Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid Large Particle Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-stage magnetic field arc ion plating and radio-frequency magnetron sputtering composite deposition method

PendingCN104975263AReduce Large Particle DefectsGuaranteed normal transmissionVacuum evaporation coatingSputtering coatingSemiconductor materialsRadio frequency magnetron sputtering

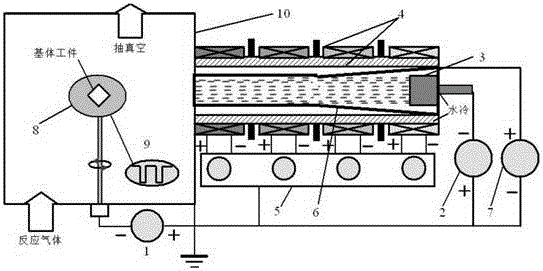

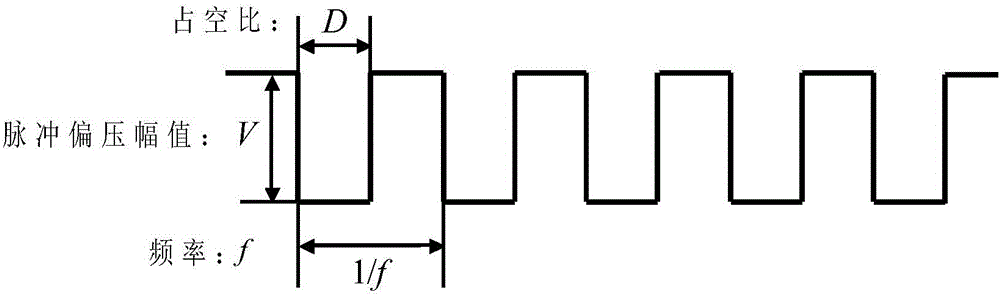

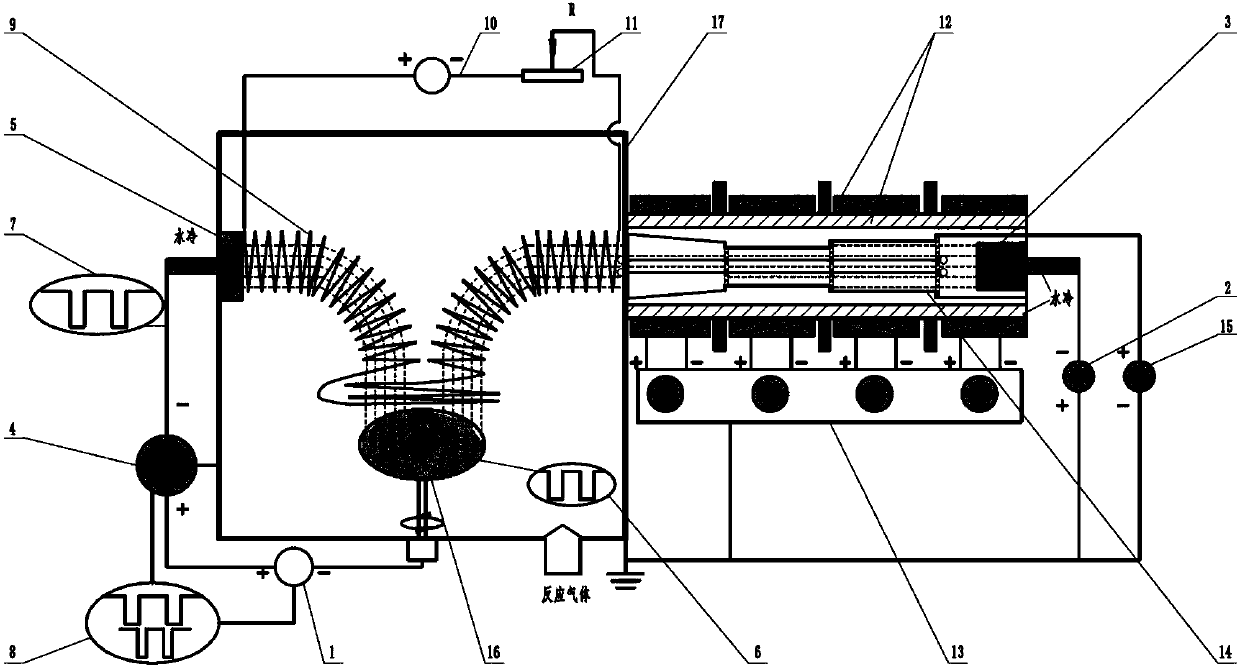

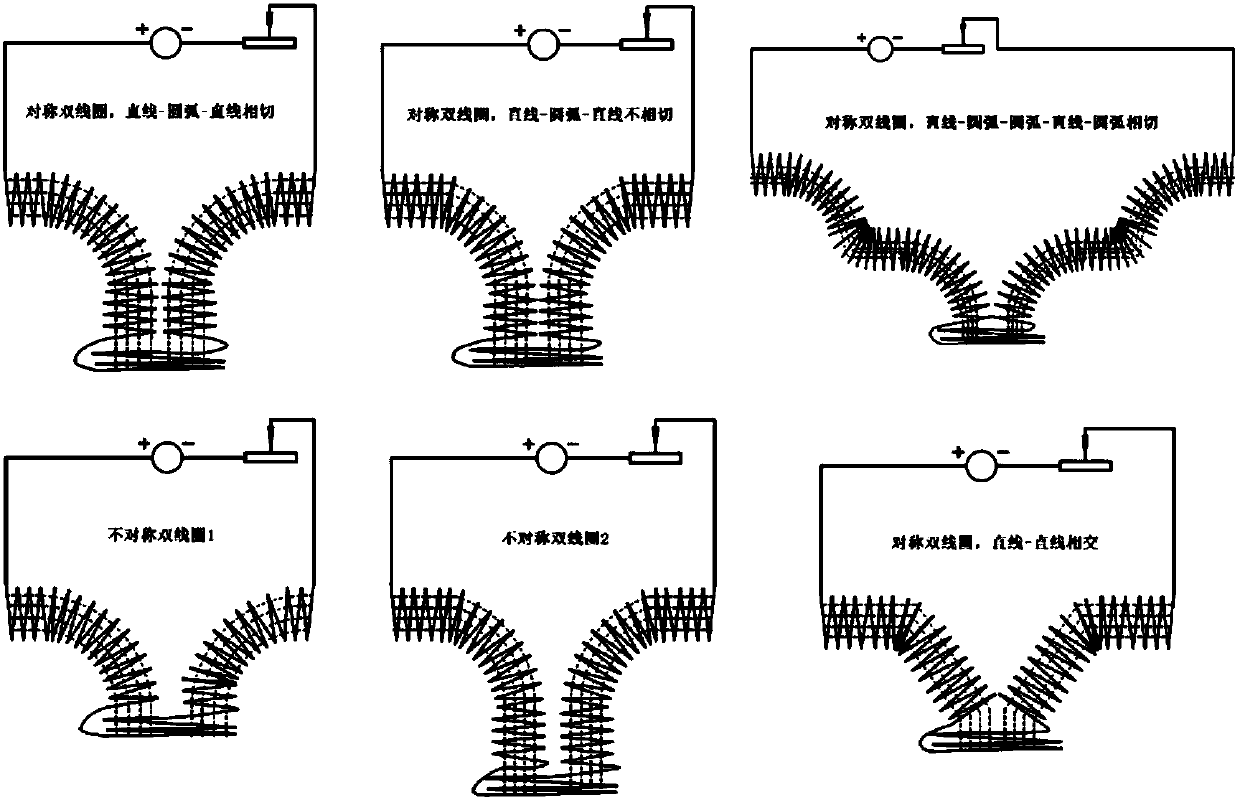

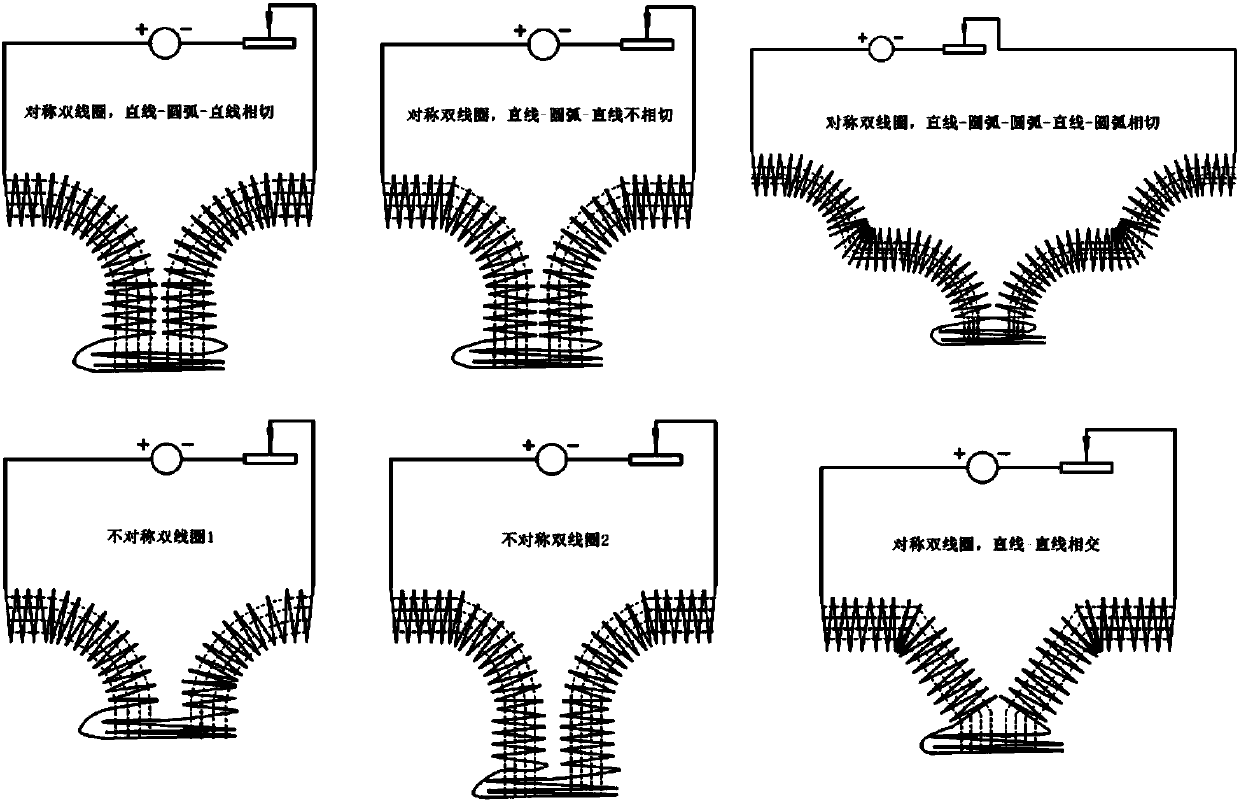

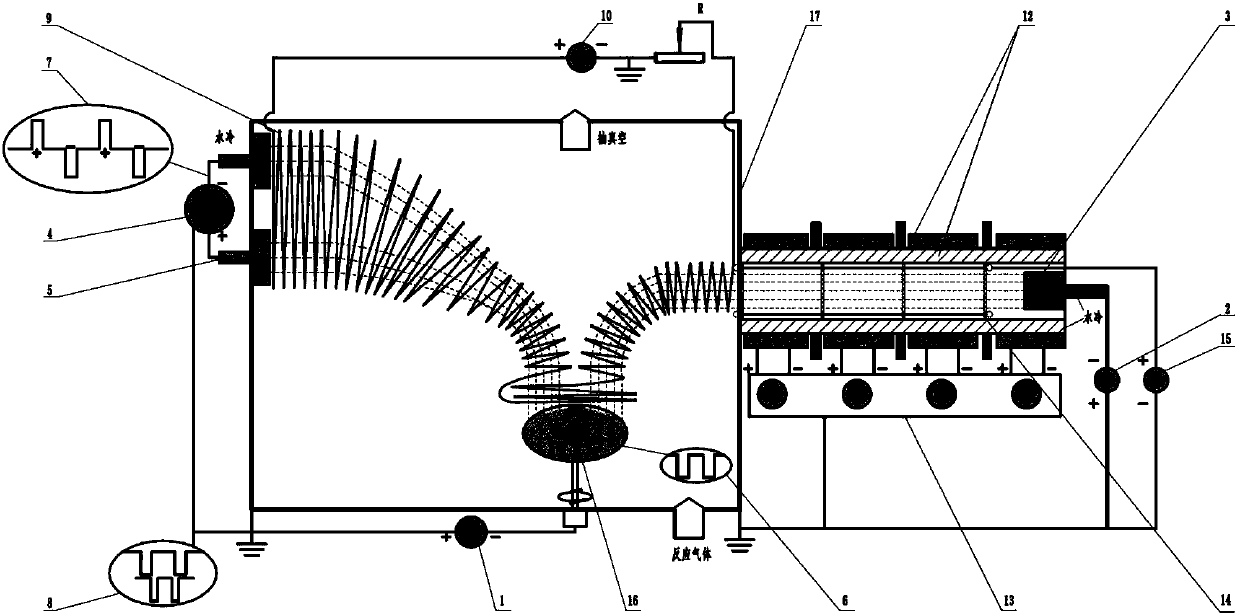

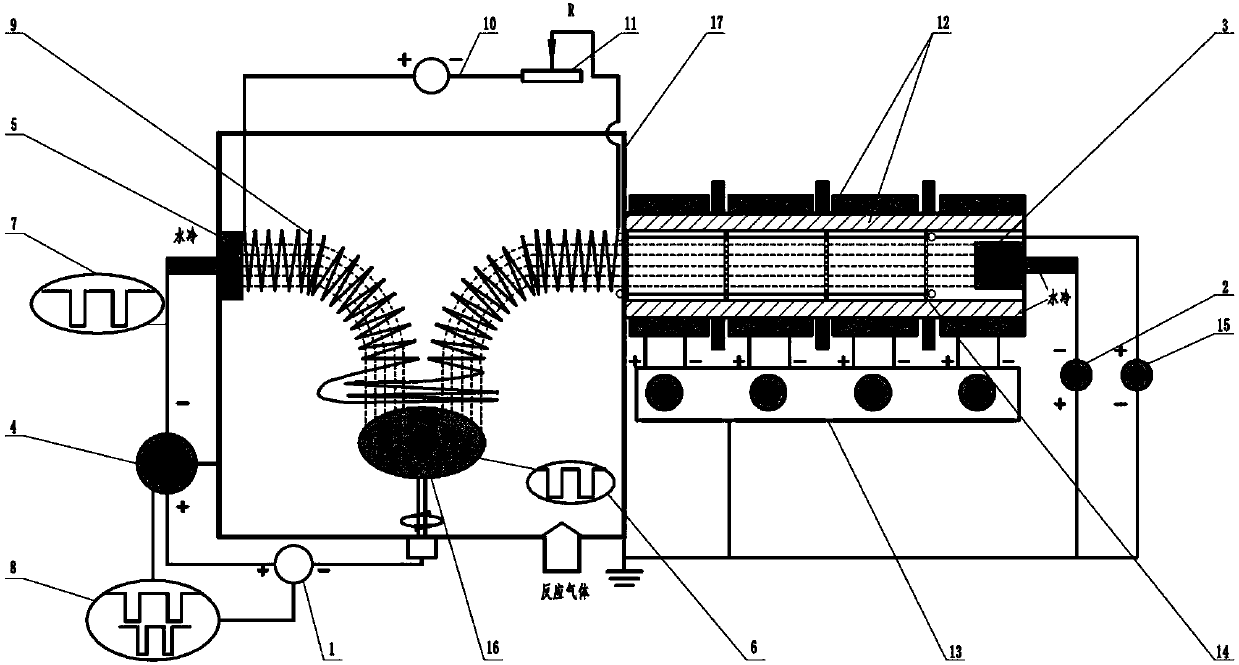

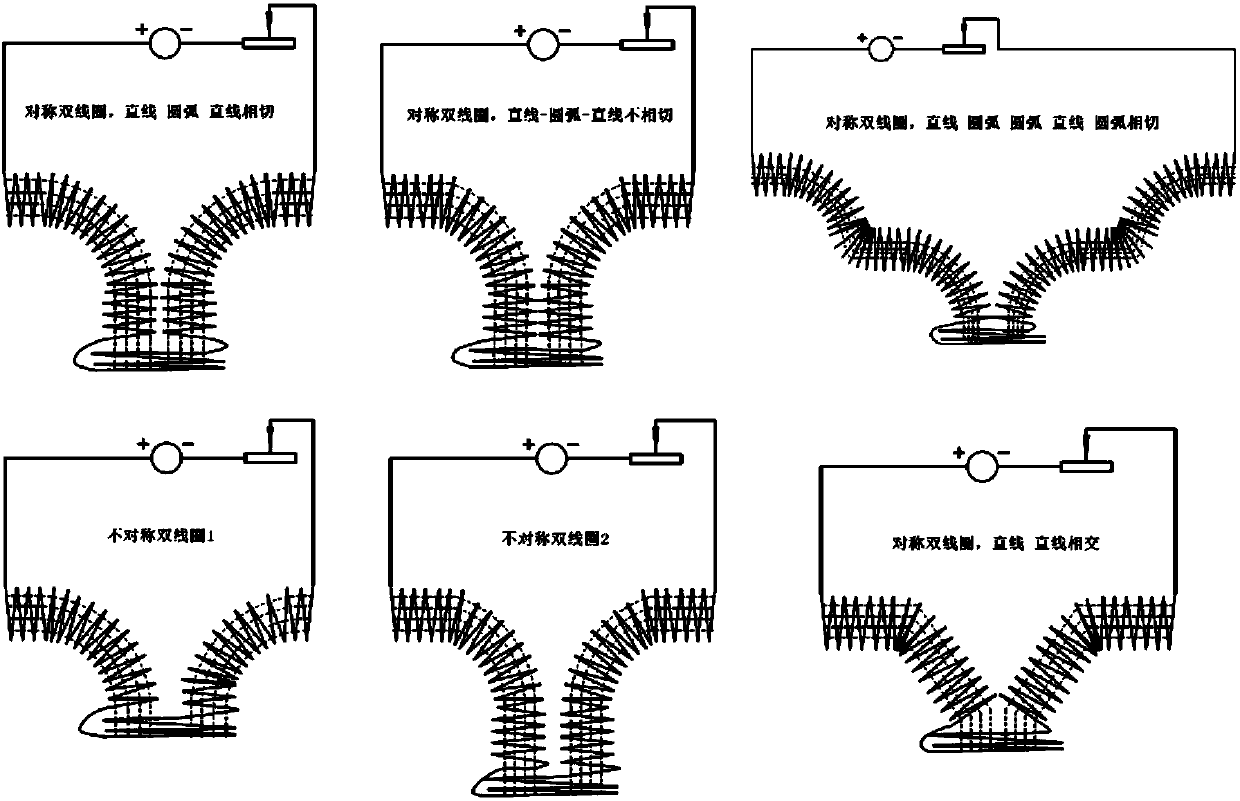

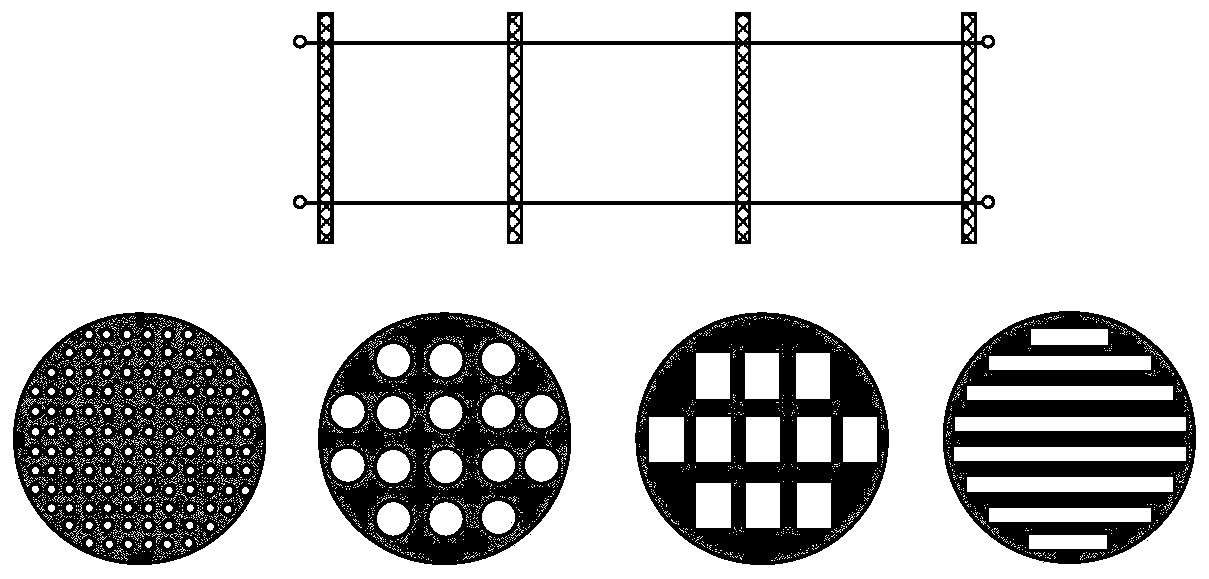

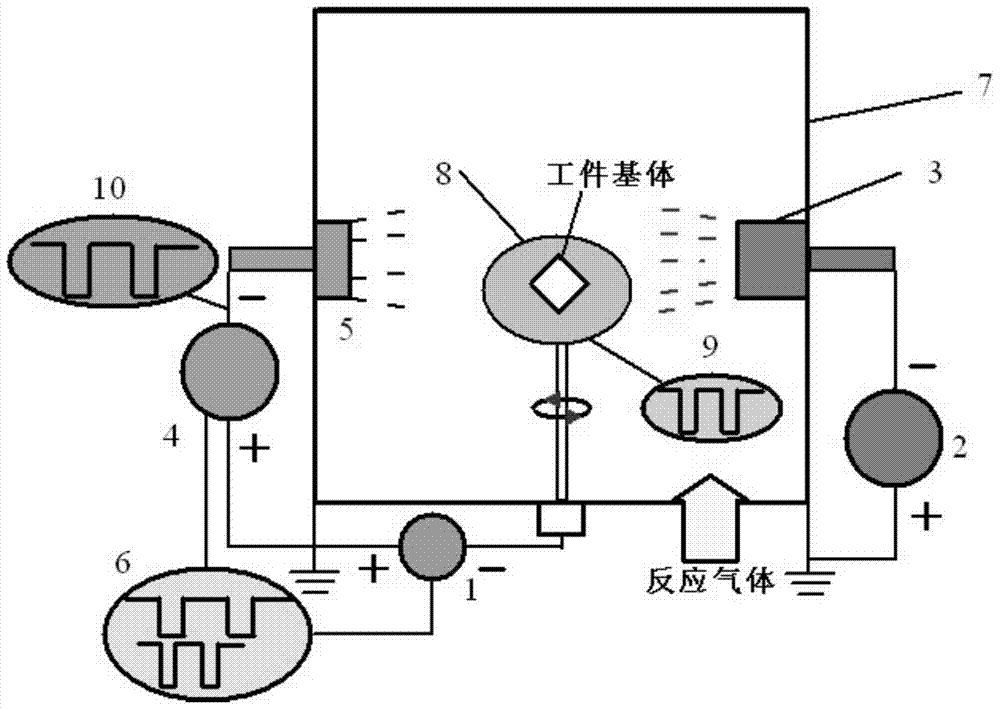

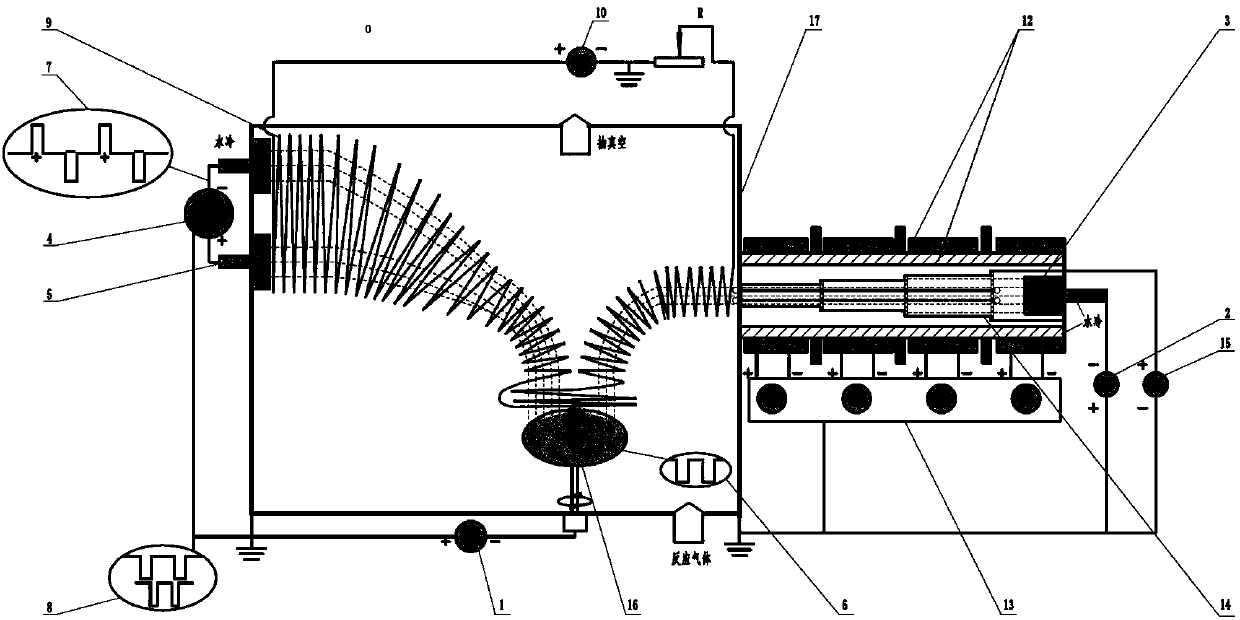

The invention provides a multi-stage magnetic field arc ion plating and radio-frequency magnetron sputtering composite deposition method and belongs to the technical field of material surface processing. The method aims to solve the problem that low-melting-point pure metal or multicomponent alloy materials and non-metal materials, such as graphite are large in particle in traditional arc ion plating, breaking through the limitations that