Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Automotive oem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

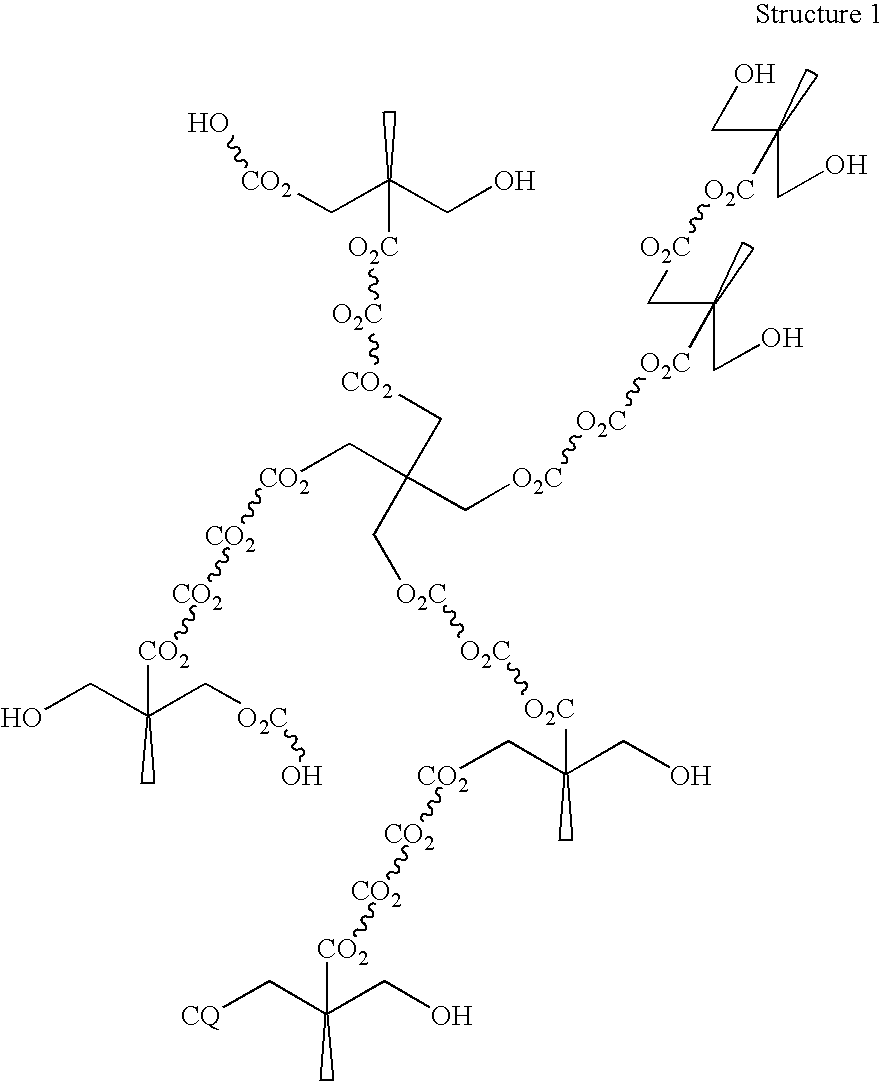

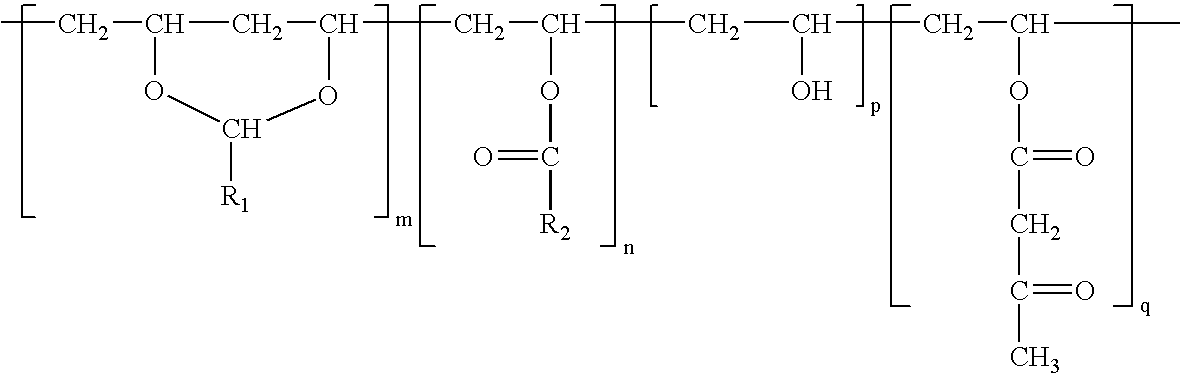

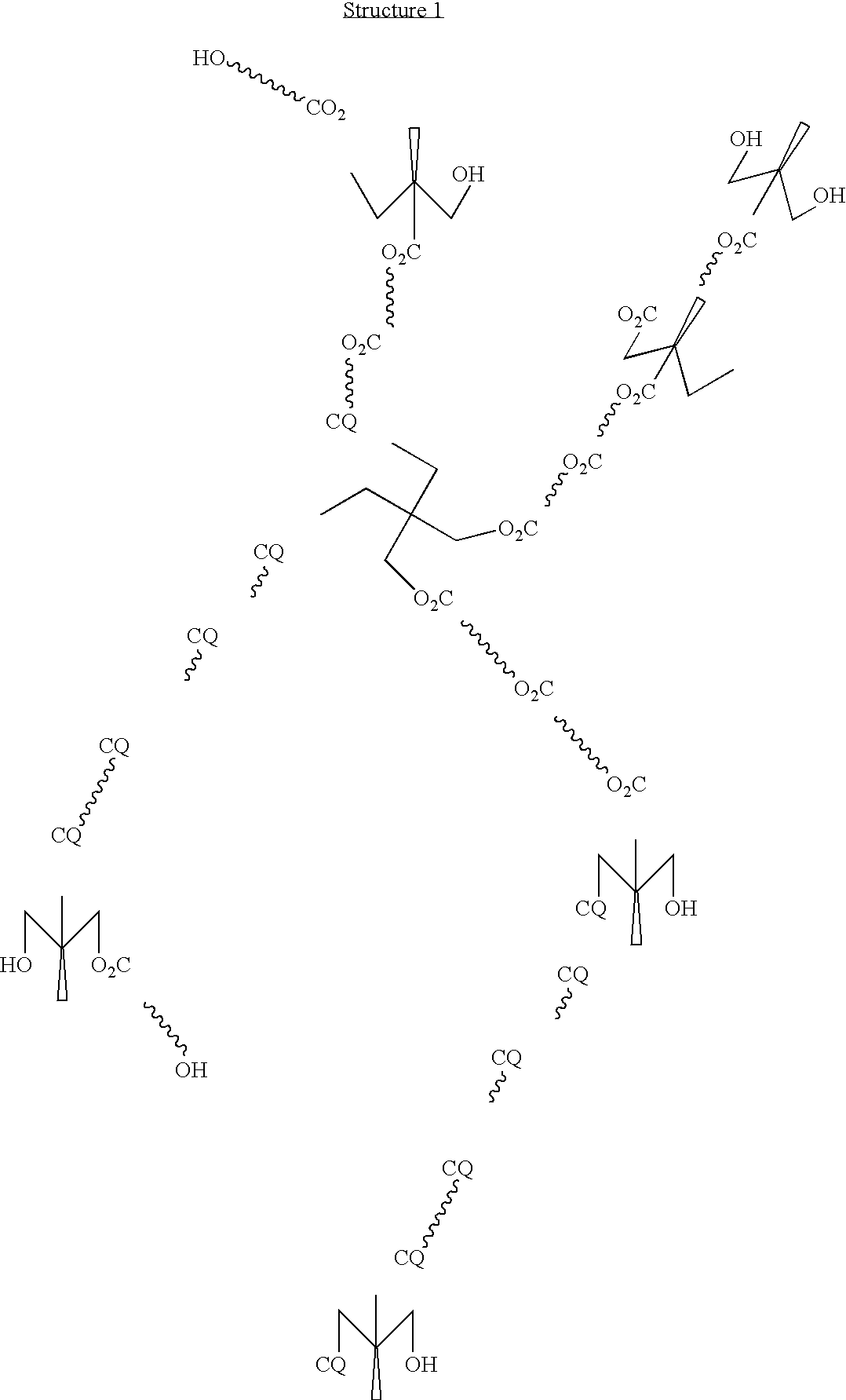

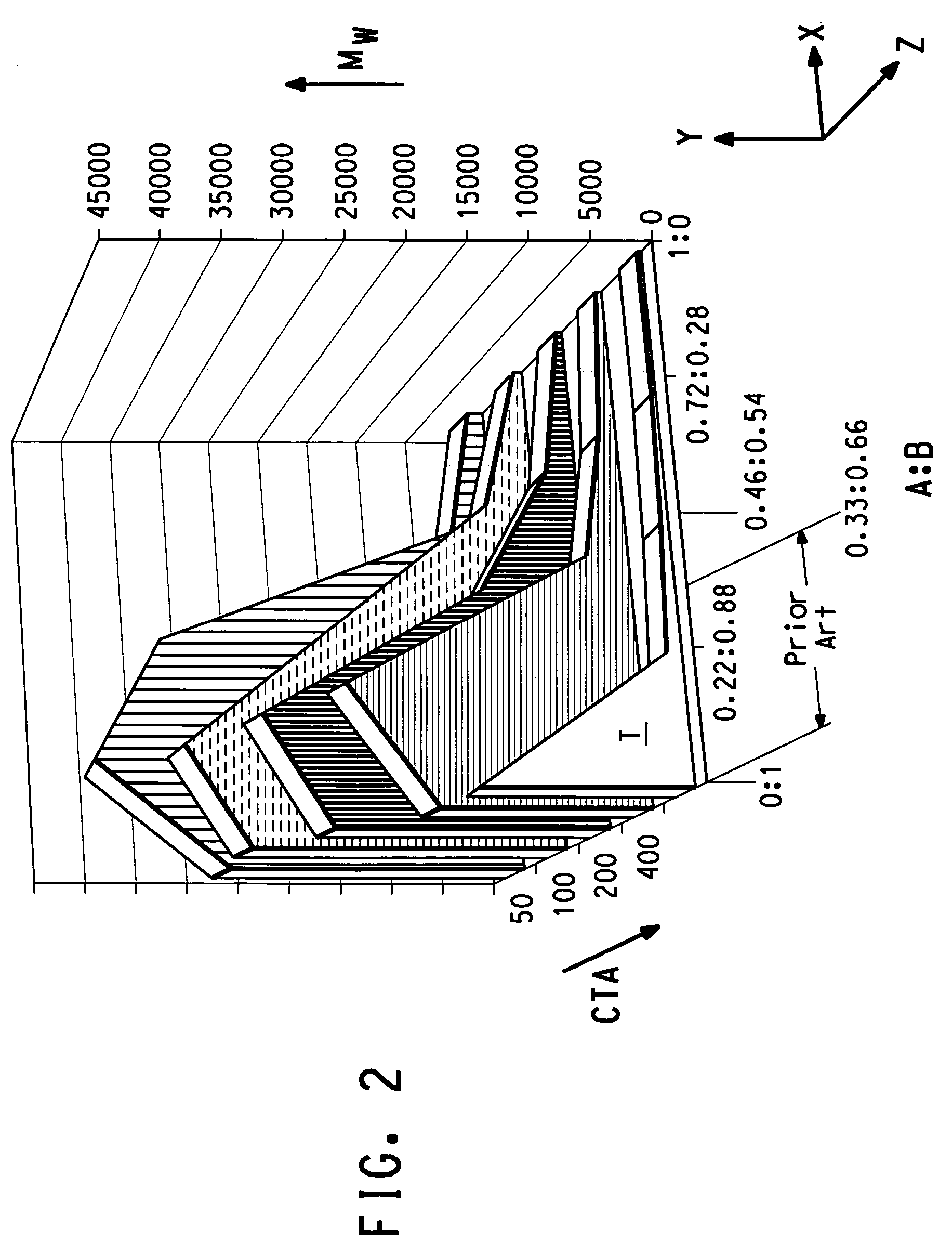

Lacquers containing highly branched copolyester polyol

Owner:AXALTA COATING SYST IP CO LLC

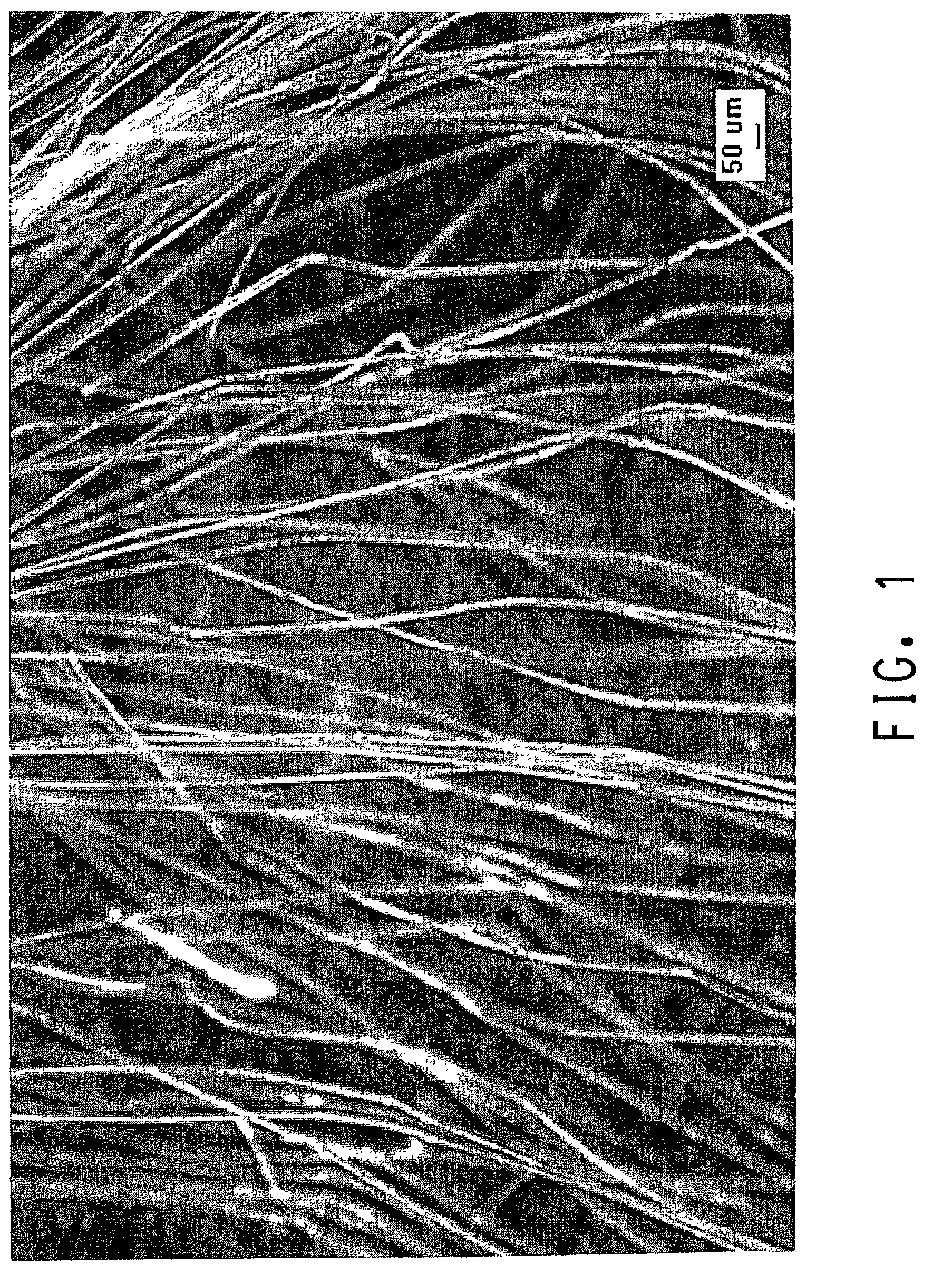

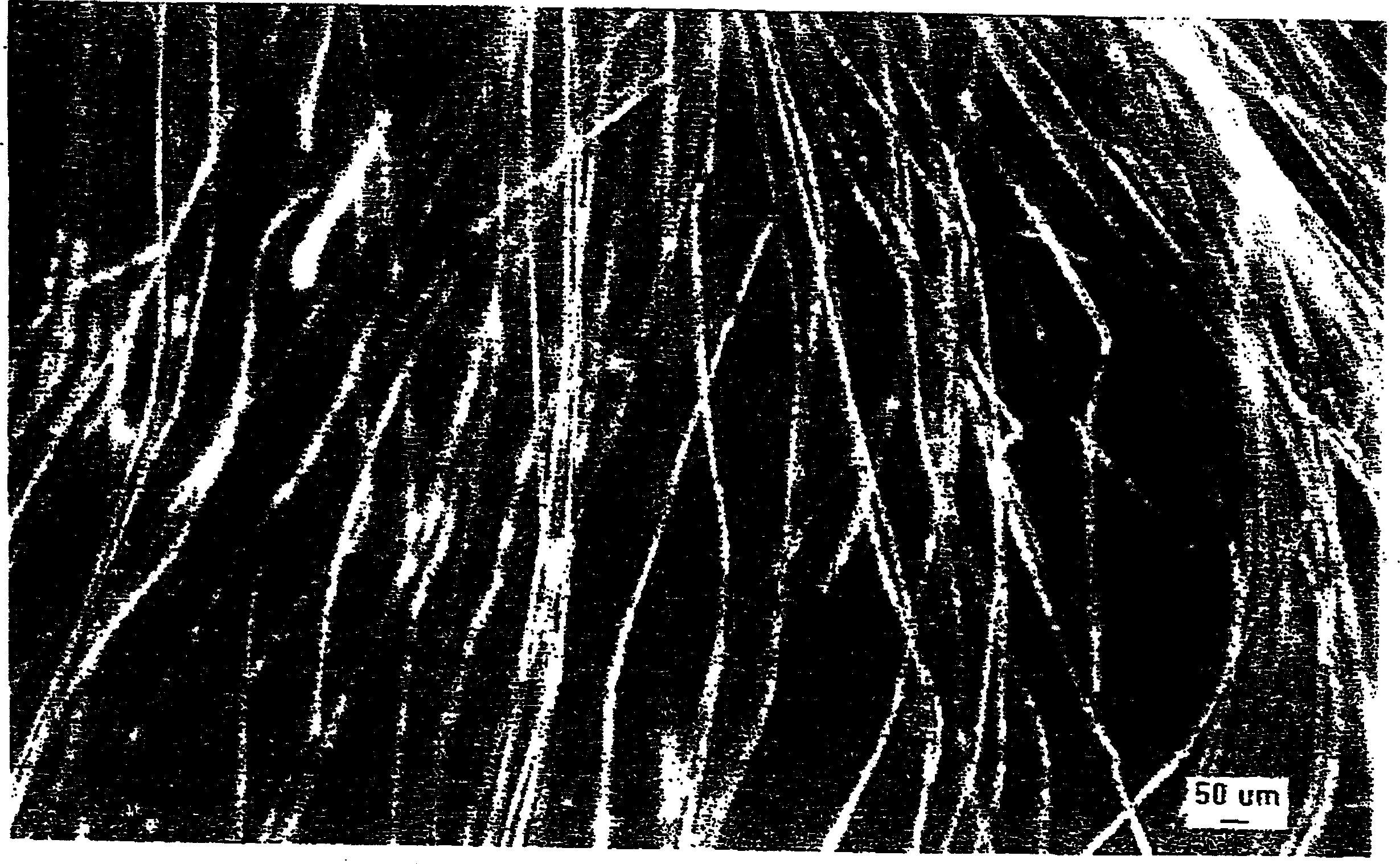

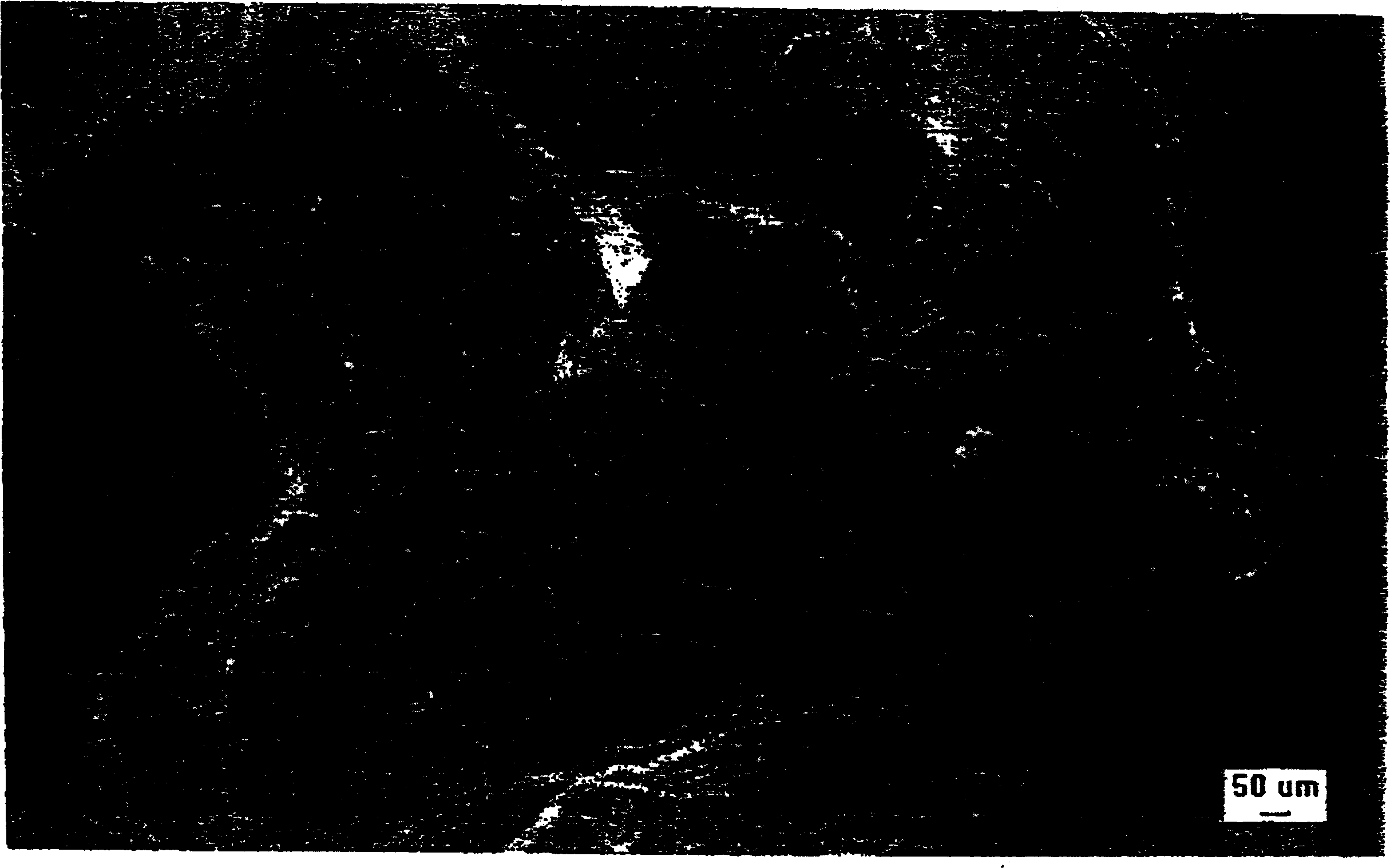

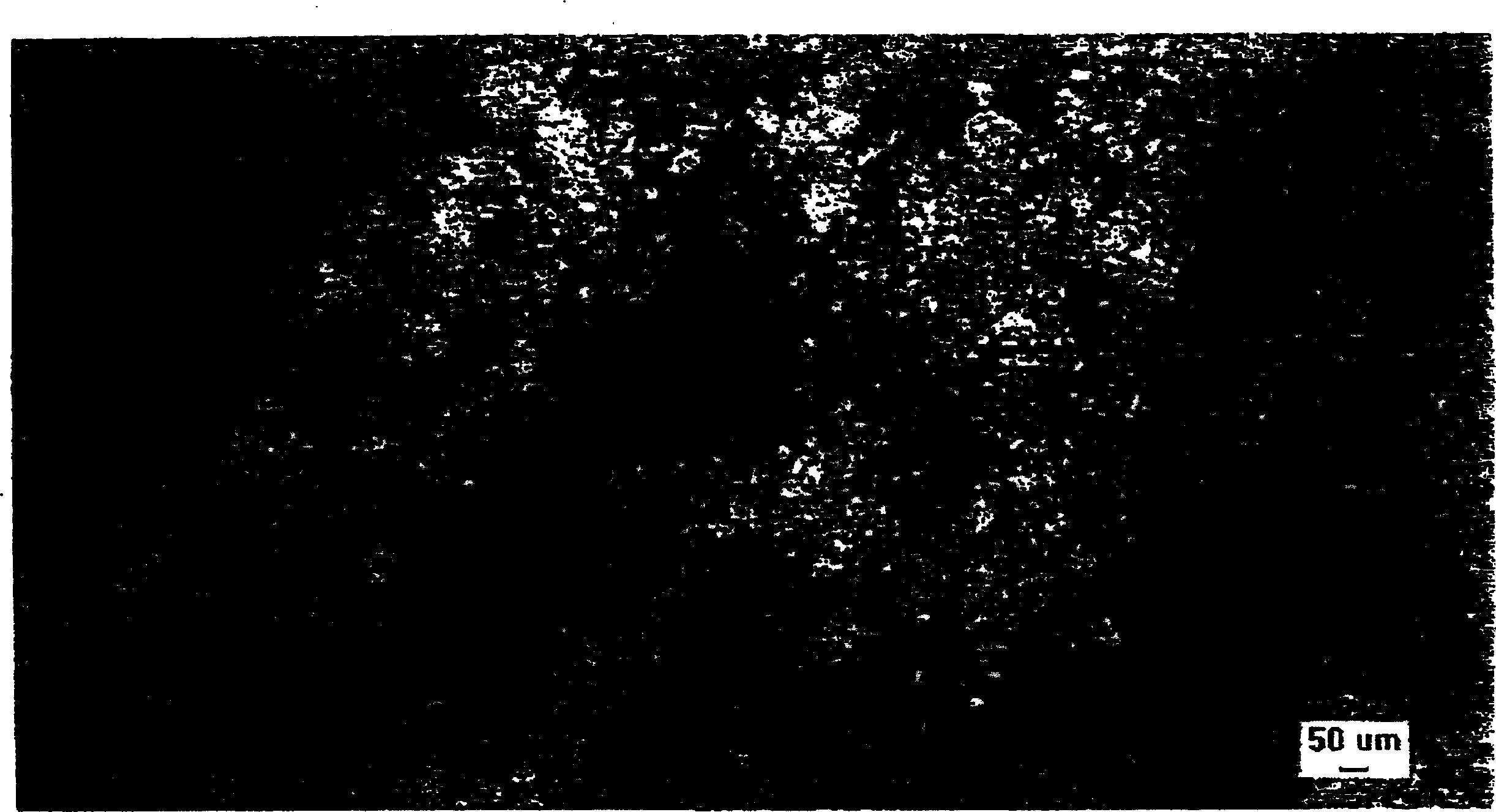

Method of producing micropulp and micropulp made therefrom

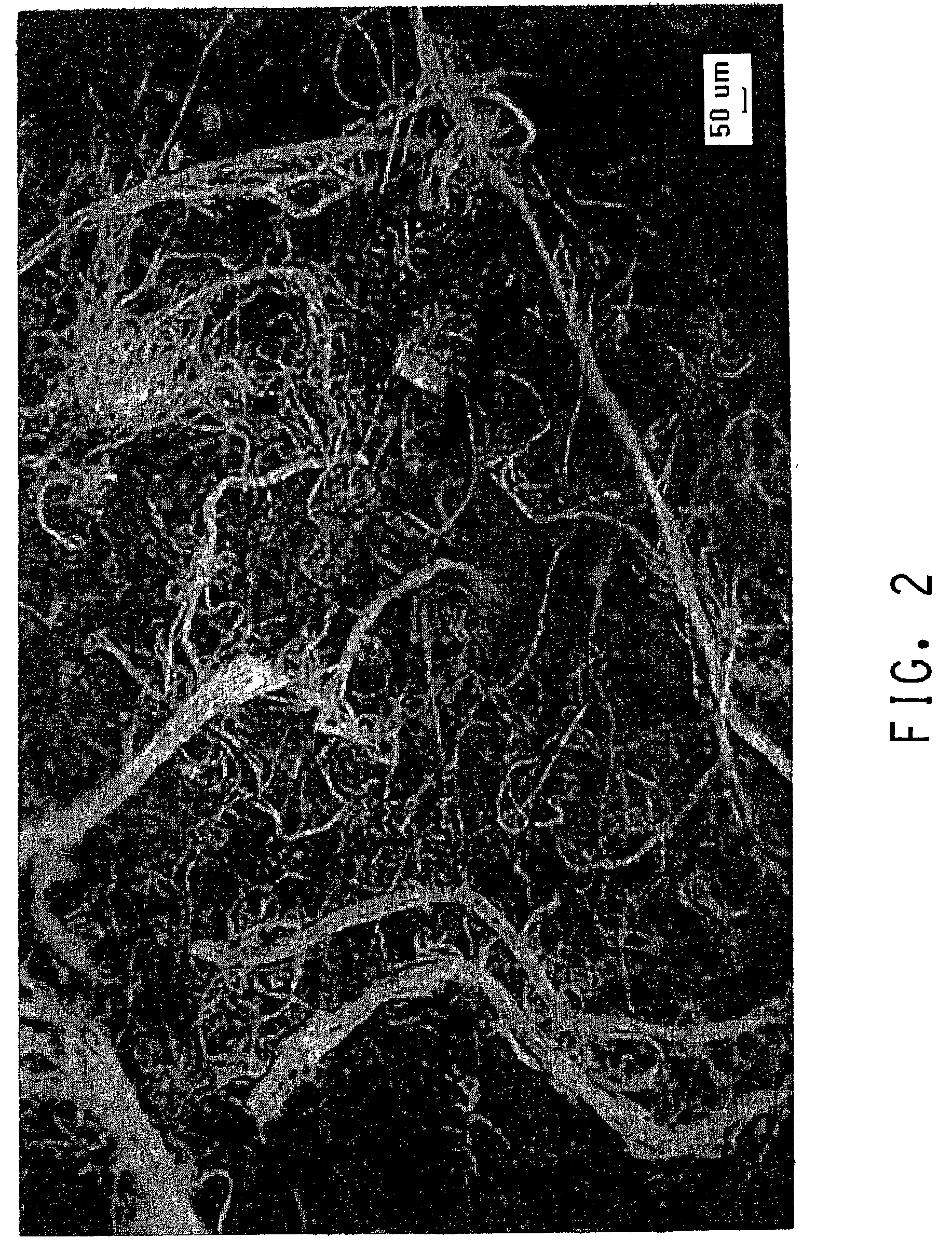

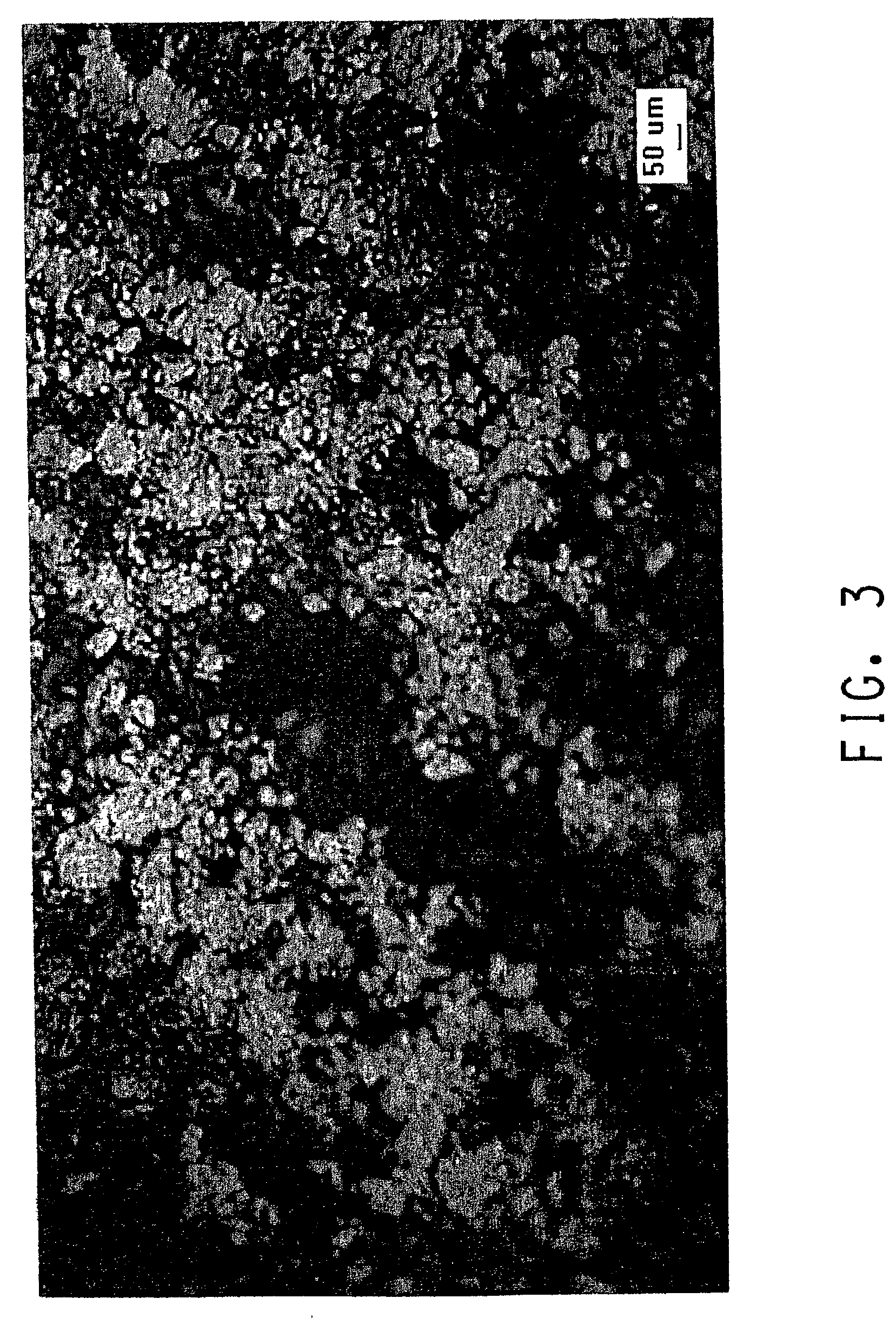

InactiveUS20030114641A1More cost-effectivelySmall sizeCellulose coatingsPaper/cardboardFiberSolid component

The present invention is directed to a process for producing micropulp. The process includes contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to transform the organic fibers into the micropulp dispersed in the medium. If desired, the slurry of the micropulp in the