Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Efficient Homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for homogenizing two or more fluids of different densities

ActiveUS8079751B2Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingVolumetric Mass DensityEngineering

A blending apparatus for blending a first fluid stream having a first density and a second fluid stream having a second fluid density, the first density being greater than said second density, is discussed. The apparatus includes a first fluid director including a plurality of baffles affixed therein to create turbulence and shear in the first fluid, a cylindrical second fluid director, a primary mixing chamber receiving the first sheared fluid from the first fluid director and receiving the second fluid from the second fluid director, wherein the first fluid and second fluid are mixed in the primary mixing chamber to form a mixed primary fluid stream, and a secondary blending chamber comprising at least one static mixer and coaxially aligned with and receiving the mixed primary fluid stream from the primary mixing chamber.

Owner:MI

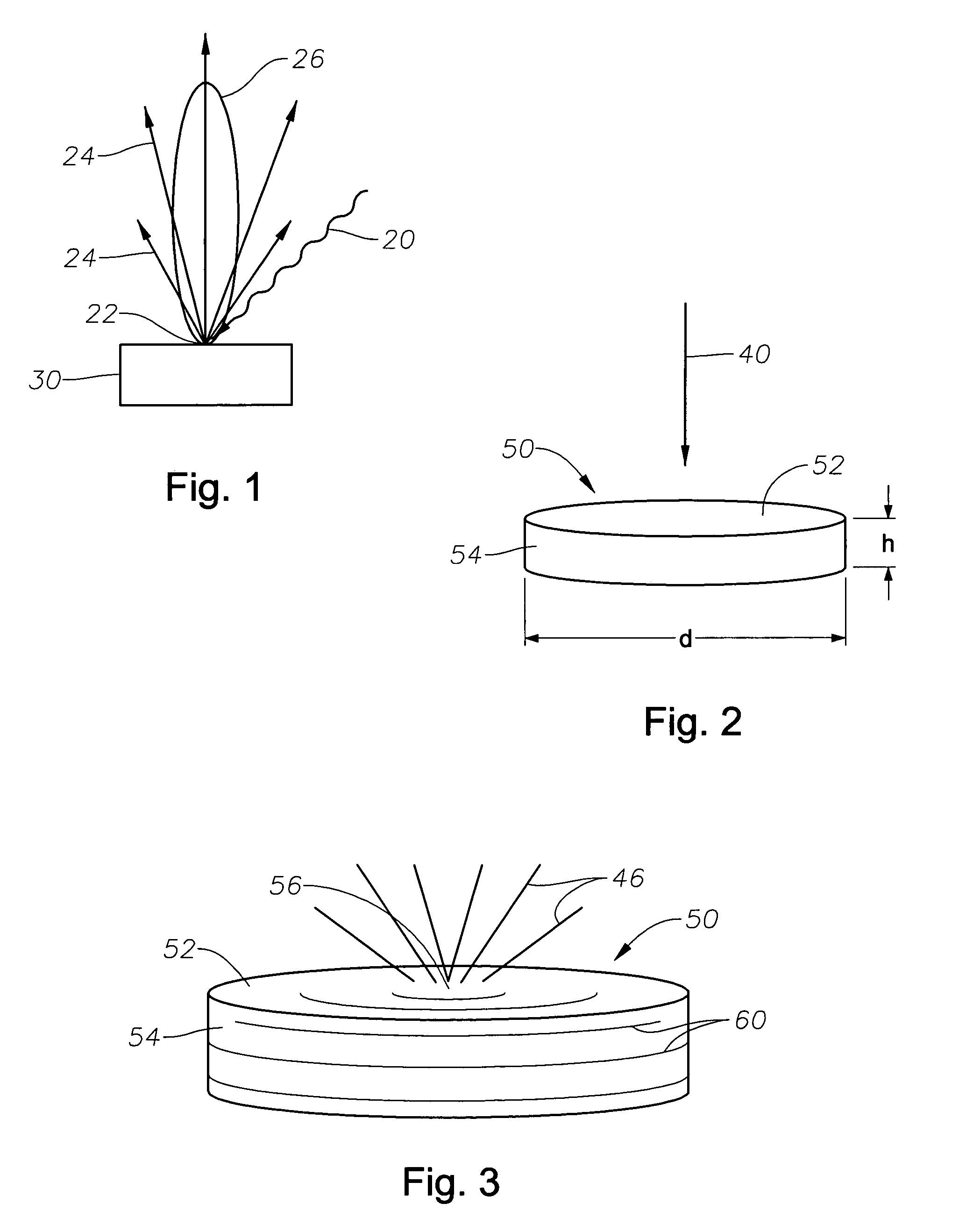

Method for preparing and processing a sample for intensive analysis

ActiveUS20050012244A1Accurate measurementReduce concentrationRadiation pyrometryLaser detailsEpoxyComposition analysis

A method for pelletizing and taking intensive measurements of a raw sample is disclosed. The method includes homogenizing and pelletizing the sample that is to be subjected to compositional or intensive analysis. The raw sample is mixed with several solutions containing epoxies and activators based in carrier solutions or solvents, and ground to a fine powder or gel. The gel is partially dried and conformed to a pellet shape. The pellet is then cured such that the epoxy and activator solutions react and form a binding agent capable of maintaining the structural integrity of the sample pellet during intensive analysis. An intensive analysis instrument, such as LIBS, may then be used to ablate the surface of the pellet. The pellet provides consistent ablation of the sample material for accurate intensive measurements.

Owner:HALLIBURTON ENERGY SERVICES INC

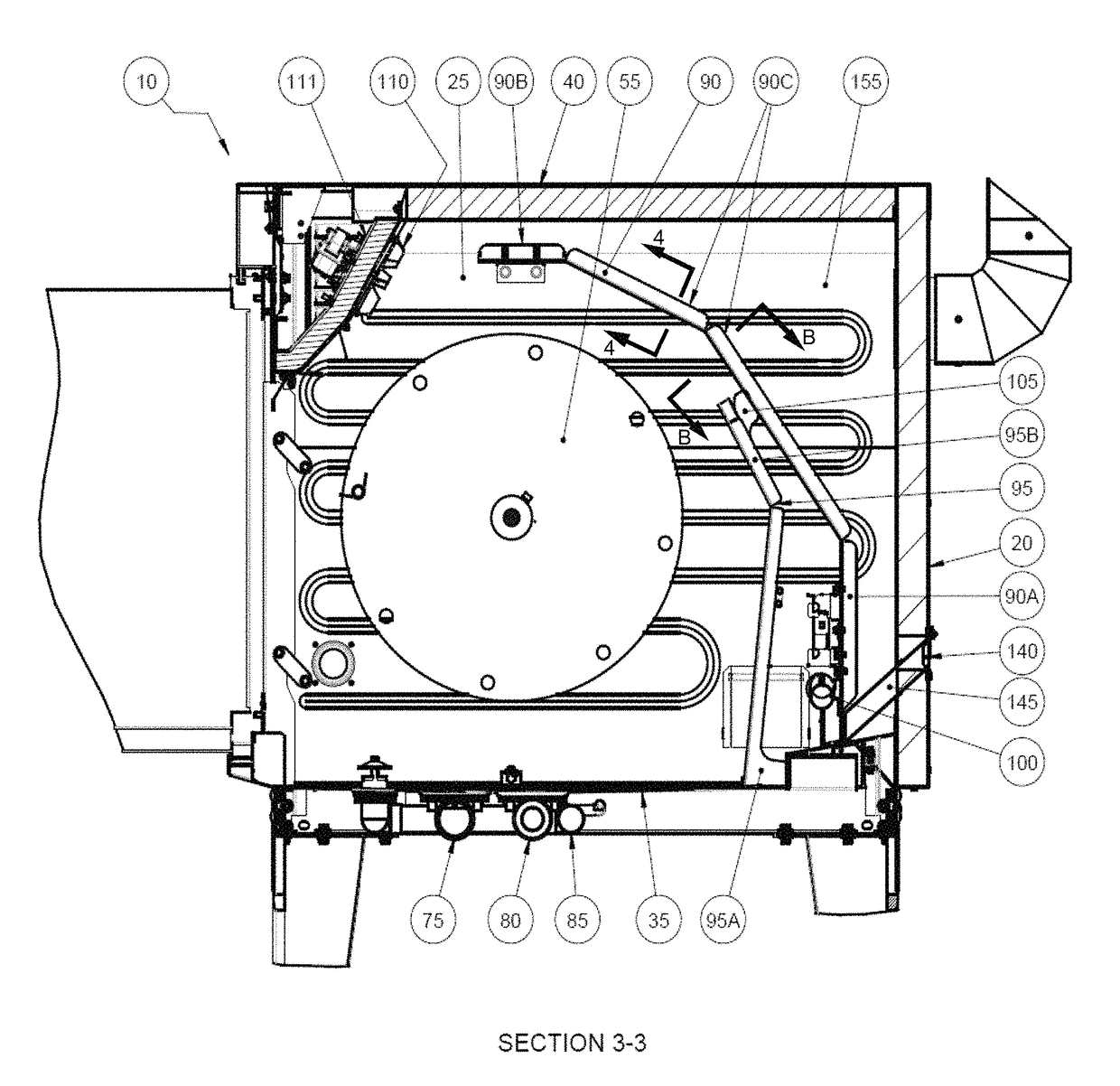

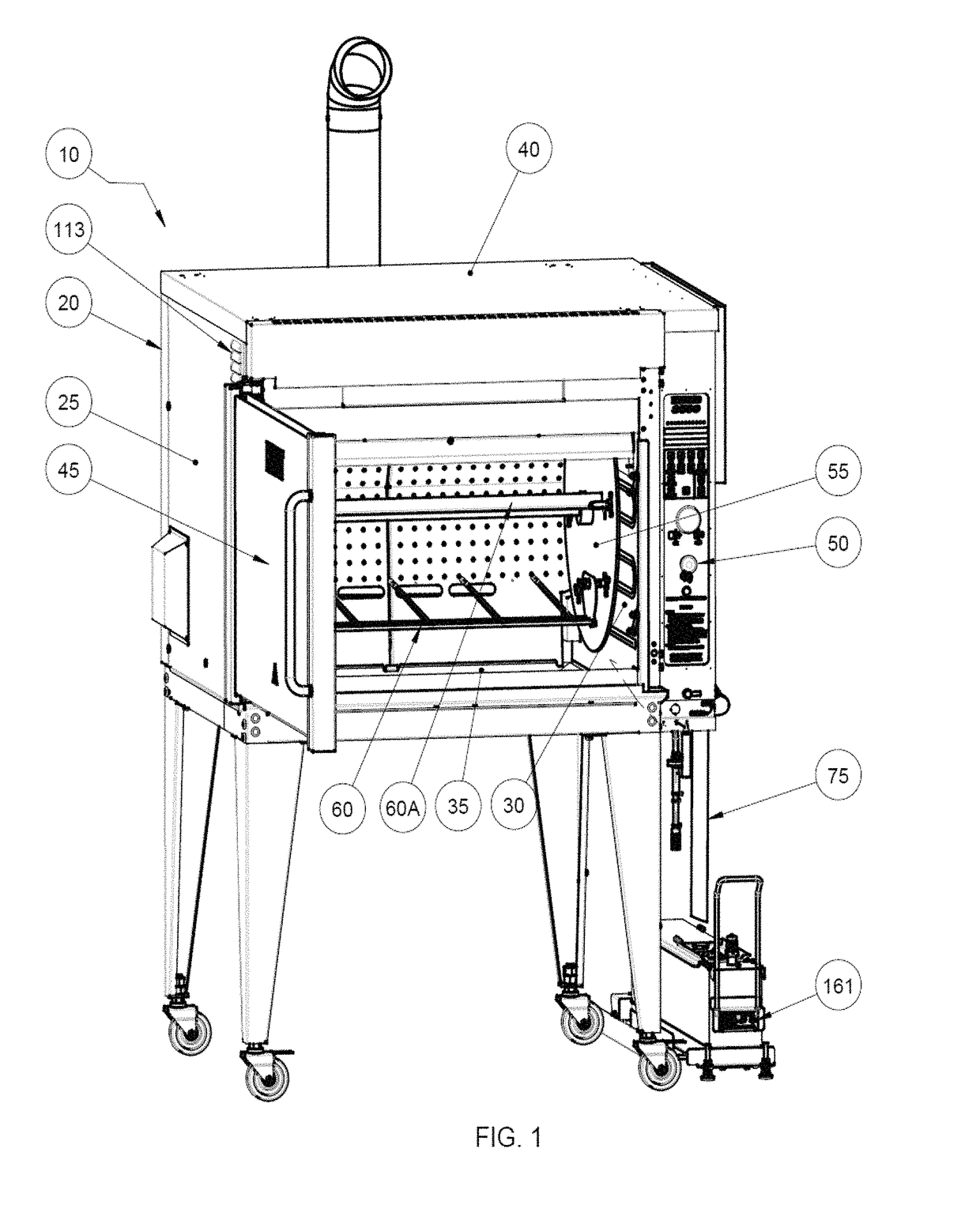

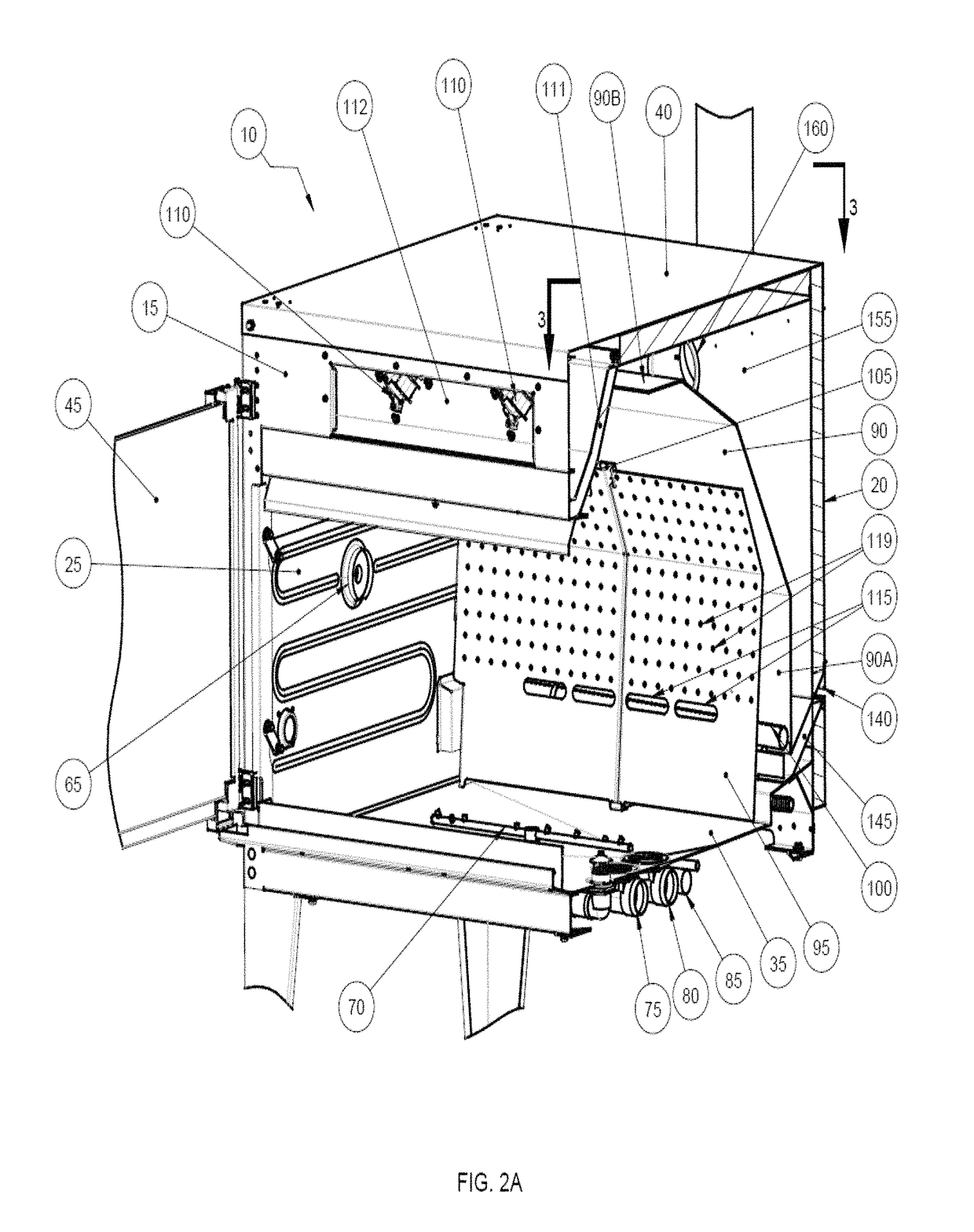

Atmospheric rotisserie burner with convection heating

ActiveUS10051995B2Utility and advantagePreventing situationRoasting apparatusRoasters/grillsAir movementEngineering

The present invention provides a device for cooking food that has a cooking cavity defined by a front wall, a back wall that opposes the front wall, two opposing side walls, a ceiling, and a floor that opposes the ceiling; a substrate for supporting a food item, the substrate substantially enclosed by the cavity; a first plenum spanning between the two opposing side walls, said plenum comprising a first segment proximal to the back wall, a second segment proximal to the ceiling, and at least one third segment that joins the first segment and the second segment; a second plenum positioned proximal to but medially displaced from the first plenum; a flame heating element located between the first plenum and the second plenum; and at least one air movement device located proximal to a region in which the front wall and ceiling intersect.

Owner:7794754 CANADA

Method for preparing and processing a sample for intensive analysis

InactiveUS7195731B2Maintain structural integritySimple structureLaser detailsRadiation pyrometryEpoxySolvent

This application relates to a method for pellerizing and taking intensive measurements of a raw sample. The method includes homogenizing and pelletizing the sample that is to be subjected to compositional or intensive analysis. The raw sample is mixed with several solutions containing epoxies and activators based in carrier solutions or solvents, and ground to a fine powder or gel. The gel is partially dried and conformed to a pellet shape. The pellet is then cured such that the epoxy and activator solutions react and form a binding agent capable of maintaining the structural integrity of the sample pellet during intensive analysis. An intensive analysis instrument, such as LIBS, may then be used to ablate the surface of the pellet. The pellet provides consistent ablation of the sample material for accurate intensive measurements.

