Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "Improve stress status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

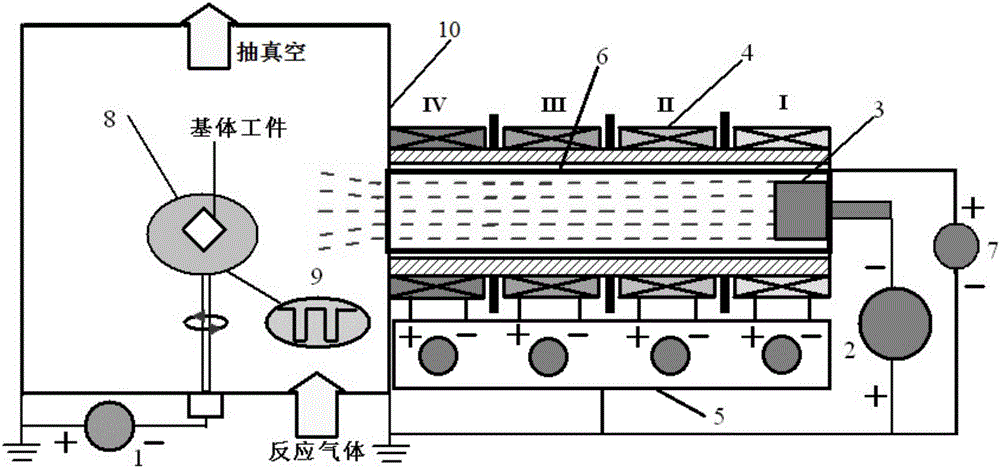

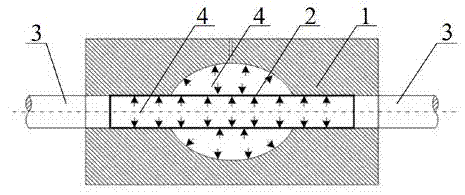

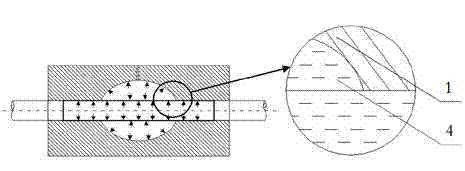

Multi-stage magnetic field arc ion plating method for lining positive bias straight pipe

InactiveCN105925940AReduce lossImprove transmission efficiencyVacuum evaporation coatingSputtering coatingPhysicsElectric arc

The invention discloses a multi-stage magnetic field arc ion plating method for a lining positive bias straight pipe, and belongs to the technical field of material surface treatment. The problems that in a multi-stage magnetic field filtering device, pollution to the inner wall of a pipeline due to macroparticles needs to be removed, and losses are caused in the plasma transmitting process need to be solved. The method comprises the steps that firstly, a workpiece to be coated is arranged on a sample table in a vacuum chamber, and a related power source is powered on; and secondly, film deposition is conducted, when the vacuum degree in the vacuum chamber is smaller than 10-4Pa, work gas is guided in, the air pressure is adjusted, a coating power source is started, meanwhile, energy of plasmas is adjusted through a grid bias power supply, the macroparticle defect is further eliminated through a lining positive bias straight pipe device, the transmission efficiency of the arc plasmas is guaranteed through the lining positive bias straight pipe device, needed technology parameters are set, and film deposition is conducted.

Owner:魏永强

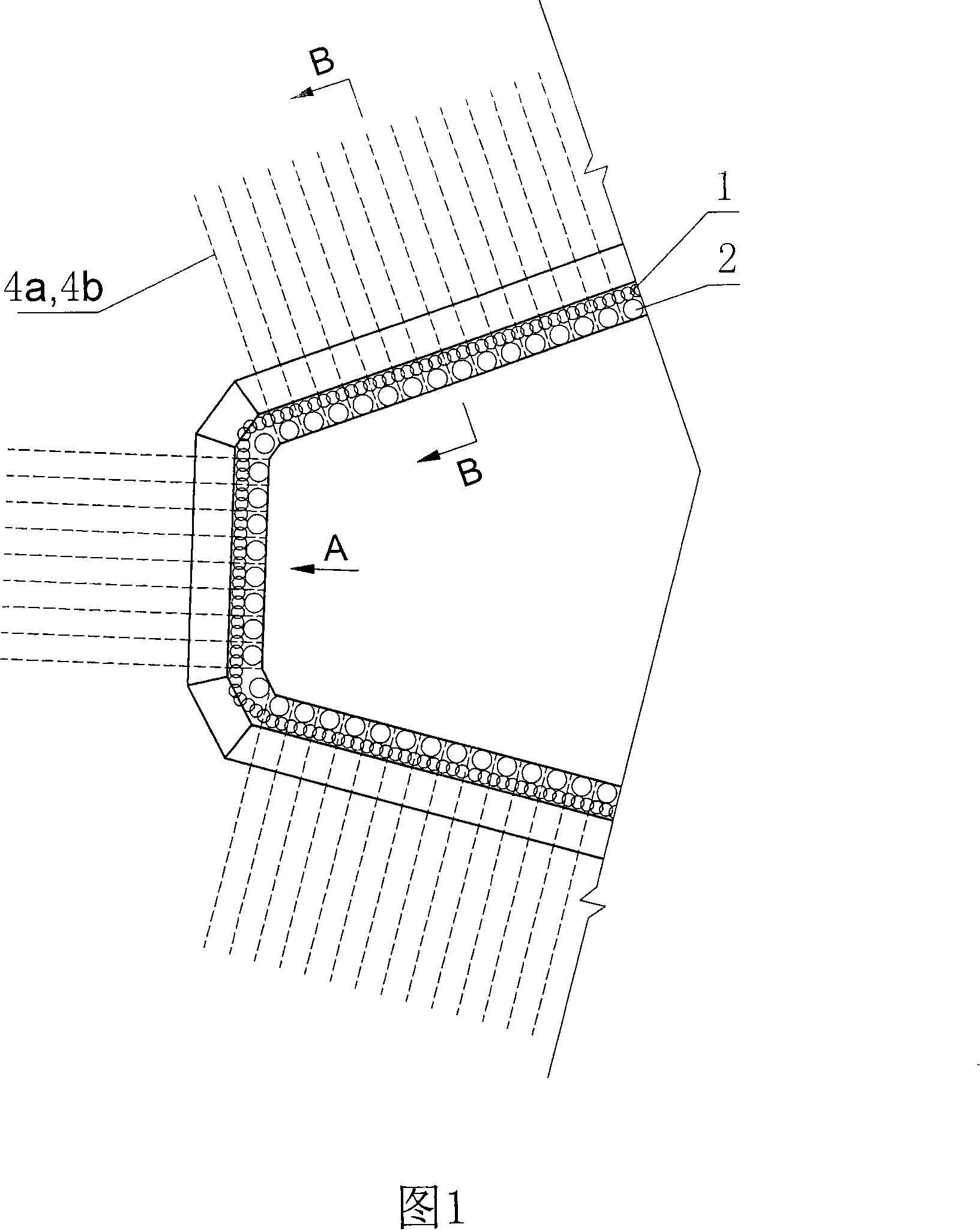

Pile-anchor foundation ditch supporting construction method

ActiveCN101225661AOpen working surfaceImprove construction progressExcavationsBulkheads/pilesBasementEngineering

The invention discloses a foundation pit support method with pile and anchor, belonging to an external staying support technique field of the supporting structural retaining of the foundation pit, comprising that: a. bored piles are constructed to form a retaining wall, after lofting of the pile location according to the planar graph of the pile location; b. the soil is excavated to the bottom elevation of the top beam; c. the bored piles are chiseled to the design elevation; d. the first row of anchors are constructed in the soil layer between the adjacent bored piles; e. the top beams are constructed; f. the soil is excavated to the constructing position of the second row of anchors; g. the second row of anchors are constructed; h. the processes of f and g can be repeated until to the last row of anchors, according to different design conditions; i. the soil is excavated to the bottom of the foundation pit. The foundation pit support method with pile and anchor has the advantages of avoiding a lot of inner supports, providing an open working face for soil excavation, creating a good condition for mechanized construction, increasing the construction progress, needing not to treat the water stop of supporting, bracing substitution, dismantling support during the subsequent construction of the basement, convenient construction, increasing the progress, reducing the construction cost.

Owner:浙江环宇建设集团有限公司

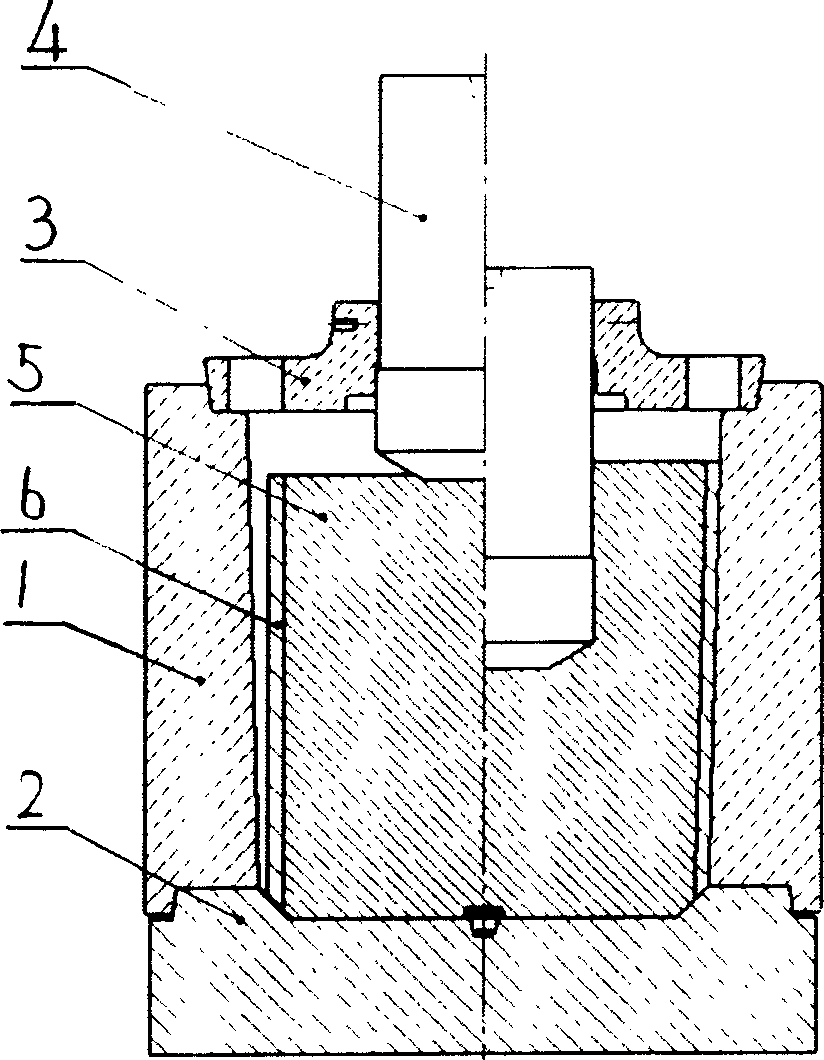

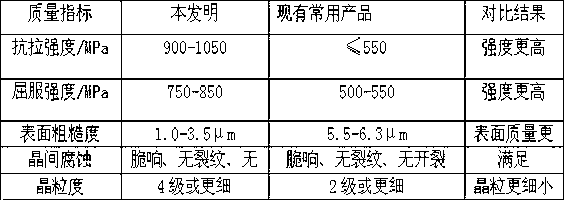

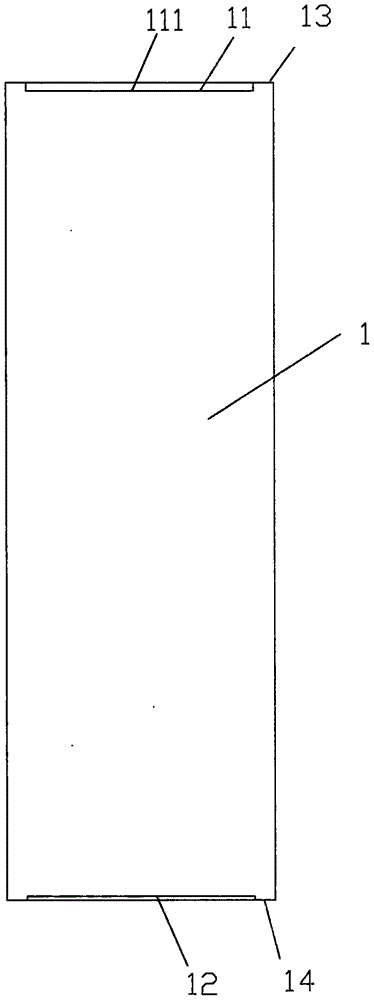

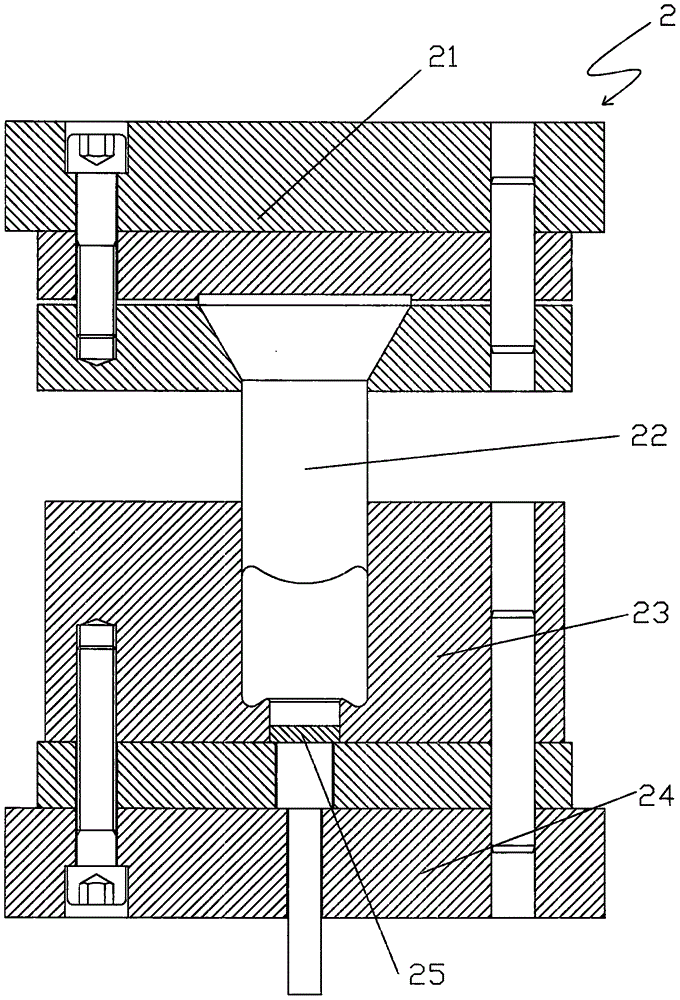

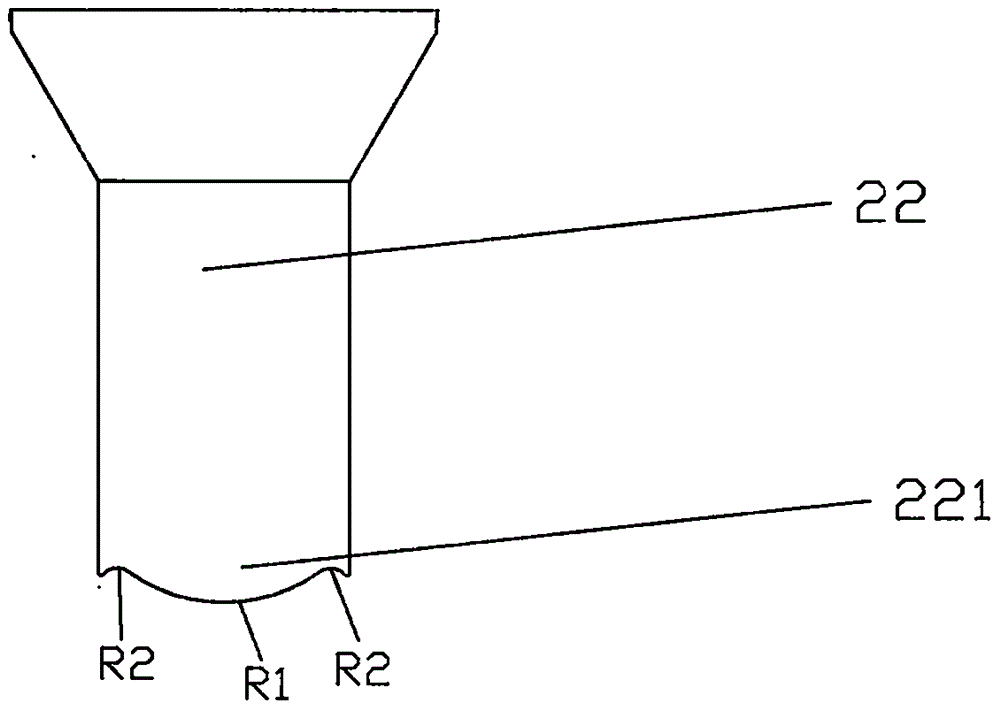

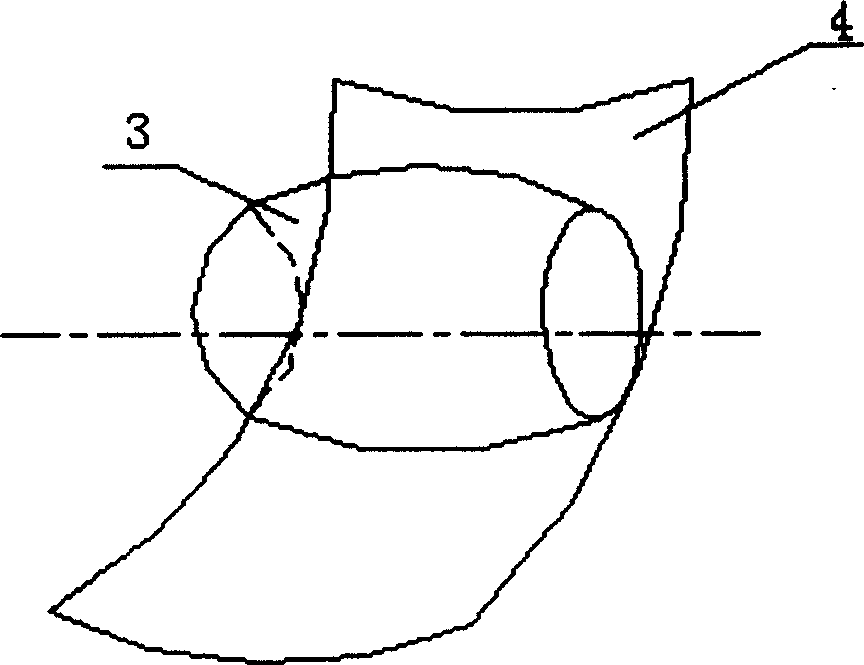

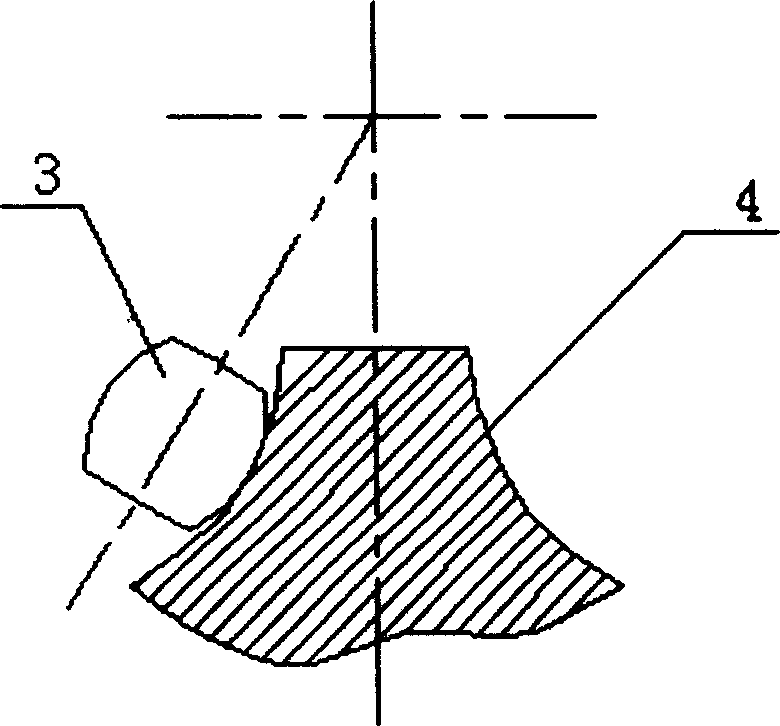

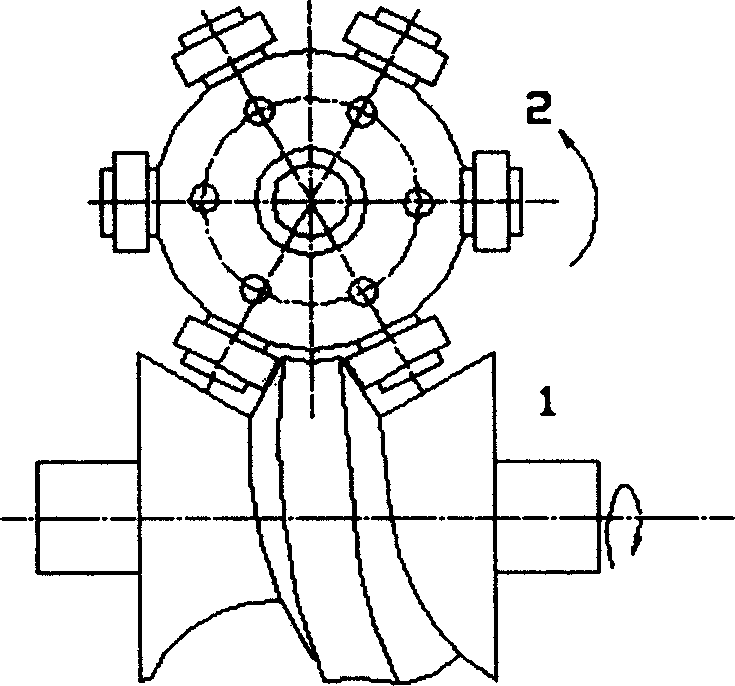

Method for producing circular cog hot forged from generator protective ring and mould

InactiveCN1736630AImprove stress statusAvoid cracksForging/hammering/pressing machinesHollow articlesCrystalliteLubrication

The invention discloses a method and the die for preparation of a hot forging ring billet of the guard ring of generator, and relates to a forging technique and the device of guard ring part of generator. The prior hot forging technique is flat-die forging, easily to produce crack in the process. The invention using confined shaping in die instead of flat-die forging, it improves the state of stress and prevents the crack effectively. With the symmetry of sphere plunger axis in the process of fan boring, the crystal particles are fine and uniform, which provides a perfect condition for cold strain intensification. With the jacket shaping of billet, it can improve lubrication and decrease friction, and can keep the temperature of the hot billet effectively, improving the plasticity and decreasing the shaping pressure. The invention solves the three problems that the crack is easy to produce, the structure property is not uniform, and the shaping pressure is large; compared with the prior technique, the invention has a projecting progress and a distinctive effect.

