Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Aspect ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

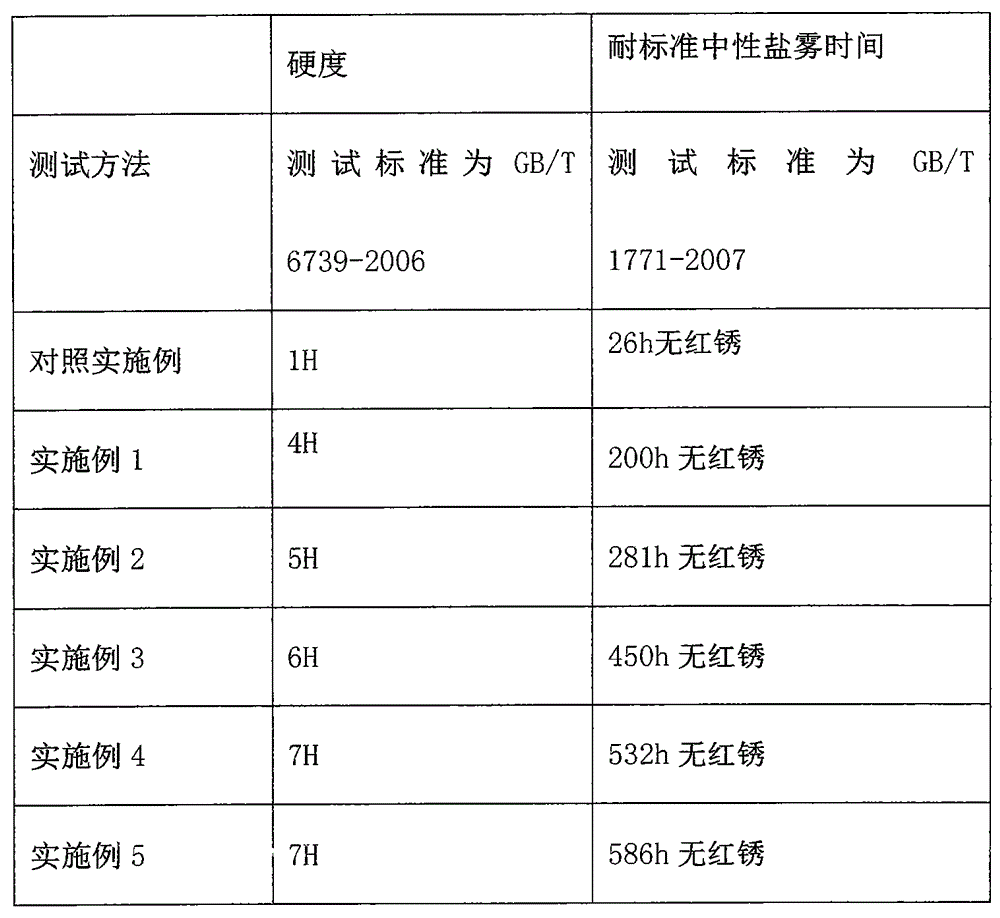

Polyaniline-graphene composite based anticorrosive paint and preparation method thereof

InactiveCN102604533AAspect RatioExcellent metal corrosion protection performanceAnti-corrosive paintsEpoxy resin coatingsSolventPliability

The invention provides polyaniline-graphene composite based anticorrosive paint and a preparation method thereof. The polyaniline-graphene composite based anticorrosive paint comprises, by weight, 20-90 parts of film former, 0.1-20 parts of polyaniline-graphene composite, 1-10 parts of pigment, 1-10 parts of filler, 0.1-3 parts of sag-proof agent, 0.1-4 parts of dispersant, 0.01-2 parts of flatting agent, 0.01-2 parts of defoaming agent, and 1-50 parts of solvent. The paint has good physical anticorrosion as graphene is high in radius-thickness ratio and high in flexibility and has electromechanical anticorrosion by the aid of polyaniline loaded on the surface of the graphene, and under synergism of the polyaniline and the graphene, the paint has fine metal corrosion resistance. The anticorrosive paint achieves passivation and corrosion inhibition of metal substrates, avoids use of heavy metals causing environmental pollution, such as chromium and the like, and is simple to prepare, low in cost and easy in industrial batch production.

Owner:HARBIN ENG UNIV

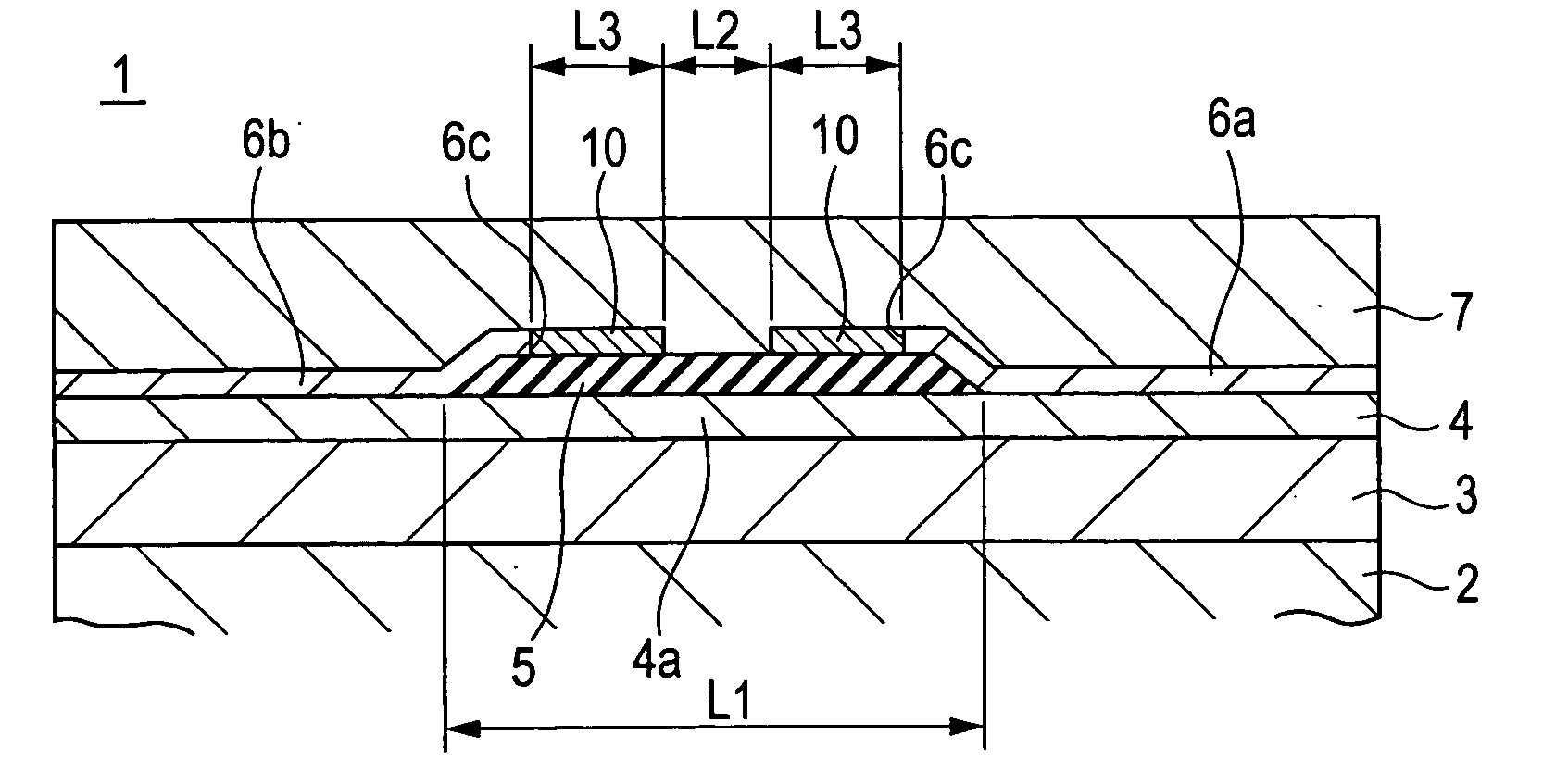

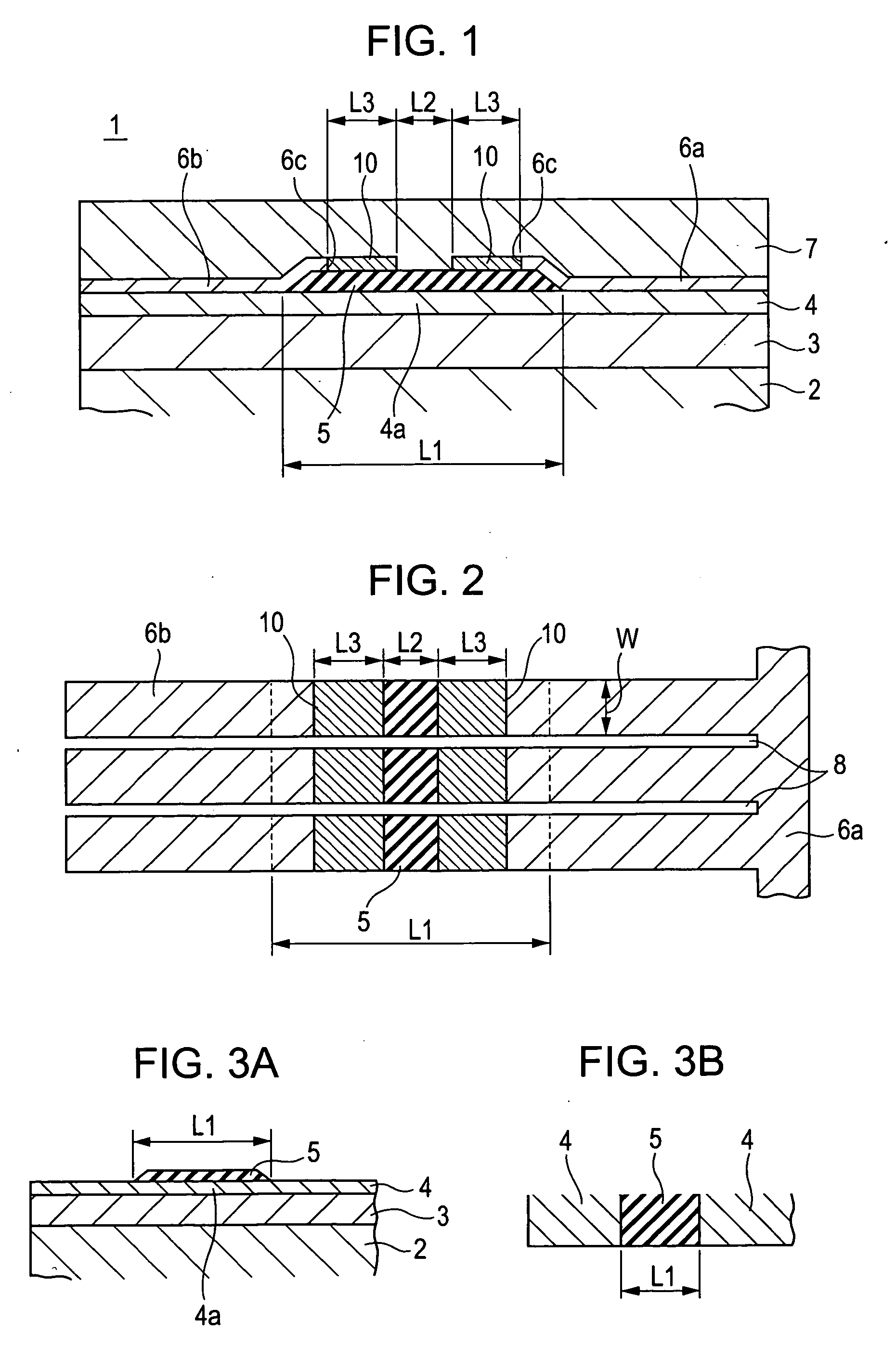

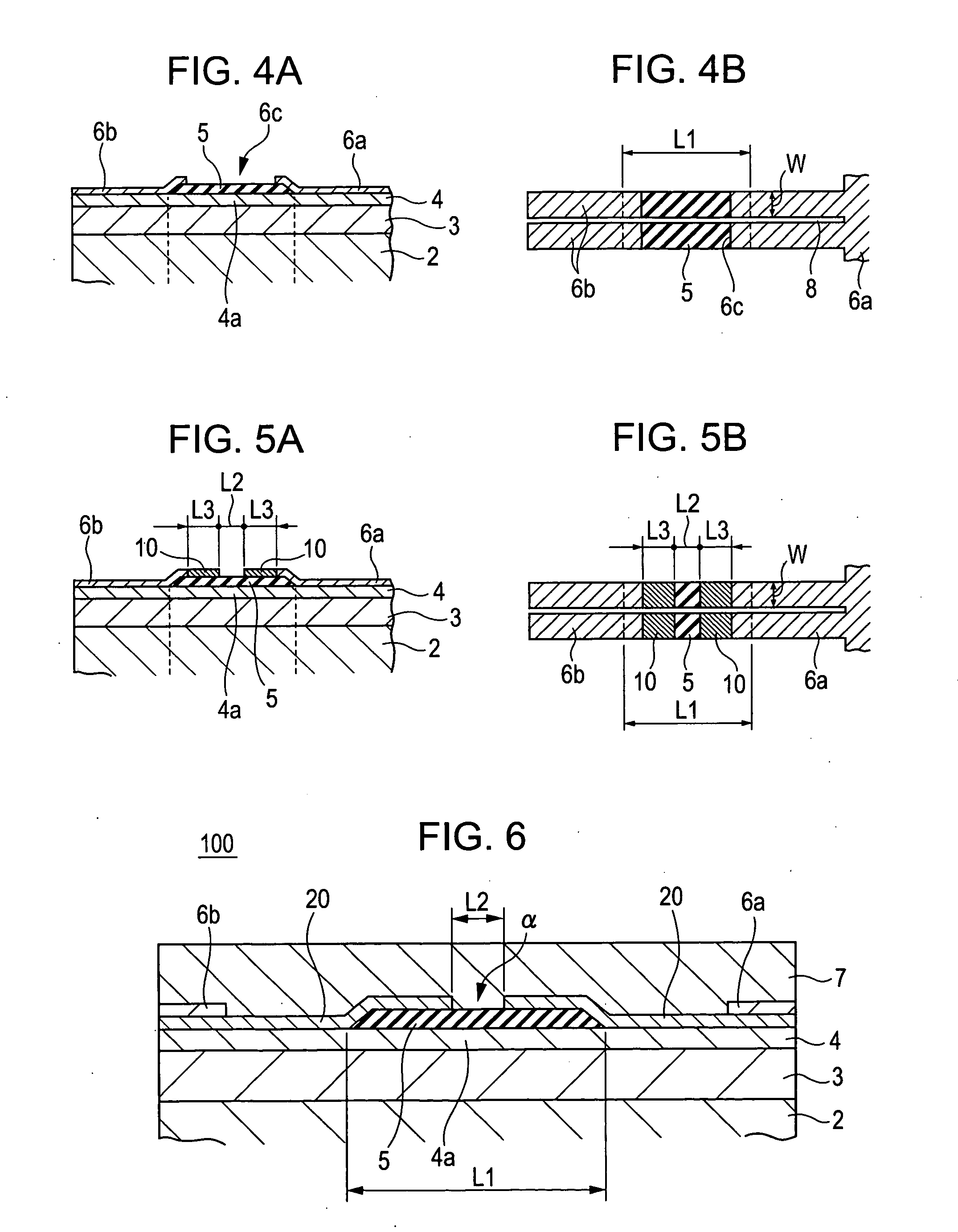

Thermal head, method for manufacturing the same, and method for adjusting dot aspect ratio of thermal head

In a thermal head provided with a resistance layer having a plurality of heating element portions which generate heat by energization, an insulating barrier layer which determines the two-dimensional size of each heating element portion by covering each heating element portion, and electrode layers electrically connected to two end portions of each of the plural heating element portions, in the length direction of the resistance, a heat transfer layer is disposed on at least the insulating barrier layer to determine the two-dimensional surface exposure area of the insulating barrier layer by covering part of the insulating barrier layer and to dissipate the heat generated from the plural heating element portions, and surface exposure regions of the insulating barrier layer are specified as effective heating regions of the plural heating element portions by adjusting the two-dimensional size of the heat transfer layer.

Owner:ALPS ALPINE CO LTD

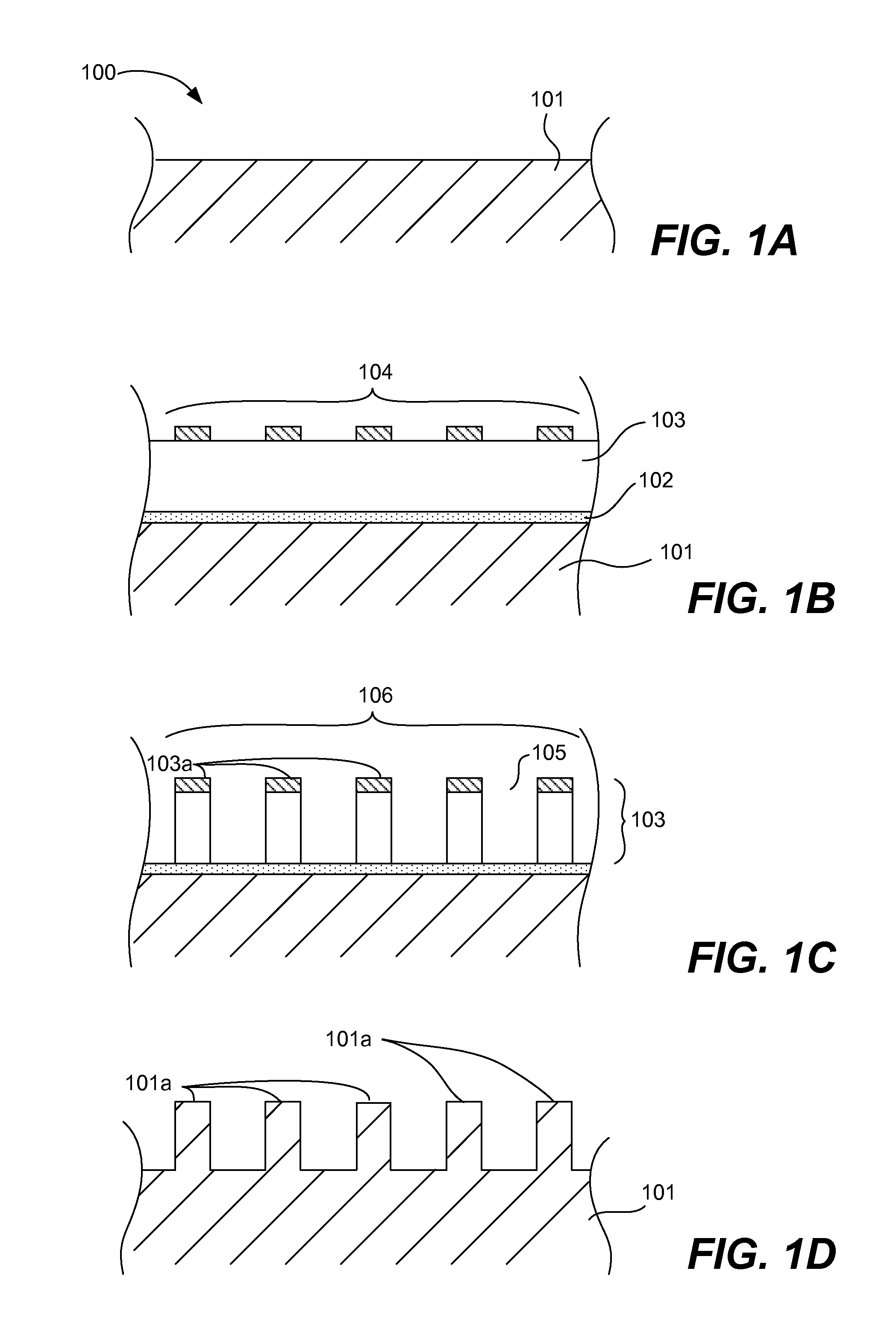

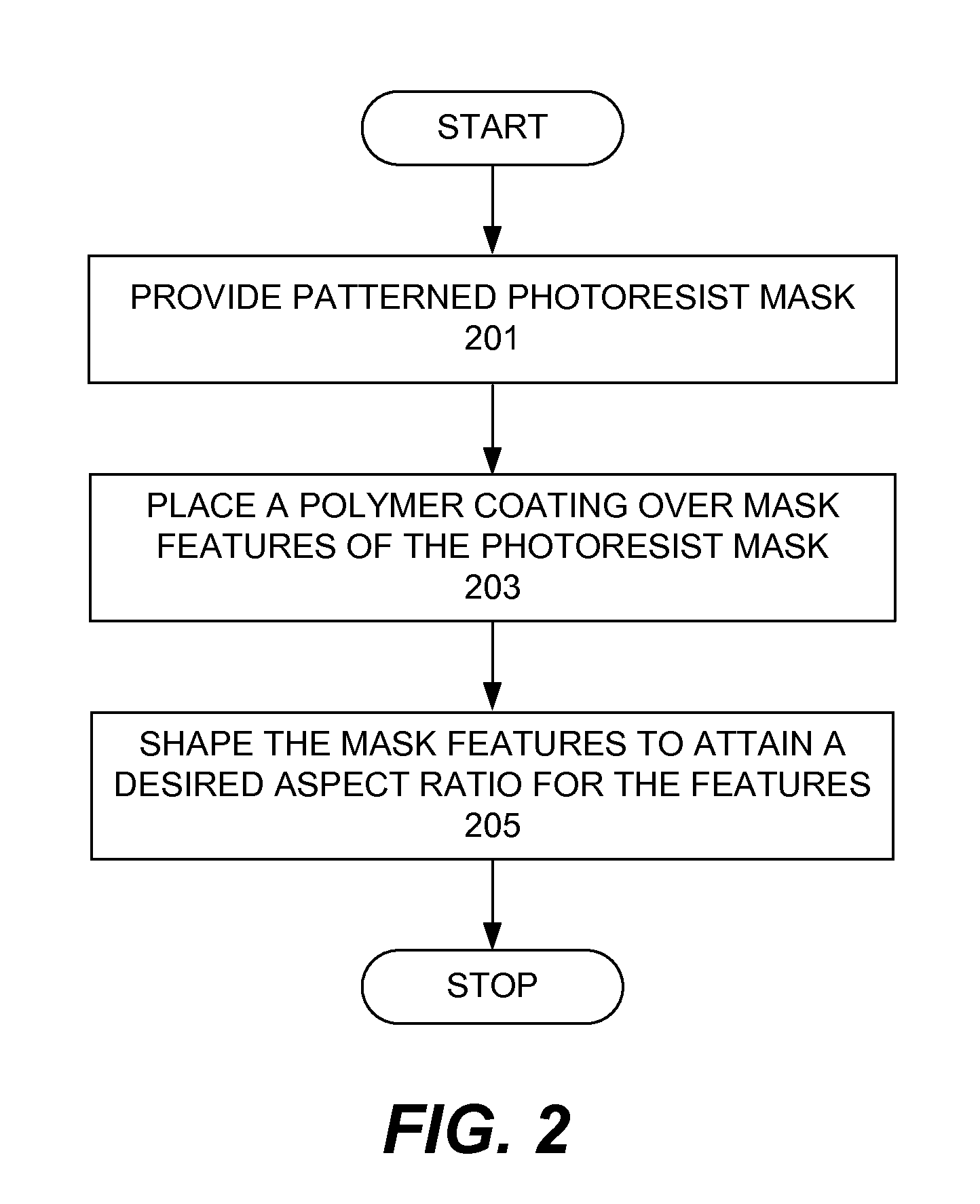

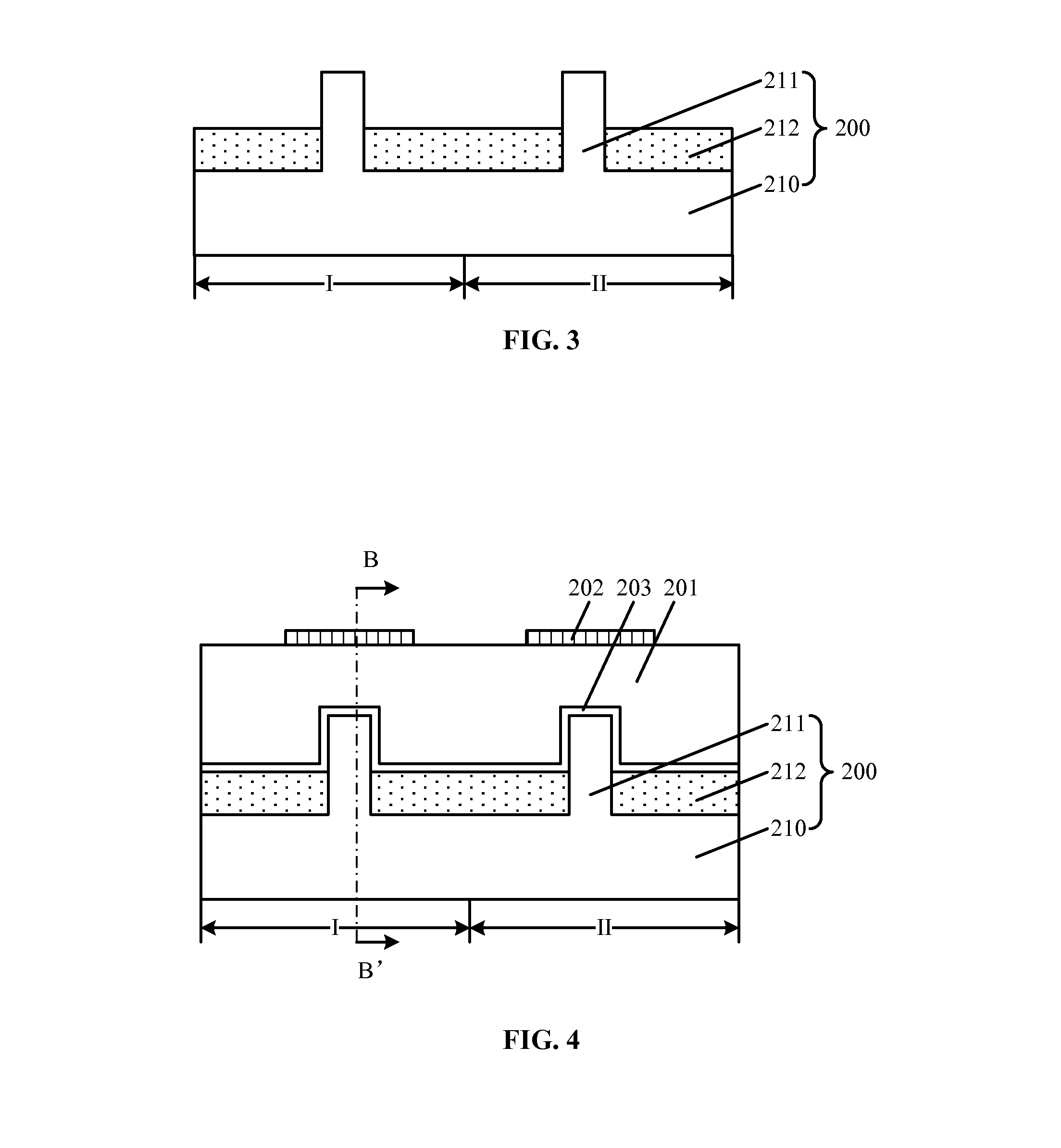

Aspect ratio adjustment of mask pattern using trimming to alter geometry of photoresist features

ActiveUS20110163420A1Improved shape and geometryAspect ratioSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistAspect ratio

A method for adjusting the geometry of photomask patterns is provided. Such adjusted pattern can be employed to achieve pattern doubling in subsequent layers. A patterned photoresist mask is provided over an underlayer. A polymer layer is placed over the mask. The mask is selectively trimmed to generate individual mask features having an increased aspect ratio. Subsequent pattern layers can be formed on the trimmed mask pattern to generate a hard mask having increased pattern density. The hard mask is selectively etched and the material of the trimmed mask pattern is removed. The underlayer is then etched to achieve pattern transfer from the hard mask to the underlayer to achieve a final double density pattern.

