Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

818 results about "Cellulose acetate-butyrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose acetate butyrate is a thermoplastic with many common uses from trim for automobiles to tool handles, pens, blister packaging, and more.

Compositions for use in embolizing blood vessels

Disclosed are compositions suitable for use in embolizing blood vessels which compositions comprise a polymer, a biocompatible solvent and a contrast agent. The polymer is selected from the group consisting of polyacrylonitrile, polyurethane, polyvinylacetate, cellulose acetate butyrate, nitrocellulose and copolymers of urethane / carbonate and copolymers of styrene / maleic acid.

Owner:MICRO THEREPEUTICS INC

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Inkjet-recording non-aqueous ink composition, inkjet recording method, and recorded matter

InactiveUS20090075036A1Improve rendering capabilitiesImprove stabilityLayered productsDecorative surface effectsAcetic acidOrganic solvent

An inkjet-recording non-aqueous ink composition including a metallic pigment, an organic solvent, and a cellulose acetate butyrate resin having a butyl content of 16.5 to 48%.

Owner:SEIKO EPSON CORP

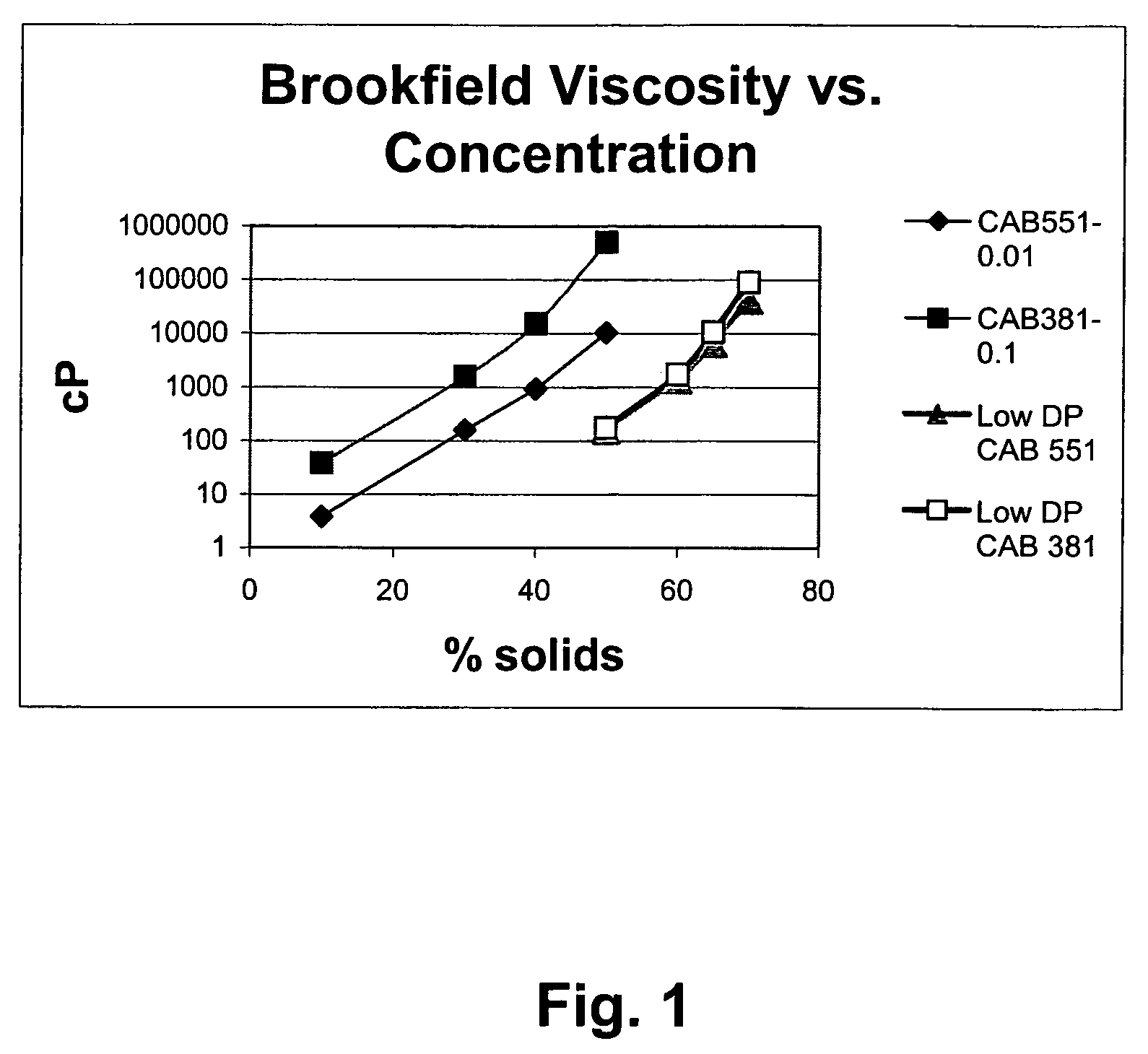

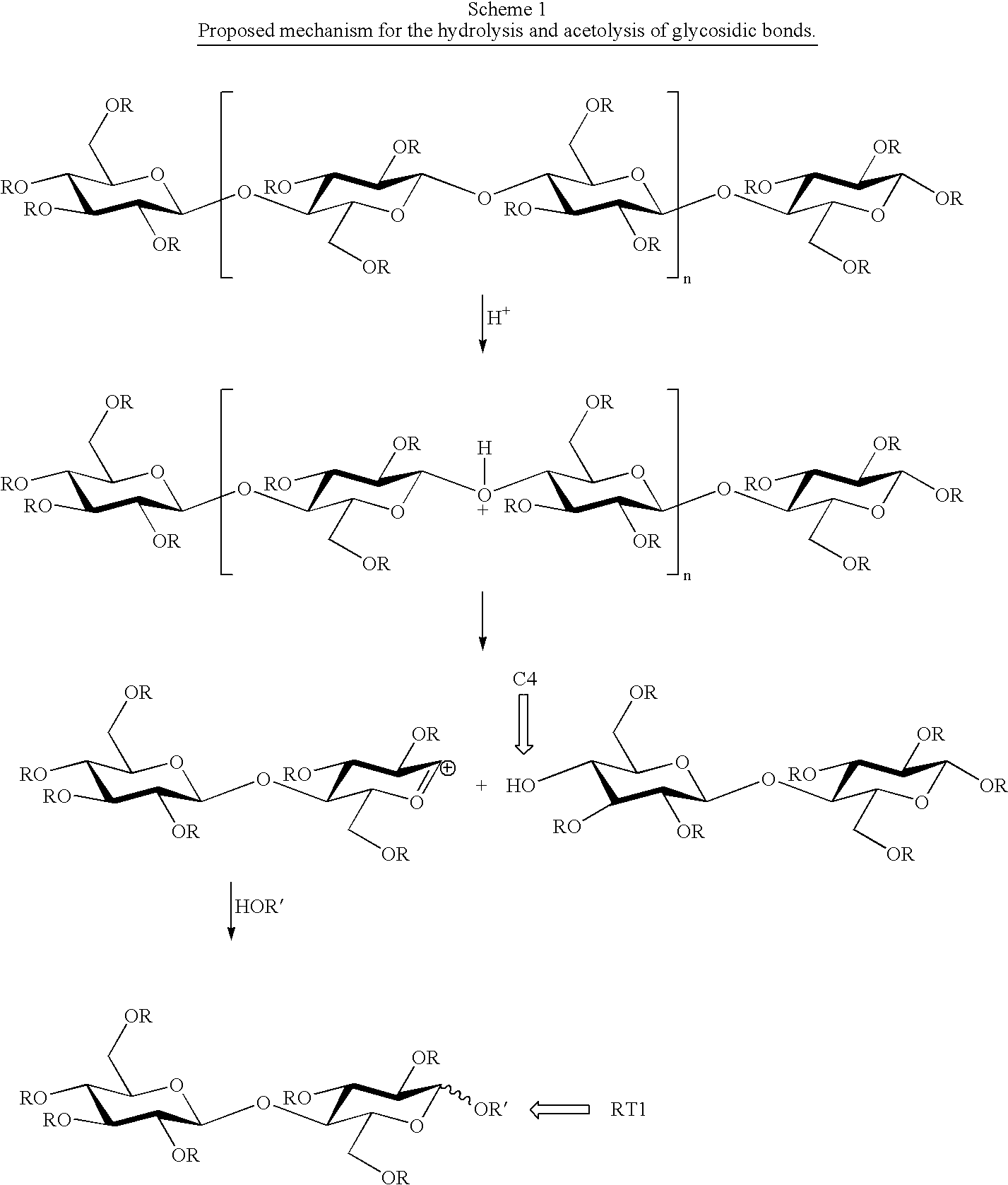

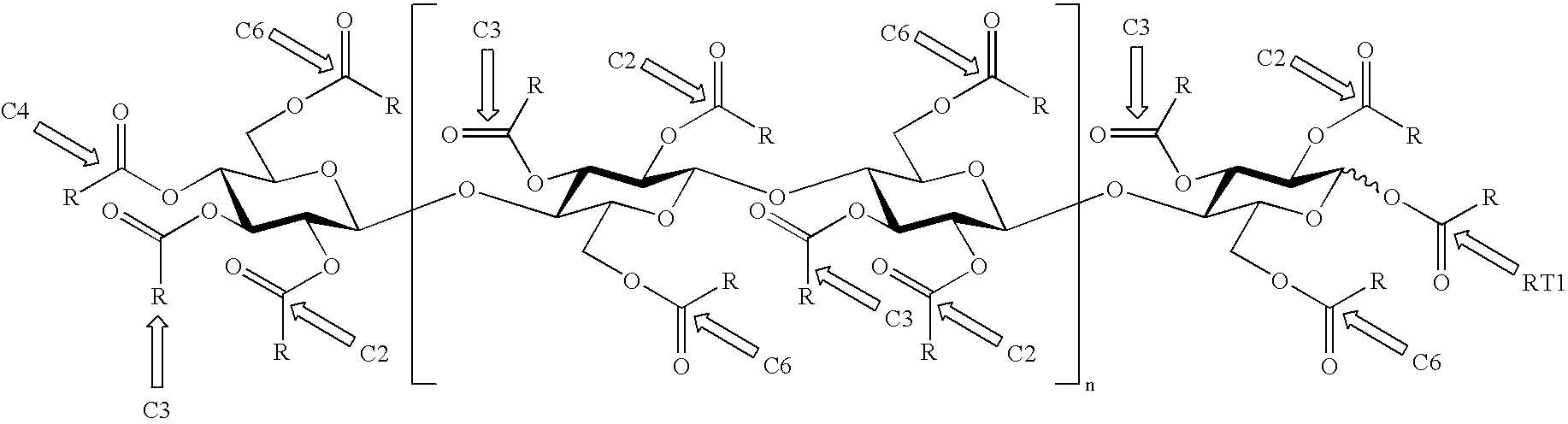

Low molecular weight cellulose mixed esters and their use as low viscosity binders and modifiers in coating compositions

ActiveUS7585905B2Reduce molecular weightHigh maximum degree of substitutionInksPolyurea/polyurethane coatingsSolubilityCellulose

Cellulose mixed esters are disclosed having low molecular weights and low degrees of polymerization. These new cellulose mixed esters include cellulose acetate propionate and cellulose acetate butyrate. The esters exhibit solubility in a wide range of organic solvents with minimal viscosity increase, are compatible with a wide variety of resins, and are useful in coatings and inks compositions as binder resins and rheology modifiers.

Owner:EASTMAN CHEM CO

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Rapid drying lacquers containing impoved rheology control additive

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel graft copolymer with segmented (or block) arms as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:AXALTA COATING SYST IP CO LLC