semiconductor materials and insulating materials can not be used, the ionization rate and thin film deposition efficiency of traditional magnetron sputtering are low and high- melting-point targets are difficult to ionize, and eliminating the limitations of an original method in the aspect of use of the targets. The composite deposition method includes the steps that 1, a workpiece to be plated is placed on a sample table in a vacuum room, and a relative power source is powered on; 2, a thin film is deposited, wherein when the vacuum degree in the vacuum room is smaller than 10-4Pa, work gas is introduced, gas pressure is adjusted, a plating power source is powered on, and energy of a composite plasma is adjusted through a grid bias power supply. By means of a multi-stage magnetic field straight tube magnetic filter device, the defect of large particles is overcome, transmission efficiency of arc plasmas is guaranteed, and required process parameters are set for thin film deposition.

Owner:魏永强

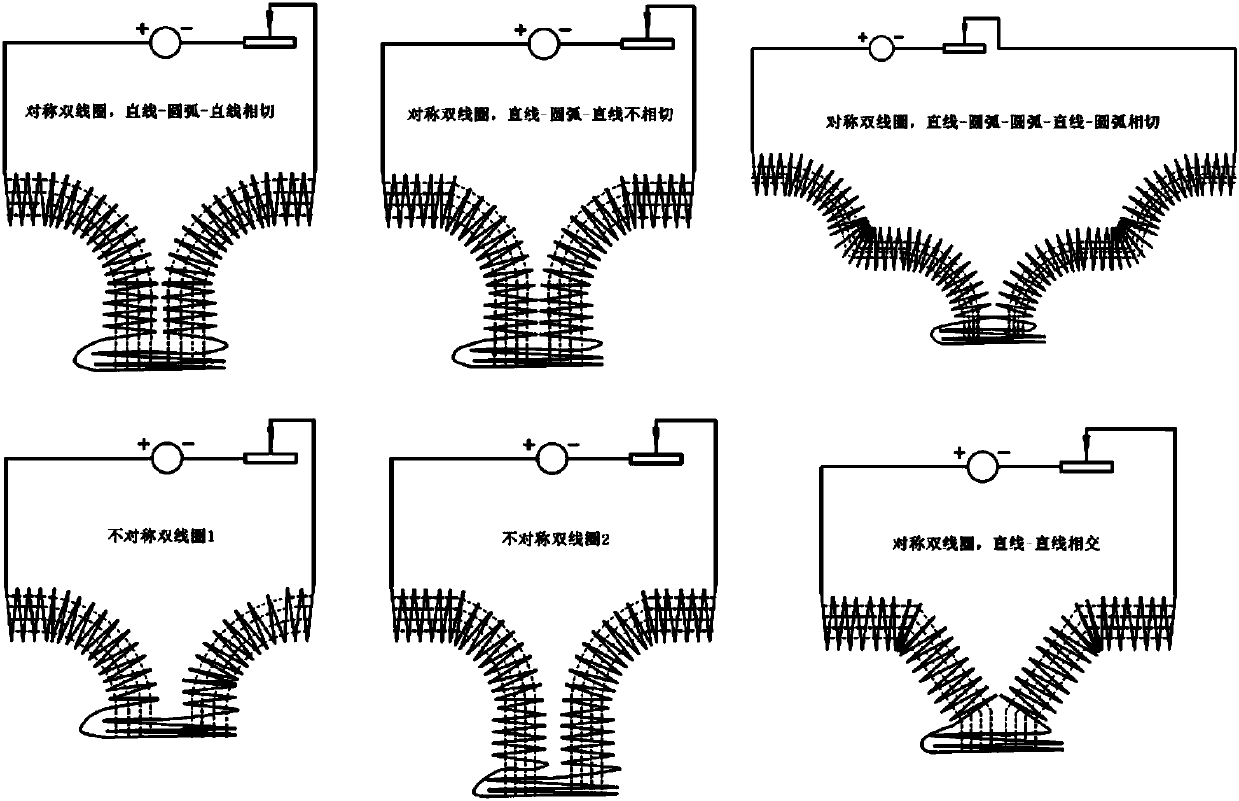

Multistage magnetic field electric arc iron plating method adopting lining positive bias tapered pipe and straight pipe compositing

ActiveCN106756823AFast depositionImprove mechanical propertiesVacuum evaporation coatingSputtering coatingEnergy regulationFilter effect

