Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Improve Particle Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

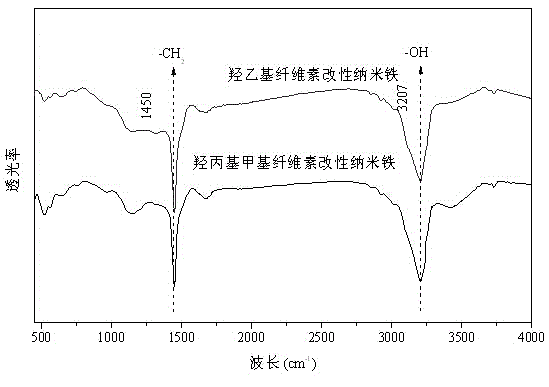

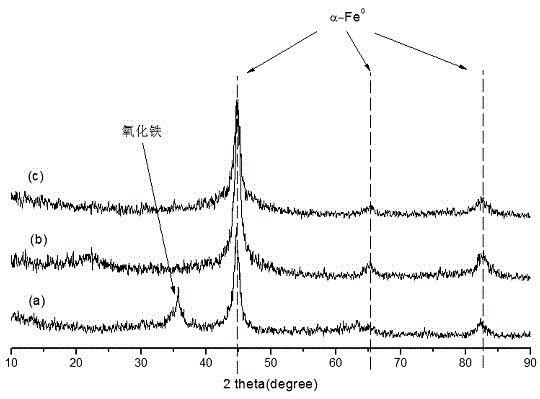

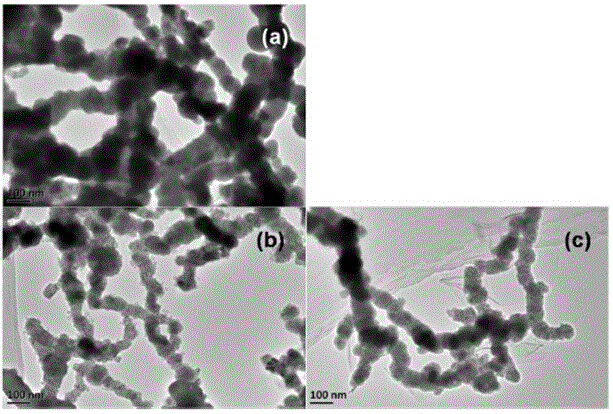

Preparation method for cellulose modification nano iron particles

ActiveCN104785793AFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentCelluloseNitrate salts

The invention discloses a preparation method for cellulose modification nano iron particles. According to the preparation method, two kinds of environment-friendly non-poisonous and innocuous cellulose are taken as dispersing agents to conduct surface modification on particles in the preparation process of the nano iron particles, and the cellulose dispersing agent modified nano iron particles are obtained. According to the preparation method for the cellulose modification nano iron particles, the process is simple and convenient, the operation is easy, the cost is low, the dispersity of the nano iron particles is good, the agglomeration of the particles in water can be reduced, and the removal efficiency of the particles to organic pollutants, dyestuff, pesticides, nitrate and heavy metal is improved.

Owner:KUNMING UNIV OF SCI & TECH

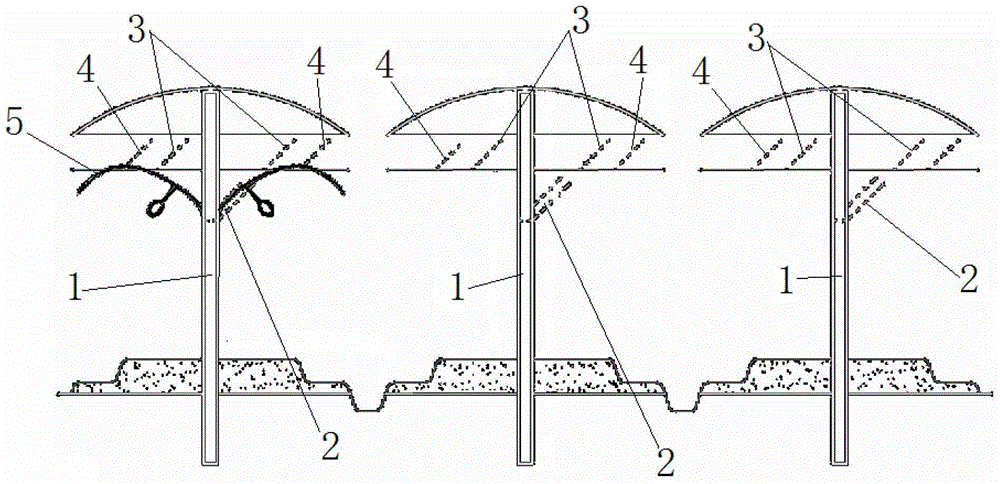

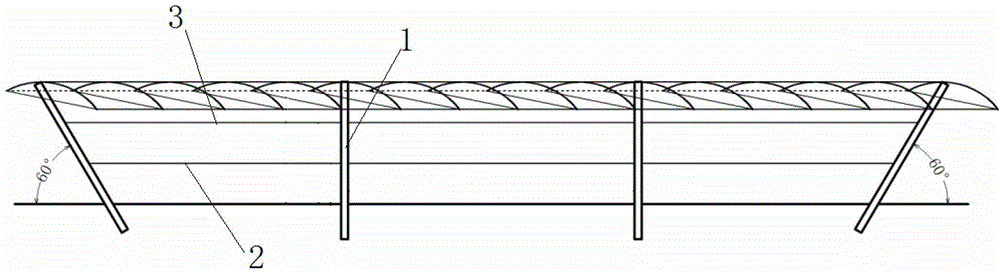

Grape cultivation method and special rack for cultivation method

InactiveCN103329774AImprove fruit setting rateImprove qualityCultivating equipmentsViticultureBiology

The invention discloses a grape cultivation method and a special rack for the cultivation method. The cultivation method is characterized in that grape branches are cultivated to an M-shaped growth trend. The special rack for the grape cultivation method comprises an upright; a first pulling rope for binding a main vine is arranged at a part, 1.4-1.6m from the ground, of the upright; second pulling ropes for binding new shoots sprouting from the main vine are arranged on the two sides of the first pulling rope on the upright respectively; a third pulling rope for breaking a side shoot and allowing the branches to grow in a falling manner is arranged on one side of each second pulling rope on the upright; a distance between each second pulling rope and the ground is greater than that between the first pulling rope and the ground; and a distance between each third pulling rope and the ground is not less than that between each second pulling rope and the ground. According to the grape cultivation method and the special rack for the cultivation method, after the new shoots grow horizontally and the branches are broken, front ends grow in a falling manner, so that apical dominance of grapes is inhibited, and the quality of the grapes is improved; light rays directly illuminate leaves, and the branches and the shoots are not crossed mutually, so that a photosynthesis effect is improved; and bearing branches are fixed on the pulling ropes according to the distances, and fruit clusters are not abraded mutually, so that the production quality of the grapes is uniform.

Owner:ANHUI WUHU RUIKANG AGRI TECH DEV

Production method of alumina multichannel ceramic membrane support

InactiveCN106242624AHigh bonding strengthImprove flexural strengthCeramic shaping apparatusClay processing apparatusTunnel kilnMicrowave

A production method of an alumina multichannel ceramic membrane support belongs to the technical field of multichannel ceramic membranes. The production method of the alumina multichannel ceramic membrane support comprises the following steps: carrying out a plastic extrusion molding technology on alumina adopted as a main raw material, drying the molded material in a natural drying and microwave drying combination mode, and sintering the dried material in a shuttle kiln or a tunnel kiln. Rare earth oxide, nanometer alumina sol and a sintering aid are mixed, so the flexural strength and the acid and alkali corrosion resistance of the above obtained product are improved; introduction of an organic binder in the production process of an alumina multichannel ceramic membrane greatly reduces deformation of a green body in the extruding, drying and sintering processes and improves the yield of the product; and the nanometer alumina sol has high intergranular binding strength, so the granule morphology is kept, thereby the channels of the produced product are smooth and have small filtering resistance, and the water flux is improved by 20% or above.

Owner:山东华瓷环保设备科技有限公司

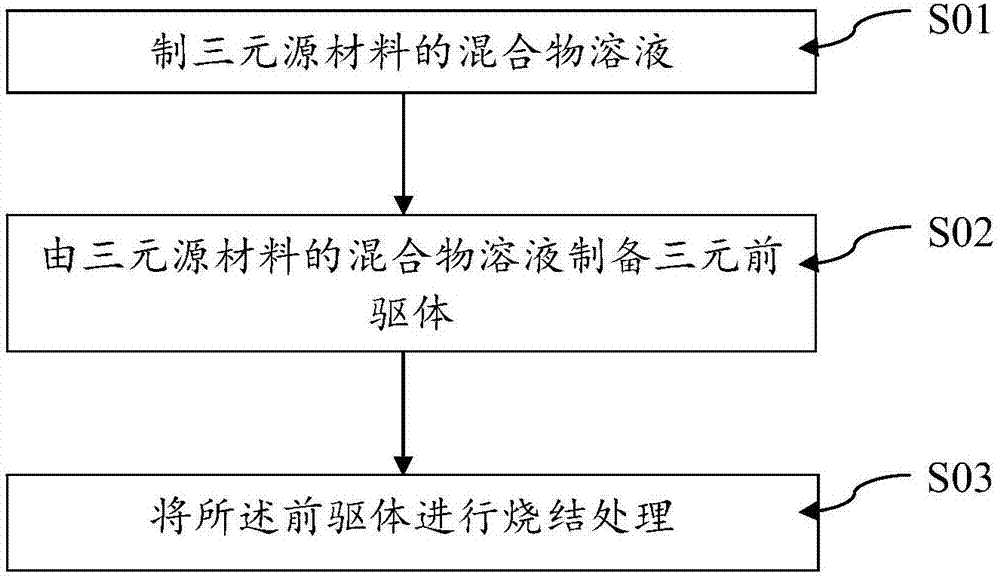

Single-crystal ternary cathode material, preparation method thereof and lithium ion battery

ActiveCN107482192ASimple manufacturing processIncrease compaction densityCell electrodesSecondary cellsSource materialPhysical chemistry

The invention discloses a single-crystal ternary cathode material, a preparation method thereof and a lithium ion battery. The preparation method of the single-crystal ternary cathode material comprises the following steps: preparing a mixture solution of ternary source materials; preparing a ternary precursor from the mixture solution of the ternary source materials; sintering the precursor. The single-crystal ternary cathode material is used as a cathode material of the lithium ion battery.

Owner:SHENZHEN DYNANONIC

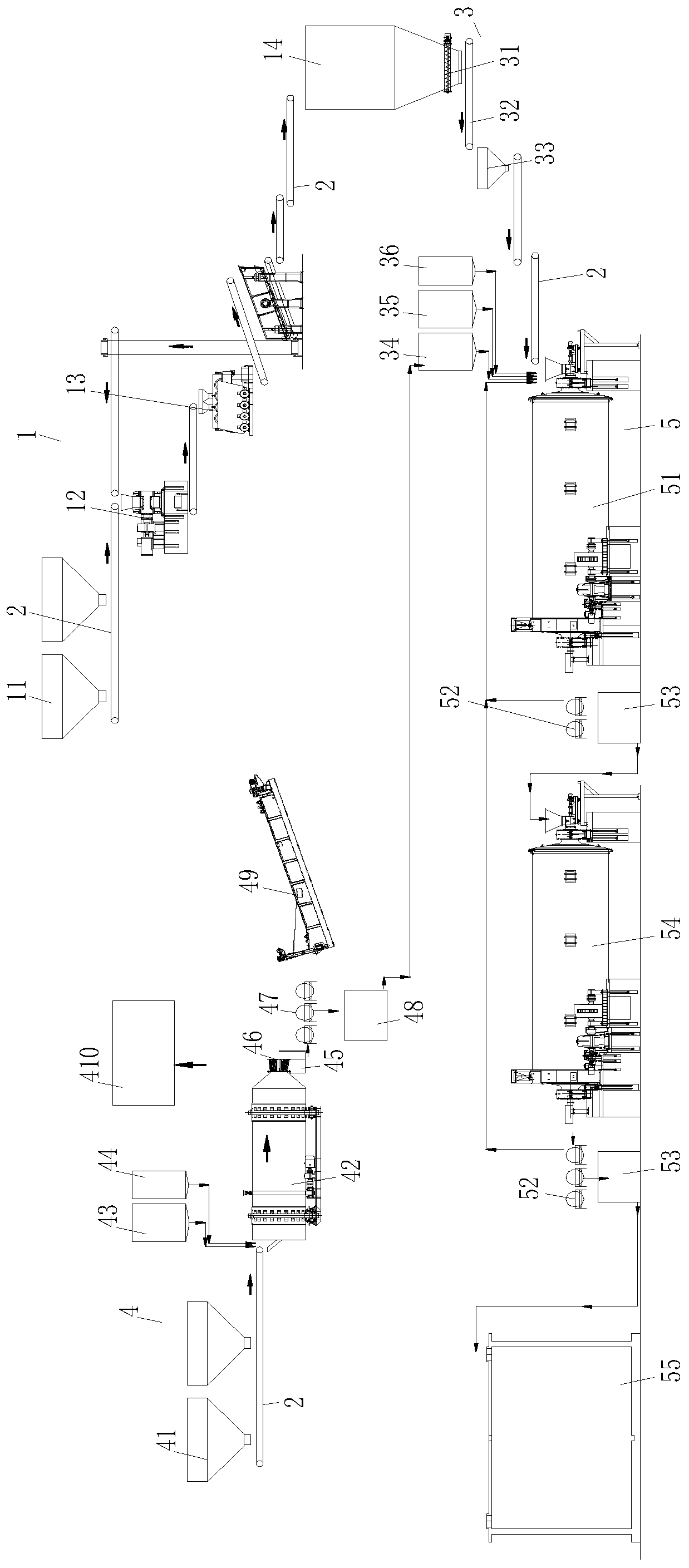

Intelligent wet powdering production technology for ceramic raw materials

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

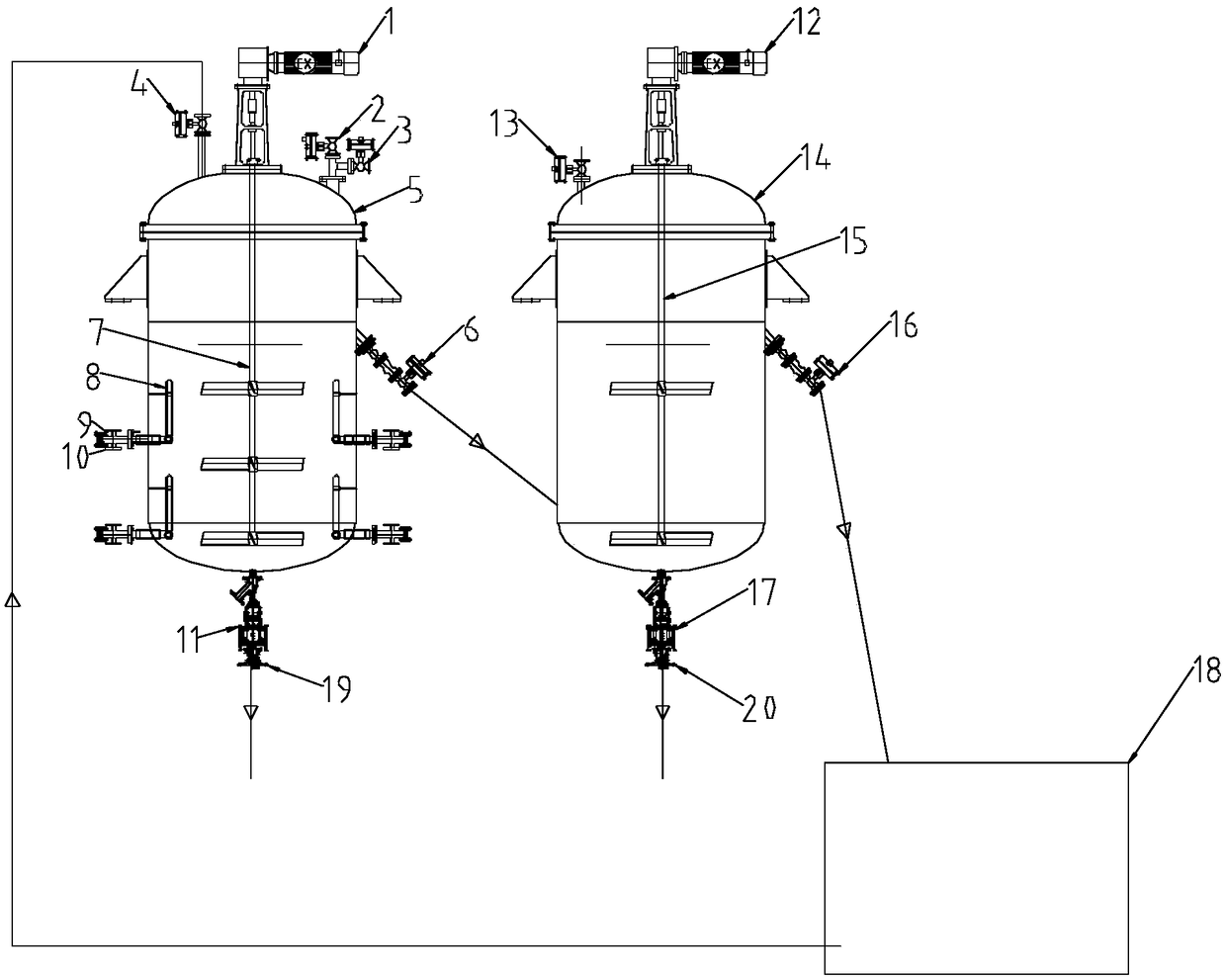

Novel filtering and concentrating device and main reaction kettle device

PendingCN109382058ASolve layeringAchieve reuseChemical/physical/physico-chemical stationary reactorsStationary filtering element filtersNitrogenPulp and paper industry

The invention discloses a novel filtering and concentrating device and a main reaction kettle device. The novel filtering and concentrating device comprises a cylinder body A, a cylinder body B, a gear motor A, a gear motor B, a stirring paddle A and a stirring paddle B, and further comprises a drain valve A, a drain valve B, a final concentrated product outlet A and a final concentrated product outlet B, wherein the gear motor A and the gear motor B are arranged at the top ends of the cylinder body A and the cylinder body B, the stirring paddle A and the stirring paddle B are arranged in theinner parts of the cylinder body A and the cylinder body B, the drain valve A and the drain valve B are arranged at the bottom ends of the cylinder body A and the cylinder body B; a nitrogen inlet, aregenerated liquid inlet and a spraying water inlet are arranged at the top end of the cylinder body A, an annular filter element is arranged on the inner wall of the cylinder body A, a back flushingport and a clear liquid outlet connected with the bottom part of the filter element and a filtered concentrated liquid outlet connected with a main reaction kettle are arranged on the side wall of thecylinder body A, a raw material feed port is arranged at the top end of the cylinder body B, an overflow port is arranged on the side wall of the cylinder body B and communicates with a middle tank,and the middle tank communicates with the top part of the filtering and concentrating device. The structure design of the novel filtering and concentrating device is more advanced and more reasonable,the mounting, dismounting and maintaining are simple and convenient, the problems of layering, shaking, sealing and the like of material liquid are effectively solved, and the filtering fineness is higher.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