Owner:HALLIBURTON ENERGY SERVICES INC

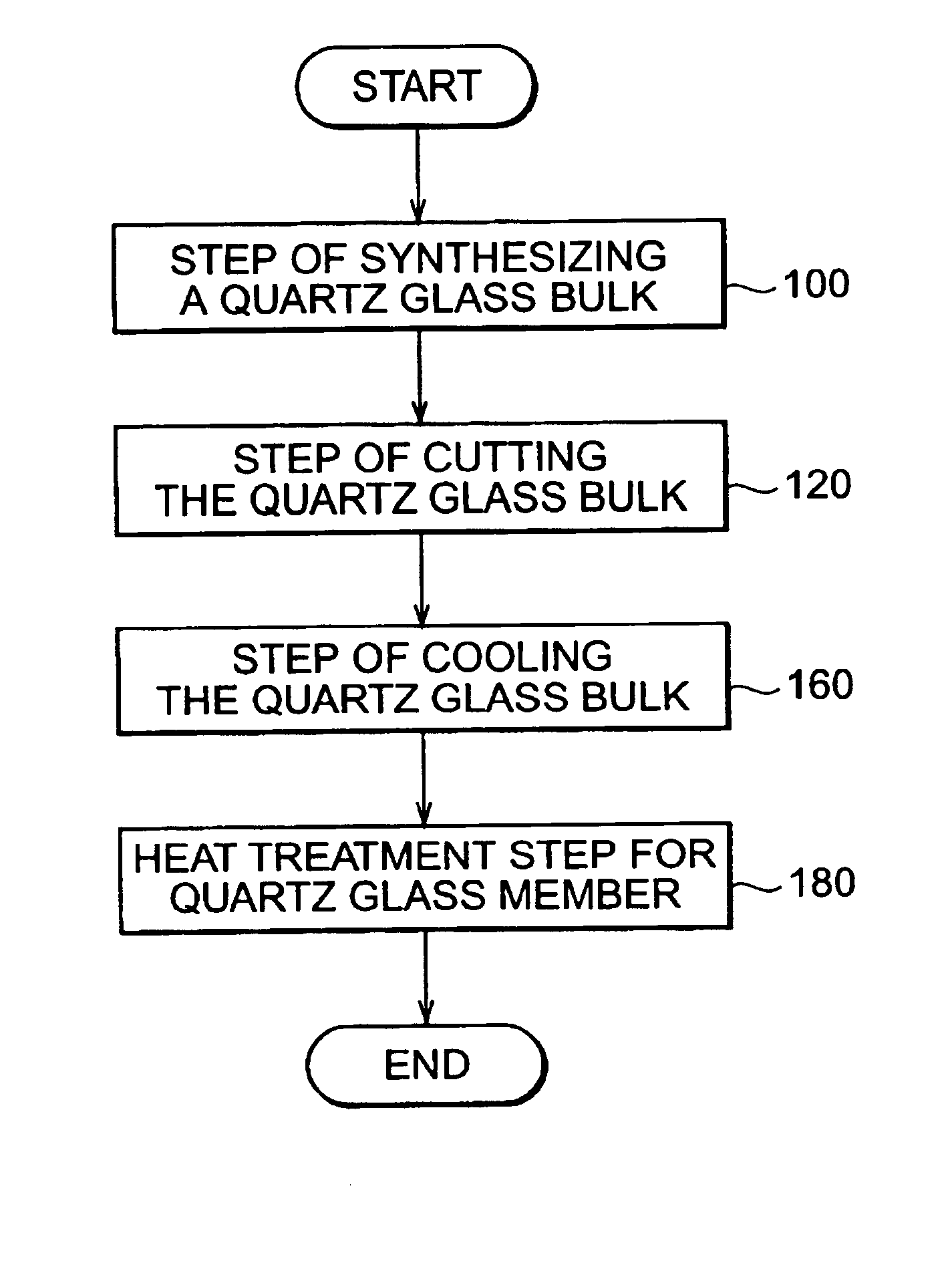

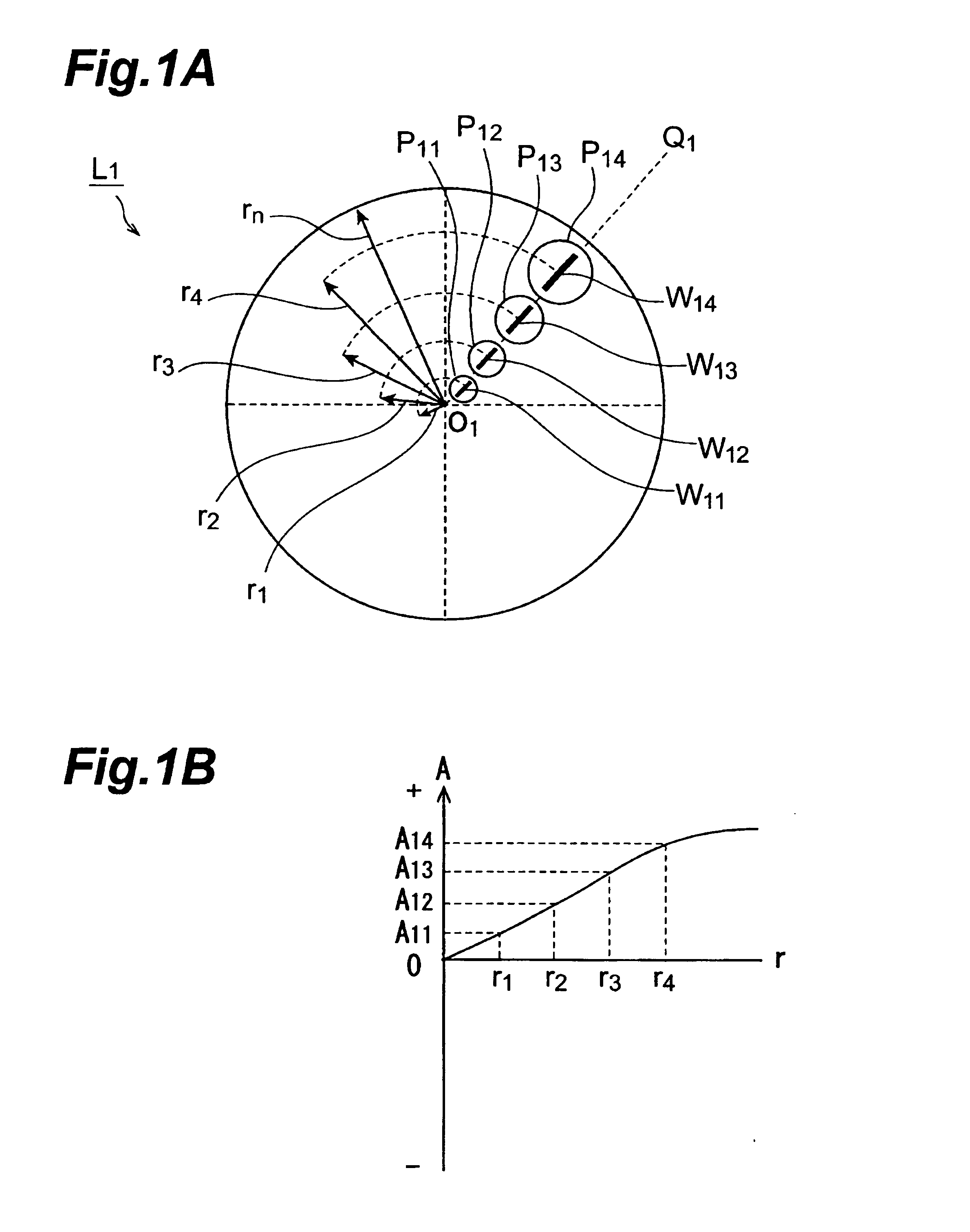

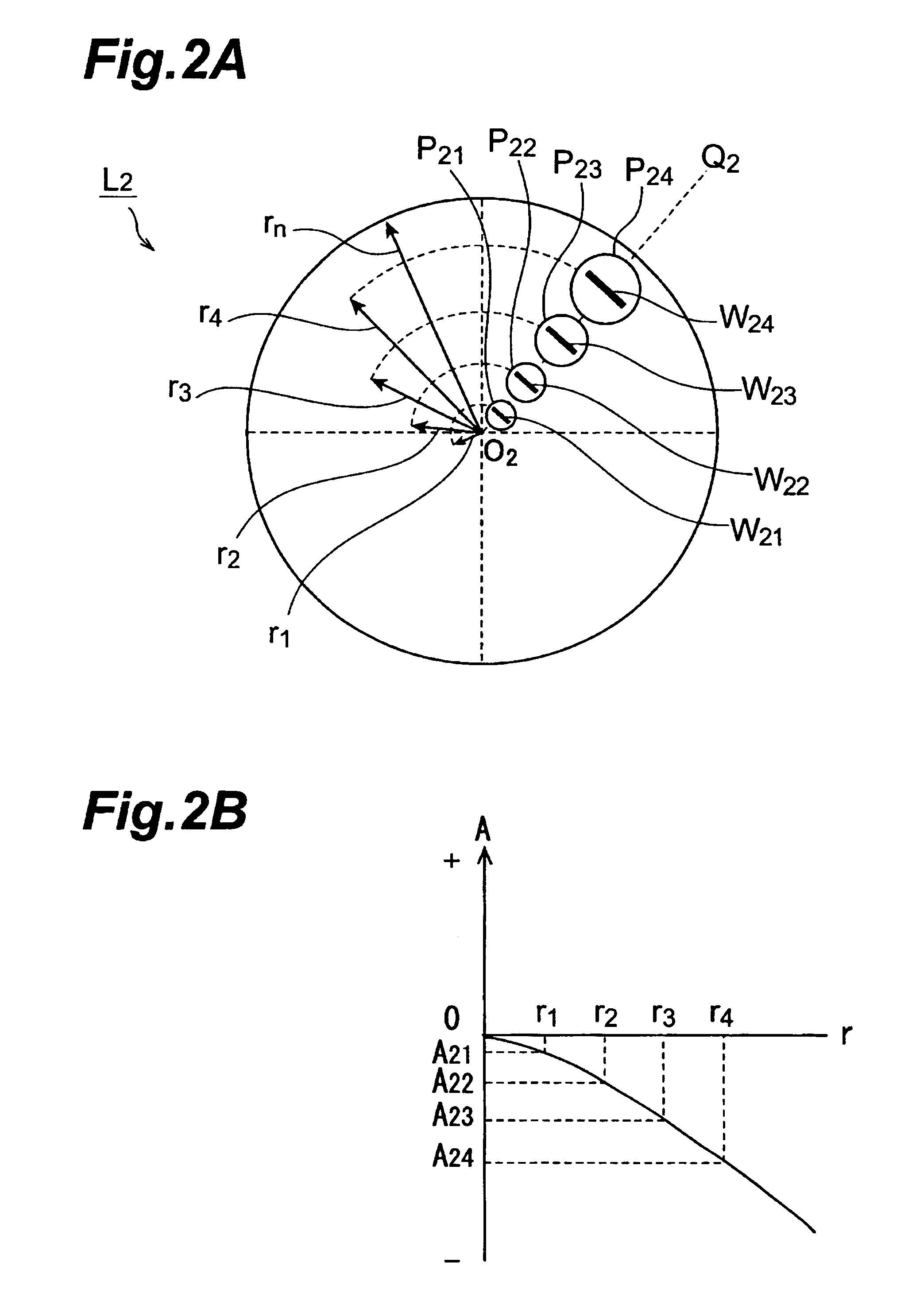

Silica glass member, method for producing the same, and projection aligners using the same

InactiveUS6672109B1Efficient HomogenizationEvenly dispersedMaterial analysis using wave/particle radiationPhotomechanical exposure apparatusHigh resistanceOptical axis

A silica glass member for use with a light having a specific wavelength of 250 nm or shorter, in which the difference in the maximum and the minimum values of hydroxyl group concentration as measured in a plurality of points within a plane vertical to an optical axis whose center is the crossing point of its optical axis with the optical axis of the silica glass member is 50 ppm or lower; and in which the plurality of signed birefringence values obtained based on the birefringence values measured on several points within a plane vertical to an optical axis whose center is the crossing point of its optical axis with the optical axis of the silica glass member and the direction of the fast axis fall within a range of from -2.0 to +2.0 nm / cm. Thus, a silica glass member having high optical transmittance and a high resistance against ultraviolet radiations is provided.

