Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

240results about How to "Fast hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoviscoelastic System Fluid and Well Treatment Method

InactiveUS20070281869A1Hydrate fastEasy and quick to prepareFlushingDrilling compositionSolubilityCross-link

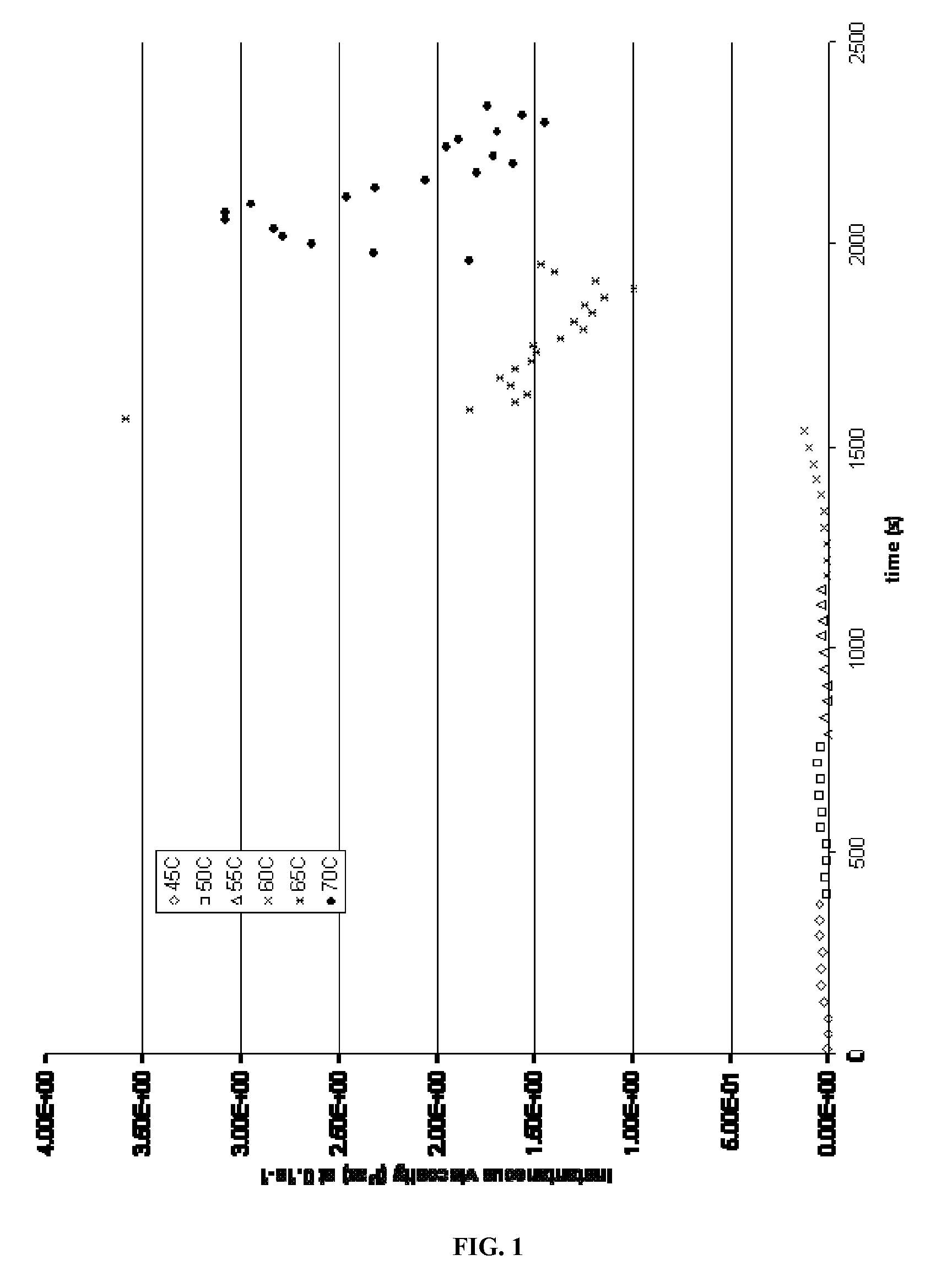

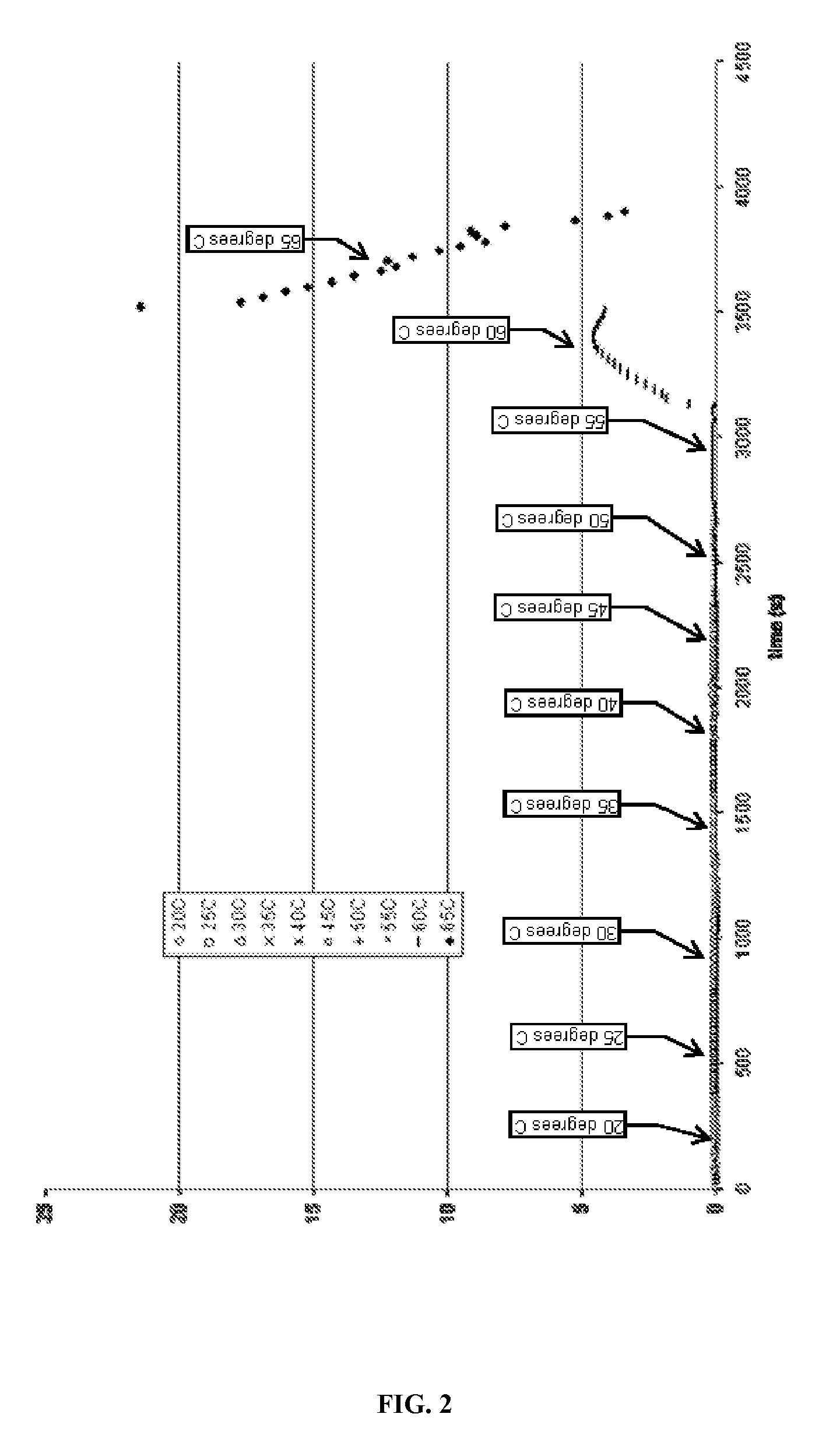

A thermoviscoelastic system (TVE) fluid useful in a well treatment method can include a hydrophobically-modified polymer and a viscoelastic surfactant (VES) in an aqueous medium, wherein the polymer has a lower critical solution temperature (LCST). The polymer can have water solubility for preparation below the LCST, and the TVE has a low viscosity for pumping down a well bore in communication with a subterranean formation. When the TVE is heated above the LCST, interaction between the hydrophobic groups of the polymer and the VES form a cross-linked network to increase the viscosity to transport proppant into a fracture. The thickened TVE can have a low leak-off rate, optionally including colloidal particles or other fluid loss control agent, and can be broken by contact with hydrocarbons as during flowback from the reservoir.

Owner:SCHLUMBERGER TECH CORP

Hemostatic compression bandage

InactiveUS20060155235A1Continuous woundFast activationAdhesive dressingsEngineeringMechanical engineering