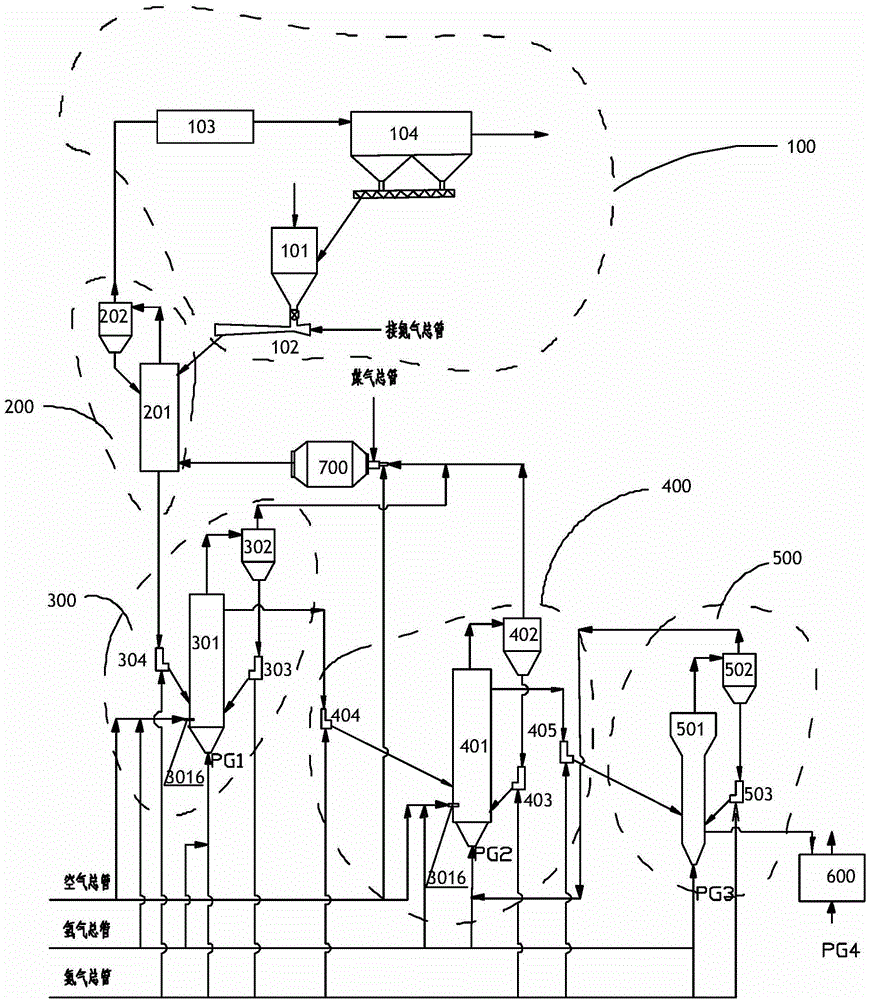

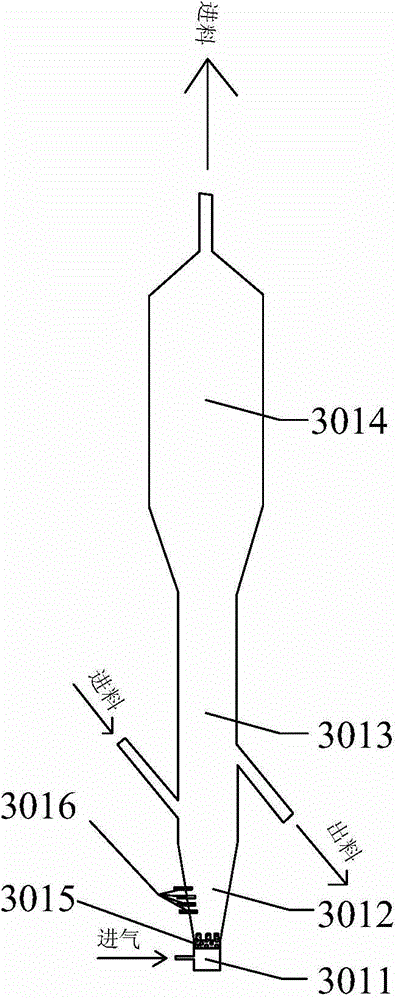

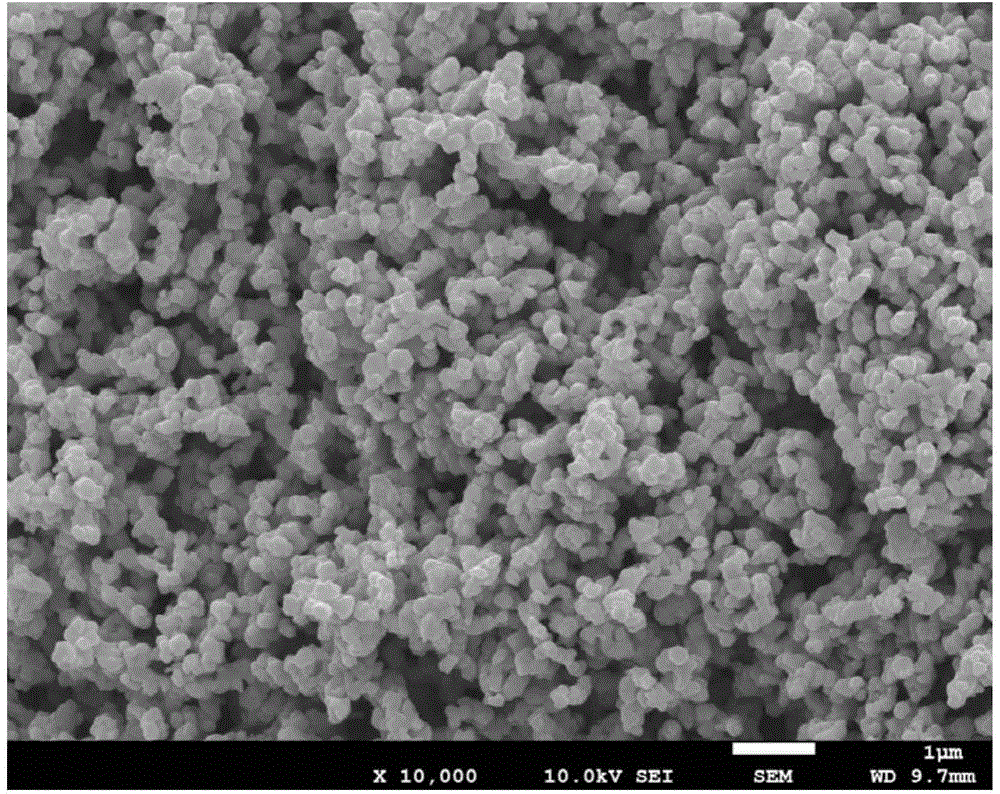

Equipment and method for preparing nanometer metal powder

The invention relates to equipment for preparing nanometer metal powder. The equipment comprises a feeding system, a preheating system, a pre-reduction system, a deep reduction system, a cooing system and a passivating device which are connected in sequence, wherein the preheating system is connected with a combustion chamber providing heat, and the combustion chamber is connected with the pre-reduction system and the deep reduction system; the pre-reduction system comprises a first fluidized bed reduction furnace for carrying out a pre-reduction reaction; the deep reduction system comprises a second fluidized bed reduction furnace for carrying out a deep reduction reaction; an internal cavity of the fluidizing section of the first fluidized bed reduction furnace and the second fluidized bed reduction furnace comprises a constant diameter section and a circular truncated cone-shaped diameter-reducing section, and the inner diameter of the lower part of the circular truncated cone-shaped diameter-reducing section is gradually reduced, and the taper angle of the circular truncated cone-shaped diameter-reducing section is smaller than or equal to 30 degrees. By using the equipment for preparing nanometer metal powder provided by the invention, the purity is 99% or above, and the grain diameter is uniform.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

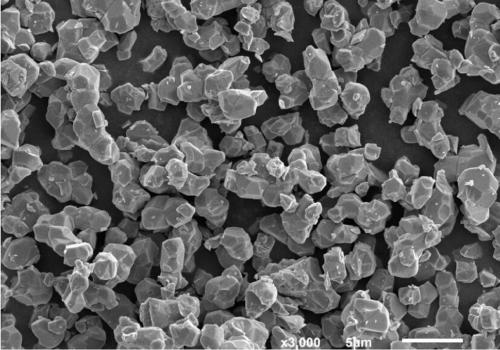

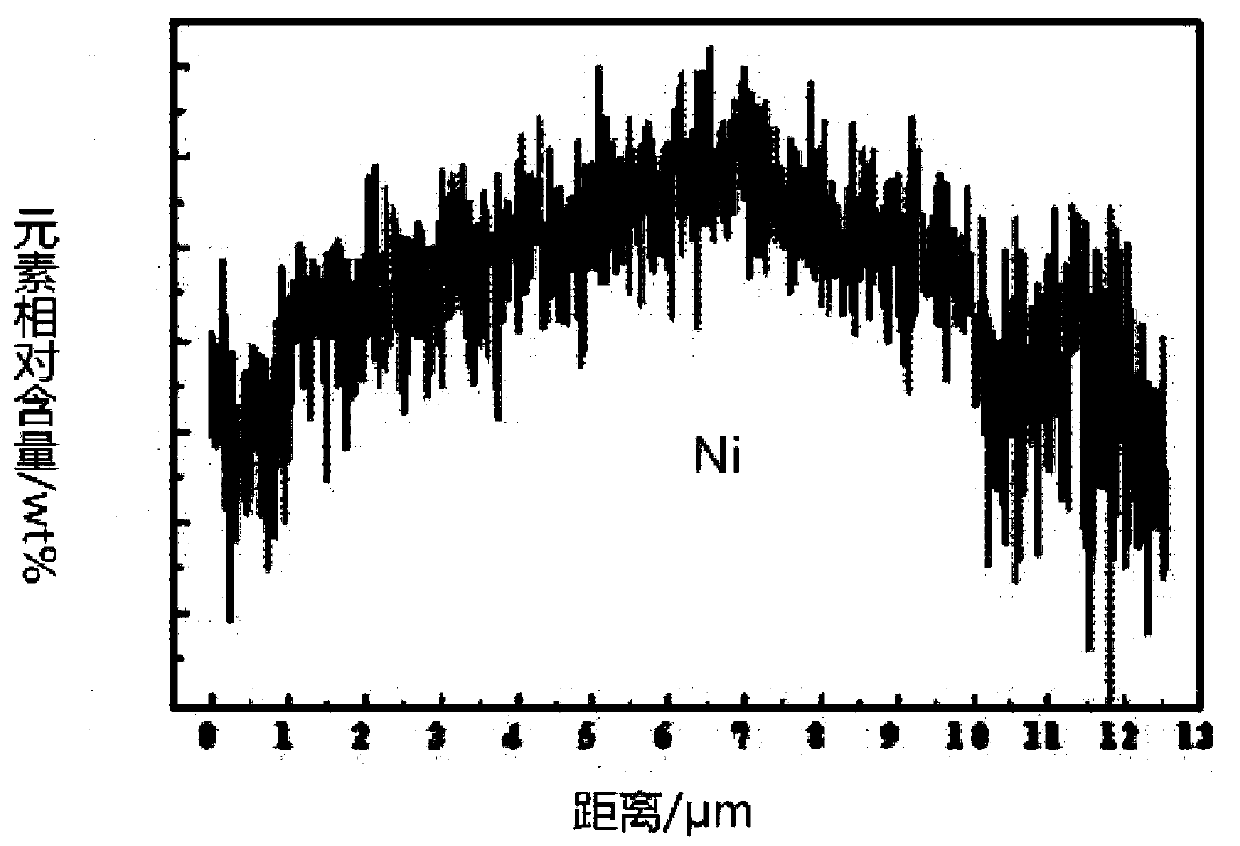

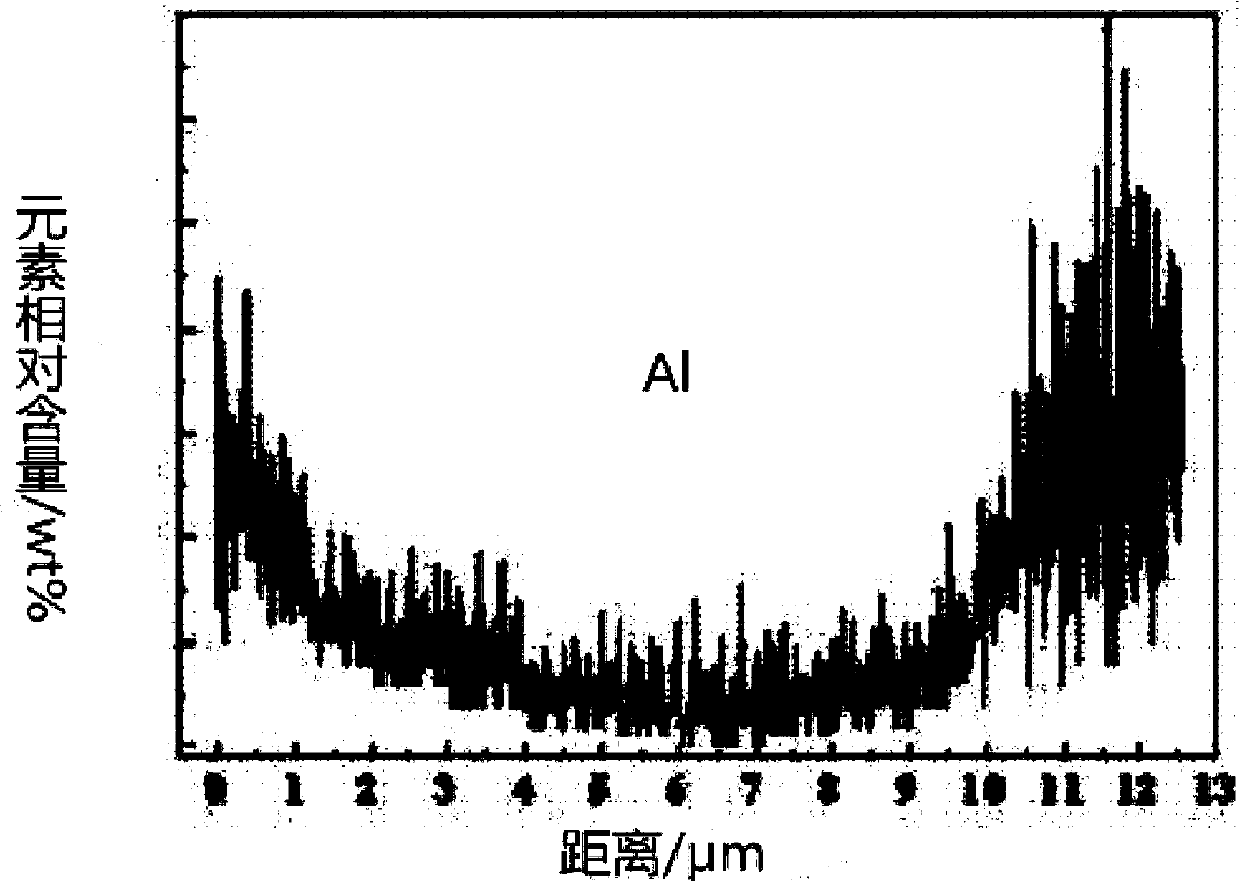

Preparation method of nickel-cobalt-manganese precursor particles

ActiveCN110190241AReduce contentIncrease contentElectrode manufacturing processesSecondary cellsNickel saltManganese

The invention relates to a preparation method of a nickel-cobalt-manganese precursor, which specifically includes the following steps: preparing nickel-cobalt solution, nickel-manganese solution and nickel-T solution by mixing soluble nickel salt with soluble cobalt salt, soluble manganese salt and soluble salt doped with metal T respectively, wherein the concentration of the nickel-cobalt solution is higher than that of the nickel-manganese solution, and the concentration of the nickel-manganese solution is higher than that of the nickel-T solution; mixing the nickel-cobalt solution with thenickel-manganese solution and adding a complexing agent to obtain a mixed solution, and adjusting the pH value of the mixed solution to 9-11.5 by adding alkali solution; and adding the nickel-T solution to the mixed solution for reaction in an inert atmosphere to obtain nickel-cobalt-manganese precursor particles with uniform size, high purity and stable chemical performance. The prepared nickel-cobalt-manganese precursor particles show a gradient decrease in the relative content of nickel element and a gradient increase in the relative content of doped element from the core to the surface.

