Martensitic stainless steel forged piece and forging and rolling heat treatment integrated production process

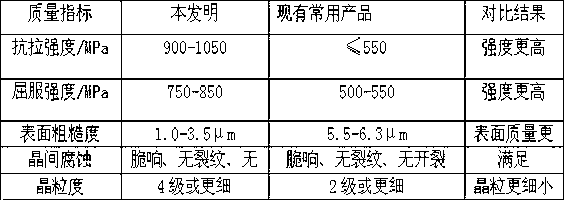

A martensitic stainless steel and forging technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of low tensile strength, yield strength elongation, end face shrinkage and corrosion resistance of stainless steel forgings, and achieve defects. Reduce the effect of obvious, toughness and low temperature impact performance, and ensure the effect of corrosion resistance

Active Publication Date: 2013-06-12

WUXI PAIKE HEAVY CASTING & FORGING

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Judging from the current technology, the tensile strength, yield strength, elongation, end face shrinkage and corrosion resistance of stainless steel forgings in steam turbines are not high, which needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a martensitic stainless steel forged piece and a forging and rolling heat treatment integrated production process. The martensitic stainless steel forged piece comprises the following chemical components: 0.4-0.7% of C, 0.1-0.3% of Si, 1.6-1.8% of Mn, 0.01% of P, 0.008% of S, 0.03-0.05% of Nb, 0.02-0.06% of V, 0.006-0.015% of Ti, 0.9-1.3% of Ni, 13.3-13.6% of Cr, 0.2-0.4% of Cu, 0.4-0.6% of Mo, 0.08-0.09% of N, 0.1-0.3% of Al, 0.008-0.009% of B, 0.1-0.3% of composite rare earth and the balance of Fe. According to the martensitic stainless steel forged piece disclosed by the invention, by limiting the components and process parameters, the corrosion resistance of the stainless steel forged piece is ensured, and the corrosion resistance at the part with splashing of water drops is especially improved.

Description

technical field [0001] The invention relates to a forging and a manufacturing process, in particular to a martensitic stainless steel forging and an integrated production process of forging, rolling and heat treatment. Background technique [0002] Many stainless steel parts in steam turbines are forgings, and the forgings are required to have good corrosion resistance; in the prior art, technicians have done a lot of research on the corrosion of stainless steel forgings in steam turbines, and have taken a series of precautions Measures, such as coating protection and cathodic protection, have also achieved a lot of research results. However, due to the special working conditions of the steam turbine, the cathodic protection does not work, and the coating protection effect is not very good. Some areas of the steam turbine are affected by a series of external factors such as alternating wet and dry, water droplets, corrosive components in the atmosphere and oxygen, as well a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58C21D8/00C21D11/00C21D1/28C21D1/18

Inventor 是玉丰

Owner WUXI PAIKE HEAVY CASTING & FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com