Packaging structure and method for manufacturing the packaging structure

A technology of packaging structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as products and methods that do not have suitable structures and methods, affect the quality of packaging structures, and reduce chip quality, etc. Achieve the effect of saving material cost, reducing volume and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

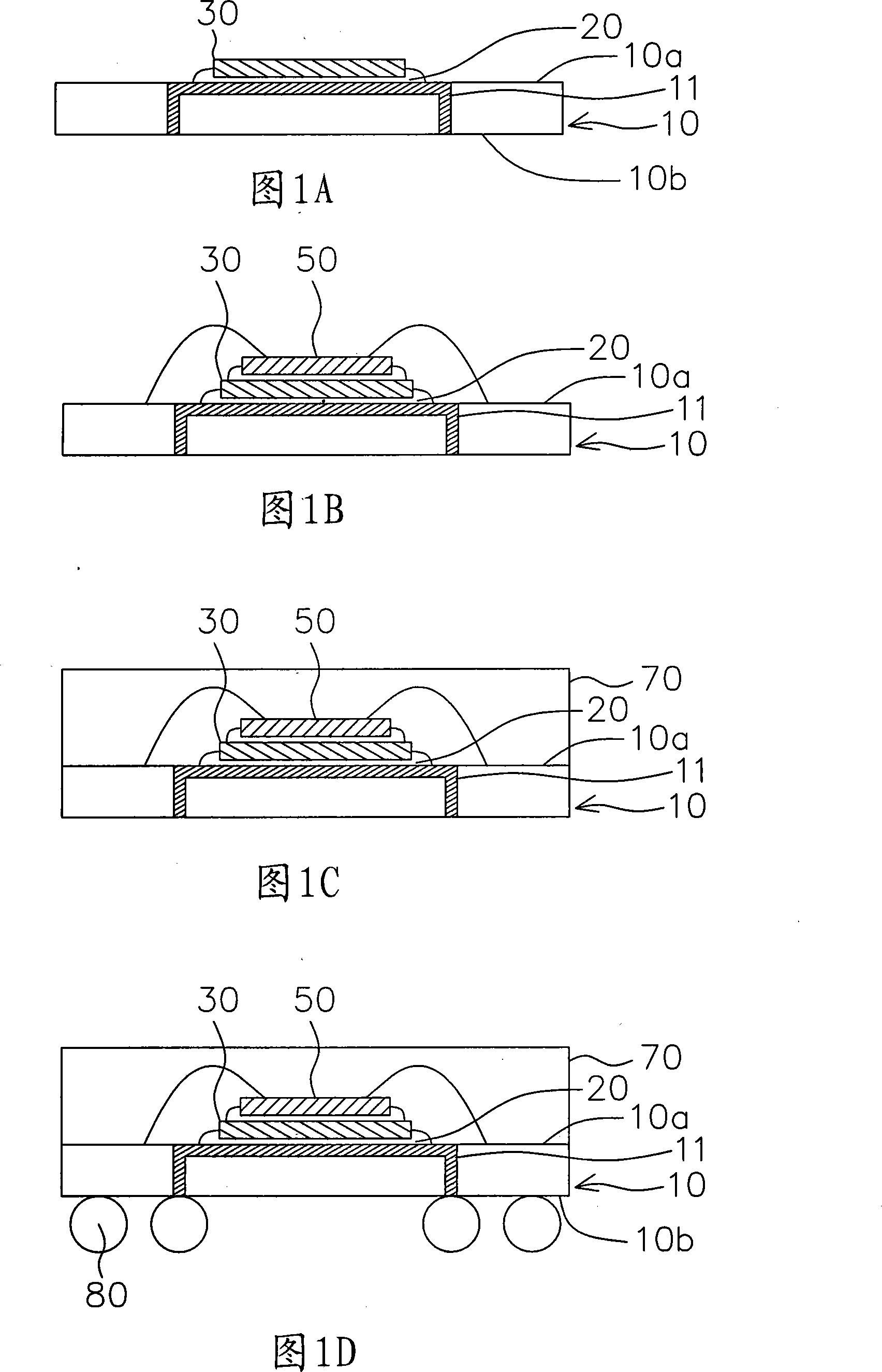

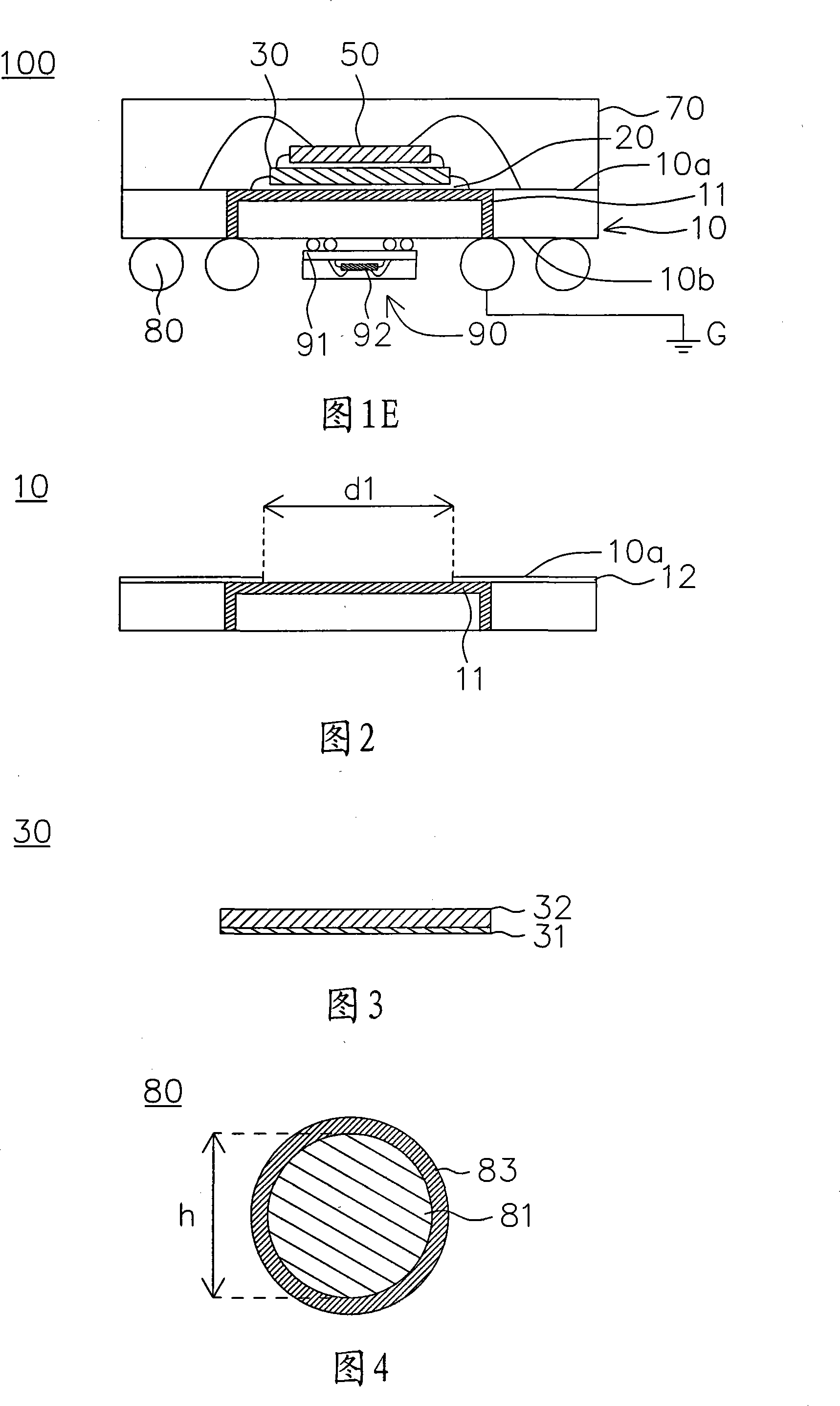

[0054] Please refer to FIGS. 1A to 1E at the same time. FIG. 1A is a schematic diagram showing a substrate and a shielding element according to a first embodiment of the present invention, and FIG. 1B is a schematic diagram showing a shielding element disposed on the substrate of FIG. 1A. 1C is a schematic diagram showing a chip disposed on the shielding element of FIG. 1B, FIG. 1D is a schematic diagram showing a sealant layer formed on the substrate of FIG. 1C, and FIG. 1E is a schematic diagram showing a package according to the first embodiment of the present invention Schematic diagram of the structure.