liquid component can be used or the micropulp can be separated from the medium. The micropulp can be readily incorporated into coating compositions such as those used in automotive OEM or refinish applications. The micropulp can also be incorporated into powder coating applications or as a thixotrope or reinforcement in polymer formulations.

Owner:EI DU PONT DE NEMOURS & CO

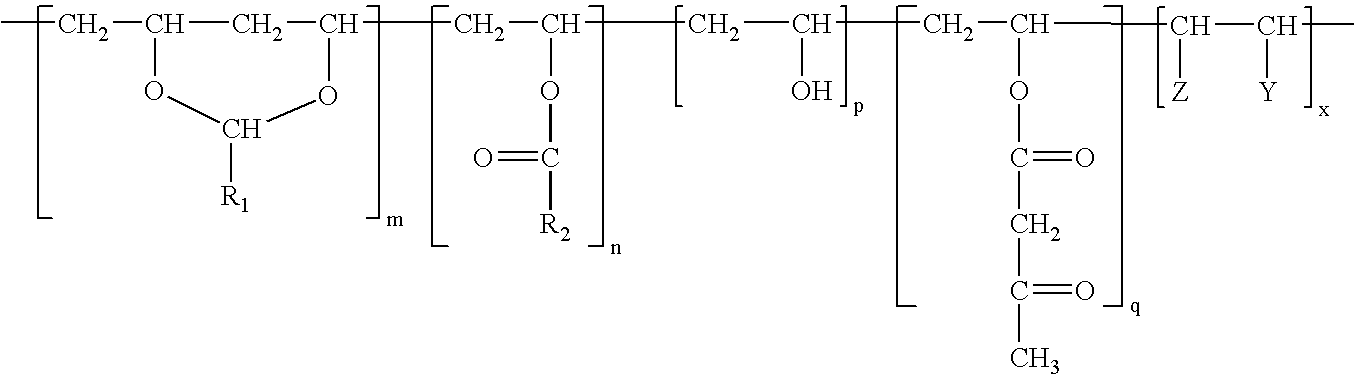

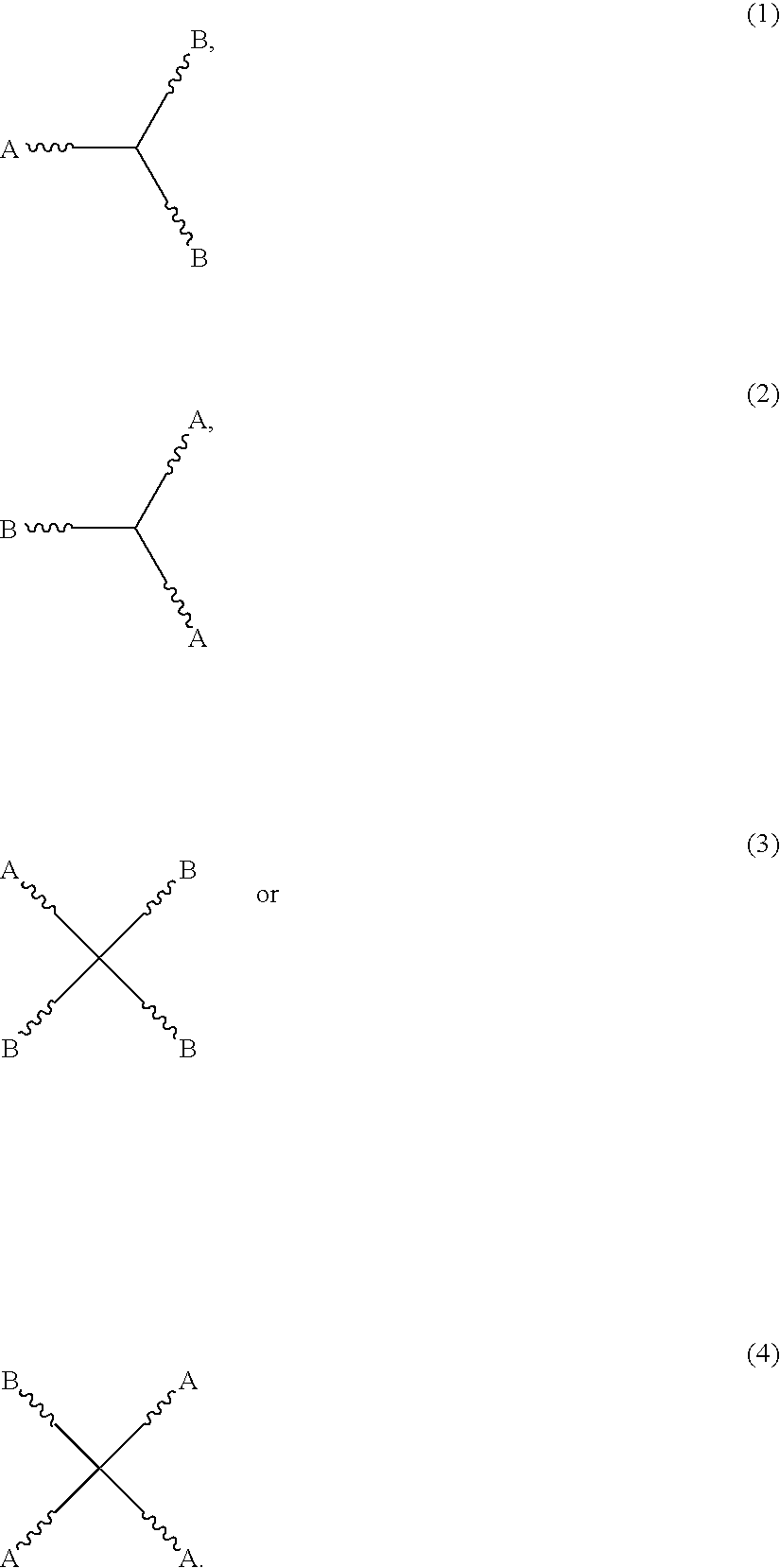

Rapid drying lacquers containing impoved rheology control additive

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel graft copolymer with segmented (or block) arms as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:AXALTA COATING SYST IP CO LLC

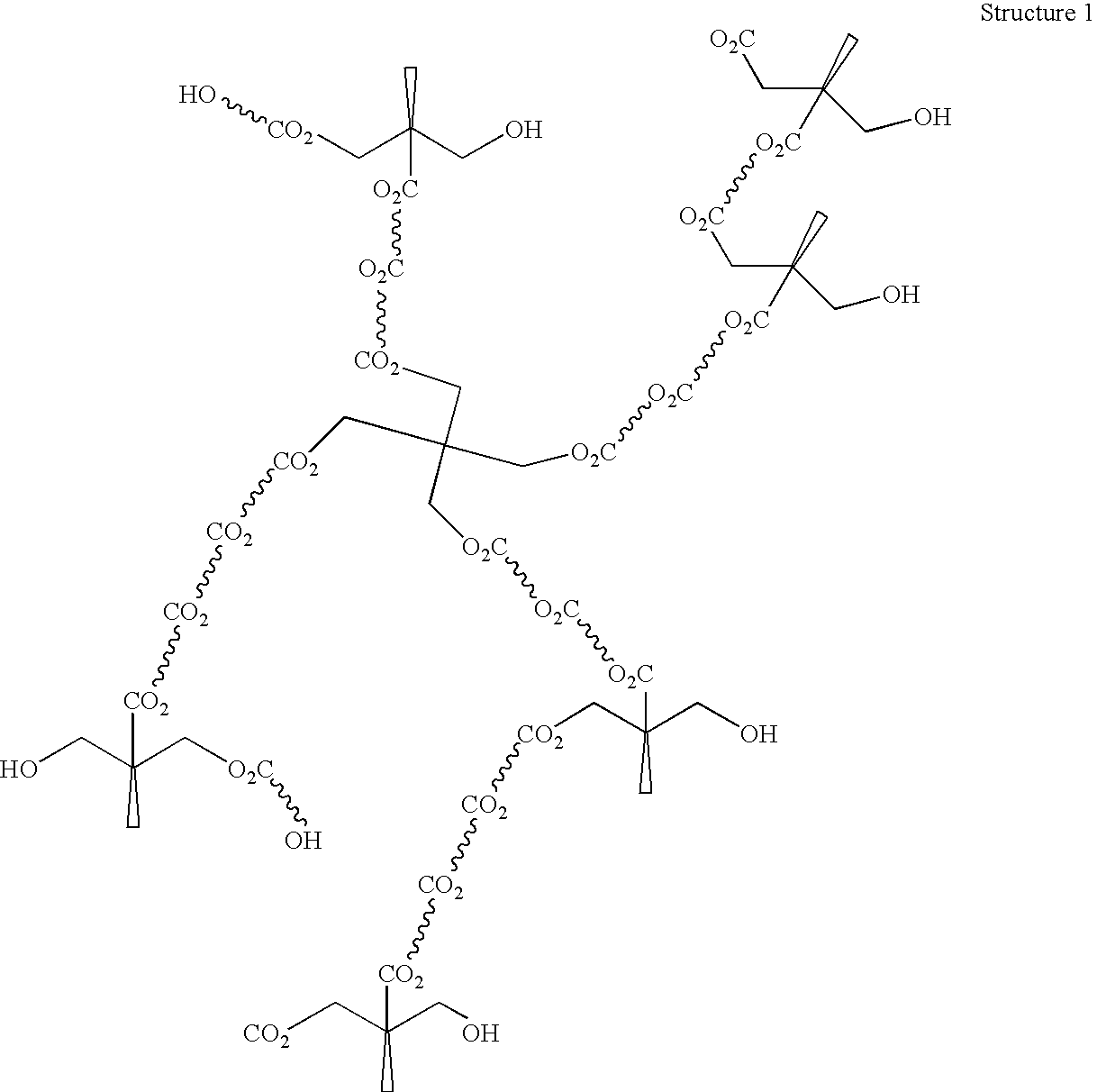

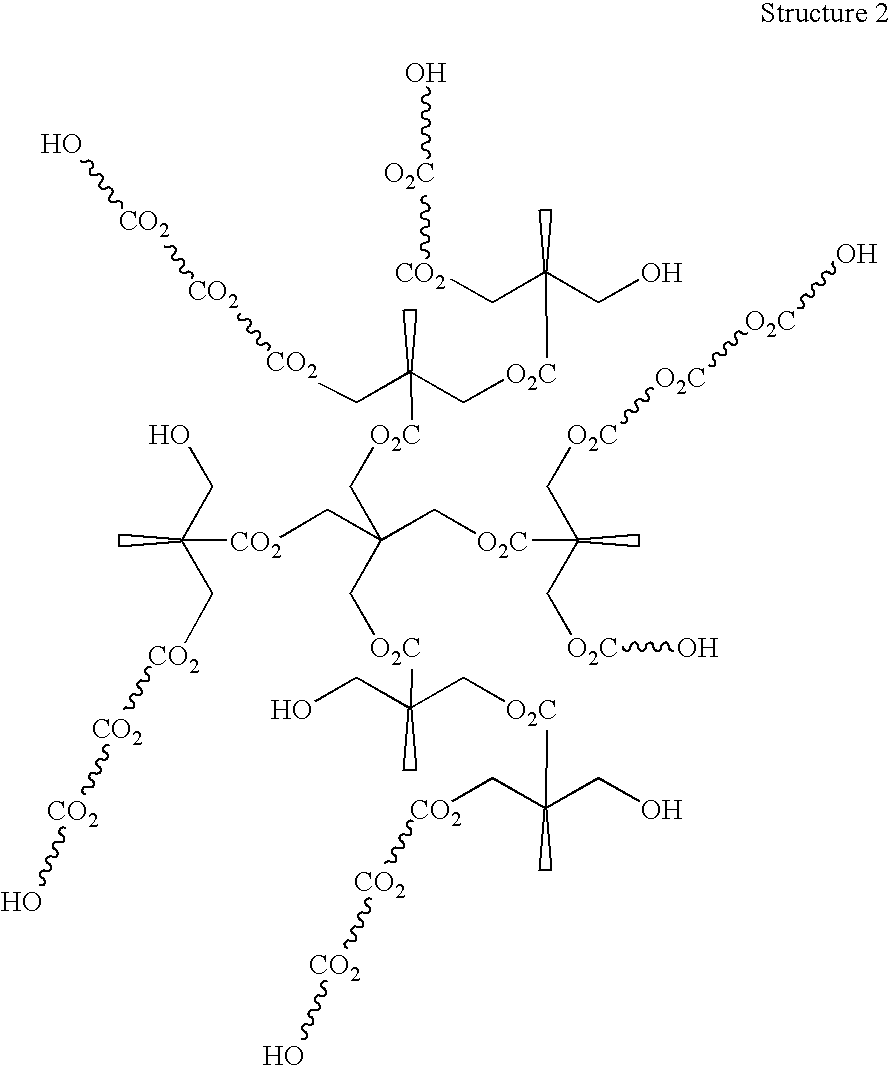

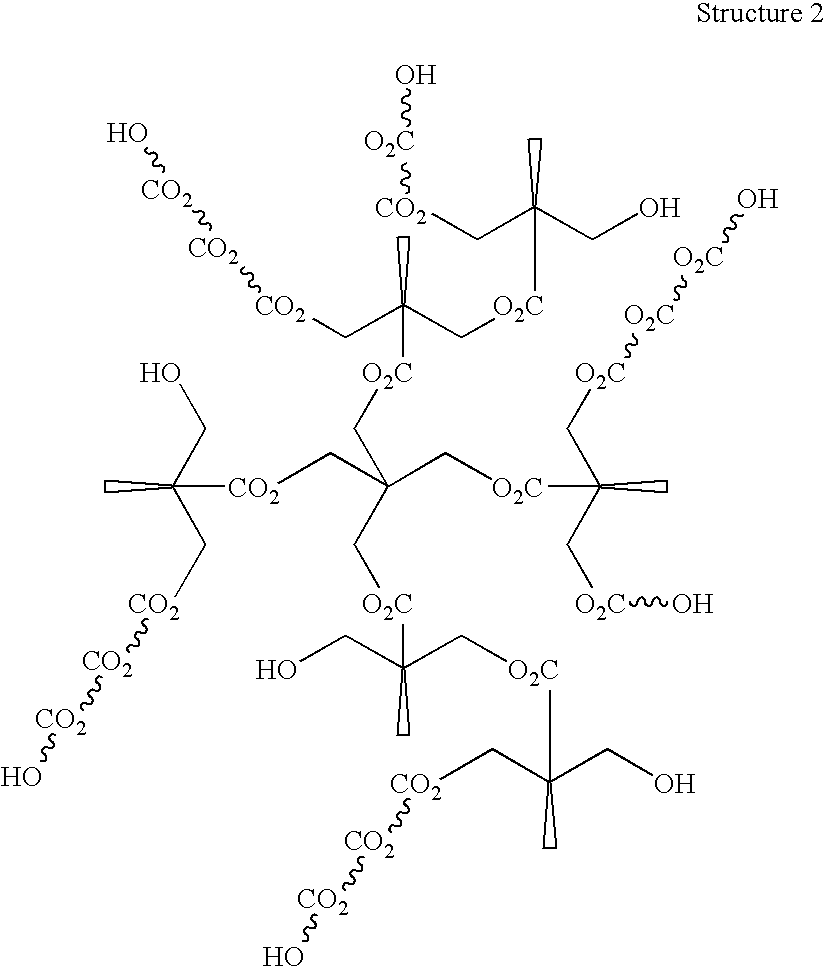

Two component coating compositions containing highly branched copolyester polyol

InactiveUS20040043152A1Prevent premature crosslinkingMaintain good propertiesSynthetic resin layered productsPretreated surfacesPolyolAutomotive oem

