High-gloss metallic paint for rolled steel substrate and preparation method and application

A high-gloss, metallic color technology, applied in the field of coatings, can solve the problems of affecting the light reflection effect, low gloss, poor orientation of aluminum powder, etc., to achieve the effect of improving gloss, high gloss, and enhancing orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

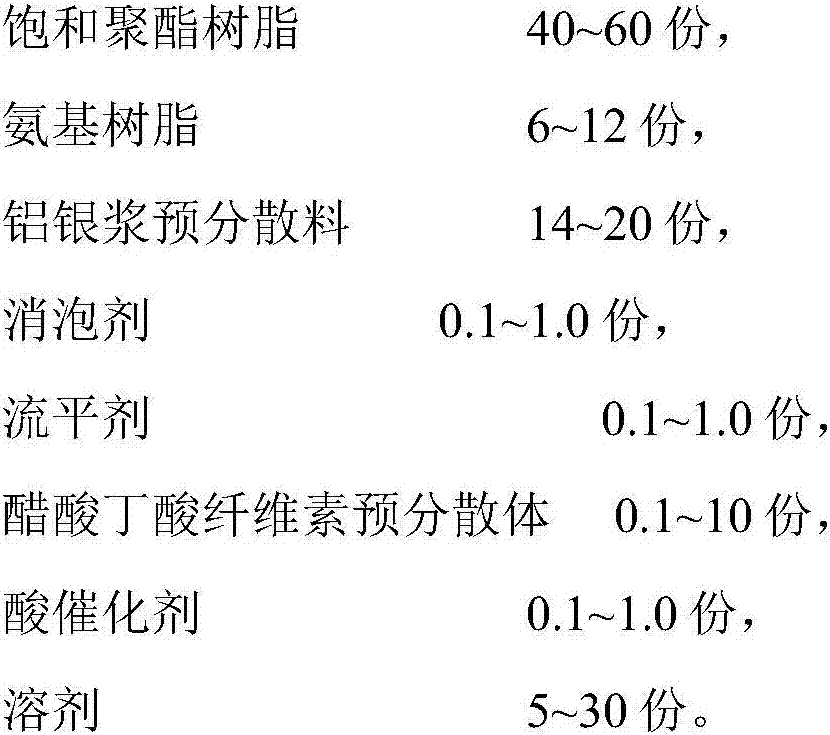

Method used

Image

Examples

Embodiment 1

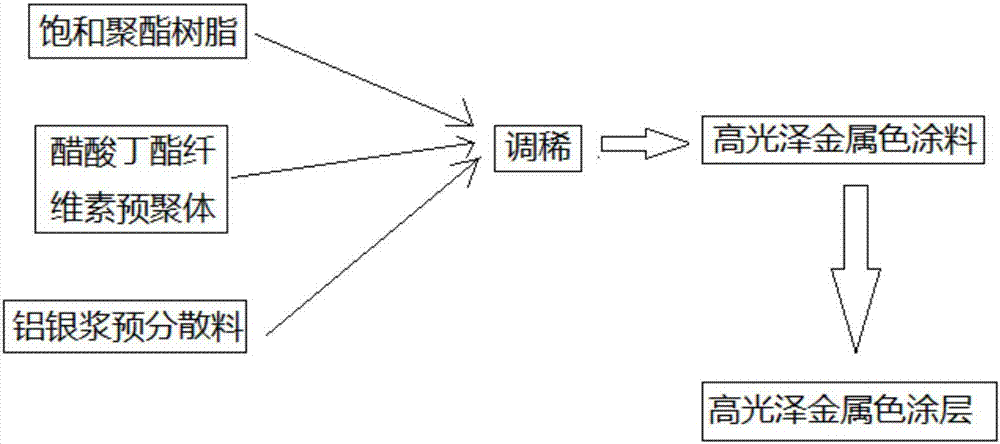

[0047] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the preparation method of the high-gloss metallic paint for coil steel substrates of the present invention.

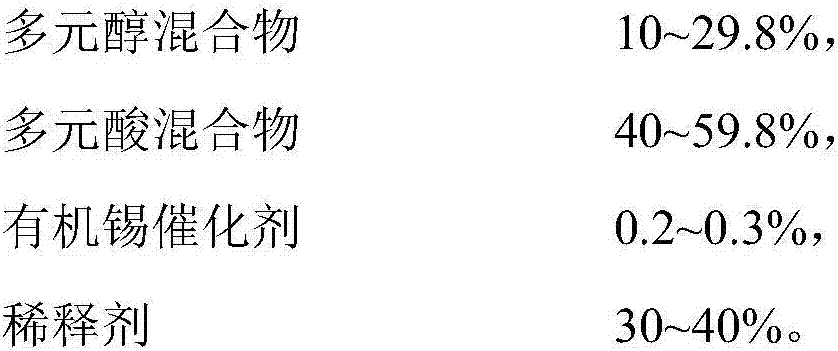

[0048] The preparation method of saturated polyester resin comprises the following steps:

[0049] Step 1: Add 130g of neopentyl glycol, 20g of trimethylolpropane, 5g of hexanediol, 158.5g of adipic acid, 8.5 g terephthalic acid, 140g isophthalic acid, start heating under the protection of nitrogen or carbon dioxide and other inert gases, start stirring when the kettle temperature reaches 140°C, then add 1.1g dibutyltin dilaurate to control the temperature of the material in the kettle At 240-250°C, react for 8 hours.

[0050] The second step: Then add 50g of xylene into the reactor, take a sample every 30 minutes, and test the acid value until the acid value of the material <3KOHmg / g is the end of the reaction.

[0051]Step 3: cool down to 120°C, add 212g of S-100 solvent oil with a solid c...

Embodiment 2

[0057] The preparation method of saturated polyester resin comprises the following steps:

[0058] Step 1: Add 70g neopentyl glycol, 20g trimethylolpropane, 10g hexanediol, 400g adipic acid, 50g para Phthalic acid, 150g of isophthalic acid, under the protection of inert gas such as nitrogen or carbon dioxide, start to heat up, start stirring when the temperature of the kettle reaches 140°C, then add 5g of dibutyltin dilaurate, and control the temperature of the material in the kettle at 240~ 250°C, react for 8 hours.

[0059] Step 2: Then add 200g of xylene into the reactor, take a sample every 30 minutes, and test the acid value until the acid value of the material <3KOHmg / g is the end of the reaction.

[0060] Step 3: Cool down to 120°C, add 200g of No. S-100 solvent oil with a solid content of 60%, filter, and set aside; the glass transition temperature of the saturated polyester resin is 22°C.

[0061] Cellulose acetate butyrate predispersion: add 10g cellulose acetate b...

Embodiment 3

[0066] The preparation method of saturated polyester resin comprises the following steps:

[0067] Step 1: Add 170g neopentyl glycol, 120g trimethylolpropane, 10g hexanediol, 100g adipic acid, 50g para Phthalic acid, 50g isophthalic acid, under the protection of inert gas such as nitrogen or carbon dioxide, start to heat up, start stirring when the kettle temperature reaches 140°C, then add 0.2g dibutyltin dilaurate, control the temperature of the material in the kettle at 240°C ~250°C, react for 8 hours.

[0068] The second step: Then add 20g of xylene into the reactor, take a sample every 30 minutes, and test the acid value until the acid value of the material <3KOHmg / g is the end of the reaction.

[0069] Step 3: Cool down to 120°C, add 10g of S-100 solvent oil with a solid content of 60%, filter, and set aside; the glass transition temperature of the saturated polyester resin is 25°C.

[0070] Cellulose acetate butyrate predispersion: add 10g cellulose acetate butyrate C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com