Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Trimethylindium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylindium (abbr: TMI or TMIn), In(CH₃)₃, (CAS #: 3385-78-2) is the preferred organometallic source of indium for metalorganic vapour phase epitaxy (MOVPE) of indium-containing compound semiconductors, such as InP, InAs, InN, InSb, GaInAs, InGaN, AlGaInP, AlInP, AlInGaNP, etc. TMI is a white, crystalline and sublimable solid, with melting point 88 °C. TMI is pyrophoric (ignites spontaneously upon contact with air), and its decomposition is often found to be uncontrollable as the temperature of its surrounding exceeds its melting point (i.e. > 88 °C) and reaches 101 °C and above. TMI is also reported to exhibit autocatalytic behavior during its thermal decomposition. TMI therefore needs to be handled with the utmost care and caution, e.g. stored in preferably cool, dry place at 0-25 °C, and operating temperatures under 50 °C in order to avoid deterioration. TMI also reacts extremely violently with oxidizers and polyhalogenated compounds (such as CCl₄ or CBrCl₃), with which TMI is therefore incompatible. Hence, mixtures of TMI with oxidizers and/or polyhalogenated compounds must be avoided as they are potentially dangerous and explosive.

Preparation method of p type GaN and AlGaN semiconductor material

ActiveCN102903615AEasy to desorbImprove bindingSemiconductor/solid-state device manufacturingDimethylhydrazineSemiconductor materials

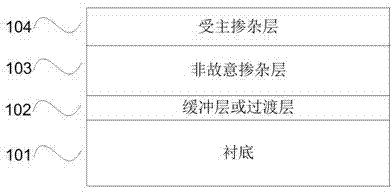

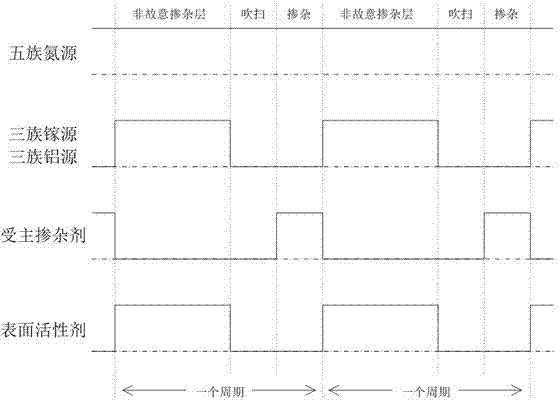

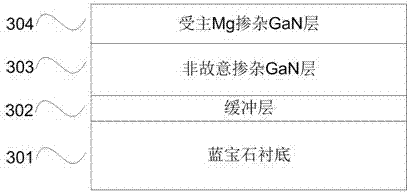

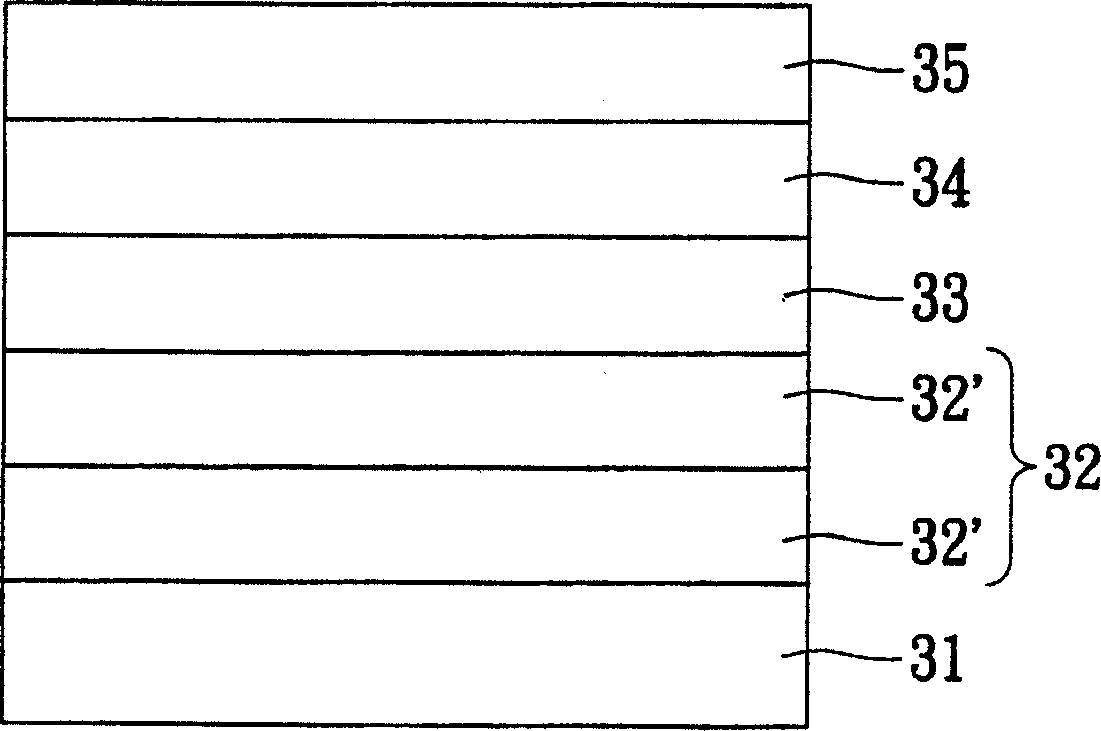

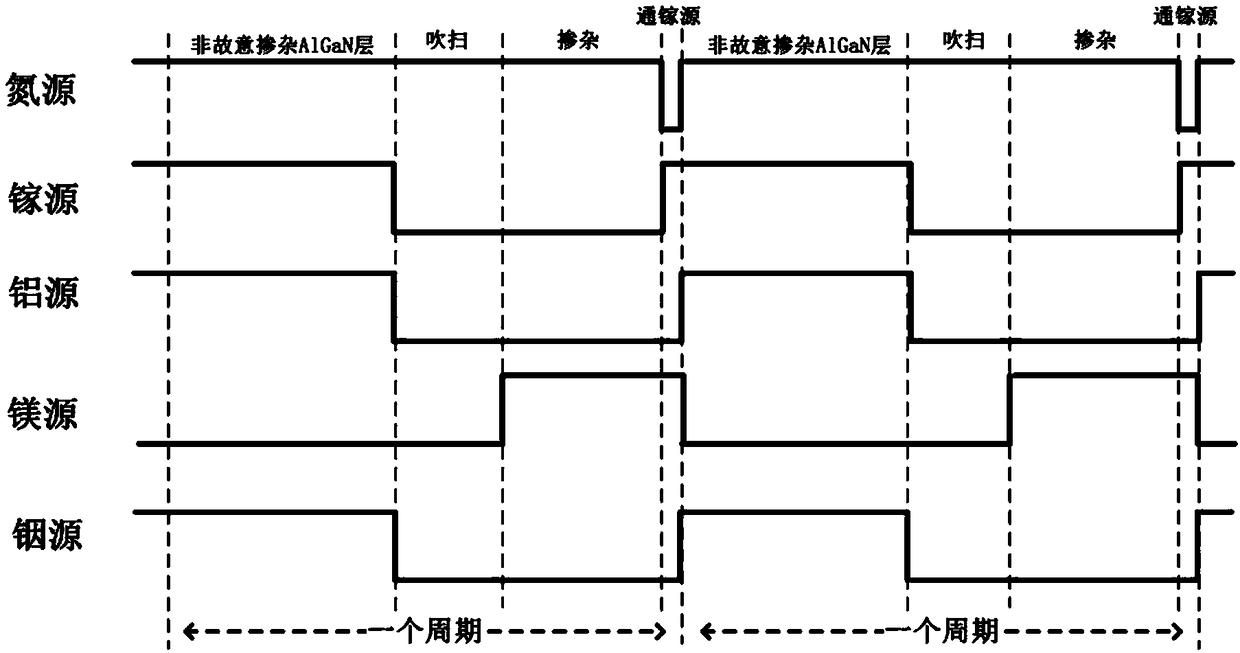

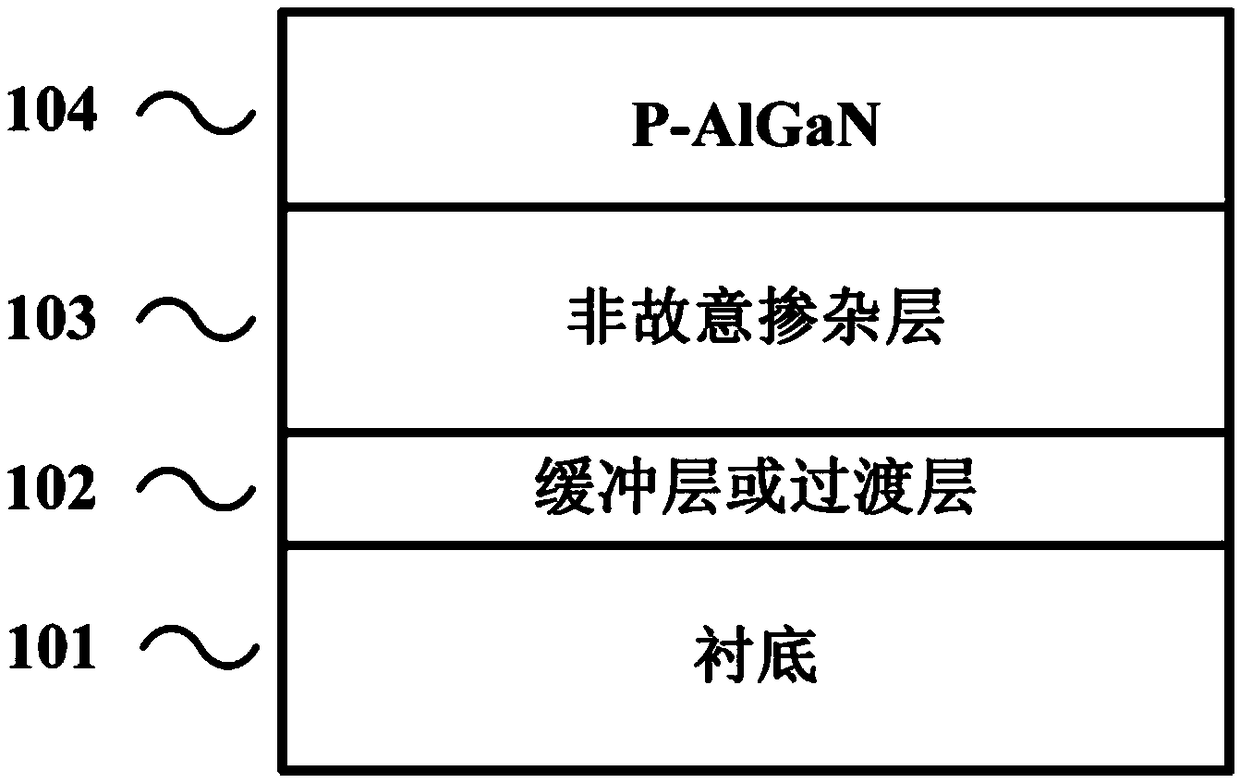

The invention discloses a preparation method of a p type GaN and AlGaN semiconductor material. A substrate, and a buffer layer or a transition layer, an unintended doped layer and an acceptor doped layer grown on the substrate from bottom to top are contained; in a growth process of the structure, ammonia or nitrogen dimethylhydrazine is used as a five-group nitrogen source; trimethyl gallium or TEGa used as a three-group gallium source, trimethylaluminium or triethyl aluminum used as a three-group aluminium source, and trimethylindium or TEIn used as a three-group indium source are collectively called three-group metal sources; and the trimethylindium or the TEIn is also used as a surface active agent and used in the acceptor doped layer. According to the method, the trimethylindium or the TEIn is used as the surface active agent to assist growth, and simultaneously, the acceptor doped layer is prepared by adopting a delta doping method. According to the method, the doping efficiency of acceptor doped magnesium atoms is increased, and simultaneously, the self-compensation effect is suppressed, so that the p type GaN and AlGaN semiconductor material with favorable crystalline quality and high hole concentration is obtained.