Owner:DEYANG WANXIN POWER STATION PROD DEV

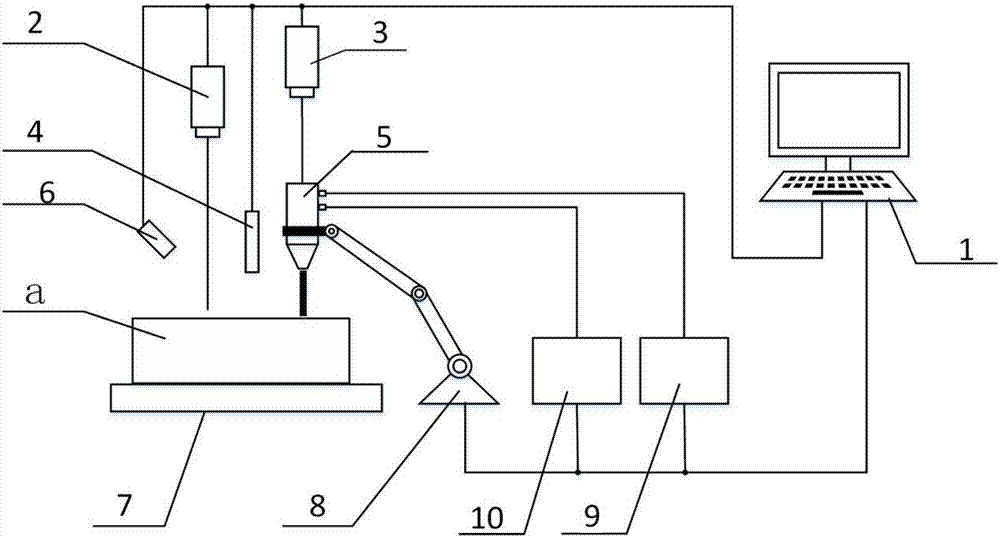

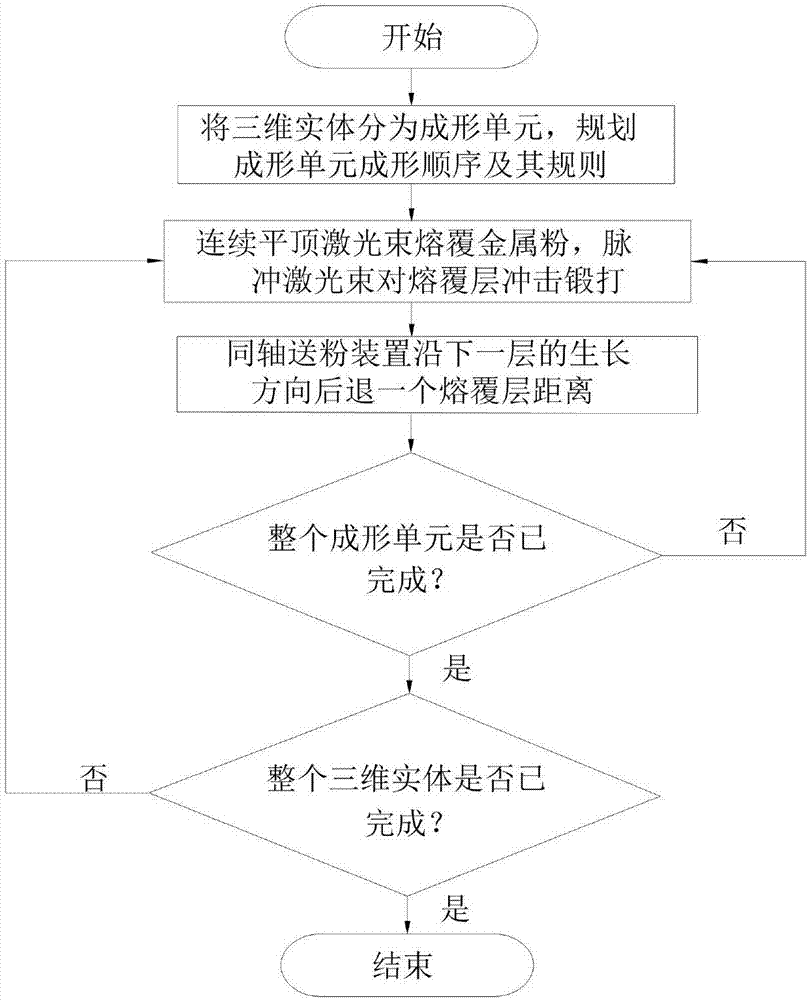

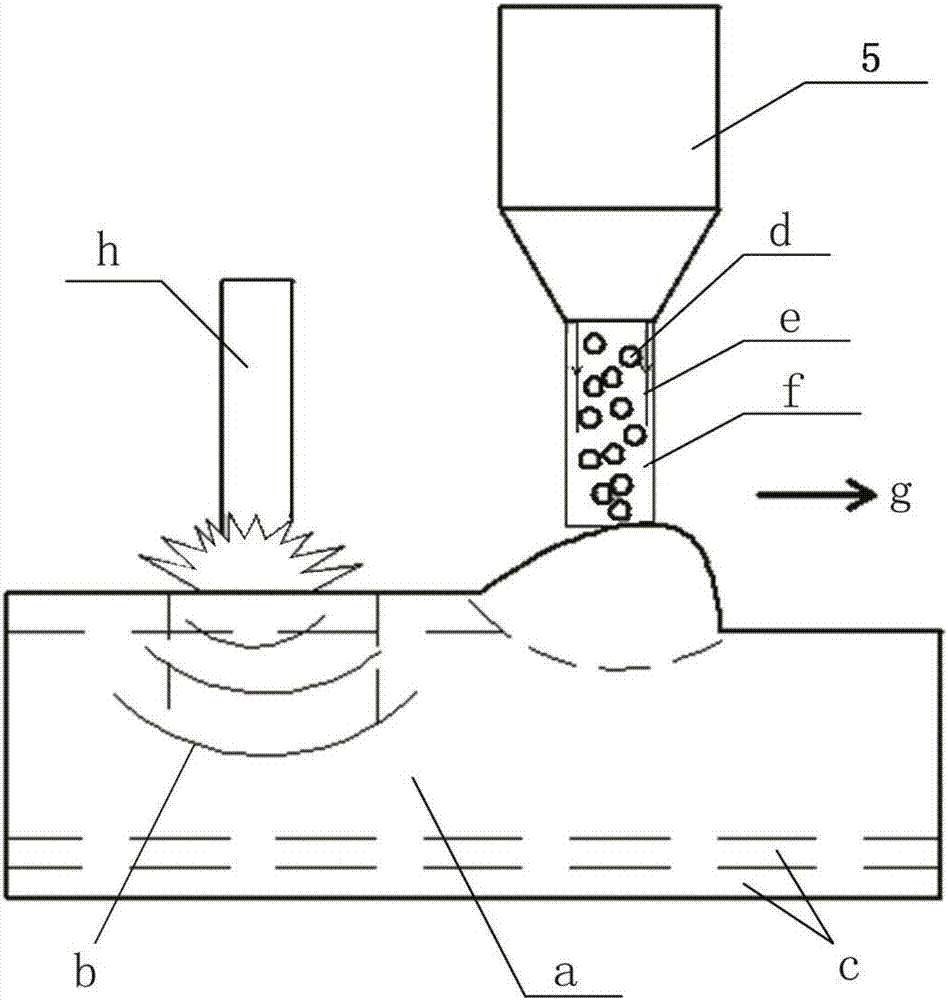

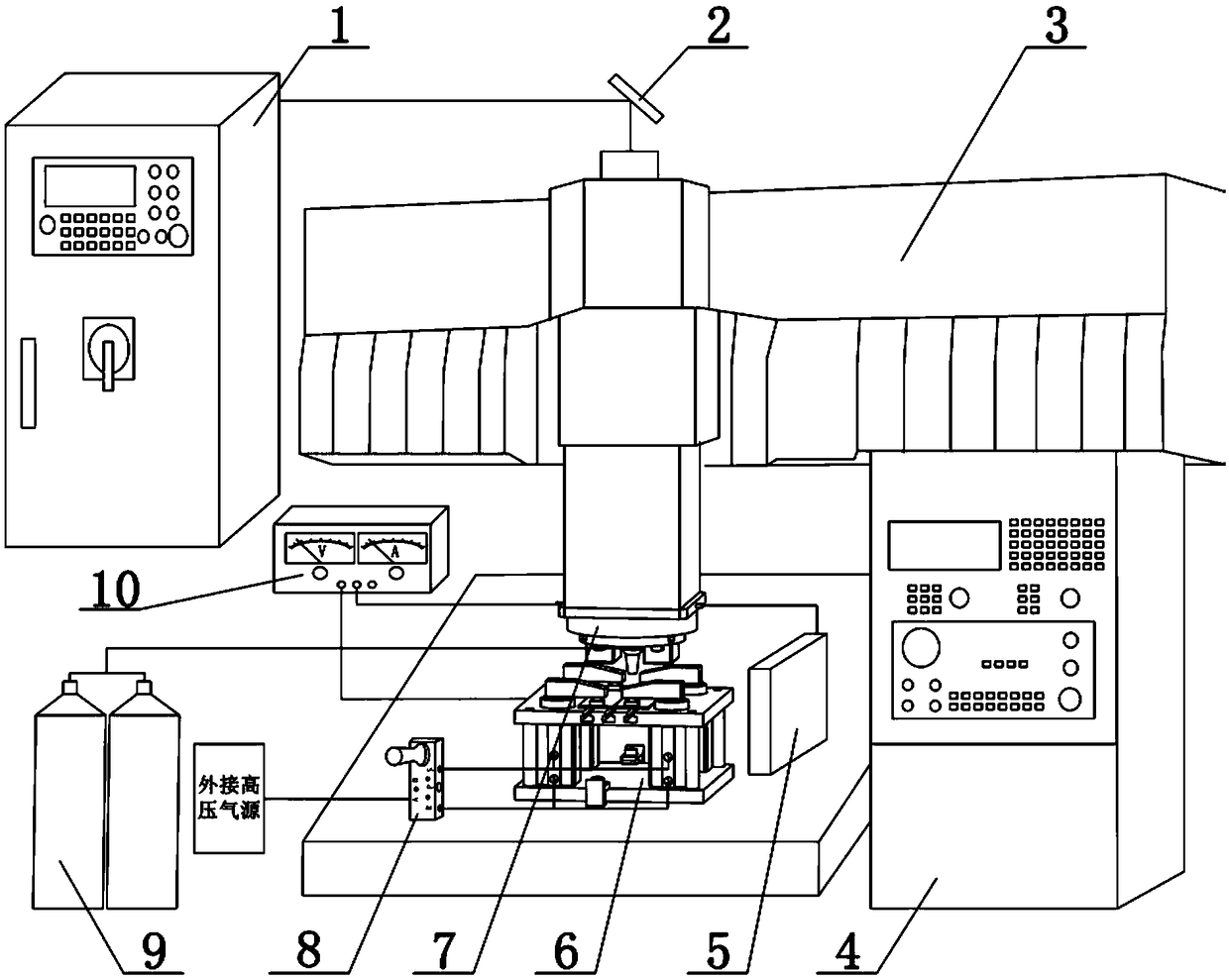

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

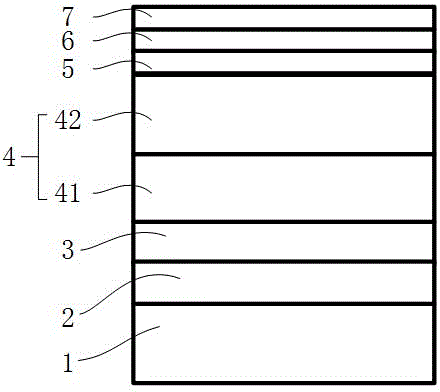

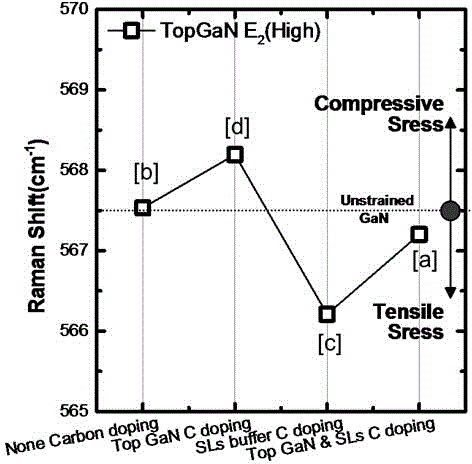

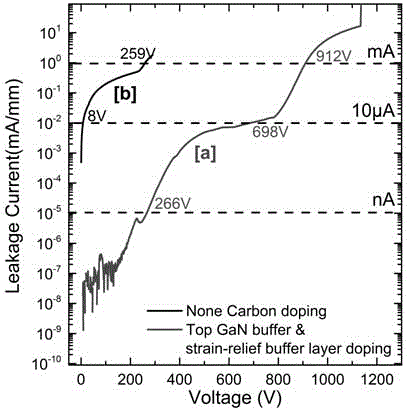

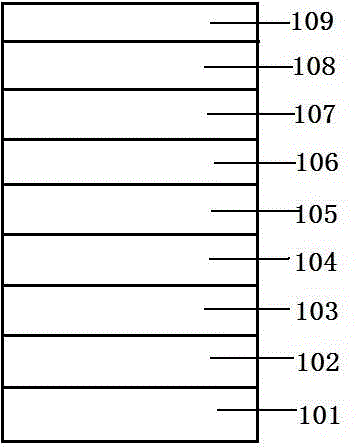

High pressure resistant nitride semiconductor epitaxial structure and growing method thereof

InactiveCN104600109AImprove stress statusLow leakage current characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHeterojunction

The invention relates to the technical field of epitaxial growth of semiconductor materials, and discloses a high pressure resistant nitride semiconductor epitaxial structure and a growing method thereof. The high pressure resistant nitride semiconductor epitaxial structure sequentially includes a substrate, a nucleating layer, an impurity filter layer, a complex nitride epitaxial buffer layer, an electron barrier layer, a non-doped gallium nitride channel layer and a heterojunction barrier layer from the bottom up; the complex nitride epitaxial buffer layer includes a high-resistance aluminum-enriched nitride stress buffer layer and a high-resistance top gallium nitride buffer layer positioned on the high-resistance aluminum-enriched nitride stress buffer layer. The high pressure resistant nitride semiconductor epitaxial structure can improve the stress status in the nitride semiconductor epitaxial layer on the silicon substrate and reduce warping of the epitaxial wafer under the premise of slightly influencing the performance of a heterojunction two-dimensional electron gas channel at the upper layer. The leak current characteristic of the nitride semiconductor epitaxial layer on the silicon substrate is greatly reduced, the unit thickness compression capacity of the nitride semiconductor epitaxial layer on the silicon substrate is improved, and thereby the growth time of epitaxy can be reduced, and the production cost is lowered.