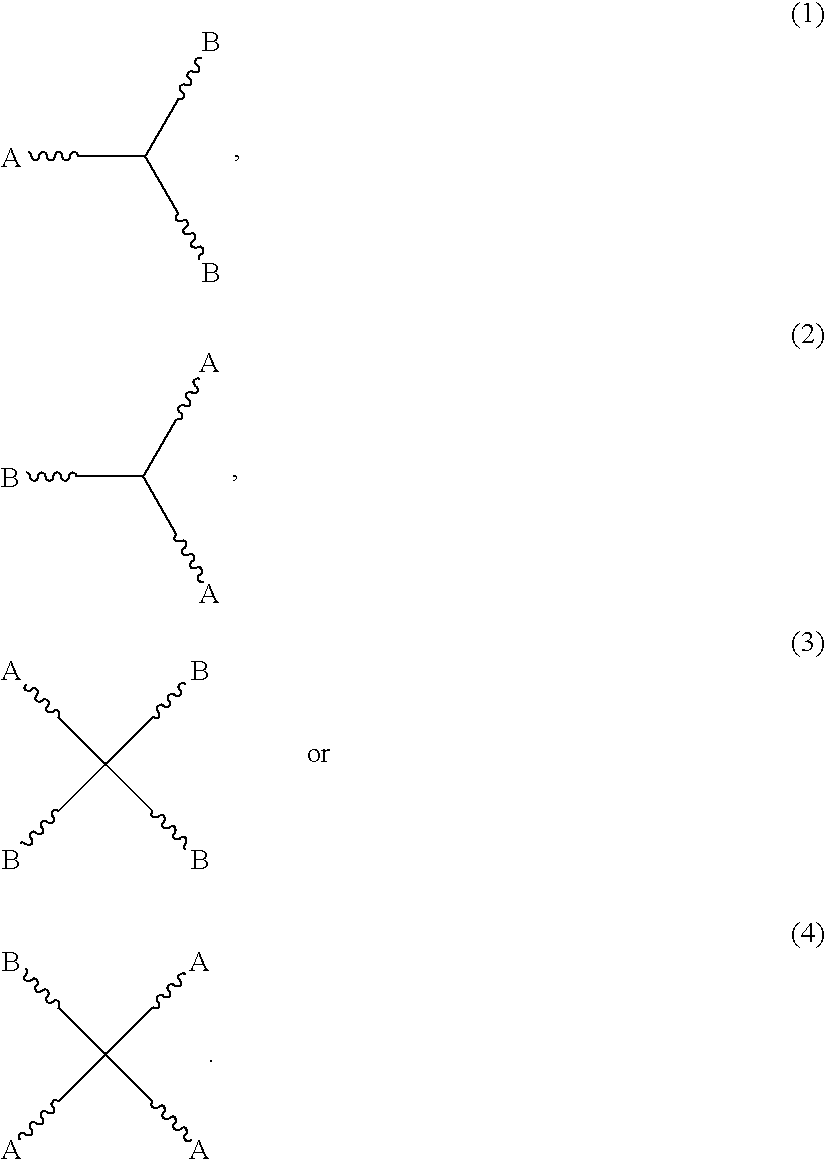

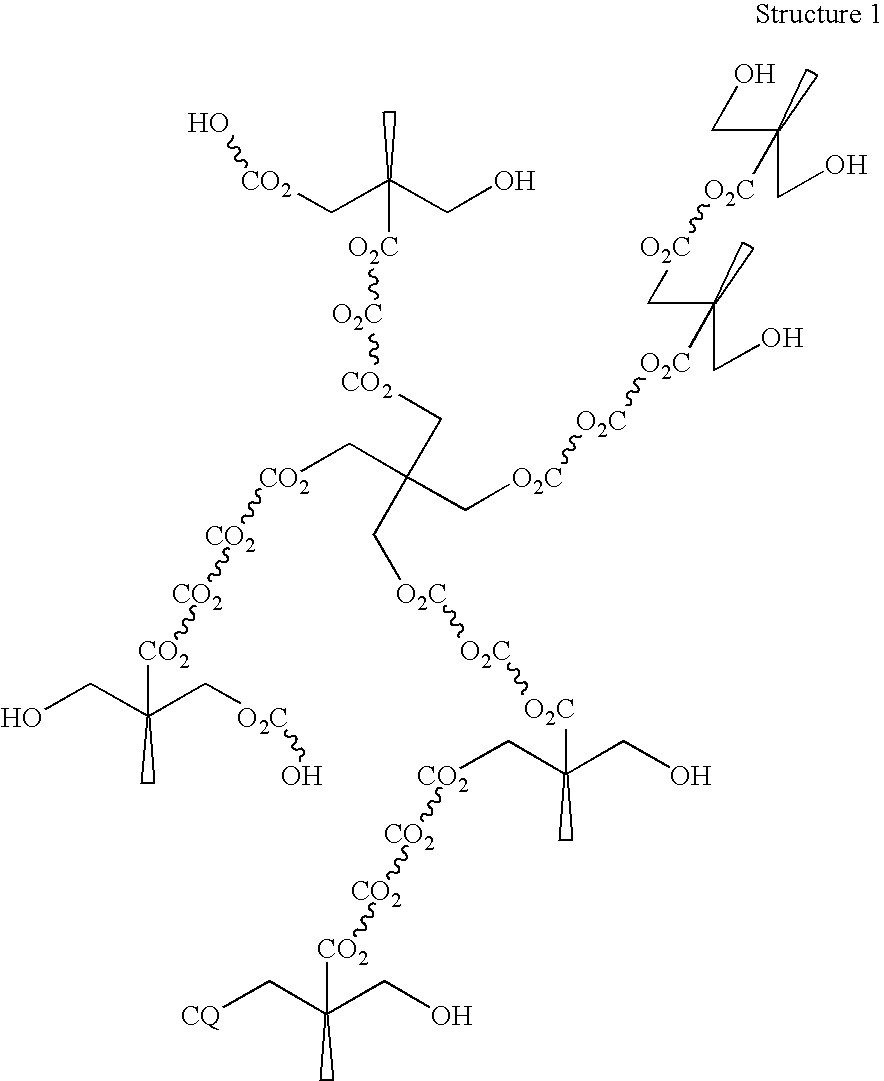

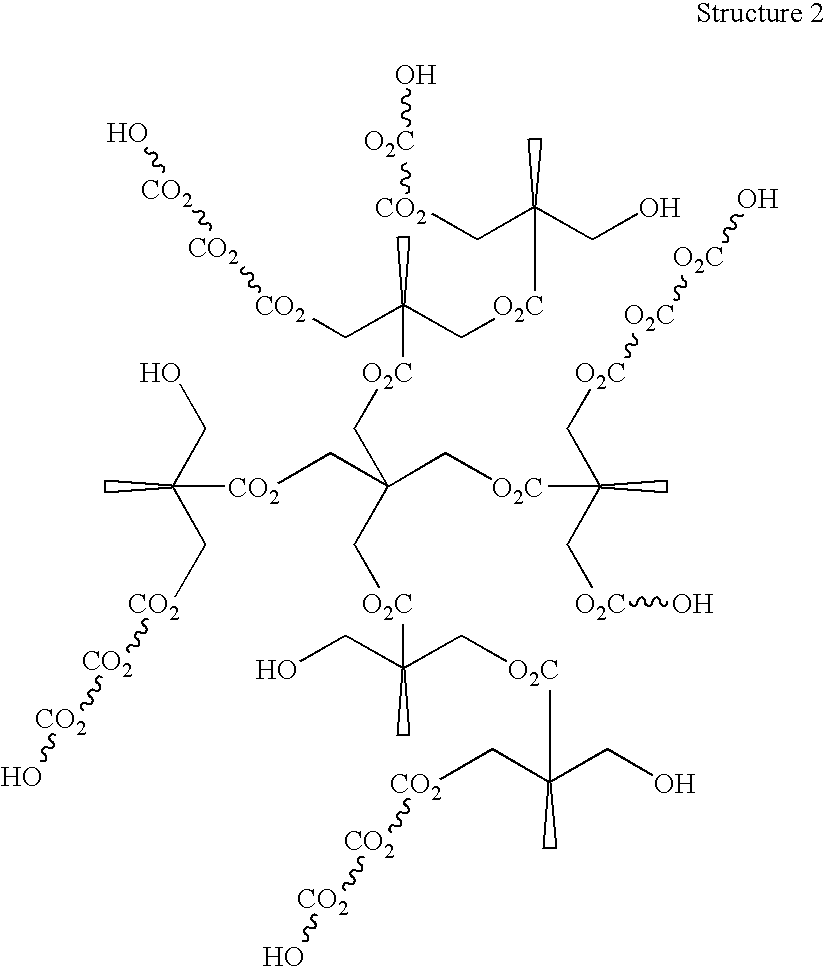

This invention relates to rapid curing coating compositions that are particularly useful for automotive OEM and refinish applications. The coating composition includes a binder component that contains a novel highly branched copolyester polyol, and a crosslinking component that contains conventional crosslinking agents, such as polyisocyanate and melamine. This invention is also directed to a process for producing coatings from the rapid curing coating compositions. These compositions are especially useful in providing for mar resistant and flexible coatings.

Owner:AXALTA COATING SYST IP CO LLC

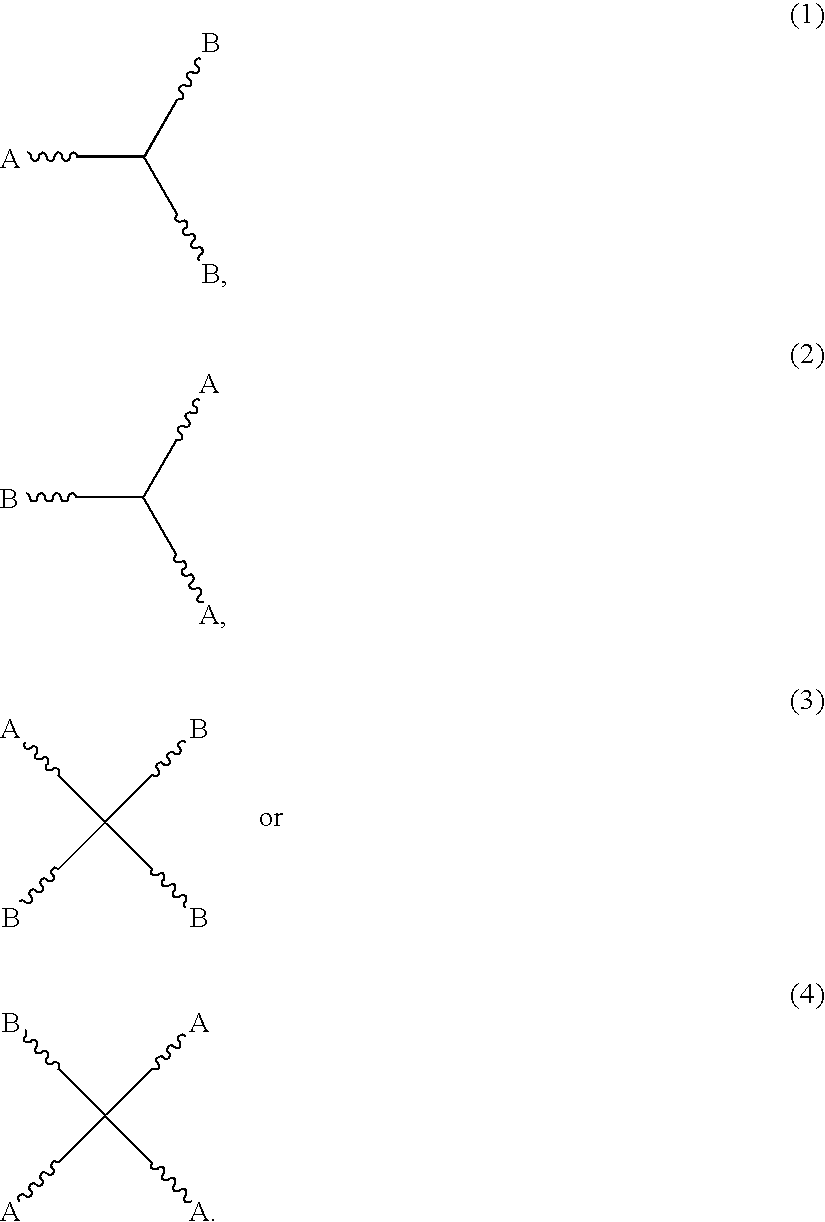

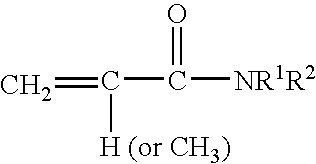

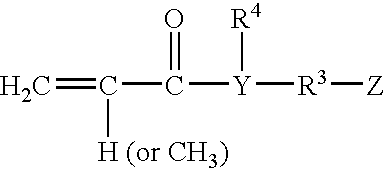

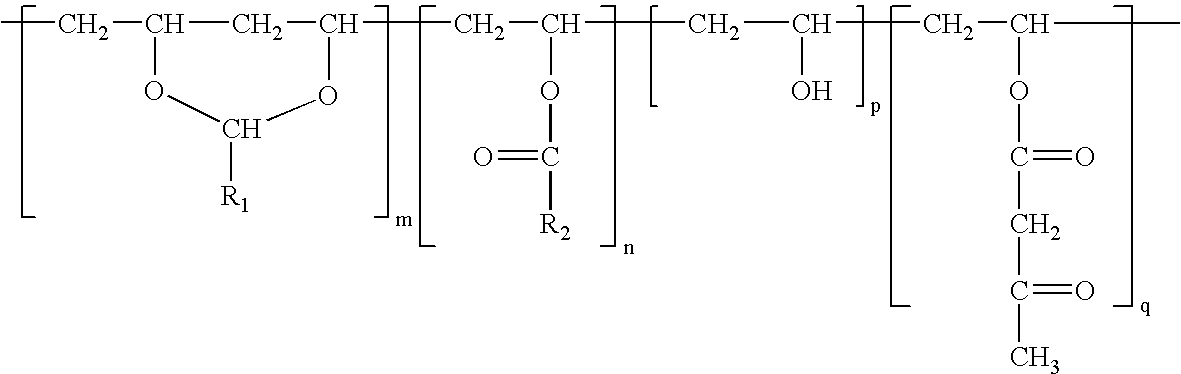

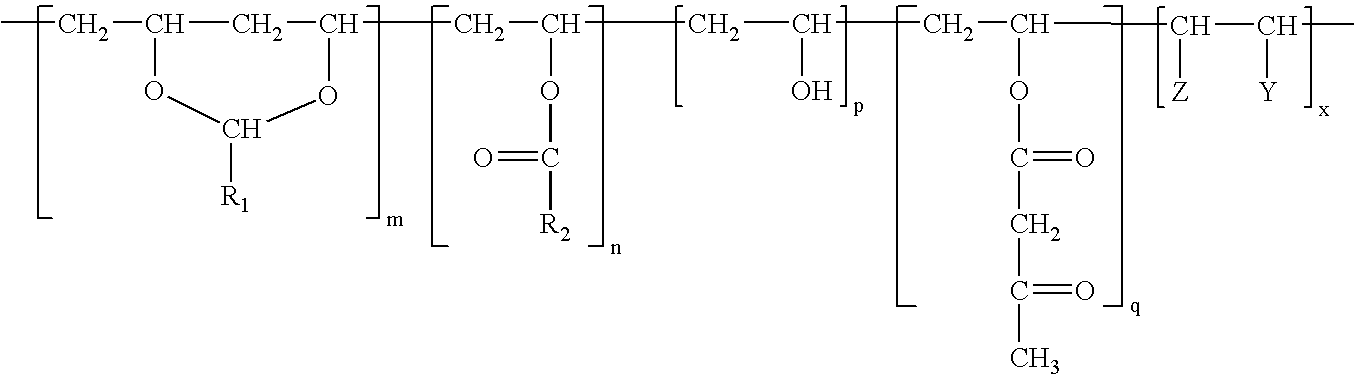

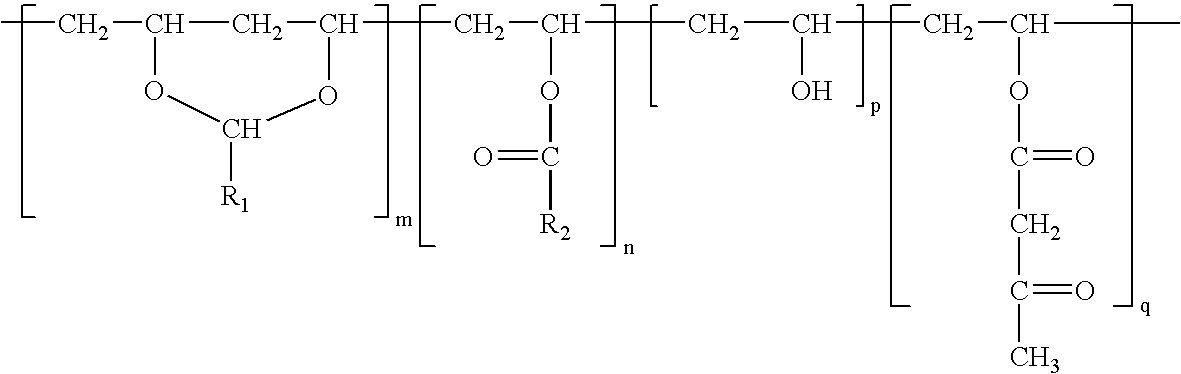

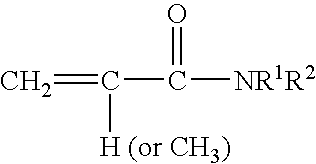

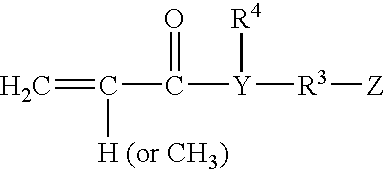

Rapid drying lacquers containing graft copolymers with segmented arms

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel acrylic graft copolymer with segmented (or block) arms. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing for chip and humidity resistant coatings having improved adhesion.

Owner:EI DU PONT DE NEMOURS & CO

Lacquers containing highly branched copolyester polyol

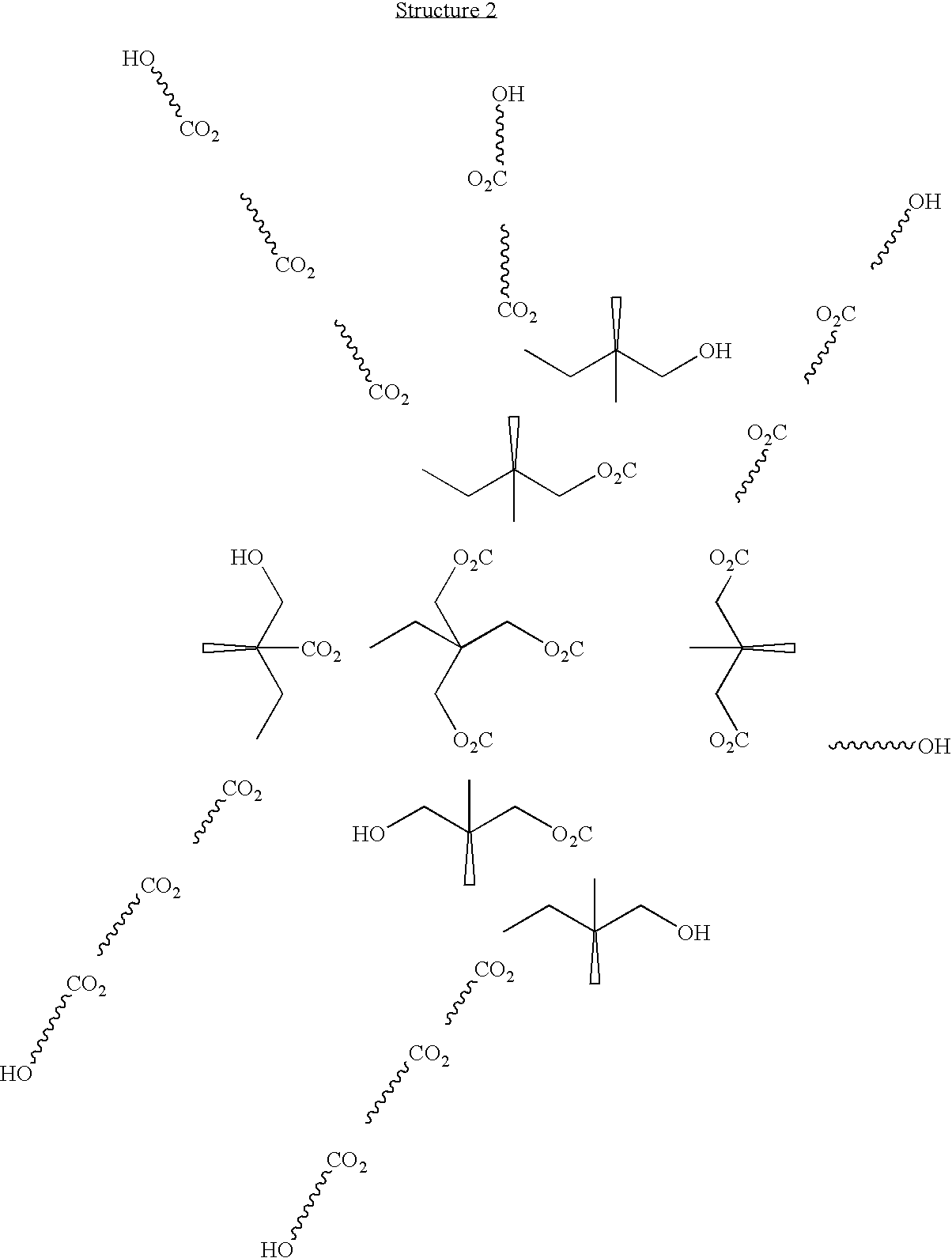

InactiveUS20030161961A1Improve chip resistanceExcellent humidity resistanceOther chemical processesPretreated surfacesPolyolAutomotive oem

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel highly branched copolyester polyol. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing for chip and humidity resistant coatings having improved adhesion.