[0055] The manufacturing method of the package structure according to the first embodiment of the present invention includes the following steps:

[0056] First, a substrate 10 is provided, and a shielding element 30 is arranged on the substrate 10. Please refer to FIG. 1A, the substrate 10 has a first surface 10a and a second surface 10b, and the first surface 10a is opposi...

no. 2 example

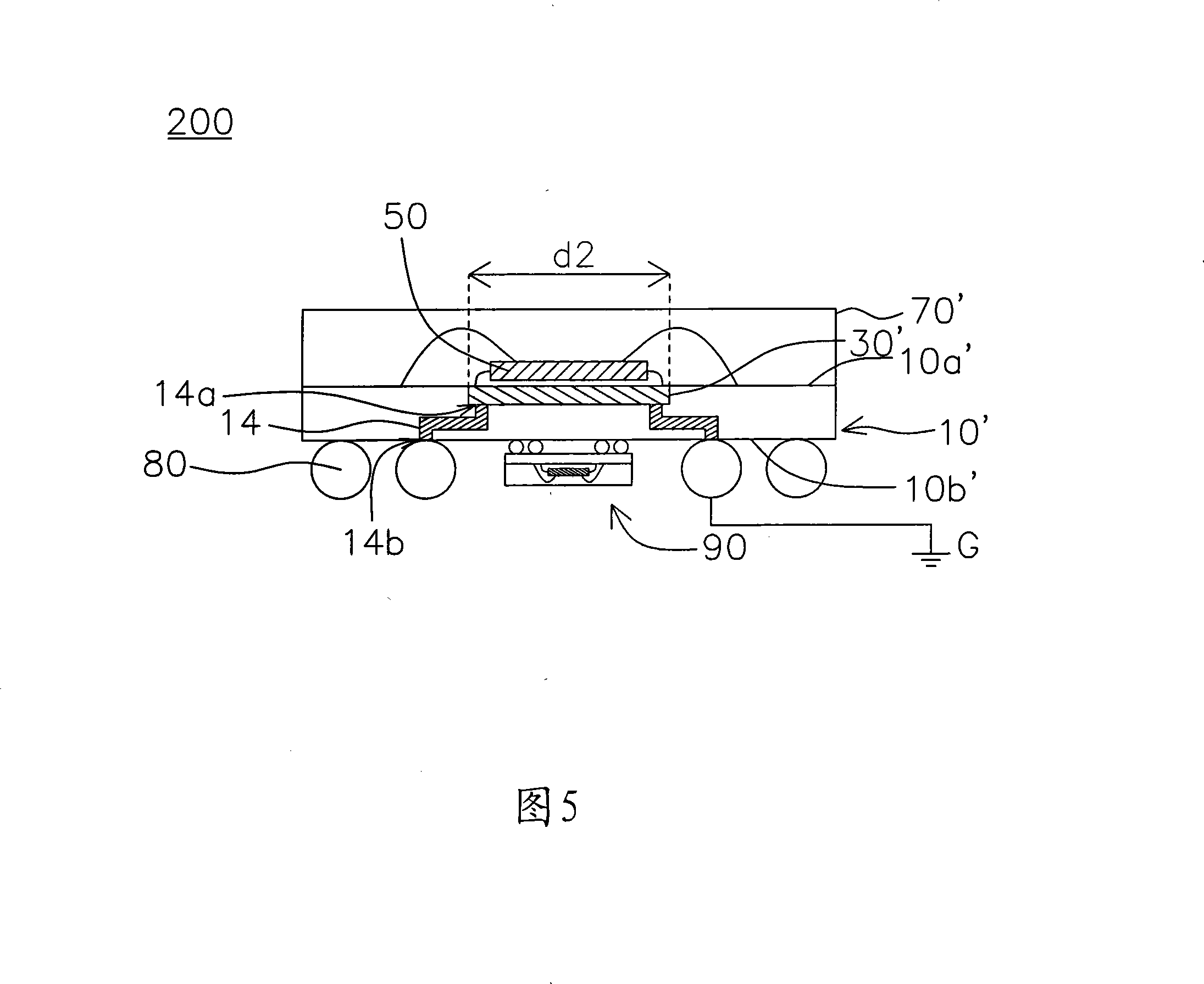

[0075]Please refer to FIG. 5, which is a schematic structural diagram of the package structure according to the second embodiment of the present invention. The package structure 200 of the second embodiment of the present invention includes a substrate 10', a chip 50, an encapsulant layer 70' and a semiconductor device 90. The package structure 200 of this embodiment is different from the package structure 100 according to the first embodiment of the present invention. The difference lies in the position of a shielding element 30' relative to the substrate 10', and the shielding element 30' is connected to a solder ball 80 The other similarities will be omitted here and will not be repeated here.

[0076] In this embodiment, the aforementioned substrate 10' has a first surface 10a' and an opposite second surface 10b', and the substrate 10' includes a shielding element 30'. The shielding element 30' is embedded in the substrate 10', and the first surface 10a' has an opening d2 to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com