Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181results about How to "With micro-expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

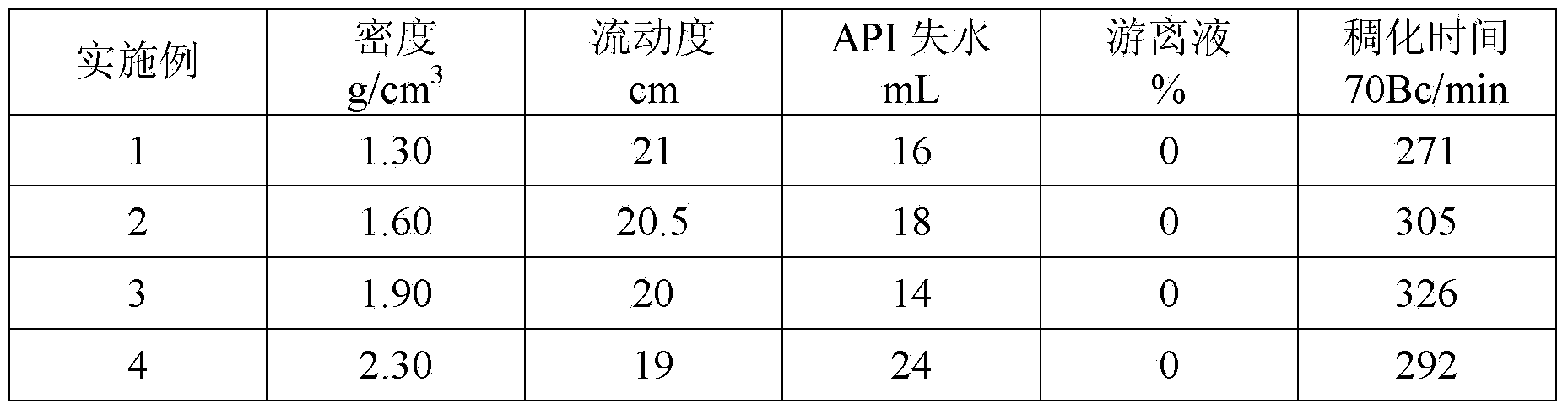

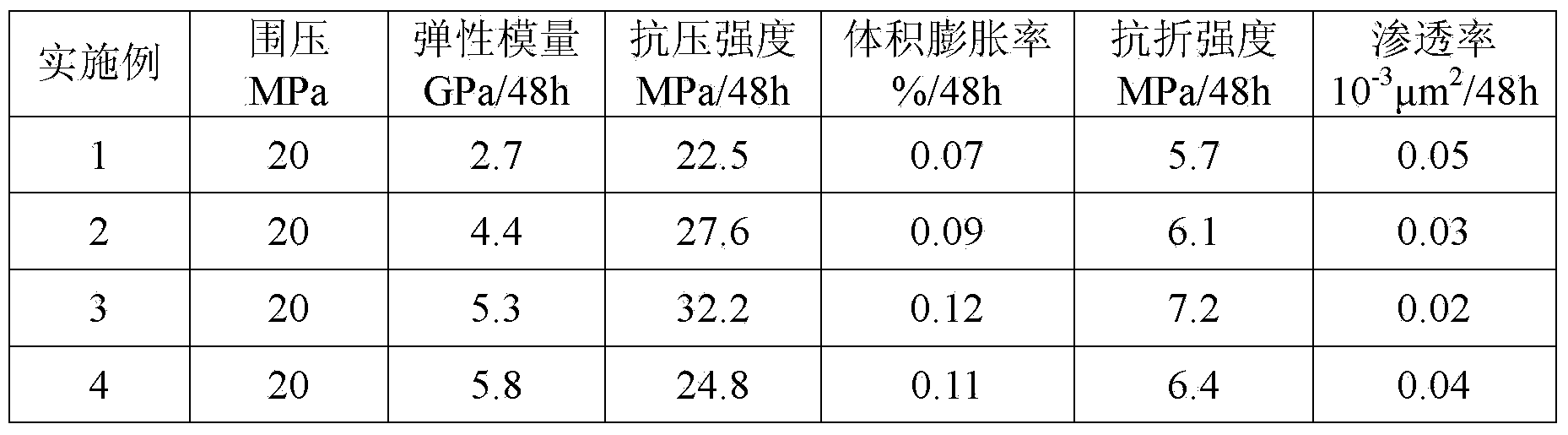

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-performance foaming cement and preparation method thereof

The invention relates to high-performance foaming cement, which comprises cement slurry and foams, wherein the cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 10-30 parts of gypsum powder, 10-50 parts of active admixtures, 10-40 parts of mineral admixtures, 1-5 parts of re-dispersible gelatine powder, 0.5-1.5 parts of cellulose ether, 0.2-1.0 part of water reducing agent, 0.1-0.5 part of water repellent and 40-90 parts of water; and the foams are prepared from the following components in parts by weight: 1 part of foaming agent, 0.2-0.8 part of foam stabilizer and 30-50 parts of water. A preparation method of the high-performance foaming cement comprises the steps of: (1) preparing the cement slurry; (2) preparing the foams by using a foaming machine; and (3) mixing and uniformly stirring the cement slurry and the foams according to the weight ratio of 1:(0.1-1), and pouring and molding. The high-performance foaming cement disclosed by the invention has high closed porosity and small shrinkage value, and integrates the performances of heat insulation, sound insulation, water repellent, shock resistance, fire protection, durability, low carbon and environmental protection into a whole.

Owner:辽宁际洲环保节能建材有限公司

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

High fluidity grouting material and production method thereof

ActiveCN101798208AImprove mobilityEasy to pump over long distancesSolid waste managementNeutral phPortland cement

