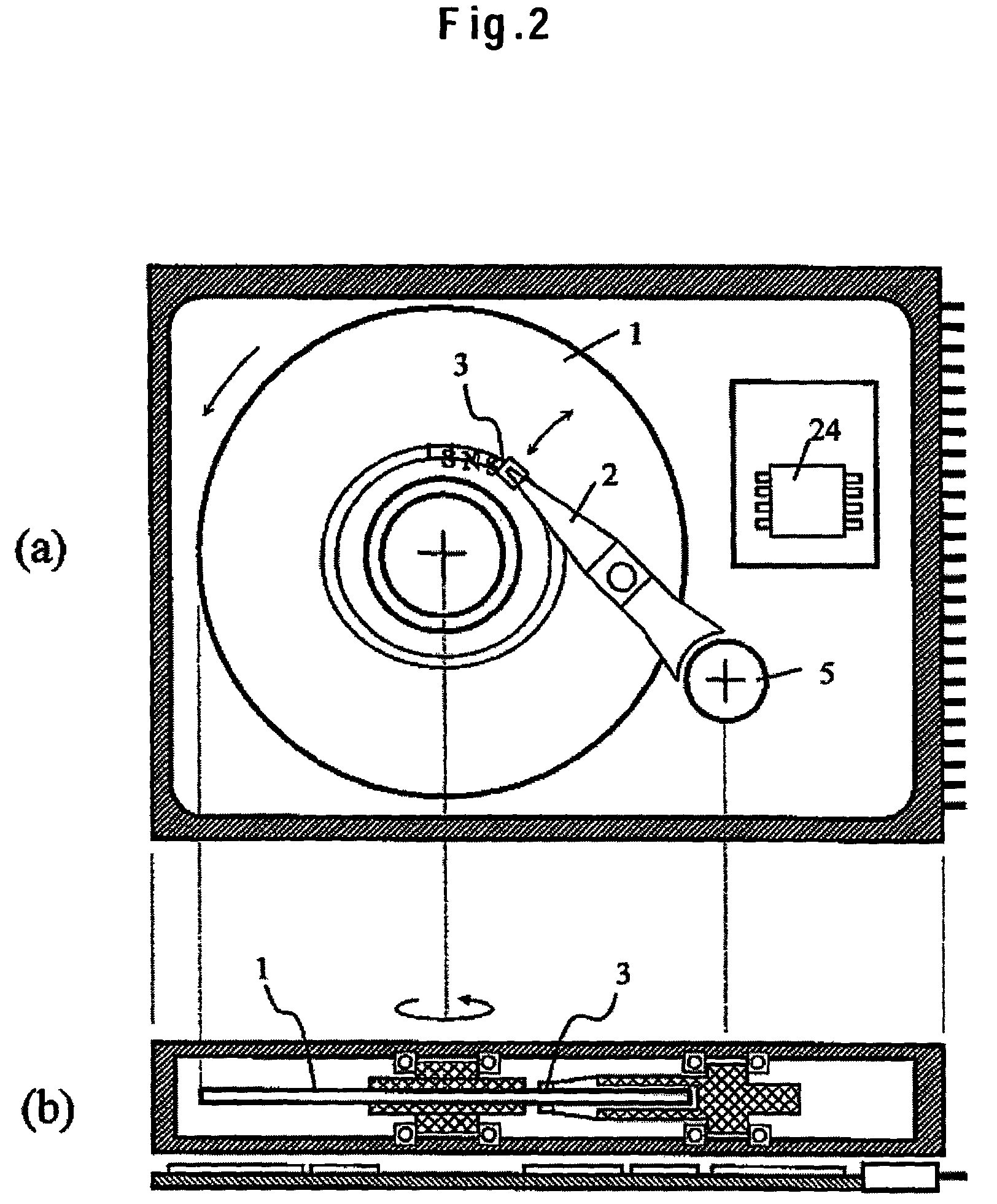

Magnetic head with electro lapping guide and manufacturing method

InactiveUS20060028770A1Throat heightImprove accuracyElectrical transducersManufacturing heads with multiple gapsElectronElectroplating

Embodiments of the invention reduce the throat height of a single pole type head with high accuracy. In one embodiment, a head with an electro lapping guide for controlling a write head's throat height during air bearing surface processing is made. Air bearing surface processing is performed using the electro lapping guide. For a read head, processing is performed using the read head itself or an electro lapping guide for the read head so that both the throat height of write head and the element height of read head are controlled.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

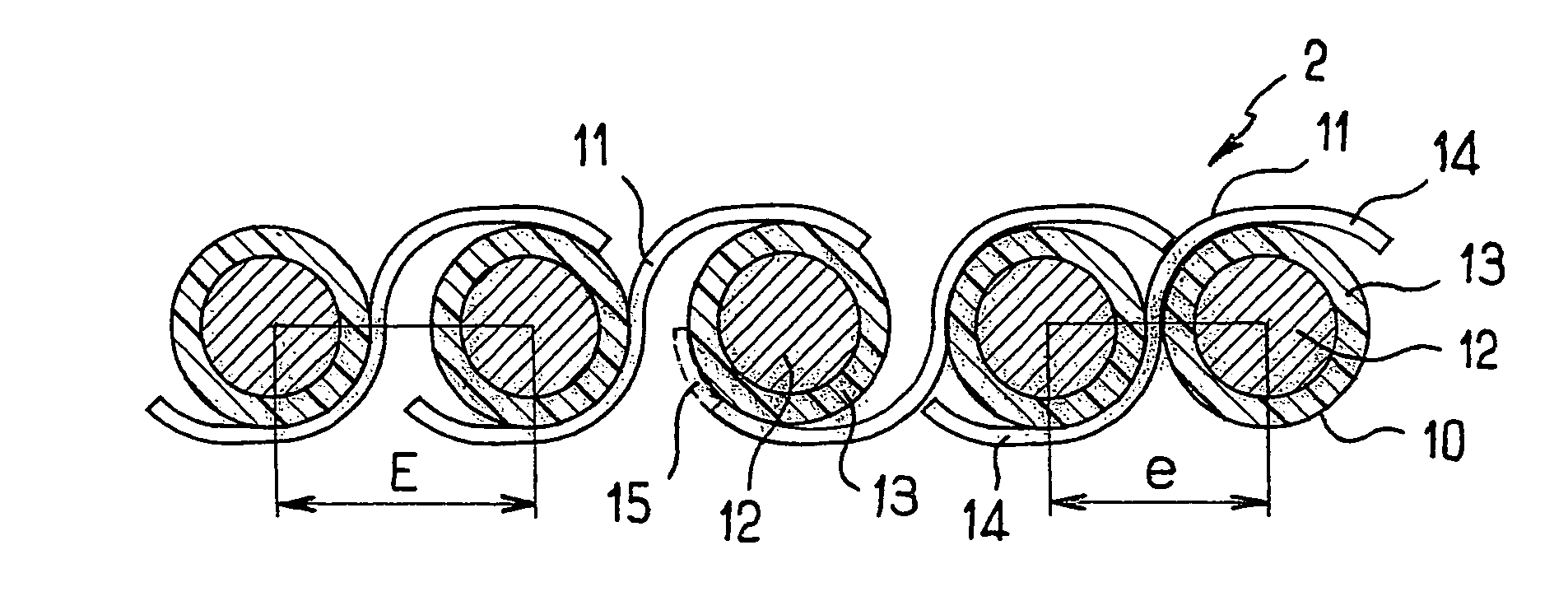

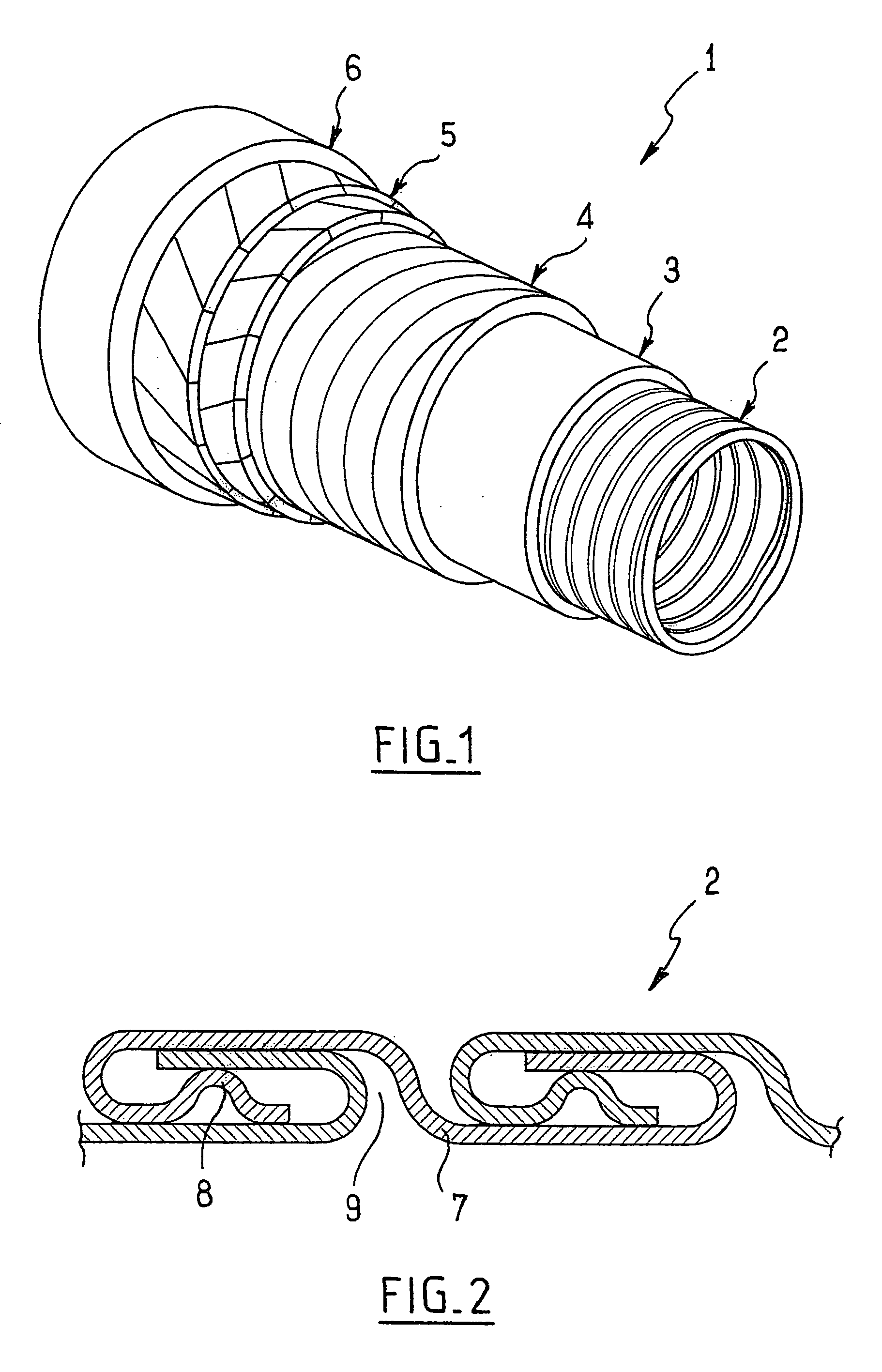

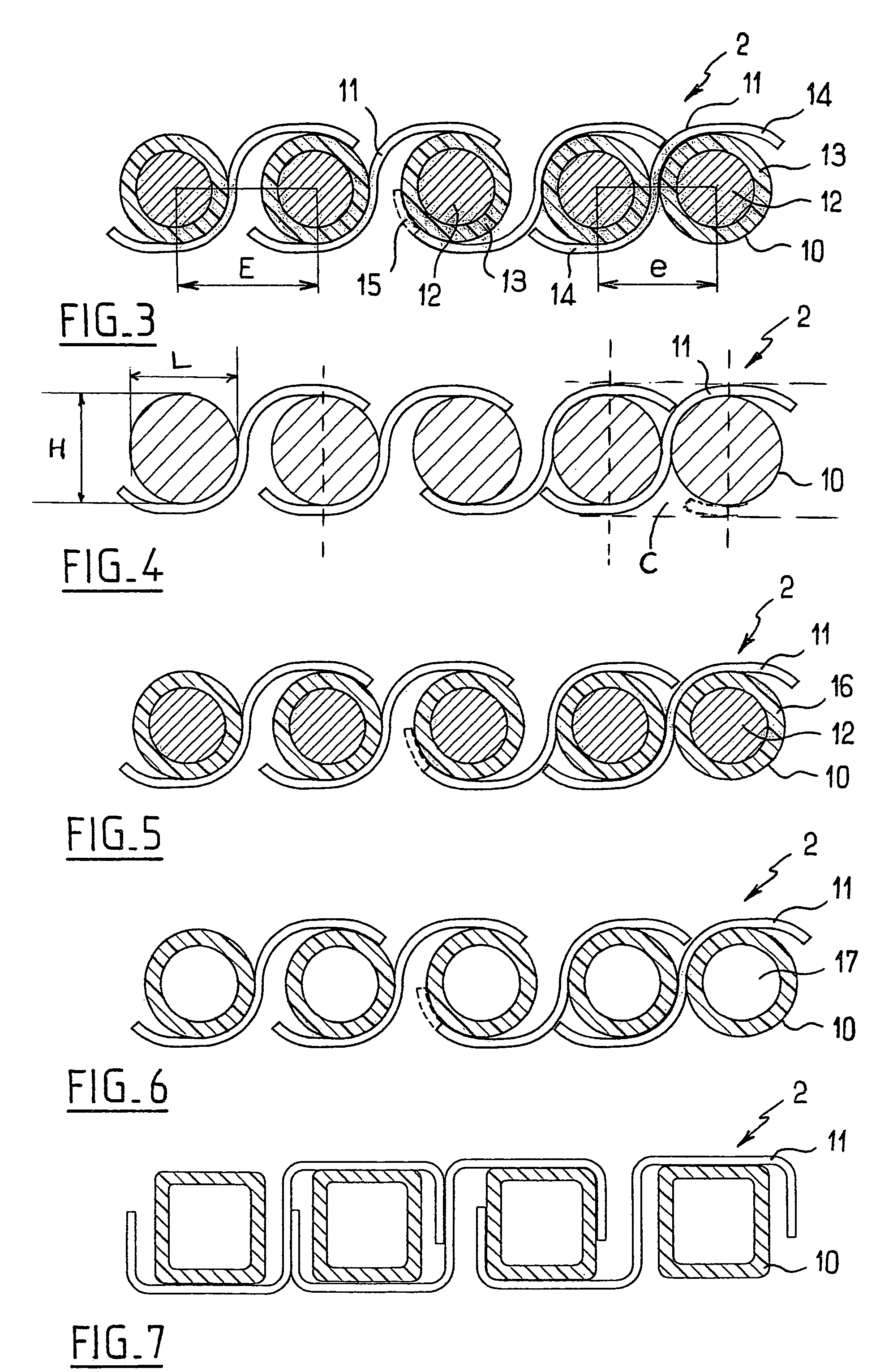

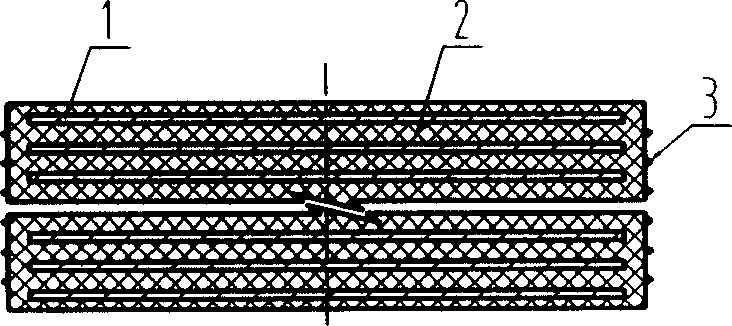

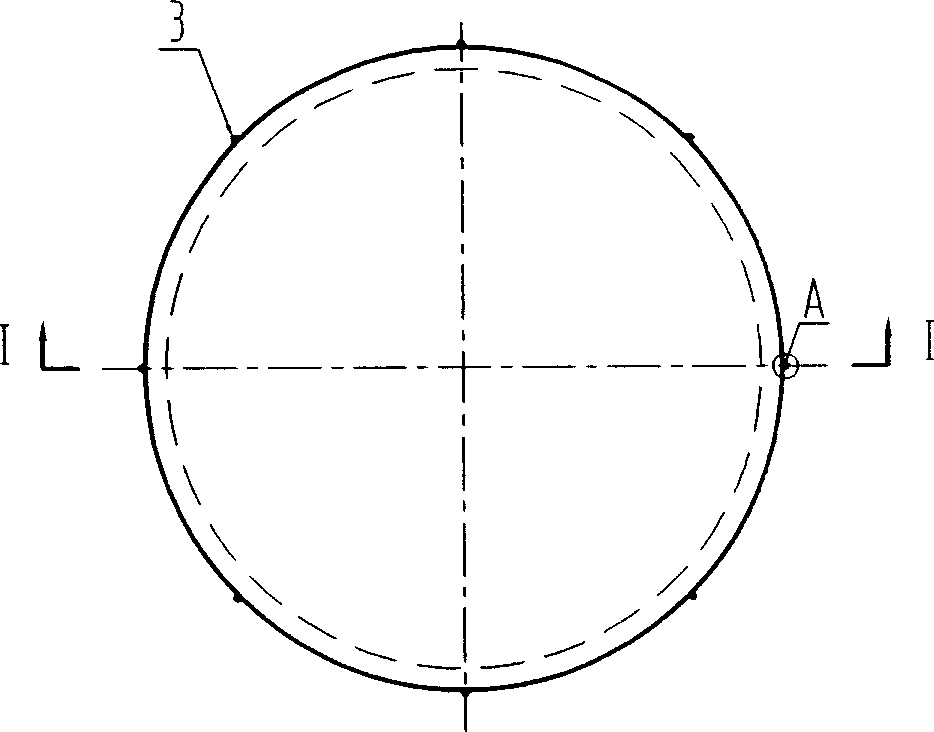

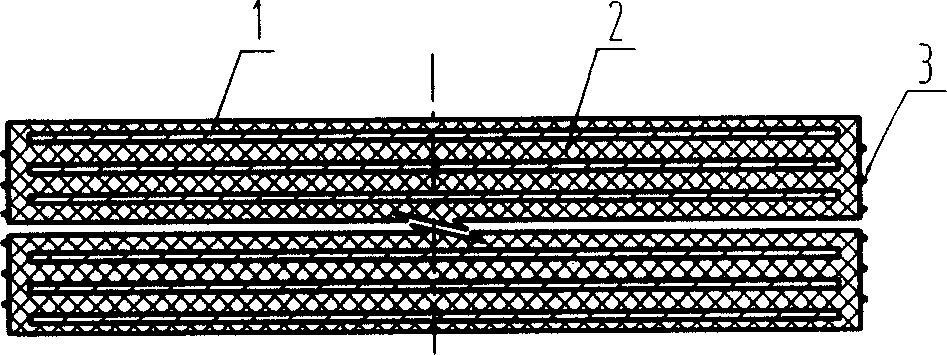

Flexible tubular pipe for hydrocarbon transport with carcass consisting of an elongated element stapled with a band iron

A flexible tubular pipe for hydrocarbon transport, comprising from inside to outside at least a carcass, an inner sheath, tensile armoring plies and an outer sheath, wherein the carcass is formed by winding of at least an anti-corrosive elongated metal element with large cross-section, with successive windings stapled with a thin anti-corrosive metal strip.

