Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Low hydroxyl value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

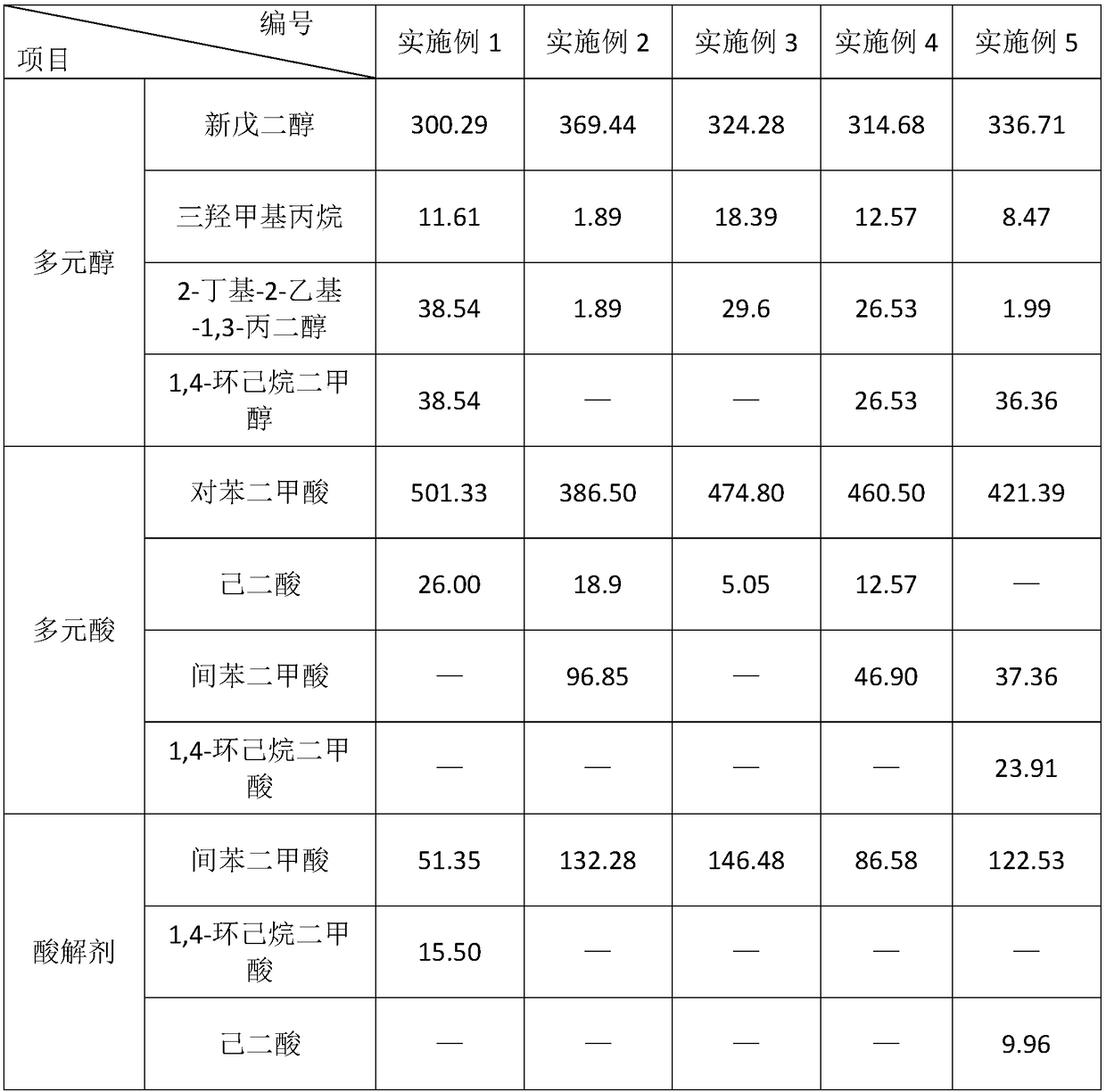

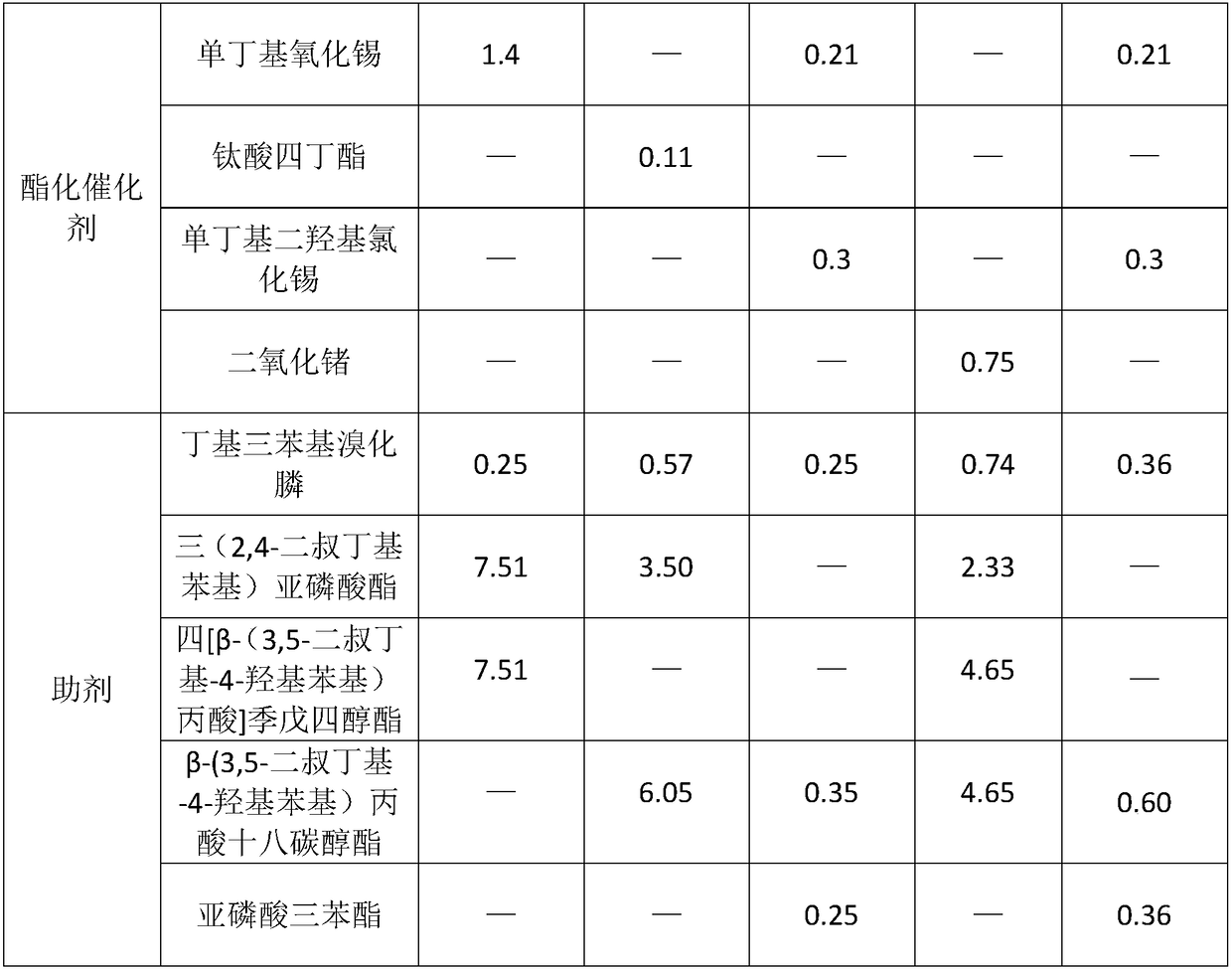

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

Esterification method of pentaerythritol

ActiveCN104086417AIncrease in positive chargePromote esterification reactionOrganic compound preparationCarboxylic acid esters preparationOctanoic AcidsAfter treatment

The invention provides an esterification method of pentaerythritol, which comprises the following step: under the action of a tin catalyst, carrying out esterification reaction on pentaerythritol and saturated fatty acid to obtain pentaerythritol ester, wherein the saturated fatty acid is one or more of butyric acid, valeric acid, hexanoic acid, heptylic acid, octanoic acid, pelargonic acid and capric acid. The esterification method provided by the invention has the advantages of higher product yield, higher product quality, simple esterification after-treatment and low pollution. The experimental result indicates that the conversion rate of the esterification reaction is greater than 99.5%, and the hydroxyl value in the reaction product is lower than 1mg KOH / g.

Owner:CHINA PETROLEUM & CHEM CORP

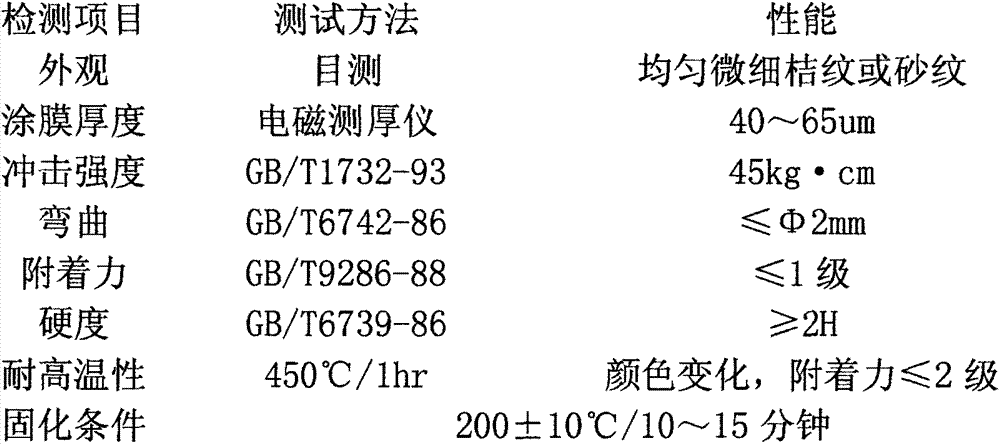

High temperature resisting powder paint and preparation method thereof

The invention discloses a high temperature resisting powder paint and a preparation method thereof. The high temperature resisting powder paint comprises the components in percentage by weight as follows: 40-55% of modified organic silicon resin, 2-3% of curing agent, 40-48% of high temperature filler, 1-2% of assistant and 0.5-3% of high temperature pigment. The method mainly comprises the following steps of: modifying the organic silicon resin; mixing; and extruding and forming. The curing temperature of a conventional high temperature resisting powder paint is reduced, and the problems that conventional high temperature resisting powder paint is easy to bubble and poor in adhesive force and the like are solved, so that the coating yield is greatly improved and the coating cost is greatly lowered.