Owner:SUN YAT SEN UNIV

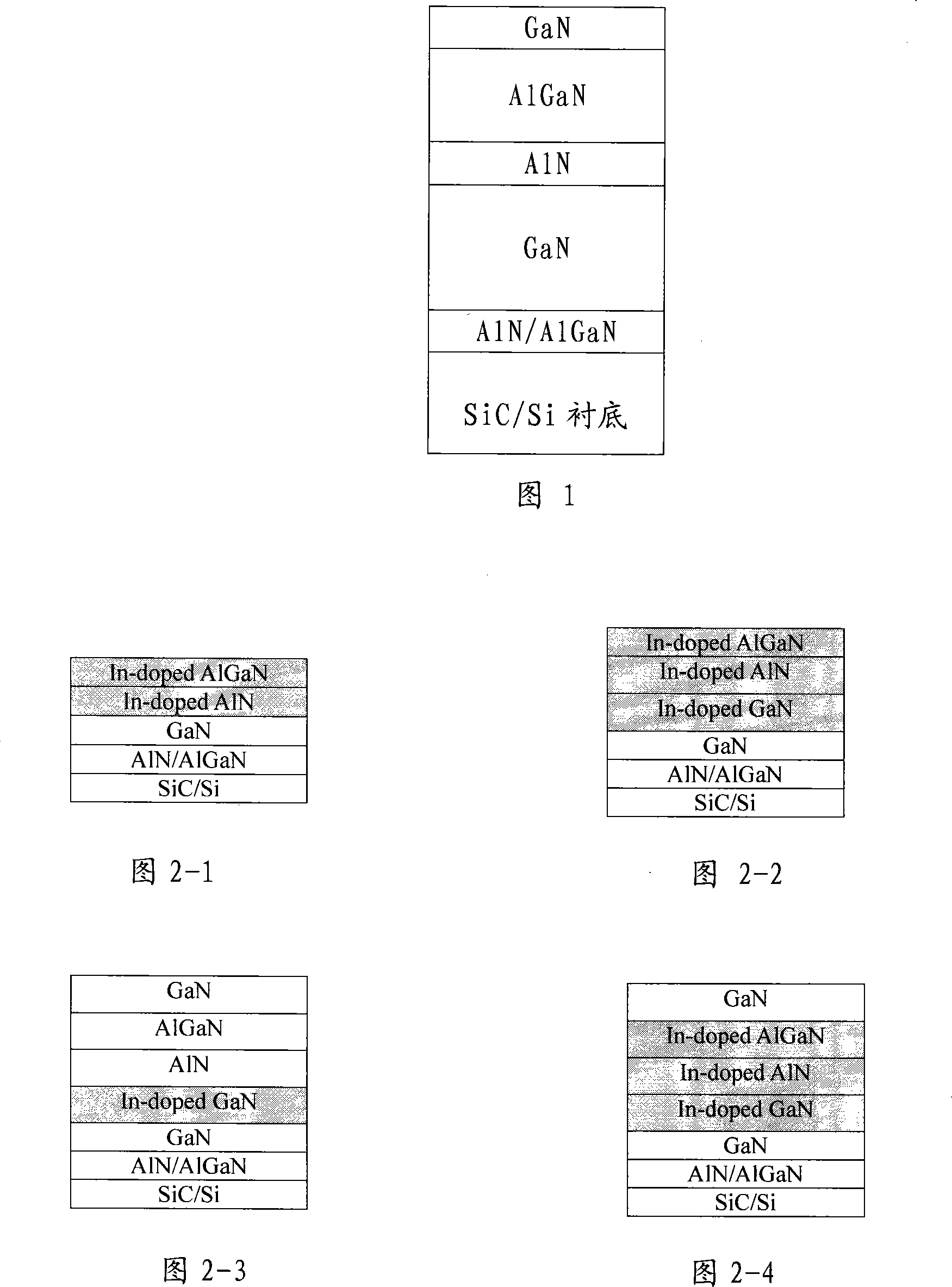

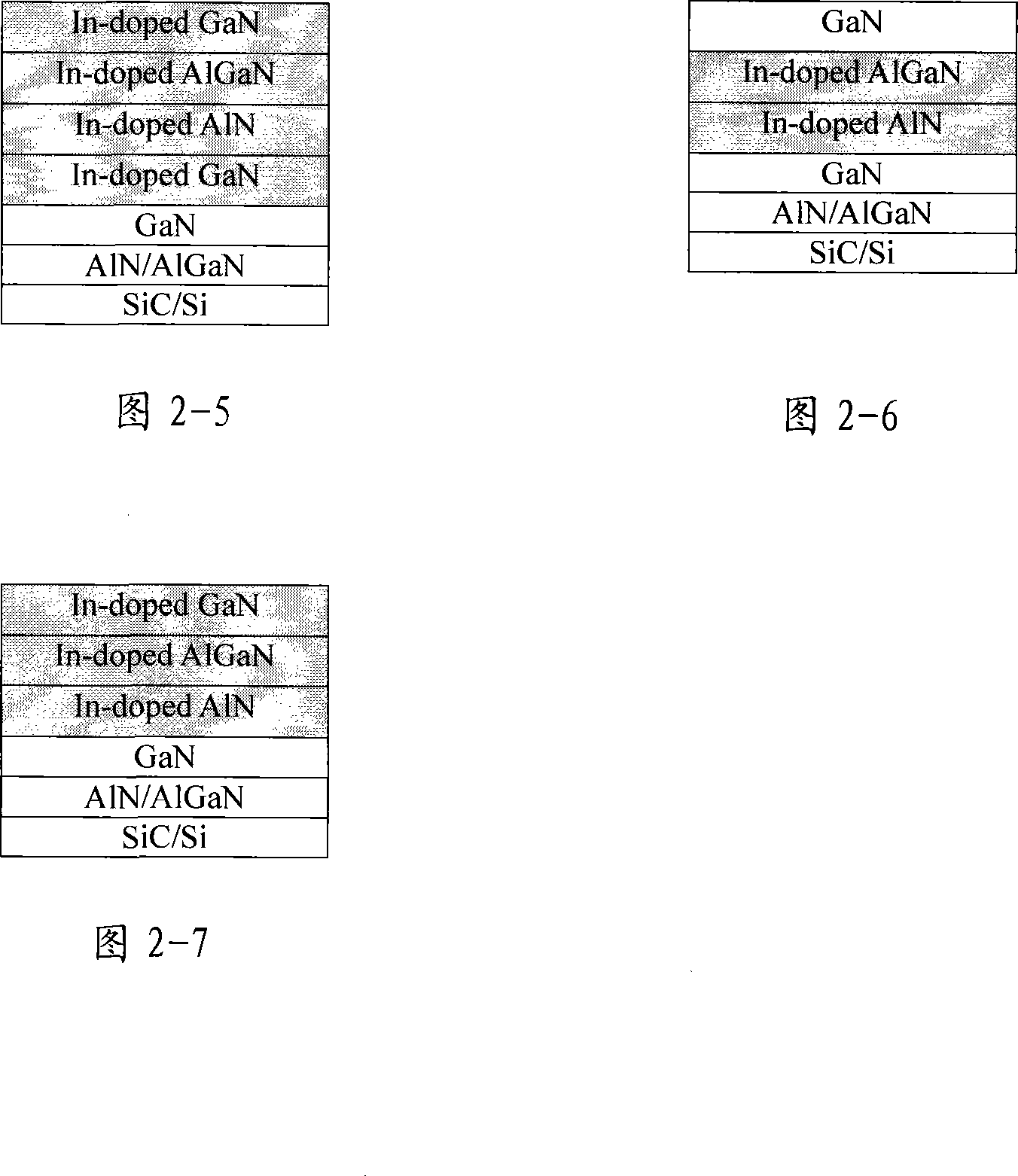

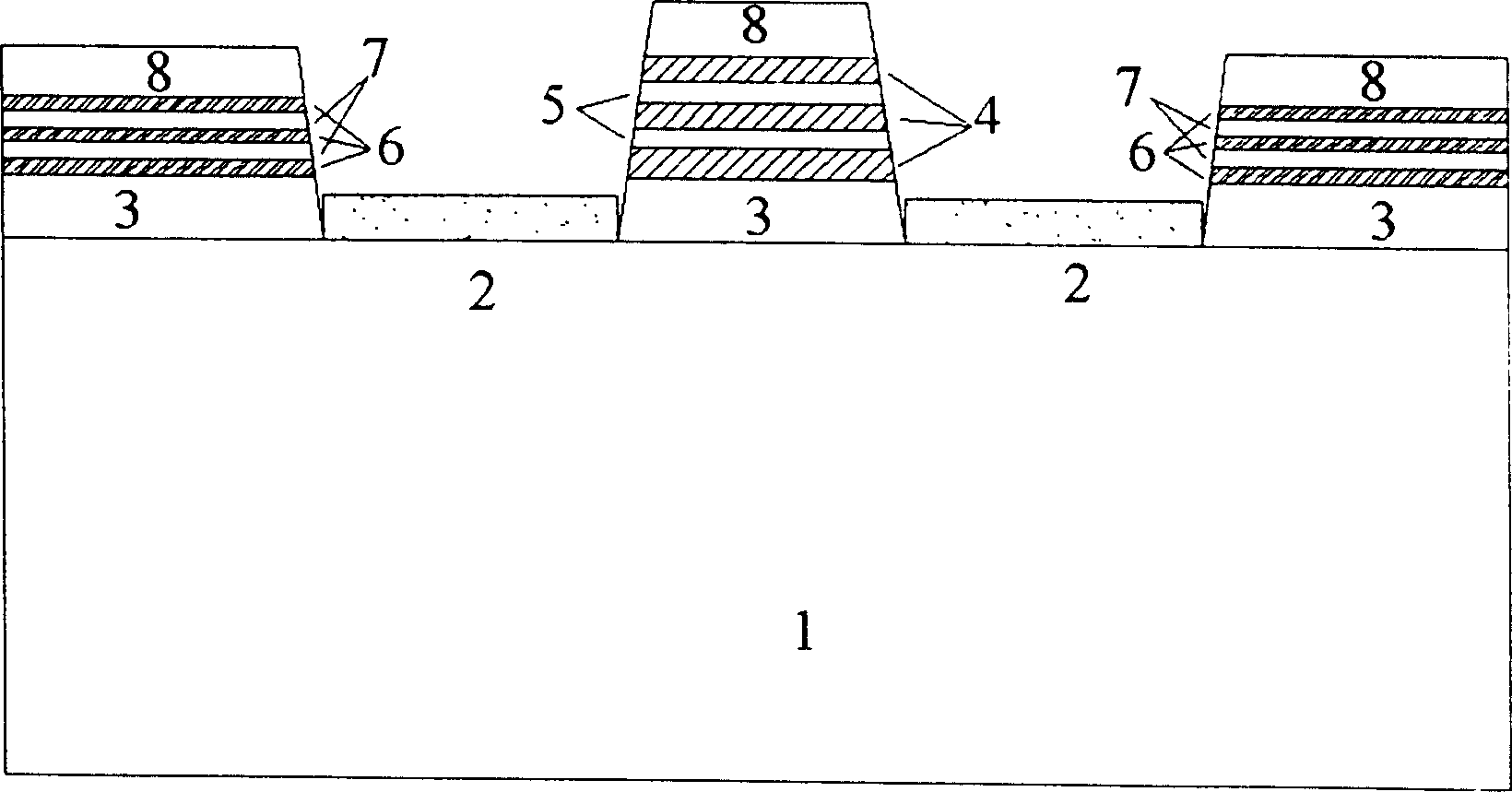

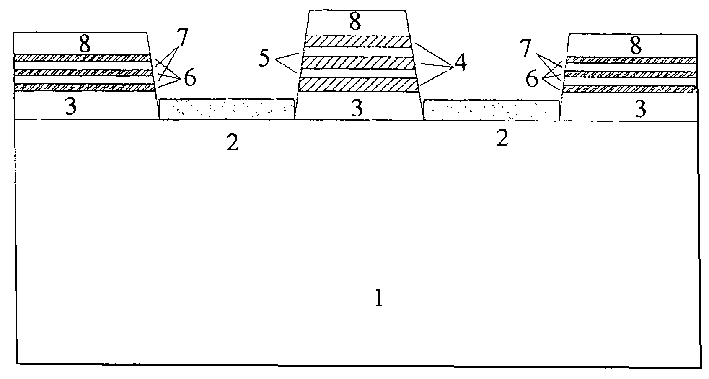

Method for improving gallium nitride based transistor material and device performance using indium doping

ActiveCN101114594AFree diffusionIncrease the diffusion distanceSemiconductor/solid-state device manufacturingGas phaseSingle crystal

The invention discloses a method of increasing the properties of the gallium nitride-based transistor material and device with indium doping and applies in the field of making gallium nitride-based HEMT or HFET materials and devices. The method and process is to form the gallium nitride-based high electron mobility transistor or heterostructure field effect transistor materials on SiC or Si single crystal substrate grown by metal-organic chemical vapor deposition epitaxial growth system. After the AlN or AlGaN nucleating layer and the GaN buffer layer are grown on the SiC or Si single crystal substrate, a GaN channel layer, an AlN insert layer, an AlGaN barrier layer and a GaN capped layer are grown, and trimethyl indium is added in the growth atmosphere to do epitaxial growth with indium doping. The dislocation of the material or device made by the method of the invention is reduced greatly. The invention improves the interfacial smoothness, increases the electron mobility of the material, increases the growth window, ensures the material grow easier, improves the current collapse of the device, reduces the leakage current and increases transconductance and gain and increases the output power of microwave power devices.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

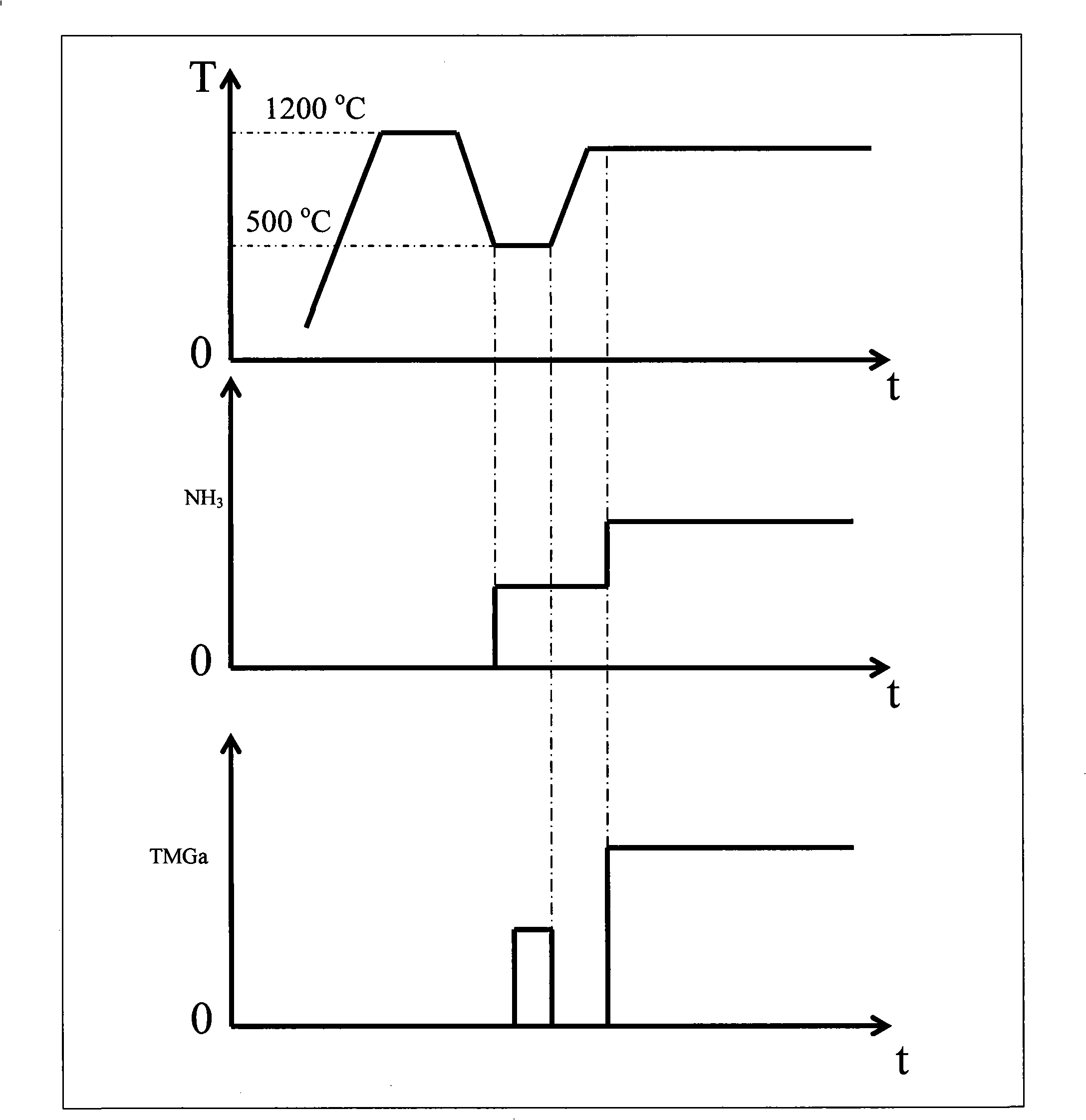

Method for MOVCD growth nitride epitaxial layer

InactiveCN101343733AEasy to removeImprove pollutionChemical vapor deposition coatingIndiumLight-emitting diode

The invention relates to a method to generate nitride epitaxial layer and nitride light emitting diode structure epitaxial wafer through MOVCD. The MOVCD technology is adopted, high purity NH3 is utilized as N source, high purity H2 or N2 is utilized as the carrier gas, and trimethyl gallium (TMGa) or triethyl gallium (TEGa), trimethyl indium (TMIn) and trimethyl aluminium (TMAl) are respectively utilized as Ga source, In source and Al source; the substrate adopts sapphire (Al2O3); the sapphire substrate is heated to 500 DEG C in the MOCVD reaction chamber, in the atmosphere of H2, trimethyl gallium (TMGa) is filled to generate a GaN layer, in the high temperature (1200 DEG C) H2 atmosphere, reaction is generated between GaN and the sapphire(Al2O3) on the substrate surface, the surface damage and the surface pollution of the sapphire can be better removed, micro pits of the nanometer grade can be corroded on the sapphire surface, the micro pits is favorable to the improvement of the epitaxial layer, and to the most important, the LED emitting efficiency is enhanced.

Owner:EPILIGHT TECH +2

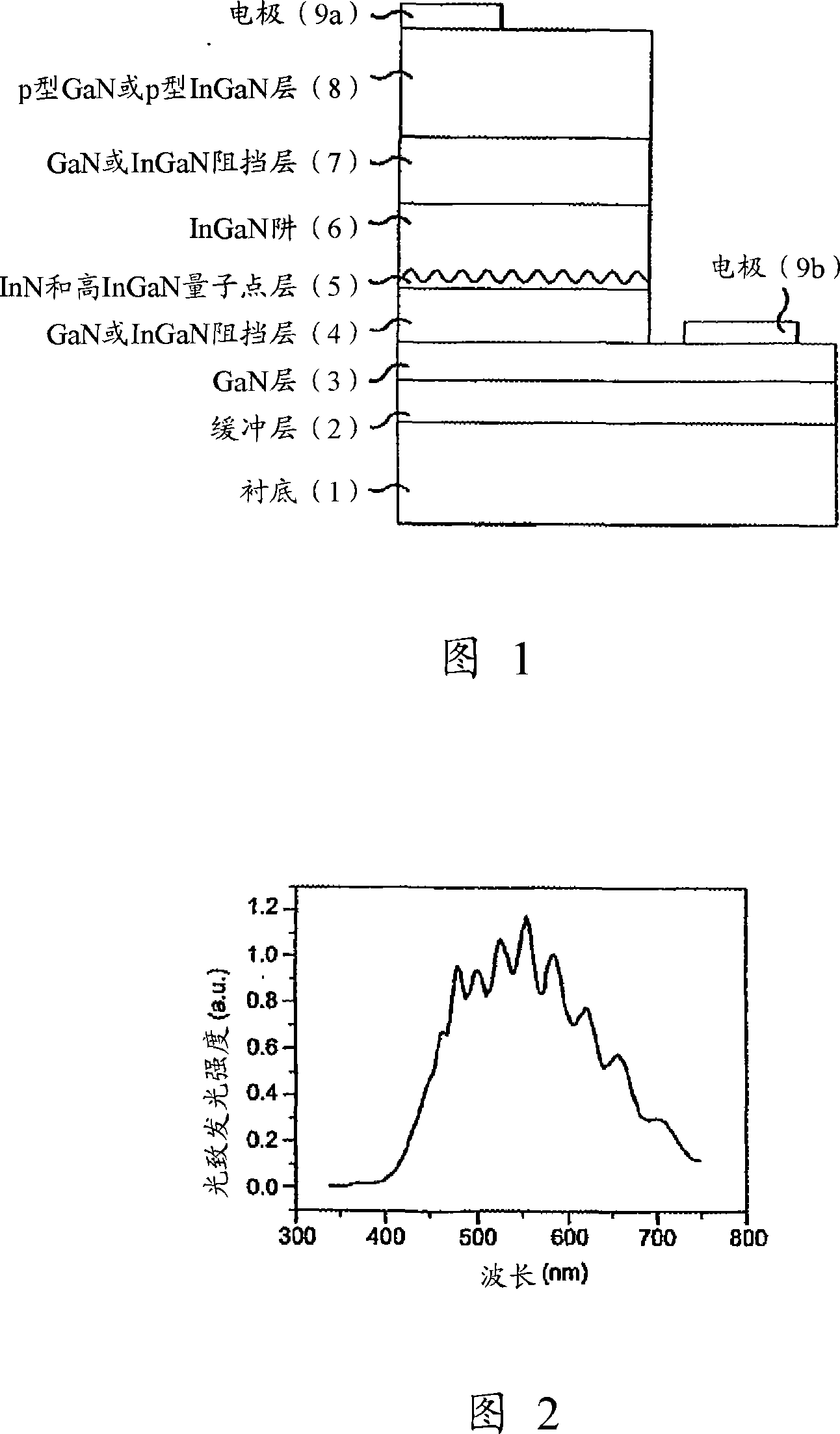

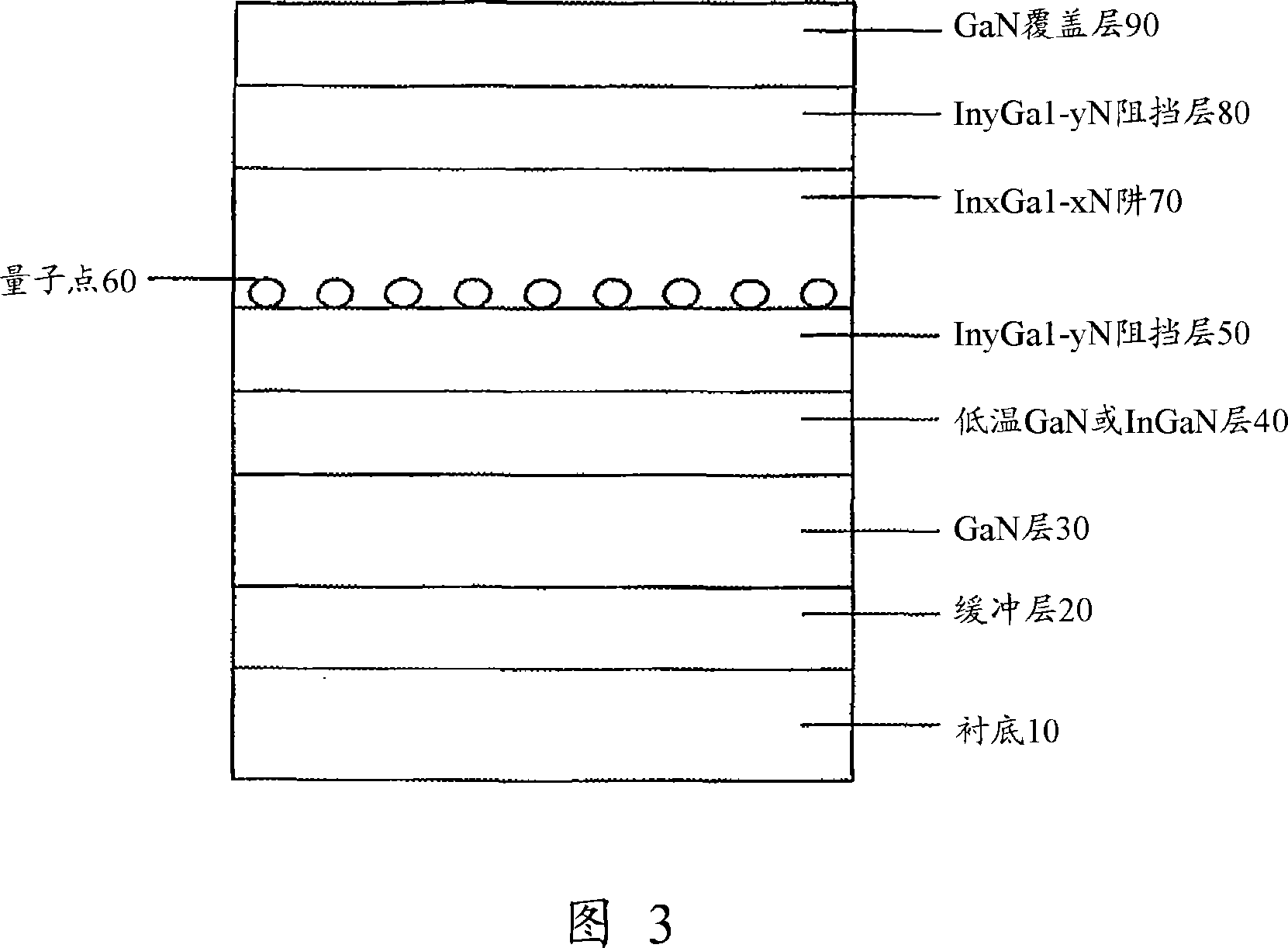

III nitride white light LED

InactiveCN101208810ANanoinformaticsSemiconductor/solid-state device manufacturingIndiumLight-emitting diode

A white light-emitting diode prepared by metal-organic chemical vapor deposition (MOCVD), which can cover indium nitride (InN) quantum dots (QD) and Indium-rich indium gallium nitride (InGaN) quantum dots produce broadband emission covering the entire visible spectral region by introducing trimethylindium (TMIn) as nuclei for growing QDs within the QW, The release of at least one of triethylindium (TEIn) and ethyldimethylindium (EDMIn) is achieved. Therefore, the diode can emit white light in the range of 400nm to 750nm by adjusting the In release parameters.

Owner:AGENCY FOR SCI TECH & RES +1

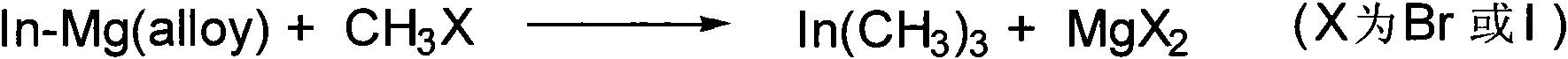

Method for industrially preparing trimethyl indium

ActiveCN102020668AProcess response is simple and stableEasy to controlGroup 3/13 element organic compoundsSpontaneous combustionIndium

The invention relates to a method for industrially preparing trimethyl indium, The method is characterized by comprising the following steps: putting indium-magnesium alloy materials into a reaction kettle filled with inert gases; adding alkyl halide step by step while stirring in the presence of ether solvents; controlling the return velocity of the solvents by controlling the dropwise adding velocity of alkyl halide; vaporizing the solvents after the reaction is finished; obtaining the compound of trimethyl indium and ethers under the condition of reduced pressure; and finally decompoundingthe compound to obtain the trimethyl indium. The process is simple and steady in reaction, easy to control, high in reaction yield and very safe in reaction process as the raw materials adopted in the reaction process do not contain the materials liable to spontaneous combustion, thus being especially suitable for large-scale industrial production.