Owner:TECH FRANCE SA

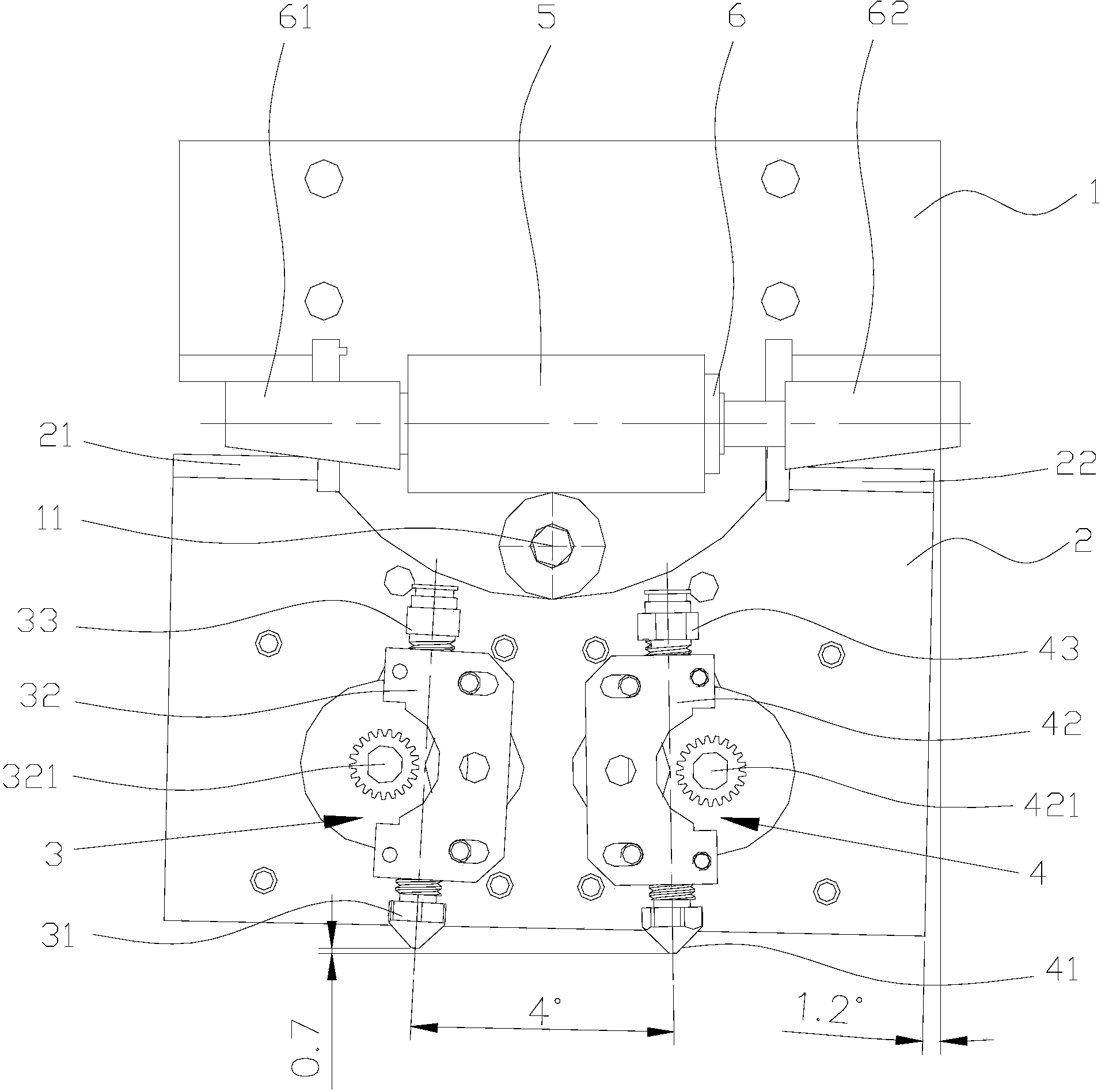

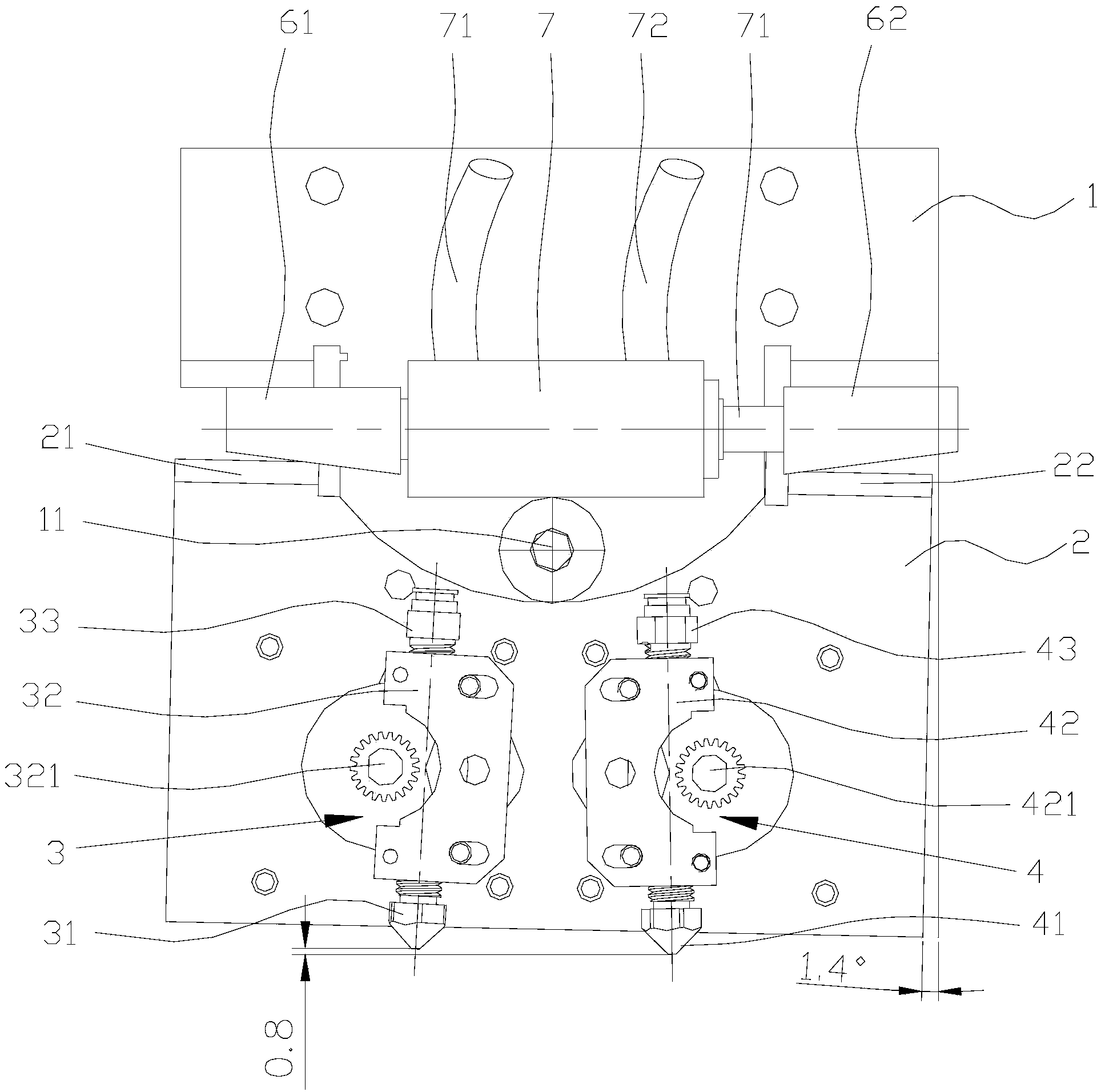

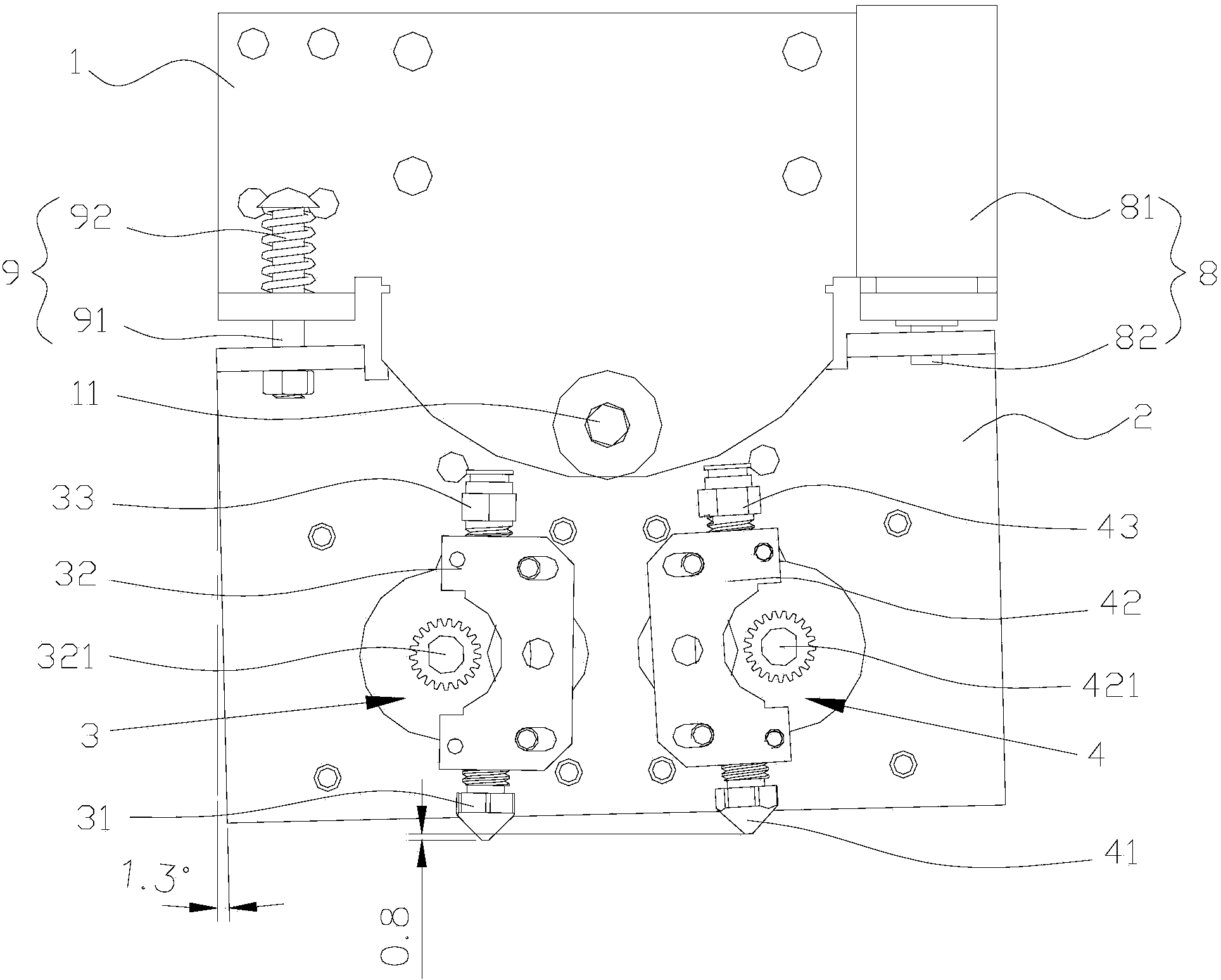

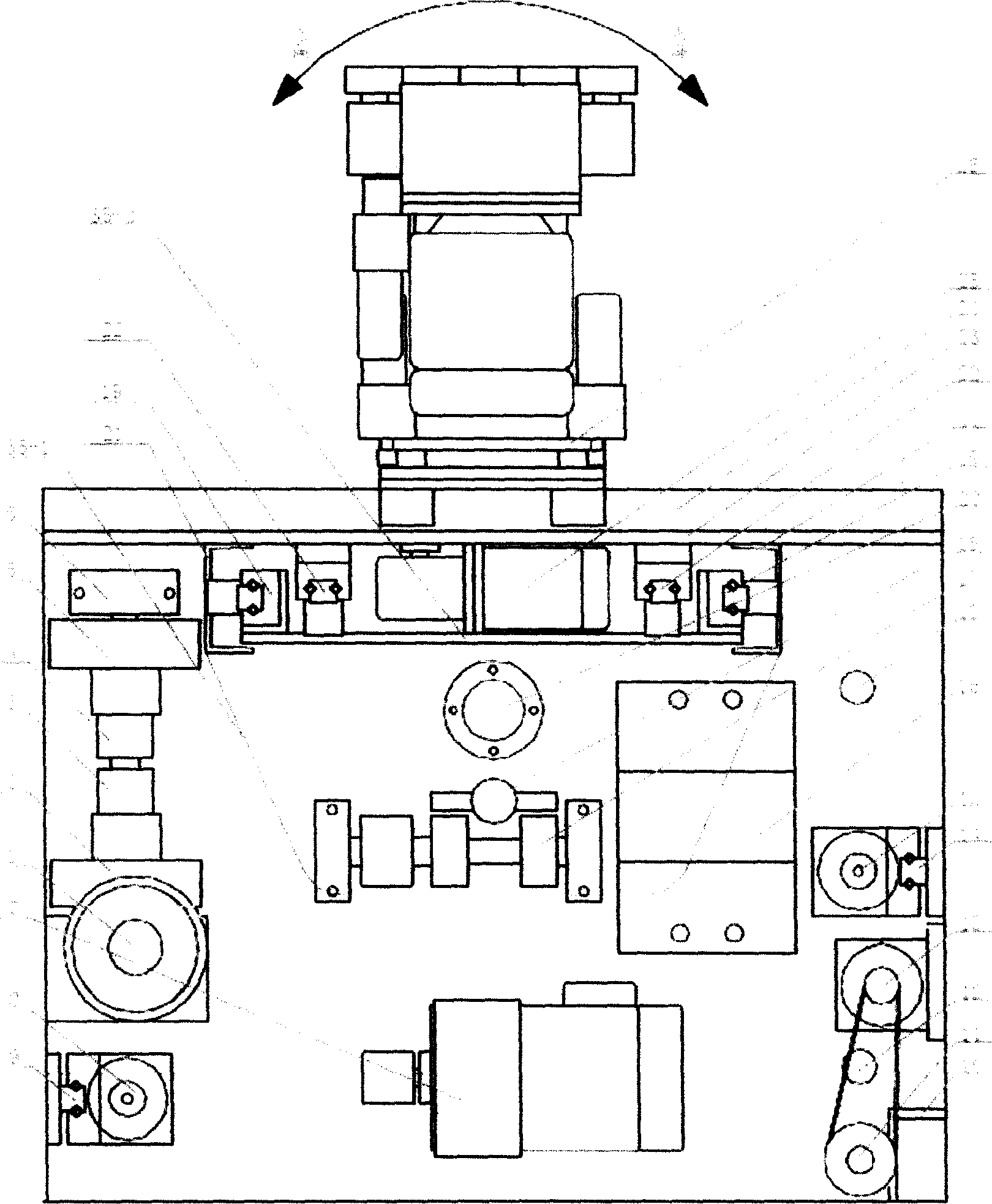

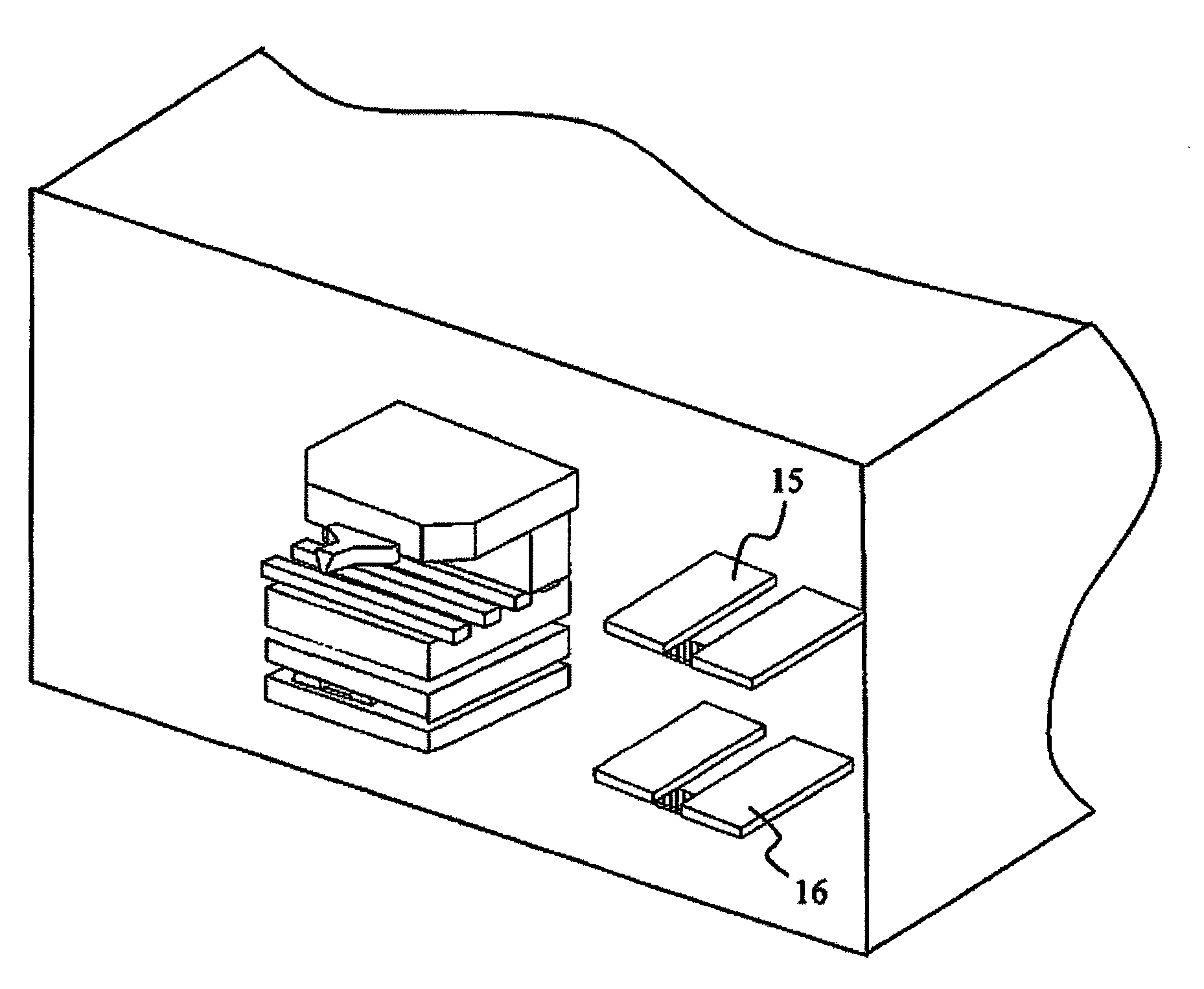

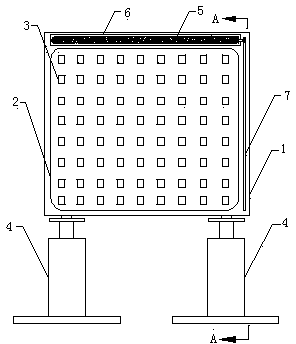

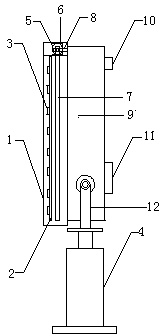

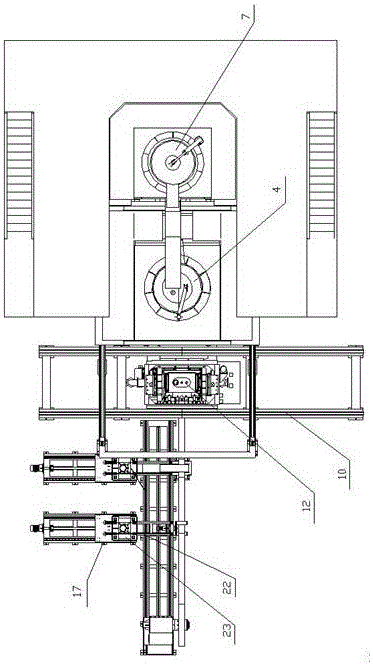

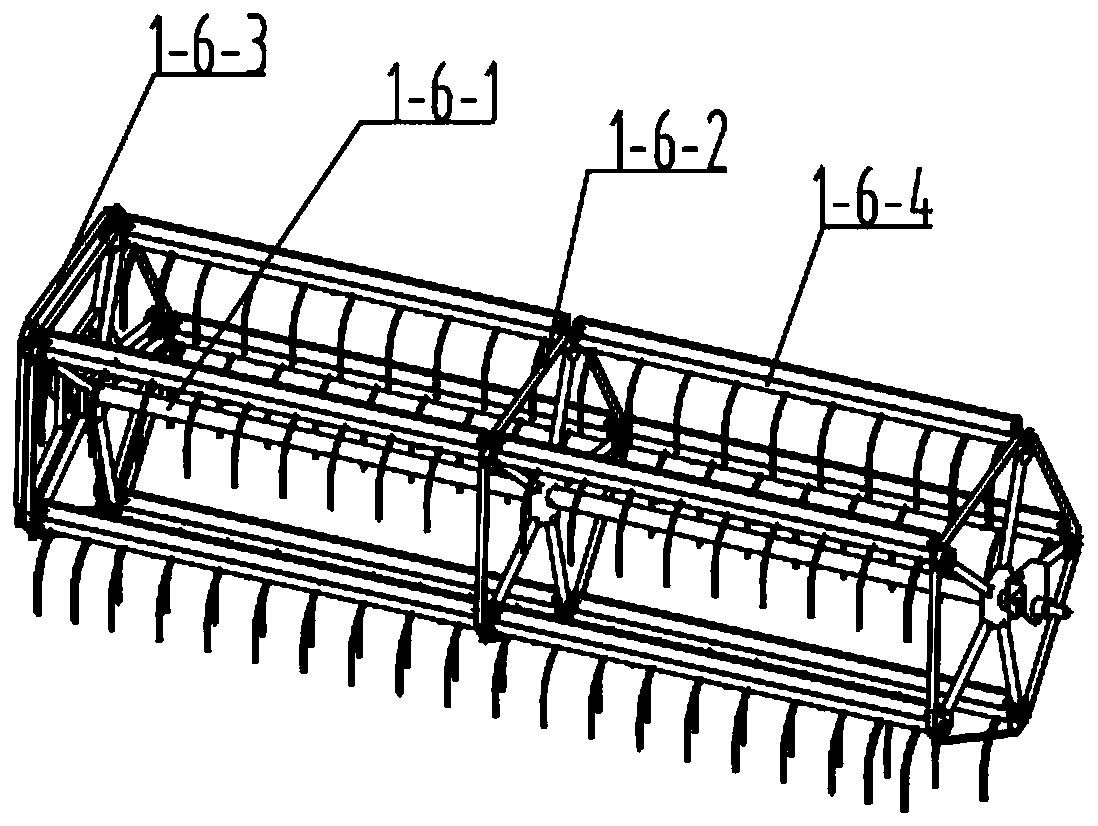

Dual-head 3D printer capable of rotatably switching printing heads

ActiveCN104228069AGuaranteed heightOvercoming problems with being at the same heightEngineering3d printer

Owner:苏州江南嘉捷光机电技术有限公司

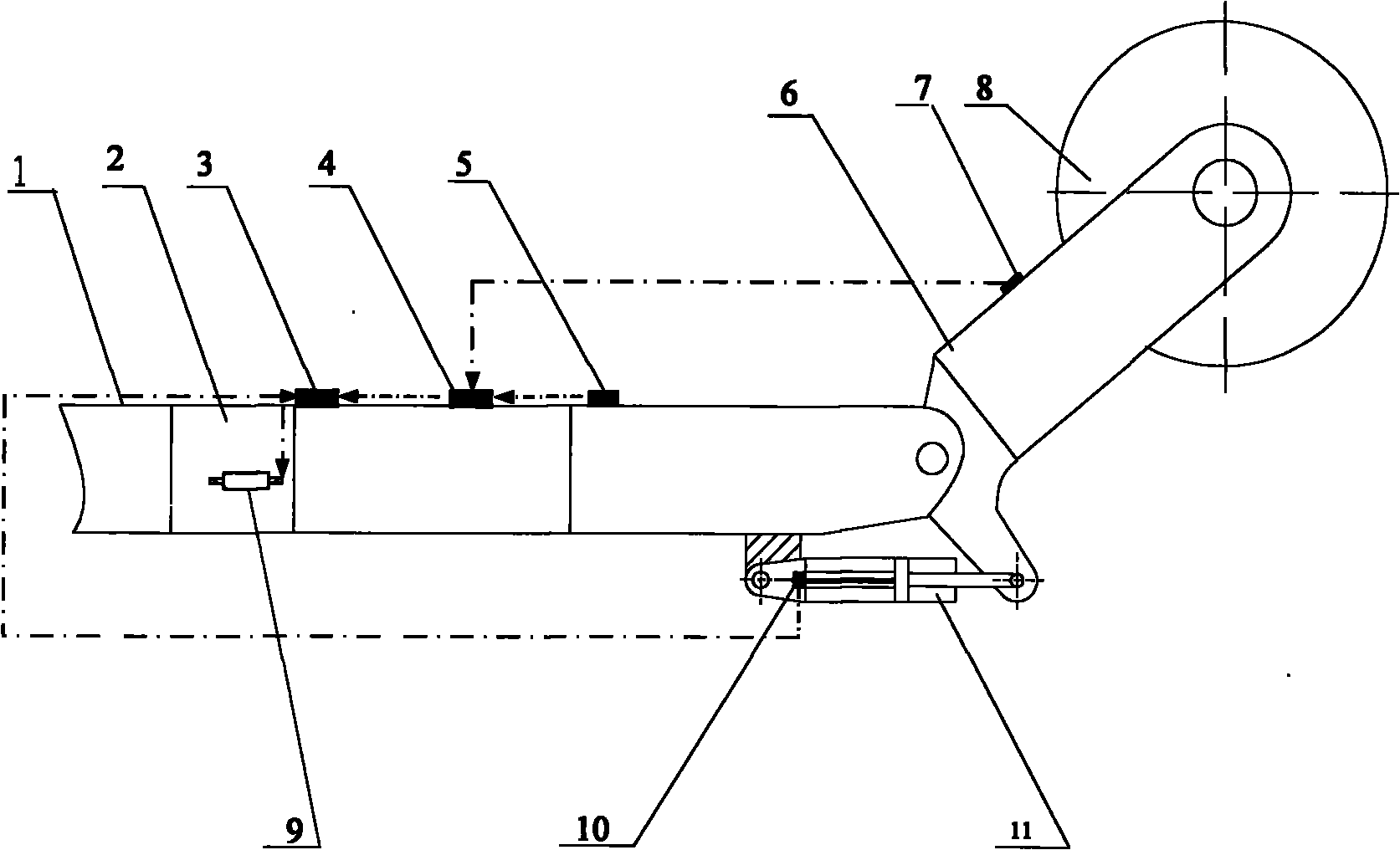

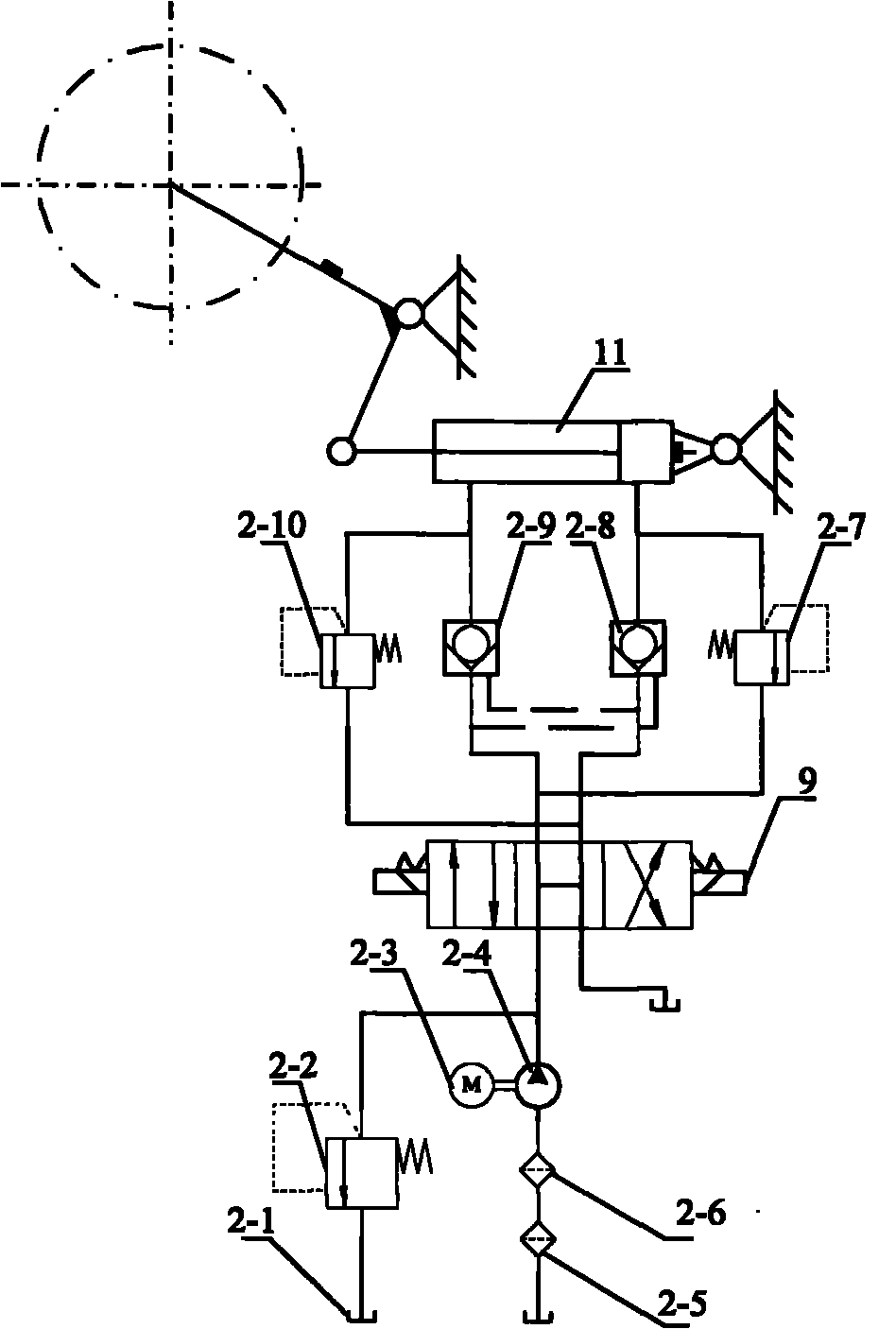

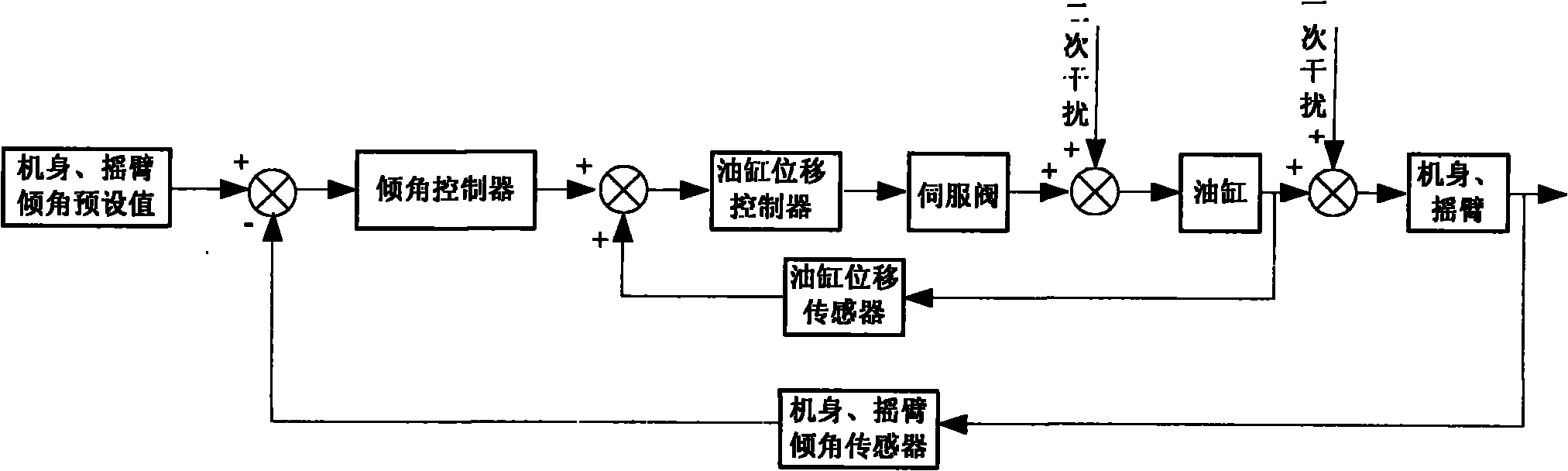

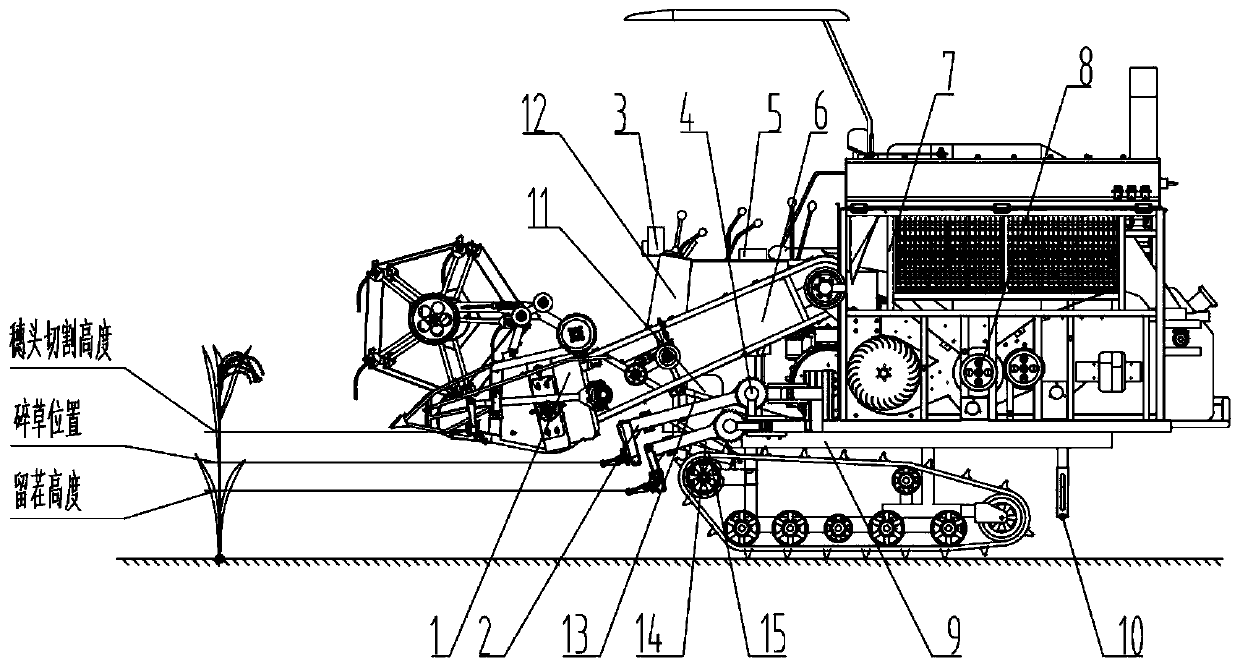

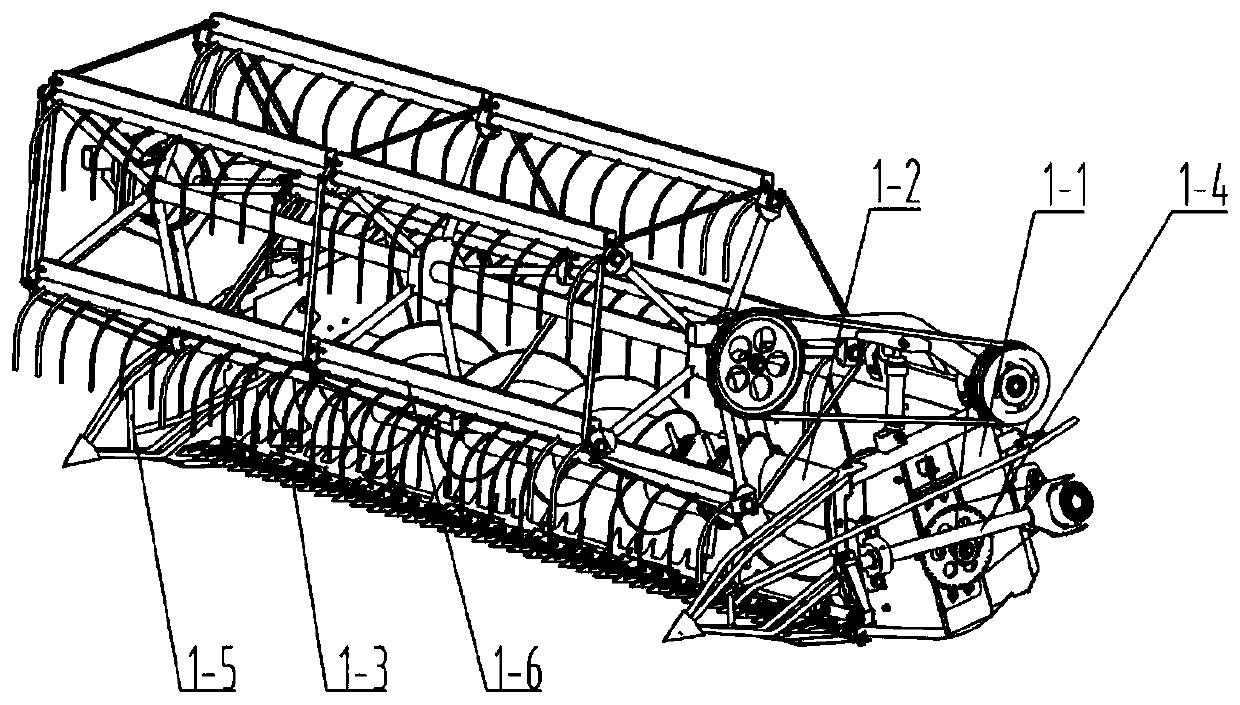

Automatic height-adjusting test device of coal mining machine roller and control method

InactiveCN101887273ATurn up fastImprove precisionControl using feedbackDriving meansDisplacement controlFuselage

The invention relates to an automatic height-adjusting test device of a coal mining machine roller and a control method. The device comprises a device body, a rocker arm, a roller, a height adjusting pump station, sensors, an inclined angle controller and a displacement controller, wherein the device body is articulated with the rocker arm; the output end of the rocker arm is connected with the roller; the height adjusting pump station is used for driving the rocker arm and the roller to move by an oil cylinder and simulating the running condition of a coal mining machine; the inclined angle sensors are arranged on both the device body and the rocker arm; the displacement sensor is arranged on the oil cylinder; the output of the inclined angle sensors on the device body and the rocker arm is compared with a corresponding inclined angle preset value, and an error is used as the input of the inclined angle controller; the output of the inclined angle controller is used as a preset value of the oil cylinder displacement controller and compared with the output data of the oil cylinder displacement controller, and an error is transmitted to the oil cylinder displacement controller; and the output of the oil cylinder displacement controller is used for controlling the opening and the direction of a servo valve and realizing the height adjustment of the roller. The invention is used for a test for researching the change of a cutting medium on the performance requirement of the roller height adjusting device and a test for researching the influence of oil cylinder displacement fluctuation on the height of the roller.