Owner:HUNAN ZOOMWE NEW ENERGY TECH CO LTD

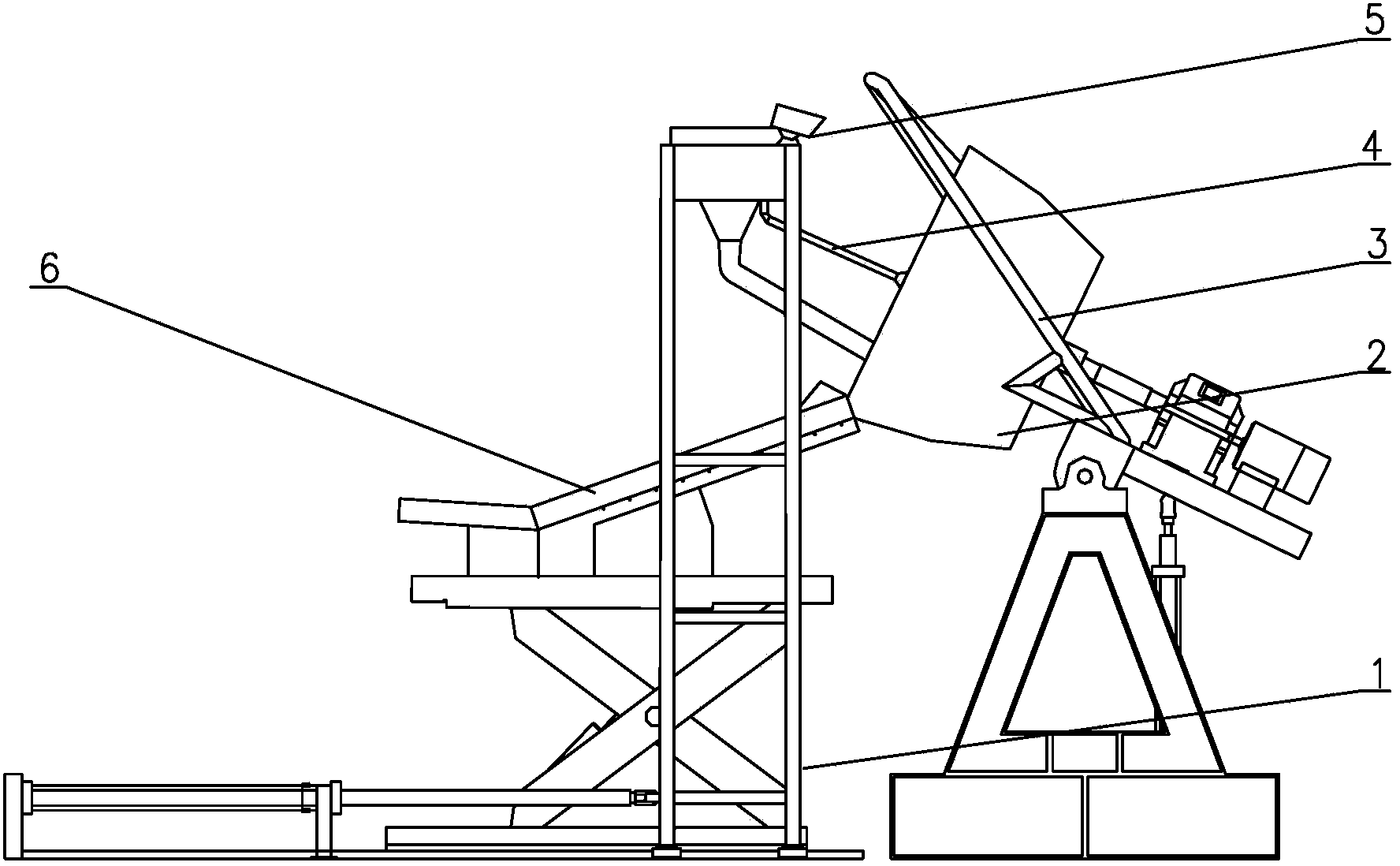

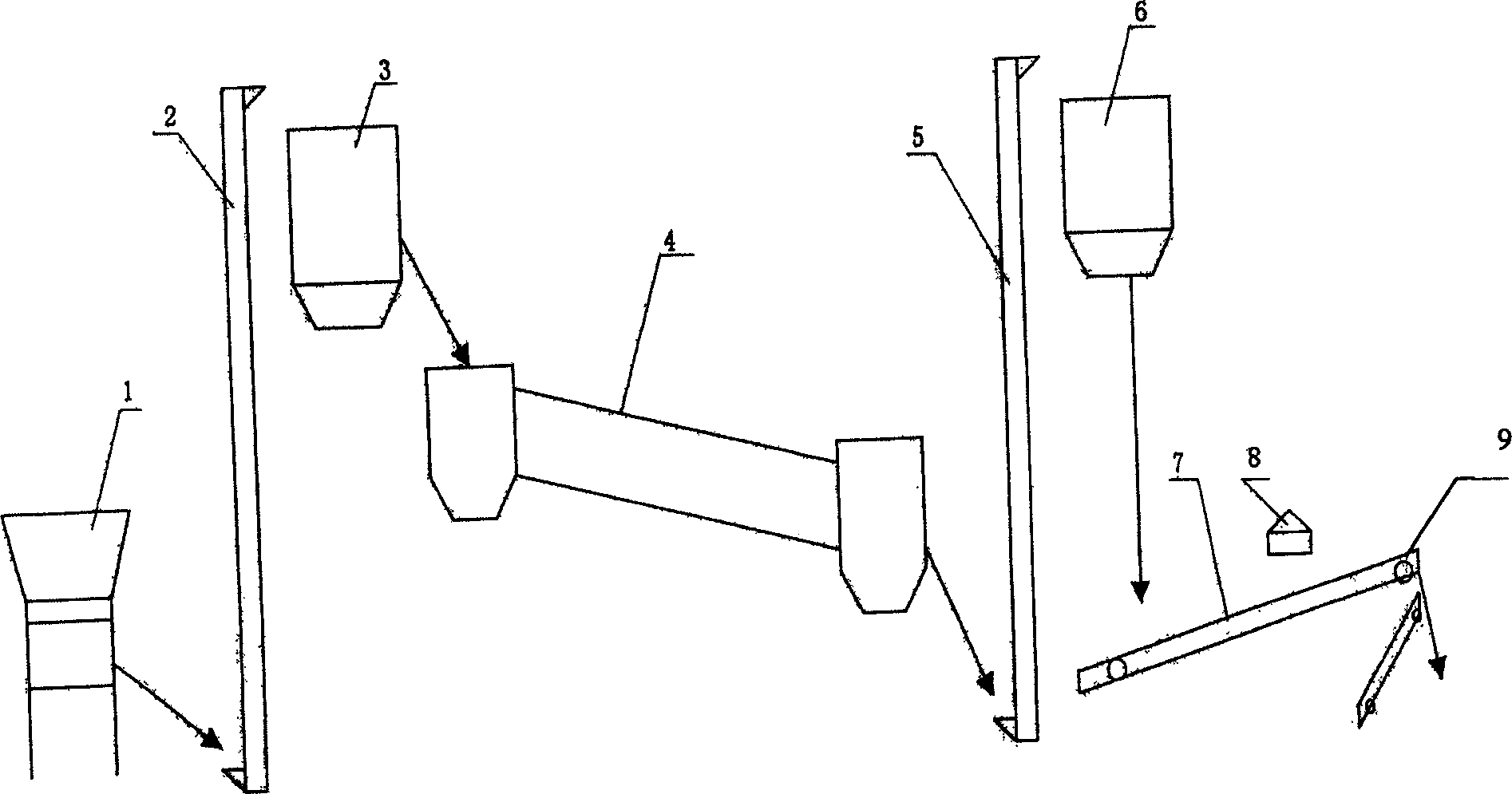

Granulation system of automatic fireworks production line

InactiveCN103822546AOperational securityIncrease productivityFireworksProduction lineBiochemical engineering

A granulation system of an automatic fireworks production line comprises a granulation device, a feeding device, a guniting device, a real-time monitoring device and a discharge device, wherein the feeding device is arranged in way of corresponding to the feed port end of the granulation device and is used for feeding to the granulation device, the guniting device is arranged on one side of the feed port end of the granulation device and is used for guniting into the granulation device, the real-time monitoring device is arranged on the top of the feeding device and is used for observing the molding condition of the bright beads in the granulation device, and the discharge device is arranged on the discharge port side of the granulation device and is used for receiving the molded bright beads. According to the granulation system of the automatic fireworks production line, the operation is safe, the production efficiency is high, the uniformity of particles is good, and the particle intensity is high. A disk granulation method is used, the powder can be rotated together with a granulation disk under the friction action, and a remote monitoring device is arranged. The granulation system of the automatic fireworks production line has the advantages that safety and reliability are realized, the production efficiency is high and the uniformity of particles is good, the particle intensity is high, the operation is smooth, the equipment is sturdy and durable, the service life is long, and the like.

Owner:TANGSHAN COLLEGE

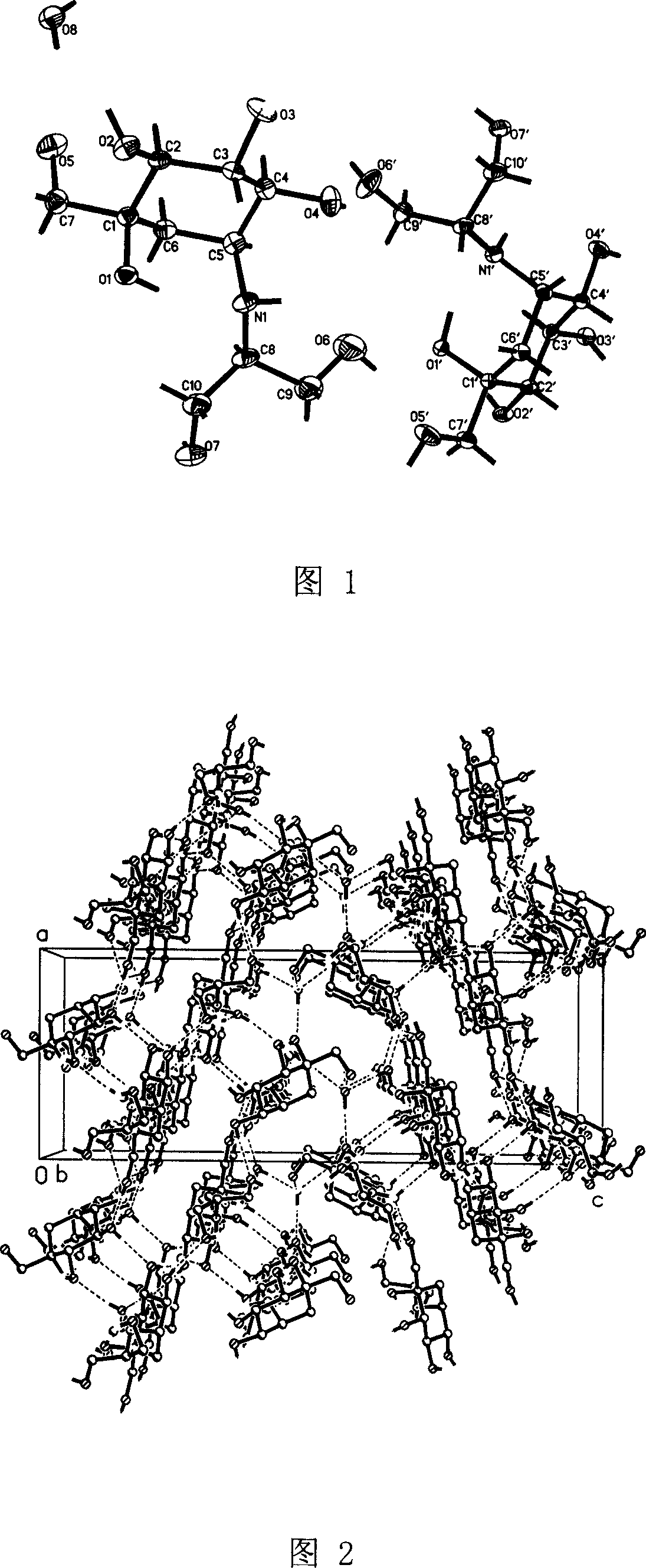

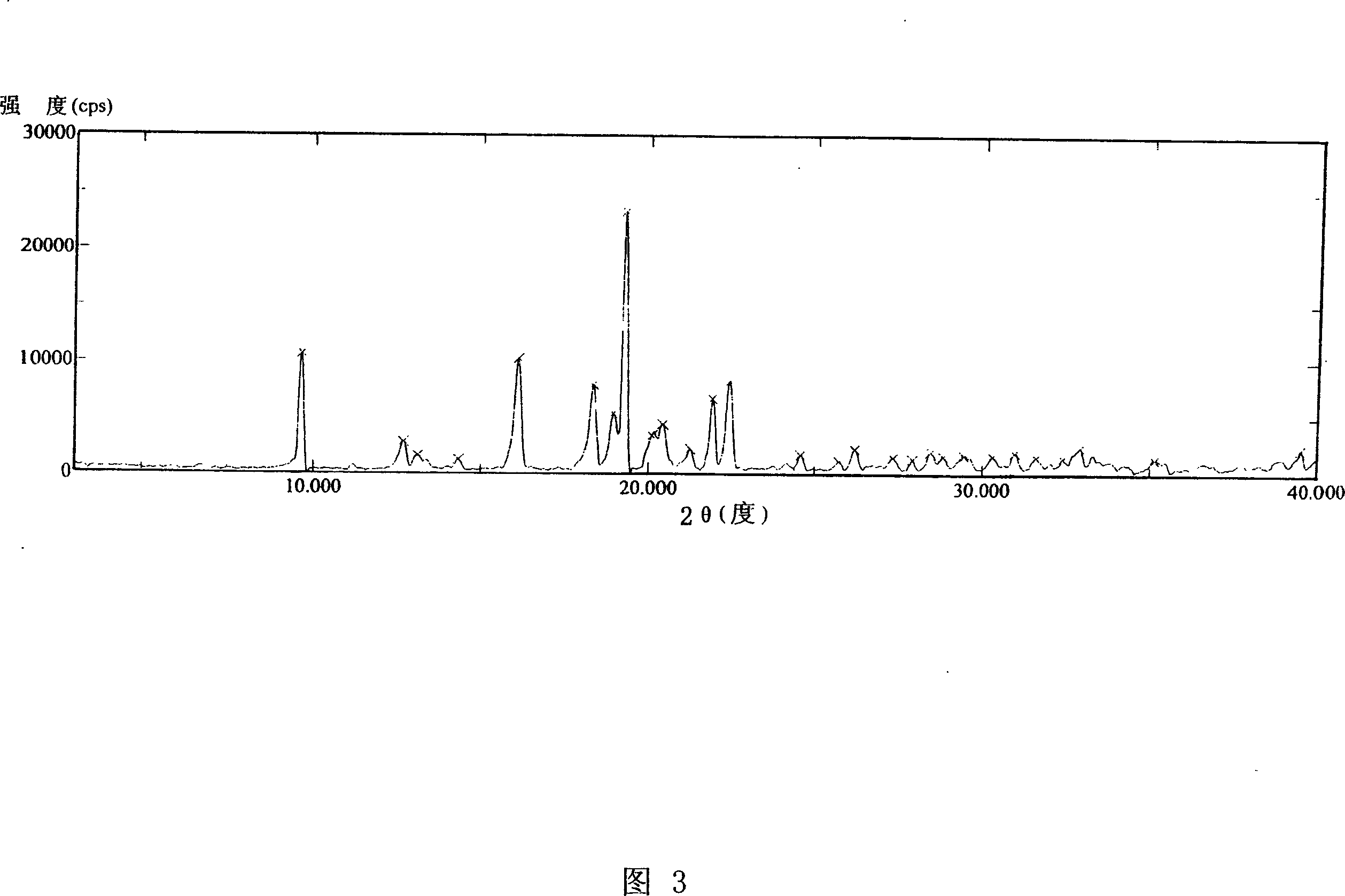

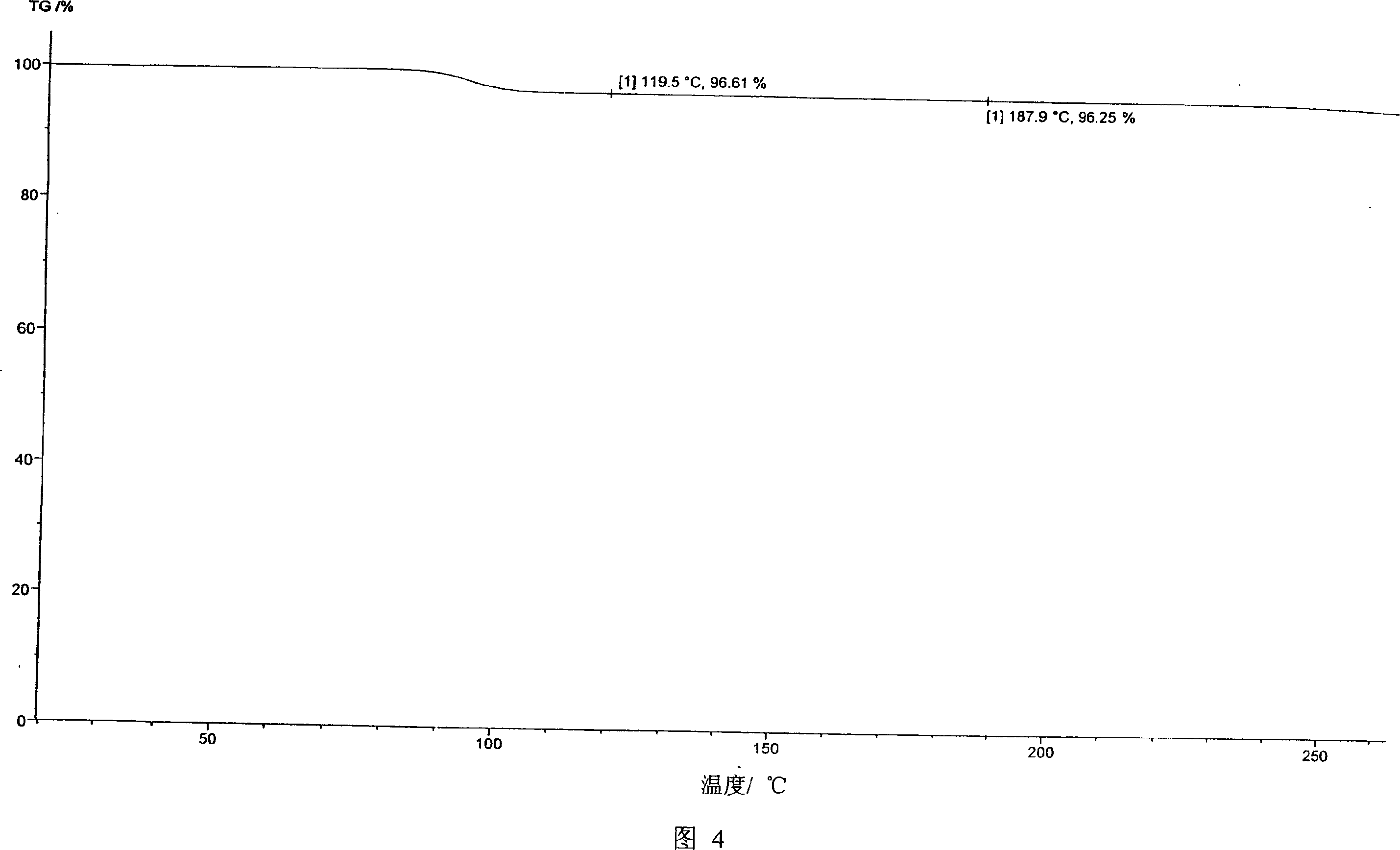

Voglibose semi-hydrated crystal, its preparation method and its uses in medicament formulation

InactiveCN101007771AHigh purityHigh yieldOrganic active ingredientsOrganic compound preparationCrystal systemInfrared

The invention discloses a Fuge train wave hemi-hydrated crystalline with 0.5 molecular crystallinic water, whose structure and character is simulated by single-crystal X-ray diffraction, powder X-ray diffraction, thermogravimetric analysis (TG), differential scanning calorimetry (DSC), infrared spectrum (IR), element analysis and specific rotation, wherein the molecular structure is C10H21NO7 .0.5H2O, which belongs to orthogonal crystal system in the P2(1)2(1)2(1) spatial group; the cell parameter a is 9.877(2); b is 9.905(2); c is 26.760(5); alpha is 90 deg; beta is 90deg; gamma is 90 deg; R is 0.0324.