Owner:LAM RES CORP

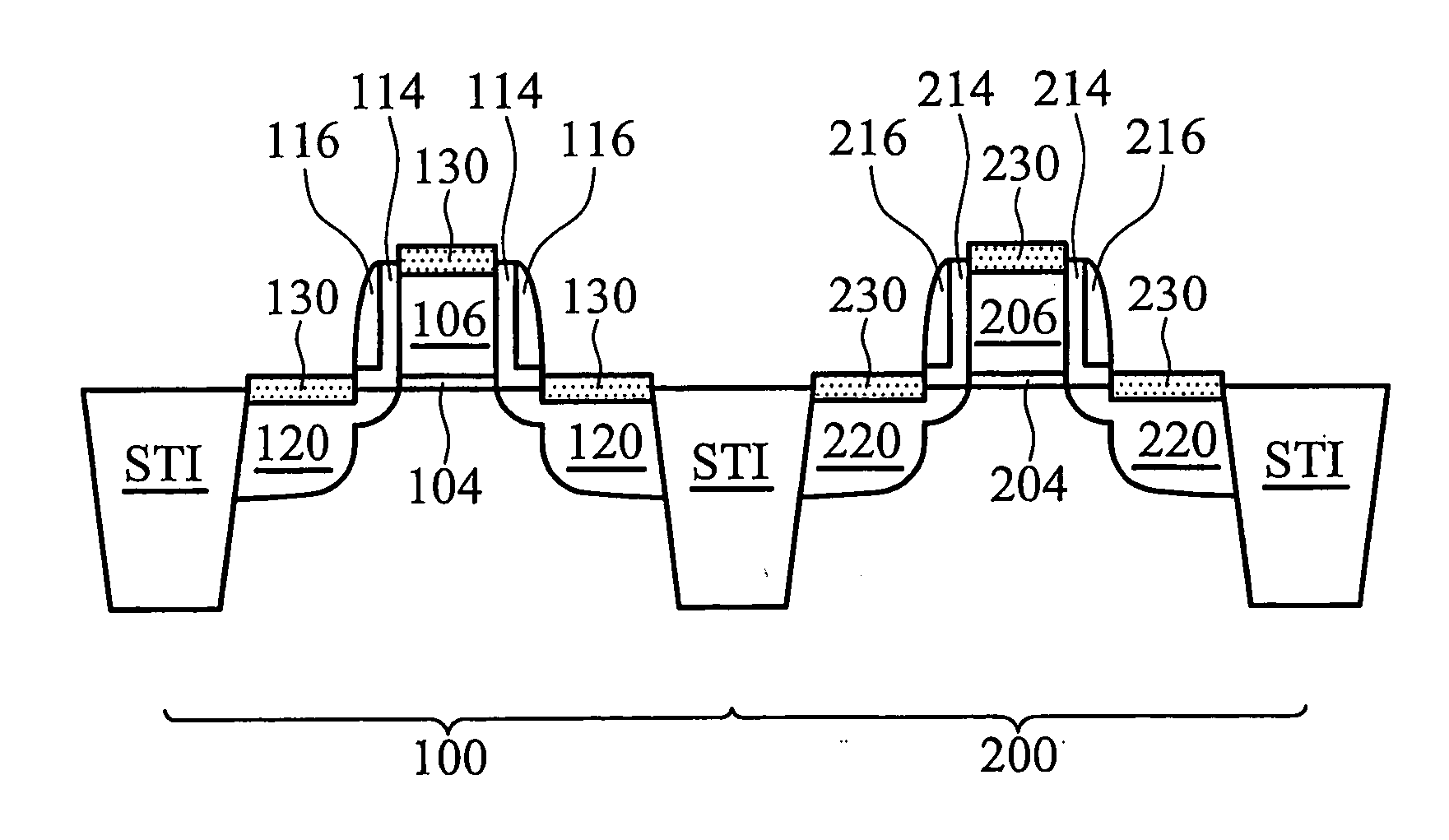

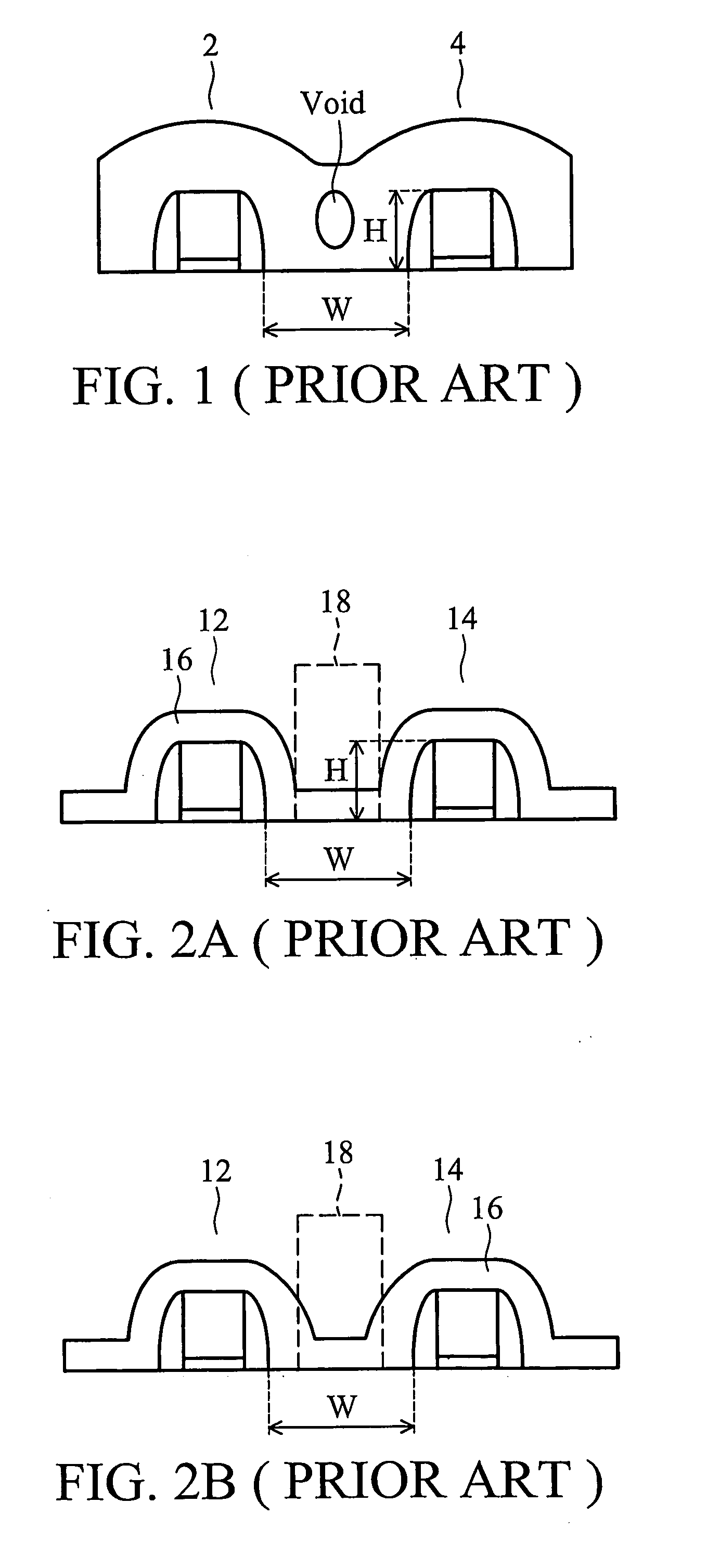

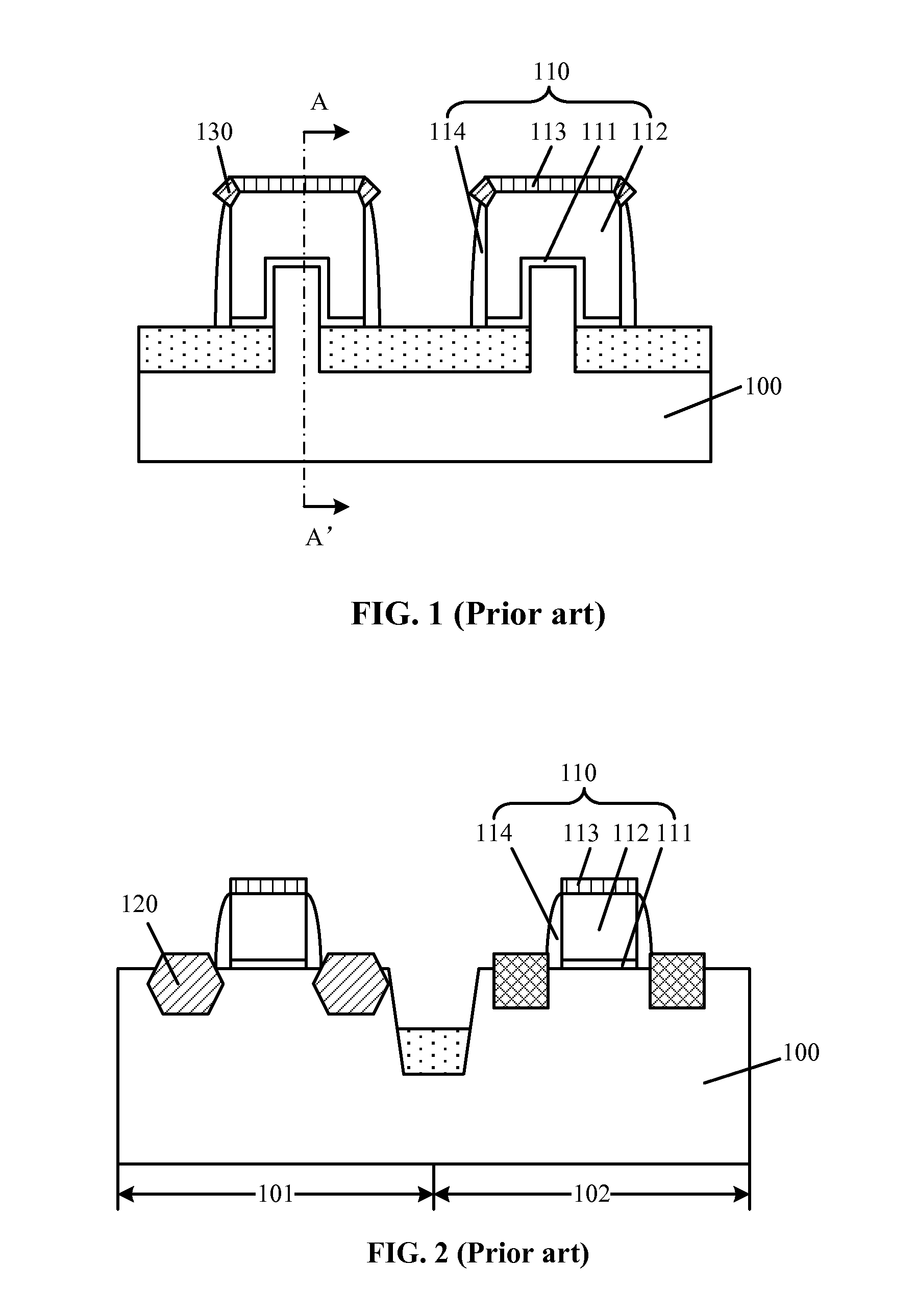

CMOS devices with improved gap-filling

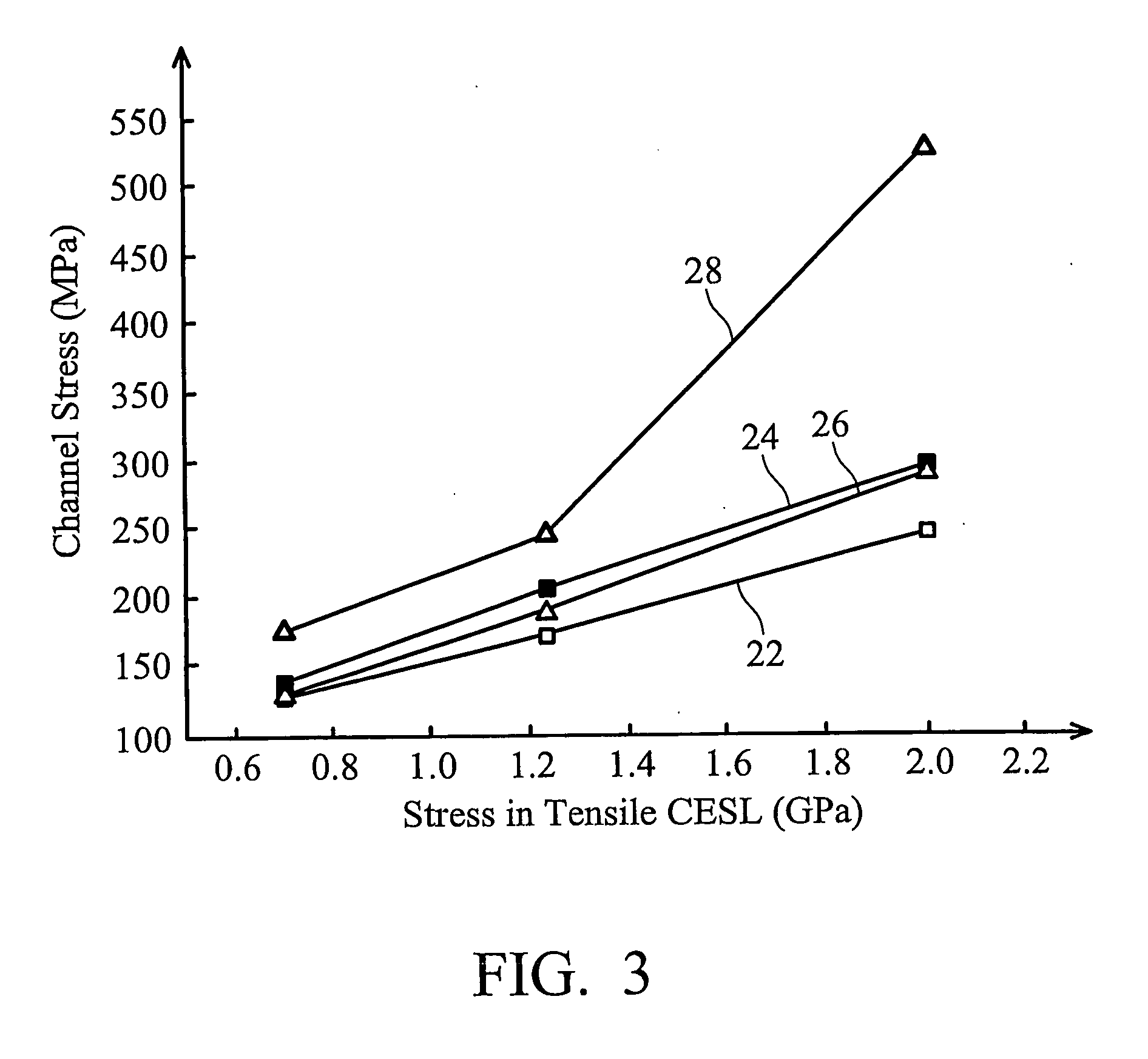

ActiveUS20070235823A1Reduce aspect ratioAspect ratioSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSGap filling

A semiconductor structure includes a substrate, and a first MOS device on the first region of the substrate wherein the first MOS device includes a first spacer liner. The semiconductor structure further includes a second MOS device on the second region wherein the second MOS device includes a second spacer liner. A first stressed film having a first thickness is formed over the first MOS device and directly on the first spacer liner. A second stressed film having a second thickness is formed over the second MOS device and directly on the second spacer liner. The first and the second stressed films may be formed of a same material.

Owner:TAIWAN SEMICON MFG CO LTD

Method for preparing high depth-diameter-ratio three-dimensional micro-channel through electronic dynamic control

InactiveCN103706955AIncrease depthAspect ratioWelding/soldering/cutting articlesLaser beam welding apparatusTime domainFree electron density

The invention relates to a method for preparing a high depth-diameter-ratio three-dimensional micro-channel through electronic dynamic control, and belongs to the technical field of femtosecond laser applying. The time domain shaping is carried out on a femtosecond laser, the partial instant electronic dynamic condition ( especially the freedom electron density distribution), of a modified area is regulated and controlled, the appearance of a periodicity nanometer structure of the modified area is affected, the high depth-diameter-ratio three-dimensional micro-channel irrelative to polarization can be achieved, and compared with a traditional femtosecond laser machining method, the method has the advantage that the depth-diameter-ratio can be multiply increased during the three-dimensional micro-channel machining.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

