Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

860results about How to "Ease of industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

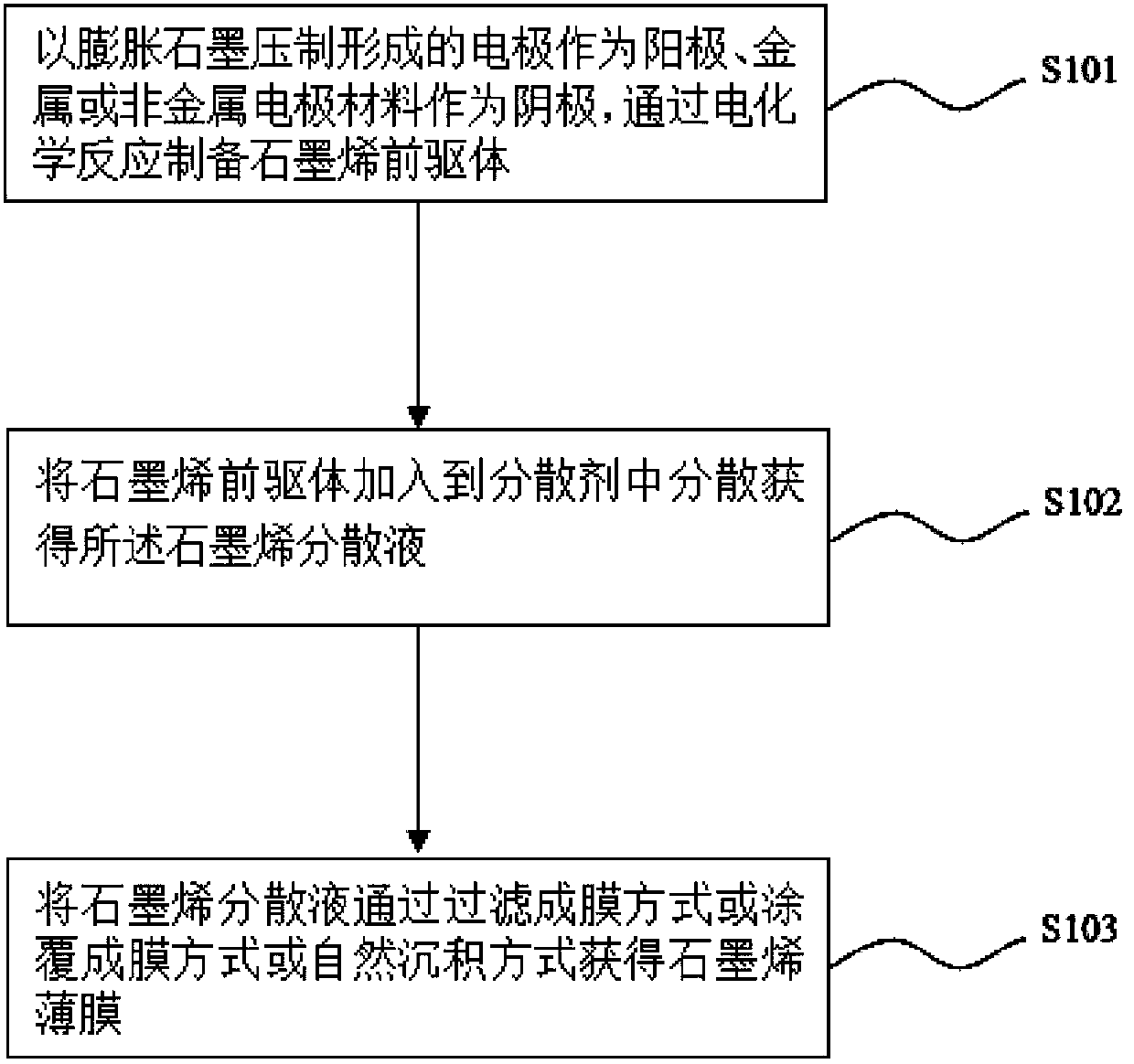

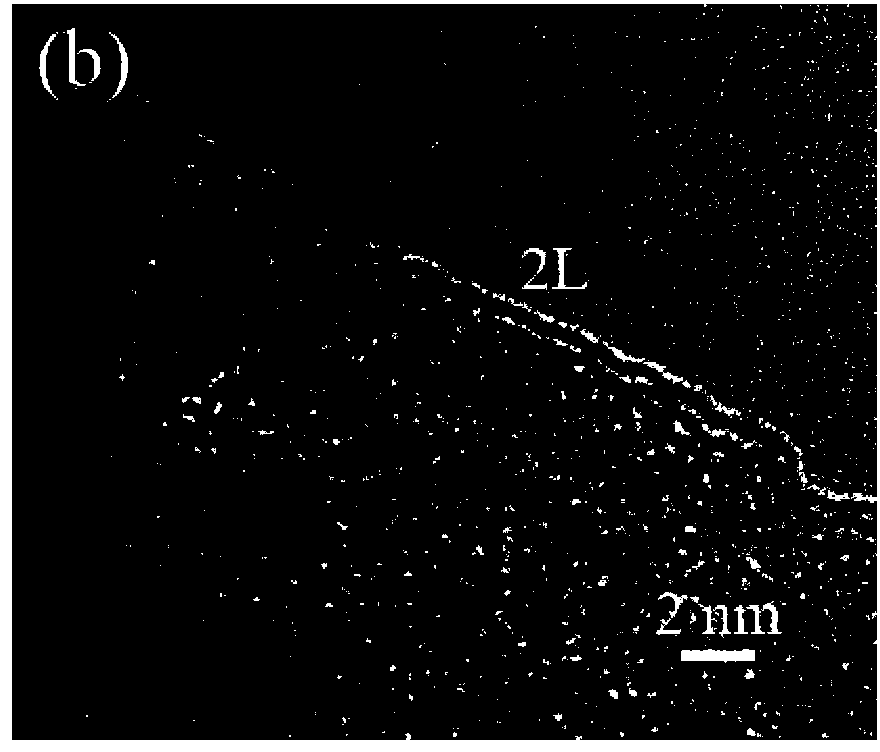

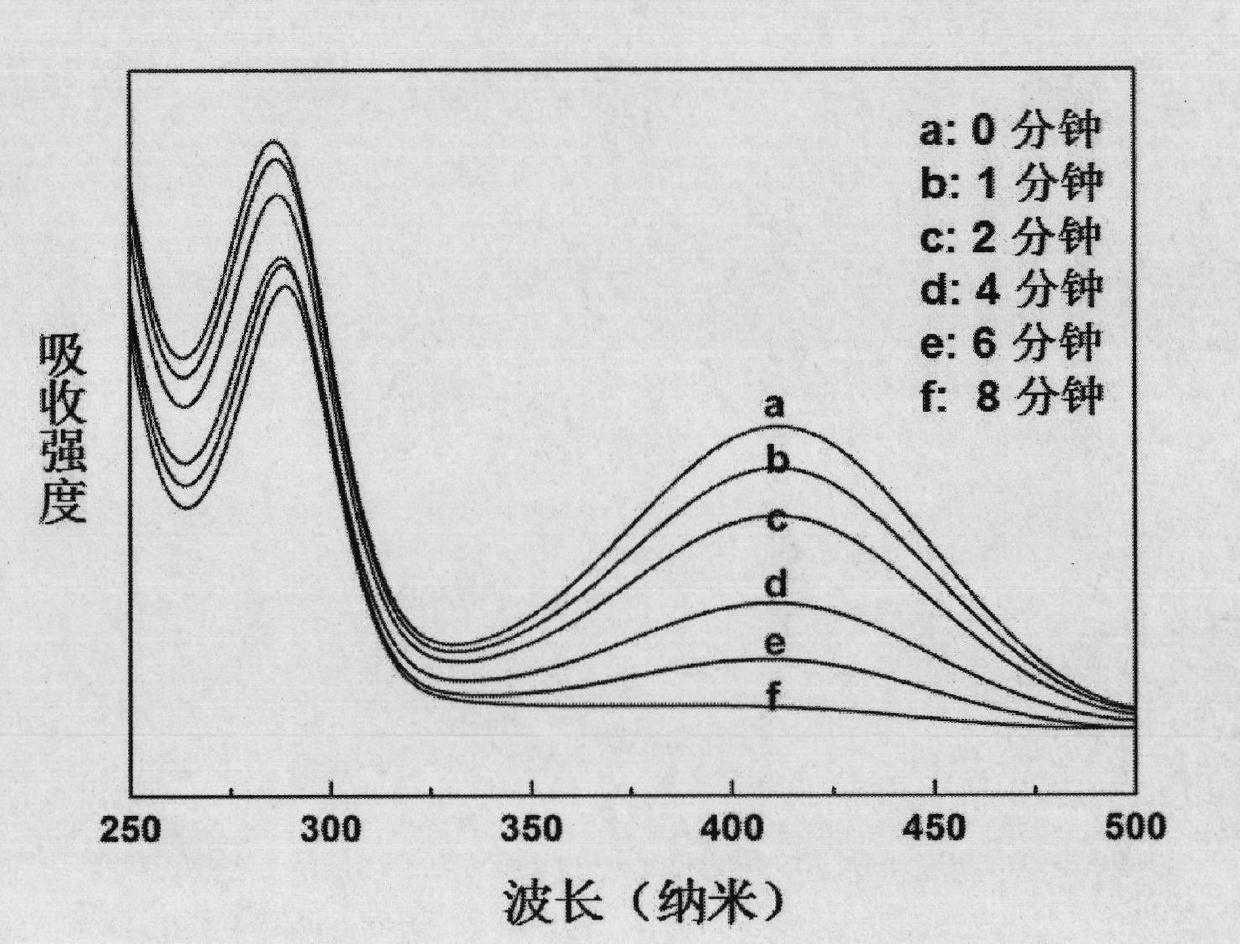

Preparation method of graphene dispersion liquid, and preparation method of graphene film

ActiveCN103466603AIncrease layer spacingIncrease concentrationMaterial nanotechnologyGrapheneElectrochemical responseMetallic electrode

The invention discloses a preparation method of a graphene dispersion liquid. The preparation method of the graphene dispersion liquid comprises the following steps: placing an expanded graphite compacted electrode and a metallic or non-metallic electrode material in an electrolyte solution as an anode and a cathode respectively, and applying a voltage of 1-20V and / or a current having a density of 1-200mA / cm<2> between the anode and the cathode for carrying out an electrochemical reaction for 1-120min; and washing an anode product obtained after the electrochemical reaction, adding to a dispersant, and carrying out ultrasonic or / and mechanical stirring dispersion to obtain the graphene dispersion liquid. The invention also discloses a preparation method of a graphene film. The graphene dispersion liquid forms the graphene film on a substrate in a filter film forming mode or a coating film forming mode or a natural deposition mode. The preparation methods have the advantages of simple process, easy operation, high controllability, low cost and mild reaction condition, and are suitable for the industrialized large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

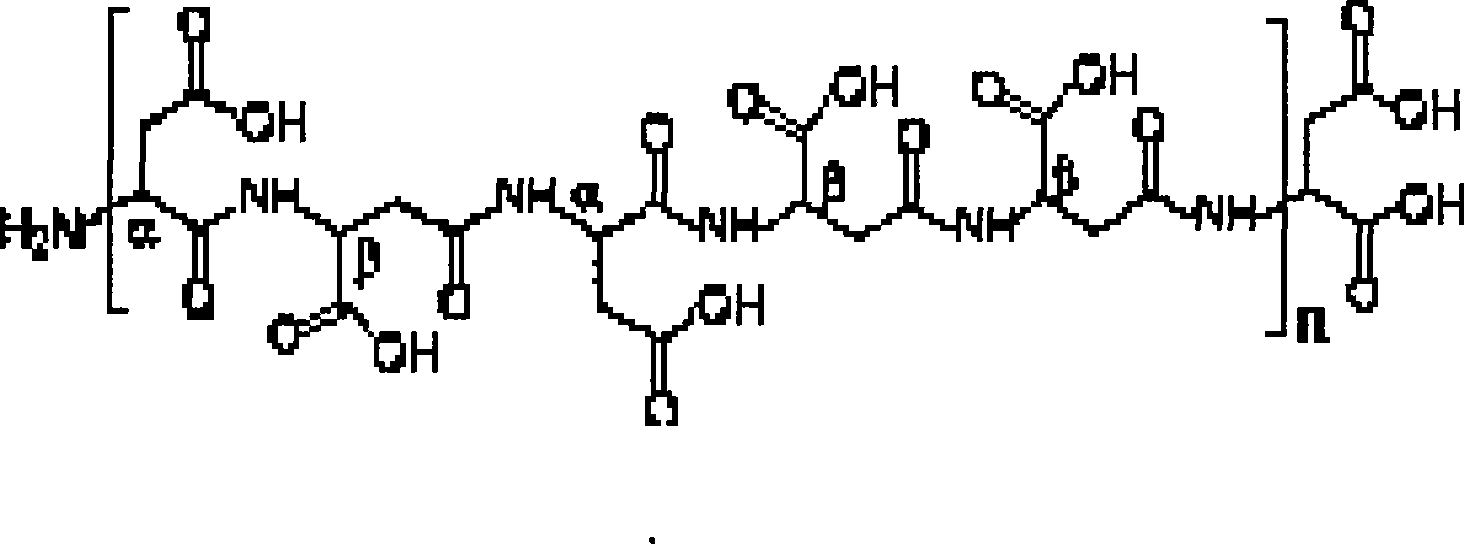

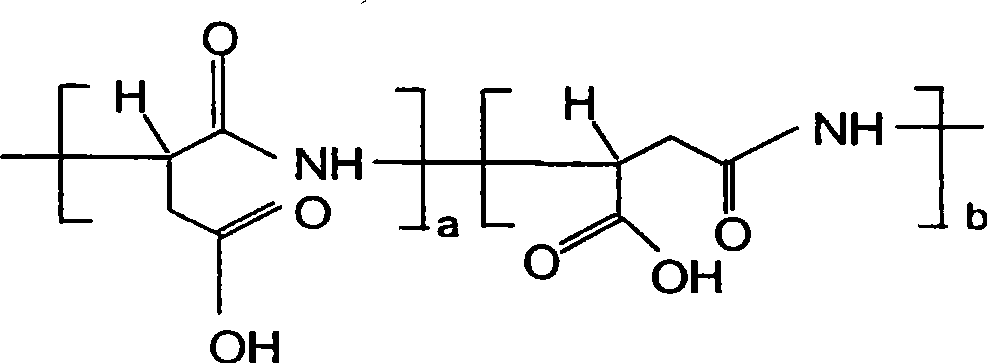

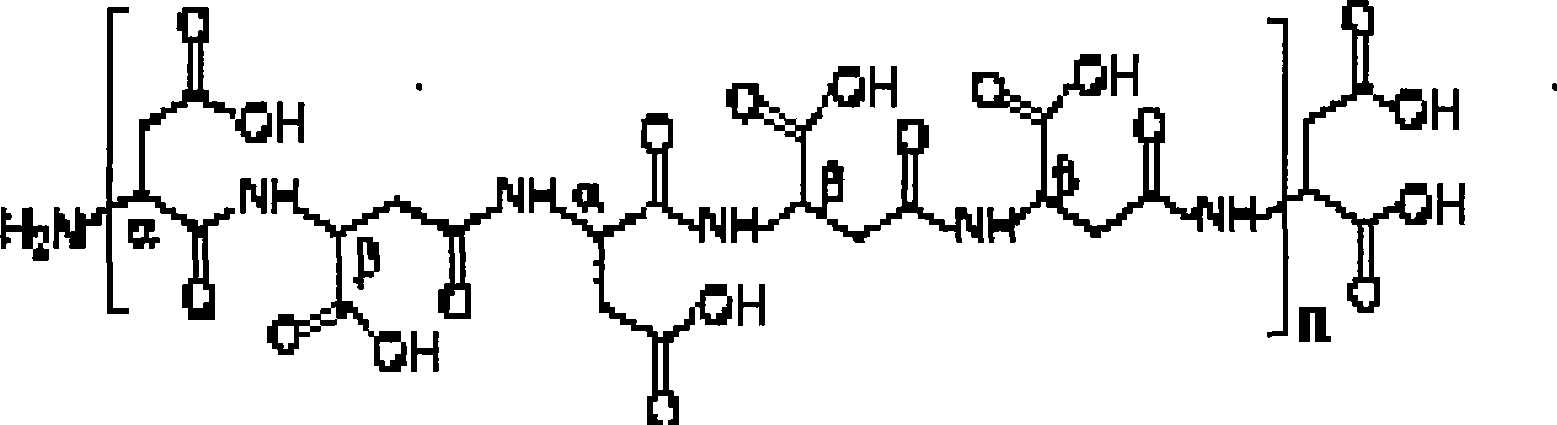

Synergistic slow release nitrogen fertilizer and preparation thereof

ActiveCN101434504AExtend the fertilizer periodIncrease profitAgriculture gas emission reductionUrea compound fertilisersMolten stateUrease Inhibitors

