Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about How to "Good settlement stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

InactiveCN103756653AGood settlement stabilityImprove bonding qualityDrilling compositionSludge cakeEthylenediamine

The invention discloses a solid-free anti-salt cleaning type well cementation spacer fluid and a preparation method thereof. The spacer is prepared from the following components in parts by weight: 100 parts of water, 20-350 parts of soluble weighting agent, 0.1-1.0 part of additive, 0.2-0.5 part of thickening agent, 0.5-3.0 parts of fluid loss agent, 5-10 parts of non-ionic surfactant, 1.5-2.5 parts of anionic surfactant, 0.1-0.3 part of pH adjusting agent and 0.1-0.5 part of defoaming agent, wherein the additive is sodium tripolyphosphate, ethylenediamine tetraacetic acid disodium or ethylenediamine tetraacetic acid sodium. The solid-free anti-salt cleaning type well cementation spacer fluid is free of solid phase, so that virtual thick sludge cake cannot be formed on a well wall, the function of effectively spacing a drilling liquid from cement slurry is achieved, and meanwhile the well cementation is improved. In the preparation process, the substances are added to reaction in different batches, so that the operation method is simple.

Owner:CNPC BOHAI DRILLING ENG

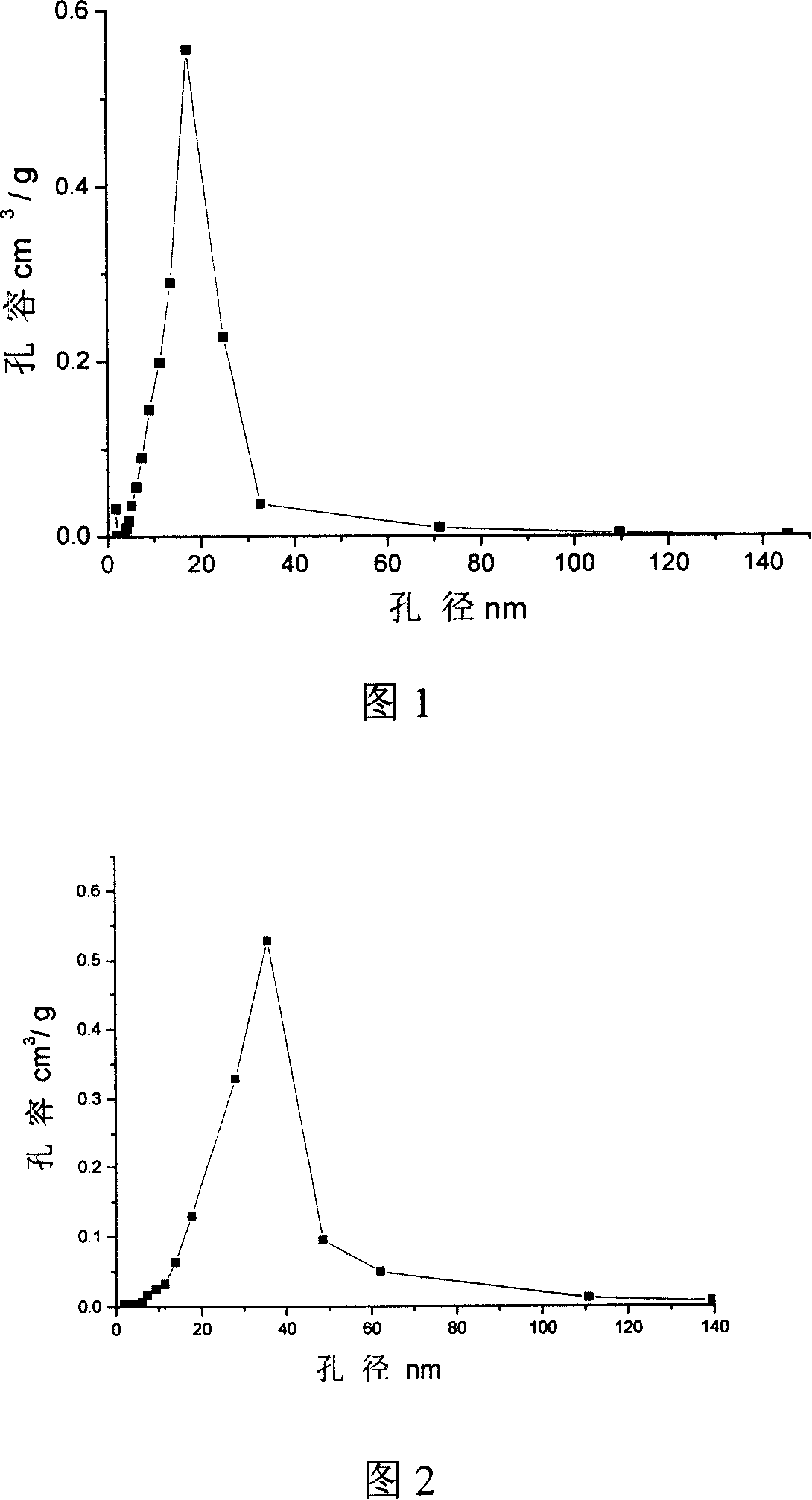

Method for preparing silicon dioxide with large pore volume and large aperture

InactiveCN101112991AImprove precipitation effectOrderly distribution of poresSilicaActive agentWater soluble

The invention relates to a preparation method of large pore volume and large pore diameter silica. With industrial water glass as silica source, water soluble polymer and surfactant as hydrophobic agent and hole forming template, by controlling reaction conditions such as temperature, hydrophobic agent, final ph value, etc., the large pore volume silica products are produced; the pore diameter is narrowly distributed, the pore volume is between 2-2.5cm3 / g and the average pore diameter is between 18-35 nm. Especially, the more optimal three-step heating regulation is more beneficial to the stability of hole forming and hole structure and that the distribution of pore diameter reaches between 25-35nm is more proper to be used as flatting agent.

Owner:BEIJING UNIV OF CHEM TECH

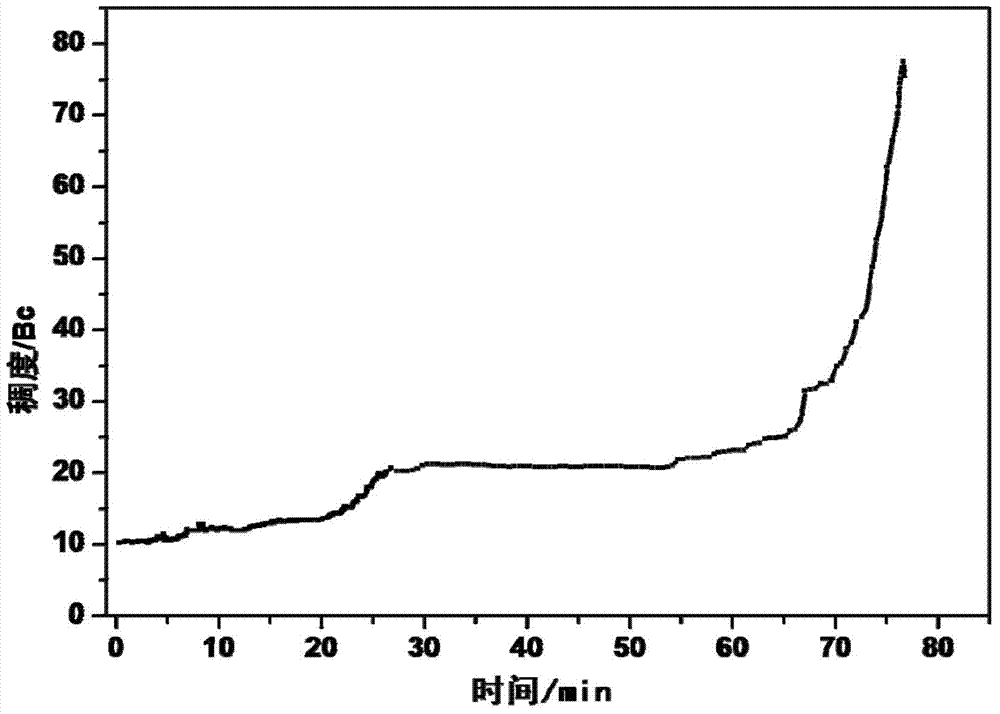

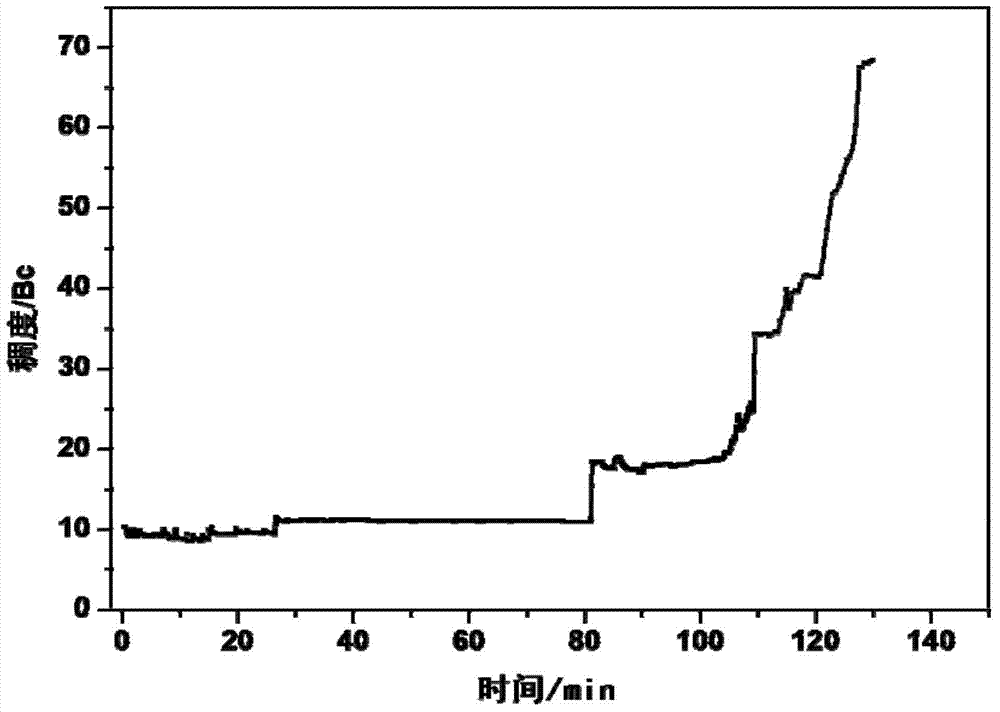

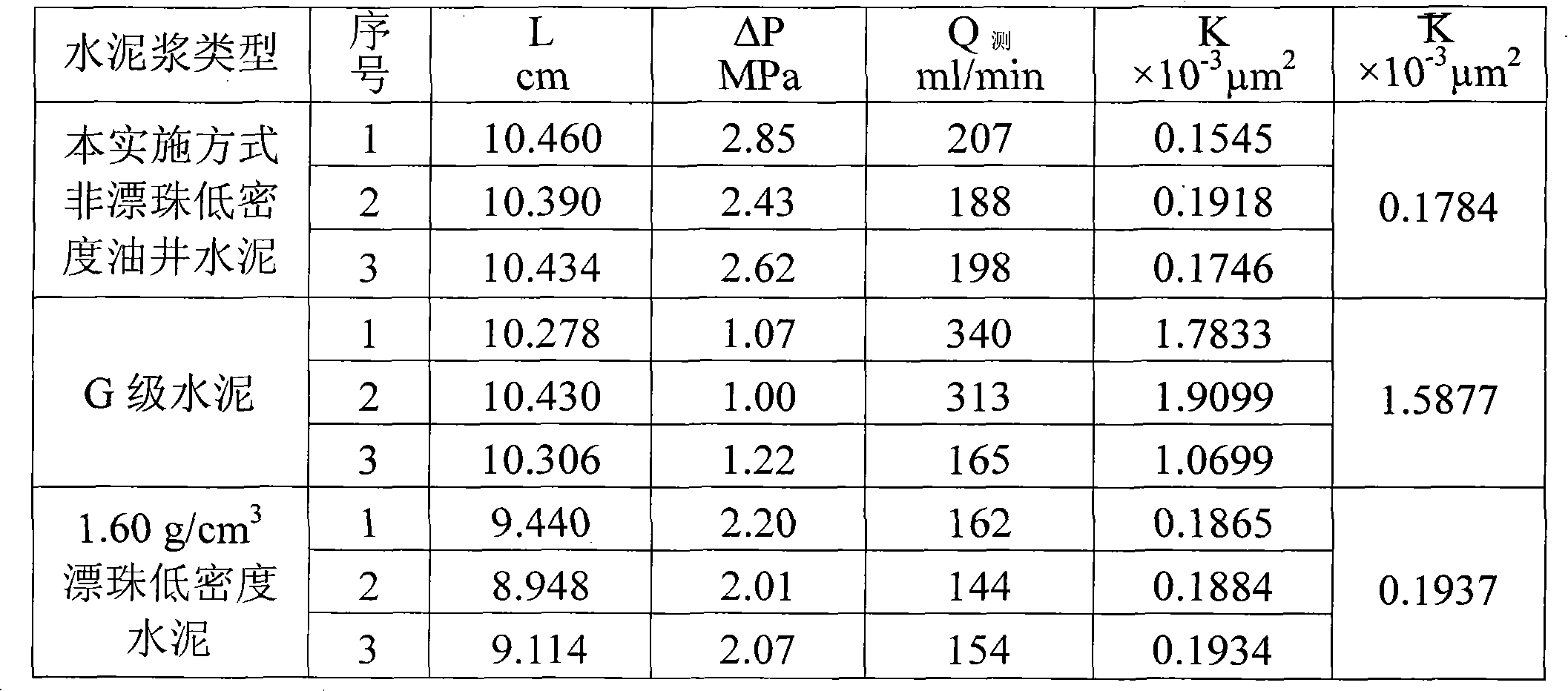

Non-floating bead low-density oil-well cement

The invention relates to low-density oil-well cement, in particular to non-floating bead low-density oil-well cement. The invention solves the problems of low early strength, poor slurry flowability and stability and short service life of the traditional non-floating bead pulverized fuel ash low-density cement. The non-floating bead low-density oil-well cement comprises oil-well cement, pulverized fuel ash, an aldosterone sulfonate condensate dispersing agent, nano silicon ash stone and an early strength agent, and the mass content of SiO2 in the nano silicon ash stone is larger than or equalto 96 percent. The cement has good stability, good compactness, high early strength, long service life, good rheological property and controllable densification time and meets the requirement of a low-pressure stratum oil field cementation well on the performance of the cement.