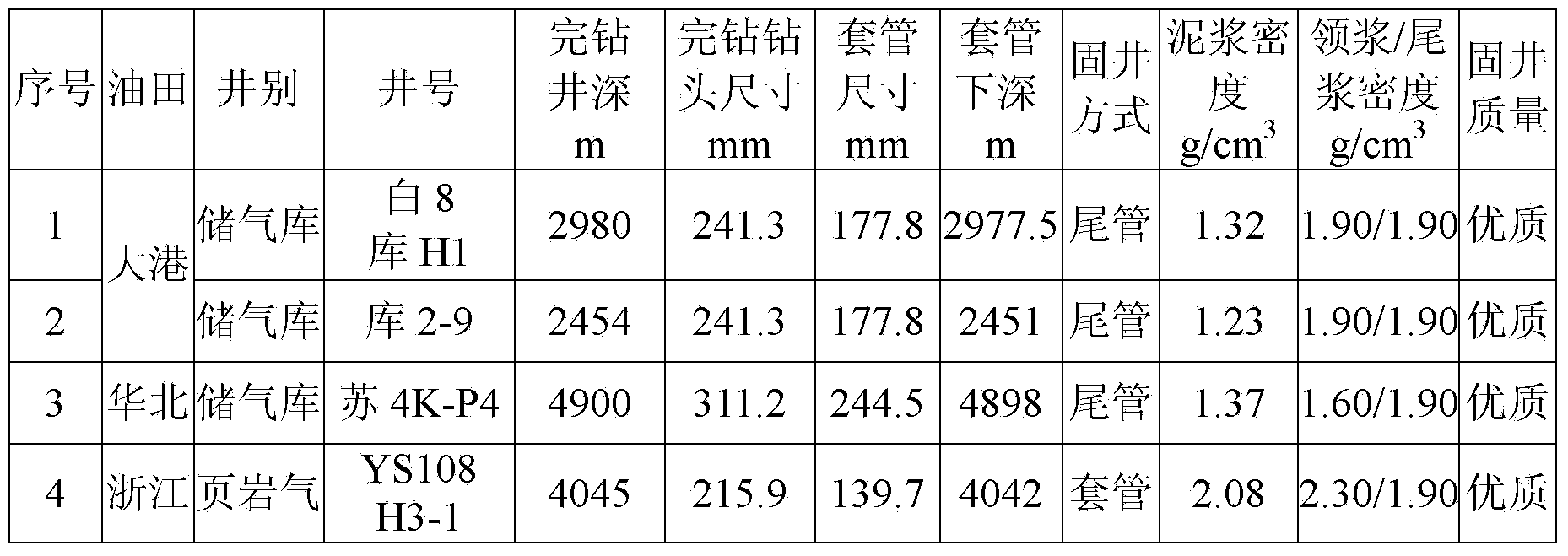

The invention discloses a high fluidity grouting material and a production method thereof. The high fluidity grouting material comprises the following components in percentage by weight: on the basis of 100 percent of total amount, 60 to 96 percent of conventional portland cement, 1 to 20 percent of calcite powder, 1 to 20 percent of a mineral modifying component, and 2 to 18 percent of swelling agent, wherein measuring on the basis of using the total amount of four substances as base number, 0.01 to 4 weight percent of high efficiency slushing agent and 0.0005 to 1 weight percent of plasticity swelling agent are added in the mixture of the four substances. The high fluidity grouting material can be made of raw materials mixed by adopting a dual-shaft paddle non-gravity high-efficiency mixer. The material has simple industrialized production process and stable product quality, adopts the water-cement ratio of between 0.24 and 0.28, is evenly blended by water with neutral pH value, and has the advantages of high fluidity, no bleeding, no segregation or layering, slight swelling, easy pump delivery, good durability and the like after the material is uniformly mixed by water.

Owner:HUBEI CHIDGE TECH

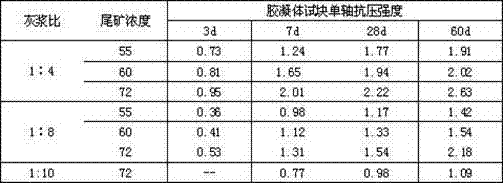

Binding material for filling fine-grain tailings

The invention discloses a binding material for filling fine-grain tailings. The binding material is prepared by milling and mixing the following components in percentage by mass: 15-40% of belite-sulphate aluminum cement, 2-10% of gypsum, 2-8% of quick lime, 40-70% of superfine-grain slag powder, 2-10% of coal ash, 1-6% of activating agent, 0.1-0.5% of activating accelerant, 0.1-0.5% of coagulant, and 0.1-0.5% of water reducer, wherein the activating agent is Na2SiO3, the activating accelerant is sodium fluosilicate, and the coagulant is any one or a mixture of two or more of LiOH, LiCO3 and LiCl; and the water reducer is a naphthalene water reducer or a polycarboxylic acid water reducer. According to the binding material for filling the fine-grain tailings, the problems that -0.074-mm fine-grain tailings and high-silt-content tailings are difficultly solidified and are low in strength after being solidified, and the strength of a filling body can meet a strength requirement on cut and fill of a mine on the filling body by using the binding material; the liquidity of slurry can be improved, and roof-contacting performance of the filling body can be improved; and the water retention capacity can be improved, and the water seepage of the slurry is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

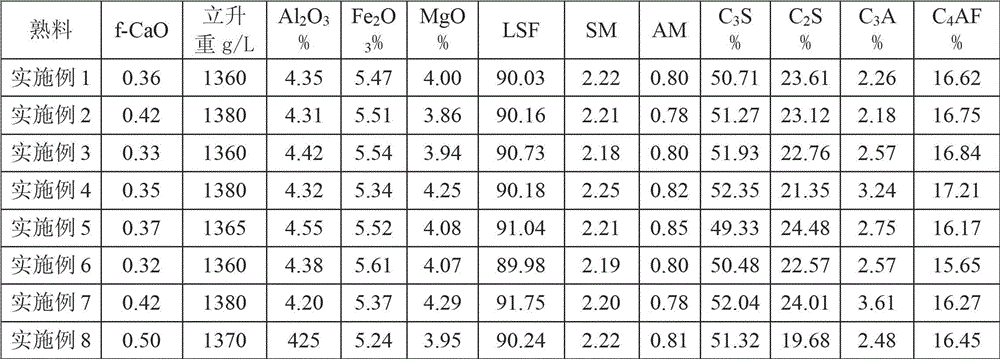

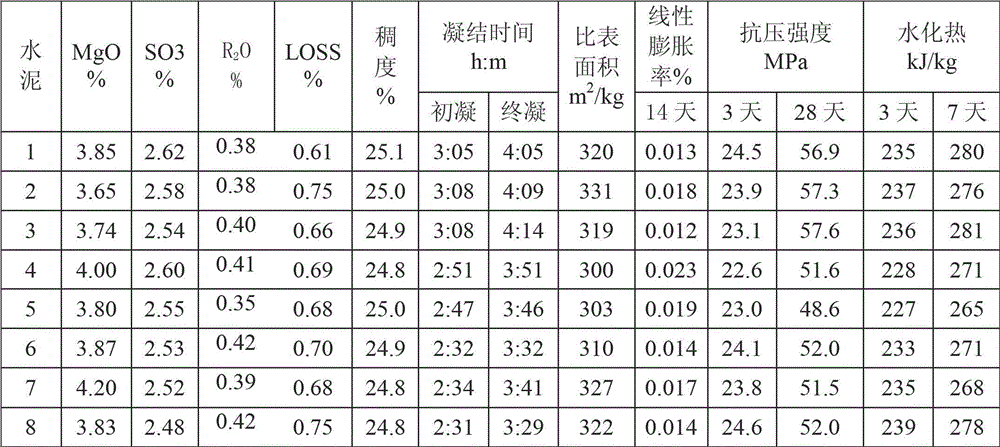

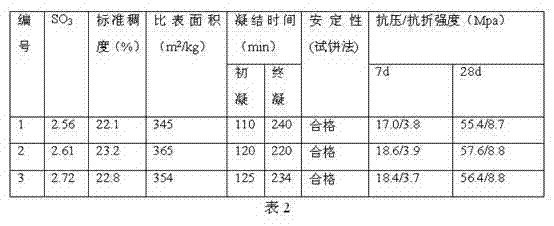

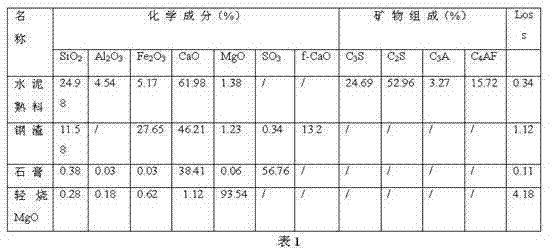

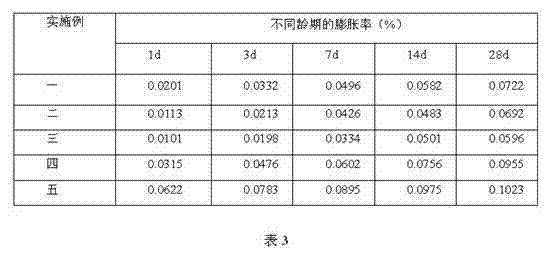

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Gelatinizing agent suitable for unclassified tailing filling

The invention discloses a gelatinizing agent suitable for unclassified tailing filling. The gelatinizing agent is prepared by grinding and mixing the following components by mass percent: 15-40% of belite-sulphate aluminium cement, 2-10% of gypsum, 0-8% of limestone, 40-70% of superfine slag powder, 0-10% of coal ash, 1-8% of an activating agent, 0.1-0.5% of an activation promoter, 0.1-0.5% of a coagulation accelerator and 0.1-0.5% of a water reducing agent. The gelatinizing agent suitable for the unclassified tailing filling disclosed by the invention solves the problems of difficult solidification and poor strength after solidification of unclassified tailings and classified tailings being -200meshes; through the gelatinizing agent, the filling material can meet strength demand required by mine filling mining, the fluidity of slurry is improved, injection performance of the filling material is improved, water retention capacity is improved, and slurry bleeding is relieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

