Continuous compounding method for fracturing fluid

A fracturing fluid and mixing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of undeveloped and mixed fracturing fluid, achieve fast liquid hydration speed, and save construction liquid , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

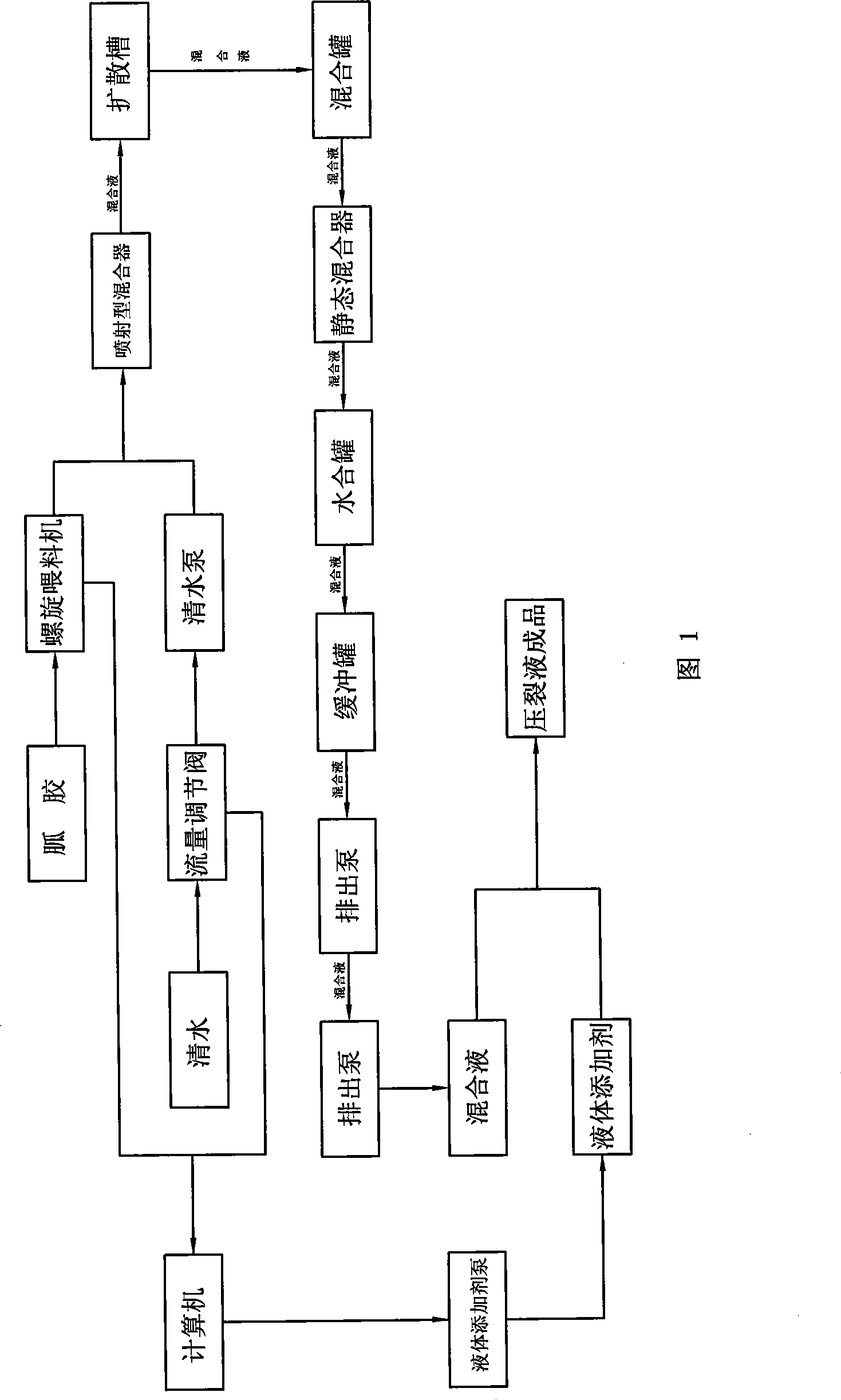

Image

Examples

Embodiment 2

[0027] In embodiment 1, the dosing ratio of described setting is that the weight ratio of guar gum powder and clear water is 0.6%. The liquid additives include bactericides, drainage aids, clay stabilizers and preservatives, and the added amount of the liquid additives accounts for 2% of the total liquid volume. The bactericides, drainage aids, clay stabilizers and preservatives used in the liquid additives are selected by those skilled in the art according to the actual situation on the spot, and the proportioning relationship can be selected according to the actual situation.

Embodiment 3

[0029] As a preferred embodiment of the present invention, the implementation process of the present invention is: utilize simple and easy crane arm to be contained in the guar gum tank in advance with instant guar gum, the guar gum is supplied to the jet mixer of automatic flow regulation through precision screw feeder, The feeding amount is adjusted by the rotating speed of the screw feeder, and the feeding amount of the screw feeding machine is controlled by the computer. The computer continuously reads the difference (feeding amount) per unit time of the electronic scale, and adjusts it according to the clean water flow and the ratio The speed of the screw feeder maintains the set liquid ratio.

[0030] The clean water pump draws clean water from the outside, and after being metered by the whole process flow regulating valve and flow meter, it is pumped into the jet mixer that automatically adjusts the flow, and mixed with guar gum.

[0031] The computer adjusts the whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com