Owner:TAISHAN GUANG AN LIN CHEM CO LTD

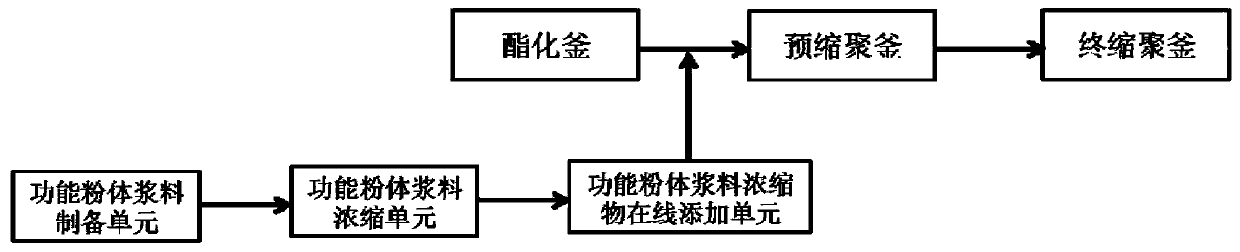

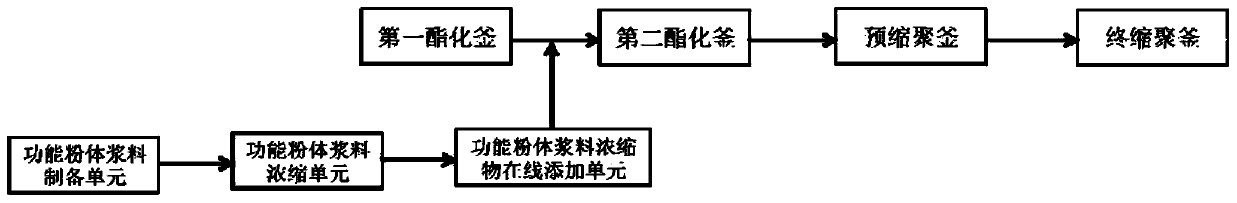

Functional polyester production method and production system and functional polyester fiber

ActiveCN109705319AHighly uniform dispersionLow hydroxyl valuePigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention belongs to the technical field of polymer material synthesis, and particularly relates to a functional polyester production system. The functional polyester production system comprises apolyester main production system, and further comprises a functional powder slurry concentrate preparation system, the polyester main production system comprises an esterification system, a pre-polycondensation system and a final polycondensation system which are connected in sequence, the functional powder slurry concentrate preparation system comprises an online adding device which is connectedwith the esterification system or a part between the esterification system and the pre-polycondensation system. The functional powder slurry concentrate preparation system is introduced in the polyester main production system, and can continuously prepare a functional powder slurry concentrate with low hydroxyl value and low pressure filtration value, and the prepared functional powder slurry concentrate and a polyester oligomer are uniformly mixed for polycondensation reaction to obtain functional polyester with uniformly dispersed functional powder. The invention further relates to a functional polyester production method.

Owner:CHINESE TEXTILE ACAD +1

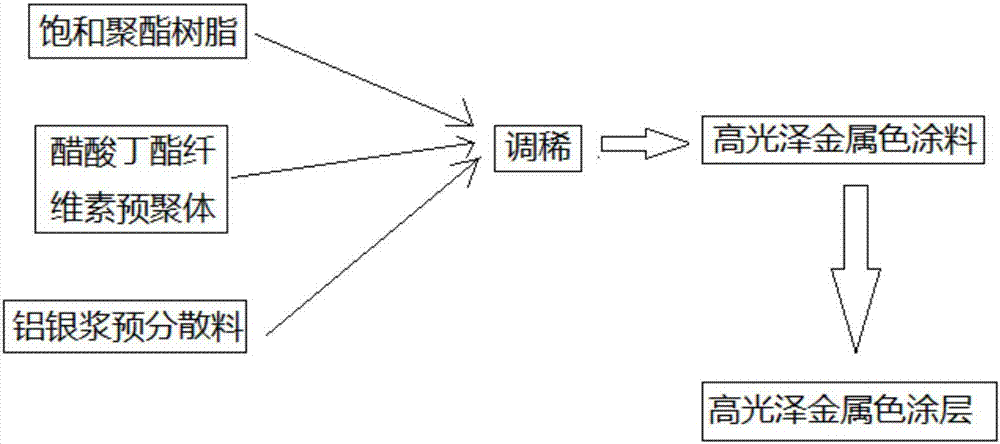

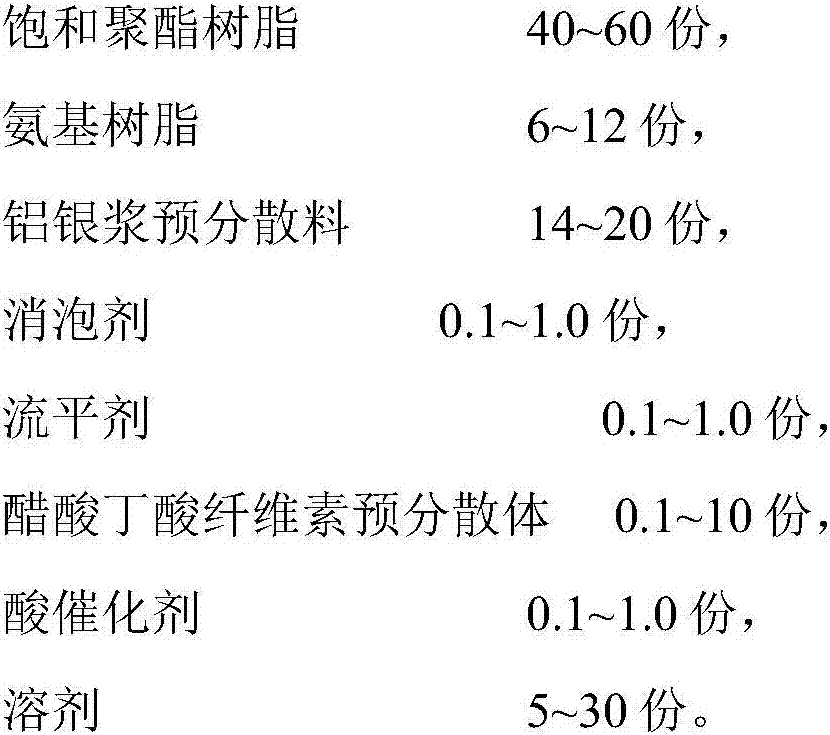

High-gloss metallic paint for rolled steel substrate and preparation method and application

The invention discloses a high-gloss metallic paint for a rolled steel substrate. The high-gloss metallic paint is prepared from the following components in parts by weight: 40-60 parts of saturated polyester resin, 6-12 parts of amino resin, 14-20 parts of an aluminum paste pre-dispersed material, 0.1-1.0 part of a defoaming agent, 0.1-1.0 part of a flatting agent, 0.1-10 parts of a cellulose acetate butyrate pre-dispersed material, 0.1-1.0 part of an acid catalyst and 5-30 parts of a solvent. The fluidity of the paint can be improved by cellulose acetate butyrate in the high-gloss metallic paint for the rolled steel substrate, and the viscosity of the paint is controlled, thereby playing a role in strengthening directional alignment of aluminum powder in a coating. The levelling property of the coating can be improved by the flatting agent in the high-gloss metallic paint for the rolled steel substrate, so that regular arrangement of the aluminum powder in the coating is driven and the glossiness is improved.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

High-temperature-resistant polyether polyol and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to high-temperature-resistant polyether polyol and a preparation method thereof. The high-temperature-resistant polyether polyol is characterized by being prepared from the following components in parts by weight: 600-1,000 parts of sorbierite, 300-600 parts of cane sugar, 3,300-3,800 parts of epoxy propane, 10-18 parts of potassium hydroxide, 20-36 parts of phosphoric acid and 140-200 parts of water. The method has the advantages: the prepared high-temperature-resistant polyether polyol is catalyzed by using potassium hydroxide; sorbierite is an ideal starting agent for preparing temperature-resistant polyether; and the polyether polyol synthesized by adopting sorbierite and cane sugar with high functionality has high functionality and low hydroxyl value. Hard urethane foam plastic prepared from polyether polyol has high heat resistance, high size stability, thermal oxidation resistance, oil resistance, bonding property and high size stability.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Preparation method of polyester resin for powder coating

InactiveCN1765952AReduce melt viscosityLow hydroxyl valuePowdery paintsPolyester coatingsPhosphoric acidMelt viscosity

The invention discloses a preparation method for polyester resin in powder coating, which comprises: on reaction late, adding the terminated agent selected one or more from acetic acid, benzoic acid, phosphoric acid and AA. This product has low melt viscosity and hydroxyl value, and has well level and mechanical properties.