Owner:SUN YAT SEN UNIV

Martensitic stainless steel forged piece and forging and rolling heat treatment integrated production process

ActiveCN103147021APrevent precipitationGuaranteed corrosion resistanceHeat treatment process controlMartensitic stainless steelCorrosion resistant

The invention relates to a martensitic stainless steel forged piece and a forging and rolling heat treatment integrated production process. The martensitic stainless steel forged piece comprises the following chemical components: 0.4-0.7% of C, 0.1-0.3% of Si, 1.6-1.8% of Mn, 0.01% of P, 0.008% of S, 0.03-0.05% of Nb, 0.02-0.06% of V, 0.006-0.015% of Ti, 0.9-1.3% of Ni, 13.3-13.6% of Cr, 0.2-0.4% of Cu, 0.4-0.6% of Mo, 0.08-0.09% of N, 0.1-0.3% of Al, 0.008-0.009% of B, 0.1-0.3% of composite rare earth and the balance of Fe. According to the martensitic stainless steel forged piece disclosed by the invention, by limiting the components and process parameters, the corrosion resistance of the stainless steel forged piece is ensured, and the corrosion resistance at the part with splashing of water drops is especially improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

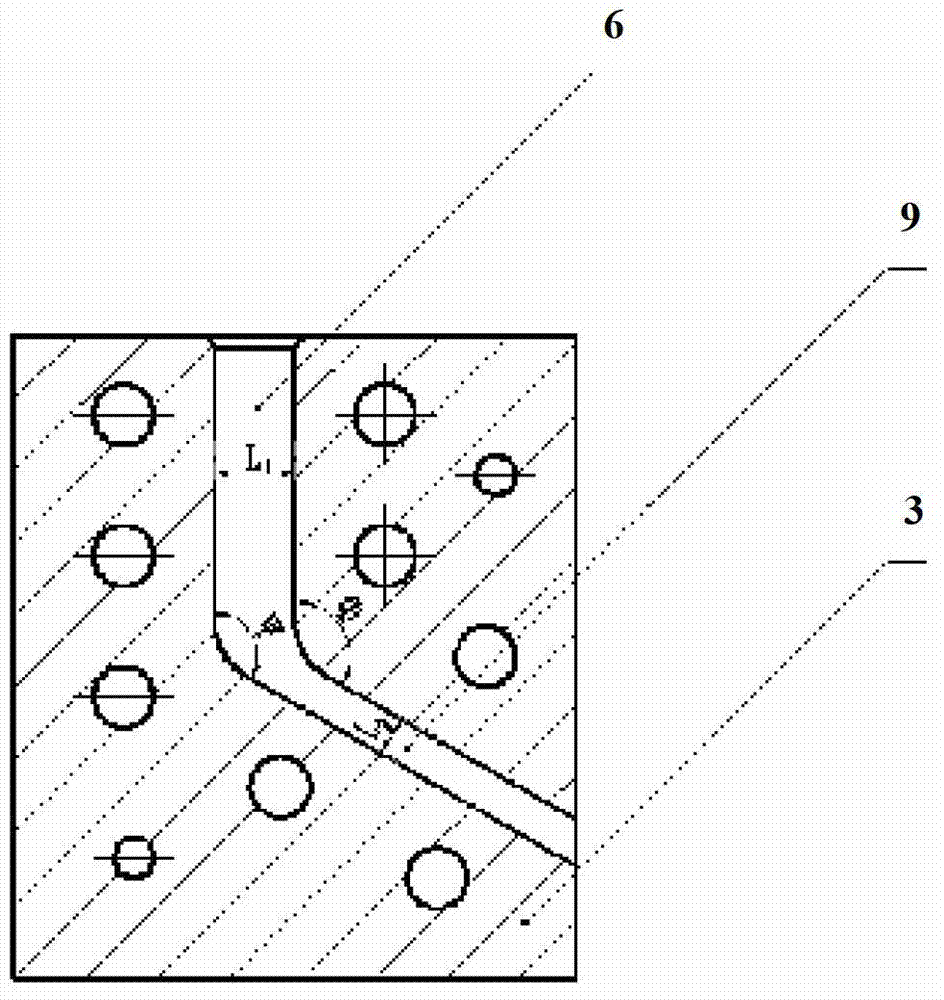

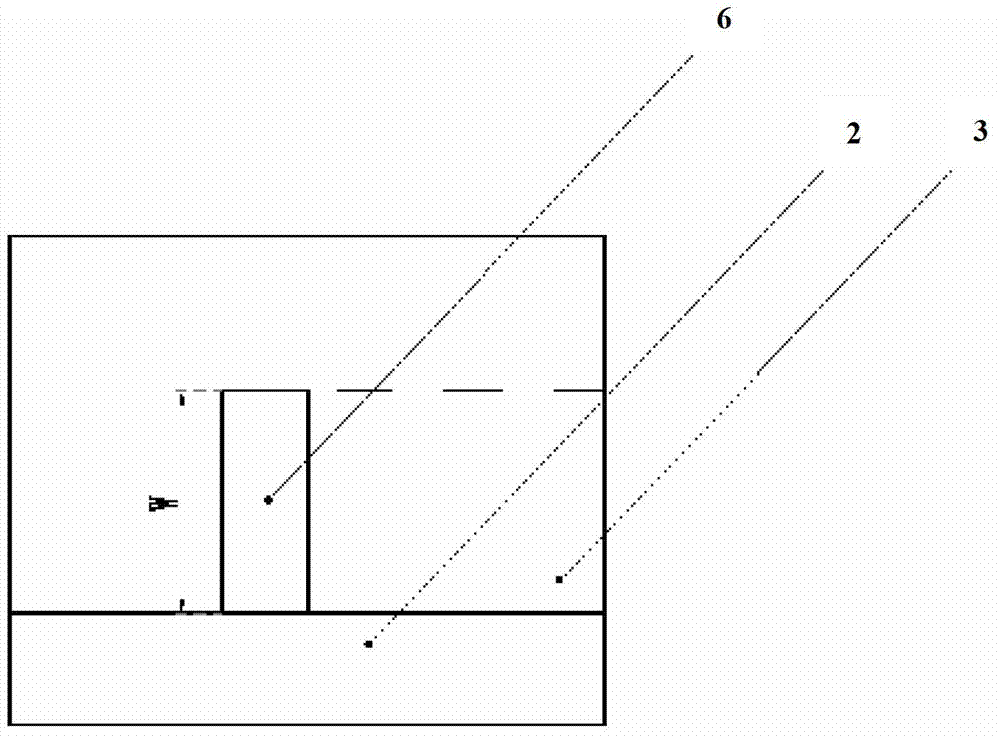

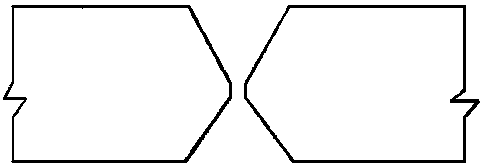

Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

The invention discloses a severe plastic deformation method and a severe plastic deformation device for pressing and rolling the corner of a non-equal channel. According to the severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel, an equal-channel angular pressing (ECAP) technology and an ARB (Accumulative Roll Bonding) technology are integrated. The concrete process comprises the following steps that pressing force is applied after a test sample, a punching head and a mould are simultaneously preheated to pressing and rolling temperature, so that the test sample passes through the position of the channel corner of the device for pressing and rolling the corner of the non-equal channel completely; compressive deformation is generated when shear deformation is generated by the test sample so as to finish a first pass pressing and rolling process; the test sample is cut into L1 / L2 parts along a length direction, and the L1 / L2 parts are placed in an I channel; and the steps are repeated so as to finish multi-pass pressing and rolling deformation. The mould of the device is provided with the I channel and an II channel which are intersected and also have non-equal sections. The design is reasonable, the structure is simple, and the manufacturing cost is low. According to the method disclosed by the invention, the advantages of the ECAP technology and the ARB technology are integrated, and the mechanical property of a material is effectively enhanced. The process is short in procedure, high in efficiency and low in cost and is simple to operate. The severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel can be widely used for the field of processing metal materials, such as pure metal and alloy.

Owner:SOUTH CHINA UNIV OF TECH

Method for forging large forging

ActiveCN102380565AImprove performanceImprove deformation unevennessMetal-working apparatusInternal temperatureForging

The invention relates to a method for forging a large forging, which comprises the following steps: heating a casting blank or continuous casting blank to a forging temperature, and keeping the temperature; 2, cooking to reduce the surface temperature of the casting blank to 700 to 800 DEG C while keeping the high temperature in a central part, and performing central compression forging with a total deformation degree of 6 to 20 percent on a blank material when the difference between the internal temperature and the external temperature reaches 400 to 450 DEG C to obtain a steel blank; and 3) cooling the whole steel blank to 700 to 800 DEG C, rising the temperature at a speed of 50 to 100 DEG C / h to a forging temperature, keeping the temperature, namely keeping the surface regional temperature of the steel blank to a forging temperature and the central temperature still between 700 and 800 DEG C, and performing forging with a total deformation amount of 6 to 20 percent of the steel blank. The large-forging forging method can effectively eliminate the drawbacks of large forgings and improve the mechanical properties and surface and central deformation uniformity and structural and mechanical property uniformity of the large forgings.

Owner:JIANGSU JINYUAN FORGE

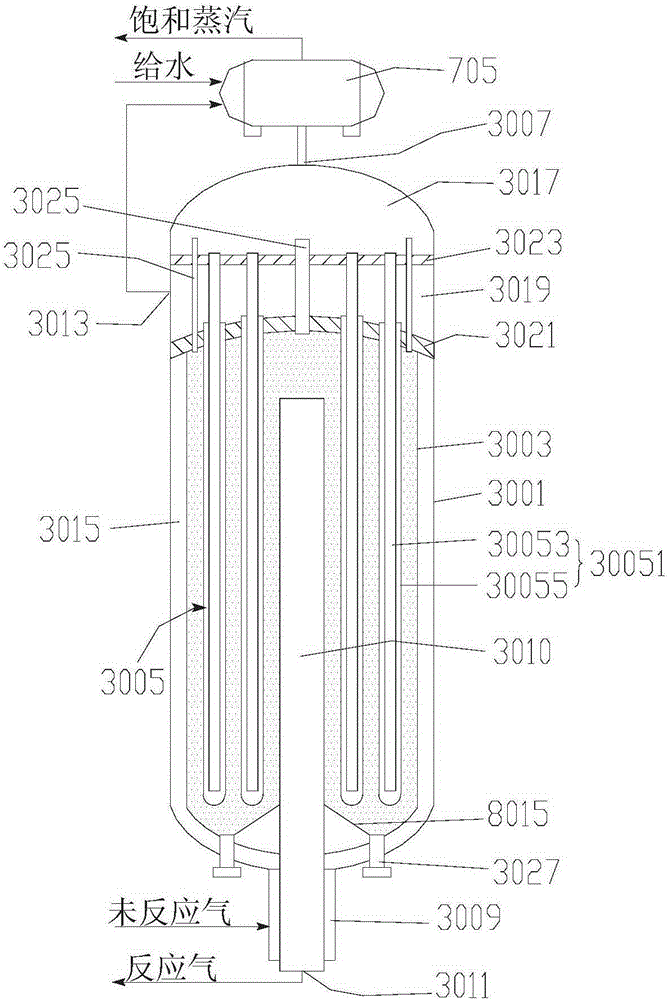

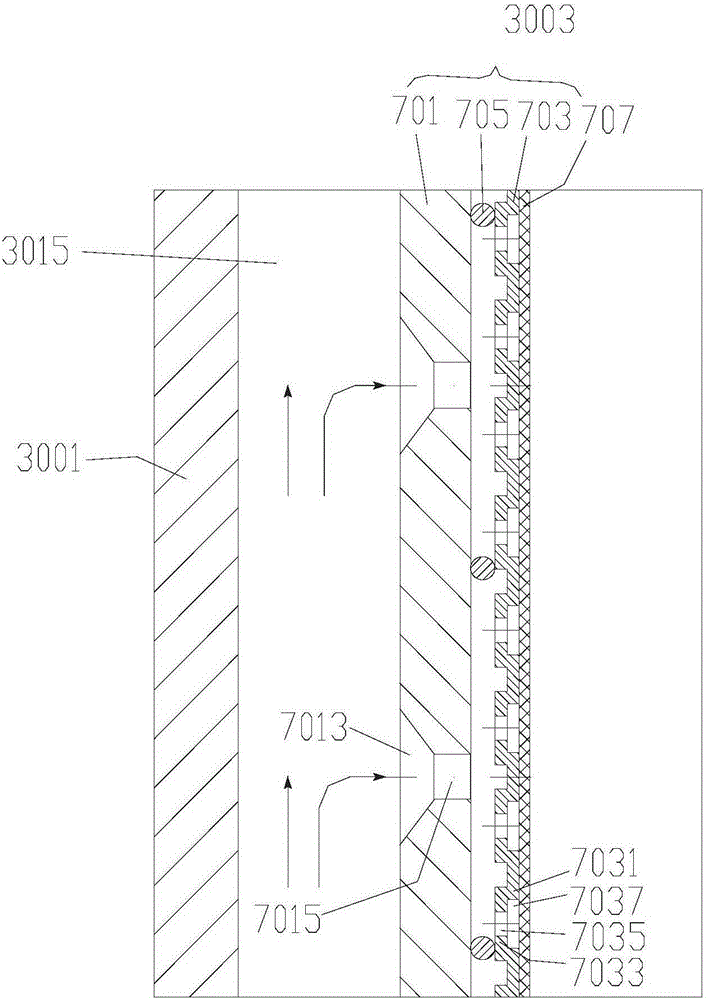

Water-cooled reactor

ActiveCN105233763AReduce weightLow costOrganic compound preparationHydroxy compound preparationEngineeringWater cooled

The invention relates to a water-cooled reactor which comprises an outer cylinder, a radial reaction basket, a water-cooled system, a central pipe, a water chamber, a steam chamber and a loading and unloading structure. The radial reaction basket is located in the outer cylinder. A gap is formed between the radial reaction basket and the outer cylinder. The water-cooled system comprises a water-cooled pipe extending into the radial reaction basket. The water-cooled pipe is communicated with both the water chamber and the steam chamber. The central pipe extends into the radial reaction basket, partly penetrates through the radial reaction basket and extends out of the outer cylinder. The water-cooled reactor further comprises a lower pipe plate and an upper pipe plate which are arranged in the outer cylinder in a spaced mode. The upper pipe plate is a certain distance away from one end of the outer cylinder. One of the water chamber and the steam chamber is formed between one end of the outer cylinder and the upper pipe plate, and the other of the water chamber and the steam chamber is formed between the lower pipe plate and the upper pipe plate. An arc-shaped pipe plate serves as the lower pipe plate. In the water-cooled reactor, the arc-shaped pipe plate serves as the lower pipe plate, and therefore the thickness of the lower pipe plate can be designed to be thin after bearing pressure, the weight of the device can be reduced, and device cost is saved.

Owner:HUNAN ANCHUN ADVANCED TECH

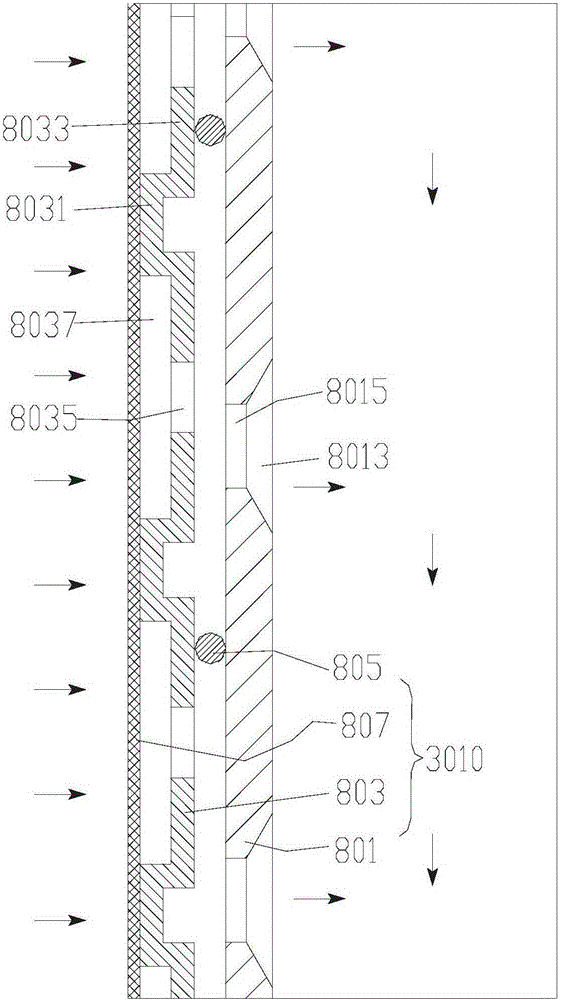

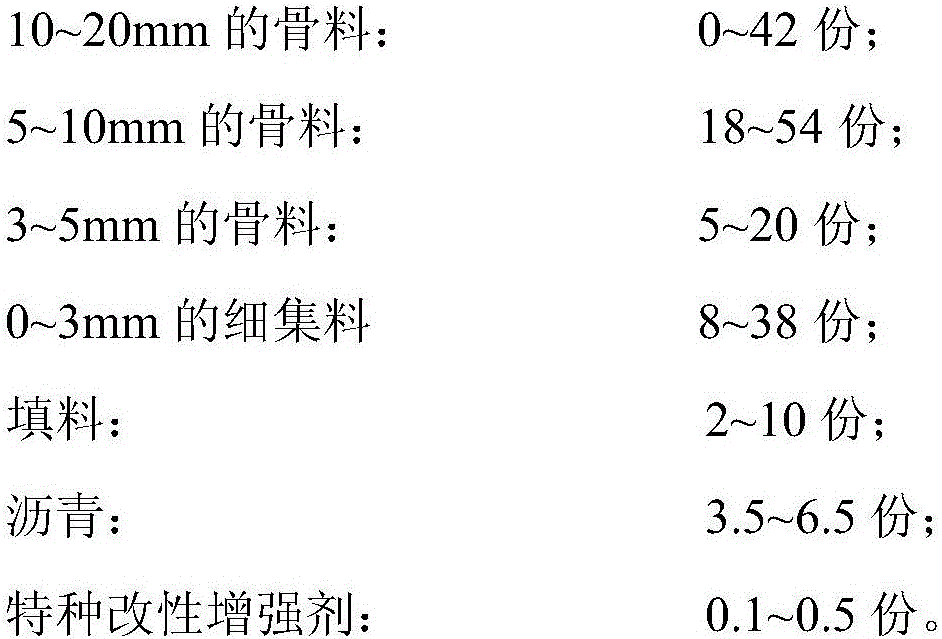

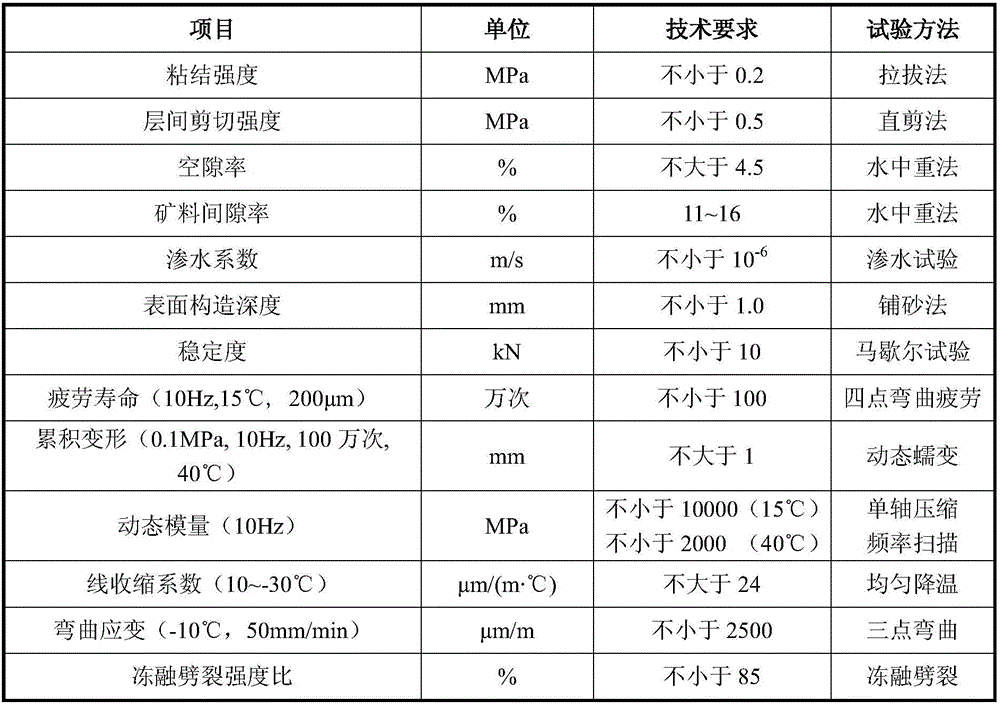

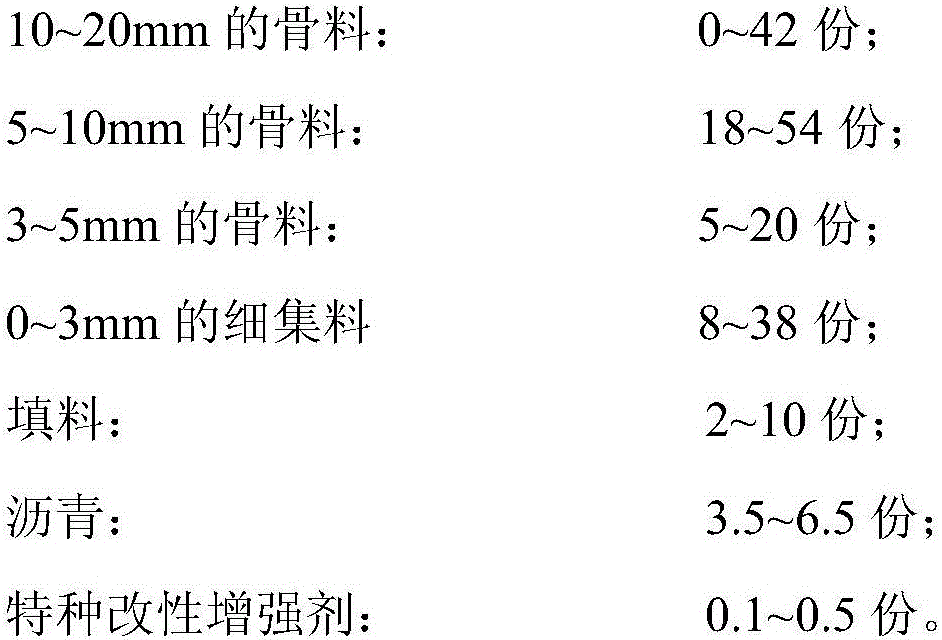

Ballastless track-structured waterproof vibration-reducing flexible protecting structure and paving method thereof

ActiveCN105714621ADrain fastComprehensive three-dimensional waterproof protectionRailway tracksSurface layerBridge deck

The invention discloses a ballastless track-structured waterproof vibration-reducing flexible protecting structure and a paving method thereof. A waterproof linking layer and a buffer protecting layer are paved between the bottom of a ballastless track foundation plate and the top surface of a surface layer / bridge deck slab of a roadbed in a full-width manner. According to the ballastless track-structured waterproof vibration-reducing flexible protecting structure, by virtue of the linking layer and the buffer protecting layer which are paved on the full fracture surface, the overall stereoscopic water proofing and the integrality are realized; by regulating the dynamic modulus, the damping characteristic and the deformation adaptability of an asphalt concrete protecting layer by virtue of a special modifying enhancer, the rigidity matching and buffer vibration reducing functions are realized; and by enhancing the load diffusivity, the fatigue durability and the water damage resistance of asphalt concrete by virtue of the special modifying enhancer, the problems of premature failure, interlayer slurry extruding, disengaging, even frost heaving and the like of waterproof layers of existing ballastless track roadbeds are effectively solved, the integrality, the smoothness, the uniformity and the long-term stability of a lower base structure of a track are improved, and good and stable support is provided for a ballastless track plate, so that the fatigue life of the track plate is prolonged. The ballastless track-structured waterproof vibration-reducing flexible protecting structure is a long-lasting protection scheme.