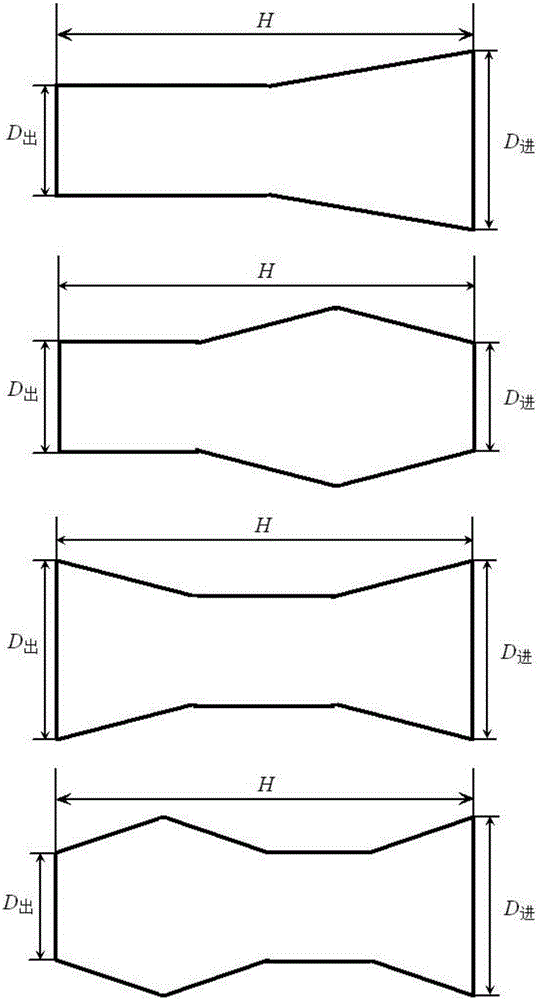

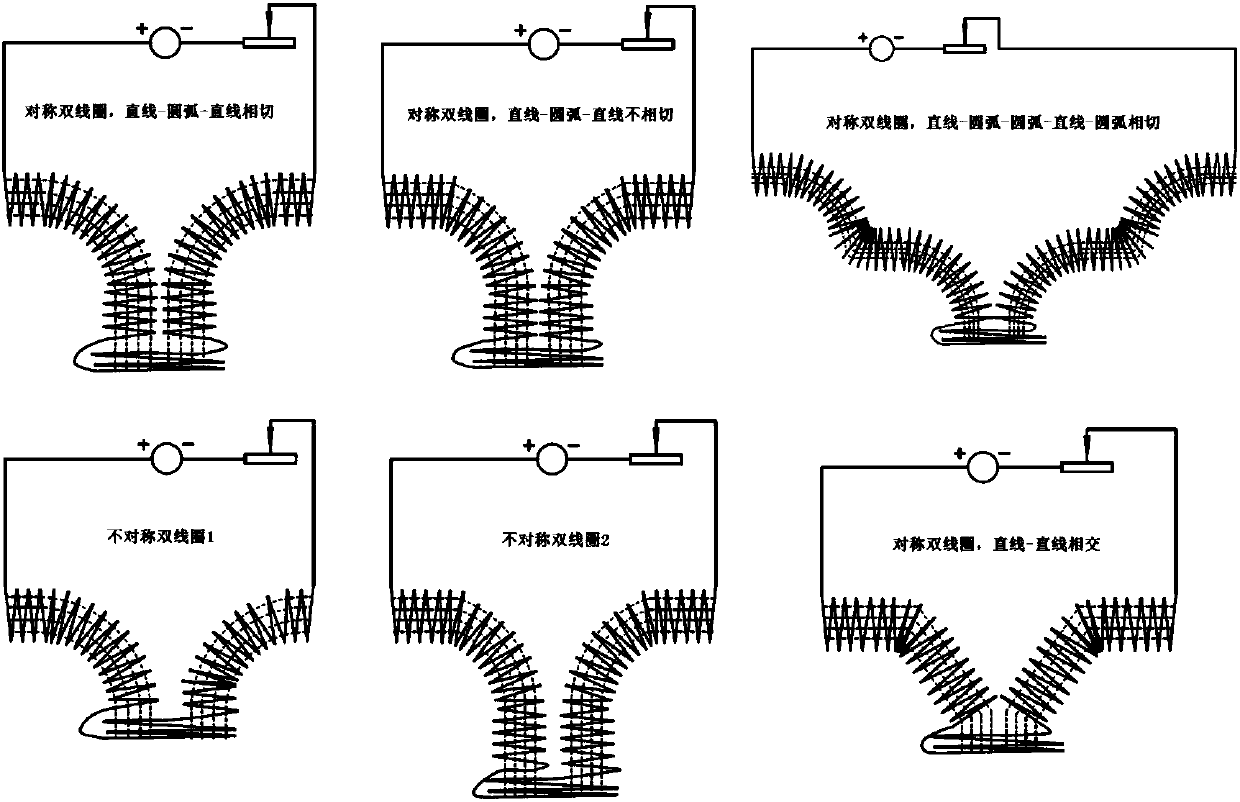

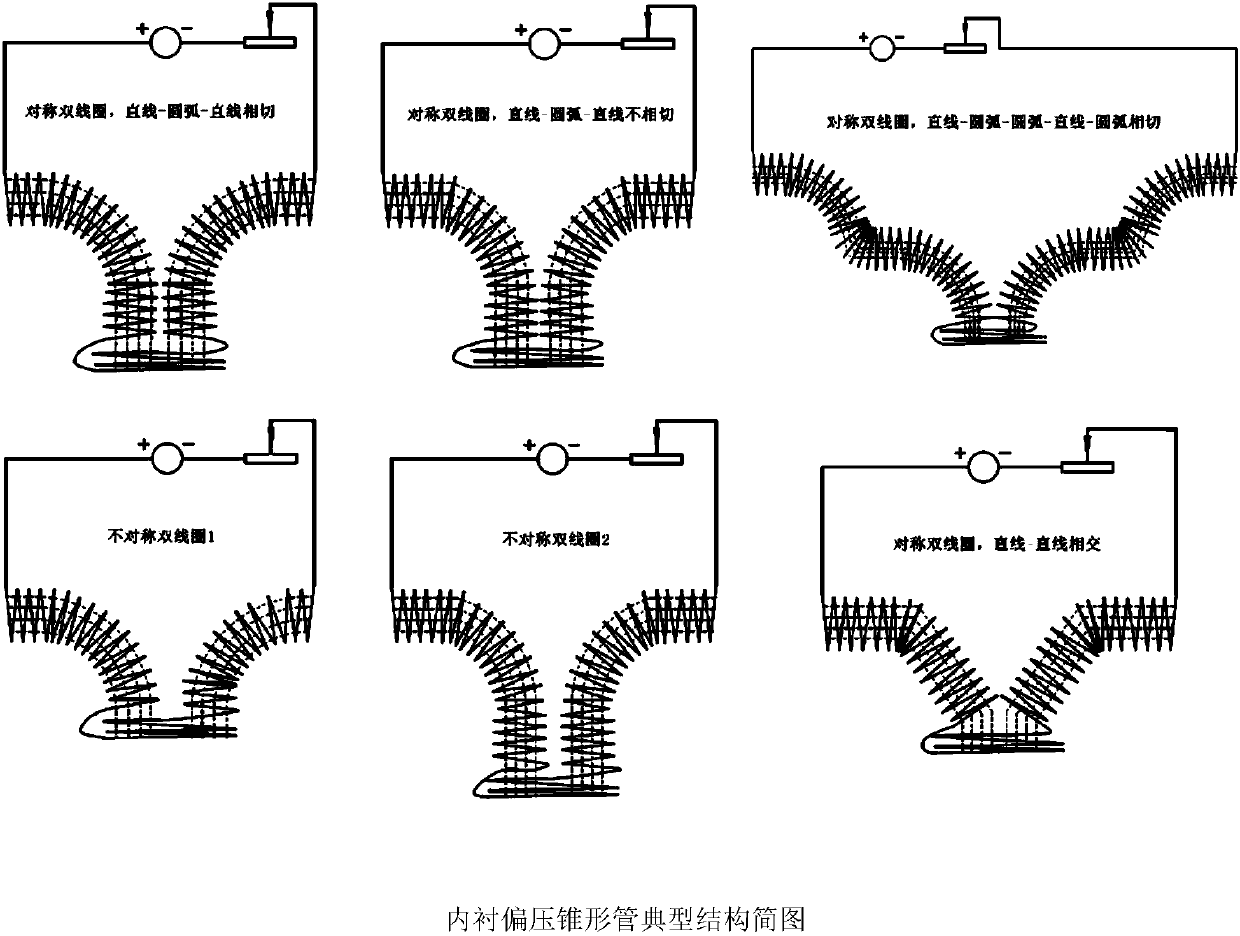

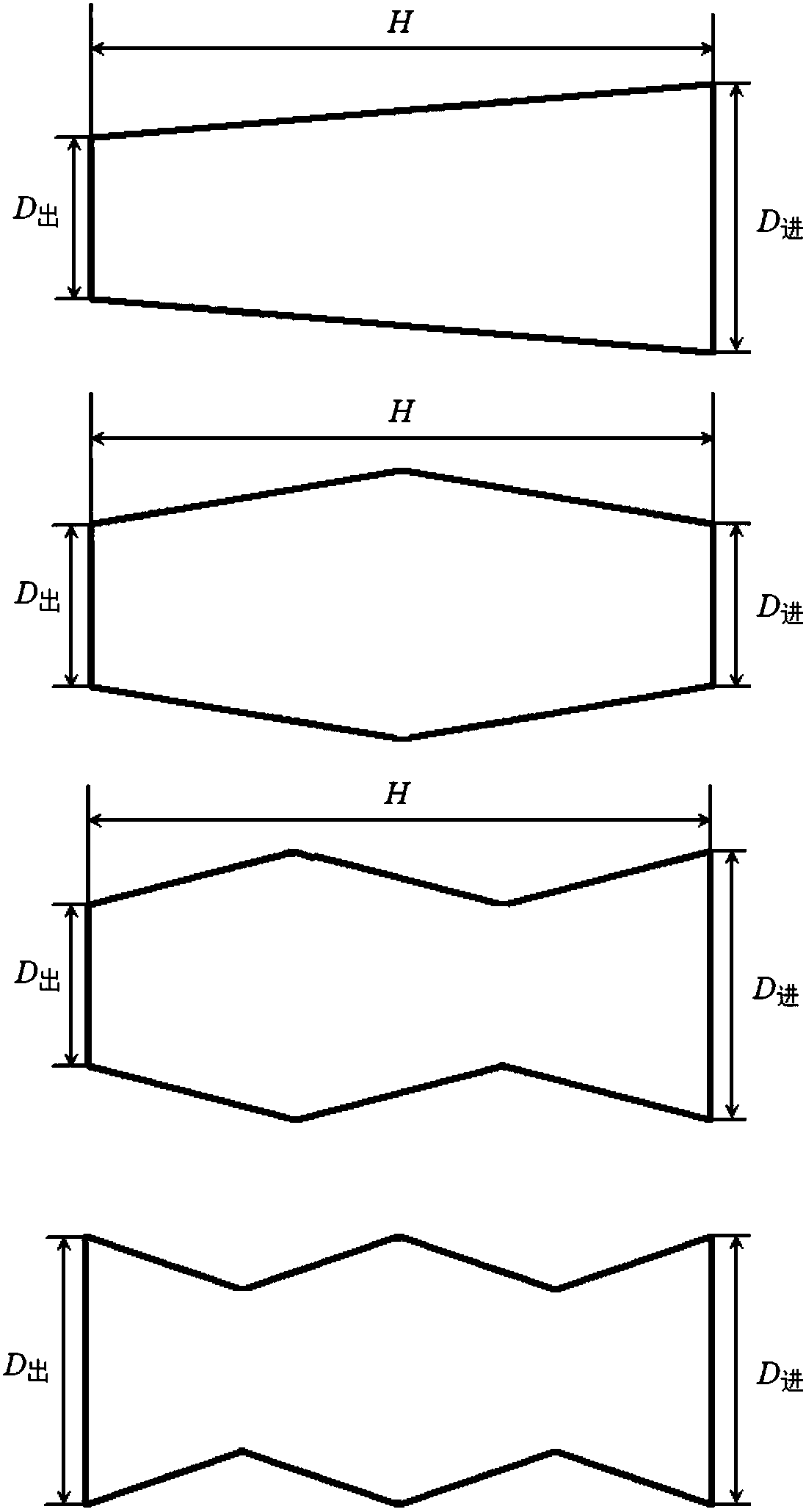

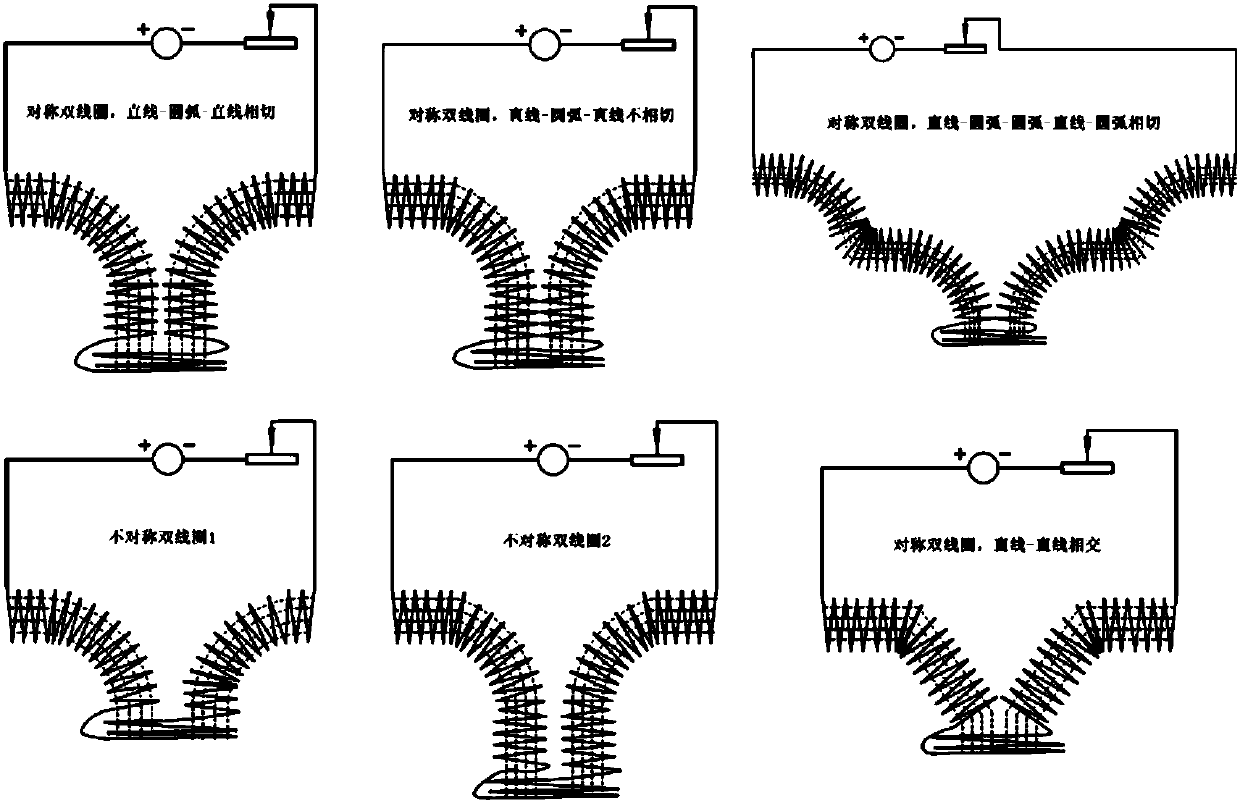

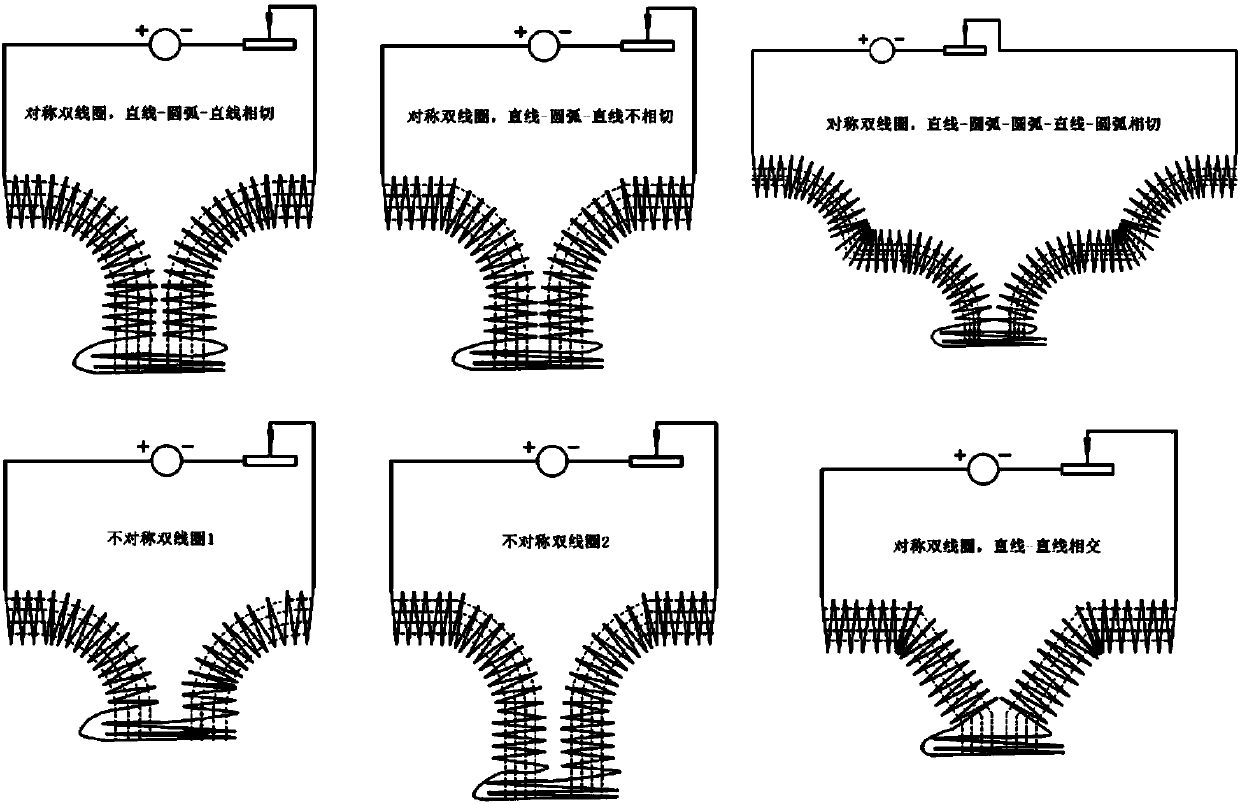

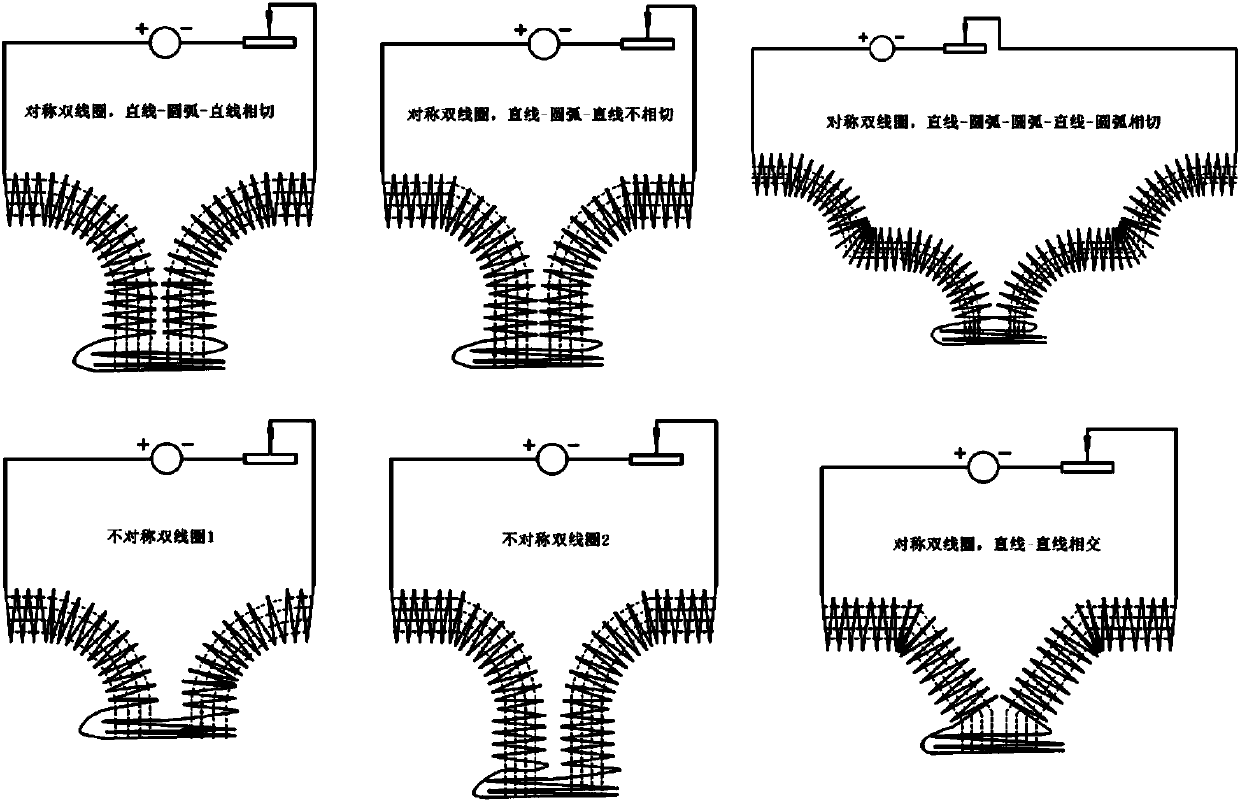

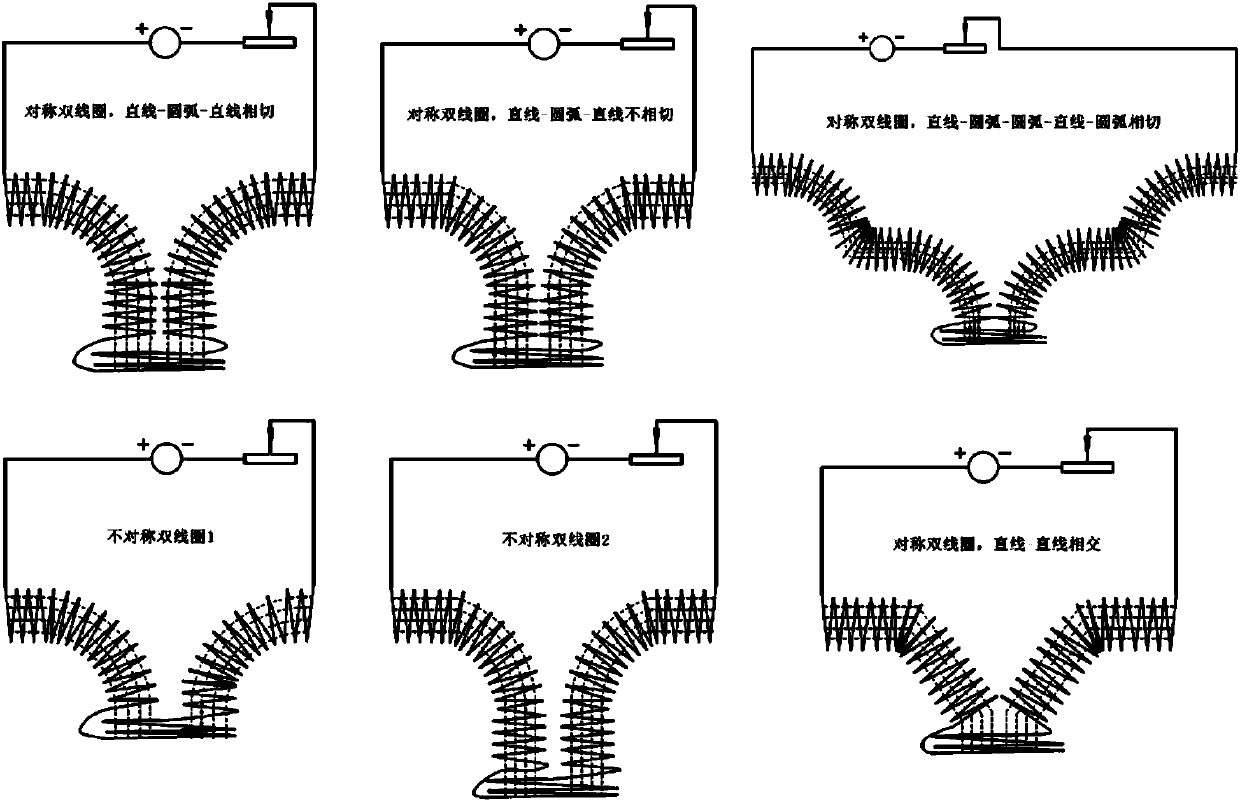

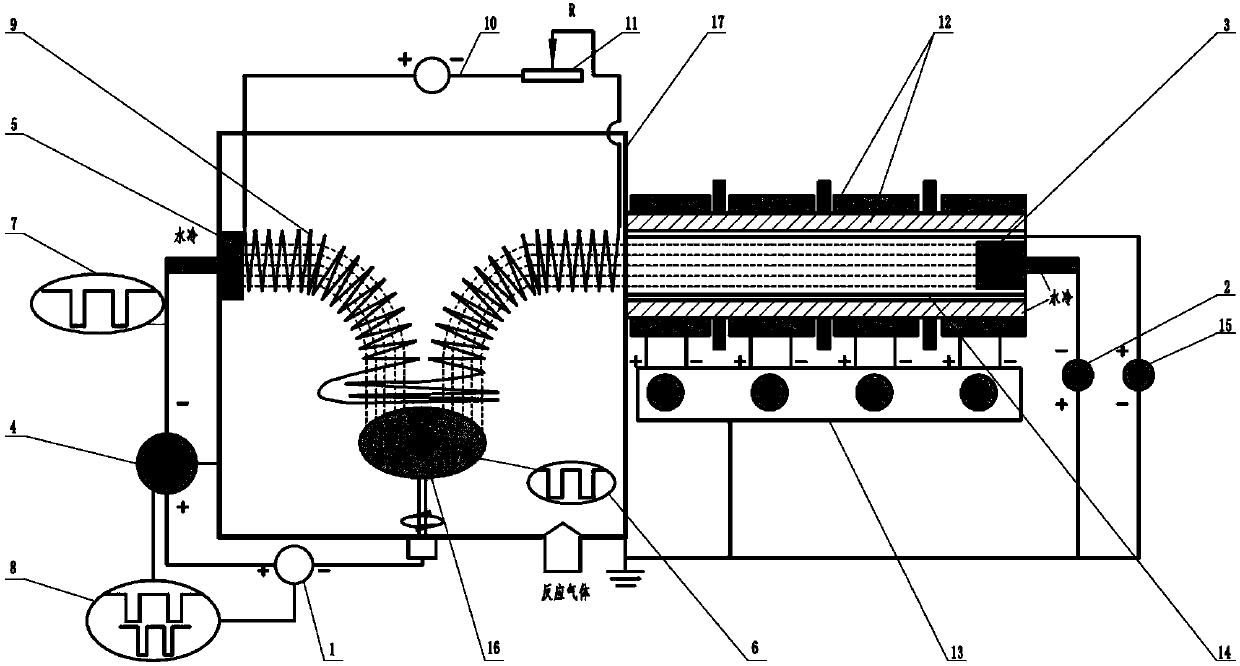

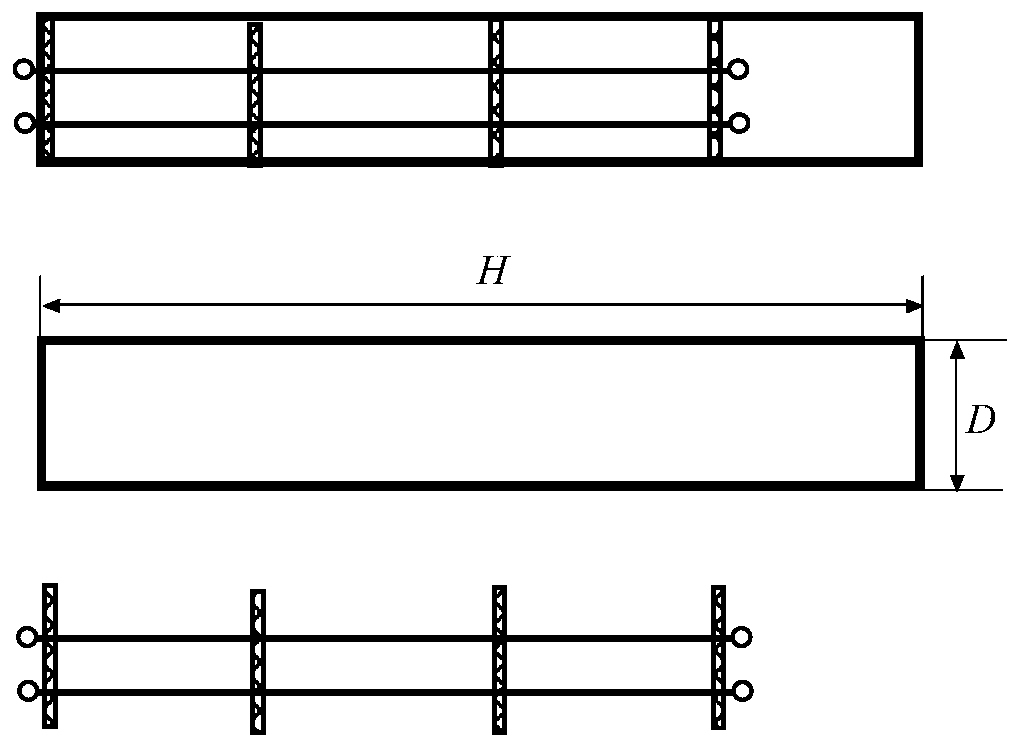

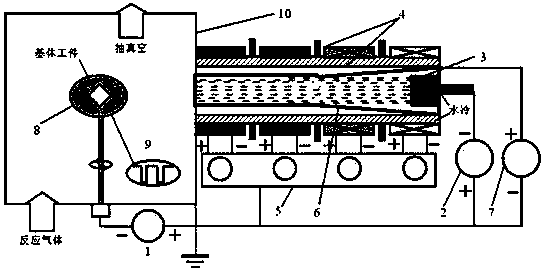

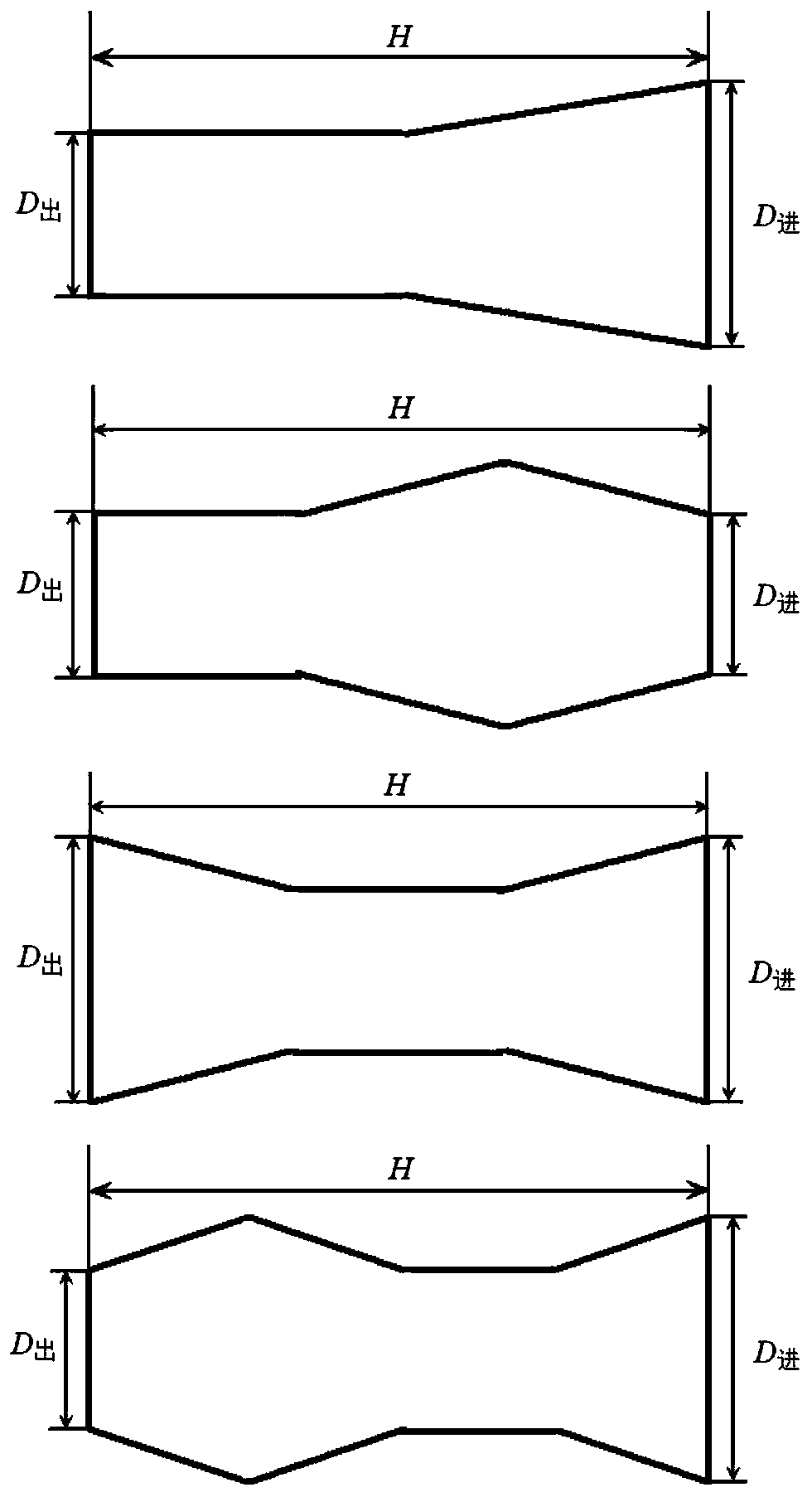

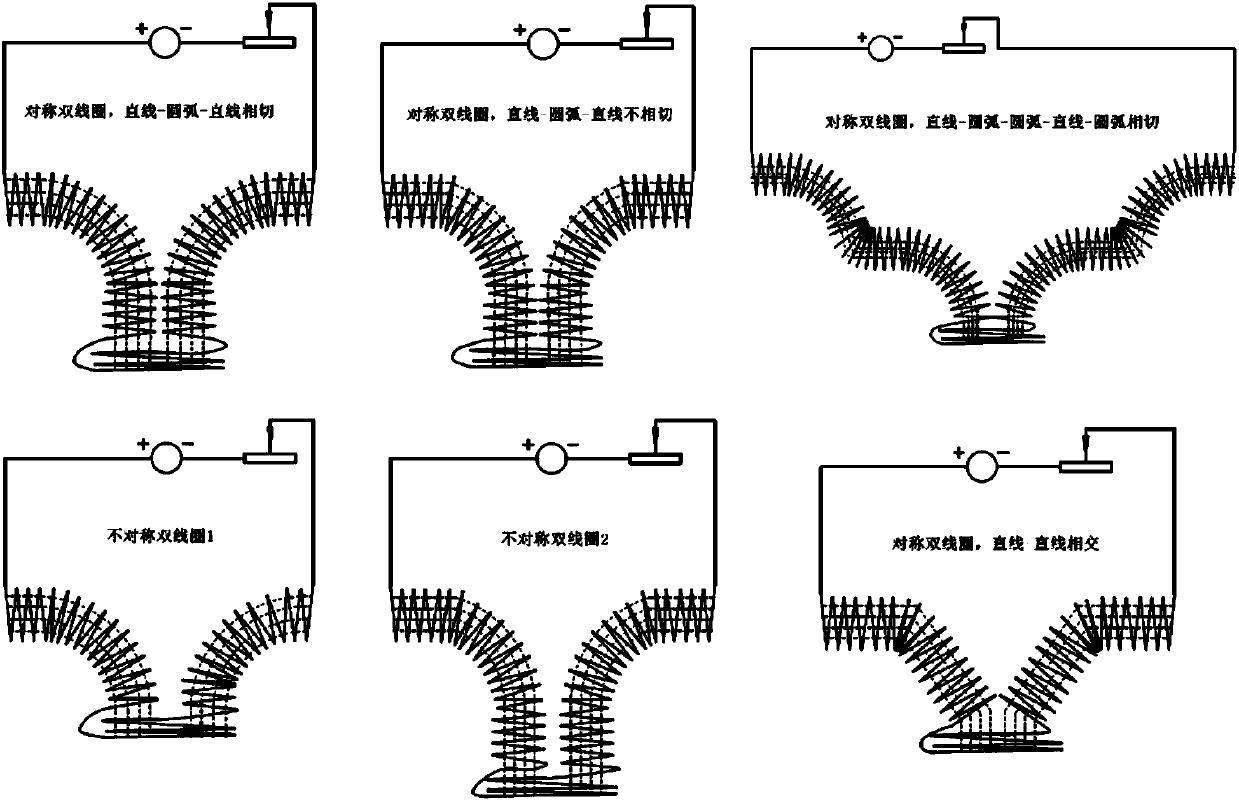

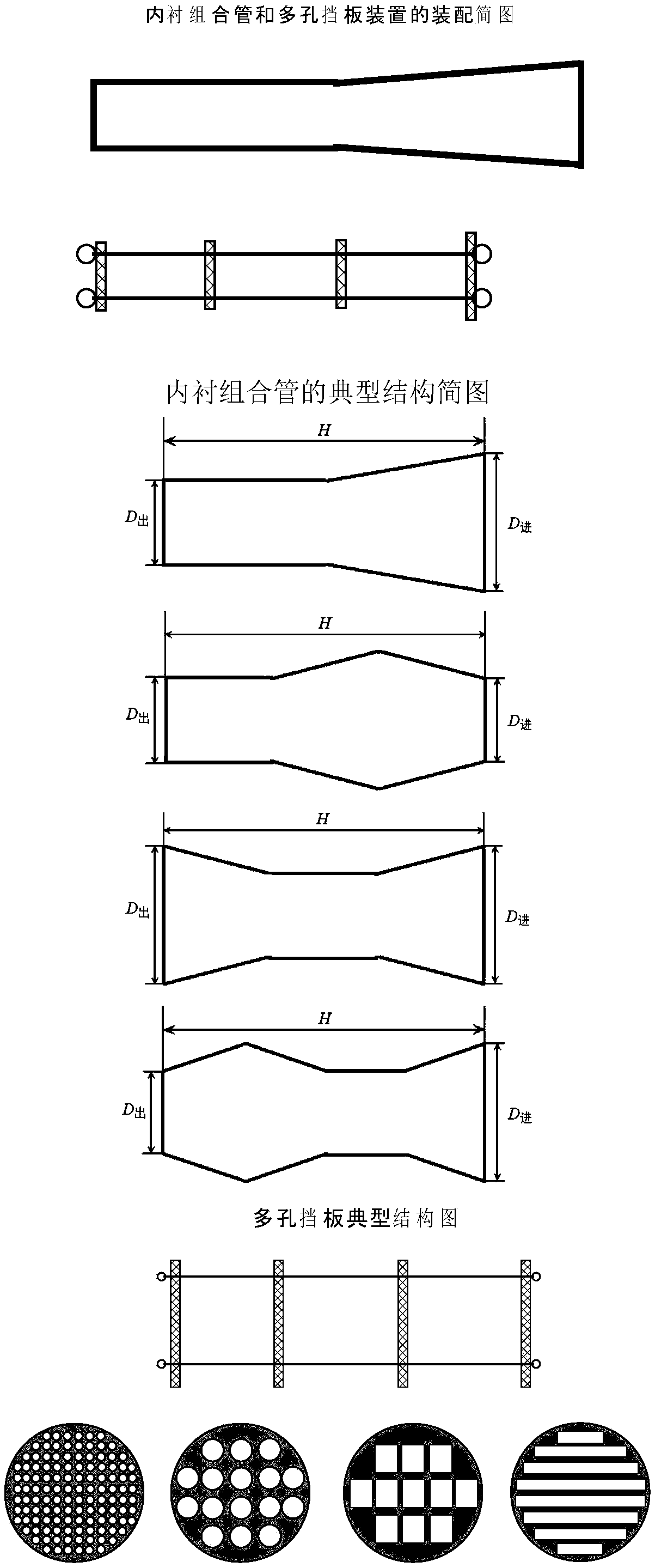

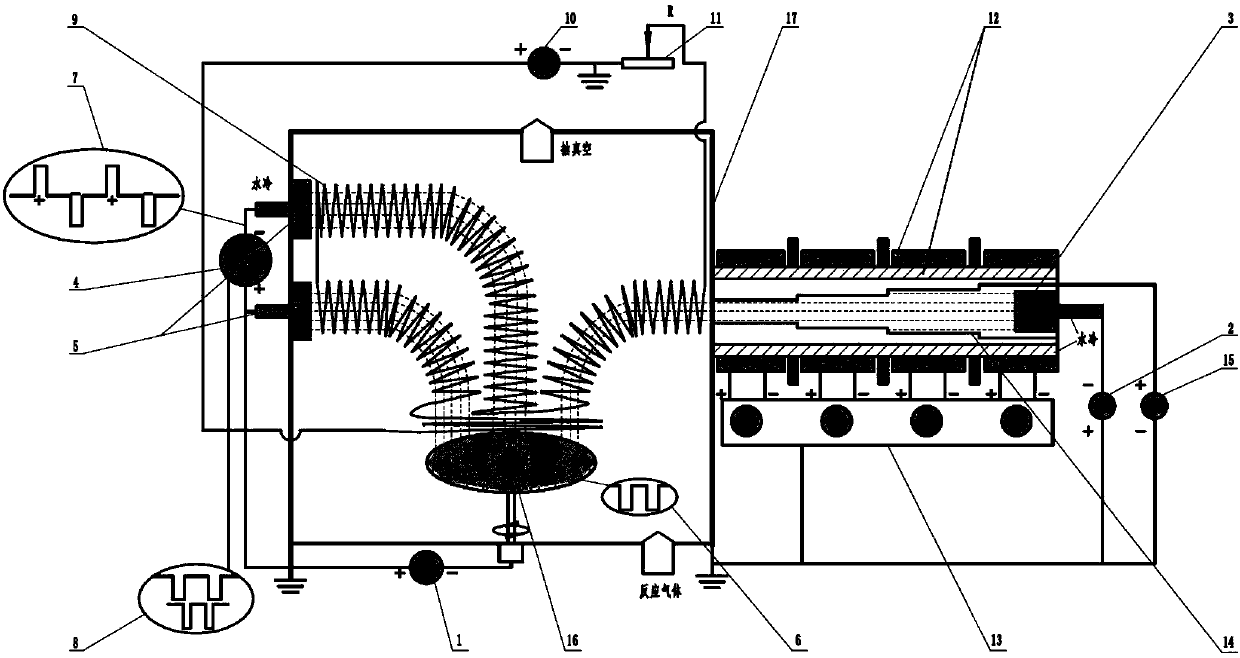

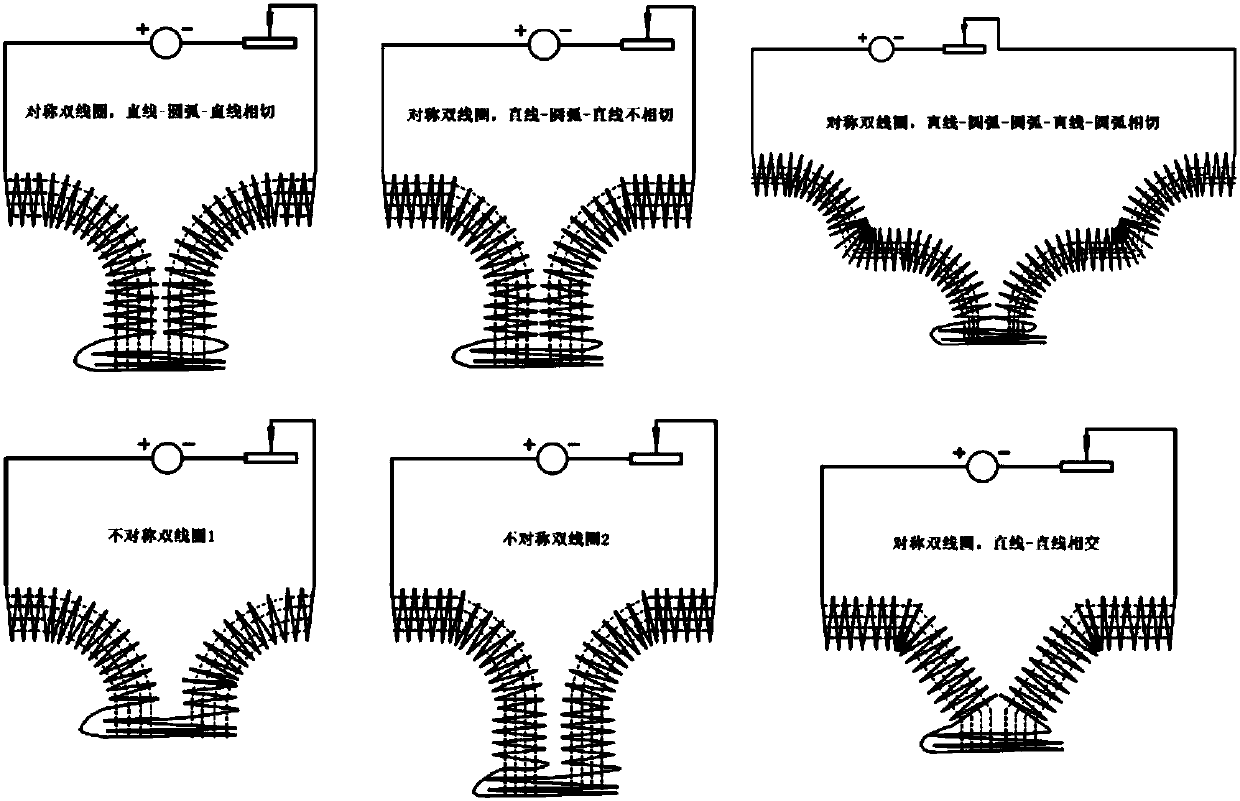

The invention relates to a multistage magnetic field electric arc iron plating method adopting lining positive bias tapered pipe and straight pipe compositing and belongs to the technical field of material surface treatment. The problem of losses in the process of pollution cleaning of macroparticles and deposited irons to the inner wall of a pipe and transmitting of electric arc plasma in a filtering device of a multistage magnetic field is solved. The method comprises the following steps that firstly, a workpiece to be subjected to film plating is placed on a sample table in a vacuum chamber, relative power supplies are powered on, and an external water-cooling system is started; secondly, a thin film is deposited, specifically, when the vacuum degree in the vacuum chamber is smaller than 10<-4> Pa, working air is pumped in, air pressure is adjusted, and a film plating power supply is started; meanwhile, a bias power supply is utilized to attract electric arc plasma in an outlet, and energy is adjusted; by means of the self obstructing shield of a lining positive bias tapered pipe and straight pipe compositing device, the inhibiting effect of a positive bias electric field and the filtering effect of the multistage magnetic field, the macroparticile defect is effectively eliminated, and the transmitting efficiency of the electric arc plasma is guaranteed; and the needed process parameters are set to prepare the thin film.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Multilevel magnetic field arc ion plating method with adjustable transmission directions

