Single-crystal ternary cathode material, preparation method thereof and lithium ion battery

A cathode material, single crystal technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low specific capacity of ternary lithium-ion batteries, complex process, unsatisfactory particle uniformity and electric specific capacity of ternary cathode materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

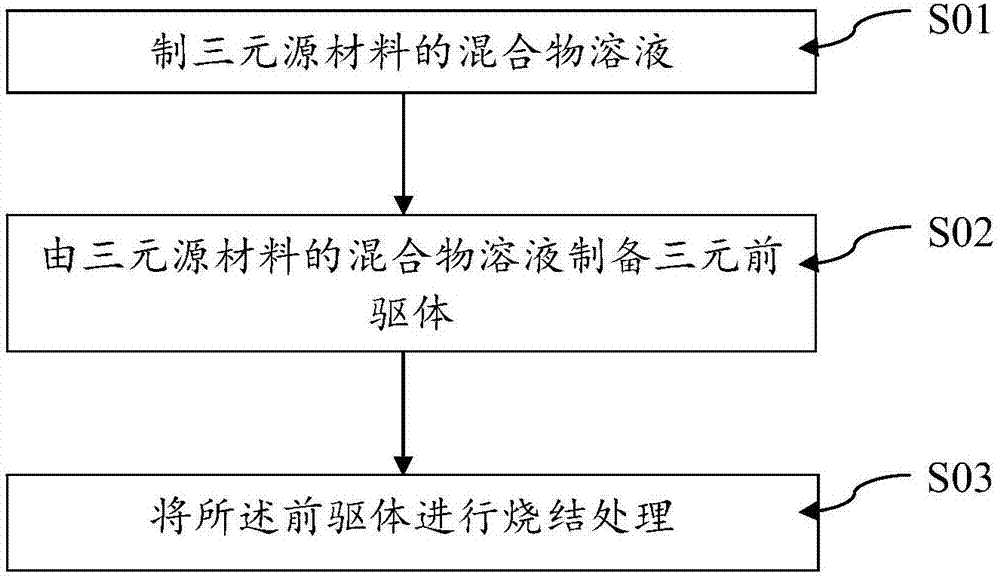

[0022] On the one hand, an embodiment of the present invention provides a method for preparing a single crystal ternary cathode material. The technological process of the preparation method of the single crystal ternary positive electrode material is as follows figure 1 As shown, it includes the following steps:

[0023] Step S01. Prepare a mixture solution of ternary source materials: prepare a mixture solution of lithium source, nickel source, cobalt source, manganese source and complexing agent;

[0024] Step S02. Prepare a ternary precursor from a mixture solution of a ternary source material: perform complex crystallization on the mixture solution to obtain a precursor of a single crystal ternary cathode material;

[0025] Step S03. Sintering the precursor.

[0026] Specifically, in the above step S01, as an embodiment of the present invention, when preparing the mixture solution of the ternary source material, the molar ratio of the lithium source, the nickel source, t...

Embodiment 1

[0038] This embodiment provides a single crystal ternary cathode material and a preparation method thereof. The preparation method of the single crystal ternary cathode material comprises the following steps:

[0039] S11: Lithium carbonate, nickel sulfate, cobalt sulfate, manganese sulfate and ethylenediamine are formulated into a mixture solution according to the molar ratio of 1.05:0.5:0.3:0.2:0.6, the solvent is deionized water, and the concentration of the mixture solution is 1.5mol / L ;

[0040] S12: heat and concentrate at 140°C prepared in step S11 for recrystallization, obtain the precursor after centrifugation to remove the solvent, and dry at 180°C;

[0041] S13: Sintering the precursor prepared in step S12 according to the following conditions:

[0042] Firstly, the temperature is raised to 300°C at 3°C / min, and after heat preservation treatment for 3 hours, then the temperature is raised to 950°C at 20°C / min for 15 hours of heat preservation and sintering.

Embodiment 2

[0044] This embodiment provides a single crystal ternary cathode material and a preparation method thereof. The preparation method of the single crystal ternary cathode material comprises the following steps:

[0045] S21: Lithium hydroxide, nickel acetate, cobalt acetate, manganese acetate and ethylenediamine are formulated into a mixture solution according to the molar ratio of 1.06:0.5:0.3:0.2:1, the solvent is ethylene glycol solution, and the concentration of the mixture solution is 1.6mol / L;

[0046] S22: Perform solvothermal treatment at 180° C. and a pressure of 4 mPa in a closed reaction kettle prepared in step S21 for 15 hours, then remove the solvent by suction filtration to obtain the precursor, and dry it at 140° C.;

[0047] S23: Sintering the precursor prepared in step S22 according to the following body conditions:

[0048] First, the temperature is raised to 350°C at 5°C / min, and after heat preservation treatment for 2 hours, then the temperature is raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com