Owner:JIANGSU NATA OPTO ELECTRONICS MATERIAL

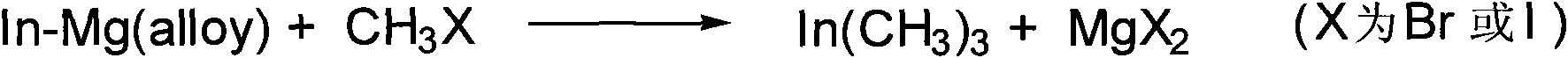

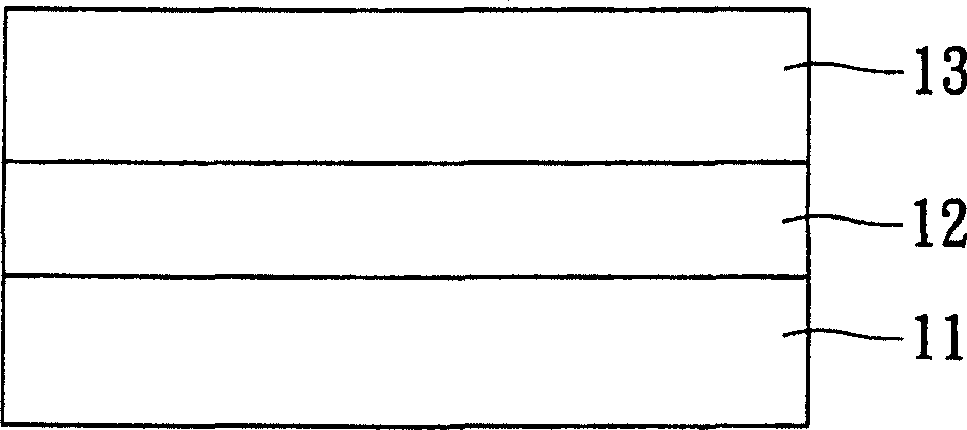

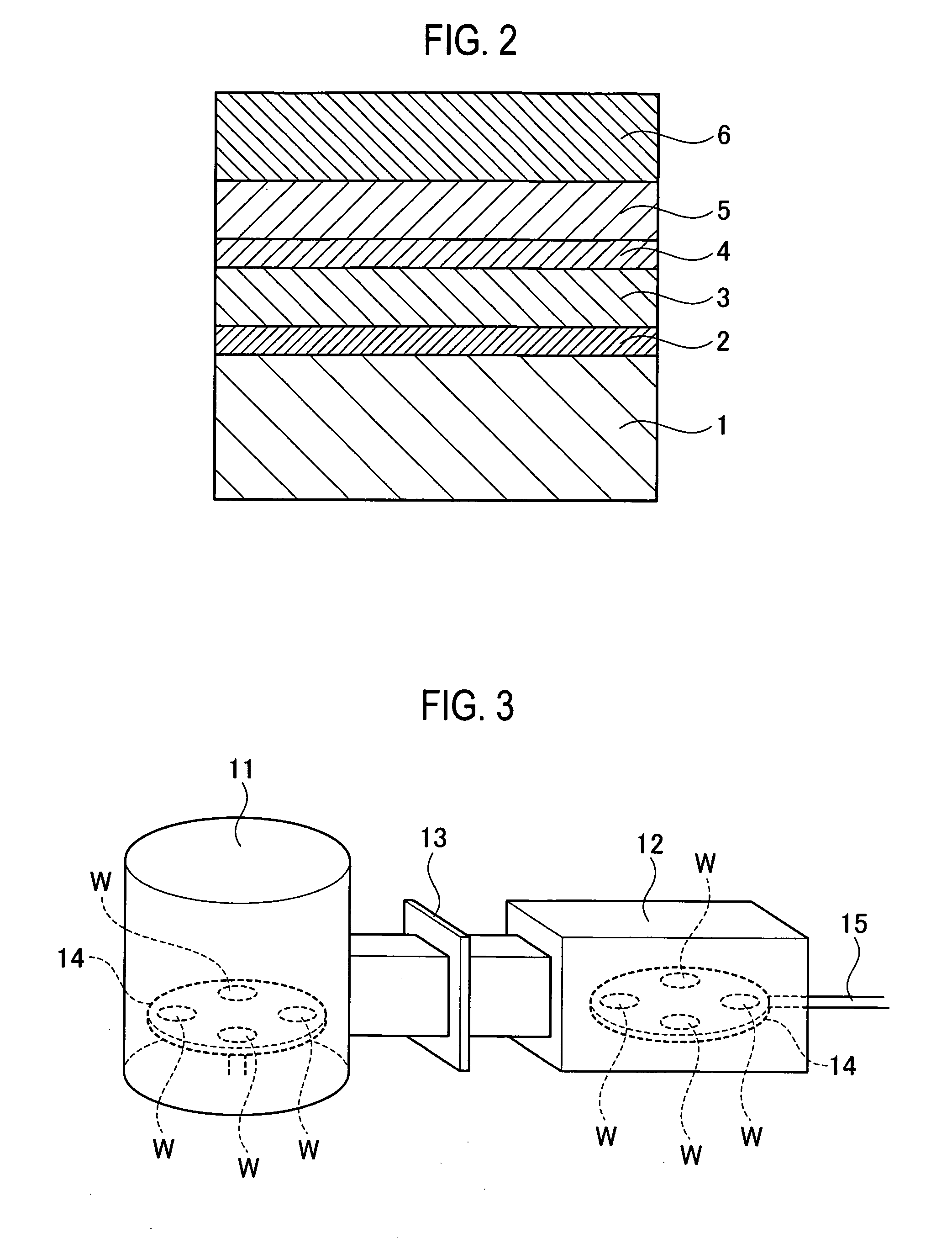

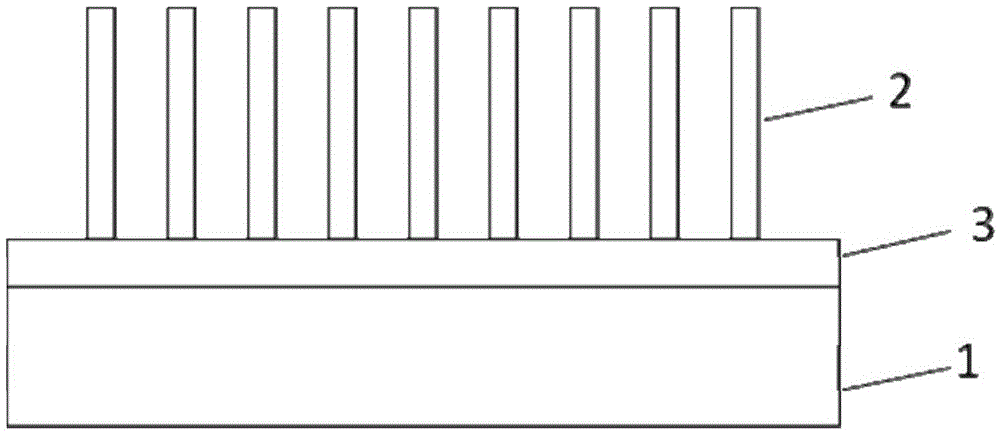

Epitaxial structure of gallium nitride series compound semiconductor and mfg. method

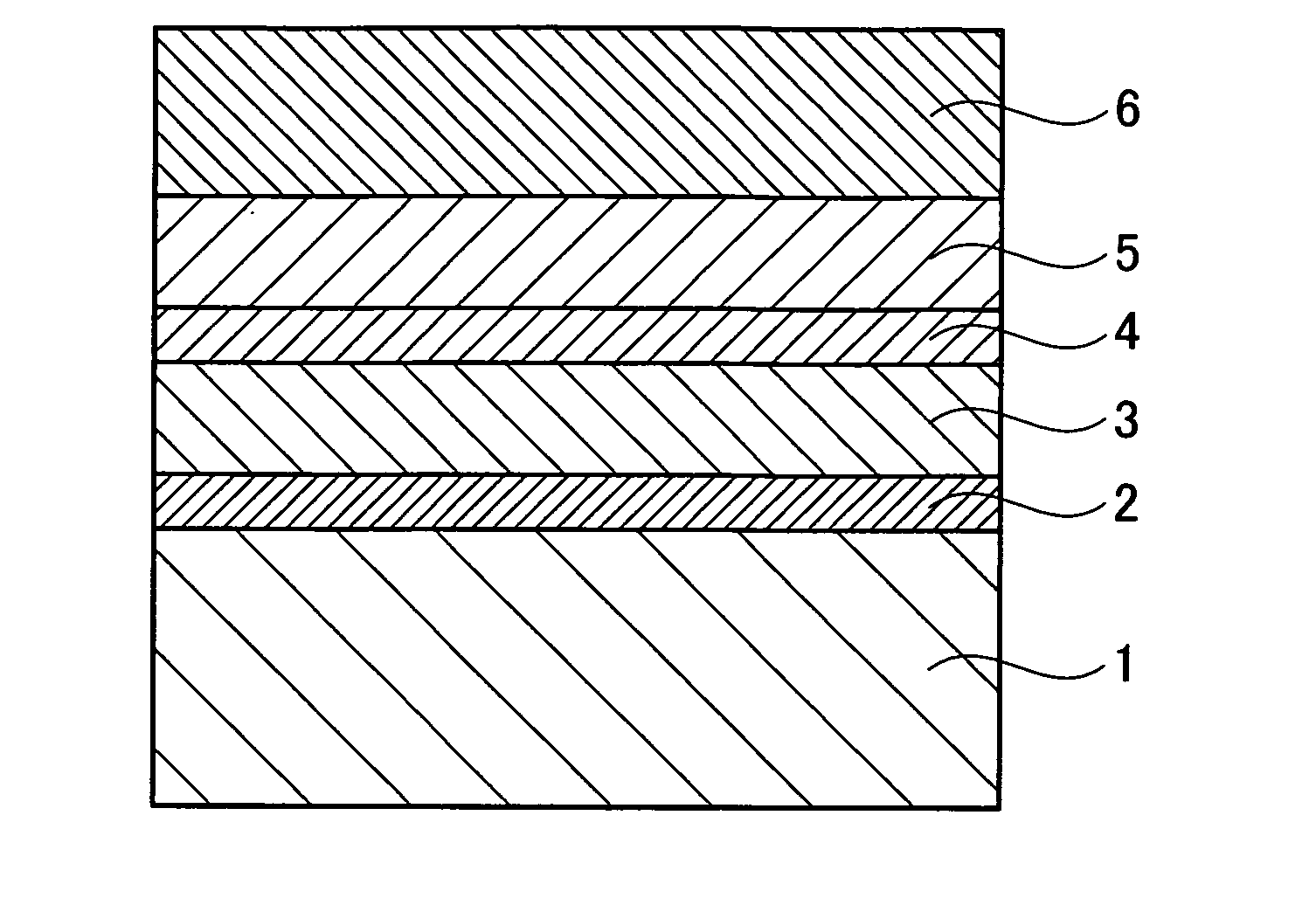

InactiveCN1677697AImprove efficiencyExtended service lifeSemiconductor/solid-state device manufacturingSemiconductor devicesCrystal structureLow density

The epitaxial structure comprises following parts: a substrate; a first buffer layer of gallium nitride formed on the substrate; a second buffer layer of gallium indium nitride formed on the first buffer layer; and a epitaxial layer of gallium nitride formed on the second buffer layer. Steps for preparing the structure are as following: forming the first buffer layer of gallium nitride on the substrate at first temperature through epitaxy; forming second buffer layer of gallium indium nitride on the first buffer layer at second temperature; in procedure of raising temperature to third temperature, carrying out surface treatment by maintaining predecessor of trimethyl aluminum and ammonia on second buffer layer; finally, epitaxial layer of gallium nitride is developed at third high temperature. Advantages are: perfective crystal structure and lower density of defects increase efficiency and lifetime of subassembly.

Owner:SUPERNOVA OPTOELECTRONICS

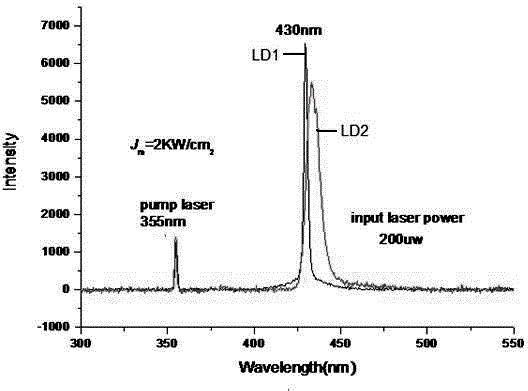

Method for preparing novel GaN-based laser and GaN-based laser

ActiveCN104319631AIncrease limit factorHigh gainLaser detailsLaser active region structureSilanesTrimethylgallium

The invention provides a method for preparing a novel GaN-based laser and a GaN-based laser. According to the method of the invention, a series of critical technologies and scientific problems in the preparation of a GaN-based laser can be solved through adopting a metal organic chemical compound vapor phase epitaxy technique. According to the technical scheme of the invention, the method for preparing the novel GaN-based laser includes the step that with trimethylgallium, trimethylindium and trimethylaluminum adopted as a III-family source, ammonia adopted as a V-family source, and silane adopted as an n type doping source, and magnesocene adopted as a P type doping source, the metal organic chemical compound vapor phase epitaxy technique is utilized to prepare the novel GaN-based laser. According to the method for preparing the novel GaN-based laser of the invention, a multi-cycle In component linear graded InxGa1-xN / GaN superlattice structure, replacing a traditional single GaN layer, is adopted as the waveguide layer of the GaN-based blue laser, and therefore, limiting factors of a light field in a laser emission region can be effectively improved, and the gain of the active regions of quantum wells can be improved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

Method for growing p-type AlGaN

InactiveCN101728250AAct as an active agentImprove surface topographyFinal product manufactureSemiconductor/solid-state device manufacturingLuminous intensityGas phase

The invention discloses a method for growing p-type AlGaN. The method comprises the following steps: introducing trimethylindium serving as an activating agent while growing a p-type AlGaN layer by a metal organic chemical vapor deposition method, generally adopting high-purity hydrogen gas as carrier gas, trimethylgallium, trimethyl aluminium and ammonia gas as a Ga source, an Al source and an N source respectively and magnesium as a p-type doping agent, introducing the trimethylindium and other raw materials into a reaction chamber for epitaxially growing p-AlGaN, and generally controlling the flow rate of the trimethylindium to between 20 and 300 sccm. The method is simple and feasible, has obvious effect, can improve the surface appearance of the p-AlGaN, and reduces square resistance of the p-AlGaN; moreover, when applied to the preparation of a device, the method can effectively reduce the series resistance and cut-in voltage of the device, enhance the luminous intensity of the device, and particularly has more remarkable effect on the p-AlGaN with high Al component and deep ultraviolet LED devices.

Owner:PEKING UNIV

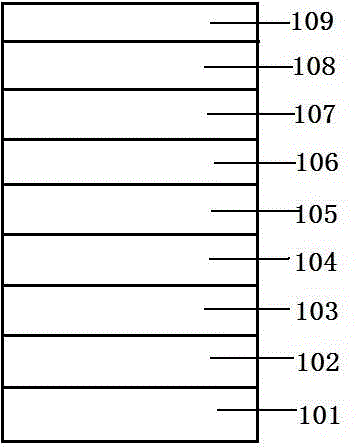

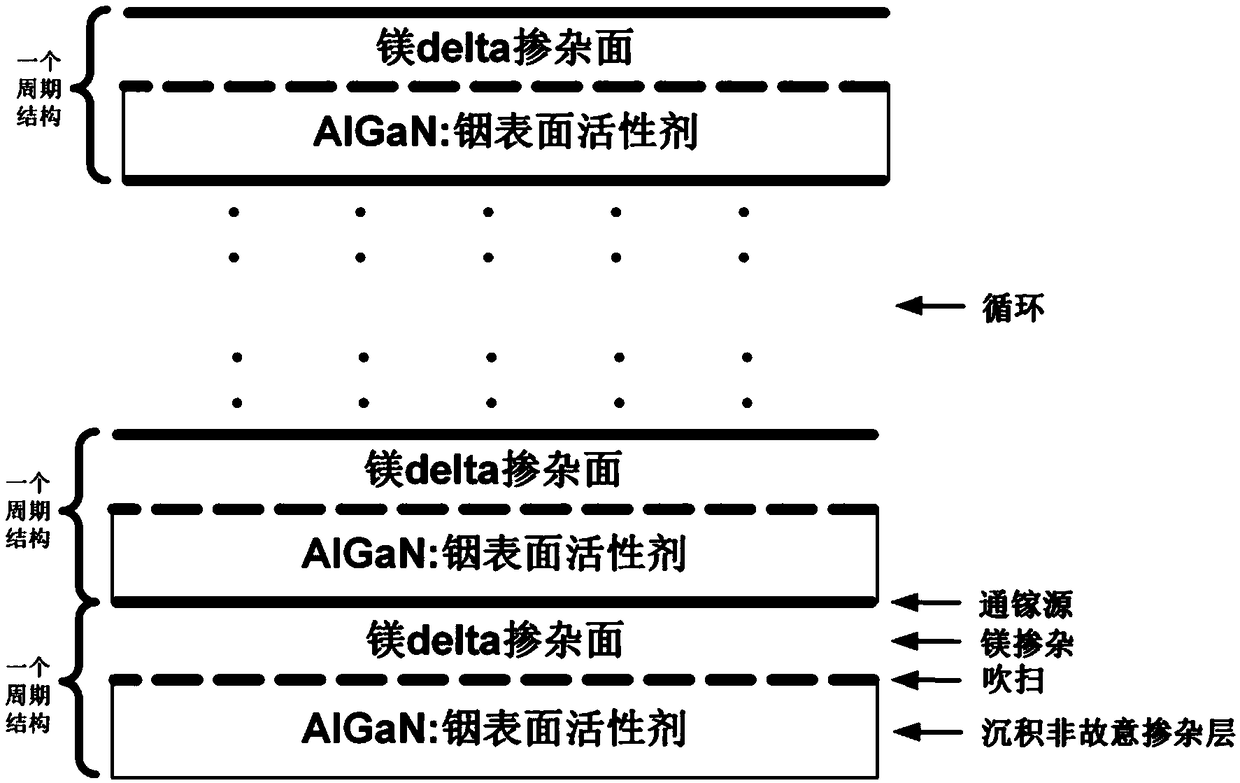

Growth method of p-type AlGaN semiconductor material

ActiveCN108987256AReduced Displacement Formation EnergyImprove retentionSemiconductor/solid-state device manufacturingDimethylhydrazineIndium

The invention discloses a growth method of p-type AlGaN semiconductor material, the semiconductor material is grown by a technical method of adding a gallium source through step into a surfactant-assisted magnesium delta doping, Ammonia gas or dimethylhydrazine nitrogen is used as group V nitrogen source in the growth of p-type AlGaN semiconductor material, Trimethylgallium or triethylgallium is used as a Group III gallium source, trimethylaluminum or triethylaluminum is used as a Group III aluminum source, trimethylindium or triethylindium is used as a Group III indium source, collectively referred to as a Group III metal source, and trimethylindium or triethylindium is also used as a surfactant in the acceptor doping layer. The method of the invention can improve crystal quality, increase doping concentration of acceptor doped magnesium atoms, reduce acceptor ionization energy by enhancing valence band modulation, and further suppress self-compensation effect, thereby obtaining p-type AlGaN semiconductor material with high crystal quality and high hole concentration.

Owner:SUN YAT SEN UNIV

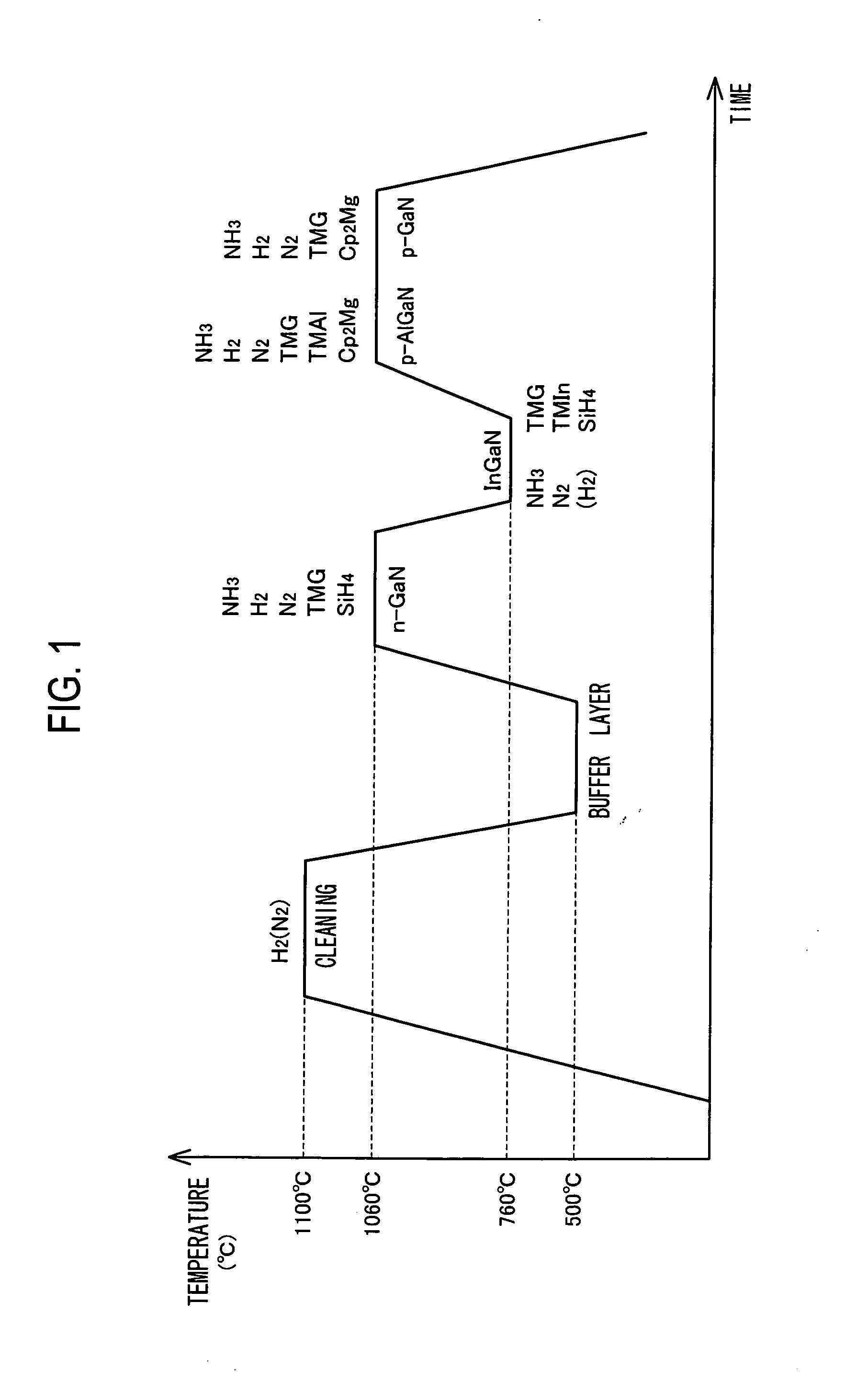

Method for Manufacturing InGaN

InactiveUS20100035410A1Reduced isolationRaise the ratioPolycrystalline material growthLaser detailsCrystallinityMaterials science

To provide a method for manufacturing InGaN which causes less segregation of In and achieves high crystallinity of an InGaN layer with the proportion of In increased.The method for manufacturing an InGaN layer including growing an InGaN layer under conditions of a growth temperature of 700 to 790° C., a growth rate of 30 to 93 Å / min, and a flow rate of trimethylindium of 0.882×10−5 to 3.53×10−5 mol / min.