ActiveCN105088150AEliminate Large Particle DefectsEliminate pinning effectVacuum evaporation coatingSputtering coatingMetallic materialsAlloy

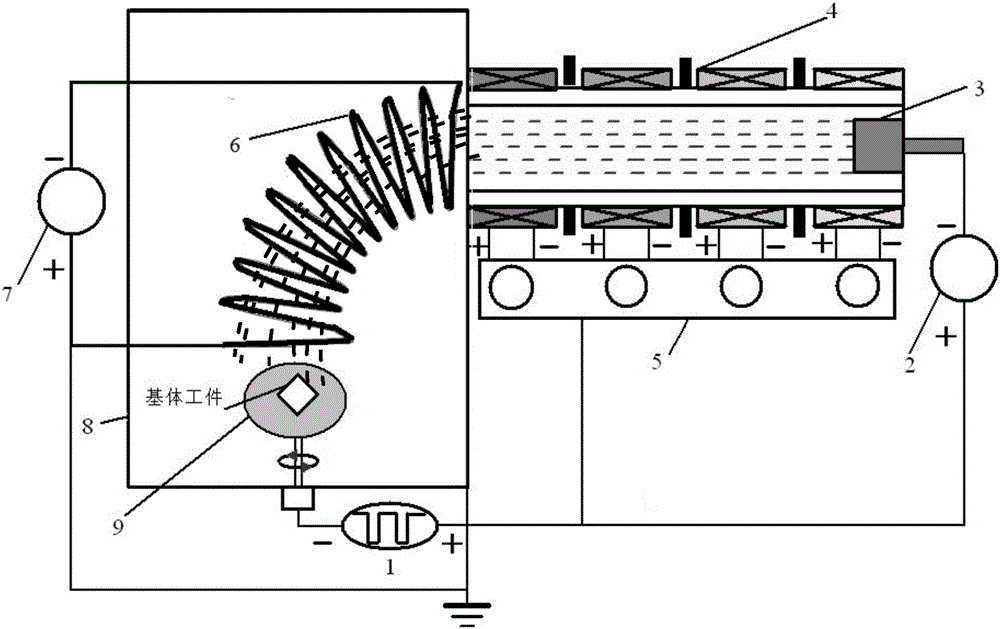

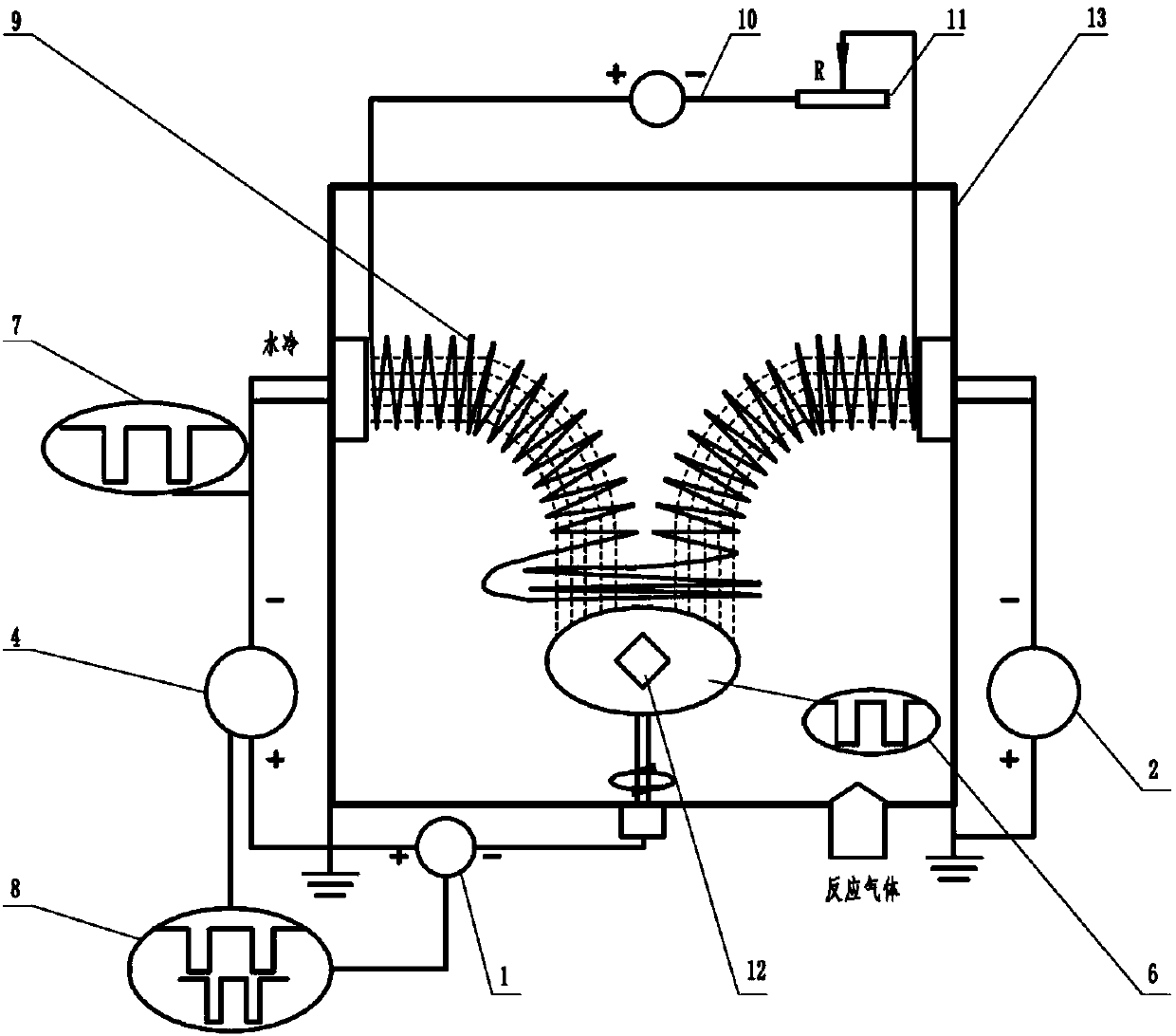

The invention relates to a multilevel magnetic field arc ion plating method with adjustable transmission directions and belongs to the technical field of the material surface treatment. According to the multilevel magnetic field arc ion plating method with the adjustable transmission directions, the large particle problem occurring in the arc ion plating process of pure metal with low-melting-point or multi-component alloy materials and non-metallic materials (such as graphite) is solved; the using limitation of target materials with the low-melting-point is broken; the usable range of arc ion plating target materials and the field of thin film preparation are expanded. The multilevel magnetic field arc ion plating method comprises the steps that 1 a workpiece to be coated with a film is placed on a sample stage in a vacuum chamber and related power sources are connected; and 2 thin film deposition is conducted, when the vacuum degree in the vacuum chamber is less than 10-2 Pa, working gases are pumped in and the air pressure is adjusted, a film plating power source, namely, a grid bias power source is started, a multilevel magnetic field straight pipe magnetic filtration device removes the defect of large particles and guarantees the transmission efficiency of arc plasma, and then the magnetic field device with the adjustable transmission directions is used for guaranteeing the arc plasma to reach substrate surfaces of optional positions in the vacuum chamber and sets up needed technological parameters to make the thin film to deposit.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

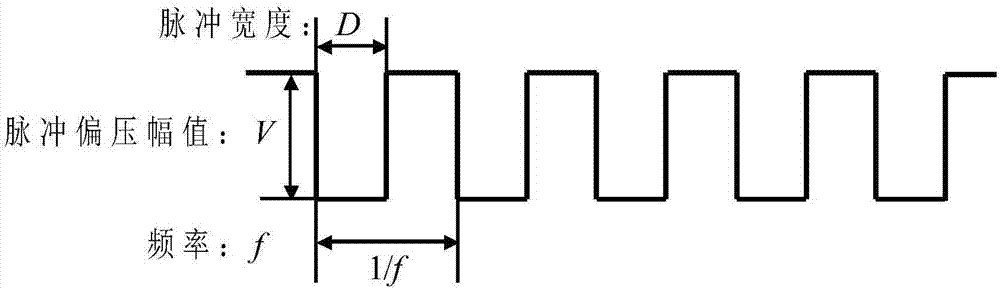

Multistage magnetic field ion plating and twin-target high-power pulse magnetron sputtering composite method

PendingCN105908135AAchieve pinning effectProduce efficientlyVacuum evaporation coatingSputtering coatingSemiconductor materialsMetallic materials

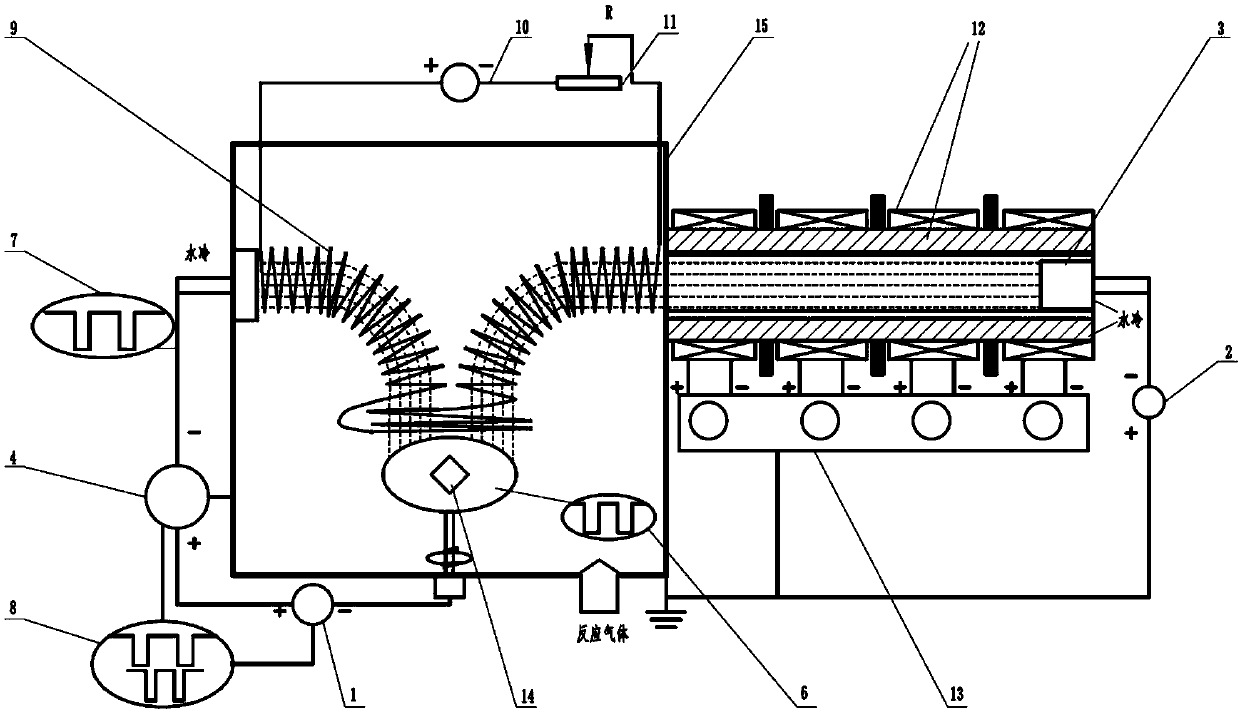

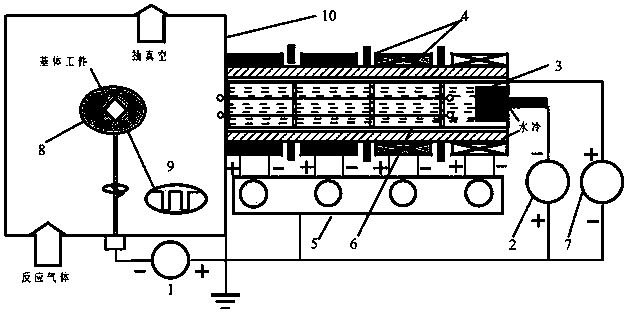

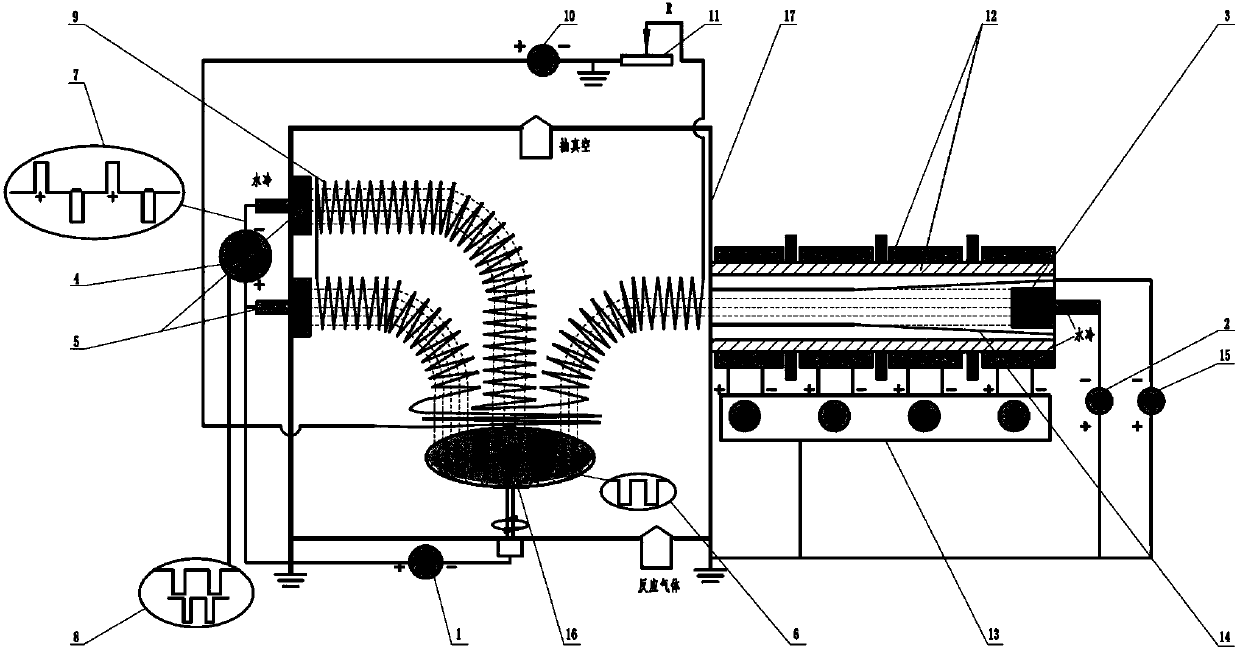

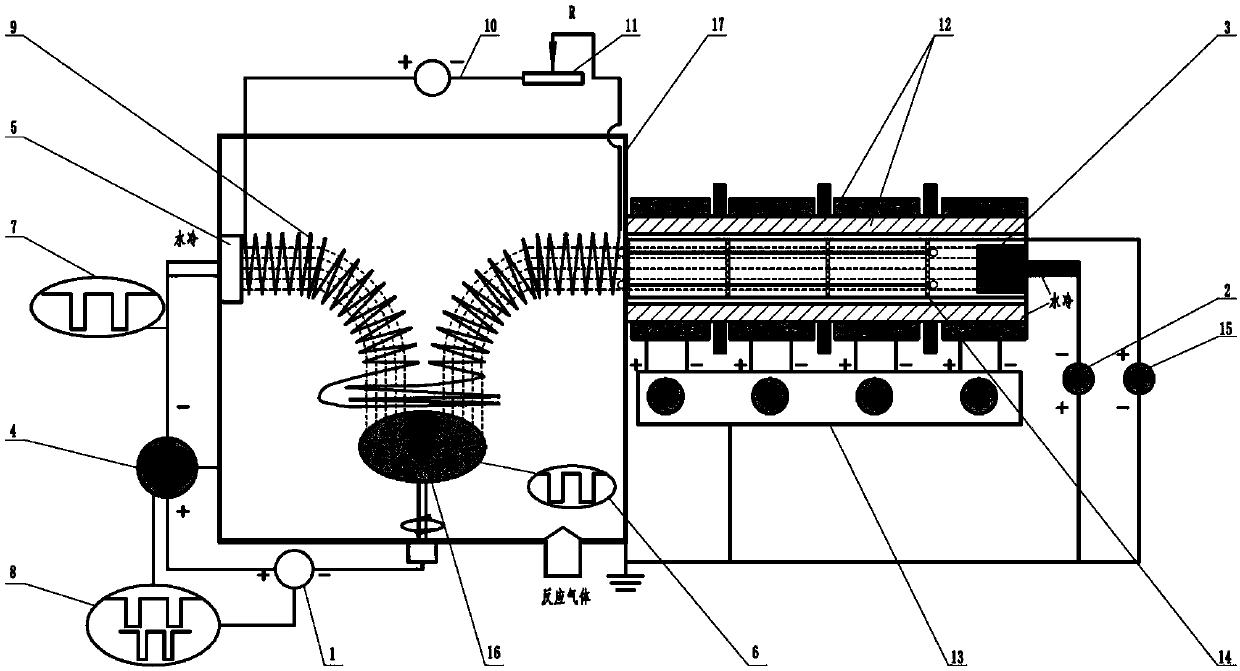

The invention discloses a multistage magnetic field ion plating and twin-target high-power pulse magnetron sputtering composite method and belongs to the technical field of material surface treatment. The problems that low-melting-point pure metal (such as aluminum) or multi-component alloy materials (such as aluminum and silicon) and non-metallic materials (such as graphite and semiconducting material silicon) have the micro-particle defect in a traditional arc ion plating method, a common magnetron sputtering technology is low in ionization rate and thin film deposition efficiency, the melting point is high, a target material difficult to ionize has using limitations, and high-power pulse magnetron sputtering discharge is unstable in ignition are solved. The multistage magnetic field ion plating and twin-target high-power pulse magnetron sputtering composite method comprises the steps that 1, a workpiece is placed on a sample stage inside a vacuum chamber and connected with related equipment; and 2, thin film deposition is conducted, specifically, vacuumizing is conducted till the pressure reaches 10-4 Pa, then, working gas is injected, a film plating power source is turned on, the energy of composite plasma is adjusted through a bias power source, the micro-particle defect is eliminated through a multistage magnetic field filtering device, the transmission efficiency of the arc plasma is ensured, and the arc plasma and twin targets are combined to produce high-ionization-rate multi-component plasma, and a thin film is prepared.