Owner:SOUTHEAST UNIV +2

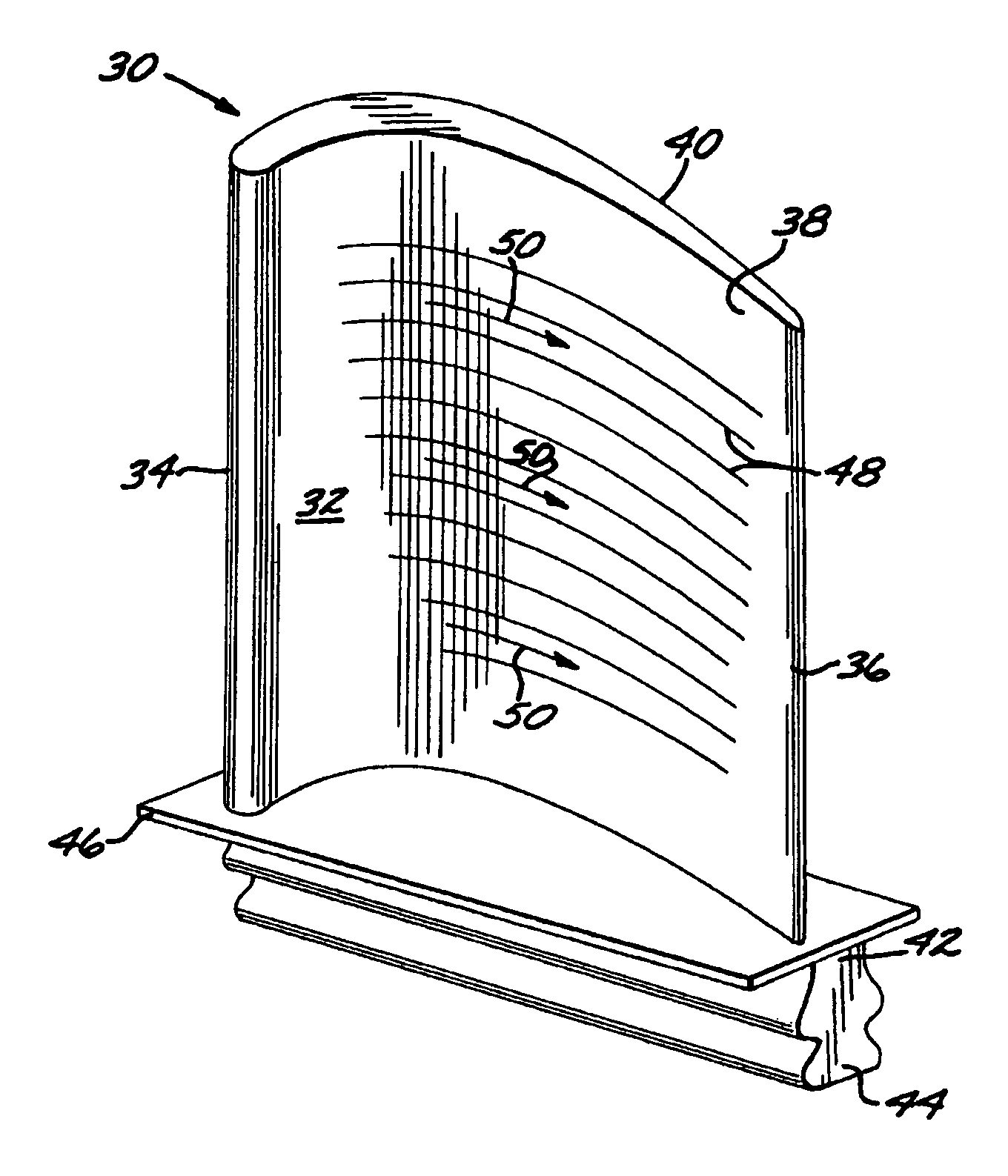

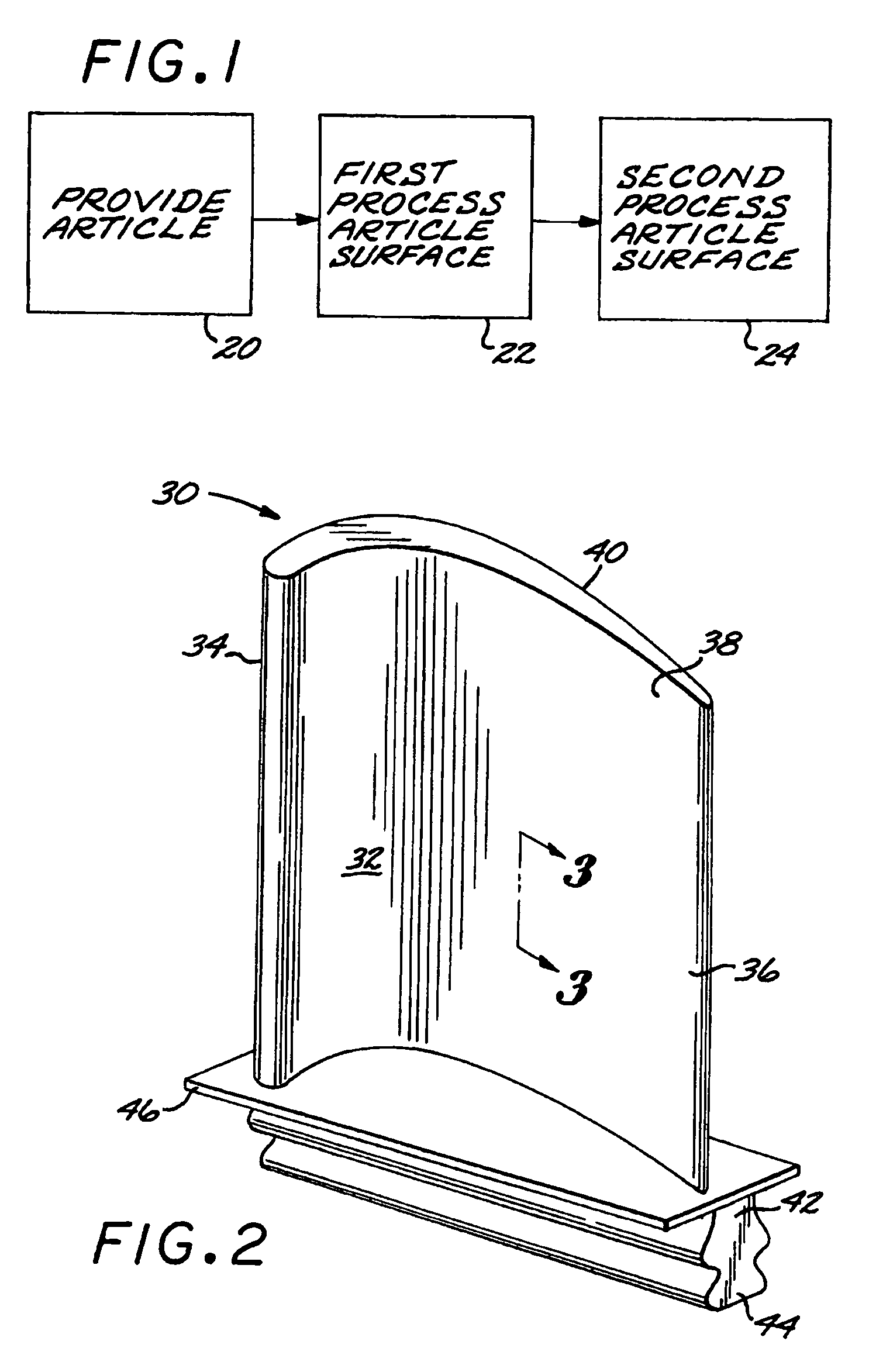

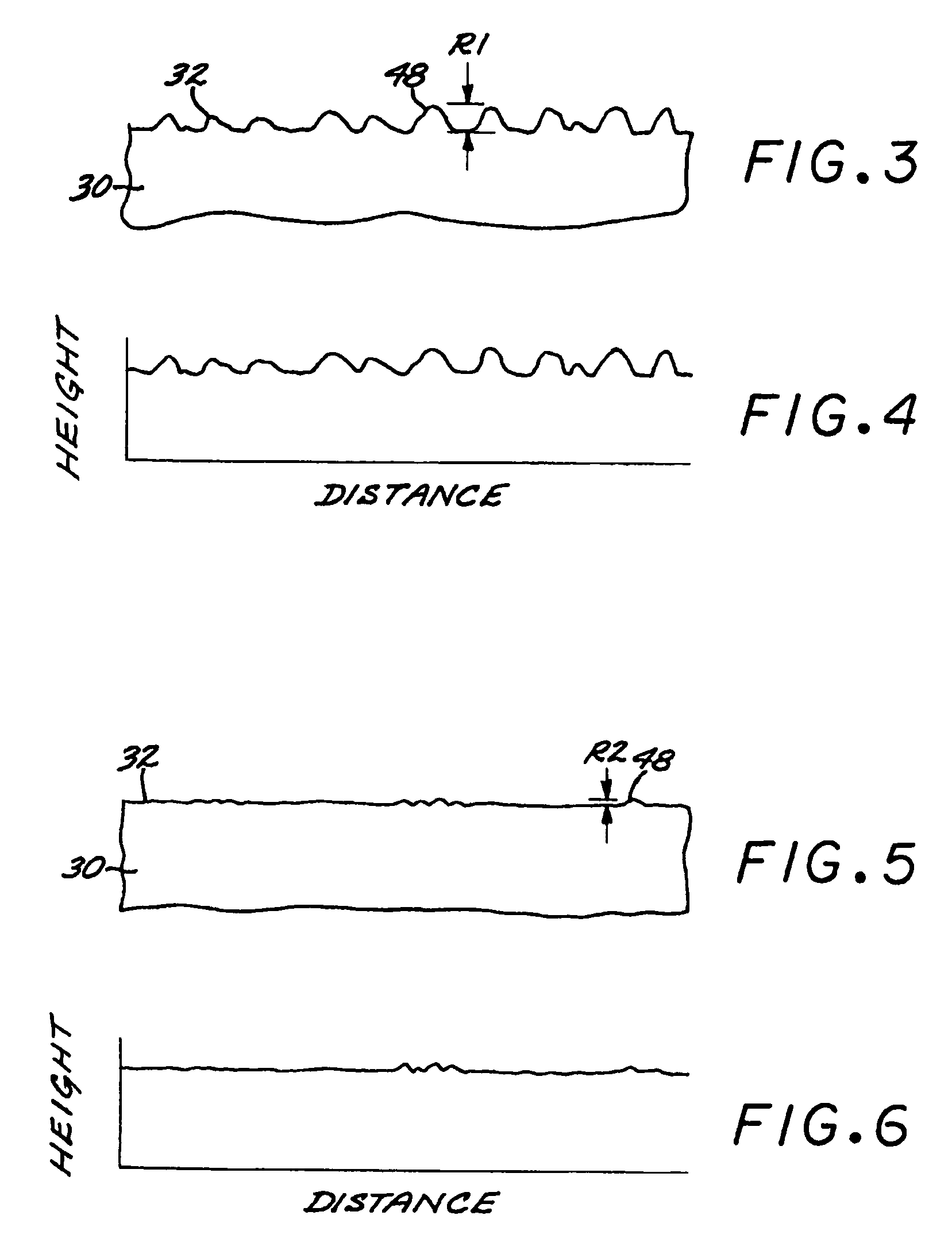

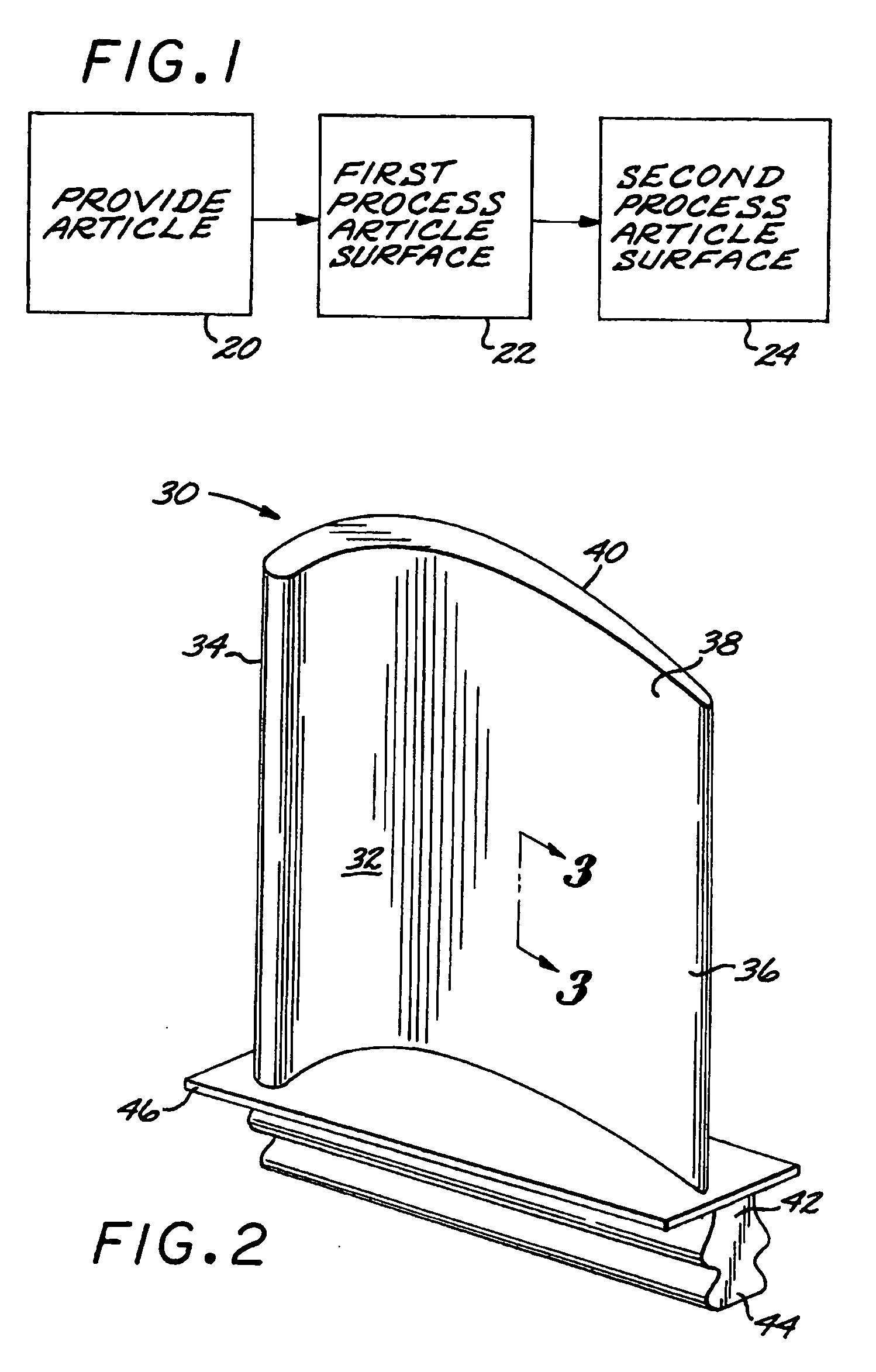

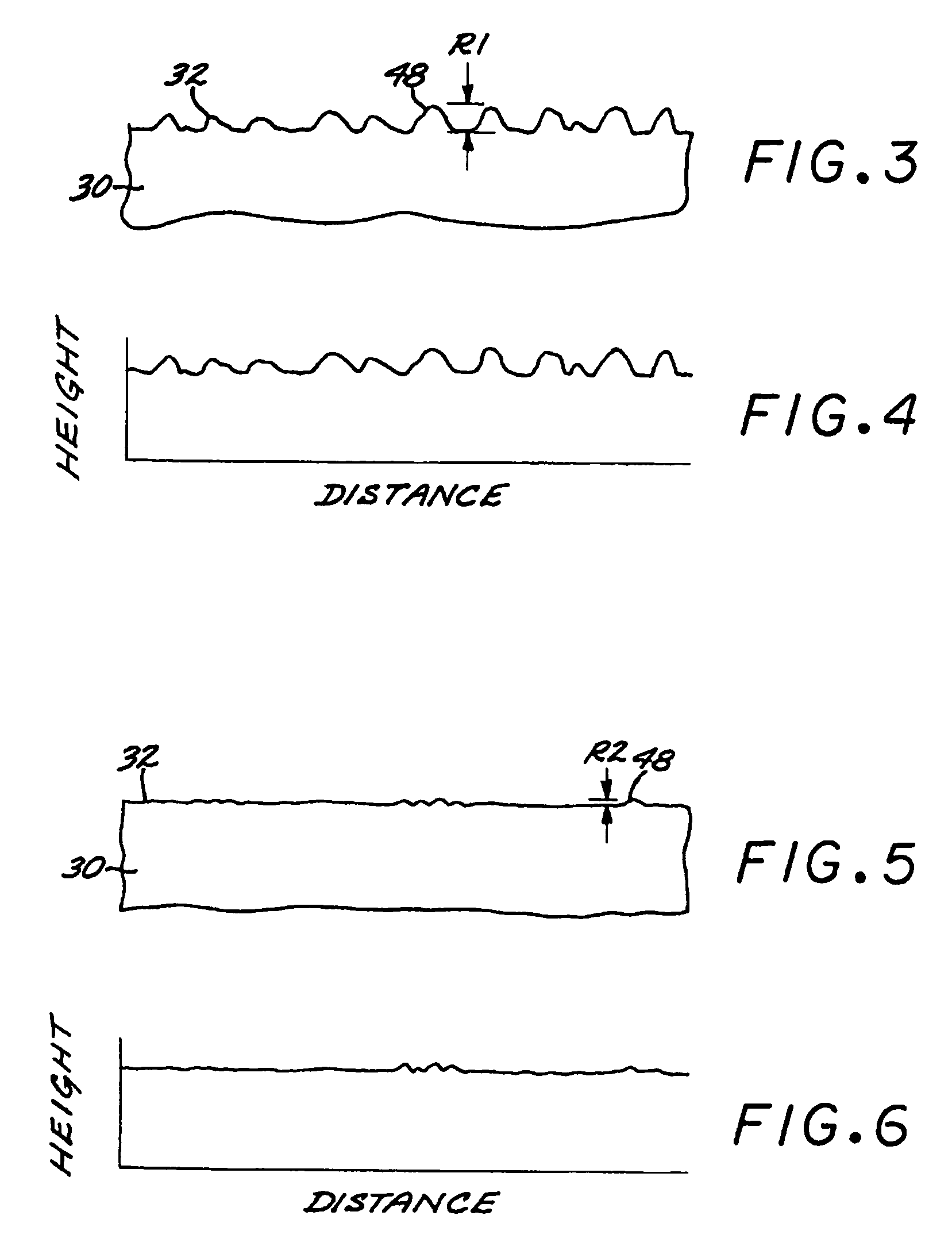

Preparation of an article surface having a surface compressive texture

ActiveUS8024846B2Reduce surface roughnessSmooth surface finishEngine manufactureBlade accessoriesSurface roughnessMaterials science

A method for preparing a surface includes providing an article having an article surface, thereafter first processing the article surface to establish a first residual compressive stress state and a first surface roughness in the article surface, and thereafter second processing the article surface by surface compressive texturing to establish a second residual compressive stress state and a second surface roughness in the article surface. The second surface roughness is quantitatively less than the first surface roughness, and substantially no material is removed from the article surface in the step of second processing.