Owner:ROHM CO LTD

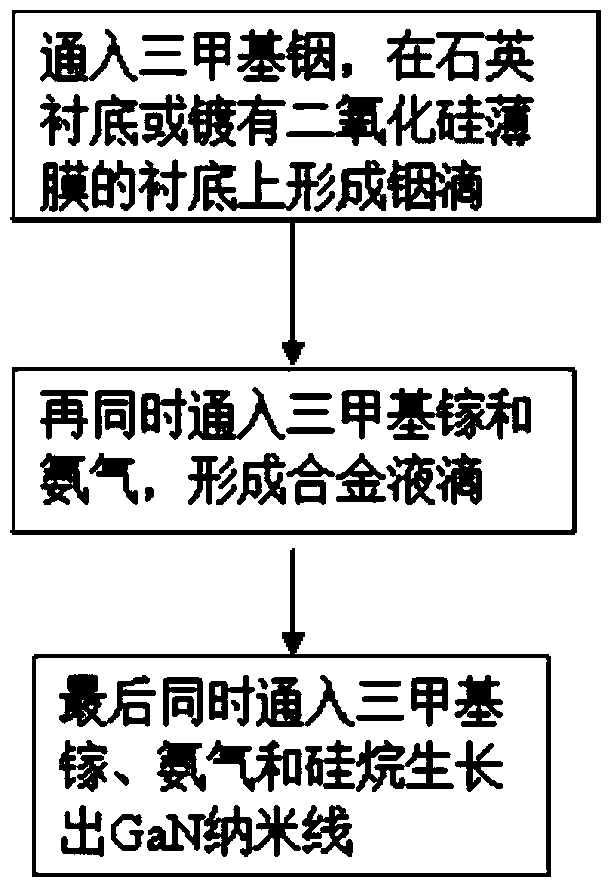

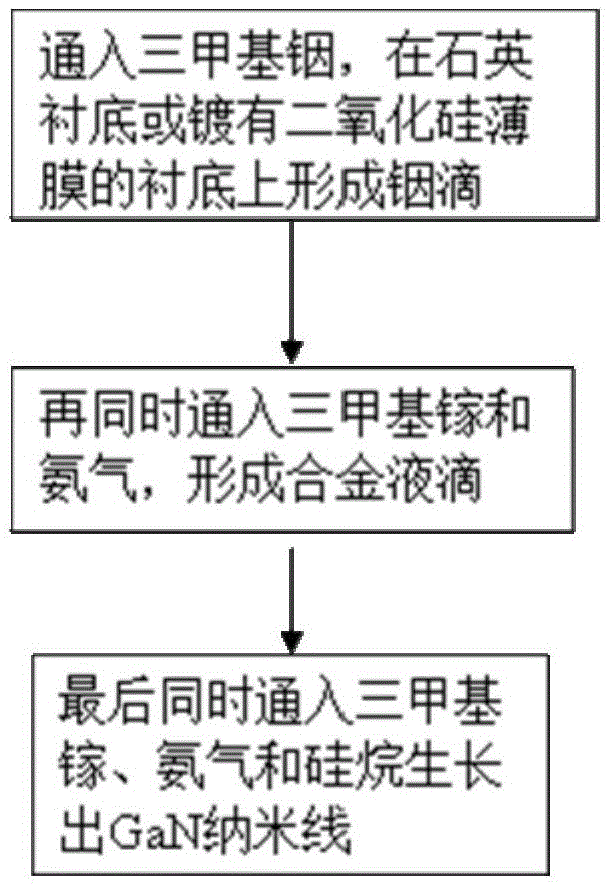

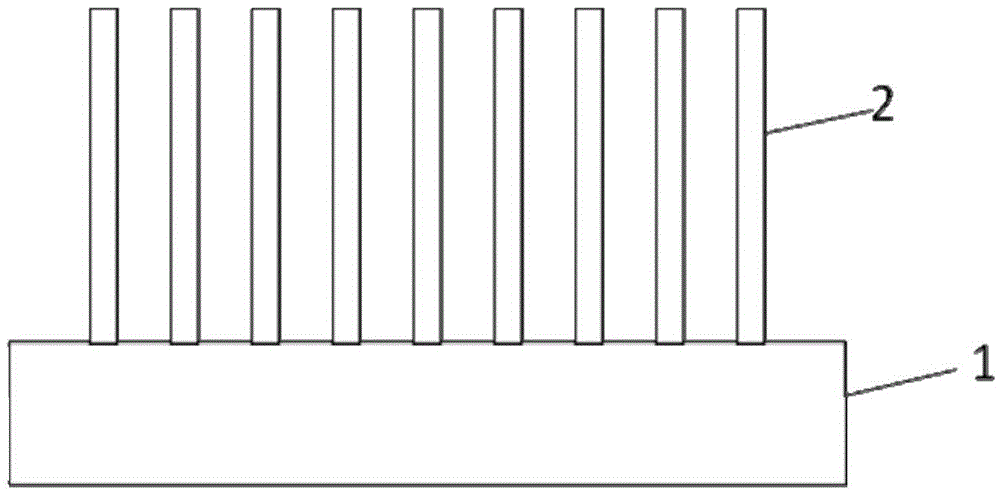

Growth method of GaN nanowire

InactiveCN103757693AAvoid tarnishingLow densityPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsNanowireIndium

The invention discloses a growth method of a GaN nanowire. The method comprises the following steps: leading trimethylindium to a quartz substrate or a substrate coated with a layer of silica film on the surface in advance, forming a liquid-phase indium drop on the bottom surface of the substrate, and then leading trimethyl gallium and an ammonia gas simultaneously, so as to form an alloy liquid drop; finally, simultaneously leading the trimethyl gallium, the ammonia gas and silicane; growing the GaN nanowire on the alloy liquid drop. By adopting the method, the trimethylindium is adopted as a tin catalyst source, a high-quality GaN nanowire grows on the cheap and available quartz or the substrate coated with the silica film on the surface, the method belongs to in-situ introduction, and is free of fussy processes of transferring and cleaning between different equipments, staining of a product in the transferring process is effectively avoided, a complicated buffer layer design is not needed, and the growth method is simple and convenient, and feasible to operate, and beneficial to industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

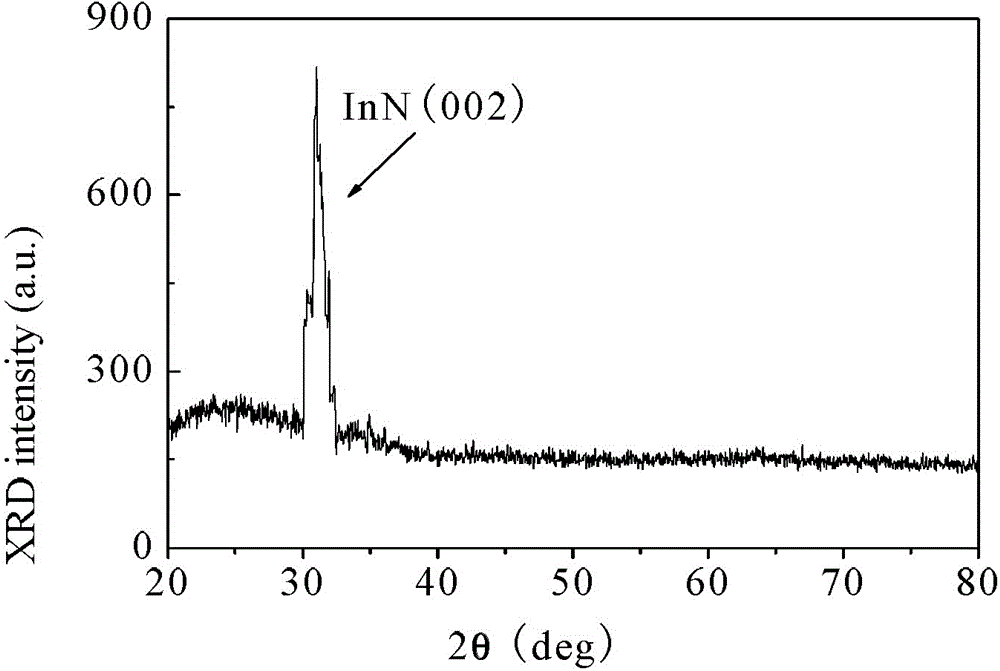

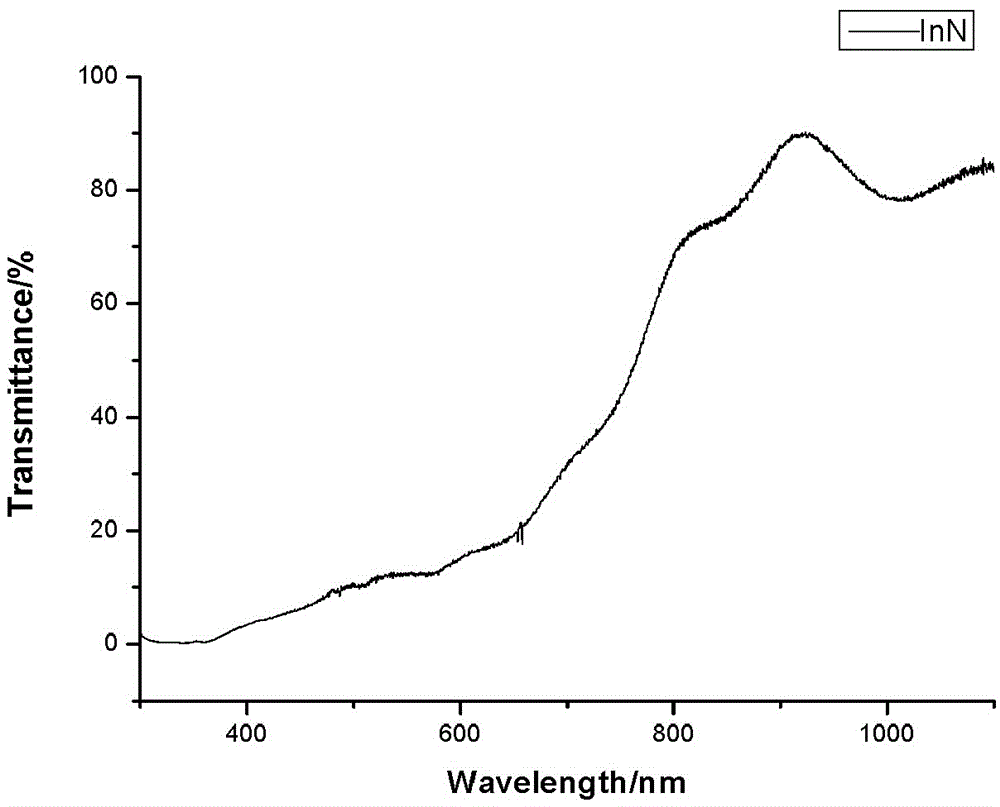

Method for low-temperature deposition of InN film on glass substrate

ActiveCN103334088ALight in massLow costChemical vapor deposition coatingLow temperature depositionNitrogen gas

The invention belongs to the technical field of novel photoelectric material deposition and preparation, and provides a method for the low-temperature deposition of an InN film on a glass substrate, from which the InN photoelectric film with favorable electrical properties can be prepared. The method comprises the following steps: 1), allowing the glass substrate to be subjected to acetone, ethanol, deionized water and ultrasonic cleaning, and then feeding to a reaction chamber after being dried by the nitrogen gas; 2), vacuumizing the reaction chamber by an ECR-PEMOCVD system, heating the glass substrate to 20-400 DEG C, pumping trimethylindium carried by hydrogen, and nitrogen gas into the reaction chamber at the flow ratio of (2-4):(100-200), wherein the overall gas pressure is controlled at 0.8-2.0 Pa, and the electronic convolution resonance vibration reaction is carried out for 30 min-3 h. Due to the adoption of the method, the InN photoelectric film on the glass substrate is prepared.

Owner:辽宁太阳能研究应用有限公司

Composite-DBR-structure-based AlGaInP light-emitting diode

InactiveCN108091739AImprove photoelectric performanceImprove optical output powerSemiconductor devicesDisilaneChemical vapor deposition

The invention provides a composite-DBR-structure-based AlGaInP light-emitting diode. The preparation method comprises: a metal organic chemical vapor deposition system uses high-purity hydrogen as carrier gas, trimethyl gallium, trimethylaluminum, trimethylindium, arsine and phosphorane as Ga, Al, In, As, and P sources, and disilane and magnesocene as N and P type dopants. According to the invention, with the three-reflected central wavelength composite DBR, the reflection efficiency is high and the luminous efficiency of the AlGaInP LED is improved substantially. The influences on the luminous efficiency of the LED by the composite DBR with many reflected central wavebands is studied.