Owner:哈尔滨太行兴隆水泥有限公司

High-temperature-resistant high-strength low-density well-cementing cement slurry

InactiveCN104263332ALow densityImprove bearing strengthDrilling compositionPhysical chemistryWell cementing

The invention discloses high-temperature-resistant high-strength low-density well-cementing cement slurry. The high-temperature-resistant high-strength low-density well-cementing cement slurry is prepared from the following components in parts by weight: 100 parts of G-level oil well cement, 15-76 parts of a lightening admixture, 20-40 parts of micro-silicon, 2-10 parts of a fluid loss agent, 1-8 parts of a dispersing agent, 0-5 parts of a retarder, 0-1.25 parts of a coagulant, 0-5 parts of an anti-fluid-channeling agent, 0.2-0.8 part of an antifoaming agent and 50-120 parts of fresh water, wherein the G-level oil well cement is high sulfate-resistant oil well cement, the lightening admixture is high-performance hollow glass beads. According to the grain grading principle, a series of low-density well-cementing cement slurries with densities of 0.90-1.50g / m<3> are prepared. The low-density well-cementing cement slurry can be used for lowering the density of the cement slurry on the premise of guaranteeing comprehensive performances such as cement slurry strength, good high-temperature high-pressure stability and low water loss, increasing the scope of application of the low-density cement slurry in complex wells such as a deep well, an ultra-deep well and a low-pressure easy-leakage well, and improving the well-cementing quality.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Non-floating bead low-density cement mortar

InactiveCN101475347AGood settlement stabilityMeet technical needsSolid waste managementMicrofine cementParticle density

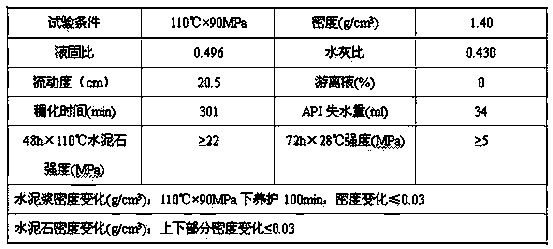

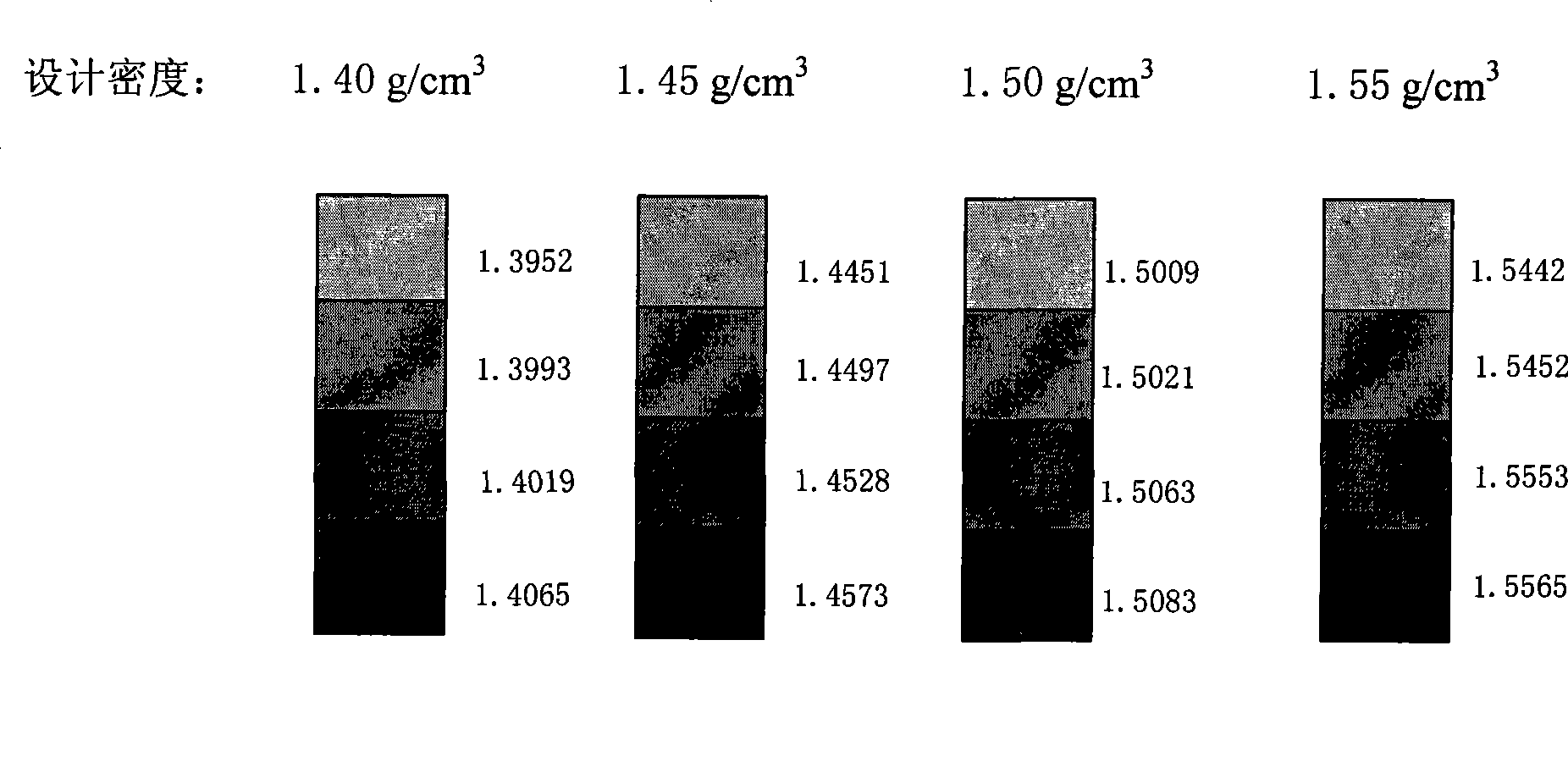

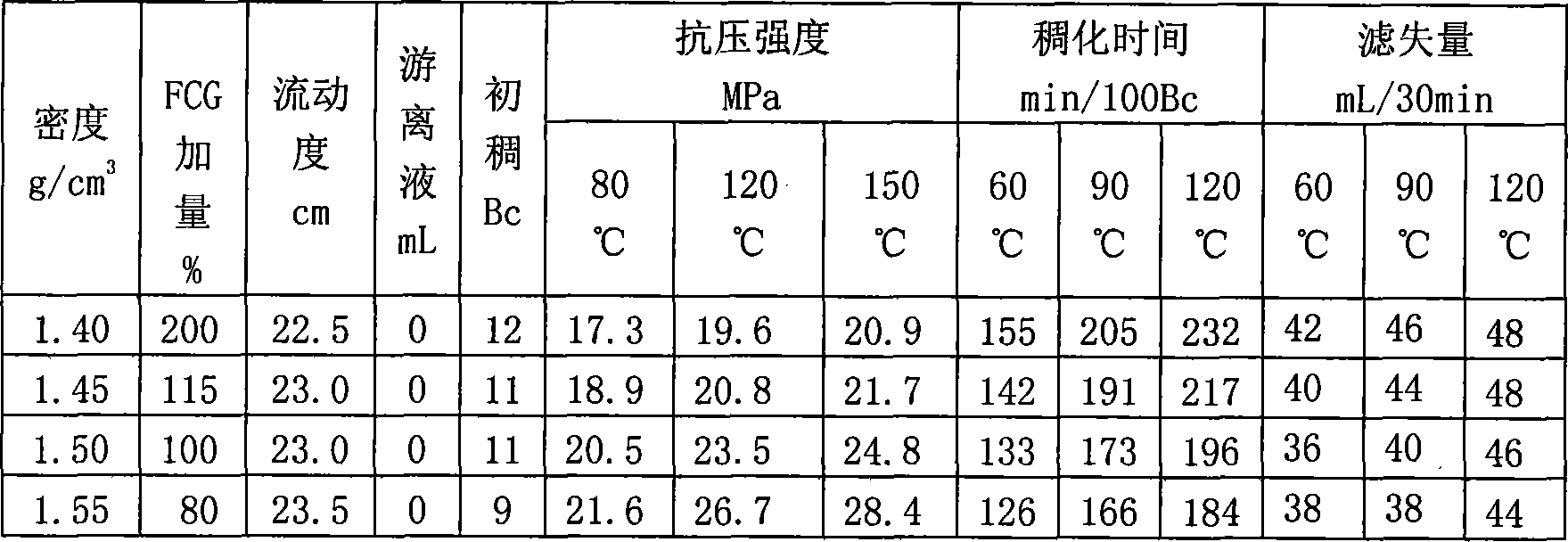

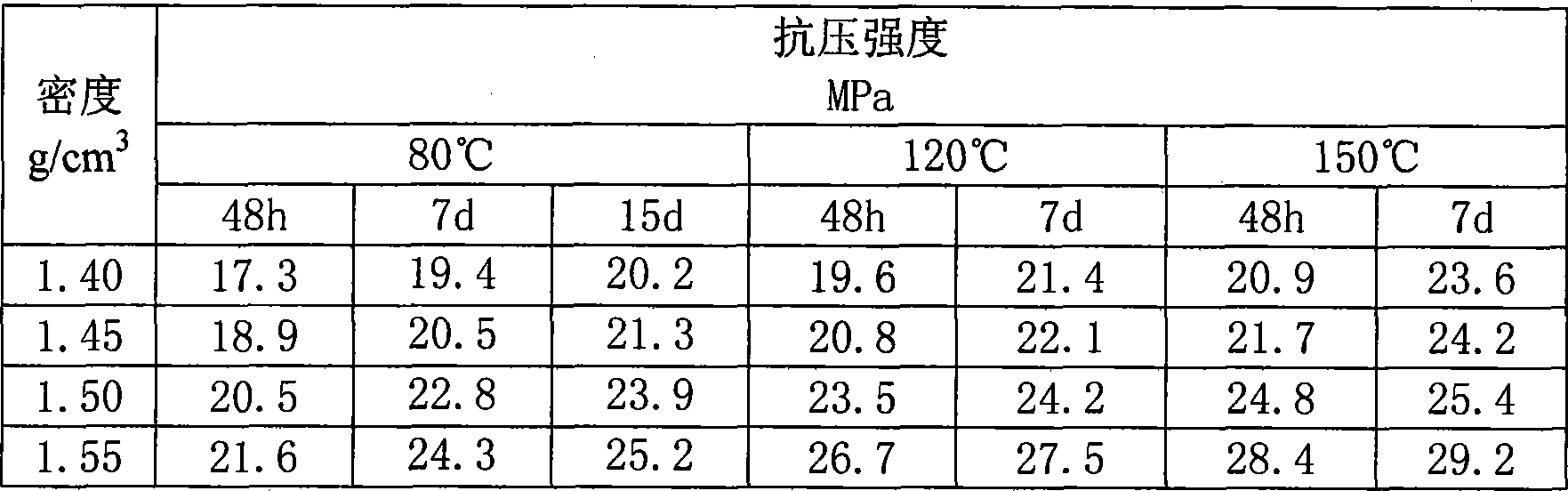

The invention relates to a non-cenosphere light weight cement slurry, which mainly solves the problem that the cement slurry cannot keep the density thereof under a high pressure condition. The non-cenosphere light weight cement slurry is characterized by comprising the following components in portion by weight: 100 portions of cement, 116 to 321 portions of water, 52 to 136 portions of fly ash, 14 to 38 portions of silica fume, 14 to 38 portions of superfine cement, and 6 to 11 portions of early strength agent, wherein the particle diameter of the silica fume (of which the SiO2 content is more than 90 percent) is more than 0 and less than 0.5 mu m, the particle density of the silica fume and the fly ash is 2.0 grams per cubic meter, and the particle diameter of the superfine cement is more than 0 and less than 2 mu m. The light weight cement slurry forms a set of incompressible light weight cement slurry system of which the density is between 1.40 and 1.55 grams per cubic meter through preferentially selecting external additives and applying a grain composition principle, wherein the flowability and the sedimentation stability of the cement slurry are good, the set cement strength is more than 15 MPa and cannot decline at a temperature of 150 DEG C so as to satisfy the technical requirements on oil field exploration and development.

Owner:DAQING OILFIELD CO LTD +1

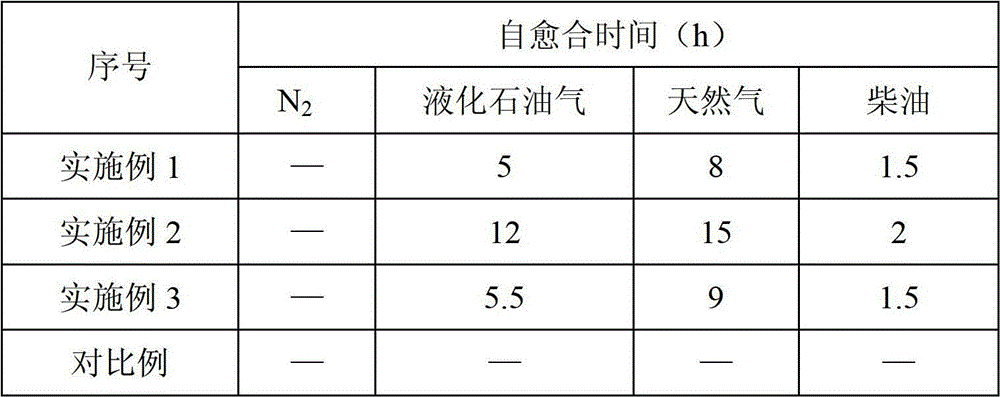

Well-cementing and self-healing cement slurry for oil-gas field

ActiveCN102746836AGood settlement stabilityThickening time adjustableDrilling compositionCement slurrySelf-healing

The invention relates to well-cementing and self-healing cement slurry for an oil-gas field, which is suitable for the field of oil well cementation. The well-cementing and self-healing cement slurry comprises the following additives percentage by weight: 2-4% of fluid loss agent, 5-40% of self-healing component, 0.2-1.0% of stabilizing agent, 0.5-2.0% of dispersing agent, 0.3-1.0% of de-foaming agent, and 0.03-0.5% of retarding agent by taking the weight of cement as benchmark. A preparation method of the well-cementing and self-healing cement slurry is as follows: controlling the water cement ratio to be 0.44, uniformly mixing the additives at a low shearing speed, weighing a certain amount of cement, adding into slurry preparation liquid, and mixing with API (American petroleum institute) standards to obtain the well-cementing and self-healing cement slurry. The well-cementing and self-healing cement slurry has the characteristics of low water loss, adjustable thickening time, gas channeling prevention and excellent impervious performance and the like, has the functions of crack prevention and self healing, and remarkably improves the mechanical property of the cement.

Owner:古莱特科技股份有限公司

High temperature resistant silicate cement paste and preparation method thereof

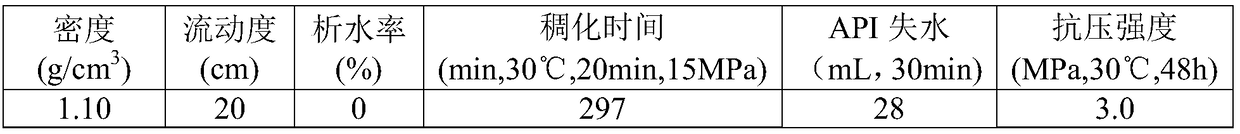

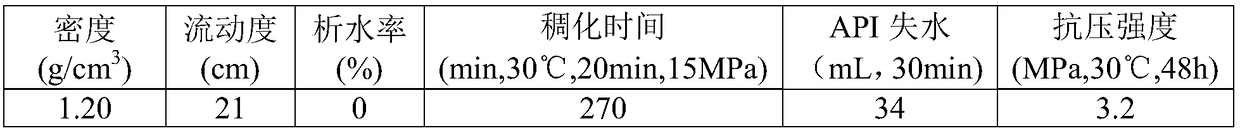

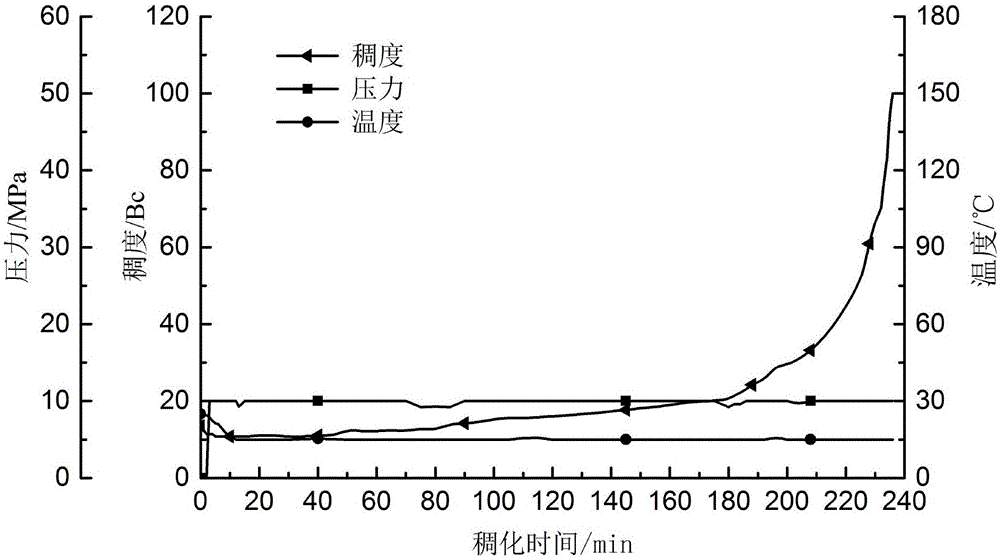

ActiveCN108298902AGood settlement stabilityRapid development of strengthDrilling compositionWell cementingFresh water