Owner:GENERAL ELECTRIC CO

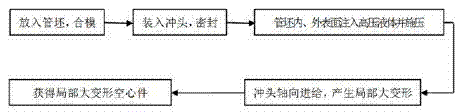

Differential pressure forming method for local large-deformation hollow pieces

InactiveCN103920788AImprove the lubrication effectSimple structureHydraulic cylinderStructural engineering

The invention discloses a differential pressure forming method for local large-deformation hollow pieces and belongs to the technical field of manufacturing of metal hollow members. The differential pressure forming method includes steps of firstly placing a pipe billet into a rear die, loading a punch into the pipe billet and sealing; injecting high-pressure liquid to the inner and outer surfaces of the pipe billet at the same time, keeping pressure in the pipe billet larger than the pressure of the outer surface of the pipe billet and forming controllable pressure difference; pushing the punch to axially feed to realize material supplement by the aid of a hydraulic cylinder, and enabling the pipe billet to generate local large deformation under the action of inside and outside hydraulic differential pressure; finally, discharging the high-pressure liquid and obtaining a local large-deformation hollow piece. By controlling inside and outside pressure difference of the pipe billet, stress state during local expansion of the pipe billet can be improved, expansion can be sufficiently realized and expansion limit is increased. Hydraulic oil is injected onto the outer surface of the pipe billet, lubricating between the outer surface of the pipe billet and a form cavity of the die is evidently improved, friction is reduced, and axial supplement and final forming are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

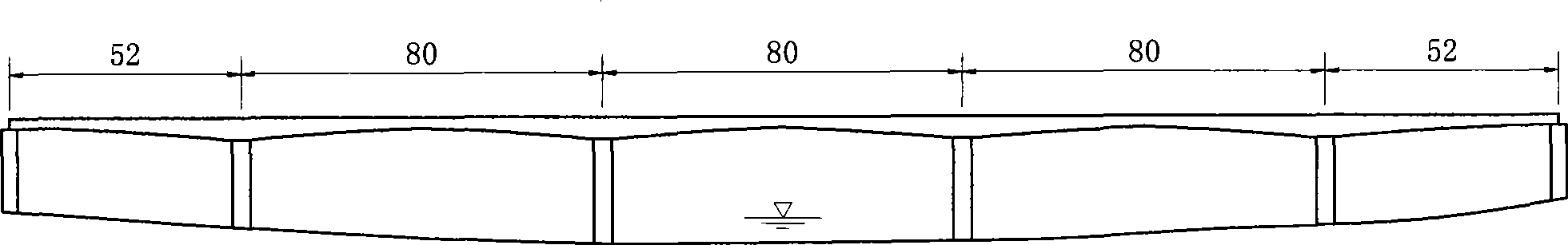

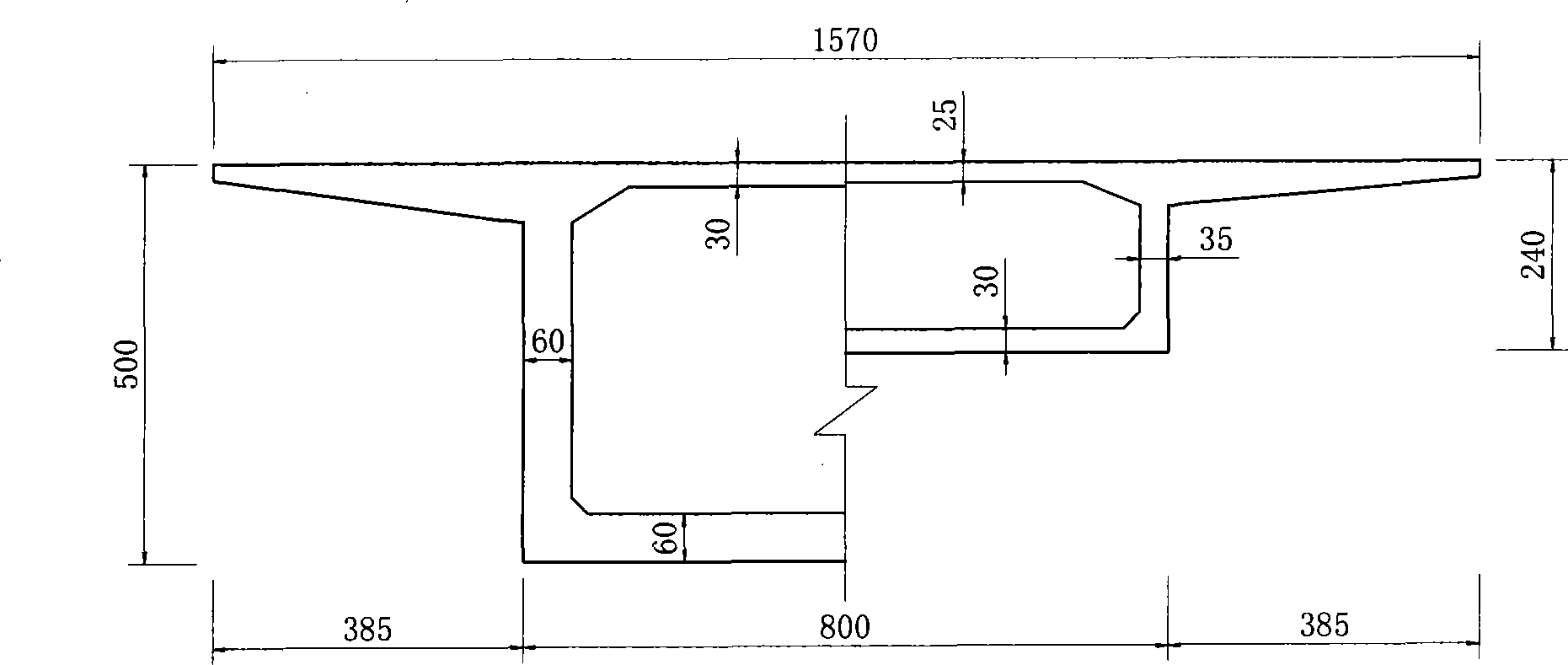

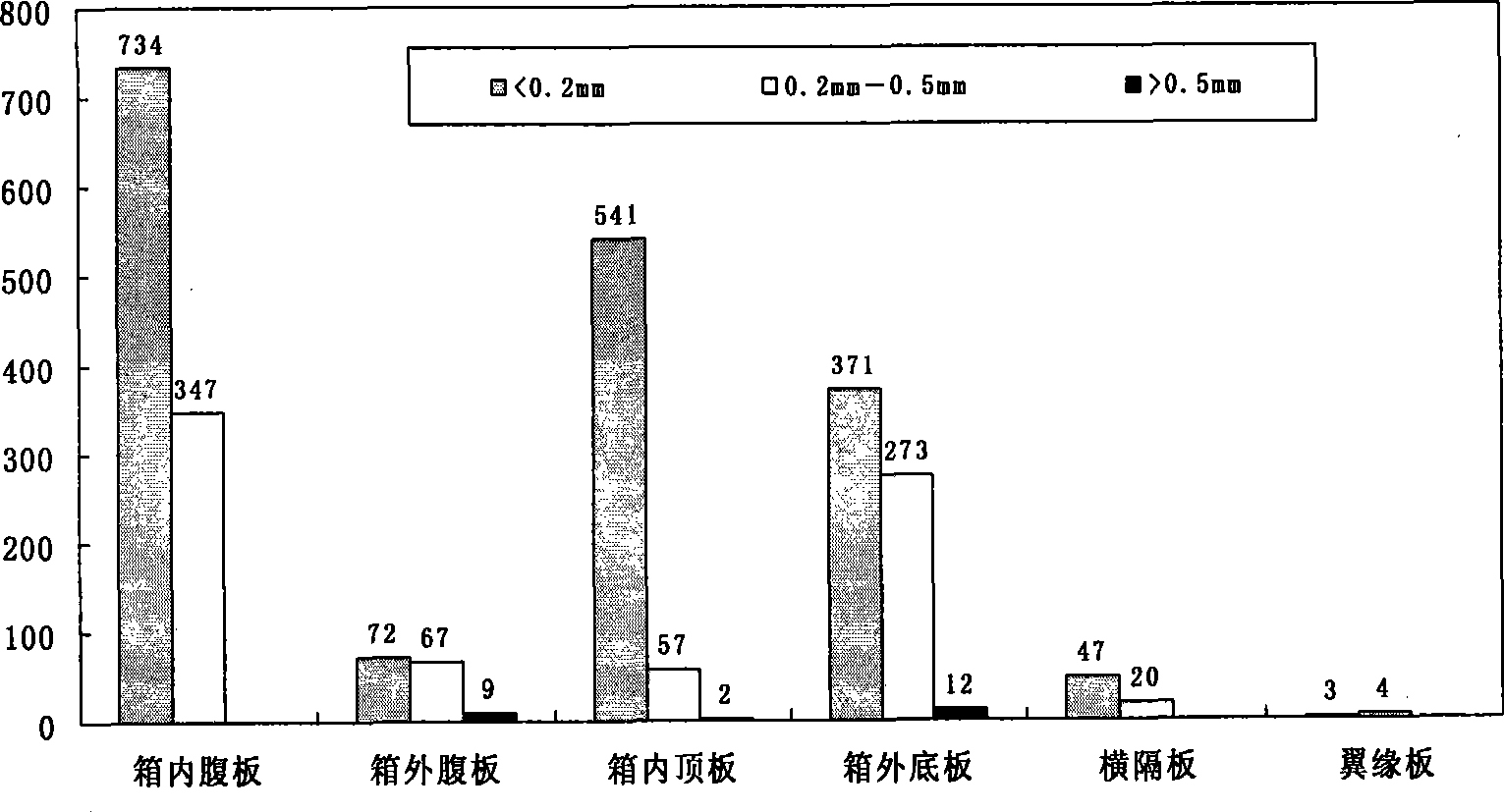

Method for actively reinforcing wide-span concrete case beam bridge web

ActiveCN101435184AImprove stress statusPrevent extensionBridge erection/assemblySpecial data processing applicationsTension stressDistribution rule

The invention relates to a reinforcing and repairing measure for existing concrete box girder bridges, and discloses a method for actively reinforcing a large-span concrete box girder bridge web plate, comprising the following steps: (1) according to the structural parameters of the concrete box girder bridge and by adopting a structural analysis method and corresponding general or special analysis software, a finite element model of a simulated reinforced plate shell concrete box girder bridge is established, thus obtaining the magnitude of the main pulling stress, the vertical stress, the longitudinal stress and the shearing stress of the box girder web plate before reinforcement and the distribution rule thereof; (2) the difference between the main pulling stress and the limited value allowed by the 'Standard' is compared to obtain the target increment value of the vertical stress of the bridge girder, and the actual reinforcement parameters are determined according to the target value; (3) drilling is carried out on the upper margin and the lower margin of the concrete box girder web plate, steel strands are installed and transversally stretched; (4) a wedge block A is used for jacking up the steel strands, then a jack is used for jacking up and pulling the steel strands to the allowed tensioning force, and the steel strands are tensioned one by one; and (5) crack is mended.

Owner:广东荣骏建设工程检测股份有限公司

Surfacing repair method for dissimilar metal pipeline of safety end of voltage stabilizer in nuclear power station

ActiveCN105945393ASimple structureSimple process structureArc welding apparatusWelding/soldering/cutting articlesAlloy surfaceDissimilar metal

The invention discloses a surfacing repair method for a dissimilar metal pipeline of a safety end of a voltage stabilizer in a nuclear power station. The surfacing repair method comprises the following steps: depositing a stainless steel cladding layer on the inner wall of a low-alloy steel pipe section; surfacing a buttering layer onto the end surfaces of the low-alloy steel pipe section and the stainless steel cladding layer; enabling the buttering layer and a transition connection pipe to form a U-shaped groove, and connecting the two parts in a welding manner to form a buttering weld; excavating out a stainless steel weld from a weld between the transition pipe section and the pipe section, carrying out repair welding on the stainless steel weld, and polishing a repair welding weld to enable the repair welding weld to be level with the pipe section; and surfacing a nickel-based alloy surfacing layer on the low-alloy steel pipe section, the buttering layer, the buttering weld and the pipe section. With the adoption of the method, the stress state of the surfacing layer is improved, the surfacing repair process is simplified, the field surfacing repair difficulty is lowered, and safe, reliable and efficient surfacing repair for a dissimilar metal joint of the safety end of the voltage stabilizer is realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

