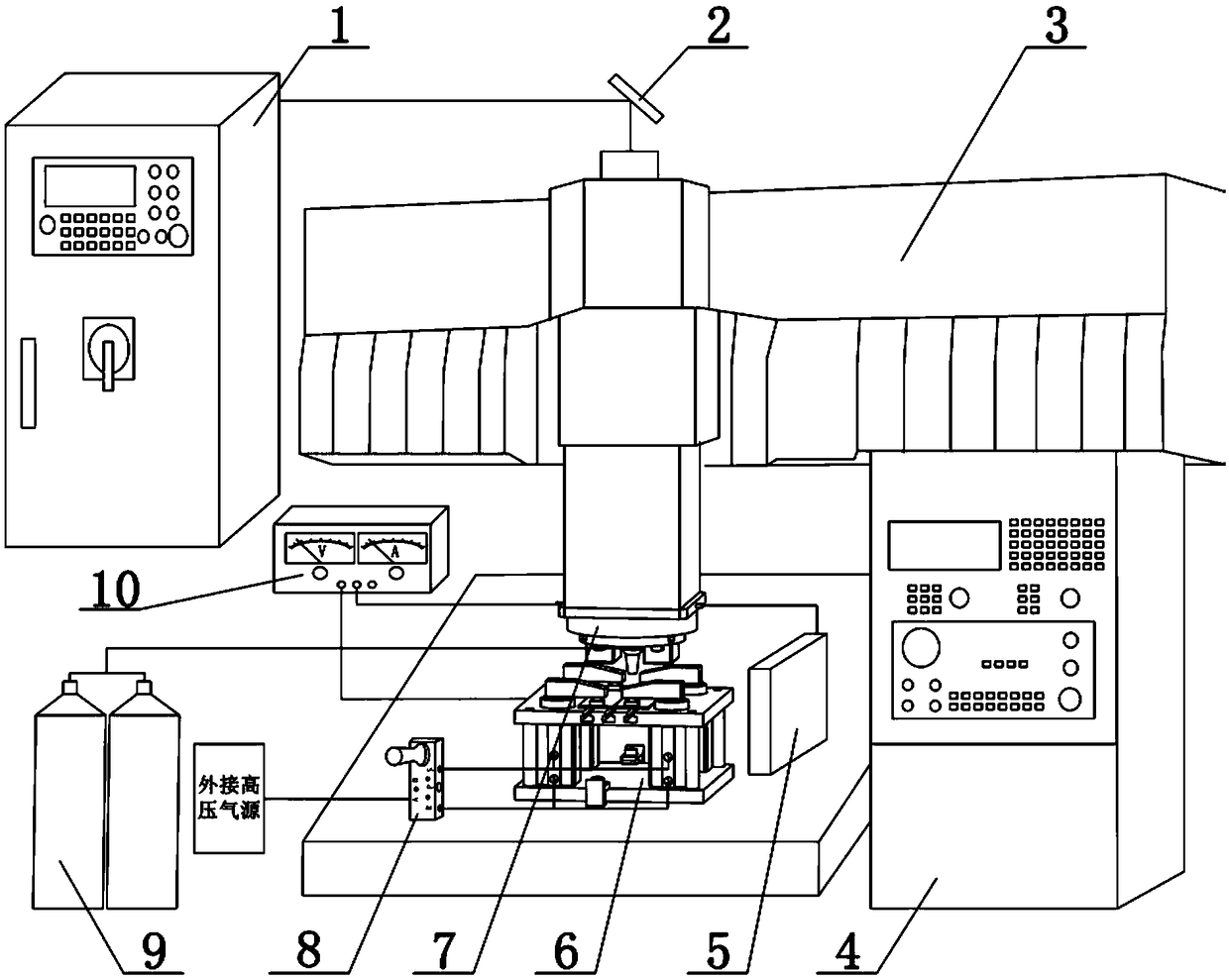

Rotary electric field and magnetic field synchronously assisted laser welding device and method

A laser welding and synchronous auxiliary technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