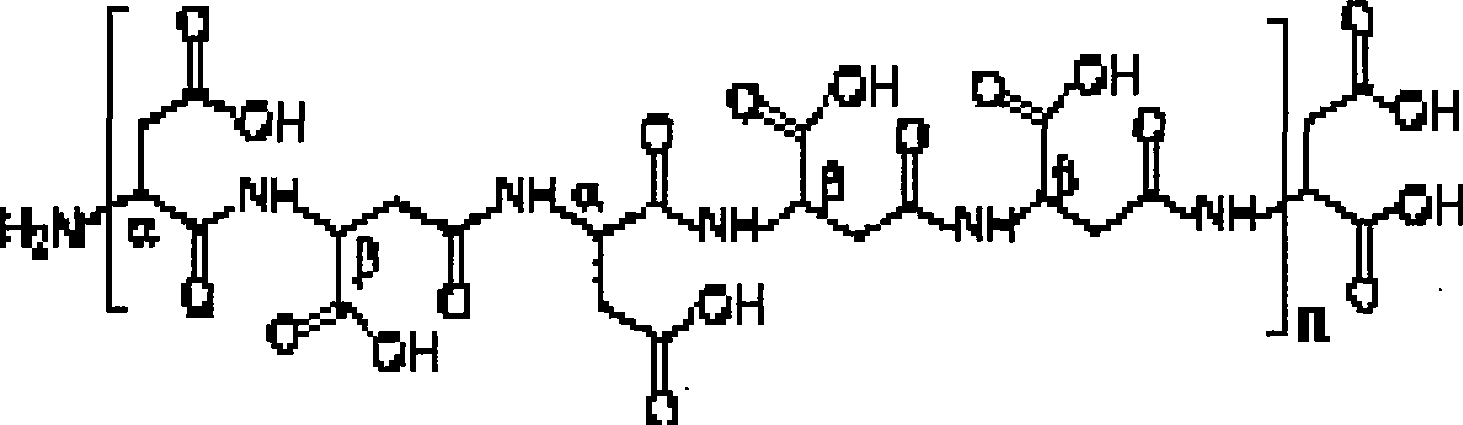

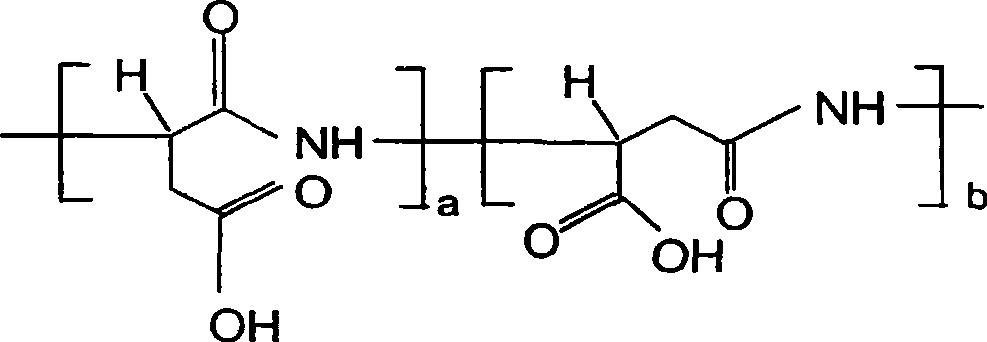

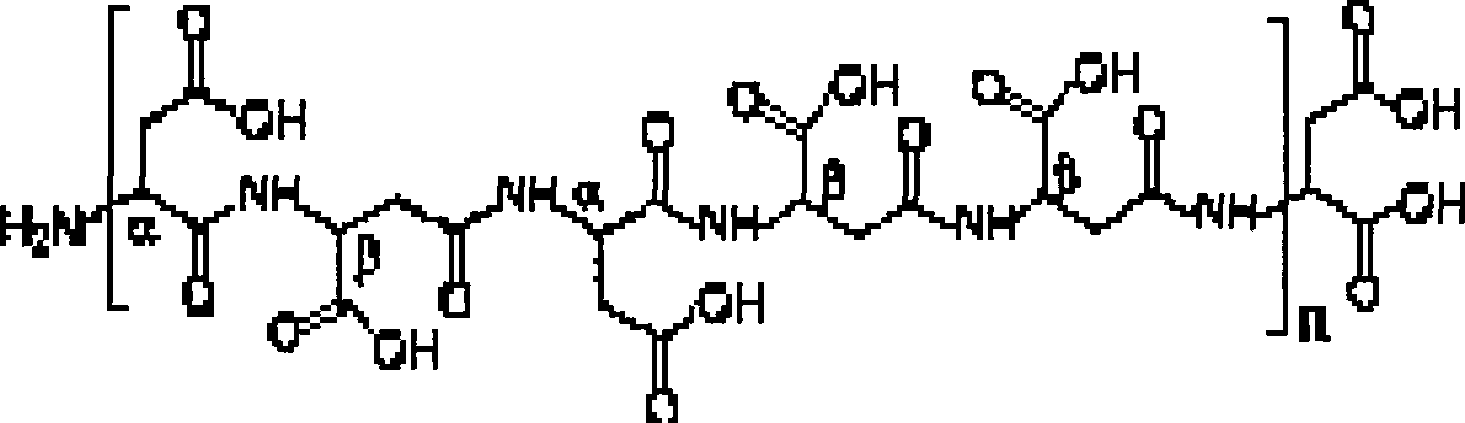

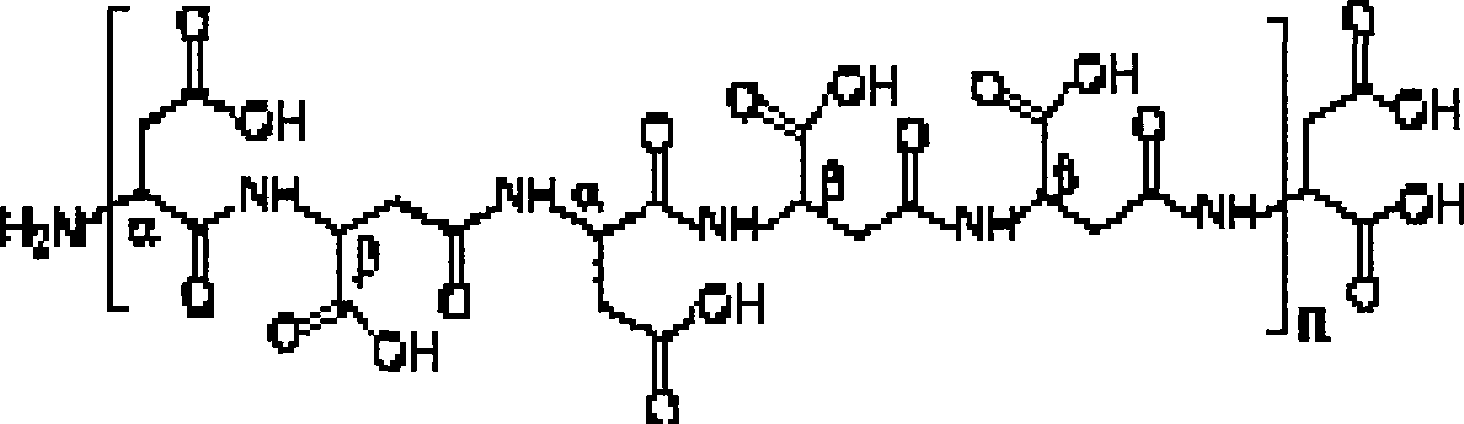

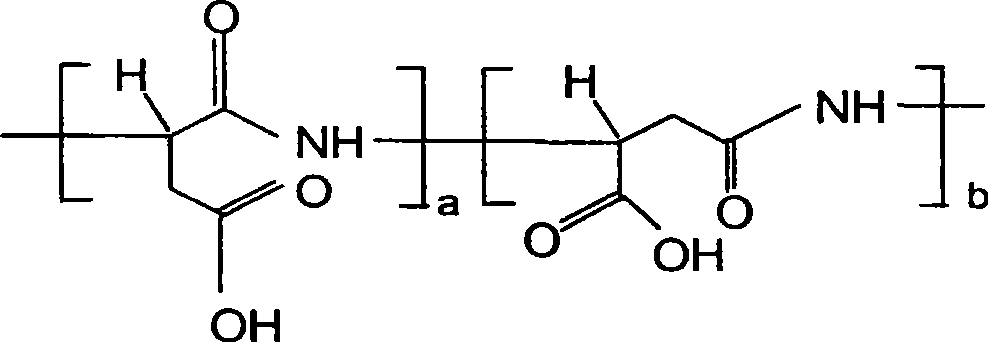

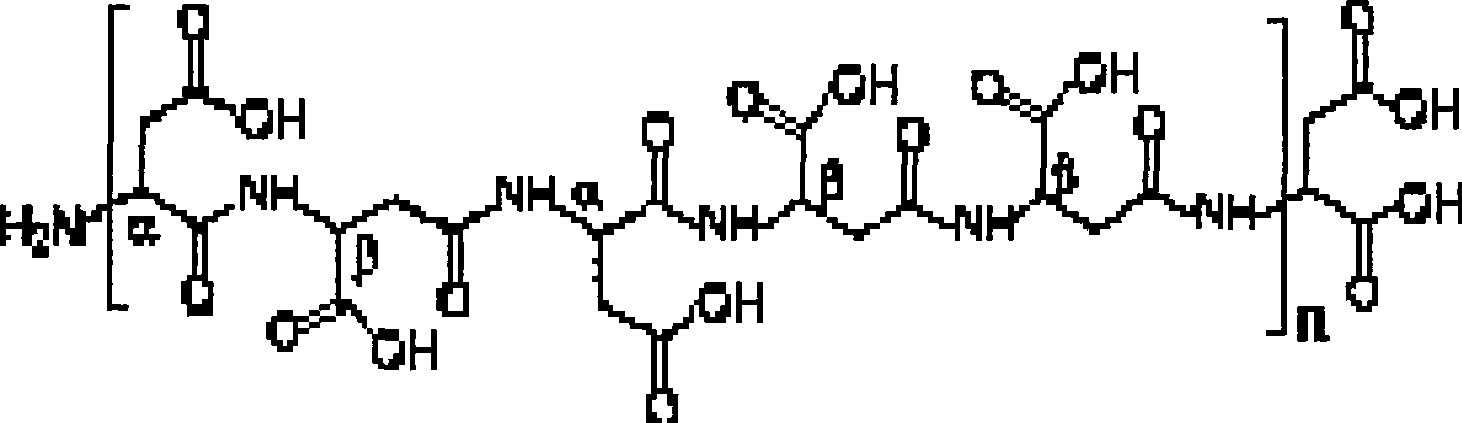

The invention relates to a nitrogen fertilizer, in particular to a synergistic slow-releasing nitrogen fertilizer and a preparation method thereof. The fertilizer comprises: urea nitrogen fertilizer, biochemical inhibitors and a synergist, wherein, the weight portion ratio of the urea nitrogen fertilizer to the biochemical inhibitors to the synergist is equal to 1:0.001 to 0.1:0.0005 to 1; the biochemical inhibitors are a nitrification inhibitor and a urease inhibitor and the synergist is poly (aspartic acid), wherein, the weight portion ratio between the urease inhibitor and the nitrification inhibitor is equal to 0.5 to 2:0.5 to 2. The preparation method is as follows: during the operation process of the nitrogen fertilizer, the biochemical inhibitor and the synergist are added into the fertilizer under the molten state of the fertilizer. The synergistic nitrogen fertilizer of the invention is suitable for various plants and soils. The fertilizer has notable disease-resistant, drought-resistant and lodging resistant effects on crops after being applied in soils, can effectively improve nutrients reserving power of soils and has certain effect on succession crops. Gain production can be increased by 8% to 30%, vegetable production can be increased by 14% to 60% and cash crop production can be increased by more than 30% by using the synergistic slow-releasing nitrogen fertilizer.

Owner:SINOCHEM AGRI LINYI R&D CENT CO LTD

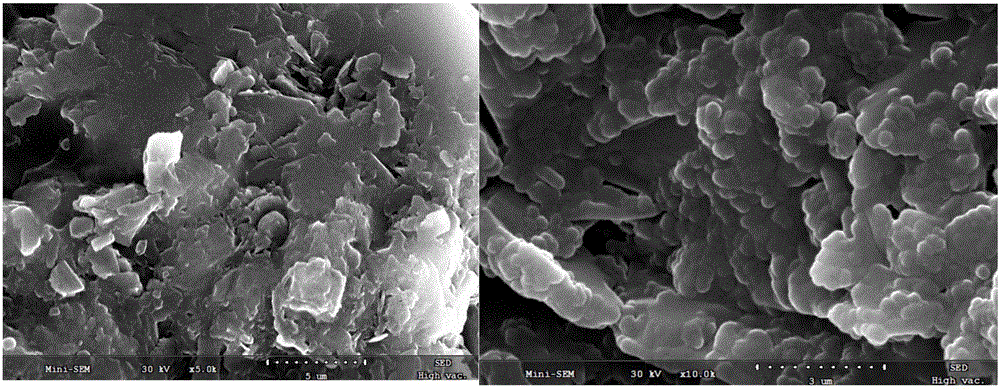

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

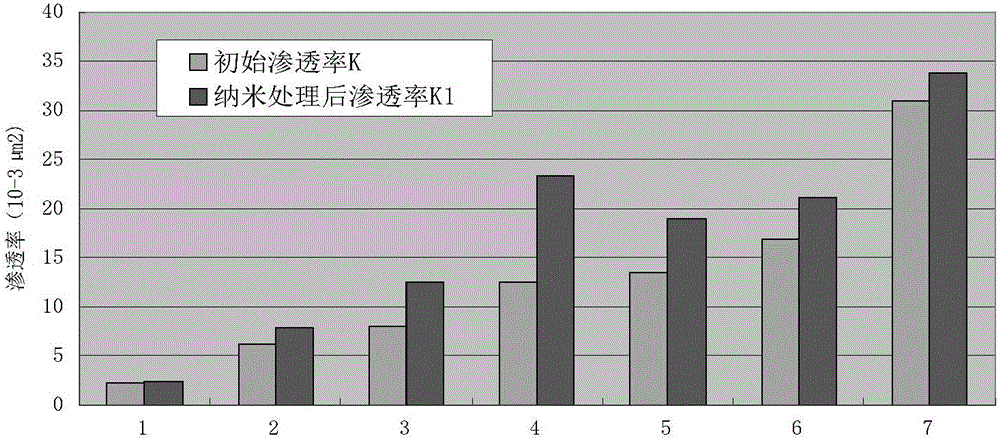

Pressure-reducing and injection-increasing agent for water injection well of low-permeability oilfield, and preparation method and application thereof

InactiveCN106085401ALarge specific surface areaReduce thicknessFluid removalDrilling compositionNanometreChemistry

The invention relates to a pressure-reducing and injection-increasing agent for a water injection well of a low-permeability oilfield, and a preparation method and application thereof. The pressure-reducing and injection-increasing agent is prepared from the following components by weight: 2.0 to 6.5% of a multifunctional surface treating agent, 0.75 to 3.15% of hydrophobic nanometer silica or nanometer poly-silicon and 2 to 8% of a pH conditioning agent, with the balance being deionized water, wherein the multifunctional surface treating agent comprises, by weight, 30 to 80% of a nonionic surfactant, 2 to 25% of an anionic surfactant and 10 to 50% of an ampholytic surfactant. The pressure-reducing and injection-increasing agent is free of pollution to strata and can overcome the problems of high water injection pressure, unqualified injection allocation of a water injection rate and a short action period of injection increase in the later stage of development. The preparation method is simple in process, free of emission of pollutants and easy for industrial large-scale production.

Owner:郑州东申石化科技有限公司

Synergistic slow release nitrogen fertilizer and preparation thereof

ActiveCN101434502AExtend the fertilizer periodImprove the absorption and utilization effectAgriculture gas emission reductionFertilizer mixturesMolten stateNitrification inhibitors

The invention relates to a synergistic fertilizer, in particular to a green and environmental protection synergistic slow-releasing nitrogen fertilizer which is mixed in ammonium nitrogen fertilizers or urea, and a preparation method thereof. The fertilizer constituents are as follows: nitrogen fertilizer, a biochemical inhibitor and a synergist, wherein, the weight portion ratio of the nitrogen fertilizer to the biochemical inhibitor to the synergist is equal to 1:0.005 to 0.1:0.0005 to 1; the biochemical inhibitor is a nitrification inhibitor, and the synergist is poly (aspartic acid). The preparation method is as follows: during the operation process of the nitrogen fertilizer, the biochemical inhibitor and the synergist are added into the fertilizer under the molten state of the fertilizer. The synergistic nitrogen fertilizer of the invention is suitable for various plants and soils. The fertilizer has notable disease-resistant, drought-resistant and lodging resistant effects on crops after being applied in soils, can effectively improve nutrients reserving power of soils and has certain effect on succession crops. Gain production can be increased by 8% to 30%, vegetable production can be increased by 14% to 60% and cash crop production can be increased by more than 30% by using the synergistic slow-releasing nitrogen fertilizer.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

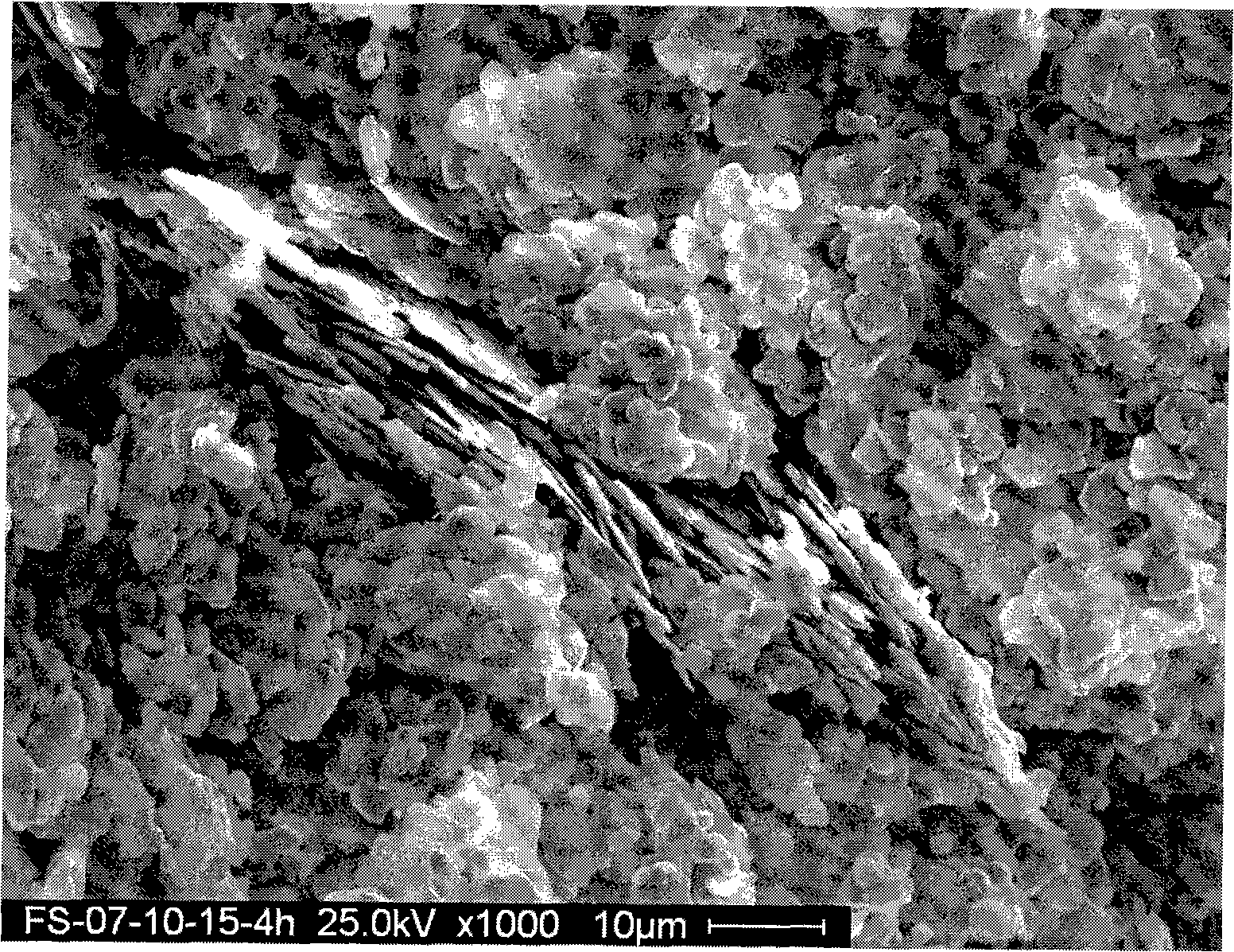

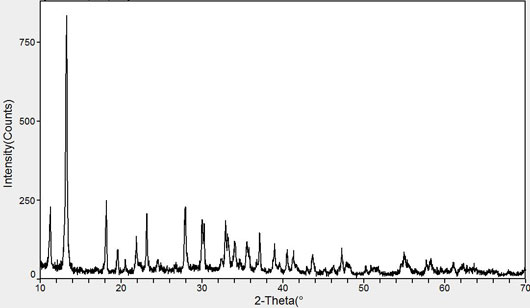

Preparation method of superfine nanometer lithium iron phosphate electrode material and application thereof

InactiveCN102674291AImprove electrochemical performanceIncrease capacityCell electrodesNanotechnologyLithium iron phosphatePhosphate

The invention discloses a preparation method of a superfine nanometer lithium iron phosphate electrode material, comprising the following steps of: firstly, taking an iron source compound and a phosphorus source compound as raw materials to obtain nanometer ferrous phosphate as a precursor; and secondly, using the ferrous phosphate and the lithium source compound to prepare the superfine nano lithium iron phosphate electrode material. The preparation method of ferrous phosphate, disclosed by the invention, has a simple production process; the obtained nanometer ferrous phosphate can be used for preparing the high-purity superfine nanometer lithium iron phosphate; and the ferrous valence state is not changed when the ferrous phosphate is used for preparing the lithium iron phosphate, thus, no carbon source compound or reducing agent needs to to be added to change the iron valence state, and then the carbon-coated lithium iron phosphate or non-carbon-coated lithium iron phosphate can be directly prepared. The nanometer lithium iron phosphate manufactured by the nanometer ferrous phosphate precursor has excellent performance, good discharge capacity and voltage platform performance under high capability and high multiplying power, and long cycle life.