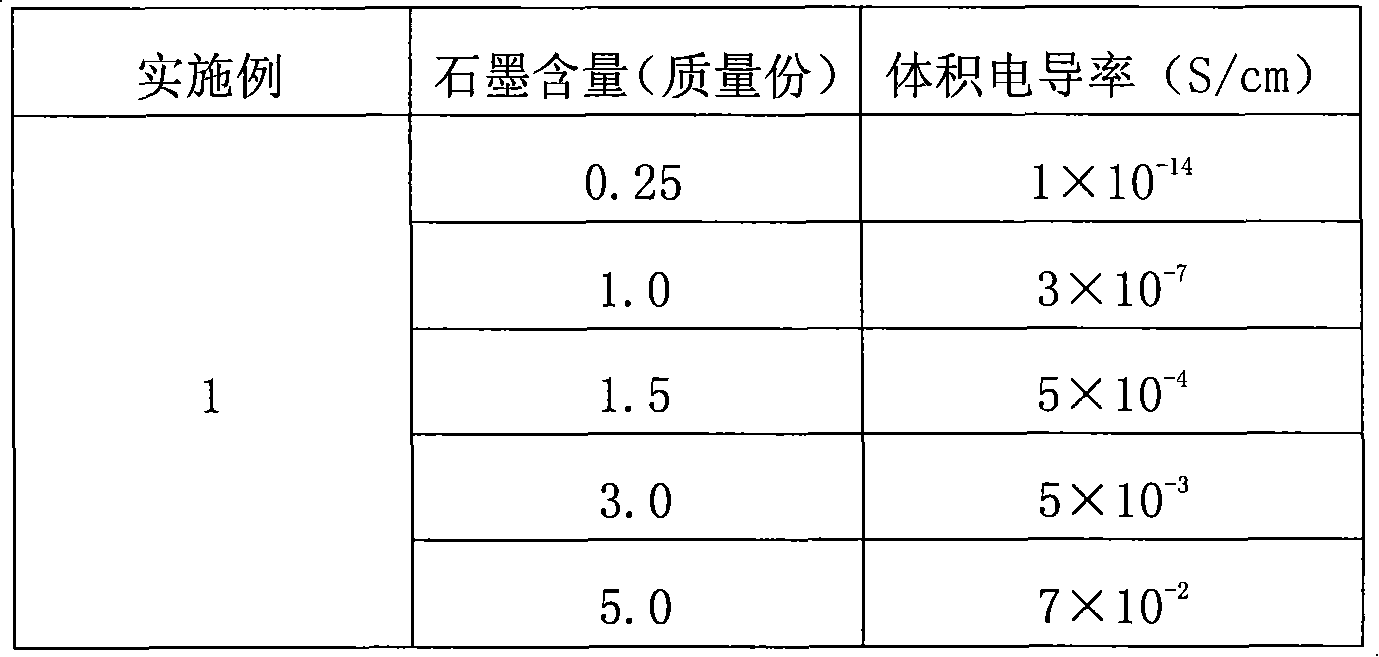

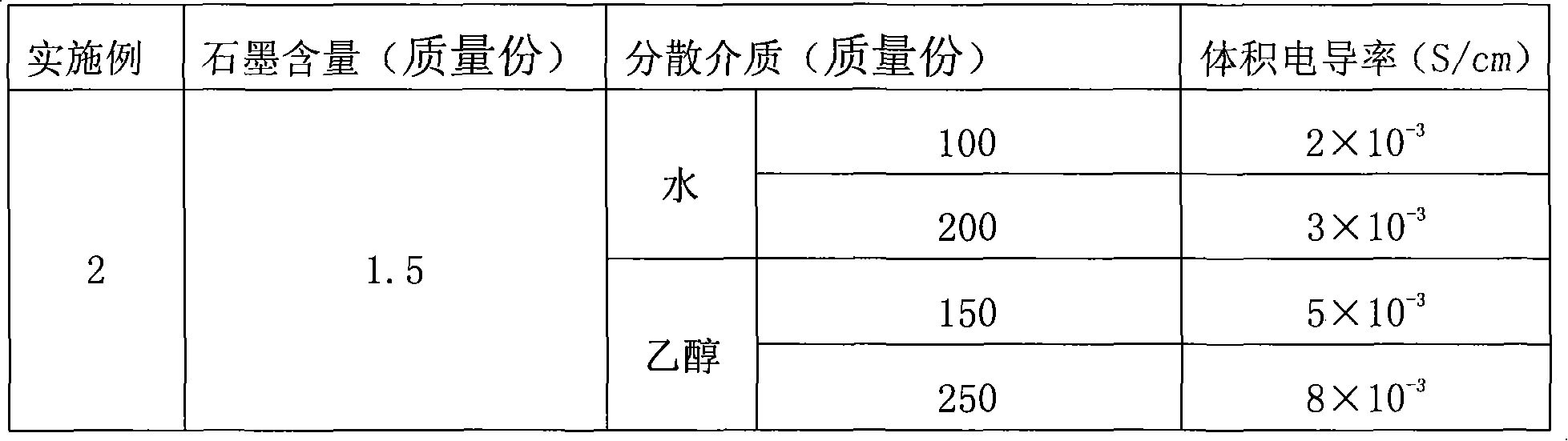

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

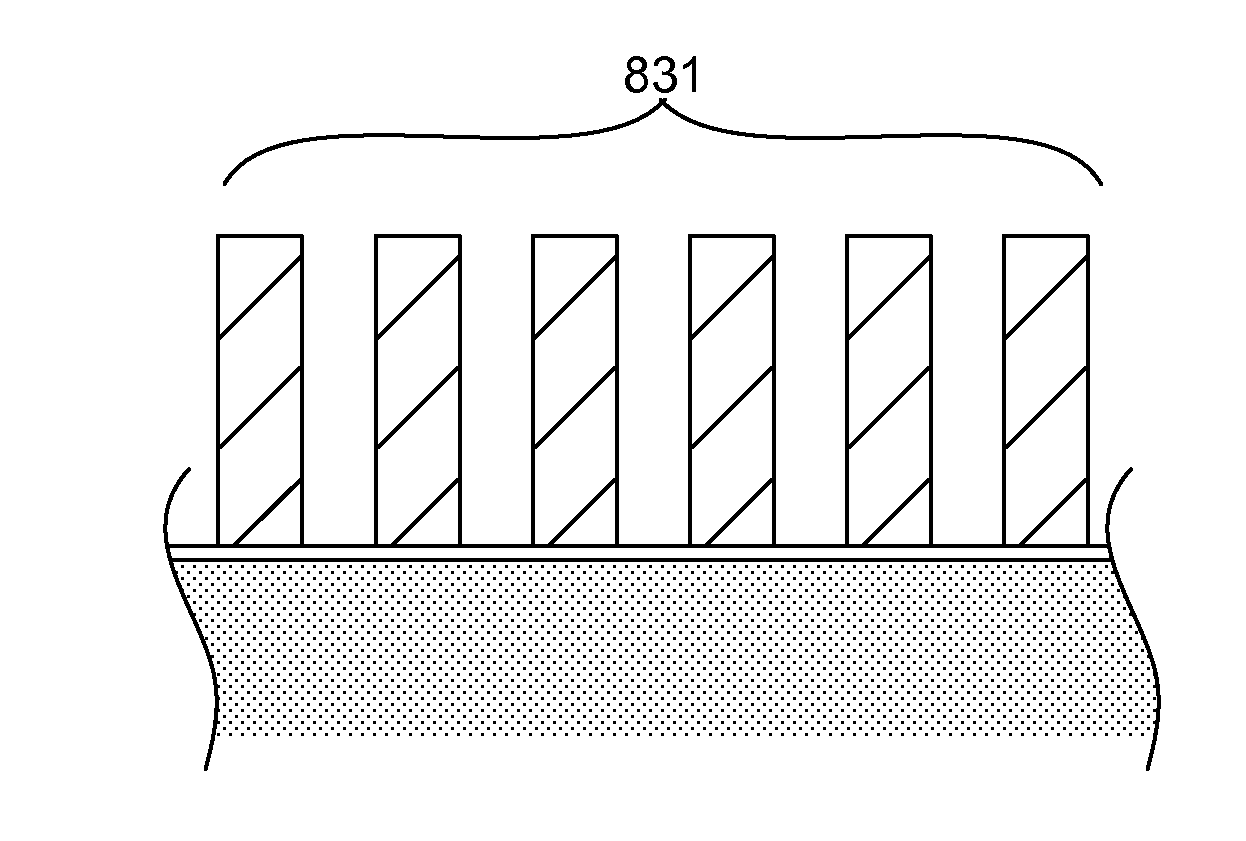

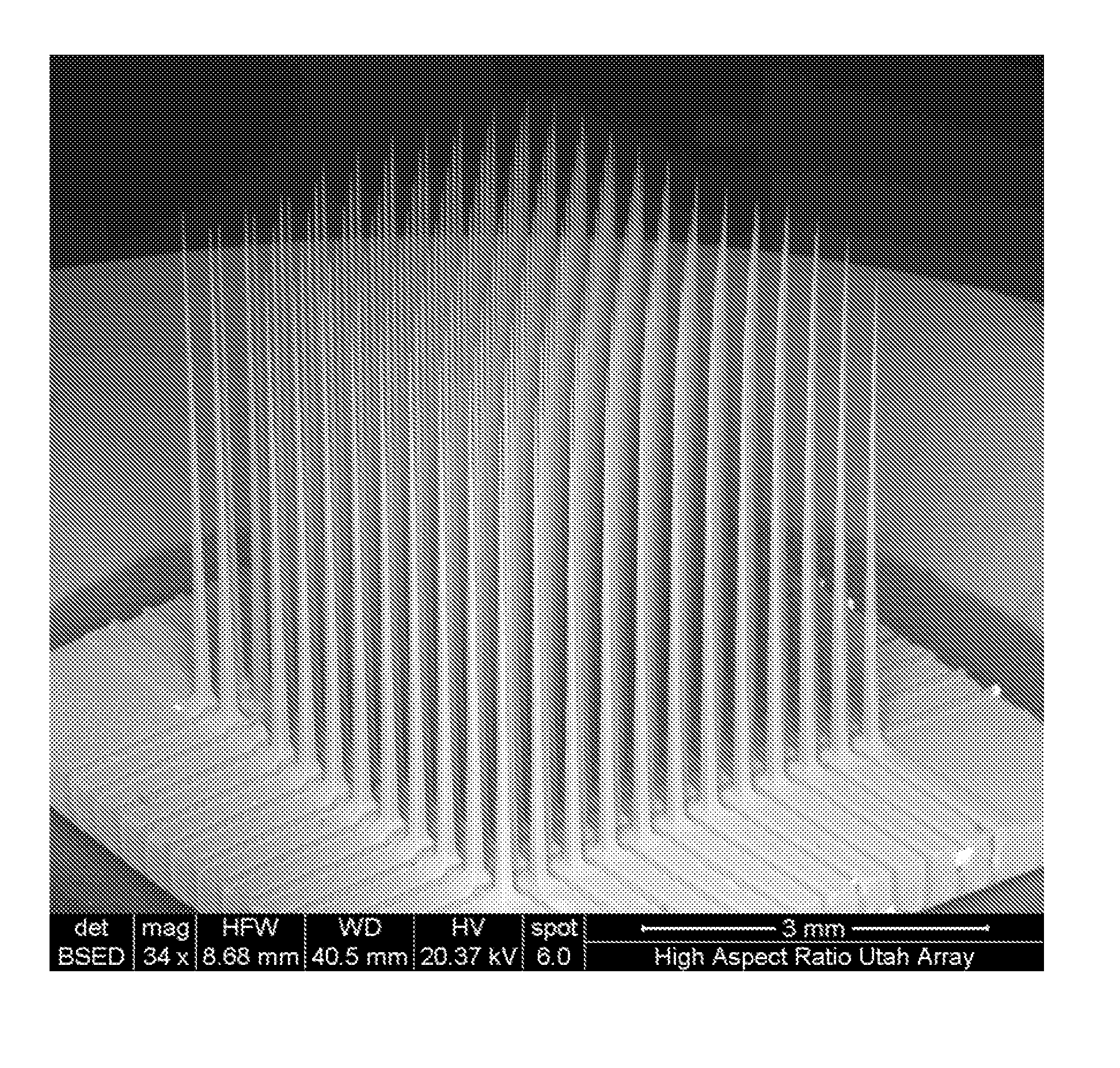

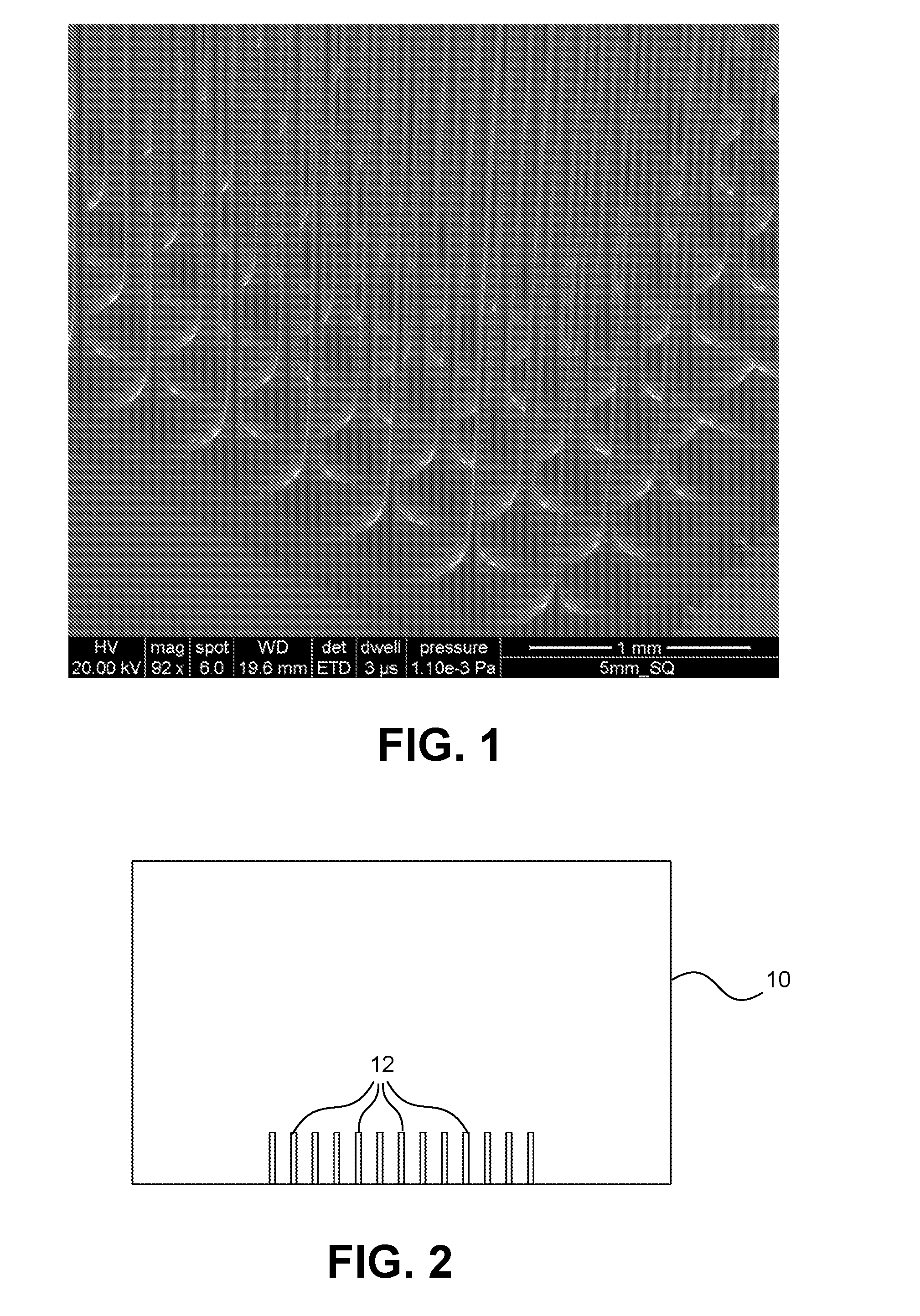

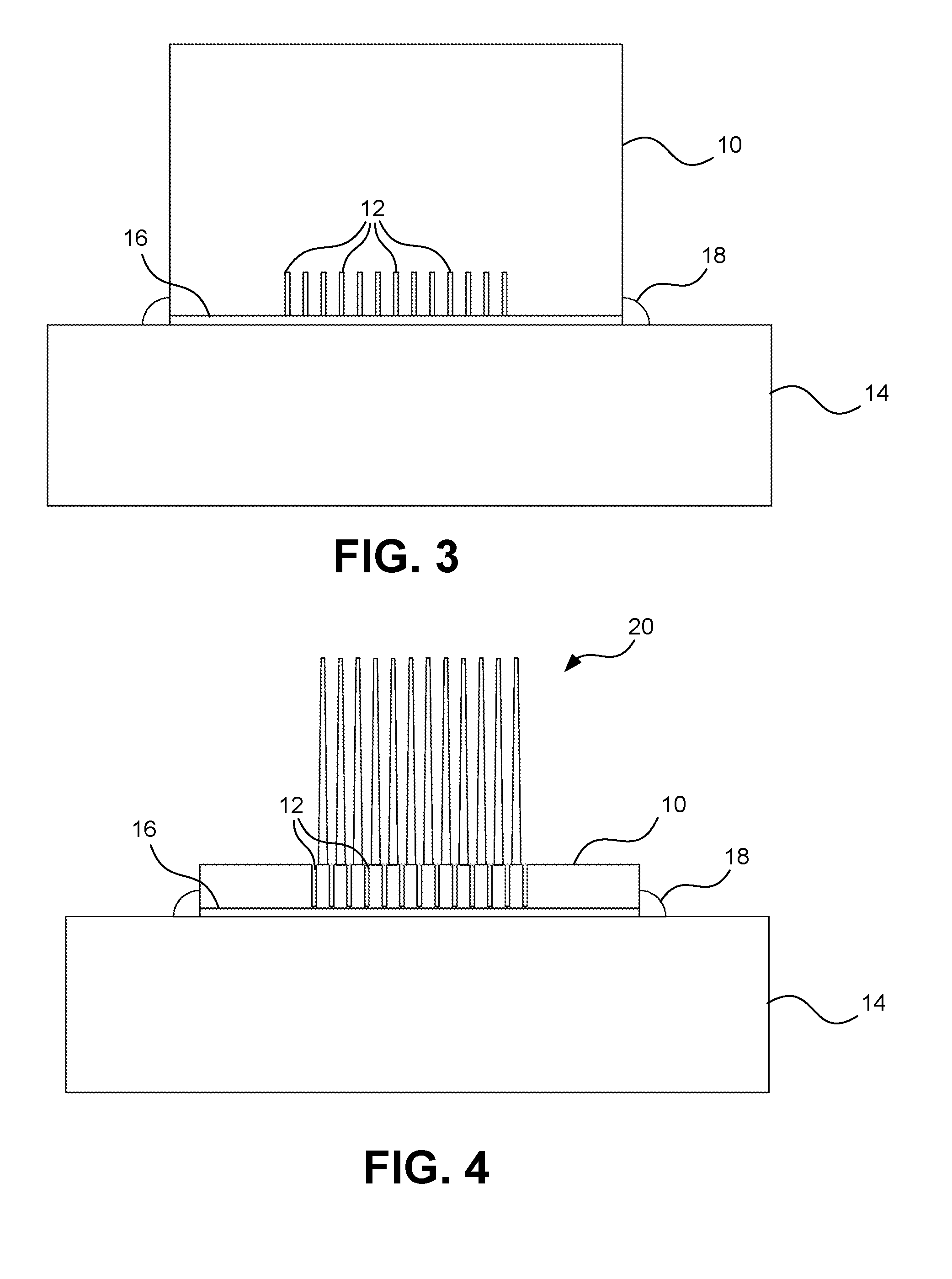

High Aspect Ratio Microelectrode Arrays Enabled to Have Customizable Lengths and Methods of Making the Same

ActiveUS20120138335A1Aspect ratioWiden the optionsElectrolysis componentsHead electrodesEngineeringMicroelectrode

A method of fabricating an array of micro electrodes enabled to have customizable lengths. A substantially criss-cross pattern of channels on a top surface of the work-piece substrate (10) is formed using electrical discharge machining to form a plurality of shaped columns (20) having tapered profiles. The shaped columns have a tapering profile which extends at least 50% of the length of the columns. The plurality of shaped columns is etched to sharpen the tapered tips into needle tips forming the array of microelectrodes.

Owner:UNIV OF UTAH RES FOUND

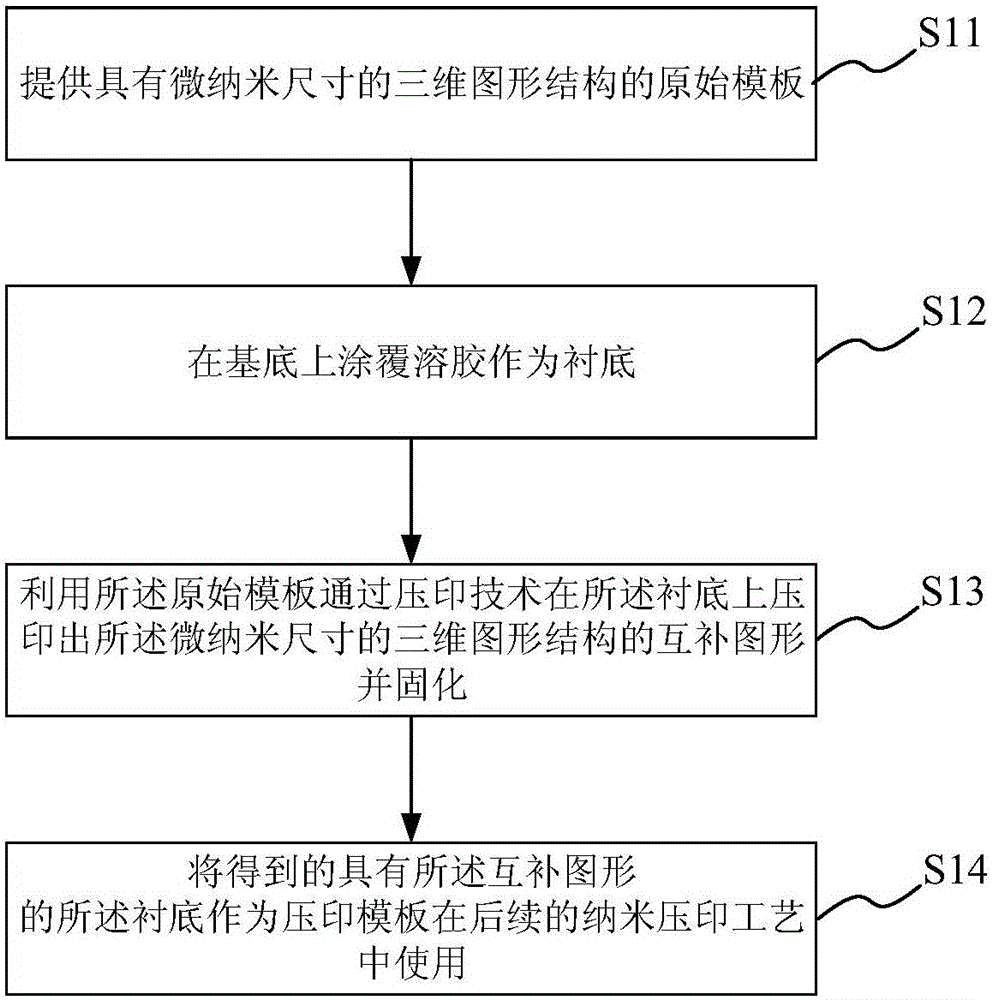

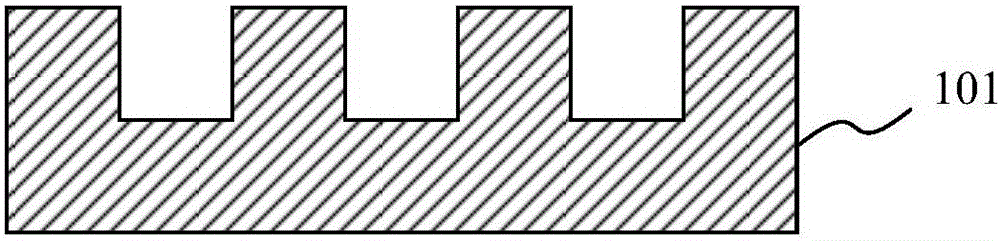

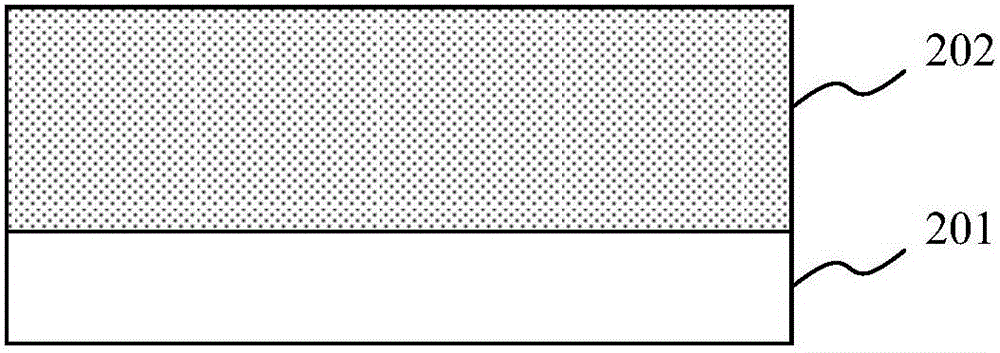

Preparing method for nanoimprint template

InactiveCN105824190AGood repeatabilityFast preparationPhotomechanical apparatusMicro nanoRepeatability

The invention provides a preparing method for a nanoimprint template .The method includes the following steps that a micro-nano original template of a three-dimensional graph structure is provided; a base is coated with sol to serve as a substrate; a complementary graph of the micro-nano three-dimensional graph structure is imprinted on the substrate with the original template through an imprinting technology; the obtained substrate with the complementary graph is used as the template in the follow-up nanoimprint process .The preparing method for the nanoimprint template is high in repeatability, capable of preparing the inorganic template fast at low cost on a large scale and capable of being used in the processes of ultraviolet imprinting and thermal imprinting, the prepared template is high in mechanical strength and reutilization, conformality in the follow-up imprinting process is good, a base material with a higher depth ratio can be obtained by using the template as a mask plate after etching, and the problem that the structure is shallow after etching when photoresist serves as the mask plate can be solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

