Electric spark small hole machining technology achieved through dispersing agent working solution and brass/nickel electrode

A technology of dispersant and working fluid, which is applied in the field of EDM small hole machining technology for making fluid and copper/nickel electrodes, can solve the problems of rising processing costs, reduce processing quality, improve processing speed, depth-to-diameter ratio, and price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0050] The new technology will be described in further detail below in combination with experiments and specific implementation methods.

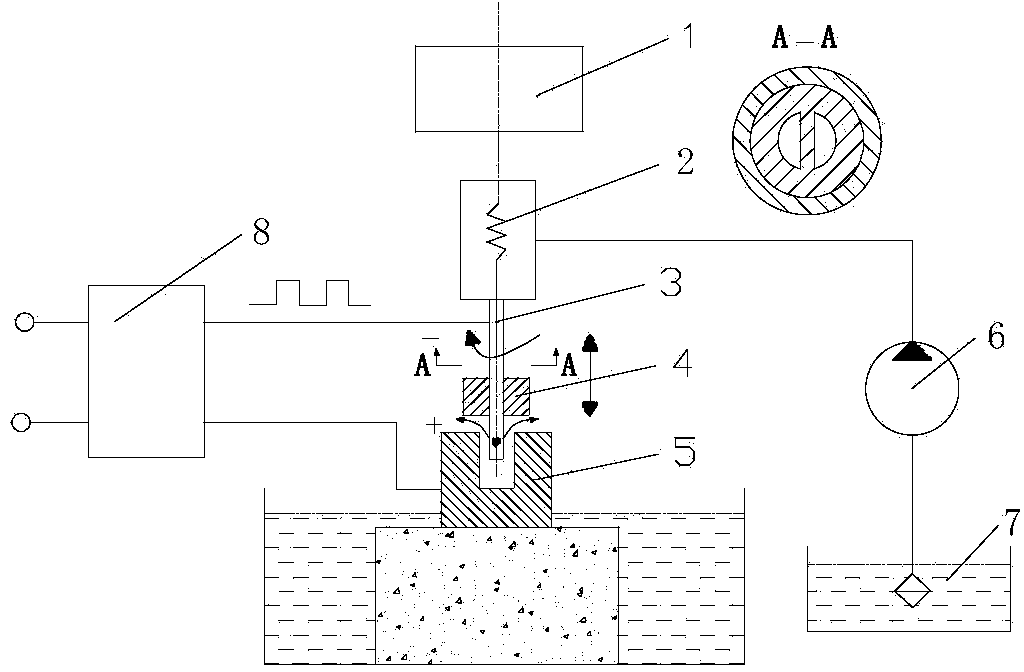

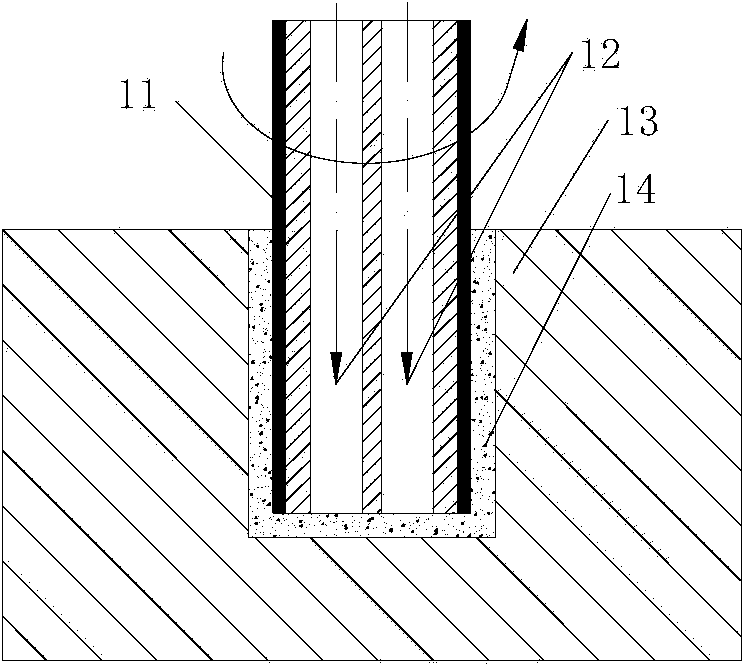

[0051] This test was carried out on D703F small hole EDM machine tool, using positive polarity machining (the workpiece and tool electrode were respectively connected to the positive and negative poles of the pulse power supply), supplemented by high-pressure (3.5MPa) working fluid to cool and remove chips, and the rotation speed of the tool electrode was 120r / min. The workpiece is stainless steel (1Cr18Ni9Ti), the thickness of the workpiece is 80mm, the tool electrode is a porous brass tubular electrode with a diameter of φ2mm and a Cu / Ni porous composite electrode with a diameter of φ2.02mm. After the working fluid medium is pressurized by the water pump, it acts on the hollow rotating tubular electrode, and is sprayed out at a high speed at the working end of the electrode to wash away the electrolytic corrosion products generated by the...

Embodiment approach 2

[0089] 1) Development of water-based dispersant working fluid

[0090] Water-based dispersant working fluid, its formula is shown in Table 7, and Table 8 is the performance of the dispersant used:

[0091] Table 7 Formula of working solution

[0092]

[0093] Table 8 T-225 Dispersant Properties

[0094]

[0095]

[0096] The specifications of T-225 dispersant are as follows:

[0097] Brand: Taihe 55719-33-0 Place of Origin: Zaozhuang, Shandong

[0098] Main ingredients: maleic anhydride, acrylic acid, hydroxypropyl acrylate

[0099] Dispersant working solution preparation process: first prepare a 35L plastic bucket and a 1L measuring cylinder; add 25L of tap water to the plastic bucket, use the measuring cylinder to take 1.0L of T-225 dispersant and pour it into the plastic bucket, and use a plastic stick or Stir with a rubber rod for 5 minutes. After fully fused, place it at room temperature for use; T-225 dispersant can well disperse small solid particles that a...

Embodiment approach 3

[0124] 1) Development of water-based dispersant working fluid

[0125] Water-based dispersant working fluid, its formula is shown in Table 11, and Table 12 is the performance of the dispersant used:

[0126] The formula of table 11 working solution

[0127]

[0128] Table 12T-225 dispersant properties

[0129]

[0130]

[0131] The specifications of T-225 dispersant are as follows:

[0132] Brand: Taihe 55719-33-0 Place of Origin: Zaozhuang, Shandong

[0133] Main ingredients: maleic anhydride, acrylic acid, hydroxypropyl acrylate

[0134] Dispersant working solution preparation process: first prepare a 30L plastic bucket and a 1L measuring cylinder; add 23L of tap water to the plastic bucket, use the measuring cylinder to take 0.75L of T-225 dispersant and pour it into the plastic bucket, use a plastic stick or Stir with a rubber rod for 5 minutes. After fully fused, place it at room temperature for use; T-225 dispersant can well disperse small solid particles th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com