Owner:GUANGXI NUOFANG ENERGY STORAGE TECH

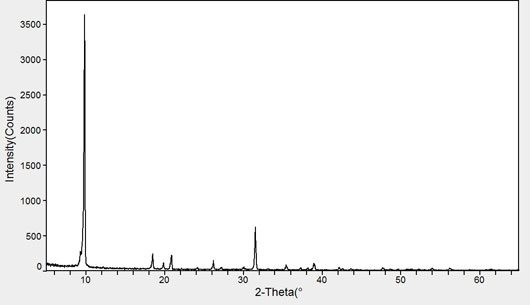

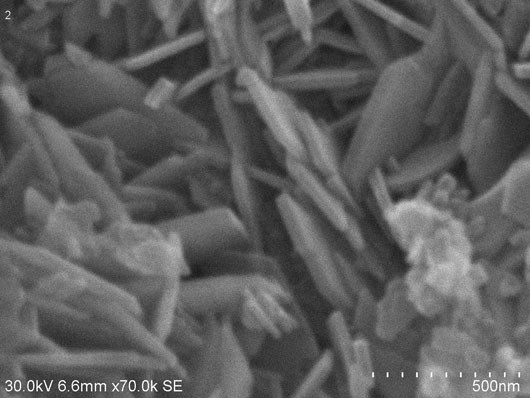

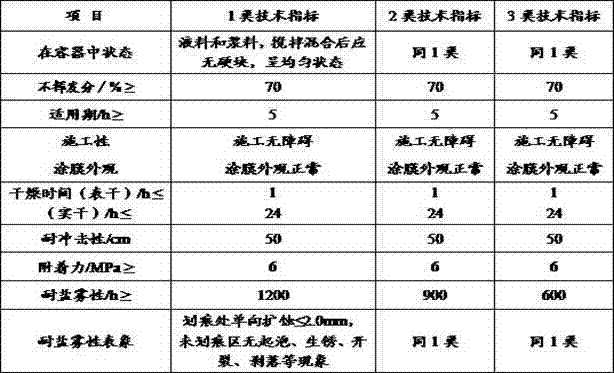

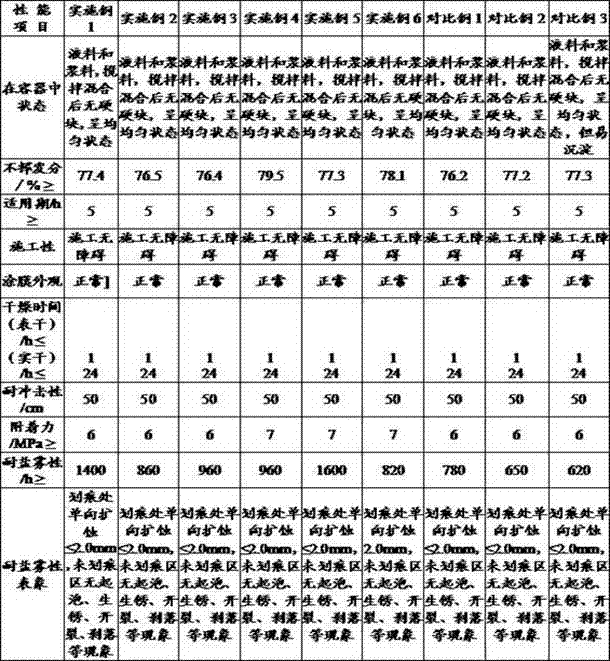

Zinc-graphene heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN103897556AReduce contentHigh mechanical strengthAnti-corrosive paintsEpoxy resin coatingsAluminium powderOrganosolv

The invention relates to a zinc-graphene heavy-duty anti-corrosive coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component B contains a curing agent; the component A contains the following components in percent by mass: 10-20% of a graphene epoxy resin solution, 0.5-2% of an anti-settling agent, 15-30% of zinc powder, 2-10% of aluminum powder, 35-50% of an antirust pigment filling material and 5-10% of an organic solvent; the graphene epoxy resin solution comprises the following components in percent by mass: 1-10% of graphene, 80-90% of an epoxy resin solution, 5-10% of an organic solvent and 1-2% of an additive. Graphene is added into the coating, so that the zinc content is reduced, zinc oxide smog generated during welding is reduced, and the coating is super-strong in water resistance and corrosion resistance. When the coating is prepared, graphene is subjected to pre-soaking treatment to be uniformly dispersed on epoxy groups of epoxy resin, so that the defect that graphene is easy to agglomerate is overcome, the excellent performance of graphene is fully played, and an intermediate with the combination of the advantages of zinc and graphene is obtained. The salt-fog resistance time of the coating prepared by the intermediate is more than 1200 hours.

Owner:江苏道蓬科技有限公司

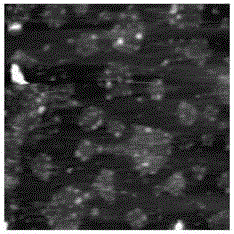

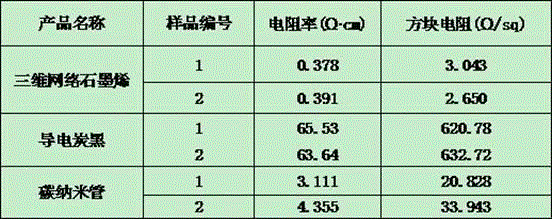

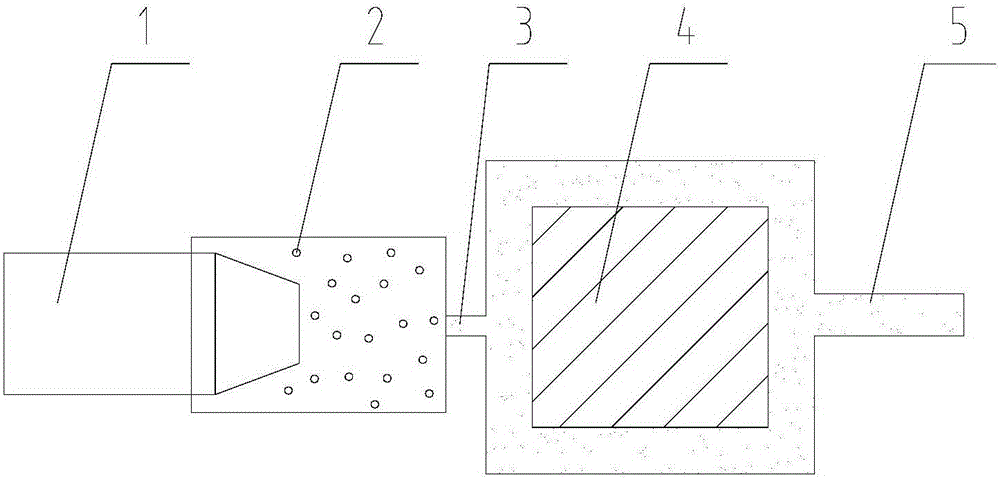

Three-dimensional network graphene for lithium battery and preparing method thereof

ActiveCN104986758AAvoid wrappingLarge specific surface areaCell electrodesElectrolytic agentElectrical battery

The invention relates to three-dimensional network graphene for a lithium battery and a preparing method thereof. The preparing method of the three-dimensional network graphene for the lithium battery comprises the steps that firstly, high-purity expanded graphite, an anion type organic surface active agent, a dispersing agent, an antifoaming agent and a solvent are fully mixed, so that thick few-layer graphene slurry is obtained; liquid swelling high polymer materials are added, composite slurry is obtained after even mixing, and the composite slurry is coated in holes of porous foam materials; finally, the porous foam materials are fully carbonized and then are further processed, so that three-dimensional network graphene powder is obtained. The graphene prepared through the method is of a porous network structure on the microscopic scale, and thus the graphene is high in specific surface area, high in conductivity, high in heat conductivity and good in electrolyte wettability; when the graphene is mixed into positive electrode and negative electrode materials of the lithium battery for manufacturing pole pieces, the electron conduction can be effectively improved, the internal resistance of the battery can be greatly lowered, the amount of heat generated when the battery is charged and discharged is educed, the power density, the energy density and the safety of the battery are further improved, and the service life of the battery is prolonged.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Preparation method of graphene dispersing liquid

The invention belongs to the technical field of preparation of graphene dispersing liquid and relates to a preparation method of the graphene dispersing liquid. The preparation method includes: dissolving a dispersing agent into a solvent to prepare a dispersing agent solution, adding a graphite raw material into the dispersing agent solution, performing primary high-shearing liquid phase stripping through high shearing force to obtain primarily stripped graphite slurry, applying pressure of 10-400MPa to the primarily stripped graphite slurry, then allowing the primarily stripped graphite slurry to pass a tiny slit and intensely collide with a breaking valve so as to allow the primarily stripped graphite slurry to be stripped by high shearing force and collision force for the second time, and allowing graphene to be evenly dispersed in the solvent to obtain the even graphene dispersing liquid. The preparation method has the advantages that the prepared graphene dispersing liquid is high in quality and good in evenness and stability, and the method is environmentally friendly in production process, capable of reducing environment pollution, simple in production process, easy in large-scale industrial production, high in yield, low in cost and friendly in application environment.

Owner:QINGDAO HUAGAO GRAPHENE CORP LTD

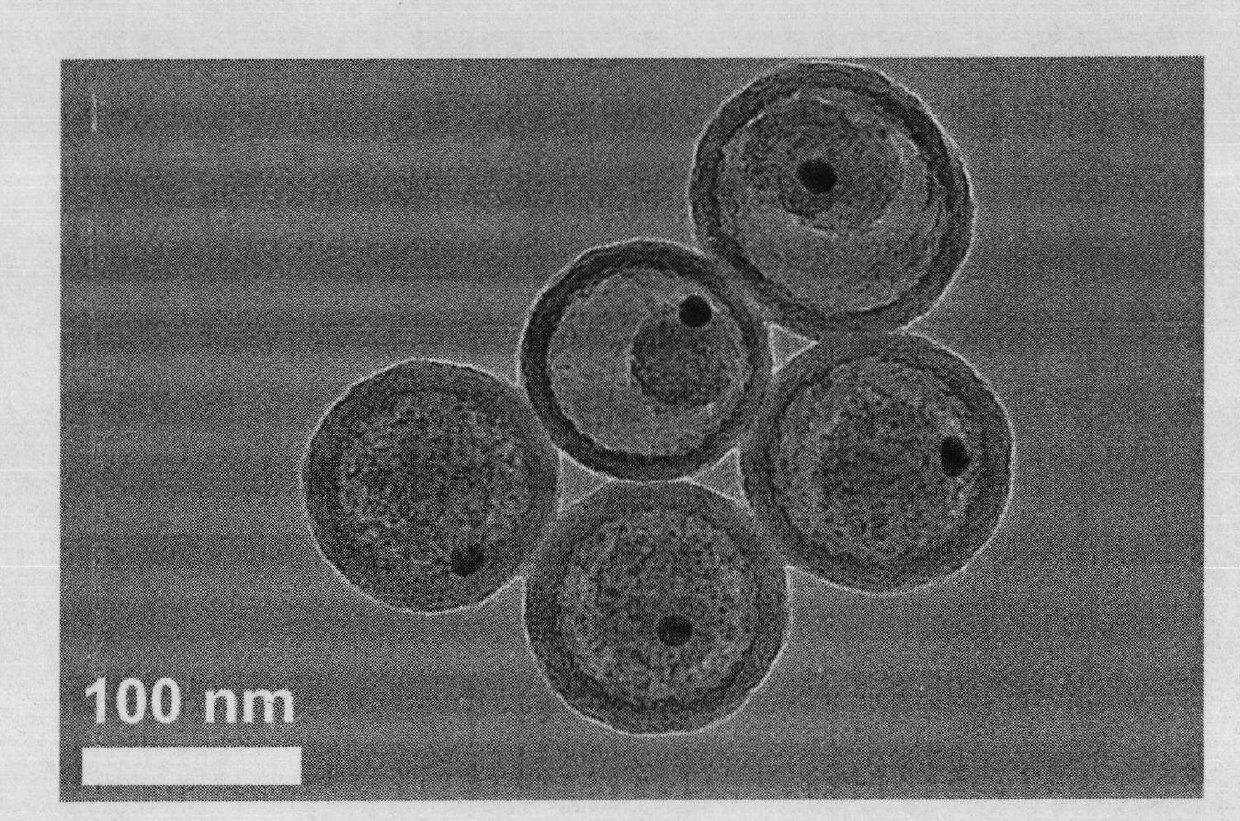

Hollow silicon dioxide sub-microsphere with nanoscale precious metal and silicon dioxide kernel and preparation method thereof

InactiveCN102198929ASimple methodEasy to operateOrganic compound preparationIndividual molecule manipulationMicrosphereSilicon dioxide

The invention relates to a hollow silicon dioxide sub-microsphere with nanoscale precious metal and a silicon dioxide kernel and a preparation method thereof. In the invention, the hollow silicon dioxide sub-microsphere with the silicon dioxide kernel is soaked with an alkaline solution and is then added in various precious metal precursor solutions with certain concentrations; the mixture is heated and reduced to obtain a movable spherical silicon dioxide kernel which is positioned in the hollow silicon dioxide sub-microsphere and simultaneously has particle size of 20-600nm as well as a precious metal particle kernel with the particle size of 2-100nm; the diameter range of the hollow silicon dioxide sub-microsphere is 50-1000nm; the thickness of the casing is 5-100nm; a casing layer hasa mesoporous structure; the average pore size of a mesopore is 1-10nm; and the specific surface area of the sub-microsphere is 110-500m<2> / g.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

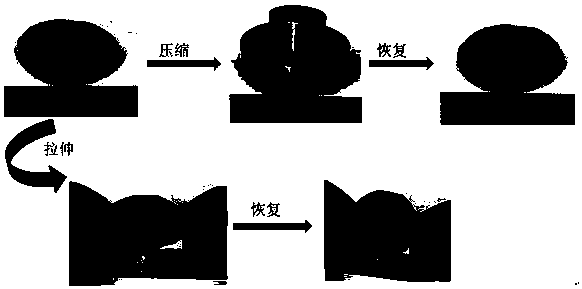

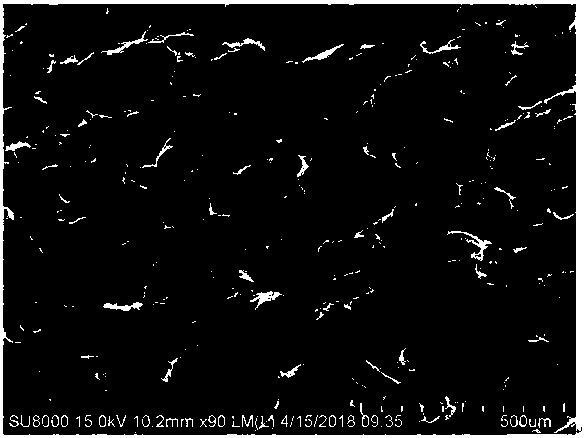

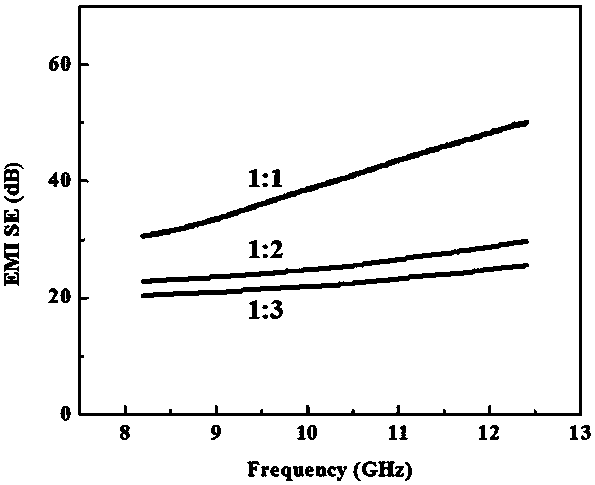

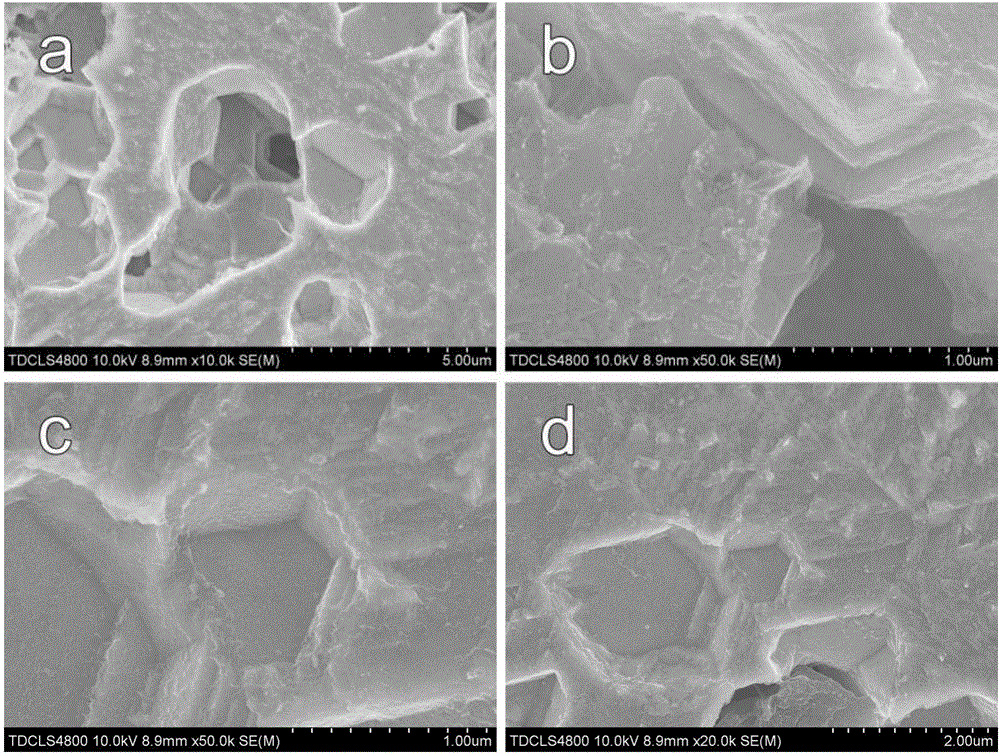

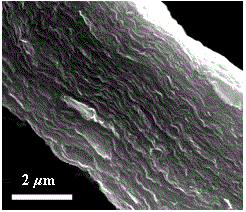

Preparation method of telescopic MXene/graphene composite aerogel with high electromagnetic shielding effect

ActiveCN108620003ALow densityImprove mechanical strengthAerogel preparationColloidal chemistry detailsOxideMechanical properties of carbon nanotubes

The invention discloses a preparation method of telescopic MXene / graphene composite aerogel with a high electromagnetic shielding effect. According to the method, the three-dimensional netlike composite aerogel with a rich pore structure is formed through compounding MXene and reduced graphene oxide, inducing the reduced graphene oxide and the MXene by utilizing a modifying agent and performing cold and dry treatment. The preparation method disclosed by the invention has the following advantages that the telescopic MXene / graphene composite aerogel with the high electromagnetic shielding effectcan be obtained through uniformly mixing the reduced graphene oxide and MXene dispersing liquid, introducing the modifying agent and finally performing the cold and dry treatment, which reduces the stacking density of the MXene, constructs a new macroscopic appearance, has extremely excellent mechanical property and scalability and promotes the application feasibility of the MXene in aerospace field.