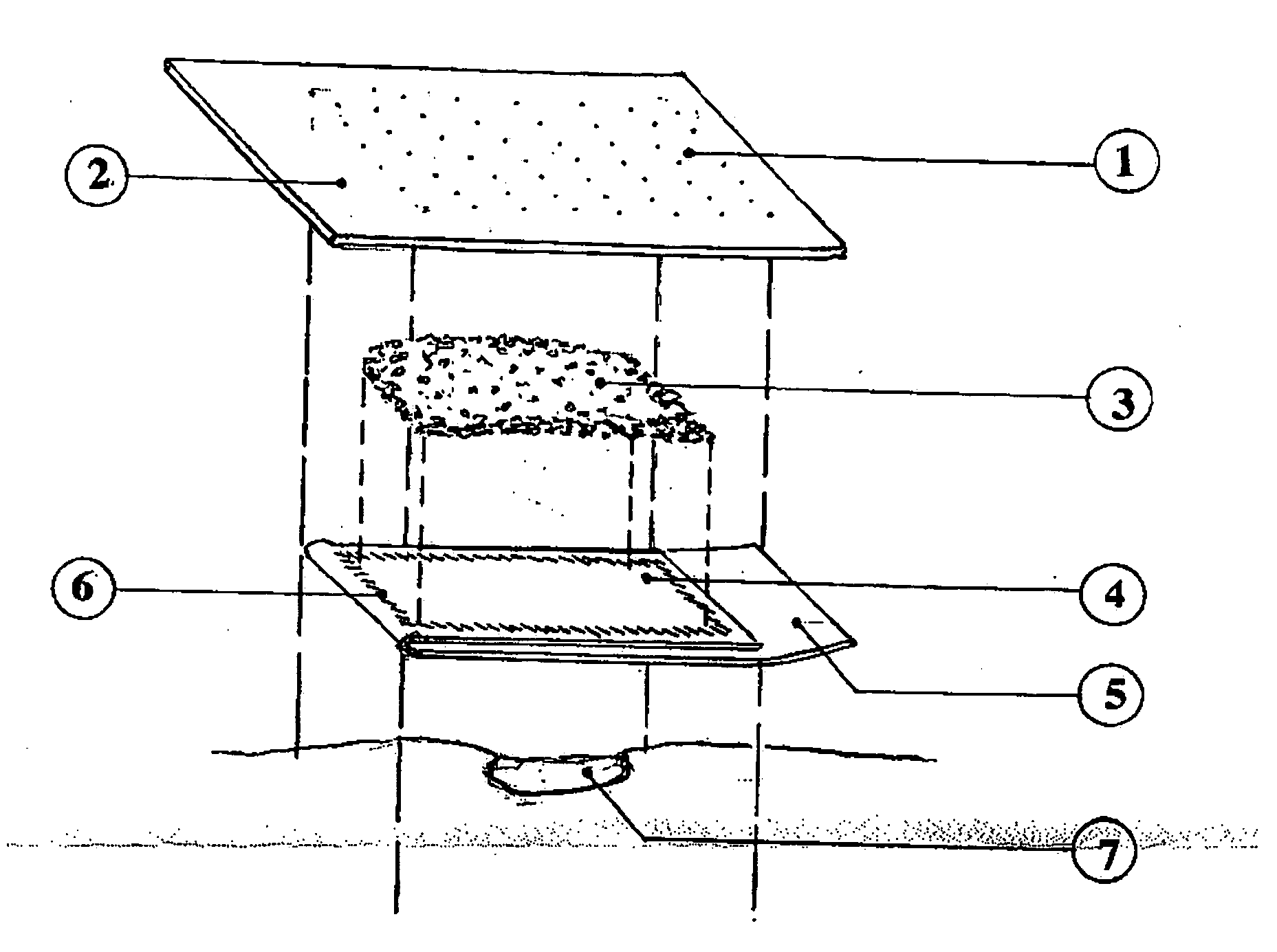

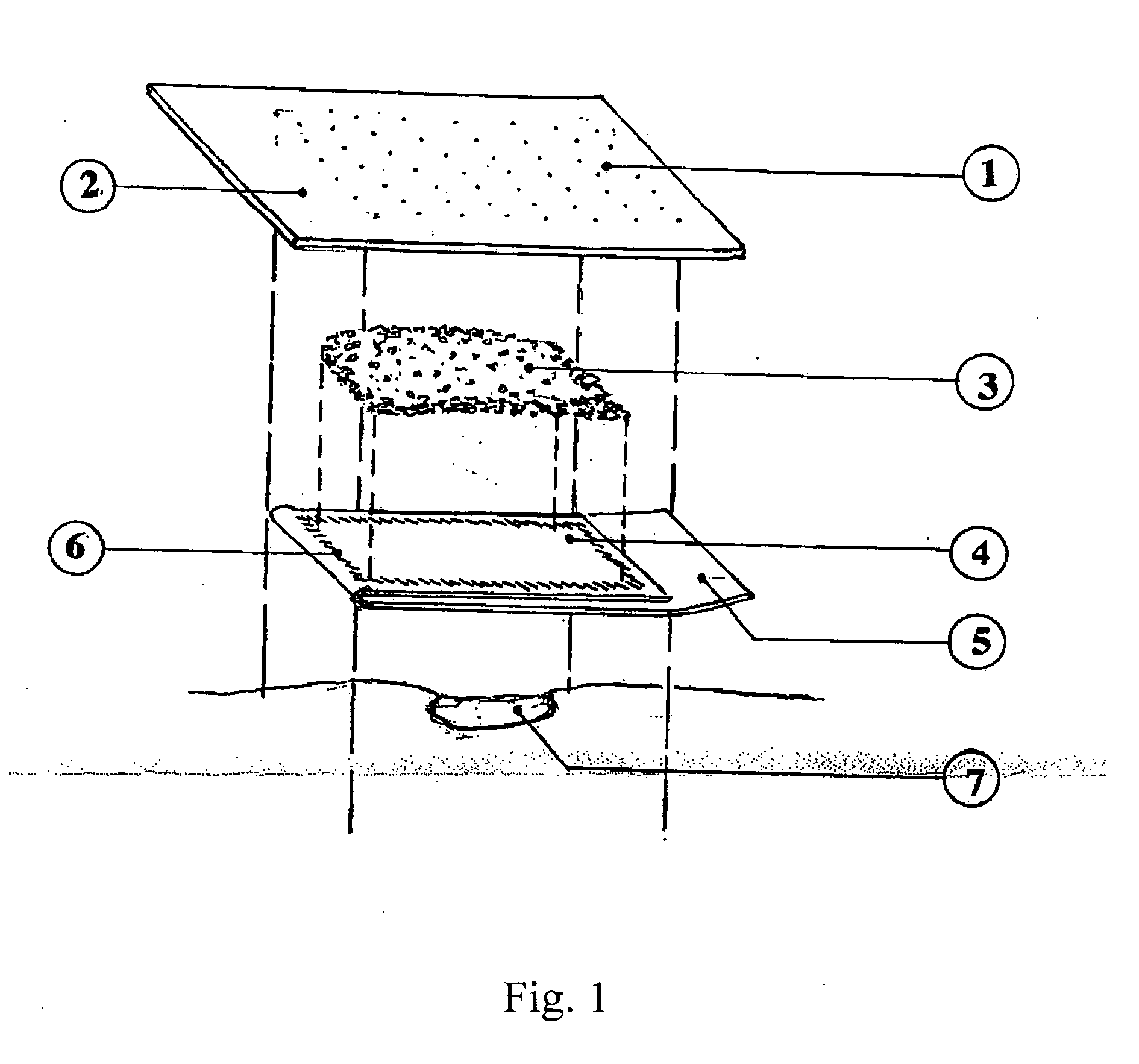

A hemostatic compression bandage includes a flexible backing element, a powdered hemostatic substance, and a flexible film element. The backing element includes a first containment region. The film element includes a second containment region corresponding to the first containment region. The film element is removably attached to the backing element so as to contain the hemostatic substance between the backing element and the film element within a volume defined by the first containment region and the second containment region. The backing element includes a pressure region located outside of the first containment region. The film element includes a pull-tab region located outside of the second containment region and at a first side of the bandage. The pull-tab region has sufficient length to be folded back across the second containment region and extending beyond a second side of the bandage that is opposite the first side of the bandage.

Owner:SAWYER EVELYN S

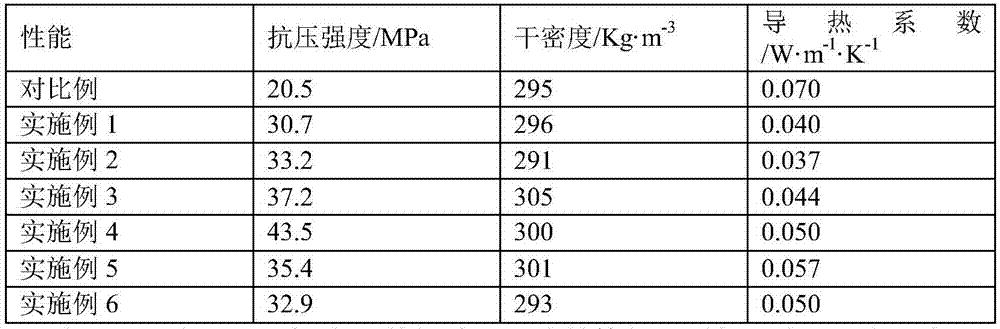

Silicate-based light-weight foam concrete and preparation method thereof

ActiveCN106966670AImproved carbonation resistanceImprove the stability of mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses silicate-based light-weight foam concrete and a preparation method thereof. The silicate-based light-weight foam concrete is prepared from silicate cement, an inorganic admixture, water, a foaming agent and an additive, wherein the mass ratio of the inorganic admixture to the silicate cement is 0.3 to 1.3; the water accounts for 35 to 65 percent by mass; and the foaming agent accounts for 3 to 10 percent by mass. The silicate-based light-weight foam concrete has the beneficial effects that the silicate cement is used as a cementing material; and compared with a sulfoaluminate-based material, the silicate-based light-weight foam concrete has the advantages that the carbonation resistance, the mechanical performance stability, the temperature tolerance and other properties are improved. By adjustment of the contents of all functional components (a thickening time control agent, a foam stabilizer, a water reducing agent, an anti-cracking component, an expanding agent and the like), the silicate-based light-weight foam concrete can conform to various preparation conditions of the silicate cement used as a base material.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

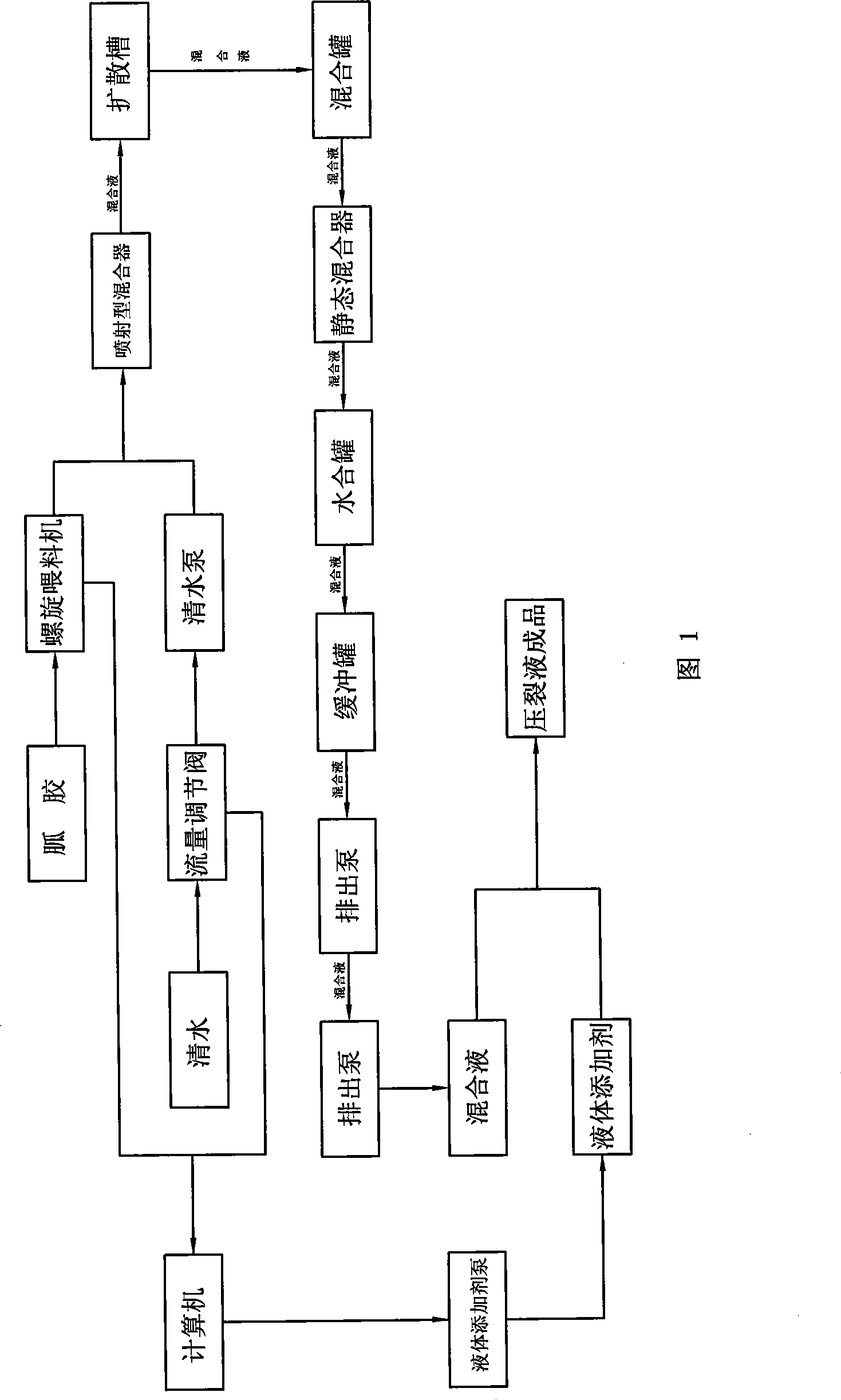

Continuous compounding method for fracturing fluid

The invention discloses a fracturing fluid continuous mixing method, comprising the steps as follows: guar gum is input into an injection-typed mixer which can automatically adjust the flux by a precise spiral feeding machine; the feeding quantity of the guar gum is adjusted by the rotation speed of the precise spiral feeding machine; the blanking quantity of the spiral feeding machine is controlled by a computer which can continuously read the difference value of an electronic balance within unit time, adjusts the rotation speed of the spiral feeding machine according to the flux and proportion of the external clean water and keeps the given liquid mixing ratio; the method is applicable to continuous mixing in-situ, the mixed fracturing fluid has good quality, the hydration speed of the liquid is fast, the labor intensity of workers is reduced, the cost payout is saved and the environmental pollution is reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