Owner:PHARMAXYN LAB

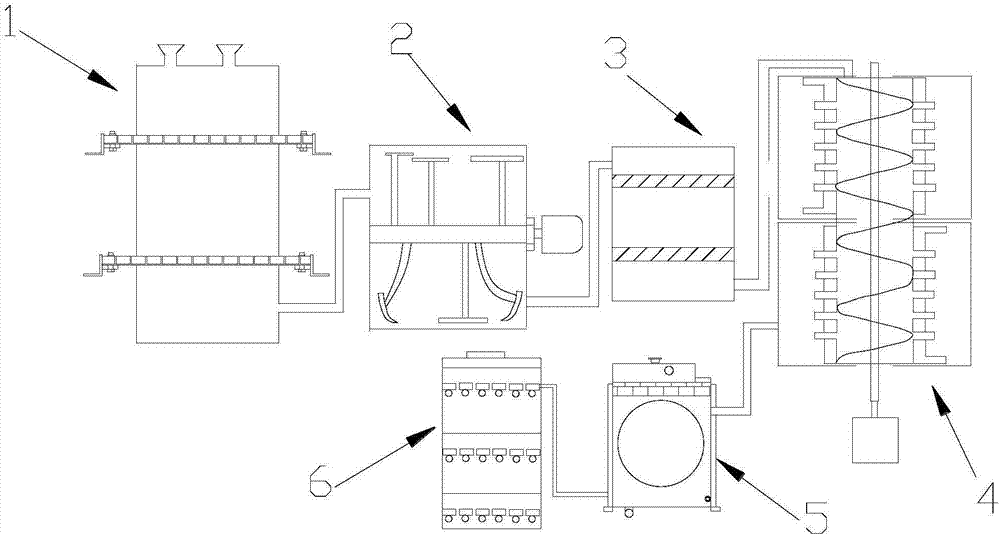

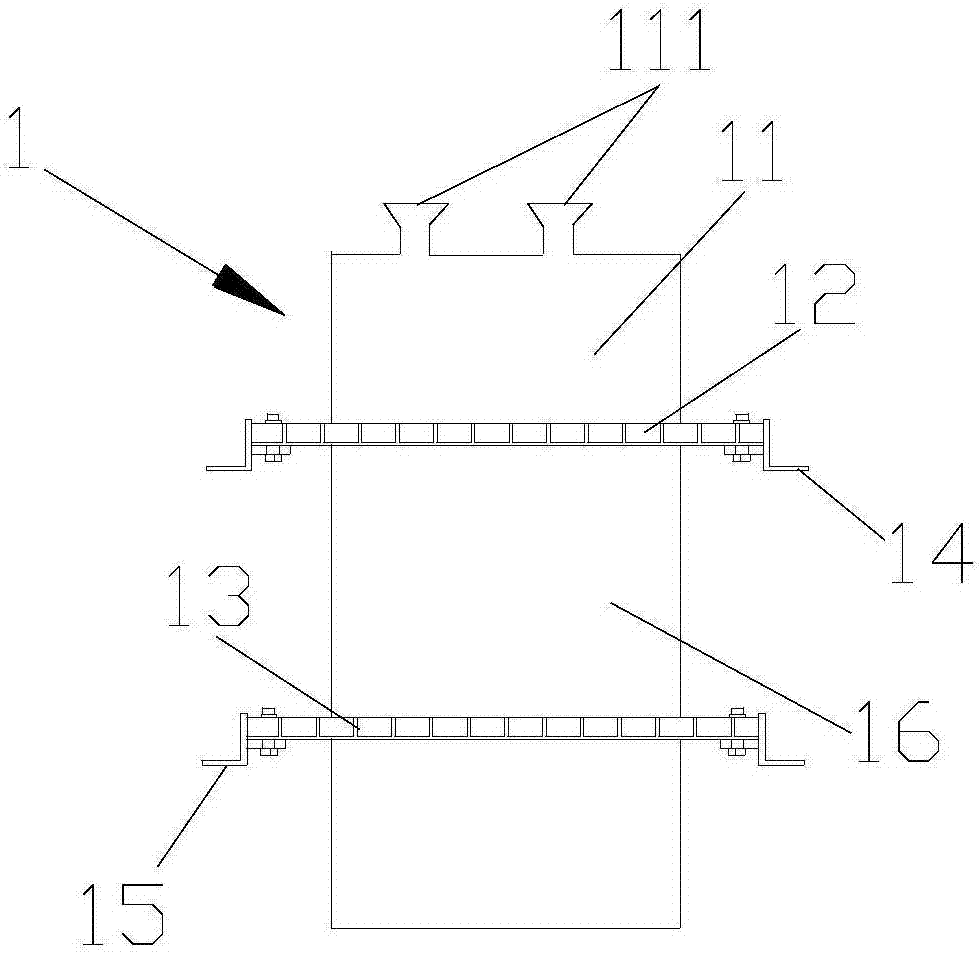

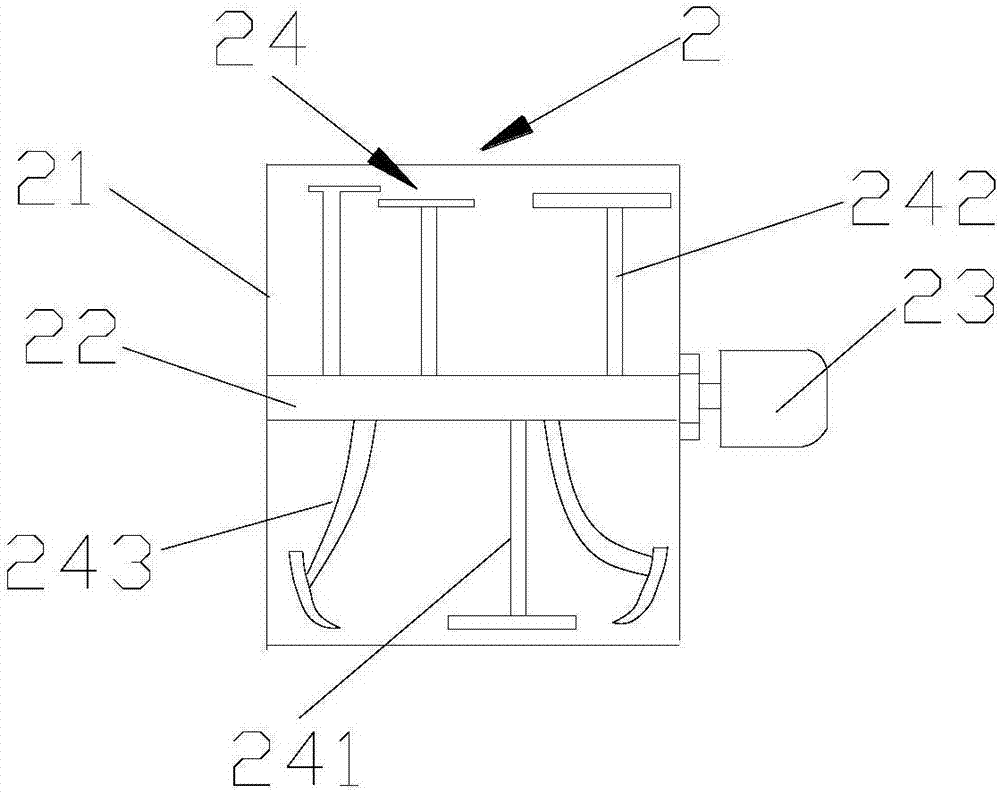

Processing equipment for lithium battery cathode material

InactiveCN107195862ARealize continuous productionReasonable structureElectrode manufacturing processesDrying gas arrangementsEngineeringMaterial storage

The invention discloses processing equipment for a lithium battery cathode material. The processing equipment can realize continuous automatic production and is good in cooling effect and high in drying efficiency. The processing equipment comprises a feeding device, a mixing device, a filter, a reaction device, a cooler and a drier, wherein the feeding device, the mixing device, the filter, the reaction device, the cooler and the drier are connected through pipelines in sequence; the cooler comprises steel channel racks and feet, the steel channel racks are arranged on two sides of the cooler, the middle part of the cooler is connected with a square boss, an inclined plane is arranged on the top of the square boss, the inclined plane is provided with a fin and a partition board, and the surface of the square boss is provided with an annular flange playing a connection role; the drier comprises a drying box, an air supplying device, a roller conveyor and a material storage box, the air supplying device is fixedly arranged on the drying box, the roller conveyor is fixedly mounted in the drying box, and the material storage box is fixedly mounted on the roller conveyor and is connected with the cooler through a pipeline. Through the structure, continuous automatic production can be realized, and the cooling effect and drying effect are good.

Owner:王映

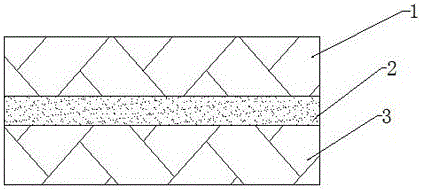

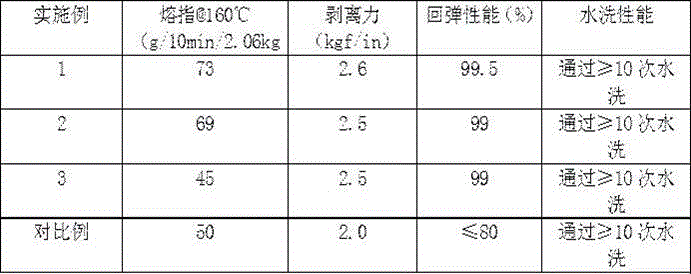

Preparation method and use method of high-resilience TPU hot-melt adhesive tape

ActiveCN105778810AHigh bonding strengthIncrease elasticityMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolymer scienceHot melt

The invention relates to a preparation method and a use method of a high-resilience TPU hot-melt adhesive tape. The preparation method mainly comprises five steps of selection of master batch raw materials, granulation, tape casting, compounding and splitting. In the tape casting step, master batches are fed into a tape casting machine in a mixing manner according to a weight ratio of 100:(5-15) for tape casting molding and rolling. When the high-resilience TPU hot-melt adhesive tape prepared by the preparation method is in use, one surface without release paper is in contact with a base material, and certain temperature and pressure are applied to pressing equipment; after adhesion is completed, the other surface is adhered to another adhered base material. The preparation method of the high-resilience TPU hot-melt adhesive tape has the advantages that the adhesion strength and the resilience of a hot-melt adhesive tape film are improved; when the prepared high-resilience TPU hot-melt adhesive tape film is in use, the equipment process is simple, and the working efficiency is high.

Owner:江苏和和新材料股份有限公司

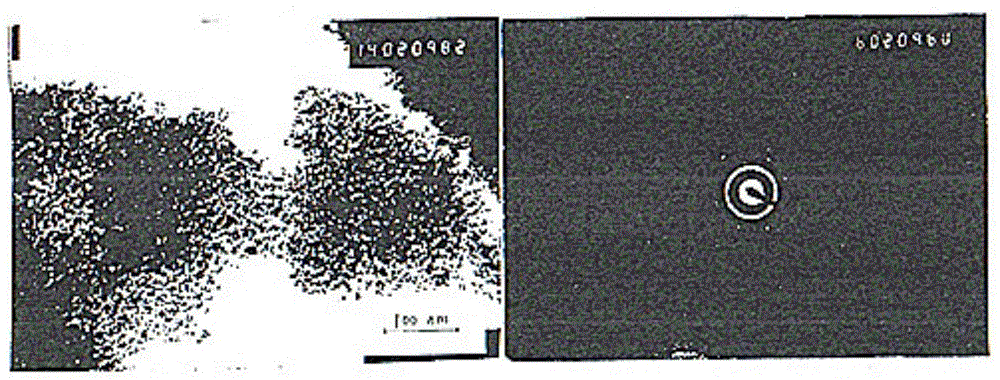

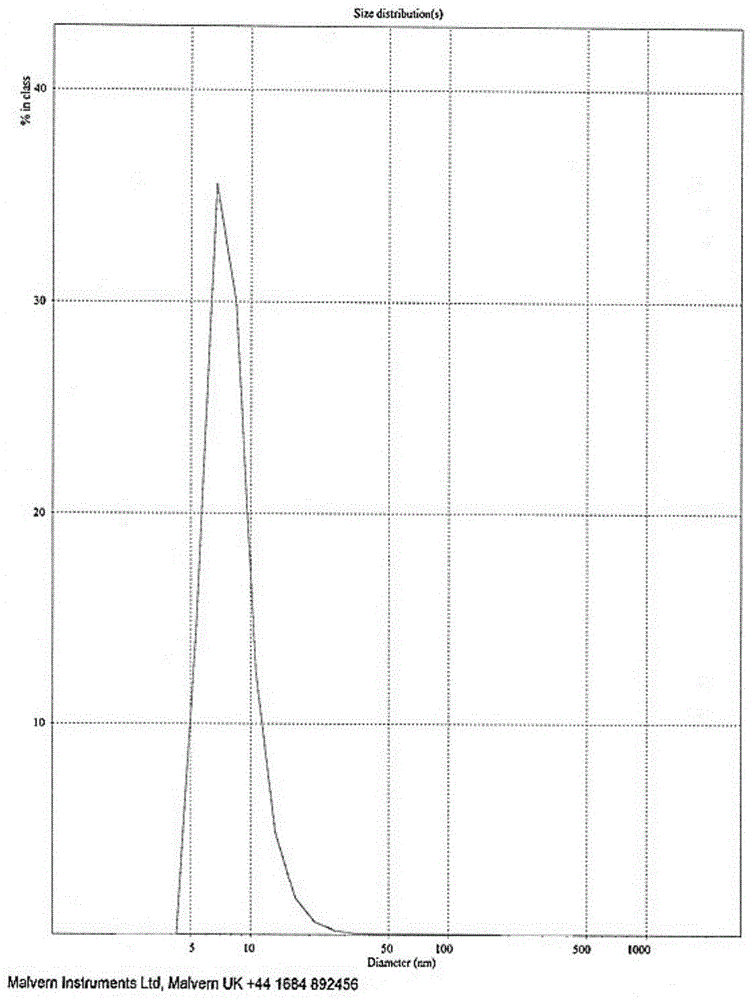

Preparation method for high-efficient photocatalyst-nanometer titanium dioxide water-based colloid

ActiveCN104098133AHigh crystallinityHigh removal ratePhysical/chemical process catalystsTitanium dioxideWater basedWater baths

The invention discloses a preparation method for a high-efficient photocatalyst-nanometer titanium dioxide water-based colloid. The preparation method comprises the following steps: adopting metal titanium as titanium source; adopting hydrogen peroxide to oxidize nulvalent metal Ti into quadrivalent TiO<2+>; further conducting complexing on the TiO<2+> and the hydrogen peroxide to obtain water-soluble TiO[H2O2]<2+> yellow complex; obtaining yellow complex colloid after evaporating and removing excess hydrogen peroxide and ammonia; conducting hydrothermal reaction by high pressure water of 150-200 DEG C; transporting the TiO[H2O2]<2+> yellow complex into pure white Ti(OH)4 water-based emulsion; adding mineral acid to adjust the pH value of the emulsion to the range of 2-4; conducting temperature control to enable the temperature of water bath to be 60-80 DEG C; continually stirring for 3-6 hours to enable the Ti(OH)4 water-based emulsion to gradually gel into nanometer titanium dioxide water-based colloid. The preparation method uses no organic solvent; no waste water or waste gas generates in the reaction process; particle diameters of colloid granular are less than 10 nanometers; degree of crystallinity is high; high photocatalytic activity is provided; coating property and film forming property on porous base material are extremely good.

Owner:江苏恒智纳米科技有限公司

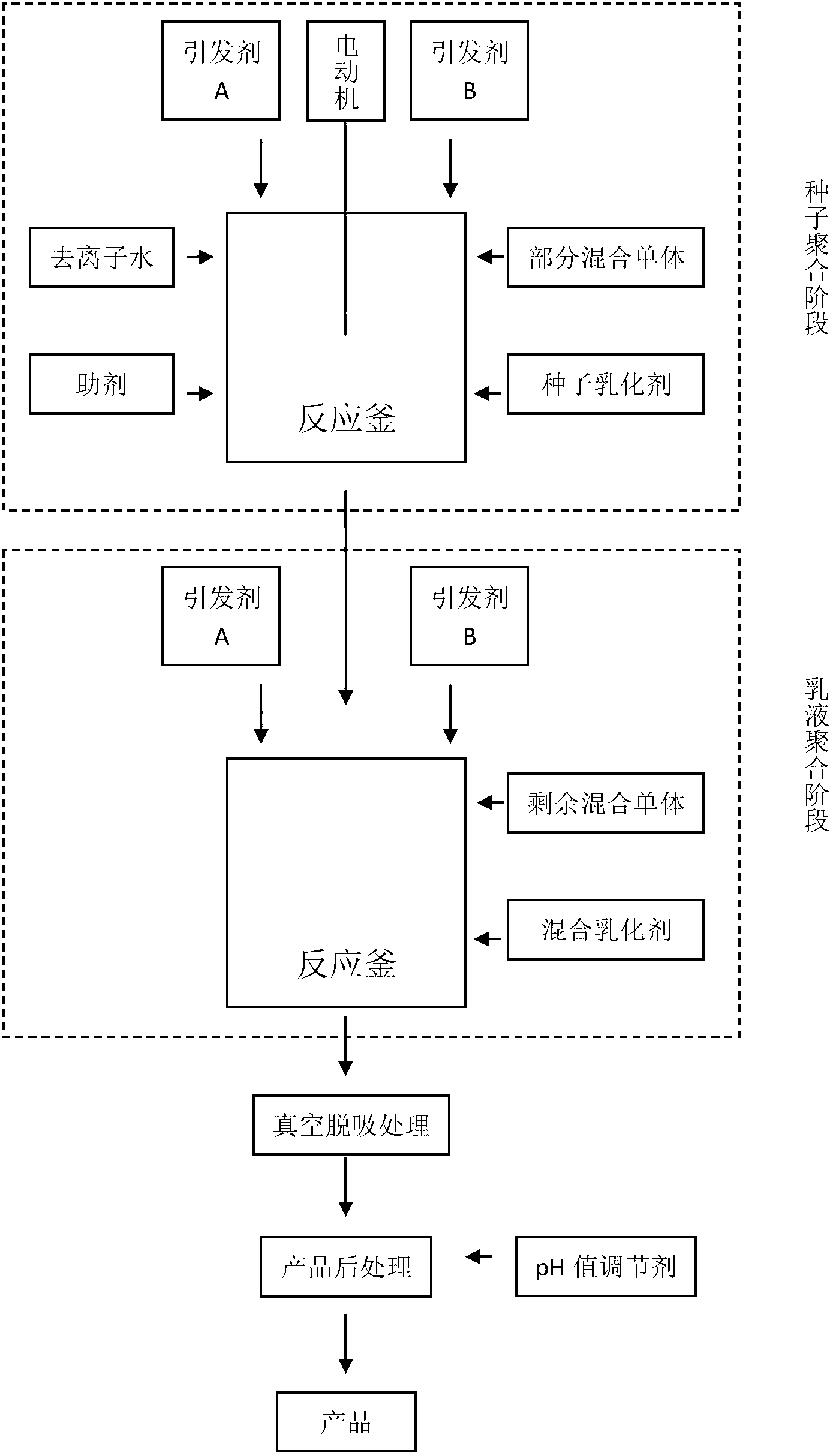

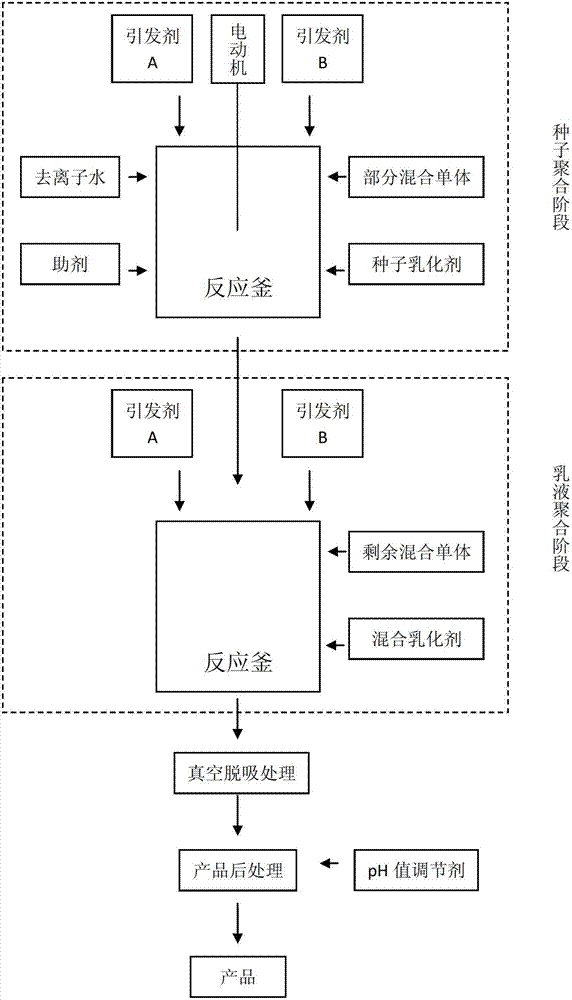

Low-temperature heat-seal acrylic emulsion and preparation method thereof and application thereof