Owner:HARBIN INST OF TECH

Preparation method of in-situ grown graphene reinforced metal-based composite material

The invention relates to a preparation method of an in-situ grown graphene reinforced metal-based composite material. Carbon-containing organic matter and metal or metal alloy powder are dissolved and mixed in a solvent, mechanically stirred, heated at the temperature of 50-150 DEG C and mixed, the solvent is evaporated, and prefabricated powder is obtained through vacuum drying at the temperature of 50-100 DEG C and grinding; and through the powder metallurgy technique of a hot-press forming method or a cold-press-sintering method or an SPS sintering method, the prefabricated powder is pressed and formed, the carbon-containing organic matter is transformed into graphene, and the three-dimensional graphene / metal-based composite material is obtained. The preparation method is simple, easy to implement and short in preparation cycle, and industrialized batch production is easy; and in addition, the graphene directly grows on a metal matrix in the preparation process, the crystallisation degree of the graphene in the obtained graphene reinforced metal-based composite material is high, the number of defects is small, and the dispersity is good. The preparation method has potential application prospects in the composite material field, the functional material field and the like.

Owner:TIANJIN UNIV

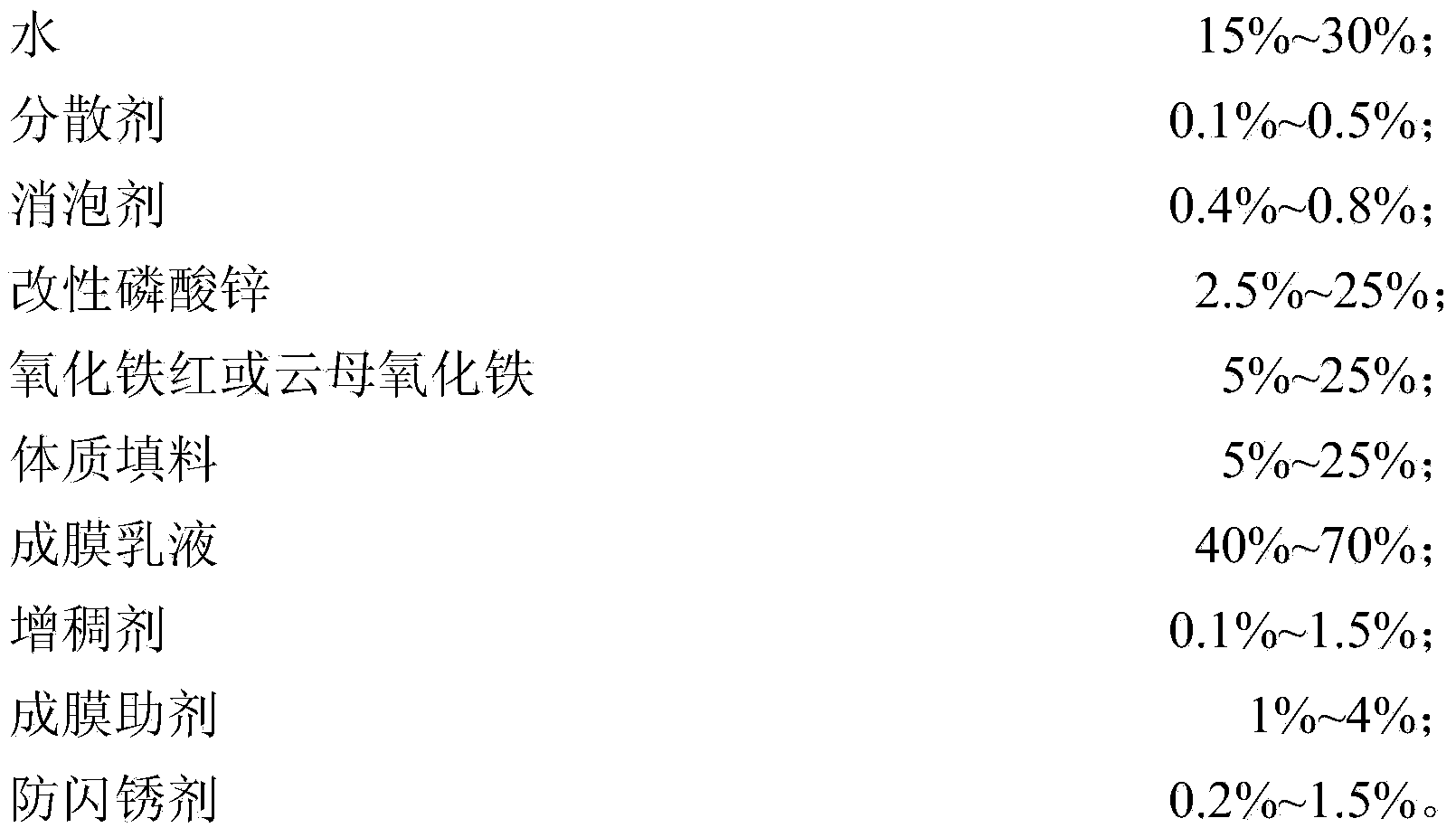

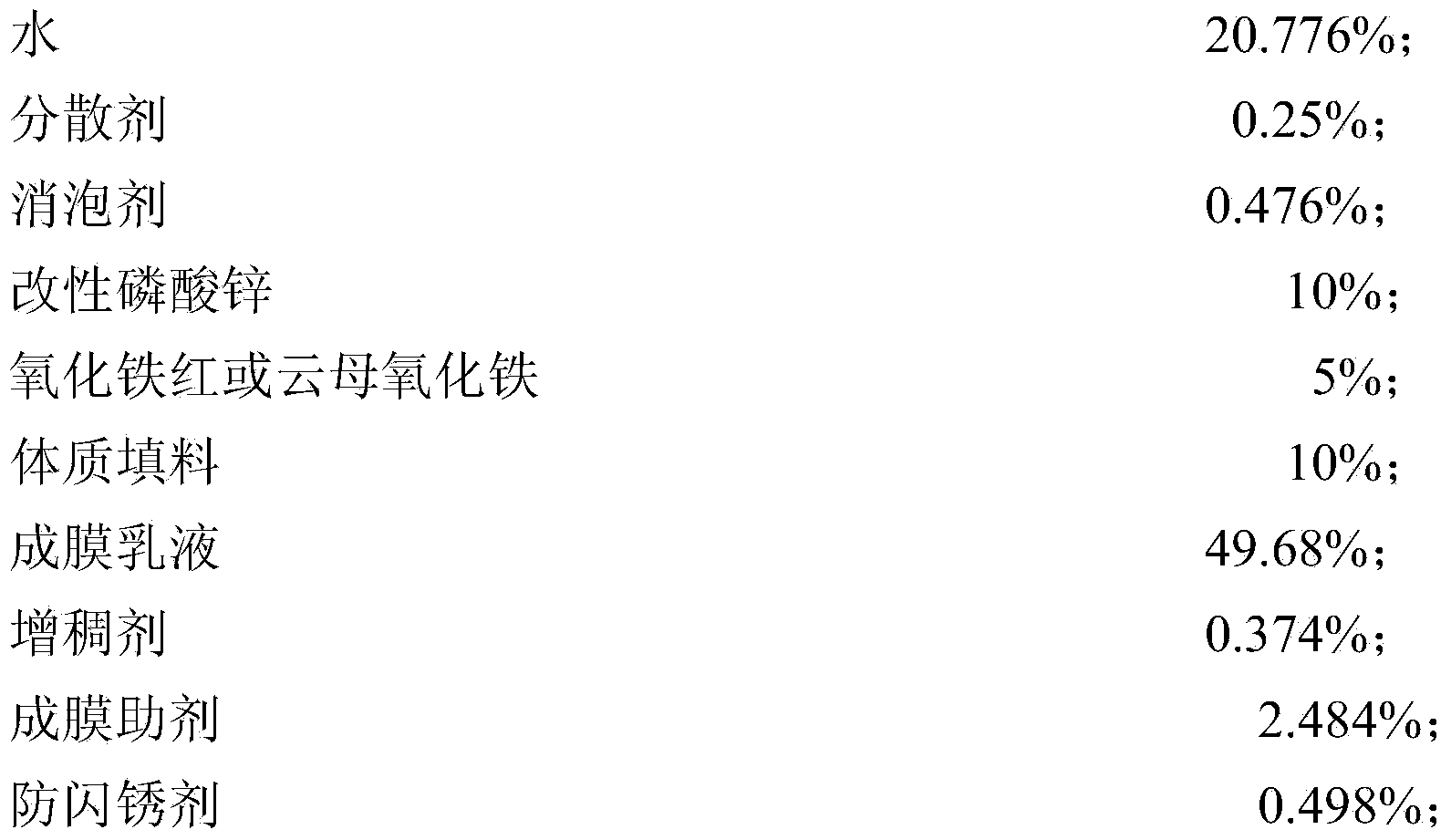

Bottom unified aqueous anticorrosive paint and preparation method

The invention discloses a bottom unified aqueous anticorrosive paint and its preparation method. the paint is composed of the following ingredients, by weight, 15-30% of water, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 2.5-25% of modified zinc phosphate, 5-25% of iron oxide red or mica iron oxide, 5-25% of a body filler, 40-70% of a film-forming emulsion, 0.1-1.5% of a thickening agent, 1-4% of a film-forming auxiliary agent and 0.2-1.5% of a flash-rust inhibitor. According to the bottom unified aqueous anticorrosive paint, each ingredient with specific weight percentage interacts with each other. Thus, comprehensive performance of the paint is raised, and in particular, anticorrosive performance of the paint is excellent. The paint is environmentally friendly. Problems of heavy odor, high pollution and the like existing in a traditional oil paint are solved. Meanwhile, each anticorrosion index is guaranteed. The product has simple preparation and construction technologies, is easy to carry out, is easy for large-scale industrial production, and has a wide application prospect.

Owner:ZHEJIANG UNIV

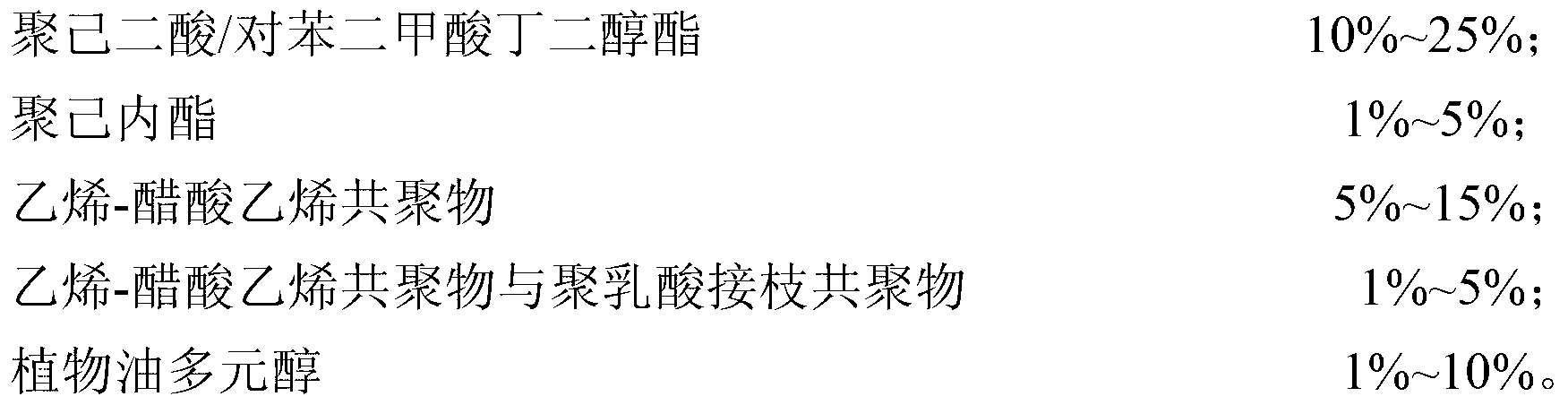

PLA/PBAT biodegradable composite material and preparation method thereof

The invention discloses a PLA / PBAT biodegradable composite material, which is prepared from the following components in percentage by weight: 60-75% of a polylactic acid, 60-75% of poly(adipic acid) / butylene terephthalate, 1-5% of poly (caprolactone), 5-15% of an ethylene-vinyl acetate copolymer, 1-5% of an ethylene-vinyl acetate copolymer and polylactic acid graft copolymer, and 1-10% of vegetable oil polyols. The PLA / PBAT biodegradable composite material disclosed by the invention is excellent in tensile strength and toughness, good in chemical stability, and easy to process, and in addition, the material is biodegradable. The invention also discloses a preparation method of the PLA / PBAT biodegradable composite material, which can be implemented through the existing equipment twin-screw extruder, therefore, the method is easy to implement, strong in maneuverability, and easy to realize industrialized mass production, and has good economic benefits and broad application prospects.