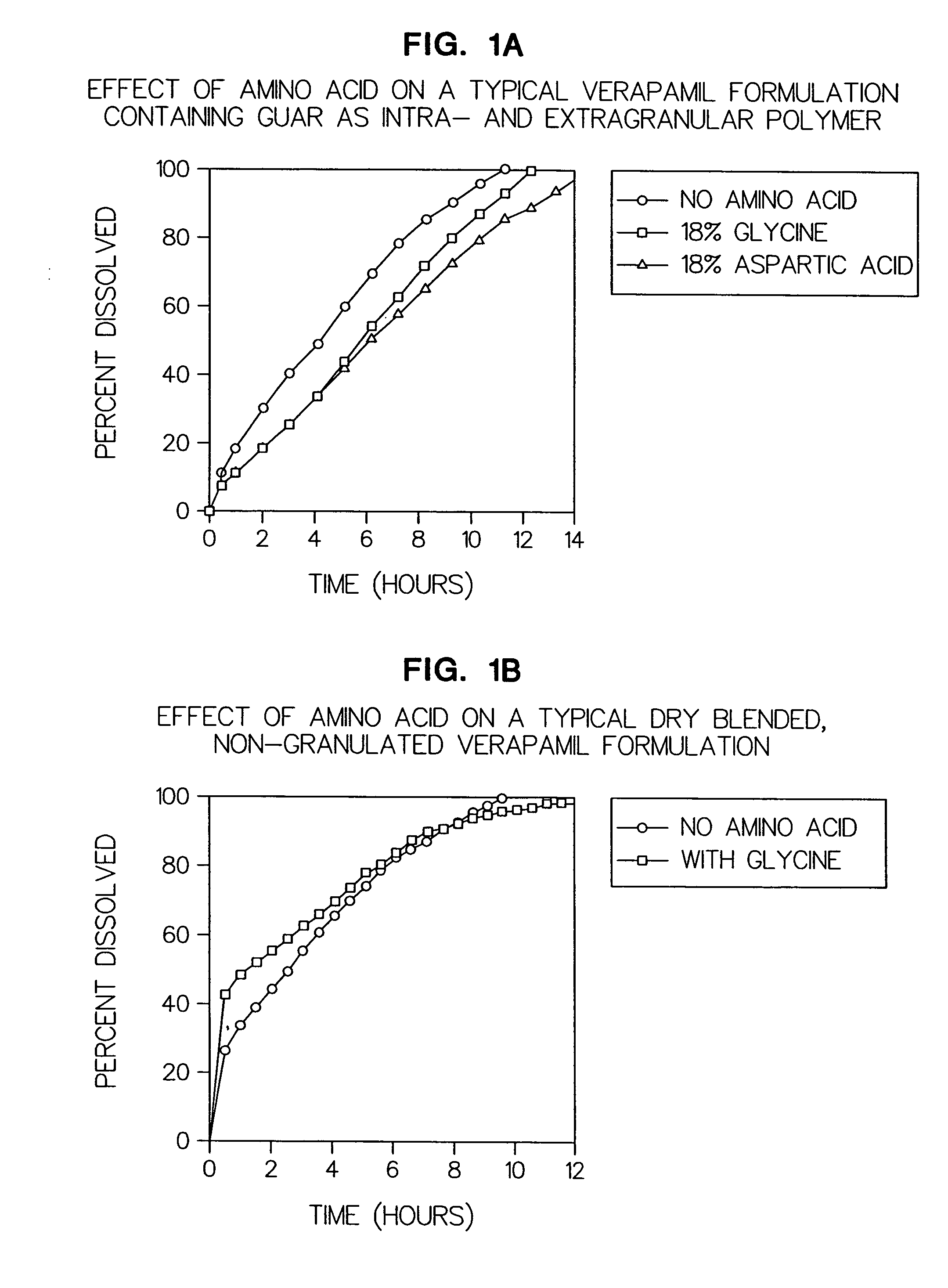

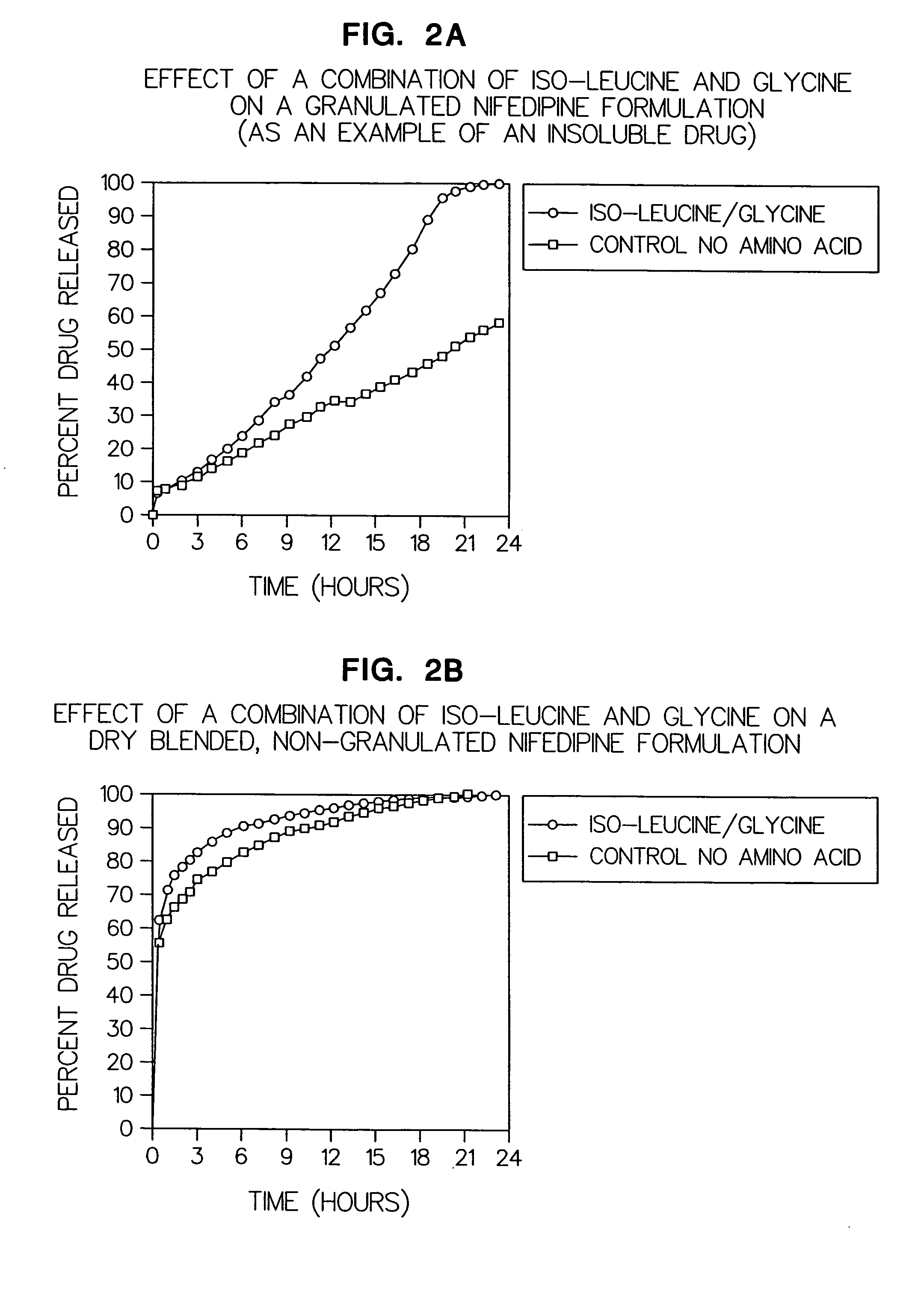

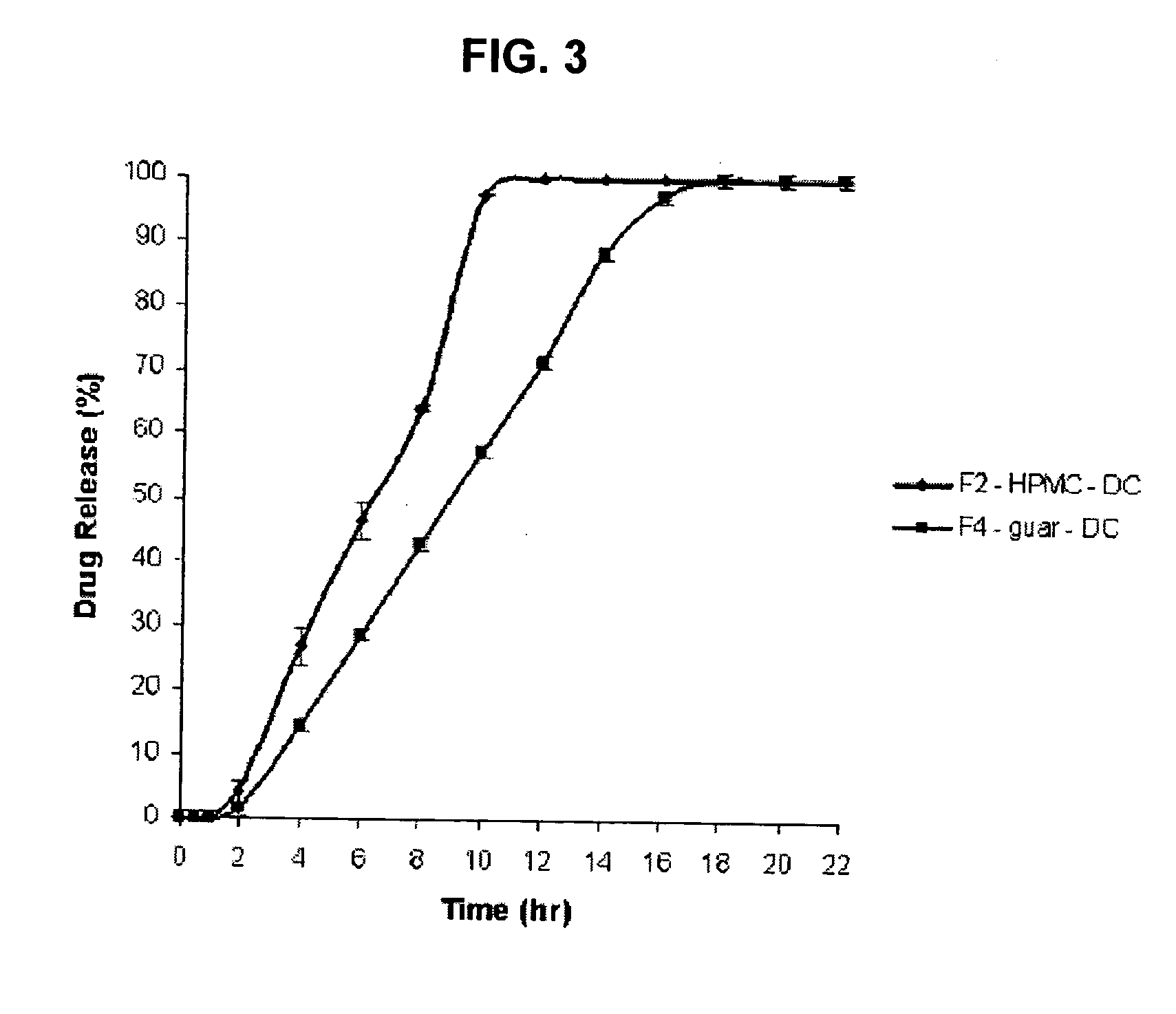

Amino acid modulated extended release dosage form

Disclosed herein is a oral extended release dosage form comprising a plurality of granules of an effective amount of a pharmaceutically active compound, at least one amino acid, and an intragranular polymer in which the granule is dispersed within a hydrophilic extragranular polymer matrix which is more rapidly hydrating than the intragranular polymer. The amino acid is selected for hydropathy characteristics depending on solubility characteristics of the active compound.

Owner:SCOLR PHARMA

Method of preparing low-density well cementation cement check block of oil well by utilizing silicon carbide ceramic microbeads

The invention provides a method of preparing a low-density well cementation cement check block of an oil well by utilizing silicon carbide ceramic microbeads. The method comprises the following steps: preparing silicon carbide closed-hole hollow ceramic microbeads; burdening; mixing; stirring and mixing; carrying out mould testing; carrying out a strength test. The method is characterized by specifically comprising the following steps: stirring and mixing 40-50wt% of G-grade well cementation cement, 10-15wt% of 13-micron superfine cement, 25-35wt% of closed-hole silicon carbide ceramic microbeads with the grain size of 5-50 microns, 5-7wt% of coal ash with the loss on ignition of 1.1%, 1.5-2wt% of calcium oxide with the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon in a stirrer for 40 seconds in a micro-silicon of 0.5-0.6(W / C); pouring and carrying out mould testing; maintaining for 24 hours and 48 hours in a water bath maintaining box at a constant temperature of 52 DEG C; soaking for 1 hour in cold water after demoulding and carrying out performance test.

Owner:鑫领域智能科技(邳州)有限公司

Composite mineral admixture for concrete

The invention discloses a composite mineral admixture for concrete. The admixture is prepared by mixing and grinding the following raw materials in percentage by weight: 40 to 60% of lithium slag, 10 to 30% of mineral slag, 5 to 20% of nickel slag, 5 to 10% of aerated concrete waste, 5 to 10% of sulfoaluminate cement clinker, and 0.1 to 0.5% of super plasticizer powder. The industrial wastes are fully utilized, the concrete production cost is reduced, and the admixture has a high activity, barely influences the early and late strength of concrete, has a shrinkage-compensating function and good anti-permeability property, and can improve the service life of concrete.