Owner:魏永强

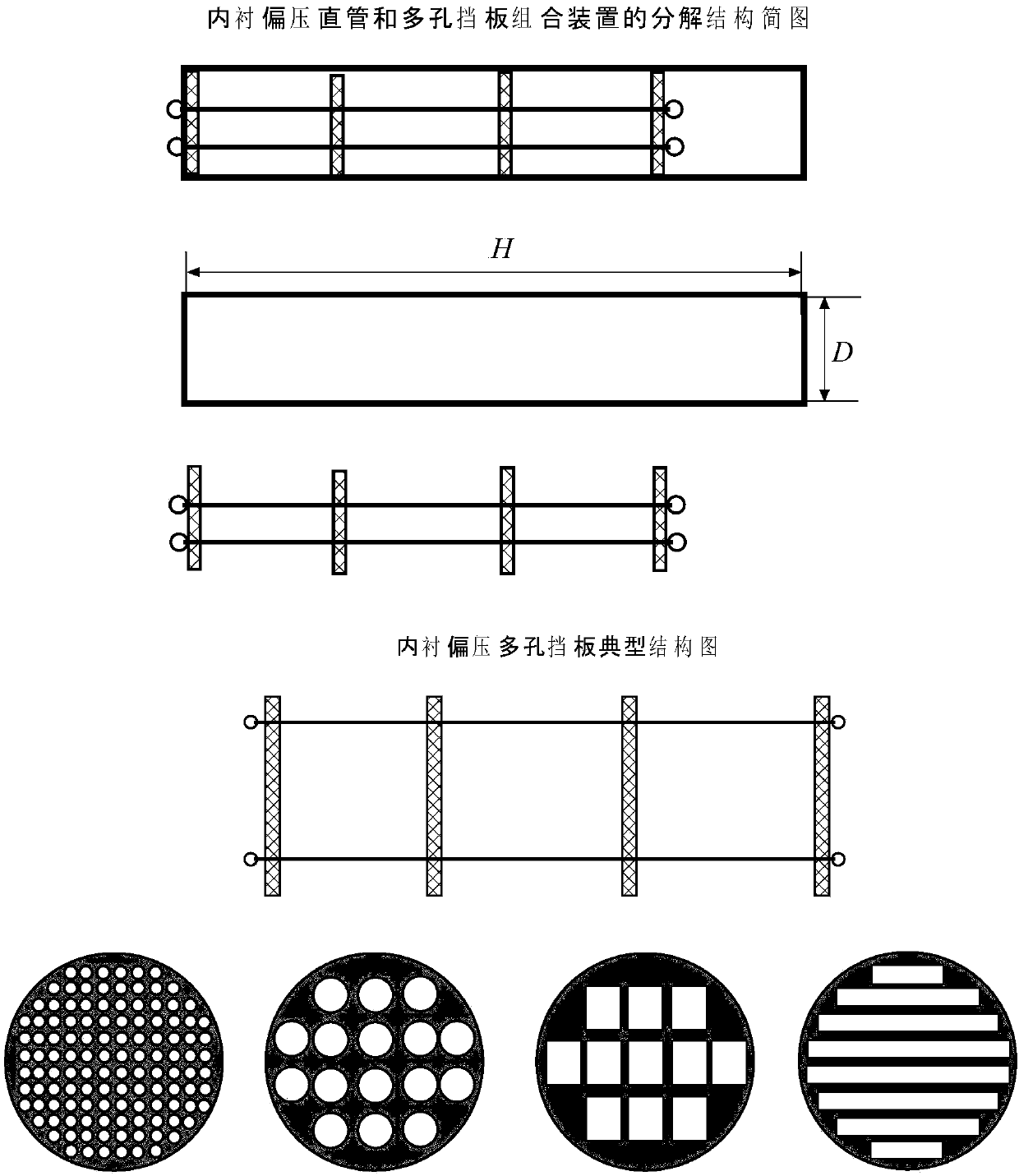

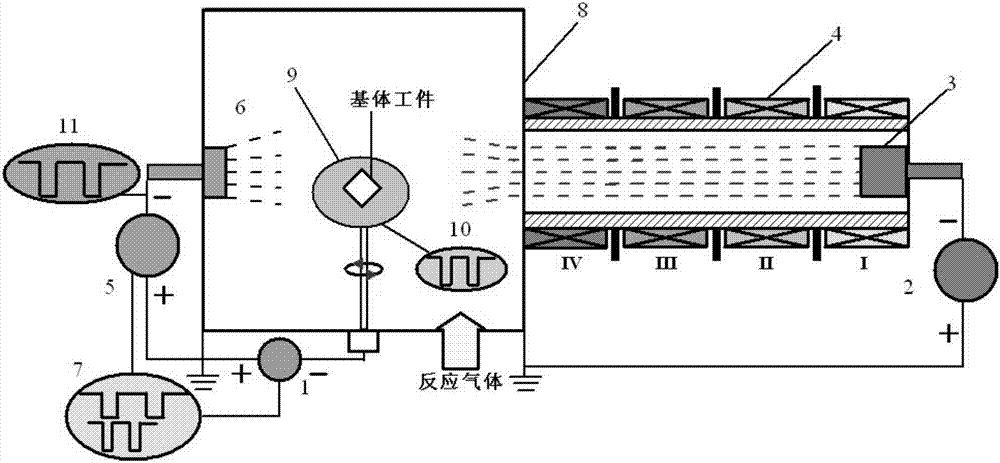

Composite vacuum deposition method of combination magnetic field, lining special-shaped tube and porous baffle

PendingCN109989011AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

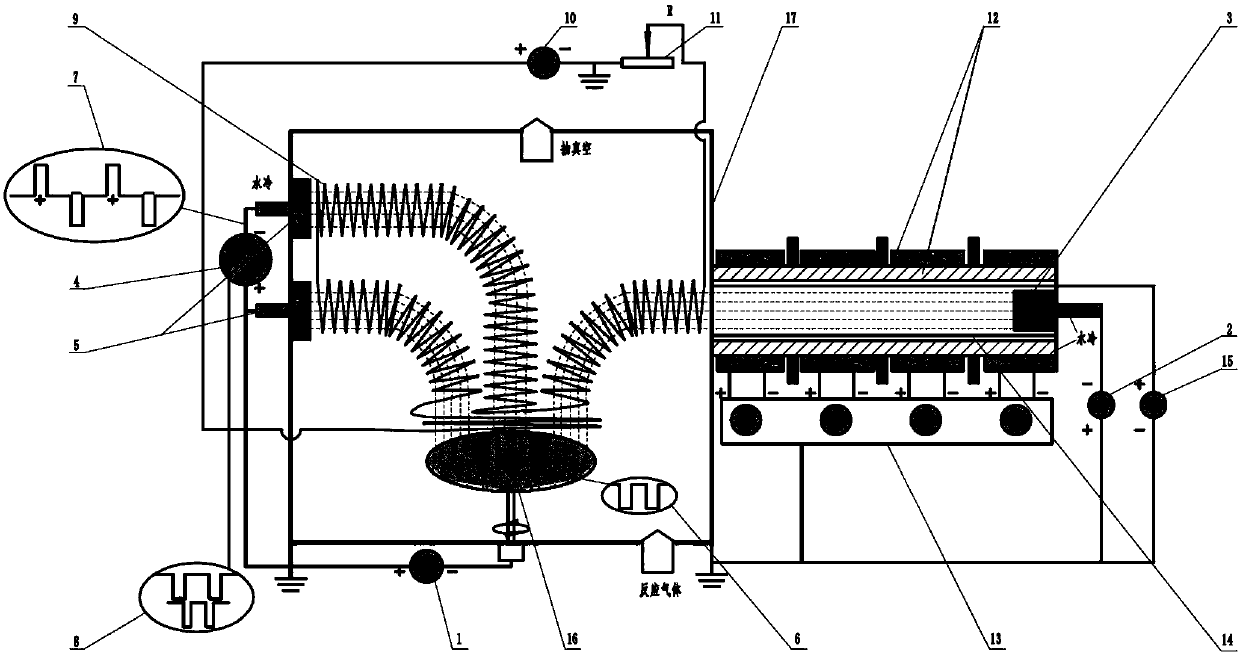

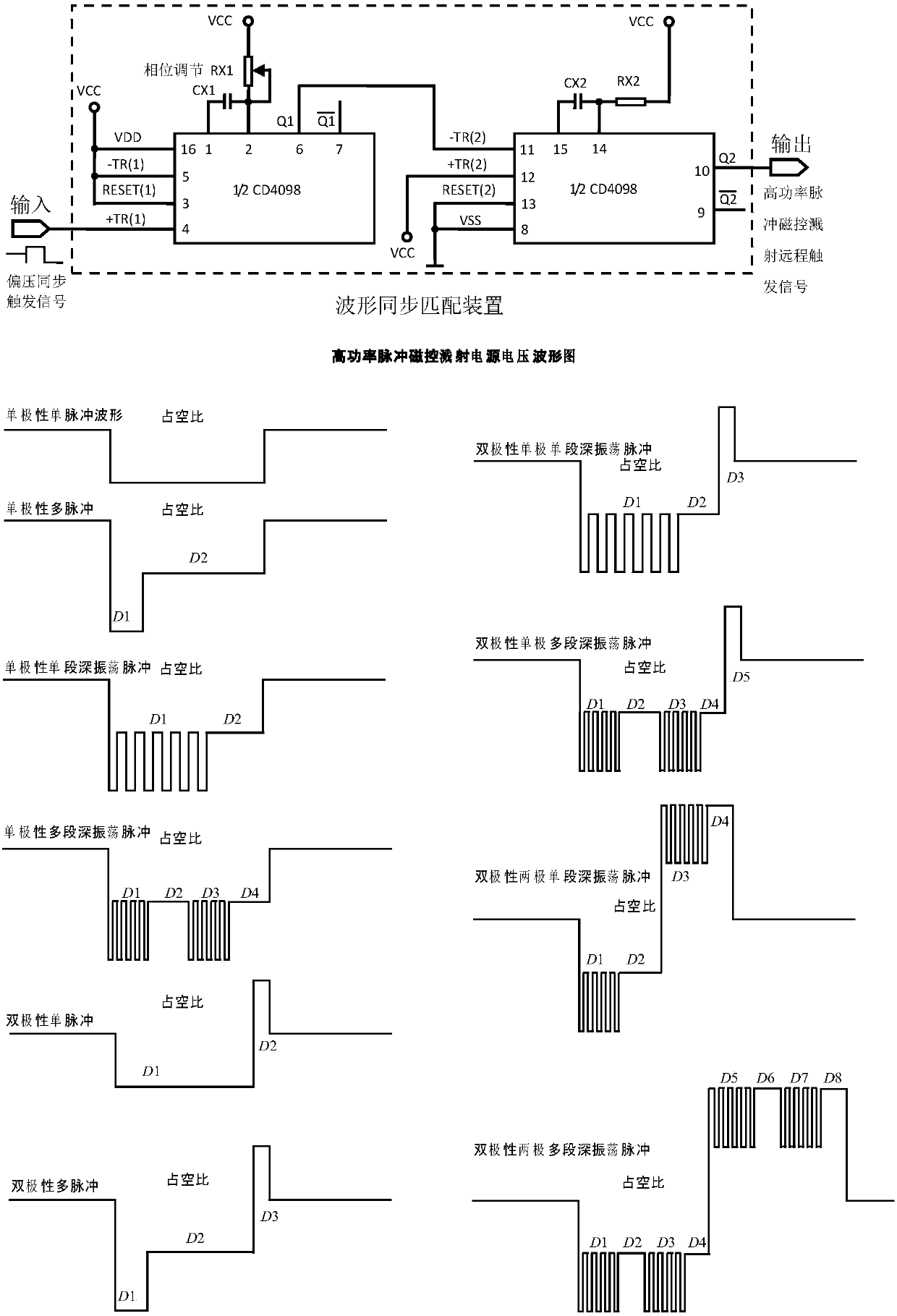

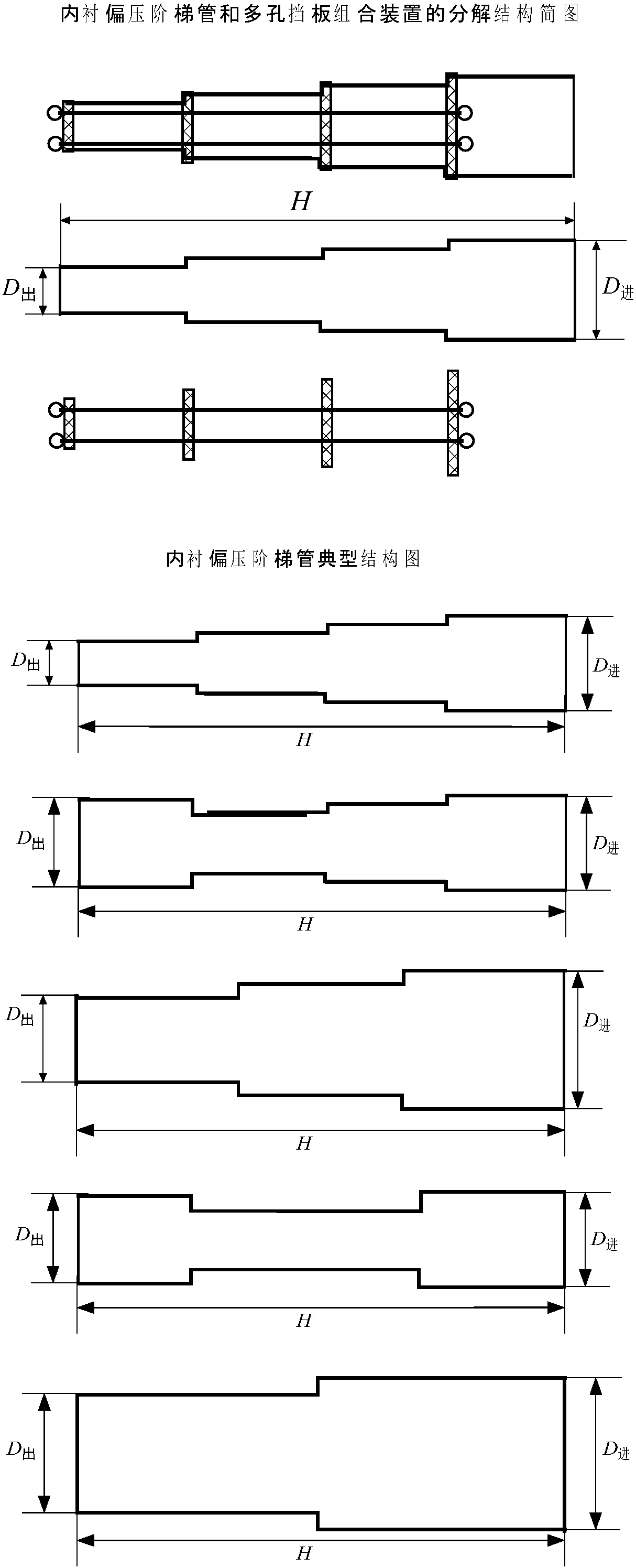

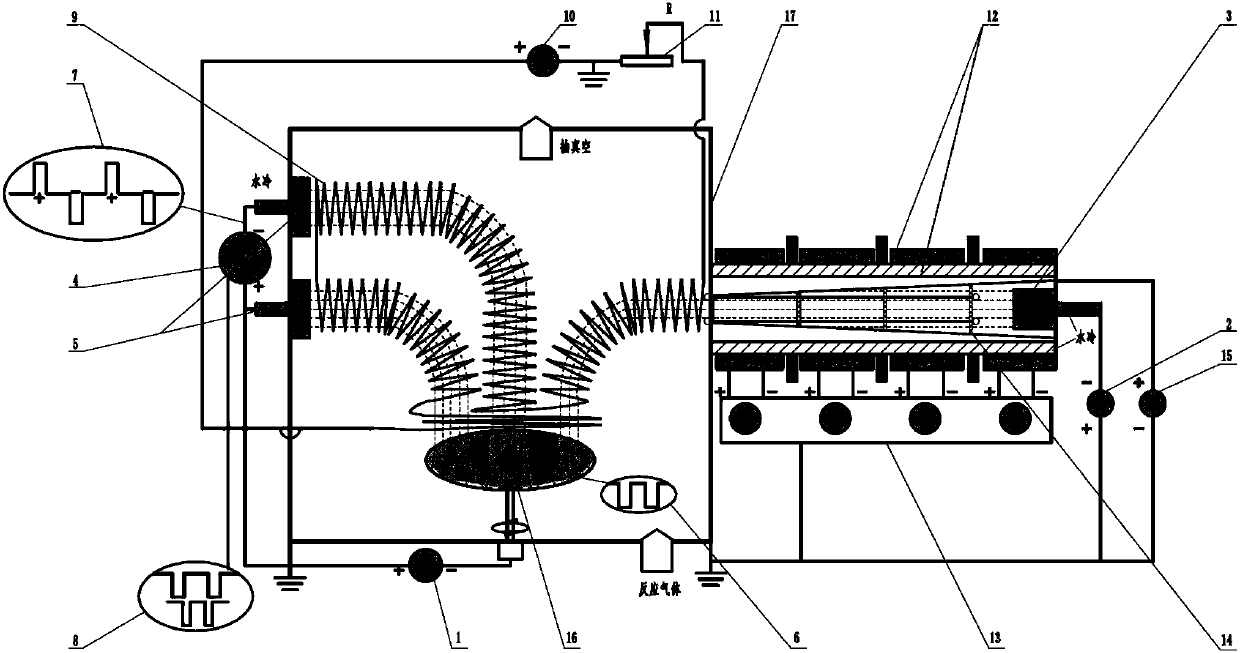

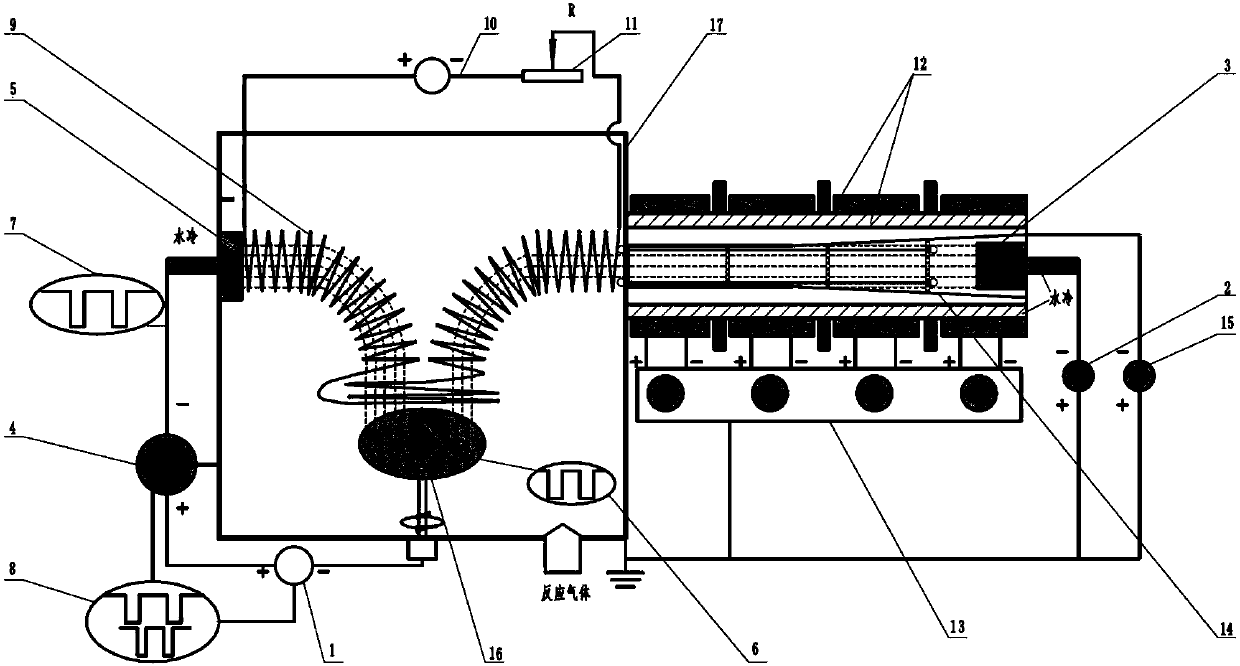

The invention discloses a composite vacuum deposition method of a combination magnetic field, a lining special-shaped tube and a porous baffle, and belongs to the technical field of material surface treatment. The problems of contamination of thin films and target material usage restrictions by large particles, loss of magnetically filtered arc plasma, and instability of high power pulsed magnetron sputtering discharge in arc ion plating are solved. A device comprises a target source of arc ion plating, a multistage magnetic field device, a lining bias voltage special-shaped tube and porous baffle combination device, a movable coil device, a high power pulsed magnetron sputtering target source and relevant power supply, a waveform matching device, a bias voltage power supply, and the like;and thin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4>Pa, a platingpower supply is turned on, the bias voltage power supply regulates energy of the plasma, the combination magnetic field and the lining special-shaped tube and porous baffle device eliminate large particle defects and guide transmission of the composite plasma, the loss in the vacuum chamber is reduced, and preparation technological parameters are set.