Owner:LINONGFENG TECH

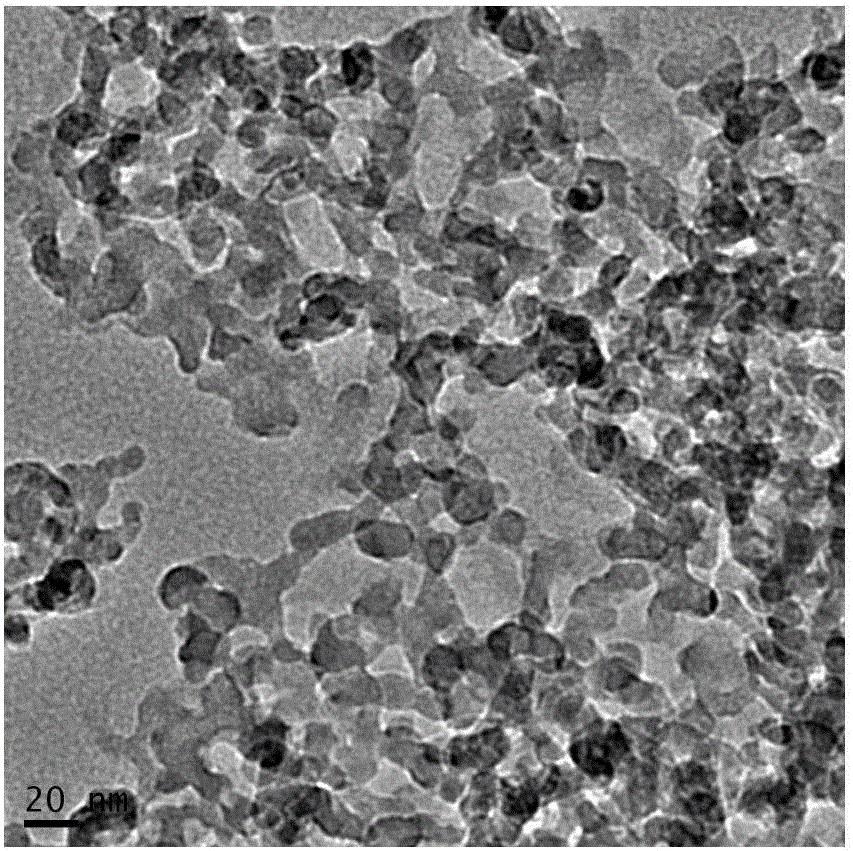

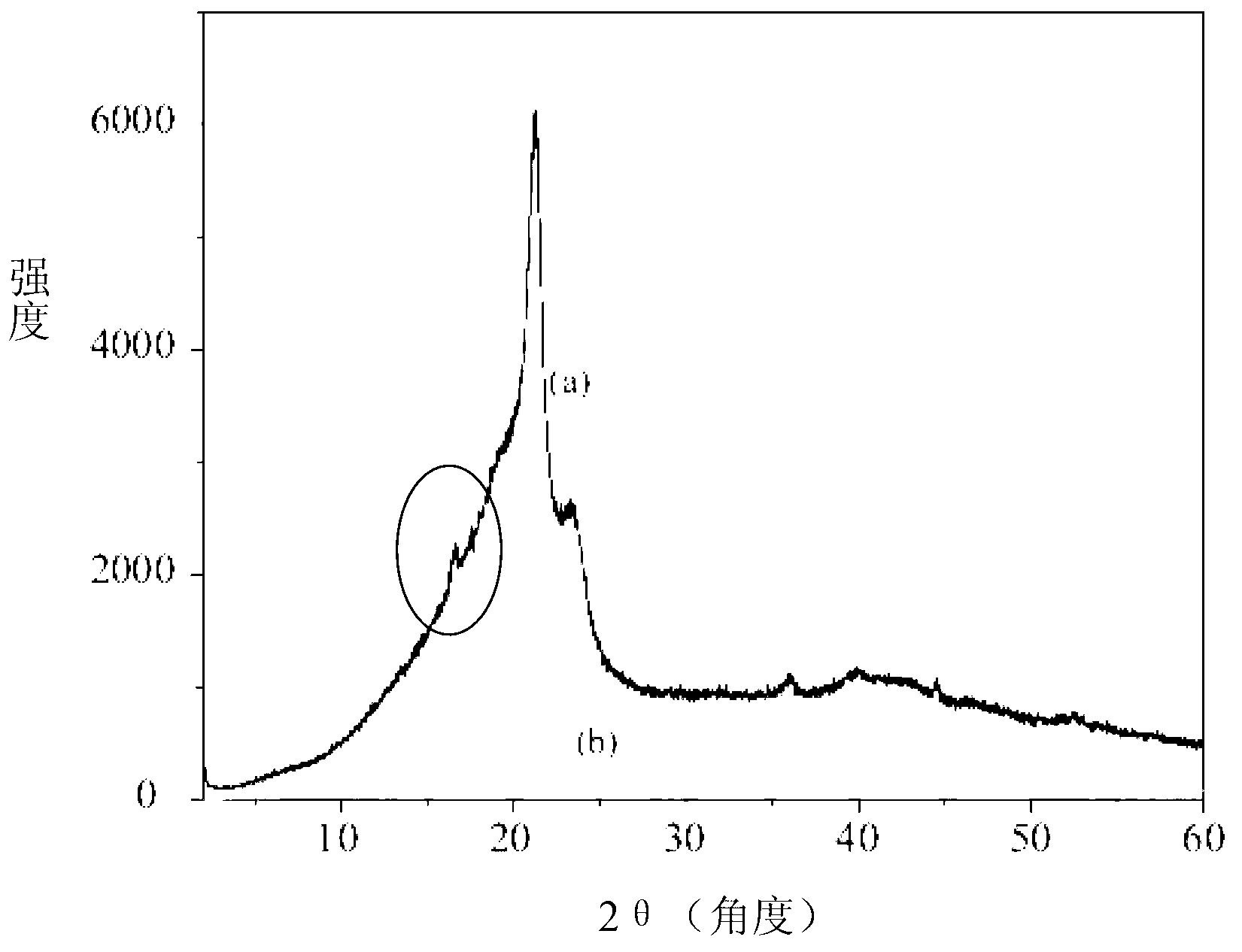

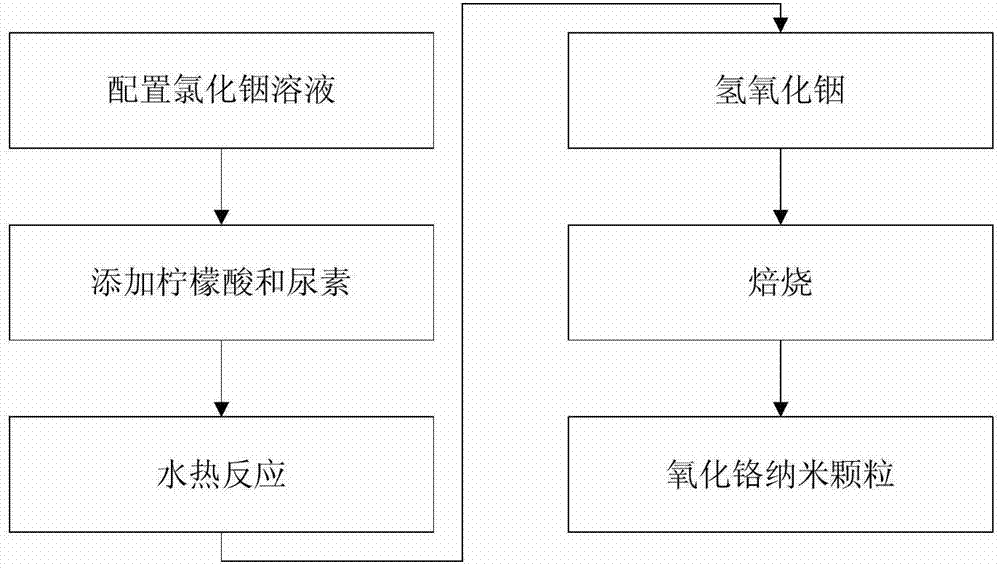

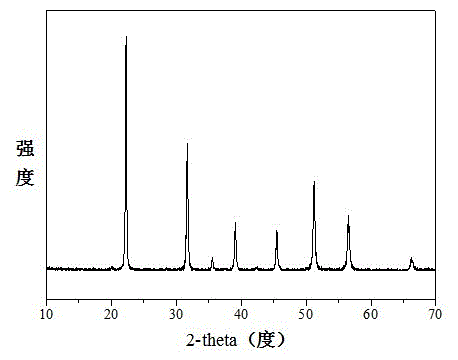

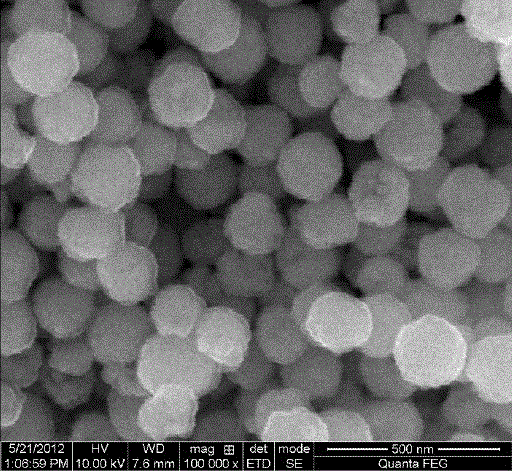

Preparation method for indium oxide nanometer material

InactiveCN102826593AUniform particle size distributionHigh purityMaterial nanotechnologyGallium/indium/thallium compoundsDispersityFlat panel display

The invention relates to a preparation method for an indium oxide (In2O3) nanometer material, and belongs to the technical field of preparation of inorganic materials. The preparation method comprises the following steps: firstly, carrying out a hydrothermal reaction on indium chloride to prepare indium hydroxide (In(OH)3) nanometer particles under the condition of taking lemon acid and urea as additives; and then carrying out a thermal calcination treatment to obtain the spherical In2O3 nanometer material. The method has the advantages of low cost, simplicity in production process, and easiness in industrial large-scale production. The prepared nanometer chromium oxide is a spherical particle with the diameter of about 30nm, and has the advantages of uniform particle distribution, high purity, good dispersity and large specific surface area. Therefore, the prepared nanometer chromium oxide is suitable for the fields of solar batteries, gas sensitive elements, flat-panel displays, electric light regulators, sensors and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

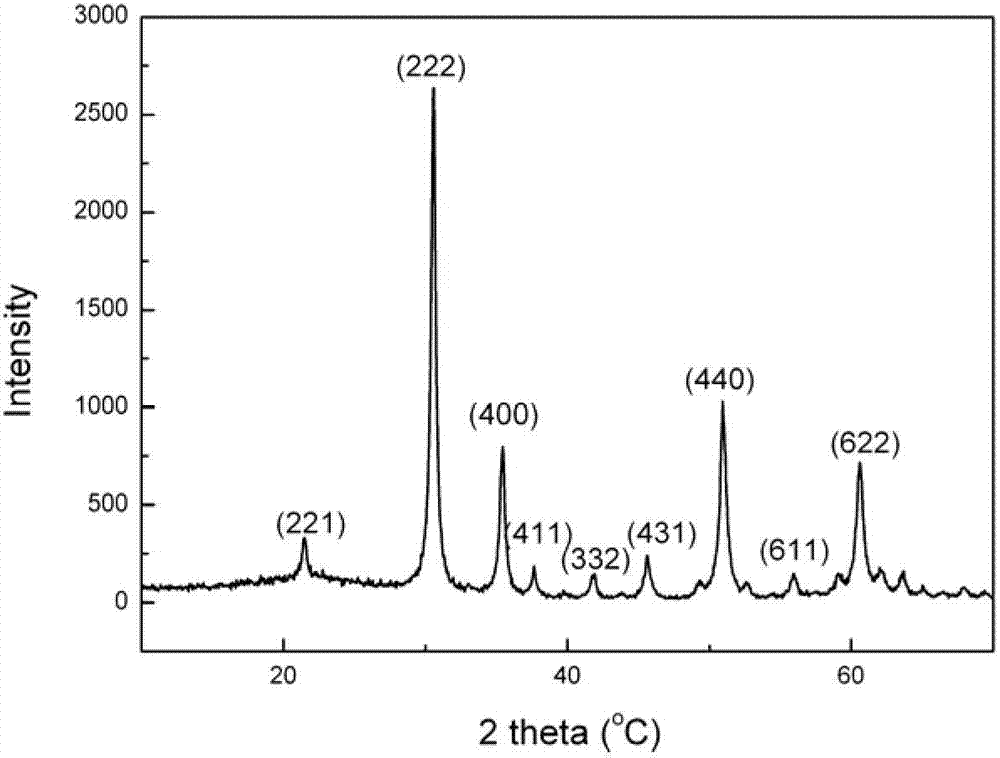

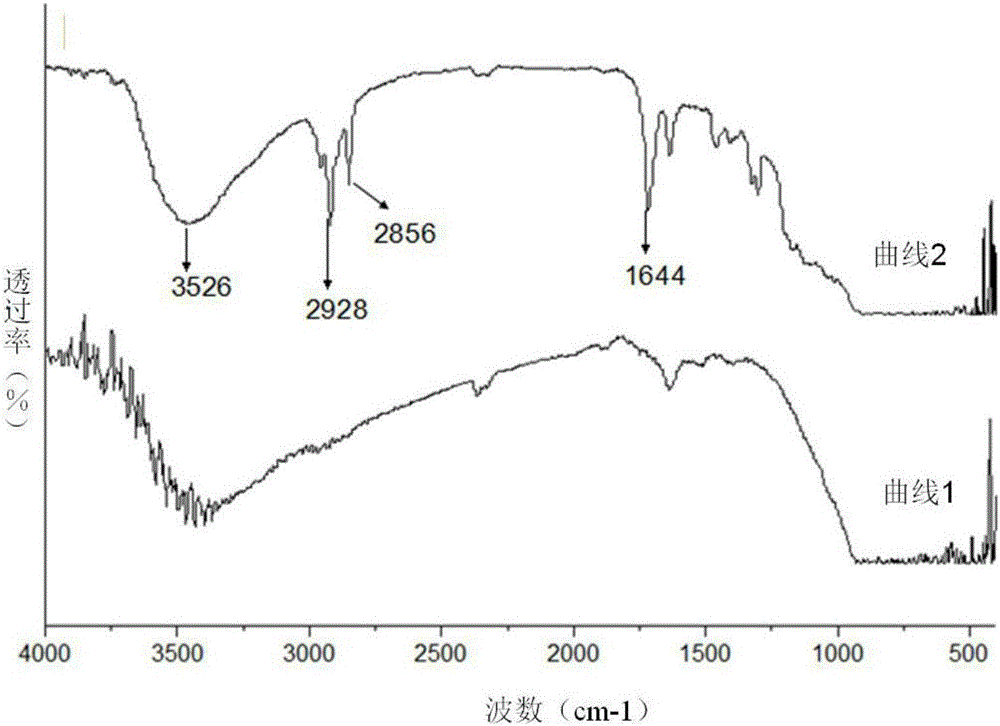

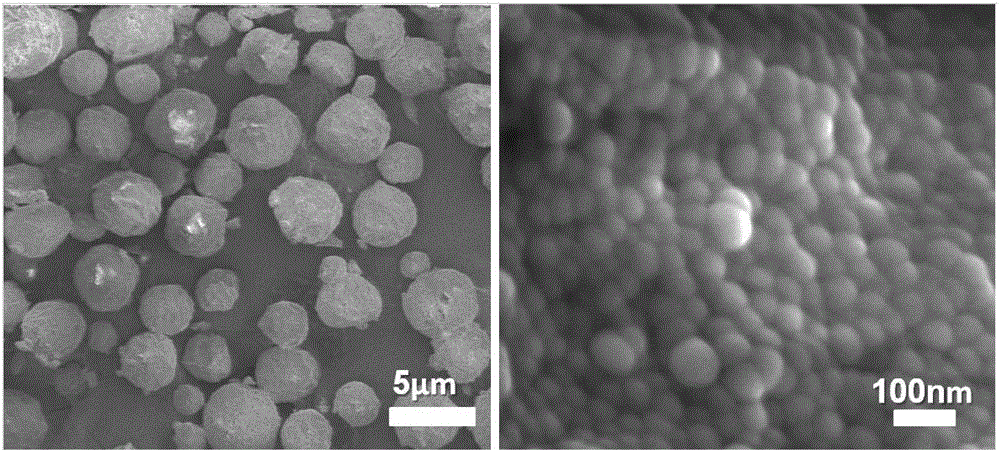

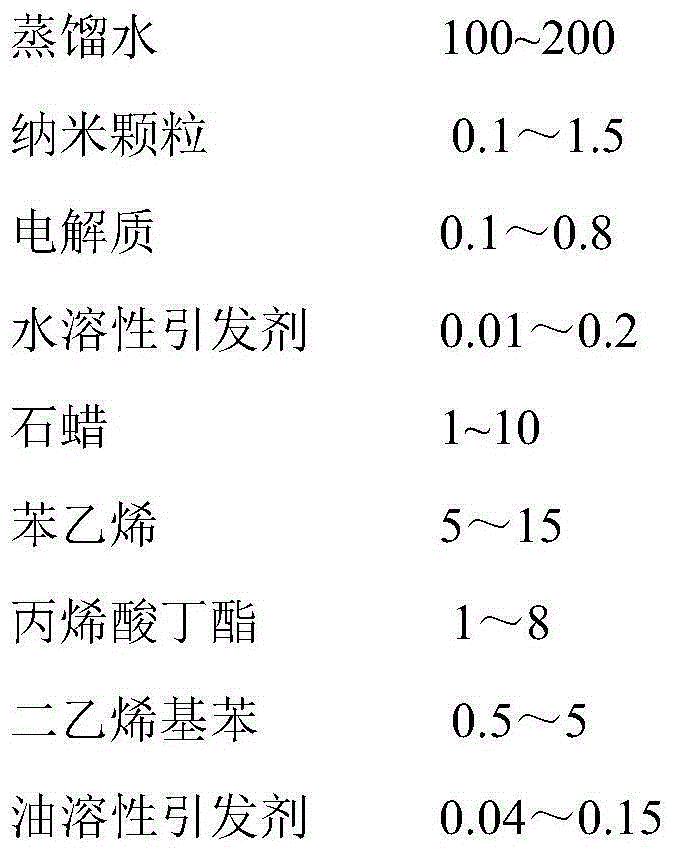

High thermal conductivity composite phase change microcapsule and preparation method thereof

ActiveCN106367031ATightly boundNot harmful to healthHeat-exchange elementsMicroballoon preparationCross-linkOil phase

The invention discloses a high thermal conductivity composite phase change microcapsule and a preparation method thereof. According to the present invention, paraffin stabilized by adopting nanoparticle as the emulsifier and a monomer form an emulsion and polymerization is performed to form the phase change microcapsule adopting the nanoparticles / polymer as the wall material and adopting the paraffin as the core material, wherein the water phase of the emulsion comprises distilled water, modified nanoparticles, an electrolyte and a water-soluble initiator, and the oil phase comprises paraffin, a monomer, a cross-linking monomer and an oil-soluble initiator; the Pickering emulsion preparation technology is used to embed the nanoparticles in the polymer wall layer and arrange densely, such that the effective heat conduction area is large, the thermal conductivity is greatly improved, and the environmental temperature can be effectively regulated; and the phase change microcapsule preparation process is simple, and has characteristics of no volatile organic solvent addition during the preparation process and the treatment process, green environmental protection, no toxicity, good theoretical significance, and good practical value.

Owner:TIANJIN CHENGJIAN UNIV

Synergistic slow release urea fertilizer and preparation thereof

InactiveCN101434503AExtend the fertilizer periodIncrease profitFertilizer mixturesUrea nitrogenMolten state

The invention relates to a nitrogen synergistic fertilizer, in particular to a synergistic slow-releasing urea fertilizers and a preparation method thereof. The fertilizer constituents are as follows: urea nitrogen fertilizer, a biochemical inhibitor and a synergist, wherein, the weight portion ratio of the urea nitrogen fertilizer to the biochemical inhibitor to the synergist is equal to 1:0.001 to 0.1:0.0005 to 1; the biochemical inhibitor is a urease inhibitor, and the synergist is poly (aspartic acid). The preparation method is as follows: during the operation process of the nitrogen fertilizer, the biochemical inhibitor and the synergist are added into the fertilizer under the molten state of the fertilizer. The synergistic urea fertilizer of the invention is suitable for various plants and soils. The fertilizer has notable disease-resistant, drought-resistant and lodging resistant effects on crops after being applied in soils, can effectively improve nutrients reserving power of soils and has certain effect on succession crops. Gain production can be increased by 8% to 30%, vegetable production can be increased by 14% to 60% and cash crop production can be increased by more than 30% by using the synergistic slow-releasing urea fertilizer.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Aqueous anticorrosive heat-insulation paint and preparation method

InactiveCN103819989AGood value for moneyWide range of applicationsAnti-corrosive paintsReflecting/signal paintsChemistryEmulsion

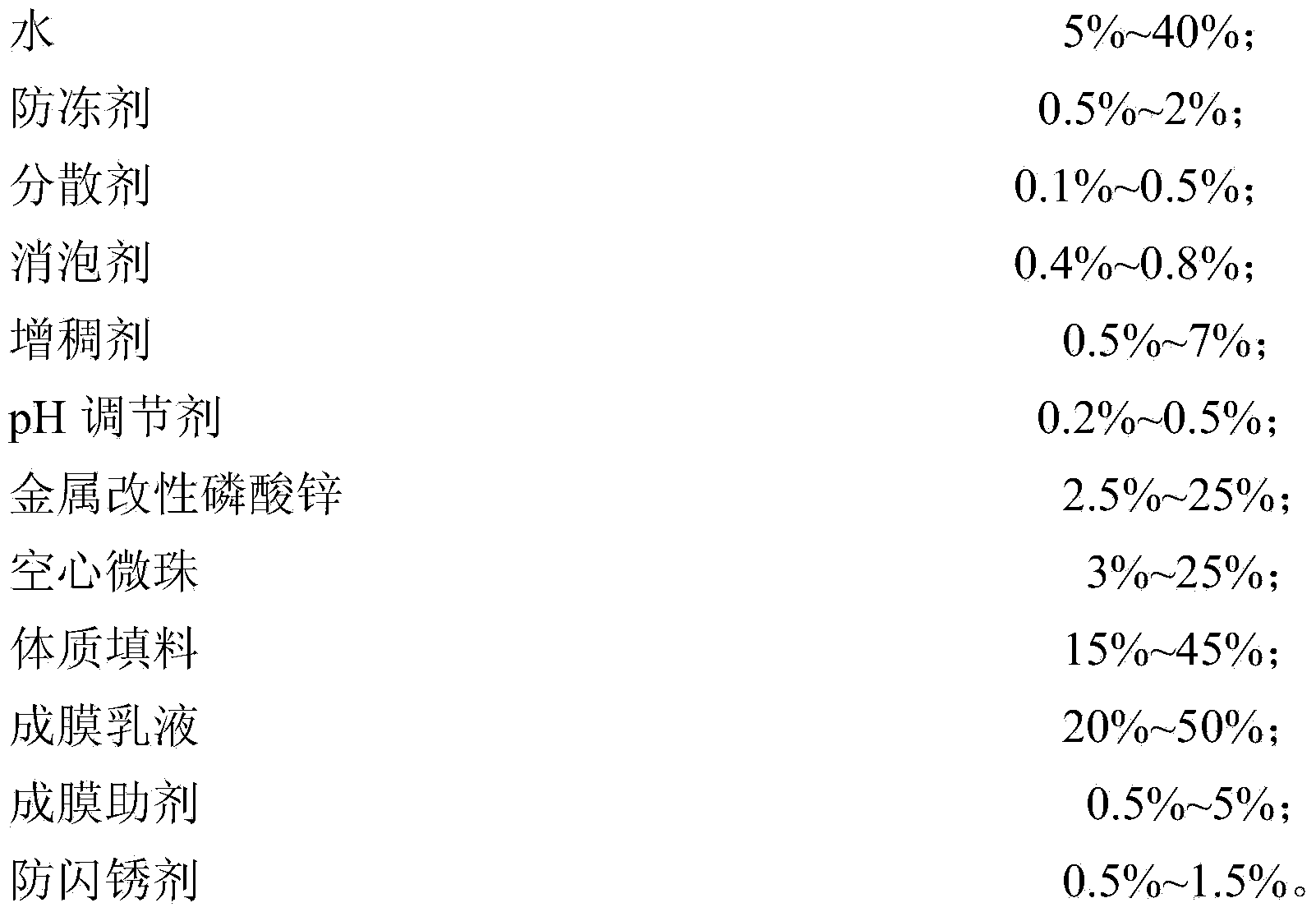

The invention discloses an aqueous anticorrosive heat-insulation paint which is prepared from the following raw materials of, by weight, 5-40% of water, 0.5-2% of an antifreezing agent, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 0.5-7% of a thickening agent, 0.2-0.5% of a pH conditioning agent, 2.5-25% of metal modified zinc phosphate, 3-25% of cenosphere, 15-45% of a body filler, 20-50% of a film forming emulsion, 0.5-5% of a coalescing agent and 0.5-1.5% of a flash-rust inhibitor. The invention also discloses a preparation method of the aqueous anticorrosive heat-insulation paint. The aqueous anticorrosive heat-insulation paint provided by the invention is a single-coating multifunctional paint, has excellent anticorrosive performance and heat-insulation performance to guarantee various anticorrosion and heat-insulation indexes, is beneficial to popularization and utilization, and has a wide application prospect. The method provided by the invention has a simple product preparation and construction process, is easy to carry out, and is easy for industrial large-scale production.