Owner:CHINA UNIV OF MINING & TECH

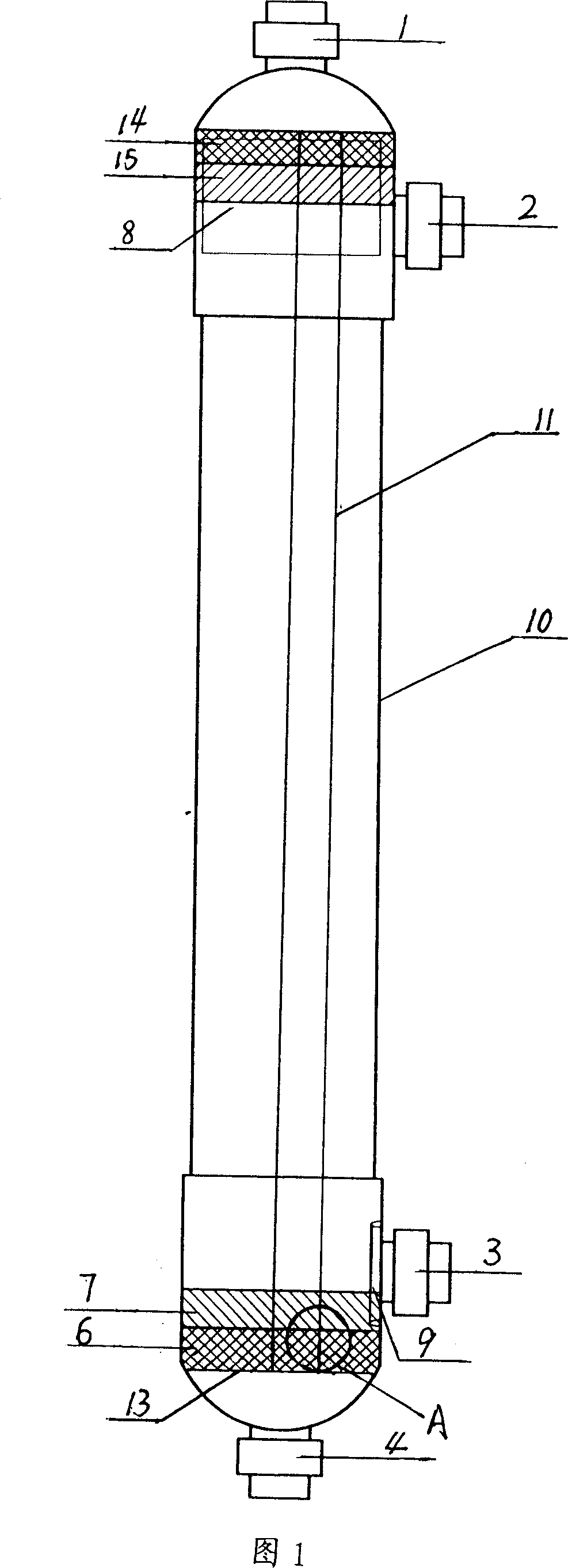

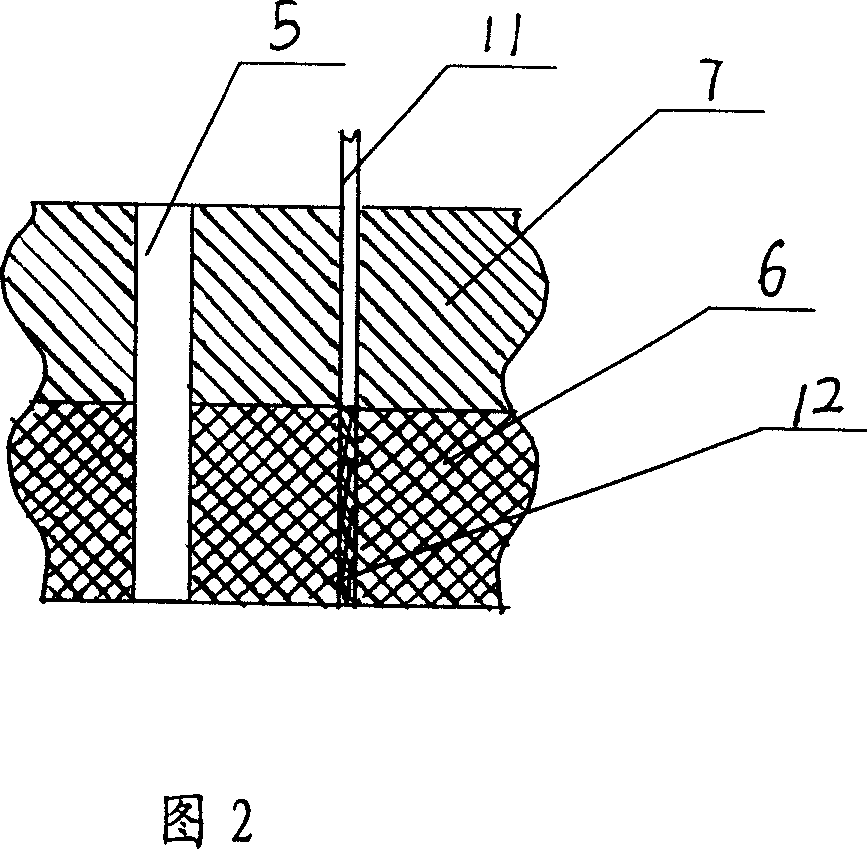

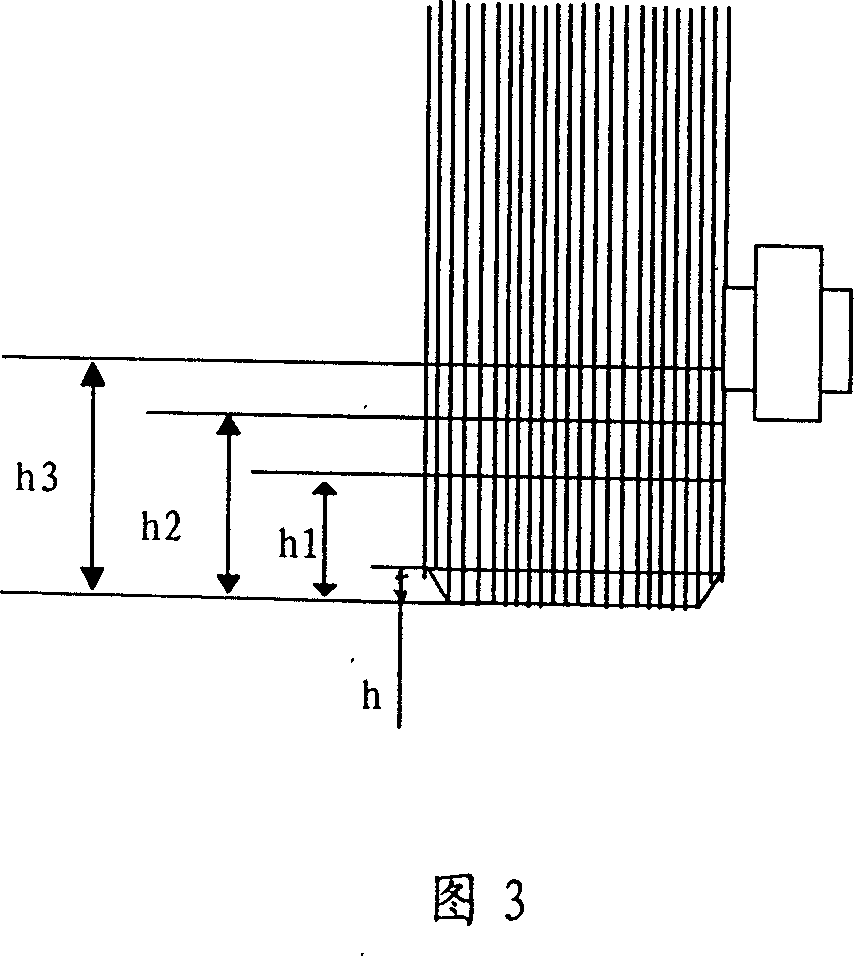

Column type membrane assembly and its producing method

ActiveCN1943844AExtended service lifePrevent leakageIon-exchange process apparatusSemi-permeable membranesFiberWater quality

The present invention discloses one kind of column type membrane assembly and its production process, and aims at providing one kind of column type membrane assembly with long service life and high output water quality. The membrane assembly is provided with water inlet, water outlet, spare port and concentrated liquid exit, and has fibers between the water inlet resin fixing layer and the water outlet resin fixing layer, water orifices inside resin fixing layers, filler inside the water inlet resin fixing layer and flexible resin protecting layer inside the water inlet resin fixing layer and the water outlet resin fixing layer. The membrane assembly has high output water quality and long service life.

Owner:TIANJIN MOTIMO MEMBRANE TECH

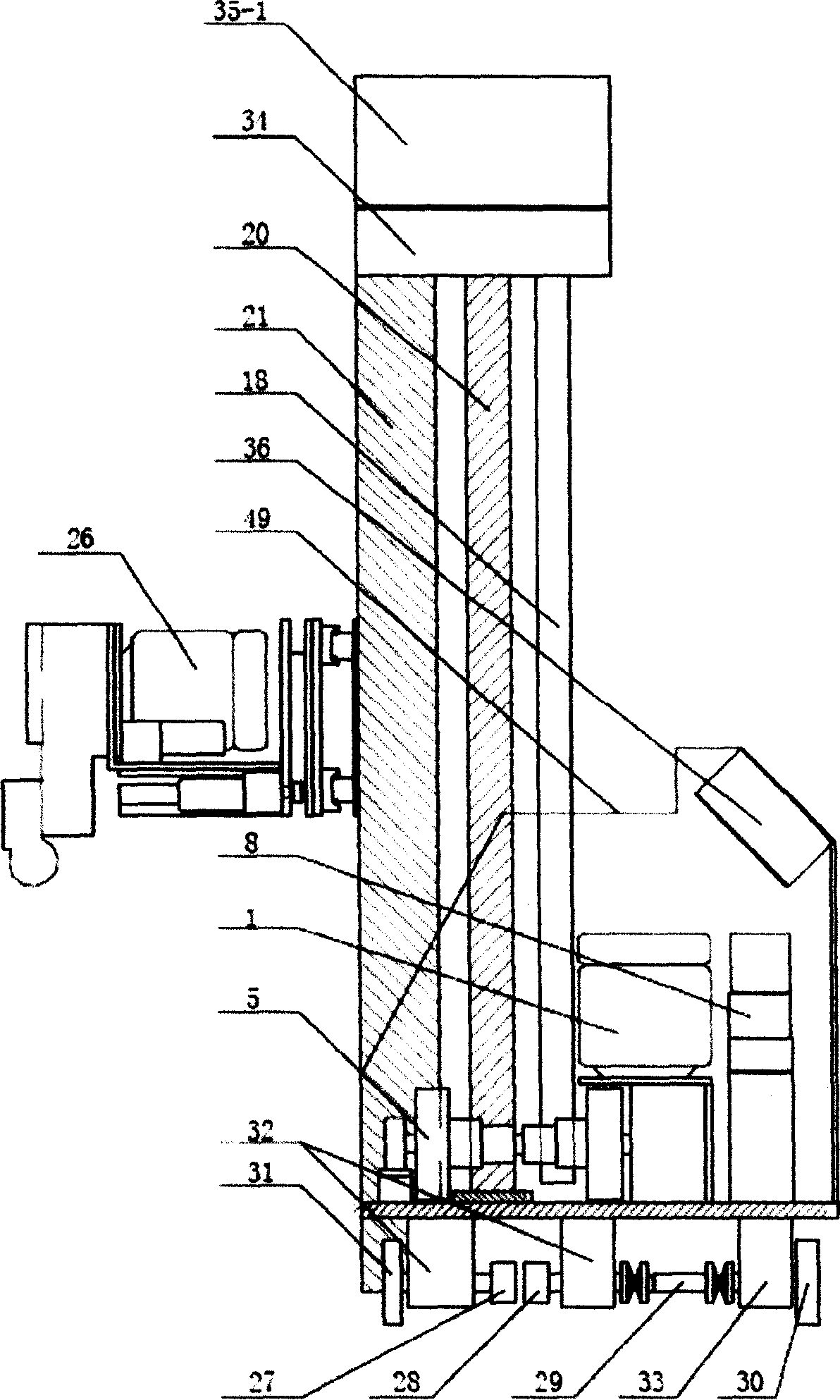

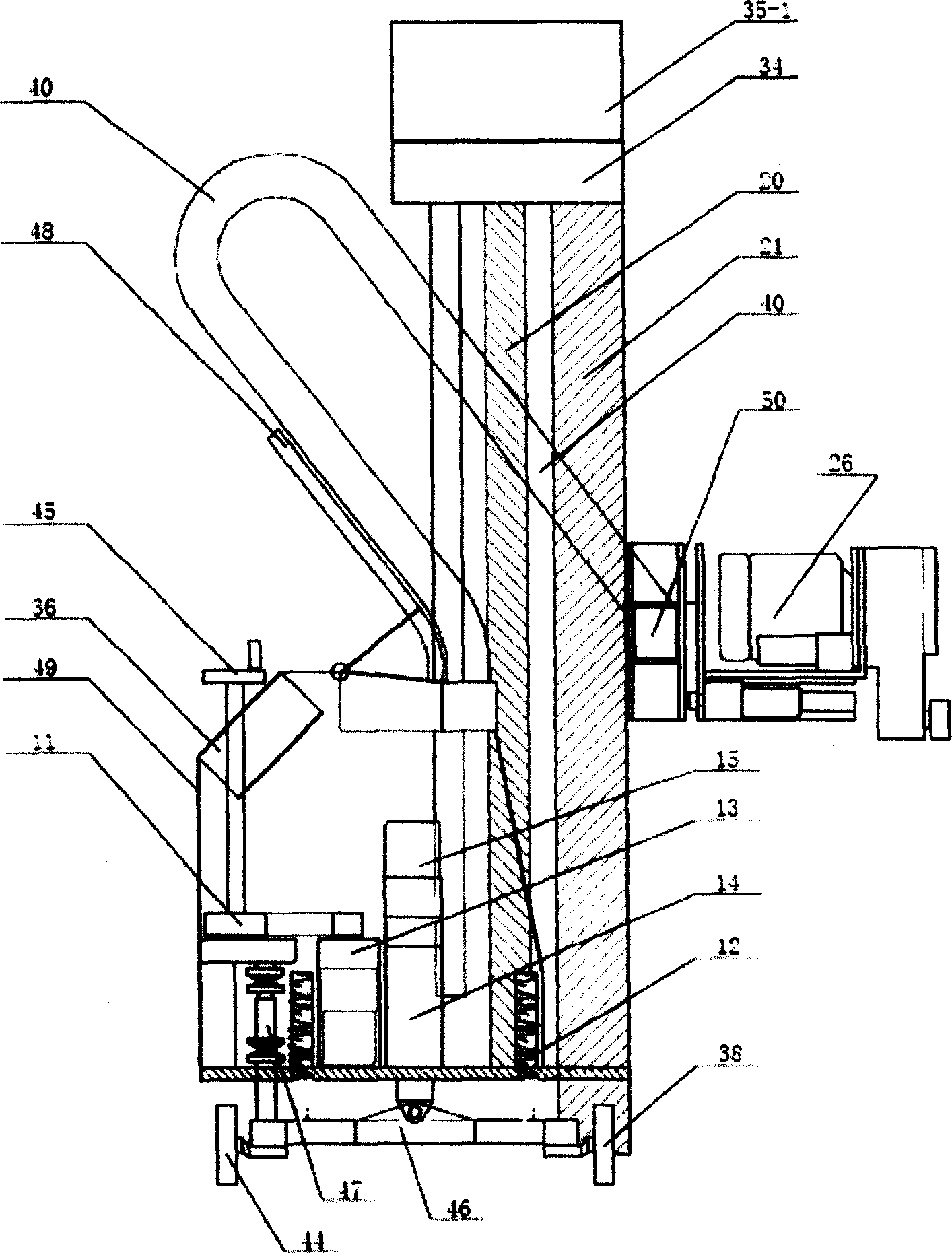

Intelligent numerically controlled plastering machine

The present invention relates to an intelligent numerically-controlled plastering machine. It includes sensing system, moving device, balancing device, lifting and falling device, working head device, system control device and main machine external shell. Said system control device is a programable micro-type computer. Besides, said invention also provides the concrete structure of the above-mentioned every device and its operation method.

Owner:蒲国民 +1

Magnetic head with electro lapping guide

InactiveUS8351162B2Throat heightImprove accuracyElectrical transducersManufacturing heads with multiple gapsControl theoryElectroplating

Embodiments of the invention reduce the throat height of a single pole type head with high accuracy. In one embodiment, a head with an electro lapping guide for controlling a write head's throat height during air bearing surface processing is made. Air bearing surface processing is performed using the electro lapping guide. For a read head, processing is performed using the read head itself or an electro lapping guide for the read head so that both the throat height of write head and the element height of read head are controlled.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

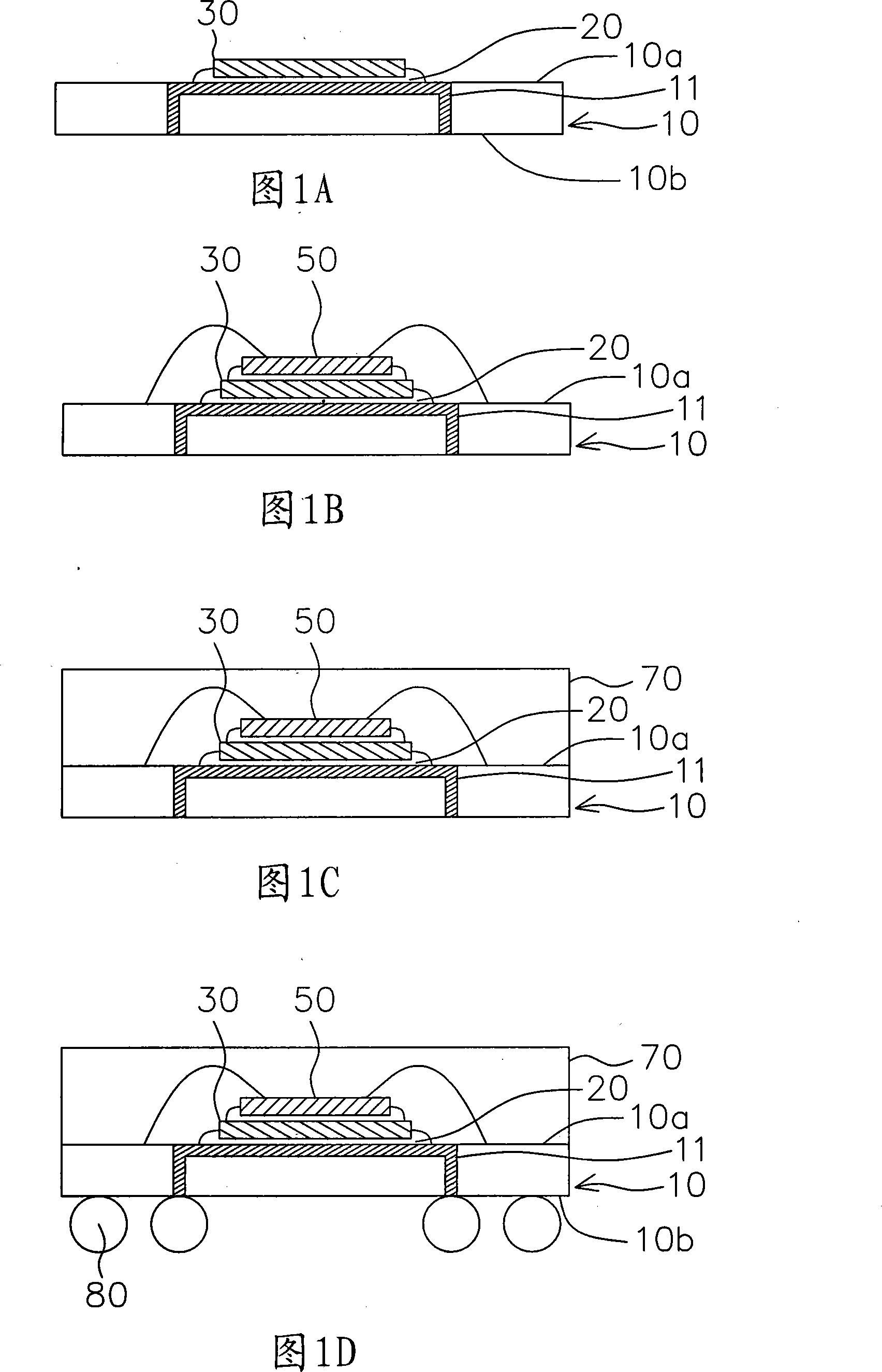

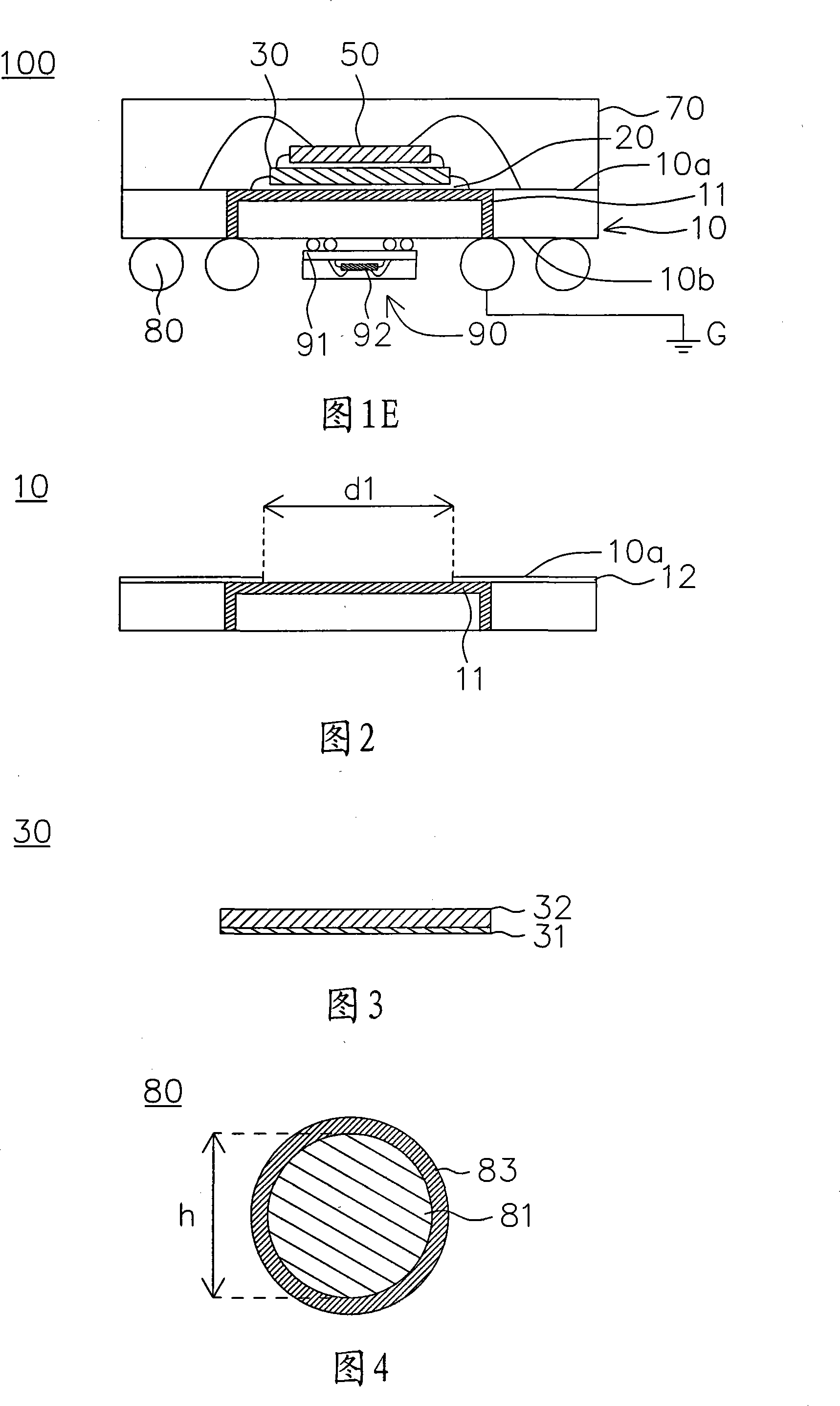

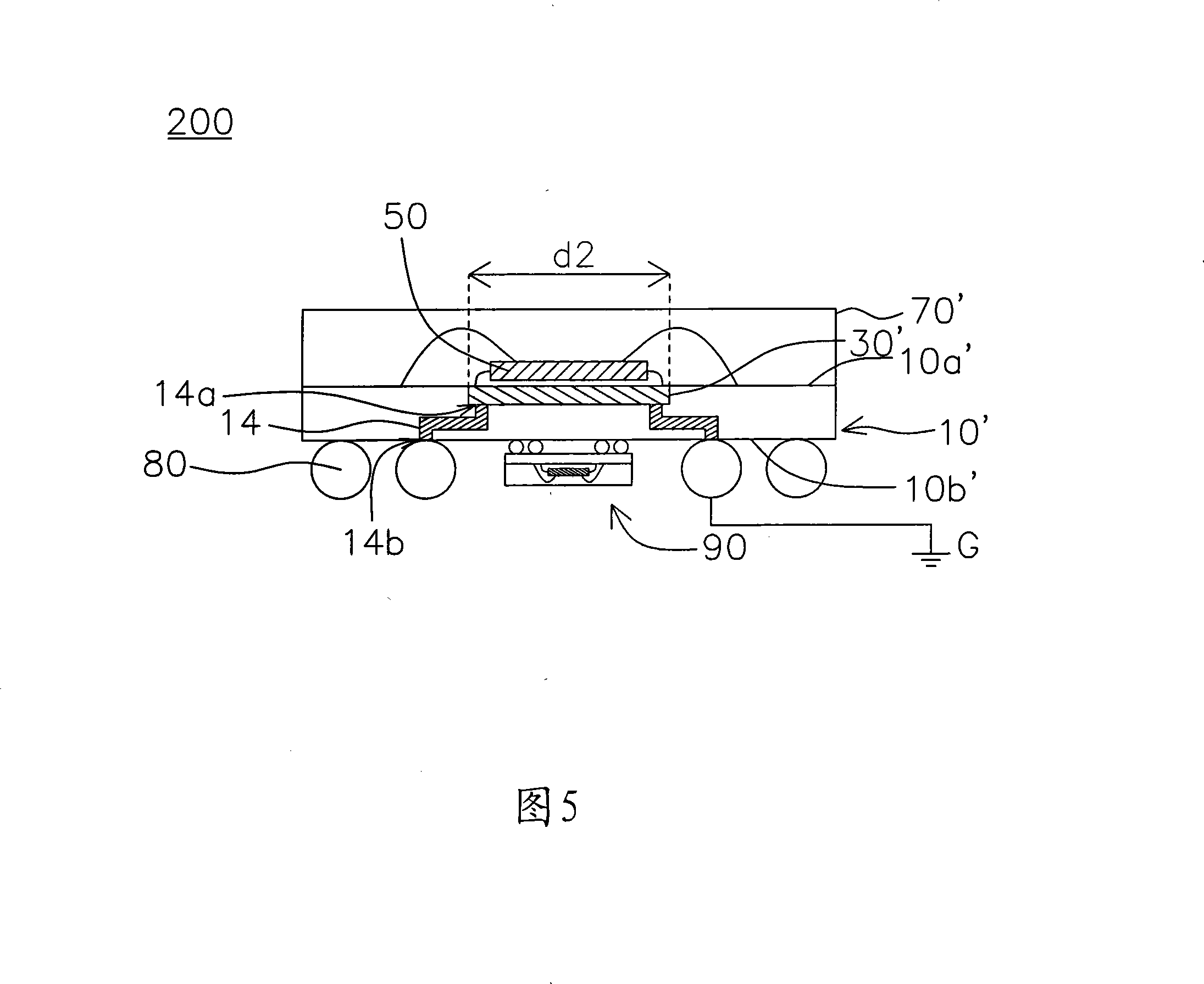

Packaging structure and method for manufacturing the packaging structure

ActiveCN101183677AImprove stabilityShield electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorElectromagnetic interference

A package structure including a substrate, a shielding element, a chip, a sealant layer and a semiconductor device is provided. The substrate has a first surface and a second surface opposite to the first surface. The shielding element is disposed on the first surface. The chip is disposed on the shielding element and is electrically connected to the substrate. The sealant layer is disposed on the first surface, and encapsulates the chip and the shielding element. The semiconductor device is disposed on the second surface.