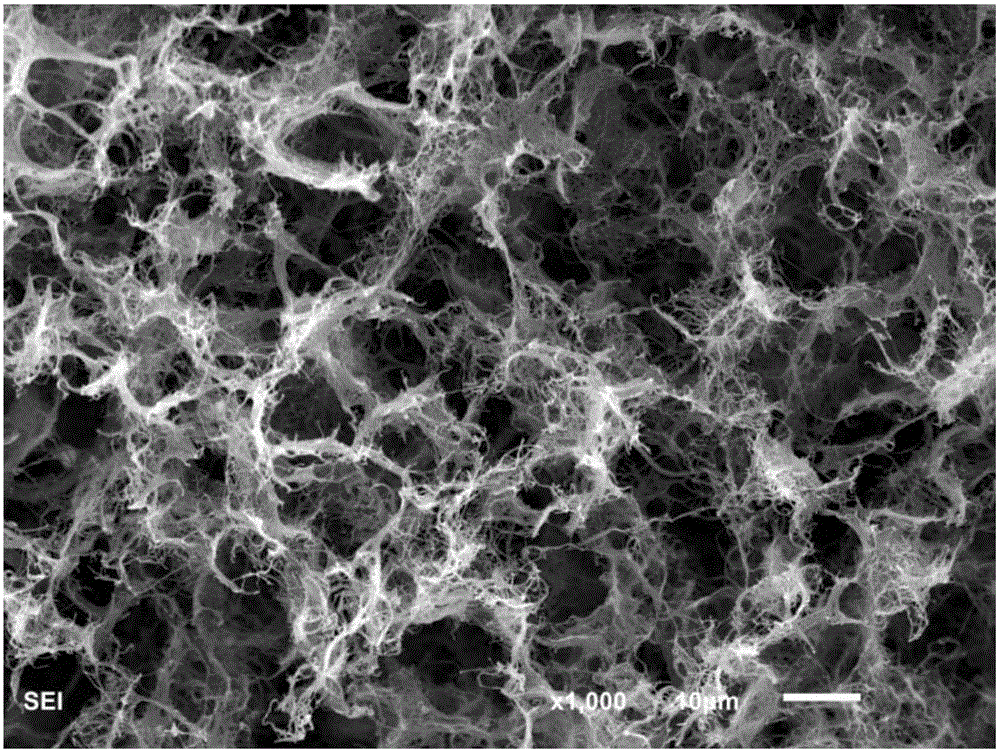

Organic and inorganic composite nanofiber membrane filtering material and preparation method thereof

ActiveCN104689724AEvenly distributedUniform and stable structureSemi-permeable membranesCelluloseComposite nanofibers

The invention relates to an organic and inorganic composite nanofiber membrane filtering material and a preparation method thereof. The organic and inorganic composite nanofiber membrane filtering material is composed of a non-woven fabric base material and an organic nanofiber membrane, which is attached to the surface of the non-woven fabric base material and scattered with inorganic nano active particles. The preparation process of organic nano fiber comprises performing blend-melt spinning with thermoplastic polymer and cellulose acetate butyrate, and performing solvent extraction to obtain thermoplastic polymer nanofiber; then proportionally dispersing the nanofiber and the inorganic nano active particles into ethanol to obtain a mixed suspension of the nanofiber and the inorganic active particles; lastly, evenly coating the suspension onto the surface of the non-woven fabric base material, and drying the coated non-woven fabric base material at room temperature to obtain the organic and inorganic composite nanofiber membrane filtering material. The preparation process of the organic and inorganic composite nanofiber membrane filtering material has the advantages of being simple in process, low in cost and energy consumption and high in yield. The nanofiber and the nano active particles in the organic and inorganic composite nanofiber membrane filtering material are three-dimensionally uniformly distributed, so that the organic and inorganic composite nanofiber membrane filtering material has the advantage of being stable in structure and excellent in absorbing and filtering performance.

Owner:WUHAN TEXTILE UNIV +1

Method for preparing cellulose acetate propionate or cellulose acetate butyrate

The invention provides a method for preparing cellulose acetate propionate or cellulose acetate butyrate. The method comprises the following steps: a. mixing fibrin and ionic liquid capable of dissolving the fibrin to obtain an ionic liquid solution containing the fibrin; b. adding acetylate and propionyl reagent (1) or acetylate and reagent (2) into the ionic liquid solution containing the fibrin, reacting for 1-24h at 40-120 DEG C, preferably 1-12h, and obtaining reaction mixture; c. adding lower fatty alcohol from C1 to C3 into the reaction mixture and filtering the reaction mixture containing the lower fatty alcohol; and d. drying a solid obtained by filtering to obtain the cellulose acetate propionate or cellulose acetate butyrate. The invention utilizes the ionic liquid as a solvent without any catalyst and has the advantages of simple process and no pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for preparing organic cellulose acid ester by solid acid catalysts

The invention discloses a method for preparing organic cellulose acid ester by solid acid catalysts, relating to the technical field for preparing organic cellulose acid ester. In the invention, the organic cellulose acid ester refers to cellulose formic acid, cellulose acetate, cellulose propionate, cellulose acetate butyrate, cellulose acetate propionate, cellulose acetate butyrate and cellulose acetate propionate butyrate. Three solid acids, namely, SO42- / MxOy solid acid, biomass carbon-based solid acid, phosphorus-aluminum molecular sieve solid acid; the organic acid is used as solvent and the organic acid anhydride is used as esterifying agent; the using amount of the catalyst is 0.01-5% of the reaction liquid; the organic cellulose acid ester is prepared under the conditions that the reaction temperature is 15-90 DEG C and the reaction time is 0.5-72 h. The method adopts the novel environment-friendly solid acid catalyst; the obtained product has good quality; the catalyst is easy to separate, recover and recycle; no device corrosion exists and the environment is protected.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

Inkjet-recording non-aqueous ink composition, inkjet recording method, and recorded matter

InactiveUS7828888B2Improve rendering capabilitiesImprove stabilityDecorative surface effectsDuplicating/marking methodsAcetic acidOrganic solvent