Owner:ZHEJIANG UNIV

Slow release, long-acting urea manure and technique of manufacturing the same

InactiveCN101108781AFully functionExtend the fertilizer periodAgriculture gas emission reductionUrea compound fertilisersOrganic solventFluidized bed

The invention relates to the nitrogen manure, in particular to the slow-release and long-effect urea fertilizer coating a layer of biochemical inhibitor on the urea surface and the preparation process. The fertilizer components are the urea, the biochemical inhibitor, the bond and the organic solvent. The process is that: the levitated solution mixed with the biochemical inhibitor, the bond and the organic solvent is sprayed and coated on the surface of the molding urea granule under the fluidized state through a fluidized bed to gain the slow-release urea fertilizer. The fertilizer of the invention makes full play of the functions and effects of two biochemical inhibitors, makes the fertilizer effect period prolonged obviously and realizes that once basal nitrogen fertilizer application can meet the requirement of whole growing seasons on the nitrogen. The agricultural production saves labor and time with low production cost and friendly environment. For the secondary processing of the urea, the preparation process of the invention has simple operation and easy realization and can carry out industrial production on a large scale.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

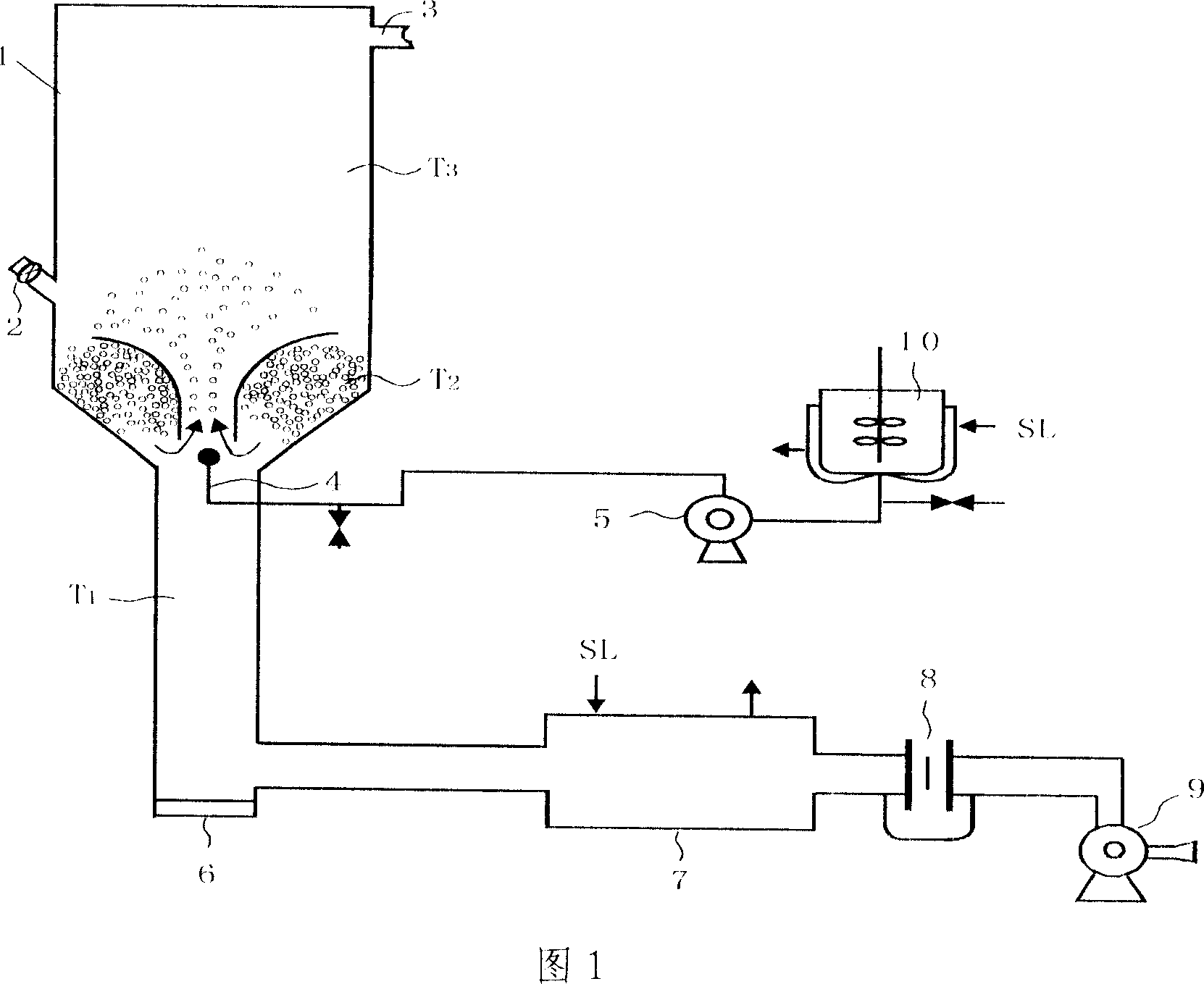

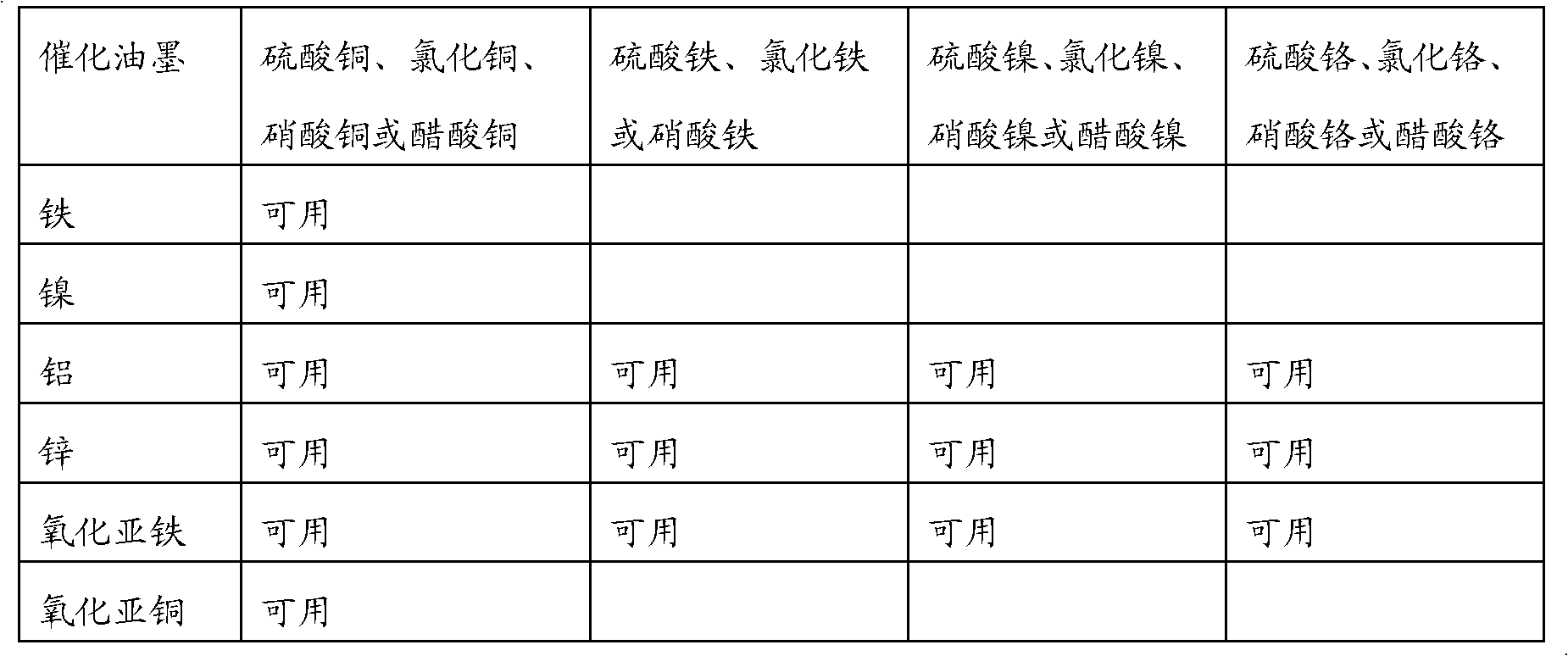

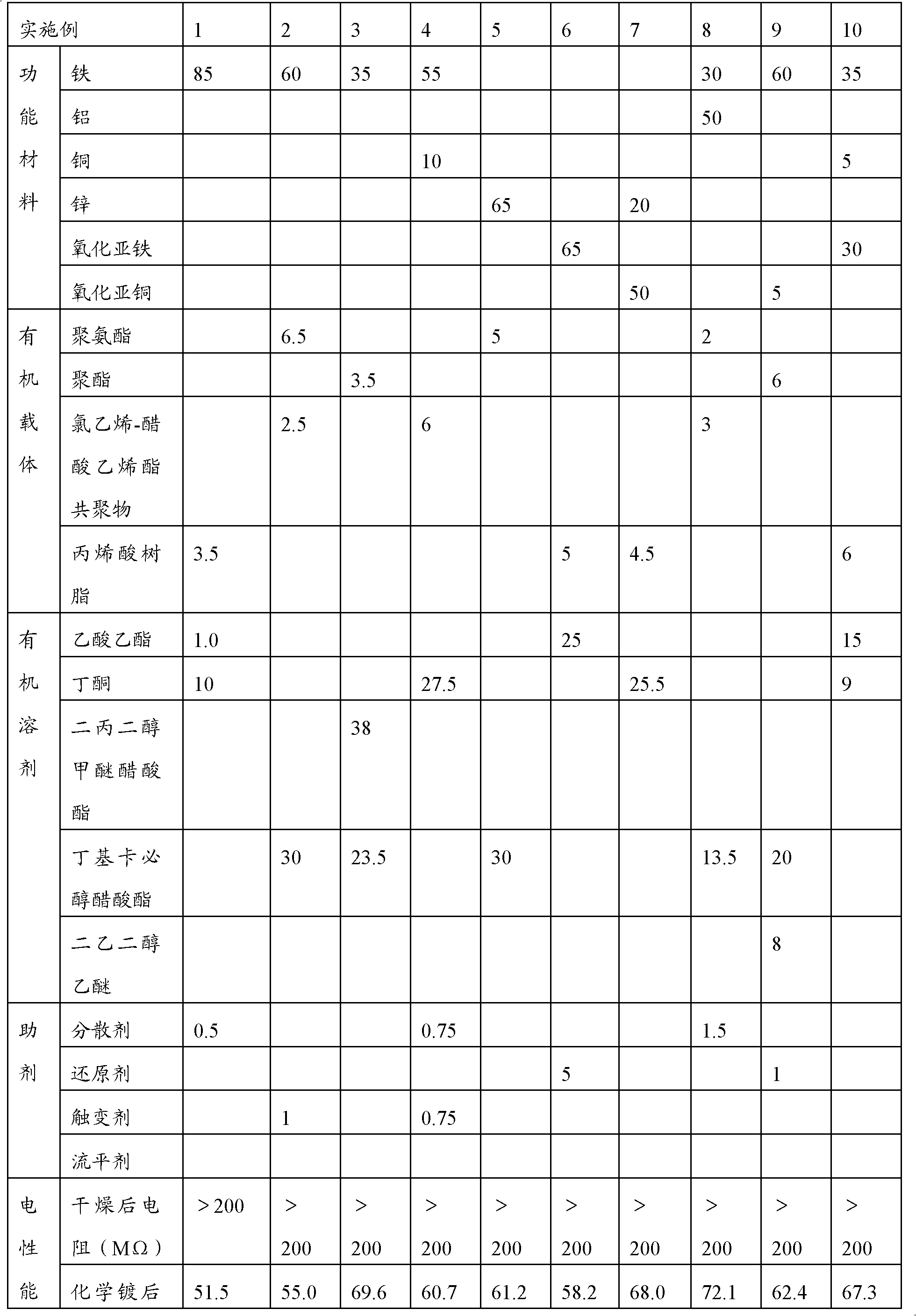

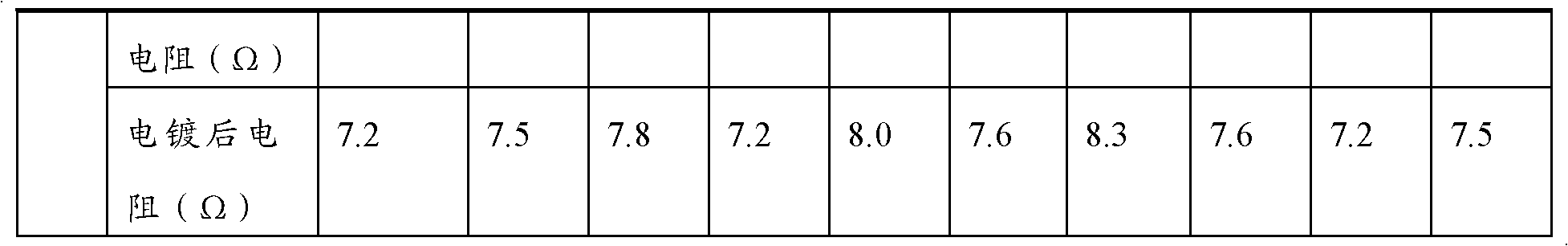

Method for utilizing base metal catalytic ink to manufacture printed circuit

InactiveCN102573313ALow priceReduce manufacturing costInksConductive pattern formationElectrical conductorDisplacement reactions

The invention provides a method for utilizing base metal catalytic ink to manufacture a printed circuit. The method is characterized in that: the ink mainly is composed of 10% to 90% of functional materials, 2% to 18% of organic carriers and 8% to 72% of organic solvents, wherein the functional materials are formed by metal or / and metal oxide powder, the metal is one selected from the group of iron, nickel, aluminum, and zinc, or a mixture of at least two metals in random mixing proportion selected from the group of iron, nickel, aluminum, zinc, and copper, and a metal oxide is selected from ferrous oxide or / and cuprous oxide. According to the invention, traditional printing modes of screen printing, gravure printing and the like can be employed to manufacture lines on insulation base material, and then the insulation base material is put into a replacement reaction solution for a displacement reaction to form a conductor printed circuit. The method has the following advantages: (1) the ink does not contain precious metals of silver, gold and the like, and manufacture cost of related products is greatly reduced; (2) the method is simple; (3) the manufactured printed circuit is reliable, electric conductivity is good, and application is wide.

Owner:SEMITEL ELECTRONICS

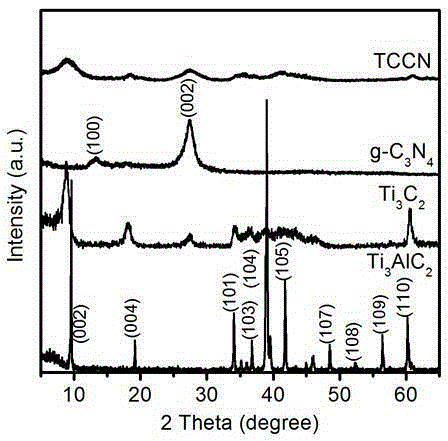

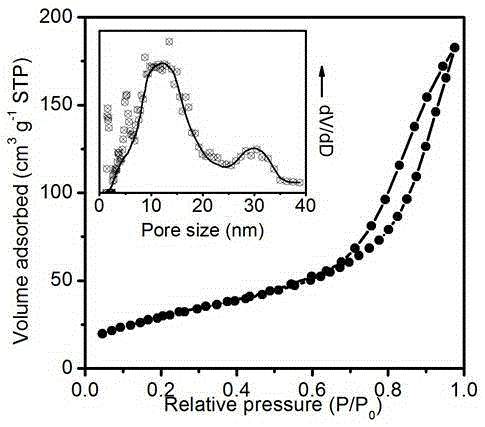

Preparation method of porous Ti3C2/g-C3N4 composite film material

InactiveCN105271230AEasy to operateMild and easy to controlNitrogen and non-metal compoundsCellulosePorosity

The invention discloses a preparation method of a porous Ti3C2 / g-C3N4 composite film material. The preparation method comprises following steps: Ti3C2 powder and g-C3N4 powder are prepared firstly, then the Ti3C2 powder and the g-C3N4 powder are mixed in a certain mass ratio and dispersed in a solution mixed by 100 ml of deionized water and isopropyl-ketone, an obtained mixed suspension is subjected to ultrasonic processing in nitrogen atmosphere at 45 DEG C for 6-10 h and then subjected to centrifugal treatment at the rotational speed of 3,000 r / min, unstripped aggregate is removed, a mixed solution with homogeneously dispersed Ti3C2 and g-C3N4 is reserved and filtered by a mixed cellulose ester filter membrane with the aperture of 0.05 mu m, the filter membrane is dried in vacuum at the room temperature for 20-30 h, substances on the mixed cellulose ester filter membrane are removed, and the Ti3C2 / g-C3N4 composite film material is obtained. Compared with the prior art, the prepared Ti3C2 / g-C3N4 composite film material has the advantages of flexibility, porosity and the like and can be applied to chemical synthesis of a catalyst, a hydrogen storage material and the like. The preparation method has the characteristics of simple operation, little pollution, mild and easily controlled conditions and easiness in implementation of industrial production.