Owner:ADVANCED SEMICON ENG INC

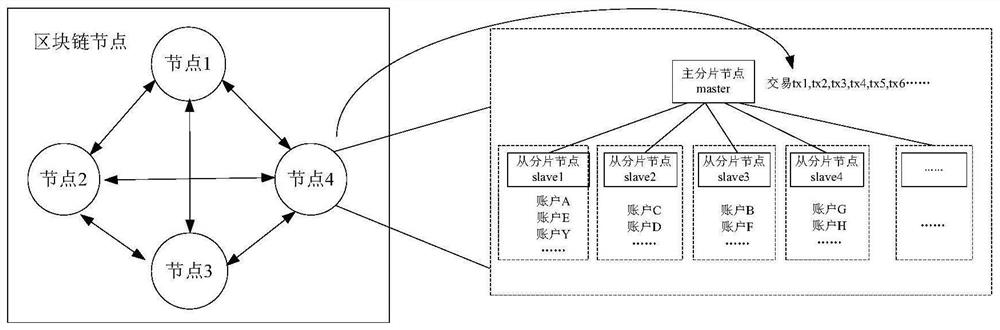

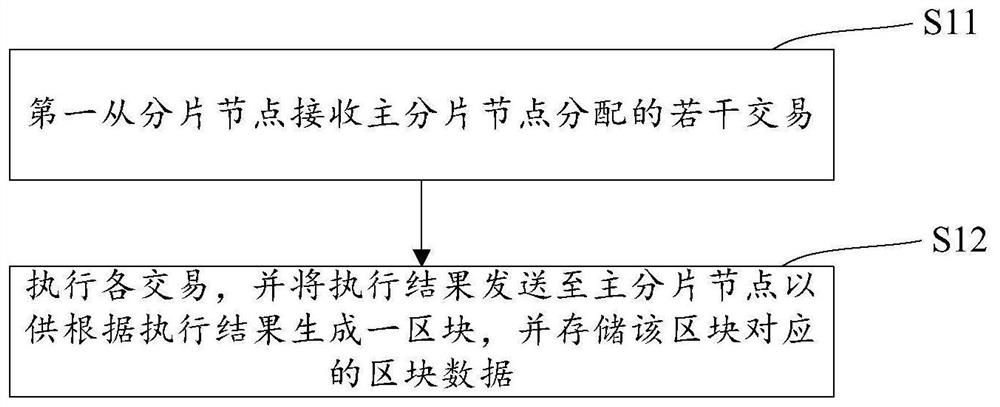

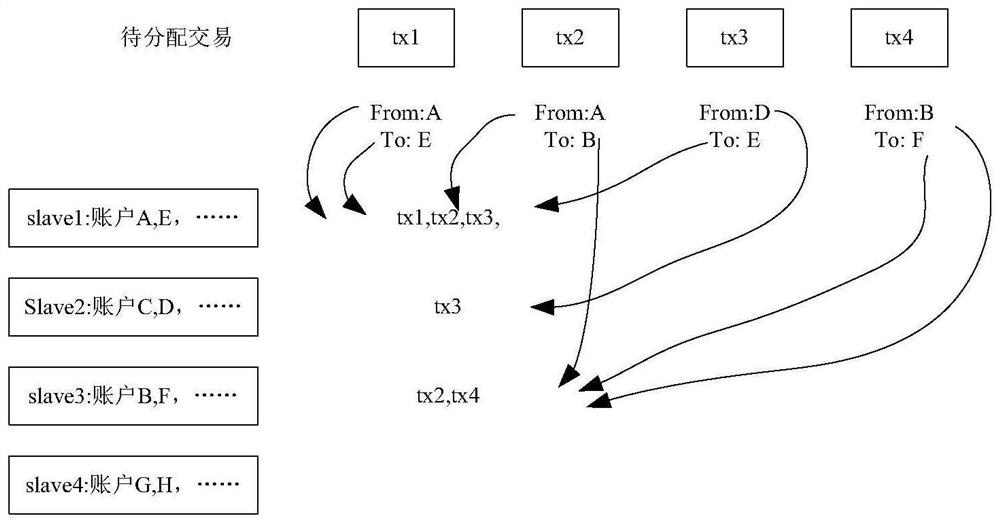

Alliance chain data fragmentation processing method and device and storage medium

ActiveCN111680050ASolve the problem of implementationGuaranteed heightDatabase updatingFinanceEngineeringFinancial transaction

The invention provides an alliance chain data fragmentation method and system, equipment and a storage medium, and the method comprises the steps of allowing a first slave fragmentation node to receive a plurality of transactions distributed by a main fragmentation node, and wherein a sender account and / or a receiver account of each transaction correspond / corresponds to the first slave fragmentation node; executing each transaction in the fragment, sending an execution result to a main fragment node so that the main fragment node generates a block according to the execution result after receiving the execution result, and storing block data corresponding to the block, wherein the execution result comprises updated account state data of each account. According to the invention, the fragmentation architecture is designed, so that the execution problem of a single node is solved, and the possibility of transverse expansion is provided for an execution module from the architecture level; and on the other hand, for the whole transaction batch, in the transaction distribution step, the transaction is distributed to each fragment according to form and to, so that unrelated transaction parallelism to a certain extent is realized, and in addition, execution of cross-fragment transactions is realized through a distributed shared memory.

Owner:HANGZHOU QULIAN TECH CO LTD

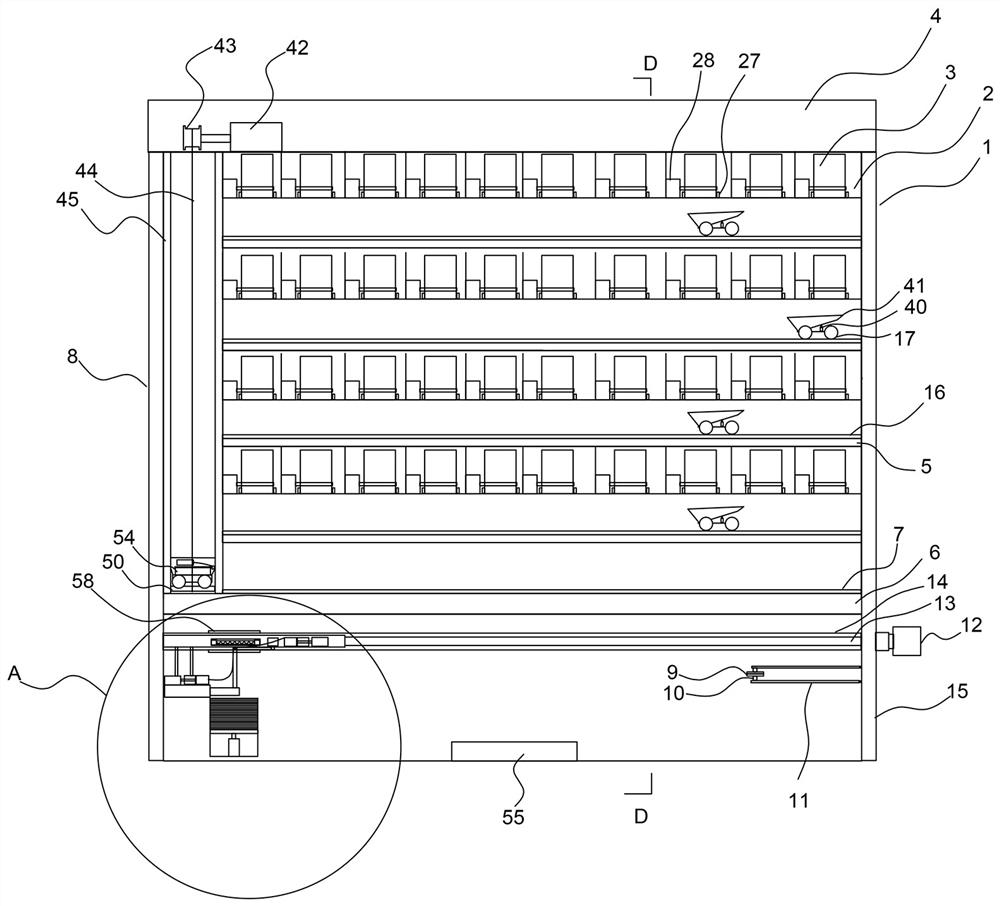

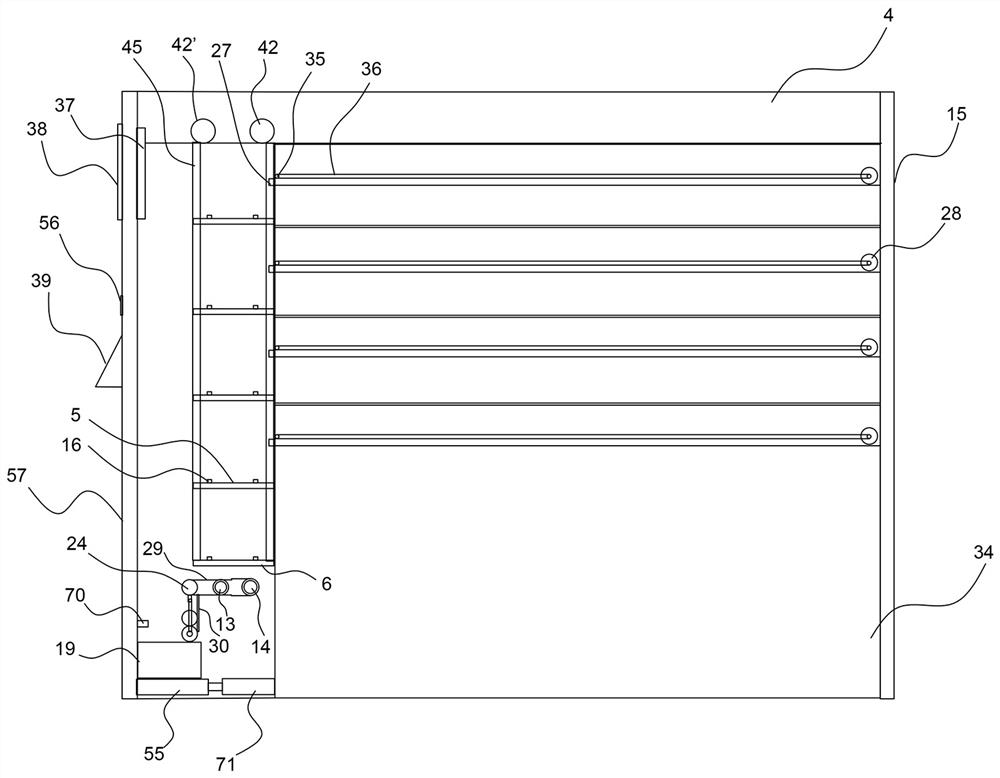

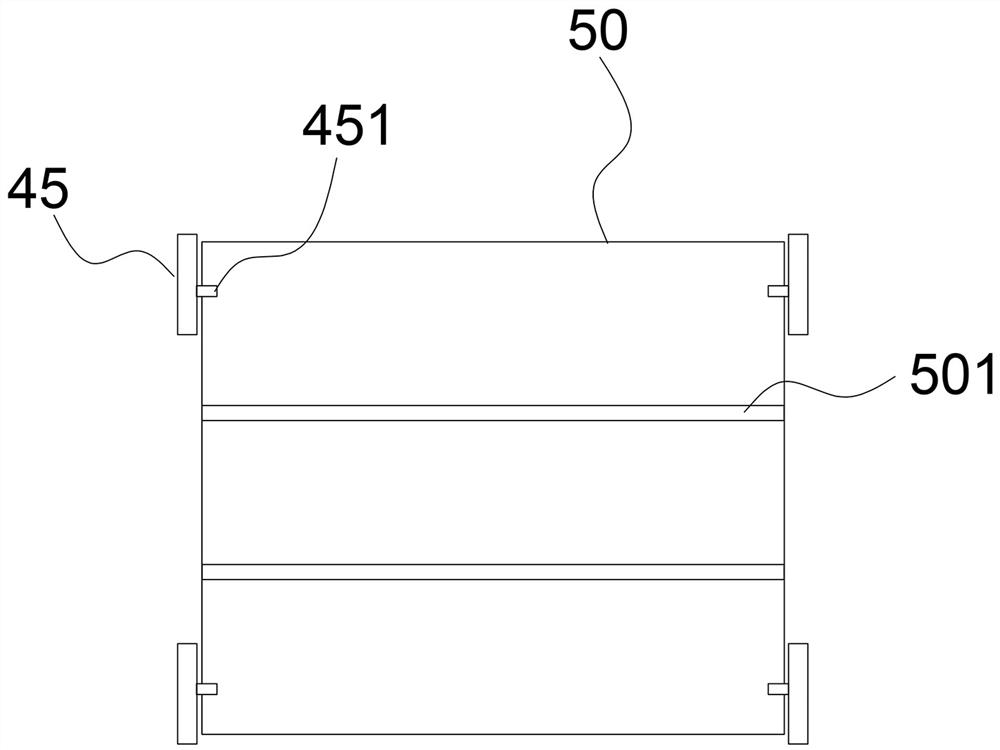

Automatic medicine taking cabinet and medicine taking method

ActiveCN112249584APrevents the risk of splinteringPrevent overdue situationsWrapper twisting/gatheringStorage devicesDrug productConveyor belt

The invention relates to an automatic medicine taking cabinet and a medicine taking method. The automatic medicine taking cabinet comprises a cabinet body, the cabinet body comprises a medicine placing rack, a front panel located in front of the medicine placing rack, a cabinet door located on the rear side of the medicine placing rack, a medicine taking mechanism and a control system. The invention further discloses the medicine taking method. According to the automatic medicine taking cabinet, a medicine taking trolley hopper of the medicine taking mechanism can reach the lower portions of medicine containing bins along medicine taking rail units, walk to the left side of the medicine taking rail units after taking medicines and pour the medicines into an adjacent medicine hopper, and then a medicine collecting trolley reaches the designated medicine outlet position through a lifting unit and a horizontal moving rail unit. By adopting the cooperation of conveyor belts and correlationsensors, the problems of a medicine feeding mode and counting are well solved, and when the medicines are placed, only the cabinet door needs to be opened, the medicines are pushed in from the back,the previous medicines are in the front, the current medicines are in the back, the operation is simple and convenient, and the situation that the previous medicines are out of date due to unreasonable medicine placement can be prevented.

Owner:HENAN CANCER HOSPITAL

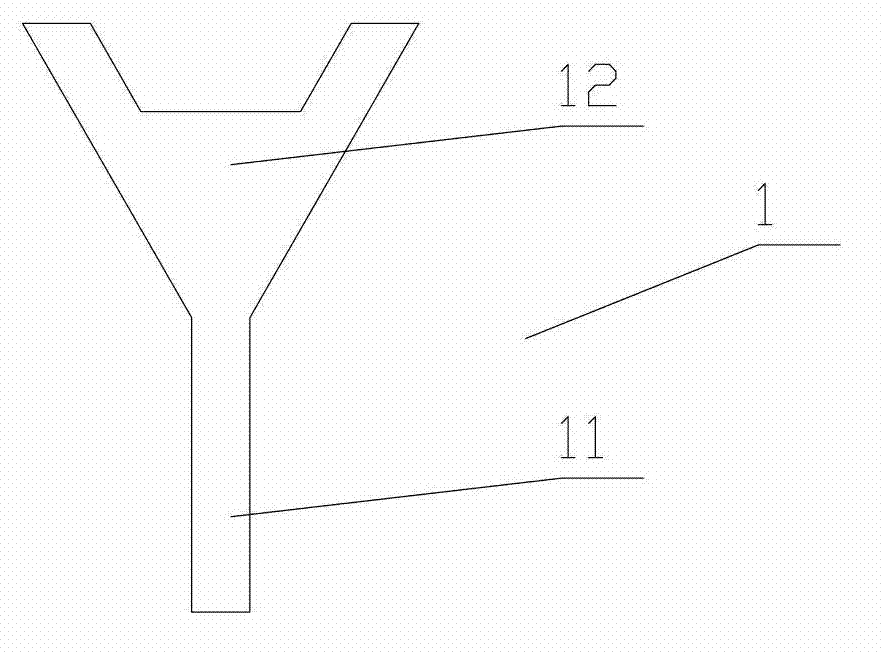

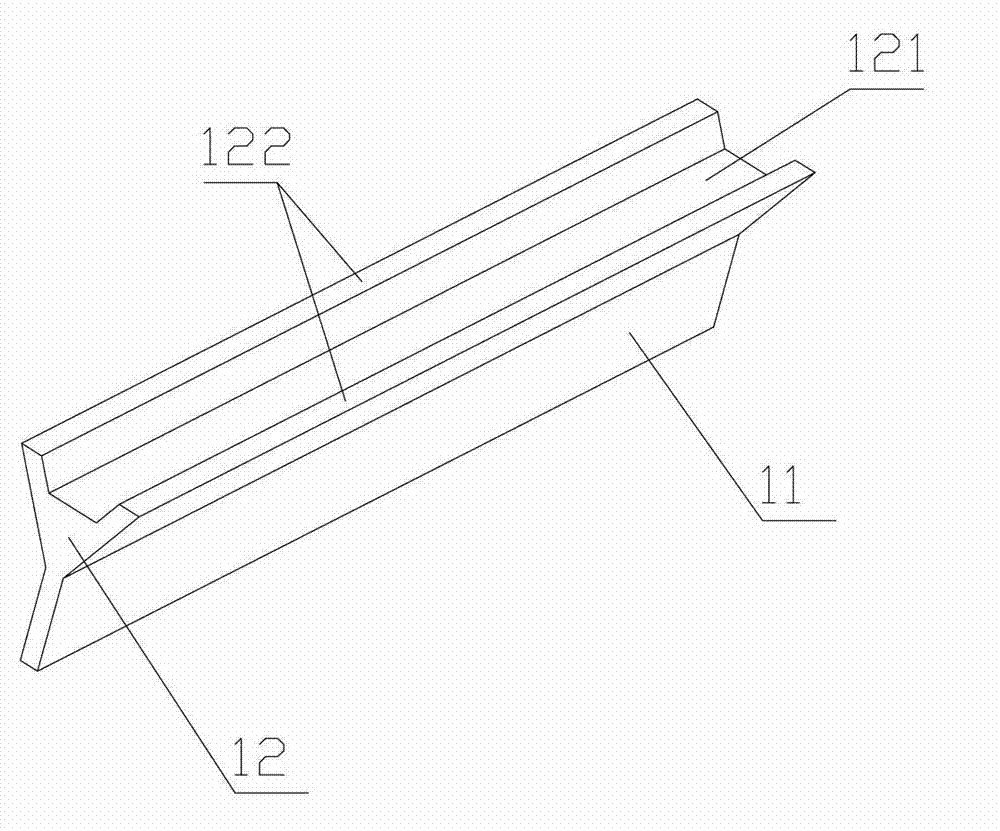

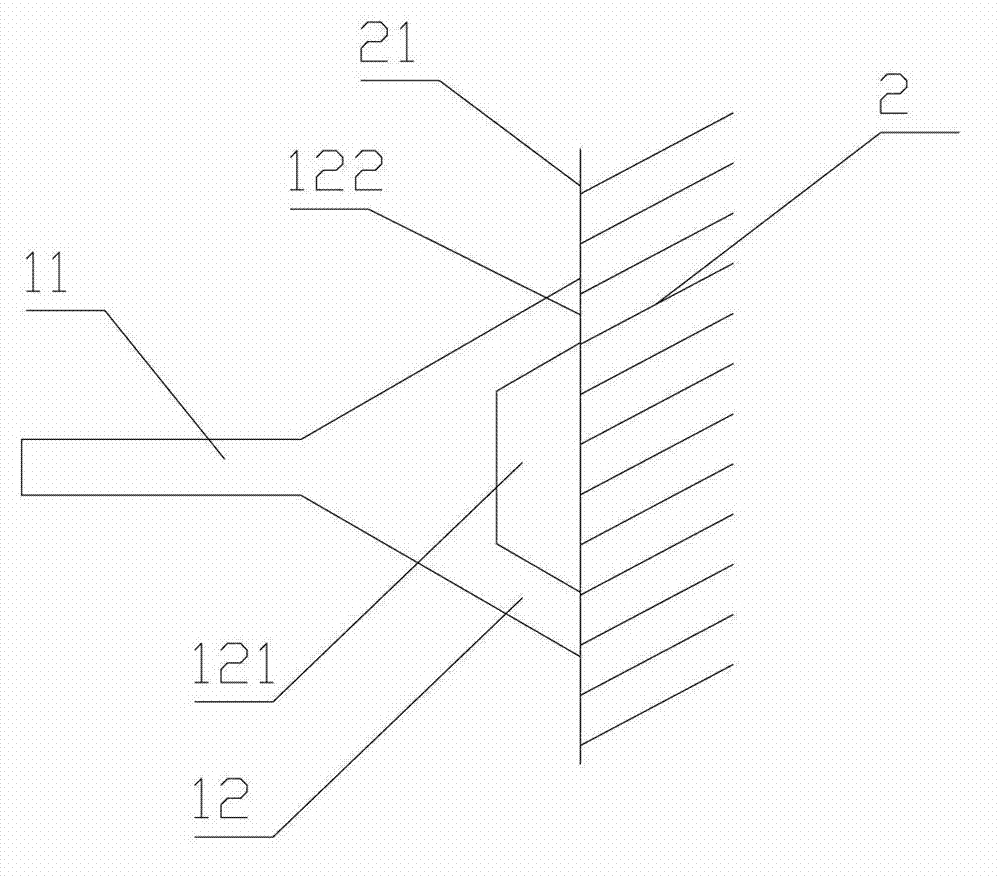

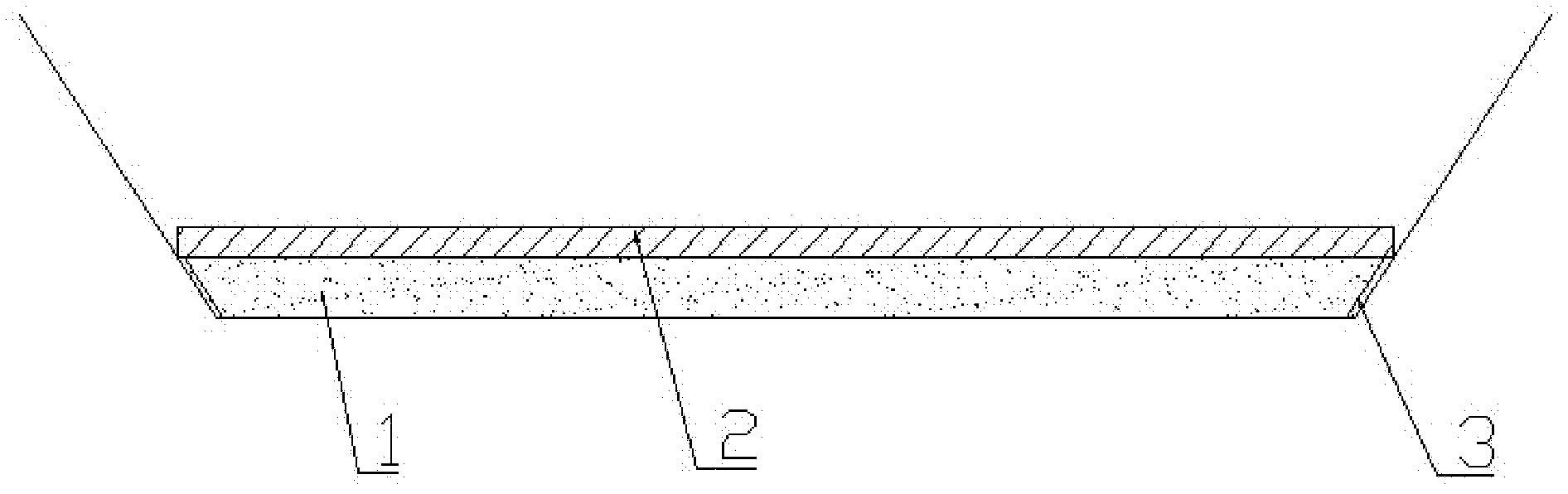

Plastering fillet and constructional plastering method

ActiveCN103088994ASimple structureHigh strengthBuilding constructionsPulp and paper industryBuilding construction

The invention relates to a plastering fillet and a constructional plastering method. The transverse section of the plastering fillet is Y type. The plastering fillet comprises a fixing end and a connecting end which is arranged on the top portion of the fixing end, wherein a groove is formed in the connecting end, and the bottom portion of the groove is a plane. The constructional plastering method comprises the following steps: screeding and plastering; the plastering fillet is adopted to be clamped by a plastering template, the levelness and verticality of the plastering template are controlled through a laser level meter, a pulp shooting machine is used for pulp shooting after fixing the plastering template and plastering fillet together on the back of a wall surface, after mortars covering the connecting end of the plastering fillet, placing to the adhesive connection between the plastering fillet and the wall surface to a fixation degree, at this time, and the pulp shooting machine can be directly used for pulp shooting and plastering. The constructional plastering method constructed with machinery has the advantages of being capable of greatly improving plastering efficiency, shortening construction working period and guaranteeing height and quality of plastering.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