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

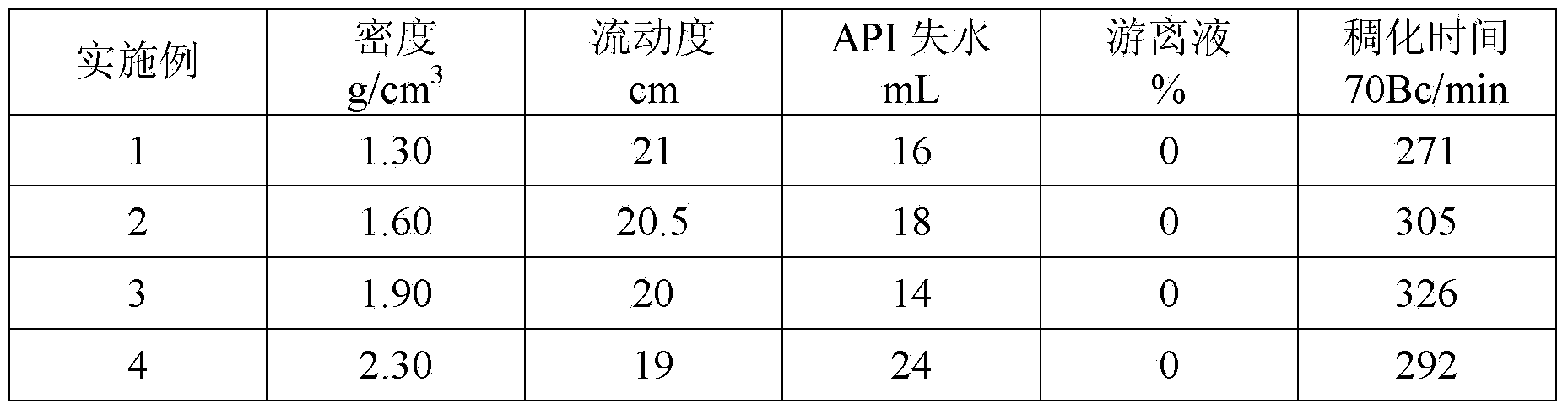

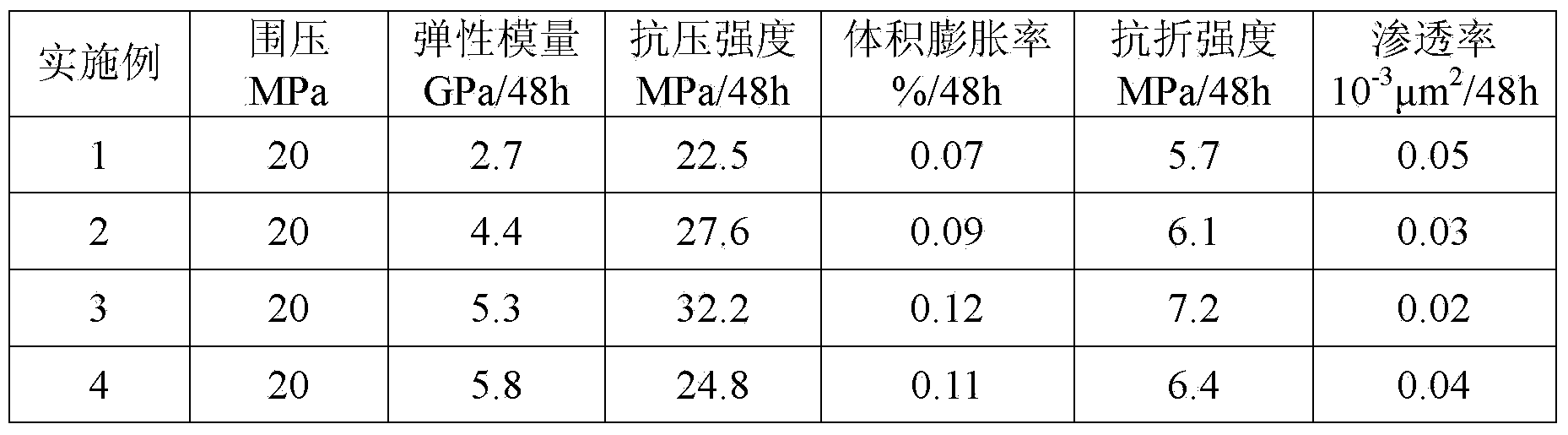

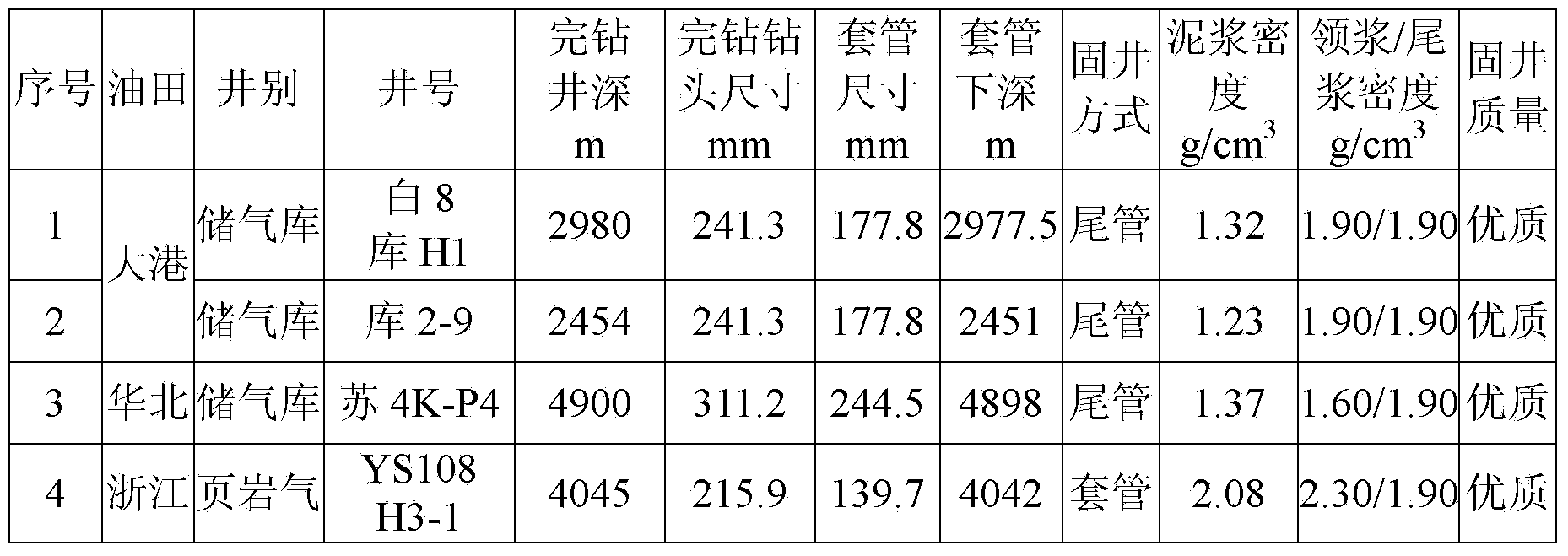

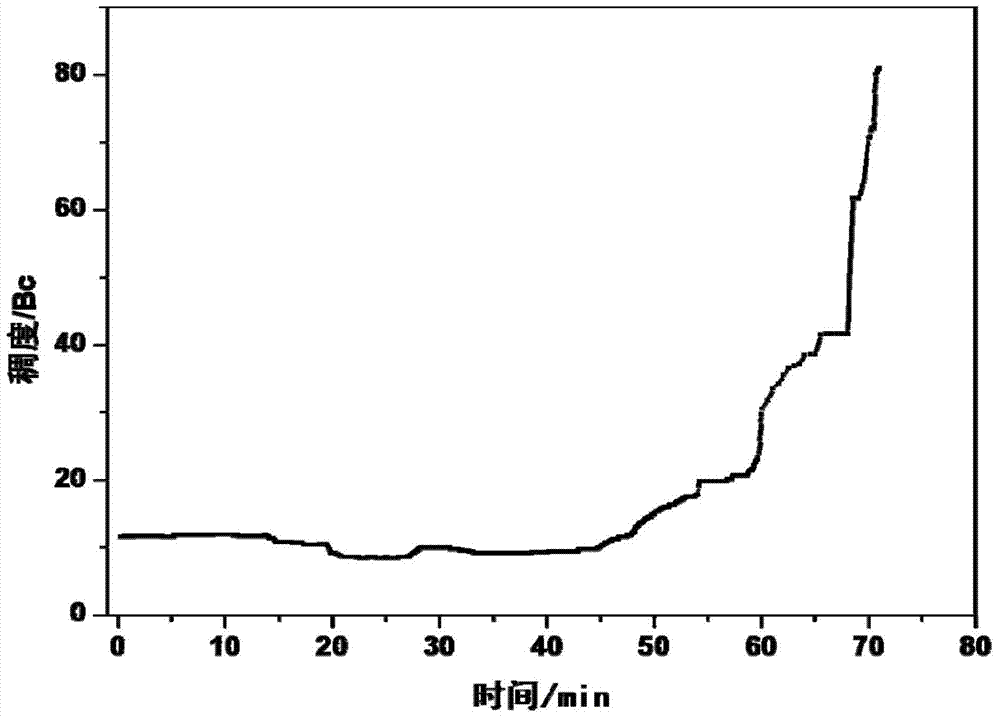

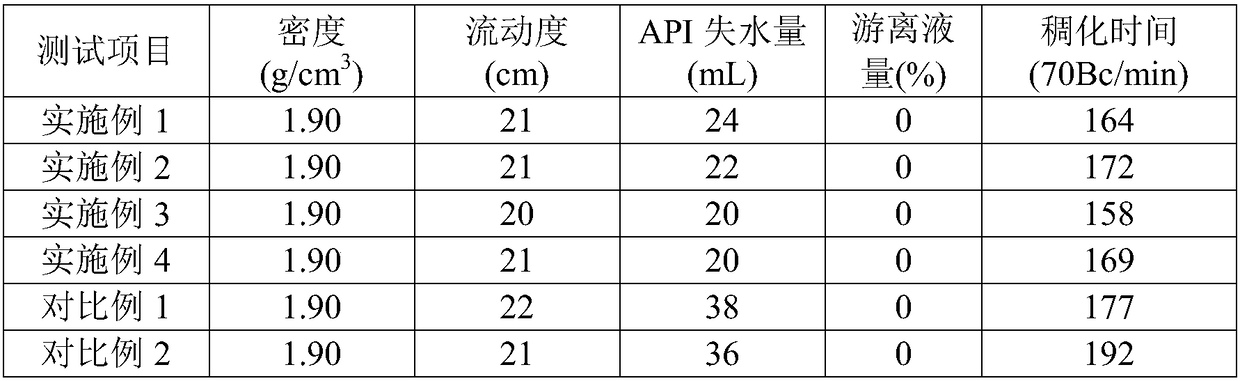

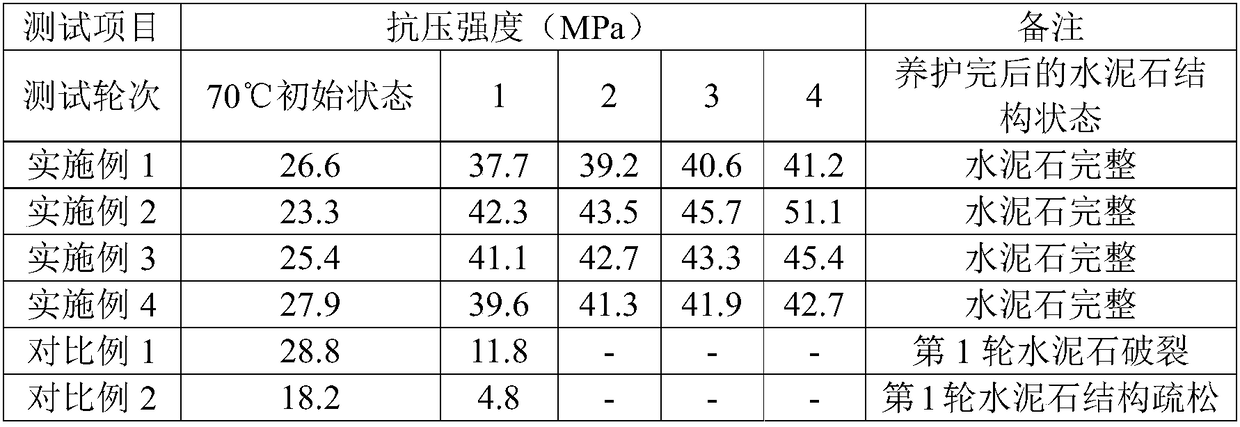

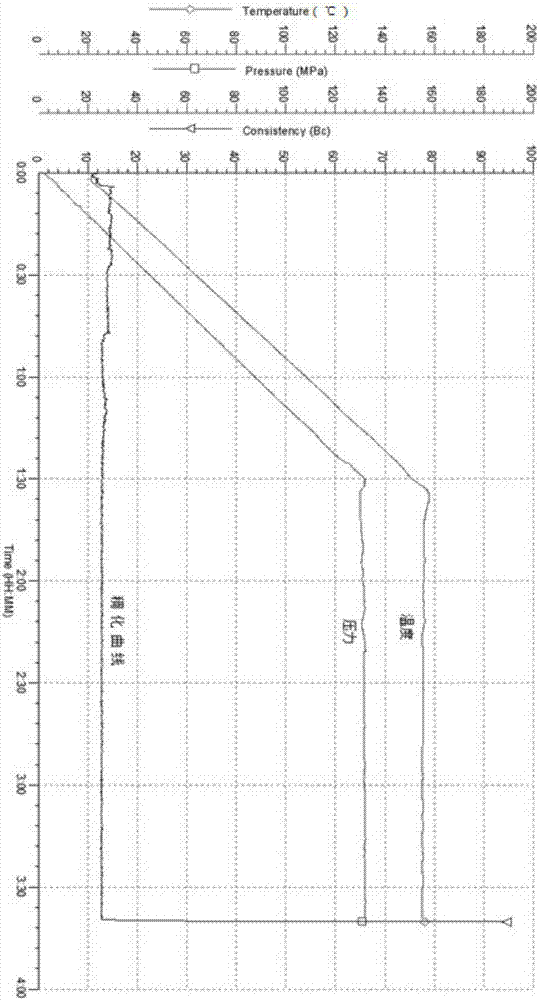

High-density cement slurry suitable for shale gas cementing and preparation method of high-density cement slurry

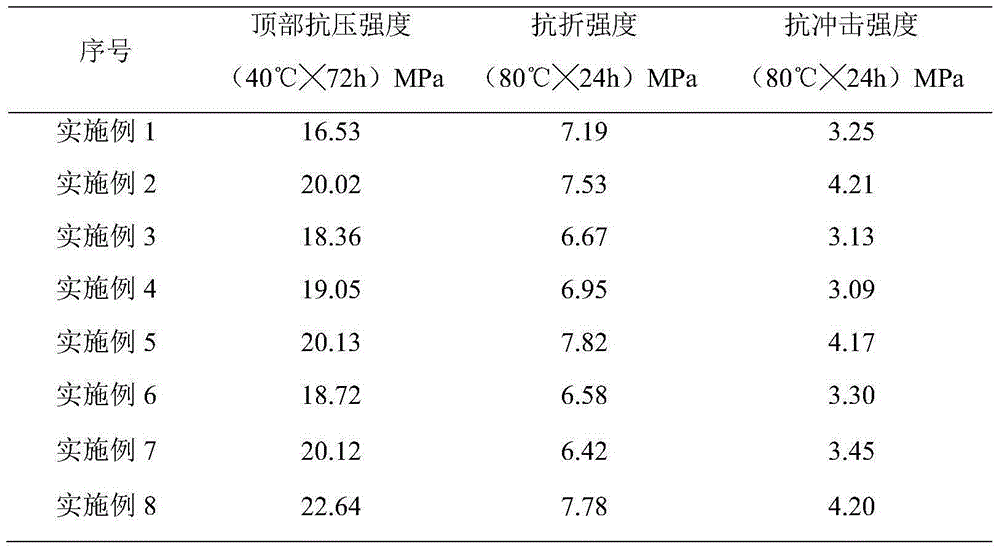

The invention discloses high-density cement slurry suitable for shale gas cementing. The high-density cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 44-57 parts of fresh water, 15-120 parts of a weighting agent, 0-30 parts of a weighting stabilizer, 30-40 parts of a high-temperature strength stabilizer, 3-5 parts of an elasto-plastic agent, 4-7 parts of a fluid loss agent, 1-2.5 parts of a retarder and 0.5-2.5 parts of a dispersant. The preparation method comprises the following steps of weighing the cement, the fresh water, the weighting agent, the weighting stabilizer, the high-temperature strength stabilizer, filler, the elasto-plastic agent, the fluid loss agent, the retarder, the dispersant and a defoaming agent according to the ratio; mixing the components, and stirring to obtain the high-density cement slurry suitable for shale gas cementing. The high-density cement slurry is easily pulped at normal temperature and is good in high-temperature sedimentation stability, capable of improving the breaking strength, shock resistance and toughness of hardened cement slurry, relatively wide in density adjustable range and capable of meeting various shale gas cementing requirements.

