Hall thruster gas distributor structure with porous material partition plates

A gas distributor, Hall thruster technology, applied in thrust reverser, using plasma, machine/engine, etc., can solve the problem of reducing anode life and other problems, so as to improve anode life, improve performance, and improve the degree of gas homogenization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

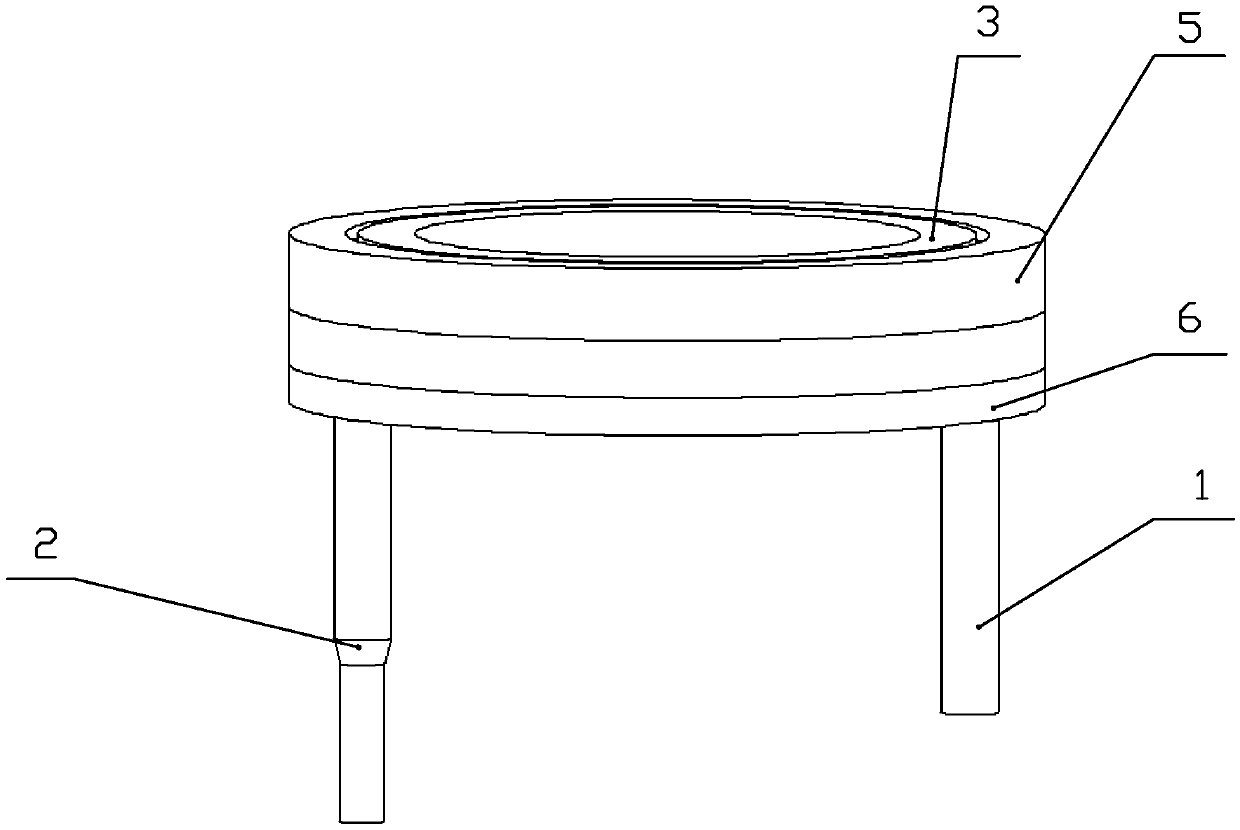

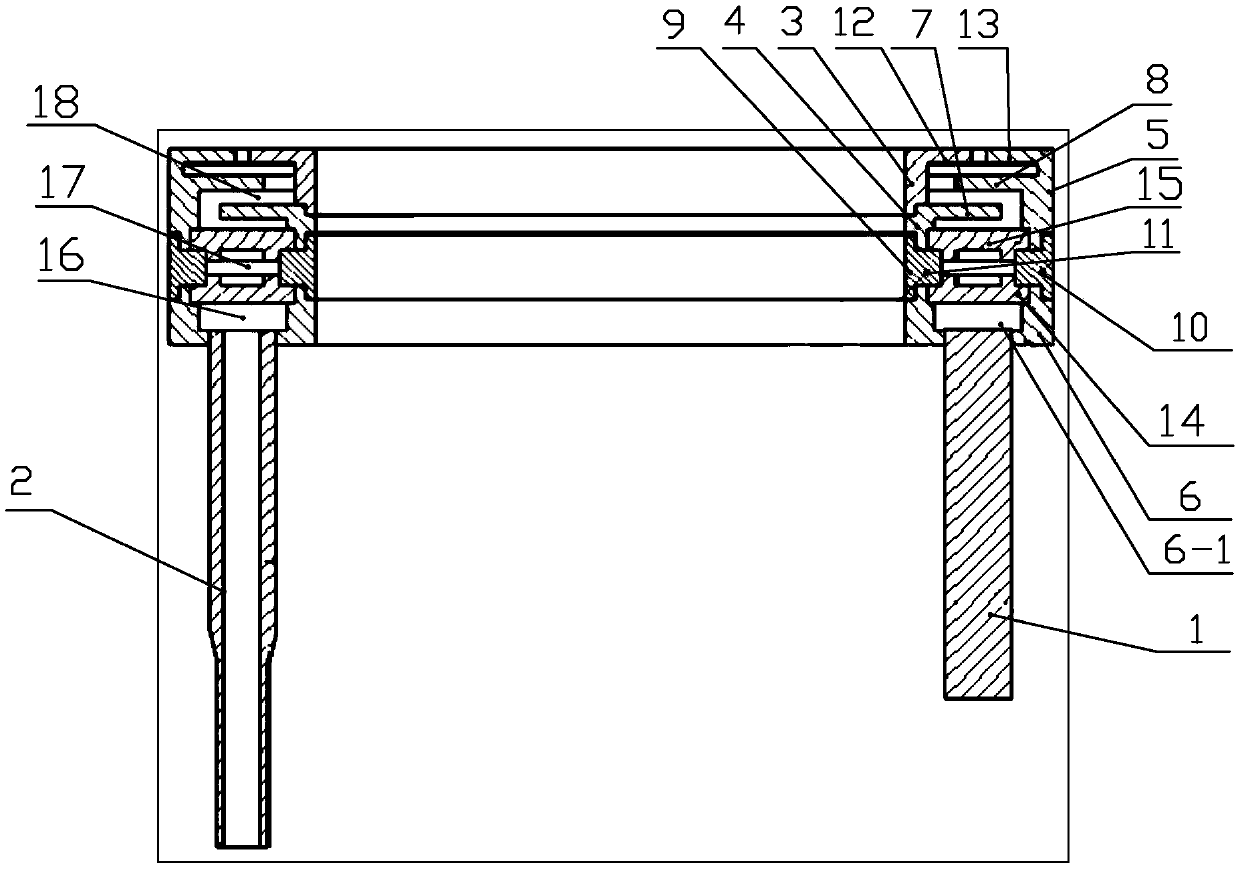

[0024] Specific implementation mode one: combine figure 1 , 2 Describe this embodiment, a Hall thruster gas distributor structure with a porous material partition, which includes a mounting pillar 1, an air guide tube 2,

[0025] It also includes a shell assembly and a bulkhead assembly disposed inside the shell assembly,

[0026] The shell assembly includes an upper inner ring 3 of the top shell, a lower inner ring 4 of the top shell, an outer ring 5 of the top shell and a bottom shell 6, wherein the bottom shell 6 is a ring structure and has openings along its circumference The upward annular groove 6-1, the mounting pillar 1 and the air guide tube 2 are respectively fixed under the bottom shell 6, and the air guide tube 2 is arranged through the annular groove 6-1, and the top shell The upper inner ring 3 and the lower inner ring 4 of the top shell are fixed on the top of the side wall of the annular groove 6-1 sequentially from top to bottom, and the top shell outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com