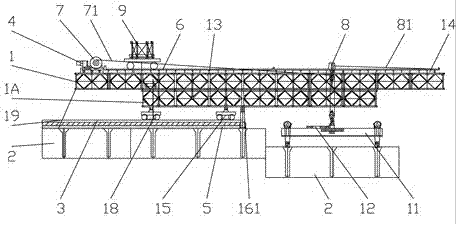

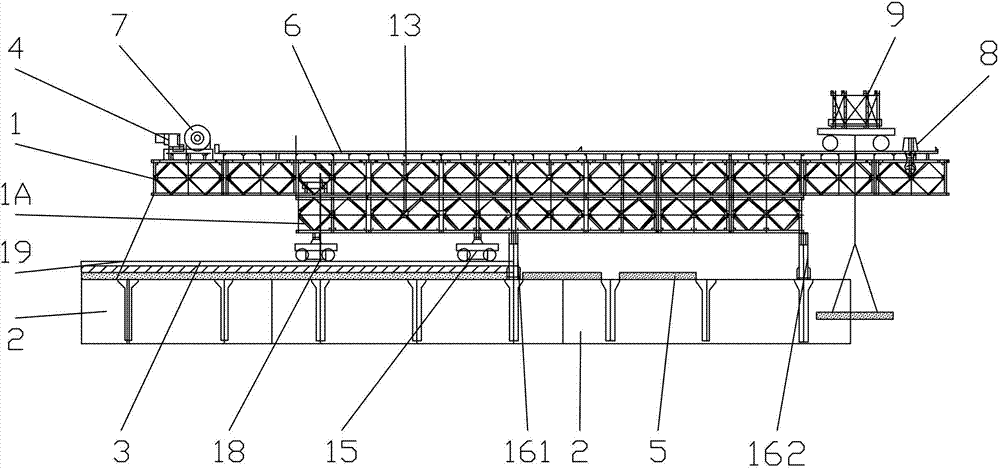

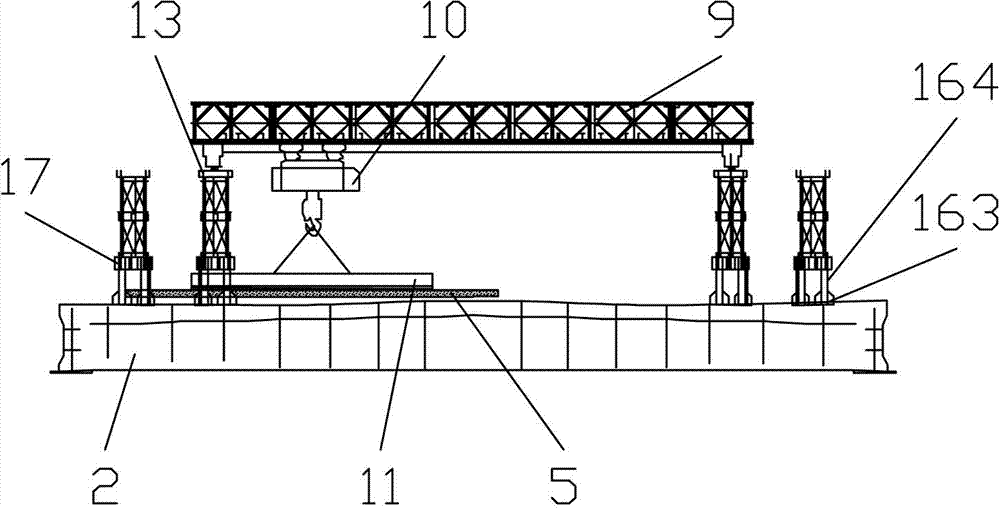

Bridge floor crane for cable-stayed bridge

InactiveCN103882811AGuaranteed stabilityImprove stabilityBase supporting structuresBraking devices for hoisting equipmentsSupporting systemArchitectural engineering

The invention relates to a construction device for a cable-stayed bridge, in particular to a bridge floor crane for the cable-stayed bridge. The bridge floor crane for the cable-stayed bridge comprises two sets of main trusses arranged oppositely, a craning system arranged above the main trusses and a walking system arranged below the main trusses, wherein the walking system comprises a main track laid on a mounted steel beam and a walking device in sliding fit with the main track, and an upper layer and lower layer structure is adopted by the main trusses. The bridge floor crane for the cable-stayed bridge further comprises a supporting system arranged on the lower portions of the main trusses, a rear anchoring system arranged on the outer sides of the two sets of the main trusses, a balance weight device and a safety device, the balance weight device and the safety device are arranged at the rear ends of the main trusses, and the supporting system comprises a middle supporting device arranged in the middles of the main trusses and a temporary supporting device arranged at the front ends of the main trusses. Through the adoption of the technical scheme, the bridge floor crane for the cable-stayed bridge has the advantages of being proper in craning height, strong in bearing capacity, good in construction stability, high in construction efficiency and high in safety.

Owner:CHONGQING CONSTR BRIDGE ENG +2

Clean LED lamp

ActiveCN103697386AIncrease exposureGuaranteed heightPoint-like light sourceOutdoor lightingEngineeringLED lamp

The invention discloses a clean LED lamp comprising a lampshade, a substrate arranged inside the lampshade, a plurality of light-emitting components mounted on the substrate and a driving area fixed outside the lampshade. Two opposite side faces of the driving area are both vertically connected with connecting plates, and a spring support is arranged at the lower end of each connecting plate. A brush groove is formed at the upper end of the substrate, an electric brush is arranged in the brush groove, one end of the electric brush is connected and fixed with a telescopic connecting rod through a brush leg, a sliding groove is formed in a manner of being perpendicular to the brush leg of the brush groove, and the telescopic connecting rod is arranged in the sliding groove. The clean LED lamp has the advantages that time and labor are saved quality of the electric brush is good, cleaning effect is good, and excellent illumination effect of the LED lamp is guaranteed; the LED lamp is stable in fixation and good in damping effect.

Owner:中山市煜景照明有限公司

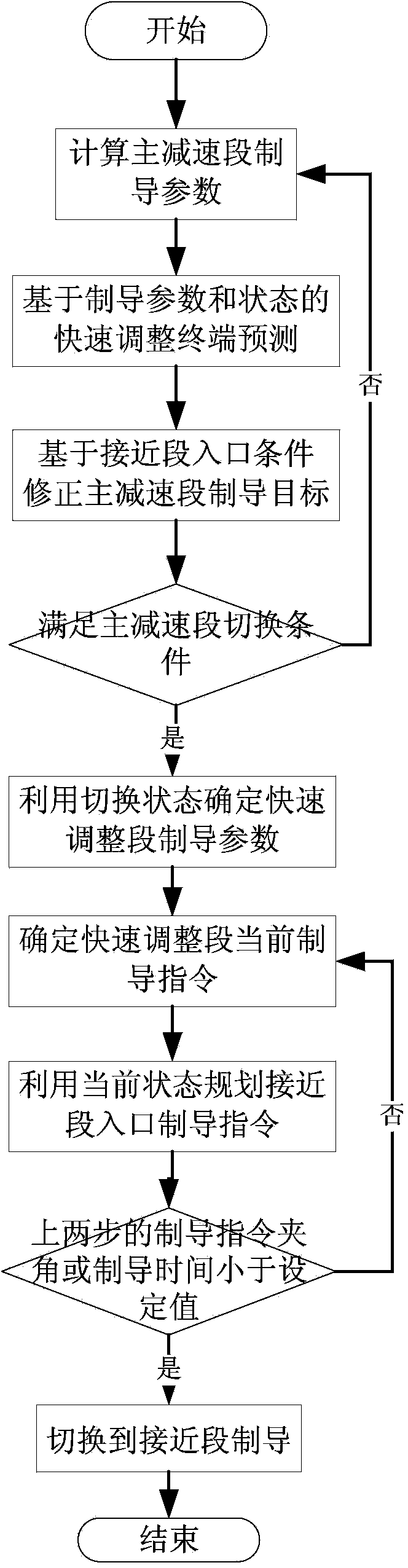

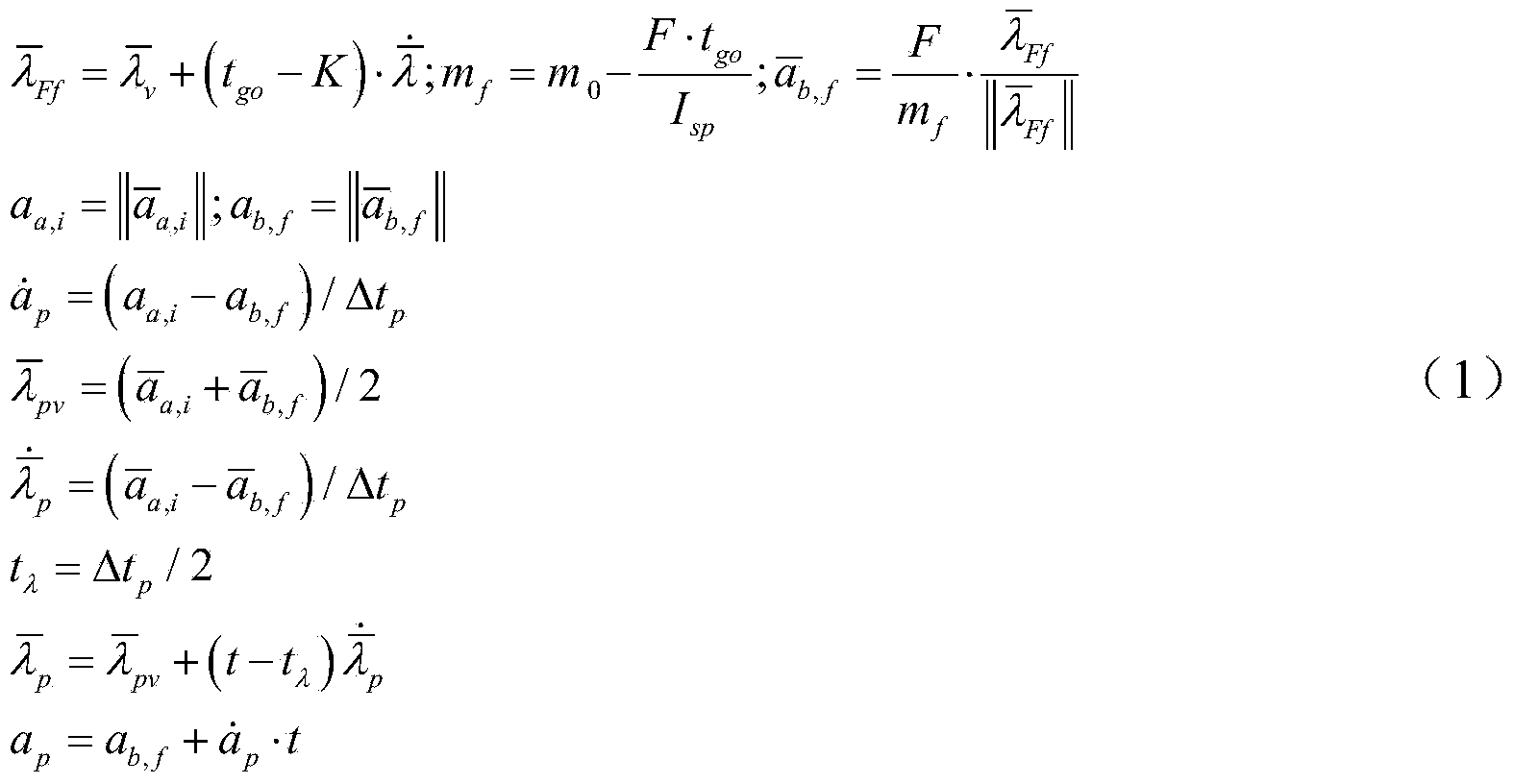

Forecasting and correcting method for joining main deceleration stage and approaching stage

ActiveCN103662092AGuaranteed attitudeGuaranteed heightExtraterrestrial carsSpacecraft guiding apparatusPoint of entryEngineering

The invention relates to a forecasting and correcting method for joining a main deceleration stage and an approaching stage. The forecasting and correcting method includes the steps of calculating main deceleration stage guidance parameters, conducting rapid adjustment stage terminal forecasting based on the main deceleration stage guidance parameters and current states of a detector, correcting a main deceleration stage guidance target based on approaching stage inlet conditions, judging whether main deceleration switching conditions are met or not, switching into rapid adjustment guidance if the approaching stage switching conditions are met, otherwise, executing the first step, the second step and the third step again until the main deceleration switching conditions are met, determining rapid adjustment stage guidance parameters according to switching time states, determining current guidance commands according to the rapid adjustment stage guidance parameters, planning approaching stage inlet guidance commands according to the current state, and when an included angle of rapid adjustment stage current guidance commands and the approaching stage inlet guidance commands is smaller than a set value, or the guidance time is completed, switching into approaching stage guidance. According to the forecasting and correcting method, requirements of an approaching stage inlet for gestures, heights, speeds and accelerated speeds are met, and the requirement of the detector for transiting from the main deceleration stage to the approaching stage is met.

Owner:BEIJING INST OF CONTROL ENG

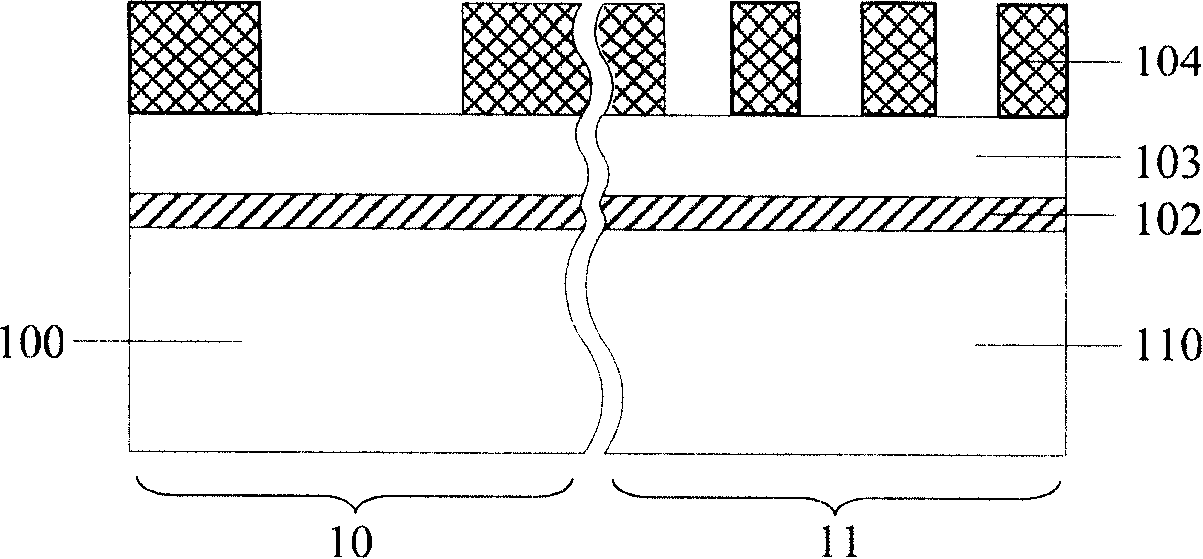

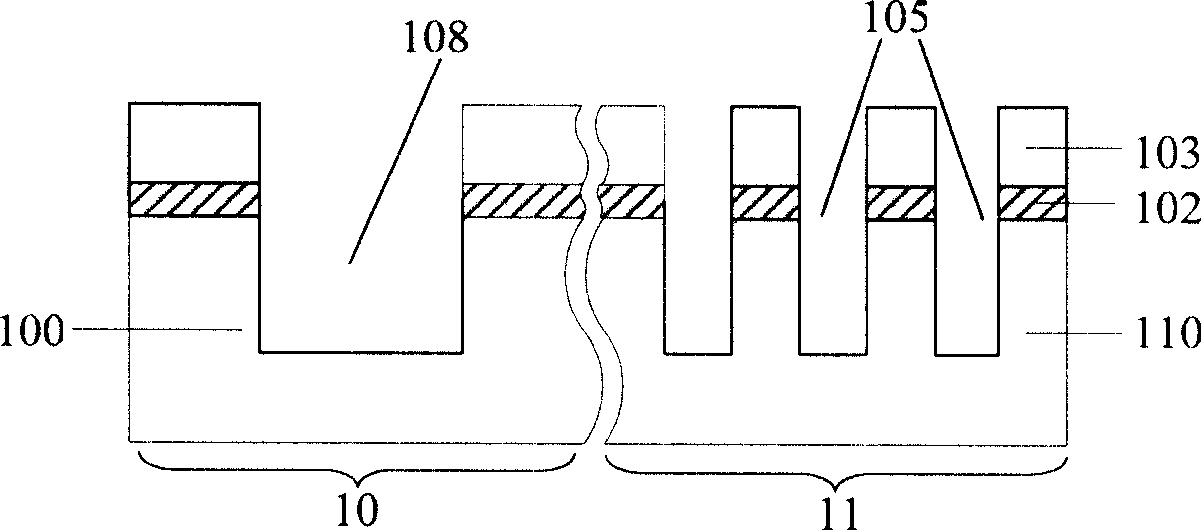

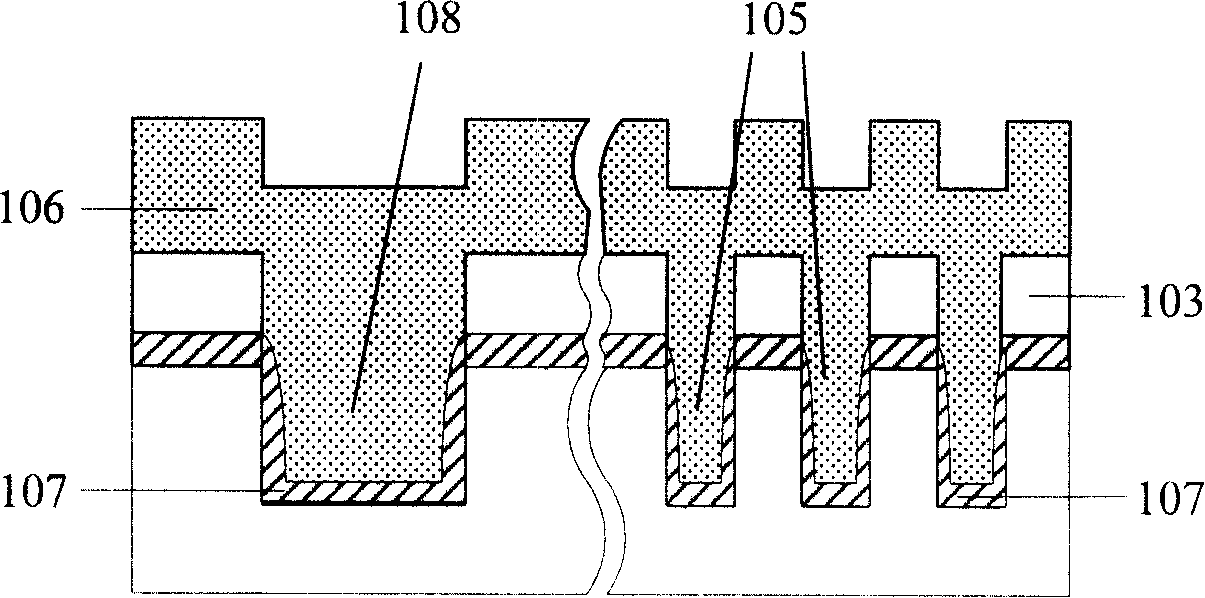

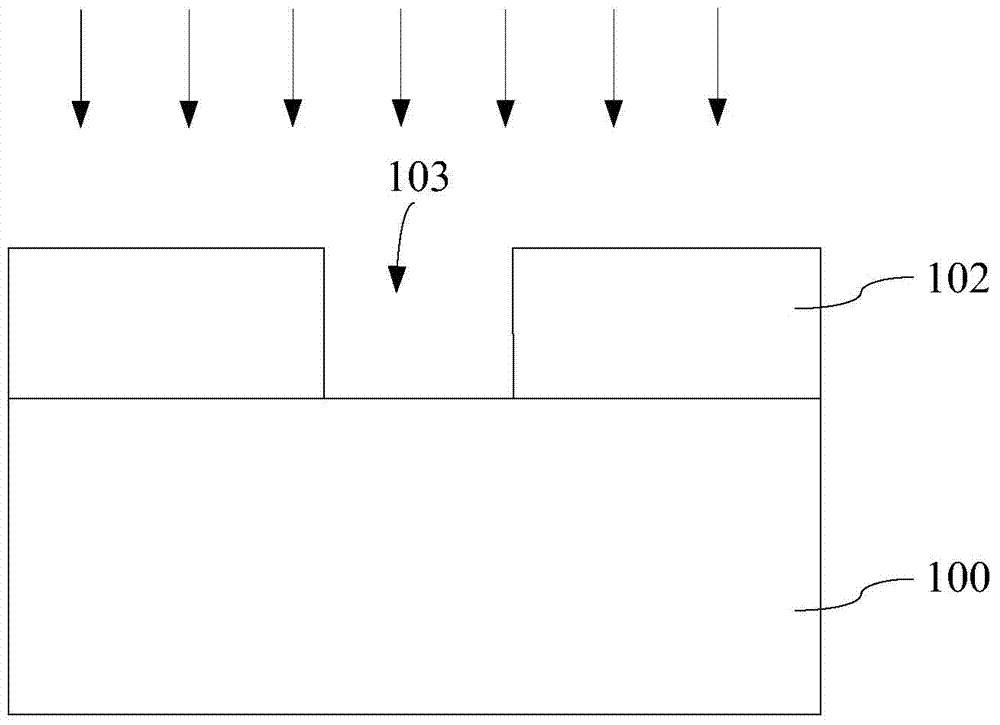

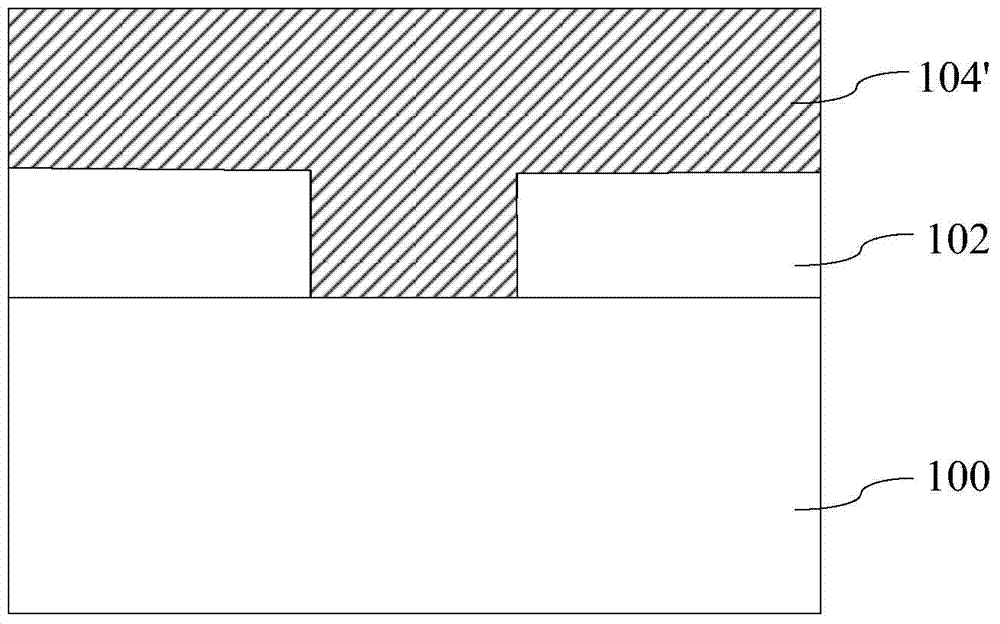

Method for forming device isolation region

InactiveCN101207064AKeep highReduced quiescent leakage currentSemiconductor/solid-state device manufacturingPhotoresistSilicon nitride

The invention relates to a formation method of a device isolation area. The method comprises the following steps: a silicon substrate comprising a peripheral circuit area and a storage unit area is provided; a pad oxide layer and a silicon nitride layer are formed on the silicon substrate in sequence; the pad oxide layer, the silicon nitride layer and the silicon substrate are etched to form a groove; an insulating oxide layer is formed on the silicon nitride layer, and the insulating oxide layer is filled into the groove; the insulating oxide layer is grounded until the silicon nitride layer is exposed; photoresist is formed on the peripheral circuit area; the photoresist is taken as a mask, the insulating oxide layer in the storage unit area is etched until the height is coincident with the height of the insulating oxide layer in the peripheral circuit area; the photoresist, the silicon nitride layer and the pad silicon oxide layer are removed, so as to form a shallow groove isolation structure. The height of shallow groove isolation structure of the storage unit is reduced through the said steps, the phenomenon that the shallow groove isolation structure of the storage unit area generates excessive grinding is avoided during the subsequent planarization process of the polysilicon layer, and the phenomenon that the residues of the polysilicon layer is generated during the etching process of the subsequent word line of the storage unit to result in the word line short circuit is also avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