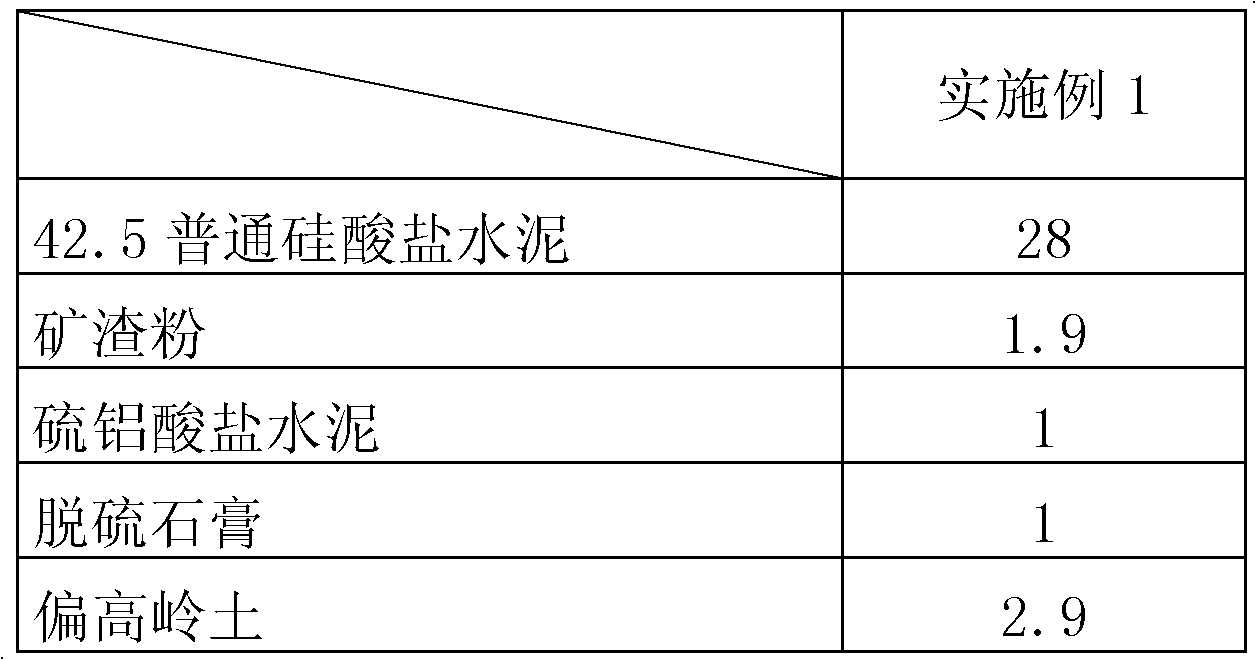

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

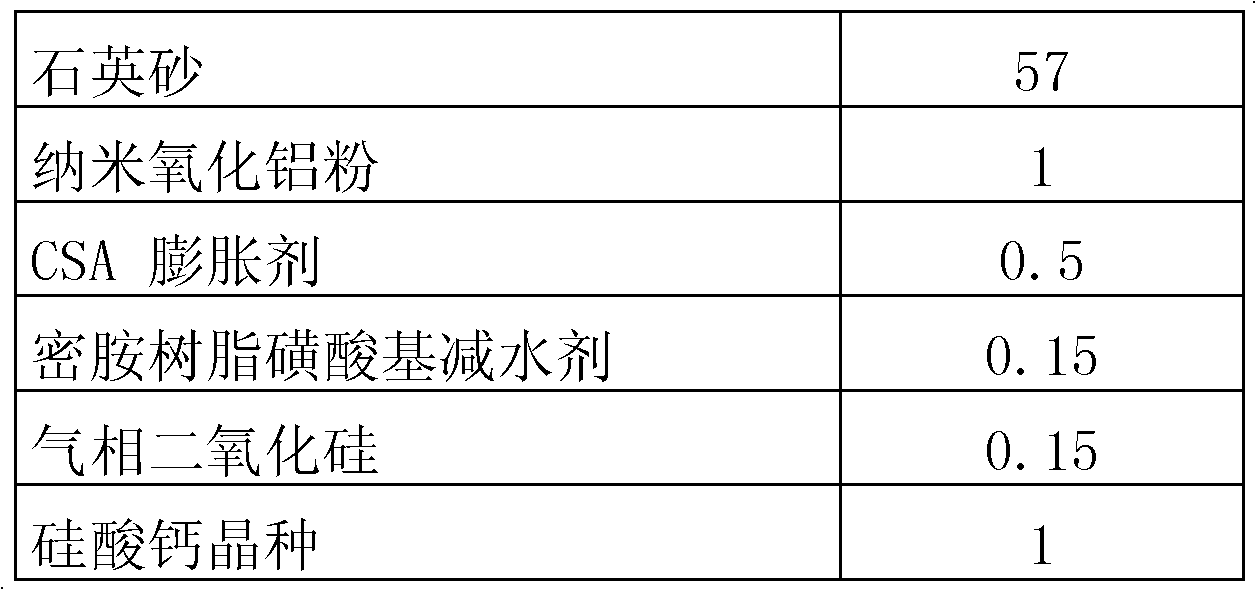

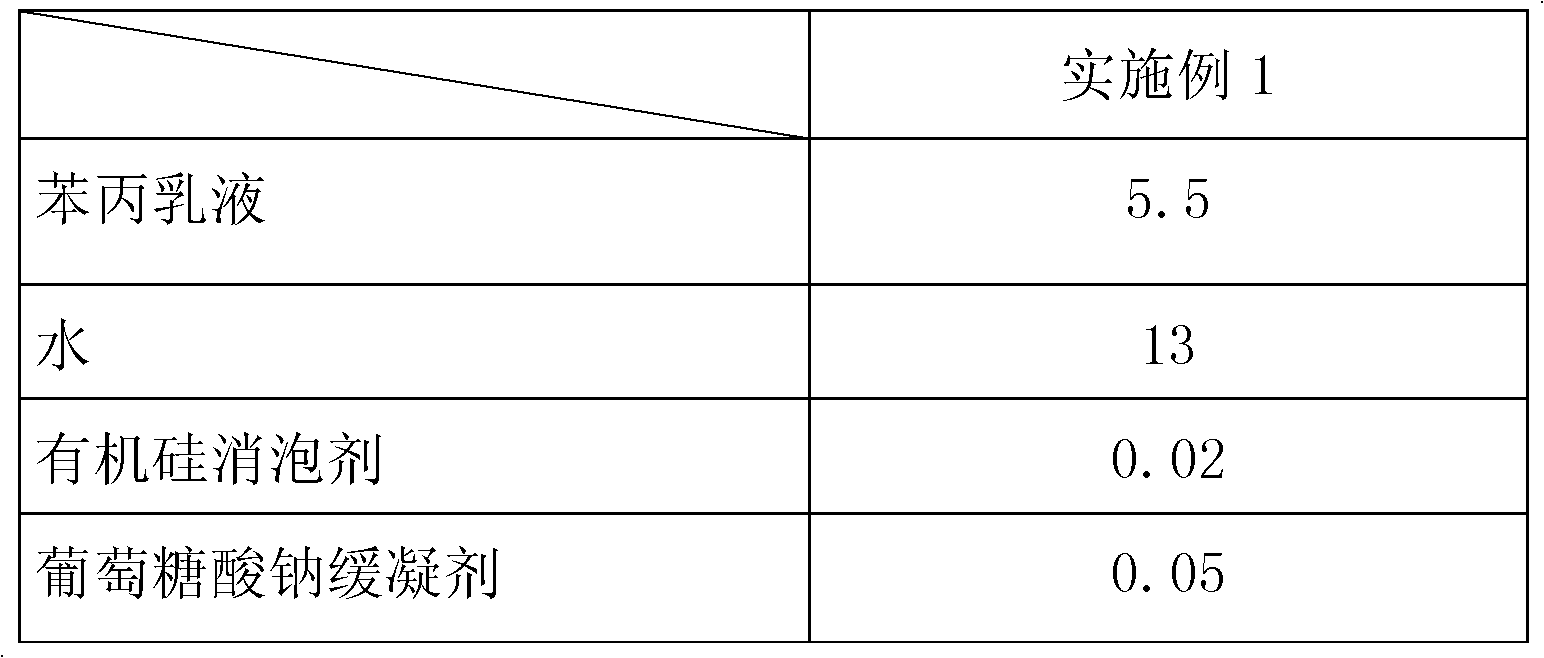

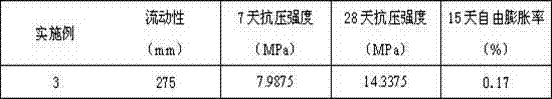

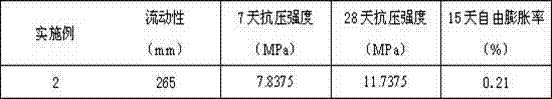

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

Belite-calcium barium sulphoaluminate cement

InactiveCN1887766ALower firing temperatureReduce dosageCement productionMaceralCalcium aluminoferrite

The present invention belongs to the field of cement material technology, and is especially one kind of Belite-calcium barium sulphoaluminate cement. The cement clinker is mainly one mineral phase system of C2S-CBAS-C3S-C3A-C4AF comprising calcium barium sulphoaluminate 5-45 wt%, dicalcium silicate 30-70 wt%, tricalcium silicate 10-45 wt%, tricalcium aluminate 2-20 wt%, and calcium aluminoferrite 2-20 wt%, where calcium barium sulphoaluminate has the molecular expression of (3-x)CaO .xBaO .3Al2O3 .CaSO4 with x=0.25-3. The present invention has the available of lower firing temperature, utilization of low quality limestone resource, high cement early strength, etc.

Owner:UNIV OF JINAN

Cementing materials with micro-expansion effect for mine filling

The invention relates to a method of using industrial waste residues, such as steel slag, blast furnace slag, and the like as main raw materials to produce a mine cementation filling material with a micro-expansion effect, which belongs to the field of environmental protection and mine filling. Aiming at the difficult problems that the cement amount required for cemented filling is large, filling cost is high, filling materials are easy in bleeding and difficult in roof-contacted filling at present, the invention provides a cementing material, which uses 30%-80% of the steel slag mixed with 15%-60% of slag and 5%-15% of desulfurized gypsum to be as an activator to form a hydraulic cementing material in a mixing way, and the hydraulic cementing material completely replaces cement as a cementing agent. The steel slag-slag full-tailing mine filling material which is prepared by the cementing material has micro-expansibility and good fluidity, compressive strength after 28 days can reach high up to 14.3Mpa, and the performance requirement of mine filling and roof-contacted filling on the compressive strength can be satisfied.

Owner:UNIV OF SCI & TECH BEIJING

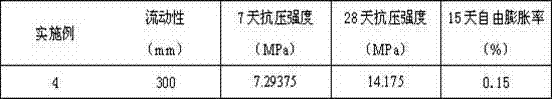

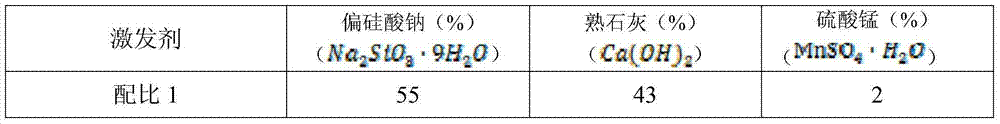

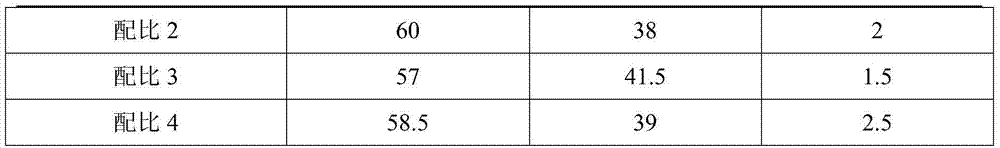

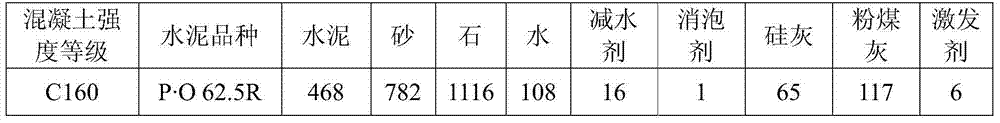

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Rapid hardening high-strength grouting material