Owner:GUANGZHOU QINGTIAN INDAL

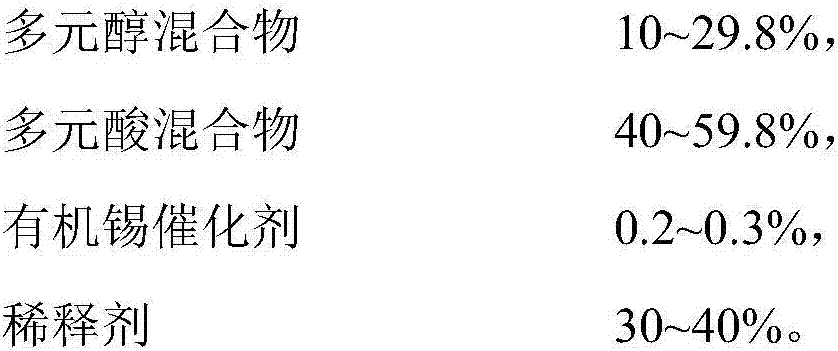

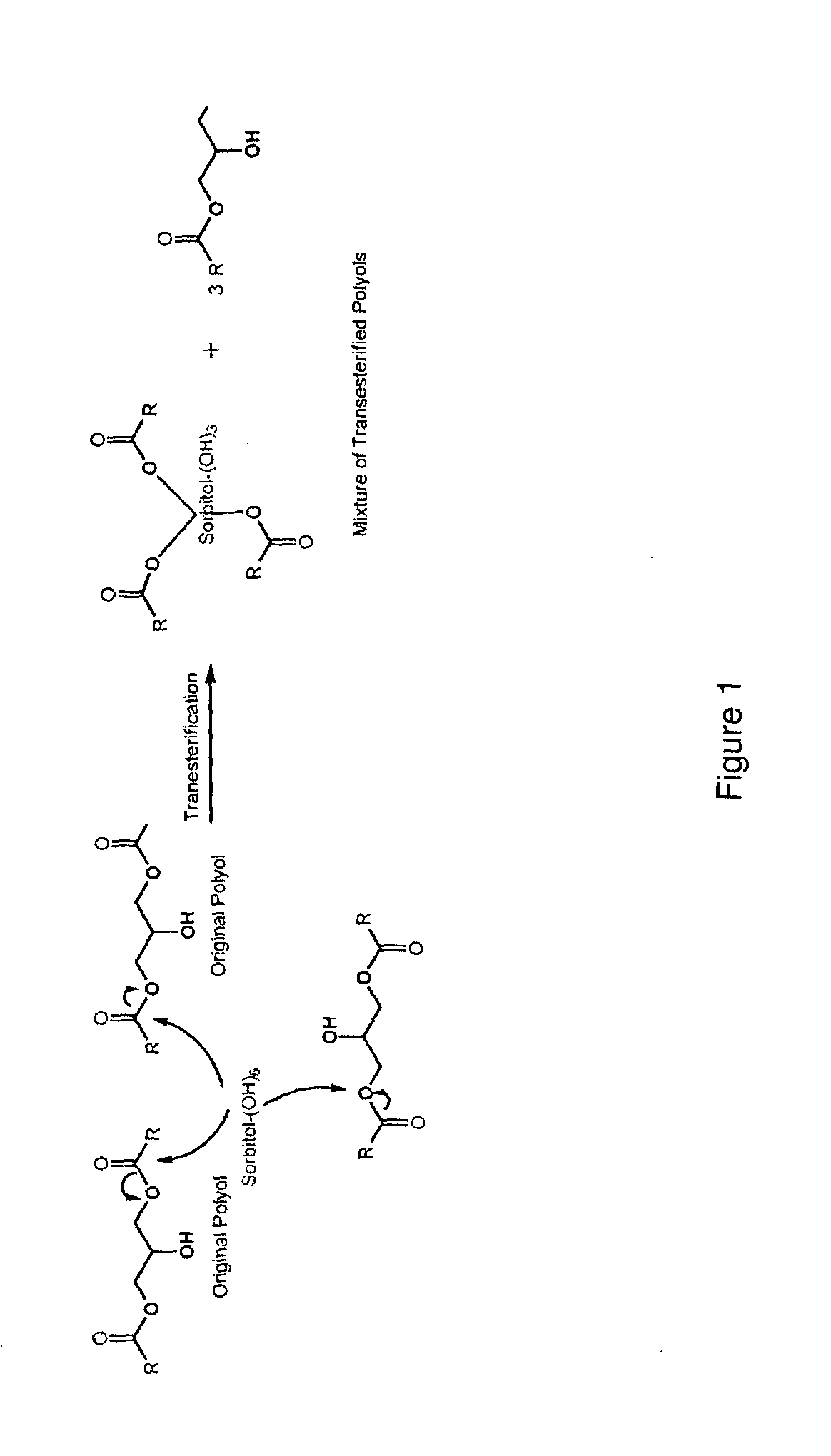

Bio-polyols for bio-lubricant and bio-polymer and methods for the preparation thereof

ActiveUS20150087850A1Increase valueSynthetic is simpleFatty acid esterificationOrganic compound preparationBiopolymerHydroxyl value

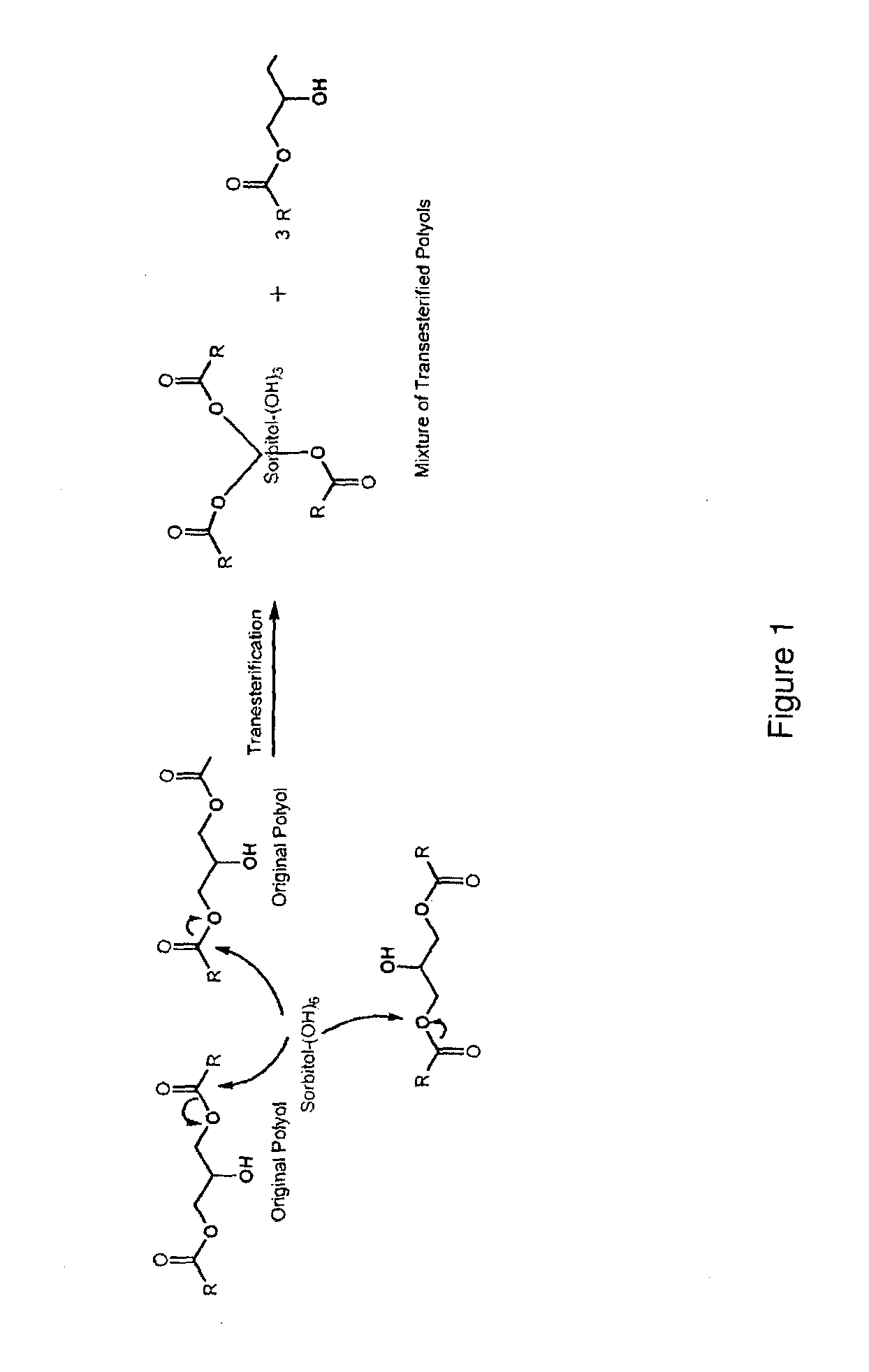

A method for producing an ester polyol, comprising transesterifying a first ester polyol with a primary polyol to produce a second ester polyol, wherein the second ester polyol has a higher hydroxyl value than the first ester polyol.