Owner:NIKON CORP

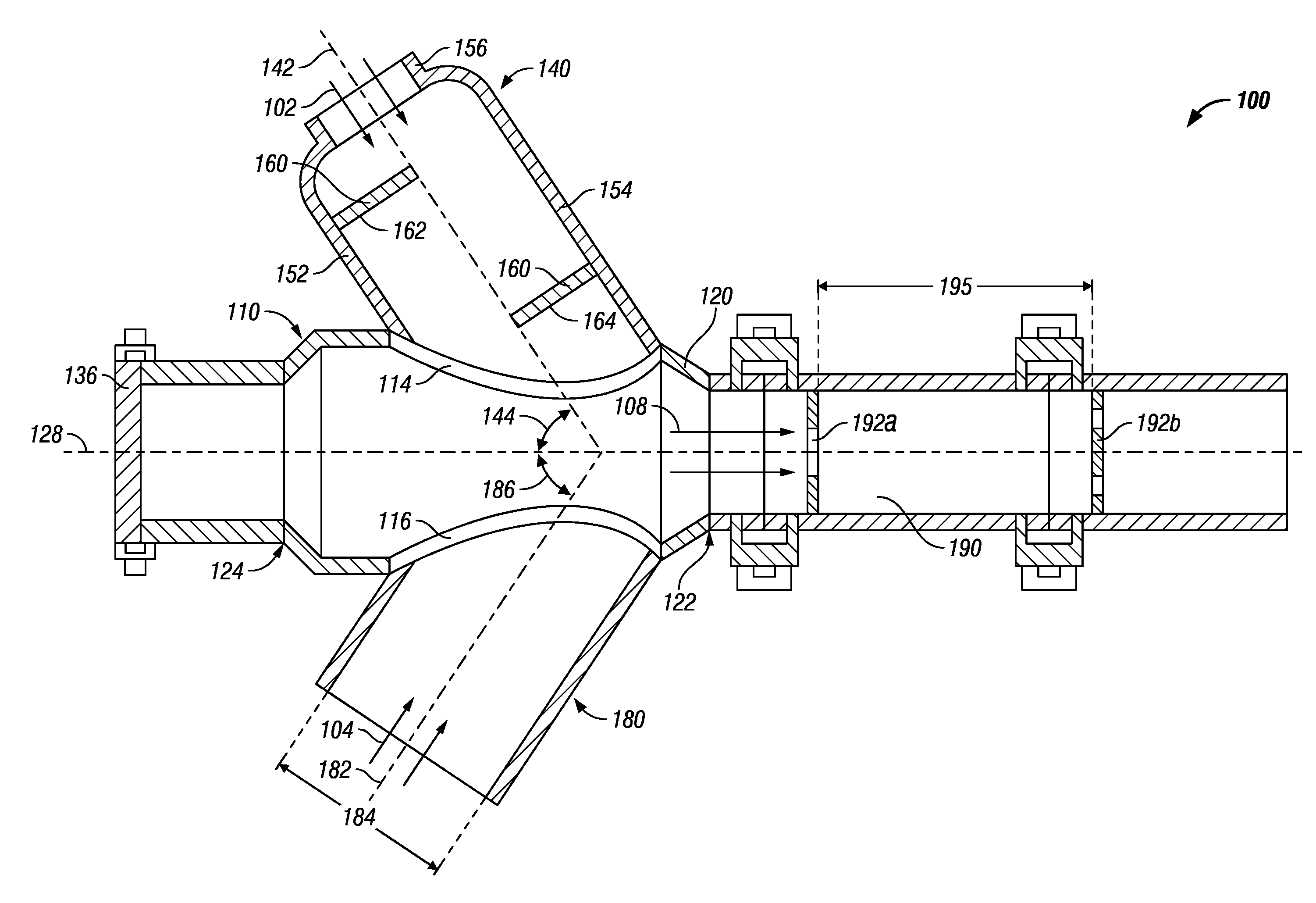

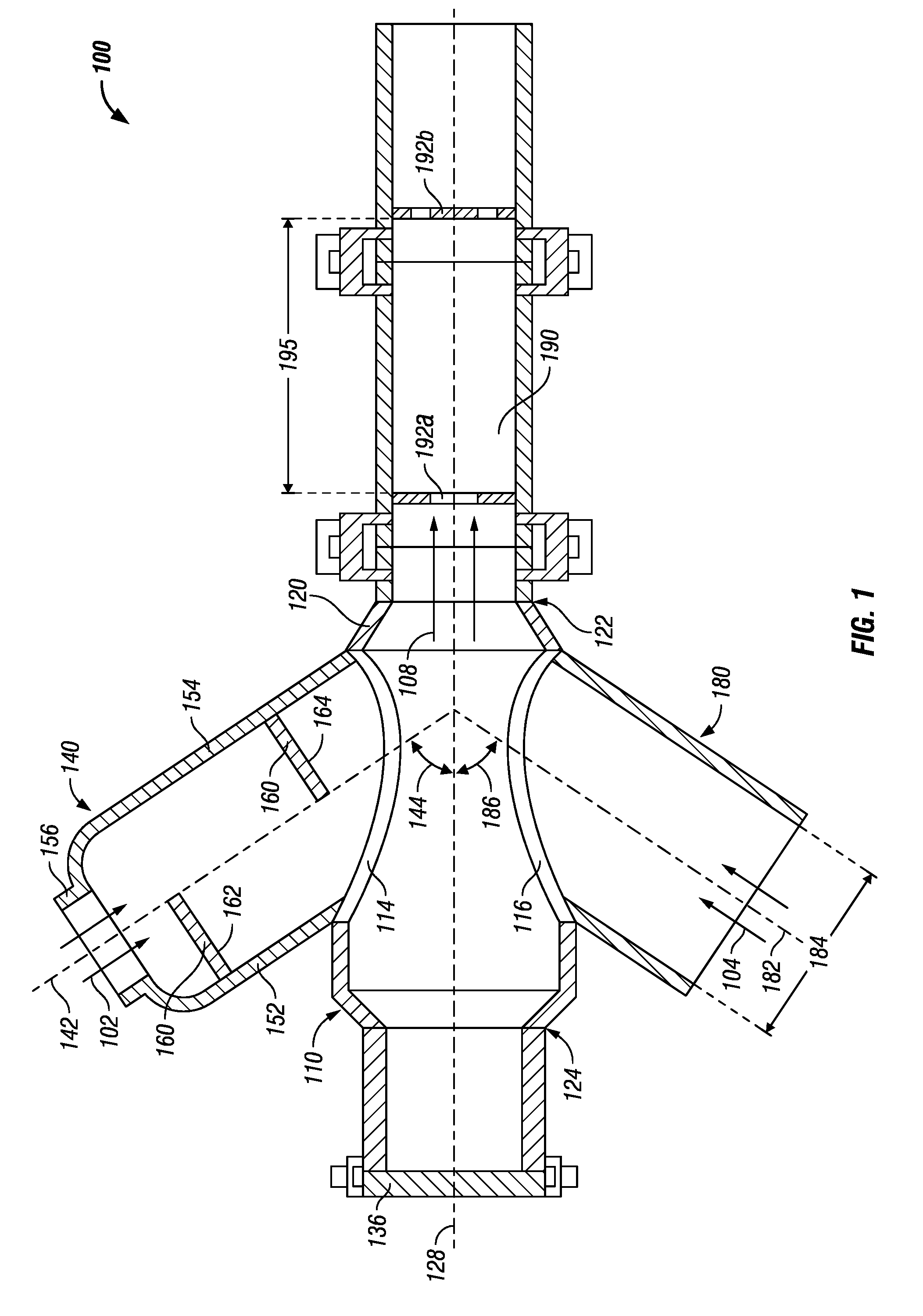

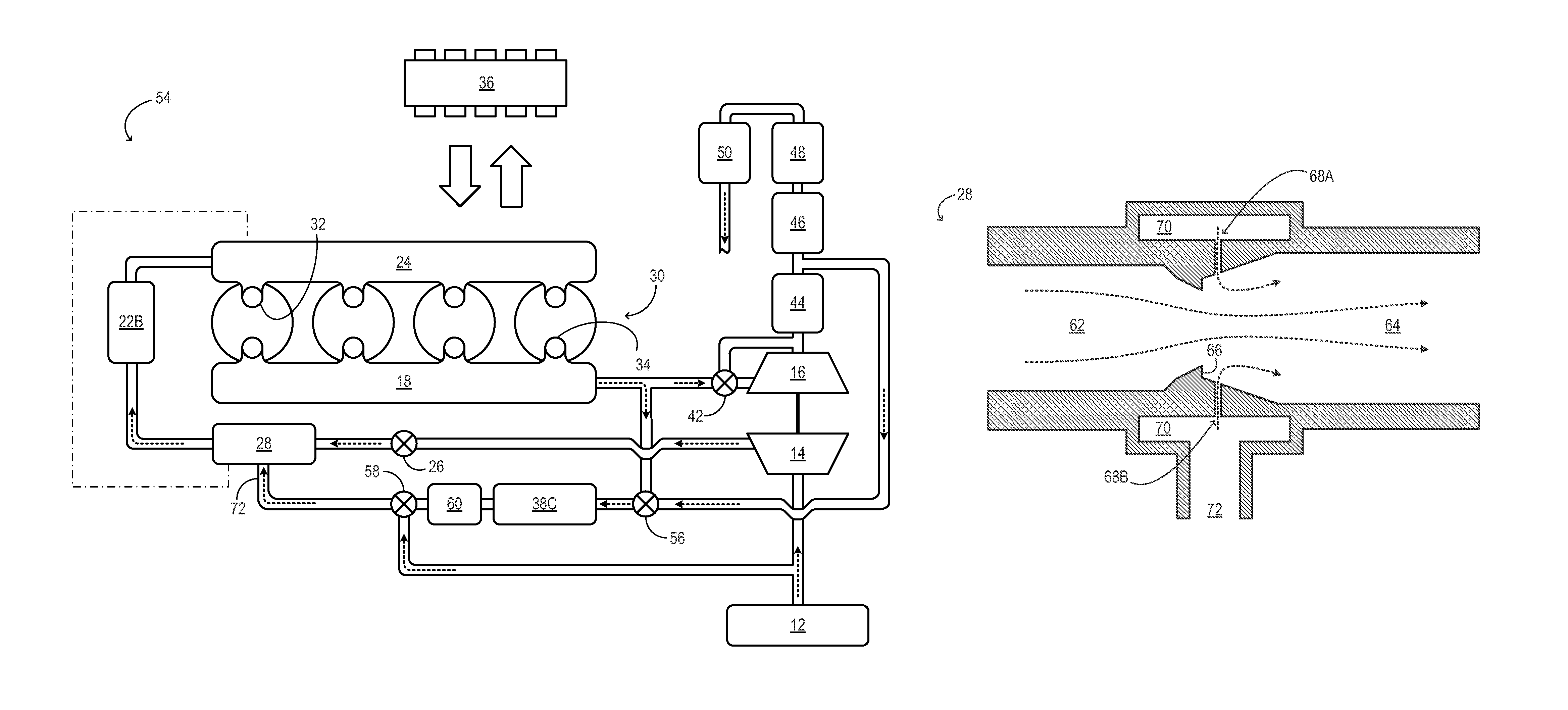

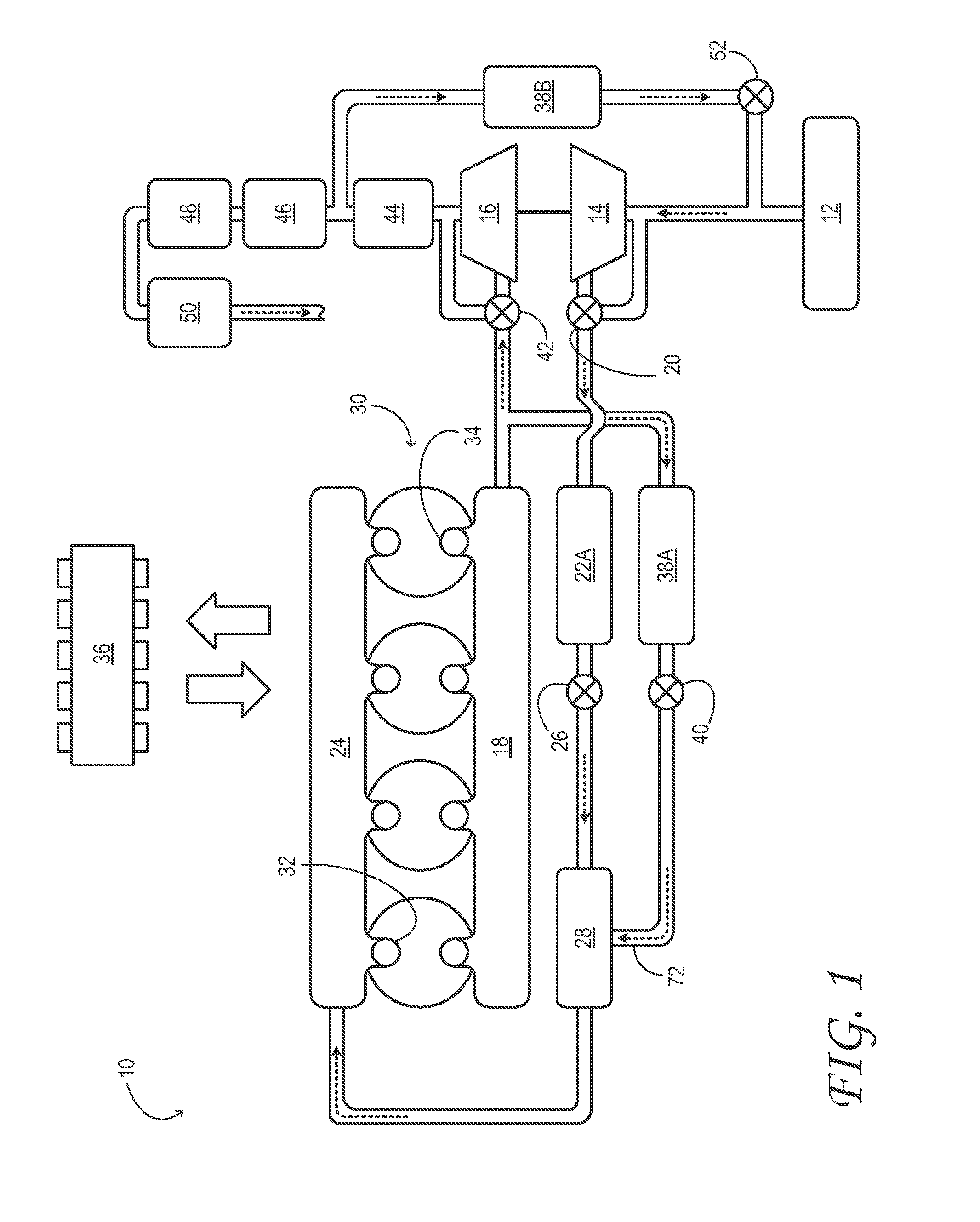

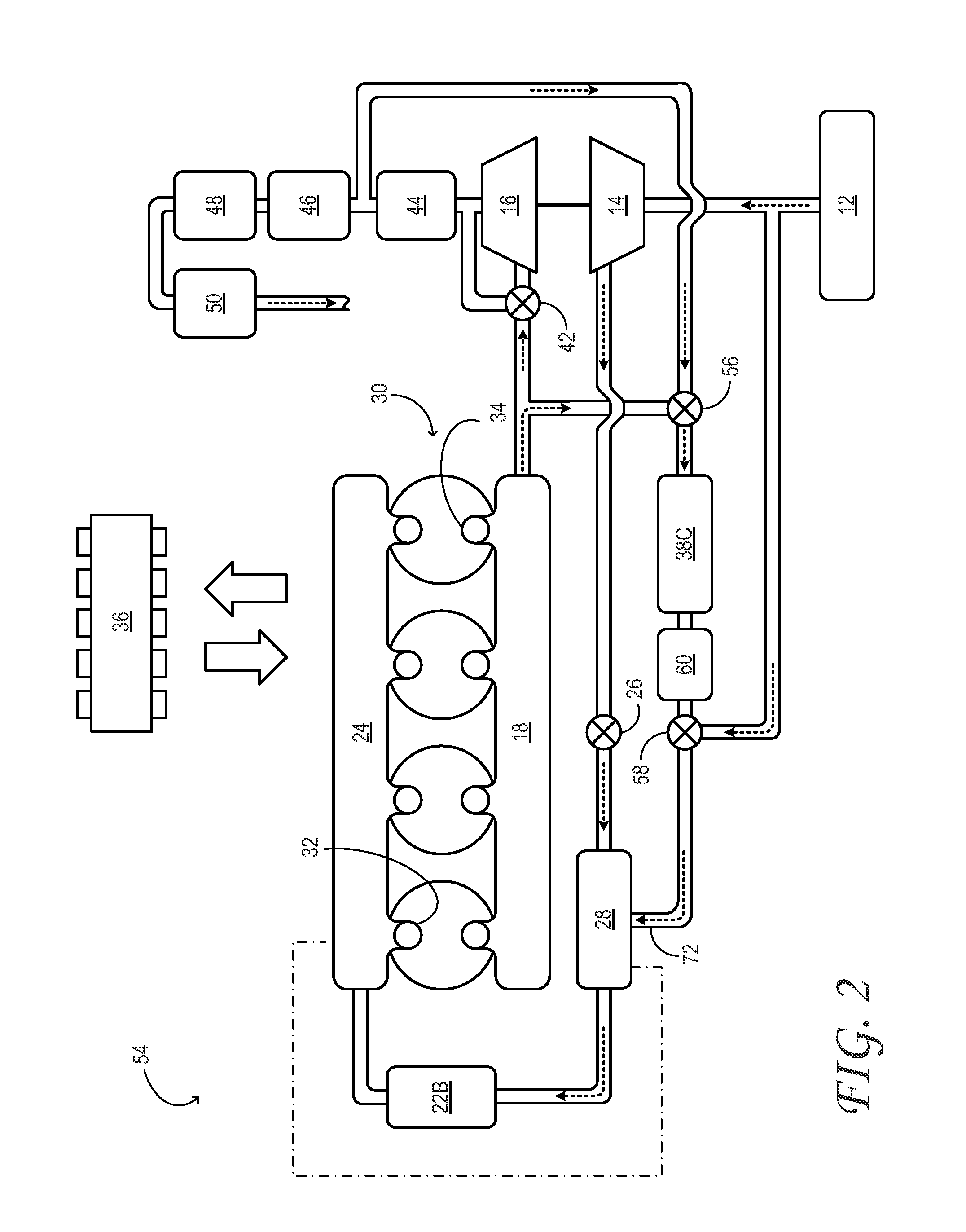

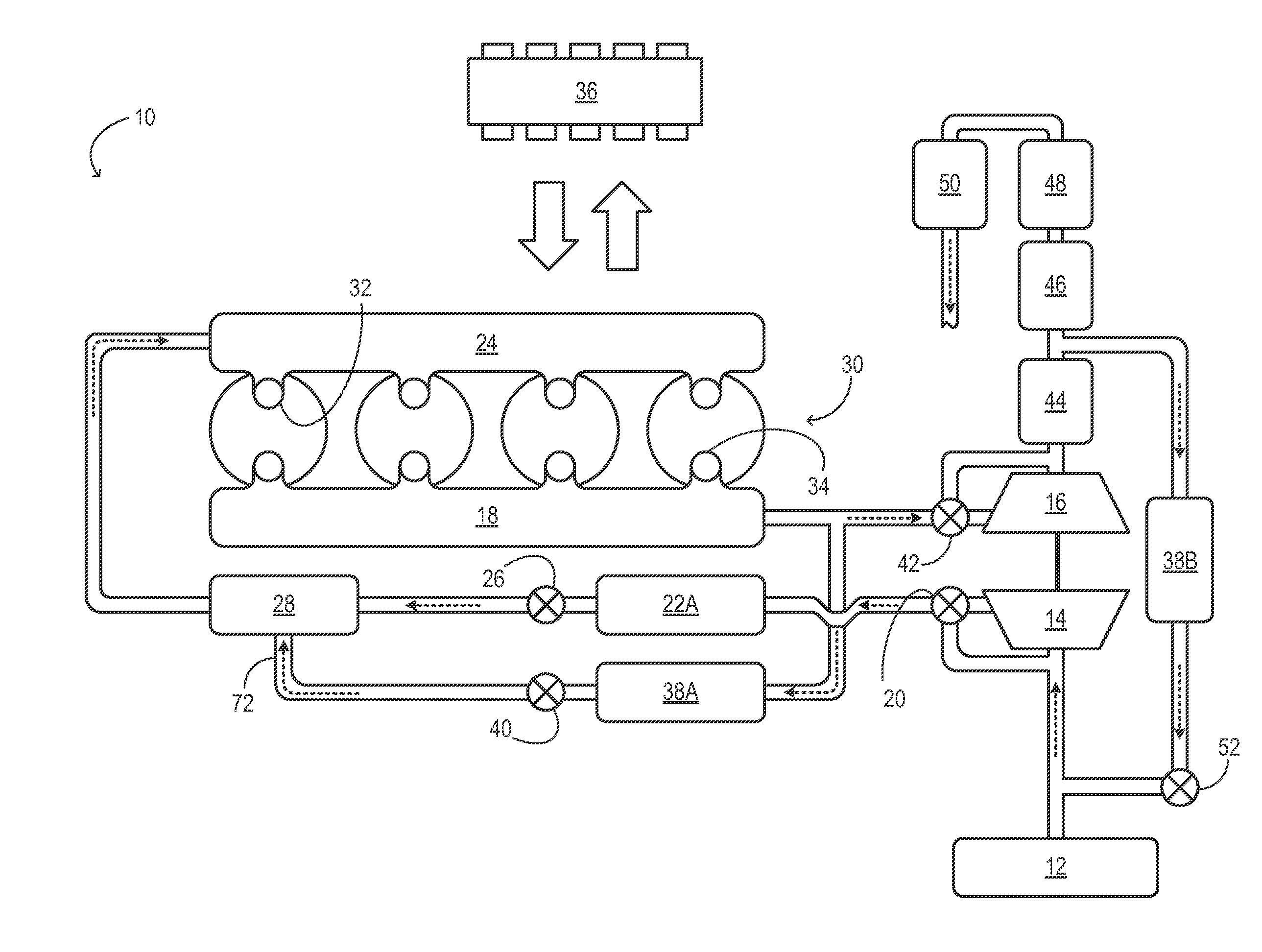

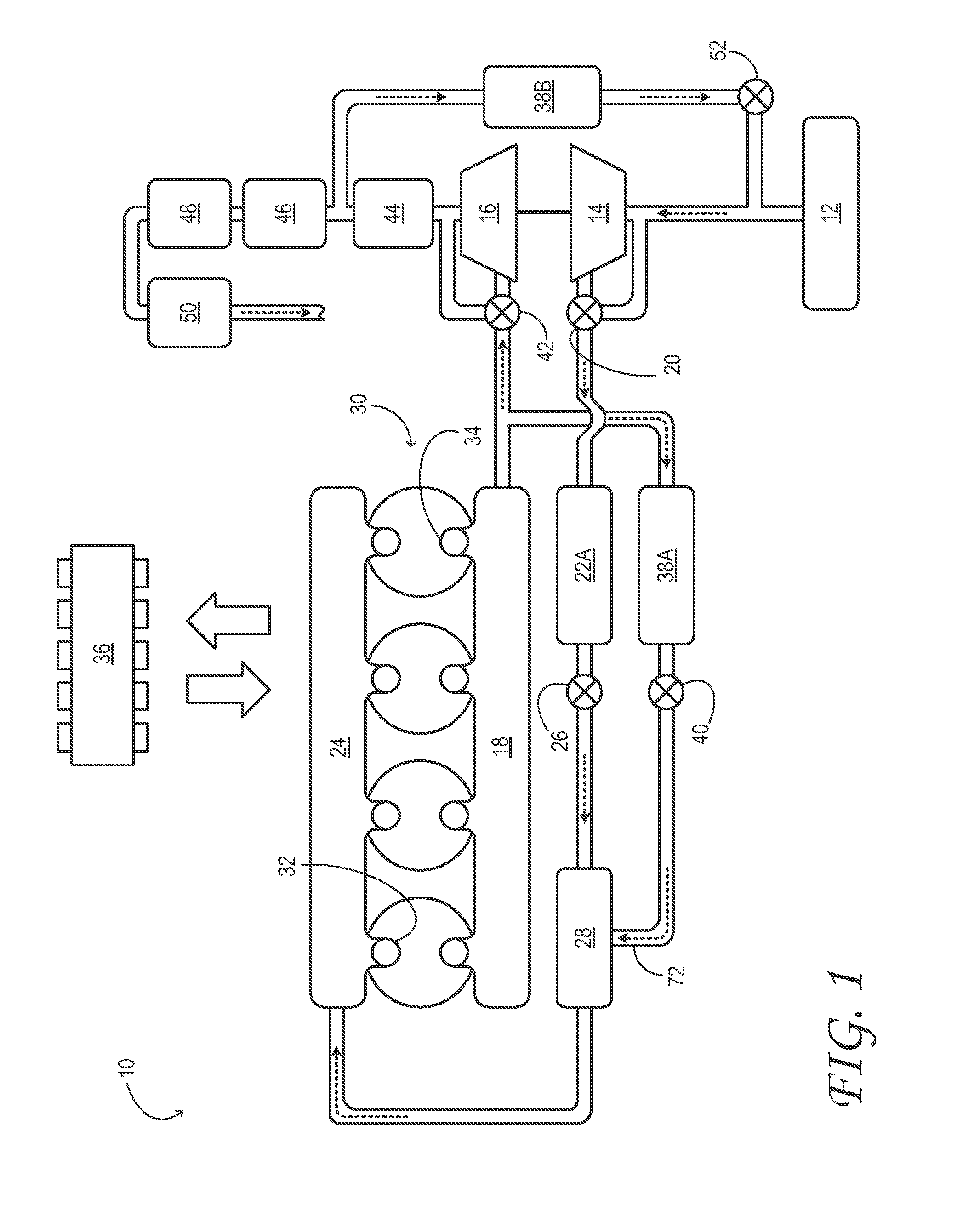

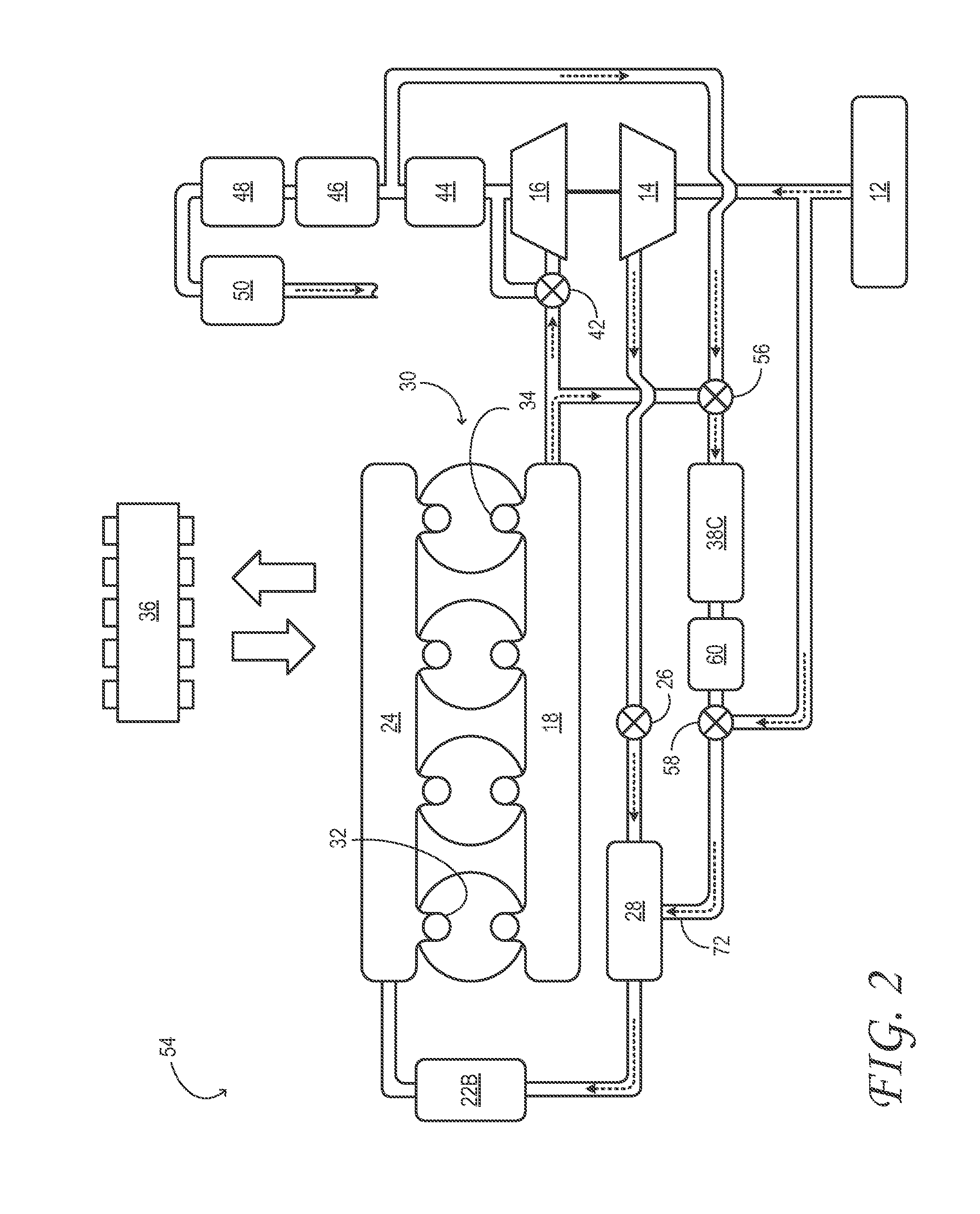

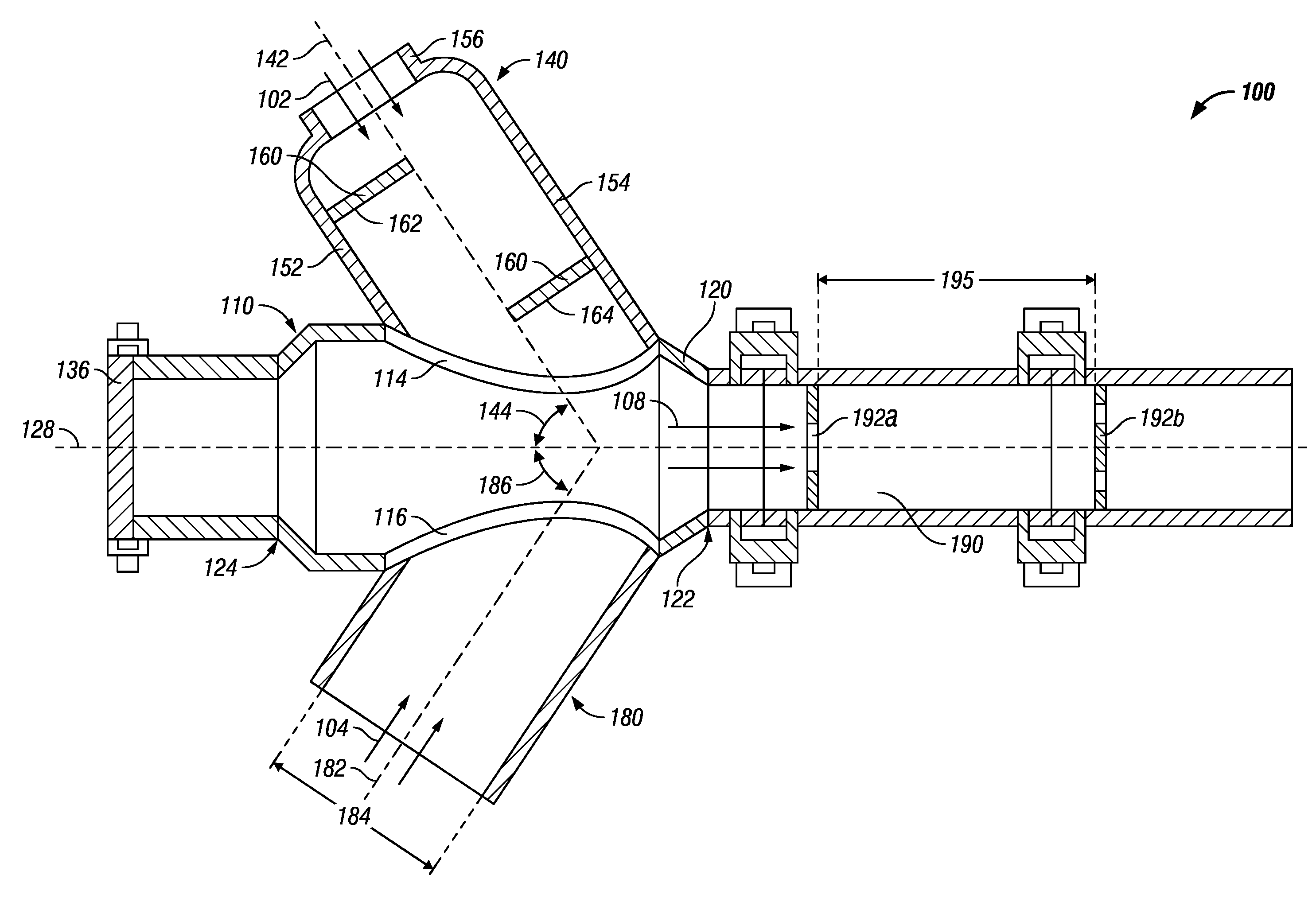

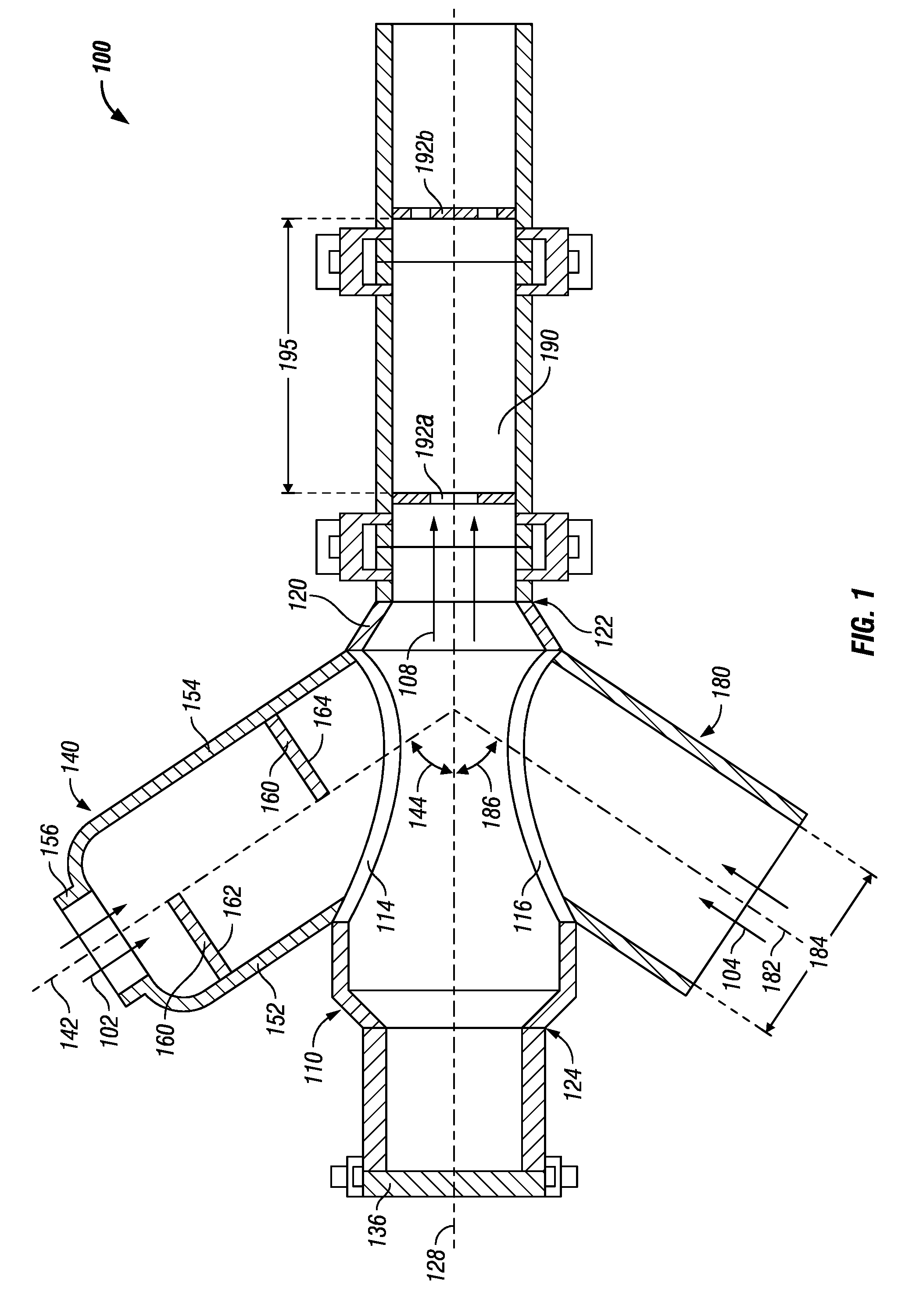

EGR mixer for high-boost engine systems

ActiveUS8056340B2Low oxygenImprove fuel economyInternal combustion piston enginesNon-fuel substance addition to fuelGuide tubeWaste management

An EGR mixer comprises an upstream conduit section having a contracting flow area in a direction of air flow through the mixer, a downstream conduit section having an expanding flow area in the direction of air flow through the mixer, a slot formed in the downstream conduit section for admitting exhaust to the air flow, and an abrupt flow-expanding ridge disposed between the upstream and downstream conduit sections. With the EGR mixer configured in this manner, recirculated exhaust may be effectively homogenized into an intake air flow with reduced drag.