Owner:SEIKO EPSON CORP

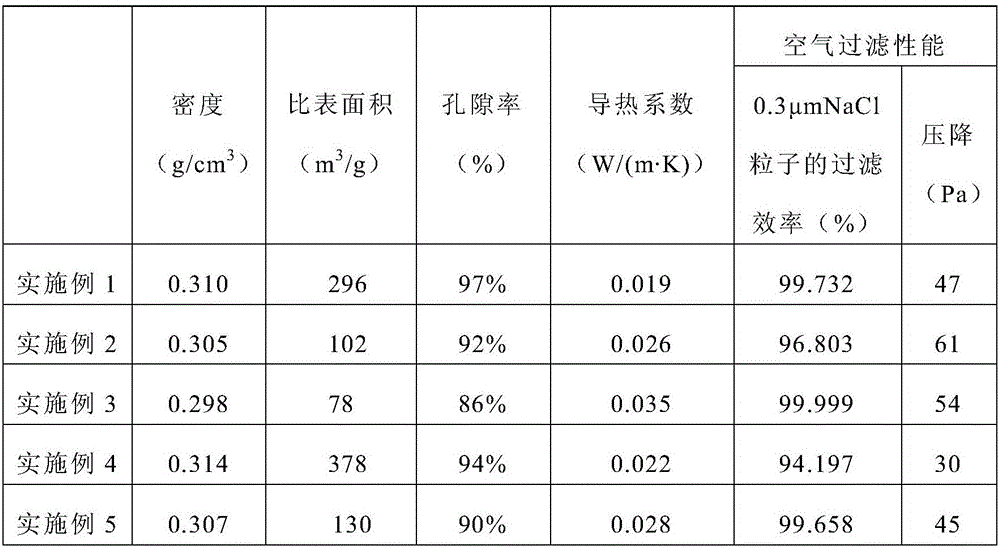

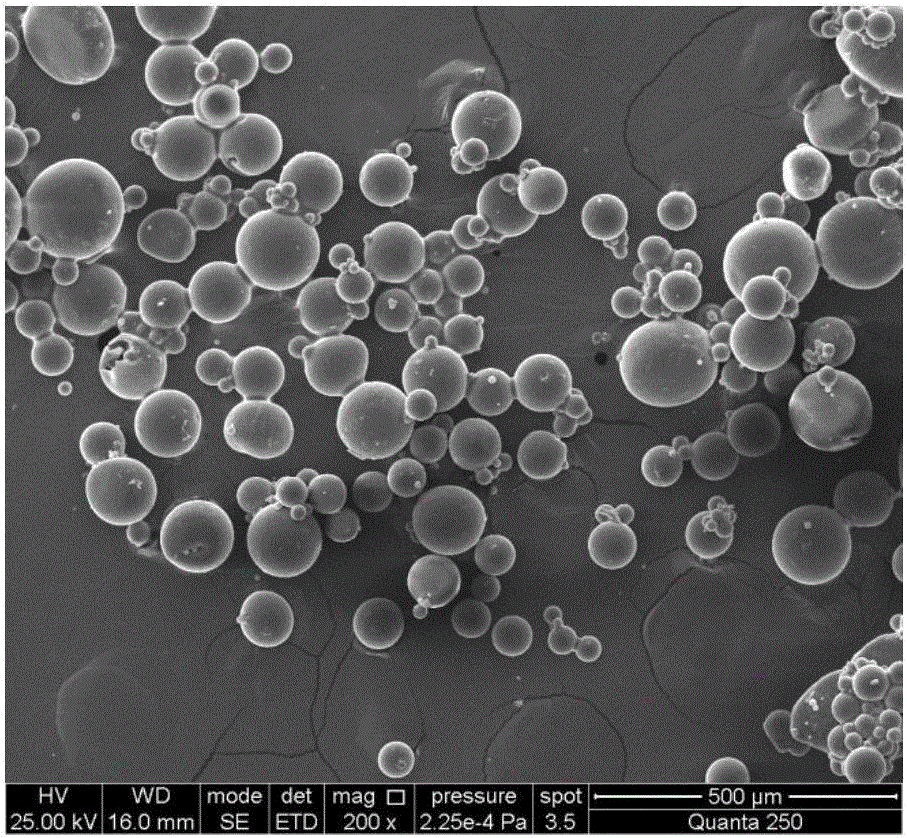

Polymeric nanofiber-based aerogel material and preparation method thereof

The invention discloses a polymeric nanofiber-based aerogel material and a preparation method thereof, and belongs to the fields of aerogel materials and preparation methods thereof. The preparation method comprises the steps that a thermoplastics polymer and cellulose acetate butyrate are subjected to melt blending, drawing, extracting and the like to prepare polymeric nanofibers, the polymeric nanofibers are added into water or a water solvent prepared from water and an organic solvent to generate polymeric nanofiber dispersion liquid, a cross-linking reaction is conducted to obtain cross-linked polymeric nanofiber suspension liquid, freeze drying is conducted on the cross-linked polymeric nanofiber suspension liquid, and then the polymeric nanofiber-based aerogel material is prepared. The polymeric nanofiber-based aerogel material prepared through the method has the advantages of being obvious in nanofiber porous structure, good in mechanical property and the like. The material prepared through the method can be applied to the fields of air filtration, thermal insulation, adsorption and the like directly or by being composited with other materials.

Owner:武汉维晨科技有限公司

Double-component ground coating matched with ultraviolet (UV) coating for coating notebook computer plastic case

The invention discloses a double-component ground coating matched with an ultraviolet (UV) coating for coating a notebook computer plastic case. The double-component ground coating comprises a main agent and a curing agent, wherein the main agent comprises the following components according to weight contents: 10-20% of hydroxylated acrylic resin with low hydroxyl value, 10-20% of hydroxylated acrylic resin with low and medium hydroxyl value, 20-40% of hydroxylated acrylic resin with medium hydroxyl value, 5-15% of cellulose acetate butyrate resin, 0-2% of adhesion promoter, 0.2-0.5% of flatting agent, 0.2-0.5% of defoaming agent, 5-30% of pigment paste and 15-25% of solvent; and the curing agent comprises the following components according to the weight contents: 70-80% of hexamethylene diisocyanate and 20-30% of solvent. The invention further relates to a method for preparing the double-component ground coating. The double-component ground coating is suitable for coating the notebook computer plastic case, has good sealing performance for plastic parts of acrylonitrile butadiene styrene (ABS), polycarbonate (PC), ABS plus PC and the like and can be well combined with UV finish paint.

Owner:GUANGZHOU KINTE IND

Removable adhesive for adhering an image to a surface and a method for removing the image

InactiveUS20070110966A1Easy to removeDecorative surface effectsDuplicating/marking methodsDiacetone alcoholTetrahydrofuranol

A removable adhesive of a combination of acrylic and urethane polymers is provided for securing, among other things, a transfer image to a hard surface. A removable top coat is provided. A top coat comprising a cellulose acetate butyrate alcohol and a diacetone alcohol is provided. A remover for removing the transferred image is provided which is a combination of tetrahydrofuryl alcohol and a dibasic ester and a surfactant.