InactiveCN101913840ASolve the problem of degraded perfusion qualityWith antifreeze functionSolid waste managementAnti freezingLithium carbonate

The invention discloses a rapid hardening high-strength grouting material, which consists of the following components in percentage by weight: 40 to 55 percent of fast hardening sulphoaluminate cement, 40 to 55 percent of quartz sand, 1 to 5 percent of silicon micro-powder, 2 to 5 percent of high-calcium powder, 0.6 to 1.0 percent of FDN water reducer, 1 to 3 percent of anhydrite powder, 0.02 to 0.14 percent of lithium carbonate, and 0.2 to 1.4 percent of sodium chloride. The components are uniformly mixed, and stirred with water in a water / cement ratio of 0.14-0.18, and the grouting material can be used after uniform stirring. The grouting material is suitable for low-temperature construction, and has the characteristics of early strength, high strength, good flowing performance, no shrinkage, good anti-freezing effect and the like.

Owner:刘茂平

Minimum inflation low heat silicate cement

ActiveCN102173700AWith micro expansionReduce water demandSolid waste managementCement productionTemperature stressSlag

The invention discloses minimum inflation low heat silicate cement. The cement comprises the following components in percentage by weight: 75 to 95 percent of low heat silicate clinker, 1 to 10 percent of gypsum, 0.01 to 6 percent of lightly-burnt MgO, and 5 to 15 percent of steel slag. The minimum inflation low heat silicate cement can effectively reduce early concrete plastic cracking and temperature stress cracking generated by later hydrating adiabatic temperature rise, caused by adverse construction and maintenance conditions when the concrete is constructed. The prepared concrete has the advantages of high flowing performance, small dry shrinkage, little temperature contraction joint and the like, and can be applied in the fields of mass concrete, hydraulic concrete, high performance concrete engineering and the like which have high requirement on anti-cracking performance.

Owner:JIAHUA SPECIAL CEMENT

Composite mineral admixture for concrete

The invention discloses a composite mineral admixture for concrete. The admixture is prepared by mixing and grinding the following raw materials in percentage by weight: 40 to 60% of lithium slag, 10 to 30% of mineral slag, 5 to 20% of nickel slag, 5 to 10% of aerated concrete waste, 5 to 10% of sulfoaluminate cement clinker, and 0.1 to 0.5% of super plasticizer powder. The industrial wastes are fully utilized, the concrete production cost is reduced, and the admixture has a high activity, barely influences the early and late strength of concrete, has a shrinkage-compensating function and good anti-permeability property, and can improve the service life of concrete.