Owner:FORD GLOBAL TECH LLC

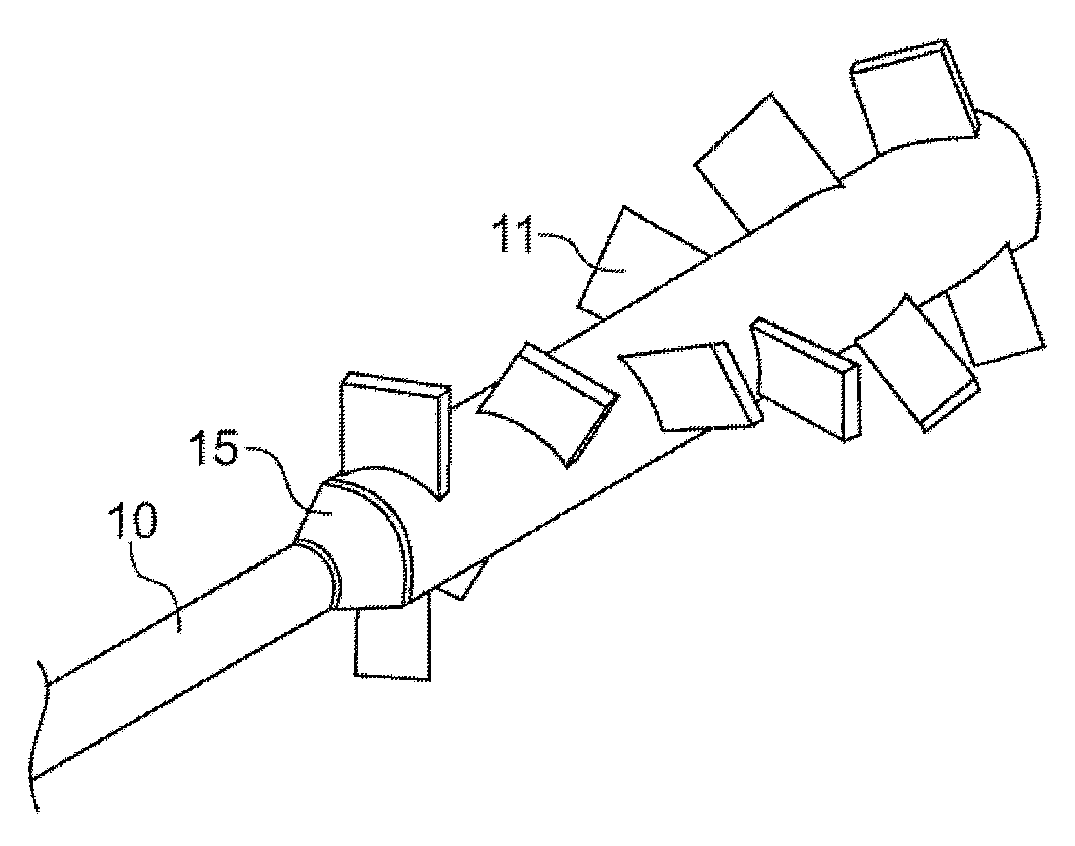

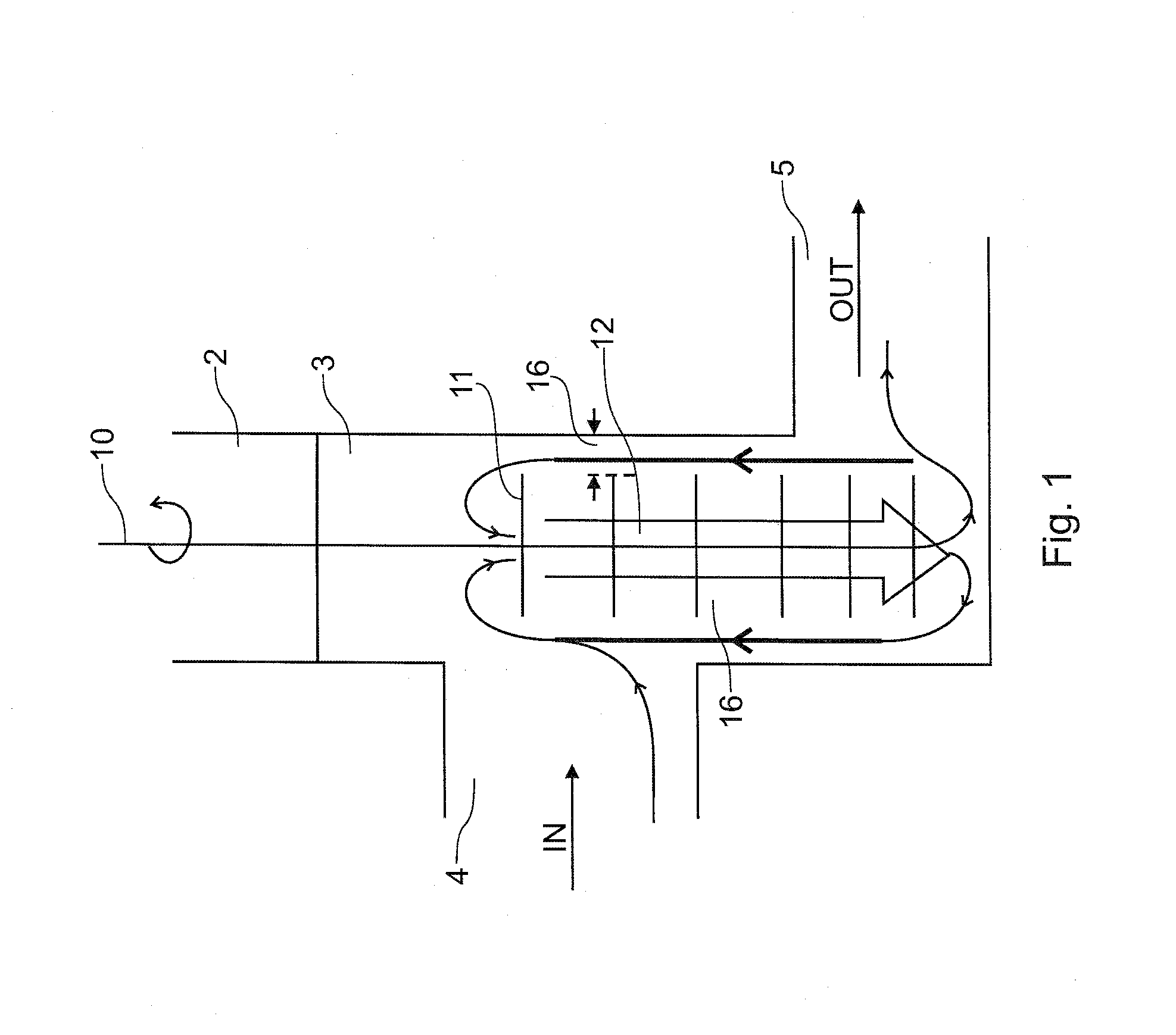

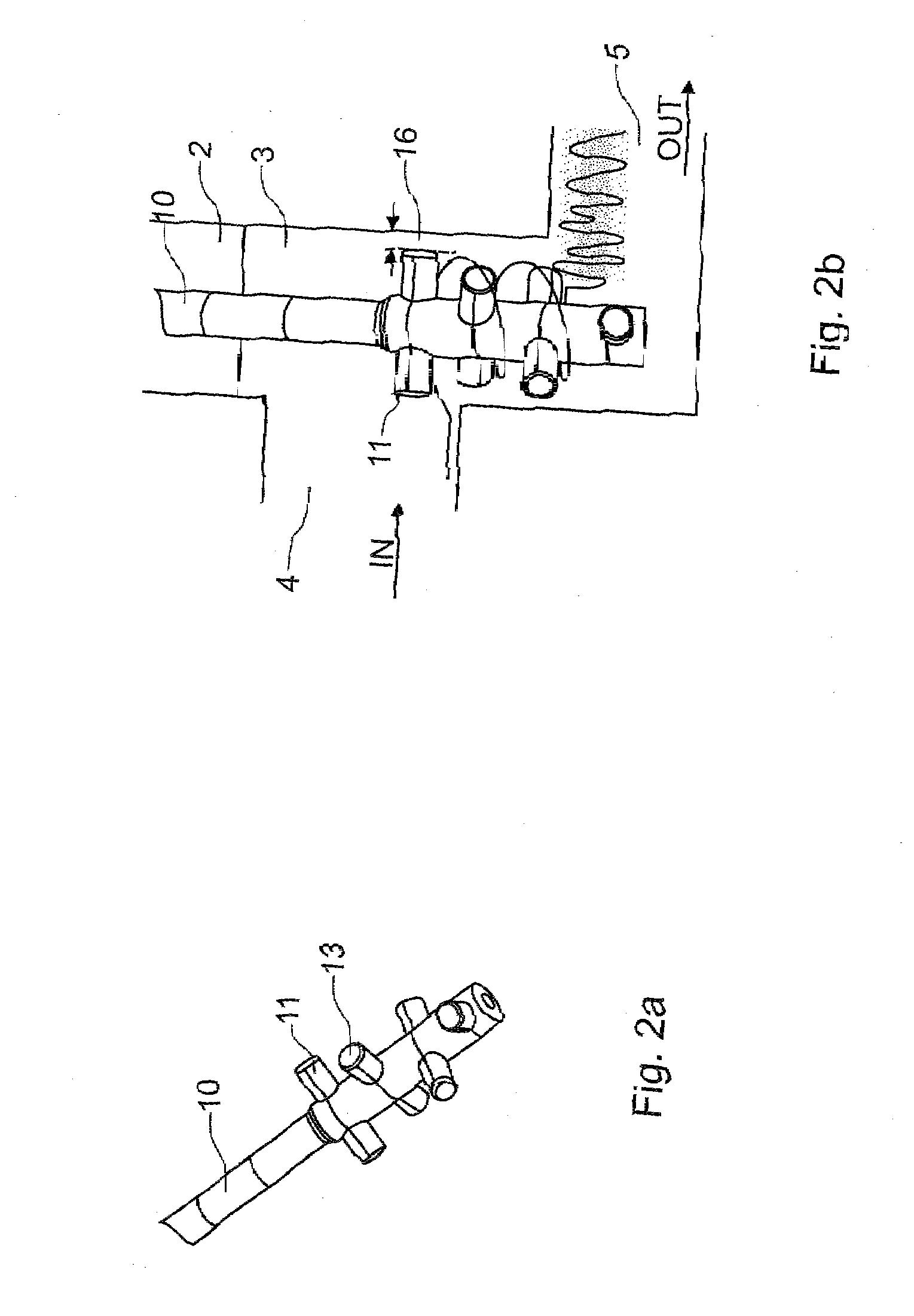

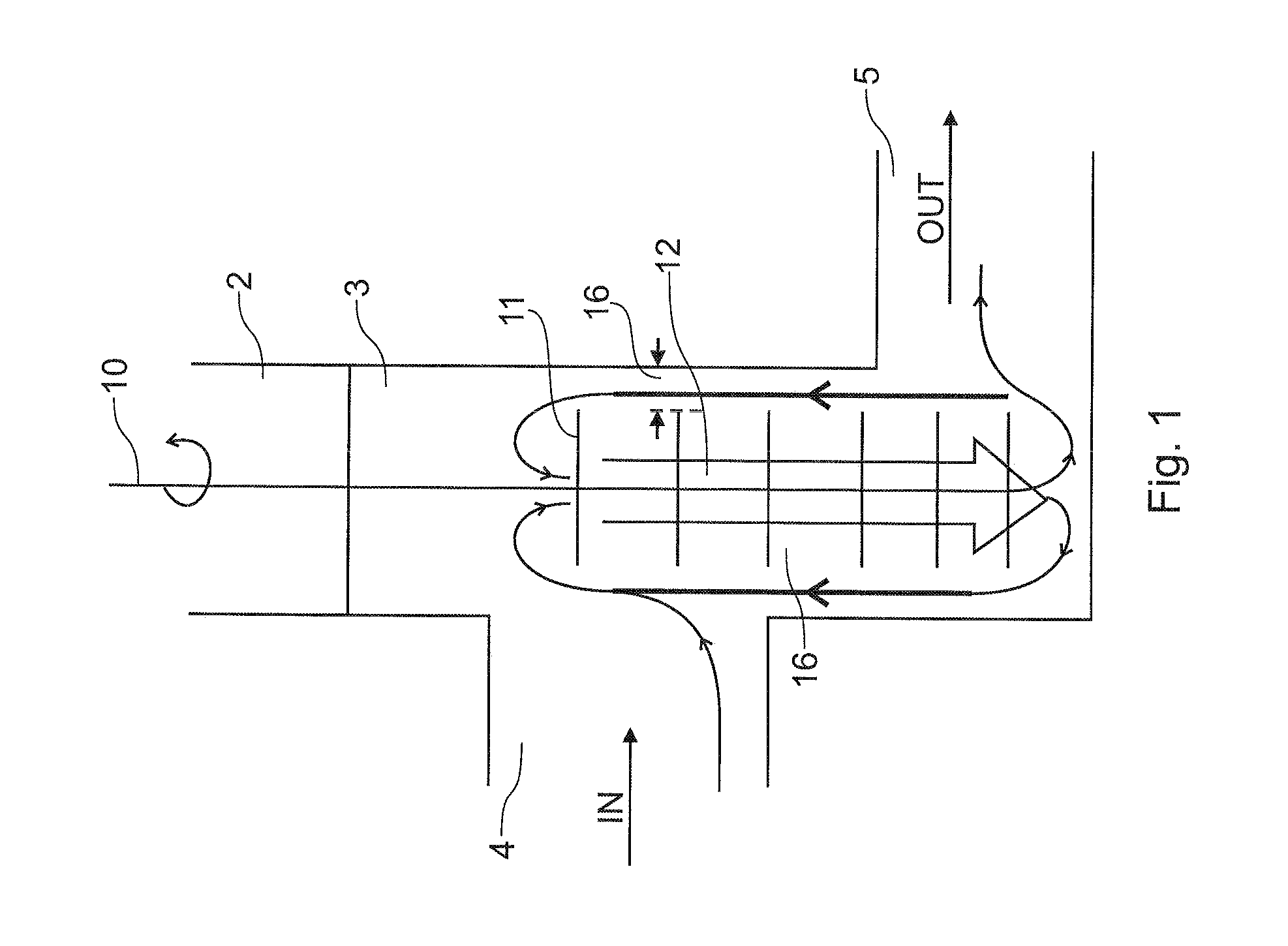

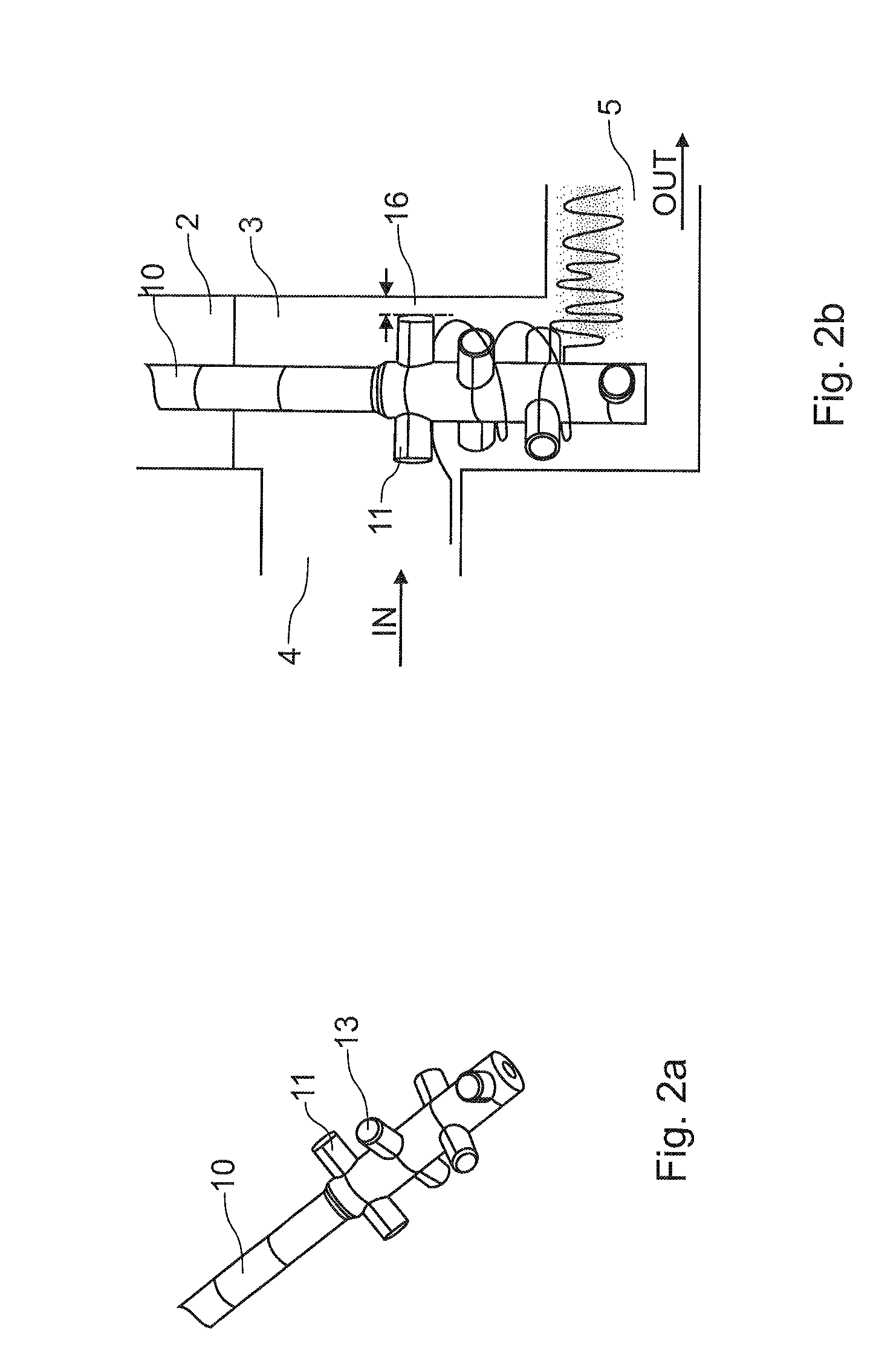

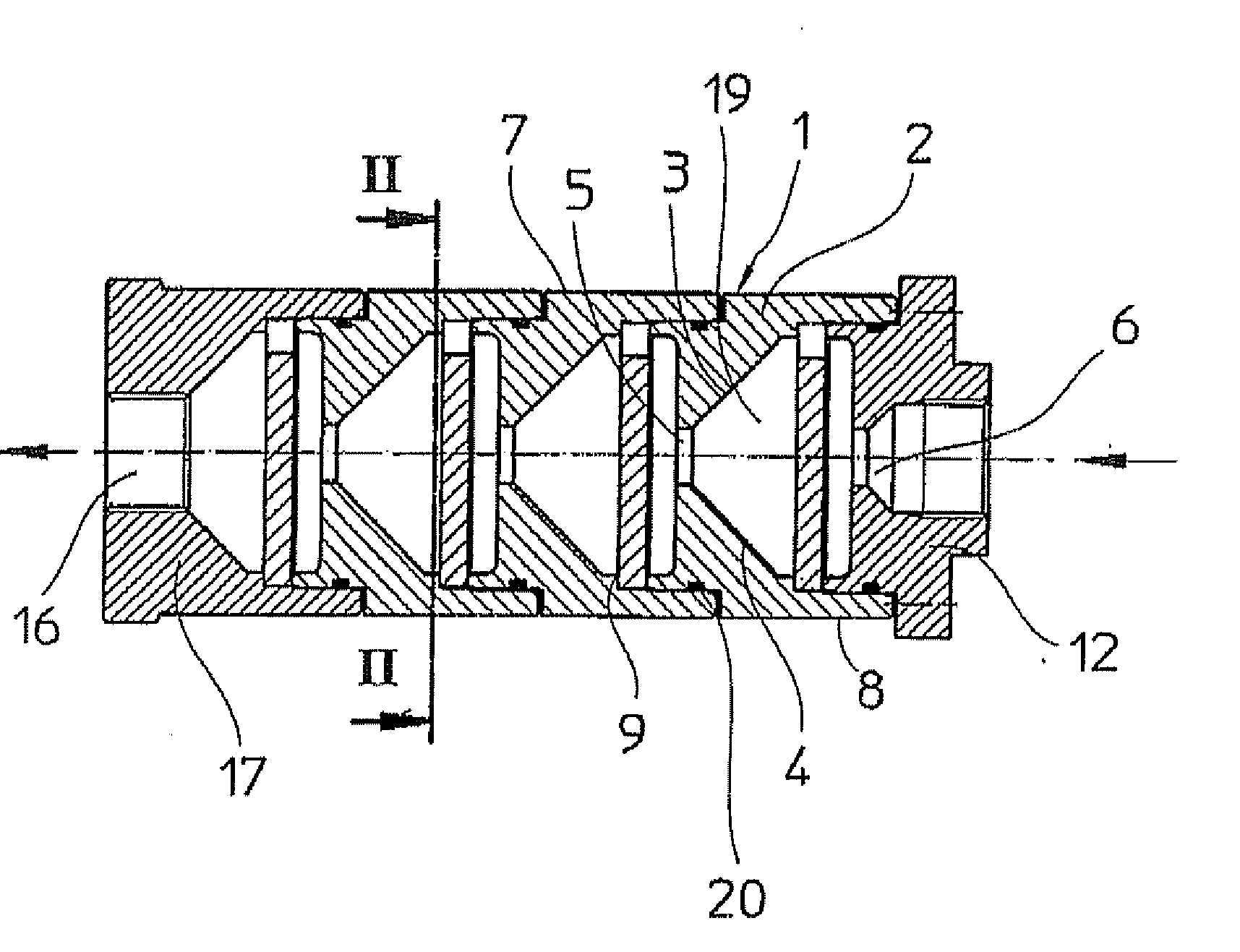

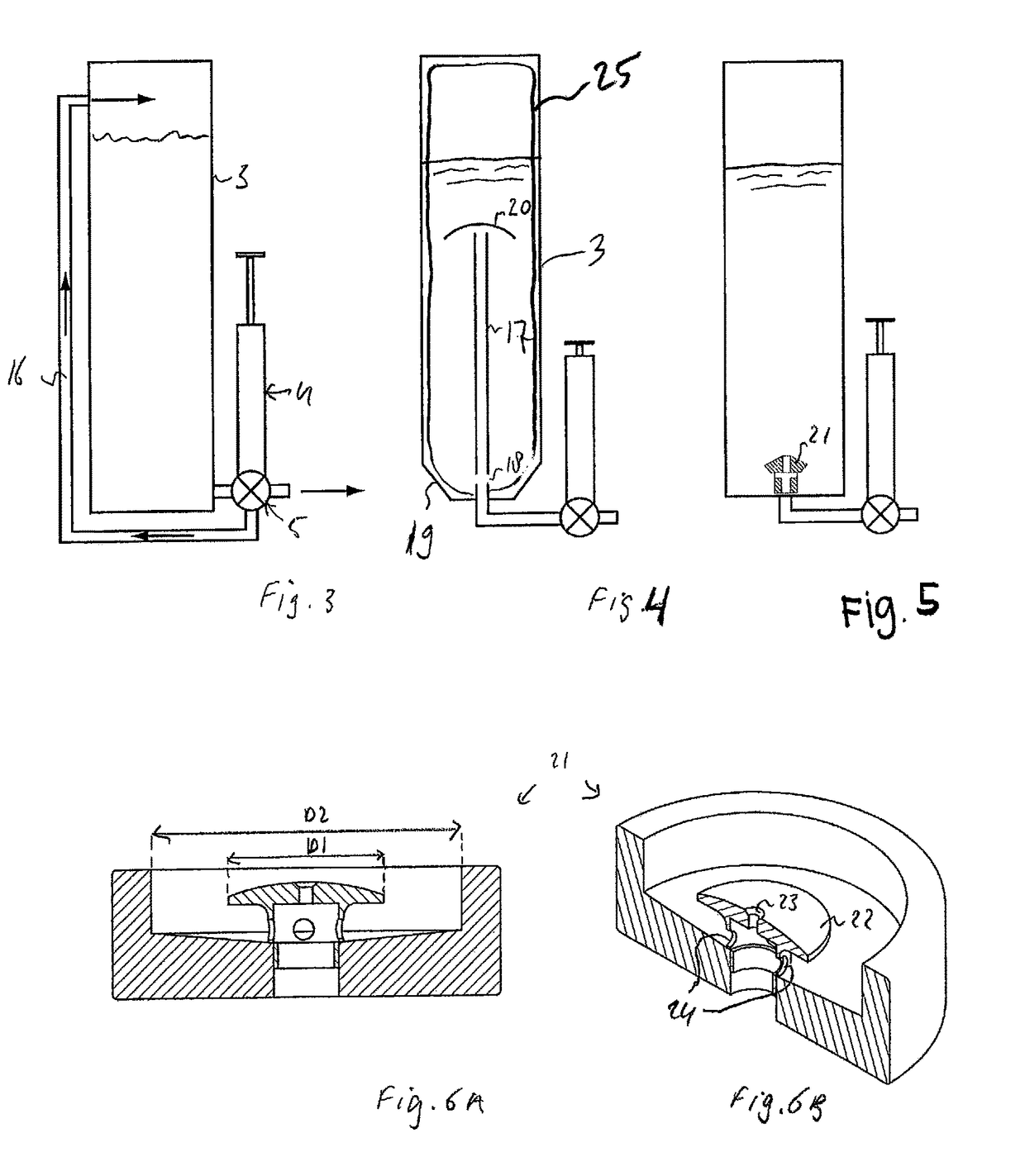

Method and device for homogenizing a glass melt

InactiveUS20090025428A1Disruptive effectEfficient HomogenizationTransportation and packagingGlass furnace apparatusEngineeringMechanical engineering

The invention relates to a method and a device for homogenizing a glass melt using at least one stirring means which is respectively arranged in a stirring vessel having an inlet (4) and an outlet (5), the respective stirring means having a plurality of stirrer blades (11, 20, 21) arranged spaced apart from one another along a common stirrer shaft (10).According to the invention, the stirring means and / or the device is configured in such a way that a net conveying effect of the stirring means overall from the inlet to the outlet is substantially imperceptible. The conveying effect of the stirring means overall from the inlet (4) to the outlet (5) is caused by the positioning of the stirring blades (11, 20, 21), by the geometric shape thereof and / or by the angular position of the stirring blades in the circumferential direction of the stirrer shaft (10).According to the invention, the rotational speed of the stirring means can be freely varied at least within certain limits, in order to set a desired degree of homogenization of the glass melt, without this leading to a significant change in the total throughput of the device.

Owner:SCHOTT AG

Egr mixer for high-boost engine systems

ActiveUS20110162360A1High combustionHigh exhaust temperatureInternal combustion piston enginesNon-fuel substance addition to fuelWaste management

An EGR mixer comprises an upstream conduit section having a contracting flow area in a direction of air flow through the mixer, a downstream conduit section having an expanding flow area in the direction of air flow through the mixer, a slot formed in the downstream conduit section for admitting exhaust to the air flow, and an abrupt flow-expanding ridge disposed between the upstream and downstream conduit sections. With the EGR mixer configured in this manner, recirculated exhaust may be effectively homogenized into an intake air flow with reduced drag.