ActiveCN103059213AImprove stabilityImprove Particle UniformityFlexible coversWrappersPolymer scienceMicrocrystalline wax

The invention provides a low-temperature heat-seal acrylic emulsion and a preparation method of the low-temperature heat-seal acrylic emulsion. The preparation method comprises the steps of adopting seeded emulsion polymerization and adding a defined amount of microcrystalline wax before a vacuum degassing and absorbing after-treatment. The parts of the components by weight are 100 parts, including 25 parts of monomer mixture which comprises 75-90 percent of crylic acid -2- ethyl acid ester, 5-20 percent of acrylonitrile and 5-10 percent of methacrylic acid, an initiating agent which comprises organic peroxides, methanal and sodium hydrogen sulfate, a mixed emulsifying agent which comprises a non-ionic surface active agent and secondary chain alkyl sodium sulfonate, a seeded emulsifying agent which comprises secondary chain alkyl sodium sulfonate and MA-80, an auxiliary agent which comprises ammonium acetate and ferrous chloride, and a potential of hydrogen (PH) conditioning agent. The heat-seal temperature of the low-temperature heat-seal acrylic emulsion is 40-48 DEG C. The low-temperature heat-seal acrylic emulsion is good in stability, good in particle evenness, and good in heat-seal evenness. The preparation method of the low-temperature heat-seal acrylic emulsion is used for high-speed packaging of food such as candies and chocolates with the requirement of low temperature and heat seal.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

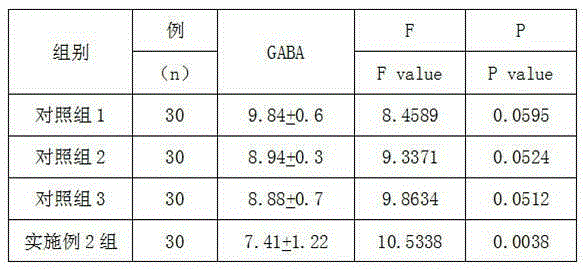

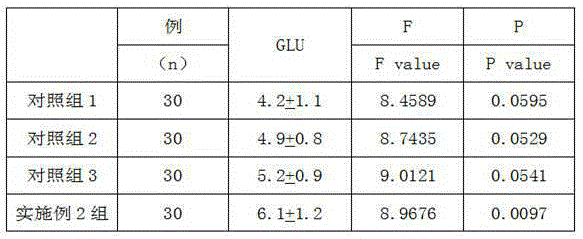

Nutrient powder bags capable of improving sleep

ActiveCN105341947ALow costGreat tasteSugar food ingredientsVitamin food ingredientsBiotechnologyIsomaltooligosaccharide

The invention discloses nutrient powder bags capable of improving sleep. The nutrient powder bags are characterized by containing the following components in percentage by mass (same as below): 4%-6% of isomaltooligosaccharide, 2.4%-3.6% of fructo-oligosaccharide, and 2.4%-3.6% of inulin. The nutrient powder bags are also mixed and compounded from the following raw materials: maltodextrin, whole milk powder, soybean milk powder (instant bean powder), whey protein, soy protein isolate, soybean phospholipid, gamma-aminobutyric acid, lily bulb extracts, coix seed extracts, poria cocos extracts, compounding vitamins and ethyl vanillin. According to the nutrient dumplings disclosed by the invention, the substances of the gamma -aminobutyric acid, the lily bulb extracts, the poria cocos extracts, the soybean phospholipid and the like are added, so that the effects of relieving uneasiness of mind and body, regulating a nervous system, and helping crowds with poor sleep quality to improve sleep quality, are achieved.

Owner:MEILU BIOTECH CO LTD

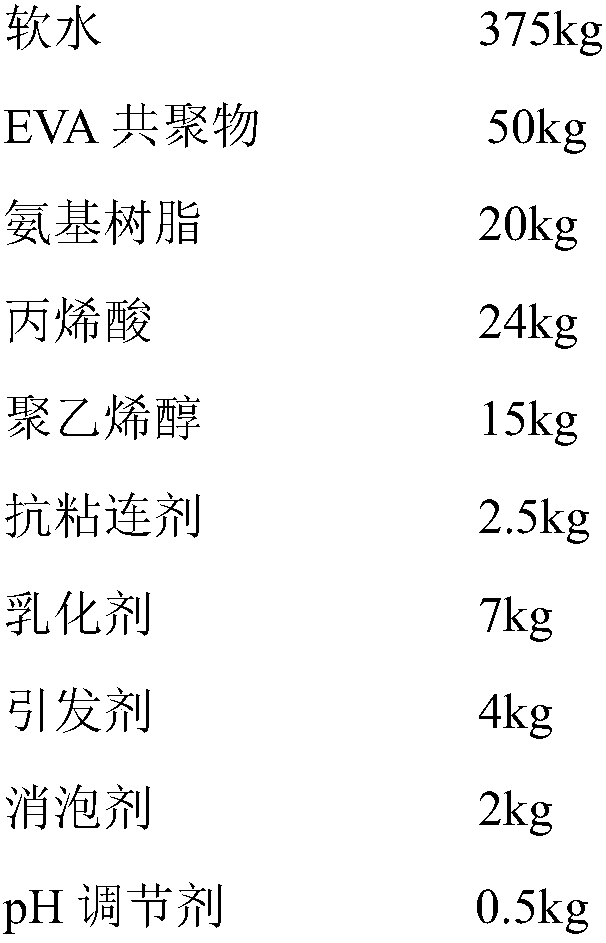

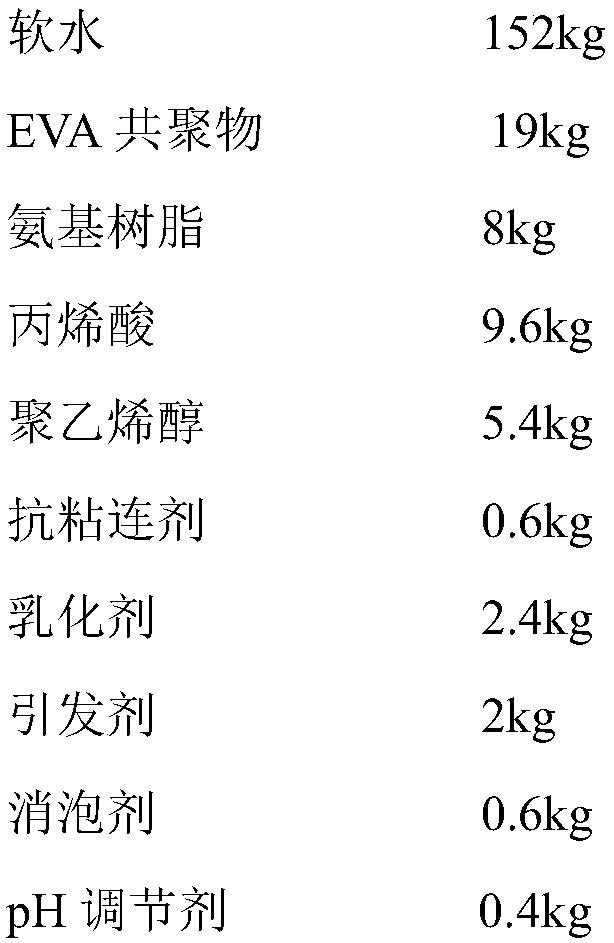

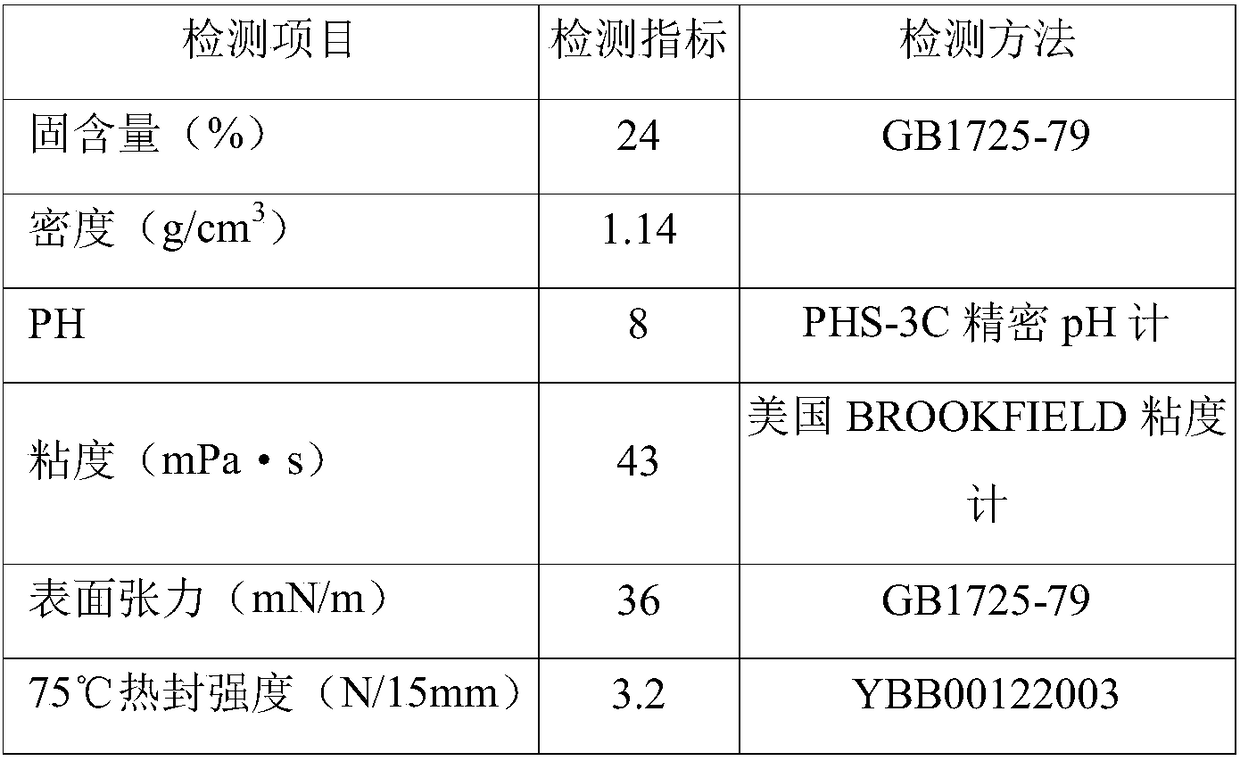

Low-temperature heat sealing EVA emulsion, and preparation method and use thereof

The invention provides a low-temperature heat sealing EVA emulsion which is prepared by high temperature and high pressure emulsification of the following components in parts by weight according to 100 parts: 7.2-10.5 parts of an ethylene-vinyl acetate copolymer (called an EVA copolymer for short), 2-4 parts of amino resin, 3-4.8 parts of acrylic acid, 2-3 parts of polyvinyl alcohol, 0.3-0.6 partof an antiblocking agent, 0.8-1.5 parts of an emulsifier, 0.1-0.5 part of a defoaming agent, 0.5-0.8 part of an initiator, 0.1-0.3 part of a pH regulator, and 75-80 parts of soft water. The heat sealing temperature of the low-temperature heat sealing EVA emulsion is 75 DEG C, the emulsion stability is good, the emulsion particle uniformity is good, the heat sealing uniformity is good, and the energy consumption of production can be effectively reduced; the emulsion is a water-based emulsion, has no need of organic solvents, is environmentally friendly, pollution-free, safe and reliable, and isquite suitable for high-speed packaging for foods such as candies and chocolate which need low-temperature heat sealing.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

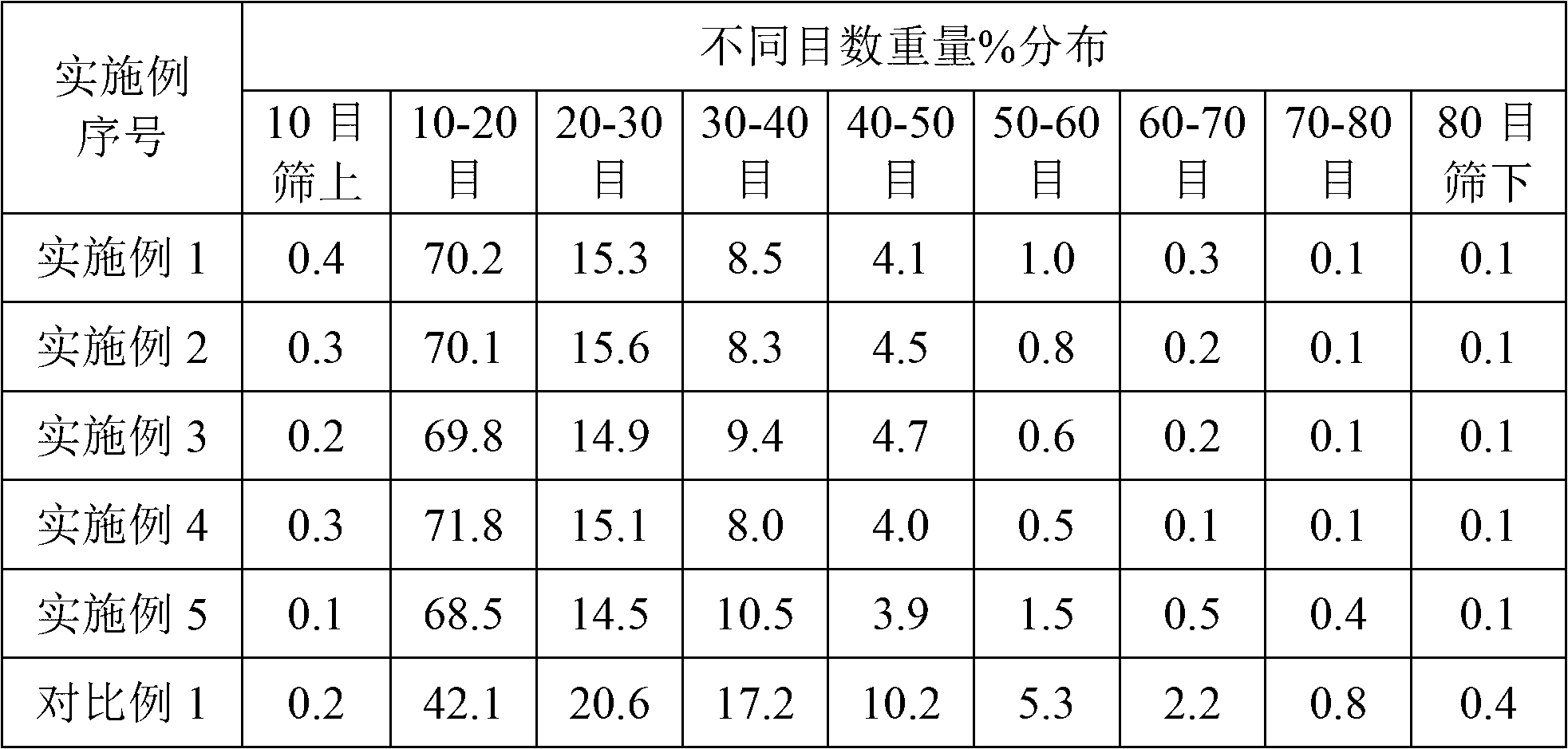

Citric acid monohydrate crystal and production method thereof

ActiveCN102838478AImprove Particle UniformityDoes not affect purityCarboxylic compound separation/purificationTemperature differenceSlurry

The invention discloses a production method of a citric acid monohydrate crystal, which comprises the following steps: heating a citric acid solution until the citric acid solution is concentrated to the concentration of 68.5-78 wt%, thereby obtaining a citric acid concentrated solution; and cooling to crystallize the citric acid concentrated solution, and carrying out solid-liquid separation on the crystal slurry containing citric acid monohydrate crystal, wherein the cooling for crystallization is carried out under the following conditions: controlling the temperature difference between the cooling medium and the citric acid concentrated solution to be not greater than 10 DEG C under the conditions capable of at least generating citric acid monohydrate crystal. The invention also provides a citric acid monohydrate crystal produced by the method. On the premise of not influencing the product purity and not increasing the techniques, the method disclosed by the invention obviously enhances the particle uniformity of the citric acid monohydrate crystal, so that the 10-20-mesh weight distribution of the citric acid monohydrate crystal can be enhanced to higher than 68%.