Owner:SOUTHEAST UNIV

Foam concrete

The invention discloses foam concrete. The foam concrete comprises following raw materials in parts by mass according to a formula: 210-300 parts of cement, 1.0-1.5 parts of a water reducing agent, 5.1-5.5 parts of an early strength agent, 2.1-2.9 parts of a coagulant, 1.7-3.4 parts of fibers, 12-20 parts of a chemical foaming agent, 0-90 parts of superfine slag powder and 100-160 parts of water, wherein the superfine slag powder is formed by aluminosilicate glass particles smaller than 15 mu m, and the specific surface area is 450-500 m<2>*kg<-1>. The compressive strength of the foam concrete is improved on the premise that the foam concrete keeps low density.

Owner:BEIJING MINJIA NEW BUILDING MATERIALS CO LTD

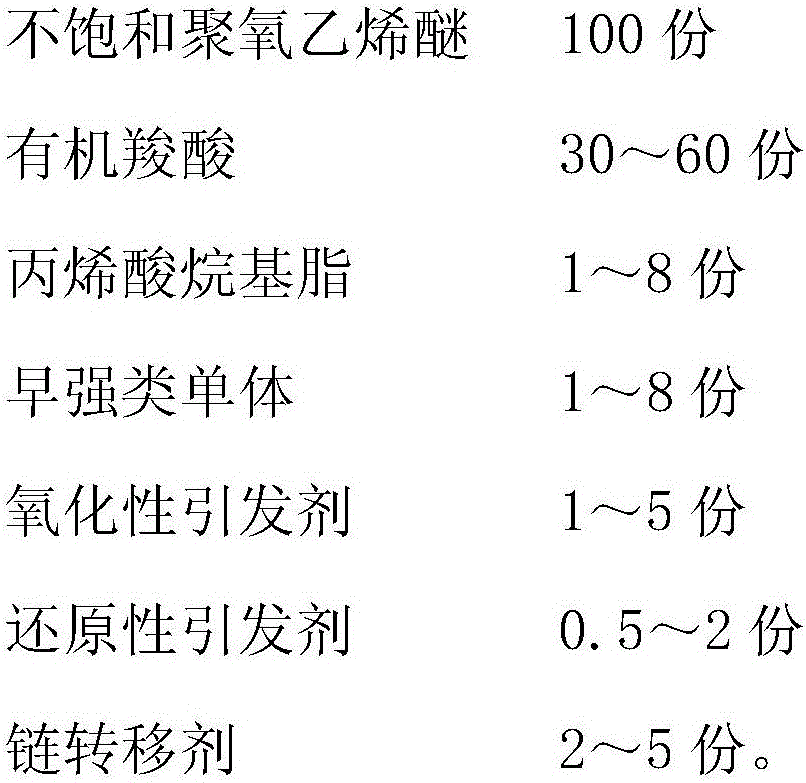

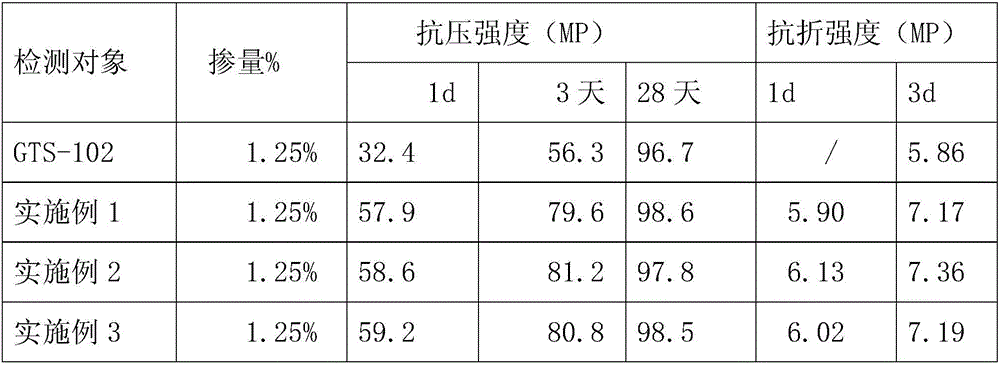

Super high-early-strength type polycarboxylate superplasticizer and preparation method thereof

The invention discloses a super high-early-strength type polycarboxylate superplasticizer and a preparation method thereof. The method comprises the following steps: putting water, unsaturated polyoxyethylene ether, early strength group monomer and oxidizing initiator into a reaction kettle; stirring till dissolving; heating to 30-80 DEG C; adding prepared solution A and solution B; maintaining the temperature for 1-2h, and then adding alkali and neutralizing till pH is 6-7; and replenishing water till the solid content is 40-45%, thereby acquiring the super high-early-strength type polycarboxylate superplasticizer. The super high-early-strength type polycarboxylate superplasticizer and the preparation method thereof have the beneficial effects that a long lateral chain is introduced into a polycarboxylic acid macromolecule main chain; the longer the lateral chain is, the better the dispersibility of the superplasticizer is; the density of the long lateral chain is reduced; the steric hindrance is reduced; the cement hydration is quicker; an early strength group is introduced into superplasticizer molecules, so that the cement hydration speed can be further increased and the early strength of the concrete can be greatly promoted; and the problems of the present polycarboxylate superplasticizer that the hydration of the cement is delayed and the early strength development is slow can be solved.

Owner:上海高铁化学建材有限公司

High-temperature-resistant well cementation cement paste system

ActiveCN111072350ALower requirementReduce dosageDrilling compositionHydration reactionPortland cement

The invention discloses a high-temperature-resistant well cementation cement paste system, and relates to the technical field of cement paste systems. The system comprises the following components: 60-75% of Portland cement; 15-25% of a strength recession resisting agent; 2-8% of a crystal form stabilizer; 0.5%-6% of a high-temperature retarder; and 3-8% of a high-temperature fluid loss agent, wherein the Portland cement is one of D-grade oil well cement or low-heat cement, and the specific surface area of the Portland cement is 280-350 m<2> / kg; the SiO2 content in the strength recession resisting agent is greater than 90%, and the mesh number is greater than or equal to 150 meshes; the content of SiO2 in the crystal form stabilizer is greater than 30%, and the mesh number is greater thanor equal to 600 meshes. The crystal form stabilizer is added and participates in hydration reaction when cement is hydrated, metal ions enter the structure of hydrated calcium silicate, so that conversion of tobermorite in a hydration product into xonotlite is prevented, the set cement is kept in a compact structure, and therefore, good high-temperature stability is achieved.