Owner:FORD GLOBAL TECH LLC

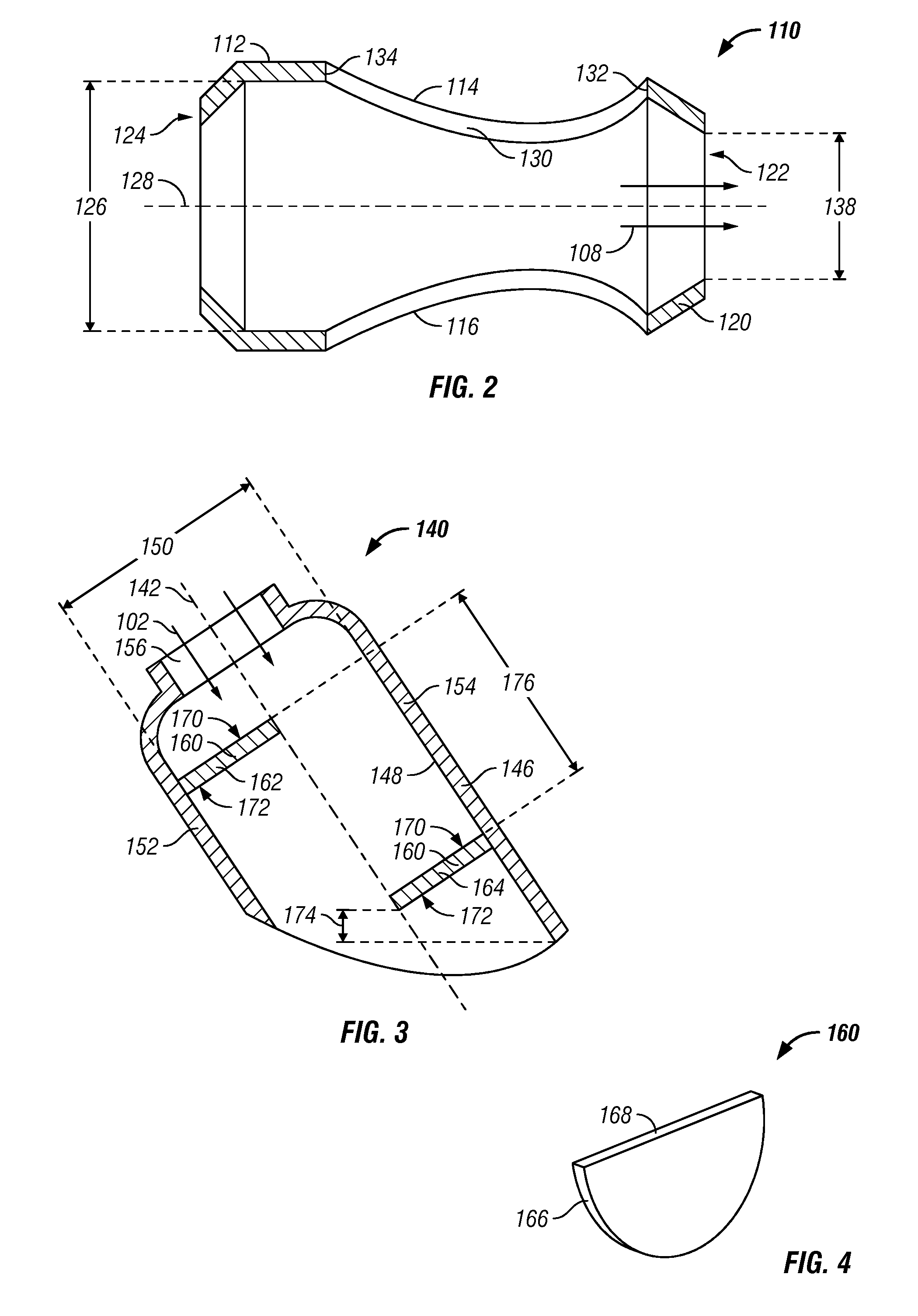

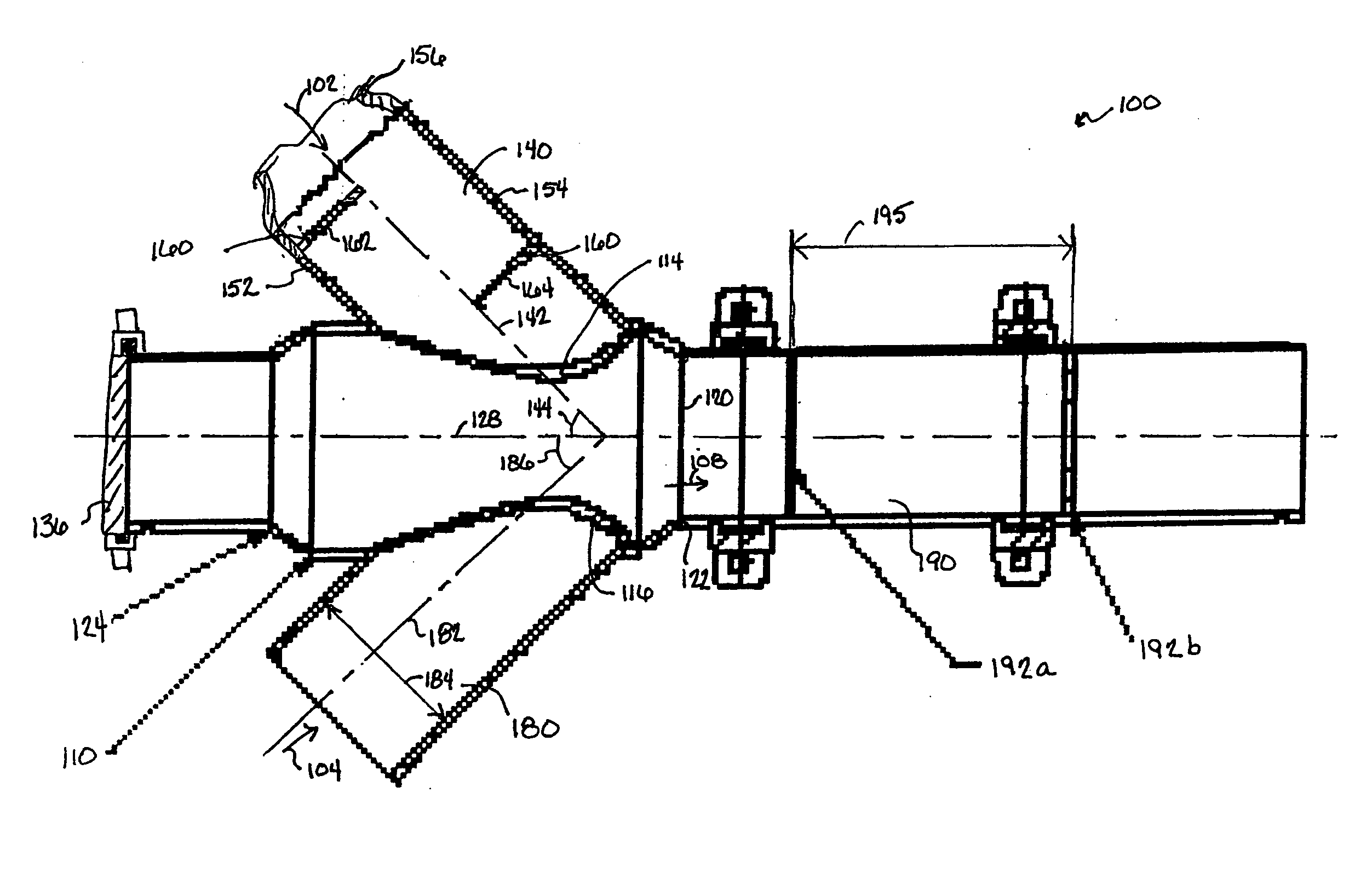

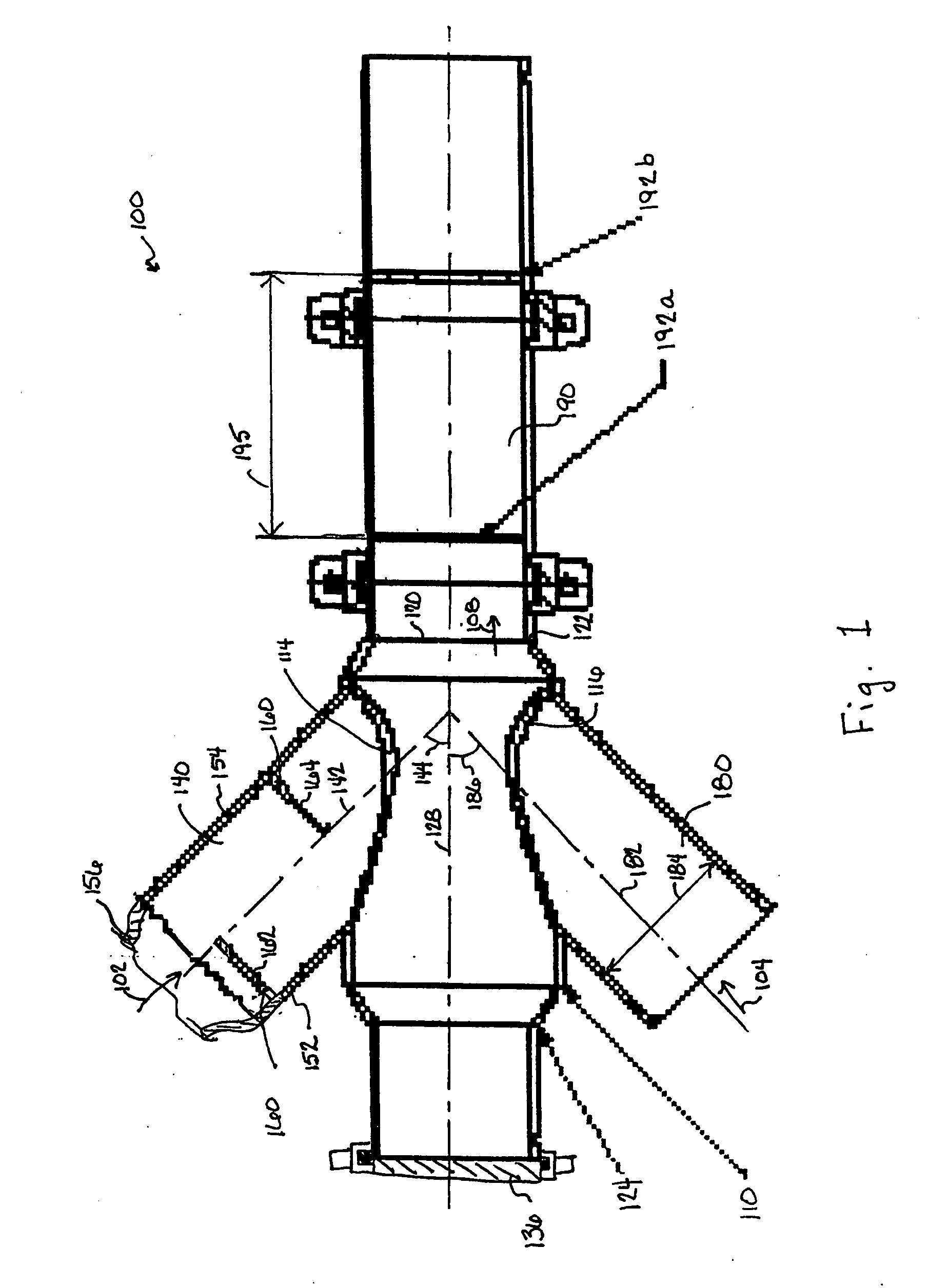

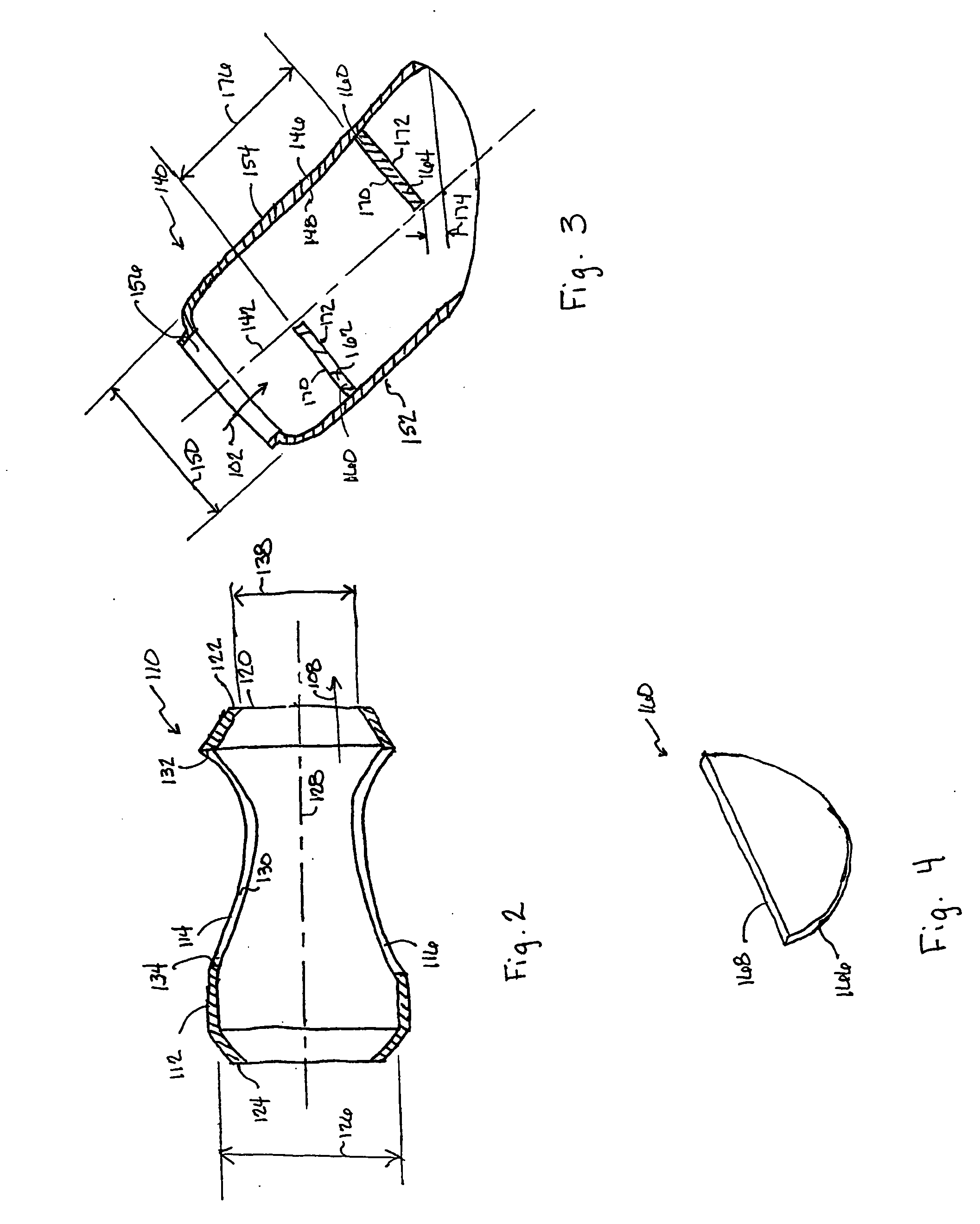

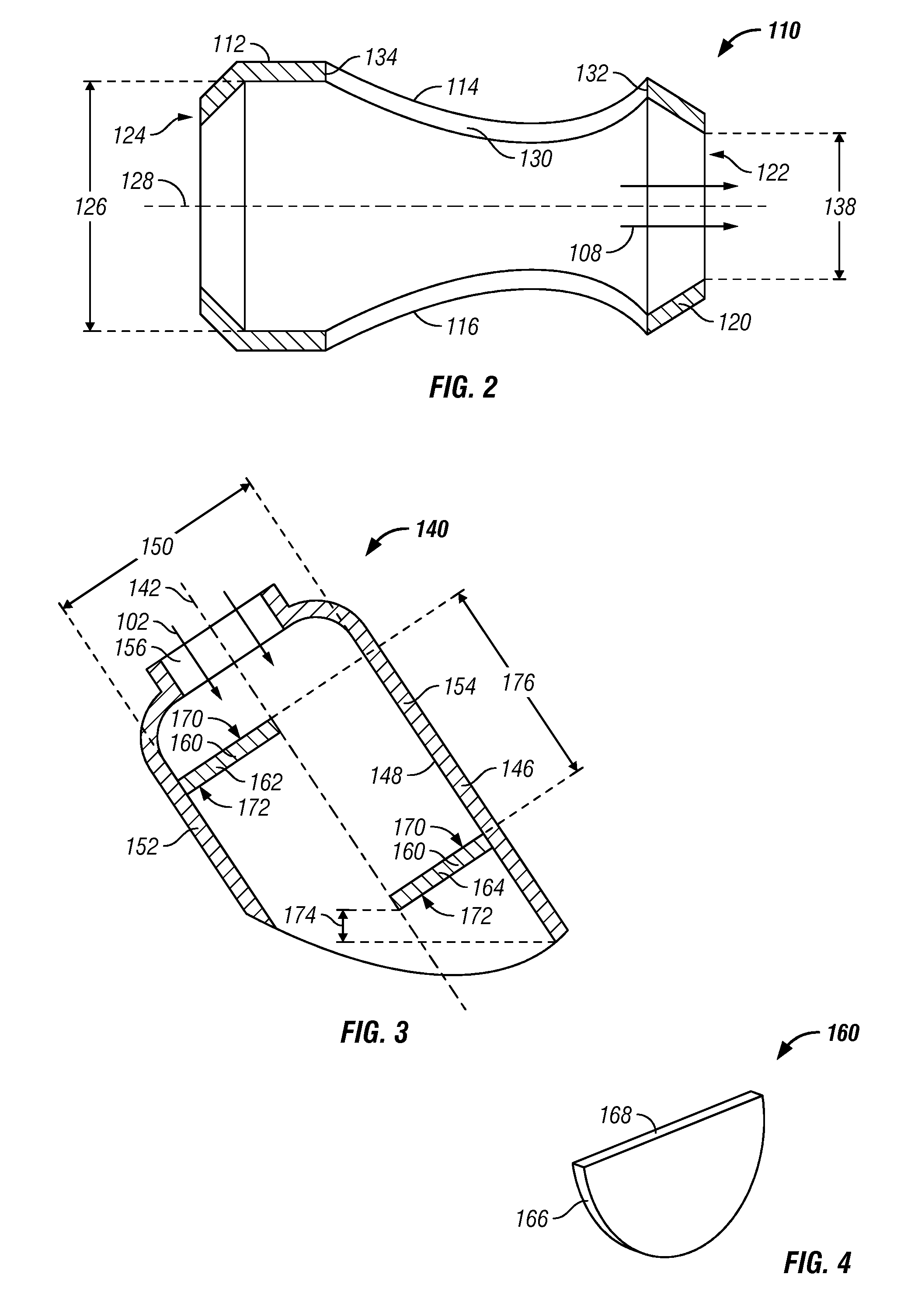

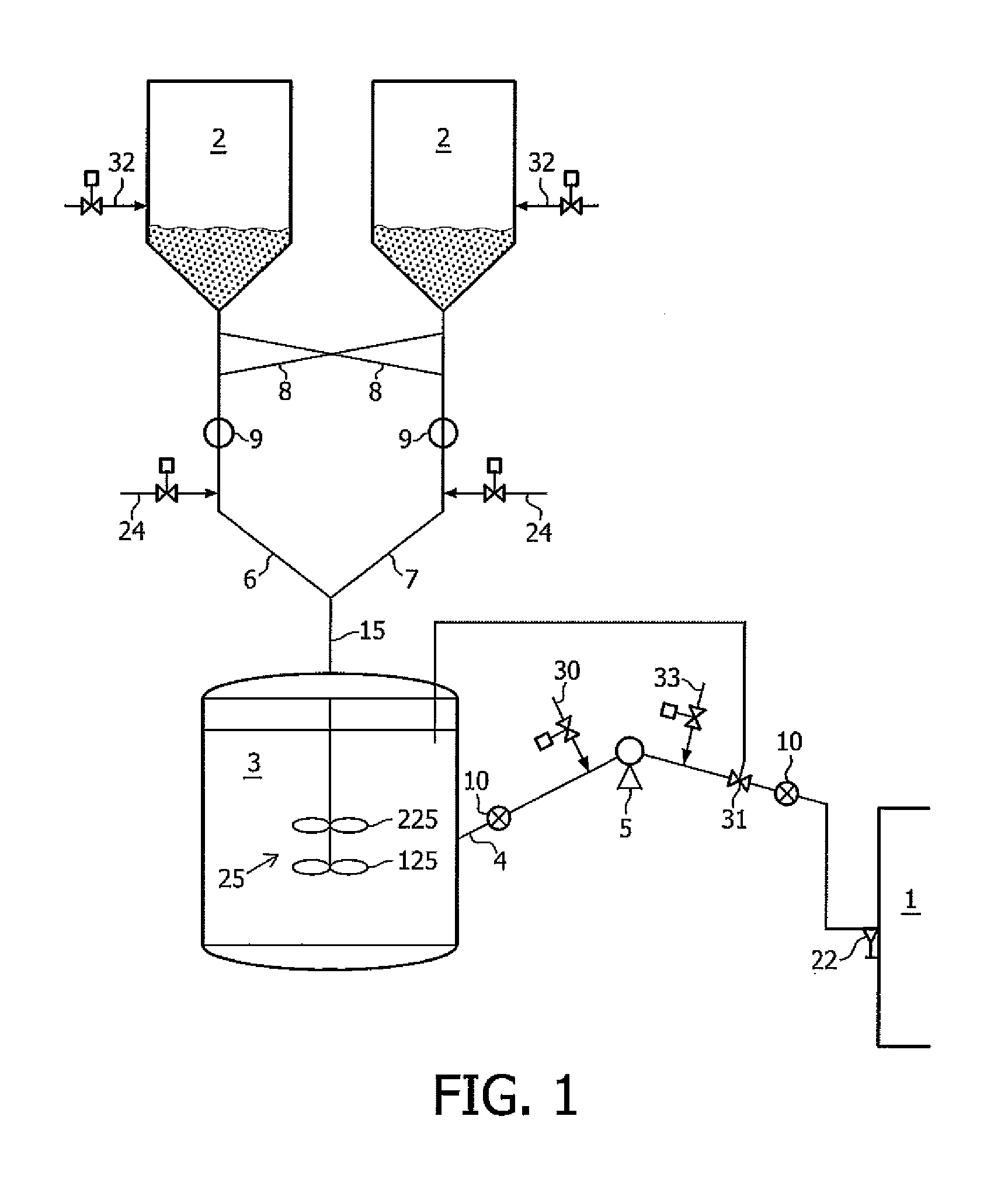

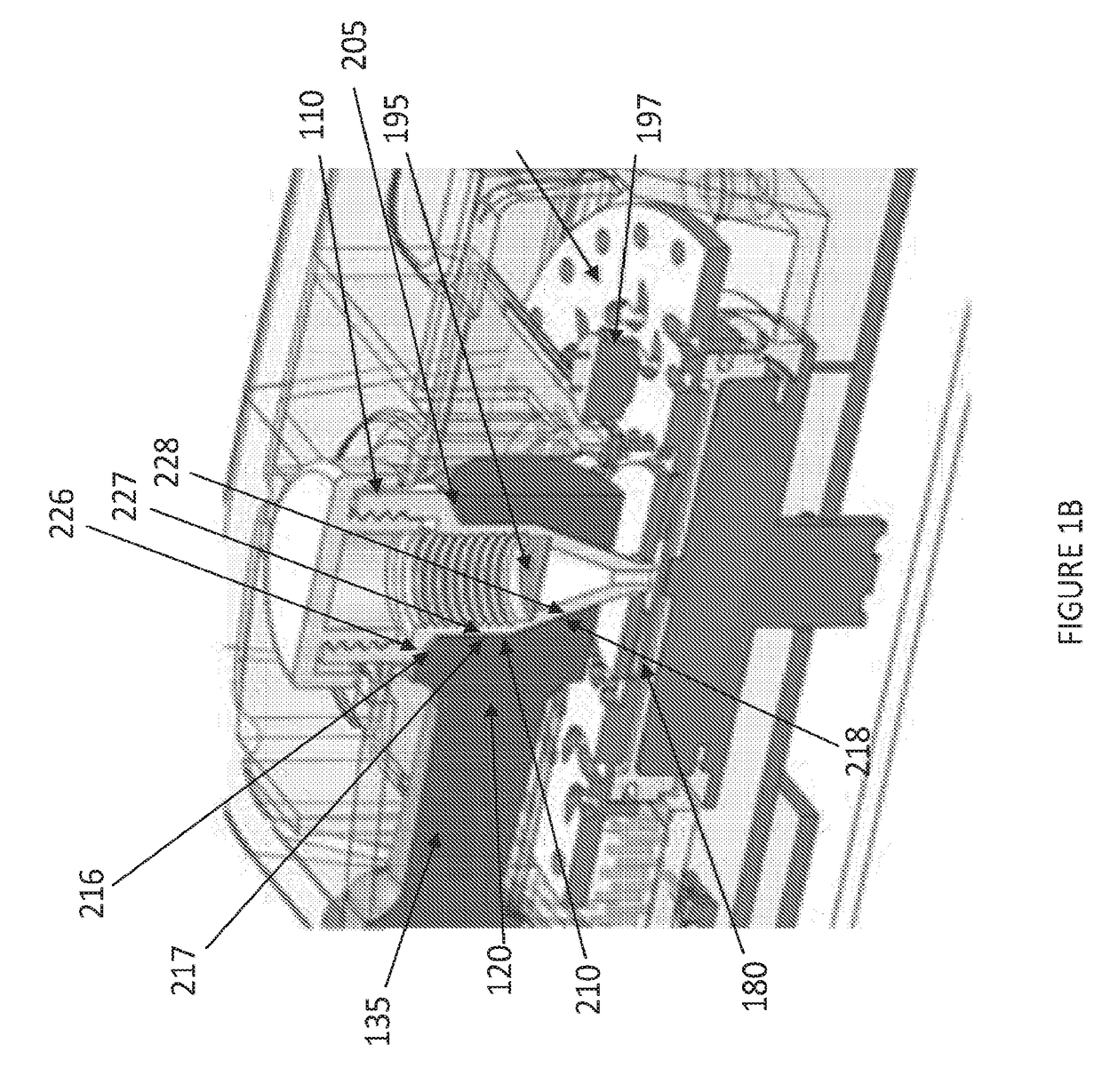

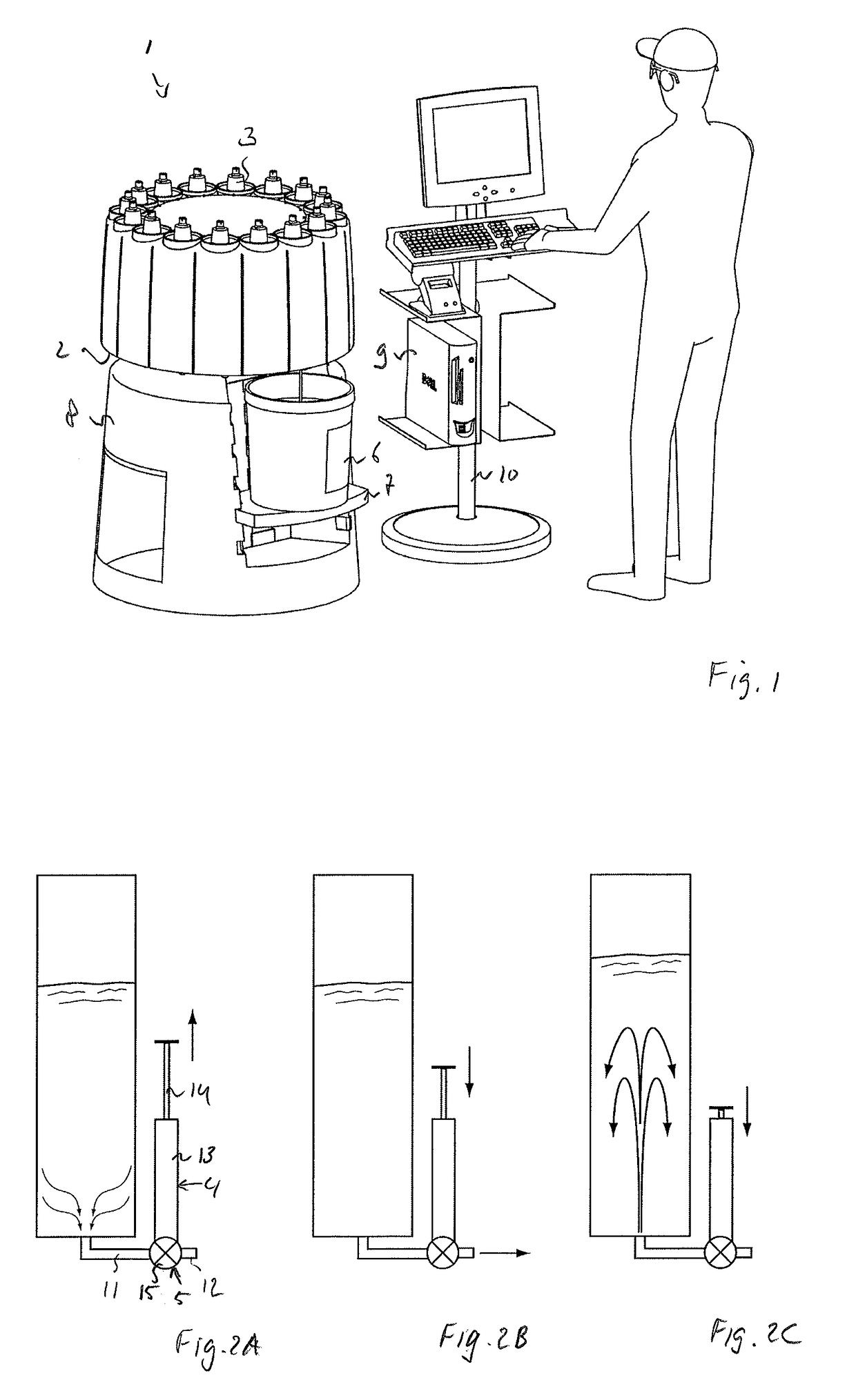

Apparatus and method for homogenizing two or more fluids of different densities

InactiveUS20060056271A1Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingHigh densityVolumetric Mass Density

An apparatus for blending two or more fluid streams, wherein a first fluid has a higher density than the other fluids, includes a first fluid director and at least a second fluid director providing fluid communication of a first and second fluid stream, respectively, to a primary mixing chamber. The first fluid director includes one or more baffles to disturb the first fluid stream and to direct it toward a rearward portion of the first inlet to the primary mixing chamber. A secondary blending chamber is in fluid communication with the primary chamber outlet and includes at least one, and preferably two static mixers. When two static mixers are serially retained in the secondary blending chamber, they may be skewed rotationally relative to each other such that the orifice profiles of each static mixer are not in alignment.

Owner:KAPILA MUKESH +1

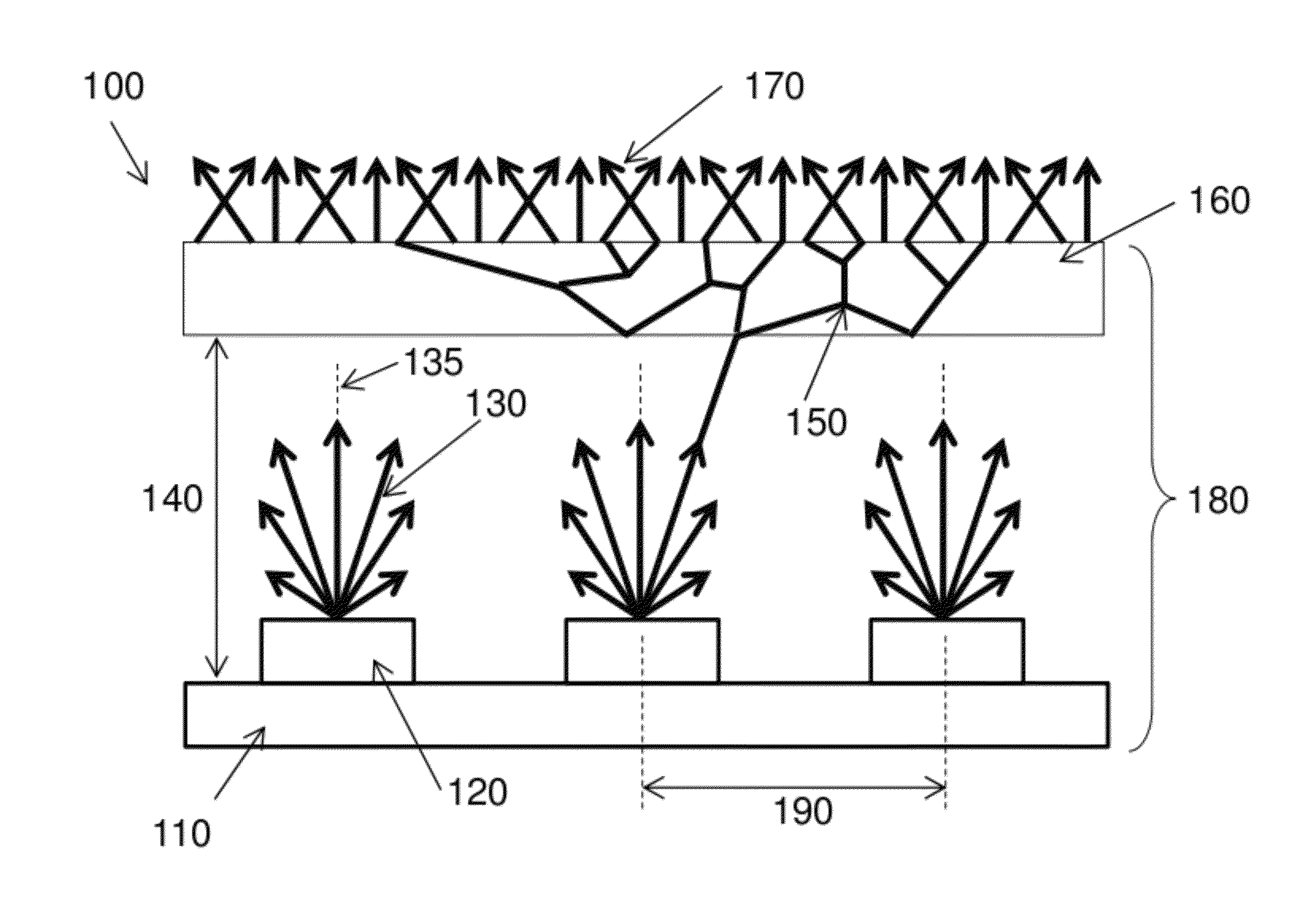

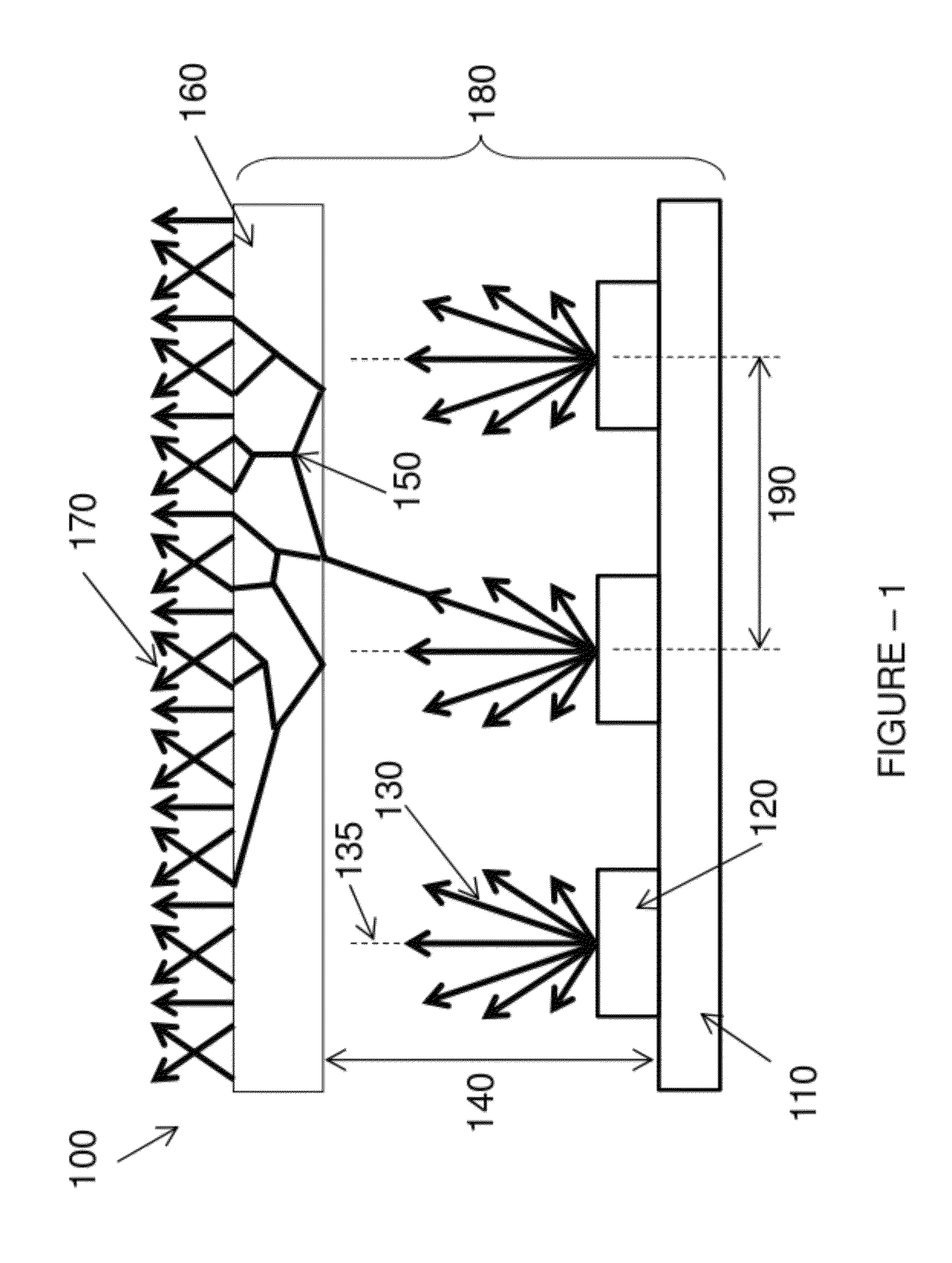

Shaped Reflectors for Enhanced Optical Diffusion in Backlight Assemblies

InactiveUS20120176786A1Increased ability to diffuseConvenient lightingNon-electric lightingPoint-like light sourceFluorescent lampReflectivity

An assembly for diffusing a plurality of light sources. A diffusing device is placed adjacent to the plurality of light sources and preferably contains a plurality of shaped reflectors placed on the diffusing device where a shaped reflector is positioned adjacent to each light source. The shaped reflectors are placed in a one-to-one relationship with the light sources, which can be LED or fluorescent or any other type of light source. The reflectors may be single-tone, multi-tone, or gradient-tone and generally have a higher amount of reflectivity near the central axis of the light source and a lower reflectivity away from the central axis of the light source. The shaped reflectors may be used in both direct-lit and edge-lit orientations.

