Hydrophobic polymer cement waterproof coating and preparation method thereof

A technology of waterproof coatings and polymers, applied in the direction of coatings, etc., can solve the problems of polymer cement waterproof coatings such as non-environmental protection, slow drying time, and poor water resistance, and achieve the effects of fast drying, good environmental protection, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

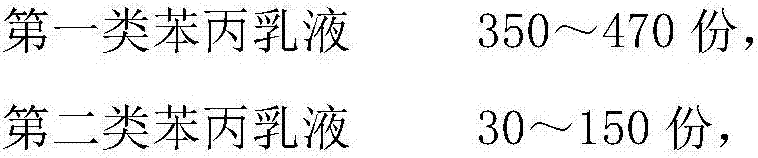

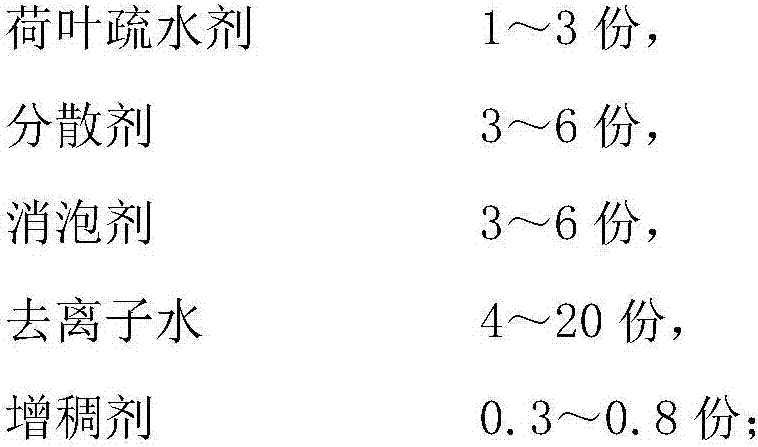

[0042] In parts by weight, each raw material is prepared according to the liquid material formula: 470 parts of the first type of styrene-acrylic emulsion (selected from Arkema 5181 emulsion, the glass transition temperature is -10 ° C), the second type of styrene-acrylic emulsion (selected from BASF 405 Emulsion, glass transition temperature is -19 ℃) 30 parts, lotus leaf hydrophobic agent 2 parts (selected from Aohan Chemical SC-011 lotus leaf effect hydrophobic agent), polyacrylic acid sodium salt 4 parts (selected from Dow 731A), poly 5 parts of ether defoamer (selected from BASF 2706), 0.5 parts of thickener (selected from Arkema 3800), 8 parts of deionized water;

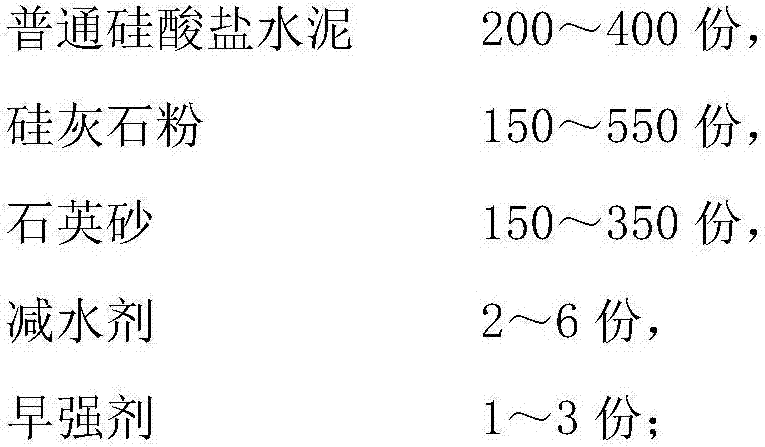

[0043] In parts by weight, each raw material is prepared according to the powder formula: 300 parts of ordinary silicate 42.5 grade gray cement, 300 parts of 350 mesh quartz powder, 400 parts of 200 mesh wollastonite powder, polycarboxylate superplasticizer (selected from Dongfangyu Rainbow CR-818) 3 parts, ea...

Embodiment 2

[0048] In parts by weight, each raw material is prepared according to the liquid material formula: 430 parts of the first type of styrene-acrylic emulsion (selected from Arkema 5181 emulsion, the glass transition temperature is -10 ° C), the second type of styrene-acrylic emulsion (selected from BASF 405 Emulsion, the glass transition temperature is -19 ℃) 70 parts, 3 parts of lotus leaf hydrophobic agent (selected from Aohan Chemical SC-011 lotus leaf effect hydrophobic agent), 6 parts of polyacrylic acid sodium salt (selected from Dow 731A), poly 5 parts of ether defoamer (selected from BASF 2706), 0.4 parts of thickener (selected from Arkema 3800), 12 parts of deionized water;

[0049] In parts by weight, each raw material is prepared according to the powder formula: 350 parts of ordinary silicate 42.5 grade gray cement, 300 parts of 350 mesh quartz powder, 350 parts of 200 mesh wollastonite powder, polycarboxylate superplasticizer (selected from Dongfangyu Rainbow CR-818) ...

Embodiment 3

[0054] In parts by weight, each raw material is prepared according to the liquid material formula: 400 parts of the first type of styrene-acrylic emulsion (selected from Arkema 5181 emulsion, the glass transition temperature is -10 ° C), the second type of styrene-acrylic emulsion (selected from BASF 405 Emulsion, the glass transition temperature is -19 ℃) 100 parts, 3 parts of lotus leaf hydrophobic agent (selected from Aohan Chemical SC-011 lotus leaf effect hydrophobic agent), 8 parts of polyacrylic acid sodium salt (selected from Dow 731A), poly 6 parts of ether defoamer (selected from BASF 2706), 0.6 parts of thickener (selected from Arkema 3800), 18 parts of deionized water;

[0055] In parts by weight, each raw material is prepared according to the powder formula: 400 parts of ordinary silicate 42.5 grade gray cement, 350 parts of 350 mesh quartz powder, 250 parts of 200 mesh wollastonite powder, polycarboxylate superplasticizer (selected from Dongfangyu Rainbow CR-818)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com