Owner:魏永强

Combined magnetic field and lining bias voltage conical pipe composite vacuum deposition method

PendingCN109989015AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingPlasma energyVacuum chamber

The invention discloses a combined magnetic field and lining bias voltage conical pipe composite vacuum deposition method, belongs to the technical field of material surface treatment, and aims at solving the problems about film pollution through large particles, the target material usage limit, magnetic filter arc plasma losses, unstable high-power pulse magnetron sputtering discharge and the like in arc ion plating. The device comprises a bias voltage power source, an arc ion plating target source and power source, a multi-level magnetic field device and power source, a lining bias voltage conical pipe device and bias voltage power source, a movable coil device and power source, a waveform matching device, a high-power pulse magnetron sputtering target source and power source and other devices. Film deposition is conducted, device connection is conducted, the system is started, and when the vacuum degree in a vacuum chamber is smaller than 10<-4>Pa, inflation of work gas is conducted, a coating power source is started, and the bias voltage power source adjusts plasma energy; and the multi-level magnetic field device and the movable coil device eliminate large particle defects andguiding composite plasma transmission, losses in the vacuum chamber are reduced, and preparing technology parameters are set.

Owner:魏永强

Combined magnetic field, combined tube and perforated baffle composite vacuum film coating method

PendingCN109989016AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingLarge particleMaterials science

The invention relates to a combined magnetic field, combined tube and perforated baffle composite vacuum film coating method, and belongs to the technical field of material surface treatment. The problems ofcontamination of thin films by large particles and using limiting of target materials in arc ion plating, loss of magnetically filtered arc plasmaand unstable high power pulsed magnetron sputtering discharging. A device of the method comprises an arc ion plating target source, a multistage magnetic field, a lining bias voltage tapered tube, straight tube and perforated baffle combination device, a twin target high power pulse magnetron sputtering target source, a movable coil device and relative power supply, a grid bias power supply, a waveform matching device and the like; thin film deposition comprises the steps that devices are connected, the system is started, when the vacuum degree of the vacuum cavity is smaller than 10-4 Pa, a working gas is introduced, a film plating powersupply is opened, energy of an arc plasma is adjusted by using the grid bias power supply, through the multistage magnetic field device and the movable coil device, the large particle defect in the arc plasma is eliminated, and the transportation of the composite plasma is guided, loss in the vacuum cavity is reduced, andtechnology parameters are set.

Owner:魏永强

Composite deposition method combined magnetic field arc ion plating and high-power pulse magnetron sputtering

PendingCN109989009AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite deposition method combined magnetic field arc ion plating and high-power pulse magnetron sputtering, and belongs to the technical field of material surface treatment. The problems such as pollution of macroparticles to thin films and the use limitation of target materials in the arc ion plating, and the losses of arc plasmas and the instability of high-power pulse magnetron sputtering discharge in the transmission process of a magnetic filter device are solved. Devices relating to the composite deposition method combined the magnetic field arc ion plating and the high-power pulse magnetron sputtering comprise a bias voltage power source, an arc ion plating target source, a power source of the arc ion plating target source, a multi-stage magnetic field device, a power source of the multi-stage magnetic field device, a movable coil device, a power source of the movable coil device, a waveform matching device, a high-power pulse magnetron sputtering target source, a power source of the high-power pulse magnetron sputtering target source, an oscilloscope and a vacuum chamber. The thin film deposition comprises the steps that the devices are connected, and a system is started; and when a vacuum degree in the vacuum chamber is less than 10<-4> Pa, a working gas is introduced, and a film plating power source is turned on. The bias voltage power source adjusts the energy of plasmas, the multi-stage magnetic field device and the movable coil device eliminate macroparticle defects and guide the transmission of composite plasmas, the losses in the vacuum chamber are reduced, and technological parameters are set.

Owner:魏永强

Combined magnetic field and lining conical pipe and ladder pipe composite vacuum coating method

PendingCN109989042AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingVacuum chamberCondensed matter physics

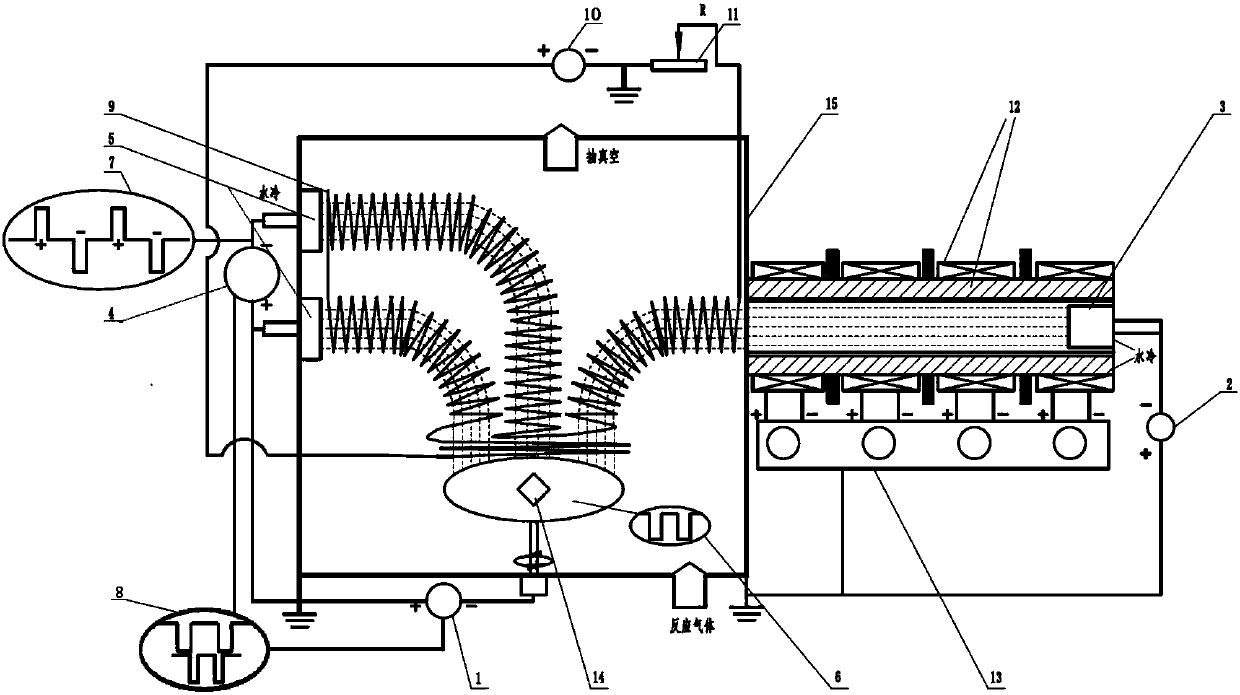

The invention discloses a combined magnetic field and lining conical pipe and ladder pipe composite vacuum coating method, and belongs to the technical field of material surface treatment. The problems that during arc ion plating, due to macroparticles, a thin film is polluted, target use is limited, magnetically filtered arc plasmas are damaged, and high-power pulse magnetic control discharge isnot stable are solved. A device comprises an arc ion plating target source, a multi-stage magnetic field device, a movable coil device, a twin target high-power pulse magnetron sputtering target source, a lining bias conical pipe and ladder pipe combined device and related power source, a grid bias power supply, a waveform matching device and the like. The method comprises the steps of thin film deposition, device connecting and system starting. When the vacuum degree in a vacuum chamber is smaller than 10<-4> Pa, work gas is led in, a coating power source is started, energy of plasmas can beadjusted through the grid bias power supply, the multi-stage magnetic field device and the movable coil device remove macroparticle defects and guide transmission of composite plasmas, losses in the vacuum chamber are reduced, and process parameters are set.

Owner:魏永强

Vacuum film plating method with combined magnetic field, lined straight pipe and multihole baffle combined

PendingCN109989024AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringInstability

The invention discloses a vacuum film plating method with a combined magnetic field, a lined straight pipe and a multihole baffle combined, and belongs to the technical field of material surface treatment. The vacuum film plating method with the combined magnetic field, the lined straight pipe and the multihole baffle combined aims to solve the problems such as the pollution of macroparticles to athin film, the use limitation of a target material, the loss of magnetically-filtered arc plasma and the instability of high-power pulsed magnetron sputtering discharge in arc ion plating. Devices relating to the vacuum film plating method comprise a bias voltage power source, an arc ion plating target source, a power source of the arc ion plating target source, a multistage magnetic field device, a power source of the multistage magnetic field device, a movable coil device, a power source of the movable coil device, a waveform matching device, a high-power pulsed magnetron sputtering targetsource, a power source of the high-power pulsed magnetron sputtering target source, a combined device of the lined bias voltage straight pipe and the multihole baffle, a power source of the combined device of the lined bias voltage straight pipe and the multihole baffle and the like. Thin film deposition comprises the steps that the devices are connected; a system is started; when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a working gas is introduced into the vacuum chamber, a film plating power source is started, the bias voltage power source adjusts the energy of the plasma, the multistage magnetic field device and the movable coil device eliminate defects of the macroparticles and guide the transmission of the composite plasma, the loss in the vacuum chamber is reduced, and technical parameters are set.

Owner:魏永强

Vacuum coating method for compounding combined magnetic field and lining bias-voltage straight tube

PendingCN109989019AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a vacuum coating method for compounding a combined magnetic field and a lining bias-voltage straight tube, belongs to the technical field of material surface treatment, and solves the problems of the pollution of the film, the target use restriction, the loss of the magnetic filtered arc plasma and the instability of high-power pulse magnetic-controlled sputtering discharging due to the macroparticles in the arc ion plating. The vacuum coating device comprises a bias-voltage power supply, an arc ion plating target source, an arc ion plating power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a lining bias-voltage straight tube device, a lining bias-voltage power supply, an movable coil device, an movable coil device power supply, a waveform matching device, a twin-target high-power pulse magnetic-controlled sputtering target source, a twin-target high-power pulse magnetic-controlled sputtering power supply and thelike. The vacuum coating method comprises the steps that the film is deposited, the device is connected, the system is started, when the vacuum degree in the vacuum chamber is less than 10 <-4>Pa, the working gas is fed, the coating power supply is started, the bias-voltage power supply adjusts the energy of the plasma, the multi-stage magnetic field device and the movable coil device eliminate the macroparticles defects and guide the transmission of the compound plasma, the loss in the vacuum chamber is reduced, and the preparation process parameters are set.

Owner:魏永强

Movable magnetic field arc ion plating and high-power pulse magnetron sputtering composite deposition method

PendingCN109989030AMake up for unstable dischargeGuaranteed high-density continuous productionVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringInstability

The invention provides a movable magnetic field arc ion plating and high-power pulse magnetron sputtering composite deposition method, and belongs to the technical field of material surface treatment.The method aims at solving the problems of contamination of large particles in arc ion plating to thin films, the use limitations of target materials, losses of arc plasma in the transmitting processof a magnetic filtering device, the instability of high-power pulse magnetron sputtering and the like. A device comprises a bias power source, an arc ion plating target source, an arc ion plating target source power source, a movable coil device, a movable coil device power source, a waveform matching device, a high-power pulse magnetron sputtering target source, a high-power pulse magnetron sputtering target source power source, an oscilloscope and a vacuum chamber. The thin films are deposited, wherein the device is connected, a system is started, when the vacuum degree in the vacuum chamber is smaller than 10-4 Pa, working gas is introduced, a plating power source is switched on, the bias power source is used for adjusting energy of arc plasma, large particle defects are eliminated andtransmitting of the composite plasma is guided through the movable coil device, losses in the vacuum chamber are reduced, process parameters are set, and the thin films are prepared.

Owner:魏永强

Vacuum film-coating method through combined magnetic field and compounding of lining special-shaped pipe and porous baffle

PendingCN109989036AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingInstabilityHigher Power

The invention provides a vacuum film-coating method through a combined magnetic field and compounding of a lining special-shaped pipe and a porous baffle, and belongs to the technical field of material surface treatment. The vacuum film-coating method is used for solving the problems of pollution of large particles to a film, target using limitation, loss of magnetic filtration arc plasma, instability of high-power pulse magnetron sputtering discharge and the like in arc ion plating. A device adopted by the vacuum film-coating method comprises an arc ion plating target source, a multi-stage magnetic field device, a lining bias-voltage special-shaped pipe and multi-porous baffle combination device, a movable coil device, a twin target high-power pulse magnetron sputtering target source andrelated power supply, a waveform matching device, a grid bias power supply and the like. Film deposition is conducted, specifically, the device is connected, a system is started, when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, working gas is introduced, a film-coating power supply is started, energy of the plasma is adjusted through the grid bias power supply, the combined magnetic field, the lining special-shaped pipe and a porous baffle device eliminate the defects of the large particles and guide transmission of the compound plasma, loss of the plasma in the vacuum chamber is reduced, and preparation process parameters are set.

Owner:魏永强

Combination magnetic field and lining tapered tube-porous baffle compounded vacuum deposition method

PendingCN109989035AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityMagnetic filtration

The invention discloses a combination magnetic field and lining tapered tube-porous baffle compounded vacuum deposition method, and belongs to the technical field of material surface treatment. In order to solve the problems of pollution to thin films by macroparticles in arc ion plating, target material using restrictions, magnetic filtration arc plasma losses, high-power pulse magnetron sputtering discharge instability and the like, the device disclosed in the invention comprises a grid bias power source, an arc ion plating target source and power source, a multistage magnetic field device and power source, a lining bias tapered tube and porous baffle combination device and power source, a movable coil device and power source, a waveform matching device, a high-power pulse magnetron sputtering target source and power source and other devices. Thin film deposition is conducted, the devices are connected and the system is started. When the vacuum degree of the inside of a vacuum chamber is smaller than 10<-4>Pa, working gas is connected in, a film coating power source is started, the grid bias power source can adjust the energy of plasma, the combination device can remove macroparticle defects and guide composite plasma conveyance, losses in the vacuum chamber are reduced and technological parameters are set.

Owner:魏永强

Vacuum coating method for compounding combined magnetic field and lining bias-voltage tapered tube

PendingCN109989021AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingCompound aInstability

The invention discloses a vacuum coating method for compounding a combined magnetic field and a lining bias-voltage tapered tube, belongs to the technical field of material surface treatment, and solves the problems of the pollution of the film, the target use restriction, the loss of the magnetic filtered arc plasma and the instability of high-power pulse magnetic-controlled sputtering discharging due to macroparticles in the arc ion plating. The vacuum coating device comprises a bias-voltage power supply, an arc ion plating target source, an arc ion plating power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a lining bias-voltage tapered tube device, a lining bias-voltage power supply, an movable coil device, an movable coil device power supply, a waveform matching device, a twin-target high-power pulse magnetic-controlled sputtering target source, a twin-target high-power pulse magnetic-controlled sputtering power supply and the like.The vacuum coating method comprises the steps that the film is deposited, the device is connected, the system is started, when the vacuum degree in the vacuum chamber is less than 10 <-4>Pa, the working gas is fed, the coating power supply is started, the bias-voltage power supply adjusts the energy of the plasma, the multi-stage magnetic field device and the movable coil device eliminate the macroparticles defects and guide the transmission of the compound plasma, the loss in the vacuum chamber is reduced, and the preparation process parameters are set.

Owner:魏永强

Composite vacuum deposition method of combination magnetic field, lining stepped tube and porous baffle

PendingCN109989012AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite vacuum deposition method of a combination magnetic field, a lining stepped tube and a porous baffle, and belongs to the technical field of material surface treatment. The problems of contamination of thin films and target material usage restrictions by large particles, loss of magnetically filtered arc plasma, and instability of high power pulsed magnetron sputtering discharge in arc ion plating are solved. A device comprises a bias voltage power supply, an arc ion plating target source and power supply, a multistage magnetic field device and power supply, alining bias voltage stepped tube and porous baffle device and power supply, a movable coil device and power supply, a waveform matching device, a high power pulse magnetron sputtering target source and power sully, and other devices; and thin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamberis less than 10<-4> Pa, a plating power supply is turned on, the bias voltage power supply regulates energy of plasma, the multistage magnetic field device and movable coil device eliminate large particle defects and guide transmission of composite plasma, the loss in the vacuum chamber is reduced, and preparation technological parameters are set.

Owner:魏永强

Combined magnetic field and lining porous baffle combined vacuum deposition method

PendingCN109989032AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingSputteringVacuum chamber

The invention provides a combined magnetic field and lining porous baffle combined vacuum deposition method and belongs to the technical field of material surface treatment. The combined magnetic field and lining porous baffle combined vacuum deposition method is provided for solving the problems of pollution of big particles to films, using restriction to target materials, losses of magnetic filtered electric arc plasmas, unstable discharge of high-power pulse magnetron sputtering and the like during arc ion plating. A device adopted in the method comprises a bias power supply, an arc ion plating target source, an arc ion plating power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a lining bias voltage porous baffle device, a lining bias power supply, a movable coil device, a movable coil device power supply, a waveform matching device, a high-power pulse magnetron sputtering target source, a high-power pulse magnetron sputtering powersupply and the like. The method comprises the steps of depositing a film, connecting the device, starting the system, introducing working gas when the internal vacuum degree of a vacuum chamber is less than 10<-4> Pa, starting a film plating power supply, conducting adjustment on energy of plasmas through the bias power supply, eliminating big particle defects and guiding transmission of the plasmas through the multi-stage magnetic field device and the movable coil device, reducing loss in the vacuum chamber, and setting parameters of the preparation process.