Owner:AXALTA COATING SYST IP CO LLC

Rapid drying lacquers containing triblock copolymer for rheology control

InactiveUS20060286302A1Improve film propertiesFilm/foil adhesivesPretreated surfacesAutomotive oemLacquer

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel acrylic triblock copolymer as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:EI DU PONT DE NEMOURS & CO

Rapid drying lacquers containing triblock copolymer for rheology control

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel acrylic triblock copolymer as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:EI DU PONT DE NEMOURS & CO

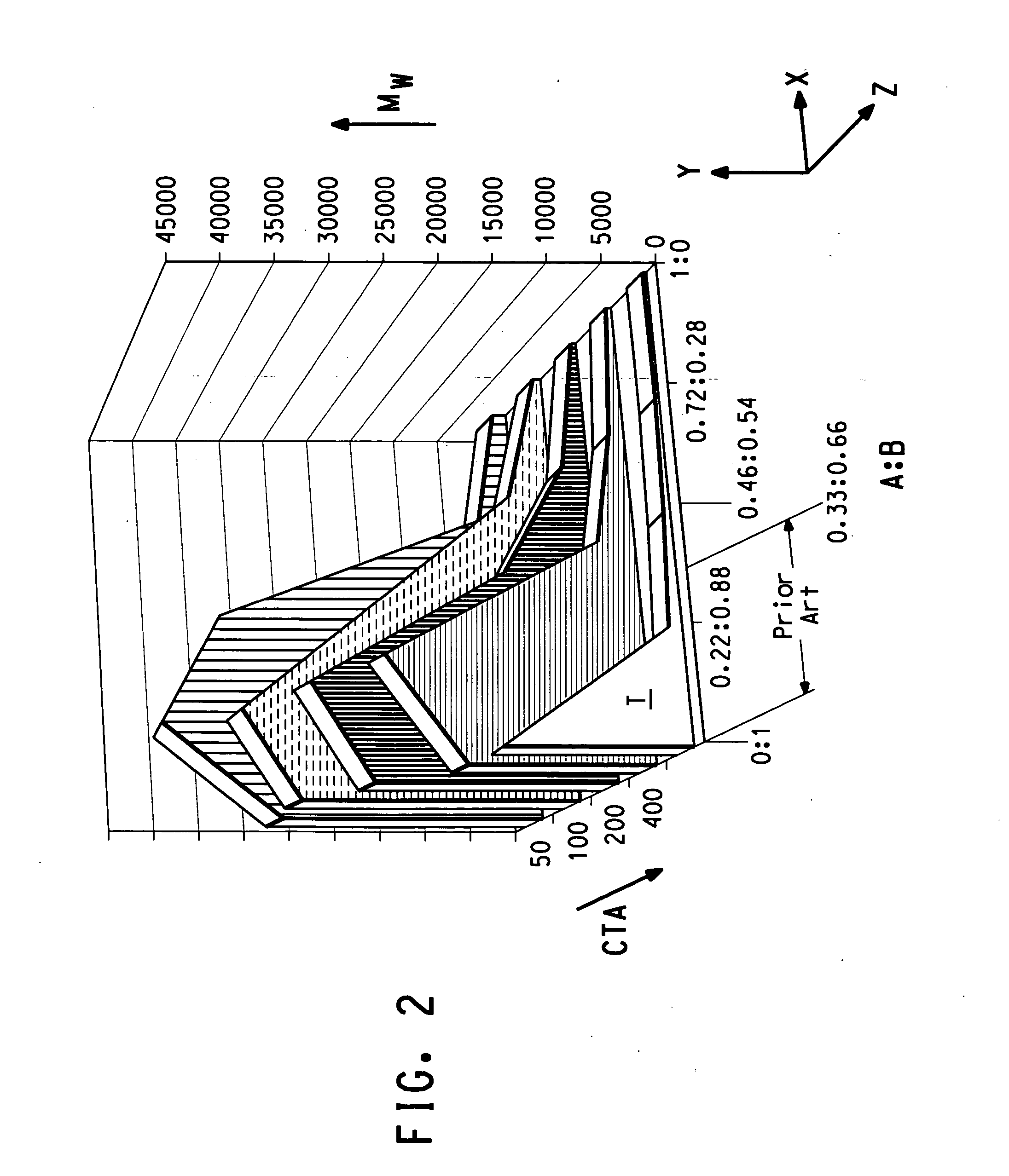

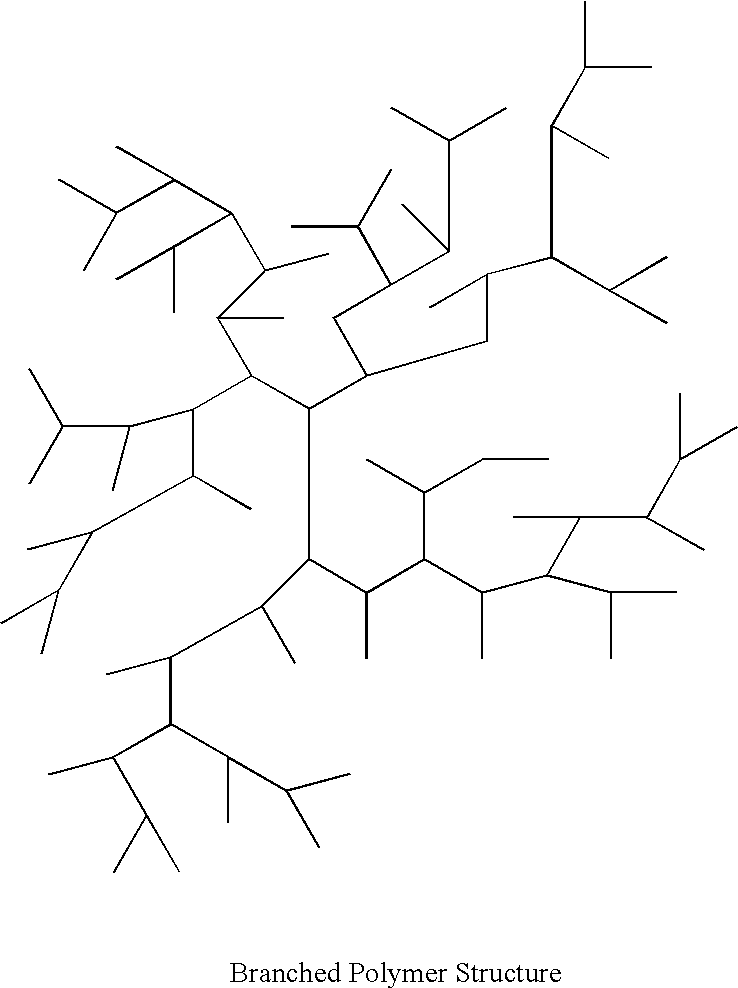

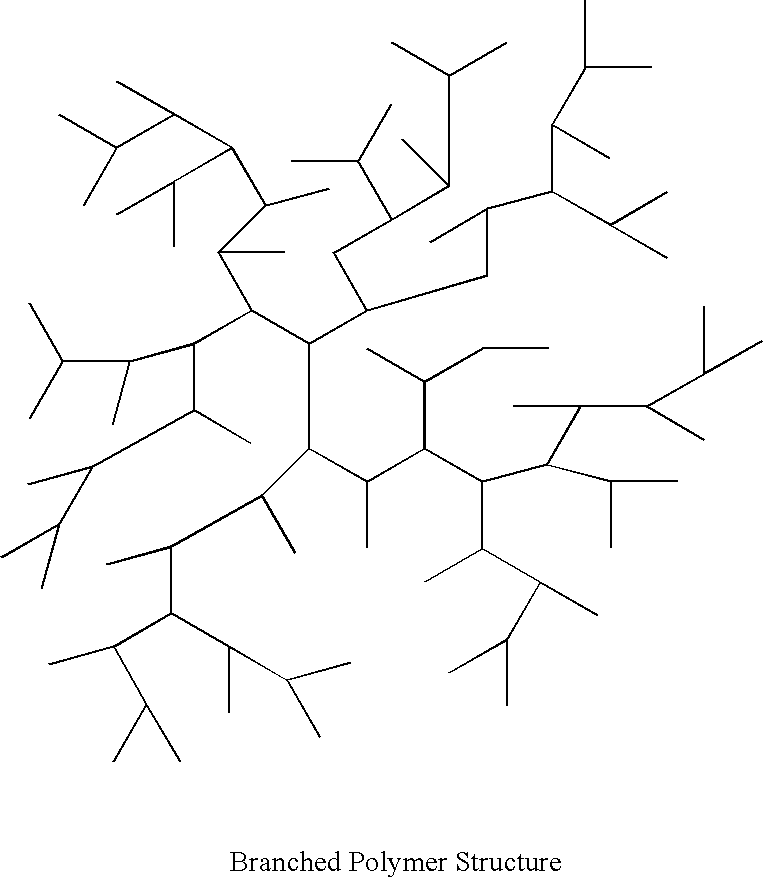

Branched polymers and coating compositions made therefrom

This invention relates to rapid curing coating compositions that are particularly useful for automotive OEM and refinish applications. The coating composition includes a crosslinkable component that contains a novel highly branched acrylic polymer, and a crosslinking component that contains conventional crosslinking agents, such as polyisocyanate and melamine. This invention is also directed to a process for producing coatings from the rapid curing coating compositions. These compositions are especially useful in providing hard highly crosslinked coatings.

Owner:AXALTA COATING SYST IP CO LLC

Acetoacetylated polyvinyl polymers and curable coating compositions made therefrom

The present invention relates to curable coating compositions containing acetoacetylated polyvinyl polymers obtained from polyvinyl polymers, such as polyvinyl butyrals. These coating compositions are especially suitable for use as wash primers in automotive OEM and refinish coating applications.

Owner:EI DU PONT DE NEMOURS & CO

Acetoacetylated polyvinyl polymers and curable coating compositions made therefrom

InactiveUS20040186217A1Extended shelf lifeImprove adhesionFilm/foil adhesivesCoatingsPolyvinyl polymerAutomotive oem

The present invention relates to curable coating compositions containing acetoacetylated polyvinyl polymers obtained from polyvinyl polymers, such as polyvinyl butyrals. These coating compositions are especially suitable for use as wash primers in automotive OEM and refinish coating applications.

Owner:EI DU PONT DE NEMOURS & CO

Process for the preparation of the top coat layer of an automotive oem multi-layer coating

A coating process wherein a precoated automotive substrate is OEM top coated with an aqueous two-component polyurethane top coating composition prepared by static mixing a non-aqueous hydrophobic polyisocyanate crosslinker component and an aqueous binder component having a binder solids content comprising at least one water-dilutable hydroxyl-functional binder and 5 to 30 wt.-% of a urethane compound A with at least two terminal urethane groups (—NHC(O)OR; R hydrocarbyl residue of a monoalcohol) and having a number-average molar mass (Mn) of from 400 to 5,000.

Owner:AXALTA COATING SYST IP CO LLC

Two component coating compositions containing highly branched copolyester polyol

This invention relates to rapid curing coating compositions that are particularly useful for automotive OEM and refinish applications. The coating composition includes a binder component that contains a novel highly branched copolyester polyol, and a crosslinking component that contains conventional crosslinking agents, such as polyisocyanate and melamine. This invention is also directed to a process for producing coatings from the rapid curing coating compositions. These compositions are especially useful in providing for mar resistant and flexible coatings.

Owner:AXALTA COATING SYST IP CO LLC

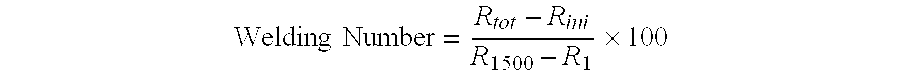

Weldable pre-primed coating composition for automotive oem and coating method thereof

InactiveUS20110311727A1Maximize adhesionMaximize corrosion resistanceConductive materialPretreated surfacesMetalworkingSpray coating

The present invention relates to a weldable pre-primed coating composition, comprising binder resins, a crosslinker, an anti-corrosive pigment, conductive metal powder, carbon nanotubes, etc. The coating composition can be applied to a metal sheet before processing of the metal sheet to maximize the weldability, adhesion, corrosion resistance and processability of the metal sheet. Also, the coating composition can be applied to a metal sheet by a roll coating process to make it possible to eliminate not only an existing electrodeposition process which is carried out by a non-environmentally-friendly wet dipping process, but also an existing electrostatic spray primer coating process which is carried out by an electrostatic spray coating process in which a solvent is scattered, whereby the metal sheet coated with the coating composition has very excellent formability and weldability after its processing. Accordingly, the composition makes it possible to reduce the number of complex automotive coating processes, thereby greatly contributing an increase in productivity, a reduction in energy and an improvement in a work environment.