Owner:成都欧美克石油科技股份有限公司

Insulating liquid for injecting cement in oil well

The invention relates to an isolating liquid used in oil well cementing, comprising fresh water, suspension agent, thinner agent and aggravation agent. The invention is characterized in that: the suspension agent is made from hydroxy ethyl cellulose, carboxymethyl cellulose, xanthan and na-bentonite; the thinner agent is made from sodium lignosulphonate, sodium dodecyl benzene sulfonate and alkyl phenol polyoxyethylene ether; the aggravation agent is made from barite, fly ash, limestone and slag. When preparing the isolating liquid, the suspension agent is dissolved in water for one hour, thereafter thinner agent is added. Before cementing, the aggravation agent is added into the solution and mixed evenly. The isolating liquid is characterized by low viscosity, good rheological performance, slow critical velocity and being easy to form turbulent flow, so as to effectively substitute and wash mud, prevent forming mixed slurry of cement slurry and mud. Meanwhile, the invention can be compatible with ordinary cement slurry and mud system, thus diluting and improving cement slurry rheological performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cement paste toughening agent and application of cement paste toughening agent in preparation of cementing flexible cement paste

ActiveCN103305197ADoes not change inherent performanceGood settlement stabilityDrilling compositionPolymer sciencePortland cement

The invention relates to a cement paste toughening agent and application of the cement paste toughening agent in preparation of a cementing flexible cement paste. The toughening agent is prepared by modification of rubber powder; the modification of rubber powder includes the steps of cleaning, activating, etching and grafting; the cementing flexible cement paste prepared by the toughening agent is prepared from the following components in parts by weight: 100 parts of portland cement, 5-50 parts of modified rubber powder, 10-40 parts of a toughing agent, 15-80 parts of a density regulator, 35-65 parts of water, 0.5-2 parts of a dispersing agent, 0.5-3 parts of a fluid loss agent, 1.5-4 parts of a retarder and 0.1-2 parts of a defoamer. The inherent performance of a substrate is not changed by plasma treatment on the rubber powder; no pollution is generated; the cement paste toughening agent is simple in process, convenient to operate, stable in hydrophilism through the grafted rubber powder, small in effect from timeliness, and low in handling expense; the flexible cement paste prepared from the modified rubber is good in sedimentation stability; the mechanical property is obviously improved; the cement construction requirements of the scene can be completely met.

Owner:SOUTHWEST PETROLEUM UNIV

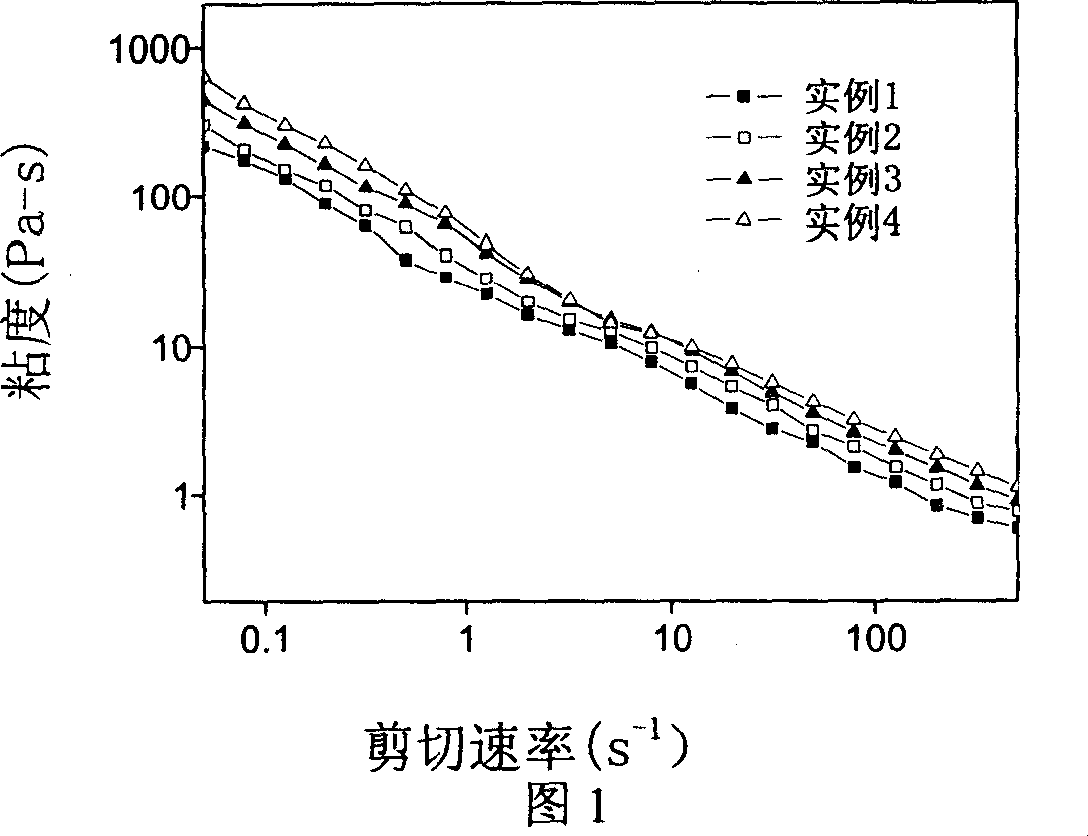

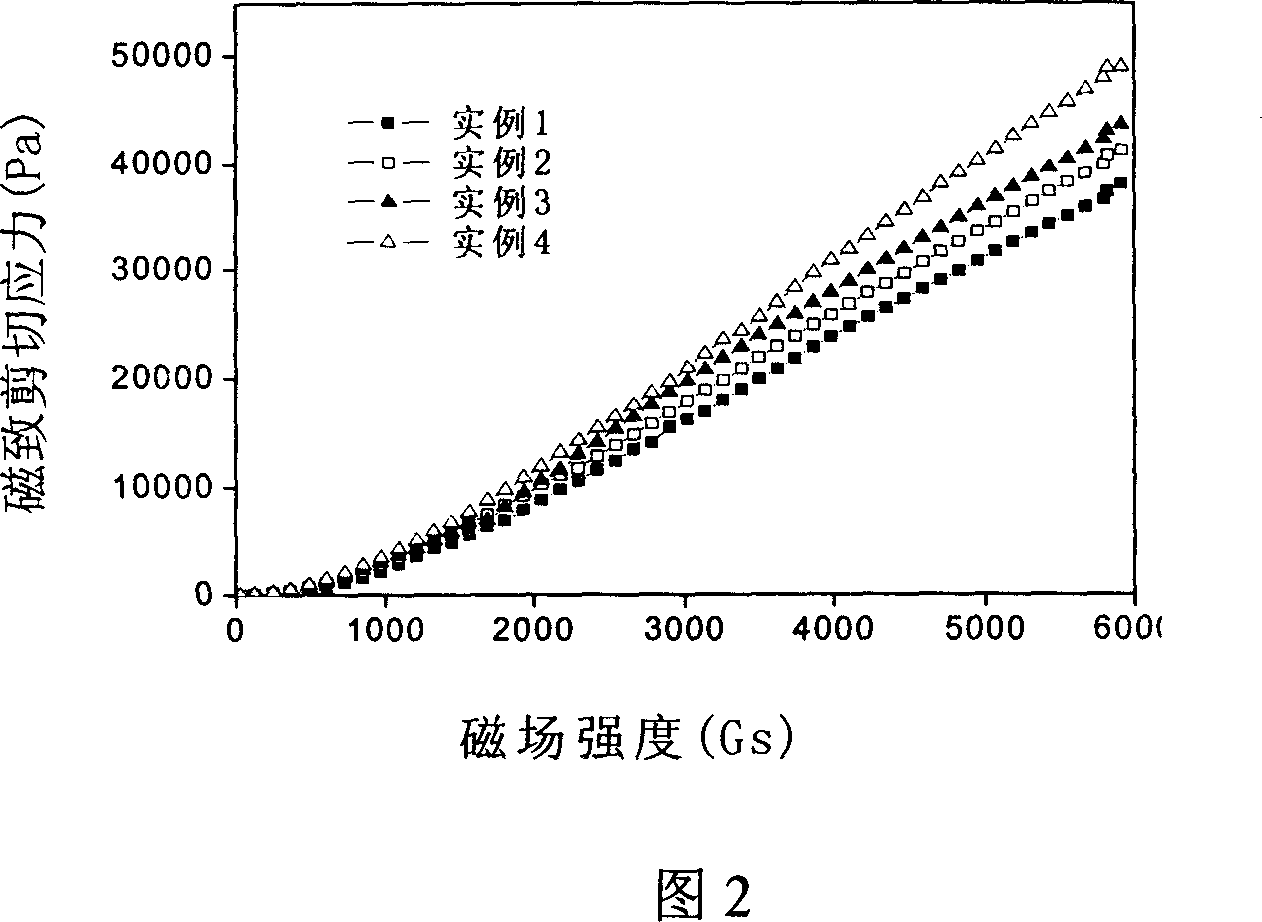

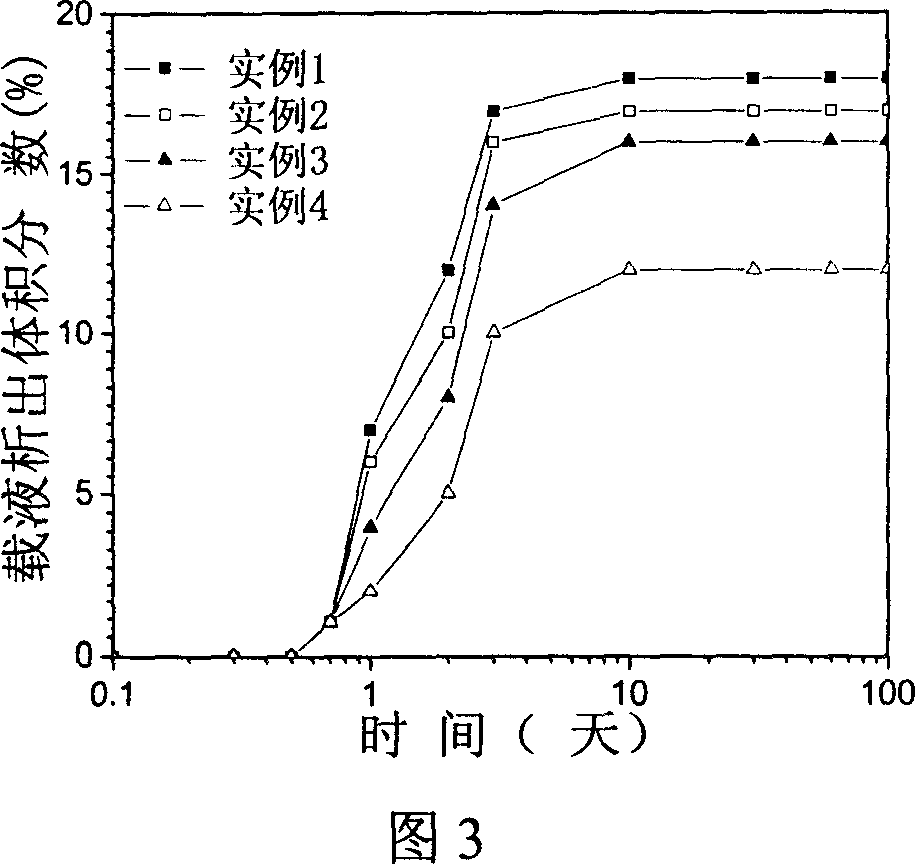

Stable silicone oil based magnetic rheologic liquid, and preparation method

InactiveCN1959872AGood settlement stabilityImprove antioxidant capacityMagnetic liquidsInductances/transformers/magnets manufactureCarrier fluidSilicone oil

The magnetic rheologic liquid is composed of components: chelation type surfactant / carbonyl iron hull type magnetic compound particles, and silicone oil based compound assorted carrier liquid prepared from silicone oil and additive. The additive includes thixotropic agent, antioxidant, antiwear additive, and surfactant. The method for preparing the liquid includes steps: mixing round surfactant being added to silicone oil; next, adding antioxidant, thixotropic agent, and antiwear agent, then mixing them to obtain silicone oil based compound assorted carrier liquid; adding magnetic compound particles to the carrier liquid, and after procedures of mixing, ballmilling, and separating out friction balls, then sealing the liquid inside plastic bottle; stable silicone oil based magnetic rheologic liquid is obtained after series of procedure: placing the plastic bottle in magnetic field, taking out the liquid, and mixing etc. The liquid is applicable to damper, variator for cars etc.

Owner:WUHAN UNIV OF TECH +1

High temperature resistant cement mortar

The invention relates to high-temperature-resistance cement slurry, which relates to the cement slurry used by oil drilling and cementing technical field, solving the problem of bad high-temperature-resistance performance of prior cement slurry. Components and proportions of the high-temperature-resistance cement slurry of the invention are as follows by weight portions: 100 portion of cement, 55-65 portion of water, 6-15 portion of filtrate loss reducer, 4.8-7.2 portion of retarder, 20-40 portion of drag reduction agent, 3-5 portion of filler and 1-3 portion of stabilizer; wherein, the filtrate loss reducer is high molecular polymer; the retarder is lignin inorganic salt; the drag reduction agent is sulphonated acetone-formaldehyde polymer; the filler is silicon dioxide with concentration more than 95 percent; the stabilizer is polyester fiber. The high-temperature-resistance cement slurry has the advantages of strong high-temperature resistance, low filtrate loss water, good slurry stability, strong anti-hydrosphere channeling ability and strong compressive strength of cement paste which can improve construction security for cementing high-deep wells, reduce damage of filtrate of the cement slurry to formation, protect oil and gas formation and can be popularized and applied for wells in complex blocks.