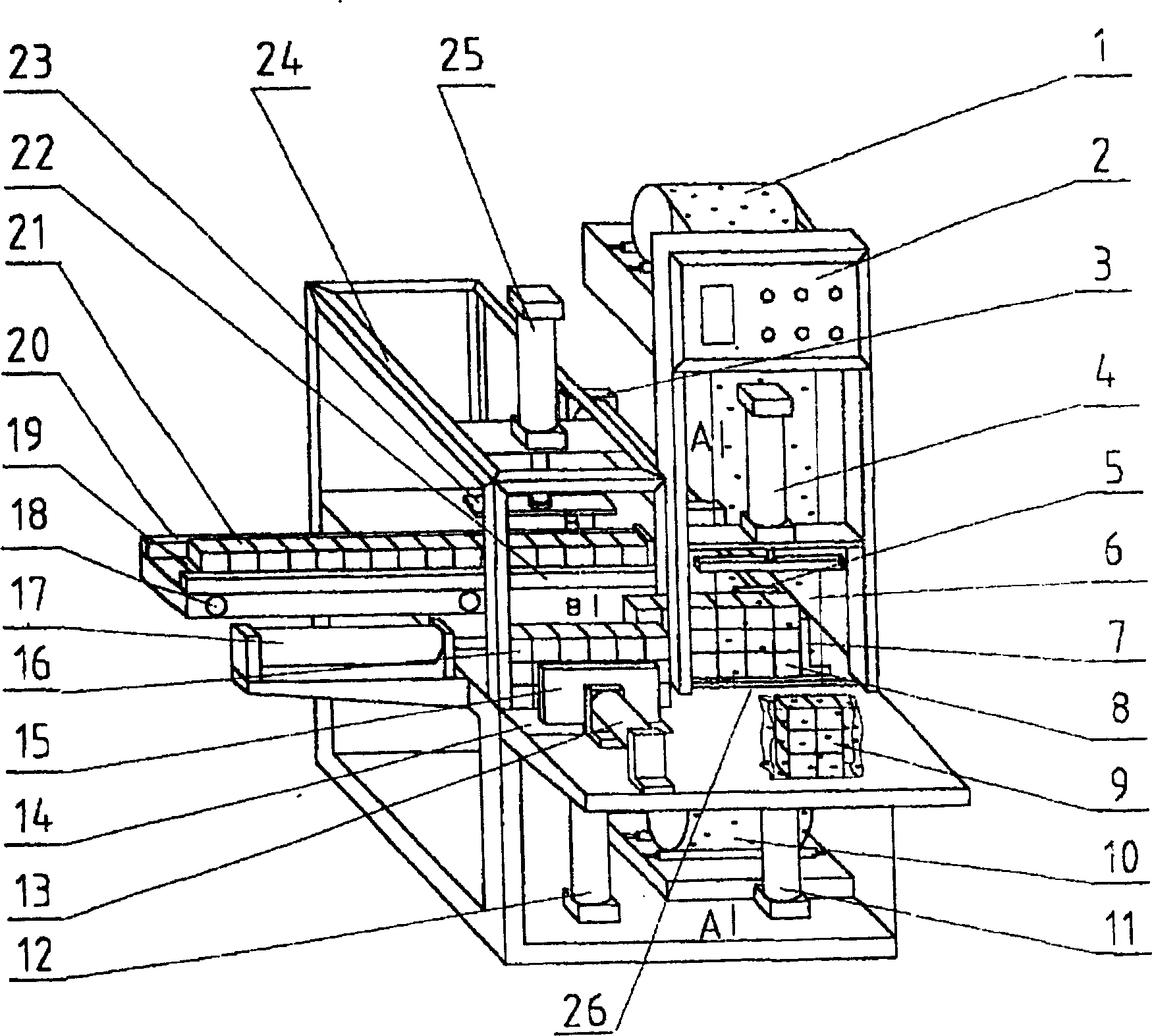

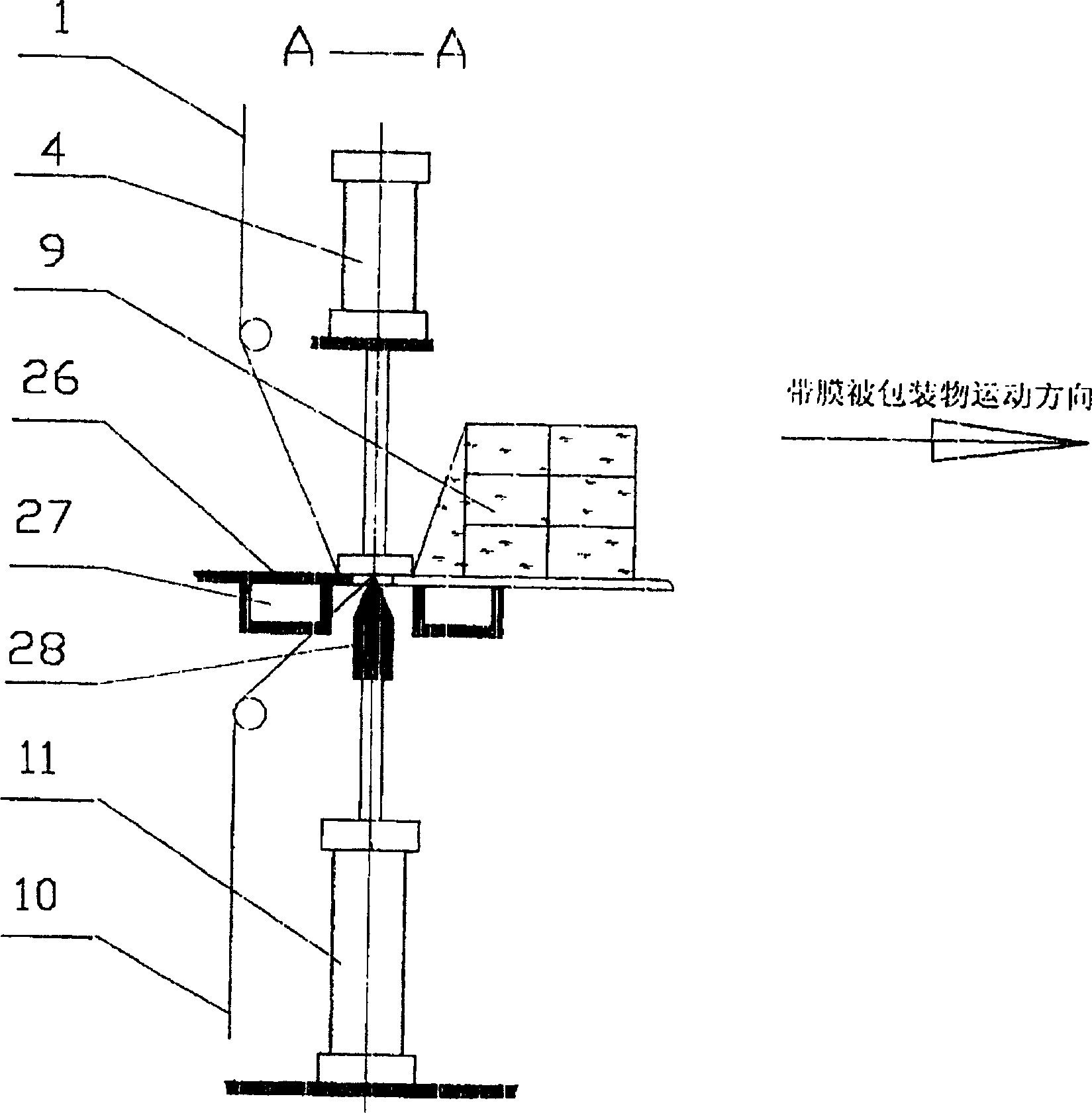

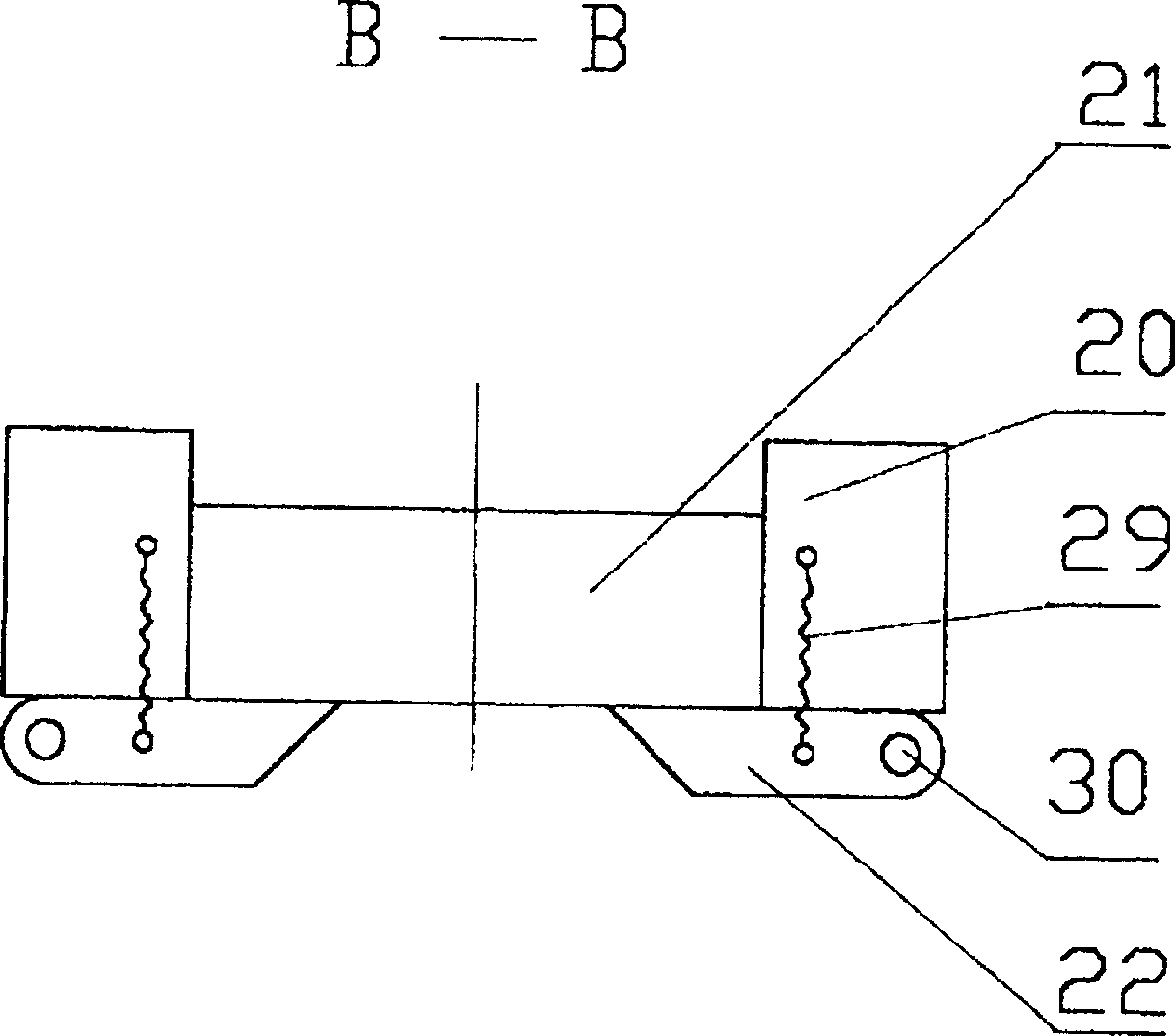

Full-automatic high speed piling and packing machine

InactiveCN1546353AReduce waiting timeIncrease productivityWrappers shrinkageWrappingElectricityEngineering

The invention refers to a kind of packaging mechanism for automatic pallet enclosing, especially refers to a high speed pallet enclosing device which has memorizing work position and cooling wind pipe. the function is that a kind of fixed packaged material is pallet collected, the collection packaged material are sent to the memorizing area to the packaging position, reaches the aim of the finally package. The invention includes the bracket, there sets with transmitting belt, upper and subjacent film sending mechanism, pallet collecting, memorizing position, cutting position and cooling structure on the bracket from forwards to backwards, there also sets a PLC electricity control part which is proper to manual operation on the bracket. The invention uses a pallet collecting mode.

Owner:李喜良

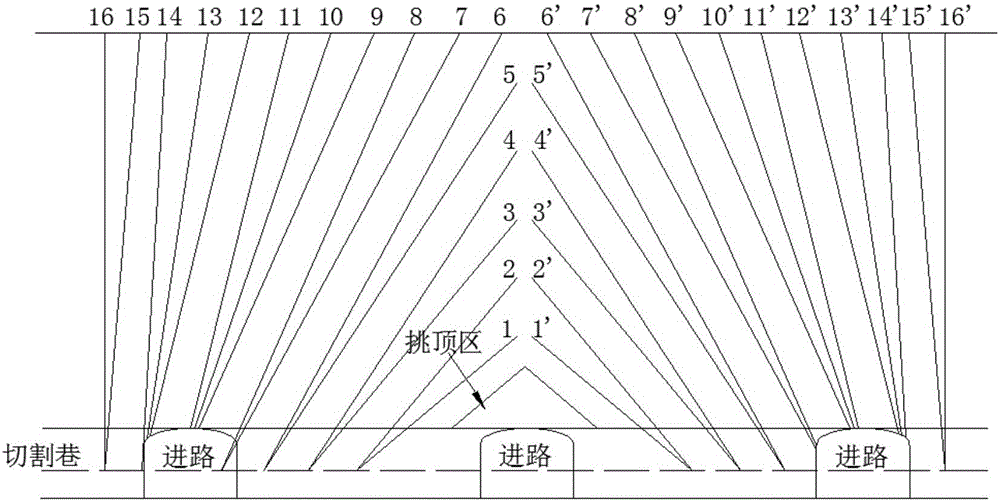

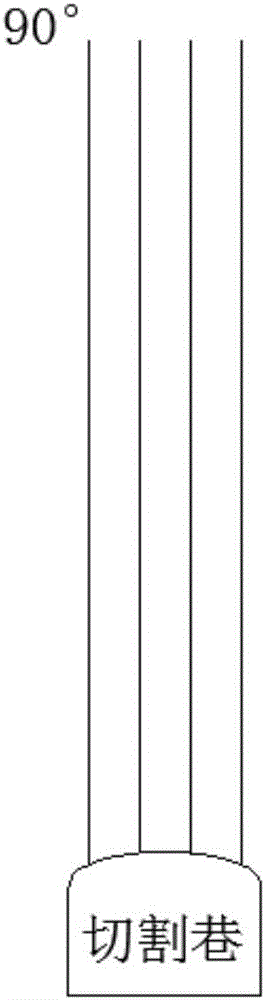

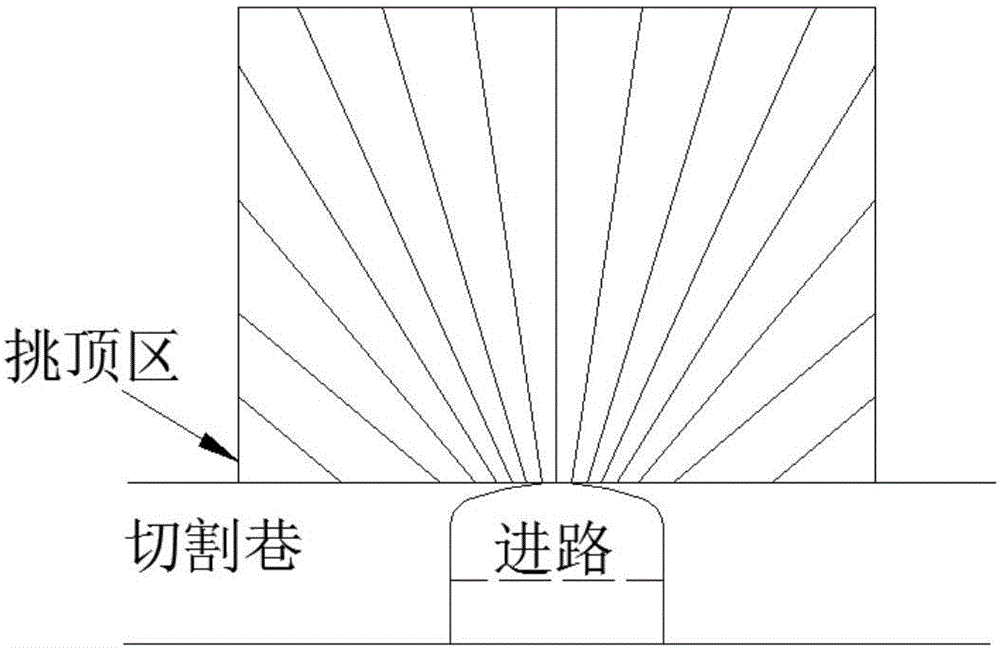

Super-high diagonal symmetric forced grooving method without grooving well

ActiveCN106247877AIncrease production intensityReduce cutting ratioBlastingEngineeringBilateral symmetry

The invention discloses a super-high diagonal symmetric forced grooving method without a grooving well, and belongs to the field of underground mining. The method includes the steps of 1, according to stope conditions, carrying out construction and completing construction of an extracted ore drift, a cutting roadway, a linked roadway and a gathering trench to form a stope; 2, carrying construction on the middle of the cutting roadway to form a roof cutting area, wherein the roof cutting area is a triangular area; 3, determining drilling construction sites at the bilateral symmetry positions of the roof cutting area of the cutting roadway through a drilling trolley, wherein drilling is carried out in the drilling construction sites according to forward inclination angles of blast hole row surfaces, the forward inclination angles are 40-88 degrees relative to the horizontal plane, and horizontal dip angles of the blast hole row surfaces from the middle to the two sides are gradually increased; and 4, after drilling is completed, carrying out filling to form a blast hole filling area, carrying out blasting sequentially according to the blast hole row surfaces, blasting the blasting holes in two symmetric hole sites each time, then carrying out blasting continuously and withdrawing ore through blasting. The method has the advantages that the sub-section height of the stope is large, the cost is low and the safety risk is low.

Owner:安徽马钢罗河矿业有限责任公司

On-site construction method for anti-seepage air bag for bottom of river channel

The invention relates to an anti-seepage air bag for the bottom of a river channel, in particular to an on-site construction method for the anti-seepage air bag. According to the on-site construction method for the anti-seepage air bag, a breathable wall bag of an appropriate size and with an opening arranged at one end is selected according to the requirement of a river channel, rigid plates matched with the size of the breathable wall bag are selected and are fixed along the length direction and the width direction of the breathable wall bag to support the inside space of the breathable wall bag, the height of the rigid plates from the ground of the river channel is equal to the thickness of the breathable wall bag, anti-seepage particles are filled in the breathable wall bag to form the anti-seepage air bag, and the opening end is sealed. According to the on-site construction method for the anti-seepage air bag for the bottom of the river channel, the appropriate breathable wall bag can be selected according to the size and scale requirements of the reformed river channel, the anti-seepage breathable particles are filled on site through inflation to form the anti-seepage air bag, and the problem of long-distance transportation of sand bags in existing river bank transforming construction can be solved. In addition, the sand bags processed on site don't have high requirements on sealing of the breathable wall bag, and on-site construction is extremely convenient.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

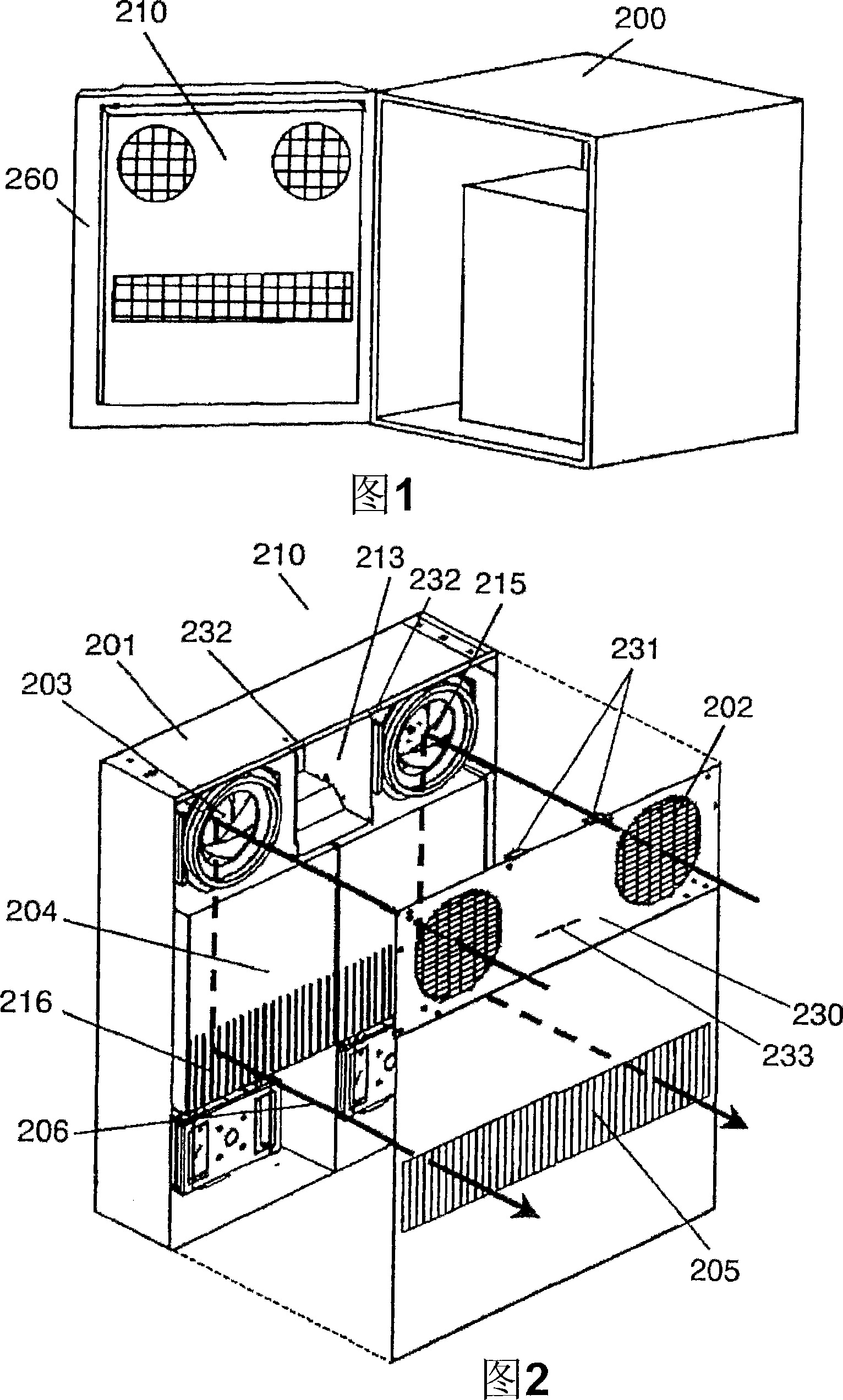

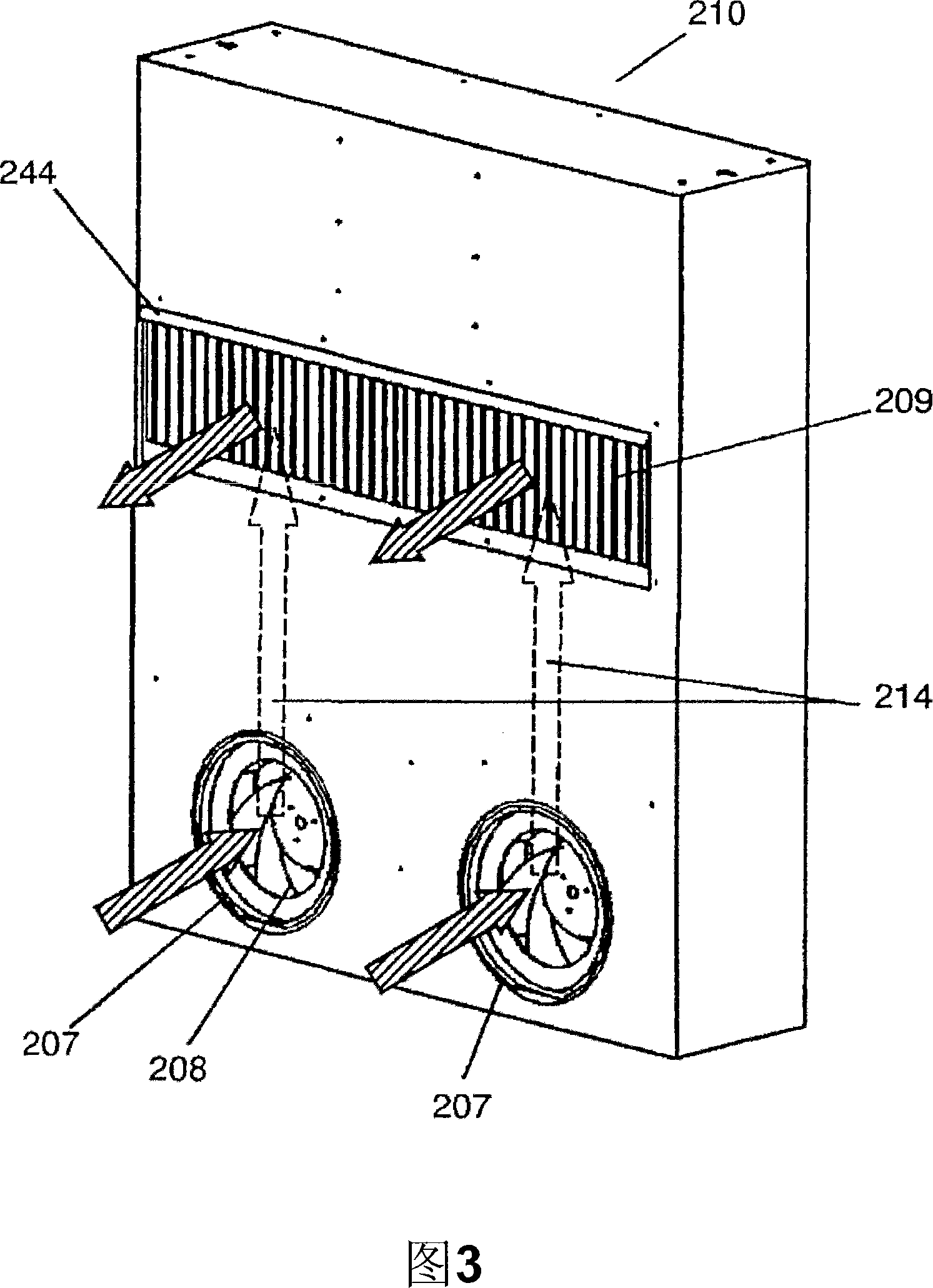

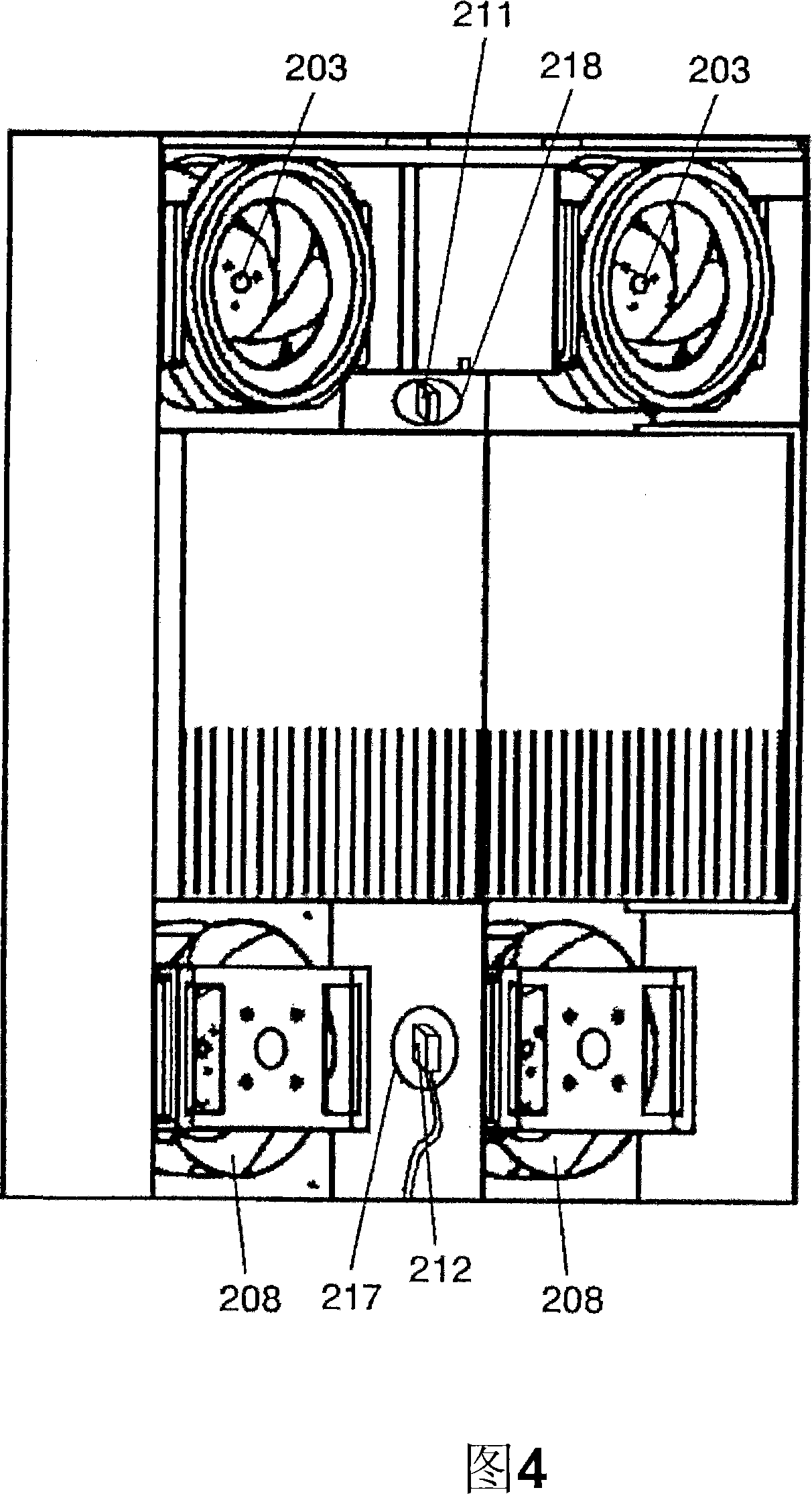

Cooler for heater-containing box

ActiveCN101233798AGuaranteed heightIncrease ventilation resistanceEnergy recovery in ventilation and heatingDomestic cooling apparatusEngineeringHeat exchanger

There is provided a cooler for heater-containing box in which an outside air fan for carrying air on an outside air path and an inside air fan for carrying air on an inside air path are arranged such that a rotating shaft of each fan is in parallel with an air intake direction, and a heat exchanger for exchanging sensible heat of outside air and inside air is arranged between the outside air path and the inside air path such that a suction port at a longitudinal air-path side of the heat exchanger is aligned with a blowout port of the fan. The cooler for heater-containing box capable of making the depth thinner can be provided.

