Steel box girder manufacturing and welding process

A welding process and technology of steel box girders, which are applied in bridges, bridge materials, bridge construction, etc., can solve the problems of large influence on geometric accuracy, large number of steel box girder segments, and large number of penetration welds, etc., to achieve convenient Tailored welding, guaranteed welding quality, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

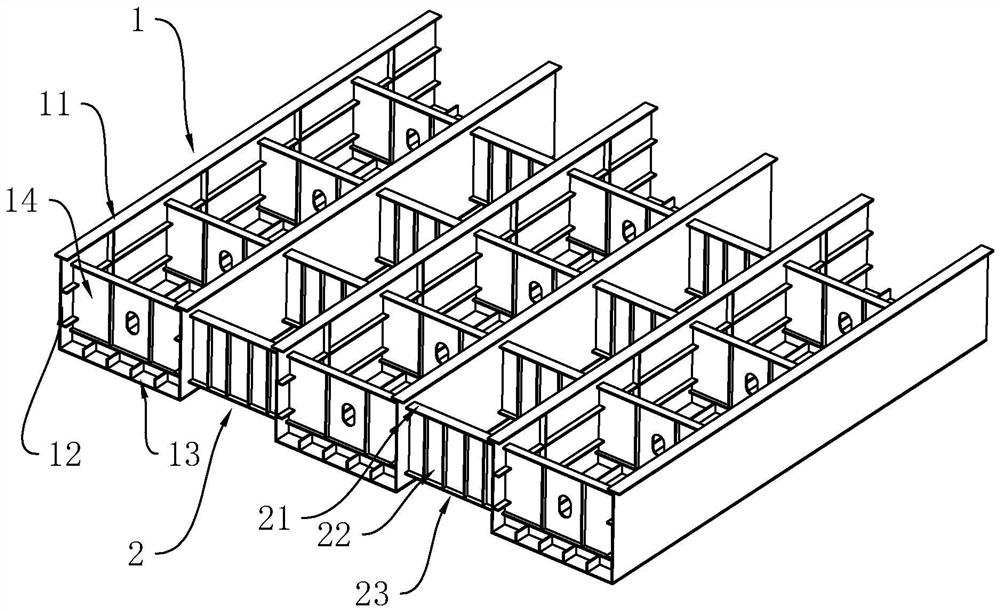

[0086] The present invention will be described in further detail below in conjunction with the accompanying drawings.

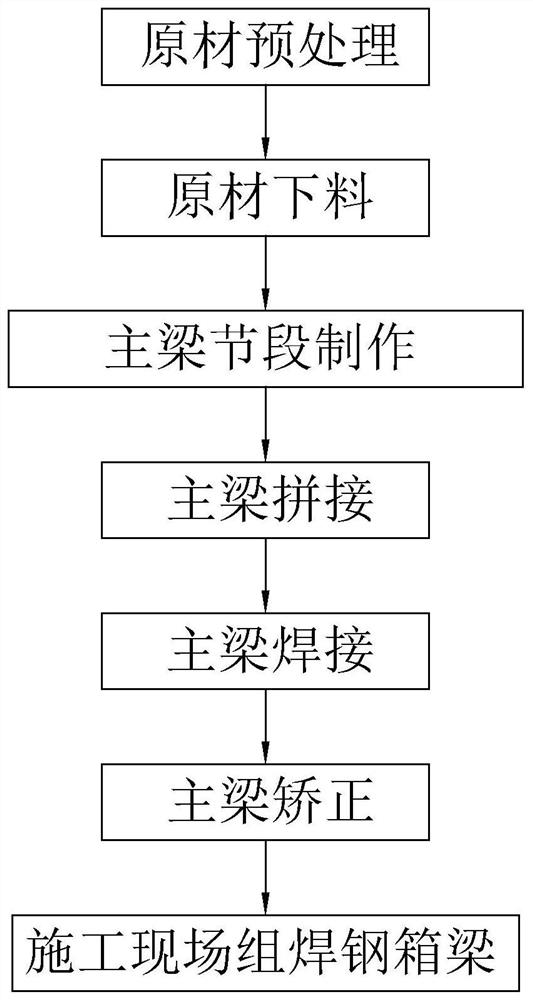

[0087] refer to figure 2 , is the manufacturing welding process of a kind of steel box girder disclosed by the present invention, comprises the following steps:

[0088] Step 1. Raw material pretreatment:

[0089] 1. Before the steel plate is unloaded, the surface quality of the steel plate is checked and the surface dirt is removed, and then the nine-roller and eleven-roller leveling machines are used to level the steel plate according to different plate thicknesses to ensure the flatness of the steel plate and eliminate the internal defects of steel plate rolling. stress;

[0090] 2. Steel plates and various profiles are shot blasted and sprayed with workshop primer on the steel pretreatment line. The workshop primer is sprayed once, and the thickness of the paint film is 25 μm.

[0091] Step 2, raw material cutting:

[0092] 1. The rolling direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com