Owner:DAQING PETROLEUM ADMINISTRATION

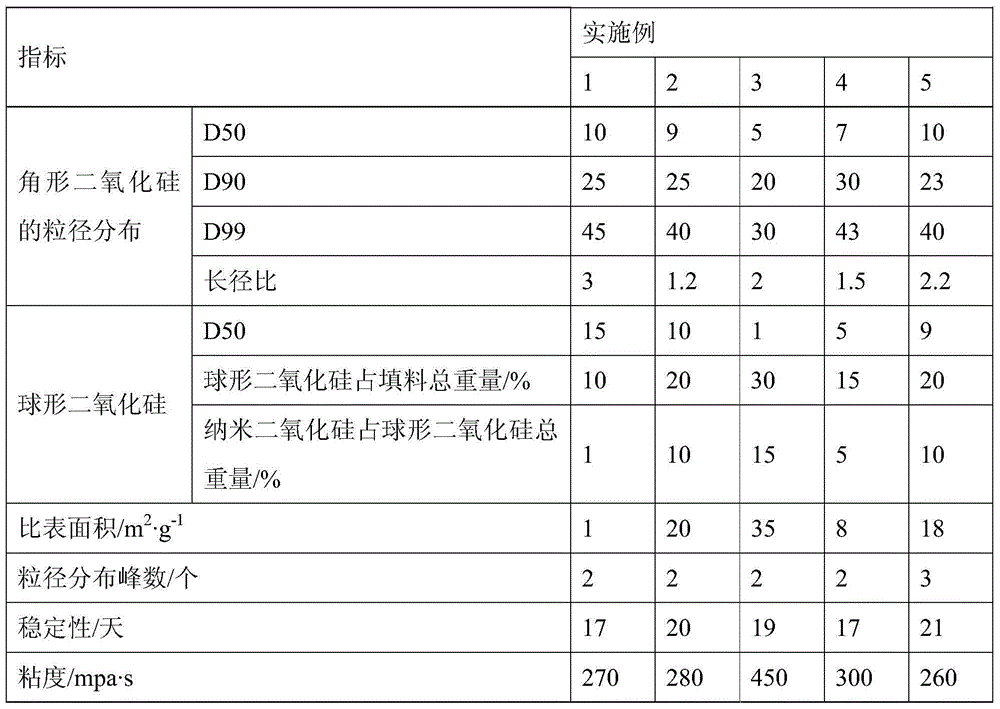

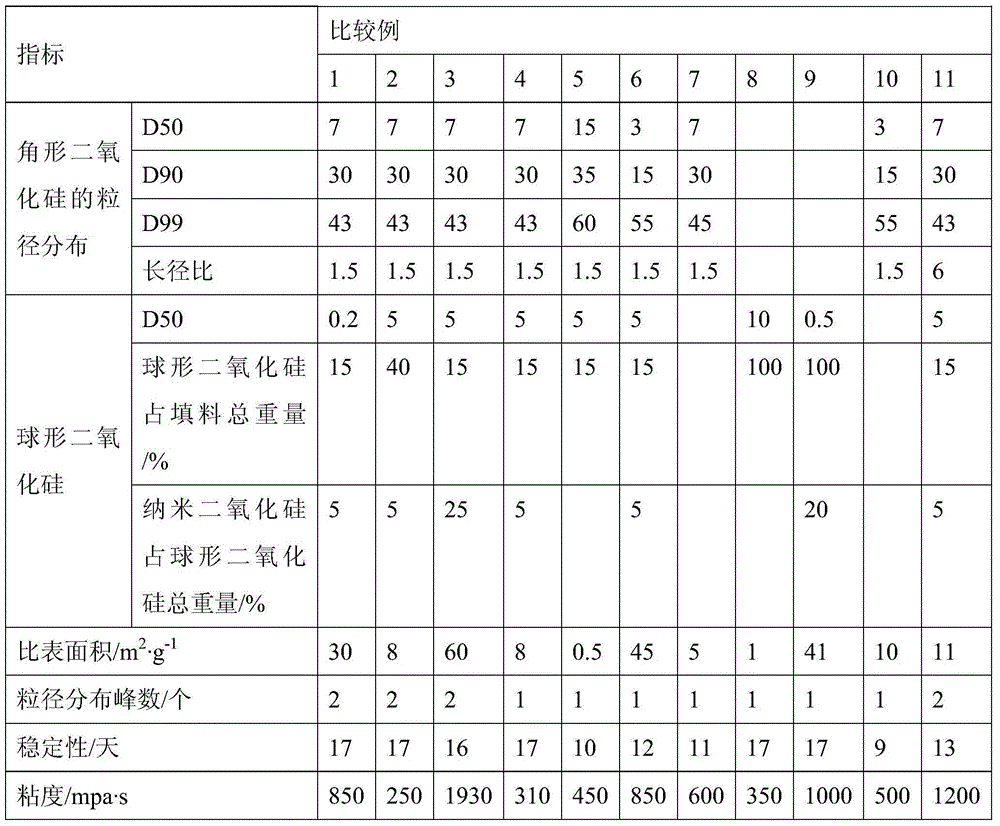

Filler composition and application thereof

ActiveCN104558688AImprove liquidityImprove mobilitySynthetic resin layered productsCircuit susbtrate materialsCopper foilParticle-size distribution

The invention relates to a filler composition and application thereof. The filler composition comprises a spherical siliceous micro powder filler and an angular siliceous micro powder filler, and can be used for preparing a copper clad laminate substrate and bonding sheet resin composition. The filler composition is formed by compounding the angular siliceous micro powder filler and the spherical siliceous micro powder filler, which have specific particle size distribution, the flowability of the composition and the sedimentary stability in a solution or resin system can be improved, the thickness uniformity and the component uniformity of the copper clad laminate substrate are improved, and not only the sagging and gummosis problems are solved, but also the production cost is reduced greatly.

Owner:GUANGDONG SHENGYI SCI TECH

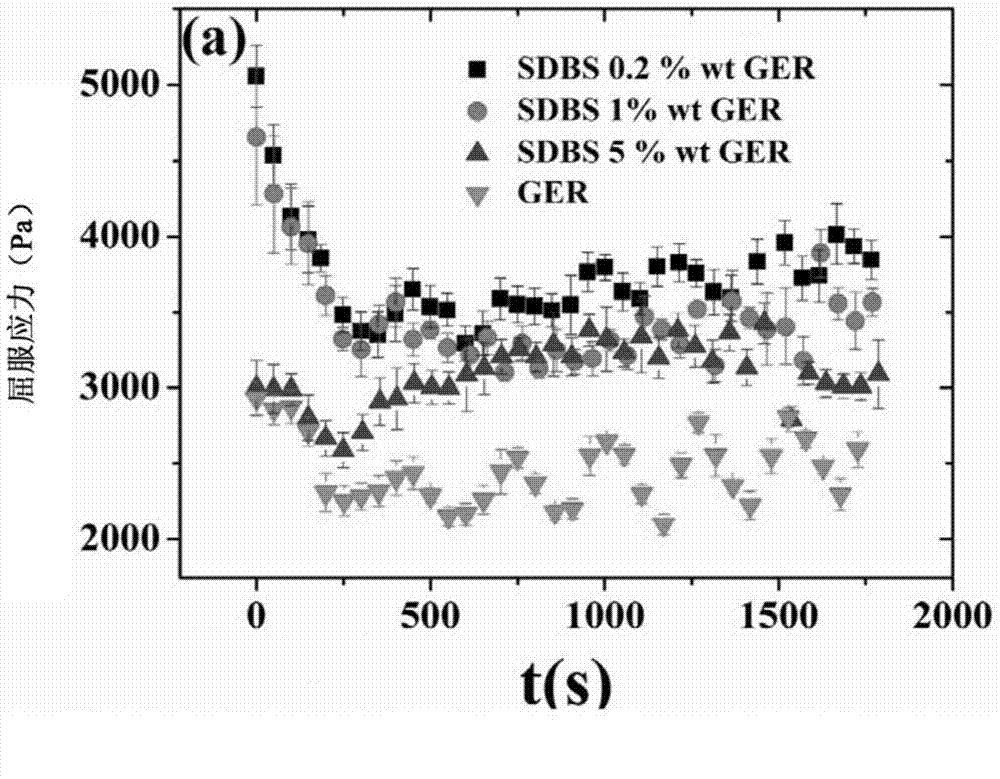

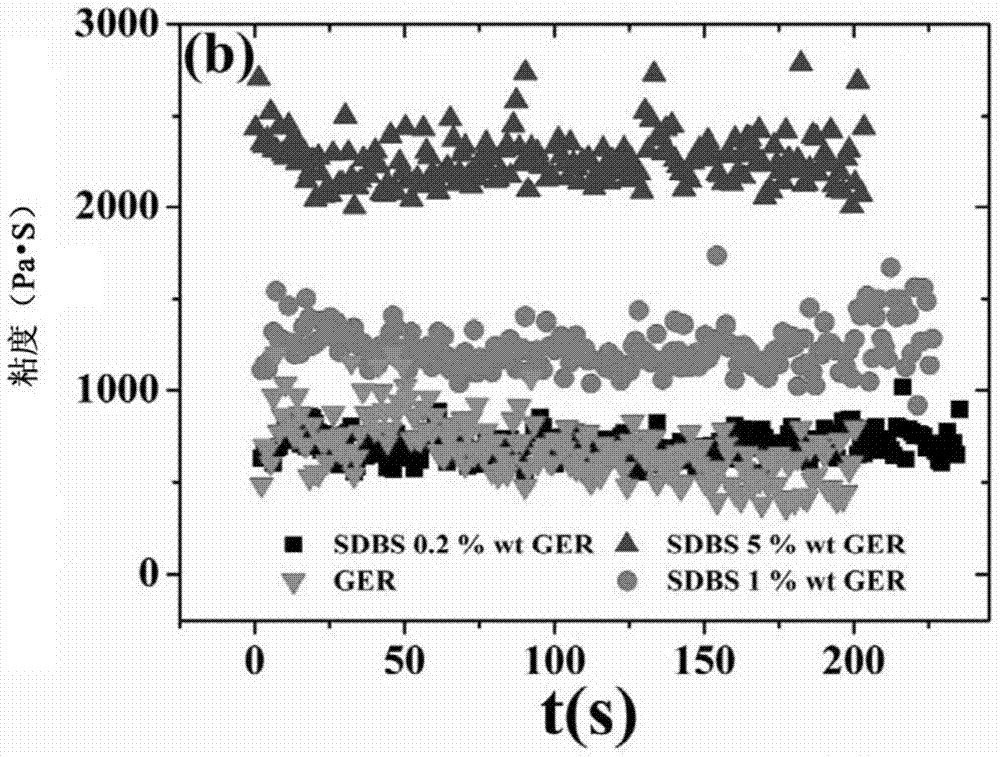

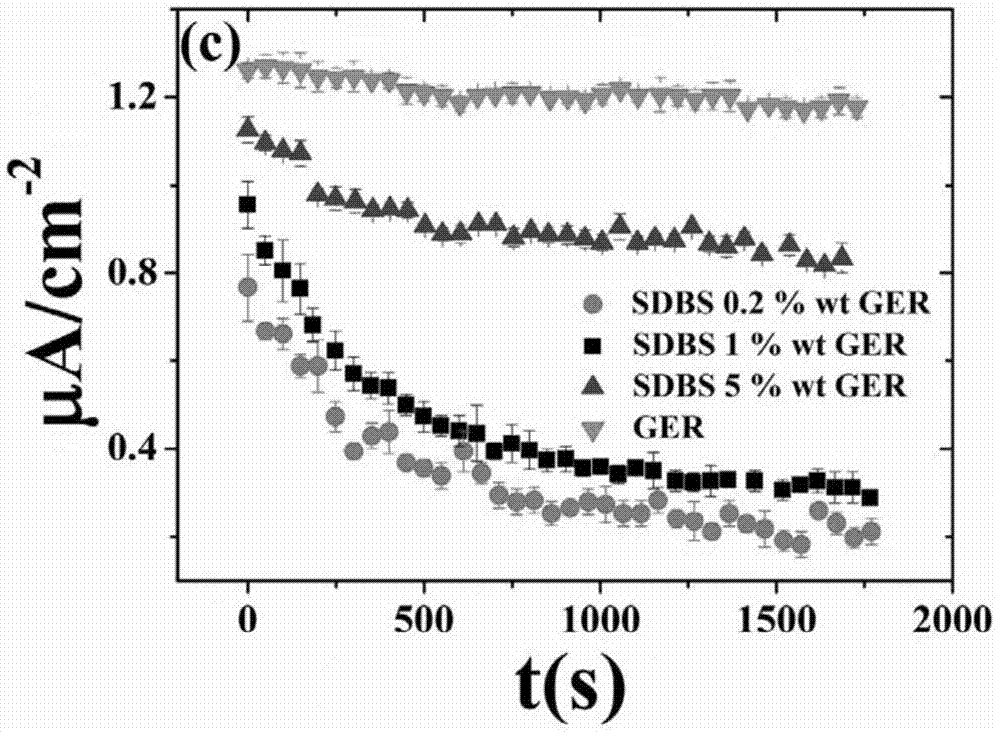

Improved giant electrorheological fluid and manufacturing method thereof

InactiveCN104774675AReduce sedimentation rateImproved redispersion propertiesAdditivesPower flowMechanical property

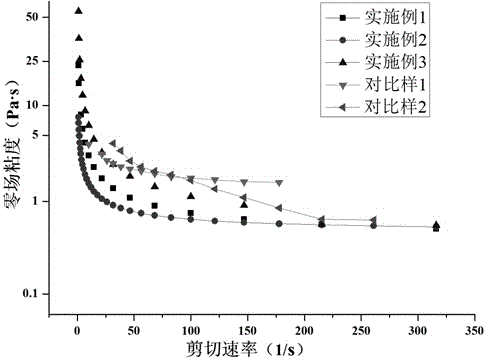

The invention relates to an improved giant electrorheological (GER) fluid and a manufacturing method thereof. The GER fluid comprises metal salt nano composite coated by urea, polar molecule additive and high-wettability insulating liquid, wherein the metal salt nano composite suspends in the high-wettability insulating liquid. By adding the polar molecule additive, the yield stress of the GER fluid under the electric field is increased by more than 50%, but the current density is reduced to 1 / 4 of that of the original GER fluid. The reversible response time maintains the same, and the sedimentary stability is obviously improved. The zero field viscosity of the improved GER fluid maintains the same as that of the GER fluid without the additive. The electrical and mechanical properties of the improved GER fluid are improved, and the improved GER fluid can be applied to vehicle clutches, hydraulic brakes and vehicle dampers.

Owner:THE HONG KONG UNIV OF SCI & TECH

Alkaline developer for radiation sensitive compositions

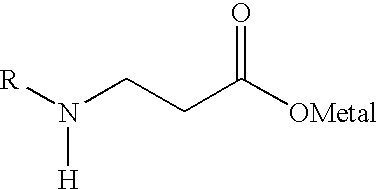

InactiveUS7186498B2Avoid excessive depositionGood settlement stabilityOrganic detergent compounding agentsX-ray/infra-red processesInorganic saltsNon ionic

The invention relates to an alkaline developer for irradiated radiation sensitive compositions, which developer is based on water and at least one inorganic salt having an alkaline reaction, wherein the developer has a pH of at least 11 and comprises at least three structurally different surfactants of formulae (A), (B) and (C), characterised in that the surfactant of formula (A) has one anionic group, the surfactant of formula (B) has two anionic groups, the surfactant of formula (C) is non-ionic and has at least one non-ionic hydrophilic group, and the concentration of each of the surfactants of formulae (A), (B) and (C) in the developer is at least 0.05 weight-% based on the total weight of the developer. The developer leads to less depositions and has a superior stability when used.

