A kind of method for preparing dehydrated castor oil

A dehydrated castor oil and castor oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of cumbersome operation and poor product quality, and achieve the effects of simplified production procedures, easy large-scale promotion, and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

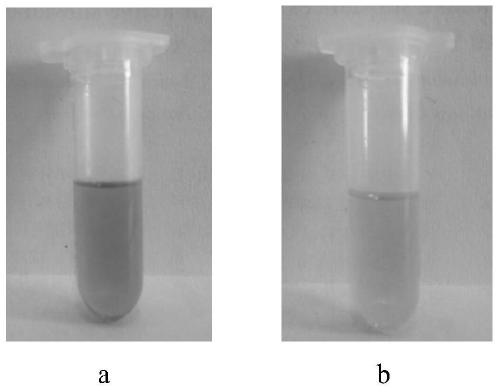

Image

Examples

Embodiment 1

[0026] Add 50mL of castor oil and 5mL of deionized water into a 100mL autoclave, tighten the lid of the kettle, purge 3 times with high-purity carbon dioxide, close the pressure relief valve, feed high-purity carbon dioxide with an initial pressure of 1MPa, and set the temperature 150°C, the stirring rate is 200n / min, after the temperature is raised to 150°C, the pressure in the kettle is 6.5MPa, and high-purity nitrogen gas is introduced to raise the pressure to 7.5MPa, and after maintaining this condition for 0.5h, stop heating and continue stirring. Cool to room temperature, depressurize, discharge, centrifugal separation, record hydroxyl value, iodine value are respectively 159mg KOH / g and 88g I 2 / 100g.

Embodiment 2

[0028] Add 50mL of castor oil and 10mL of deionized water into a 100mL autoclave, tighten the lid of the kettle, purge 5 times with high-purity carbon dioxide, close the pressure relief valve, feed high-purity carbon dioxide with an initial pressure of 5MPa, and set the temperature 180°C, the stirring rate is 800n / min, after the program temperature rises to 180°C, the pressure in the kettle is 13.3MPa, after maintaining this condition for 1.0h, stop heating, continue stirring, cool to room temperature, release the pressure, discharge, centrifuge, The measured hydroxyl value and iodine value are 107mg KOH / g and 96g I respectively 2 / 100g.

Embodiment 3

[0030] Add 50mL of castor oil and 15mL of deionized water into a 100mL autoclave, tighten the lid of the kettle, purge once with high-purity carbon dioxide, close the pressure relief valve, feed high-purity carbon dioxide with an initial pressure of 3MPa, and set the temperature 250°C, the stirring rate is 600n / min, after the temperature is programmed to 250°C, the pressure in the kettle is 11.6MPa, and after maintaining this condition for 3.0h, stop heating, continue stirring, cool to room temperature, release the pressure, discharge, and centrifuge. The measured hydroxyl value and iodine value are 95mg KOH / g and 89g I respectively 2 / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com