Improved giant electrorheological fluid and manufacturing method thereof

一种电流变、绝缘液的技术,应用在润滑组合物、添加剂、石油工业等方向,能够解决屈服应力降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Preparation of metal salt nanocomposites

[0040] Dissolve 3.63g of rubidium chloride and 73.35g of barium chloride in 225ml of 50-70°C distilled water. At the same time, 94.56g of oxalic acid was dissolved in 750ml of a warm water bath at 65°C and ultrasonicated. Slowly add 330 g of titanium chloride aqueous solution (titanium chloride accounts for 10 wt% of the solution) into the above-mentioned warm water bath. The mixed solution of rubidium chloride and barium chloride was mixed with the warm water bath added with titanium chloride, and 45 g of urea was added simultaneously to form a white colloid, which was then cooled to room temperature. After washing and filtering, the precipitate is dried. The precipitate is a metal salt nanocomposite coated with urea.

Embodiment 2

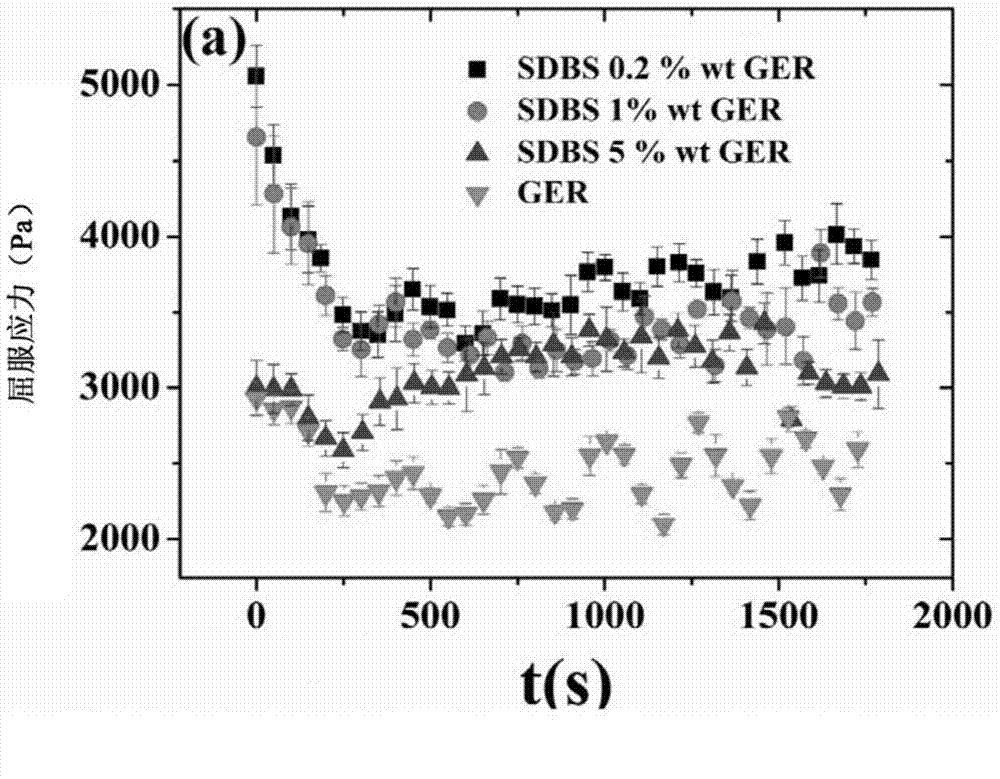

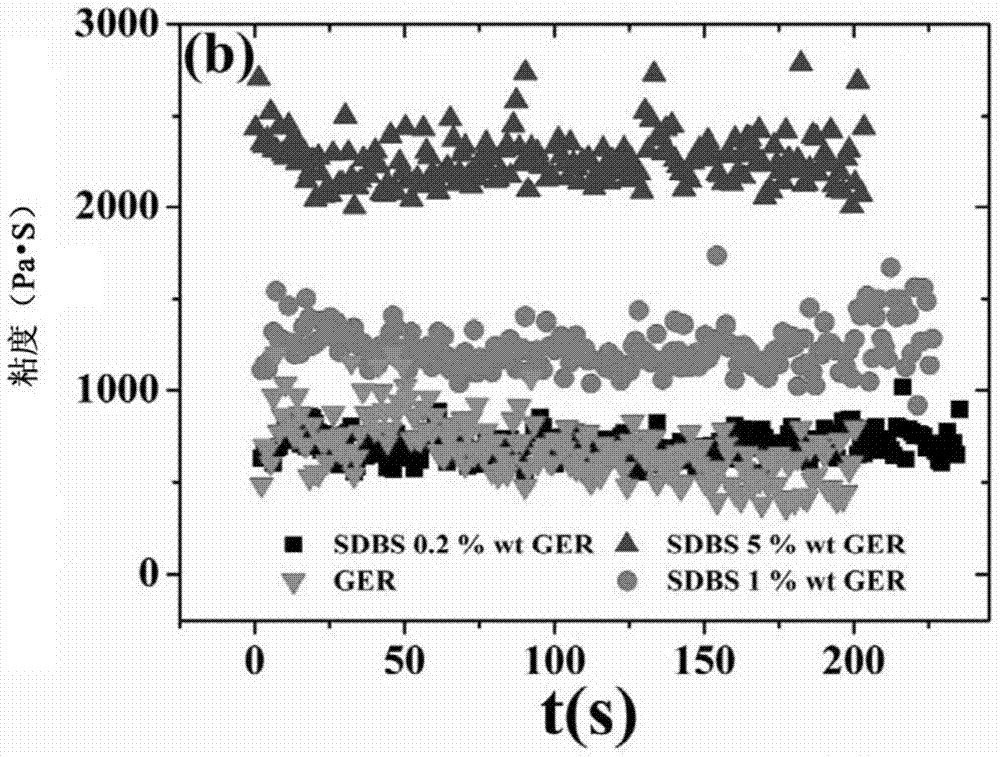

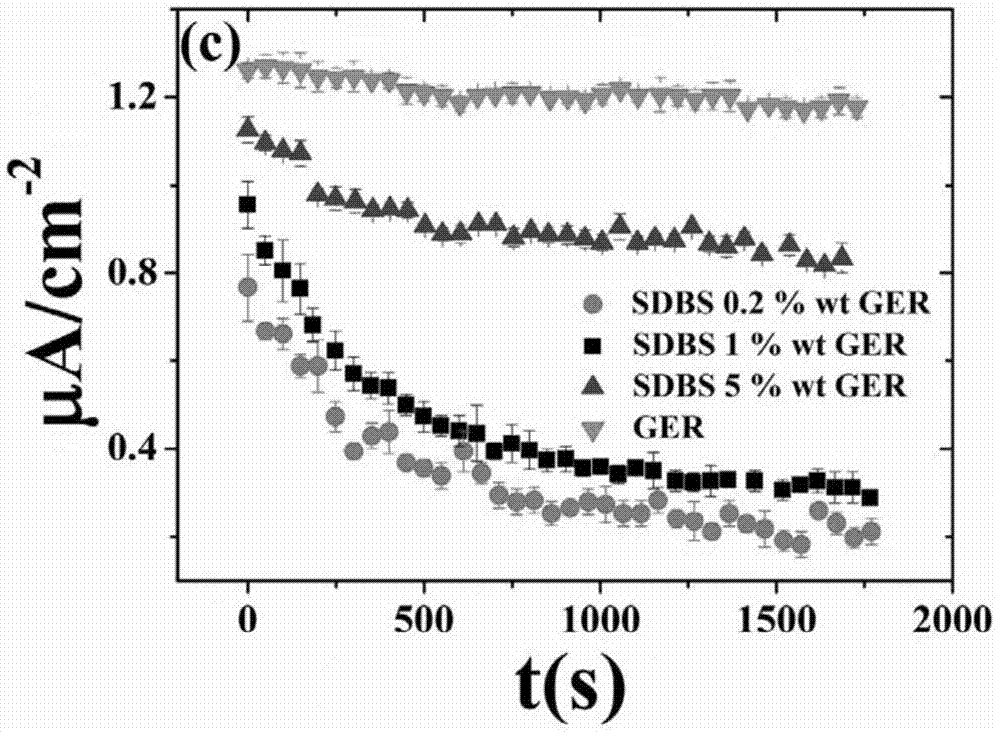

[0041] Embodiment 2: adding polar molecular additives to prepare GER liquid

[0042] The metal salt nanocomposite prepared by 30g embodiment 1 was combined with 0.2g SDBS and 70g silicone oil, and the mixture was ground for 30 minutes in a ball mill, and then under 20-40°C, ultrasonic treatment was carried out with maximum power (ultrasonic instrument: LUKADENT company , 28H Ultrasonik,, C") for 1 hour. The mixture was conditioned in a vacuum freeze dryer for 12 hours to remove any excess water. Various properties of the surfactant-added GER fluid were then tested.

Embodiment 3

[0043] Embodiment 3: adding polar molecular additives to prepare GER liquid

[0044] The metal salt nanocomposite prepared by 30g embodiment 1 was combined with 1.0g SDBS and 70g silicone oil, and the mixture was ground for 30 minutes in a ball mill, and then under 20-40°C, ultrasonic treatment was carried out with maximum power (ultrasonic instrument: LUKADENT company , 28H Ultrasonik,, C") for 1 hour. The mixture was conditioned in a vacuum freeze dryer for 12 hours to remove any excess water. Various properties of the surfactant-added GER fluid were then tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com