Owner:AMERICAN PANEL CORP INC

Method and device for homogenizing glass melt

ActiveUS20080148780A1Efficient HomogenizationEasy to adjustRotary stirring mixersGlass furnace apparatusEngineeringMechanical engineering

The invention relates to a method and to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device (10, 11) is disposed in the melt receptacle, which comprises a stirrer shaft (10) and a plurality of stirrer blades (11), and wherein a gap (16) is formed between a wall region of the melt receptacle (2) and the stirrer blades (11).According to the invention, the respective stirring device causes an axial feed action in an inner stirring region (12) between the stirrer shaft (10) and the stirrer blades (11) in order to feed the melt in the stirring region along the stirrer shaft (10). A melt flow brought about by the axial feed action seals the gap (16) against direct passage of the melt.According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

Apparatus and Method for Homogenizing Two or More Fluids of Different Densities

ActiveUS20100226198A1Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingHigh densityVolumetric Mass Density

An apparatus for blending two or more fluid streams, wherein a first fluid has a higher density than the other fluids, includes a first fluid director and at least a second fluid director providing fluid communication of a first and second fluid stream, respectively, to a primary mixing chamber. The first fluid director includes one or more baffles to disturb the first fluid stream and to direct it toward a rearward portion of the first inlet to the primary mixing chamber. A secondary blending chamber is in fluid communication with the primary chamber outlet and includes at least one, and preferably two static mixers. When two static mixers are serially retained in the secondary blending chamber, they may be skewed rotationally relative to each other such that the orifice profiles of each static mixer are not in alignment.