Owner:FOSHAN DONGSHEN METAL PROD CO LTD

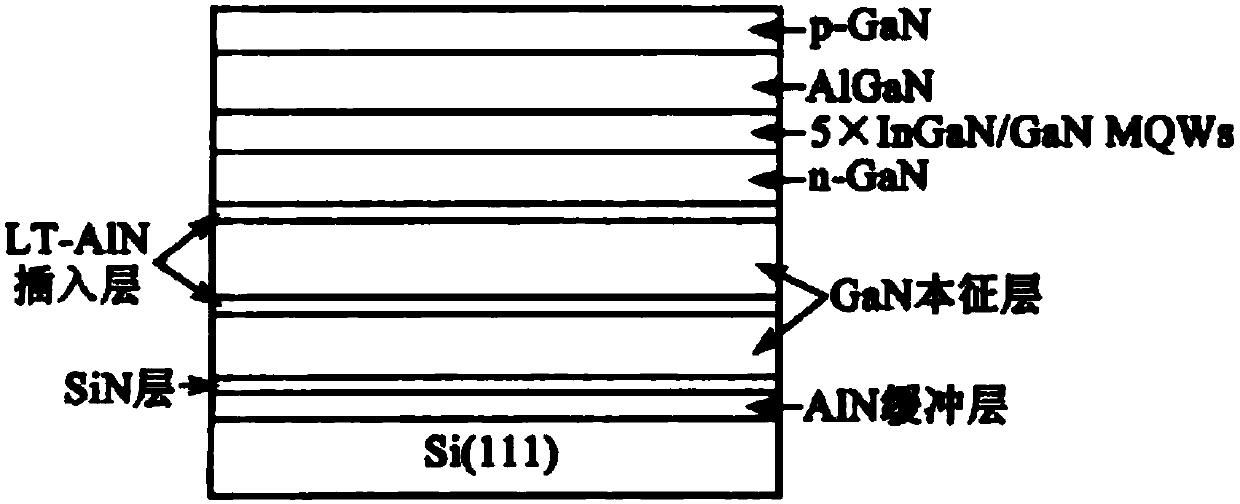

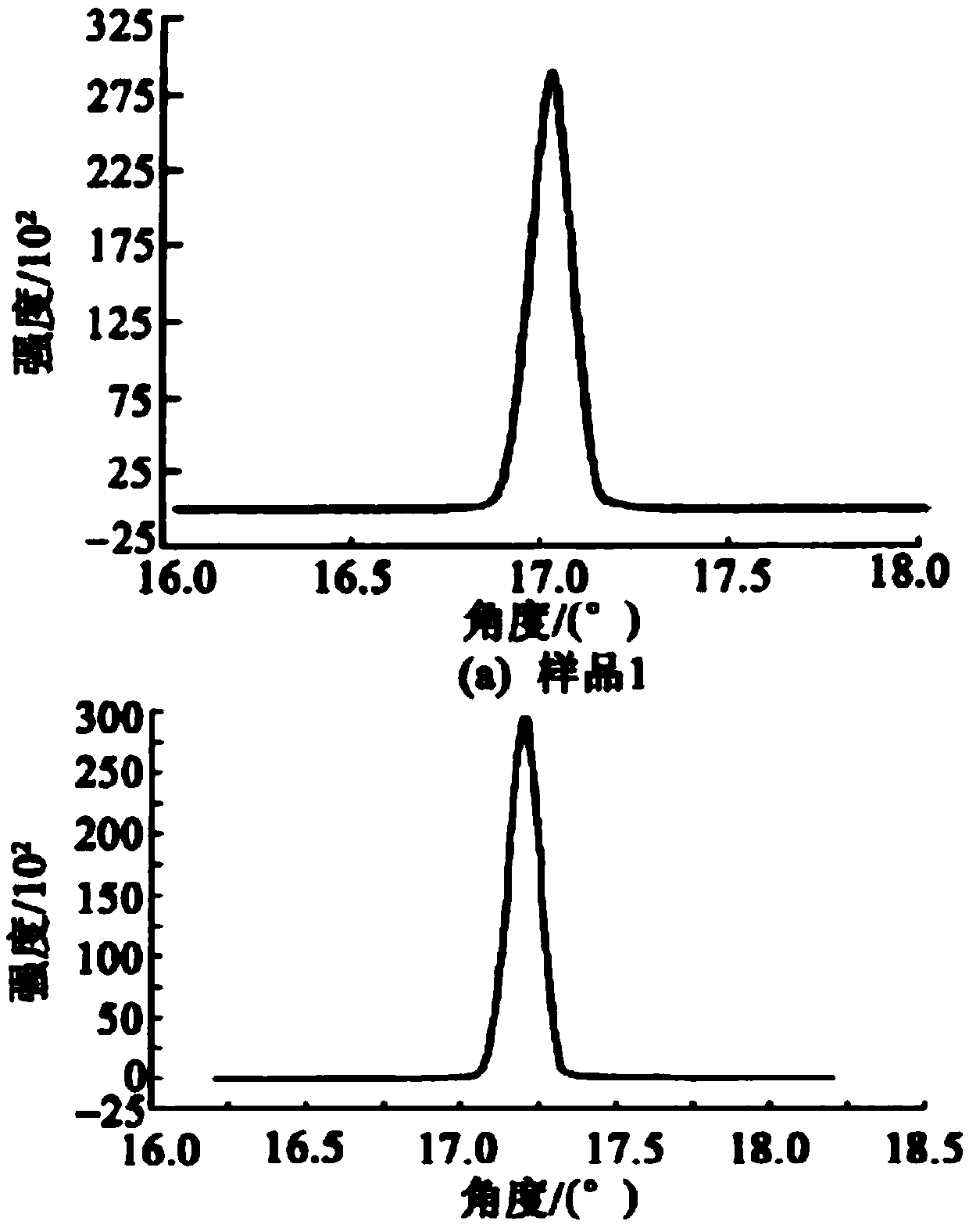

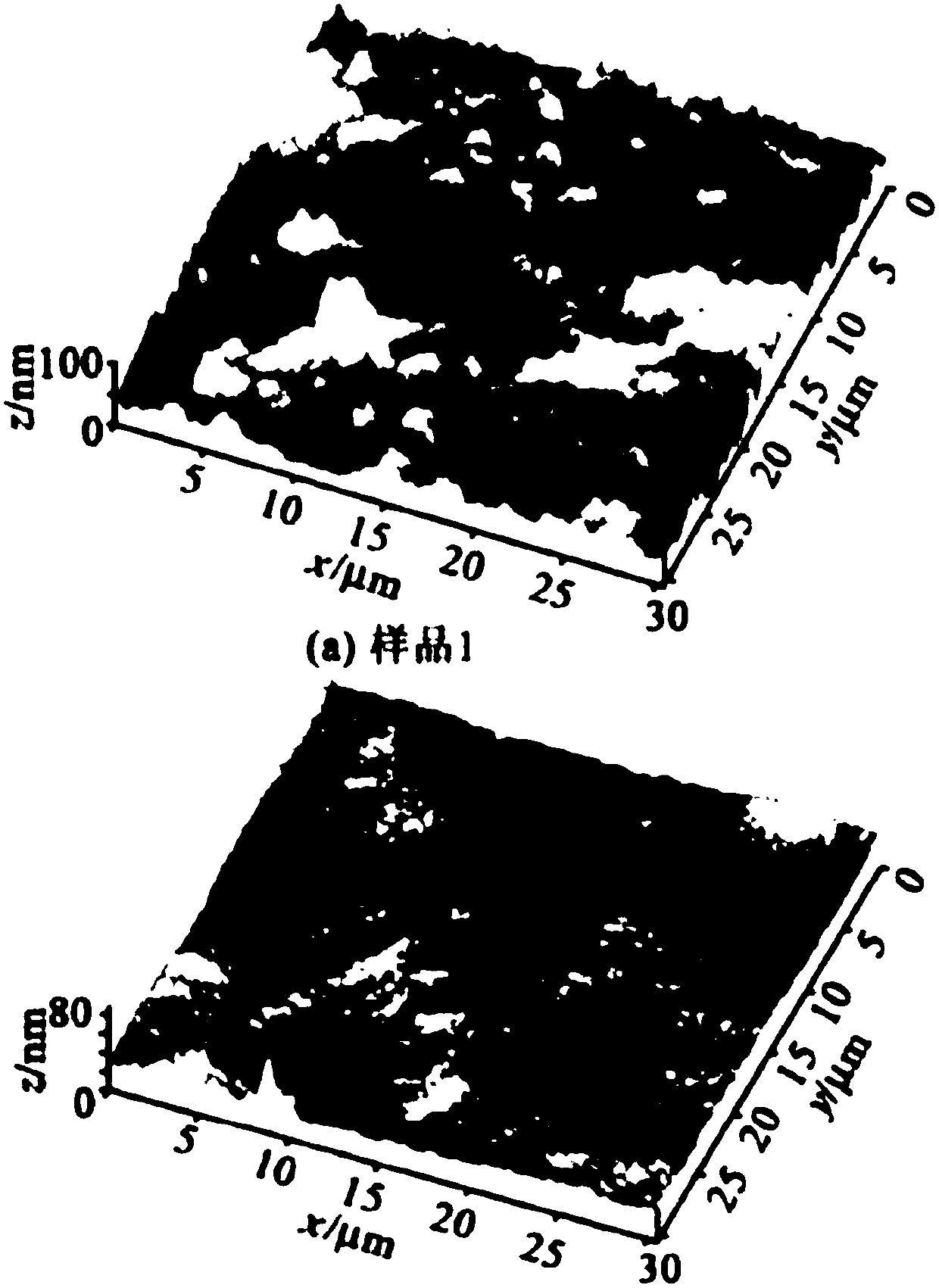

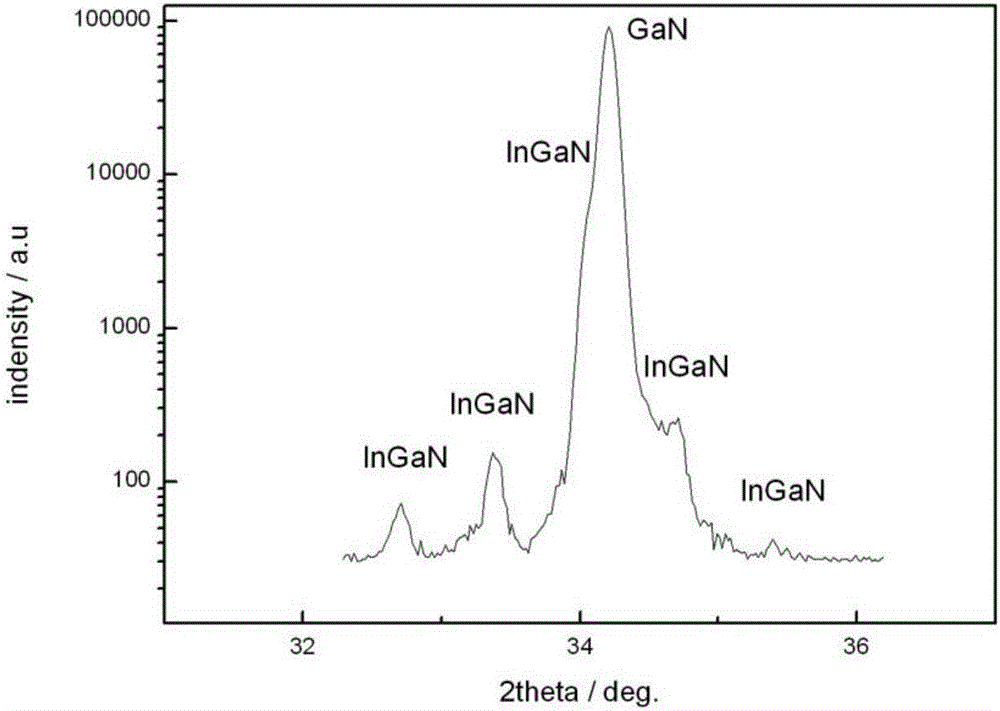

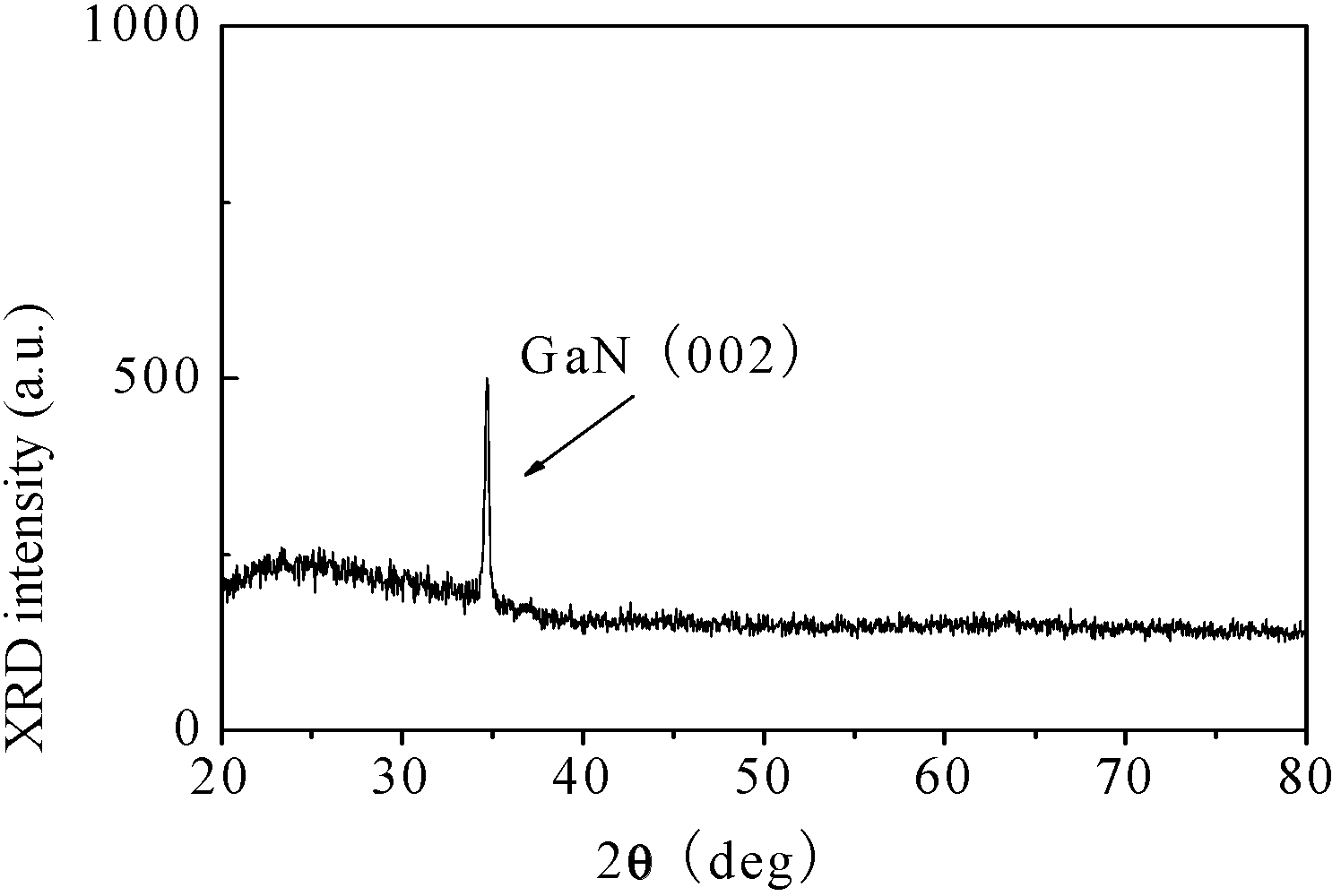

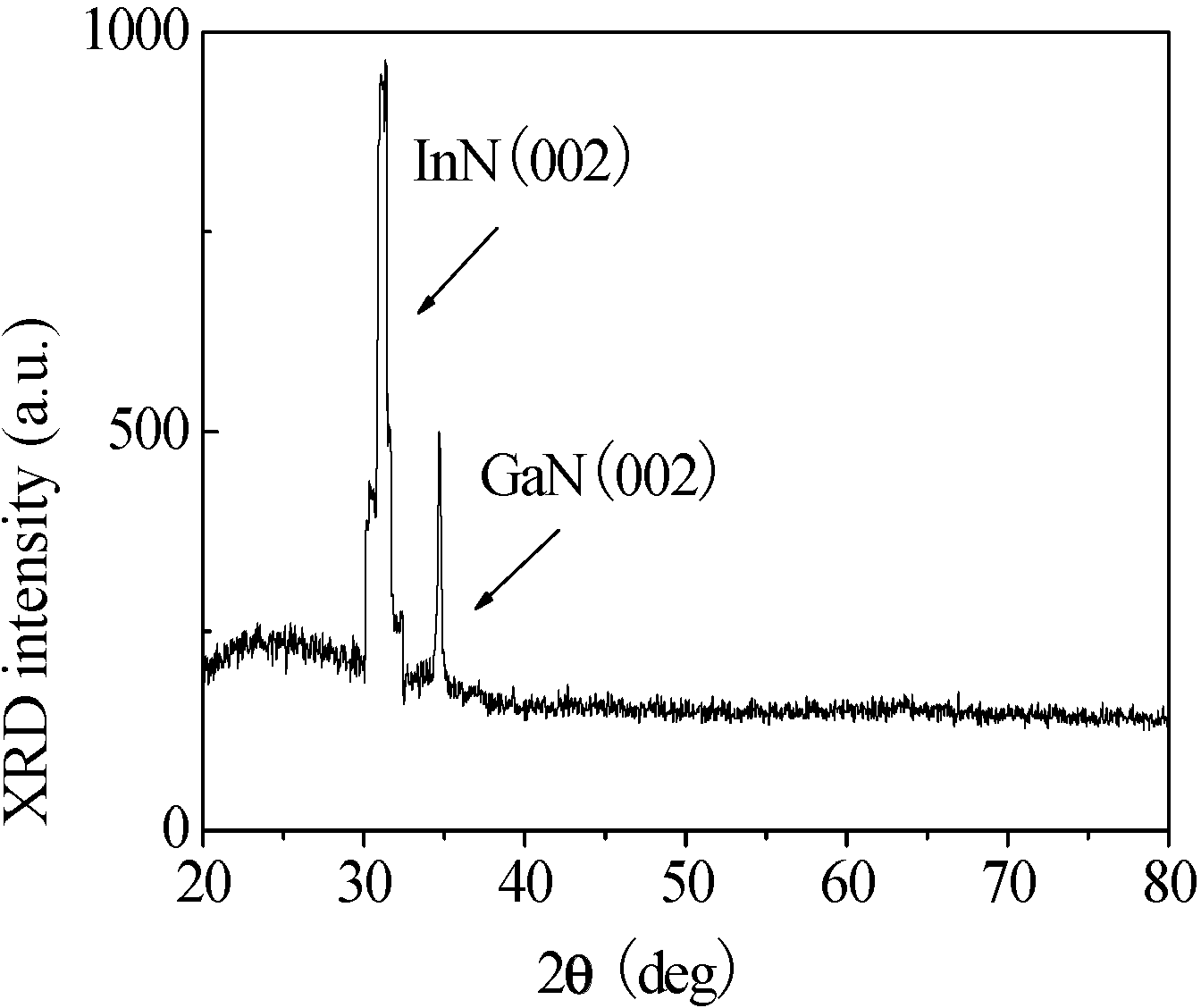

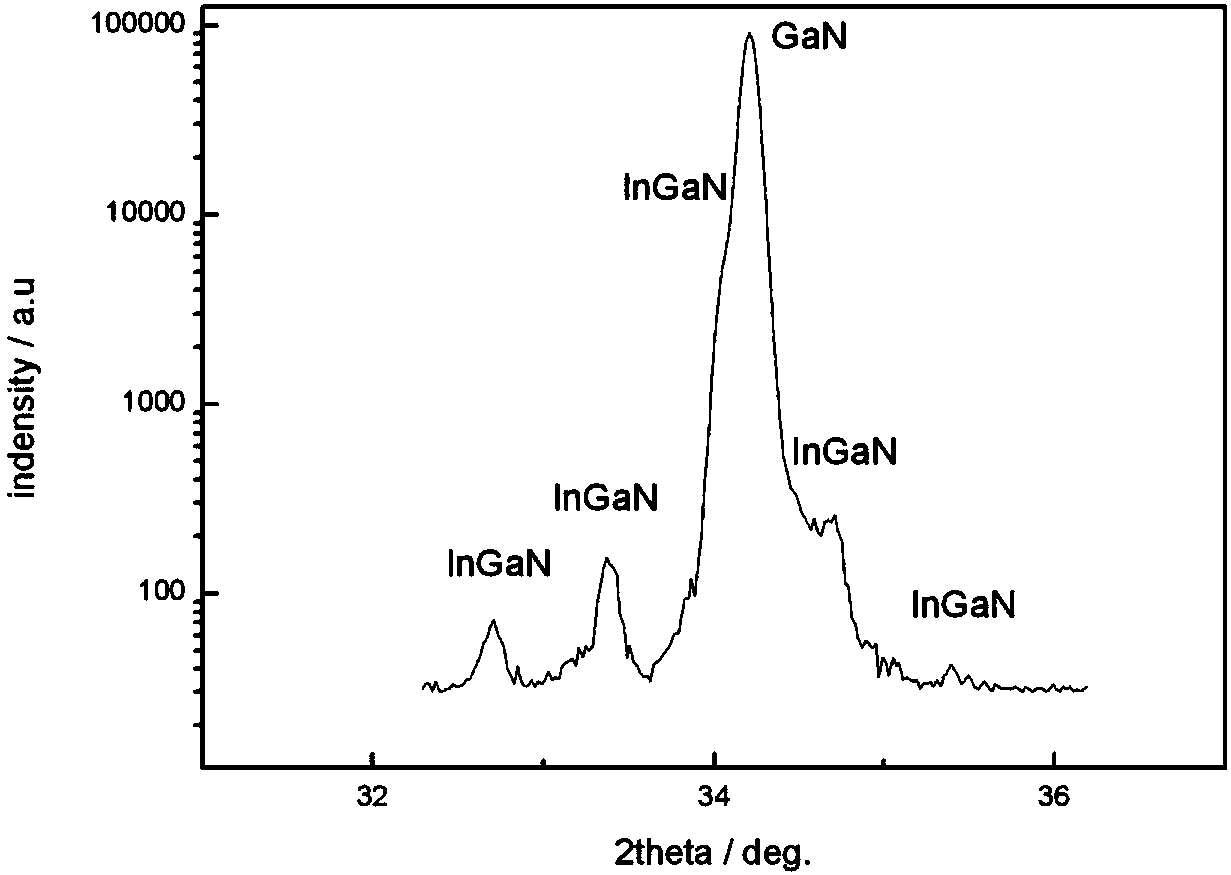

Epitaxial growth method of silicon substrate GaN-based LED

InactiveCN108110093AReduce dislocation densitySmooth interfacePolycrystalline material growthFrom chemically reactive gasesTrimethylindiumPhysics

The invention provides an epitaxial growth method of a silicon substrate GaN-based LED. An LP-MOCVD system of Thomas Swan is adopted, Si (111) is selected as a substrate, TMGa, TMAl, TMIn and high-purity NH3 are respectively sources of Ga, Al, In and N, H2 and N2 are adopted as carrier gases, and SiH4 and CP2Mg are respectively n-type and p-type doping agents; the Si substrate is cleaned before growth to remove pollutants and impurities and obtain a clean surface; and an epitaxial wafer of the silicon substrate GaN-based LED is grown in an epitaxial manner, and the crystallization quality thereof is tested and analyzed by employing DCXRD. It is indicated through a result that the interface of an InGan / GaN multi-quantum well is flat, and the crystallization quality is good; and the period thicknesses of the quantum well, obtained through calculation by employing two methods, are fundamentally consistent.