Owner:GASOLINEIAM NASIONAL BERHAD

Coating for ship water ballast space

InactiveCN101280151AGood acid and alkali resistanceAvoid harmAnti-corrosive paintsEpoxy resin coatingsEpoxyMarine engineering

The invention relates to ship ballast tank coating which part by weight comprises 30-60 portions of epoxy resin, 5-15 portions of coumarone indene resin, 10-20 portions of curing agent, 30-50 portions of pigment and filler, 3-5 portions of auxiliary agent and 5-10 portions of solvent, based on the total weight of the ship ballast tank coating as the reference. The coumarone indene resin adopted by the ship ballast tank coating is thermoplastic non-reaction resin, has excellent acid-alkali resistance and no harm to human body; the coumarone indene resin is used to replace the epoxy coal pitch in the prior art; thereby, the acid-alkali resistance of the coating is improved; the ship ballast tank coating adopts the epoxy resin which has good acid-alkali resistance; meanwhile, the cross linking degree of the paint film can be improved greatly.

Owner:常州市天安特种涂料有限公司

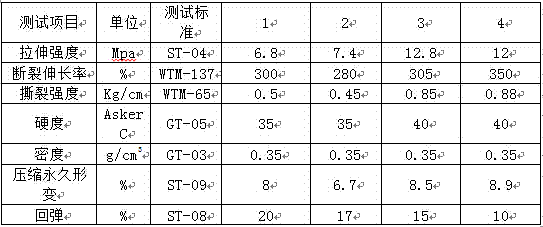

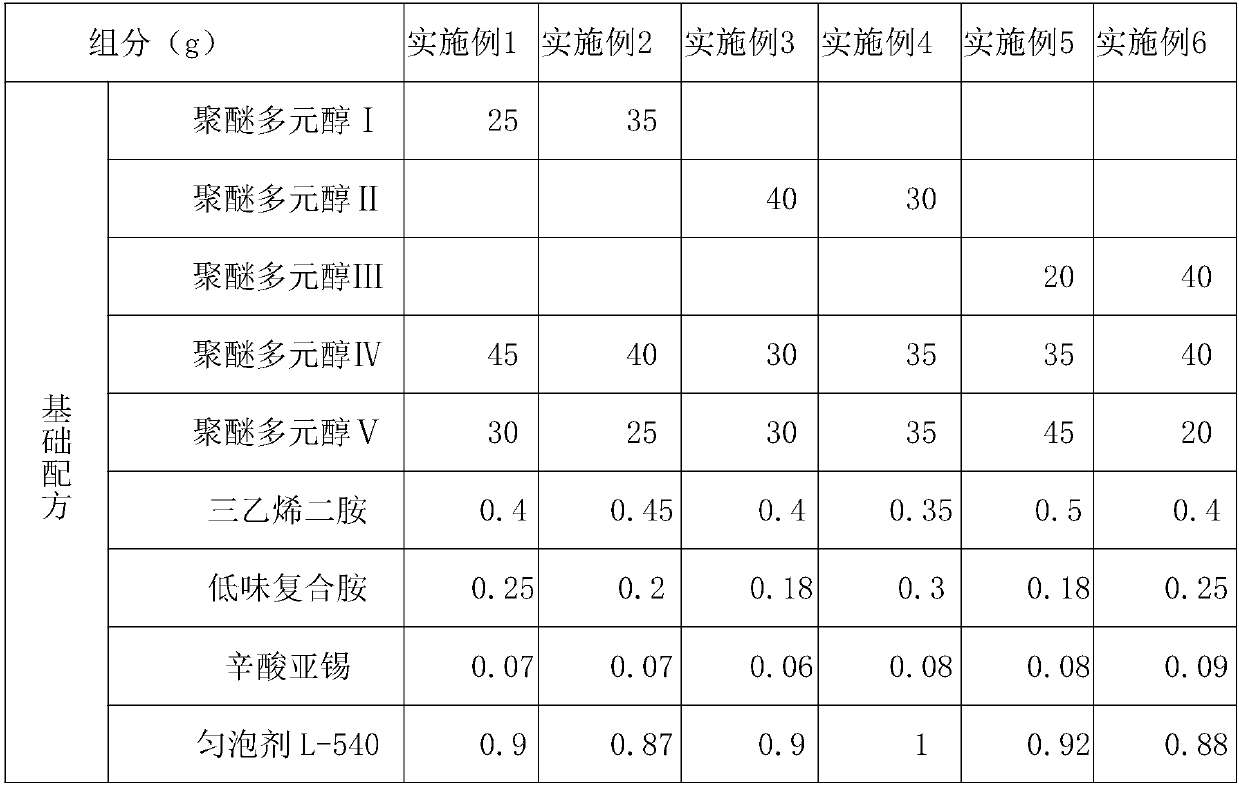

Slow rebound polyurethane foam sound insulation material

The invention discloses a slow rebound polyurethane foam sound insulation material. The slow rebound polyurethane foam sound insulation material is characterized by being prepared from the following components in parts by weight: 35-55% of a material B, 5-35% of polyether polyol A, 10-30% of polyether polyol B, 5-20% of polyether polyol C, 0-0.5% of A-1, 0.1-1% of A-33, 0.1-1% of dimethylethanolamine (DMEA), 1-5% of ethylene glycol (EG), 0.1-1% of mixed silicone oil and 2-8% of fluoro-dichloroethane, wherein the material B is a prepolymer modified by diphenylmethane diisocyanate and derivatives thereof as well as polyol; the A-33 is an alcoholic solution prepared by melting triethylene diamine into small molecular dihydric alcohol; the A-1 is prepared from bis(dimethylamino-ethyl) ether and dipropylene glycol (DPG). The slow rebound polyurethane foam sound insulation material provided by the invention has a unique foam structure and a high loss factor; when incoming sound waves are transmitted to the slow rebound polyurethane material, the sound energy is further consumed, so that the slow rebound polyurethane material is good in sound insulation; furthermore, the slow rebound polyurethane foam sound insulation material is uniform in openings, and has better tensile strength and tear strength.

Owner:GUANGZHU COLORTECH NEW MATERIALS CO LTD

Method for synthesizing novel polyether polyol

The invention provides a method without an after-treatment process for synthesizing a novel polyether polyol which has a good intersolubility with a hydrocarbon foaming agent. A synthesis process of the invention adopts an amine complex catalyst system, has the advantages of high reaction activity, short production cycle, no need of an after-treatment process and low production cost. Meanwhile the invention overcomes the problem of inactivation of a pure amine catalyst in the later reaction, and can synthesize polyether polyol with relatively high molecular weight and low hydroxyl value. Compared with a polyether polyol for common hard foam, the polyether polyol synthesized in the invention has a good intersolubility with the hydrocarbon foaming agent, such as n-pentane, cyclopentane, isopentane and a mixture of n-pentane, cyclopentane and isopentane. The composite material prepared can realize transparency at a low temperature, and can meet the requirements of long-term storage by customers.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

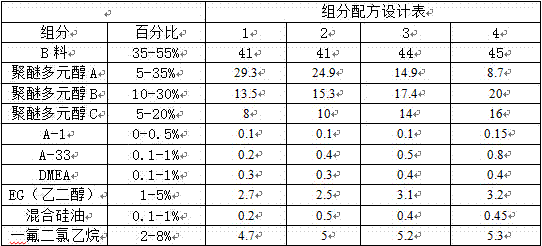

Totally bio-based vegetable oil polyol and preparation method and use thereof

InactiveUS20190119496A1High viscosityImprove mechanical propertiesOrganic chemistryChemical/physical/physico-chemical microreactorsState of artVegetable oil

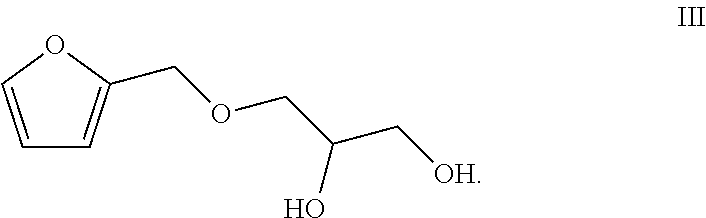

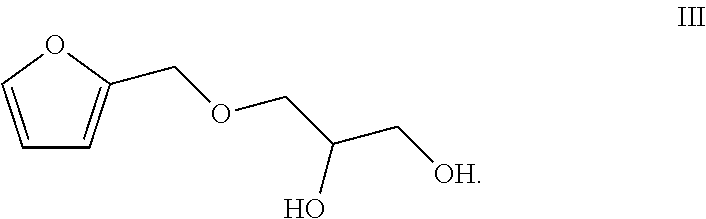

A method comprises enabling epoxy vegetable oil to react with a compound of a formula III in a second microstructured reactor to obtain the vegetable oil polyol. Compared with the existing technology, the present invention adopts a novel, environment-friendly ring-opening agent, the obtained polyol is novel in structure, high in hydroxyl value, even in distribution and low in viscosity, and can completely replace traditional petrochemical polyol to be applied to the preparation of polyurethane foam materials.