Owner:PPG IND KOREA

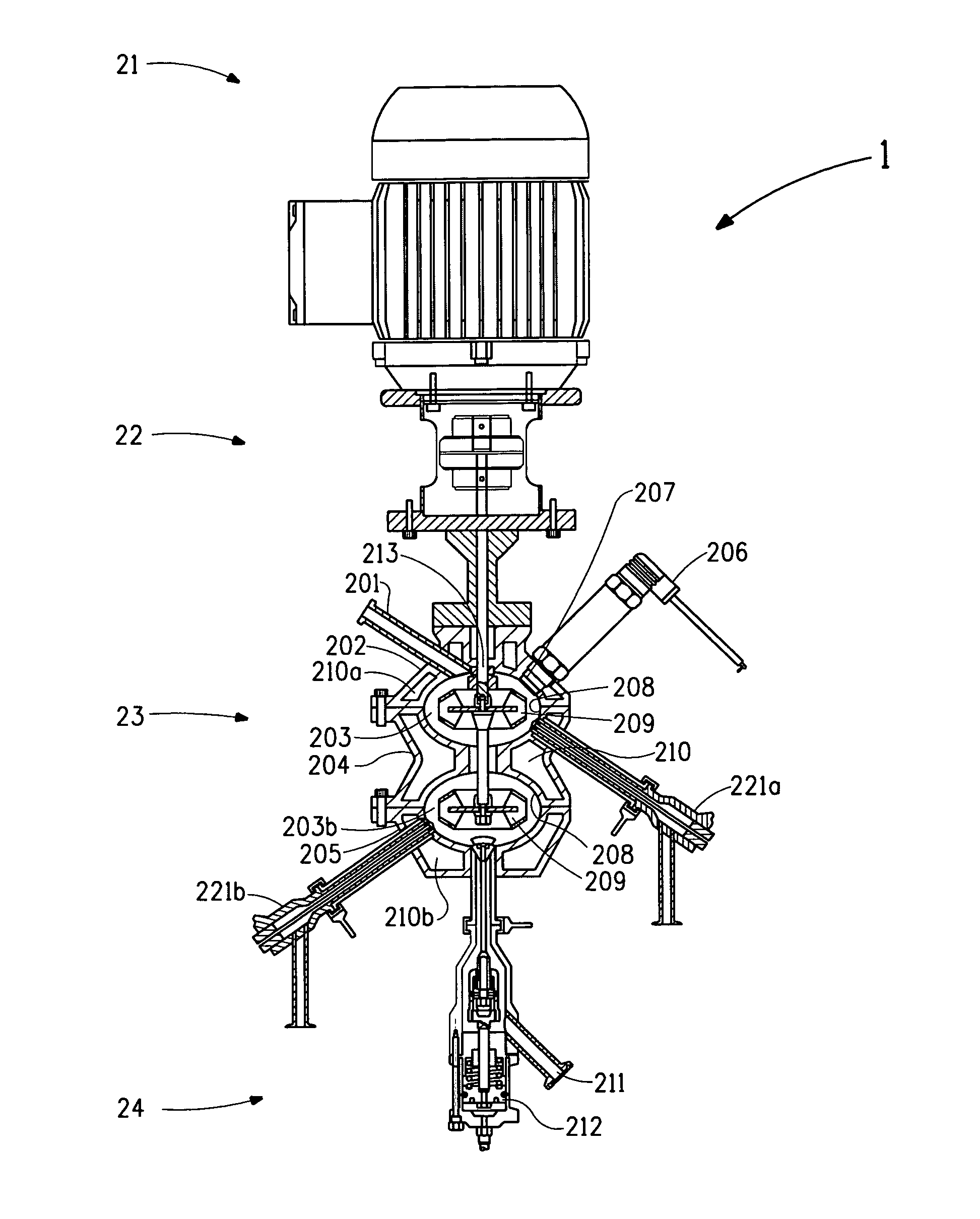

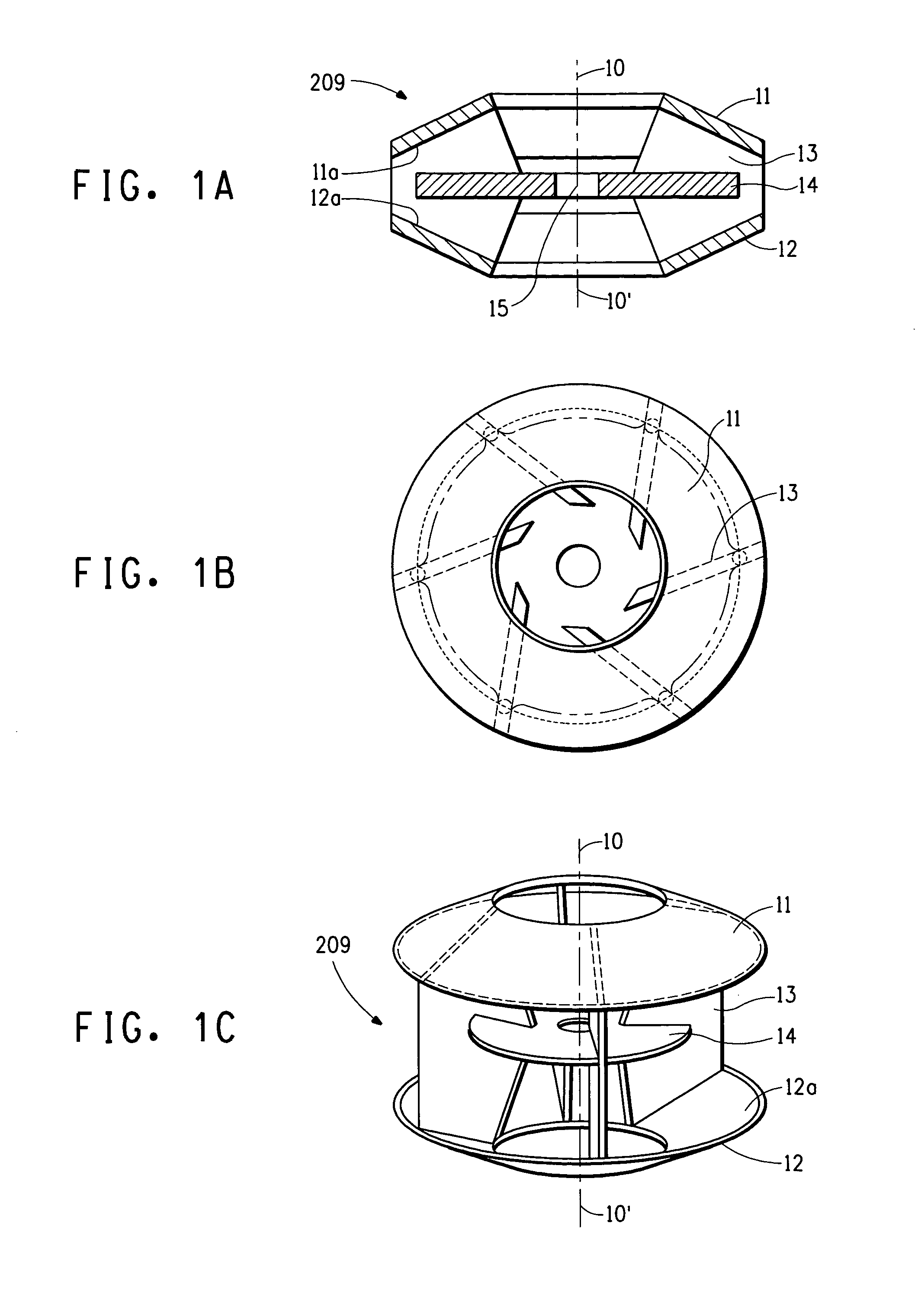

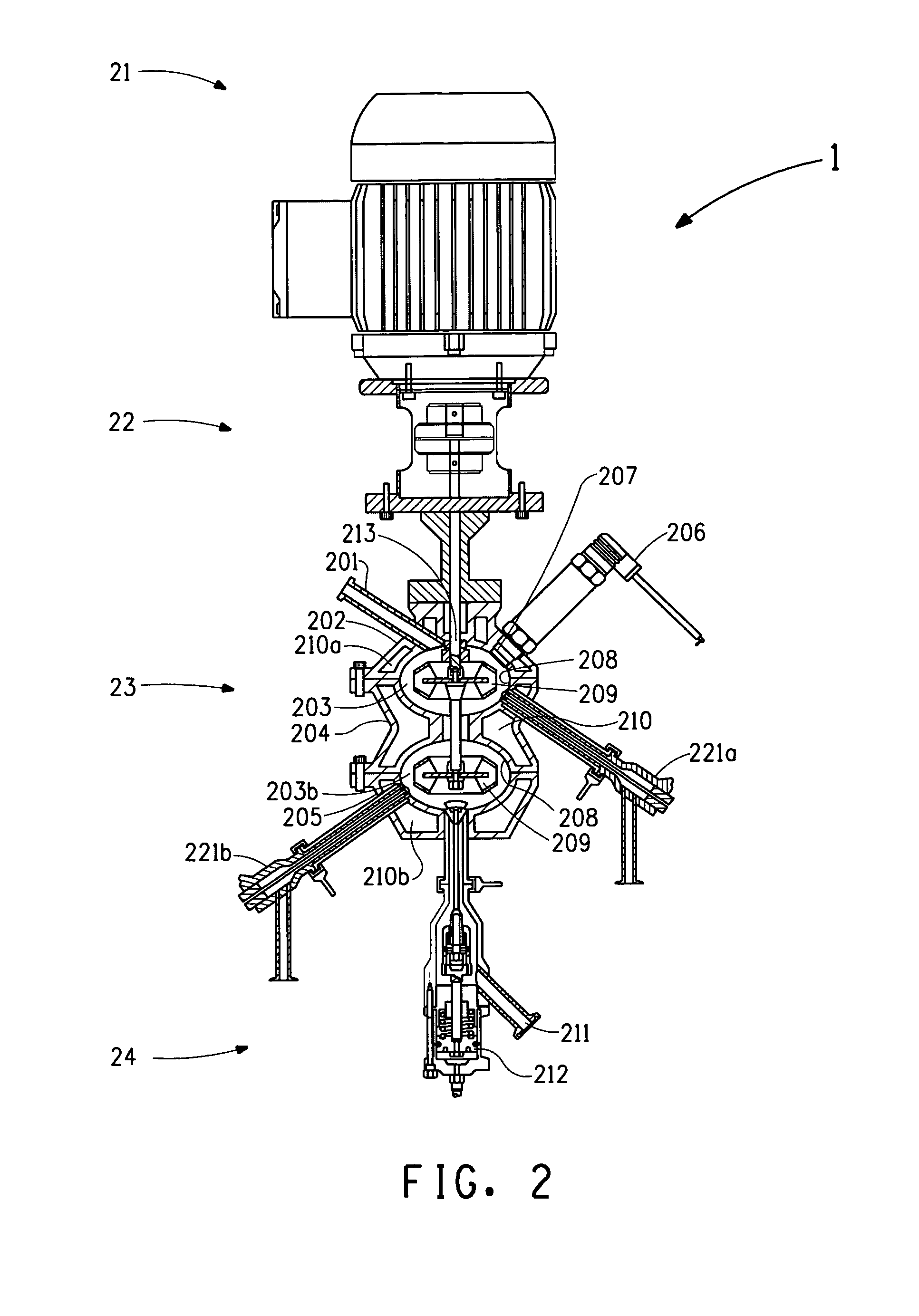

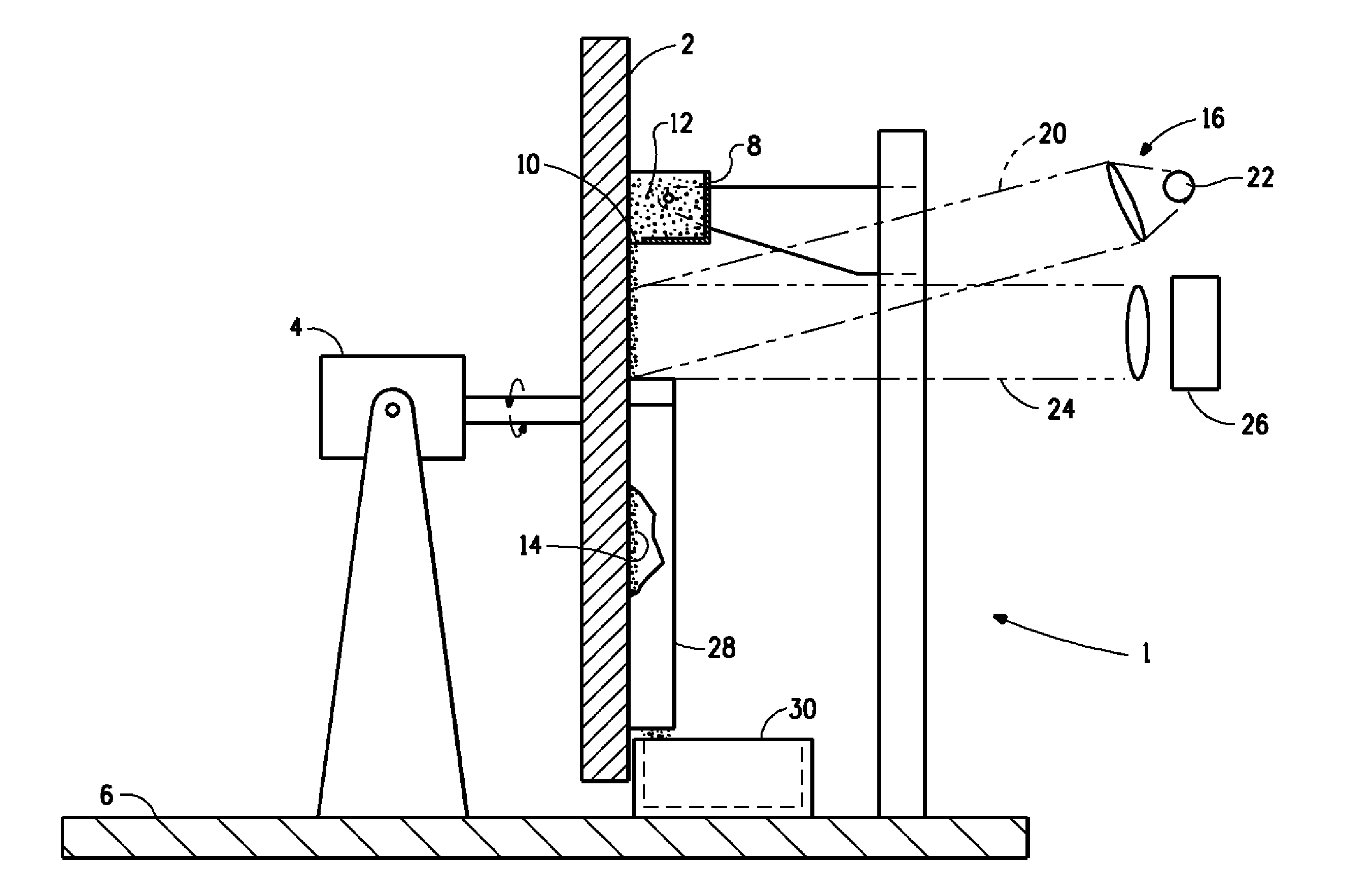

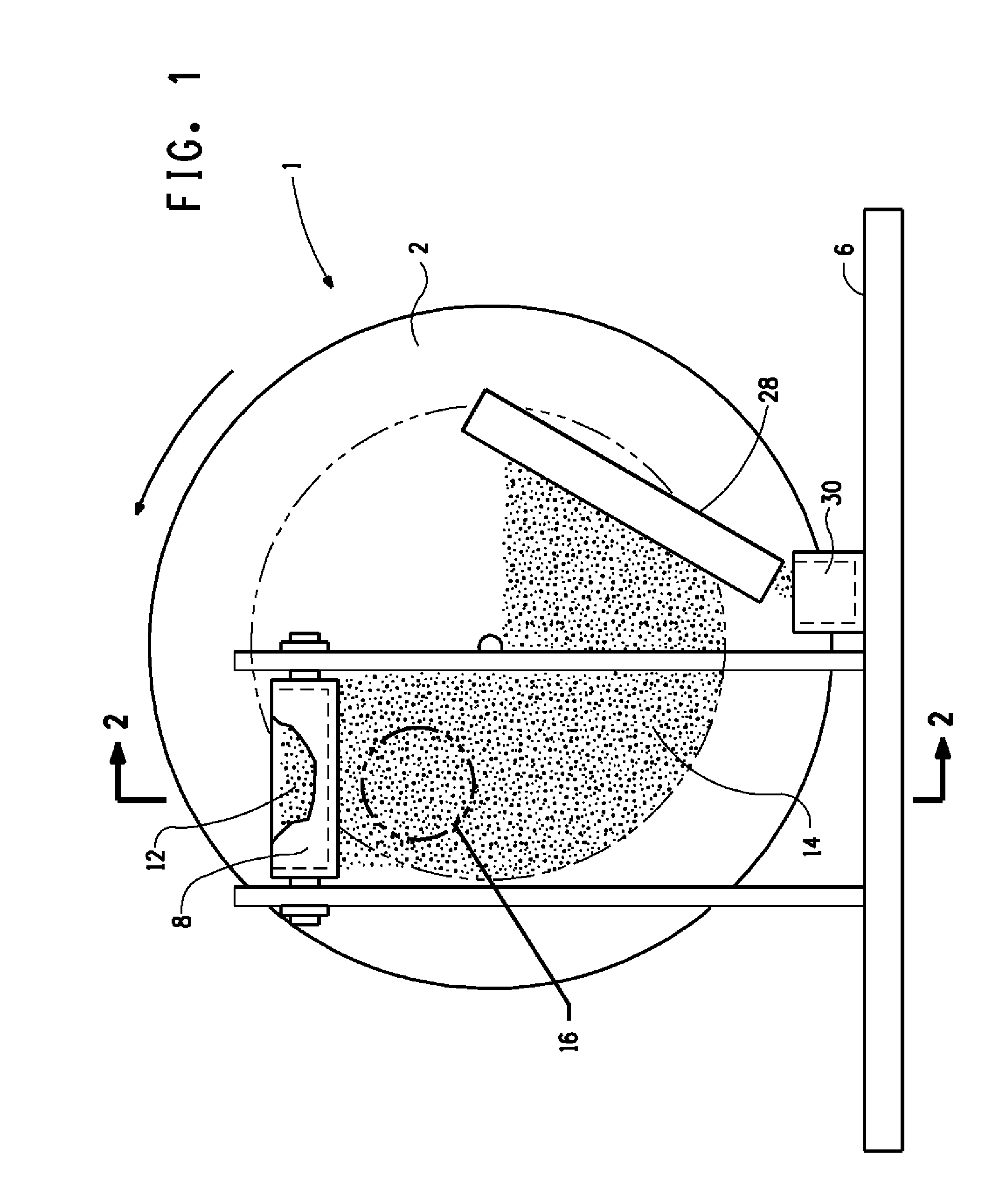

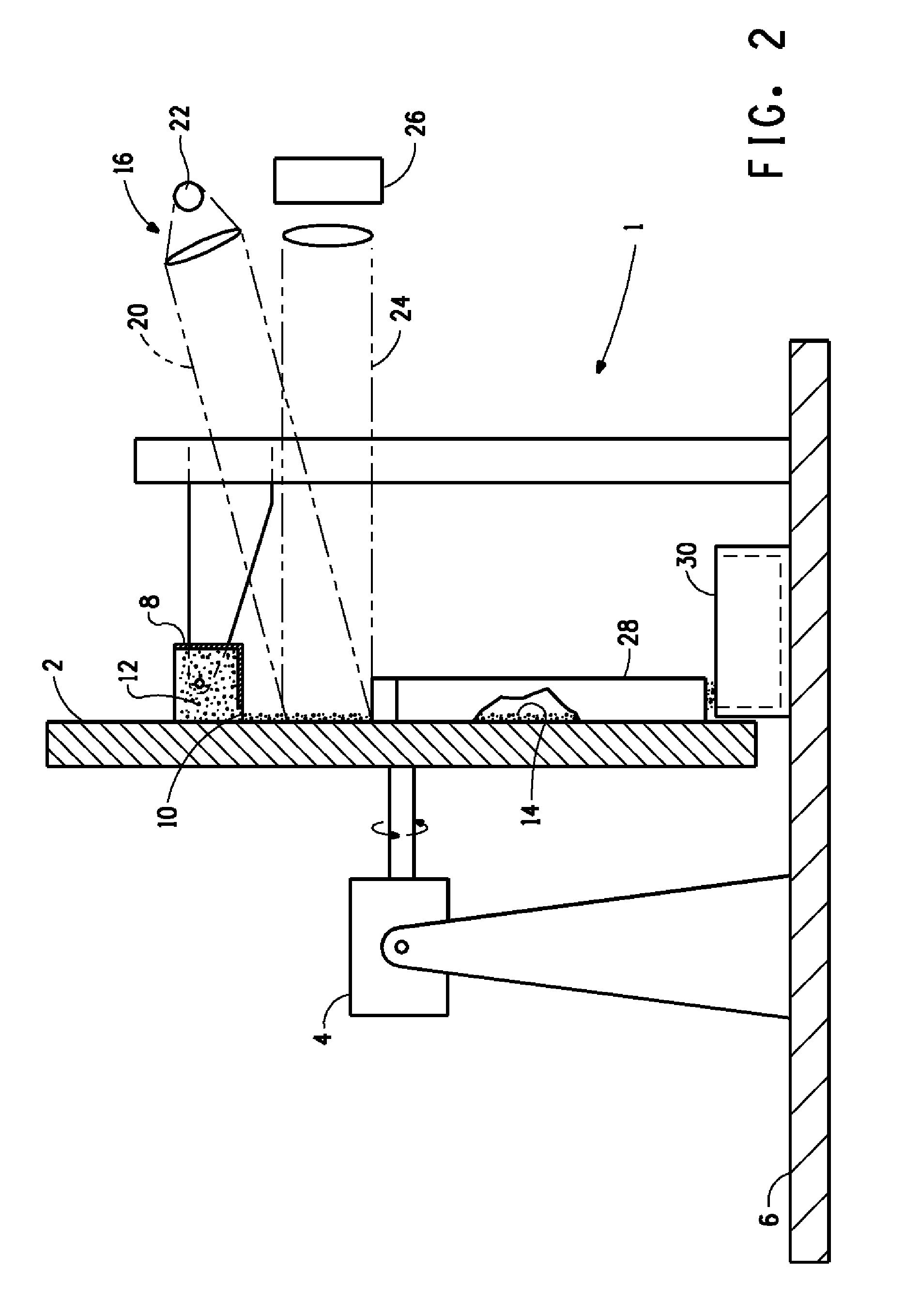

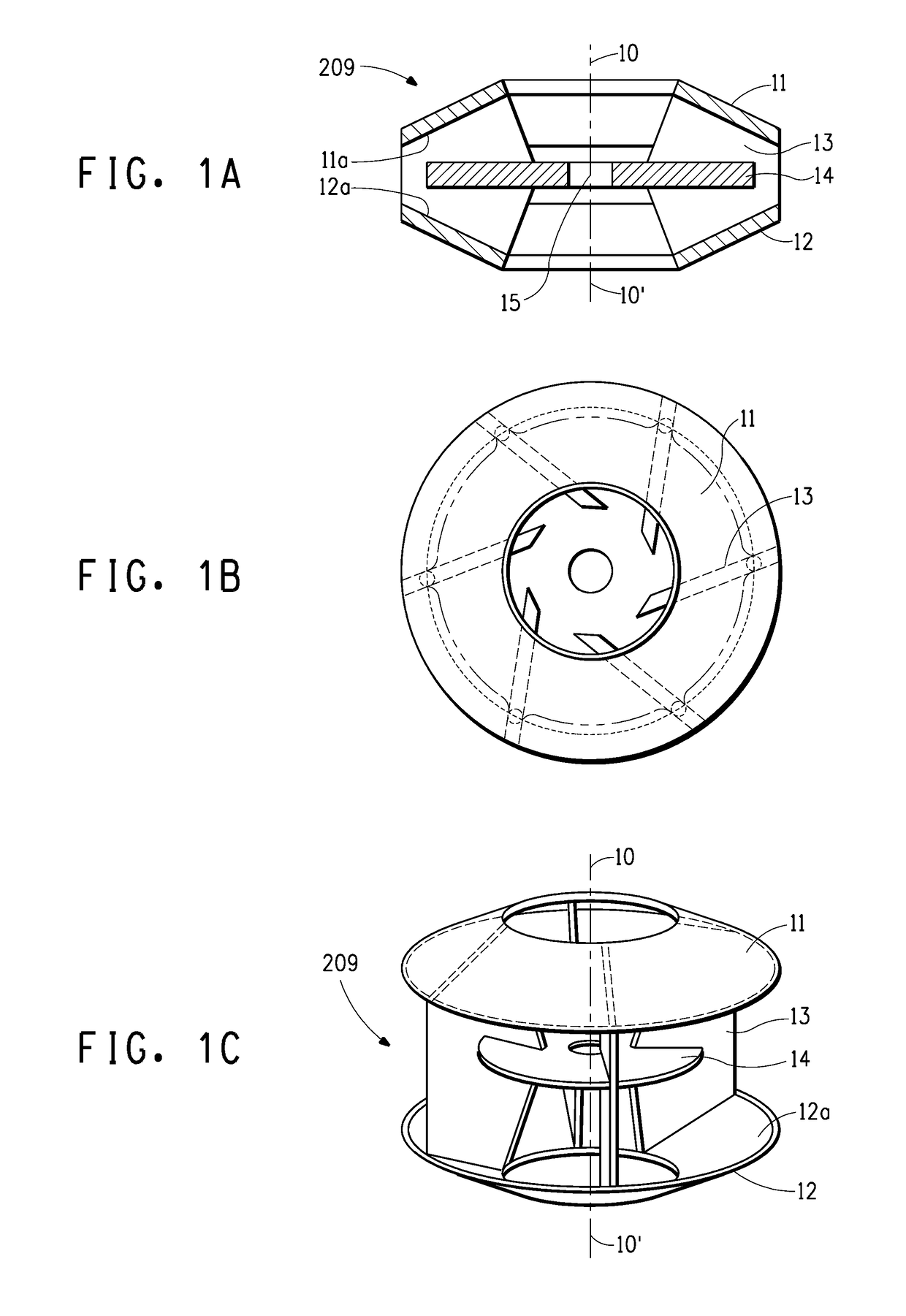

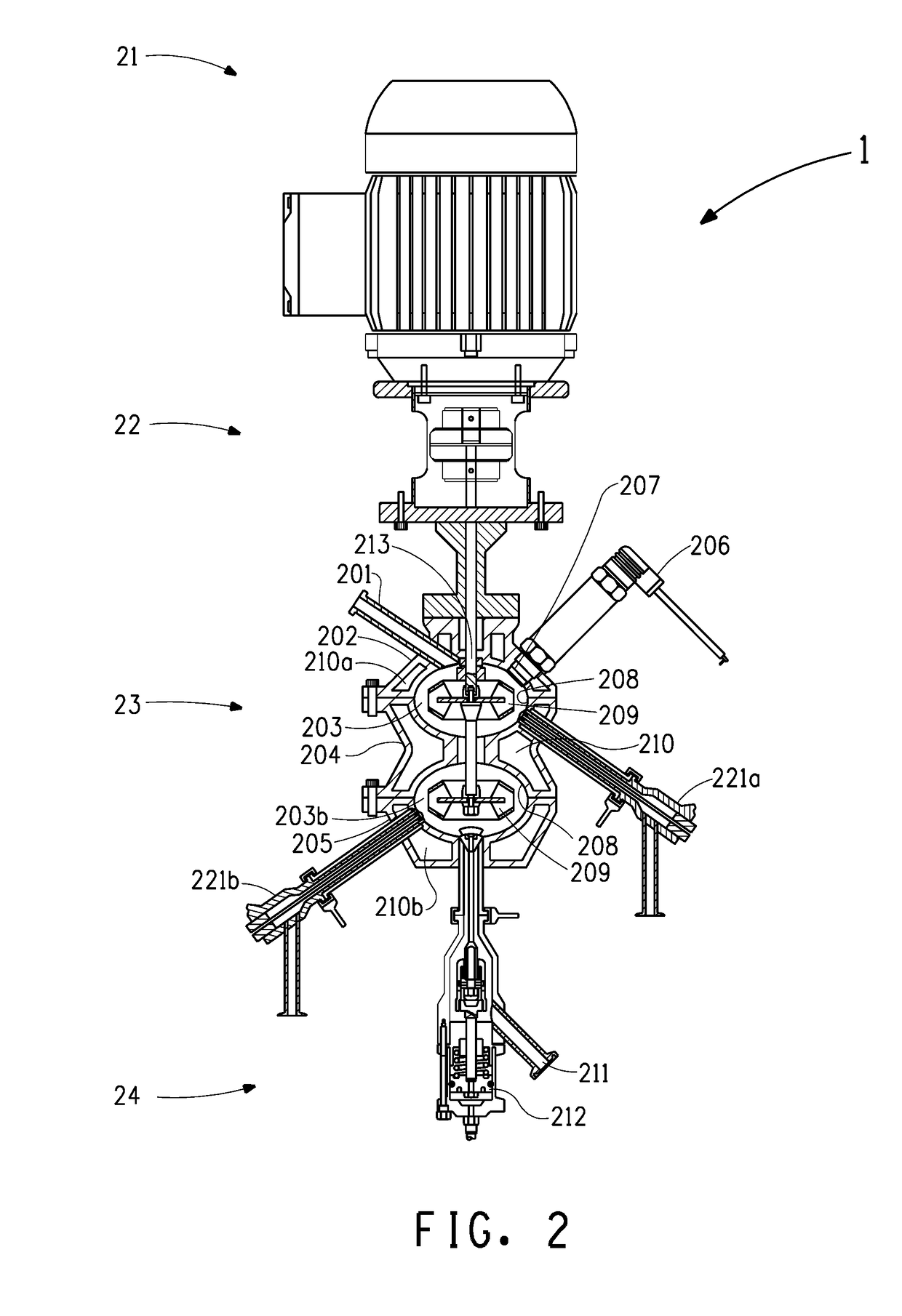

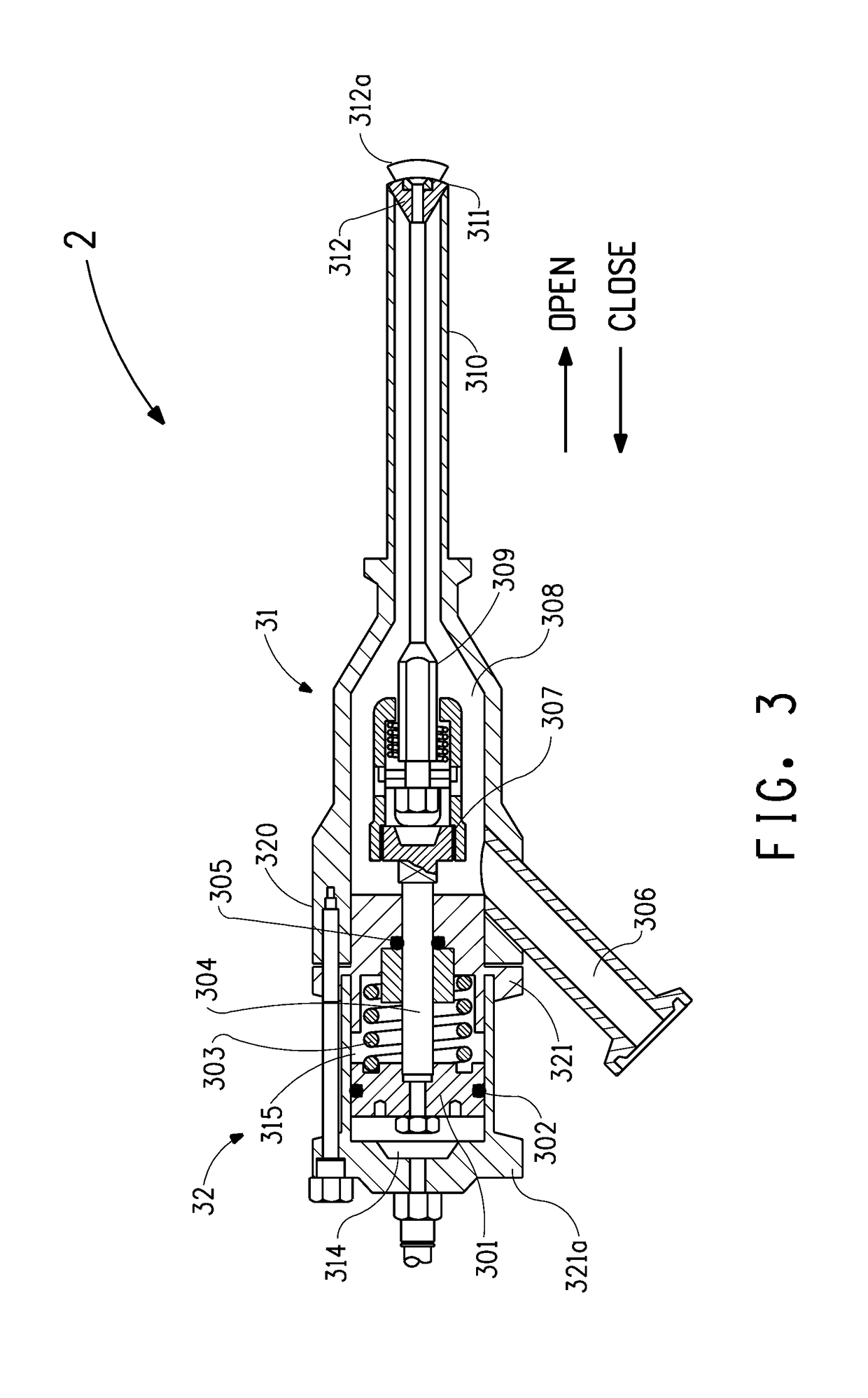

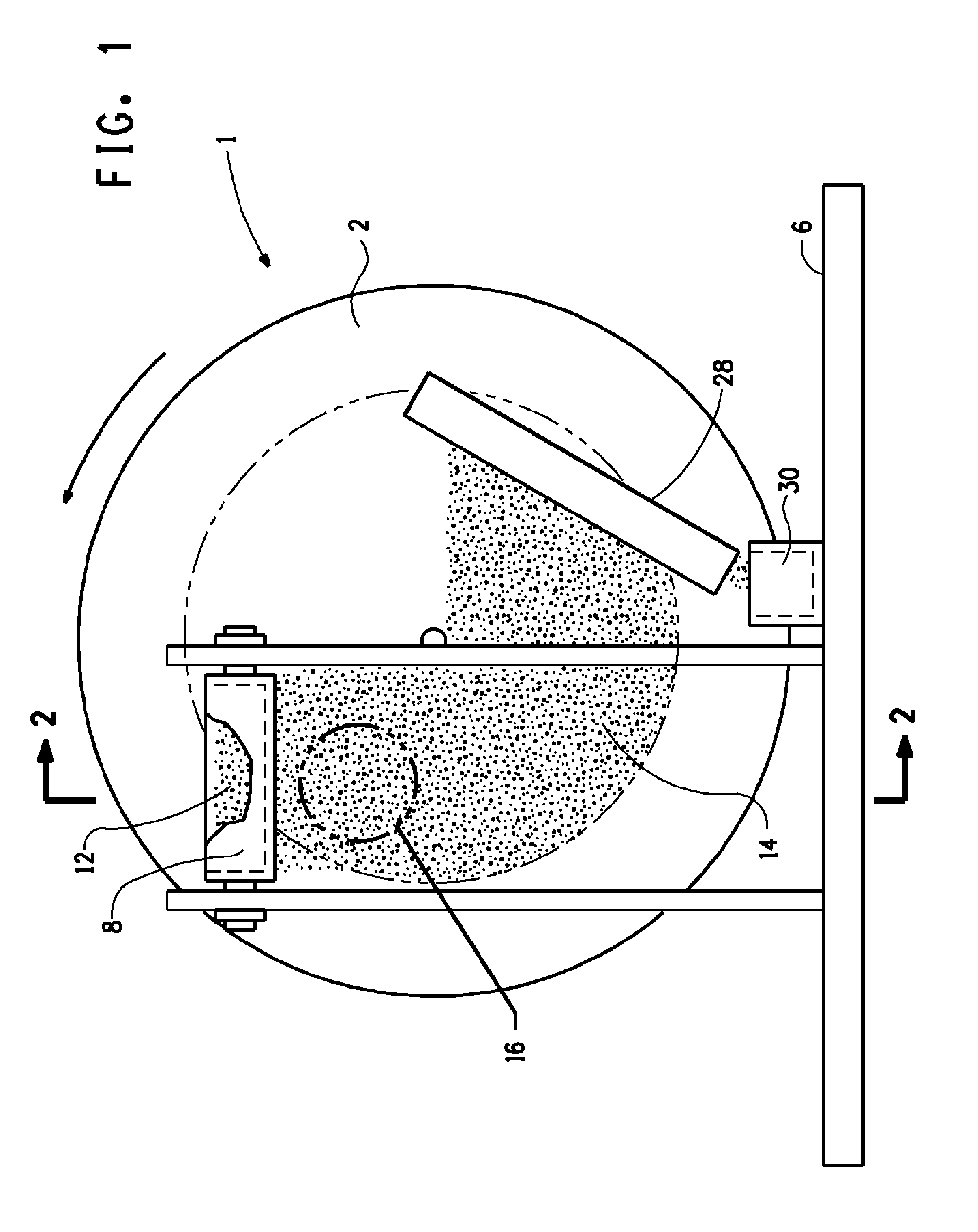

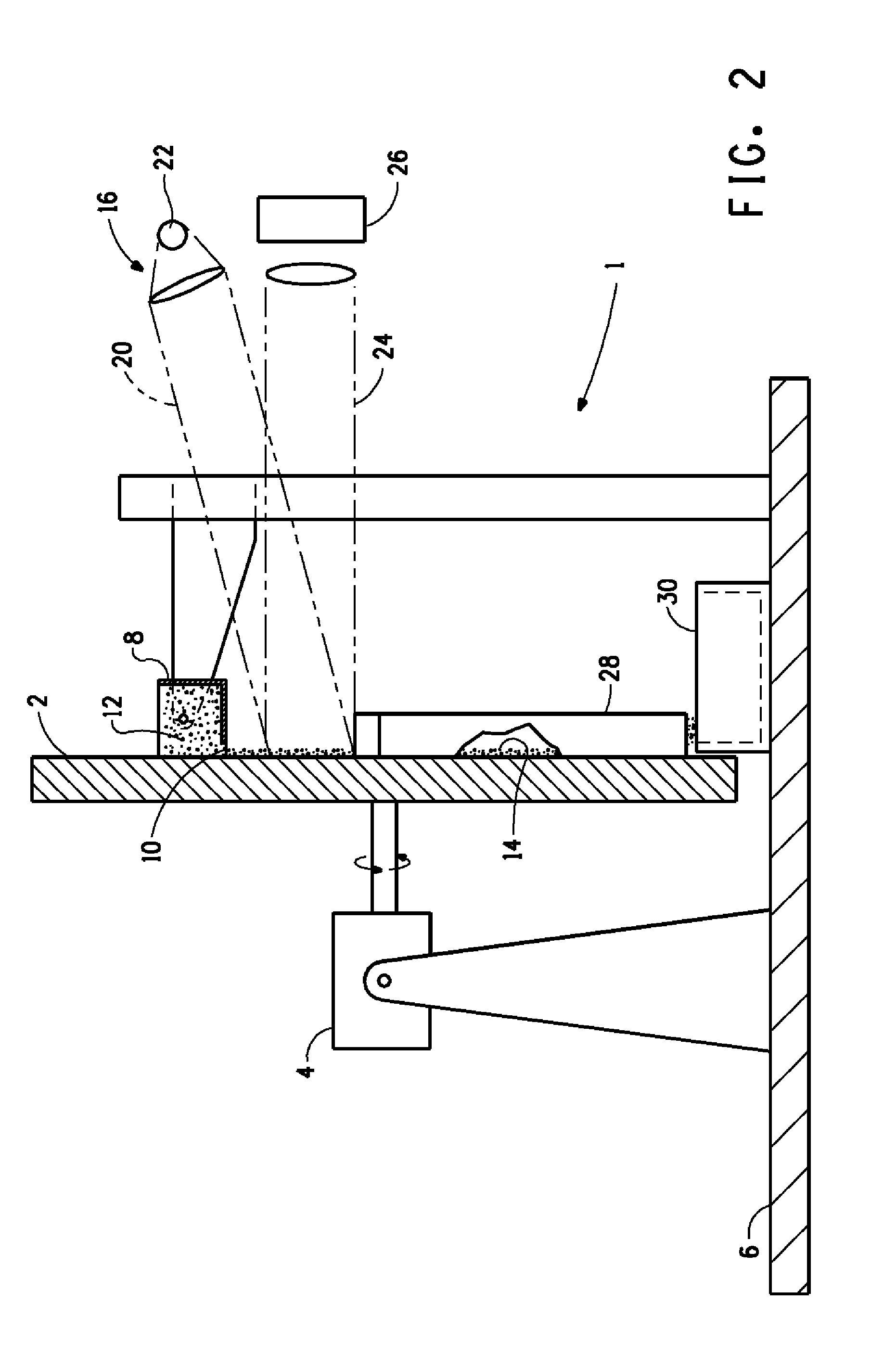

In-line multi-chamber mixer

The present invention is directed to an in-line mixer for mixing a plurality of fluids to produce a mixed product. The mixer includes one or more mixing chambers, an impeller in each of the mixing chambers, one or more inlets coupled to injection valves for conveying the fluids into the mixing chamber, and an outlet for conveying the mixed product out of the mixing chamber. The in-line mixer is well suited to components, such as those used in making automotive OEM and refinish paints.

Owner:AXALTA COATING SYST IP CO LLC

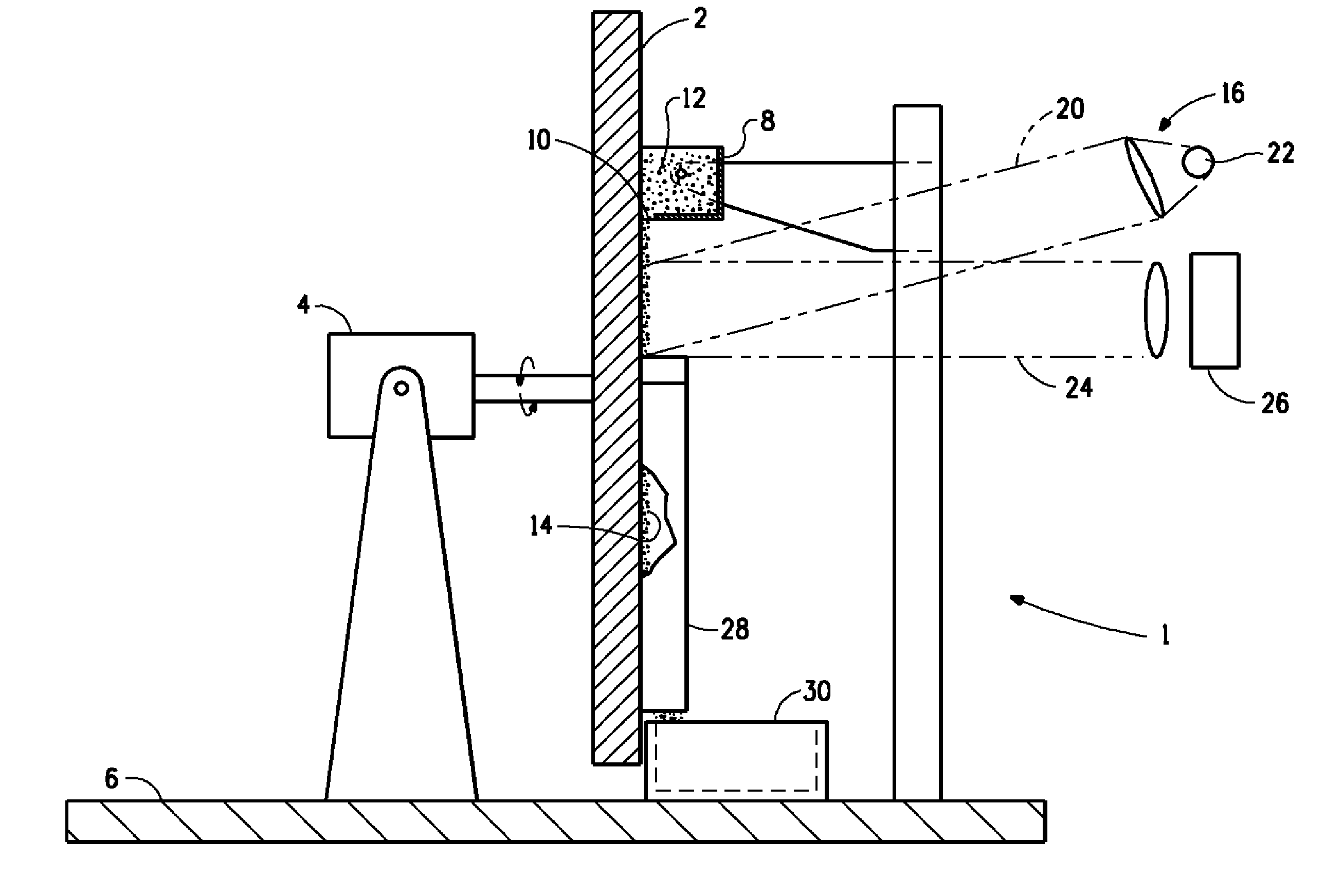

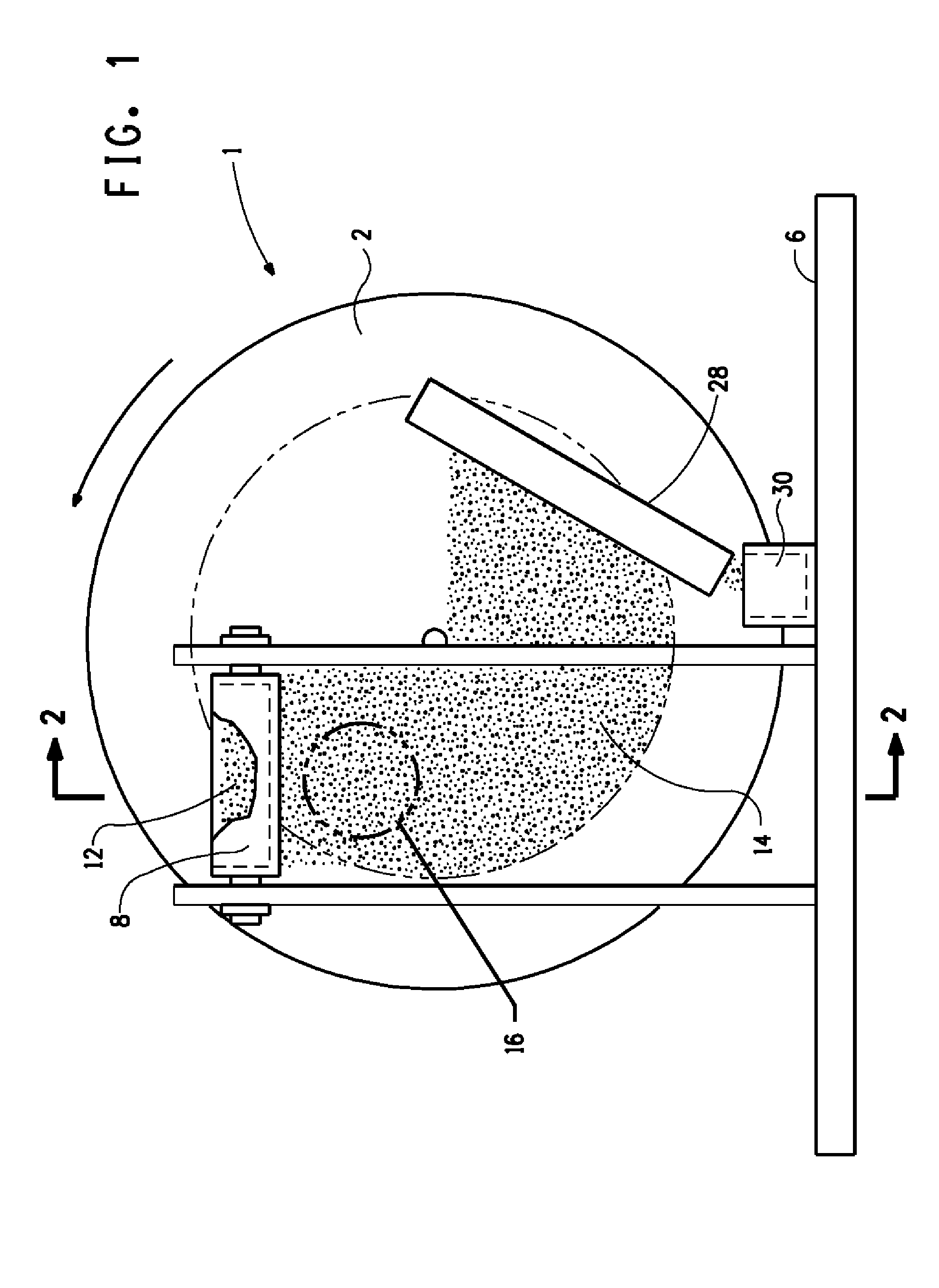

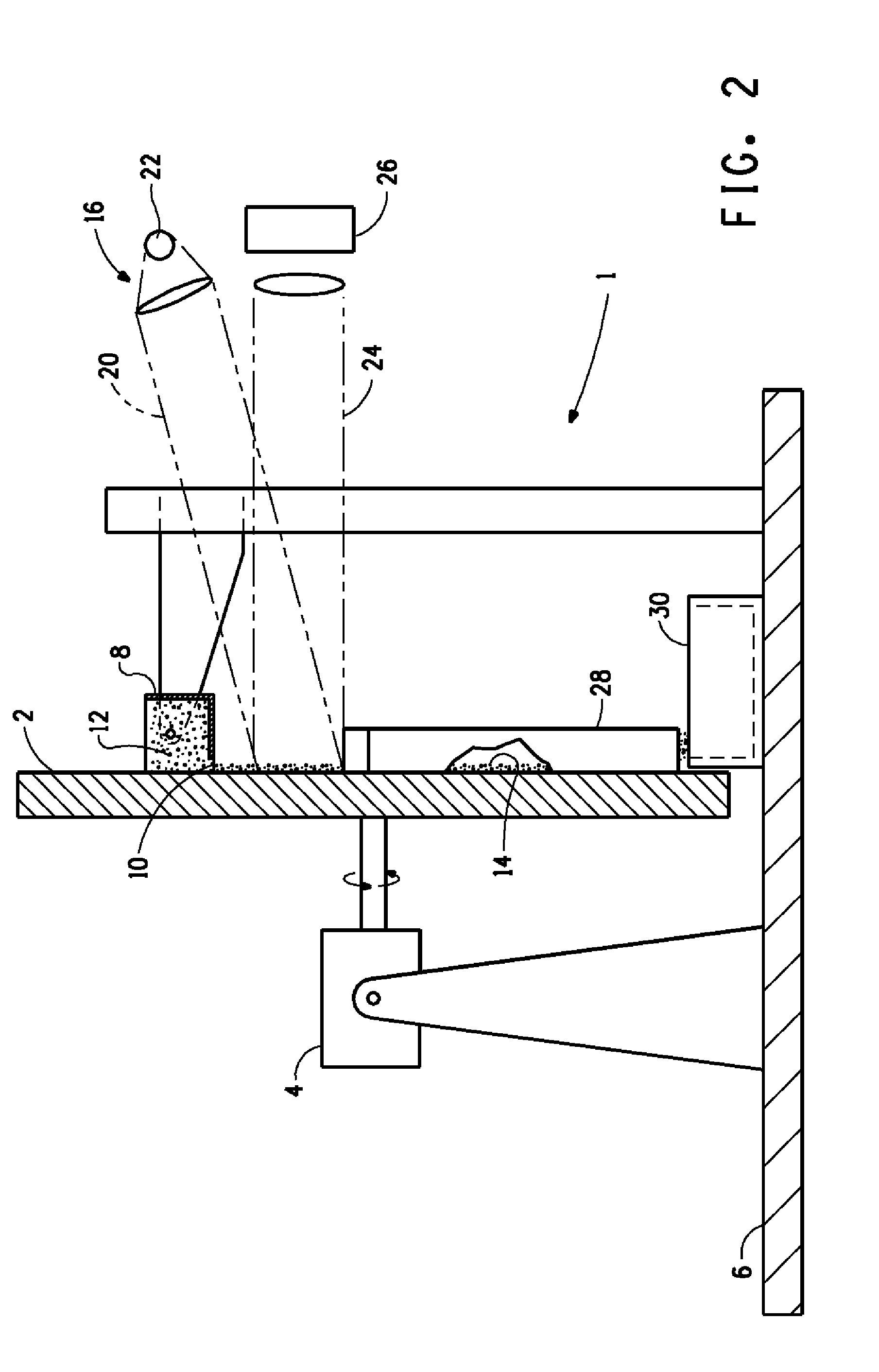