Owner:魏永强

Vacuum film plating method with combined magnetic field, lined cone-shaped tube and multihole baffle combined

PendingCN109989025AReduce the suck back effectGuaranteed deposition rateVacuum evaporation coatingSputtering coatingConical tubeInstability

The invention discloses a vacuum film plating method with a combined magnetic field, a lined cone-shaped tube and a multihole baffle combined, and belongs to the technical field of material surface treatment. The vacuum film plating method with the combined magnetic field, the lined cone-shaped tube and the multihole baffle combined aims to solve the problems such as the pollution of macroparticles to a thin film, the use limitation of a target material, the loss of magnetically-filtered arc plasma and the instability of high-power pulsed magnetron sputtering discharge in arc ion plating. Devices relating to the vacuum film plating method comprise a bias voltage power source, an arc ion plating target source, a power source of the arc ion plating target source, a multistage magnetic fielddevice, a power source of the multistage magnetic field device, a combined device of the lined bias voltage cone-shaped tube and the multihole baffle, a power source of the combined device of the lined bias voltage cone-shaped tube and the multihole baffle, a movable coil device, a power source of the movable coil device, a waveform matching device, a twin target high-power pulsed magnetron sputtering target source, a power source of the twin target high-power pulsed magnetron sputtering target source and the like. Thin film deposition comprises the steps that the devices are connected; a system is started; when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a working gas is introduced into the vacuum chamber, a film plating power source is started, the bias voltage power source adjusts the energy of the plasma, the combined device eliminates defects of the macroparticles and guides the transmission of the composite plasma, the loss in the vacuum chamber is reduced, andtechnical parameters are set.

Owner:魏永强

Movable magnetic field arc ion plating and twin target high-power pulse magnetron sputtering method

PendingCN109989041AGuaranteed deposition rateIncrease ionization rateVacuum evaporation coatingSputtering coatingPlasma energyVacuum chamber

The invention discloses a movable magnetic field arc ion plating and twin target high-power pulse magnetron sputtering method, belongs to the technical field of material surface treatment, and aims atsolving the problems about film pollution through large particles in arc ion plating, the target material usage limit, arc plasma losses in the magnetic filter device transmission process, unstable high-power pulse magnetron sputtering discharge and the like. The device comprises a bias voltage power source, an arc ion plating target source and power source, a movable coil device and power source, a waveform matching device, a twin target high-power pulse magnetron sputtering target source and power source, an oscilloscope and a vacuum chamber. Film deposition is conducted, device connectionis conducted, the system is started, and when the vacuum degree in the vacuum chamber is smaller than 10<-4>Pa, inflation of work gas is conducted, a coating power source is started, and the bias voltage power source is utilized for adjusting arc plasma energy; and the movable coil device is used for eliminating large particle defects and guiding the composite plasma transmission path, losses in the vacuum chamber are reduced, and technology parameters are set for film preparing.

Owner:魏永强

Combined magnetic field arc ion plating and twin-target high-power pulse magnetron sputtering method

PendingCN109989027AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringInstability

The invention provides a combined magnetic field arc ion plating and twin-target high-power pulse magnetron sputtering method, and belongs to the technical field of material surface treatment. The method aims at solving the problems of contamination of large particles in arc ion plating to thin films, the use limitations of target materials, losses of magnetic filtering on arc plasma, the instability of high-power pulse magnetron sputtering and the like. A device comprises a bias power source, an arc ion plating target source, an arc ion plating target source power source, a multi-stage magnetic field device, a multi-stage magnetic field device power source, a movable coil device, a movable coil device power source, a waveform matching device, a twin-target high-power pulse magnetron sputtering target source, a twin-target high-power pulse magnetron sputtering target source power source, an oscilloscope and a vacuum chamber. The thin films are deposited, wherein the device is connected, a system is started, when the vacuum degree in the vacuum chamber is smaller than 10-4 Pa, working gas is introduced, a plating power source is switched on, the bias power source is used for adjusting energy of arc plasma, large particle defects are eliminated and transmitting of the composite plasma is guided through the multi-stage magnetic field device and the movable coil device, losses in the vacuum chamber are reduced, and preparation process parameters are set.

Owner:魏永强

Combined magnetic field and lining bias voltage straight pipe composite vacuum deposition method

PendingCN109989014AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingVacuum chamberPlasma energy

The invention discloses a combined magnetic field and lining bias voltage straight pipe composite vacuum deposition method, belongs to the technical field of material surface treatment, and aims at solving the problems about film pollution through large particles, the target material usage limit, magnetic filter arc plasma losses, unstable high-power pulse magnetron sputtering discharge and the like in arc ion plating. The device comprises a bias voltage power source, an arc ion plating target source and power source, a multi-level magnetic field device and power source, a lining bias voltagestraight pipe device and power source, a movable coil device and power source, a waveform matching device, a high-power pulse magnetron sputtering target source and power source and other devices. Film deposition is conducted, device connection is conducted, the system is started, and when the vacuum degree in a vacuum chamber is smaller than 10<-4>Pa, inflation of work gas is conducted, a coatingpower source is started, and the bias voltage power source adjusts plasma energy; and the multi-level magnetic field device and the movable coil device eliminate large particle defects and guiding composite plasma transmission, losses in the vacuum chamber are reduced, and preparing technology parameters are set.

Owner:魏永强

Multi-level magnetic field arc ion plating method based on lined straight pipe and porous baffle

ActiveCN106676483BReduce lossImprove transmission efficiencyVacuum evaporation coatingSputtering coatingEnergy regulationFilter effect

The invention relates to a lining straight pipe and porous baffle compound type multistage magnetic field arc ion plating method, and belongs to the technical field of material surface treatment. The problems of pollution of large particles and deposition ions in a multistage magnetic field filtering device to pipe inner walls and losses of arc plasmas in the transporting process are solved. The method includes the steps that (1) workpieces to be subject to film coating are placed on a sampling table in a vacuum chamber, a related power source is on, and an external water cooling system is started; (2) thin film deposition is carried out, wherein after the vacuum degree in the vacuum chamber is smaller than 10<-4> Pa, working gas is led in, the air pressure is adjusted, a film coating power source is started, meanwhile, a grid bias power source is used for attracting the arc plasmas at the an outlet and conducting energy adjustment, through stopping shield of the self shape and the structure combination of a lining positive bias straight pipe and porous baffle compound type device, the restraining effect of a positive bias electric field and a filtering effect of a multistage magnetic field, large particles defects are effectively eliminated, the transmission efficiency of the arc plasmas is guaranteed, the technological parameter is set, and thin film preparing is carried out.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

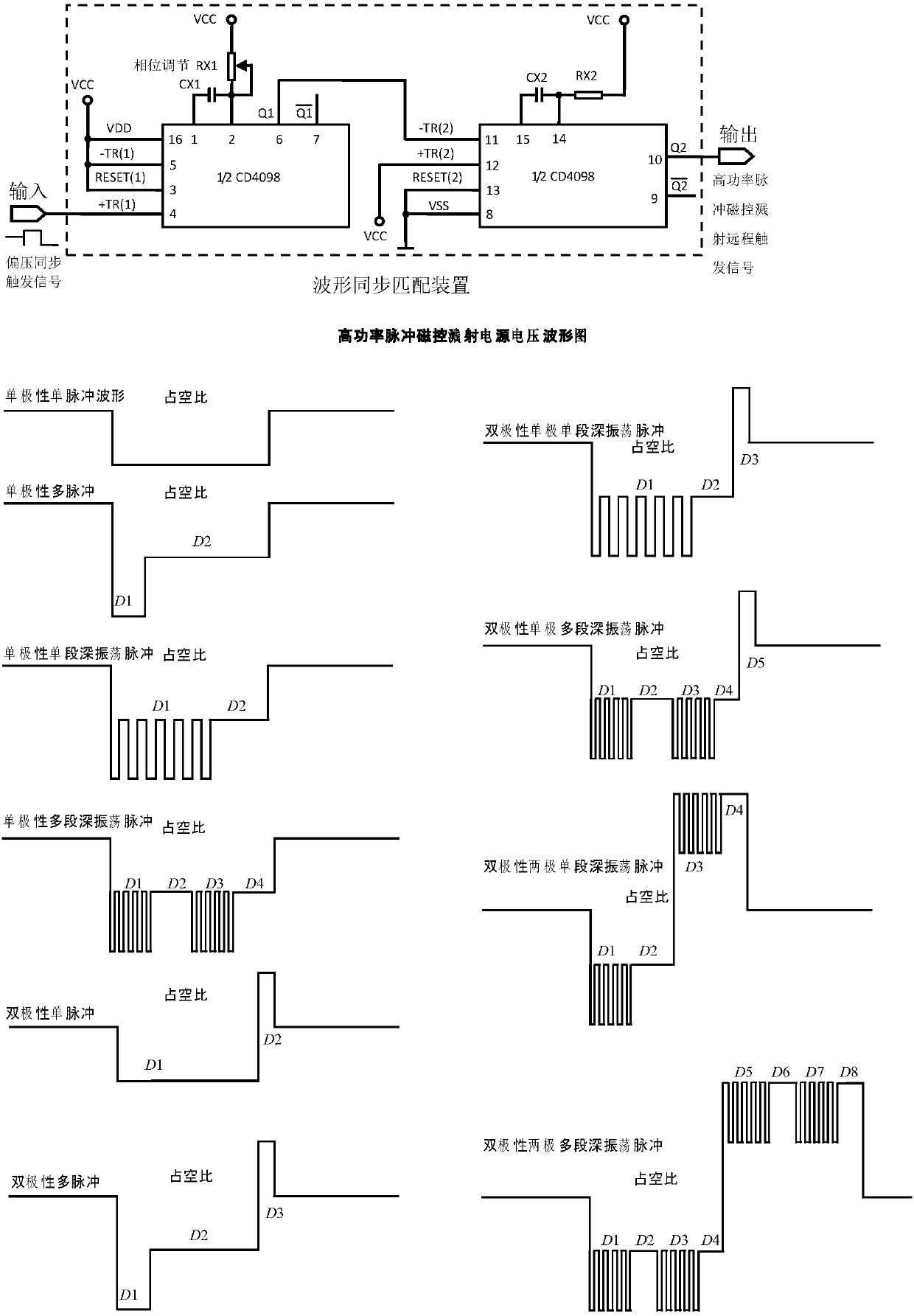

Combination deposition method of arc ion plating and high power pulse magnetron sputtering

ActiveCN104862653BAchieve pinning effectGuaranteed normal transmissionVacuum evaporation coatingSputtering coatingSemiconductor materialsAlloy

The invention provides a deposition method adopting combination of arc ion plating and high power pulsed magnetron sputtering, belongs to the technical field of material surface treatment, and aims to solve the problems of large particles caused by the fact that low-melting-point pure metal or a multi-element alloy material and a non-metal material, especially a semiconducting material and an insulating material, are taken as target materials to be applied in a traditional arc ion plating method, limitation of use extension of arc ion plating target materials, low ionization rate and low thin film deposition efficiency of a traditional magnetron sputtering technology as well as unstable discharging of conventional high power pulsed magnetron sputtering. The method comprises steps as follows: step one, a to-be-coated workpiece is placed on a sample table in a vacuum chamber, a related power supply is switched on; step two, thin film deposition is performed and comprises steps as follows: when the vacuum degree in the vacuum chamber is lower than 10<-2> Pa, working gas is introduced, gas pressure is adjusted, the related power supply is switched on, after the target surface is cleaned, a synchronous waveform matching device is adopted to adjust waveforms output by a grid bias power supply and a high power pulsed magnetron sputtering power supply, required technological parameters are set, and thin film deposition is performed.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Vacuum film plating method with combined magnetic field, lined bias voltage cone-shaped tube and straight tube combined

PendingCN109989023AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingStraight tubeInstability

The invention discloses a vacuum film plating method with a combined magnetic field, a lined bias voltage cone-shaped tube and a straight tube combined, and belongs to the technical field of materialsurface treatment. The vacuum film plating method with the combined magnetic field, the lined bias voltage cone-shaped tube and the straight tube combined aims to solve the problems such as the pollution of macroparticles to a thin film, the use limitation of a target material, the loss of magnetically-filtered arc plasma and the instability of high-power pulsed magnetron sputtering discharge in arc ion plating. Devices relating to the vacuum film plating method comprise an arc ion plating target source, a multistage magnetic field device, a combined device of the lined bias voltage cone-shaped tube and the straight tube, a twin target high-power pulsed magnetron sputtering target source, a movable coil device, related power sources, a waveform matching device, a bias voltage power source,a sample table and a vacuum chamber. Thin film deposition comprises the steps that the devices are connected; a system is started; when the vacuum degree in the vacuum chamber is less than 10<-4> Pa,a working gas is introduced into the vacuum chamber, a film plating power source is started, the bias voltage power source adjusts the energy of the plasma, the multistage magnetic field device and the movable coil device eliminate defects of the macroparticles and guide the transmission of the composite plasma, the loss in the vacuum chamber is reduced, and technical parameters are set.

Owner:魏永强

Multistage Magnetic Field Arc Ion Plating Method of Lining Positively Biased Conical Tube and Straight Tube Composite

ActiveCN106756823BFast depositionImprove mechanical propertiesVacuum evaporation coatingSputtering coatingConical tubeFilter effect

The invention relates to a multistage magnetic field electric arc iron plating method adopting lining positive bias tapered pipe and straight pipe compositing and belongs to the technical field of material surface treatment. The problem of losses in the process of pollution cleaning of macroparticles and deposited irons to the inner wall of a pipe and transmitting of electric arc plasma in a filtering device of a multistage magnetic field is solved. The method comprises the following steps that firstly, a workpiece to be subjected to film plating is placed on a sample table in a vacuum chamber, relative power supplies are powered on, and an external water-cooling system is started; secondly, a thin film is deposited, specifically, when the vacuum degree in the vacuum chamber is smaller than 10<-4> Pa, working air is pumped in, air pressure is adjusted, and a film plating power supply is started; meanwhile, a bias power supply is utilized to attract electric arc plasma in an outlet, and energy is adjusted; by means of the self obstructing shield of a lining positive bias tapered pipe and straight pipe compositing device, the inhibiting effect of a positive bias electric field and the filtering effect of the multistage magnetic field, the macroparticile defect is effectively eliminated, and the transmitting efficiency of the electric arc plasma is guaranteed; and the needed process parameters are set to prepare the thin film.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Composite vacuum deposition method of combination magnetic field, lining tapered tube and stepped tube

PendingCN109989040AIncrease ionization rateReduce the suck back effectVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite vacuum deposition method of a combination magnetic field, a lining tapered tube and a stepped tube, and belongs to the technical field of material surface treatment. The problems of contamination of thin films and target material usage restrictions by large particles, loss of magnetically filtered arc plasma, and instability of high power pulsed magnetron sputtering discharge in arc ion plating are solved. A device comprises a target source of arc ion plating, a multistage magnetic field device, a movable coil device, a high power pulse magnetron sputteringtarget source, a lining bias voltage tapered tube and stepped tube combination device and relevant power supply, a bias voltage power supply, a waveform matching device, and other devices; and thin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a plating power supply is turned on, the bias voltage power supply regulates energy of plasma, the multistage magnetic field device and movable coil device eliminate large particle defects and guide transmission of composite plasma, the loss in the vacuum chamber is reduced, and preparation technological parameters are set.

Owner:魏永强

Composite vacuum deposition method of composite magnetic field, composite tube and porous baffle

PendingCN109989039AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite vacuum deposition method of a composite magnetic field, a composite tube and a porous baffle, and belongs to the technical field of material surface treatment. Theproblems of contamination of thin films and target material usage restrictions by large particles, loss of magnetically filtered arc plasma, and instability of high power pulsed magnetron sputtering discharge in arc ion plating are solved. A device comprises a target source of arc ion plating, a multistage magnetic field device, a lined bias voltage tapered tube, a straight tube and porous bafflecomposite device, a high power pulse magnetron sputtering target source, a movable coil device, a relevant power supply, a bias voltage power supply, a waveform matching device, and other devices; andthin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a plating power supply is turned on, the bias voltage power supply regulates energy of plasma, the multistage magnetic field device and the movable coil device eliminate large particle defects and guide transmission of composite plasma, the loss in the vacuum chamber is reduced, and technological parameters are set.

Owner:魏永强

Vacuum plating method adopting combination of composite magnetic field, lining ladder pipe and porous baffle

PendingCN109989038AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a vacuum plating method adopting combination of a composite magnetic field, a lining ladder pipe and a porous baffle, and belongs to the technical field of material surface processing. The problems of pollution of macroparticles in arc ion plating towards a thin film, use limitation of a target material, loss of magnetically filtered arc plasma, instability of high-power pulse magnetron sputtering discharge and the like are solved. A device comprises a bias voltage power source, an arc ion plating target source, an arc ion plating power source, a multi-level magnetic field device, a multi-level magnetic field device power source, a lining bias voltage ladder pipe and porous baffle device, a lining bias voltage power source, a movable coil device, a movable coil device power source, a waveform matching device, a high-power pulse magnetron sputtering target source, a high-power pulse magnetron sputtering power source and the like. The vacuum plating method adopting the combination of the composite magnetic field, the lining ladder pipe and the porous baffle comprises a step of thin film deposition, specifically, the devices are connected, a system is turned on, when a vacuum degree is lower than 10<-4>Pa, working gas is introduced, the bias voltage power source is started to adjust the energy of plasma, the multi-level magnetic field device and the movablecoil device eliminate macroparticle defects and guide transmission of composite plasm, loss in a vacuum chamber is reduced, and preparation technology parameters are set.

Owner:魏永强

Combined magnetic field and lining straight pipe and perforated baffle composite vacuum deposition method

PendingCN109989034AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingSputteringStraight tube

The invention discloses a combined magnetic field, lining straight pipe and perforated baffle composite vacuum deposition method, and belongs to the technical field of material surface treatment. Theproblems that during arc ion plating, due to macroparticles, a thin film is polluted, target use is limited, magnetically filtered arc plasmas are damaged, and high-power pulse magnetic control discharge is not stable are solved. A device comprises a grid bias power supply, an arc ion plating target source and power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a movable coil device, a movable coil device power supply, a waveform matching device, a high-power pulse magnetron sputtering target source, a high-power pulse magnetron sputtering powersource, a lining bias straight pipe and porous baffle combined device and power source and the like. The method comprises the steps of thin film deposition, device connecting and system starting. When the vacuum degree in a vacuum chamber is smaller than 10<-4> Pa, work gas is led in, a coating power source is started, energy of plasmas can be adjusted through the grid bias power supply, the multi-stage magnetic field device and the movable coil device remove macroparticle defects and guide transmission of composite plasmas, losses in the vacuum chamber are reduced, and process parameters areset.

Owner:魏永强

Composite deposition method of multi-level magnetic field arc ion plating and high power pulse magnetron sputtering

ActiveCN104947046BGuaranteed normal transmissionGuaranteed deposition rateVacuum evaporation coatingSputtering coatingElectric dischargeInstability

The invention discloses a multistage magnetic field arc ion plating and high power pulse magnetron sputtering compound deposition method, and belongs to the technical field of material surface treatment. According to the method, the problems of the low-melting-point pure metal or multi-component alloy material and nonmetallic materials (such as graphite) that particles in arc ion plating are large, the magnetron sputtering ionization rate and the deposition efficiency is low and the use of high-melting-point target materials is limited are solved, the electric discharge instability of the high power pulse magnetron sputtering is broken through, and the use range of the arc ion plating target materials is expanded. The method comprises the following steps: 1, placing a workpiece to be plated onto a sample table in a vacuum chamber, and switching in related power supplies; 2, conducting film deposition: when the vacuum degree in the vacuum chamber is less than 10<-2> Pa, introducing working gas and adjusting air pressure, turning on the film plating power supply, adjusting the output waveforms of the bias power supply and the magnetron sputtering power supply through a waveform synchronous matching device, utilizing a multistage magnetic field straight pipe magnetic filtering device to eliminate the large particle defect and ensure the transmission efficiency of arc plasmas, setting needed processing parameters, and conducting film deposition.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com