Owner:WARREN DONALD

Inorganic hydrous salt phase change microcapsule energy-storage material and preparing method

InactiveCN106221674AAchieve solidificationImprove heat transfer efficiencyHeat-exchange elementsCalcium Chloride HexahydrateSodium Thiosulfate Pentahydrate

The invention relates to a preparing method of an inorganic hydrous salt phase change microcapsule energy-storage material and belongs to preparing methods of energy-storage materials. The energy-storage material comprises a core material and a wall material, wherein the core material is prepared from one or more of calcium chloride hexahydrate, sodium sulfate decahydrate, sodium thiosulfate pentahydrate, disodium hydrogen phosphate dodecahydrate, sodium acetate trihydrate and sodium carbonate decahydrate inorganic hydrous salt, and the wall material is prepared from one or more of polystyrene, polymethyl methacrylate, poly(ethyl acrylate), polyurethane, cellulose acetate butyrate (CAB) and a diphenylmethane diisocyanate polymer, the core material accounts for 30-80% of the microcapsule energy-storage material by mass, and the wall material is prepared from the polymer and accounts for 20-70% of the microcapsule energy-storage material by mass. The phase change point of the obtained phase change microcapsule energy-storage material ranges from 20 DEG C to 90 DEG C, and the particle size ranges from 1 micrometer to 100 micrometers. The phase change microcapsule energy-storage material prepared with the method is high in encapsulation rate, good in sealing performance, large in phase change latent heat value, simple in preparing method and large in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

High-wear-resistant antibacterial acrylate paint

InactiveCN106366899AImprove wear resistanceGood solvent resistanceFireproof paintsAntifouling/underwater paintsWear resistantUnsaturated polyester

The invention discloses high-wear-resistant antibacterial acrylate paint. The high-wear-resistant antibacterial acrylate paint is prepared from the raw materials: an aqueous acrylate emulsion, alkyd resin, organosilicon modified unsaturated polyester resin, silica sol, cellulose acetate butyrate, polyvinyl pyrrolidone, modified nano-titania, calcium carbonate whiskers, octadecyl trimethyl ammonium chloride modified montmorillonite, hollow glass beads, zinc oxide, ethylene glycol mono-n-propyl ether, di-propanediol butyl ether, triethylene glycol monoethyl ether, an anti-settling agent, a humectant, an antifoamer, per-methoxylation melamine resin, 3,5-dimethyl-2-aminobenzoic acid, trimethylaniline, a leveling agent, vinyl triethoxysilane and deionized water. The high-wear-resistant antibacterial acrylate paint provided by the invention is high in hardness, good in wear resistance, excellent in antibacterial performance and long in service life.

Owner:ANHUI JINDUN PAINT

Ultraviolet (UV)-natural matte finishing paint

InactiveCN103305120AHigh surface flatnessLow softnessPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

The invention discloses ultraviolet (UV)-natural matte finishing paint. The finishing paint comprises the following components in percentage by weight: 40 to 80 percent of 100 percent UV matte resin, 10 to 20 percent of cellulose acetate butyrate, 0.1 to 0.5 percent of antifoaming agent, 1.0 to 2 percent of dispersant, 5 to 10 percent of stuffing, 3 to 8 percent of initiator, 0.1 to 1 percent of flatting agent, 1 to 1.5 percent of anti-settling agent and the balance of monomers; the 100 percent UV-resin is one or a mixture of polyurethane acrylic resin, modified epoxy acrylate and polyester acrylic resin; and the 100 percent UV matte resin is one or a mixture of the polyurethane acrylic resin, the modified epoxy acrylate and the polyester acrylic resin. The UV-natural matte finishing paint has high liquidity, fine surface and high fullness; and a formed paint film structure is high in scratch resistance, particularly on open or semi-open or imitation antique floors, thereby protecting the surfaces of wood furniture and wood floors for a long time.

Owner:JIANGSU HIMONIA TECH

Black single-component solid color paint for automobile repair and preparation method thereof

InactiveCN102391726AGood storage stabilityGood flexibilityPolyester coatingsWeather resistanceUltraviolet lights

The invention relates to black single-component solid color paint for automobile repair and a preparation method thereof. The black single-component solid color paint is prepared from the following components in parts by weight: 2.0-4.0 parts of carbon black pigment, 20.0-25.0 parts of resin, 18.4-21.4 parts of solvent, 45-50.0 parts of cellulose acetate butyrate, 2-8 parts of dispersing agent, 0.3-0.5 part of rheological aid, 0.02-0.05 part of flatting agent and 0.4-1 part of ultraviolet light absorbing agent. Compared with the prior art, the blackness of the solid color paint prepared by the method provided by the invention is greatly improved, and the hue of the prepared solid color paint is more partial to blue phase; and the prepared solid color paint has the advantages of excellent storage stability, flexibility, impact resistance, weather resistance and interlayer adhesive force, high drying speed and the like, and is more suitably used as automobile repair paint.

Owner:DONGLAI COATING TECH SHANGHAI

Environment-friendly skip hot-stamping alumite hot-stamping foil and preparation method thereof

ActiveCN105818560AIncrease usageIncrease profitPolyurea/polyurethane coatingsThermographyHot stampingEnvironmental resistance

The invention discloses environment-friendly skip hot-stamping alumite hot-stamping foil and a preparation method thereof. The adhesive force of an existing alumite hot-stamping foil coating to a base film layer and the adhesive force between coatings are low. A coloring layer of the hot-stamping foil is prepared from, by weight percent, 20%-40% of thermosetting acrylic resin, 2%-10% of blocked isocyanate, 3%-8% of a styrene-maleic anhydride copolymer, 1%-8% of cellulose acetate butyrate, 2%-10% of adhesive force promotion resin, 2%-7% of dye, 30%-60% of butanone and 1%-10% of cosolvent. The special adhesive force promotion resin is added in the formula, so that the adhesive force of the coloring layer and a base film layer and the adhesive force of the coloring layer and a vacuum aluminum coating layer are effectively improved. A water-soluble paint formula is adopted in a water-based back glue layer, an adhesion promoter is added, and therefore the usage amount of a low-softening-point low-molecular-weight auxiliary is reduced, meanwhile, the adhesive force of the water-based back glue layer to the vacuum aluminum coating layer and the temperature resistance of the water-based back glue layer are improved, and the utilization rate can be increased to 90% or above from original 40%-50%.

Owner:云南玉溪东魅包装材料有限公司

Dope for plastic decorative cover of automotive wheel and preparation method thereof

InactiveCN101613553AImprove wear resistanceCorrosion resistant to mediumCoatingsButyl acetateAcrylic resin

The invention discloses a dope for a plastic decorative cover or an automotive wheel and a method for preparing the dope. The dope comprises the following components by weight portion: 4-8 portions of aluminum powder, 14-28 portions of butyl acetate, 20-30 portions of hydroxylated acrylic resin, 18-25 portions of cellulose acetate butyrate resin, 1.2-5.1 portions of accessory agent and 3-8 portions of solvent, wherein the solid part of the hydroxylated acrylic resin is 55%, hydroxyl value is 84+ / -5, acid value is less than 5 mg KOH / g, glass transition temperature is 21 DEG C, and viscosity is Y-Z2. The dope is used for painting the plastic decorative cover of the automotive wheel with convenient construction, and the performance of the product cannot be damaged.