Owner:JIAHUA SPECIAL CEMENT +1

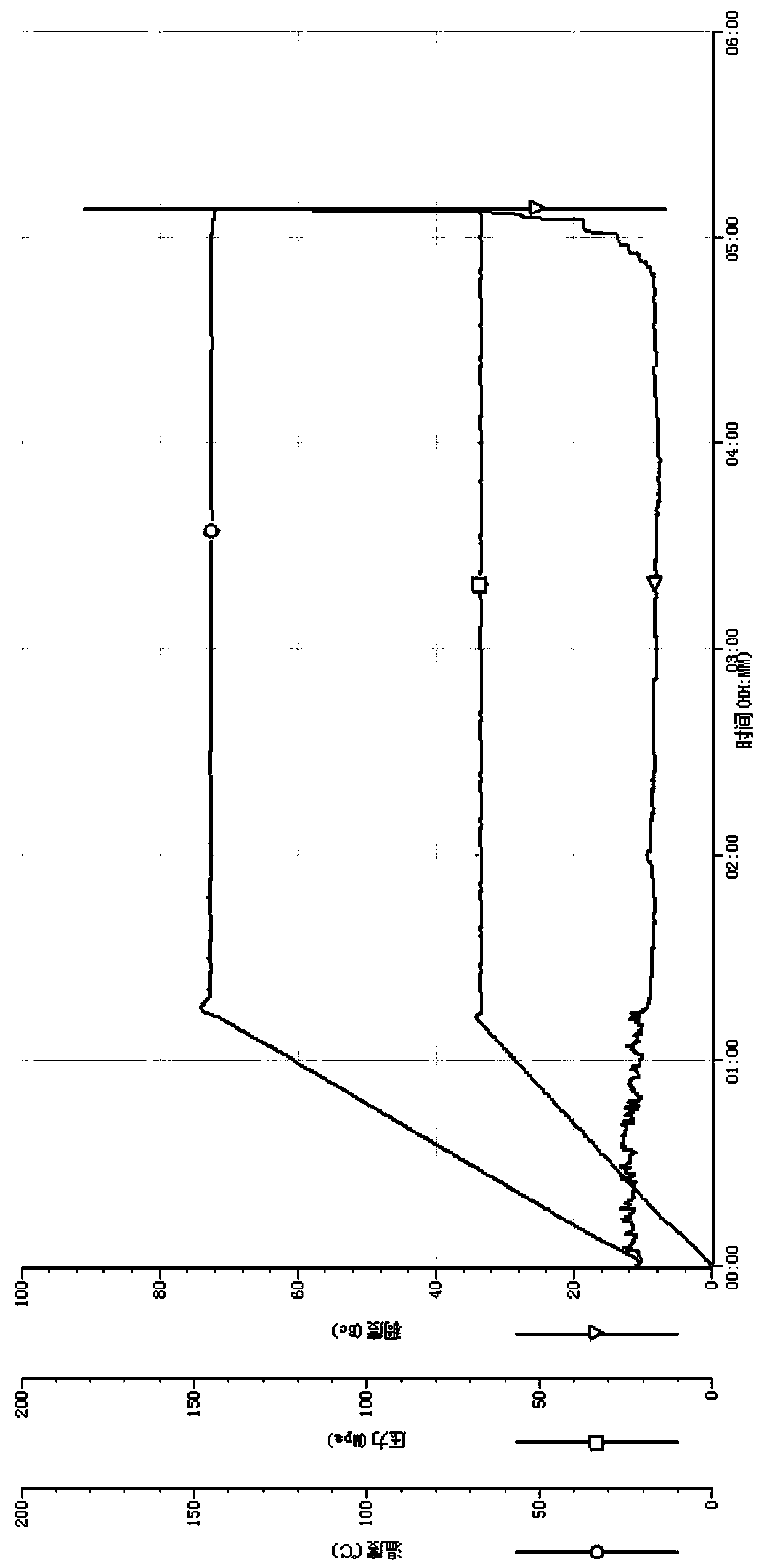

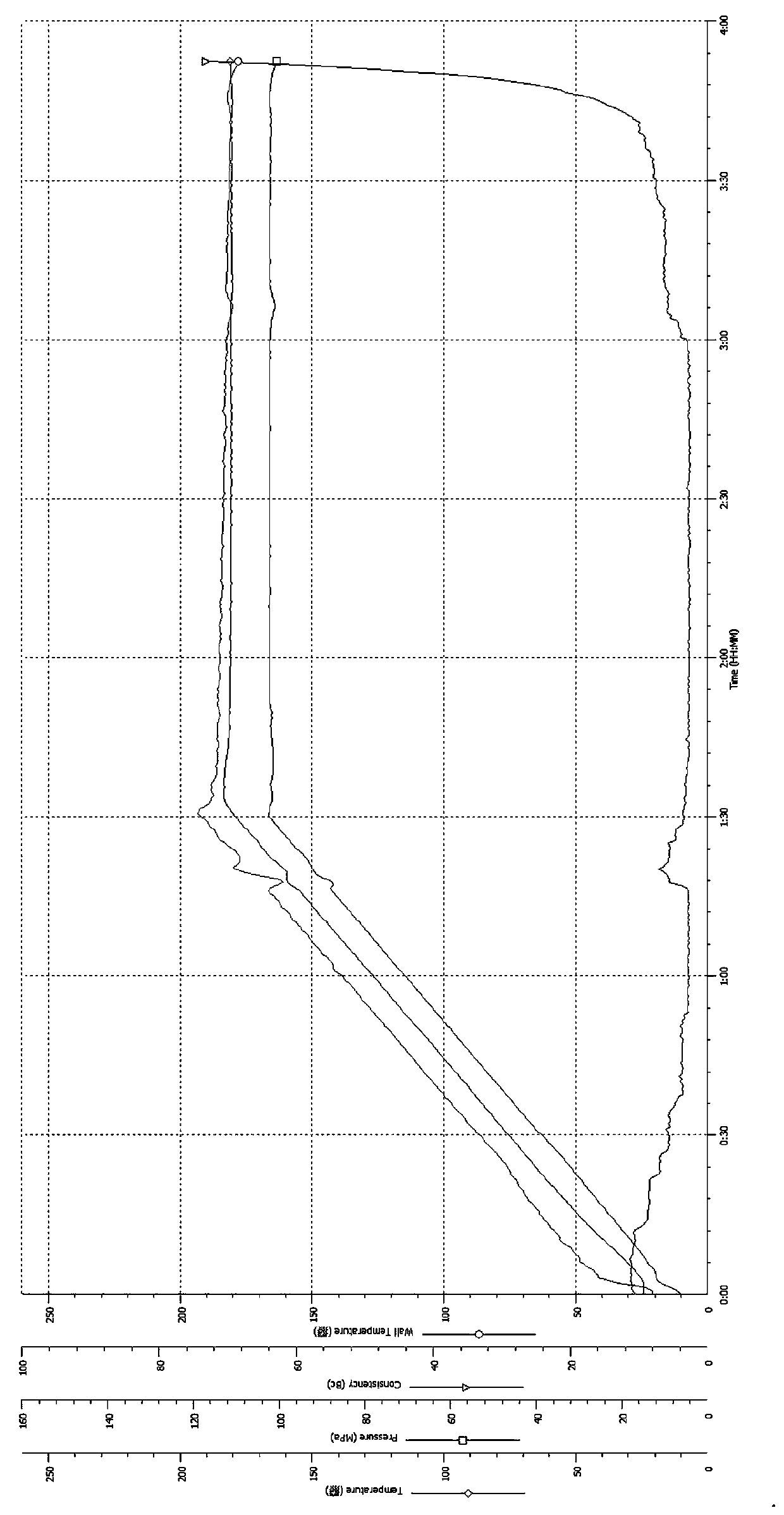

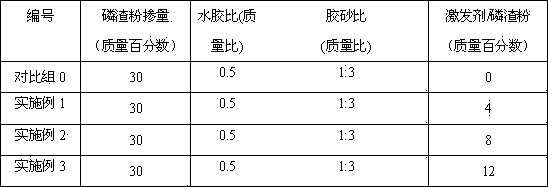

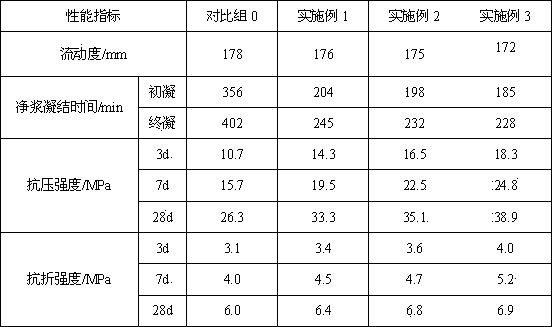

Active compound activator of phosphorous slag powder and using method thereof

The invention belongs to the technical field of a building material, and particularly relates to an active compound activator of phosphorous slag powder and a using method thereof. The active compound activator is compounded of industrial waste carbide slag, desulfurized gypsum, and chemical reagents (or industrial materials) sodium silicate, aluminum sulfate and sodium hydroxide. A plurality of activation compound effects of alkali-activation, basic salt-activation, sulfate activation and the like are mainly utilized to completely activate the activity of the phosphorous slag powder. By adopting the product disclosed by the invention, the activity of the phosphorous slag powder can be effectively activated; the problems of delayed coagulation, low early strength, slow strength development and the like existing when the phosphorous slag powder is used as concrete or mortar admixture are obviously relieved. By adopting the active compound activator, application of the phosphorous slag powder as the admixture in the industries such as cement and concrete can be facilitated, waste materials are changed into precious materials; the economic benefits are improved; meanwhile, the problems of environmental pollution, soil waste and the like caused by stocking of a lot of phosphorous slag also can be solved; the environmental benefits are improved. In addition, the problem of shortage of excellent admixtures such as coal ash, slag powder and the like in the industries such as cement and concrete also can be relieved.

Owner:TONGJI UNIV

Method for source modification treatment of fluoro-gypsum

The invention discloses a method for source modification treatment of fluoro-gypsum which comprises the steps of, (1) raw material selection, charging composite active triggering agent and alkaline material into the fluoro-gypsum, wherein the mass fraction of each components are, fluoro-gypsum 93-97, composite active triggering agent 1-2, alkaline material 2-5, (2) agitating and mixing, transferring to rainproof yard, stewing, (3) stacking, trickling and maintaining. The modified fluoro-gypsum is applied to cement production.

Owner:WUHAN UNIV OF TECH

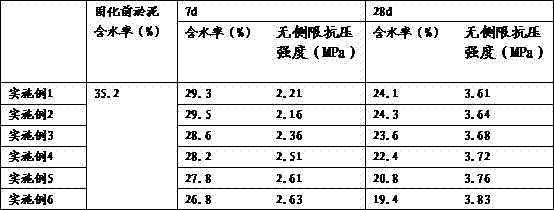

Compound curing agent for dredged silt and preparation method thereof

ActiveCN107226661AFully and evenly absorbedNo localized underabsorptionFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentFiberGraphite

The invention relates to a compound curing agent for dredged silt and a preparation method thereof. The compound curing agent for dredged silt comprises the following components in parts by weight: 20-30 parts of aluminum sulfate cement clinker, 30-40 parts of expandable graphite, 5-10 parts of organobentonite, 3-8 parts of pozzolanic material, 1-3 parts of calcined diatomite, 3-5 parts of enhanced aggregate, 6-12 parts of quicklime, 10-15 parts of sodium hydroxide, 8-10 parts of expansible resin, 5-8 parts of sodium silicate and 5-8 parts of carbon fiber. The curing agent provided by the invention combines the respective advantages of multiple traditional soil stabilizers, and the various effective components are organically combined together according to a proper ratio, thereby giving full play to the characteristics and synergistic action of the components. The curing agent provided by the invention has the advantages of favorable early strength performance, excellent strength stability, favorable water stability and the like, can obviously improve the properties of silt such as high water content, low strength and the like, and converts the waste dredged silt into a reproducible geomaterial for utilization, thereby achieving excellent curing effects and economic effects.

Owner:余思哲

Gunning material for main tapping channel of single-taphole blast furnace

ActiveCN102557696AImprove high temperature slag erosion resistanceImprove high temperature strengthNano siliconSlag

The invention discloses a gunning material for a main tapping channel of a single-taphole blast furnace. The gunning material comprises the following components in part by mass: 45 to 52 parts of dense corundum or brown corundum, 24 to 32 parts of silicon carbide, 6 to 12 parts of white corundum, 5 to 10 parts of alpha-Al2O3 micro powder, 1 to 3 parts of micro silicon powder, 2 to 3 parts of purecalcium aluminate cement, 1 to 5 parts of spherical asphalt, 2 to 4 parts of silicon metal powder, 1 to 1.5 parts of nano silicon-aluminum gel powder, 0.5 to 0.8 part of boron nitride, 0.3 to 0.5 part of neodymium oxide, 0.5 to 0.8 part of zirconia, 2 to 2.5 parts of compound additive and 0.3 to 0.5 part of compound explosion-proof agent. The high temperature slag corrosion resistance, high temperature strength, hydration rate and early strength of the gunning material are improved, the gunning material has high explosion-proof property and quickly achieves high temperature strength at high temperature, and the gunning stack cannot fall.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

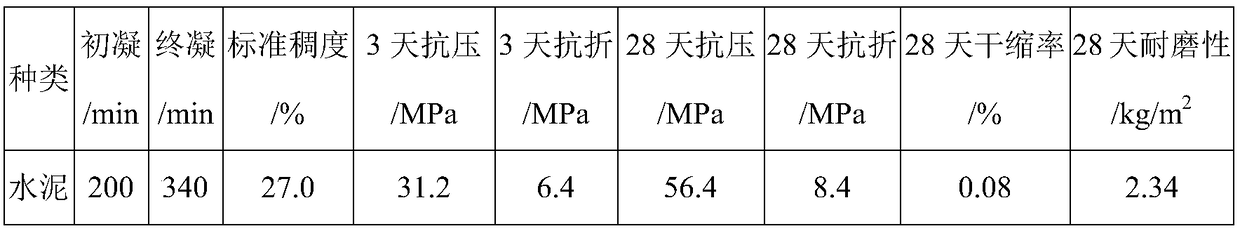

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

Method for activating waste concrete micro powder

InactiveCN102992669AFast curing reactionFull curing reactionSolid waste managementRoom temperatureSodium silicate

The invention relates to a method for activating waste concrete micro powder, comprising the following steps of: (1) mixing waste concrete micro powder and powdered sodium silicate, heating to 250-350 DEG C, preserving heat for 1-2 hours, and decreasing the temperature to room temperature, wherein the weight of the added powdered sodium silicate is 1-3% of that of the added waste concrete micro powder; and (2) mixing the mixture of the waste concrete micro powder and the powdered sodium silicate with desulfurization gypsum and an admixture, grinding for 15-60 minutes to obtain the powder with the fineness and the specific surface area of more than 450m<2> / kg, wherein the weight of the desulfurization gypsum is 1-5% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate, and the weight of the admixture is 1-3% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate. The method can improve the activity of the waste concrete micro powder so that the waste concrete micro powder is fully utilized.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Low-water-absorption foamed concrete and preparation method thereof

InactiveCN104150951AShort initial setting timeReduced open porosityCeramicwareFoam concreteAluminate