Owner:HENAN POLYTECHNIC UNIV

Method for synergistically improving arc ablation performance of CuW contact material

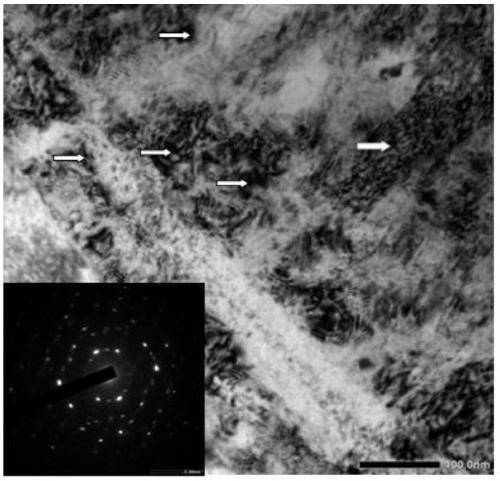

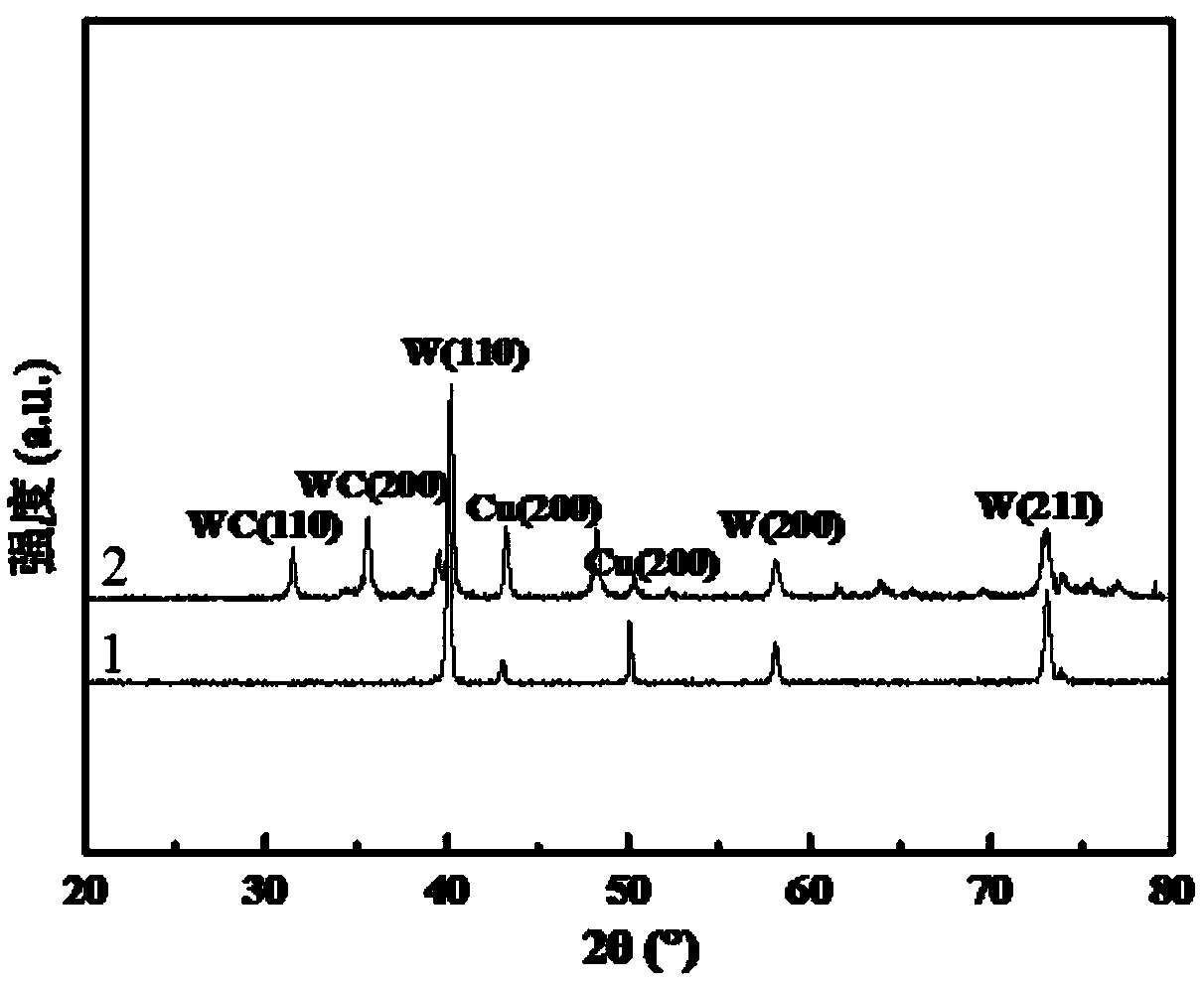

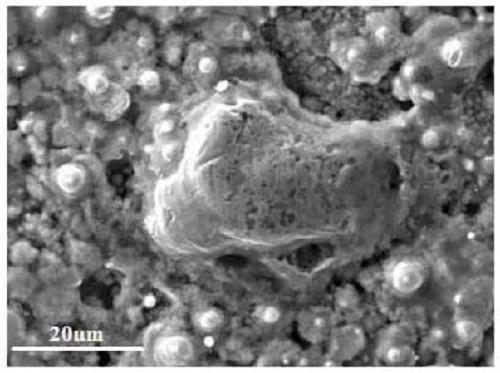

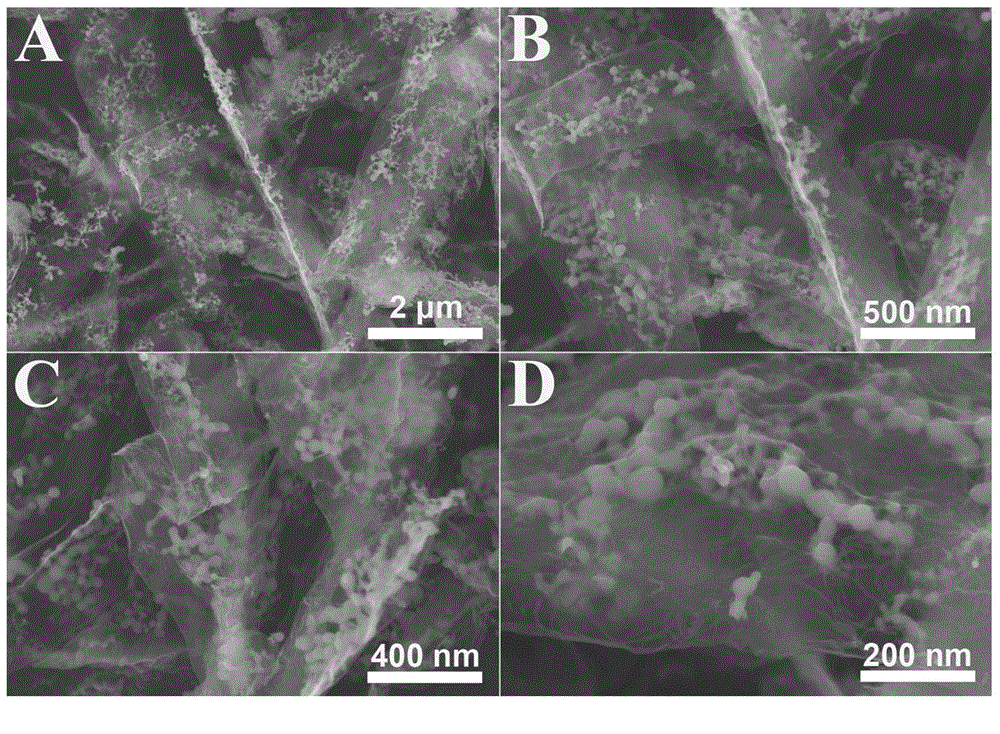

ActiveCN108950279AImproved arc ablation performanceImprove protectionContactsElectrolysisMaterials science

The invention discloses a method for synergistically improving the arc ablation performance of a CuW contact material. The method comprises the steps that firstly, spherical electrolytic copper powderis rolled into a sheet, then reduced tungsten powder is added for ball milling, even mixing is conducted, and tungsten-copper modified mixed powder is obtained; secondly, expanded graphite is sequentially subjected to low temperature intercalation oxidation, medium temperature intercalation oxidation and high temperature intercalation oxidation, and graphene oxide is obtained; thirdly, the tungsten-copper mixed powder and the graphene oxide are added into an ethanol-water mixed solution to be mixed evenly, drying is conducted, graphene oxide / tungsten-copper composite powder is obtained and then subjected to low-temperature thermal reduction, and reduced graphene oxide / tungsten-copper composite powder is obtained; and fourthly, the reduced graphene oxide / tungsten-copper composite powder issubjected to discharge plasma liquid phase sintering, and the CuW contact material is obtained. The graphene oxide is added into the tungsten-copper modified mixed powder, thermal reduction is conducted at first, the reduced graphene oxide is obtained, then discharge plasma liquid phase sintering is conducted, tungsten carbide nanoparticles are generated, and the arc ablation performance and mechanical performance of the CuW contact material are synergistically strengthened through the reduced graphene oxide and the tungsten carbide nanoparticles.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

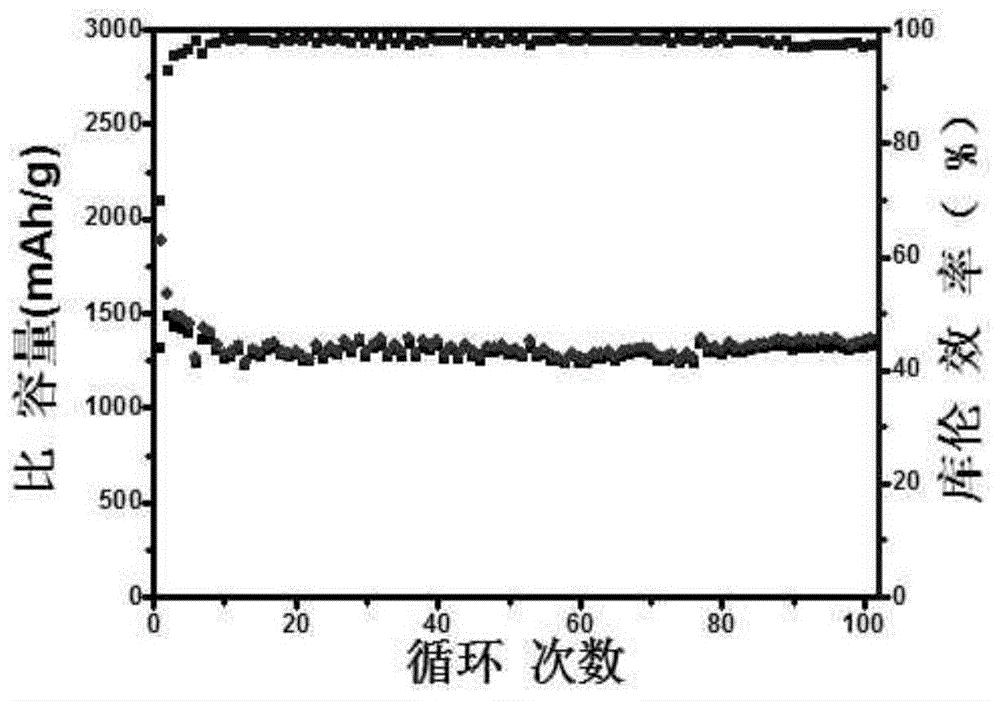

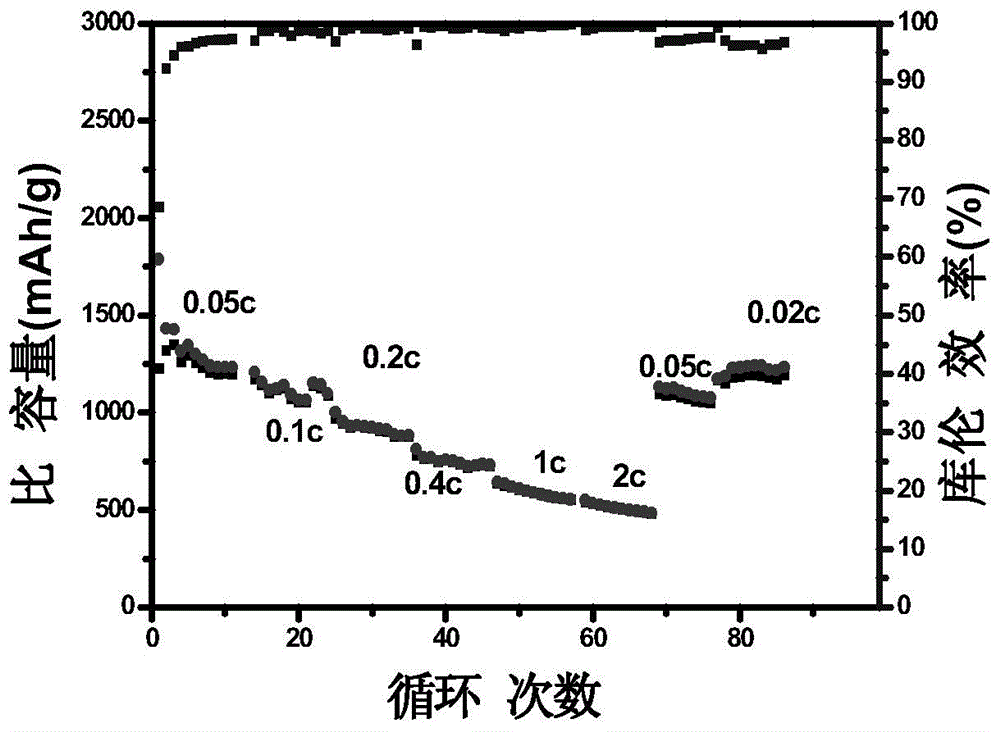

Preparation method of graphene-carbon nanotube aerogel supported nano-silicon composite electrode material

ActiveCN105576194AImprove conductivityExcellent rate performanceCell electrodesFreeze-dryingCarbon nanotube

The invention relates to a preparation method of a graphene-carbon nanotube aerogel supported nano-silicon composite electrode material. The preparation method comprises the following steps: preparing a graphene oxide dispersion liquid, respectively preparing nano-silicon and a carbon nanotube dispersion liquid, carrying out ultrasonic dispersion, adding a surfactant to the carbon nanotube dispersion liquid, adding the nano-silicon and the surfactant-containing carbon nanotube dispersion liquid to the graphene oxide dispersion, carrying out ultrasonic dispersion to obtain a uniformly mixed dispersion liquid, freeze-drying the uniformly mixed dispersion liquid, calcining the obtained dried powder in protection atmosphere, and naturally cooling the calcined powder to obtain the graphene-carbon nanotube aerogel supported nano-silicon composite electrode material. The composite electrode material prepared in the invention has the advantages of high capacity, high efficiency, good cycle performances and high safety; and the method is simple, is easy to implement, and is suitable for industrial large-scale production.

Owner:NANJING UNIV OF TECH

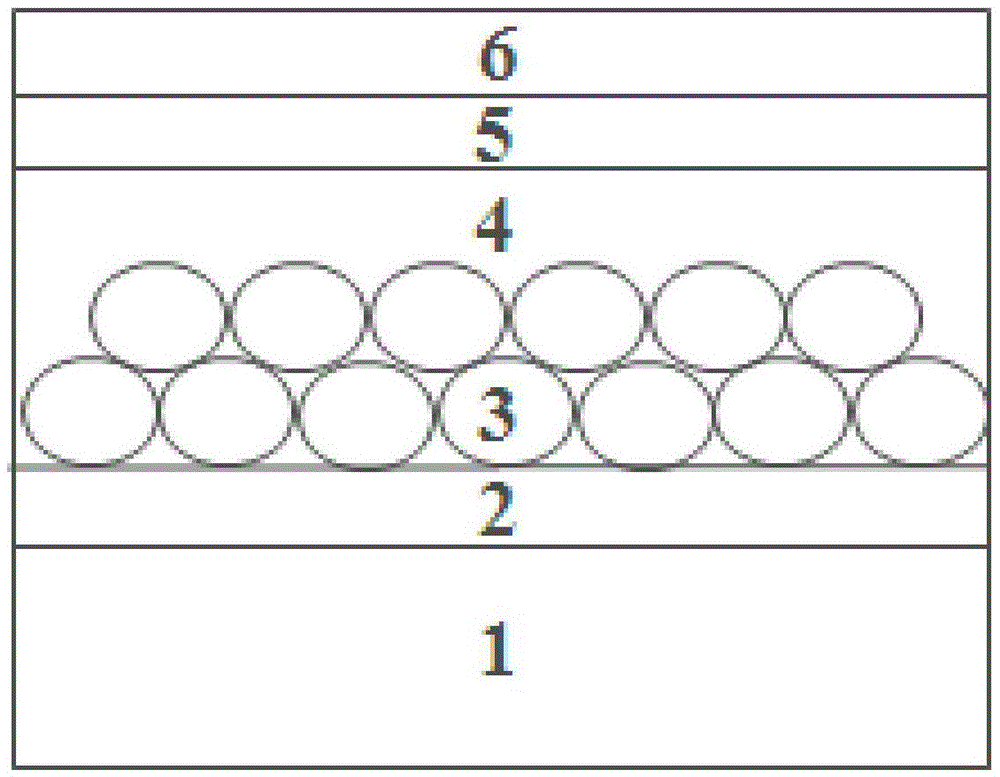

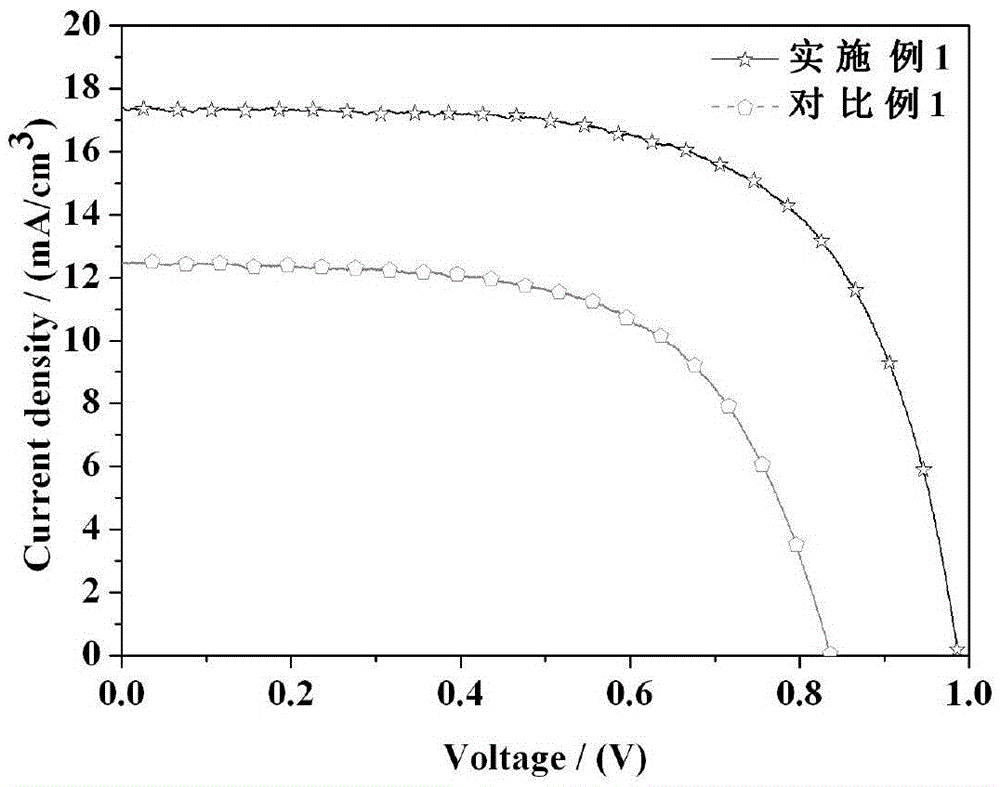

Method for modifying perovskite solar cell light-absorbing layer

InactiveCN105529403ALarge grainReduce porositySolid-state devicesSemiconductor/solid-state device manufacturingPorosityPerovskite solar cell

The invention discloses a method for modifying a perovskite solar cell light-absorbing layer, and belongs to the field of the solar cell. The method comprises the steps of 1) preparing a hole barrier layer on a substrate; and 2) adding a light-absorbing layer precursor liquid in a dropwise manner on the surface of the substrate with the hole barrier layer, performing spin coating, after the solvent of the light-absorbing layer precursor liquid is fully evaporated, adding modifying liquid in a dropwise manner and continuing to perform spin coating, wherein the modifying liquid is mixed liquid of organic solvent of a soluble light-absorbing layer material and organic solvent of an insoluble light-absorbing layer material; the volume ratio of the organic solvent of the insoluble light-absorbing layer material to the organic solvent of the soluble light-absorbing layer material is 16-21, and the volume ratio of the total volume of the modifying liquid to the volume of the light-absorbing layer precursor liquid is 1-1.5; and drying after completing spin coating. According to the light-absorbing layer preparation process, the light-absorbing layer is modified by the modifying liquid; namely, a perovskite layer is subjected to film formation firstly; then the modifying liquid is adopted to dissolve and modify the light-absorbing layer so as to enlarge the crystal grains of the light-absorbing layer and reduce the porosity of the light-absorbing layer; and consequently, the performance of the perovskite solar cell is effectively improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