Owner:辽宁久奈化工集团股份有限公司

Heat-resisting waterproof wallpaper and production method thereof

InactiveCN106703311AImprove waterproof performanceImprove heat resistanceCovering/liningsFibre treatmentMaterials scienceGlycerol Ethers

The invention discloses a heat-resisting waterproof wallpaper. The heat-resisting waterproof wallpaper comprises a base material layer, a waterproof layer and a heat-resisting layer, wherein the heat-resisting layer is made of waterborne silicon-acrylate resin, hydroxyl-polyacrylate emulsion, cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethylethanolamine, thiethylamine, triethanolamine, 2-amino-2-methylpropanol, ammonium hydroxide, acrylic glycidyl ether, ethylene glycol monobutyl ether, waterborne aluminum powder, charcoal powder, talcum powder, sodium bicarbonate, glass fiber, vermiculite powder, perlite powder, EVA (ethylene-vinyl acetate copolymer) wax, polyethylene wax, nano titanium dioxide, waterborne polyisocyanate curing agent, wetting agent, magnesium stearate, polyoxypropylene glycerol ether, carboxymethyl cellulose and anti-setting agent. The invention also discloses a preparation method of the heat-resisting waterproof wallpaper. The prepared heat-resisting waterproof wallpaper is excellent in heat-resisting and waterproof performance.

Owner:安徽易有墙纸有限公司

Die pressing coating capable of being transferred onto composite metal surface and laser film comprising die pressing coating

InactiveCN102912673AAvoid deformationImprove compactnessCoatingsCoatings without pigmentsCelluloseAcrylic resin

The invention discloses a die pressing costing capable of being transferred onto a composite metal surface. The die pressing costing comprises 6-10% of cellulose acetate butyrate, 4-8% of acrylic resin, 2-6% of nitrocotton liquid, 25-35% of butanone, 10-20% of propylene glycol monomethyl ether and 28-32% of ethyl acetate, and is 1.3-1.5 micrometers in thickness. The die pressing coating is compact in surface, not easy to erode by solvent utilized in follow-up processing, suitable in strength for die pressing, good in stripping, and particularly suitable for being transferred onto an aluminum foil surface of composite aluminum foil paper to be colored and embossed after the die pressing, so that the composite aluminum foil paper with laser effect can be obtained. The invention further provides a laser film comprising the die pressing coating. The laser film comprises a basic film, and the die pressing coating which is provided with laser patterns after die pressing treatment is coated on the basic film, and a vacuum aluminum coated layer is arranged on the die pressing coating. The composite aluminum foil paper with bright, smooth and massive laser effect can be obtained by compositing the laser film with the composite aluminum foil paper and peeling the same off, and the process is easy to control.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH +1

Damping device for cellulose acetate butyrate production

PendingCN108591359AReduce vibrationReduce noiseVibration dampersNon-rotating vibration suppressionPulp and paper industryCellulose acetate-butyrate

The invention discloses a damping device for cellulose acetate butyrate production. The device comprises a base, a telescoping air bag, an arc-shaped spring sheet, a gear and a rack, wherein a mounting groove is formed in the base, and a positioning plate is arranged in the mounting groove; first sliding blocks are mounted at the left side and the right side of the positioning plate; first chuteswhich fit the first sliding blocks are formed in the inner wall of the mounting groove, and an elastic ball is mounted between the bottom part of each first sliding block and the bottom part of an inner chamber of the corresponding first chute; a thick pipe is mounted at the bottom part of the inner chamber of the mounting groove, and a first compressing spring is arranged in the thick pipe; the bottom end of the first compressing spring is fixedly connected to the bottom part of the inner chamber of the mounting groove; a moving block is fixedly connected to the top end of the first compressing spring; a thin rod passes through the thick pipe to be fixedly connected to the bottom part of the positioning plate; and T-shaped sliding rods are arranged at parts, close to two sides, on the bottom part of the inner chamber of the mounting groove. With the adoption of the device, the vibration produced by a stirring machine in working can be effectively reduced, and thus the noise produced by the stirring machine in working can be reduced.