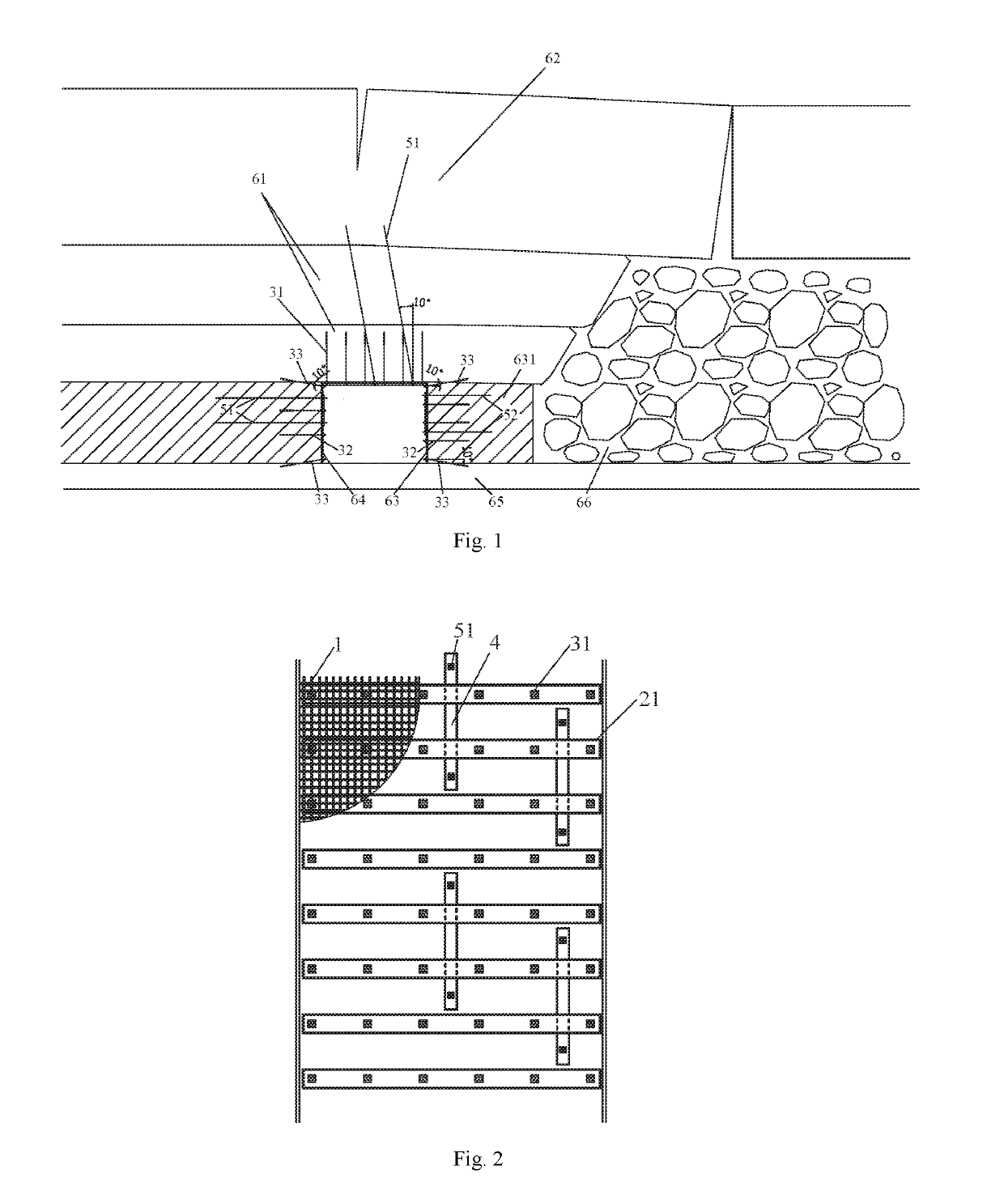

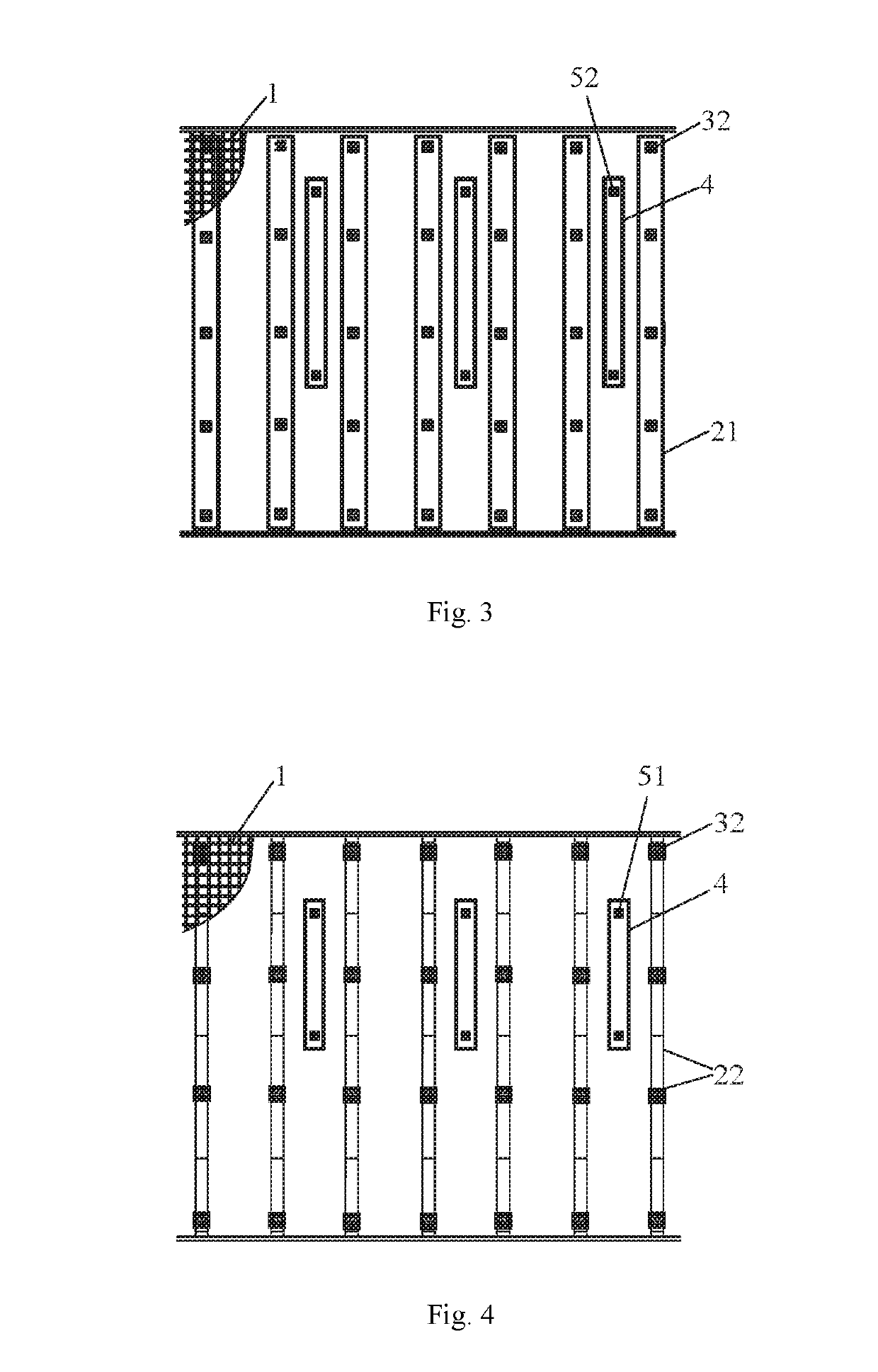

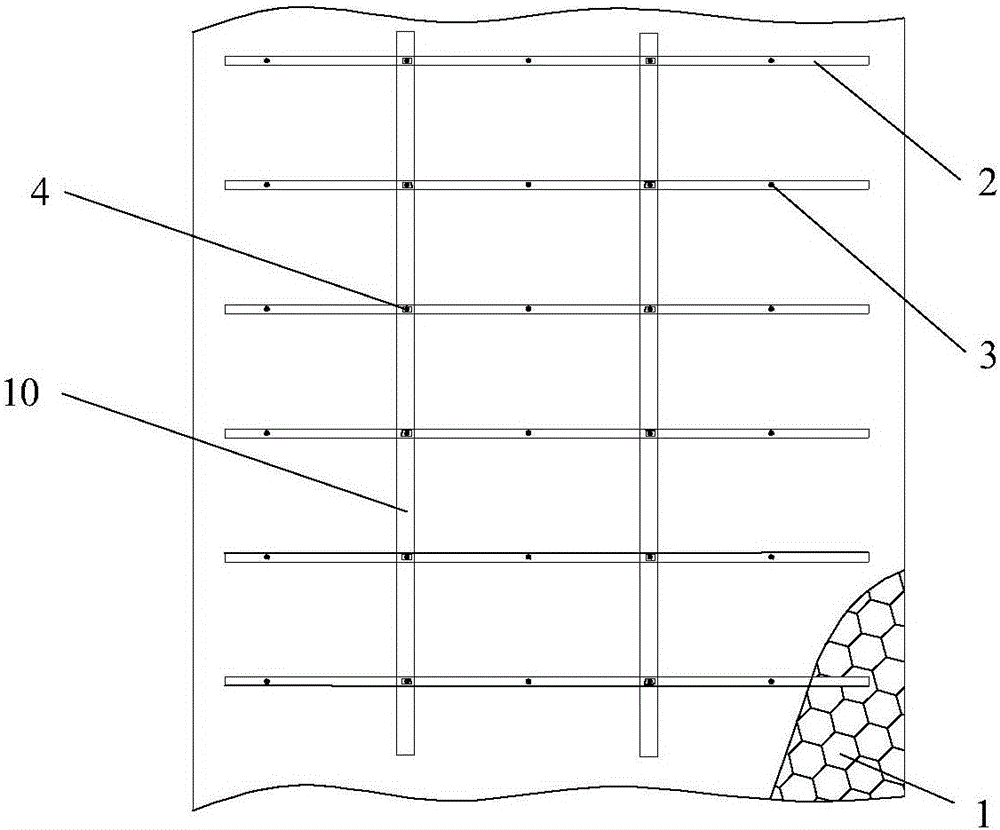

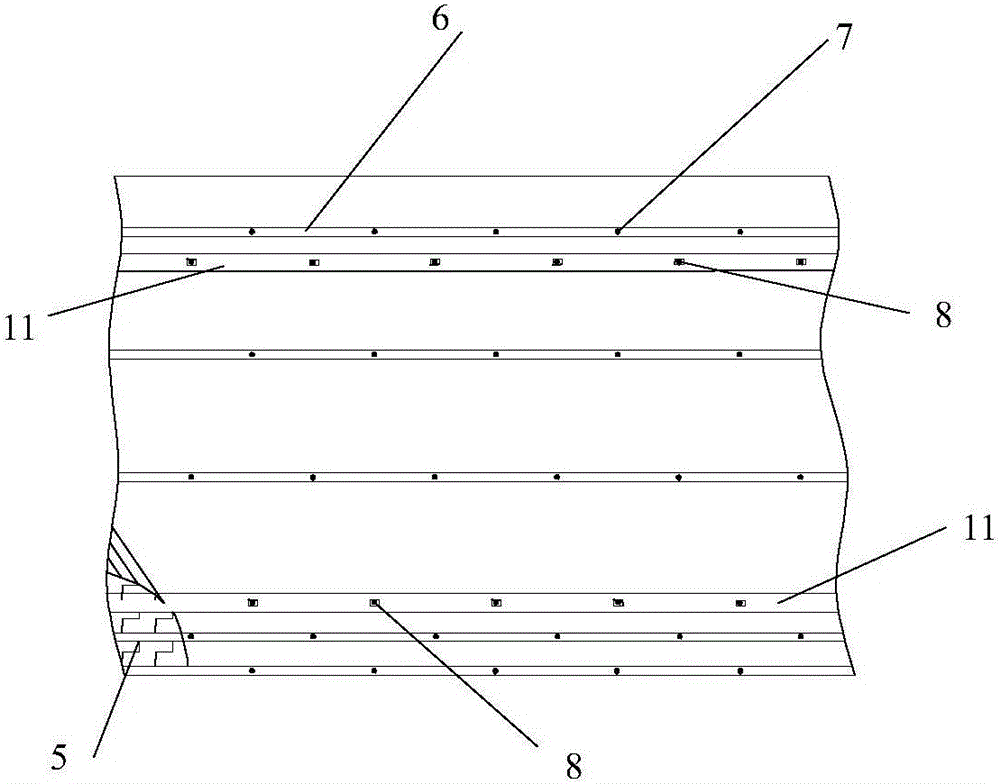

Asymmetric support structure of entry driven along gob-side under unstable roof in deep mines and construction method thereof

ActiveUS20190218910A1Control deformationEffective controlUnderground chambersUnderground miningUltimate tensile strengthSteel belt

An asymmetric support structure of entry driven along, gob-side (EDG) under unstable roof in deep mines and construction method thereof. The asymmetric support structure includes roadway roof support structure, a gob-side support structure and a solid coal seam-side support structure. The roadway roof support structure includes a reinforcing wire mesh, a W-section steel strap, high-strength pretensioned bolts, and cable bolts and matching steel straps. The gob-side support structure includes a reinforcing wire mesh, a W-section steel strap, high-strength pretensioned yielding bolts and grouting cable bolts and its matching steel straps. The solid coal seam-side support structure includes a reinforcing wire mesh, a reinforced beam and steel strap pallet subassembly, high-strength pretensioned yielding bolts and cable bolts and its matching steel straps. The roadway roof support structure, gob-side support structure and solid coal seam-side support structure beneficially together form the asymmetric support structure.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation of an article surface having a surface compressive texture

ActiveUS20070175030A1Reduce surface roughnessSmooth surface finishEngine manufactureBlade accessoriesSurface roughnessMaterials science

A method for preparing a surface includes providing an article having an article surface, thereafter first processing the article surface to establish a first residual compressive stress state and a first surface roughness in the article surface, and thereafter second processing the article surface by surface compressive texturing to establish a second residual compressive stress state and a second surface roughness in the article surface. The second surface roughness is quantitatively less than the first surface roughness, and substantially no material is removed from the article surface in the step of second processing.

Owner:GENERAL ELECTRIC CO

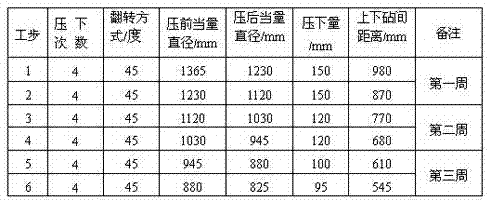

Process utilizing upper flat and lower V-shaped anvil to forge stepped shafts

InactiveCN102527912AImprove stress statusImprove forgeabilityEngine componentsEngineeringInternal stress

The invention relates to a process for forging stepped shafts, in particular to a process utilizing an upper flat and lower V-shaped anvil to forge stepped shafts. The method utilizing the upper flat and lower V-shaped anvil to forge the stepped shafts includes the following steps of rotating a blank by 45 degrees once the anvil is pressed, rotating the blank by 180 degrees at each step including four times of pressing of the anvil, and finally rotating the blank by 360 degrees in each cycle including two steps. The process has the advantages that a deformation area of a forged part has fine stress states, a center area of the forged part has excellent forge penetration, the offset of the axis of the deforming portion is low, the internal stress of the blank is fine, no tensile stress is applied to the transverse direction, and center compaction is facilitated.

Owner:ZHONGYUAN SPECIAL STEEL +1

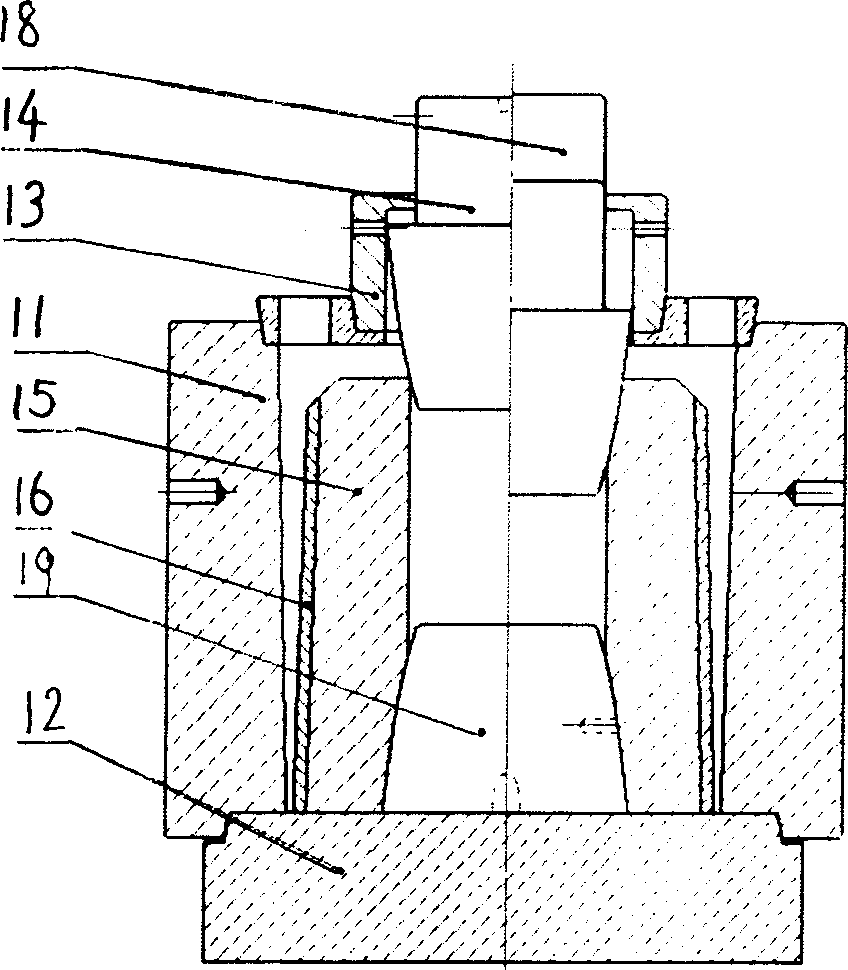

Uniform upsetting forming method for large-height-diameter-ratio magnesium alloy bar

ActiveCN105772614AImprove stress statusImprove liquidityForging/hammering/pressing machinesWave shapeDiameter ratio

The invention discloses a uniform upsetting forming method for a large-height-diameter-ratio magnesium alloy bar. The uniform upsetting forming method includes the steps that firstly, a large-height-diameter-ratio upsetting forming die is designed, wherein the die comprises a male die body and a female die body, the end face of a punch of the male die body is in the shape with the convex middle and the concave periphery and has a wave outline composed of a concave arc, a convex arc and a concave arc in sequence when seen from the axial section, a plane is formed in the middle portion of the bottom of a die cavity of the female die body, a groove is formed in the periphery of the bottom of the die cavity of the female die body, the plane and the groove in the periphery are in smooth transition, and the wave shape with the two concave sides and the plane middle is shown when the bottom of the die cavity of the female die body is seen from the axial section; secondly, a circular shallow groove, namely, an upper groove, is turned in the surface of the upper end of a magnesium alloy cylinder blank, a circular shallow groove, namely, a lower groove, is turned in the surface of the lower end of the magnesium alloy cylinder blank, and a certain number of lubricant is smeared and reserved in each groove; thirdly, the die is preheated, and the magnesium alloy cylinder blank is placed in the die to be subjected to heat preservation and upsetting; and fourthly, upsetting extrusion forming is conducted on the magnesium alloy cylinder blank through the die, and die disassembling is performed. By means of the method, the forming uniformity is improved, the friction force between the die and the magnesium alloy bar is reduced, and performance of forgings is improved.

Owner:ZHONGBEI UNIV

Rotary electric field and magnetic field synchronously assisted laser welding device and method

ActiveCN109128502AAchieve overlapEasy to adjustLaser beam welding apparatusElectric machineryDrive motor

The invention discloses a rotary electric field and magnetic field synchronously assisted laser welding device and method and belongs to the field of laser welding. The welding device comprises an electricity and magnet regulating device and a positioning and clamping tooling. Supporting columns and rotary air cylinders in the positioning and clamping tooling are mounted on a bottom plate. An electric field generation bottom plate is mounted on the supporting columns. Press blocks are mounted on the rotary air cylinders correspondingly. Neodymium iron boron permanent magnets in the electricityand magnet regulating device are fastened to a magnetic field regulating disc. Insulation sleeves, a welding laser head and the magnetic field regulating disc are mounted on a direct drive motor. Thedirect drive motor is mounted on a main shaft. The two poles of an electric field power source are connected to the electric field generation bottom plate and the welding laser head correspondingly.By means of the device and method provided by the invention, easy, convenient and fast regulation of a rotary magnetic field and a steady electric field can be achieved, continuous regulation of the intensity can be achieved, synchronous movement of the electric field and the magnetic field along with welding laser beams is guaranteed, and therefore, the forming quality of laser welding joints isimproved by setting the reasonable laser technological parameters including the power, the focal length, the defocusing amount, the helium protective gas flow rate and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

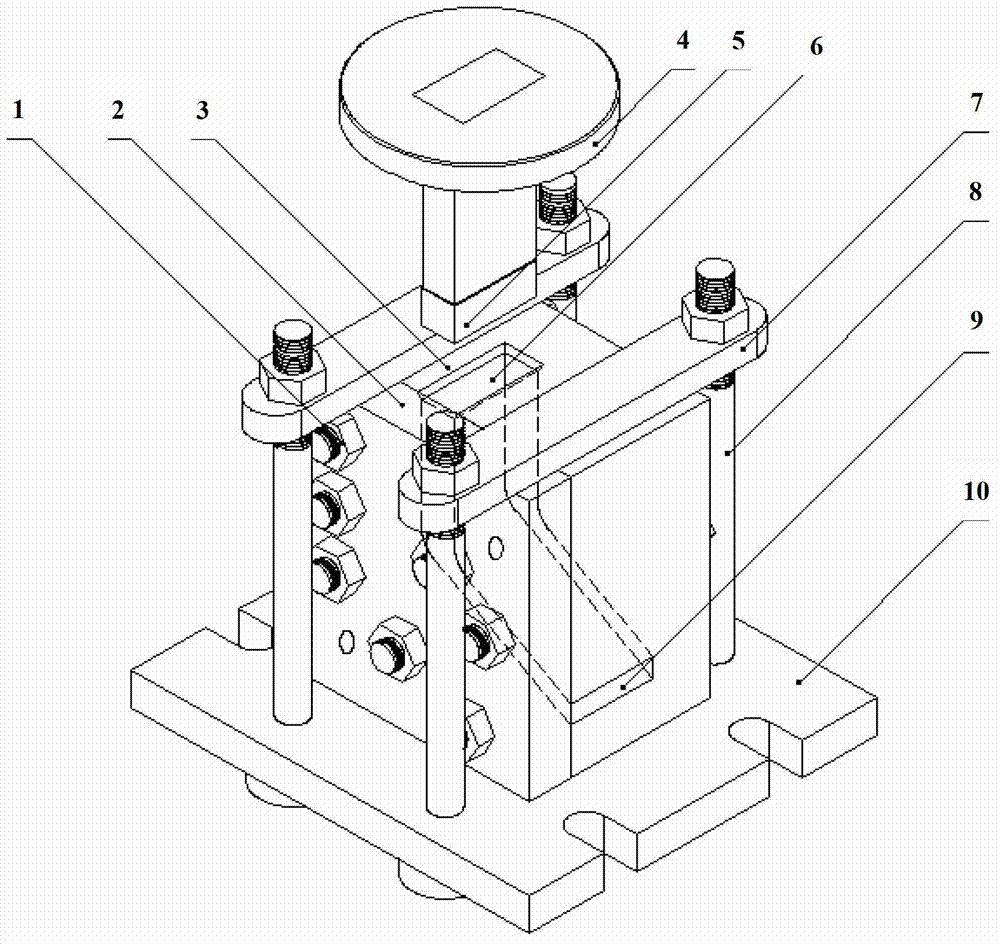

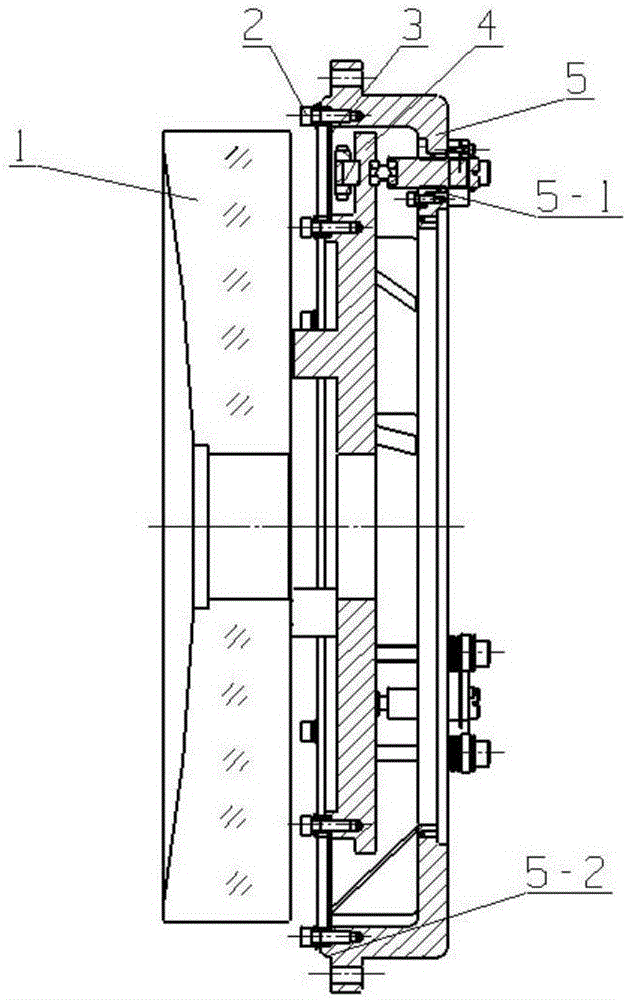

Primary mirror mounting regulating mechanism

ActiveCN106383397AEasy to adjustOptimize the adjustment methodMountingsThree degrees of freedomEngineering

The invention relates to a primary mirror mounting regulating mechanism. The problems that the existing telescope primary mirror is complicated in regulating mode and bad in stability, and has the axial and radial intercoupling are solved. A reflecting mirror is adhered on three support lug bosses on a bearing seat; a primary mirror chamber and the bearing seat are concentrically arranged; an adjusting component comprises a primary mirror chamber insert inlaid on the primary mirror chamber, a stacking ball socket inlaid on the bottom of the bearing seat, an adjusting screw arranged in the primary mirror chamber insert, a screw ball socket inlaid on the upper end part of the adjusting screw, a steel ball arranged between the stacking ball socket and the screw ball socket, and a lock nut mounted on the bottom of the adjusting screw; a lock component comprises a roller inlaid on the bearing seat, a wane mounted on the roller, a lock ball, and a lock ball socket which are mounted on a lock bolt, and a butterfly-shaped gasket. The mechanism disclosed by the invention can adjust the primary mirror with three degrees of freedom without influencing the shape of the primary mirror plane.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

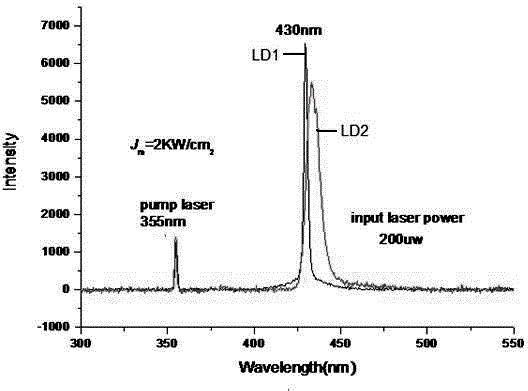

Method for preparing novel GaN-based laser and GaN-based laser

ActiveCN104319631AIncrease limit factorHigh gainLaser detailsLaser active region structureSilanesTrimethylgallium

The invention provides a method for preparing a novel GaN-based laser and a GaN-based laser. According to the method of the invention, a series of critical technologies and scientific problems in the preparation of a GaN-based laser can be solved through adopting a metal organic chemical compound vapor phase epitaxy technique. According to the technical scheme of the invention, the method for preparing the novel GaN-based laser includes the step that with trimethylgallium, trimethylindium and trimethylaluminum adopted as a III-family source, ammonia adopted as a V-family source, and silane adopted as an n type doping source, and magnesocene adopted as a P type doping source, the metal organic chemical compound vapor phase epitaxy technique is utilized to prepare the novel GaN-based laser. According to the method for preparing the novel GaN-based laser of the invention, a multi-cycle In component linear graded InxGa1-xN / GaN superlattice structure, replacing a traditional single GaN layer, is adopted as the waveguide layer of the GaN-based blue laser, and therefore, limiting factors of a light field in a laser emission region can be effectively improved, and the gain of the active regions of quantum wells can be improved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