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

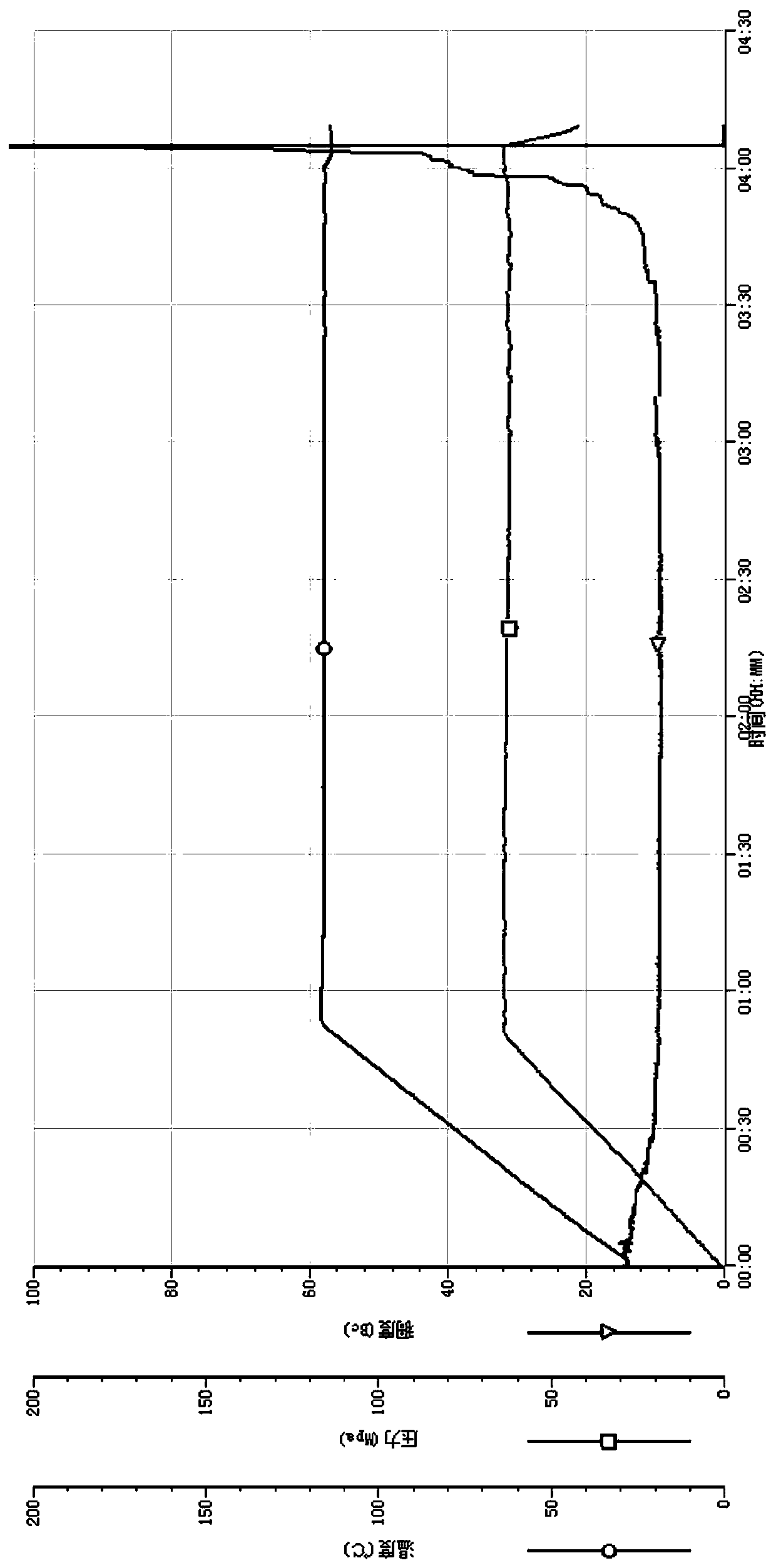

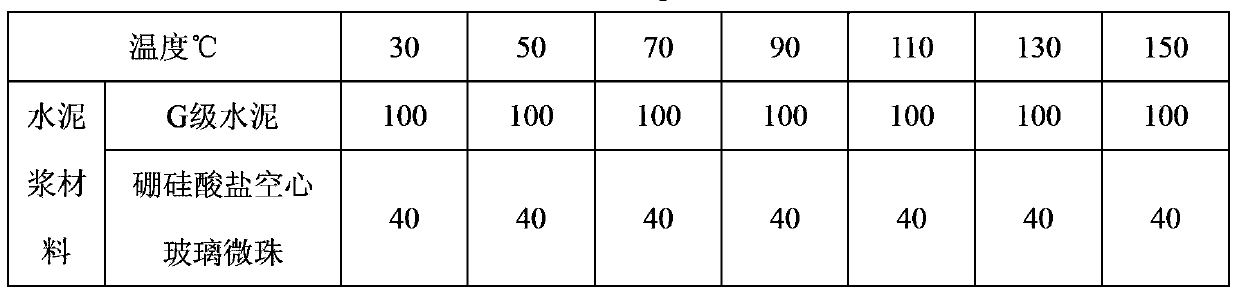

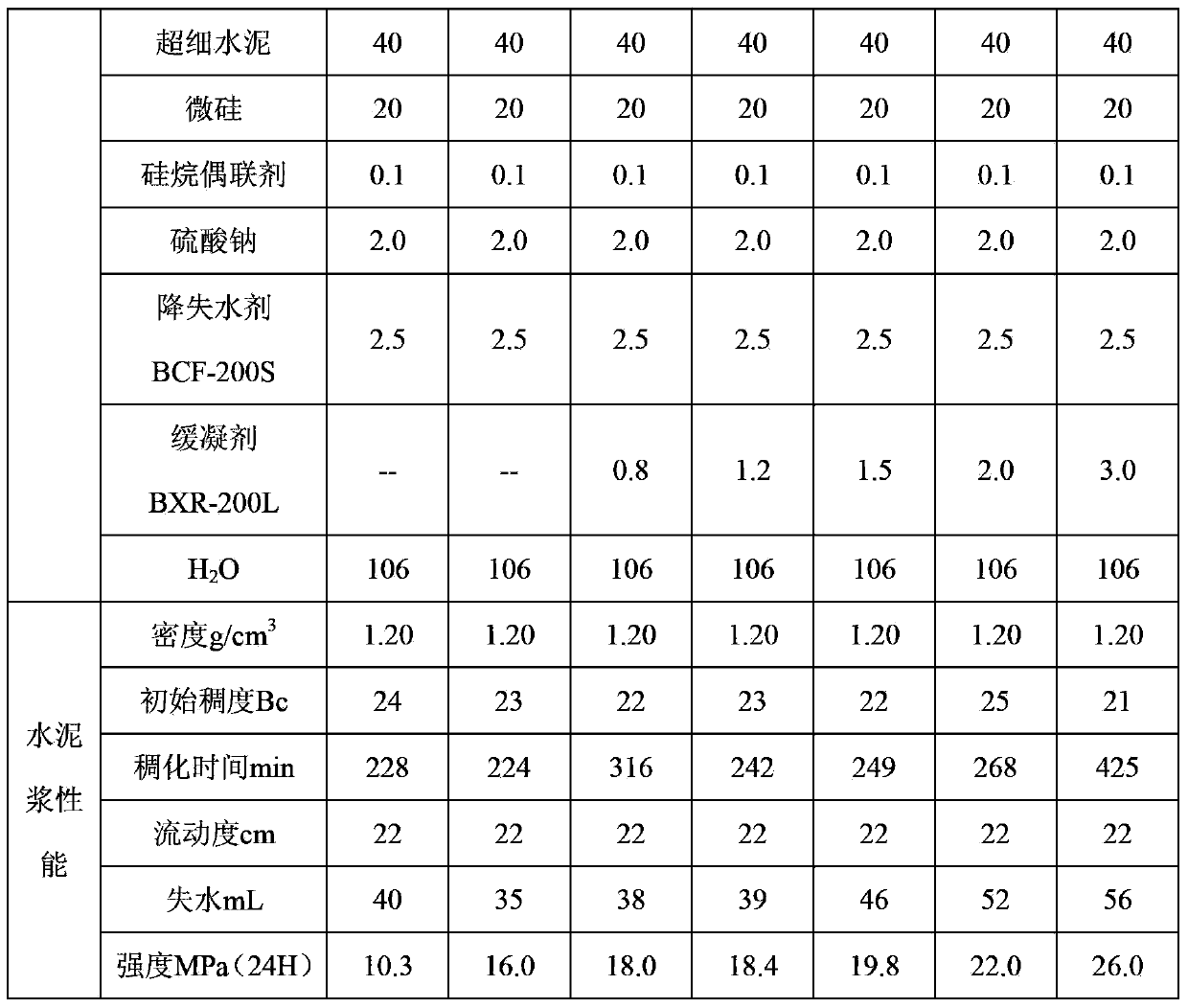

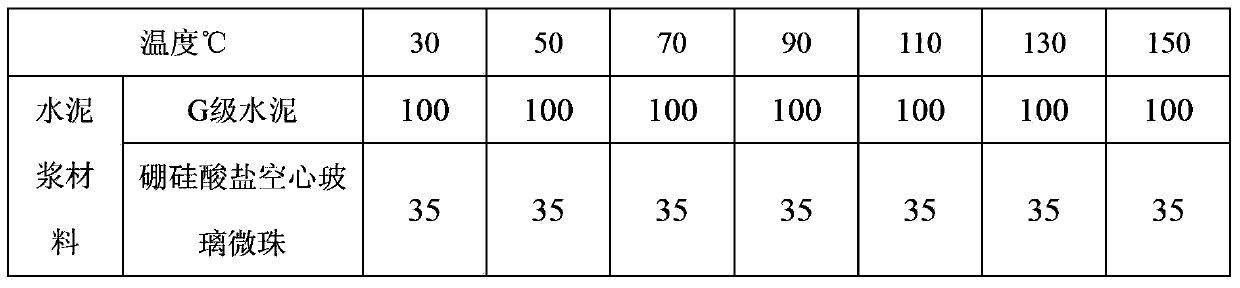

Low-density cement paste system

InactiveCN104178096AStrong hydration abilityFast hydrationDrilling compositionWell cementingVolumetric Mass Density

The invention relates to a low-density cement paste system. The cement paste system comprises following components by weight: 100 parts of oil well cement, 65-106 parts of water, 6-40 parts of borosilicate hollow glass beads, 0.05-0.1 part of a silicone coupling agent, 25-40 parts of ultrafine cement, 10-20 parts of microsilica, 2-2.5 parts of a fluid loss agent, and 0.5-1.5 parts of sodium sulfate. The particle size of the microsilica having a SiO2 content larger than 94% is 0.1-0.5 [mu]m. The particle size of the ultrafine cement is 2-10 [mu]m. The density range of the cement paste is 1.20-1.60 g / cm<3>. The particle size of the borosilicate hollow glass beads is 25 [mu]m. The thickening time of the cement paste is adjustable. The 24-h compressive strength (taking 1.50 g / cm<3> as an example) is higher than 16 MPa. The cement paste system has good sedimentation stability and incompressibility, and improves construction safety of the low-density cement paste in well cementing operation.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Extinguishment composition, purpose of extinguishment composition and extinguishment method

InactiveCN104001298AEasy to transportMeet the requirements of fire extinguishing grouting materialsDust removalFire preventionSpontaneous combustionSlurry

The invention discloses an extinguishment composition. The extinguishment composition comprises extinguishment powder and water, wherein the weight ratio of the extinguishment powder to the water ranges from 1:0.8 to 1:1.2. The extinguishment powder is composed of, by weight, 3 parts to 7 parts of calcium silicon residues, 1 part to 3 parts of fly ash, 1 part to 3 parts of flue gas desulfurization gypsum, and 0.5 part to 1.5 parts of cement. The invention further discloses an extinguishment method for spontaneous combustion of coal in a goaf. The method includes the first step of mixing and stirring the extinguishment powder with the water according to the weight ratio ranging from 1:0.8 to 1:1.2 to form extinguishment slurry, and the second step of injecting or spraying the extinguishment slurry manufactured in the first step into the goaf with the requirement for extinguishment so as to conduct grouting extinguishment. The invention further provides the purpose of using the extinguishment composition for conducting extinguishment for spontaneous combustion of the coal in the goaf. According to the method, less clay or loess is used, workloads for processing the extinguishment slurry are reduced, and acid gas produced by coal combustion can be solidified.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

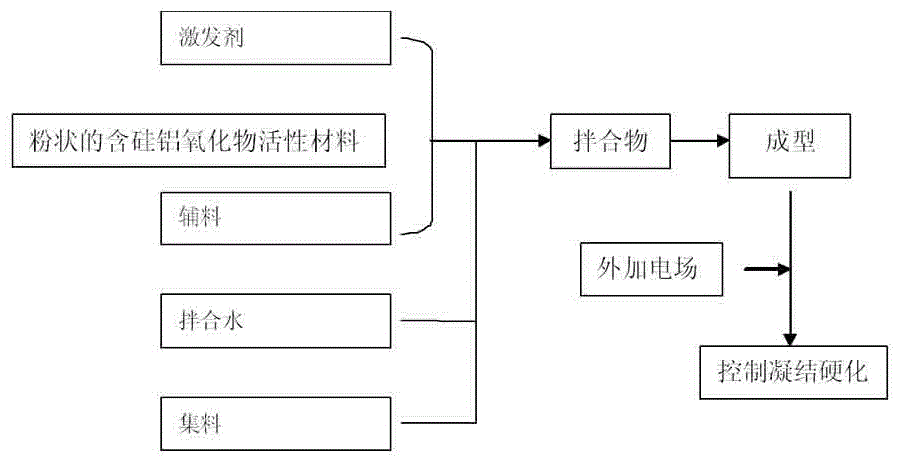

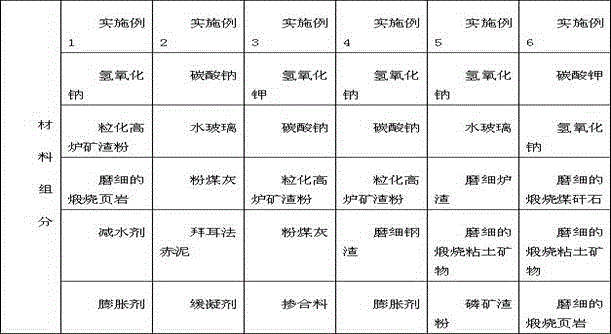

Alkali-activated cementing material capable of controlling setting time as well as control method and application thereof

InactiveCN105731947ASolve the problem of improper hydrationProlong clotting timeSolid waste managementCement productionThermodynamicsProcess engineering

The invention relates to a cementing material capable of controlling setting time as well as a setting time control method thereof and application of the cementing material in concrete, comprising the adopted cementing material, a method for controlling the setting time of an alkali-activated cementing material by virtue of an external electric field as well as a product and a method which apply the material and the method to the concrete. By adopting the material and method of the technical scheme, hydration process of the concrete can be sped up according to requirements after the concrete is moulded, setting and hardening time is controlled, and the prepared concrete has long setting time, so that construction performance requirements are met; meanwhile, the setting and hardening time can be shortened and early strength can be improved according to requirements; besides, environmental temperature during hydration can be guaranteed by utilizing concentrated and rapidly released hydration thermal produced by controlling the setting time, and the problem that normal hydration can not be carried out in negative temperature environment is solved.