Owner:福建鸿燕化工有限公司

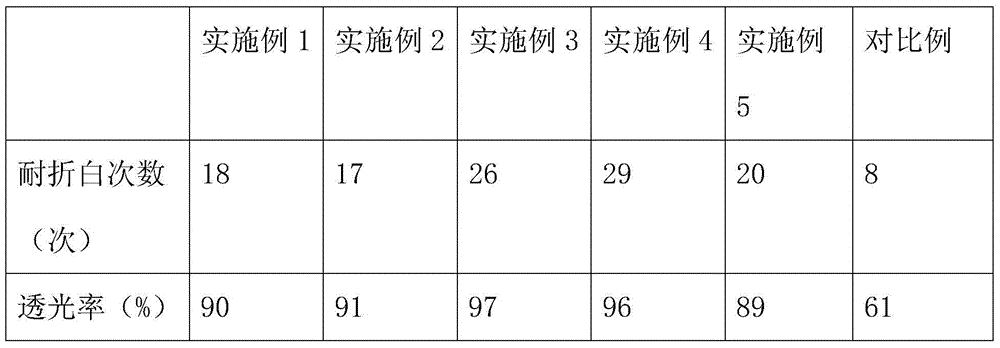

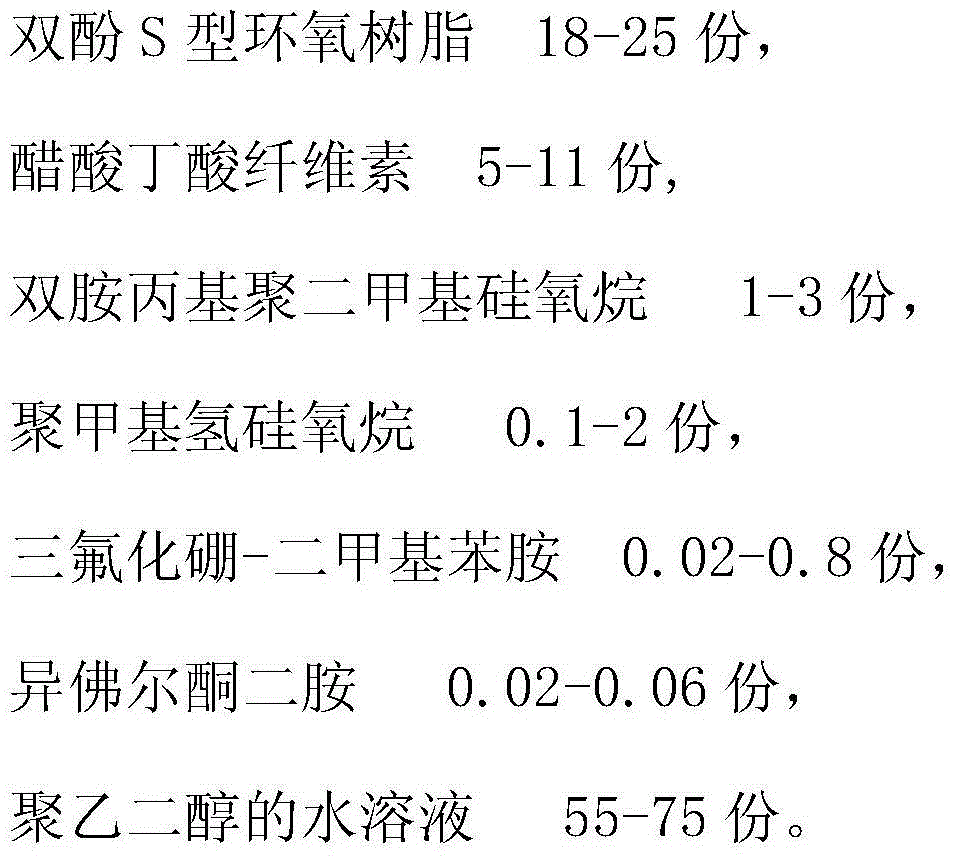

Fold-resistant white plastic film and preparation method thereof

InactiveCN104877310AGood light transmissionImprove high temperature resistanceEpoxyDimethylaniline N-oxide

The invention relates to a fold-resistant white plastic film and a preparation method thereof. The fold-resistant white plastic film is prepared from the following components in parts by weight: 18 to 25 parts of bisphenol S-type epoxy resin, 5 to 11 parts of cellulose acetate butyrate, 1 to 3 parts of diaminopropyl polydimethylsiloxane, 0.1 to 2 parts of polymethyl hydrogen siloxane, 0.02 to 0.8 parts of boron trifluoride-dimethylaniline, 0.02 to 0.06 parts of isophorone diamine and 55 to 75 parts of aqueous solution of polyethylene glycol. The invention also provides the preparation method of the fold-resistant white plastic film.

Owner:苏州靖羽新材料有限公司

Photocureable coating and curing method thereof

InactiveCN102220084AImprove performanceSimple processPretreated surfacesPolyurea/polyurethane coatingsCellulosePolyester

The invention provides a photocureable coating and a curing method thereof. The photocureable coating comprises main resin, a main photoinitiator, an active monomer, a coloring agent and organic solvent, wherein the main resin contains urethane acrylate resin and / or polyester acrylate, the activation wave length of the main photoinitiator ranges from 380 to 430nm, and the coloring agent is an acetic acid butyrate cellulose colored sheet. By adopting the photocureable coating, monolayer of the colored coating is realized, the process steps can be simplified, and the production efficiency is improved; the coating has good performance in various aspects, good apparent performance, and uniform color without dazzling.

Owner:BYD CO LTD

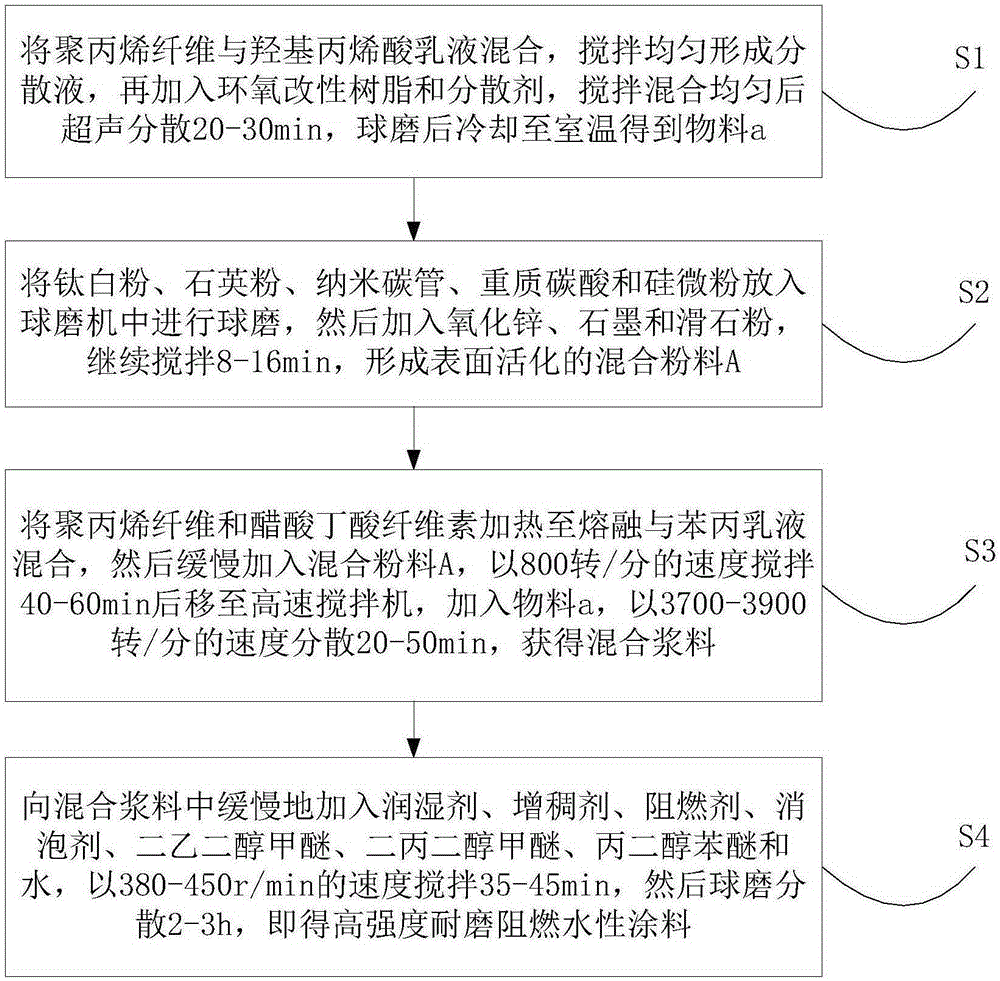

High-strength wear-resistant flame-retardant water-based paint and preparation method thereof