Owner:MI

Method and device for homogenizing glass melt

ActiveUS20110083474A1Efficient HomogenizationEasy to adjustGlass furnace apparatusRotary stirring mixersEngineeringMechanical engineering

The invention relates to a method and to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device (10, 11) is disposed in the melt receptacle, which comprises a stirrer shaft (10) and a plurality of stirrer blades (11), and wherein a gap (16) is formed between a wall region of the melt receptacle (2) and the stirrer blades (11).According to the invention, the respective stirring device causes an axial feed action in an inner stirring region (12) between the stirrer shaft (10) and the stirrer blades (11) in order to feed the melt in the stirring region along the stirrer shaft (10). A melt flow brought about by the axial feed action seals the gap (16) against direct passage of the melt.According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

Method and device for homogenizing glass melt

ActiveUS8347652B2Efficient HomogenizationEasy to adjustRotary stirring mixersGlass furnace apparatusMechanical engineeringPhysics

The invention relates to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device is disposed in a melt receptacle, which comprises a stirrer shaft and a plurality of stirrer blades, and wherein a gap (16) is formed between a wall region of the melt receptacle and the stirrer blades. According to the invention, the respective stirring device causes an axial feed action in an inner stirring region between the stirrer shaft and the stirrer blades in order to feed the melt in the stirring region along the stirrer shaft. A melt flow brought about by the axial feed action seals the gap against direct passage of the melt. According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

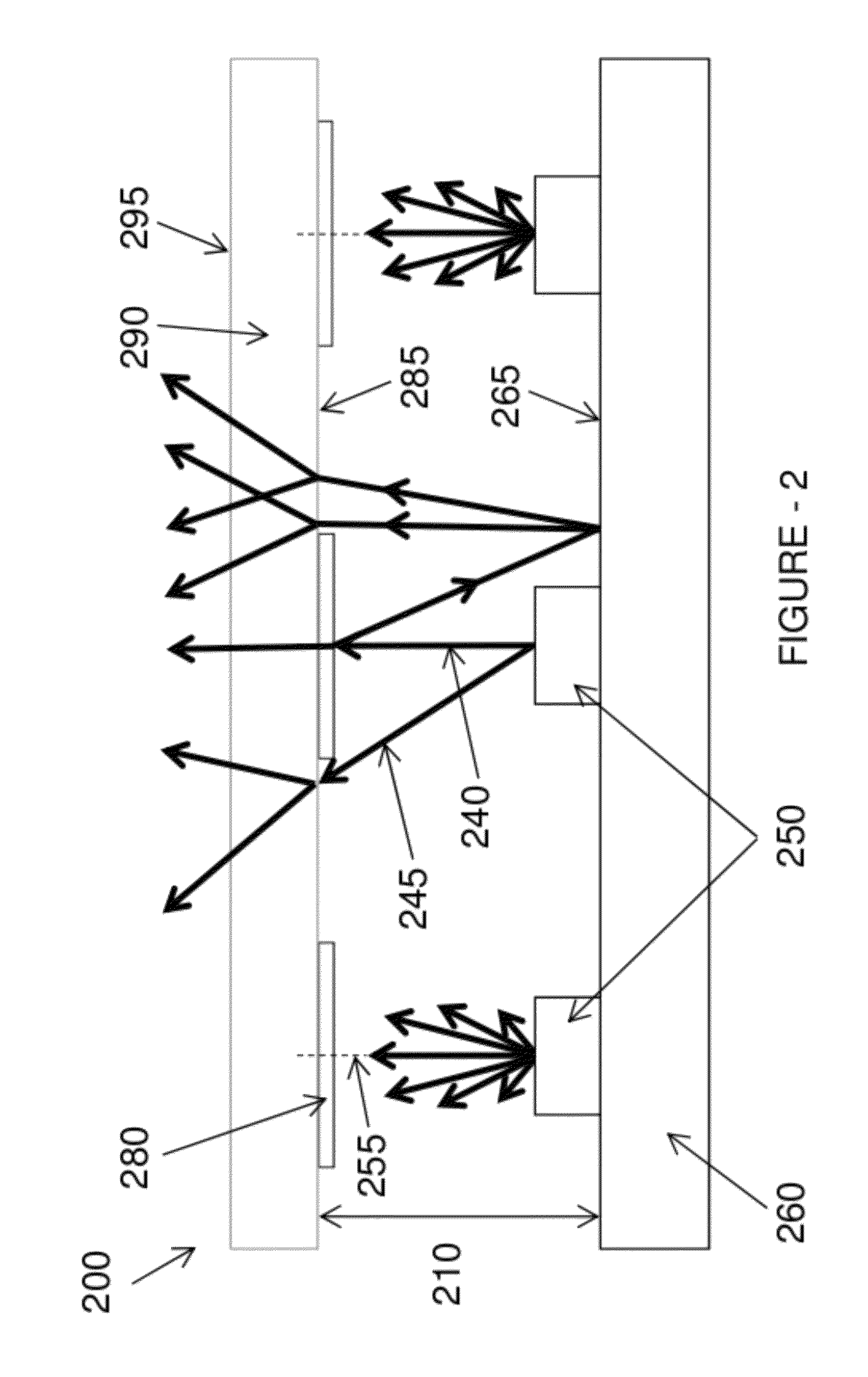

Anti-speckle system for coherent illumination system

InactiveUS20150309326A1Increase effective sizeAvoid damageVehicle headlampsLighting and heating apparatusDirect illuminationDiffuse illumination

This invention in phase homogenization of coherent light from illuminators used for surveillance imaging systems provides a coherent light emitter aligned with a light source ray path along an optical axis with at least two separated microdiffractive diffusers, the microdiffractive diffusers comprising holographically generated surfaces of microdiffractive structure that statistically tend to diffract light at selectable angles or distribution patterns, the microdiffractive diffusers disposed upon a substrate and separated from each other by a distance determined by wavelength phase and irradiance characteristics of the coherent light emitter and by refractive characteristics of at least two microdiffractive diffusers, followed by a homogenized exit ray path in order to produce a diffused pattern of illumination optimized for long distance surveillance imaging.

Owner:ROBERT BOSCH GMBH

Static mixing element and method of mixing a drilling liquid

InactiveUS20070211570A1Efficient HomogenizationEffective dispersionFlow mixersTransportation and packagingEngineeringStatic mixer

Static mixer element for homogenizing media and methods of mixing a drilling liquid are disclosed. The static mixer includes a housing and a deflection surface arranged within the housing at a selected angle with respect to the flow direction.

Owner:TT SCHMIDT

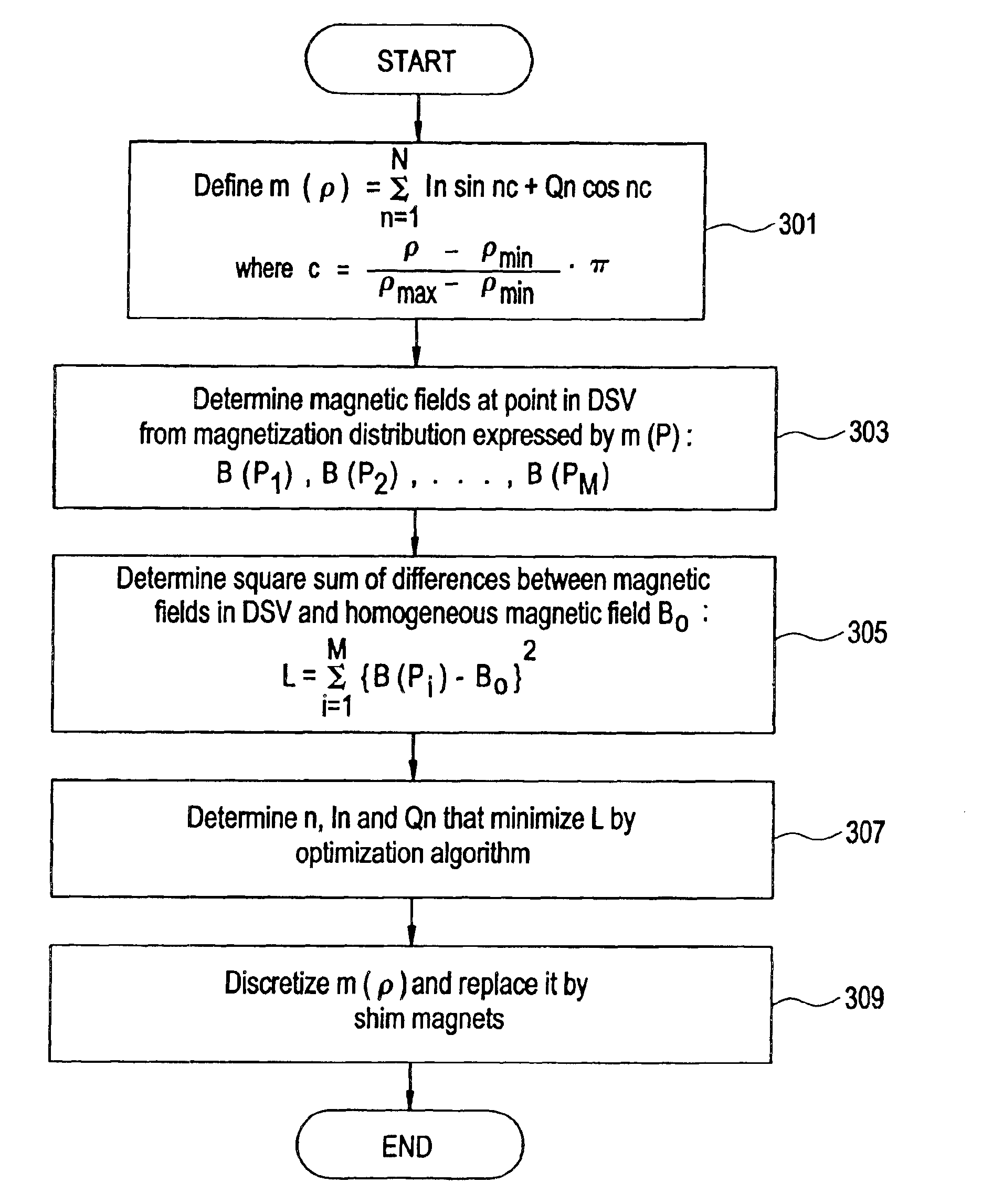

Magnetic field homogenizing method and apparatus, and magnetic field generating apparatus

InactiveUS6897656B2Efficiency of space use can be improvedImprove efficiencyPermanent magnetsDiagnostic recording/measuringMagnetizationLeast squares

For the purpose of efficiently homogenizing a magnetic field, when homogenizing a strength distribution of a magnetic field generated in a space between a pair of facing pole surfaces, a continuous magnetization distribution for homogenizing the strength distribution of the magnetic field is determined with respect to planes on which magnetic elements are to be disposed for homogenizing the strength distribution of the magnetic field; and magnetic elements are disposed based on the magnetization distribution. The magnetic distribution is determined as a polynomial of an orthogonal function. The polynomial is determined by an optimization method. The optimization method is a method of least squares.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Catalyst slurry preparation system and use thereof

ActiveUS9273157B2Efficient HomogenizationNo risk of leakageTransportation and packagingRotary stirring mixersParticulatesImpeller

Owner:TOTAL RES & TECH FELUY

Method for forming through silicon via

ActiveCN104465495AReduce thickness differenceEliminate Surface ChippingSemiconductor/solid-state device manufacturingOptoelectronicsCopper

The invention provides a method for forming a through silicon via. The method for forming the through silicon via includes the steps that a wafer is provided; the through silicon via is formed in the wafer; an insulating layer is formed on the surface of the through silicon via; metallic copper layers are arranged in the through silicon via and on the upper surface of the wafer; the surfaces of the metallic copper layers are homogenized through laser thermal annealing; the metallic copper layers are flattened till the surface of the wafer is exposed. By the adoption of the method for forming the through silicon via, the surface of the formed through silicon via is flat, and the conductivity and the reliability of the formed through silicon via are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Catalyst slurry preparation system and use thereof

ActiveUS20130130890A1Promote homogenizationEfficient HomogenizationTransportation and packagingOrganic-compounds/hydrides/coordination-complexes catalystsParticulatesImpeller

The present invention relates to the use of a catalyst preparation system for the preparation of a diluted catalyst slurry. In particular, the invention relates to a catalyst preparation system comprising a mixing vessel for mixing a particulate catalyst and a liquid hydrocarbon diluent. According to the invention, diluted catalyst slurry is prepared in a mixing vessel comprising a rotatable axial impeller system comprising at least two double-bladed hubs. The invention also relates to a process for preparing diluted catalyst slurry for use in the preparation of a particulate polyethylene product in a loop reactor with the catalyst preparation system as described herein.

Owner:TOTAL RES & TECH FELUY

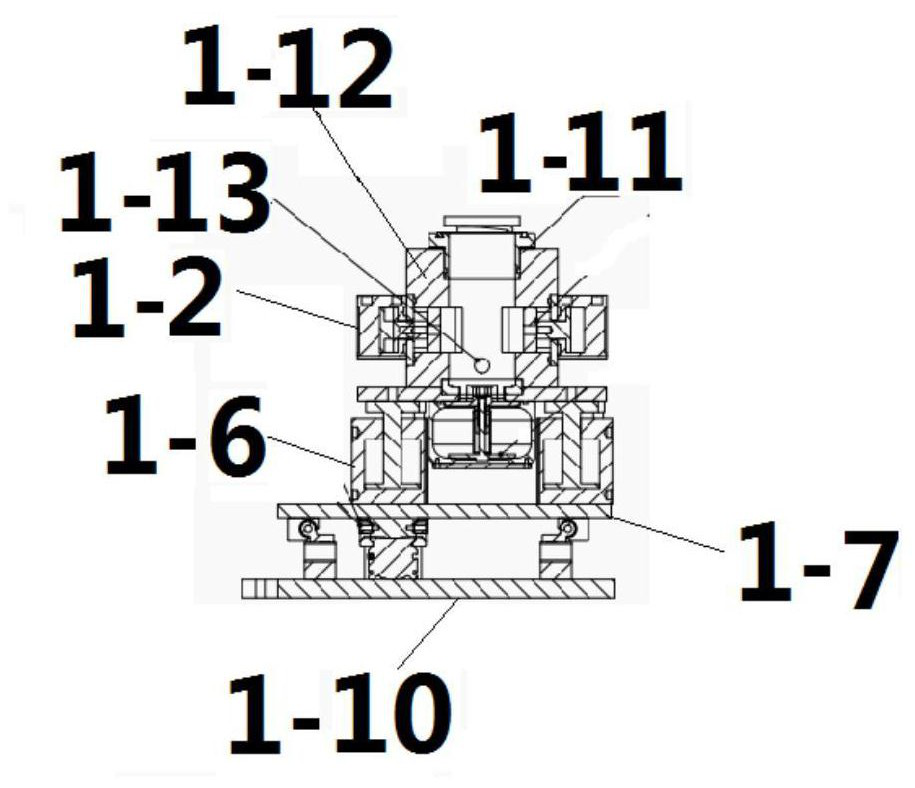

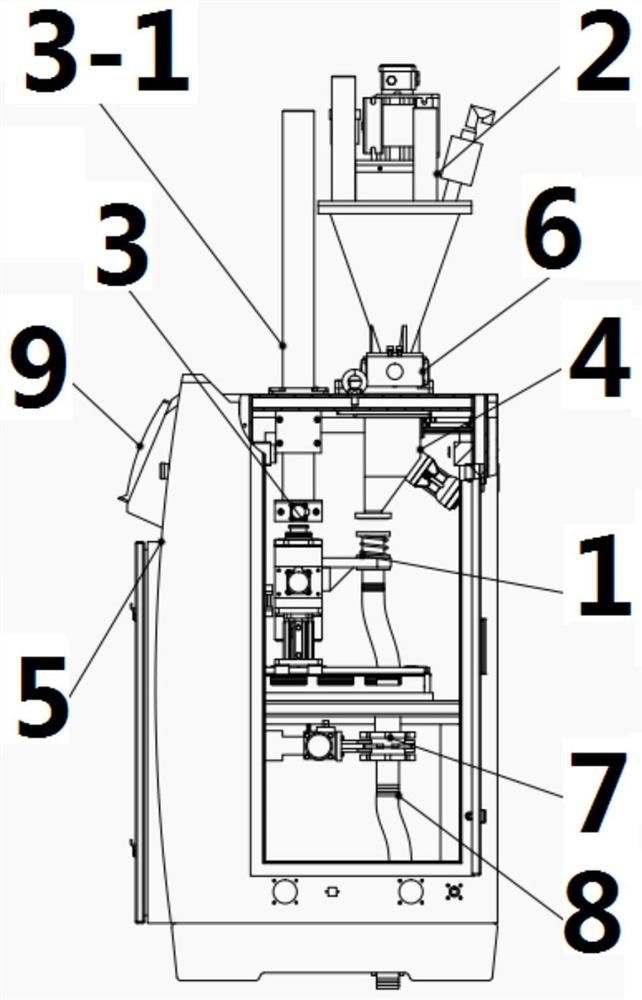

Automatic material sending station

ActiveCN113060317AAchieve clampingAchieve releaseConveyorsRotary stirring mixersControl engineeringPipe

The invention provides an automatic material sending station, and belongs to the technical field of automatic material sending. The automatic material sending station comprises a frame (5) and an object clamping and translating mechanism (1), a material homogenizing device (2) and a cover clamping mechanism (3) are arranged on the upper portion of the frame (5), and a material quantifying device (4) is arranged below the material homogenizing device (2); and the object clamping translation mechanism (1) is mounted on the frame (5) below the cover clamping mechanism (3) and the material quantifying device (4), and the object clamping translation mechanism (1) is connected with a discharging pipe (8). According to the automatic material sending station, automatic homogenization treatment, quantitative material treatment, separation and clamping of a sample tank and a tank cover, translation and lifting and lowering of the sample tank and material canning treatment of different materials can be efficiently achieved with high quality, the labor intensity of workers is reduced, automatic material sending operation in the whole link is achieved, the large-batch material sending requirement is met, and the overall material sending efficiency and quality are effectively improved.

Owner:上海智质科技有限公司 +3

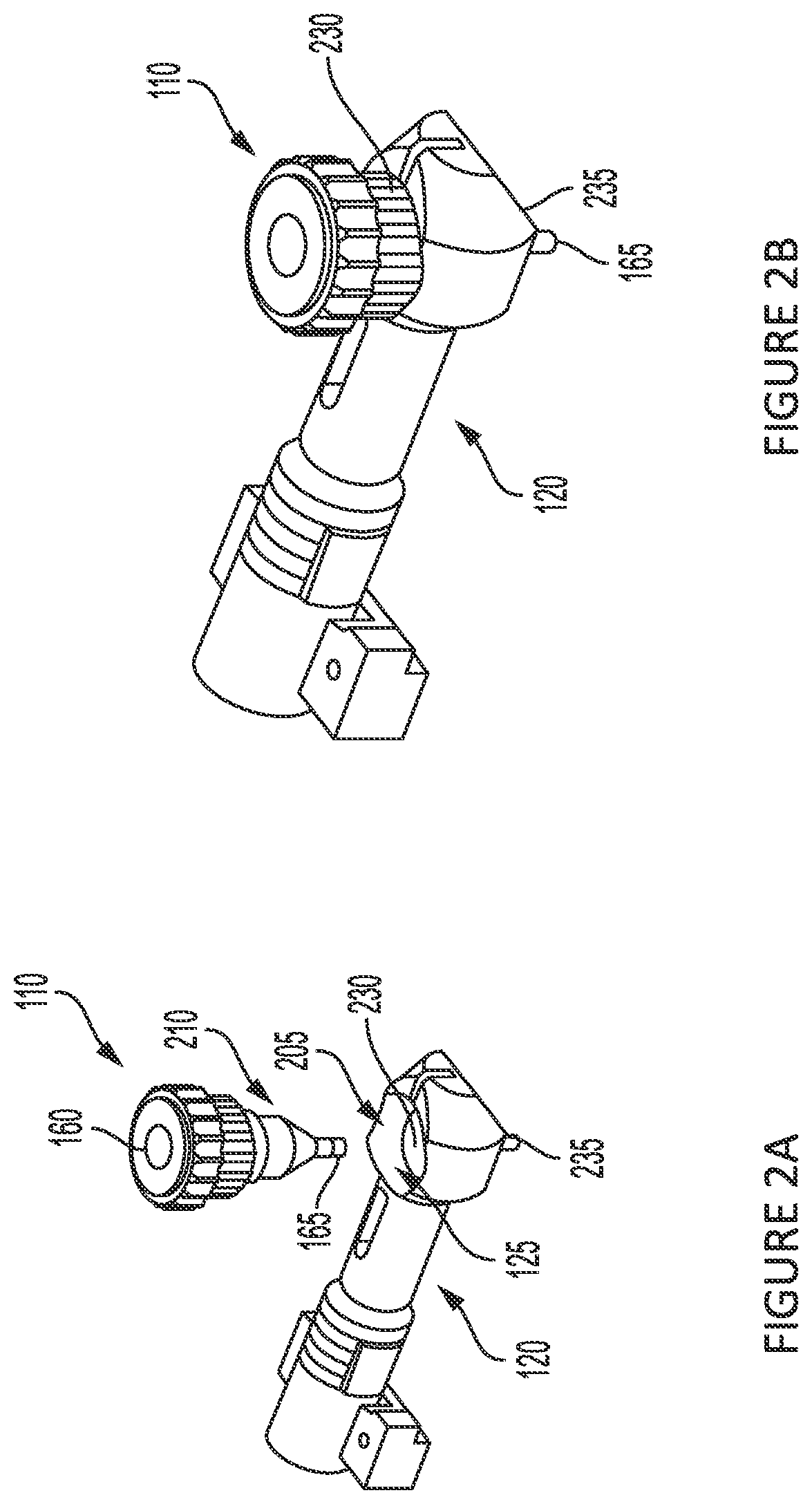

Apparatus and method for cell, spore, or virus capture and disruption

ActiveUS20170333891A1Improve efficiencyHigh detection sensitivityBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersSporeLysis

Embodiments disclose an apparatus and methods for biological sample processing enabling isolation and enrichment of microbial or pathogenic constituents from the sample. A vessel for sample containment and extraction is further disclosed for engagement with a transducer capable of efficient sample disruption and lysis. Together these components provide a convenient and inexpensive solution for rapid sample preparation compatible with downstream analysis techniques.