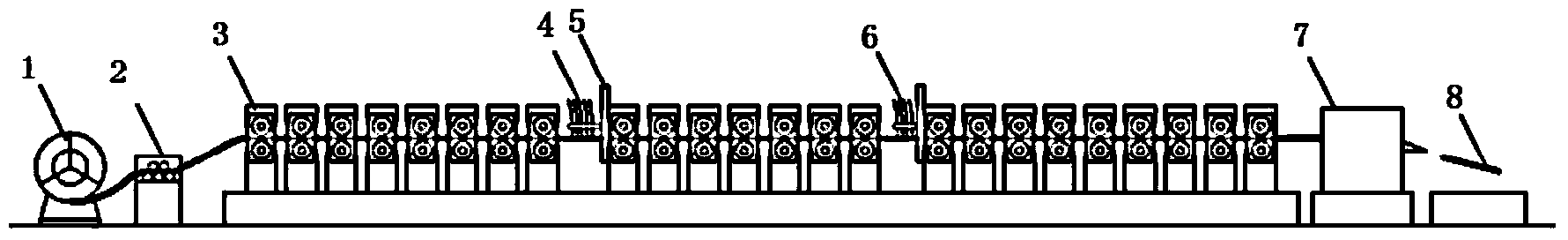

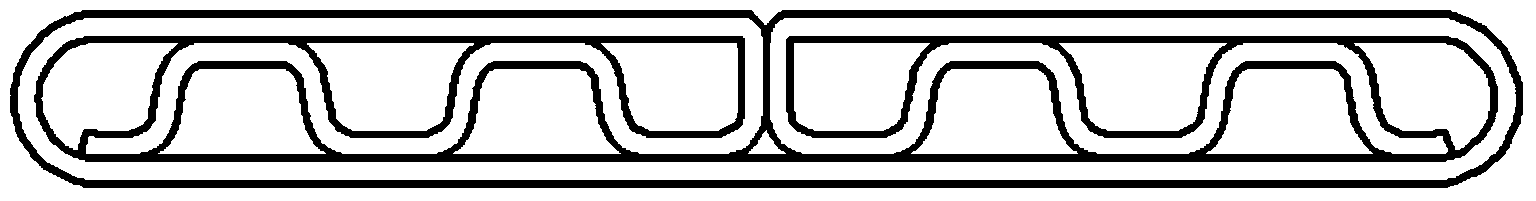

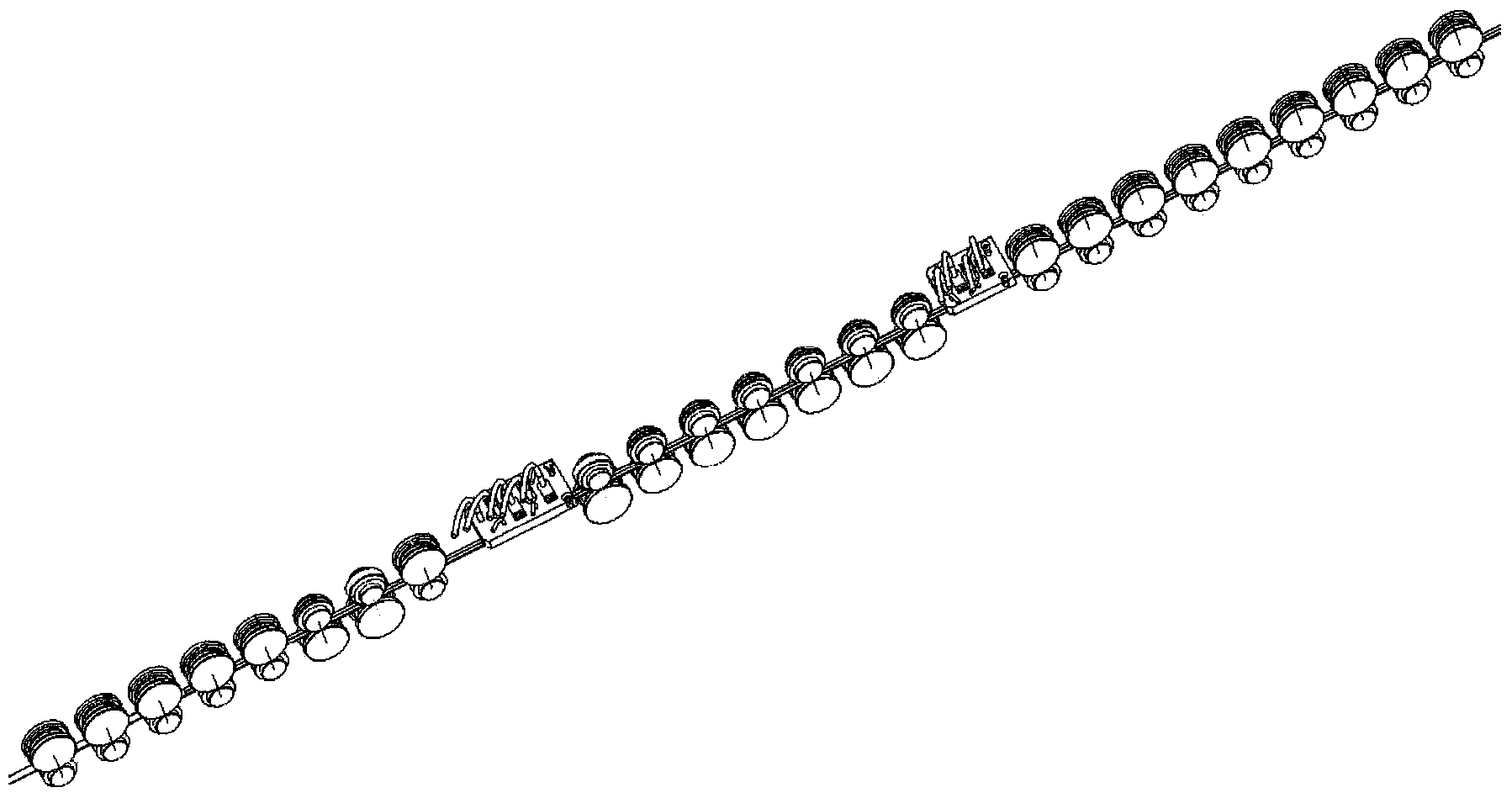

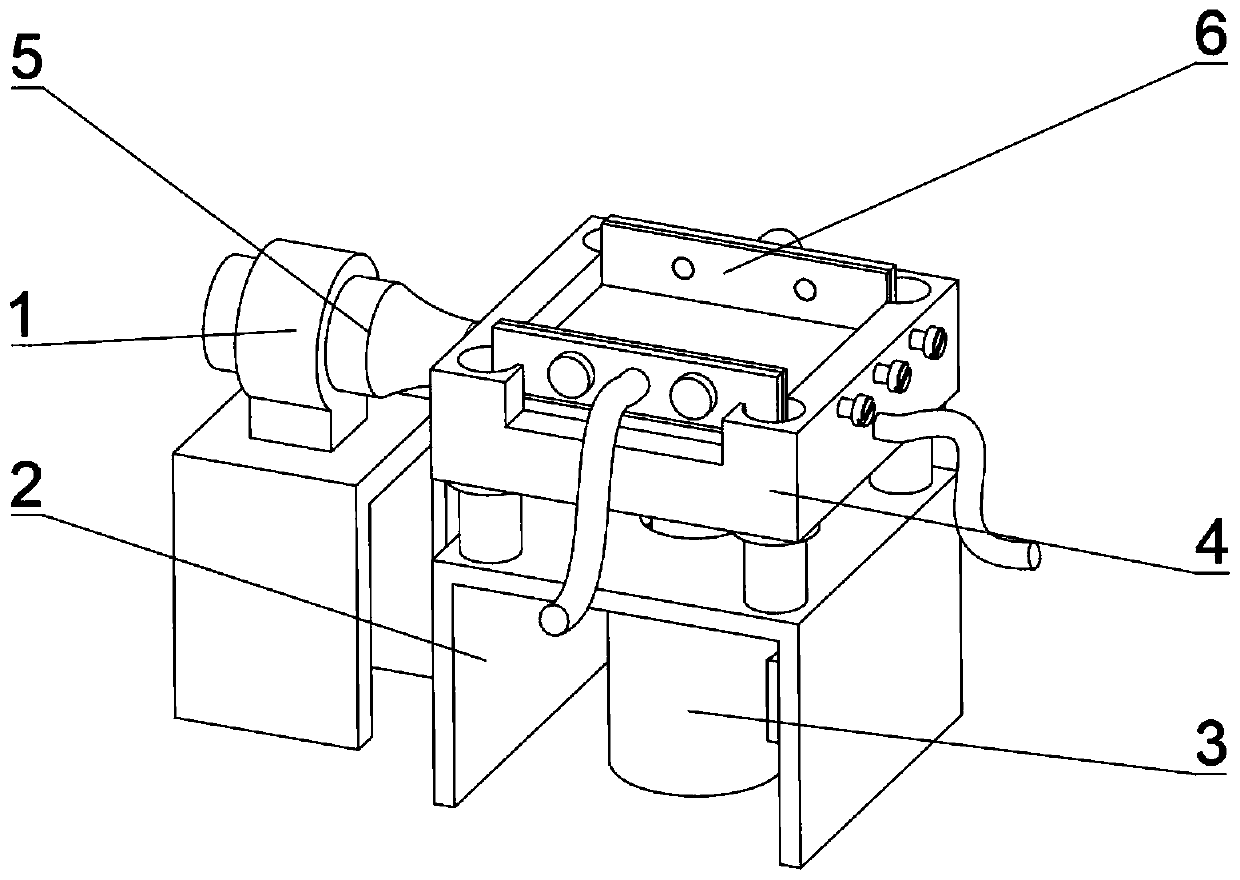

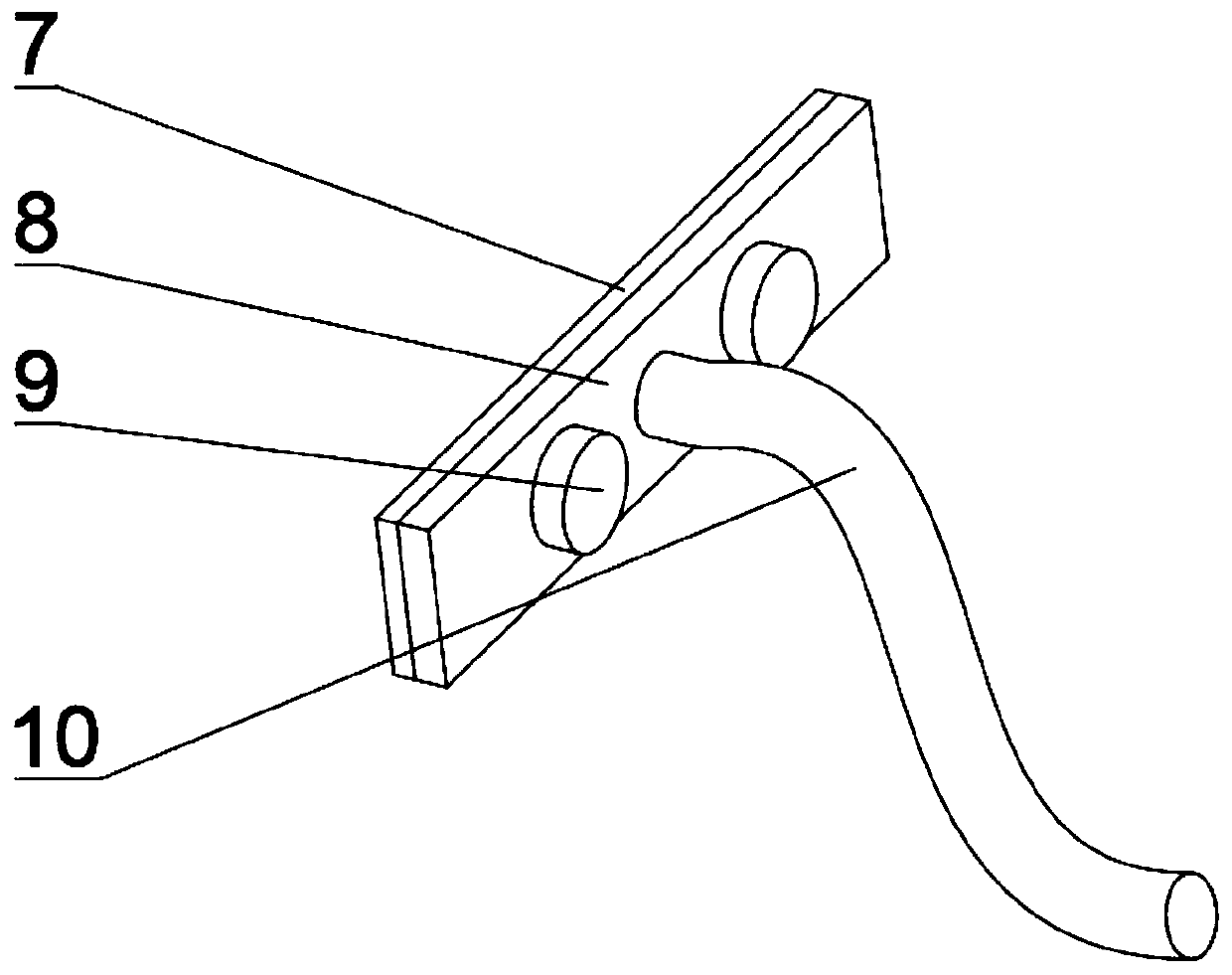

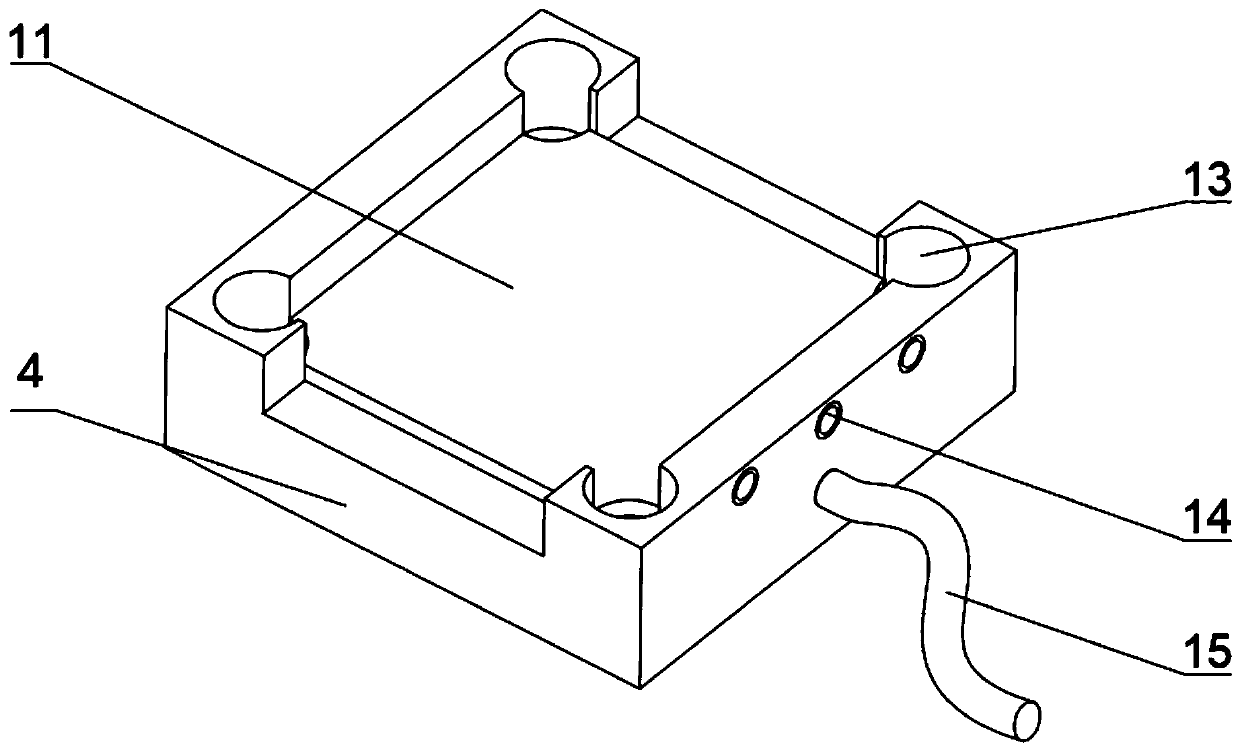

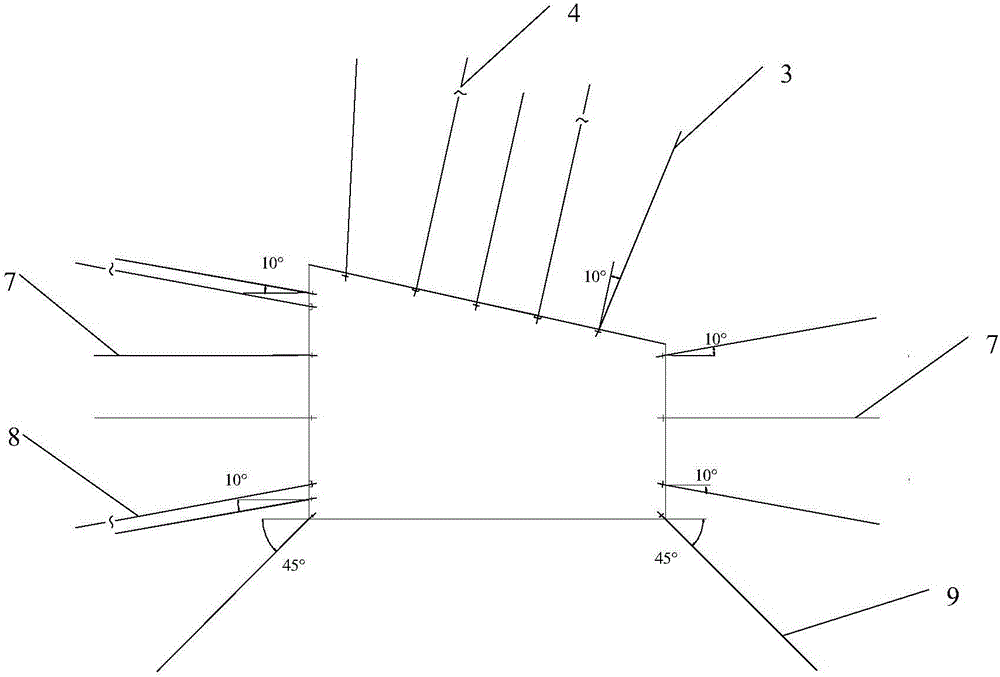

Roll bending forming device and forming method for ten-hole micro-channel flat tubes

ActiveCN103753162AImprove stress statusSolution to short lifeOther manufacturing equipments/toolsEngineeringWelding process

The invention discloses a roll bending forming device for ten-hole micro-channel flat tubes. The roll bending forming device comprises an uncoiling machine, a straightening machine and a roll bending forming unit which are sequentially arranged. The roll bending forming unit comprises an upper row of mill rolls, a lower row of mill rolls, a brazing flux coating device and a product straightening device, multi-pass roll bending forming roll pairs are sequentially configured to form the upper row of mill rolls and the lower row of mill rolls, the brazing flux coating device and the product straightening device are arranged among the roll bending forming roll pairs, gaps are reserved between the upper row of mill rolls and the lower row of mill rolls, and the shapes and the sizes of the gaps are matched with the shapes and the sizes of the ten-hole micro-channel flat tubes. The invention further discloses a forming method implemented by the forming device. The roll bending forming device and the forming method have the advantages that precision dies can be omitted, a series of problems caused during continuous extrusion can be solved, and the manufactured flat tubes are stable in quality; the extrusion speed normally ranges from 2 meters per minute to 3 meters per minute when ten-hole micro-channel flat tubes are manufactured in an extrusion mode, but the roll bending technological manufacturing speed is higher than 80 meters per minute, and the manufacturing efficiency can be improved by 20 times as compared with the traditional extrusion mode; additional welding techniques are omitted in roll bending forming procedures, and integral heat exchangers can be manufactured only by the aid of a brazing technique.