Owner:COFCO BIOTECHNOLOGY CO LTD

Rollscale impurity-removing system and process

InactiveCN1640560AGood effect of removing impuritiesImprove Particle UniformitySievingDrying solid materials with heatEngineeringMagnetic separation

The present invention relates to a high-temperature steel-rolling forging scale impurity-removing equipment and its process. It is formed from equipments of bar grizzly, drying kiln, iron-remover and high-temperature magntic drum. Said invention utilizes the multistage impurity-removing process of using bar grizzly to make separation, using drying kiln to make high-temperature drying treatment and using high-temperature magnetic drum to make magnetic separation so as to can effectively remove most of harmful impurities from forging scale raw material, and can raise quality of forging scale raw material and can produce high-quality ironoxide powder.

Owner:宝钢集团上海梅山有限公司

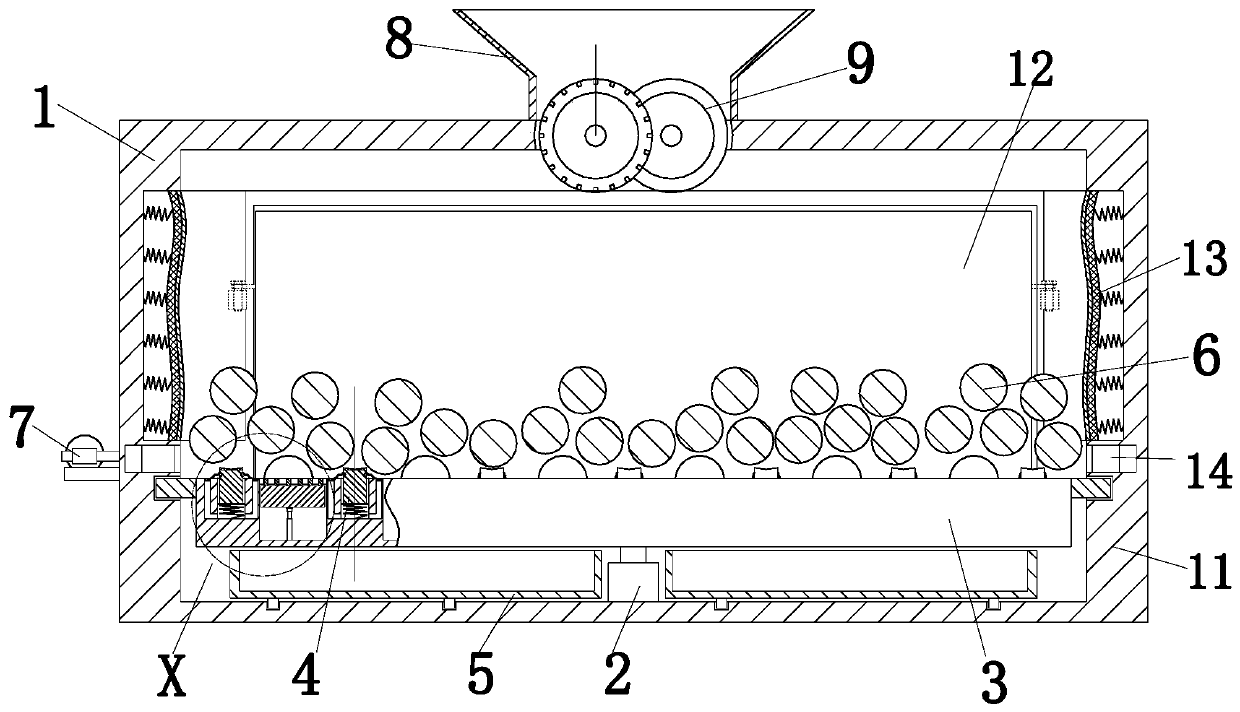

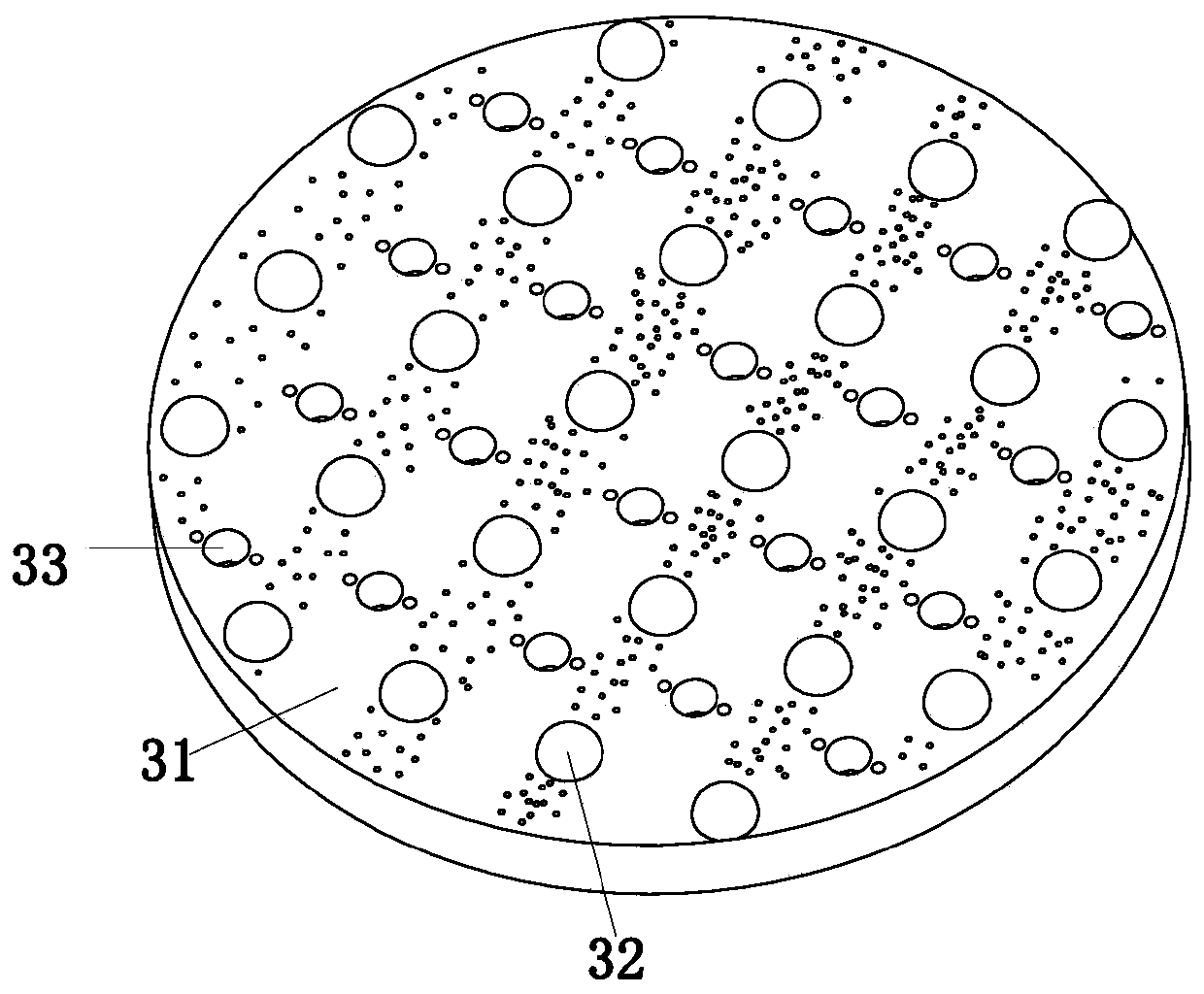

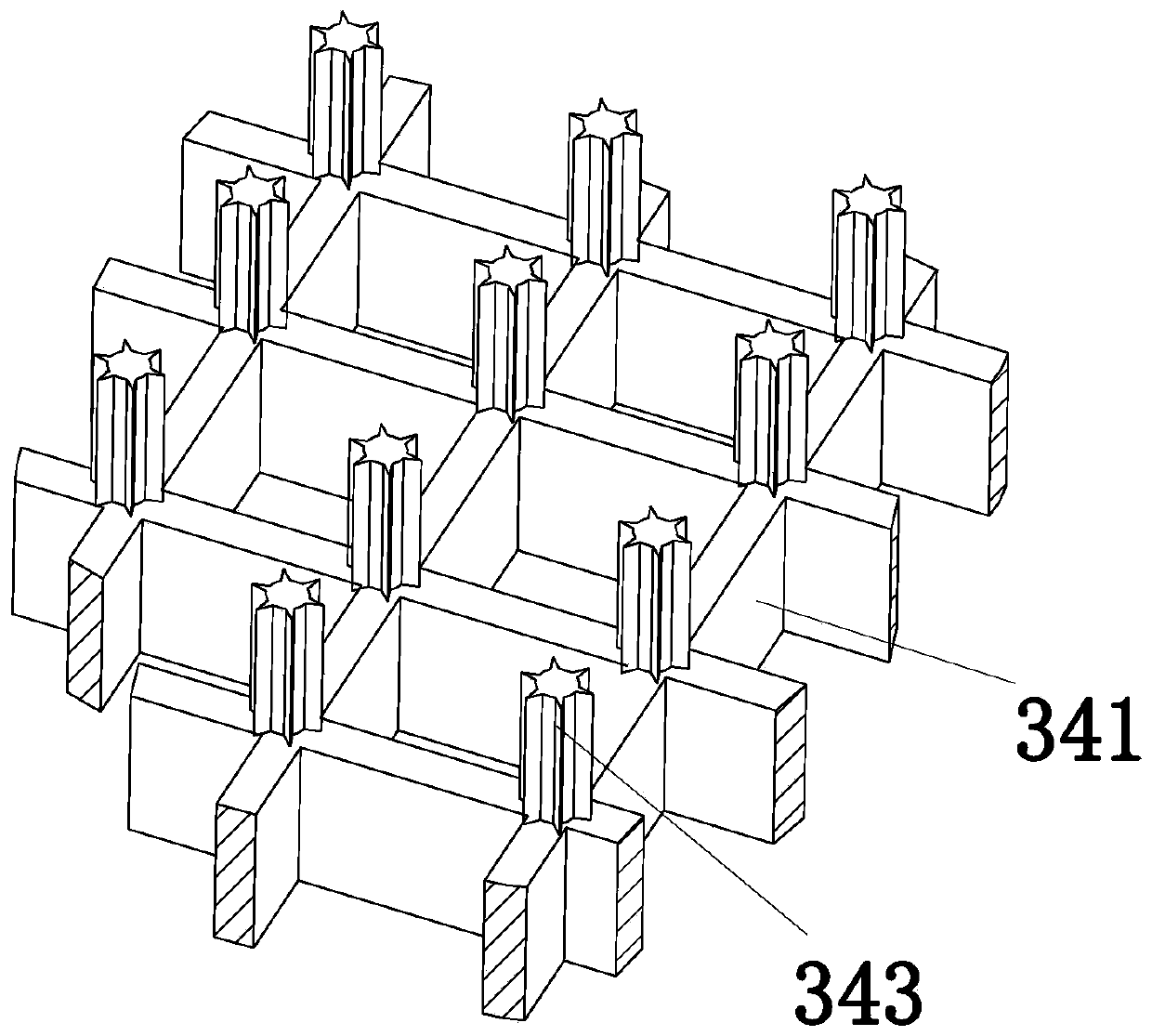

Automatic grinding system for calcium carbonate preparation raw materials

The invention relates to an automatic grinding system for calcium carbonate preparation raw materials. The system comprises a frame body, a driving motor, a rotating disc, a material turning device, two pulling frames, grinding beads, an inflator pump, a feeding hole and a grinding device, wherein the driving motor is arranged in the middle of the bottom end of the frame body; the rotating disc isarranged on an output shaft of the driving motor; the grinding beads are arranged on the rotating disc; the material turning device is uniformly arranged on the rotating disc; the two pulling framesare arranged on the left side and the right side of the bottom end of the frame body; the inflator pump is arranged at the left end of the frame body through a base; the feeding hole is arranged in the upper end of the frame body; and the grinding device is arranged in the feeding hole. The automatic grinding machine can solve the problems that an existing grinding machine usually uses grinding discs to grind the raw materials, the raw materials entering the middle of a raw material powder layer between the grinding discs are difficult to be ground in a grinding process, so that the contact areas between the raw materials and the grinding discs are different, the situations that the ground raw materials are not uniform in size and poor in fineness are caused, and the quality of products and other problems are greatly influenced.

Owner:江西春景钙业有限公司

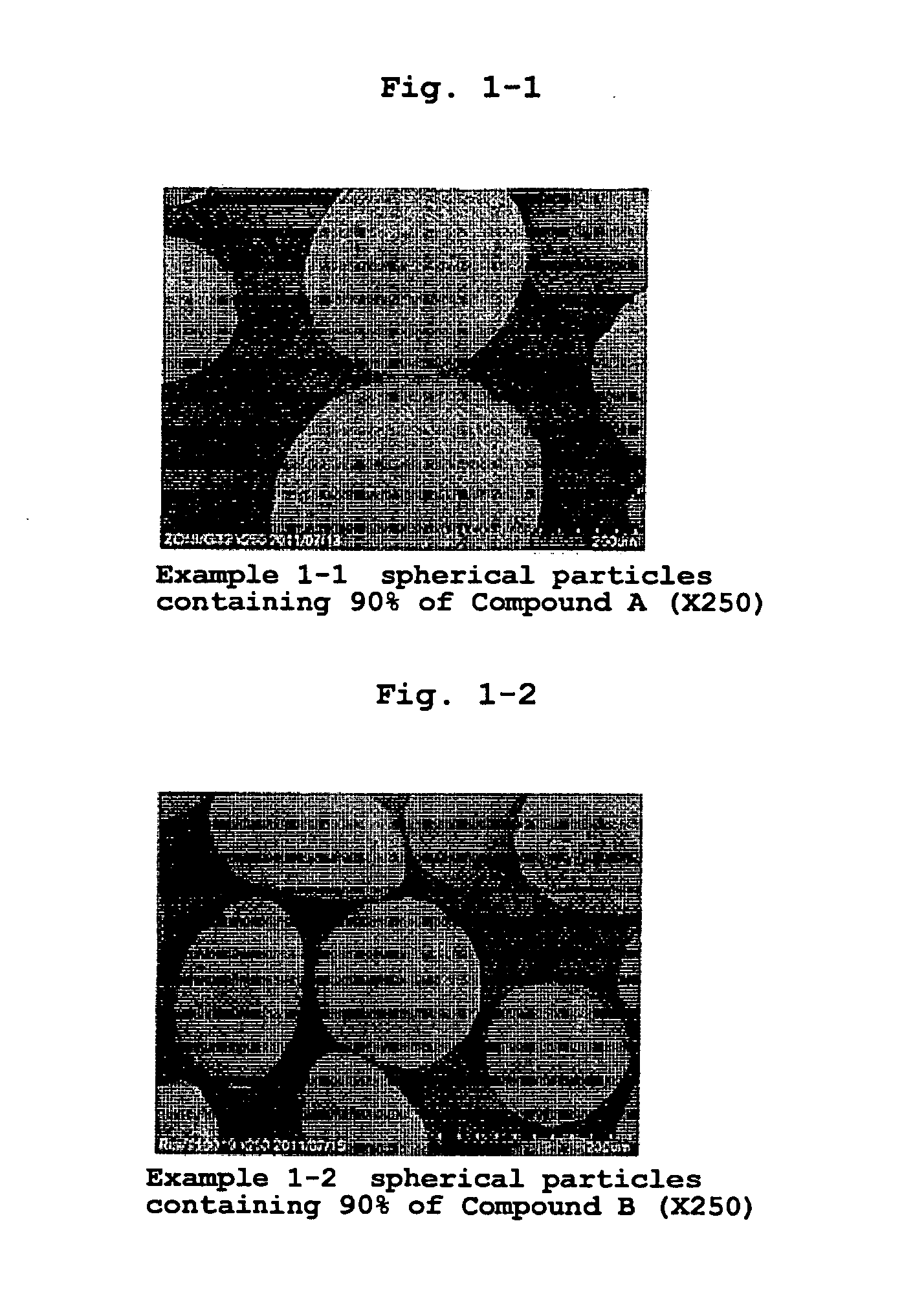

Medicament-containing hollow particle

InactiveUS20150297520A1High strengthDisintegrates quicklyBiocidePowder deliveryPowder mixtureSolvent

The invention provides a particle composed of a shell and a hollow, wherein the shell contains a medicament and a polymer, and a volume ratio of the hollow relative to the whole particle is 1%-50%. The invention also provides a process for preparation of the hollow particle, which includes a step of granulating a powder mixture containing a medicament and a polymer, while spraying a solvent capable of dissolving the polymer.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

Preparation method of nano antimony thioantimonate

InactiveCN108163890AImprove leaching rateIncrease profitMaterial nanotechnologyAdditivesSulfurPotassium sodium tartrate

The invention discloses a preparation method of nano antimony thioantimonate, wherein the preparation method comprises the steps: adding a sodium thioantimonate solution into a complex solution of trivalent antimony, dispersing with ultrasonic waves, controlling the temperature of the reaction system at 20-35 DEG C, adjusting the pH value of the reaction system to 6.3-7.8 with hydrochloric acid, after completion of addition of the sodium thioantimonate solution, continuing to disperse for 10-15 min by ultrasonic waves, filtering to take a filter residue, washing the filter residue with a potassium sodium tartrate solution and purified water, and grinding for 3-5 h by a ball mill, and thus obtaining the product. The content of sulfur in antimony thioantimonate obtained by the preparation method provided by the invention is low, the product is stable and pure, the yield is high, the properties are good, the particles are in nanoscale, and the nano antimony thioantimonate has the advantages of good compatibility with lubricating grease, good extreme pressure wear resistance and good lubrication performance; as an additive, the nano antimony thioantimonate has various properties far beyond the requirements of the national standards on extreme pressure lubricating grease, can be industrially produced and has a good application prospect.