Owner:SOUTHEAST UNIV

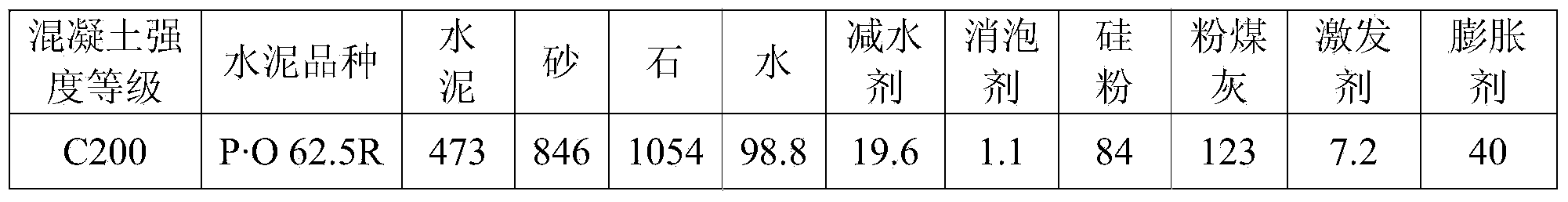

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

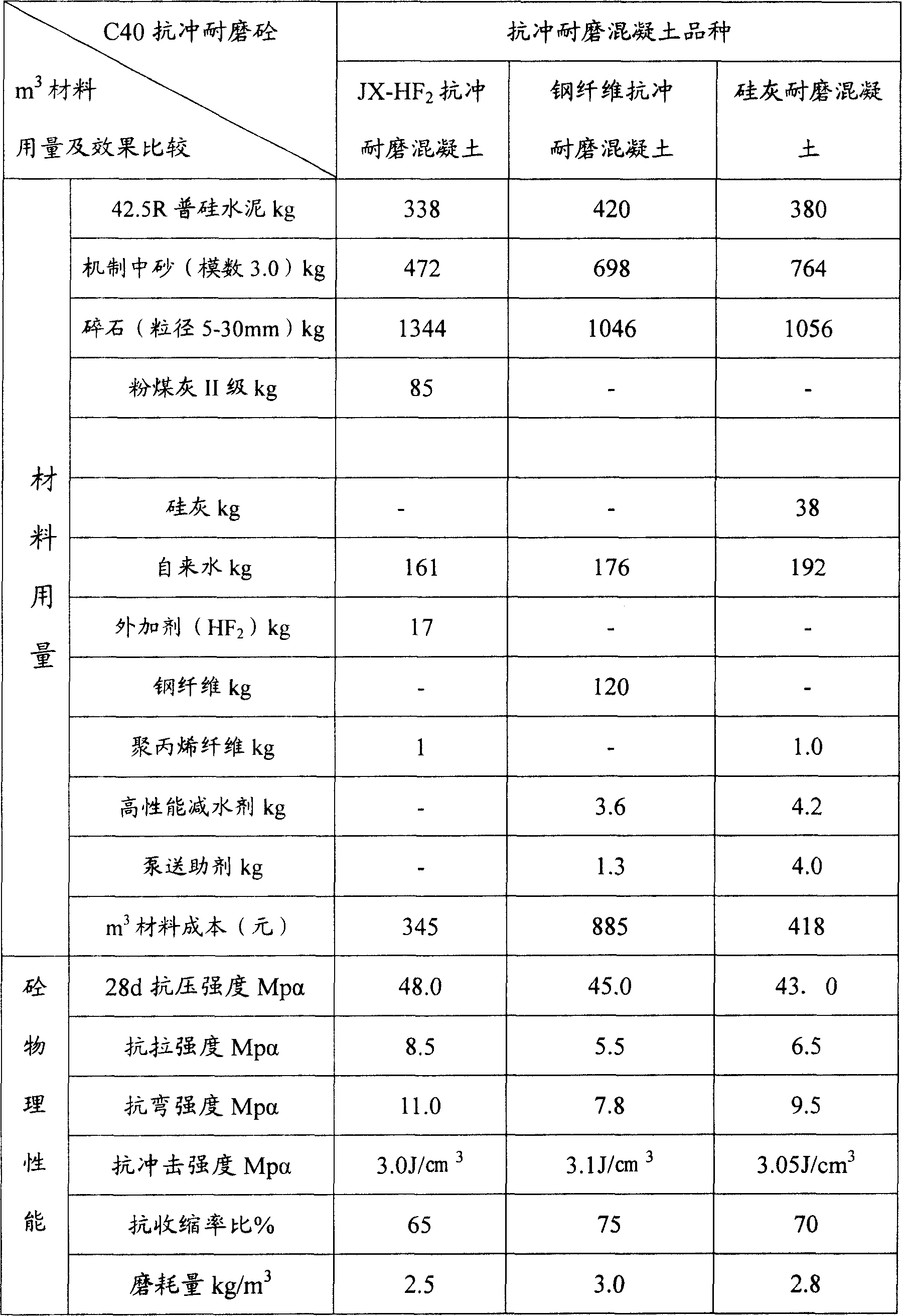

Concrete impact-resistant wearable agent composition and preparation method thereof

The present invention provides one kind of antishock and antiwear composition for concrete and its preparation process. The antishock and antiwear composition for concrete consists of plasticizing agent in 35-80 wt%, triethanolamine in 2.0-6.0 wt% and chloride in 1.0-6.0 wt%. The antishock and antiwear composition for concrete in powder or liquid form has high density, slight expansion, water reducing performance, plasticizing performance, capacity of strengthening concrete, etc, and is used in raising the antishock and antiwear performance of concrete and increasing its service life.

