System for realizing continuous mixing by utilizing liquid-state guar gum and mixing technology thereof

A liquid guar gum and mixing technology, which is applied in mixers, mixer accessories, mixers with rotary stirring devices, etc., can solve the problems of high viscosity of liquid guar gum, liquid dispensing, and no liquid guar gum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

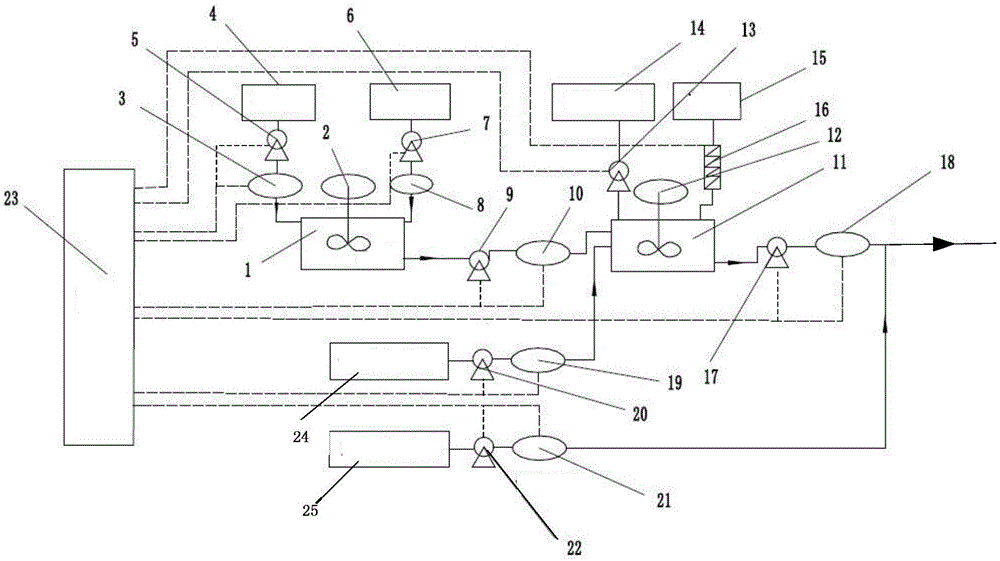

[0029] Such as figure 1 As shown, the continuous mixing system utilizing liquid guar gum includes a mixed solution preparation system, a fracturing fluid preparation system, a fracturing fluid delivery system and a computer control system 23, wherein:

[0030]Described mixed solution preparation system comprises clear water tank 4, liquid guar gum tank 6, clear water delivery system, liquid guar gum delivery system, mixing tank 1 and mixed solution delivery system, and described clear water delivery system comprises the communication tank 4 and the The connecting pipeline between the mixing tank 1 and the first large displacement liquid pump 5 and the first flow meter 3 arranged on the connecting pipeline; The connecting pipeline between the mixing tank 1 and the high-viscosity liquid pump 7 and the second flow meter 8 installed on the connecting pipeline; the mixed liquid delivery system includes connecting the mixing tank 1 and the sand mixing tank The connecting pipeline b...

Embodiment 2

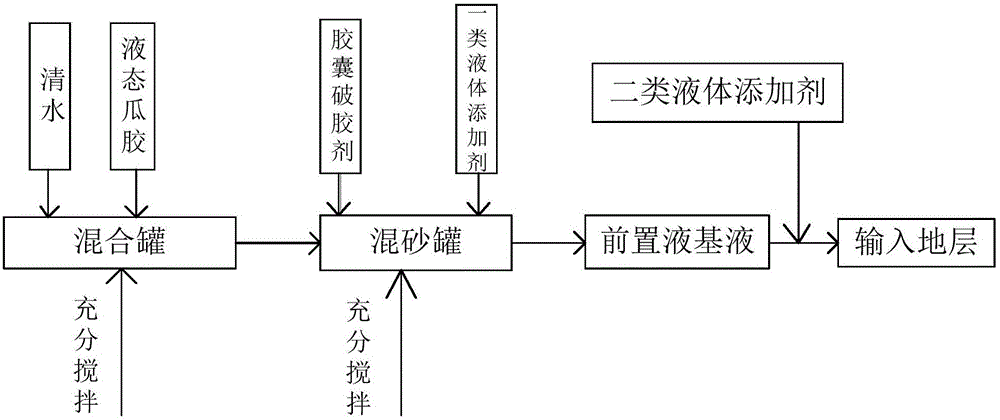

[0035] Embodiment 2 (pre-fluid dosing example)

[0036] Such as figure 2 As shown, the specific steps for preparing the pre-flush by using the continuous mixing system are:

[0037] 1) Input the preparation process parameters of the front liquid through the man-machine interface of the computer control system: comprise the mass ratio of liquid guar gum and clear water (such as setting the liquid guar gum quality as 0.35% of the clear water quality), the first type of liquid additive Addition amount, the addition amount of capsule gel breaker, the addition amount of the second type liquid additive, the rotating speed of the first high-speed mixer 2, the rotating speed of the second high-speed mixer 12, and the initial rotating speed of each pump located on the connecting pipeline;

[0038] 2) Turn on the first large-displacement liquid pump 5 and the high-viscosity liquid pump 7, so that clear water and liquid guar gum are pumped into the mixing tank 1 through the first large...

Embodiment 3

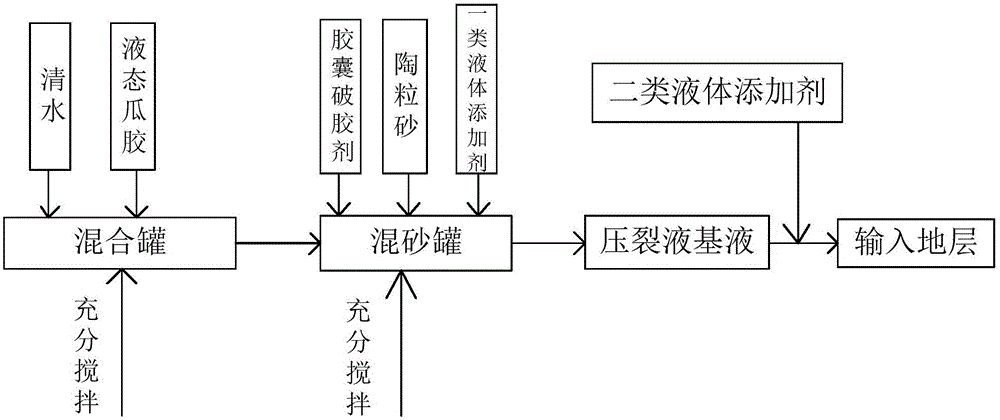

[0043] Embodiment 3 (fracturing fluid dosing example)

[0044] Such as image 3 As shown, the specific steps of using the continuous mixing system to prepare fracturing fluid are:

[0045] 1) Input the preparation process parameters of the front liquid through the man-machine interface of the computer control system: comprise the mass ratio of liquid guar gum and clear water (such as setting the liquid guar gum quality as 0.35% of the clear water quality), the first type of liquid additive Addition amount, the addition amount of capsule gel breaker, the addition amount of the second type liquid additive, the rotating speed of the first high-speed mixer 2, the rotating speed of the second high-speed mixer 12, and the initial rotating speed of each pump located on the connecting pipeline;

[0046] 2) Turn on the first large-displacement liquid pump 5 and the high-viscosity liquid pump 7, so that clear water and liquid guar gum are pumped into the mixing tank 1 through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com