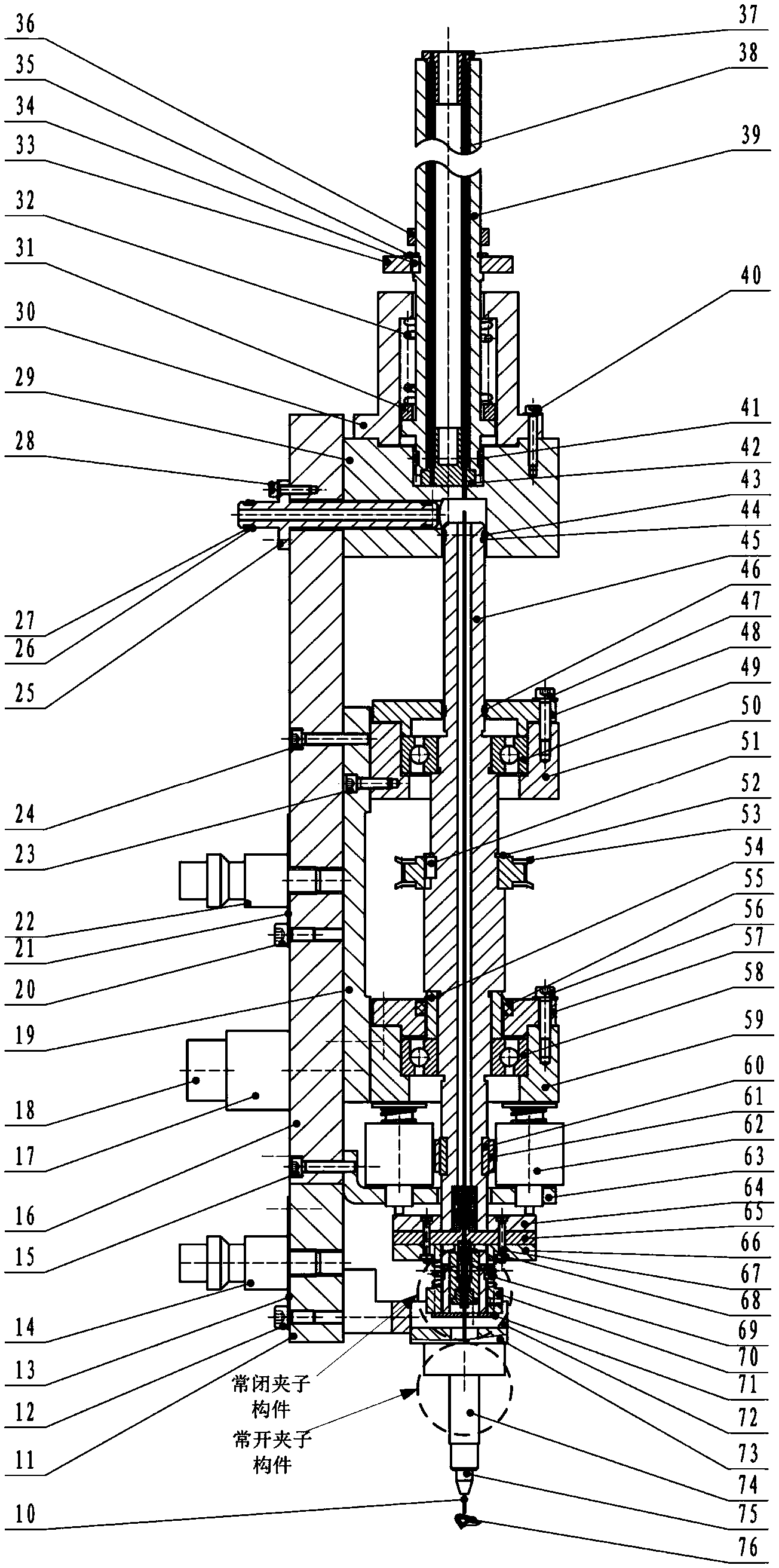

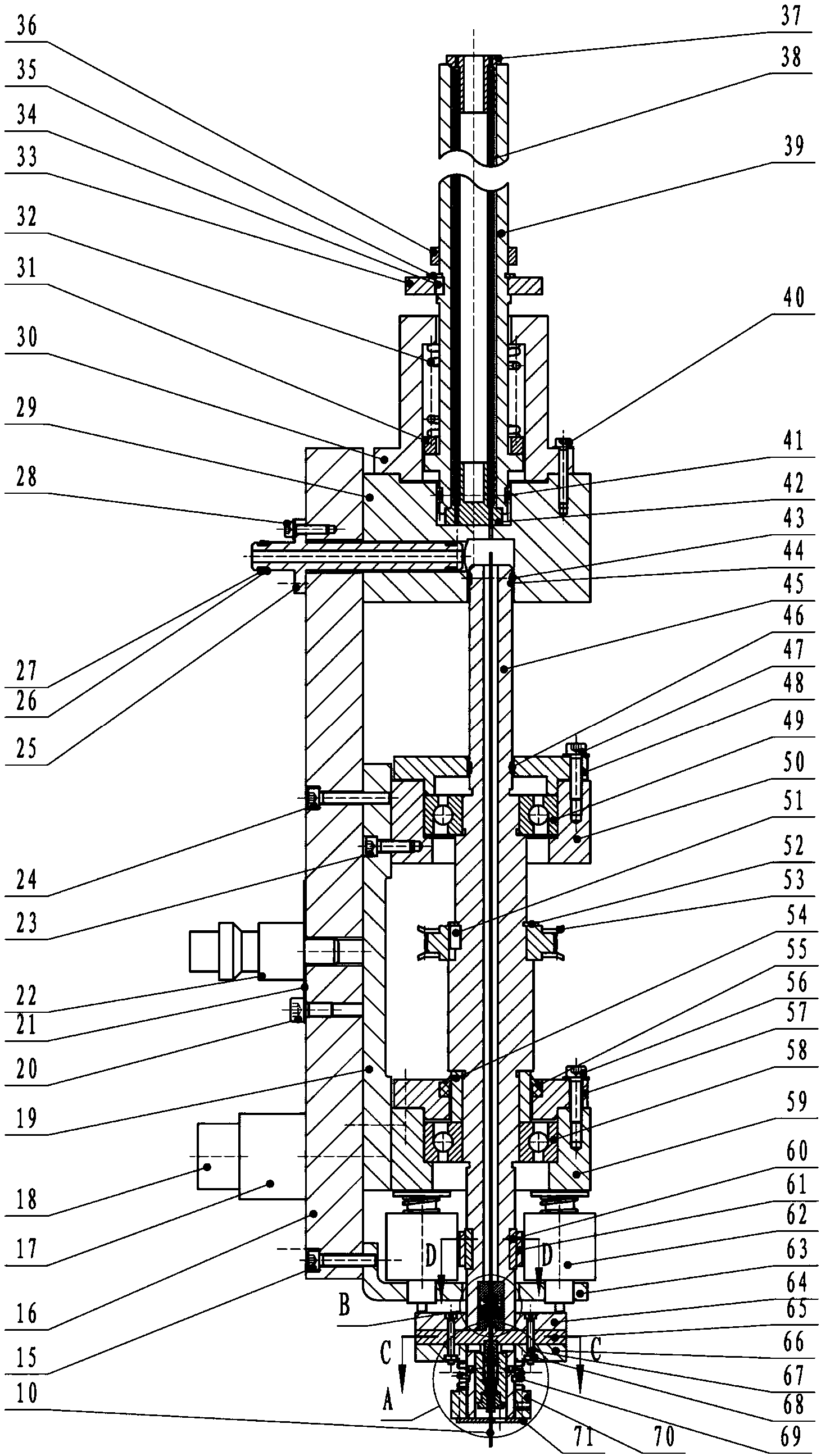

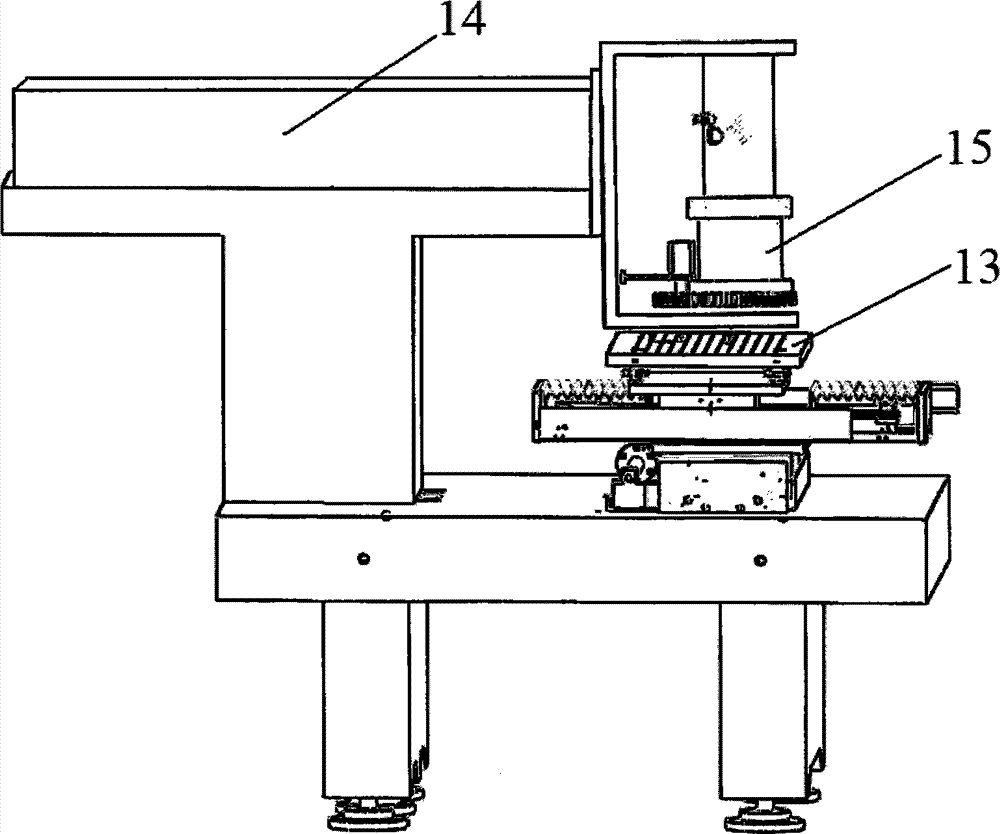

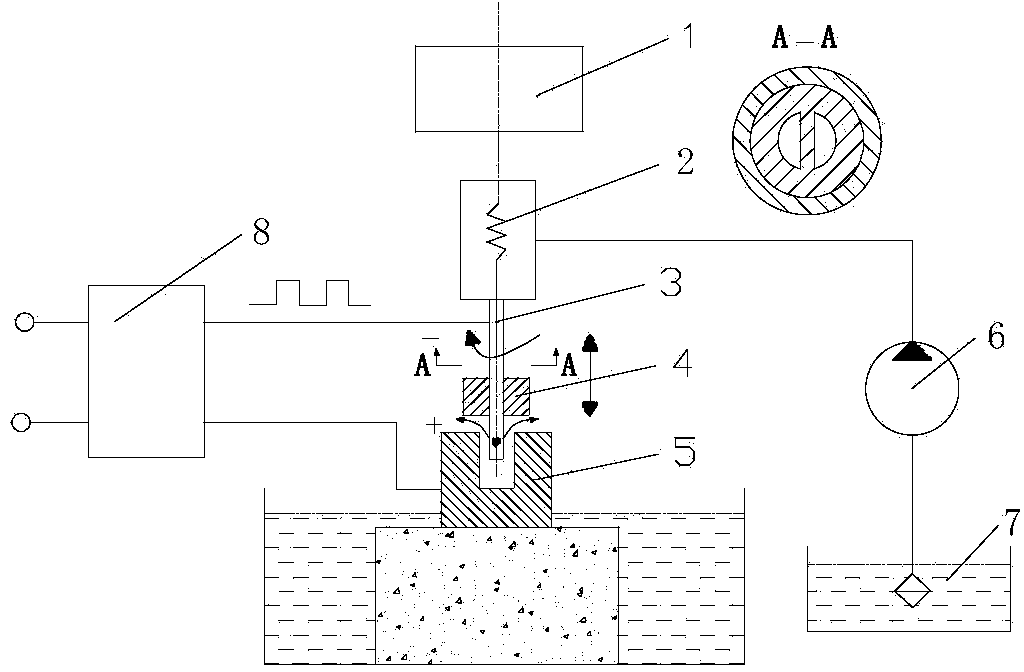

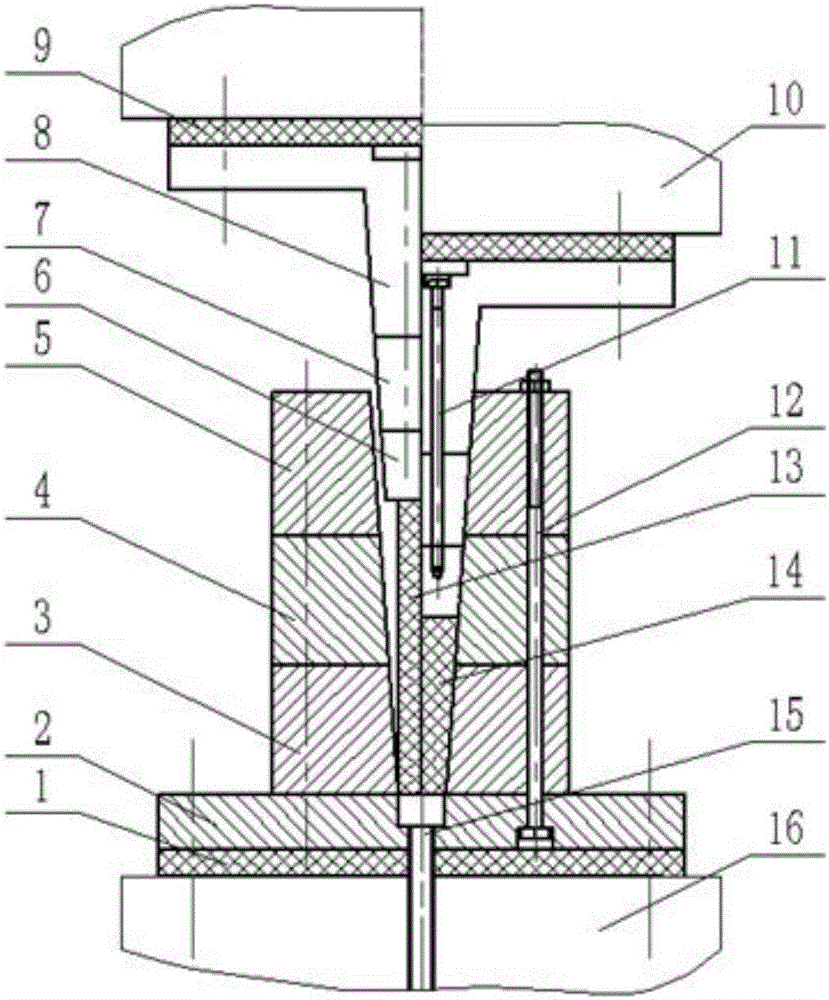

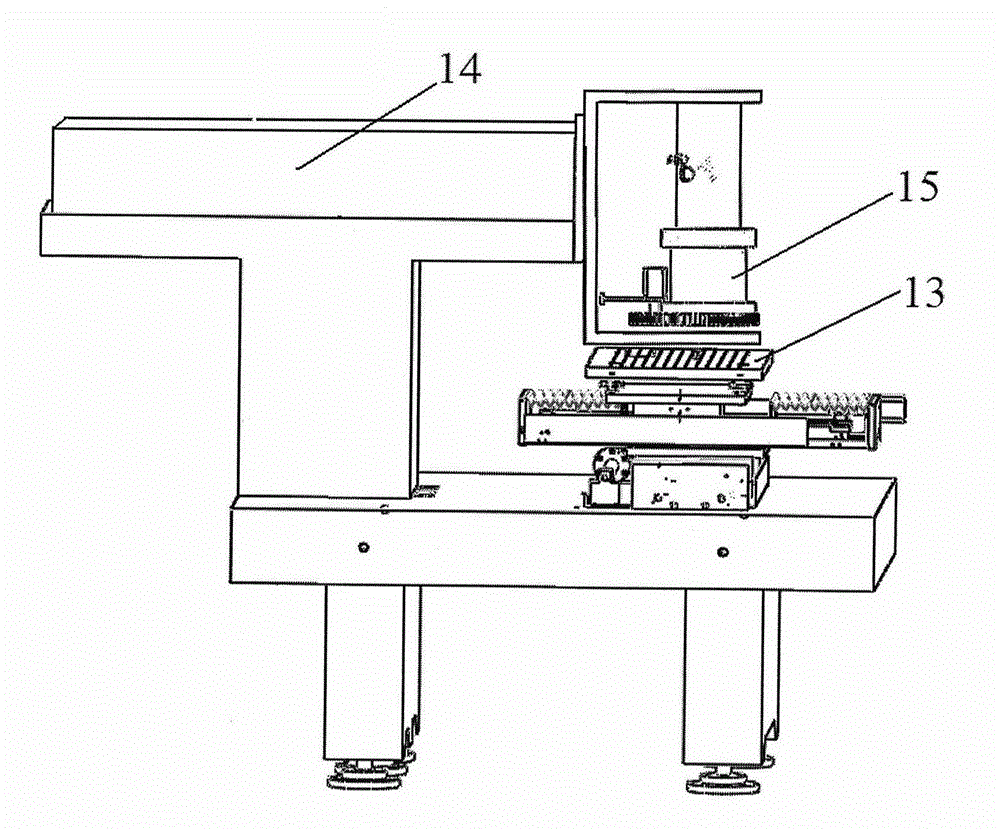

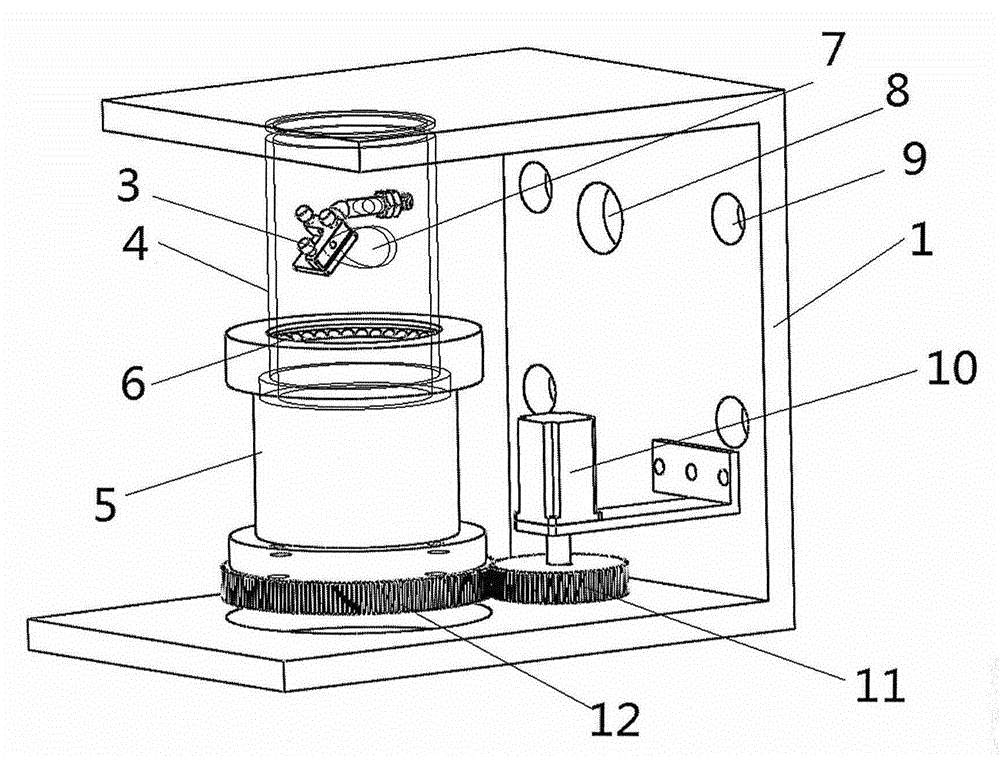

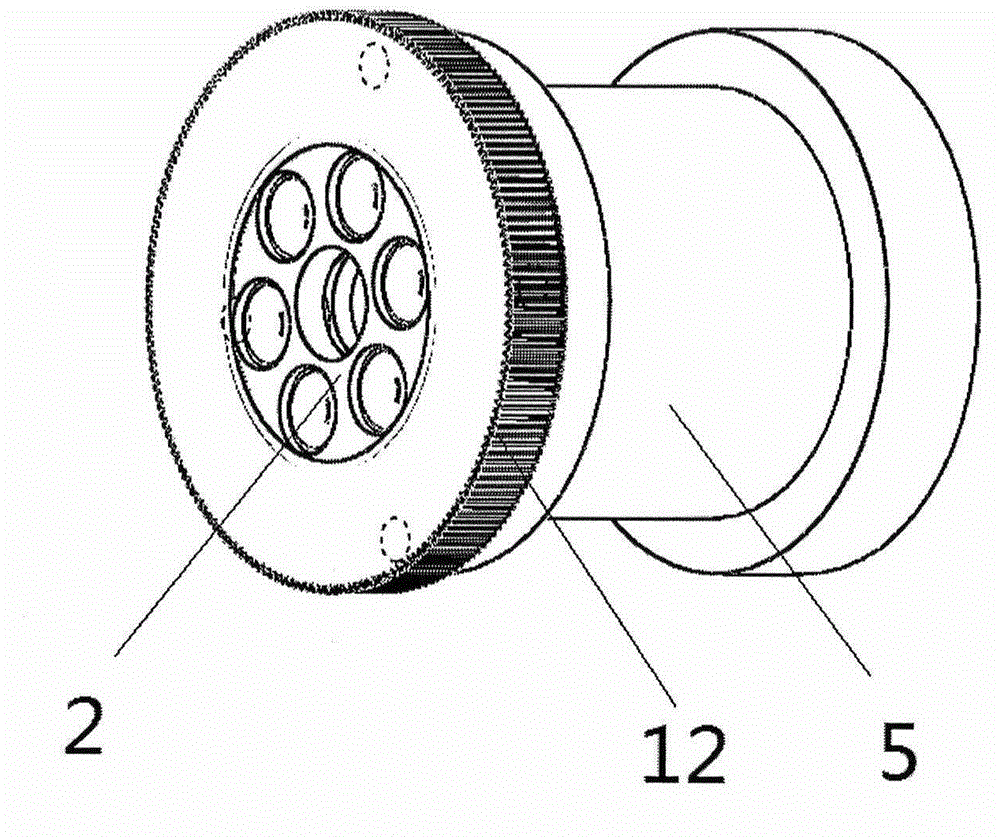

Multi-functional spindle mechanism used for small deep holes electrical discharge machining

InactiveCN103769705AImproved electrode feed stiffness and spindle servo stabilityImproved dimensional accuracy and aspect ratioElectrical-based auxillary apparatusGas turbinesEngineering

The invention discloses a multi-functional spindle mechanism used for the small deep holes electrical discharge machining, belonging to the technical field of micro non-traditional machining. The multi-functional spindle mechanism comprises a rotating spindle mechanism, a transmission mechanism, a normally closed clamp mechanism, a sealing mechanism, an electric brush mechanism, a wire replacing mechanism, a normally opened clamp mechanism, a guide mechanism and a connecting mechanism, wherein the rotating spindle mechanism, the transmission mechanism, the normally closed clamp mechanism, the sealing mechanism, the electric brush mechanism and the wire replacing mechanism are fixedly mounted on an upper mounting plate, and the normally opened clamp mechanism is mounted on a lower mounting plate; the upper mounting plate is connected to the lower mounting plate through the guide mechanism and a degree of freedom of relative movement in the z direction is kept; the upper mounting plate is connected to a z-axis top plate through the connecting mechanism, and the lower mounting plate is connected to a z-axis bottom plate through the connecting mechanism. The mechanism processes the film cooling group holes in the hot components of the aero-engines and the gas turbines, which can realize multiple functions of the forward pushing creep feed, the high precision rotation and the hollow high pressure flushing of the tool electrodes, and the on-line replacement of the electrodes.

Owner:TSINGHUA UNIV

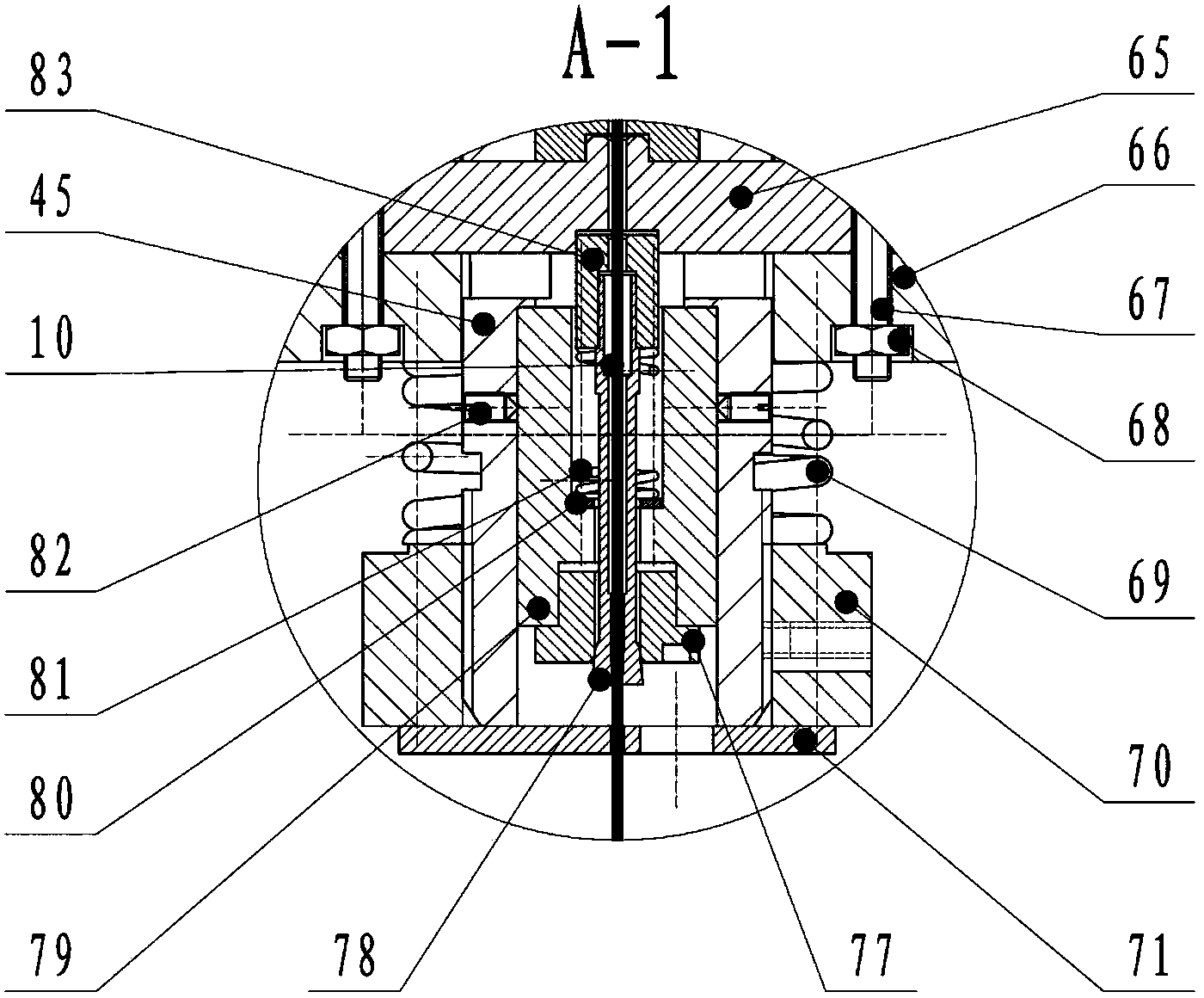

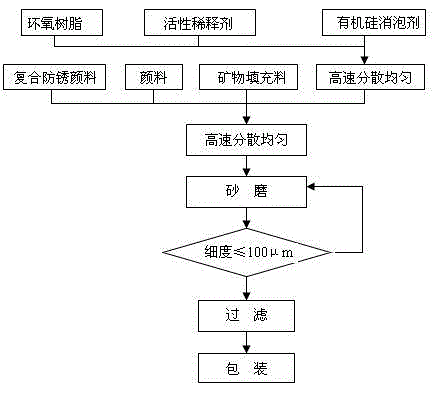

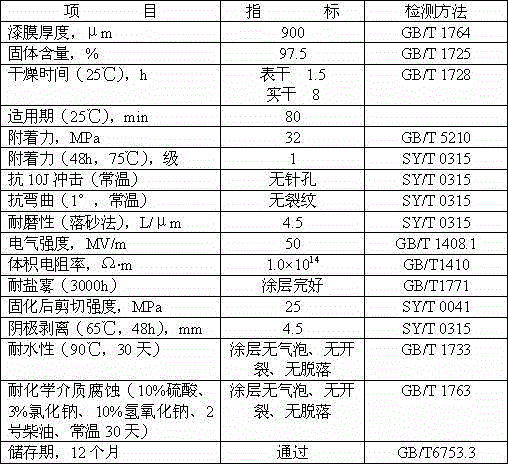

Solvent-free epoxy weight anticorrosion paint used for coated joints of steel buried pipeline

ActiveCN102719171AModerate viscosityEasy constructionAnti-corrosive paintsEpoxy resin coatingsSolvent freePolyamide

The invention introduces a solvent-free epoxy weight anticorrosion paint used for coated joints of a steel buried pipeline, which comprises a component A and a component B; wherein the mass percentage of each raw material in the component A comprises: 30-45% of epoxy resin, 5-15% of glycidyl ether active diluent, 0.05%-1% of silicone defoamer, 20-35% of compound anti-rust pigment, 3-10% of other pigments, 5-15% of barium sulfate mineral filler, 10-20% of other mineral fillers and 0.3-1.5% of polyamide wax; the mass part of each raw material in the component B comprises: 10-25 parts of polyamide curing agent, 5-15 parts of Mannich base and 0.5%-2 parts of curing accelerator; and the mass ratio of the component A to the component B is 100 to 15-35. The paint provided by the present invention has the advantages of pure epoxy, environmental friendly performance and saved resource due to solvent-free property; and is capable of raising the anti-corrosive property, chemical resistance property and insulating property; and is capable of raising the toughness resistance, wear resistance and impact resistance of the coating by employing the mineral fillers.