Owner:胡晓霞

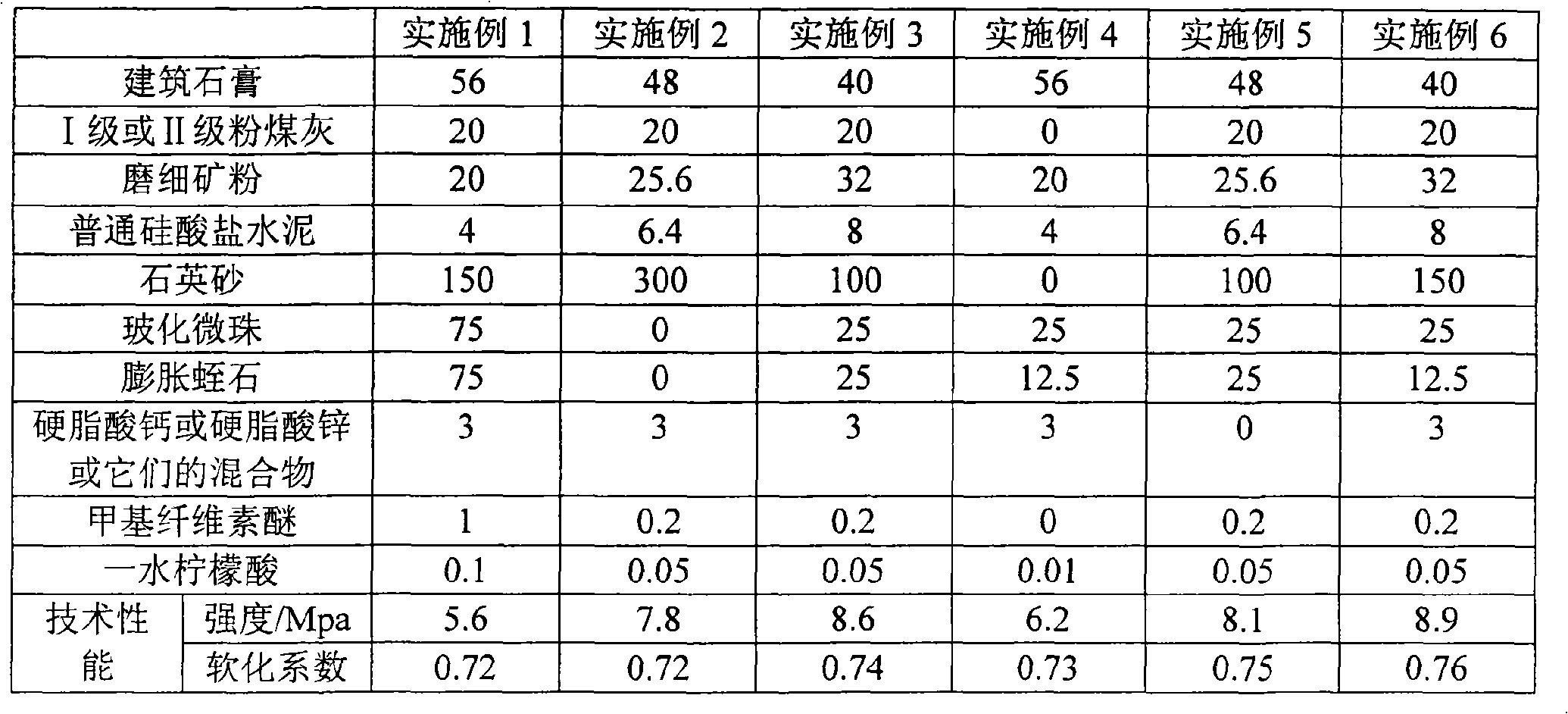

Waterproof fireproofing inorganic plugging material

InactiveCN101353261AFast hydrationHigh strengthSolid waste managementCitric Acid MonohydrateMaterials science

The invention discloses a waterproof and fireproof inorganic blocking material which is prepared by mixing the following raw materials with the parts by weight: 40-56 parts of construction gypsum, 0-20 parts of grade I fly ash or grade II fly ash, 24-40 parts of fine mineral powder and common Portland cement, 0-1 part of methyl cellulose ether, 0-3 parts of calcium stearate or zinc stearate or the mixture thereof, 0-0.1 part of citric acid monohydrate, 0-300 parts of quartz sand, 0-75 parts of vitrified micro bead and 0-75 parts of expanded vermiculite. The waterproof and fireproof inorganic blocking material of the invention has the advantages of superior waterproof and fireproof performance, fast coagulating and hardening speed, quick increase in early strength, moderate later strength, convenient disassembly, simple construction, immediate use after being mixed, free adjustment of coagulating time, convenient storage and transportation, environmental protection, etc.

Owner:NANJING EFFUL

Concrete synergist and preparation method thereof

InactiveCN108585592AOverall performance unchanged or improvedImprove performanceDispersityEnvironmental resistance

The invention provides a concrete synergist and a preparation method thereof. The concrete synergist comprises polyacrylamide, sodium sulfite, polyol, triisopropanolamine, calcium formate, diethylenetriamine pentacarboxylic acid sodium, sodium hexametaphosphate and the rest water. According to the concrete synergist, the dispersity of cement particles is efficiently stimulated, cement hydration rate is promoted, and cement is more sufficiently hydrated. Powder filling of cement components is reduced, the usage of the cement components can be effectively reduced without changing the comprehensive performance of concrete, and concrete cost is greatly reduced. Moreover, by cooperation of the components of the concrete synergist, the early and later strength of the concrete can be improved, and the overall comprehensive performance of the concrete can be greatly improved. The production process is simple, free from pollutant emission and environmentally friendly.

Owner:北京人众创新工贸有限公司

Anti-cracking reinforced ecological cement

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

Method for manufacturing high temperature resisting and high pressure resisting oil well cementation briquette through silicon bauxite ceramic microbeads

InactiveCN104478418AChange the dependence of floating beadsLow densityWell cementingPulverized fuel ash

A method for manufacturing a high temperature resisting and high pressure resisting oil well cementation briquette through silicon bauxite ceramic microbeads comprises the steps that the silicon bauxite closed-hole hollow ceramic microbeads are manufactured, burdening, mixing, stirring and size mixing are carried out, 55-65wt percent of G-class oil well cement, 25-35wt percent of the silicon bauxite closed-hole hollow ceramic microbeads with the grain size of five microns to 50 microns, five to seven wt percent of pulverized fuel ash with the loss on ignition of 1.1 percent and the grain size of 20 microns to 50 microns, 1.5 to two wt percent of calcium oxide with the purity of 99.9 percent, 0.5-1.0wt percent of sodium sulfate and one to three wt percent of micro-silicon with the grain size of five microns to 20 microns are mixed, size mixing is carried out according to the water cement ratio of 0.5 to 0.7, the mixtures are poured into a set of two briquette molds with the length of 53 mm, the width of 53 mm and the height of 53 mm, are maintained in a water bath maintenance box for 24 hours and 48 hours respectively at the constant temperature of 52 DEG C, and are soaked in cold water for one hour after demolding, and a performance index test is carried out.

Owner:SHANDONG UNIV OF TECH

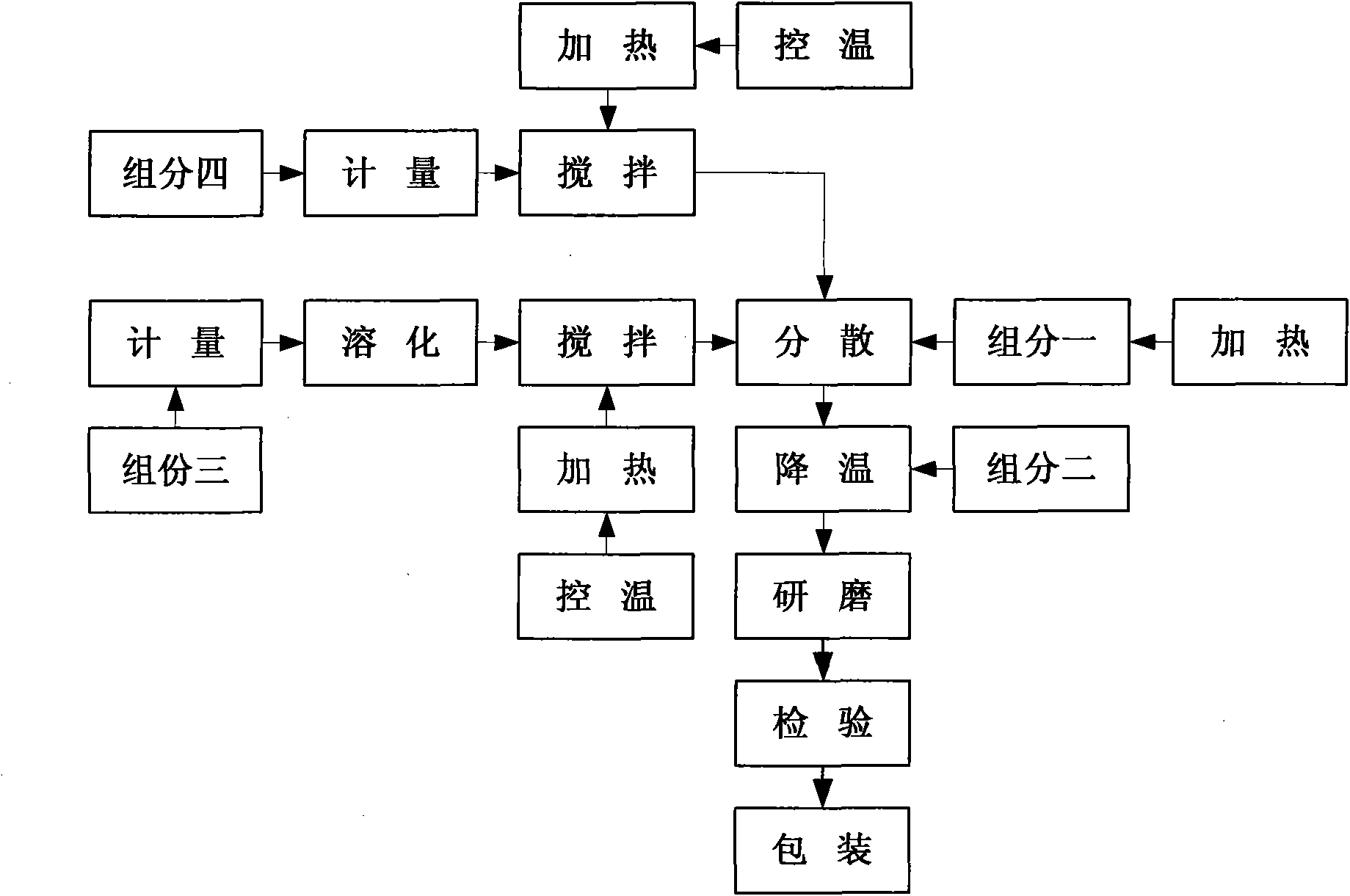

Waterfroof agent for cement mortar and its preparation method

The invention relates to a waterfroof agent used in cement mortar and a preparation method thereof. The waterfroof agent comprises the following raw materials of: by weight, 5.0-15.0 parts of paraffin, 3.0-5.0 parts of silicone oil, 0.5-3.0 parts of aliphatic acid, 1.0-3.0 parts of triethanolamine, 0.4-2.5 parts of sodium hydroxide and 60.0-100.0 parts of deionized water. The preparation method comprises the following steps of: firstly respectively weighing the above raw materials, mixing, melting, heating, saponifying, cooling, homogenizing, examining, and packaging to obtain a milky thick liquid waterfroof agent. The waterproof agent is aqueous and environmentally friendly, is nontoxic and tasteless, causes no pollution, is convenient to use, and has good compatibility with cement mortar. With the addition of the waterproof agent, cured and dried cement mortar has a strong waterproof function and can effectively avoid entry of rainwater, thus guaranteeing construction quality and service life.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

No-baking and no-steaming environment protection solid fly ash-cinder brick

InactiveCN1931772AImprove early strengthGood compatibilitySolid waste managementCooking & bakingFly ash brick

The present invention relates to green building material, and features that the no-braking and no-steaming green brick is produced with cementing industrial waste, small amount of cement, aggregate and admixture. Cementing industrial waste, such as fly ash, calcium carbide slime, etc, cement, aggregate and admixture in certain weight proportion are produced into the no-braking and no-steaming green brick through mixing, forming, curing, stocking, naturally curing and inspection. The brick meets the requirement of fly ash brick, and has the features of saving clay resource, no need of steam curing, simple production and low cost.