Owner:NANJING UNIV OF TECH

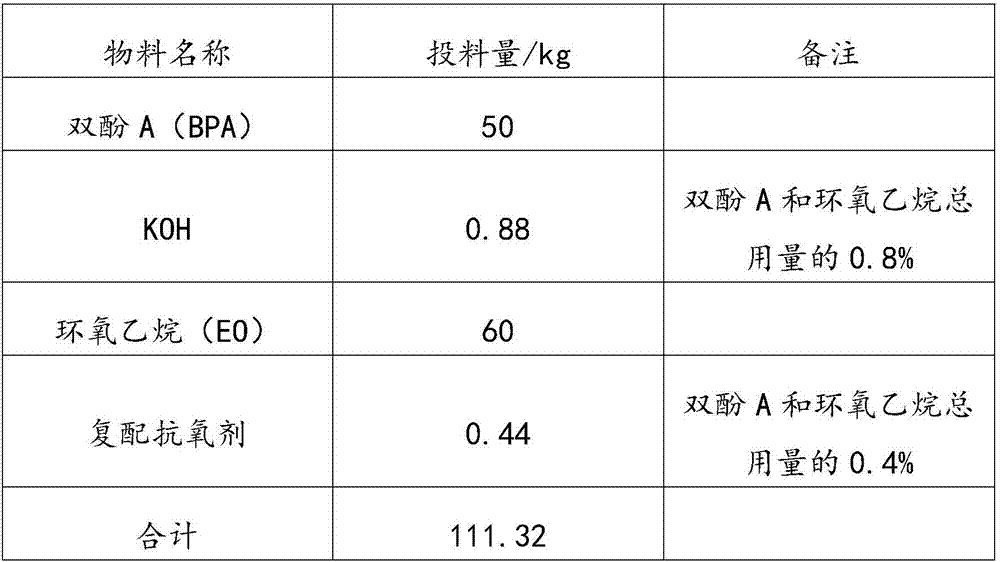

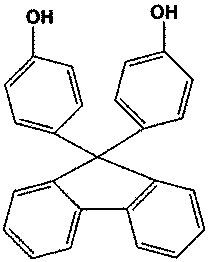

Bisphenol A polyether and preparation method thereof

The invention provides bisphenol A polyether and a preparation method thereof. The preparation method of the bisphenol A polyether is simple in process; and a bisphenol A polyether product is obtained through reaction of bisphenol A and epoxyalkane, curing, degassing and antioxidant addition. By adopting a specific process, the uniform bisphenol A polyether product with low hydroxyl value, low viscosity and low chromaticity can be obtained. The bisphenol A polyether product is low in hydroxyl value, low in viscosity and low in chromaticity, can be kept uniform and stable for a long period of time, subsequent application can be better carried out, and mixing with other materials is facilitated.

Owner:于天荣

Method for producing terpene-phenolic resins

The invention provides a method for producing terpene-phenolic resins. The terpene-phenolic resins with high tackifying property are obtained, so that the performance of the terpene-phenolic resins is improved. The method for producing the terpene-phenolic resins comprises the following steps of: A, dipping a-pinene with the purity of not less than 98 percent into a mixed liquid of phenol and methylbenzene under a temperature condition of 30-50 DEG C; adding boron trichloride serving as a catalyst into the mixed liquid to stir at least for one hour; and standing for 3-4 hours under a temperature condition of 40-60 DEG C to obtain a primary reactant; B, putting the primary reactant into hot water with the temperature of 90-100 DEG C to wash away boron trichloride to obtain the resin liquid of the terpene-phenolic resins; and C, clearing the water of the resin liquid of the terpene-phenolic resins; and putting the liquid into a distilled pot to distill and heat to 180 DEG C to obtain methylbenzene serving as a solvent; vacuumizing, distilling and heating methylbenzene; heating methylbenzene to 260 DEG C under a vacuum degree ranging from -0.08Mpa to -0.1Mpa; reducing the temperature to 240 DEG C after the vacuum is destroyed to package so as to obtain the solid terpene-phenolic resins.

Owner:XINYI SONGYUAN CHEM CO LTD

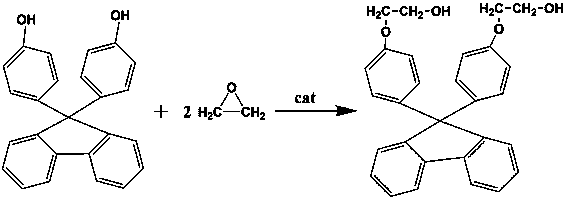

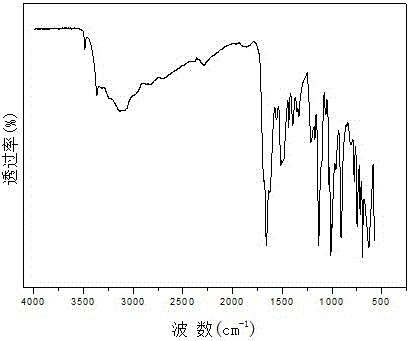

Preparing method of dihydroxyethyl bisphenol fluorene ether

ActiveCN109651093AImprove efficiencyLow hydroxyl valueEther preparation from oxiranesDesorptionEthylene oxide

The invention belongs to the technical field of fine chemical synthesis, and particularly relates to a preparing method of dihydroxyethyl bisphenol fluorene ether. The preparing method of dihydroxyethyl bisphenol fluorene ether comprises the following steps of 1, putting and replacement of nitrogen, wherein bisphenol fluorene, a triisopropylphosphine catalyst and a solvent are added into a reaction still in sequence, stirring is started, vacuumizing is conducted under N2 protection, and after replacement is repeatedly conducted several times until the vacuum degree is larger than or equal to minus 0.095 MPa, temperature rise begins; 2, reactions, wherein when the temperature in the reaction still is increased to 100 DEG C, a small amount of oxirane begins to be introduced, after the temperature rises to the reaction temperature, oxirane begins to be stably introduced, the pressure of the reaction still is controlled to be within 0.4 MPa, after adding of oxirane is finished, and the reactions continue at preserved temperature and preserved temperature and are finished until the pressure is not reduced; 3, desorption of the solvent, wherein after curing is finished, cooling is conducted for solvent desorption at negative pressure; 4, discharging, wherein the temperature is reduced to 80 DEG C, 30 min after degassing, discharging begins to obtain a dihydroxyethyl bisphenol fluorene ether product with the content larger than 98%.

Owner:ZHEJIANG HUANGMA TECH +3

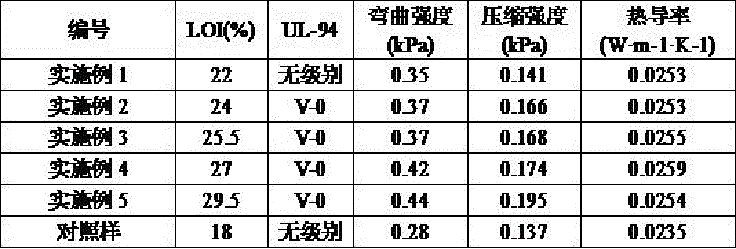

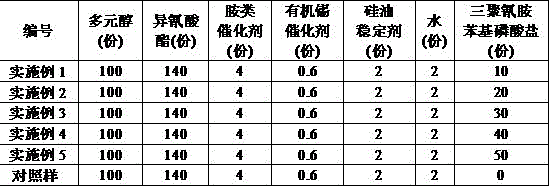

Preparation method of halogen-free flame retardant and application of halogen-free flame retardant to rigid polyurethane foam

InactiveCN105669943ARaw materials are easy to getEasy to makeGroup 5/15 element organic compoundsPolyolPolymer science

The invention belongs to the technical field of materials and particularly relates to a preparation method and an application of a halogen-free flame retardant. The component of the halogen-free flame retardant is melamine phenyl phosphate formed by reacting melamine with phenyl phosphoric acid, the preparation method comprises the specific steps as follows: melamine and phenyl phosphoric acid are added to a conical flask in the molar ratio being 1:1, then water with the amount accounting for 150-500 times that of melamine is added, the mixture is evenly stirred and heated to 70-95 DEG C and reacts for 3-5 h, a product is filtered, washed with water and dried, and melamine phenyl phosphate is obtained. For 100 parts of polyether polyol by weight in halogen-free flame retardant rigid polyurethane foam, 10-50 parts of halogen-free flame retardant melamine phenyl phosphate are used. The obtained halogen-free flame retardant rigid polyurethane foam has good flame retardation and mechanical properties. The method adopts a simple process, has low requirements for equipment, and is convenient to operate and environment-friendly.

Owner:TONGJI UNIV

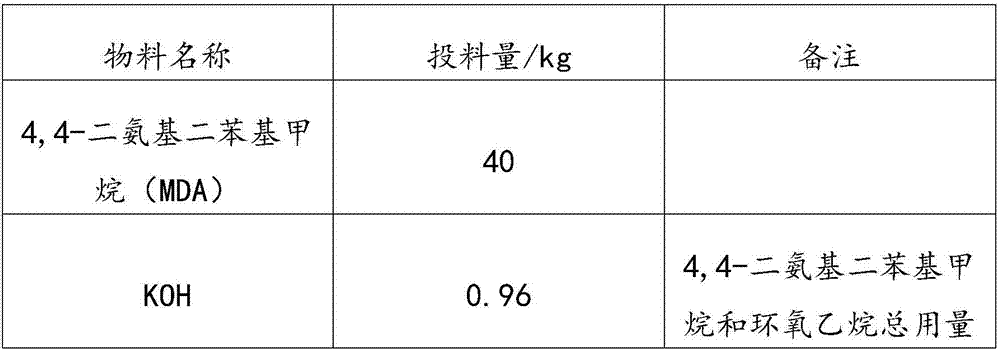

4,4-diaminodiphenyl methane polyether and preparation method thereof

The invention provides 4,4-diaminodiphenyl methane polyether and a preparation method thereof. The preparation method of 4,4-diaminodiphenyl methane polyether is simple in process and spends a short time. The preparation method comprises the steps of enabling 4,4-diaminodiphenyl methane to react with alkyleneoxide, adding an antioxidant, and carrying out ripening, degassing and neutralization, so as to obtain the 4,4-diaminodiphenyl methane polyether product. The 4,4-diaminodiphenyl methane polyether product synthesized by virtue of a specific process is low in hydroxyl value, viscosity and chromaticity and high in reaction activity, does not contain water, can remain uniform and stable for a long time, can be well applied to subsequent use and can be well mixed with other materials.