Owner:FOSHAN DONGSHEN METAL PROD CO LTD

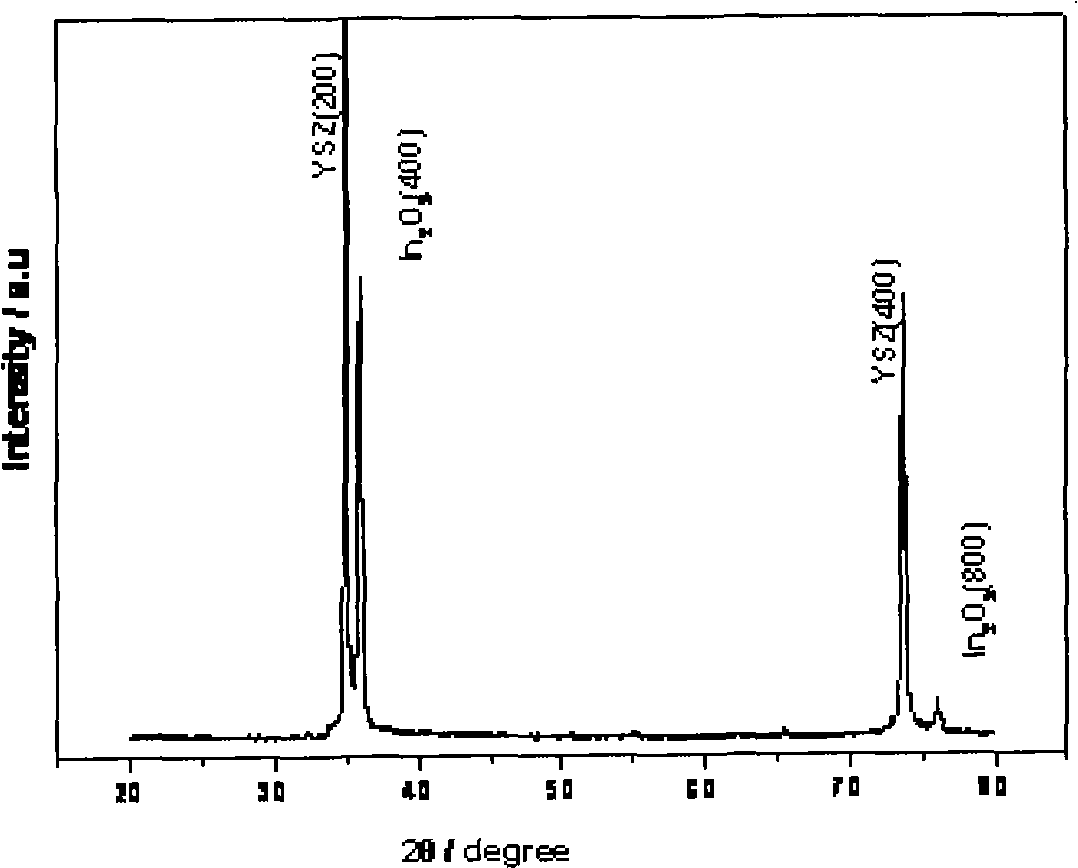

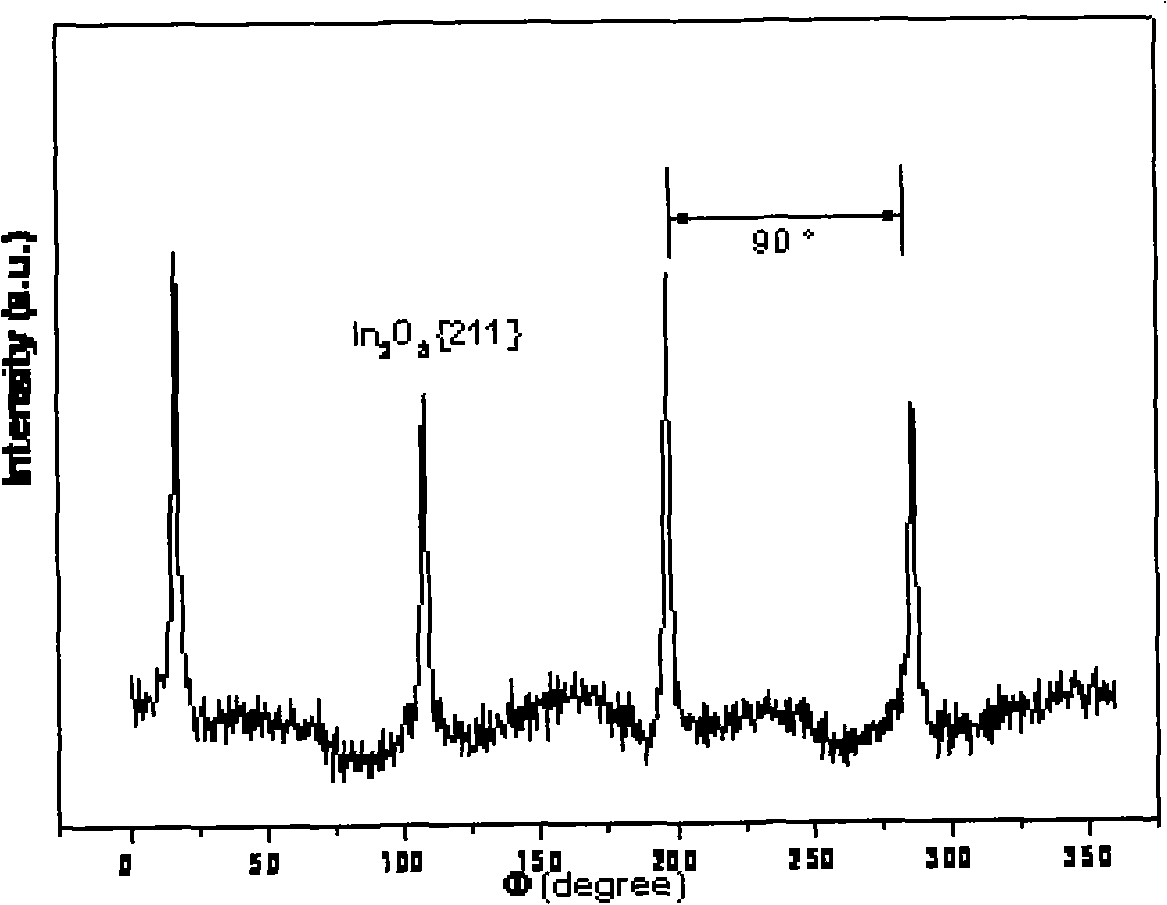

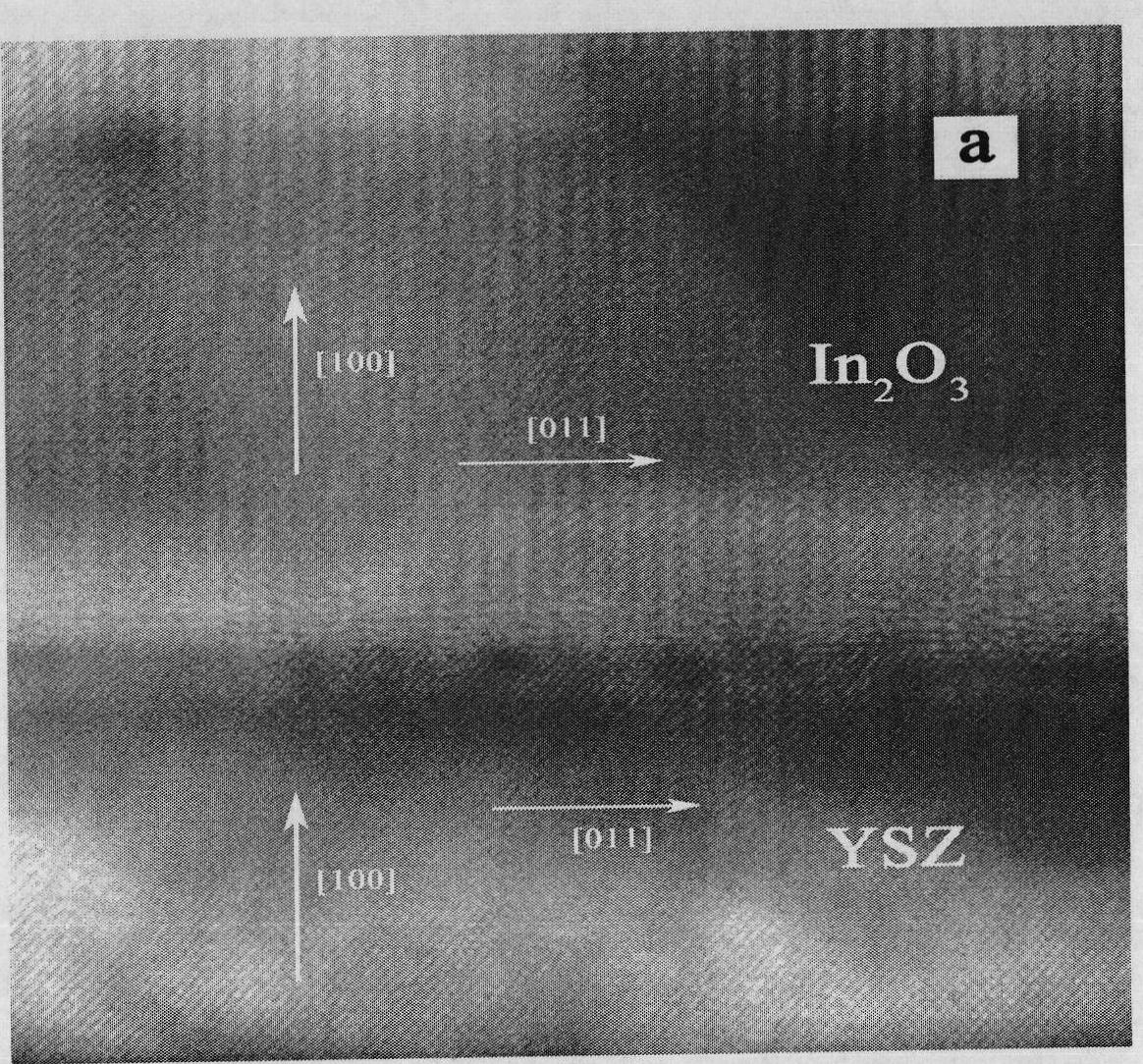

Method for preparing cubic indium oxide single-crystal film on yttrium-doped zirconia substrate

InactiveCN101792901AGood adhesionImprove photoelectric performanceChemical vapor deposition coatingOrganometallic chemistryIndium

The invention relates to a preparation method for a cubic indium oxide single-crystal epitaxial film. By adopting the organic metal chemical gas deposition technology, trimethylindium is used as an organic metal source, nitrogen is used as carrier gas, oxygen is used as oxidizing gas and an organic metal chemical gas deposition device is used to epitaxially grow indium oxide single-crystal film on an yttrium-doped zirconia substrate under vacuum conditions. The film is the epitaxial material with single-crystal structure, twin crystals and domain structures do not exist in the film, and the mobility of the current carrier of the film is higher than 61.2 cm<2>V<-1>s<-1>.

Owner:SHANDONG UNIV

Epitaxial growth method of high-resistance GaN thin film

ActiveCN107887255AFree installationImprove economySemiconductor/solid-state device manufacturingHigh resistanceImpurity doping

The invention relates to an epitaxial growth method of a high-resistance GaN thin film. The method is performed in MOCVD equipment and includes a substrate baking stage, a nucleation stage and an epitaxial growth stage. The method is characterized in that a metal organic matter trimethylindium is used as a C impurity doping source during the epitaxial growth stage. With the method adopted, the high resistance of the GaN thin film can be achieved; the TMIn is unlikely to form In-N bonds in crystal lattices under high temperature, and therefore, high growth temperature can assist in avoiding theformation of InGaN alloys and ensuring the integrity of the lattice structure of the GaN thin film; the concentration of C impurities in a GaN epitaxial layer can be effectively controlled by changing the flow rate of the dopant TMIn, and therefore, doping efficiency is high, and repeatability is stable; and a doping source pipeline is not required to be added into an MOCVD system, other C dopingsources are not required to be installed, and therefore, the resources of existing device can be fully utilized. The method is of simplicity and easy to operate. The epitaxial material has good performance. The high-quality and low-cost growth of the high-resistance GaN thin film can be realized.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