Owner:TANGEN BIOSCIENCES INC +1

Automatic material sending station control system

ActiveCN113060318AAchieve clampingAchieve releaseConveyorsRotary stirring mixersControl systemControl engineering

The invention provides an automatic material sending station control system applied to the technical field of automatic material sending. The automatic material sending station control system comprises the following steps that a clamping tank (1-1) of an object clamping and horizontally-moving mechanism (1) clamps a sample tank; materials are homogenized through a material homogenizing device (2) and then enter a material quantifying device (4); a cover clamping mechanism (3) clamps a tank cover of the sample tank, and the sample tank is separated from the tank cover; the overflowed and redundant materials are discharged from a discharging pipe (8); a quantifying material cup (4-6) is turned over, and the materials fall into the sample tank from a discharging opening (4-4); and the sample tank and the tank cover are clamped, and the sample tank is closed. According to the automatic material sending station control system, automatic homogenizing treatment, material quantifying treatment, separation and clamping of the sample tank and the tank cover, horizontal moving and lifting of the sample tank and material canning treatment of different materials can be efficiently achieved with high quality, the manual labor intensity is relieved, and automatic material sending operation of the whole link is achieved.

Owner:上海智质科技有限公司 +3

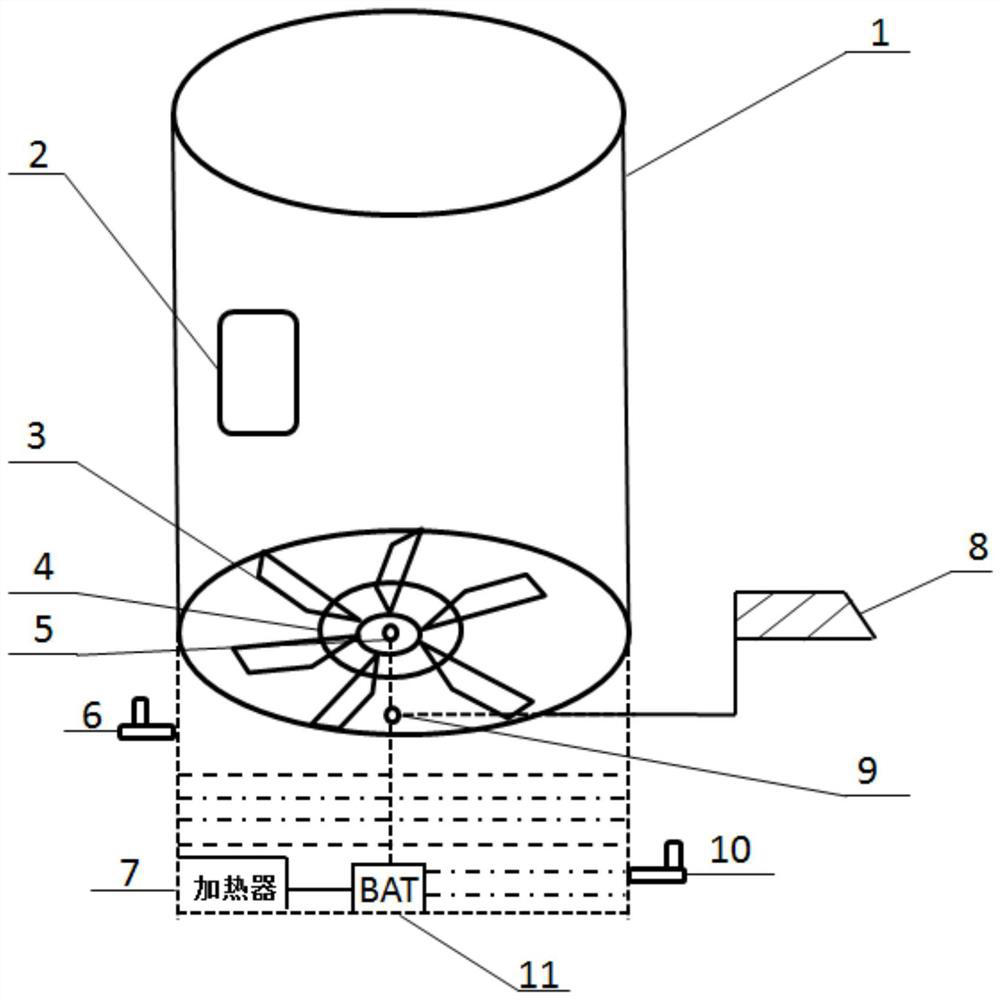

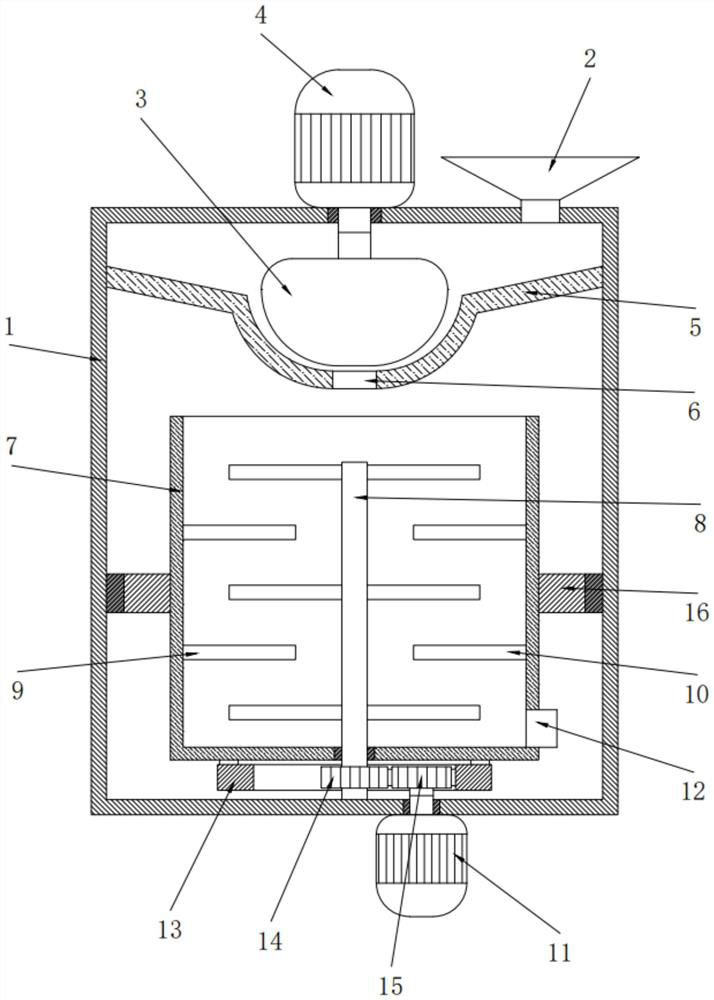

Tobacco feed liquid homogenizing device

PendingCN112090327ANovel and compact structureReasonable designRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a tobacco feed liquid homogenizing device which comprises a machine shell, a power pedal is arranged on the side wall of the machine shell, a stirring assembly and a transmission assembly are arranged in the machine shell, one end of the transmission assembly is connected with the power pedal, the other end of the transmission assembly is connected with the stirring assembly, and the other end of the transmission assembly is connected with the transmission assembly; therefore, the stirring assembly is driven to rotate by kinetic energy generated by the power pedal through the transmission assembly. The tobacco feed liquid homogenizing device is novel and compact in structure and reasonable in design, kinetic energy generated by the power pedal drives the stirring assembly to rotate through the transmission assembly, feed liquid is fully mixed and homogenized in the rotating process, the feed liquid can be efficiently, conveniently and rapidly homogenized and mixed, and the uniformity and stability of the feed liquid in the tobacco production and processing process are guaranteed.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method of forming through silicon vias

ActiveCN104465495BReduce thickness differenceEliminate Surface ChippingSemiconductor/solid-state device manufacturingCopperThrough-silicon via

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method of homogenizing a liquid

Owner:FAST & FLUID MANAGEMENT

Homogenizing device for medical examination

PendingCN114405377AImprove efficiencyEfficient HomogenizationRotating receptacle mixersTransportation and packagingElectric machineryEngineering

The homogenizing device comprises a case shell, a grinding block driven by a grinding motor to rotate is rotationally arranged at the top in the case shell, a grinding groove matched with the grinding block is formed in the lower side of the grinding block, a stirring barrel with an upward opening is rotationally arranged on the inner side of the case shell, and a rotating shaft is rotationally arranged at the inner bottom of the case shell; a plurality of stirring blades I are fixed on the inner wall of the stirring barrel, the rotating shaft penetrates through the bottom of the stirring barrel and is in rotary sealing connection with the stirring barrel, a plurality of stirring blades II are fixed on the rotating shaft, and the stirring blades I and the stirring blades II are uniformly distributed at intervals from top to bottom. Compared with the prior art, the device has the advantages that a to-be-detected sample is ground through work of the grinding motor, then ground sample powder is homogenized through work of the stirring motor, and the stirring motor can drive the first stirring blade and the second stirring blade to conduct stirring at the same time and conduct bidirectional stirring; therefore, efficient homogenization can be realized.

Owner:连艳珍

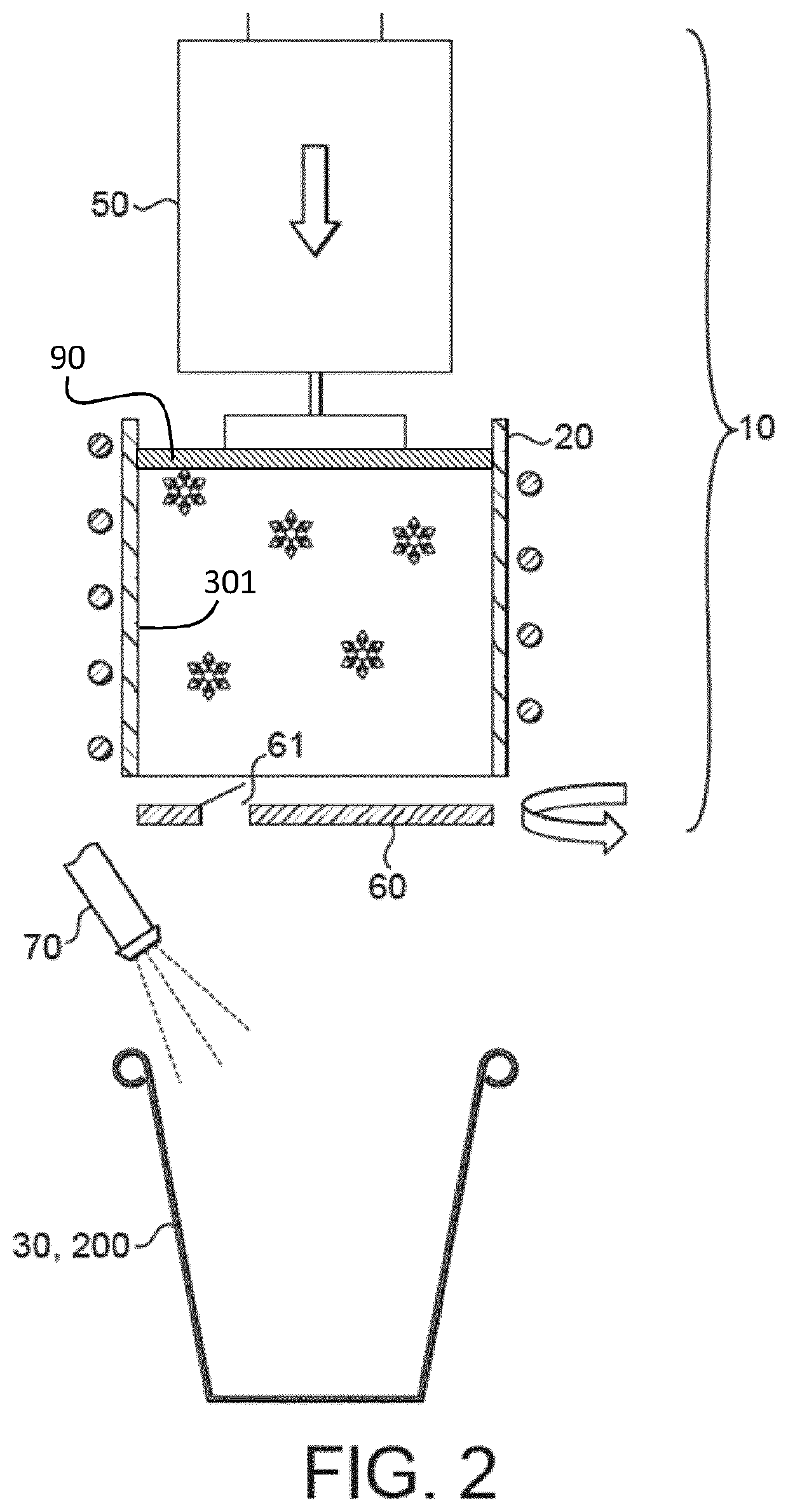

System for delivering frozen or chilled beverages

The invention relates to a system (100) for delivering frozen or chilled beverages. The system (100) comprises a device (10) and a container (20), the container (20) comprising a frozen product and the device (10) being configured for receiving the container (20) and for processing the frozen product of the container (20) to deliver the final beverage. The device (10) comprises: a slicing element (60), the slicing element (60) and the frozen product being relatively rotatable to each other about a rotation axis in order to slice the frozen product, and a driving unit (50) configured to provide the relative rotation between the slicing element (60) and the frozen product. The container (20) comprises a container inner wall (301) being in contact with the frozen product, wherein the container inner wall (301) has a cross-section, which is shaped such that a relative rotation between the container (20) and the frozen product about the rotation axis is blocked.

Owner:SOC DES PROD NESTLE SA

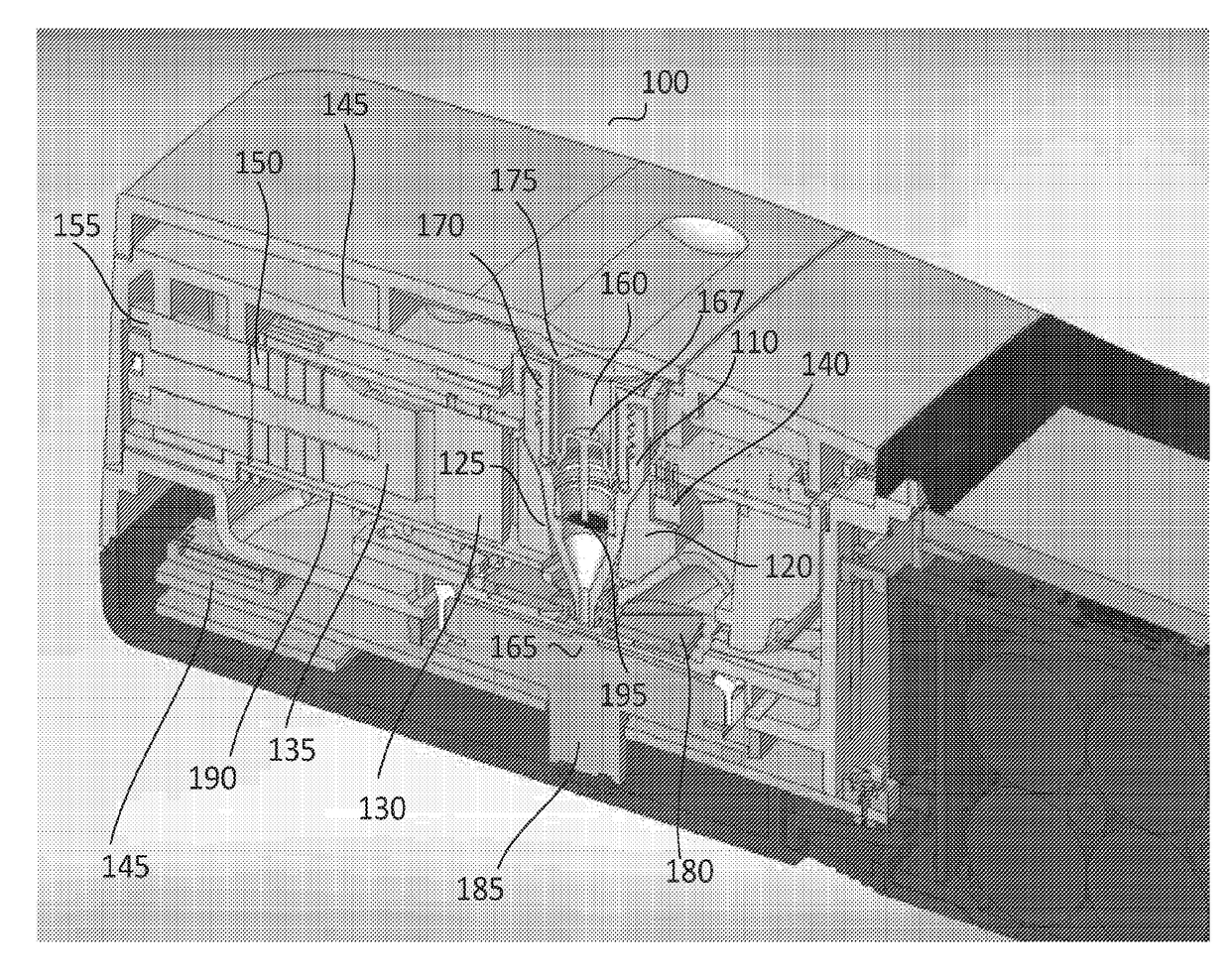

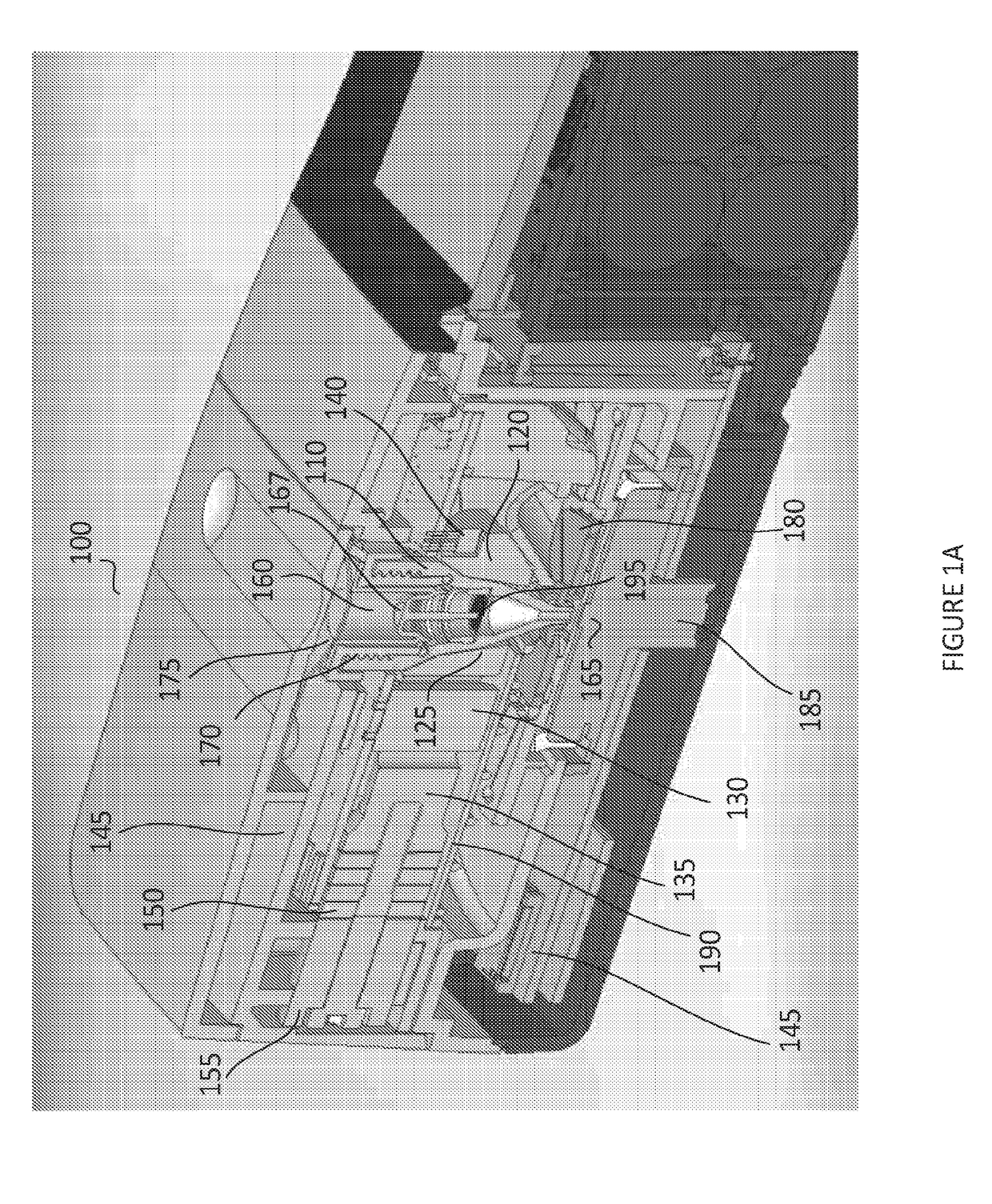

Fuel vapor processing apparatus

ActiveUS11187194B2Well mixedEfficient HomogenizationNon-fuel substance addition to fuelMachines/enginesThermodynamicsEngineering

A fuel vapor processing apparatus includes a casing, an adsorbent, and a mixer. The casing includes an atmospheric port and a purge port. In addition, the casing forms an atmospheric port-side adsorption chamber, an agitation chamber, and a purge port-side adsorption chamber therein. The atmospheric port-side adsorption chamber, the agitation chamber, and the purge port-side adsorption chamber are continuously arranged in a gas flow direction from the atmospheric port through the casing to the purge port. The adsorbent fills the atmospheric port-side adsorption chamber and the purge port-side adsorption chamber. The adsorbent is configured to adsorb and desorb fuel vapor. The mixer is disposed in the agitation chamber and includes a spiral flow forming part configured to spirally guide gas flowing through the agitation chamber.

Owner:AISAN IND CO LTD

Apparatus and method for cell, spore, or virus capture and disruption

InactiveUS20220126283A1Guaranteed normal transmissionReduce degradationBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismSpore

Embodiments disclose an apparatus and methods for biological sample processing enabling isolation and enrichment of microbial or pathogenic constituents from the sample. A vessel for sample containment and extraction is further disclosed for engagement with a transducer capable of efficient sample disruption and lysis. Together these components provide a convenient and inexpensive solution for rapid sample preparation compatible with downstream analysis techniques.

Owner:TANGEN BIOSCIENCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com