Owner:于天荣

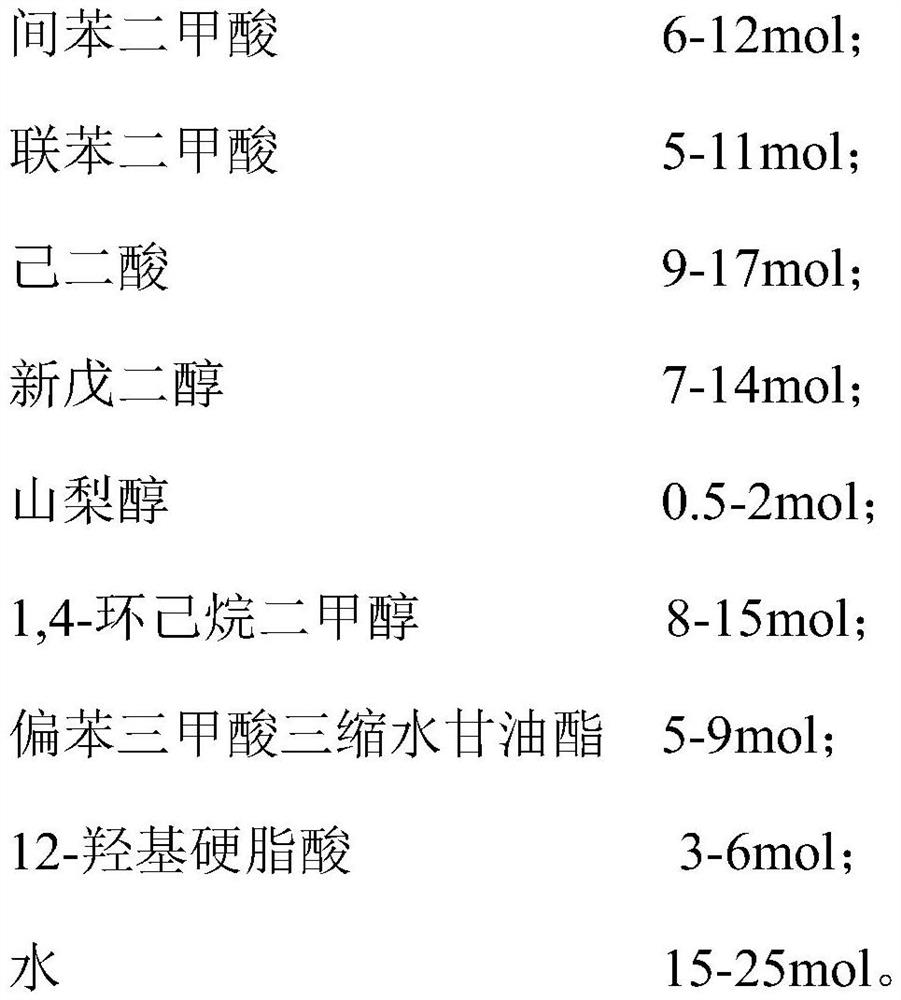

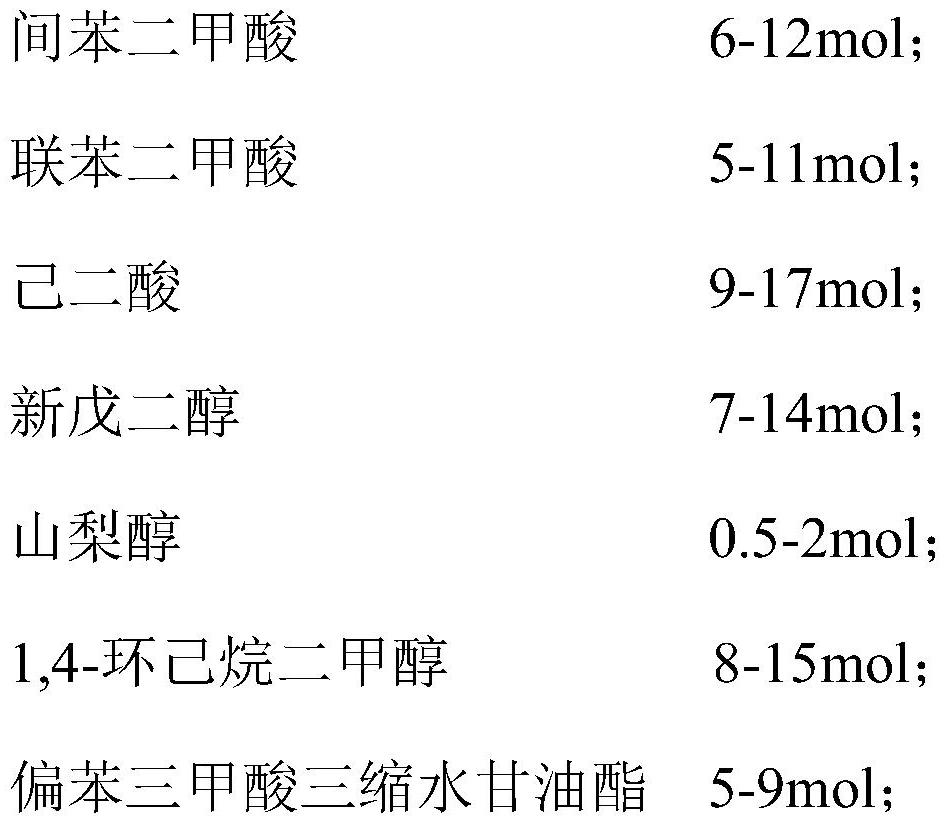

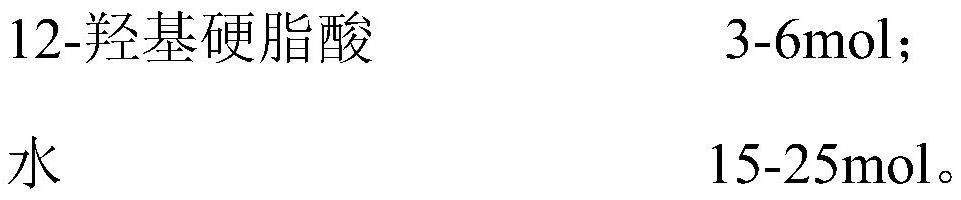

High-hydroxyl-value polyester resin for extinction type powder coating and preparation method and application thereof

ActiveCN112552497AReduced OH rangeStrong incompatibilityPowdery paintsPolyester coatingsStearic acidDicarboxylic acid

The invention belongs to the technical field of powder coating curing agents, particularly relates to high-hydroxyl-value polyester resin for an extinction type powder coating, and further discloses apreparation method and application of the high-hydroxyl-value polyester resin. The high-hydroxyl-value polyester resin for the extinction type powder coating is prepared from isophthalic acid, biphenyl dicarboxylic acid, adipic acid, neopentyl glycol, sorbitol, 1, 4-cyclohexanedimethanol, triglycidyl trimellitate and 12-hydroxy stearic acid as raw materials through polymerization. According to the polyester resin, by increasing the types and differences of active hydroxyl groups, the hydroxyl value of the polyester resin is reduced while the extinction effect of the polyester resin is not influenced, so that the defects of high hygroscopicity and high cost caused by a polyester resin product with an ultrahigh hydroxyl value are overcome, and the polyester resin has a relatively high application value.

Owner:HUANGSHAN ZHENGJIE NEW MATERIALS

Method for preparing dehydrated castor oil

The invention discloses a method for preparing dehydrated castor oil. The dehydrated castor oil is prepared through a dehydration reaction of castor oil in supercritical carbon dioxide environment. Compared with the prior art, the method has the advantages of only additioin of a proper amount of deionized water to a reaction system without other catalysts, reduction of the viscosity and the mass and heat transfer resistance through using a supercritical fluid technology, simplification of the production process of dehydrated castor oil, great shortening of the reaction time, production cost reduction, and easy large-scale promotion. The dehydrated castor oil prepared in the invention has the advantages of high purity, light color, high and stable iodine number, and low hydroxyl value.