Owner:HENAN POLYTECHNIC UNIV

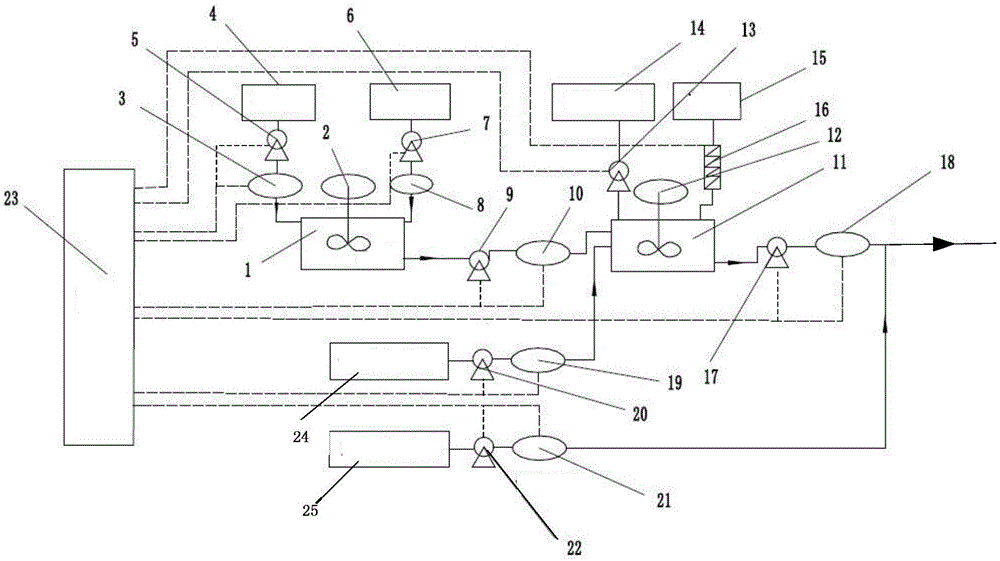

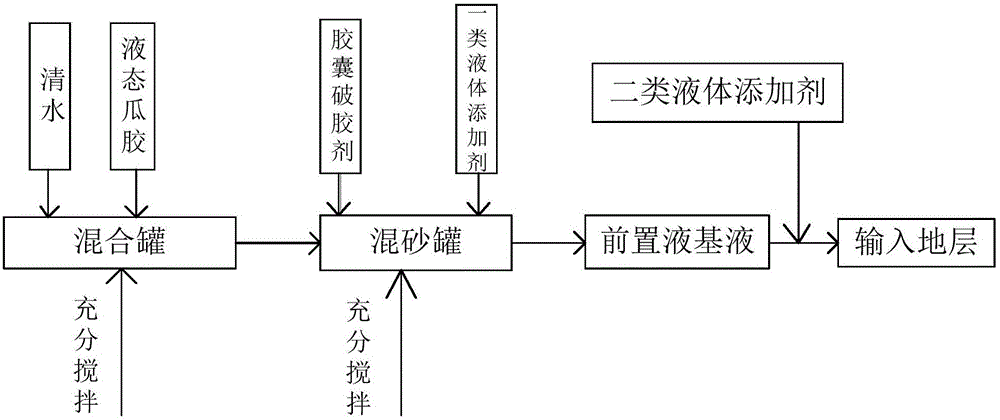

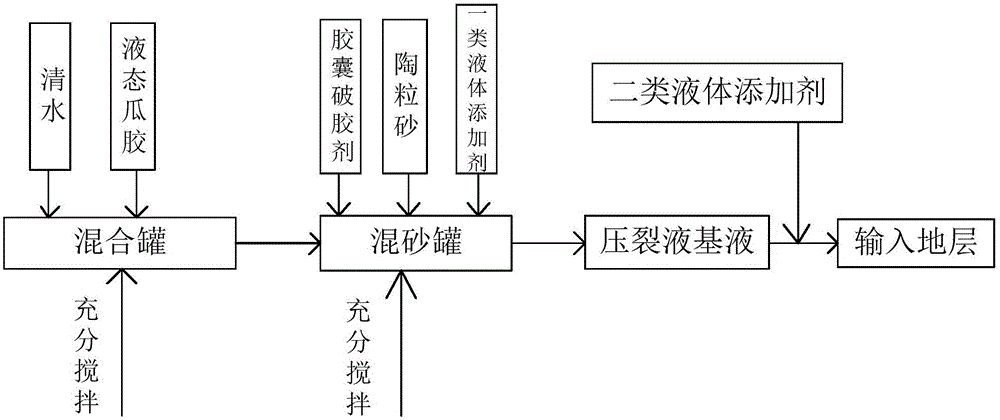

System for realizing continuous mixing by utilizing liquid-state guar gum and mixing technology thereof

InactiveCN105126669AFast hydrationSimple configurationRotary stirring mixersFluid removalComputer control systemLiquid state

The invention discloses a system for realizing continuous mixing by utilizing liquid-state guar gum and a mixing technology thereof. The system for realizing continuous mixing by utilizing liquid-state guar gum comprises a mixed-solution preparation system, a fracturing-fluid preparation system, a fracturing-fluid conveying system and a computer control system, and through computer parameter setting and control realization of fracturing-fluid continuous mixing, the mixing efficiency is improved, worker labor intensity is reduced and cost expenditure is saved. According to the mixing technology utilizing the system for realizing continuous mixing by utilizing liquid-state guar gum, different materials are transported according to different kinds and addition subsequences by a liquid conveying system, and are controlled by a computer control system for being precisely successively sent to a mixing tank and a sand mixing tank for fully mixing, and finally the fracturing fluid is injected into the stratum by an output pump, so that the technological requirements of continuous fracturing construction simultaneously performing preparation and injection are completely satisfied.

Owner:CNPC BOHAI DRILLING ENG

Recycled aggregate water-permeable brick and production method thereof

ActiveCN110407533AHigh strengthIncrease added valueSolid waste managementCeramicwareBrickCompressive strength

The invention provides a recycled aggregate water-permeable brick and a production method thereof. The recycled aggregate water-permeable brick comprises a base layer, and the base layer comprises, byweight, 95-105 parts of recycled aggregates, 14-16 parts of cement, 14-16 parts of fly ash and 0.22-0.32 part of a water reducer. The production method comprises the following steps: uniformly mixingthe cement, the fly ash and the water reducer, adding water, performing stirring, and adding wetted aggregates; adding the obtained mixture into a mold, and carrying out vibration extrusion molding under 1.5-3 MPa for 15-30 s; and demolding the obtained water-permeable brick, standing the water-permeable brick for 2 h, transferring the water-permeable brick into an autoclave, and curing the water-permeable brick under 0.8-1 MPa at 173-185 DEG C for 6-10 h. The aggregates are recycled aggregates, the use amount of the cement is small, the water-permeable brick has a high compressive strength and a high water permeability, the molding process is quick and simple, and has a low cost, and the environmental pollution can be effectively reduced, so the recycled aggregate water-permeable brick is suitable for large-scale industrial production.

Owner:QINGDAO AGRI UNIV

Low-temperature hydro-thermal synthesis method for high-viscosity and high-transparency aluminium-magnesium silicate

InactiveCN108439421AHas a new chemical structureHigh puritySilicon compoundsChemical structureSynthesis methods

The invention discloses a low-temperature hydro-thermal synthesis method for high-viscosity and high-transparency aluminium-magnesium silicate. The low-temperature hydro-thermal synthesis method is characterized in that rare earth substances, soluble aluminum salt, soluble magnesium salt, soluble sodium salt, water glass and the like are adopted as reaction raw materials, the proportion and reaction parameters of all ions are reasonably adjusted, then hydro-thermal treatment is carried out at a low temperature, and then filtering, washing and drying are carried out so as to obtain the aluminium-magnesium silicate with high hydration speed, high transparency, high viscosity and a brand-new chemical structure. The aluminium-magnesium silicate can be widely applied to the industries of foods,drugs, cosmetics, detergents, coatings and the like.

Owner:JIANGSU HEMINGS NEW MATERIALS TECH CO LTD

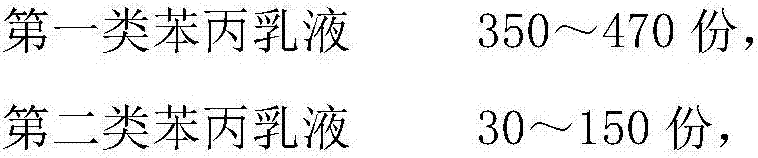

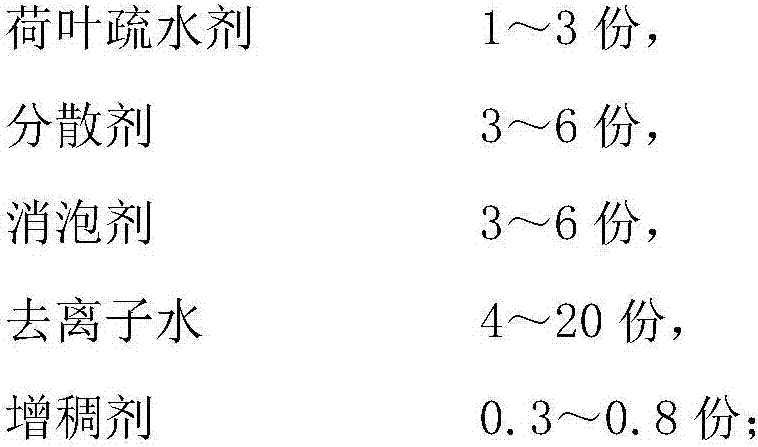

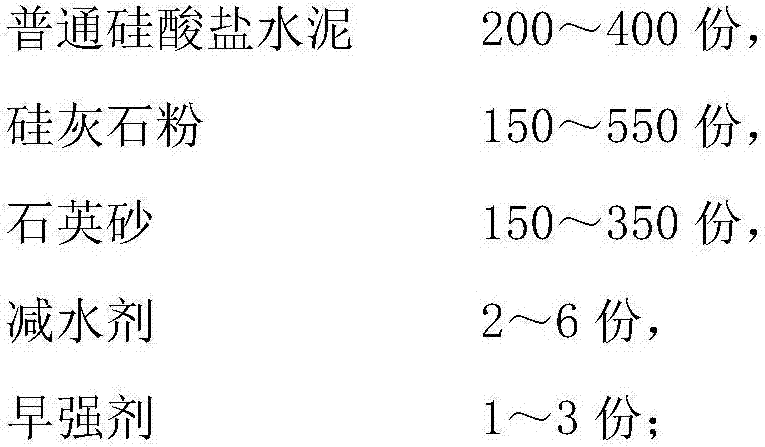

Hydrophobic polymer cement waterproof coating and preparation method thereof

The invention discloses a hydrophobic polymer cement waterproof coating and a preparation method thereof and relates to the technical field of building materials. The waterproof coating disclosed by the invention is prepared from a liquid material and a powder material, wherein the liquid material is prepared from the following components in parts by weight: 350-470 parts of the first kind of styrene-acrylic emulsion, 30-150 parts of the second kind of styrene-acrylic emulsion, 1-3 parts of lotus-leaf water repellent agent, 3-6 parts of dispersing agent, 3-6 parts of antifoaming agent, 4-20 parts of deionized water and 0.3-0.8 part of thickening agent; the powder material is prepared from the following components in parts by weight: 200-400 parts of ordinary Portland cement, 150-550 parts of wollastonite powder, 150-350 parts of quartz sand, 2-6 parts of water reducing agent and 1-3 parts of early strength agent; the glass transition temperature of the first kind of styrene-acrylic emulsion is minus 10 DEG C to minus 5 DEG C; the glass transition temperature of the second kind of styrene-acrylic emulsion is minus 20 to minus 15 DEG C. The waterproof coating has the advantages of fast drying, high environmental friendliness and excellent mechanical property.

Owner:青岛东方雨虹建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com