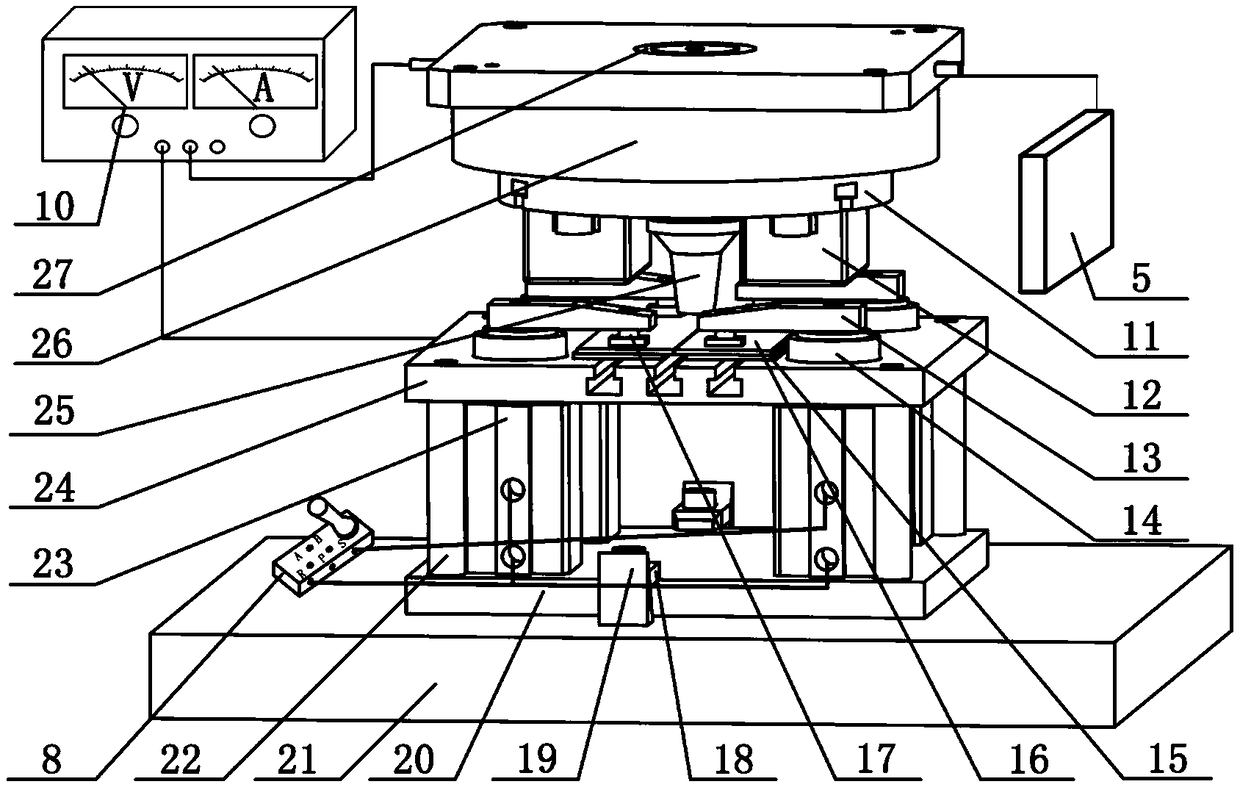

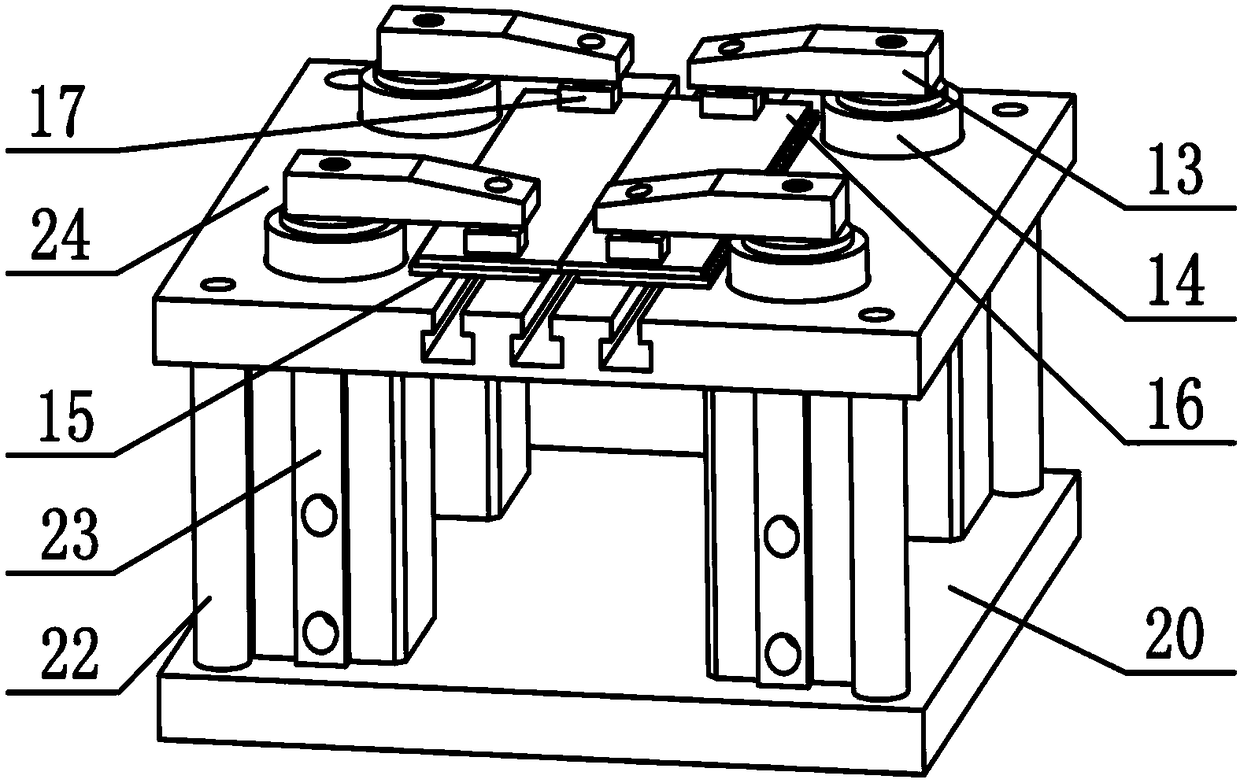

[0080] Implementation case 1: Electric-magnetic field assisted laser welding industrial pure nickel Ni201

[0081] First, wipe off the oil stains and other dirt on the surface of many pieces of industrial pure nickel Ni201 to be welded with acetone, and then dry them with wind after wiping, and keep them dry and clean. Put industrial pure nickel on the base plate of the electric field, and control the manual switch 8 of the pneumatic valve in the external air circuit connected to the rotary cylinder 23 (the electric-magnetic valve can be used to control the on-off of the air circuit in automatic production), and the rotation can be realized. The transition between the working states of the cylinder 23. Switch the cylinder to working mode, as figure 2 Shown is the clamping working state of the rotary cylinder 23.

[0082] Secondly, set the welding parameters of pure nickel in CNC welding industry: laser power P=1500W, welding speed V=600mm / min, use the mixed gas of helium an...

Embodiment example 2

[0086] After the test case 1 is completed, take another piece of processed industrial pure nickel and put it on the electric field generating base plate 24, and toggle the manual switch 8 of the pneumatic valve to make the workpiece pressing block 17 press the workpiece 13. Loosen the screws that fix the NdFeB permanent magnets, shorten the distance between the two permanent magnets, use a magnetic field strength tester to test that the magnetic field strength at the laser focus position is 70mT, and set the parameters of the encoder to control the speed of the direct drive motor. 200r / min. The electric field does not interact with the weld puddle.

[0087] Then start the CO2 laser to weld the industrial pure nickel sheet. After the welding is completed, adjust the manual switch 8 of the pneumatic valve to make the piston of the rotary cylinder 23 rise, and the workpiece pressing block 17 leaves the workpiece surface to take off the workpiece. Using wire cutting along the di...

Embodiment example 3

[0089] After the test case 2 is completed, another piece of processed industrial pure nickel is placed on the electric field generating base plate 24, and the manual switch 8 of the pneumatic valve is toggled to make the workpiece pressing block 17 press the workpiece 13. The magnetic field strength is still 70mT, and the parameters of the encoder are set to control the speed of the direct drive motor to 600r / min. Start the power supply 10 and adjust the output voltage to 20V.

[0090] Then start the CO2 laser to weld the industrial pure nickel sheet. After the welding is completed, adjust the manual switch 8 of the pneumatic valve to make the piston of the rotary cylinder 23 rise, and the workpiece pressing block 17 leaves the workpiece surface to take off the workpiece. Using wire cutting along the direction perpendicular to the welding direction, the metallographic sample is cut in the cross section. The surface of the sample is ground and polished, corroded by nitric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com