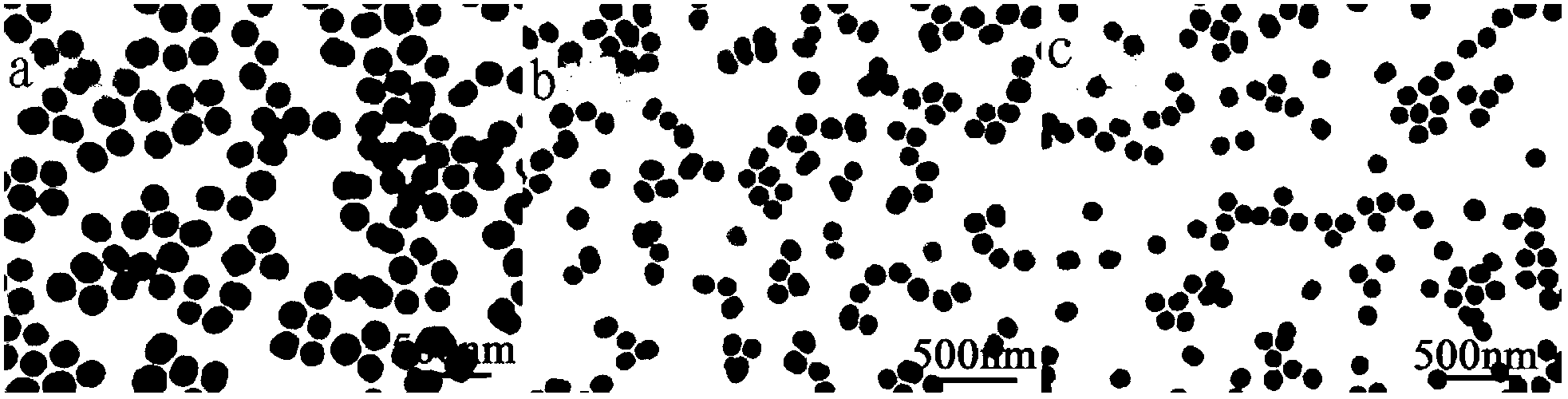

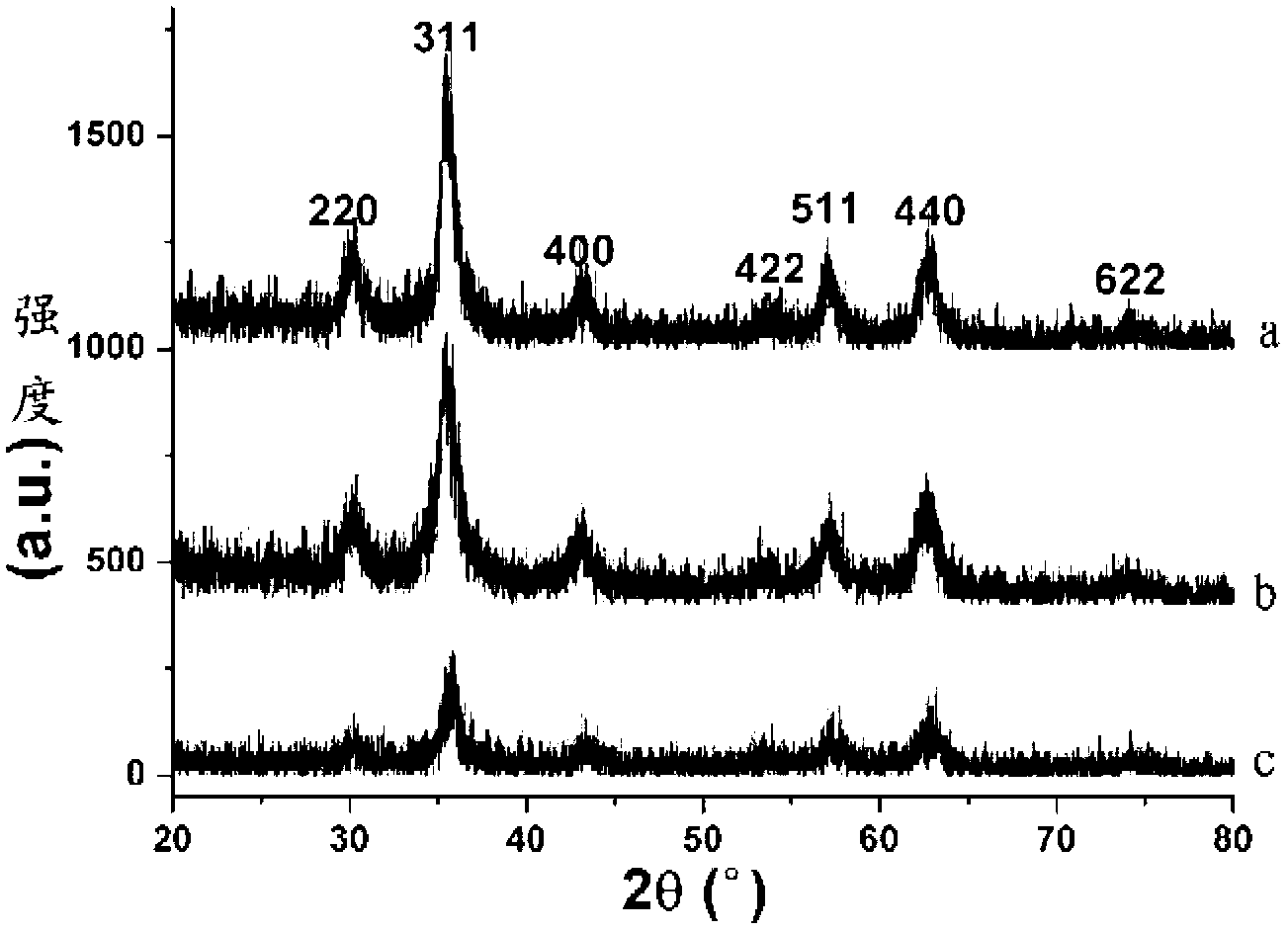

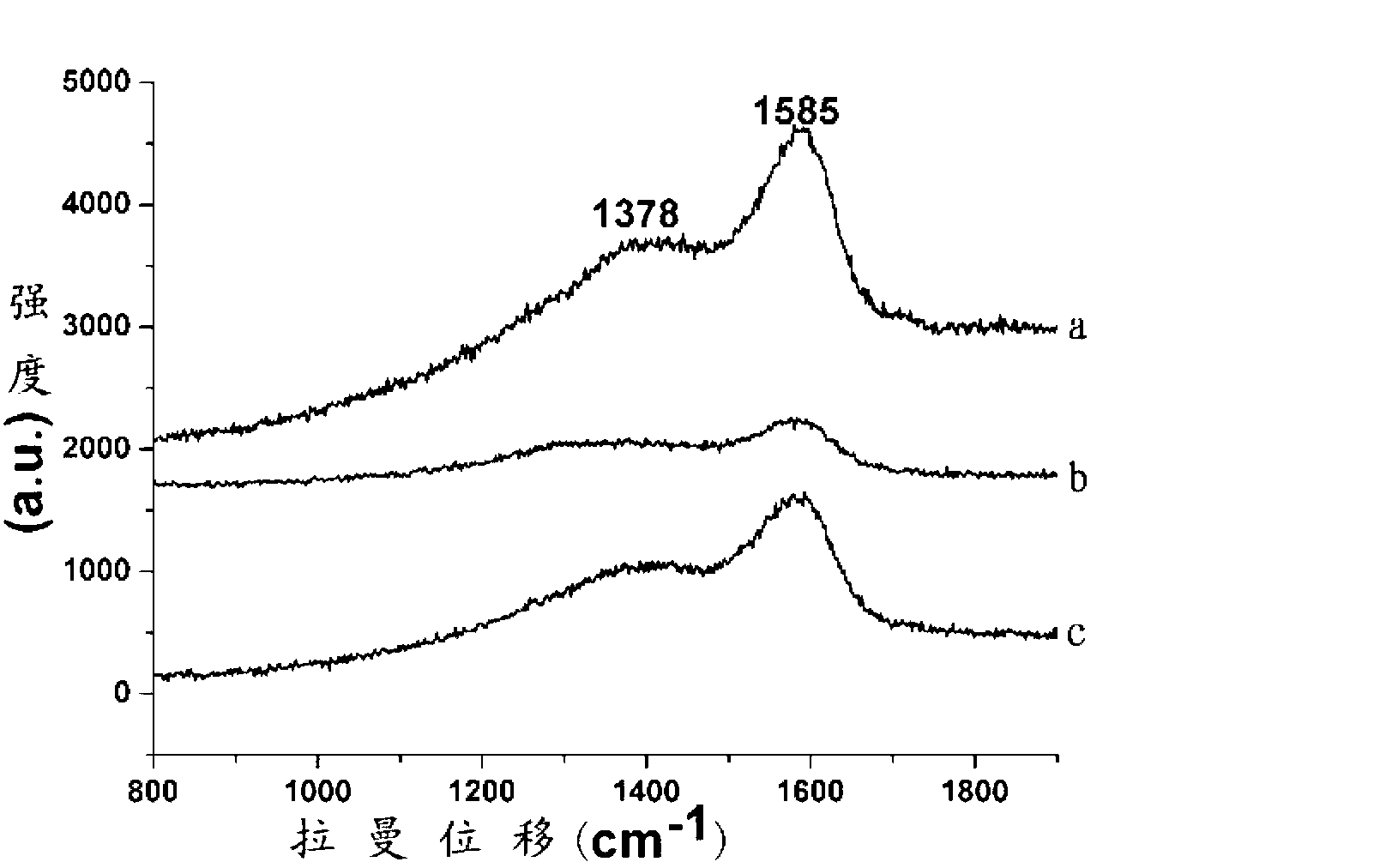

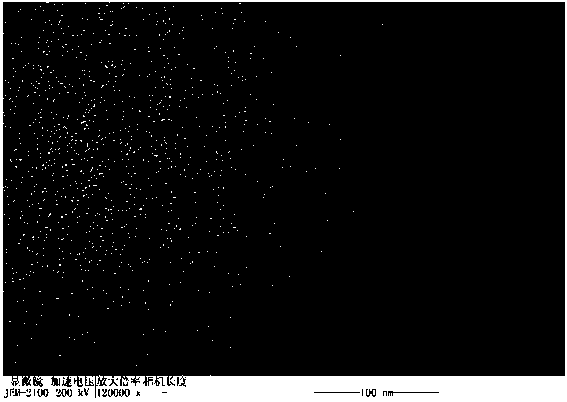

Magnetic response photonic crystal anti-fake label and manufacturing method thereof

InactiveCN102708773ALarge induced magnetic momentThe induced magnetic moment is sufficientStatic indicating devicesSuperparamagnetismMagnetic response

The invention provides a magnetic response photonic crystal anti-fake label and a manufacturing method thereof. The magnetic response photonic crystal anti-fake label provided by the invention comprises a plurality of patterns, wherein the patterns comprise polymer substrates and ethylene glycol micro droplets which contain carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles and are encapsulated in the polymer substrates; single pattern among the patterns at least comprises two kinds of carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles of different particle diameters. In the magnetic response photonic crystal anti-fake label provided by the invention, the carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles of different particle diameters are self-assembled respectively to acquire a multi-photon band gap structure under the action of magnetic fields, so that visible light of different wavelengths can be reflected and is superposed to acquire a new colour; and the color can not be copied by common pigment or dye color, has a good anti-fake effect and good color adjustability, and is beneficial to application.

Owner:UNIV OF SCI & TECH OF CHINA

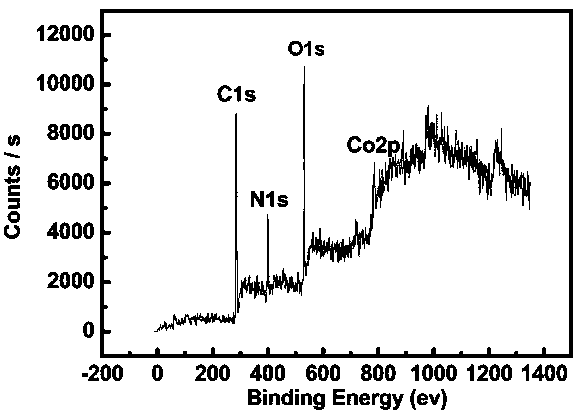

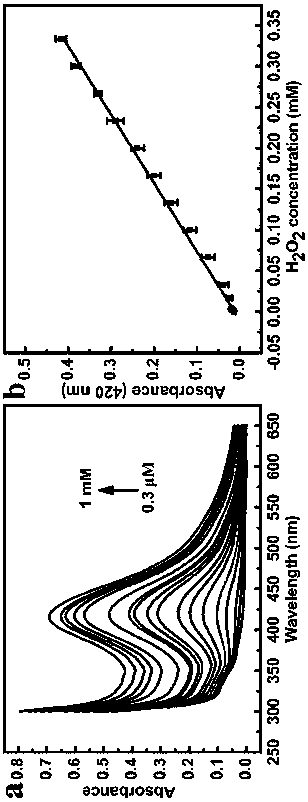

Preparation method of carbon nano-enzyme co-doped with active metal and nitrogen element and application thereof as nano biological probe for detecting hydrogen peroxide

PendingCN109107596AEasy to prepareRaw materials are cheap and easy to getMaterial analysis by observing effect on chemical indicatorCatalyst activation/preparationFluoProbesPhotochemistry

The invention discloses a preparation method of a carbon nano-enzyme co-doped with active metal and nitrogen element and application thereof as a nano biological probe for detecting hydrogen peroxide.The method comprises the steps that: EDTA disodium and active metal are used as precursors, and are chelated to obtain an intermediate, the intermediate is subjected wot thermal polymerization underan inert atmosphere, and the reactant is ground, dispersed in water, ultrasonicated, filtered, dried to finally obtain the carbon nano-enzyme co-doped with the active metal and the nitrogen element. The method is simple and convenient to operate, and the large-scale preparation of carbon fluorescent quantum dots can be co-doped with the active metal and the nitrogen element without harsh reactionconditions, obtained carbon dots have good dispersibility and wider fluorescence emission range in aqueous solution. The nano-enzyme can be applied to the detection of hydrogen peroxide as a fluorescent probe, and has potential application value in the fields of medical imaging and detection of other biomolecules.

Owner:HENAN NORMAL UNIV

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

Method for processing barometric pressure, normal-temperature plasma modification on carbon nano-tube surface

InactiveCN101428789AStrong process controllabilitySimple replacement processPigment physical treatmentNanometreSurface modification

The invention relates to a processing method for modifying atmospheric pressure on the surface of a carbon nanometer tube and a normal temperature plasma, which comprises the following steps: placing the carbon nanometer tube on a special transmission device of a plasma processing device; spraying the e plasma to the surface of the carbon nanometer tube under the atmospheric pressure and the openenvironment, so that the carbon nanometer tube moves in the atmosphere of the plasma, wherein the processing power is 10W to 5000W and the time is 0.01s to 6000s; and then generating the surface modification of the carbon nanometer tube. The invention can directly improve the surface property, the structure and the shape of the carbon nanometer tube for one step under the atmospheric pressure andthe normal temperature, and has the advantages of strong process controllability, simple replacement process and less environmental pollution by adopting the dry process. The effect of isosexual repulsion is generated on the particle surface of the carbon nanometer tube, so that the possibility on the reunion of nanometer particles is reduced.

Owner:DONGHUA UNIV +1

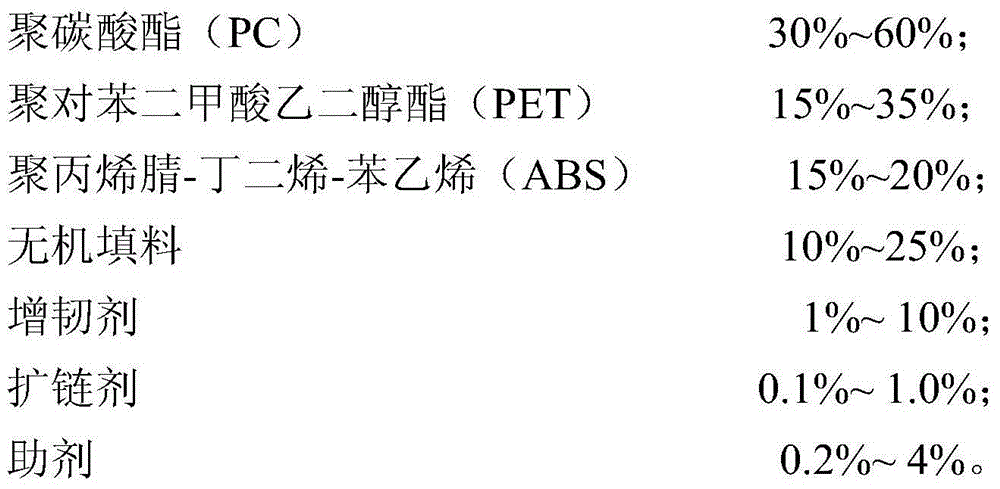

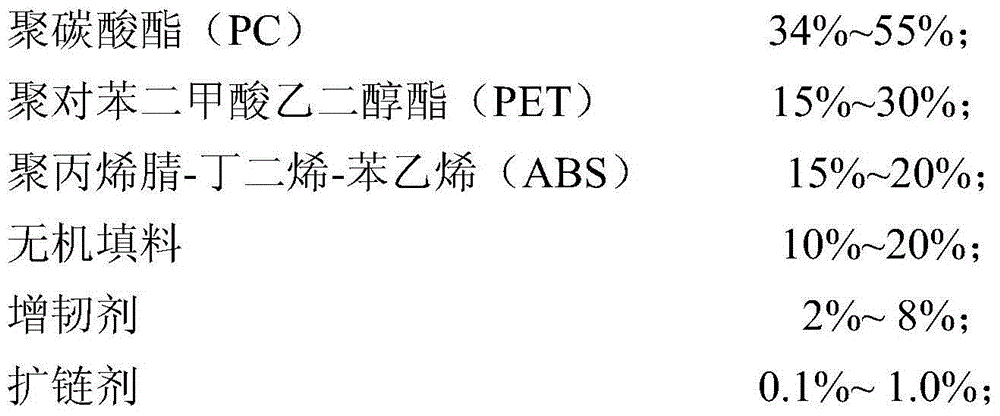

PC/PET (polycarbonate/polyethylene terephthalate) alloy material and preparation method thereof

ActiveCN104559110AImprove toughnessTo achieve the perfect effectPolyethylene terephthalate glycolAlloy

Owner:CGN JUNER NEW MATERIALS +1

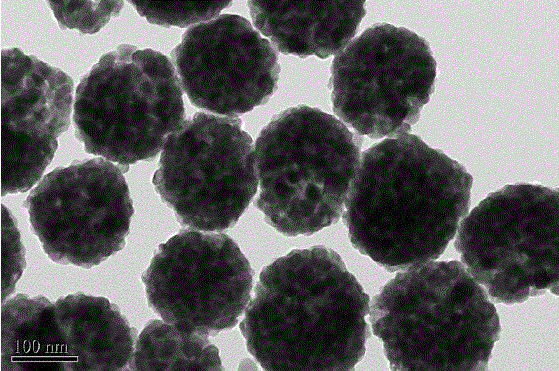

Method for preparing monodisperse indium oxide nanometer porous microsphere

InactiveCN103183374ALow costImprove protectionGallium/indium/thallium compoundsNanotechnologyManufacturing technologyDisplay device

The invention provides a method for preparing a monodisperse indium oxide nanometer porous microsphere, and belongs to the technical field of function materials. The preparation method particularly comprises the following steps: adding citric acid with a certain molar ratio in indium chloride aqueous solution, mixing intensively, adding moderate urea as a precipitant, and dispersing uniformly; sealing the mixed solution in an autoclave and conducting water thermal reaction for a period of time, and then centrifugalizating, washing and drying; calcining in a muffle furnace in air to obtain the monodisperse indium oxide nanometer porous microsphere. The method provided by the invention has low cost, simple manufacturing technology, high productivity, and is easy to realize industrialization and mass production. The indium oxide nanometer microsphere produced by the method has a neat appearance, uniform disperse, has a porous structure and a larger specific surface area, and can be applied in the field of solar cells, FPDs (Flat Panel Display), photo-electron devices, gas sensors and the like.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com