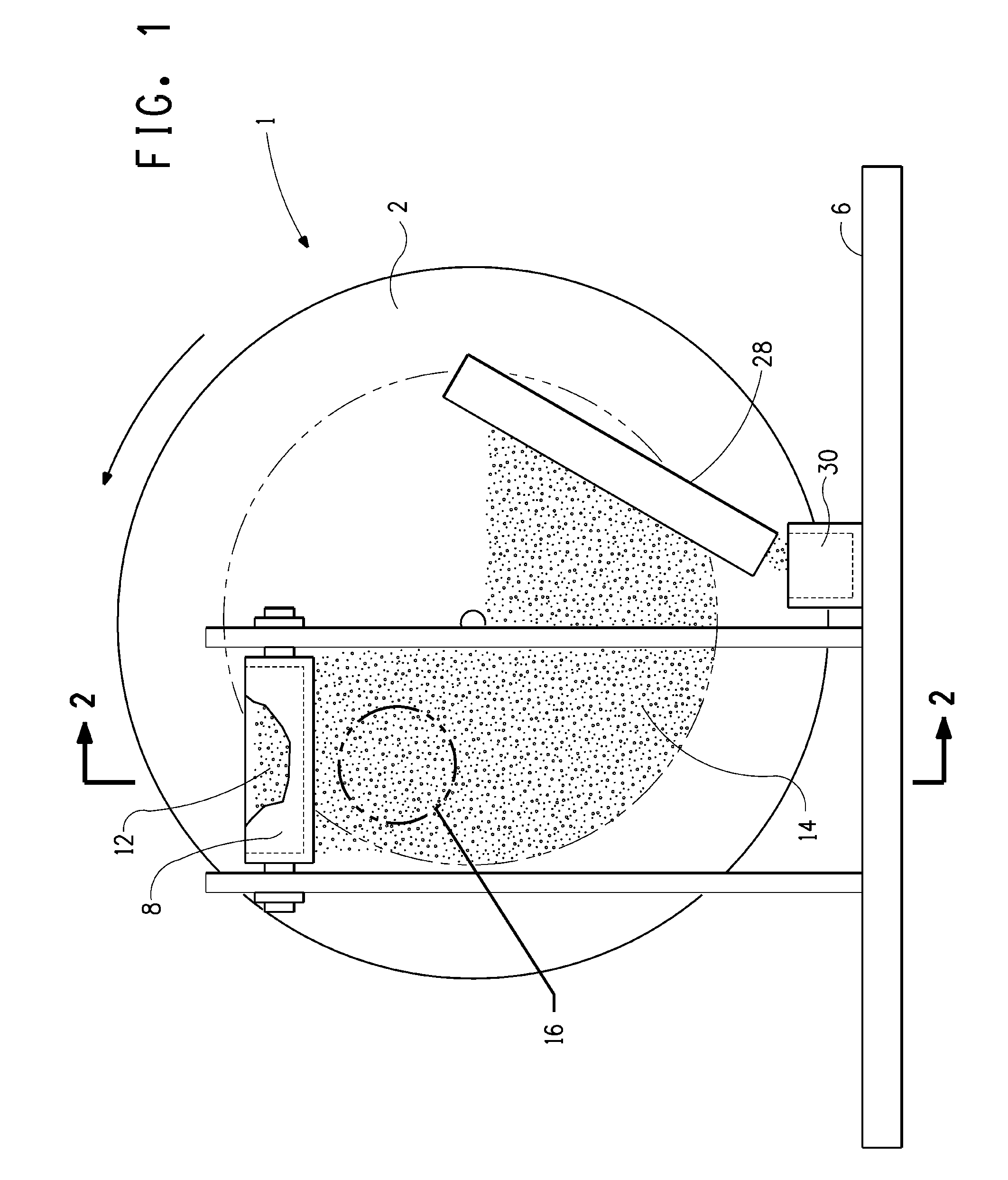

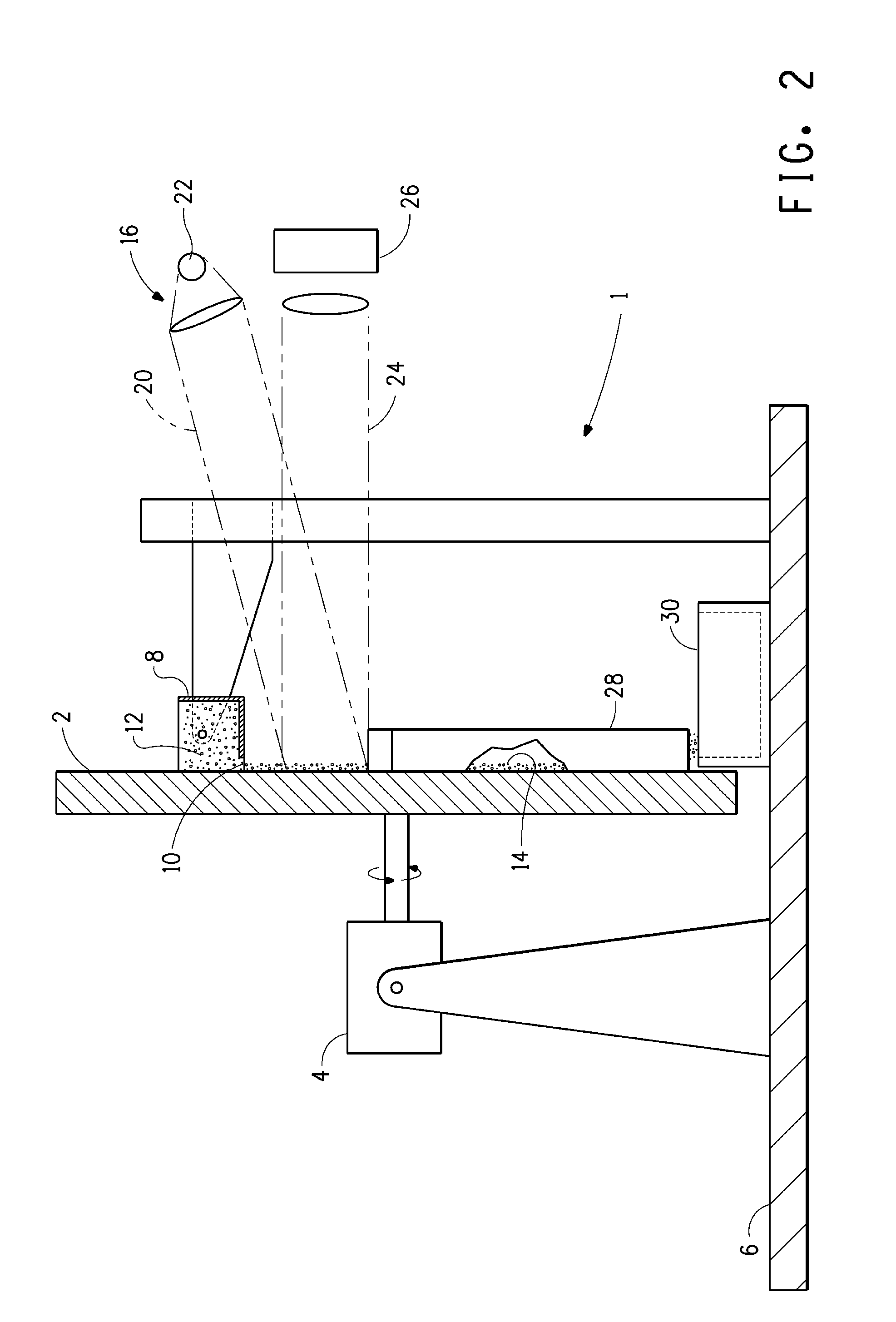

Process For Predicting Tint Strength Of Coating Compositions By Wet Color Measurement

ActiveUS20130141724A1Radiation pyrometryScattering properties measurementsAutomotive oemCurve fitting

The present invention is directed to a process for predicting the tint strength of a pigmented coating composition, such as automotive OEM or refinish paint, on a real time basis while it is being made. The tint strength of a coating resulting from a layer, obtained by adding a reference binder to the coating composition, is measured. The process is repeated by subjecting the coating compositions to successive grinding intervals. The tint strength vs. reflectance is plotted on a graph and then by using a curve fitting equation, a tint strength prediction curve is obtained. By measuring the reflectance of a wet layer of a target coating composition, the tint strength of that target coating composition can then be predicted by using the tint strength prediction curve. The process is most useful during the manufacture of coating compositions, such as automotive OEM and refinishes paints.