Owner:AGFA NV

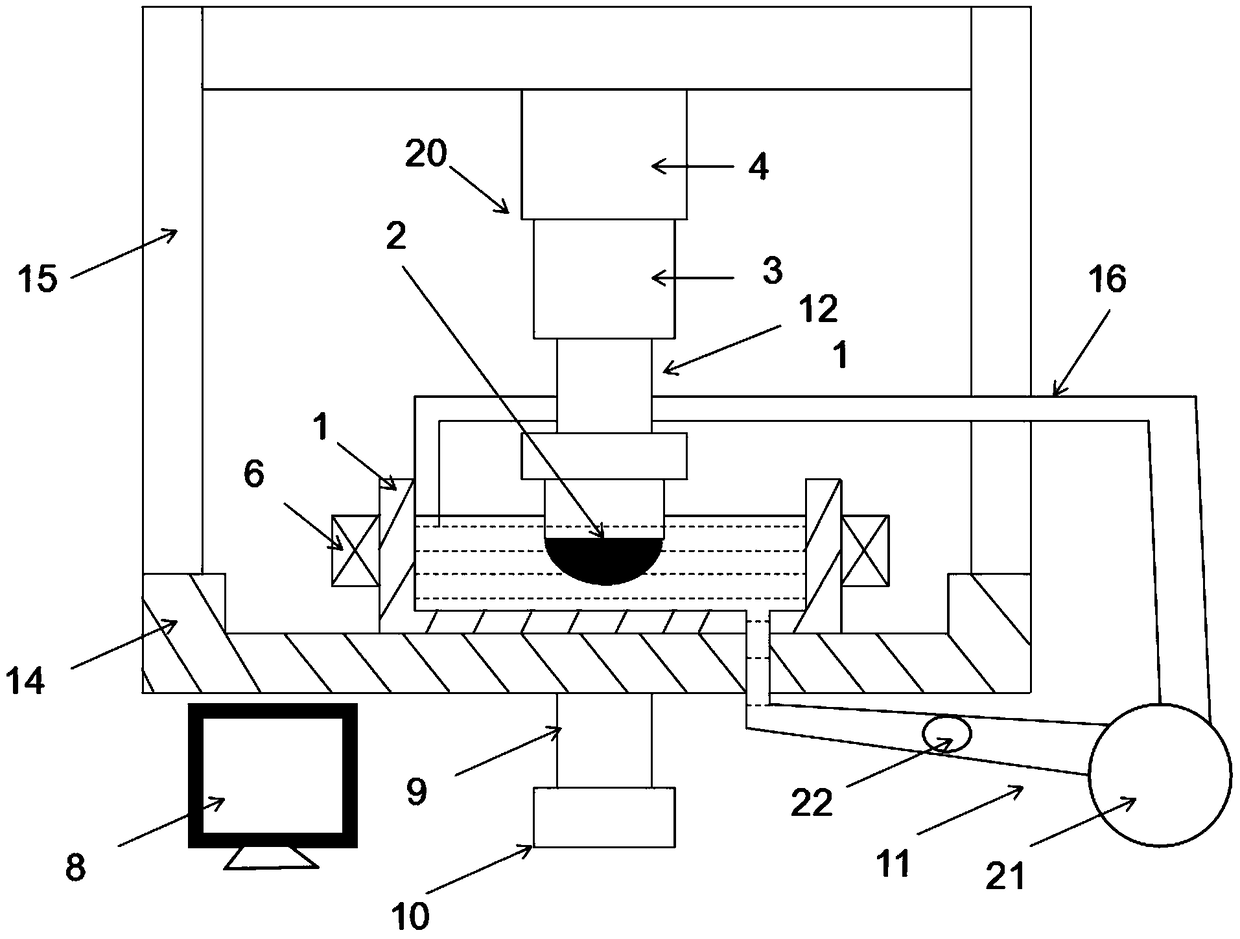

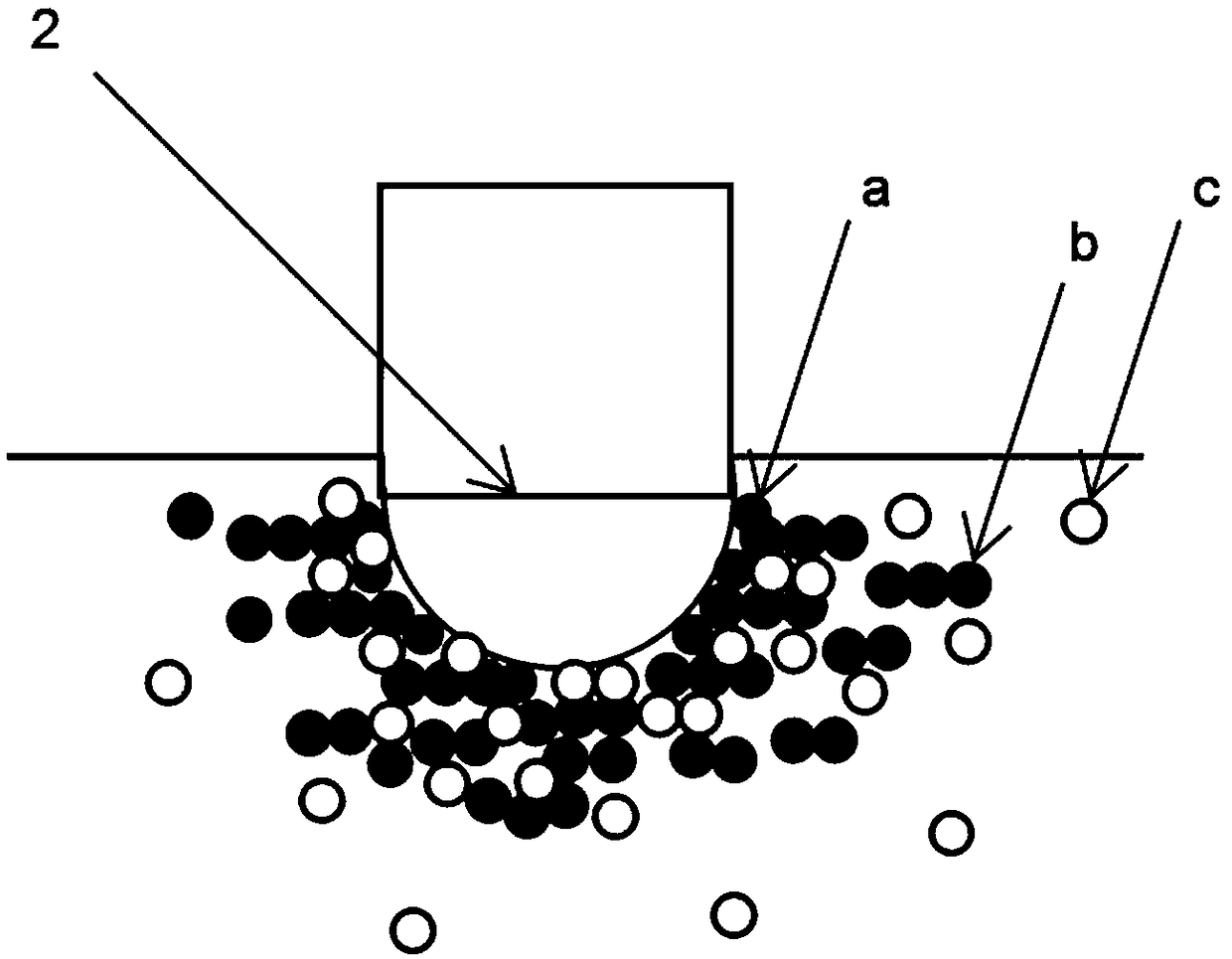

Non-Newtonian fluid thickening polishing method and polishing system based on magnetic field assist

ActiveCN109079590AUniform distribution of magnetic field strengthImprove processing efficiencyEngineeringUltra precision

The invention discloses a non-Newtonian fluid thickening polishing method based on a magnetic field assist. The method comprises the following steps: S1: adding non-Newtonian fluid polishing liquid with magnetorheological properties into a polishing liquid tank, and immersing a polishing workpiece in the non-Newtonian fluid polishing liquid through a holding device with a driving system, and turning on a magnetic field generating device; S2: under the action of the driving system, driving the polishing workpiece to rotate by the holding device, enabling the polishing workpiece and the non-Newtonian fluid polishing liquid to move relative to each other, and cutting the surface of the polished workpiece by abrasive grains in the non-Newtonian fluid polishing liquid, thereby completing the polishing process. The invention further correspondingly provides a non-Newtonian fluid thickening polishing system based on the magnetic field assist. The non-Newtonian fluid thickening polishing method provided by the invention is low in consumables cost, high in polishing efficiency and good in polishing effect, and can realize ultra-precision polishing of the polished workpiece.

Owner:HUNAN UNIV

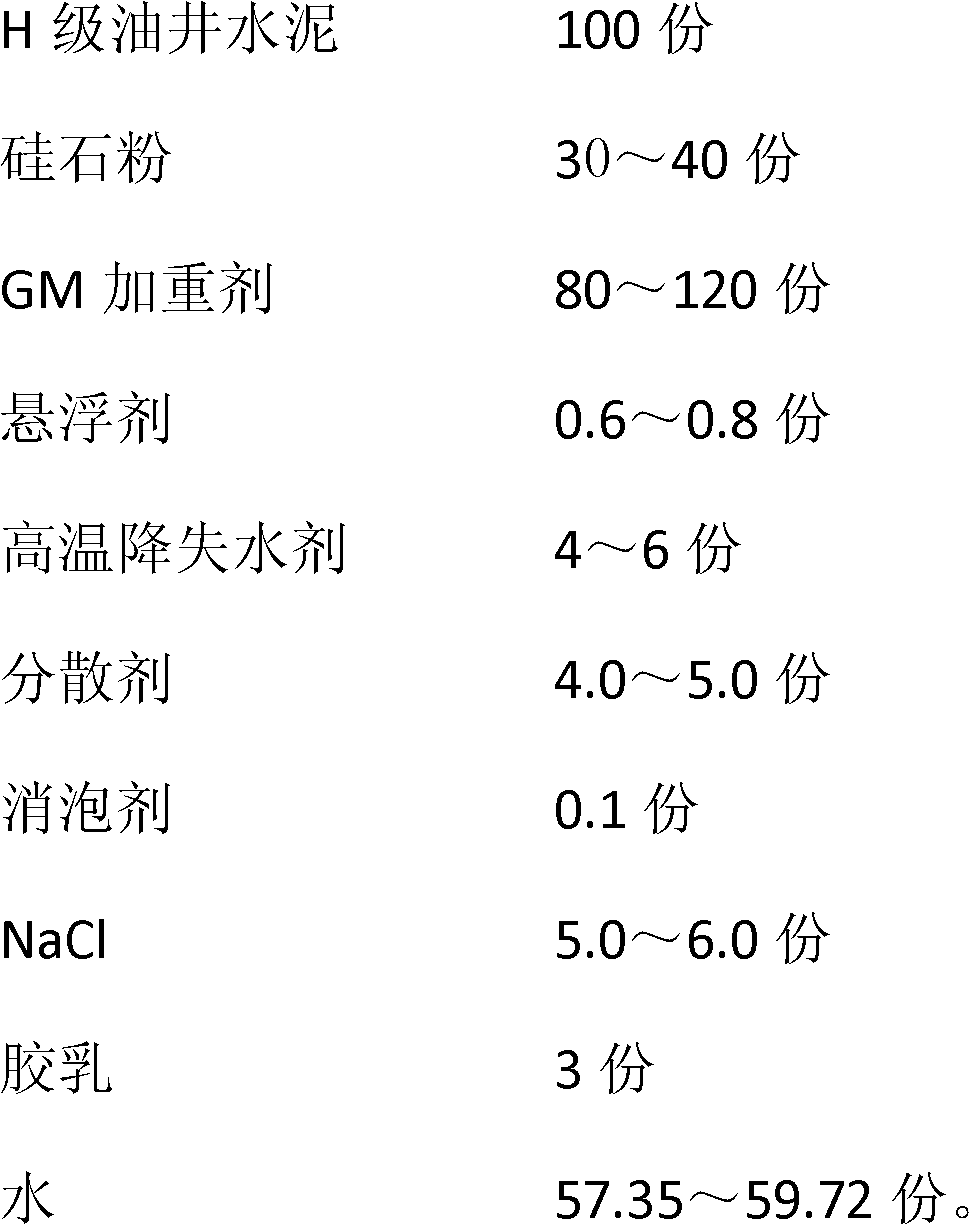

Cementing slurry with high temperature, high density and high toughness

ActiveCN102516965AHigh densityGood settlement stabilityDrilling compositionHigh densitySuspending Agents