Owner:苏笮斌

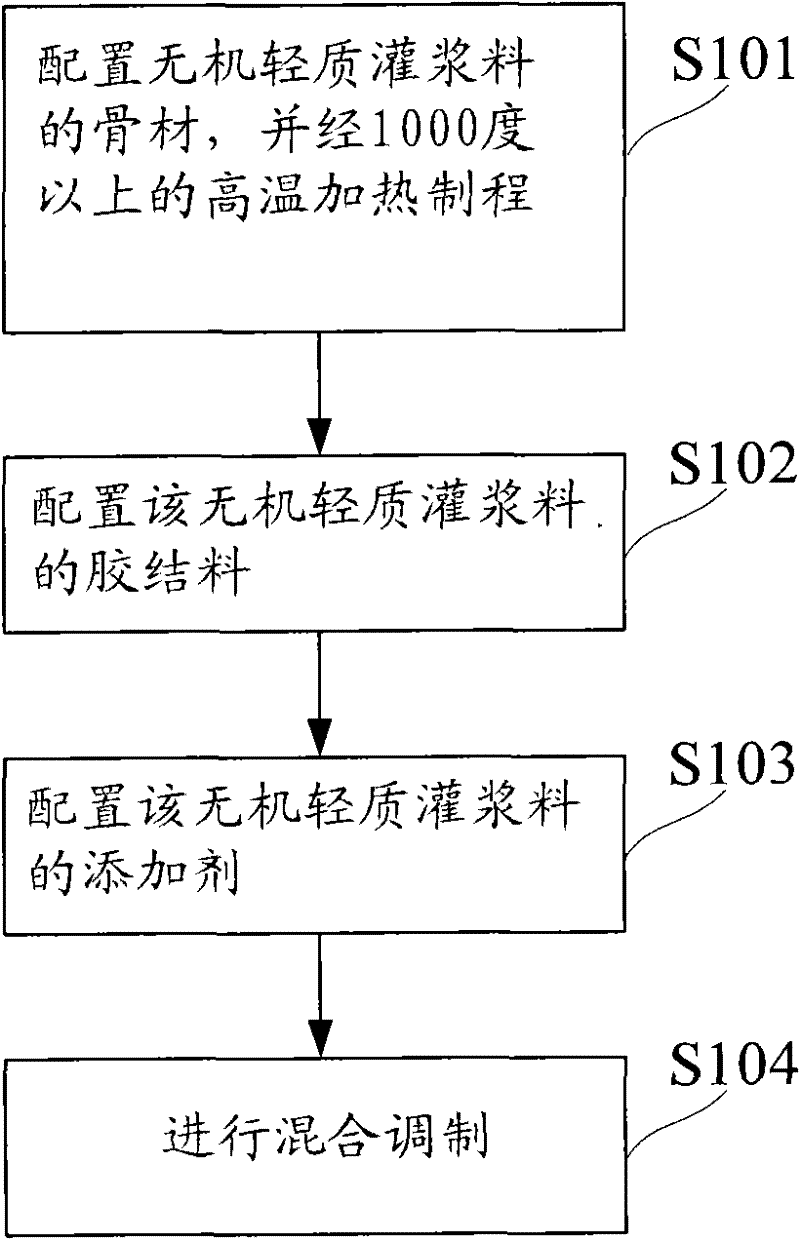

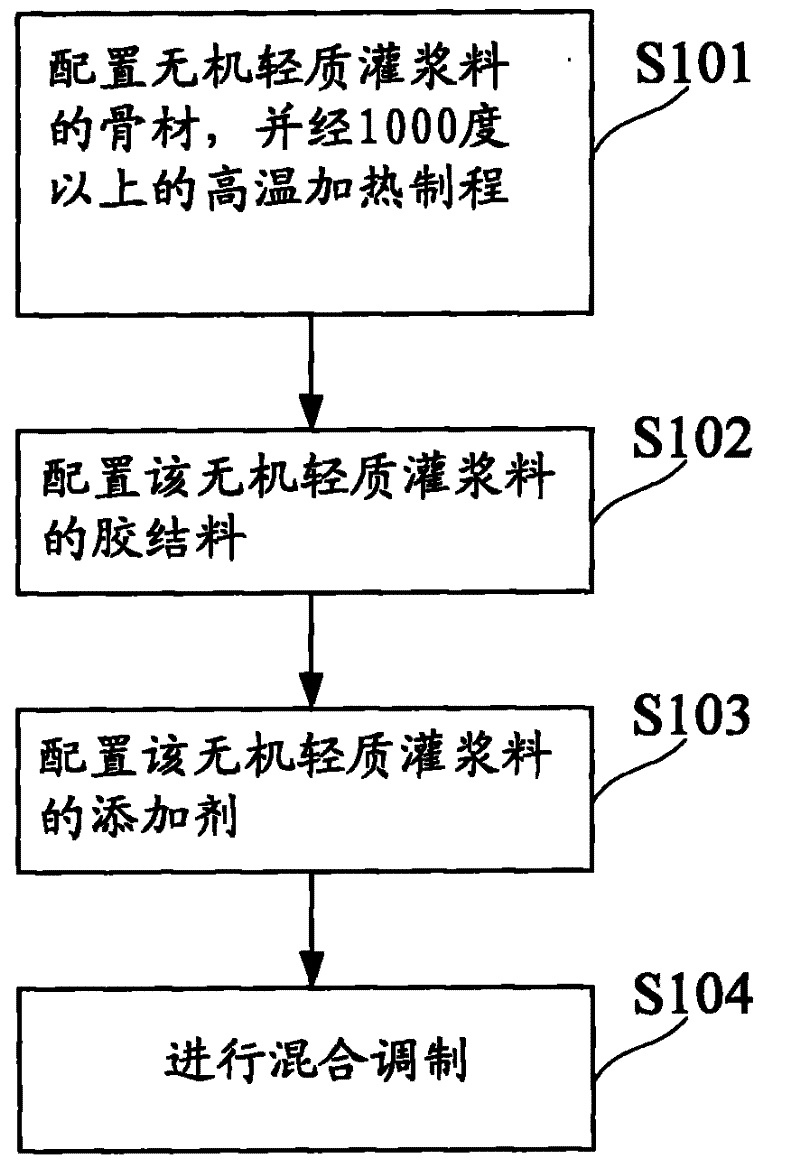

Inorganic lightweight grouting material, and manufacture method thereof

The invention discloses an inorganic lightweight grouting material, and a manufacture method thereof. The inorganic lightweight grouting material provided by the invention is manufactured from a low-density, surface-sealed and inside-hollow granular expanded ore such as pitch stone or perlite as main raw material, a powdery adhesive, an additive and the like through blending at a proper ratio. The inorganic lightweight grouting material is practically used by adding water according to a certain ratio, uniformly stirring, pouring into building wall and carrying out hydration reaction to form the grouting material for wall filling. The grouting material has the advantages of slight expansion, low specific gravity (smaller than water), good heat preservation and fireproof effects, strong high-temperature resistance, good sound absorbing property, low cost, etc.

Owner:古金盛 +1

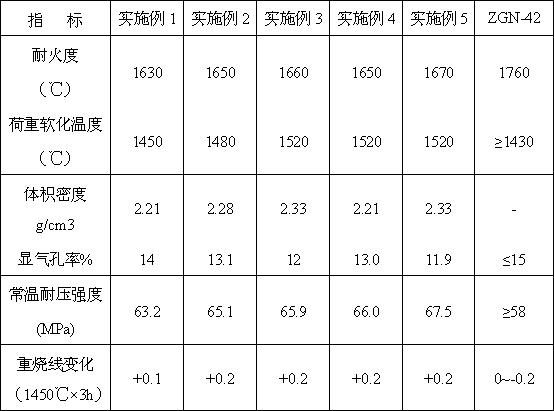

Pyrophyllite brick and preparation method thereof

The invention belongs to semi-silica refractory materials, and in particular relates to a pyrophyllite brick and a preparation method thereof. The pyrophyllite brick is prepared by mixing a pyrophyllite raw material, a pyrophyllite clinker, clay, an additive and a binding agent, and performing the processes of material preparing, aging, shaping, drying and sintering. The pyrophyllite brick prepared by the method has the characteristics of high load softening temperature, stable volume and slight expansion at an operating temperature, and can ensure that a brickwork is compact in structure, small in brickwork joint and good in integrity; and meanwhile, when the pyrophyllite brick is in contact with slag, because a high-viscosity liquid-phase 'enamel layer' formed on the surface, the pyrophyllite brick can block up slag infiltration, and the erosion resistance of the pyrophyllite brick is improved.

Owner:宜兴新威利成耐火材料有限公司

Pit backfill material, preparation method thereof and application method thereof

The invention discloses a pit backfill material and an application method thereof. The pit backfill material comprises cement, calcined activated coal gangue, steel slag powder, lime hydrate powder, phosphogypsum, an expanding agent, glass quartz sand tailings, machine-made sand, a water reducer, and modified starch ether. The material can be constructed through pumping only by adding water with 35-90% of the total weight on a building site and stirring according to requirements. The pit backfill material which is prepared from a large amount of industrial solid wastes in the invention and allows workability, water retention, fluidity and self-compaction fallibility to be good, compressive strength to be high, bonding strength and sulphate erosion resistance to satisfy relevant requirements, and slight dilatability to be possessed has the advantages of simple production technology, convenient application, waste utilization, energy saving, consumption reduction, low carbon, and good market prospect.