Owner:XIAMEN SUNRUI SHIP COATING

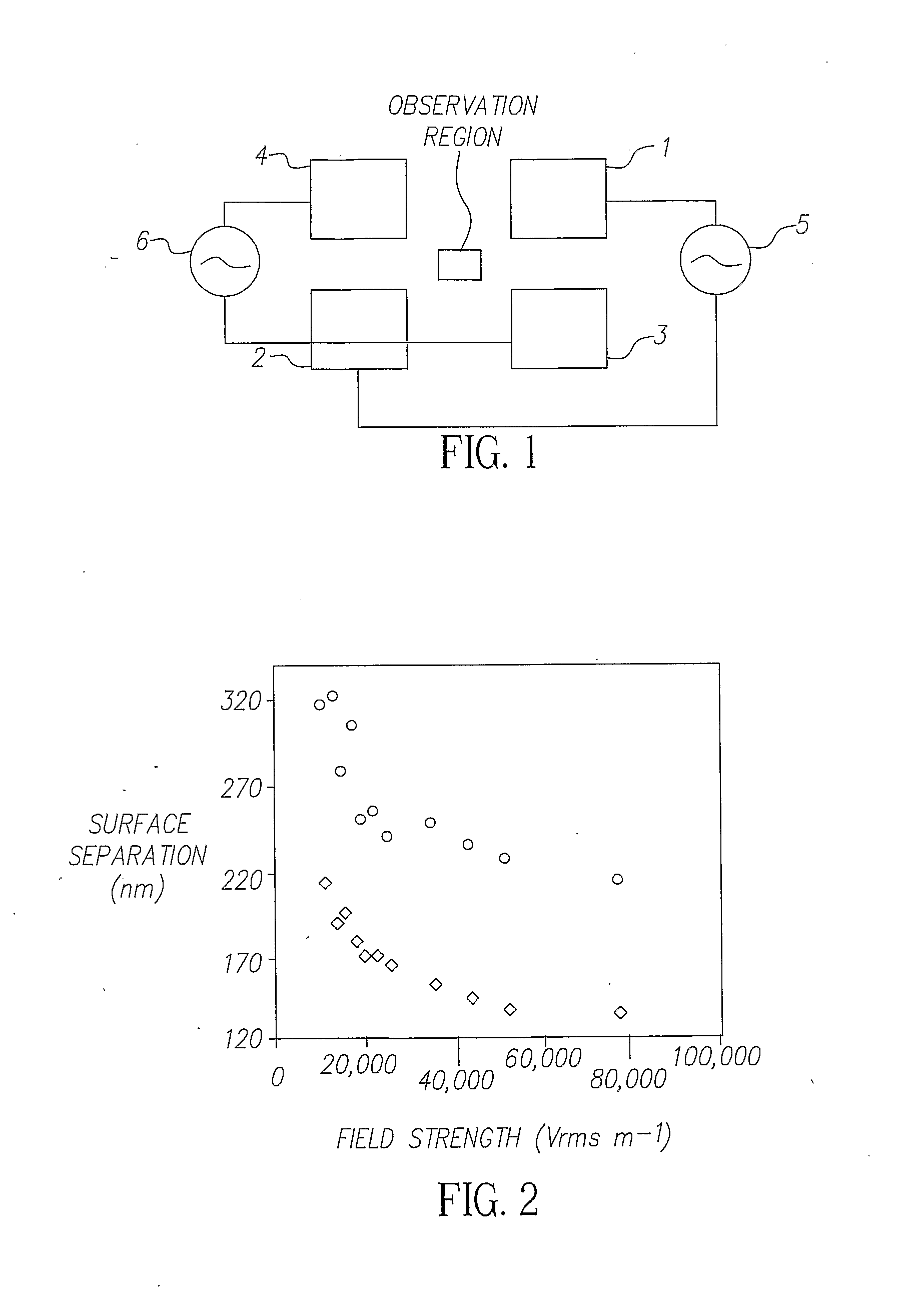

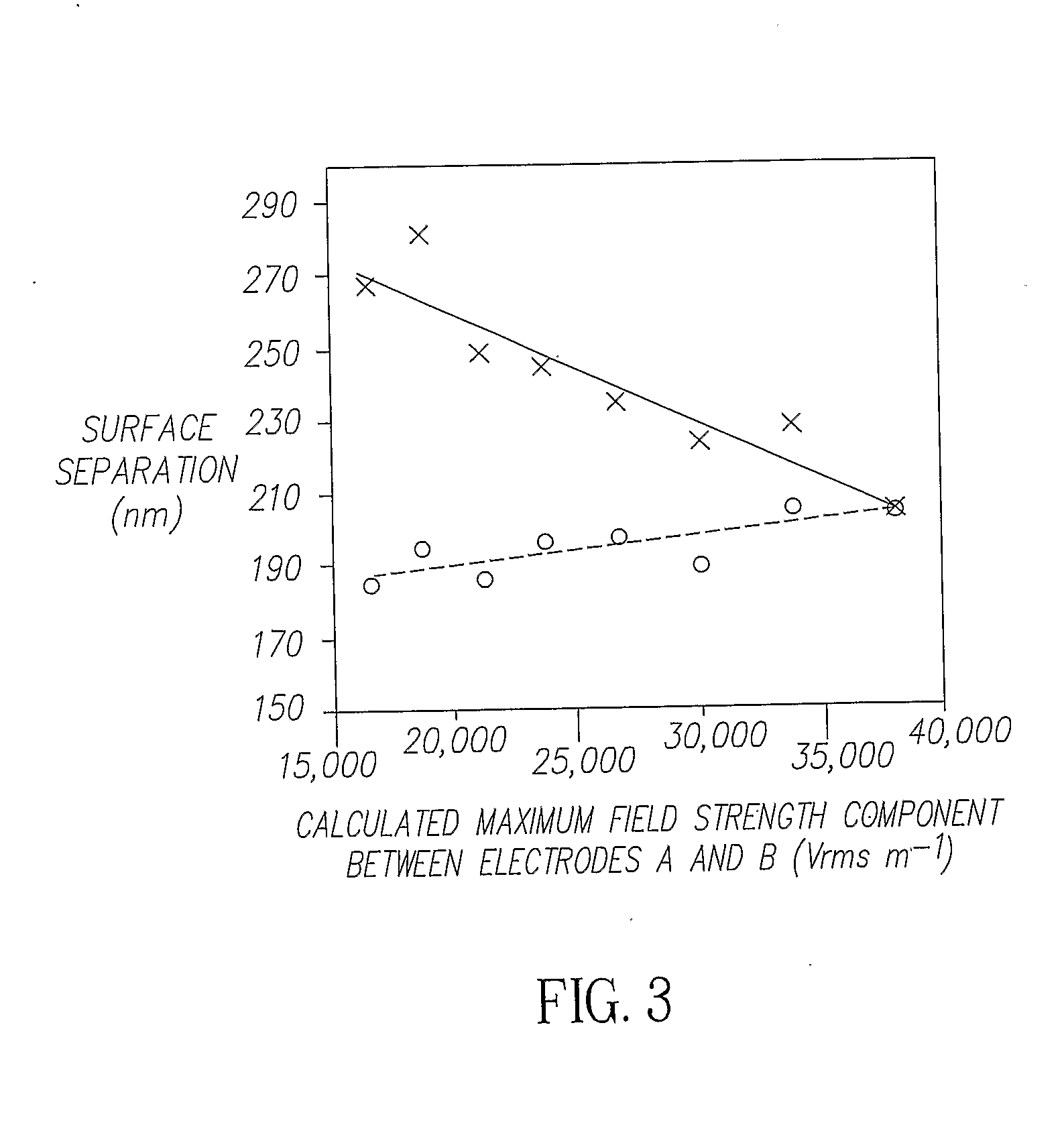

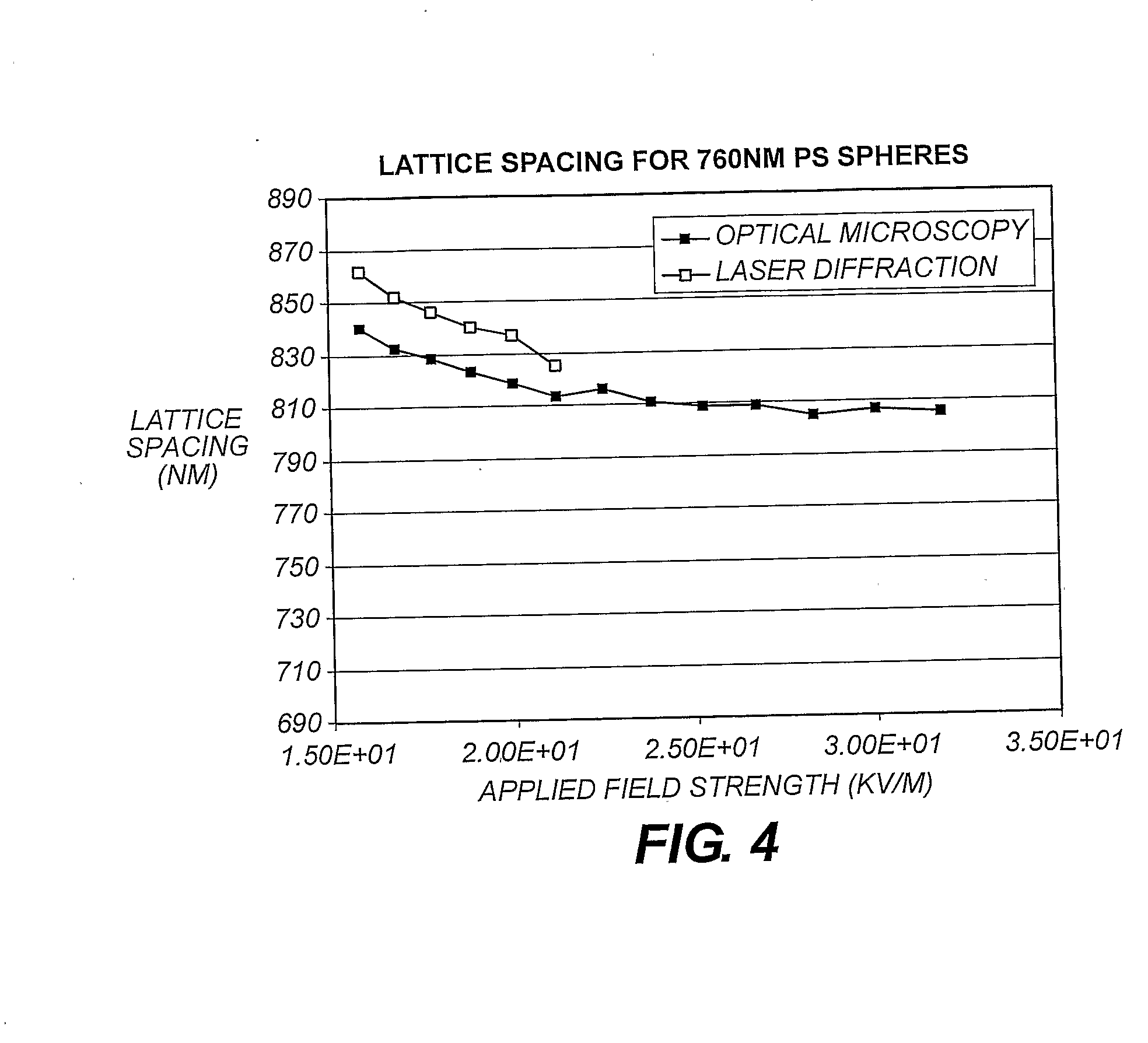

Control of Lattice Spacing Within Crystals

InactiveUS20080230752A1Accurate and reversible and dynamic positioningAspect ratioOptical filtersNanoopticsCondensed matter physicsElectric field

A method of creating and controlling the particle spacing of a regular lattice of monodisperse particles or a mixture of monodisperse particles by using an electric field.

Owner:EASTMAN KODAK CO

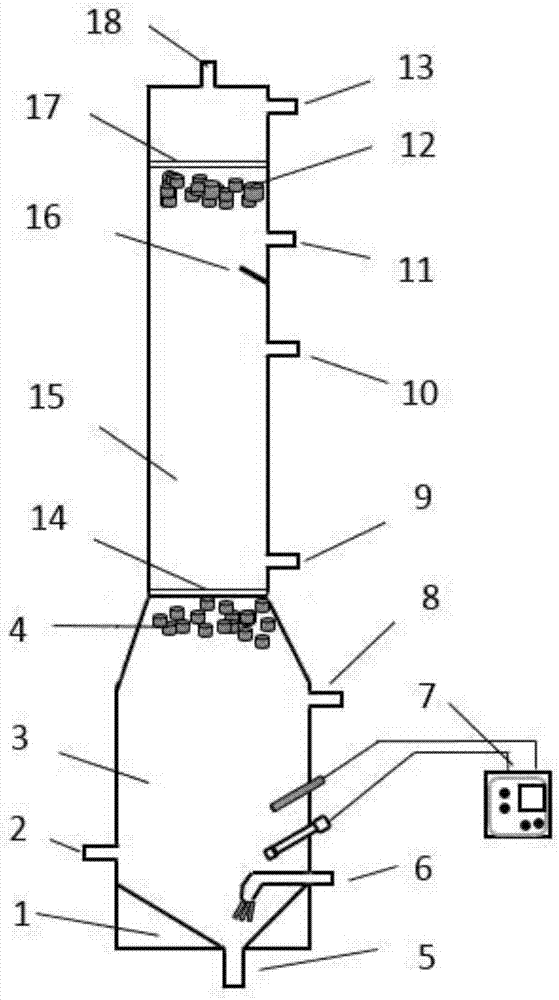

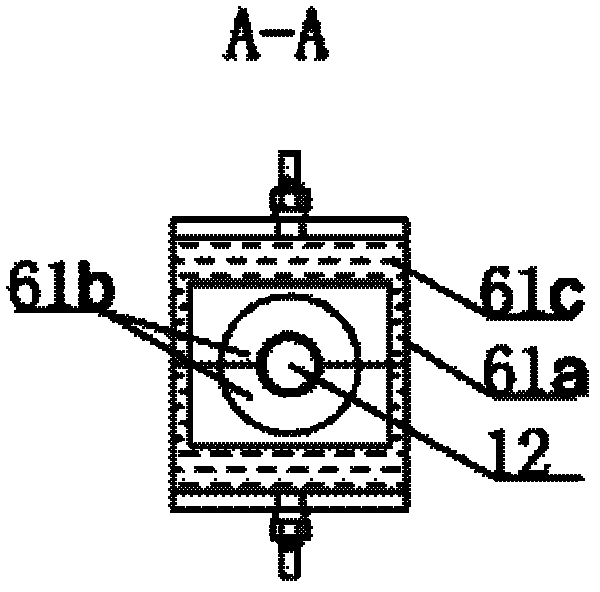

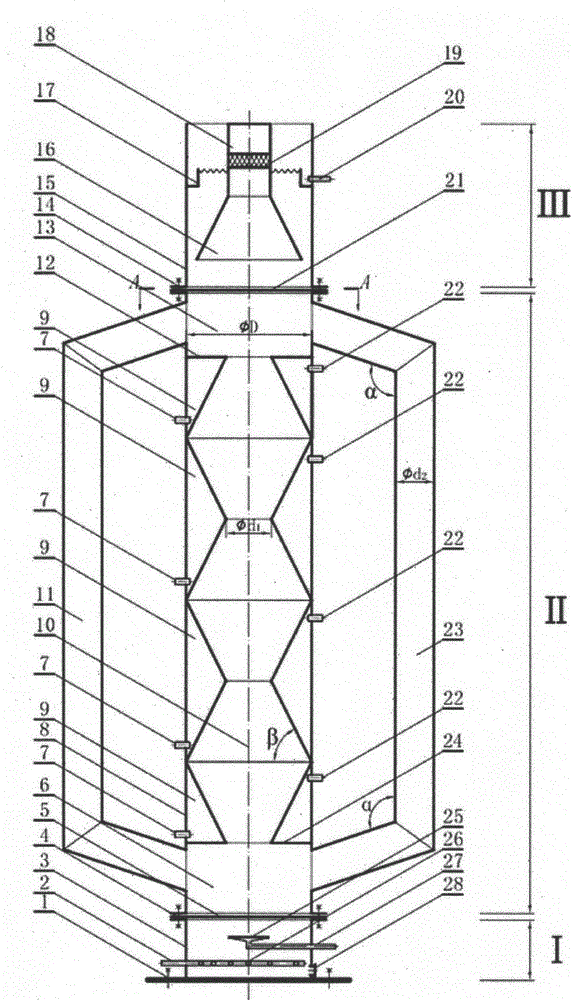

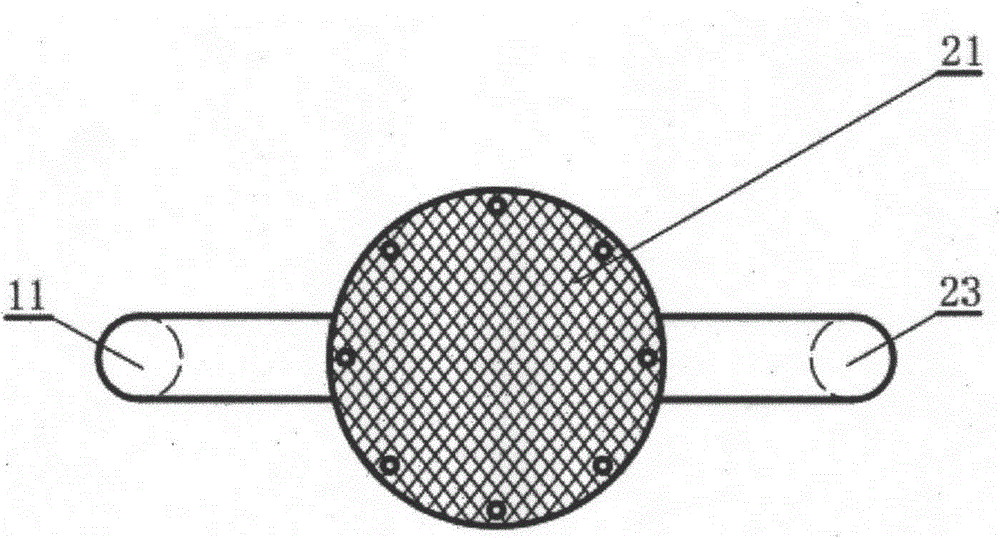

Integral two-stage type anaerobic ammoxidation coupling denitrification denitriding decarbonizing device and operation control method thereof

ActiveCN107399811AAvoid incomplete treatmentFully degradedWater treatment parameter controlWater treatment compoundsWater dischargeInstability

The invention relates to an integral two-stage type anaerobic ammoxidation coupling denitrification denitriding decarbonizing device and an operation control method thereof. A device body mainly consists of an anaerobic ammoxidation coupling denitrification reaction chamber and an anaerobic ammoxidation reaction chamber; the top of each of the two reaction chambers is provided with a filling layer and a reticular baffle plate with holes; the side wall of the body is sequentially provided with a water distributor, a mud discharging opening, a determining instrument, a sample taking opening, a mud inlet, a backflow opening, an inclined backflow cutoff preventing baffle plate, a water discharging pipe and an exhaust pipe from bottom to top. The ammonia nitrogen concentration range is controlled to be 160 to 360mg / L; the ratio of ammonia nitrogen to nitrite nitrogen is 1:(0.5 to 0.8); functional bacterial flora can be domesticated and cultured in the reaction chambers with different height-diameter ratio in the staged way; the major bacterial flora in the anaerobic ammoxidation coupling denitrification reaction chamber are anaerobic ammoxidation bacteria and denitrification bacteria, and the auxiliary bacterial flora are ammoxidation bacteria; the major bacterial flora in the anaerobic ammoxidation reaction chamber are anaerobic ammoxidation bacteria; through the longitudinal distribution characteristics of the bacterial flora and the control of the backflow ratio, the defects of low impact resistance load and operation instability of a traditional biological coupling device are overcome.

Owner:CHINA UNIV OF MINING & TECH

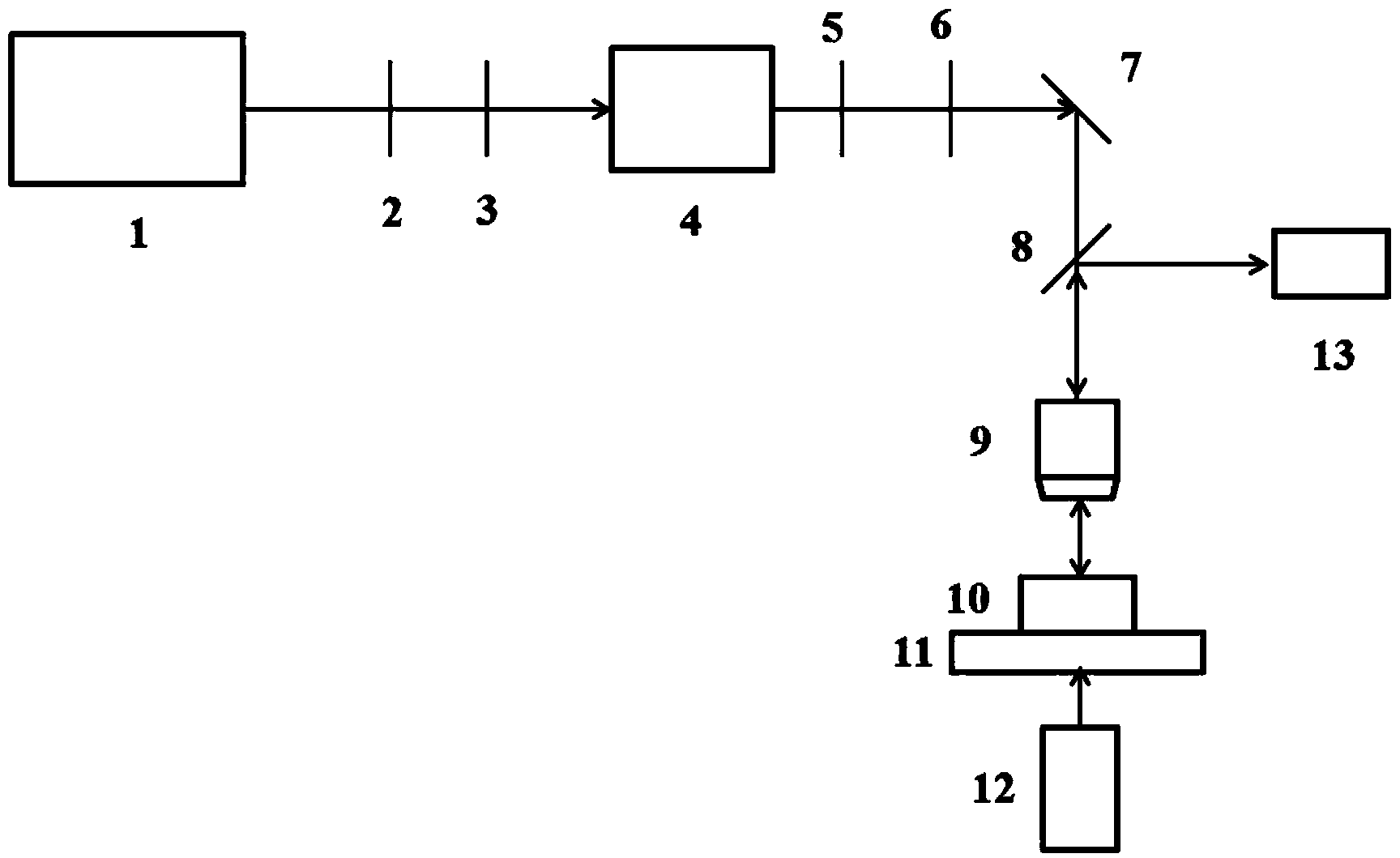

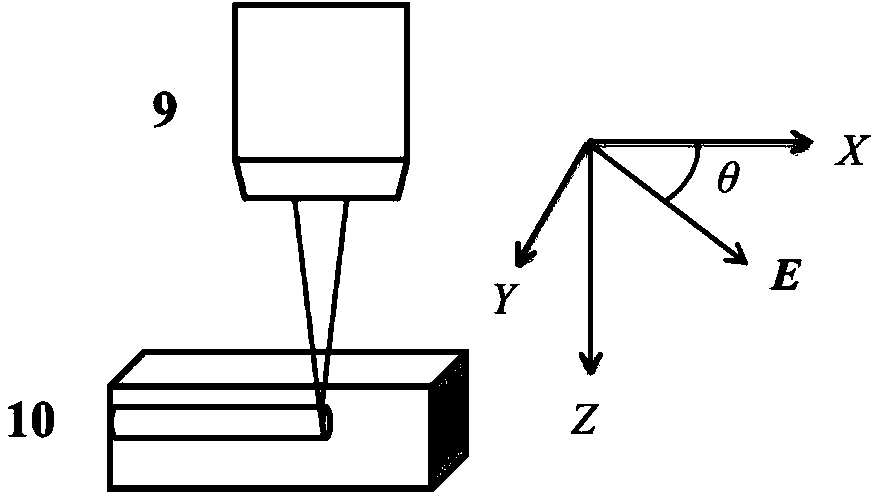

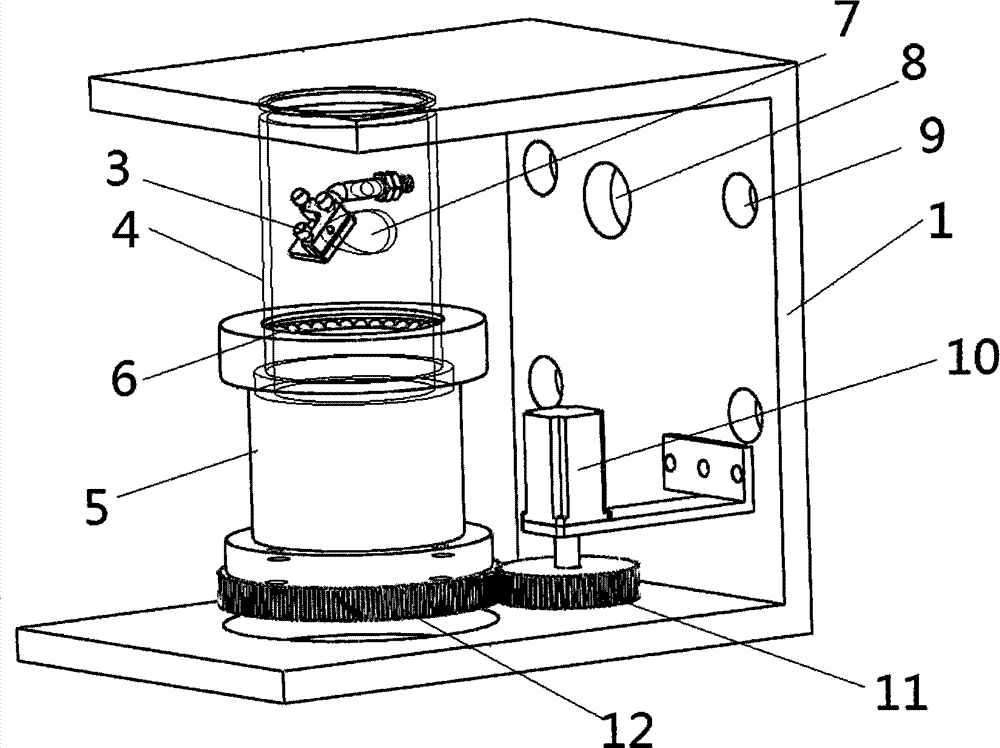

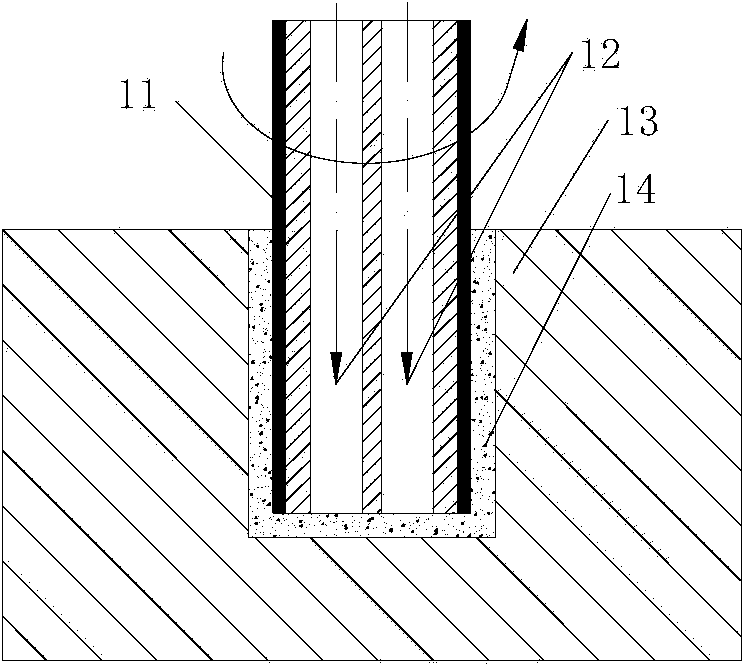

Method and device for precisely machining deep groove and deep hole by varifocal lasers

InactiveCN103878495AEnergy concentrationLarge hole depthLaser beam welding apparatusEngineeringDeep hole

The invention provides a method for precisely machining a deep groove and a deep hole by varifocal lasers. The method comprises the steps that a plurality of focusing lenses with different focal lengths and workpieces are clamped; if deep groove machining is carried out, a laser beam is continuously output; laser etching machining is completed once; if deep hole machining is carried out, N laser pulses are output; the lasers are closed, and a working table moves to the original position; whether machining meets the requirements or not is detected; if machining meets the requirements, machining is finished; if machining does not meet the requirements, a focusing lens base is rotated, the next focusing lens is moved to the position of the current focusing lens, and laser machining is carried out again until machining meets the requirements. The pulse laser beam sequentially penetrates through the focusing lenses with the different focal lengths by rotating the focusing lens base, the focal lengths are progressively changed, the lasers are focused on the new exposed surface in the laser etching or punching process all the time, energy is more concentrated, the punching deep is larger, and the efficiency is higher. The invention provides a device for precisely machining the deep groove and the deep hole by the varifocal lasers at the same time.

Owner:WENZHOU UNIVERSITY +1

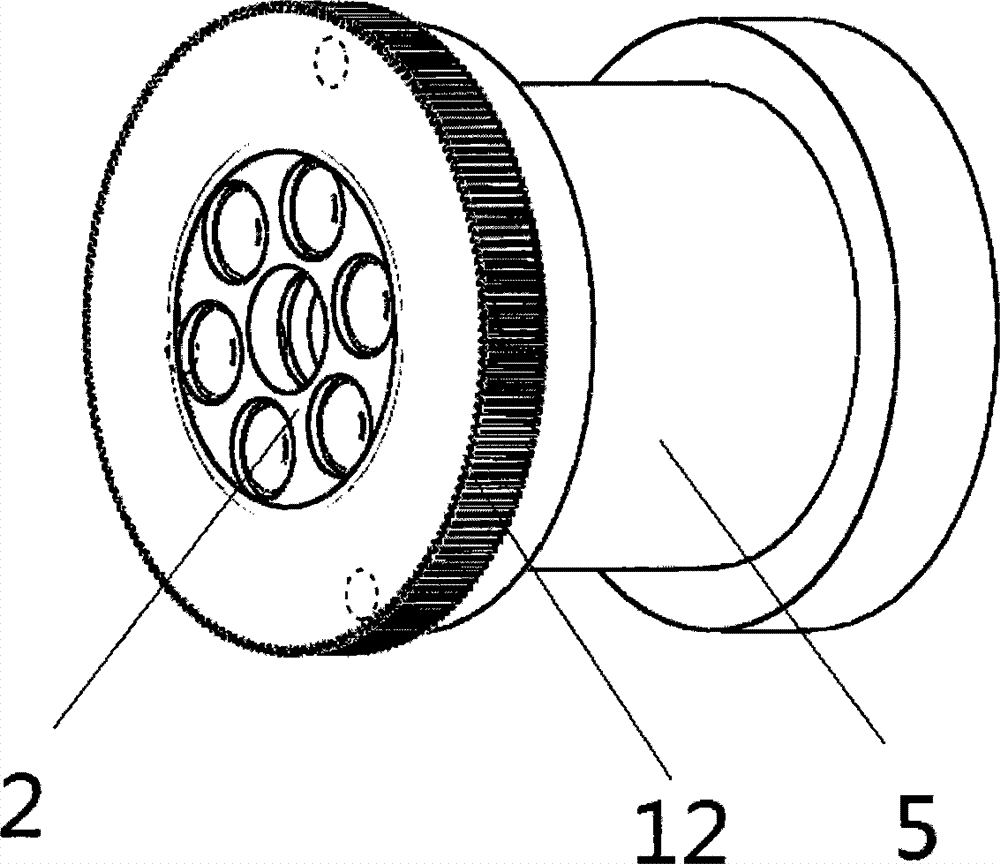

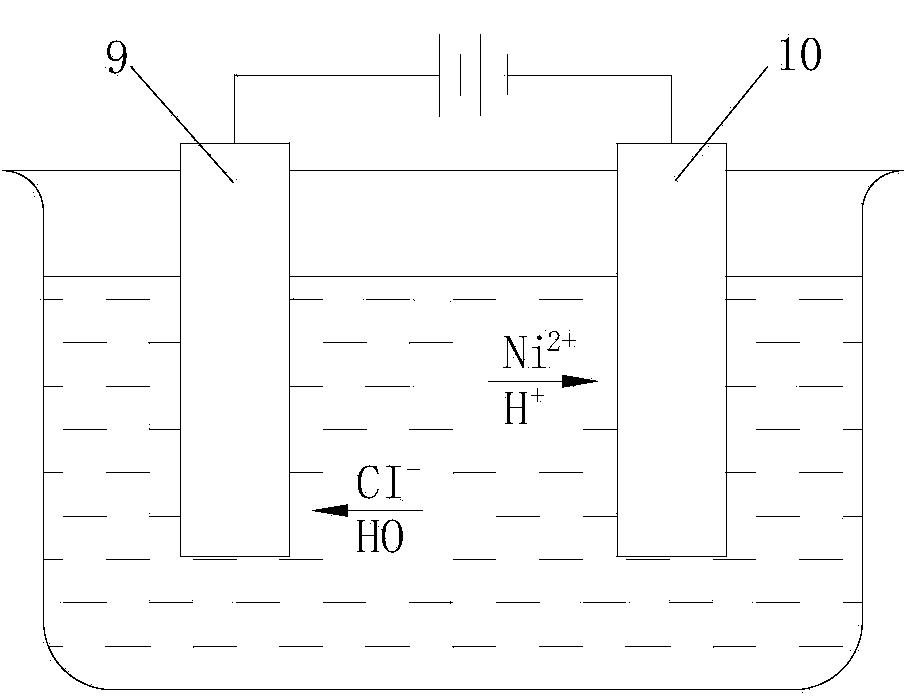

Electric spark small hole machining technology achieved through dispersing agent working solution and brass/nickel electrode

The invention provides an electric spark small hole machining technology achieved through a dispersing agent working solution and a brass / nickel electrode and belongs to the field of non-traditional machining of an advanced manufacturing technology. The technology is characterized in that the water-based working solution and the brass / nickel composite electrode are used for conducting electric spark small hole machining, no improvement on an electric spark small hole machining lathe is needed, it is only required that the outer surface of the water-based dispersing agent working solution is used and the surface of a brass tubular electrode is electroplated with a layer of metal nickel with the melting point higher than that of an internal base material, and therefore the composite electrode is formed; the electroplating technology is mature, a core raw material of the working solution is low in cost, preparation is simple and practical, the technology is economical and easy to achieve, the speed, the depth-to-diameter ratio and the quality for electric spark small hole machining can be improved to a great extent through small investment, and the relative loss rate of a tool is reduced. The electric spark small hole machining speed and the depth-to-diameter ratio are improved, the electrode loss of the tool is reduced, the machining quality is improved, and the technology is wide in application prospect and high in popularization value.