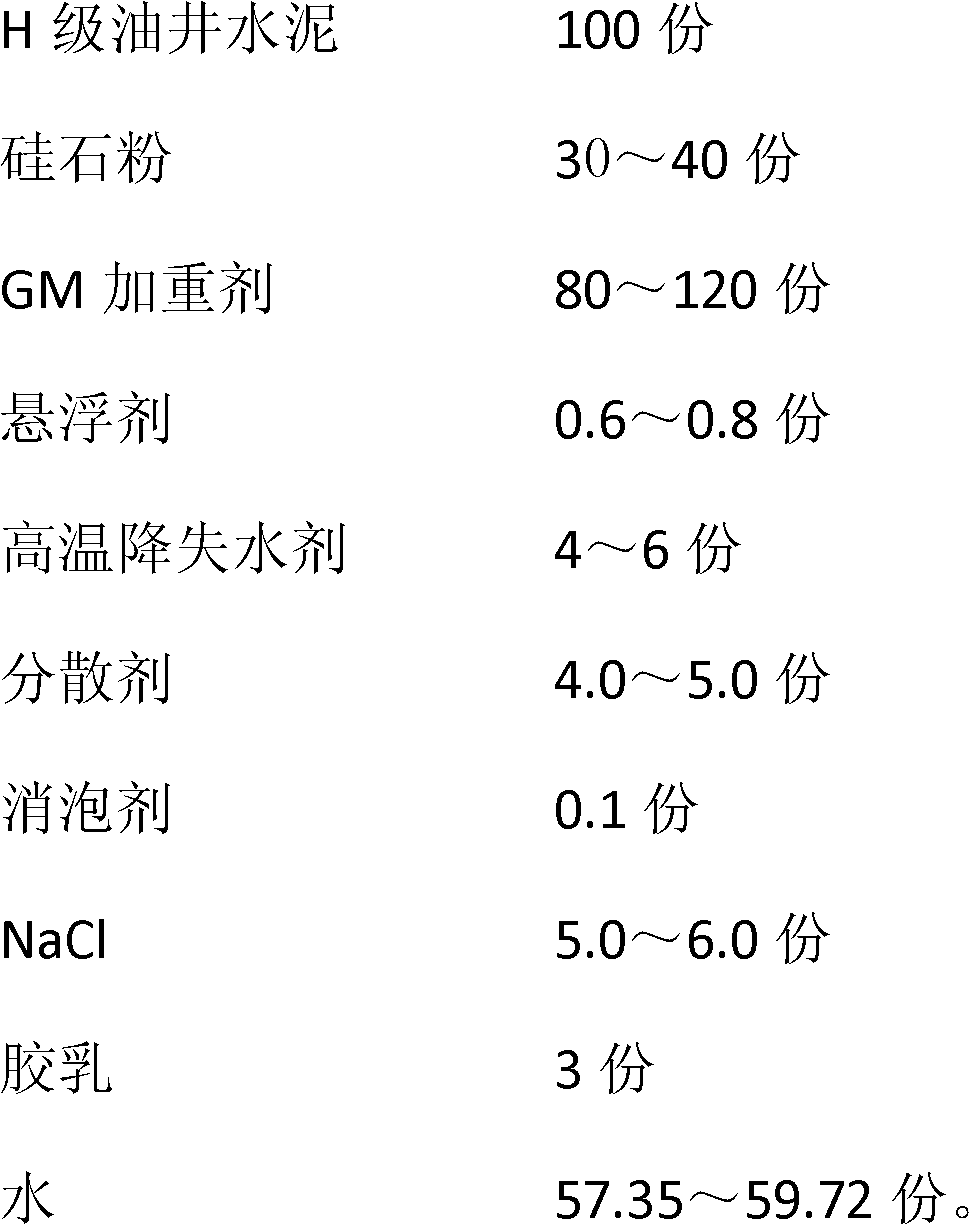

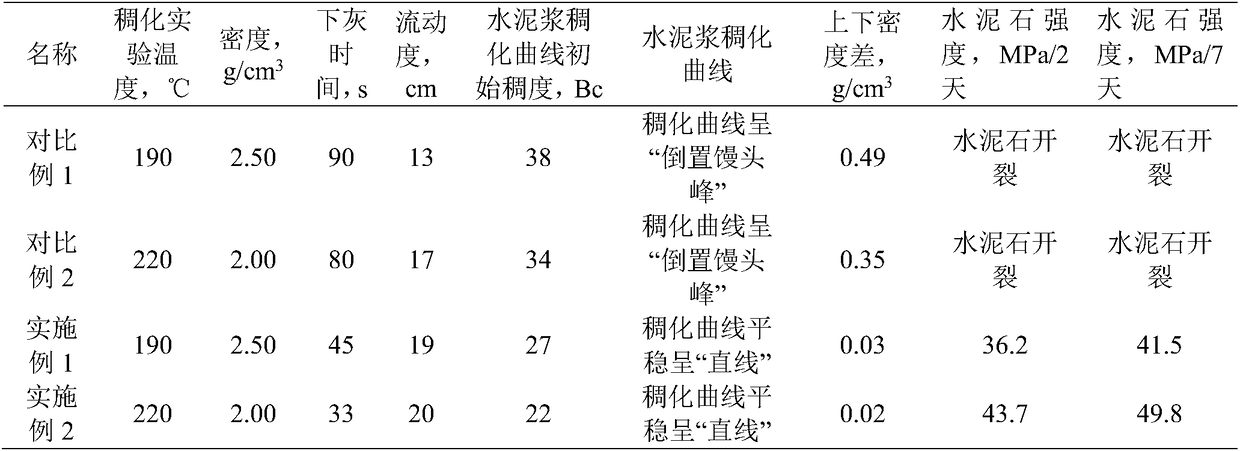

The invention discloses a cementing slurry with high temperature, high density and high toughness, which comprises the following ingredients by weight 100 parts of H grade oil well cement, 30-40 parts of silicon powder, 80-120 parts of a GM weighting agent, 0.6-0.8 parts of a suspending agent, 4-6 parts of a high temperature fluid loss reducer, 4.0-5.0 parts of a dispersant, 0.1 parts of an antifoaming agent, 5.0-6.0 parts of NaCl, 3 parts of latex and 57.35-59.72 parts of water. The density of the cementing slurry can reach 2.40-2.50gcm3, the cementing slurry can resist a temperature of 160 DEG C, and the cementing slurry has the advantages of good rheological property under high temperature, good settlement stability and good cement stone toughness, is suitable for cementing depth wellsand ultra-deep wells, and is in favor of improving the sealing quality and raising the quality of the wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Well cementing cement material with high thermal conductivity for geothermal exploitation

The invention discloses a well cementing cement material with high thermal conductivity for geothermal exploitation. The well cementing cement material comprises water, ordinary Portland cement (P.O442.5), a thermal conductive reinforcing material, a JSS water reducing agent, sodium chloride (NaCl) and triethanolamine (TEA); according to the water cement ratio, the weight ratio of the water to theordinary Portland cement is 0.5-0.7; with the mass ratio of the ordinary Portland cement as reference, the mass ratio of the thermal conductive reinforcing material is 10%, the mass ratio of the JSSwater reducing agent is 0.2-0.4%, the mass ratio of the sodium chloride (NaCl) is 0.3-1.3%, and the mass ratio of the triethanolamine (TEA) is 0.01-0.03%. The well cementing cement material with highthermal conductivity for geothermal exploitation has the advantages of being conductive to reducing the density of cement grout, having a good effect when low-density cement grout needs to be utilized, shortening the coagulating time, being better in sedimentary stability, meeting requirements in compressive strength and being greatly improved in thermal conductivity.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Suspension stabilizer for high-temperature cement paste and high-temperature-resistant cement paste prepared by same

ActiveCN108706927AIncrease surface tensionEnhance structural strengthDrilling compositionAluminium chlorideIron sulfate

The invention discloses a suspension stabilizer for high-temperature cement paste and high-temperature-resistant cement paste prepared by the same. The suspension stabilizer is formed by the followingcomponents according to the parts by weight: 0.5-4 parts of a fiber material, 1-5 parts of a surfactant powder material, and 0.5-2 parts of a flocculant powder material. The fiber material is a mixture of one or two materials in whisker, sepiolite, ceramic fibers, basalt fibers, and brucite fibers. The surfactant powder material is one of lauryl sodium sulfate, sodium dodecyl sulfate, hexadecylsulfonic acid sodium salt, sodium octadecyl benzene sulfonate, petroleum sodium sulfonate, white dextrin and yellow dextrin. The flocculant powder material is one of polyferric sulfate, aluminum polychlorid, and poly-aluminum ferric silicate sulfate. The high-temperature-resistant cement paste prepared by using the suspension stabilizer is low in initial consistence, and good in sedimentation stability. The suspension stabilizer is capable of improving the high-temperature suspension stability and the set cement strength of the cement paste, and providing technical support for the exploration and development of deep oil and gas resources.

Owner:CNPC DRILLING RES INST +2

Mineral oil based magnetorheological fluid for high power transmission and preparation method thereof

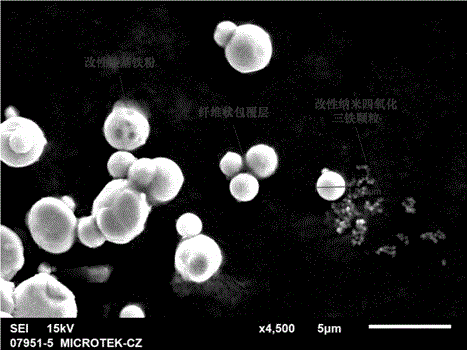

The invention discloses mineral oil based magnetorheological fluid for high power transmission. The mineral oil based magnetorheological fluid comprises the following components by mass percent: 60-80% of magnetic particles, 15-40% of carrier liquid and 2-5% of additives, wherein the magnetic particles are carbonyl iron powder particles and nano ferriferrous oxide particles; the carrier liquid is mineral oil; the additives comprise a surface active agent, a thixotropic agent, an antioxidant and an antiwear agent, meanwhile, the invention further provides a preparation method of the magnetorheological fluid, and the prepared magnetorheological fluid has excellent sedimentation stability, lower zero field viscosity, higher shear yield stress and long service life, and can meet the application requirements of high power transmission devices.

Owner:CHINA UNIV OF MINING & TECH

Well cementation cement paste with high water-cement ratio, low cost and low density and preparation method thereof

InactiveCN109437710AShort thickening transition timeImprove cementing effectDrilling compositionDefoaming AgentsCoal

The invention discloses well cementation cement paste with a high water-cement ratio, low cost and a low density. The well cementation cement paste is prepared from the following raw materials in parts by weight: 40 to 100 parts of oil well cement, 25 to 60 parts of coal ash, 30 to 40 parts of silica fume, 2 to 3 parts of an early strength agent, 2 to 8 parts of a ternary exciting agent, 3 to 3.5parts of a fluid loss agent, 0 to 0.2 part of a dispersing agent, 0.2 part of a defoaming agent and 180 to 272 parts of clean water, wherein the ternary exciting agent is a mixture of soda lime and magnesium sulfate, the mass ratio of the soda lime to the magnesium sulfate is 9 to 1, and the soda lime and the magnesium sulfate are both sieved by a 100-mesh sieve. Meanwhile, the invention further discloses a preparation method of the well cementation cement paste preparation method. The well cementation cement paste has low cost; after the ternary exciting agent is added, the compressive strength is improved, and a requirement of well cementation for the strength of low-density cement paste is met; furthermore, expansibility is improved, cement paste micro annular spaces caused by the inherent shrinkage character are reduced, and the risk of poor wellhole sealing safety is reduced.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Ultralow-density cement paste system for well cementing

InactiveCN109265093AReduce water lossWith low temperature quick settingDrilling compositionPalygorskiteWell cementing

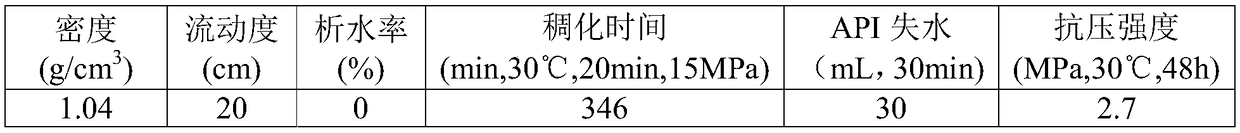

The invention discloses an ultralow-density cement paste system for well cementing. The system comprises, by weight, 100 parts of oil well cement, 5-8 parts of micro silicon, 0-4 parts of oil well ultrafine cement, 25-40 parts of lightening materials, 2-5 parts of suspension stabilizer, 0-5 parts of coagulant, 1.0-1.2 parts of fluid loss agent, 1.0-1.5 parts of dispersing agent and 95-125 parts ofwater, wherein the particle size of the micro-silicon is 0.2-2 micron; the lightening materials comprise at least two of sodium bentonite, palygorskite, expanded perlite, hollow glass beads and hollow ceramic micro-beads. The ultralow-density cement paste system for the well cementing is suitable for well cementing operation of a low-pressure stratum which is likely to leak, and the manimum density can be 1.04 g / cm<3>. The ultralow-density cement paste system has the advantages of being rapid in setting at low temperature, rapid in strength development in the early stage, good in sedimentation stability and low in water loss.

Owner:CNPC BOHAI DRILLING ENG

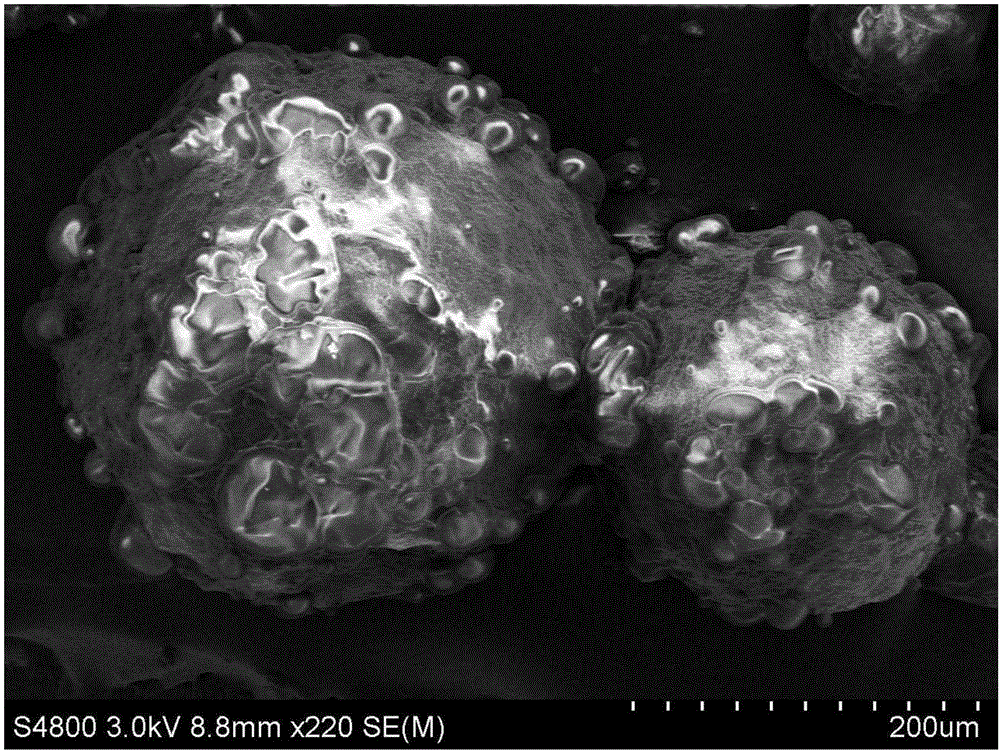

A carbon nanometer tube based lightweight magnetic composite particle for magnetic rheological fluid and method for preparing same

InactiveCN1632890AGood settlement stabilityHigh shear yield stressMagnetic liquidsIron saltsCarbon nanotube

This invention belongs to compound material and function material technique field and in detail to light magnetic particles with magnetic rheologic liquid and its process method. The material uses nanometer tube special electromagnetism property and a layer of Fe#-[3] O#-[4] on the surface. It in detail is processed with the nanometer tube, dispersant, strong acid, trivalence iron salt, two iron salt and alkali as certain weight proportion through certain process.

Owner:TONGJI UNIV

Process for covering silicas with wax

InactiveUS6921781B2Good settlement stabilityGood dispersionAlkali metal silicate coatingsSpecial tyresSilica particleWax

The present invention provides a process, which includes:coating at least a portion of a surface of at least one silica particle with at least one wax, wherein the coating is carried out in at least one gas at a temperature above the melting point of the wax and below the decomposition temperature of the wax, to obtain at least one wax-coated silica particle. Other embodiments of the present invention provides processes for impregnating the silica particle with wax and uses of the wax-coated or wax-impregnated particles.

Owner:EVONIK DEGUSSA GMBH

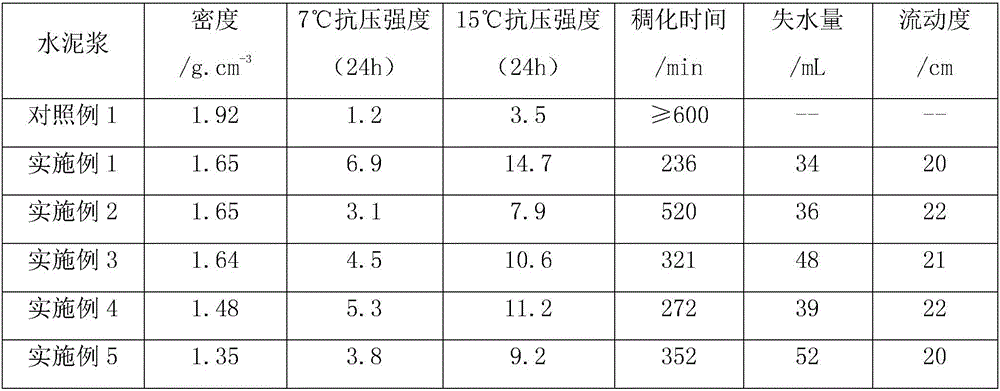

A liquid colloid filling low-temperature well-cementing cement mortar system

A liquid colloid filling low-temperature well-cementing cement mortar system is provided. The system is characterized in that the system includes 100 parts by mass of Portland cement, 80-120 parts by mass of ultrafine Portland cement, 10-30 parts by mass of hollow glass microbeads, 10-20 parts by mass of micro-silicon, 8-12 parts by mass of liquid colloid, 2-6 parts of an early strength agent, 1-2 parts by mass of drag reducer, 4-8 parts by mass of a water loss reducing agent, 1-2 parts by mass of a defoamer and 120-150 parts of water. According to the system, the density of the system is adjustable in a range of 1.35-1.65 g / cm<3>, the low-temperature early strength is high, thickening performance and fluidity are good, the water loss amount is low, and the system has excellent anti-fluid-channeling performance, can be used for well cementing for deepwater surface layer sections, can save working time and costs and can provide safe and efficient technical supports for deepwater oil and gas exploitation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-temperature-resistant suspending agent for flexible cement mortar and preparation method thereof, and cement mortar

ActiveCN107973537AGood settlement stabilitySmall density changeDrilling compositionFiberSuspending Agents

The invention relates to a high-temperature-resistant suspending agent for flexible cement mortar and a preparation method thereof, and cement mortar, belonging to the field of oil exploration. The suspending agent comprises, on the basis of 100 parts by weight of water, 100 parts of water, 20 to 50 parts of spherical oxide, 5 to 8 parts of short fibers, 3 to 8 parts of silicate and 3 to 8 parts of latex. After addition of the suspending agent provided by the invention, the cement mortar has excellent settlement stability and has density difference of no more than 0.02 g / cm<3>; obvious upward-floating of elastic particles does not occur; and rheological properties of the cement mortar with the suspending agent are almost same at different temperatures.