Owner:上海瀚兰通科技有限公司

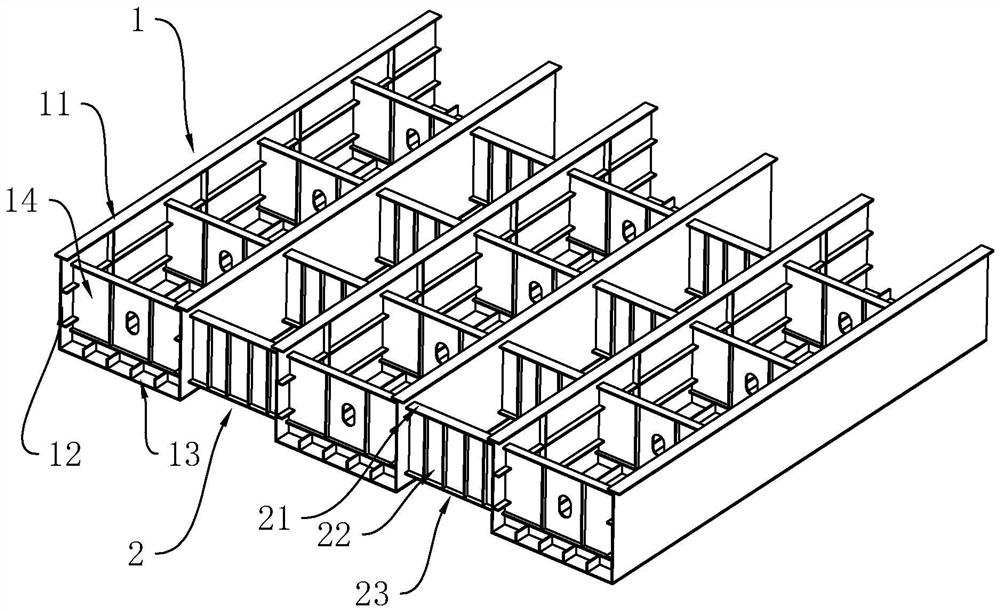

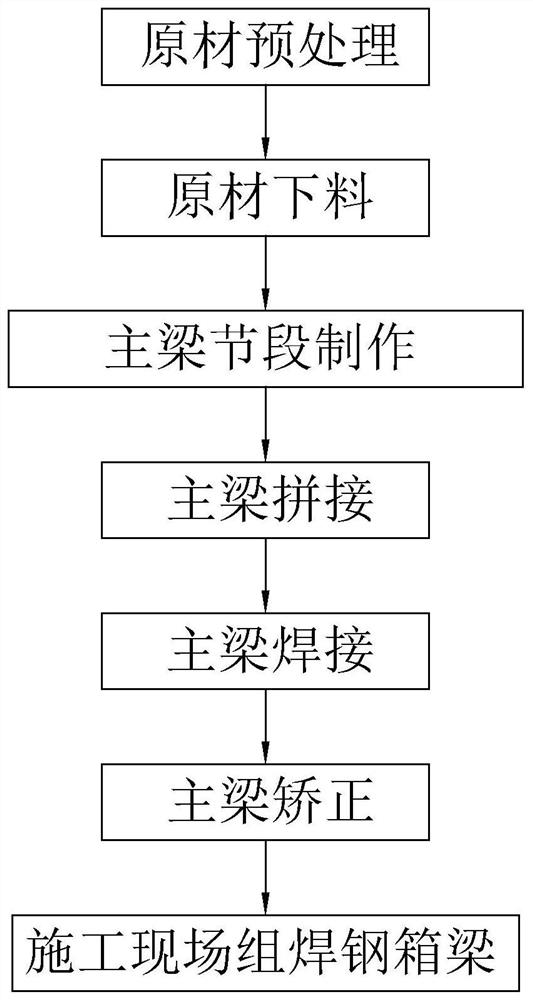

Steel box girder manufacturing and welding process

PendingCN112453831AQuality assuranceReduce distortionBridge materialsStressed stateMechanical engineering

The invention relates to a steel box girder manufacturing and welding process. The steel box girder manufacturing and welding process comprises the following steps that step 1, raw materials are pretreated; step 2, raw material blanking is carried out; step 3, steel box girder sections are manufactured; step 4, main beams are spliced; step 5, the main beams are welded; step 6, the main beams are corrected; and step 7, the steel box girder is assembled and welded on a construction site. The steel box girder manufacturing and welding process has the effects that welding deformation can be reduced, the part stress state is improved, and the box girder quality is guaranteed.

Owner:THE 5TH ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

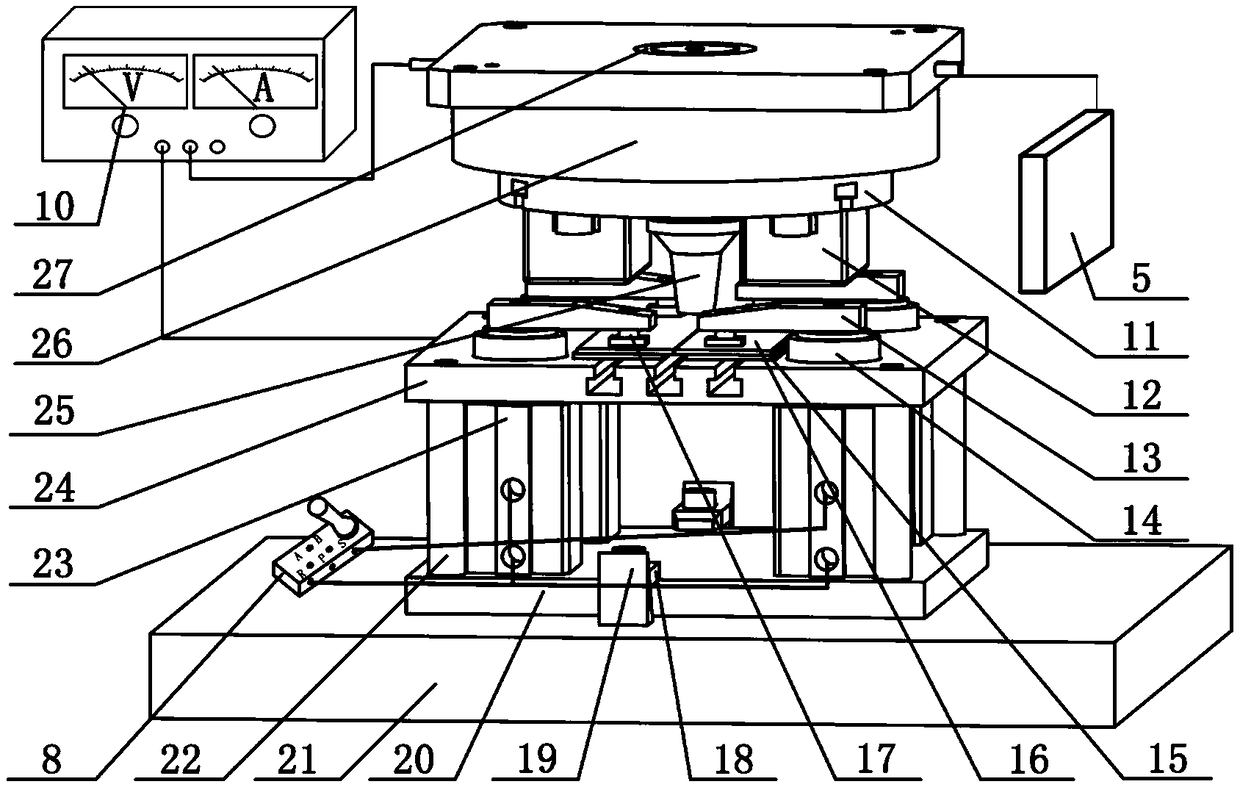

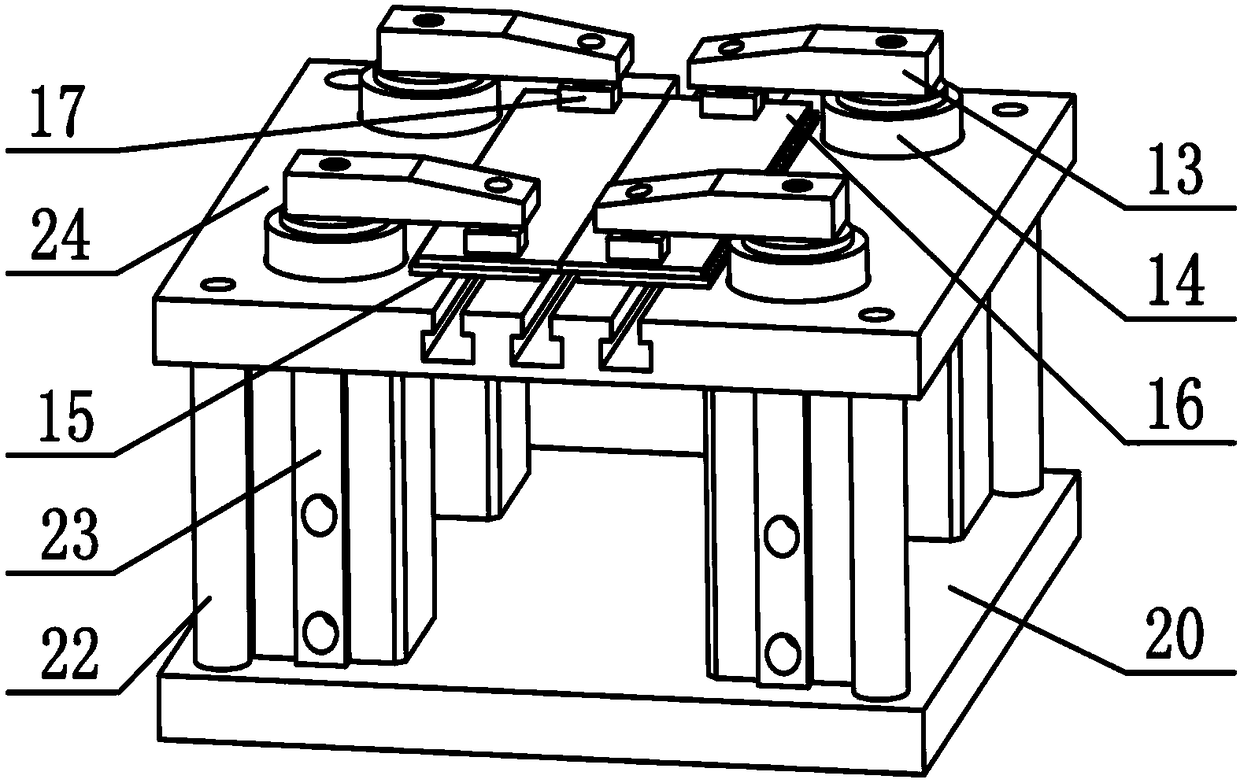

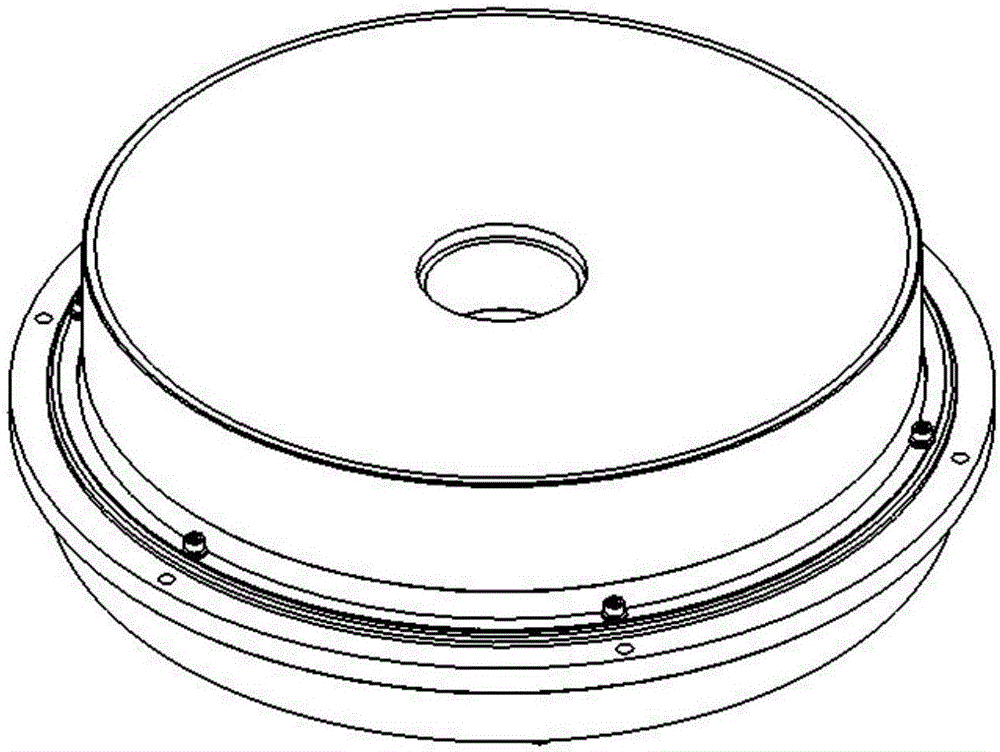

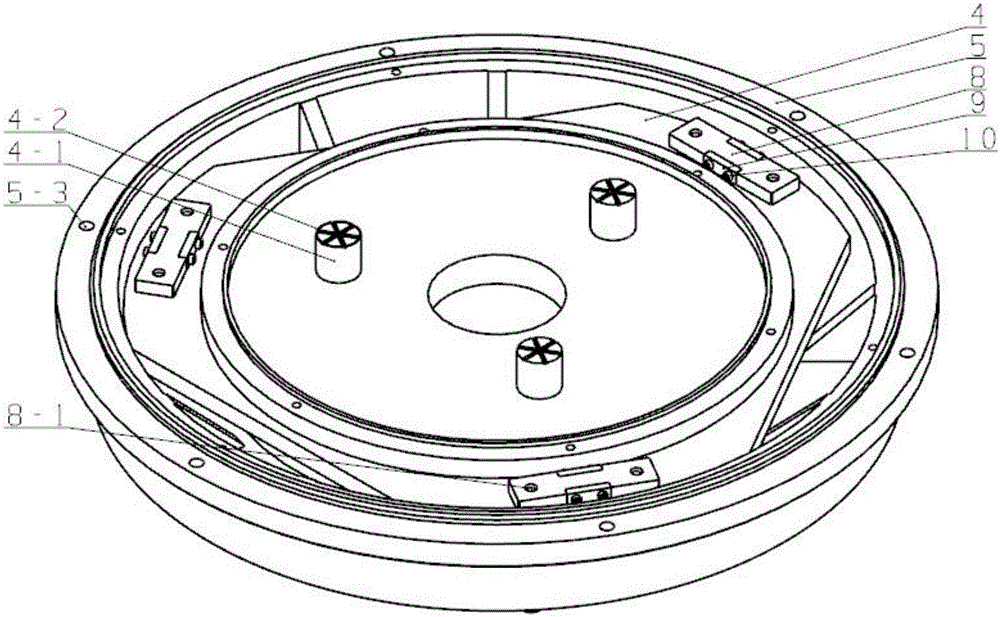

Multi-field collaborative coupling rolling platform

PendingCN111037207AImprove stress statusReduce the activation energy of intergranular dislocationsMechanical vibrations separationFeeding apparatusVibration amplitudeEngineering

The invention discloses a multi-field collaborative coupling rolling platform. The platform comprises a rack, a clamp groove which is mounted on the rack, used for clamping a workpiece and provided with a permanent magnet field, a vortex heating piece capable of achieving vortex effect heating of the workpiece, two high-energy electrode assemblies and two ultrasonic vibration generators capable ofachieving ultrasonic vibration. The clamp groove is made of an insulation material, a permanent strong magnet is buried in the groove bottom face of the clamp groove, the two ultrasonic vibration generators comprise a transverse ultrasonic vibration generator and a vertical ultrasonic vibration generators, under the collaborative effect of the two ultrasonic vibration generators, a two-dimensional ultrasonic field can be formed on different amplitudes, different vibration frequencies or different vibration phases, and stress loading and releasing cycle between a tool and the workpiece in themachining process can be optimized. The multi-field collaborative coupling rolling platform can machine different plane materials, and material surface reinforcing layers of a laboratory and actual application can be achieved.

Owner:ZHEJIANG UNIV OF TECH

Secondary ettringite type expanding agent and preparation method and application thereof

ActiveCN102167536AReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

Deep three-soft coal seam asymmetric tunnel supporting structure

ActiveCN105909289AReduce displacementIncrease anchoring forceAnchoring boltsNon symmetricStressed state

The invention discloses a deep three-soft coal seam asymmetric tunnel supporting structure comprising a tunnel top support, a roadside support, and a tunnel bottom support; the tunnel top support comprises a metal net used for supporting the tunnel top, and top steel bar ladder beams, top anchor poles and top anchor cables used for reinforcing the tunnel top,; the roadside support comprises a high side support and a low side support, each of which comprises an electric welding plain net used for supporting the roadside, and side steel bar ladder beams and side anchor poles used for reinforcing the tunnel roadside; the high side support also comprises side cables; the tunnel bottom support comprises base angle anchor poles vertically and symmetrically arranged along the tunnel, wherein the base angle anchor poles are arranged on two side base angles formed by the tunnel bottom and the roadside, and the angle of depression is 45 degrees. The anchor-beam-net-cable combined support mode is employed; the anchor poles, anchor cables and steel bar ladder beams of the tunnel top and roadside can improve tunnel surrounding rocks stress states; the side cables are arranged so as to reinforce tunnel high side local support; the base angle anchor poles are arranged so as to effectively control the tunnel bottom heaves.

Owner:CHINA UNIV OF MINING & TECH

Method for supporting tunnel roof below mined-out area

InactiveCN102155249AIncrease the areaStrong watch protectionMine roof capsAnchoring boltsShortest distanceHigh pressure water

The invention relates to a method for supporting a tunnel roof below a mined-out area. In the method, steel belt combination hydraulic power expansion anchor rods are used for supporting the tunnel roof below the mined-out area. The method comprises the following steps of: erecting temporary supports for the tunnel roof dug out below the mined-out area and at both sides of the tunnel roof, laying a metal net and a steel belt on the roof so as to lead the steel belt to push down the metal net, using a single prop to support the steel belt, and punching holes and drilling holes on the tunnel roof through orifices of the steel belt; then sequentially placing the hydraulic power expansion anchor rods in boreholes, leading the steel belt to be clung to a top plate by a tray, injecting high pressure water with the pressure of 20 to 22MPa into the hydraulic power expansion anchor rods one by one, wherein the liquid injection time for each steel belt combination hydraulic power expansion anchor rod is not less than 2min; and repeating the steps till finishing the support of the tunnel roof below the mined-out area. The method solves the difficult problem that a traditional resin anchoring anchor rod can not be anchored in the mined-out area and can not effectively support the top plate of the tunnel roof below the mined-out area at a very short distance; and the method has simple process and is convenient to operate.

Owner:CHINA UNIV OF MINING & TECH

Arc surface calibratkon cam mechanism and its processing method

InactiveCN1556340AExtended service lifeGuaranteed accuracyGearingGearing detailsLow noiseEngineering

Convex profile surface includes position section, transition section and division section. Characters are that the transition section and division section are concave surface, and radius of curvature of drum type roller is less than radius of curvature of the concave surface to be matched. The manufacturing method is method of four coordinates interlock of processing in single side face including interlock between z1 rotation axis of cam and z2 rotation axis of cutting tool as well as straight-ahead travel of cutting tool along y2 and z2 coordinates. Features are: small abrasion, low noise, long service life and raised manufacturing accuracy and efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

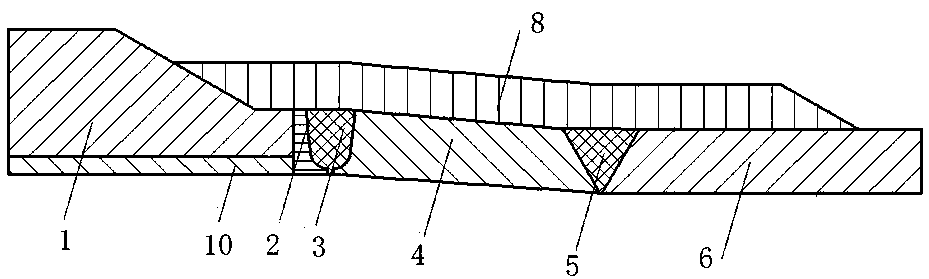

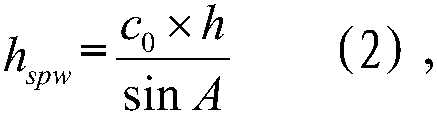

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com