Owner:TAIYUAN UNIV OF TECH

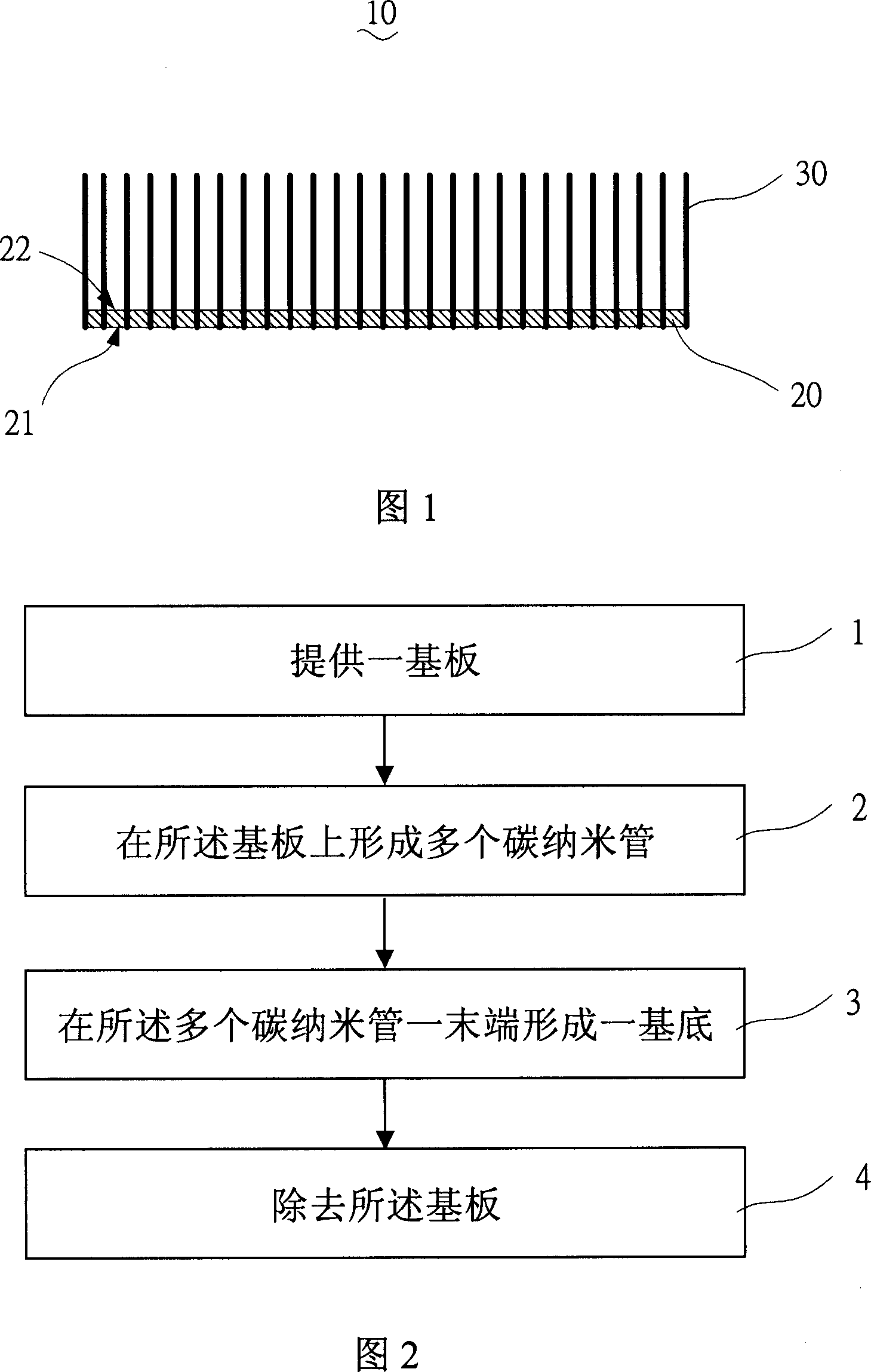

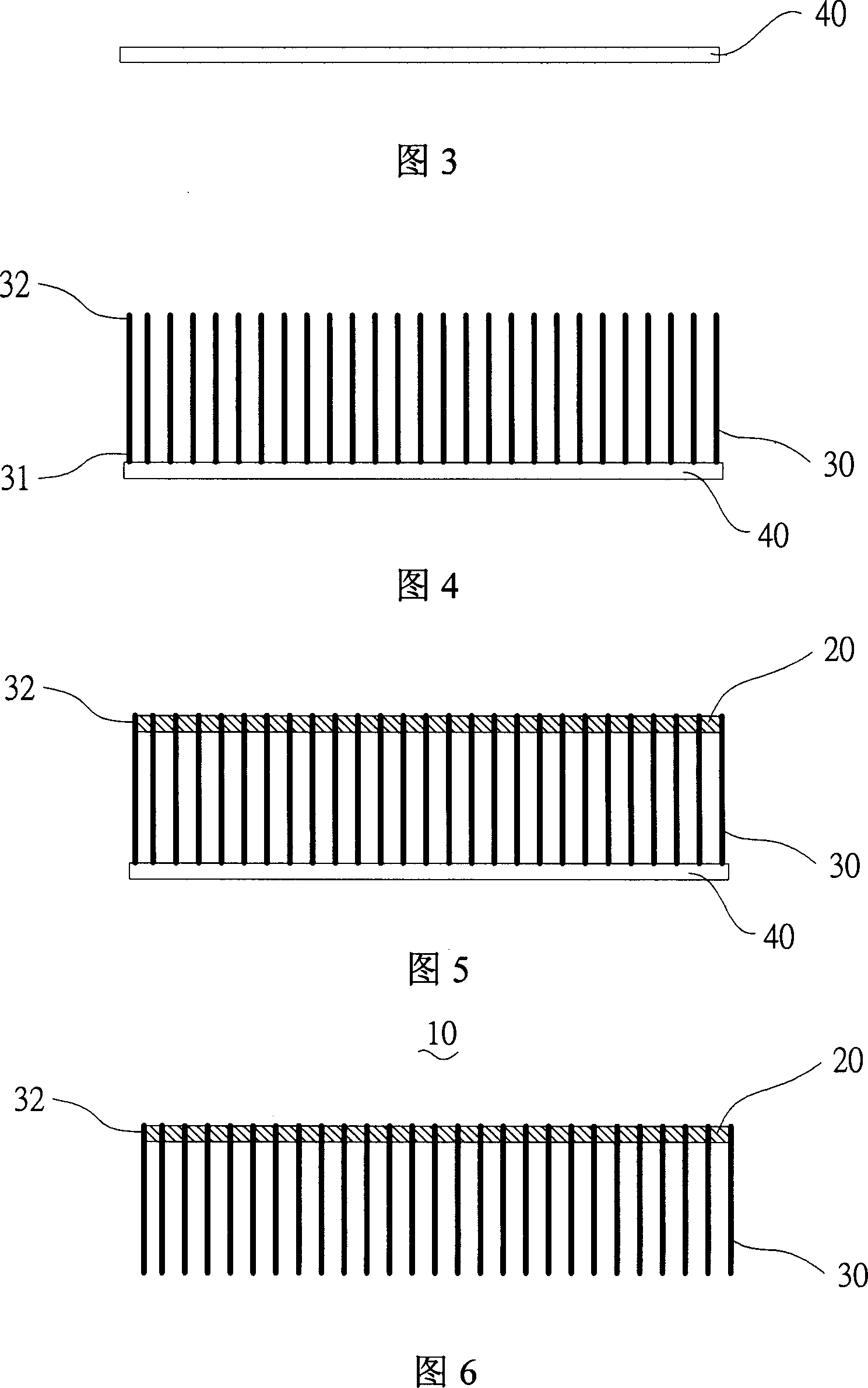

Radiator

InactiveCN1964028AIncrease cooling areaImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeNano carbon

The provided radiator comprises: a substrate with two surfaces, and multiple nano carbon pipes to pass through the second surface from the first one of the substrate outwardly. This invention makes full use of supper performance of nano carbon pipe to have well performance and small size.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

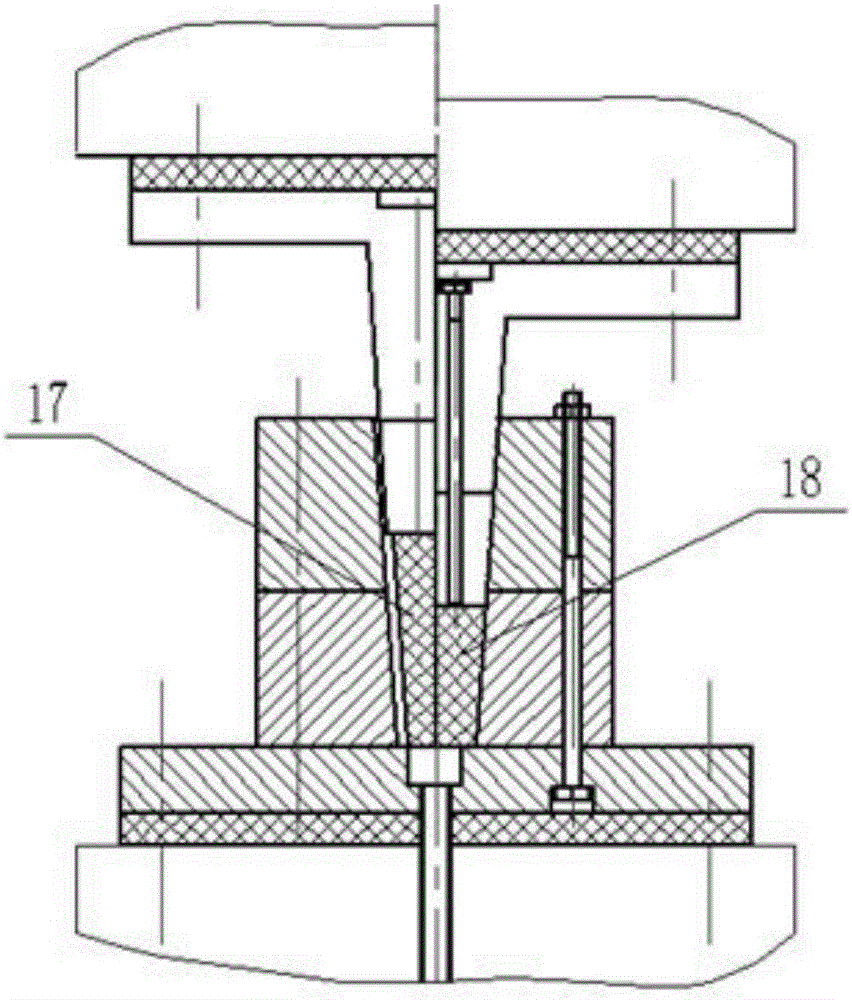

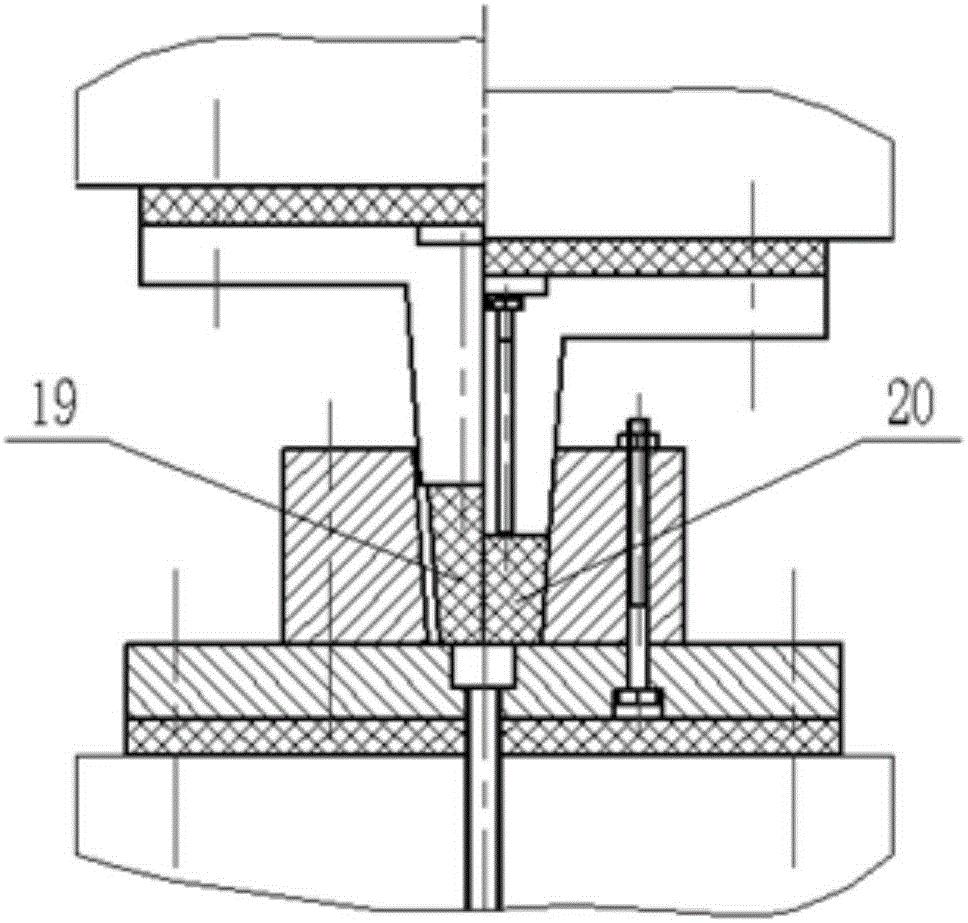

Continuous tapered upsetting die and upsetting method for bar material with superhigh height-diameter ratio

ActiveCN106623718AAspect ratioNo foldingForging/hammering/pressing machinesInstabilityDiameter ratio

The invention discloses a continuous tapered upsetting die and upsetting method for a bar material with the superhigh height-diameter ratio. The method comprises the steps that 1, the height of the bar material is obtained according to the diameter of the bar material and the size of a forge piece; 2, the taper degree of a forming wall surface of a male die and the taper degree of a forming wall surface of a female die are selected, and the upsetting frequency, the layer number of the male die, the layer number of the female die, the height of each layer of male die modules and the height of each layer of female die modules are determined according to the taper angles of the forming wall surfaces, the height of the bar material and the upsetting ratio every time; 3, after the bar material, the female die and the male die are heated, first-time upsetting forming is conducted; 4, after first-time upsetting forming is completed, the male die module with the minimum average outer diameter and the female die module with the minimum average inner diameter are removed, second-time upsetting is conducted, and in this way, the steps are conducted till the height-diameter ratio of an upsetting part is smaller than the maximum height-diameter ratio of non-instable upsetting. According to the die, the female die is designed into multiple layered modules of which the inner walls have the certain taper degree, instability of blanks is constrained through the oblique wall of the female die, and then a folding phenomenon cannot be generated.

Owner:SHANDONG UNIV +1

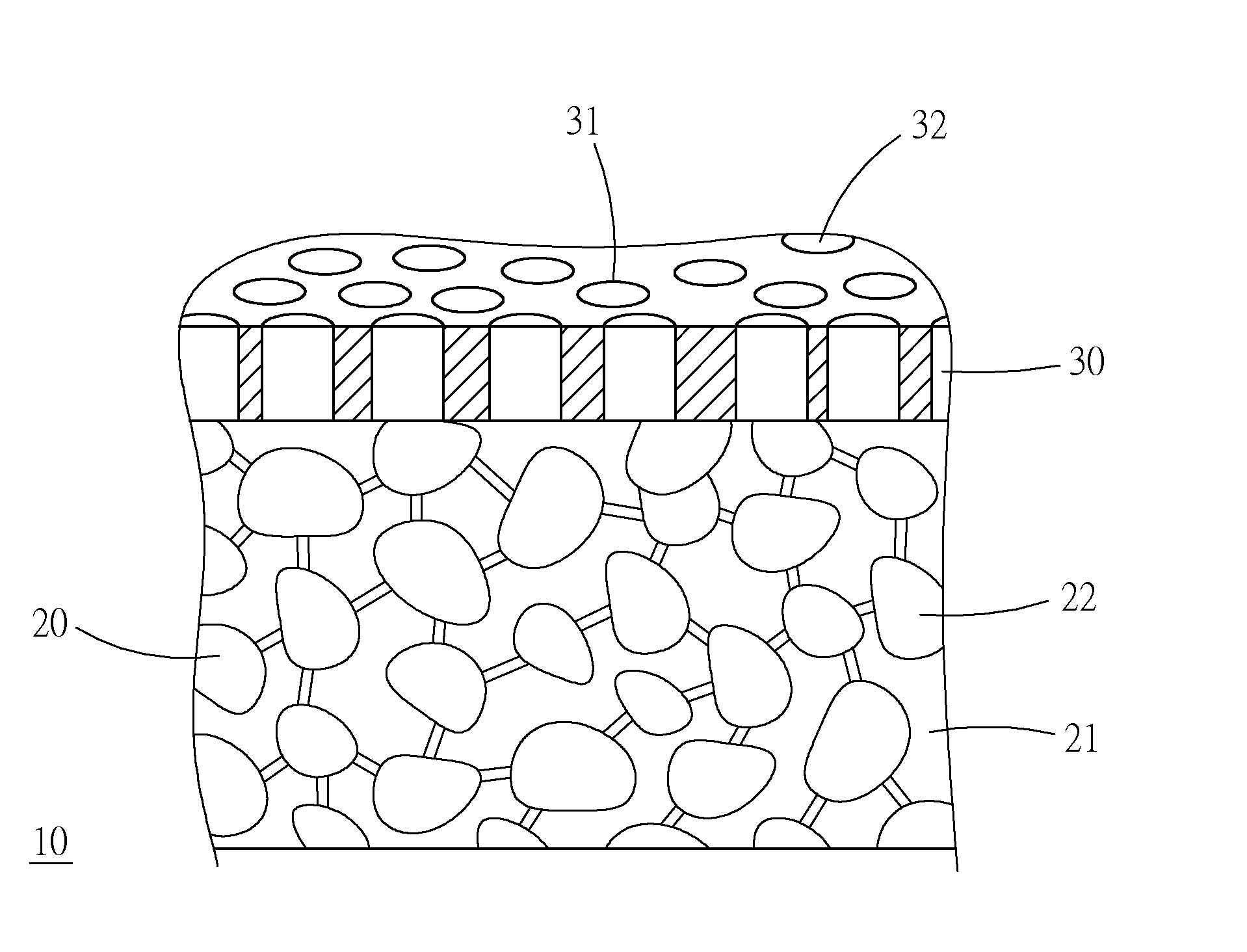

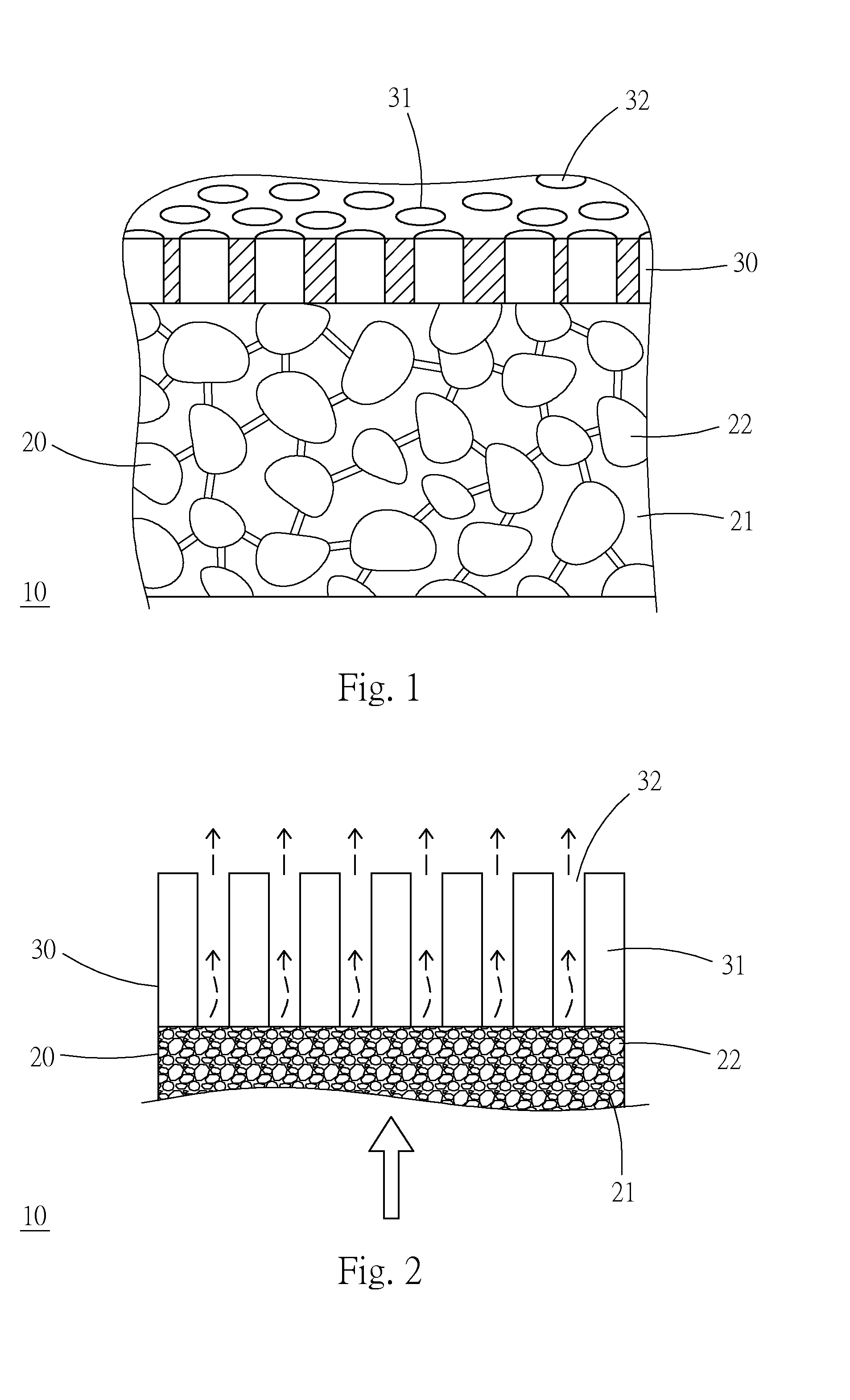

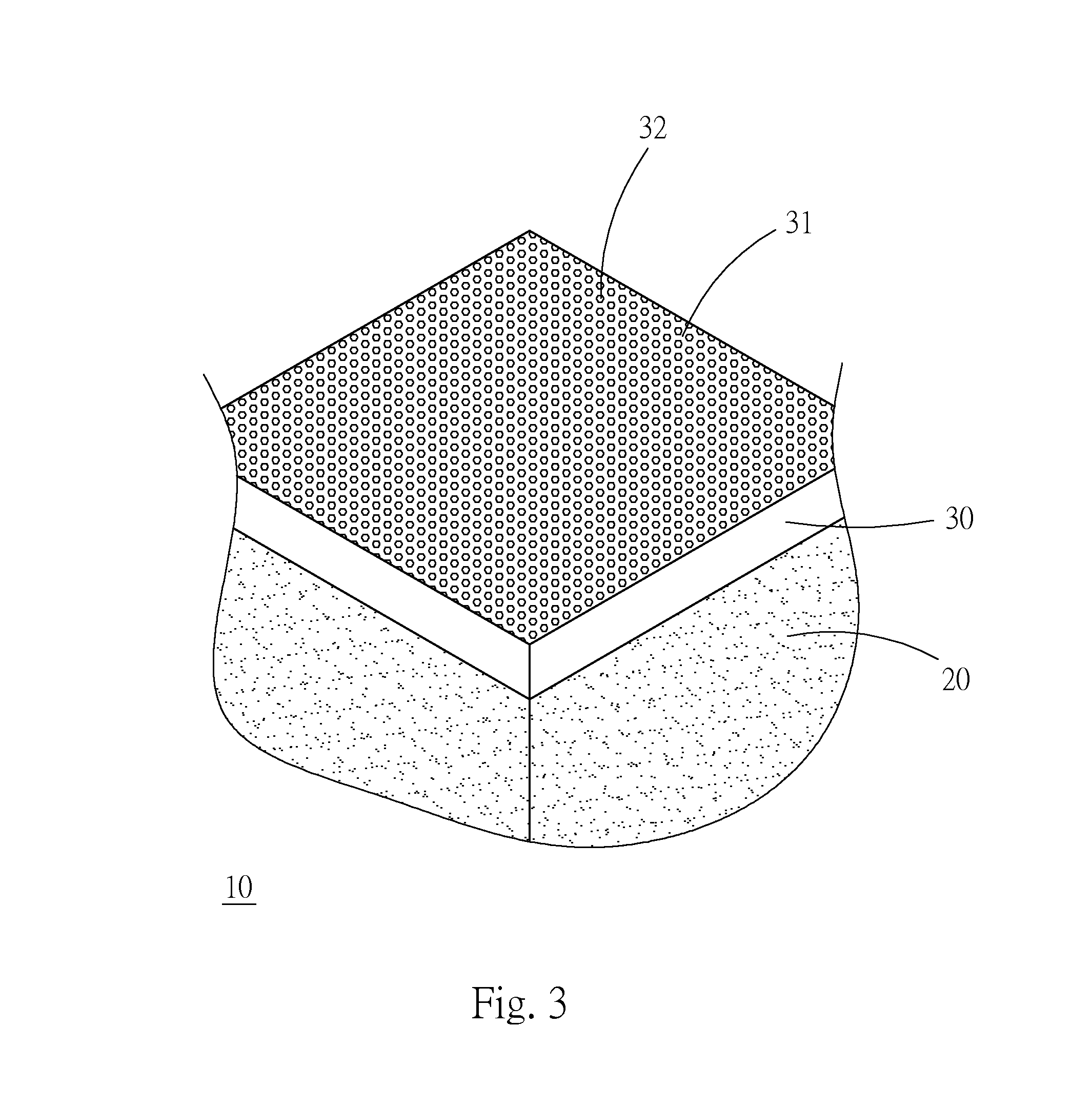

Air bearing structure

An air bearing structure, which is a porous air bearing. In the air bearing structure, a porous material is combined with an aluminum layer with vents to provide double restrictions so as to enhance the degree of freedom in adjusting the diameter parameter of porous material. The vents are distributed in a matrix pattern and have a diameter of nanometer order. Therefore, the uniformity of the vents and the unification of the infiltration can be ensured. Also, the vents can be directed in the same direction to enhance the bearing ability, air film stability and static rigidity.