Owner:CHINA PETROLEUM & CHEM CORP +1

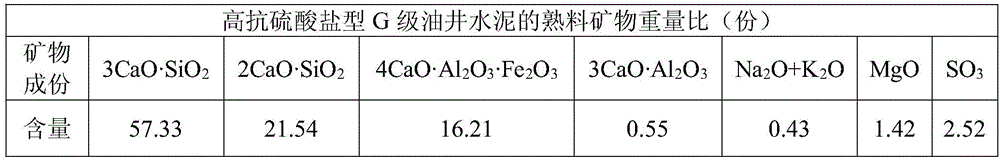

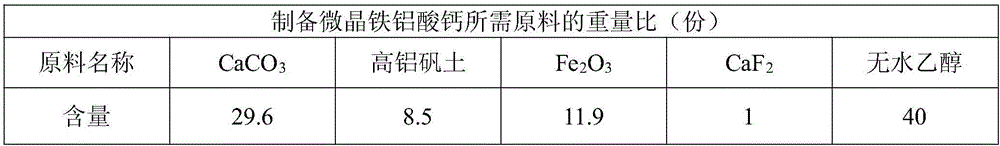

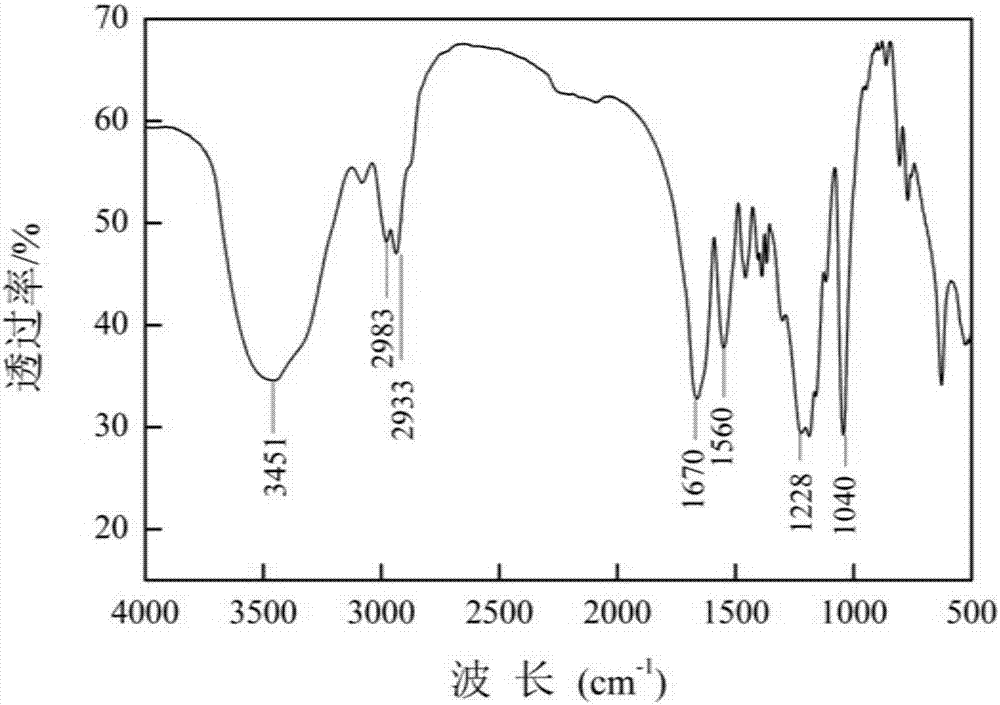

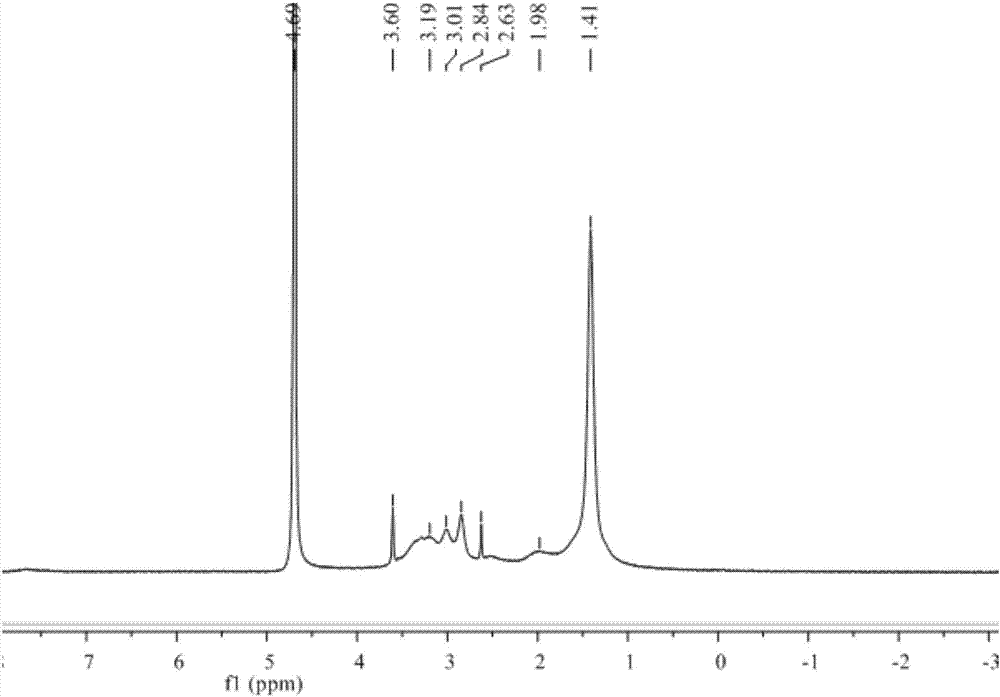

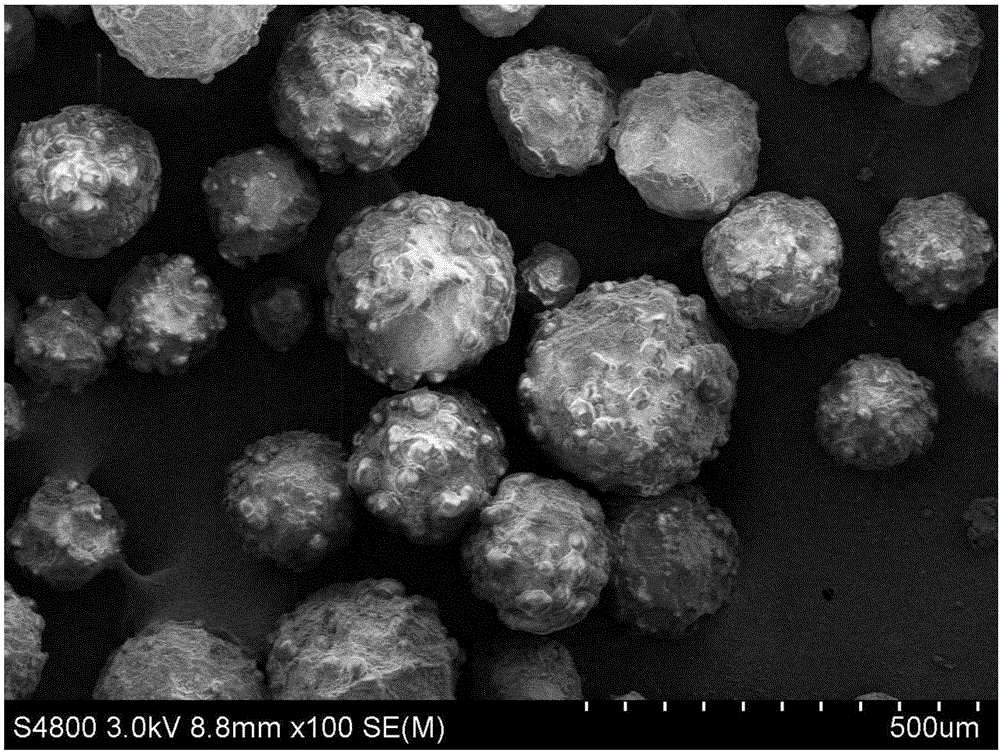

Endogenous toughened corrosion-resistant cement mortar system

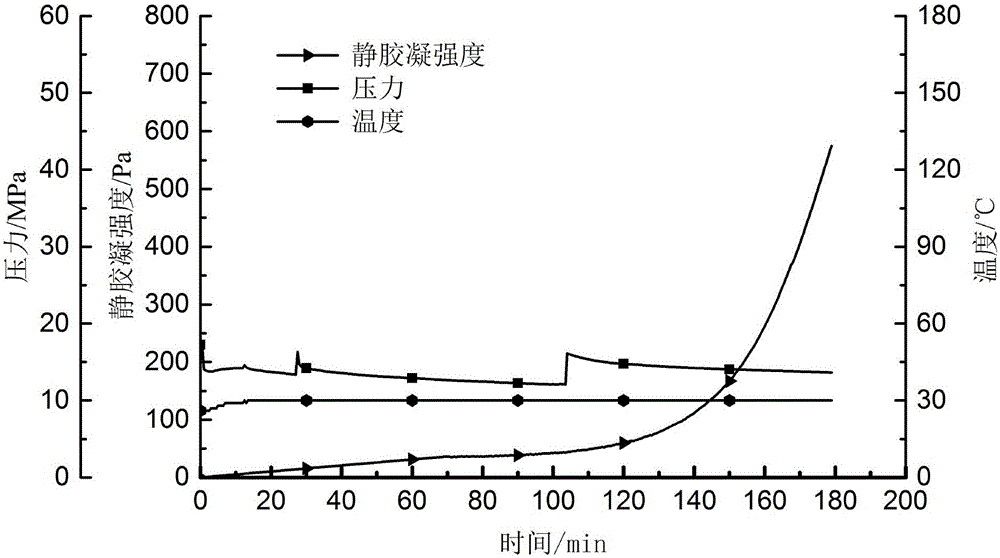

ActiveCN105967600AGood settlement stabilityReduce water lossDrilling compositionPorosityPolyvinyl alcohol

The invention discloses an endogenous toughened corrosion-resistant cement mortar system which is composed of the following components in parts by weight: 100 parts of high-sulfate-resistance Grade-G oil well cement, 5-35 parts of microcrystal calcium aluminoferrite, 0-25 parts of micro silicon, 1.0-4.5 parts of water-loss control agent, 0.5-3.0 parts of dispersing agent, 0.2-3.0 parts of thickening time control agent and 44-80 parts of water. The microcrystal calcium aluminoferrite is prepared by high-temperature calcination and shock cooling. The micro silicon is a density regulator. The water-loss control agent is polyvinyl alcohol, polyacrylamide or carboxymethyl cellulose. The dispersing agent is sodium hexametaphosphate, melamine formaldehyde resin, sodium lignosulfonate or methyl cellulose. The thickening time control agent is boric acid, gypsum, sodium borate or a mixture thereof. The endogenous toughened corrosion-resistant cement mortar system has the advantages of excellent impact resistance, higher compression strength, high volume stability and small changes of porosity and permeability, has important meanings for ensuring safe and efficient development of shale gas, and thus, has broad market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Dispersive solid fluid loss agent for seawater cement slurry and preparation method of dispersive solid fluid loss agent

The invention discloses a dispersive solid fluid loss agent for seawater cement slurry and a preparation method of the dispersive solid fluid loss agent. The preparation method comprises the following steps: (1) dissolving allyl polyethylene glycol and carboxylic acid monomers into water; (2) adding 2-acrylamido-2-methylpropanesulfonic acid and acrylamide monomers, uniformly stirring, heating, and adjusting the pH value, so as to obtained a mixed solution; and (3) adding an initiating agent into the mixed solution to react to generate faint yellow viscous liquid, and carrying out freeze drying, grinding or crushing. The dispersive solid fluid loss agent disclosed by the invention is capable of blocking pores of cement without thickening a cement slurry system and is suitable for being used as an oil-well cement fluid loss agent. The dispersive solid fluid loss agent has relatively strong dispersive capacity and hydrability to cement slurry, so that the fluid loss control effect and salt tolerance of the fluid loss agent are improved, and the fluid loss control capacity of nonionic group acylamino enhanced cement slurry is improved. The dispersive solid fluid loss agent is easy to store and convenient to transport, and the slurry is easily stirred. The sedimentary stability of a slurry body is good, thixotropy does not easily occur, and the delayed coagulation side effect is avoided.

Owner:TIANJIN UNIV

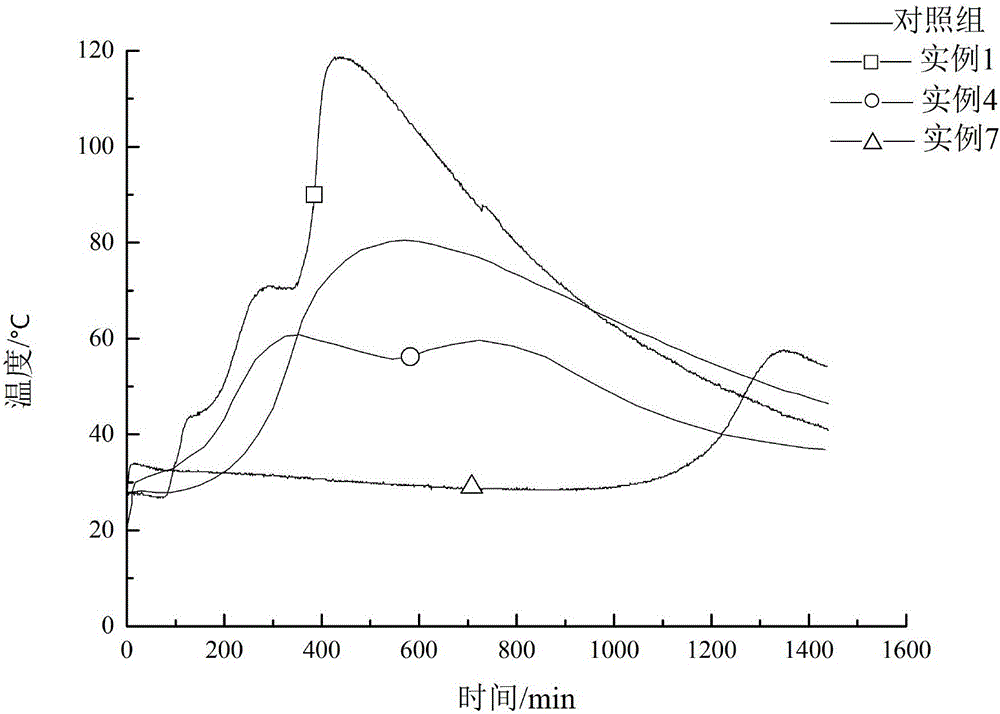

Early-strength low-hydration heat evolution cement paste system applicable to deepwater shallow cementation

The invention discloses an early-strength low-hydration heat evolution cement paste system applicable to deepwater shallow cementation. The system is prepared from 100 parts of cement, 5-10 parts of phase-change heat absorption materials, 10-30 parts of a density reducing agent, 8-15 parts of suspension materials, 0.5-1 part of a drag reducer, 0.3-0.55 part of retarder, 0.7-1 part of a fluid loss agent, 0.7-1 part of a defoaming agent, 0.06-0.1 part of an early strength agent and 68.2-82.3 parts of water. The cement paste system has the good early strength property at low temperature, is small in hydration heat evolution amount and good in thickening property, flowing property and sedimentation stability, has right-angle thickening property and small water loss, and meets on-site construction requirements. According to the system, surface cementation in the deepwater hydrate layer can be achieved, operation time and cost can be saved, and a technical support is provided for mining of oil and gas resources in the deepwater hydrate layer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com