Owner:GUANGDONG REDWALL NEW MATERIALS

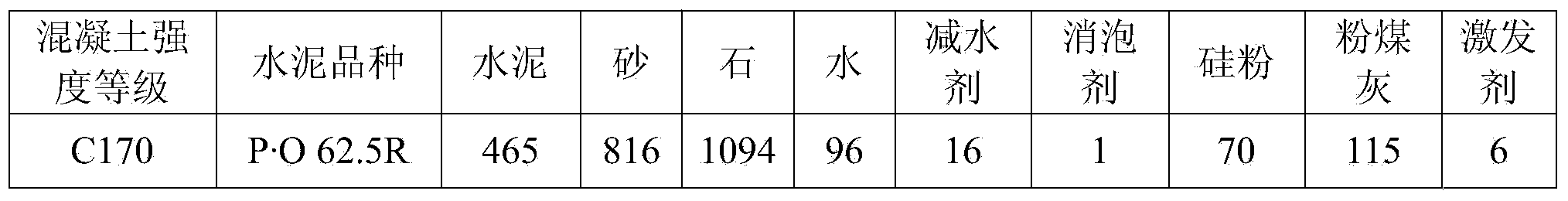

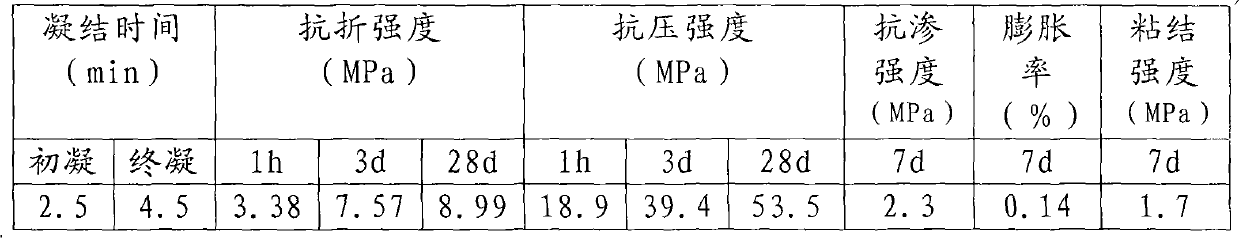

C170 strength-grade concrete for formed steel concrete composite structure

The invention discloses a C170 strength-grade concrete for a formed steel concrete composite structure, which is composed of 465 parts of cement, 816 parts of fine aggregate, 1094 parts of coarse aggregate, 96 parts of water, 16 parts of concrete superplasticizer, 1 part of defoaming agent, 70 parts of silicon powder, 115 parts of fly ash and 6 parts of activator. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has favorable working performance and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Low-density micro-expansion early-strength channeling-preventive oil well cement slurry and preparation method thereof

InactiveCN105062441AImprove performanceReduce free waterDrilling compositionVolumetric Mass DensityCement slurry

The invention discloses low-density micro-expansion early-strength channeling-preventive oil well cement slurry and a preparation method thereof. The density of the cement slurry is 1.05-1.55g / cm<3> and can be adjusted. The cement slurry is composed of oil well cement, lightening agents, stabilizing agents, early-strength agents, expansion agents, styrene-butadiene latex channeling-preventive agents, fluid loss agents, dispersing agents, defoaming agents and water, wherein the lightening agents are hollow glass micro beads, the stabilizing agent are superfine cement and micro silicone. The cement slurry is little in system free water, small in fluid loss amount, high in channeling-preventive performance, micro-expansion performance and mobility, good in slurry stability and adjustable in thickening time, has the advantages of being fast in low-temperature strength development, capable of preventing gas channeling and the like, and can be used for low-pressure leakage zones and low-pressure oil and gas reservoirs, and medium and low temperature region well cementation construction.

Owner:CNPC BOHAI DRILLING ENG

Semiflexible rapid leakstopping mortar with high impermeability

InactiveCN102001852ASolve the problem of compositional fluctuationsControllable setting and hardening timeSolid waste managementBasementUltimate tensile strength

The invention provides semiflexible rapid leakstopping mortar with high impermeability and certain flexibility, which comprises the following components in percentage by weight: 45-65% of aluminate cement used as a gelled material, 20-40% of mineral filler, 0.5-2% of bentonite used as a waterproofing agent, 2-5% of plaster used as an expanding agent, 0.1-0.5% of coagulant, 0.2-0.5% of water reducing agent, 2-4% of spurrite and 1-2% of redispersible latex power, wherein the coagulant, the water reducing agent, the spurrite and the redispersible latex power are used as auxiliary materials. The leakstopping mortar has the advantages of high setting speed, high strength, no later strength shrinkage, high bonding strength, high impermeability, microdilatancy, high deformation resistance and the like and can be widely applied to leakstopping of concrete structures, such as a water pool, a house, a basement and a tunnel.

Owner:广东龙湖科技股份有限公司

Recycled concrete commercial mortar

The invention discloses recycled concrete commercial mortar which consists of the following components in percentage by weight: 15-25% of recycled concrete micro powder, 50-60% of recycled concrete fine aggregate, 7-10% of desulfurized gypsum, 10-15% of caustic sludge, 3-5% of washing slurry, 3-5% of portland cement clinker, 1-3% of aluminum slag and 0.5-1.5% of additive. The recycled concrete commercial mortar disclosed by the invention relieves the environmental protection stress on the urban construction, alkali production and power enterprises and the stress in lack of resources of building material enterprises, reduces the burden of waste discharge on enterprises, increases the income and improves the ecological environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Red mud-based slip-casting plugging material

ActiveCN108329004AGood water retention performanceReduce autogenous shrinkage drying shrinkageCoalPulverised fuel ash

The invention discloses a red mud-based slip-casting plugging material. The red mud-based slip-casting plugging material comprises the following components by weight percentage: 20-40% of red mud, 20-40% of fly ash, and 20-45% of cement, and the sum of the weight percentage is 100%; the red mud-based slip-casting plugging material also comprises an expansion component with an applied doping amountbeing 0.6-9% and a rheological component with the applied doping amount being 1.3-6%; wherein the expansion component comprises an expanding agent and an antifoaming agent, and the rheological component comprises a water reducer and silica micropowder. The red mud-based slip-casting plugging material mainly aims at a coal-mine gas hole-sealing leak-stopping material, and has the advantages of good plugging effect, high intensity after plugging, good air tightness, and less self-constriction at a later period.