Owner:广西生富锑业科技股份有限公司

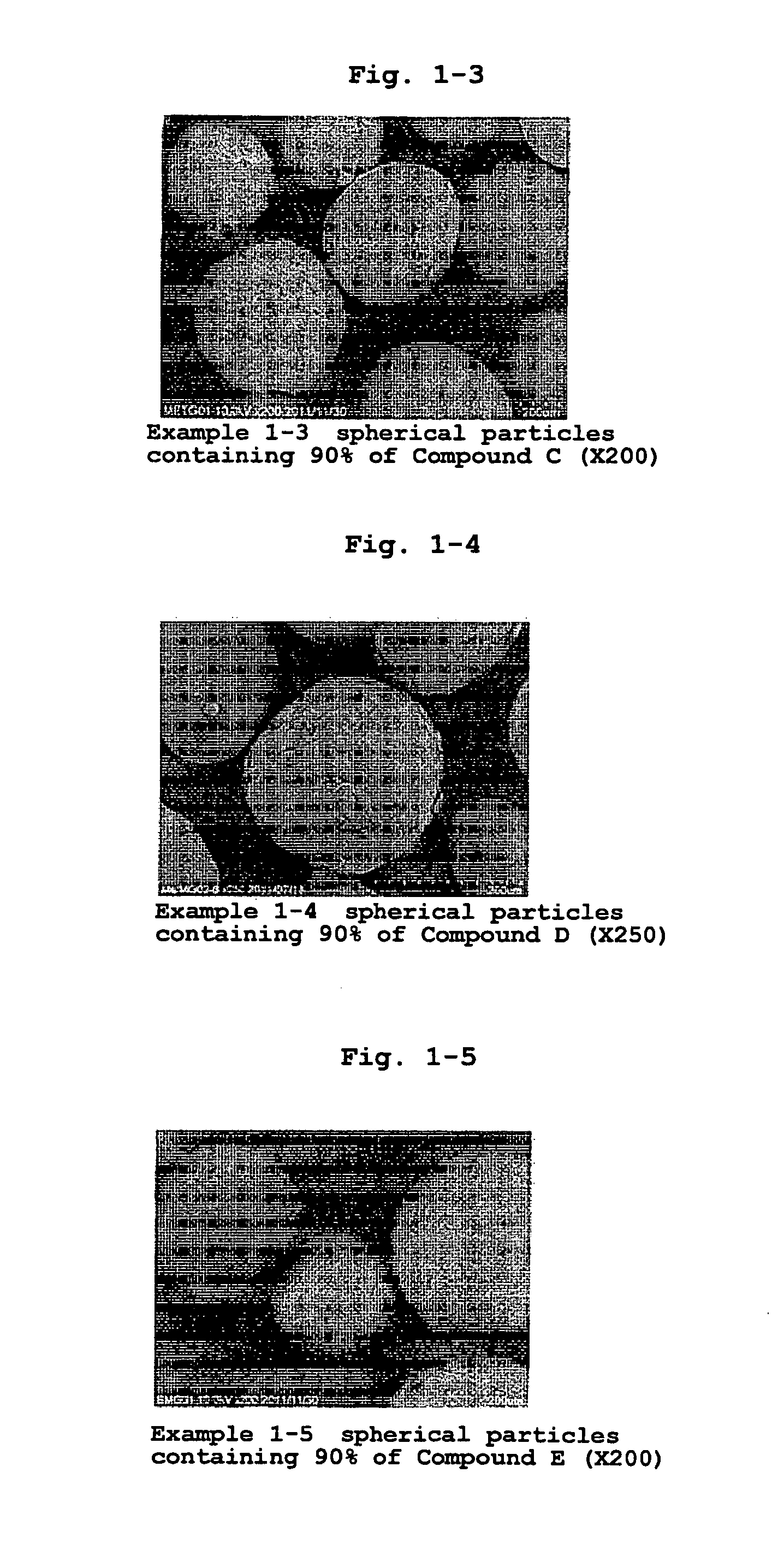

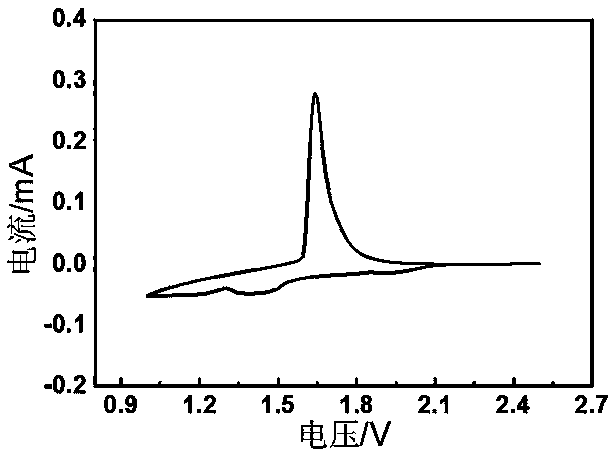

All-solid-state lithium battery composite positive electrode and preparation method thereof

InactiveCN107910523AEasy to prepareLow costElectrode rolling/calenderingSecondary cellsFiberArgon atmosphere

An all-solid-state lithium battery composite positive electrode and a preparation method thereof belong to the technical field of a lithium ion battery. The composite positive electrode is prepared from lithium titanate, vapor-phase growth carbon fiber VGCFs and a binary sulfide electrolyte LPSCI according to a mass ratio being (1-5):(1-5):1. The method comprises the following steps of (1) taking10-100mL of 200# gasoline in a weighting bottle, weighing and adding lithium titanate powder, VGCFs and the LPSCI electrolyte in an amount of 10-50g according to a mass ratio into the weighing bottle,and performing mixing and stirring for 12-24 hours; (2) drying the obtained mixed solution to obtain Li4Ti5O12 and Li6PS5Cl mixed powder, wherein the temperature is 50-100 DEG C, the time is 10-24 hours, and the drying atmosphere is argon atmosphere; and (3) pressing the obtained mixed powder to form a ceramic sheet per 1-30mg, thereby obtaining the composite positive electrode, wherein the pressing pressure is 100-550MPa, and the pressing time is 1-60 minutes. The preparation method has the advantages of simplicity and low cost, and the obtained composite positive electrode material is relatively good in particle uniformity, relatively high in lithium ion conductivity and excellent in electrochemical performance.

Owner:HARBIN INST OF TECH

Zinc powder pigment and manufacturing method by dry milling

InactiveCN103342905AAspect RatioImprove Particle UniformityPigment physical treatmentChemistryStearic acid

The invention provides a zinc powder pigment which is prepared by mixing the following components in parts by weight: 97-98.5% of zinc powder, 1-2% of stearic acid, 0.4-0.7% of coupling agent and 0.1-0.3% of dispersing agent. The manufacturing method of the zinc powder pigment by dry milling comprises the following steps: ball milling, graded screening, synthesis of primary finished product, and synthesis of secondary finished product. The high-polymer coupling agent with coordination group is used as a protective agent, and the stearic acid has the effect of assisting milling, thereby integrally changing the milling mode; the graded uniform-speed impact-free grinding, three-stage screening and two-stage discharging are utilized to enhance the radius-thickness ratio and particle uniformity of the product; and nitrogen cooling and automatic temperature control protection are used as auxiliary means to reduce the phenomenon of increased zinc powder oxidation rate due to temperature rise in the preparation process and effectively solve the problem of high oxidation tendency of the zinc powder surface in the working process, thereby obtaining the flake zinc powder pigment with strong oxidation resistance and enduring, bright and adjustable color.

Owner:林海松

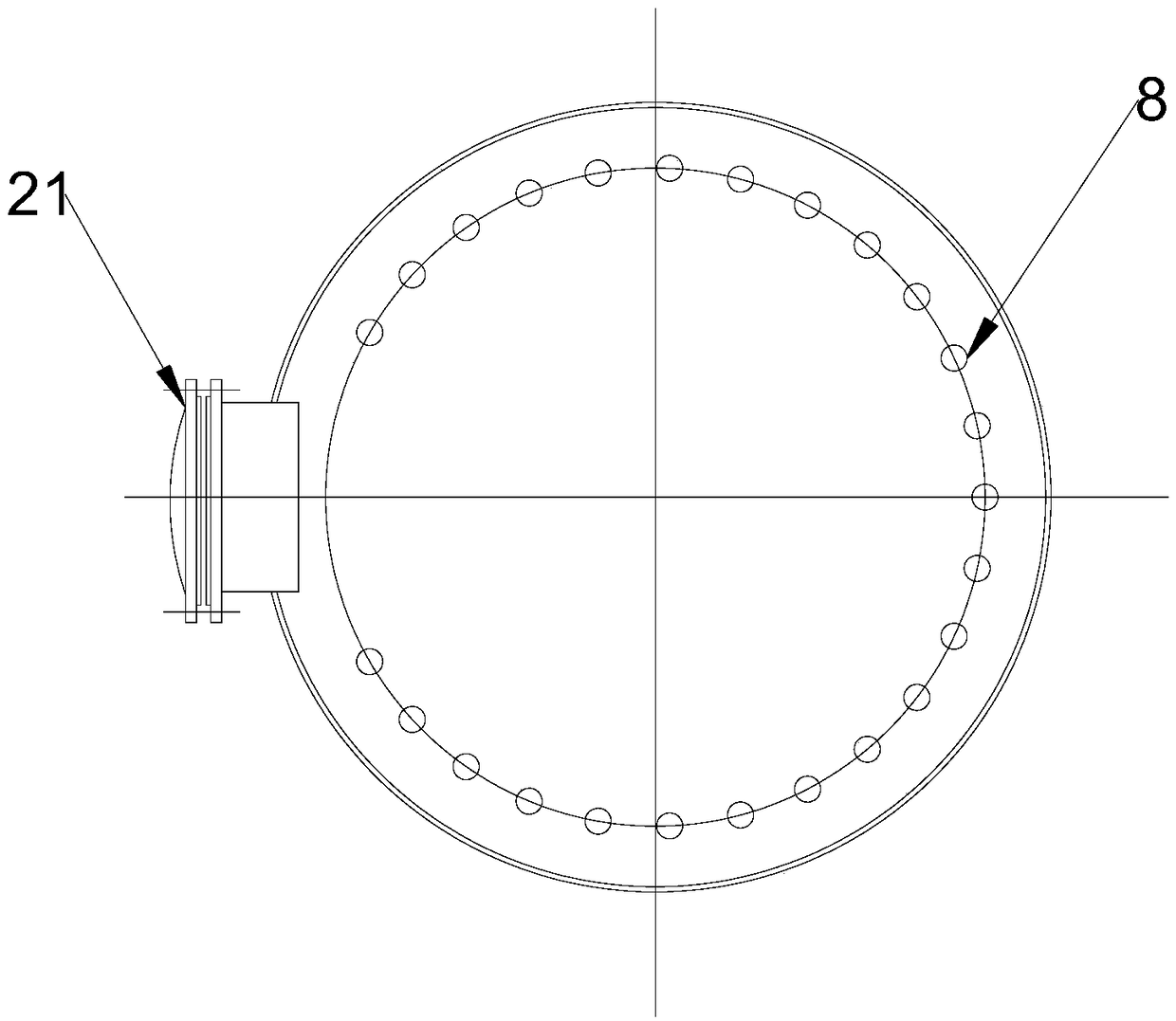

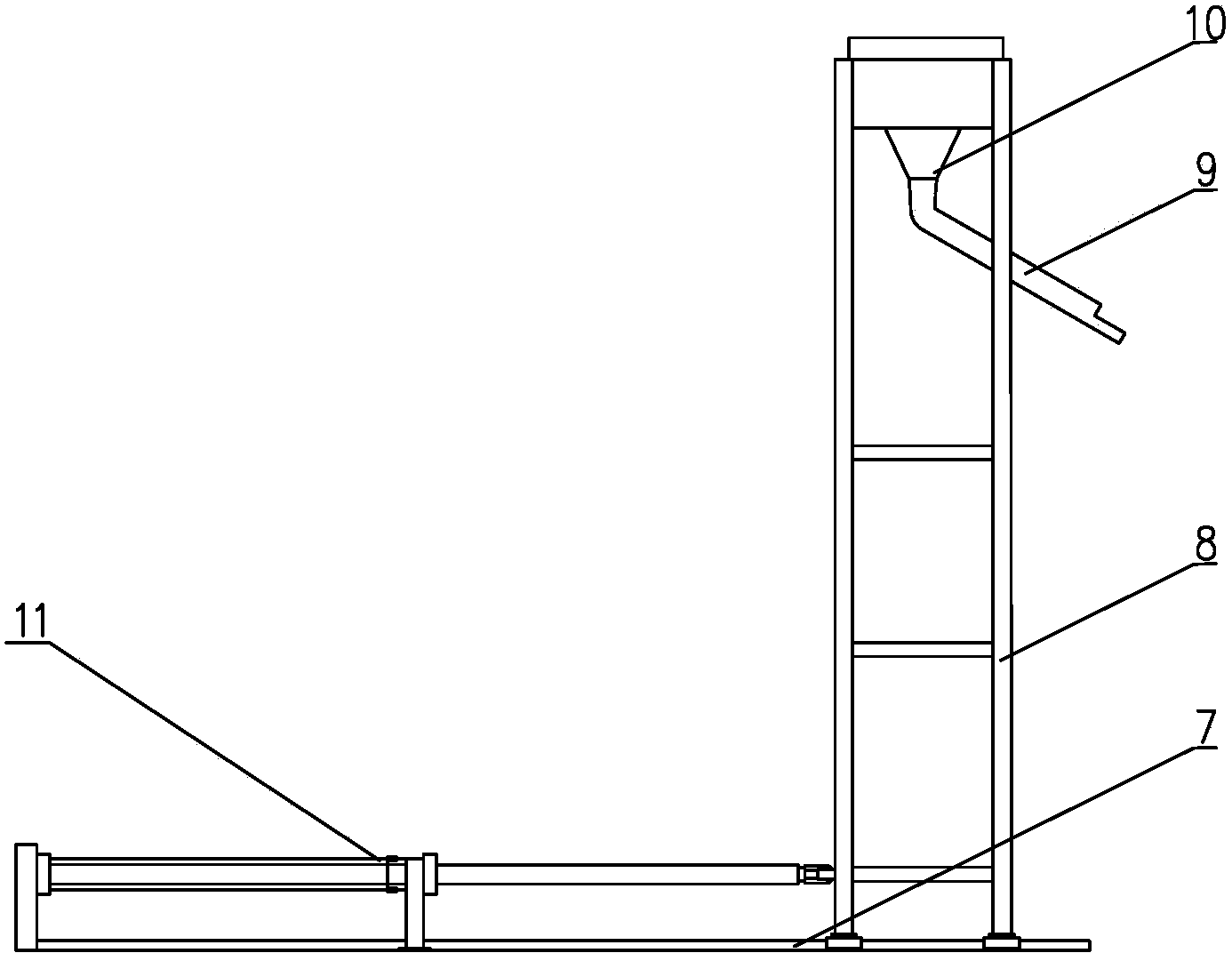

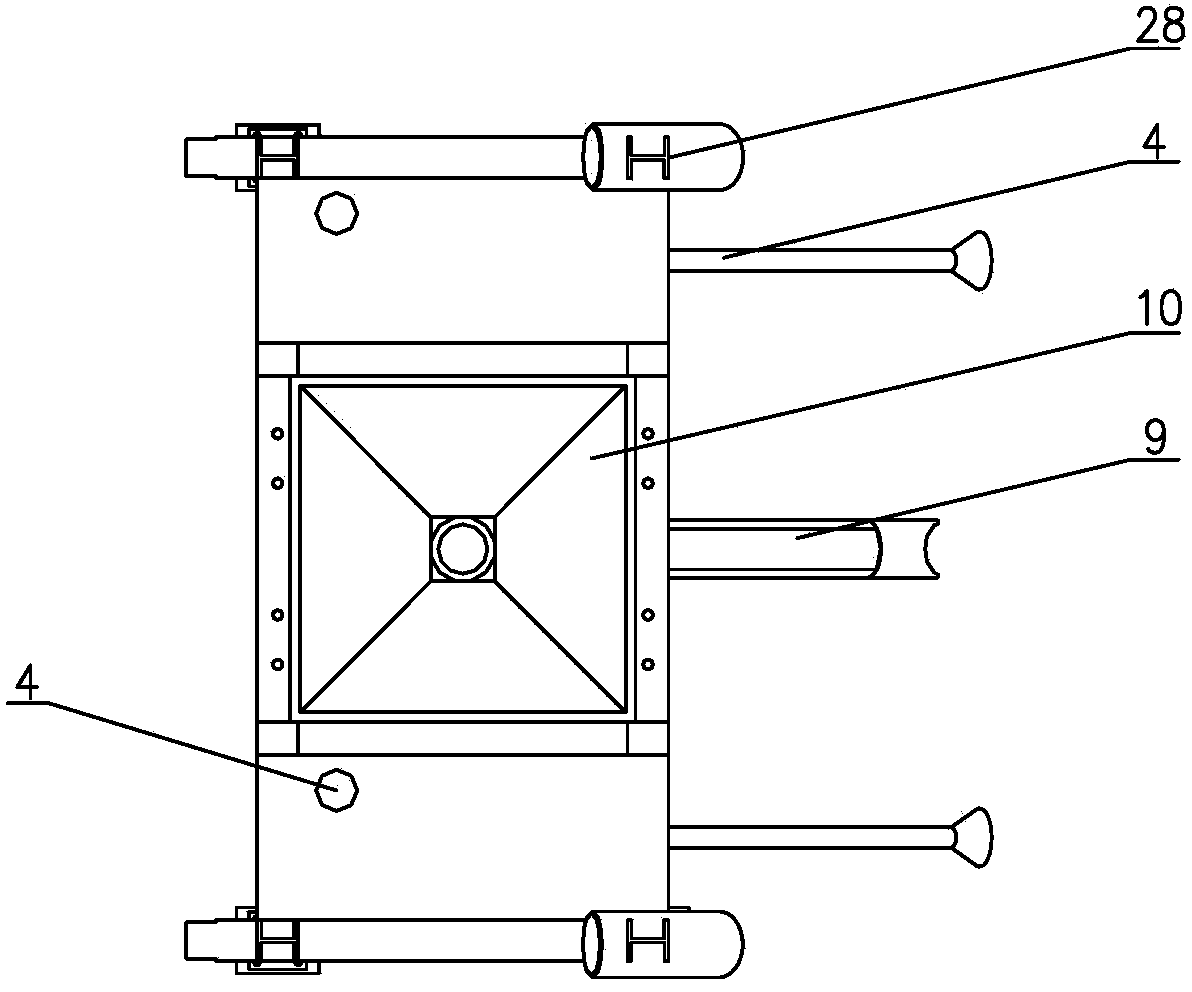

Vanadium slag pelleting device

InactiveCN109999721AImprove Particle UniformityReduce labor intensityGranulation by pressingSlagPre compression

The invention discloses a vanadium slag pelleting device, and relates to the technical field of metallurgy. The problem that vanadium slag pellets prepared by a disc granulator are poor in uniformityand low in pelletizing rate is solved. According to the technical scheme, the vanadium slag pelleting device comprises a feeding system, a pre-pressing forming system and a screening system; the pre-pressing forming system comprises a pre-pressing hopper and a forming hopper; the feeding system is used for supplying materials to the pre-pressing hopper; a pre-pressing roller press and a first edgecutting machine are arranged in the pre-pressing hopper, wherein a discharging opening of the feeding system directly faces a gap between two pressing rollers of the pre-compression roller press, andthe first edge cutting machine is arranged below the pre-compression roller press; a forming pressing roller and a second edge cutting machine are arranged in the forming hopper, wherein a discharging opening of the pre-pressing hopper directly faces a middle line between two pressing rollers of the forming roller press, and the second edge cutting machine is arranged below the forming pressing machine; the screening system is arranged below a discharging opening of the forming hopper; and a finished product bin is connected on a screen of the screening system and a fine powder bin is arranged below the screen. The vanadium slag pelleting device is applicable to vanadium slag pelleting.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Environment-friendly slow-release fertilizer for aquaculture aquatic plants

InactiveCN106116805AGood sustained release effectGood bonding performanceCalcareous fertilisersMagnesium fertilisersFertilizerChemistry

The invention discloses an environment-friendly slow-release fertilizer for aquaculture aquatic plants. The environment-friendly slow-release fertilizer is prepared from, by weight, 10-20 parts of potassium chloride, 5-15 parts of urea, 5-20 parts of potash magnesium sulphate fertilizer, 0.5-2 parts of decomposed coal, 1-2 parts of turf, 1-3 parts of zeolite powder, 0.5-1.2 parts of calcium humate, 0.5-1 part of magnesium humate, 0.1-0.6 part of boron humate, 0.2-0.8 part of sodium humate, 0.15-0.4 part of compound sodium nitrophenolate, 1-2 parts of olive oil, 1.2-3 parts of sodium carboxymethylcellulose and 2-5 parts of a controlled-release coating agent. The coat of the fertilizer is not likely to break, the fertilizer is good in granule uniformity and environmentally friendly, and the fertilization property accords with the fertilizer requirement law of aquatic plants.