Owner:EI DU PONT DE NEMOURS & CO

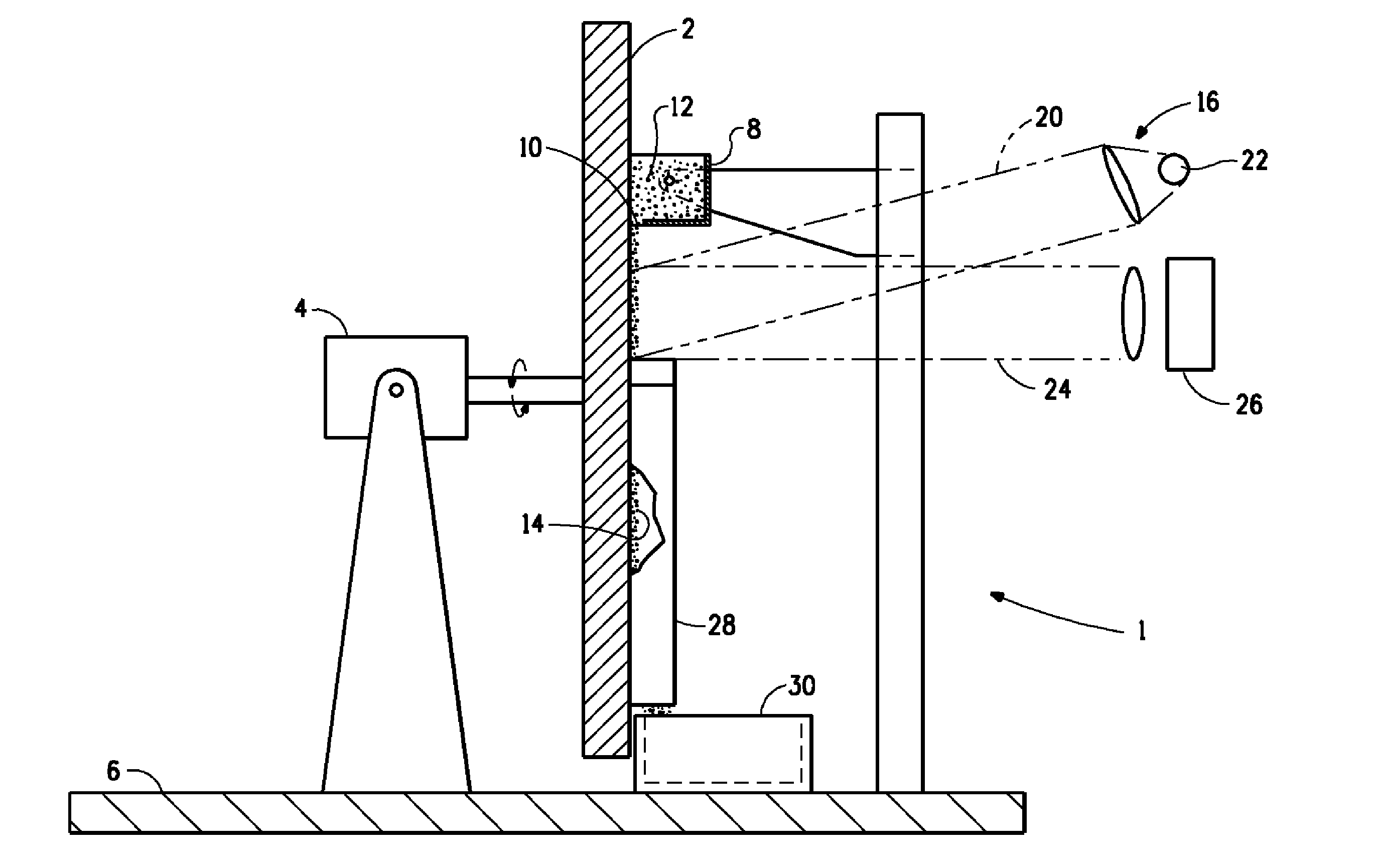

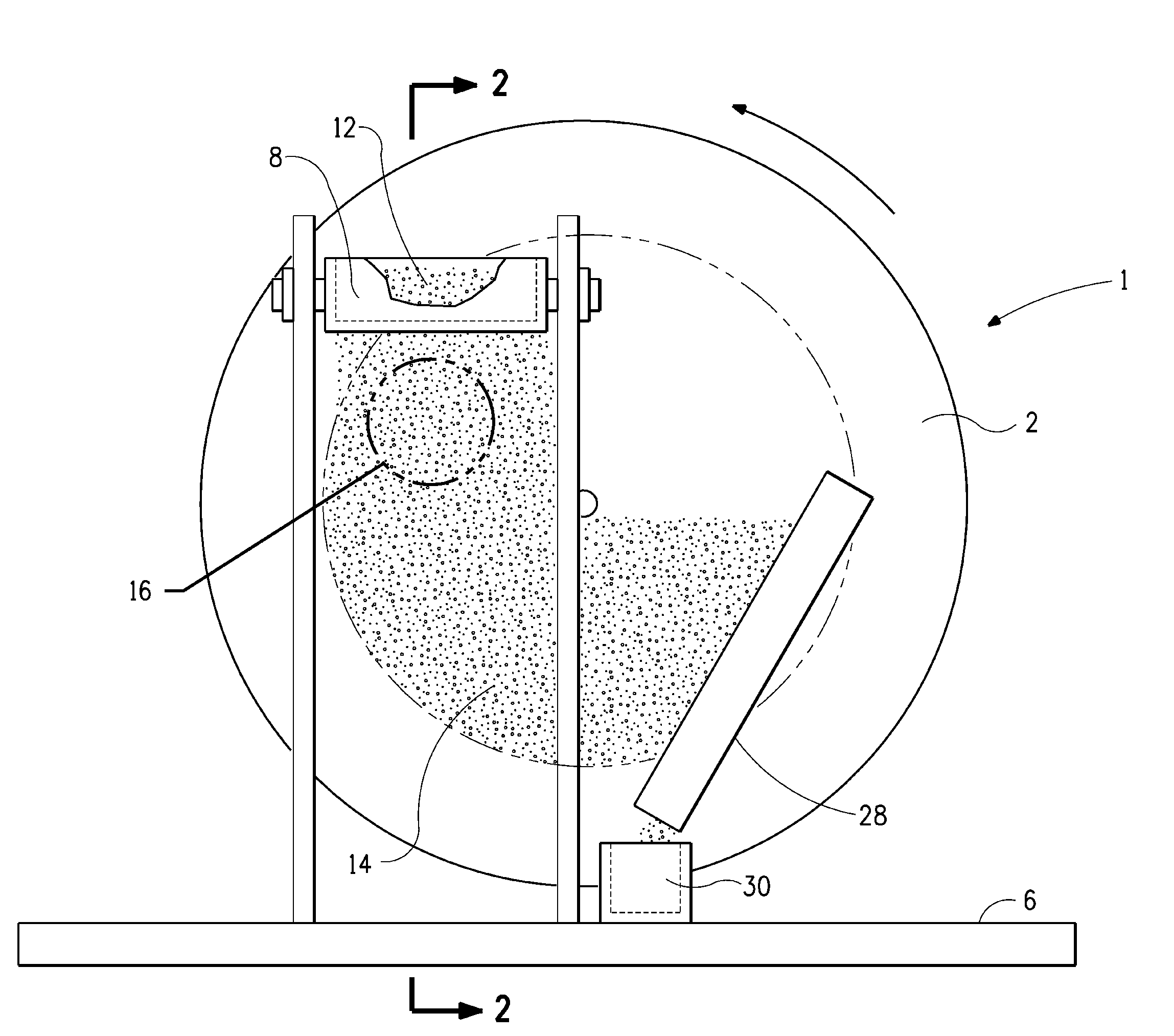

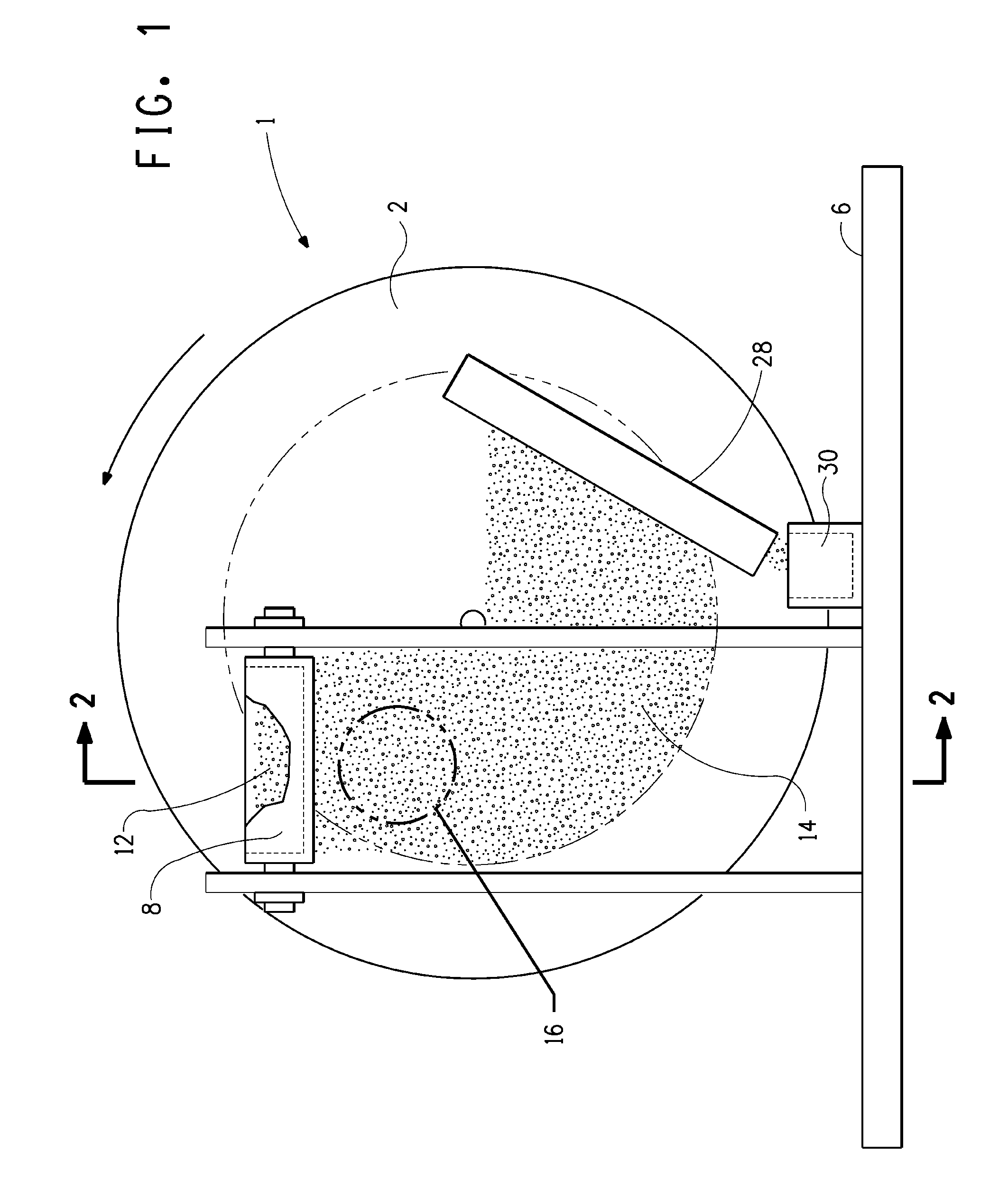

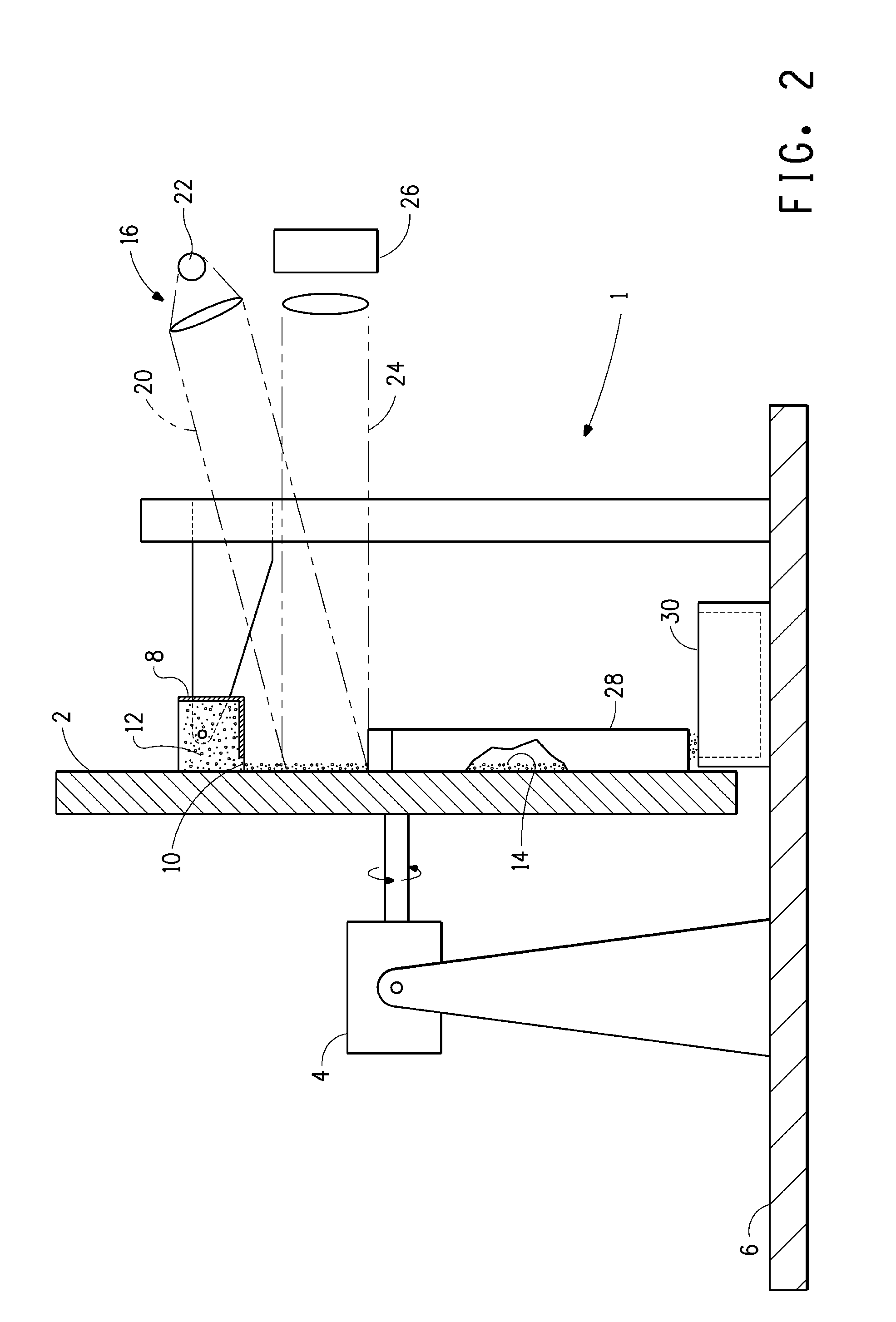

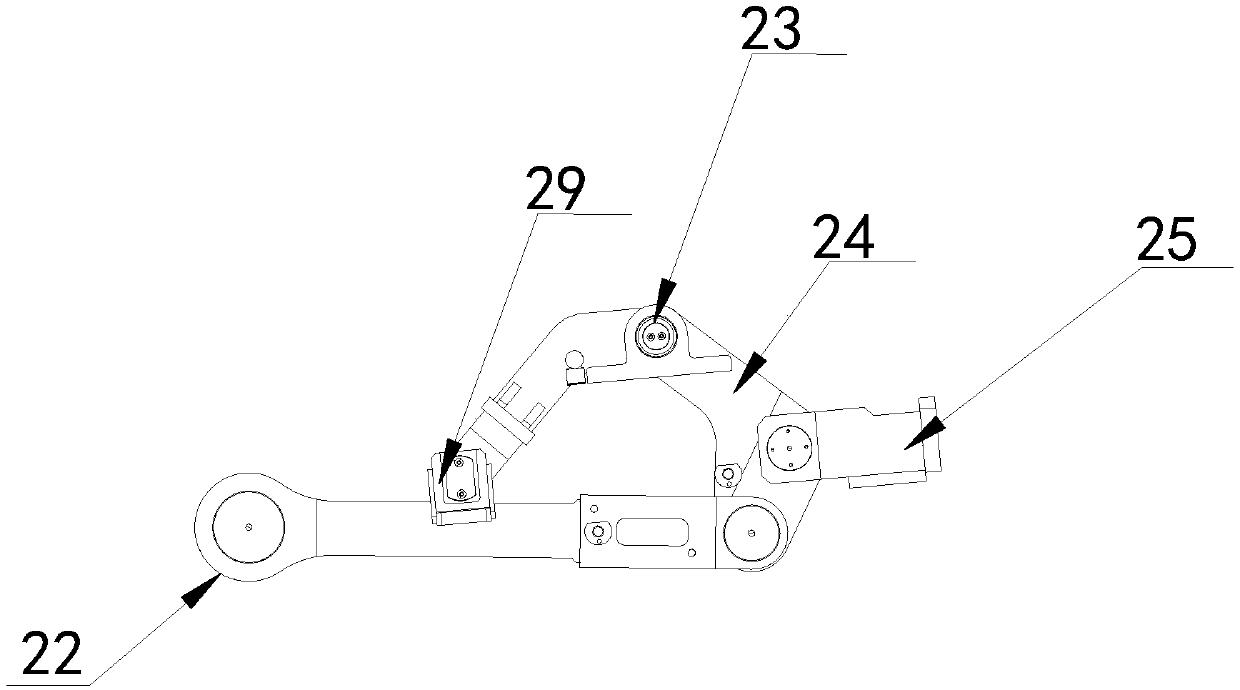

Process For Predicting Amount Of Coarse Flakes In Coating Compositions By Wet Color Measurement

The present invention is directed to a process for predicting amount of coarse flakes, such as metallic aluminum flakes present in a coating composition, such as automotive OEM or refinish paint. The process includes measuring flop of a layer of the coating composition applied over a test substrate by using flop prediction device of the present invention. The process is repeated with varying amounts of one or more different types of coarse flakes added to the composition and the flop vs. amount of coarse flakes present in the coating composition is plotted on a graph and then by using a curve fitting equation, a flake amount prediction curve is obtained. By measuring the flop of a wet layer of a target coating composition, the amount of coarse flakes present in the target coating composition can then be predicted by using the flake amount prediction curve. The process is most useful during the manufacture of coating compositions, such as automotive OEM and refinishes paints.

Owner:AXALTA COATING SYST IP CO LLC

Branched polymers and coating compositions made therefrom

This invention relates to rapid curing coating compositions that are particularly useful for automotive OEM and refinish applications. The coating composition includes a crosslinkable component that contains a novel highly branched acrylic polymer, and a crosslinking component that contains conventional crosslinking agents, such as polyisocyanate and melamine. This invention is also directed to a process for producing coatings from the rapid curing coating compositions. These compositions are especially useful in providing hard highly crosslinked coatings.

Owner:AXALTA COATING SYST IP CO LLC

In-line multi-chamber mixer

The present invention is directed to an in-line mixer for mixing a plurality of fluids to produce a mixed product. The mixer includes one or more mixing chambers, an impeller in each of the mixing chambers, one or more inlets coupled to injection valves for conveying the fluids into the mixing chamber, and an outlet for conveying the mixed product out of the mixing chamber. The in-line mixer is well suited to components, such as those used in making automotive OEM and refinish paints.

Owner:AXALTA COATING SYST IP CO LLC

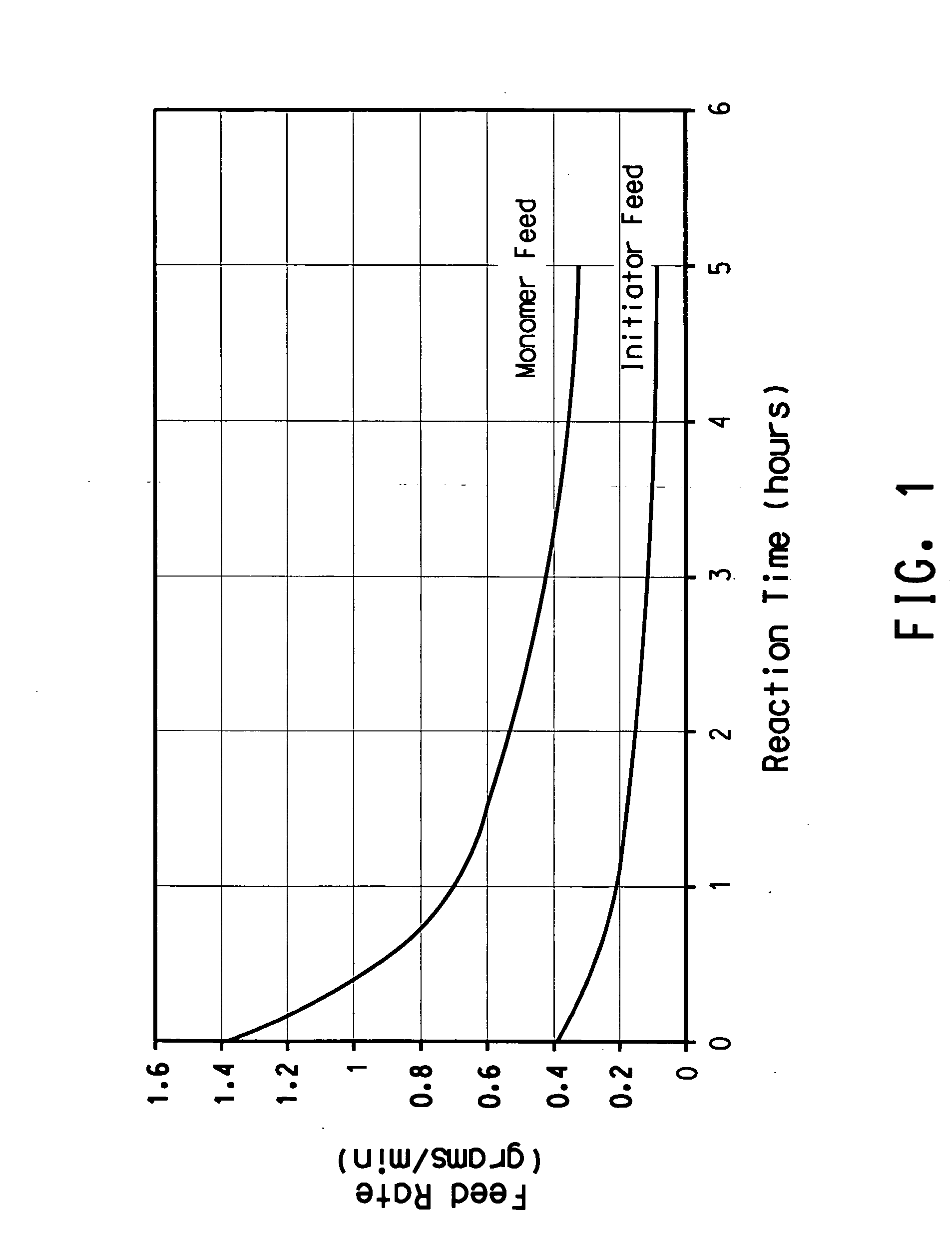

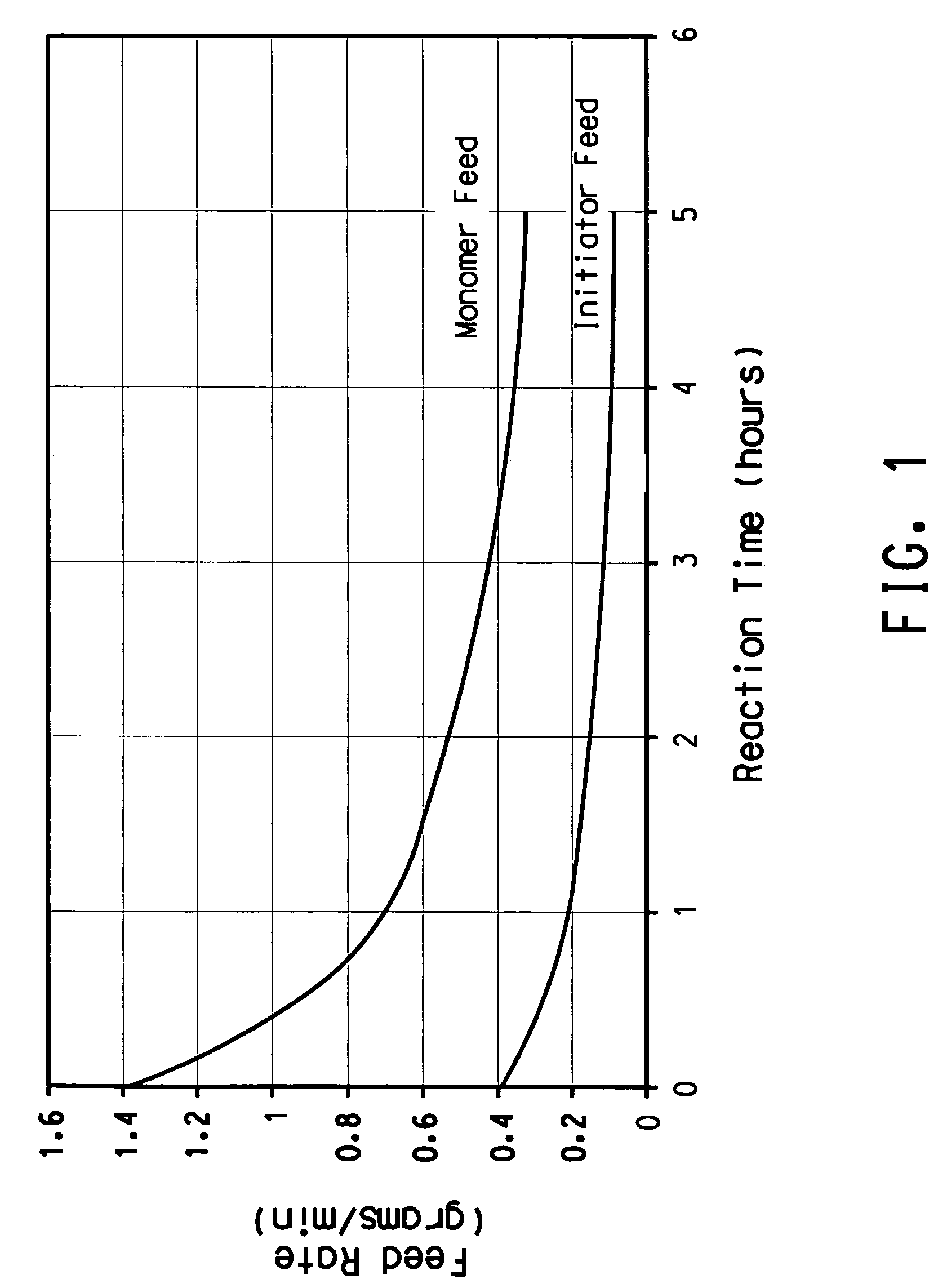

Thermally initiated polymerization process

The present invention is directed to a thermally initiated polymerization process. The process provides for heating in a reactor a reaction mixture comprising one or more acrylate monomers to a polymerization temperature ranging from 120° C. to 500°0 C., and polymerizing the reaction mixture into a polymer. Applicants made an unexpected discovery that acrylate monomers can be used as thermal initiators, which makes the process more economical than conventional thermally initiated polymerization processes. The reaction mixture can also include non-acrylate monomers. Several novel steps are also disclosed to control the molecular weight and the polydispersity of the resulting polymer are also disclosed. The polymers made by the low cost process of the present invention have wide application, such as in automotive OEM and refinish coating compositions.