Owner:PANASONIC CORP

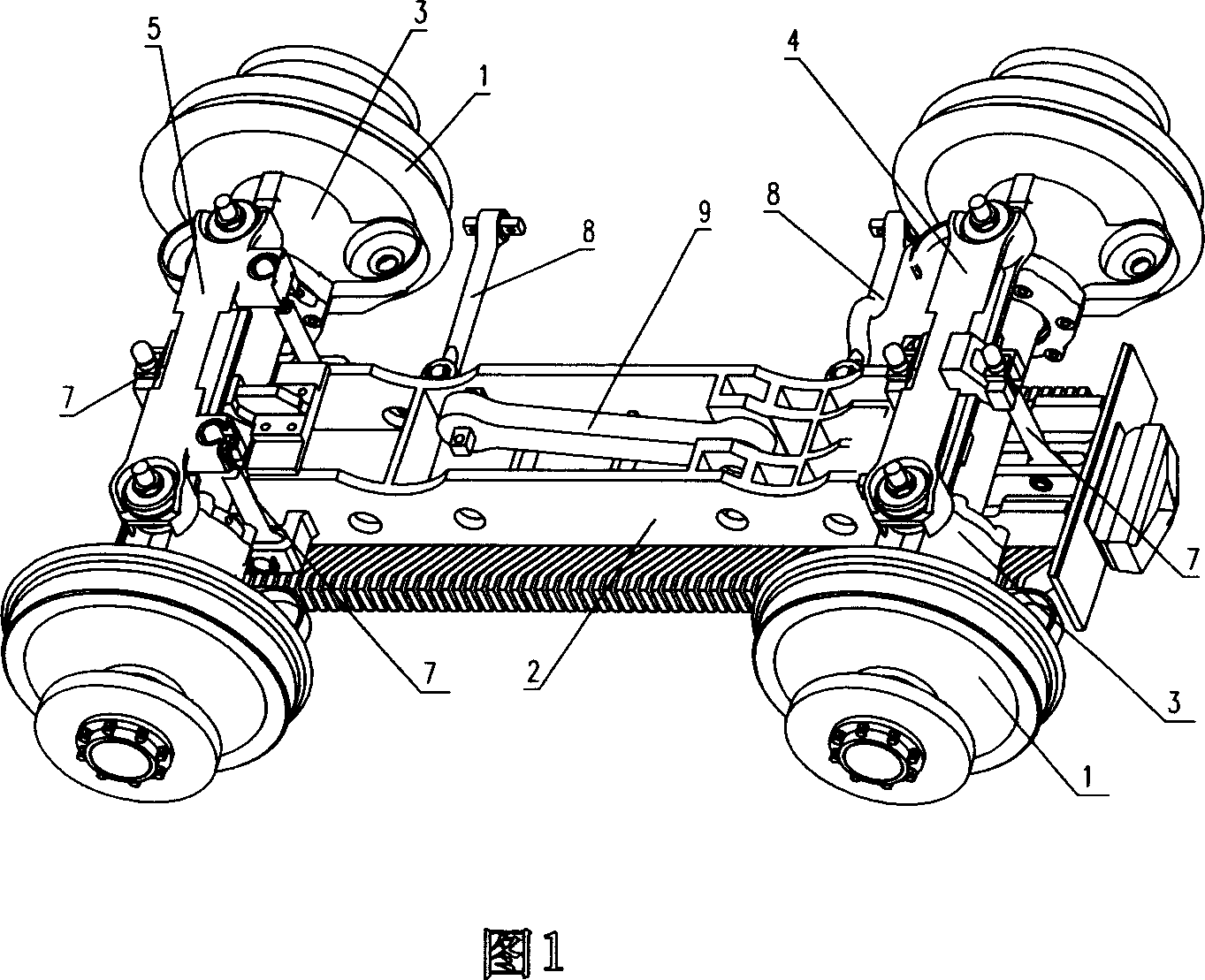

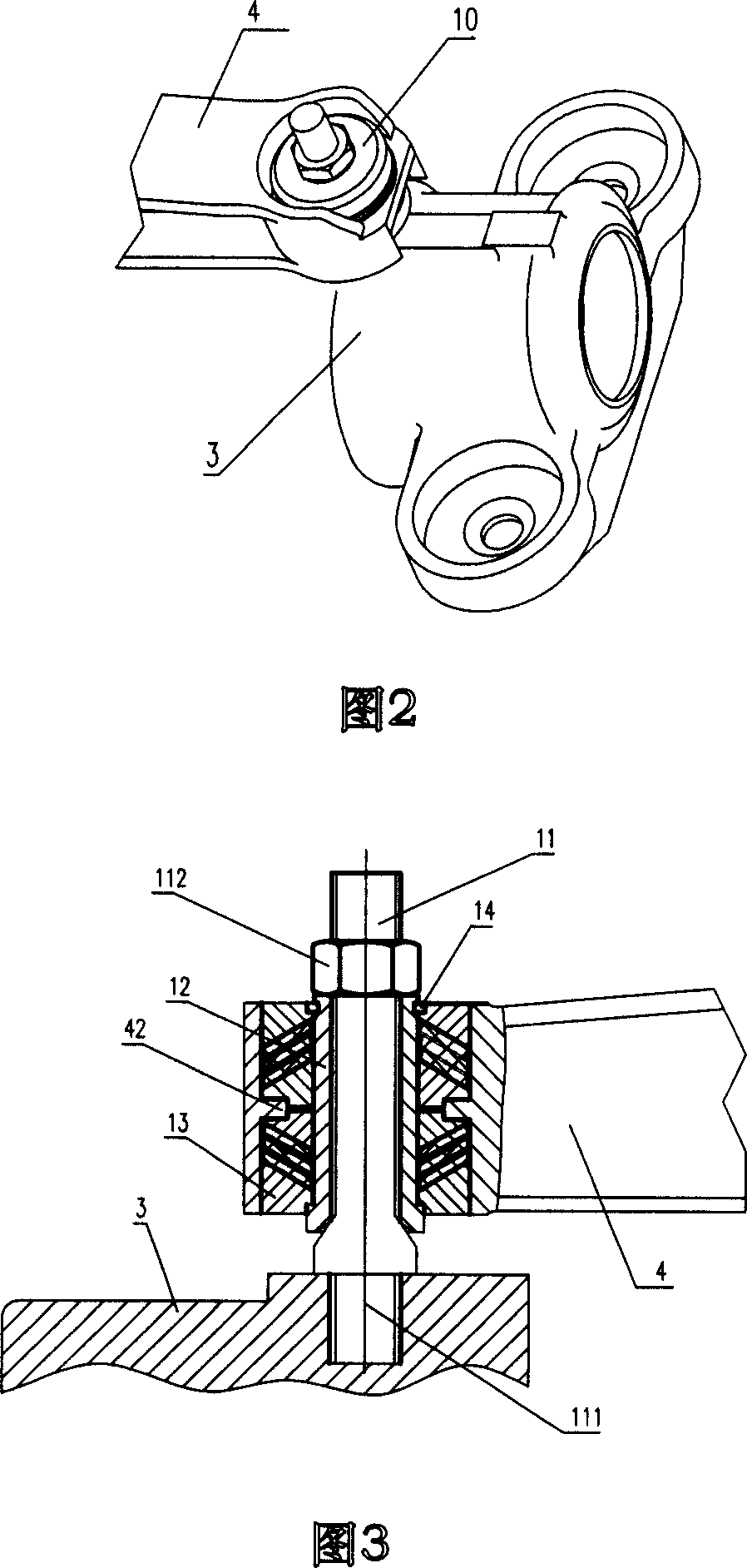

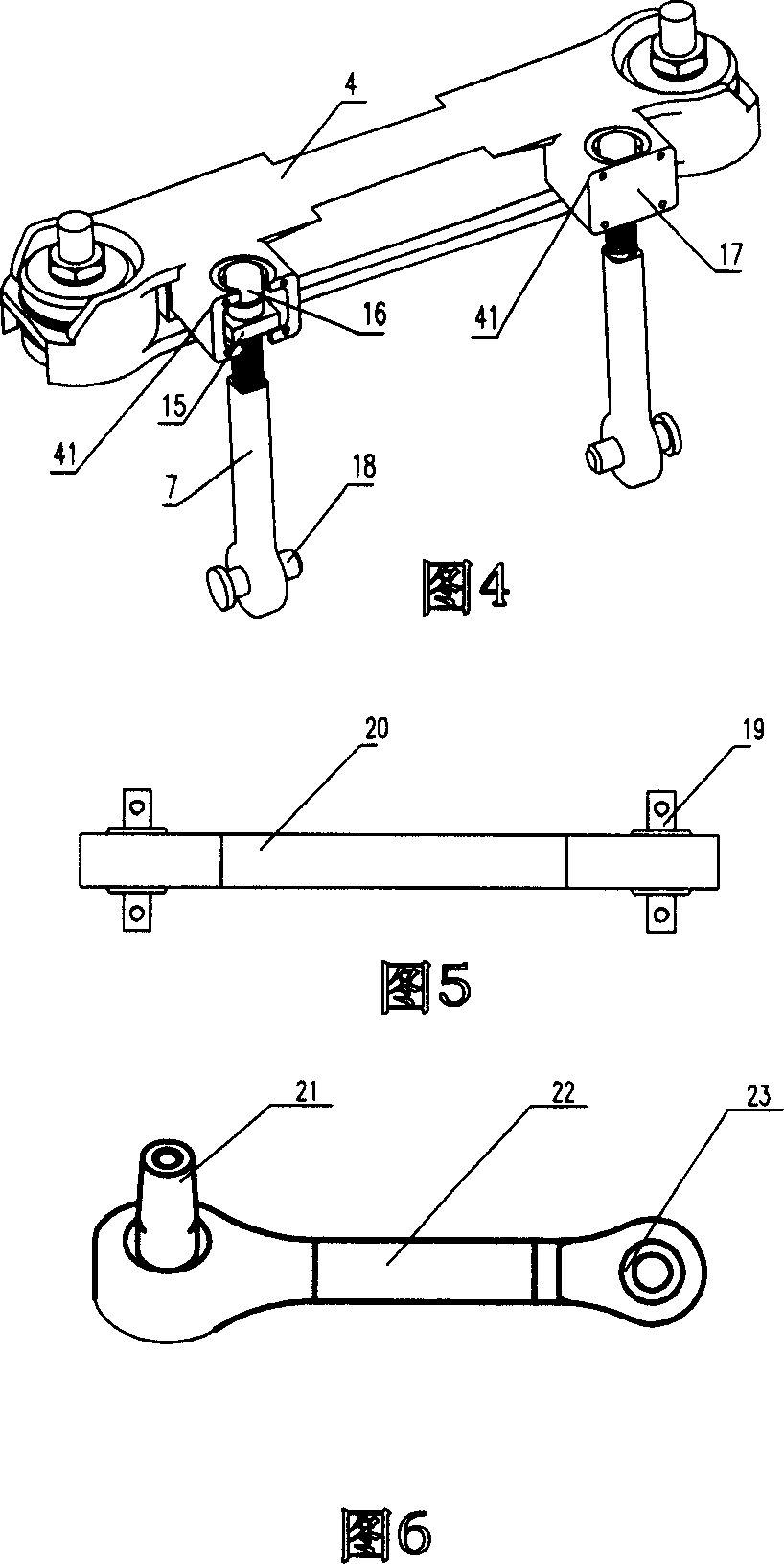

Tension rod type hanging and height adjusting mechanism

ActiveCN101117124AGuaranteed heightNot affected by elastic ups and downsElectric locomotivesAxle-boxes mountingBogieElectric machinery

The tie rod type hanging and height adjustment mechanism of the invention adopts a special separate type design in the vertical direction of the movement between a linear motor and a truck frame, and the tie rod type hanging and height adjustment mechanism is arranged at the joint between the linear motor and a supporting beam. An elastic connection between the supporting beam and the axle box of front and rear wheel pairs is adopted to provide the hanging elasticity of the linear motor and realize the bending and twisting of the truck within an allowable range. When height adjustment is required, the linear motor can be adjusted through the height adjustment mechanism to enable the clearance between the linear motor and a rail induction board to meet design requirements. That is to say, the linear motor can be adjusted to any required height within the wheel wear range. The invention not only realizes simple and stepless adjustment of the linear motor but also reduces the maintenance time of railway vehicles to the farthest degree. Additionally, the invention also ensures the tractive of the linear motor on the truck and the high-speed running of railway vehicles.

Owner:CRRC QINGDAO SIFANG CO LTD

Rubber base and manufacturing method thereof

ActiveCN1831363AGuaranteed heightUniform exhaustBridge structural detailsShock absorbersEngineeringAtmosphere

The invention relates to a rubber bracket and the manufacturing method thereof, where the rubber bracket is of a cuboid, or cylinder or other geometrical shape formed of multiple layers of elastic rubber and multiple layers of reinforced steel plates by in turn laminating and sulfuration, the vertical side surface of the rubber bracket has a protective rubber layer with 1-1500 uniformly distributed small bumps, the shape of the bump is a cylinder, or cuboid or circular truncated cone or their combined body, and the manufacturing method comprises the steps of stock preparing, mould processing, mould splicing, mould assembling, vulcanizing, demoulding, etc, where a side mould has N air and glue discharge holes and the shape of the side mould is that one end is big and the other end is small, where the big end is located at the inner wall of the side mould and the small end is externally made with glue discharge groove connected with the atmosphere, the air and glue discharge can be performed on the side surface of the mould, and the air discharge is uniform to make upper and lower covers tightly contact with the side mould, and the rubber bracket has good planeness, accurate height but no inclined plates in the steel plates.

Owner:柳州东方工程橡胶制品有限公司

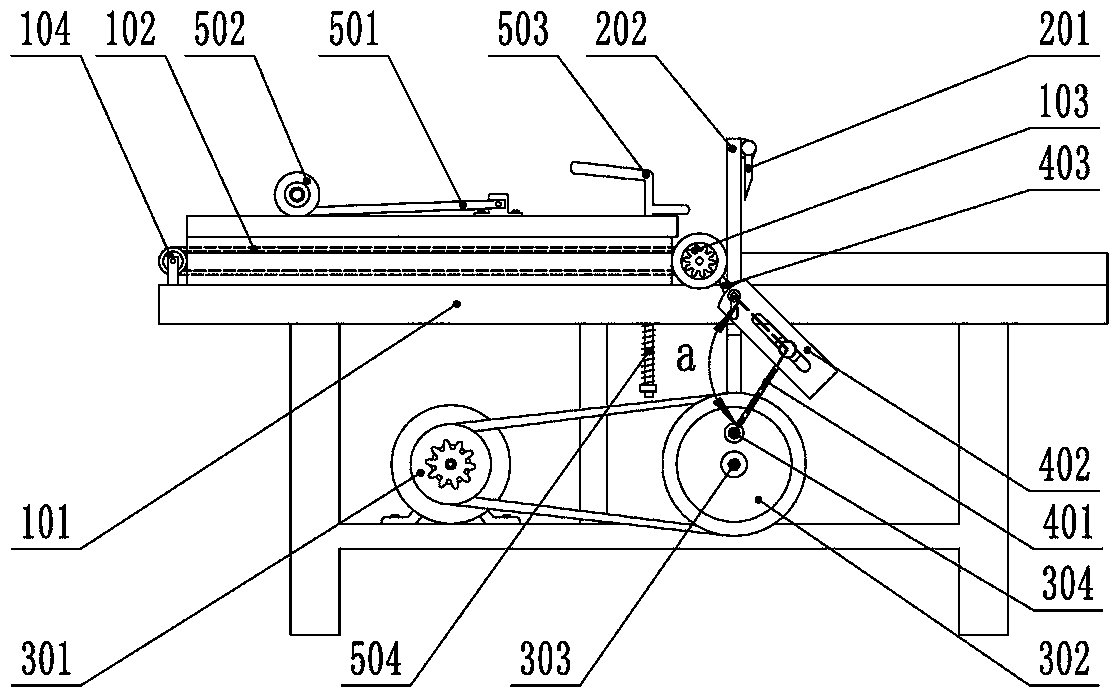

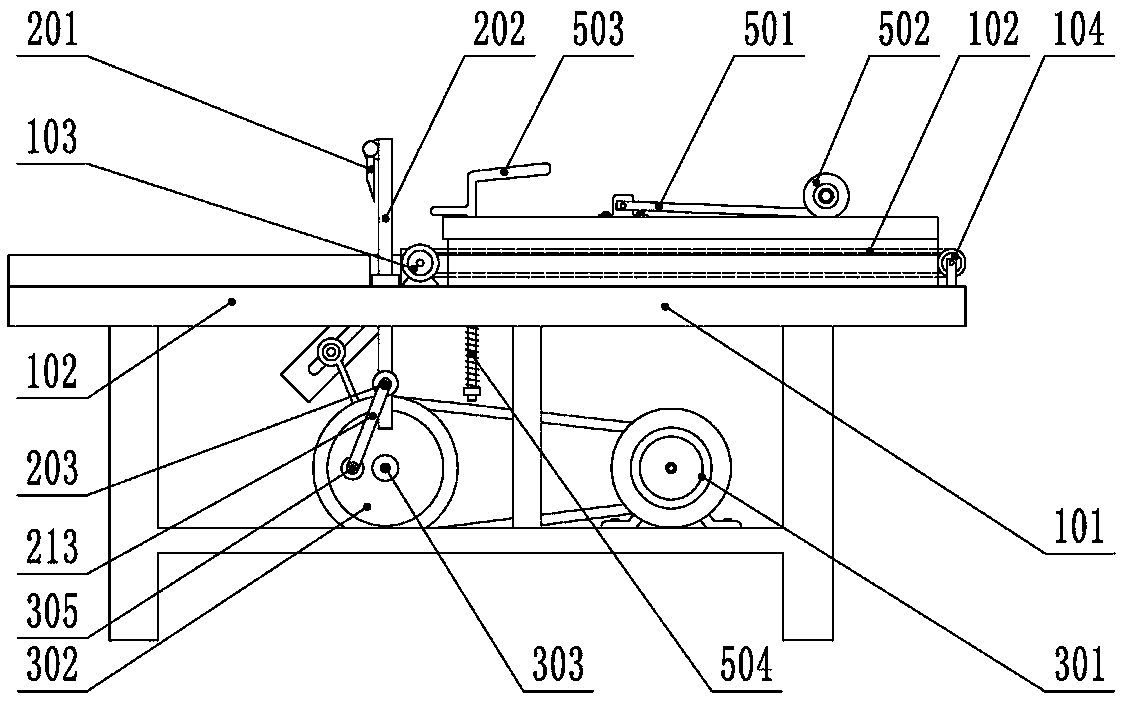

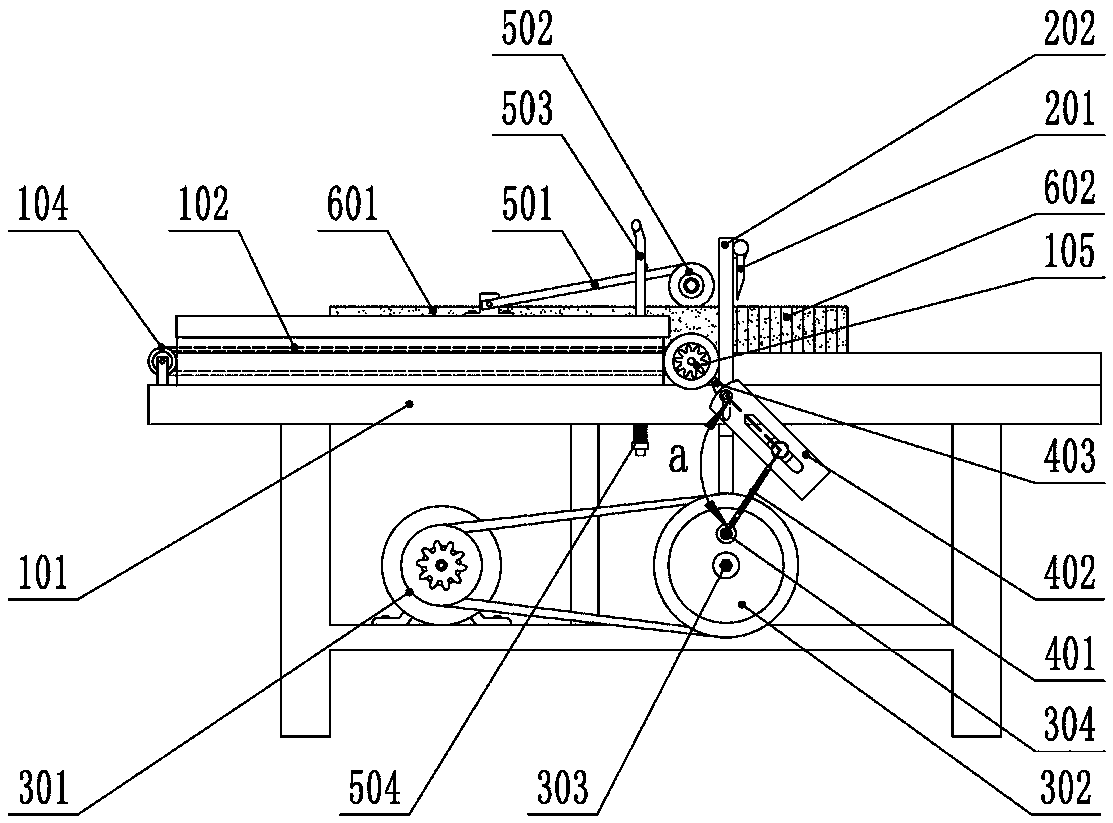

White square rice cake slicer

InactiveCN107718076AAdjustable thicknessGuaranteed smoothnessMetal working apparatusSlice thicknessDrive wheel

The invention discloses a white square rice cake slicer and relates to the technical field of food processing machines. The white square rice cake slicer comprises a storage rack and a cutter; the storage rack is provided with a conveying belt, and a driving wheel of the conveying belt is installed on the storage rack through a driving shaft; a pressing device is arranged in the part, above the conveying belt, of the storage rack, a lifting cutter frame vertically provided with the cutter is arranged in the position, in front of an upward moving part of the conveying belt in the moving direction, of the storage rack, and the lifting cutter frame is hinged with a transmission wheel driven by a motor through a rocking bar in an offset distance; and a connection rod is hinged with the transmission wheel in an offset distance, and is connected with an orientation ratchet wheel arranged on the driving shaft through a conveying belt push device. According to the white square rice cake slicer, compared with the prior art, the problems that by means of an existing mode, the white square rice cake slicing efficiency is low, and the slice thickness is not uniform can be solved.

Owner:何韦明

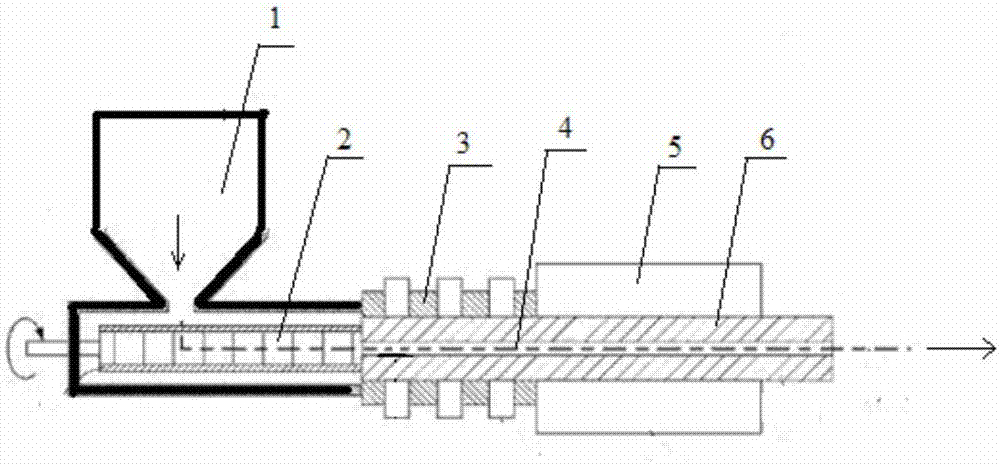

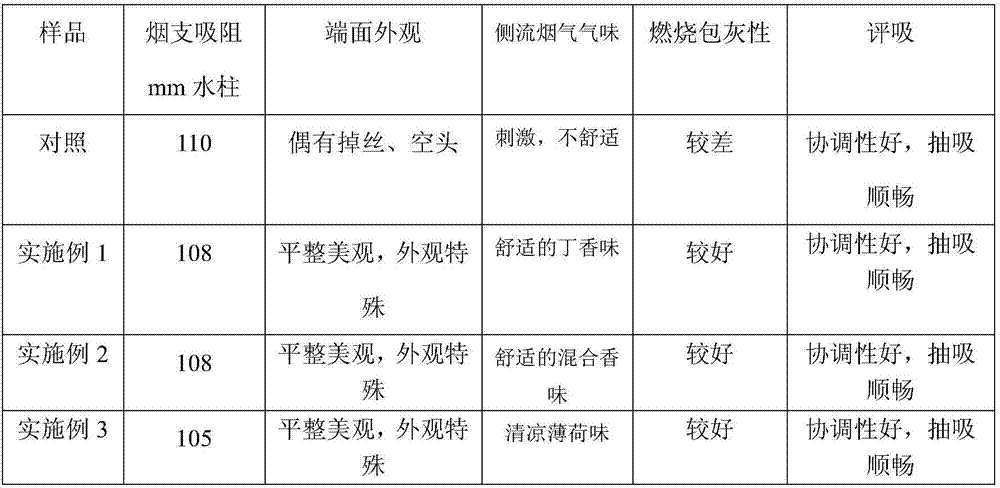

Preparation method of specially-shaped cigarettes with naturally endowed aroma

The invention discloses a preparation method of specially-shaped cigarettes with naturally endowed aroma. The preparation method comprises the following steps: respectively grinding a tobacco raw material and natural plant perfumes into powder, and uniformly mixing the powder, thus obtaining mixed powder; uniformly stirring a combustion promoter, an adhesive and a humectant, thus obtaining a mixedsolution; carrying out mixed granulation on the mixed powder and the mixed solution, and carrying out drying, thus obtaining tobacco particles; preparing the tobacco particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding withfilter sticks, thus obtaining the specially-shaped cigarettes with high homogenization, good stability and naturally endowed aroma. The cigarettes are smooth in smoking, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

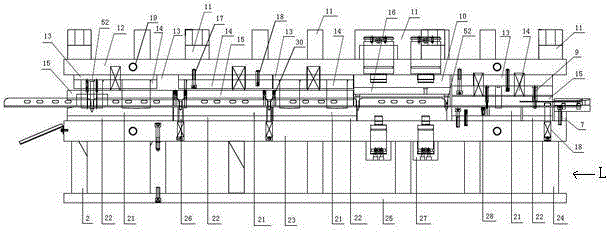

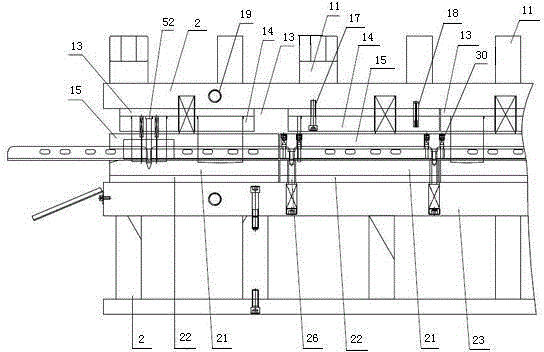

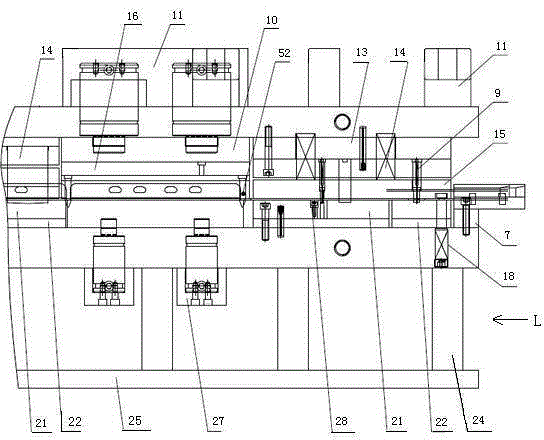

Progressive die for surface plate of electric vehicle seat lock

InactiveCN103949543AIncrease heightEasy to assemble and disassembleShaping toolsMetal-working feeding devicesCar seatPunch press

The invention relates to a progressive die for a surface plate of an electric vehicle seat lock and belongs to dies in the field of electric vehicles. The progressive die comprises an upper die, a lower die, a lifer pin, a guide needle, a quick change device, a safety device, a trimming die, a folding die, a punching die and a cut-off separation die, wherein the lifter pin is arranged on a lower die plate; the guide needle is fixedly arranged on a stripper plate; the safety device is fixedly arranged on a lower die holder; the quick change device comprises a male die punch and a male die insert; the male die punch is fixedly arranged on an upper die fixing plate; the male die insert is fixedly arranged on a lower die plate; male dies in the trimming die, the folding die, the punching die and the cut-off separation die are sequentially and fixedly arranged on the upper die fixing plate. According to the progressive die disclosed by the invention, the punch is enabled to finish punching work procedures for multiple times at different positions of a workpiece in the primary stroke, and thus the cost is reduced, the production efficiency is increased and the stability is improved.