Owner:HIWIN MIKROSYST

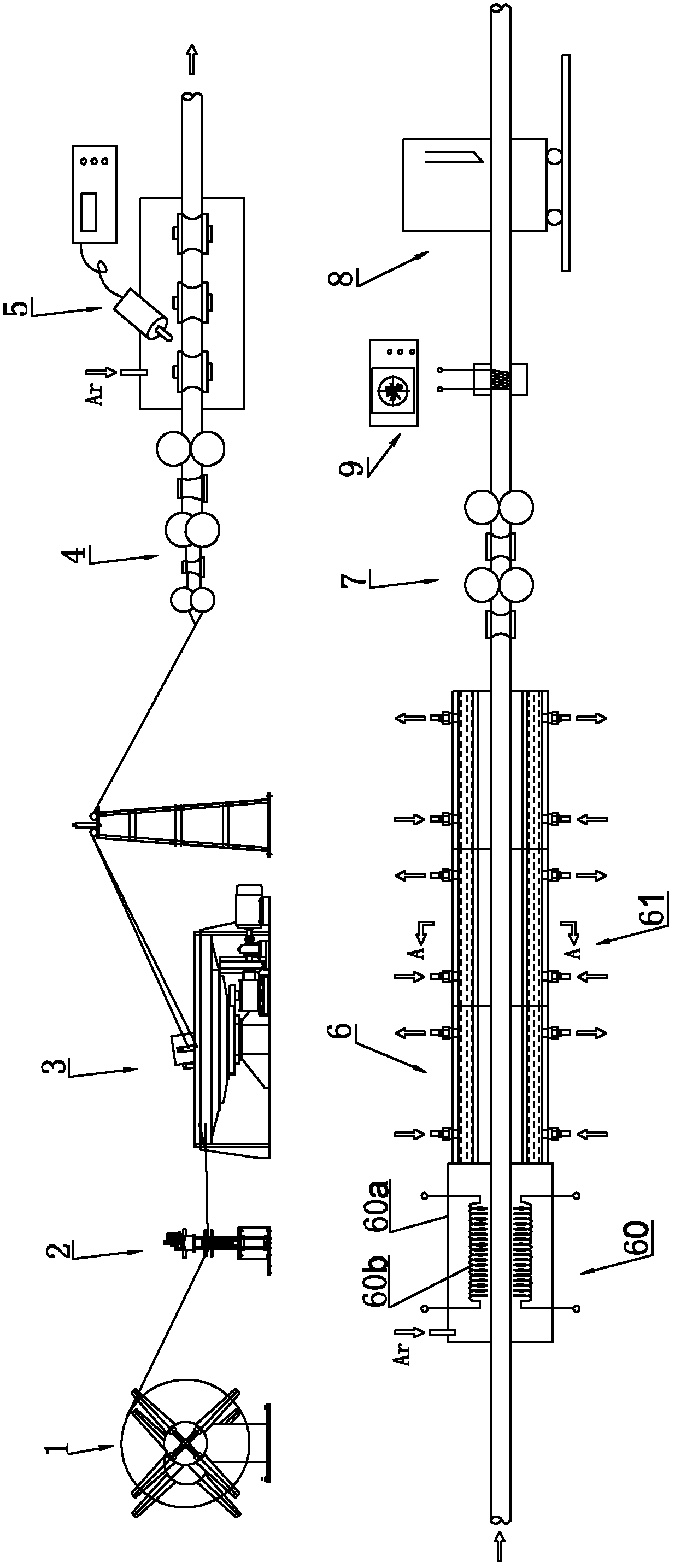

Method for producing seamless titanium and titanium alloy welded pipe

The invention relates to a method for producing a seamless titanium and titanium alloy welded pipe. By the method, the welded pipe is obtained by welding a pipe material on an automatic precise welded pipe production line; and particularly, the production method comprising the step of performing one-time or repeated cold rolling-thermal treatment on the welded pipe. The cold rolling-thermal treatment process comprises the following steps of: (1) cold-rolling the welded pipe by using a multi-roller pipe milling machine, and lubricating the inner and outer surfaces of the pipe material in the cold rolling process, wherein the total machining rate of a cold-rolling finished product is controlled to 50 to 70 percent, the machining rate in all processes is controlled to 15 to 50 percent, and a cold rolling process is performed for 2 to 3 times; (2) after the cold rolling process, degreasing the pipe material, and cleaning; and (3) annealing the degreased and cleaned pipe material in a vacuum annealing furnace. By the method, the seamless welded pipe can be obtained; and the method is high in production efficiency, low in cost and light in environmental pollution.

Owner:张家港华裕有色金属材料有限公司

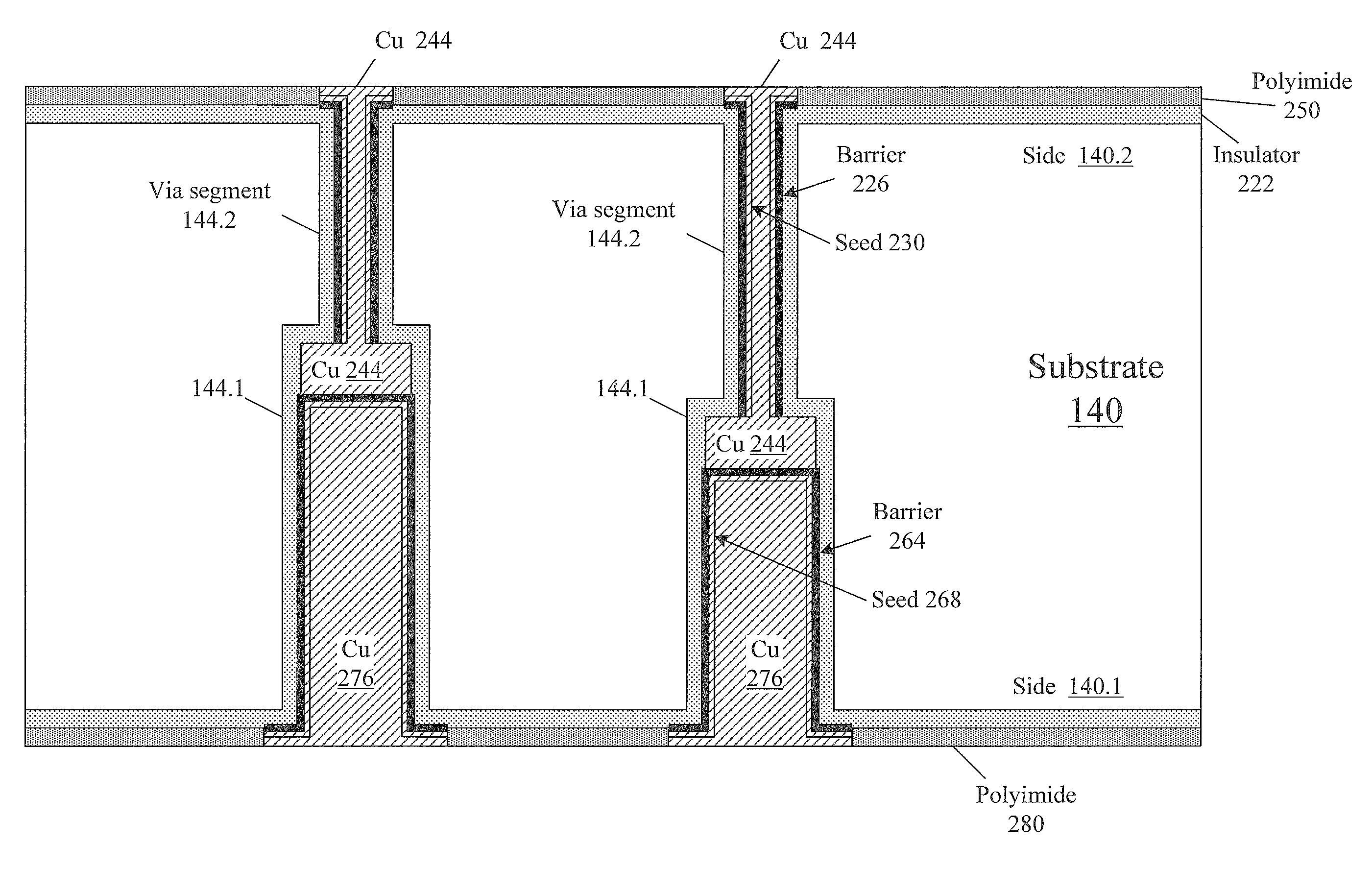

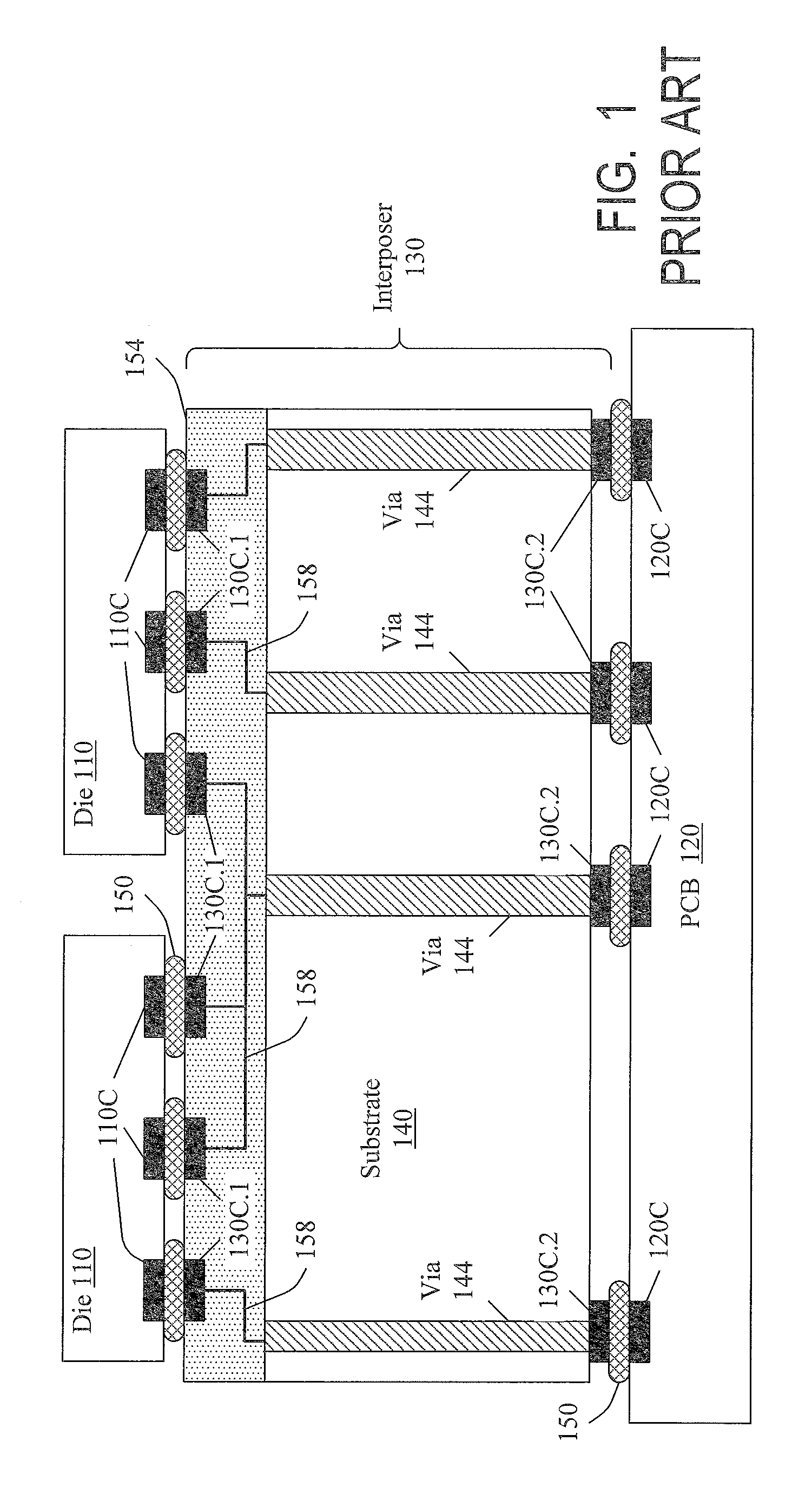

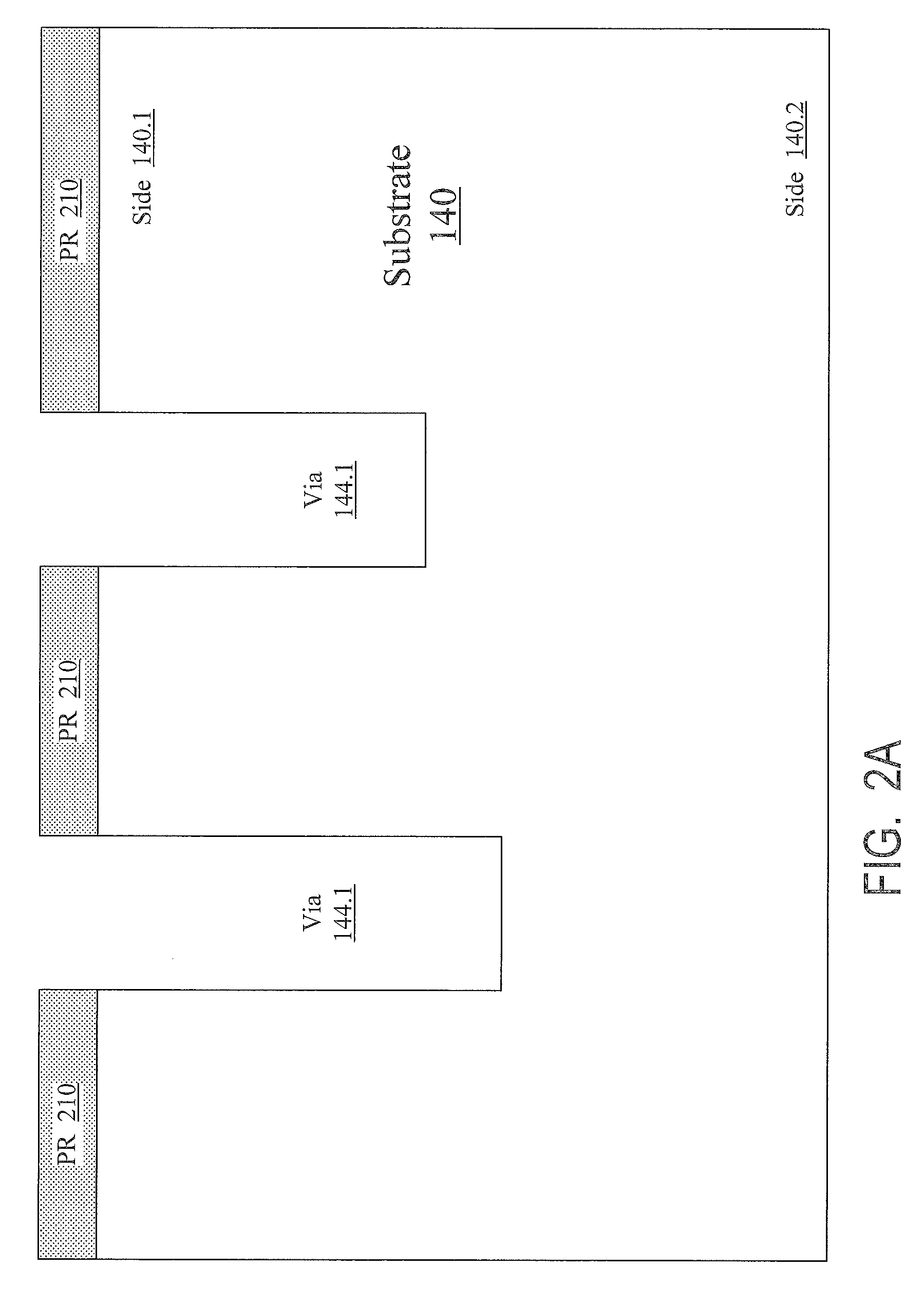

Substrates with through vias with conductive features for connection to integrated circuit elements, and methods for forming through vias in substrates

ActiveUS9018094B2Shorten the lengthReduce aspect ratioSemiconductor/solid-state device detailsPrinted circuit aspectsConductive materialsIntegrated circuit

A through via (144) contains a conductor (244, 276) passing through a substrate (140) for connection to an integrated circuit element. The through via consists of two segments (144.1, 144.2) formed from respective different sides (140.1, 140.2) of the substrate and meeting inside the substrate. Each segment is shorter than the entire via, so via formation is facilitated. The second segment is etched after deposition of an etch stop layer (214) into the first segment. Due to the etch stop layer, the first segment's depth does not have to be rigidly controlled. The conductor is formed by separate depositions of conductive material into the via from each side of the substrate. From each side, the conductor is deposited to a shallower depth than the via depth, so the deposition is facilitated. Other embodiments are also provided.

Owner:INVENSAS CORP

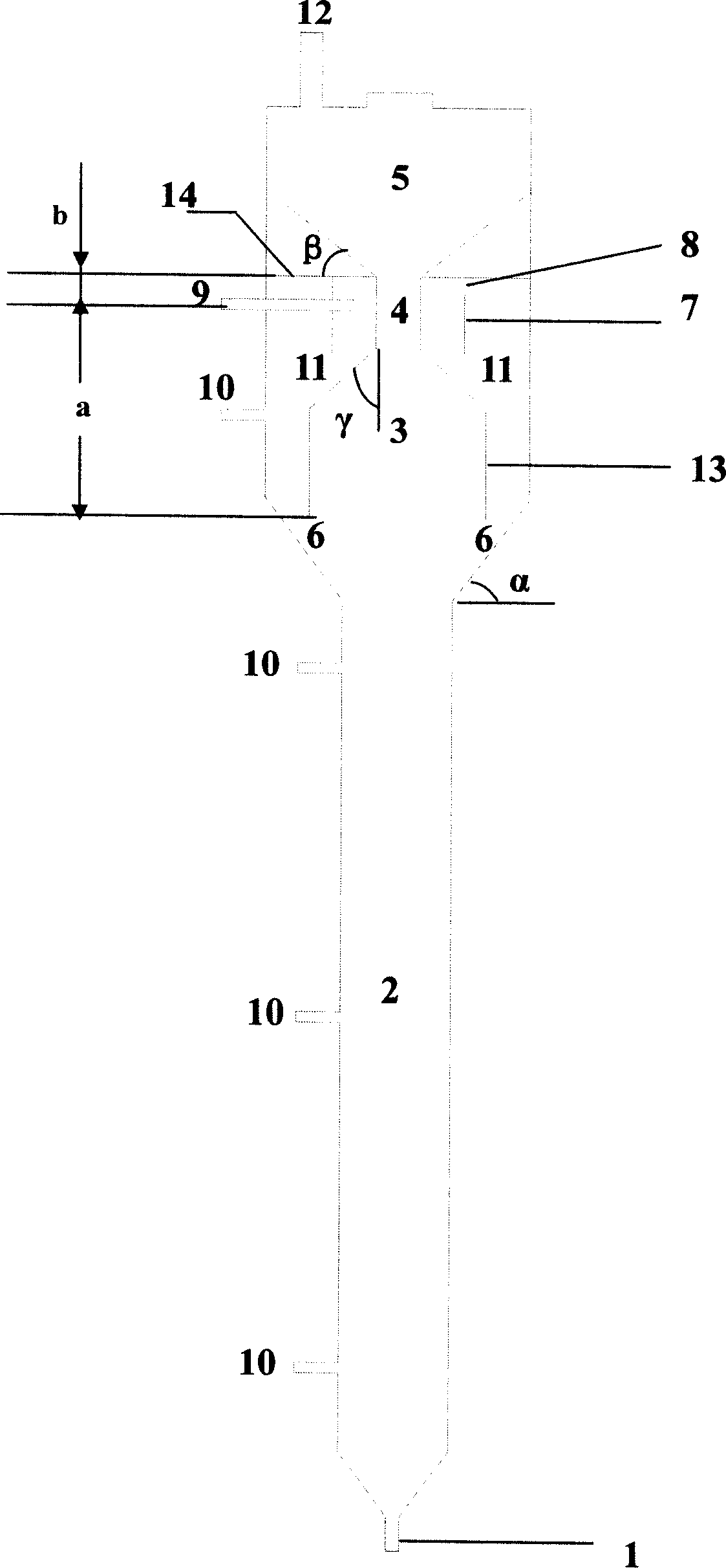

Air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor

InactiveCN104085986AImproved resistance to shock loadsSimple structureTreatment with aerobic and anaerobic processesNitrogen removalOxygen

The invention discloses an air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor. The air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor is characterized by comprising a water distributing section, a reaction section and a separating section, wherein the water distributing section comprises a lower short circular barrel; a water distributor and a microporous aeration plate are arranged in the barrel, and the water distributor is communicated with a water inlet tube; the microporous aeration plate is communicated with a gas inlet tube; the reaction section comprises a long circular barrel, and a multi-stage Venturi tube is arranged in the long circular barrel; a flow-splitting region and a mixing region are respectively formed between the two ends of the multi-stage Venturi tube and the port of the long circular barrel, and are communicated by left and right circulating tubes to form circulation; the separating section comprises an upper short circular barrel, and a water outlet and gas outlet system is arranged in the barrel. By virtue of arranging the microporous aeration plate, the mixing region and the multi-stage Venturi tube, vortex flow fields are formed in the multi-stage Venturi tube, so that the mass transfer efficiency among gas, liquid and solid phases is effectively enhanced. Besides, the structure is combined with the flow-splitting region, the left circulating tube and the right circulating tube to form external circulation, so that an aerobic-anoxic alternating environment is formed, and therefore, the reactor has a nitrification and denitrification biological nitrogen removal function.

Owner:DONGHUA UNIV +1

Polylactic acid composite material used for three-dimensional printing and preparation method therefor

ActiveCN104845300AAvoid deformationEasy to slideAdditive manufacturing apparatusMetal powder3 dimensional printing

The invention discloses a polylactic acid composite material used for three-dimensional printing. The polylactic acid composite material is characterized by comprising sheet-like micro metal powder, and being prepared from raw materials of the following components in parts by weight: 70-80 parts of polylactic acid, 5-15 parts of sheet-like micro metal powder, 1-2 parts of a surface modifier, 0.5-1 part of a crystallizing agent, 0.2-0.3 part of an antioxidant and 0.2-0.3 part of a processing aid. The sheet-like micro metal powder with flexibility and good thermal capacity is introduced into the polylactic acid, so that the thermal performance of the polylactic acid is changed by utilizing the thermal capacity of the sheet-like micro metal powder, and the polylactic acid is prevented from being quickly cooled to generate deformation. Especially, the sheet-like metal powder has good sliding property and flexibility, so that the flow uniformity and the toughness of the polylactic acid are improved, and the polylactic acid composite material is suitable for manufacturing a high-precision product by three-dimensional printing.

Owner:珠海金骆驼科技有限公司

Highly effective anaerobic bioreacto

InactiveCN101007680AEfficient separationEffective coverageTreatment with anaerobic digestion processesRefluxSludge

The invention discloses a high-effective anaerobic biological reactor, which comprises the following parts: reactor bulk, inlet pipe on the bottom of reactor bulk and upflow typed reacting chamber, wherein the upflow typed reacting chamber connects external cylinder of sediment chamber through increaser; the three-phased separator I chamber, mud gas elevating pipe are set in the sediment chamber; the three-phased separator II chamber is set on the top of mud gas elevating pipe with increaser on the bottom; the top of three-phased separator I chamber is reducer with gas collecting lid on the bottom; the reflux seam is set between gas collecting lid and increaser on the external cylinder to sediment mud; the mud gas elevating pipe connects the external cylinder through level support board, which connects flow baffle; the sediment chamber is set on the exterior of mud gas elevating pipe.

Owner:ZHEJIANG UNIV

Improved high-temperature-resistant metal anti-corrosive paint

The invention relates to improved high-temperature-resistant metal anti-corrosive paint, which consists of the following components in parts by mass: 30-40 parts of GHNK high-temperature-resistant adhesive, 15-20 parts of polyaniline / graphene composite material, 15-20 parts of coloring pigment, 5-10 parts of superfine talcum powder, 5-10 parts of superfine mica powder, 5-10 parts of kaolin, 0.2-0.5 parts of SN-612 flatting agent, 0.3-0.5 parts of wetting agent X-405, 0.1-0.3 parts of dimethyl ethanolamine, 0.1-0.3 parts of anti-corrosive agent 981, 0.5-1 part of GHP 101 thickening agent, 0.1-0.3 parts of tributyl phosphate and 4-13 parts of water. The paint prepared by the invention has the advantages of excellent water-proof and anti-corrosive properties, high temperature resistance, alkaline resistance, weathering resistance, scrub resistance, artificial aging resistance and the like, passivation and corrosion inhibition of a metal base material can be realized, meanwhile, the use of heavy metals such as chromium which can cause environmental pollution is avoided, and the paint is easy to prepare, low in cost and is easy for industrial batch production.