Owner:EI DU PONT DE NEMOURS & CO

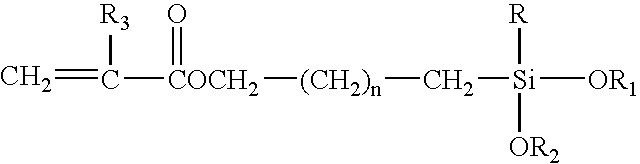

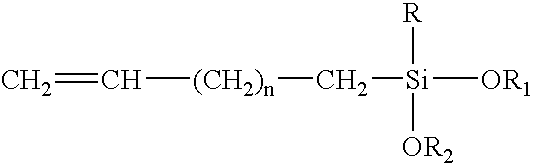

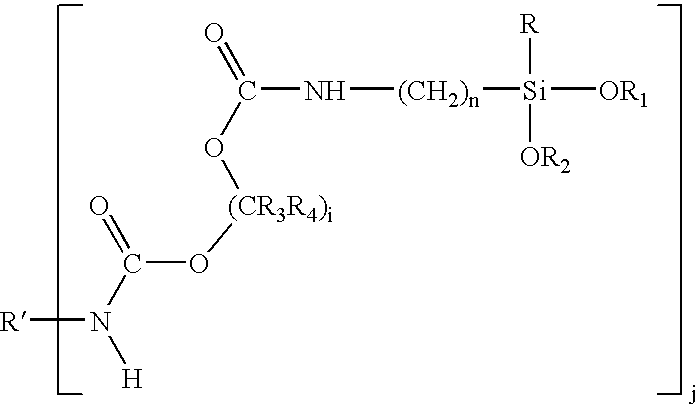

One-pack primer sealer compositions for SMC automotive body panels

InactiveUS20060115611A1Reduces paint defectEliminates extensive reworkingLiquid surface applicatorsSynthetic resin layered productsAutomotive oemMelamine

The present invention provides for a one-pack primer-sealer composition for molded SMC parts such as automotive body panels that significantly reduces paint defects (such as paint pop and cracking defects) in the sealing and automotive OEM finishing operations. The coating composition includes silane and melamine components. The composition is sufficiently stable to be formulated as a one-pack coating composition.

Owner:HAZAN ISIDOR +4

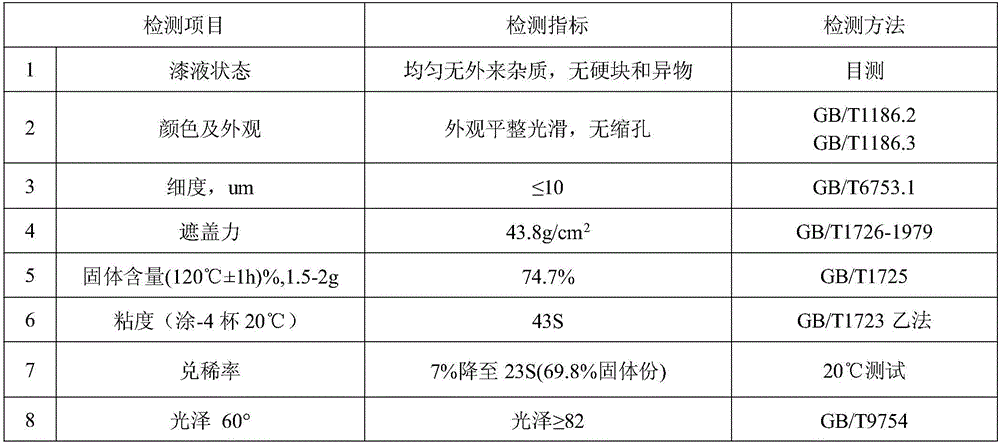

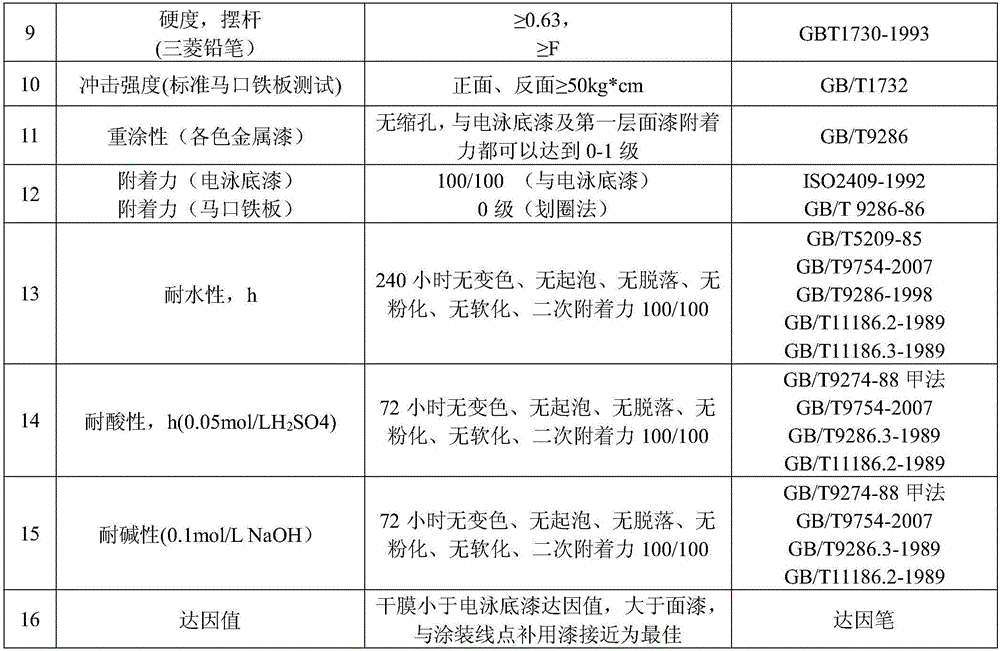

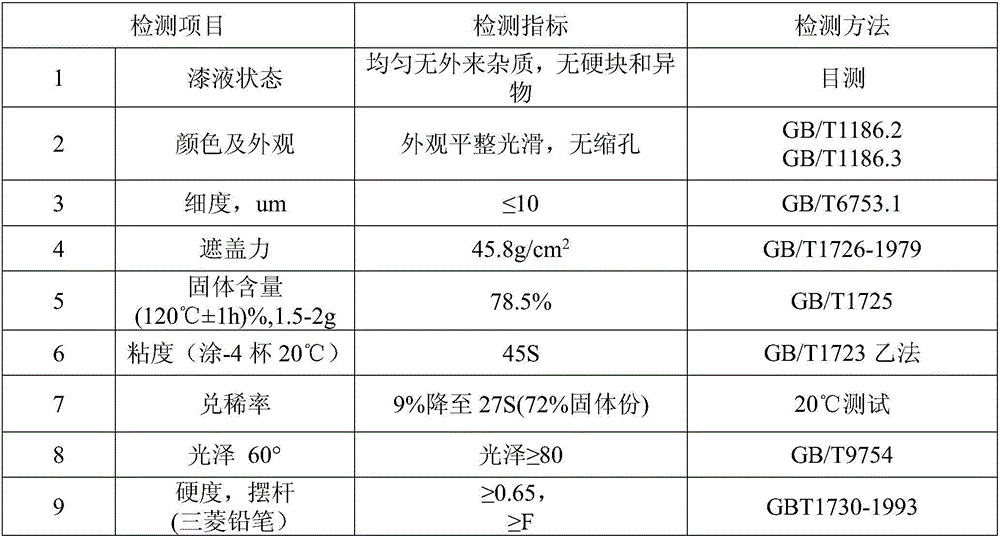

Automotive OEM (original equipment manufacturer) intermediate coat with high solid content and low viscosity and preparation method of intermediate coat

ActiveCN106118388ASmall molecular weightHigh solidsPolyester coatingsEthylene glycol monoethyl ether acetateGlass microsphere

The invention mainly relates to the field of coatings, in particular to an automotive OEM (original equipment manufacturer) intermediate coat with high solid content and low viscosity and a preparation method of the intermediate coat. The intermediate coat comprises raw materials in percentage by mass as follows: 25%-35% of polyester resin, 5%-12% of anti-sagging resin, 15%-25% of rutile titanium dioxide, 0-2% of hollow glass microspheres, 12%-18% of superfine precipitated barium sulfate, 1%-3% of a dispersing agent, 0.1%-0.3% of white carbon black, 0.1%-0.3% of an organosilicon leveling agent, 0.3%-0.6% of an acrylate leveling agent, 0.2%-0.5% of a surfactant, 0-2% of an anti-settling agent, 0-4% of cyclohexanone, 3%-5% of ethylene glycol monoethyl ether acetate, 0.05%-0.2% of carbon black, 20%-28% of butylated amino resin and 2%-4% of partial methylated amino resin. The intermediate coat is low in applicable viscosity, good in appearance, economical and environment-friendly and has high content of applicable solids.

Owner:山东时风(集团)有限责任公司

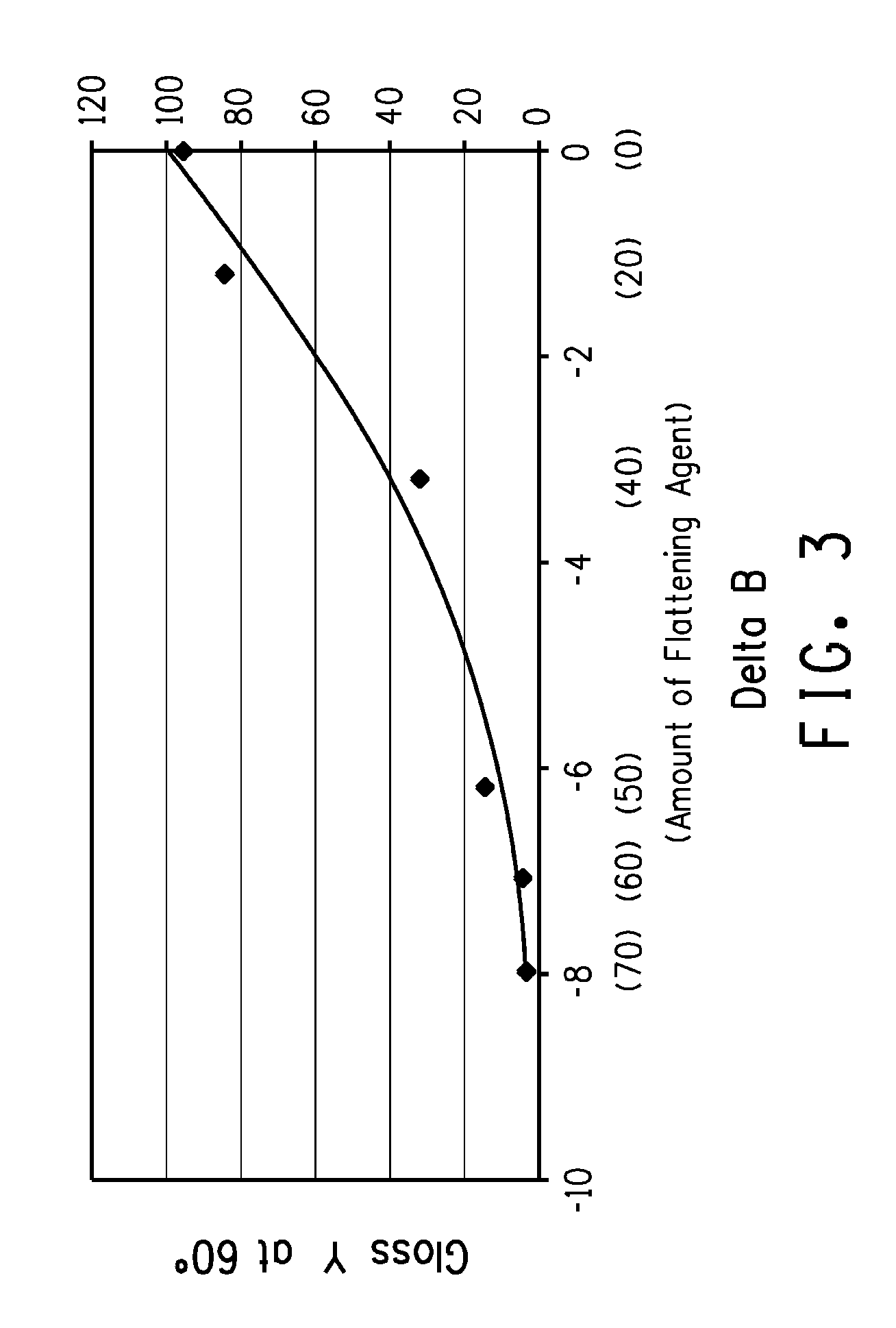

Process For Predicting Metallic Gloss Of Coating Resulting From Coating Compositions By Wet Color Measurement

The present invention is directed to a process for controlling the metallic gloss of a coating resulting from a coating composition, such as automotive OEM or refinish paint, that contains flakes, such as metallic aluminum flakes. Thus, by adjusting the amount of flattener added to the coating composition, the gloss of a coating resulting therefrom can be controlled from glossy to flat (matte) finish. The process includes measuring reflectance (L-value) of a layer of the coating composition applied over a test substrate by using gloss prediction device of the present invention. The metallic gloss of a coating resulting from the layer is then measured. The process is repeated with varying amounts of one or more flatteners added to the composition and the metallic gloss vs. reflectance is plotted on a graph. Then by means of a curve fitting equation, a metallic gloss prediction curve is plotted. By measuring the reflectance of a wet layer of a target coating composition, the metallic gloss that would be produced by a coating from that target coating composition can then be predicted by using the gloss prediction curve. The process is most useful during the manufacture of coating compositions, such as automotive OEM and refinishes paints.

Owner:AXALTA COATING SYST IP CO LLC

Rapid drying lacquers containing triblock copolymer for rheology control

ActiveUS20100286313A1Improve film propertiesFilm/foil adhesivesPretreated surfacesAcetic acidAutomotive oem

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel acrylic triblock copolymer as a replacement material for all or part of the cellulose acetate butyrate binder component. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing chip and humidity resistant coatings, especially metallic effect coatings, having excellent adhesion and down flop or metallic effect.

Owner:AXALTA COATING SYST IP CO LLC

Process for predicting gloss of low gloss coating by wet color measurement

ActiveUS20120189764A1Scattering properties measurementsPretreated surfacesAutomotive oemCurve fitting

The present invention is directed to a process for process for predicting gloss of a coating resulting from a wet layer of a low gloss coating composition, such as automotive OEM or refinish paint. The process includes measuring reflectance of the layer of the coating composition applied over a test substrate and then allowing the layer to dry and / or cure into a coating. Thereafter, its gloss is measured with a gloss meter. The process is repeated with varying amounts of one or flatting agents added to the composition and the reflectance vs. gloss is plotted on a graph and by using a curve fitting equation a gloss prediction curve is obtained. By measuring the reflectance of a wet layer of a target low gloss coating composition the gloss of a coating that would result from such a layer is then predicted by using the gloss prediction curve. The process is most useful during the manufacture of coating compositions, such as automotive OEM and refinishes paints.

Owner:AXALTA COATING SYST IP CO LLC

Method of producing coating composition and coating composition made therefrom

The present invention relates to a method of producing coating compositions having improved chip resistance. The method comprises contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to convert the organic fibers into a microslurry dispersed in the medium, separating the solid components from the medium to form a slurry; and adding the slurry or an aliquot thereof to the coating composition. The coating composition can be used in automotive OEM or refinishing applications as well as in industrial coating applications.

Owner:EI DU PONT DE NEMOURS & CO

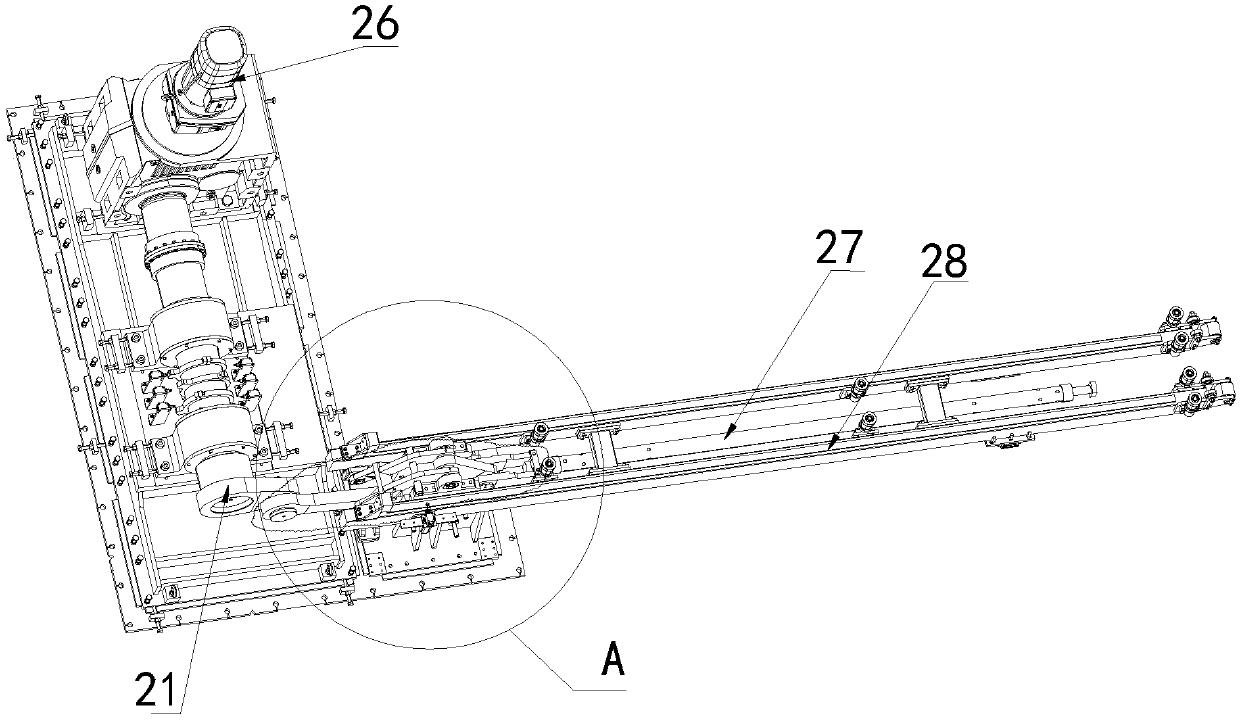

Reciprocating rod conveying system

PendingCN109533813AGood lift synchronizationRunning speed is stableConveyorsGear wheelAutomotive oem

The invention discloses a reciprocating rod conveying system. The reciprocating rod conveying system comprises a lifting mechanism and a horizontal conveying mechanism, wherein the lifting mechanism comprises a driving lifting mechanism and a plurality of driven lifting mechanisms, the driving lifting mechanism comprises a crank, a connecting rod hinged to the free end of the crank and a first lifting rocker rod, wherein the driven lifting mechanism comprises a pull rod and a lifting rocker rod, the horizontal conveying mechanism comprises a universal coupling, the free end of the universal coupling is connected with a gear shaft, and the gear shaft is provided with gears. According to the reciprocating rod conveying system, a first motor is arranged to drive the rocker to realize the lifting reciprocating motion of a rail, the second motor is arranged to drive the gears and racks to be matched to realize the reciprocating motion of the horizontal position of the rail, the structure issimple, the synchronism is good, the inside is mostly of a connecting rod structure, the reciprocating rod conveying system is not sensitive to dust welding slag and the like, is high in anti-jammingcapability and can be applied to most automotive OEMs.

Owner:安徽双骏智能科技有限公司

Process for predicting gloss of low gloss coating by wet color measurement

The present invention is directed to a process for process for predicting gloss of a coating resulting from a wet layer of a low gloss coating composition, such as automotive OEM or refinish paint. The process includes measuring reflectance of the layer of the coating composition applied over a test substrate and then allowing the layer to dry and / or cure into a coating. Thereafter, its gloss is measured with a gloss meter. The process is repeated with varying amounts of one or flatting agents added to the composition and the reflectance vs. gloss is plotted on a graph and by using a curve fitting equation a gloss prediction curve is obtained. By measuring the reflectance of a wet layer of a target low gloss coating composition the gloss of a coating that would result from such a layer is then predicted by using the gloss prediction curve. The process is most useful during the manufacture of coating compositions, such as automotive OEM and refinishes paints.

Owner:AXALTA COATING SYST IP CO LLC

Polyurethane coating composition, multilayer surface coatings having a matt surface produced therefrom and processes for producing the multilayer surface coatings

ActiveUS9546285B2Good settlement stabilityGood reproducibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxOrganic solvent

The invention relates to coating compositions based on organic solvents and comprising at least one hydroxyl-containing compound (A), at least one crosslinking agent (B) having groups reactive toward hydroxyl groups, and at least one silica gel based matting agent (M), wherein(i) the matting agent (M) is surface-modified with one or more waxes,and(ii) the coating composition further comprises at least one hydrophobic silica based rheological assistant (R).The present invention further provides multistage coating methods using these coating compositions, and also the use of the coating compositions as clearcoat or application of the coating method for automotive OEM finishing, for the finishing of parts for installation in or on automobiles, and for automotive refinishing.

Owner:BASF COATINGS GMBH

Pseudoplastic powder lacquer slurry free of organic solvents, method for production and the use thereof

InactiveUS20050004301A1Improve homogeneityLiquid surface applicatorsPolyurea/polyurethane coatingsOrganic solventLacquer

A pseudoplastic powder clearcoat slurry which is free from organic solvents and comprises solid and / or highly viscous, particles which are dimensionally stable under storage and application conditions and have an average size of from 0.8 to 20 μm, at least 99% of the particles having a size ≦30 μm, which is preparable by 1) emulsifying an organic solution comprising binder and crosslinking agent to give an emulsion of the oil-in-water type, 2) removing the organic solvent or solvents, and 3) wet grinding the resulting slurry; and also the use of the powder clearcoat slurry to produce clearcoats for automotive OEM finishing and automotive refinish, for furniture coating and for industrial coating, including coil coating, container coating and the coating of electrical components.

Owner:ROCKRATH ULRIKE +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com