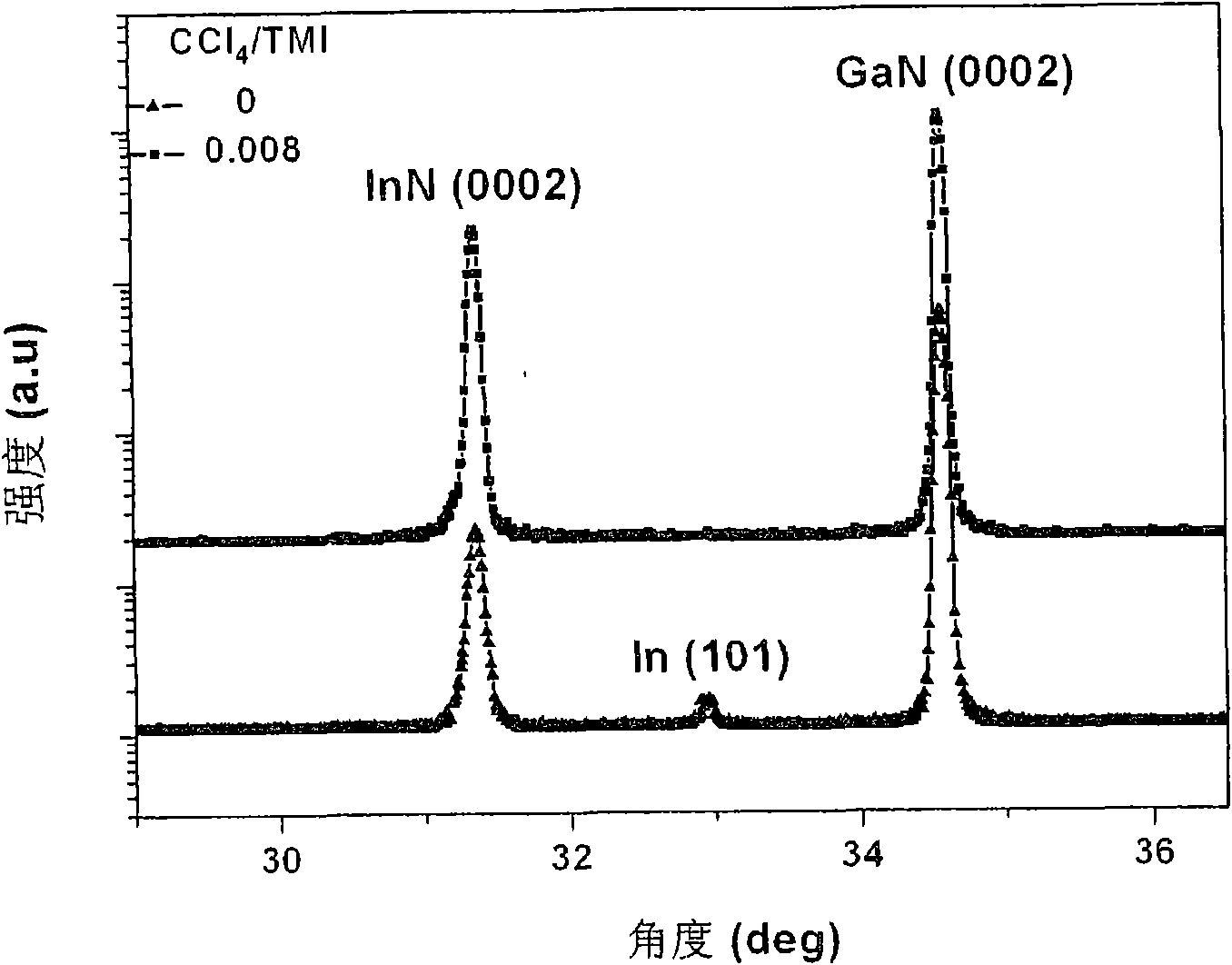

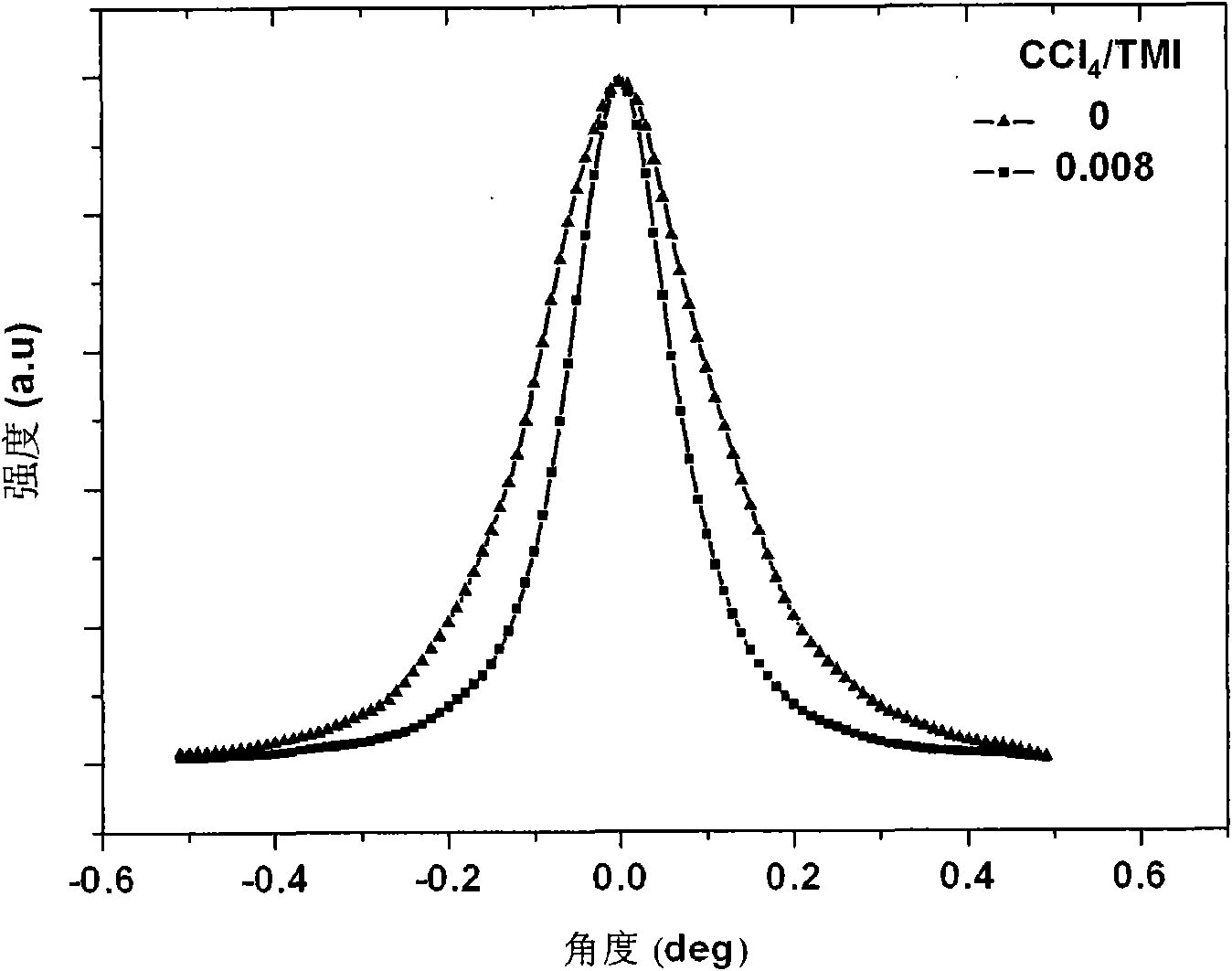

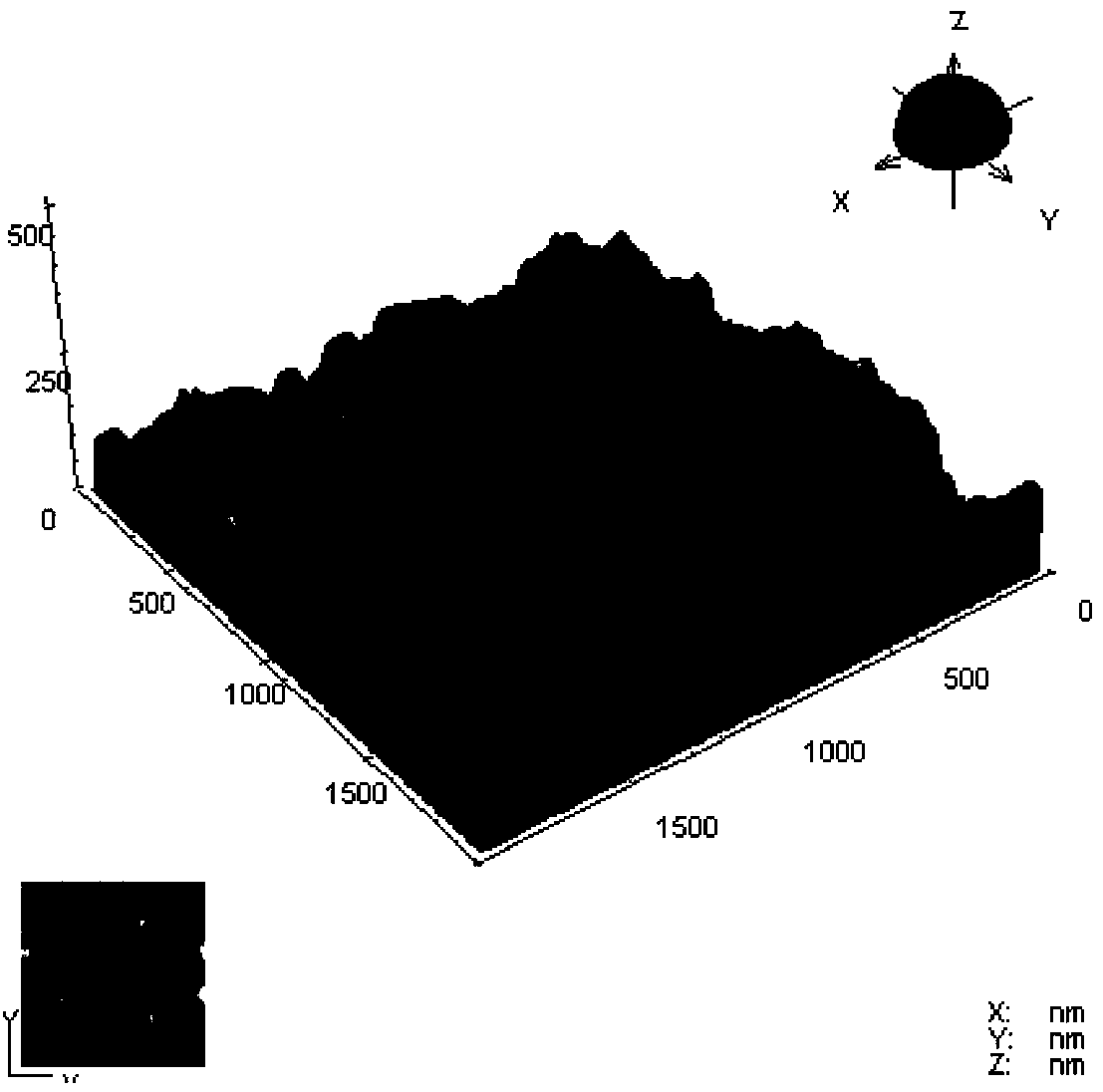

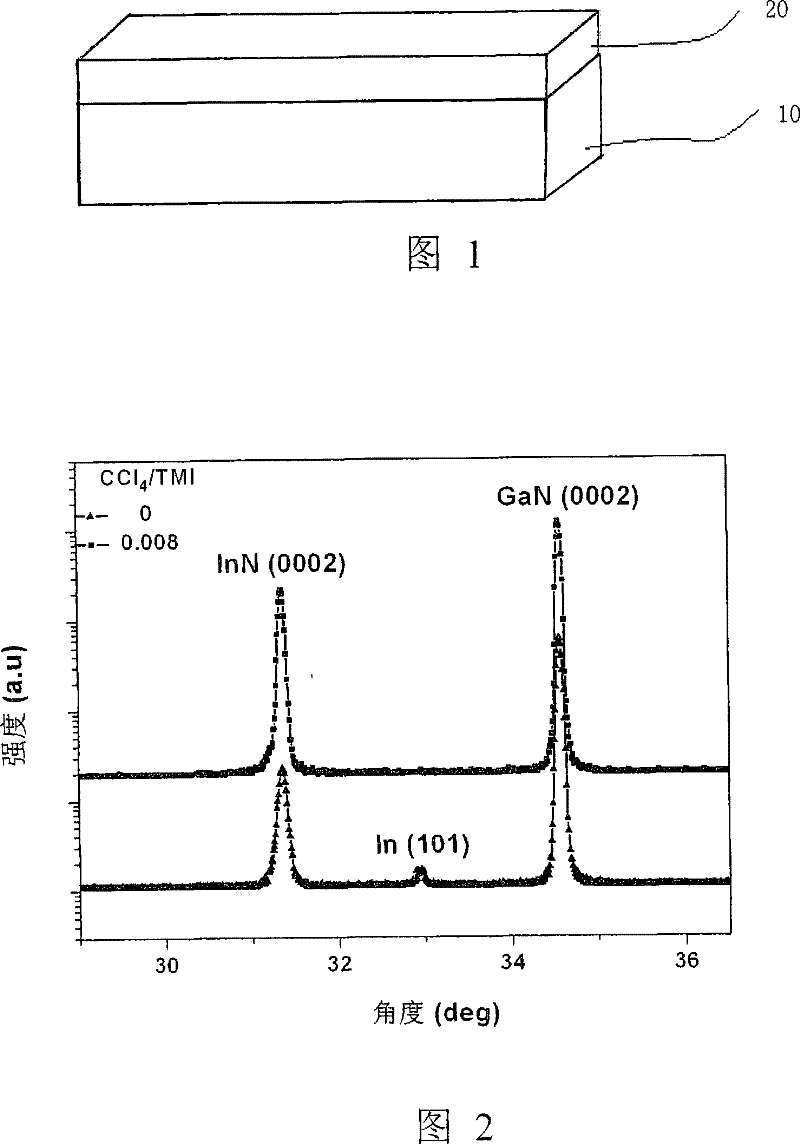

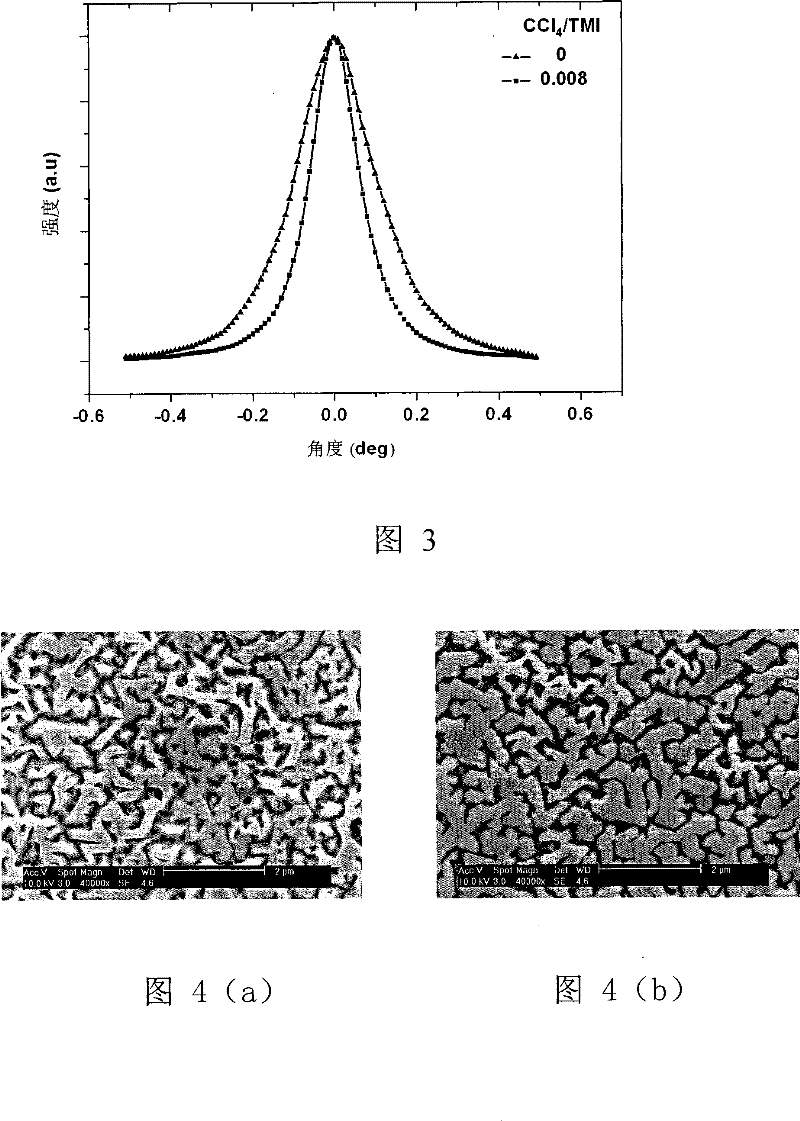

Method for growing high-quality indium nitride single crystal epitaxial film

InactiveCN101525740AEnhancing Lateral Migration CapabilitiesSuppressing Indium DropsChemical vapor deposition coatingGas phaseSingle crystal

The invention provides a method for growing a high-quality indium nitride single crystal epitaxial film, which is to introduce small amount of halide while growing indium nitride, and comprises the following steps: selecting a substrate; placing the substrate in a metal-organic chemical vapor deposition system, raising the temperature, and introducing ammonia gas for pretreatment; and reducing temperature to a growth temperature, and simultaneously introducing trimethylindium (TMI), the ammonia gas (NH3) and the small amount of the halide to grow the high-quality indium nitride single crystal epitaxial film. The method can improve the crystallization quality of InN and the surface smoothness.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

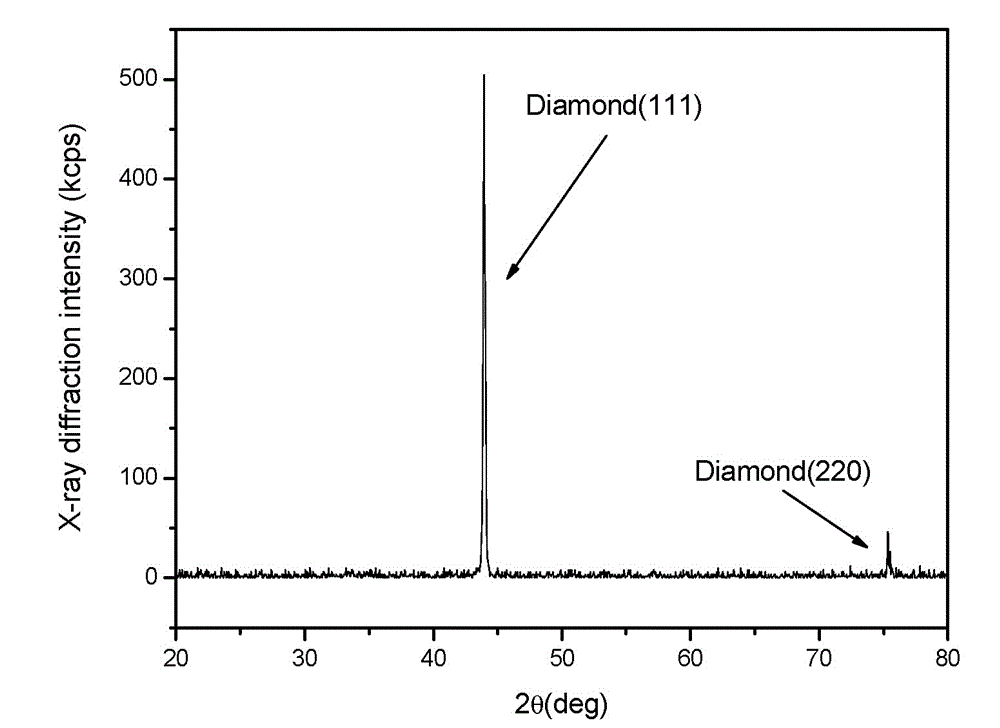

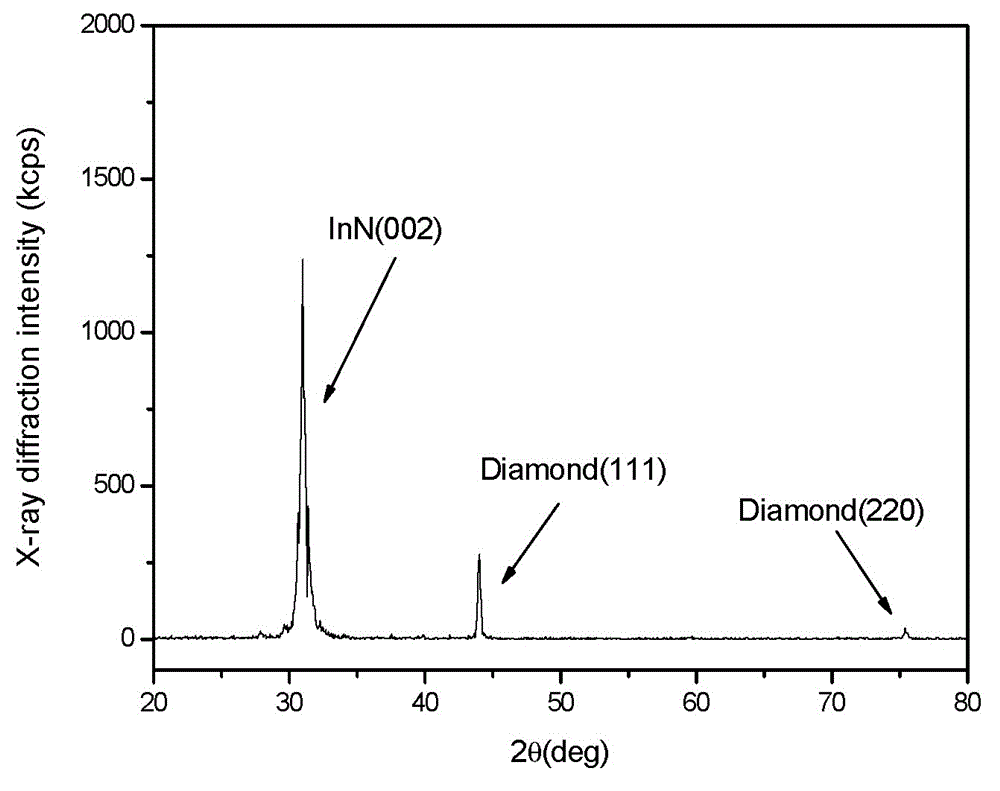

Preparation method of InN (indium nitride) thin film through low-temperature deposition on self-supporting diamond thick film by ECR-PEMOCVD (electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition)

ActiveCN103334089ALow costImprove thermal conductivityChemical vapor deposition coatingLow temperature depositionNitrogen gas

The invention belongs to the technical field of novel photoelectric material deposition preparation, and provides a preparation method of an InN thin film through low-temperature deposition on a self-supporting diamond thick film by the ECR-PEMOCVD, and by means of the preparation method , the InN photoelectric thin film with good electrical properties and heat dissipation performance can be prepared. The preparation method comprises the steps as follows: 1), a self-supporting diamond thick film substrate is ultrasonically cleaned by acetone, ethanol and deionized water in sequence, blow-dried by nitrogen and sent to a reaction chamber; and 2), the ECR-PEMOCVD system is adopted to vacuumize the reaction chamber, the substrate is heated in a range from 20 DEG C to 600 DEG C, then trimethylindium carried by hydrogen and nitrogen are introduced into the reaction chamber, a flow ratio of trimethylindium to nitrogen is (1-2):(100-200), total gas pressure intensity is controlled in a range from 0.8 Pa to 2.0 Pa, electron cyclotron resonance reaction is performed for 30 min-3 h, and the InN photoelectric thin film on the self-supporting diamond thick film substrate is obtained.

Owner:SHENYANG JIAYUE ELECTRIC POWER TECH CO LTD

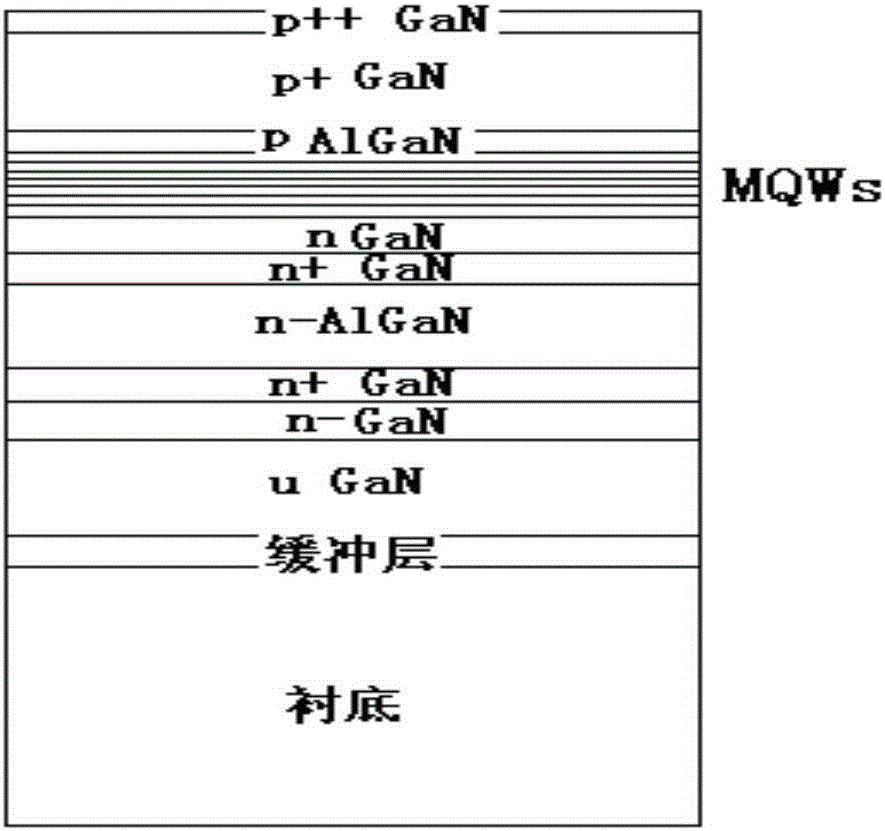

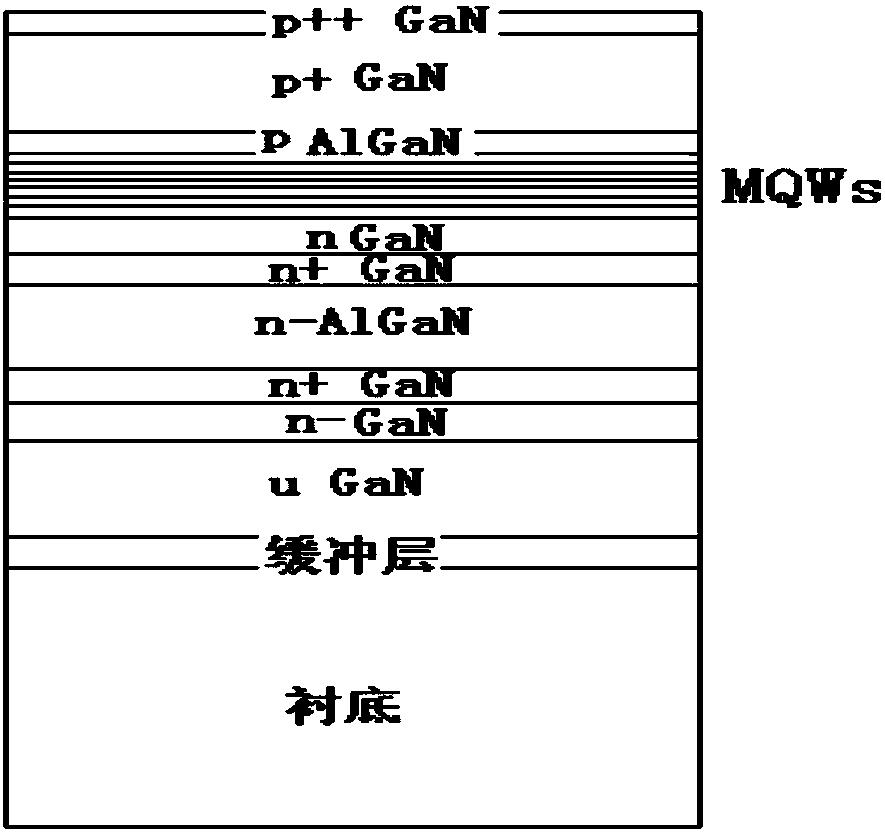

Method for preparing InGaN/AlGaN MQW ultraviolet LED

ActiveCN106206880ALarge adjustment rangeSuitable for batch growthSemiconductor devicesUltravioletP type doping

The invention discloses a method for preparing a high-performance InGaN / AlGaN MQW ultraviolet LED. Blue ammonia, high-purity trimethylindium and high-purity trimethyl gallium serve as an N source, an In source and a Ga source respectively, and SiH4 and Cp2Mg serve as an n type doping agent and a p type doping agent respectively. The method comprises the following steps that firstly, a sapphire substrate or a SiC substrate or a Si substrate is nitrided; secondly, a buffering layer is grown and crystallized, and then a uGaN nucleating layer is grown; thirdly, a low Si-doped n-GaN layer is grown first, and then a high Si-doped n+GaN layer is grown; fourthly, an n-AlGaN layer is grown; fifthly, a Si-doped n+GaN layer is grown, and then an nGaN layer without Si is grown; sixthly, three cycles of InGaN / GaN superlattices without Al are grown, and then eight cycles of Al-doped InGaN / GaN is grown; seventhly, a PAlGaN layer is grown; eighthly, a Mg-doped P+GaN layer is grown; ninthly, a high Mg-doped P++GaN layer is grown. According to the method, InGaN / AlGaN MQW ultraviolet LED epitaxy pieces of the specific structure are grown with an LP MOCVD system, the preparing cost is low, time is saved, the prepared ultraviolet LED is good in performance, and the ultraviolet LED epitaxy industrialization is promoted.

Owner:江苏晶曌半导体有限公司

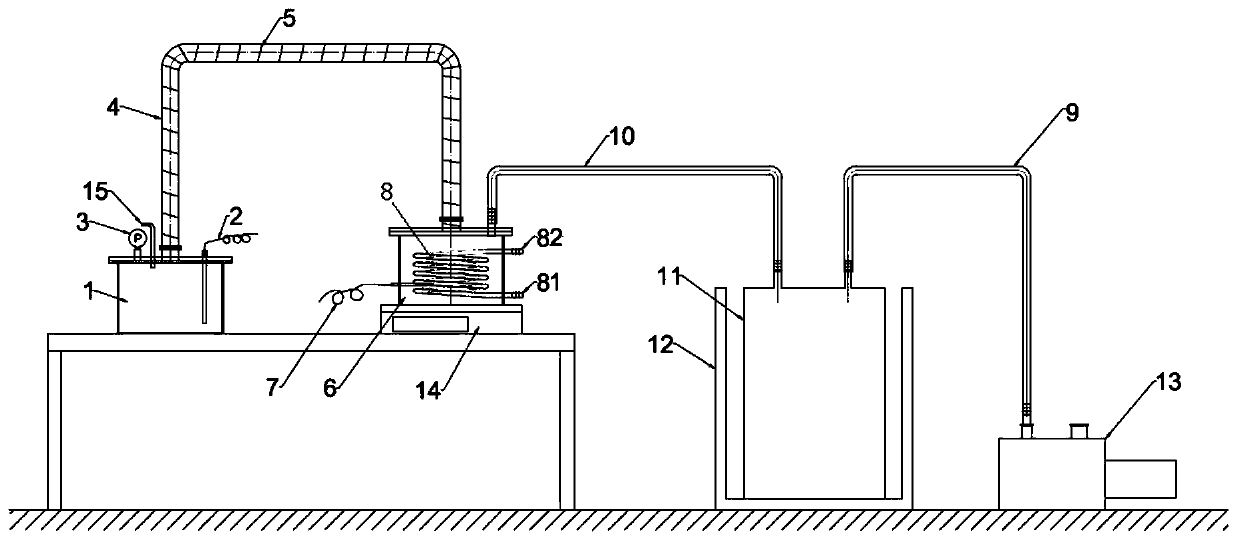

Trimethylindium low-temperature purification device and low-temperature purification method

PendingCN110420537AHigh purityImprove Particle UniformityDispersed particle separationVapor condensationPurification methodsEngineering

The invention discloses a trimethylindium low-temperature purifying device, which comprises a purifying raw material kettle, a receiving tank, a vacuum protection device and a vacuum pump, wherein a solid trimethylindium material is arranged in a purifying raw material kettle; a high-purity gas carrier pipe is connected to the purifying raw material kettle; the purifying raw material kettle is connected with a receiving tank through a heat- tracing pipe; the receiving tank is connected with the vacuum protection device; the vacuum protection device is connected with a vacuum pump; and a condensing device is arranged in the receiving tank. The invention also discloses a trimethylindium low-temperature purification method. In the method, the pressure in the purifying raw material kettle is less than 50 Torr, the temperature in the purifying raw material kettle is controlled to be 30-80 DEG C, the temperature in the receiving tank is controlled to be -30 to 30 DEG C, and a high-purity carrier gas drives the trimethylindium material to enter the receiving tank, and after cooling, purified trimethylindium is obtained. The purifying method has low requirements on equipment, low equipmentcost investment and simple operation, improves the purity of the trimethylindium, and greatly improves the safety and stability of the purification process.