Owner:冯斌

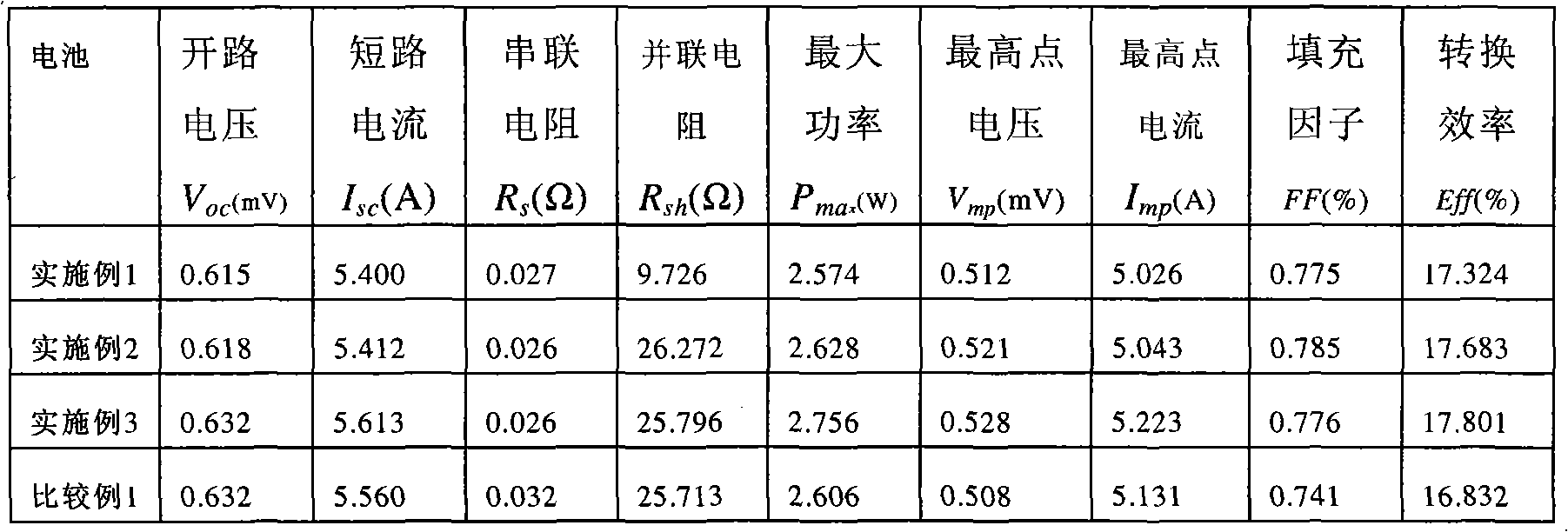

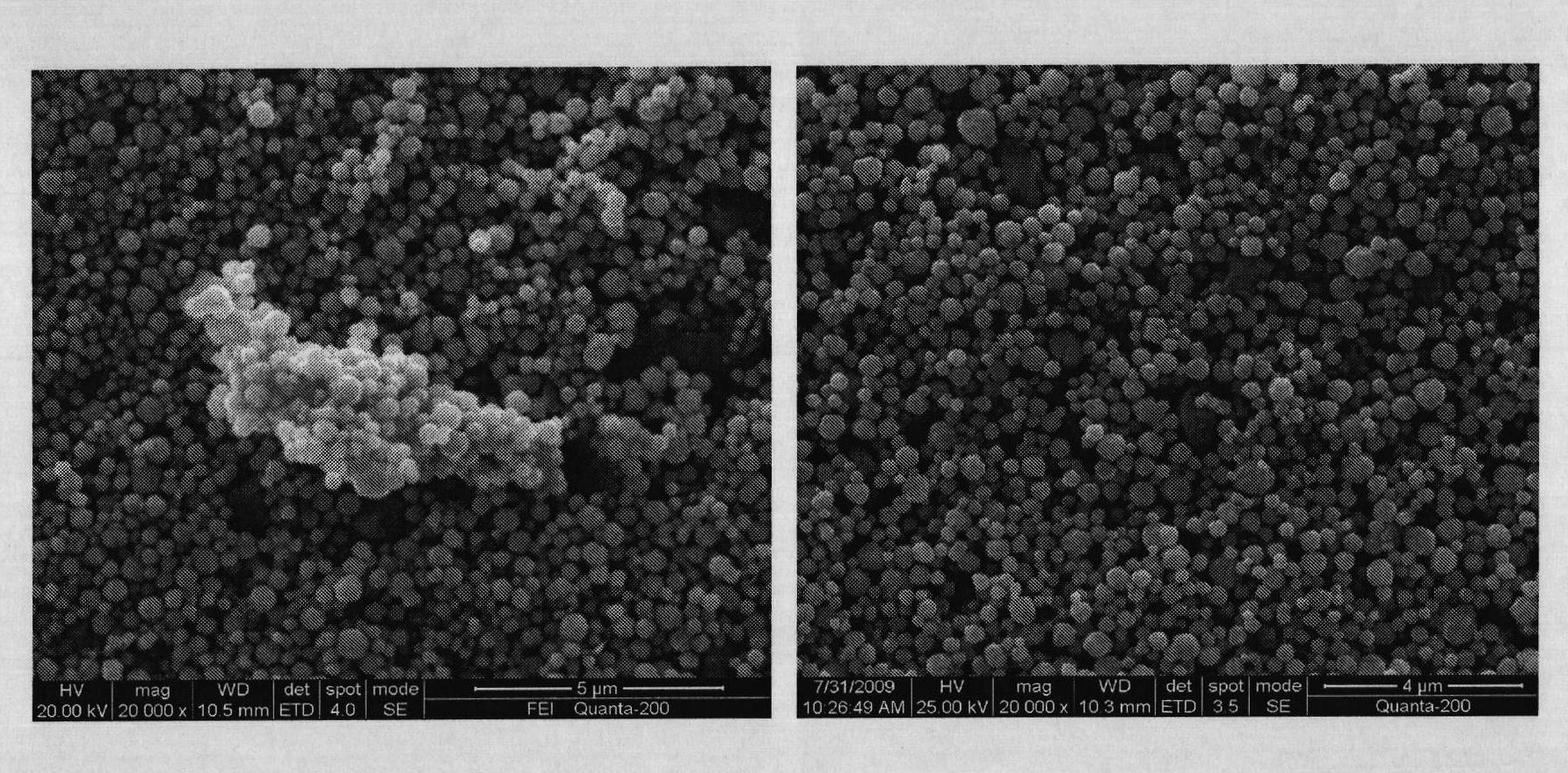

Silver paste used for positive electrodes of solar batteries and grid lines, preparation method thereof and solar battery containing same

InactiveCN102103895AInhibit easy agglomerationImprove dispersionFinal product manufactureNon-conductive material with dispersed conductive materialElectrical batteryHigh definition

The invention discloses a silver paste used for positive electrodes of solar batteries and grid lines, which comprises silver powder, glass powder, additive and an organic carrier. The silver paste is prepared by the following steps of: preparing a highly dispersed superfine silver grout used as the silver powder through a chemical liquid phase reduction method, then obtaining wet silver powder through solid-liquid separation, and preparing the agglomerate-free silver paste through direct mixing of the wet silver powder and the glass powder, the additive and the organic carrier according to the specified proportion without drying. The method for preparing the positive silver paste directly by using the wet silver powder comprises the steps of: preparation of the superfine silver powder through the chemical liquid phase reduction method, solid-liquid separation, washing, and direct preparation of the silver paste without a drying procedure in which the silver powder is easily agglomerated. The silver paste is characterized by high dispersity, no agglomeration and smaller fineness; and positive electrodes of solar batteries and grid lines, prepared through the screen printing and fast sintering process, have high definition, high evenness, high electrical conductivity and excellent photoelectric conversion efficiency.

Owner:湖南威能新材料科技有限公司

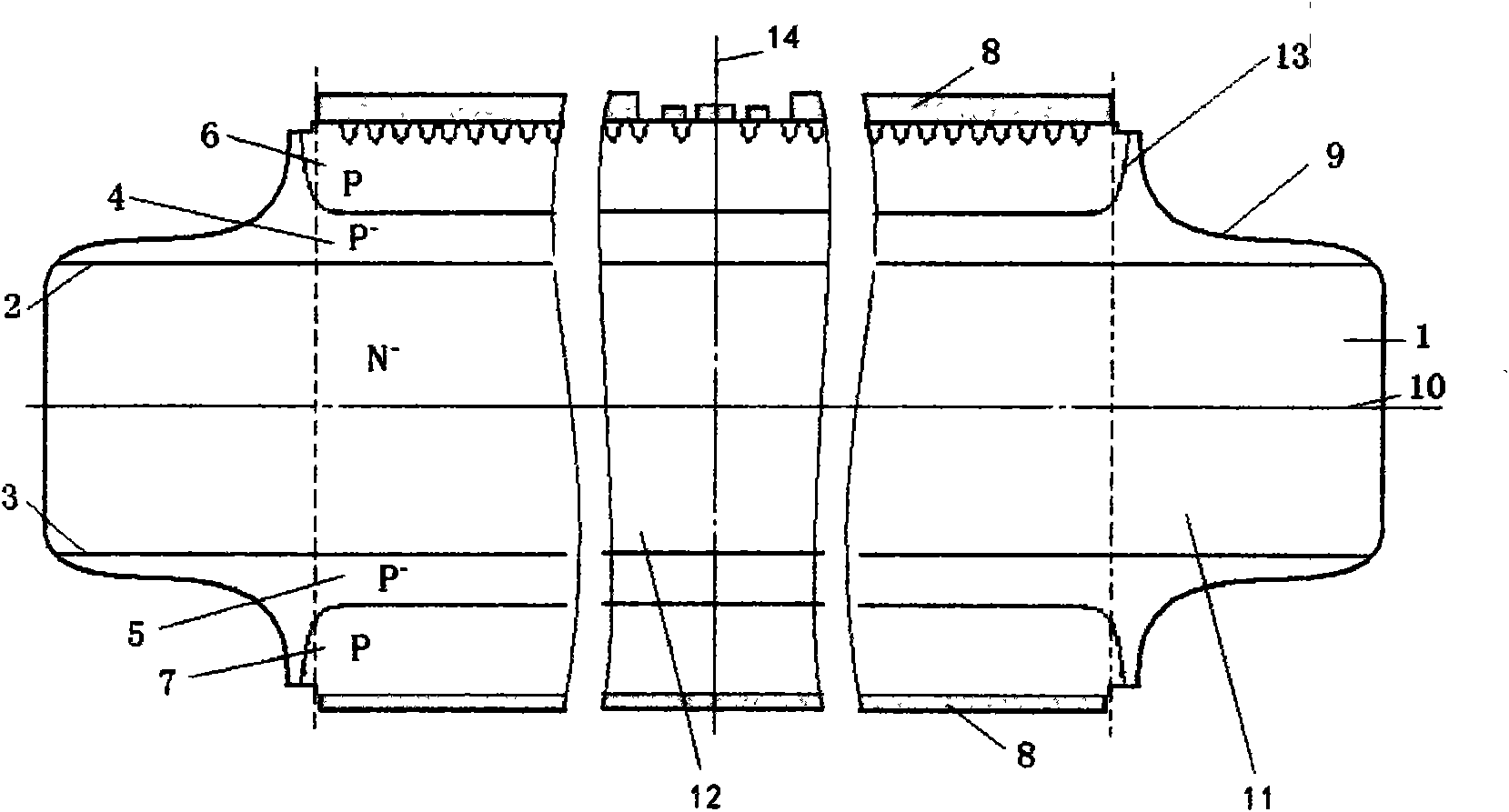

Forwardly and reversely symmetrical P-type radial varying doping and similar table-board negative angle shaped junction terminal thyristor

The invention relates to a forwardly and reversely symmetrical P-type radial varying doping and similar table-board negative angle shaped junction terminal thyristor. A higher concentration P-type doped layer forms a high-low junction which is a non-parallel plane junction on a low-concentration P-type doped layer; a junction surface bends to prevent higher concentration P-type impurities from entering junction terminal areas; and the edges of the forward and reverse junction terminal areas have similar table-board negative angle shapes. The forwardly and reversely symmetrical P-type radial varying doping has an effect of thinning P-area from double sides; and the forwardly and reversely symmetrical similar table-board negative angle shapes have effects of thinning a long base area, reducing occupied area per se, increasing cathode area and balancing forward and reverse voltage resistance. The forwardly and reversely symmetrical P-type radial varying doping and similar table-board negative angle shaped junction terminal thyristor has the characteristics of symmetrical forward and reverse block voltages, no additional thickness of long and short base areas and maximum cathode area. Compared with the thyristor made from an original silicon material with the same resistivity and diameter, the forwardly and reversely symmetrical P-type radial varying doping and similar table-board negative angle shaped junction terminal thyristor has the advantages of highest blocking voltage, highest ratio of breakover voltage to chip thickness and maximum cathode area.

Owner:西安派瑞功率半导体变流技术股份有限公司

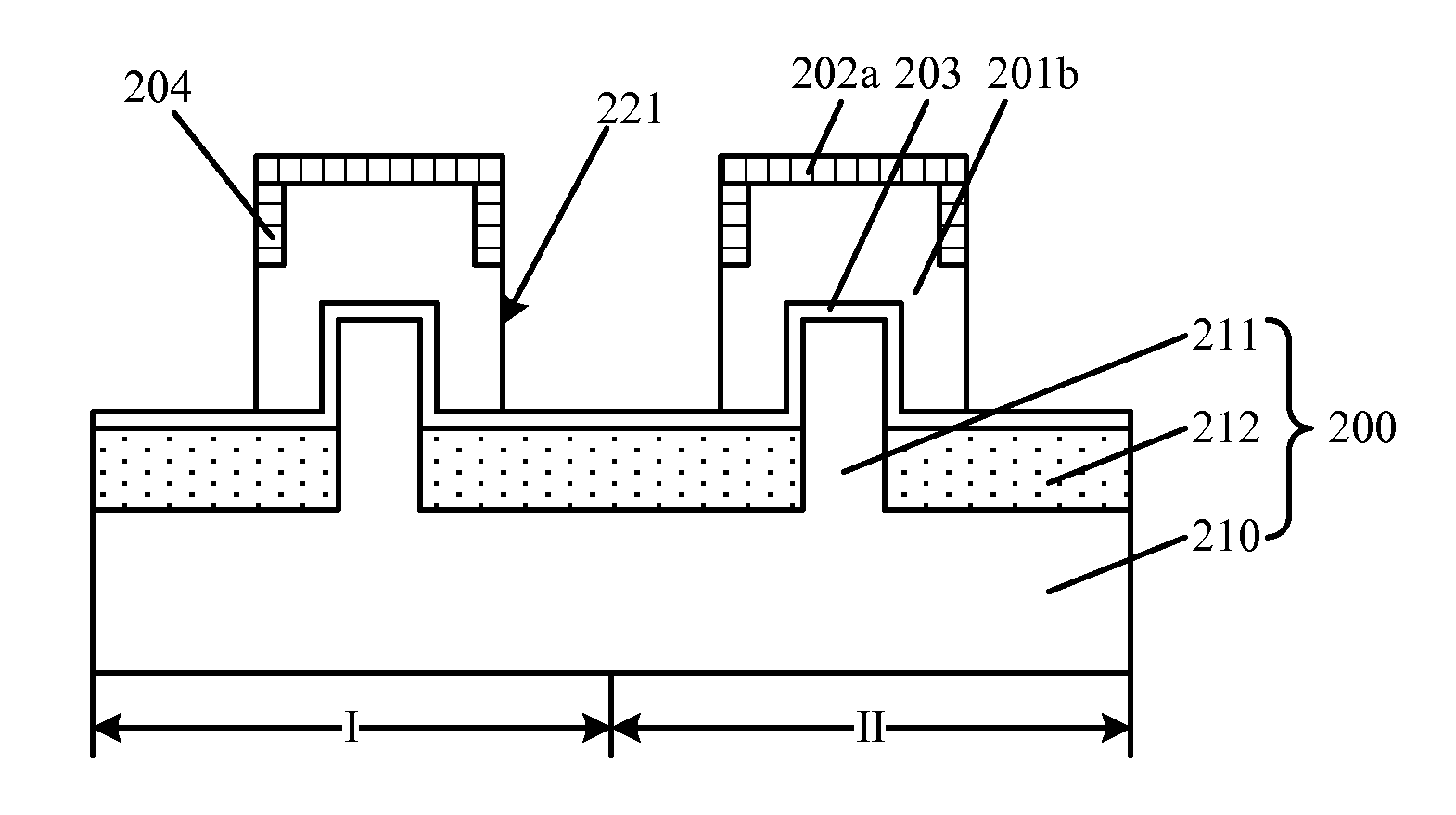

Transistor and fabrication method thereof

ActiveUS20160126338A1Avoid contactInhibit currentSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

Owner:SEMICON MFG INT (SHANGHAI) CORP

Graphene-based nanometer zero-valent iron coating and preparation method thereof

InactiveCN104387911AImprove anti-corrosion performanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySulfide

The invention discloses a graphene-based nanometer zero-valent iron coating comprising the following components in parts by weight: 1-20 parts of graphene-based nanometer zero-valent iron, 1-15 parts of graphene-based nanometer titanium dioxide, 1-15 parts of graphene-based nanometer aluminum oxide, 1-15 parts of graphene-based nanometer silicon dioxide, 1-15 parts of graphene-based nanometer calcium carbonate, 5-60 parts of epoxy resin, 3-30 parts of polyphenylene sulfide resin, 1-15 parts of an amino resin crosslinking agent, 3-50 parts of a mixed-type organic alcohol solvent, 0.5-1.9 parts of a nonionic surfactant, 0.8-1.6 parts of a dispersing agent, 0.5-1.5 parts of a thickening agent, 0.1-0.3 part of a defoaming agent, 0.1-5 parts of a plasticizer, 0.2-0.5 part of a flatting agent, 1-10 parts of a pigment and 0.5-1.0 part of a filler. The invention also provides a preparation method of the coating. The performances such as high temperature resistance, corrosion resistance, hardness, surface adhesion, weather resistance, acid and alkaline resistance and impact resistance of the coating disclosed by the invention are remarkably improved.

Owner:HUNAN ORIENTOP GRAPHENE APPL TECH

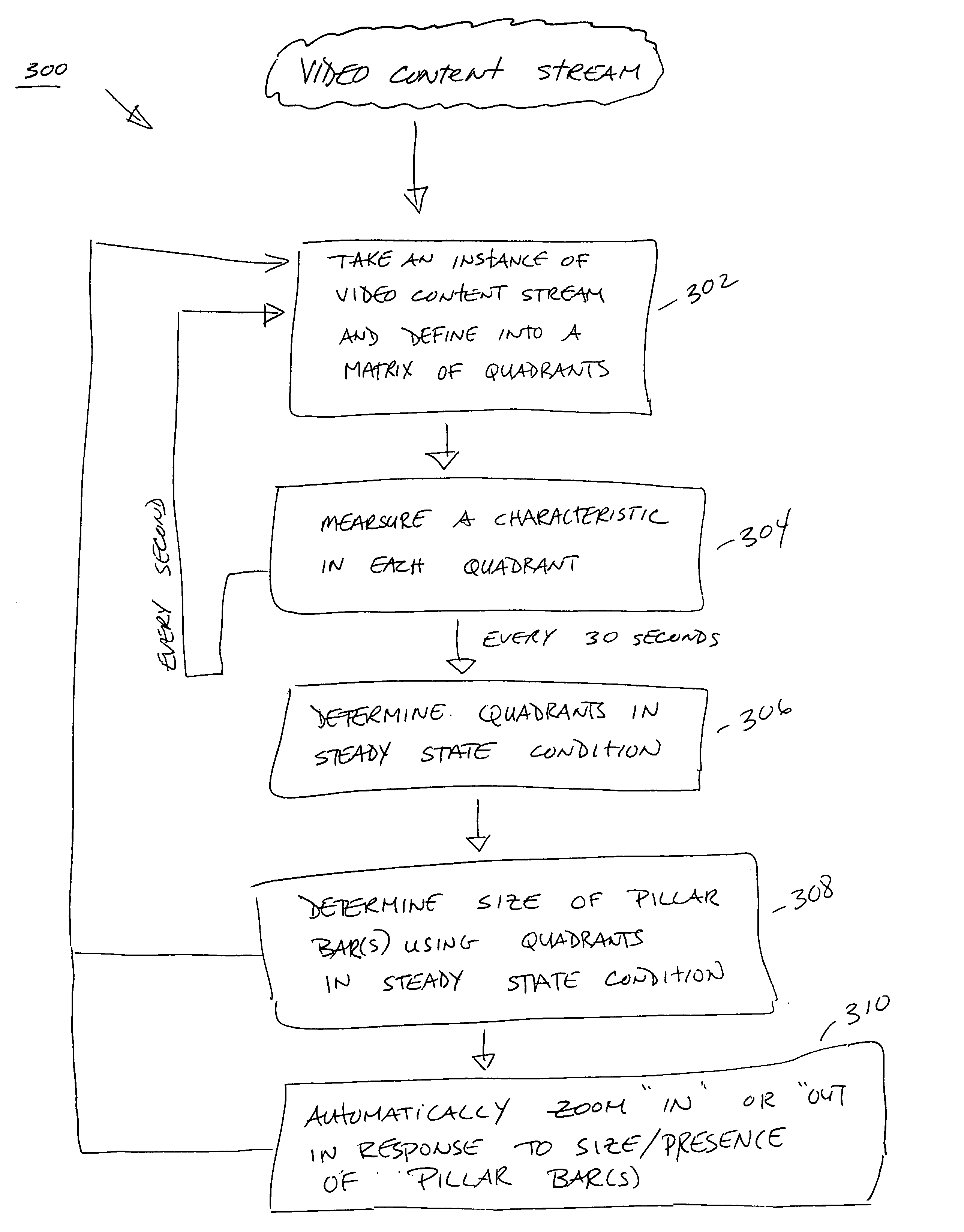

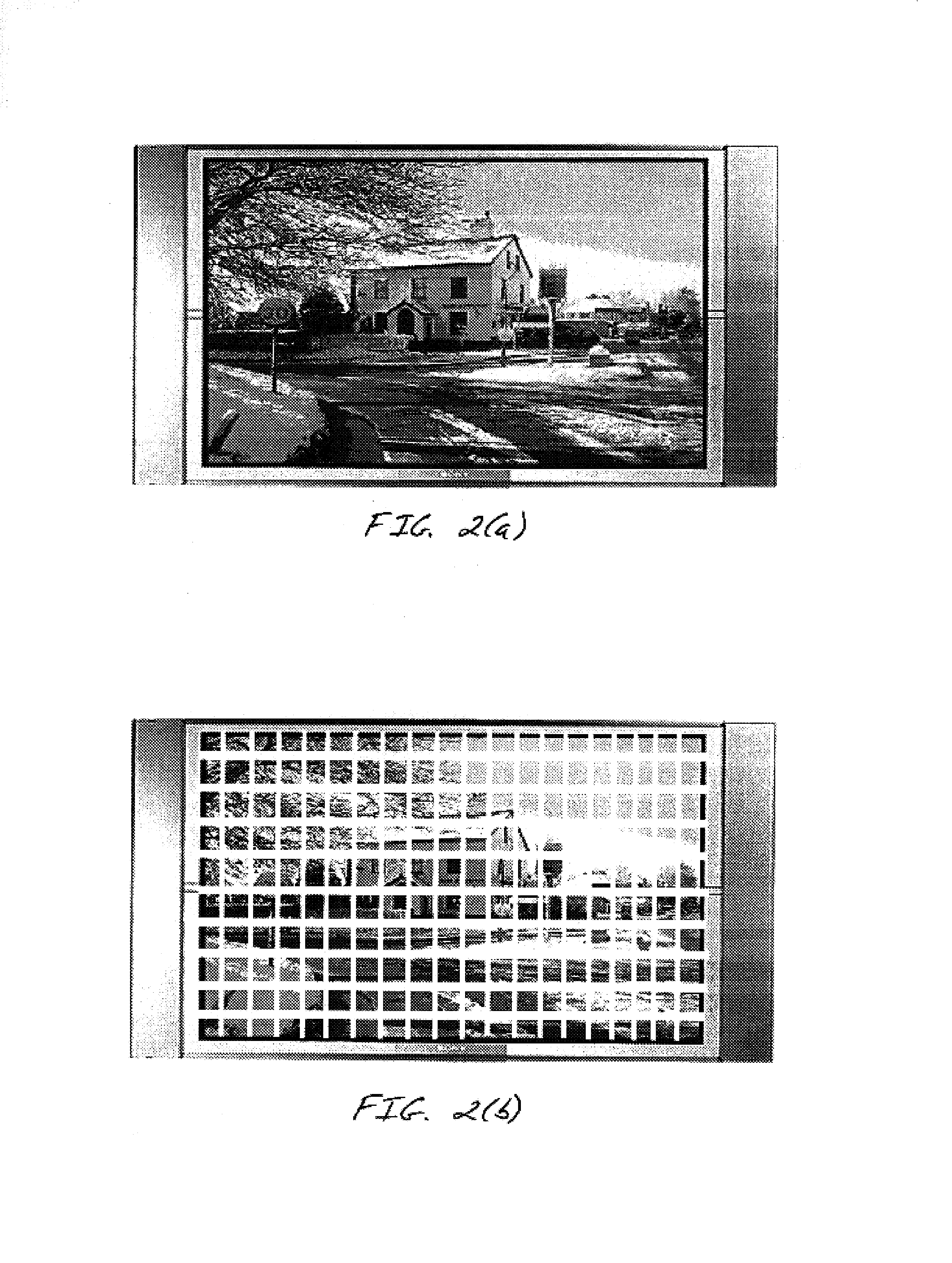

System and method for automatic zoom

ActiveUS7262811B2Aspect ratioTelevision system detailsColor signal processing circuitsComputer graphics (images)Computer science

A system and method for automatically zooming “in” and “out” a video content stream to adjust for Ratio Mismatches is disclosed. The present invention is particularly applicable to 4:3 video content delivered in a 16:9 video content stream. The present invention scans for the presence of Pillar Bars. When Pillar Bars are detected by the present invention, after waiting a pre-determined period to confirm the presence and size of the Pillar Bars, the present invention initiates a slow stretching the video content stream to eliminate the Pillar Bars. When the video content stream changes back to without Pillar Bars, the present invention initiates a slow zooming out to a full pixel representation of the video content stream.

Owner:GOOGLE TECH HLDG LLC

Pressure-resistant impact-resistant PE pipe material and preparation method thereof

The invention provides a pressure-resistant impact-resistant PE pipe material and a preparation method thereof, and belongs to the technical field of PE pipe materials. The pressure-resistant impact-resistant PE pipe is composed of the following components in parts by weight: 60-80 parts of polyethylene, 5-30 parts of coupled inorganic silica, 2-10 parts of heat stabilizer, 0.5-2 parts of dispersing agent, 0.5-3 parts of toughening agent, and 0.5-5 parts of paraffin. The invention also provides a preparation method of the pressure-resistant impact-resistant PE pipe material. The PE pipe material of the invention has good pressure and impact resistance.

Owner:芜湖万隆新材料有限公司

Device for precisely processing deep groove and deep hole by variable-focus laser

ActiveCN104907704AEnergy concentrationLarge hole depthLaser beam welding apparatusLaser etchingPunching

The invention provides a method for precisely machining a deep groove and a deep hole by varifocal lasers. The method comprises the steps that a plurality of focusing lenses with different focal lengths and workpieces are clamped; if deep groove machining is carried out, a laser beam is continuously output; laser etching machining is completed once; if deep hole machining is carried out, N laser pulses are output; the lasers are closed, and a working table moves to the original position; whether machining meets the requirements or not is detected; if machining meets the requirements, machining is finished; if machining does not meet the requirements, a focusing lens base is rotated, the next focusing lens is moved to the position of the current focusing lens, and laser machining is carried out again until machining meets the requirements. The pulse laser beam sequentially penetrates through the focusing lenses with the different focal lengths by rotating the focusing lens base, the focal lengths are progressively changed, the lasers are focused on the new exposed surface in the laser etching or punching process all the time, energy is more concentrated, the punching deep is larger, and the efficiency is higher. The invention provides a device for precisely machining the deep groove and the deep hole by the varifocal lasers at the same time.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com