Owner:太原理工恒基岩土工程科技有限公司

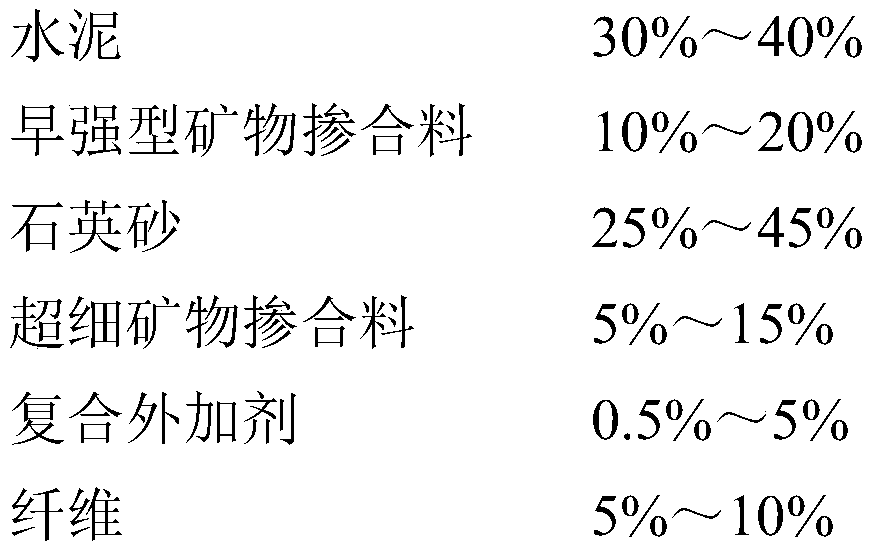

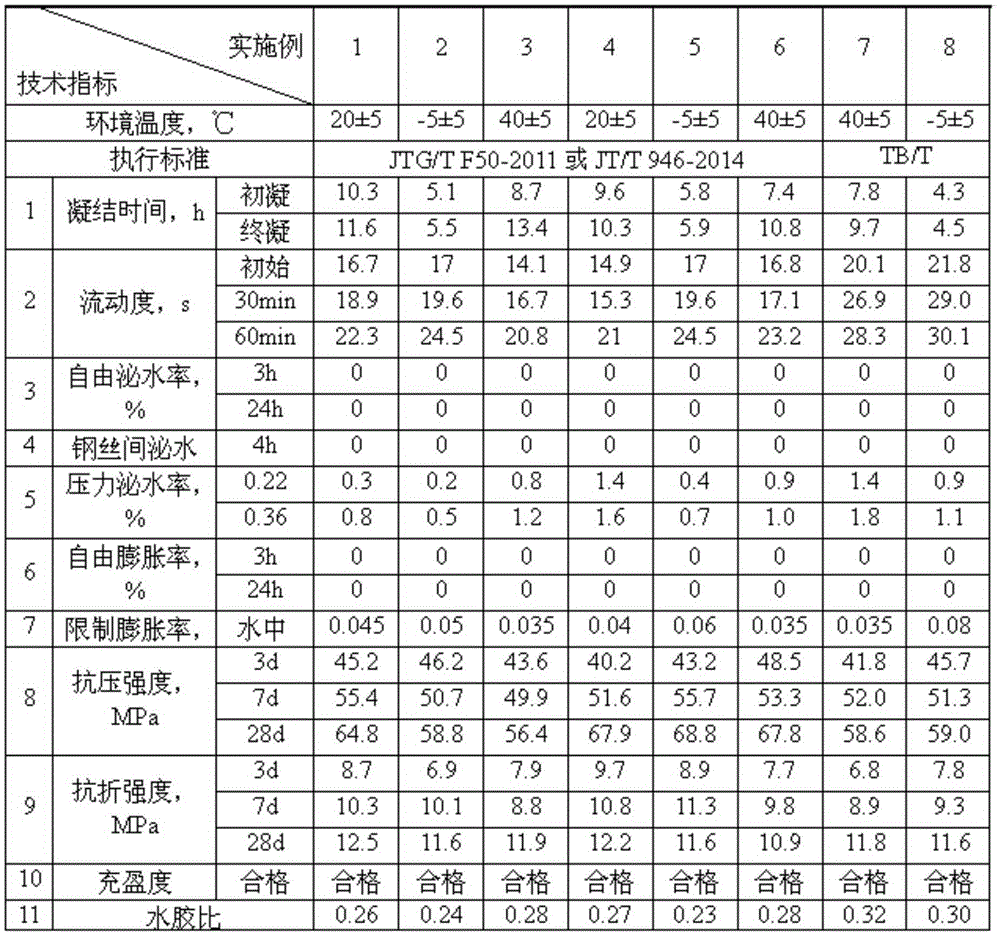

Grouting material for composite structure and fabricated building joint and preparation method thereof

InactiveCN111116132ARealize regionalized commercial supplyWith micro expansionSilicon dioxideUltimate tensile strength

The invention relates to a grouting material for composite structure and prefabricated building node pouring. The grouting material is prepared from, by mass, 30%-40% of cement, 10%-20% of an early-strength mineral admixture, 25%-45% of quartz sand, 5%-15% of a superfine mineral admixture, 0.5%-5% of a composite additive and 5%-10% of fiber, and the superfine mineral admixture is two or three of microbeads, silica fume and nano-silicon dioxide. The composite additive comprises an expanding agent, a retarder, a defoaming agent, a reinforcing agent and a water reducing agent; the fiber is a mixture of steel fibers and organic fibers. The invention also discloses a preparation method of the grouting material, and the method comprises the following steps: mixing the components of the groutingmaterial into a dry mixture, packing and packaging, and the preparation method is simple. The grouting material has the advantages of micro-expansion, high filling property, ultrahigh strength, high ductility and high vibration resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Pre-stressed duct grouting agent, and preparation and application methods thereof

The invention provides a pre-stressed duct grouting agent which has the characteristics of high fluidity, bleeding prevention and the like. The pre-stressed duct grouting agent comprises the following components: 2 to 10 percent of a water reducing agent, 0.1 to 10 percent of a viscosity modifying agent, 0 to 1 percent of a defoaming agent, and 35 to 78 percent of a coagulation time regulating agent; the coagulation time regulating agent comprises the following components: 28 to 52 percent of clinker, 42 to 68 percent of plaster, 4 to 30 percent of fillers, and 0 to 3 percent of a coagulation accelerator. The invention further provides a preparation method and an application method of the pre-stressed duct grouting agent. The invention has the advantages that the pre-stressed duct grouting agent contains the cement coagulation time regulating agent, so that the coagulation time of a cement-based composite material can be regulated based on external temperature changes to guarantee the normal use and normal strength growth of the cement-based composite material; meanwhile, the cement-based composite material achieves micro-expansion at the later stage due to the addition of the cement coagulation time regulating agent.

Owner:WUHAN BILLION TECH DEV CO LTD

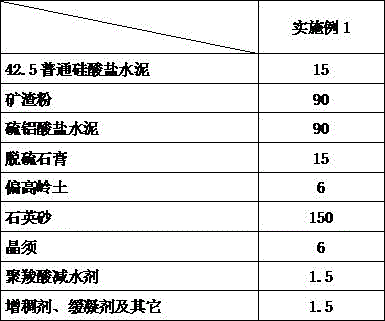

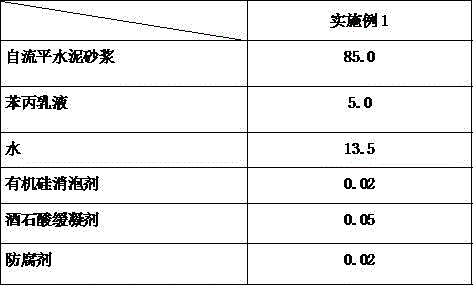

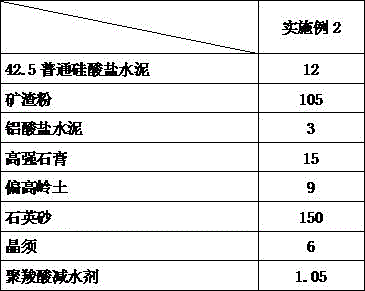

Whisker reinforcement-based self-leveling cement mortar and application thereof

The invention discloses whisker reinforcement-based self-leveling cement mortar. The whisker reinforcement-based self-leveling cement mortar comprises the following components in parts by weight: 10 to 20 parts of ordinary Portland cement, 50 to 150 parts of slag powder, 3 to 20 parts of special cement, 10 to 20 parts of gypsum, 5 to 10 parts of metakaolin, 100 to 160 parts of quartz sand, 1 to 10 parts of a crystal whisker and 1 to 1.5 parts of a water-reducing agent, wherein the special cement adopts sulphoaluminate cement or aluminate cement; the gypsum adopts one of or a mixture of more than two of high-strength gypsum, fluorgypsum, desulfurized gypsum and citric acid gypsum; and the crystal whisker adopts one of or a mixture of more than two of gypsum crystal whiskers, a magnesium hydroxide crystal whisker, a magnesium oxide crystal whisker, an ettringite crystal whisker and a calcium carbonate crystal whisker. A terrace prepared from the whisker reinforcement-based self-leveling cement mortar has high surface hardness and high anti-compression and anti-bending strength, and can meet the wear-resistant requirement of most occasions.

Owner:江苏蓝圈新材料股份有限公司

All-solid-waste cementing material for fine tailing filling and preparation method thereof

The invention provides an all-solid-waste cementing material for fine tailing filling and a preparation method, and belongs to the technical field of tailing filling mining. According to the material,steel slag is used for replacing clinker or lime or other alkaline materials, the synergistic and self-excitation action mechanism of steel slag and chemical gypsum is utilized, no artificial material is added, and the cementing material is prepared from, by weight, 35%-50% of steel slag, 15%-25% of chemical gypsum and 25%-50% of slag. The cementing material is high in utilization rate of low-quality solid waste, wide in source, low in material cost and suitable for preparation of fine tailing filling slurry for filling method mining, the fine tailing filling body has micro-expansibility, roof contact of a filling stope is facilitated, and therefore the stability of the filling stope is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com