Owner:ZHEJIANG LONGSHENG AUTO PARTS

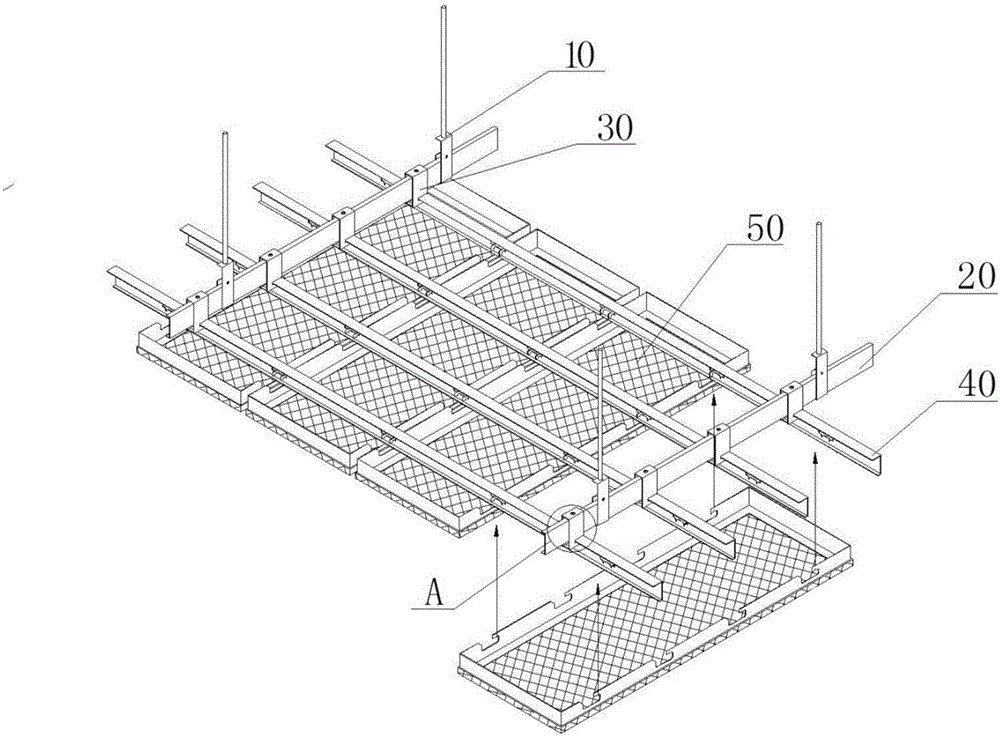

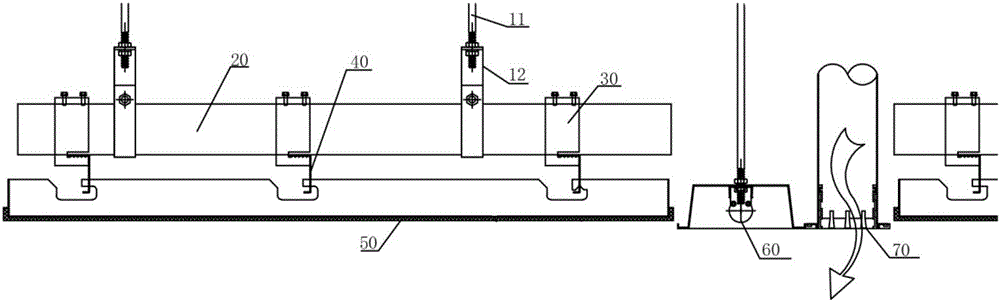

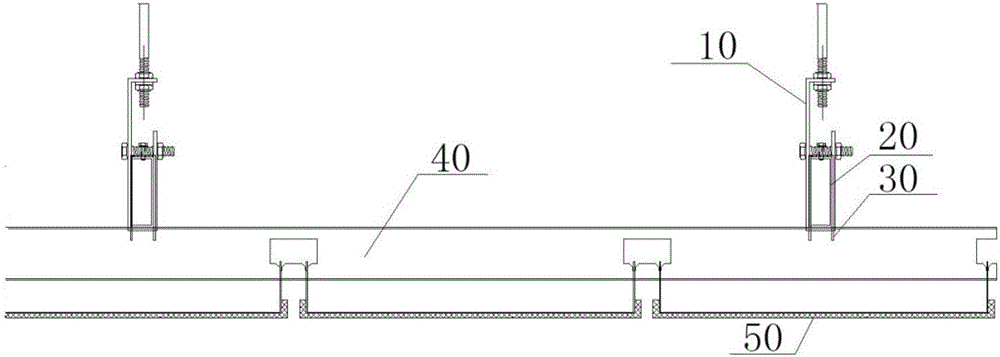

Roof suspended ceiling assembly

The invention discloses a roof suspended ceiling assembly, and belongs to the technical field of building decoration. The roof suspended ceiling assembly comprises a suspended ceiling part, a first keel, a hanging element, a second keel and a panel, wherein at least one part of the suspended ceiling part is connected with a roof board; the first keel is assembled with the suspended ceiling part so as to hang the first keel; the hanging element sleeves or is clamped on the first keel; the second keel sleeves or is clamped on the hanging element; an included angle is formed between the length direction of the first keel and the length direction of the second keel; a plurality of separated clamp grooves are formed in the length direction of the second keel; a clamp hook matched with the clamp groove is arranged on the panel; the clamp hook hooks the clamp groove so that the panel is fixed on the second keel. The roof suspended ceiling assembly has the advantages that the process is simple; the mounting and the dismounting repair are convenient; the cost is low; the roof suspended ceiling assembly is suitable for being widely applied.

Owner:芝加哥金属制品(深圳)有限公司

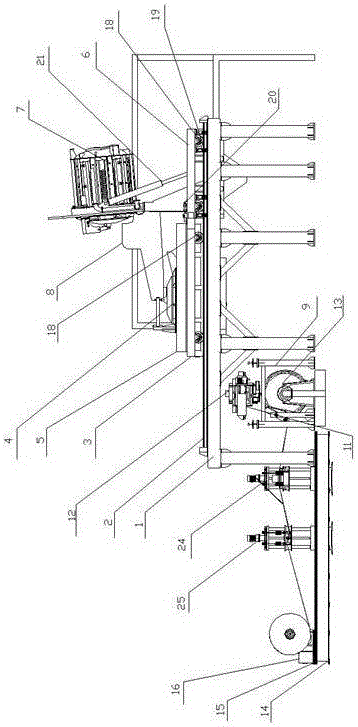

Mobile smelting furnace amorphous thin ribbon production overall machine system structure and control method thereof

The invention discloses a mobile smelting furnace amorphous thin ribbon production overall machine system structure and a control method thereof. The mobile smelting furnace amorphous thin ribbon production overall machine system structure comprises a railway frame; a railway is arranged on the railway frame; a tundish bracket and a furnace vehicle frame are arranged on the railway; a smelting furnace is mounted on the furnace vehicle frame; a tundish is arranged on the tundish bracket; a ribbon spraying ladle is arranged below the tundish bracket; a thin ribbon cooling copper roller is arranged below the ribbon spraying ladle; a thin ribbon winding machine is arranged in the ribbon outlet direction of the thin ribbon cooling copper roller; amorphous thin ribbons which are arranged in coils are prepared by smelting, molten liquid transferring, ribbon spraying, cooling and sizing, and winding; according to the system, a discontinuous production mode is changed into a continuous production mode, so that the production efficiency is greatly improved, and meanwhile, the stability of the product is also greatly improved.

Owner:JIANGSU GUONENG ALLOY TECH CO LTD

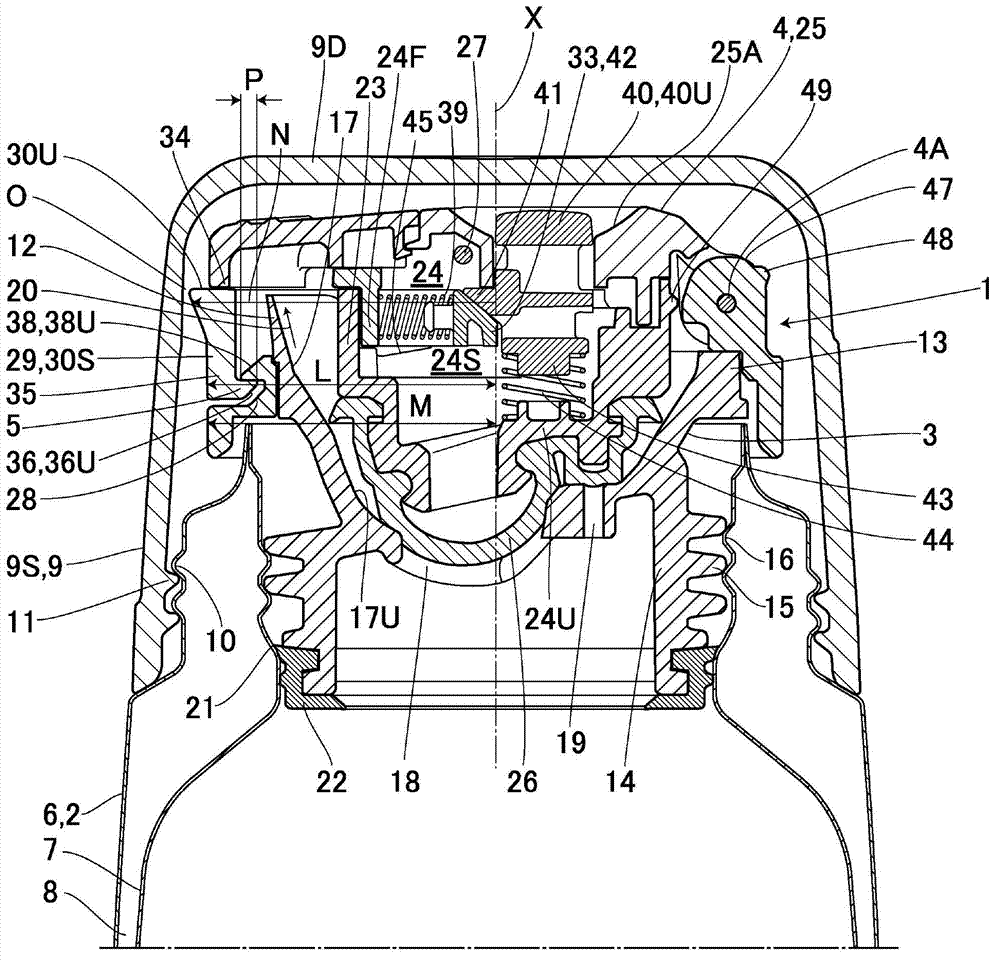

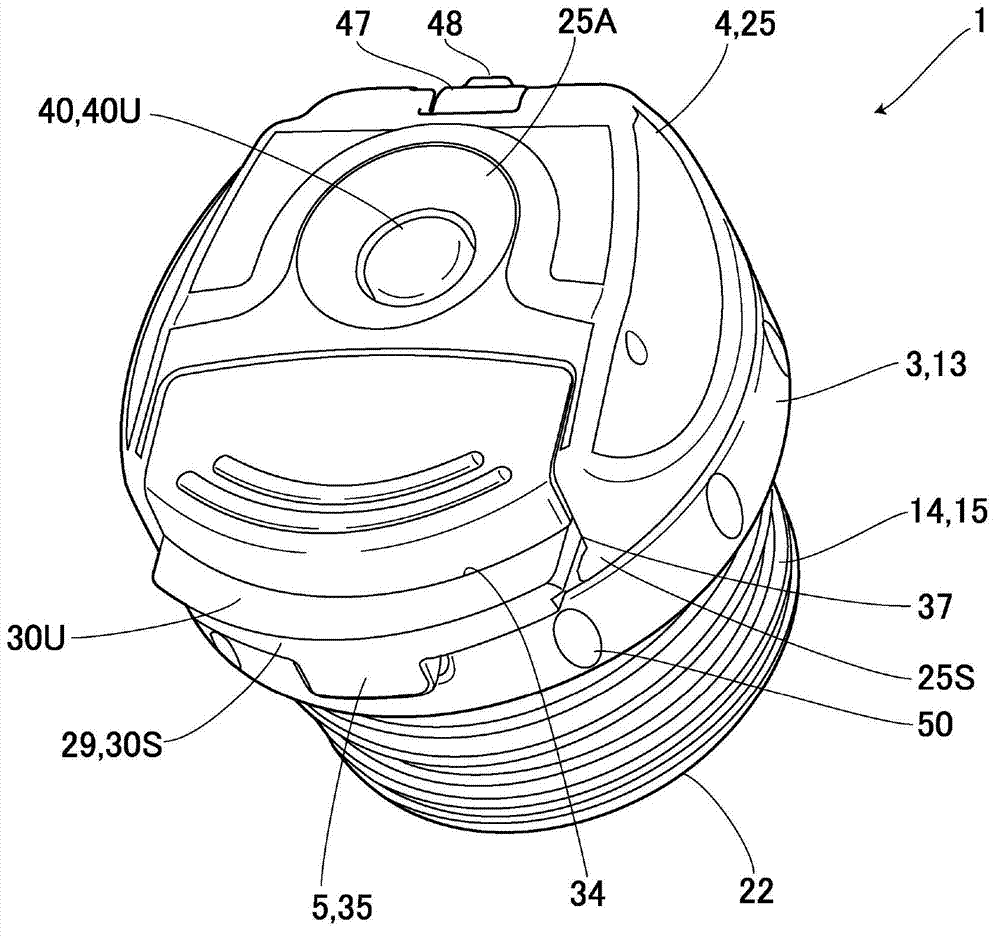

Intermediate pour stopper of portable beverage container

ActiveCN103086059AGood visual confirmationAccurateClosuresVenting meansEngineeringMechanical engineering

Owner:THERMOS CHINA HOUSEWARES +1

Forming method of metal grid electrode

ActiveCN104752185AAvoid etchingReduce the overall heightSemiconductor devicesDielectric layerFiller metal

A forming method of a metal grid electrode comprises the following steps: providing a semiconductor substrate, forming a pseudo grid electrode on the surface of the substrate, forming an interlayer dielectric layer on the substrate, allowing the top of the interlayer dielectric layer to level with the top of the pseudo grid electrode; utilizing an epitaxial growth to form a first sacrificial layer at least covering the top of the pseudo grid electrode; forming a second sacrificial layer on the interlayer dielectric layer, allowing the top of the second sacrificial layer to level with the top of the first sacrificial layer; removing the first sacrificial layer, forming an opening inside the second sacrificial layer, and exposing the bottom of the opening outside the top of the pseudo grid electrode; removing the pseudo grid electrode after removing the first sacrificial layer, and forming a grid electrode groove inside the interlayer dielectric layer; removing the second sacrificial layer, and forming the metal grid electrode by filling a metal layer inside the grid electrode groove. By the forming method of the metal grid electrode, the interlayer dielectric layer can be well protected from being damaged during the processing of removing the pseudo grid electrode, without reducing the depth of the grid electrode groove, accordingly the height of the subsequently formed metal grid electrode is not reduced, thereby increasing the performance of a subsequently formed device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

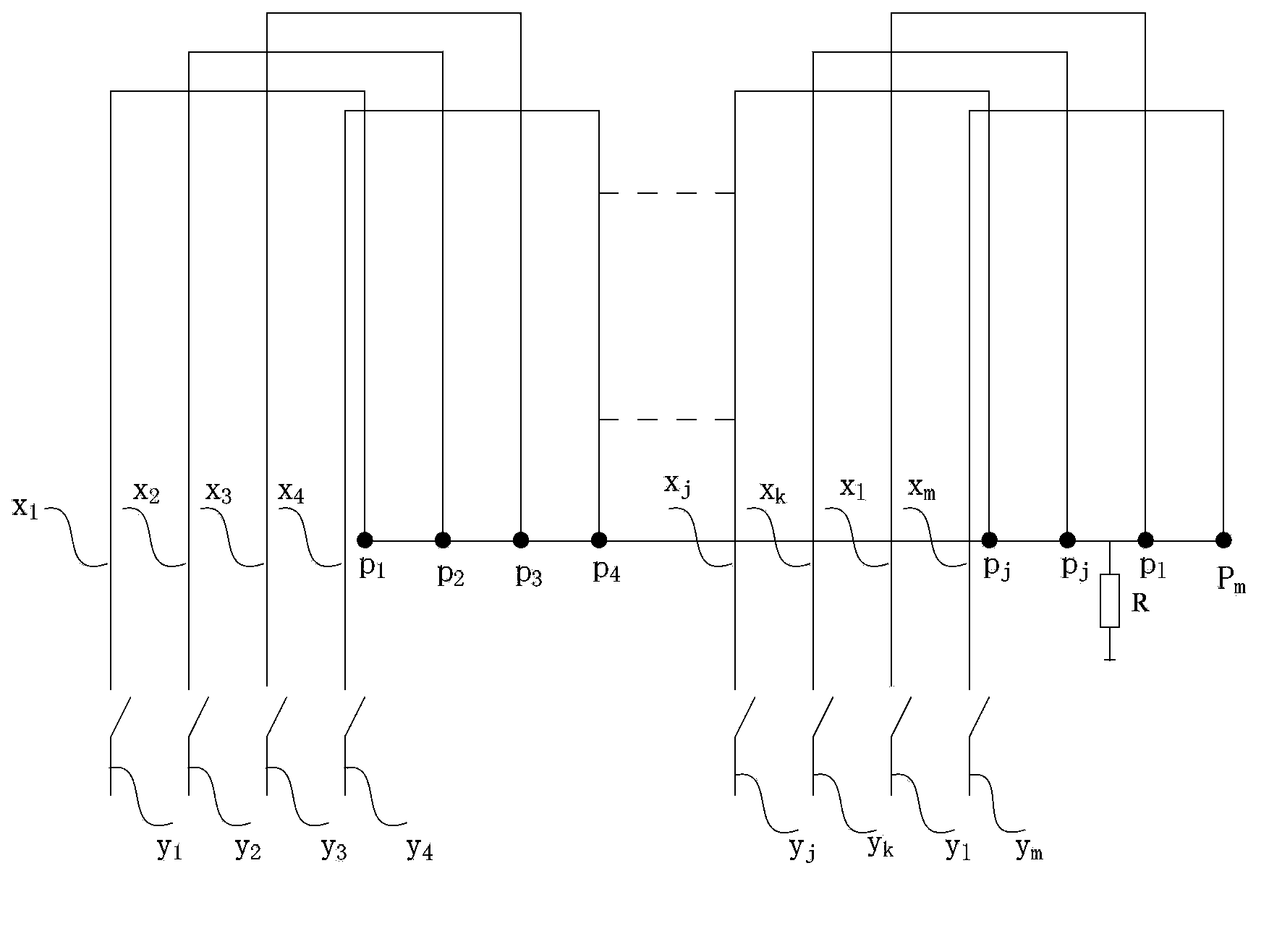

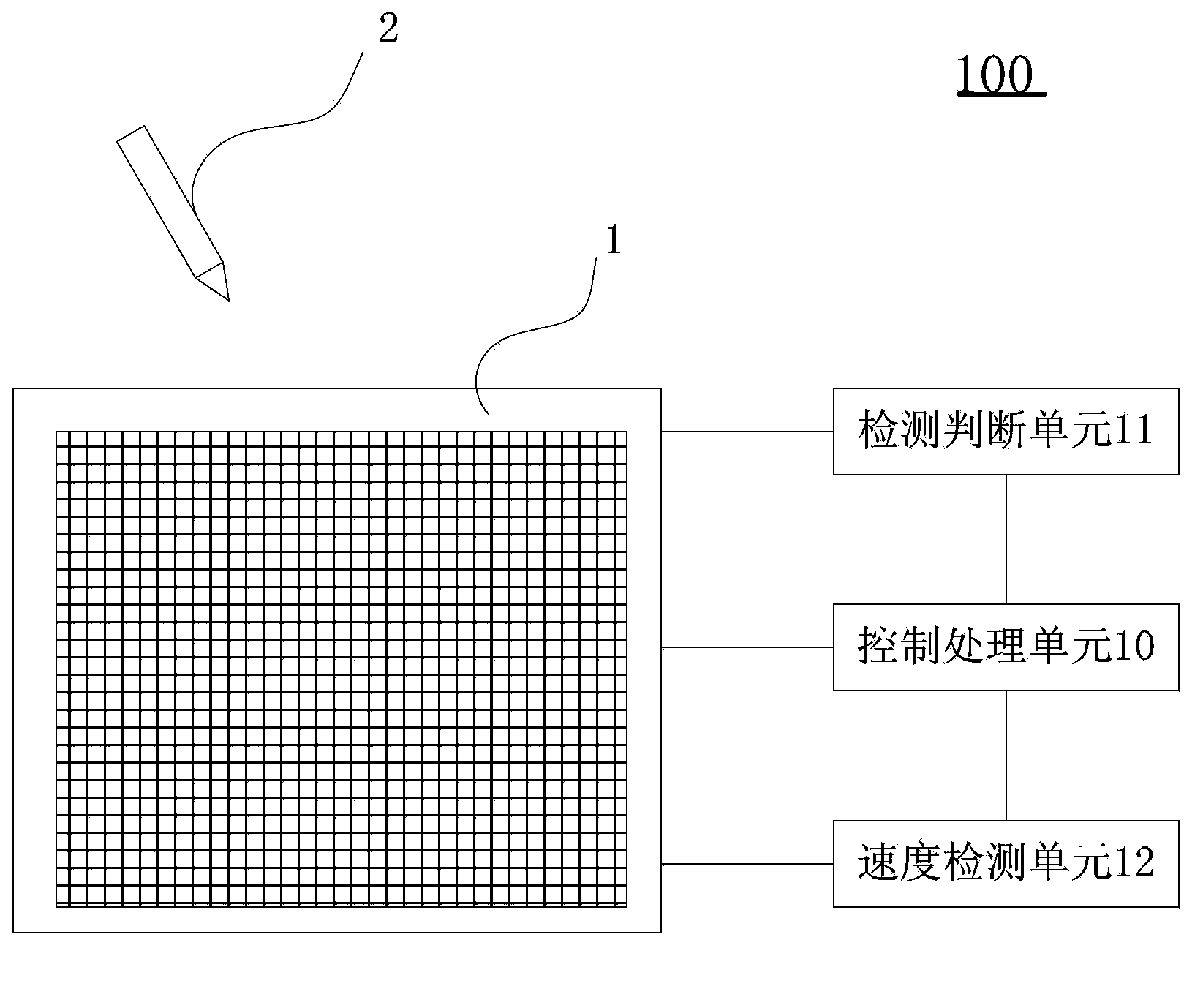

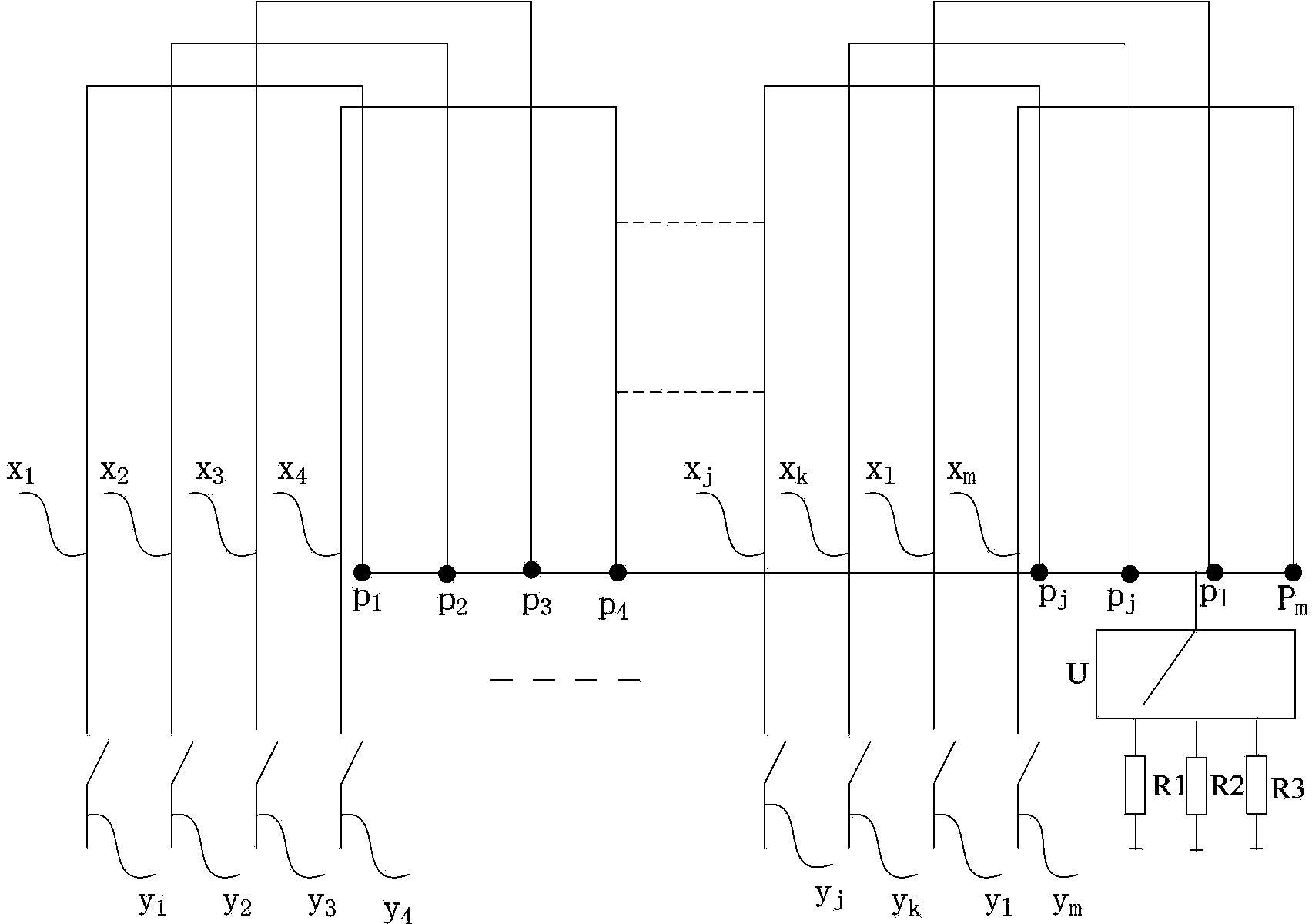

Electromagnetic touch device and electromagnetic touch method

ActiveCN103793122AGuaranteed heightGuaranteed speedInput/output processes for data processingAcousticsVIT signals

The invention provides an electromagnetic touch device which comprises an antenna board (1), a control processing unit (10) and a detection and judgment unit (11), wherein a transmitting coil and a receiving coil are arranged on the antenna board (1), the transmitting coil is used for transmitting electromagnetic waves to an electromagnetic pen (2), while the receiving coil is used for receiving a resonance signal generated after the electromagnetic pen (2) resonates with the electromagnetic waves transmitted by the transmitting coil, the control processing unit (10) is used for controlling the transmitting coil to transmit signals and the receiving coil to receive signals and processes the signals received by the receiving coils, and the detection and judgment unit (11) is used for detecting the relative position of the electromagnetic pen (2) to the antenna board (1) and sends the position information of the electromagnetic pen (2) to the control processing unit (10); the control processing unit (10) sets the transmission power of the transmitting coil and the induction threshold of the receiving coil according to the relative position of the electromagnetic pen (2) to the antenna board (1).

Owner:HANVON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com