Owner:泰州杜伦复合新材料有限公司

Crystal growth inhibitor for fats and oils

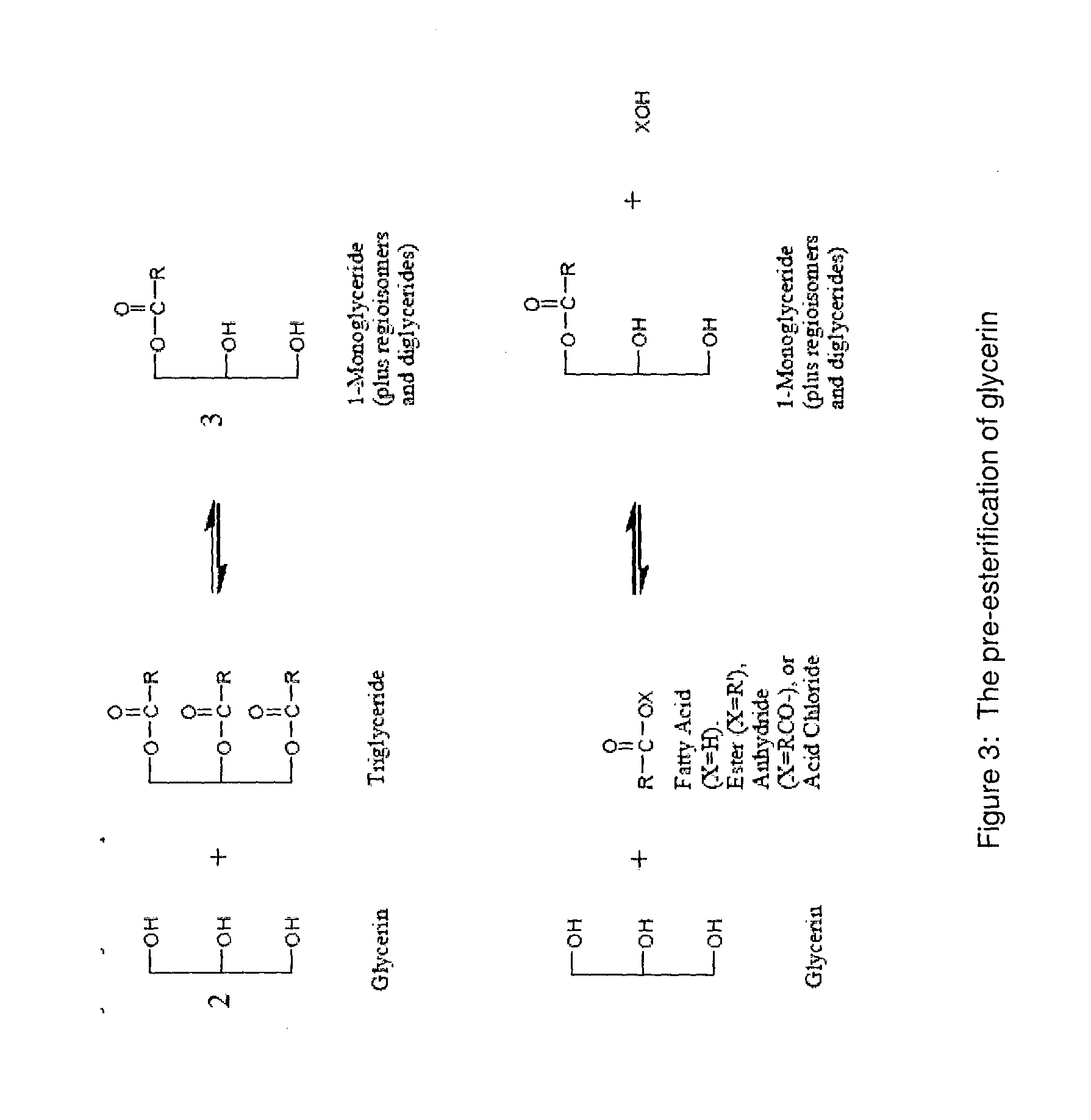

ActiveUS20110123695A1Easy to handleInhibit crystal growthOrganic chemistryFinished edible oils/fats preservationGrowth retardantGlycerol

An inhibitor for crystal growth of fats and oils, containing a polyglycerol fatty acid ester, which is an esterified product formed between a polyglycerol and a fatty acid, the polyglycerol having a hydroxyl value of 850 mg KOH / g or less and a ratio of primary hydroxyl groups to all the hydroxyl groups of the polyglycerol of 50% or more, wherein the polyglycerol fatty acid ester has a hydroxyl value of 100 mg KOH / g or less. Since the inhibitor for crystal growth of fats and oils of the present invention can inhibit crystal growth of fats and oils by adding the inhibitor to fats and oils, storage property of the fats and oils in a refrigerator, cold climates, or the like, so that the inhibitor can be suitably used in liquid fats and oils such as salad oil for which transparency is important.

Owner:TAIYO KAGAKU CO LTD

Two-component quick-drying intermediate coating and preparation method thereof

The invention relates to the coating field, specifically to a two-component quick-drying intermediate coating and a preparation method thereof. The two-component quick-drying intermediate coating is composed of components A and B, wherein the component A comprises the following ingredients by mass percent: 30-35% of low hydroxyl acrylic resin, 40-50% of hydroxyl filler, 1-2% of auxiliaries and 20-25% of diluent; and the component B comprises the following ingredients by mass percent: 70-80% of a curing agent and 20-30% of butyl acetate. The preparation method comprises the following steps of: firstly, mixing the ingredients of the component A and the component B according to own formulas, and secondly, evenly mixing the mixed component A with the mixed component B, wherein the weight of the component B accounts for 8-10% of the component A; and after defoaming by standing for a while, the mixture can be used for painting. Compared with the traditional intermediate coating, the two-component quick-drying intermediate coating provided by the invention is improved in hardness, good in matching performance, good in adhesion capability and good in grinding performance; and besides, the hard drying time is greatly shortened.

Owner:XUZHOU HUARI CHEM IND

Crystal growth inhibitor for fats and oils

ActiveUS9271512B2Easy to handleInhibit crystal growthOrganic chemistryEdible oils/fatsGrowth retardantGlycerol

An inhibitor for crystal growth of fats and oils, containing a polyglycerol fatty acid ester, which is an esterified product formed between a polyglycerol and a fatty acid, the polyglycerol having a hydroxyl value of 850 mg KOH / g or less and a ratio of primary hydroxyl groups to all the hydroxyl groups of the polyglycerol of 50% or more, wherein the polyglycerol fatty acid ester has a hydroxyl value of 100 mg KOH / g or less. Since the inhibitor for crystal growth of fats and oils of the present invention can inhibit crystal growth of fats and oils by adding the inhibitor to fats and oils, storage property of the fats and oils in a refrigerator, cold climates, or the like, so that the inhibitor can be suitably used in liquid fats and oils such as salad oil for which transparency is important.

Owner:TAIYO KAGAKU CO LTD

Lipophilic load type NaHSO4 catalyst as well as preparation method and application thereof

InactiveCN106179511AImprove hydrophobicityImprove lipophilicityOrganic-compounds/hydrides/coordination-complexes catalystsFatty-oils/fats refiningSilanesHydroxyl value

The invention provides a preparation method of a lipophilic load type NaHSO4 catalyst, and belongs to the field of catalytic chemistry. The preparation method comprises the following step: a loading material and an alkyl silane solution are uniformly mixed, filtering and drying are carried out, and a lipophilic carrier material is obtained; the lipophilic carrier material is dipped in an aqueous solution of NaHSO4, separation and drying are carried out, and the load type NaHSO4 catalyst is obtained. The method has the advantages of simple operation, stable process, and safety without toxicity; and the method is suitable for large scale industrial production. The invention also provides a lipophilic load type NaHSO4 catalyst which is prepared by the method; the catalyst has good hydrophobicity and lipophilicity, and has substantial catalysis effects for oil and fat substrates. The invention also provides an application of the lipophilic load type NaHSO4 catalyst to a dehydrated reaction of castor oil, conversion rate and yield of the reaction are good, quality of dehydrated castor oil which is obtained by the reaction is excellent, and the castor has high iodine number and low hydroxyl value.

Owner:YANCHENG INST OF TECH

A kind of method for preparing dehydrated castor oil

The invention discloses a method for preparing dehydrated castor oil. The dehydrated castor oil is prepared through a dehydration reaction of castor oil in supercritical carbon dioxide environment. Compared with the prior art, the method has the advantages of only additioin of a proper amount of deionized water to a reaction system without other catalysts, reduction of the viscosity and the mass and heat transfer resistance through using a supercritical fluid technology, simplification of the production process of dehydrated castor oil, great shortening of the reaction time, production cost reduction, and easy large-scale promotion. The dehydrated castor oil prepared in the invention has the advantages of high purity, light color, high and stable iodine number, and low hydroxyl value.

Owner:泰州杜伦复合新材料有限公司

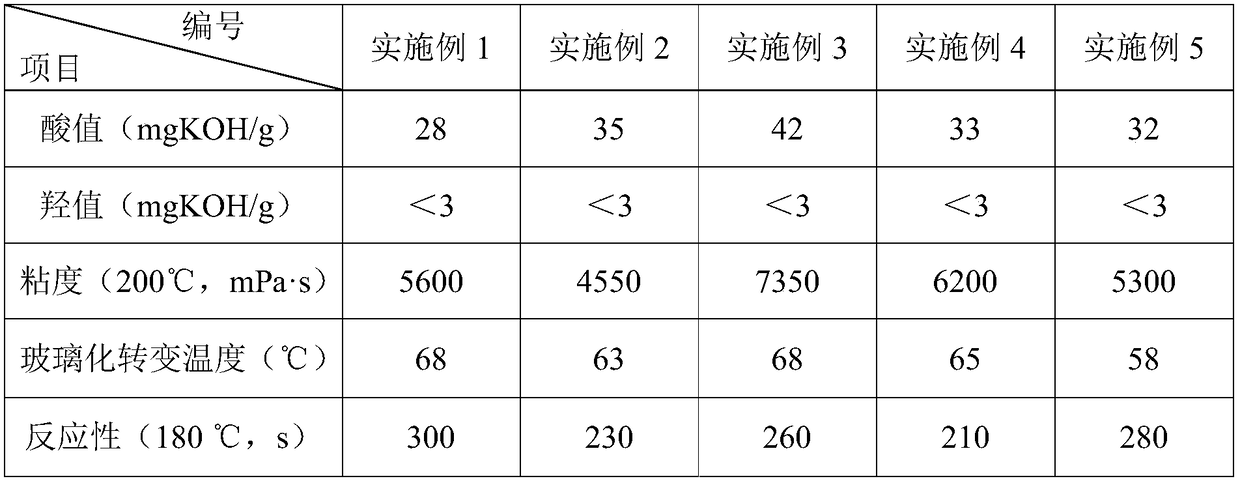

Polyester resin with high humidity and heat resistance and high irradiance as well as preparation method and application thereof

ActiveCN109054004AHigh glass transition temperatureLow hydroxyl valuePowdery paintsPolyester coatingsGlass transitionMechanical property

The invention discloses polyester resin with high humidity and heat resistance and high irradiance as well as a preparation method and application thereof. An acid value of the polyester resin is 25 to 45 mg KOH / g, a hydroxyl value is smaller than 3mgKOH / g, a glass transition temperature is 55 to 70 DEG C, 200 DEG C melt viscosity is 4500 to 7500 mPa.s, and 180 DEG C reactivity is 210 to 310s. Thepolyester resin disclosed by the invention has the performance of appropriate acid value, lower hydroxyl value, appropriate glass transition temperature, melt viscosity, reactivity and the like. Thepolyester resin disclosed by the invention has the advantages of concise preparation technology short synthesizing time and low preparation cost; the prepared polyester resin has good hue and is favorable for large-scale production and wide application; meanwhile, when the polyester resin is prepared into powdery paint, the powdery paint has excellent mechanical property, further has very strong weather resistance under the high humidity and heat environment and is especially suitable for protecting outdoor products under the weather with high humidity and heat and high irradiance in southernof China.