Owner:苏州普耀光电材料有限公司

Preparation method of InGaN/GaN multi-quantum well-based red light LED structure

PendingCN111916538AAchieve red light emissionIncrease the density of statesSemiconductor devicesIndiumPhysical chemistry

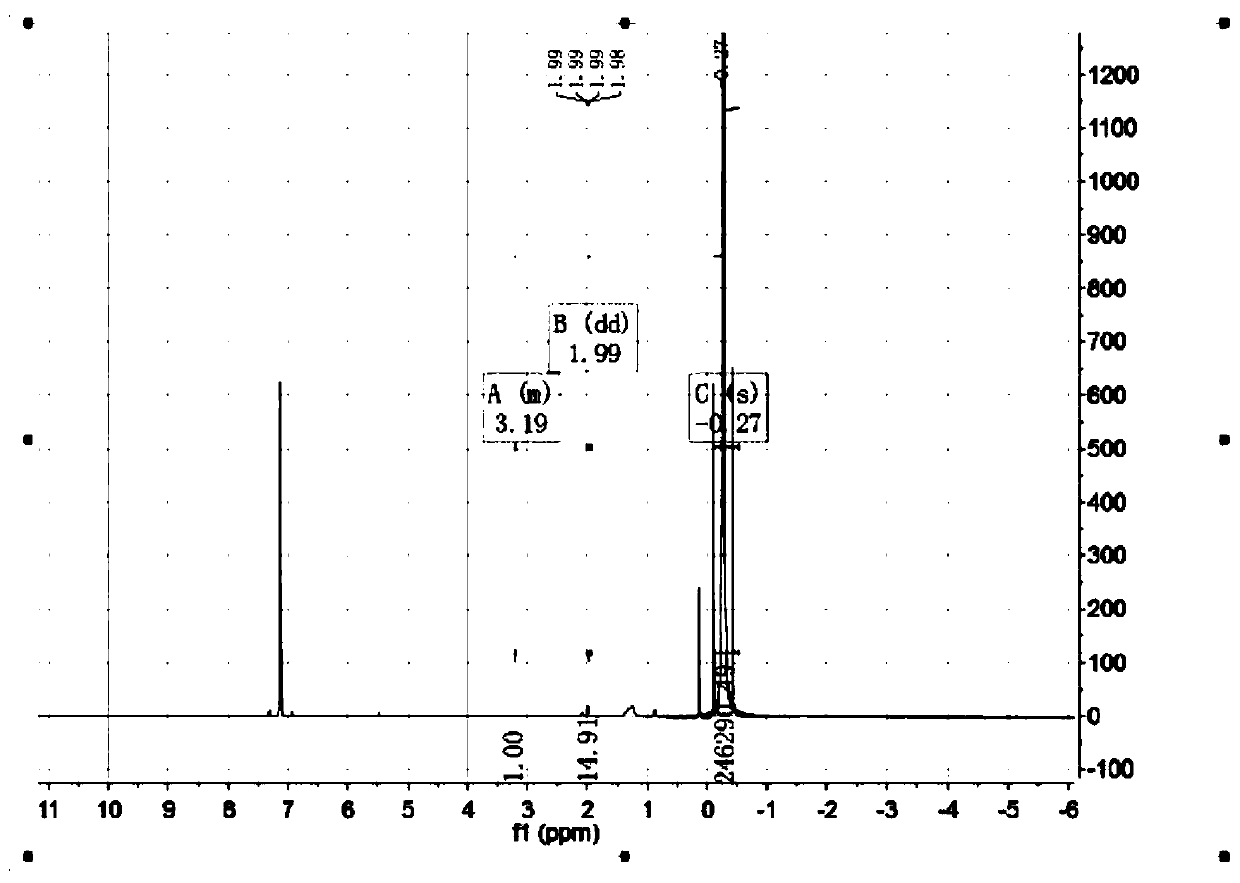

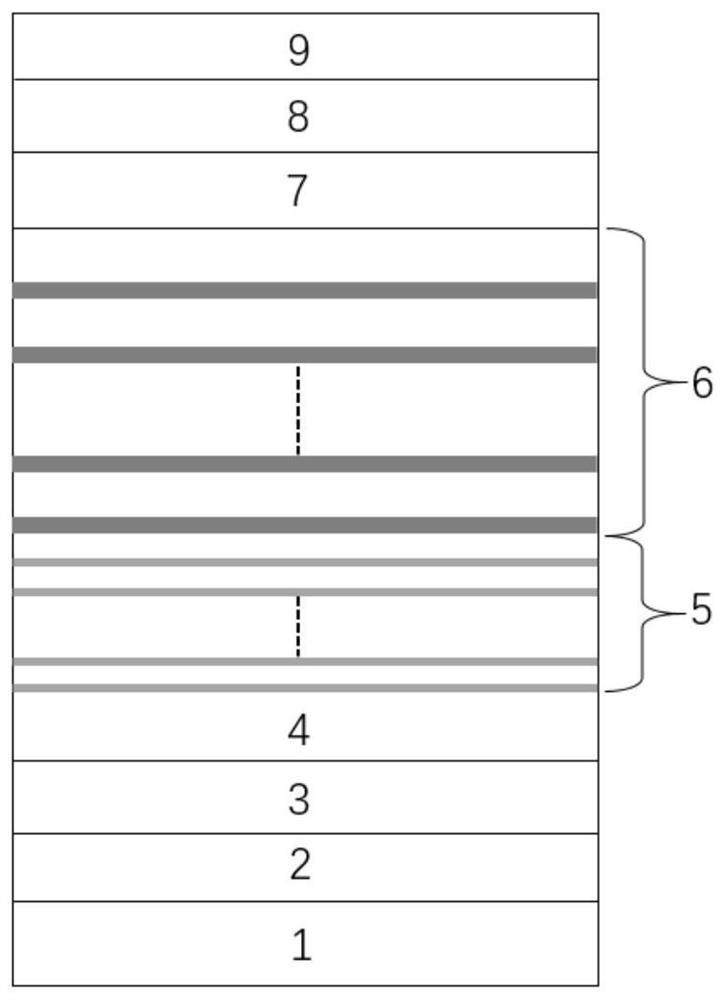

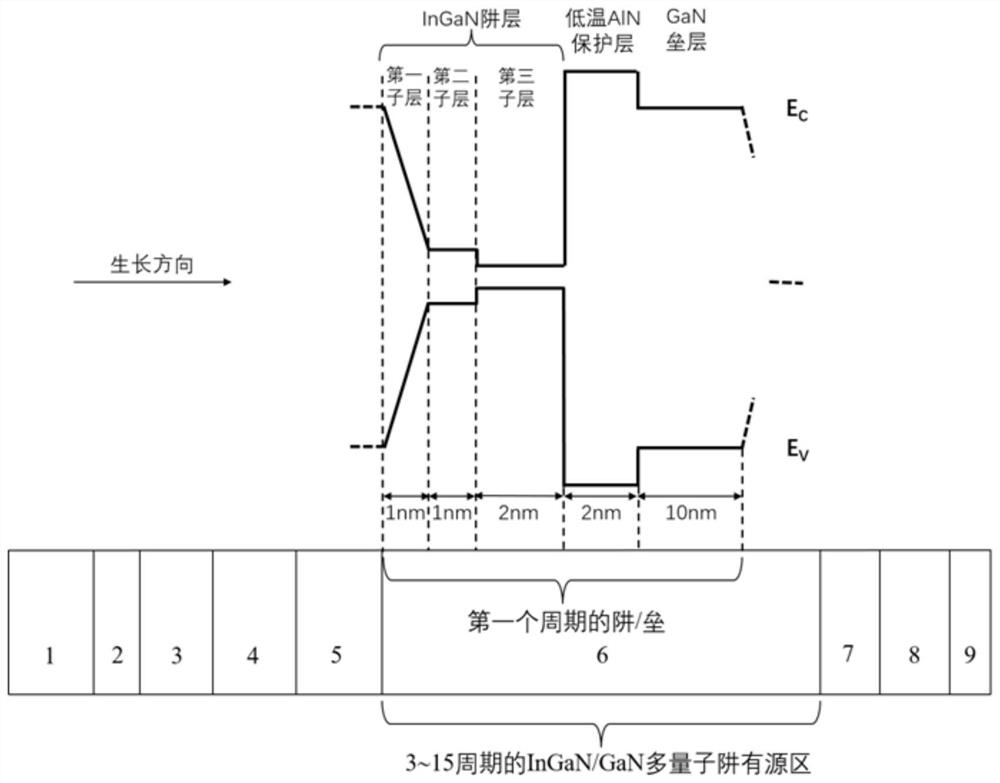

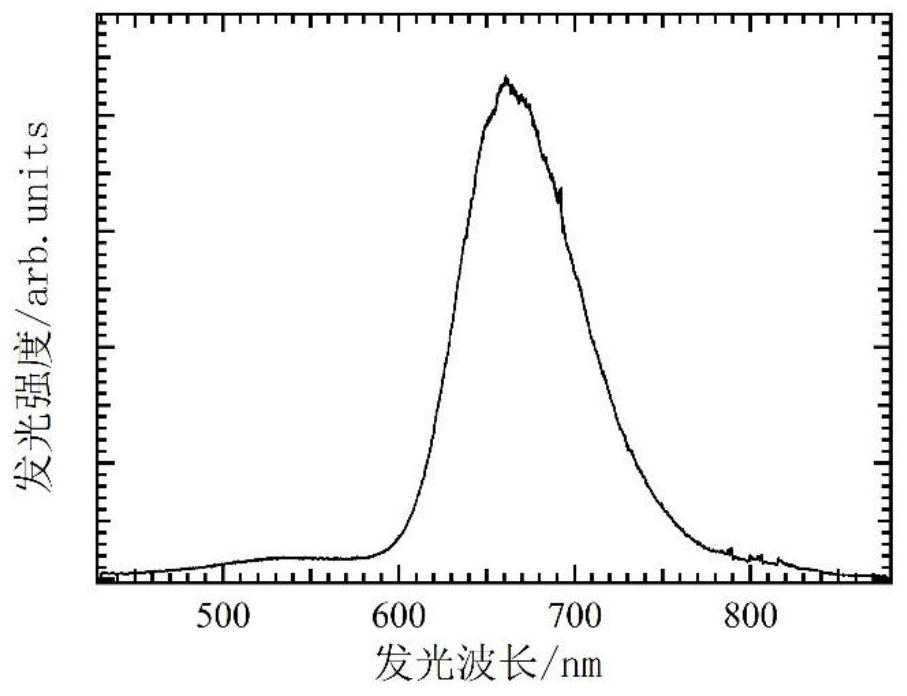

The invention discloses a preparation method of an InGaN / GaN multi-quantum well-based red light LED structure. The preparation method comprises the following steps: (1) sequentially growing a low-temperature GaN buffer layer, a non-doped GaN layer, an n-type GaN layer and an InGaN / GaN superlattice stress release layer on a sapphire substrate; (2) growing an InGaN / GaN multi-quantum well active region, wherein the growth process of each InGaN well layer is as follows: 1, at 680-710 DEG C, gradually increasing the flow rate of trimethyl indium from 0 to 600-700sccm, and growing a first sub-layer;2, growing a second sub-layer under the condition that the temperature and the maximum trimethyl indium flow rate in the step 1 are not changed; 3, performing cooling to 20-30 DEG C, and growing a third sub-layer; (3) sequentially growing a p-type AlGaN electronic barrier layer, a p-type GaN layer and a p-type InGaN ohmic contact layer. According to the invention, the spontaneous radiation efficiency is improved, the state density of a long-wavelength radiation area is increased, and the radiation light is expanded in the long-wavelength direction.

Owner:SHANDONG UNIV

Growth method of light emitting diode and light emitting diode

The invention provides a growth method of a light emitting diode and the light emitting diode. The growth method comprises the following steps: 1) nitrogen, ammonia, trimethylaluminum, trimethylgallium and trimethylindium are introduced into reaction equipment at 800-930 DEG C and 200Torr to grow a first AlxInyGa1-x-yN layer on a quantum well luminescent layer and then the introduction of nitrogen, ammonia, trimethylaluminum, trimethylgallium and trimethylindium is stopped; 2) hydrogen is introduced into the reaction equipment to enable the first AlxInyGa1-x-yN layer to be converted into a first AlxGa1-xN layer; and 3) the step 1) to the step 2) are cyclically performed for T times so as to obtain an electron barrier layer AlxGa1-xN, wherein 0 <x<1, 0<y<1 and x>y. The method is helpful togrow the high-quality electron barrier layer on the basis of no negative influence on the quantum well structure.

Owner:EPITOP PHOTOELECTRIC TECH

Method for mixing organic gallium source selective zone growing indium-gallium-arsenic-phosphor multiple quantum well

InactiveCN1209861CLower threshold current densityImprove efficiencyLaser detailsLaser active region structureElectro-absorption modulatorIndium

The method for growing indium gallium arsenide phosphorus multiple quantum wells in selected regions by mixing organic gallium sources in the present invention is to use triethylgallium and trimethylindium to grow confinement layers and barriers when selectively growing indium gallium arsenide phosphorus multiple quantum wells, and three Methylgallium and trimethylindium growth wells; the quantum well material grown by this method has a large strain in the selective growth region, while in the non-selective growth region, the well region has a small strain; the barrier and the confinement layer are in The strain change of the two growth regions is very small, which makes the quantum well with the selective growth region have high luminous efficiency, and ensures the realization of high-performance electroabsorption modulation DFB laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of high-purity trimethylindium

ActiveCN104860972BEasy to operateImprove the purification effectGroup 3/13 element organic compoundsStationary phaseCombinatorial chemistry

The invention relates to a preparation method of high-purity trimethyl indium, belonging to the technical field of preparing group III metallic compounds in the periodic table of elements. The preparation method disclosed by the invention comprises the following steps: (1) taking diethyl ether as a solvent to prepare a trimethyl indium crude product; (2) carrying out purification to the trimethyl indium crude product obtained in step (1), wherein the purification method comprises the step of adopting a first chromatographic column to carry out purification to the trimethyl indium crude product; and the stationary phase adopted by the first chromatographic column is grafted silica, and the grafted silica is silica of which the surface is grafted with tri-n-octylamine. The preparation method disclosed by the invention adopts the two steps of synthesis and separation and obtains the trimethyl indium of which the purity can reach 6N; above all, the purity method adopted is combined with the solid-liquid separation means, a certain coordination agent is loaded on the silica, not only is the operation simple, but also the purification effect is improved further.

Owner:苏州普耀光电材料有限公司

Industrial purification method of trimethylindium

ActiveCN104193773AEasy to getNo toxicityGroup 3/13 element organic compoundsPurification methodsEther

The invention discloses an industrial purification method of trimethylindium. The industrial purification method comprises the following steps: adding a trimethylindium.ether complex in a reactor protected by an inert atmosphere, and then adding cycloalkane CnH2n (n is equal to or greater than 6) and reacting, wherein the temperature of the reaction system is always kept at 30-100 DEG C, and during the dropwise adding process, the dissociated ether is cooled by virtue of a condenser and is directly received in a receiving tank to achieve the complete dissociation of ether from trimethylindium. The reagents adopted by the method disclosed by the invention are conventional reagents and are inexpensive and easily available, the reaction process is mild and has no security risk; and as ether is continuously separated from the reaction system, the dissociation efficiency of ether is improved. No waste is generated in the reaction, the cost is reduced and no environment pollution is caused.

Owner:安徽亚格盛电子新材料有限公司

Preparation method for InN/GaN/glass structure

ActiveCN103352209ALight in massLow costGlass/slag layered productsChemical vapor deposition coatingIndiumGallium

The invention belongs to the technical field of novel photoelectric material sediment preparation, and provides a preparation method for an InN / GaN / glass structure which has excellent electric performance and stability. The preparation method comprises the following steps: 1), a glass substrate is subjected to ultrasonic cleaning by acetone, ethanol, and deionized water sequentially, and then is blow-dried by nitrogen gas and sent to a reaction chamber; 2), the reaction chamber is vacuumized by adopting an ECR-PEMOCVD system, the glass substrate is heated, and trimethyl gallium carried by hydrogen and nitrogen gas are introduced into the reaction chamber, wherein the flux of the trimethyl gallium and the flux of the nitrogen gas are 0.5 sccm-0.8 sccm and 80 sccm-120 sccm respectively, and the total pressure of the gas is controlled, a GaN buffer layer film of the glass substrate can be obtained after the reaction under the electron cyclotron resonance condition; 3), the reaction chamber is vacuumized by adopting the ECR-PEMOCVD system for the second time, the glass substrate is heated to 200-400 DEG C, and the trimethyl gallium carried by hydrogen and the nitrogen gas are pumped into the reaction chamber.

Owner:辽宁太阳能研究应用有限公司

Method for growing high-quality indium nitride single crystal epitaxial film

InactiveCN101525740BEnhancing Lateral Migration CapabilitiesSuppressing Indium DropsChemical vapor deposition coatingGas phaseSingle crystal

The invention provides a method for growing a high-quality indium nitride single crystal epitaxial film, which is to introduce small amount of halide while growing indium nitride, and comprises the following steps: selecting a substrate; placing the substrate in a metal-organic chemical vapor deposition system, raising the temperature, and introducing ammonia gas for pretreatment; and reducing temperature to a growth temperature, and simultaneously introducing trimethylindium (TMI), the ammonia gas (NH3) and the small amount of the halide to grow the high-quality indium nitride single crystalepitaxial film. The method can improve the crystallization quality of InN and the surface smoothness.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A kind of method for preparing ingan/algan MQW violet light LED

ActiveCN106206880BLarge adjustment rangeSuitable for batch growthSemiconductor devicesUltravioletGallium

The invention discloses a method for preparing a high-performance InGaN / AlGaN MQW ultraviolet LED. Blue ammonia, high-purity trimethylindium and high-purity trimethyl gallium serve as an N source, an In source and a Ga source respectively, and SiH4 and Cp2Mg serve as an n type doping agent and a p type doping agent respectively. The method comprises the following steps that firstly, a sapphire substrate or a SiC substrate or a Si substrate is nitrided; secondly, a buffering layer is grown and crystallized, and then a uGaN nucleating layer is grown; thirdly, a low Si-doped n-GaN layer is grown first, and then a high Si-doped n+GaN layer is grown; fourthly, an n-AlGaN layer is grown; fifthly, a Si-doped n+GaN layer is grown, and then an nGaN layer without Si is grown; sixthly, three cycles of InGaN / GaN superlattices without Al are grown, and then eight cycles of Al-doped InGaN / GaN is grown; seventhly, a PAlGaN layer is grown; eighthly, a Mg-doped P+GaN layer is grown; ninthly, a high Mg-doped P++GaN layer is grown. According to the method, InGaN / AlGaN MQW ultraviolet LED epitaxy pieces of the specific structure are grown with an LP MOCVD system, the preparing cost is low, time is saved, the prepared ultraviolet LED is good in performance, and the ultraviolet LED epitaxy industrialization is promoted.

Owner:江苏晶曌半导体有限公司

Efficient purifying method of trimethylindium

ActiveCN104817580AEasy to operateImprove the purification effectComponent separationSolid sorbent liquid separationStationary phasePurification methods

The invention relates to an efficient purifying method of trimethylindium, belonging to the technical field of compound purification. The purifying method comprises the following steps of (1) pouring a crude product of trimethylindium into a first chromatographic column with a stationary phase as filler, naturally and downwards flowing the crude product of trimethylindium by virtue of gravity, and collecting a solution when all the liquid flows up; (2) pouring the collected solution into a second chromatographic column with a stationary phase as surface grafted filler, naturally and downwards flowing the solution by virtue of gravity, and collecting the solution when all the liquid flows up; then, pouring the collected solution into the second chromatographic column, and repeating the operation 2-5 times, wherein the surface grafted filler is filler of which the surface is grafted with tri-n-octylamine; and (3) heating and disassembling the second chromatographic column treated in the step (2), and collecting by vacuumizing at the bottom of the chromatographic column to obtain purified trimethylindium. The purifying method disclosed by the invention is combined with a solid-liquid separation means, and a specific coordination agent is loaded on the filler, so that not only is the method simple, but also the purifying effect is further improved.

Owner:苏州普耀光电材料有限公司

A kind of growth method of gan nanowire

InactiveCN103757693BAvoid tarnishingLow densityPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsNanowireIndium

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com