Owner:ANQING FUJIANG FISHERIES BREEDING CO LTD

Special coating attaching abrasive tool abrasive cloth for surface decoration texture treatment of stainless steel product and preparation method thereof

InactiveCN110216600AGood flexibilityImprove water resistance and oil resistanceFibre treatmentAbrasion apparatusBright lineMetal

The invention relates to the technical field of stainless steel product and metal surface treatment, and particularly relates to a special coating attaching abrasive tool abrasive cloth for surface decoration texture treatment of a stainless steel product and a preparation method thereof. The coating attaching abrasive tool abrasive cloth is prepared by technical steps such as dipping a base cloth, scraping slurry on the base cloth, shaping an abrasive material, gluing a flat texture surface of the base cloth, inserting the milling material into a glue layer, drying the coated glue, drying again, curing, and finishing flexibility. The production test shows that the coating attaching abrasive tool abrasive cloth in surface decoration texture treating and milling process of the stainless steel product enables milling with water and oil and is hard to deform; the flexibility of the coating attaching abrasive tool abrasive cloth is high, and the coating attaching abrasive tool abrasive cloth is close to the stainless steel surface, so that the uniformity and the consistency of the surface decoration texture effect are ensured; the milling material particles are high in uniformity, so that defects such as bright lines, scratches and bright points can be effectively prevented in the surface decoration texture treatment process of the stainless steel product; in addition, decoration textures have different effects in different use situations such as bright, snowflake, colorful light, long silks and short silks.

Owner:JIANGSU SANLING ABRASIVES CO LTD

Low-temperature heat-seal acrylic emulsion and preparation method thereof and application thereof

ActiveCN103059213BImprove stabilityImprove Particle UniformityFlexible coversWrappersPolymer scienceMicrocrystalline wax

The invention provides a low-temperature heat-seal acrylic emulsion and a preparation method of the low-temperature heat-seal acrylic emulsion. The preparation method comprises the steps of adopting seeded emulsion polymerization and adding a defined amount of microcrystalline wax before a vacuum degassing and absorbing after-treatment. The parts of the components by weight are 100 parts, including 25 parts of monomer mixture which comprises 75-90 percent of crylic acid -2- ethyl acid ester, 5-20 percent of acrylonitrile and 5-10 percent of methacrylic acid, an initiating agent which comprises organic peroxides, methanal and sodium hydrogen sulfate, a mixed emulsifying agent which comprises a non-ionic surface active agent and secondary chain alkyl sodium sulfonate, a seeded emulsifying agent which comprises secondary chain alkyl sodium sulfonate and MA-80, an auxiliary agent which comprises ammonium acetate and ferrous chloride, and a potential of hydrogen (PH) conditioning agent. The heat-seal temperature of the low-temperature heat-seal acrylic emulsion is 40-48 DEG C. The low-temperature heat-seal acrylic emulsion is good in stability, good in particle evenness, and good in heat-seal evenness. The preparation method of the low-temperature heat-seal acrylic emulsion is used for high-speed packaging of food such as candies and chocolates with the requirement of low temperature and heat seal.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Method for preparing superfine manganese dioxide from potassium permanganate

The invention relates to a method for preparing superfine manganese dioxide from potassium permanganate. The method comprises the following steps: crystal seed preparation, material proportioning, hydrothermal reaction, filter separation, roasting and the like. The method has the advantages of short technical process, mild conditions and no need of complex equipment. The manganese dioxide product has higher purity, and the maximum particle size can reach nano scale.

Owner:广西下田锰矿有限责任公司

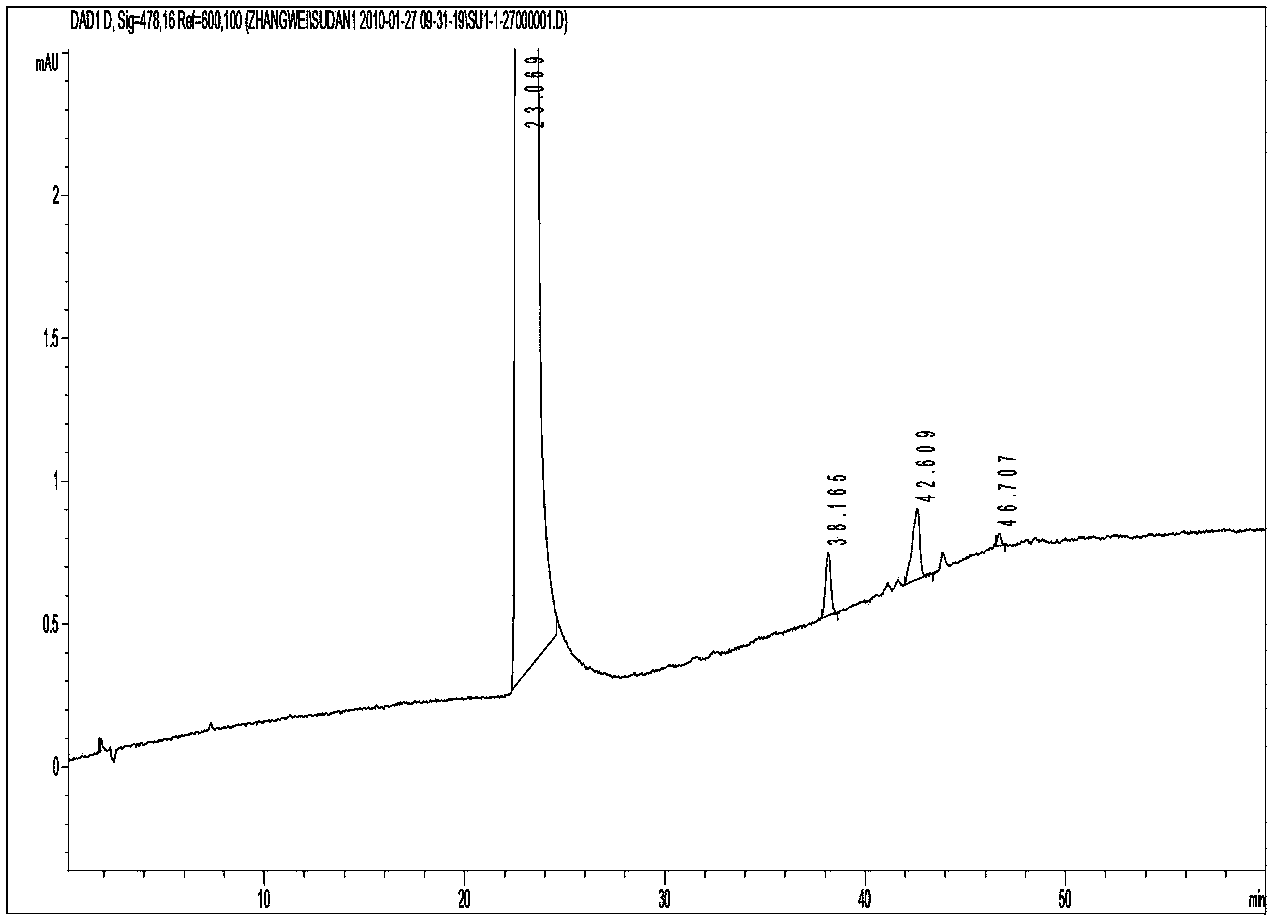

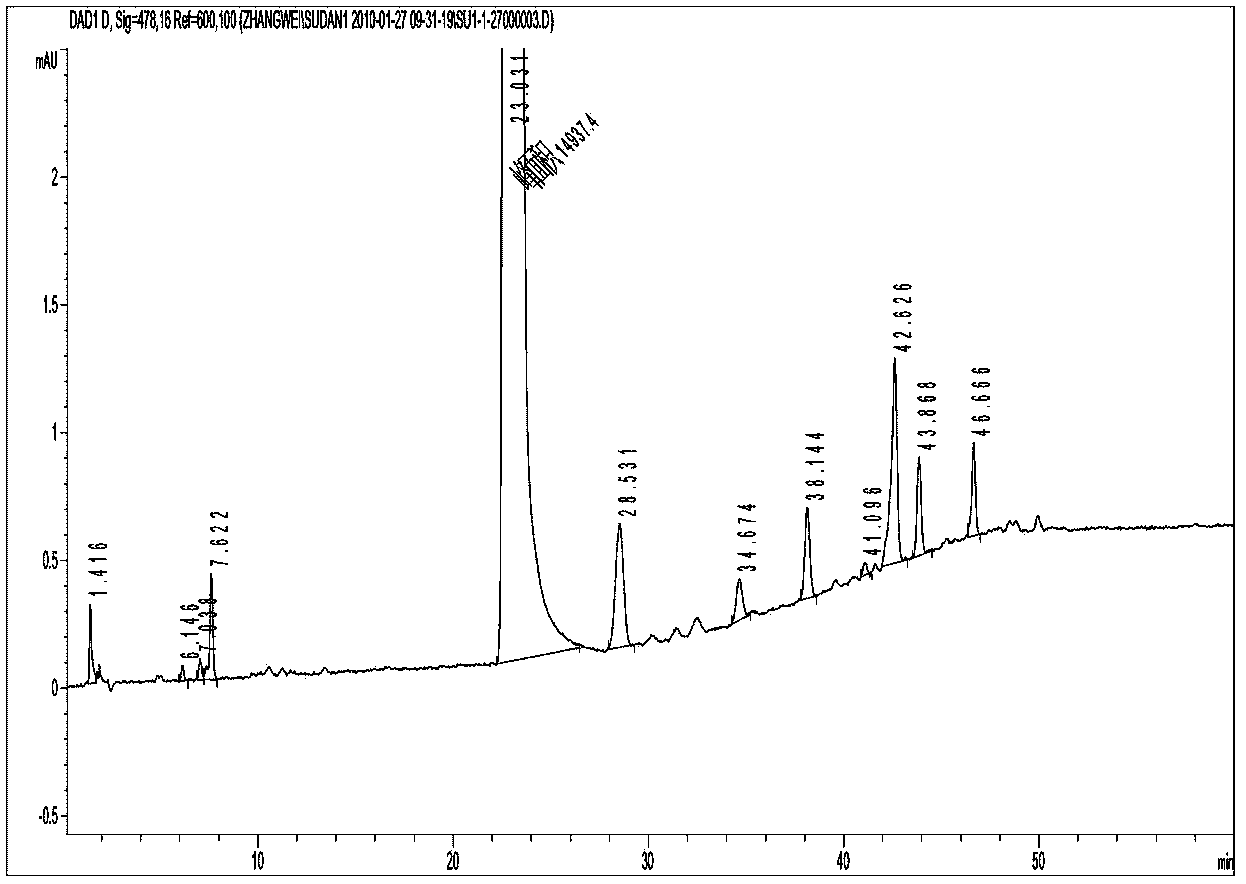

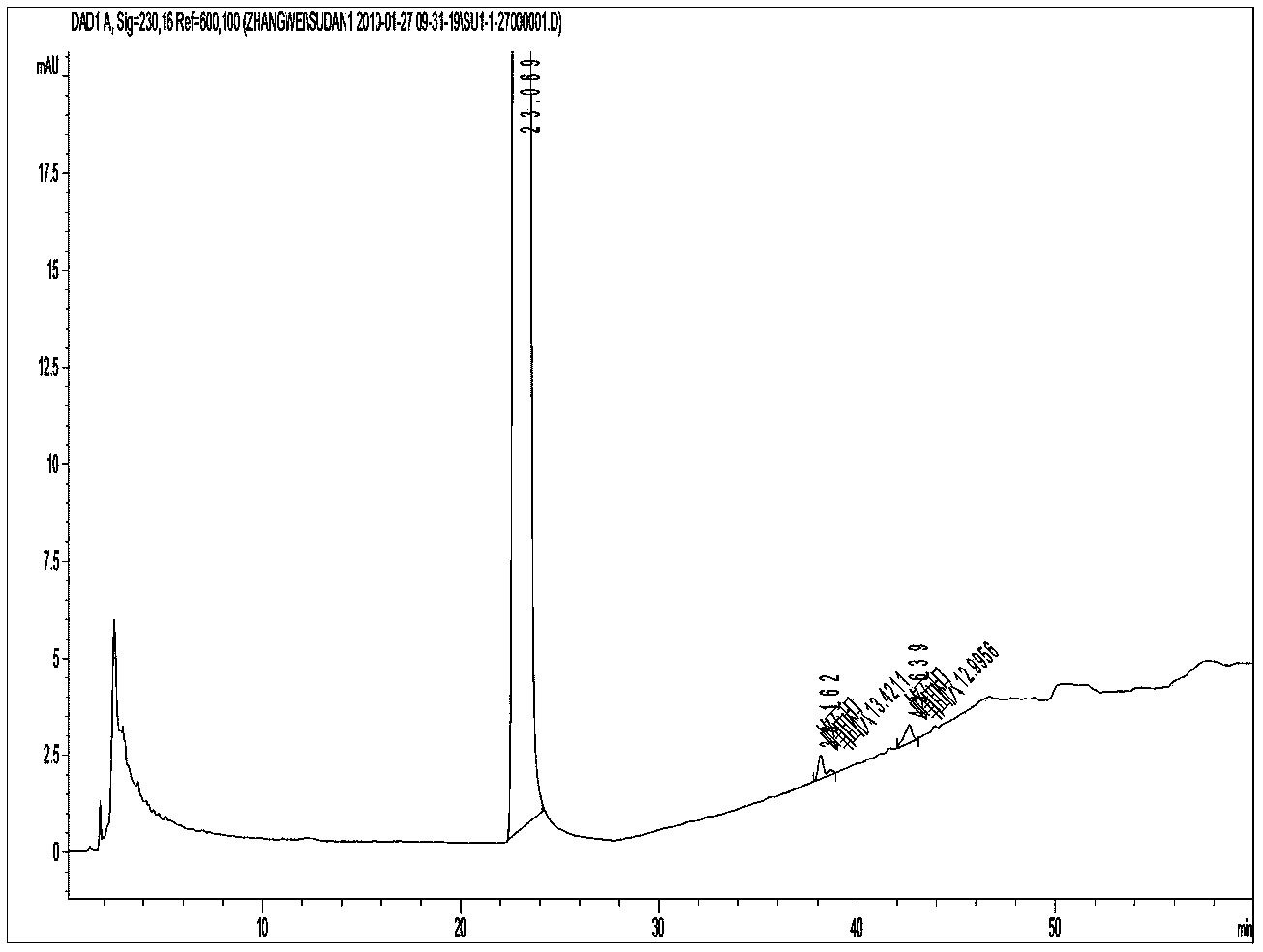

Sudan red I crystal A and preparation method thereof

InactiveCN104262192AEfficient removalHigh purityOrganic chemistryComponent separationX-rayPowder diffraction

The invention relates to Sudan red I crystal A. Crystal Sudan red I exists in a polymorphic form with a main crystal form and other multiple auxiliary crystal forms, and the polymorphic form is identified through X-ray powder diffraction. The invention further provides a preparation method of the Sudan red I crystal A; the purity of the Sudan red I crystal A is greatly improved, the content of the Sudan red I crystal A is greatly increased, a prepared sample meets the technical index for detection of Sudan red I in a food as an external marker, and a special Sudan red I standard substance for food detection is further prepared.

Owner:NAT INST OF METROLOGY CHINA

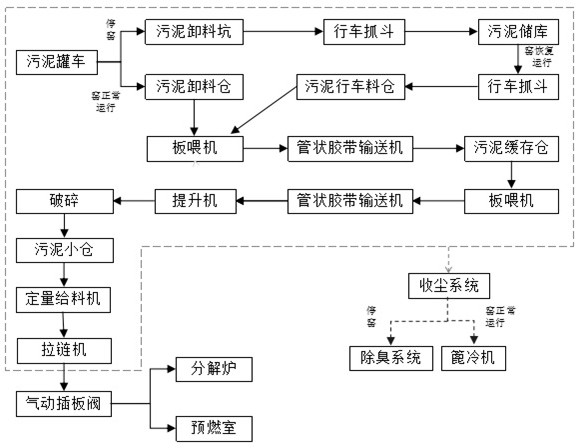

Cement kiln co-treatment process for urban dried sludge

PendingCN112484053ACause secondary pollutionImprove Particle UniformitySludge treatmentIncinerator apparatusSludgeProcess engineering

The invention discloses a cement kiln co-treatment process for urban dried sludge, and relates to the technical field of dried sludge treatment. Sludge passes through a sludge discharging bin and a sludge traveling stock bin, passes through a plate feeder, then is conveyed to a tubular rubber belt conveyor and then is conveyed to a transfer station; the transfer station is provided with a sludge temporary storage bin; then the sludge passes through the plate feeder, is conveyed to an elevator through the tubular rubber belt conveyor, is conveyed to the kiln tail through the elevator, is crushed and then is conveyed to a small sludge bin; and after being metered by a quantitative feeder, the sludge is fed into a decomposing furnace and a pre-combustion chamber through a flow chain conveyorto be incinerated, most of toxic organic matters are thoroughly decomposed, a small amount of large-particle sintering slag falls into a rotary kiln from a kiln tail ascending flue and then is calcined into cement clinker through a rotary kiln system, so that harmless treatment of the sludge is thoroughly achieved.

Owner:蓝天众成环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com