Owner:GUANGZHOU KINTE IND

Preparation method of polyether polyol for all-water flame-retardant system

The invention relates to a preparation method of polyether polyol for an all-water flame-retardant system, and belongs to the technical field of polyether polyol modification. According to the preparation method of the polyether polyol for the all-water flame-retardant system, trihydroxyethyl isocyanurate, hydroxymethyl melamine and small molecular alcohol are used as composite initiators and subjected to a polymerization reaction with alkylene oxide under the catalytic action of alkali, and the polyether polyol is obtained. The preparation method is scientific and reasonable in design, the cost is reduced, and the prepared polyether is low in viscosity, good in compatibility with water and auxiliaries and good in flame-retardant effect.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Bio-polyols for bio-lubricant and bio-polymer and methods for the preparation thereof

ActiveUS9302976B2Increase valueSynthetic is simpleFatty acid esterificationOrganic compound preparationBiopolymerHydroxyl value

A method for producing an ester polyol, comprising transesterifying a first ester polyol with a primary polyol to produce a second ester polyol, wherein the second ester polyol has a higher hydroxyl value than the first ester polyol.

Owner:GASOLINEIAM NASIONAL BERHAD

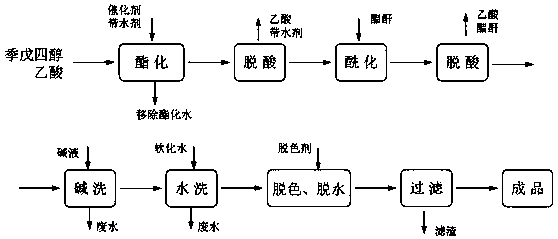

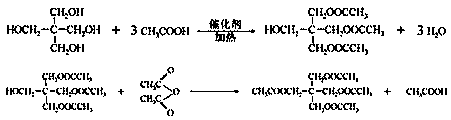

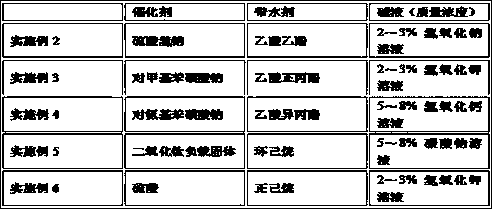

Preparation method of pentaerythritol tetraacetate

InactiveCN108191650ALow acid valueLow hydroxyl valueOrganic compound preparationCarboxylic acid esters preparationAcetic acidPentaerythritol

The invention discloses a preparation method of pentaerythritol tetraacetate and belongs to the field of chemical engineering. According to the method, a high-quality pentaerythritol tetraacetate product is obtained by taking pentaerythritol as a raw material through a series of processes of esterifying, deacidifying, acylating, alkali-washing, water-washing, decoloring, dehydrating, filtering andthe like. The product indexes are as follows: the content is more than or equal to 99.0 percent, the hydroxyl value is less than or equal to 1.0 mgKOH / g, the water content is less than or equal to 0.10 percent, the acid value is less than or equal to 0.1 mgKOH / g, the saponification value is 730 to 740 mgKOH / g, and the melting point is 79 to 81 DEG C. The pentaerythritol tetraacetate product produced by the method has low acid value, low hydroxyl value and low water content and can be applied to a formula of a high-quality base oil. The method has important reference value on industrial production of fatty acid ester of pentaerythritol.

Owner:江苏雷蒙新材料有限公司

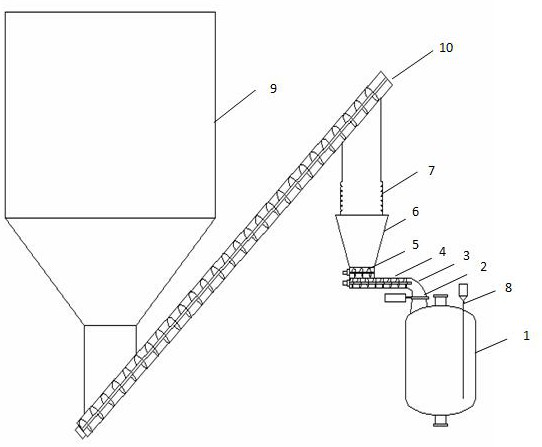

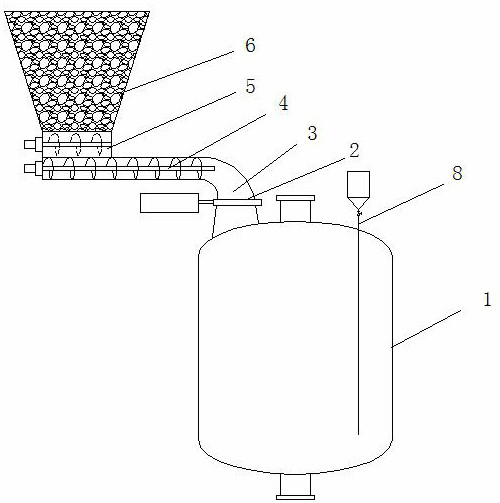

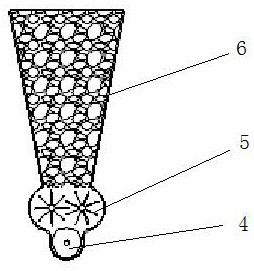

An industrial pure pu foam alcoholysis recovery method and special recovery feeding device

ActiveCN109320764BLow hydroxyl valueMass ratio is stablePlastic recyclingChemical recyclingPolyolPtru catalyst

The invention discloses an industrial pure PU foam alcoholysis recovery method and a special recycling feeding device, which is characterized in that the recycling feeding device includes a reaction kettle, a pneumatic gate valve, a feeding variable diameter elbow, and a main feeding screw conveying Machine, auxiliary feeding double-screw feeding conveyor, feeding hopper, soft connection and catalyst, hexamethylenetetramine and hydrogen peroxide and other small material feeding devices; the alcoholysis recovery method includes feeding, alcoholysis and recovery steps; The invention has the advantages of fast feeding speed and accurate feeding, which ensures that the quality of the pure PU foam feed and the mass ratio of the added main recovery alcoholysis agent are stable, and ensures that the catalyst, hexamethylenetetramine and hydrogen peroxide can be added in time according to the process requirements. In the reaction system, the control indicators of each batch of recycled polyols are guaranteed to be stable. The pure PU foam feeding method is combined with the recycling process to produce recycled polyols with stable performance, moisture content, and relatively low VOC indicators.

Owner:YANTAI ZHENGHAI HIGH TECH

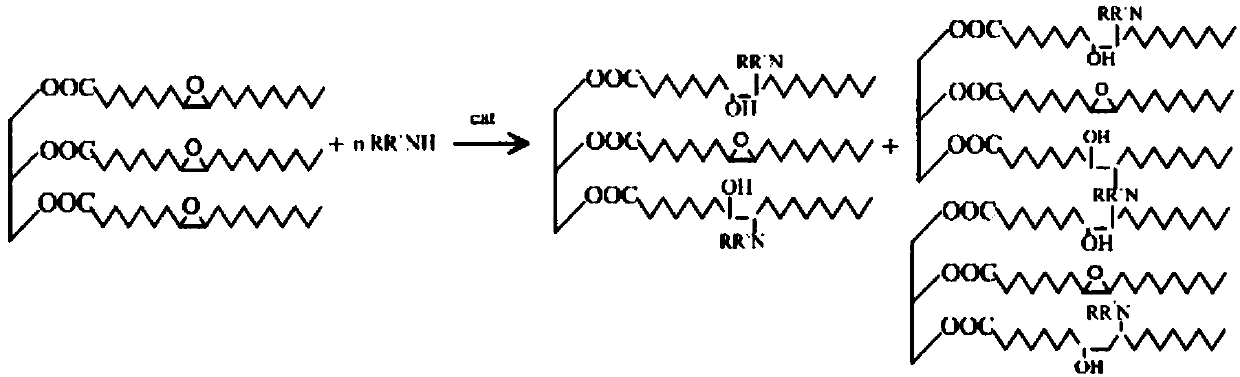

Preparation method of bio-based modified amino polyol

The invention discloses a preparation method of bio-based modified amino polyol. The preparation steps include: reacting a nucleophilic reagent with an epoxy compound under the action of a catalyst and the conditions of 50-200DEG C and 0-1MPa for 4-24h, carrying out gradual dropwise adding reaction or mixing reaction, and performing vacuum pumping, dehydration and filtering to obtain bio-based modified amino polyol; and subjecting the bio-based modified amino polyol and a neutralizing refining agent to acid-base neutralization reaction, carrying out adsorption, refining, dehydration and decolorization, and conducting vacuum pumping, dehydration and filtering so as to obtain refined bio-based modified amino polyol. The preparation method of the bio-based modified amino polyol adopts the epoxy compound and nucleophilic reagent as the main raw materials for comprehensive modification, the prepared bio-based modified amino polyol has the characteristics of high amino activity, high degreeof functionality and low hydroxyl value, and the obtained flexible product has the characteristics of low odor, low VOC content, and little residue of toxic and harmful substances.

Owner:广州市友聚米新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com