InactiveCN105199510AGood color retentionGood flexibilityFireproof paintsPolyurea/polyurethane coatingsWater basedWear resistant

The invention discloses high-strength wear-resistant flame-retardant water-based paint. The paint is prepared from, by weight, 100 parts of hydroxy acrylic acid emulsion, 75 parts of epoxy modified resin, 50 parts of water-based polyurethane emulsion, 40 parts of silicon-acrylic emulsion, 10 parts of styrene-acrylic emulsion, 5 parts of titanium dioxide, 3.5 parts of quartz powder, 3.5 parts of polypropylene fibers, 5.5 parts of cellulose acetate butyrate, 3 parts of silica powder, 4.5 parts of zinc oxide, 3.5 parts of carbon nano-tubes, 3.5 parts of graphite, 5 parts of coarse whiting, 5 parts of talcum powder, 3.5 parts of wetting agents, 6 parts of thickener, 2.5 parts of dispersant, 3.5 parts of flame retardant, 2 parts of antifoaming agents, 3 parts of diethylene glycol monomethyl ether, 4 parts of dipropylene glycol monomethyl ether, 5 parts of propylene glycol phenyl ether and 20 parts of water. The invention further provides a preparation method of the high-strength wear-resistant flame-retardant water-based paint. The water-based paint is high in strength, good in wear resistance and great in flame retardancy.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Preparation method of medium-viscosity cellulose acetate butyrate

The invention discloses a preparation method of medium-viscosity cellulose acetate butyrate. The preparation method comprises the following steps of pulverizing wood pulp; uniformly spraying a mixture of acetic acid and butyric acid into the pulverized wood pulp, and activating for 1h to 6h at the normal temperature; cooling a mixture of acetic anhydride, butyric anhydride, butyric acid and a liquid acid catalyst to minus 5 DEG C to minus 20 DEG C for standby use; slowly throwing the activated wood pulp into the well-cooled mixture, and maintaining the temperature to be less than or equal to 65 DEG C; adding magnesium acetate solution into the reacted system, and adding 200 to 500 parts by weight of acetic acid with the mass percentage of 50 to 70 percent for hydrolysis, wherein the system temperature is controlled at 60 to 70 DEG C, and the hydrolysis time is 2h to 5h; continuing adding magnesium acetate to neutralize the liquid acid catalyst, and adding the material into water for chromatographic solid-liquid separation; washing the separated CAB (cellulose acetate butyrate) solids with water until the acid value is less than 300ppm, and drying the CAB solids to obtain the CBA finished product. Through the method, a method for preparing medium / high-viscosity CAB is developed, and the content of butyryl in CAB is 36 to 40 percent; the power viscosity is 400cps to 1000cps.

Owner:JIANGSU RUICHEN CHEM

Rapid drying lacquers containing triblock copolymer for rheology control

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel acrylic triblock copolymer as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of solvent-based nano-carbon black paste

InactiveCN103013230AGood storage stabilityHigh tinting strengthPigment pastesCooking & bakingPolymer science

The invention relates to a preparation method of solvent-based nano-carbon black paste. The solvent-based nano-carbon black paste comprises the following basic formation: 6-20% of CAB (cellulose acetate butyrate) resin, 3-15% of wetting dispersant, 6-25% of carbon black pigment and 65-80% of solvent; and the grain diameter D50 of the solvent-based nano-carbon black paste is controlled to be 40-150nm. The nano-carbon black paste has the characteristics of good storage stability, high coloring capability, high transparency, good compatibility and the like, can substitute metal complex dyes, is widely used as a surface coating colorant for packaging materials for children toys, furniture, leather and cloth products, plastic products, metal products, metal coils, aluminum foils and plating films, cigarette packets, candies, food, paper boards and the like, and can be also used as a transparent colorant for gold-stamped films, glass products, high-grade metal baking paint, plastic baking paint and UV (ultraviolet) vacuum coating paint, as well as a colorant for printing ink, jetting ink and the like.

Owner:广州市番禺科迪色彩有限公司

Preparation method of nano-fiber membrane with three-dimensional porous structure for lithium ion battery diaphragm

InactiveCN103618056ALarge specific surface areaHigh specific surface energyMaterial nanotechnologyFibre treatmentNonwoven fabricLithium-ion battery

The invention relates to a preparation method of a nano-fiber membrane with a three-dimensional porous structure for a lithium ion battery diaphragm. The preparation method comprises the steps of blending and extruding inorganic nanoparticles, ethylene-vinyl alcohol copolymer and cellulose acetate butyrate; extracting by using acetone to obtain inorganic nanoparticle / ethylene-vinyl alcohol copolymer nano-fibers; then, preparing the nano-fibers into a suspension; uniformly spraying the suspension on two surfaces of a non-woven fabric; drying to obtain an inorganic nanoparticle / ethylene-vinyl alcohol copolymer nano-fiber membrane; then, uniformly spraying the suspension prepared from the inorganic nanoparticles on a membranous layer of the nano-fiber membrane; drying to obtain the nano-fiber membrane with a three-dimensional porous structure for the lithium ion battery diaphragm. The nano-fiber membrane has the advantages of high porosity, high liquid absorption rate, good heat resistance and the like, can effectively absorb an electrolyte solution required by an electrochemical reaction, is favorable for transmission of lithium ions in the diaphragm, and improves the specific capacity, coulomb efficiency and safety performance of a lithium ion battery. The preparation method disclosed by the invention is simple in process, low in production cost, high in efficiency and capable of meeting requirements for industrial production.

Owner:WUHAN TEXTILE UNIV

Mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate

The invention relates to the field of cellulose processing, and in particularly relates to a mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate. The method comprises the following steps: weighing reactants including cellulose, butyric acid, acetic anhydride and a catalyst in a ratio of 10g:(30-100g):(10-30g):(0.1-0.5g), putting all the reactants into a ball mill, controlling the ratio of the reactants to pellets at 100g:(100-300ml), controlling the temperature of a circulating water bath at 50-80 DEG C, stirring at a low speed to perform an acylation reaction for 1-4 hours to obtain a crude product, separating the crude product and the pellets, standing the crude product in 50% ethanol water to separate out a solid, separating the separated solid, and washing the separated solid with deionized water until the solid is neutral, thereby obtaining a cellulose acetate-butyrate or cellulose acetate-propionate product. Compared with the existing method for producing cellulose acetate-butyrate or cellulose acetate-propionate, the method disclosed by the invention has the characteristics of simple process, high efficiency, no pollution, high product quality and the like.

Owner:福建鸿燕化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com